Patents

Literature

66results about How to "No softening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High oil absorption resin and synthetic method thereof

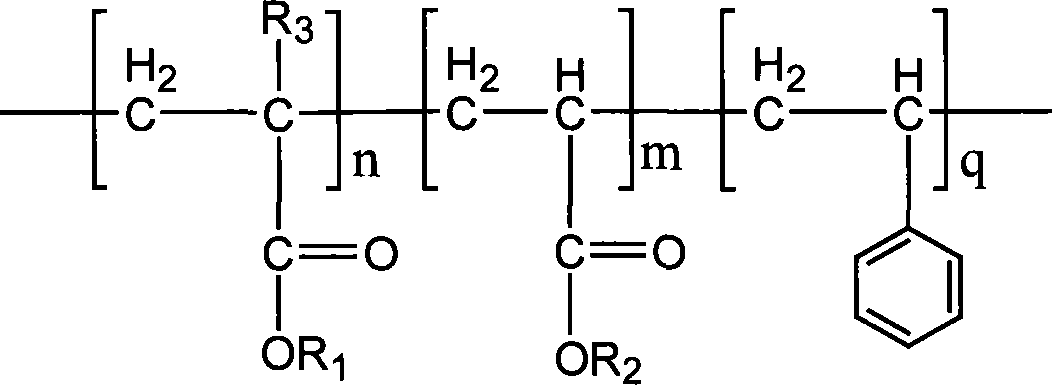

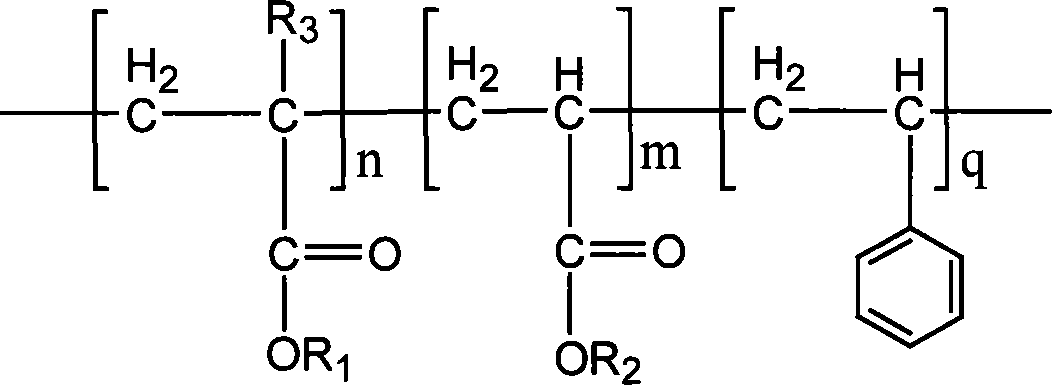

The invention discloses a high oil absorbing resin, and a process for preparation comprises utilizing short-chain ester of (metyl group) acrylic acid, long-chain ester of acrylic acid and styrene monomer to be monomers, adding dispersing agent and surface active agent, and getting through suspension polymerization and random copolymerization under the condition of the existence of cross linker and initiating agent. The process for synthesizing has lithe time consumption, which can be industrialized, and high oil absorbing resin which is got has high oil absorbing efficiency, fast oil absorbing speed, and which can be recycled to be repeatedly used.

Owner:SUZHOU TIMELYBLUE ENVIRONMENTAL TECH

Fluorine rubber seal element and preparing method thereof

ActiveCN101168656AExtended service lifeGood process performanceOther chemical processesCarbon blackCalcium hydroxide

The invention provides a fluorinated rubber sealing element; the invention is characterized in that the sealing element is produced by the raw material with the following quality parts: binary fluorinated elastomer of 60 to 80 parts, tetrafluoroethlene propylene rubber of 20 to 40 parts, carbon black of 20 to 40 parts, calcium hydroxide of 3 to 5 parts, metal oxide of 3 to 6 parts, hexafluoride sonitroso propyl diphenol of 1.5 to 2 parts, benzyl triphenyl phosphorus chloride of 0.3 to 0.5 part, processing aid of 0.5 to 2 part, dicumyl peroxide of 0.5 to 1.2 parts, and triene propyl isocyan urate of 0.5 to 1.2 parts. The invention has the preparation method that sulphation for 8 to 12 minutes is molded on a compression machine under 165 to 180 DEG C through being extruded and formed after the raw material with the quality parts are added in mixing equipment to be mixed uniformly under 60 to 80 DEG C, and then the sealing element is produced after performing secondary cure for 8 to 24 hours in hot air of 200 to 250 DEG C. The fluorinated rubber sealing element produced has long service life and can be high temperature water vapor resistant and high and low impact resistant.

Owner:广州国机智能橡塑密封科技有限公司

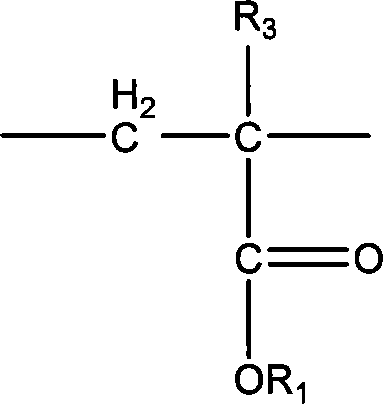

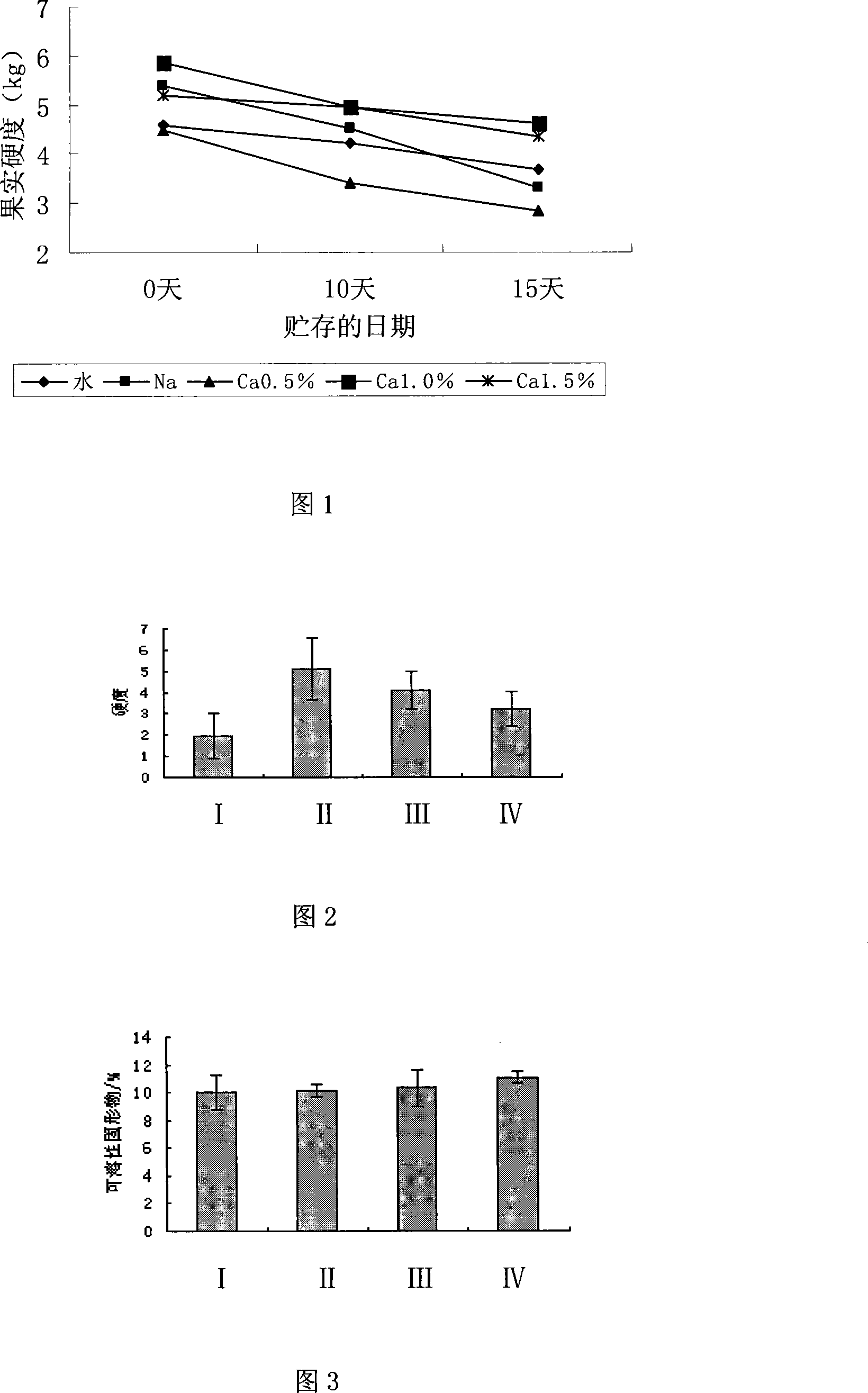

Method for fruits biological freezing point preservation and the storehouse

InactiveCN101204173AGuaranteed storage qualityEasy to combineFruits/vegetable preservation by coatingFruits/vegetable preservation by freezing/coolingPre coolingProduct processing

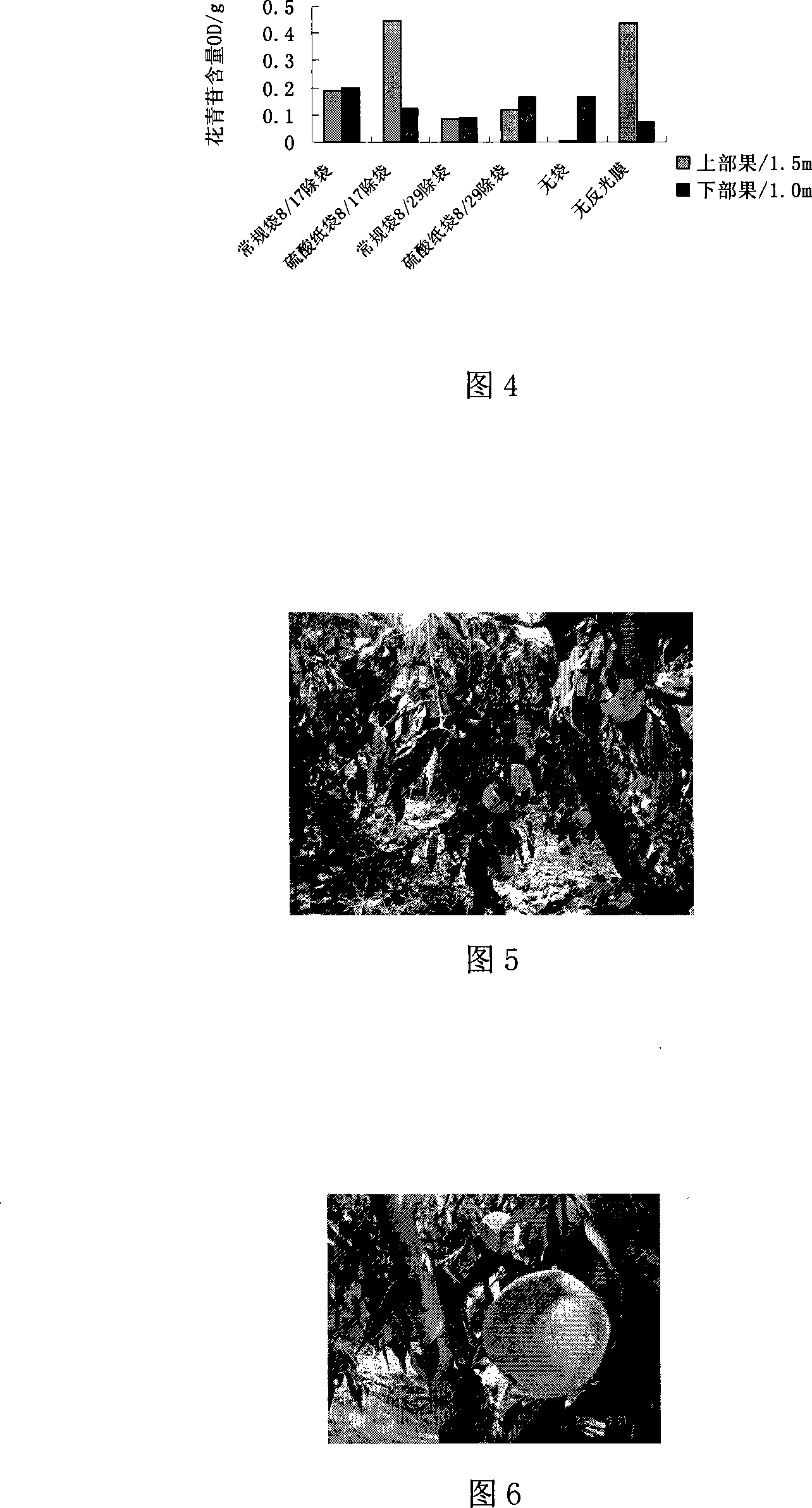

The invention relates to a fresh-keeping method and a fresh-keeping storehouse of a biological freezing point for fruits belonging to an agricultural products processing field. The fresh-keeping method of the biological freezing point for the fruits includes the steps: spraying calcium salt in the process of cultivating, sleeving a transparent bag or spreading a reflecting film to improve hardness and sugar degree of the fruits; carrying out rapid cooling before putting in the fresh-keeping storehouse in a pre-cooling room; after putting in the fresh-keeping storehouse, processing with a preservative; then regulating the temperature to a critical point of the freezing point with humidity of over 90%; adopting stage heating after leaving the fresh-keeping storehouse. Preservation period of late maturing peach is prolonged to 3 months; the fruits processed by the steps are fresh as before and the phenomenon such as browning, softening and rotting do not exist. The cost of the supporting fresh-keeping storehouse constructed based on the invention is about 1.2 times of that of a low temperature cold storage and 1 / 2-2 / 3 times of that of an air conditioned storehouse with the same volume; fresh-keeping effect is remarkably superior to the low temperature cold storage and the air conditioned storehouse; the invention can promote the creativity and development of relevant industries such as a transport case and a transport vehicle of the biological freezing point as well as the relevant culture of the biological freezing point; the invention is a technology with a wide prospect and favorable economic benefits.

