Patents

Literature

529 results about "Salt formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating compositions for glass substrates

InactiveUS20110045219A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolyurethane dispersionPolyol

The present invention relates to an aqueous polyurethane coating composition comprising:1) 1 to 99 wt. % of the reaction product of:a) a polyol component, which is soluble or dispersible in water and is the reaction product of a polyisocyanate component containing 50 to 100 wt. % of an aliphatic diisocyanate, a polyol component containing one or more polyether polyols and having an OH number of 25 to 350 mg KOH / g solids and an isocyanate-reactive component containing at least one group capable of salt formation; andb) polyisocyanate component, which is soluble or dispersible in water, has blocked isocyanate groups and is the reaction product of one or more polyisocyanates having an isocyanurate group content of 2 to 30 wt. %, a reversible, monofunctional blocking agent for isocyanate groups, a nonionic hydrophilic component and a stabilizing component which has 1 to 2 hydrazide groups and a molecular weight of 70 to 300; and2) 1 to 99 wt. % of an aqueous polyurethane dispersion prepared from at least one polycarbonate polyol,wherein the total wt. % of components 1) and 2) add up to 100%.

Owner:COVESTRO LLC

Emulsifying and viscosity-decreasing method of thick oil

ActiveCN101768462AStrong resistance to mineral saltLow viscosityFluid removalDrilling compositionHydrocarbon solventsViscosity

The invention relates to an emulsifying and viscosity-decreasing method of thick oil. The method comprises the following steps: mixing oil-soluble component with hydrocarbon solvent to prepare an agent A; mixing nonionic-anionic surfactant, straight chain or branched chain macromolecular compound containing hydrophilic groups with water to prepare an agent B; firstly mixing the agent A with thickoil, secondly adding the agent B in the mixture of the agent A and thick oil and mixing to form an oil-in-water emulsion. The method can be used for the emulsifying and viscosity-decreasing of thick oil and especially for the emulsifying and viscosity-decreasing of thick oil under the condition of ultrahigh rock salt formation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyisocyanate curing agent and preparation method thereof

The invention relates to a polyisocyanate curing agent and a preparation method thereof, belonging to the curing agent field. The preparation method comprises the following steps: adopting diisocyanate monomer and a mixture of divalent alcohol and trivalent alcohol to react in cosolvent and obtain branched polyisocyanate, performing hydrophilic chain-extending reaction in the presence of catalyst,adding sealing agent to seal end and protect, adding neutralizer for neutralization and salt-formation, using a small amount of visbreaking protective solvent for dilution to ensure the total mass content to be 50-70% and preparing the ionic room temperature hydrolysis capped polyisocyanate curing agent, wherein, the molar ratio of diisocyanate monomer to divalent alcohol and trivalent alcohol 1:0.1-0.4:0.01-0.20. The invention is a polyisocyanate curing agent with low viscosity, good dispersibility and dendritic molecular structure which can increase the mechanical properties, water resistance and adhesive force of waterborne polyurethane surface material in sport fields and meet the pavement demand of sport fields and venues.

Owner:广州市合工大实力新材料研究院有限公司 +1

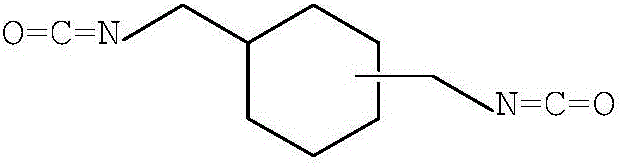

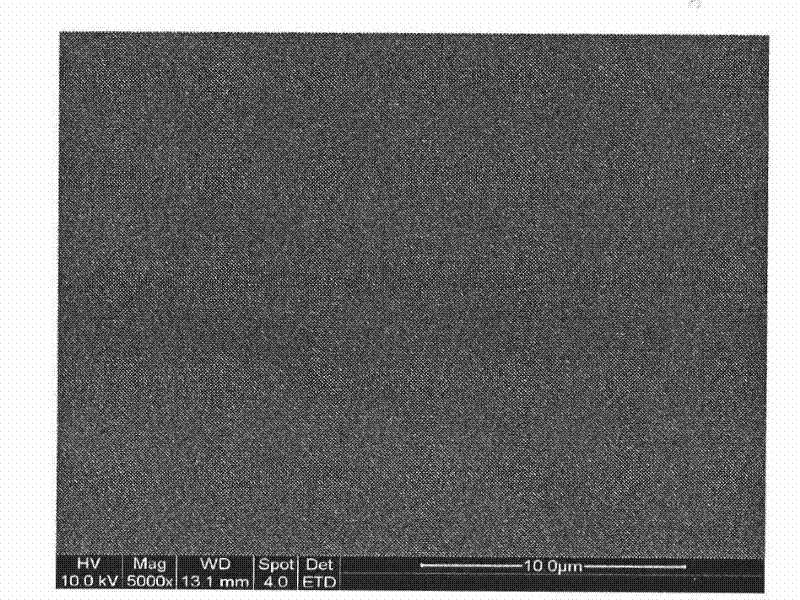

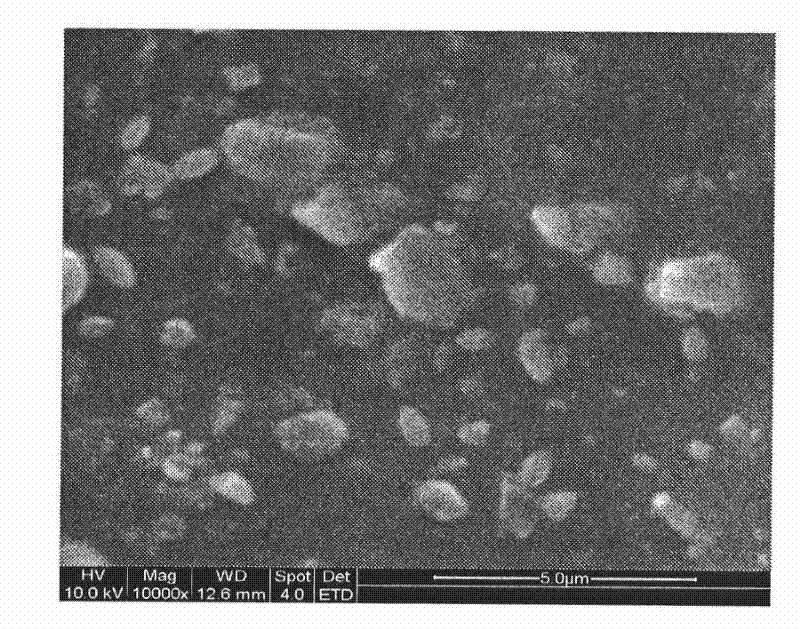

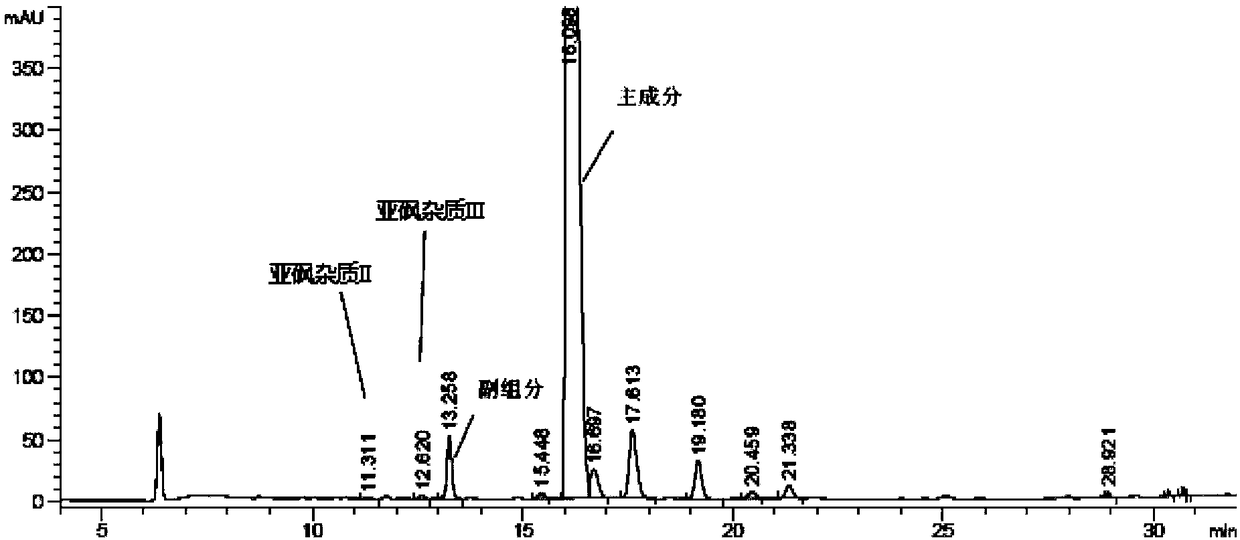

Preparation method of hydrogenated xylylene diisocynate

ActiveCN106674056AGood dispersionImprove liquidityOrganic compound preparationIsocyanic acid derivatives purification/separationXylyleneN dimethylformamide

The invention discloses a preparation method of hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate comprises the following steps: (1) performing salt forming reaction on 1,3-cyclohexanol dimethylamine and concentrated hydrochloric acid in a two-phase reaction solvent to obtain amine salt, wherein the two-phase reaction solvent consists of water and an inert organic solvent insoluble in water ; (2) performing photochemical reaction on the ammonium salt obtained in the step (1) and phosgene in an inert solvent by taking N,N-dimethylformamide or N,N-dimethylacetamide as a catalyst to obtain reaction liquid, and performing aftertreatment on the reaction liquid to obtain the hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate has the advantages of complete ammonium salt formation, small grain size of the ammonium salt, low viscosity of the ammonium salt, high space-time conversion rate of photochemical reaction, simple process, low cost and the like.

