Patents

Literature

5527 results about "Pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure resistance. [′presh·ər ri‚zis·təns] (fluid mechanics) In fluid dynamics, a normal stress caused by acceleration of the fluid, which results in a decrease in pressure from the upstream to the downstream side of an object acting perpendicular to the boundary. Also known as pressure drag.

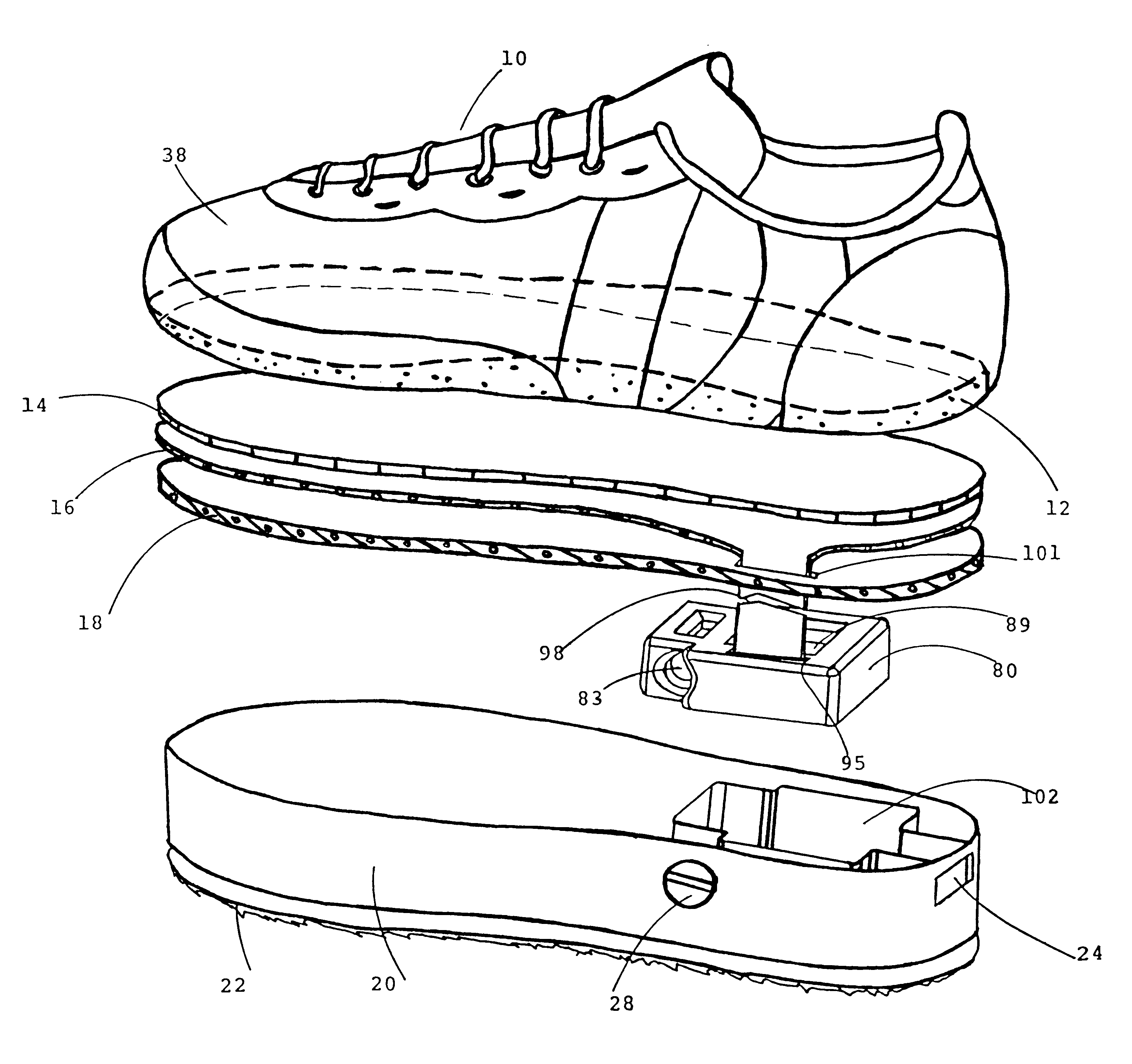

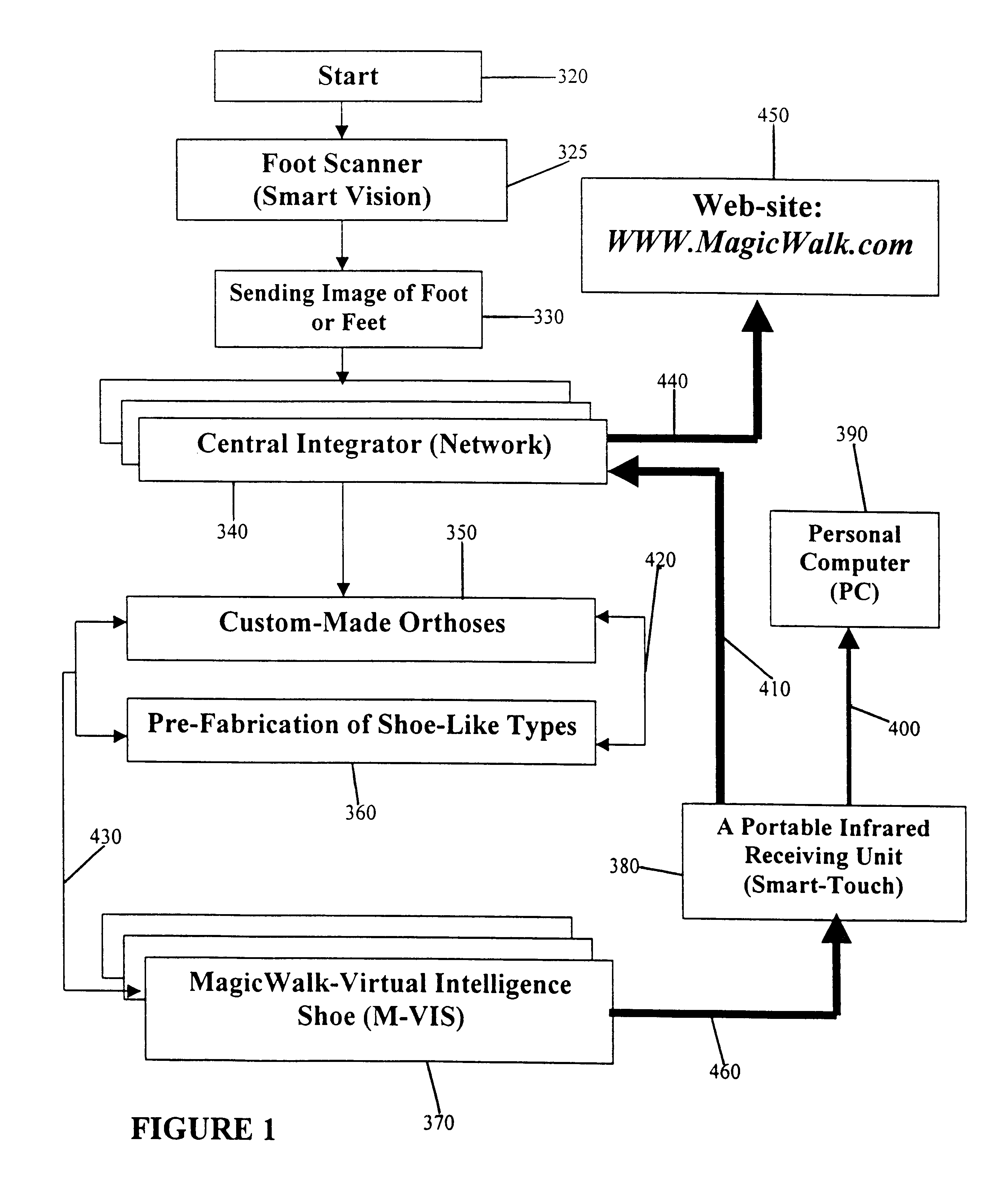

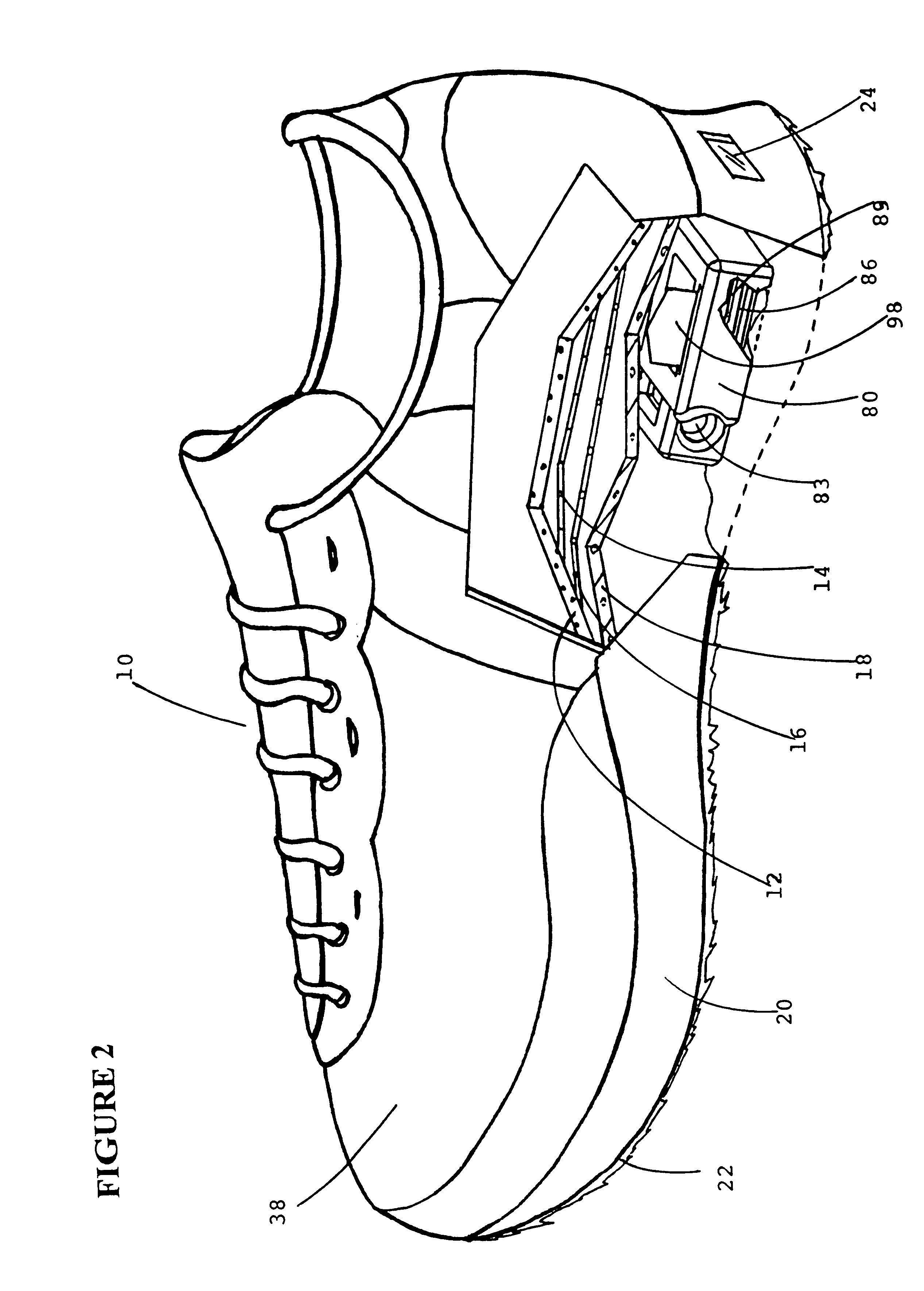

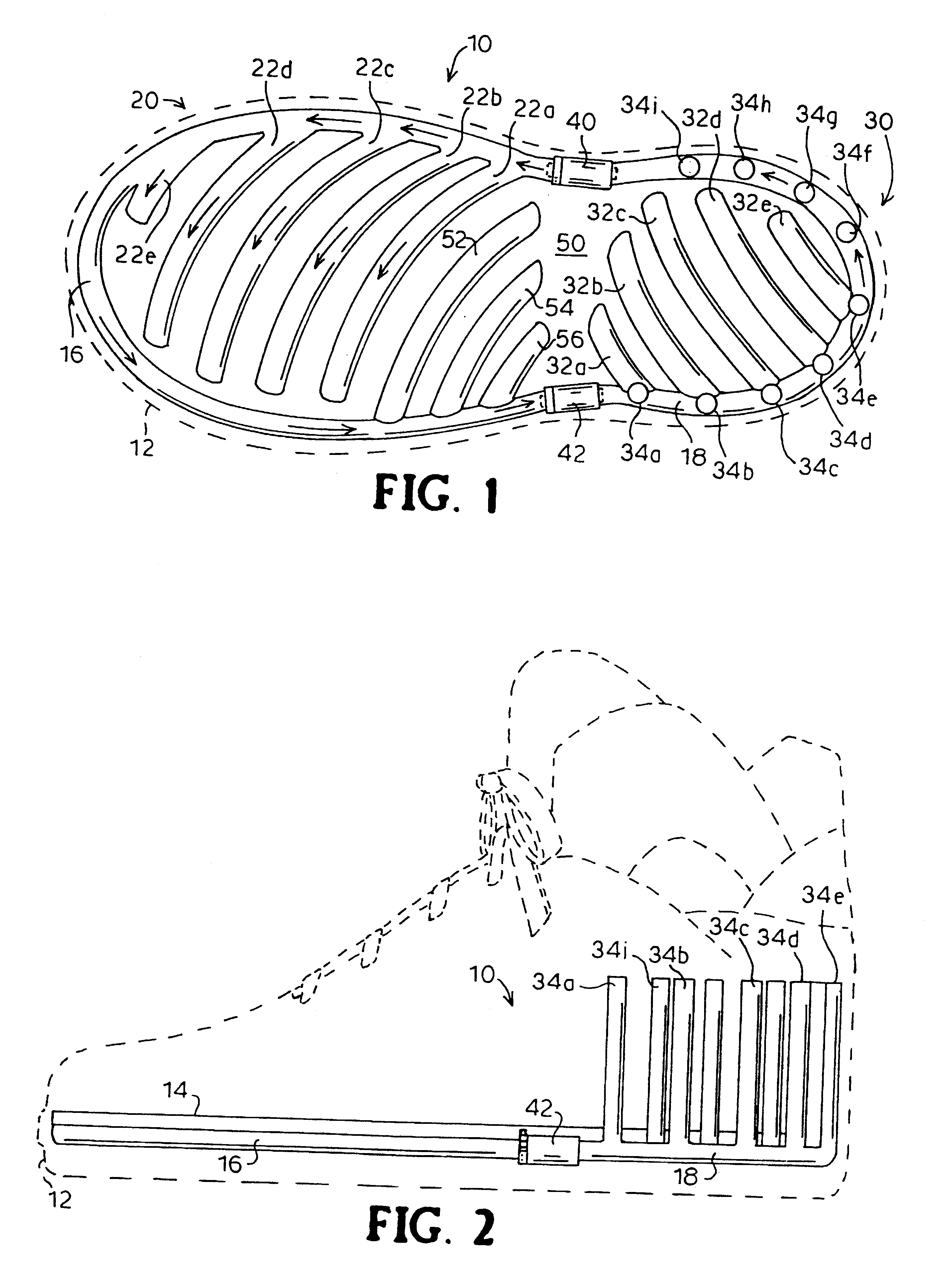

Virtual intelligence shoe with a podiatric analysis system

The virtual intelligence shoe with a podiatric analysis system provided with a portable pair of shoe-like body types thereof, into two of which a miniature electronic module and an enclosed sensor mat are permanently embedded in the shoe-like with a mechanical air package enclosing the electronic module to serve as a shock absorption. A miniature electronic module comprises a transmitting circuit with pressure resistance, shoe temperature and warning buzzer for full memory capacity, which receives the variable pressure and temperature voltage signals, convert them into resistance (ohm) and Celsius, respectively. The electrical signals can be emitted in an infrared light signal. An enclosed sensor mat constitutes a thin, flexible, planar, resilient, and dielectric material that arrays seventy-four positions at strategic geometrical pattern to produce the precision of collecting data exerted by a foot or feet continuously and instantaneously in static and dynamic event during the full weight bearing in various activities. The conjunction of a pair of shoe-like body types, a digital foot scanner, a portable infrared light-receiving unit and a central integrator (servers) form a podiatric analysis system for enabling accurate information. An obtained information of each individual can be stored and analyzed for diagnostic means with respect to the foot or feet maladies. The virtual intelligence shoe with a podiatric analysis system is an unconventional, which can ultimately be used by anyone and capable to produce consistent foot or feet information to implement the changes in the foot or feet biomechanics by altering the shoes, orthoses or other modes. In a preferred form, a pair of shoe-like body types is virtually applied to any type of foot or feet maladies and worn daily as if they were conventional shoes under various terrain conditions.

Owner:TRUONG VINNCENTE HOA GIA

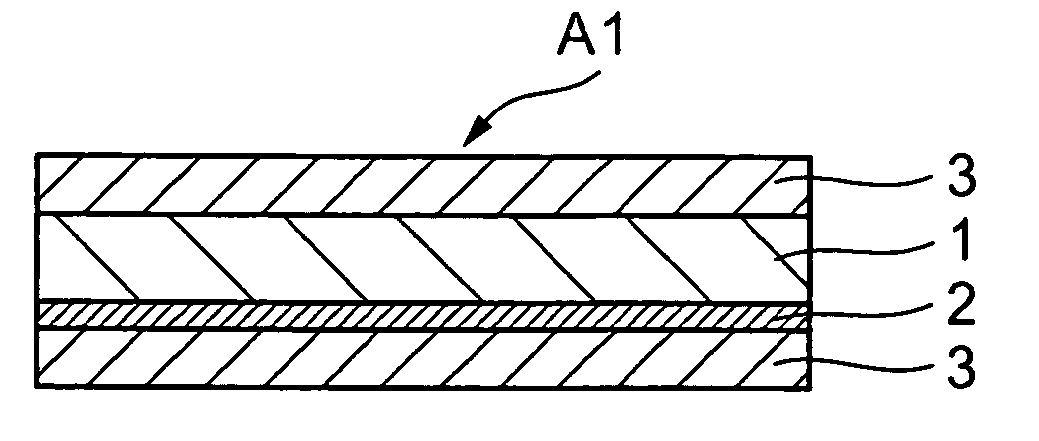

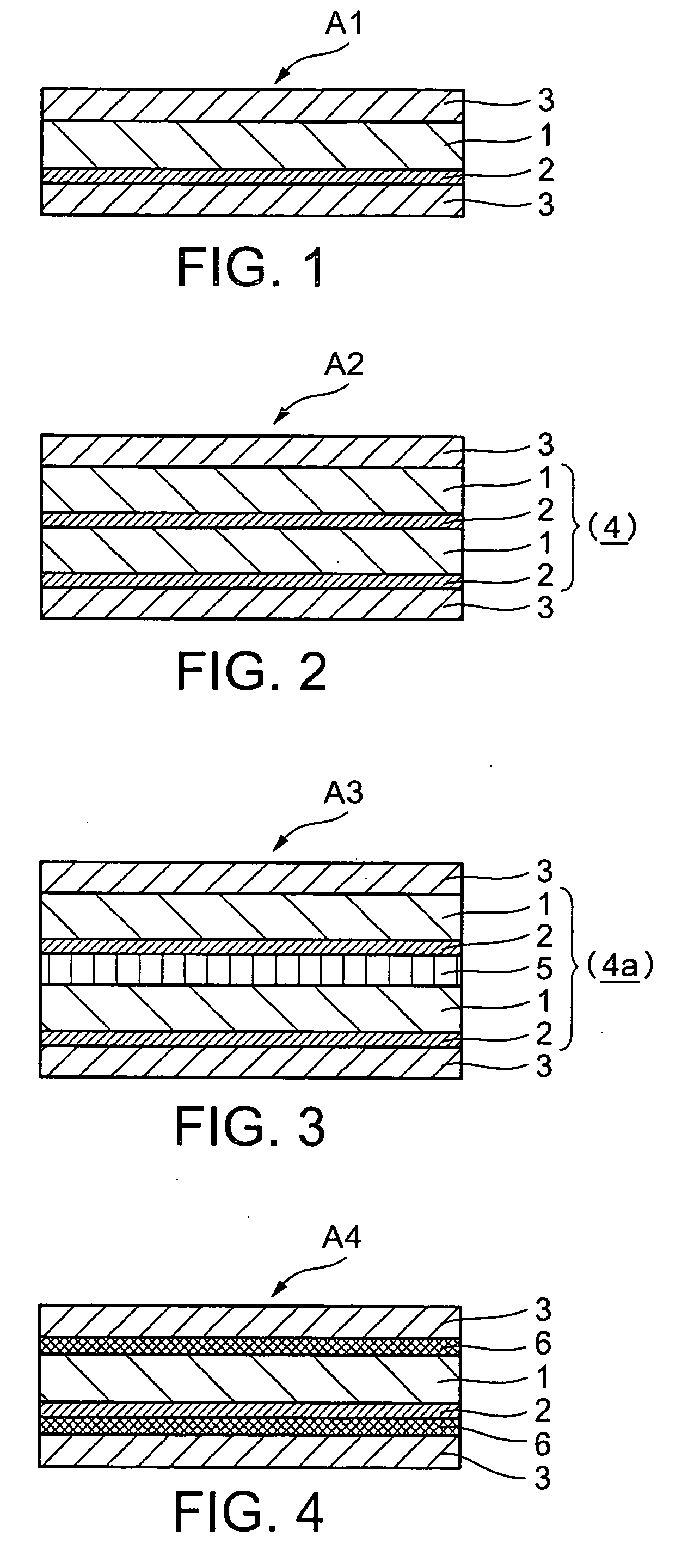

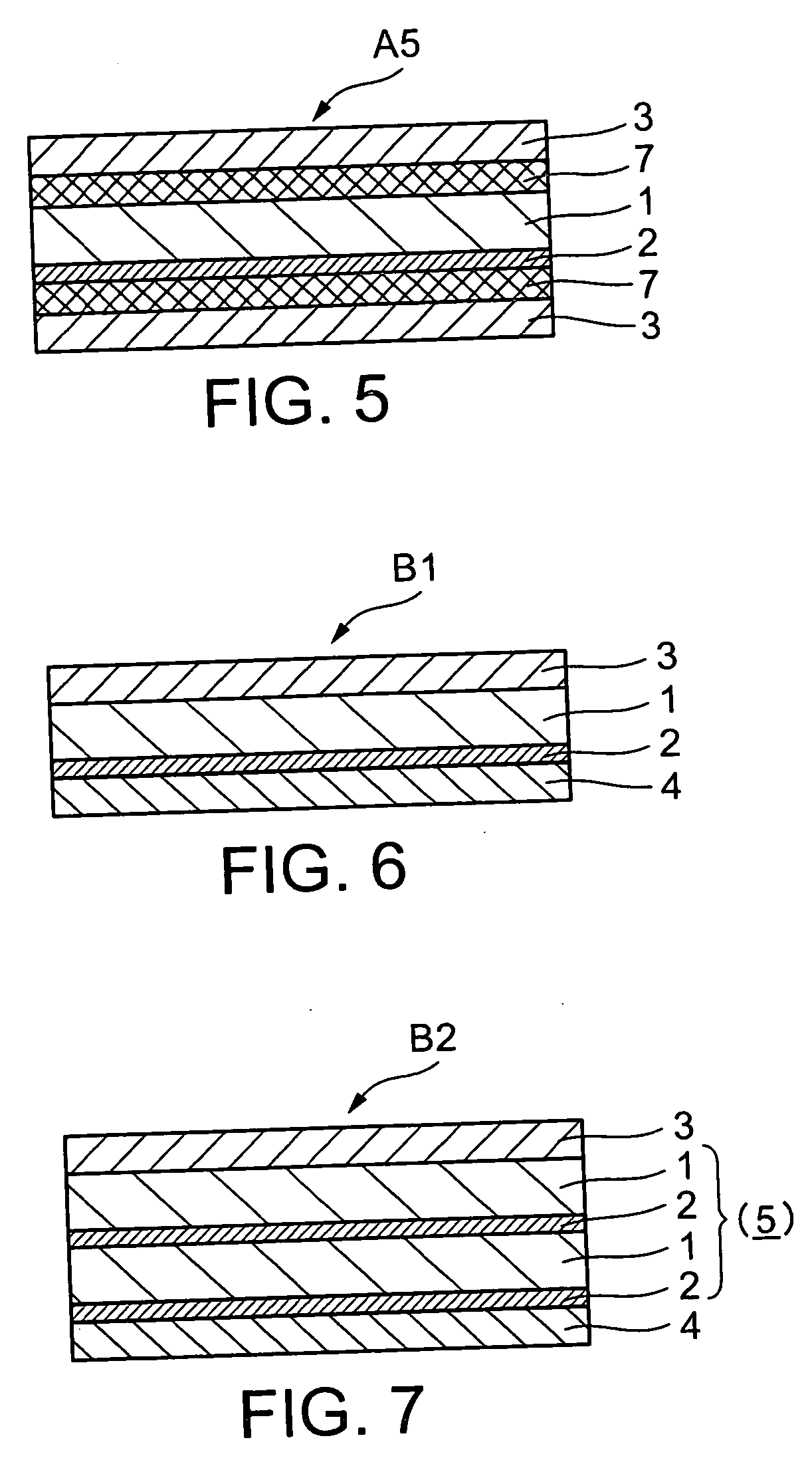

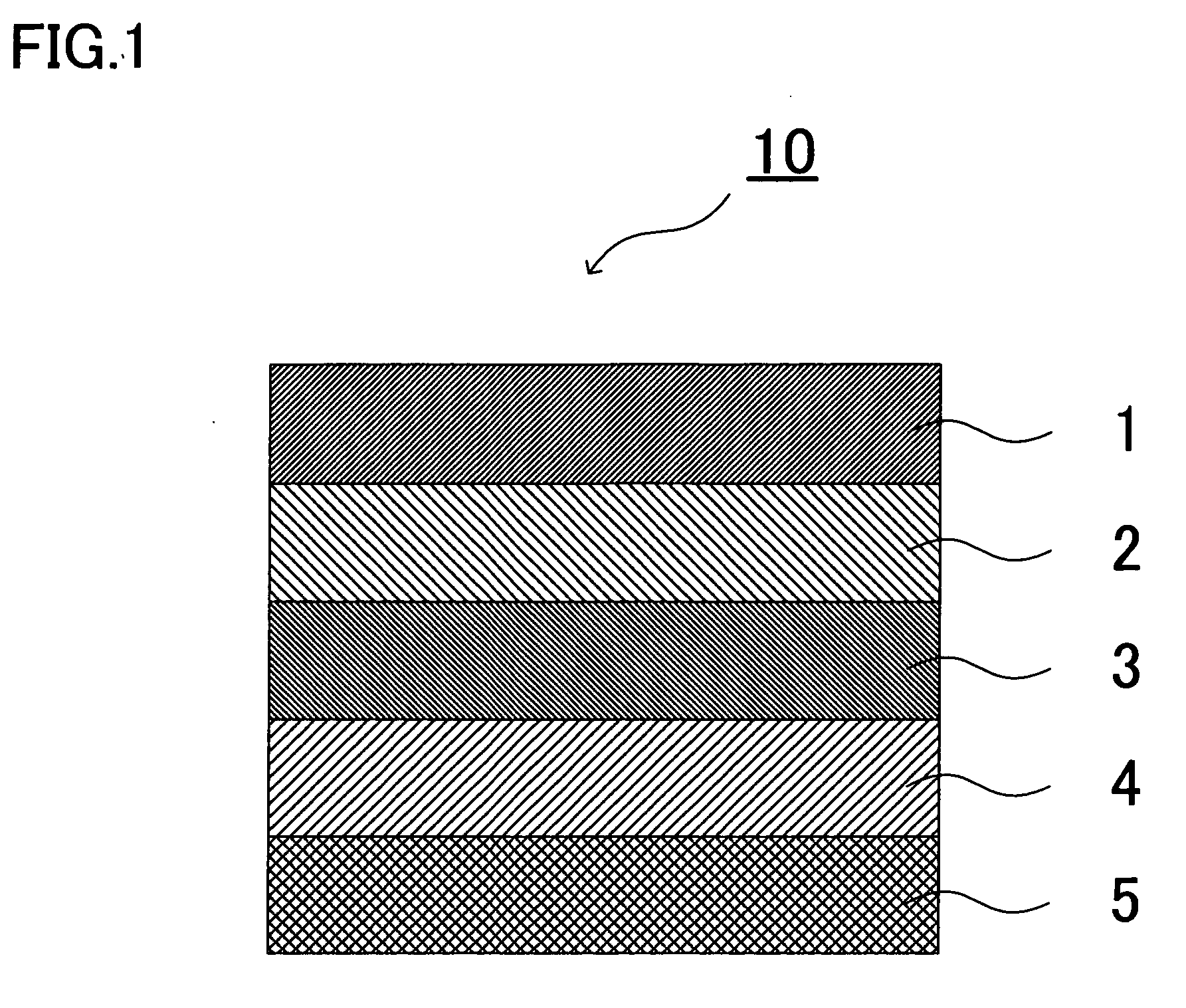

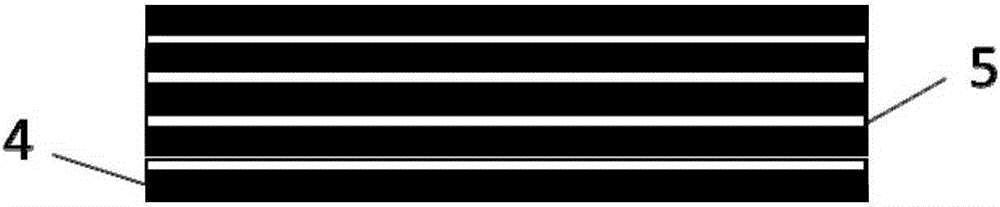

Backside protective sheet for solar battery module and solar battery module using the same

InactiveUS20060166023A1High strengthConvenient inventory managementSynthetic resin layered productsGlass/slag layered productsPolyolefinElectrical battery

There is provided a backside protective sheet for a solar battery module that is excellent in strength as well as in various properties such as weathering resistance, heat resistance, water resistance, light resistance, wind pressure resistance, hailstorm resistance, chemical resistance, moisture resistance, antifouling properties, light reflectivity, light diffusivity, and design, and is particularly excellent in the so-called “moisture resistance,” which is the ability to prevent the entry of moisture, oxygen and the like, and durability against performance degradation with time, particularly against hydrolytic degradation and the like, and is also excellent in protective capability. There is also provided a backside protective sheet for a solar battery module, which can facilitate inventory control by properly using the front side and back side of the protective sheet depending upon applications and is excellent in cost performance, and a solar battery module using the same. The backside protective sheet for a solar battery module comprises: a deposited assembly comprising a vapor-deposited film of an inorganic oxide provided on at least one side of a substrate; and a transparent or translucent heat-resistant polyolefin resin layer provided on both sides of the deposited assembly.

