Patents

Literature

81results about How to "Solve emulsification problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

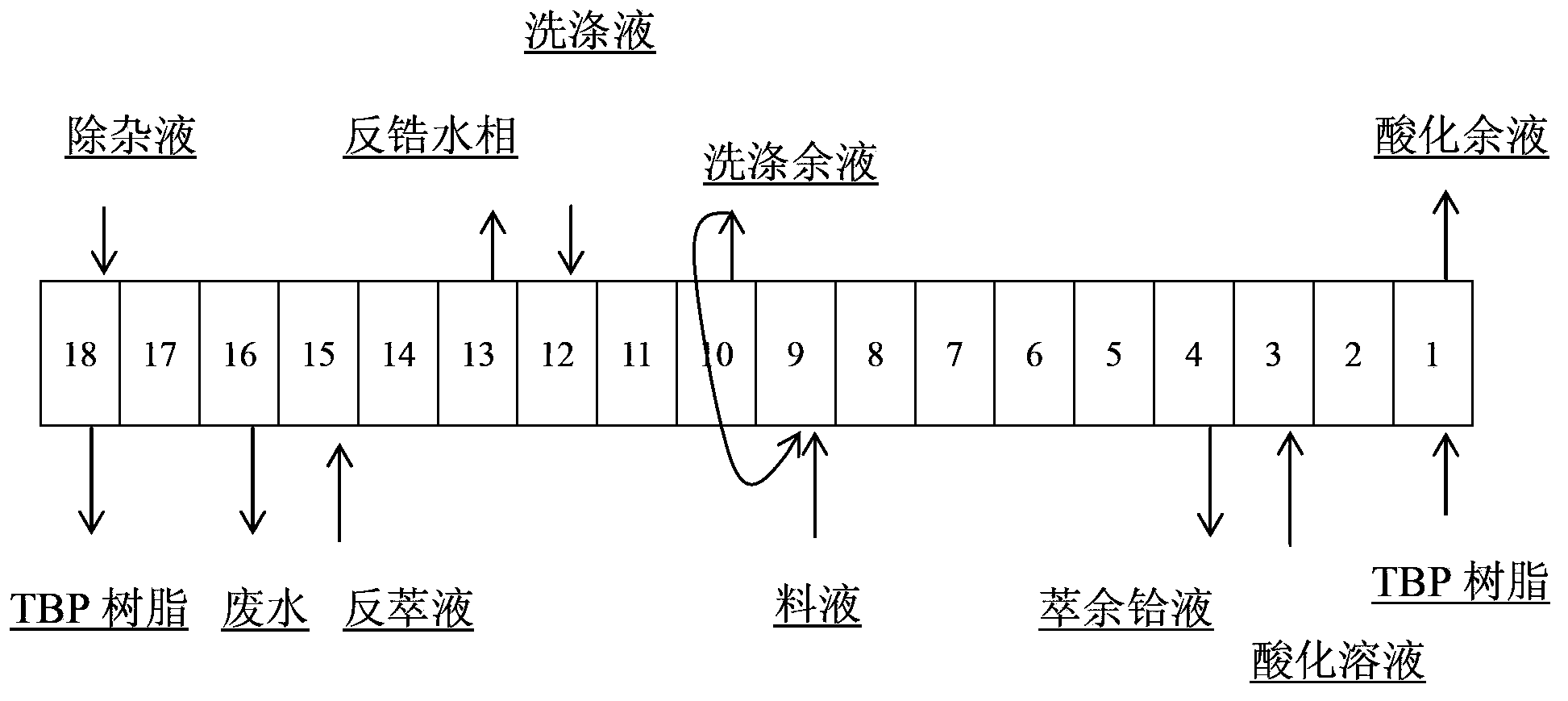

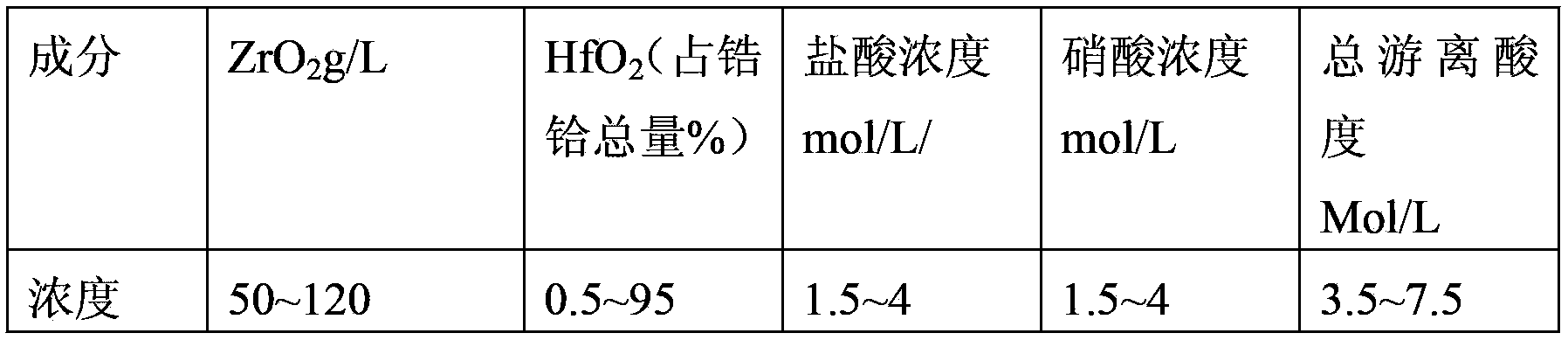

Method for separating zirconium hafnium by tributyl phosphate extraction chromatography method

ActiveCN101209858AHigh separation factorReduce consumptionLiquid solutions solvent extractionZirconium oxidesHafniumChromatographic column

The invention relates to a separation method of zirconium and hafnium by adopting extraction chromatography, in particular to extraction chromatography of zirconium and hafnium by employing tributylphosphate. The method comprises the following steps that: extractant-containing resin TBP is adopted to load the extraction chromatographic column; mixed solution of chlorhydric acid and nitric acid with total free acid acidity being 3.5-7.5 mol / l is adopted for eluting the extraction chromatographic column; then the obtained material is added with material liquid which is the mixed solution of chlorhydric acid and nitric acid with total free acid acidity being 3.5-7.5 mol / l; the total concentration of zirconium and hafnium is 0.05-1.5 mol / l; next, the mixed solution of chlorhydric acid and nitric acid with total free acid acidity being 4-8 mol / l is used for eluting the obtained material, until the concentration of overflowed hafnium solution is less than 0.01 g / l; then the mixed solution containing 0-1.5mol / l chlorhydric acid and nitric acid or 0-1.5mol / l chlorhydric acid solution is used for eluting, so as to get the zirconium solution containing no hafnium.

Owner:有研资源环境技术研究院(北京)有限公司

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

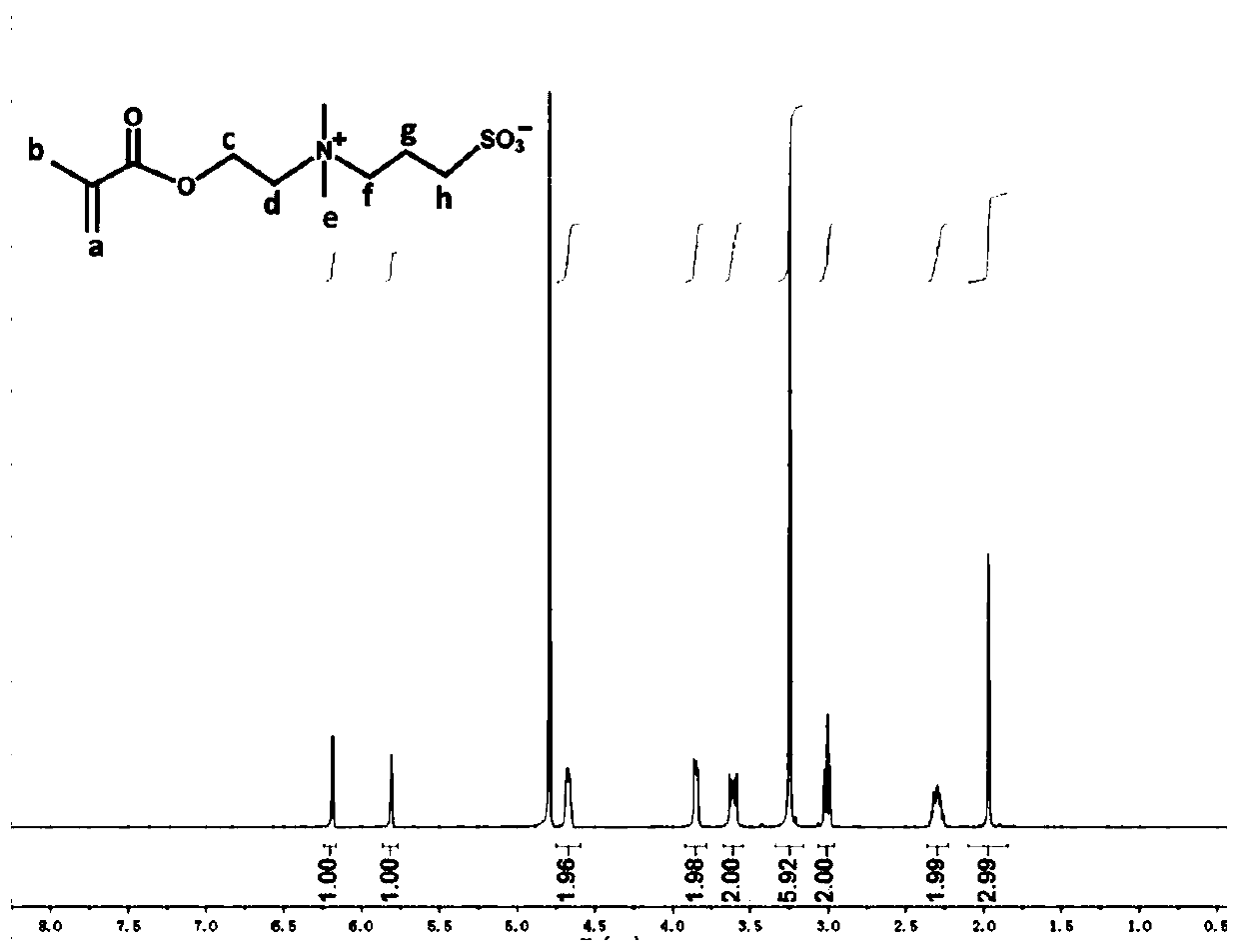

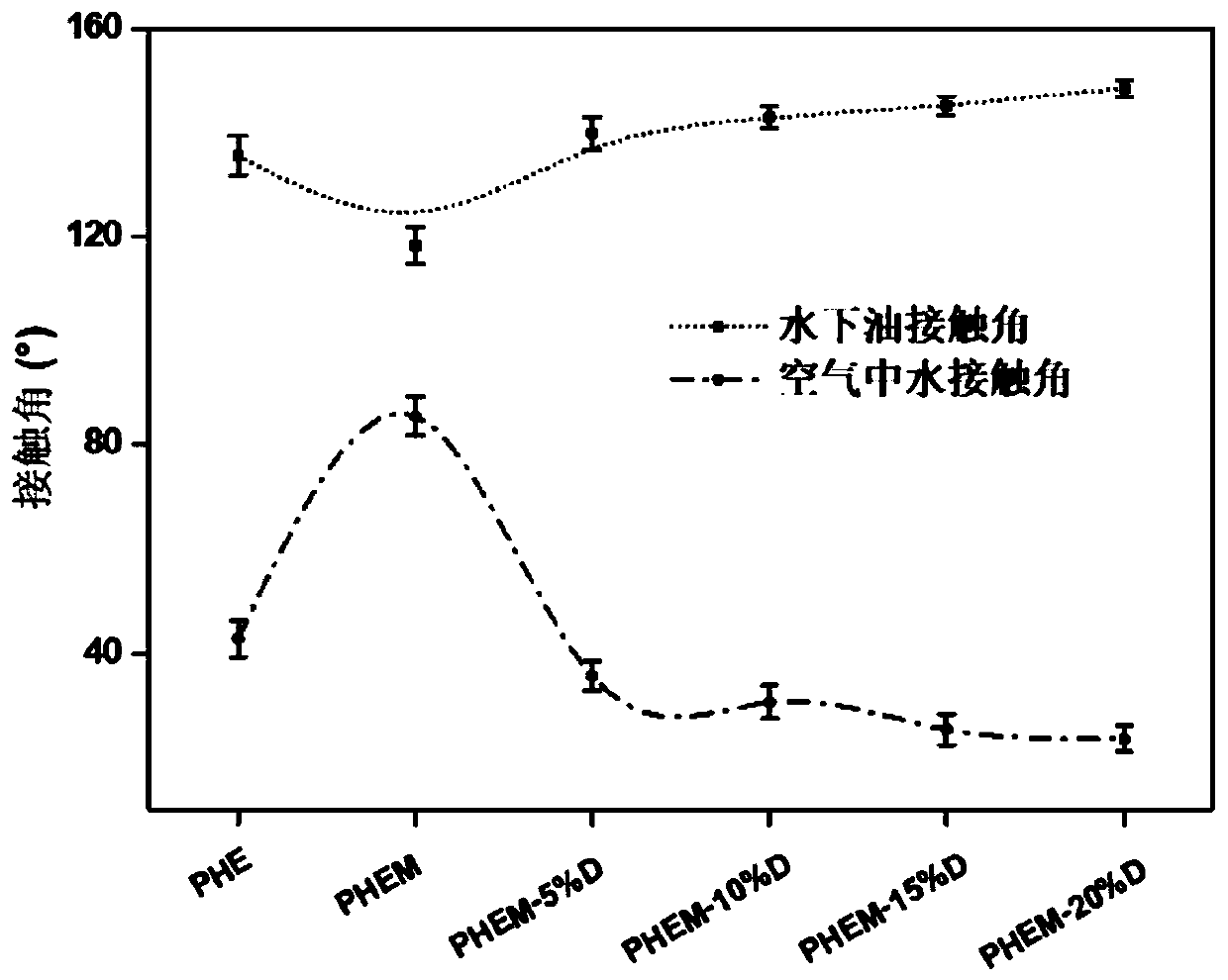

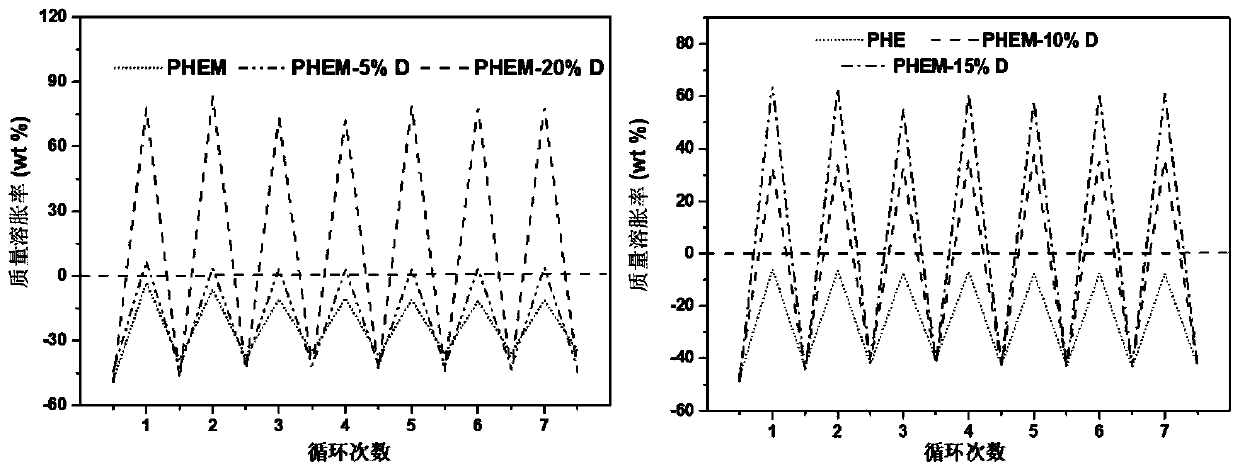

Hydrogel capable of being used for marine antifouling, preparation method and uses thereof

ActiveCN110358006ANo change in compression resistanceExcellent anti-biofouling performanceAntifouling/underwater paintsPaints with biocidesDehydration rehydrationBiofouling

The present invention provides a hydrogel capable of being used for marine antifouling, a preparation method and uses thereof. According to the present invention, the hydrogel does not swell while other gels such as acrylic acid, clay, acrylamide and the like swell heavily; the hydrogel can completely restore to the original state after water loss while other hydrogels such as a PVA gel cannot berecovered; the compression resistance of the gel of the present invention can remain unchanged after dehydration-rehydration circulation, the gel of the present invention has good stability under different shear frequencies at different temperatures, and the hydrogel is transparent while other oil hydrogels are less transparent; and the gel of the present invention has excellent biofouling performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Process for preparing Danshensu

InactiveCN1670008AReduce solvent lossImprove extraction rateCarboxylic compound separation/purificationMacromolecular SubstancesUltrafiltration

The invention relates to a method for preparing danshensu which comprises: getting extract liquid from the water or alcohol with danshensu and danshensu precursors using danshen as the materials, inverting the danshensu precursors of the said extract liquid into danshensu using diluted alkali, super filtering the macromolecular substance of the said extract liquid after conversion using a hyperfiltration membrane, extracting the danshensu from the said extract liquid after hyperfiltration, and separating the said extraction using the normal phase chromatography to get the danshensu.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

