Patents

Literature

1942results about How to "Reduce interfacial tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

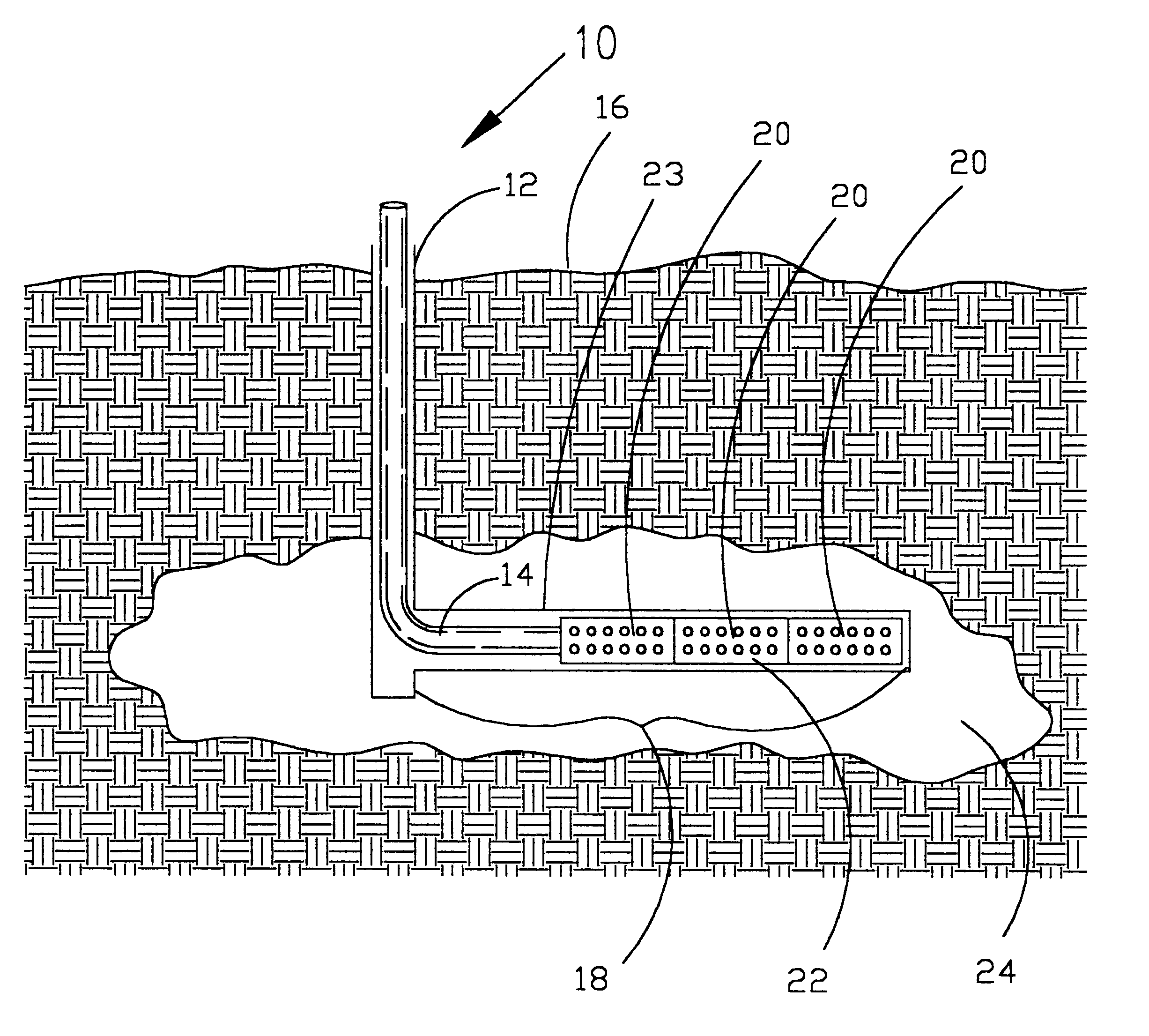

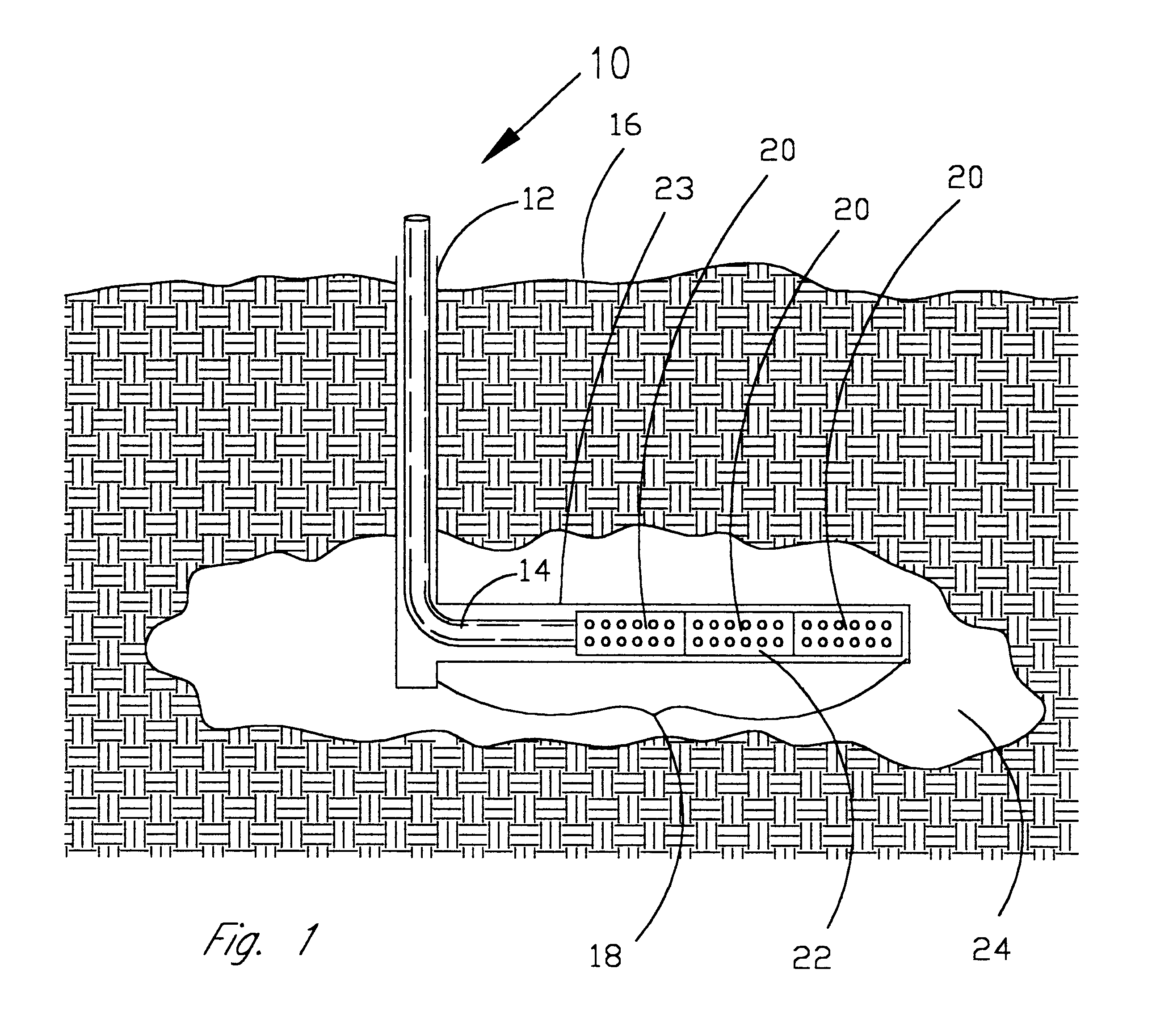

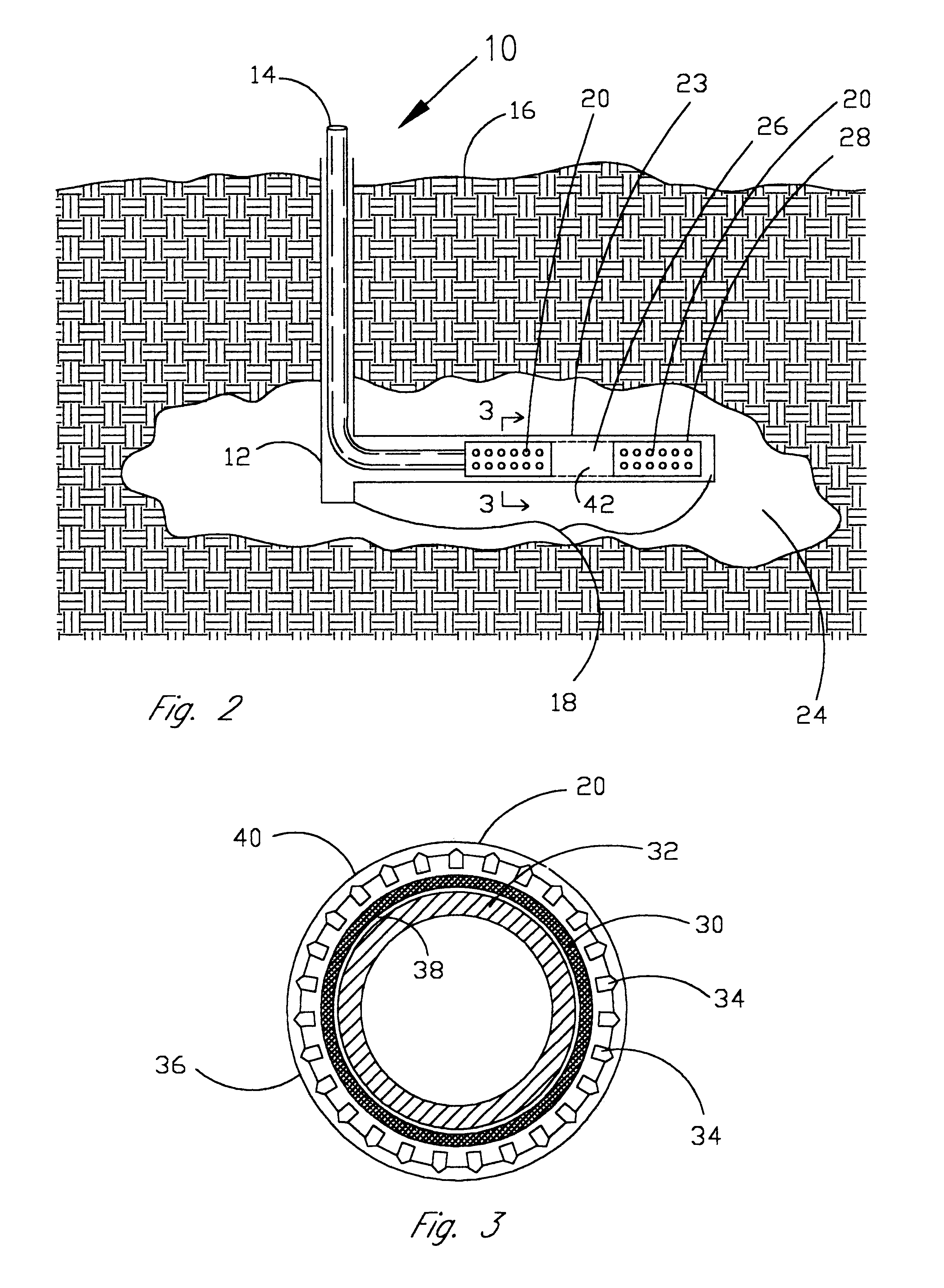

Product and process for coating wellbore screens

InactiveUS6394185B1Material efficiencyReduce interfacial tensionCleaning apparatusFluid removalEnzymeChemistry

Coatings for well screens that protect the screens from damage as they are inserted into the wellbore and once in the well, release reactive materials to react with and degrade potentially plugging materials such as drill solids, fluid filtercakes, fluid loss additives, and drilling fluids. The coatings can be specifically designed for individual well conditions and are comprised of a binder that either melts or dissolves within the wellbore and one or more reactive materials such as acids, enzymes, surfactants, chelants, oxidizers or free radical generators and the like which are released into the screen and the near wellbore area and which are effective in degrading or dissolving materials which could potentially plug the screen.

Owner:CONSTIEN VERNON GEORGE

Personal cleansing and shaving films

InactiveUS20060228319A1Improve aestheticsCleansing hairCosmetic preparationsHair removalPersonal carePlasticizer

Personal care composition in the form of a dry film useful in cleansing or shaving. The film includes at least one water soluble polymer in an amount of about 45 to about 82 weight %, based on total weight of dry film, and, when used for cleansing, at least one surfactant in an amount of about 18 to about 55 weight %; based on total weight of dry film. The at least one water soluble polymer can include blends of polymers. Other additional ingredients for use in the film include plasticizers and / or neutralizing agents. The personal cleansing dissolvable films provide improved aesthetics, foaming, cleansing, moisturizing and lubricity.

Owner:AKZO NOBEL NV

Reaction bonding type node sealant and preparation method thereof

ActiveCN102911638AImprove stabilityImprove bindingNon-macromolecular adhesive additivesOther chemical processesChemical LinkagePolyvinyl chloride

The invention provides a reaction bonding type node sealant and a preparation method thereof. The sealant comprises asphalt, modifiers, an emulsifier, a crosslinking agent, thickeners, a reinforcing agent and water. In the formula system, more appropriate modifiers are adopted compared with the prior art, so that a rubber asphalt mixture can achieve good emulsification effect, elasticity and strength of a sealing layer after drying are greatly improved, and the sealing effect can be good and lasting; the chemical linkage effect with concrete is formed by using the crosslinking agent, and bonding force with the concrete is improved; and a lot of thickeners are used for adjusting the stickness of the sealant system, so that the reaction bonding type node sealant can better adhere to the surface of a pentatricopeptide repeats (PPR) or polyvinyl chloride (PVC) pipe, and good sealing at positions where PPR or PVC water supply and drainage pipes are connected with base surfaces of concrete.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