Owner:HUNAN HAILI CHEM IND

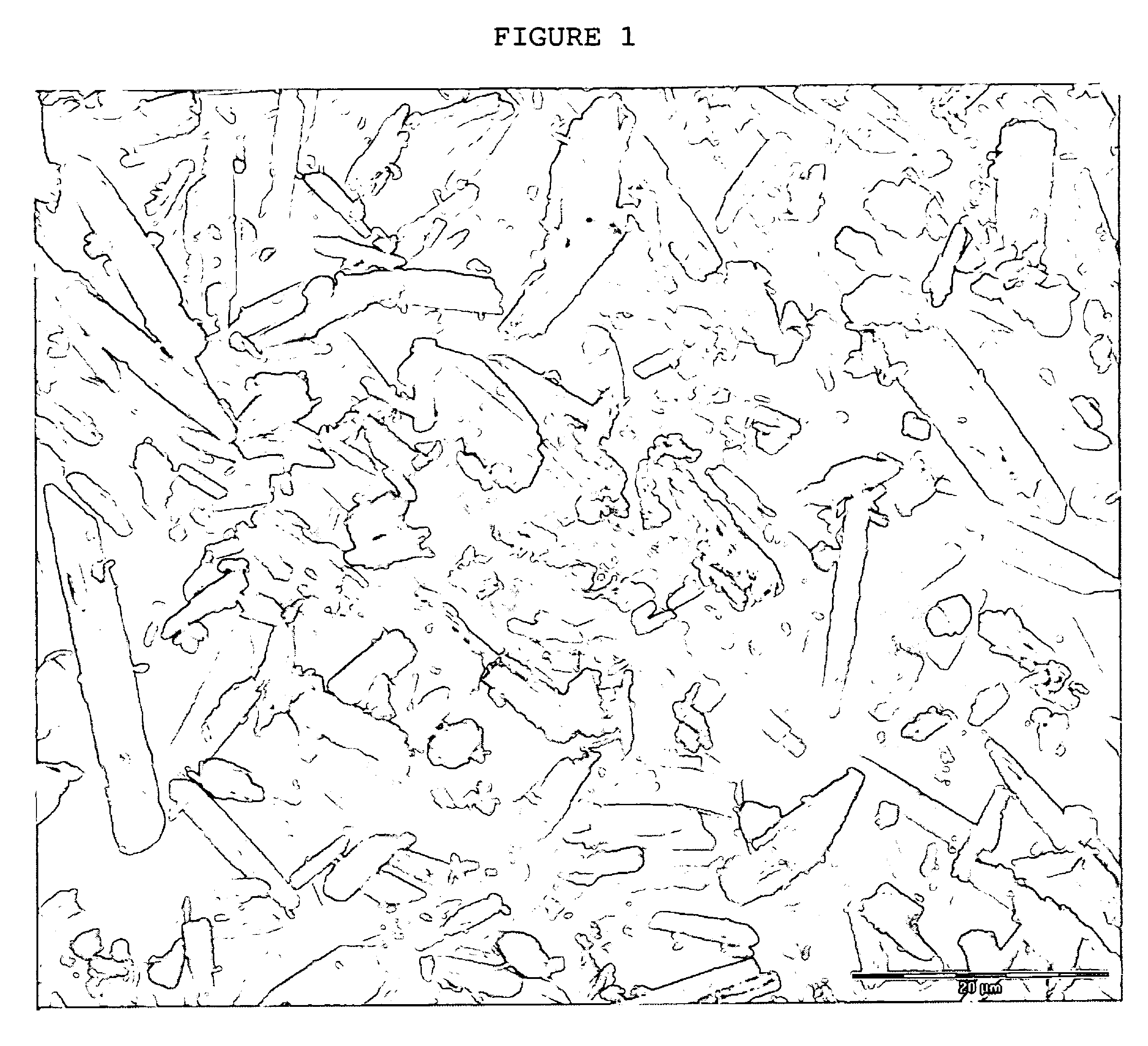

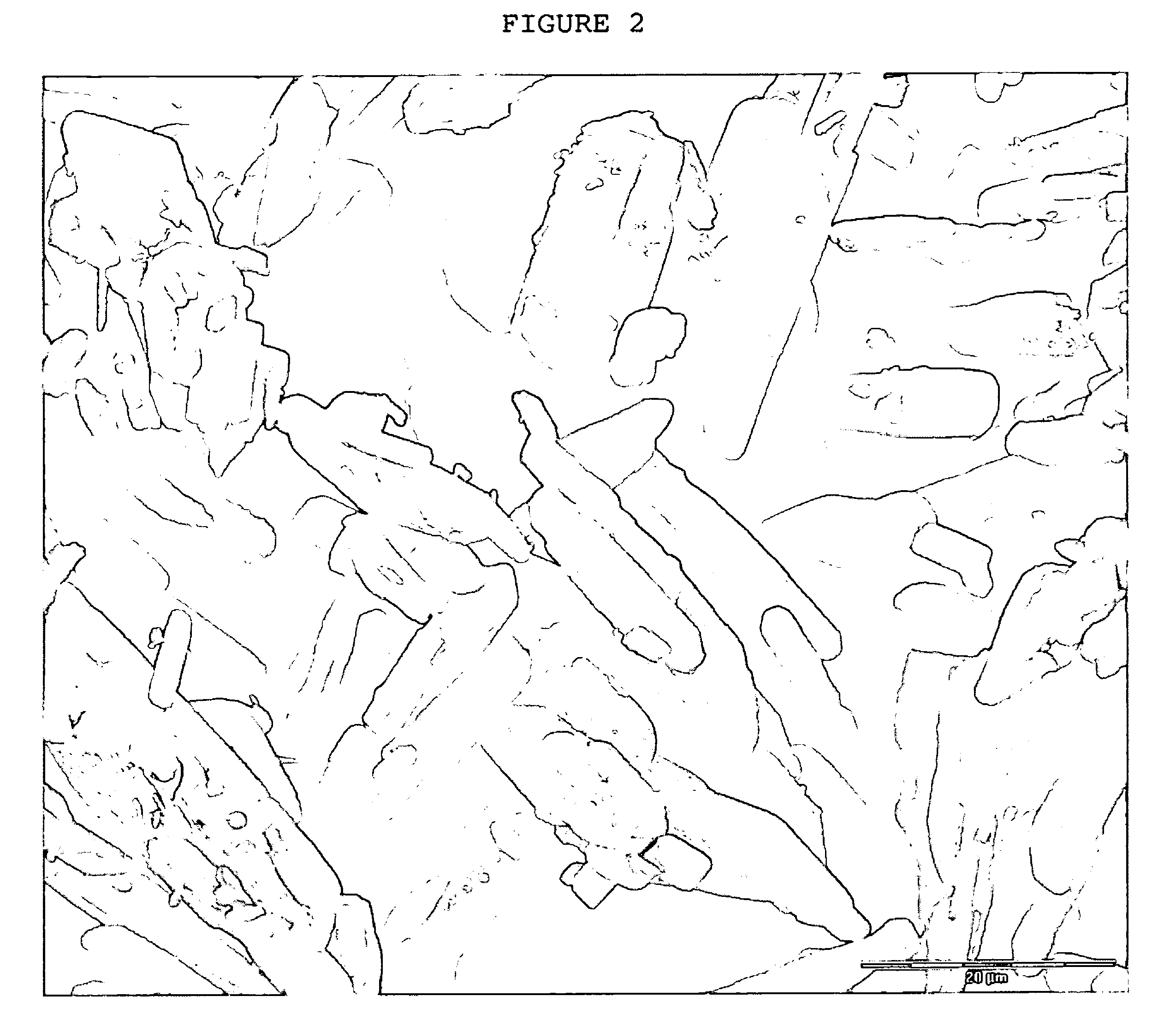

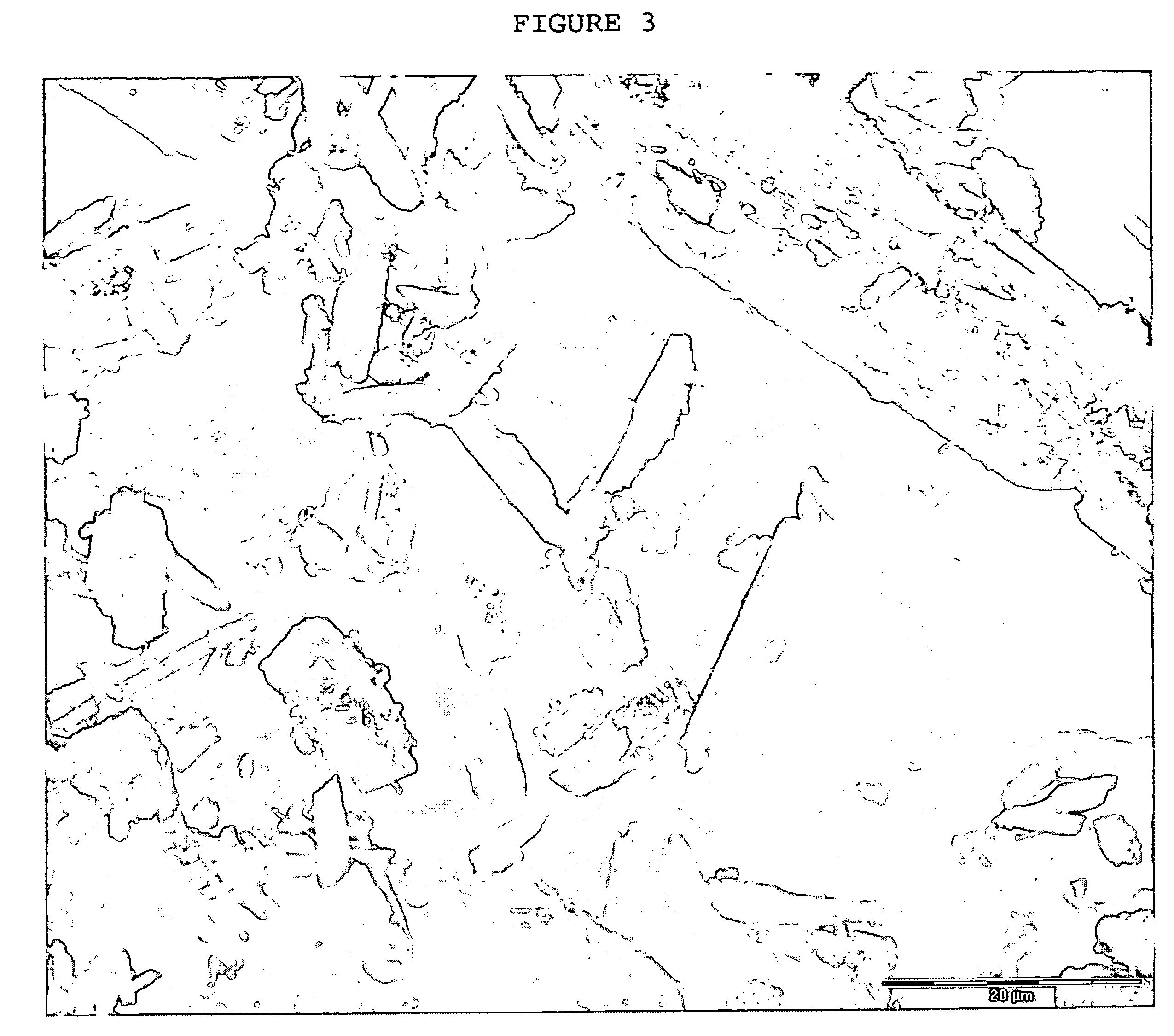

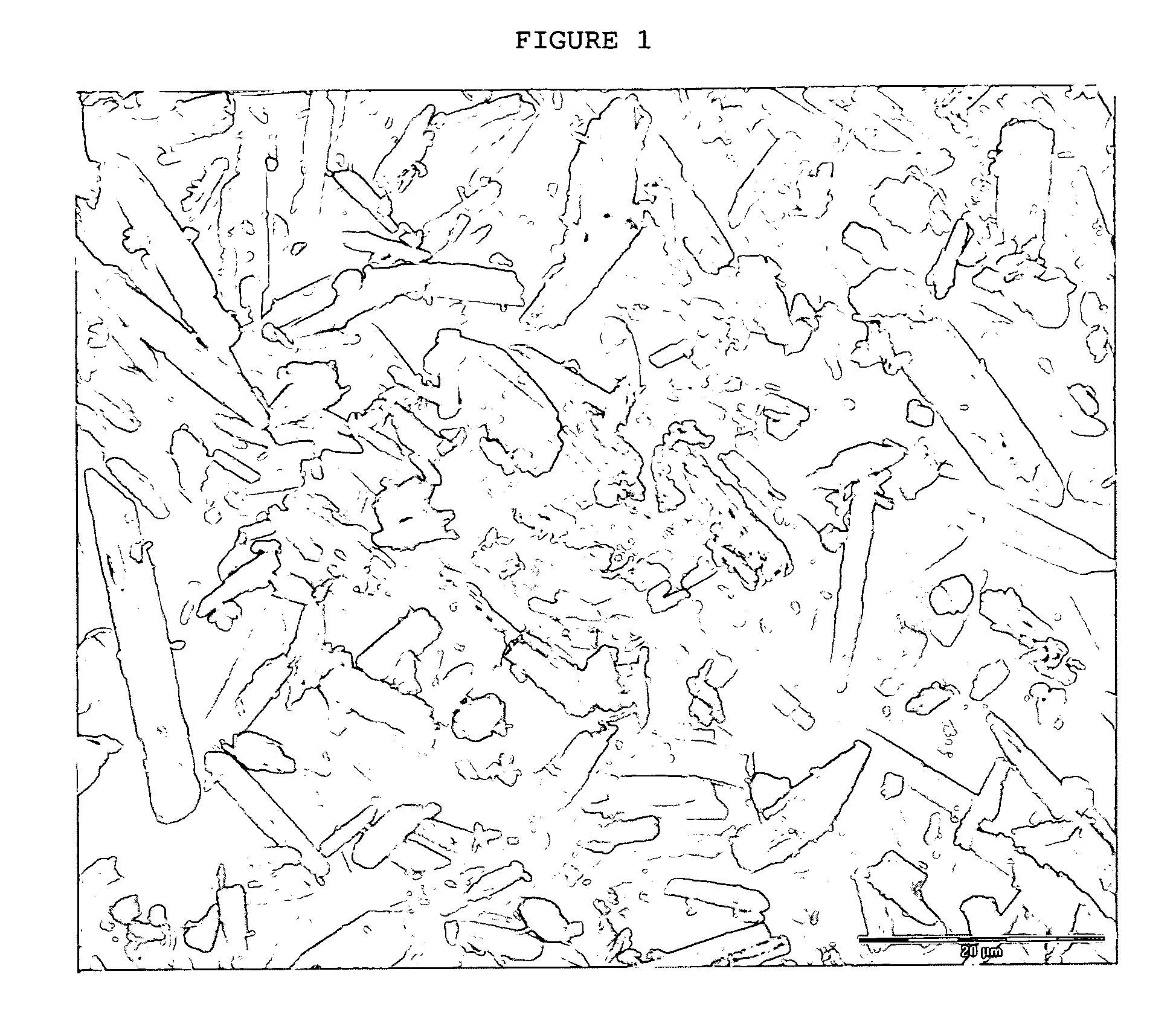

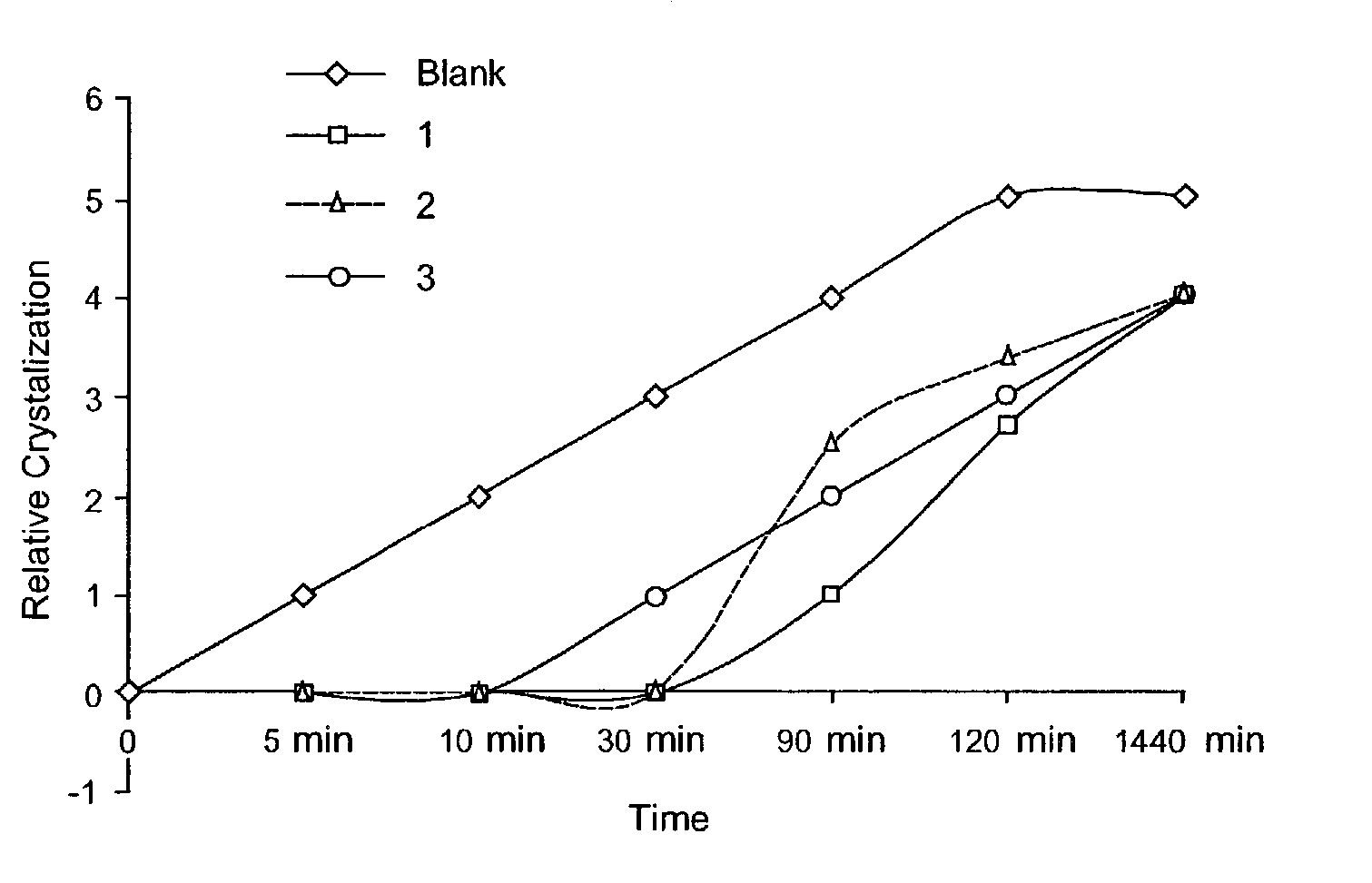

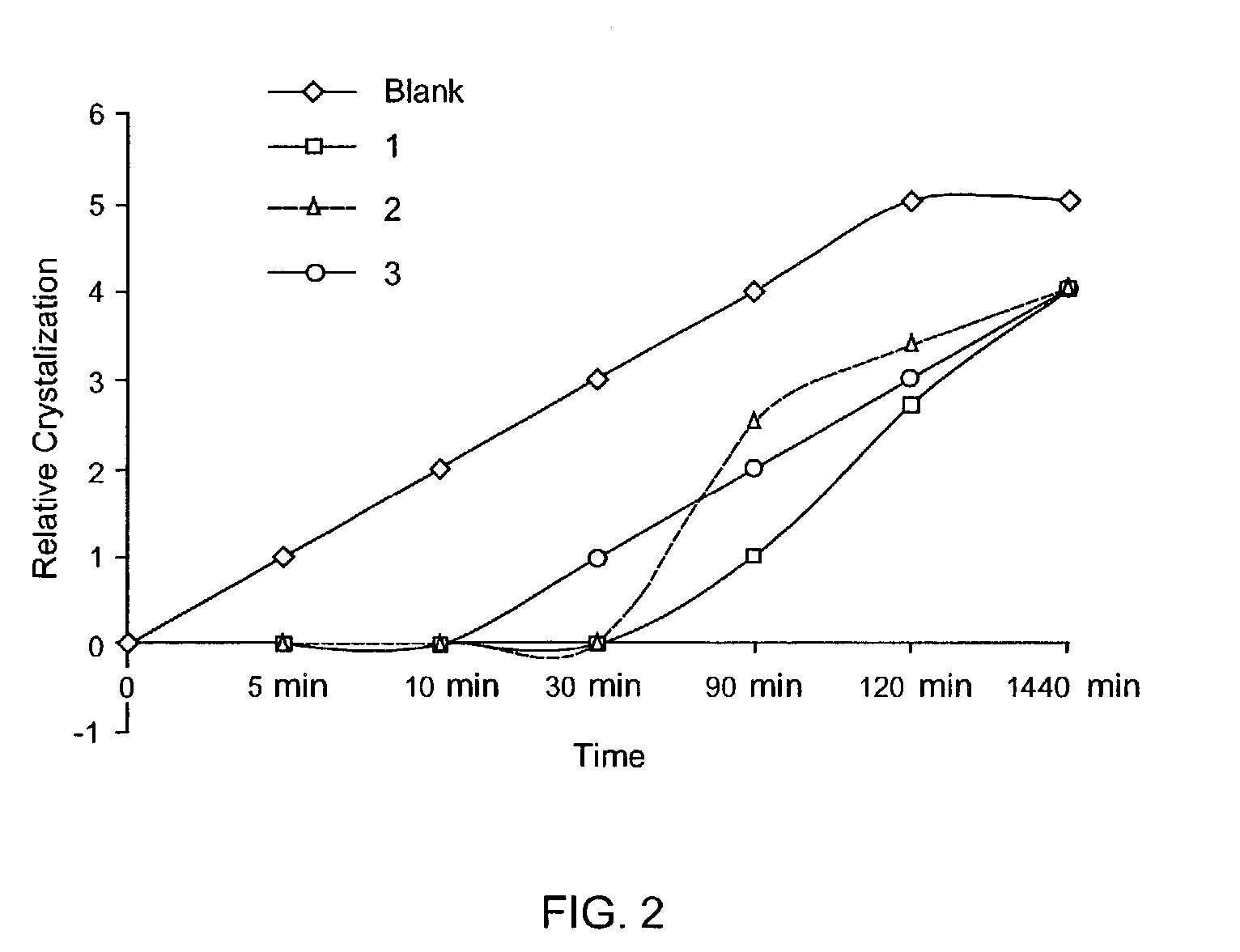

Crystals of laquinimod sodium, and process for the manufacture thereof

InactiveUS7884208B2High purityImprove crystallization propertiesBiocideNervous disorderImpurityLaquinimod Sodium

Disclosed is a process for the preparation of laquinimod sodium which removes the impurities after the salt formation step, thus resulting in crystals of higher purity as well as crystals having improved crystalline characteristics.

Owner:TEVA PHARMA IND LTD

Preparation method of temperature-resistant and salt-tolerant nano oil displacement agent

ActiveCN103725278AWon't fall offImprove performanceMaterial nanotechnologyDrilling compositionActive agentSurface-active agents

The invention provides a preparation method of a temperature-resistant and salt-tolerant nano oil displacement agent. The preparation method comprises the following steps: modifying polyacrylamide to surfaces of silica nanoparticles through chemical bonds to obtain nano-composite particles with stable performance, and then using the nano-composite particles together with alkali and a surfactant to prepare the nano oil displacement agent. The nano oil displacement agent can solve the problem about high possibility of falling off of a polymer on the surface of a traditional nano oil displacement agent in the formation moving process, so as to achieve an excellent oil displacement effect. Especially in the high-temperature and high-salt formation, the nano oil displacement agent can overcome harsh formation conditions and cannot reduce the oil displacement effect.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