Owner:CHINA AGRI UNIV

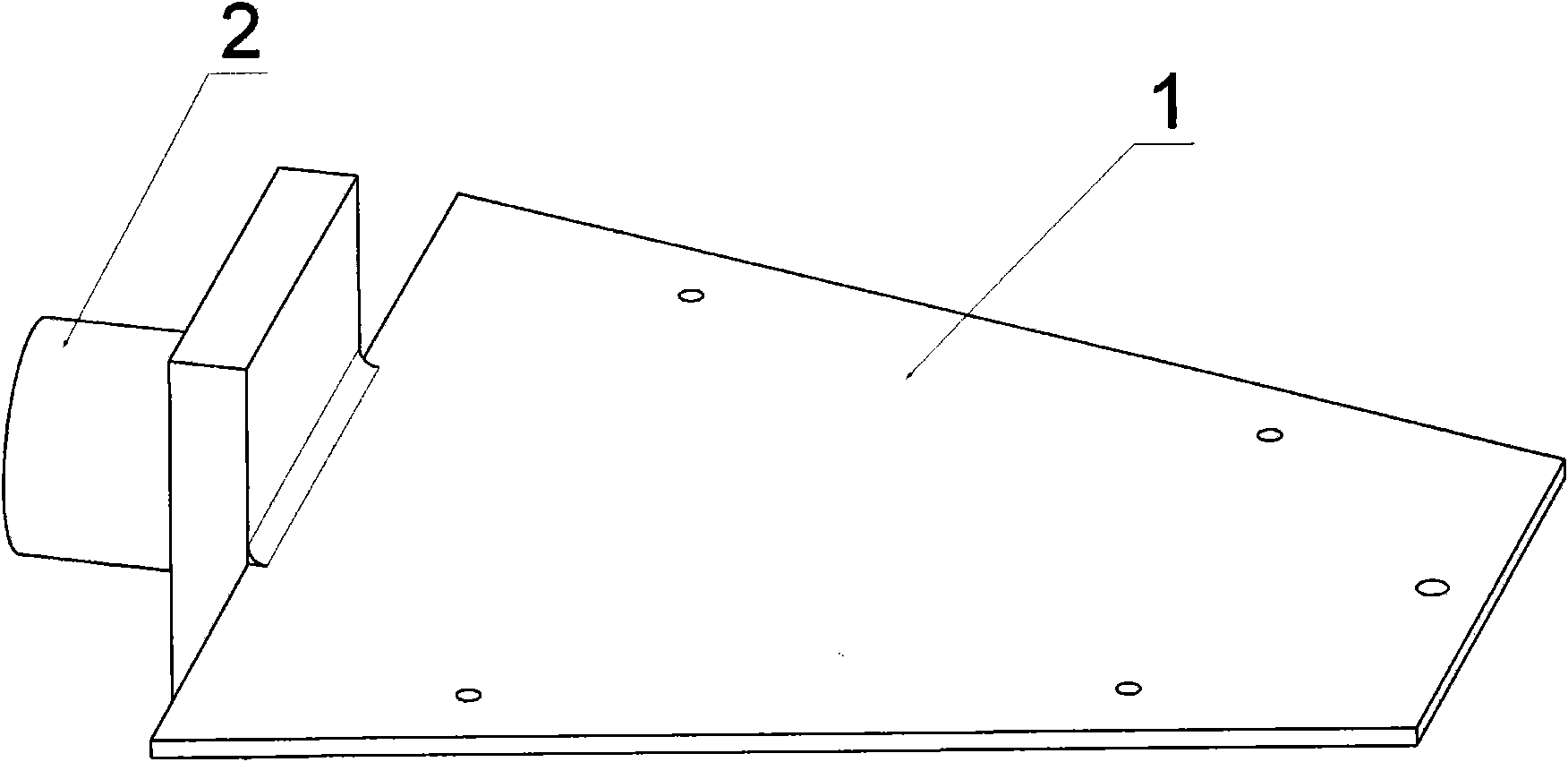

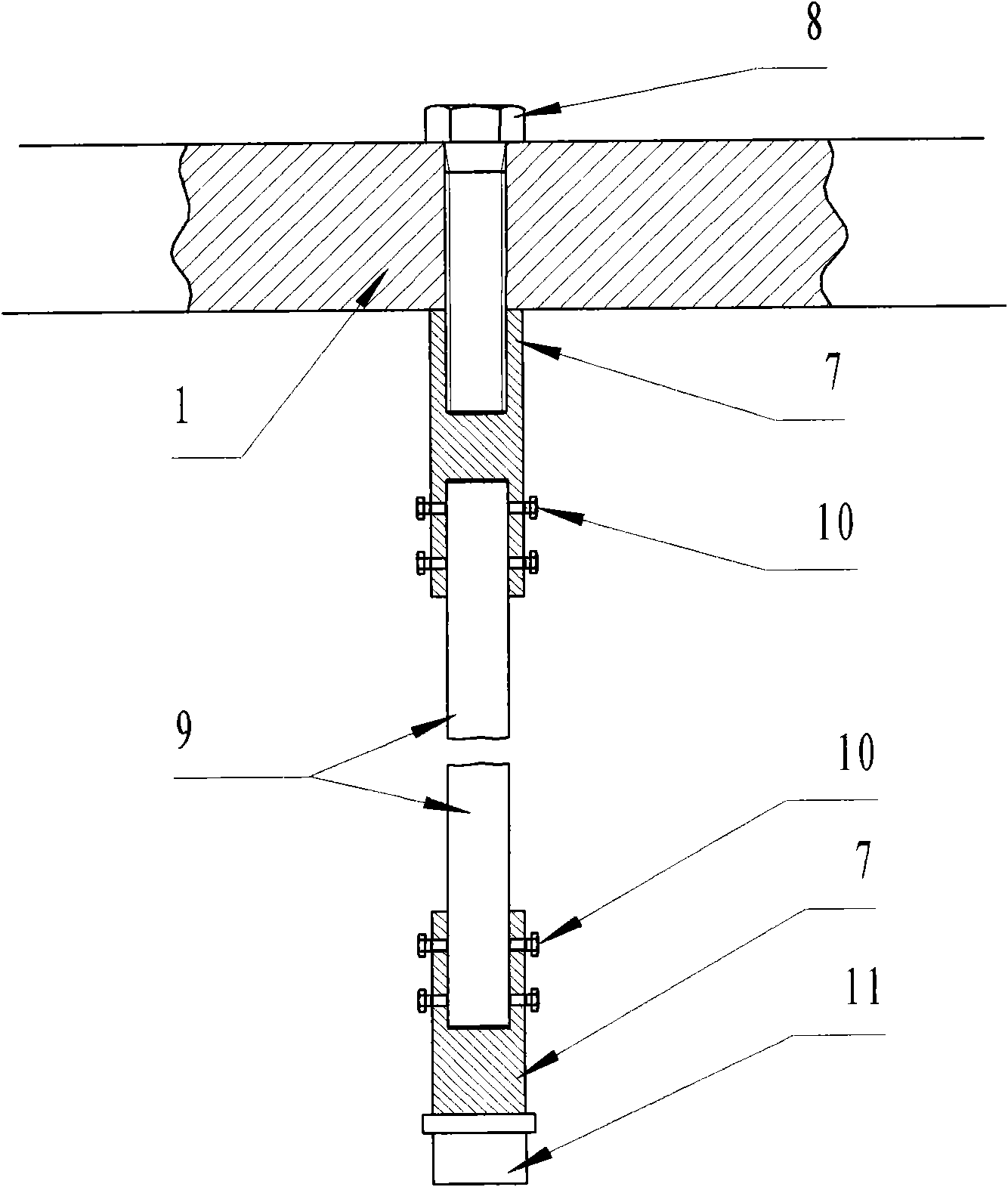

Inherent frequency measuring device for 600 DEG C high-temperature thermal vibration coupling test of high-speed cruise missile airfoil surface

InactiveCN102042870AReduce special requirementsReduce special requirements on temperature environmentSubsonic/sonic/ultrasonic wave measurementSignal onQuartz

The invention discloses an inherent frequency measuring device for 600 DEG C high-temperature thermal vibration coupling test of a high-speed cruise missile airfoil surface. The device comprises a missile airfoil surface structure test piece, a quartz lamp heating array, a vibration exciter, a ceramic extension rod, an acceleration transducer, a computer and a heat insulation baffle plate. In the high-temperature thermal vibration coupling test of the cruise missile airfoil surface, the missile airfoil surface is quickly heated by using the quartz lamp heating array and generates random vibration through the vibration exciter at the same time to form a 600 DEG C high-temperature thermal vibration coupling test environment. The rigid ceramic extension rod with high rigidity and high temperature resistance is arranged on the missile airfoil surface to guide the vibration signals on the missile airfoil surface out of the high-temperature thermal field, and the high-temperature resistant lightweight ceramic fiber heat insulation baffle plate is used for implementing thermal diffusion prevention shielding for the radiation thermal field. The normal temperature acceleration transducer arranged at the cold end of the ceramic extension rod dynamically tracks and measures the vibration signals guided to the missile airfoil structure of the normal temperature zone to acquire the change rule of the inherent frequency of the missile airfoil surface under the high-temperature thermal vibration coupling test environment; and the device provides an effective dynamic high-temperature thermal vibration coupling test means for researching and manufacturing high-speed cruise missiles.

