Patents

Literature

4041results about "Cleaning apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dissolvable downhole tools

A disposable downhole tool comprises a material that dissolves when exposed to a chemical solution, an ultraviolet light, a nuclear source, or a combination thereof. In an embodiment, the material comprises an epoxy resin, a fiberglass, or a combination thereof. In another embodiment, the material comprises a fiberglass and a binding agent. The material may also be customized to achieve a desired dissolution rate of the tool. In an embodiment, the disposable downhole tool further comprises an enclosure for storing the chemical solution. The tool may also comprise an activation mechanism for releasing the chemical solution from the enclosure. In an embodiment, the disposable downhole tool is a frac plug. In another embodiment, the tool is a bridge plug. In yet another embodiment, the tool is a packer.

Owner:HALLIBURTON ENERGY SERVICES INC

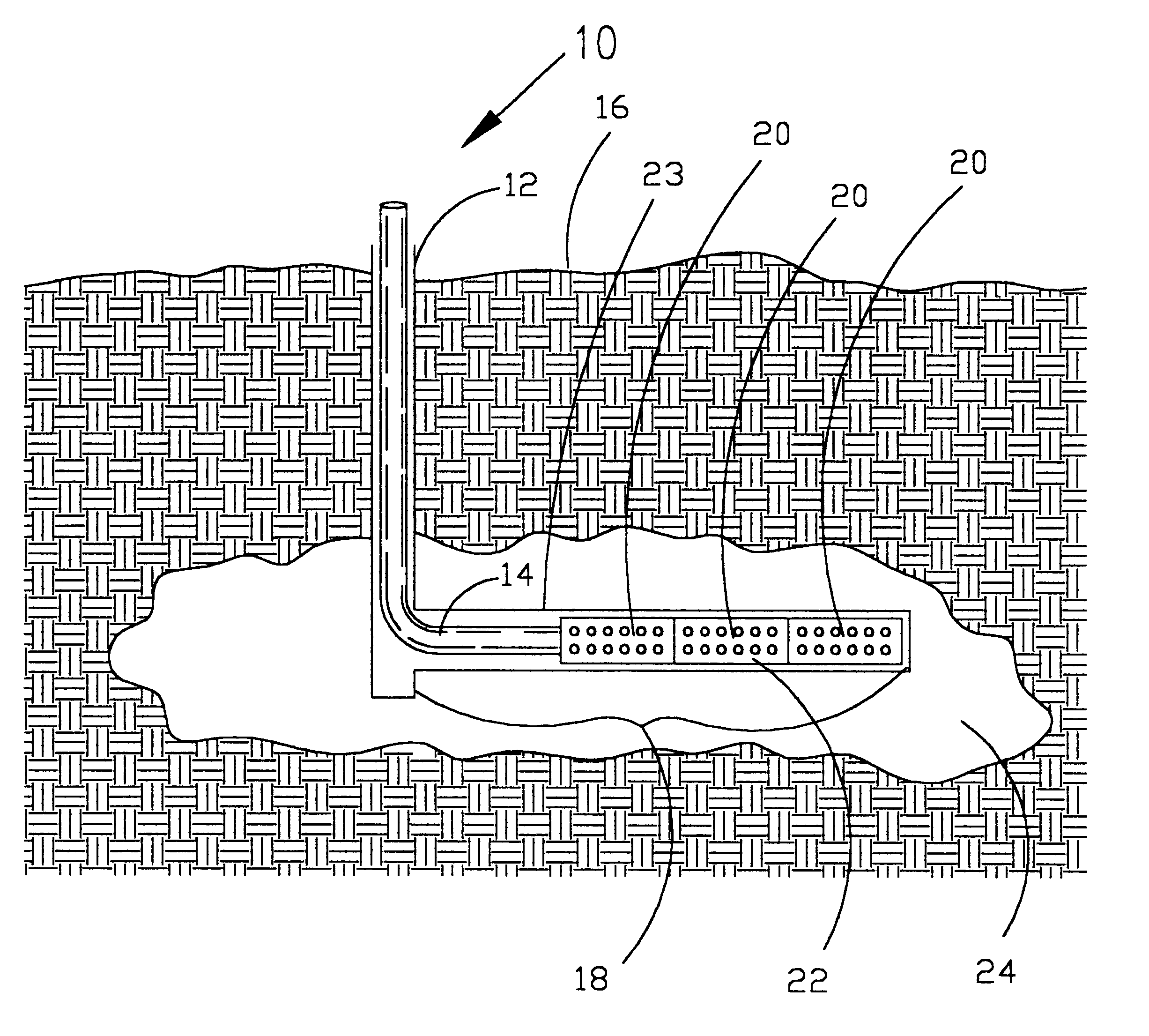

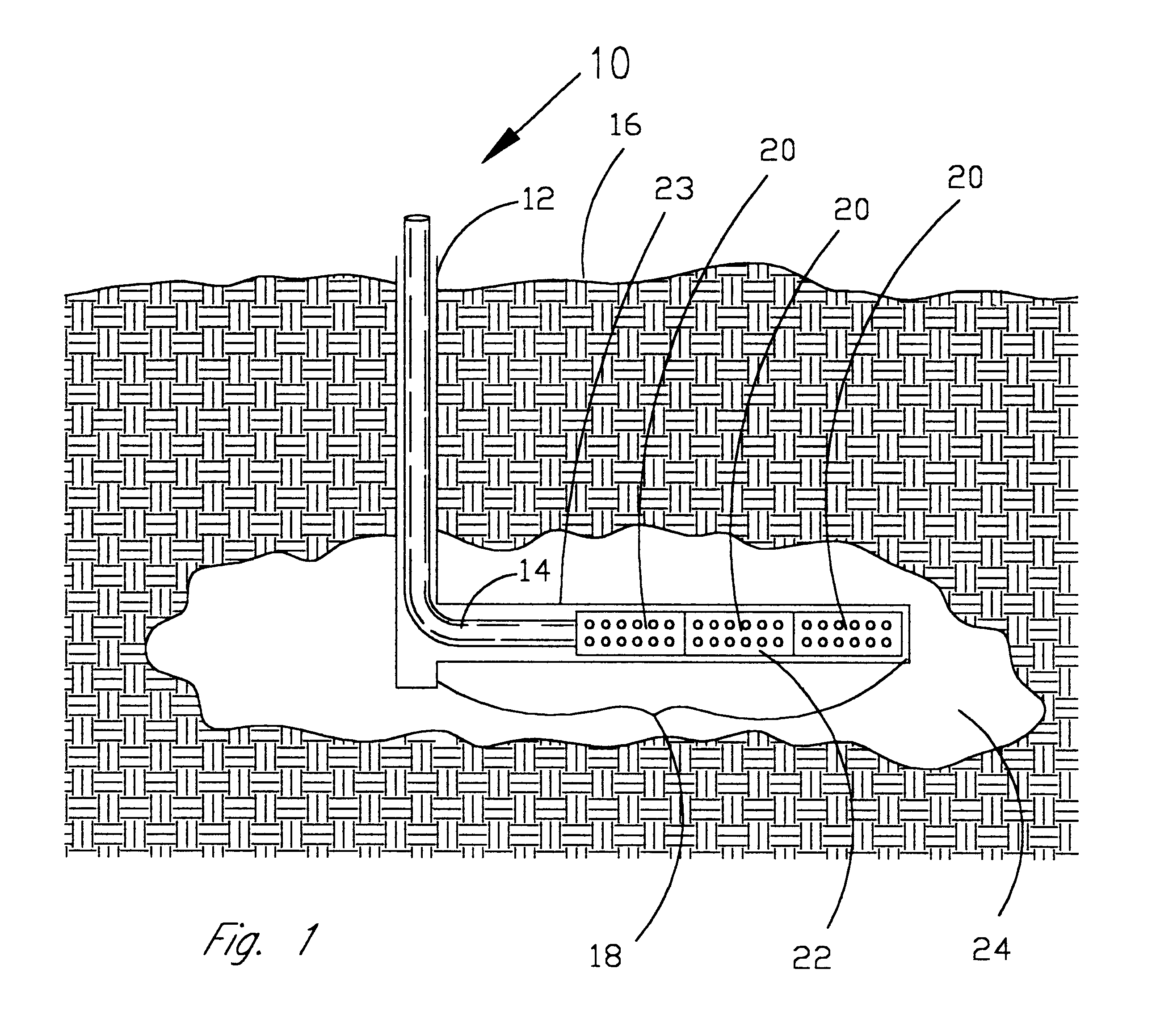

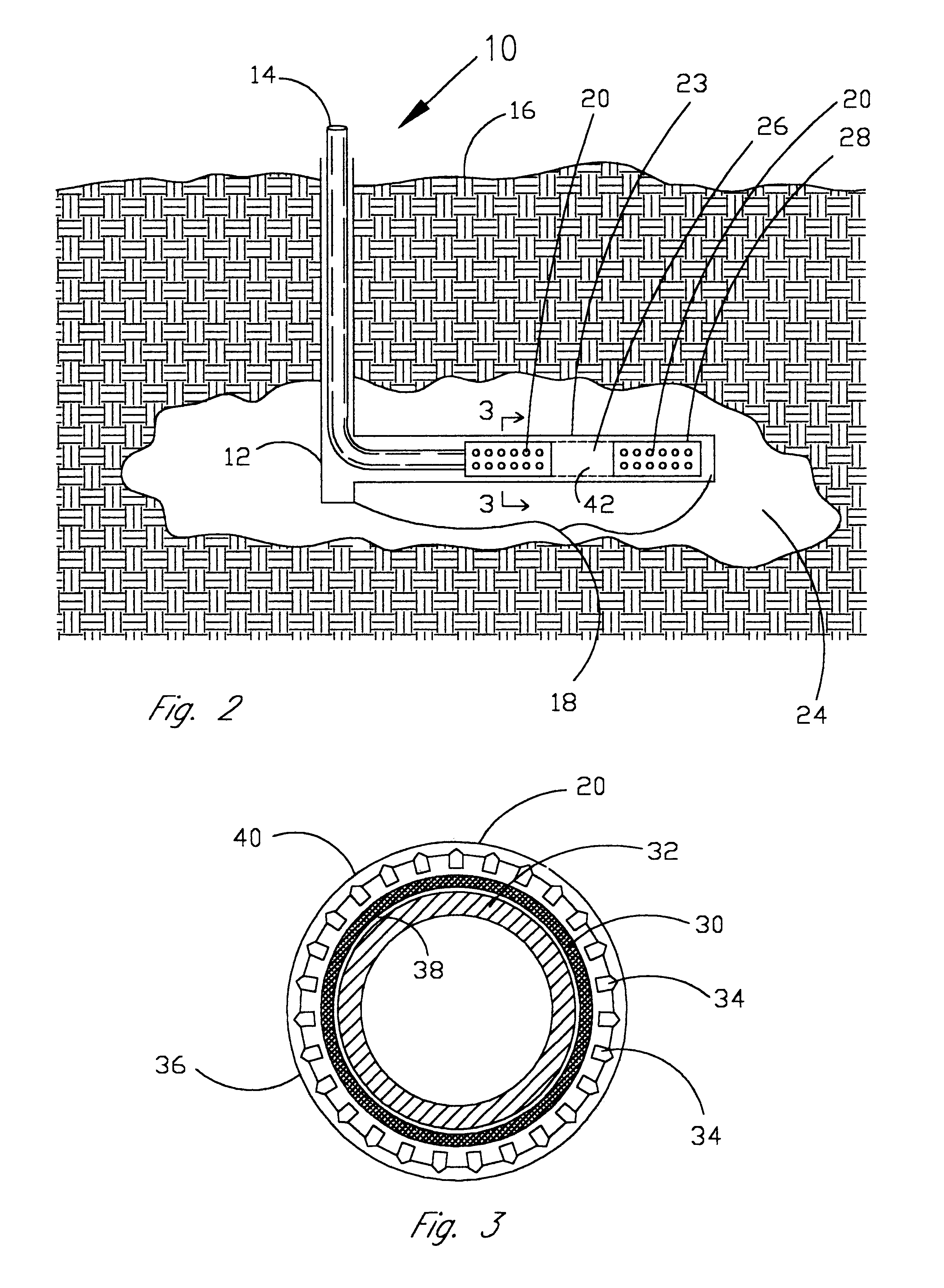

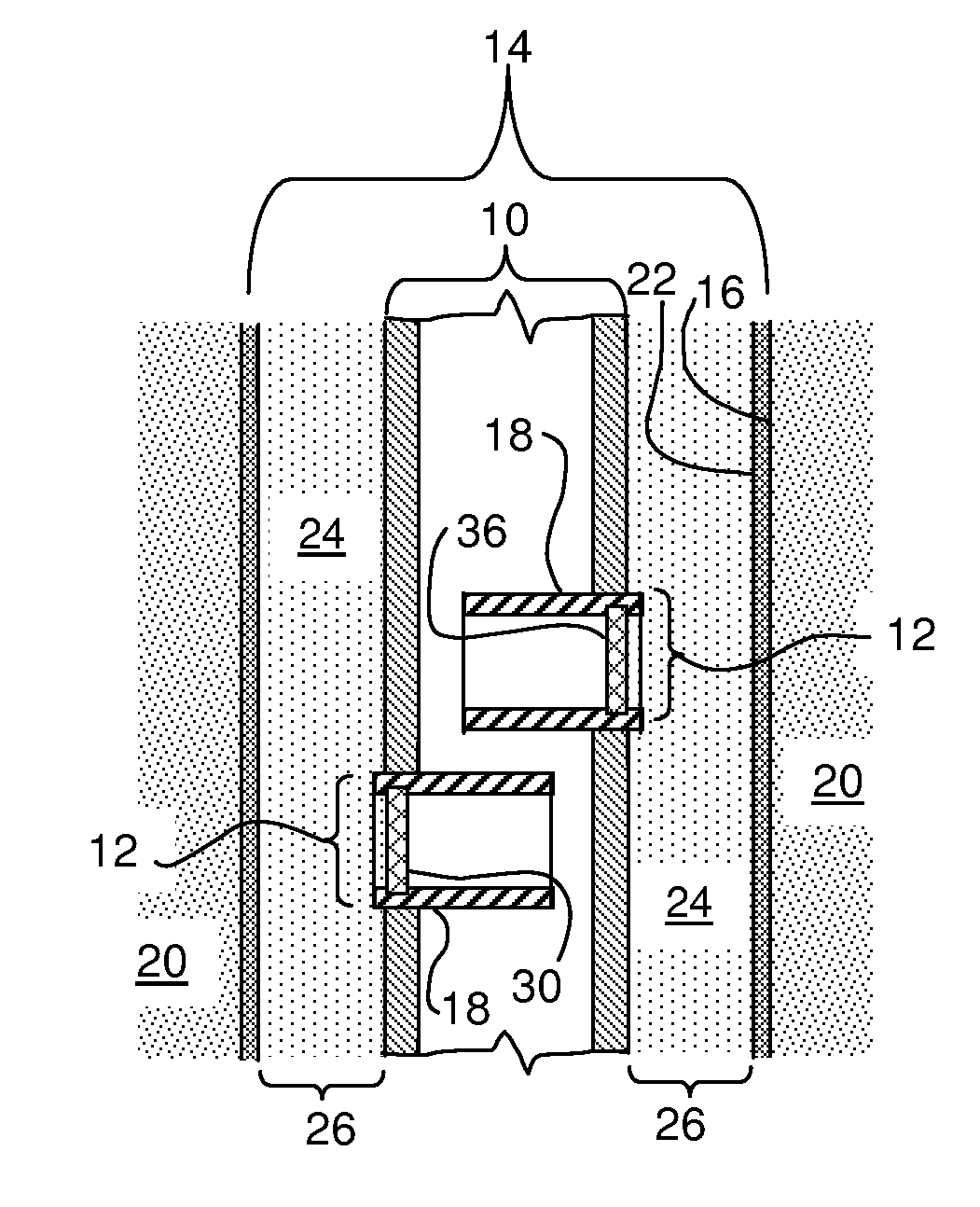

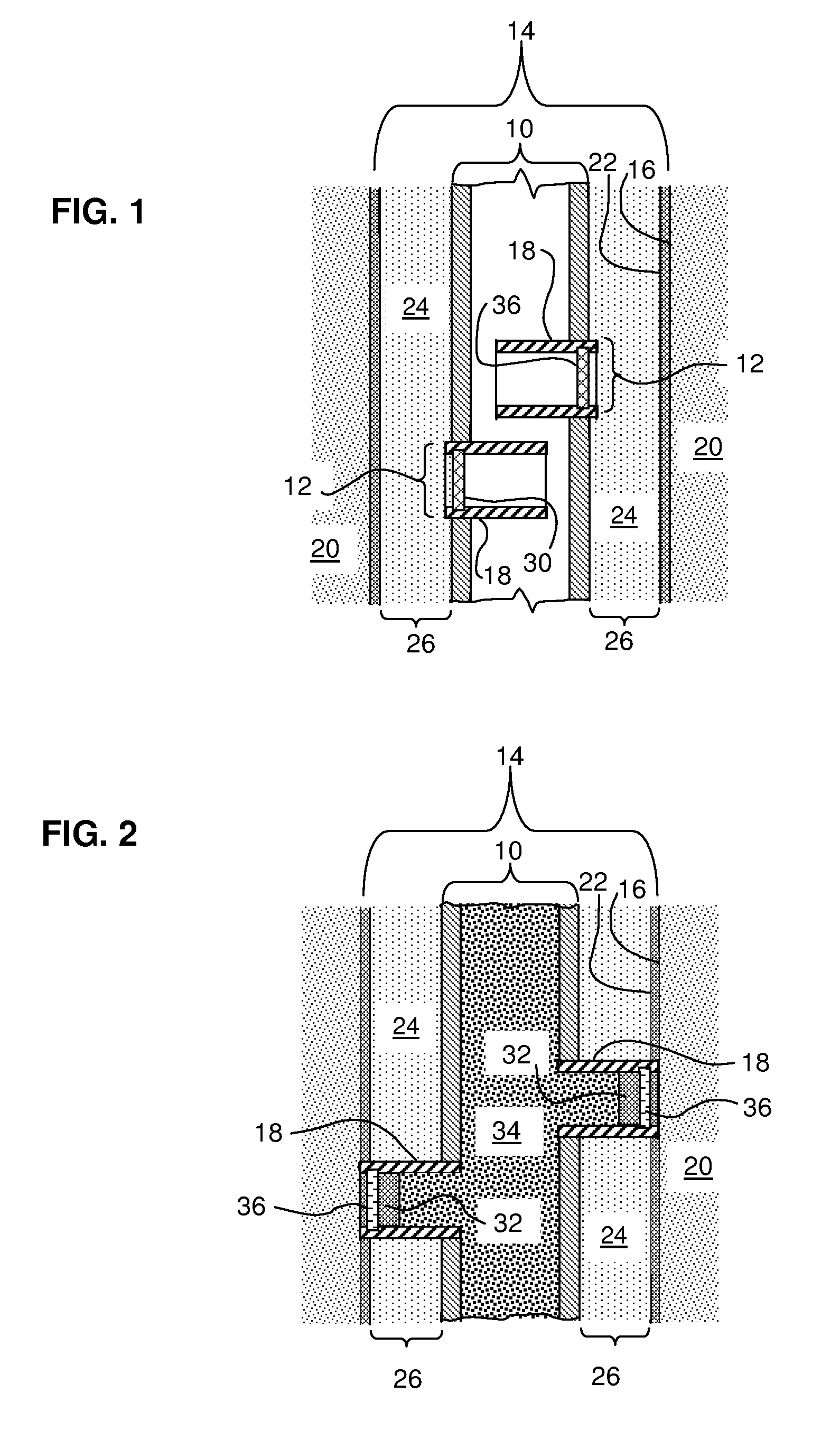

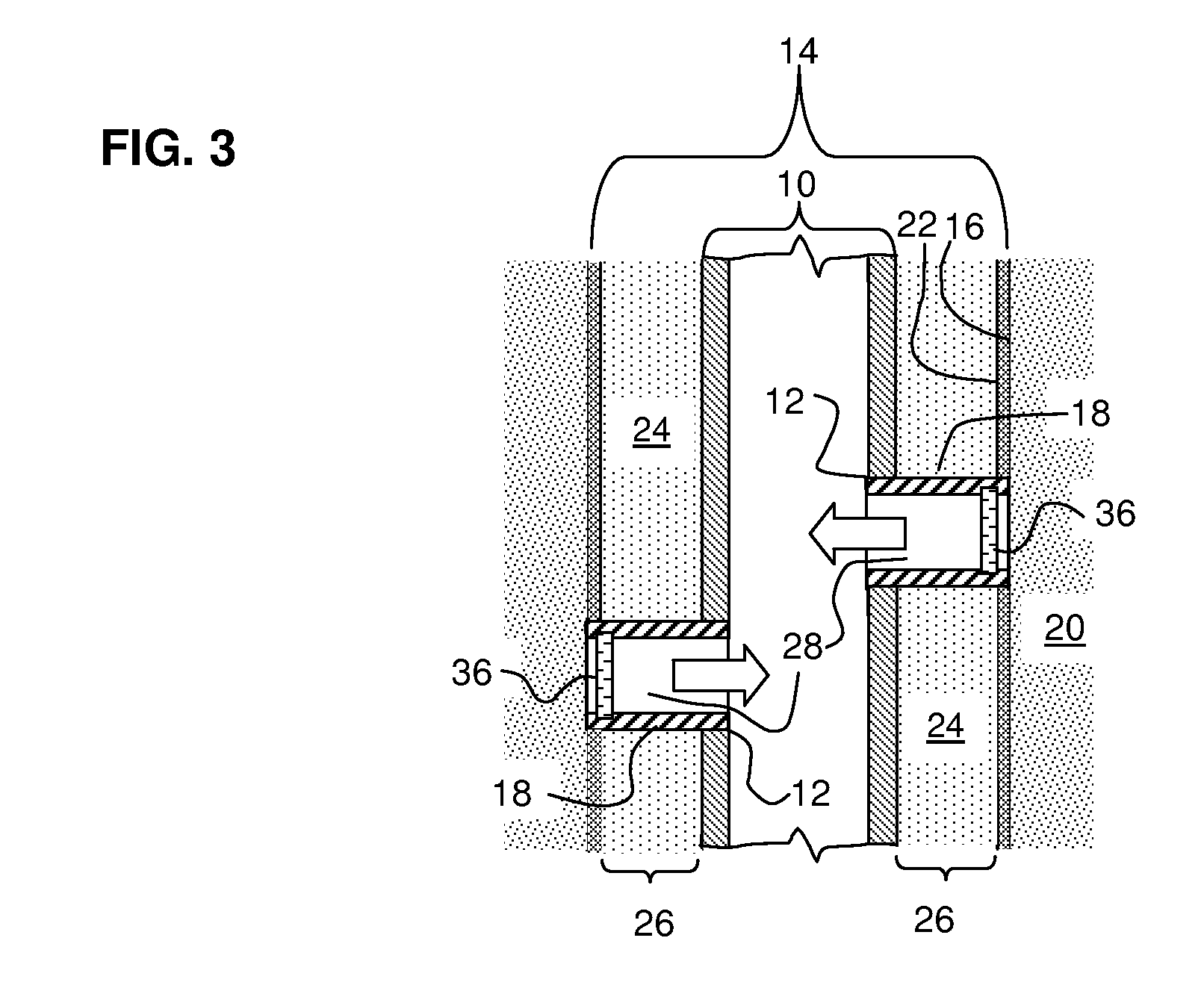

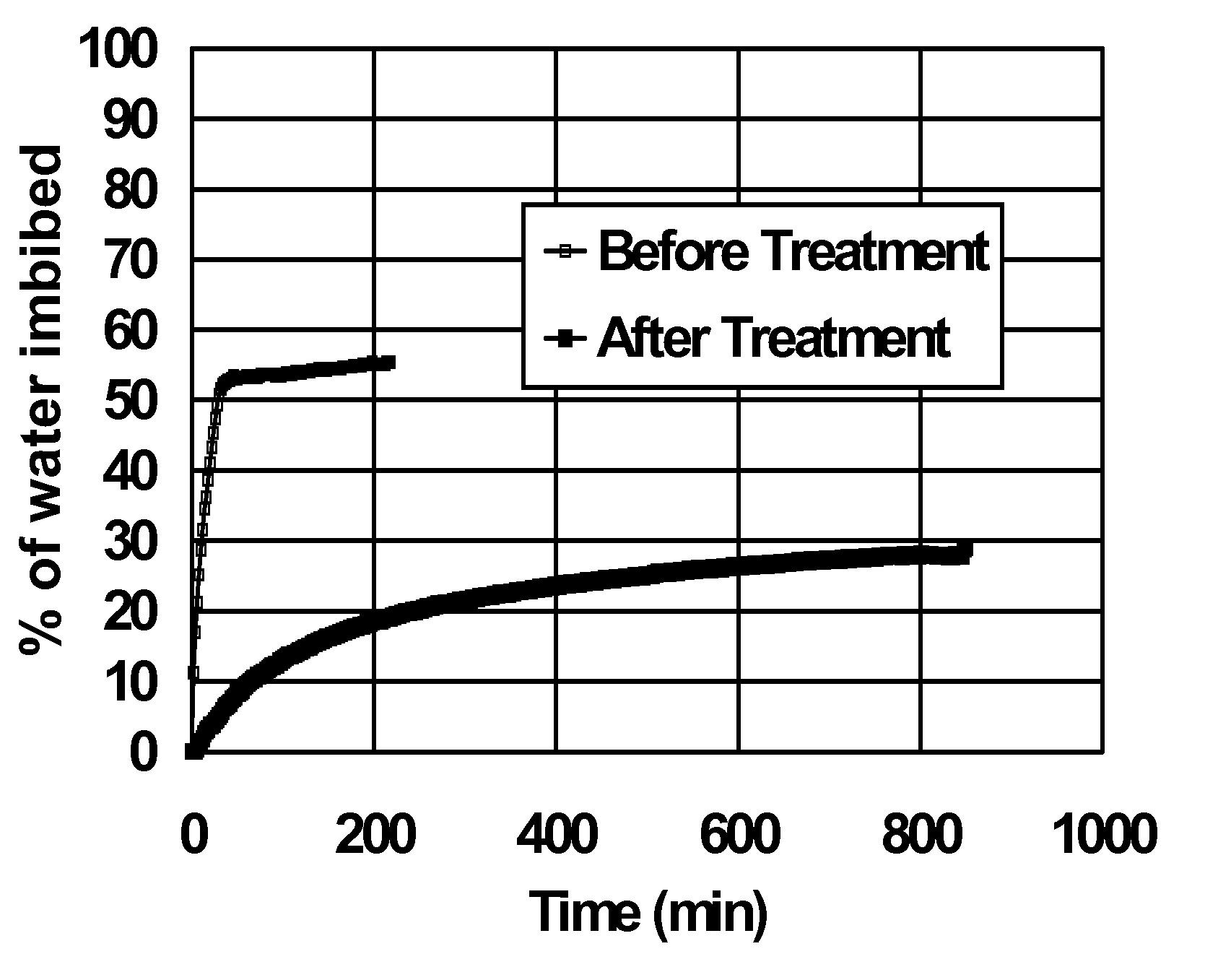

Product and process for coating wellbore screens

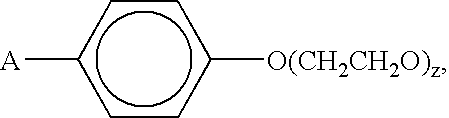

InactiveUS6394185B1Material efficiencyReduce interfacial tensionCleaning apparatusFluid removalEnzymeChemistry

Coatings for well screens that protect the screens from damage as they are inserted into the wellbore and once in the well, release reactive materials to react with and degrade potentially plugging materials such as drill solids, fluid filtercakes, fluid loss additives, and drilling fluids. The coatings can be specifically designed for individual well conditions and are comprised of a binder that either melts or dissolves within the wellbore and one or more reactive materials such as acids, enzymes, surfactants, chelants, oxidizers or free radical generators and the like which are released into the screen and the near wellbore area and which are effective in degrading or dissolving materials which could potentially plug the screen.

