Patents

Literature

12750 results about "Filter cake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A filter cake is formed by the substances that are retained on a filter. The filter cake grows in the course of filtration, becoming "thicker" as particulate matter is retained. With increasing layer thickness, the flow resistance of the filter cake increases. After a time, the filter cake has to be removed from the filter, e.g. by backflushing. If this is not accomplished, the filtration is disrupted because the viscosity of the filter cake gets too high; hence, too little of the mixture to be filtered can pass through the filter cake and the filter plugs. The specifications of the filter cake dictate the filtration method of choice.

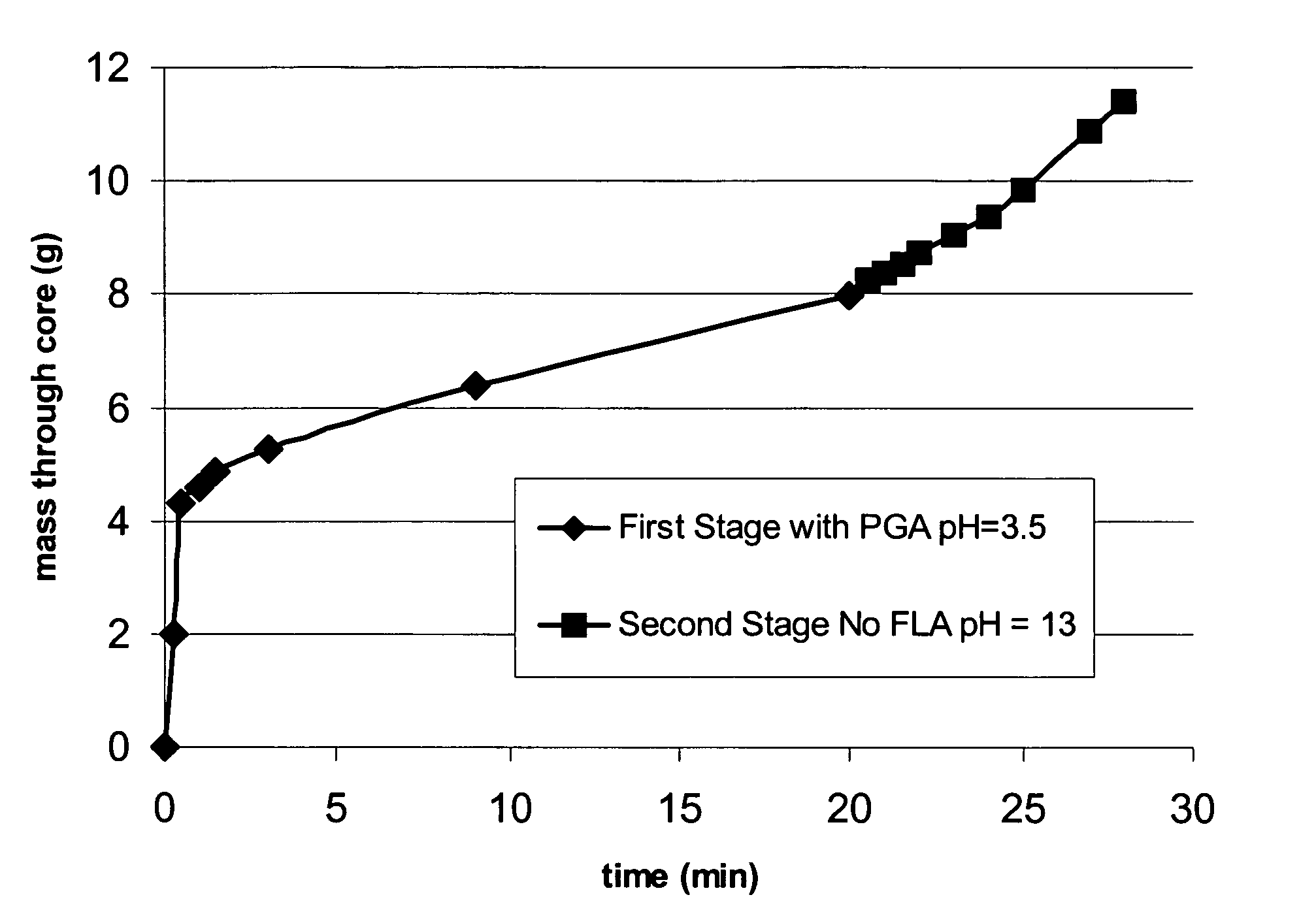

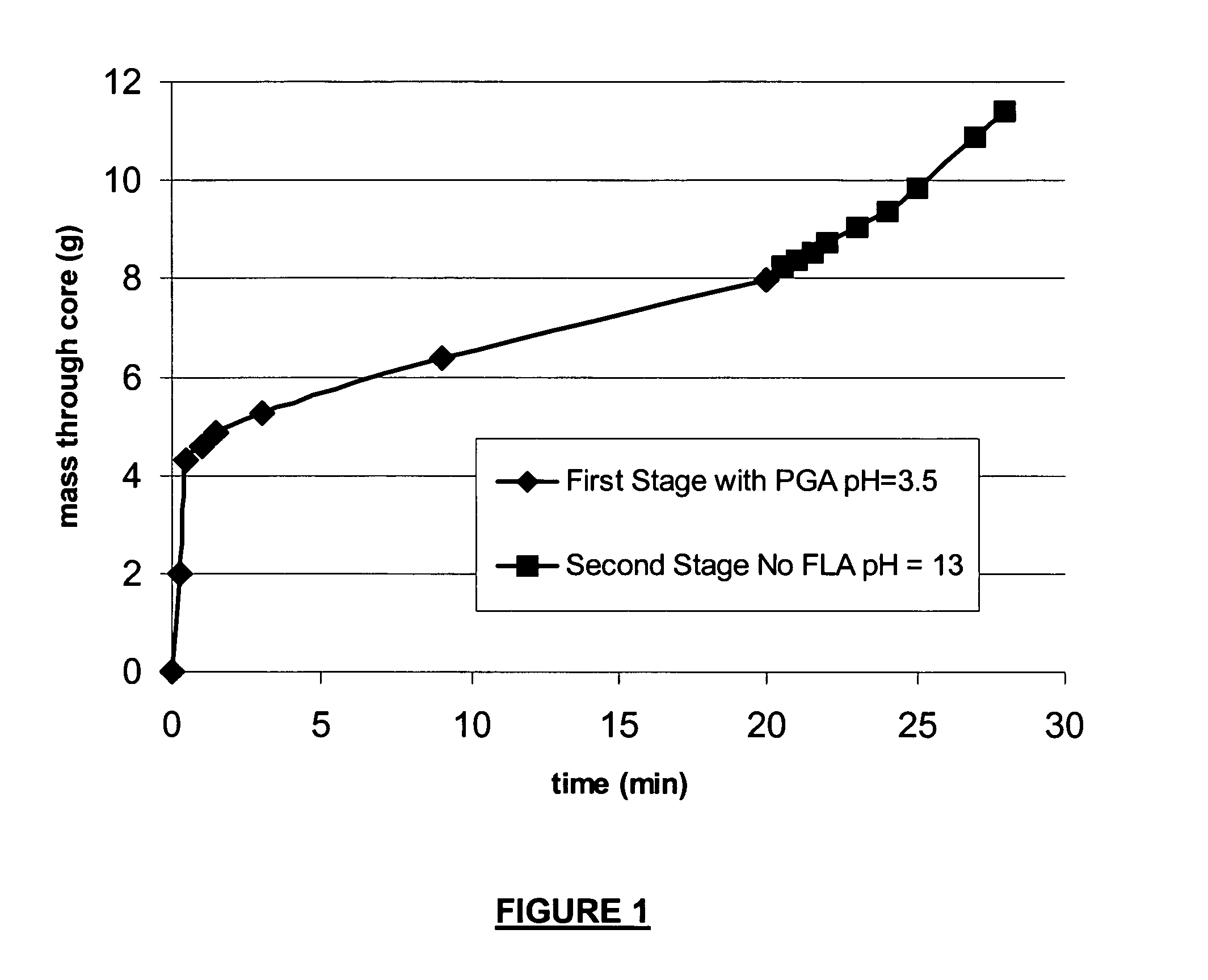

Acid coated sand for gravel pack and filter cake clean-up

InactiveUS20040055747A1Enhances filter cake removalSpeed up the flowCleaning apparatusFluid removalCarboxylic acidGlycollic acid