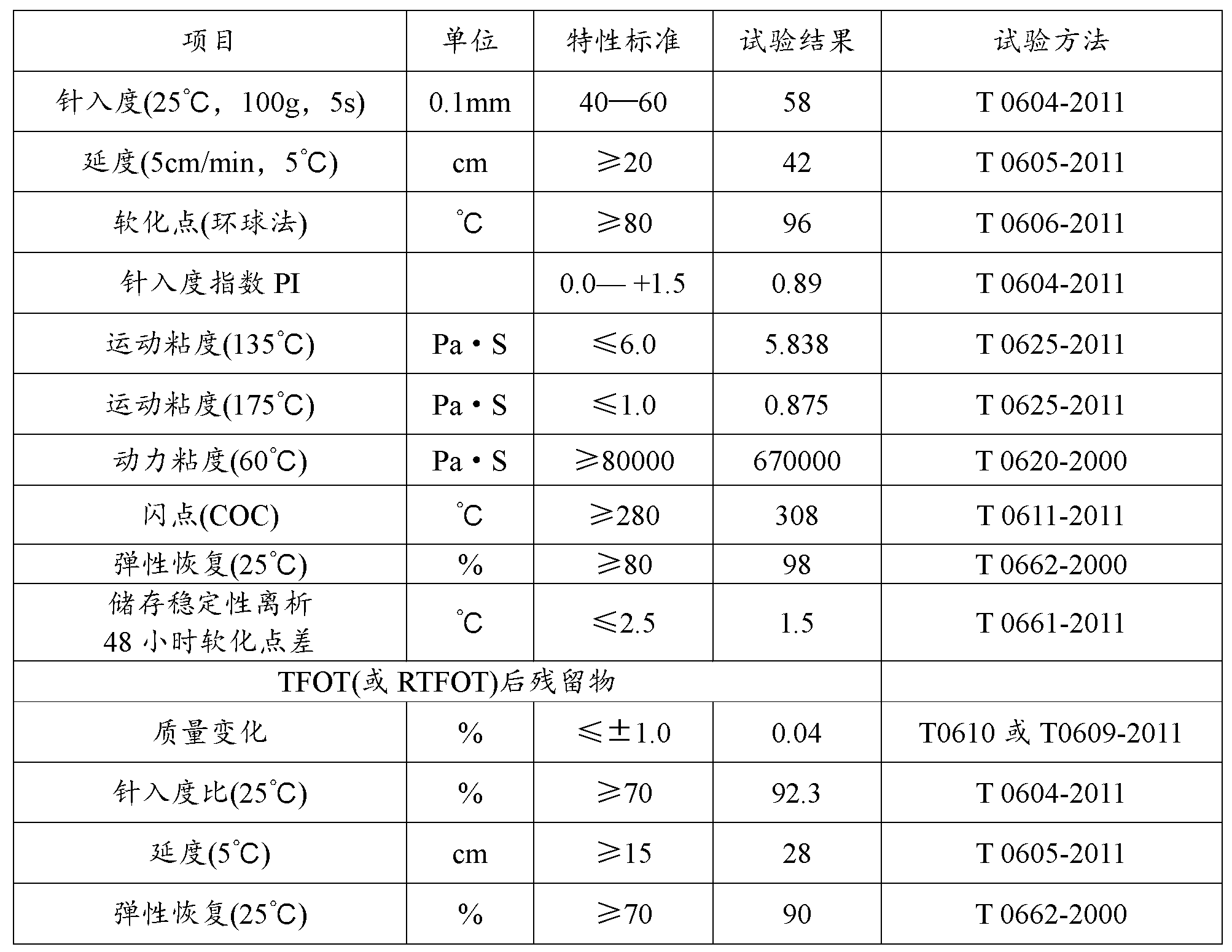

Asphalt modifier, modified asphalt and asphalt mixture

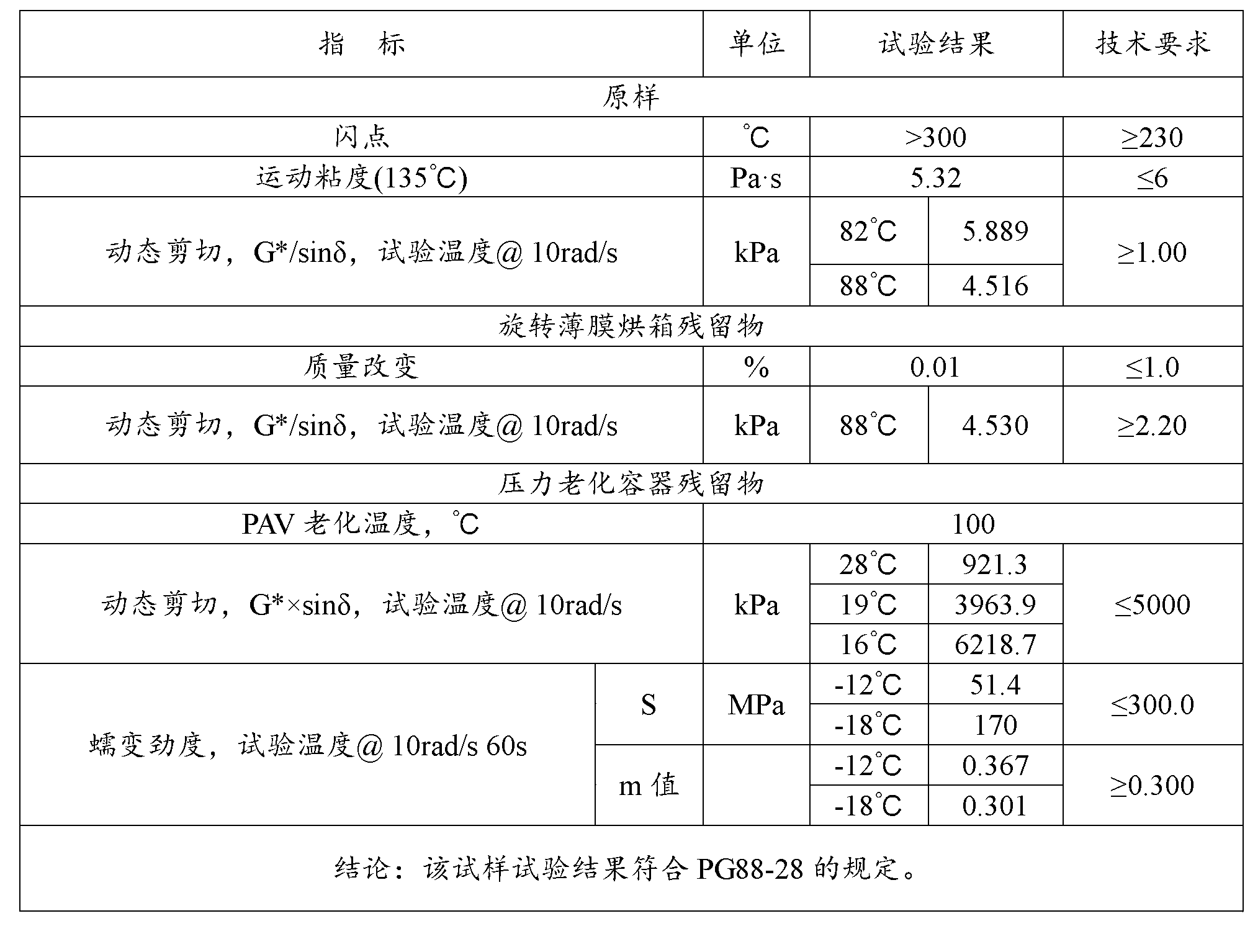

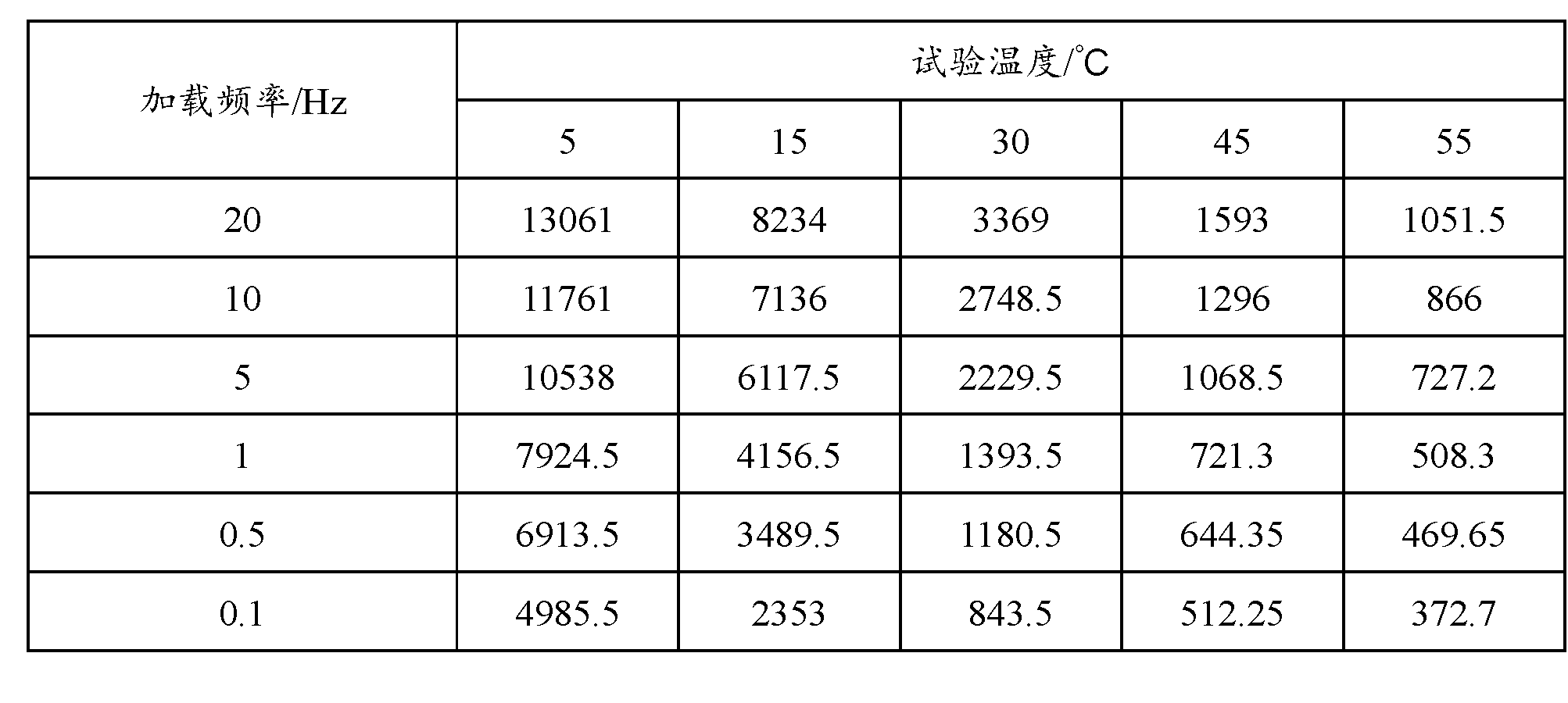

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

Use of nanomaterials as effective viscosity modifiers in lubricating fluids

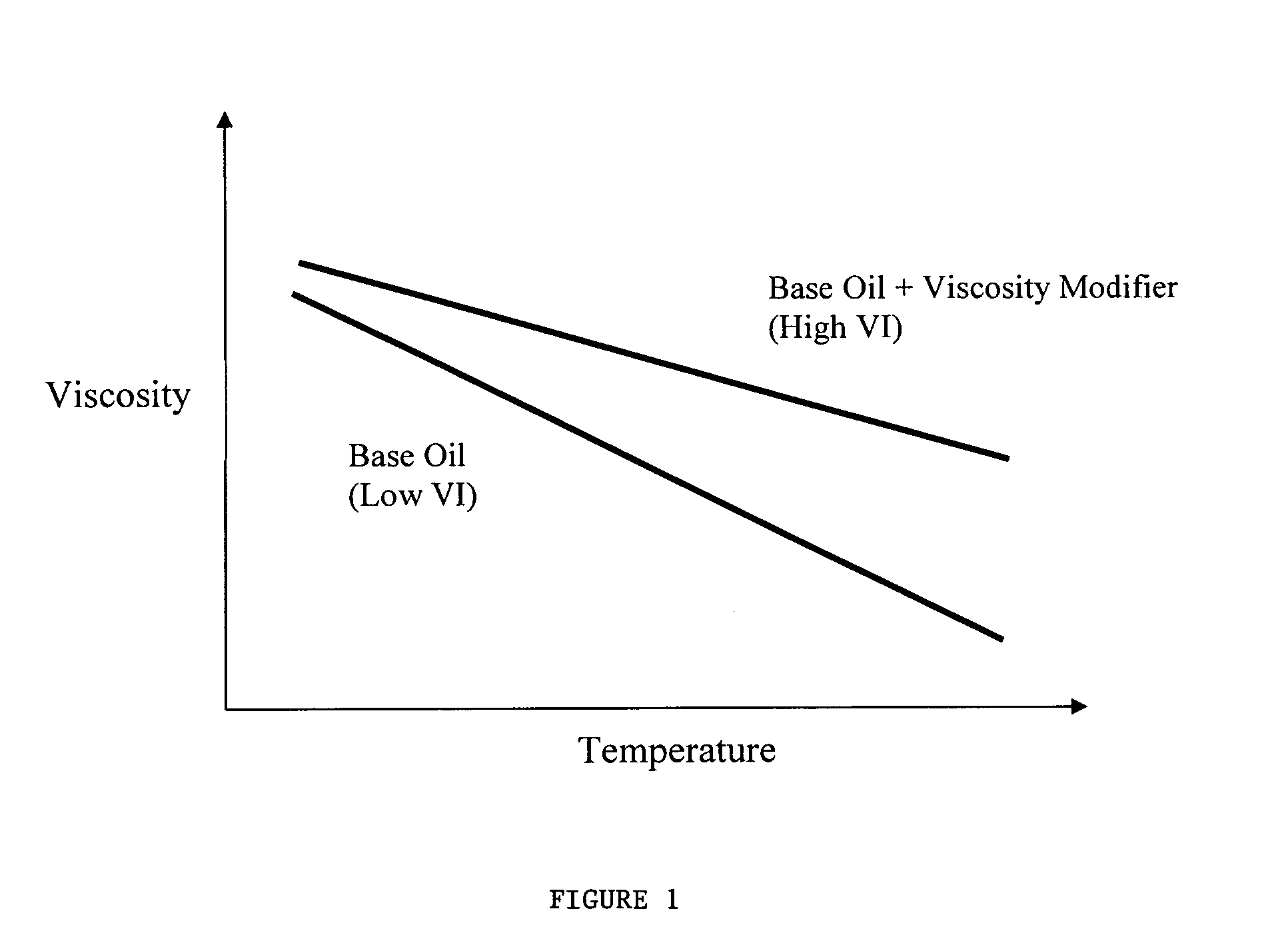

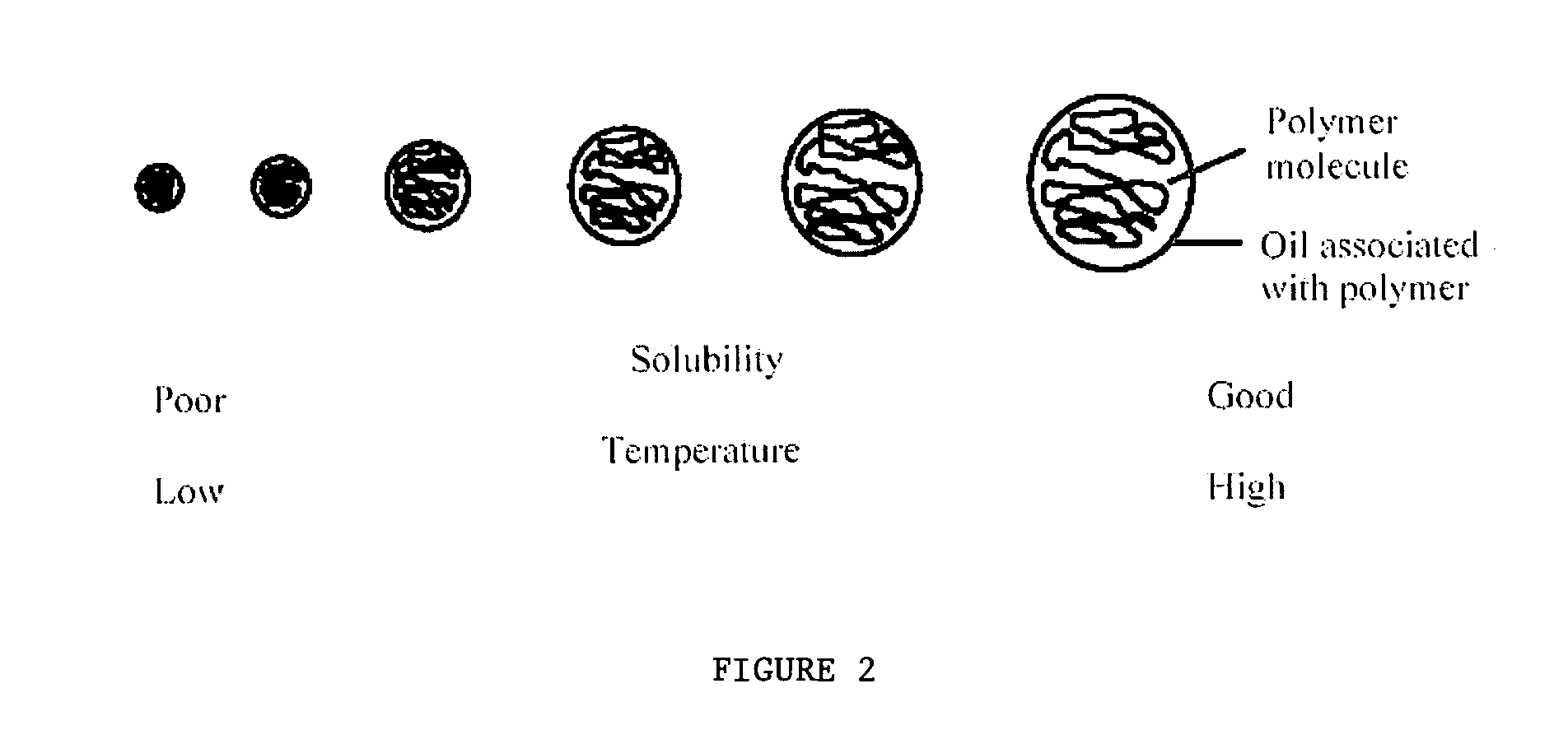

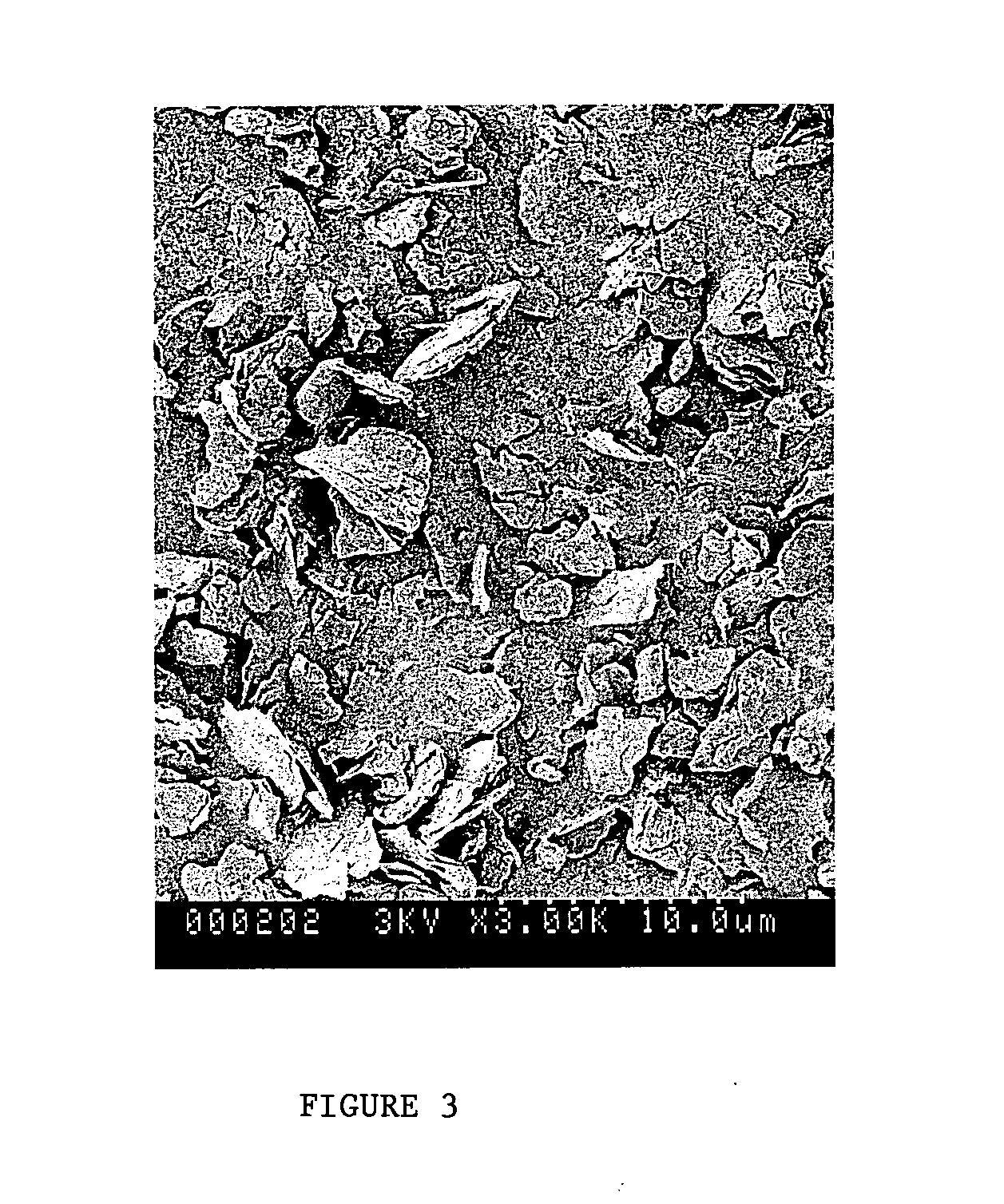

InactiveUS20070293405A1Uniform and stable dispersionHigh indexMaterial nanotechnologyBase-materialsViscosity indexGraphite

Nanomaterials have been used as a supplement or replacement of traditional polymer-based viscosity modifiers for lubricants and other related fluids. Compared with traditional polymer-based viscosity modifiers, nanomaterials possess better viscosity-index modification functions, i.e., more even viscosity increase across the whole temperature range. Meanwhile, a cost-effective way of making nanomaterials have been developed based on commercially available graphite materials, and the resulting nanoparticles of graphite are nanodisks (nanoplates). Furthermore, it provides a viscosity modifier which exhibits temporary shear loss, which can contribute to fuel economy, but no permanent shear loss.