Owner:CONSTIEN VERNON GEORGE

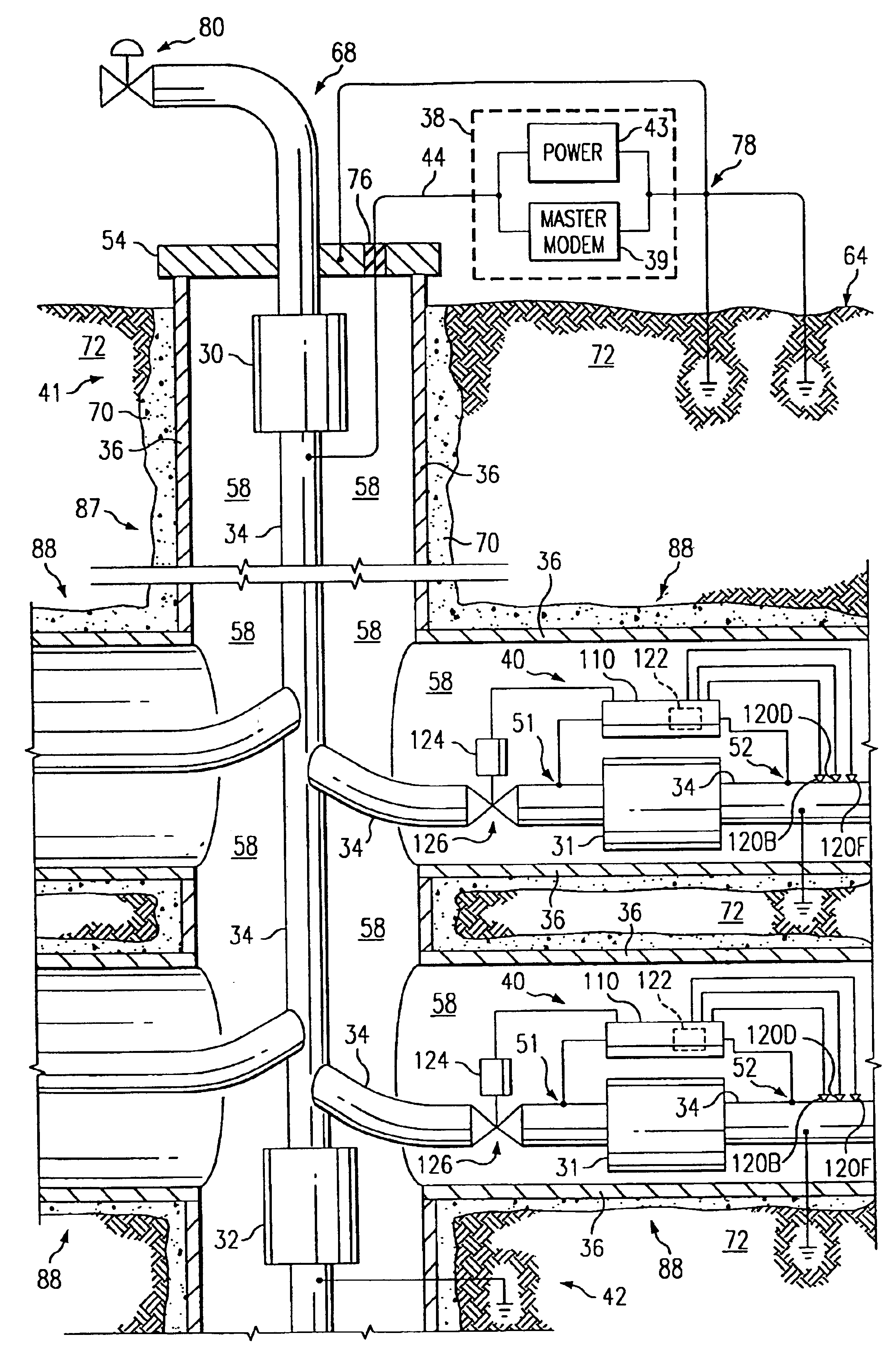

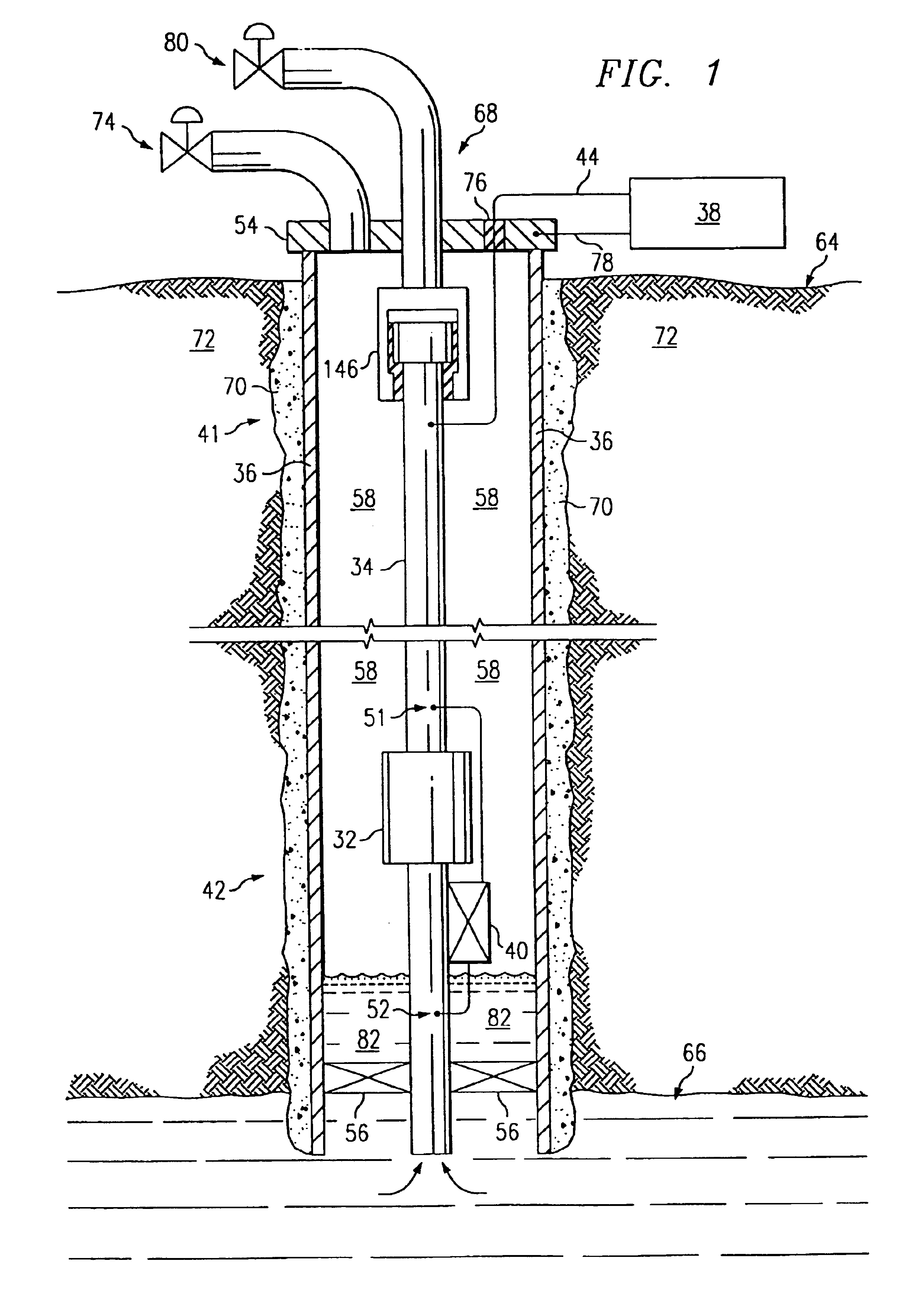

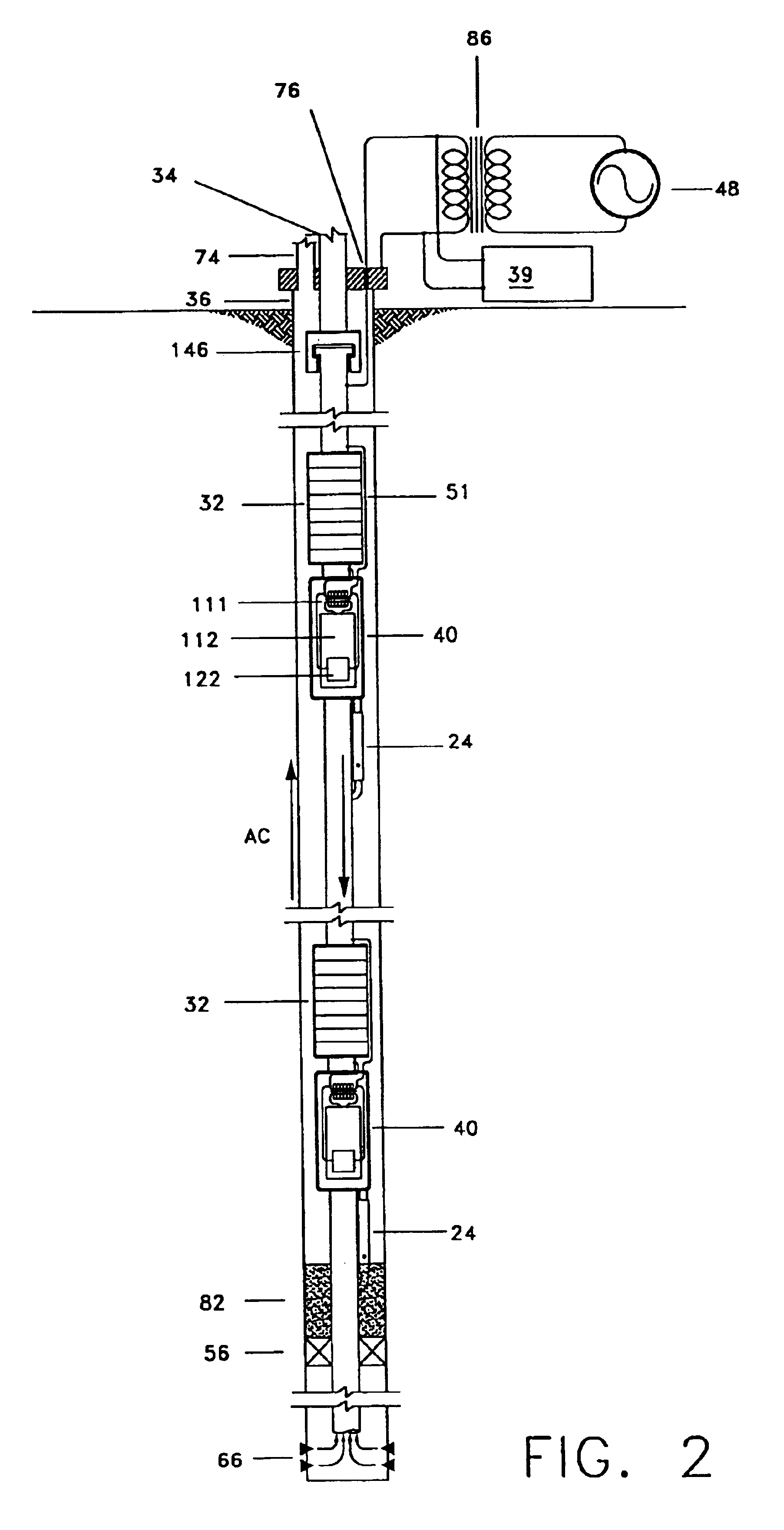

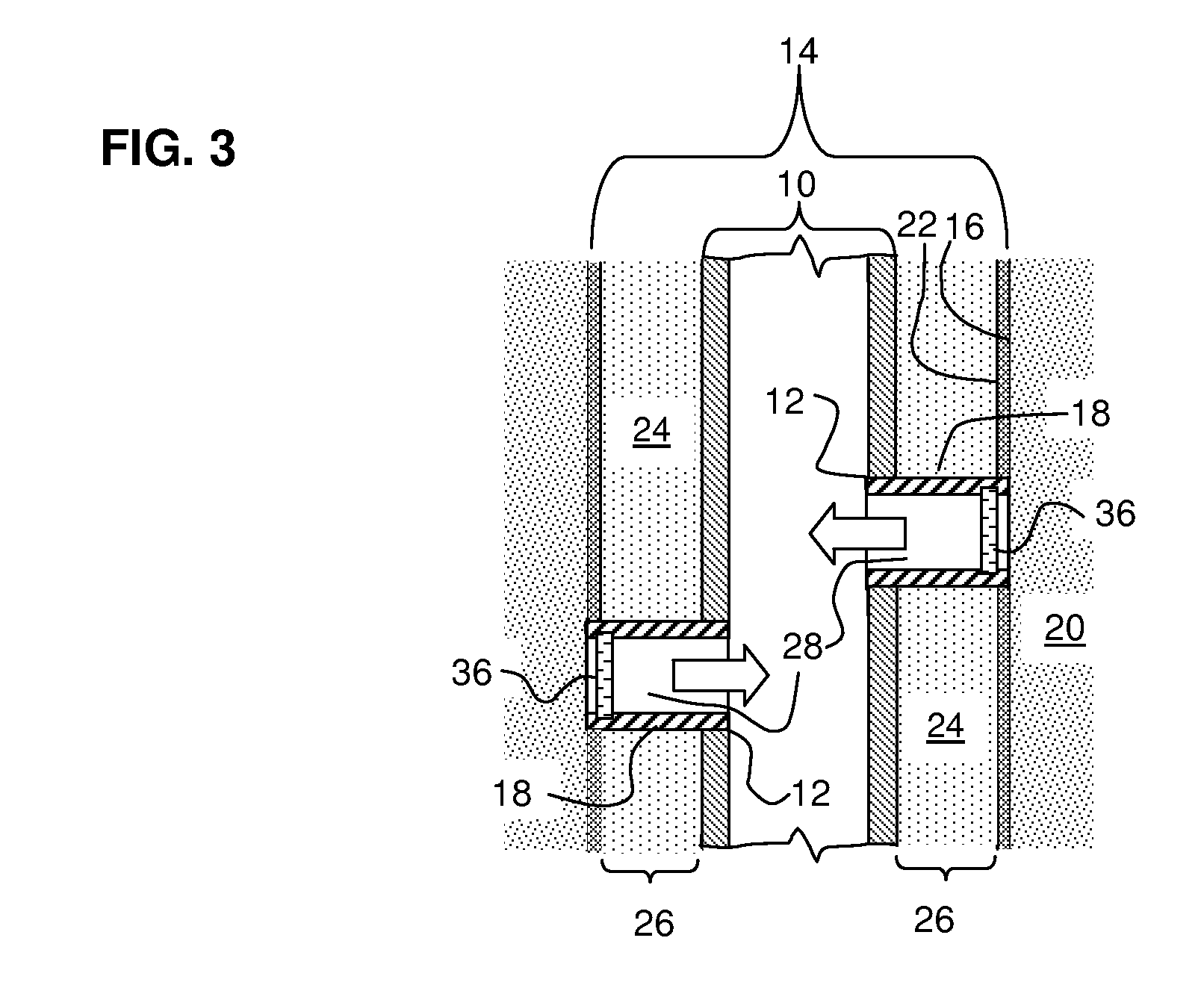

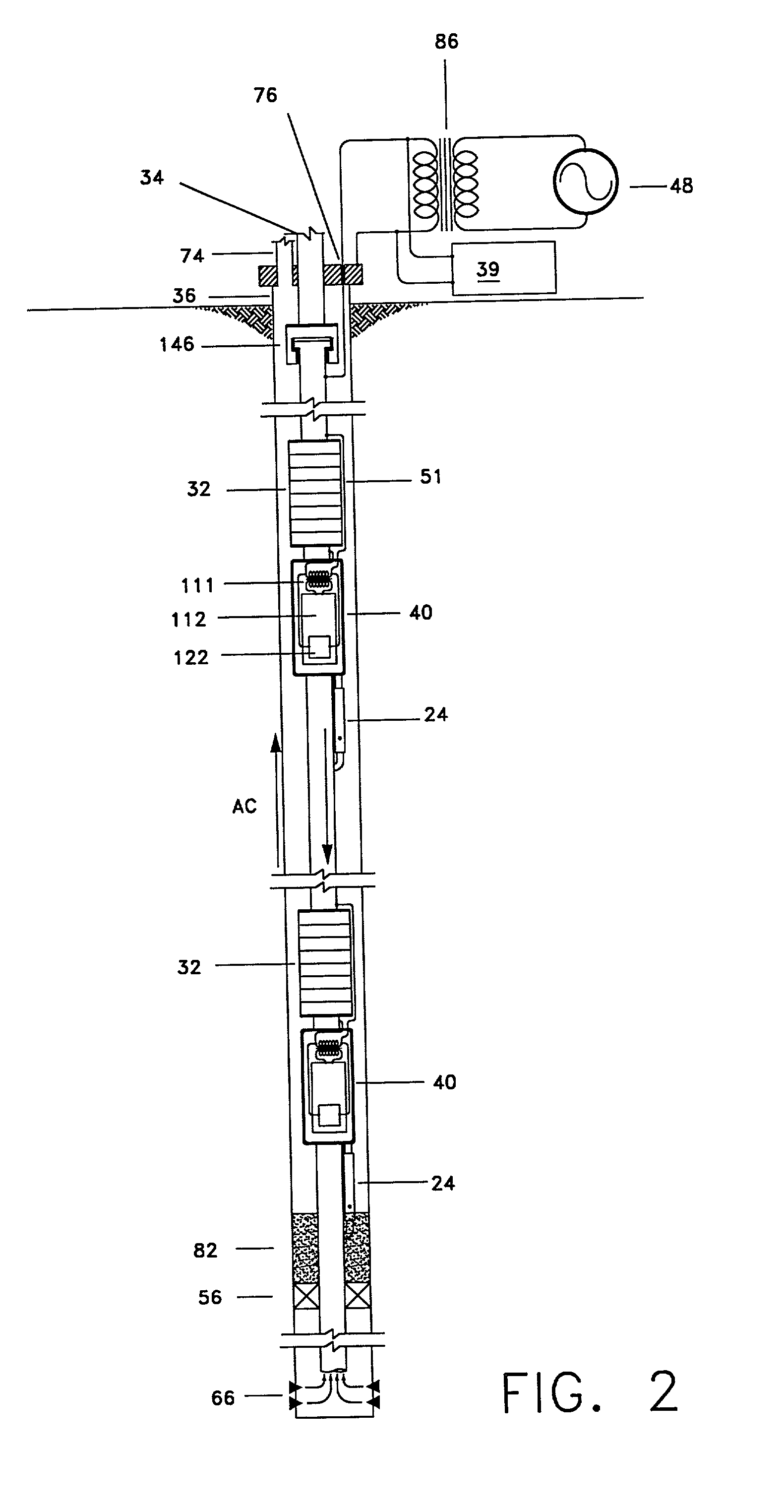

Permanent downhole, wireless, two-way telemetry backbone using redundant repeaters

A system and method of communicating among devices via a piping structure using at least one induction choke about the piping structure to route a time-varying current carrying communication signals between the devices. A communications system comprises a piping structure, a first communication device, a second communication device, and an induction choke. The piping structure comprises a first location, a second location, and an electrically conductive portion extending between the first and second locations. The first and second locations are distally spaced along the piping structure. The first and second communication devices are each electrically connected to the electrically conductive portion of the piping structure along the first location and second location, respectively, and each is adapted to send and receive communication signals via time-varying current. The induction choke is located about an electrically choked portion of the electrically conductive portion of the piping structure, such that the induction choke is adapted to route time-varying current within the piping structure between the electrical connection location for the first communication device and the electrical connection location for the second communication device, and such that the first communication device can communicate with the second communication device via the piping structure. A preferred application of the present invention is a well for producing petroleum products (e.g., oil, natural gas), comprising a communication system as described above.

