Acrylic ester emulsion and preparation method thereof

A technology of acrylate and emulsion, applied in the direction of coating, etc., can solve the problems of poor wear resistance, insignificant performance improvement, poor anti-blocking property of paint film, etc., and achieve the effect of improving wear resistance and anti-blocking property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

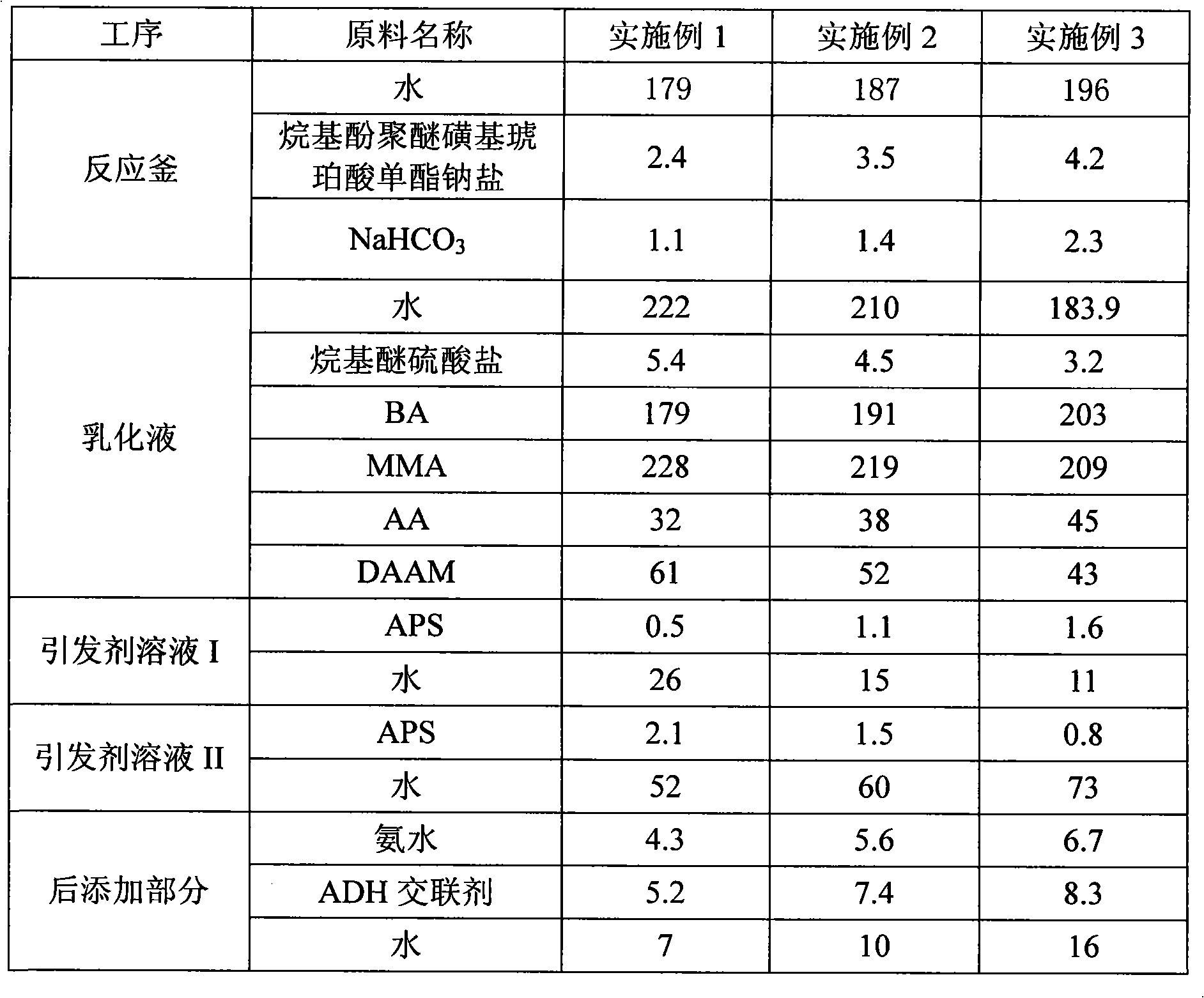

[0020] The preparation method of embodiment 1~3 acrylate emulsion

[0021] (1), preparation of emulsion, initiator I, initiator II

[0022] Add water, alkyl ether sulfate, BA, MMA, AA, and DAAM into the emulsification tank in sequence, and stir for 30-40 minutes to obtain an emulsion;

[0023] APS is dissolved in water to obtain initiator solution I;

[0024] The preparation method of the initiator II is the same as that of the initiator solution I, except that the parts by weight of each component are different. The parts by weight of the above raw materials are shown in Table 1.

[0025] Table 1 list of raw materials

[0026]

[0027] (2) Response

[0028] Add water, alkylphenol polyether sulfosuccinic acid monoester sodium salt and buffer Na 2 CO 3 , stirring, heating;

[0029] When the temperature rises to 85-88°C, stop heating, add initiator solution I into the reaction kettle, and stir;

[0030] Add the emulsion and initiator solution II to the reaction kettle...

Embodiment 4

[0033] The performance of embodiment 4 acrylate emulsion

[0034] Using the wood paint emulsion prepared by free radical polymerization in the prior art as a contrast, add 10% film-forming aids to the acrylate emulsion prepared in Example 3, and make water-based wood paint. The performance is tested, and the results are shown in Table 2. Show. Among them, the method stipulated in the national standard of GB / T1762-1980 (1989) paint film back tackiness determination method is used, and the high temperature back tackiness of the paint film is characterized by hot pressure resistance; the method stipulated in ISO 7784-2:1997 is used, and CS -10 size grinding wheel tested for abrasion resistance.

[0035] The performance of table 2 acrylate emulsion

[0036] Test items

[0037] The results show that the anti-blocking and abrasion resistance of the acrylate emulsion prepared by the method of the present invention are obviously better than those of the wood paint emulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com