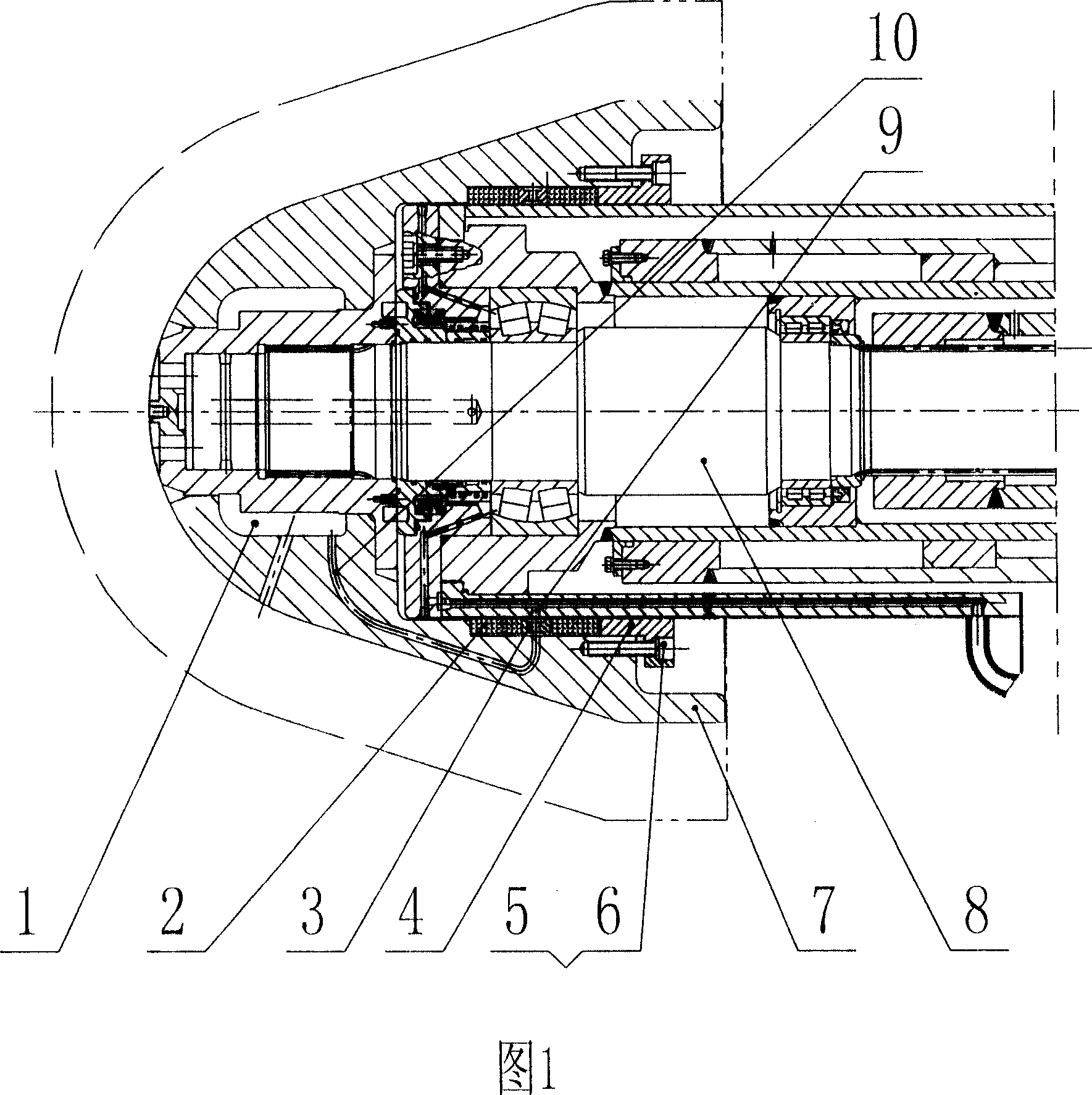

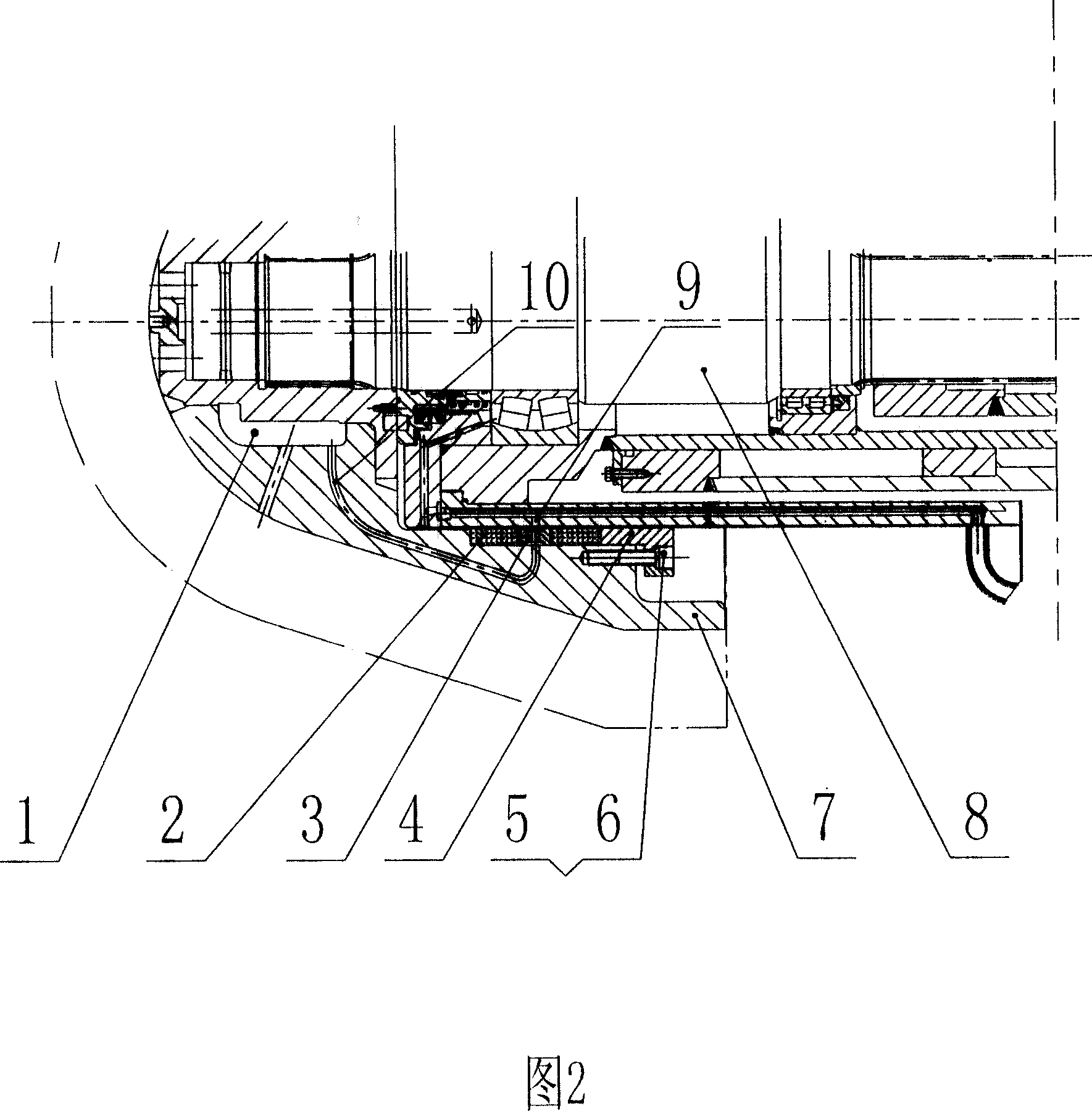

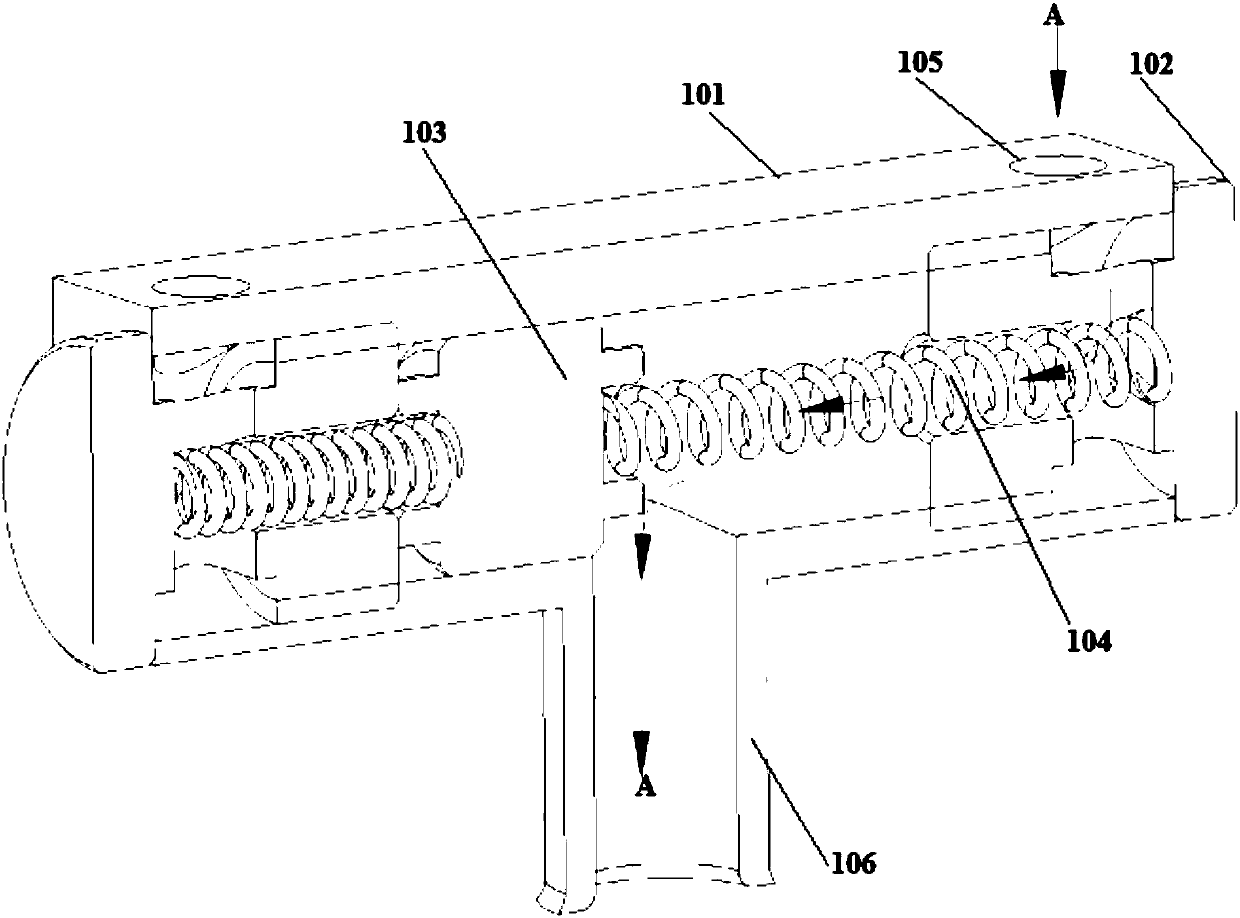

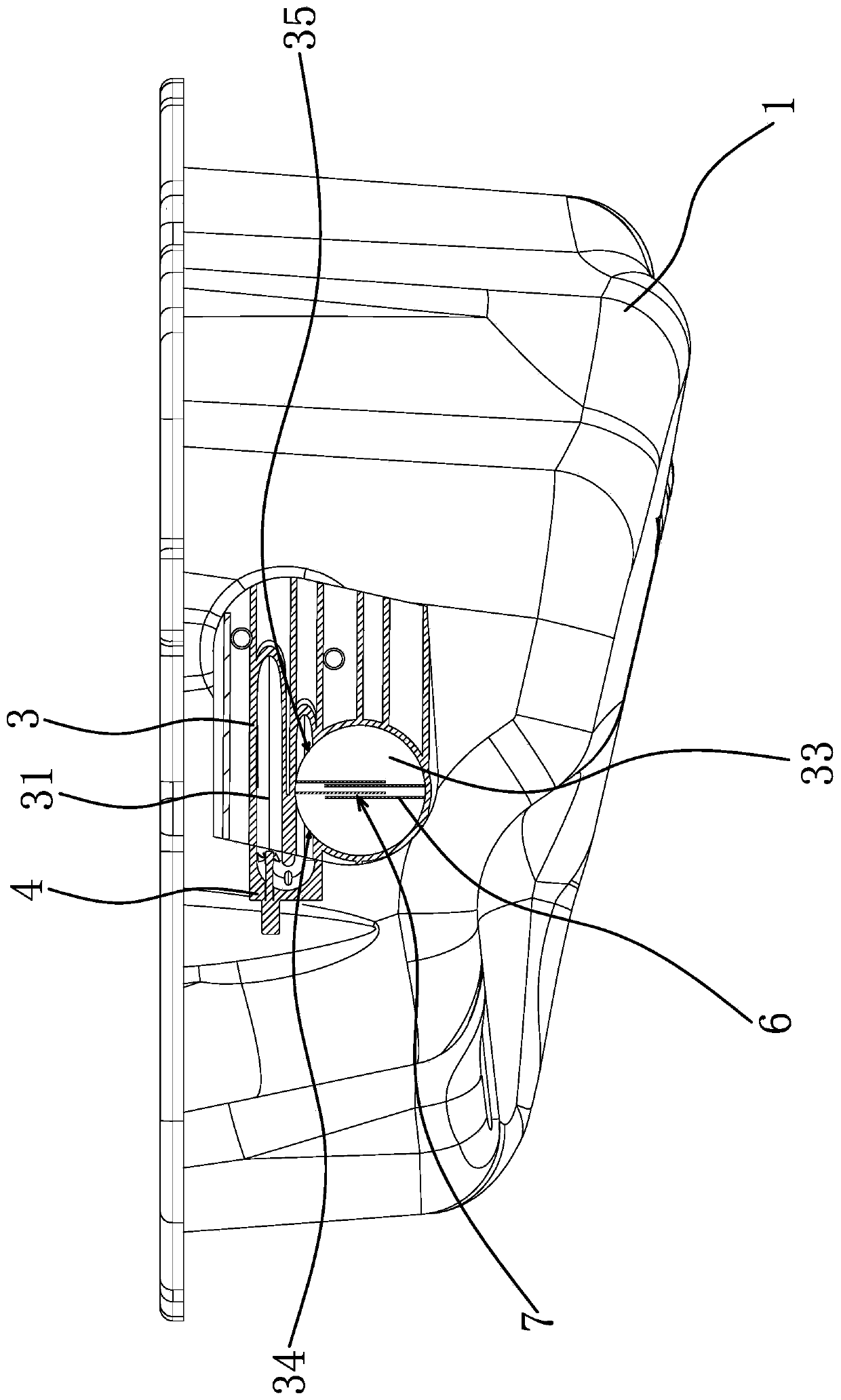

External tunneling machine cutting part cutting head for sealing water

InactiveCN101086207ASolve emulsification problemsExtended maintenance cycleCutting machinesWater leakageMechanical engineering

The invention relates to cutting part (or as incision part) cutting head of water seal external development machine, for specific the inner spray waterhead of the cutting head from the center cutting head axis diverts directly input the external cutting head, and no longer by cutting head axis, so as to avoid water leakage oil cavity defects solving the problem of the oil (water) emulsion in the development machine flexing part. The invention reasonable structure, constitution simple, changed the cutting head spray water supply lines, significantly extended examine cycle and use life of the development machine.