Owner:ASHLAND LICENSING & INTPROP LLC

Preparation method of profile control and oil displacement system of polyacrylamide nanometer microsphere with low interfacial tension

InactiveCN101759838AReduce interfacial tensionEnhanced overall recoveryDrilling compositionOrganic acidMicrosphere

The invention relates to a preparation method of a profile control and oil displacement system of polyacrylamide nanometer microsphere with low interfacial tension, which comprises the steps of: inversely preparing microemulsion with oil phase, combined emulsifying agents and water phase containing crosslinking agents, initiating polyreaction with a redox initiation system used as initiating agents, neutralizing the obtained polyacrylamide nanometer microsphere with alkali, and preparing highly active sulphonate or carboxylate surfactants with the reaction of the alkali and the substance of organic acid in the combined emulsifying agents; the oil water interfacial tension can be greatly reduced by the surfactants. The profile control and oil displacement system is applied to enhancing enhanced recovery ratio, has good effect on enhancing oil cleaning efficiency, and is a novel profile control and oil displacement system with the dual functions of profile control and oil displacement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Modified emulsified asphalt waterproof sealant and preparation method thereof

InactiveCN102898850AImprove stabilityImprove bindingOther chemical processesBuilding insulationsBituminous waterproofingPolypropylene

The invention aims to provide a modified emulsified asphalt waterproof sealant and a preparation method thereof. The modified emulsified asphalt waterproof sealant comprises asphalt, a modifying agent, an emulsifying agent, a thickening agent and water. In a formula system of the modified emulsified asphalt waterproof sealant, more modifying agent in an appropriate amount is adopted than that of the prior art, so that a rubber-asphalt mixture can achieve a good emulsifying effect, the elasticity and strength of a dried sealing layer are greatly improved, and the sealing effect can be better and lasting; and a large amount of the thickening agent is used to adjust the appropriate viscosity of a modified emulsified asphalt waterproof sealant system, so that the modified emulsified asphalt waterproof sealant can be well adhered to the surface of a relatively smooth polypropylene random copolymer (PPR) or polyvinyl chloride (PVC) pipe to well seal the connection part of a PPR or PVC water supply and drainage pipe and a concrete base.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Reaction bonding modified emulsified asphalt waterproof paint and preparation method thereof

ActiveCN102898947AImprove stabilityImprove bindingConjugated diene hydrocarbon coatingsChloropene polymer coatingsCross-linkBituminous waterproofing

The invention aims to provide a reaction bonding modified emulsified asphalt waterproof paint and a preparation method thereof. The reaction bonding modified emulsified asphalt waterproof paint comprises asphalt, a modifying agent, an emulsifying agent, a cross-linking agent and water. In the formula system of the reaction bonding modified emulsified asphalt waterproof paint, more modifying agents in an appropriate amount are adopted compared with the prior art, so that a rubber-asphalt mixture can achieve a good emulsifying effect, the elasticity and strength of a dried sealing layer are greatly improved, and the sealing effect can be better and lasting; and by using the cross-linking agent, a chemical coupling effect is achieved between the paint and concrete, so that the cohesive force of the concrete is promoted. The reaction bonding modified emulsified asphalt waterproof paint can be applied to waterproof construction of wall surfaces, roofs, roads, bridges and the like, and has a very high practical value.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Temperature-resistant salt-resistant composite foam oil displacement agent for tertiary oil recovery and preparation method thereof

InactiveCN102086389ARaw materials are easy to getReduce manufacturing costDrilling compositionSulfonateActive agent

The invention relates to a temperature-resistant salt-resistant composite foam oil displacement agent for tertiary oil recovery and a preparation method thereof, belonging to the field of chemical oil displacement for increasing the crude oil recovery ratio of the oil field. The oil displacement agent is compounded by 0.5-1% of alpha-alkene sulfonate as a main surfactant and other auxiliary agents and comprises the following components in percentage by mass:0.1-1.5% of anionic surfactant, 0.2-0.8% of zwitterionic surfactant, 2-10% of organic solvent, 5-12% of stabilizing agent and the balance of a salt solution added to be 100%. Compounds related to the oil displacement agent are industrially produced fine chemical products, the raw materials are easy to obtain, the production cost is low, and the preparation is simple; the oil displacement agent has performances of temperature resistance, salt resistance, ultralow interfacial tension and the like; the persistence of the foam is strong, and the half-life period can be more than 120min at 85 DEG C; the oil displacement age has excellent compatibility with other surfactants, and the comprehensive recovery ratio of the crude oil can be increased by about 10-15%.

Owner:SHANGHAI UNIV

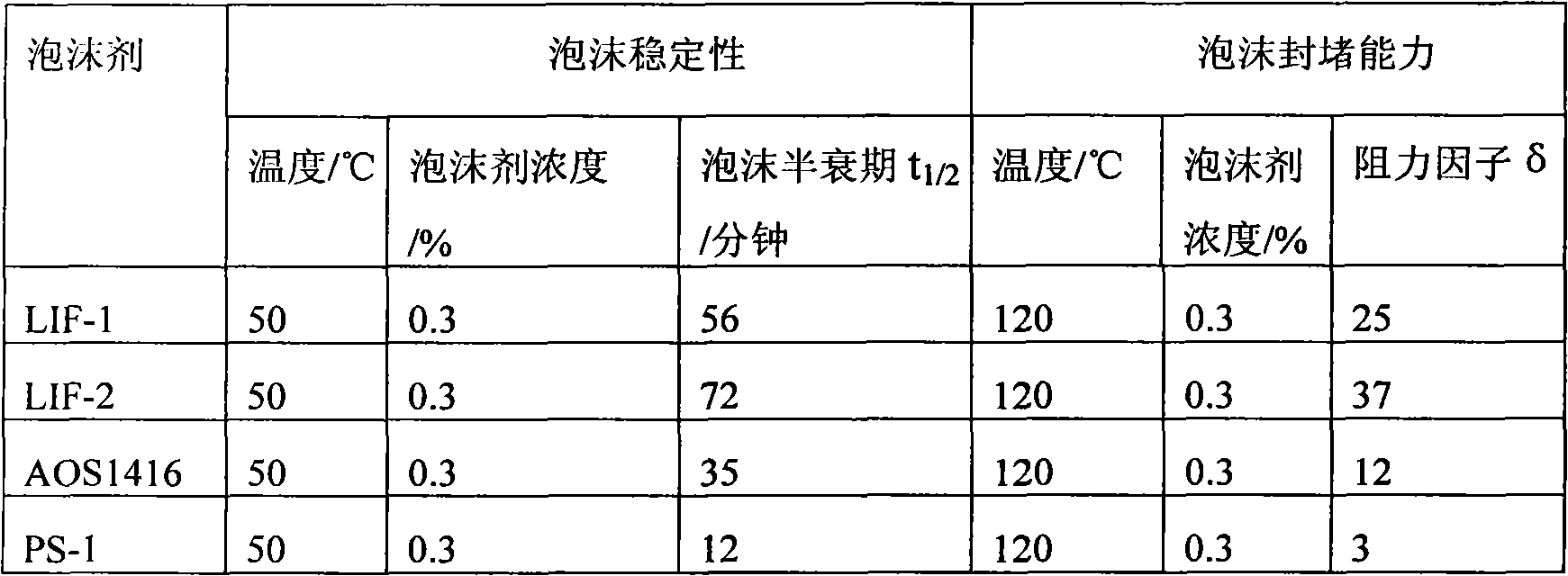

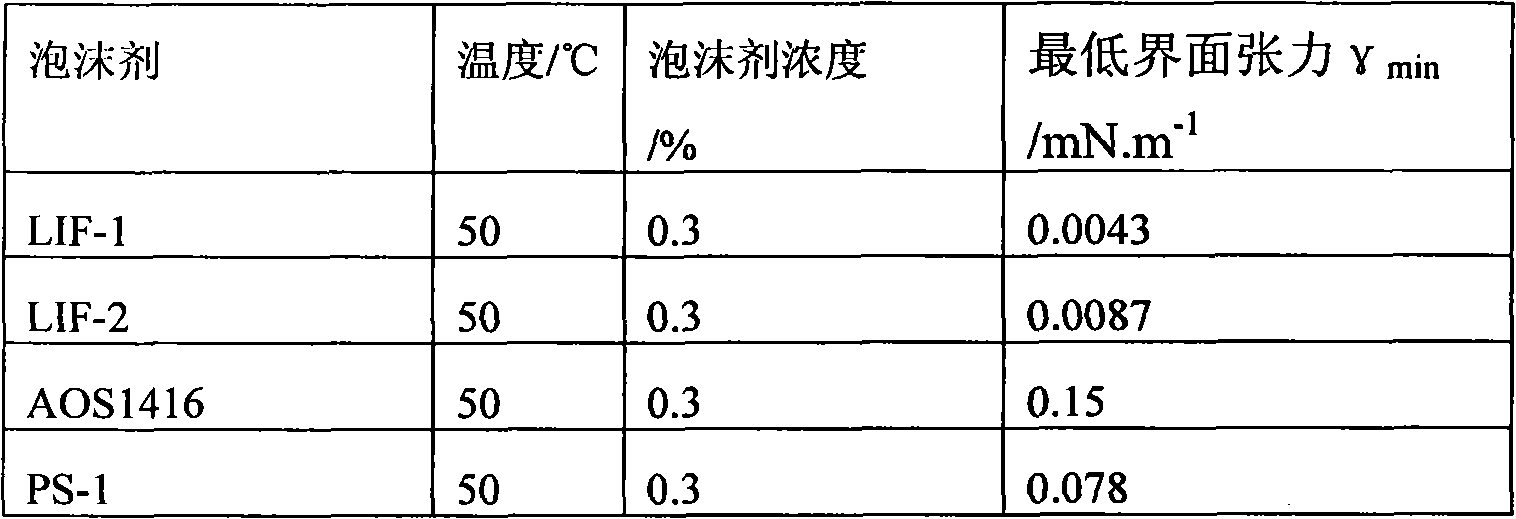

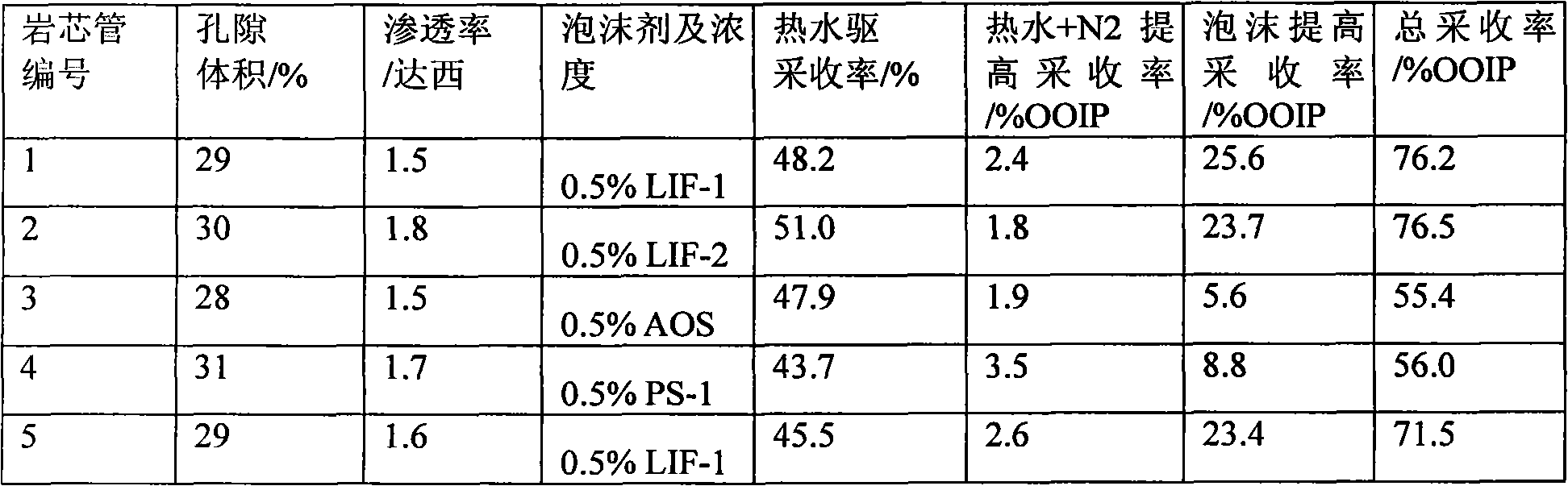

Temperature-resistant, salt-resistant and low-tension foam flooding agent and preparation method thereof

ActiveCN102020981AImprove stabilityReduce interfacial tensionFluid removalDrilling compositionFoaming agentActive agent

The invention relates to a temperature-resistant, salt-resistant and low-tension foam flooding agent and a preparation method thereof. The temperature-resistant, salt-resistant and low-tension foam flooding agent is prepared by continuously stirring alkanolamide, bipolar surfactant and water at 40-60DEG C until the alkanolamide, the bipolar surfactant and the water are completely dissolved. The temperature-resistant, salt-resistant and low-tension foam flooding agent provided by the invention is suitable for tertiary recovery under the conditions that the temperature is 50-120DEG C and the mineralization is 0-100000ppm. Compared with other common foam agents in the prior art, the oil-water interfacial tension is reduced from 10<-2>mN.m<-1> to 10<-3>mN.m<-1>; and compared with common interfacial active agents in the prior art, the half foam life period at 50DEG C is increased from 15 minutes to more than 40minutes, and the recovery ratio of an indoor model is increased by more than 15%.