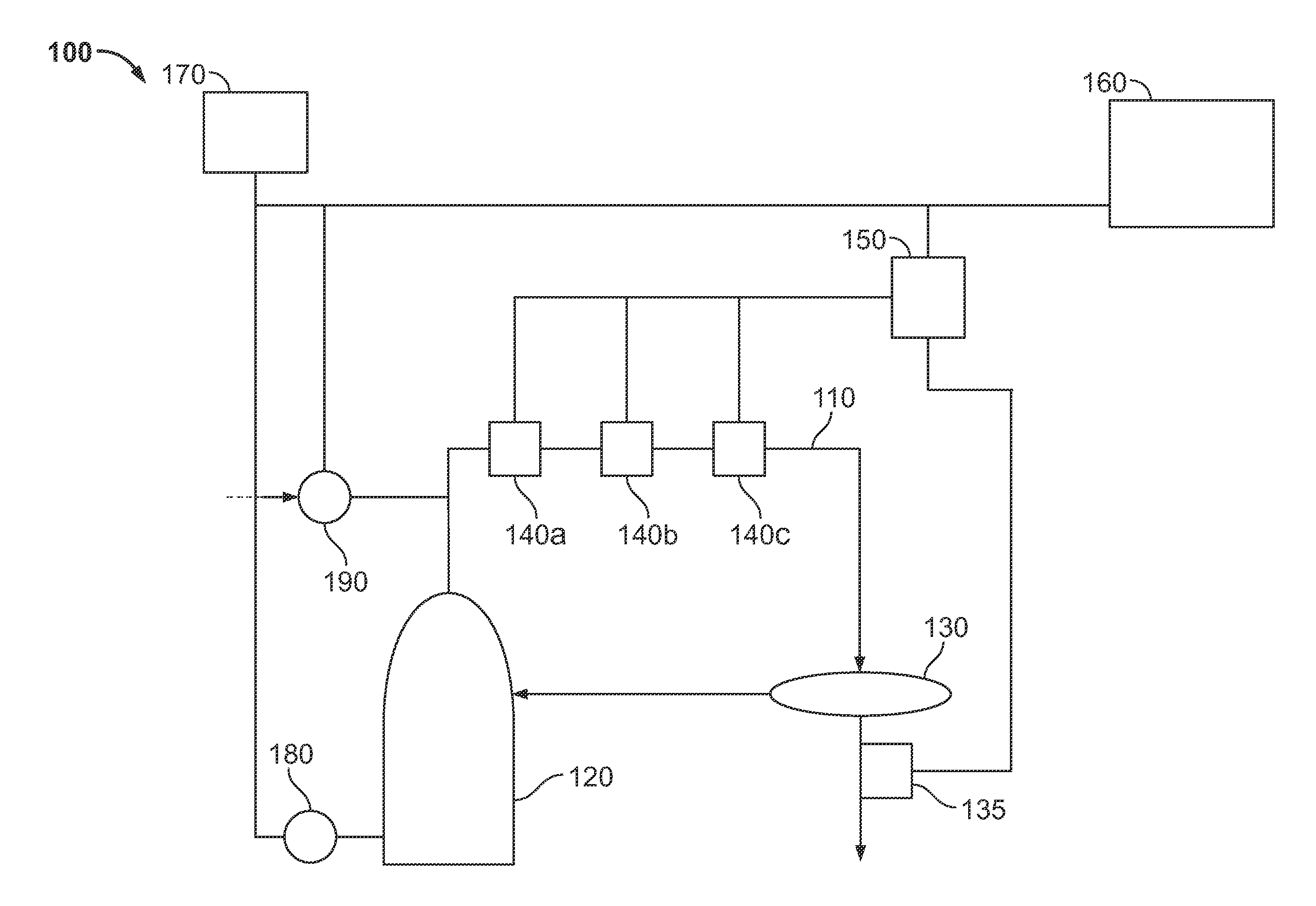

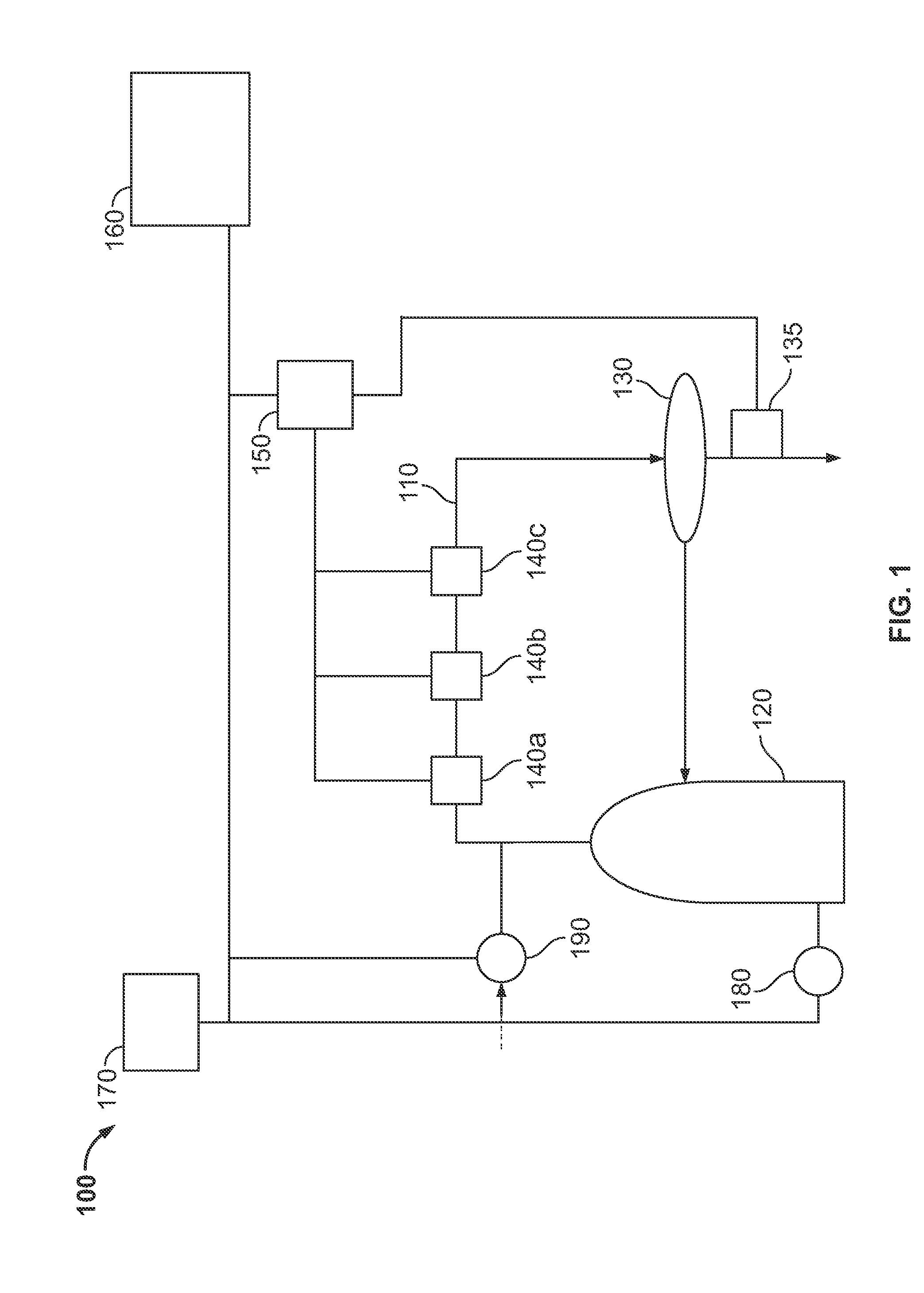

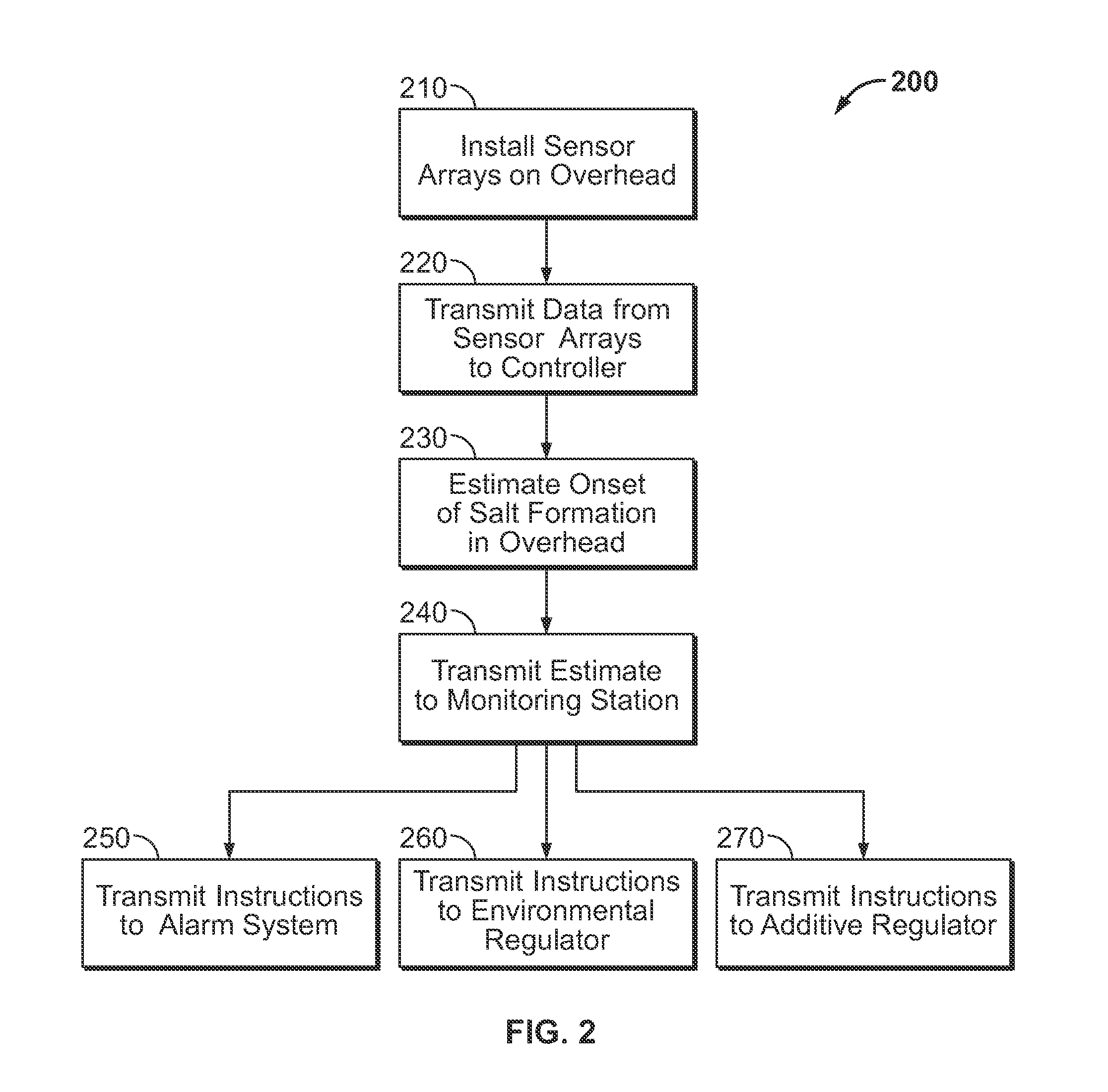

On-line monitoring and prediction of corrosion in overhead systems

InactiveUS20120053861A1Flow propertiesFluid pressure measurement by mechanical elementsSensor arrayDistillation

The present disclosure describes a method and system for estimating the onset of salt formation in an overhead fluid system. The method may include measuring parameters of a process stream by collecting data from one or more sensor arrays on an overhead line, such as from a distillation column, and then estimating the onset of salt formation corrosion using the data from the sensor arrays. The method may be implemented in real-time. The method may include transmitting data to monitoring facilities and / or sending instructions to alarms and / or regulators. Also described is a system for performing the method.

Owner:BAKER HUGHES INC

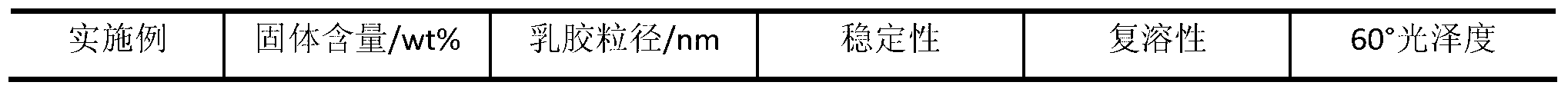

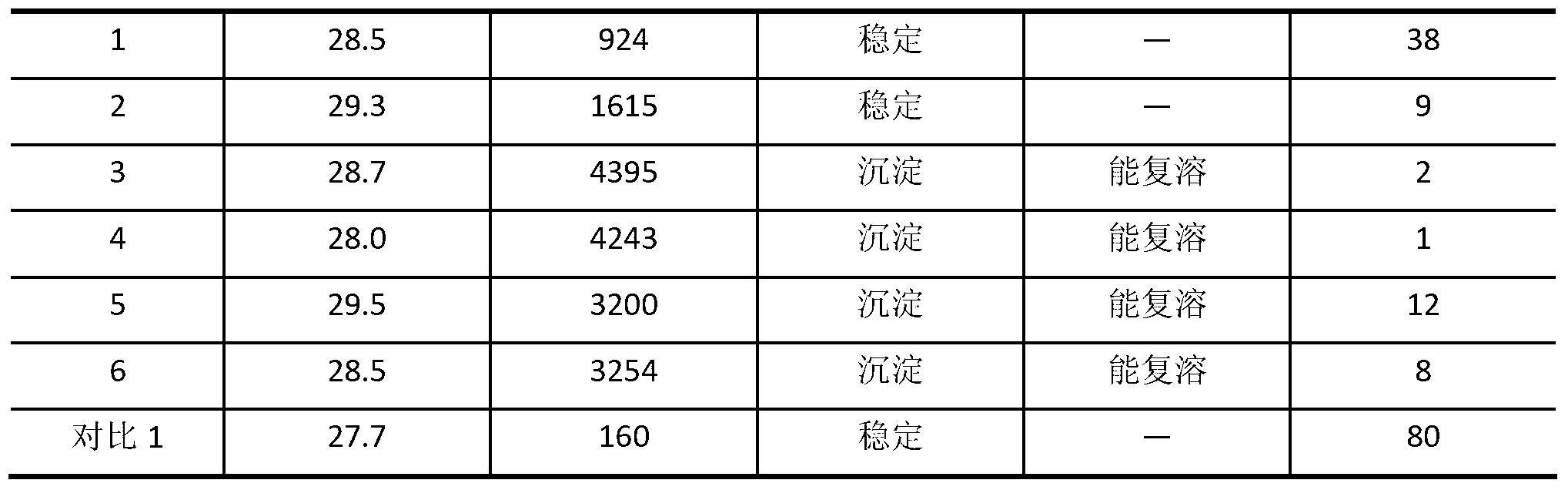

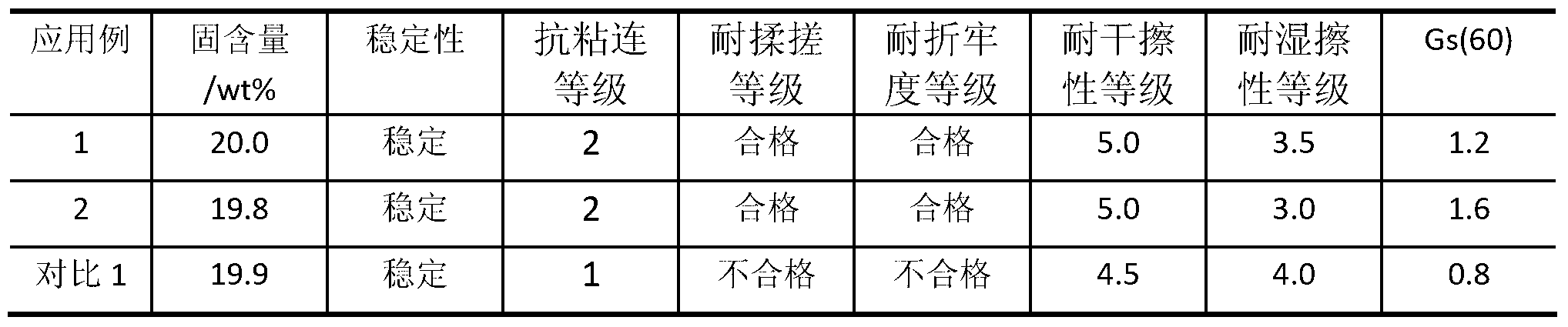

Low-luster aqueous polyurethane dispersion for leather, and preparation method and application thereof

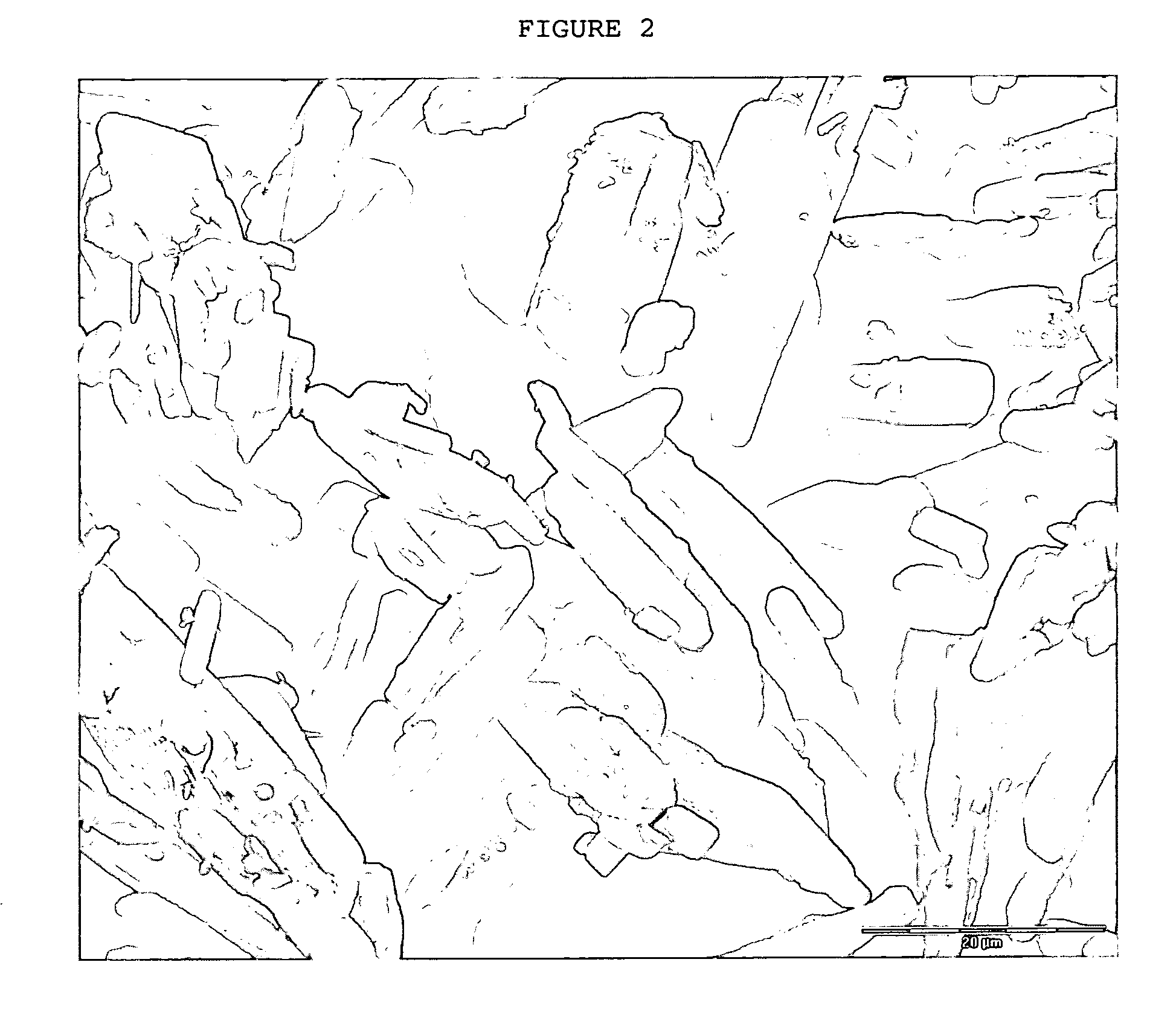

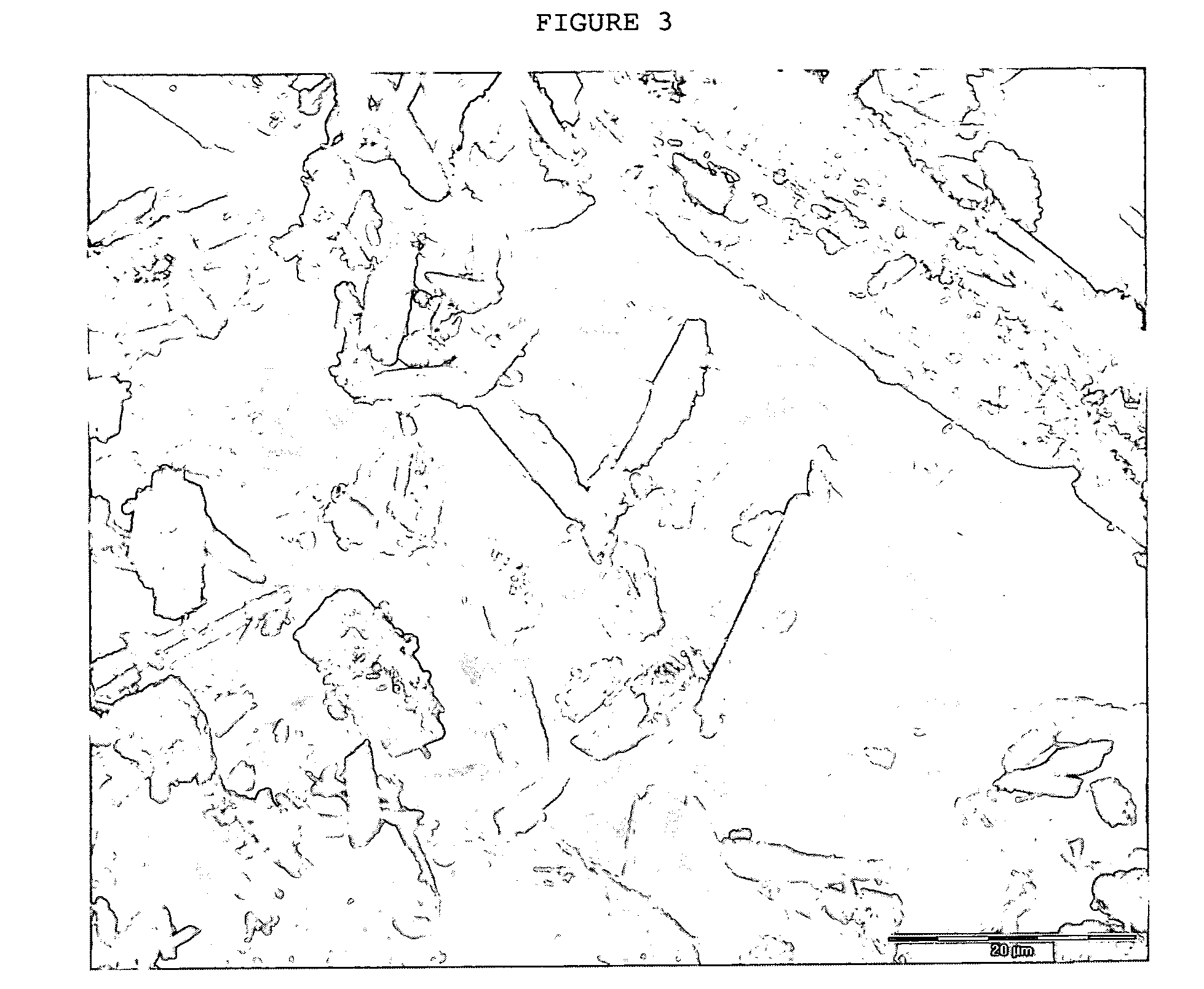

ActiveCN103319682AIncreased micro-roughnessTo achieve the purpose of natural extinctionFibre treatmentPolyurea/polyurethane coatingsPolyurethane dispersionSurface finish

The invention discloses a low-luster aqueous polyurethane dispersion for leather, and a preparation method and an application thereof. The preparation method comprises the following steps: dehydrating aliphatic polymeric diol and dihydroxymethylpropionic acid, cooling to 60-80DEG C, and adding an organic bismuth catalyst and diisocyanate for a prepolymerization reaction; neutralizing by a neutralizing agent for salt formation; carrying out emulsification and chain extension in a sodium sulfamate chain extender; and completely reacting isocyanate residual in the dispersion with the an added hydrazine chain extender to obtain the aqueous polyurethane dispersion having a solid content of 25-35wt% and an average emulsion particle size of 180-5000nm. A low luster film effect can be obtained through the dispersion. The low luster effect of the polyurethane dispersion is completely generated through a film forming resin, so the polishing resistance of a low luster surface is improved, thereby the dispersion is especially suitable for the formulas of surface mist-surface finishing agents for frequently bent scratched and tensioned vamp leather, clothing leather and automobile interior decorations.

