Patents

Literature

74 results about "Dehydration Technique" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triangular belt type filter press

InactiveCN101279163AReasonable structureDesign sciencePressesMoving filtering element filtersCounter pressureEngineering

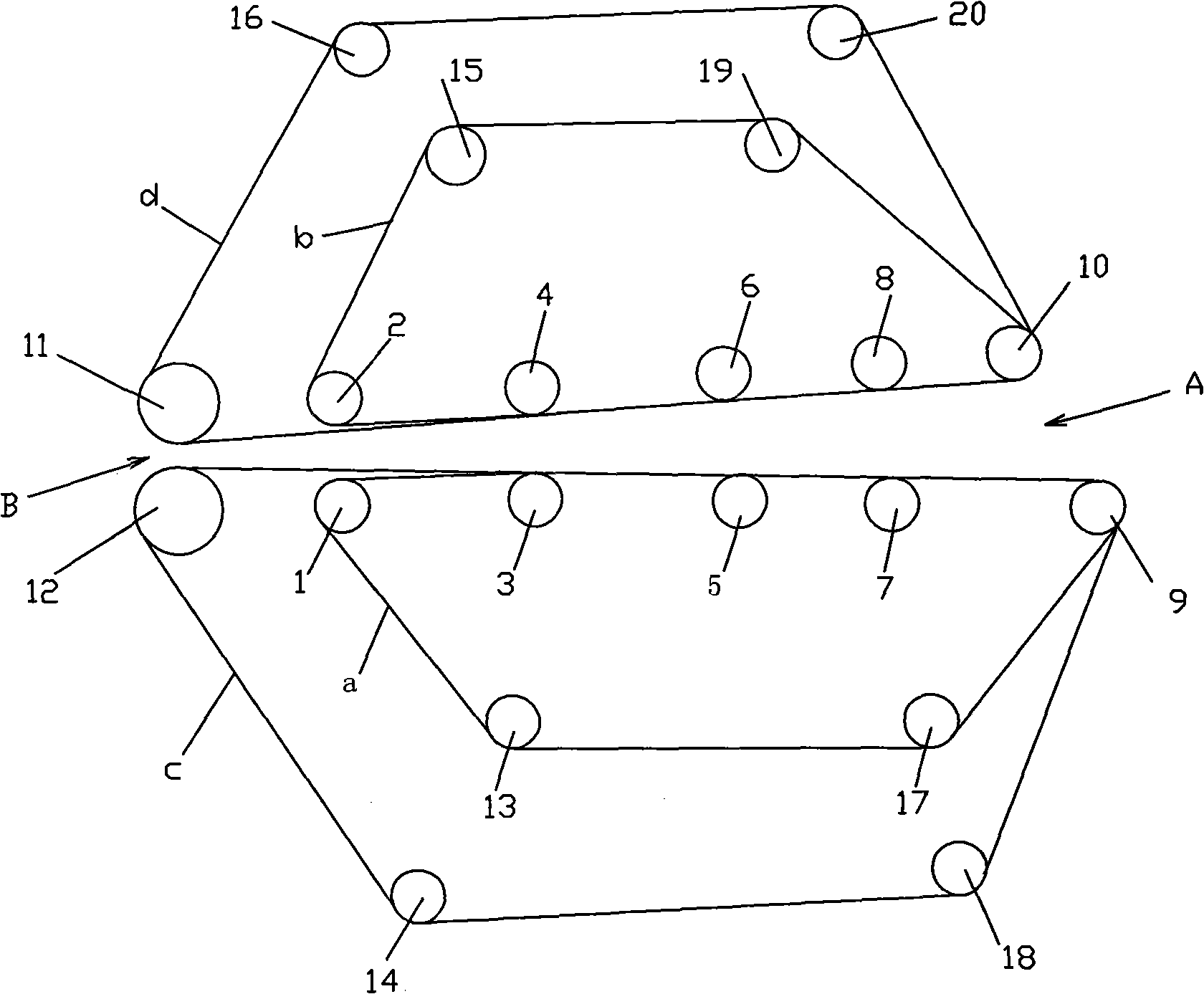

The invention discloses a wedge-shaped draper-type press filter which consists essentially of a chassis, a pressing area, a driving device, a feeding device, a scrapper assembly, a deviation-rectifying device, a rinsing device and a water receiving device. The structure of the wedge-shaped draper-type press filter is characterized in that the pressing area is a wedge-shaped pressing area with an included angle more than zero degree but less than 15 degrees between an upper filter strip and a lower filter strip; the wedge-shaped pressing area is divided into an upper press area and a lower press area; respective tension band and filter strip of the upper press area and the lower press area are stacked and wrapped outside respective press roll in parallel; the tension band is stuck to the press roll and the filter strip is firmly stuck outside the tension band; the press rolls of two press areas are arranged in a counter pressure way. The draper-type press filter of the invention adopts a single wedge-shaped press area, changes press dehydration technique of the prior art that adopts a plurality of press rolls to enwind and operate in snaking way, realizes that the press roll operates press dehydration in a counter pressure and liner way, greatly reduces the abrasion of the filter strips caused by tension, effectively prolongs the service life of the filter strips and can reduce operation energy consumption of the press filter.

Owner:ZHEJIANG HUAZHANG TECH

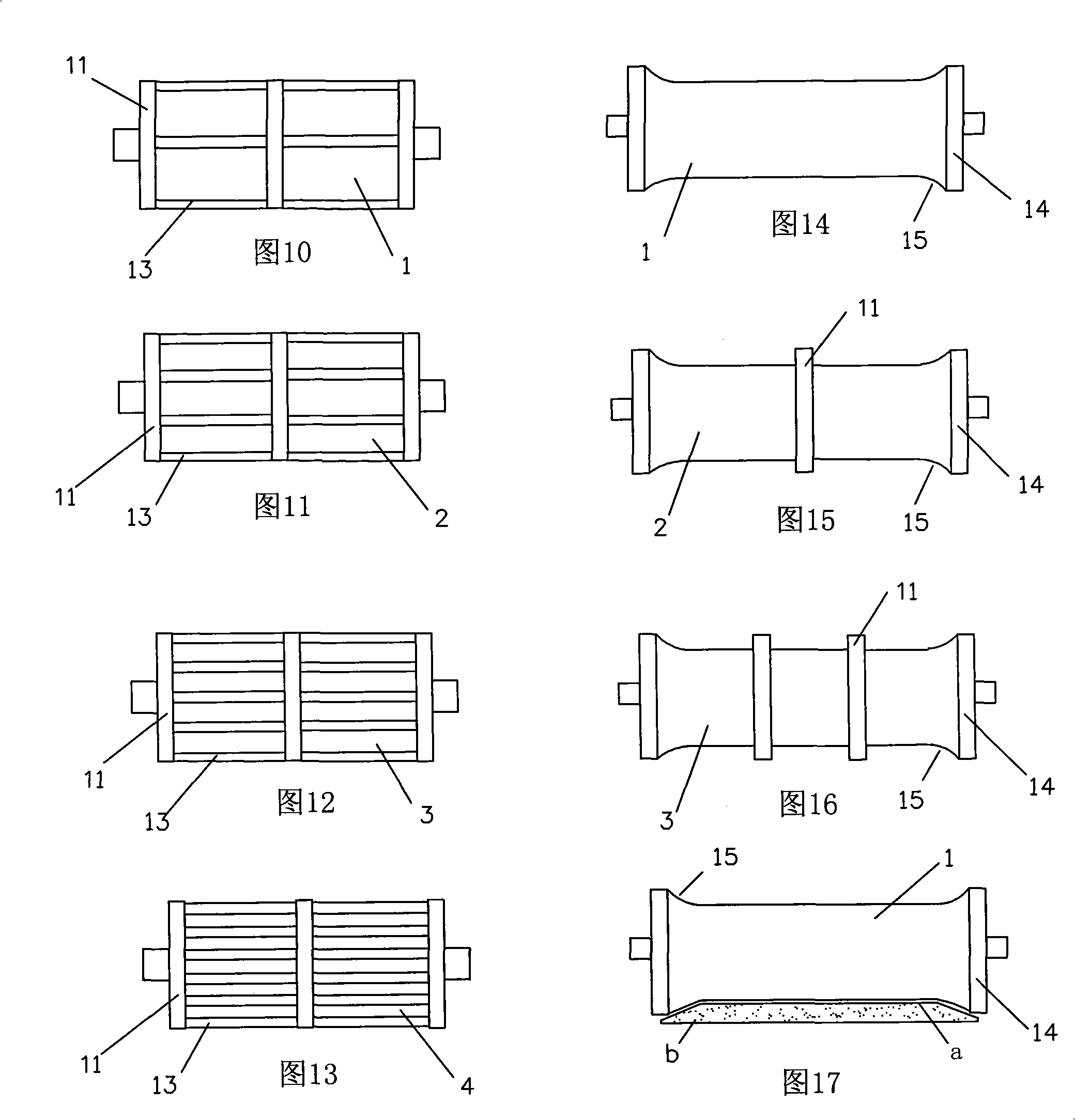

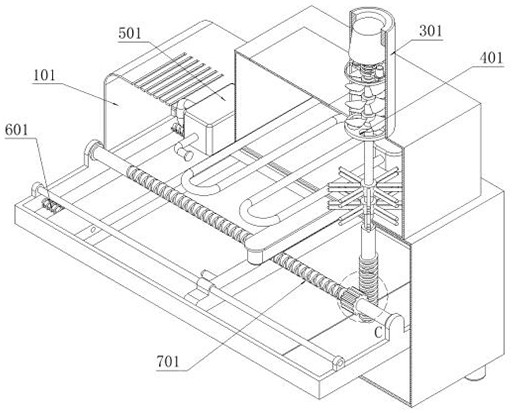

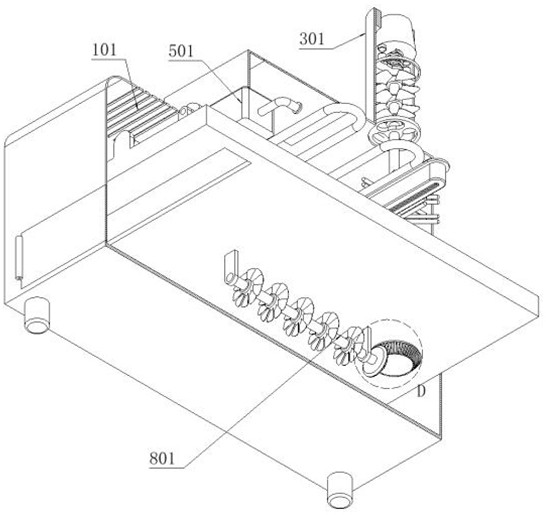

Strap filter-press dehydration technique and device

ActiveCN101306273AEnhanced dehydration pressTo achieve the purpose of pressing and dehydrationPressesMoving filtering element filtersSludgeEngineering

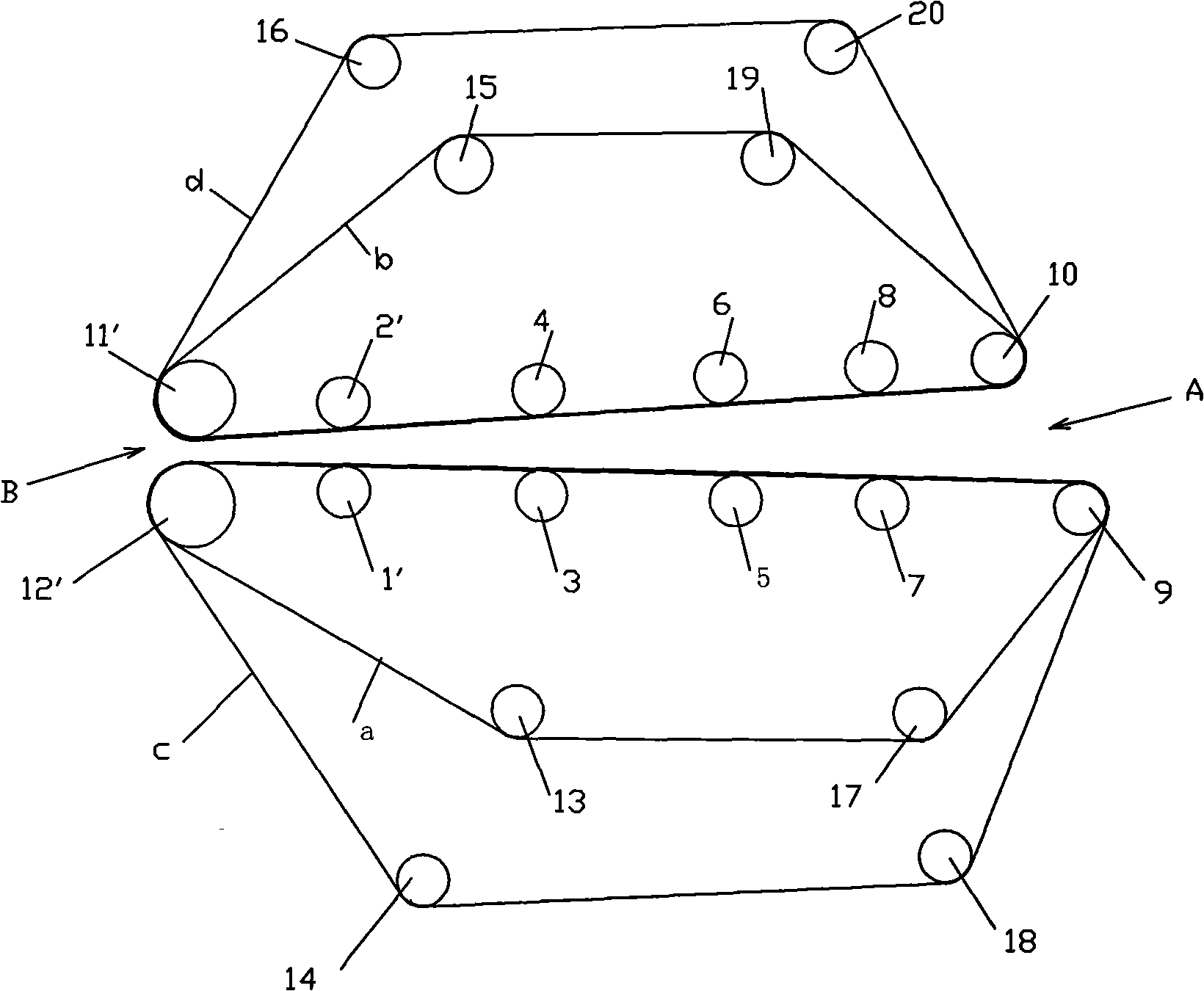

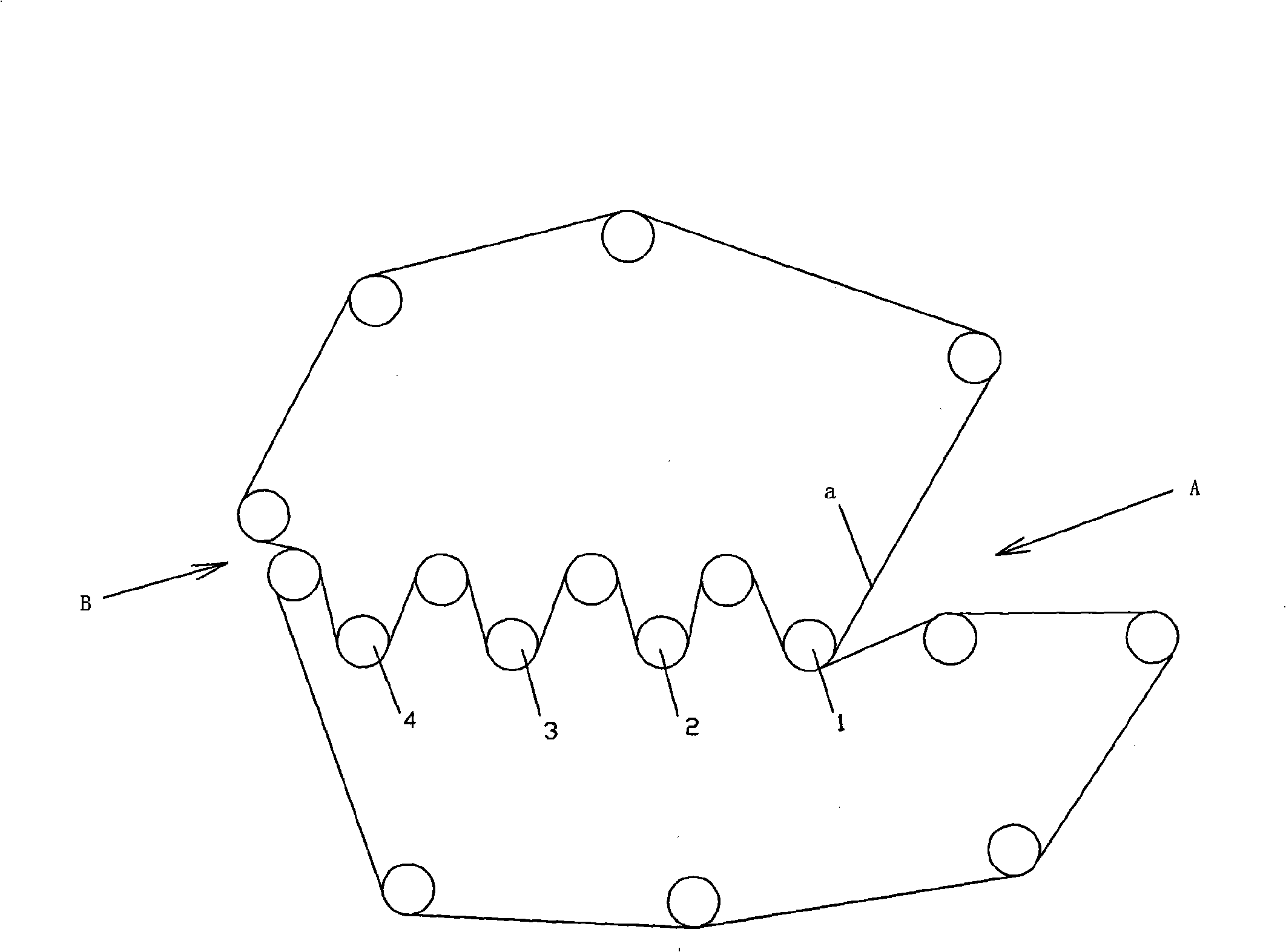

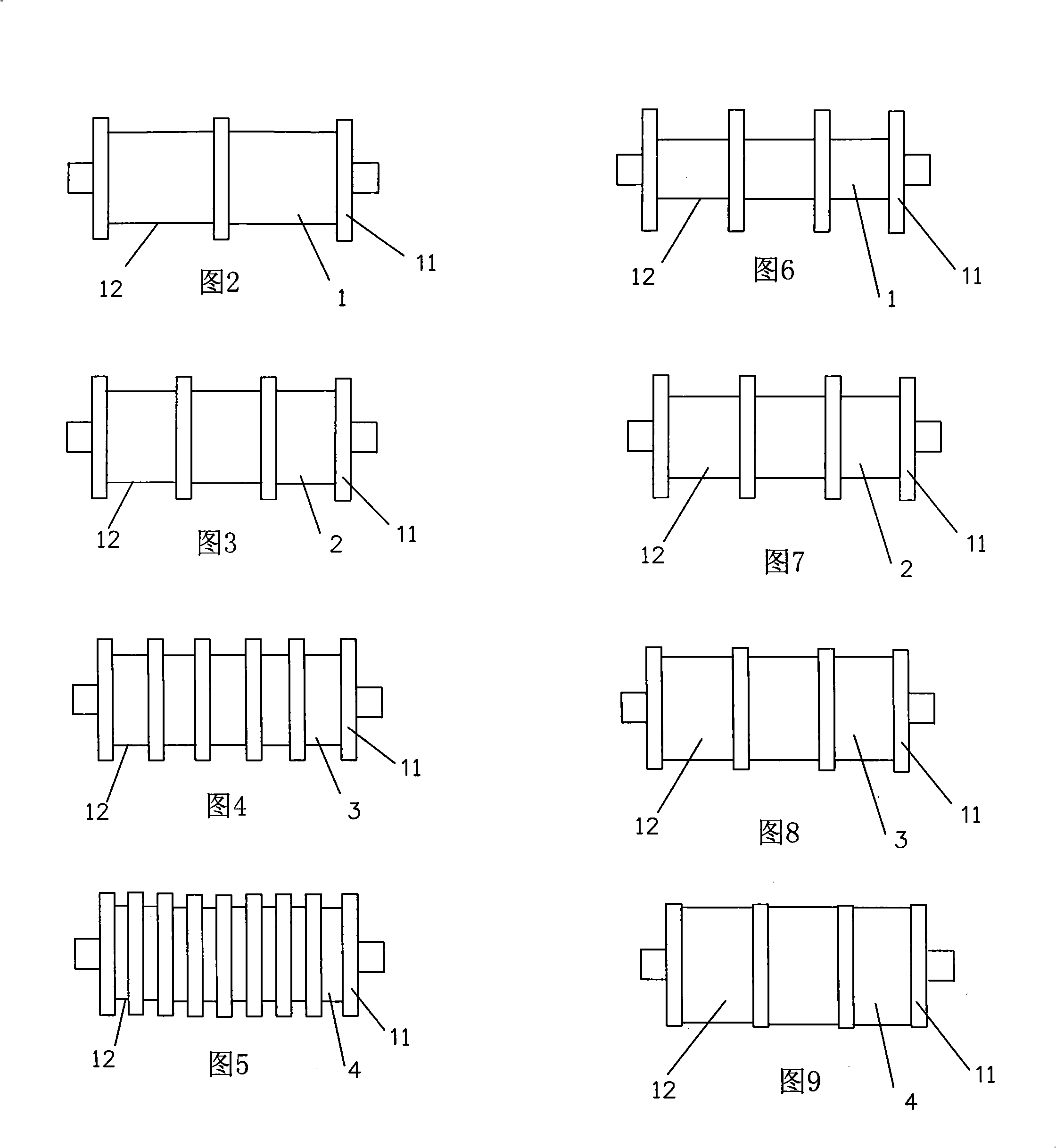

The invention discloses a belt press filtering dehydration process and a device. The belt press filter dehydration process increases the area of pressure for press filtering dehydration of dehydrated materials from small to large according to the running direction of a filter belt, and the received dehydration pressure is gradually increased from small to large according to the running direction of the filter belt. The outside diameter of a press roller body of the belt press filtering dehydration device is constant, two or more bosses or grooves are formed on the surface of the roller body, and the surface area of the press roller body is gradually increased from small to large according to the running direction of the filter belt. The process of the invention can gradually strengthen the dehydration press of the dehydrated materials under the condition of keeping the tension and the diameter of the press roller unchanged, and has the advantages of convenient implementation and good press effect; and the device of the invention can simplify the structure of a belt press filter, and avoid the phenomena that the filter belt becomes looser and looser or tighter and tighter, and sludge leaking, creasing or lengthening of the filter belt and so on occur in the operation of the prior art on the premise of ensuring the press effect, thereby effectively preventing the sludge from transverse leaking and improving the efficiency of the press dehydration.