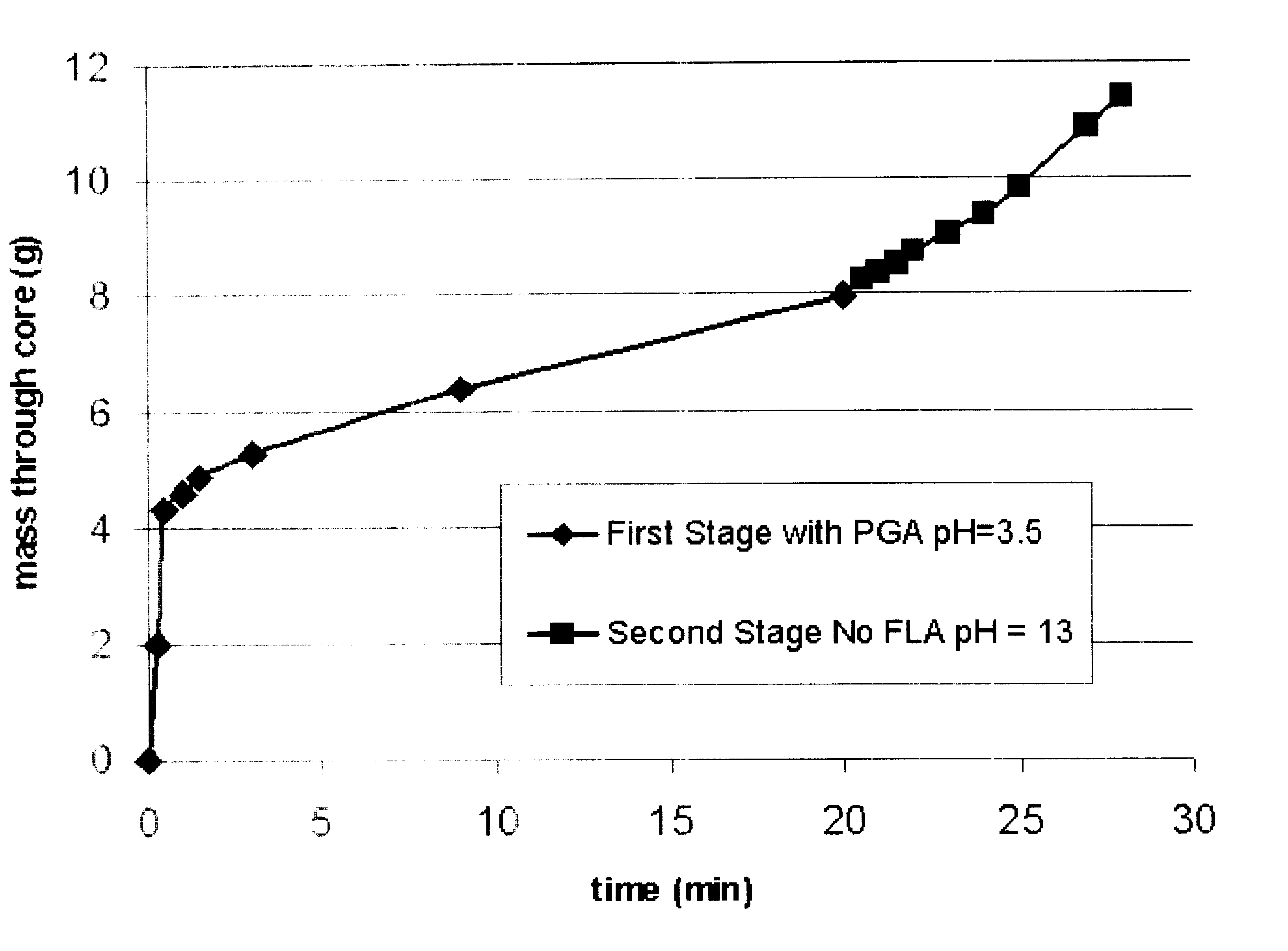

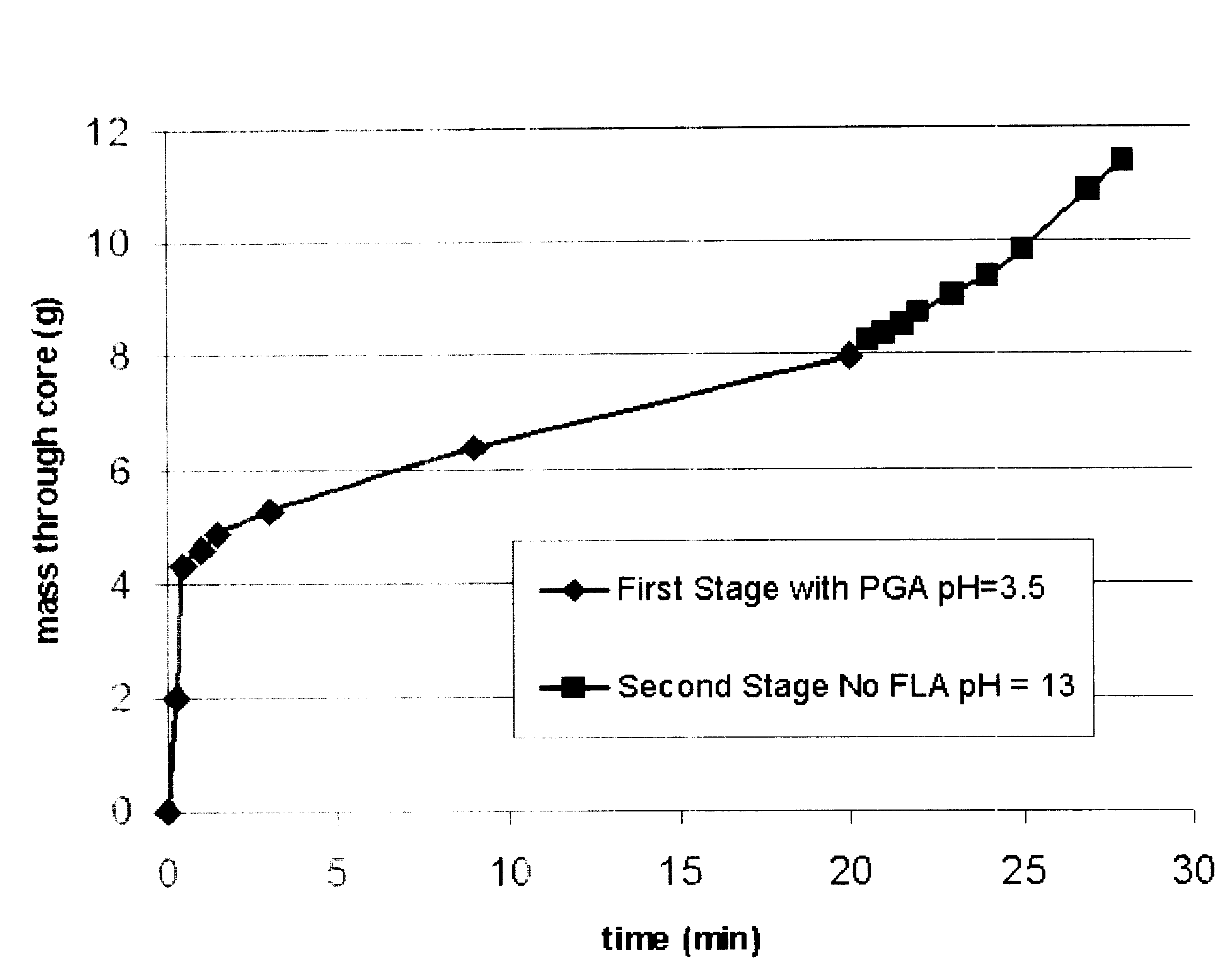

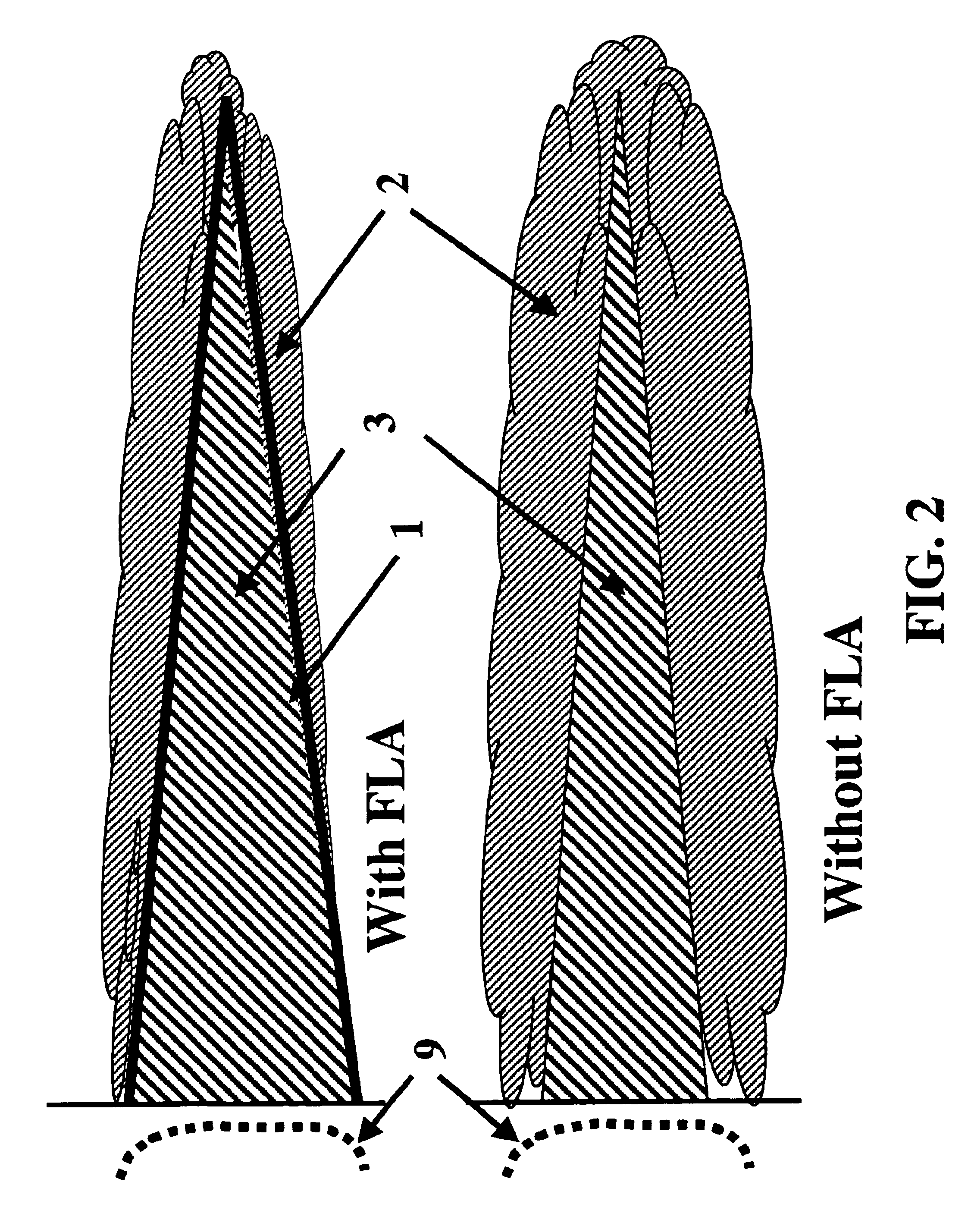

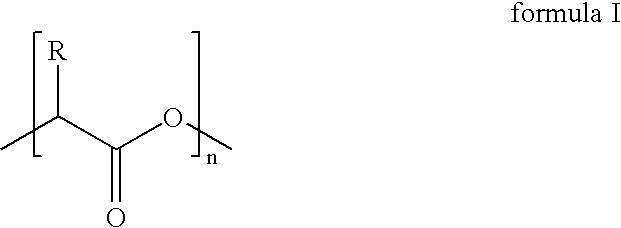

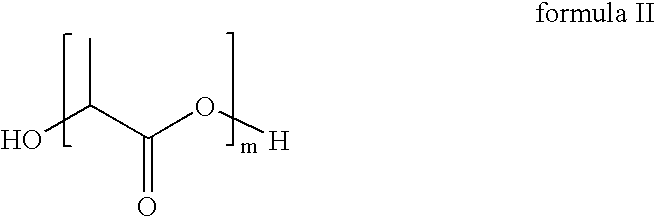

A method of the preparation and utilization of polymerized alpha-hydroxycarboxylic-acid-coated proppants for gravel pack and removal of filter cake that was deposited by reservoir drilling fluid. In a preferred example, polyglycolic-acid-coated sand is used to replace conventional gravel pack sand typically used for gravel packing. Under downhole conditions, the acidic by-product generated from the hydration of polyglycolic-acid-coated sand can break down acid-soluble and / or acid-breakable components embedded in the filter cake. This reaction enhances the filter cake removal and the flow of hydrocarbon from the producing formation. The polyglycolic-acid-coated sand may be produced by polymerizing a glycolic acid with a natural or synthetic proppant like 20-40 mesh commercial sand, at temperatures of about 210° F. or higher.

Owner:MI

Dissolving Filter Cake

InactiveUS20040094300A1Needed propertyWider fractureCleaning apparatusFluid removalSolid baseCarrier fluid

Methods are presented to induce a screenout during a subterranean formation fracturing or combined fracturing and gravel packing treatment having a viscoelastic surfactant-based carrier fluid by laying down a filter cake at least a portion of which is a base-soluble material, injecting proppant slurry, and causing hydrolysis and dissolution of the solid base-soluble material by adding base so that leak-off increases, the concentration of proppant in the fracture increases, and the proppant screens out. A method of gravel packing with a viscoelastic surfactant-based carrier fluid by laying down a filter cake at least a portion of which is a base-soluble material, injecting gravel, and causing hydrolysis and dissolution of the solid base-soluble material by adding base. Methods of slowing or accelerating the hydrolysis and dissolution are given, and addition of bridging-promoting materials is included.

Owner:SCHLUMBERGER TECH CORP

Methods of forming a chemical casing

InactiveUS6848519B2High mechanical strengthInhibit migrationLiquid/gas jet drillingFluid removalParticulatesCross-link

Methods of forming chemical casings include drilling a well bore with a drilling fluid having a pH in the range of from about 6 to 10 and comprising water, a water soluble or water dispersible polymer which is capable of being cross-linked by a thermoset resin and causing the resin to be hard and tough when cured, a particulate curable solid thermoset resin, a water soluble or dispersible thermoset resin, and a delayed dispersible acid-catalyst for curing the solid thermoset resin and the water soluble thermoset resin, whereby the drilling fluid forms a filter cake on the walls of the wellbore that cures into a hard and tough cross-linked chemical casing thereon.

Owner:HALLIBURTON ENERGY SERVICES INC

On-the fly coating of acid-releasing degradable material onto a particulate

ActiveUS20050034861A1Reduce molecular weightLiquid surface applicatorsFluid removalParticulatesPlasticizer

The present invention relates to methods and compositions for treating subterranean formations, and more specifically, to improved methods and compositions for degrading filter cake deposited on a subterranean formation. One embodiment of the present invention provides a method of creating particulates coated with acid-releasing degradable material on-the-fly comprising the step of: combining an acid-releasing degradable material with a solvent or a plasticizer to create a coating solution; and, coating the coating solution onto a particulate on-the-fly to create coated particulates. Another embodiment of the present invention provides a gravel pack comprising gravel particles coated on-the-fly with an acid-releasing degradable material.

Owner:HALLIBURTON ENERGY SERVICES INC

Acid coated sand for gravel pack and filter cake clean-up

InactiveUS6817414B2Speed up the flowGood removal effectCleaning apparatusFluid removalGlycollic acidCarboxylic acid

A method of the preparation and utilization of polymerized alpha-hydroxycarboxylic-acid-coated proppants for gravel pack and removal of filter cake that was deposited by reservoir drilling fluid. In a preferred example, polyglycolic-acid-coated sand is used to replace conventional gravel pack sand typically used for gravel packing. Under downhole conditions, the acidic by-product generated from the hydration of polyglycolic-acid-coated sand can break down acid-soluble and / or acid-breakable components embedded in the filter cake. This reaction enhances the filter cake removal and the flow of hydrocarbon from the producing formation. The polyglycolic-acid-coated sand may be produced by polymerizing a glycolic acid with a natural or synthetic proppant like 20-40 mesh commercial sand, at temperatures of about 210° F. or higher.

Owner:MI

Method of releasing stuck pipe or tools and spotting fluids therefor

Aphron-containing spotting fluids and their use in releasing pipe or tools stuck in the filter cake on the sides of a borehole are disclosed. The spotting fluids comprise a liquid, either aqueous, oleaginous, or mixtures thereof, a viscosifier which imparts a low shear rate viscosity to the fluids of at least 10,000 centipoise, an aphron-generating surfactant, and aphrons. The spotting fluids are used in a conventional method of releasing pipes or tools stuck in the filter cake on the sides of a borehole during conventional drilling or well servicing operations.

Owner:ENVENTIVES LLC

Compositions and methods for degrading filter cake

Improved methods and compositions for degrading filter cake deposited in a subterranean formation are provided. These methods and compositions utilize particulates coated with acid-releasing degradable material wherein the released acid is used to degrade a filter cake.

Owner:HALLIBURTON ENERGY SERVICES INC

Procedures and Compositions for Reservoir Protection

ActiveUS20080296024A1High viscosityLow viscosityCleaning apparatusFluid removalSolventSURFACTANT BLEND

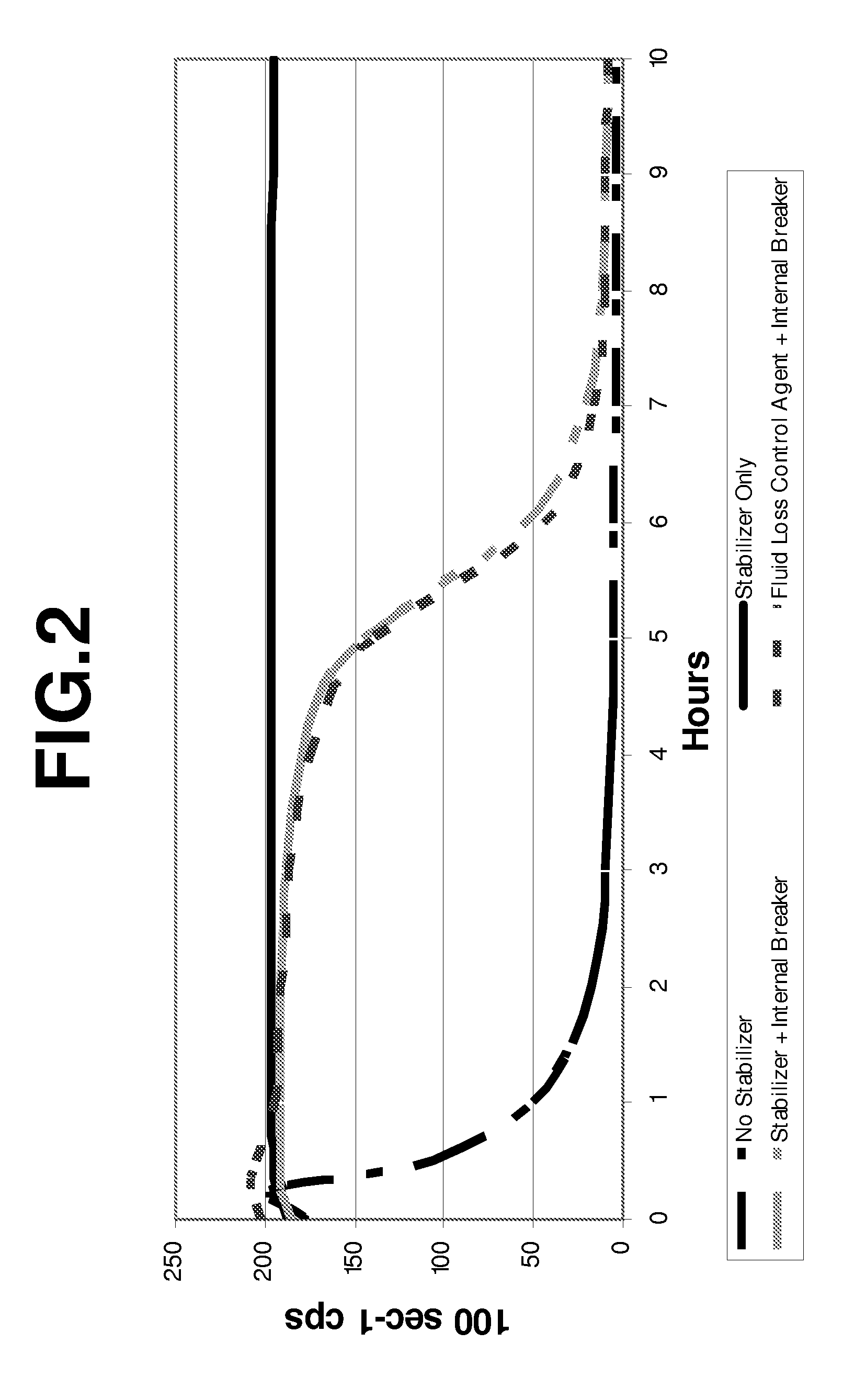

A flow conduit having at least one orifice is placed in the vicinity of a flow source, which in one non-limiting embodiment may be a hydrocarbon reservoir. The flow pathway between the orifice and the source is temporarily blocked with a degradable barrier. Once the flow pathway is physically placed, the degradable barrier is removed under the influence of an acid, a solvent, time and / or temperature. The flow source and the flow pathways are at least partially covered (and flow blocked by) a temporary coating such as a pseudo-filter cake formed by a viscoelastic surfactant-gelled aqueous drill-in fluid, and the flow conduit is extended to the flow source. The pseudo-filter cake is removed when viscosity is reduced by an internal breaker, and flow is then allowed. The method is useful in one context of recovering hydrocarbons where the flow conduit is a telescoping sleeve or tube that contacts the borehole wall.

Owner:BAKER HUGHES INC

Method For Completing Injection Wells

InactiveUS20040014606A1Reducing surface storage capacity requirementEliminate needCleaning apparatusFluid removalEngineeringWater well

This invention proposes a method for completing an interval of an open-hole injection wellbore penetrating a subterranean formation, said wellbore being communicating with the formation by way of an interface that comprises at least a filter cake invaded zone comprising bridging materials and other embedded solid materials, said method comprising the steps of injecting a clean-up fluid and contacting it with the filtercake for a period of time sufficient to loose some of the other solids embedded in the filter cake; removing the loosened solids by a high-rate displacement fluid comprising suspending additives; and then injecting a dissolving fluid comprising a diverter and an effective amount of a salt or acid capable of dissolving the bridging material.