Owner:清远市美佳乐环保新材股份有限公司 +1

Compositions containing alpha -sulfofatty acid esters and methods of making and using the same

InactiveUS6057280AInhibition formationAccelerate and increase di-salt formationAnionic surface-active compoundsCoated detergent compositionsMedicinal chemistrySalt formation

The invention includes compositions containing one or more alpha -sulfofatty acid esters, and methods for making and using the same. At least one alpha -sulfofatty acid ester is included in an inner portion. The invented composition can further include an outer portion which protects the alpha -sulfofatty acid ester from di-salt formation. The resulting composition improves the stability of the alpha -sulfofatty acid ester after manufacture, during shipping and storage, and in detergents. The invention further included detergents containing the invented composition, and methods of making such detergents.

Owner:HENKEL IP & HOLDING GMBH

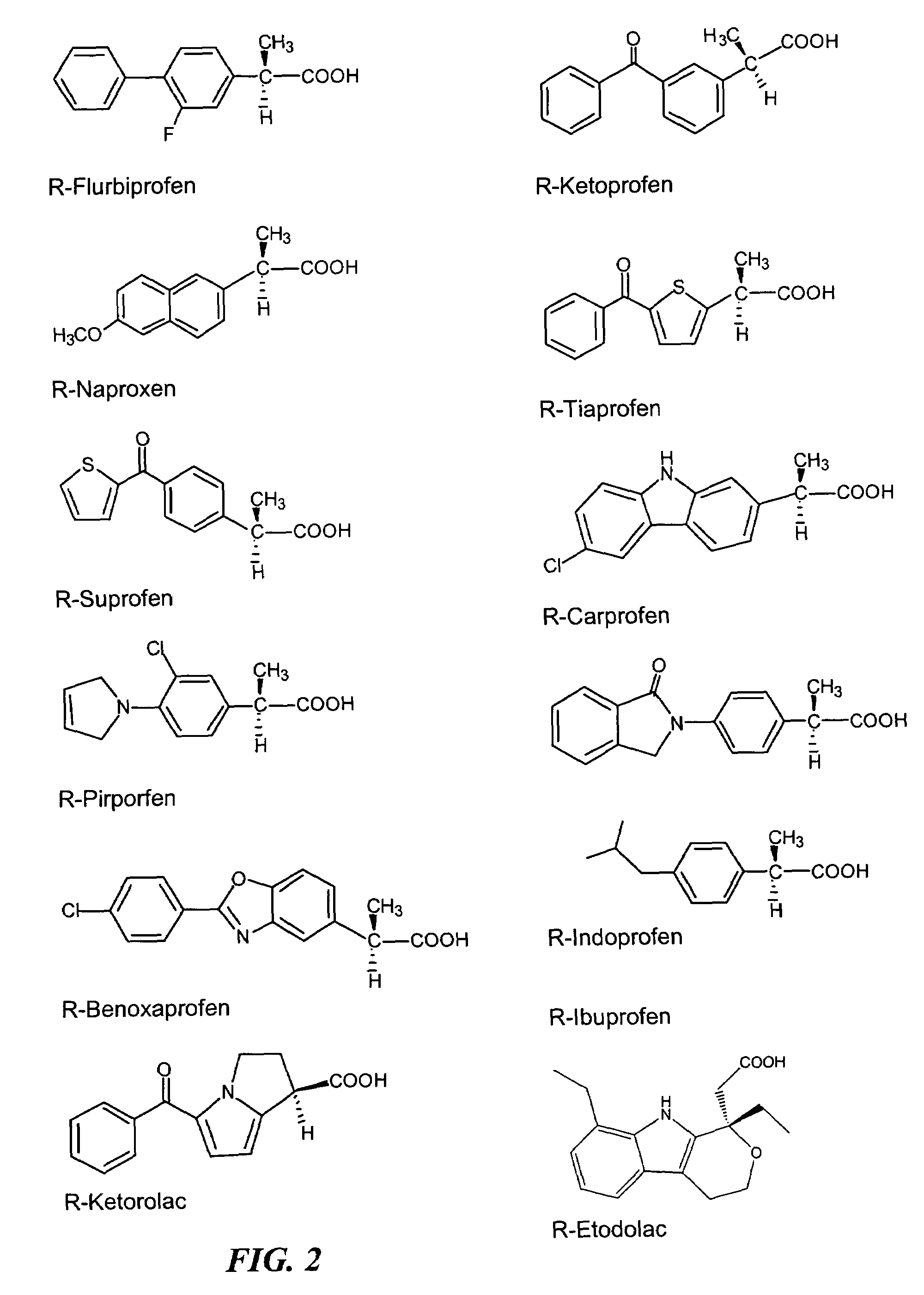

R-NSAID esters and their use

The present invention concerns esters of R-enantiomers of a non-steroidal anti-inflammatory drug, which is substantially free from the S-enantiomer. The compounds of the invention may be used in treating a disease or illness in a mammal. To this end, a composition comprising a compound mentioned above, or a pharmaceutically acceptable salt thereof where salt formation occurs, is administered to the mammal in an amount sufficient to elicit a chemopreventative effect or a chemoprotective effect or a therapeutic effect or a prophylactic effect.

Owner:ENCORE PHARMA

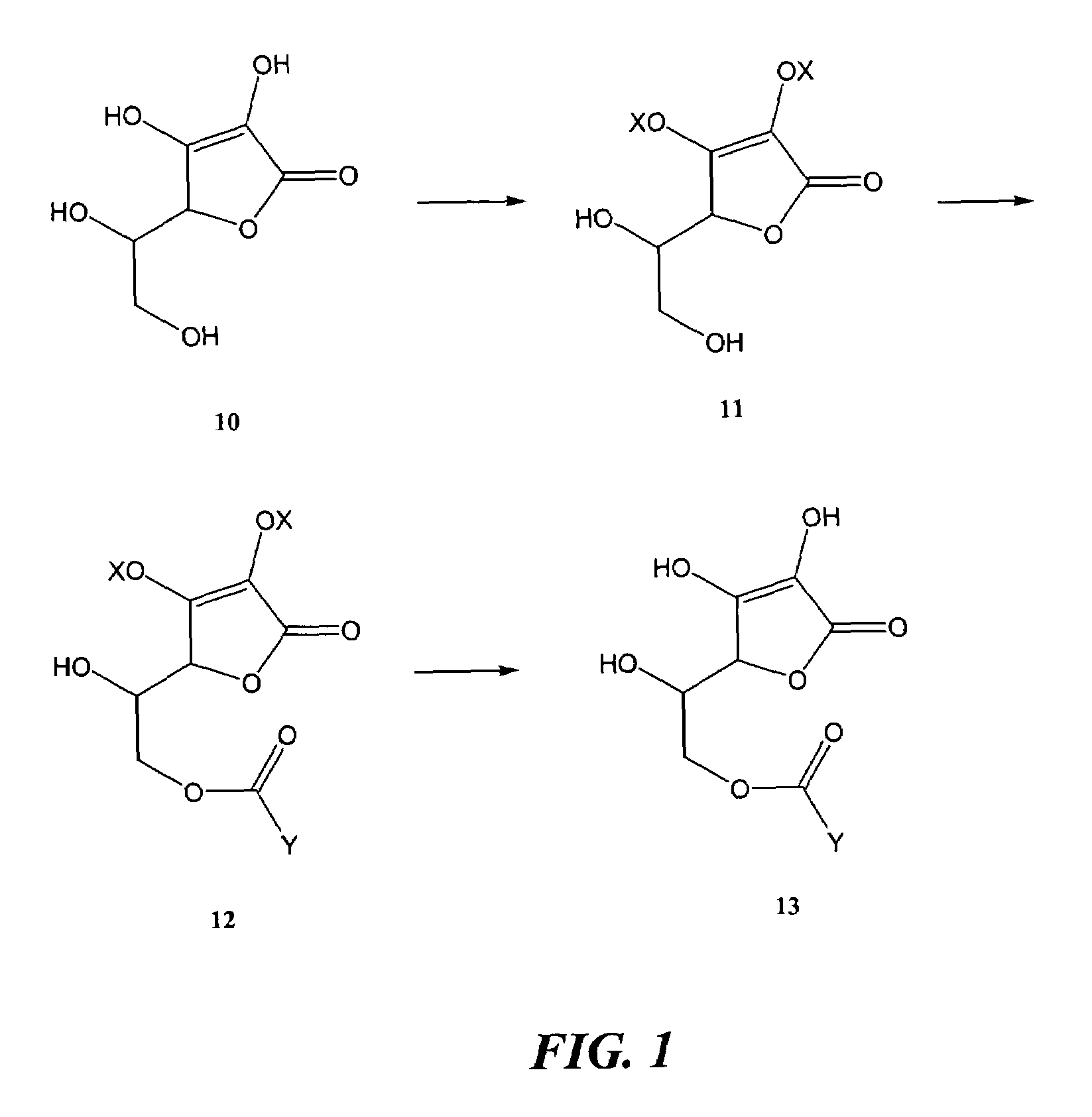

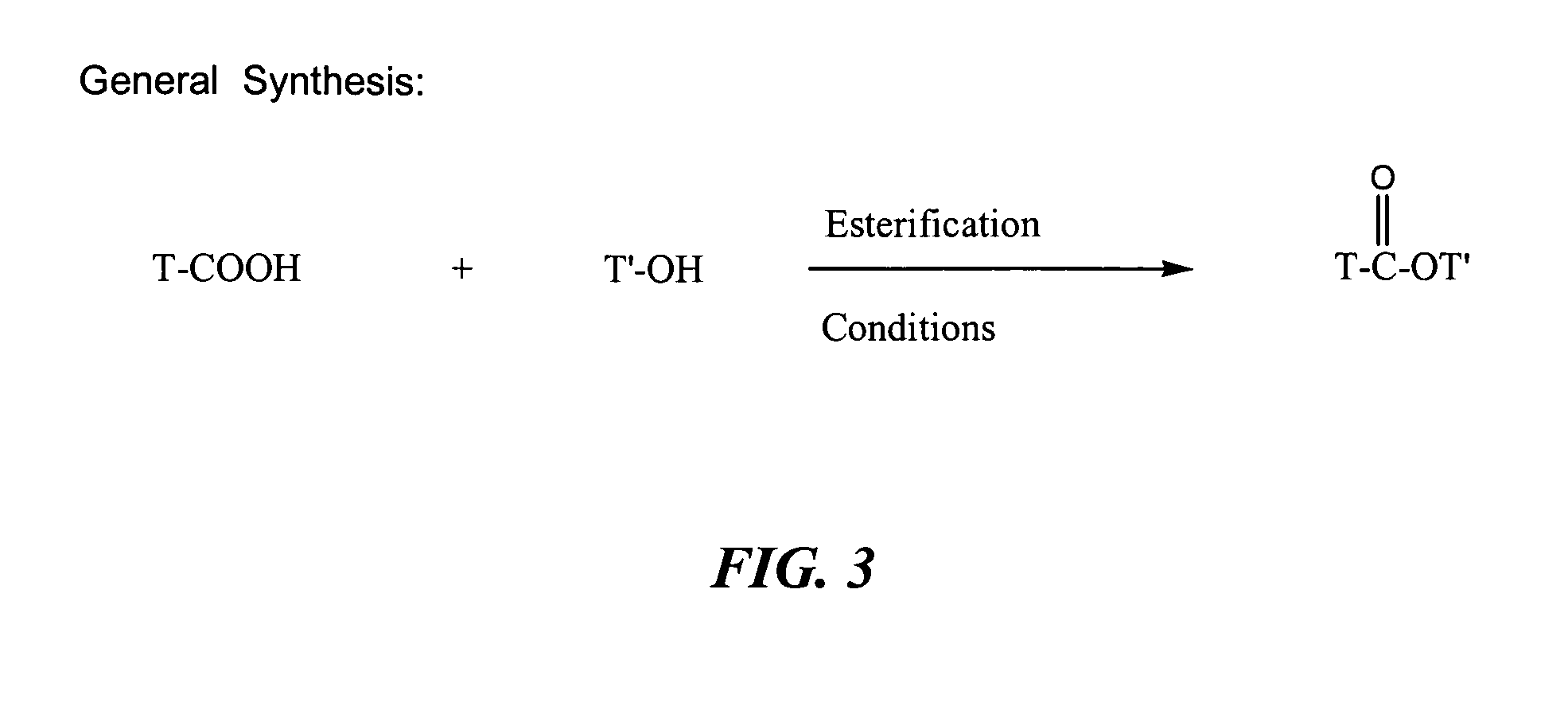

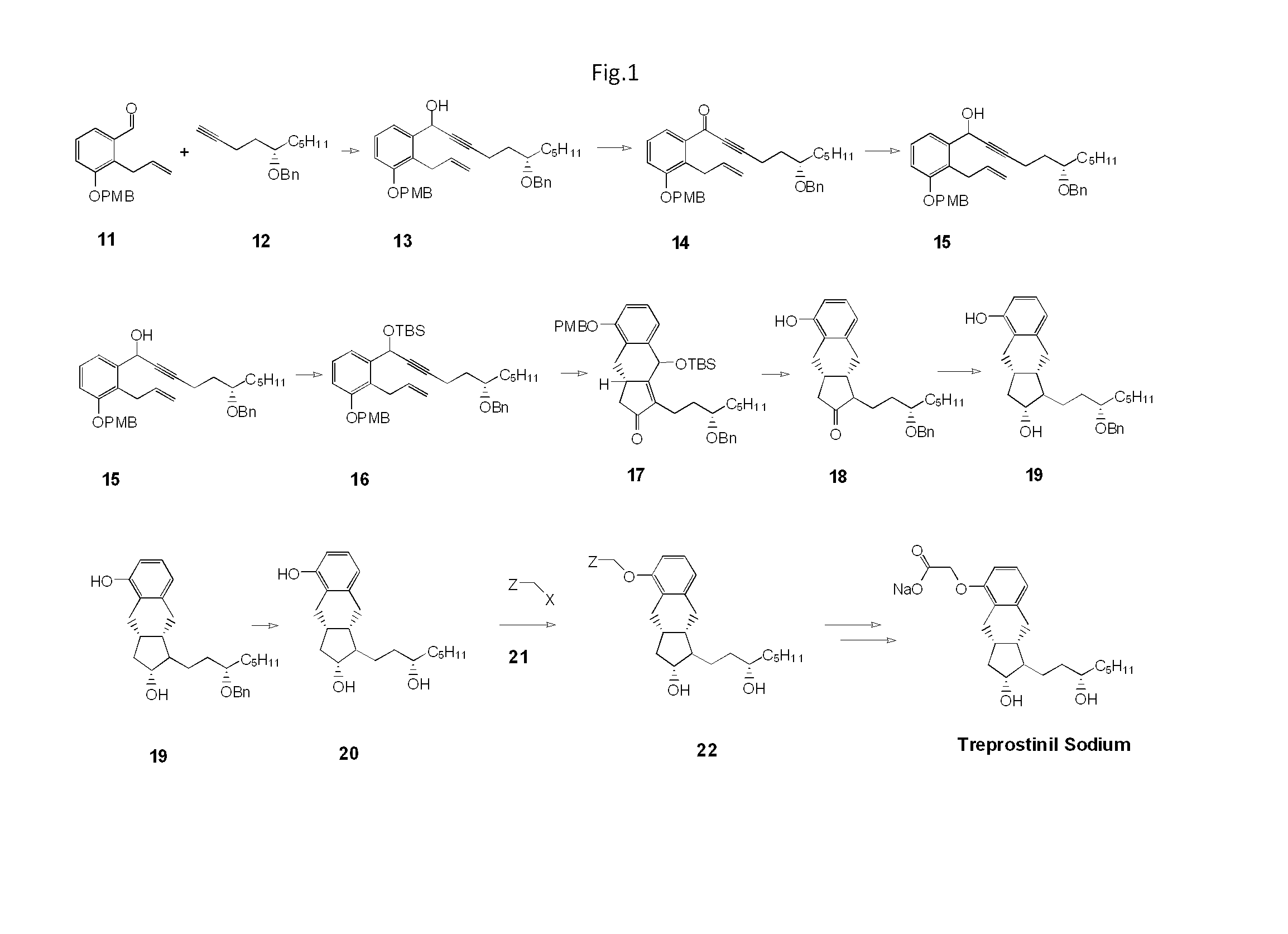

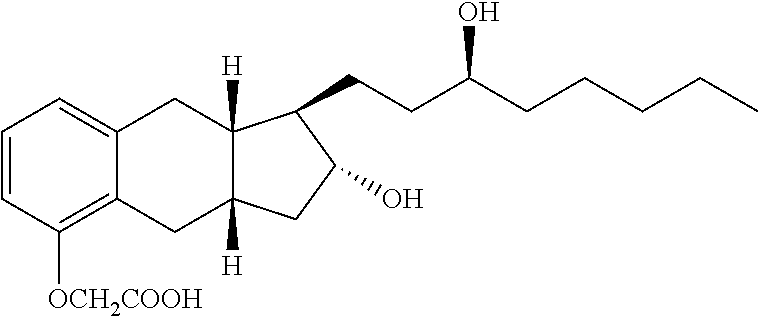

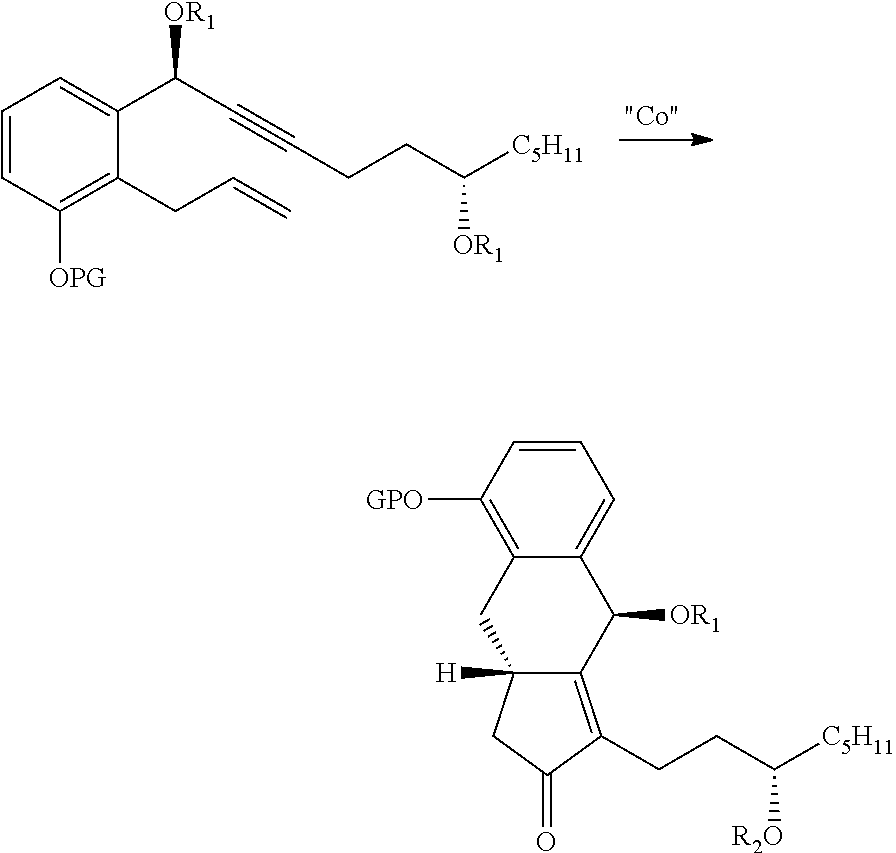

Synthesis Of Treprostinil And Intermediates Useful Therein

InactiveUS20130331593A1Enhanced chromatographic propertyGood flexibilitySilicon organic compoundsOrganic compound preparationAlkyneHydrolysis

Treprostinil is prepared by a process which involves Pauson-Khan cyclization of an an alkene-substituted, alkyne-substituted benzene corresponding to formula: (I) where PMB represents para-methoxy benzyl protecting group and R1 and R2 are alcohol protecting groups. Following cyclization, the resulting compound can be subjected to several chemical trans-formations followed by alkylation, hydrolysis and salt formation to yield treprostinil sodium. The use of para-methoxybenzyl group as the phenolic protecting group confers several process advantages that result in simplified purification of the final product and improved yields.