Owner:SANY HEAVY EQUIP

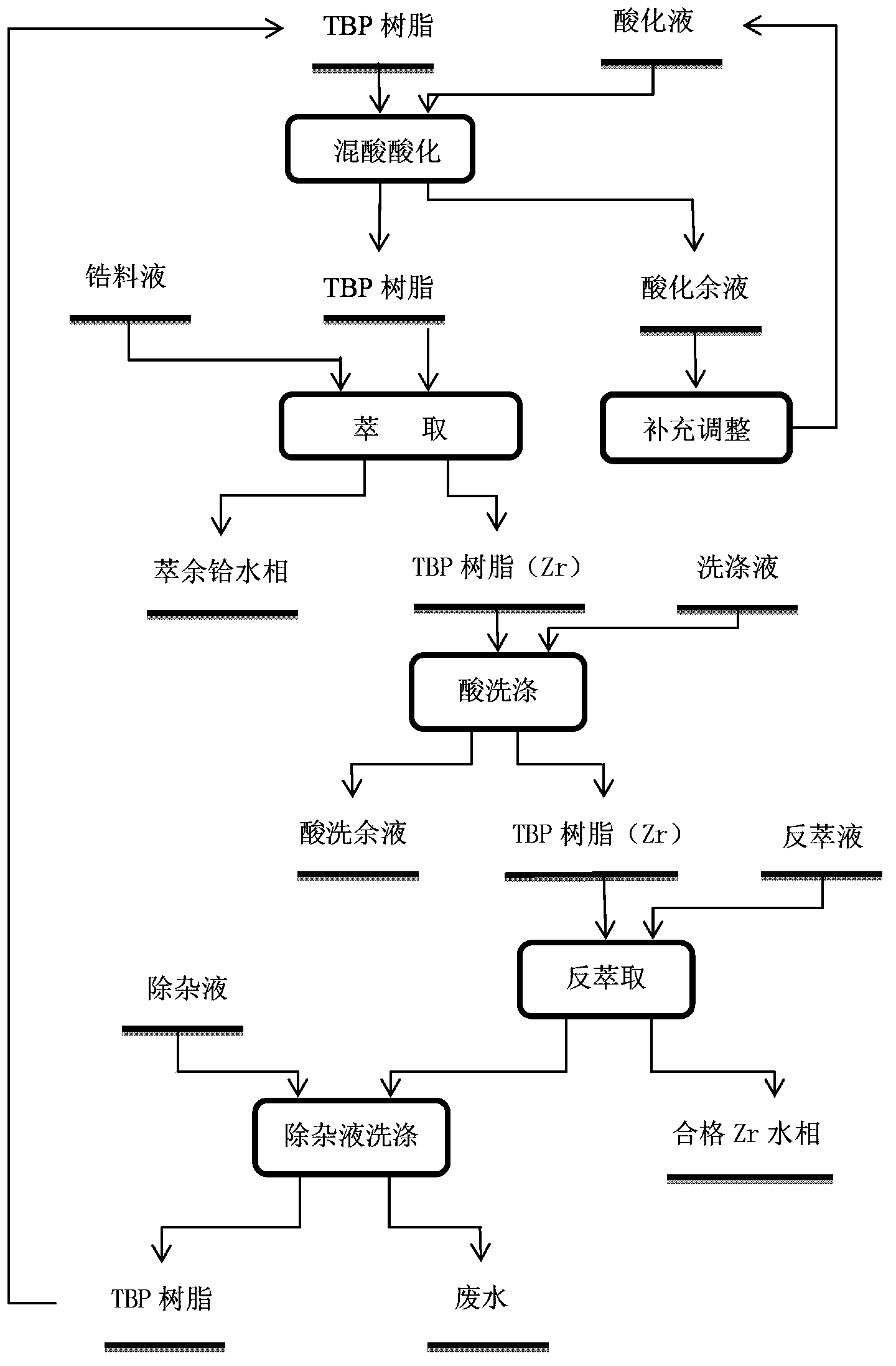

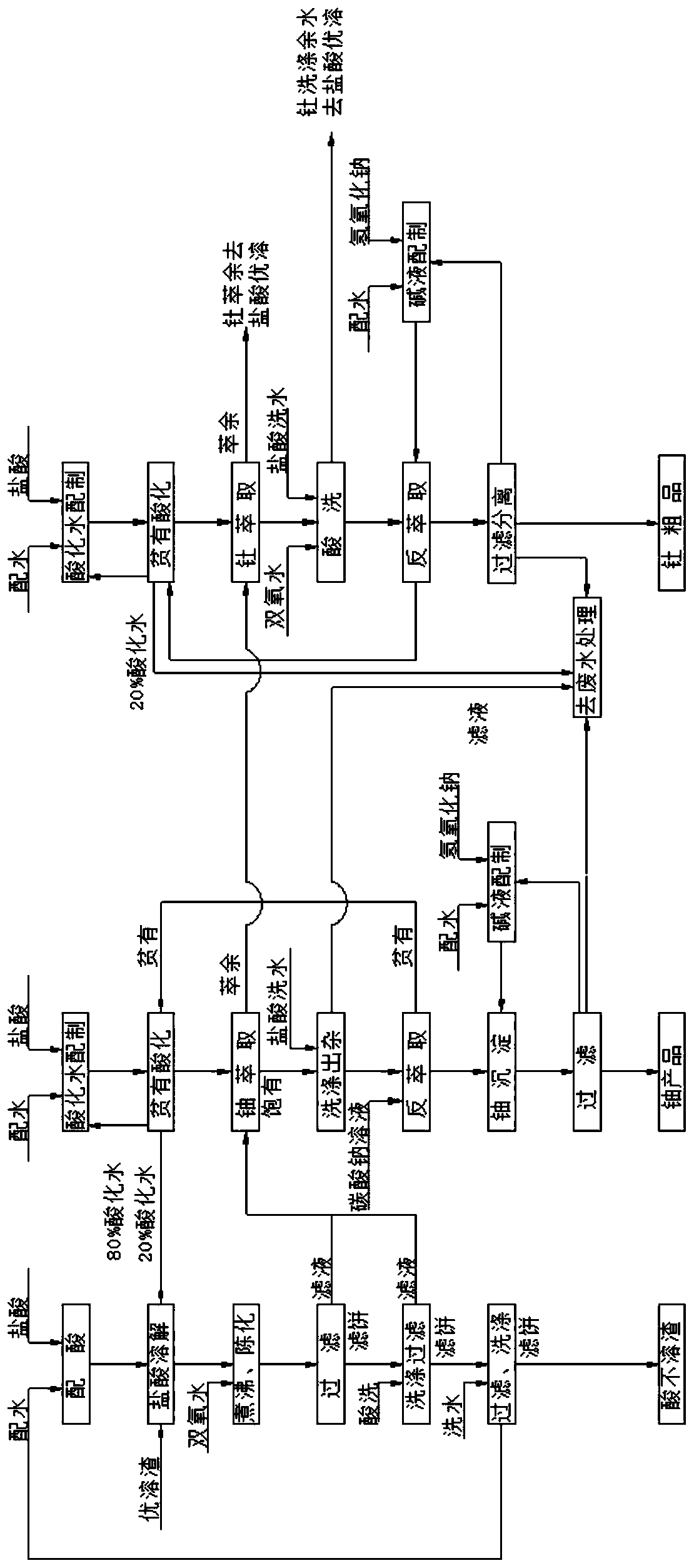

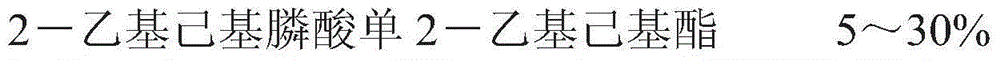

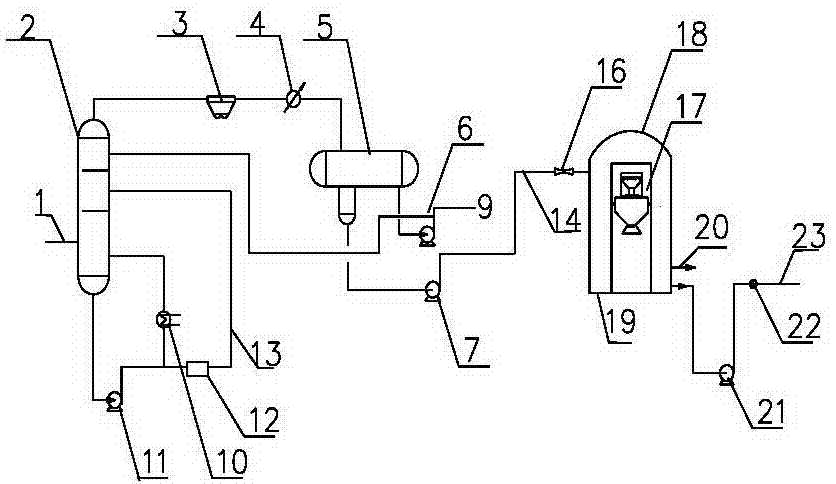

Method using tributyl phosphate resin for fractional extraction to separate zirconium and hafnium

InactiveCN104046777ASolve emulsification problemsReduce corrosionProcess efficiency improvementScrapChemistry

The invention relates to a method using tributyl phosphate resin for fractional extraction to separate zirconium and hafnium; the tributyl phosphate resin is used as an extraction agent, and the zirconium and hafnium are extracted and separated by use of a box-countercurrent mode; the method comprises the following sections: 1), acidification section, to be more specific, using the tributyl phosphate resin as the extraction agent, putting an extraction phase and a mixed acid solution into a box-type extraction tank for countercurrent acidification; (2) extraction section, to be more specific, putting the acidified extraction phase and a material liquid containing the zirconium and hafnium into the box-type extraction tank for countercurrent acidification; (3) washing section, to be more specific, performing reverse-phase washing on the extraction phase with the zirconium being extracted; (4) back extraction section, to be more specific, performing reverse-phase back extraction on the washed extraction phase; and (5) impurity removal section, to be more specific, performing reverse-phase impurity removal on the back extracted extraction phase, using an impurity removal liquid for washing, wherein effluent is used as waste for emissions, and an outflow extraction phase is recycled. The method has the advantages of large extraction phase capacity, high production capacity, no emulsification, low product cost, stable operation, and high product quality.

Owner:有研资源环境技术研究院(北京)有限公司

Method for smelting and separating uranium, thorium and rare earth from residual slag of processed monazite

ActiveCN111004920AReduce consumptionHigh recovery rateProcess efficiency improvementSlagWater chlorination

The invention provides a method for smelting and separating uranium, thorium and rare earth from residual slag of processed monazite. The residual slag of processed monazite is used as the raw material. The method comprises the following steps of performing hydrochloric acid complete dissolving, performing dissolving liquid aging, performing liquid-solid separation, extracting uranium by an amineextraction agent and performing extracting and enriching, extracting thorium from an acidic phosphorus-containing extraction agent and performing wastewater treatment. A raffinate phase obtained afterthorium extraction is returned to a monazite hydrochloric acid optimum solubilizing procedure to recover a rare earth chloride mixture, after extraction and separation, a single uranium product and athorium product are obtained through precipitation, and the recovery rate of resources such as uranium, thorium and rare earth is greater than 95%; and most of process water in the production processis directly returned to a system for cyclic utilization, a small amount of wastewater is recycled back to the system after comprehensive treatment, and zero drainage of the wastewater is realized. Bythe adoption of the technical scheme, the flow is simple and flexible, and large-scale production is achieved easily; the chemical material consumption is low, valuable resources such as rare earth,uranium and thorium can be efficiently recovered, and the resource recovery rate is increased; and the comprehensive treatment and environmental-friendly, efficient and clean production of the monazite resources are guaranteed.

Owner:湖南中核金原新材料有限责任公司

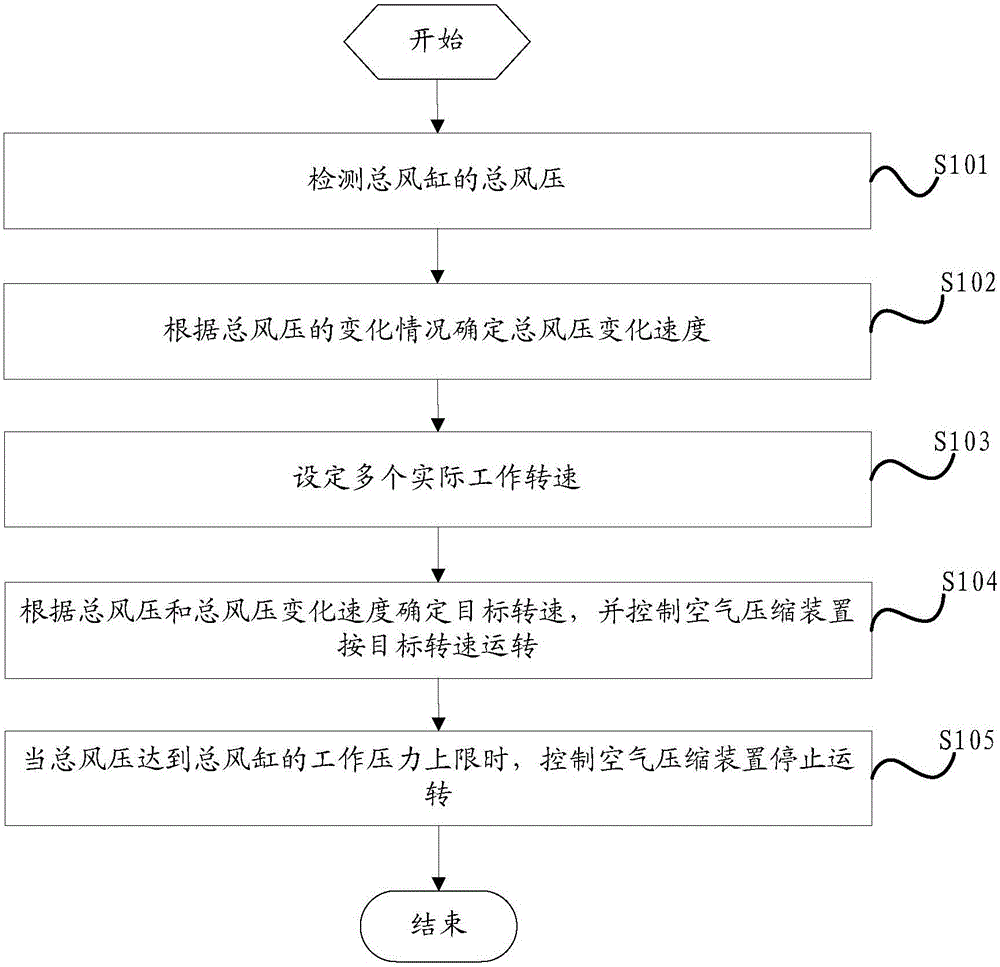

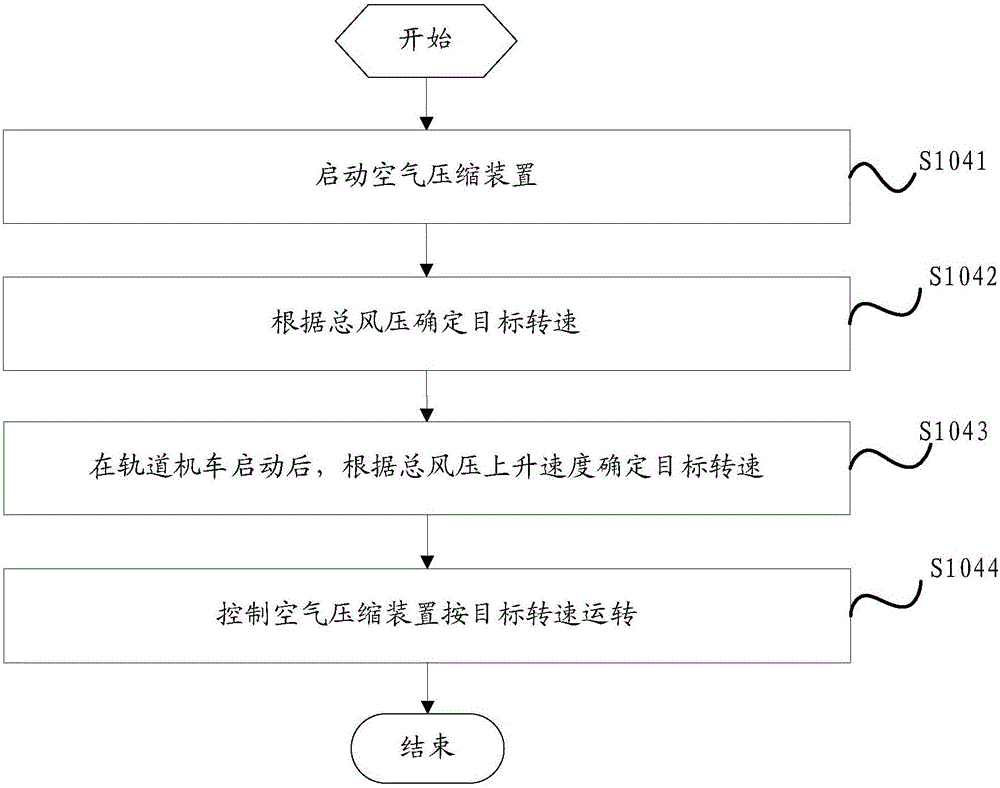

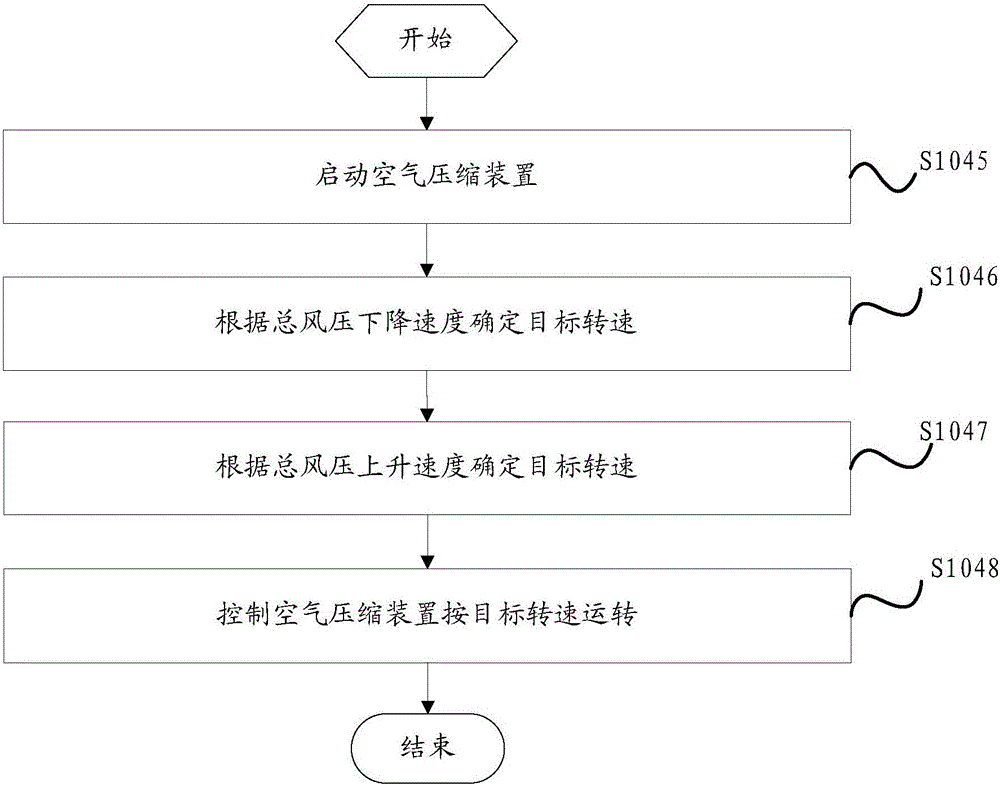

Operation control method, system and air compressor system

ActiveCN106438321AExtended single run timeSolve emulsification problemsPump controlPositive-displacement liquid enginesAxial compressorAir compression

The application discloses an operation control method, system and an air compressor system. The method and the system are used for controlling the air compressor system of track locomotives. The total blast pressure of a total air cylinder is detected; when the total blast pressure changes, the total blast pressure change rate is calculated according to the change conditions of the total blast pressure, wherein the total blast pressure change rate comprises the total blast pressure rising rate and the total blast pressure descending rate; multiple actual operating rotating rates which successively descend are determined according to the maximum operation rotating rate of the air compressing device; a target rotating rate is selected from the multiple actual operating rotating rates according to the total blast pressure and total blast pressure changes and the air comprising device is controlled to operate at the target rotating rate; when the total blast pressure value reaches at the maximum operating pressure of the total air cylinder, the air compressing device is controlled to stop rotating. The technical scheme of the application can solve the problem of emulsification of lubricant due to short single operation time of an air compressor system.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

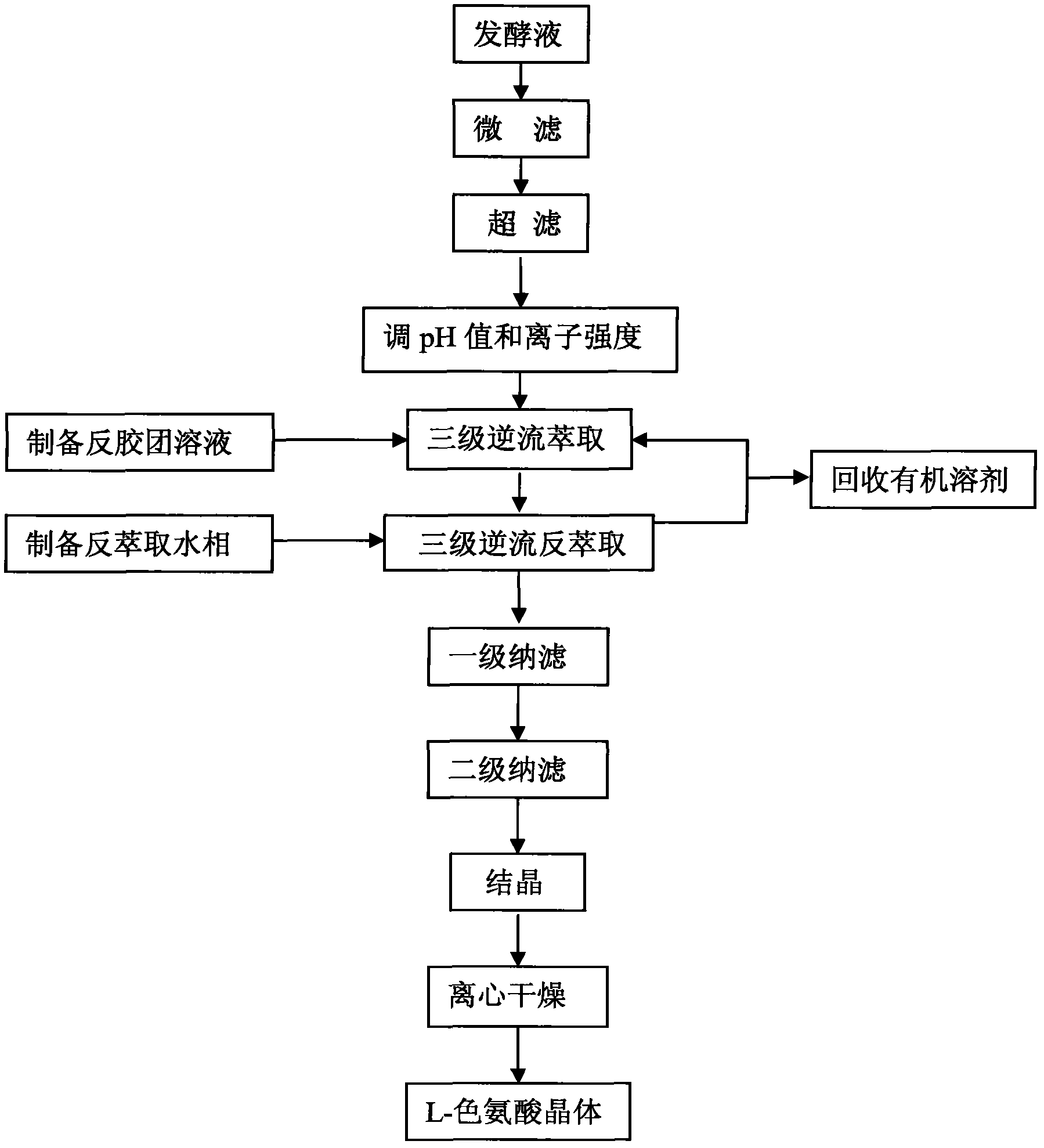

Separation and purification process for L-tryptophane

InactiveCN102382030AReduce maintenance costsSolve emulsification problemsOrganic chemistrySeparation technologyFermentation

The invention discloses a method for separating and purifying L-tryptophane from fermentation liquor. Through microfiltration, ultrafiltration and adjustment to pH values and ionic strength, three-stage counter-current extraction and three-stage counter-current back extraction are performed on dilute L tryptophane fermentation liquor by adopting reverse micelle extraction technology, and L-tryptophane with the content higher than 98.0 percent is obtained from aqueous phase enriched with L-tryptophane through secondary nanofiltration, crystallization and centrifugal drying. The method disclosed by the invention adopts the membrane separation technology, the reverse micelle extraction technology and the like, has the characteristics of high extraction yield, simple extraction process, speediness, effectiveness, recyclability in using extracting agent and the like, can save operating cost, and is convenient for industrial magnification and continuous operation.