Owner:DAI NIPPON PRINTING CO LTD

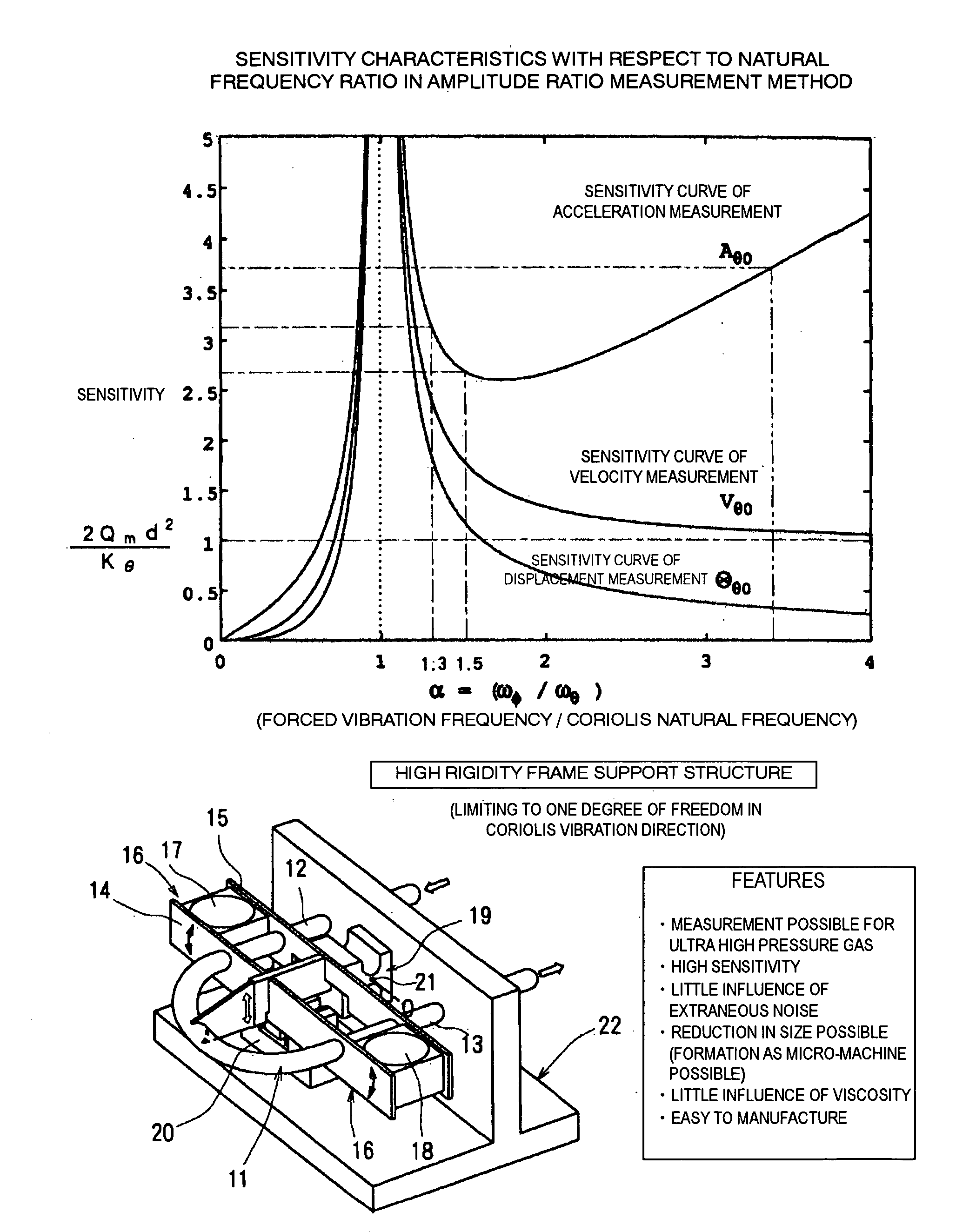

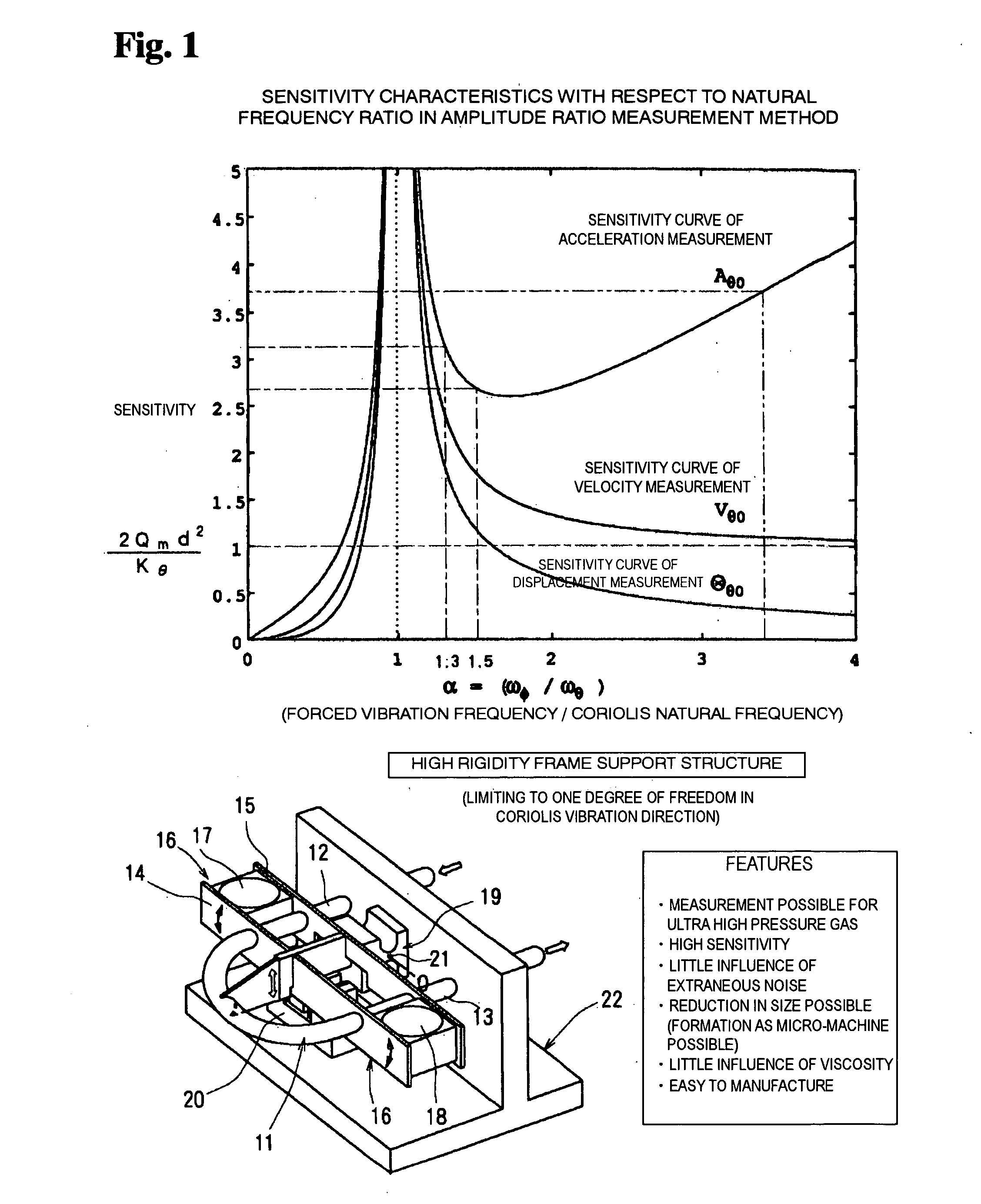

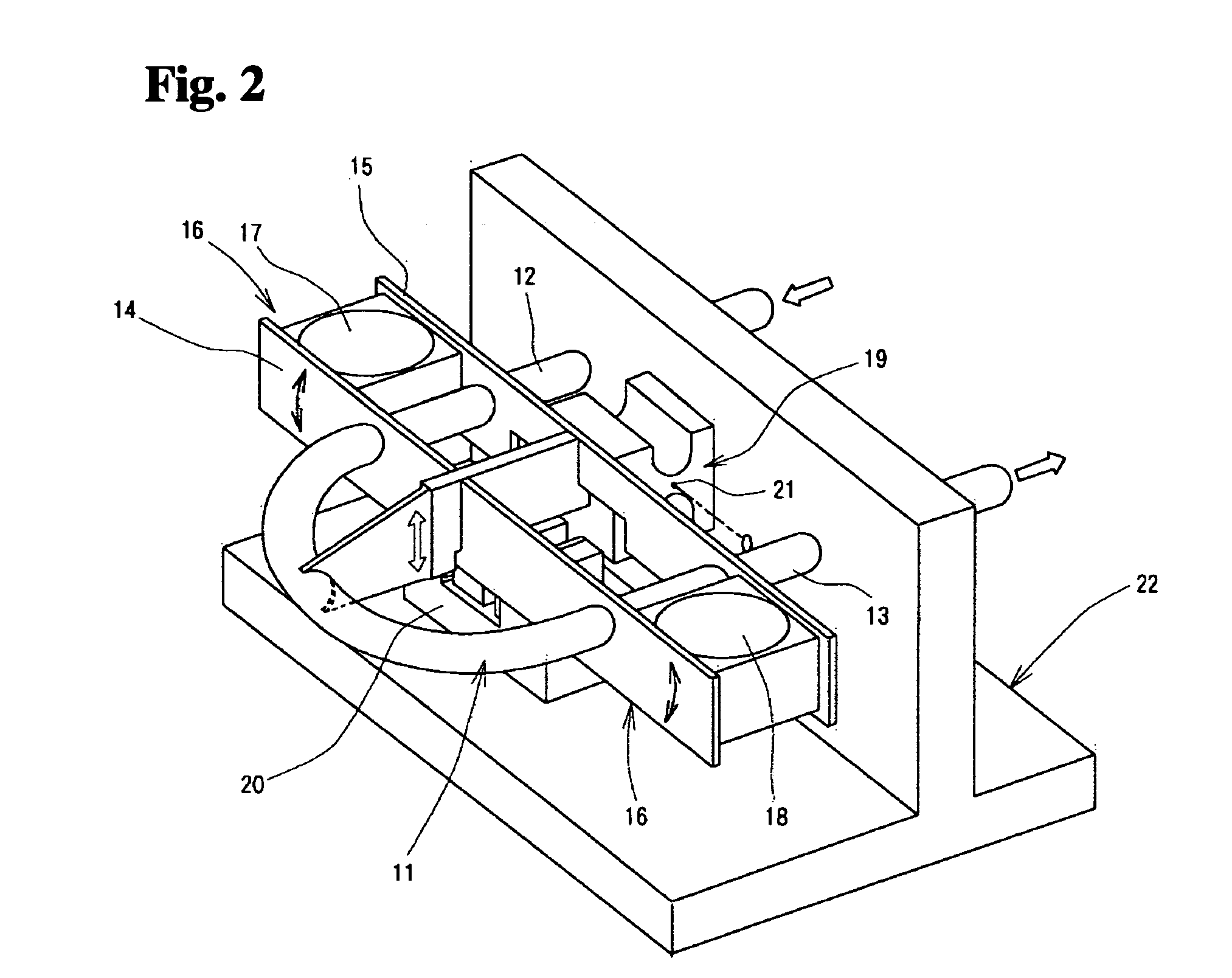

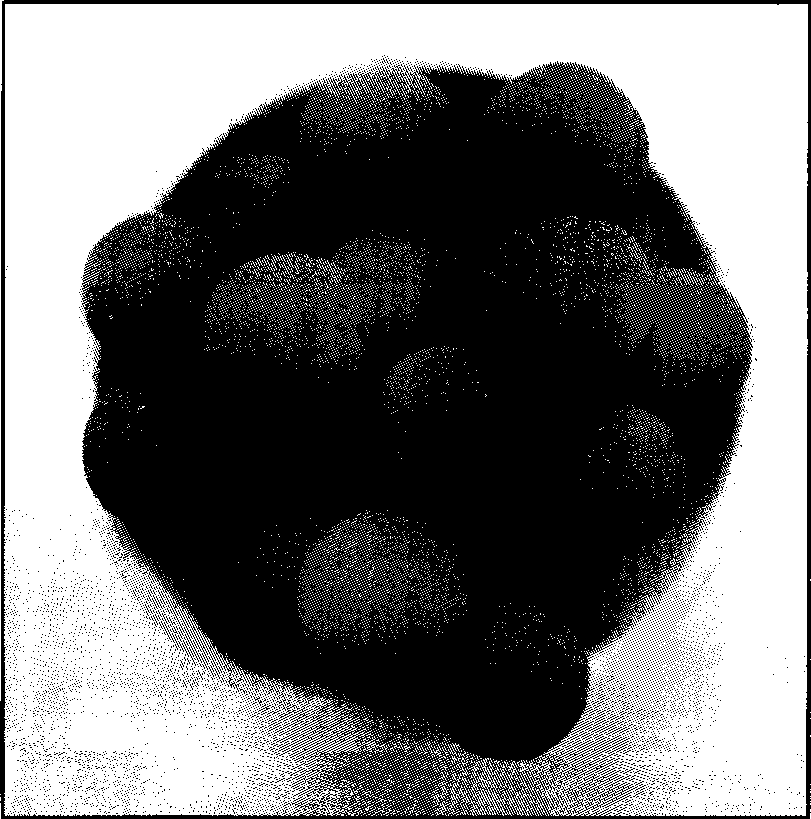

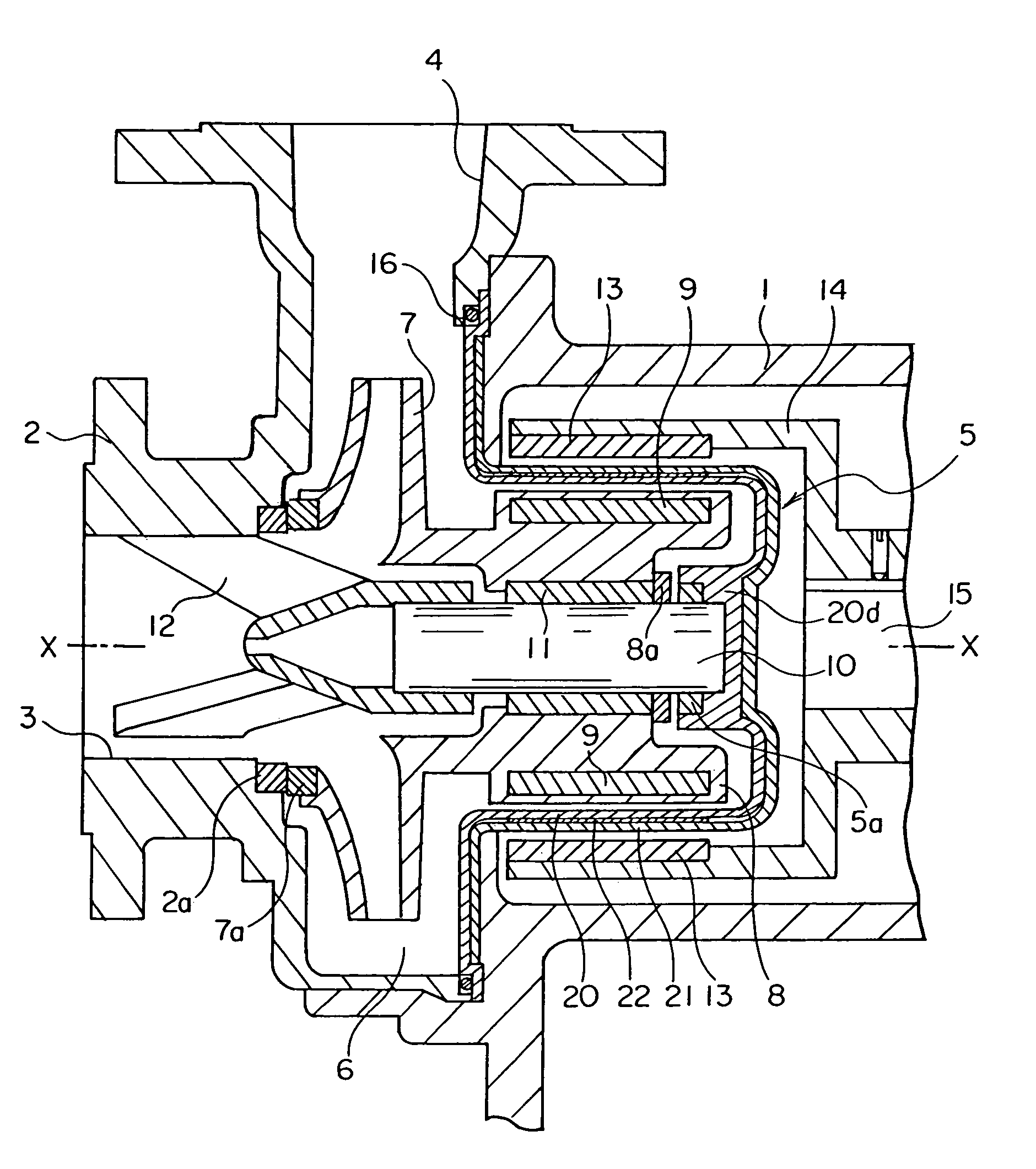

Coriolis flowmeter

ActiveUS20070034019A1Efficient removalReduce the impactDirect mass flowmetersPhase differenceClassical mechanics

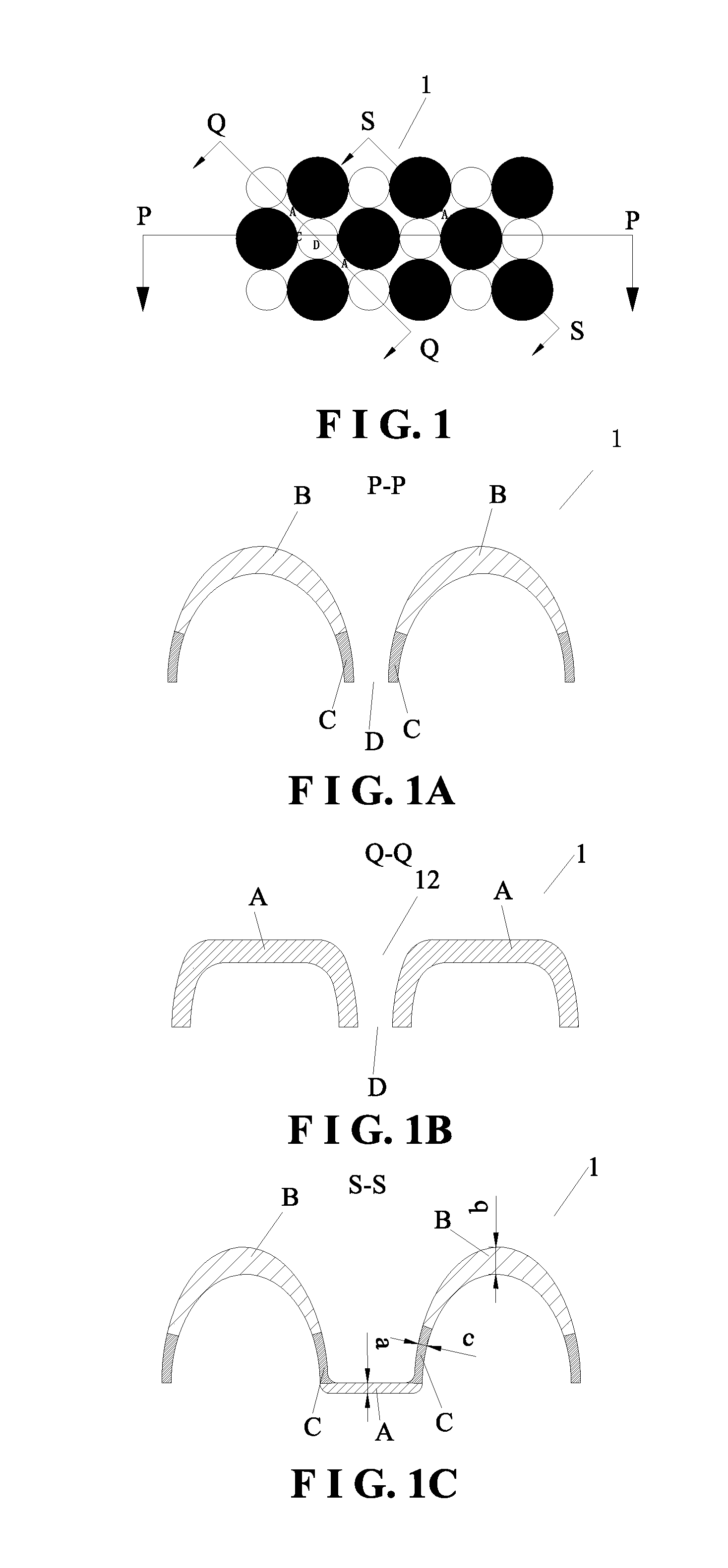

When outputs from two vibration detection sensors are measured by a Coriolis flowmeter in a form of phase difference time, a tube must be thinned to increase a sensitivity of the flowmeter to enable measurement and accordingly flow velocity and pressure loss increase, and a thickness of the flowmeter must be reduced and therefore a pressure resistance cannot be readily enhanced. In particular, the sensitivity of signals to flow rate is difficult to increase and, accordingly, a flow rate of a low-density gas cannot be accurately measured. In the present invention, a Coriolis vibration frame 16 carrying a U-shaped tube is swingably fixed to a forced vibration frame 19 fixed to a support base 22 to form a highly rigid frame structure limiting a vibrating direction to one degree of freedom in a Coriolis vibration direction. The forced vibration frame 19 is vibrated by a vibration exciter 20 so that a ratio of a forced vibration frequency to the Coriolis frequency of a pipeline is at least 1 to 10. The ratio of the amplitude of the forced vibration to the amplitude of the Coriolis vibration is calculated based on signals from two vibration sensors such as acceleration sensors 17 and 18 to measure the mass flow rate of a fluid flowing in the pipeline.