Owner:SCHLUMBERGER TECH CORP

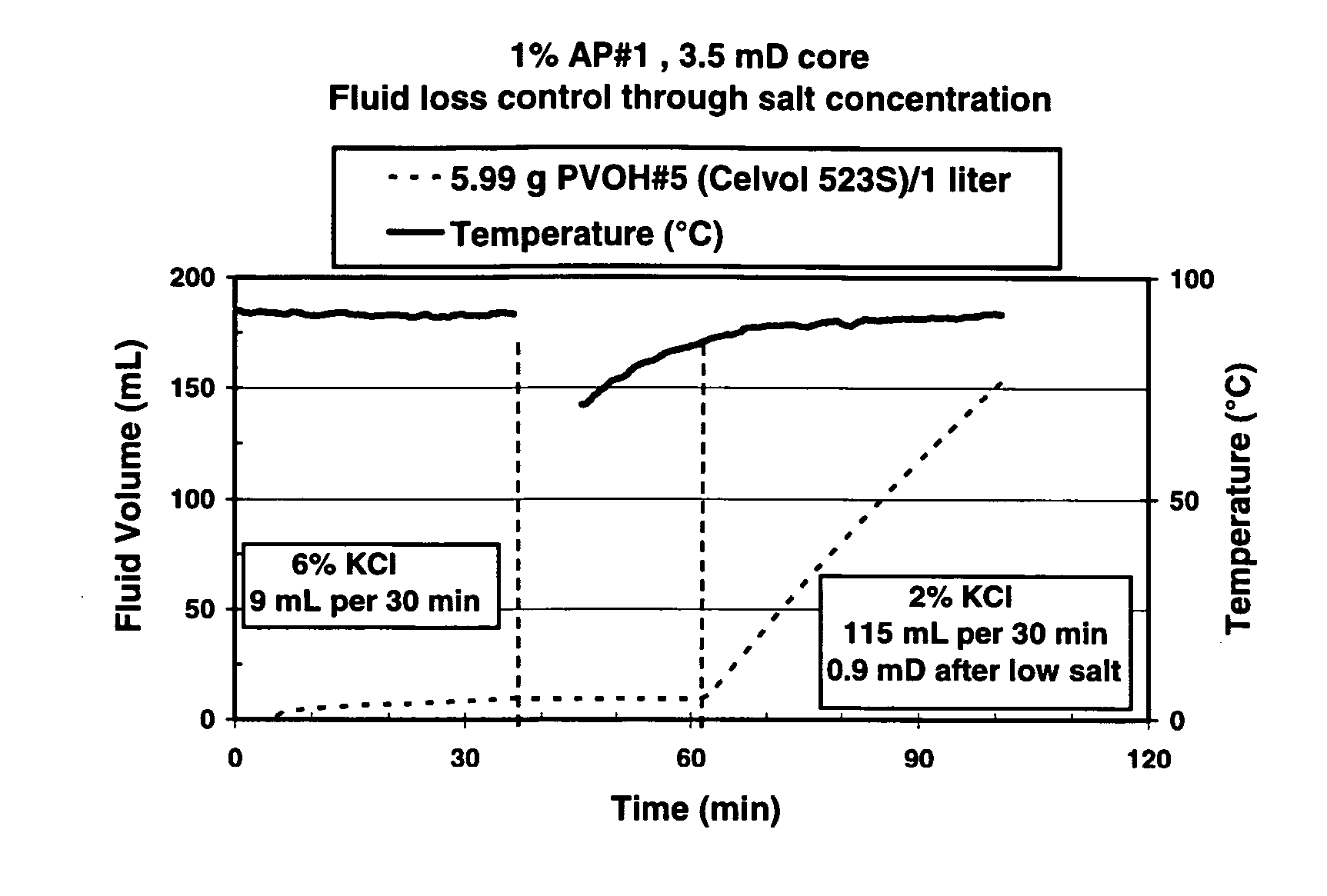

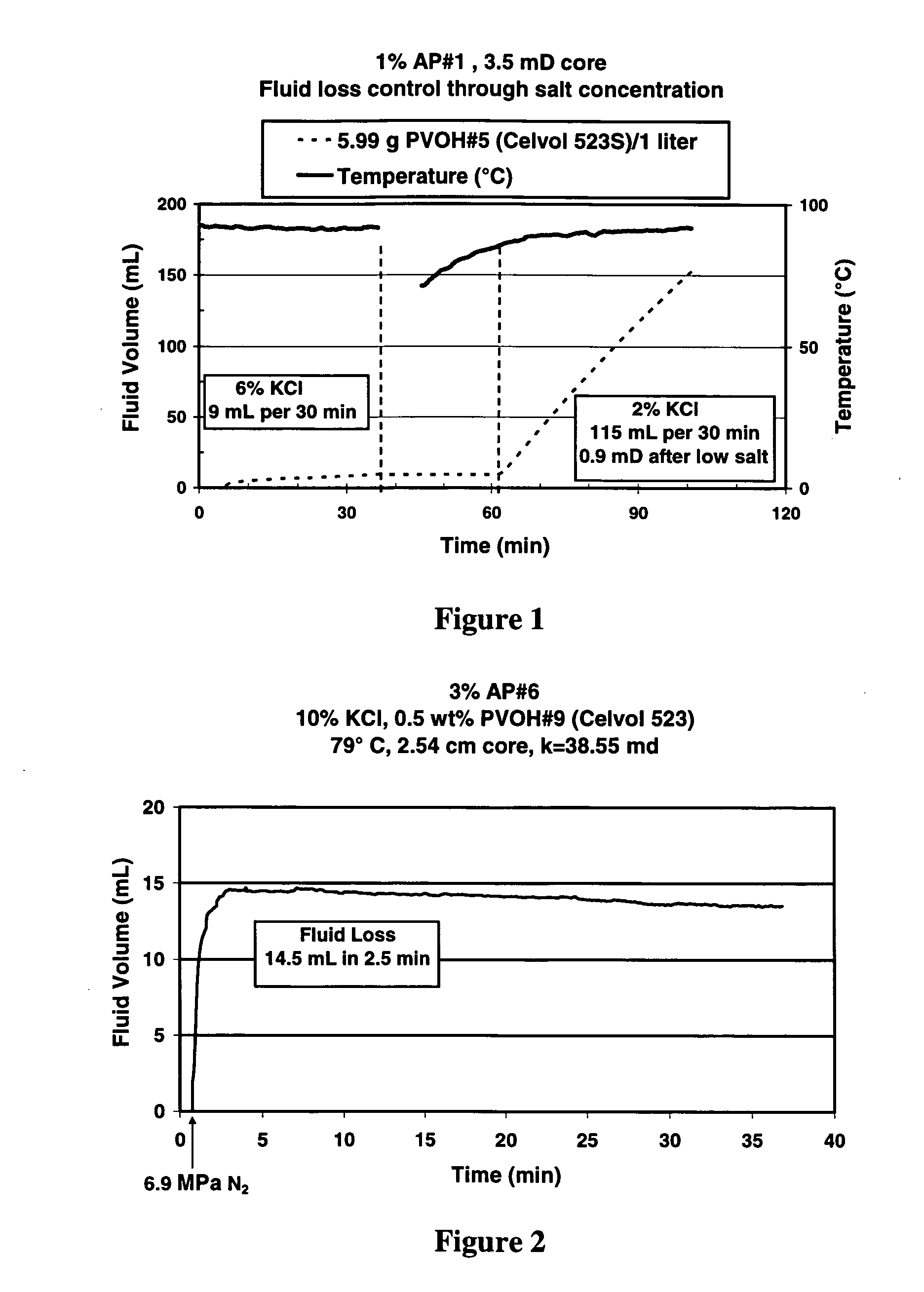

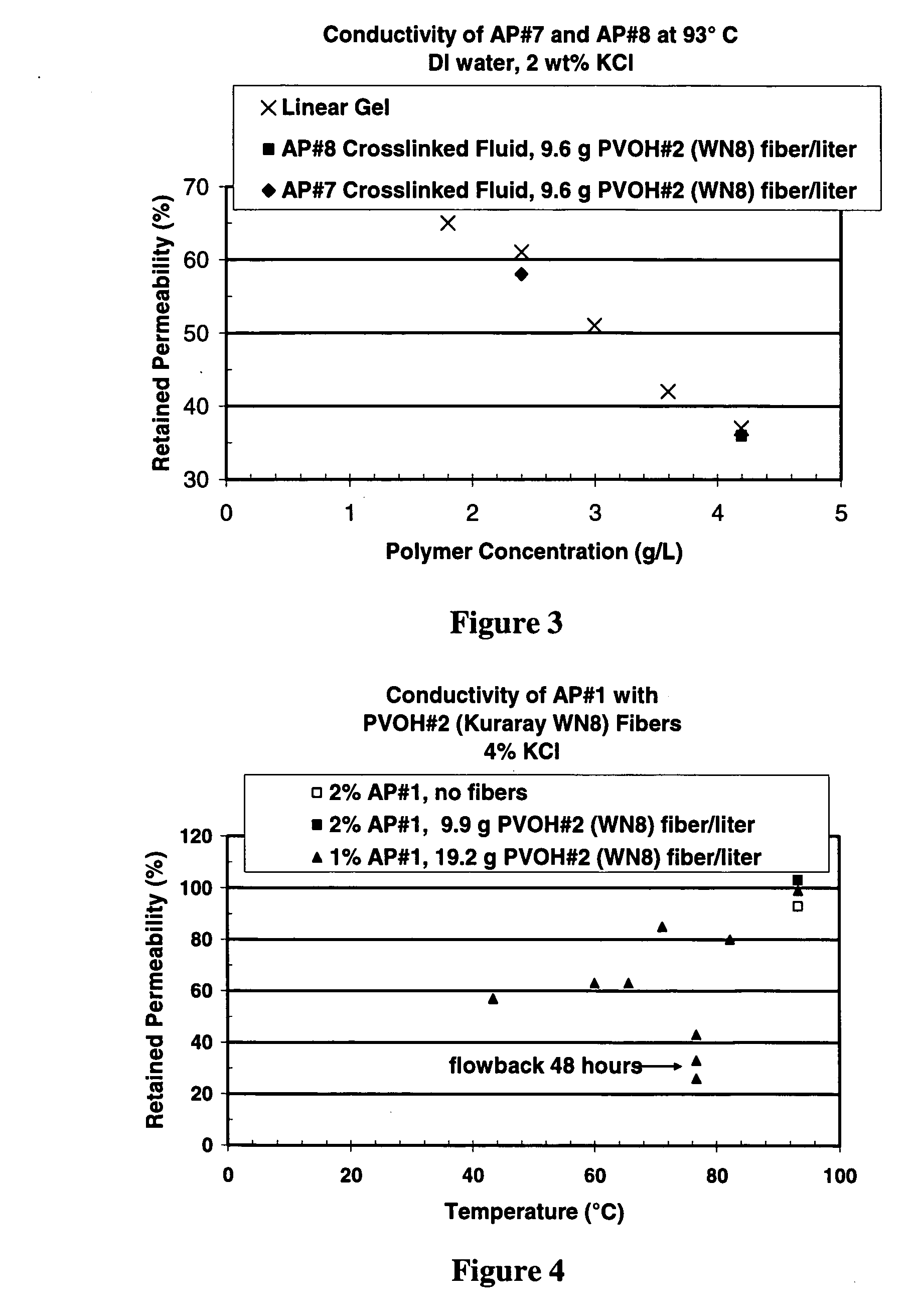

Well treatment with dissolvable polymer

InactiveUS20060157248A1Ease and flexibility for subsequent completion processEasy to processInsulationLiquid/gas jet drillingPolyvinyl alcoholDissolution

Well treatment is disclosed that includes injecting a well treatment fluid with insoluble polyol polymer such as polyvinyl alcohol (PVOH) dispersed therein, depositing the insoluble polymer in the wellbore or an adjacent formation, and thereafter dissolving the polymer by reducing salinity and / or increasing temperature conditions in the environment of the polymer deposit. The method is disclosed for filter cake formation, fluid loss control, drilling, hydraulic fracturing and fiber assisted transport, where removal of the polyol at the end of treatment or after treatment is desired. The method is also disclosed for providing dissolved polyol as a delayed breaker in crosslinked polymer viscosified systems and viscoelastic surfactant systems. Also disclosed are well treatment fluids containing insoluble amorphous or at least partially crystalline polyol, and a PVOH fiber composition wherein the fibers are stabilized from dissolution by salinity.

Owner:SCHLUMBERGER TECH CORP

Orthoester compositions and methods of use in subterranean applications

The present invention relates to methods and compositions for treating subterranean formations, and more specifically, to improved methods and compositions for generating acids for use downhole, for example, to at least partially degrade the acid-soluble portions of filter cakes deposited in subterranean formations. In one embodiment, the present invention provides a method of degrading an acid-soluble portion of a filter cake comprising contacting the acid-soluble portion of the filter cake with an acid generated from an orthoester.