Owner:EON LABS

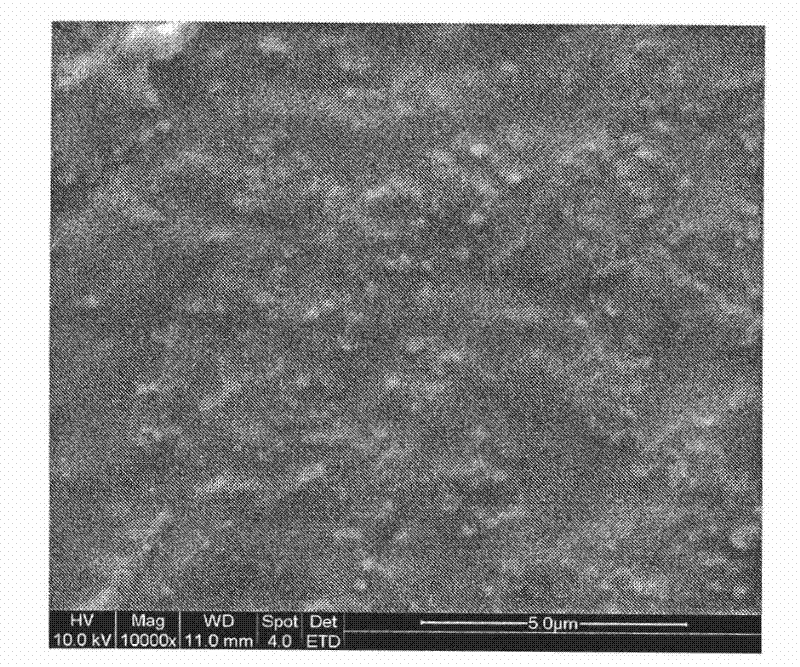

Preparation method of ultraviolet cured silica sol modified aqueous urethane acrylate dispersoid

InactiveCN101747487AExpand particle size rangeLarge particle size rangePolyurea/polyurethane coatingsUltravioletSilica gel

A preparation method of ultraviolet cured silica sol modified aqueous urethane acrylate dispersoid belongs to the technical field of ultraviolet cured aqueous paint. The preparation method of the invention comprises: mainly using diisocyanate compounds, polyether polyol, polyhydroxycarboxylic acid and hydroxyl acrylate monomer as main raw materials to prepare a urethane acrylate prepolymer through an acetone process; adding amine compounds and water for salt formation and emulsification, introducing aqueous silicon dioxide sol in the emulsification process to obtain the ultraviolet cured silica sol modified aqueous urethane acrylate dispersoid. The invention introduces the aqueous nanometer-sized silicon dioxide in situ in the synthesis of the aqueous urethane acrylate dispersoid to obtain the silica sol modified aqueous urethane acrylate dispersoid. The introduction of the inorganic nanometer-sized silicon dioxide obviously improves the mechanical property of a light-cured coating. The dispersoid can be widely applied to the surface coating field of woodware, metal and plastic rubber and the like with high scratch resistance and wearing resistance.

Owner:JIANGNAN UNIV

Crystals of laquinimod sodium, and process for the manufacture thereof

InactiveUS20070088050A1High purityImprove crystallization propertiesBiocideNervous disorderMedicinal chemistryImpurity

Disclosed is a process for the preparation of laquinimod sodium which removes the impurities after the salt formation step, thus resulting in crystals of higher purity as well as crystals having improved crystalline characteristics.

Owner:TEVA PHARMA IND LTD

Method for preparing water-base cation blocked polyisocyanates crosslinking and curing agent

The invention discloses a method for preparing a water-base cation blocked polyisocyanates crosslinking and curing agent. Firstly, under the action of cosolvent and catalyst respectively with an appropriate amount, at a certain temperature, micromolecular trifunctional polyhydroxy compound is slowly dripped into a polyisocyanates system so as to prepare a self-crosslinking prepolymer; cation hydrophilic chain extender and other diatomic alcohol-type or diamine-type chain extenders are introduced onto a main molecular chain; and light-yellow transparent liquid can be obtained by adding a mixture consisting of blocking agent and water after the salt-formation resulted from the neutralization of acid salt forming agent. The method has simple process and is environment-friendly. The crosslinking and curing agent can be widely used in a plurality of fields such as the adhesive field, the coating field, and the like and can bring the outstanding performance thereof into full and effective play after the deblocking.

Owner:WUJIANG HUIFENG MATERIAL TECH

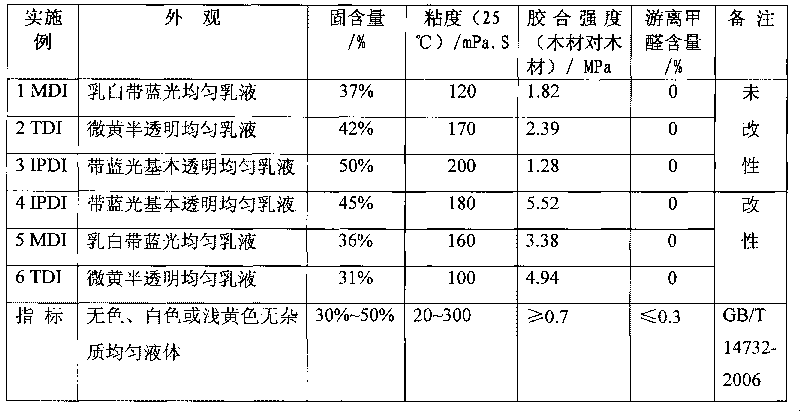

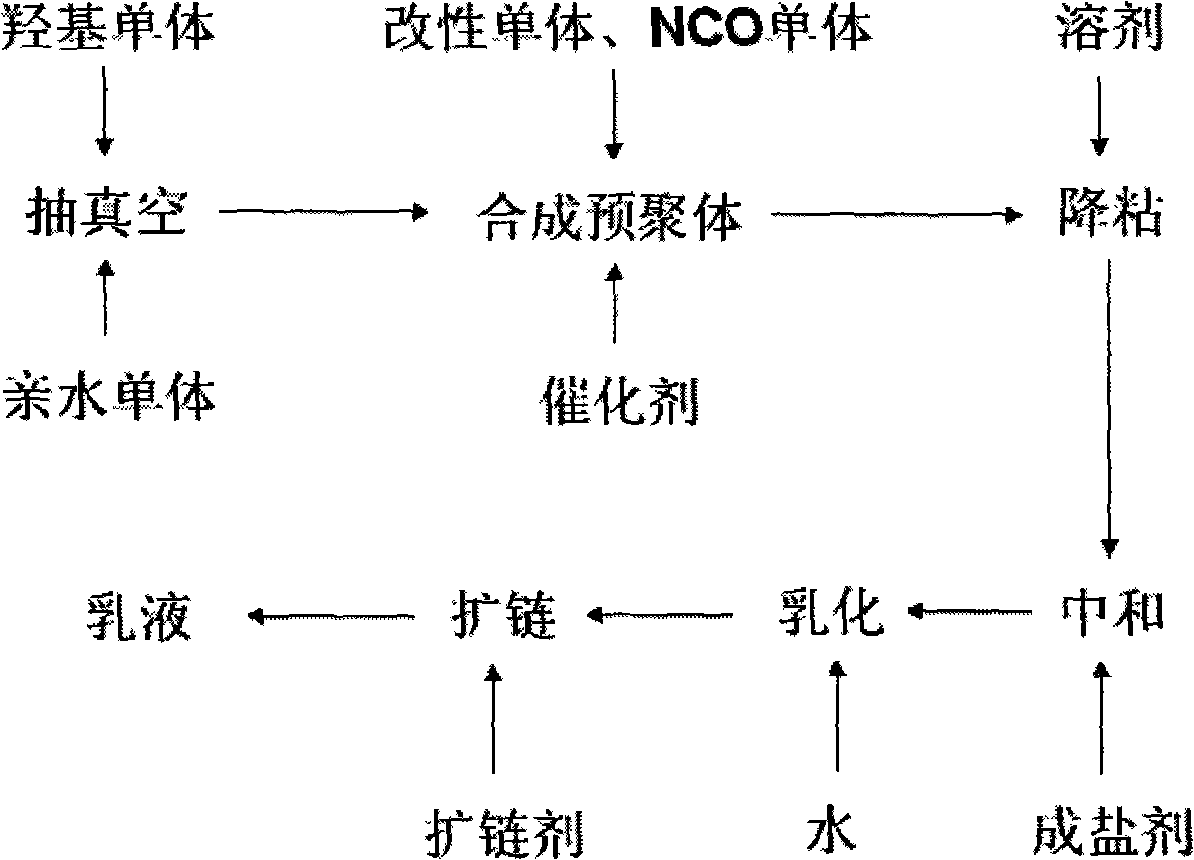

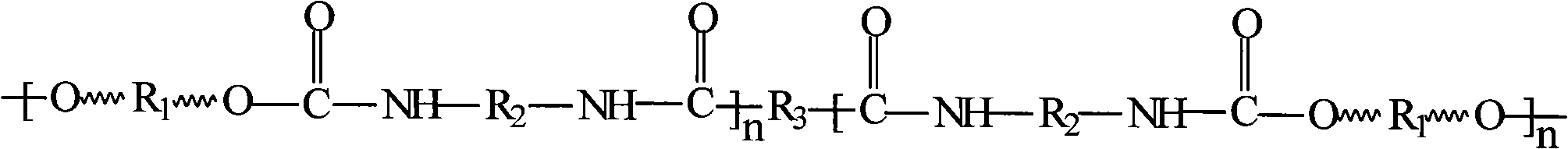

Preparation method and application in wood processing of water-based polyurethane adhesive

InactiveCN101701140ALow viscosityImprove performancePolyureas/polyurethane adhesivesWater basedHydrophilic monomer

The invention relates to a water-based polyurethane adhesive, in particular to a preparation method of a water-based polyurethane adhesive used in the wood processing. The preparation method comprises three stages, wherein the first stage is stepwise polymerization, namely polyol oligomer, hydrophilic monomer, isocyanate and modified monomer are adopted to prepare modified polyurethane prepolymer through stepwise polymerization and radical polymerization; the second stage is to disperse the modified polyurethane prepolymer in water after neutralization and salt formation; the third stage is to add chain extender to form water-based polyurethane emulsion, wherein the R value of the modified polyurethane prepolymer is 1.02-2.0 and R value refers to the ratio of the total mole number of NCO to the total mole number of OH in the system, the synthesis conditions are as follows: the vacuum degree is 0.090-0.1MPa, the polymerization temperature is 65-90 DEG C, the polymerization reaction time is 2-4h, the neutralization temperature is 40-60 DEG C and the solid content is 20-50%. The preparation method of the invention adopts proper amount of modified monomer to graft and crosslink with polyurethane so as to obviously increase the water resistance, solvent resistance and bonding strength, thus optimizing the product performance.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

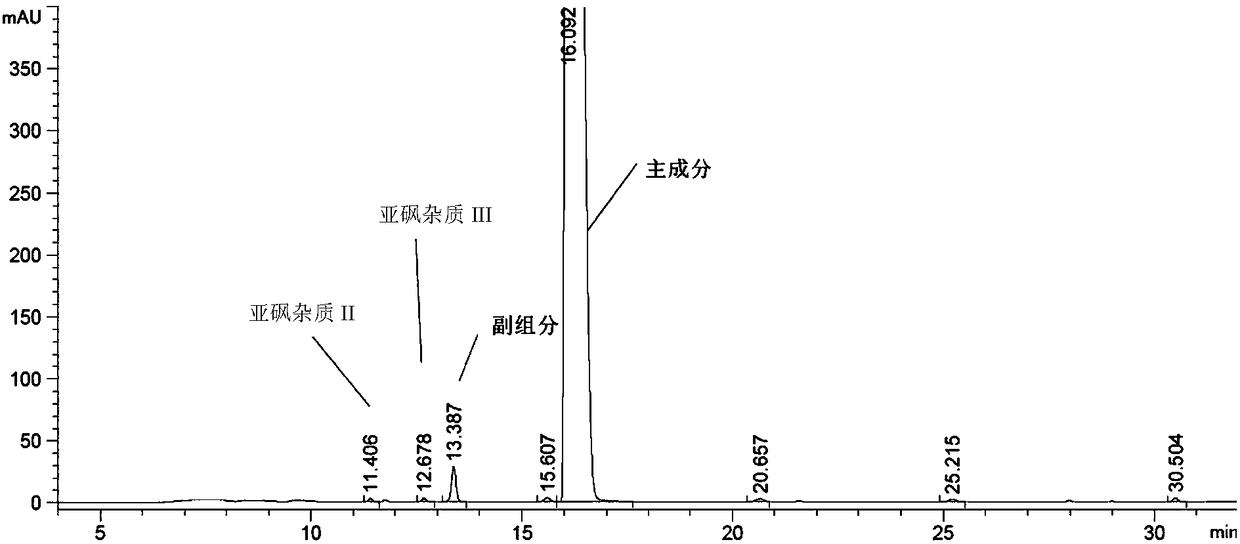

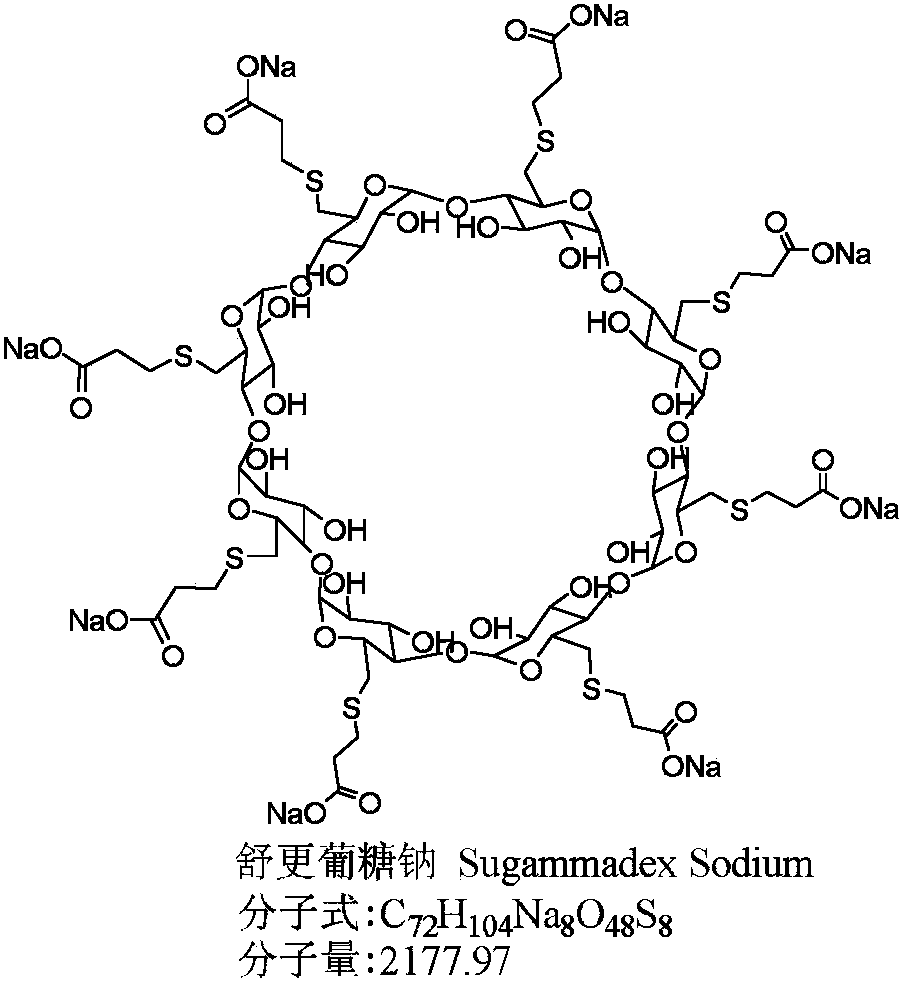

Method for purifying sugammadex sodium

ActiveCN109021147AGood purification effectGood for maintaining stabilityOrganic active ingredientsMuscular disorderPurification methodsImpurity

The invention discloses a method for purifying sugammadex sodium. The method is characterized in that a sugammadex sodium crude product is subjected to dissociation in an organic acid-organic alkali-reducing agent mixture system into sugammadex acid, the free condition is mild, the product stability is high, and the purification effect of the sugammadex acid is better, and after further recrystallization purification and salt formation, the high-purity sugammadex sodium can be obtained. Both the dissociation and recrystallization steps of the purification method introduce a reducing agent so that the reaction system has oxidation resistance, and effectively controls the formation of oxidized impurities, the reagent is easy to obtain, and the operation is simple and safe, compared with theprior art, a large amount of activated carbon, multitime long-time dialysis and preparation of HPLC are employed, the sugammadex sodium is purified, the method is more suitable for industrial amplification, and provides bulk drugs of sugammadex sodium which can meet the purity requirements and impurity limitation for preparation production. The invention further discloses high-purity sugammadex sodium with content being more than 99.5% and single impurity of less than 0.1%, and a preparation and use thereof.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