Owner:BEIHANG UNIV

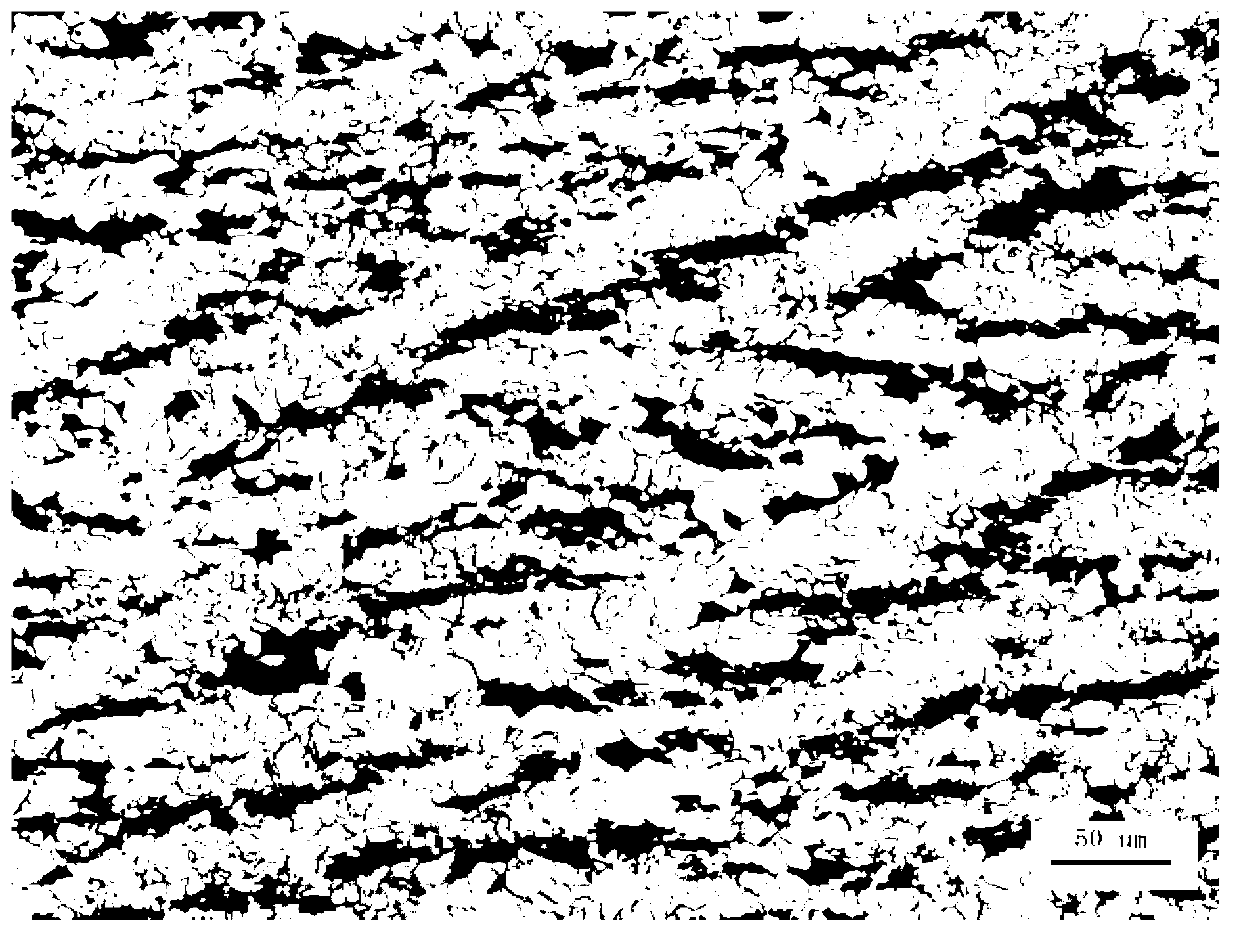

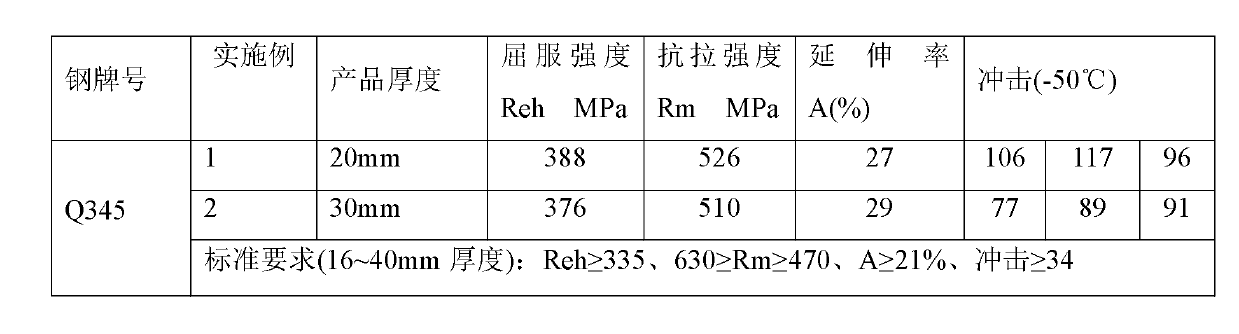

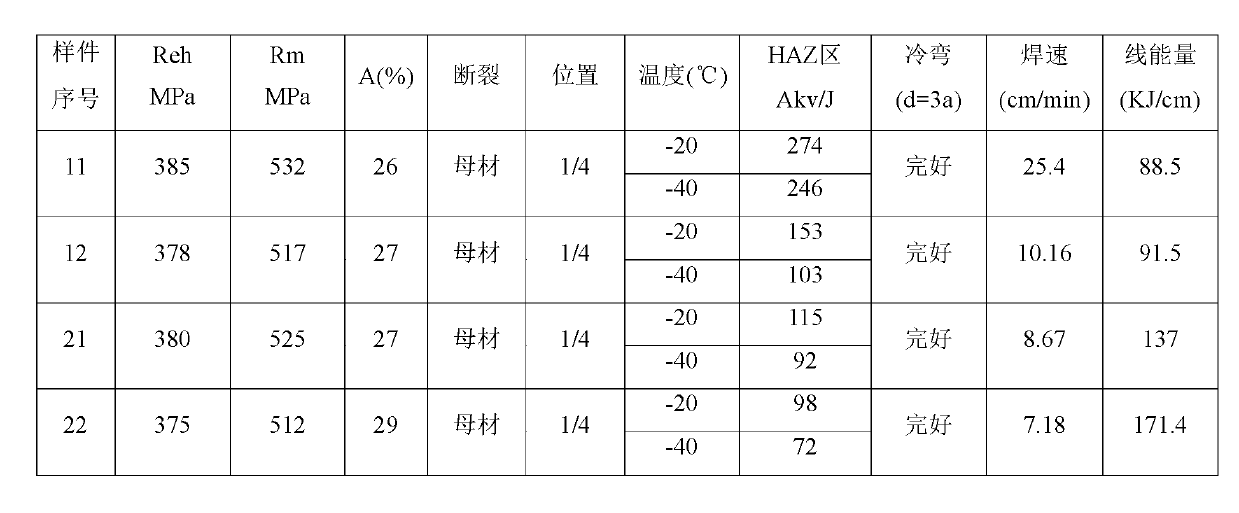

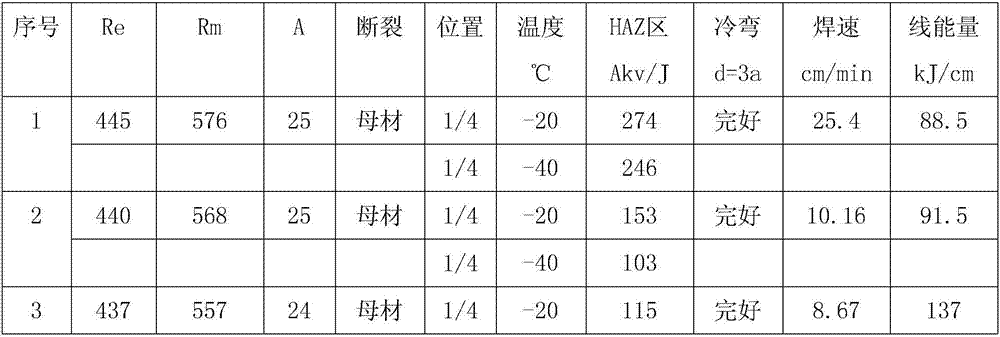

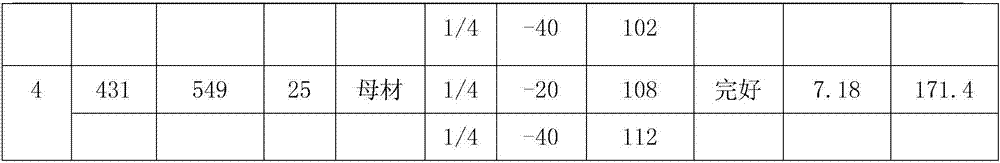

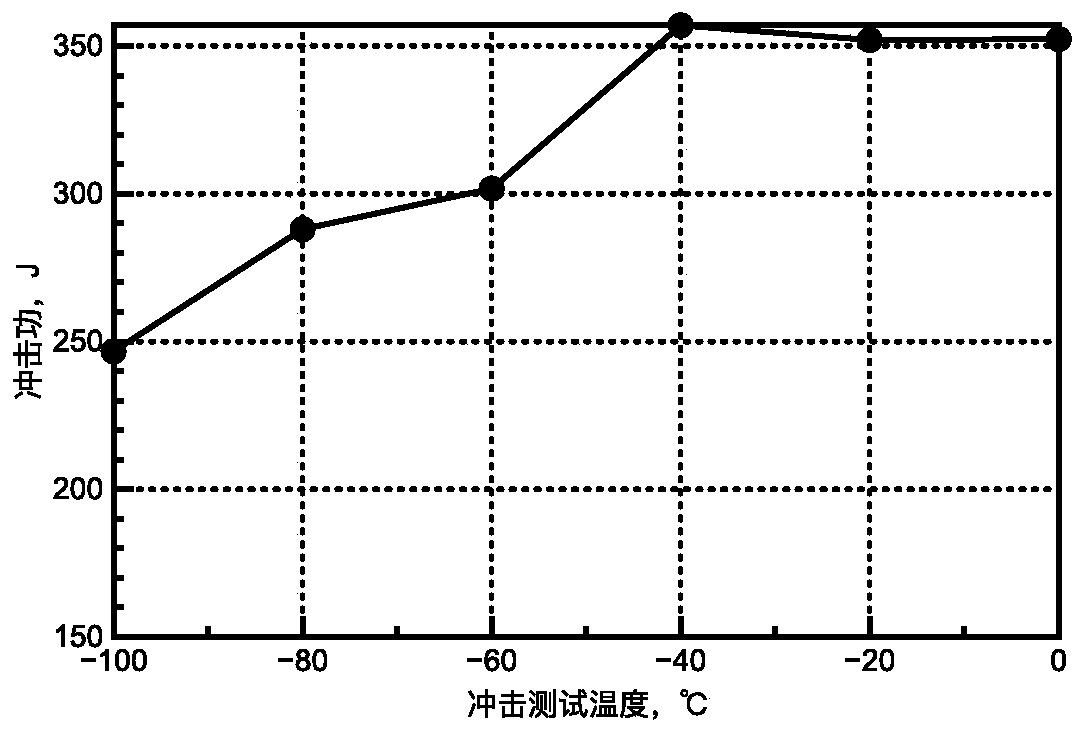

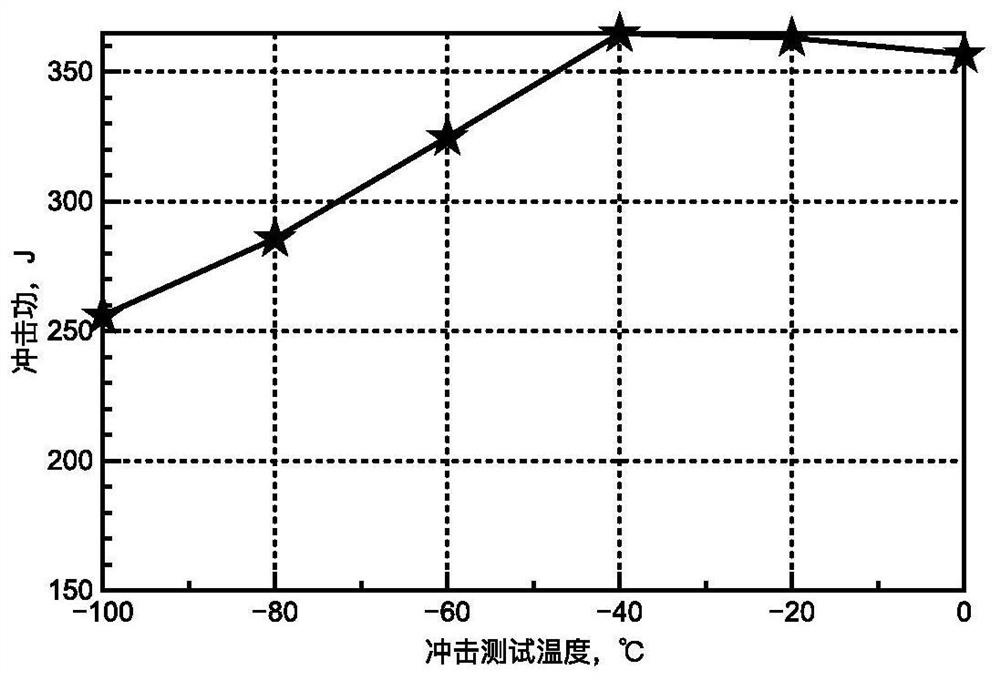

Method for producing high heat input welding Q345-level steel plate

The invention relates to the field of iron and steel products and in particular relates to a method for producing a high heat input welding Q345-level steel plate. The process flow comprises the following steps of: smelting, continuous casting, heating, phosphorous removal, controlled rolling and cooling, thermal straightening, stacking, slow cooling, and cracking off to obtain the finished product. Three key points, such as design of smelting components, controlled rolling and cooling and cooling after final rolling, are controlled, wherein in the design of the smelting components, Ti / (N)is equal to 2.4-3.2. Compared with the prior art, the method has the beneficial effects that according to filed practice, the high heat input welding Q345-level steel plate produced by the method has good performance of a welded joint, the sample fracture occurs on a base metal, and the phenomenon that the welded joint is softened is avoided; along with increase of heat input, lateral impact values in an HAZ area at the temperatures of -20 DEG C and -40 DEG C are reduced; the cold bending performance is good, and the mechanical property and welding performance completely exceed the standard requirements; moreover, the method has the advantages of short production flow, low production cost, suitableness for mass production and the like.

Owner:ANGANG STEEL CO LTD

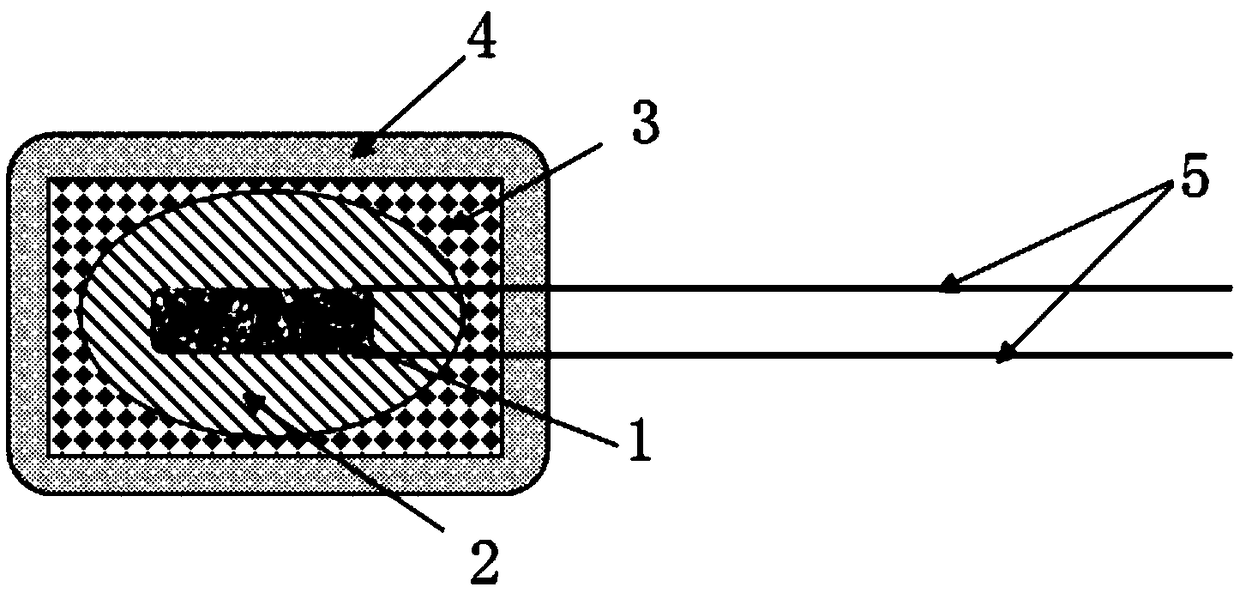

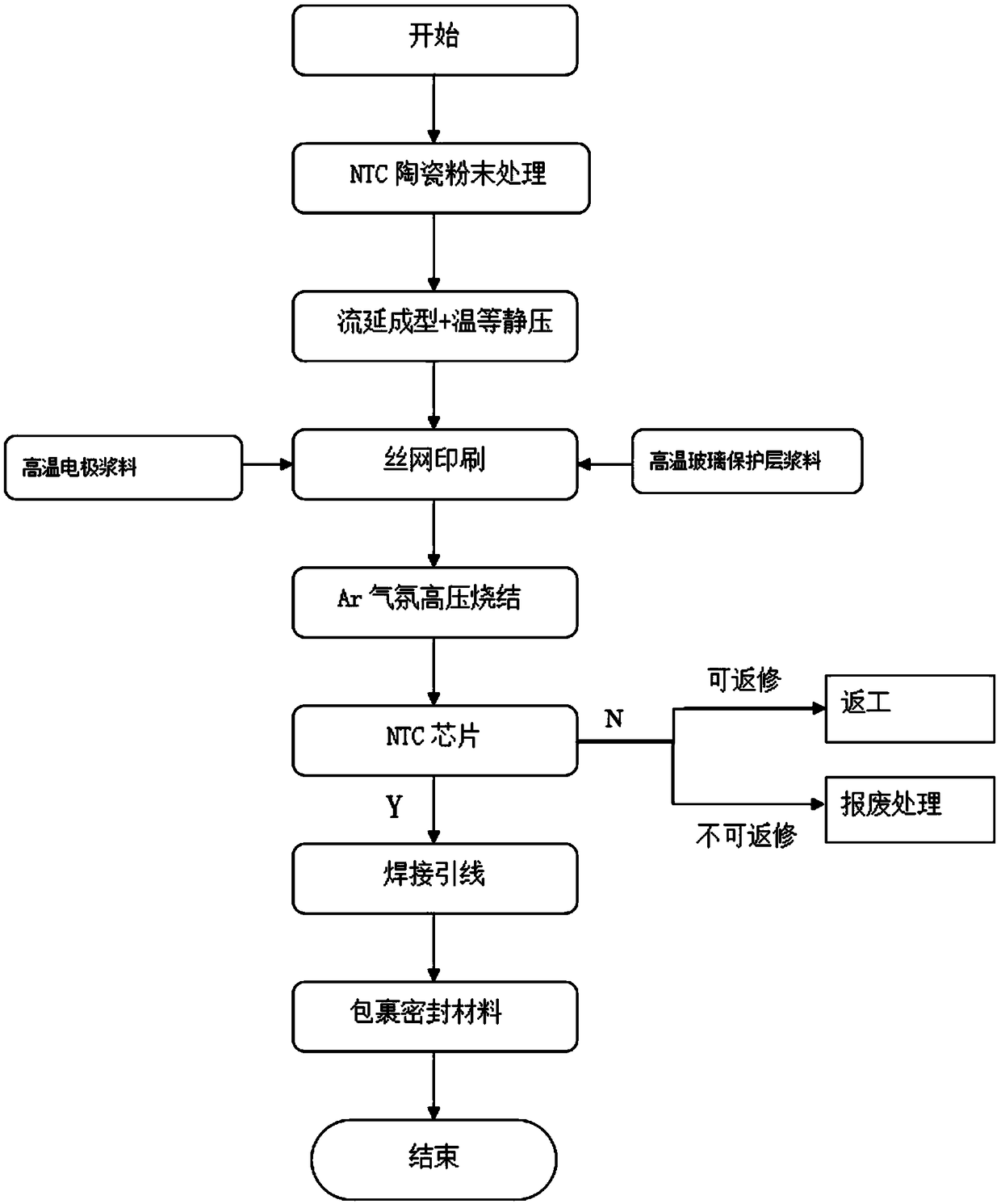

Thermosensitive ceramic powder, NTC thermosensitive chip, temperature sensor and preparation method

ActiveCN109053158AStrong reliabilityNo breakageThermometers using electric/magnetic elementsUsing electrical meansRare earthMechanical pressure

The invention discloses thermosensitive ceramic powder, a NTC thermosensitive chip, a temperature sensor and a preparation method. The ceramic powder disclosed by the invention is prepared from the following components in percentage by weight: 18-38% of manganese dioxide powder, 12-20% of cobalt oxide powder, 4-14% of iron oxide powder, 21-41% of nickel oxide powder and 2-10% of rare earth oxide powder. The temperature sensor disclosed by the invention has the advantages of perfect softness, bending resistance, vibration resistance, wear resistance, corrosion resistance and the like, and is adapted to quite harsh environment of oil stain, EMI, mechanical pressure and the like in a motor; the temperature sensor is required to work stably for a long time in bad conditions.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