Owner:SHELL OIL CO

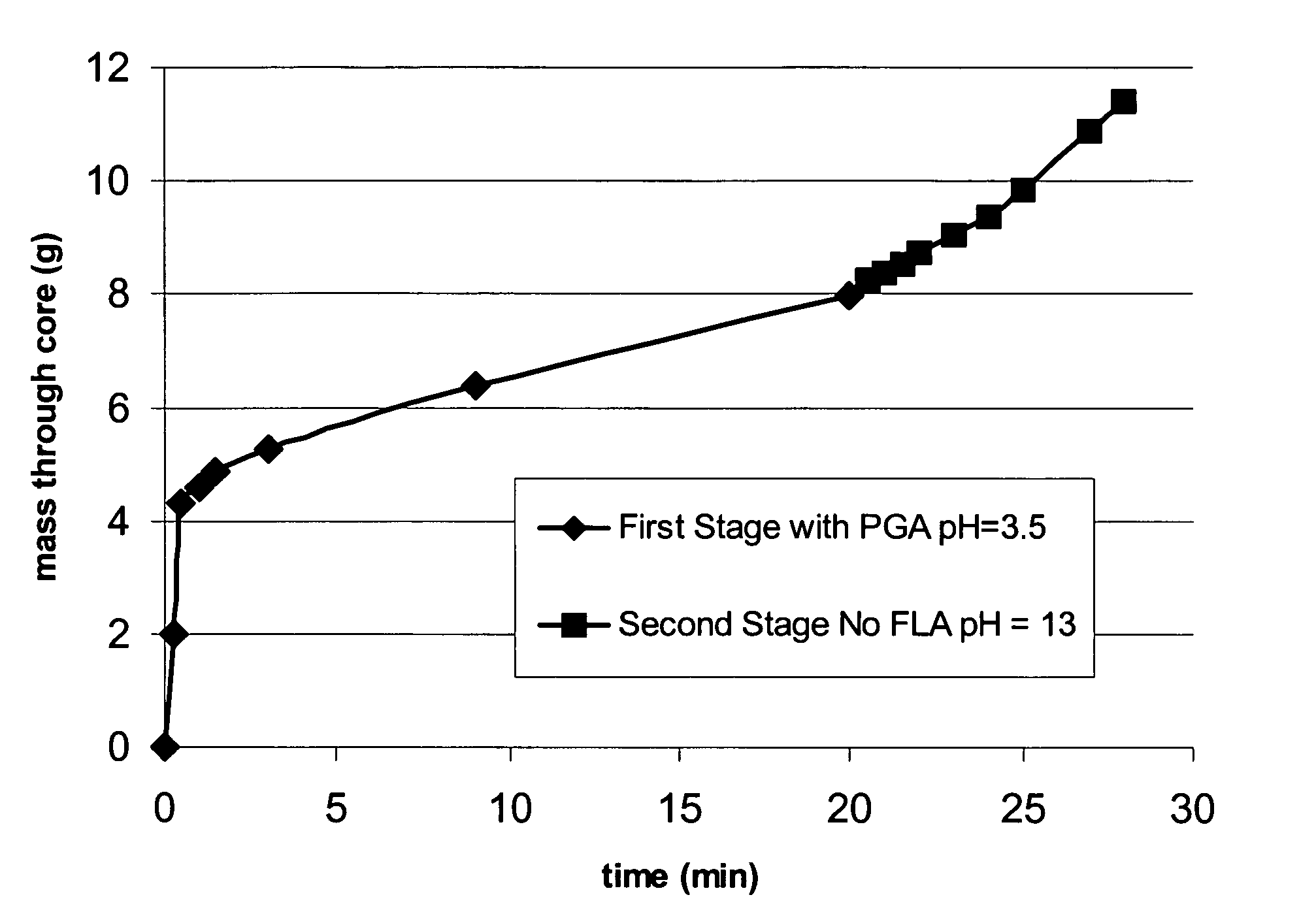

Acid coated sand for gravel pack and filter cake clean-up

InactiveUS20040055747A1Enhances filter cake removalSpeed up the flowCleaning apparatusFluid removalCarboxylic acidGlycollic acid

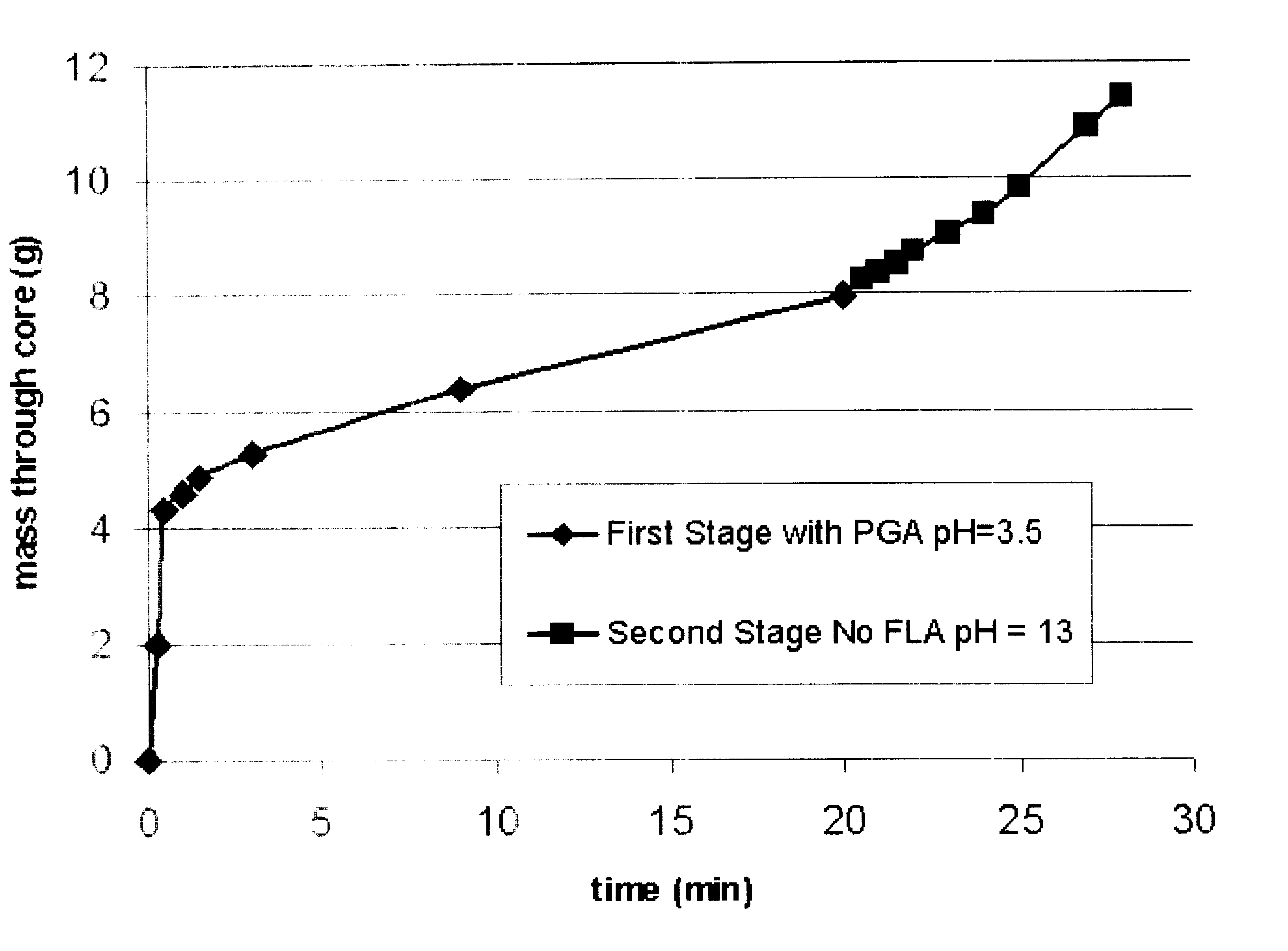

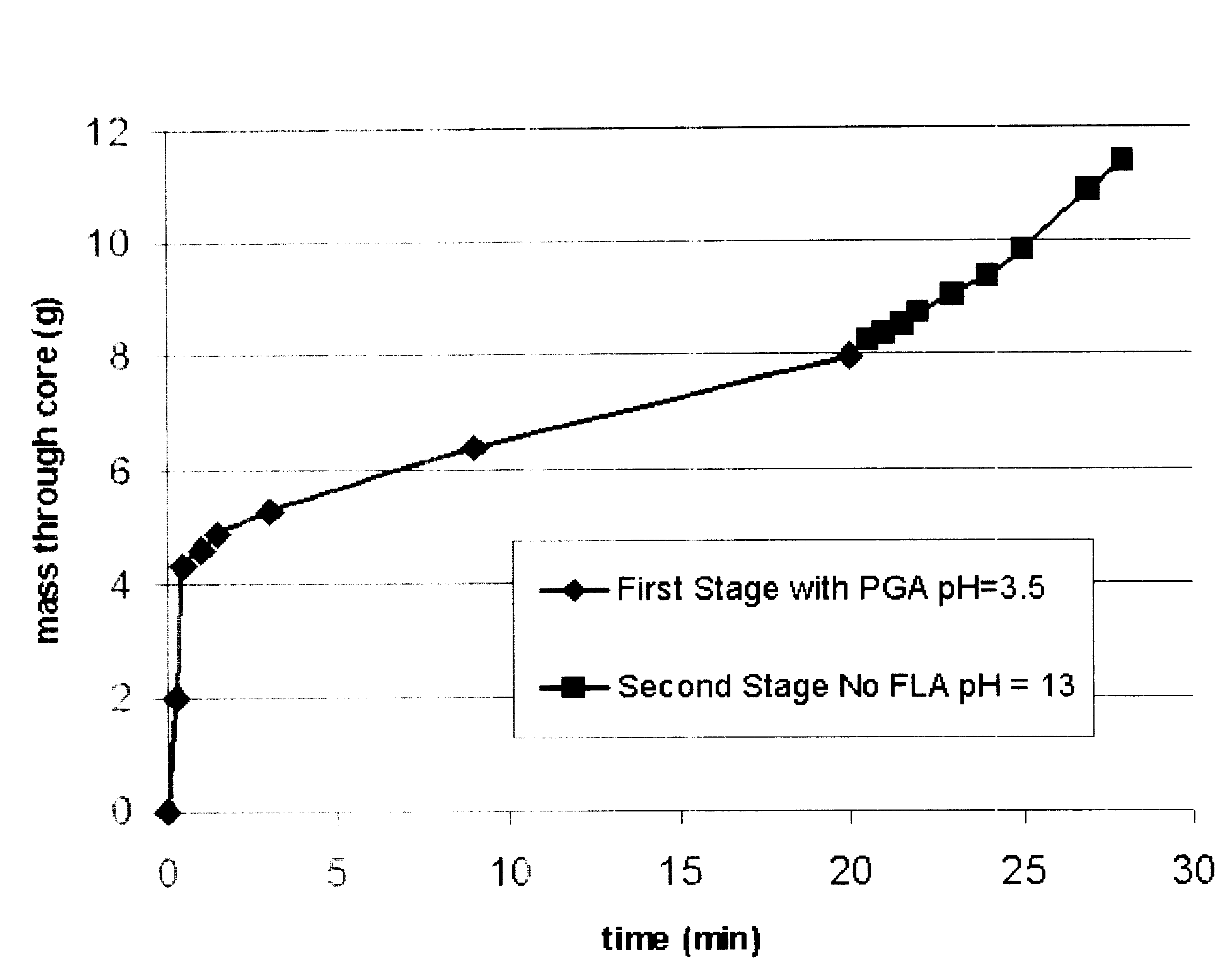

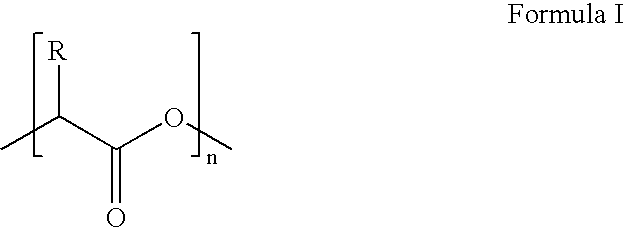

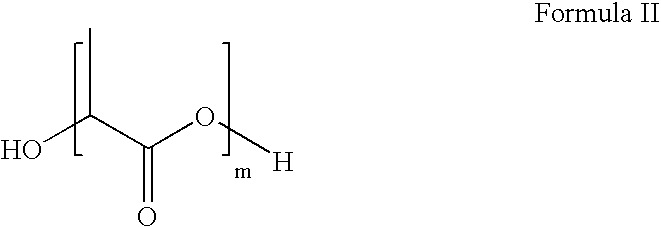

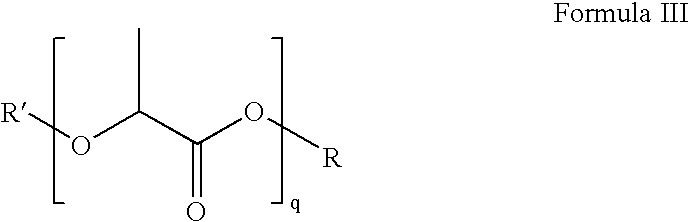

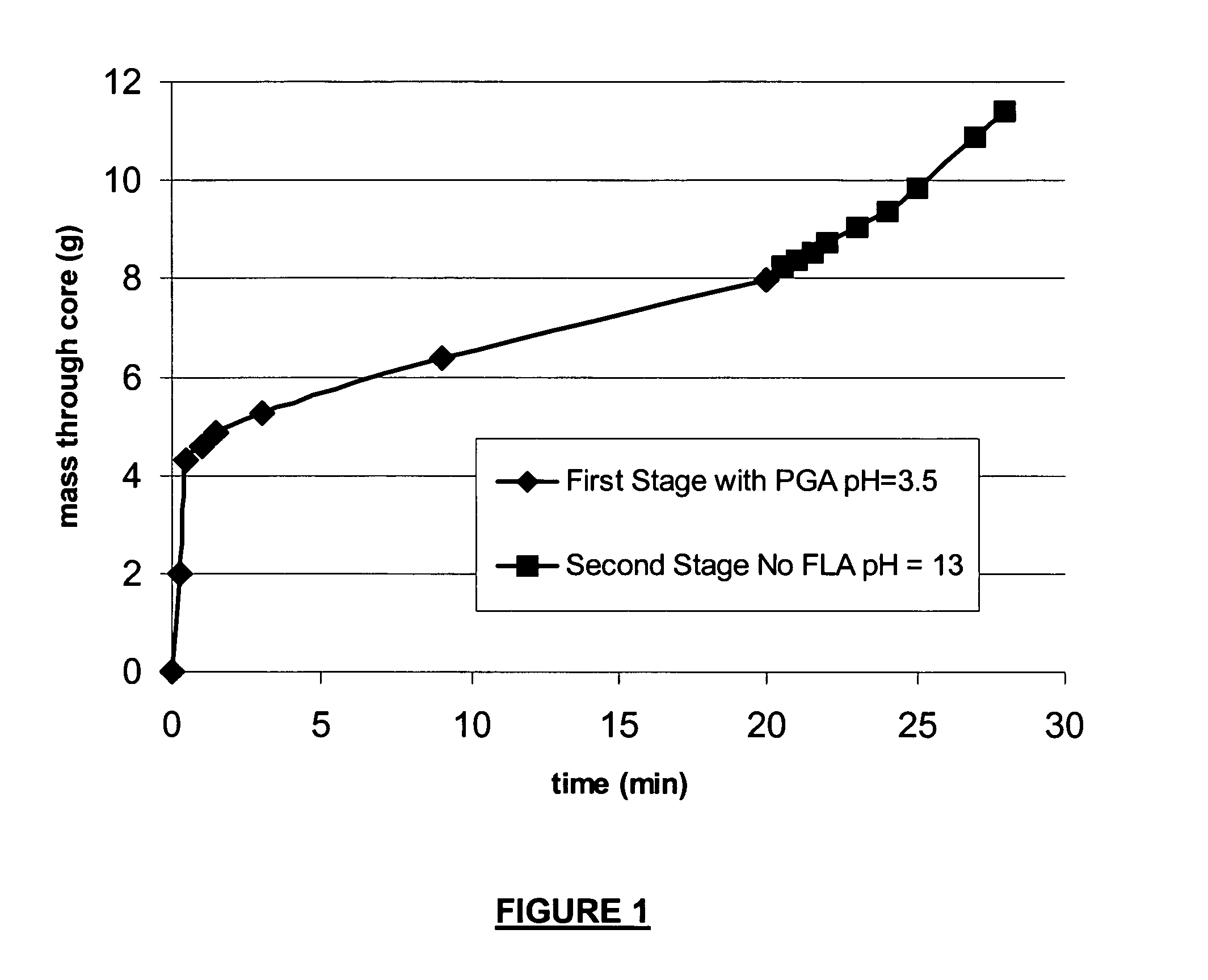

A method of the preparation and utilization of polymerized alpha-hydroxycarboxylic-acid-coated proppants for gravel pack and removal of filter cake that was deposited by reservoir drilling fluid. In a preferred example, polyglycolic-acid-coated sand is used to replace conventional gravel pack sand typically used for gravel packing. Under downhole conditions, the acidic by-product generated from the hydration of polyglycolic-acid-coated sand can break down acid-soluble and / or acid-breakable components embedded in the filter cake. This reaction enhances the filter cake removal and the flow of hydrocarbon from the producing formation. The polyglycolic-acid-coated sand may be produced by polymerizing a glycolic acid with a natural or synthetic proppant like 20-40 mesh commercial sand, at temperatures of about 210° F. or higher.

Owner:MI

Dissolving Filter Cake

InactiveUS20040094300A1Needed propertyWider fractureCleaning apparatusFluid removalSolid baseCarrier fluid

Methods are presented to induce a screenout during a subterranean formation fracturing or combined fracturing and gravel packing treatment having a viscoelastic surfactant-based carrier fluid by laying down a filter cake at least a portion of which is a base-soluble material, injecting proppant slurry, and causing hydrolysis and dissolution of the solid base-soluble material by adding base so that leak-off increases, the concentration of proppant in the fracture increases, and the proppant screens out. A method of gravel packing with a viscoelastic surfactant-based carrier fluid by laying down a filter cake at least a portion of which is a base-soluble material, injecting gravel, and causing hydrolysis and dissolution of the solid base-soluble material by adding base. Methods of slowing or accelerating the hydrolysis and dissolution are given, and addition of bridging-promoting materials is included.