Owner:NAT INST OF ADVANCED IND SCI & TECH

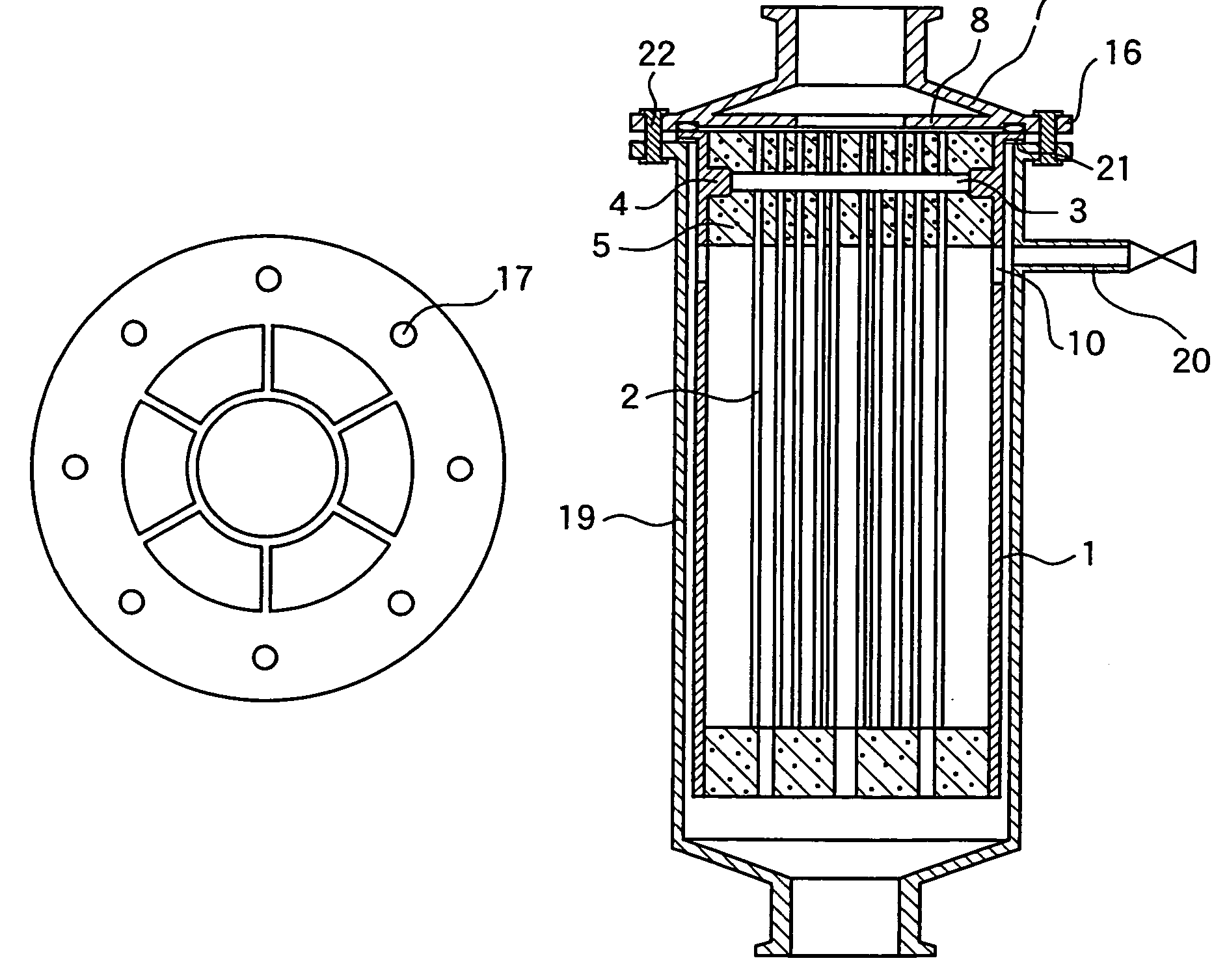

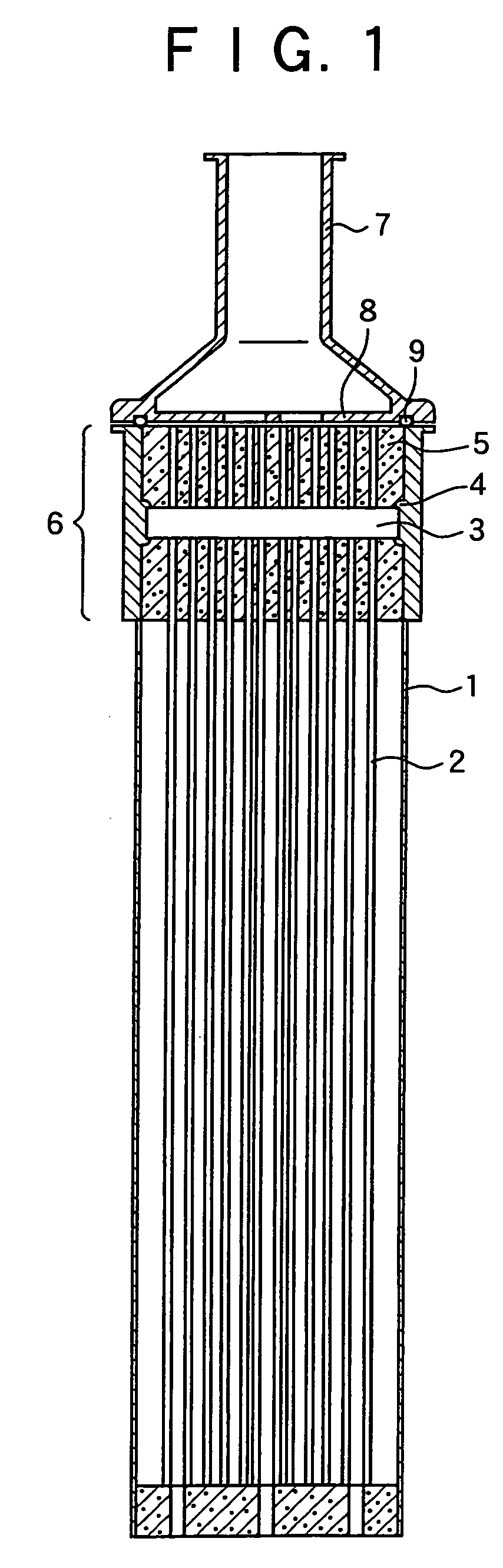

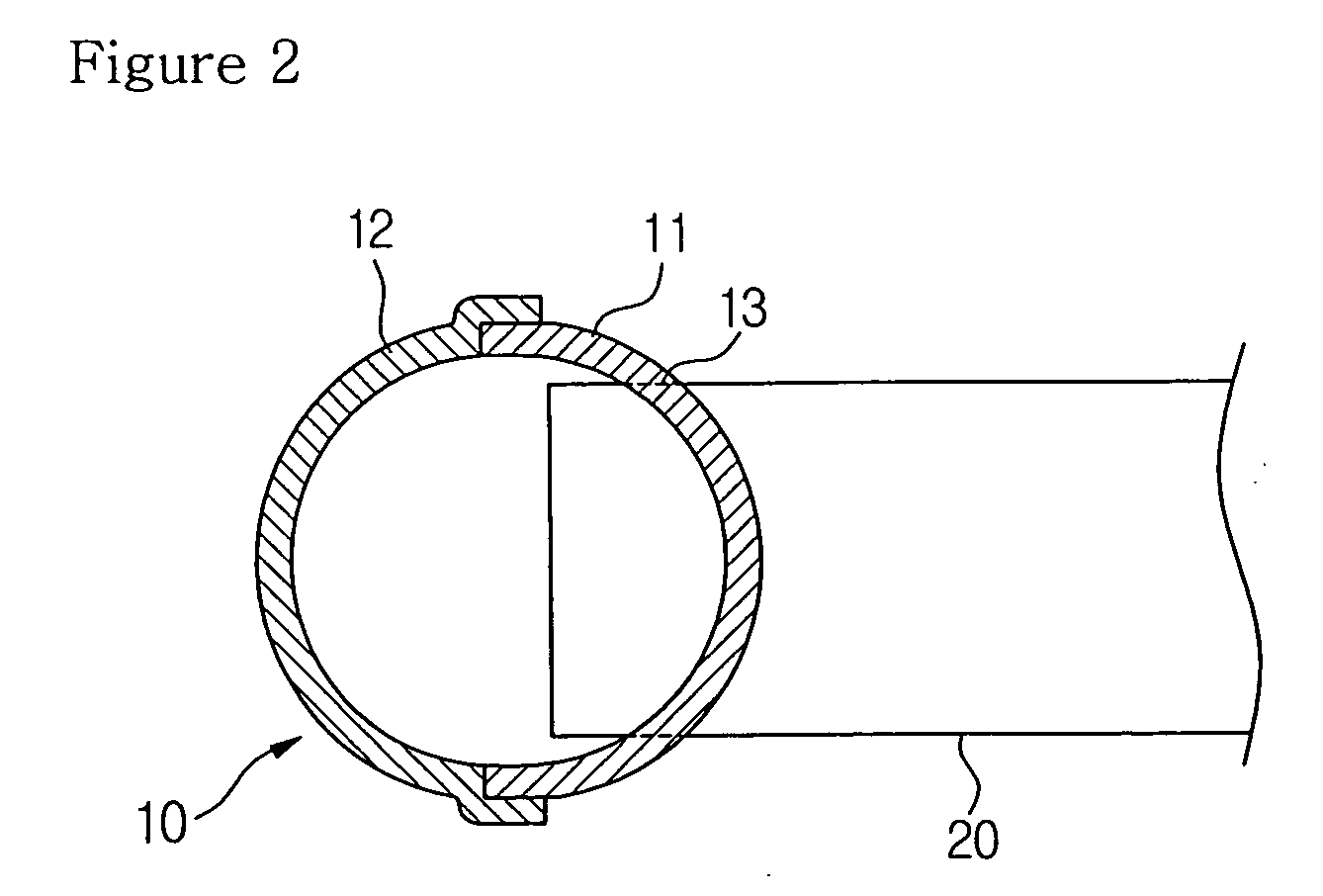

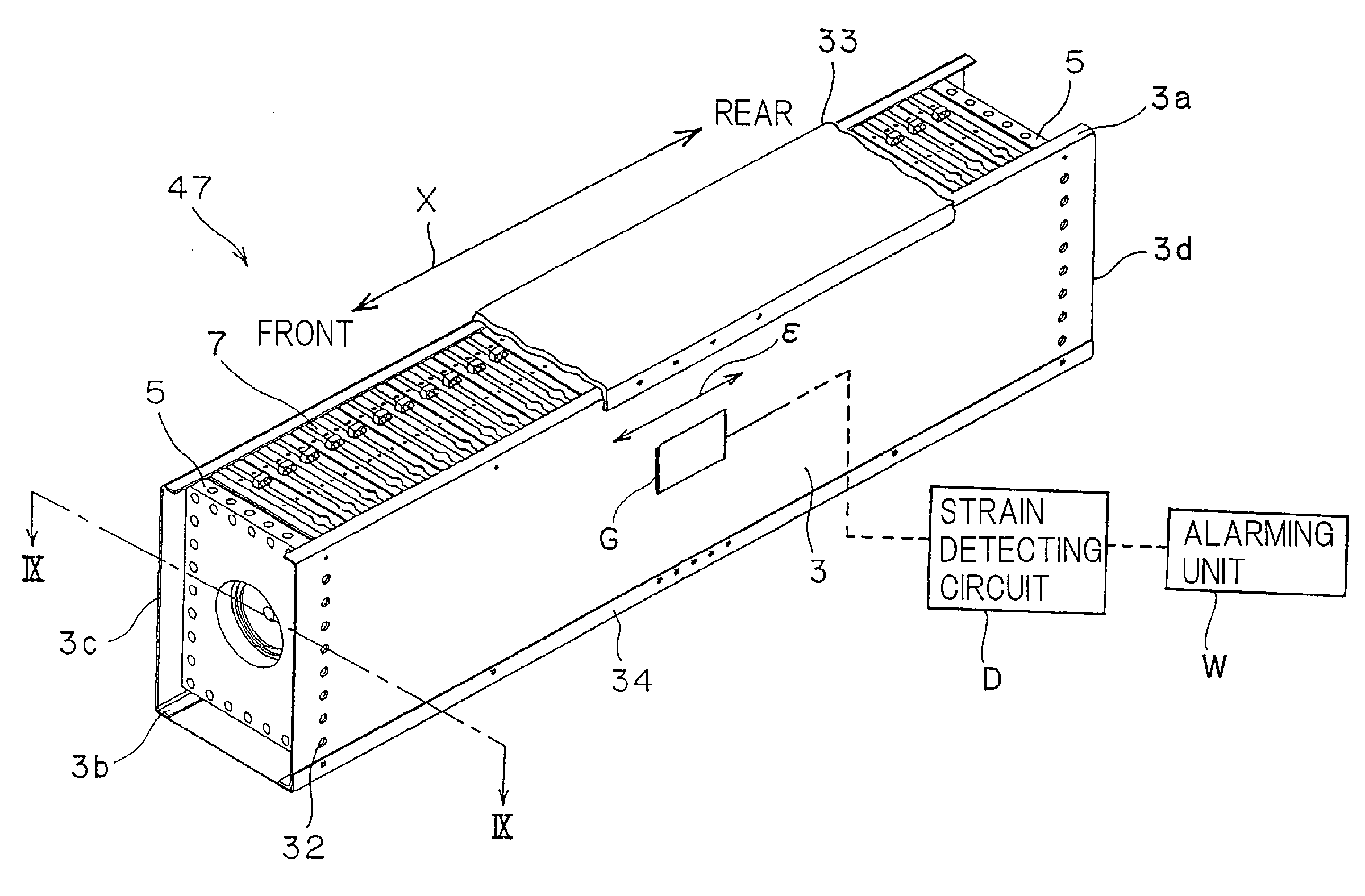

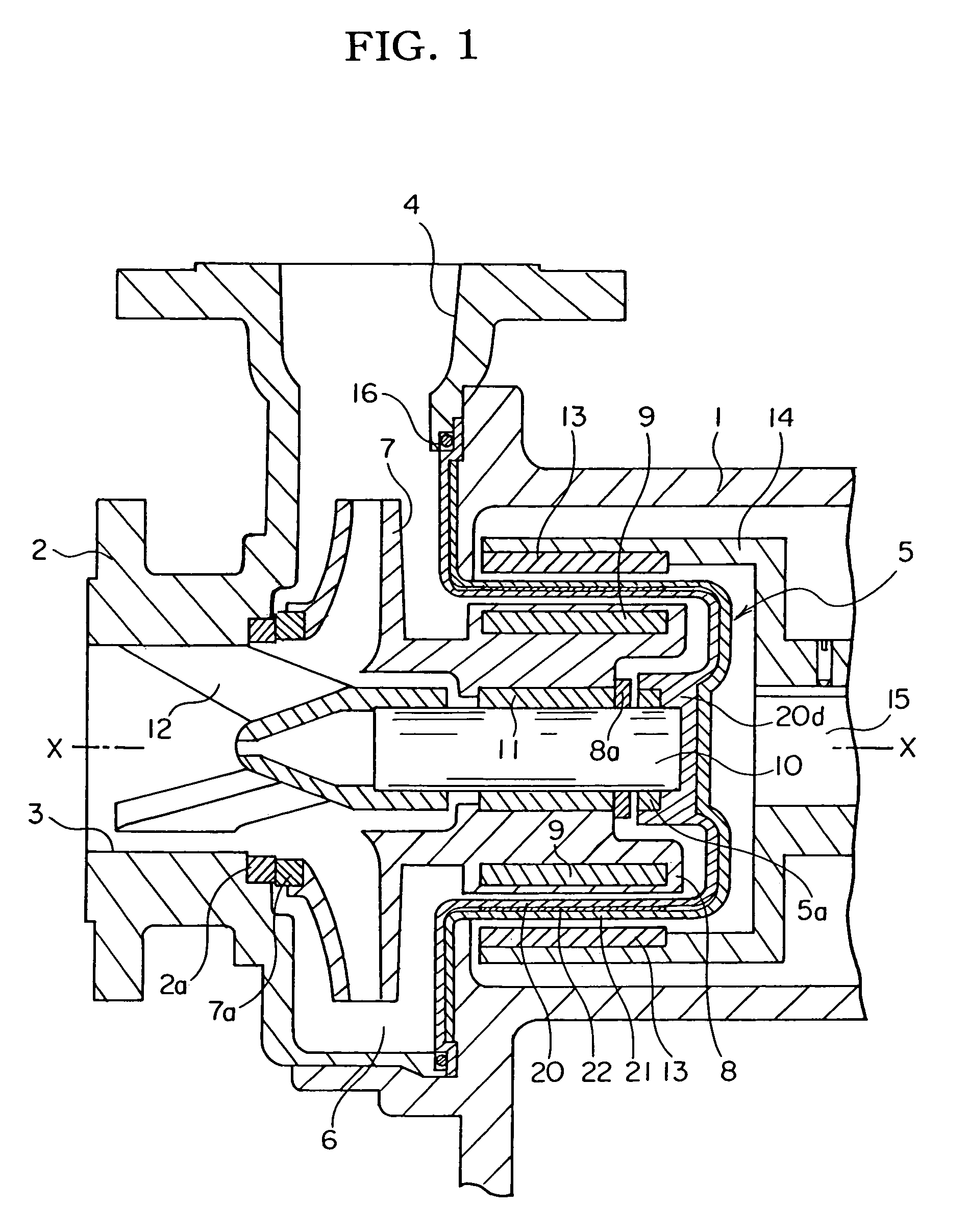

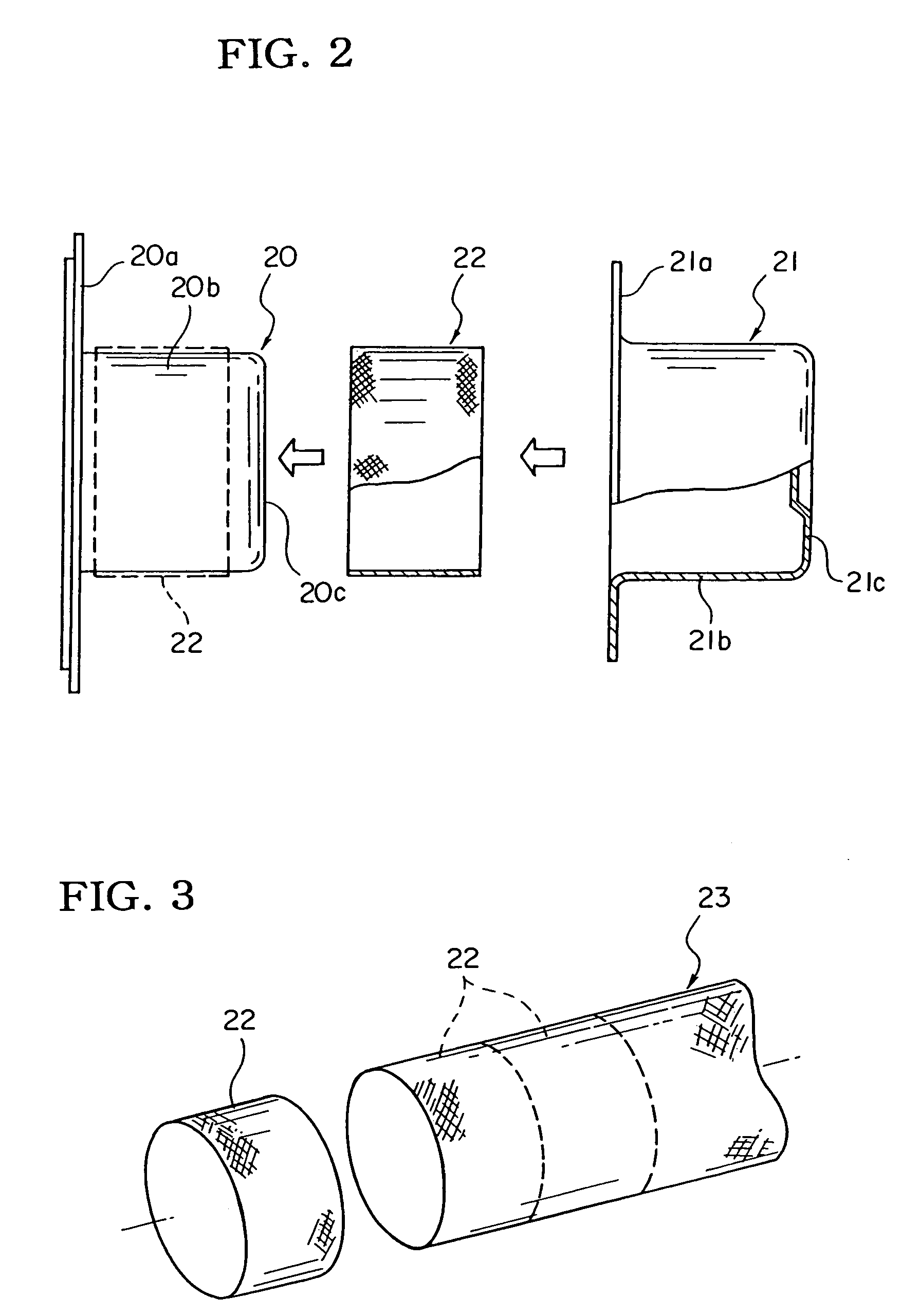

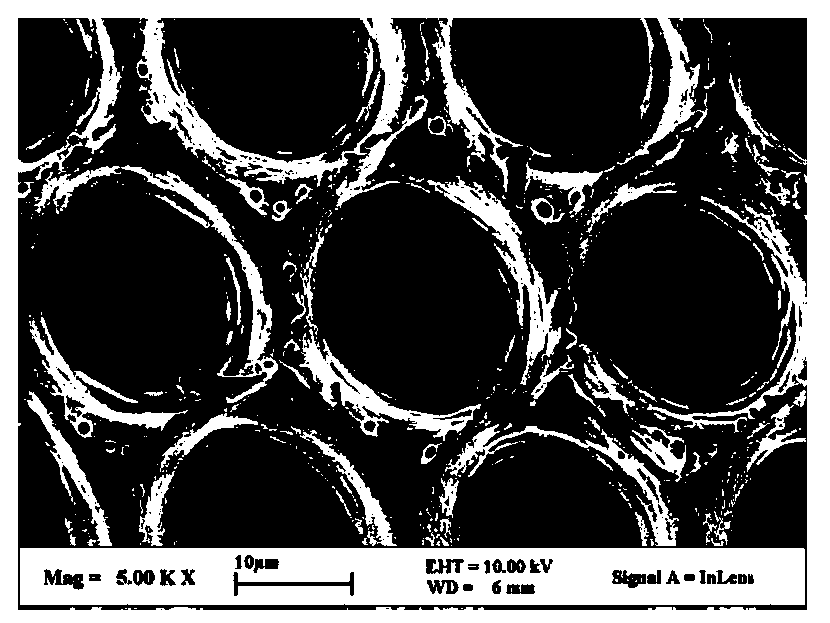

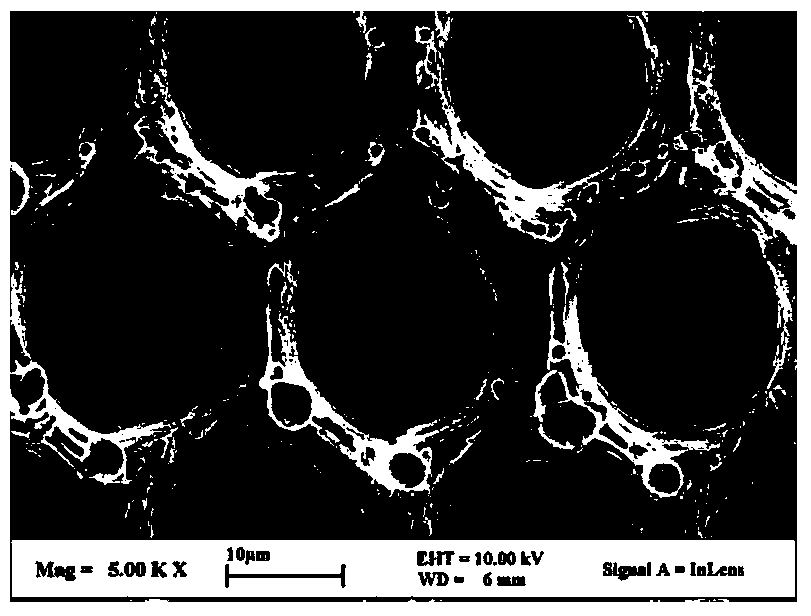

Hollow fiber membrane module

InactiveUS7160455B2Practical pressure resistanceReduce breakageMembranesSemi-permeable membranesFiltrationMechanical engineering

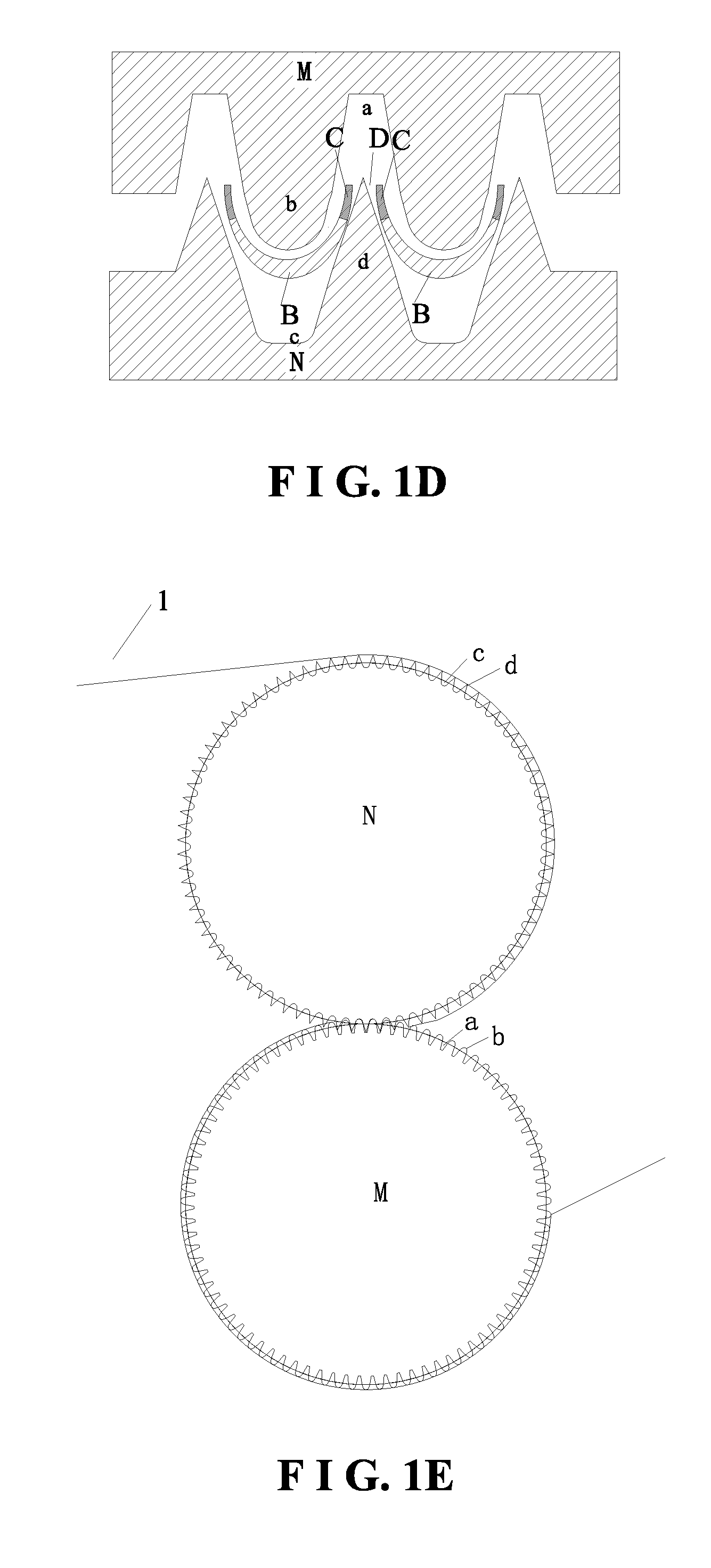

A hollow fiber membrane module comprising a module housing, a hollow fiber membrane bundle comprising a plurality of hollow fiber membranes, at least one end portion of the bundle being fixed on the housing through a flexible potting material, and a rib or ring embedded in the potting portion, the rib or ring being fixed on an inner wall of the housing, and the rib or ring being embedded in the potting portion without directly contacting the hollow fiber membrane, and the filtration method using the same. The hollow fiber membrane module can maintain a practical pressure resistance.