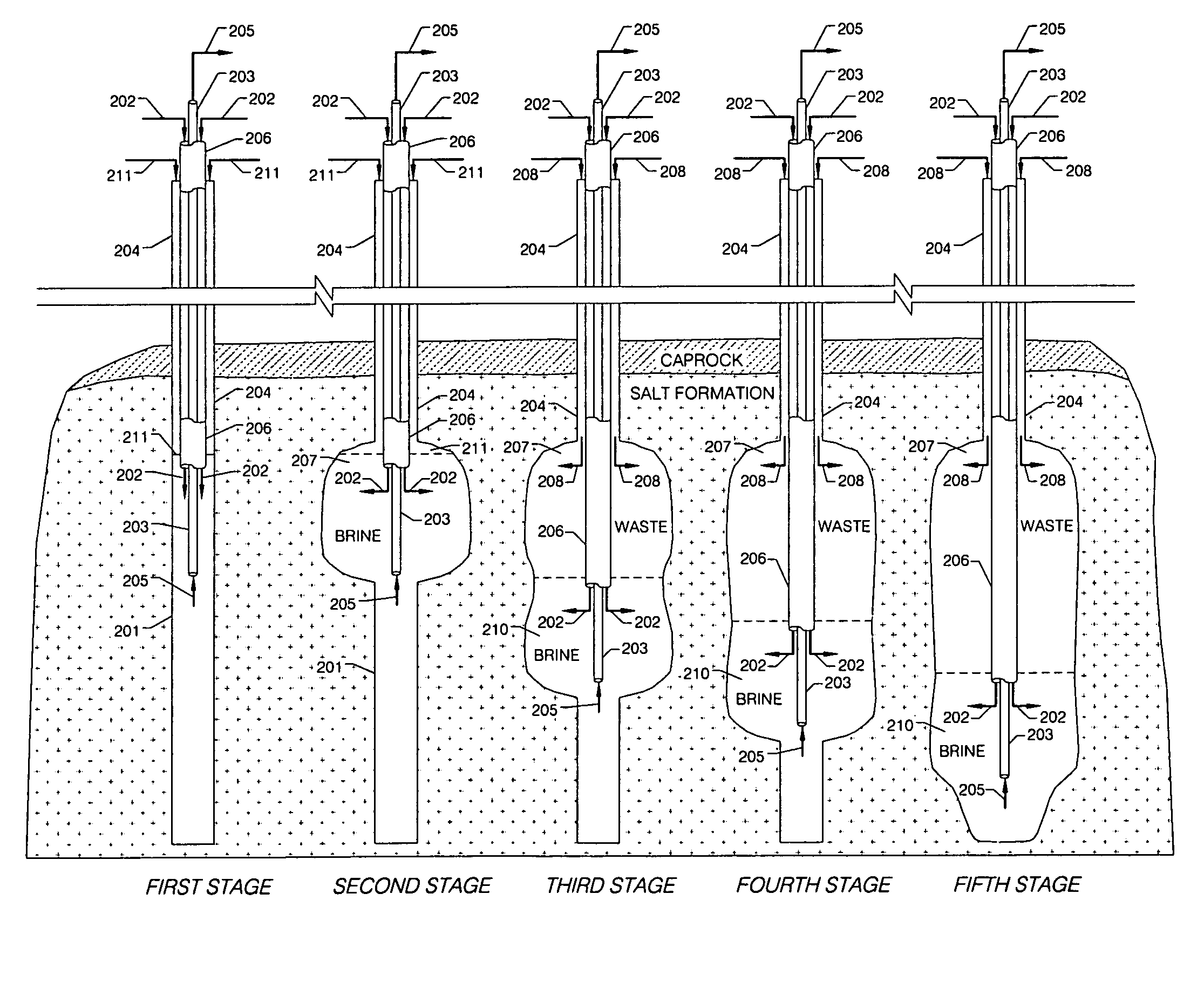

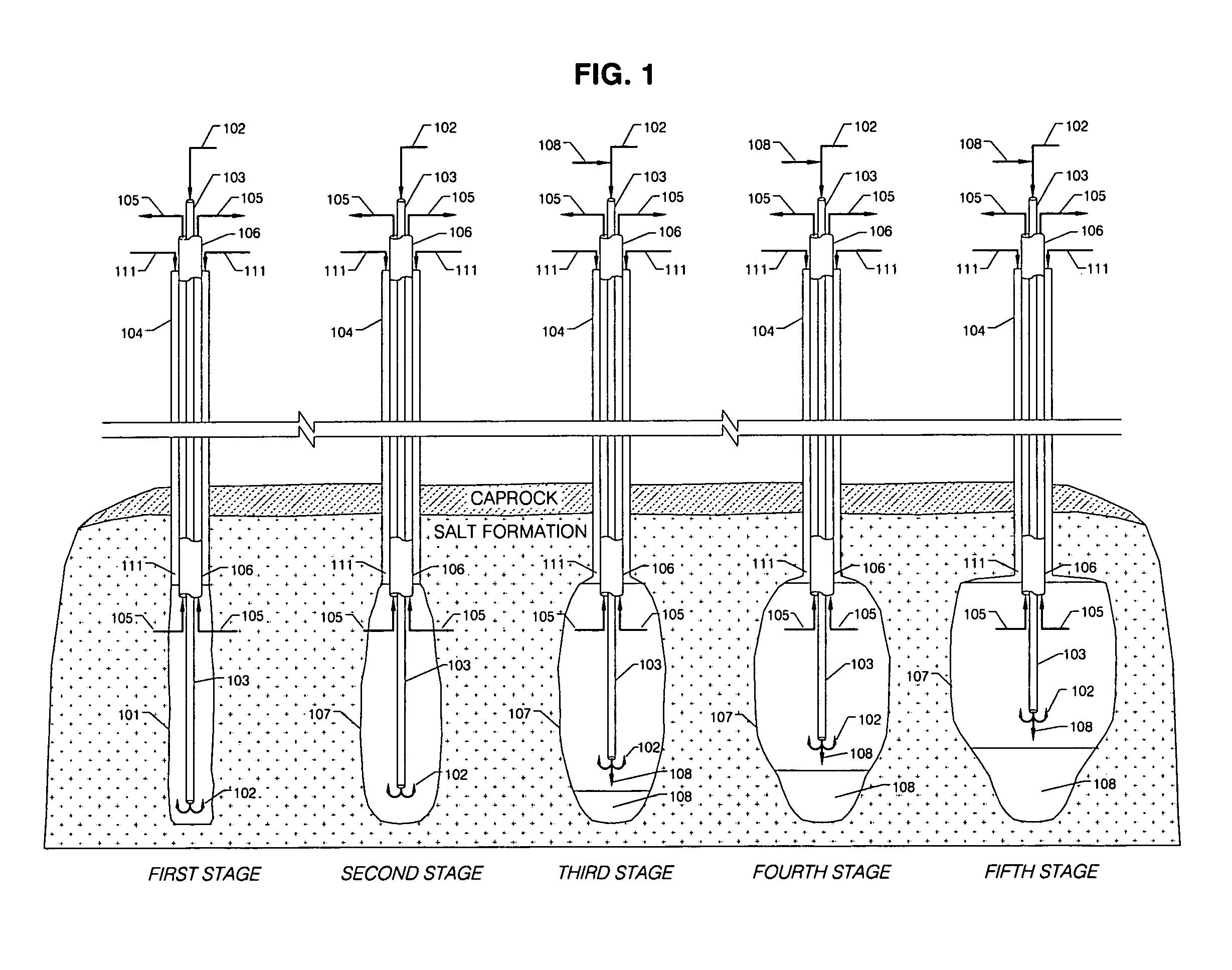

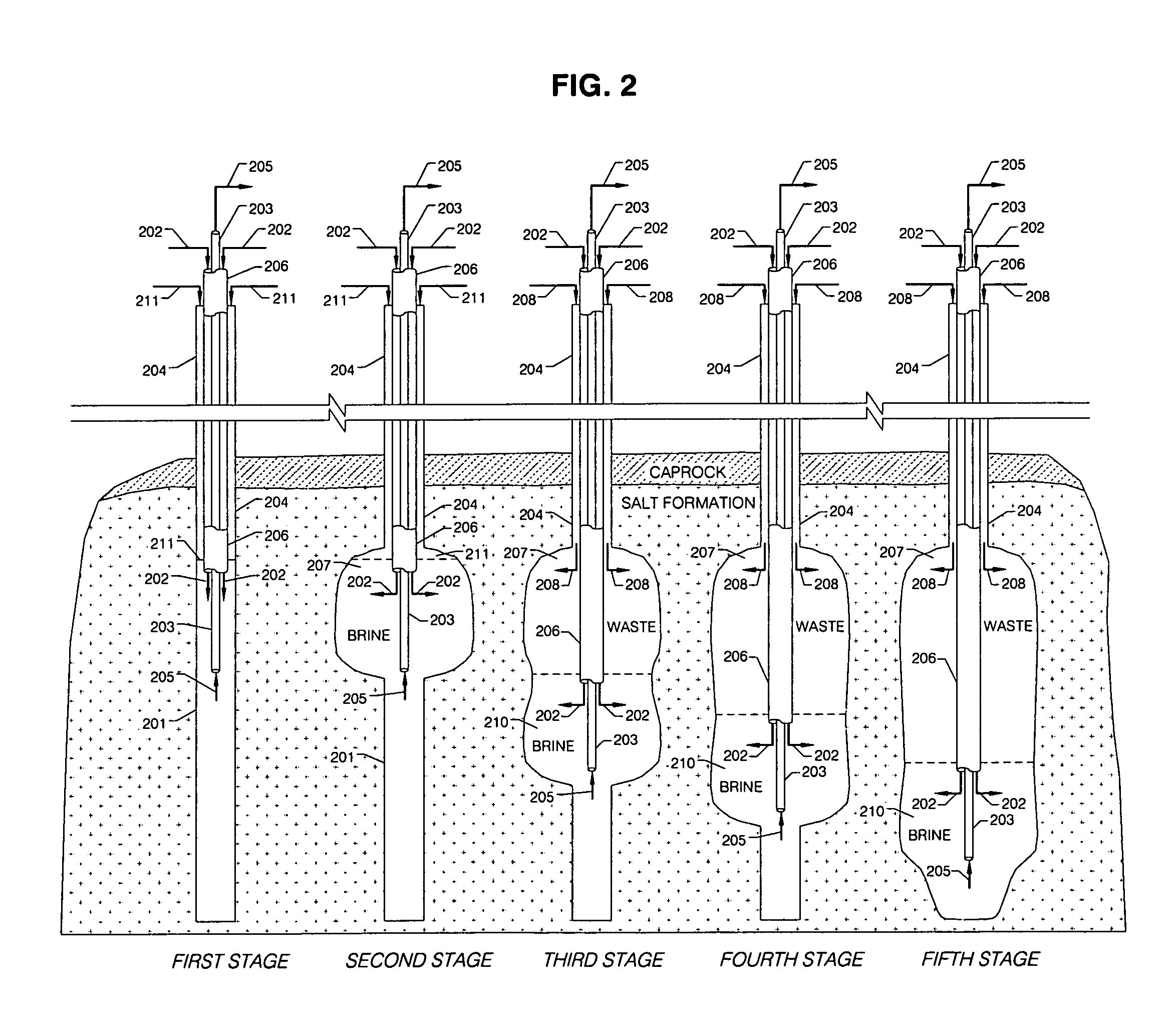

Simultaneous development of underground caverns and deposition of materials

A method is provided for simultaneously developing caverns while depositing wastes or other materials in them. A well is first drilled into a salt formation and the development of a salt cavern by means of solution mining is initiated. When the development of the cavern has been carried out to an extent sufficient to accommodate the injection of a prescribed amount of wastes or other materials, injection of the wastes or other materials through the well is started while continuing to develop the cavern by solution mining. The injection of the wastes or other materials may be carried out continuously or intermittently. The proportion and rates of wastes or other materials and mining water injected into the well are monitored and regulated so that cavern development continues at a rate that allows the cavern to reach an intended prescribed size while the wastes or other materials are injected and deposited into the cavern.

Owner:MPEH LLC

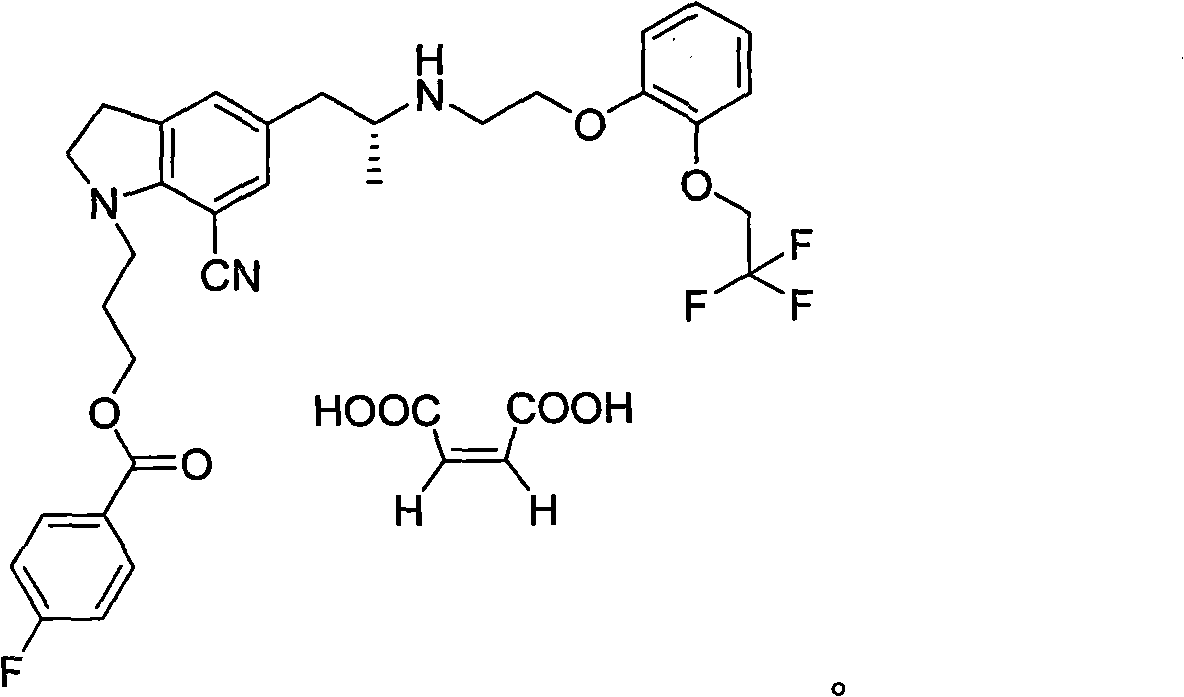

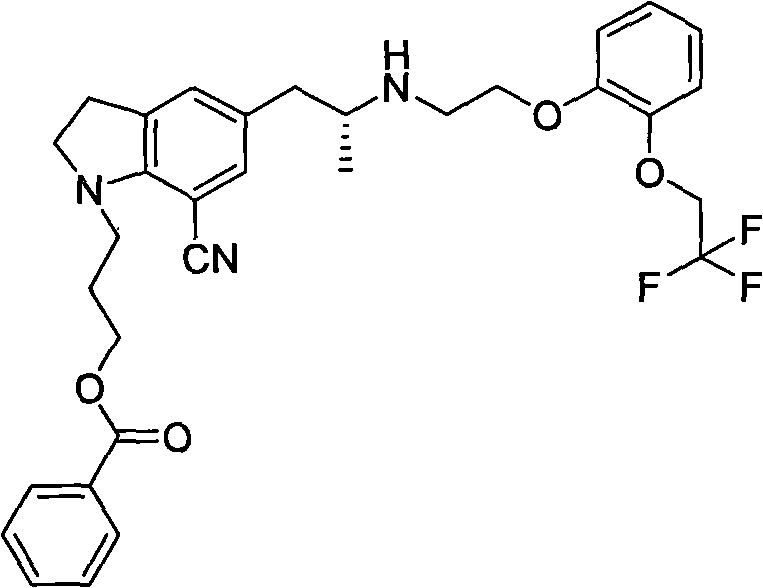

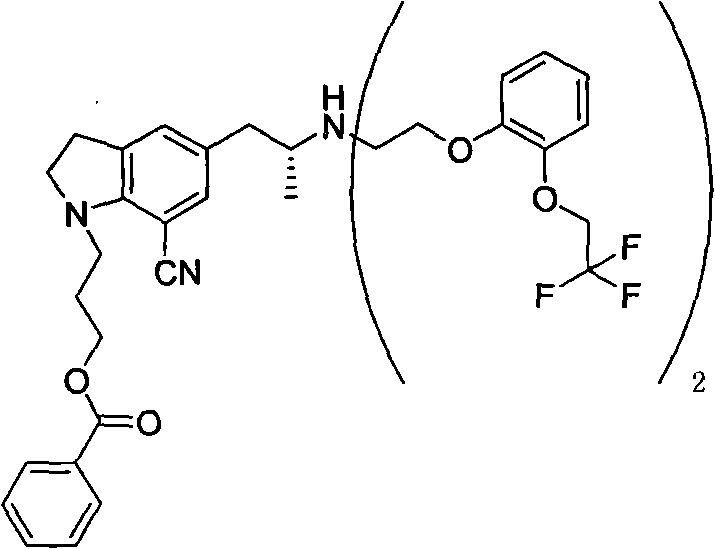

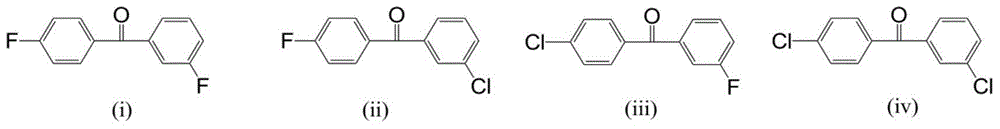

Preparation method of salt formation of silodosin intermediate

The invention relates to a method of maleate formation of a silodosin intermediate indoline compound 1 - (3 - (4 - fluoro benzoyl) hydroxypropyl) -5 - ((2R) -2 - (2 - (2 - (2,2,2 - trifluoroethoxyl) phenoxy) ethylamine) propyl) indoline -7 - cyano (compound (1)), i.e., a crude product of the compound (1) forms a salt with maleic acid in a mixed solvent of a good solvent and a poor solvent. The maleate of the compound can be stably obtained by the method, and the method has the advantages of good impurity removal effect, stable process, high yield, simpleness in operation and the like.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD

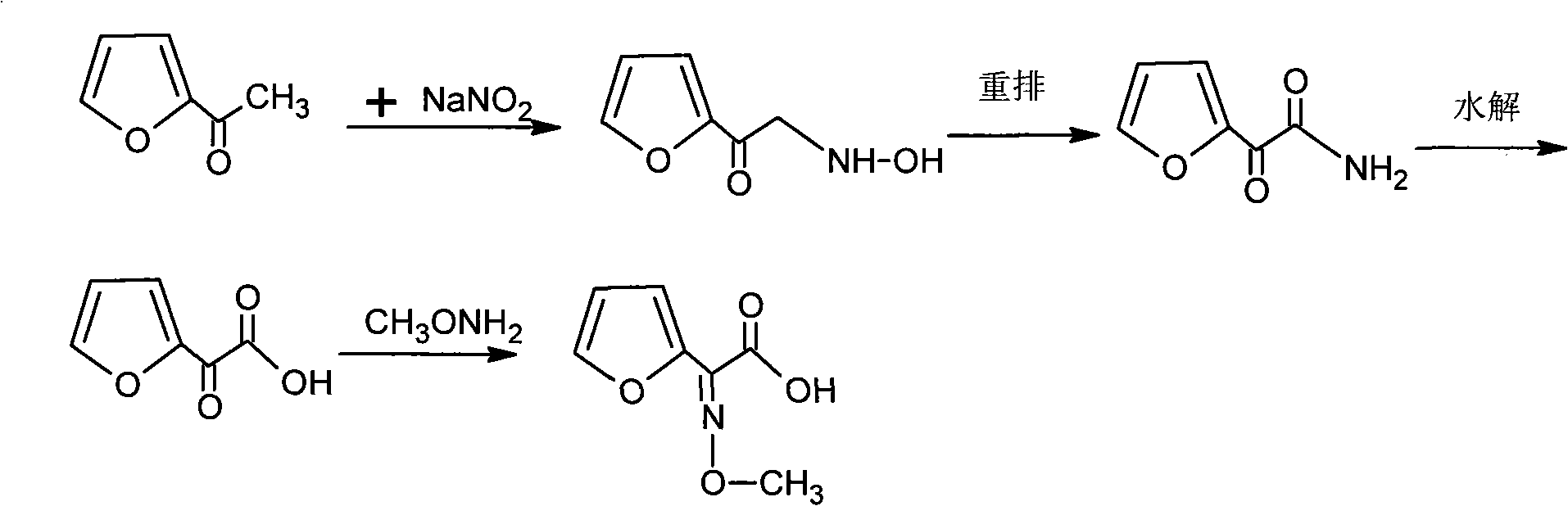

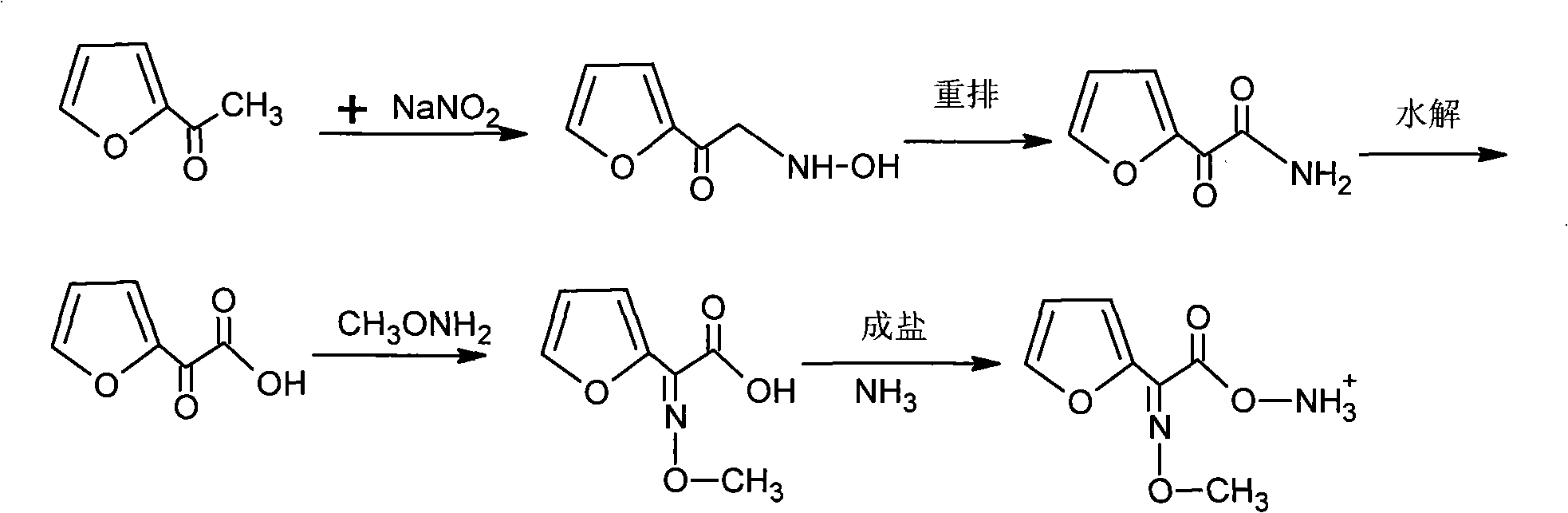

Preparing method of 2-methoxy imino group 2-furan ammonium acetate

InactiveCN101538255AReduce spawn rateReduce unit consumptionOrganic chemistryFuranReaction temperature

The invention relates to a preparing method of 2-methoxy imino group 2-furan ammonium acetate which comprises the following steps: (1) sodium nitrite reacts with acetate furan to generate furan keto acid by oximation, rearrangement and hydrolysis; (2) the furan keto acid is extracted; (3) condensation reaction is carried out on the furan keto and methoxy ammonium hydrochloride to generate 2-imino group 2-furan acetic acid; (4) the 2-imino group 2-furan acetic acid is extracted; (5) ammonia is introduced for salt formation to generate the 2-methoxy imino group 2-furan ammonium acetate; wherein, solvent adopted in the furan keto extraction of step (2) is butyl acetate. Under the same condition, the dissolution loss of the ethyl acetate in water is four times larger than that of the butyl acetate. With the butyl acetate being adopted as the solvent, the unit consumption is lowered by 50 percent, and the production cost is lowered. Furthermore, 58-60 DEG C of the reaction temperature for oximation is adopted by the invention, the production rate of furoic acid is smaller than 1 percent, and the product yield is improved greatly.

