Continuous post-treatment technique and device of ethylhexyl nitrate

A technology of isooctyl nitrate and post-processing device, applied in nitrate preparation, organic chemistry and other directions, can solve the problems of emulsification layer waste, product loss, long settling time, etc., to reduce floor space, reduce energy consumption, increase The effect of a large mass transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

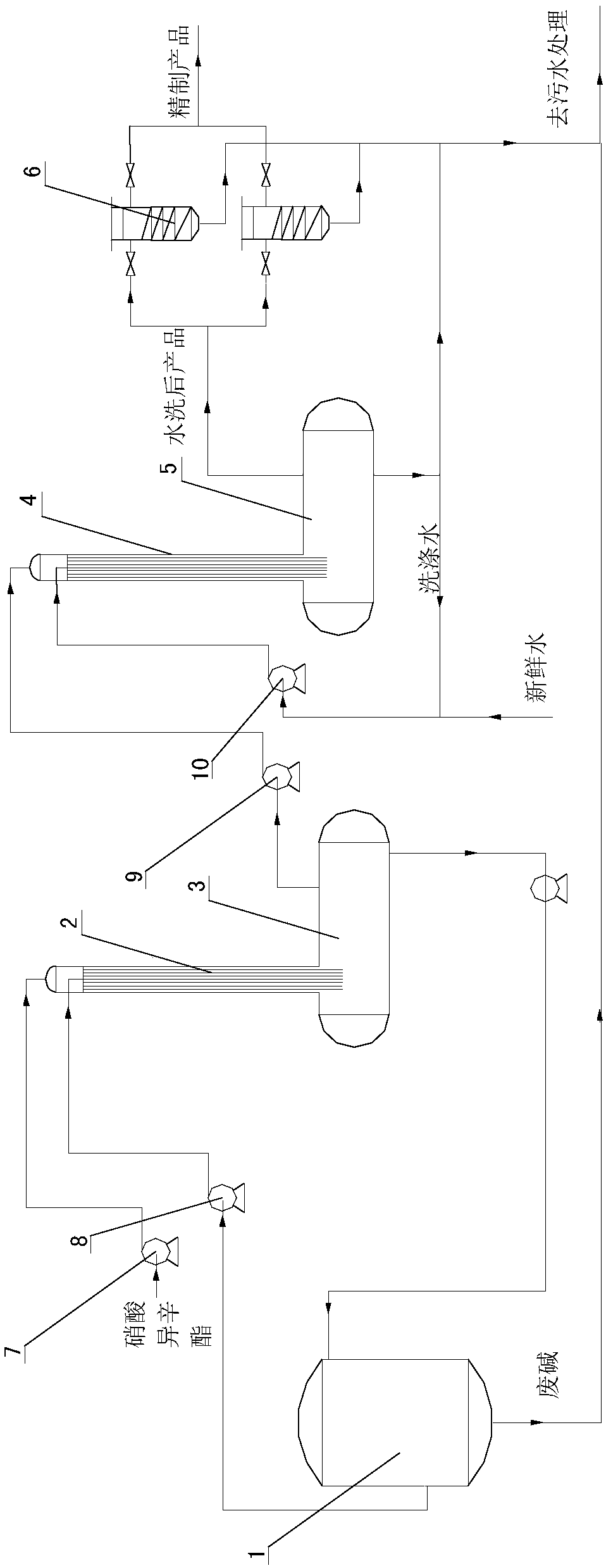

[0026] A continuous post-treatment process of isooctyl nitrate, comprising sequentially connected crude product alkali washing, water washing and separation and dewatering processes, wherein the specific steps are:

[0027] The prepared isooctyl nitrate crude ester is transported from the crude ester tank through the isooctyl nitrate delivery pump to the top of the alkali washing membrane separation device on the top of the alkali washing phase separation tank, where the top is mixed with the alkali solution transported by the alkali solution delivery pump. In contact with lye, the lye has been circulated before starting to work, firstly wet the fiber membrane of the alkali cleaning membrane separation equipment, and flow down along the fiber filaments, and isooctyl nitrate flows in parallel with the lye along the fiber bundle, making the nitric acid Between the isooctyl ester and the lye, a flowing film is formed on the fiber bundle, thereby increasing the mass transfer area a...

Embodiment 2

[0036] All steps of this embodiment are consistent with the steps in embodiment 1,

[0037] Wherein said lye is selected from sodium hydroxide solution, and the mass percentage is 30%;

[0038] The number of alkali washing is first-level alkali washing;

[0039] The crude isooctyl nitrate feed flow pump and the lye feed flow weight ratio are at 10:1, and the control isooctyl nitrate crude ester feed flow and washing water feed flow weight ratio is at 3:1;

[0040] After testing, the acidity of isooctyl nitrate crude ester is 200-700mgKOH / g, the metal content (the sum of sodium, potassium, magnesium, calcium, iron and zinc content) is 100-200ppm, and the moisture content is 5000-7000ppm;