Owner:ASAHI KASEI KK

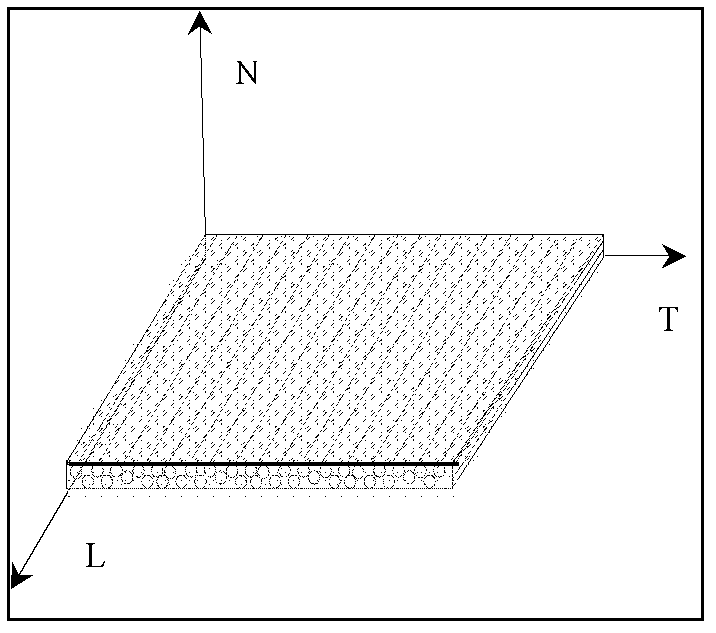

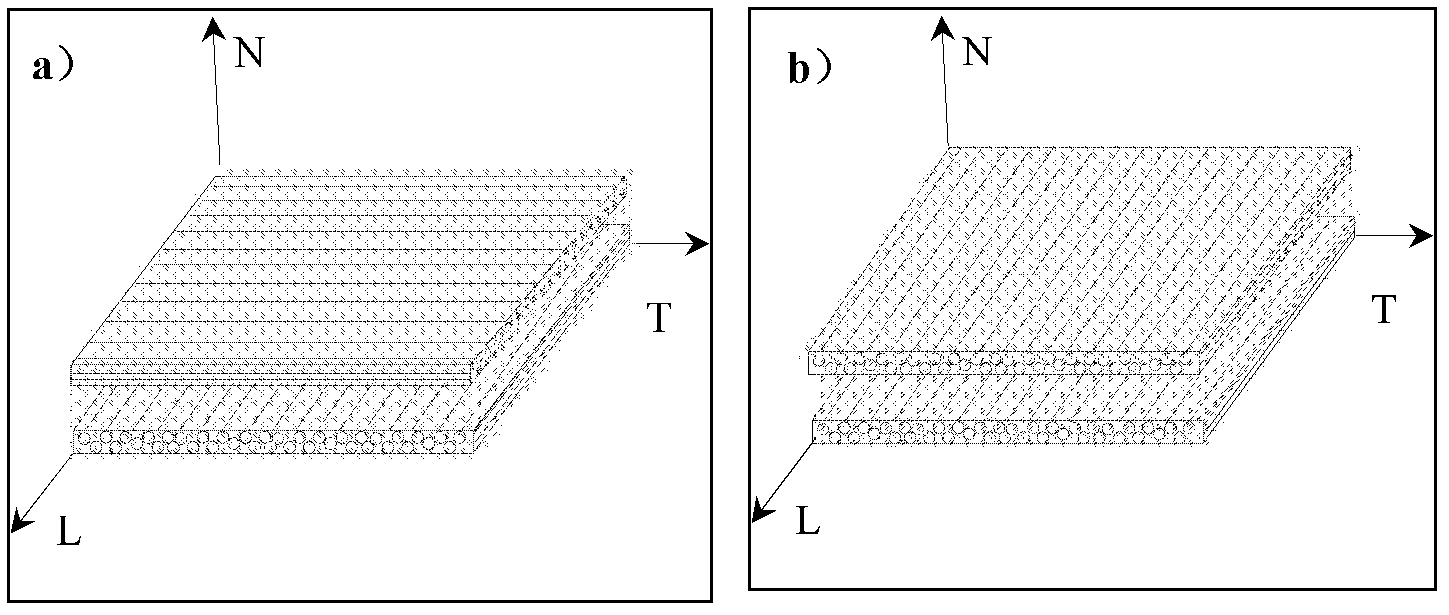

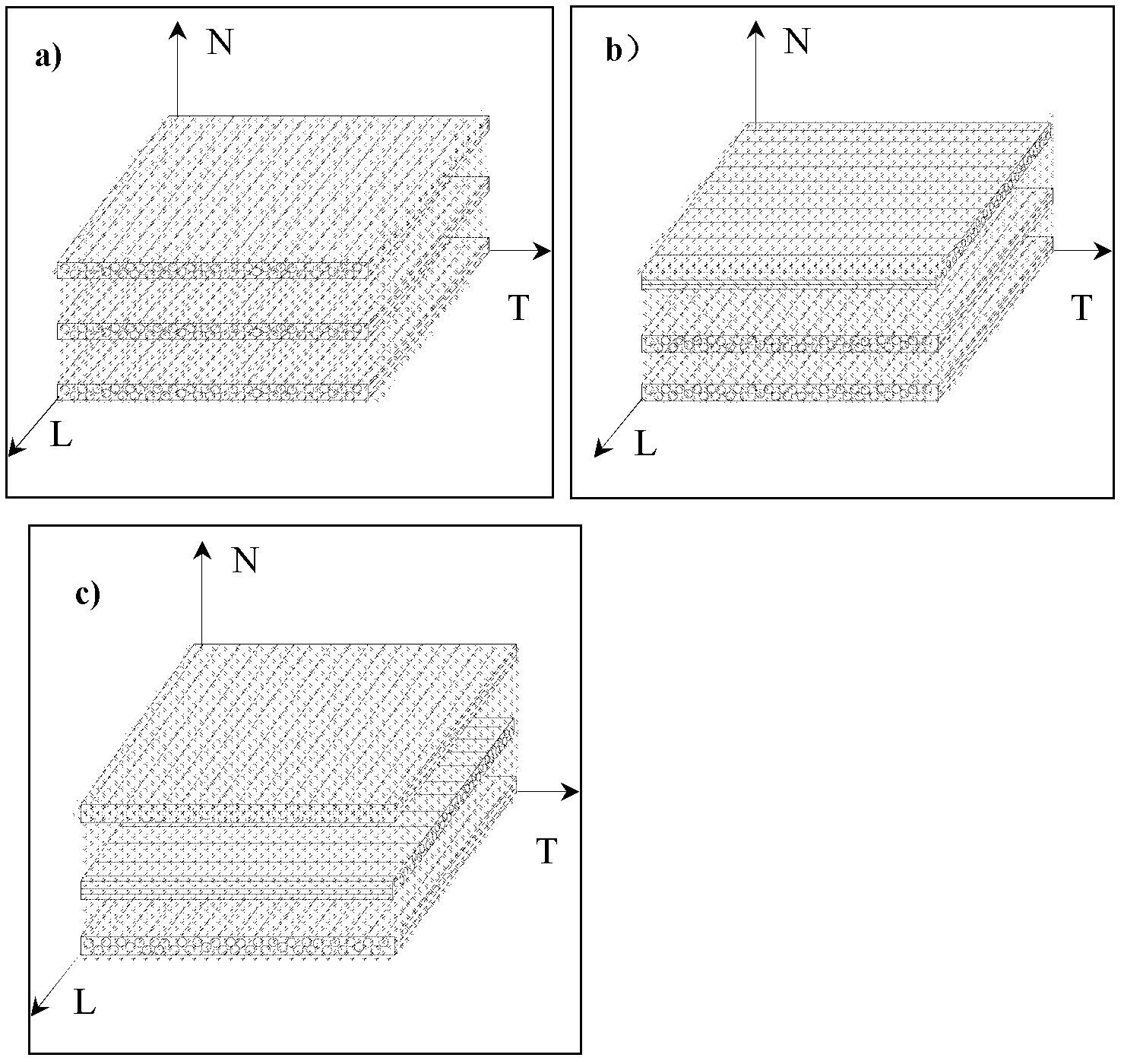

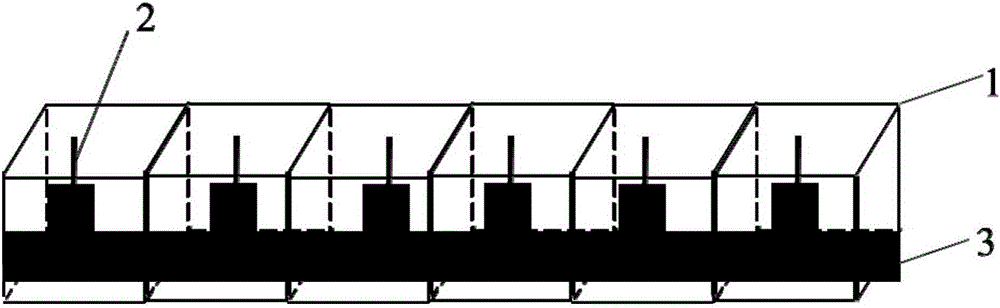

Three-dimensional nonwoven fabric with pore structure

InactiveUS20170014281A1Soft and comfortableGood compressibilityNon-woven fabricsBandagesHigh densityEngineering

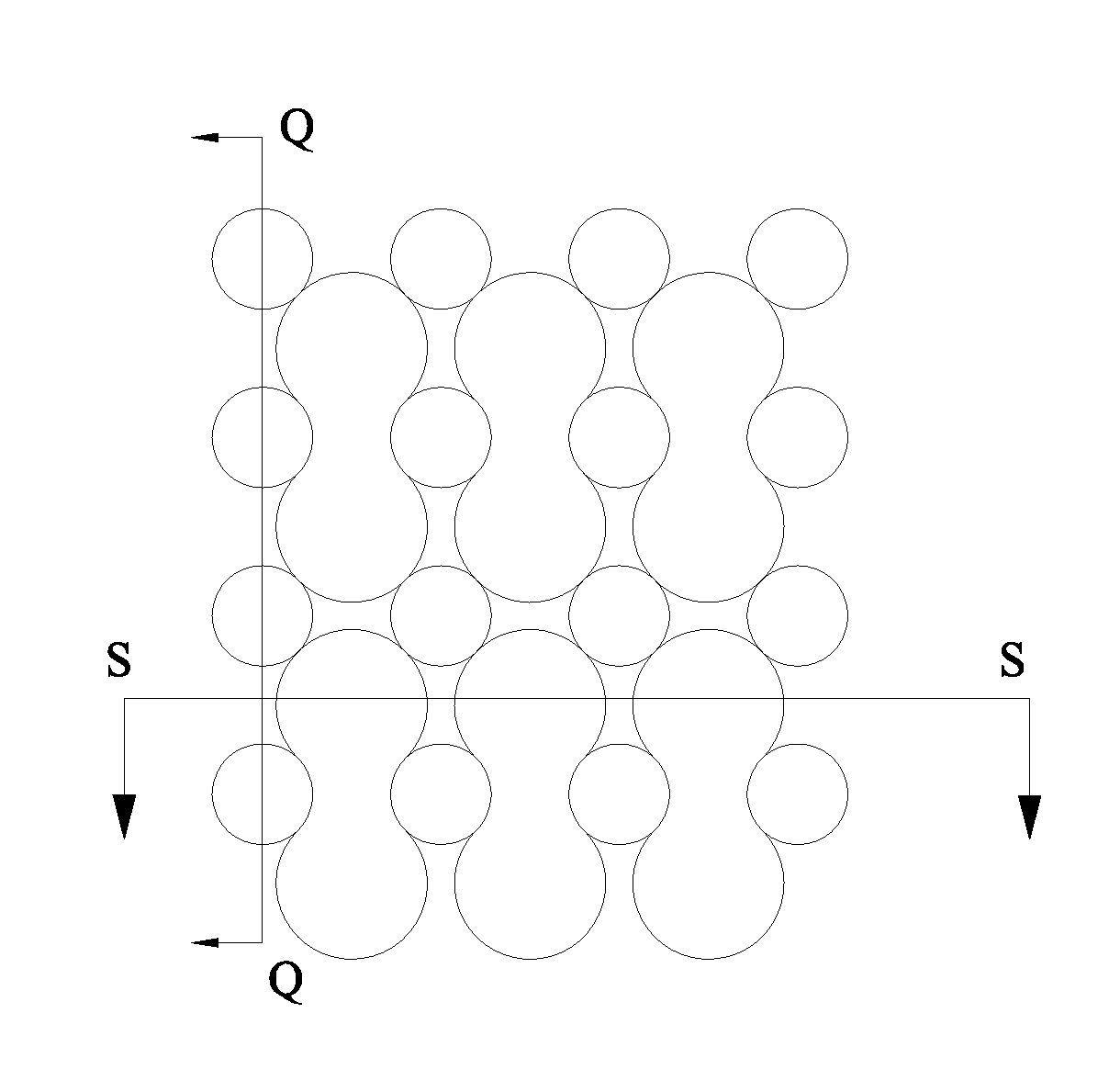

A three-dimensional nonwoven fabric with a pore structure includes raised regions, recessed regions, and the pore structure. Fiber densities from the raised regions to the recessed regions are gradient. That is, the fiber density of the edges transiting from the raised regions to the recessed regions is higher than that of the tops of the raised regions. Pressure resistance performance of the high-density fiber regions keeps the three-dimensional nonwoven fabric significantly uneven, and quickens liquid permeation and reduces residues, and the three-dimensional nonwoven fabric has a high permeating speed and is dry and comfortable.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

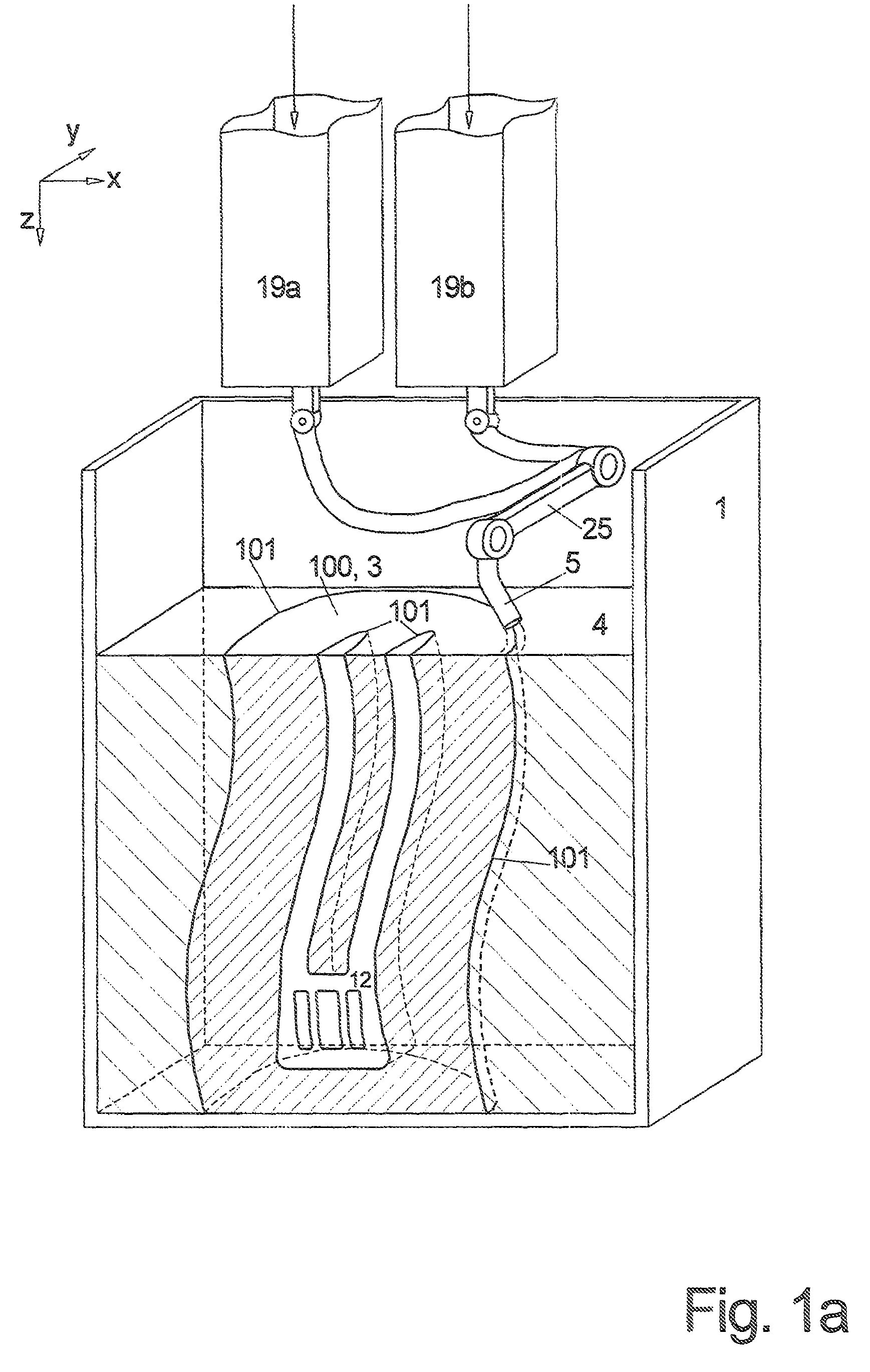

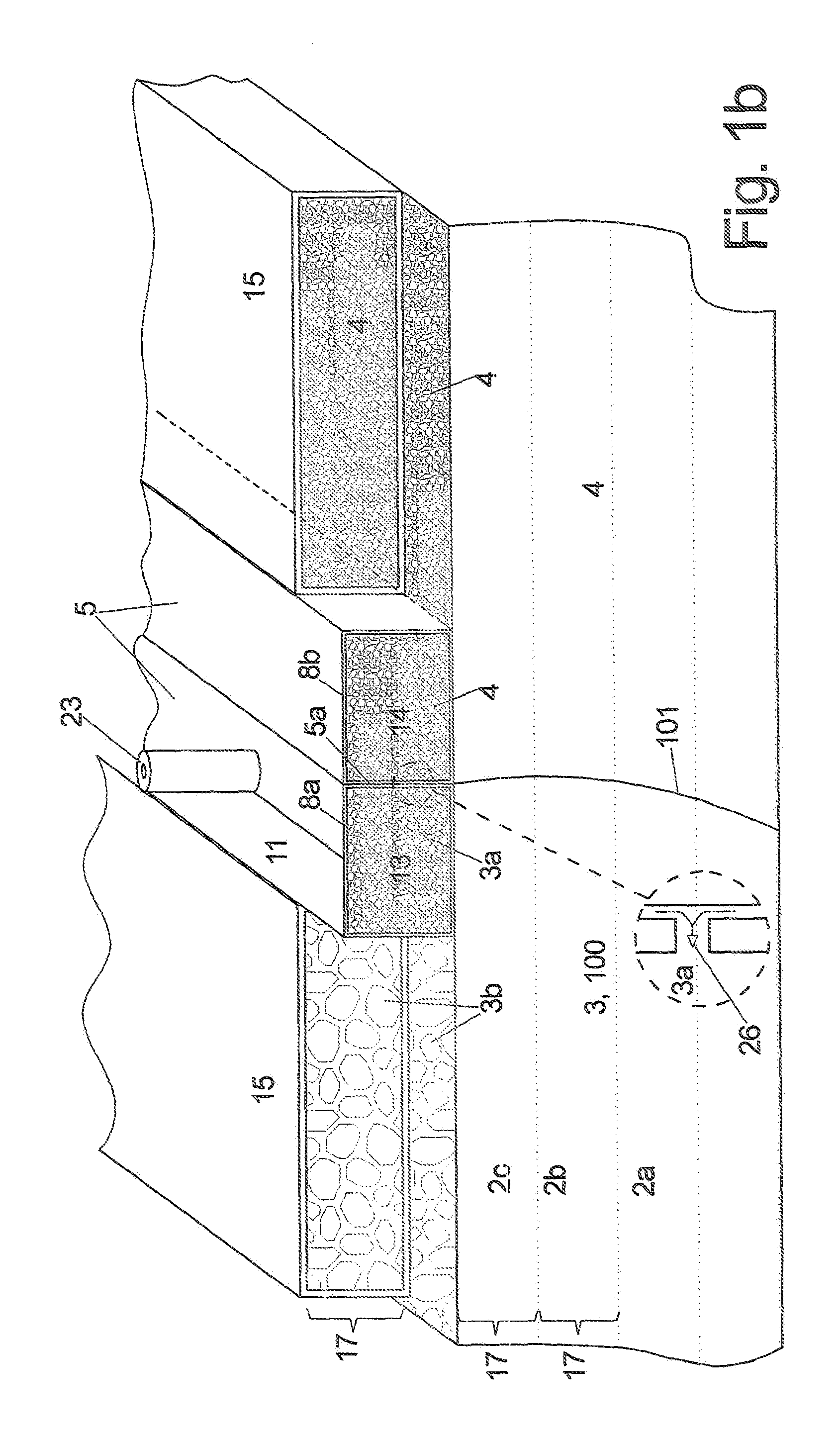

Method and device for layered buildup of a shaped element

ActiveUS9457514B2Accelerate buildingAdditive manufacturing apparatusConfectioneryEngineeringSupport materials

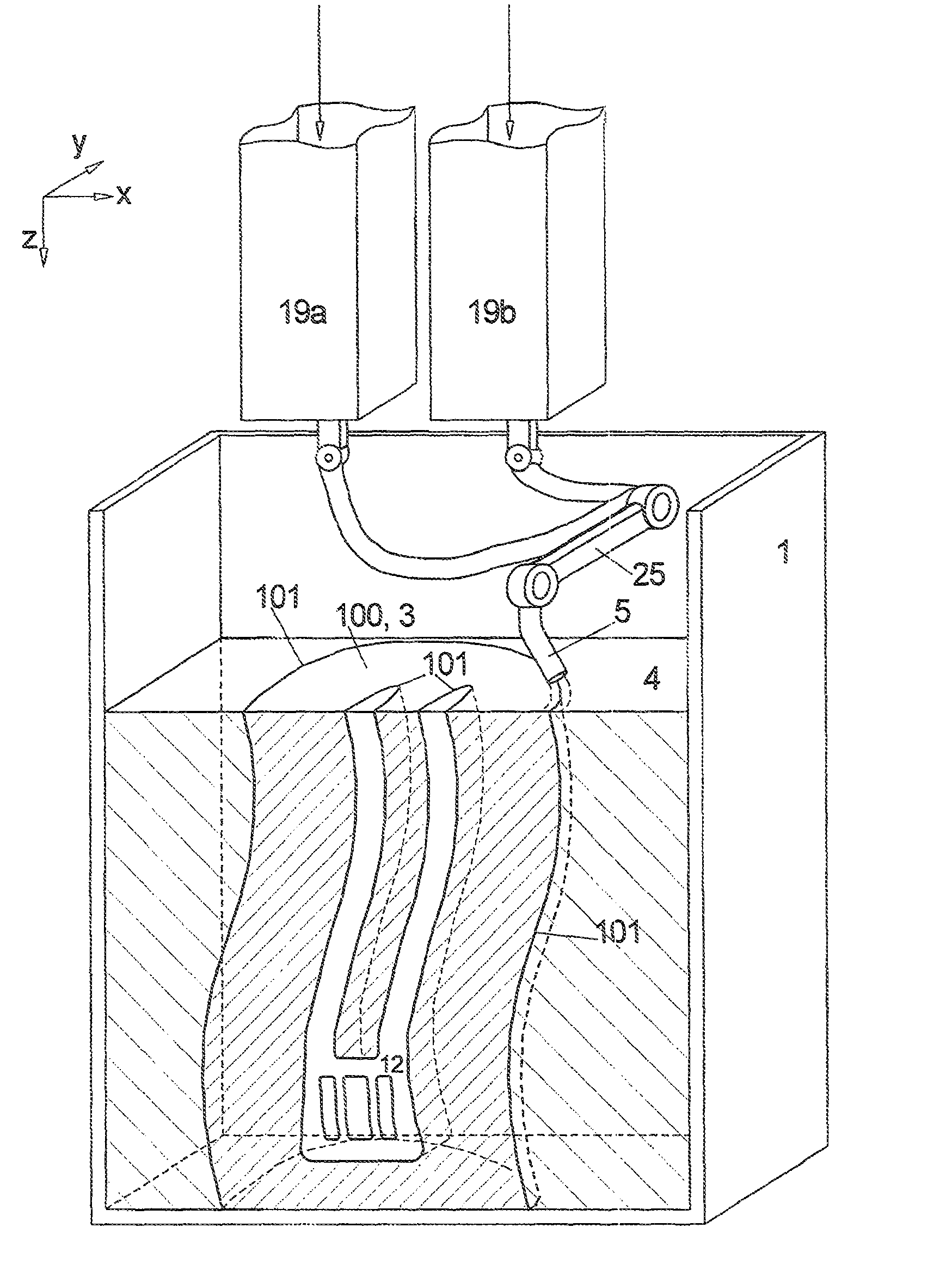

Since concrete materials do not cure quick enough when prototyping methods are used, so that a lower layer (2a) is already completely cured when the next layer (2b) is applied, a support material (4) is applied about the formed element (100) that is being built up in order to compensate for the lack of pressure resistance of the lower layer (2a), wherein the support material preferably has the same specific weight as the material (3) of the formed element (100). Thus, 3D-printing as well as selective curing are facilitated as build up methods.

Owner:SCHWARZLER KLAUS

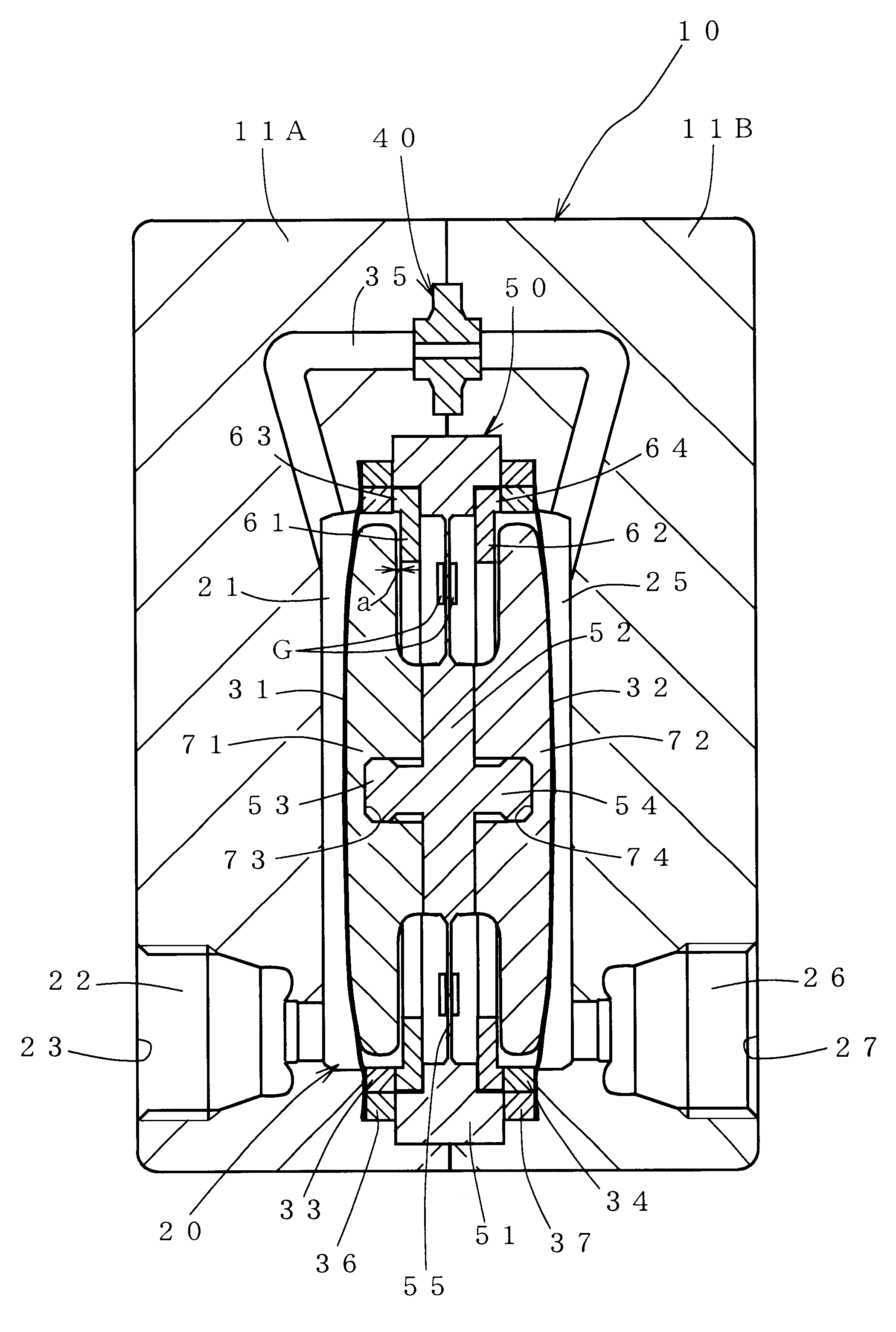

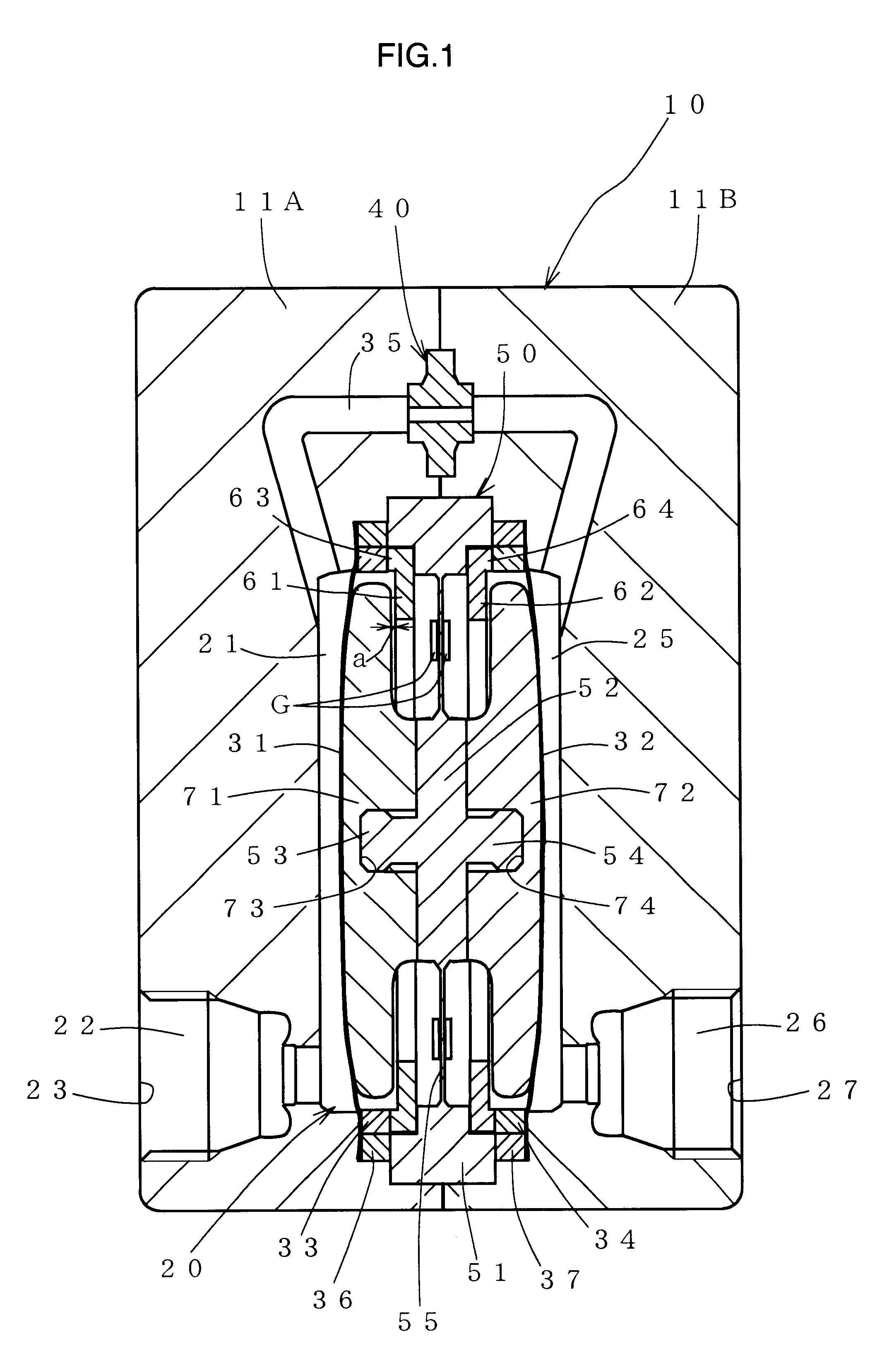

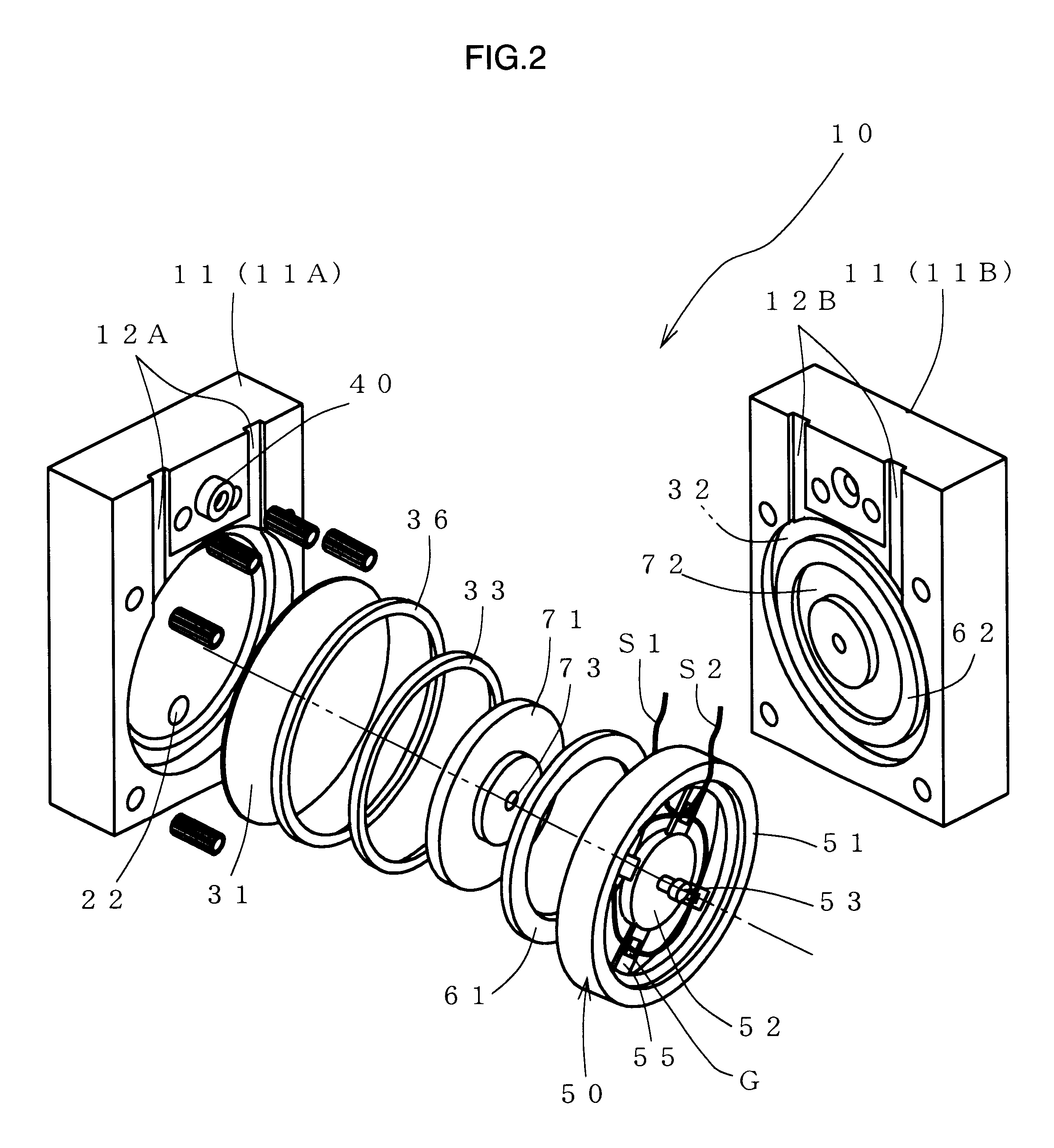

Dual-diaphragm differential pressure flow rate sensor

InactiveUS6640650B2Volume/mass flow by differential pressurePressure difference measurement between multiple valvesDifferential pressureEngineering

