Strap filter-press dehydration technique and device

A belt-type filter press and dehydration equipment technology, which is applied in presses, filter separation, manufacturing tools, etc., can solve problems affecting the service life of filter belt filter presses, restrict pressing dehydration efficiency, prolong pressing time, etc., to achieve the pressing effect Good, easy to implement, simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

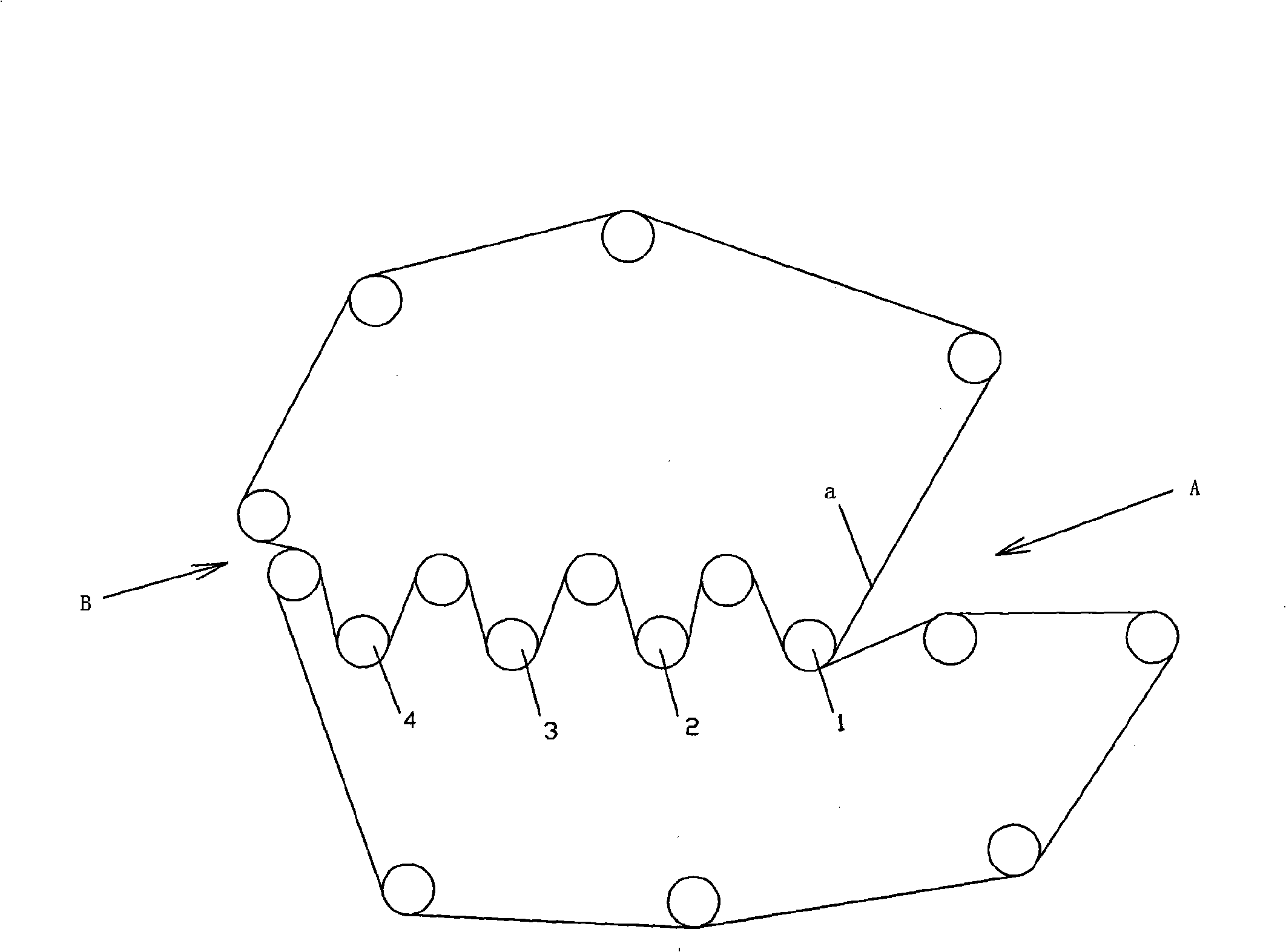

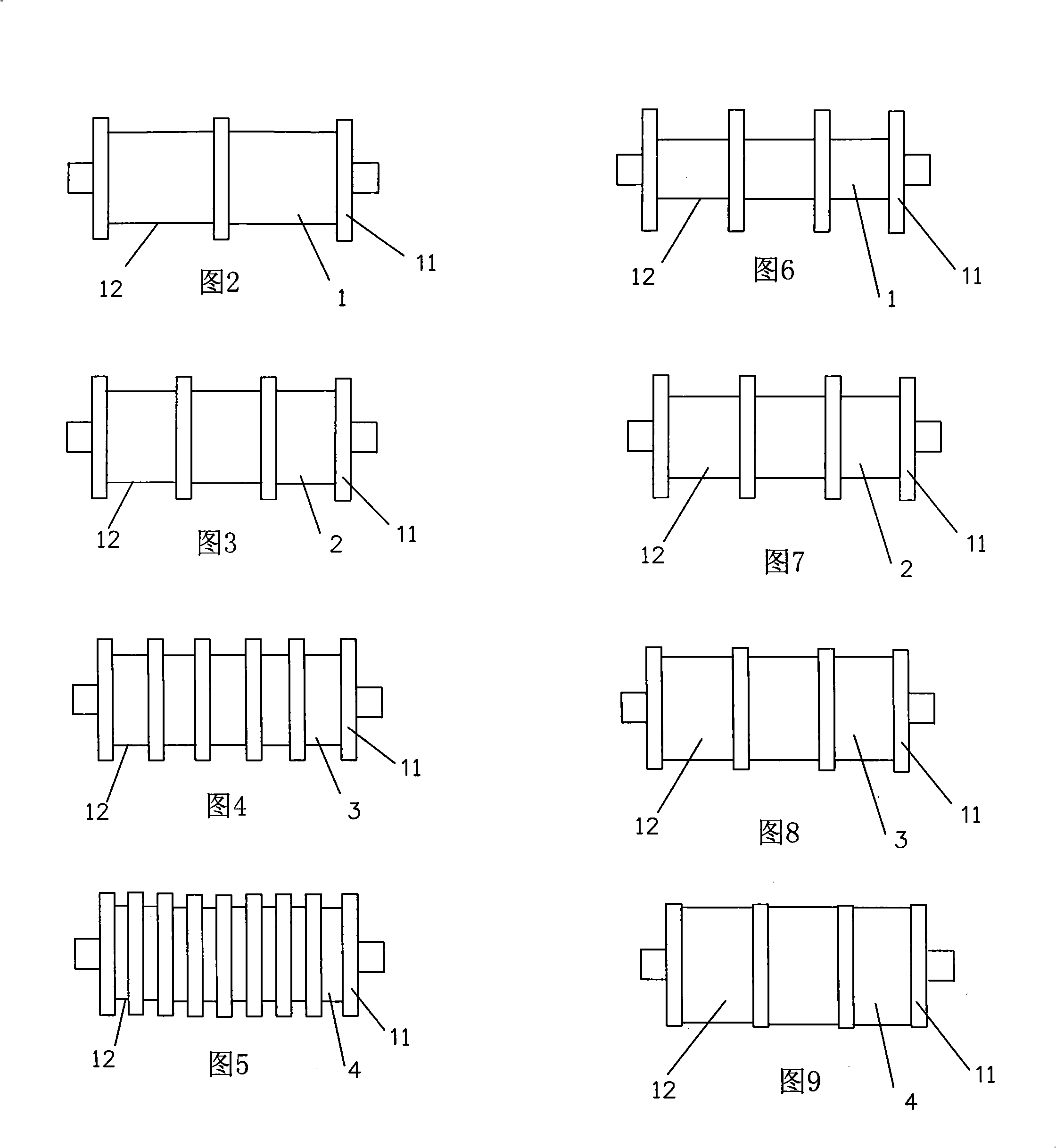

[0042] see figure 1 ~Figure 5, the belt filter press dehydration equipment belt filter press, it is mainly composed of filter belt a, 1 arranged in sequence according to the equipment running direction # ,2 # 、3 # 、4 # Squeeze rollers 1-4, filter belt driving device, filter belt tensioning device, filter belt deflection adjustment device, filter belt cleaning device, feeding device and unloading device. The belt filter press 1 # ,2 # 、3 # 、4 # Press rolls 1-4 are rubber-covered press rolls, and the surface of the roll body is provided with 2 or more protrusions or grooves with a recessed depth of 2-20 mm and a width of 3-25 mm. 12. By setting the number, width and depth of the bosses and grooves 12, the surface area of the press rolls 1 to 4 increases from small to large in accordance with the running direction of the filter belt a, thereby adjusting the pressure of the dehydrated material on the press rolls 1 to 4. Pressing area and volume, along the moving directio...

Embodiment 2

[0046] see figure 1 , Figures 6-9, 1 of the belt filter press dehydration equipment # ,2 # 、3 # 、4 # The bosses provided on the surface of the press rolls 1, 2, 3, and 4 are the same as in Embodiment 1, and are also raised rings 11 perpendicular to the roll axis. Four press rolls are provided with 4 raised rings 11, and the raised rings The width of 11 is 5-10mm, but the convex height of the rib ring 11 set on each press roll decreases from high to low according to the running direction of the filter belt a, and the outer diameters of the press rolls 1-4 after rubberizing are the same The diameters of the grooves 12 are different, and they increase sequentially according to the order of the rubber-coated press rolls. Like Example 1, the inner area of the grooves 12 decreases in order accordingly. During pressing and dehydration, the dehydration pressure transmitted to the dehydrated material through the four press rolls gradually increases.

[0047] The other structures ...