Owner:ZHEJIANG HUAZHANG TECH

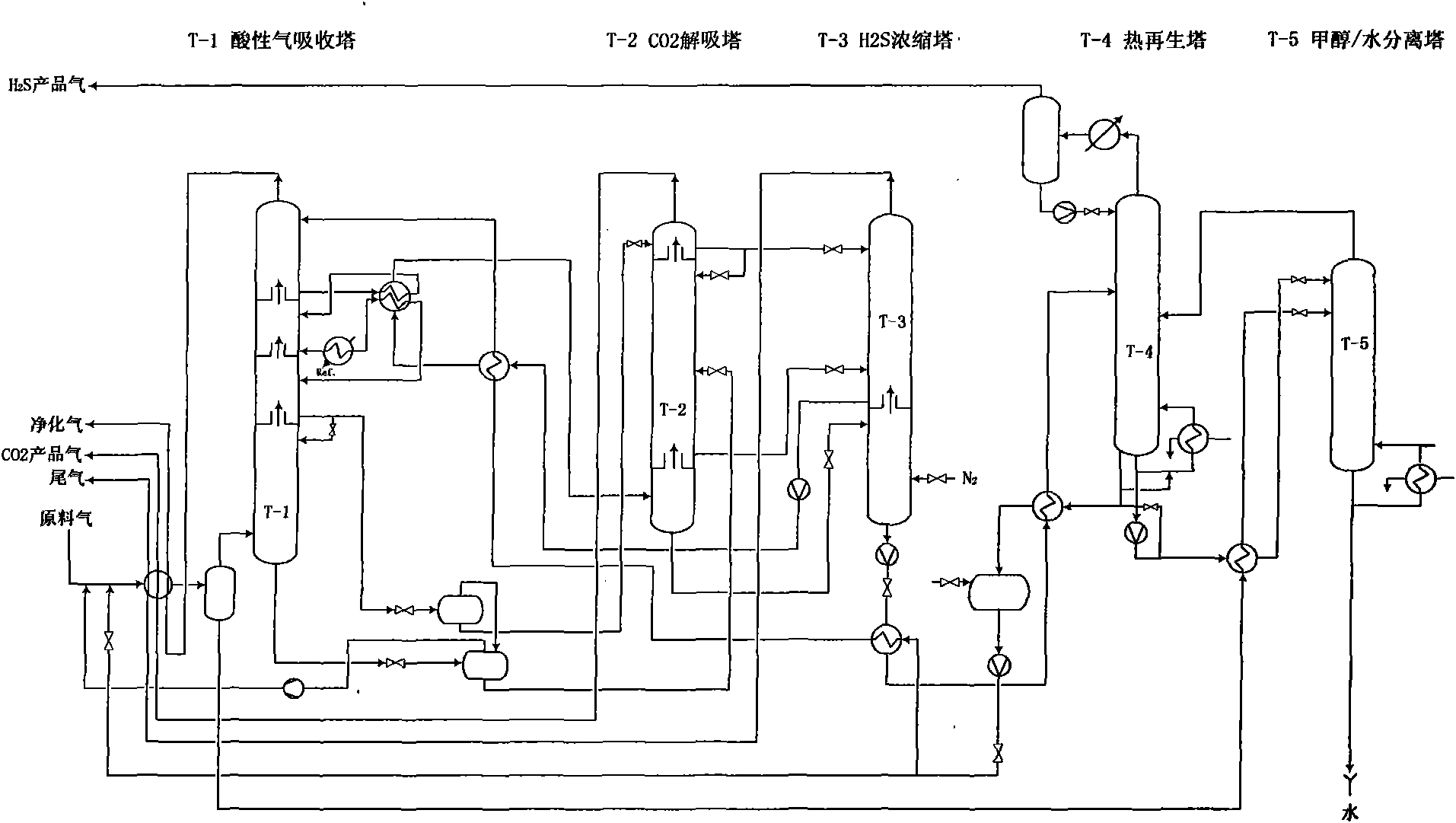

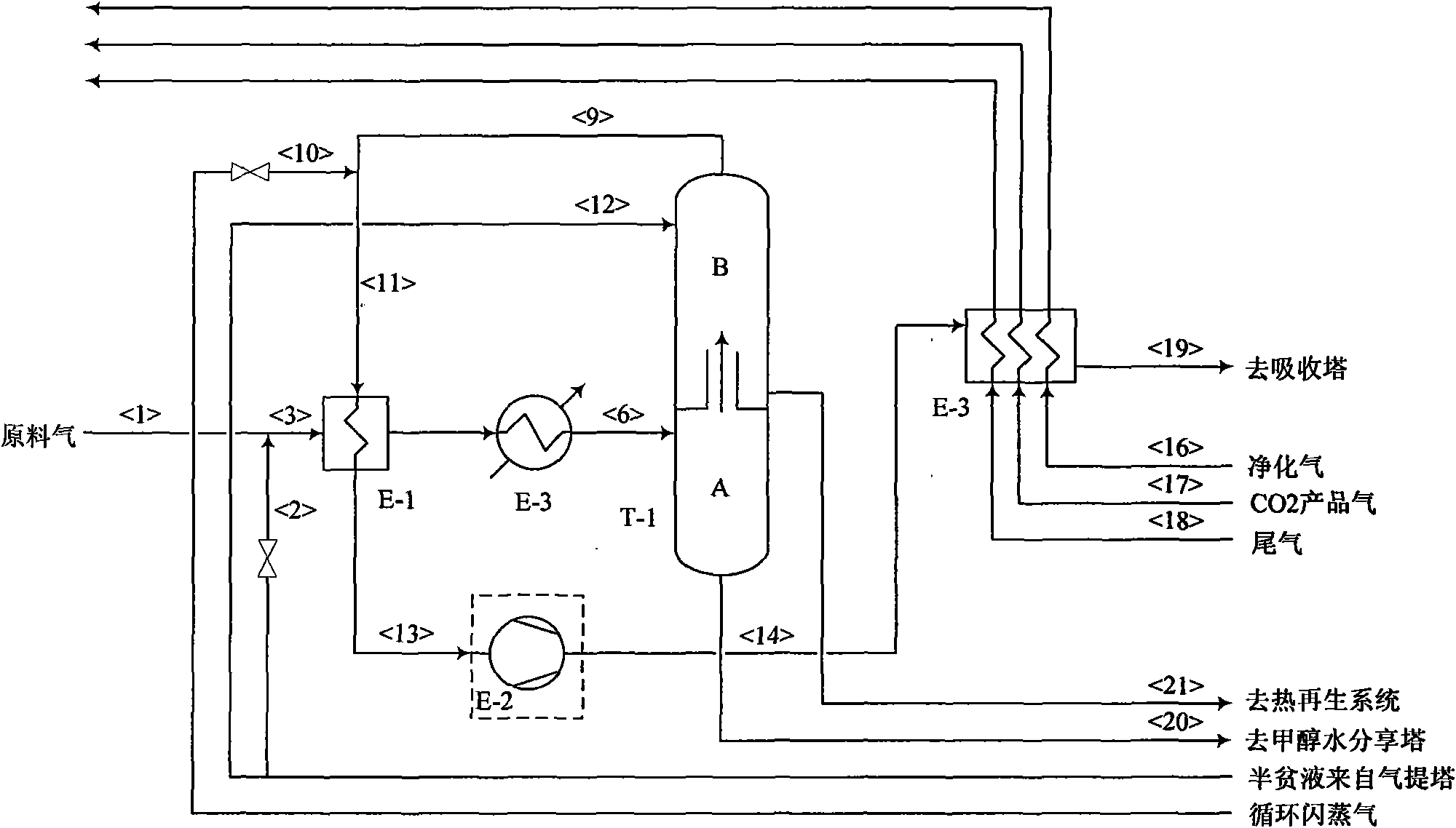

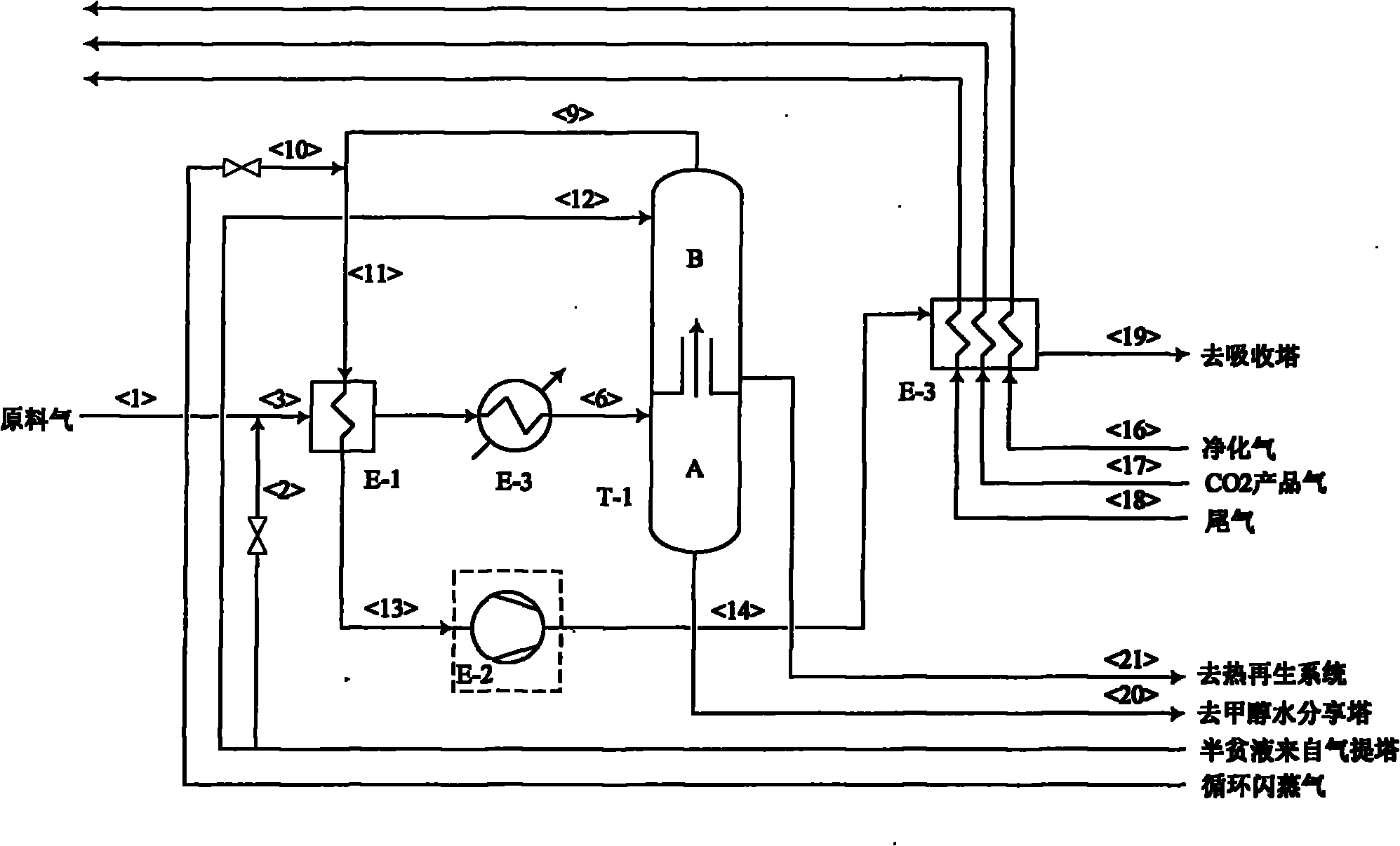

Low-temperature methanol washing method for low-pressure raw gas

ActiveCN102078742AAvoid corrosionReduce energy consumptionDispersed particle separationSulfurSolvent

The invention relates to a low-temperature methanol washing method for low-pressure raw gas, belonging to the technical field of gas purification. The method is characterized in that low-pressure raw gas containing H2S, CO2 and water is precooled to low temperature, and is washed with low-temperature partially stripped solvent in a prewashing tower, wherein the low-temperature partially stripped solvent is subjected to gas stripping of a low-temperature methanol washing device; the raw gas subjected to water removal and effective gas recycled in the low-temperature methanol washing device, i.e. circulating flash evaporation gas, converge, and are reheated and compressed, or directly compressed without reheating; and the raw gas, which is compressed to the required pressure, enters the subsequent low-temperature methanol washing device, thereby removing acid gas in the raw gas. The invention solves the problem that the low-pressure raw gas can not be purified by the low-temperature methanol washing technique since the sulfur-bearing water-containing raw gas which is gasified under low pressure can not be directly compressed by a compressor. The invention widens the application range of the low-temperature methanol washing technique, combines the prewashing dehydration technique and the conventional low-temperature methanol washing technique, and has the advantages of low energyconsumption and investment saving.

Owner:DALIAN UNIV OF TECH

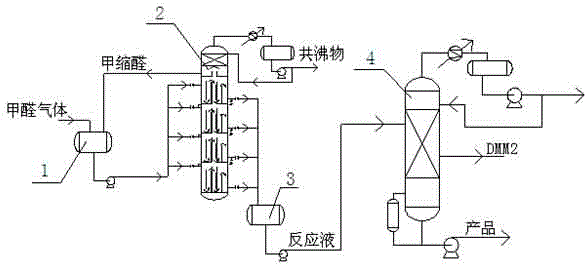

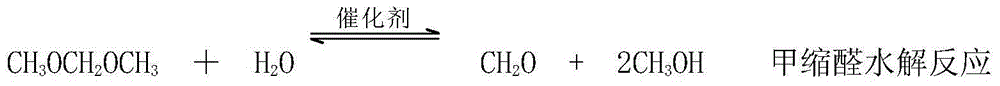

Dehydration technique and dehydration device for synthesizing poly-methoxy-dimethyl ether

InactiveCN104817437AReduce bring inRelieve pressureOrganic chemistryOrganic compound preparationHigh concentrationAcid catalysis

The invention discloses a dehydration technique and a dehydration device for synthesizing poly-methoxy-dimethyl ether. The dehydration technique comprises the following steps: selecting a formaldehyde gas of which the moisture content is within 0.1% and high-concentration dimethoxymethane to form a methylal solution of formaldehyde as a reactant; obtaining a poly-methoxy-dimethyl ether product under the acid catalysis condition; further carrying out hydrolysis reaction on high-concentration dimethoxymethane, and further consuming moisture, so as to control the reaction system in an anhydrous state. Therefore, the poly-methoxy-dimethyl ether yield is improved; furthermore, the reaction condition of the reaction system is also reduced; and the reaction energy consumption is reduced.