Owner:SHANDONG UNIV

Oil-In-Water Emulsion and Its Use for the Delivery of Functionality

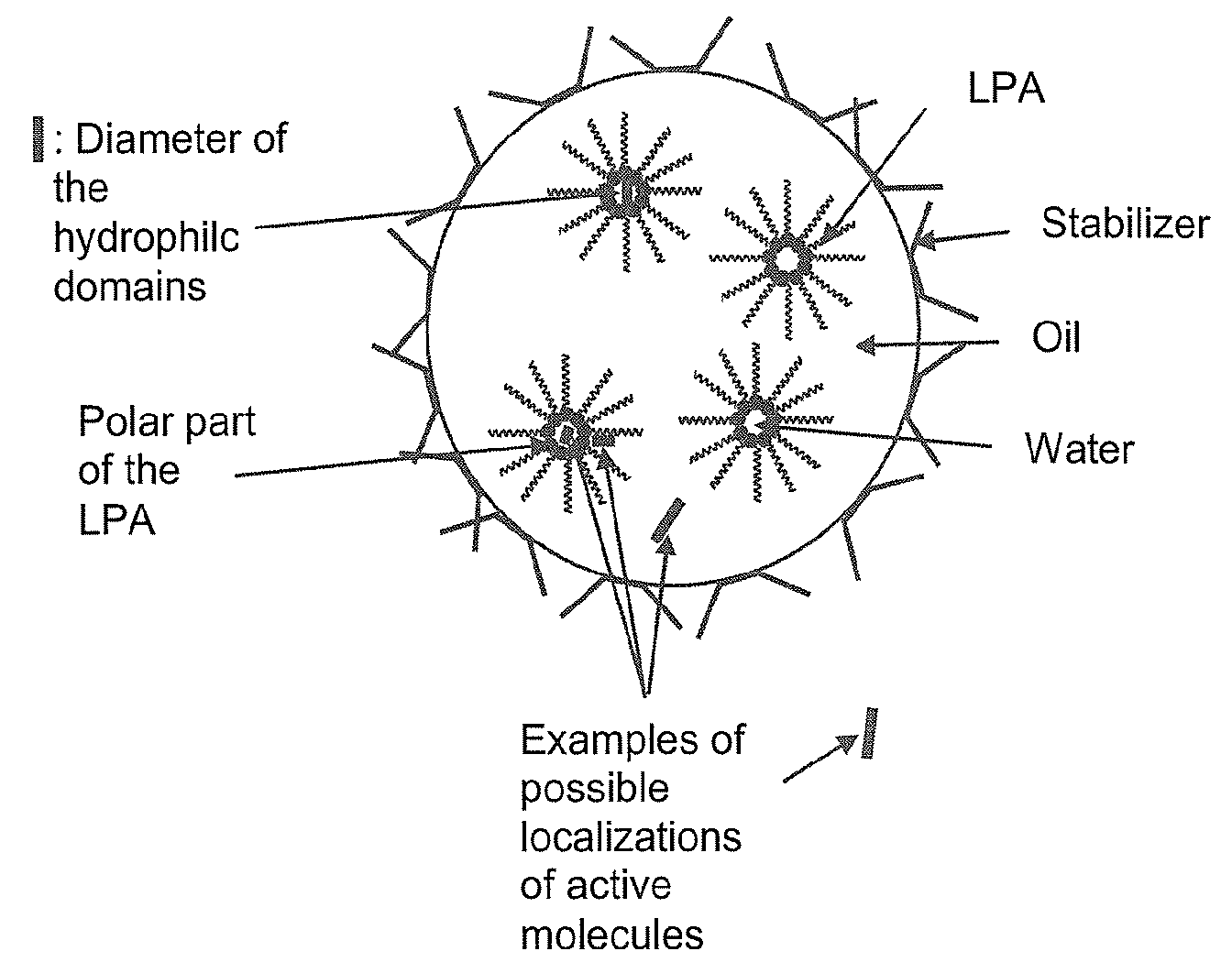

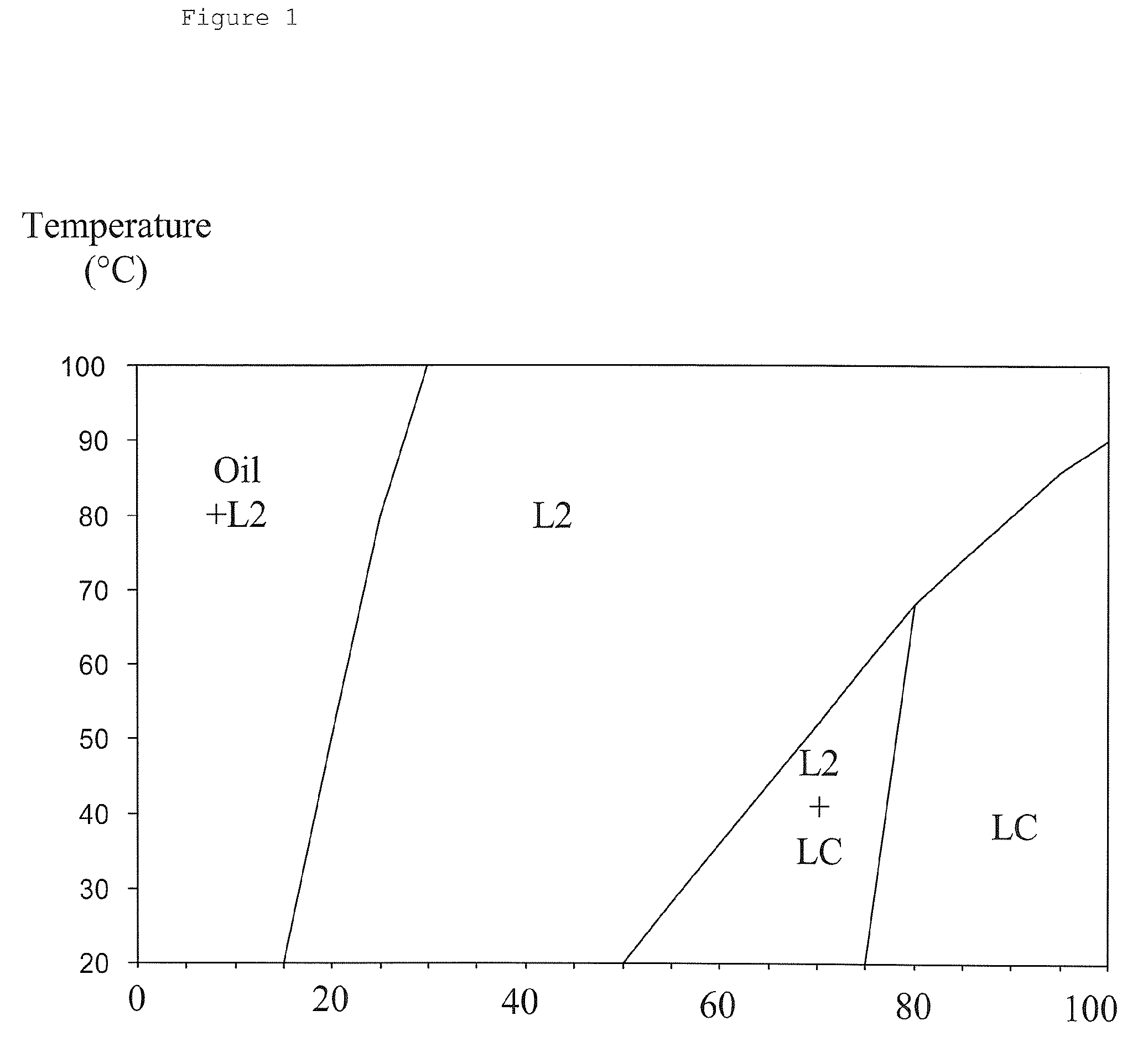

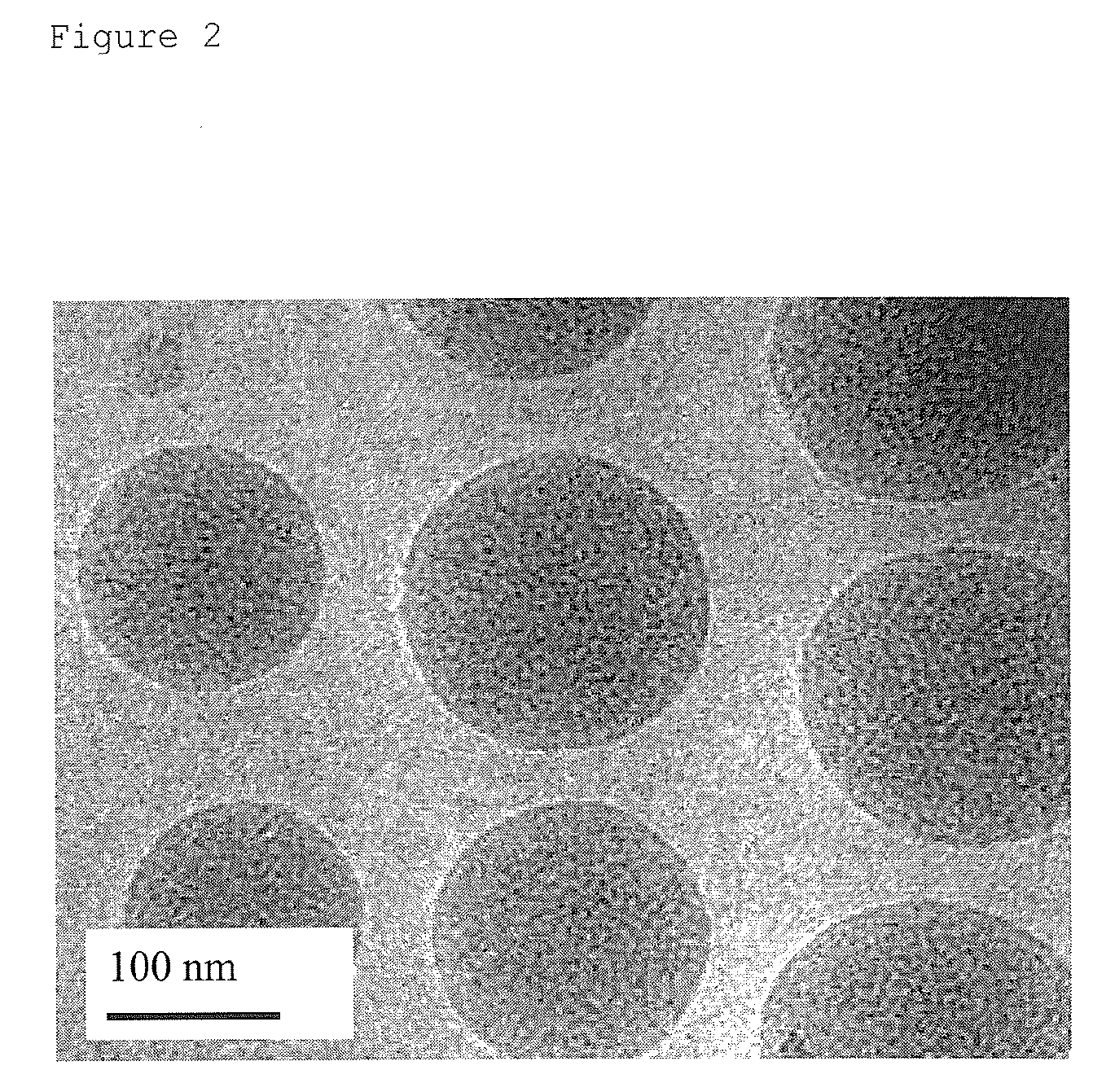

InactiveUS20080255247A1Improve protectionImprove stabilityBiocideCosmetic preparationsMicrometerNanometre

The present invention concerns an oil-in-water emulsion wherein the oil droplets of a diameter in the range of 5 nm to hundreds of micrometers exhibit a nano-sized self-assembled structurization with hydrophilic domains having a diameter size in the range of 0.5 to 200 nm, due to the presence of a lipophilic additive and the oil-in-water emulsion contains an active element being present in the range comprised between 0.00001 and 79% based on the total composition.

Owner:NESTEC SA

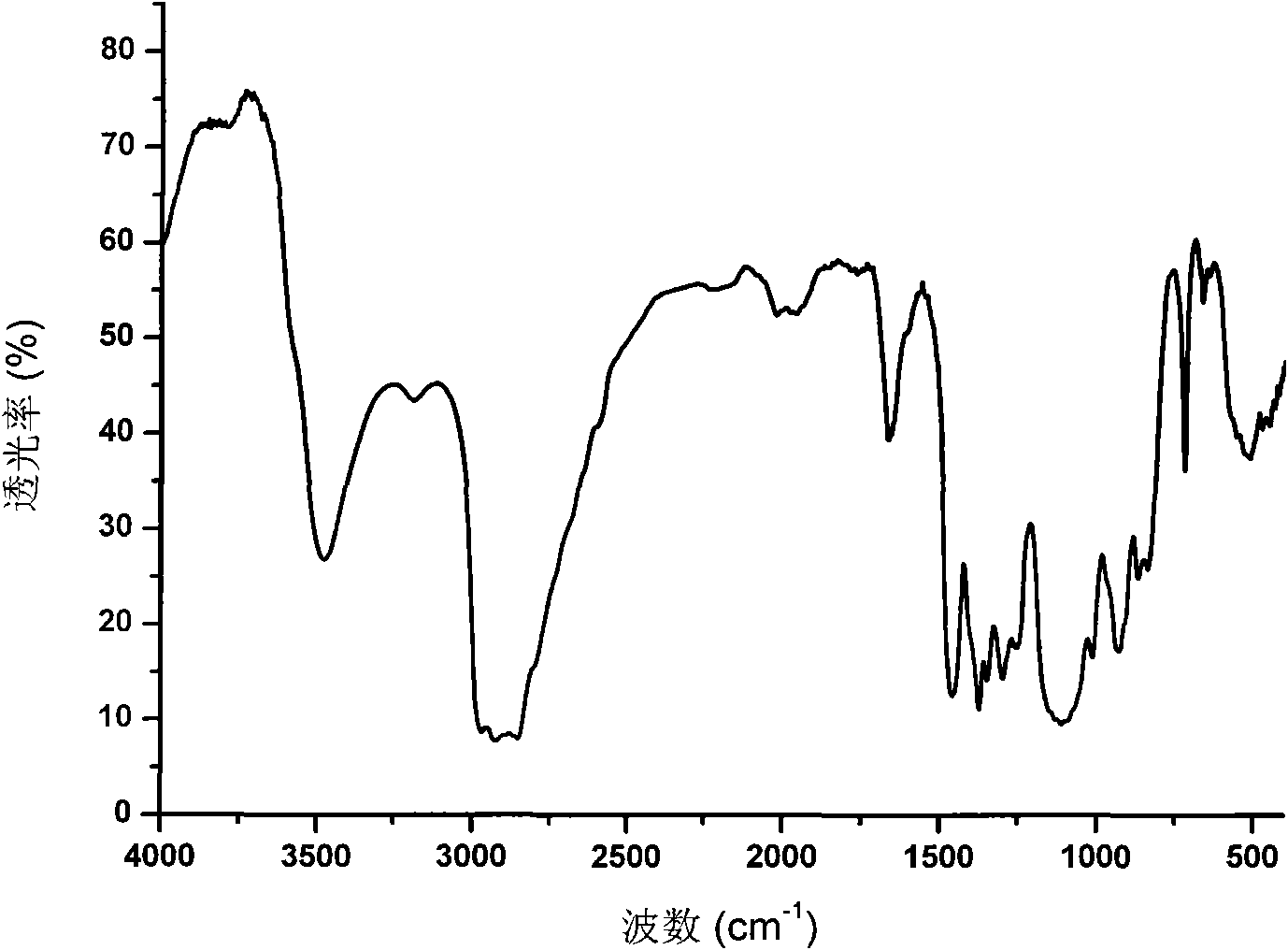

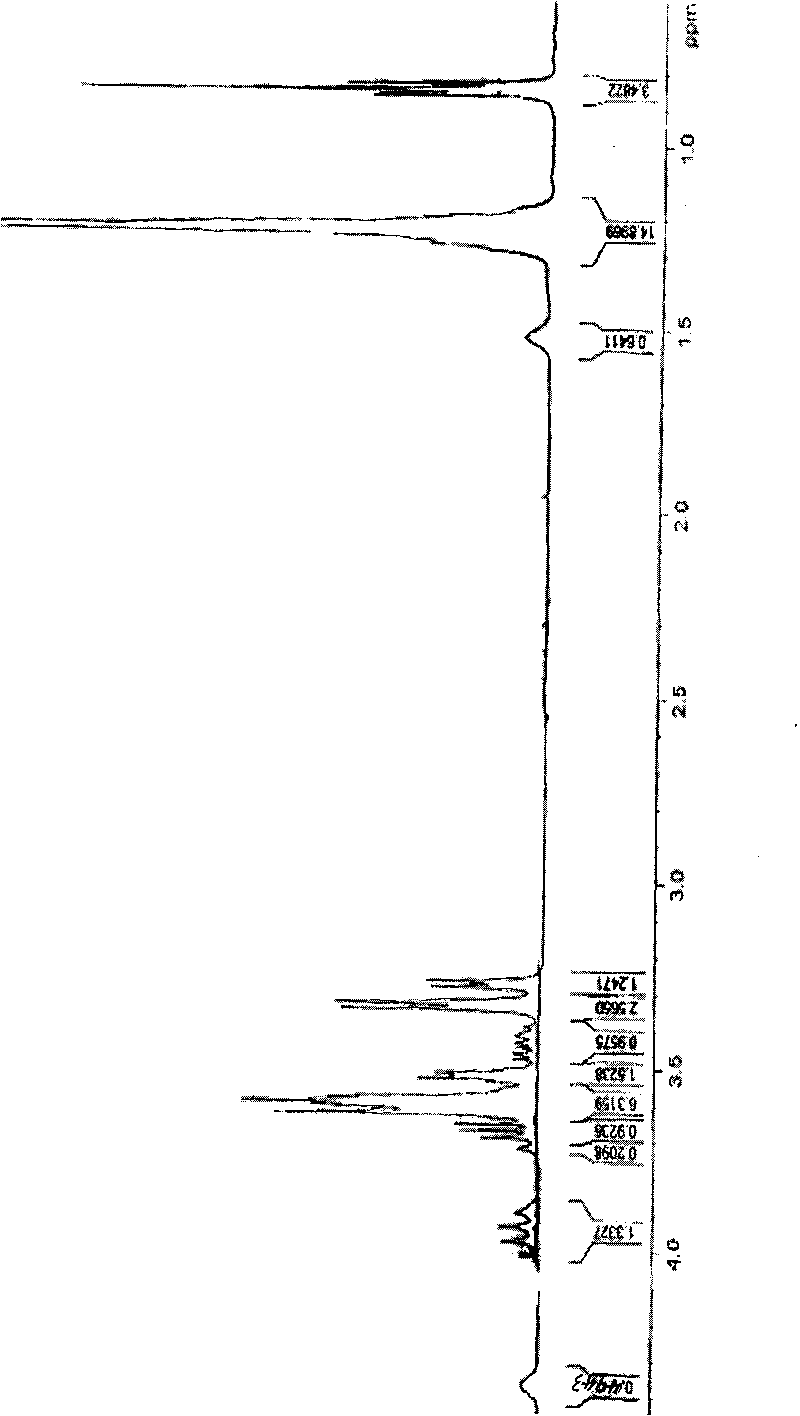

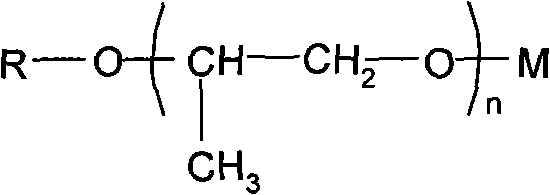

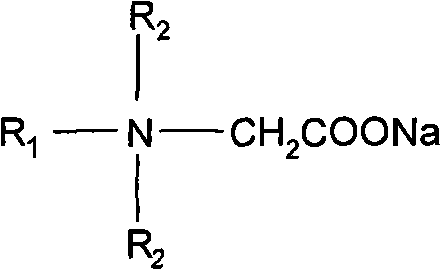

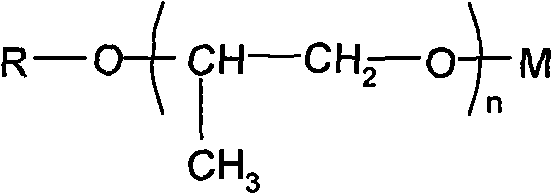

Fatty alcohol polyoxypropylene polyoxyethylene ether carboxylate, preparation thereof and application thereof

InactiveCN102485771ACarboxylationMeet the needs of tertiary oil recoveryOrganic compound preparationDrilling compositionFatty alcoholSURFACTANT BLEND

The invention relates to a fatty alcohol polyoxypropylene polyoxyethylene ether carboxylate, a preparation thereof and an application thereof. The structural general formula of the fatty alcohol polyoxypropylene polyoxyethylene ether carboxylate is RO(PO)n(EO)mCH2COOX, wherein R is an aliphatic alkyl group or an alkylphenyl group; (PO)n is polyoxypropylene; n is between 6 and 12; (EO)m is polyoxyethylene; m is between 1 and 4; X is an alkali metal, the fatty alcohol and the polyoxypropylene at the left terminal of the structural general formula are lipophilic groups; and polyoxyethylene and the carboxyl group at the right terminal of the structural general formula are hydrophilic groups. Polyoxypropylene is added to increase the lipophilicity of fatty alcohol carboxylate surfactants to adapt to the application of tertiary oil recovery, and a small amount of polyoxyethylene is added to adjust the hydrophilicity and simultaneously carboxylate fatty alcohol polyoxypropylene esters on condition that the current fatty alcohol raw material is unchanged.

