Preparation methods of hot melt pressure-sensitive adhesive and protective film as well as hot melt pressure-sensitive adhesive

A pressure-sensitive adhesive and protective film technology, applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., can solve the problems of releasing toxic and harmful waste gas, polluting protective materials, low production efficiency, etc., and achieve environmental friendliness. , The effect of good initial viscosity and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

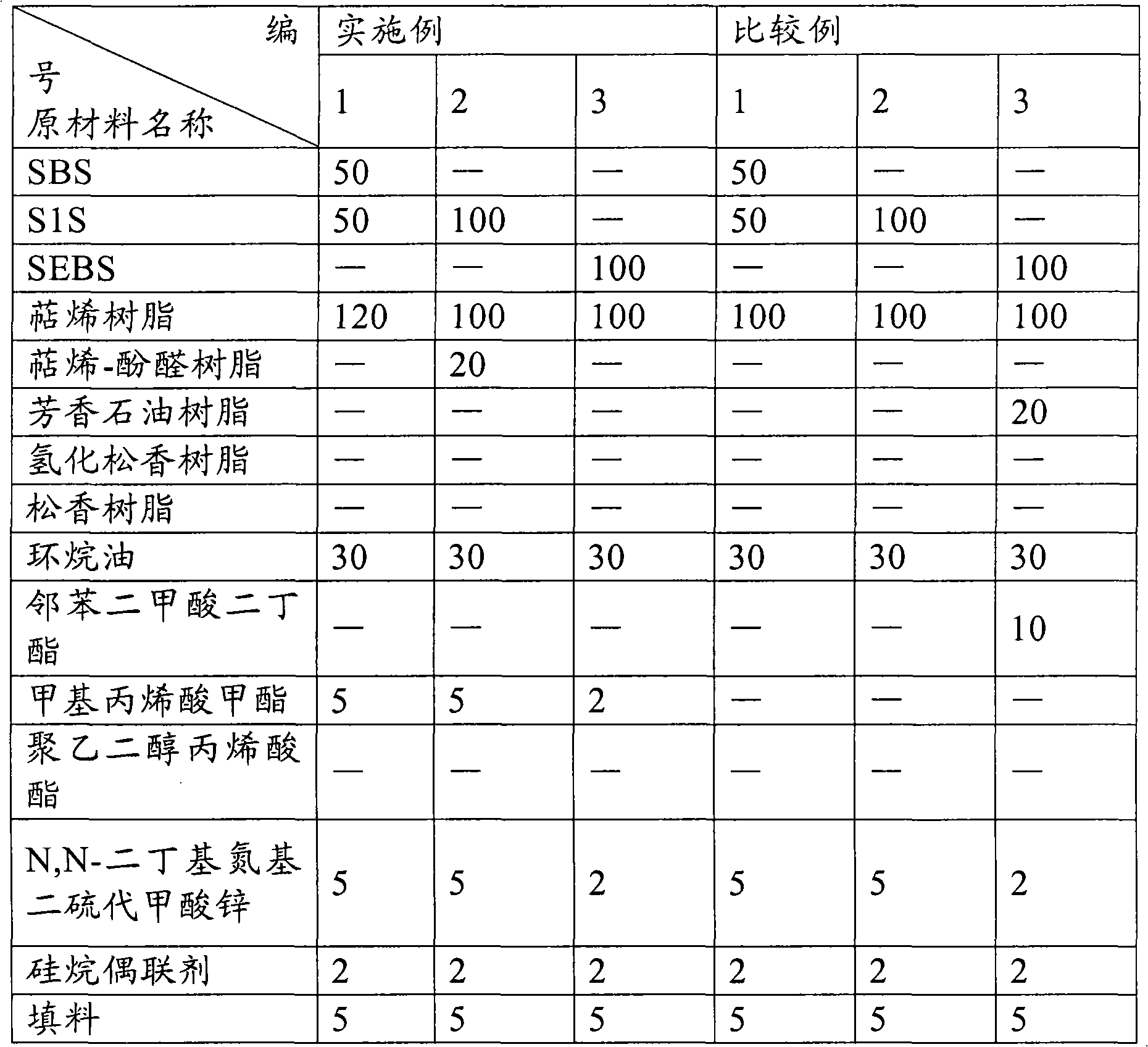

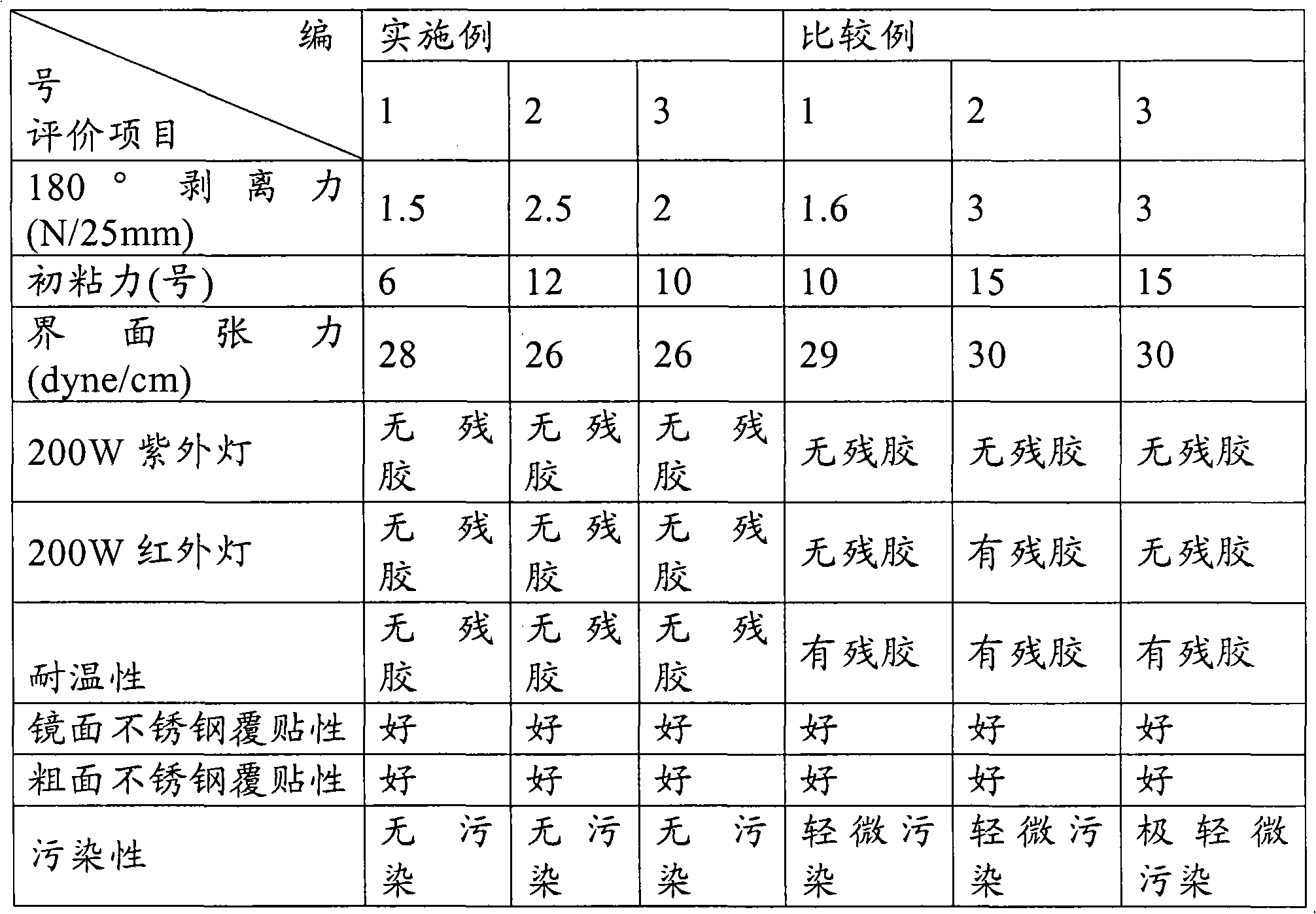

[0026] A hot-melt pressure-sensitive adhesive mainly composed of thermoplastic elastomers of the present invention is mainly composed of the following materials in terms of mass composition. a. Hot melt elastomer: 100 parts, b. Tackifying resin: 100~150 parts, c. Softener: 50~60 parts, d. Antiaging agent: 1~3 parts, e. Peroxide: 0.1~ 0.5 parts, f. acrylate: 5-10 parts, g. filler: 2-6 parts, h. coupling agent: 0.5-2 parts.

[0027] The thermoplastic elastomer may be one of SBS, SIS, SEBS, SEIS or a mixture of two or more.

[0028] Described tackifying resin can be selected as terpene resin, coumarone resin, hydrogenated rosin resin, C5~9 stone One or a mixture of two or more oil resins.

[0029] The filler can be one or a mixture of aerosol silicon dioxide and titanium dioxide.

[0030] The coupling agent can be a silane coupling agent.

[0031] The acrylate refers to one or a mixture of methyl methacrylate, butyl methacrylate, and methacrylic acid.

[0032] The anti-agi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com