Owner:北京明新高科技发展有限公司

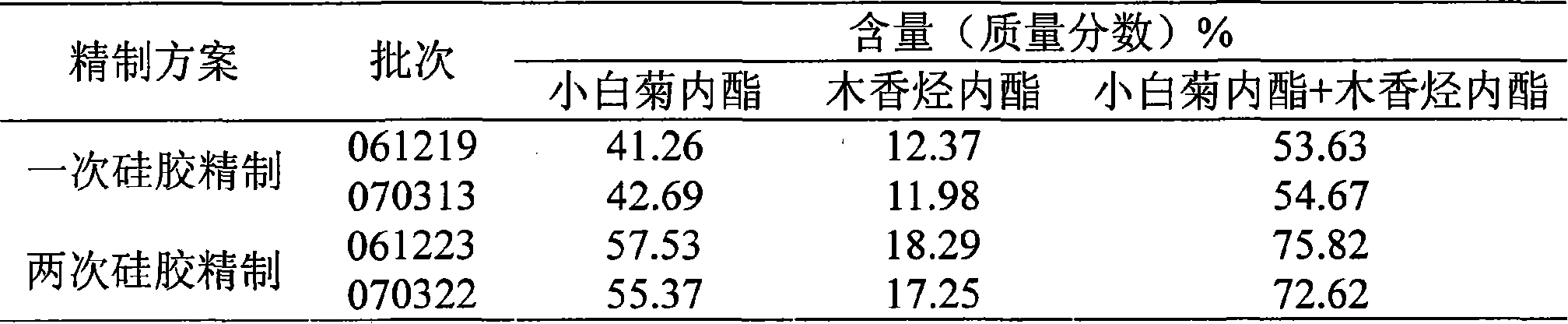

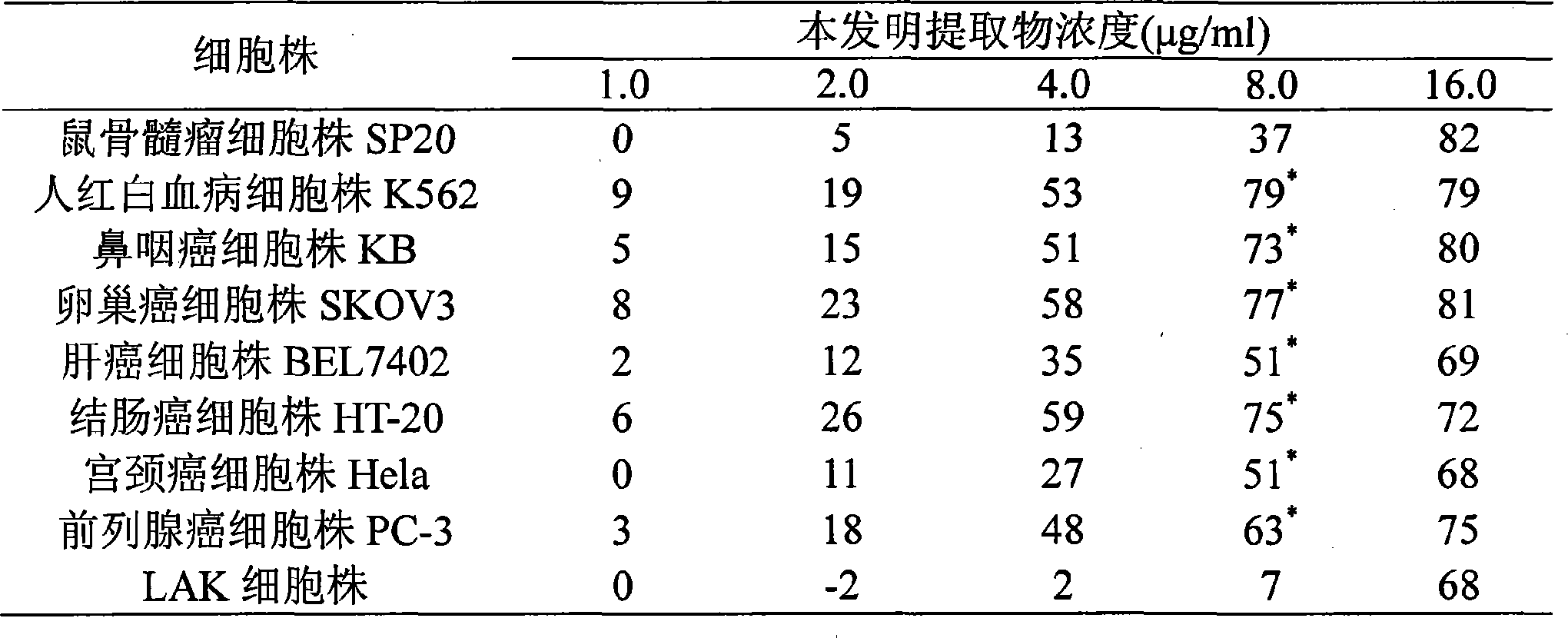

Southern magnolia total lactone extract and preparation method and application thereof

InactiveCN101190259AAvoid emulsificationAvoid lostAntineoplastic agentsPlant ingredientsOrganic solventSilica gel

The invention relates to a yulan magnolia total lactone extract, the preparation method and application thereof. Yulan magnolia leaves and / or flower is extracted with ethonal after being soaked in water; crude lactone can be obtained by low polarity organic solvent extract; the crude lactone is treated with the silica-gel column chromatography to obtain the extract of the invention. The invention has simple and feasible technique, definite components of the extract, and is suitable for industrialized production. The yulan magnolia total lactone in the invention has anti-tumor function, and can be used for preparing drugs with anti-tumor effects.

Owner:BEIJING SUNHO PHARMA

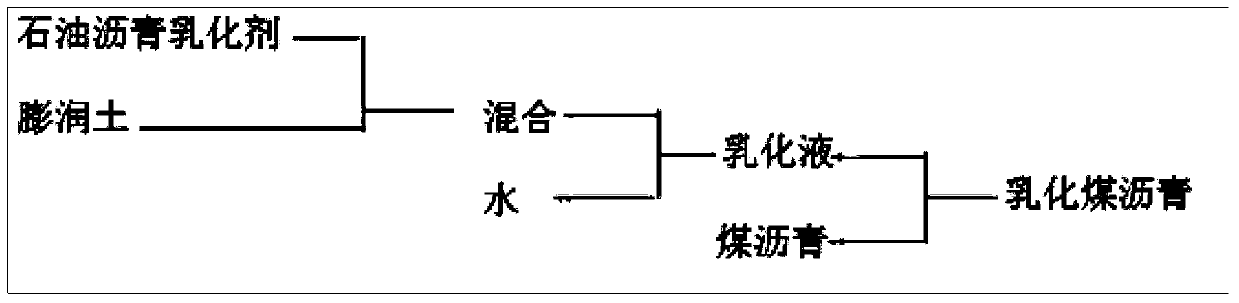

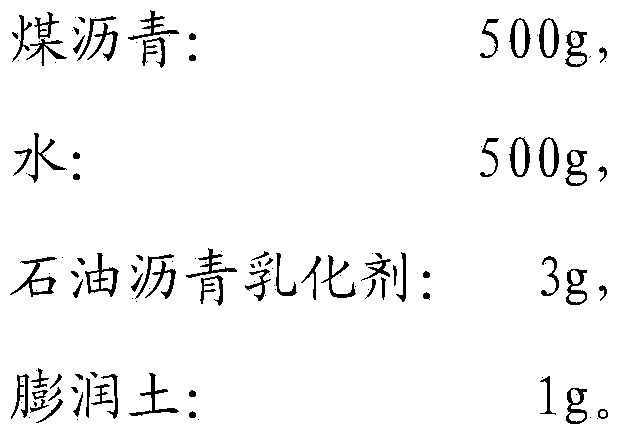

Emulsified coal tar pitch

InactiveCN103819916AFix stability issuesSolve emulsification problemsBuilding insulationsEmulsionCoal Tar Pitches

The invention discloses an emulsified coal tar pitch which is prepared from the following raw materials: 500 g of coal tar pitch, 500 g of water, 3 g of an asphalt emulsifier and 1 g of bentonite. A preparation method of the emulsified coal tar pitch comprises the following steps: adding bentonite into the asphalt emulsifier; mixing the mixture of bentonite and the asphalt emulsifier with water to obtain an emulsion; and using coal tar pitch and the emulsion to prepare the emulsified coal tar pitch. According to the preparation method of the emulsified coal tar pitch, coal tar pitch is emulsified by adding bentonite into the asphalt emulsifier. Thus, problems of coal tar pitch emulsification and stabilization after emulsification are solved.

Owner:SHANXI YUANZHENG CHEM CO LTD

Process for preparing Danshensu

InactiveCN1303052CSolve emulsification problemsReduce lossCarboxylic compound separation/purificationAlcoholUltrafiltration

The invention relates to a method for preparing danshensu which comprises: getting extract liquid from the water or alcohol with danshensu and danshensu precursors using danshen as the materials, inverting the danshensu precursors of the said extract liquid into danshensu using diluted alkali, super filtering the macromolecular substance of the said extract liquid after conversion using a hyperfiltration membrane, extracting the danshensu from the said extract liquid after hyperfiltration, and separating the said extraction using the normal phase chromatography to get the danshensu.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

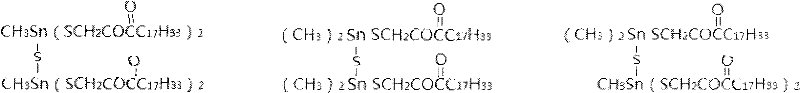

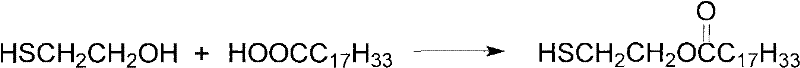

Preparation method of sulfur bridge-containing reverse ester thiol methyltin

The invention discloses a preparation method of sulfur bridge-containing reverse ester thiol methyltin. The method comprises two stages: in a first stage, preparing mercaptoethanol oleate, and controlling the vacuum degree in a first reaction container to descend stepwise in a reacting process; and in a second stage, preparing sulfur bridge-containing reverse ester thiol methyltin by taking mercaptoethanol oleate obtained at the first stage as a raw material, dropwise adding a methyl tin chloride aqueous solution and a sodium sulfide aqueous solution into the mercaptoethanol oleate simultaneously, and undergoing a condensation reaction and a bridging reaction simultaneously to control sulfur atoms in sodium sulfide and tin atoms in methyl tin chloride to be connected in a sulfur bridge form. The preparation method is easy to implement, the problems of emulsification, saponification and the like in a production process can be solved effectively, and the productivity and production efficiency are increased; and meanwhile, the ratio of a sulfur bridge is controlled, so that the thermal stability of a product is in an optimal state.

Owner:HUBEI NANXING CHEM GENERAL FACTORY

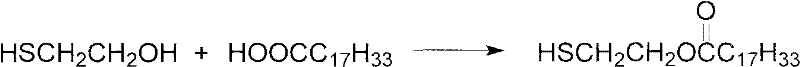

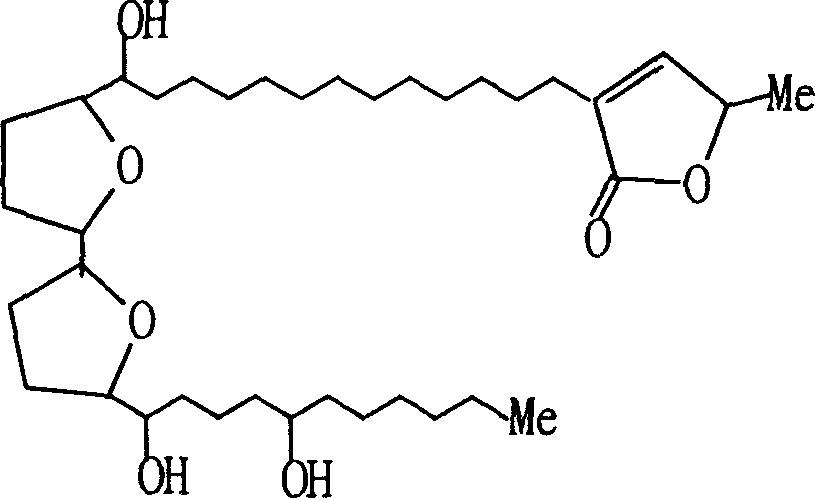

Anti-tumour effective constituent cherimoya essence preparation method

InactiveCN1544423AHigh puritySolve emulsification problemsOrganic active ingredientsOrganic chemistryChemistryColumn chromatography

Owner:浙江康恩贝药品研究开发有限公司

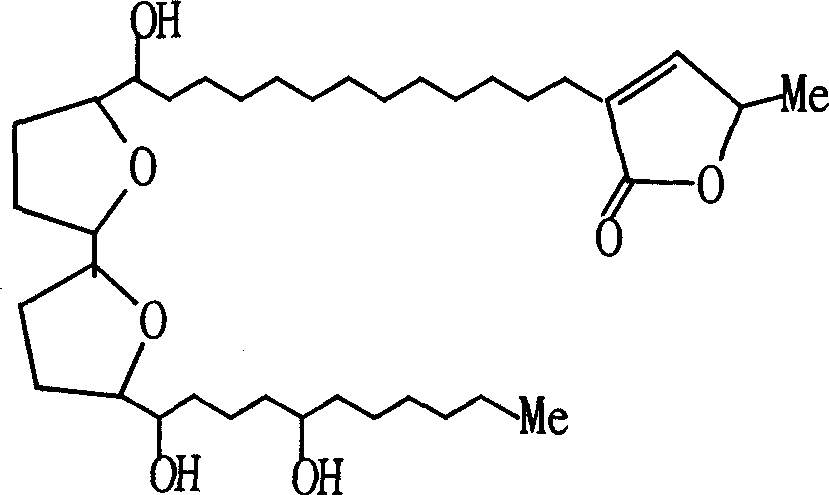

Method for processing base oil of tea oil cosmetic

ActiveCN105296145ASolve emulsification problemsImprove qualityCosmetic preparationsToilet preparationsLife qualityNational standard

The invention discloses a method for processing base oil of a tea oil cosmetic. The method comprises the steps that 1, tea oil squeezed crude oil meeting the national standard is finely filtered, and a citric acid solution accounting for 0.02% of oil weight is added; 2, after an acid reaction, caustic soda liquid is added at normal temperature for an alkali reaction, and after the tea oil is heated, soap removing is carried out; 3, acid is added to the tea oil obtained after soap removal, washing is carried out, and after the washed oil is subjected to vacuum drying, polishing filter is carried out; 4, the tea oil obtained after polishing filter is heated, and meanwhile a mixed decolorising agent is added for decoloration in a bleaching tower; 5, the decolored oil is deodorized at low temperature; 6, the deodorized oil is winterized and filtered, and then the base oil of the tea oil cosmetic is obtained if the oil passes inspection. After the method is adopted, the color reversion problem of the base oil is solved, the micronutrient content of the product is effectively increased, production cost is obviously reduced, the processing rate is greatly increased, the product can be directly smeared as suntan oil and can also be used for daily skin care, and the life quality of people is improved.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Method for processing poor organic phase after solvent extraction indium extracting

InactiveCN103014338ASolve emulsification problemsSolve agingProcess efficiency improvementIndiumPickling Agents

Disclosed is a method for processing a poor organic phase after solvent extraction indium extracting. The method includes: A, poor organic phase regeneration, namely, mixing the poor organic phase after solvent extraction indium extracting with regenerant, standing for layering, and separating to obtain a regenerated organic phase, wherein the regenerant is a mixture of oxalic acid and hydrofluoric acid; B, dechlorinating, namely, mixing the regenerated organic phase with water, standing for layering, and separating to obtain a dechlorinated organic phase; and C, acid pickling, namely, mixing the dechlorinated organic phase with pickling agent sulfuric acid solution for acid pickling, standing for layering, and separating to obtain a purified organic phase. By the method, the poor organic phase is continuously purified and regenerated, so that impurities such as iron, arsenic, tin, silicon dioxide, antimony, chlorine entrained in the organic phase are eliminated, and the service life of the organic phase is prolonged. In addition, by the method, the rate of removal of chlorine in the poor organic phase is higher than 85wt%, and a condition for subsequent recovery of zinc in indium extracting residual liquid is provided.

Owner:ZHUZHOU SMELTER GRP

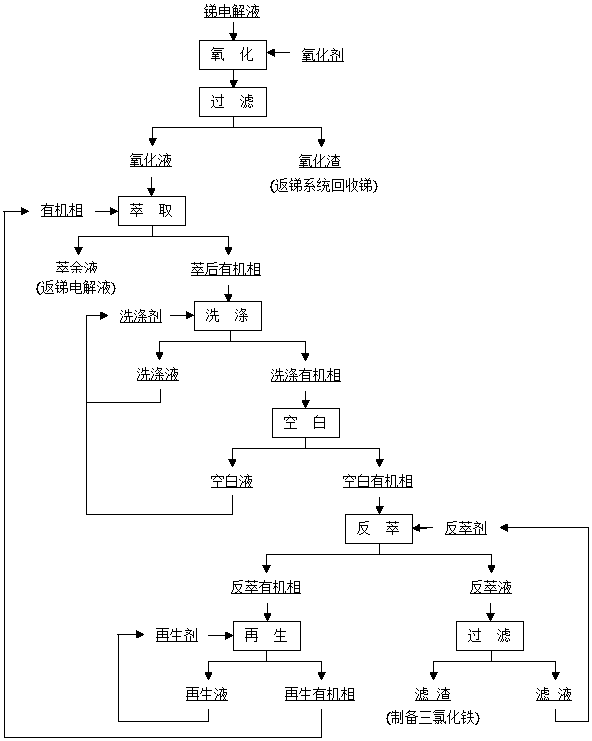

Purifying method of pulp electrolyte containing antimony concentrates

ActiveCN107916434AReduce entrainmentEliminate the effects ofElectrolysis componentsChemical recyclingIonSodium carbonate

The invention discloses a purifying method of pulp electrolyte containing antimony concentrates. The purifying method comprises the following steps: (A) oxidation: part of divalent iron ions are oxidized as trivalent iron ions; (B) extraction: oxide liquid and an organic phase are mixed in a mixing tank for extraction; (C) washing: less antimony in the organic phase is transferred into washing liquid; (D) blank: a washing organic phase flows to clarifying tank component phases on a blank stage by the mixing tank; (E) reverse extraction: such substances as iron, copper and silicon dioxide in the organic phase are transferred into sodium carbonate solution to generate precipitations; and (F) regeneration: the reversely extracted organic phase is mixed with a prepared regeneration agent in the mixing tank for regeneration. The purifying method solves the problem the entrainment problem of antimony in the organic phase, and realizes recycling of the organic phase.

