Preparation method of waterborne polyurethane adhesive and application in roads reflecting material

A water-based polyurethane and adhesive technology, used in polyurea/polyurethane adhesives, surface pretreatment adhesive methods, adhesive types, etc., can solve the problem of low proportion of polyurethane emulsion and modified monomer dosage. Restriction, poor emulsion stability, etc., to achieve the effect of reducing hidden dangers in production safety, excellent performance, and easier control of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

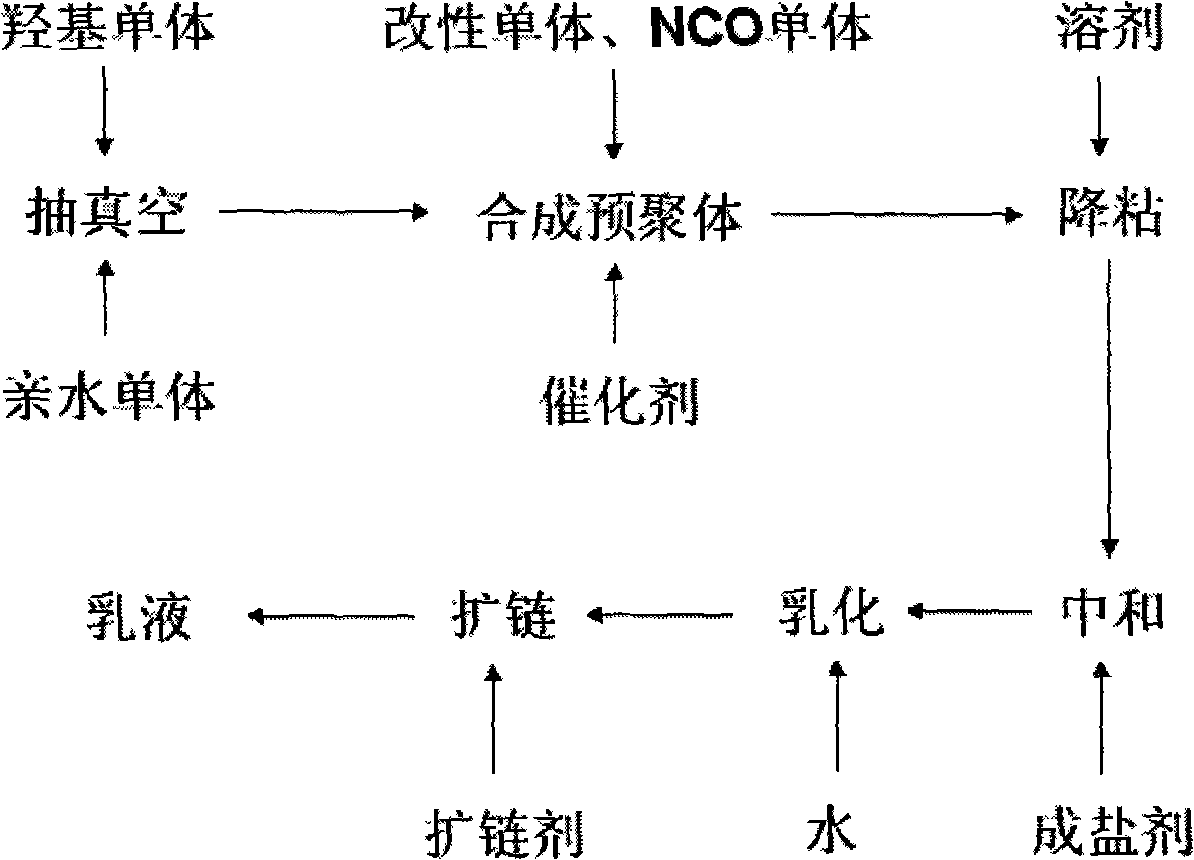

Method used

Image

Examples

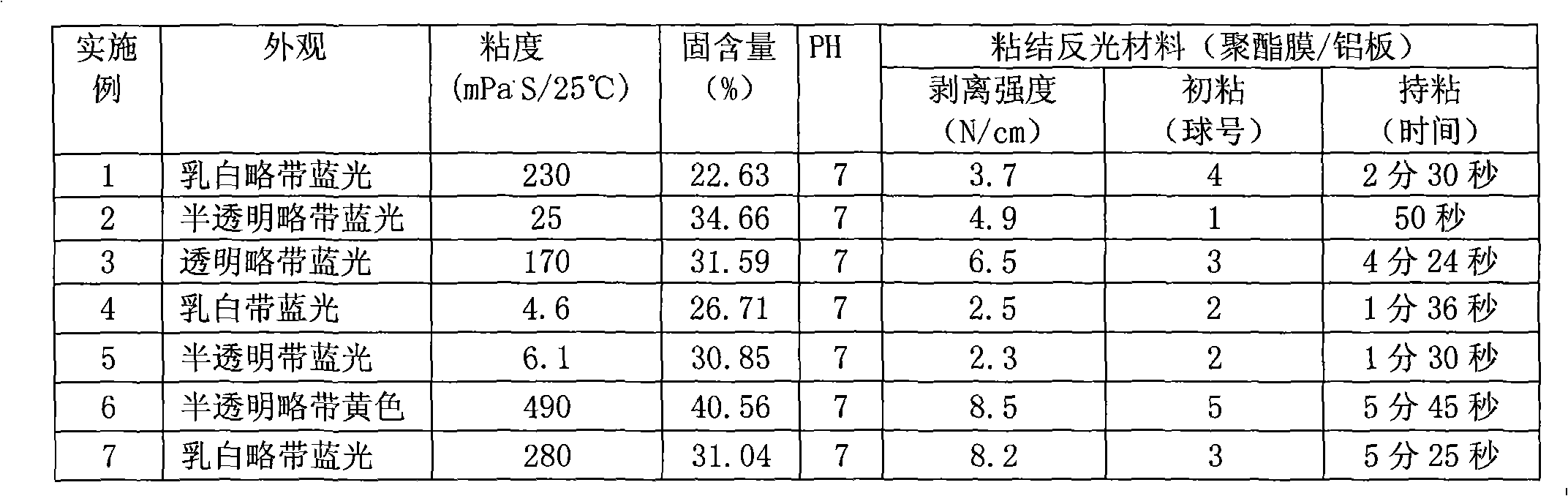

Embodiment 1

[0030] Add 0.61g of poly-1,4-butylene adipate diol, 33.0g of polyether 330 and 2.2g of DMPA into a three-neck flask, mix and stir, and vacuum dehydrate at 80°C for 1.5h, with a vacuum degree of 0.095MPa. Then add 1.9gNMP (1-methyl-2-pyrrolidone), 0.76gHEA (hydroxyethyl acrylate), 7.54gIPDI and a small amount of catalyst successively, and heat the reaction until the NCO value in the system reaches the theoretical value substantially to obtain a prepolymer, and Start to cool down. Cool the prepolymer to 60°C and dilute it with an appropriate amount of acetone. After the viscosity is reduced, add 1.2 g of triethylamine dropwise under high-speed stirring for shear