Owner:无锡智归科技有限公司

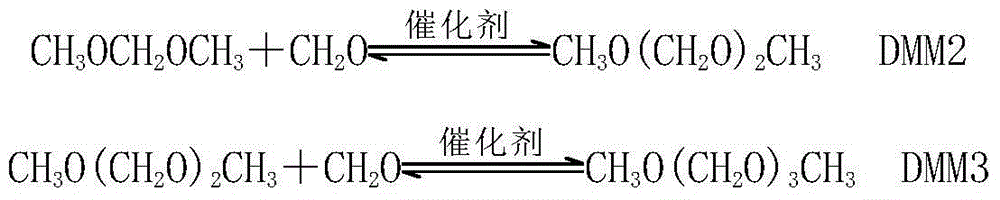

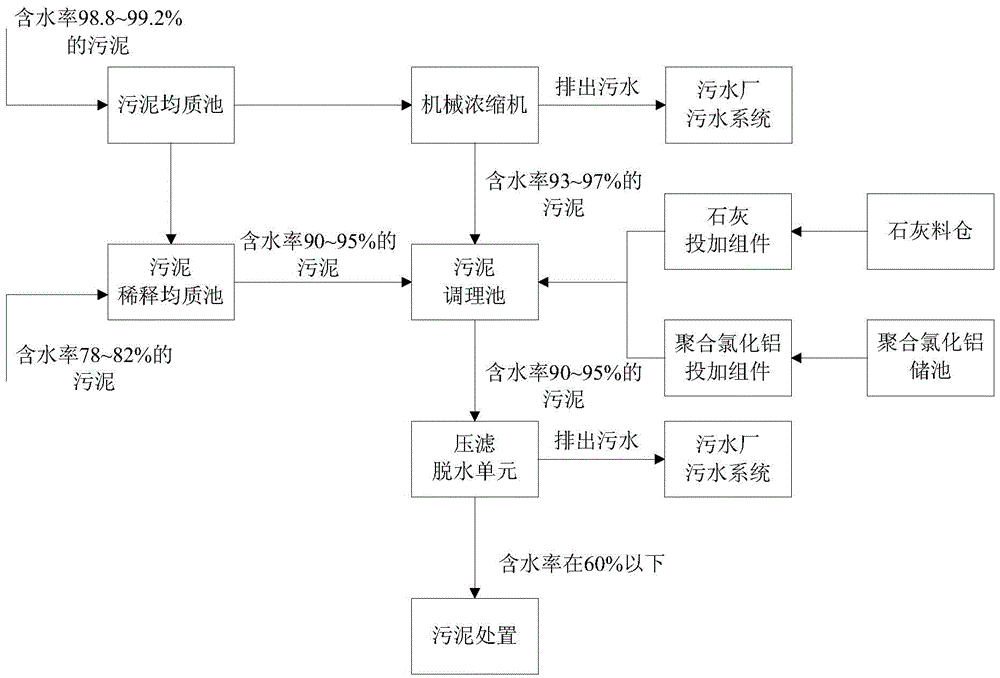

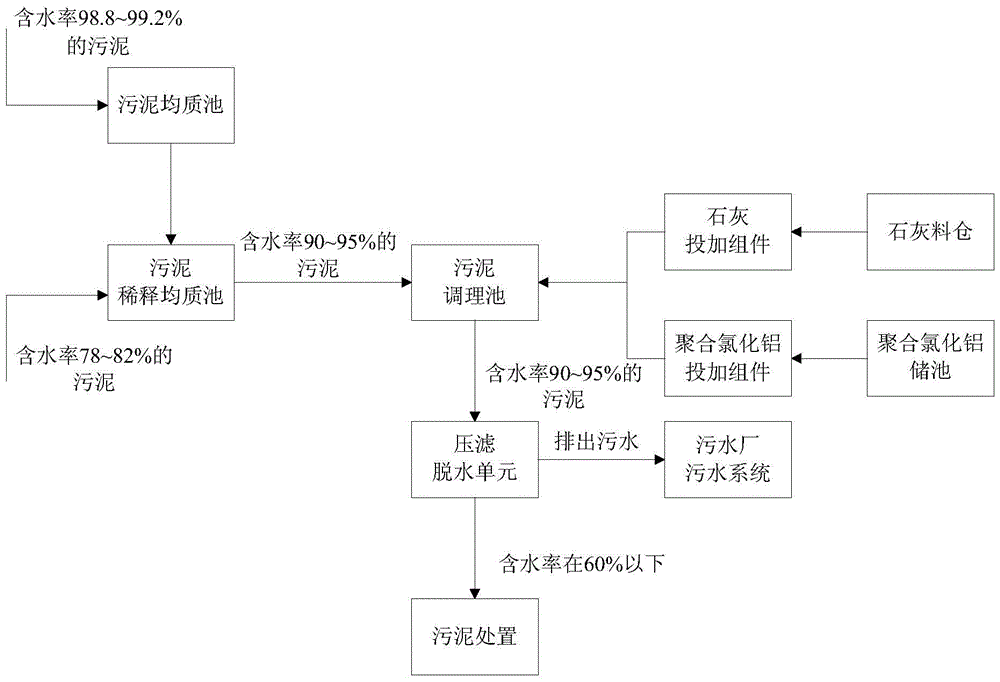

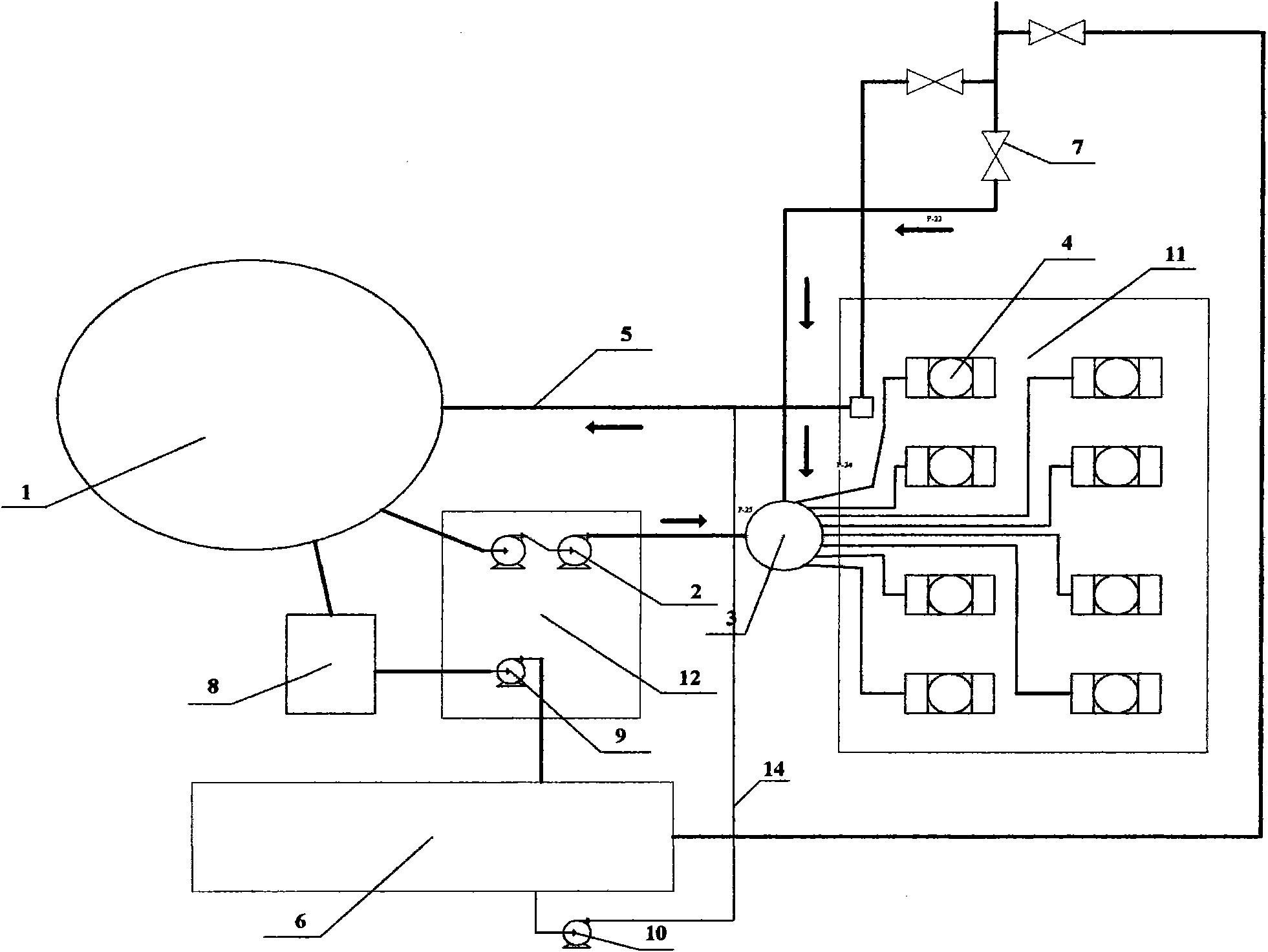

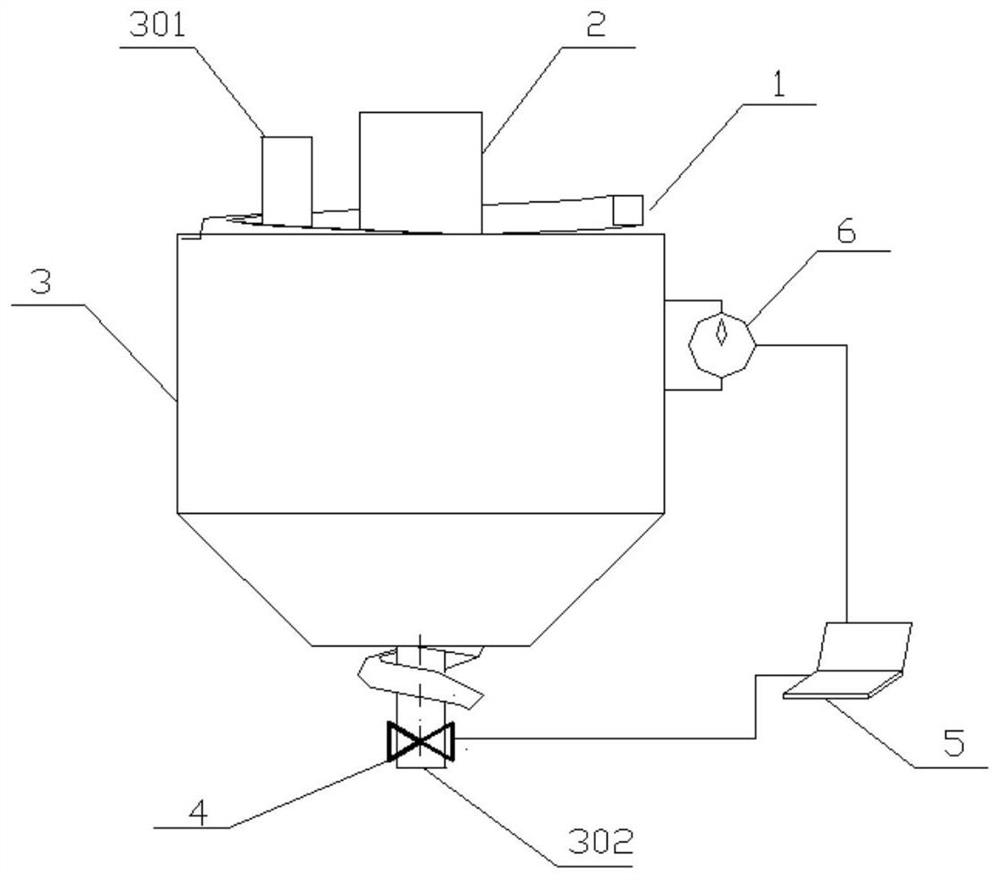

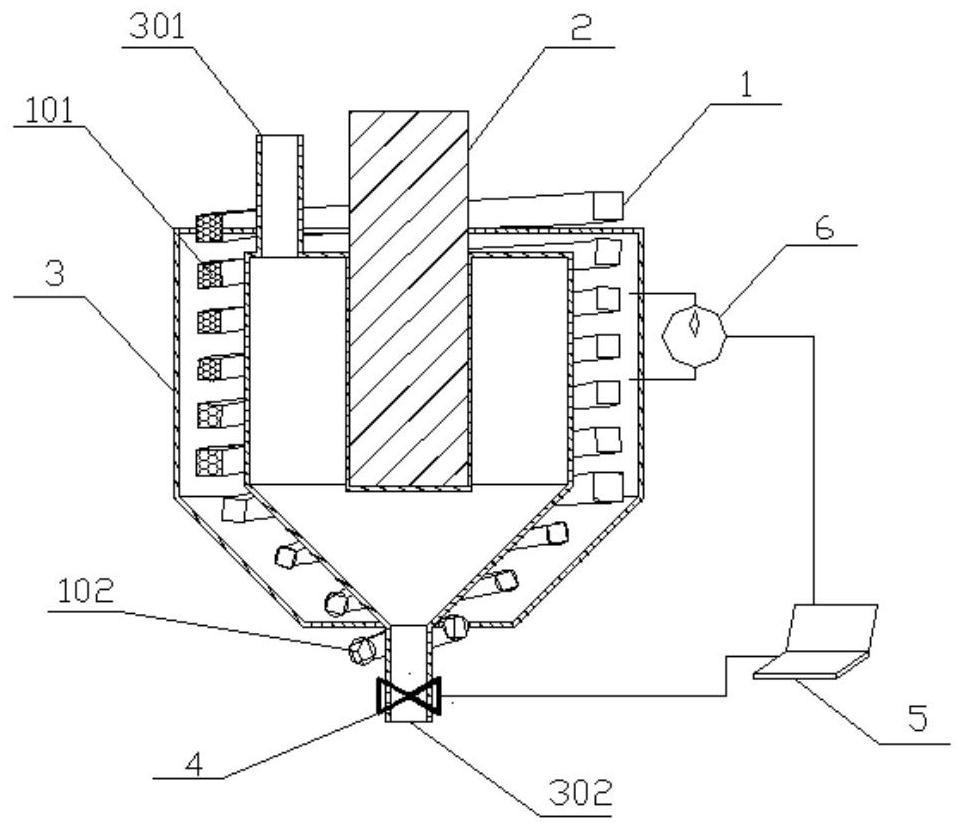

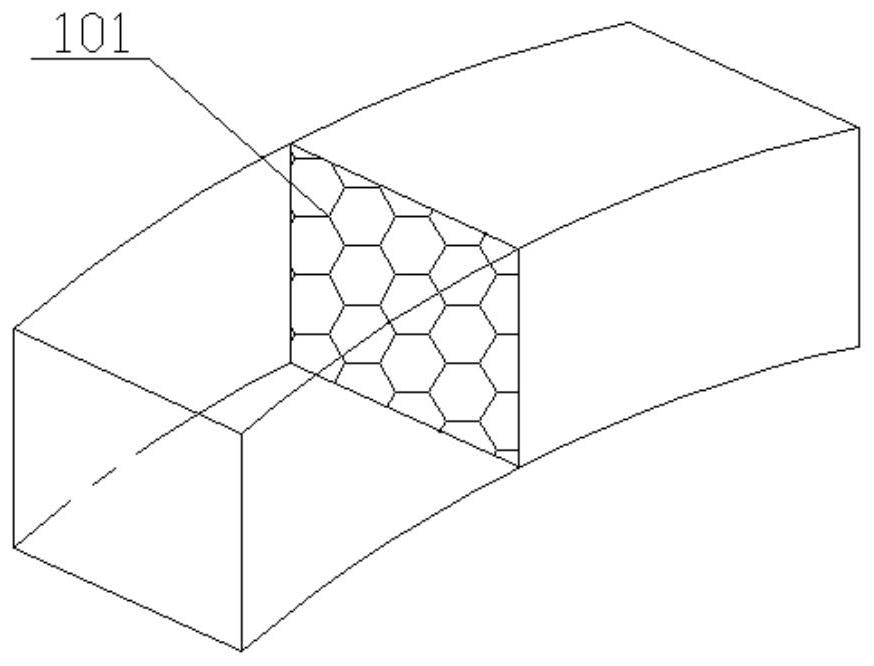

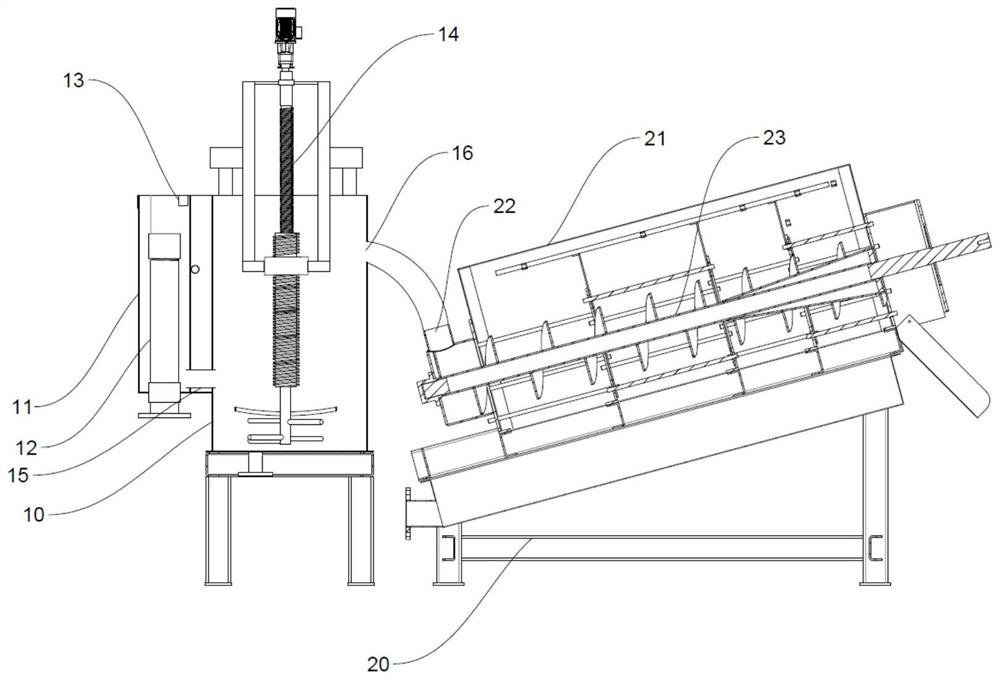

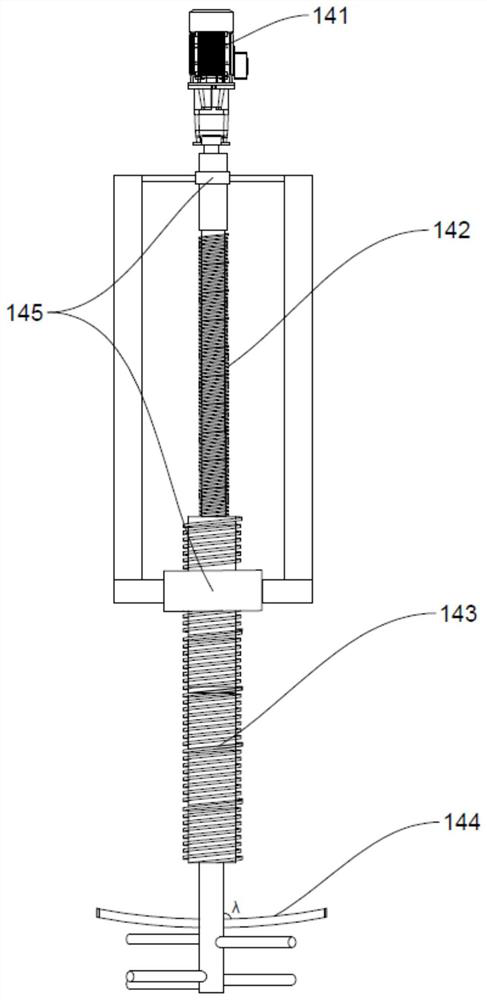

Combined sludge deep dehydration system and deep dehydration technique

InactiveCN105461189AAdaptableGuaranteed uptimeSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFiltrationSludge

The invention provides a combined sludge deep dehydration system and deep dehydration technique. The dehydration system comprises a sludge feed unit, a sludge conditioning modification unit and a pressure filtration dehydration unit, wherein the sludge feed unit comprises a sludge dilution homogenization tank and a sludge mixing delivery assembly; the sludge dilution homogenization tank is connected with the sludge conditioning modification unit through the sludge mixing delivery assembly; and the sludge conditioning modification unit is connected with the pressure filtration dehydration unit. The deep dehydration technique comprises the following steps: (1) treating sludge by the sludge feed unit to obtain the sludge of which the water content is within a certain range; (2) sending the sludge obtained in the step (1) to the sludge conditioning modification unit, and adding a conditioner to perform conditioning; and (3) sending the sludge obtained in the step (2) to the pressure filtration dehydration unit to perform treatment. By optimizing the design, the whole technique has high adaptability, and can flexibly regulate the operation group number and time of the system according to the actual sludge feed quantity and water content condition, thereby ensuring the stable operation of the system.

Owner:SHANGHAI ATON ENVIRONMENTAL LIABILITY

Ceramic filtering machine dehydrating system and dehydration technique thereof

ActiveCN101920137AIncrease production capacityAvoid cloggingFiltration circuitsMaterials scienceDehydration Technique

The invention discloses a ceramic filtering machine dehydrating system and a dehydration technique thereof. The system comprises a distribution barrel (3), a ceramic filtering machine (4), a concentration basin (1), an accident basin (6), a base flow pump (2) and an overflow pipe (5). The distribution barrel (3) is connected to an ore pulp pipeline through a distribution valve (7) for distributing the ore pulp to the ceramic filtering machine (4), and the overflow pipe (5) is connected with the ceramic filtering machine (4) and the concentration basin (1) for conveying the ore pulp and cleaning water overflowing from the ceramic filtering machine (4) to the concentration basin (1) to precipitate. The invention is characterized in that a pipeline is provided to connect the ore pulp pipeline and the concentration basin, and the pipeline is controlled by a concentration valve (10) and is used for concentrating the ore pulp in the concentration basin and then distributing the ore pulp to the ceramic filtering machine for carrying out solid-liquid separation. The invention can avoid mass blockage of a ceramic filtering plate and improve capacity of the ceramic filtering machine.

Owner:YUNNAN DAHONGSHAN PIPELINE

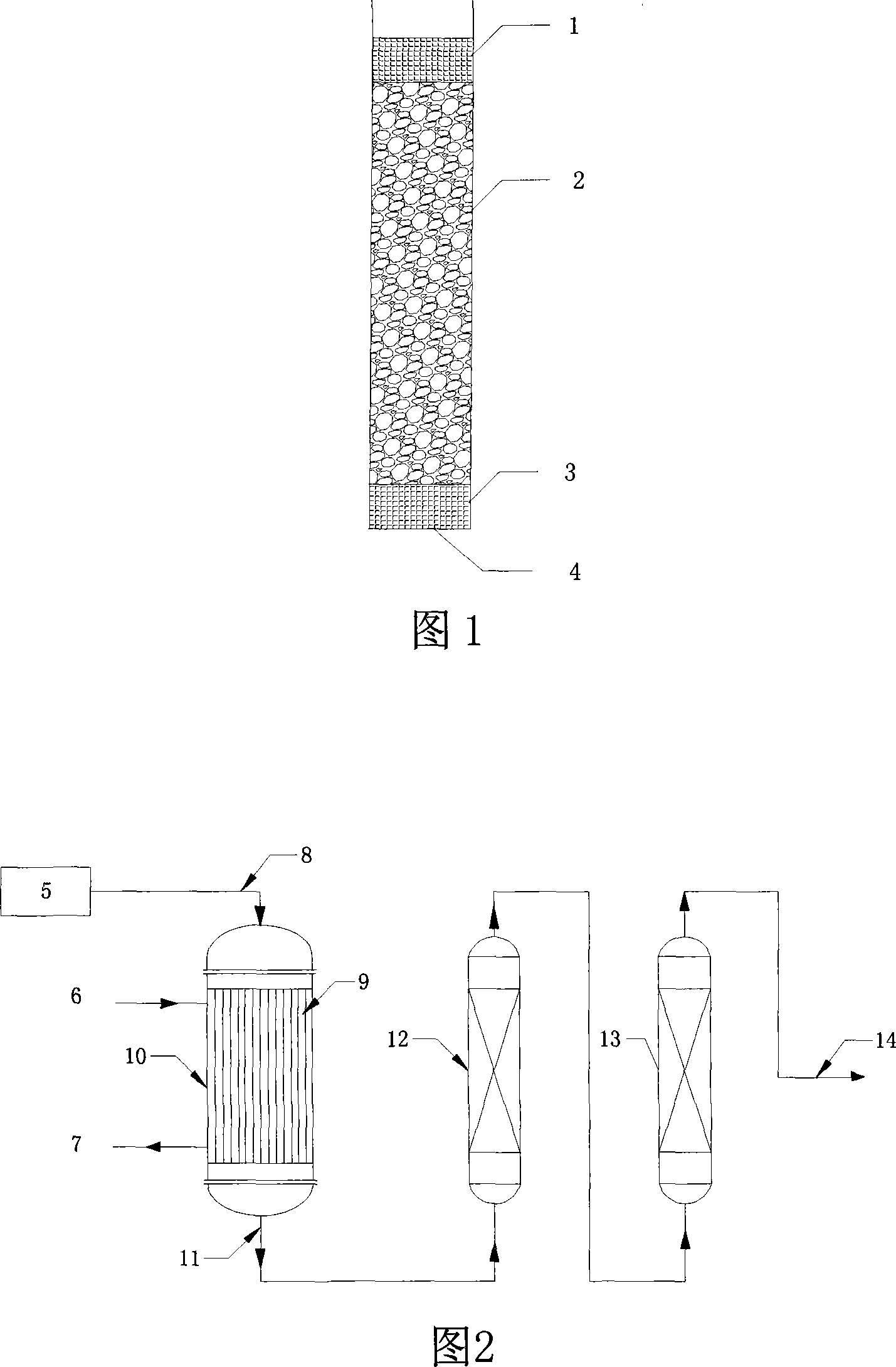

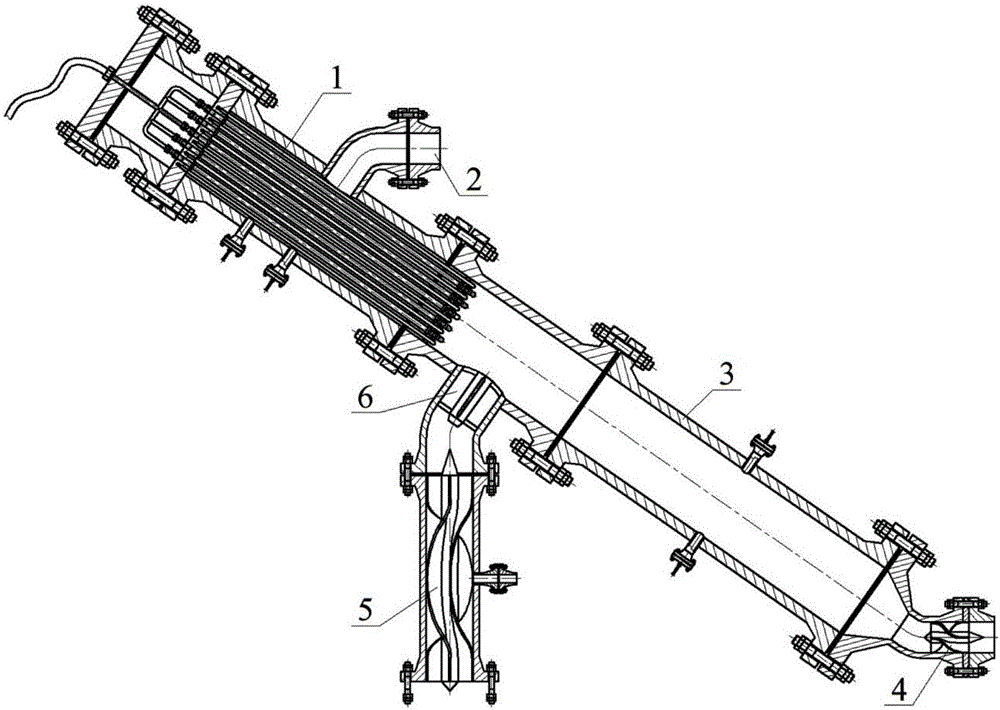

Ethanol dehydration technique adopting molecular sieve catalyst

InactiveCN101219920AHigh yieldImprove conversion rateMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveReaction temperature

The invention discloses a high-efficiency ethanol dehydration process by using a molecular sieve catalyst; ethanol is taken as raw material and the modified molecular sieve as the catalyst to prepare ethylene through dehydration reaction; the invention comprises the specific steps that two or above two multitubular packed-bed reactors are serially connected and the catalyst is put into the reactors; the ethanol which passes through the reactor in a liquid hourly space velocity of 0.4 to 4.5 h <MINUS 1> is converted to the ethylene under a temperature ranging from 150 DEG C to 400 DEG C. The invention can effectively improve yield of the ethylene and conversion rate of the raw material; the invention has the advantages of energy saving, flexible reaction condition, high application efficiency of the catalyst, high reaction activity, long service life, high strength, low reaction temperature and great industrialization application value.

