Patents

Literature

1124 results about "Butyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bioactive agent release coating

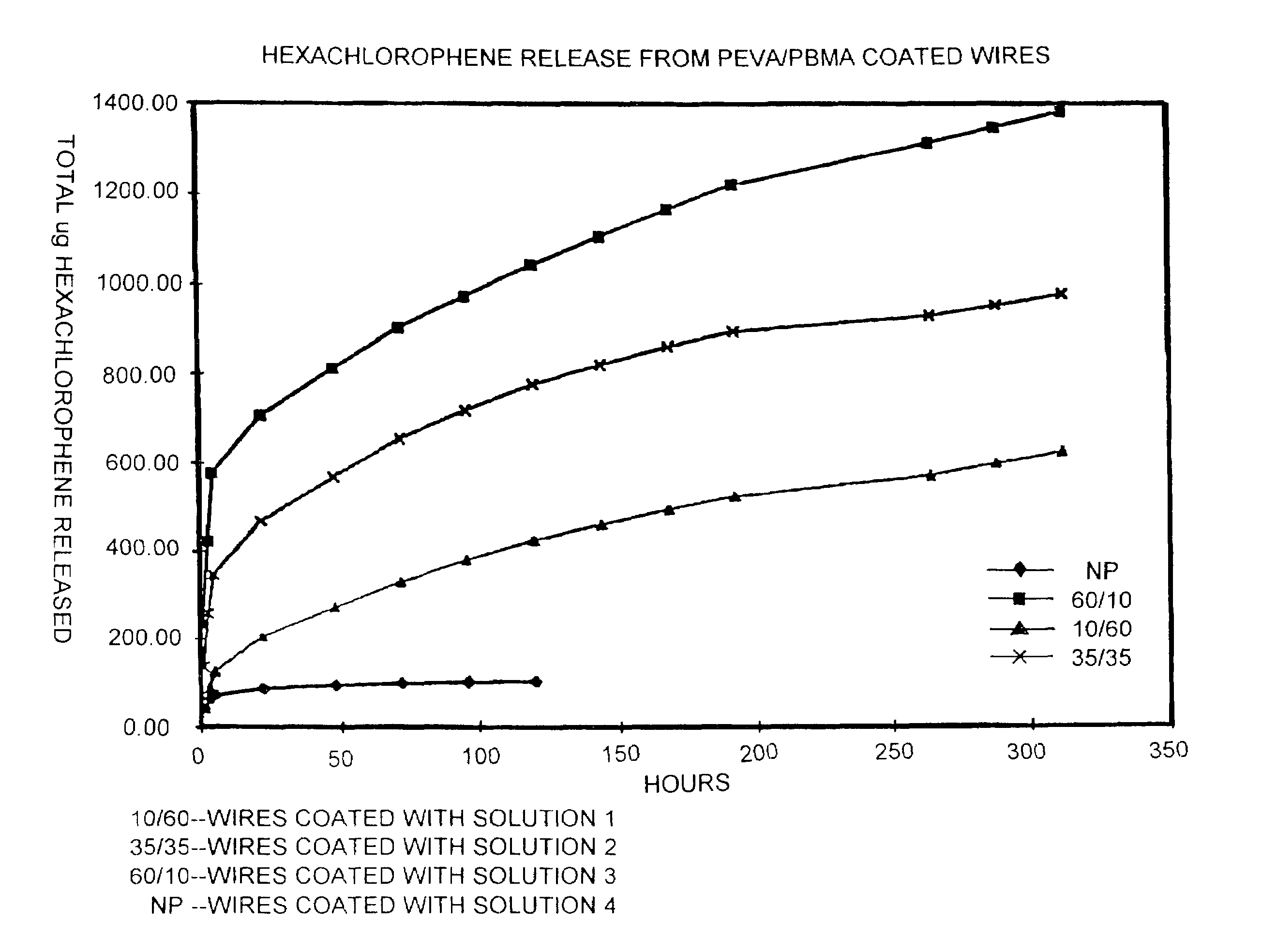

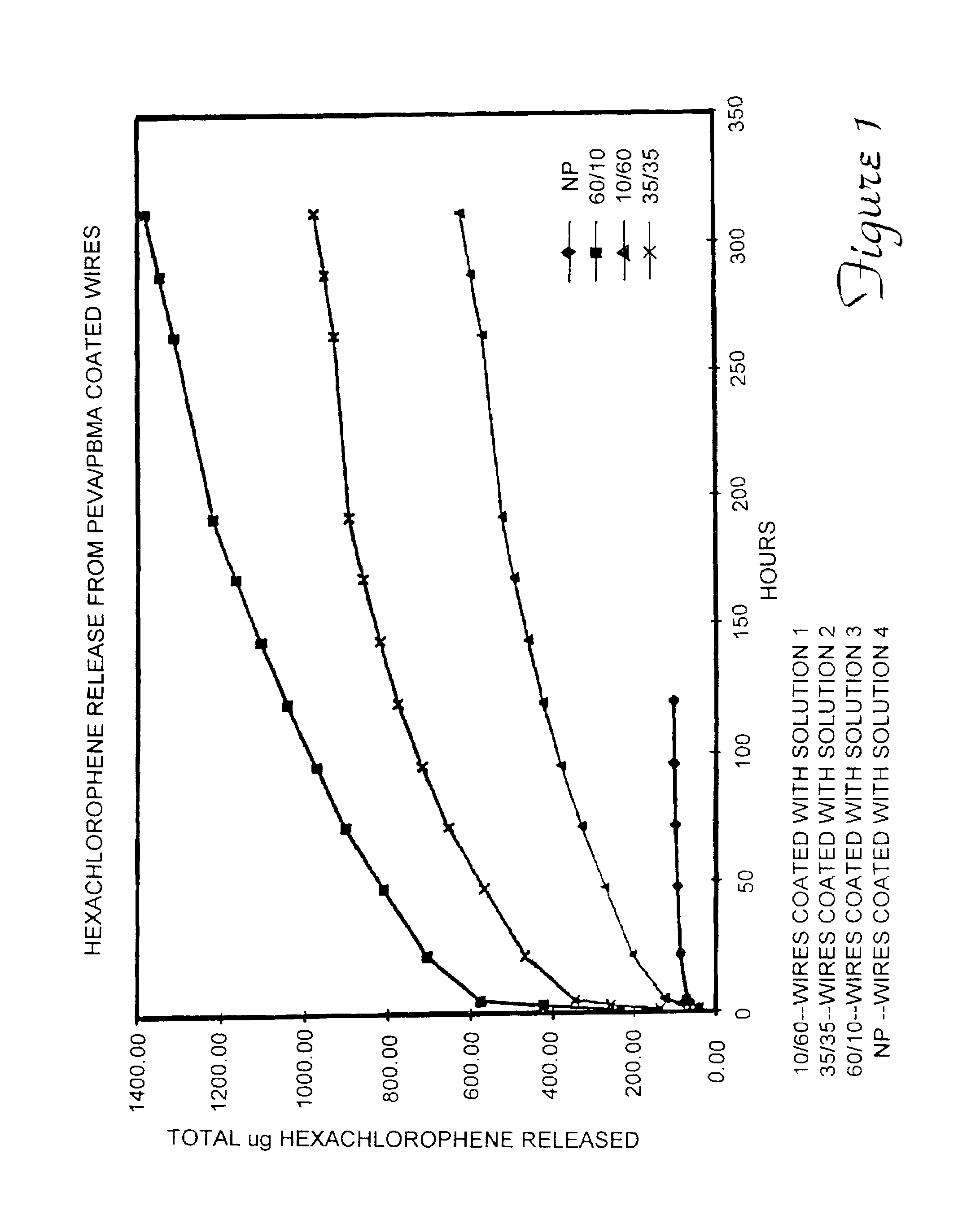

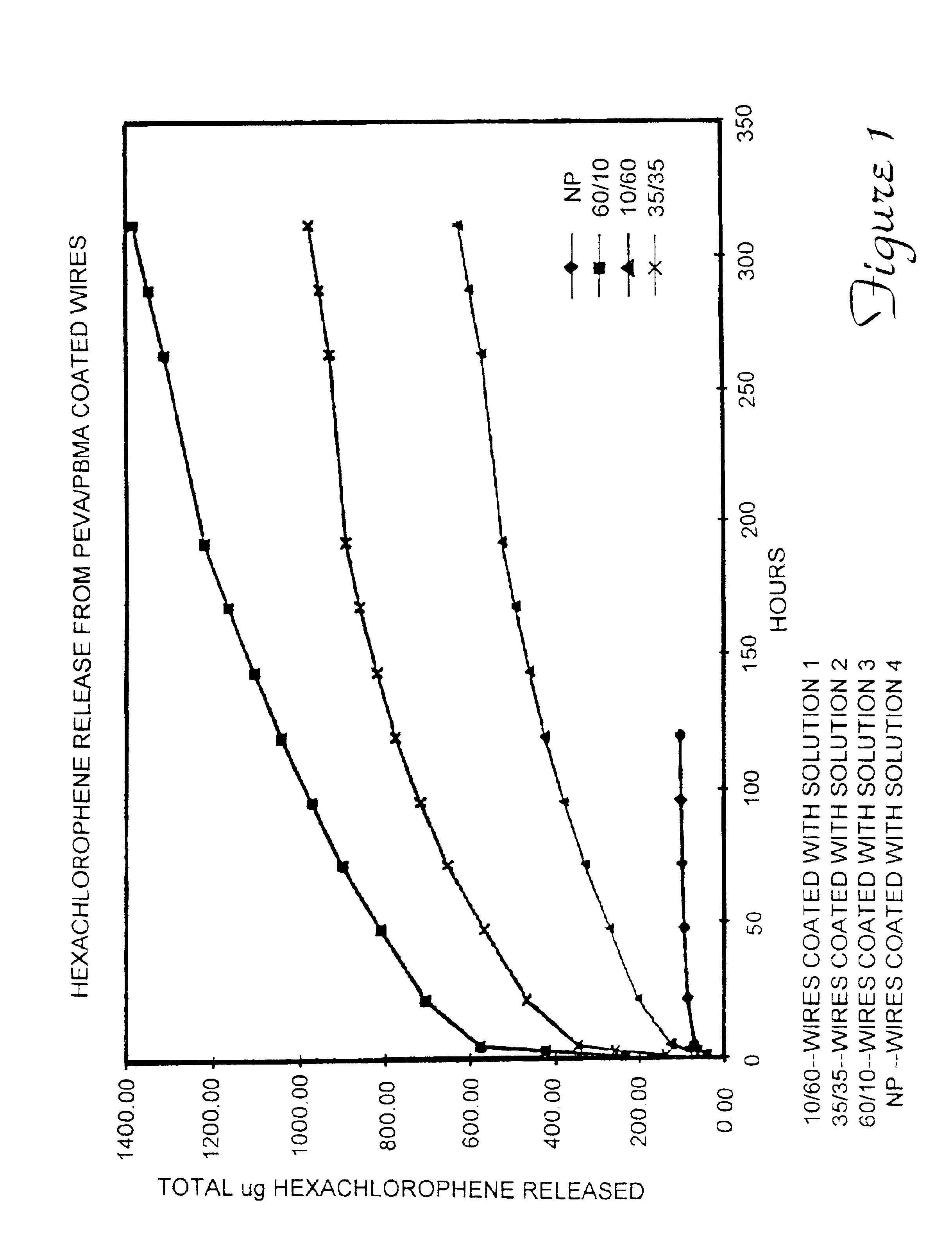

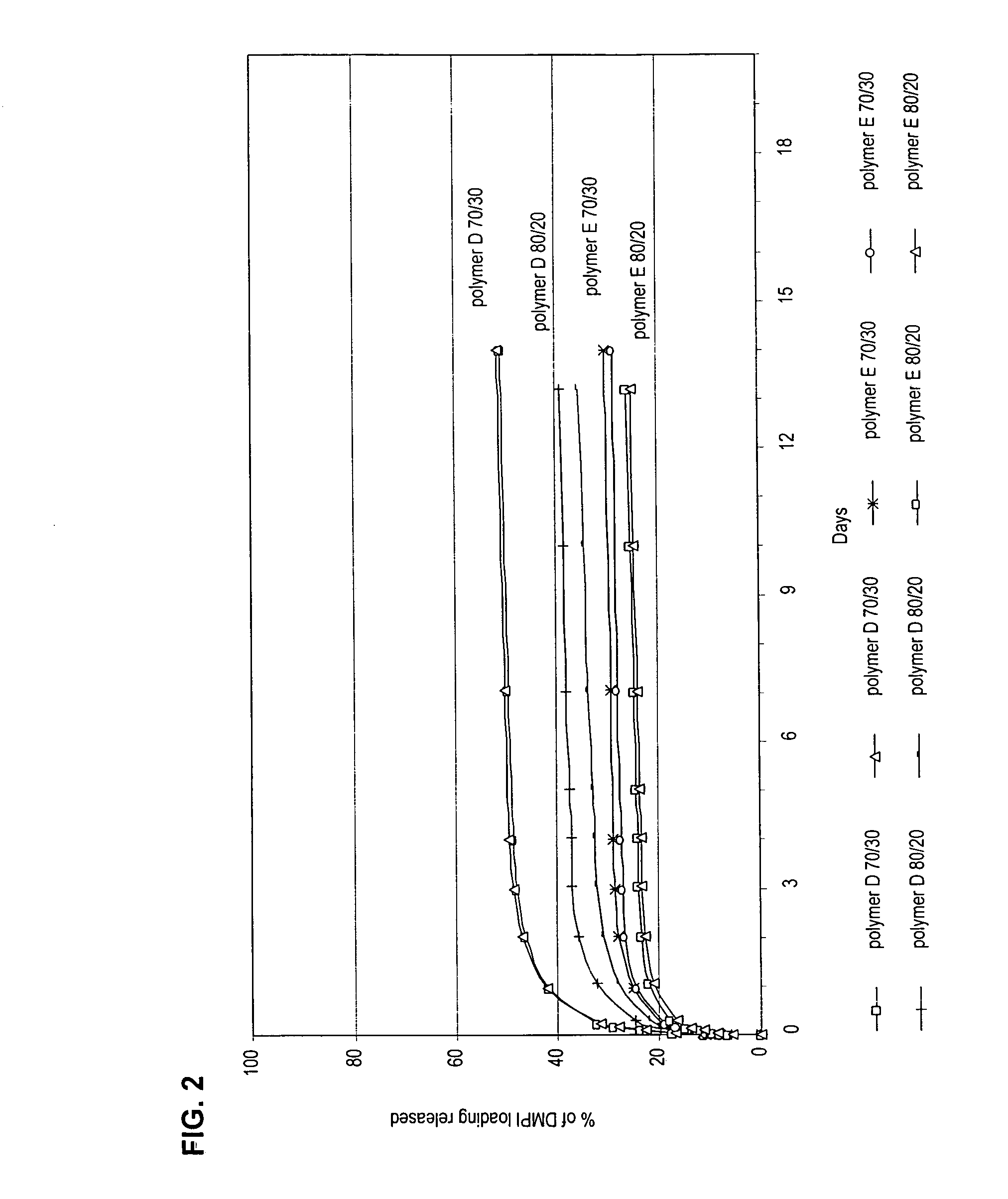

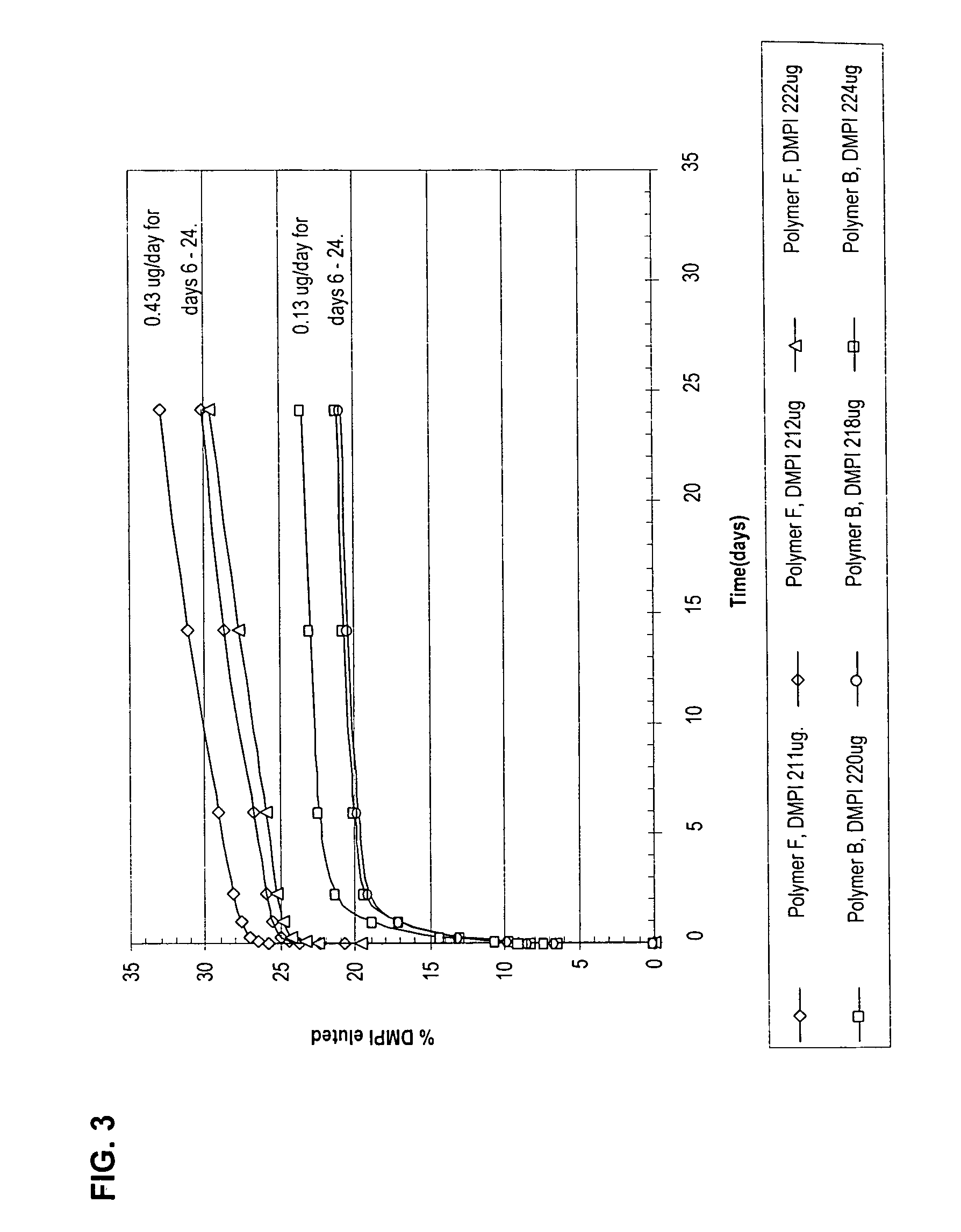

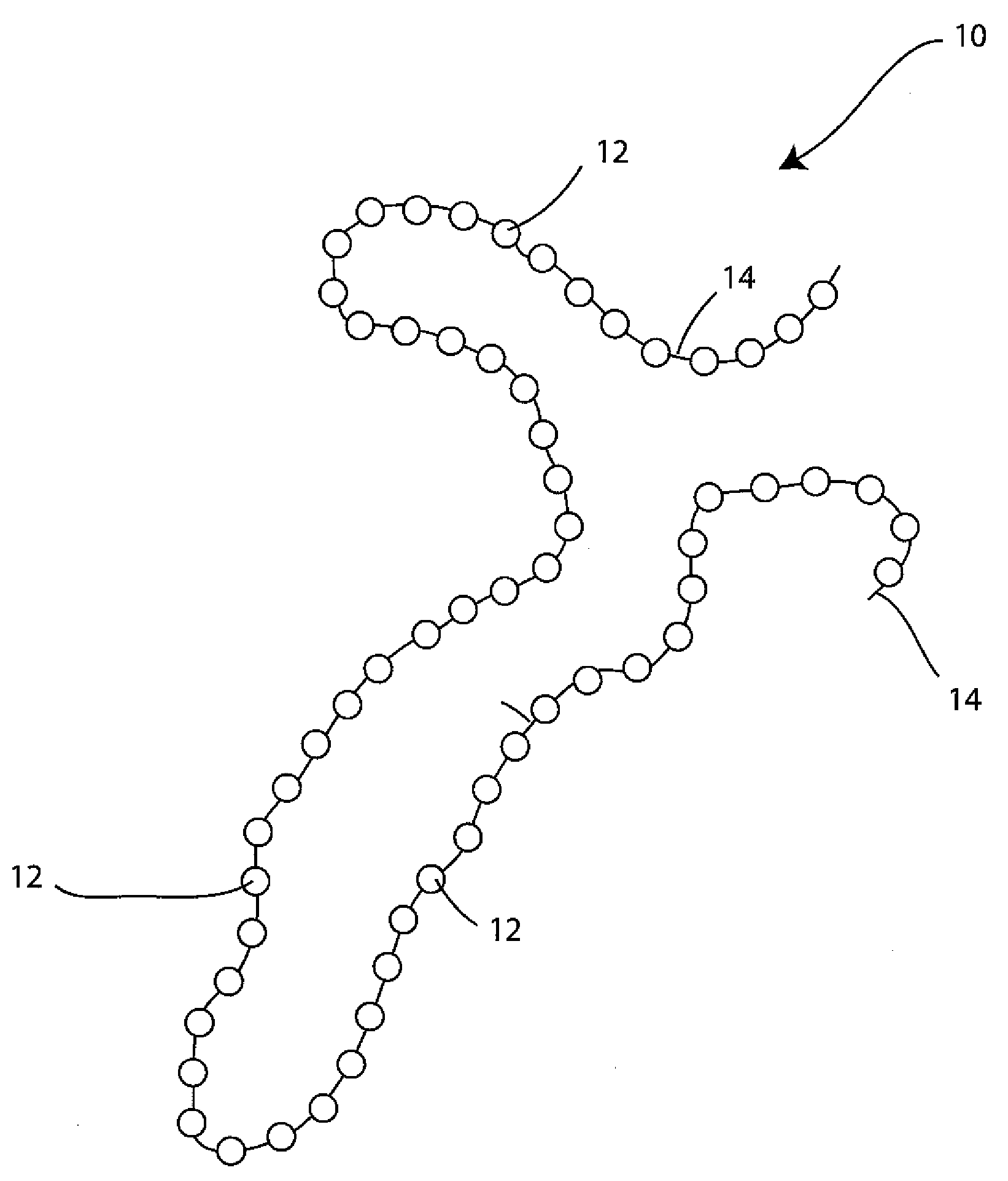

A coating composition for use in coating implantable medical devices to improve their ability to release bioactive agents in vivo. The coating composition is particularly adapted for use with devices that undergo significant flexion and / or expansion in the course of their delivery and / or use, such as stents and catheters. The composition includes the bioactive agent in combination with a mixture of a first polymer component such as poly(butyl methacrylate) and a second polymer component such as poly(ethylene-co-vinyl acetate).

Owner:SURMODICS INC

Bioactive agent release coating

A coating composition for use in coating implantable medical devices to improve their ability to release bioactive agents in vivo. The coating composition is particularly adapted for use with devices that undergo significant flexion and / or expansion in the course of their delivery and / or use, such as stents and catheters. The composition includes the bioactive agent in combination with a mixture of a first polymer component such as poly(butyl methacrylate) and a second polymer component such as poly(ethylene-co-vinyl acetate).

Owner:SURMODICS INC

Devices, articles, coatings, and methods for controlled active agent release or hemocompatibility