Owner:PETROCHINA CO LTD

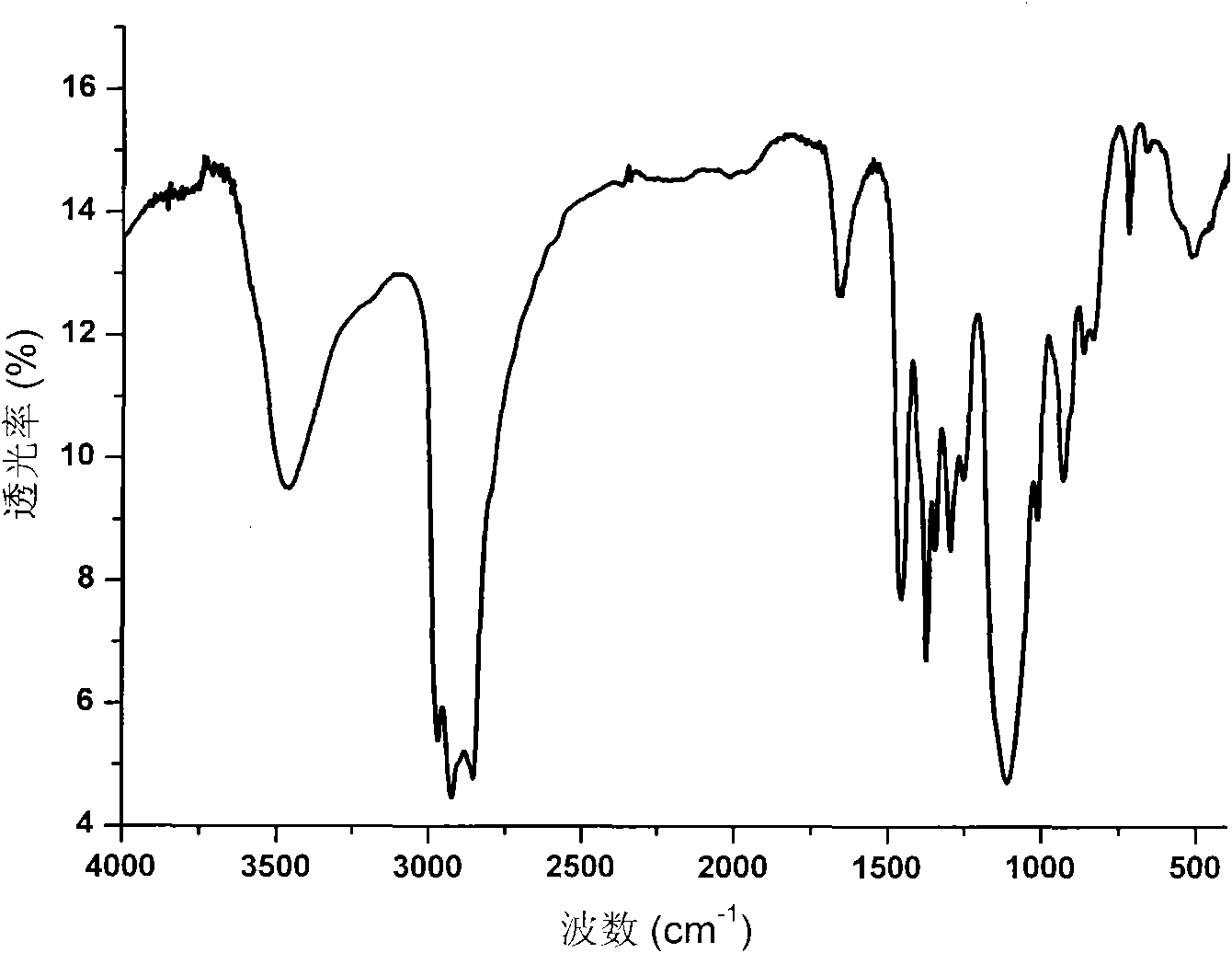

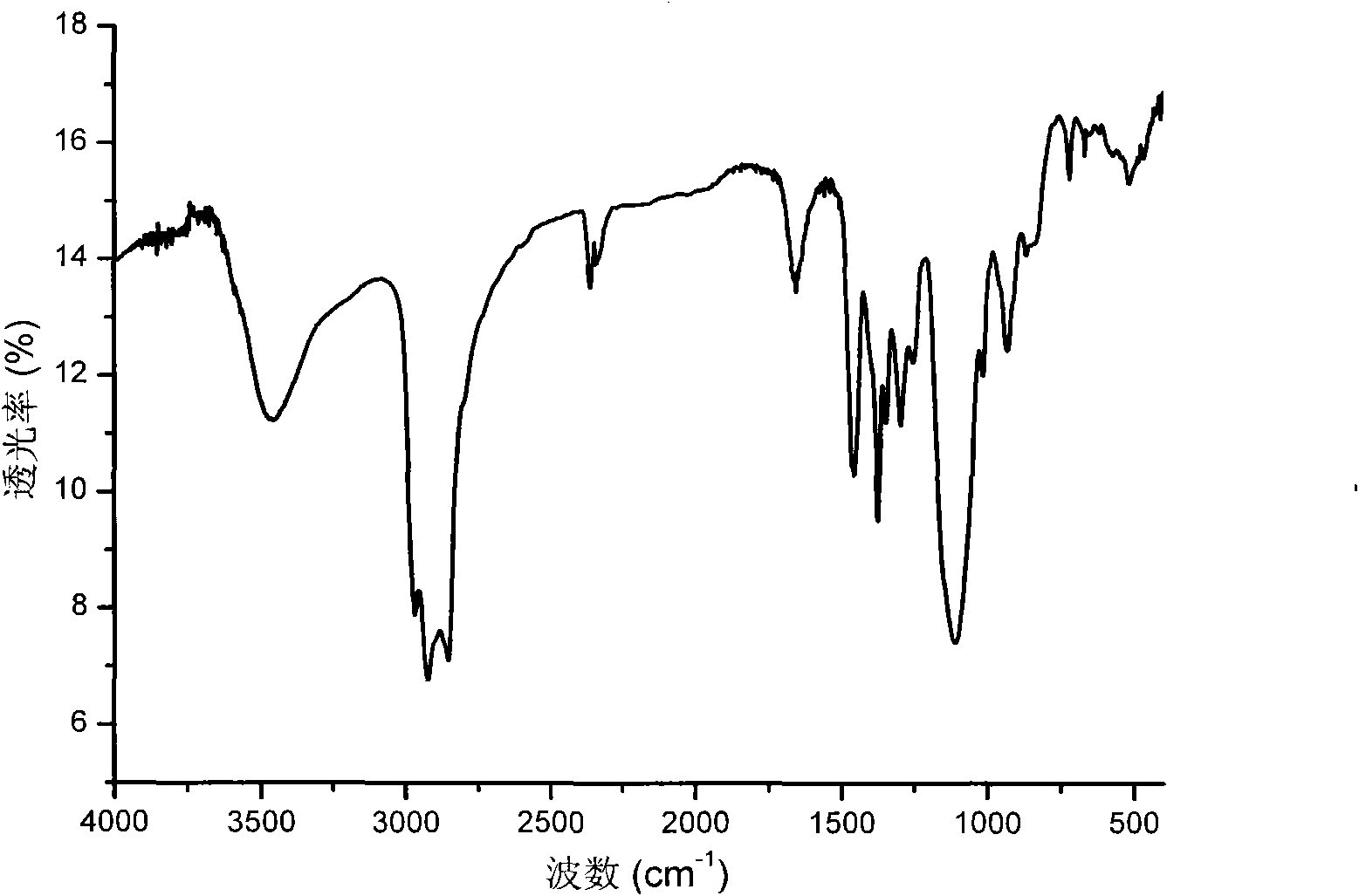

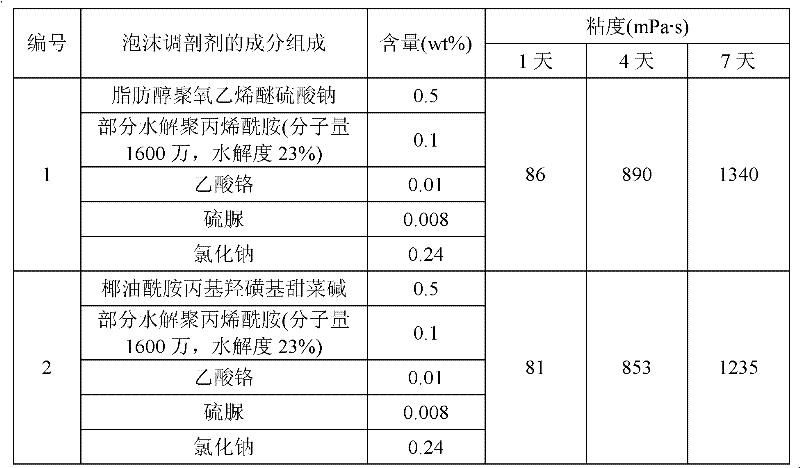

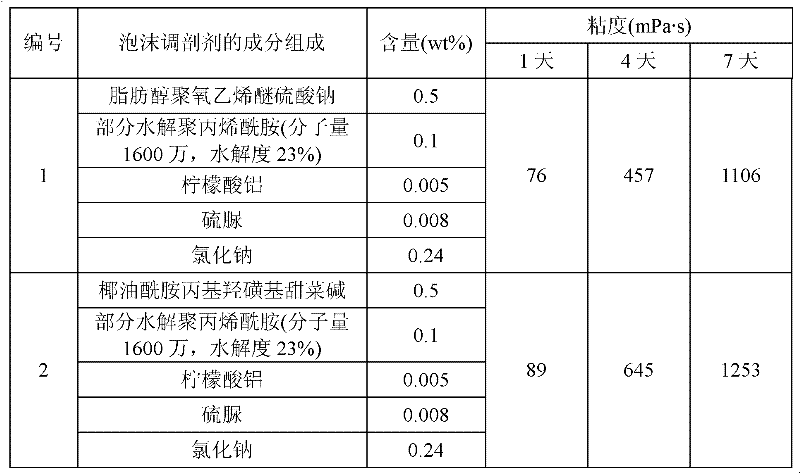

Foam profile control agent applicable to oil field in-depth profile control

The invention provides a foam profile control agent applicable to oil field in-depth profile control. The foam profile control agent provided in the invention comprises a polymer cross-linking solution and gas; under formation pressure, a volume ratio of the gas to the polymer cross-linking solution is 0.2: 1 to 1: 1; and the polymer cross-linking solution of the foam profile control agent comprises, by weight, 0.3 to 1.2 wt% of a surfactant, 0.01 to 0.8 wt% of a polymer, 0.001 to 0.2 wt% of a cross-linking agent, 0.001 to 0.1 wt% of a stabilizing agent and 0.05 to 1.5 wt% of inorganic salt, with the balance being water. The foam profile control agent has an effect on delaying cross-linking, can effectively plug a high-permeability zone, can reduce oil-water interfacial tension and has the effects of enlarging swept volume and improving oil displacement efficiency.

Owner:PETROCHINA CO LTD +1

Enhancing thermal conductivity of fluids with graphite nanoparticles and carbon nanotube

InactiveUS7348298B2Improve thermal conductivityGood enhancement of thermal characteristicMaterial nanotechnologyAdditivesNanoparticleGraphite

A fluid media such as oil or water, and a selected effective amount of carbon nanomaterials necessary to enhance the thermal conductivity of the fluid. One of the preferred carbon nanomaterials is a high thermal conductivity graphite, exceeding that of the neat fluid to be dispersed therein in thermal conductivity, and ground, milled, or naturally prepared with mean particle size less than 500 nm, and preferably less than 200 nm, and most preferably less than 100 nm. The graphite is dispersed in the fluid by one or more of various methods, including ultrasonication, milling, and chemical dispersion. Carbon nanotubes with graphitic structure is another preferred source of carbon nanomaterial, although other carbon nanomaterials are acceptable. To confer long term stability, the use of one or more chemical dispersants is preferred. The thermal conductivity enhancement, compared to the fluid without carbon nanomaterial, is proportional to the amount of carbon nanomaterials (carbon nanotubes and / or graphite) added.

Owner:ASHLAND OIL INC +1

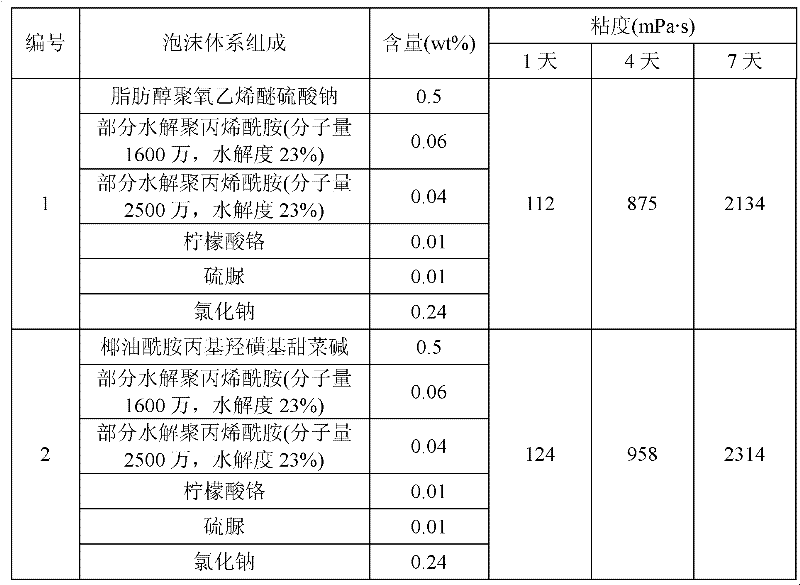

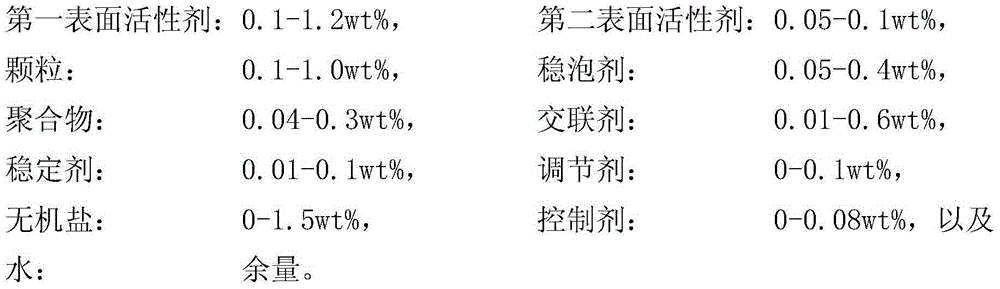

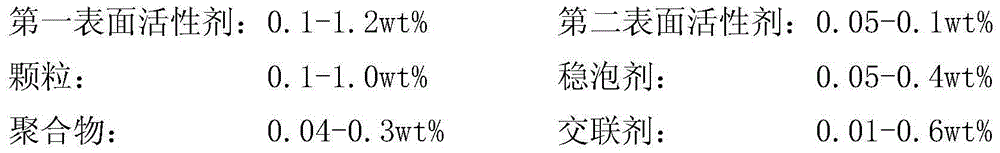

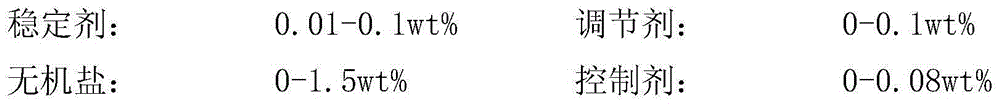

Foam profile control system suitable for advanced profile control of oilfield and preparation method of foam profile control system

ActiveCN104152126AStrong salt toleranceStrong deep sealing abilityFluid removalDrilling compositionSalt resistanceInorganic salts

The invention discloses a foam profile control system suitable for advanced profile control of an oilfield. A liquid of the system is prepared from a first surfactant, a second surfactant, granules, a foam stabilizer, a polymer, a crosslinking agent, a stabilizer, an adjustor, inorganic salt, a control agent and water. The foam profile control system has three characteristics of foam, gels and granules at the same time, and has a strong deep sealing capacity to a high-permeability oil layer, namely, has an effect on expanding the swept volume. The system further can reduce the oil-water interface tension, and mainly exerts a gel performance at a low-permeability layer and a foam property at a high-permeability layer, that is, the system has the effects on improving the oil dispelling efficiency and selectively plugging water. When the system is used, as gases exist, the use level of the foam profile control system is reduced, and the foam profile control system has the characteristics of temperature resistance and salt resistance at the same time.

Owner:PETROCHINA CO LTD +1

Methods of using natural products as dewatering aids for fine particles

InactiveUS6526675B1Reduce moistureImprove hydrophobicityPigmenting treatmentDrying using combination processesLipid formationSlurry

A method of dewatering fine particulate materials is disclosed. In this method, an aqueous slurry of fine particles is treated with appropriate hydrophobizing reagents so that the particulate material becomes moderately hydrophobic. A lipid of vegetable or animal origin is then added to the slurry in solutions of light hydrocarbon oils and short-chain alcohols, so that the hydrophobic lipid molecules adsorb on the moderately hydrophobic surface and, thereby, greatly enhance its hydrophobicity. By virtue of the enhanced hydrophobicty, the water molecules adhering to the surface are destabilized and more readily removed during the process of mechanical dewatering. The moisture reduction can be further improved using appropriate electrolytes in conjunction with the lipids, spraying surface tension lowering reagents onto the filter cake, subjecting the cake to a suitable vibratory means, and using combinations thereof.

Owner:YOON ROE HOAN

Method for reducing minimum miscible phase pressure between CO2 and crude oil of miscible phase displacement

The invention relates to a method for reducing the minimum miscible phase pressure between CO2 and crude oil of miscible phase displacement of CO2-containing oil deposits, overcoming the defect that the minimum miscible phase pressure between the CO2 and the crude oil is high, so CO2-containing miscible phase displacement cannot be achieved. In the technical scheme, surfactant slug is injected into an oil well at first, and when surfactants are dissolved in the in-place oil, the viscosity of the in-place oil is reduced to the viscosity range of the CO2-containing miscible phase displacement; and CO2 slug is injected under the pressure of 18.00-23.00 MPa, and since the surfactants injected at first can be dissolved in the supercritical CO2, the interface tension between a gas phase and an oil phase can be reduced rapidly due to the surfactants after injection of the CO2, the minimum miscible phase pressure between the CO2 and the crude oil can be reduced, the miscible phase can be achieved rapidly, and the miscible phase displacement can be realized. The invention has dual characteristics of reducing the viscosity and decreasing the minimum miscible phase pressure; the consumption of the surfactants and the cost are low; and the recovery rate of the crude oil is 5-14 percent higher than the recovery rate in the pure CO2 displacement under the same pressure.

Owner:SOUTHWEST PETROLEUM UNIV

Real stone paint, and preparation method and construction method thereof

The invention provides a real stone paint. The real stone paint comprises, by weight, 90-130 parts of water, 2-5 parts of hydroxyethyl cellulose, 2-5 parts of a dispersant, 1-3 parts of a wetting agent, 4-8 parts of an antifoaming agent, 2-3 parts of an antiseptic, 100-150 parts of an emulsion, 5-12 parts of a film forming assistant, 1-3 parts of a pH adjusting agent, 5-20 parts of an antifreeze agent and 400-900 parts of a color sand component, wherein the color sand component comprises two or more than two natural stone flours with similar color. The invention further provides a preparation method of the real stone paint. The natural stone flowers with similar color in raw materials are blended in the embodiment of the invention to balance the color difference of all the natural stone flours, so even the color of one of the natural stone flours changes, the color difference of real stone paint products in batches is very small under the contrast of other natural stone flours with similar color, thereby the color difference change of the real stone paint is well controlled.