Owner:NANJING UNIV OF TECH

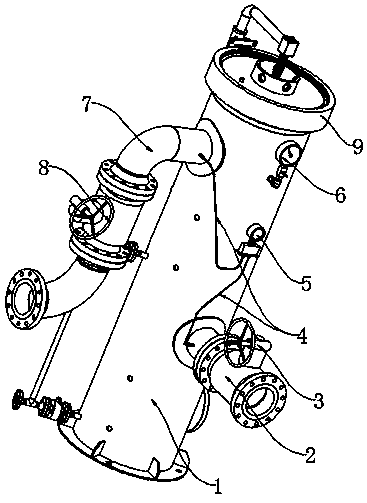

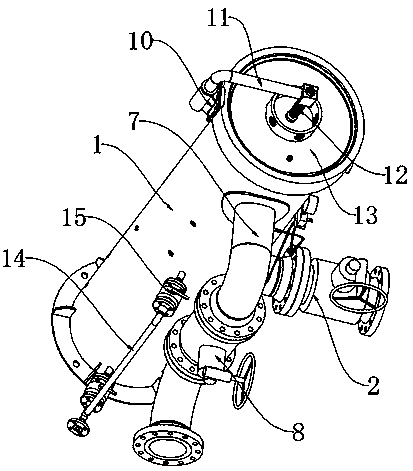

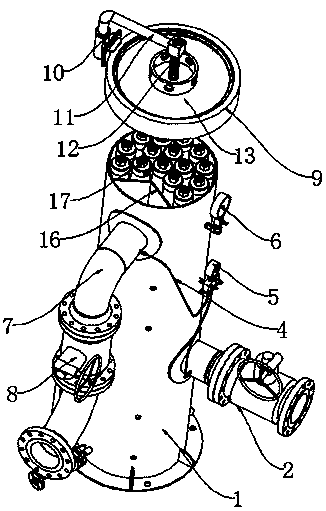

Natural gas filtration and dehydration equipment

The invention belongs to the technical field of natural gas filtration and dehydration, and discloses natural gas filtration and dehydration equipment. The top of a folded plate is welded with an upper supporting plate, and a cavity is formed between the folded plate and a tank body. A cyclone separator is arranged at the upper part of the upper supporting plate; one end of an air inlet pipeline is communicated with the cavity in the tank body; one end of an exhaust pipeline is communicated with the bottom of the tank body; and a cover body assembly covers the top of the tank body. The cycloneseparator and the demister are arranged, natural gas entrained with liquid and solid particles enters the cavity formed by the tank body and the folded plate through the gas inlet pipeline and then the entrained liquid and solid particles are filtered through the cyclone separator and the demister, the gas is exhausted from the exhaust pipeline after filtering, the gas component analyzer arrangedin the exhaust pipeline can detect the filtered gas, the detection information is displayed on the upper part of the display screen and the operator can check the detection information conveniently.

Owner:长沙星沙新奥燃气有限公司

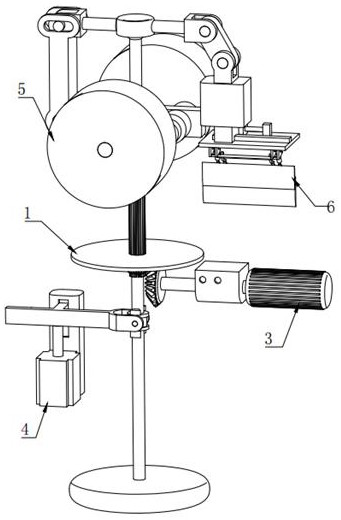

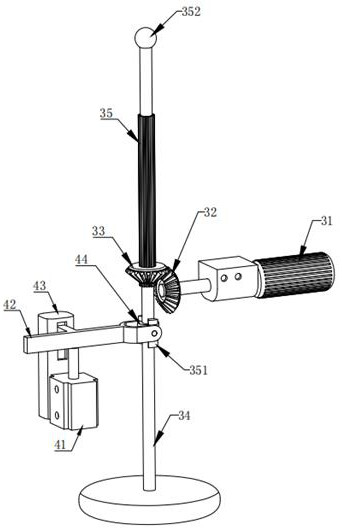

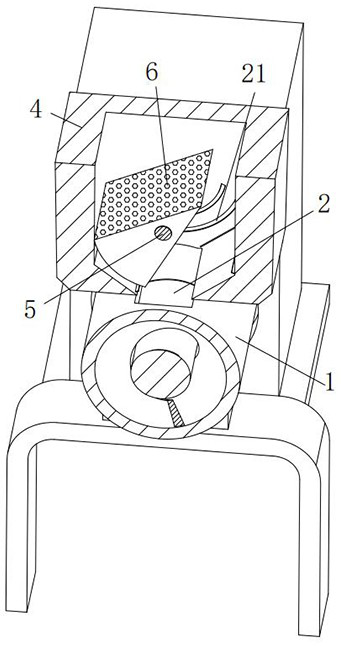

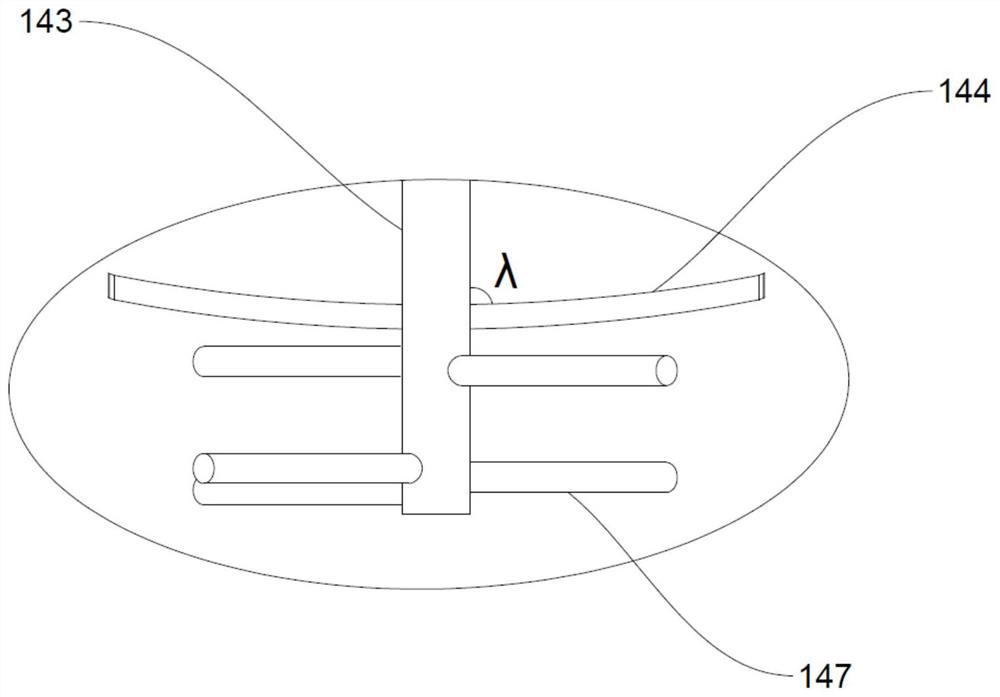

Oblique tube type row-column electrode array underwater online electric dehydration unit

ActiveCN106833728AReduce moisture contentDehydration fastDewatering/demulsification with electric/magnetic meansHydrocarbon oils treatmentWater dischargeHigh pressure

The invention provides an oblique tube type row-column electrode array underwater online electric dehydration unit applied to underwater direct electric dehydration of pre-separated crude oil. Vertical-horizontal online separation technique for crude oil and parallel high-voltage electric field dehydration technique for crude oil are combined organically herein; efficient oil-water separation and underwater quick dehydration are achieved according to oblique tube type structure and row-column electrode array; the pre-separated crude oil and an emulsifier are stirred by a flow stabilizer through flow stabilizing rods and a flow stabilizing blade wheel, the formed crude oil emulsion is adjusted into a uniform flow, and the crude oil emulsion is then re-organized into a stable flow through a liquid coming wheel shaft and a liquid incoming wheel; row-column bare electrodes are of row-column electrode array, producing a parallel high-voltage electric field, quick dehydration of crude oil based on row-column parallel high-voltage electric field is carried out in a dehydration separation tube, and residual water phase in the pre-separated crude oil is removed; the qualified crude oil is discharged from an oil discharge pipe; a water discharge pipe discharges low-oil-content produced water according to an anti-vortex wheel and an anti-vortex wheel shaft, while preventing the water from producing vortexes.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

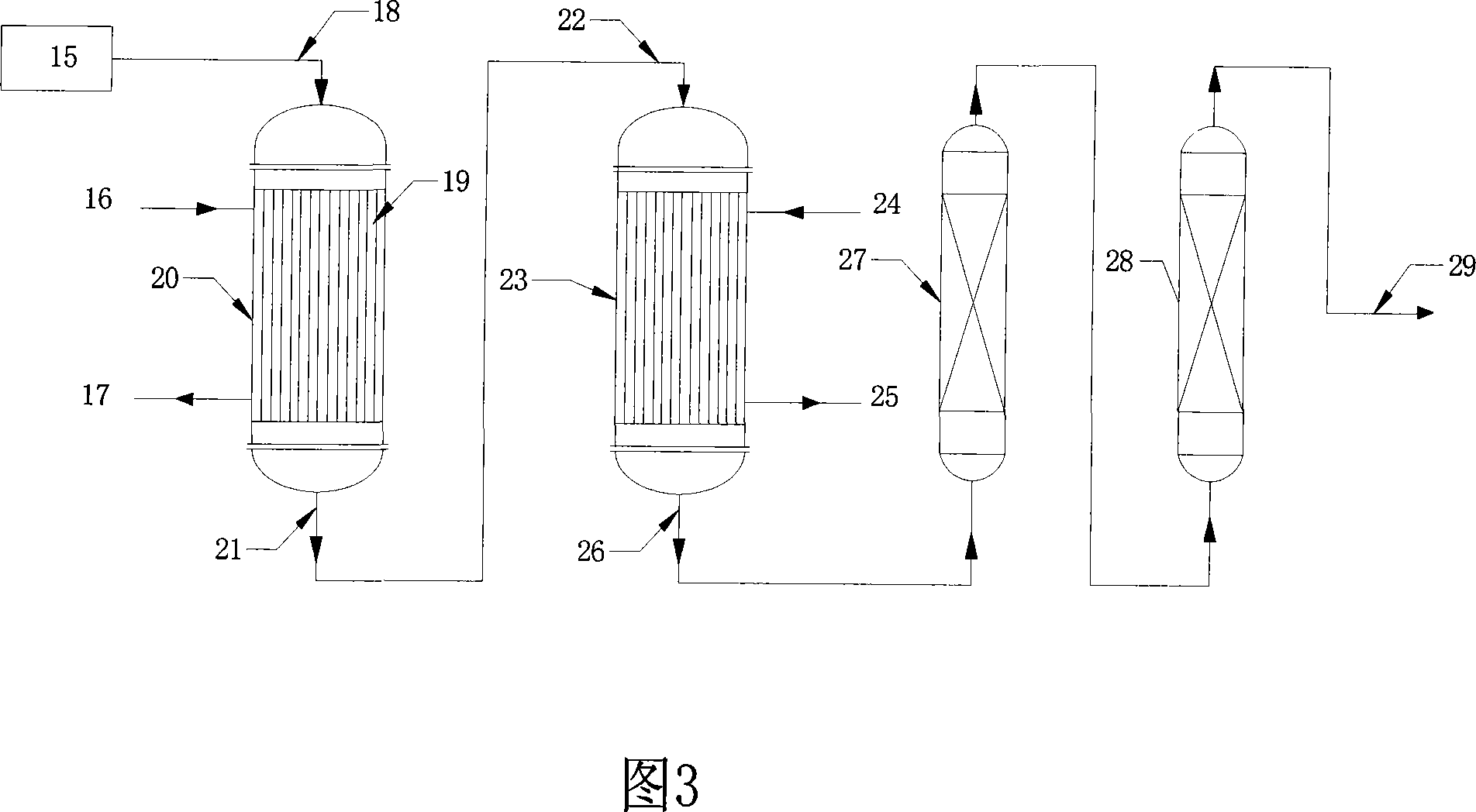

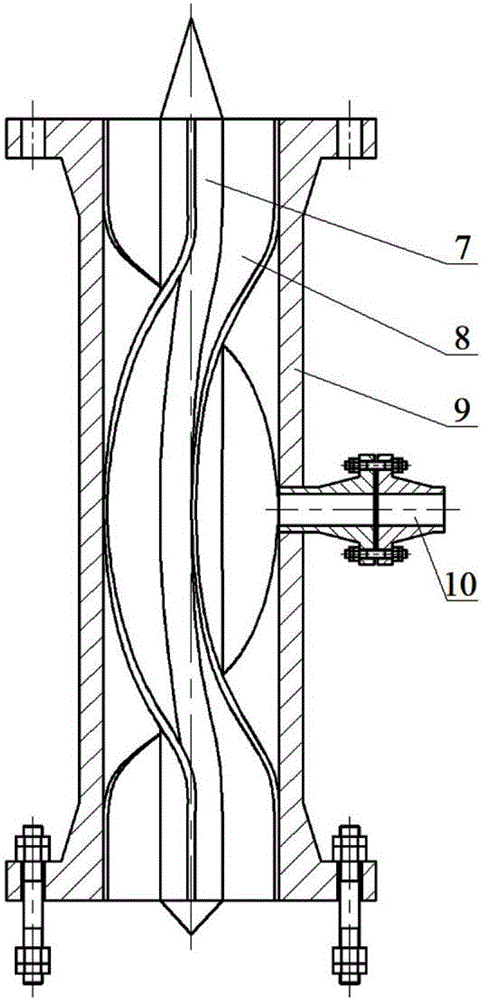

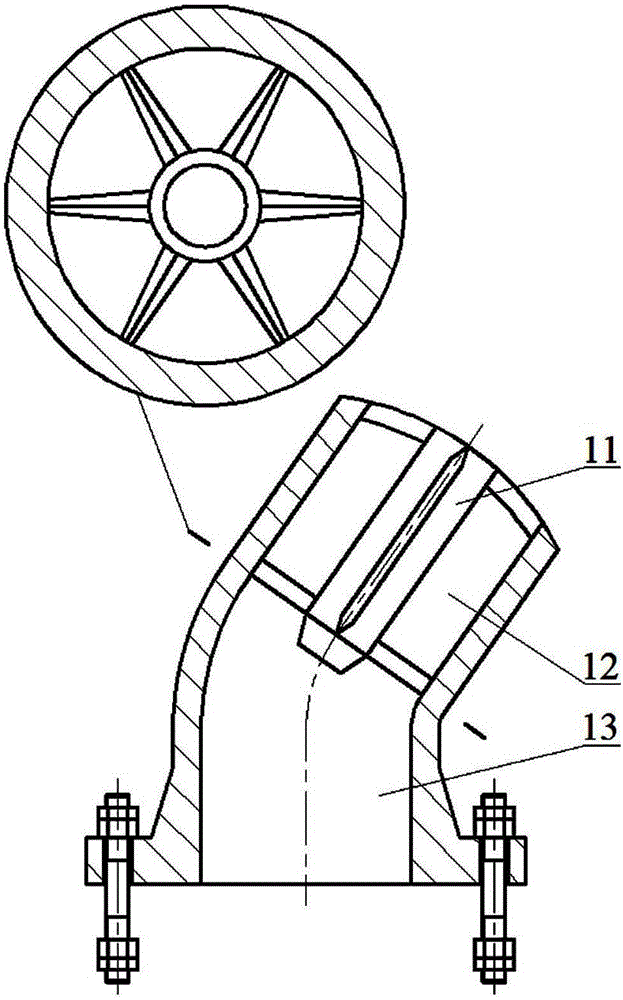

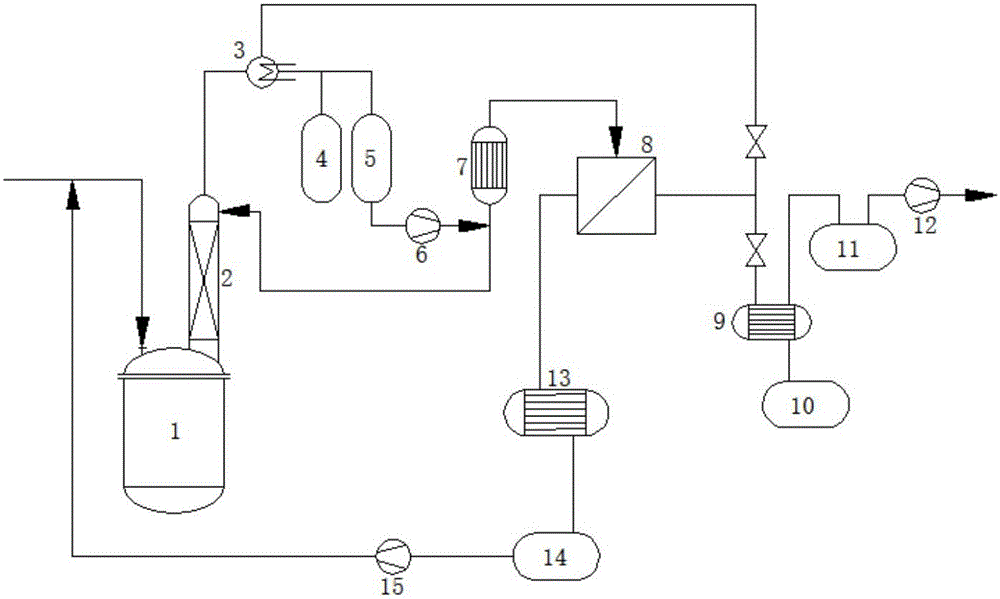

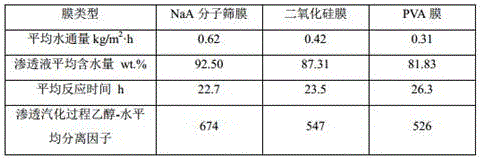

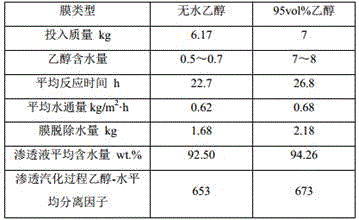

Method and device for synthesizing triethyl citrate by applying vapor permeation dehydration technique

InactiveCN106518683AReduce moisture contentShort water contentOrganic compound preparationCarboxylic acid esters separation/purificationTowerPermeation

The invention relates to a method and a device for synthesizing triethyl citrate by applying a vapor permeation dehydration technique, belonging to the technical field of permeation gasification membrane separation application and organism synthesis. The method comprises the following steps: adding citric acid, ethanol and a catalyst into a reaction kettle according to a certain ratio, and heating to certain temperature, wherein triethyl citrate and water are mainly generated from reactants under the catalytic action of the catalyst. In the reaction process, rising vapor and downstream backflow liquid inside the reaction kettle play roles of heat conduction and mass transfer in a rectifying column, generated ethanol and water are distilled out from the tower top of the rectifying column, and the distillate is dehydrated as a vapor permeation dehydration raw material. After the distillate is dehydrated, ethanol vapor with relatively high purity is condensed and fed back to the reaction kettle. As ethanol is adopted as a water carrying agent, water carried by the raw materials and water generated in the reaction process can be continuously removed, the reaction can be promoted to the direction of ester production, and thus the conversion rate of the reaction can be increased. According to the method and the device, the triethyl citrate is high in esterification rate and purity, ethanol amount is low, recycling process is not needed, the process is simple and the operation energy consumption is low.