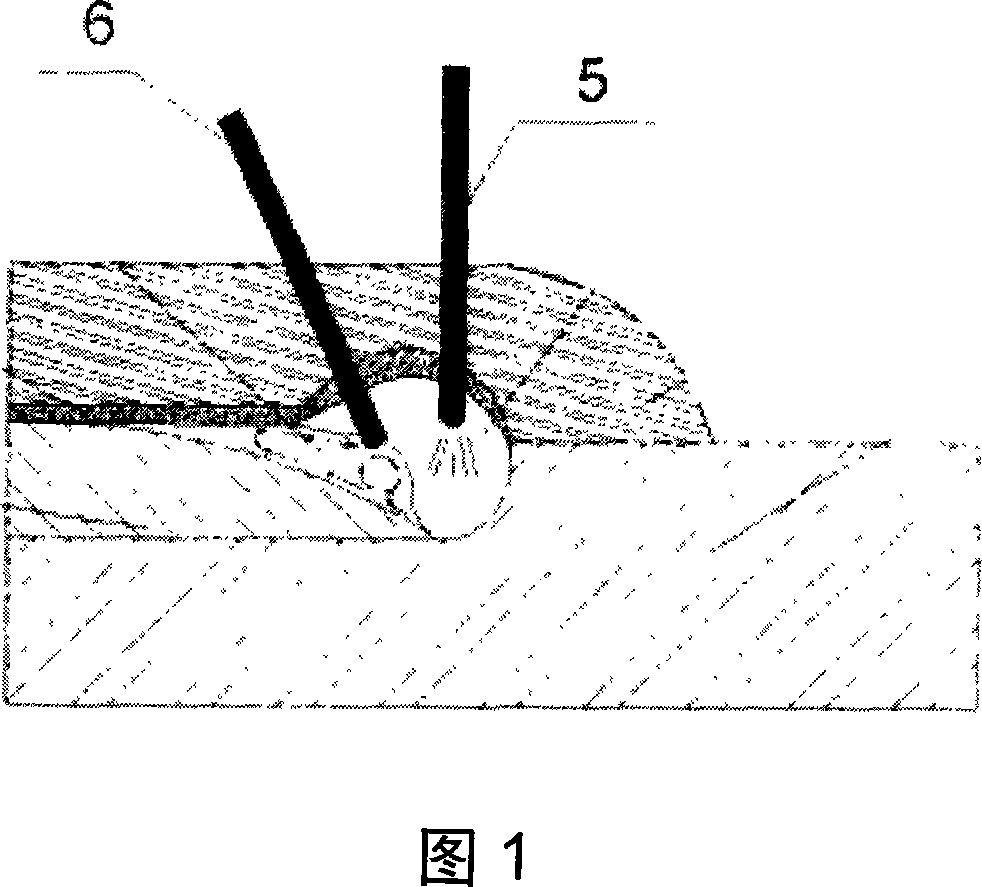

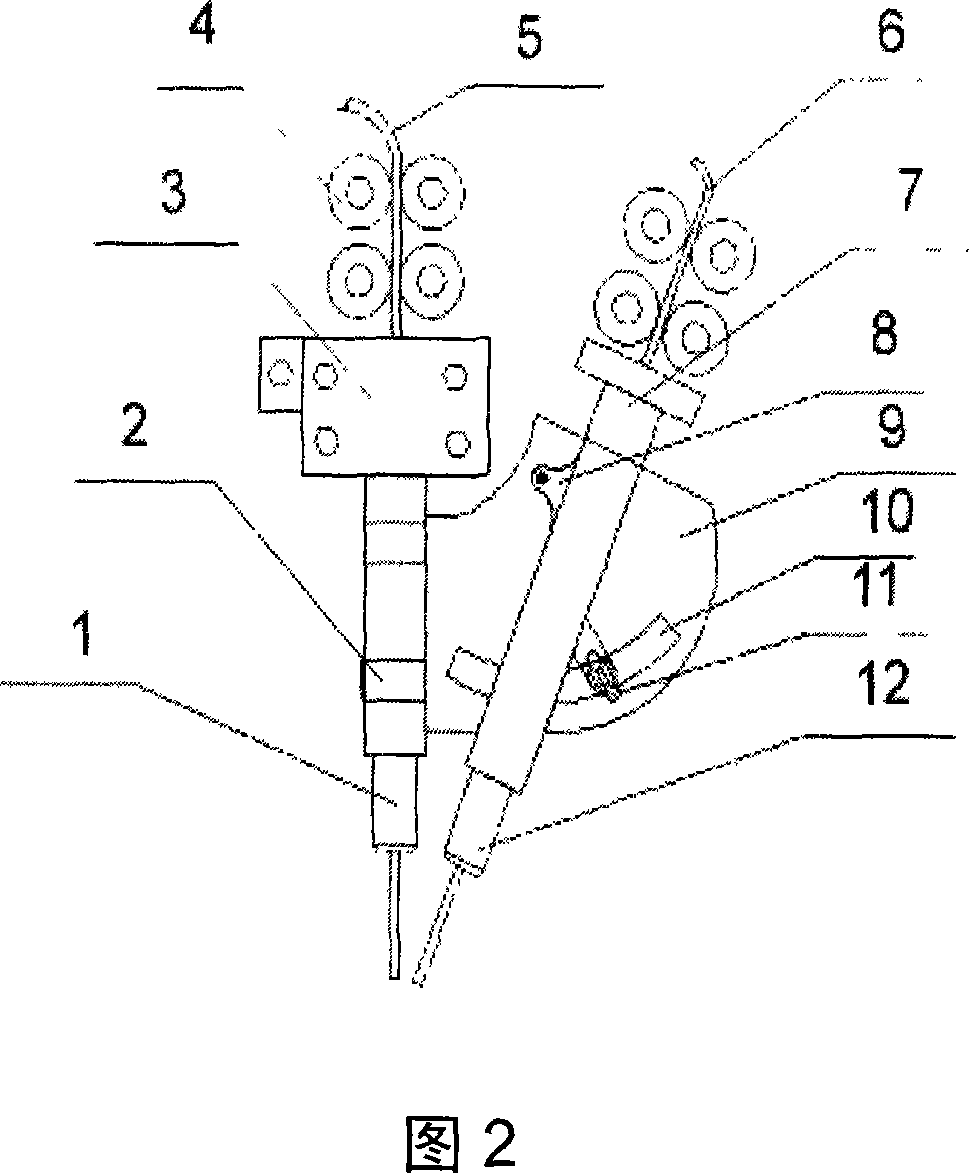

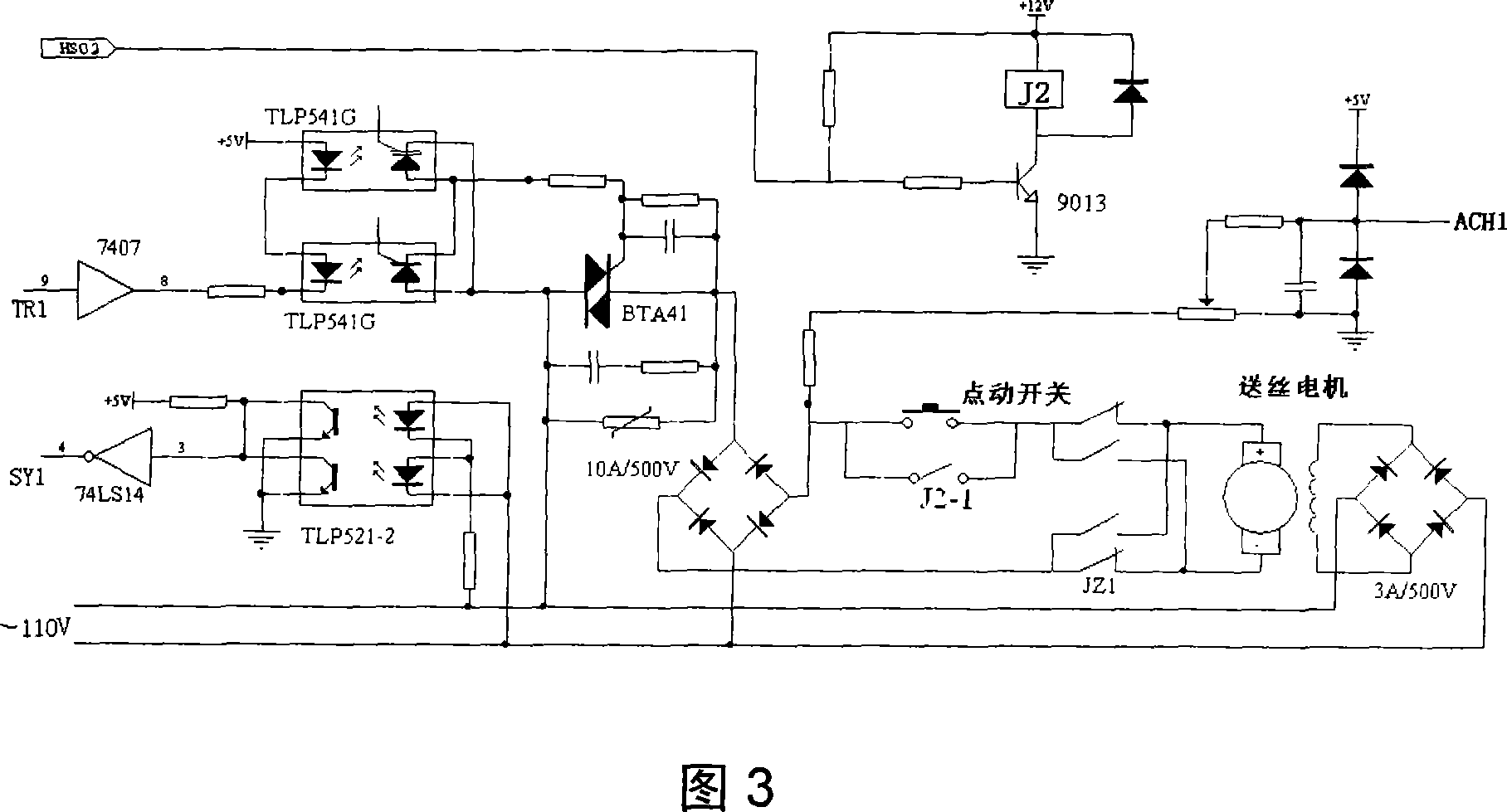

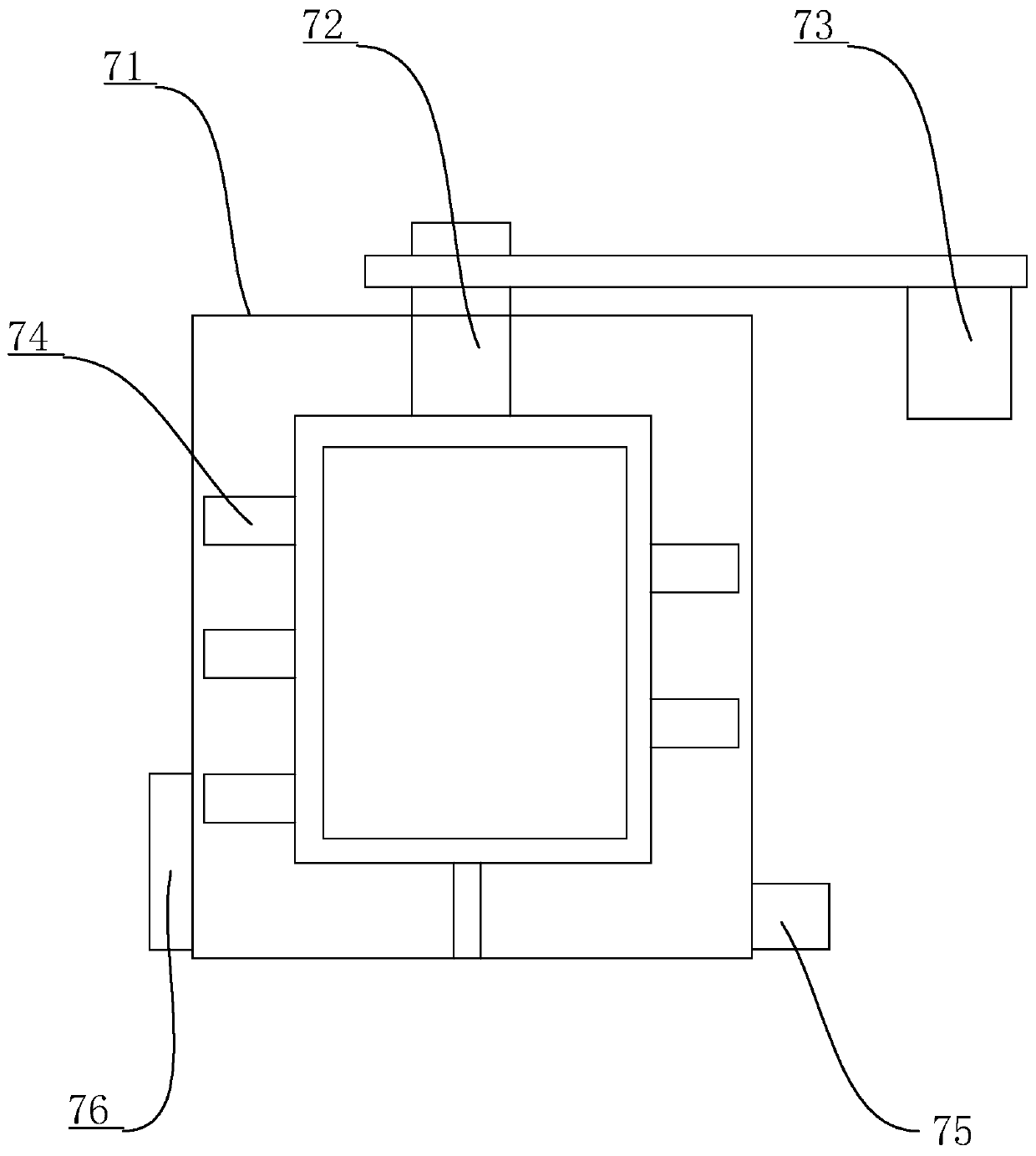

Cold wire submerged-arc welding method and device, control system and control method

InactiveCN101058126ANo softeningGood welding performanceArc welding apparatusMicrocontrollerControl system

The invention relates to a cold wire submerged arc welding method and control system, using a piece of cold wire inserted in to the overheated fuse pool, stuffing the central part of the high temperature fuse pool, the cold wire driven by the wire feeding wheel, sticking out from the positioning nozzle of the zigzag hose inside the positioning sleeve which sliding along the circumference with rotary subsidiary as the axis, the positioning plate installed on the fixed sleeve, control system made of two subsystems with same single chip machines, through RXD, TXD generating synchronic pulses, by determining the inserting location, cold wire stuffing inside the high temperature fuse pool center, flaming arc welding wire forming the fuse pool, timely collected welding current, electric arc voltage, determining the fuse pool length threshold value, and starting feeding the cold wire when the length of the fuse pool bigger than that of the fuse length threshold value.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

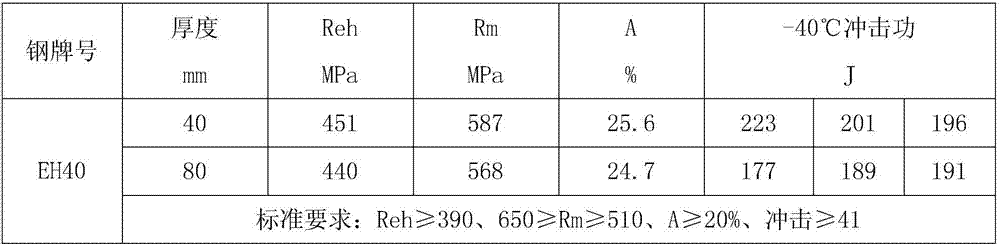

Production method for 40 kg class ship plate for large heat input welding

A production method for a 40kg-class large heat input welding ship plate, chemical composition: C0.07~0.11%, Si0.15~0.35%, Mn1.45~1.60%, Nb0.015~0.035%, Ti0.012~ 0.018%, Ni0.15-0.30%, Cu0.20-0.35%, Als0.015-0.040%, P≤0.020%, S≤0.005%, Ceq: 0.36-0.40%. Converter slag blocking and tapping, slag layer thickness < 100mm; vacuum treatment pressure holding or RH molten steel circulation time ≥ 10min; target superheat degree of tundish < 25°C; continuous casting slab stacking and slow cooling for 45-48h. The billet heating temperature is 1180-1220°C, and the time is 9-10min / cm; the second-stage rolling temperature is 760-800°C, the second-stage total reduction is >60%, and the final rolling temperature is 740-780°C. The water inlet temperature of ACC is 710-750°C, the cooling rate is 4-8°C / s, and the red return temperature is 550-620°C. Stacking slow cooling temperature 250 ~ 350 ℃, time ≥ 24 hours. The Reh of the ship plate of the present invention is 445MPa, the Rm is 577MPa, the elongation is 25.1%, and the average impact value at -40°C is 159J.