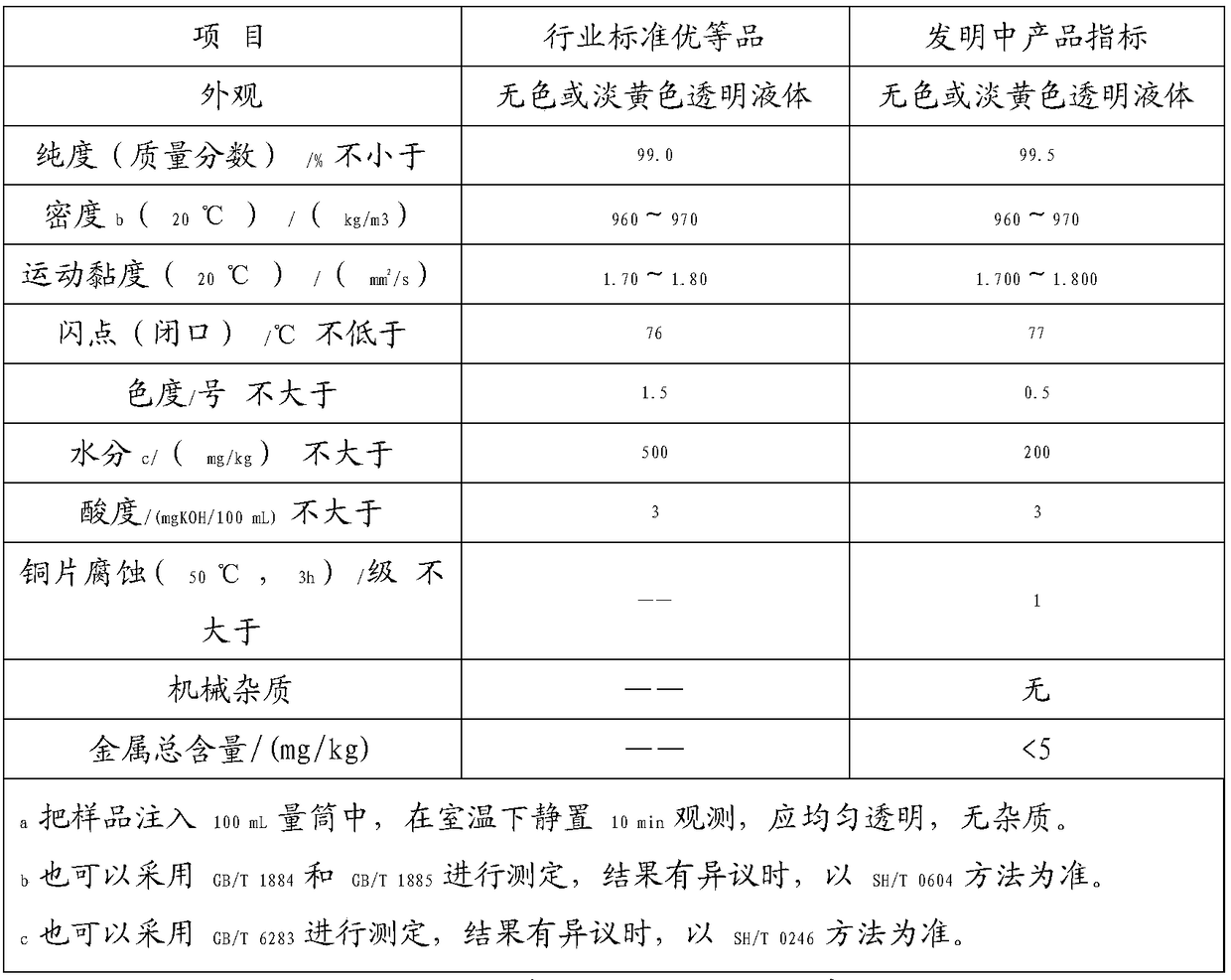

[0041] After treatment, the acidity of isooctyl nitrate is 3.36mgKOH / g, the metal content is 4.0ppm, and the moisture content is 163ppm; it can be seen that the continuous post-treatment process of isooctyl nitrate provided by the present invention can effectively improve the quality of isoo...

Embodiment 3

[0043] All steps of this embodiment are consistent with the steps in embodiment 1,

[0044] Wherein said lye is selected from sodium hydroxide solution, and the mass percentage is 40%;

[0045] The number of alkali washing is first-level alkali washing;

[0046] The crude isooctyl nitrate feed flow pump and the lye feed flow weight ratio are at 10:1, and the control isooctyl nitrate crude ester feed flow and washing water feed flow weight ratio is at 5:1;

[0047] After testing, the acidity of isooctyl nitrate crude ester is 200-700mgKOH / g, the metal content (the sum of sodium, potassium, magnesium, calcium, iron and zinc content) is 100-200ppm, and the moisture content is 5000-7000ppm;

[0048] After treatment, the acidity of isooctyl nitrate is 1.38mgKOH / g, the metal content is 3.6ppm, and the moisture content is 121ppm; it can be seen that the continuous post-treatment process of isooctyl nitrate provided by the present invention can effectively improve the quality of isoo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com