Owner:SCHLUMBERGER TECH CORP

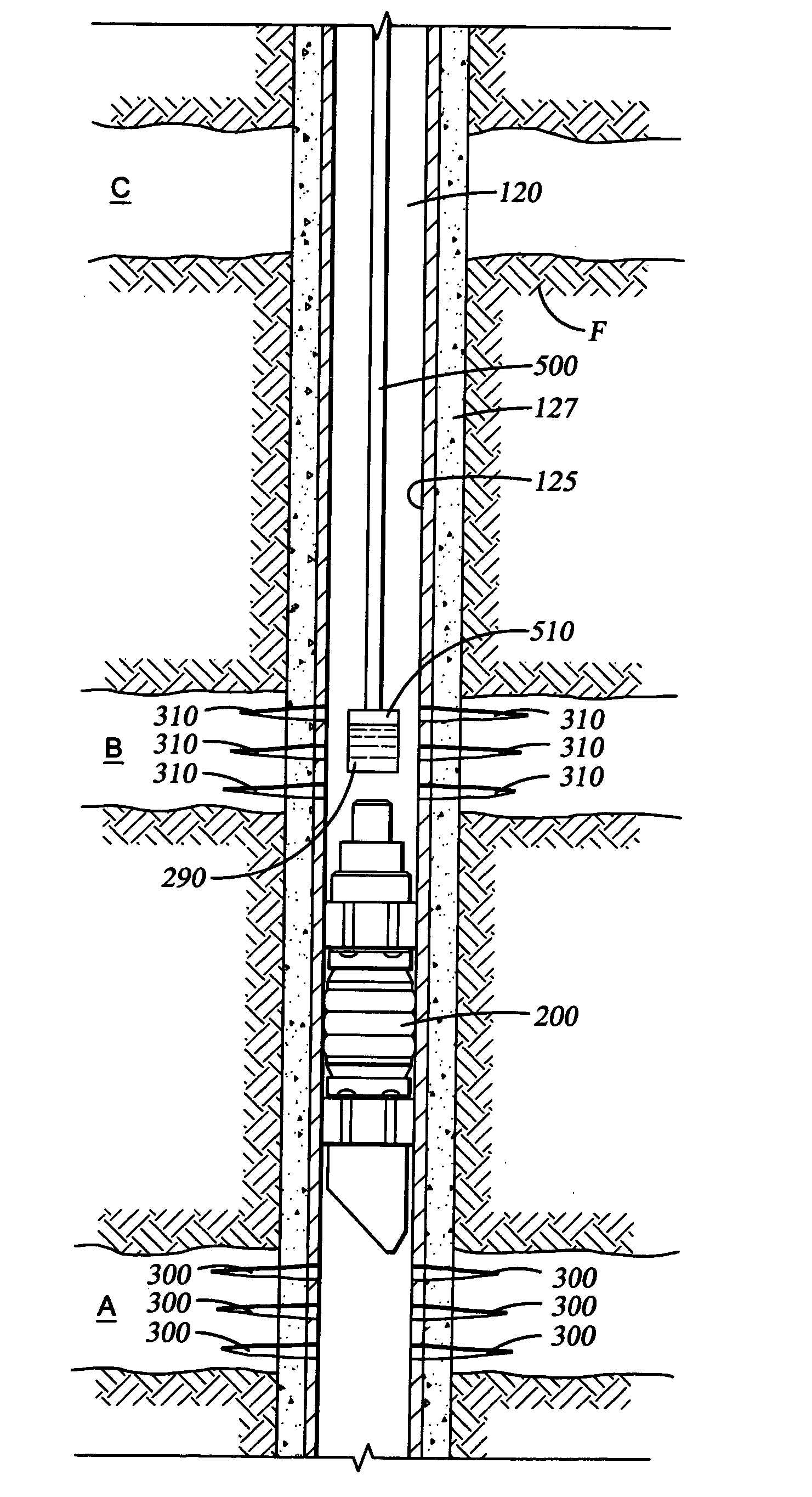

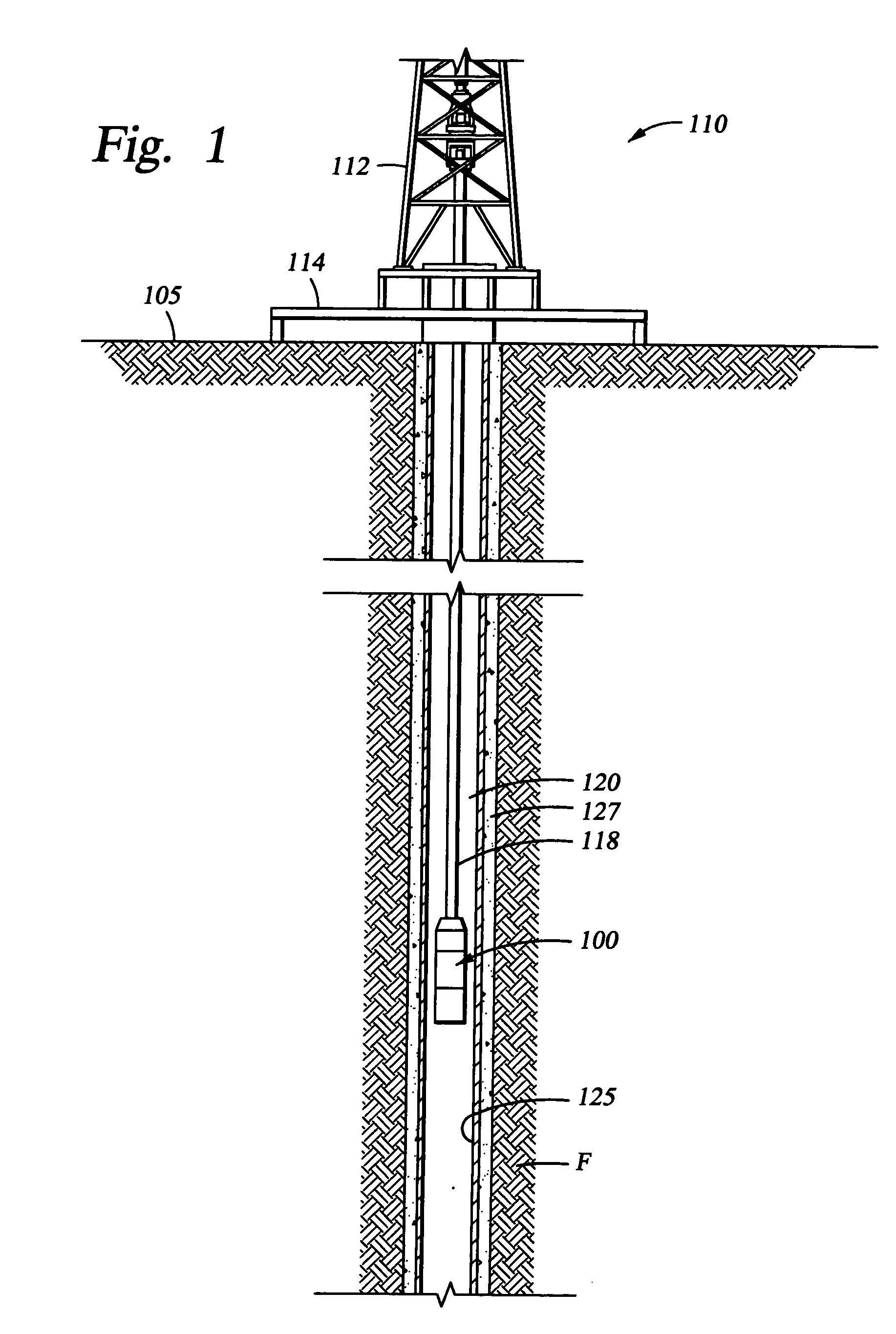

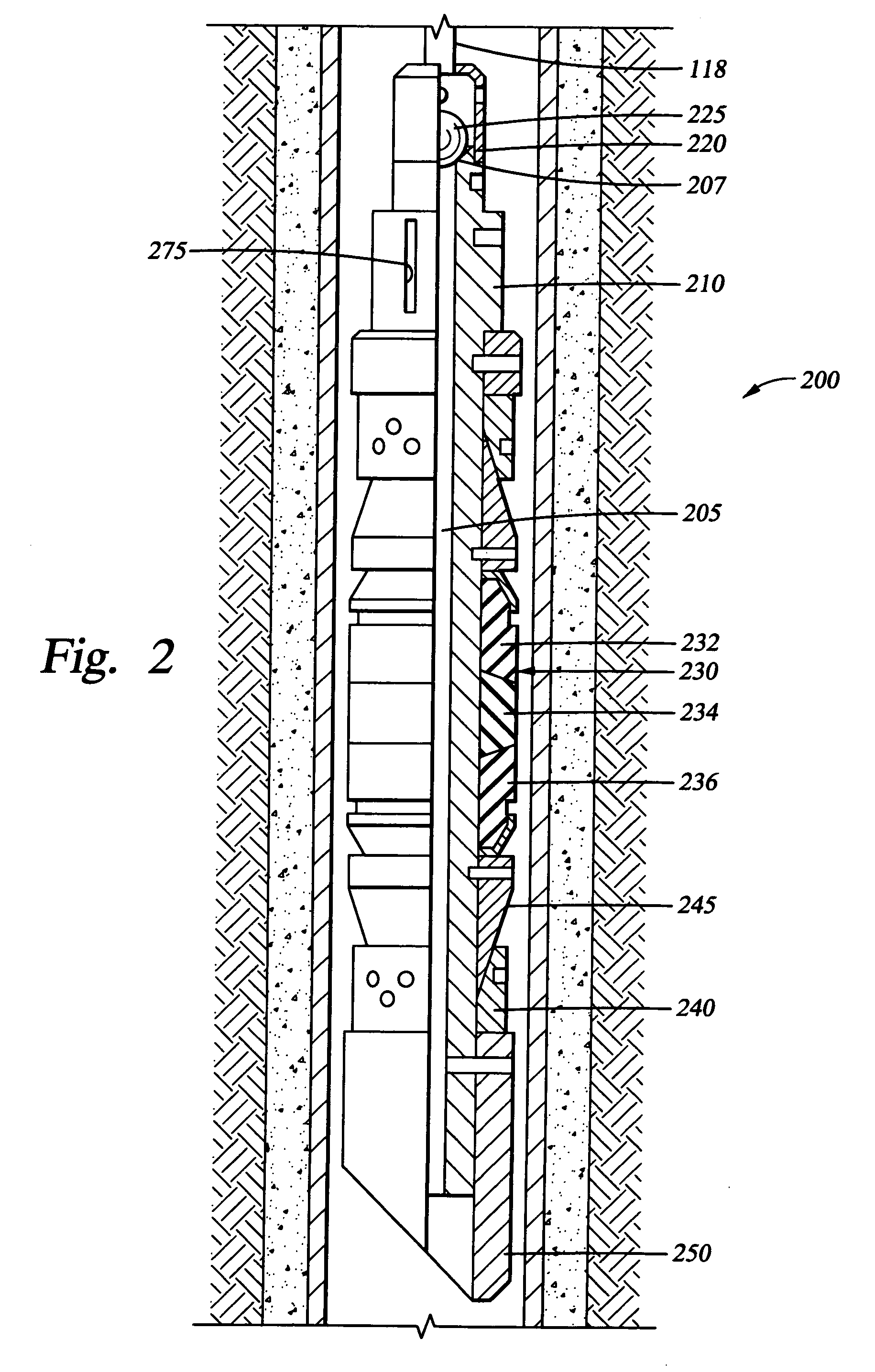

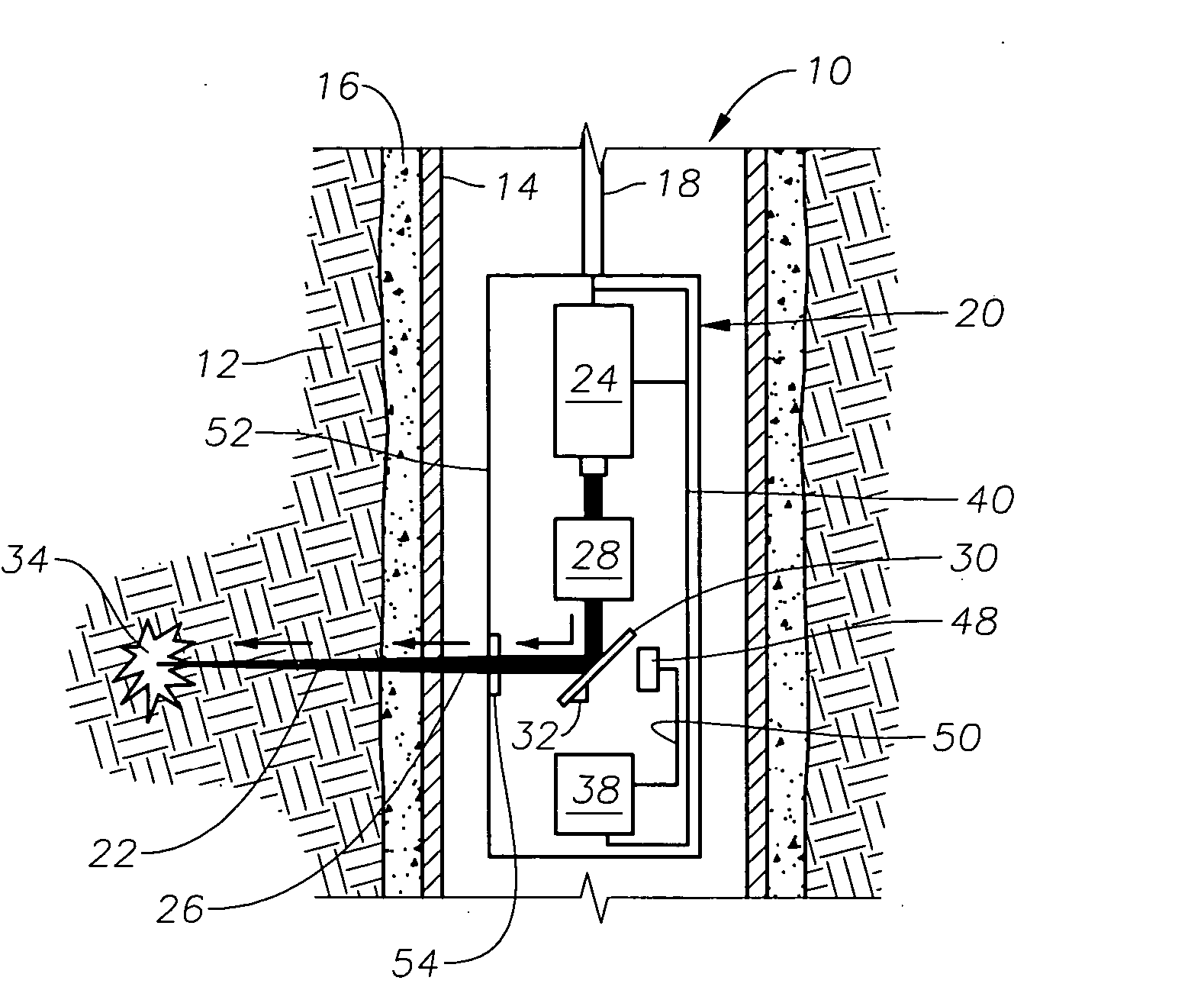

Drilling, perforating and formation analysis

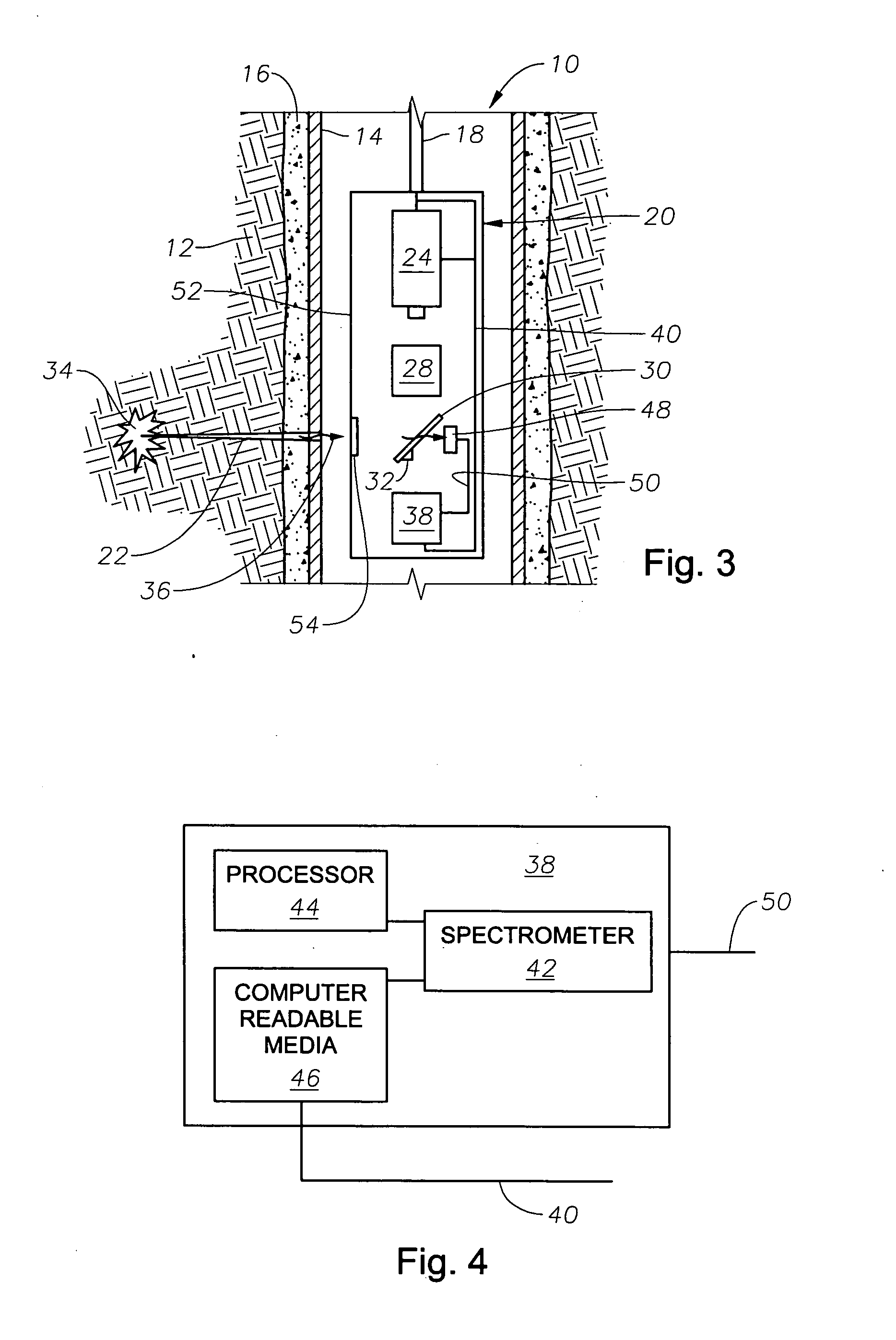

ActiveUS20060102343A1Easy to useImprove breathabilitySpectrum investigationConstructionsMaterial removalWell drilling

A system and method of drilling and / or perforating uses a laser beam to remove material, such as to perforate the casing, cement and formation or drill a well bore. The system and method can further or alternately encompass material analysis that can be performed without removing the material from the well bore. The analysis can be performed apart from or in connection with drilling operations and / or perforating the casing, cement and formation. The analysis can be used in a feed back loop to adjust material removal, adjust material analysis, determine the location of future material removal, and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

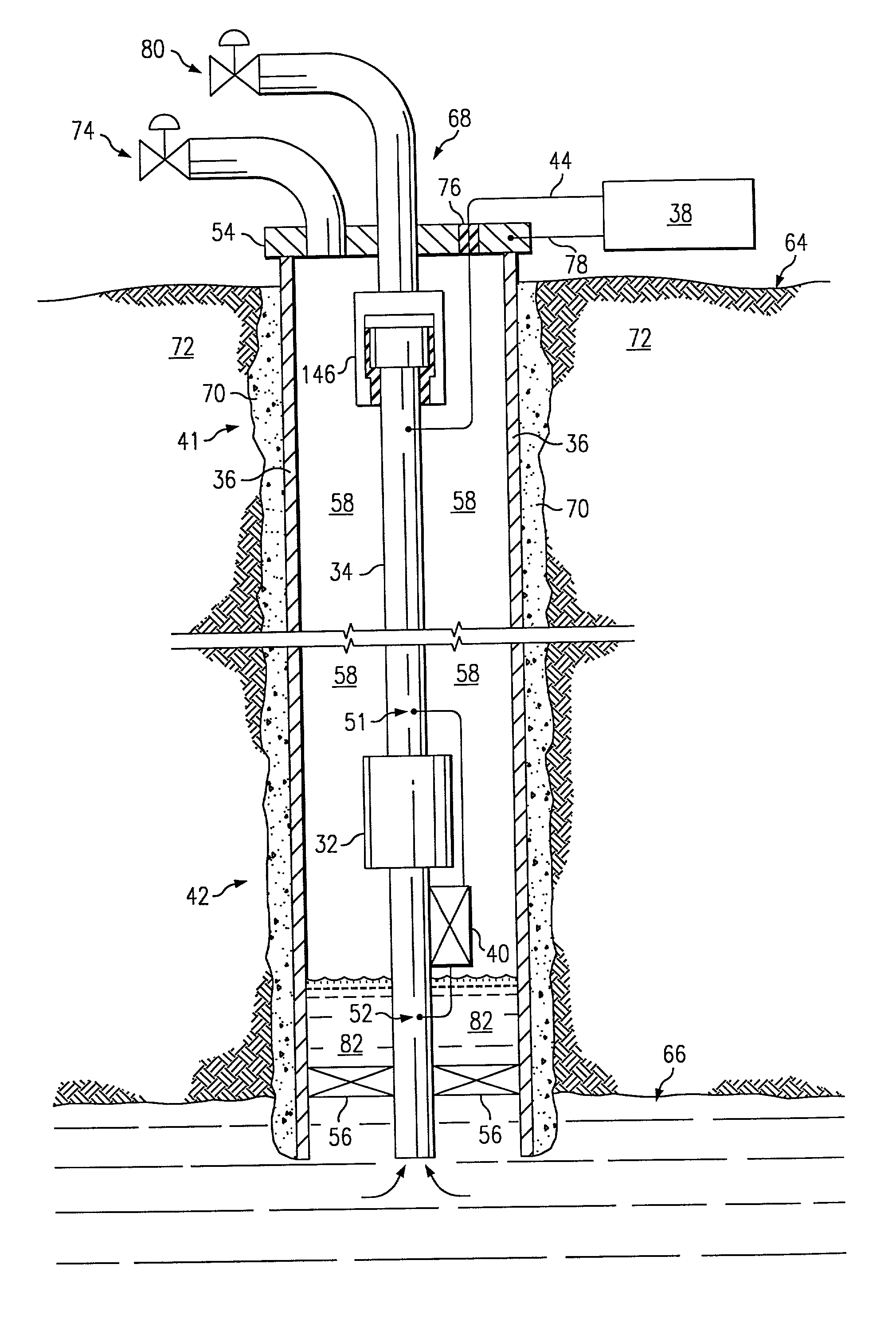

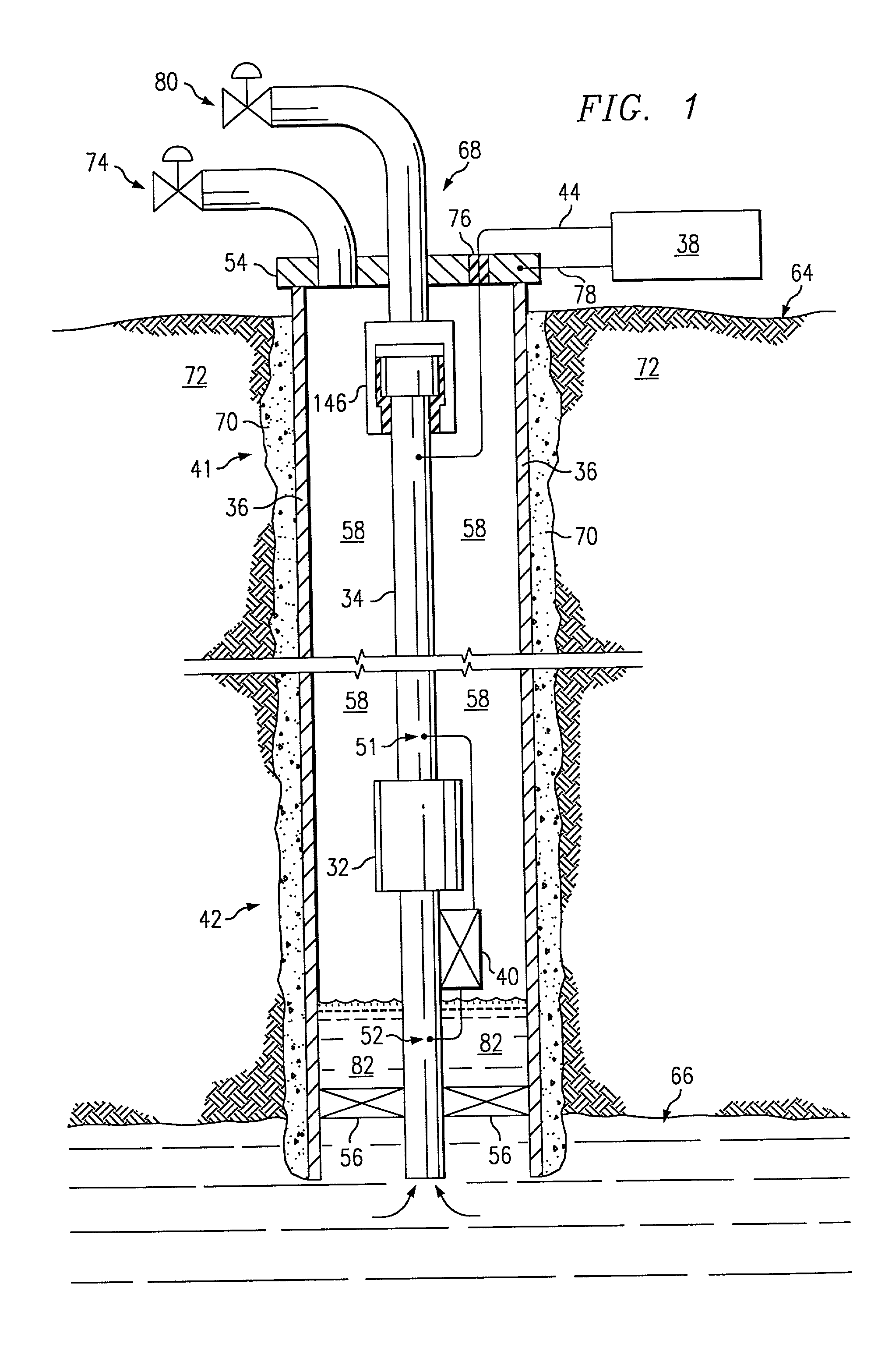

Controlled downhole chemical injection

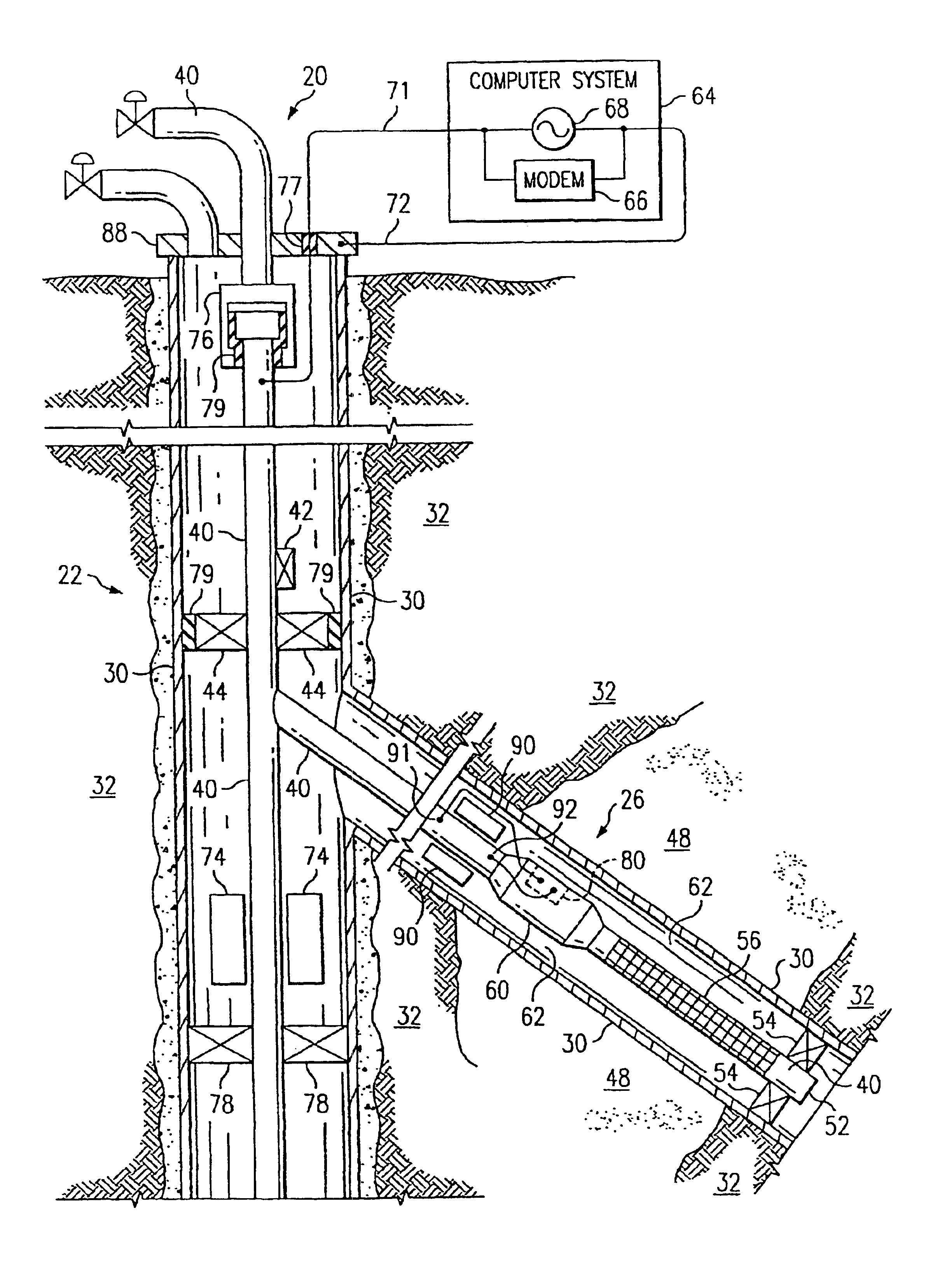

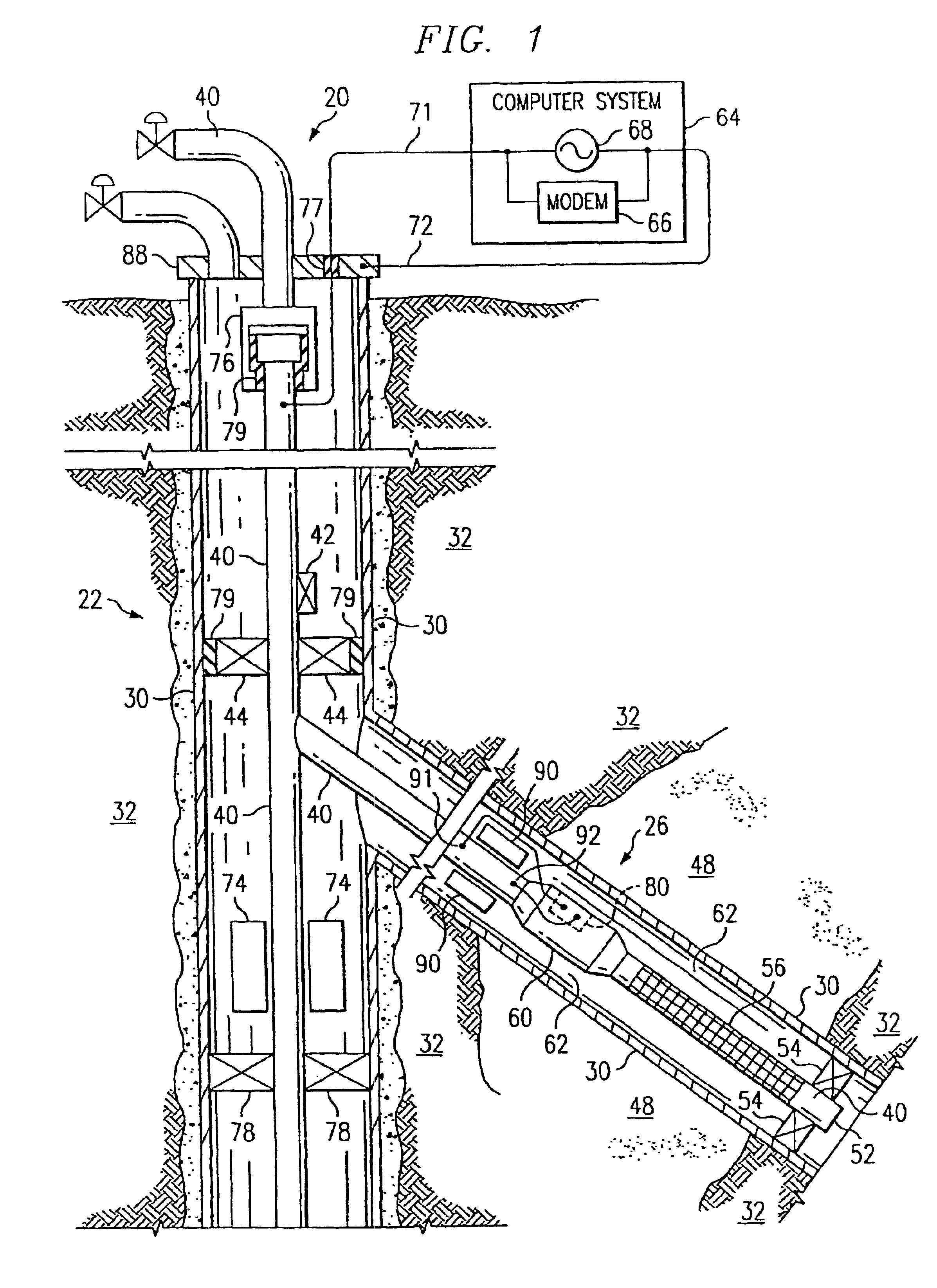

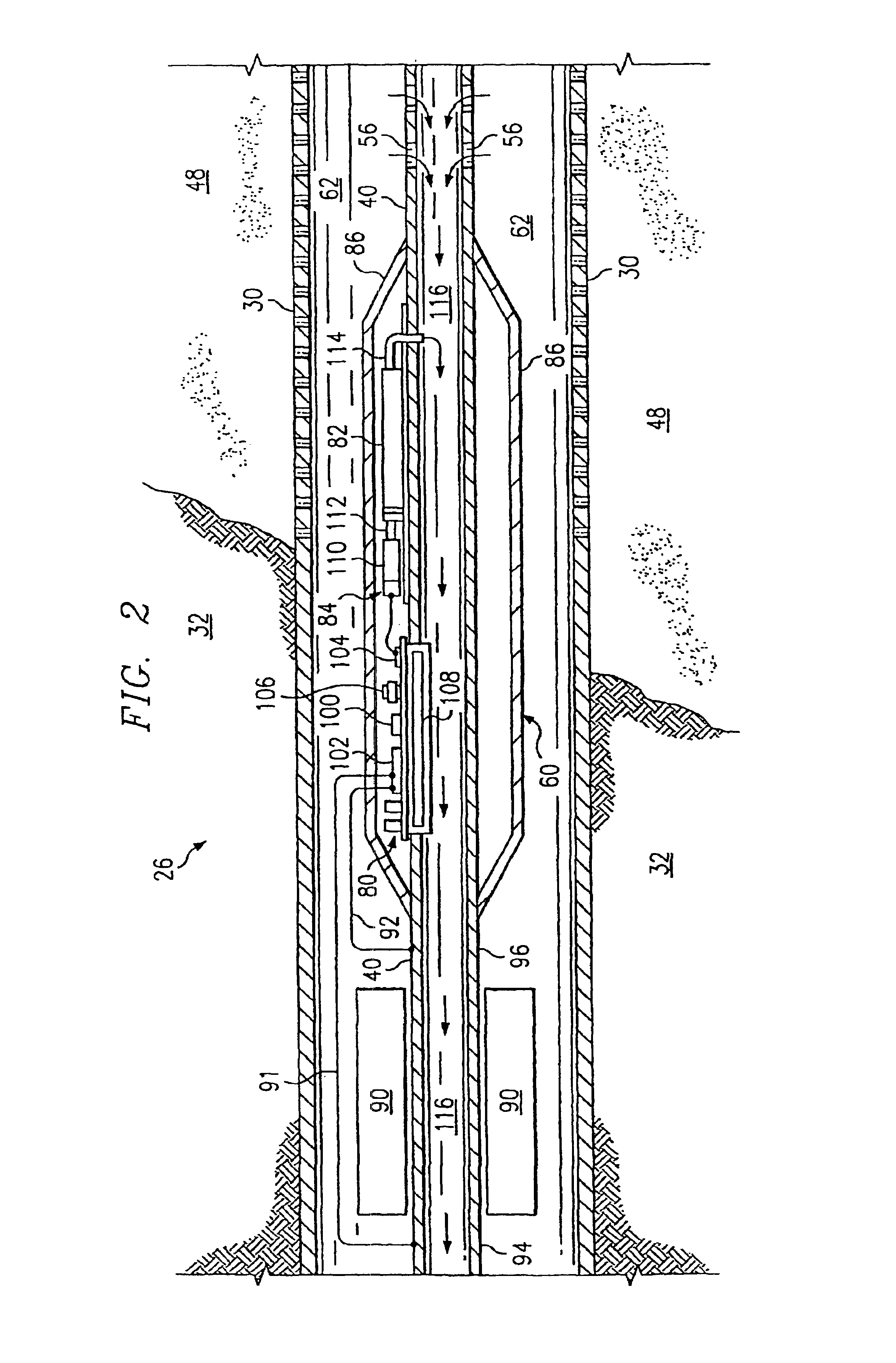

InactiveUS6981553B2Improve efficiencyImprove flow characteristicsNear-field transmissionSurveyElectrical conductorPetroleum

