Spherical formed active carbon and method for preparing same

A technology for forming activated carbon and activated carbon, which is used in the field of environmental purification and pollutant treatment to achieve the effects of high strength, good wear resistance and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

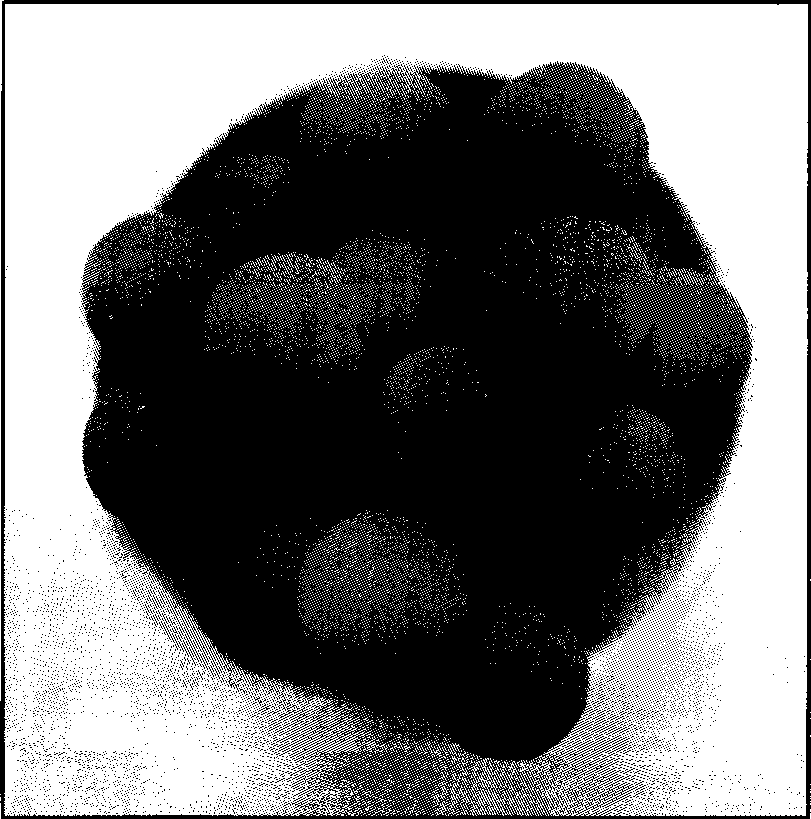

Image

Examples

Embodiment 1

[0017] (1) Weigh 75% of powdered activated carbon, 10% of bentonite, and 15% of attapulgite according to mass percentage, and mix them evenly.

[0018] (2) Silica sol solution is prepared according to the fact that silica sol accounts for 5% of the total mass of the powdery material, and the mass concentration of silicon dioxide in the silica sol is 15%.

[0019] (3) Add the silica sol solution to the powdery material mixture, mix evenly to make a soft material, extrude it into a smooth and dense strip with a diameter of 6 mm in diameter, and then cut it into sections with a length of 4 mm. The material is placed in a spheronizer and rolled into balls, and the extrusion-spheronization process is used to make balls to obtain spherical particles with a diameter of φ5mm.

[0020] (4) The spherical particles are dried and calcined at 360° C. for 60 minutes to obtain spherical activated carbon.

Embodiment 2

[0022] (1) Weigh 30% of powdered activated carbon, 30% of bentonite and 40% of attapulgite according to mass percentage, and mix them evenly.

[0023] (2) Prepare a silica sol solution according to the silica sol accounting for 15% of the total mass of the powdery material, and the mass concentration of silicon dioxide in the silica sol is 25%.

[0024] (3) Add the silica sol solution to the powdery material mixture, mix evenly to make a soft material, extrude it into a smooth and dense strip with a diameter of φ12mm, and then cut it into sections according to the length of 8mm. The finished material is placed in a spheronizer and rolled into balls, and the extrusion-spheronization process is used to make balls to obtain spherical particles with a diameter of φ12mm.

[0025] (4) Drying the spherical particles and calcining them at 400° C. for 30 minutes to obtain spherical shaped activated carbon.

Embodiment 3

[0027] (1) Weigh 50% of powdered activated carbon, 10% of bentonite, and 40% of attapulgite according to mass percentage, and mix them evenly.

[0028] (2) Prepare a silica sol solution according to the silica sol accounting for 10% of the total mass of the powdery material, and the mass concentration of silicon dioxide in the silica sol is 40% to 50%.

[0029] (3) Add the silica sol solution into the powdery material mixture, mix evenly to make a soft material, extrude it into a smooth and dense strip with a diameter of φ9mm, and then cut it into sections according to the length of 6mm. The finished material is placed in a spheronizer and rolled into balls, and the extrusion-spheronization process is used to make balls to obtain spherical particles with a diameter of φ9mm.

[0030] (4) The spherical particles are dried and calcined at 320° C. for 150 minutes to obtain spherical activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com