Owner:ZHEJIANG TOP MEDICINE

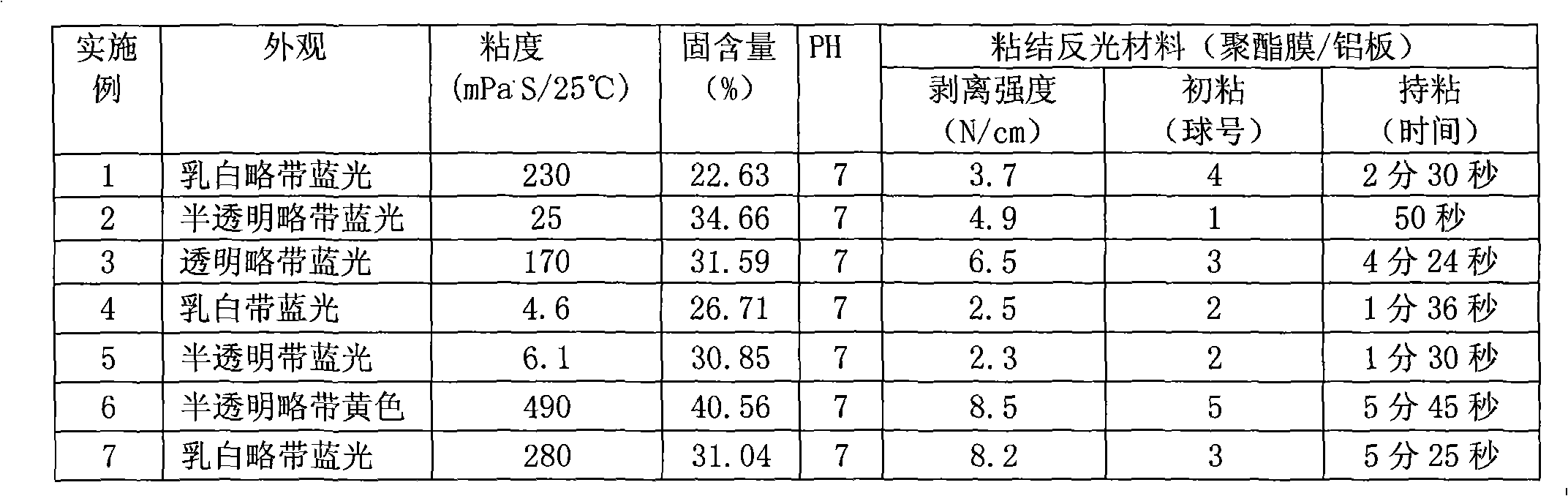

Preparation method of waterborne polyurethane adhesive and application in roads reflecting material

ActiveCN101284980AReduce pollutionProduction process cleaningPolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentHydrophilic monomerEpoxy

The invention relates to the nano-powder preparation field, in particular to a method for preparing nearly spherical nanometer oxide powder having good monodispersity and uniform particle size distribution with ultrasonic atomization. The method is characterized in that: the synthesis of water polyurethane is divided into three stages; a first stage is stepwise polymerization, i.e. polyurethane prepolymer is formed from oligomer polylol, hydrophilic monomers, modified monomers and isocyanate through stepwise polymerization; a second stage is the dispersion of the prepolymer in water after neutralization and salt formation; a third stage is the formation of water polyurethane emulsion after hydrophilic chain extender is added. The invention adopts a route of polymerizing modified monomers and polyurethane monomers jointly with different reaction mechanisms to ensure that modified monomers and polyurethane monomers are interpenetrated or grafted, thus obtained products have multiple material characteristics, i.e. the characteristics of acrylic acid, epoxy, hydroxyl silane and other materials are led into the products at the same time when the advantages of polyurethane material are maintained, so as to ensure that target products have stronger adaptability and better performance.

Owner:溧阳常大技术转移中心有限公司

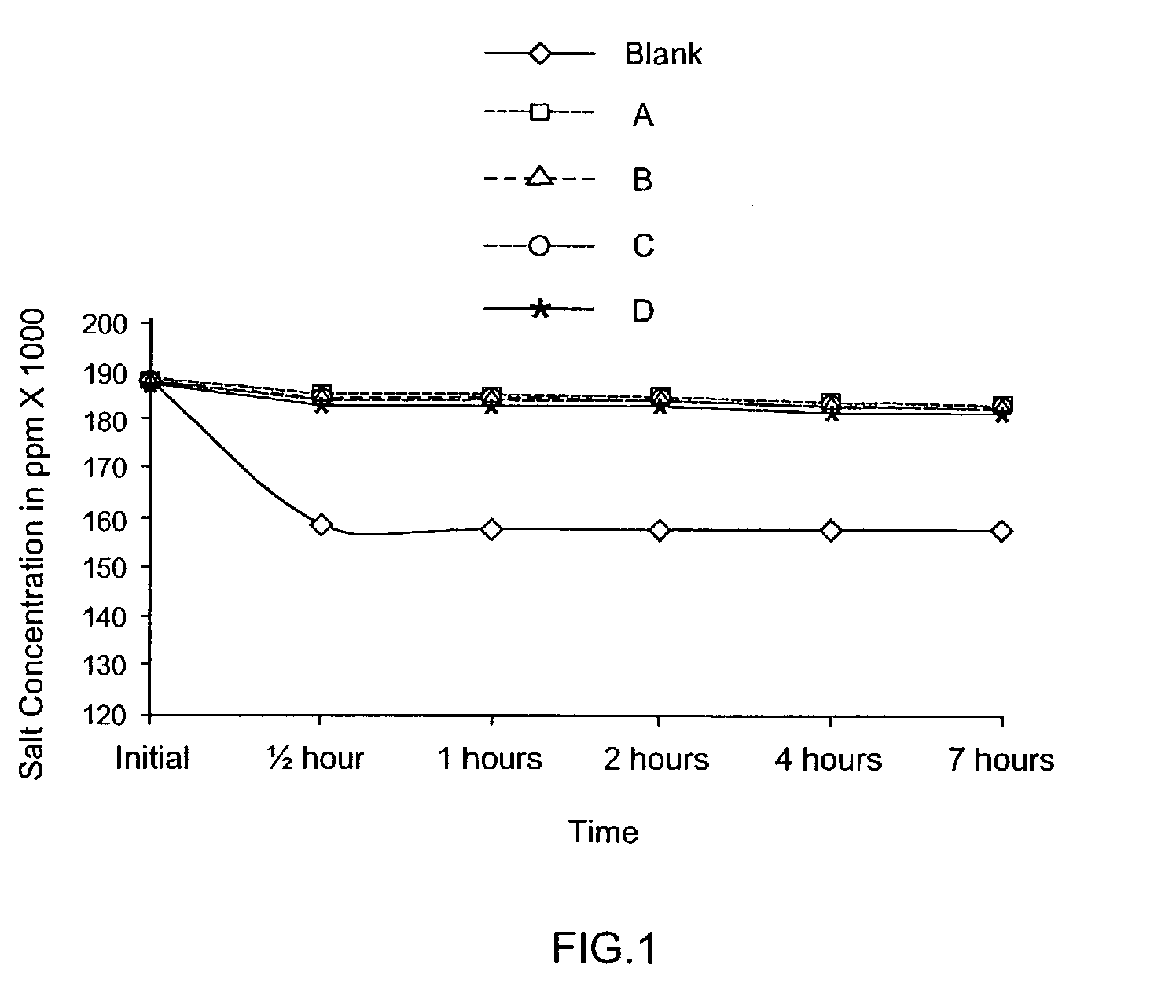

Multi-amine neutralizer blends

ActiveUS20050051462A1Avoid corrosionMinimizes reduces depositThermal non-catalytic crackingCatalytic crackingDistillationNuclear chemistry

Amine and amine blend compositions neutralize acid environments in distillation overheads of hydrocarbon processing facilities. The neutralizers are composed of certain combinations of amines which are relatively stronger bases and more resistant to hydrochloride salt formation. The amines, when blended together, provide greater neutralization of condensed water present without increased potential for corrosive hydrochloride salt formation.

Owner:BAKER HUGHES INC

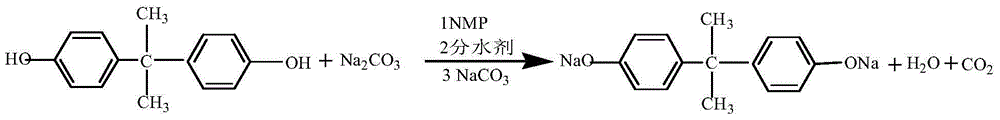

Industrial synthesis method of high-thermal-stability terminated polysulfone resin

The invention discloses an industrial synthesis method of high-thermal-stability terminated polysulfone resin. The industrial synthesis method comprises the following steps: adding a solvent into a reaction kettle under nitrogen filled protection, then increasing the temperature to 60-80 DEG C, sequentially adding 4,4-dichlorodiphenyl sulfone and bisphenol A to be used as reaction monomers, wherein the content of solid in the system is 20-40%; adding a salt forming agent after the monomers are thoroughly dissolved, subsequently adding a water dividing agent, increasing the temperature to 180-190 DEG C, and carrying out salt formation reaction for 1-2 hours; then increasing the temperature to 200-220 DEG C, carrying out constant-temperature polymerization reaction for 5-6 hours, adding a terminating agent, continuing to react for 10-30 minutes to obtain a polymerized adhesive liquid; and cooling, crushing, filtering, washing and drying the polymerized adhesive liquid to obtain polysulfone resin. The added terminating agent has an excellent terminating effect; the system is not depolymerized; the terminated polysulfone resin synthesized by the method is high in thermal stability and low in gloss; and the process can be used for greatly shortening the reaction time, improving the productivity and widening the application field of the products.

Owner:JIANGMEN YOUJU NEW MATERIALS

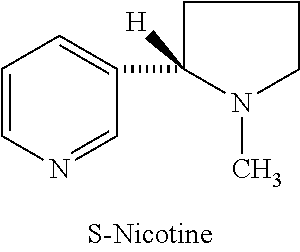

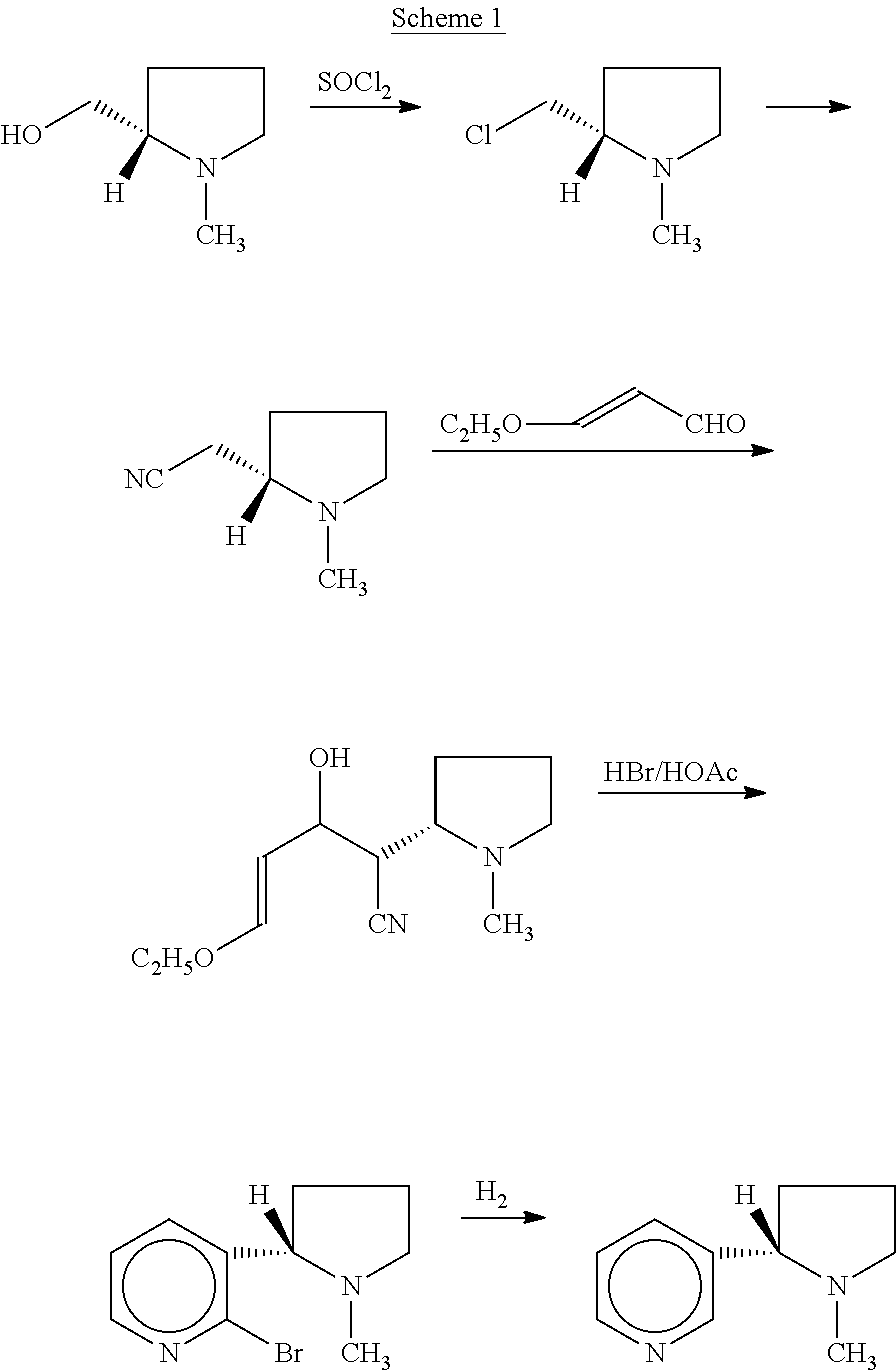

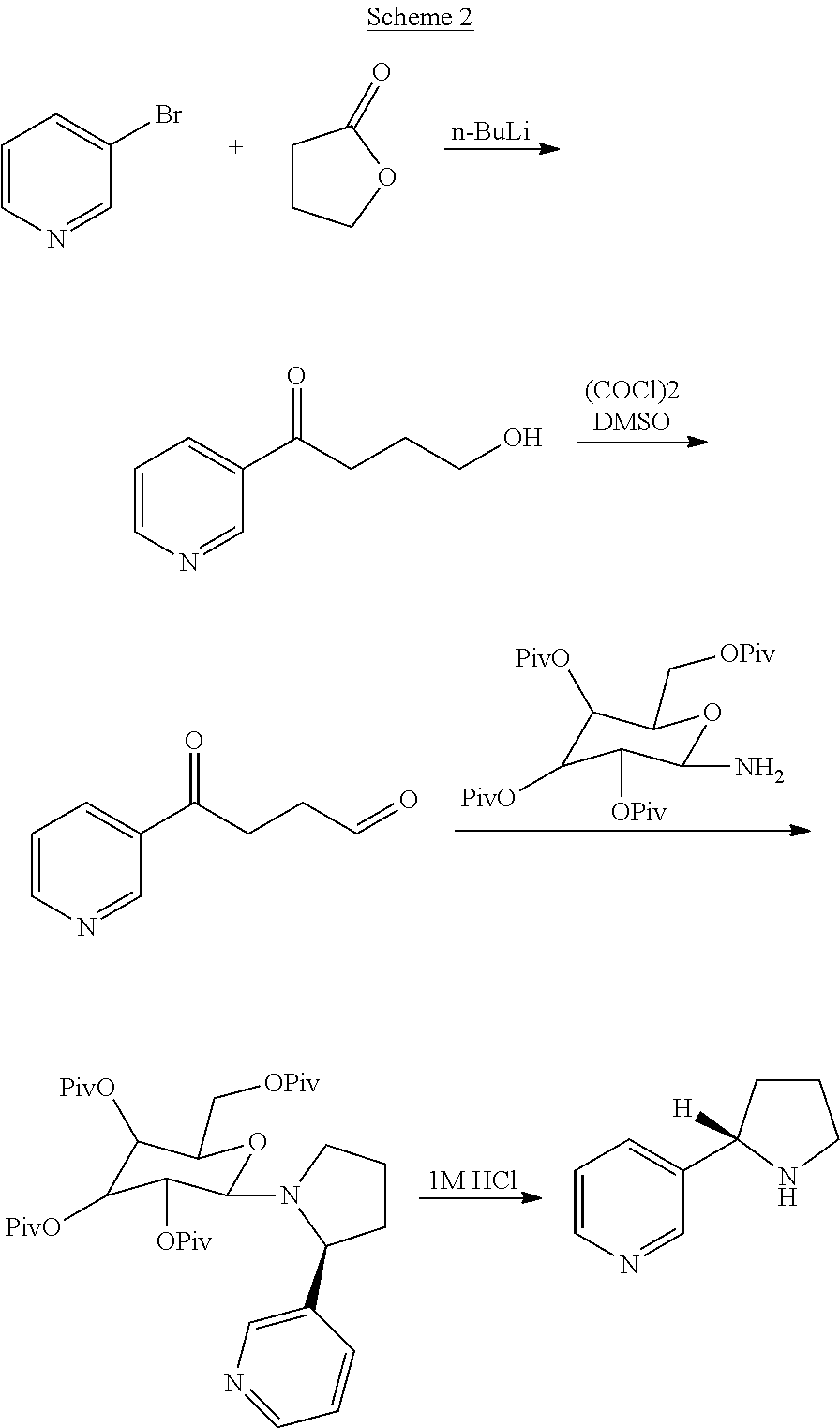

Process for the resolution of (R,S)-nicotine

(R,S)-Nicotine was resolved through diastereomeric salt formation using dibenzoyl-d-tartaric acid and dibenzoyl-l-tartaric acid to obtain enantiomerically pure (S)-nicotine and (R)-nicotine.