Owner:ANGANG STEEL CO LTD

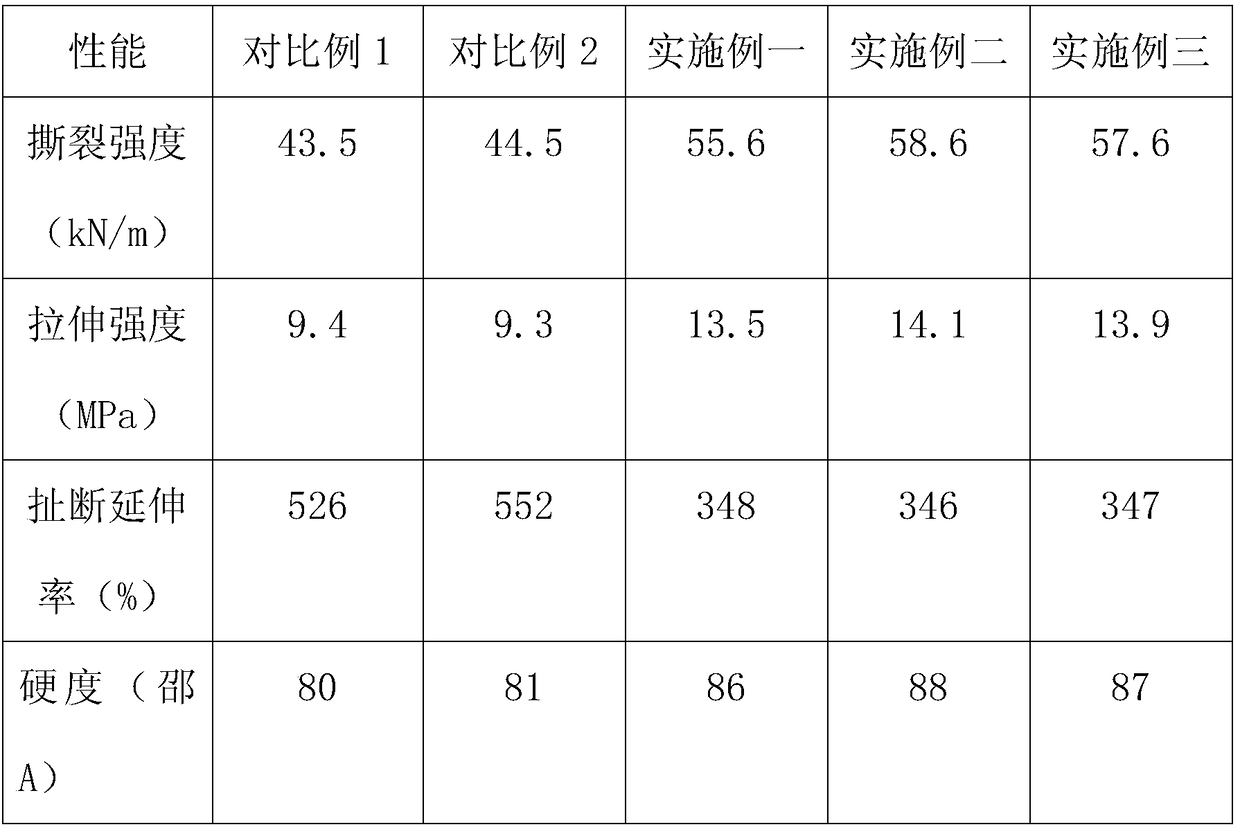

Sole material for high temperature resistant labor protection shoes

The invention relates to a material for manufacturing a labor protection article, in particular to a sole material for high temperature resistant labor protection shoes used in a high temperature environment. The material comprises the following components in portion by weight: 38.5 to 40.5 portions of butyronitrile, 7.6 to 8.2 portions of sulfur, 2.51 to 3.05 portions of accelerating agent DM, 11.3 to 13.1 portions of accelerating agent TMTD, 4.3 to 4.9 portions of zinc oxide, 1.8 to 2.2 portions of carbon black, 4.9 to 5.5 portions of calcium carbonate, 7.6 to 8.2 portions of stearic acid, 0.107 to 0.1198 portion of dibutyl phthalate, 0.38 to 0.60 portion of zinc stearate, 4.53 to 5.02 portions of coumarone resin, and 8.9 to 9.5 portions of magnesium oxide. The components of the materialare mixed reasonably; and actual detections show that a sole product manufactured by adopting a component formula of the material has good high temperature resisting capacity and can meet high temperature resistant use requirements.

Owner:JIANGSU PROVINCE PAIDENG SHOES IND

Water enviromental-protection paint for woodenware

The invention is a kind of water environment prevention woodware paint, which includes following ingredient: water acroleic acid latex, assistant, water. The weight shares of water acroleic acid latex is: ethyl ester, acroleic acid resin, acrylonitrile, propyl ester, QP-10:, N-acryamide, water. It hasn't any noxious gas, at the same time, it has excellent adhesive power, the paint film doesn't turn soft under 60deg.C, the rigidity is high and the impact resisting performance is good.

Owner:李兆珉

Hot-melt splicing adhesive tape

InactiveCN106800896AGood taping effectEasy to fixNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesRaw materialChemistry

The invention discloses a hot-melt splicing adhesive tape. The hot-melt splicing adhesive tape comprises a textured paper base material, a release layer and a hot melt adhesive layer, wherein the hot melt adhesive layer is prepared from the following raw materials in parts by weight: polyacrylate pressure-sensitive adhesive, diisocyanate, tackifying resin, a plasticizer and other auxiliary agents. The hot-melt splicing adhesive tape provided by the invention is very low in initial bonding property; when being heated for use, the hot-melt splicing adhesive tape can firmly stick metal pins, and the adhesive strength is more than or equal to 75N / in; the hot-melt splicing adhesive tape is easy in sticking and good in hydrolysis resistance. The hot-melt splicing adhesive tape gives full play to the oxidation resistance and anti-aging property of acrylate, and also can reach the very excellent high temperature resistance, high humidity resistance and anti-aging property even if an antioxidant is not added into the hot-melt splicing adhesive tap. The tensile strength of the hot-melt splicing adhesive tap is more than or equal to 100N / in, and the elongation at break of the hot-melt splicing adhesive tap is more than or equal to 10%. The polyacrylate pressure-sensitive adhesive used by the hot-melt splicing adhesive tape is synthesized in a way of overall copolymerization, so that the hot-melt splicing adhesive tape is simple in synthetic process and stable in quality.

Owner:HUIZHOU XINHAOYUAN DEV

Cementing material, and concrete suitable for plant growth

InactiveCN111302750AGuaranteed bond strength performanceDoes not produce strong basesCeramicwareSlagMining engineering

The invention discloses a cementing material, and concrete suitable for plant growth. The concrete comprises the following components in parts by mass: 50-80 parts of clay, 10-20 parts of fly ash, 5-10 parts of the cementing material as described in claim 1, 2-10 parts of sawdust, 2-8 parts of a fermented organic fertilizer, 0.1-1 part of calcium superphosphate and 0.1-2 parts of water-retaining resin, wherein the cementing material comprises 70% of gypsum, 20% of blast furnace slag and 10% of low-alkali sulphoaluminate cement. According to the concrete in the invention, a combination of the gypsum, the blast furnace slag and a small amount of the low-alkali sulphoaluminate cement is adopted to replace common Portland cement as the cementing material, so generation of strong alkali and useof rubber powder can be avoided, and the anti-scouring strength of the concrete is improved; a part of generated alkalinity can be consumed through a reaction of the fly ash, the blast furnace slag and a small amount of the low-alkali sulphoaluminate cement, so a neutral environment suitable for plant growth is created; and the strength of the vegetation concrete is improved through the synergistic effect of gypsum.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

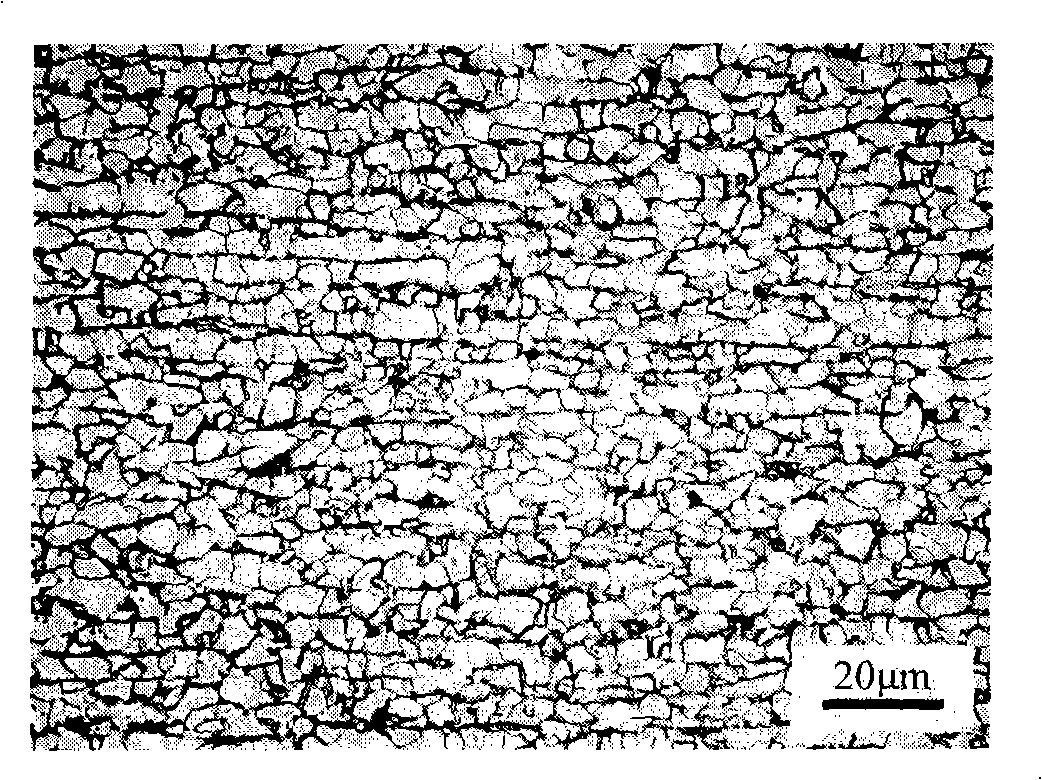

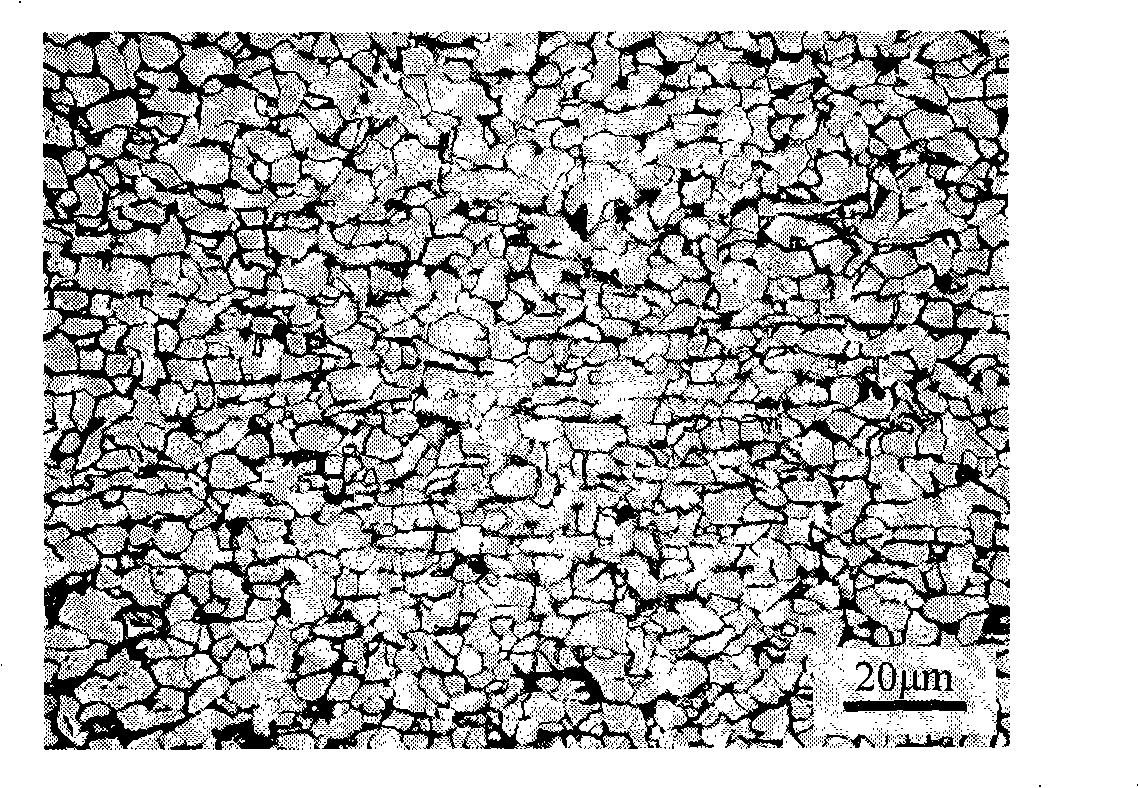

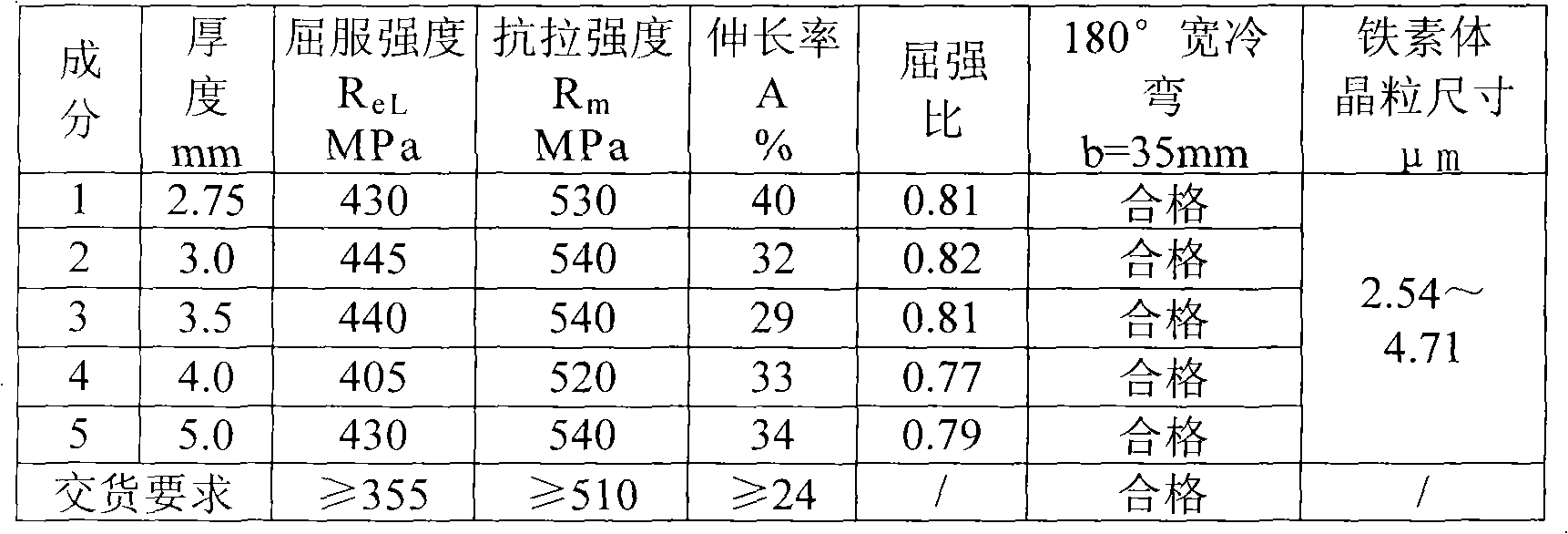

Production method of ultrafine microstructure hot rolling carbon steel strip with yield strength of 355MPa

InactiveCN101306433ASmall hardenability tendencyHigh strengthTemperature control deviceMetal rolling arrangementsChemical compositionLaminar cooling

The invention relates to a method for manufacturing a hot rolling carbon steel strip with 355Mpa-grade yield strength and ultrafine microstructure. The method includes five steps of slab heating, slab rough-rolling, slab precision-rolling, laminar cooling and coiling, wherein the slab heating temperature ranges from 1,080 DEG C to 1,120 DEG C; the outlet temperature of the slab rough-rolling ranges from 960 DEG C to 1,000 DEG C; the finishing rolling temperature ranges from 760 DEG C to 800 DEG C; the coiling temperature ranges from 450 DEG C to 800 DEG C; and the laminar cooling is controlled at a cooling rate of high than or equal to 20 DEG C / s. On the premise that the chemical composition and the production condition of the present carbon steel with approximately 200Mpa-grade remain almost unchanged, the method of the invention allows the carbon steel to be refined to a grain size of lower than 5 microns, and allows the yield strength of the steel to be increased to the 355Mpa-grade; the toughness of the steel plate is greatly improved, therefore, the carbon steel strip has good performance of shaping, welding and so on, and is widely applicable to the manufacture of the automobile structural member.