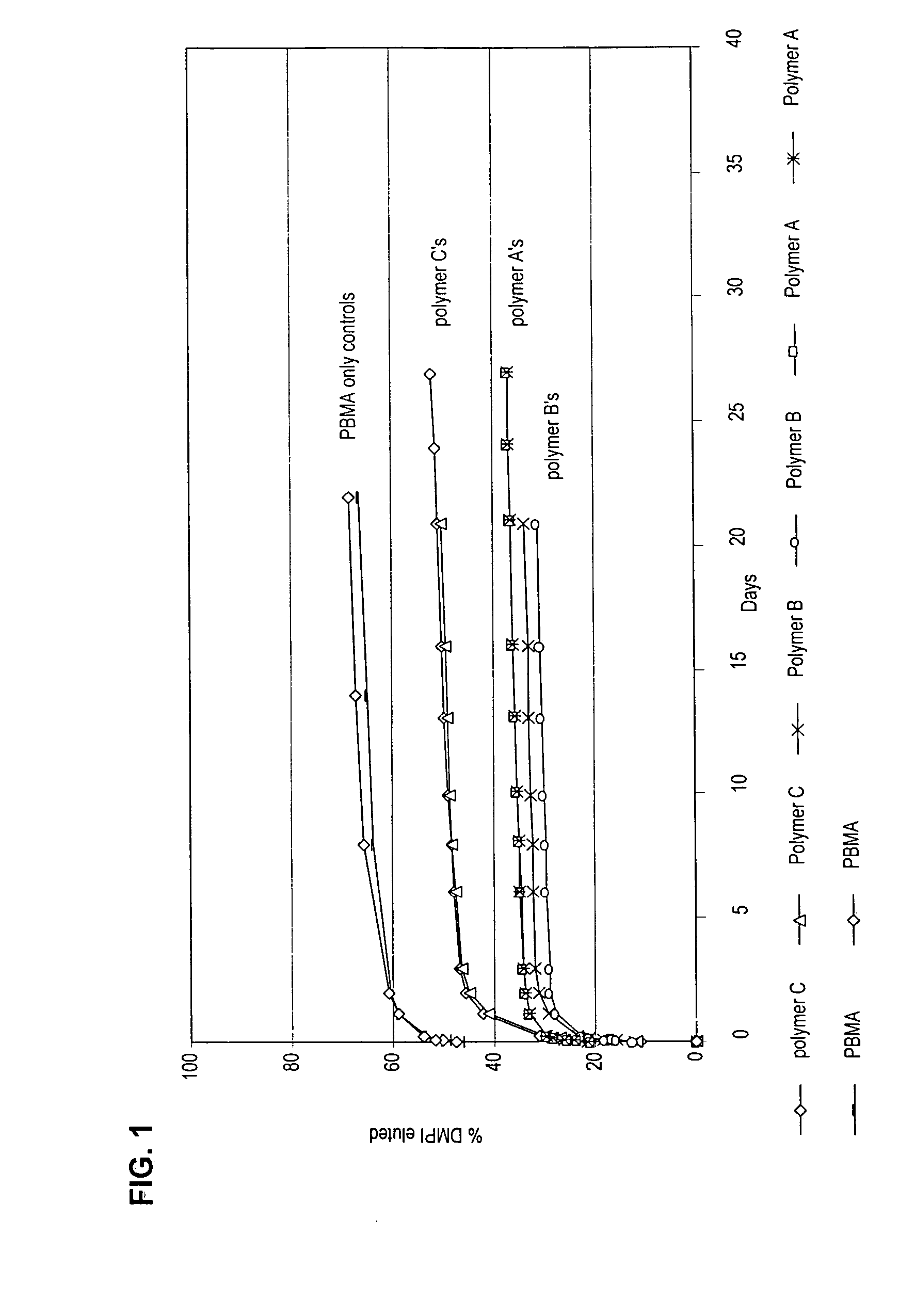

The present invention relates to devices, articles, coatings, and methods for controlled active agent release and / or for providing a hemocompatible surface. More specifically, the present invention relates to copolymer compositions and devices, articles, and methods regarding the same for controlled active agent release. In an embodiment, the present invention includes a copolymer composition. The copolymer composition can include a copolymer and an active agent. In an embodiment, the copolymer includes an effective portion of a monomeric unit including a polar moiety. The active agent can be polar. The active agent can be charged. The active agent can be non-polar. In an embodiment, the copolymer composition includes a random copolymer. In an embodiment, the random copolymer includes butyl methacrylate-co-acrylamido-methyl-propane sulfonate copolymer, which can provide reduced platelet adhesion.

Owner:SURMODICS INC

Stent with polymer coating containing amorphous rapamycin

InactiveUS20090062909A1Extensive adhesionBulk propertiesStentsSurgeryPolymer coatingsPolybutyl methacrylate

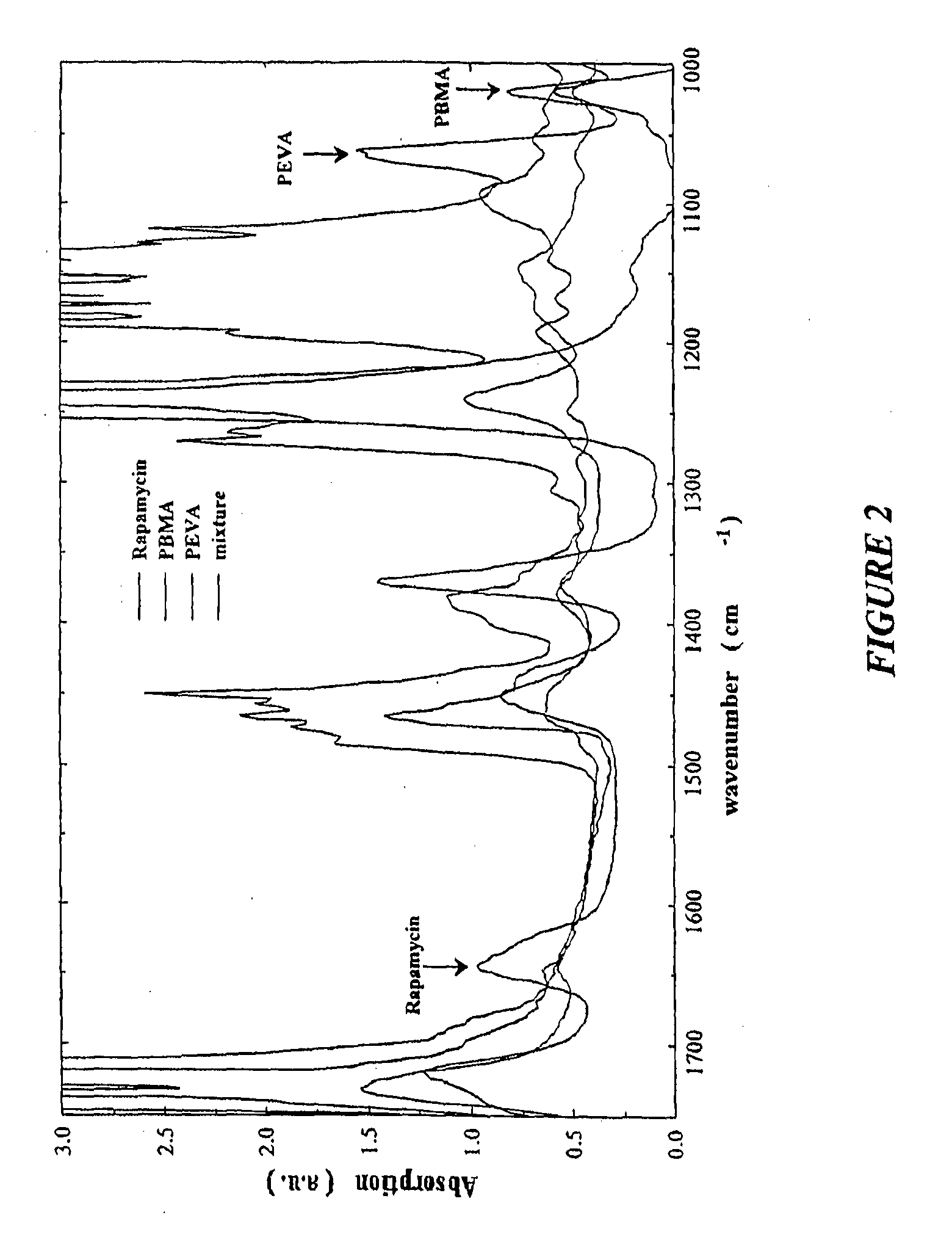

A coated coronary stent, comprising: a stainless steel sent framework coated with a primer layer of Parylene C; and a rapamycin-polymer coating having substantially uniform thickness disposed on the stent framework, wherein the rapamycin-polymer coating comprises polybutyl methacrylate (PBMA), polyethylene-co-vinyl acetate (PEVA) and rapamycin, wherein substantially all of the rapamycin in the coating is in amorphous form and substantially uniformly dispersed within the rapamycin-polymer coating.

Owner:MICELL TECH INC

Dosage form and method for producing the same

ActiveUS20050152977A1Quick releaseDelay releasePowder deliveryNervous disorderAdditive ingredientCoated drugs

The invention relates to a process for producing a coated drug form or a drug form in the form of an active ingredient matrix, by processing a copolymer, an active pharmaceutical ingredient, a core if present and / or pharmaceutically customary excipients in a conventional manner by melting, injection molding, extrusion, wet granulation, casting, dipping, spreading, spraying or compression to form a coated drug form and / or to form an active ingredient matrix, characterized in that a copolymer is used which is composed of 20 to 33% by weight methacrylic acid, 5 to 30% by weight methyl acrylate, 20 to 40% by weight ethyl acrylate and more than 10 to 30% by weight butyl methacrylate and, if desired, 0 to 10% by weight further vinylically copolymerizable monomers, with the proviso that the glass transition temperature of the copolymer in accordance with ISO 11357-2, section 3.3.3, is 55 to 70° C. The invention further relates to the drug form produced in accordance with the invention, to the copolymer, and to the use thereof.

Owner:EVONIK OPERATIONS GMBH

Medical device with coating composition

InactiveUS20090202609A1Good adhesionImproved handling of deviceSurgeryCoatingsSecondary layerButyl methacrylate

Coating compositions containing bioactive agents, and medical devices coated with compositions containing bioactive agents are described. In certain embodiments the coating compositions comprise a first layer, said first layer containing a bioactive agent and a polymeric material derived from poly[vinylpyrrolidone]; and a second layer outside said first layer, said second layer comprising poly(butylmethacrylate) and poly(ethylene-co-vinyl acetate). In some example embodiments the coating composition further comprises a third layer outside said first layer, said third layer comprising poly(butylmethacrylate).

Owner:SURMODICS INC

Preparation method of foamed porous graphene/polypyrrole composite oil absorption material

InactiveCN102617853AEasy to operateMild reaction conditionsOther chemical processesPotassium persulfatePorous graphene

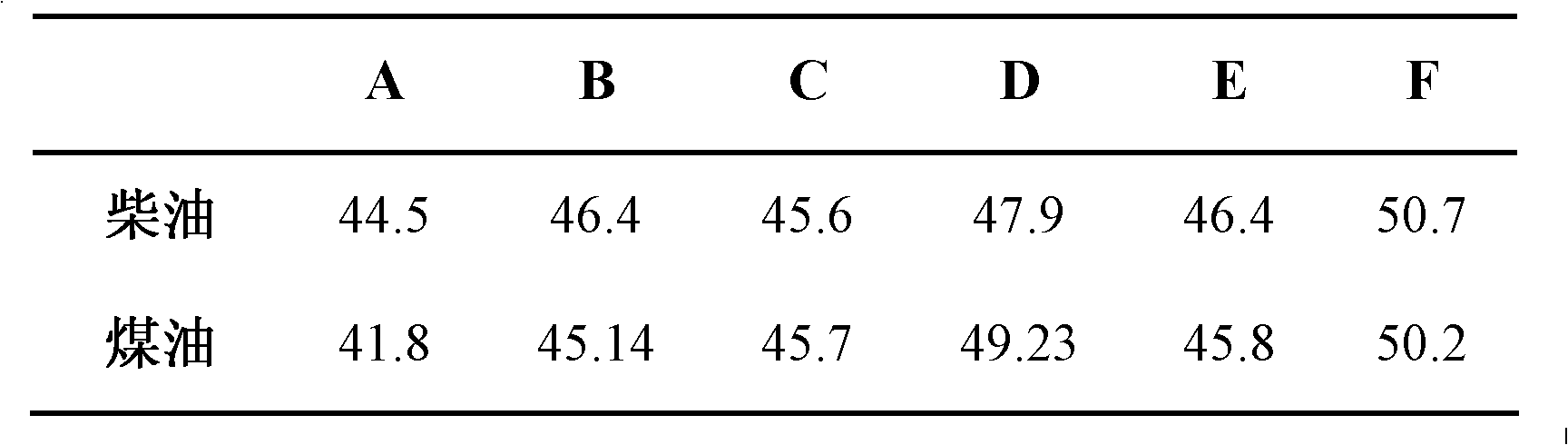

The invention relates to a preparation method of a foamed porous graphene / polypyrrole composite oil absorption material, belonging to the technical fields of environmental protection and composite materials. The method is characterized by comprising the following steps: carrying out KH570 functionalization on graphite oxide prepared from graphite; carrying out ultrasonic treatment on the functionalized graphite oxide product to obtain a graphene oxide aqueous solution with a certain concentration, adding certain amounts of pyrrole, styrene or butyl methacrylate or lauryl methacrylate and an initiator (ammonium persulfate or potassium persulfate); carrying out thermostatic reaction in a hydrothermal reaction kettle for 10 hours, thereby obtaining a black solid; and carrying out freeze-drying on the black solid to obtain the foamed porous graphene / polypyrrole composite oil absorption material in a three-dimensional structure. The graphene / polypyrrole composite oil absorption material ina three-dimensional structure is prepared by a chemical process, so the material has hydrophobicity and large specific area of the graphene, can contain abundant oil molecules, and has high oil adsorbability. The preparation method is simple to operate, and has the advantage of mild reaction conditions.

Owner:DALIAN UNIV OF TECH

Oil absorbing fibre and perparing method thereof

InactiveCN1584148ABroaden the fieldLarger specific surface area for oil absorptionWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberBenzoyl peroxide

The invention relates to a kind of oil-absorbed fiber and its producing method. Its prescription is: 100% polymer monomer, 10-40% of potential gemel agent, 0.1-0.5% solicitation, 0.5-1% dispersant. Moreover the water-like body is 3-4 times more in volume than polymer monomer. The polymer monomer is methacrylate monomer involving butyl methacrylate, the potential gemel agent is 2-hydroxyethyl methacrylate, the solicitation is benzoyl peroxide, and dispersant is poly-vinyl-alcohol. The process is (1) use water-suspending polymerization to produce butyl methacrylate under 70-80 deg.C for blending and polymerizing for 8-10 hours. (2) dissolve the polymer into proper solvent to deploy 20-25% liquid and then insert potential gemal agent and solicitation to polymerize for 3-5 hours under 75-80 deg.C to obtain the original liquid. (3) take off dunking. (4) spin using one of wet or dry method or both, (5) treat with fibre for 10-60 minutes under 120-165 deg.C to obtain the production. The solvent discussed above is one of DMF, DMAC or dimethoxysulfoxide.