A flow rate sensor high in pressure resistance has a structure to facilitate the measurement of a minuscule differential pressure for measurement of a very small flow rate. A chamber (20) is defined into a primary chamber (21) and a secondary chamber (25) by two diaphragms (31, 32) arranged in an opposed relation to each other. A fluid is passed from the primary chamber to the secondary chamber through a bypass (35) having an orifice portion (40) thereby to generate a differential pressure. The load generated by the fluid pressure fluctuations received by the first and second diaphragms is detected as a difference of displacement by a load difference sensor (50) arranged between the first and second diaphragms thereby to detect the flow rate of the fluid. Displacement limiting members (61, 62) are provided for the diaphragms or the load difference sensor so that the displacement due to the fluid pressure fluctuations received by the first and second diaphragms may not exceed a predetermined amount.

Owner:ADVANCE DENKI KOUGYOU

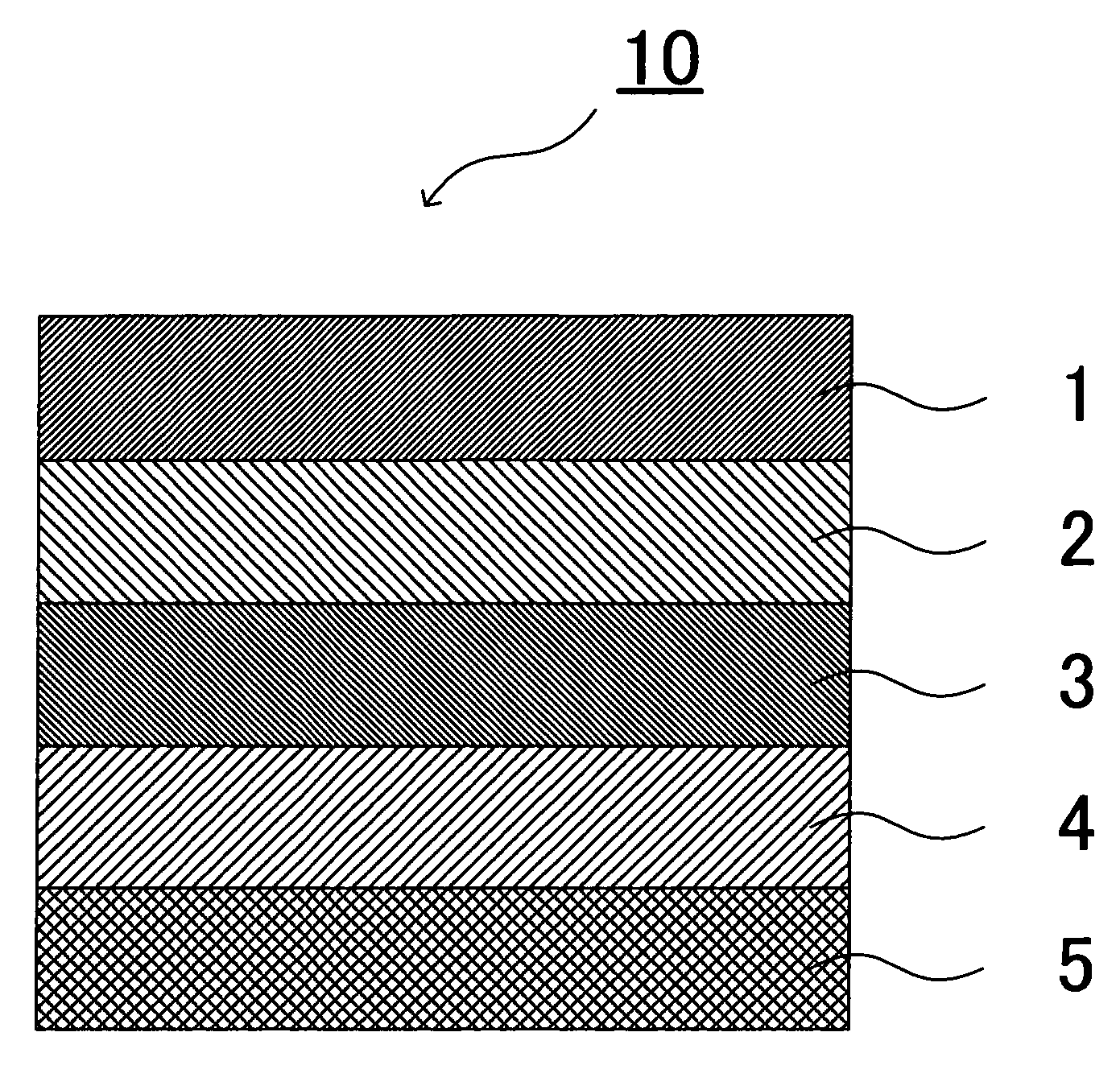

Filler sheet for solar cell module, and solar cell module using the same

InactiveUS20060201544A1High strengthLow costPV power plantsSynthetic resin layered productsPolyolefinEngineering

A main object of the invention is to provide a filler sheet for a solar cell module which is excellent in various properties such as strength, endurance, weatherability, heat resistance, water resistance, light resistance, wind pressure resistance, hailstorm resistance, and vacuum laminating suitability, and has very good thermal melting / bonding property without being affected by production conditions and others, and which makes it possible to produce a solar cell module, suitable for various use purposes, stably at low costs; and a solar cell module using the same. In order to attain the object, the invention provides, as a filler sheet for solar cell element, a filler sheet made of a resin film produced by a resin composition comprising a copolymer of an α-olefin and an ethylenic unsaturated silane compound, or a modified or condensed body thereof, and one or more selected from the group consisting of a light resisting agent, an ultraviolet absorbent and a thermal stabilizer; and a filler sheet made of a resin film produced by a resin composition comprising a maleic anhydride modified polyolefin.

Owner:DAI NIPPON PRINTING CO LTD

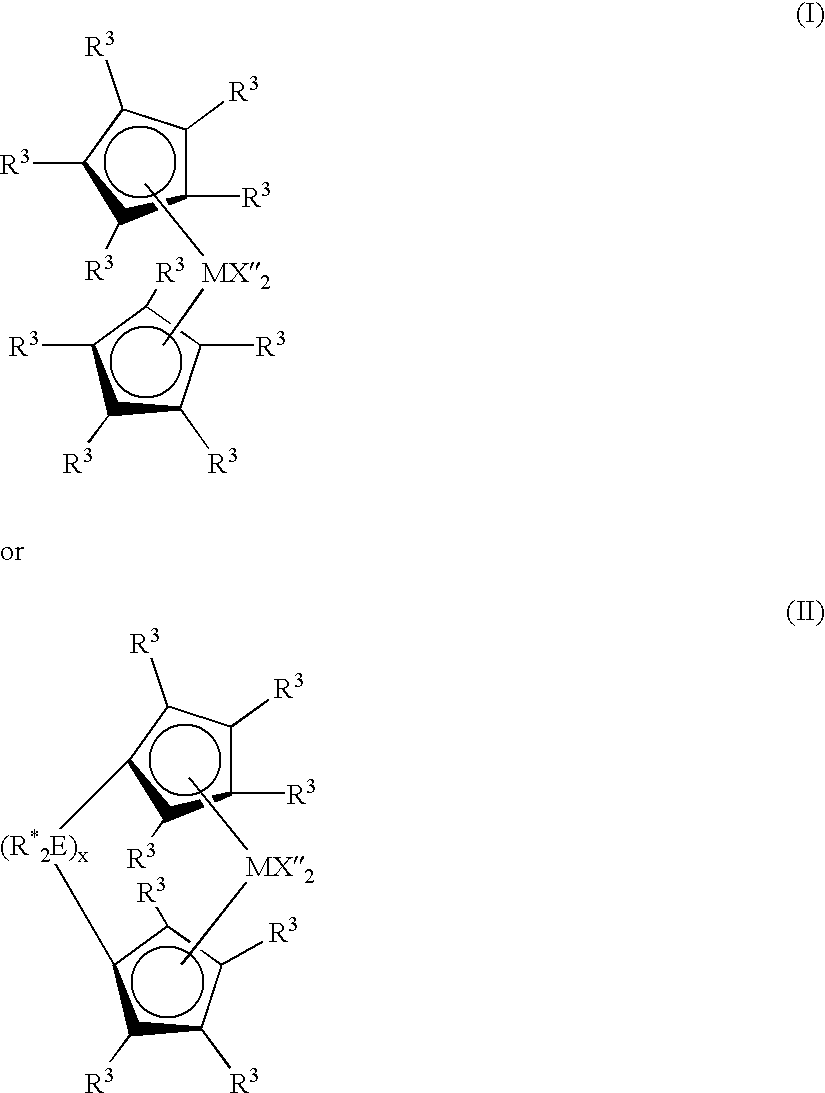

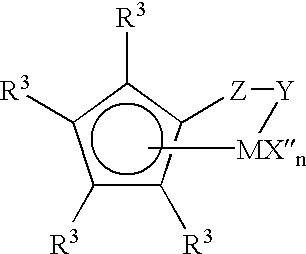

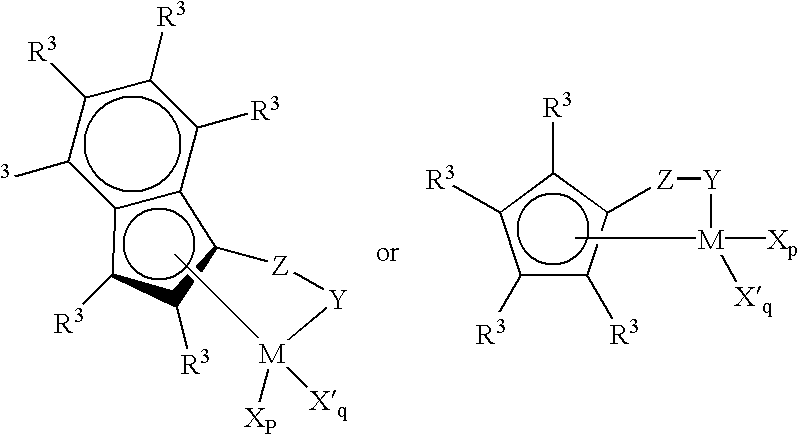

High density ethylene homopolymers and blend compositions

InactiveUS7153909B2High densityIncreased formationMetallocenesEthylene HomopolymersMechanical property

Blend compositions containing a novel homopolymer, the use of which allows the incorporation of more comonomer in the additional components of the blend (for the same overall density) resulting in increased tie molecule formation and improvement in properties such as ESCR, toughness and impact strength are disclosed. The homopolymers are important for applications where a high density is needed to ensure certain mechanical properties like abrasion resistance, indentation resistance, pressure resistance, topload resistance, modulus of elasticity, or morphology (for the chlorination of PE to CPE) and additional advantages such as melt processability. The blend can be obtained by dry or melt mixing the already produced components, or through in-situ production by in parallel and / or in series arranged reactors. These resins can be used in applications such as films, blow molded, injection molded, and rotomolded articles, fibres, and cable and wire coatings and jacketings and, various forms of pipe.

Owner:DOW GLOBAL TECH LLC

High base number composite calcium sulfonate lubricating grease and its preparation method

A composite lubricating grease contains high-basicity petroleum calcium sulfonate or synthetic calcium sulfonate, acetic acid, C12-C22 hydroxy fatty acid, boric acid, arylamine-type antioxidizing agent and basic lubricating oil. Its advantages are excellent extreme-pressure resistance to friction, water, salt fog and corrosion, high drop point and thermal stability, good viscosity and long service life.

Owner:SINOPEC LUBRICANTS TIANJIN

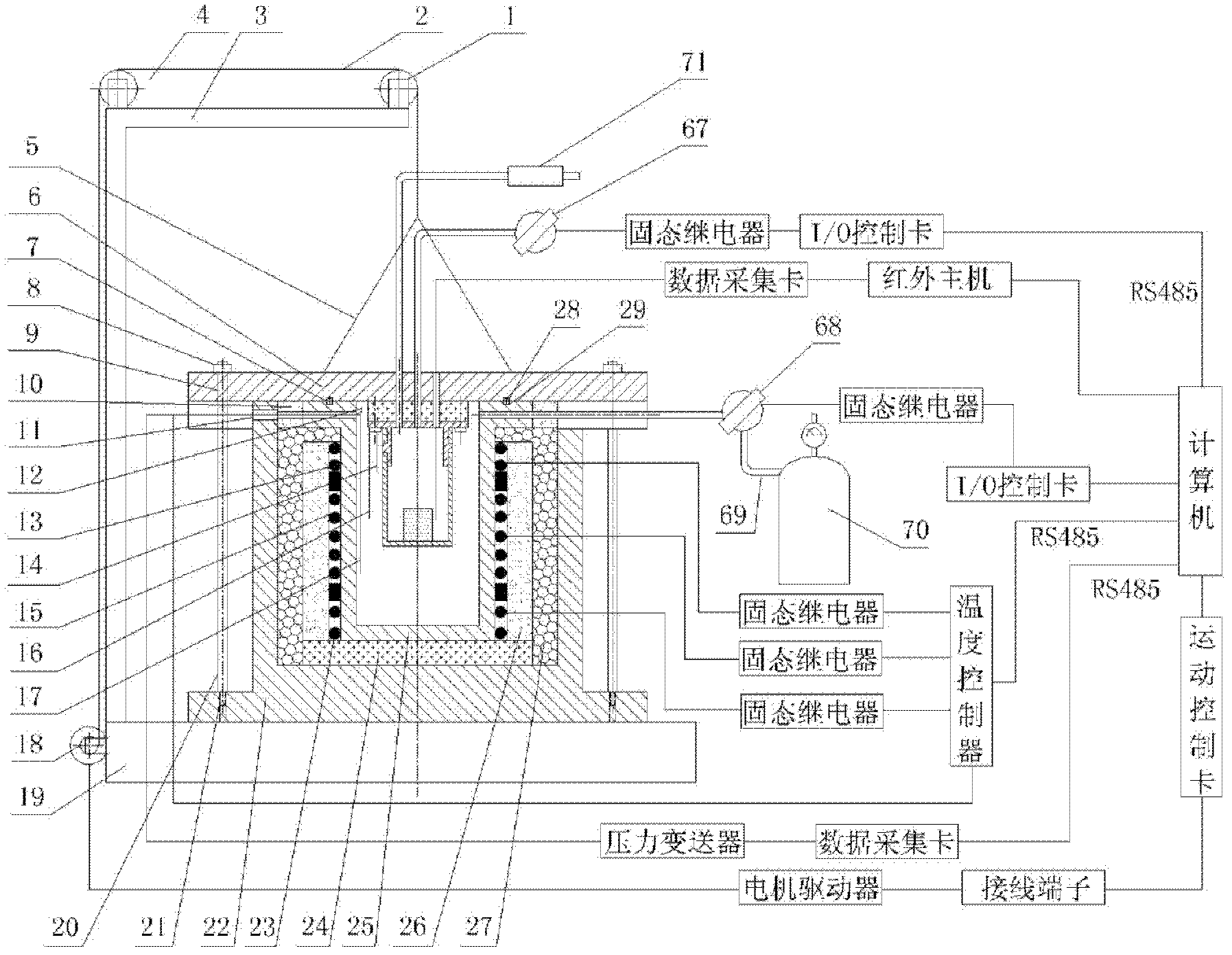

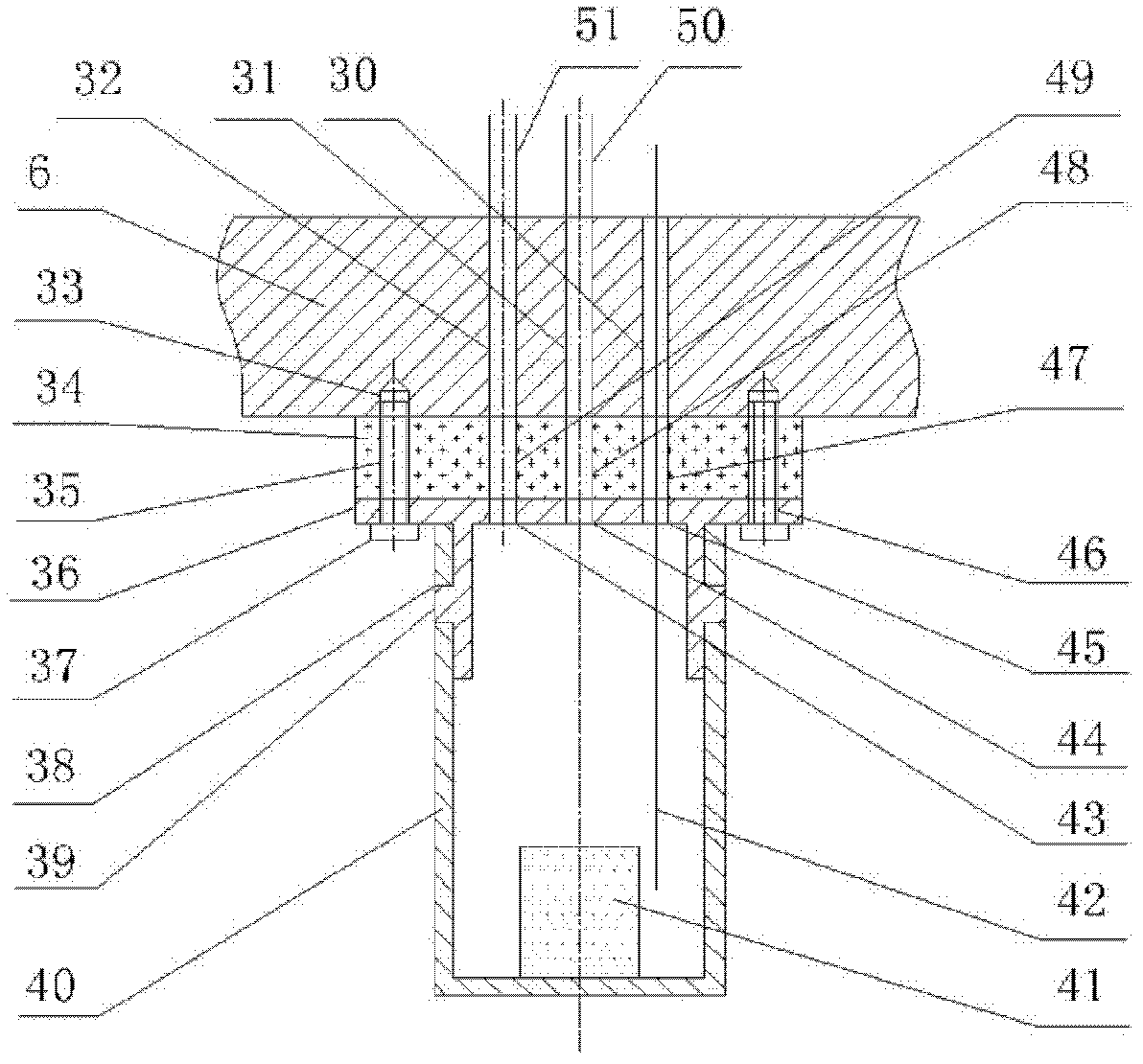

Testing system for critical pressure during thermal explosion of explosives

InactiveCN102608160ARealize multi-point temperature controlImprove uniformityMaterial exposibilityData acquisitionData treatment

The invention discloses a testing system for critical pressure during thermal explosion of explosives. The testing system comprises a pressure-resistance heating unit, a pressure control unit, a sample loader unit, a decomposed product detection unit and a computer; the pressure-resistance heating unit comprises a single-cavity heating furnace body, wherein a temperature sensor which is connected with the computer is arranged in a furnace cavity, and temperature, temperature rise speed and pressure of the single-cavity heating furnace body are controlled by the computer; the pressure control unit comprises a high-pressure gas cylinder, a pressurizing gas channel pipe, a pressurizing electromagnetic valve, a heat conduction layer extension edge pressurizing pipe, a pressure-releasing gas channel pipe, a pressure-releasing electromagnetic valve, a safety valve gas channel pipe, a safety valve and a pressure sensor; the sample loader unit comprises an L-shaped bracket, a stepping motor, two fixed pulleys, a steel wire rope, a furnace cover, a sample reservoir bracket and a sample reservoir; the decomposed product detection unit comprises an infrared sensor which is arranged in the sample reservoir; and the computer is provided with a data acquisition card, a graphic display control and a data processing unit and can be used for identifying the critical state of thermal decomposition to combustion or explosion and acquiring a critical pressure parameter.

Owner:XIAN MODERN CHEM RES INST

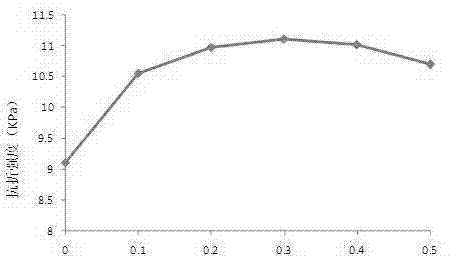

High-strength polypropylene fiber polymer cement mortar and preparation method thereof

The invention discloses a high-strength polypropylene fiber polymer cement mortar and a preparation method thereof. The mortar is composed of the following components in parts by mass: 0.28-0.3 part of silica fume, 0.68-0.7 part of cement and 1.97-2 part of sand. The SiO3 content in the silica fume is higher than 95%; the water-cement ratio is 0.31; the volume content of the polypropylene fiber is 0.9 kg / m<3>; the water reducer:cementing material ratio is 0.9-1%; the defoaming agent:cementing material ratio is 0.5-0.55%; the coupling agent and diluter:cementing material ratio is 0.3%; the polymer modifier:cementing material ratio is 10-11%; and the reducer:cementing material mass ratio is 3-3.5%. By combining the excellent physical and chemical characteristics of the silica fume, when the silica fume is substituted for cement, the consumption of the cement clinker is saved, and the industrial waste is reutilized, thereby greatly enhancing the pressure resistance and bending resistance of the modified cement mortar.