Owner:ZHUZHOU SMELTER GRP

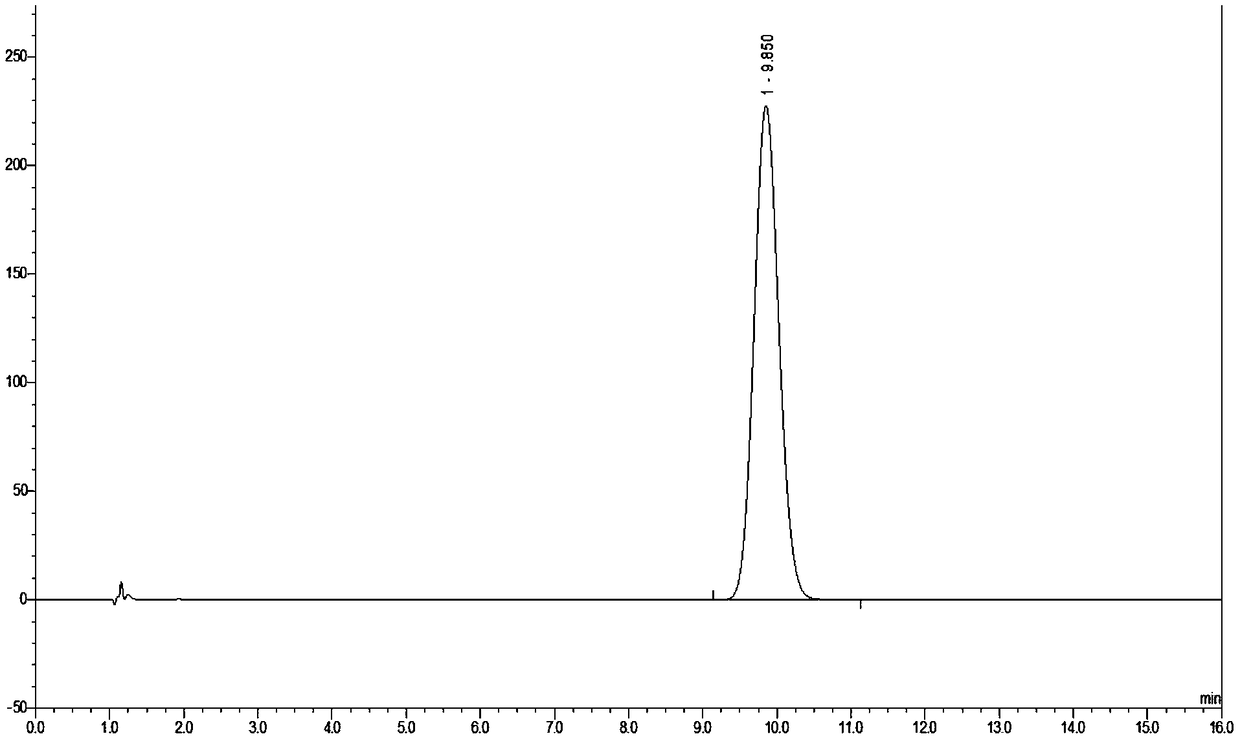

Extracting-purifying method for coenzyme Q10 and prepared coenzyme Q10

The invention relates to an extracting-purifying method for coenzyme Q10 and prepared coenzyme Q10. The extracting-purifying method is used for extracting coenzyme Q10 from coenzyme Q10 thallus, and purifying the extracted coenzyme Q10. The method comprises the following steps of extraction, precipitation, decolorization and chromatography. Impurities such as bacterial pigments, nonpolar lipids, neutral lipids, polar lipids and quinones homologs are removed specifically. The method has the advantages of simple operation steps, and small product loss. The product coenzyme Q10 can be 99.8 percent or more in purity, and can be 98.5 percent or more in total yield.

Owner:ZHEJIANG NHU CO LTD +2

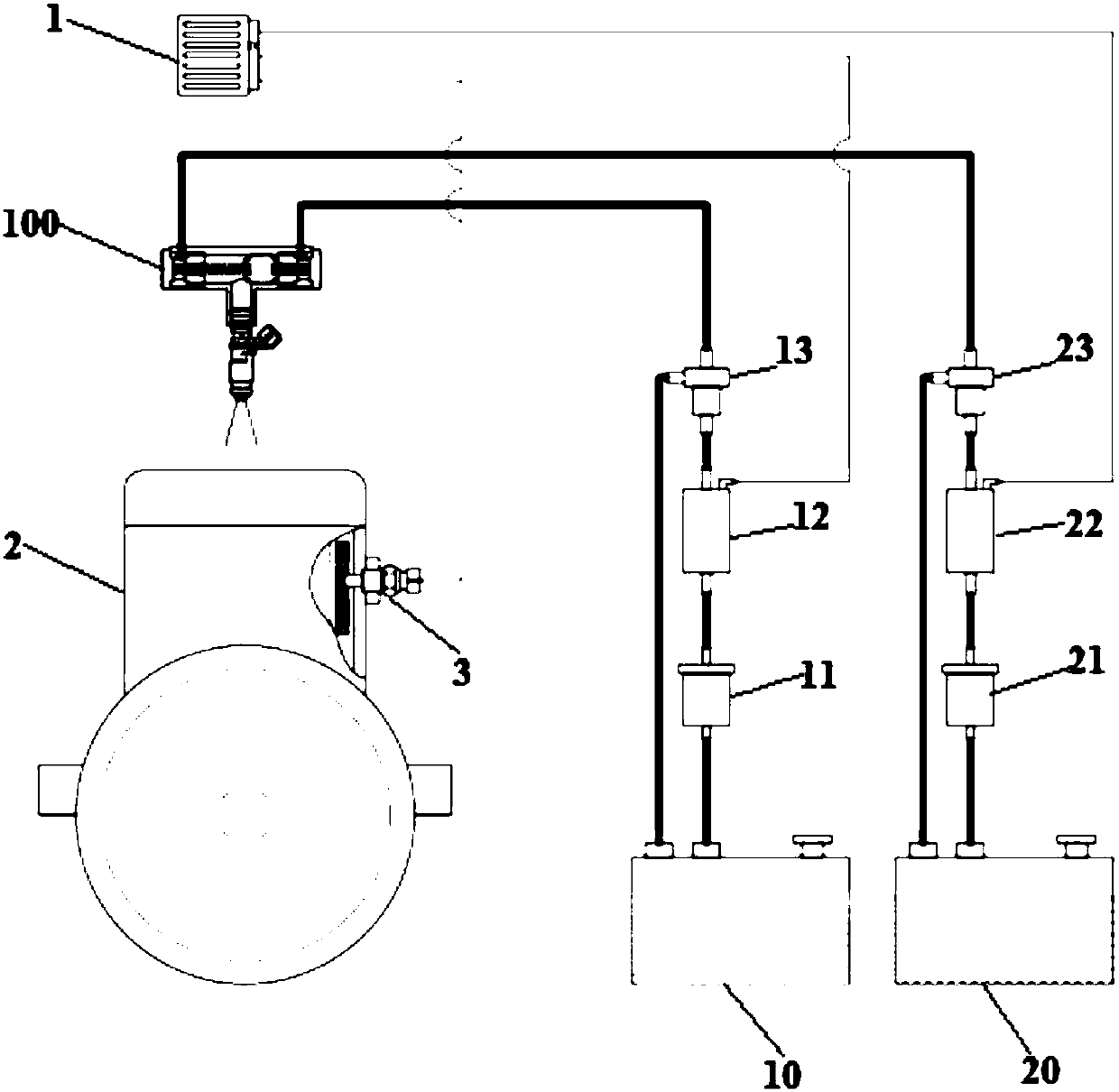

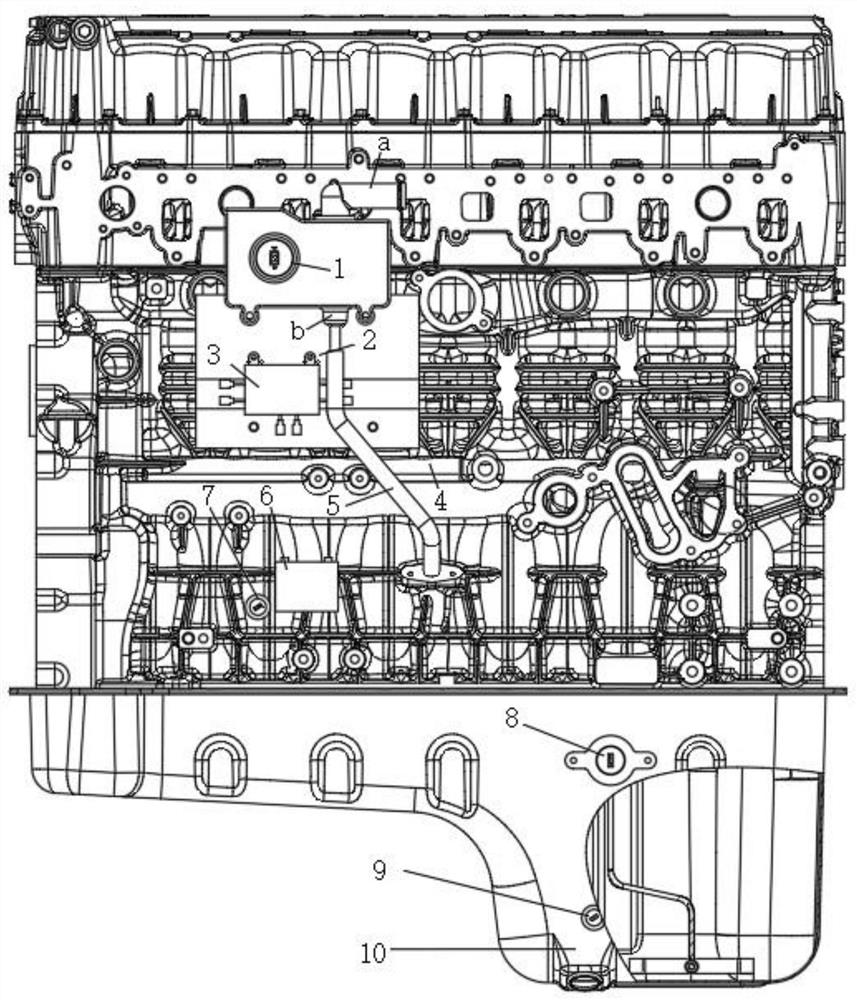

Dual-fuel supply device used for vehicle, engine system and vehicle

InactiveCN107842430AAchieve normal drivingSimple structureInternal combustion piston enginesEngine controllersEngineeringFuel supply

The invention provides a dual-fuel supply device used for a vehicle, an engine system and the vehicle. An engine of the vehicle can work under a work mode of any one fuel of dual fuels. The dual-fuelsupply device comprises a shell, two oil supply structures and a piston structure, wherein the shell is provided with two oil inlet ports and one oil outlet port; the two oil inlet ports are located in the side walls close to the two ends of the shell; the two oil supply structures are located inside a cavity of the shell and extend out of the two ends of the shell, so that the fuel entering any one oil supply structure through the corresponding oil inlet port is supplied to a cylinder of the engine through the oil outlet port, and is combusted to generate power; and the piston structure is located inside the cavity of the shell and located between the two oil supply structures, so that the dual fuels are prevented from being mixed in the cavity of the shell or one fuel is prevented from entering the oil outlet port operating under a work mode of the other fuel. The problems that a dual-fuel supply spraying rail structure is complex, compactness is low, and consequently arrangement isdifficult in the prior art are solved.

Owner:ZHEJIANG GEELY NEW ENERGY COMML VEHICLES CO LTD +1

Extractor with circumrotating and stabilizing type magnetic stirring

The invention relates to an extraction device in magnetic mixing dispersion system adopting acidity hydrophobic ionic liquid with magnetic function as extractant. There is a reaction tank, of which the bottom middle part is concave. In the concave groove there is a vertical round Nd-Fe-B permanent magnet connected with the shaft of rotary motor. The outlet port for magnetic ionic liquid is set on the wall at one side of lower part of reaction tank. The inlet port for magnetic ionic liquid and inlet port for substance liquid are set on the wall at the other side. Magnetically stabilized bed coil is set on the outer side wall of upper part of reaction tank. Liquid inlet port of a ring dispersion device is docked with the port for substance liquid in the reaction tank. The magnetically stabilized bed coil controls mutual impact and condensation of magnetic ionic liquid pearls with dispersion phase. The extraction device realizes two operation states of one tower. Water solution in magnetic ionic liquid phase is in dispersion phase and ionic liquid in water solution phase is in dispersion phase. So entrainment phenomena are decreased. The device power is far lower than normal mixing device and energy consumption in extraction process is decreased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

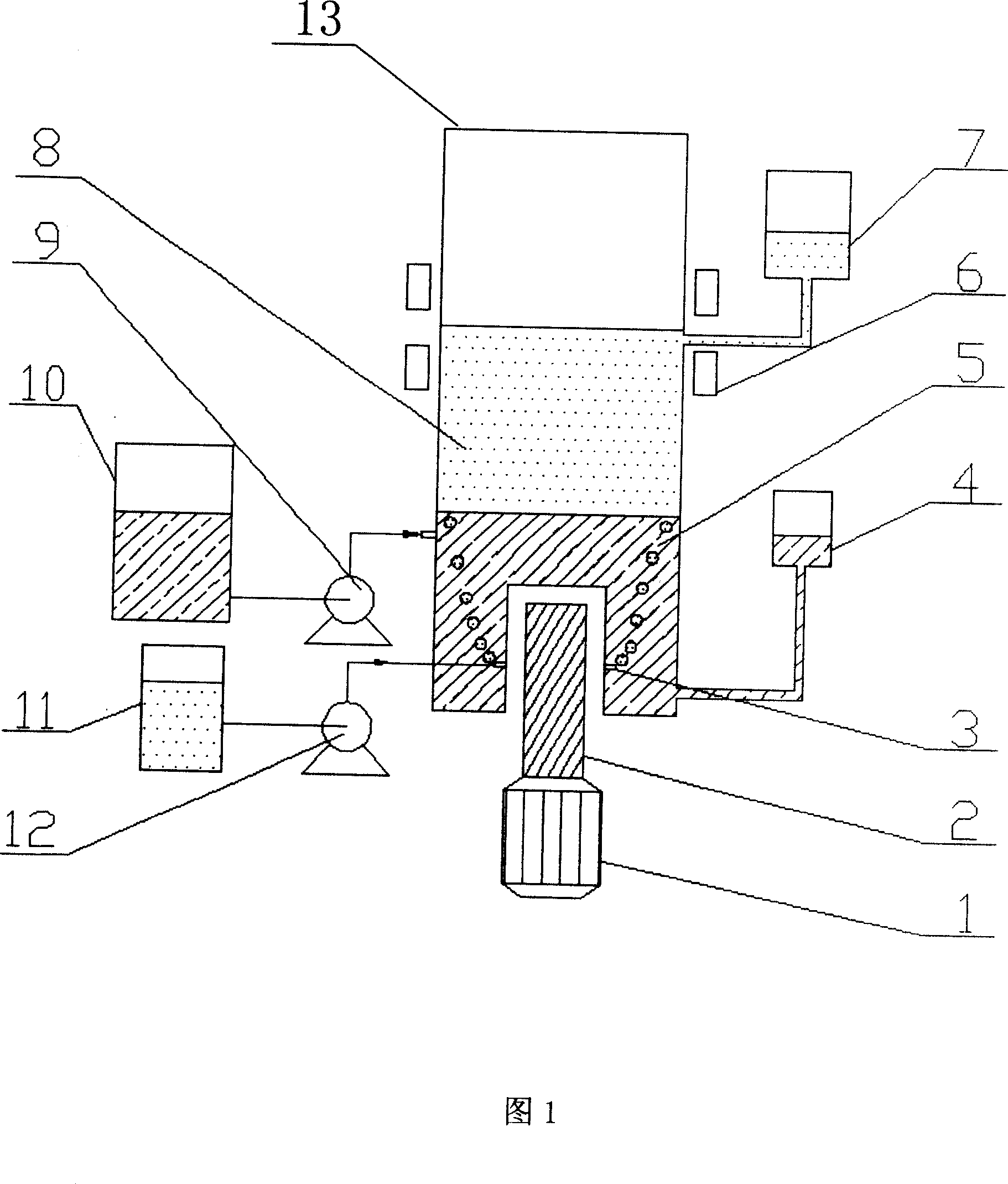

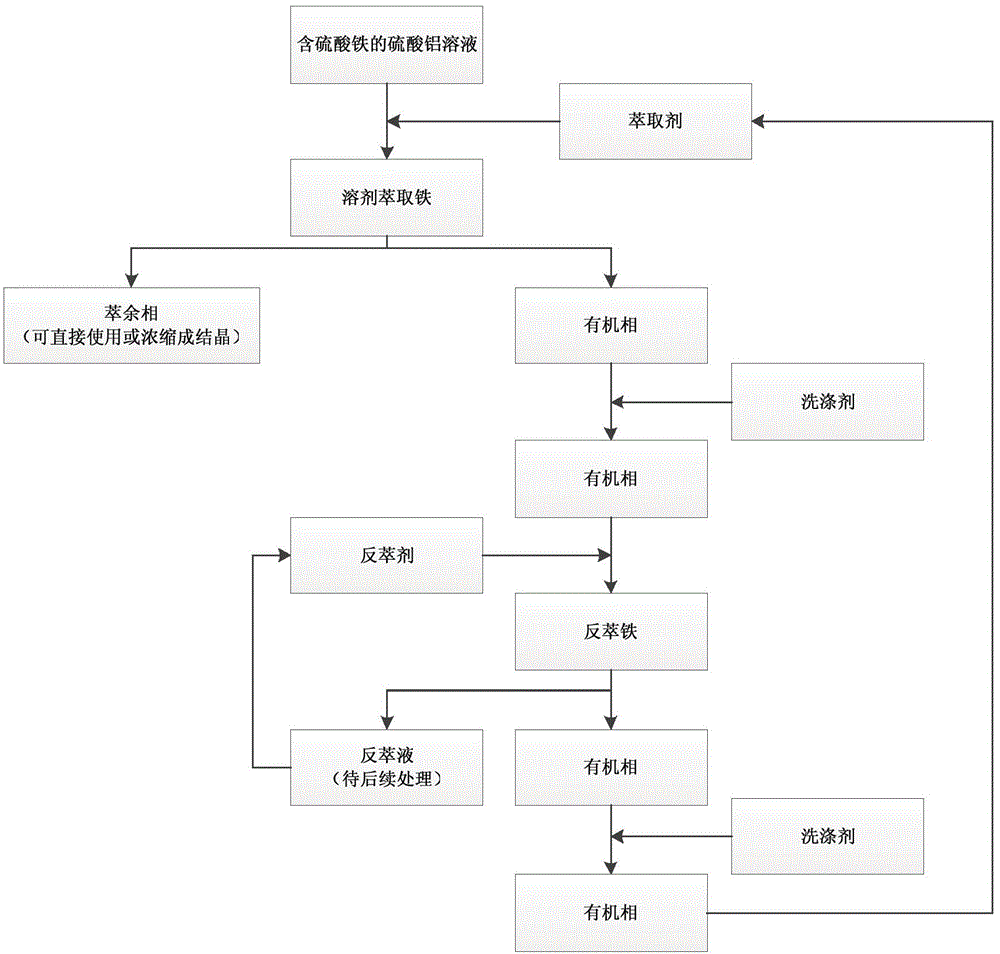

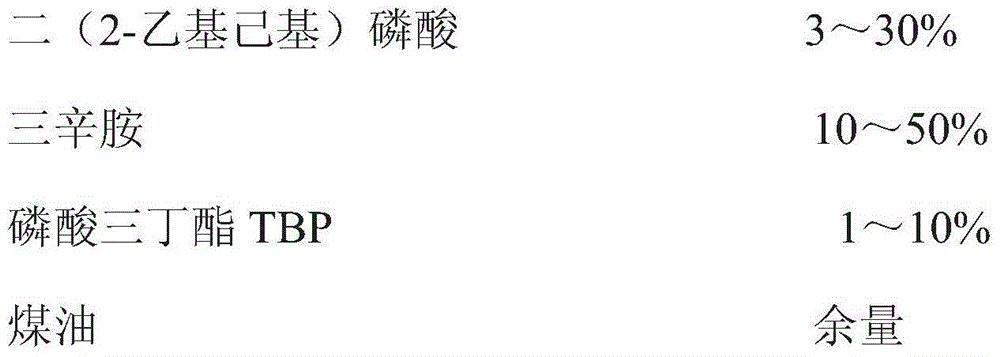

Compound ferric sulfate extractant

ActiveCN105314665ASolve emulsification problemsReduce extraction timeLiquid solutions solvent extractionAluminium sulfatesIron sulfatePhosphate

The invention relates to a compound ferric sulfate extractant. The main components of the extractant comprise one or more of 2-ethylhexylphosphoric acid mono-2-ethylhexyl ester, bis(2-ethylhexyl)phosphate, trioctylamine, and TBP, and the diluent is kerosene. The technical problem of separating ferric sulfate from aluminum sulfate is effectively solved. The extractant has the advantages that a modifier namely TBP is used in the extraction system, the problems of extractant emulsification and phase separation in extraction are effectively solved, the extraction time is shortened, the cost is saved; only through a primary treatment, the extraction rate and reverse extraction rate can exceed 97%, the processed aluminum sulfate can be used as a raw material to produce metallurgy level alumina; the extractant can be used repeatedly, the flow is simple, the process is environment-friendly, the separation effect is good, the production efficiency is high, the cost is low, and the extractant can be applied to industry easily.