Owner:JIANGSU NINE HEAVEN HIGH TECH

Dehydration technique for carnaillite water feeding chloromagnesite

The invention belongs to the chemical field of salt lakes, in particular relates to a dehydration technology of carnallite adding bischofite, and aims at carrying out dehydration for the natural carnallite adding bischofite to prepare the refining agent of magnesium metal, raw materials for producing the magnesium metal by electrolysis, waste water purifying agent and dry powder extinguishing agent, etc. The dehydration technology has the technical processes that the dehydration technology of carnallite adding bischofite is characterized in that a certain amount of accessories is added in the carnallite to carry out mixing, added to a reaction vessel and heated to the molten state of 700 DEG C to 800 DEG C, and the bischofite is slowly added, and flashes and dehydrates instantly. At 700 DEG C to 800 DEG C, standing to preserve heat is carried out for 10 to 60 minutes, and the product can be obtained after discharging. The dehydration technology has the advantages of short technological process, low energy consumption, no pollution, simple operation, etc., thereby providing a new way for the comprehensive utilization of magnesium resources in salt lakes.

Owner:部燕茹 +1

Tower type continuous dehydration technique for trichloroacetaldehyde monohydrate

InactiveCN101215228AImprove mass transfer effectShort stayCarbonyl compound separation/purificationSmall footprintAcetaldehyde

Disclosed is a tower type continuous dewatering technology of chloral hydrate, technical characteristic of which is that dilute sulphuric acid is discharged out from the bottom of the tower, the chloral hydrate enters from a certain portion at the bottom of the tower, concentrated sulfuric acid enters from the top of the tower, and refined chloral is discharged out from the top of the tower. The whole process is the continuous dewatering operation and the technique is simple, fast and fluently, which realizes continuous dewatering of chloral hydrate with relatively less equipments and relatively low energy consumption. The technique can be controlled easily and operated relatively stably. Compared with other existing dewatering techniques, the invention not only can reduce investment of equipments, but also is small in area and low in energy consumption. Further, the invention can decrease dewatering cost of chloral hydrate obviously and improve product quality.

Owner:荆州沙隆达控股有限公司

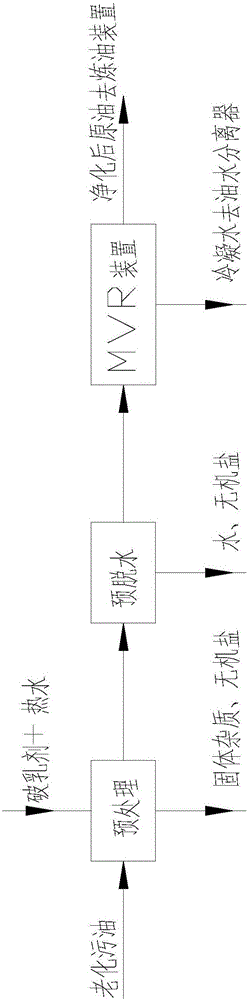

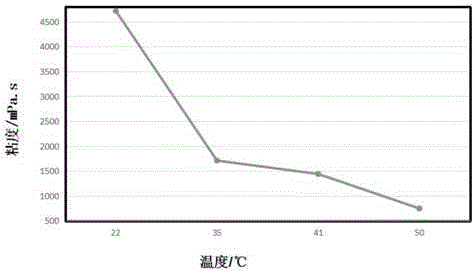

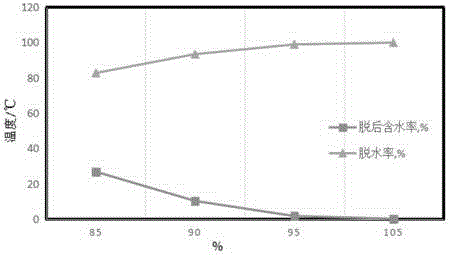

Aged sump oil treatment process

InactiveCN105950212ASolve the problem of water quality deterioration beyond the standardRelieve pressureTreatment with plural serial refining stagesSocial benefitsThermal treatment

The invention relates to an oil treatment process, in particular to an aged sump oil treatment process. According to the technique of the process, aged sump oil is mainly treated with the combination of techniques of ultrasonic wave hot water washing, chemical thermal treatment, supergravity separation and an MVR negative pressure dehydration technique, so that the applicability of the techniques can be improved, the equipment treatment capacity can be improved, and the energy consumption can be reduced. The deep aged sump oil treatment technique is simple in process, good in applicability, low in energy consumption and convenient to operate, various types of aged sump oil can be treated, hidden safety and environment hazards caused by aged sump oil can be reduced, normal production of production devices of oil fields and oil refineries can be ensured, and meanwhile the aged sump oil can be recycled and reused, so that remarkable economic, environment and social benefits can be achieved.

Owner:天博蓝创(天津)科技有限公司

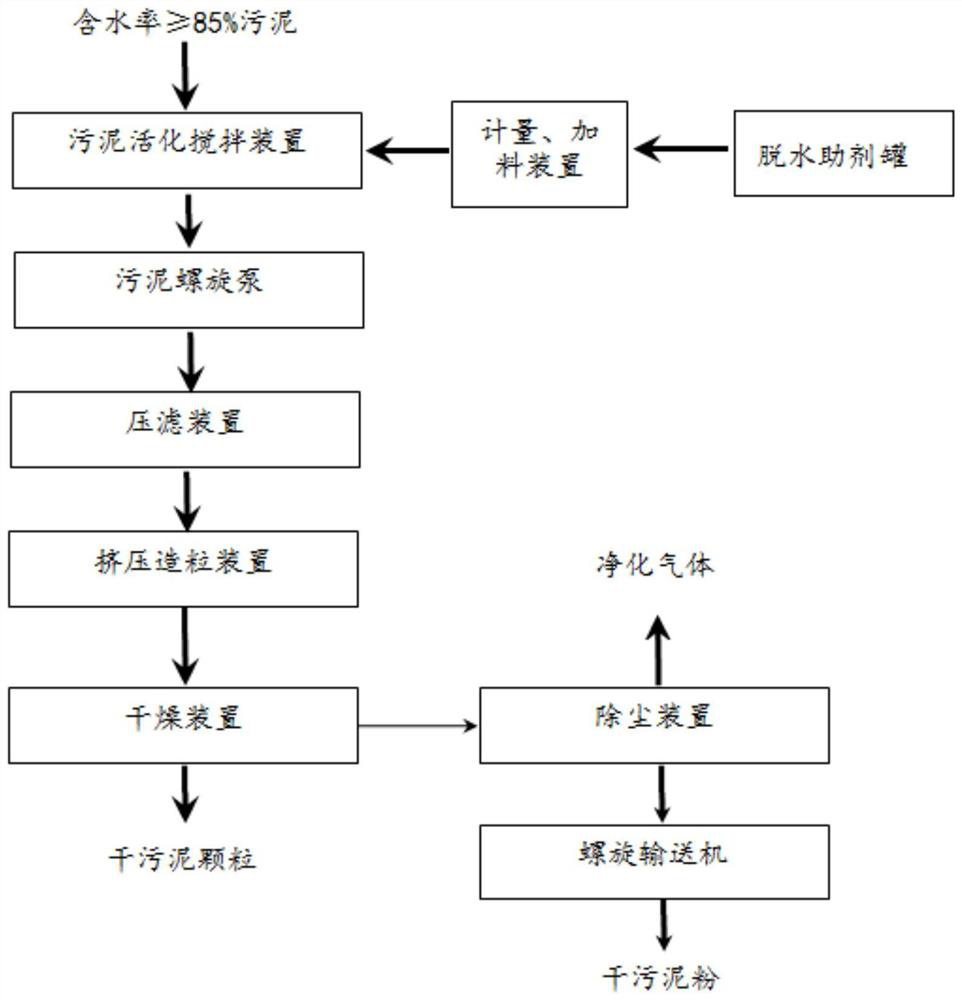

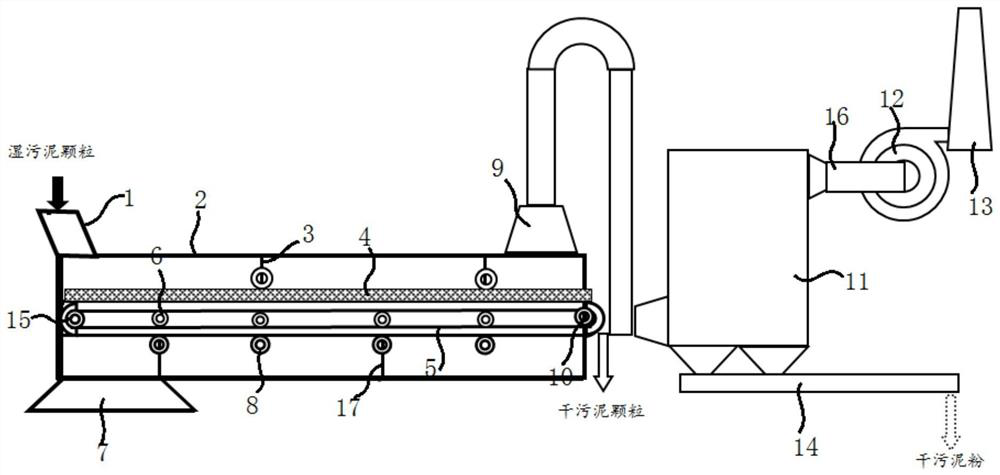

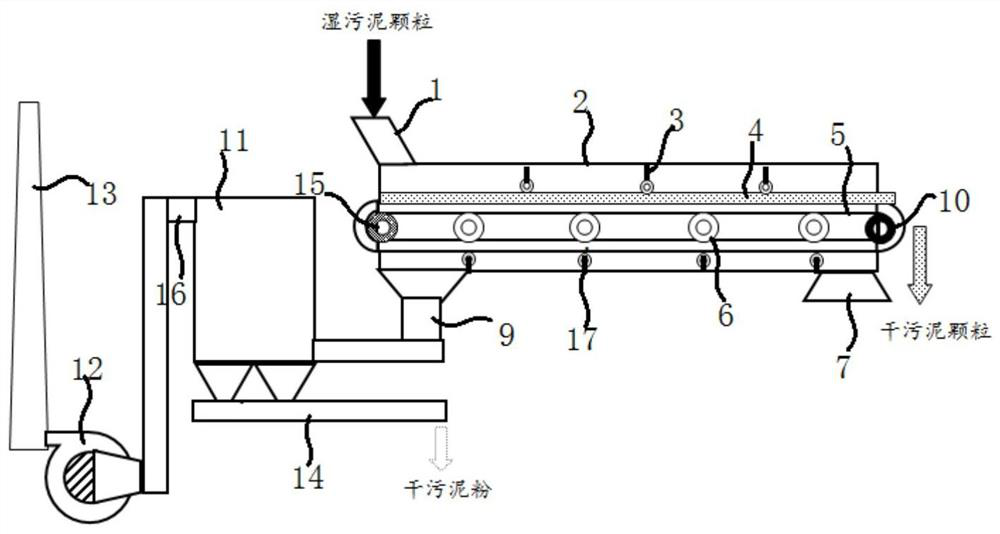

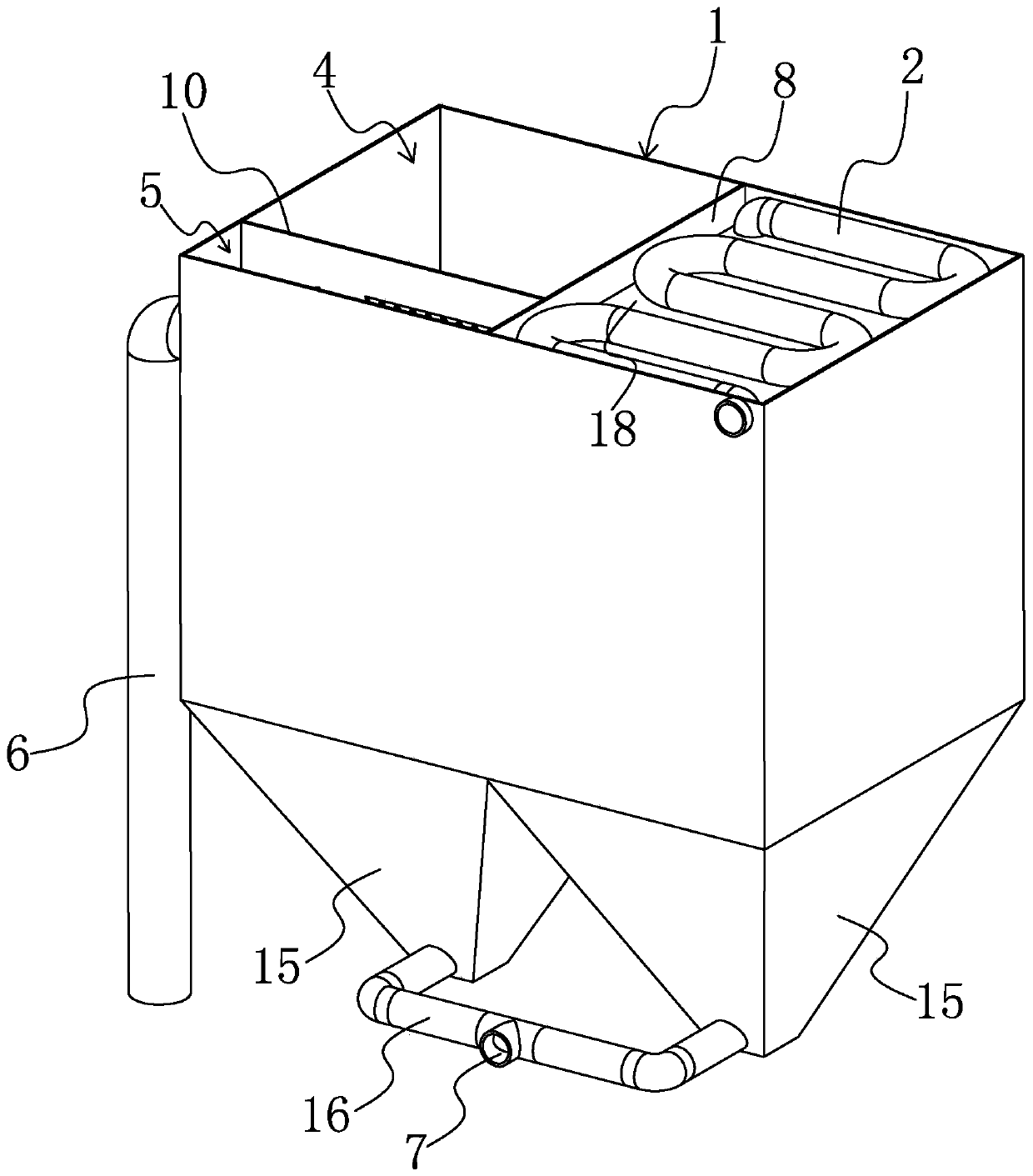

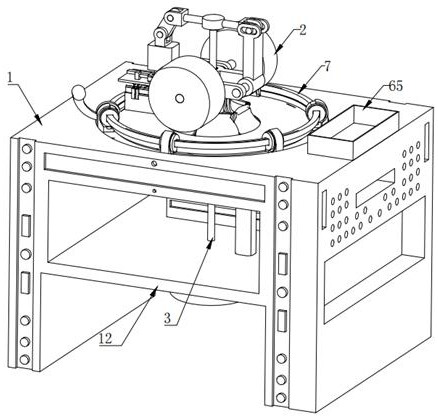

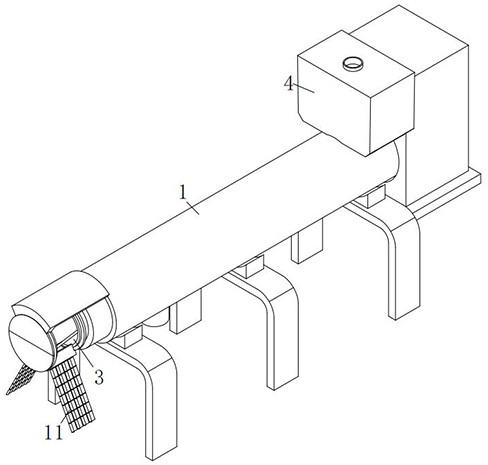

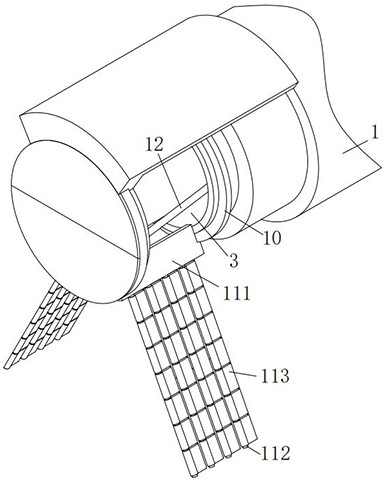

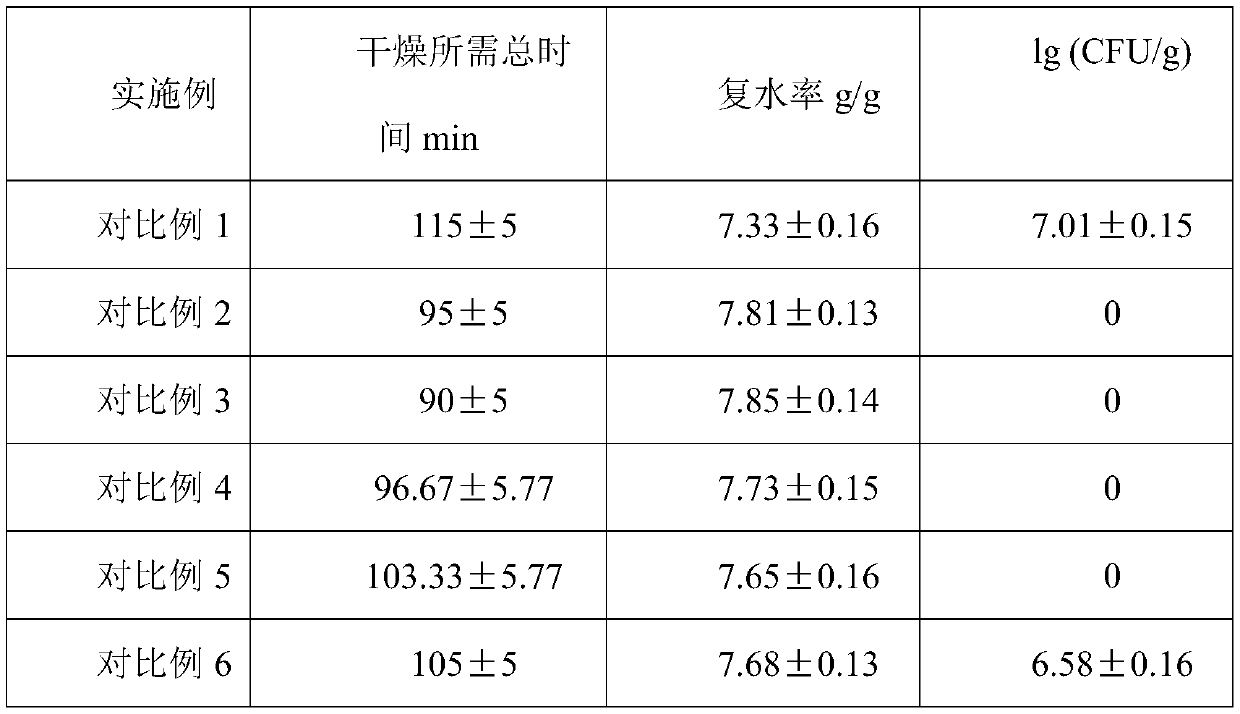

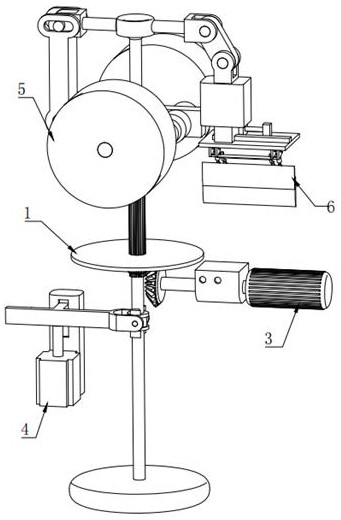

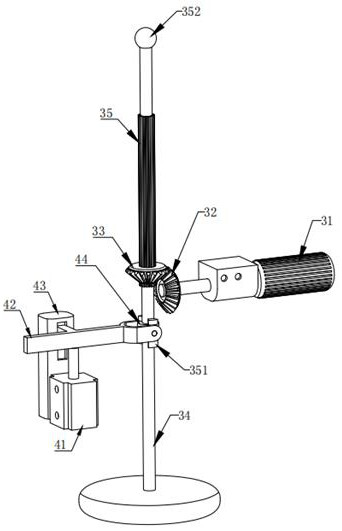

Rapid sludge dewatering system and dewatering method

PendingCN112159074ADehydration fastEfficient dehydrationSludge treatment by de-watering/drying/thickeningGranulation by material expressionProcess engineeringFilter press

The invention discloses a rapid sludge dewatering system and a dewatering method, and belongs to the technical field of sludge dewatering. The sludge rapid dehydration system comprises a dehydration auxiliary agent tank, a sludge activation stirring device, a filter pressing device, an extrusion granulation device and a drying device, the drying device comprises a machine shell, and the interior of the machine shell is divided into an upper space and a lower space through a breathable conveying belt horizontally distributed in the length direction of the machine shell; wherein the upper spaceis divided into a plurality of air entraining channels through an upper partition baffle, the lower space is divided into a plurality of air entraining channels through a lower partition baffle, and air enters through an air inlet in one end of the machine shell and then sequentially and alternately enters the lower air entraining channels and the upper air entraining channels. By the adoption ofthe scheme, sludge can be dewatered rapidly and efficiently, deep dewatering of the sludge is achieved, the application process is easy to operate, and energy consumption is low.