Embodiment 3

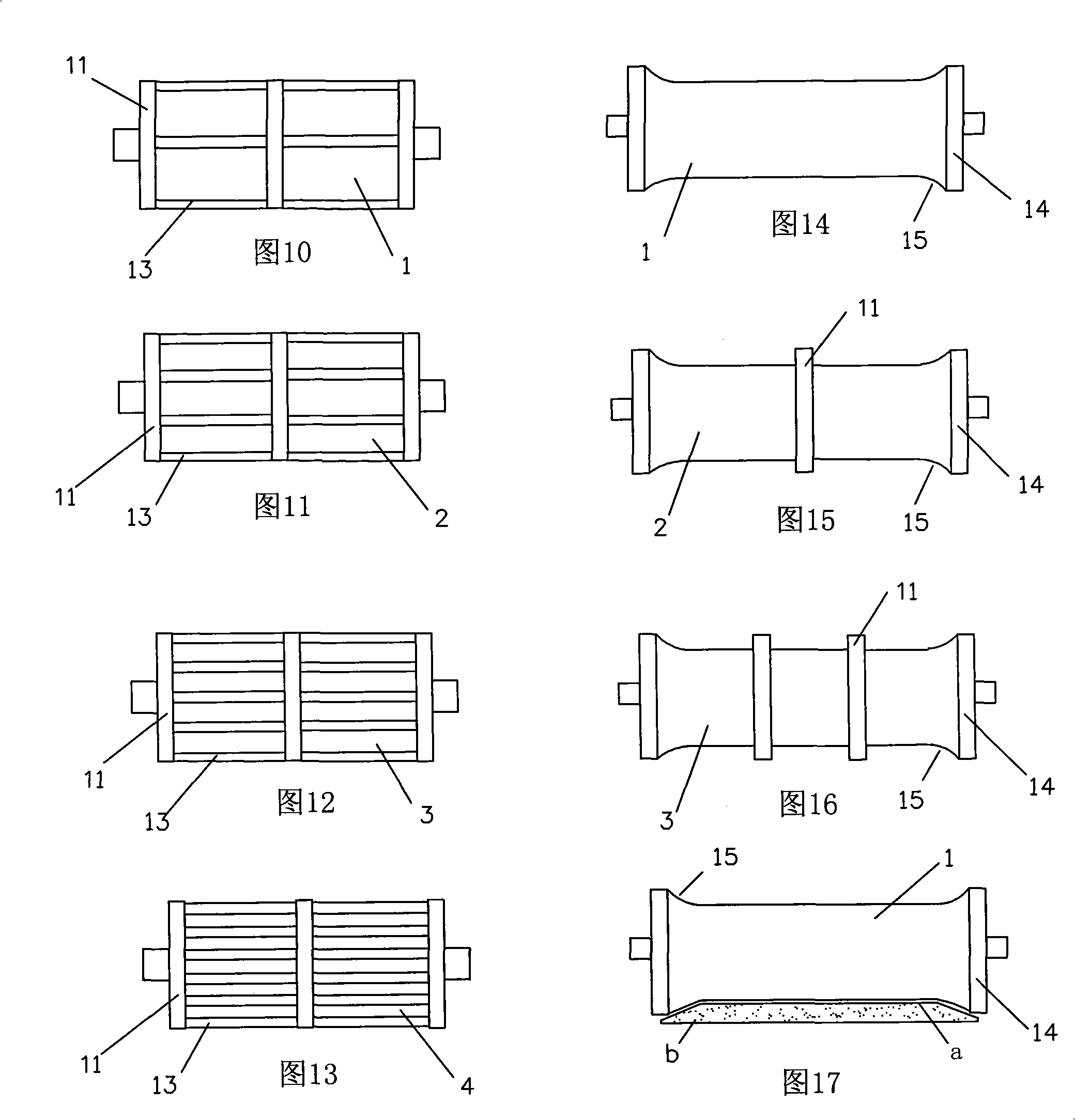

[0049] see figure 1 , Fig. 10~13, this embodiment belt type filter press dehydration equipment 1 # ,2 # 、3 # 、4 # The bosses provided on the surface of the press rolls 1, 2, 3, and 4 have 2 or more raised rings 11 perpendicular to the roll axis and 2 or more transverse ribs 13 parallel to the roll axis. 1 in the running direction of the filter belt a # ,2 # 、3 # 、4 # There are 3 protruding rings set on the press rollers 1, 2, 3, and 4, the width of which is the same as the height of the protrusions, the width is 5-10 mm, and the height of the protrusions is 3-6 mm; as shown in Figures 10-13, The quantity of transverse convex bar 13 increases from few to many according to the running direction of filter belt a, 1 # 4 horizontal ribs 13, 2 are set on the press roll 1 # 6 horizontal ribs 13, 3 are set on the press roll 2 # 8 horizontal ribs 13, 4 are set on the press roll 3 # Ten transverse ribs 13 are arranged on the squeeze roll 4 , and the width and protrusion heigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com