Owner:EAST CHINA UNIV OF SCI & TECH

Delayed-coking exhaust gas treatment method

InactiveCN106914068AOptimize the venting processExtended operating cycleFatty/oily/floating substances removal devicesDispersed particle filtrationExhaust gasEngineering

The invention discloses a delayed-coking exhaust gas treatment method. According to the method, sulfur-bearing sewage enters a steaming-out vent tower for cooling and oil-water separation, part of heavy sump oil of a tower bottom of the steaming-out vent tower flows back to the bottom of steaming-out vent tower, the other part of the heavy sump oil enters the middle part of the steaming-out vent tower, light sump oil and sewage of a tower top of the steaming-out vent tower enter an oil-water separating tank for oil-water separation at the temperature of 30 DEG C to 60 DEG C, the light sump oil is discharged from the top of the oil-water separating tank, the sewage enters a sewage tank for treatment, by the treatment of the sewage tank, coke powder is discharged from the bottom of the sewage tank, the light sump oil is discharged from the upper part of the sewage tank, and purified sewage is discharged from the lower part of the sewage tank. According to the method, the problem that sulfur-bearing sewage of the top of the vent tower is emulsified and is high in oil and coke powder content is solved.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

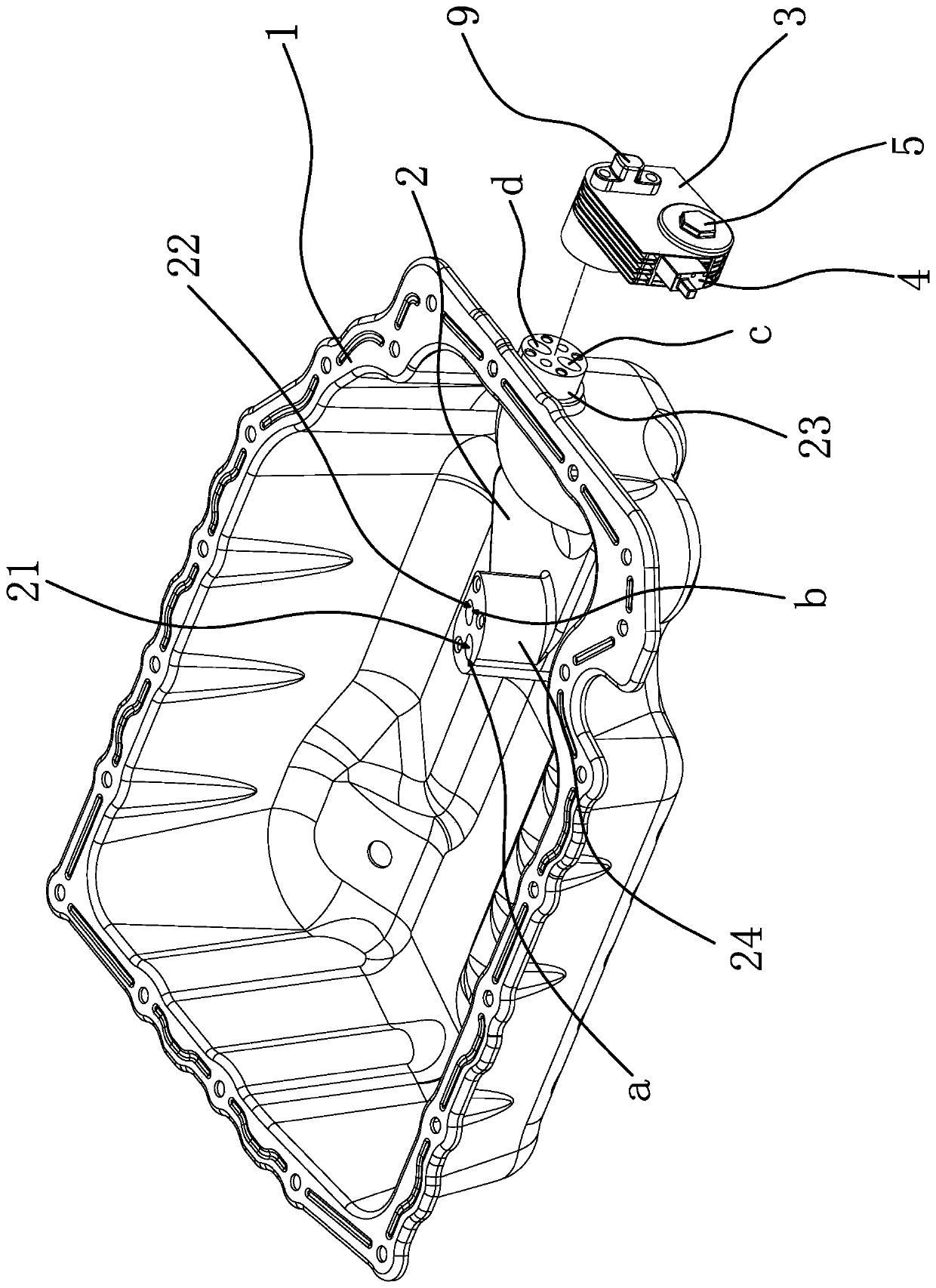

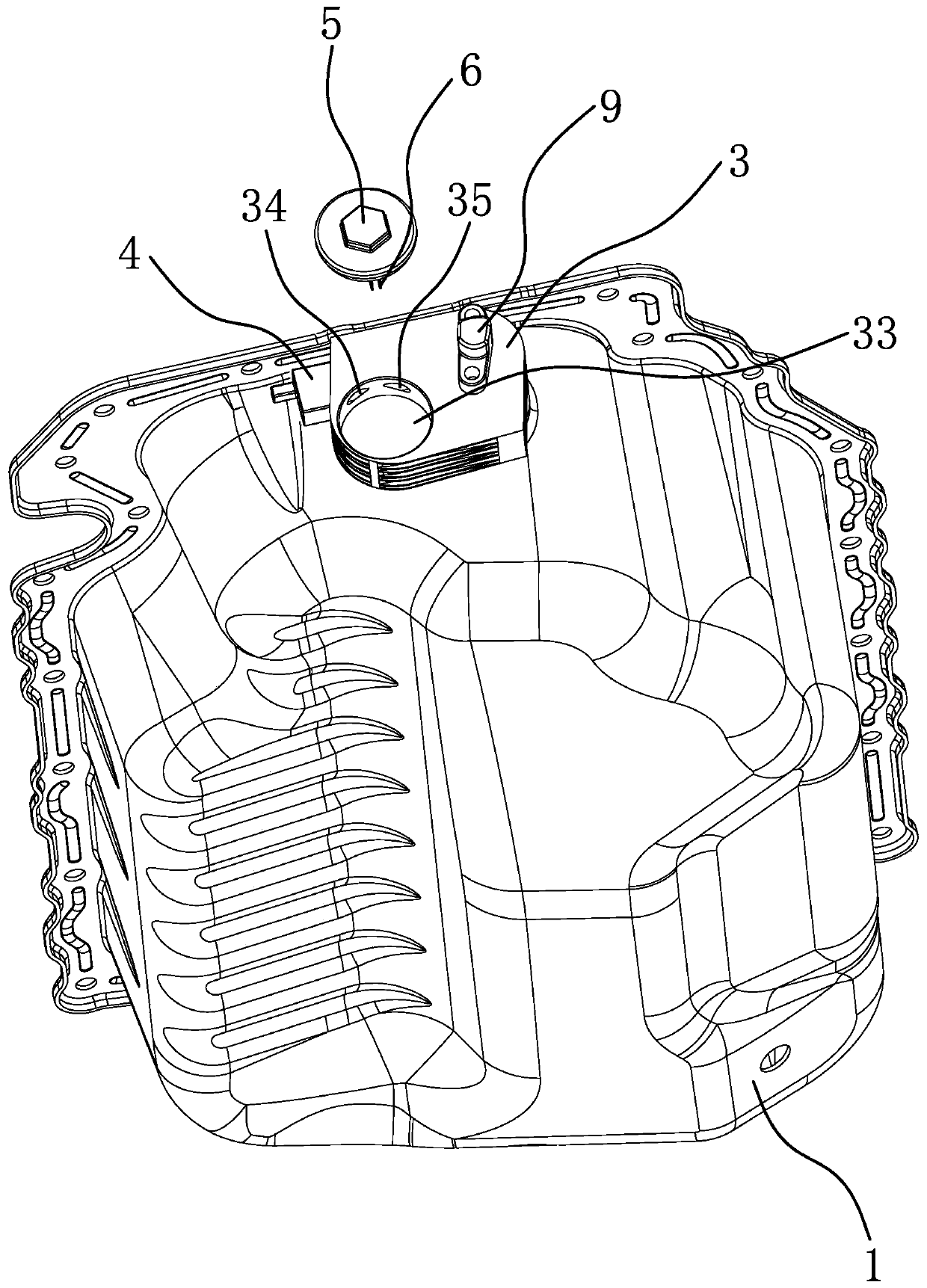

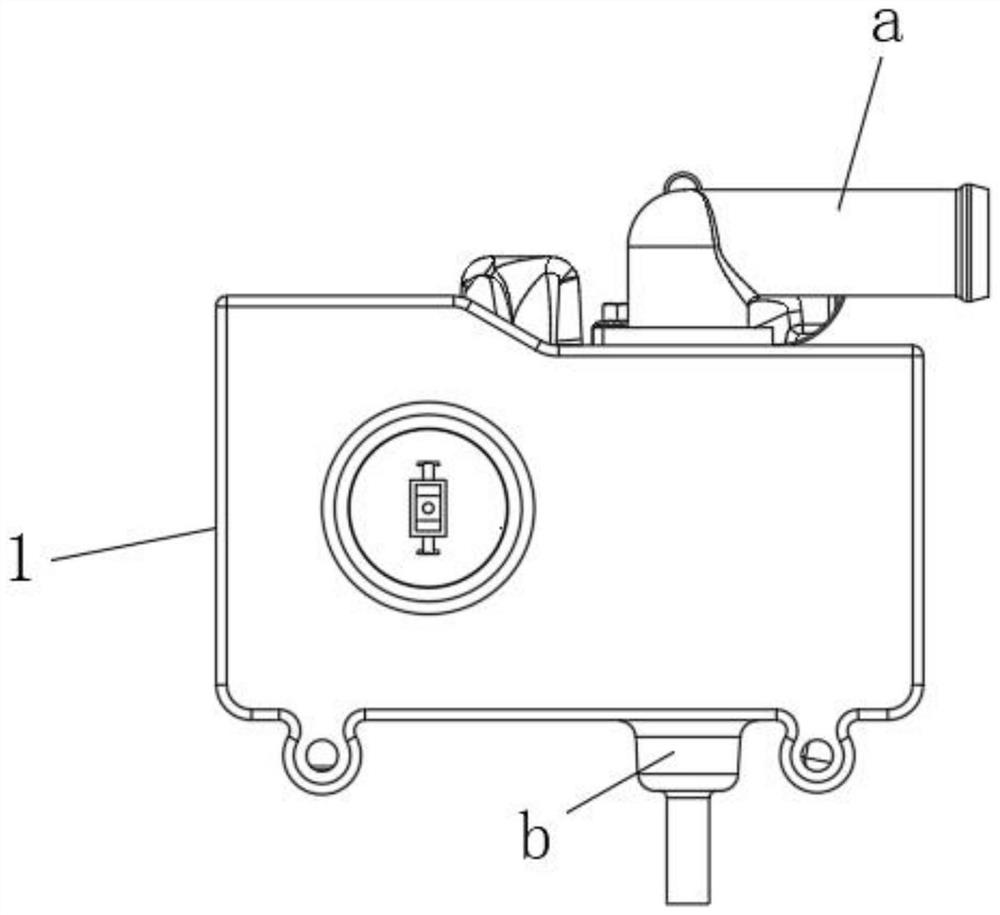

Oil pan assembly

ActiveCN111058920ASolve emulsification problemsSolve the icingEvaporator accessoriesOilsumpsOil canAir pump

The invention provides an oil pan assembly, and belongs to the technical field of oil pans. The oil pan assembly solves the problem that water in engine oil can not be removed in the short-distance starting and stopping process of an existing vehicle. The oil pan assembly comprises an oil pan and an electric heating block at least partially arranged in the oil pan, wherein the electric heating block is internally provided with a gas inlet channel and a gas outlet channel, and a gas inlet of the gas inlet channel and a gas outlet of the gas outlet channel are both positioned in the oil pan; andthe oil pan assembly also comprises a crankcase ventilation shell positioned outside the oil pan, wherein a condensation channel is arranged in the crankcase ventilation shell, one end of the condensation channel is in communication with the gas inlet channel, the other end of the condensation channel is in communication with the gas outlet channel, and an electric gas sucking pump communicatingwith the condensation channel is arranged on the crankcase ventilation shell. The oil pan assembly can remove the water in the engine oil in the short-distance starting and stopping process of the vehicle.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS +1