Owner:安徽省融工博大环保技术材料研究院有限公司

Deep dehydration technique of Vc two-step fermentation ultrafiltration waste slag liquid

InactiveCN103506009AEmission reductionShorten the ultrafiltration cycleUltrafiltrationUltrafiltrationSlag

The invention discloses a deep dehydration technique of Vc two-step fermentation ultrafiltration waste slag liquid. Ultrafiltration raffinate with 3-5 g / 100ml of contained slag concentration and 70-120 mg / ml of gulonic acid concentration is used for regulating pH within 2-4, is stood for 20 minutes, is heated to 70-90 DEG C for keeping 20-30 minutes, is cooled to the room temperature, and is centrifugated for 10-15 minutes with 1500 rpm; supernate is shifted into originally ultrafiltered filtrate and participated in following techniques with the same; precipitate is centrifuged to form cake-shaped sediment, has 80%-84% of water content, and is dried to prepare feed protein; the protein content is 35%-55%. The deep dehydration technique is adopted to reduce 75% of emission of the ultrafiltration waste slag liquid; the water content of the ultrafiltration waste slag liquid is decreased from 95% to 80%, so that the preparation of the feed protein is guaranteed; the deep dehydration technique can shorten 30% of an ultrafiltration period, and can improve equipment utilization rate by 20%.

Owner:SHENYANG AGRI UNIV

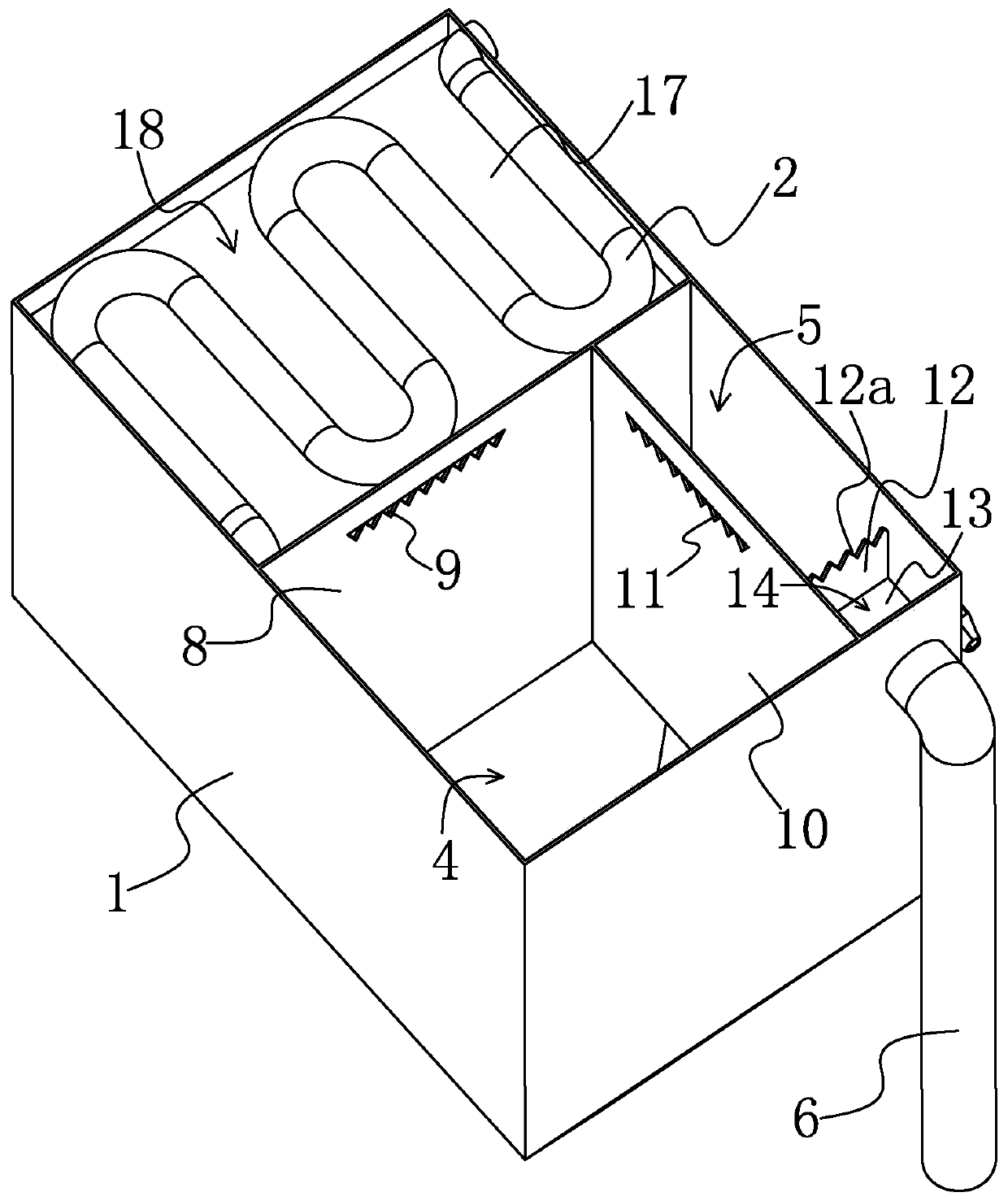

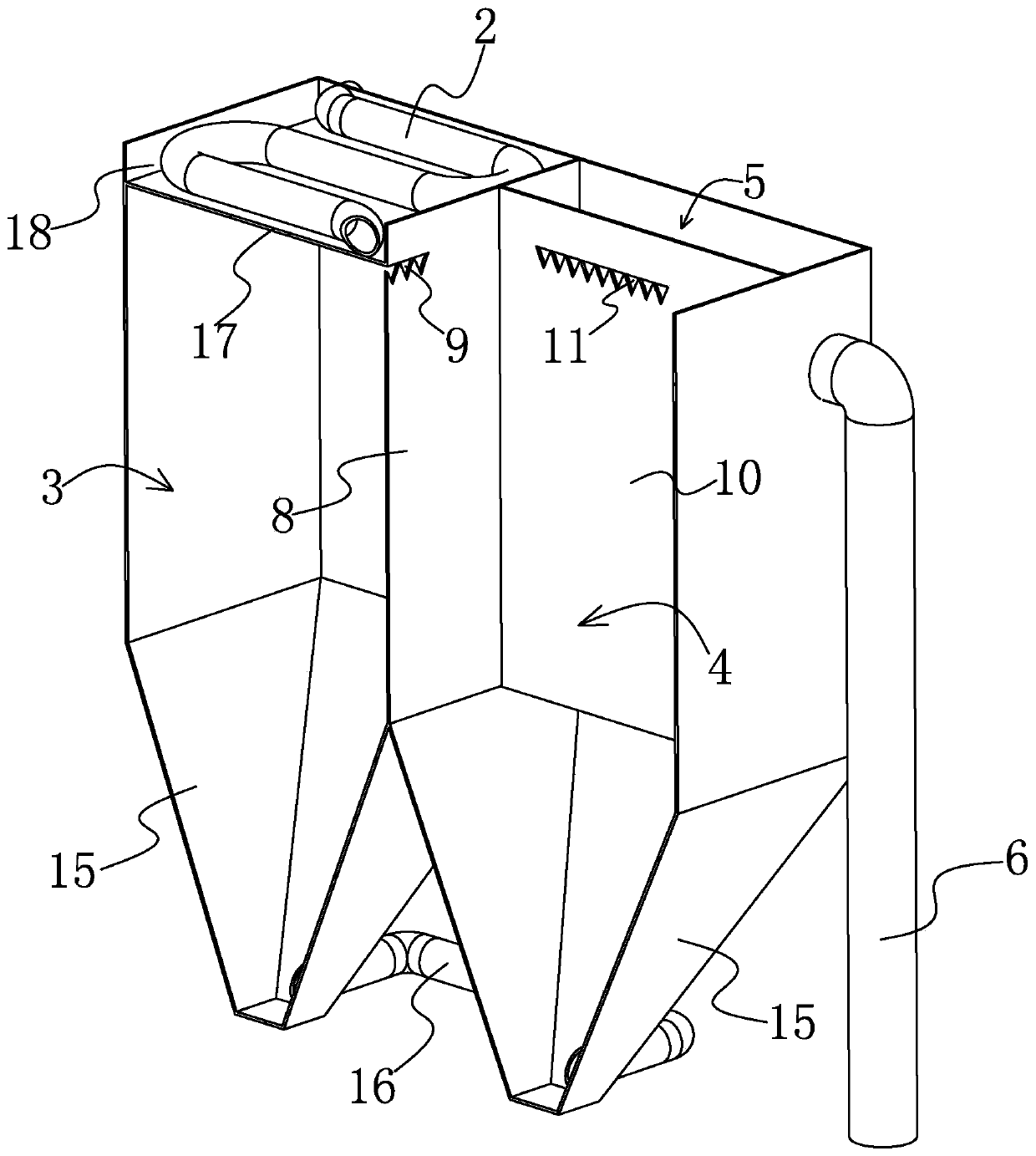

Concentration device for solid-liquid separation dehydration

PendingCN110921886ASimple structure and principleOmit energy consumptionMultistage water/sewage treatmentTreatment involving sedimentationFlocculationSludge

The invention provides a concentration device for solid-liquid separation dehydration, and belongs to the technical field of sludge dehydration. The technical problem that an existing concentration device is low in solid-liquid separation efficiency and high in energy consumption is solved. The concentration device for solid-liquid separation dehydration comprises a concentration tank which is vertically arranged, a flocculation pipe which is arranged at the top of the concentration tank and is communicated with a sewage conveying pipe, a first concentration cavity which is positioned in the concentration tank and is communicated with the flocculation pipe, a second concentration cavity which is arranged in the concentration tank and is spaced apart from and communicated with the first concentration cavity, a third concentration cavity which is arranged in the concentration tank and is adjacent to and communicated with the second concentration cavity, a supernatant discharge pipe whichis fixedly arranged on the concentration tank and is communicated with the third concentration cavity, and a sludge outlet which is formed in the bottom of the concentration tank and is respectivelycommunicated with the first concentration cavity, the second concentration cavity and the third concentration cavity. The whole process can be realized through the flowing of sewage, the structure principle is simple, the energy consumption required by stirring is saved, the cost is controlled, and the efficiency is further improved.

Owner:象山德曼机械有限公司

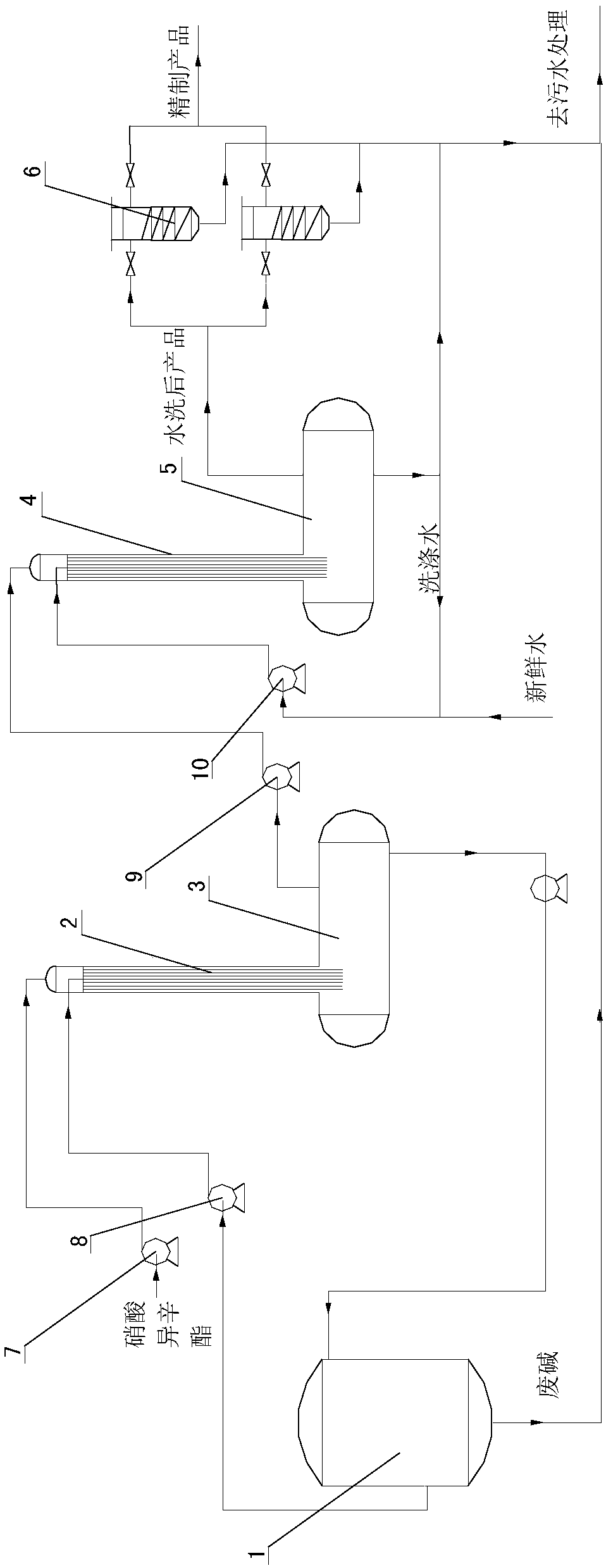

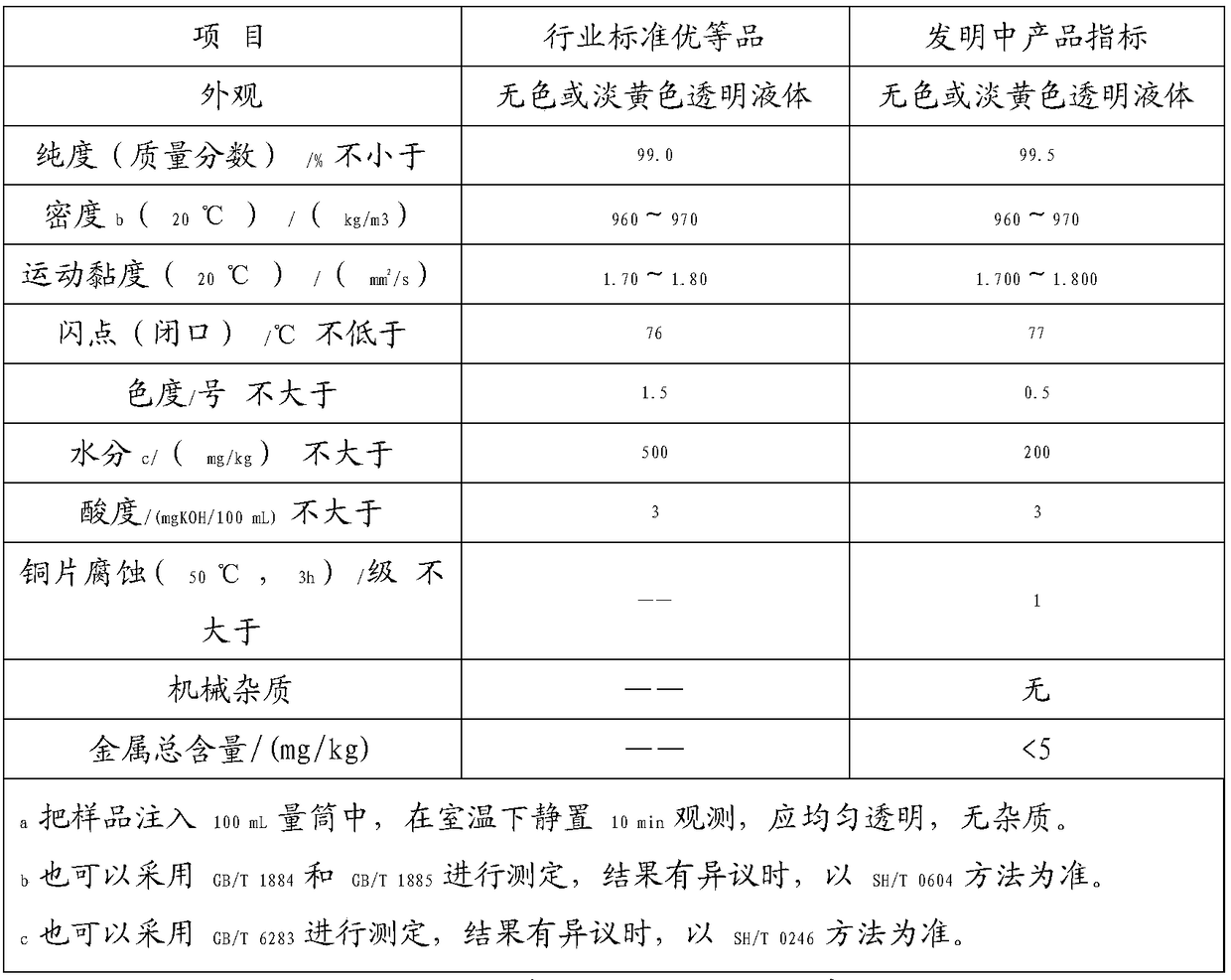

Continuous post-treatment technique and device of ethylhexyl nitrate

The invention relates to a continuous post-treatment technique of ethylhexyl nitrate and a continuous post-treatment device of ethylhexyl nitrate. The technique includes alkali washing, water washing,and separated dehydration technique of a crude product; alkali washing and water washing devices connected in order are applied to continuously treat ethylhexyl nitrate; the back end of the water washing device is provided with a dehydration device to refine the ethylhexyl nitrate and obtain a final product. By adopting the technique and the device, the continuous separating and purifying processes of the ethylhexyl nitrate are successfully realized, the separated settling time is reduced, and the production efficiency is improved; the consumption of alkali fluid and washing water is reduced,the waste liquid is greatly reduced; quality of the product for purifying is much better than the industrial standard requirement, thus the oil water emulsion in the water washing process is solved,the mass transfer area is enlarged, and the mass transfer rate is improved; the mass transfer between different object phases is realized, the mass transfer function is enhanced, and the energy consumption in the mass transfer process is effectively reduced; the continuous post-treatment technique has the advantages of saving investment, reducing floor area, saving operation cost, and effectivelyreducing waste liquid.

Owner:山东京博众诚清洁能源有限公司

Collecting electric field-ultrasonic wave field-centrifugal field coupled anti-scaling temperature control electric coalescence dehydrator

ActiveCN111704926AIncreased chance of collision coalescenceCoalescence failureDewatering/demulsification with mechanical meansDewatering/demulsification with electric/magnetic meansTemperature controlEngineering

The invention discloses a collecting electric field-ultrasonic wave field-centrifugal field coupled anti-scaling temperature control electric coalescence dehydrator, which comprises a heat preservation system, an ultrasonic wave generating device and a demulsification device, wherein the demulsification device comprises a spiral demulsification chamber, the spiral demulsification chamber is spirally wound on the heat preservation system, and temperature conditions are provided for demulsification through the heat preservation system; the ultrasonic generation device is arranged in the heat preservation system and used for generating an ultrasonic field; an electrode is arranged on the spiral demulsification chamber, wherein a negative electrode is arranged on the inner side of the spiral demulsification chamber, and a positive electrode is arranged on the outer side of the spiral demulsification chamber, the electrode being used for generating an electric field in the spiral demulsification chamber. The electric dehydration technology, the ultrasonic demulsification dehydration technology, the hydrocyclone separation dehydration technology and the heat treatment dehydration technology are combined, and the demulsification efficiency of the device is improved through the synergistic effect.

Owner:申文初

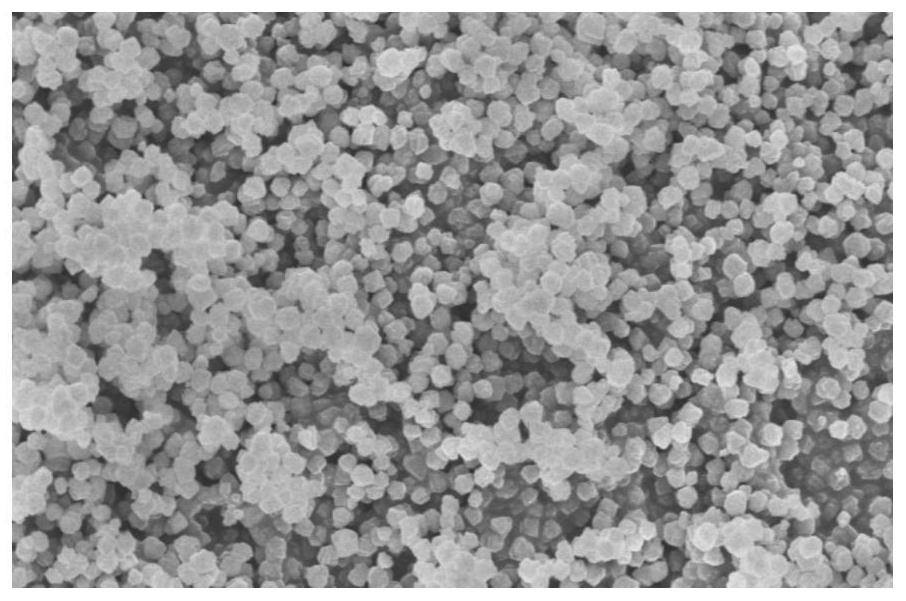

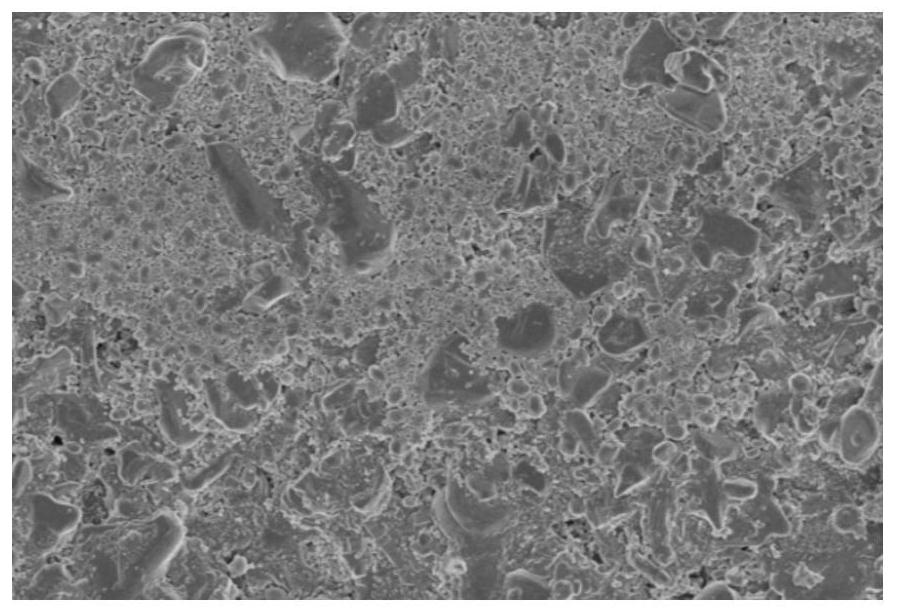

New flotation molybdenum concentrate filter dehydration technique

InactiveCN101391163AEliminate microporosity issuesDrain controlFlotationFiltration separationMaterials scienceDehydration Technique

The invention relates to a flotation molybdenum concentrate filtering dehydration process. The flotation molybdenum concentrate is pretreated before being fed into a ceramic filter for filtering dehydration; MT07 No. modifying additive with the weight of 0.05 percent to 0.10 percent of that of dried concentrate is firstly added into the flotation molybdenum concentrate, and the mixture is agitated and mixed evenly to modify the flotation molybdenum concentrate; then the modified flotation molybdenum concentrate is fed into the ceramic filter for filtering dehydration, so as to obtain the concentrate with qualified dehydration indexes. The invention can effectively eliminate the problems such as blockage of a ceramic filter plate of the ceramic filter, and obviously improve the equipment capacity.