Owner:DRAGON BRAND COATINGS (BEIJING) CO LTD

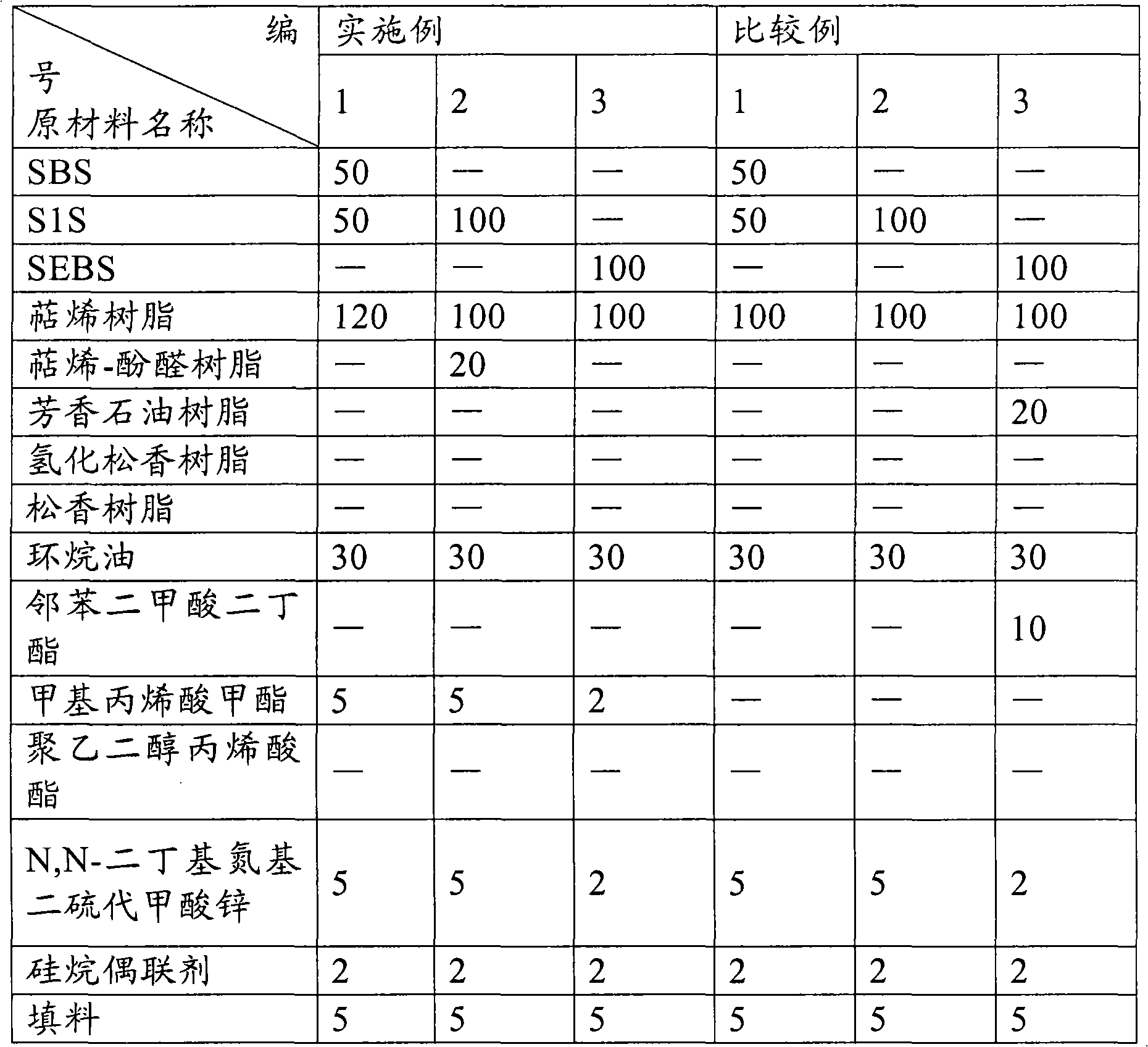

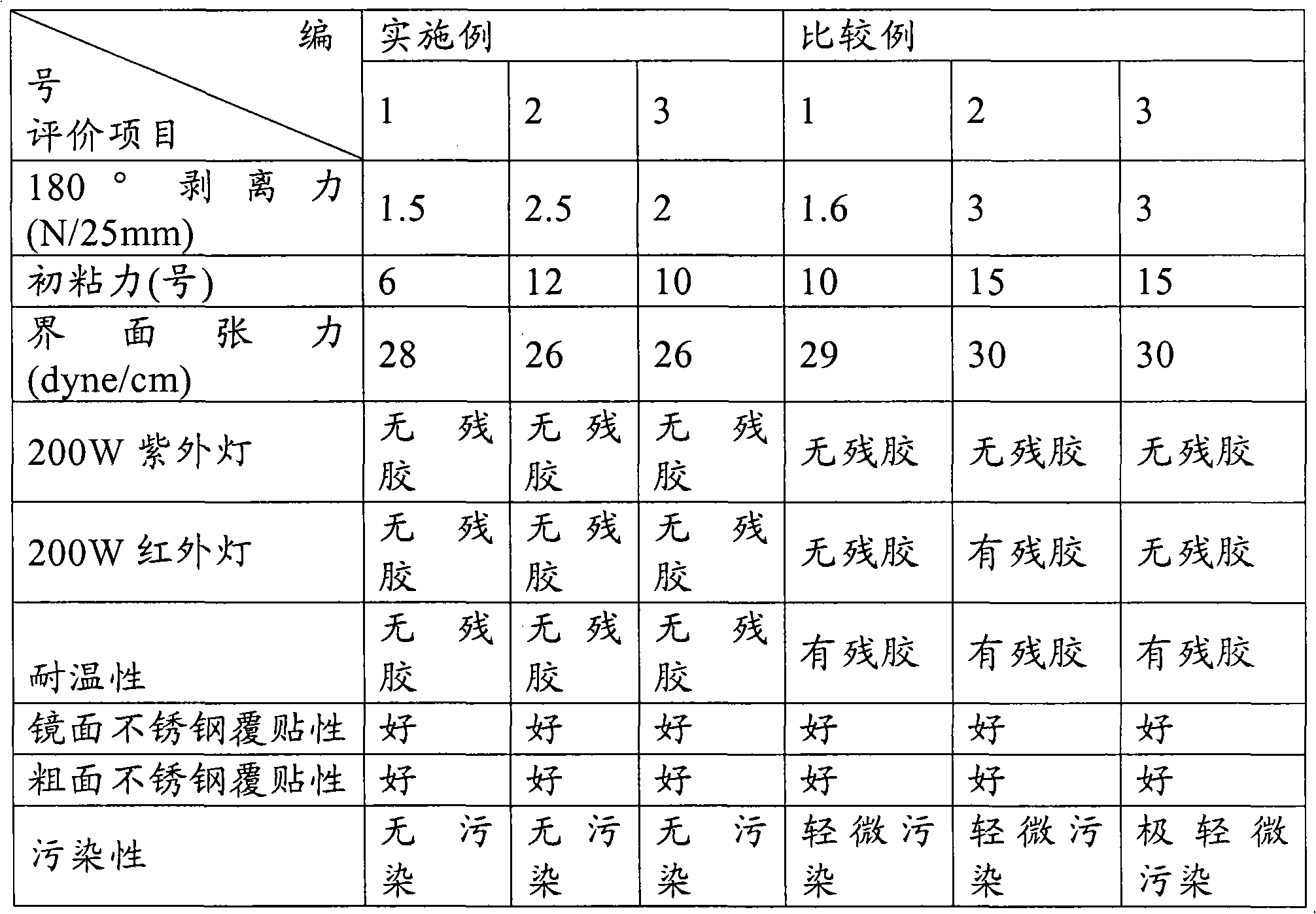

Preparation methods of hot melt pressure-sensitive adhesive and protective film as well as hot melt pressure-sensitive adhesive

ActiveCN102051149AImprove heat resistanceGood weather resistanceLiquid surface applicatorsNon-macromolecular adhesive additivesTectorial membranePolyolefin

The invention discloses preparation methods of a hot melt pressure-sensitive adhesive and a protective film as well as the hot melt pressure-sensitive adhesive. The preparation method of the hot melt pressure-sensitive adhesive comprises the following steps: adding thermoplastic elastomers, a tackifier, a plasticizer, an antiager, an antioxidant, a crosslinker, a filler and the like into a double-mixed column mixer, stirring, heating until the materials are melted down, and uniformly mixing to obtain the pressure-sensitive adhesive. The preparation method of the protective film comprises the following steps: directly pumping the melted and uniformly mixed pressure-sensitive adhesive into a coating roll of the a hot melt coating machine by a heat transfer pump, coating the pressure-sensitive adhesive onto one face of a polyolefin plastic film or thin plastic-coated paper, cooling, and rolling to obtain the protective film (paper). The hot melt pressure-sensitive adhesive disclosed by the invention can obtain good initial stickiness, cohesion and age stripping property by changing the different ratio of the thermoplastic elastomer as well as the variety and usage amount of the tackifier. The prepared polyethylene (PE) film substrate protective film has low interfacial tension, good initial stickiness, high cohesion and high temperature resistance, light resistance and weather resistance, and the comprehensive performance and product cost of the hot melt pressure-sensitive adhesive disclosed by the invention are better than those of the traditional solvent pressure-sensitive adhesive taking natural rubber as the main material.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

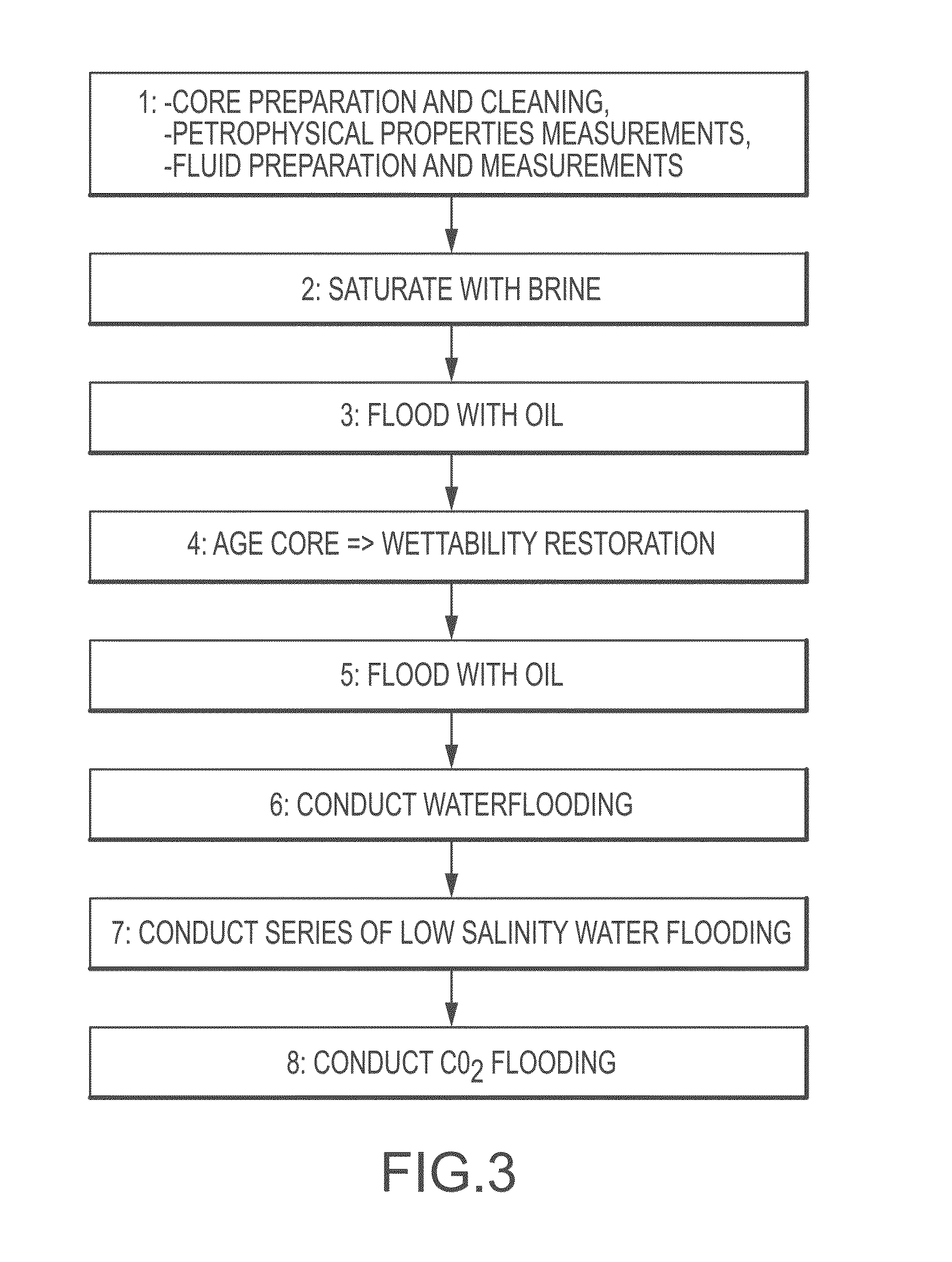

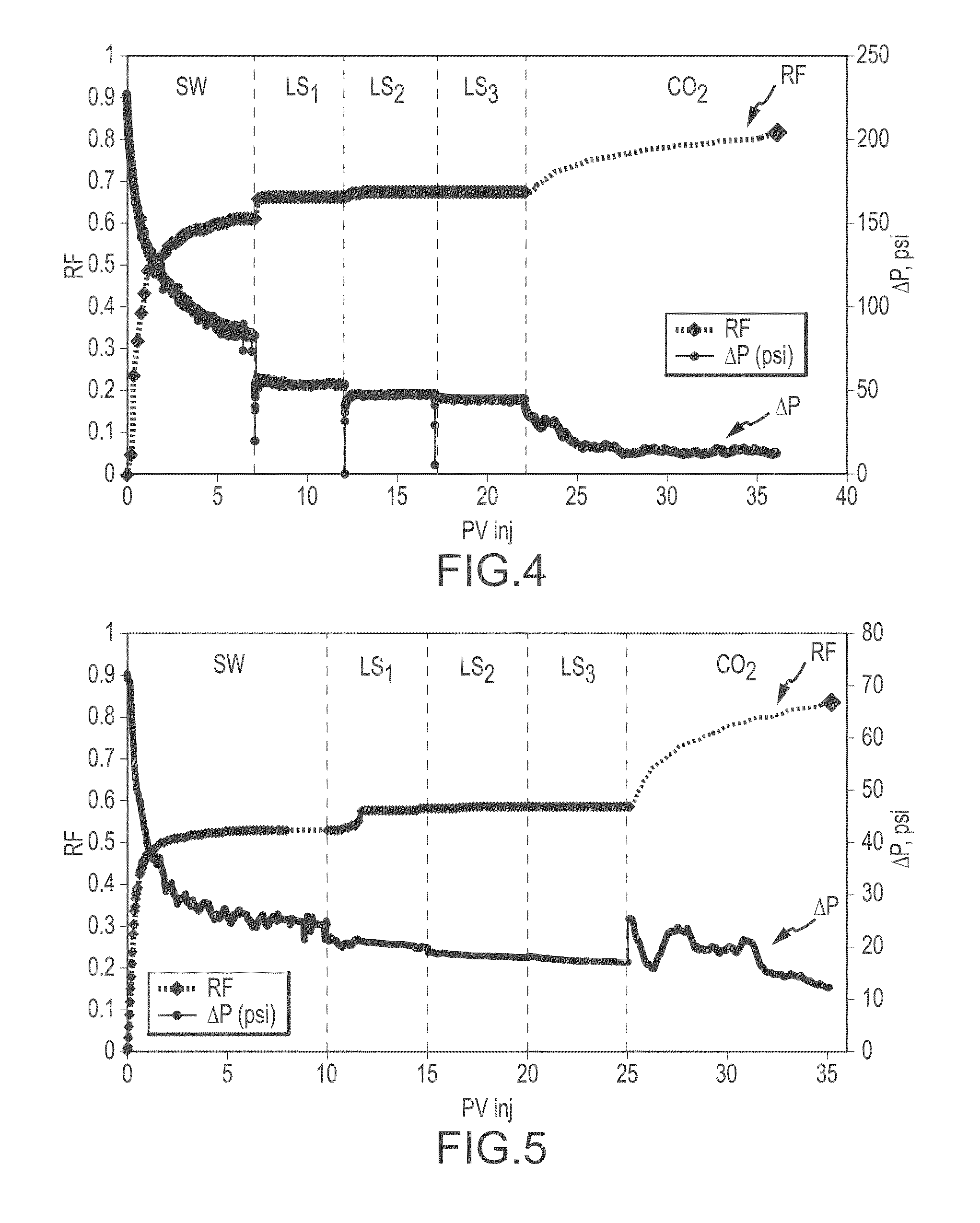

Enhanced oil recovery process to inject low salinity water and gas in carbonate reservoirs

InactiveUS20150233222A1Speed up recoverySignificant amount of additionalFluid removalDrilling compositionLow salinityEnvironmental engineering

The present invention relates to a method to enhance oil recovery from a hydrocarbon reservoir. One aspect of the invention includes injecting high salinity water into the reservoir followed by alternating the injection of low salinity water and gas.