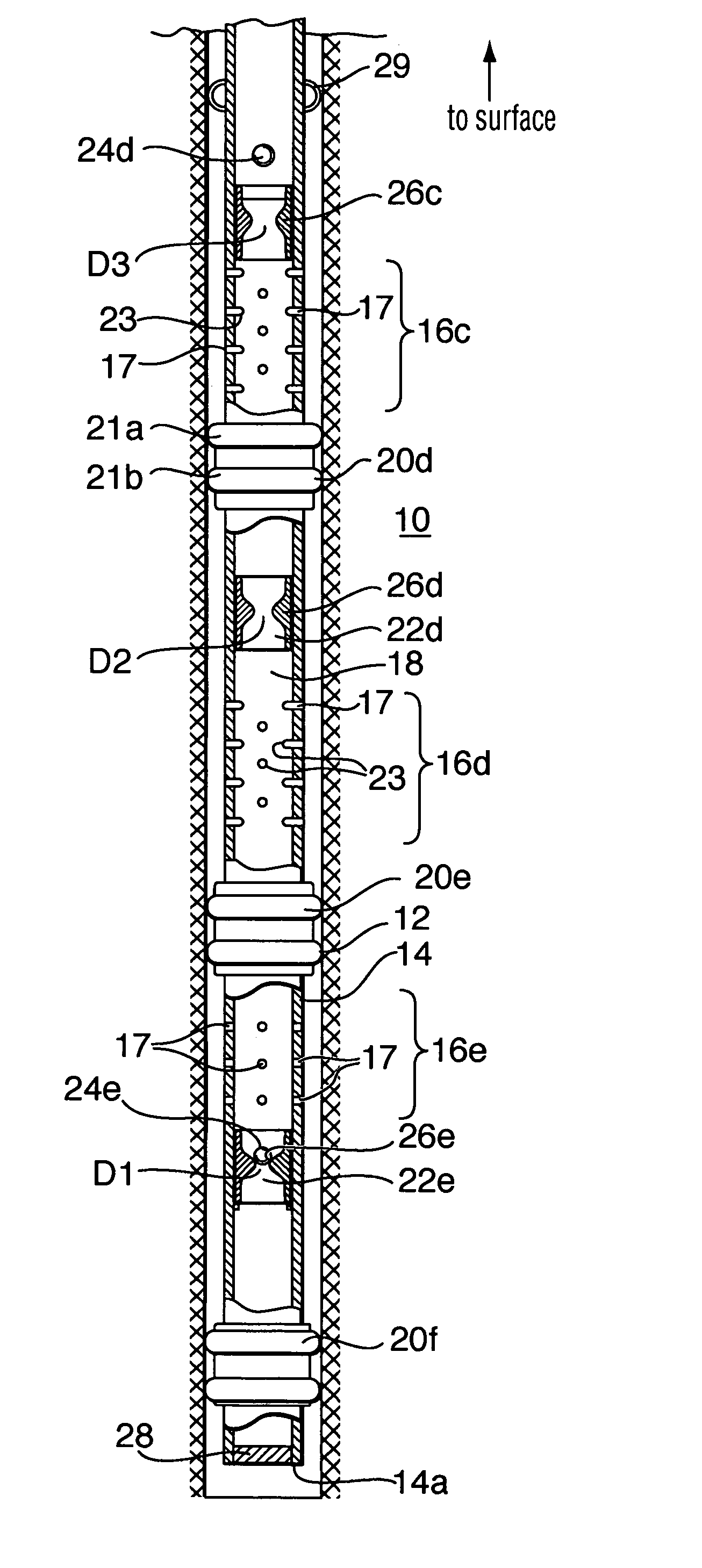

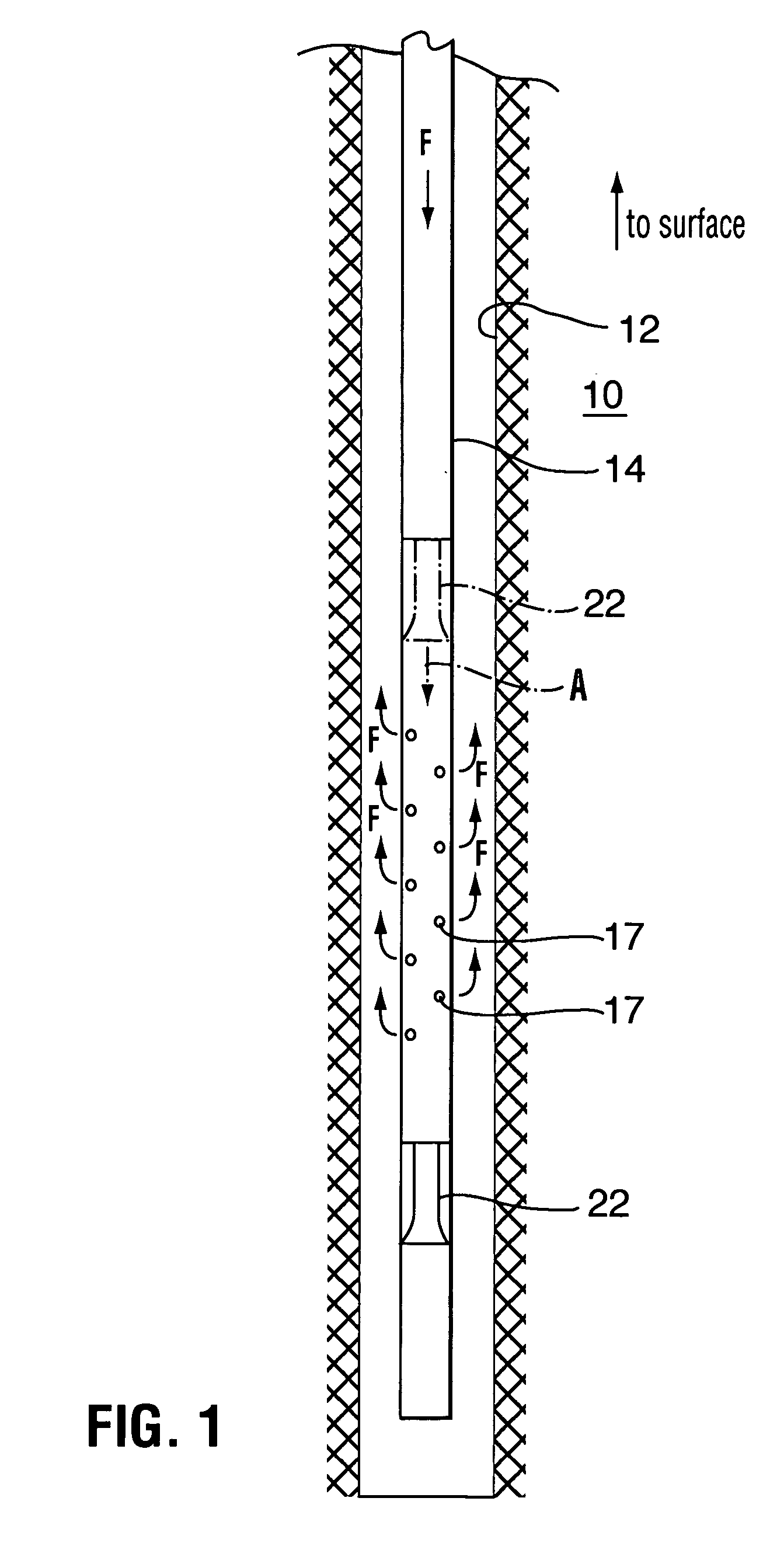

A petroleum well having a well casing, a production tubing, a source of time-varying current, a downhole chemical injection device, and a downhole induction choke. The casing extends within a wellbore of the well. The tubing extends within the casing. The current source is located at the surface. The current source is electrically connected to, and adapted to output a time-varying current into, the tubing and / or the casing, which act as electrical conductors for providing downhole power and / or communications. The injection device having a communications and control module, a chemical container, and an electrically controllable chemical injector. The communications and control module is electrically connected to the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The induction choke is adapted to route part of the electrical current through the communications and control module by creating a voltage potential between one side of the induction choke and another side of the induction choke. The communications and control module is electrically connected across the voltage potential. Also, a method is provided for controllably injecting a chemical into the well downhole, which may be used to: improve lift efficiency with a foaming agent, prevent deposition of solids with a paraffin solvent, improve a flow characteristic of the flow stream with a surfactant, prevent corrosion with a corrosion inhibitor, and / or prevent scaling with scale preventers.

Owner:SHELL OIL CO

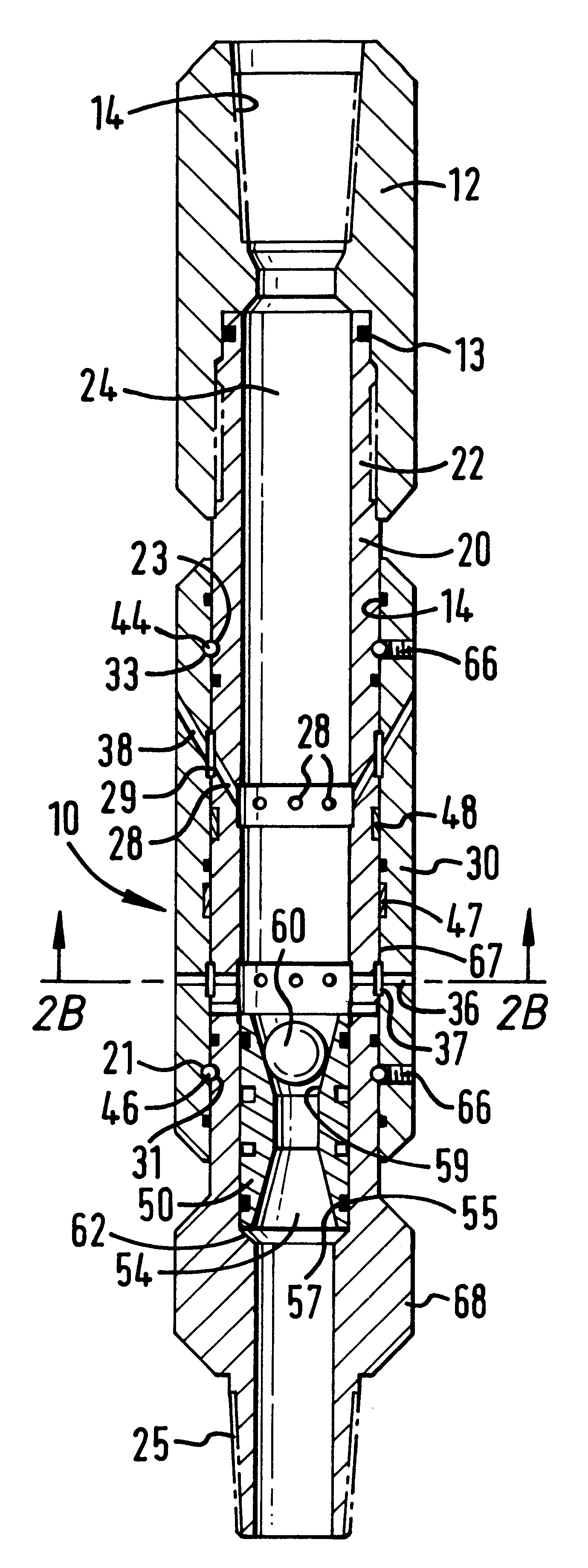

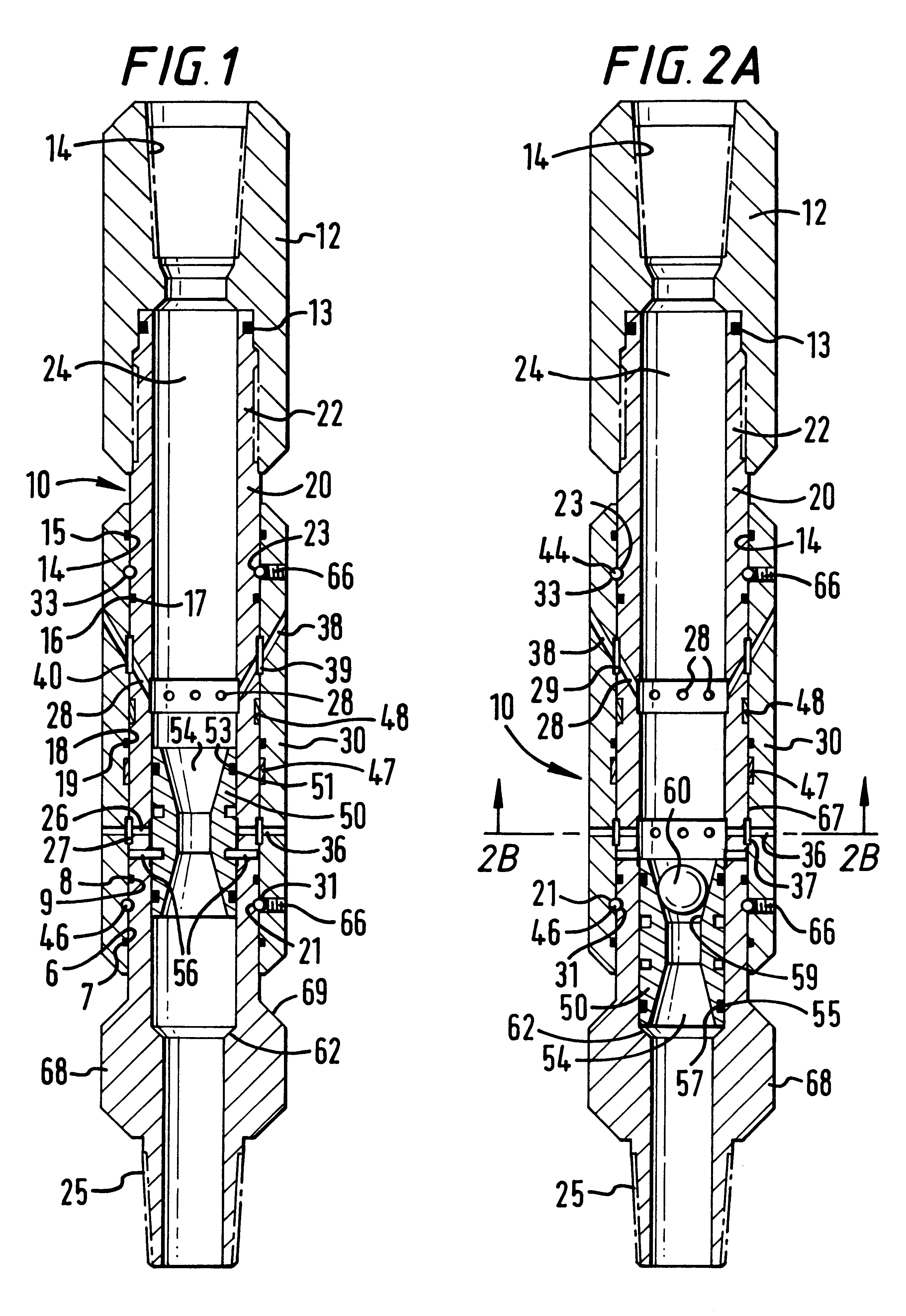

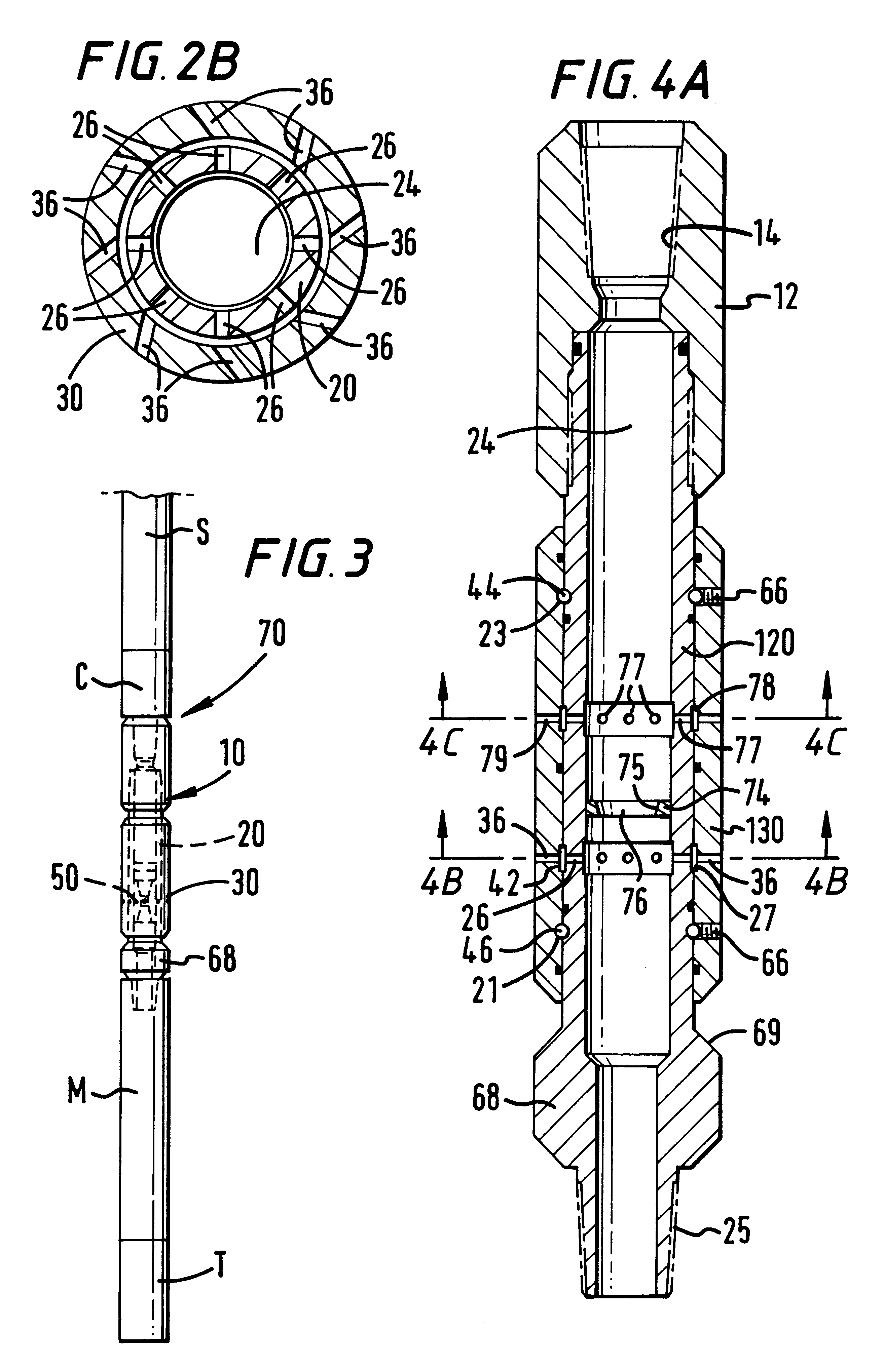

Wellbore wash nozzle system

A wash nozzle for wellbore washing operations has been invented, the wash nozzle, in one aspect having a central mandrel with a top, a bottom, and a fluid flow bore therethrough from top to bottom, at least one mandrel port through the central mandrel for fluid flow from within the central mandrel's fluid flow bore to an exterior of the central mandrel, a hollow sleeve rotatably mounted around the central mandrel, and at least one sleeve port through the sleeve for fluid flow from within the sleeve from the exterior of the central mandrel to an exterior of the sleeve, the at least one sleeve port defined by a wall on the sleeve. In one aspect the wash nozzle includes apparatus for selective rotation of the sleeve about the mandrel. In one aspect flow through the wash nozzle is stopped to effect sleeve rotation and, in one particular aspect, flow through the nozzle is then re-established. Methods have been invented using such wash nozzles for wellbore washing operations and / or cuttings removal.

Owner:WEATHERFORD TECH HLDG LLC

Methods of diverting treating fluids in subterranean zones and degradable diverting materials

ActiveUS7036587B2Readily apparentCleaning apparatusFluid removalParticulatesEnvironmental engineering

Owner:HALLIBURTON ENERGY SERVICES INC

Composition and process for well cleaning

Disclosed is a microemulsion well treatment microemulsion that is formed by combining a solvent-surfactant blend with a carrier fluid. In preferred embodiments, the solvent-surfactant blend includes a surfactant and a solvent selected from the group consisting of terpenes and alkyl or aryl esters of short chain alcohols. The disclosed well treatment microemulsion can be used in well remediation, stimulation and hydrogen sulfide mitigation operations. Additionally, the well treatment microemulsion can be used in the production of benzothiophenes through interaction with hydrogen sulfide.

Owner:PNC BANK NAT ASSOC +2

Acid coated sand for gravel pack and filter cake clean-up

InactiveUS6817414B2Speed up the flowGood removal effectCleaning apparatusFluid removalGlycollic acidCarboxylic acid

A method of the preparation and utilization of polymerized alpha-hydroxycarboxylic-acid-coated proppants for gravel pack and removal of filter cake that was deposited by reservoir drilling fluid. In a preferred example, polyglycolic-acid-coated sand is used to replace conventional gravel pack sand typically used for gravel packing. Under downhole conditions, the acidic by-product generated from the hydration of polyglycolic-acid-coated sand can break down acid-soluble and / or acid-breakable components embedded in the filter cake. This reaction enhances the filter cake removal and the flow of hydrocarbon from the producing formation. The polyglycolic-acid-coated sand may be produced by polymerizing a glycolic acid with a natural or synthetic proppant like 20-40 mesh commercial sand, at temperatures of about 210° F. or higher.