Owner:HALLIBURTON ENERGY SERVICES INC

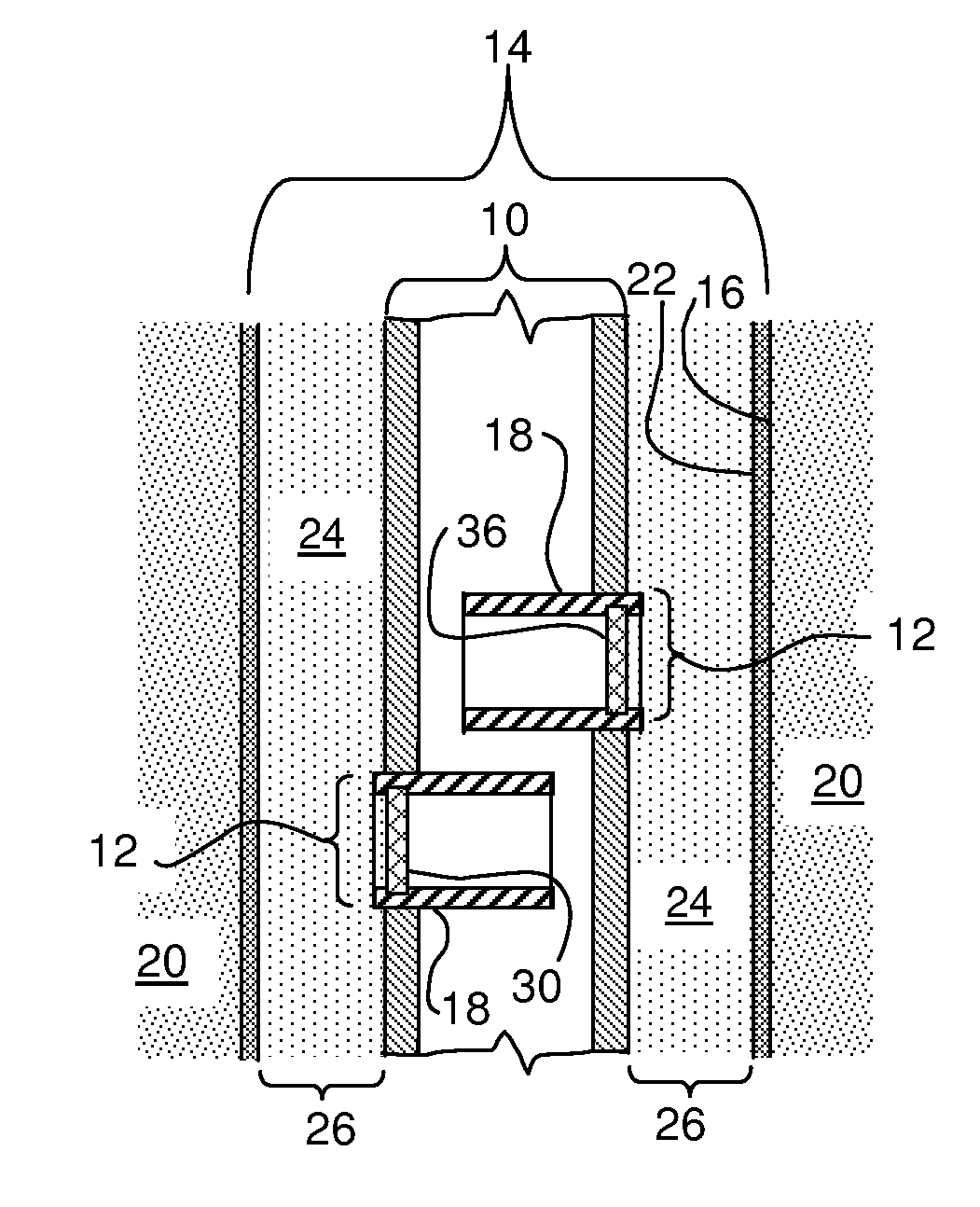

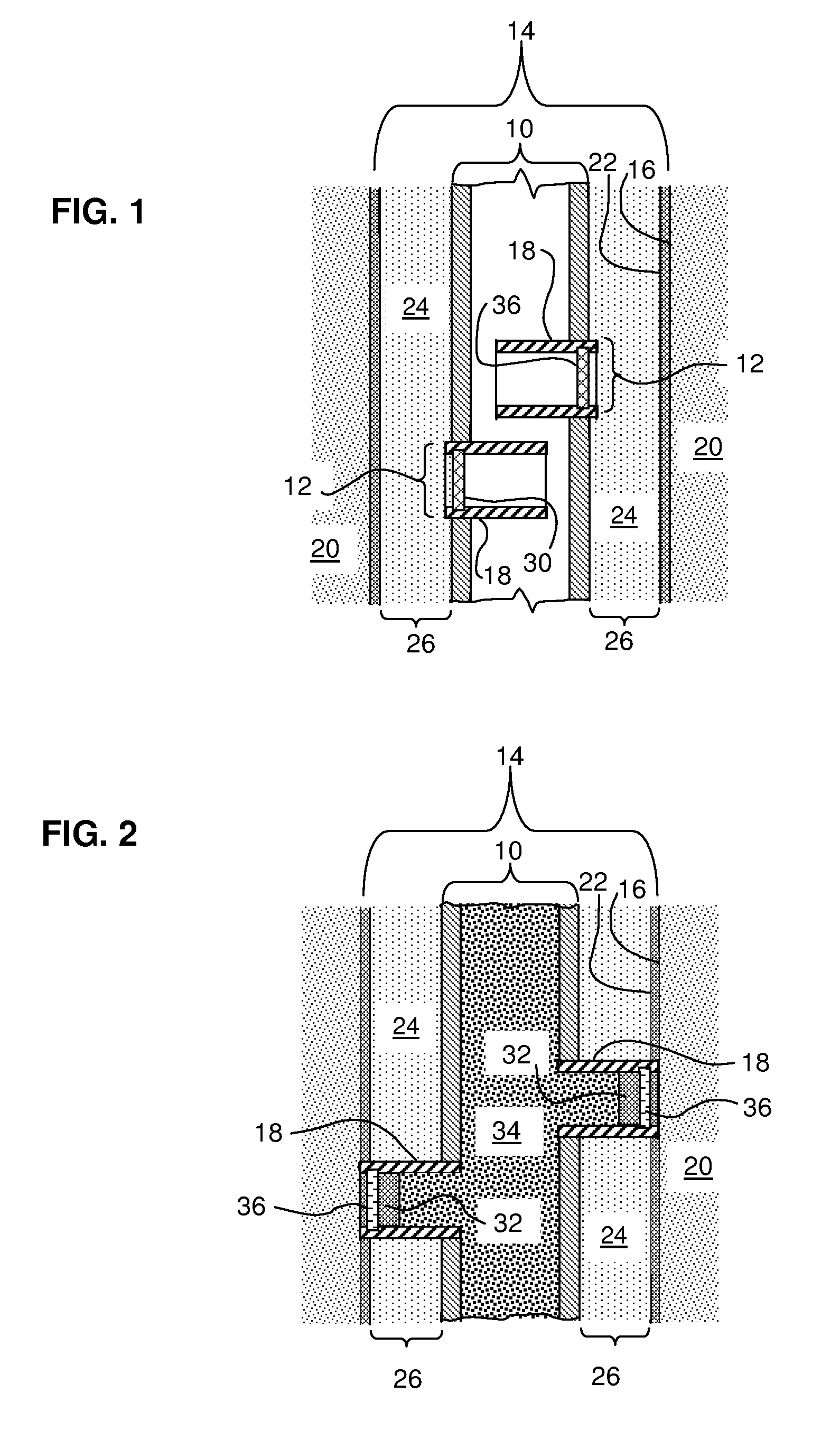

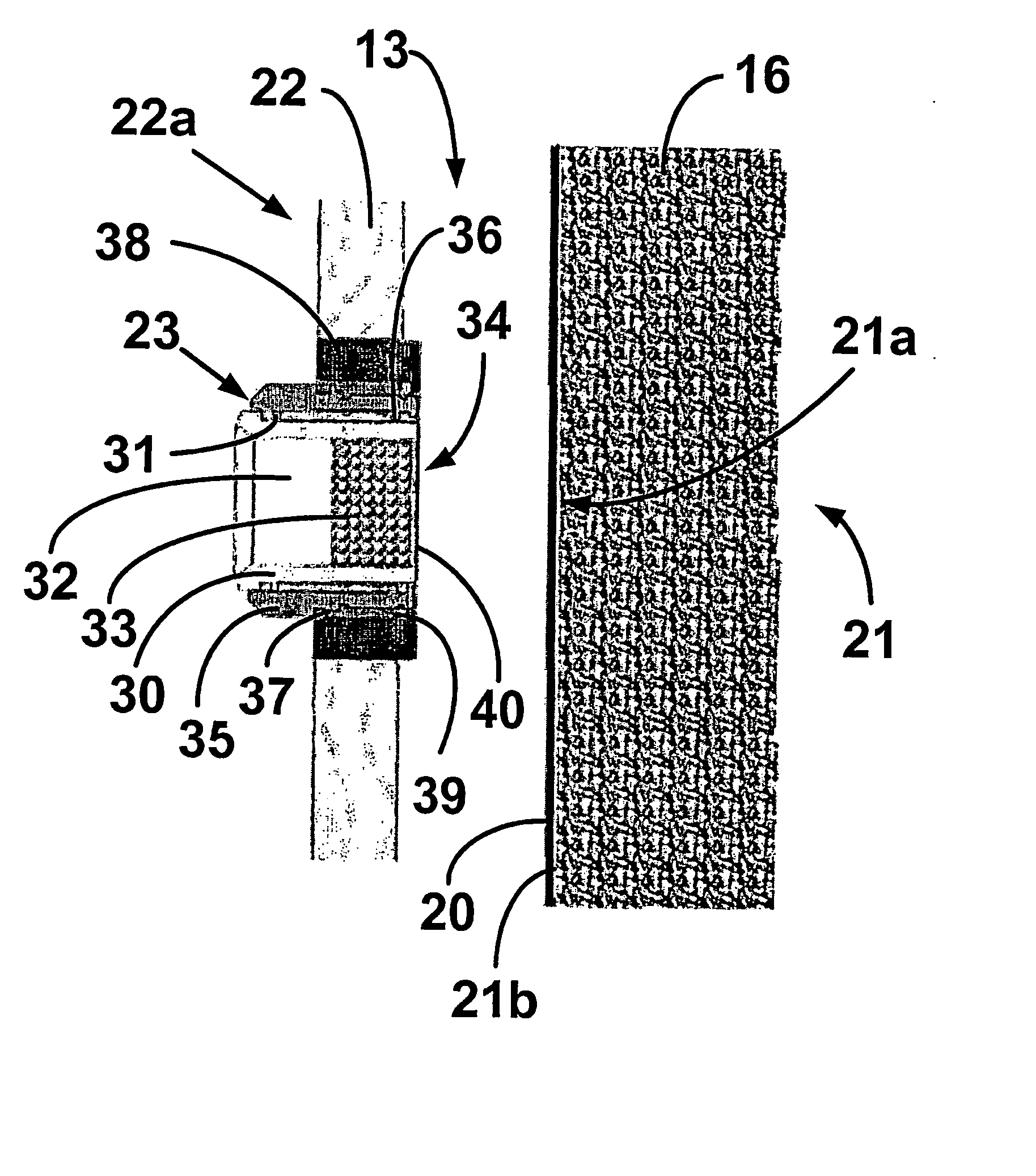

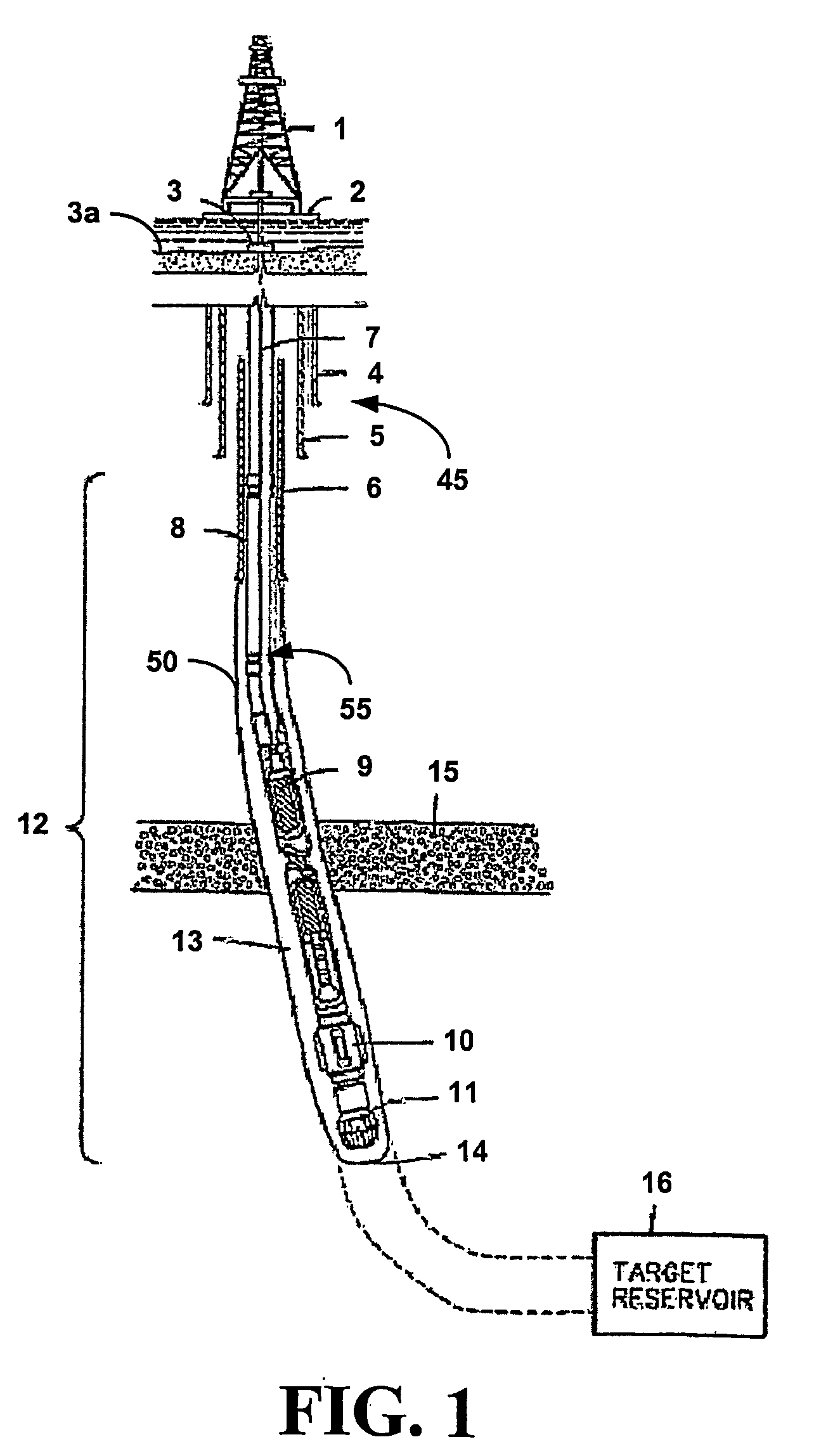

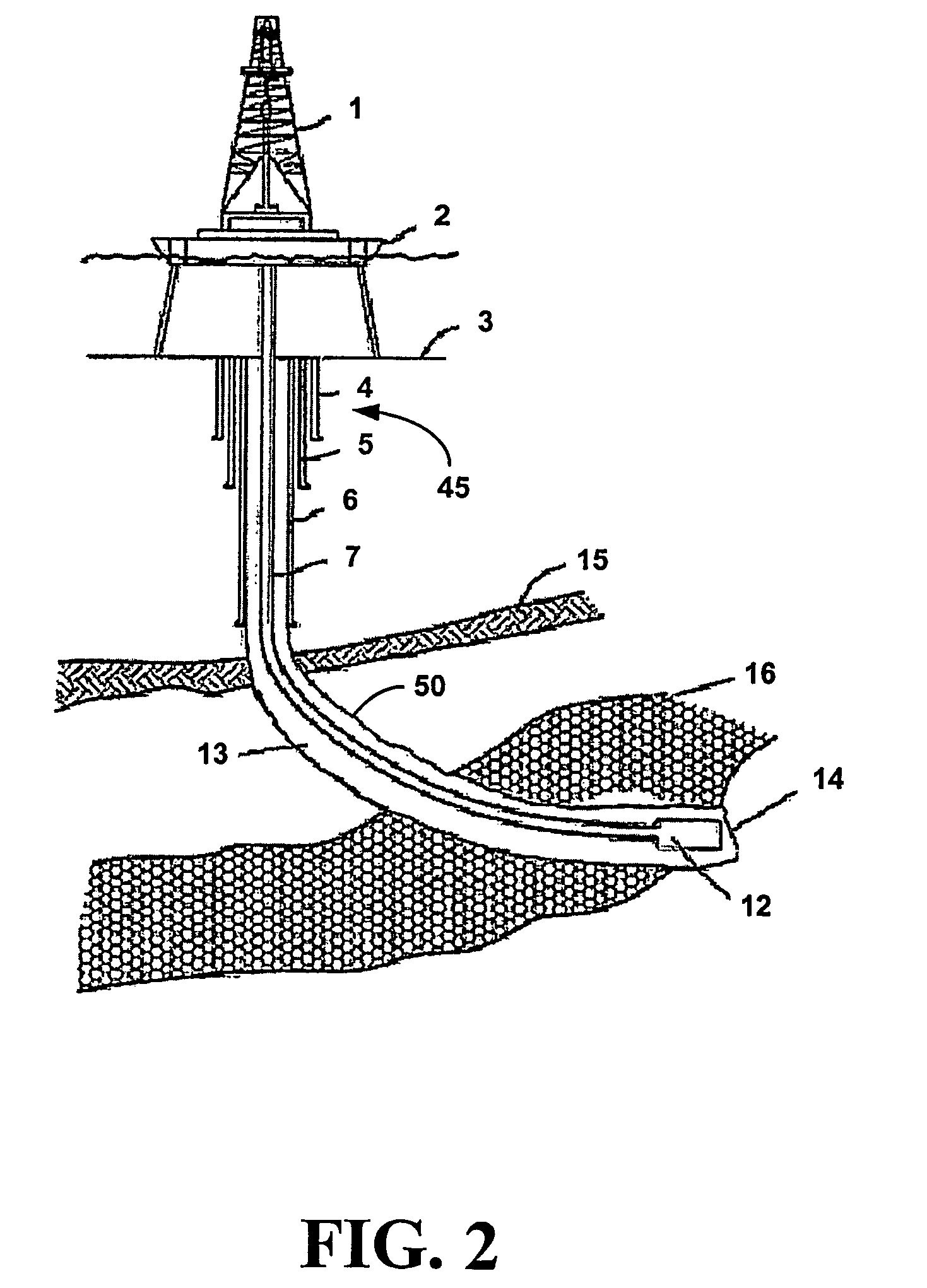

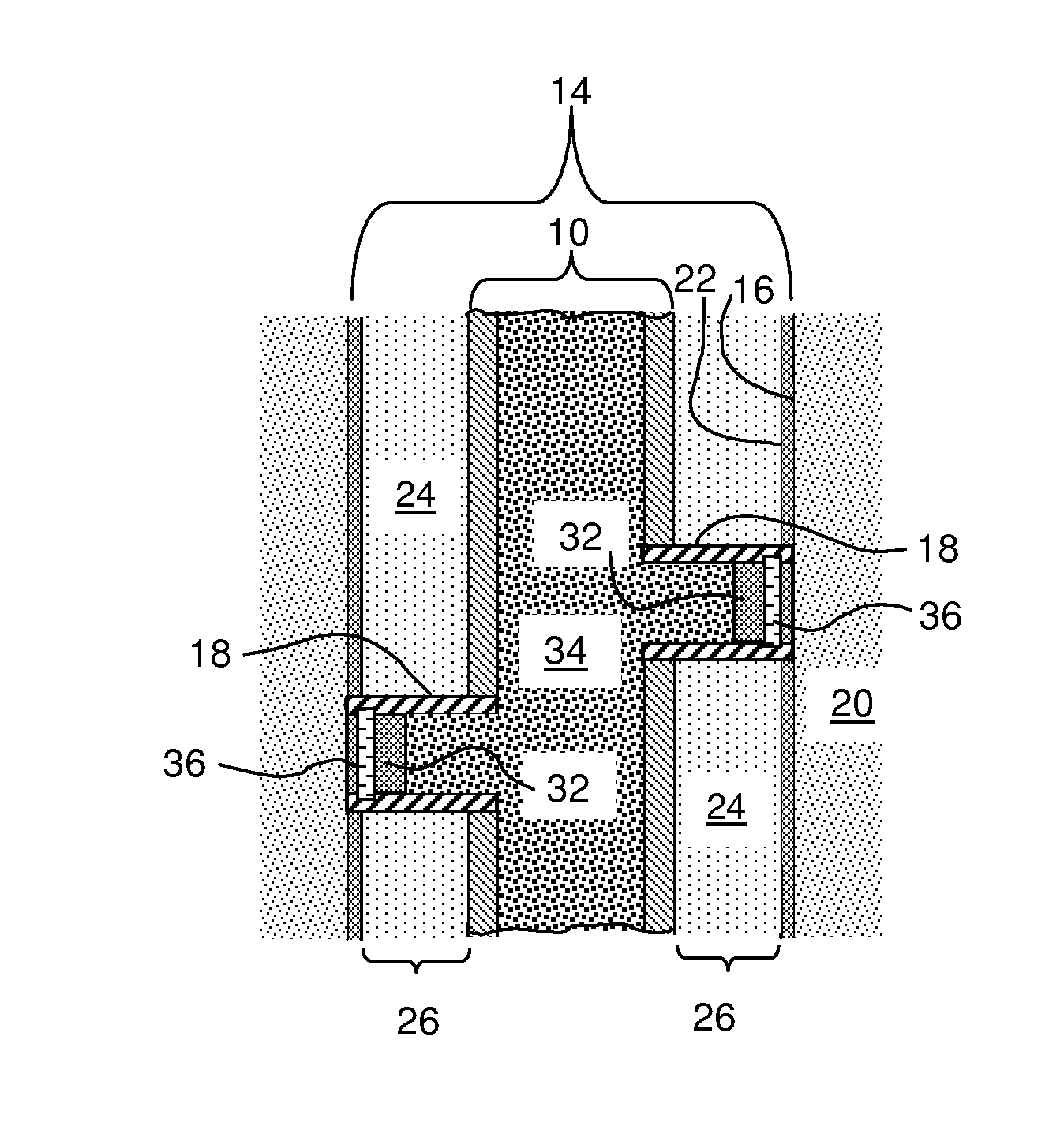

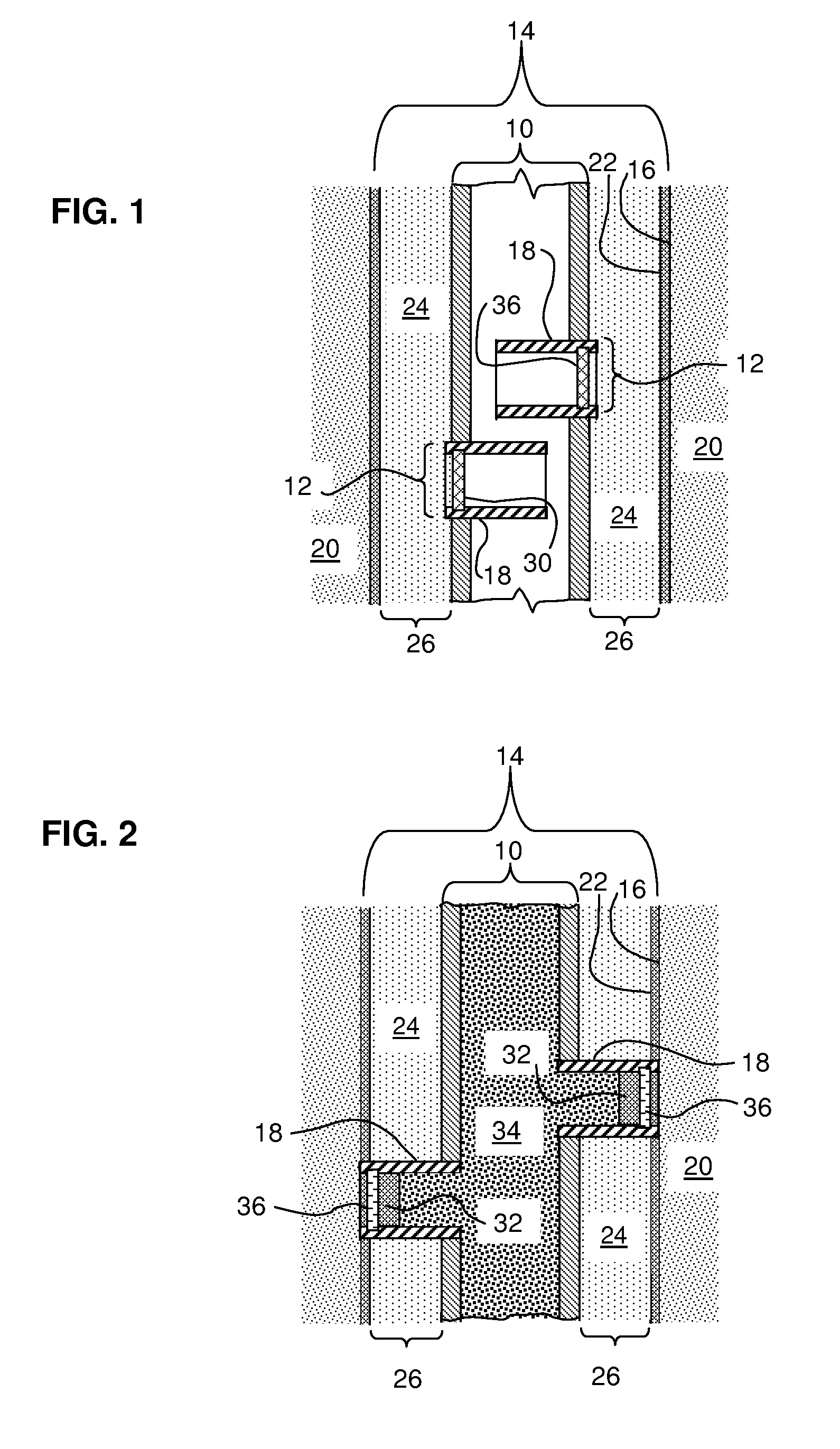

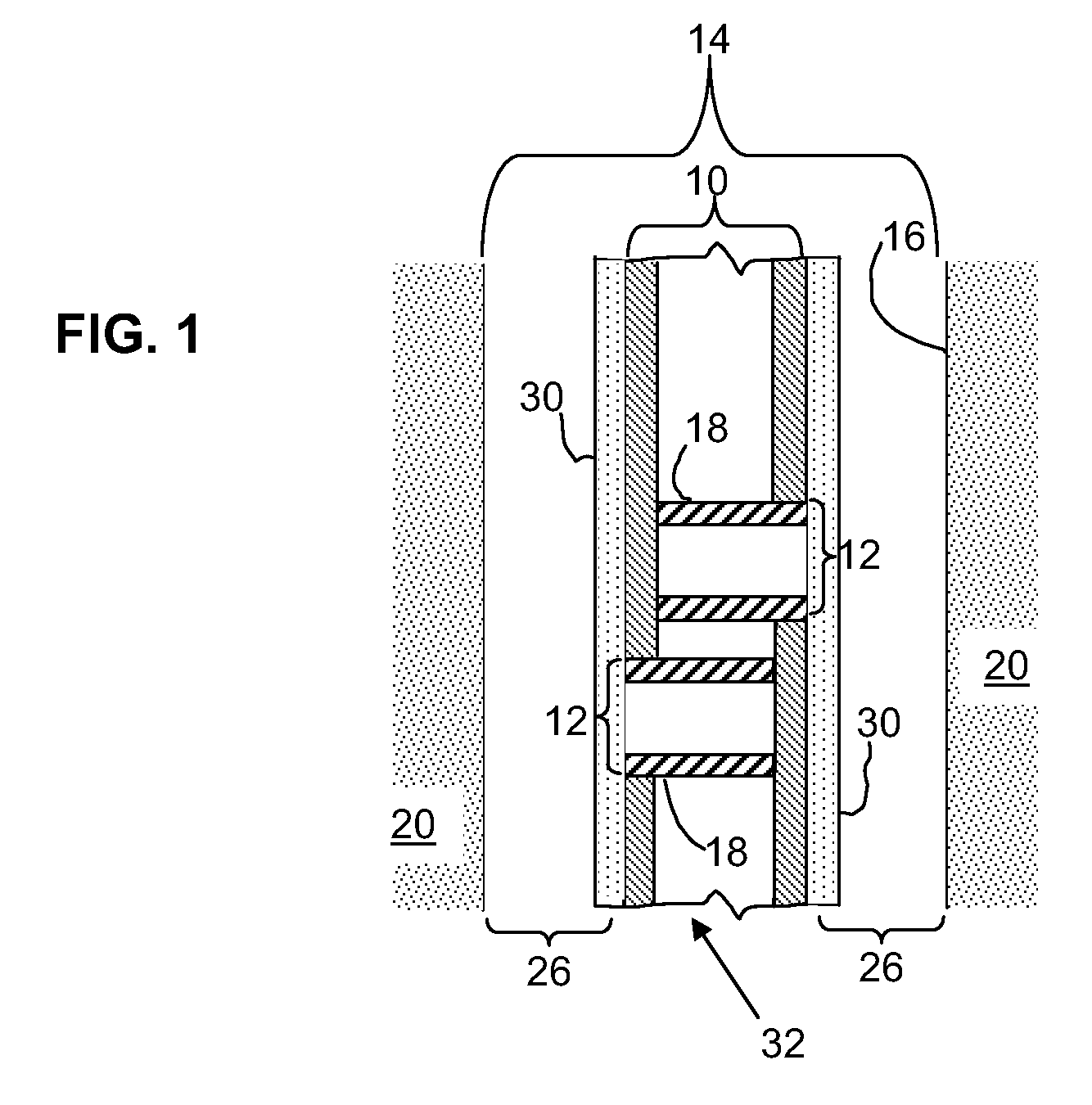

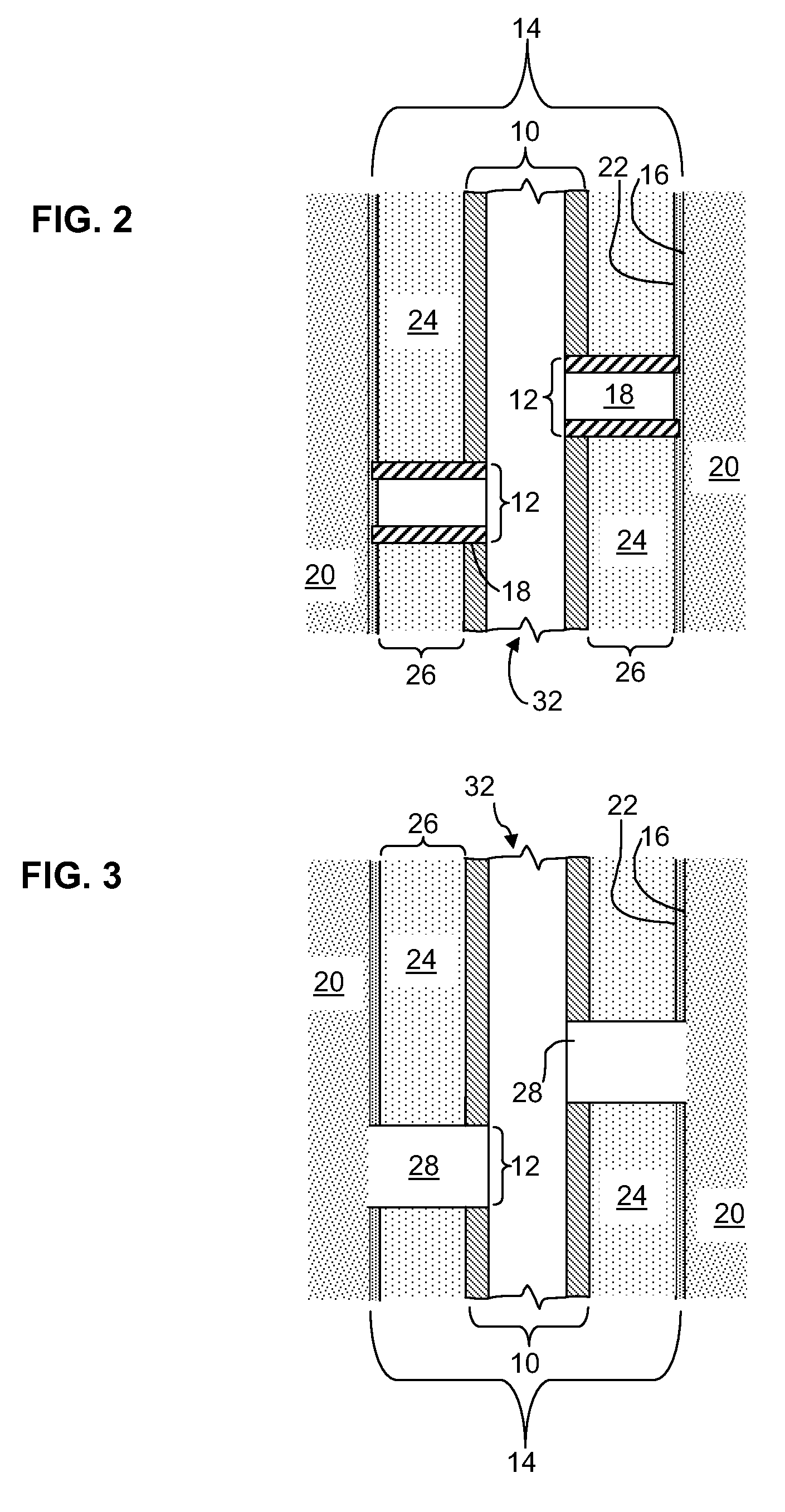

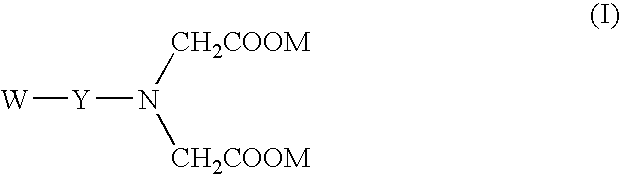

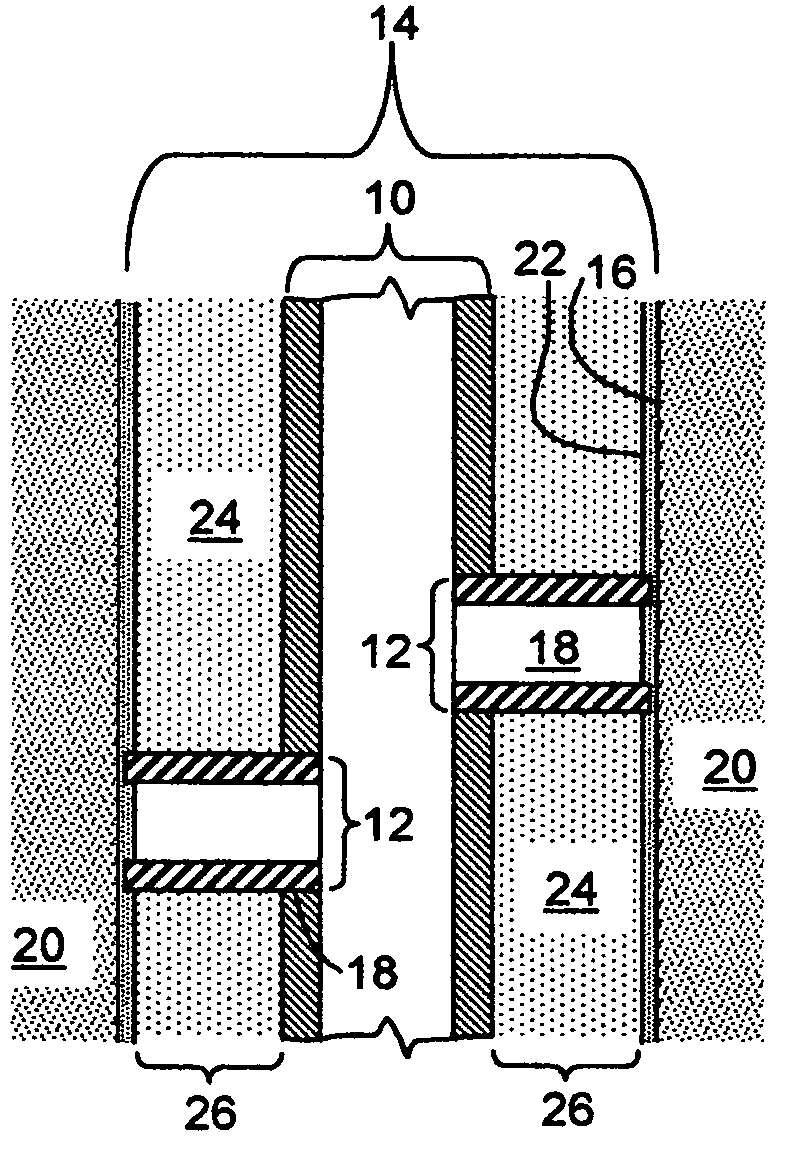

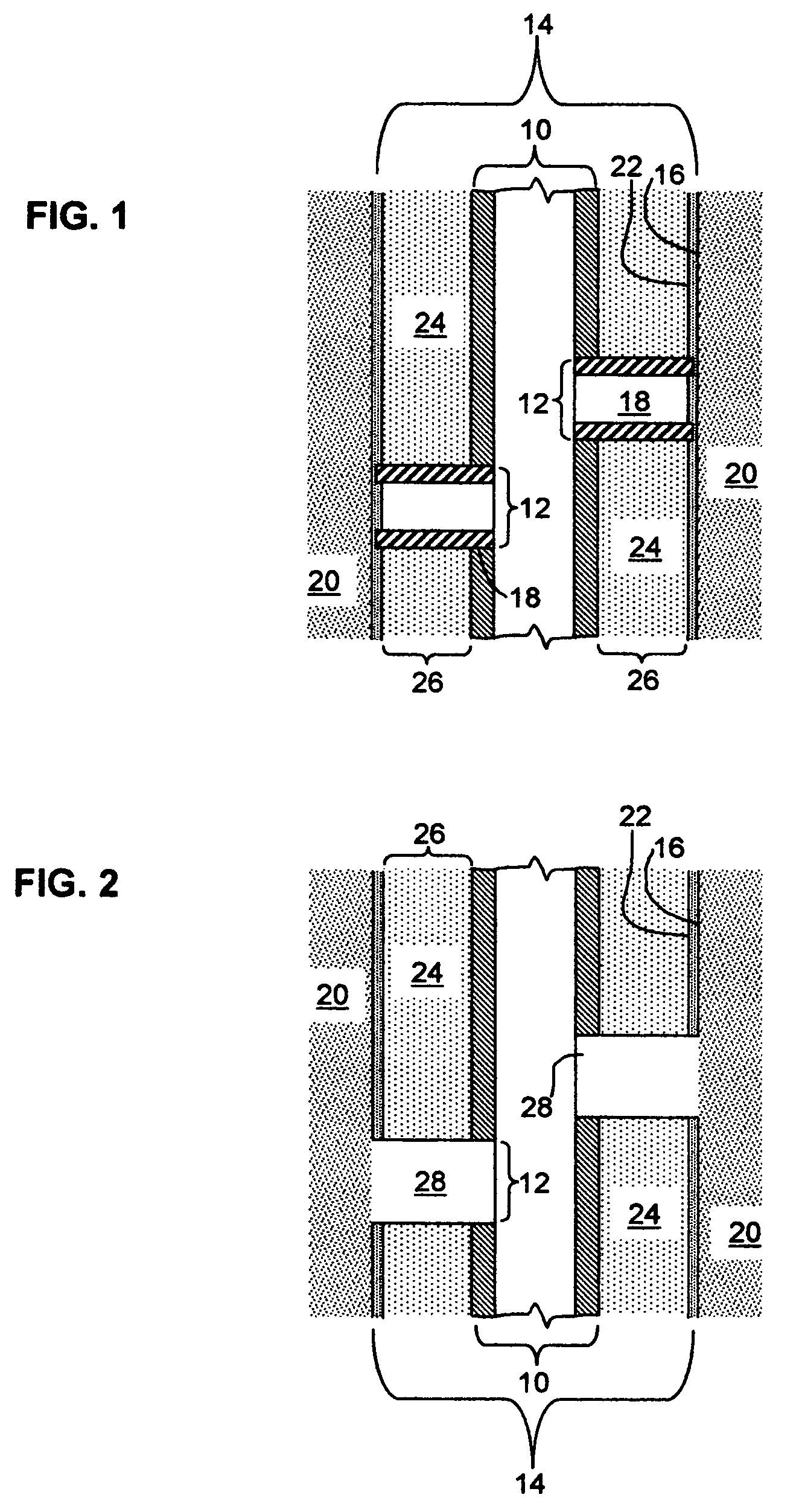

Drilling method for maintaining productivity while eliminating perforating and gravel packing

InactiveUS20060108114A1Improved formation productivityImprove productivityFluid removalProduction rateWell drilling

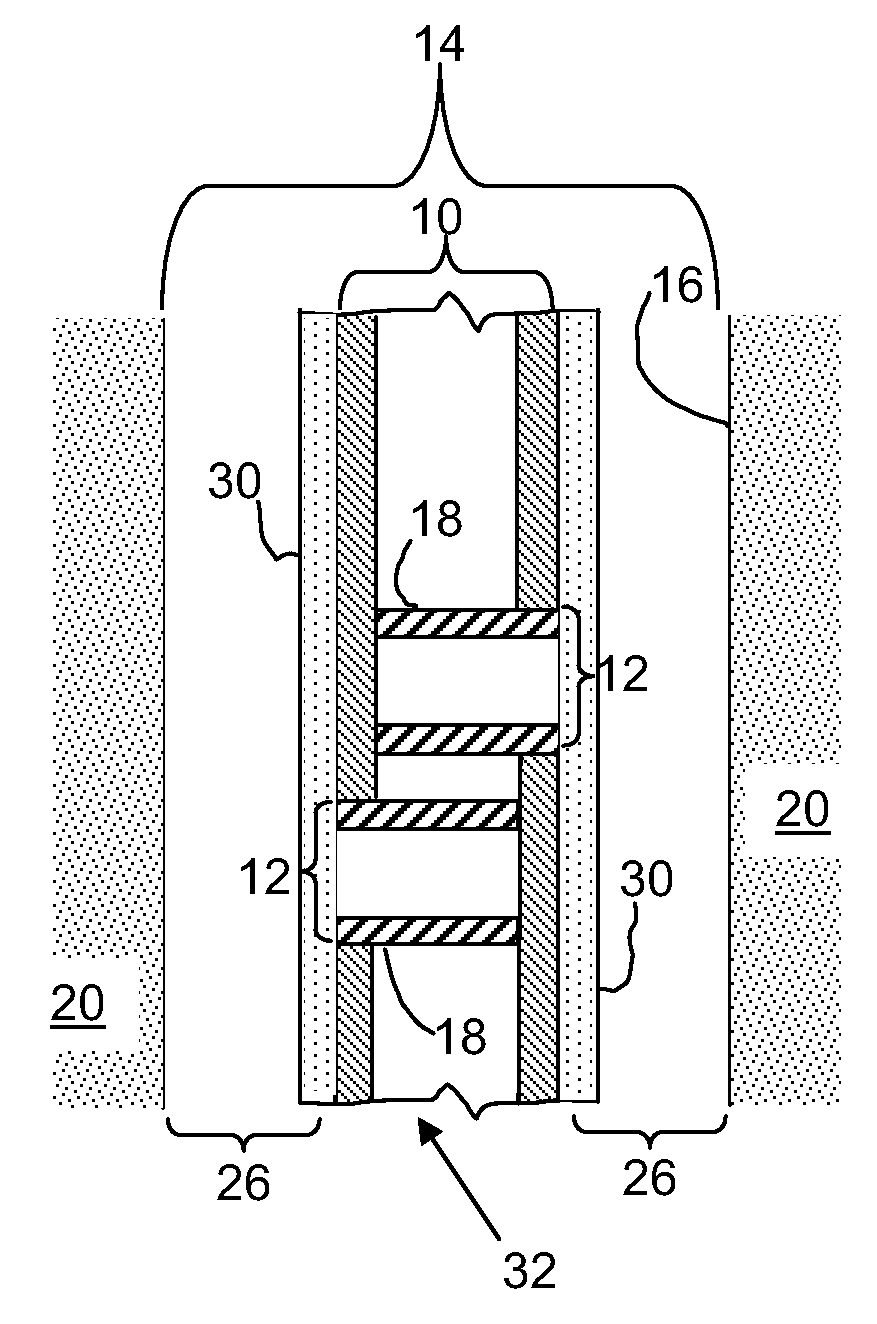

A method for well construction and completion is disclosed. First, a productive section of a well is drilled in the presence of a fluid system that controls fluid losses, is substantially non-damaging to the formation and includes particles in a particle size distribution sufficient to form a low