Owner:DIVI S LAB LTD

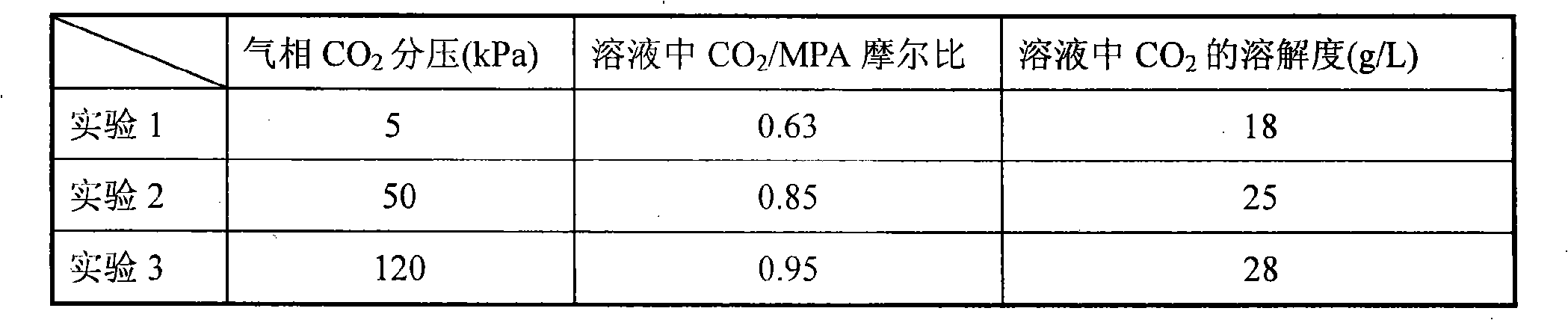

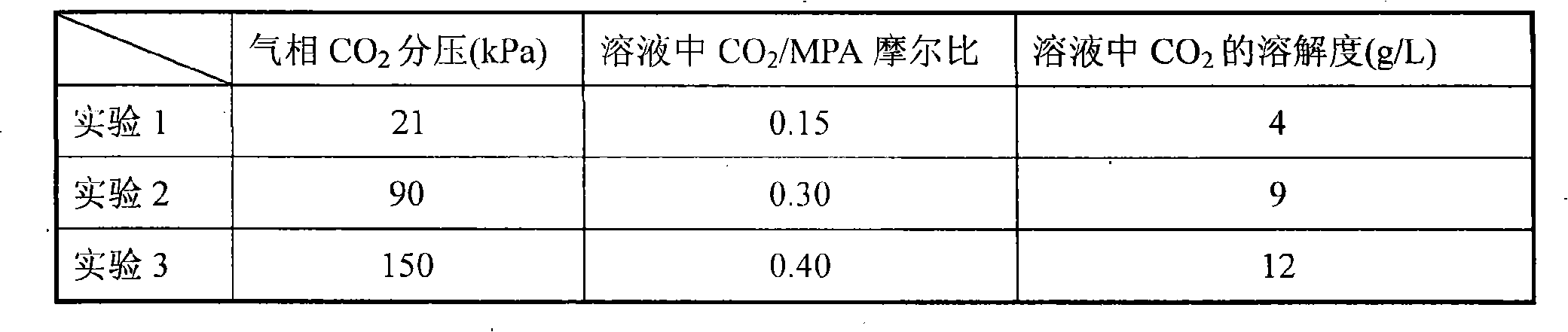

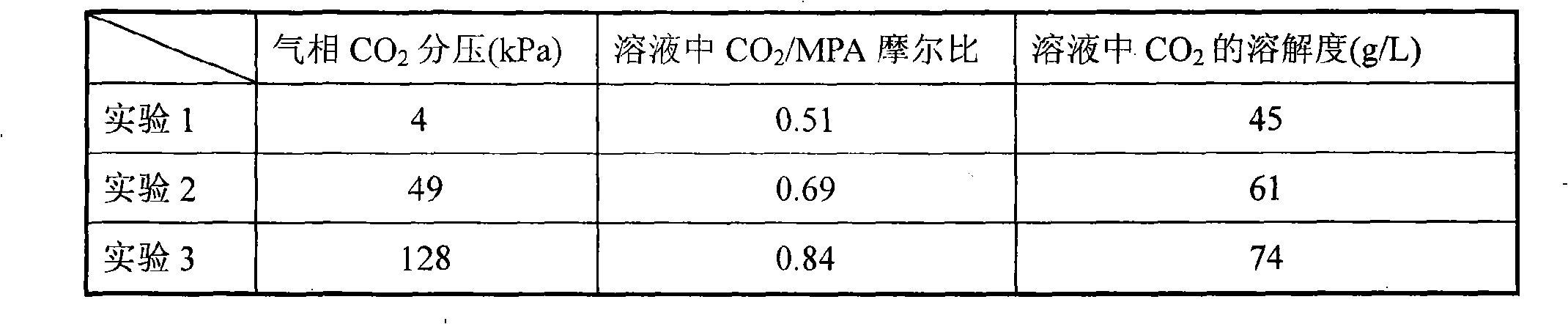

Absorbing solvent for capturing or separating carbon dioxide from gas mixture or liquid gas

The invention pertains to the field of chemical materials and in particular relates to a sorption solvent which catches or separates carbon dioxide from gaseous mixtures or liquefied gases. The solvent comprises n-propanolamine with a content range of 5-60wt% and other components with a total content range of 40-95wt%; other components comprise monoethanol amine, diethanolamine, methyl diethanolamine, diisopropanol amine, 2-amido-2-methyl-1-propyl alcohol, organic amine, water, physical solvent, inorganic salt and one or more accessory ingredients. The number of carbon atoms between the amidocyanogen and the hydroxide radical of the n-propanolamine is three; nitrogen atoms can form a hydrogen bond with the hydrogen atoms on oxygen atoms, or oxygen atoms can form a hydrogen bond with the hydrogen atoms on nitrogen atoms, thus forming a ring structure composed of six atoms; such molecular structure is similar to that of secondary amine, can reduce the formation of amino carbonates and improve the solubility and desorption degree of CO2; meanwhile, the formation of the six-element ring molecular structure increases the stability of molecular and can reduce the degradation loss of solvents in service process.

Owner:TSINGHUA UNIV

Methods for the inhibition of salt blockages in oil and gas wells

InactiveUS7028776B2Reduces and eliminates formationAccelerates the removal of moistureCleaning apparatusFluid removalNitrilotriacetamideSediment

Compositions and methods for the inhibition of salt formation in oil and gas wells are disclosed. In particular, nitrilotriacetamide and its salts are effective at treating existing salt formations, and in inhibiting formation of new deposits.

Owner:BJ SERVICES CO

Preparation method of attapulgite/aqueous polyurethane compound binder

ActiveCN101768418AImprove mechanical propertiesImprove thermal stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesHydrophilic monomerEmulsion

The invention relates to a preparation method of an attapulgite / aqueous polyurethane compound binder, belonging to the field of organic binders and comprising the following steps of: (1) modified polyurethane prepolymer preparation: vacuumizing hydroxy monomers and hydrophilic monomers at the temperature of 90 DEG C under the vacuum degree of 0.09-0.1MPa, then adding metric isocyanate monomers on the basis of regulating the prepolymerizing temperature to 65-90 DEG C, and controlling the R value at 1.02-2.0; (2) prepolymer neutralization and dispersion: lowering uniform temperature by 40-70 DEG C on the basis of the first step, and adding a neutralizer to neutralize into salt; after 30 minutes, controlling the solid content at 20-40 percent; dispersing metric attapulgite suspension into salt-formation modified polyurethane prepolymer and stirring at high speed for 30 minutes to prepare an attapulgite / aqueous polyurethane compound emulsion; and (3) chain extension stage: adding an chain extender on the basis of the second step, and continuously stirring for 30 minutes and discharging to prepare a final product of the emulsion of the attapulgite / aqueous polyurethane compound binder. The compound binder can be made into an artificial board which has excellent performance and meets the environmental protection requirements.

Owner:溧阳常大技术转移中心有限公司

Method for preparing linear polyurethane phase change material

The invention discloses a method for preparing a linear polyurethane phase change material. The method comprises the following steps: dissolving polyethylene glycol and diisocyanate into solvent in inert atmosphere, reacting in the presence of optional catalyst, adding tertiary amine type chain extender containing hydroxyl for chain extension, adding an optional neutralizer for salt formation so as to obtain the linear polyurethane phase change material, wherein the molar ratio of the sum of hydroxyl of polyethylene glycol and hydroxyl of chain extender to the isocyanate group of diisocyanate is 1:1, the add amount of the catalyst accounts for 0-1% the total weight of the polyethylene glycol, diisocyanate and chain extender, the molar ratio of neutralizer to tertiary amine type chain extender is 0-1, and the molecular weight of the polyethylene glycol is higher than 2000. The linear polyurethane phase change material prepared by the method has a linear structure and large enthalpy of phase change, has a simple preparation method, is low in cost, has stable property, can be stored for long time, is not solidified and cross-linked, is easy to process and shape, and is beneficial to large-scale popularization and application.

Owner:温州东润新材料科技有限公司

Superfine oil-base drilling fluid used for high temperature high temperatur high pressure superdeep well and preparation method thereof

ActiveCN104610946AIncreased steric hindranceOvercoming the tendency to coalesceDrilling compositionFiltrationHigh pressure

The invention provides a superfine oil-base drilling fluid used for a high temperature high pressure superdeep well, the superfine oil-base drilling fluid contains the following raw materials by weight: 20-40 parts of water, 250-500 parts of diesel, 2-10 parts of an emulsifier, 3-15 parts of a wetting agent, 2-8 parts of organic soil, 15-25 parts of a filtrate loss agent, 5-10 parts of calcium chloride, 5-10 parts of calcium oxide, 450-800 parts of API barite, and 350-660 parts of an ultra aggravating material. The oil-base drilling fluid is weighted by compounding superfine mineral powder and ordinary barite, the superfine high density oil-base drilling fluid density can reach 2.8g / cm<3>, has better settling stability and high temperature and high pressure filtration loss compared with that of ordinary barite weighted drilling fluid, and can meet drilling of deep wells, superdeep wells and composite salt formations.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Salt-tolerant latex cement slurry for well cementation

InactiveCN102093862AReduce the burden of fresh water transportationReduce operating costsDrilling compositionSaline waterSalt water

The invention discloses salt-tolerant latex cement slurry for well cementation, which comprises the following components: cement, salt tolerant latex which is 4-40% of weight of cement, water-loss control agent which is 3-4% of weight of cement, slow-release agent which is 0-2% of weight of cement, dispersant which is 0.5-3% of weight of cement, saline or seawater with concentration not higher than 15% which is 18-51% of weight of cement, and antifoaming agent which is 0.5-1.3% of weight of cement. The salt-tolerant latex cement slurry provided by the invention overcomes the shortcoming that ordinary latex is not salt tolerant, so that the salt-tolerant latex cement slurry system can be used for cementing a complex well with a salt bearing rock formation (salt formation, salt and gypsum formations, saltwater formation). In addition, the salt-tolerant latex cement slurry provided by the invention can be also directly prepared from seawater, so as to reduce the fresh water transportation load of well cementing operation in an offshore drilling platform, and reduce operation cost.

Owner:CNPC OFFSHORE ENG +1

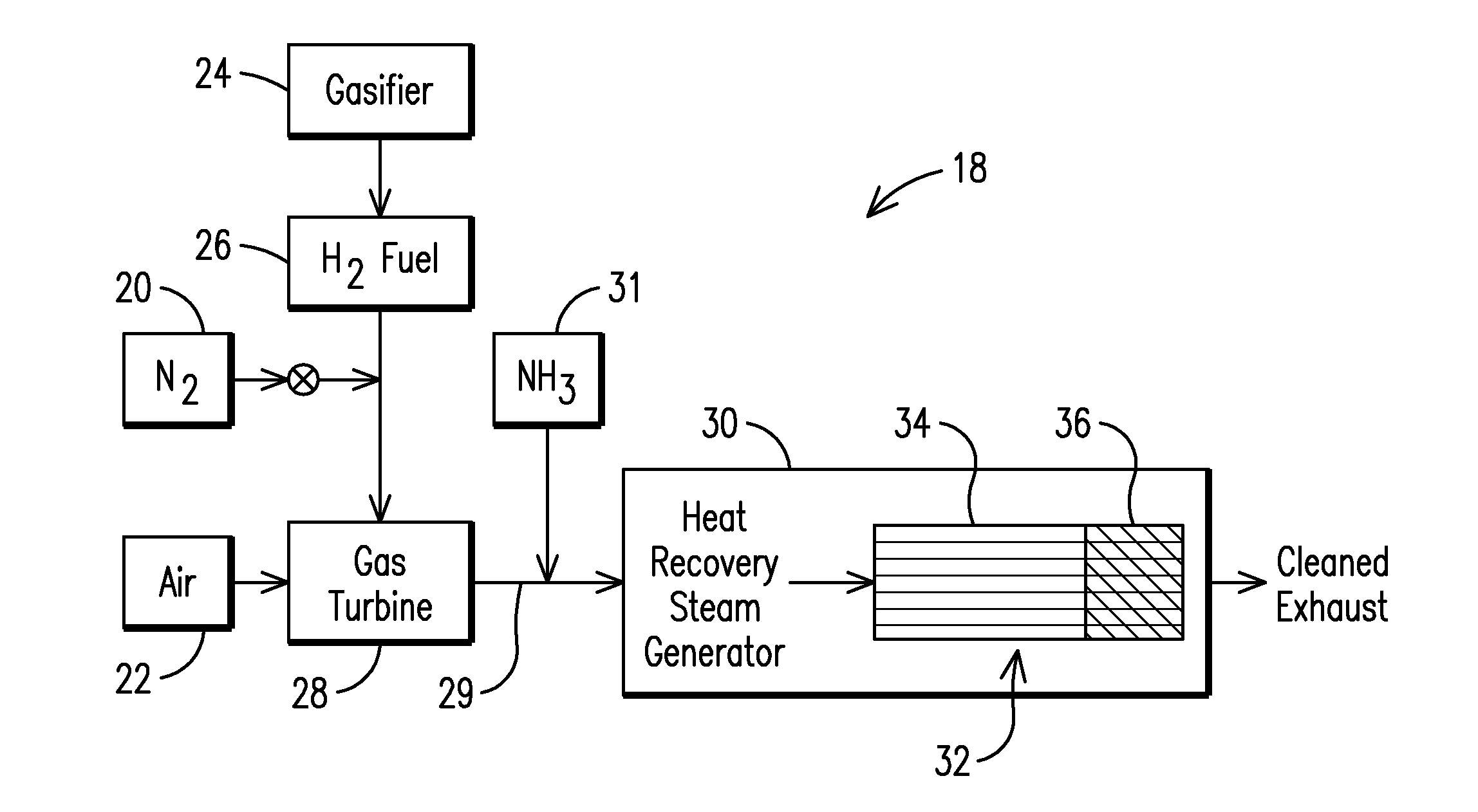

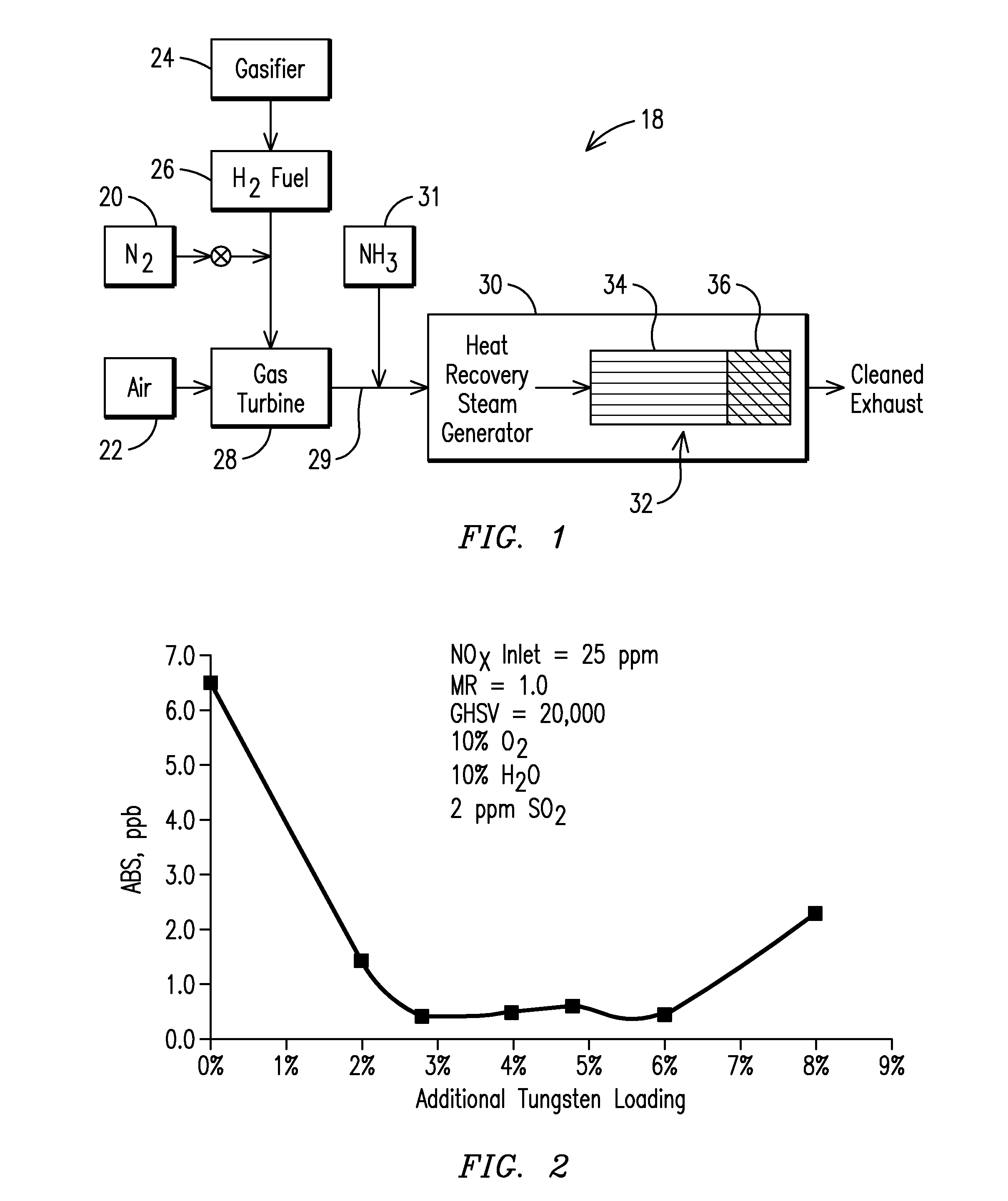

SELECTIVE CATALYTIC REDUCTION SYSTEM AND PROCESS FOR CONTROL OF NOx EMISSIONS IN A SULFUR-CONTAINING GAS STREAM

An exhaust gas treatment process, apparatus, and system for reducing the concentration of NOx, CO and hydrocarbons in a gas stream, such as an exhaust stream (29), via selective catalytic reduction with ammonia is provided. The process, apparatus and system include a catalytic bed (32) having a reducing only catalyst portion (34) and a downstream reducing-plus-oxidizing portion (36). Each portion (34, 36) includes an amount of tungsten. The reducing-plus-oxidizing catalyst portion (36) advantageously includes a greater amount of tungsten than the reducing catalyst portion (36) to markedly limit ammonia salt formation.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com