Owner:COLORADO SCHOOL OF MINES

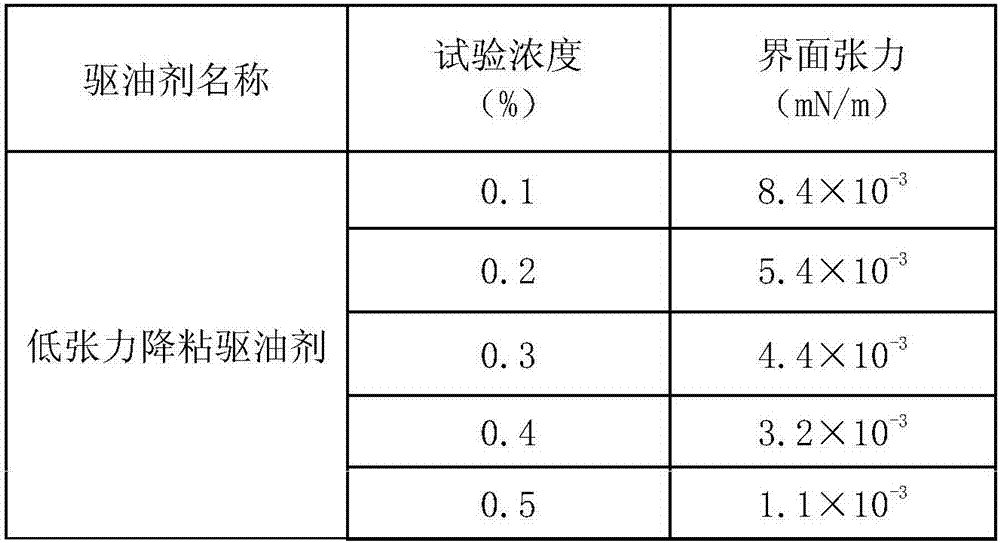

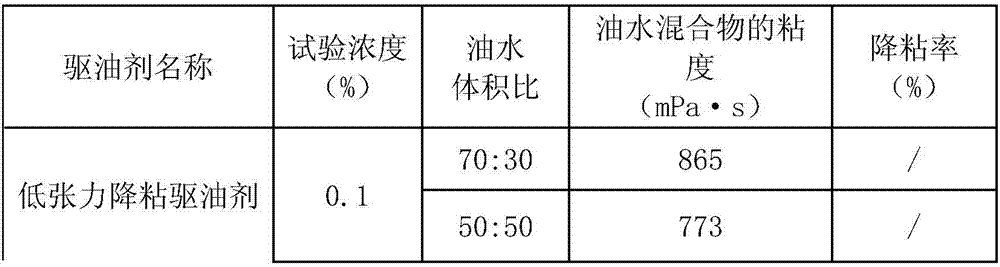

Viscosity-reducing oil displacement agent for common heavy oil reservoirs, and preparation method thereof

ActiveCN107365574ALower mobility ratioReduce interfacial tensionDrilling compositionPolyacrylamidePOLYOXYETHYLENE ETHER

The invention discloses a low-tension viscosity-reducing oil displacement agent, which is used for common heavy oil reservoirs, has a good viscosity-reducing effect, has good compatibility with formation water, can form ultra-low interfacial tension with crude oil, and is prepared from the following components by weight: 30-50% of an alkyl alcohol polyoxyethylene ether sulfate salt, 15-25% of a nonionic surfactant, 15-25% of an anionic surfactant, 2-5% of an organic solvent, 0.1-3% of sodium chloride, and 5-25% of water. According to the present invention, during the use, the low-tension viscosity-reducing oil displacement agent and the polyacrylamide polymer form the composite oil displacement system, wherein the polyacrylamide polymer can provide effects of water phase viscosity increasing, water-oil mobility ratio reducing, conformance expanding and profile control expanding, and the low-tension viscosity-reducing oil displacement agent can provide effects of oil-water interface tension reducing, oil displacement efficiency improving and crude oil viscosity reducing so as to further improve the water-oil mobility ratio, such that the extraction rate of the common heavy oil reservoir can be substantially improved through the synergetic effect of the polyacrylamide polymer and the low-tension viscosity-reducing oil displacement agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

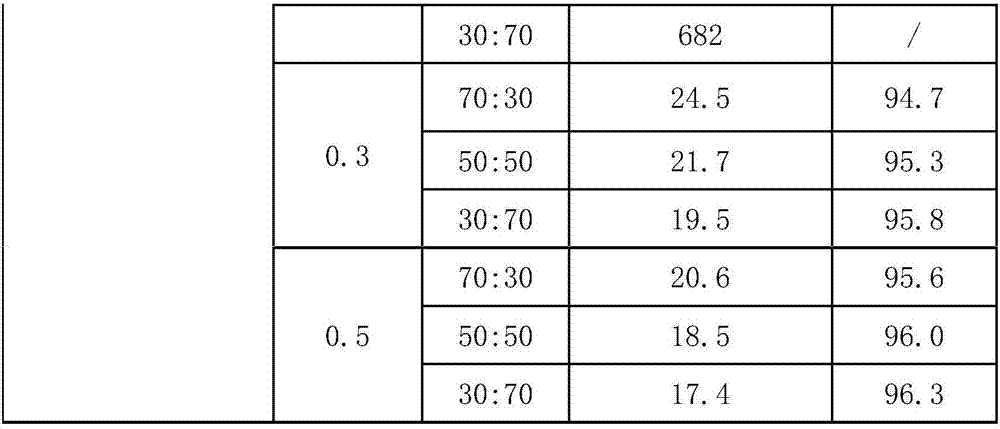

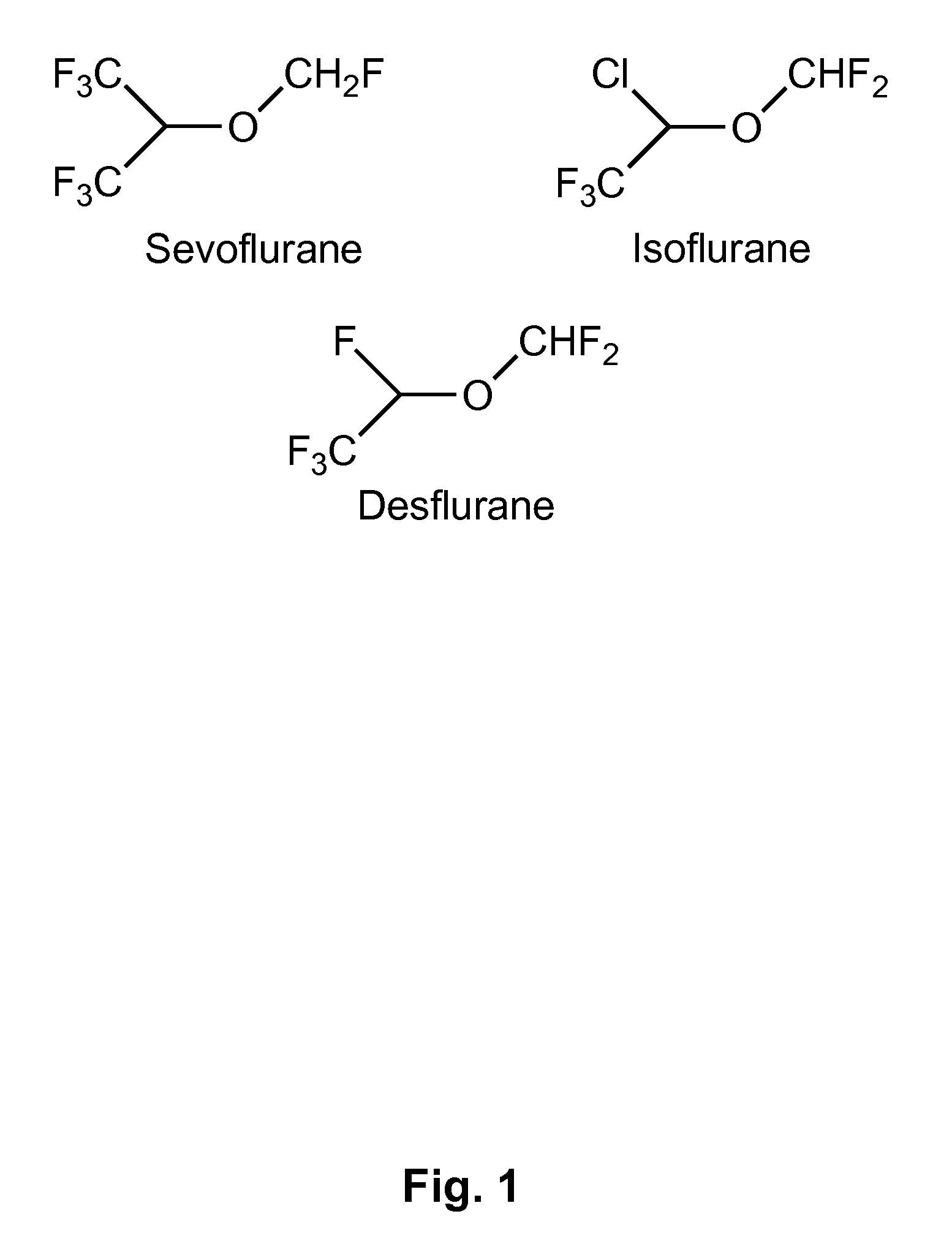

Fluoropolymer-based emulsions for the intravenous delivery of fluorinated volatile anesthetics

InactiveUS20080234389A1Maintenance can be inducedReduce interfacial tensionBiocideNervous disorderAnesthetic AgentEmulsion

The present invention provides therapeutic formulations, including therapeutic emulsions and nanoemulsions, and related methods for the delivery of fluorinated therapeutic compounds, including an important class of low boiling point perfluorinated and / or perhalogenated volatile anesthetics. Emulsion-based fluorinated volatile anesthetic formulations compatible with intravenous administration are provided that are capable of delivering and releasing amounts of fluorinated volatile anesthetic compounds effective for inducing and maintaining anesthesia in patients. Intravenous delivery of the present emulsion-based fluorinated volatile anesthetic formulations permits anesthetic levels in a patient to be selectively adjusted very rapidly and accurately without the need to hyperventilate patients and without the use of irritating agents.

Owner:WISCONSIN ALUMNI RES FOUND

Nanohybrid-stabilized emulsions and methods of use in oil field applications

ActiveUS20120181029A1Reduce interfacial tensionMaterial nanotechnologyFluid removalEmulsionAqueous solution

Methods of using nanohybrid-stabilized emulsions in a well are provided. The methods include the steps of: (a) forming an emulsion comprising: (i) a nanohybrid; (ii) water or an aqueous solution; and (iii) a water-immiscible liquid; (b) introducing a well fluid comprising the emulsion into a well; and (c) after the step of introducing, modifying the nanohybrid to break the emulsion in the well. The methods can be used in various applications, such as in drilling, completion, or intervention operations.

Owner:HALLIBURTON ENERGY SERVICES INC

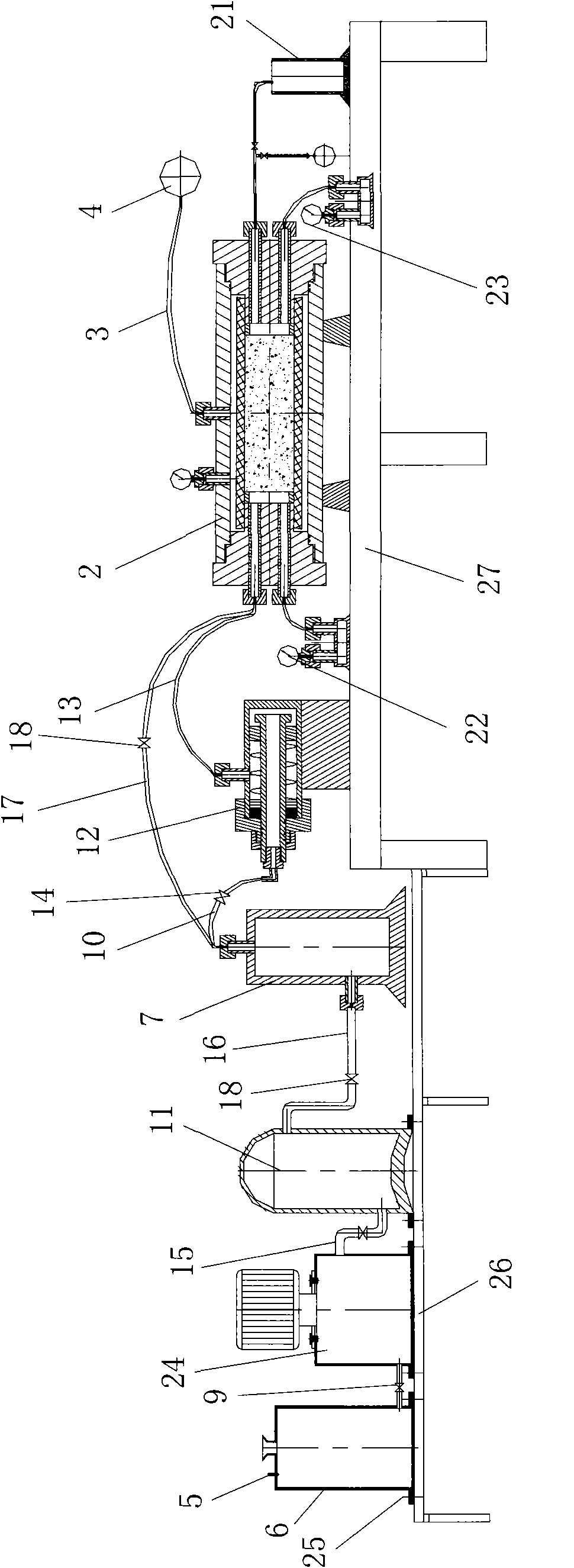

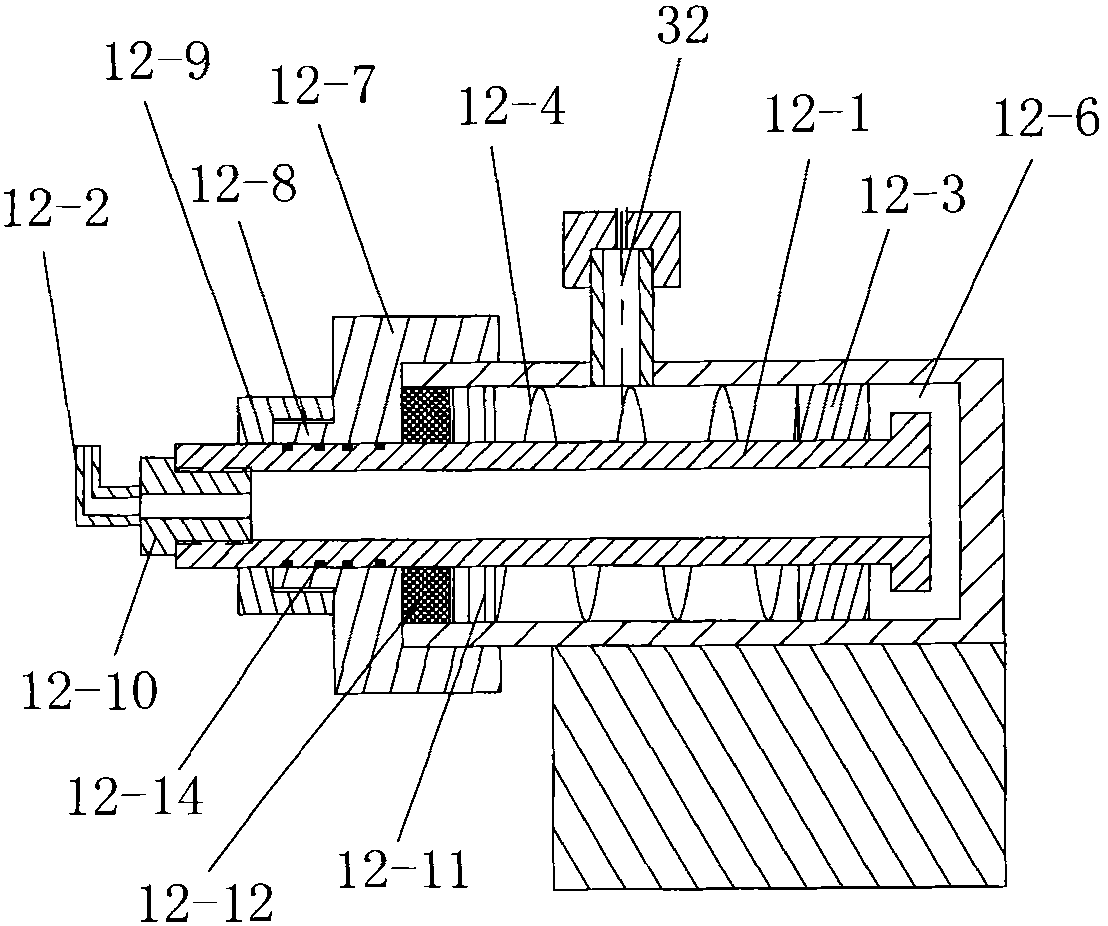

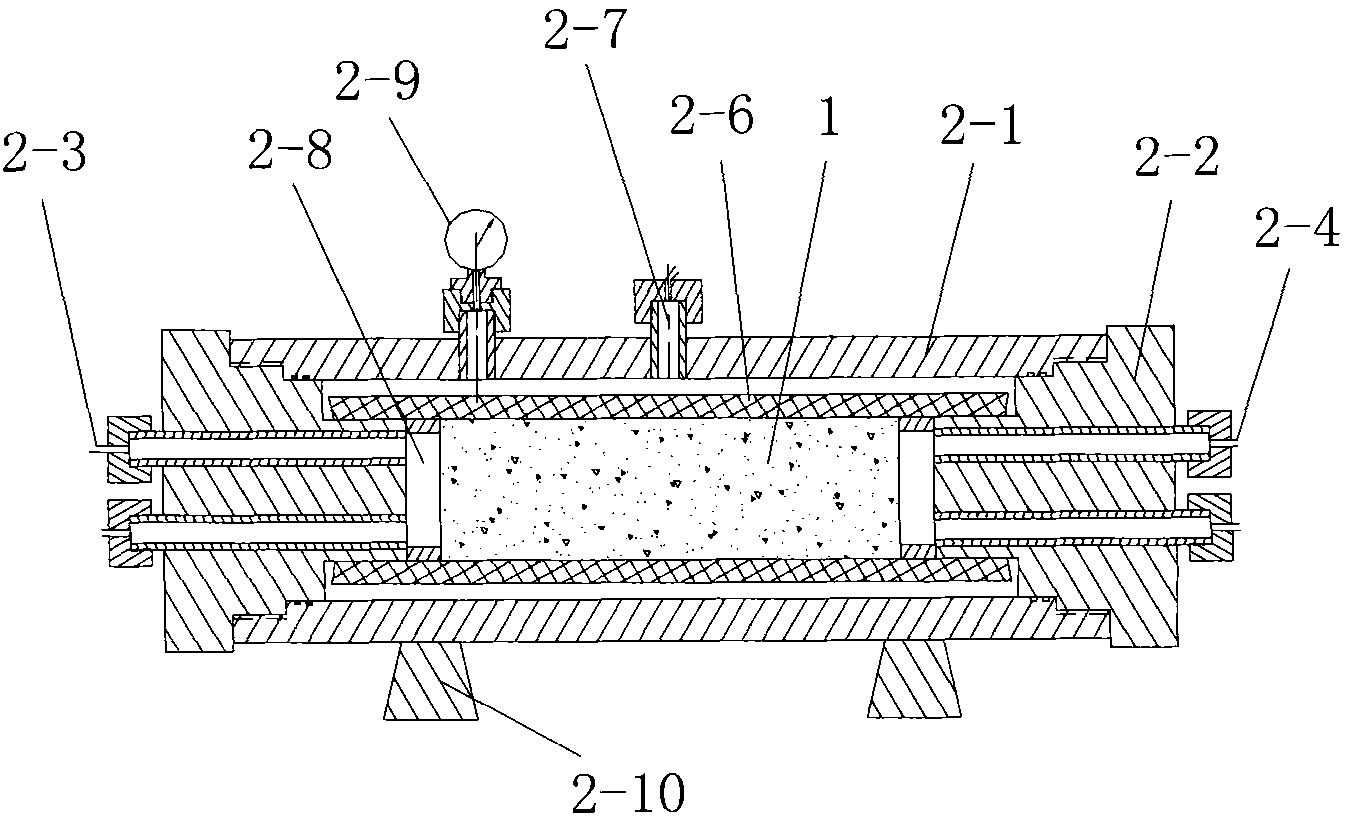

Hydraulic power pulse oil displacement experimental facility and experimental method thereof