permeability filter cake on a formation face and to allow the majority of the filter cake particles to flow back into the borehole after well completion. after drilling, a casing includes at least one and preferably a plurality of extendable permeable elements or member is run in the well so that the elements are positioned and aligned with sites in the producing formation and once extended form production conduits between the formation and an interior of the casing. A completed borehole is also disclosed including a casing having production conduits formed from the extendable members or elements.

Owner:BAKER HUGHES INC

Methods of drilling and completing well bores

Methods of drilling and completing open hole well bores and methods of removing filter cake comprised of a gelling agent and calcium carbonate are provided. A method of the invention for removing filter cake comprised of a gelling agent and calcium carbonate from the walls of an open hole well bore is basically comprised of the steps of contacting the filter cake with a delayed clean-up solution comprised of water and a formate ester and removing the clean-up solution from the well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

Procedures and compositions for reservoir protection

A flow conduit having at least one orifice is placed in the vicinity of a flow source, which in one non-limiting embodiment may be a hydrocarbon reservoir. The flow pathway between the orifice and the source is temporarily blocked with a degradable barrier. Once the flow pathway is physically placed, the degradable barrier is removed under the influence of an acid, a solvent, time and / or temperature. The flow source and the flow pathways are at least partially covered (and flow blocked by) a temporary coating such as a pseudo-filter cake formed by a viscoelastic surfactant-gelled aqueous drill-in fluid, and the flow conduit is extended to the flow source. The pseudo-filter cake is removed when viscosity is reduced by an internal breaker, and flow is then allowed. The method is useful in one context of recovering hydrocarbons where the flow conduit is a telescoping sleeve or tube that contacts the borehole wall.