Owner:郴州市黄沙坪铁选矿有限责任公司 +1

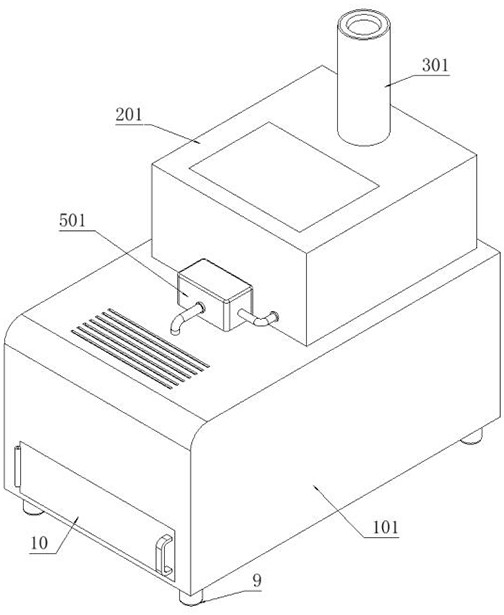

Extracting solution dehydration device for processing ginkgo biloba extract

ActiveCN114470814AAchieving multiple levels of isolationImprove dehydration qualityEvaporator accessoriesHollow article cleaningEngineeringMechanical engineering

The invention provides an extracting solution dehydration device for ginkgo biloba extract processing, relates to the technical field of extracting solution dehydration, and aims at solving the problems that an existing ginkgo biloba extract extracting solution dehydration device is low in dehydration efficiency, high in energy consumption in the dehydration process, low in dehydration essence yield, extremely prone to causing pollution to dehydration essence and ginkgo biloba crystals and low in dehydration cost. The device comprises a shell device, a water inlet device and a water outlet device, the four corners of the bottom of the shell device are fixedly connected with anti-skid ground feet. A sealing door is hinged to the front side of the shell device; an evaporation device is fixedly connected to the shell device, and a pressure relief device is mounted on the evaporation device; a driving part is mounted on the pressure relief device; a flow guide part is mounted on the shell device; an extracting solution in the evaporation box is pumped out through the flow guide pump and then is uniformly sprayed to the film heating plate through the spraying rod arranged at the top of the mounting shell, so that the dehydration efficiency is higher, the heating contact area is effectively increased, and the dehydration quality of the extracting solution is improved.

Owner:江苏大墩子银杏生物科技有限公司

Plant extract decolorizing device

InactiveCN110812889AImprove practicalityIncrease the degree of mixingRotary stirring mixersTransportation and packagingHydraulic cylinderAgricultural engineering

The invention discloses a plant extract decolorizing device, and relates to the technical field of extract dehydration. In the prior art, the existing plant extract is mixed with a decolorizing agentafter being decolorized so as not to easily separate. A purpose of the invention is to solve the problem in the prior art. The plant extract decolorizing device specially comprises a bottom plate, wherein four supporting columns are arranged on the outer wall of the top of the bottom plate, the outer walls of the tops of every two supporting columns are provided with the same supporting plate, theouter walls of the tops of the two supporting plates are provided with the same decolorizing box, the inner walls of the two sides, close to the bottom end, of the decolorizing box are respectively provided with a plurality of hydraulic cylinders, the other ends of the multiple hydraulic cylinders located on one side are provided with the same extrusion plate, and the decolorizing box is providedwith a stirring assembly. According to the invention, by arranging the hydraulic cylinders and the extrusion plate, after the plant extract is decolorized, the hydraulic cylinders are adjusted to drive the extrusion plate to extrude the mixture of the plant extract and the decolorizing agent, so that the decolorizing agent is extruded out of the mixture and discharged from the liquid passing holes in the fixed plate so as to improve the practicability of the device.

Owner:湖南朝露生物科技有限公司

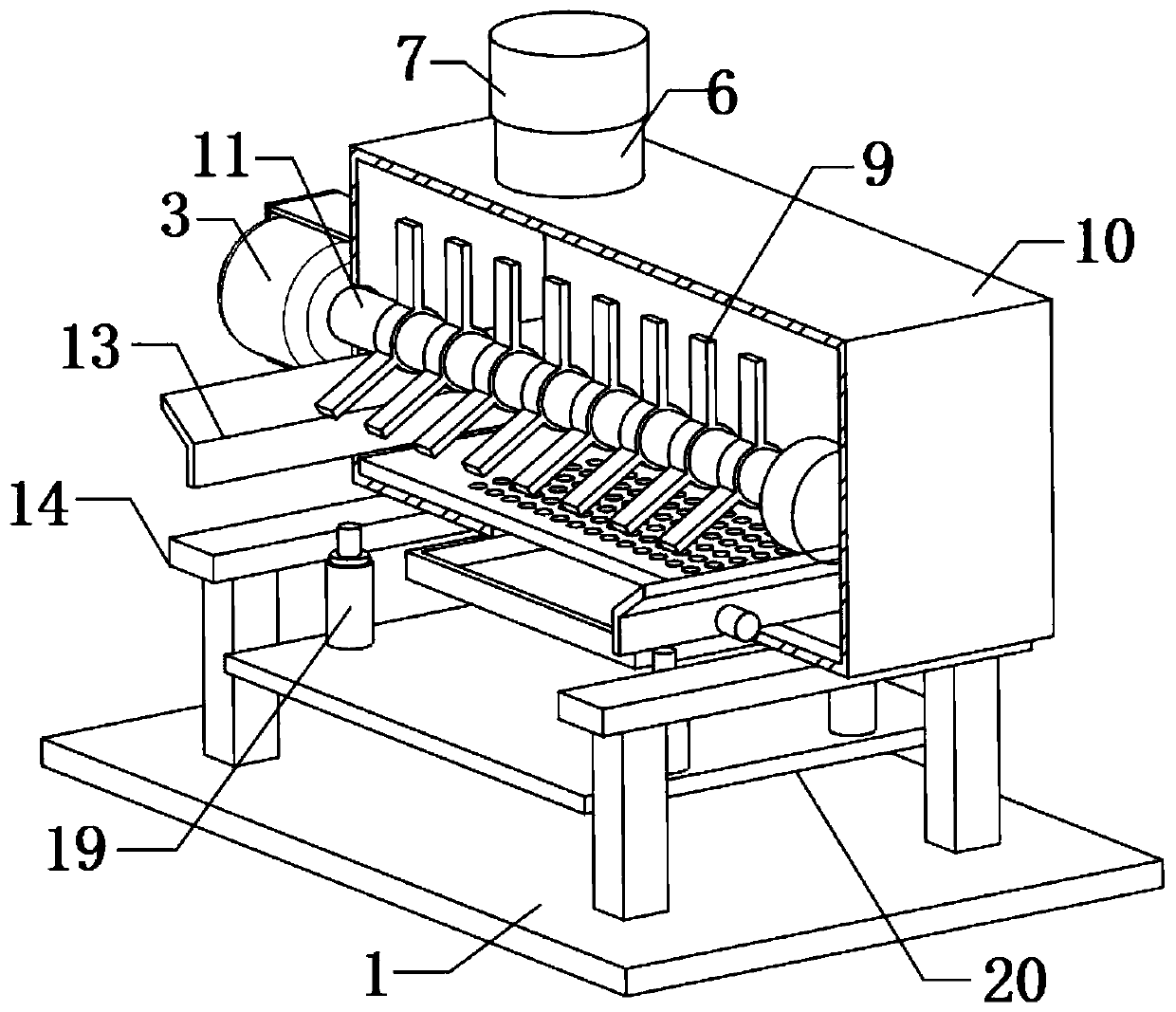

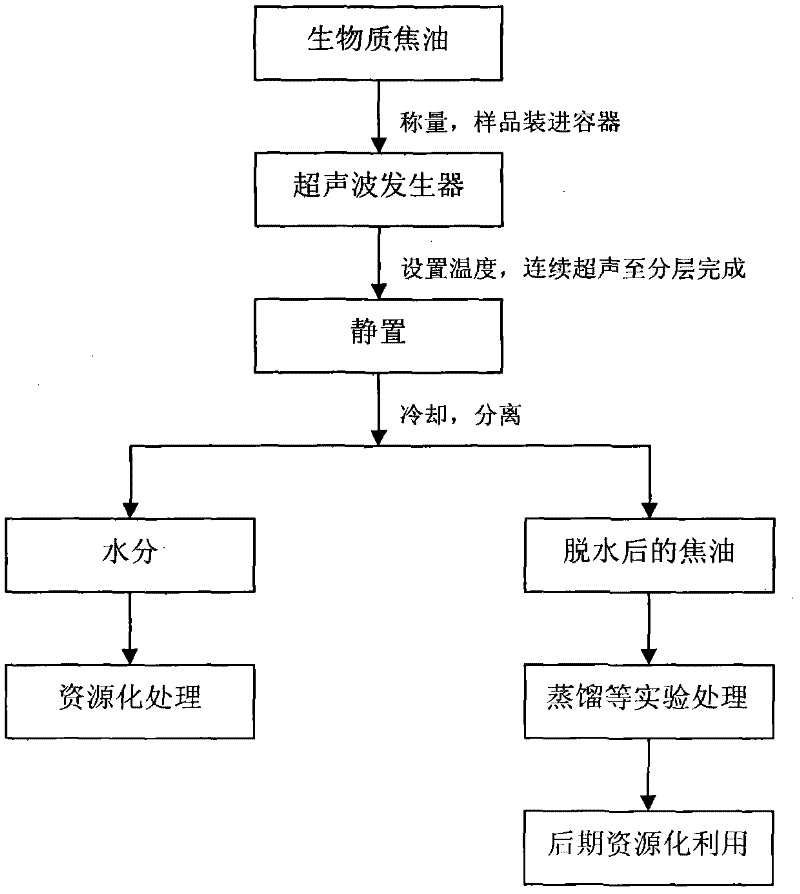

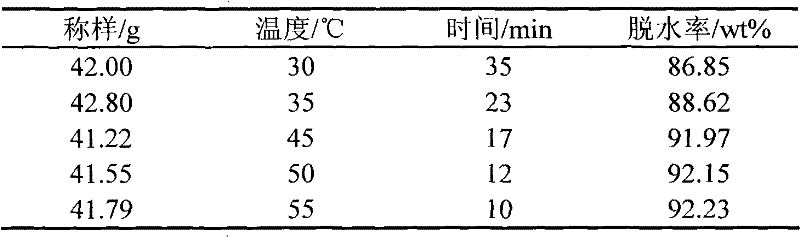

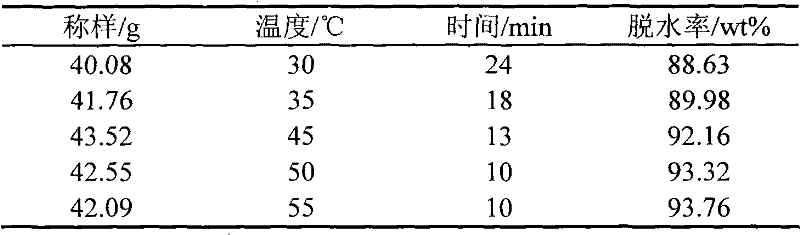

Application of an ultrasonic wave in the dehydration of biomass tar

InactiveCN102260512AHigh removal rateReduce consumptionTar working-up by water removalUltrasonic cavitationEngineering

The invention relates to the application of ultrasonic waves in the dehydration of biomass tar. This application method mainly includes sampling, weighing, sample loading, ultrasonication, separation and other processes. The obtained components enter the later stage of resource utilization. The frequency range of ultrasonic waves is greater than 50KHz and less than 100KHz. The ultrasonic intensity is greater than 0.5w / cm2 and the ultrasonic temperature is 20 -55°C, ultrasonic time is 15-60 minutes. With the help of ultrasonic penetration and cavitation effect, the present invention breaks the emulsion state of water in tar, so that water and organic components of tar can be efficiently and clearly separated, and then separated by standing, the water content of biomass tar is reduced from the original 20-50% of the tar is reduced to less than 10%, laying a good foundation for the later application of biomass tar resources. In addition, the ultrasonic instruments and other equipment used are low-power and low-energy-consuming equipment. Compared with other dehydration technologies, it achieves the goals of low energy consumption, high efficiency and large dehydration capacity.

Owner:EAST CHINA UNIV OF SCI & TECH

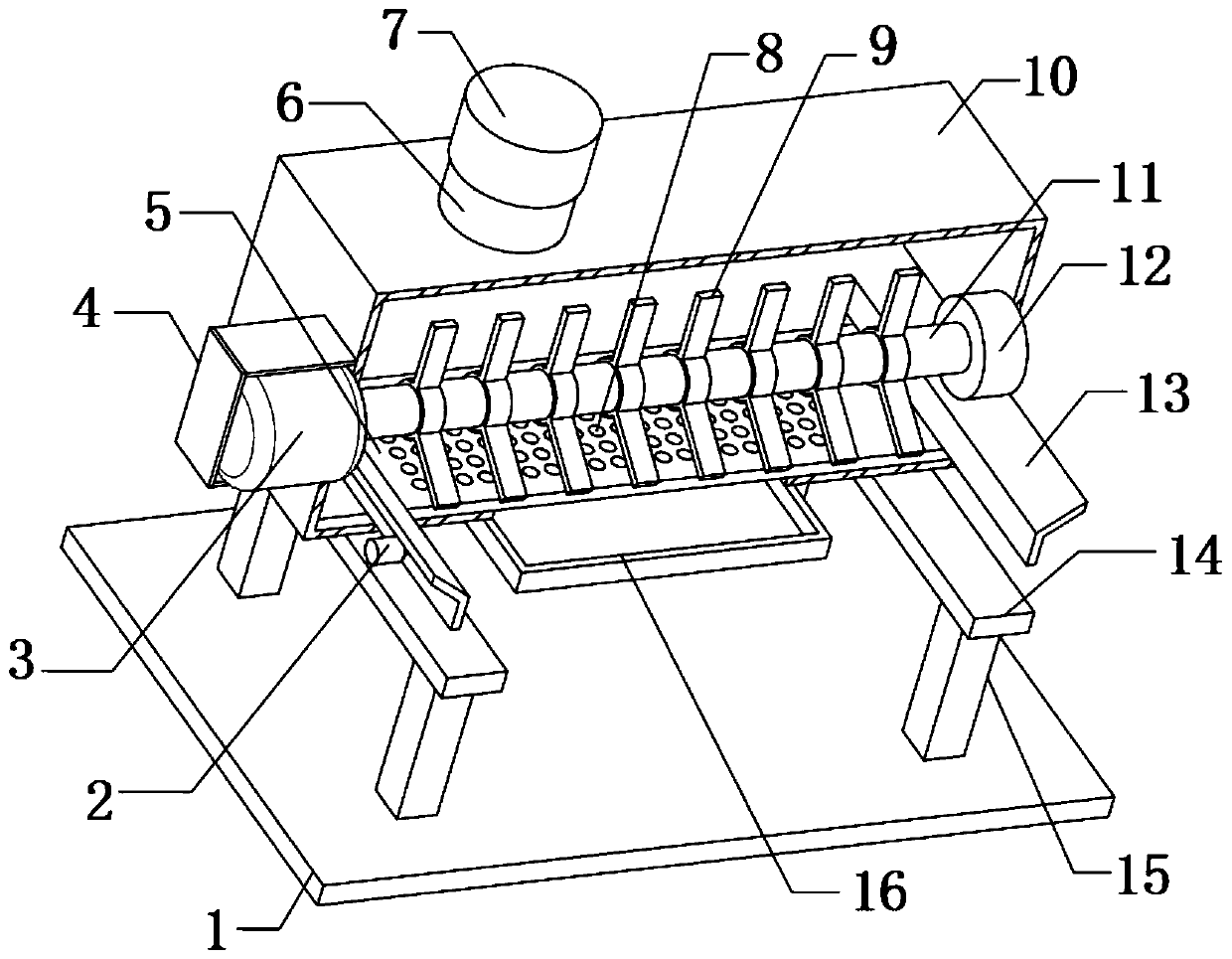

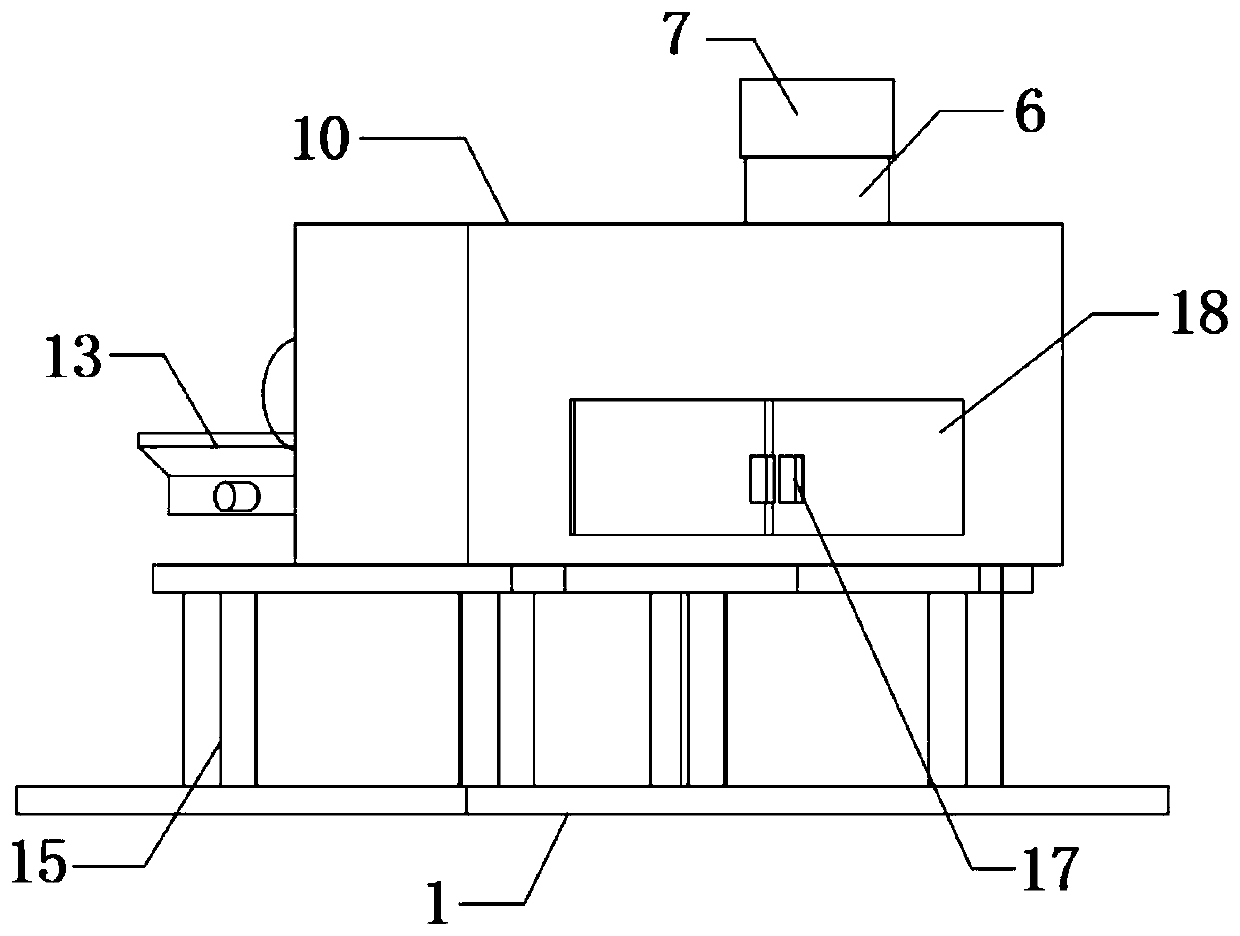

Starch dehydration equipment

ActiveCN113354746AImprove dehydration efficiencyReduced residual moisturePolymer scienceMaterials science

The invention discloses starch dehydration equipment, and belongs to the technical field of starch dehydration. The starch dehydration equipment comprises an operation table and a dehydration device; the operation table is placed on the ground, a sandwich plate is arranged on the operation table, and the dehydration device is mounted at the top of the operation table and is in running fit with the operation table; the dehydration device comprises a driving assembly, an adjusting assembly, a dehydration assembly and a scraping assembly, the driving assembly is installed on the side wall of the operation table, the adjusting assembly is installed at the top of the sandwich plate, the dehydration assembly is installed on the driving assembly, and the scraping assembly is installed on the dehydration assembly and is in sliding fit with the dehydration assembly; according to the starch dehydration device, most of water in starch can be effectively extruded and discharged through the dehydration device, the starch dehydration efficiency is improved, the residual amount of the water in the starch is low, the dehydration starch can be scraped and collected, the starch collecting efficiency is improved, and the situation that the starch is difficult to collect due to the fact that the starch adheres to elastic filter cloth is prevented.