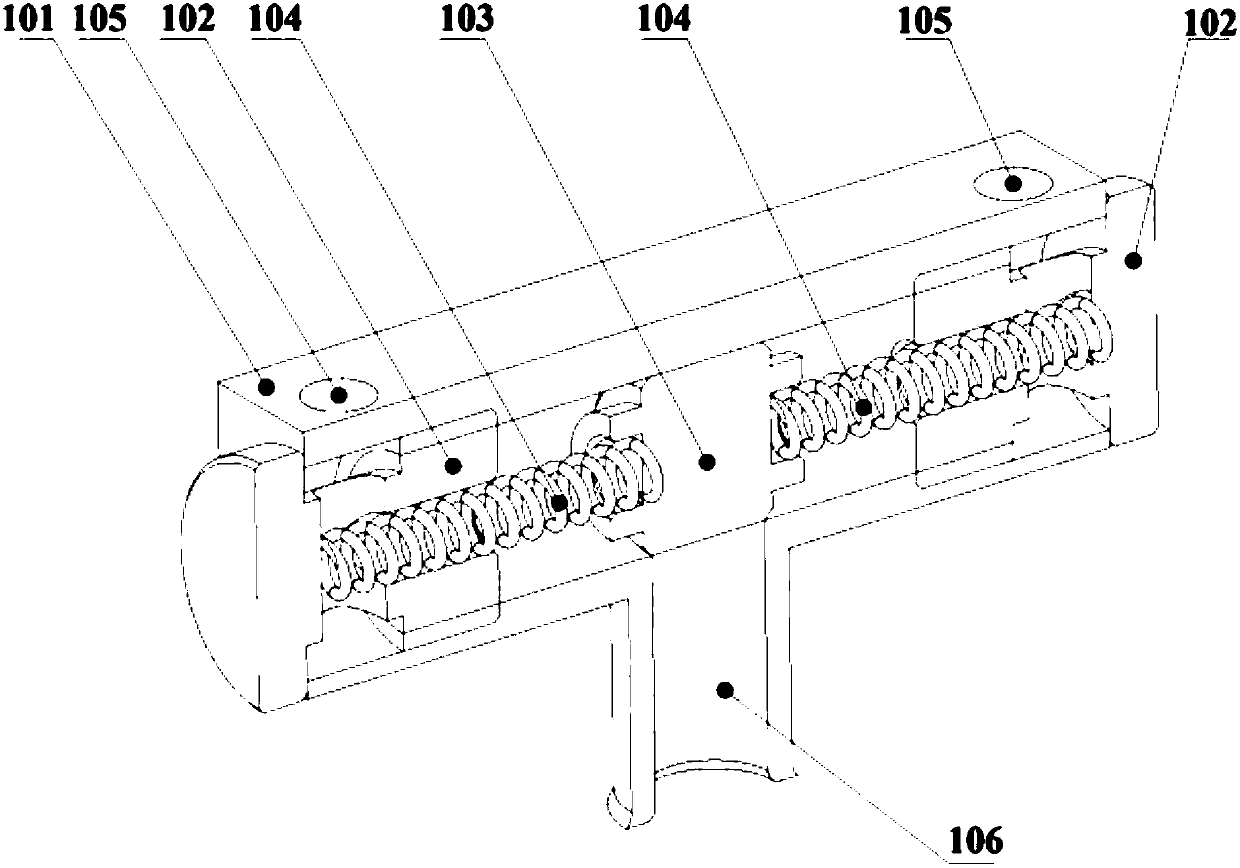

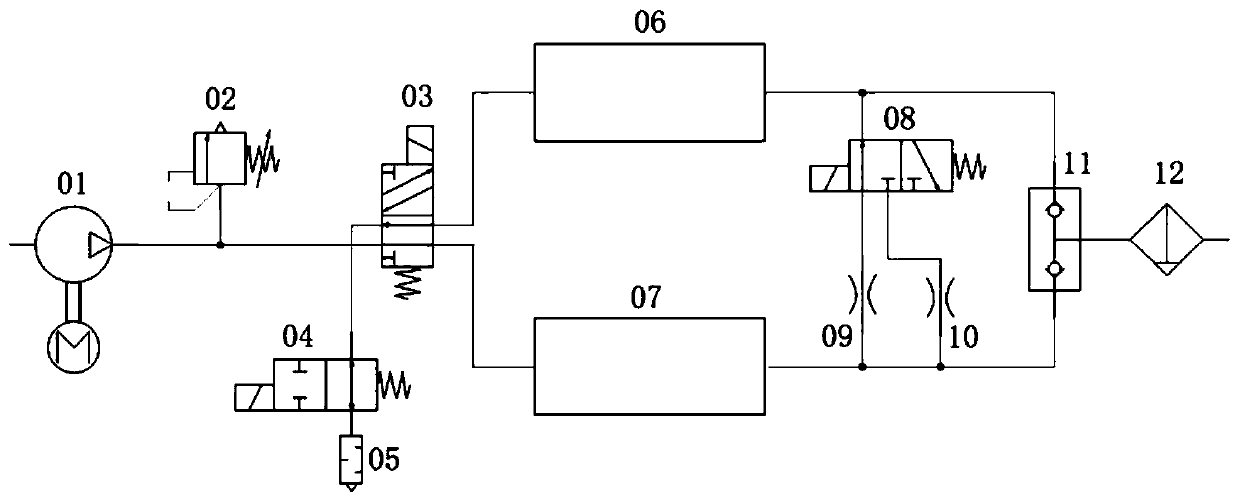

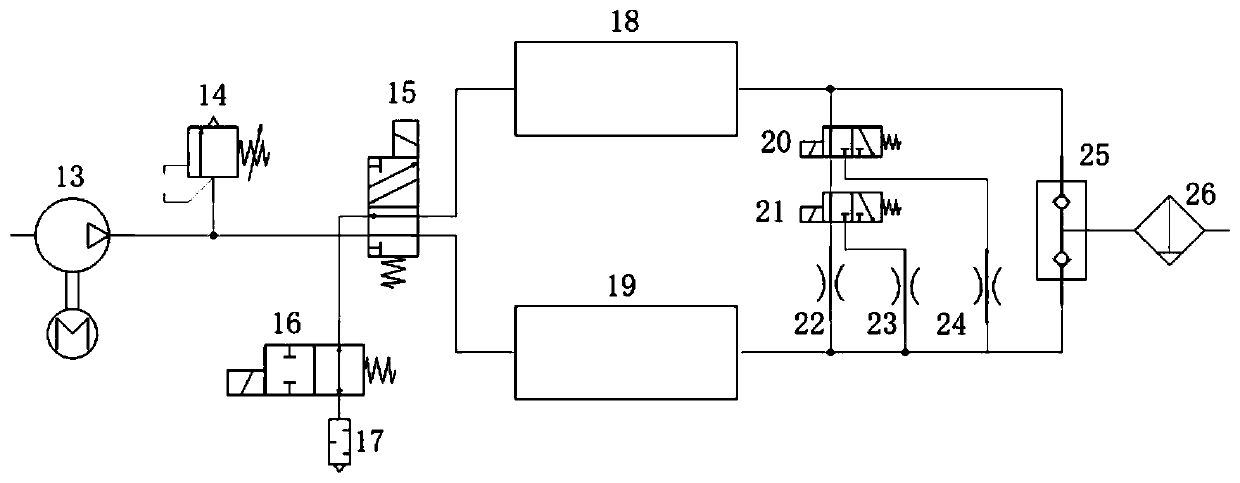

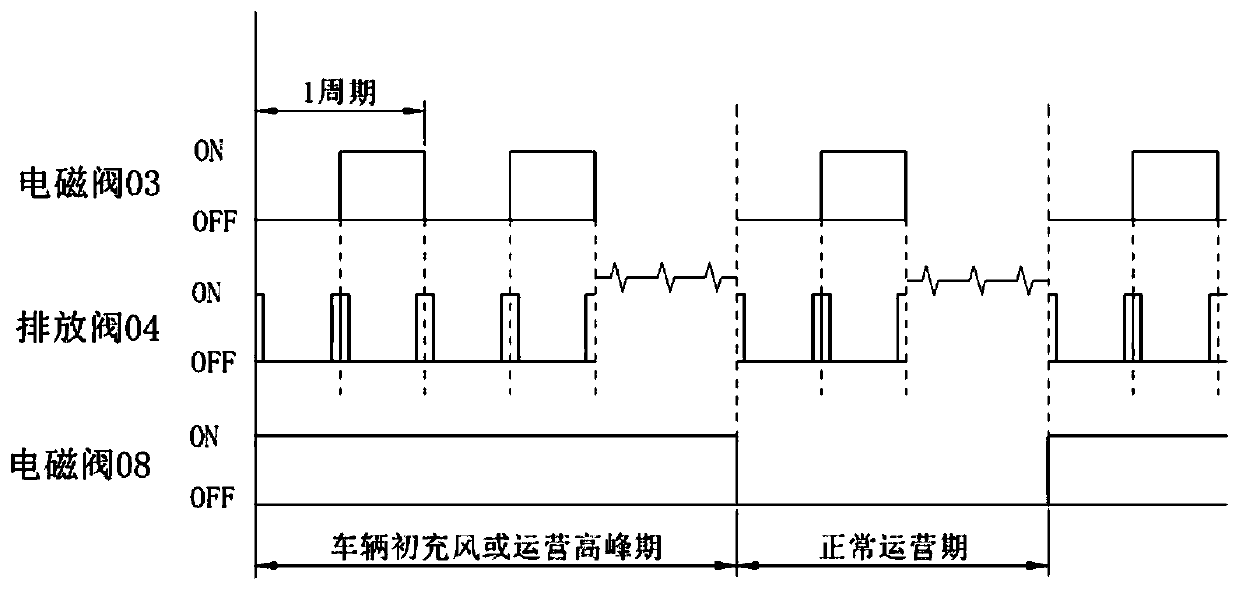

Train wind source system and lubricating oil emulsification prevention method

ActiveCN110497896ASolve emulsification problemsImprove operating rateBraking action transmissionPump/compressor arrangementsEngineeringTower

The invention provides a train wind source system and lubricating oil emulsification prevention method. A first valve and a second valve are adopted for switching backflow branches with different displacements to carry out grading adjustment on flow of compressed air flowing through a drying tower, thus the final displacement of a wind source system is adjusted, and at the premise of meeting the requirement for normal wind use of a train, the wind source system has a large displacement during the passenger peak season and the vehicle starting initial wind supplementing stage, and has a relatively small displacement during the normal operation period or other working conditions with few passengers. The system and the method have the final effect that the wind source system always maintainsa high operation rate during the train operation period, and therefore the problem of emulsification of lubricating oil of the system is solved.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

Anti-tumour effective constituent cherimoya essence preparation method

InactiveCN1228334CHigh puritySolve emulsification problemsOrganic active ingredientsOrganic chemistryOrganic solventAdditive ingredient

The invention provides a process for preparing Fanlixin, an active antineoplastic ingredient in custard apple from custard apple seeds as raw material through organic solvent extraction, abstraction, preparing custard apple total lactone, refined isolation through column chromatography and / or reversed phase C18filling column. The Fanlixin content amounts to above 90.0%.

Owner:浙江康恩贝药品研究开发有限公司

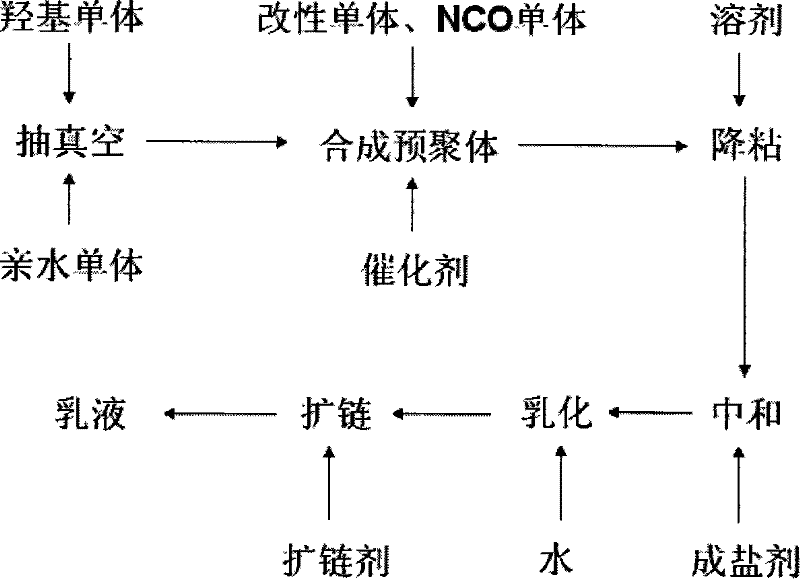

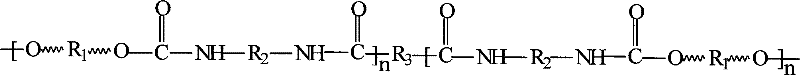

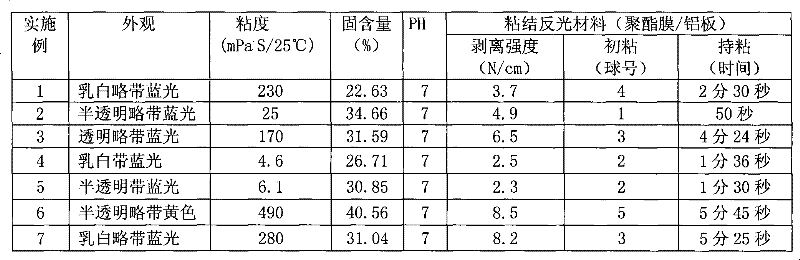

Preparation method of waterborne polyurethane adhesive and application in roads reflecting material

ActiveCN101284980BImprove performanceAdaptablePolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentHydrophilic monomerEpoxy

The invention relates to the nano-powder preparation field, in particular to a method for preparing nearly spherical nanometer oxide powder having good monodispersity and uniform particle size distribution with ultrasonic atomization. The method is characterized in that: the synthesis of water polyurethane is divided into three stages; a first stage is stepwise polymerization, i.e. polyurethane prepolymer is formed from oligomer polylol, hydrophilic monomers, modified monomers and isocyanate through stepwise polymerization; a second stage is the dispersion of the prepolymer in water after neutralization and salt formation; a third stage is the formation of water polyurethane emulsion after hydrophilic chain extender is added. The invention adopts a route of polymerizing modified monomers and polyurethane monomers jointly with different reaction mechanisms to ensure that modified monomers and polyurethane monomers are interpenetrated or grafted, thus obtained products have multiple material characteristics, i.e. the characteristics of acrylic acid, epoxy, hydroxyl silane and other materials are led into the products at the same time when the advantages of polyurethane material are maintained, so as to ensure that target products have stronger adaptability and better performance.

Owner:溧阳常大技术转移中心有限公司

Method for recycling aniline in preparation process of diphenylmethane series diamine and polyamine

PendingCN112250584ASolve emulsification problemsPhase separation effect is goodAmino compound purification/separationDiphenylmethaneAniline

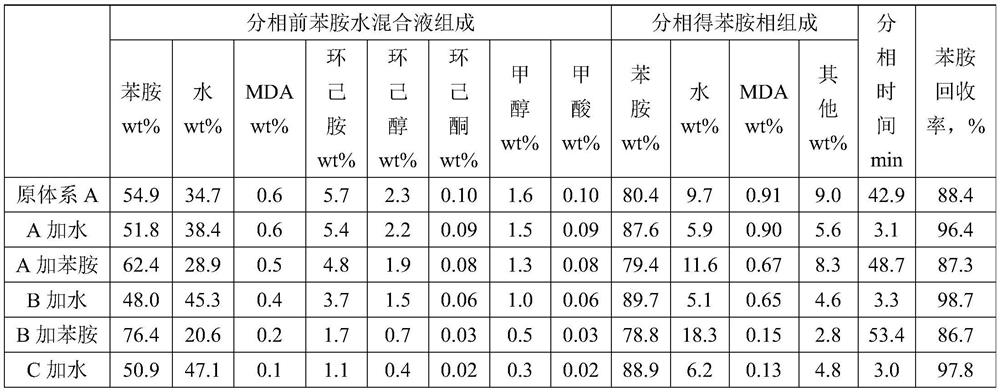

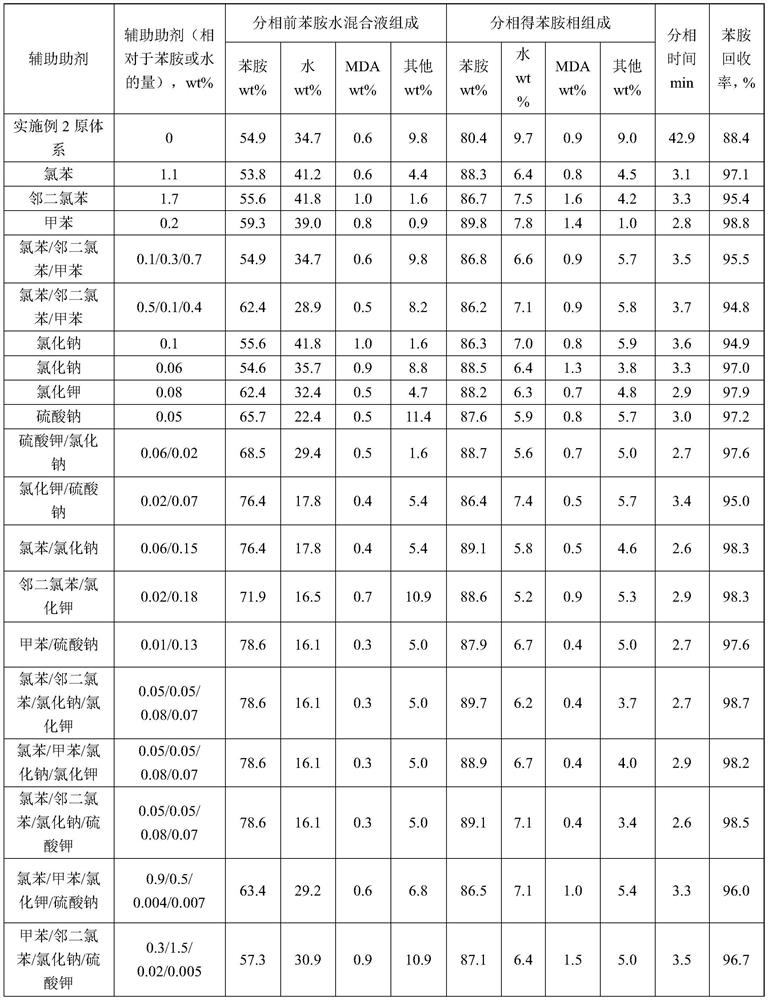

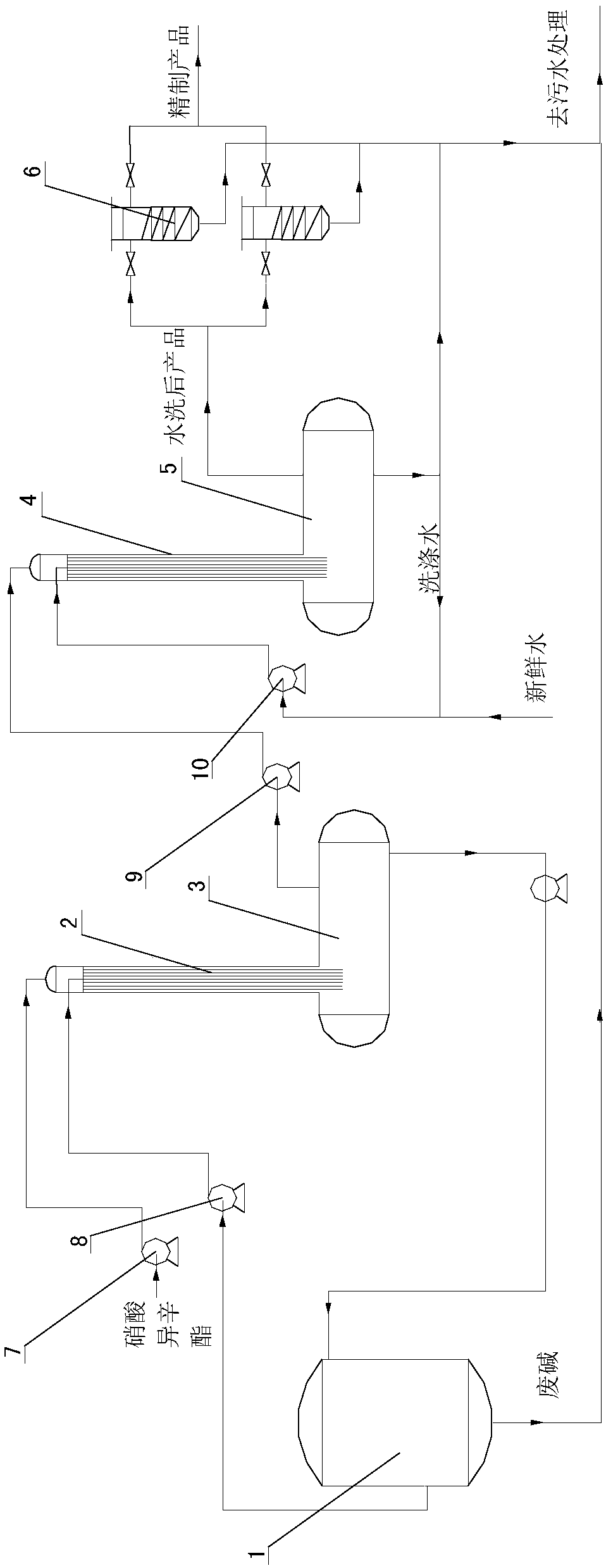

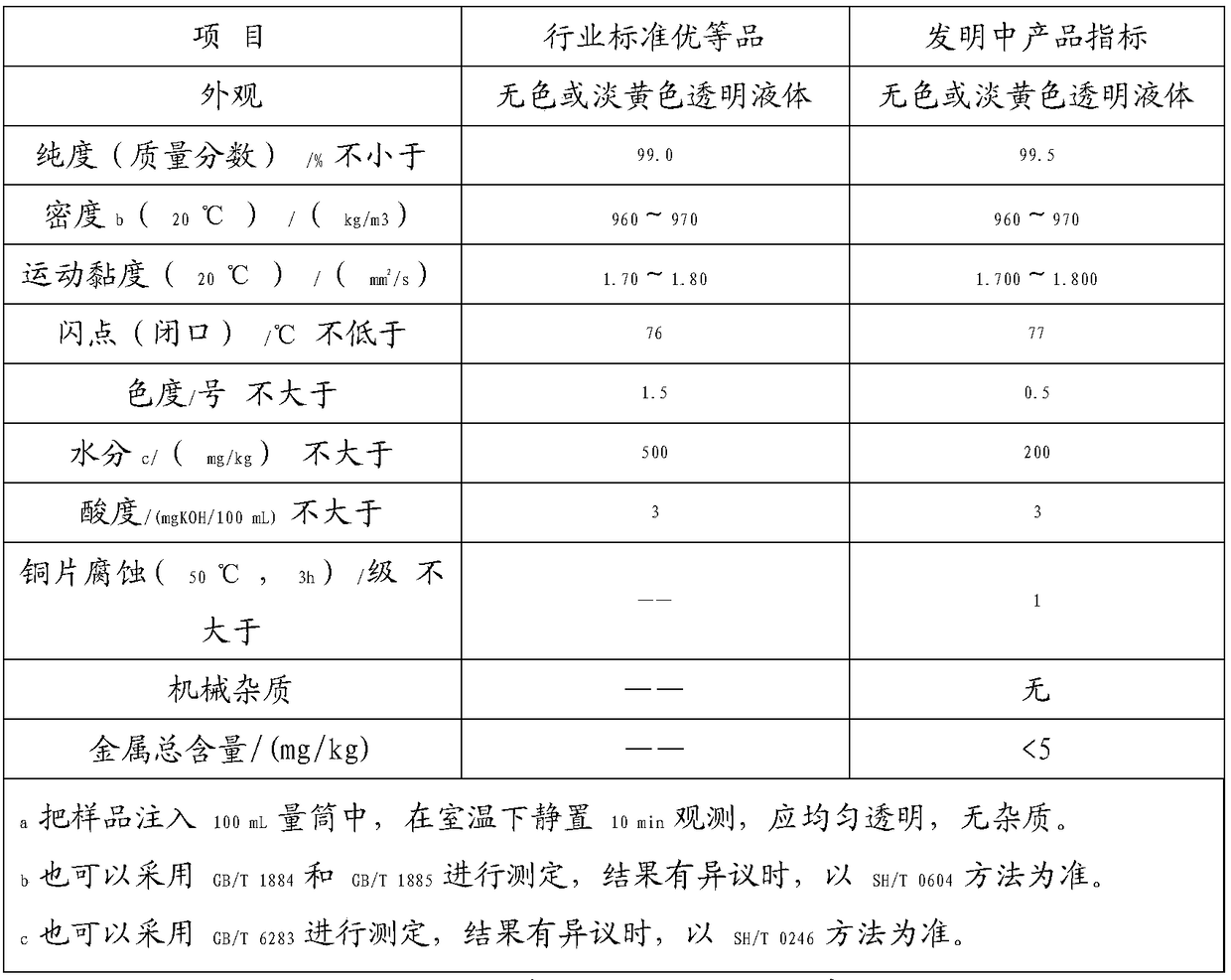

The invention relates to a method for recycling aniline in a preparation process of diphenylmethane series diamine and polyamine. The method is used for recycling aniline from an aniline-water mixed solution generated in a DAM refining process through liquid-liquid two-phase standing layering, wherein particularly the aniline content of 53 wt% in the aniline-water mixed solution is taken as a boundary value, when the aniline content is less than 53 wt%, the aniline-water mixed solution is directly layered, and when the aniline content is more than or equal to 53 wt%, the aniline content in theaniline-water mixed solution is adjusted to be less than 53 wt% and then layering is performed, or an auxiliary aid is added into the aniline-water mixed solution and then layering is performed, wherein the auxiliary aid is one or more of water-insoluble micromolecular aromatic hydrocarbon or chlorinated aromatic hydrocarbon and hydrochloride or sulfate of alkali metal. The method has the advantages of being simple, high in separation efficiency, high in recovery rate, high in recovered aniline concentration and the like, stable phase splitting of aniline water generated by the DAM refining unit can be achieved, and recovered aniline can be directly used as a raw material for producing DAM.