Owner:BAKER HUGHES INC

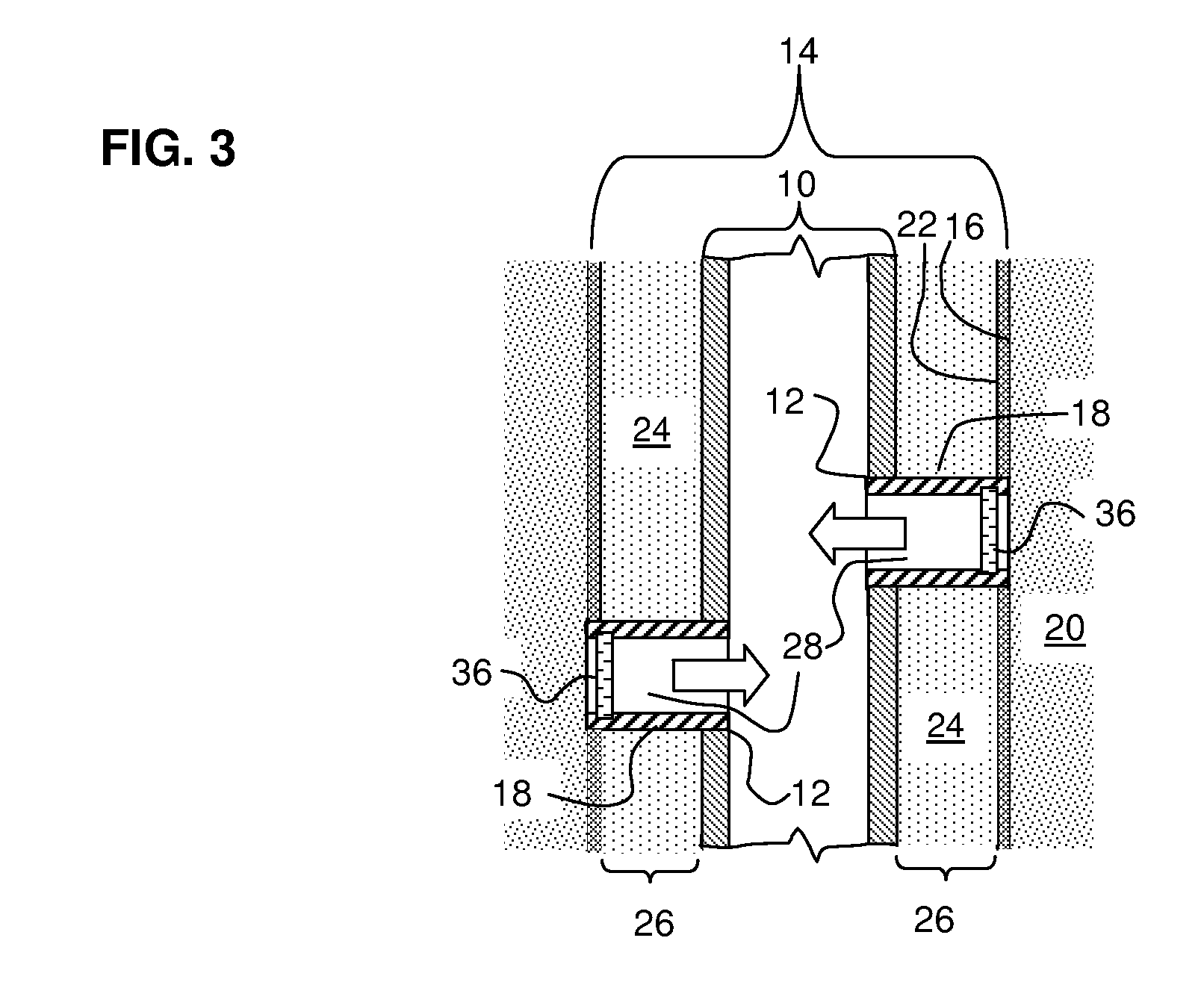

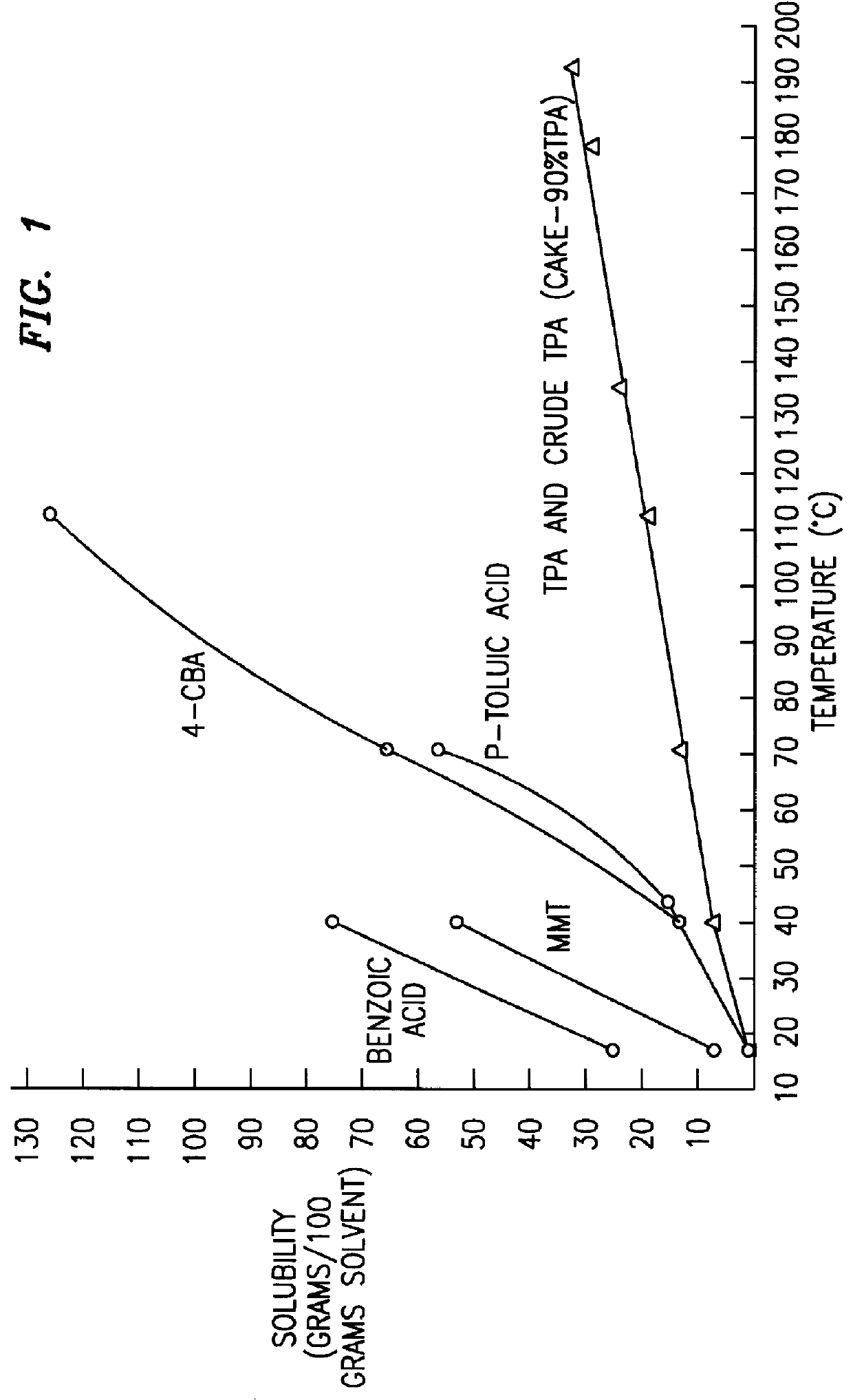

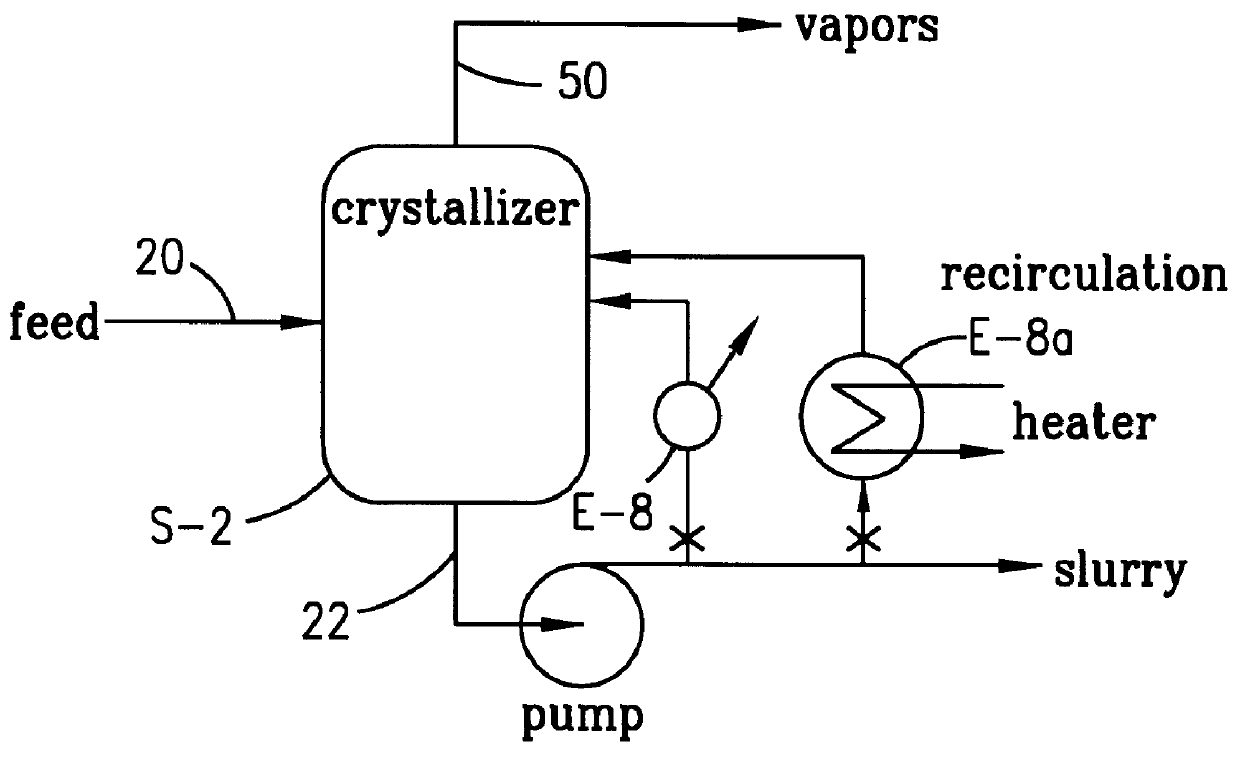

Method and apparatus for preparing purified terephthalic acid

InactiveUS6013835AOrganic compound preparationCarboxylic preparation by oxidationPolyester resinSide reaction

A method and apparatus for purifying crude terephthalic acid from a liquid dispersion thereof also containing impurities selected from unreacted starting materials, solvents, products of side reactions and / or other undesired materials is provided. The method comprises the steps of filtering the dispersion to form a crude terephthalic acid filter cake, dissolving the filter cake in a selective crystallization solvent at an elevated temperature to form a solution, crystallizing purified terephthalic acid from the solution in the crystallization solvent by reducing the pressure and temperature of the solution, and separating the crystallized purified terephthalic acid from the solution. According to the invention, the selective crystallization solvent is non-aqueous, non-corrosive and essentially non-reactive with terephthalic acid. Preferably, the selective crystallization solvent is N-methyl pyrrolidone. The method and apparatus produces purified terephthalic acid having a purity desired for use in forming polyester resin and other products at an economically attractive rate and at operating conditions of reduced severity which require a lower capital investment and simplified processing.

Owner:GTC TECHNOLOGY INC

Dissolving filter cake

Owner:SCHLUMBERGER TECH CORP

Filter cake degradation compositions and methods of use in subterranean operations

InactiveUS7195068B2Cleaning apparatusLiquid/gas jet drillingAcid derivativeHydrogen peroxide degradation

The present invention relates to methods and compositions for degrading filter cakes in subterranean formations, and more specifically, to improved methods and compositions for degrading filter cakes that comprise acid-soluble portions and polymeric portions. In one embodiment, the present invention provides a method of degrading a filter cake comprising an acid-soluble portion and a polymeric portion in a subterranean formation comprising the steps of: introducing a filter cake degradation composition comprising a delayed-release acid component and a delayed-release oxidizer component to a well bore penetrating the subterranean formation; allowing the delayed-release acid component to release an acid derivative and the delayed-release oxidizer component to release an acid-consuming component; allowing the acid-consuming component to interact with the acid derivative to delay a reaction between at least a portion of the acid derivative and at least a portion of the acid-soluble portion of the filter cake and to produce hydrogen peroxide; allowing the acid derivative to degrade at least a portion of the acid-soluble portion of the filter cake after a delay period; and allowing the hydrogen peroxide to degrade at least a portion of the polymeric portion of the filter cake.

Owner:HALLIBURTON ENERGY SERVICES INC

Method of removing an invert emulsion filter cake after the drilling process using a single phase microemulsion

Owner:BAKER HUGHES HLDG LLC

Methods for controlling screenouts

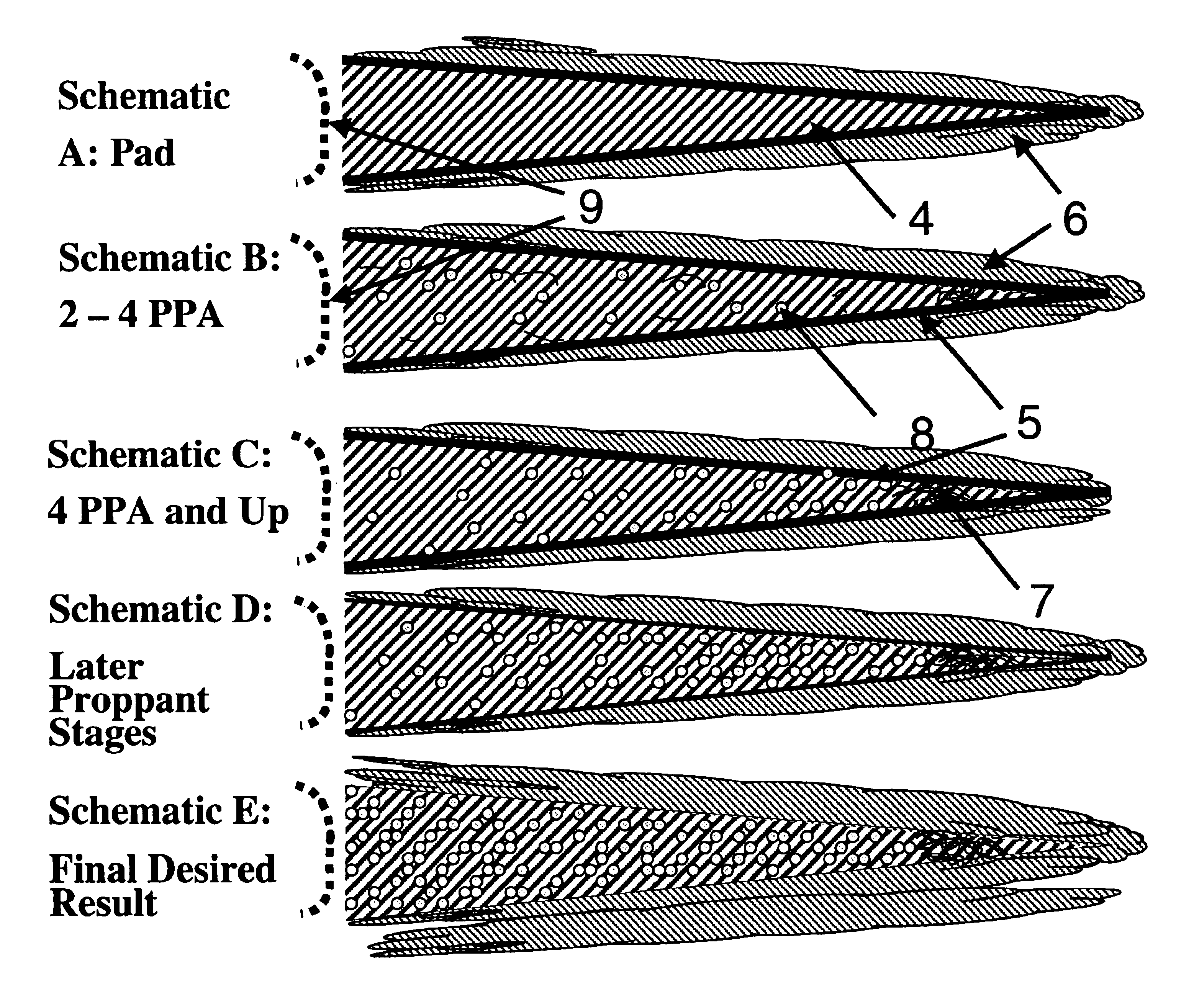

Methods are presented to induce a screenout during a subterranean formation fracturing or combined fracturing and gravel packing treatment by laying down a filter cake early in the treatment, then injecting proppant slurry, and then while proppant slurry injection continues chemically damaging the filter cake with one or more filter cake degradation agents so that leak-off increases, the concentration of proppant in the fracture increases, and the proppant screens out. The additional use of filter cake degradation agent aids and bridging-promoting materials is included.

Owner:SCHLUMBERGER TECH CORP

Treatment fluids and methods of use in subterranean formations

The present invention relates to subterranean treatment operations. More particularly, the present invention relates to improved treatment fluids and methods of using such improved treatment fluids in subterranean formations. An example of a method of the present invention is a method of treating a subterranean formation. Another example of a method of the present invention is a method of drilling in a subterranean formation. Another example of a method of the present invention is a method of degrading a filter cake in a subterranean formation. An example of a composition of the present invention is a treatment fluid comprising a degradable diverting agent. Another example of a composition of the present invention is a degradable diverting agent for use in a subterranean treatment fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

Method for providing a temporary barrier in a flow pathway

A flow conduit may have at least one orifice, which conduit is in the vicinity of a flow source. The source is at least partially covered (and flow blocked by) an optional temporary coating or barrier (e.g. filter cake). The flow pathway between the orifice and the source is temporarily blocked with a degradable material. A delayed degradation material layer is present over or covering the degradable material. The delayed degradation material layer degrades at a rate slower than the degradable barrier. The degradable material and delayed degradation material layer disintegrate (e.g. via time, temperature, a solvent). The degradable material optionally produces a product that removes the temporary coating. The method is useful in one context of recovering hydrocarbons where the flow conduit is the casing or liner of the well and the flow source is a subterranean reservoir where the coating is filter cake.

Owner:BAKER HUGHES INC

Compositions and methods for weighting a breaker coating for uniform distribution in a particulate pack

The present invention involves methods and compositions for treating subterranean formations, and more specifically, relates to improved methods and compositions for degrading filter cake deposited in a subterranean formation by effecting a uniform distribution of a filter cake breaker. One embodiment of the present invention provides a weighted encapsulated breaker comprising a breaker material; and, a coating material comprising a polymer material and a filler material having a specific gravity of at least about 6.5.

Owner:HALLIBURTON ENERGY SERVICES INC

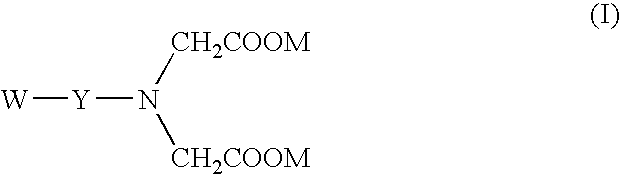

Breaker and displacement fluid and method of use

ActiveUS20080200354A1Sufficient hydrostatic controlEasy to placeFlushingDrilling compositionWater basedEmulsion

A method of cleaning a wellbore prior to the production of oil or gas is disclosed, wherein the wellbore has been drilled with an invert emulsion drilling mud that forms an invert emulsion filter cake. The method may include the steps of circulating a breaker fluid into the wellbore, where the breaker fluid includes an aqueous fluid, and imino diacetic acid or salt thereof. Optionally an acid buffering agent, and a weighting age are also included. The breaker fluid is formulated such that after a predetermined period of time and the filter cake present in the wellbore or on the wellbore face is substantially degraded. Other methods may also include drilling the wellbore with a water-based drilling mud that forms a water-based filter cake, wherein the method may include the steps of circulating a breaker fluid into the wellbore, where the breaker fluid may include an aqueous fluid, and an iminodiacetic acid or a salt thereof.

Owner:MI

Treatment fluids and methods of use in subterranean formations

The present invention relates to subterranean treatment operations, and more particularly to improved bridging agents comprising a degradable material, improved subterranean treatment fluids comprising such improved bridging agents, and methods of using such improved subterranean treatment fluids in subterranean formations. An example of a method of the present invention is a method of drilling a well bore in a subterranean formation. Another example of a method of the present invention is a method of forming a self-degrading filter cake in a subterranean formation. Another example of a method of the present invention is a method of degrading a filter cake in a subterranean formation. An example of a composition of the present invention is a treatment fluid including a viscosifier, a fluid loss control additive, and a bridging agent comprising a degradable material. Another example of a composition of the present invention is a bridging agent comprising a degradable material.

Owner:HALLIBURTON ENERGY SERVICES INC

Method for providing a temporary barrier in a flow pathway

A flow conduit may have at least one orifice is in the vicinity of a flow source. The source is at least partially covered (and flow blocked by) an optional temporary coating or barrier. The flow pathway between the orifice and the source is temporarily blocked with a degradable material or barrier. The material disintegrates (e.g. under the influence of time or temperature) to optionally produce a product that removes the temporary coating in the area adjacent the barrier. The method is useful in one non-limiting context of recovering hydrocarbons where the flow conduit is the casing or liner of the well and the flow source is a subterranean reservoir where the temporary coating is a filter cake.