Owner:TIANJIN POLYTECHNIC UNIV

High-solid low-viscosity hydroxy acrylic resin and preparation process thereof

The invention discloses a high-solid low-viscosity hydroxy acrylic resin and a preparation method thereof. The hydroxy acrylic resin comprises the following raw materials in part by mass: 25 to 35 parts of solvent, 0.2 to 2 parts of acrylic acid, 7 to 16 parts of methyl methacrylate, 15 to 35 parts of styrene, 3 to 10.5 parts of butyl methacrylate or butyl acrylate, 12 to 23 parts of hydroxy-containing acrylic monomer and 1.5 to 8 parts of initiator. During preparation, the product is obtained by pressurized reaction. The solid of the hydroxy acrylic resin can reach 65 to 75 percent, and the viscosity is only 1,00 to 2,500mps. The solvent used in the process is cheap, the expensive solvent with high boiling point is not needed, the preparation process is simple, and the production cost is low.

Owner:JIANGMEN PAINT FACTORY

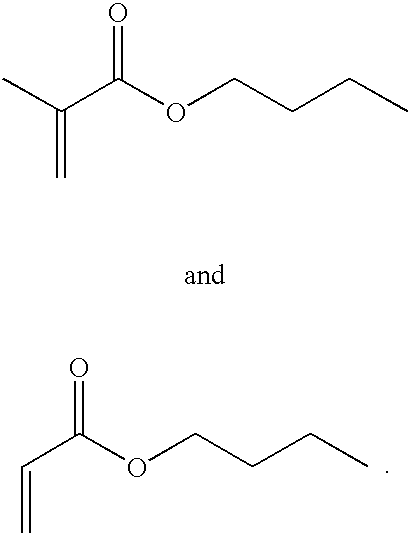

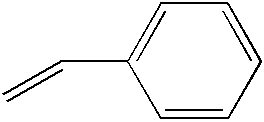

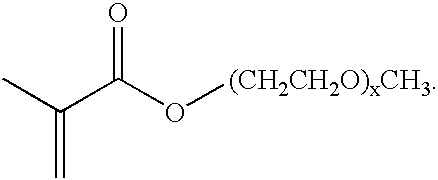

Water-based acrylic emulsion dispersants utilized as grind resins for pigments and method of preparing the same

The present invention is directed to a water-based acrylic emulsion dispersant to be used as a grind resin to incorporate inorganic pigment into a pigment dispersion for a coating composition. The acrylic emulsion dispersant is the reaction product of butyl methacrylate, butyl acrylate, styrene, methyl ether polyethylene glycol methacrylate, polyethylene glycol methacrylate, and polyphosphoric acid. The present invention is also directed to a method of preparing the acrylic emulsion dispersant. In this method, the butyl methacrylate, butyl acrylate, and styrene are combined with water to establish a first reaction blend. Similarly, the methyl ether polyethylene glycol methacrylate and the polyethylene glycol methacrylate are combined with water to establish a second reaction blend. Next, the first and second reaction blends are polymerized to form an intermediate emulsion polymer containing a hydroxyl group from the functionality of the polyethylene glycol methacrylate. Finally, the hydroxyl group from the polyethylene glycol methacrylate is reacted with polyphosphoric acid to form the acrylic emulsion dispersant which is utilized for efficient wetting and grinding of the pigment.

Owner:BASF CORP

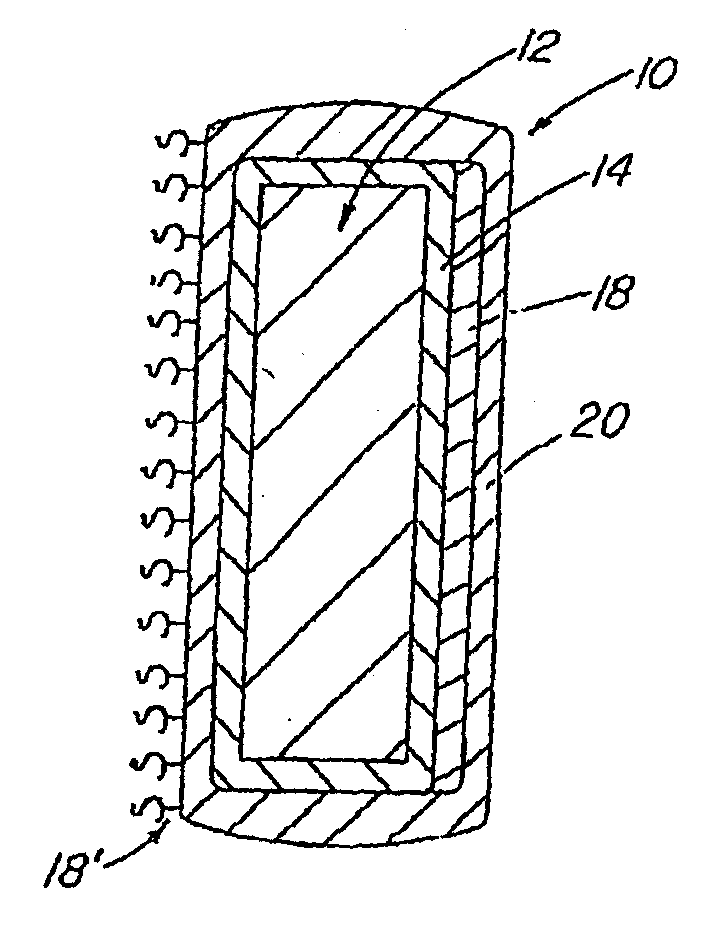

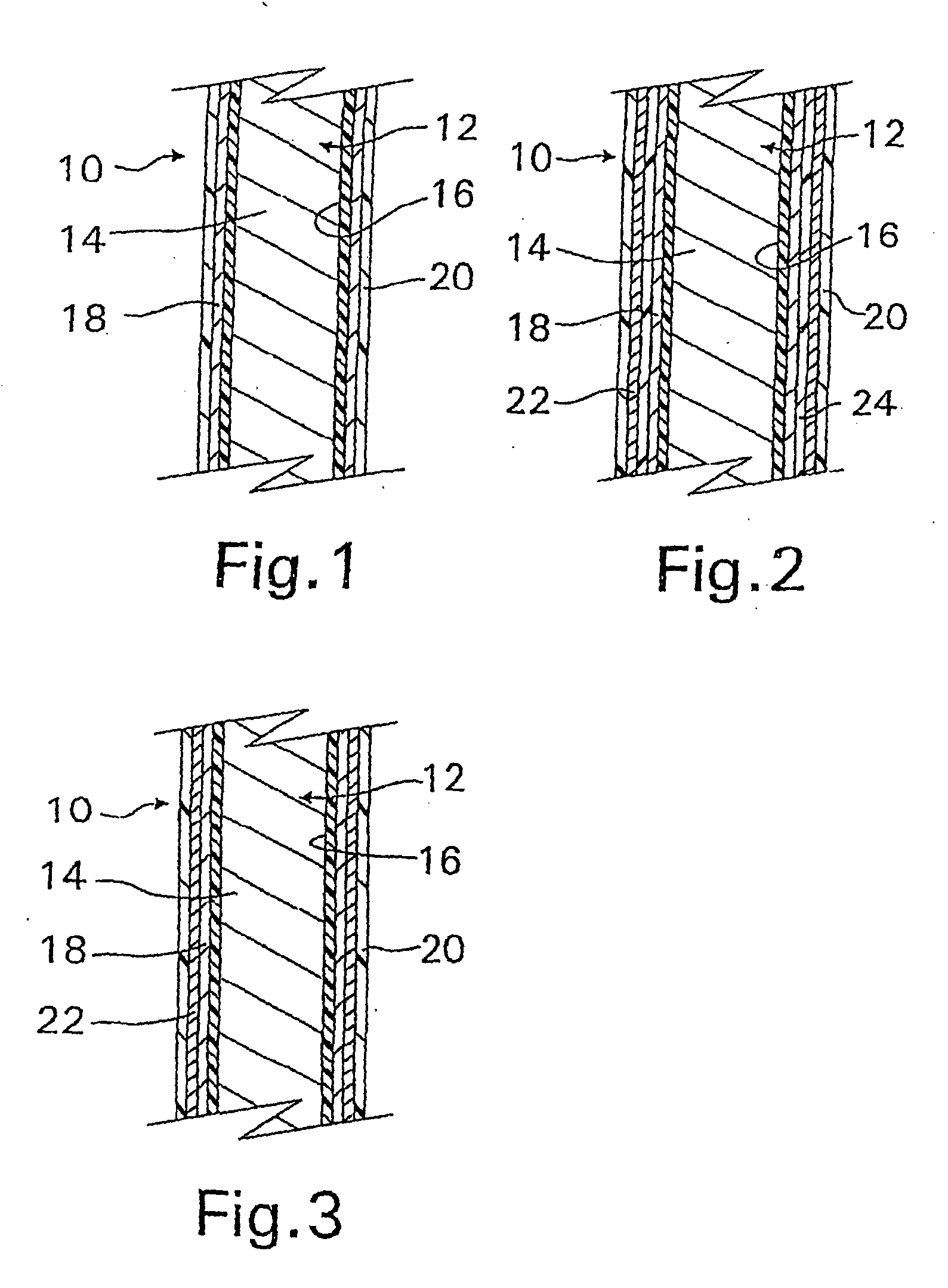

Coated implantable medical device

InactiveUS20060195176A1Prevent degradationIncrease release rateHeart valvesSurgeryParylenePorous layer

Bioactive-coated medical devices are provided, including coated vascular stents. The medical device coating can include a coating layer posited over at least a portion of the medical device surface, and can include a butyl methacrylate polymer or an ethylene-vinyl acetate copolymer in combination with a bioactive material that can function as both an immunosuppressive agent and an antiproliferative agent. Optionally, multilayer coatings can further include an adhesion promoting layer comprising parylene positioned between the coating layer and the medical device surface, a porous layer comprising butyl methacrylate positioned over at least a portion of the coating layer, or both. The coating layer preferably comprises between about 0.5 and 2.0 μg / mm2 of the bioactive material on the outer surface of the medical device. The bioactive material can be absorbed into the coating layer, which can have a thickness of between about 0.5 μm to about 5 μm.