Owner:ZHENGZHOU UNIV

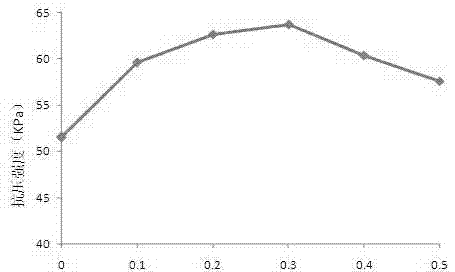

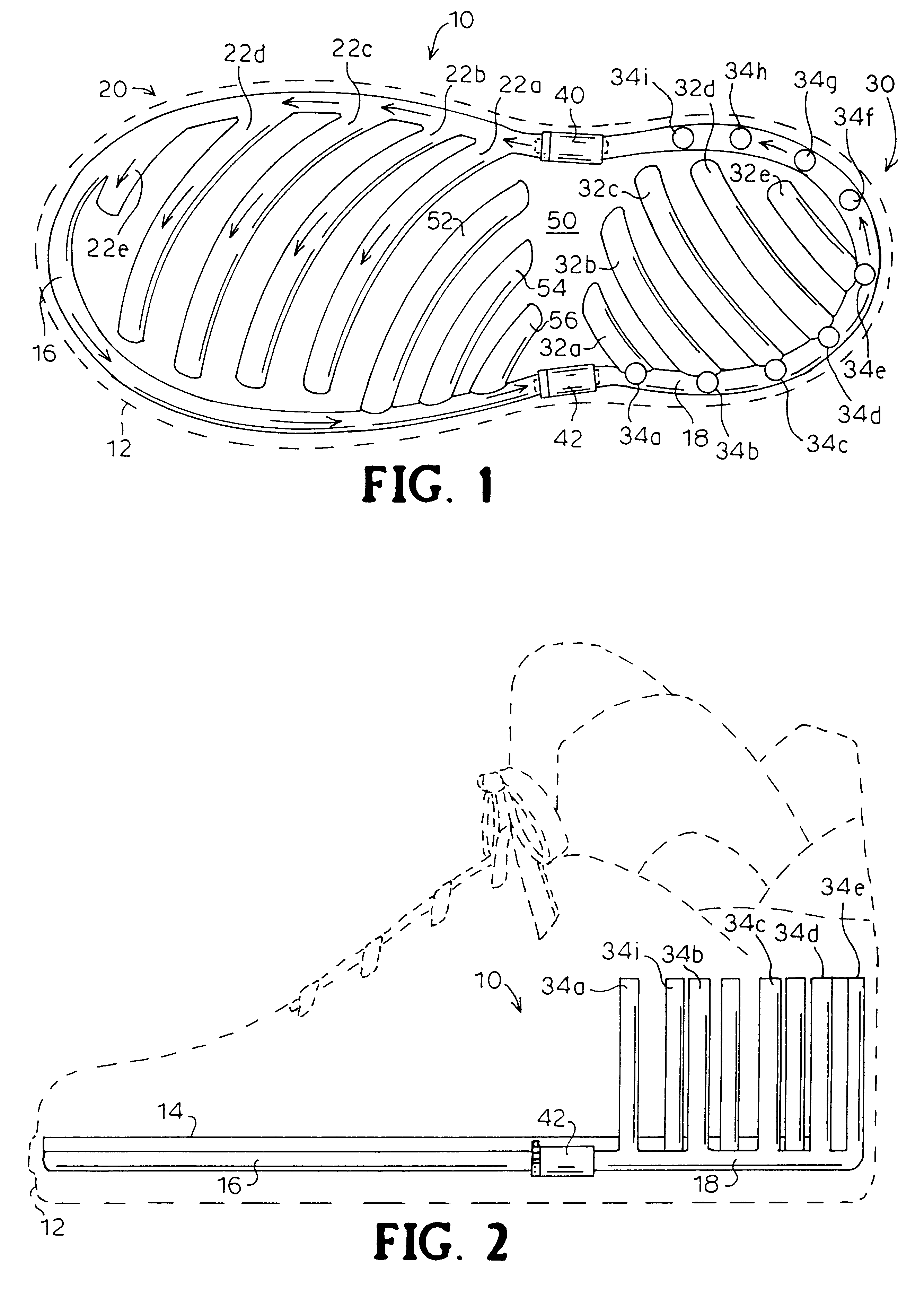

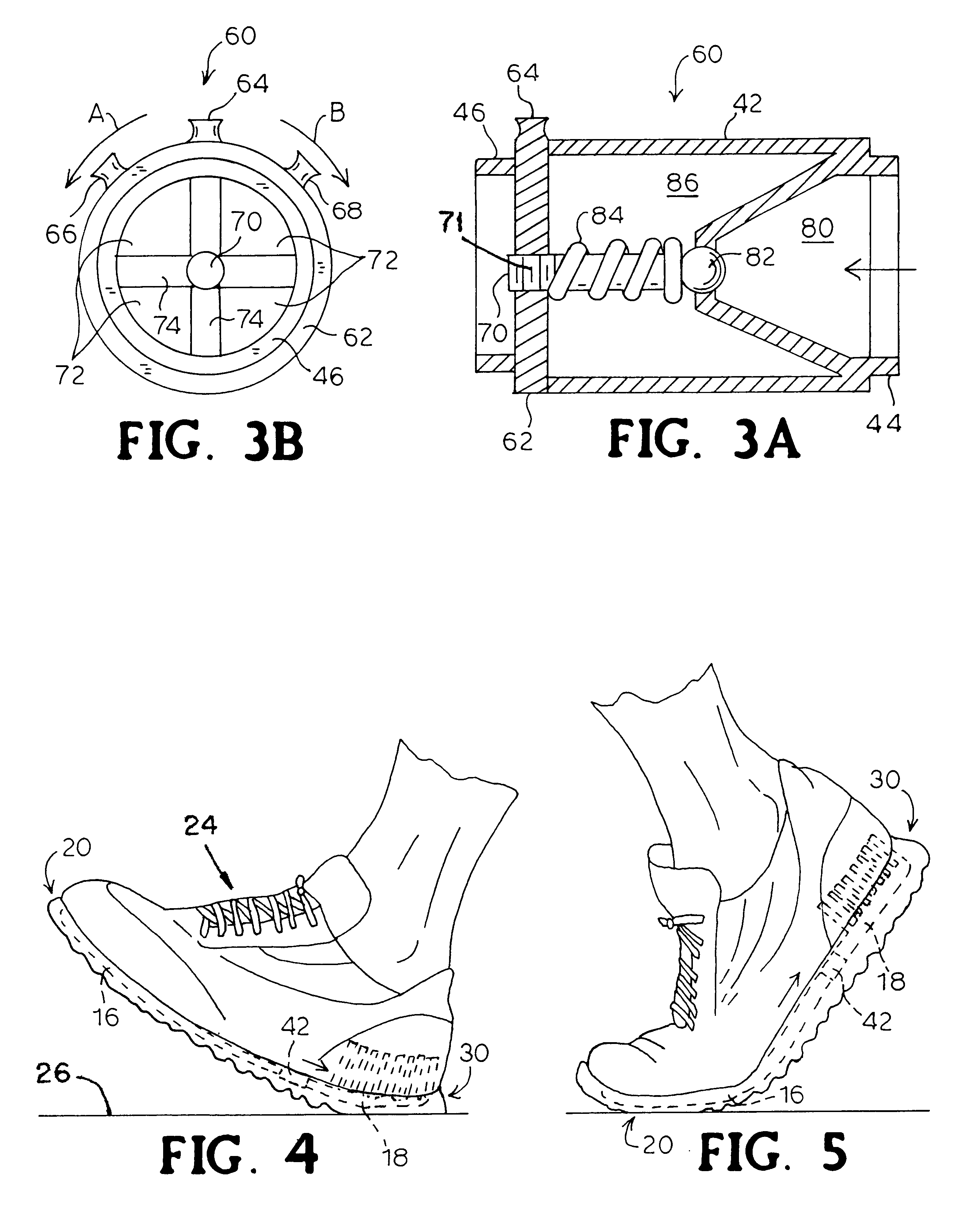

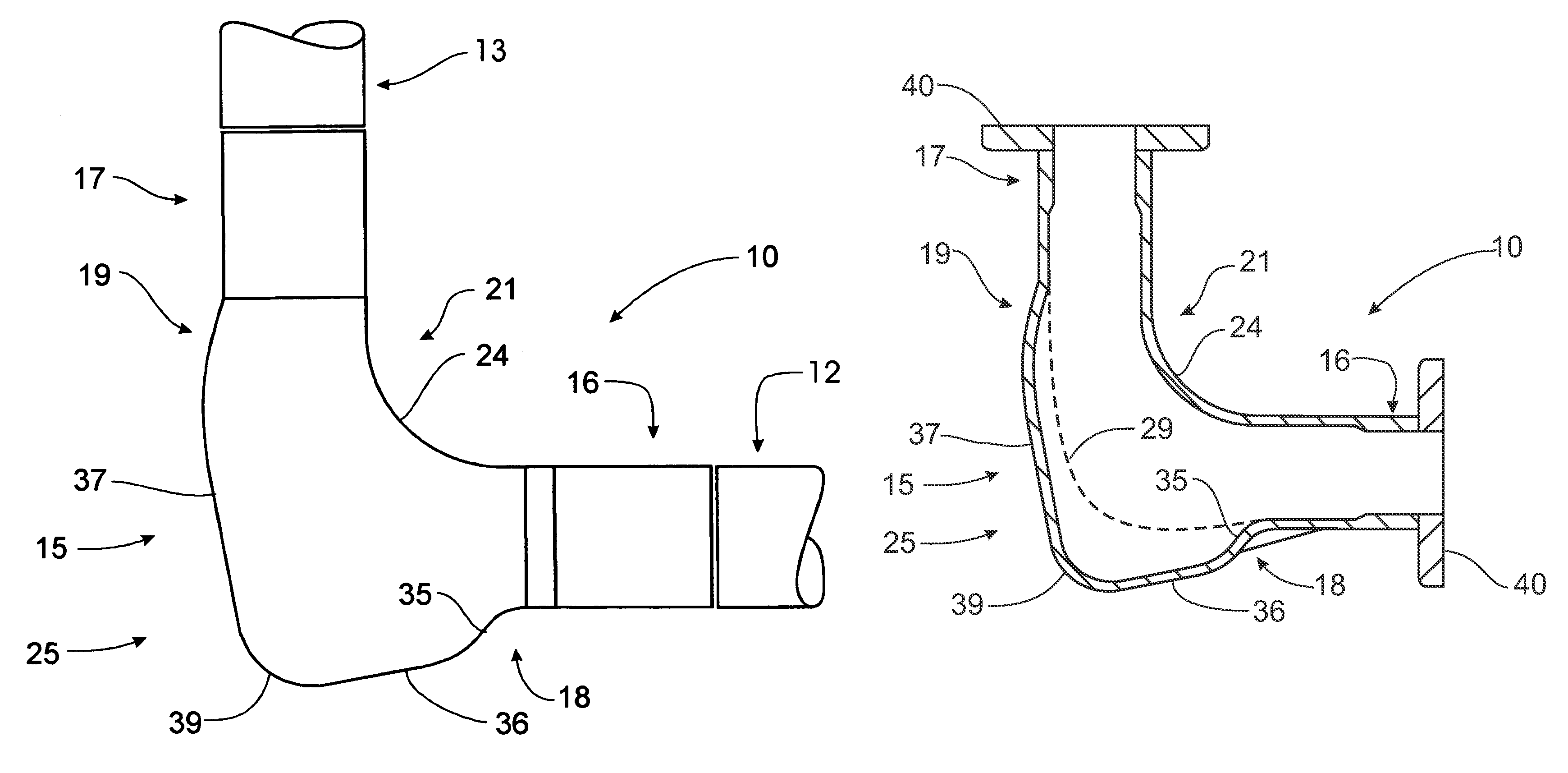

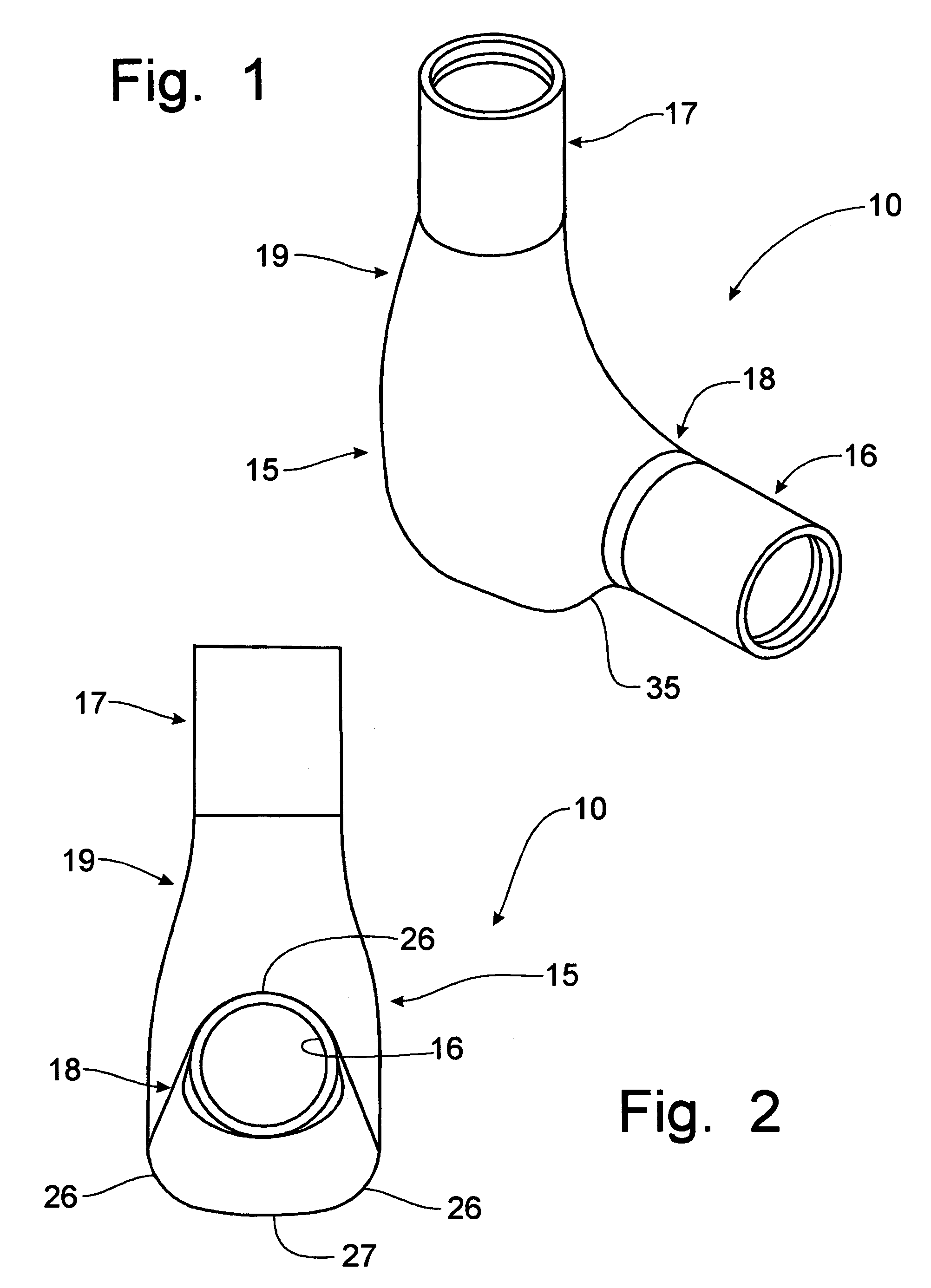

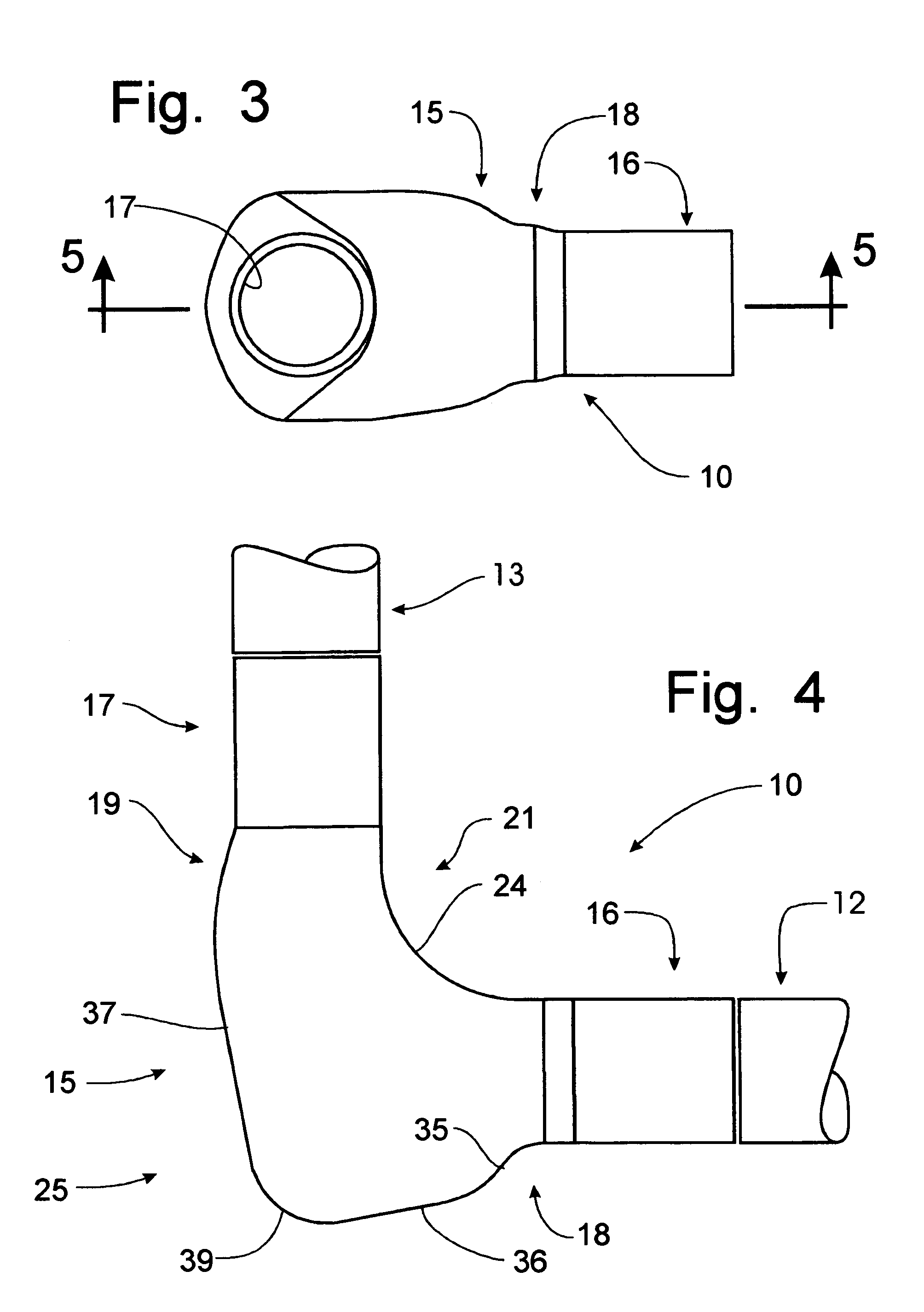

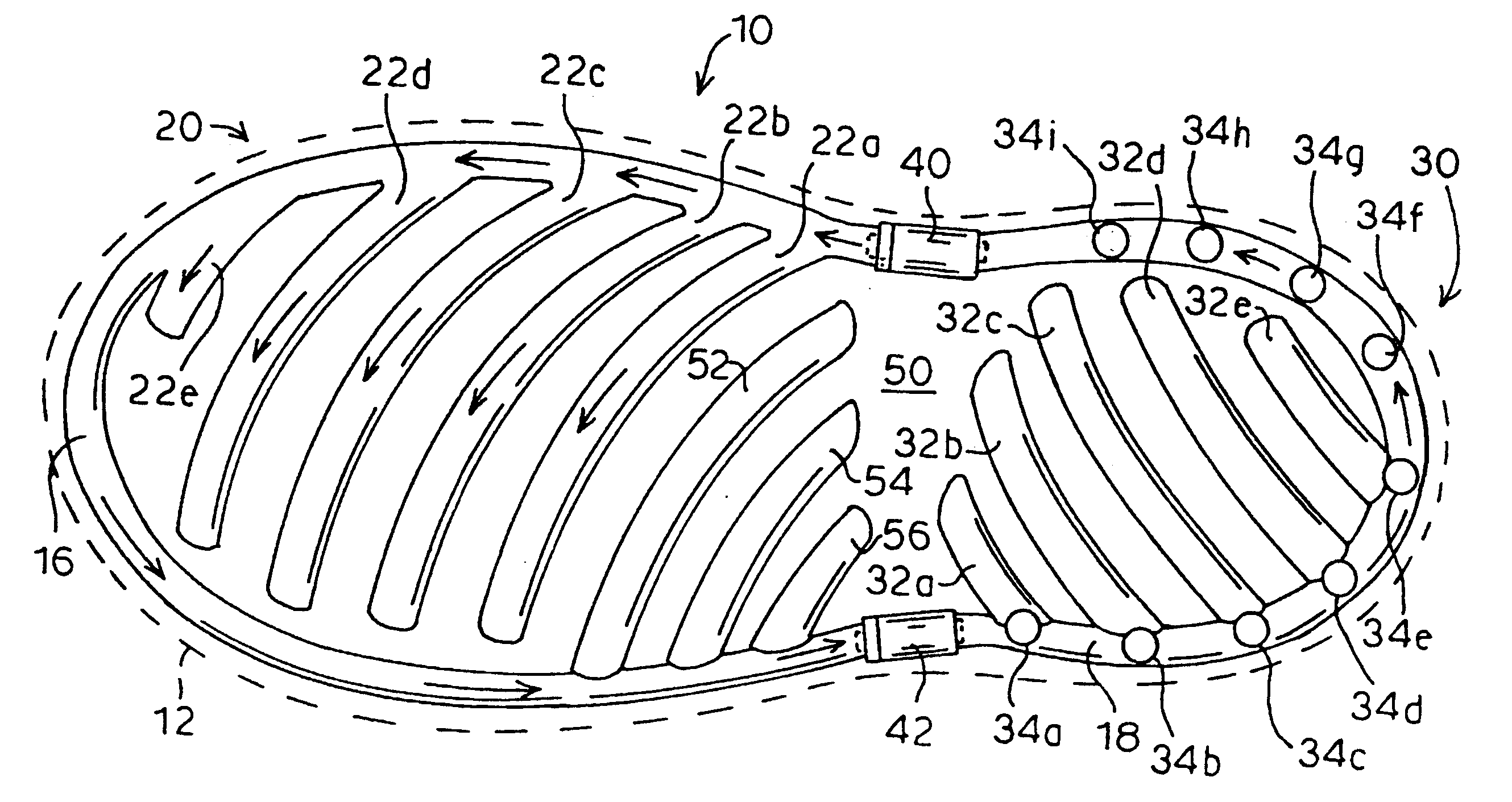

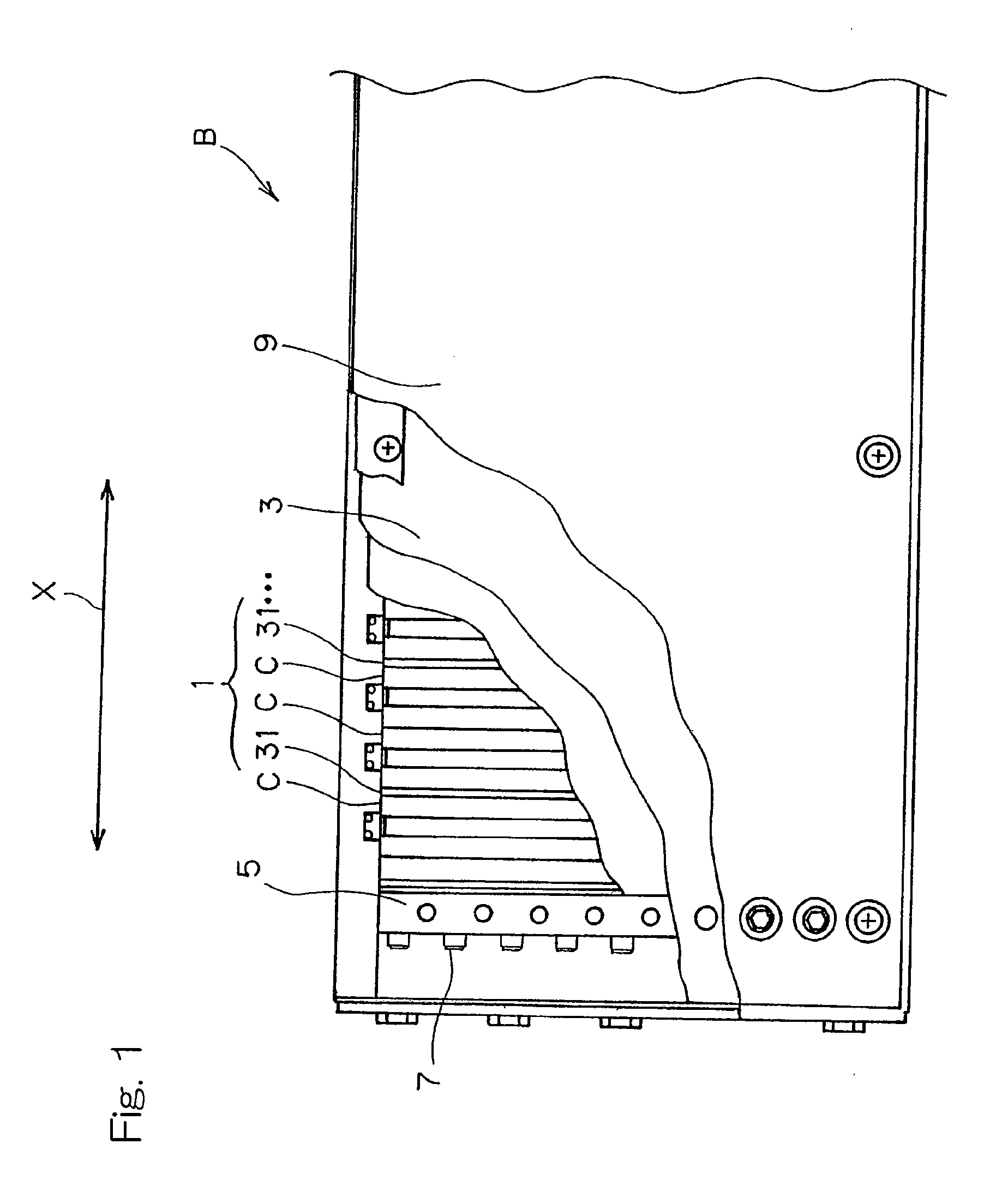

Method and apparatus for fluid flow transfer in shoes

A method and apparatus for transferring the flow of fluid through tubes in the sole of shoes. The apparatus includes a pair of fluid filled tubes along the periphery of the sole of the shoe. One tube is connected to cross tubes that provide flow paths and cushions the for the ball and instep portions of the foot. The other tube is connected to cross tubes that provide flow paths and cushions heel portion of the foot. Adjustable pressure valves interposed between the fluid filled tubes permit a method of controlling the flow of fluid through the valves in one direction only. The pressure resistance of the valves are pre-set for a certain internal pressure level required for triggering the transfer of fluid from one tube to the other. The method include steps of controlling pressure resistance by adjusting valve pressure adjustment rings either in a clockwise direction about a rod for increasing internal pressure resistance, or in a counter-clockwise direction for decreasing internal resistance.

Owner:CASTON GAYFORD

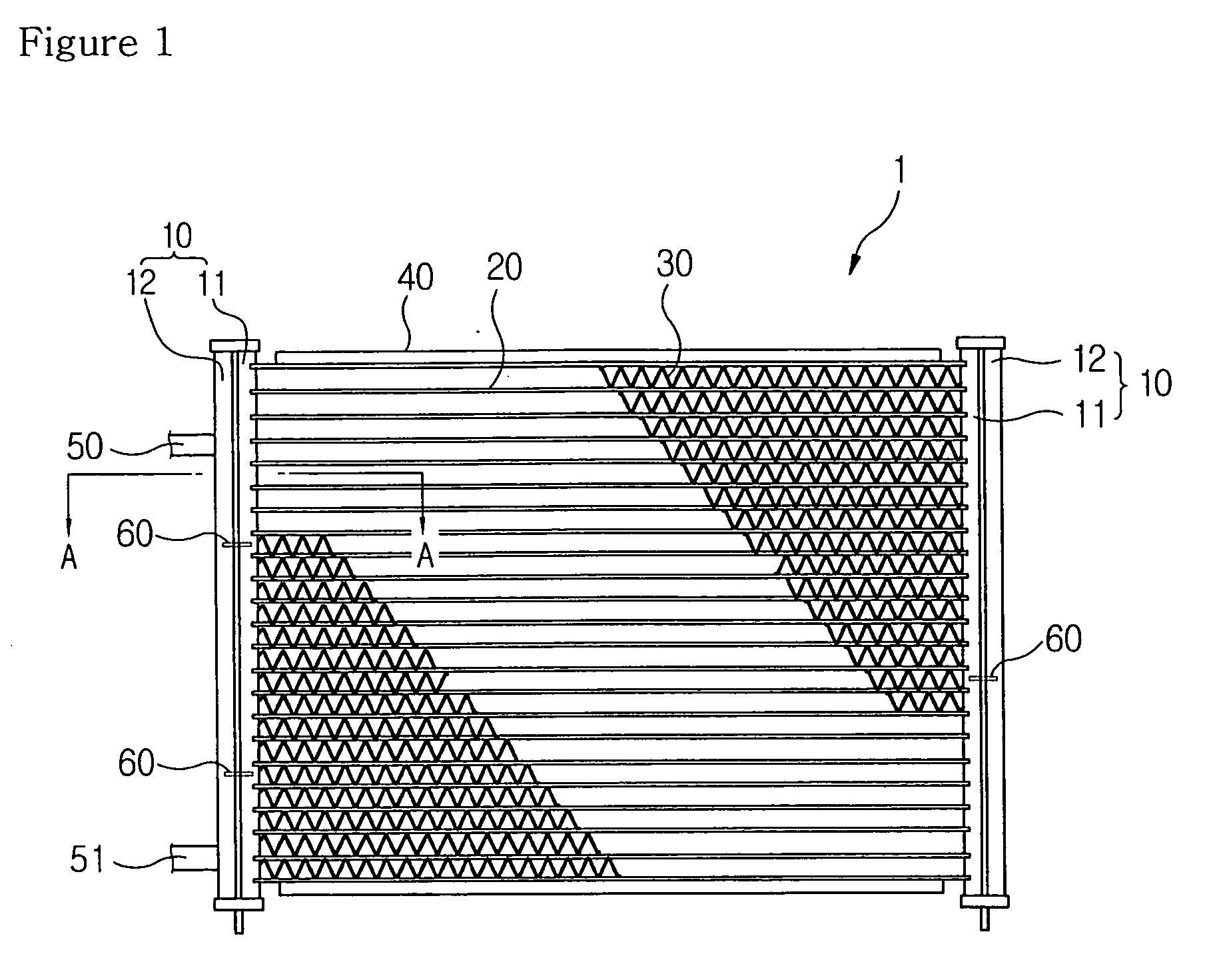

Heat exchanger

InactiveUS20060162917A1Easy to changeLower the volumeEvaporators/condensersHeat exchanger casingsProduction rateEngineering

The present invention relates to a heat exchanger for carbon dioxide, in which a tank having a number of domes is coupled with a header and a connection member having a connection flow channel is interposed between the header and the tank, thereby easily changing a refrigerant flow channel, reducing the volume of a header tank, and improving productivity, pressure resistance and durability.