Owner:武钢集团有限公司

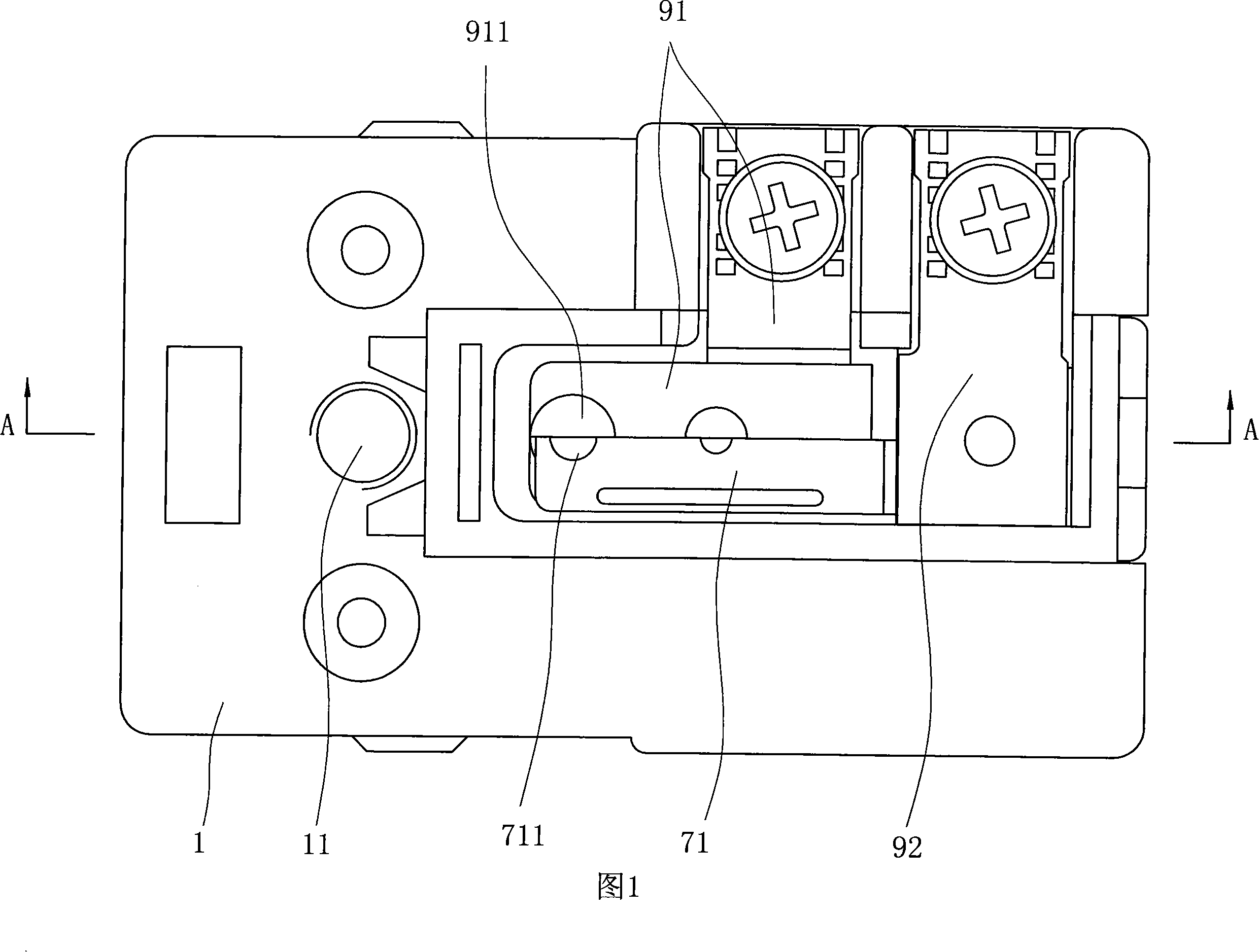

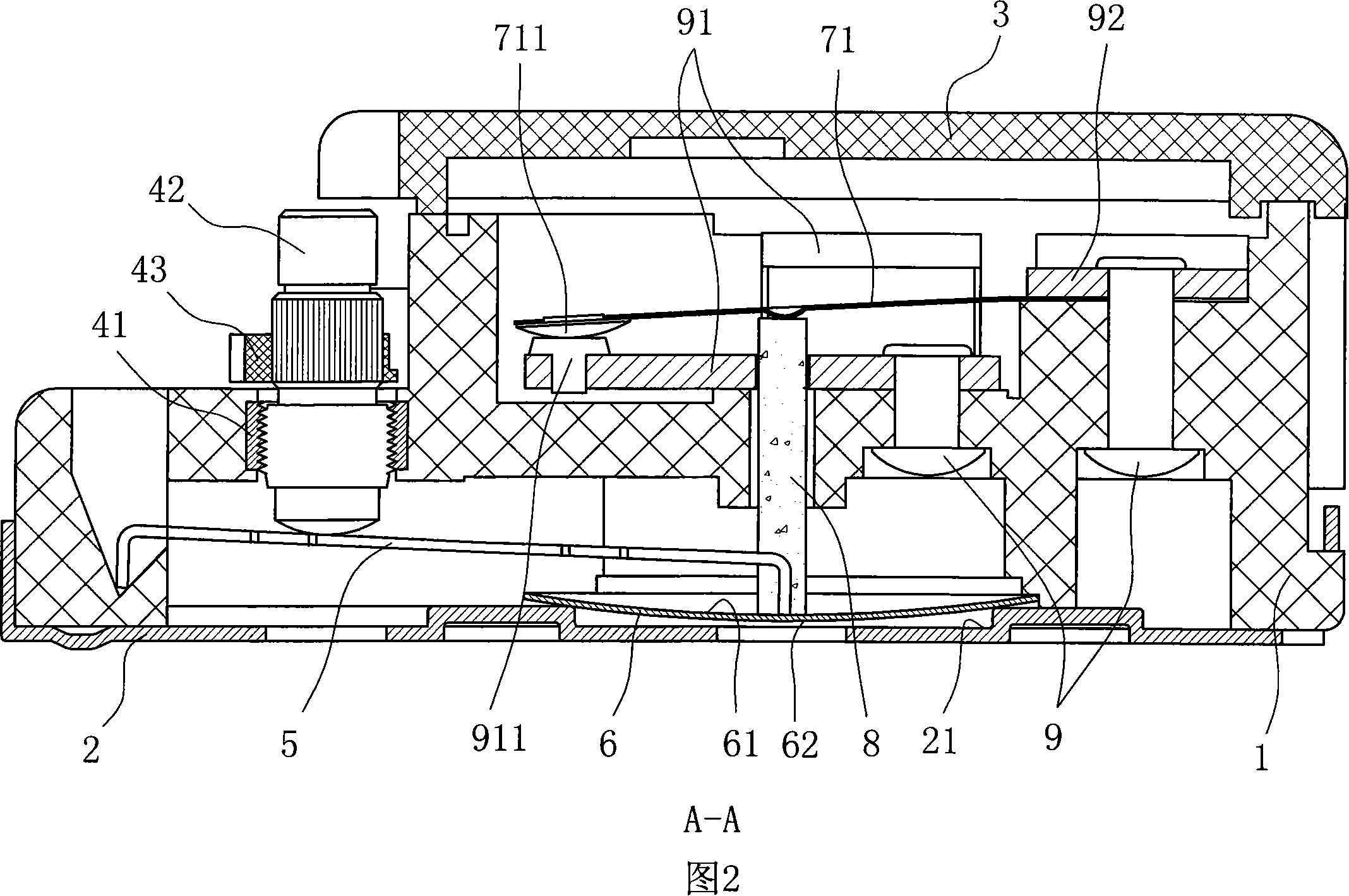

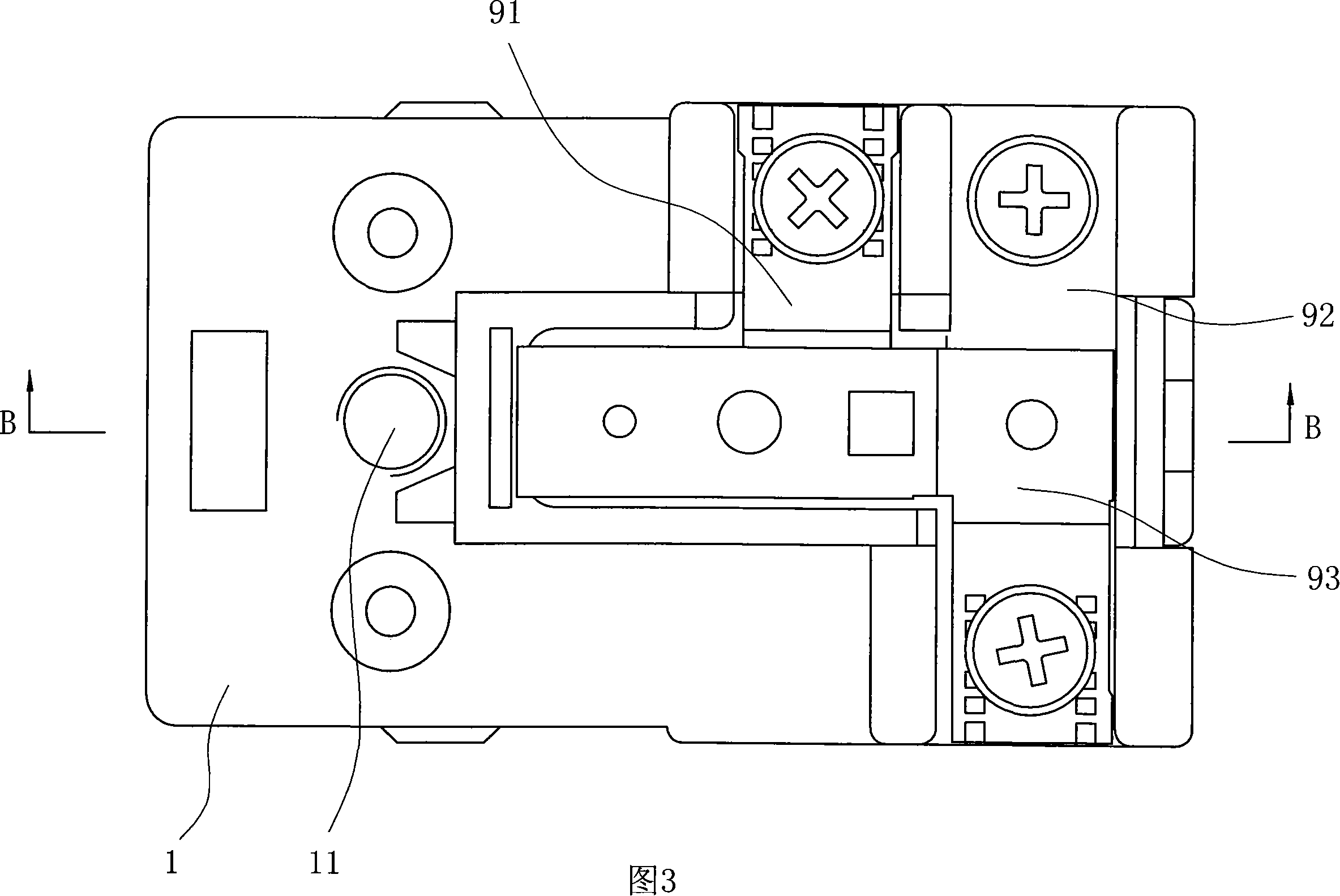

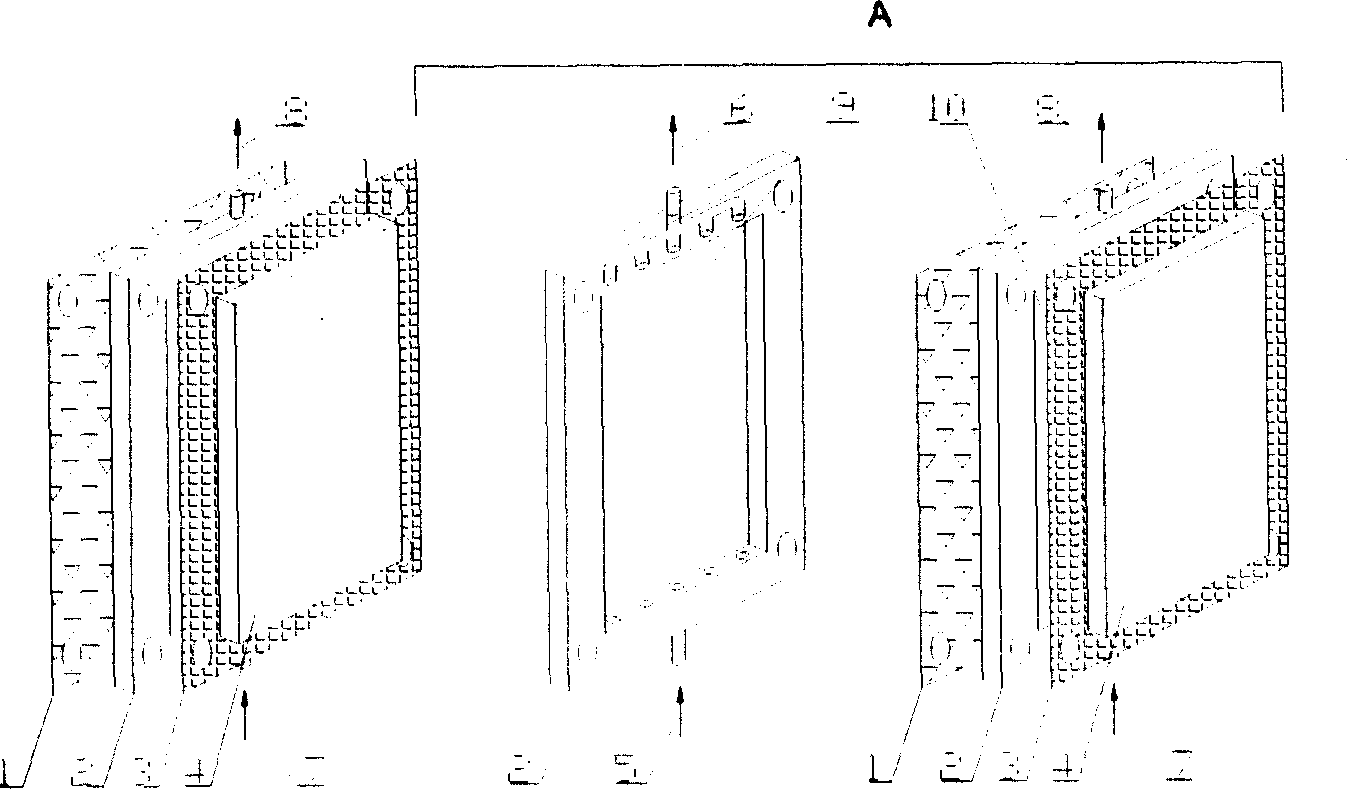

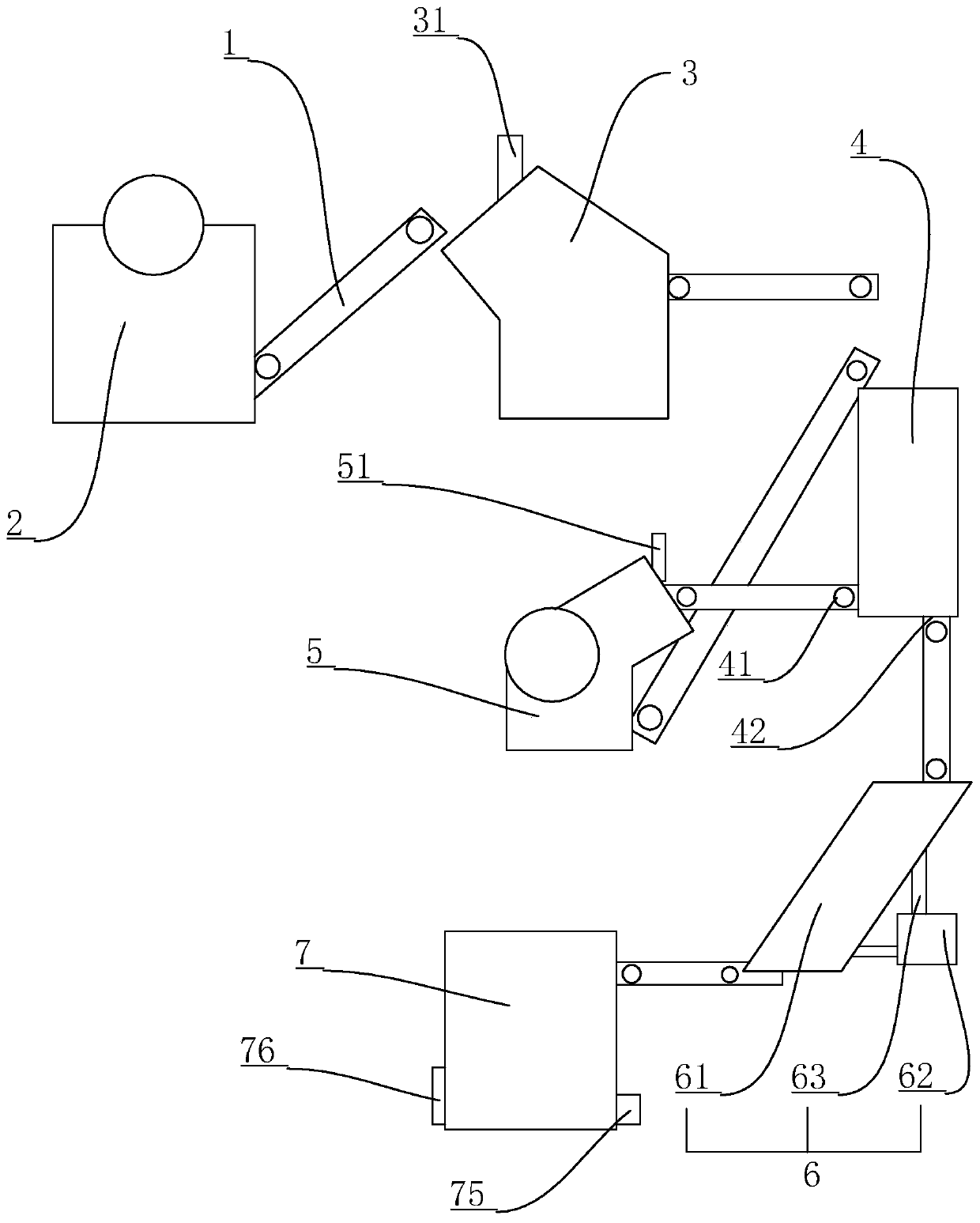

Adjusting temperature controller

InactiveCN101216713AHigh precisionLarge carrying working currentTemperature control without auxillary powerEngineeringThermostat

An adjustable thermostat comprises a shell (1) with a through hole (11), a temperature adjusting device with an adjusting screw (42) which is arranged in the through hole (11) and a link gear which is provided with a bimetallic strip (6) as a temperature sensing element. The adjustable thermostat is characterized in that the through hole (11) is provided with a metal nut (41) which matches with the adjusting screw (42) and an elastic temperature adjusting piece (5) which counterbalances the adjusting screw (42) at the tail; one end of the temperature adjusting piece (5) is fixed on the shell (1), and the other end is a moveable end which counterbalances the inner part of the central bending surface of the bimetallic strip (6). The invention applies pressure on the bimetallic strip via the temperature adjusting piece, and no current passes through the temperature adjusting piece so that no softening results; thereby improving the adjustment precision; a copper nut is embedded and fixed in the shell during the process of molding the shell, so that the cooper nut is integral with the shell and metal threads thereof are not prone to abrasion, thereby improving the service life of the product.

Owner:朱英年

Production technology of polypropylene building template

InactiveCN103012958AExcellent impact resistanceExcellent deformation resistanceForming/stuttering elementsConstruction engineeringProcess engineering

The invention provides a production technology of a polypropylene building template, which is the technology for producing the building template by adopting waste plastics as the raw materials. The production technology comprises the steps of pretreating the raw materials, mixing the materials, and carrying out extrusion molding. The raw materials are treated based on a certain ratio and prepared into the product building template under a certain condition. The product building template has the characteristics that the construction quality is high, the building template can be recycled for a plurality of times, the cost is reduced, the benefit is increased, the energy conservation and environment protection are realized, and the residues can be recycled; and the product building template has a large market demand and wide prospect, and is an excellent substitute for steel templates, bamboo plywood and wood plywood.