Owner:MI

Grafted polymers as gas hydrate inhibitors

InactiveUS6867262B1Low ground water pollution classificationReduce security risksThermal non-catalytic crackingUsing liquid separation agentPolymerHydrate

Owner:BASF AG

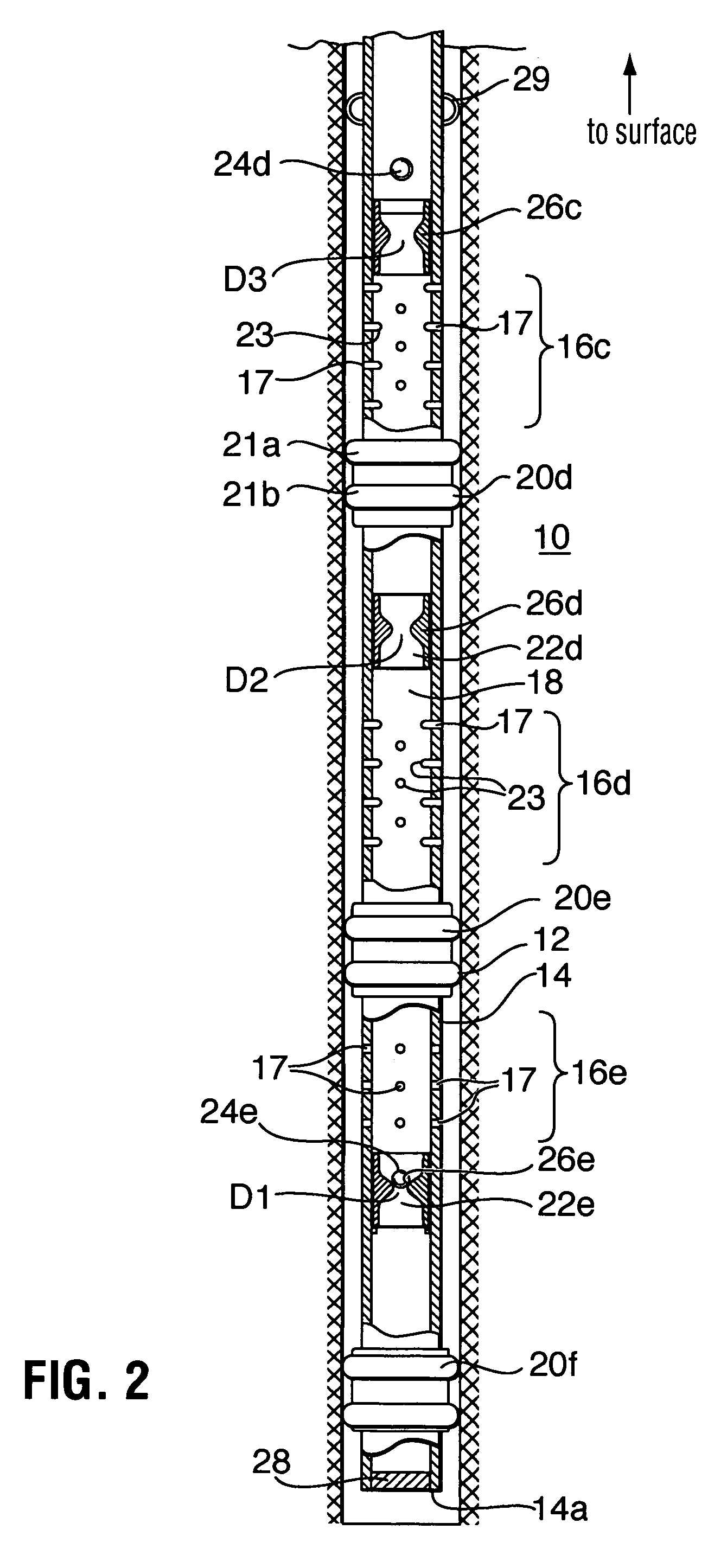

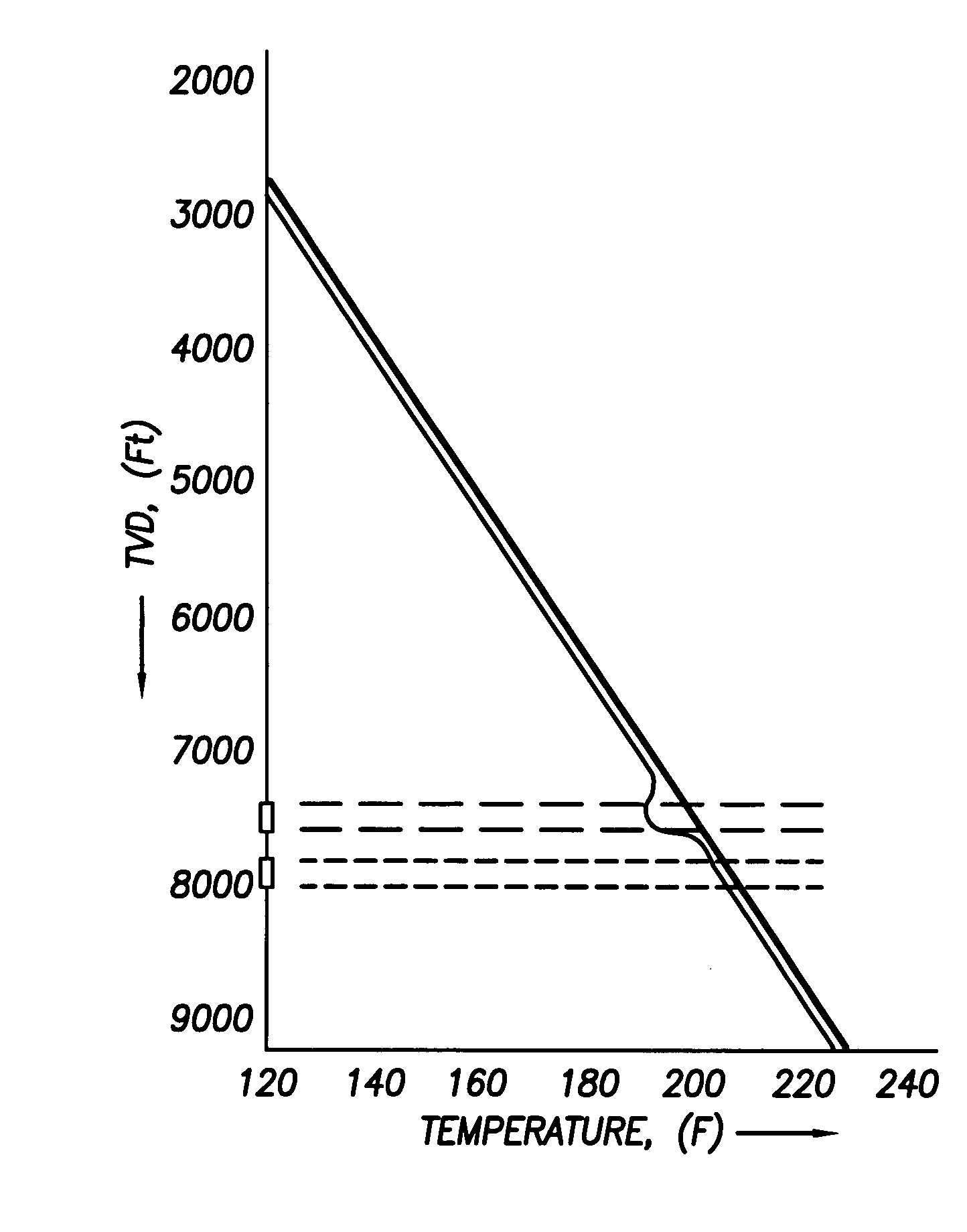

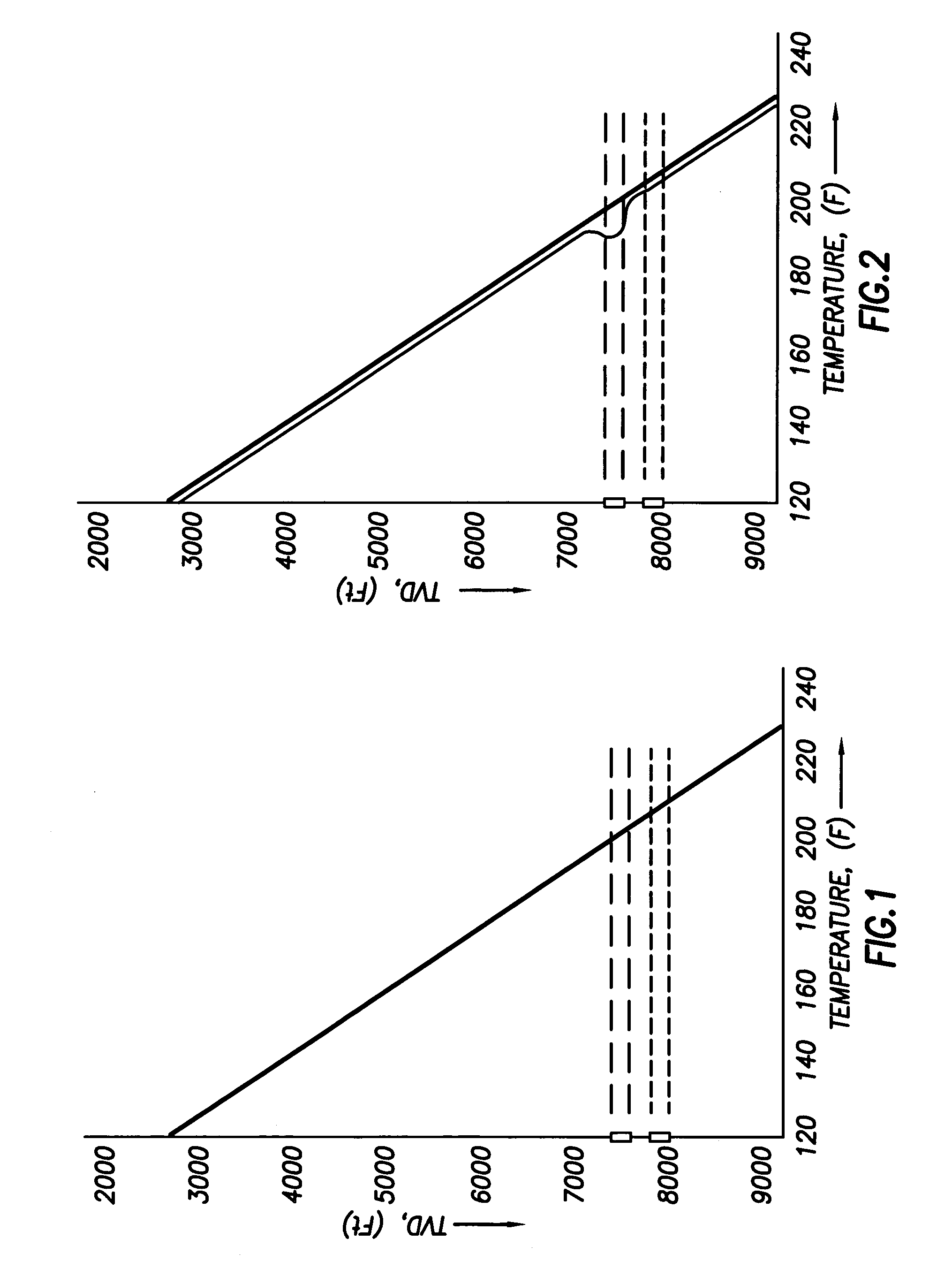

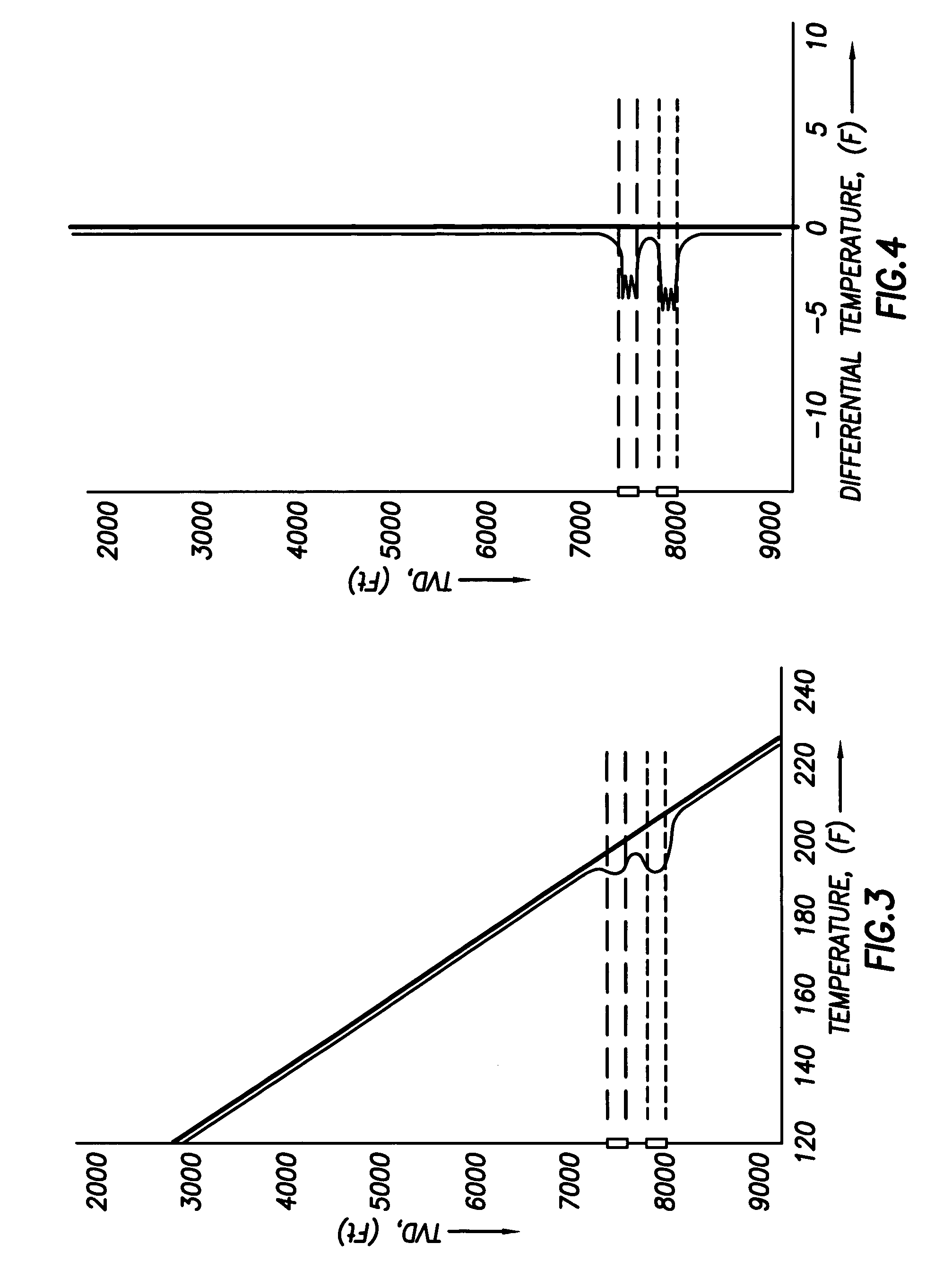

Use of distributed temperature sensors during wellbore treatments

The invention relates to a method for treating subterranean formation comprising providing distributed temperature sensors, injecting a treatment fluid and monitoring the temperature across the treatment interval during the injection process.

Owner:SCHLUMBERGER TECH CORP

Compositions and methods for degrading filter cake

Improved methods and compositions for degrading filter cake deposited in a subterranean formation are provided. These methods and compositions utilize particulates coated with acid-releasing degradable material wherein the released acid is used to degrade a filter cake.

Owner:HALLIBURTON ENERGY SERVICES INC

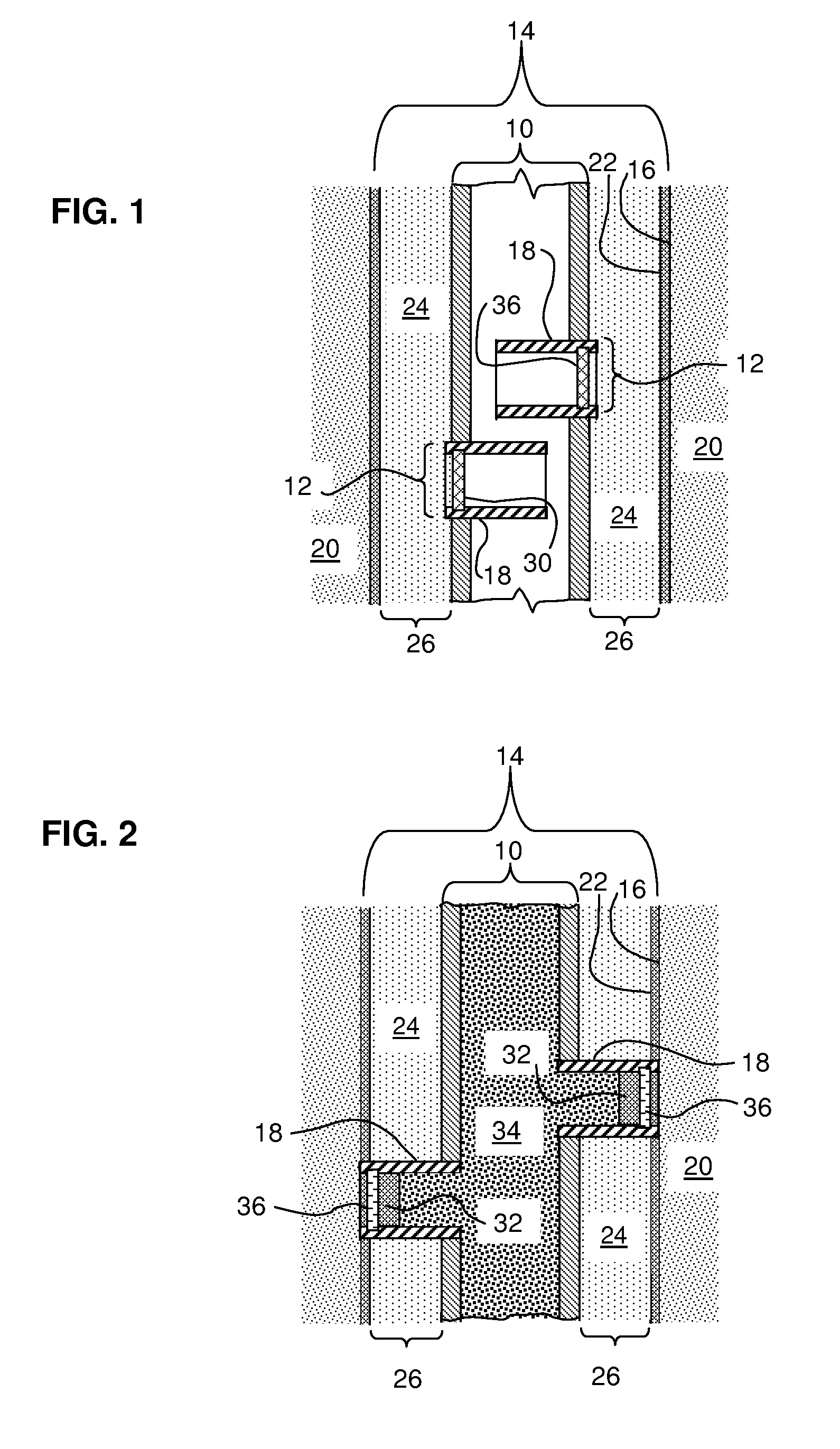

Procedures and Compositions for Reservoir Protection

ActiveUS20080296024A1High viscosityLow viscosityCleaning apparatusFluid removalSolventSURFACTANT BLEND

A flow conduit having at least one orifice is placed in the vicinity of a flow source, which in one non-limiting embodiment may be a hydrocarbon reservoir. The flow pathway between the orifice and the source is temporarily blocked with a degradable barrier. Once the flow pathway is physically placed, the degradable barrier is removed under the influence of an acid, a solvent, time and / or temperature. The flow source and the flow pathways are at least partially covered (and flow blocked by) a temporary coating such as a pseudo-filter cake formed by a viscoelastic surfactant-gelled aqueous drill-in fluid, and the flow conduit is extended to the flow source. The pseudo-filter cake is removed when viscosity is reduced by an internal breaker, and flow is then allowed. The method is useful in one context of recovering hydrocarbons where the flow conduit is a telescoping sleeve or tube that contacts the borehole wall.