Owner:HANON SYST

Oriented fiber aerogel heat-insulating compound material and preparation method thereof

ActiveCN102503356AImprove resistance to damageFlexible structure and controllabilitySupercritical dryingFiber

The invention provides an oriented fiber aerogel heat-insulating compound material and a preparation method thereof, belonging to the technical field of functional materials, and heat insulation and energy conservation. The oriented fiber aerogel heat-insulating compound material comprises a fiber skeleton and aerogel, wherein the aerogel is filled in the fiber skeleton; and fibers in the fiber skeleton are tidily arranged in the same direction, and the fiber skeleton is an oriented fiber skeleton. The oriented fiber aerogel heat-insulating compound material has a superhigh heat-insulating performance (the coefficient of heat conductivity is 0.013 W / m.K) and good pressure resistance and fracture resistance, and the heat-insulating performance, the pressure resistance and the fracture resistance are directionally controllable; the oriented fiber aerogel heat-insulating compound material can be widely applied to fields which require heat-insulating and heat-preserving measures; and the preparation method adopts a normal-pressure drying technology and a supercritical drying technology in the conventional aerogel preparing process is not used, so that the preparation cost of the aerogel heat-insulating compound material can be greatly reduced and the aerogel heat-insulating compound material is applicable to industrial production.

Owner:GUANGZHOU UNIVERSITY

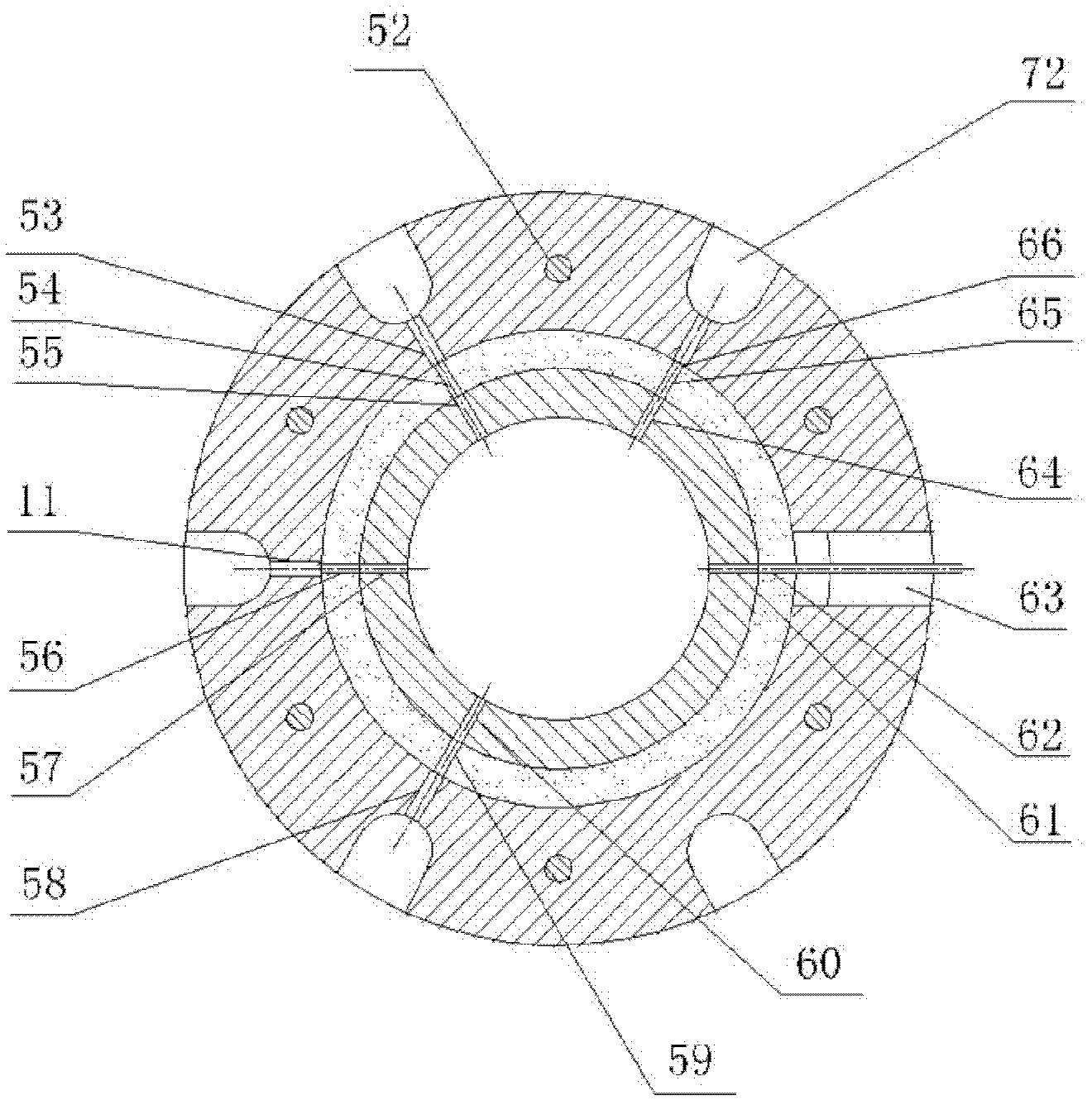

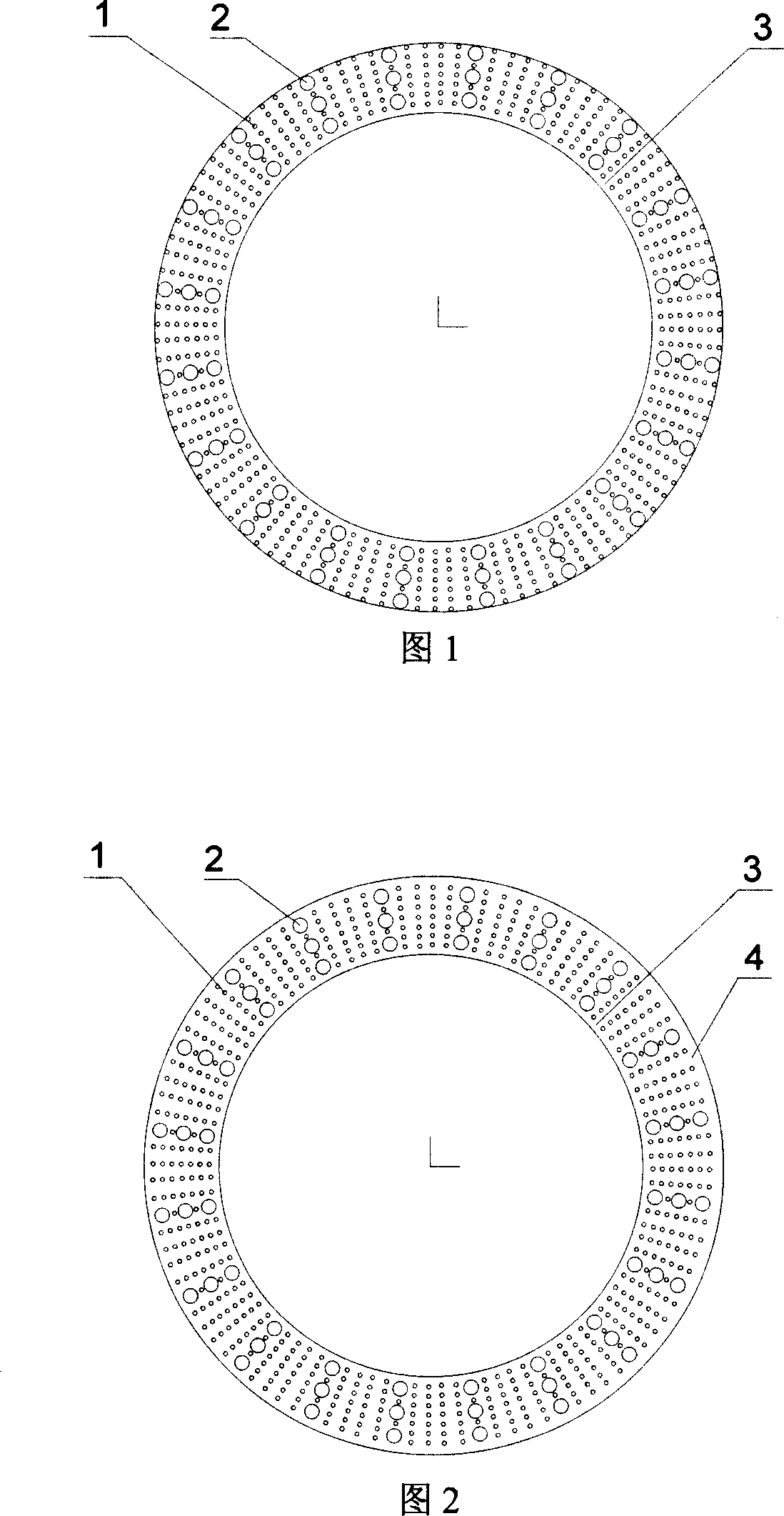

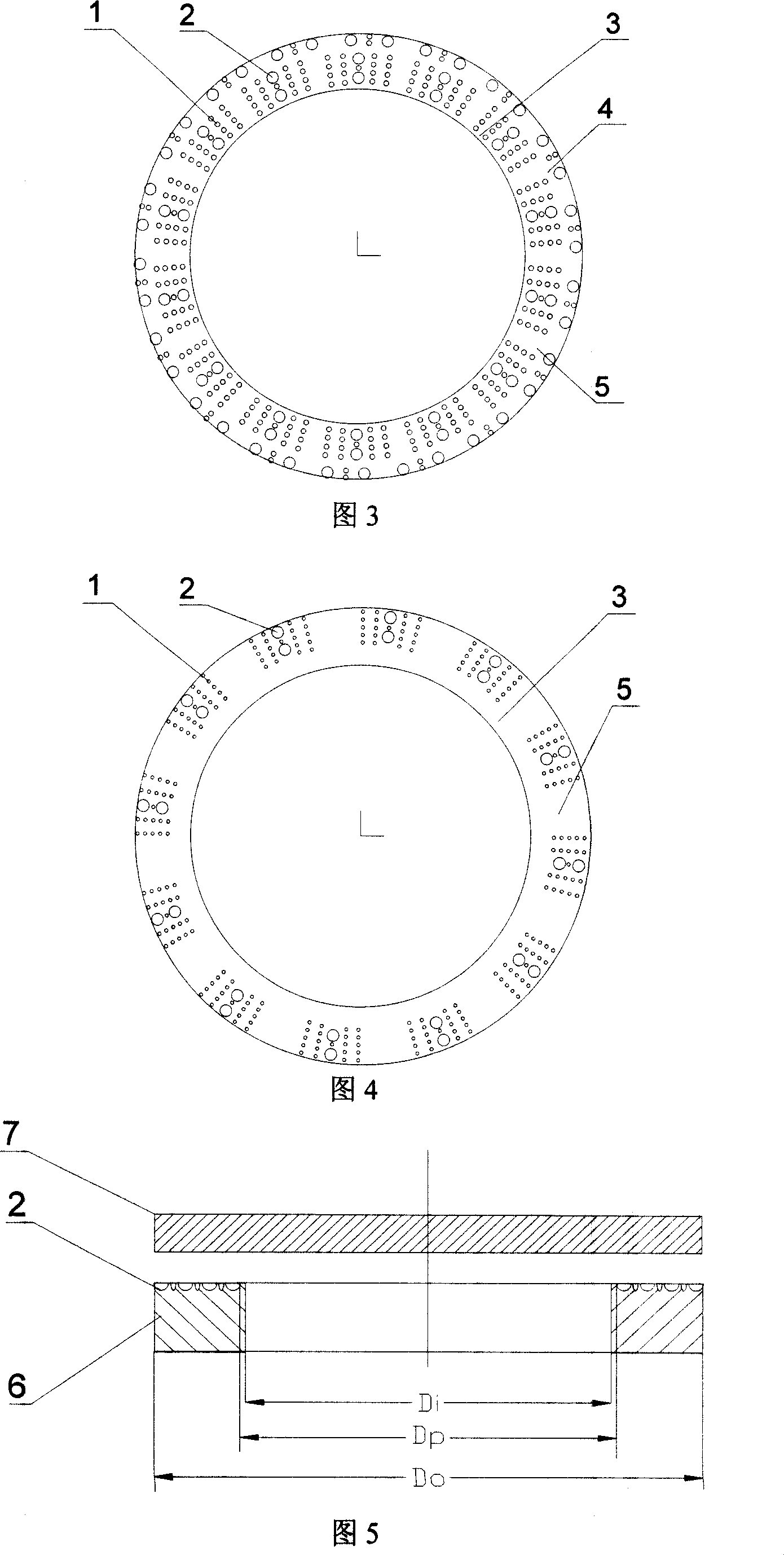

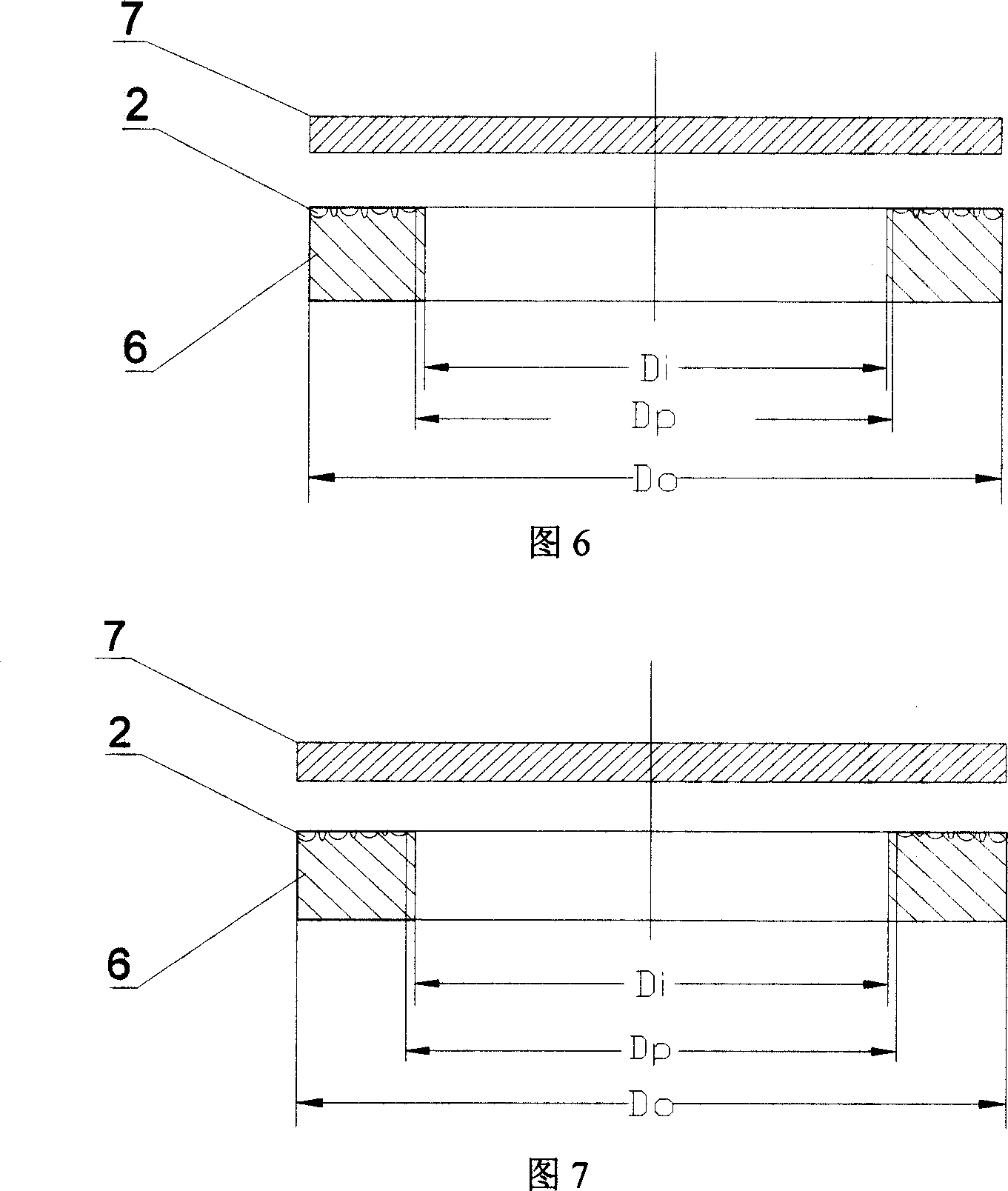

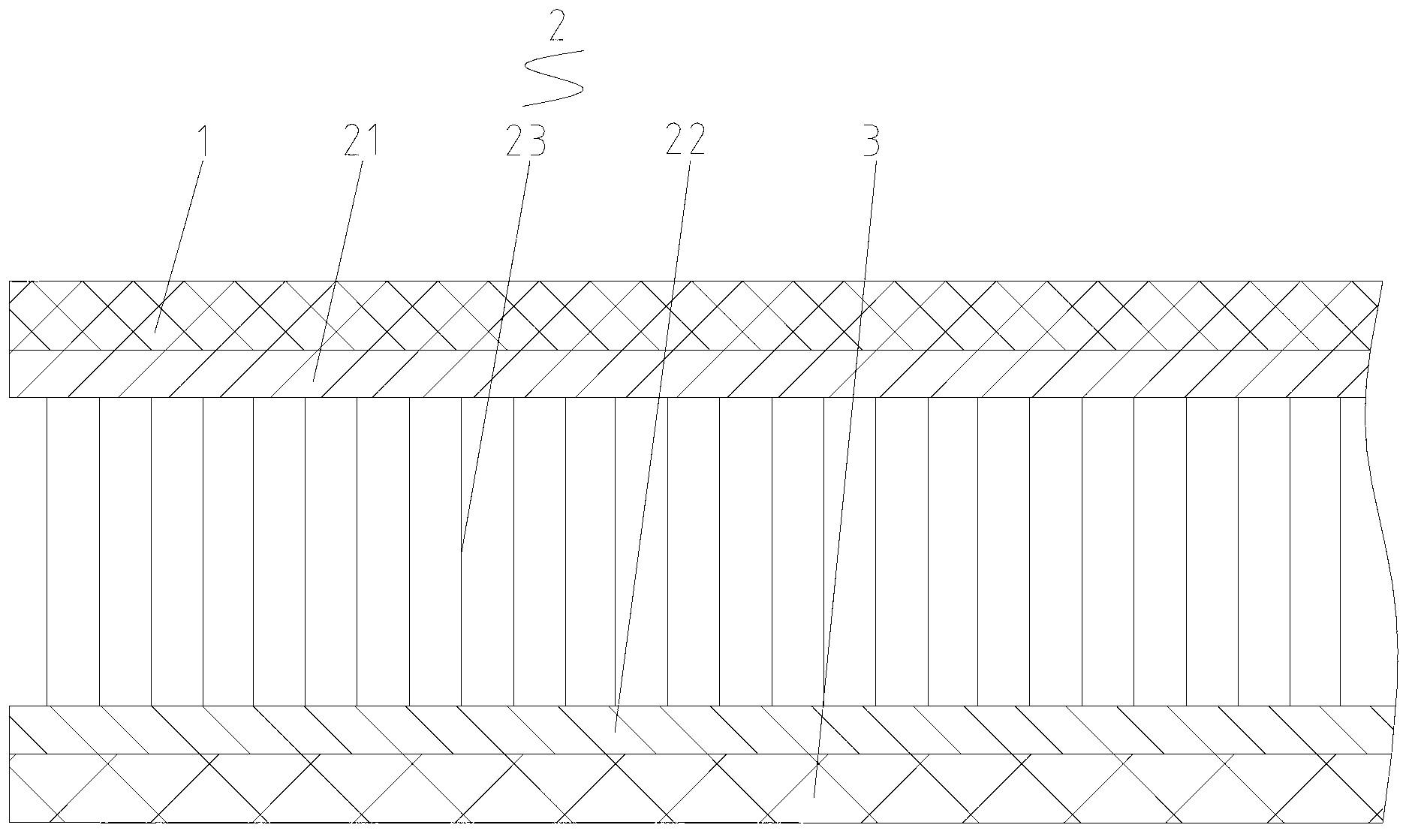

Variable distribution porous end face mechanical sealing structure

ActiveCN101016949AImprove wear resistanceImproved opening/stopping performanceEngine sealsHigh pressureWear resistance

The invention relates ton a variable-distribution porous end mechanical sealing structure, comprising a movable ring and a stable ring which are mechanically sealed, to form an annular sealing end. One side of the sealing end is high pressure side as ascending, while another end is low pressure side as descending, at least one sealing end is disposed with porous structure in different sizes symmetry distributed on the sealed end. Compared with present screw or groove mechanical sealing structure, the invention has better pressure resistance, abrasion resistance and better dynamic pressure effect on fluid membrane, to improve the carrier ability of fluid membrane.

Owner:ZHEJIANG UNIV OF TECH

Space netted fabric compound material and preparation method thereof

InactiveCN102794967AFlat surfaceNice appearanceLamination ancillary operationsSynthetic resin layered productsEngineeringPoly vinyl chloride

The invention discloses a space netted fabric compound material which comprises a PVC (Poly Vinyl Chloride) top film layer, a space netted fabric layer and a PVC bottom film layer from top to bottom, wherein the space netted fabric layer comprises upper and lower netted fabric layers and a drawn wire; the upper and lower netted fabric layers are arranged in parallel; and the drawn wire is vertically arranged between the upper and lower netted fabric layers. A preparation method for the space netted fabric compound material comprises the following steps: 1) coating paste on the space netted fabric layer; 2) preheating; 3) gluing; and 4) cooling, scrapping edge and coiling. According to the space netted fabric compound material provided by the invention, the space netted fabric layer is arranged between the PVC top film layer and the PVC bottom film layer, so that an air cushion product after being aerated has a smooth surface and a beautiful outline after the space netted fabric compound material is applied to the air cushion product; the bearing capability is excellent and the air cushion product is difficult to explode during an aerating process; and the air cushion product is excellent in elasticity and pressure resistance, due to the middle space netted fabric layer.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Elbow fitting with step feature for pneumatic transport system

ActiveUS7300074B1Lower energy requirementsReduce resistanceBulk conveyorsSiphonsTransport systemEngineering

An elbow fitting is used in a pneumatic product conveying system in which the fitting expands from the inlet pipe along the outer side of the elbow fitting to enable a layer of accumulated product particles to be formed so as to move at a lower velocity than the velocity of the incoming product stream while establishing a moving contact surface for deflecting incoming product particles toward the outlet pipe with a minimum of pressure resistance and product attrition. The accumulated product particles are discharged from the elbow fitting by incorporating a step in the outer surface of the elbow fitting to create a Bernoulli effect causing the accumulated product particles to enter the air flow after the incoming flow of product particles has ceased. The particles in the accumulated layer are replenished from the incoming flow during operation of the elbow fitting.

Owner:PELLETRON CORP

Closed origin and arrival construction method of shield machine

ActiveCN101608551ASafety tightnessSafe wayUnderground chambersTunnel liningArrival processFilling materials

The invention discloses a closed origin and arrival construction method of a shield machine, comprising the following steps: (1) using a tight continuous wall enclosure structure as a plain concrete continuous wall; (2) opening slanting periphery observation holes on a cavity door to observe the stable and leak conditions of soil bodies; (3) chiseling concrete and steel bars on the cavity door sectionally, and using plain concrete to replace the original continuous wall synchronously; (4) installing a receiving device of the shield machine, and applying pre-applied force; (5) filling materials in a steel sleeve barrel of the receiving device to a request height; (6) testing the pressure resistance of the steel sleeve barrel; (7) carrying out the digging construction of the shield machine until a shield tail of the shield machine enters or separates the cavity door; and (8) decompressing and disassembling the steel sleeve barrel of the receiving device. The closed origin and arrival construction method of the shield machine is safe, economical, efficient and simple, changes uncontrollable factors into controllable factors in a shield origin and arrival process, greatly reduces risks in a construction process, better controls land subsidence and provides the effectively ensured closed origin and arrival construction method of the shield machine.

Owner:CHINA TUNNEL CONSTR GUANGDONG

Method of controlling fluid flow transfer in shoes

Owner:CASTON GAYFORD

Spherical formed active carbon and method for preparing same

The invention relates to a spherical formed active carbon and a method for preparing the same. The formed active carbon consists of inorganic binder silica sol and powdered materials of active carbon, attapulgite and bentonite, and the powdered materials comprise the following components in percentage by mass: 30 to 80 percent of the active carbon, 10 to 60 percent of the bentonite and 10 to 60 percent of the attapulgite; and the inorganic binder silica sol accounts for 4 to 15 percent of the total mass of the powdered materials, and the mass concentration of silicon dioxide in the silica sol is between 15 and 50 percent. The spherical formed active carbon is prepared by adopting the inorganic binder, has the advantages of high compressive strength, good pressure resistance and abrasion resistance, and can prevent active carbon chippings and dust from falling off; the inorganic binder dose not have water-solubility any more after solidification and cannot be softened by water so as to still keep higher strength; and the active carbon has the advantages of spherical appearance, smooth surface, good abrasion resistance, high packing density, even particle distribution and pore space, and small fluid flow resistance, and is advantageous for controlling parameters of the fluid thereof, and the like.