Owner:HUNAN FENGSHUO TECH

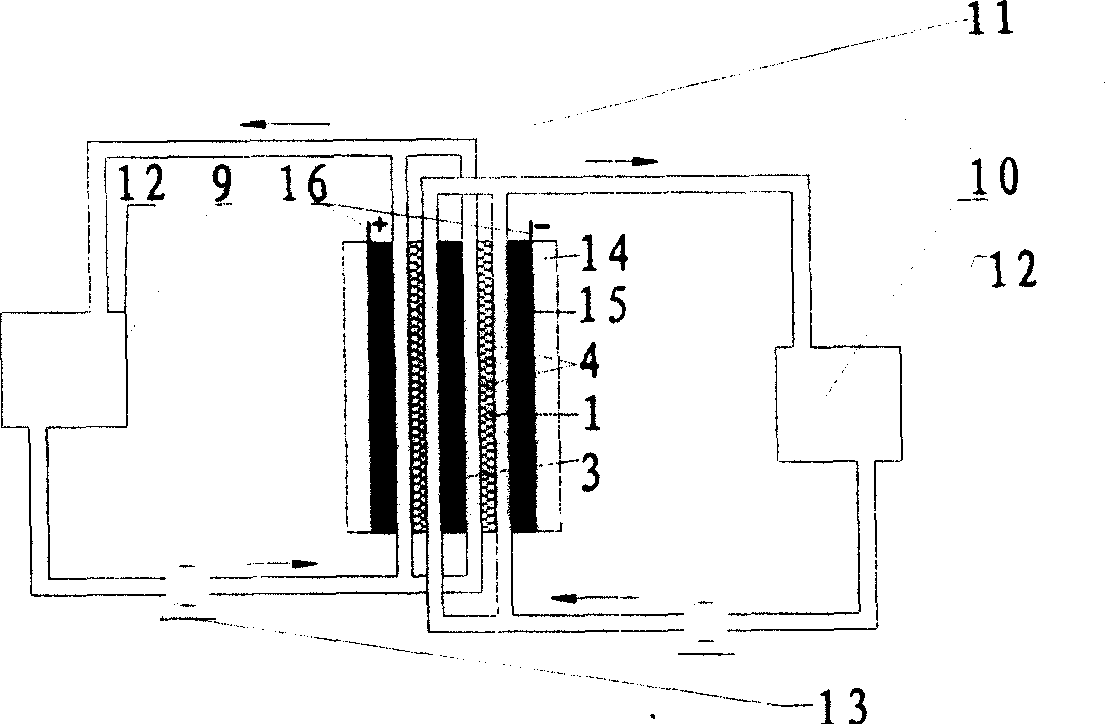

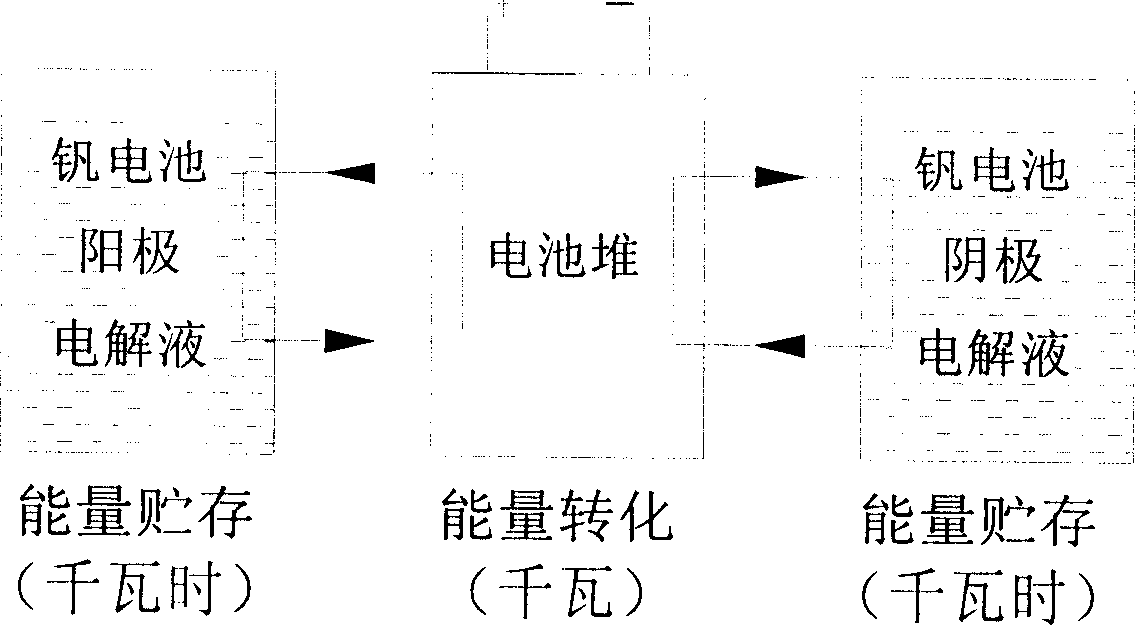

Vanadium ion liquid flow accumulator battery

InactiveCN1848506ARenewable energyNo softeningFinal product manufactureRegenerative fuel cellsVanadyl ionPhysical chemistry

The present invention relates to a vanadium ion fluid-flow battery. Said invention is characterized by that on the electrochemical principle it uses liquid vanadium ion as active substance, and makes the vanadium ions with different valences produce oxidation reduction reaction to store or release electric energy.

Owner:フォンリエレクトリックグループカンパニーリミテッド

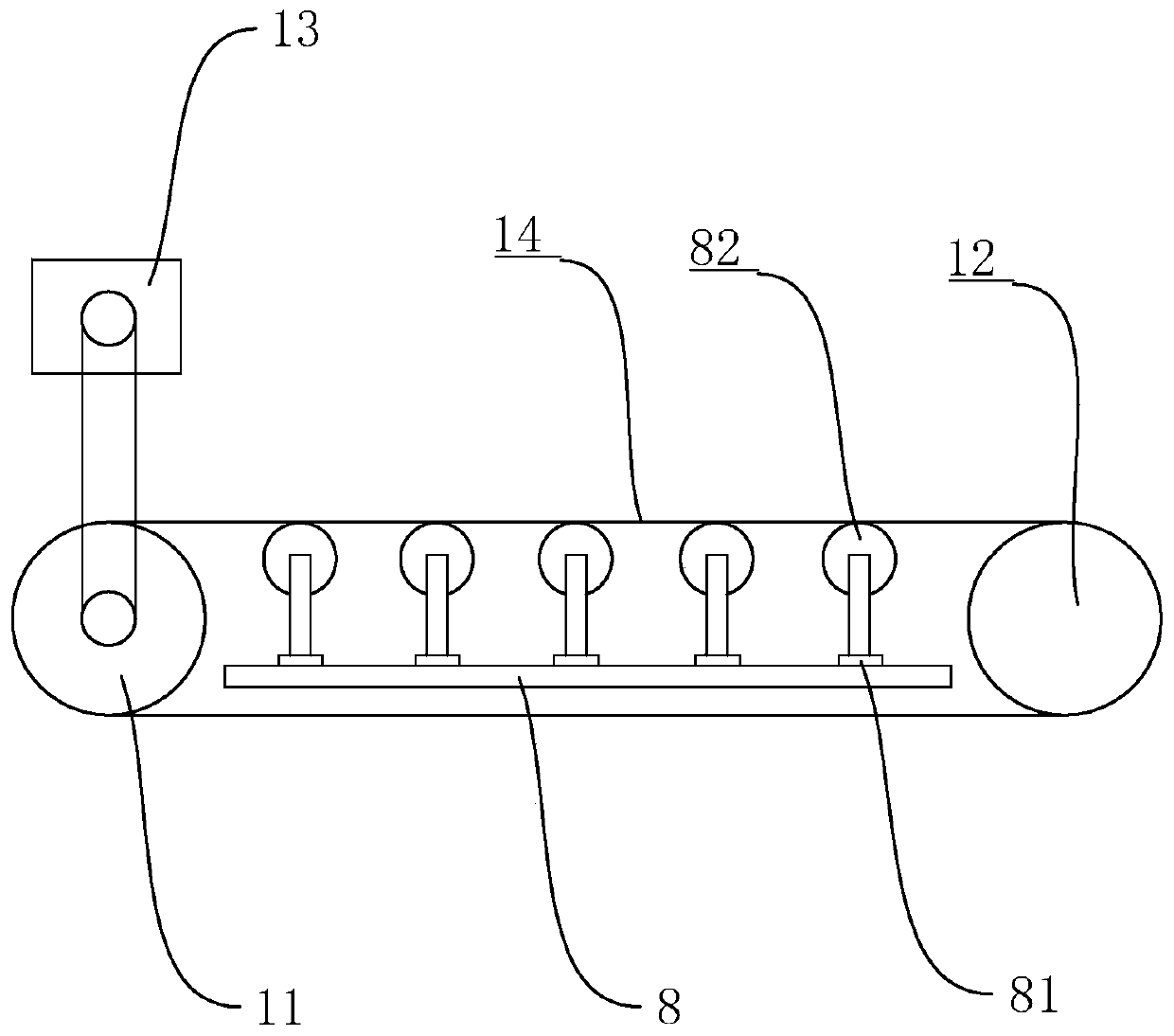

Waste asphalt pavement material separation and regeneration treatment system and processing technology thereof

InactiveCN110512504AImprove utilization efficiencyLow costRoads maintainenceInterference fitMotor drive

The invention discloses a waste asphalt pavement material separation and regeneration treatment system and a processing technology thereof, and relates to the technical field of old asphalt treatment.According to the key points of the technical scheme, the waste asphalt pavement material separation and regeneration treatment system includes crushing equipment, coarse stripping equipment, screening equipment, fine stripping equipment, drying equipment, fine grinding equipment and a conveying device, wherein a first high-pressure water sprayer is arranged above the coarse stripping equipment, adischarge port of the fine stripping equipment is connected with a feed port of a vibrating screen, the fine grinding equipment includes a shell, a central shaft arranged in the shell, a motor driving the central shaft to rotate and a plurality of hammers fixedly connected with the central shaft, the conveying device includes a driving roller, a driven roller, a driving motor driving the drivingroller to rotate and a transmission belt arranged on the outer surface of the driving roller and the driven roller in sleeving and interference fit modes. The advantages that the utilization efficiency of the waste asphalt pavement materials is improved, the cost of recycling is reduced, and the application scope is expanded are achieved.