ActiveCN101975053AImprove work efficiencyEnhanced overall recoveryFluid removalVibration devicesExperimental methodsWater storage tank

The invention discloses a hydraulic power pulse oil displacement experimental facility and an experimental method thereof. The experimental facility comprises a core clamping device, an annular pressure supply device, a hydraulic power pulse wave generating device, a water storage tank and an oil storage tank which are connected with the liquid inlet of the core clamping device by virtue of a water pipeline and an oil pipeline as well as a liquid container which is connected with the liquid outlet of the core clamping device; wherein the water pipeline and the oil pipeline are all provided with an intermediate container, a pumping device used for generating high pressure liquid flow and an energy storage tank. The experimental method includes the following steps: firstly, oil displacementexperiment is carried out under the condition that no hydraulic power pulse is added; secondly, oil displacement experiment is carried out while frequency and amplitude hydraulic power pulse wave of core are replaced, and meanwhile hydraulic power pulse auxiliary chemical oil displacement experiment is completed; thirdly, data processing is carried out. The invention has reasonable design, mounting convenience, simple operation and good simulation effect, can improve efficiency of oil displacement by water and crude oil recovery ratio, and experiment of hydraulic pulse wave oil displacement and hydraulic pulse wave auxiliary reservoir core oil displacement by water can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

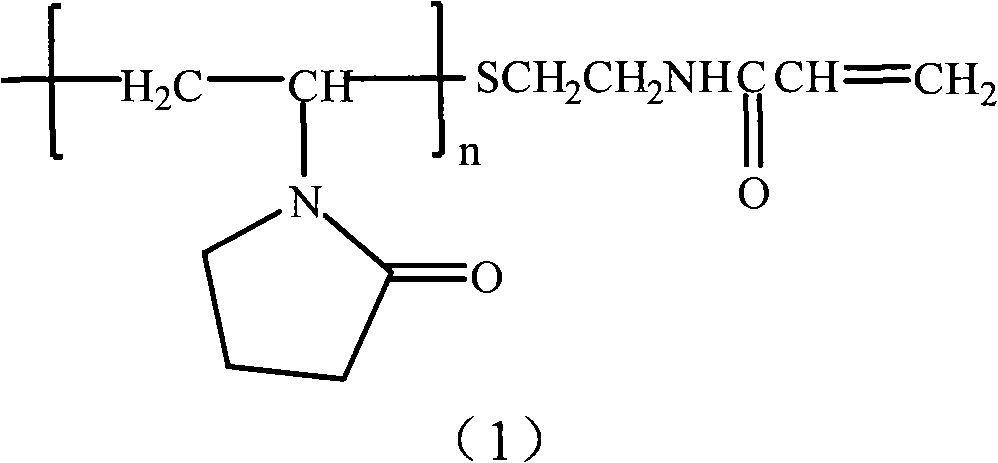

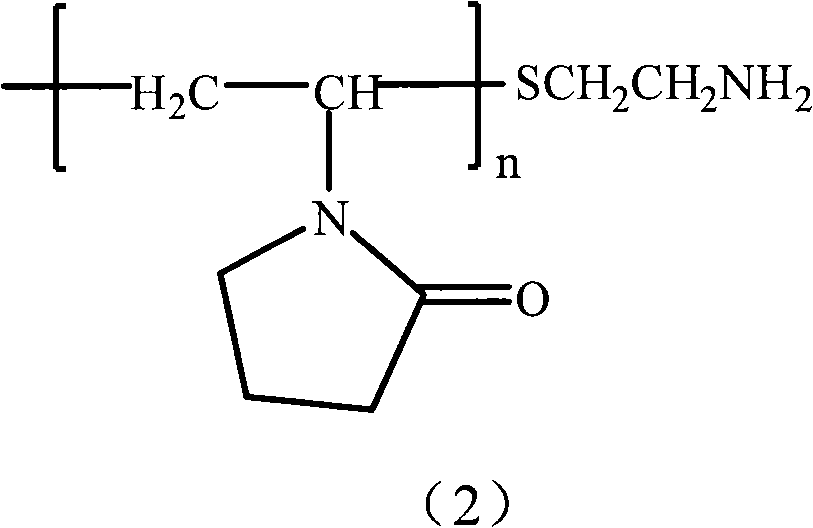

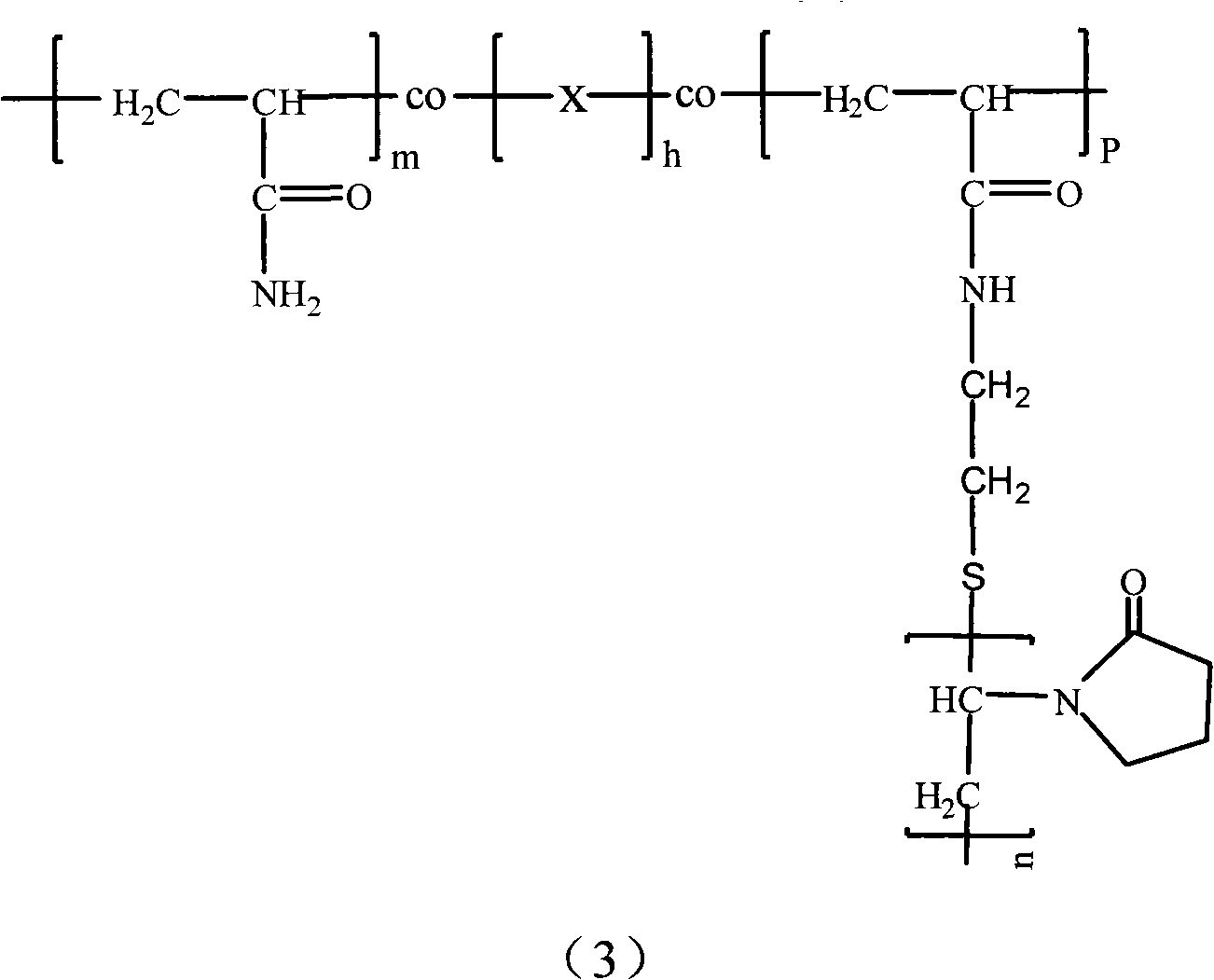

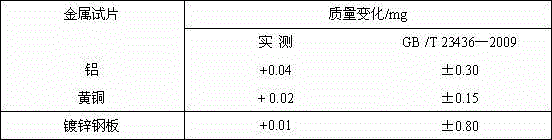

Heat-resistant salt-tolerate graft polyacrylamide and preparation method thereof

ActiveCN102050926AGood chemical stabilityReduce interfacial tensionDrilling compositionMethacrylamideSide chain

The invention belongs to the field of water-soluble flooding polymer study, particularly relates to a high-molecular-weight heat-resistant salt-tolerate graft polyacrylamide synthesized with macromolecule monomer route. The preparation method of the heat-resistant salt-tolerate graft polyacrylamide comprises obtaining poly(N-vinyl pyrrolidone)acrylamide macromolecule monomer through chain transfer free radical polymerization and terminal group replacement; and copolymerizing the macromolecule monomer with acrylamide, N-vinyl pyrrolidone, N,N-dimethylacrylamide, 2-acrylamido-2-methylpropanesulfonic acid or other heat-resistant salt-tolerate monomer in the present of an oxidation-reduction composite initiation system to obtain target product. The invention ensures the heat-resistant salt-tolerate performance of the copolymer from molecular design, and the functional long graft side chain can increase the viscoelasticity of polymer modules and reduce solution surface tension. The inventive product is used for type III oil reservoir, and provides a possible solution for increasing recovery efficiency of chemical flooding.

Owner:CHINA PETROLEUM & CHEM CORP +1

Geo-polymer recycled concrete and preparation method thereof

InactiveCN101570426ADelayed activationImprove liquiditySolid waste managementCement productionRoad engineeringSlag

The invention belongs to the fields of civil engineering and environmental material engineering, and in particular relates to geo-polymer recycled concrete and a preparation method thereof. The geo-polymer recycled concrete is prepared from raw materials of recycled coarse aggregate, recycled fine aggregate, fly ash, slag powder, water, sodium silicate, sodium hydrate, naphthalene sulfonate formaldehyde condensation compound and calcium saccharate according to certain mixing proportion by adopting a special stirring process. The product of the geo-polymer recycled concrete not only has simple preparation process, but also has good working performance, mechanical property, durability and heat-insulating property. Simultaneously, the geo-polymer recycled concrete and the preparation method can efficiently use a great deal of waste concrete and two industrial byproducts of the fly ash and blast furnace slag, are significant in saving resources, saving energy sources and protecting the environment, and accord with the sustainable development strategy of the building industry. The product of the geo-polymer recycled concrete can be widely applicable to road engineering, structural engineering and other various civil engineering constructions.

Owner:TONGJI UNIV

Anhydrous car washing liquid

ActiveCN104974859AImprove conductivityPotential window widthInorganic/elemental detergent compounding agentsCationic surface-active compoundsEmulsionActive agent

The invention belongs to the field of automobile surface washing, and relates to an anhydrous car washing liquid. The washing liquid is mainly composed of the following raw materials in parts by weight: 10 to 35 parts of paint film protective agent, 3 to 15 parts of luster-enhancing / lubricating conditioning agent, 2 to 18 parts of ionic liquid, 5 to 32 parts of surfactant, 4 to 16 parts of auxiliary surfactant, 0.1 to 5 parts of scratch filler, 0 to 10 parts of deionized water, and 0.01 to 0.3 part of essence. The selected ionic liquid and surfactant can generate a synergetic effect, under the help of a co-emulsifier, a thermally-stable micro-emulsion system can be formed, the system is stable, the dirt removing performance is greatly improved, and the organic attachment such as bird manure can be easily removed by the provided washing liquid.

Owner:陈士友

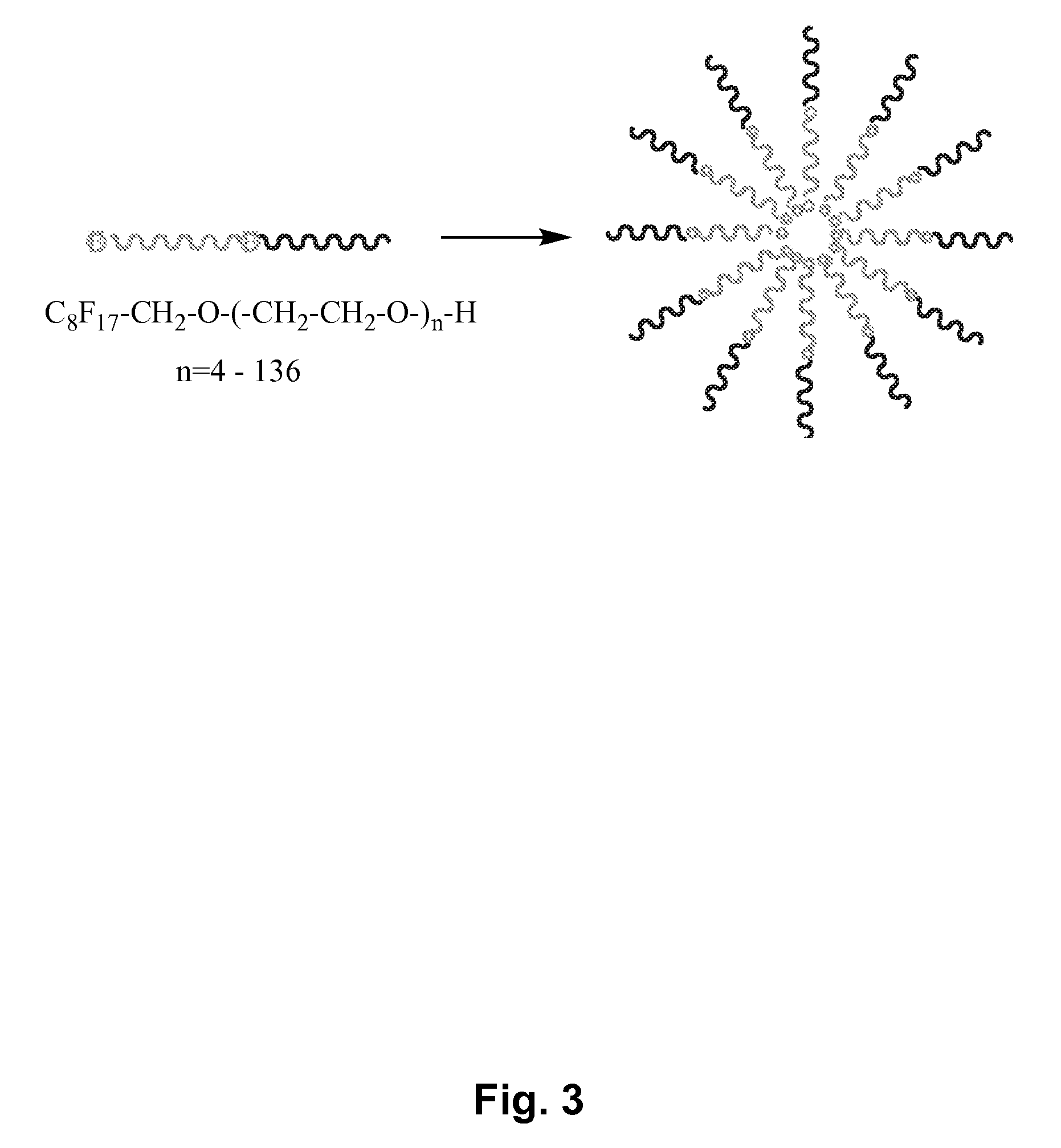

Alkyl group polyoxyethylene ether surface active agent with Guerbet structure and preparation method and application thereof

ActiveCN101745343AGood water solubilityLow critical micelle concentrationTransportation and packagingMixingChemical structureSolubility

The invention relates to an alkyl group polyoxyethylene ether surface active agent with a Guerbet structure and a preparation method and the application thereof, which is applied to the tertiary oil recovery technology; alpha-olefin with dialkyl, which is obtained by catalyzing dimerization by the alpha-olefin with short carbon chain, is used as starting material, and after a series of the chemical reaction, the corresponding alkyl group polyoxyethylene ether surface active agent with the Guerbet structure is prepared; the surface active agent comprises a quaternary ammonium cationic surfactant of alkyl polyoxyethylene ether hydroxypropyl and a carboxylic acid oxyneurines amphoteric surfactant of alkyl group polyoxyethylene ether hydroxypropyl, a special molecular structure determines the alkyl group polyoxyethylene ether surface active agent to have good water solubility, low critical micelle concentration, good surface or interface tensile force reduction capacity and high-efficiency foaming capacity, ultra-low oil-water interface tensile force (10-3mN / m) is formed between the brine solution energy and crude oil, therefore, the alkyl group polyoxyethylene ether surface active agent which is used as an effective oil displacement agent has application potential in the tertiary oil recovery; the surface active agent has the following chemical structure.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Gel foam selective water blockoff agent and use thereof

InactiveCN101481604AImprove stabilityLong water blocking periodDrilling compositionFoaming agentHexamethylenetetramine

The invention relates to gel-foam selective plugging agent and the application thereof, belonging to the technical field of oilfield chemistry. The plugging agent comprises the components: 30-50% of acrylamide, 20-40% of hexamethylenetetramine, 5-15% of phenol, 5-15% of tetraethylene pentamine and 5-15% of foaming agent. The aqueous solution with the mass ratio of 0.5-2% can be prepared in site and is injected into a well after being evenly dissolved, so that the plugging agent is used for plugging water in the oil well at the temperature of 90-150 DEG C. The plugging agent uses organic cross linker for cross bonding polymer to form gel foam under the condition of high temperature, so as to be resistant to the high temperature of 90-150 DEG C and have long period of validity in plugging water.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Foaming agent with low gas liquid ratio foam for common heavy oil reservoir and injection method thereof

InactiveCN101580705AReduce interfacial tensionHigh interface activityFluid removalDrilling compositionFoaming agentLiquid ratio

The invention provides a foaming agent for low gas liquid ratio foam flooding for improving recovery ratio of common heavy oil reservoir and an injection method thereof. The foaming agent is prepared from a nonionic-anionic surfactant, a betaine type amphoteric surfactant and water, wherein the nonionic-anionic surfactant accounts for 0.01 to 0.03 weight percent of the total weight; the betaine type amphoteric surfactant accounts for 0.05 to 0.3 weight percent of the total weight; and the balance is oil field injection water. The foaming agent has good foaming tendency, can reduce the interfacial tension of oil and water to the lowest under the condition of not adding alkali, and can give full play to the foam flooding and the improvement of conformance factor and displacement efficiency. On the basis of the foaming agent, when the gas liquid ratio is between 0.1:1 and 0.3:1 (volume ratio), the generated foam can improve the recovery ratio by over 10 percent, and the technology with low cost and good effect for improving the recovery ratio of the heavy oil reservoir is realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com