Method for providing a temporary barrier in a flow pathway

a flow pathway and temporary barrier technology, applied in the direction of sealing/packing, drilling pipes, borehole/well accessories, etc., can solve the problems of mud invasion into the formation, poor drilling mud performance, and formation damage to debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

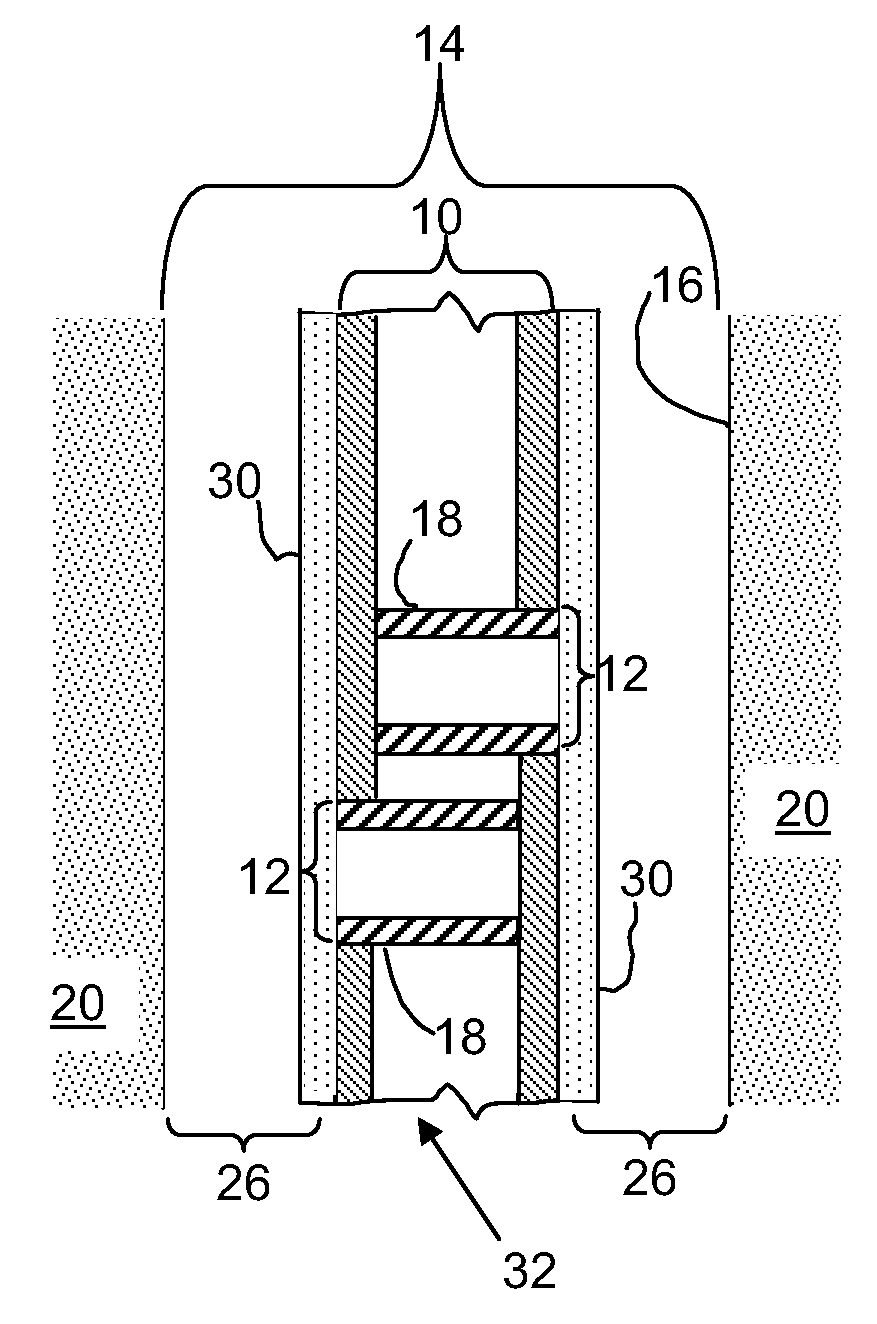

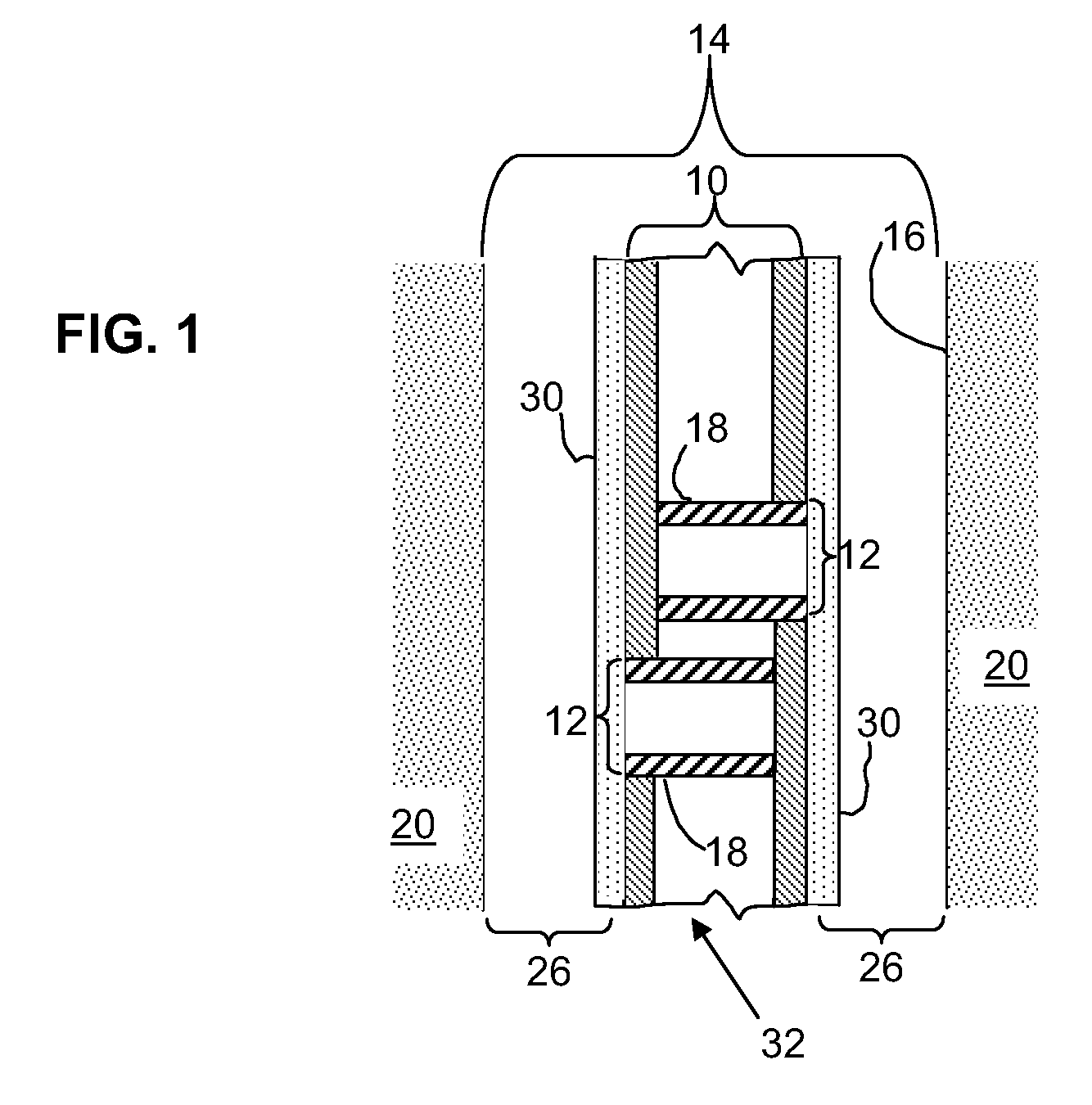

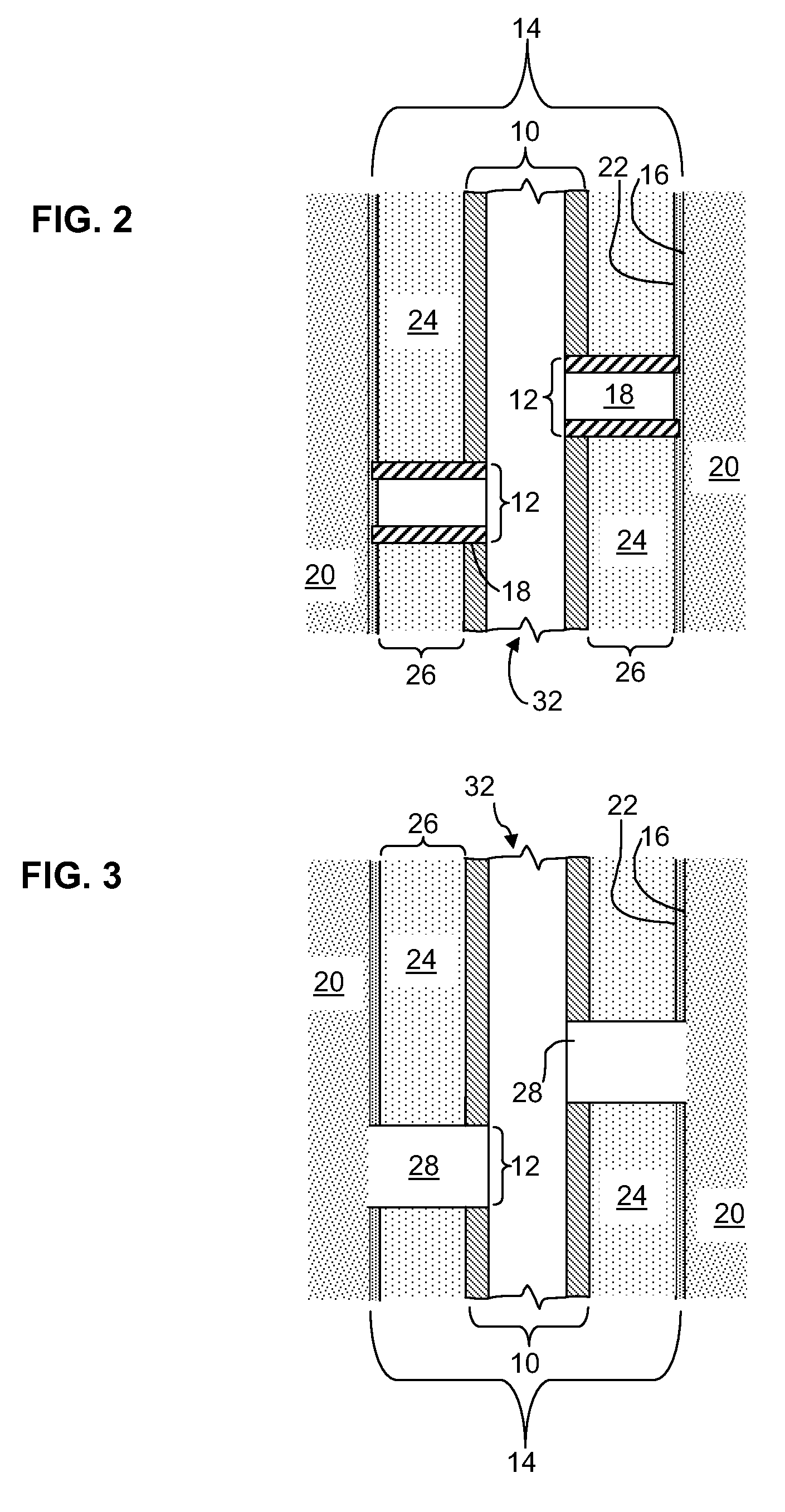

[0016]It has been discovered, in one non-limiting embodiment, that biodegradable polymers or other degradable or reactive materials may effectively serve as temporary barriers, films, coatings and the like on downhole filtration tools, such as sand control screens. Optionally, the degradable barriers may degrade, disintegrate or decompose into products that in turn can remove a temporary coating, such as a drill-in fluid filter cake breaker for oil well, gas well or injection well completion methods. However, as noted elsewhere herein, the method is not limited to this particular embodiment. For instance, the decomposition or degradation product may also subsequently remove materials including, but not necessarily limited to, formation damaging debris left from perforating operations in case-hole completions and other operations and mud placed by undesirable mud invasion due to poor drilling mud performance.

[0017]In another non-limiting form, the method may include wrapping a film o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com