Owner:BAKER HUGHES INC

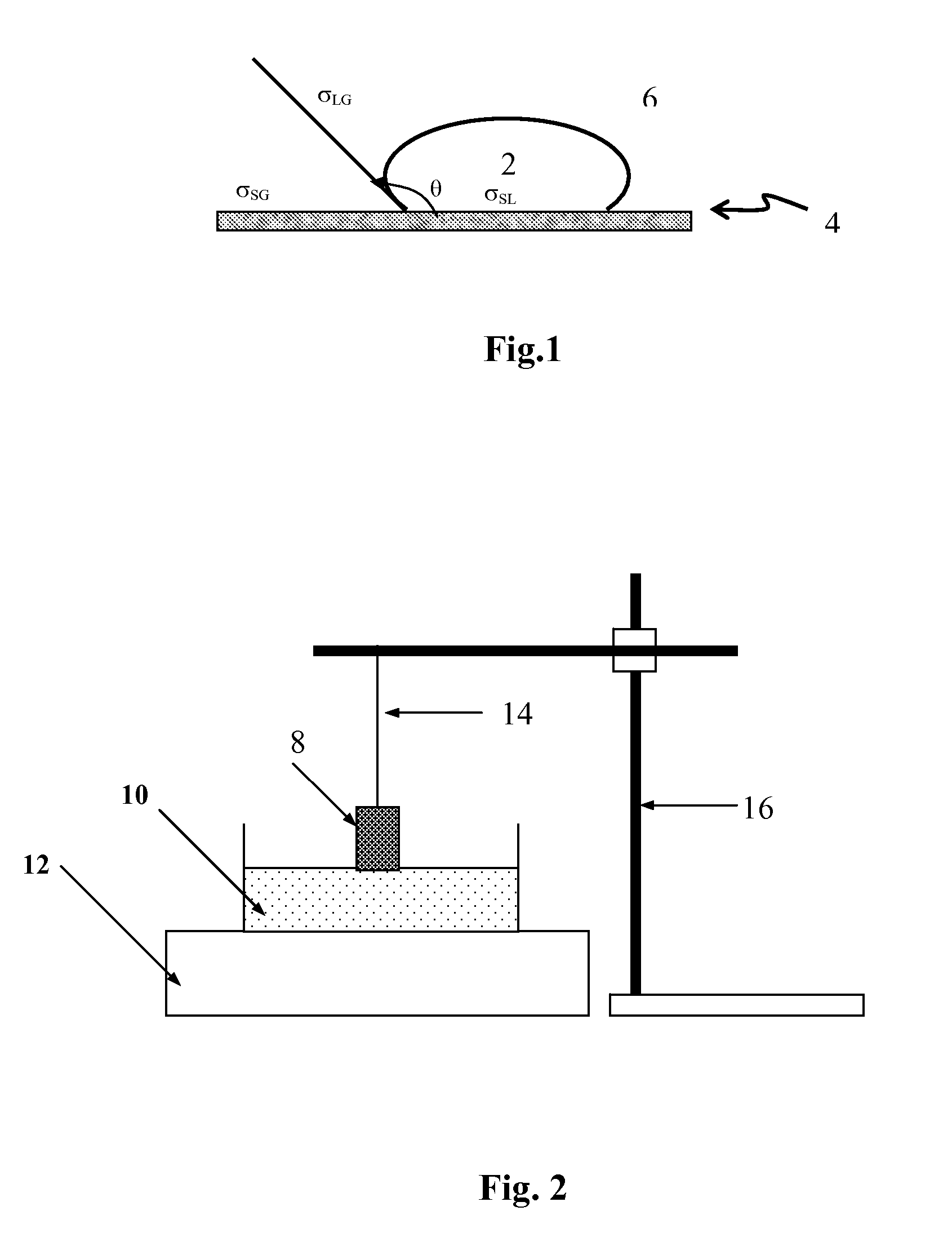

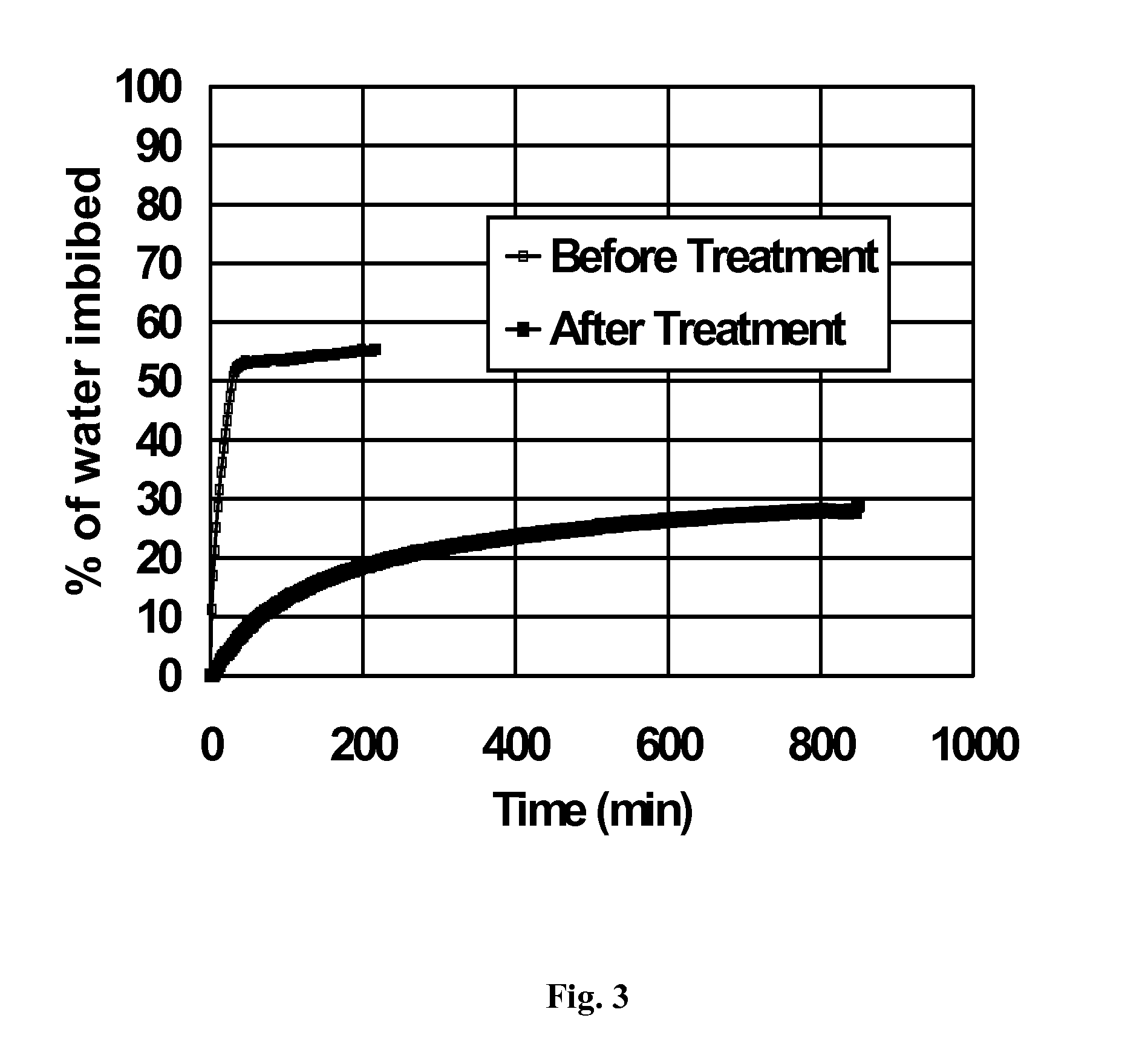

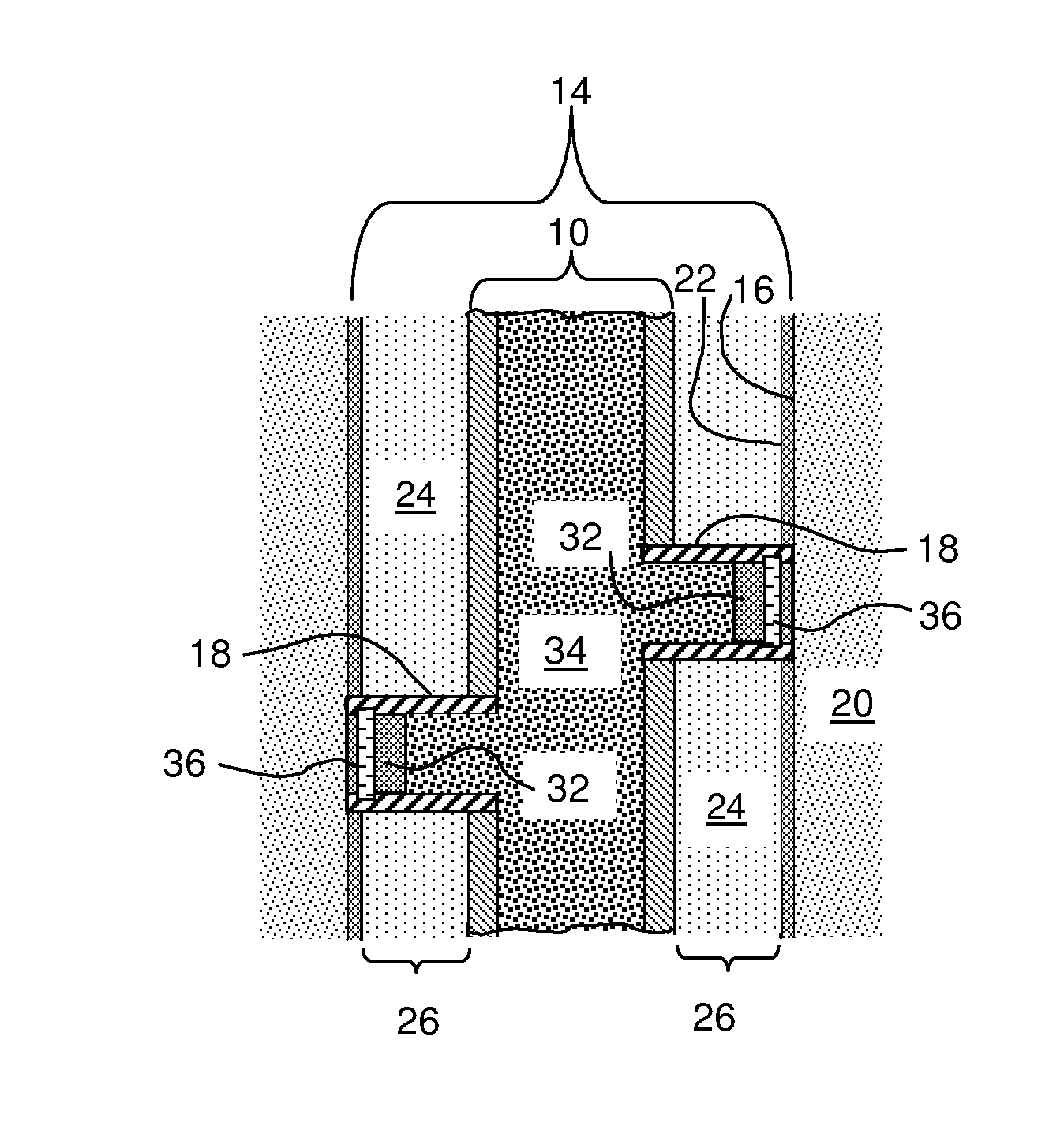

Prevention of Water and Condensate Blocks in Wells

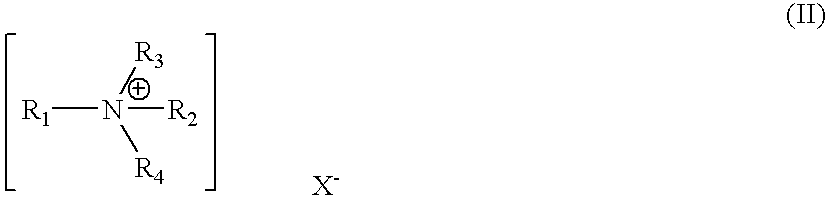

InactiveUS20070029085A1Better placementReduce capillary pressureCleaning apparatusFluid removalBetaineCarbamate

Compositions and methods are given to prevent, alleviate and remedy water blocks and gas blocks (condensate block or condensate banking). Wettability modifiers are contacted with the formation to change the surfaces from water wet or oil wet to intermediate wet or gas wet. Preferred wettability modifiers include partially or completely fluorinated surfactants or polymers, for example fluorosilanes such as perfluorosilanes, urethane oligomers containing perfluoro alkyl moieties, fluoroacrylates, and fluoroalkyl containing terpolymers or their mixtures. Other examples include surfactants, for example viscoelastic surfactants such as cationic surfactants such as quaternary amines, and zwitterionic surfactants, such as betaines, optionally mixed with co-surfactants.

Owner:SCHLUMBERGER TECH CORP

Method For Completing Injection Wells

InactiveUS20040014606A1Reducing surface storage capacity requirementEliminate needCleaning apparatusFluid removalEngineeringWater well

This invention proposes a method for completing an interval of an open-hole injection wellbore penetrating a subterranean formation, said wellbore being communicating with the formation by way of an interface that comprises at least a filter cake invaded zone comprising bridging materials and other embedded solid materials, said method comprising the steps of injecting a clean-up fluid and contacting it with the filtercake for a period of time sufficient to loose some of the other solids embedded in the filter cake; removing the loosened solids by a high-rate displacement fluid comprising suspending additives; and then injecting a dissolving fluid comprising a diverter and an effective amount of a salt or acid capable of dissolving the bridging material.

Owner:SCHLUMBERGER TECH CORP

Orthoester compositions and methods of use in subterranean applications

The present invention relates to methods and compositions for treating subterranean formations, and more specifically, to improved methods and compositions for generating acids for use downhole, for example, to at least partially degrade the acid-soluble portions of filter cakes deposited in subterranean formations. In one embodiment, the present invention provides a method of degrading an acid-soluble portion of a filter cake comprising contacting the acid-soluble portion of the filter cake with an acid generated from an orthoester.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods of drilling and completing well bores

Methods of drilling and completing open hole well bores and methods of removing filter cake comprised of a gelling agent and calcium carbonate are provided. A method of the invention for removing filter cake comprised of a gelling agent and calcium carbonate from the walls of an open hole well bore is basically comprised of the steps of contacting the filter cake with a delayed clean-up solution comprised of water and a formate ester and removing the clean-up solution from the well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

Procedures and compositions for reservoir protection

A flow conduit having at least one orifice is placed in the vicinity of a flow source, which in one non-limiting embodiment may be a hydrocarbon reservoir. The flow pathway between the orifice and the source is temporarily blocked with a degradable barrier. Once the flow pathway is physically placed, the degradable barrier is removed under the influence of an acid, a solvent, time and / or temperature. The flow source and the flow pathways are at least partially covered (and flow blocked by) a temporary coating such as a pseudo-filter cake formed by a viscoelastic surfactant-gelled aqueous drill-in fluid, and the flow conduit is extended to the flow source. The pseudo-filter cake is removed when viscosity is reduced by an internal breaker, and flow is then allowed. The method is useful in one context of recovering hydrocarbons where the flow conduit is a telescoping sleeve or tube that contacts the borehole wall.

Owner:BAKER HUGHES INC

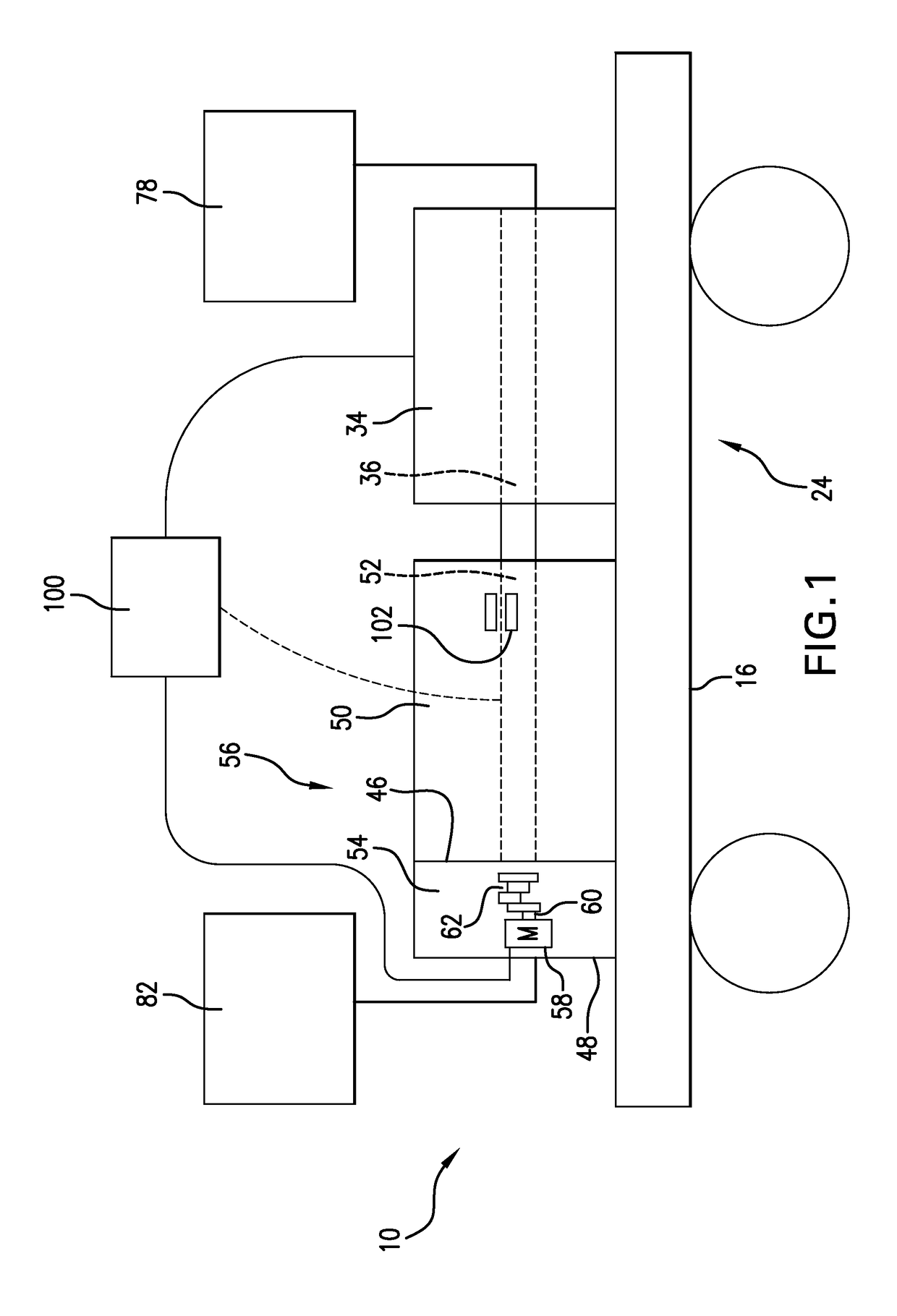

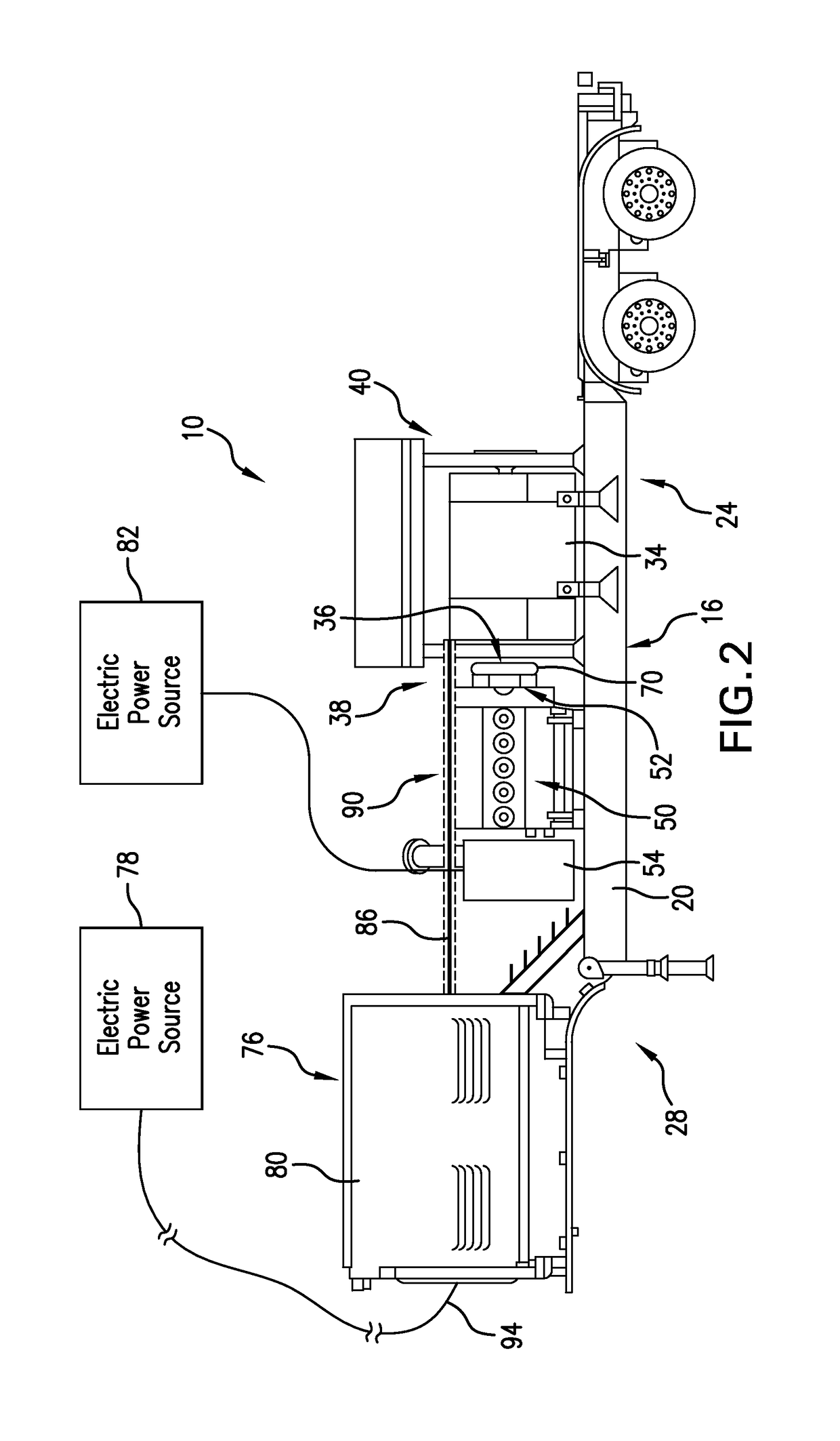

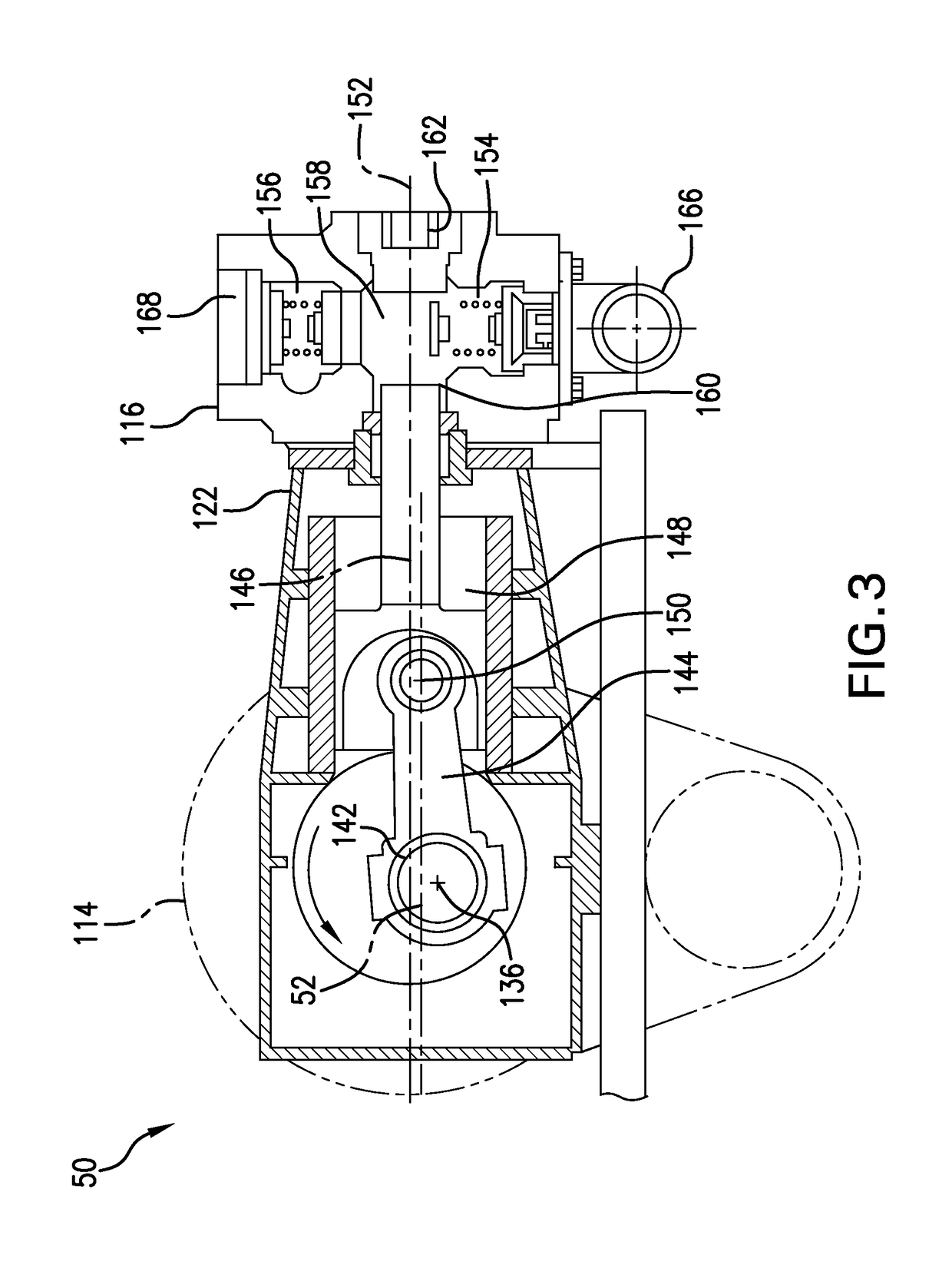

Pump system and method of starting pump

A pump system positionable at a surface of a well site for downhole operations includes a pump assembly having a pump and a starting assist. The pump includes a crankshaft and is operable by a first motor. The starting assist includes a second motor and a gear system.

Owner:BJ ENERGY SOLUTIONS LLC +1

Method of improving the permeability of an underground petroleum-containing formation

InactiveUS6972274B1Restore permeabilityEasy injectionOther chemical processesJoints with sealing surfacesAmmonium compoundsAlcohol

The present invention generally relates to a method and a composition useful in restoring the permeability of a porous underground petroleum containing formation. Restoring permeability to the formation enhances the injectivity thereby accelerating petroleum recovery. The method of the invention comprises treating said formation with a composition which comprises a combination of at least one nonionic compound, preferably an alkoxylated alcohol, with at least one cationic compound, preferably a quaternary ammonium compound, in an amount effective to improve the permeability of the formation. The composition may also optionally contain an alkyl glycoside.

Owner:AKZO NOBEL CHEM INT BV

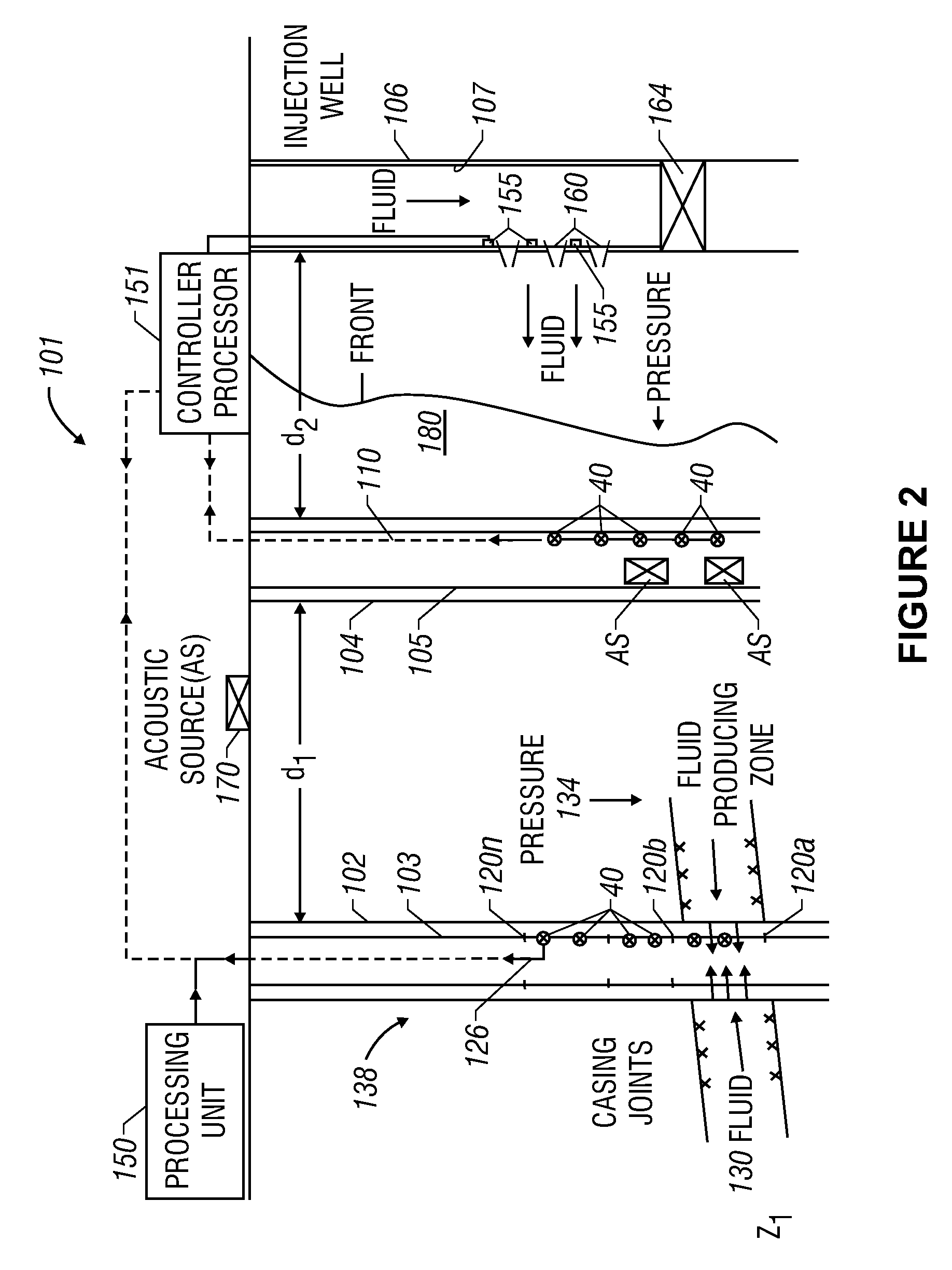

Monitoring of Downhole Parameters and Tools Utilizing Fiber Optics

The present disclosure provides systems utilizing fiber optics for monitoring downhole parameters and the operation and conditions of downhole tools and controlling injection operations based on measurements in an injection well and / or a production well.