Owner:COOK MEDICAL TECH LLC

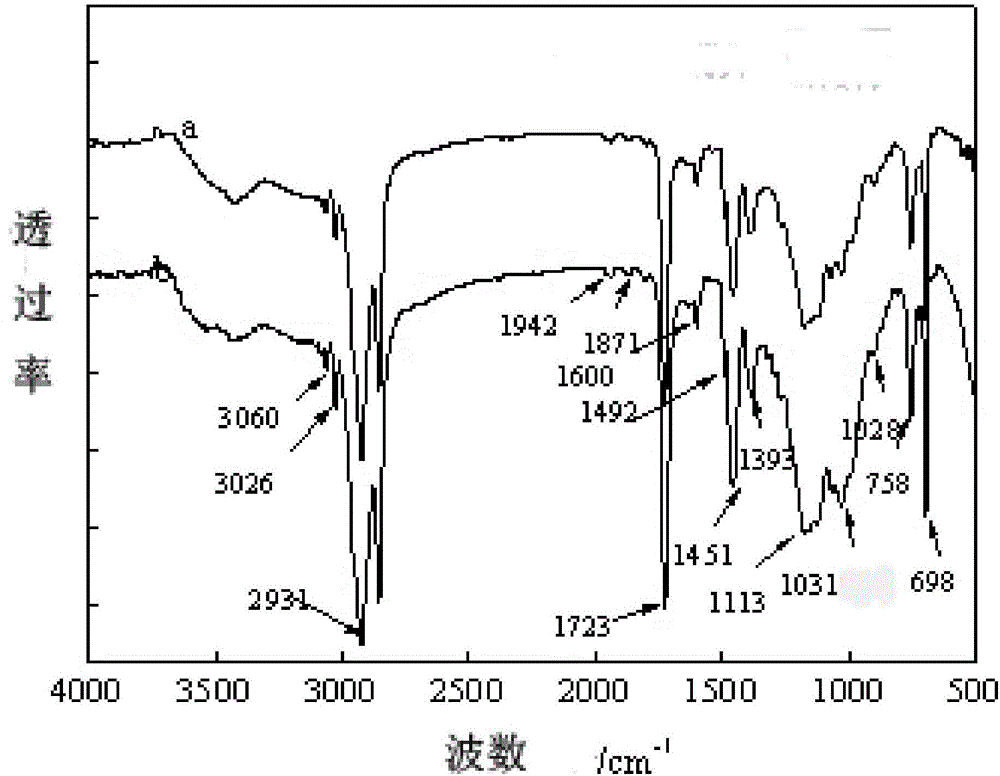

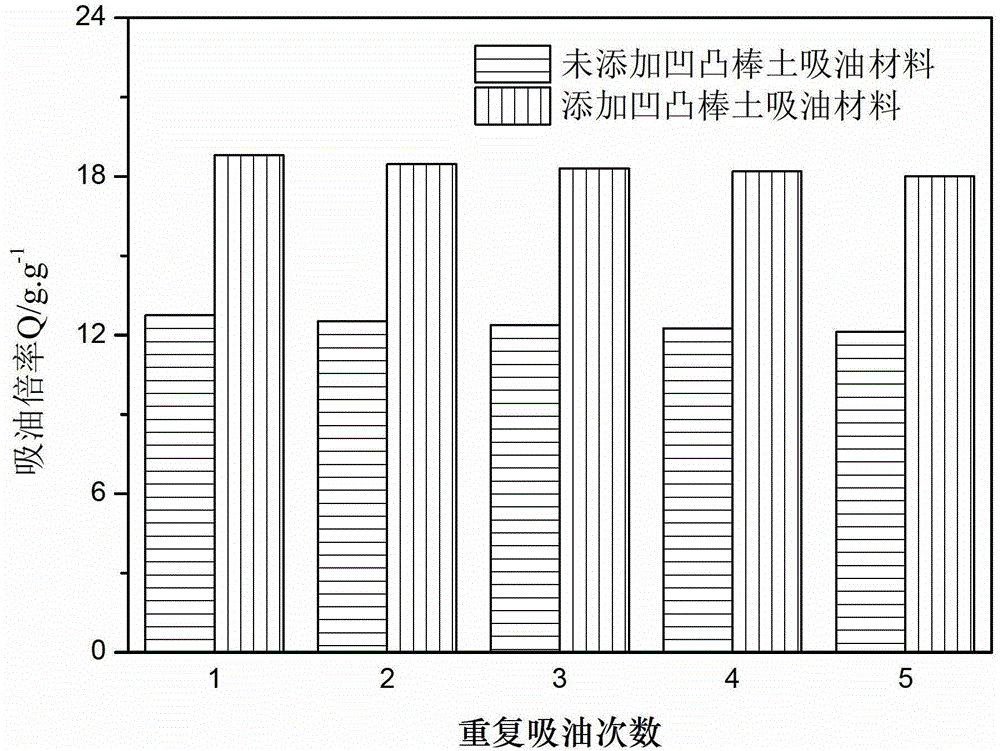

Acrylic ester-attapulgite composite oil-absorbing material and preparation method thereof

The invention relates to an organic-inorganic composite oil-absorbing material formed by compounding an acrylic ester monomer with attapulgite, and a preparation method thereof. The oil-absorbing material takes the following components as raw materials in parts by weight: 50-60 parts of acrylic ester, 35-50 parts of styrene, 0.5-2 parts of initiator, 0.2-1 part of cross-linking agent, 1-5 parts of dispersant and 1-10 parts of the attapulgite. The preparation method comprises the following steps of: based on a polyvinyl alcohol water solution as a reaction system, adding a mixed solution formed by uniformly mixing butyl methacrylate, styrene, the initiator, the cross-linking agent, and attapulgite under the protection of inert gas to react; and then washing to obtain the product. Compared with the traditional oil-absorbing material, the organic-inorganic composite oil-absorbing material has the advantages of high oil-absorbing multiplying power, oil retention rate and repeated oil-absorbing times, and has a potential application prospect on the aspect of environmental protection.

Owner:常熟紫金知识产权服务有限公司

Preparation method of nano particles with high refractive index and polymer nano composite film material

The preparation method of nano composite film material by using nano microparticles with high refractive index and polymer includes the following three steps: preparing ZnS nano microparticles for surface modification, preparing organic polymer monomer and polymer with high refractive index and preparing nano composite film. In the organic solvent of zinc metal salt the organic small molecule surface modifier with function group is added, and the hydrogen sulfide gas is introduced to synthesize ZnS nano colloidal microparticles, and the polymer base material for combining ZnS nano microparticles can be polymethyl methacrylate, polybutyl methacrylate, polystyrene, epoxyresin, polymer large monomer, optimally can be polyurethane oligomer and polyurethane acrylate large monomer with high refractive index, finally the above-mentioned materials can be made into the invented nano composite film.

Owner:JILIN UNIV

Moisture-absorbing and perspiring anti-bacterial fabric and preparation technology thereof

InactiveCN105421055AImprove antibacterial propertiesSoft and wear-resistantBiochemical fibre treatmentLiquid/gas/vapor removalWater basedMoisture

The invention relates to a moisture-absorbing and perspiring anti-bacterial fabric and a preparation technology thereof. The moisture-absorbing and perspiring anti-bacterial fabric is blended and weaved by the following raw materials in parts by weight: 40 to 80 parts of bamboo fibers, 40 to 80 parts of long staple, 10 to 30 parts of ramie, 10 to 30 parts of coolmax fibers, 10 to 20 parts of corn fibers, 10 to 20 parts of Delight fibers, and 5 to 20 parts of Tancel, and then is treated by anti-bacterial finishing liquid; the anti-bacterial finishing liquid comprises 5 to 10 parts of chitosan, 5 to 10 parts of silk fibroin, 0.5 to 3 parts of butyl ricinoleate sodium sulfate, 0.5 to 3 parts of lemon acid, 0.5 to 2 parts of butyl methacrylate, 5 to 8 parts of dodecyl diphenyl ether sodium disulfonate, 5 to 10 parts of hydroxypropyl methyl cellulose, 5 to 10 parts of polyhexamethylene biguanidine, 5 to 15 parts of organosilicon quaternary ammonium salt, 3 to 8 parts of dodecyl trimethyl ammonium chloride, and 5 to 10 parts of water-based polyurethane. The moisture-absorbing and perspiring anti-bacterial fabric has the advantages that the anti-bacterial property is higher, the moisture-absorbing, perspiring, anti-pilling and air-ventilation properties are realized, the softness is realized, and the abrasion is resisted; the moisture-absorbing and perspiring anti-bacterial fabric is particularly suitable for being applied to the fields of underwear, overwear, sportswear and bedding articles.

Owner:杜名胜

Coloring agent for textile fabric

The invention discloses a coloring agent for a textile fabric. The coloring agent consists of the following ingredients in parts by weight: 1 to 2 parts of polypropylene glycol, 2 to 3 parts of tetracarboxydiphthalic ether dianhydride (ODPA), 1 to 2 parts of zinc stearate, 4 to 5 parts of trimethylolpropane, 4 to 5 parts of mica powder, 5 to 6 parts of butyl methacrylate, 4 to 5 parts of dibutyltin dilaurate, 3 to 4 parts of polyurethane, 6 to 7 parts of iron oxide red, 1 to 2 parts of dibutyl phthalate, 3 to 4 parts of ethyl acetate, 3 to 4 parts of an initiator, 5 to 6 parts of closed blocked isocyanate, 5 to 6 parts of water and 2 to 3 parts of polyvinylpyrrolidone. The coloring agent for the textile fabric is easy for coloring and unlikely to fade.

Owner:江苏金牛华尔车服饰有限公司

Water-based room temperature crosslinking acrylic acid emulsion and preparation method thereof

InactiveCN101597355AImprove performanceThe application process is convenient and easy to useInksCoatingsSodium bicarbonateWater based

The invention provides a water-based room temperature crosslinking acrylic acid emulsion and a preparation method thereof, wherein, the water-based room temperature crosslinking acrylic acid emulsion comprises the following components by weight percent: 10-40% of methylmethacrylate, 0-40% of styrene, 0-3% of methacrylic acid, 0.5-1.5% of acrylic acid, 0.5-2% of N-hydroxylacrylamide, 1-3% of ethylmethacrylate, 1-23% of butyl methacrylate, 1-3% of emulsifier, 0.3-1% of initiator, 0.1-0.5% of sodium bicarbonate, 3-9% of neutralizer, 30-60% of water, 0.1-1% of inhibition stabilizer and 0.05-2% of crosslinking agent. In the process of polymerization, the crosslinking monomers (modified monomers) like acrylic acid, methacrylic acid and N-hydroxylacrylamide are introduced to perform carboxyl crosslinking, hydroxyl crosslinking and amido crosslinking with copolymer so that the cohesive strength, heat resistance and ageing resistance of emulsion are obviously increased and the stability of emulsion is increased; the inhibition stabilizer is used so as to prolong the service life.

Owner:彭文表

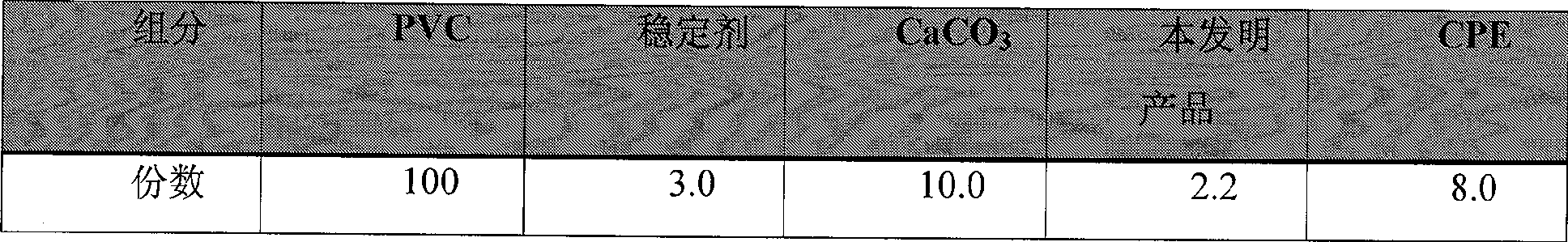

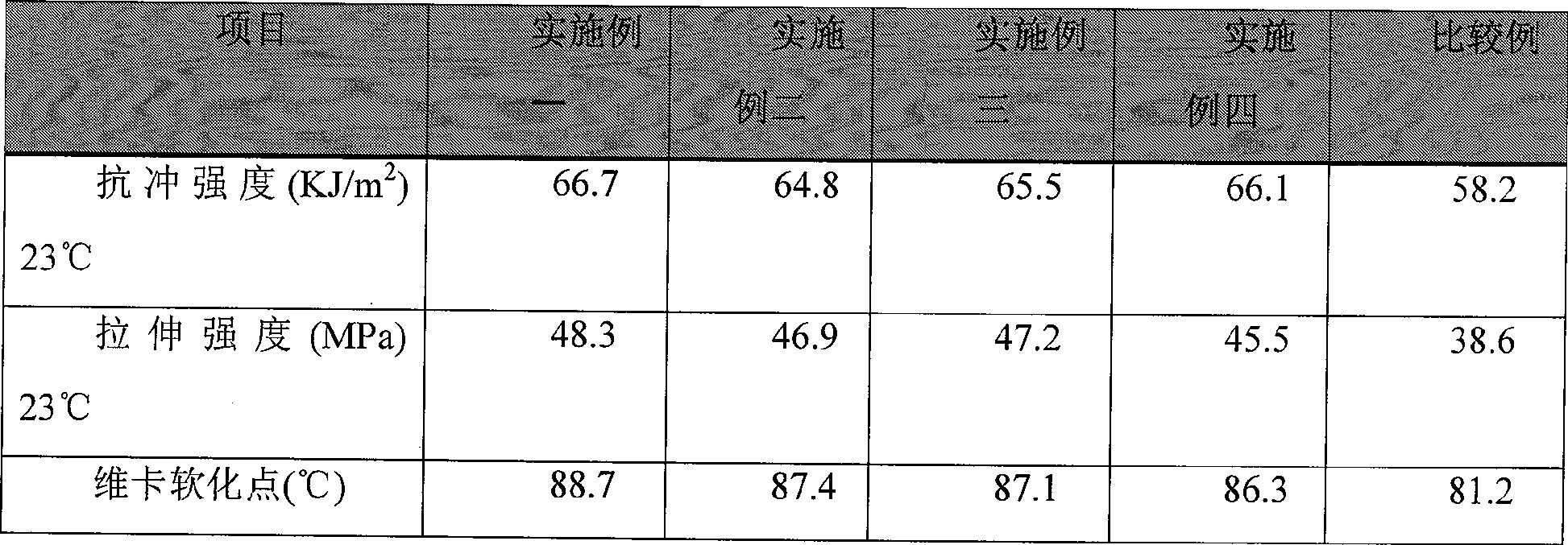

Preparation method of nano SiO2/ACR composite particles and application thereof

The invention discloses a preparation method of nano SiO2 / ACR composite particles and application thereof. The method comprises the following steps: adopting ultrasonic to assisting in pre-emulsifying a monomer, and taking an anionic / nonionic compound emulsifier as the emulsifier; taking ethyl acrylate as the monomer to prepare seed latex; taking butyl methacrylate and the ethyl acrylate as the monomers and a compound crossinking agent consisting of N,N'-methylene bisacrylamide (BIS) and a compound CH2=CHRCH2COOR' to prepare an inner core; taking the methyl methacrylate and the butyl methacrylate as the monomers and the compound crosslinking agent consists of the BIS and the CH2=CHRCH2COOR' to prepare a shell; adding nano SiO2 emulsion which is modified by soft water and a siloxane coupling agent while preparing the shell so that SiO2 produces a grafting reaction at the shell of core-shell polyacrylate (ACR); and finally obtaining the nano SiO2 / ACR composite particles with excellent impact resistance and the like. The prepared composite particles are applied to preparing PVC as an impact modifier, and have excellent impact resistance, good dispersivity and good mechanical properties.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD

Polymer-type water glass curing agent and application in water glass chemical grouting materials

InactiveCN101885591AResolution timeSolve the strength problemOther chemical processesBuilding constructionsSolubility(Hydroxyethyl)methacrylate

The invention relates to a polymer-type water glass curing agent with easily-controlled curing time and high toughness. The curing agent is mainly formed by polymerizing and copolymerizing double bonds-containing acids such as crylic acid, methacrylic acid and the like and double bonds-containing esters such as butyl methacrylate, vinyl acetate, hydroxy-ethyl methacrylate and the like by latex. The polymer-type water glass curing agent of the invention is a novel water-soluble water glass curing agent, which can control the curing time of the water-soluble grouting materials by controlling the content of carboxyl and ester group in a polymer. By using the curing agent, a water glass consolidating body has vey high compressive strength and toughness, synthetically overcomes the shortages of too fast curing time, high corrosiveness, low consolidating body strength and the like of an acid curing agent which is commonly used in the water glass grouting materials and the shortages of poor water solubility, slow curing time and the like of an organic ester curing agent, and can be widely applied in the field of anti-seepage stoppage engineering.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Ground calcium carbonate powder surface modification method

InactiveCN103421142AExcellent performance indexImprove application featuresPigment treatment with macromolecular organic compoundsPolymer scienceIn situ polymerization

The invention discloses a modification method for ground calcium carbonate powder (referred to as coarse whiting powder, the same below). The modifying agent of the coarse whiting powder is the composite compatilizer which comprises the components of polymer maleic anhydride-acrylamide-n-butyl methacrylate and stearic acid. Two-time modification is performed, the first modification adopts a wet method about in-situ polymerization with the modifying agent of polymer maleic anhydride-acrylamide-n-butyl methacrylate, and the second modification adopts a dry method with the modifying agent of stearic acid; the brief method comprises the steps as follows: fully mixing the coarse whiting powder, the polymer maleic anhydride-acrylamide-n-butyl methacrylate and the stearic acid, and dissolving the mixture into the mixed liquor formed by liquid paraffin and swill-cooked dirty oil, wherein the total organic matters account for 1 to 3 percent of the coarse whiting powder (mass fraction); the volume ratio of liquid paraffin to swill-cooked dirty oil is 1:1, and mass ratio of the polymer maleic anhydride-acrylamide-n-butyl methacrylate to the stearic acid is 2:1. According to the invention, the active coarse whiting powder can be used as filler of chlorinated polyvinyl chloride, polyvinyl chloride and polyethylene. The active coarse whiting powder is good in dispersion uniformity in the resin, and low in cost, and oriented towards industrialized production.

Owner:HEZHOU UNIV +1

Aqueous self-crosslinking copolymer dispersions, a process for preparing them and their use in binders for coating materials

InactiveUS6515042B2Solve the lack of lifeHigh film hardnessLiquid surface applicatorsPlastic/resin/waxes insulatorsDicarboxylic acidCompound c

Aqueous self-crosslinking copolymer dispersions ABC obtainable by free-radically initiated copolymerization in the first stage of a monomer mixture A comprising olefinically unsaturated monomers A1 having carbonyl groups, unsaturated carboxylic acids or monoesters of unsaturated dicarboxylic acids A2, monomers A3 selected from vinylaromatic compounds, n-butyl methacrylate and also alkyl esters of unsaturated carboxylic acids or dialkyl esters of unsaturated dicarboxylic acids, esters A4 selected from alkyl esters of unsaturated carboxylic acids of dialkyl esters of unsaturated dicarboxylic acids, and other free-radically polymerizable monomers A5, and subsequent addition of a second monomer mixture B and further polymerization in the second stage, the mixture B comprising olefinically unsaturated monomers B1 corresponding to A1, esters B2 corresponding to A4, and monomers B3 corresponding to A5, and subsequently adding compounds C having hydrazine or hydrazide groups.

Owner:ALLNEX AUSTRIA GMBH

CBN (cubic boron nitride) resin grinding wheel and preparation method thereof

ActiveCN102814747ANot easy to fall offImprove heat resistanceAbrasion apparatusGrinding devicesPolyamideBoron nitride

The invention discloses a CBN (cubic boron nitride) resin grinding wheel and a preparation method of the CBN resin grinding wheel. The CBN resin grinding wheel is prepared from the following components in parts by weight, 50-60 parts of CBN grinding material, 5-10 parts of white corundum grinding material, 5-10 parts of silicon carbide powder, 5-15 parts of phenolic resin powder, 2-6 parts of phenolic resin liquid, 1-2 parts of n-butyl methacrylate, 5-10 parts of nano dolomite dust, 5-10 parts of nano quartz sand powder, 2-5 parts of micro polyamide wax mist and 2-5 parts of steel scrap powder. According to the CBN resin grinding wheel and the preparation method of the CBN resin grinding wheel, as a ceramic material is added into padding, the adhesive property is good, the grinding materials hardly fall off, the heat resistance and hardness of the resin grinding wheel are improved, and cracks formed by rigid grinding are reduced, thereby the use efficiency and service life of the resin grinding wheel are improved further; and in addition, as steel power is added, fast heat dissipation effect is achieved, a great deal of heat generated in a cutting process of the grinding wheel can be dissipated quickly, and the effect of lowering cutting temperature is achieved.

Owner:安徽威铭耐磨材料有限公司

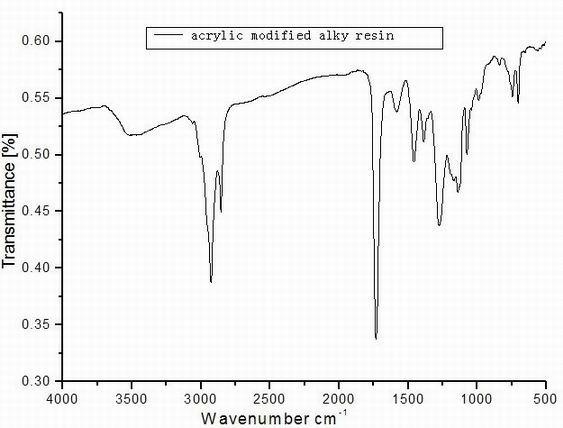

Waterborne acrylic alkyd resin and preparation method and application thereof

The invention provides waterborne acrylic alkyd resin and emulsion thereof. The waterborne acrylic alkyd resin is prepared by the following steps of: performing free radical polymerization on four acrylic monomers, namely acrylic acid, methyl methacrylate, methyl acrylate and butyl methacrylate, an initiating agent and a chain transfer agent in an organic solvent to obtain an acrylic prepolymer, then performing ester exchange reaction on vegetable oil and trimethylolpropane to obtain an alcoholysis product, and performing polycondensation reaction on the acrylic prepolymer and the alcoholysisproduct to obtain the product; and the emulsion is prepared by adding a neutralizer, a cosolvent and distilled water to the waterborne acrylic alkyd resin. In the waterborne acrylic alkyd resin provided by the invention, long alkane structures are connected with carbon atoms on the alpha and beta positions on two sides of an ester bond in the resin molecule, thus improving the hydrolytic stability of the ester bond. Therefore, the waterborne acrylic alkyd resin has good hydrolytic resistance and storage stability and can be used as a main component of waterborne paints and adhesives, and varnish prepared from the resin provided by the invention has good dryness, adhesive force and hardness.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Mirror back paint resin and spraying paint

The invention relates to mirror back paint resin and curtain flow coating. Its features are that the resin solid component includes 50-70% medium oil length alkyd resin, 20-40% multi-hydroxy acrylic acid resin, and 10-20% polyurethane resin; middle resin is formed by medium oil length alkyd resin, acrylamide, ethoxyl methacrylate, and butyl methacrylate monomer; the mirror back paint resin is formed by the middle resin and toluene diisocynate. Its viscosity is 100-300s; acid value is under 5mgKOH / g. The coating is formed by the resin, proper cross-linking resin, pigment, extender pigment, auxiliary agent, and solvent has low curing temperature, high-speed, high hardness of paint film, good flexibility, adhesive force, and chemical resistance. It can be applied to our country silver mirror production line to ensure the product quality.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

Attapulgite-modified polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995446AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationEpoxySurface layer

The invention discloses attapulgite-modified polyvinyl chloride (PVC) synthetic leather. The attapulgite-modified PVC synthetic leather comprises a surface layer, a foamed layer, a bonding layer and a brushing fabric, and is characterized in that the surface layer is prepared by mixing the following raw materials in parts by weight to form slurry: 70 to 80 parts of SG-2 type PVC resin, 30 to 40 parts of SG-5 type PVC resin, 10 to 15 parts of triethyl citrate, 30 to 35 parts of epoxy butyl oleate, 20 to 25 parts of n-butyl methacrylate, 5 to 6 parts of PVC color paste, 1 to 2 parts of dibasic lead phosphate, 1 to 2 parts of tribasic lead sulfate and 5 to 10 parts of modified diatomite. Through the improvements of the formula and the process, the flexibility of the synthetic leather is improved, and the synthetic leather has a natural comfortable hand feeling similar to that of natural leather and is difficult to damage or tear after being used for 3 to 5 years.

Owner:HEFEI ANSHAN COATING FABRICS

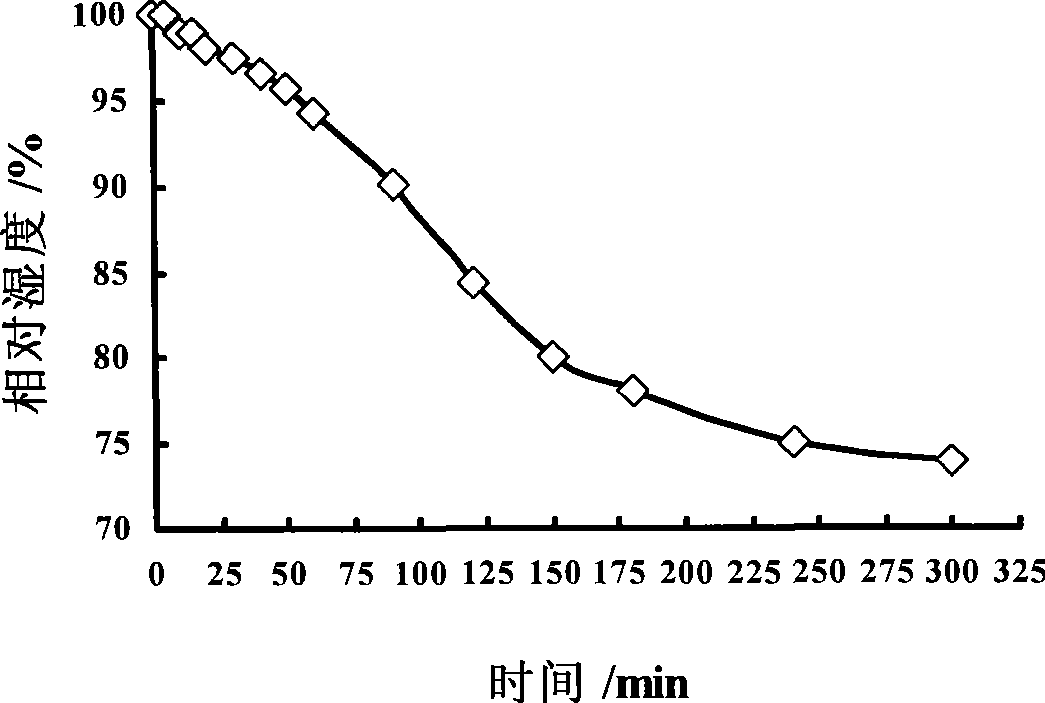

Soap-free core-shell emulsion type amphiphilic polymer resin and preparation and application thereof in preparation of function humidity controlling coating

InactiveCN101423581AGood lookingImprove water resistanceCoatingsPolymer science(Hydroxyethyl)methacrylate

The invention provides a nonsoap nuclear shell latex type amphipathic polymer resin, which is polymerized from methyl methacrylate, styrene, methyl methacrylate, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, hydroxyethyl methacrylate, acrylamide, diacetone acrylamide and other monomers. The nonsoap nuclear shell latex type amphipathic polymer resin is used as a main film forming material for a paint and is combined with various inorganic macromolecular fillers to prepare the paint; the prepared paint integrates decoration, dampness regulation, permeability, heat insulation, dewing resistance, water and alkali resistance, antisepsis and the like, and can also prevent a coating film from falling off caused by various leakage and water condensation of a wall body so that the coating film is more lasting and durable; and the paint contains no organic solvent and no emulsifier, is safer and more environment-friendly, and has more superior coating property.