Owner:WANHUA CHEM GRP CO LTD +1

Continuous post-treatment technique and device of ethylhexyl nitrate

The invention relates to a continuous post-treatment technique of ethylhexyl nitrate and a continuous post-treatment device of ethylhexyl nitrate. The technique includes alkali washing, water washing,and separated dehydration technique of a crude product; alkali washing and water washing devices connected in order are applied to continuously treat ethylhexyl nitrate; the back end of the water washing device is provided with a dehydration device to refine the ethylhexyl nitrate and obtain a final product. By adopting the technique and the device, the continuous separating and purifying processes of the ethylhexyl nitrate are successfully realized, the separated settling time is reduced, and the production efficiency is improved; the consumption of alkali fluid and washing water is reduced,the waste liquid is greatly reduced; quality of the product for purifying is much better than the industrial standard requirement, thus the oil water emulsion in the water washing process is solved,the mass transfer area is enlarged, and the mass transfer rate is improved; the mass transfer between different object phases is realized, the mass transfer function is enhanced, and the energy consumption in the mass transfer process is effectively reduced; the continuous post-treatment technique has the advantages of saving investment, reducing floor area, saving operation cost, and effectivelyreducing waste liquid.

Owner:山东京博众诚清洁能源有限公司

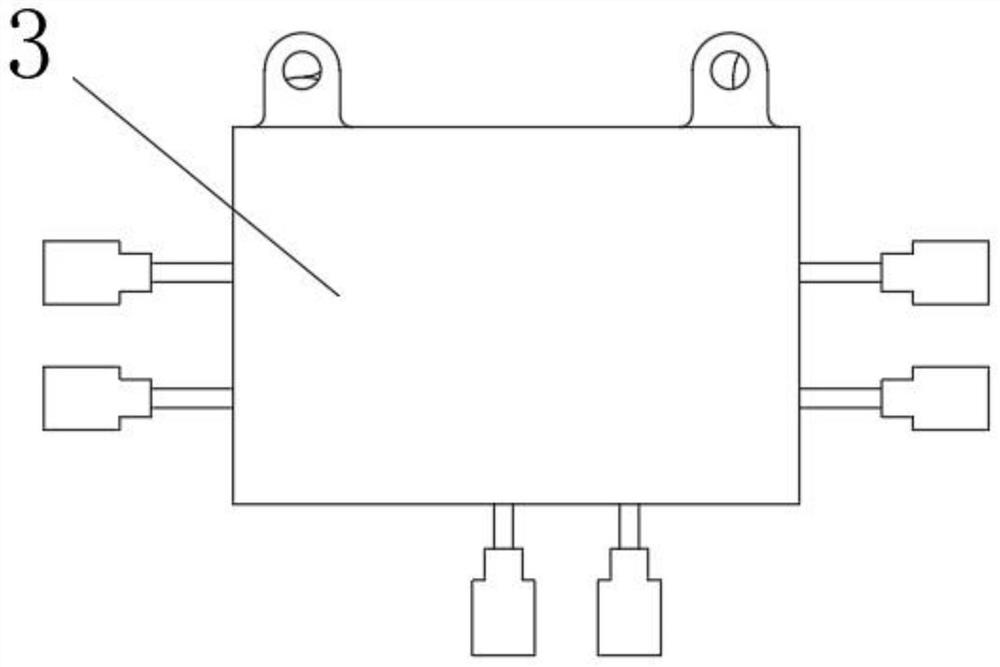

Method and device capable of preventing engine oil emulsification of gas engine

ActiveCN112523836ASolve emulsification problemsGuaranteed to workInternal combustion piston enginesLubrication temperature controlSmart controlStress sensors

The invention discloses a method and device capable of preventing engine oil emulsification of a gas engine, and the device capable of preventing engine oil emulsification comprises an electric control oil-gas separation device, a connecting plate, a high-temperature protection and power-off prevention device, an engine body, an oil return pipe, a power supply and energy storage device, a pressuresensor, a heating device, a temperature sensor and an oil pan. The electric control oil-gas separation device and the high-temperature protection and power-off prevention device are both installed onthe connecting plate, and the connecting plate and the pressure sensor are both installed on the machine body. The oil return pipe and the electric control oil-gas separation device are both connected with the machine body. The high-temperature protection and power-off prevention device is connected with the heating device through a wire. The method and device capable of preventing engine oil emulsification are suitable for the gas engine, intelligent control is achieved, the negative effect of engine oil emulsification caused by liquid water formed by condensation of combustion product watervapor of the gas engine can be quickly eliminated, the normal operation of the engine is ensured, and the engine oil replacement time of the engine is prolonged. Engine oil cost is reduced for a user, value is created for the user, and the problem of engine oil emulsification of an existing gas engine can be solved.

Owner:GUANGXI YUCHAI MASCH CO LTD

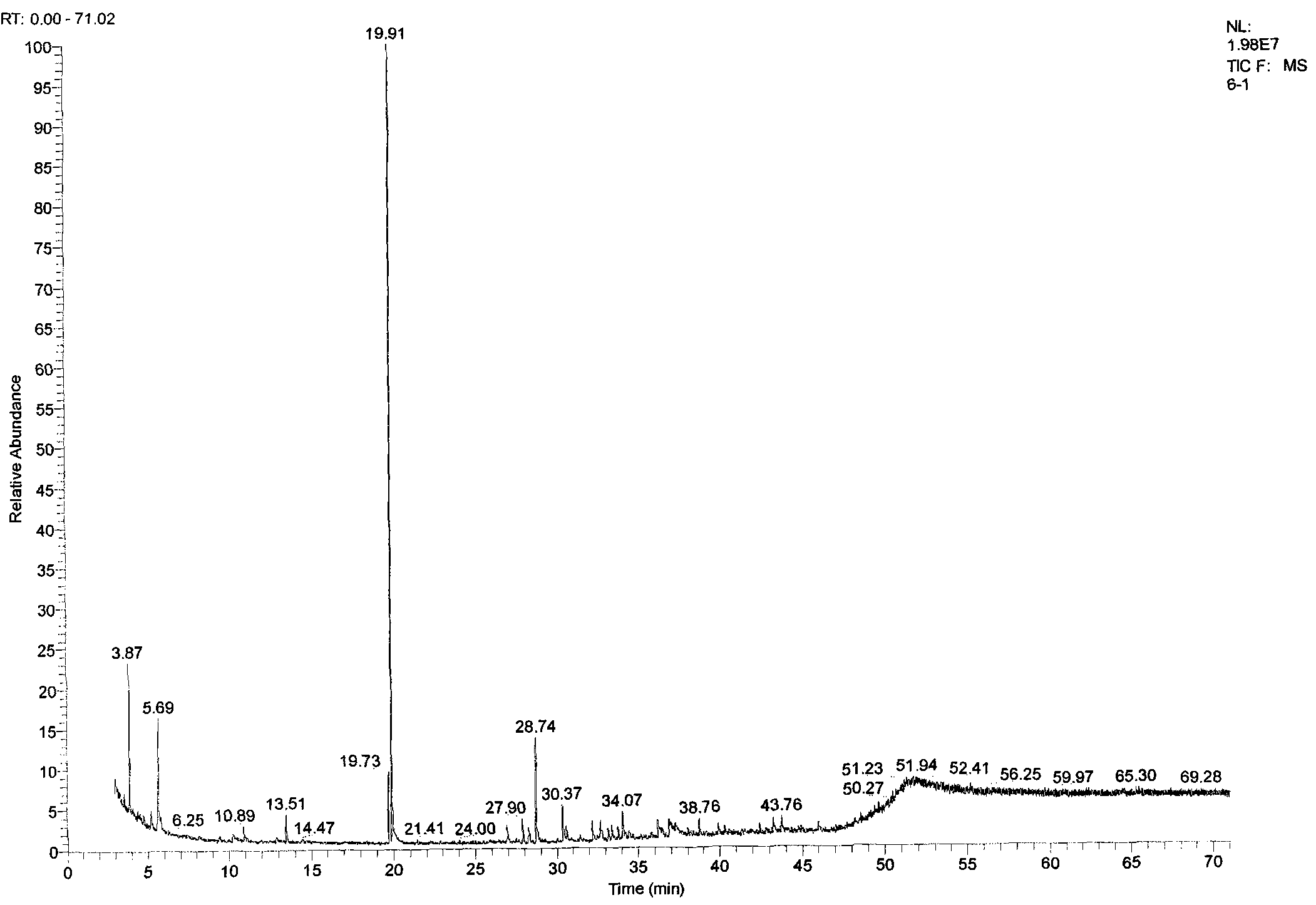

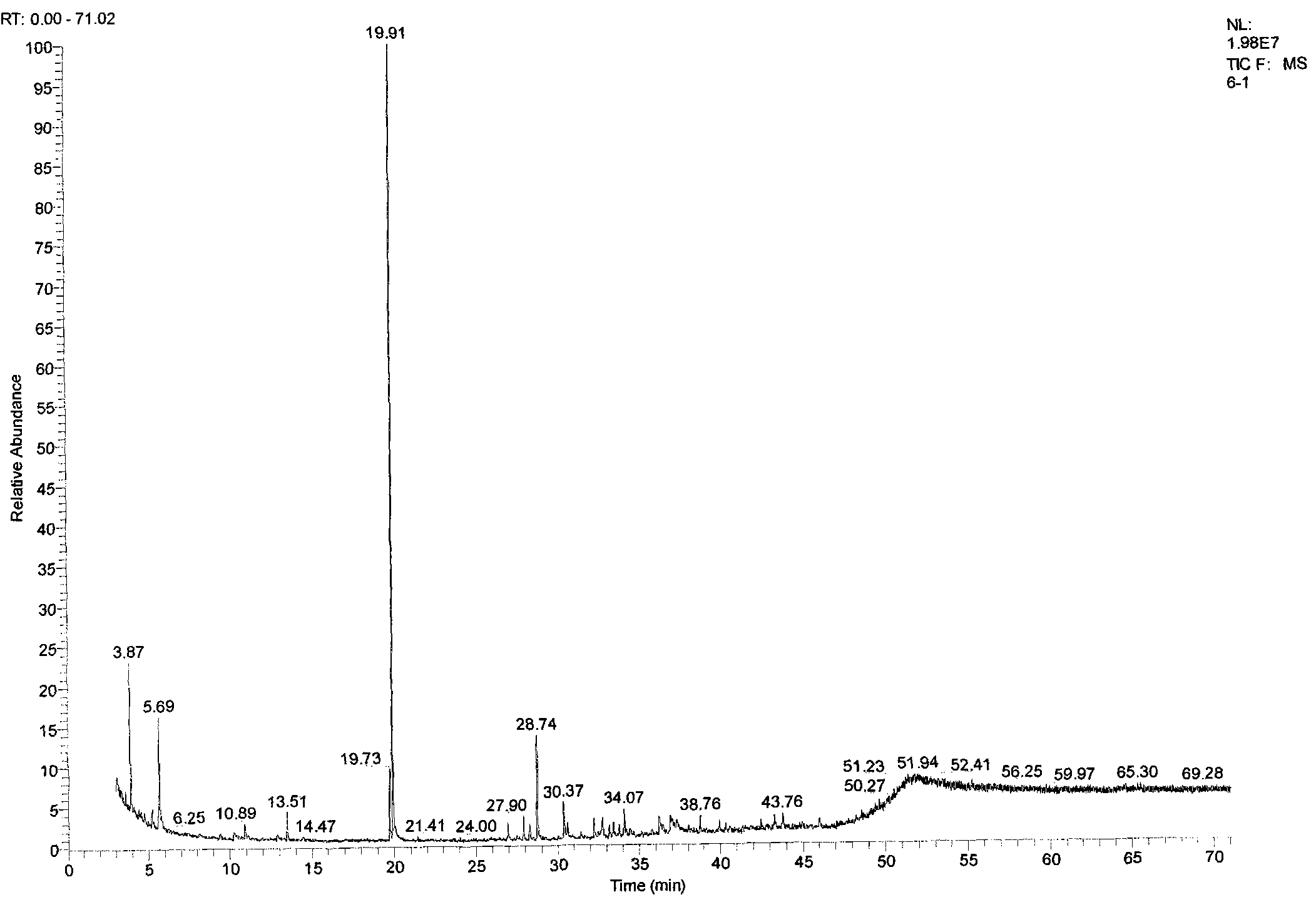

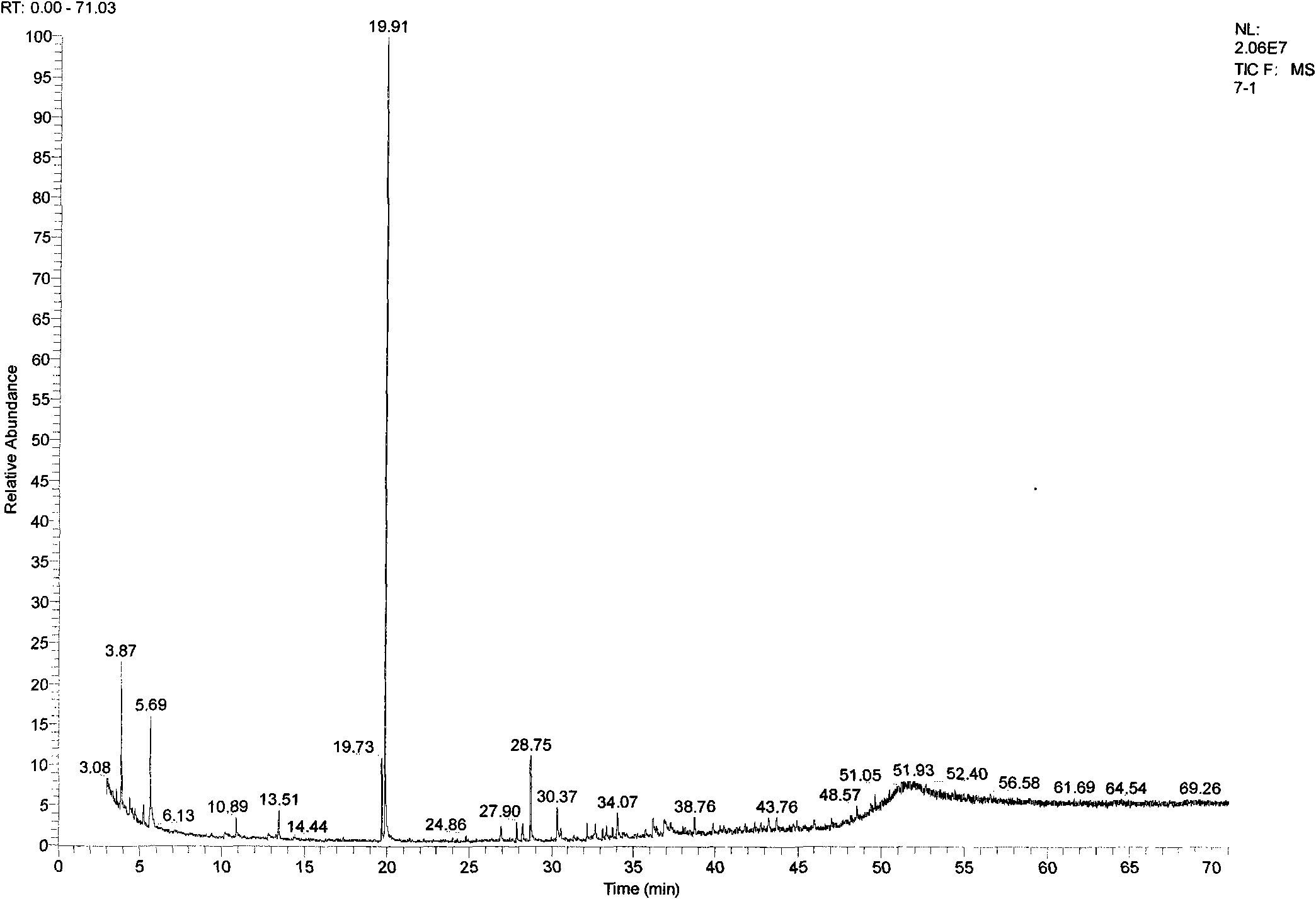

Preprocessing Method for GC-MS (Gas Chromatography-Mass Spectromete) analysis of essence and spice

InactiveCN102012332ASolve emulsification problemsComponent separationPreparing sample for investigationInternal standardDigestion

The invention relates to a method for analyzing essence and spice, in particular to a preprocessing method for GC-MS (Gas Chromatography-Mass Spectromete) analysis of essence and spice. The method comprises the following steps of: (1) dissolving the weighted internal standard substance in dichloromethane to prepare 100ppm of internal standard solution; (2) adding purified water into the essence and spice to be detected, oscillating and uniformly shaking to obtain the essence and spice solution; (3) adding the internal standard solution into the essence and spice solution and oscillating for 30min under the condition of 150Hz for fully contacting and extracting; and (4) centrifugally separating for 5min under the condition of 3,000rpm after the oscillating is finished, microware digesting the obtained centrifugally separating solution and taking the lower-layer supernate for GC-MS analysis after microware digestion.

Owner:HUBEI CHINA TOBACCO IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com