Owner:BAKER HUGHES INC

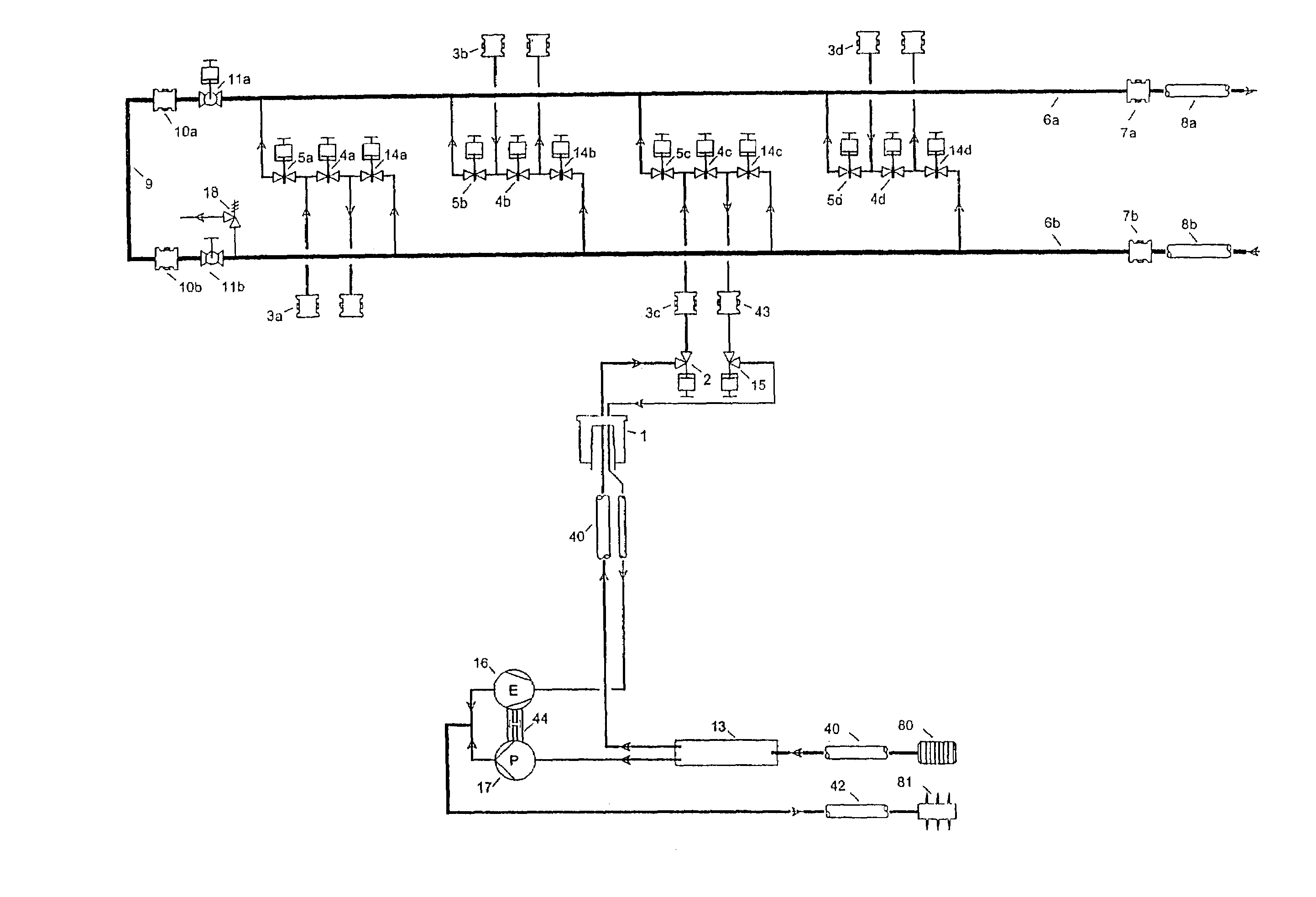

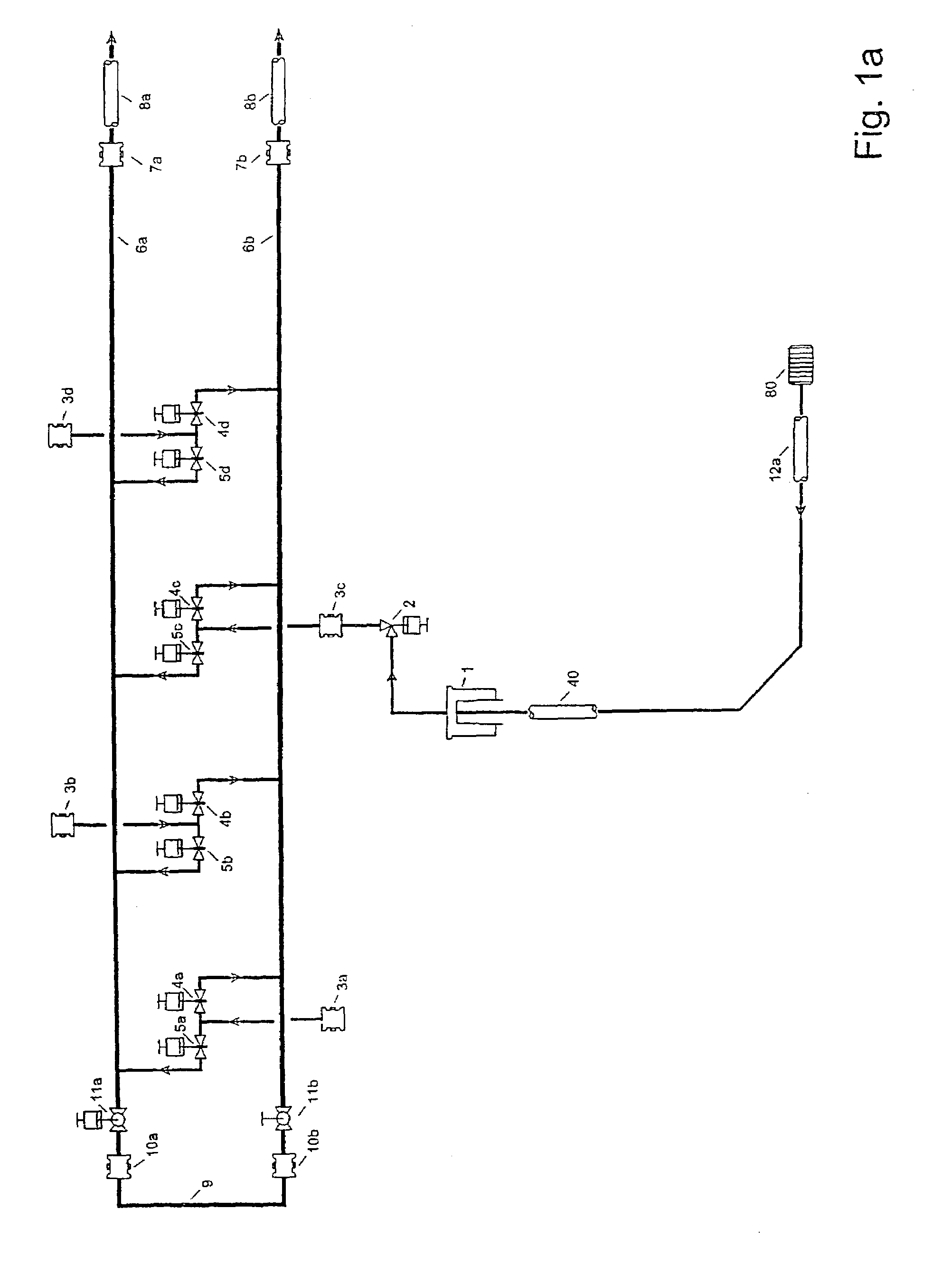

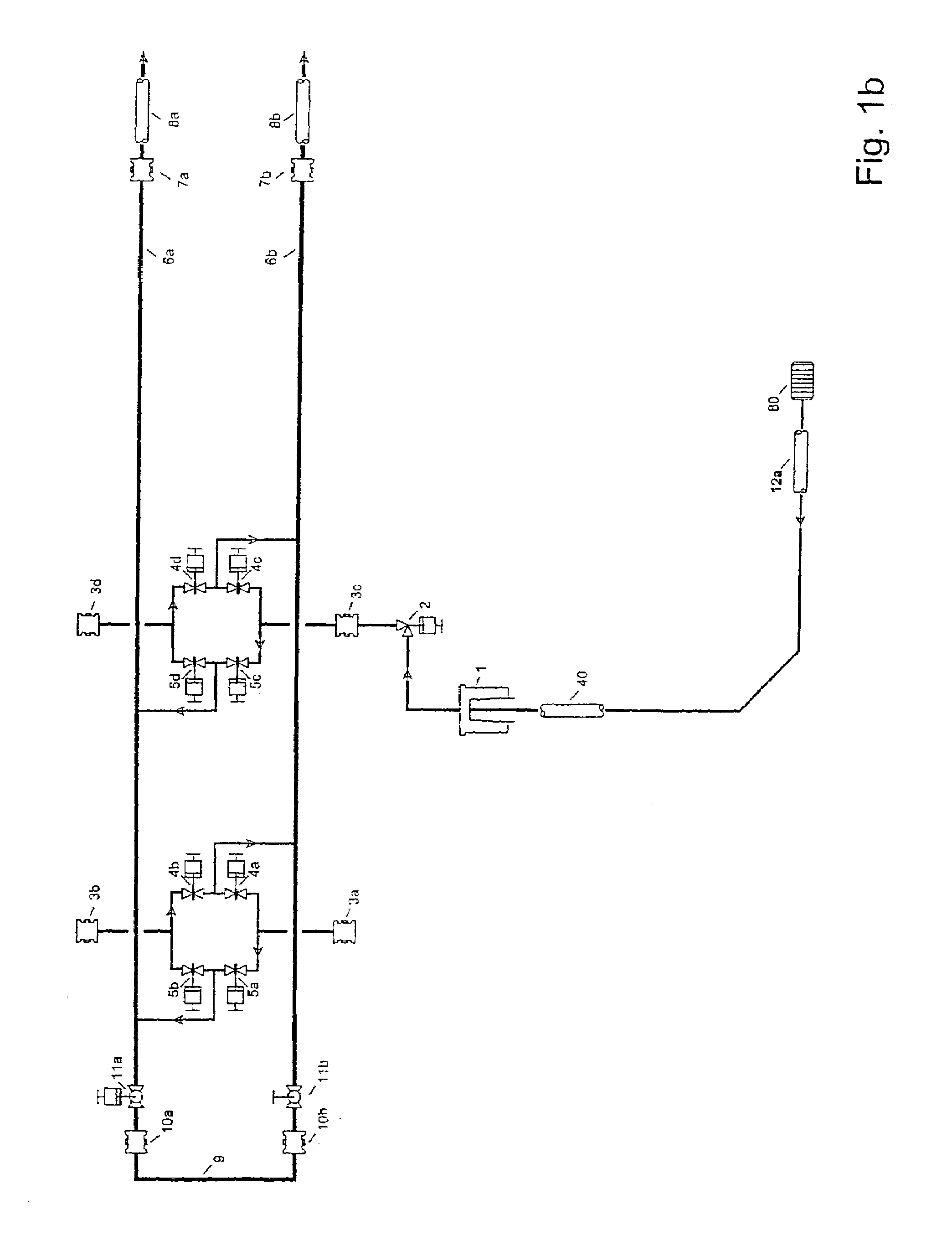

Subsea production system

InactiveUS7093661B2Increase supplyEasy to controlCleaning apparatusSettling tanks feed/dischargePetroleum productPigging

Methods and arrangements for production of petroleum products from a subsea well. The methods comprise control of a downhole separator, supplying power fluid to a downhole turbine / pump hydraulic converter, performing pigging of a subsea manifold, providing gas lift and performing three phase downhole separation. Arrangement for performing the methods are also described.

Owner:AKER SUBSEA LTD

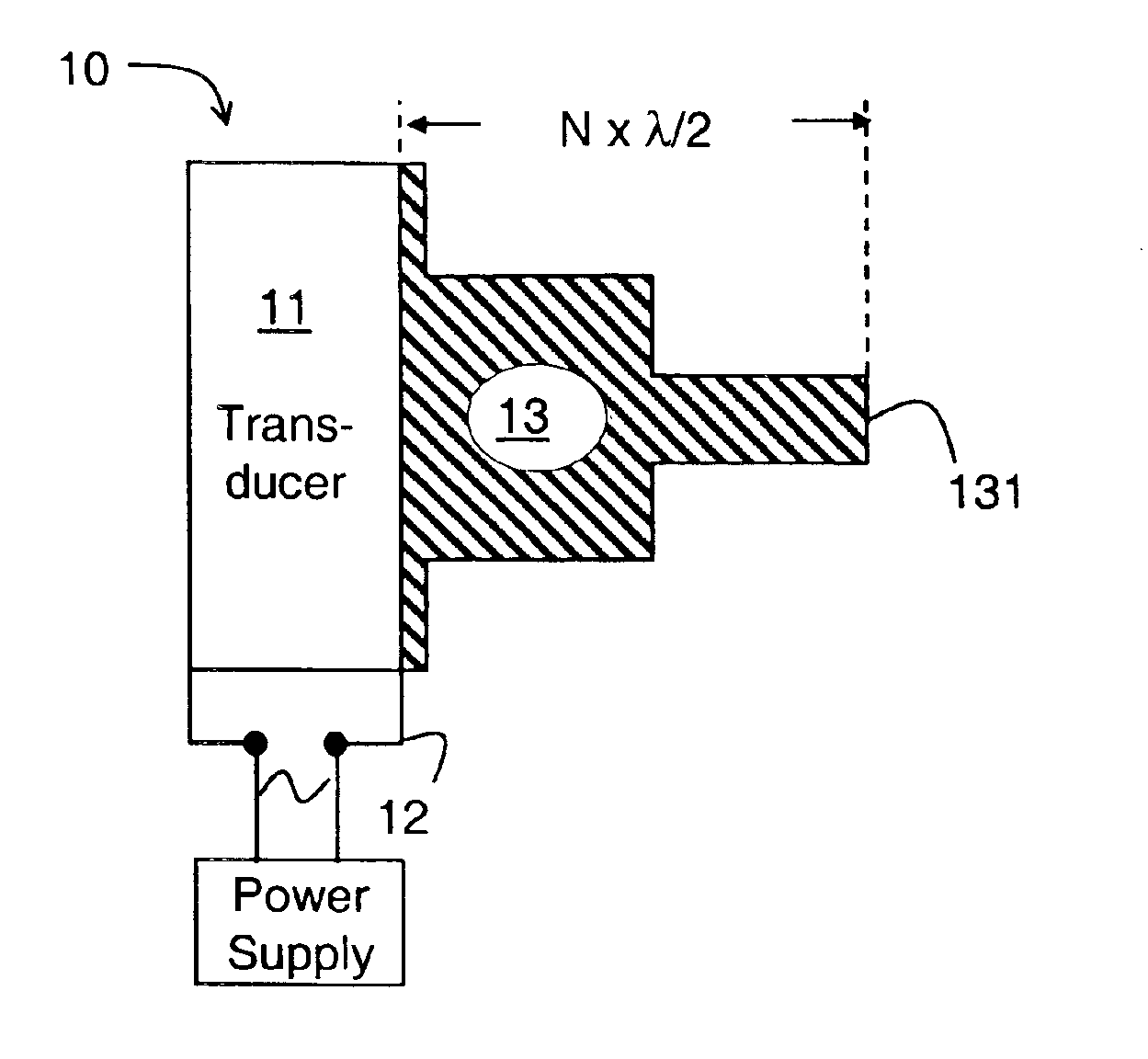

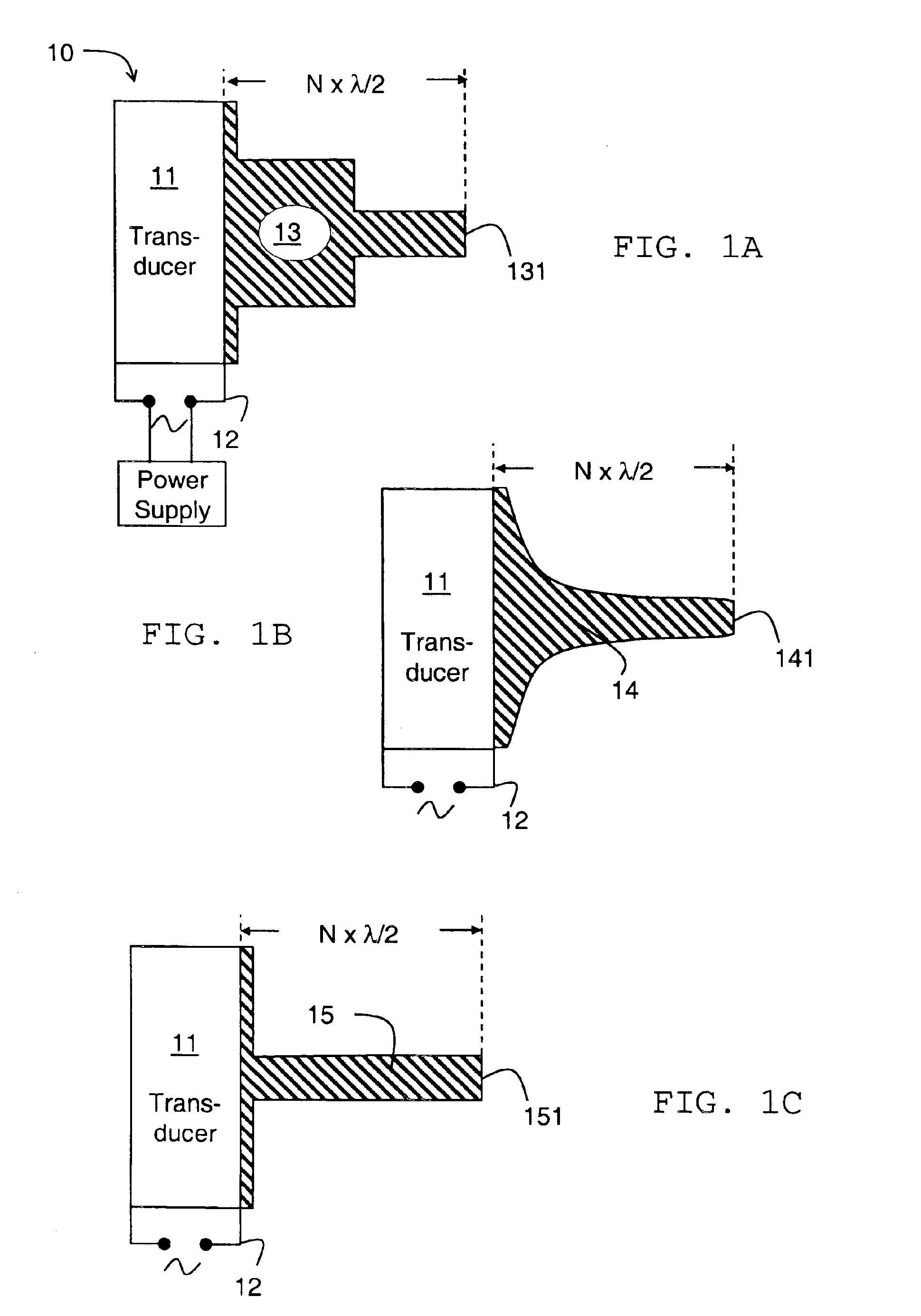

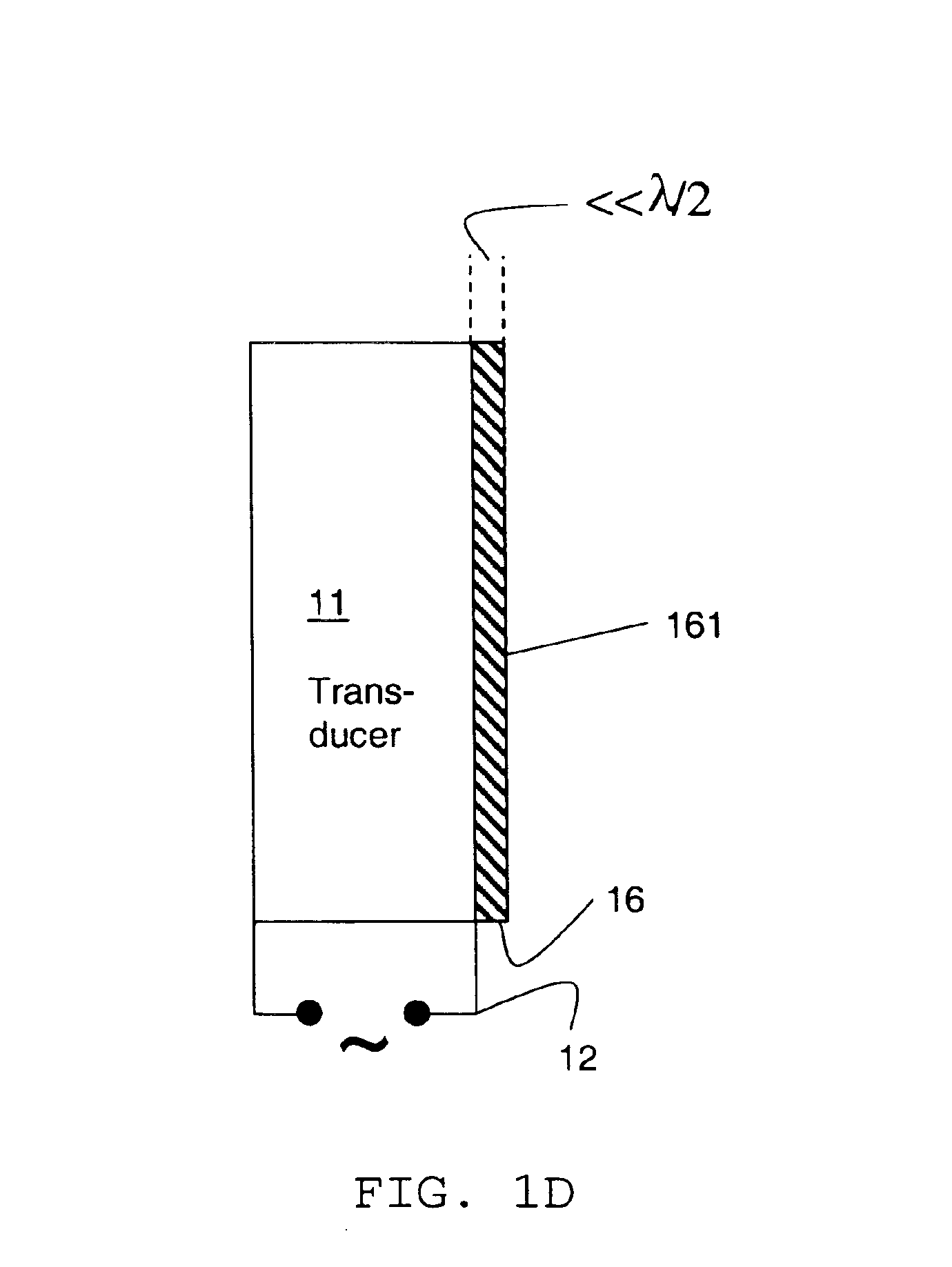

Toroidal choke inductor for wireless communication and control

An induction choke in a petroleum well where a voltage potential is developed across the choke to power and communicate with devices and sensors in the well. Preferably, the induction choke is a ferromagnetic material and acts as an impedance to a time-varying current, e.g. AC. The petroleum well includes a cased wellbore having a tubing string positioned within and longitudinally extending within the casing. A controllable gas lift valve, sensor, or other device is coupled to the tubing. The valve sensor, or other device is powered and controlled from the surface. Communication signals and power are sent from the surface using the tubing, casing, or liner as the conductor with a casing or earth ground. For example, AC current is directed down a casing or tubing or a lateral where the current encounters a choke. The voltage potential developed across the choke is used to power electronic devices and sensors near the choke. Such induction chokes may be used in many other applications having an elongated conductor such as a pipe, where it is desirable to power or communicate with a valve, sensor, or other device without providing a dedicated power or communications cable.

Owner:SHELL OIL CO

Process for mitigation of wellbore contaminants

InactiveUS6942037B1Lessened potential hazardSimple treatmentCleaning apparatusFluid removalFoaming agentWater flow

A method is disclosed for intermittently mitigating hazardous sulfur compounds, such as hydrogen sulfide, mercaptans and sulfur oxides, from a fluid in the head space of a wellbore. The method comprises contacting the fluid with a foamed aqueous stream comprising an active scavenging agent, such as a triazine, and a stiff foaming agent. The scavenging agent reacts with hazardous sulfur compounds to eliminate the compounds from the fluid stream in the vapor space of the wellbore without withdrawing the hydrocarbon from the wellbore and without releasing hazardous sulfur compounds to the environment.

Owner:CLARIANT INT LTD

Dissolving filter cake

Owner:SCHLUMBERGER TECH CORP

Deposition monitoring system

InactiveUS6880402B1Increase deposition thicknessConveniently determinedVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMonitoring systemOperation mode

Described is an apparatus for detecting and removing deposits from a surface exposed to wellbore fluids. The apparatus can monitor the rate of deposition and subsequently remove the deposited material. The combination of detection apparatus and removal apparatus provides an instrument with self-cleaning operation mode.

Owner:SCHLUMBERGER TECH CORP

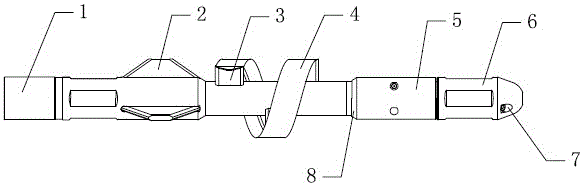

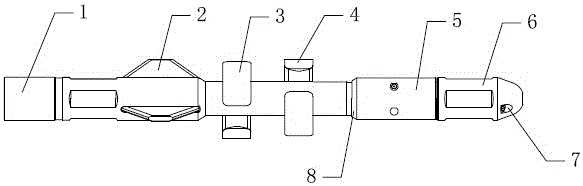

Oil and gas field coiled tubing paraffin removal and contaminant release process and tool thereof

PendingCN106761561AWill not artificially cause blockageImprove cleanlinessCleaning apparatusWaxCoiled tubing

The invention relates to an oil and gas field coiled tubing paraffin removal and contaminant release process and a tool thereof. Paraffin removal is performed by using coiled tubing, and removed paraffin can be recycled to the ground, and therefore a wellbore cannot be blocked due to human factors. A flushing port is designed at the upper end of a flushing tool, and then paraffin remaining on mechanical scraping portions can be cleared. The coiled tubing is connected with the paraffin removal and contaminant release tool for paraffin removal and contaminant release. The flushing tool at the front end of a pipe string can first perform 360 degree hydraulic cleaning on the wellbore, and then along with descending of the pipe string, a paraffin remover in the pipe string performs mechanical cleaning on the wellbore, and therefore dual cleaning mode combining the hydraulic cleaning with mechanical scraping is achieved, removal effects are greatly improved, cost is saved, and work efficiency is improved.

Owner:JEREH ENERGY SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com