Owner:SOUTHEAST UNIV

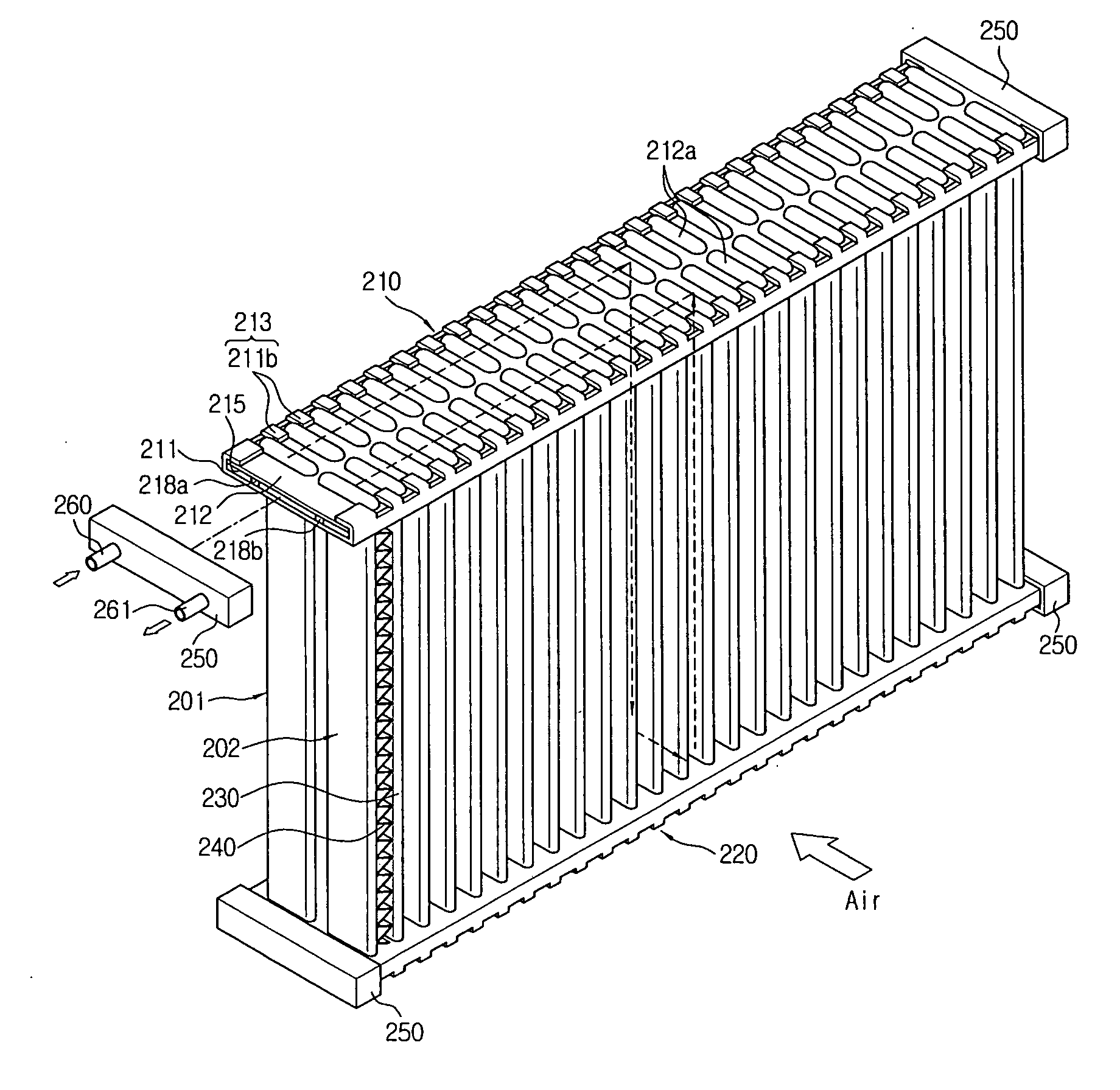

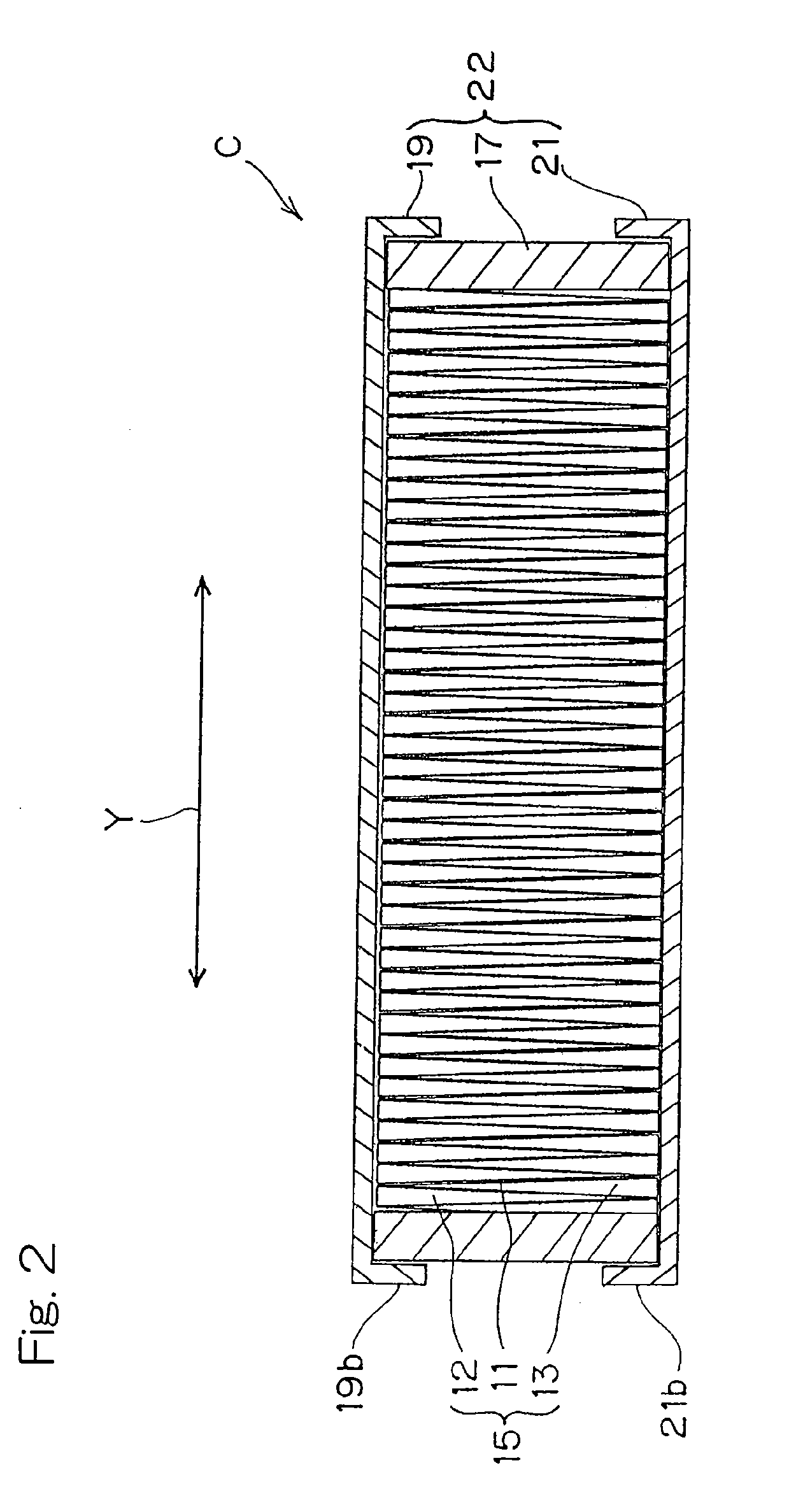

Sealed rectangular battery and battery module using same

ActiveUS20110027630A1Improve side strengthEasy to installCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesEngineeringElectrolyte

A sealed rectangular battery excellent in volumetric efficiency and pressure resistance is provided. The sealed rectangular battery includes an electrode group having a positive electrode and a negative electrode and a cell casing for accommodating therein the electrode group and an electrolyte solution, which casing includes a rectangular frame member, a first lid member and a second lid member. Each of the first and second lid members includes a body portion for covering one of the openings of the frame member, and a side portion formed so as to protrude from the body portion substantially along at least one set of sides opposite to each other.

Owner:KAWASAKI MOTORS LTD

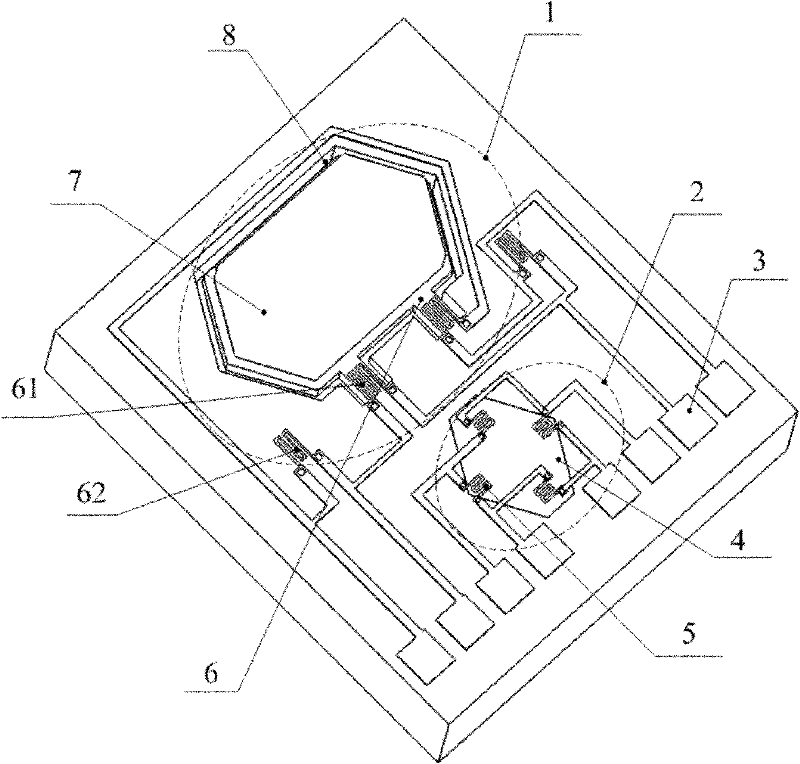

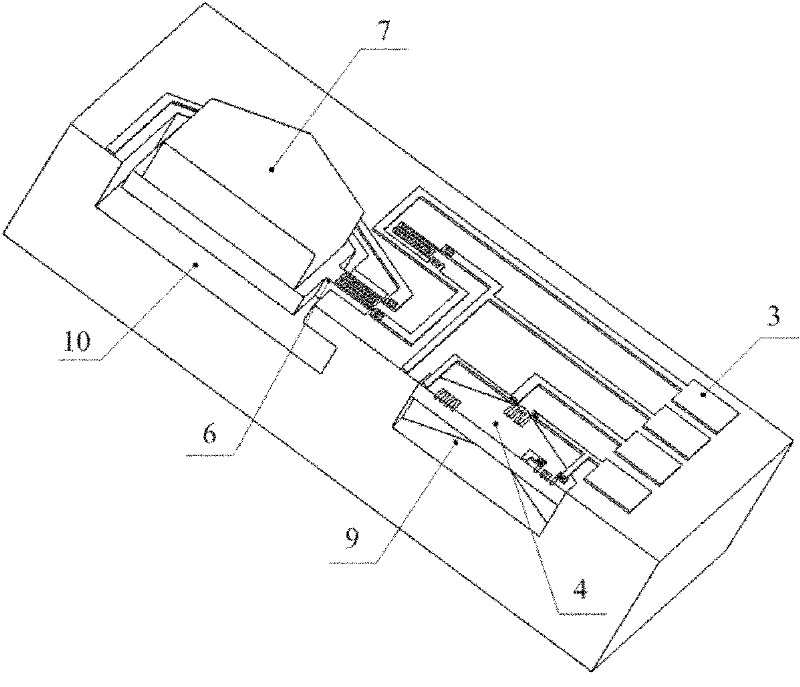

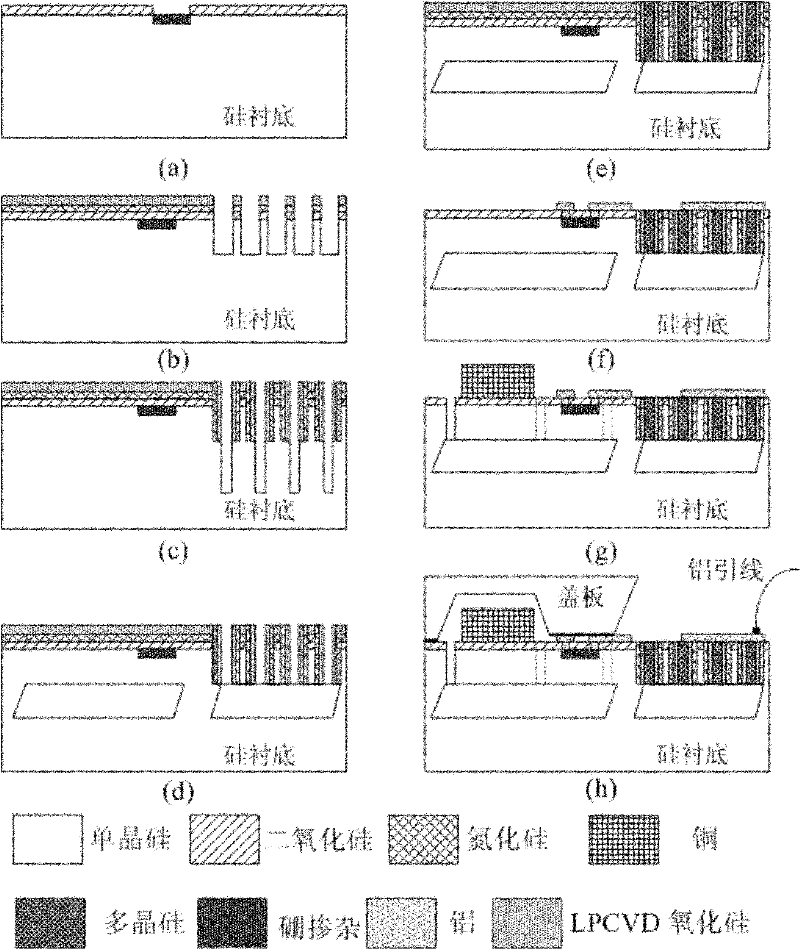

Single silicon chip integrated chip combining acceleration sensor and pressure sensor and manufacturing method of single silicon chip integrated chip

ActiveCN102476786ASmall sizeEasy to packAcceleration measurement using interia forcesFluid pressure measurement using ohmic-resistance variationHigh volume manufacturingCantilever

The invention relates to a single silicon chip integrated chip combining an acceleration sensor and a pressure sensor and a manufacturing method of the single silicon chip integrated chip. The single silicon chip integrated chip comprises a single crystal silicon substrate and an acceleration sensor and a pressure sensor both integrated on the single crystal silicon substrate. The acceleration sensor and the pressure sensor are integrated on the same surface of the single crystal silicon substrate through adopting a single silicon chip single-side micro-processing method; a single crystal silicon thin film with a uniform and controllable thickness and an embedded cavity are formed through adopting the side wall root transversal etching technology, and pressure resistance is reasonably distributed on the upper surface of the single crystal silicon thin film to manufacture the pressure sensor; and the acceleration sensor adopts double cantilever beams and a mass block, both the mass block and the cantilever beams are processed and released through the follow-up optional galvanizing and etching to the single crystal silicon thin film, and the quality of the mass block is increased through adopting an electrocoppering method, so as to improve sensitivity. The single silicon chip integrated chip disclosed by the invention has the advantages that the structure is simple; and a non-bonding single silicon chip micro-machinery technology is adopted to realize the manufacturing of a single-side structure of the integrated chip, thereby meeting the requirements on small dimension, low cost and mass production of the sensor chip in TPMS (Tire Pressure Monitor System) application.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Microcapsule for retarding oil gas well working fluid additive release and preparation method thereof

InactiveCN101144011AReduce releaseImprove stress resistanceDrilling compositionWorking fluidFracturing fluid

The invention provides a microcapsule for delaying the release of working fluid additives in oil and gas well and a method for preparing the same, which belongs to oilfield chemical field. The invented microcapsule is formed by 3.5-25 percent of working fluid additive in oil and gas well, 70-94 percent of aluminosilicate beads, 2-5 percent of polymer membrane, wherein the working fluid additive in oil and gas well is one of oil well cement early strength accelerator, gel strength accelerator, retarder or fracturing fluid crosslinking agent, gel breaker, the aluminosilicate beads are waste catalysts with 10-250 um particle size and 0.20-0.60cm3 / g pore volume 0.20-0.60cm3 / g, the polymer membrane is non water-soluble polymer with 0.02-03 million relative molecular mass. The prepared microcapsules have good effect of delaying release, pressure resistance, temperature resistance, and wide application range. The main raw material of aluminosilicate beads for preparing microcapsules belongs to waste reutilization, which is economical and environment-friendly. Furthermore, the microcapsule preparation technology of the invention is simple and the production cost is low, which is beneficial for industrial production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

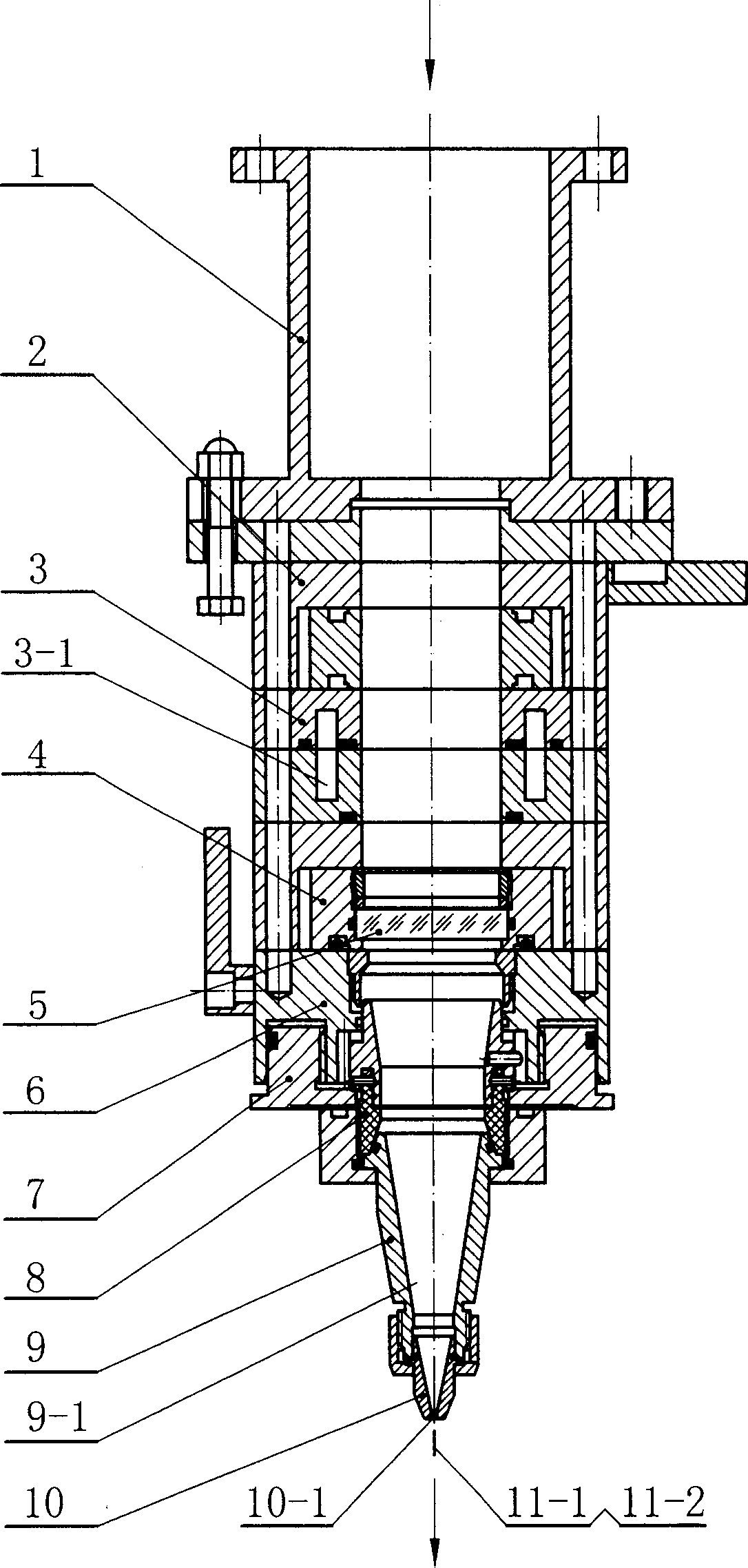

Digital-control laser cutting head and method for making same

InactiveCN1827282AIncreasing the thicknessIncrease profitLaser beam welding apparatusLight energyLaser cutting

The invention discloses a digital control laser cutter head used in CO2 digital control laser cutter and relative producing method. Wherein, the digital control layer cutter head comprises a connecting tube 1, a glass base box 2, a water cooling element 3, a focusing glass base element 4, a focusing glass 5, an aeration element 6, an adjusting nut 7, a high-strength insulated separating sheath 8, a transition nozzle 9, and a cutting nozzle 10. The inner hole 9-1 of said transition nozzle is in reverse taper shape; the upper and lower parts of water cooling element are integrated annular cooling water channels, while the annular cooling water channel 3-1 is one-time mechanically processed; the main elements as glass base box 2, water cooling element 3, focusing glass base element 4, aeration element 6 and adjusting nut 7 are made from ultrahigh strength rigid duralium LC4. With said invention, the consumed pressure and light energy of digital control laser cutter head is lower and the focusing effect is better. And said invention has better sealing property, thicker cut plate, high plate utilization, high strength, high pressure resistance and high heat conductivity.

Owner:LONGYAN LISHANG PRECISION MACHINERY

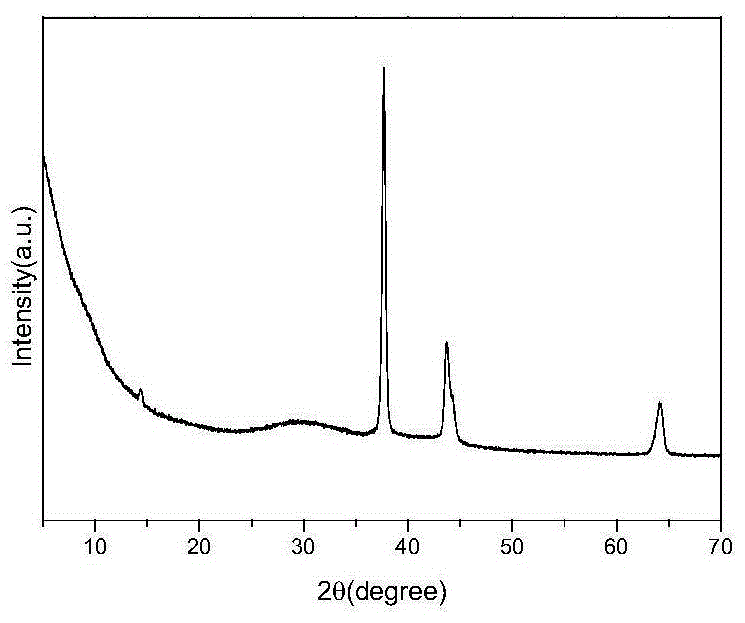

Silver nanowire/graphene composite elastic aerogel, and preparation method and application thereof

InactiveCN105032354ARaw materials are easy to getEasy to prepareMaterial nanotechnologyOther chemical processesNetwork structureCvd graphene

The invention discloses a silver nanowire / graphene composite elastic aerogel, and a preparation method and application thereof. The silver nanowire and graphene composite elastic aerogel adopts a three-dimensional network structure in which silver nanowires are distributed on the surface of graphene to be used as elastic supporting and conductivity enhancement units. The preparation method for the aerogel comprises the following steps: firstly, preparing silver nanowires and an oxidized graphene dispersion solution; secondly, mixing the silver nanowires and the graphene dispersion solution with a reducing agent for reduction reaction to obtain silver nanowire and graphene hydrogel; finally, drying the obtained silver nanowire and graphene hydrogel to obtain the silver nanowire and graphene composite elastic aerogel. The silver nanowire and graphene composite elastic aerogel has the characteristics of being high in specific surface area, compression resistance and resistance adjustability, and the like, and has a high application value in the field of organic pollutant adsorption, catalysis, pressure resistance switches and the like.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

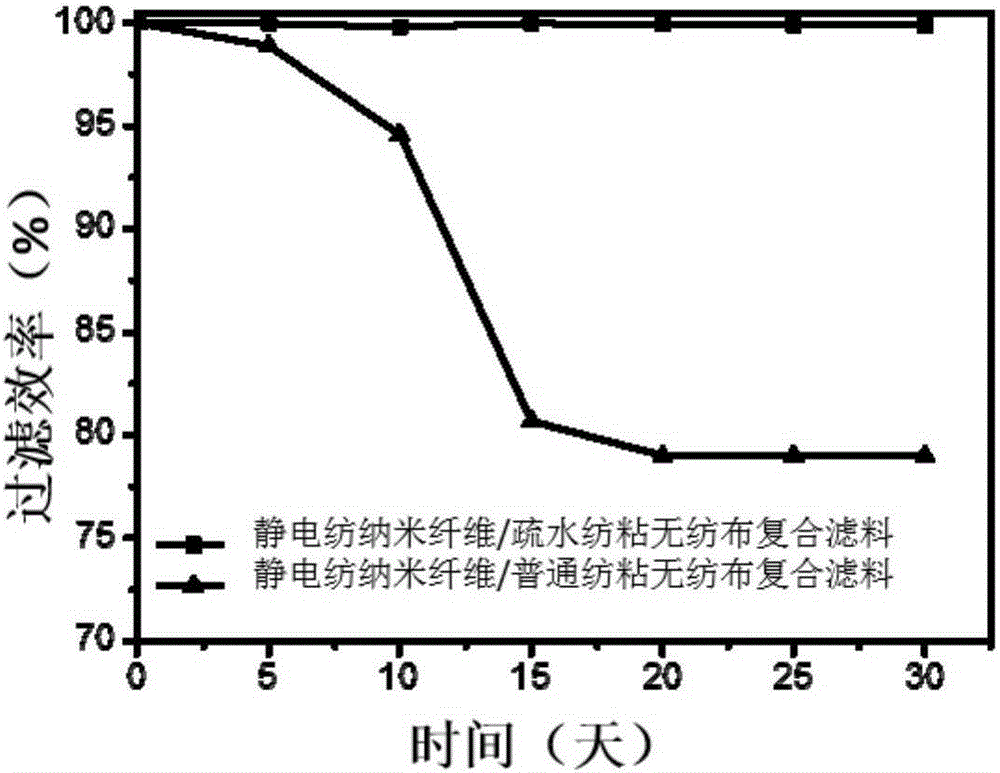

Electrostatic spinning method and nanometer fiber/anti-sticking non-woven fabric composite filter material prepared through electrostatic spinning method

ActiveCN105200539AImprove uniformityElectric field interference weakenedFilament/thread formingFiltration separationWoven fabric compositeElectrospinning

The invention relates to an electrostatic spinning method and a nanometer fiber / anti-sticking non-woven fabric composite filter material prepared through the electrostatic spinning method. Multi-needle electrostatic spinning is adopted in the electrostatic spinning method, and needles of multi-needle electrostatic spinning are insulated from one another. The prepared nanometer fiber / anti-sticking non-woven fabric composite filter material is formed by overlapping and compositing materials for overlapping from bottom to top according to the low-to-high sequence of filtering efficiency of a filtering material, the face, with electrostatic spinning fiber, of each layer of material for overlapping faces upwards, the uppermost layer of material for overlapping is covered with anti-sticking non-woven fabric, and therefore it is ensured that the top layer and the bottommost layer are both anti-sticking non-woven fabric layers; of every two adjacent layers of materials for overlapping, the filtering efficiency value for particles with grain size of 0.02 micron to 10 microns of the upper layer is 1.03-1.3 times that of the lower layer, the number of overlapping layers of the materials for overlapping ranges from 2 to 6, the anti-sticking non-woven fabric and the interlayer structure with electret effect nanometer fibers arrayed at intervals are formed, and the nanometer fiber / anti-sticking non-woven fabric composite filter material is formed; the filtering efficiency of the nanometer fiber / anti-sticking non-woven fabric composite filter material for particles with grain size of 0.02 micron to 10 microns reaches 99.999% or higher, and the pressure resistance is kept between 10 Pa and 30 Pa.

Owner:DONGHUA UNIV

Rear casing arrangement for magnetic drive pump

ActiveUS7249939B2Improve reinforcement effectAvoid deformationPositive displacement pump componentsPump installationsHeat resistanceBand shape

It is sought to provide a rear casing arrangement for a magnetic drive pump, which can sufficiently provide such functions pressure resistance and heat resistance, which give rise to problems in the case of manufacturing the rear casing from a material based on a synthetic resin, and can also be manufactured at low cost.A reinforcing belt-like ring member is woundly fitted on the outer periphery of a cylindrical barrel part of an inner casing member constituting a rear casing. The belt-like ring member has a width smaller than the length of the barrel part. A casing cover member is fitted on the belt-like ring member in the above fitted state. Alternatively, it is possible to fit the belt-like ring member on the outer periphery of a barrel part of the casing cover member. These parts can be disassembled.

Owner:IWAKI

Fused iron catalyst for producing light olefins from syngas and preparation method and application thereof

ActiveCN101757925APreparation raw materials are cheapRaw materials are readily availableHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasFluidized bed

The invention provides fused iron catalyst for producing light olefins from syngas and a preparation method and application thereof. The fused iron catalyst includes iron oxide and cocatalyst and the proportion of the components is as follows by weight percent: 0.1-5 alumina, 0.1-6 potassium oxide, 0.1-4.0 calcium oxide and 0.01-8.5 other oxides, and balance iron oxide. The fused iron catalyst has the beneficial effects that (1) the materials of the fused iron catalyst are cheap and easy to get, the preparation process is simple, and the fused iron catalyst is low in cost and is suitable for industrial production; (2) the fused iron catalyst is of high mechanical strength as well as good pressure resistance and abrasion resistance and is suitable for a fixed bed, a fluidized bed and a slurry bed reactor; and (3) the fused iron catalyst has high Fischer-Tropsch synthesis activity and selectivity, the conversion per pass can be more than 95%, the selectivity of the methane is less than 10% and the content of the light olefins can reach 80-90%.

Owner:ZHEJIANG UNIV OF TECH

Metal die for coining super-hydrophobic micro-nanometer surface and laser manufacturing method thereof

ActiveCN103521929AHigh structural fidelityIncrease flexibilityNanotechnologyLaser beam welding apparatusPicosecond laserOptoelectronics

The invention discloses a metal die for coining a super-hydrophobic micro-nanometer surface and a laser manufacturing method thereof. The laser manufacturing method comprises the following steps that an ultra-short pulse laser is used for ablating a metal base material, a symmetrical negative structure of a lotus leaf micro-nanometer structure is obtained on the surface of the metal base material through laser ablating removing, and then the metal die is obtained; the symmetrical negative structure of the lotus leaf micro-nanometer structure is a micrometer-level pit and a nanometer-level substructure on the inner surface of the micrometer-level pit. The invention provides the micro-nanometer coining metal die for coining a non-metal material or a light-metal material so as to form the lotus leaf micro-nanometer structure with the surface being super hydrophobic and the laser manufacturing method of the metal die, and particularly relates to the micro-nanometer coining metal die which is manufactured efficiently in a large area by the utilization of high-power picosecond lasers and the manufacturing method of the metal die. The metal die for coining the super-hydrophobic micro-nanometer surface and the laser manufacturing method of the metal die have the comprehensive advantages that the manufacturing efficiency is high, the micro-nanometer coining die is high in temperature resistance, high in pressure resistance and wide in coning material range, the micro-nanometer structure is precise and adjustable in parameter and the lotus structure is vivid. Moreover, the manufacturing method is far superior than other methods.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com