emulsification, neutralization, and salt formation. Add 163.14g of water after the phase transition is basically completed, then slowly add 0.65g of chain extender ethylenediamine dropwise, and further chain extension and emulsification reaction for about 30 minutes, to obtain a slightly blue white emulsion (theoretical ...

Embodiment 2

[0032] Under the operating conditions of Example 1, the amount of polyadipate-1,4-butylene glycol ester diol was adjusted to 20.85g, polyether 330 was adjusted to 3.0g, DMPA was 2.0g, and IPDI was adjusted to 8.05 gMDI, the amount of water used is 72.43g, and finally a translucent slightly blue PU emulsion (theoretical solid content is 34.66%) is obtained. Among them, hydrophilic monomer accounts for 5%, modified monomer accounts for 2%, isocyanate accounts for 22%, and NCO / OH is 1.00.

Embodiment 3

[0034] Under the operating conditions of Example 1, the hydroxyl component was changed to 15.9g polyether 330 and 5.4g polyether 220, and 1.0g epoxy E-51 was added, the amount of IPDI was 6.5g, and the amount of water was 76.47g. Obtained transparent PU emulsion with blue light (theoretical solid content is 31.59%). Among them, hydrophilic monomer accounts for 7%, modified monomer accounts for 2.4%, isocyanate accounts for 21%, and NCO / OH is 1.07.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com