Owner:烟台云汇智能科技有限公司

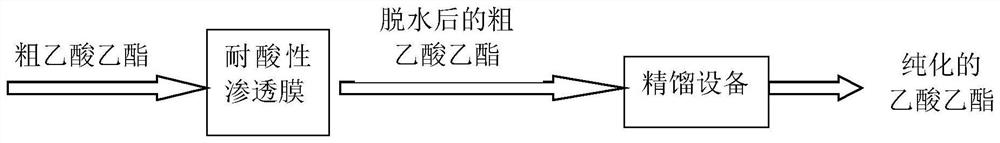

Method for purifying ethyl acetate

ActiveCN112500292AHigh yieldImprove the efficiency of removing other impuritiesSemi-permeable membranesMembranesEthyl acetateSolvent

The invention provides a method for purifying ethyl acetate. The method comprises the following steps: dehydrating crude ethyl acetate to be treated through an acid-resistant permeable membrane, and removing other impurities through a rectification technique. Compared with a single rectification process, the method has the advantages that water in ethyl acetate is removed in advance through an acid-resistant permeable membrane dehydration technology, so that a ternary or higher azeotropic system formed by ethyl acetate, water, ethanol and the like is broken through, the efficiency of removingother impurities through the rectification technology is remarkably improved, and the yield of ethyl acetate is increased; besides, moisture in the crude ethyl acetate solvent can be effectively removed by the crude ethyl acetate through the acid-resistant permeable membrane, other substances do not need to be added, new pollution is not generated, subsequent additional treatment is not needed, the permeable membrane can be continuously operated, the dehydration efficiency is high, the energy consumption is low, the ethyl acetate purification energy consumption is greatly reduced, and the purification cost is reduced.

Owner:宁波大膜科技有限公司

Automatic dehydration treatment equipment for livestock manure

ActiveCN114380478AReduce work stressReduce intensitySludge treatmentClimate change adaptationAnimal scienceAgricultural science

The invention provides automatic dehydration treatment equipment for livestock manure, and belongs to the technical field of manure dehydration, the automatic dehydration treatment equipment comprises a feed port and a discharge port, the feed port is provided with a preliminary separation part, the preliminary separation part comprises a treatment chamber, the treatment chamber is internally connected with a fan-shaped separation chamber through a connecting shaft, and the fan-shaped separation chamber is internally provided with a guide plate in a sliding manner; and a diffusion part is arranged at the discharging opening and comprises rotating rings which are symmetrically arranged, the rotating rings do intermittent swing motion in the left-right direction, and guiding diffusion assemblies which are symmetrical in the left-right direction are arranged between the rotating rings. According to the automatic dehydration treatment equipment for the livestock manure, the overall working pressure of the dehydration equipment is effectively reduced, the stability of the dehydration process and the dehydration effect are correspondingly improved, the equipment has the advantage of being more stable than the solid-liquid separation effect, meanwhile, the accumulation coverage of the dehydrated manure is enlarged, the accumulation height increasing time of the manure is prolonged, and the dehydration efficiency is improved. And the labor intensity and the use frequency are effectively reduced.

Owner:昌邑市畜牧业发展中心

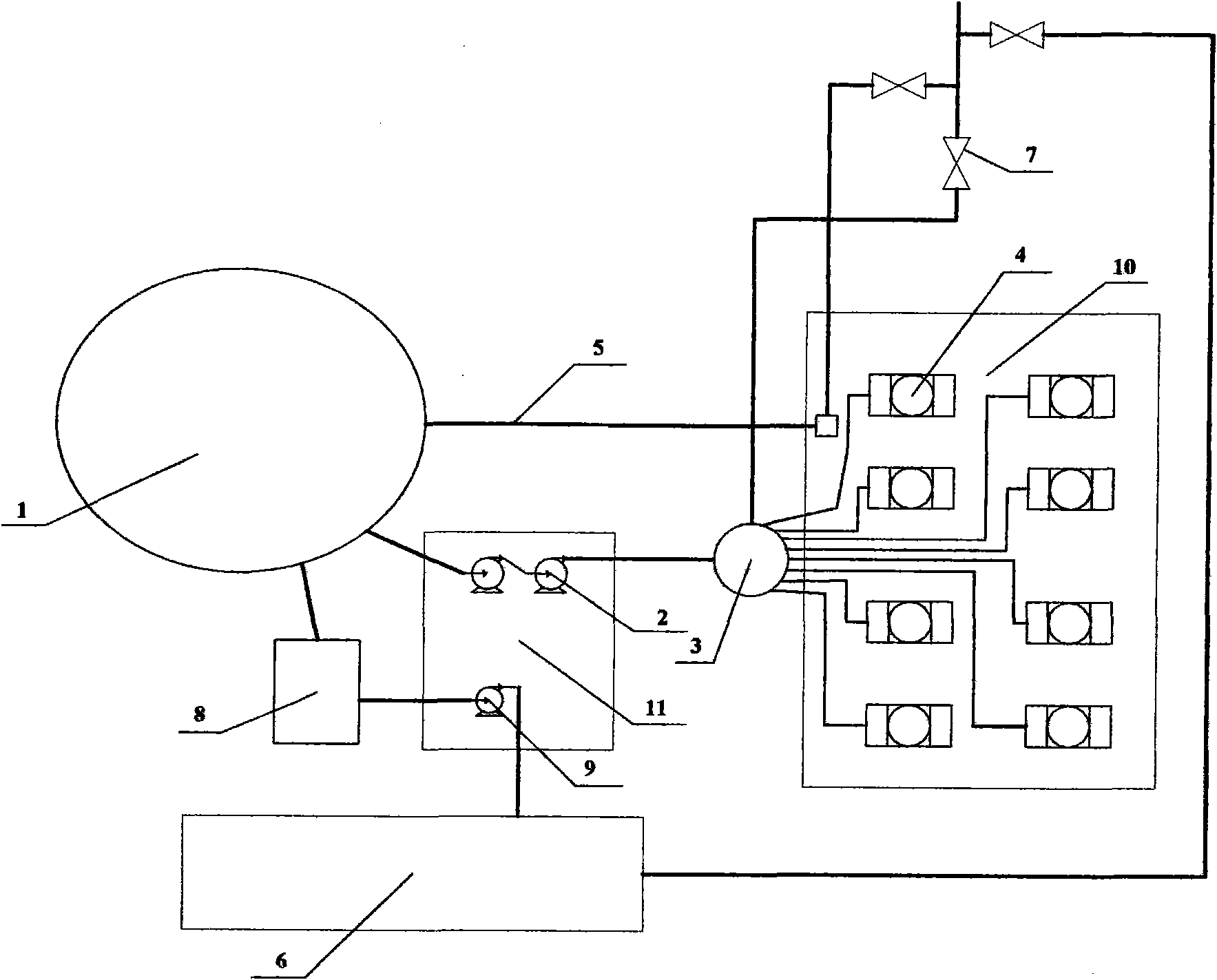

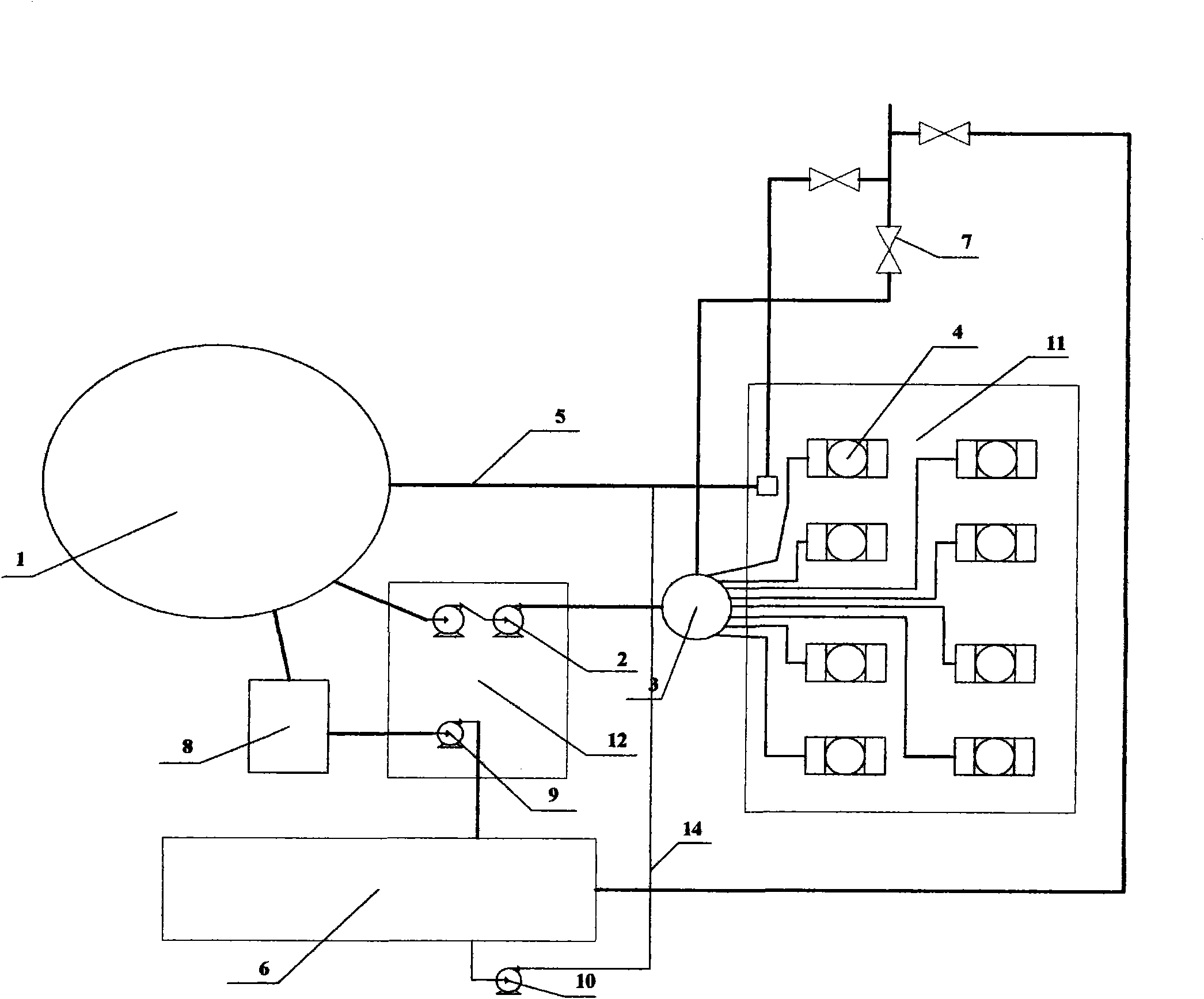

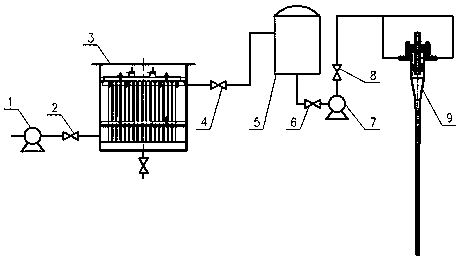

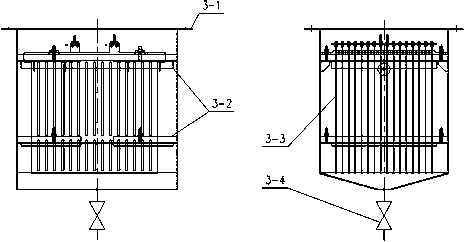

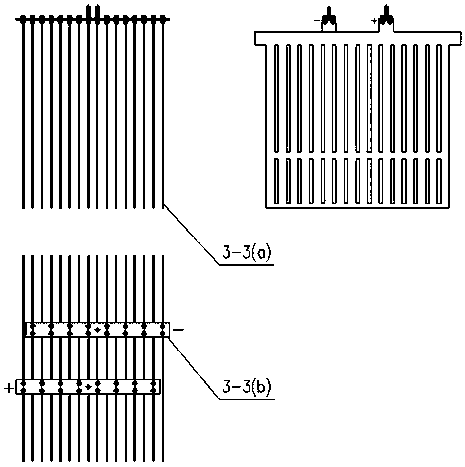

High-voltage pulsed electric field-cyclone centrifugal field combined lubricating oil demulsification and dehydration device

ActiveCN111349457AFast and efficient demulsification and dehydrationImprove demulsification and dehydration efficiencyDewatering/demulsification with mechanical meansDewatering/demulsification with electric/magnetic meansHigh voltage pulsePulse electric field

The invention discloses a high-voltage pulsed electric field-cyclone centrifugal field combined lubricating oil demulsification and dehydration device comprising an oil inlet pump 1 (1), an oil delivery valve 1 (2), a high-voltage pulsed electric field demulsification and dehydration device (3), an oil delivery valve 2 (4), a buffer oil storage tank (5), an oil delivery valve 3 (6), an oil inlet pump 2 (7), an oil delivery valve 3 (8) and a cyclone centrifugal demulsification and dehydration device (9); the device is characterized in that the oil inlet pump 1 (1) is connected with lubricatingoil needing demulsification and dehydration treatment through an oil pipeline, and then is connected with the oil delivery valve 1 (2), the high-voltage pulsed electric field demulsification and dehydration device (3), the oil delivery valve 2 (4), the buffer oil storage tank (5), the oil delivery valve 3 (6), the oil inlet pump 2 (7), the oil delivery valve 3 (8) and the cyclone centrifugal demulsification and dehydration device (9) through oil pipelines. The demulsification and dehydration efficiency can be improved, rapid and efficient demulsification and dehydration of high-water-content lubricating oil is achieved, and the technology and economic advantages are obvious.

Owner:CHONGQING TECH & BUSINESS UNIV

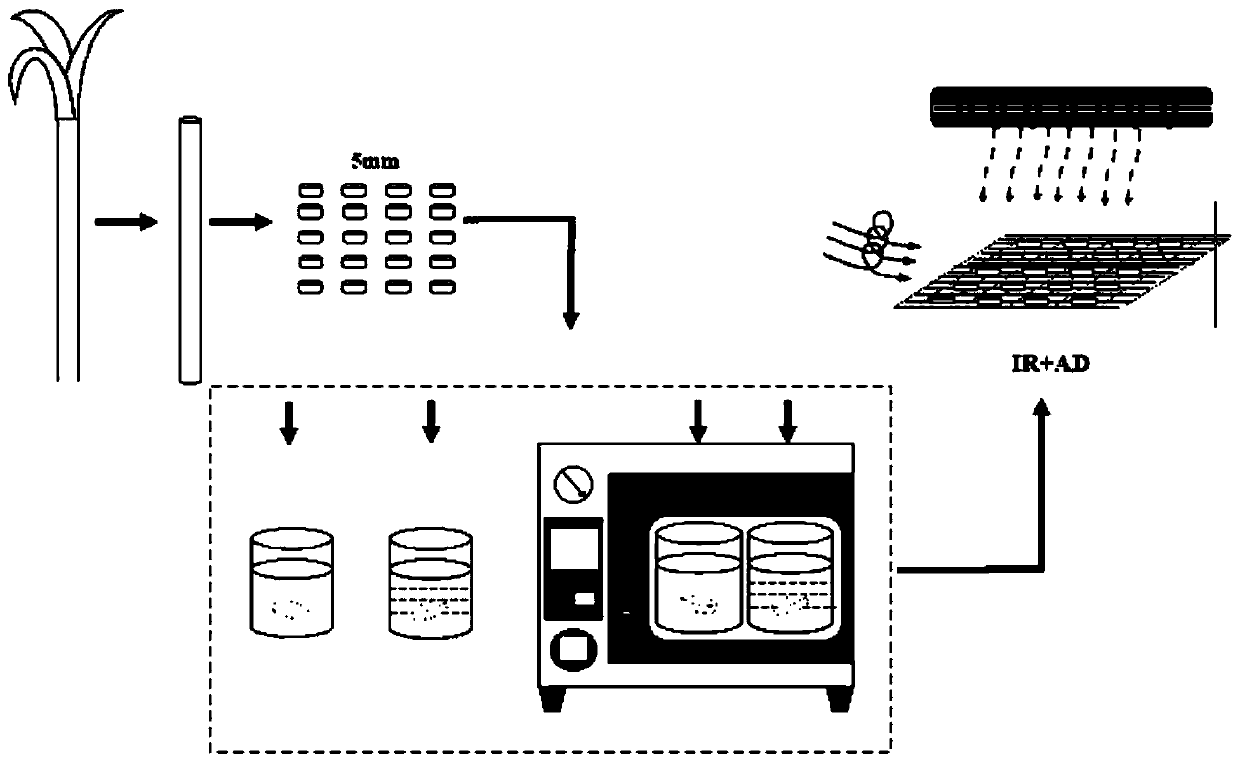

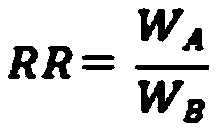

Infrared hot air drying method of fistular onion stalks pretreated through union of vacuum and ethanol

InactiveCN110447707AImprove drying rateAvoid pollutionFruit and vegetables preservationFood ingredientsCuticleInsect pest

The invention belongs to the technical field of processing of agricultural products, and particularly discloses an infrared hot air drying method of fistular onion stalks pretreated through union of vacuum and ethanol. The method comprises the following steps of sorting fresh fistular onion stalks of which the surfaces are free from mechanical damage and free from insect pests, removing outer coating, performing cleaning, and performing cutting into segments, to obtain fistular onion stalk rings; performing union of vacuum and ethanol for permeation treatment; and performing infrared hot air drying, and finally, obtaining dehydrated fistular onion stalk products. Compared with infrared hot air drying for fistular onion stalks which are not pretreated, a permeation dehydration technique combining vacuum with ethanol has the advantages that product quality of the infrared hot air drying efficiency, the rehydration properties, the sterilizing effects and the like of the fistular onion stalks are improved, and a new method is provided for industrial production and dry making of fistular onion stalk products. The ethanol is used as a permeation dehydration solution, and compounds on cell walls dissolve, so that the permeability is improved, the permeation dehydration efficiency is improved, the subsequent infrared hot air drying rate can be increased, the ethanol also has the effectof sterilization, and environmental pollution caused by conventional sterilization can be solved.

Owner:CHUZHOU UNIV

Starch dehydration equipment

ActiveCN113354746BImprove dehydration efficiencyReduced residual moistureProcess engineeringSandwich panel

Owner:烟台云汇智能科技有限公司

Composite sludge dewatering treatment method and equipment thereof

PendingCN114085022AImprove dehydration efficiencyIncrease contentWater treatment parameter controlSludge treatmentFlocculationProcess engineering

The invention discloses composite sludge dewatering treatment equipment, and belongs to the technical field of sludge dewatering. The equipment comprises a flocculation mechanism and a dehydration mechanism; the flocculation mechanism at least comprises a stirring part capable of moving up and down while rotating, and a fluid outlet; the dehydration mechanism at least comprises a fluid inlet; and the stirring part is arranged to move to the lowest position of the fluid outlet from bottom to top during stirring, so that the entrained and precipitated fluid flows into the fluid outlet from the fluid outlet. When the stirring part moves to the lowest point of the fluid outlet and the height of the sludge fluid in the flocculation box is higher than the lowest height of the fluid outlet, the sludge fluid carries large-particle bulk flocculate to flow into the dewatering mechanism. Compared with the prior art, the content of large-particle bulk flocculates in the sludge fluid flowing into the dewatering mechanism in unit time is increased, so that the sludge dewatering efficiency is improved.

Owner:NANJING DEYI ENVIRONMENTAL TECH DEV CO LTD

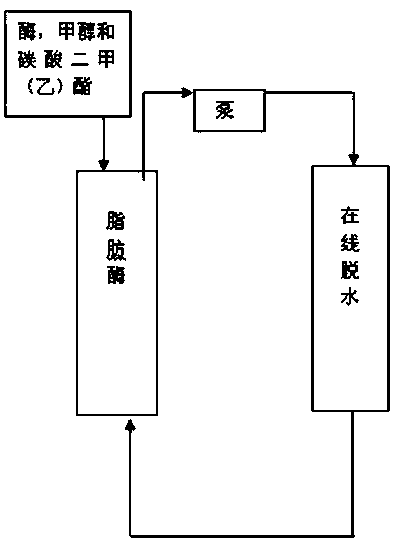

Method for preparing biodiesel from enzymatic oil

InactiveCN108103116AReduce use costImprove operational stabilityBiofuelsFermentationSingle stageAlcohol

The invention provides a method for preparing biodiesel from enzymatic oil. The process comprises the following step: oil, short-chain alcohol, dimethyl carbonate (or diethyl carbonate) and lipase areadded to a single-stage or multi-stage enzyme reactor for a reaction, and online dehydration is performed in the reaction process. Pretreatment of oil raw materials is not needed, byproduct glyceringenerated in transesterification of short-chain alcohol and oil is subjected to further reaction with dimethyl carbonate or diethyl carbonate on line, the online dehydration technique is introduced inthe reaction process, yield of the biodiesel exceeds 98%, acid value of the product is lower than 0.5 mg KOH / g, total glycerin content is lower than 0.2%, and the process has quite good industrial application prospect.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com