Owner:NORTHWEST NORMAL UNIVERSITY

Acoustic wool with high impact resistance and preparation method thereof

InactiveCN105506857AIncreased durabilityImprove featuresNon-woven fabricsMonocomponent polyolefin artificial filamentHazardous substancePolyethylene glycol

The invention discloses acoustic wool with high impact resistance. The acoustic wool is prepared from, by weight, 1-2 parts of barium stearate, 0.5-1 part of sodium xylene sulfonate, 5-10 parts of zircon powder, 3-5 parts of silicon carbide, 1-2 parts of ethylene bis stearamide, 80-100 parts of polypropylene, 2-4 parts of styrene, 1-2 parts of epoxy rice bran oleic acid butyl ester, 3-5 parts of butyl methacrylate, 1-2 parts of polyethylene glycol, 0.05-0.1 part of azodiisobutyronitrile, 0.5-1 part of castor oil and 3-5 parts of functional powder. The acoustic wool is good in sound absorption effect and mechanical performance, high in durability, high in impact resistance, less prone to deformation, good in processing performance, capable of absorbing harmful substances in air, effectively purifying the air and protecting human health, high in comprehensive value and high in practicality.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

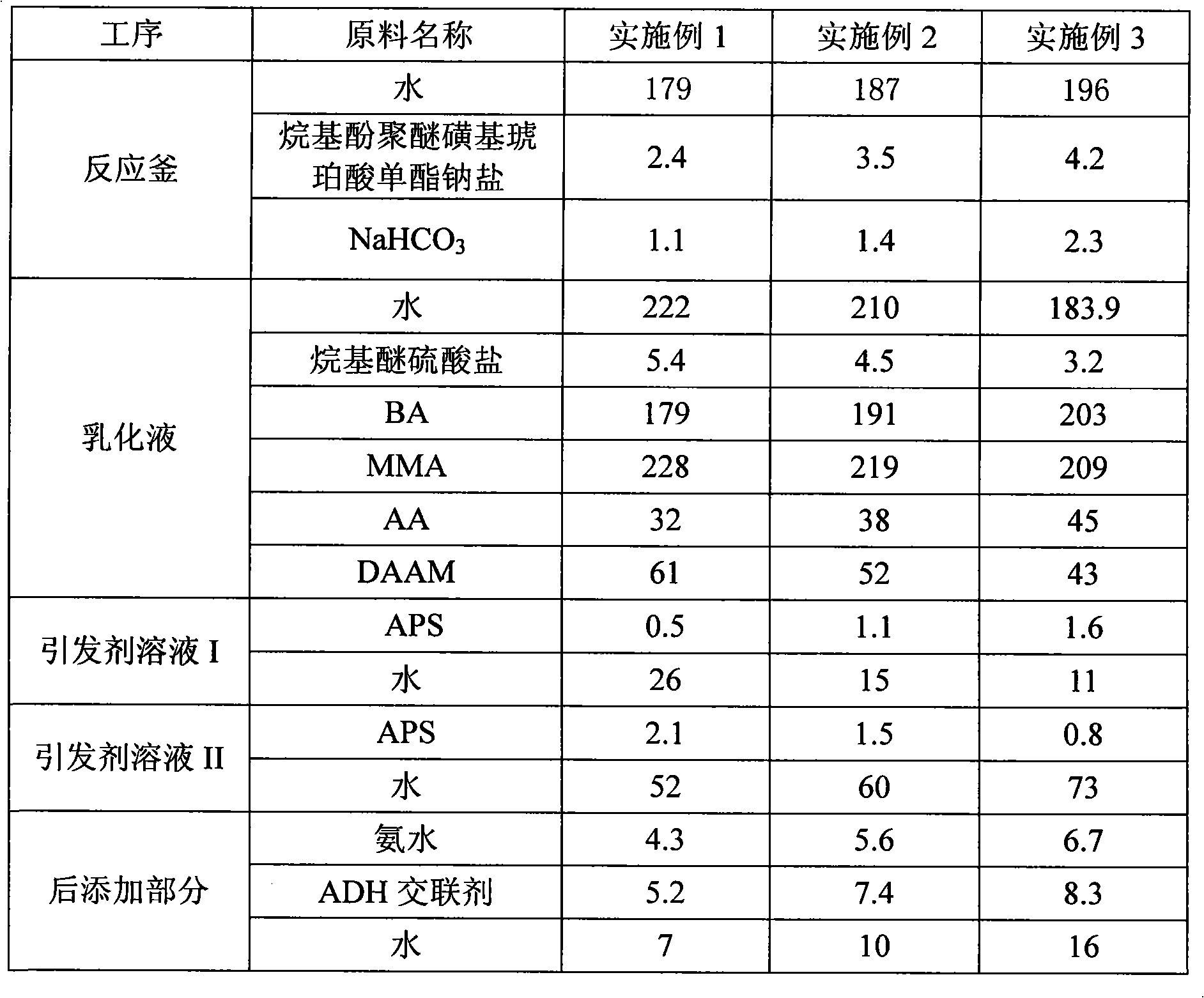

Acrylic ester emulsion and preparation method thereof

The invention discloses acrylic ester emulsion and a preparation method thereof. The preparation method comprises the following steps of: gradually dropwise adding emulsion which contains an anion emulsifier, butyl acrylate, butyl methacrylate, acrylic acid and diacetone acrylamide, and initiator solution into solution which contains sodium alkylphenol polyether sulfosuccinate and an initiator with stirring, controlling the temperature to be between 85 and 88 DEG C, after dropwise adding, reducing the temperature to between 35 and 40 DEG C, adding water, ammonia water and an ADH cross linkingagent, and stirring to obtain the acrylic ester emulsion. The acrylic ester emulsion obtained by the preparation method has relatively high blocking resistance and wear resistance.

Owner:上海展辰涂料有限公司

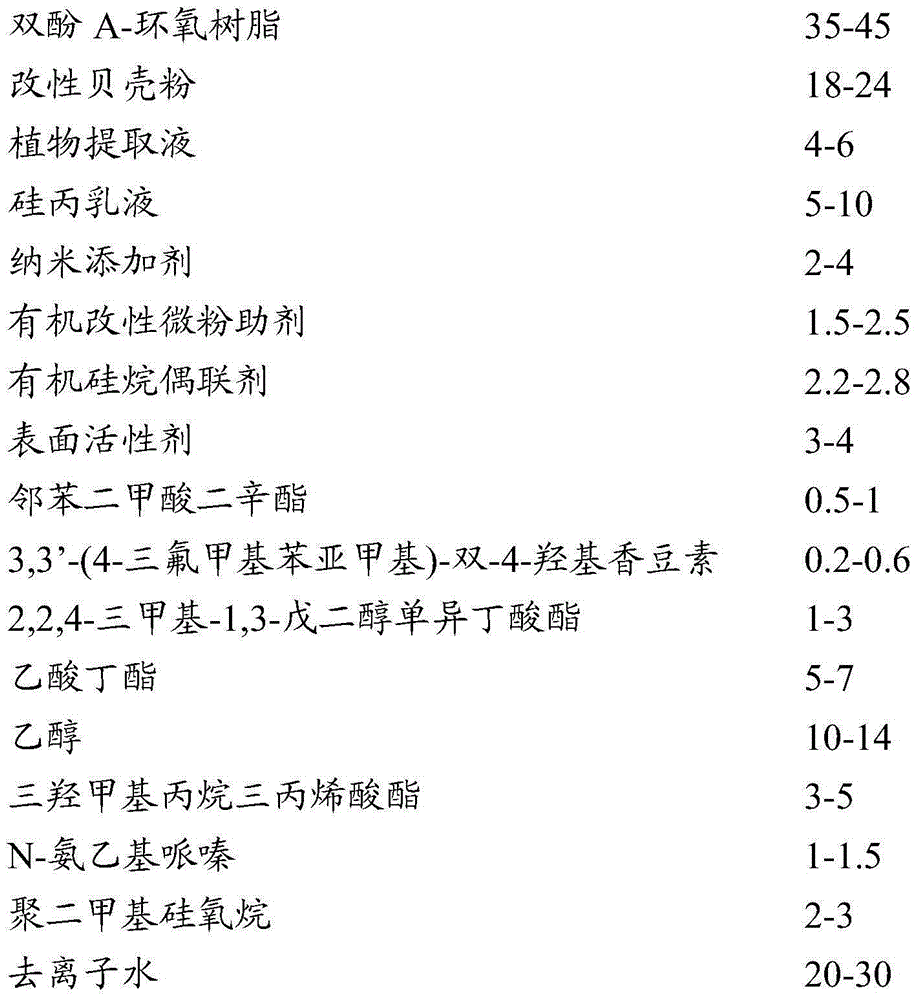

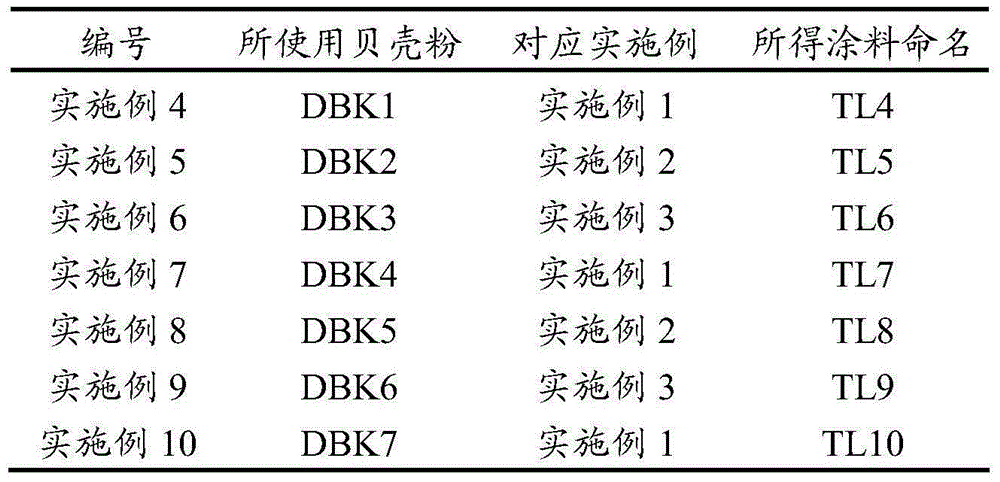

Environmentally friendly shell powder functional coating and preparation method therefor and uses thereof

ActiveCN104987808AImprove performancePractical application value is greatEpoxy resin coatingsDimethyl siloxaneIsoprene

The present invention relates to an environmentally friendly shell powder functional coating, a preparation method therefor and uses thereof. The coating comprises: bisphenol A-epon, modified shell powder, vegetable extract, propyl silicone emulsion, a nano additive, a modified organic micro powder agent, a surfactant, dioctylphthalate, 3, 3'-(4-trifluoromethyl methyl)-bi-4-hydroxy coumarin, 2,2,4-amino trimethyl-1,3-isoprene glycol mono iso-butyl methacrylate, butyl acetate, ethanol, trimethylol propane triacrylate, N-ammonia amino ethyl piperazine, polydimethylsiloxane and deionized water. In the present invention, by modification of a variety of components and materials, selection and collocation of specific components and a specific preparation method, the variety of components exert a synergistic effect, so as to make the prepared coating have significant antimicrobial, environmental-cleaning and wear-resisting properties. The coating has a huge application potential and extensive value in industrial production.

