Preparing method of 2-methoxy imino group 2-furan ammonium acetate

A technology of methoxyimino and amine furanoacetate is applied in the field of preparation of 2-methoxyimino-2-furanoacetate amine, and can solve the problems of many types of solvents, large amount of by-product furoic acid, large solvent consumption and the like , to reduce costs and improve yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A detailed description will be given below of specific embodiments of the present invention.

[0020] The preparation method of 2-methoxyimino 2-furan acetate amine, the method comprises the following steps:

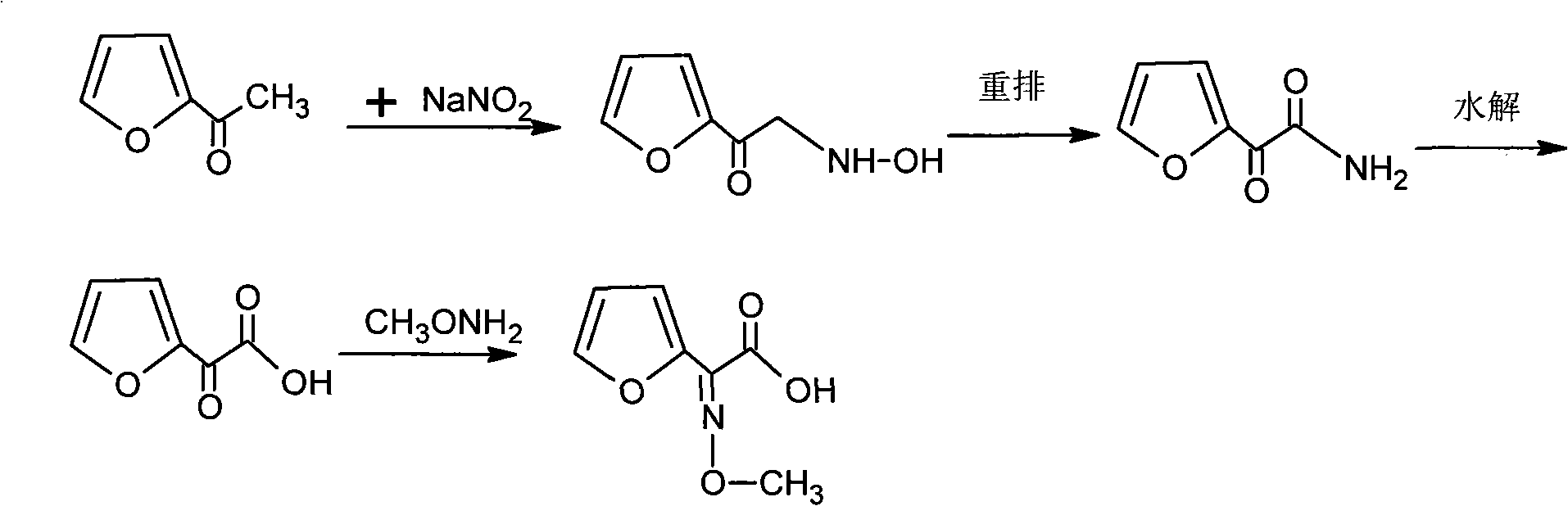

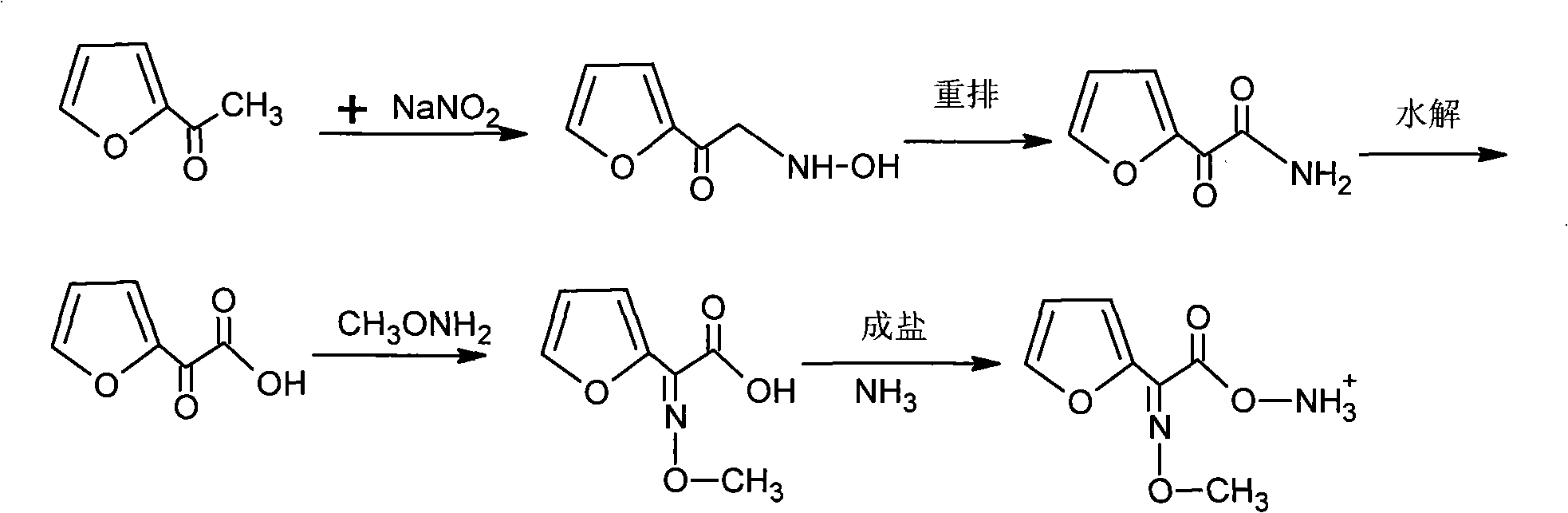

[0021] ①. Reaction of sodium nitrite and furan acetate, the reaction temperature is 59°C±1°C, and furanonic acid is generated through oximation, rearrangement, and hydrolysis;

[0022] ②, add hydrochloric acid, adjust the pH to 0.2, use butyl acetate to extract, then add Na 2 CO 3 Solution stripping obtains furanone acid;

[0023] ③. Condensation of furanone acid and methoxyammonium hydrochloride to generate 2-imino 2-furan acetic acid;

[0024] ④, adjust the pH to 0.5, use butyl acetate to extract 2-imino-2-furanacetic acid, add activated carbon for dehydration and decolorization;

[0025] ⑤. Add methanol with solvent volume of 5-10% in the reaction solution, and then pass ammonia gas to form a salt to generate 2-methoxyimino 2-furanacetate amine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com