Owner:BAKER HUGHES HLDG LLC

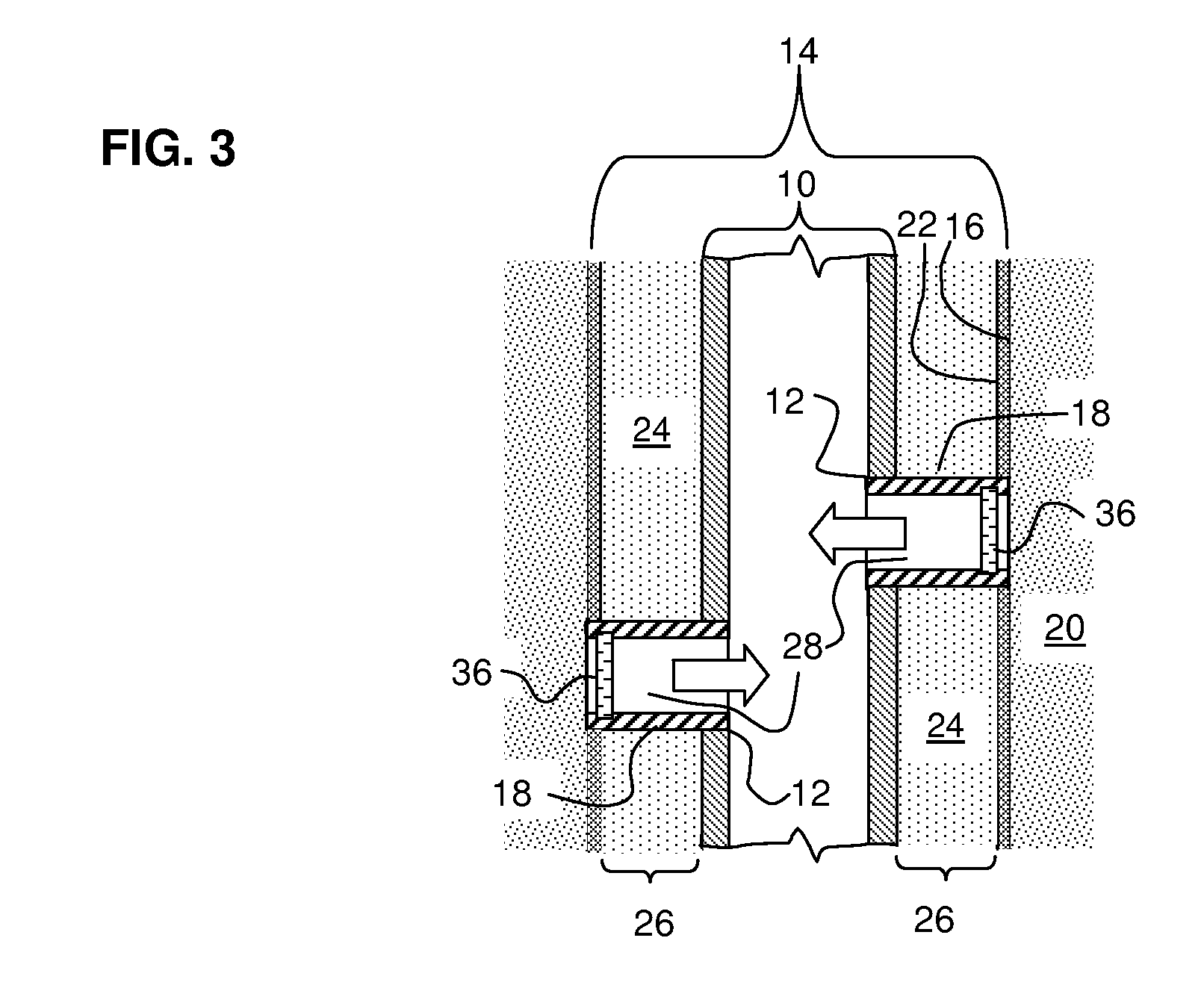

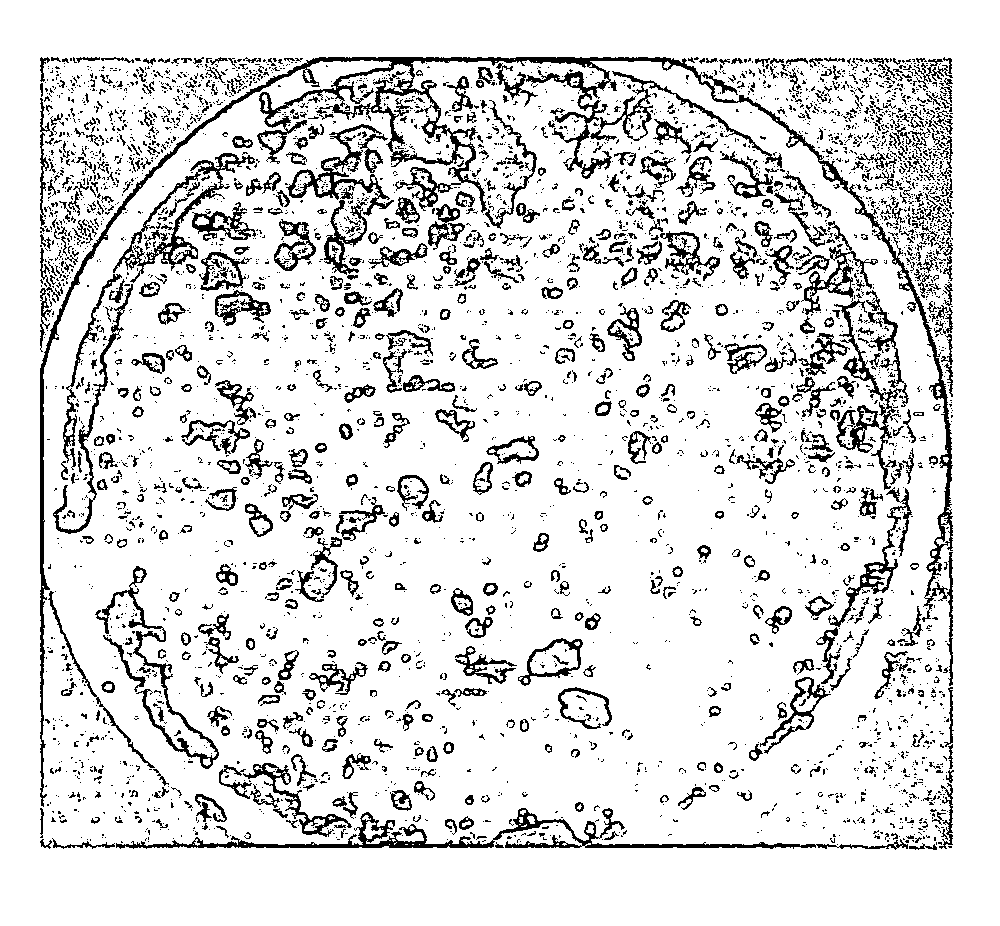

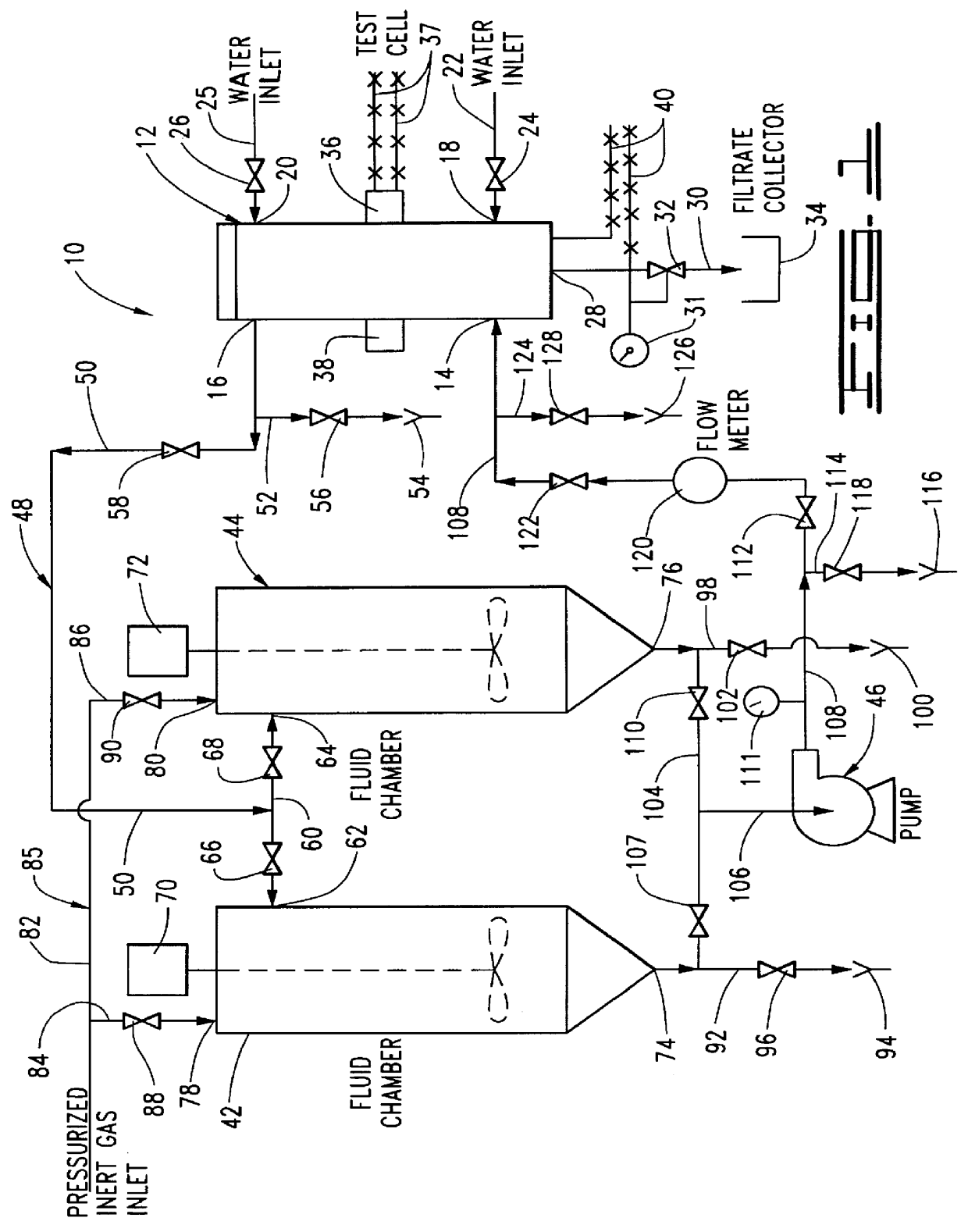

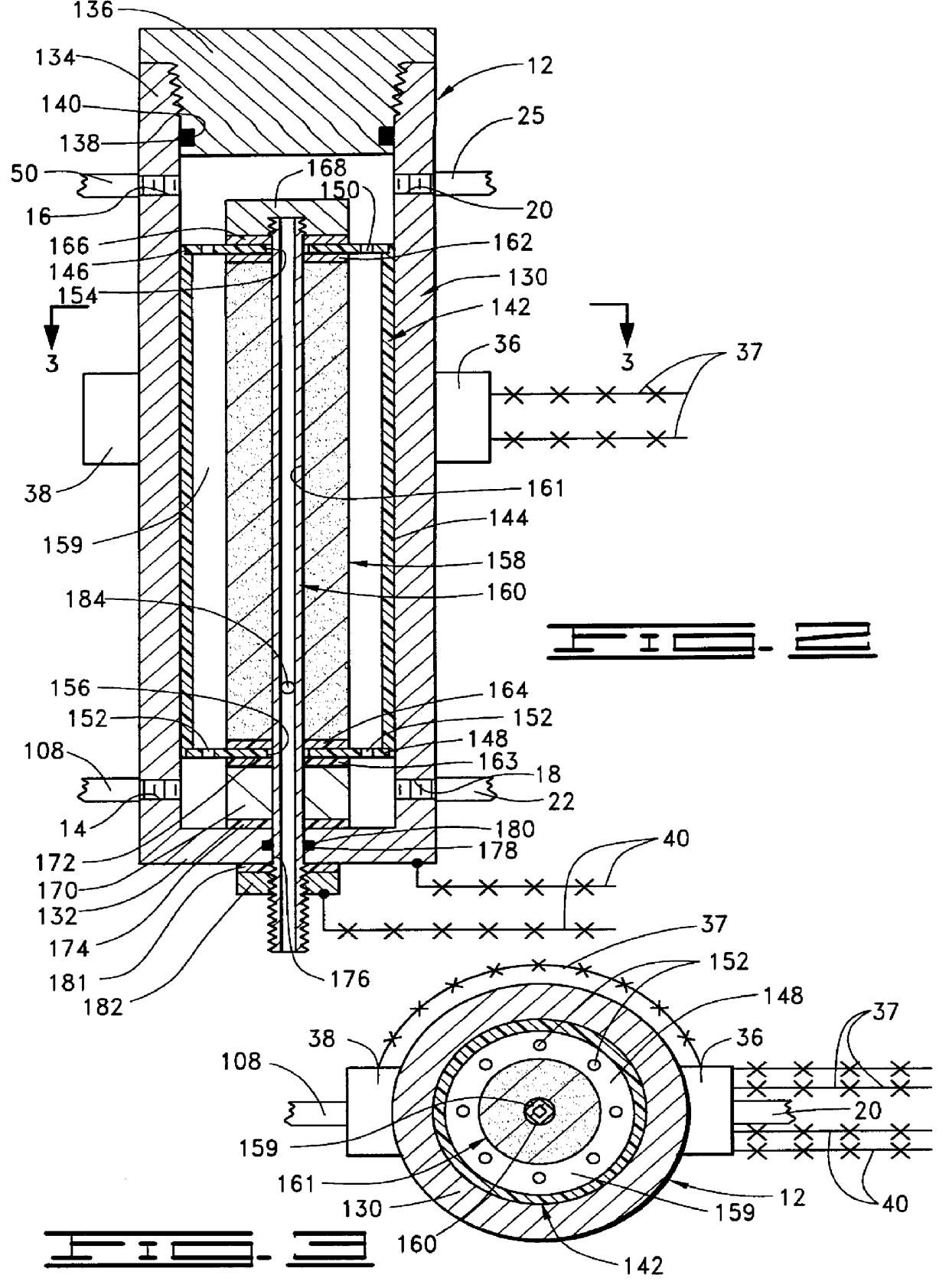

Apparatus and method for simulating well bore conditions

InactiveUS6055874AMaterial analysis using sonic/ultrasonic/infrasonic wavesSamplingRock coreWell drilling

The present invention provides methods and apparatus for simulating well bore conditions before and after cementing therein. The methods of the invention are basically comprised of the steps of circulating a drilling fluid through a closed test cell containing a permeable rock core while maintaining a selected pressure differential across the rock core to form a layer of filter cake thereon, circulating a filter cake removal fluid through the test cell to simulate the clean-up of the well bore and then determining the condition of the rock core with respect to the effectiveness of the filter cake removal fluid thereon.

Owner:HALLIBURTON ENERGY SERVICES INC

Preparation method for aluminum oxide by direct forming method

InactiveCN102923744AReduce drynessReduce stepsAluminium oxide/hydroxide preparationAluminium hydroxide preparationHydrated aluminaAluminium hydroxide

The invention discloses a preparation method for aluminum oxide by a direct forming method. The method is characterized in that the aluminum oxide is directly formed by a wet filter cake, wherein pore volume is 0.3-0.8ml / g; a specific surface area is 150-300 m<2> / g; and crushing strength is 30-120 N / particle; the preparation process comprises the steps: a) meta-aluminate containing aluminum or a strong acid salt compound is neutralized with a precipitator solution at a temperature of 30-80 DEG C and pH of 6-9; accessory ingredient is added in a neutralizing process; mixture is aged for at least 10min after neutralizing; b) prepared aluminium hydroxide gel is washed by de-ionized water for 4-10 times; dosage of the de-ionized water for each time is 10-40 times of mass of a dried substrate of prepared aluminium hydroxide; a hydrated alumina filter cake is obtained after washing and filtering; content of the aluminium hydroxide in the filter cake is controlled to be 5-50%; and c) the accessory ingredient is added into one or various liquid in the step a) and step b); the filter cake after washing is formed by a normal forming method; and the formed filter cake is dried at a temperature of 80-120 DEG C and calcined at a temperature of 450-1000 DEG C to obtain a finished product of the aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Compositions and methods for degrading filter cake

Owner:HALLIBURTON ENERGY SERVICES INC

Method for removing filter cake from injection wells

InactiveUS6978838B2Eliminate needReduce capacity requirementsCleaning apparatusFluid removalBridge materialHigh rate

A method is given for completing an interval of an open-hole injection well penetrating a subterranean formation when the interface between the wellbore and the formation includes a zone invaded by a filter cake that includes bridging materials and other embedded solid materials. The method includes the steps of injecting a clean-up fluid and contacting it with the filtercake for a period of time sufficient to loosen some of the other solids embedded in the filter cake; removing the loosened solids by a high-rate displacement fluid containing suspending additives; and then injecting a dissolving fluid containing a diverter and an effective amount of a salt or acid capable of dissolving the bridging material.

Owner:SCHLUMBERGER TECH CORP

Methods and compositions for fracturing subterranean formations

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com