Owner:广西世家丽环保投资有限公司

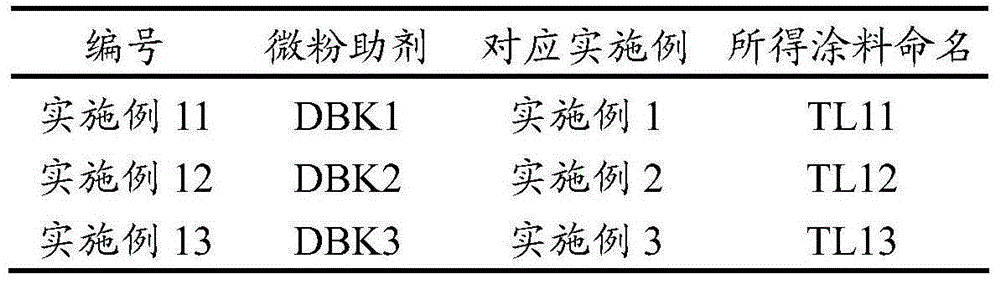

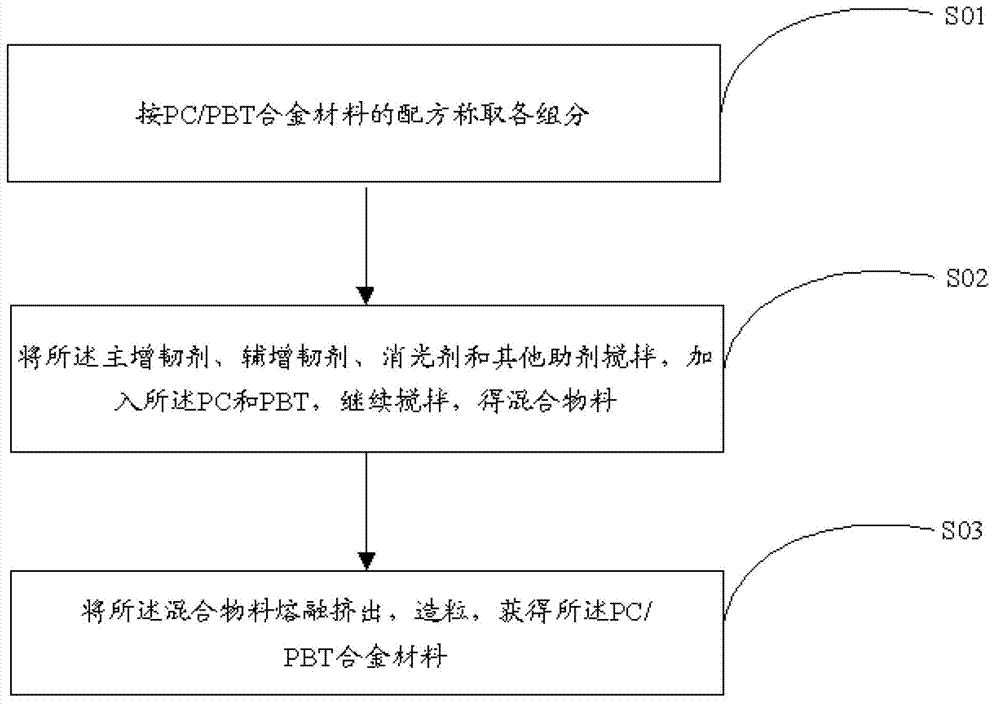

Low-luster PC/PBT (polycarbonate/polybutylene terephthalate) alloy material and preparation method thereof

InactiveCN102850746AMaterials are readily availableGood fluidityPolyethylene terephthalateAlloy composite

The invention provides a low-luster PC / PBT (polycarbonate / polybutylene terephthalate) alloy material which comprises the following components in percentage by weight: 60-72% of PC, 12-18% of PBT, 2-8% of main toughener, 1-4% of auxiliary toughener, 2-7% of flatting agent and 6-15% of other assistants. The main toughener is an ethylene-butyl methacrylate-glycidyl acrylate multipolymer, and the auxiliary toughener is a methyl methacrylate-butadiene-styrene impact modifier in a core-shell structure. The invention also provides a preparation method of the low-luster PC / PBT alloy composite material. The low-luster PC / PBT alloy material has the advantages of excellent comprehensive properties, favorable low-temperature-resistant effect and favorable matte effect, and can be used on automobile internal decorations, satellite receiving antenna and satellite signal receiver shells, and other devices in need of matting.

Owner:SHENZHEN KEJU NEW MATERIAL

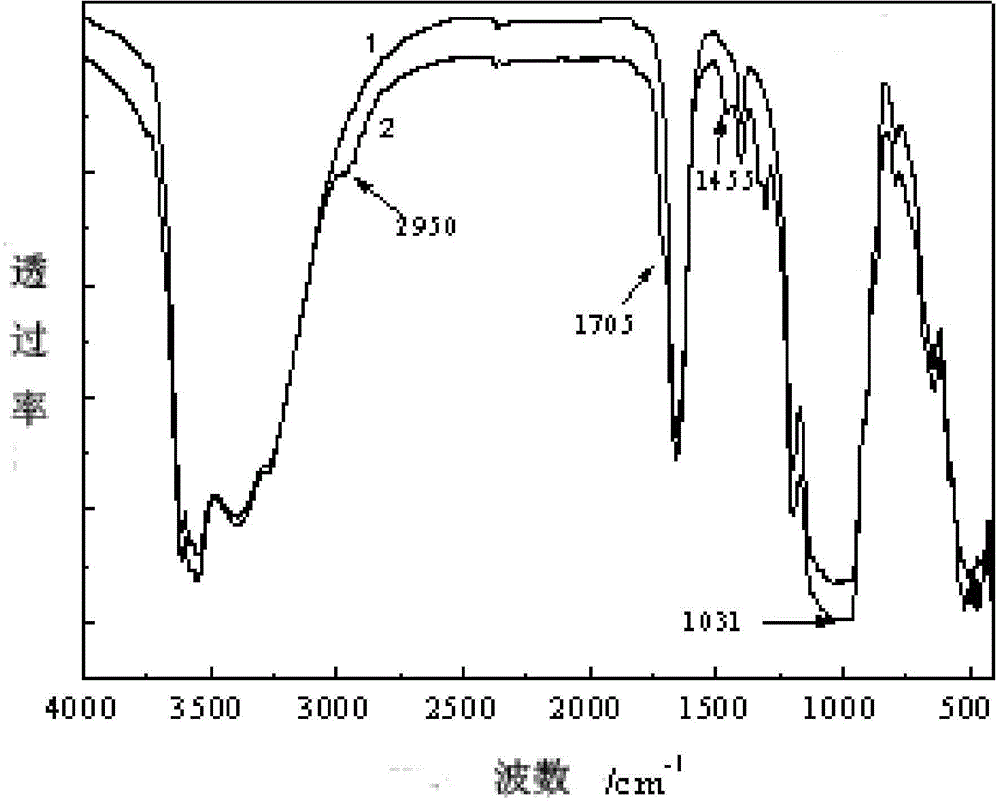

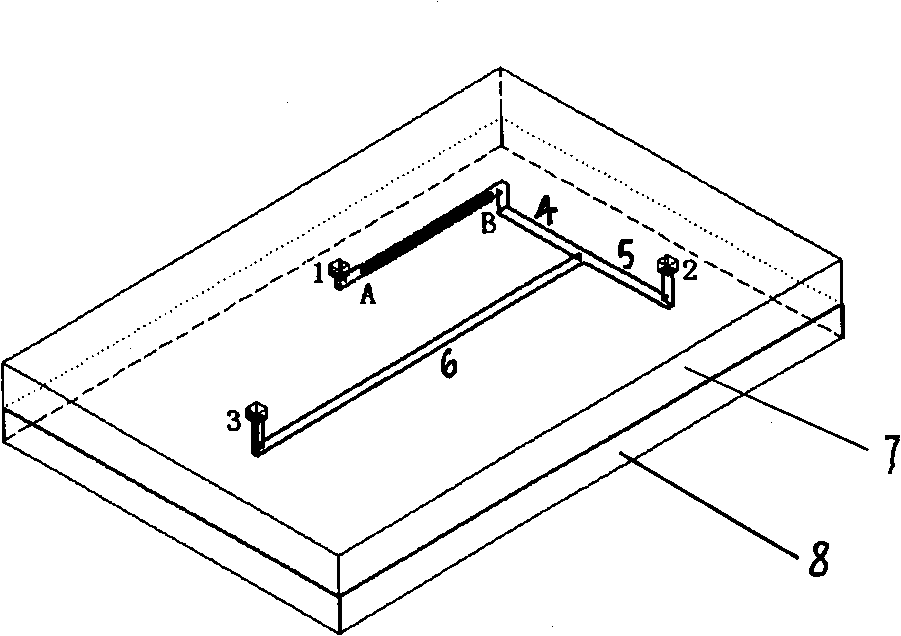

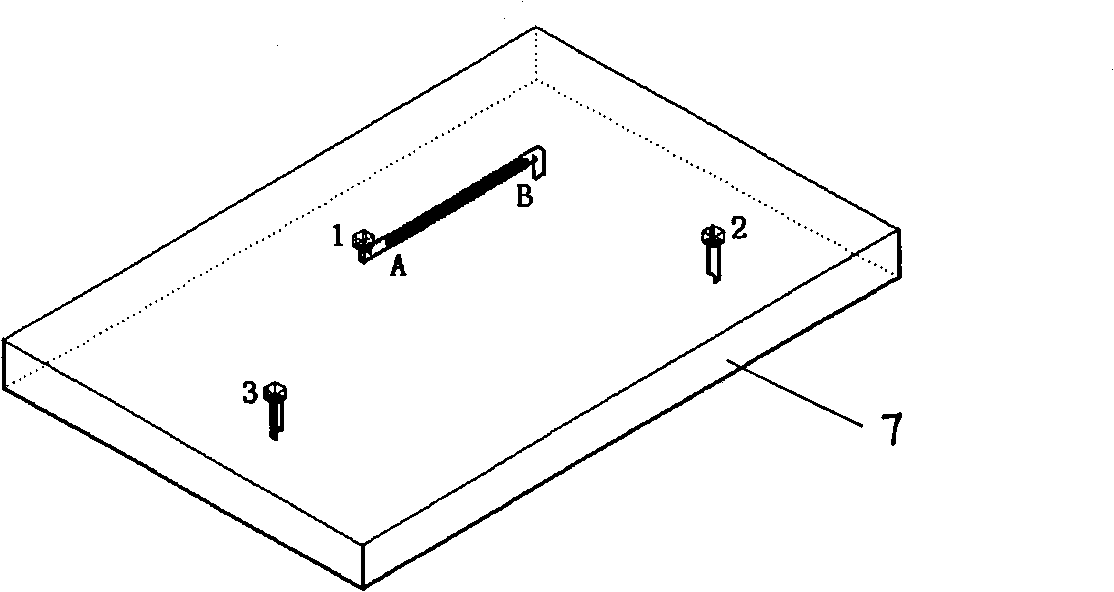

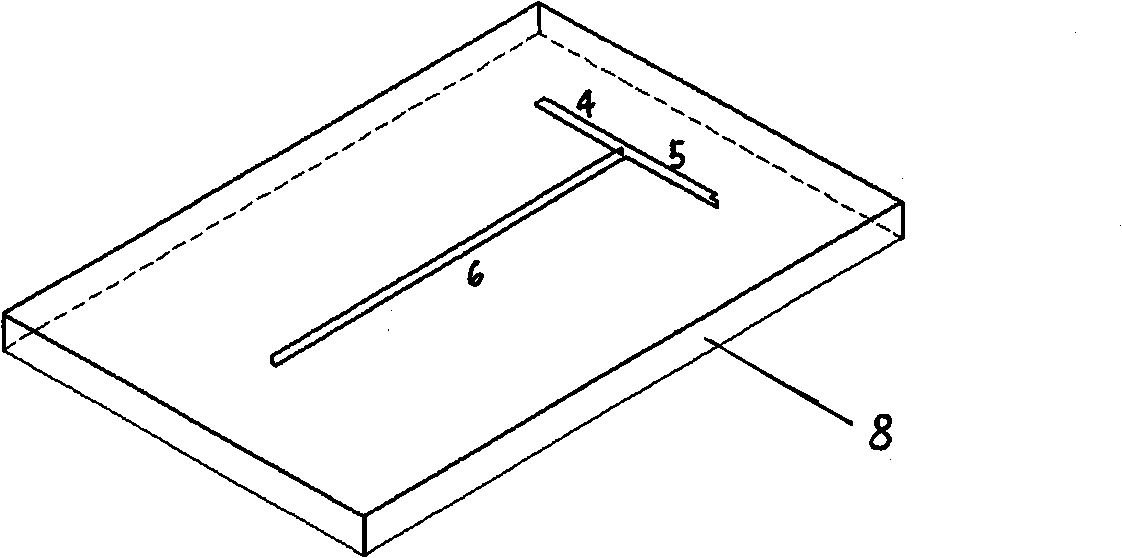

Three-dimensional microflow control chip containing in-situ poly(butyl methacrylate) preprocess integral column

InactiveCN101358912ARealize integrationEffective control positionPreparing sample for investigationBiological testingIn situ polymerizationPolymethyl methacrylate

The invention pertains to the technology field of micro total analysis, relating to a three-dimensional micro-flow control chip which includes an in-situ polybutyl methacrylate pretreatment integral pole. The polymer butyl methacrylate pretreatment integral pole is prepared by ultraviolet-radiated in-situ polymerization in the micro-channel on the micro-flow control chip; the substrate of the micro-flow chip can adopt glass, silicon, polymethyl methacrylate (PMMA) or poly(dimethylsiloxane) (PDMS), and the like as base materials, and etched with micro-channel networks for fluid mixing and reaction; the cover plate adopts PDMS integral casting method to fabricate the micro-channels of the solid-phase extracting and processing unit, a fluid lead-in / lead-out hole is arranged at the position corresponding to each micro-channel opening of the substrate, and is directly bounded with the substrate, and integration of the sample pretreatment integral pole and the micro-flow control chip micro-pipeline network is realized. The chip has the advantages of easy fabrication, low cost, small sampling quantity, rapid compartment analysis, and is applicable to pretreatment, analysis and test of sophisticated biochemical samples.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com