Owner:济南通达公路工程有限公司

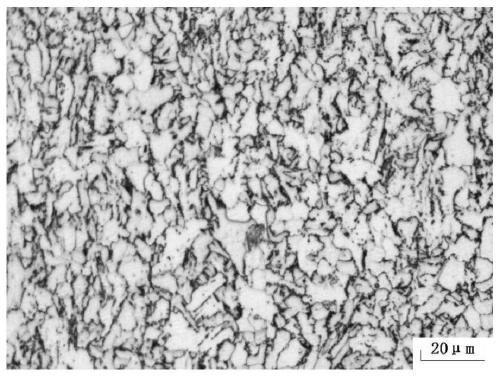

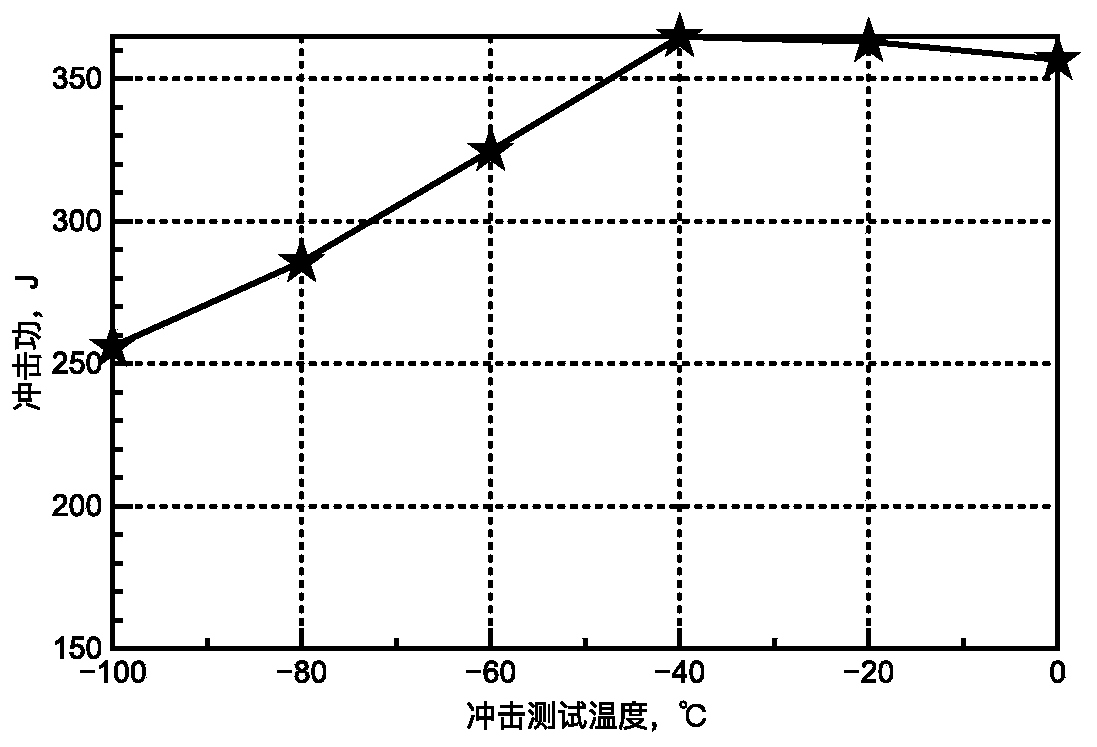

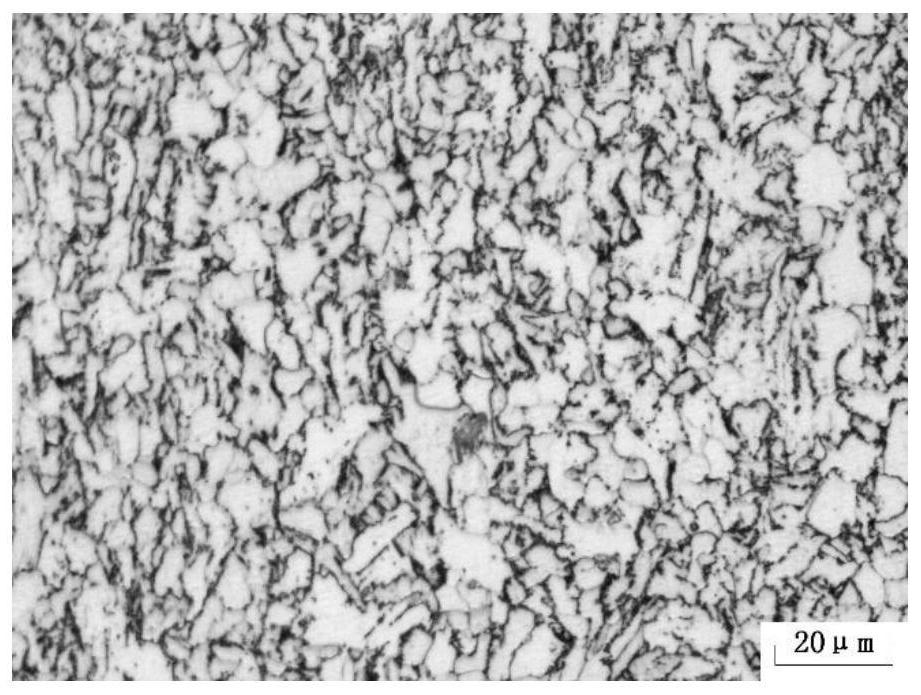

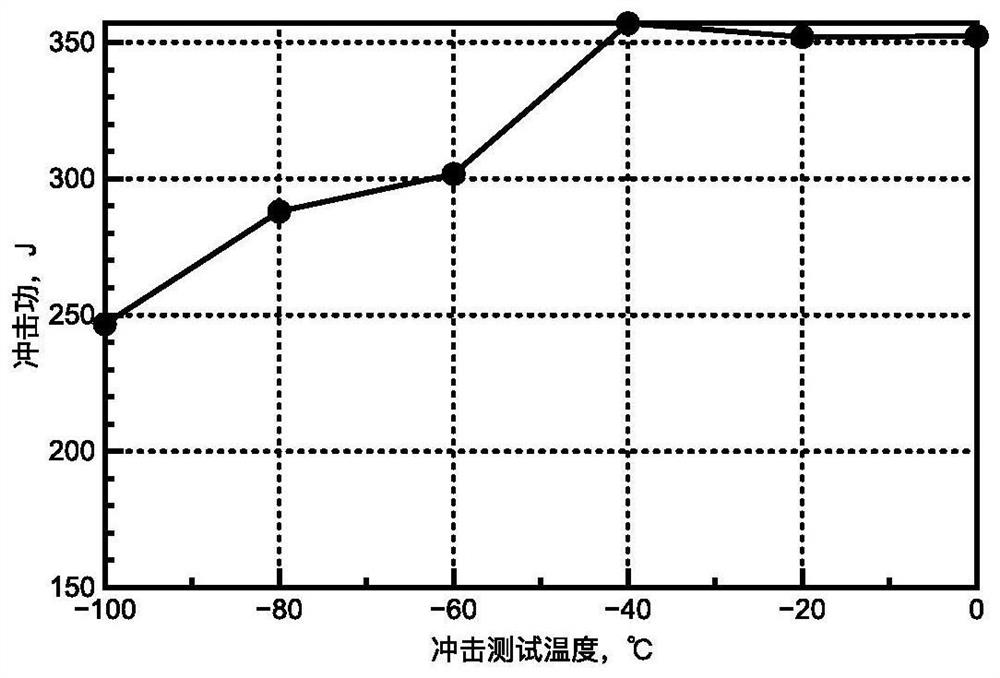

390 MPa-grade polar hull structural steel with low-temperature toughness and preparation method of 390 MPa-grade polar hull structural steel

ActiveCN111155022ASimple production processImprove organizationProcess efficiency improvementHull structureFiber

The invention relates to 390 MPa-grade polar hull structural steel with low-temperature toughness and a preparation method of the 390 MPa-grade polar hull structural steel, and belongs to the technical field of microalloyed steel. The steel and the method are used for solving the problems that an existing steel type cannot meet the polar environment temperature use condition and the production cost is high. The method comprises the following steps that 1, molten iron pretreatment is carried out; 2, high-quality scrap steel is added, a converter is adopted for smelting, Al is adopted in a steelladle for deep deoxidation, and ferrocolumbium is added after deoxidation; 3, alloying treatment is carried out; 4, whole-process protection pouring is adopted in the continuous casting process, thesuperheat degree of molten steel is guaranteed to range from 10 DEG C to 30 DEG C, the casting speed is controlled to range from 0.6 m / min to 1.5 m / min, and the strength of secondary cooling water isadjusted so that the temperature of the molten steel can range from 920 DEG C to 970 DEG C; and 5, controlled rolling and controlled cooling are carried out, and the polar hull structural steel is prepared. According to the hull structural steel prepared through the method, the yield strength is larger than or equal to 390 MPa, the impact energy at the quarter position of -100 DEG C is larger thanor equal to 200 J, the impact fracture fiber rate is larger than or equal to 80%, and the hull structural steel can be used for building ships serving in polar regions.

Owner:CENT IRON & STEEL RES INST

Mixed gas shielded welding process for ensuring strength of precipitation strength high-strength steel joint

InactiveCN102658416AEasy to Procure and RealizeEasy to implementArc welding apparatusPrecipitationWelding process

The invention discloses a mixed gas shielded welding process for ensuring the strength of a precipitation strength high-strength steel joint, which belongs to the technical field of high-strength steel welding. In the process, precipitation strength high-strength steel of which the tensile strength is over 600MPa is welded by adopting technologies such as mixed gas shielded welding, single-sided welding double-sided shaping and the like. The mixed gas shielded welding process has the advantages that: the widths of a welding heat influencing region and a softening region can be reduced, the hardness of the heat influencing region is ensured, the loss of welding joint strength is lowered, the joint strength loss is controlled within 40MPa, and using requirements are met.

Owner:SHOUGANG CORPORATION

Pulsed flashing butt welding method for 780Mpa-grade hot-rolled dual-phase wheel steel

PendingCN112605512AReduce splashNo thinningResistance welding apparatusMetallurgyMechanical engineering

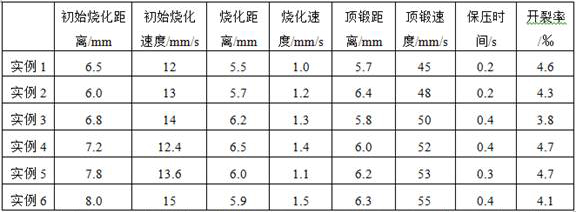

The invention discloses a pulsed flashing butt welding method for 780Mpa-grade hot-rolled dual-phase wheel steel. The thickness of a rim is 4.0-4.5 mm. The pulsed flashing butt welding comprises a pulsed flashing stage and an upsetting stage; in the pulsed flashing stage, the initial burning distance is selected to be 6-8 mm, the initial burning speed is selected to be 12-15 mm / s, the burning distance is 5.5-6.5 mm, and the burning speed is 1.0-1.5 mm / s; and in the upsetting stage, the upsetting distance is 5.7-6.4 mm, the upsetting speed is 45-55 mm / s, and the holding time is 0.2-0.4 s. According to the method, under the conditions of low splashing and high efficiency, the ultra-lightweight wheel rim without thinning and softening and with a high-quality welding joint can be obtained, and the welding cracking rate is controlled within 0.5%.

Owner:HANDAN IRON & STEEL GROUP +1

Ice-temperature fresh-keeping method for lotus seeds and lotus seeds kept fresh

PendingCN110973232AEfficient killingMeet the requirements of green productionFruits/vegetable preservation by freezing/coolingModified atmosphereHorticulture

One aspect of the invention provides an ice-temperature fresh-keeping method for lotus seeds and lotus seeds kept fresh. The fresh-keeping method includes the following steps: 1) performing sterilization: immersing the lotus seeds in electrolyzed oxidizing water for sterilization; 2) performing color protection and fresh keeping: immersing the lotus seeds treated in the step 1) in a color-protecting fresh-keeping solution, and performing drying; 3) performing ice burying: putting the lotus seeds treated in the step 2) in a modified atmosphere packaging bag filled with electrolyzed oxidizing water ice; 4) performing gas flush packaging: introducing modified atmosphere fresh-keeping gas into the modified atmosphere packaging bag in the step 3); and 5) performing ice-temperature storage: performing ice-temperature storage on the packaged lotus seeds. The method provided by the invention is used for keeping freshness of the fresh lotus seeds, under the condition of -1 DEG C to -3 DEG C, the product can be kept fresh for at least 5 to 6 months or even 6 months or more, lotus seed skin has no obvious browning or no softening phenomena in the fresh keeping stage, and the lotus seeds haveno softening phenomena, do not generate odor, and meet relevant health standards of fruit and vegetable products.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation technology for New Year cake

The invention discloses a preparation technology for a New Year cake. The preparation technology comprises the following steps: S1, washing raw material rice, conveying to a rice soaking bucket, adding chlorine dioxide water solution to sterilize, and dredging out impurities floated on the water surface; S2, draining off the sterilized raw material rice, feeding into a pulping machine for pulping,adding sodium chloride, and uniformly stirring, to obtain rice pulp; S3, sending the rice pulp to a plate-frame filter press for filter-pressing, to obtain a solid filtering block, and smashing, to obtain crushed raw flour; S4, steaming the crushed raw flour thoroughly, until the total raw flour is completely cooked, extrusion-forming while hot, to obtain a semi-finished product of the New Year cake, and cooling; S5, enabling the cooled semi-finished product of the New Year cake to be placed in an aging library, aging, and delivering from the library; and S6, slicing the aged semi-finished product of the New Year cake, packaging, sterilizing, and cooling, to obtain the New Year cake. The New Year cake prepared by the preparation technology does not contain any preservatives and the like,and is long in quality guarantee period. In a storage process, cracking and yellowing phenomena do not occur.

Owner:ZHEJIANG WUFANGZHAI INDAL

An alkali-resistant heatproof glass material and a preparation method thereof

ActiveCN103833220AGood alkali resistanceSmall coefficient of thermal expansionHeat stabilityGlass material

The invention relates to an alkali-resistant heatproof glass material and a preparation method thereof. The alkali-resistant heatproof glass material comprises following components by weight: 5-7 parts of TeO2, 4-9 parts of K2O, 12-13 parts of SiO2, 4-9 parts of PbO, and 2-3 parts of Y2O3. The glass material is prepared by steps of smashing raw materials, screening, smelting at high temperature, annealing, and the like. The prepared glass material has good alkali resistance and heat stability and can prevent glass product deformation caused by alkali solution corrosion and overhigh temperature so that the glass product can be used for a long time.

Owner:JIANGSU AOLAN ARCHITECTURE GLASS

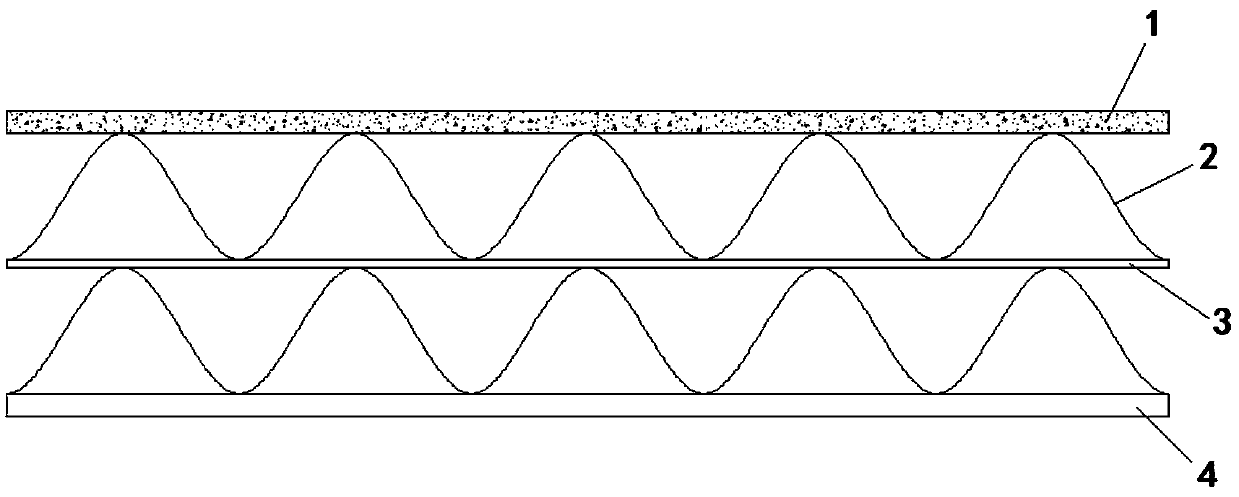

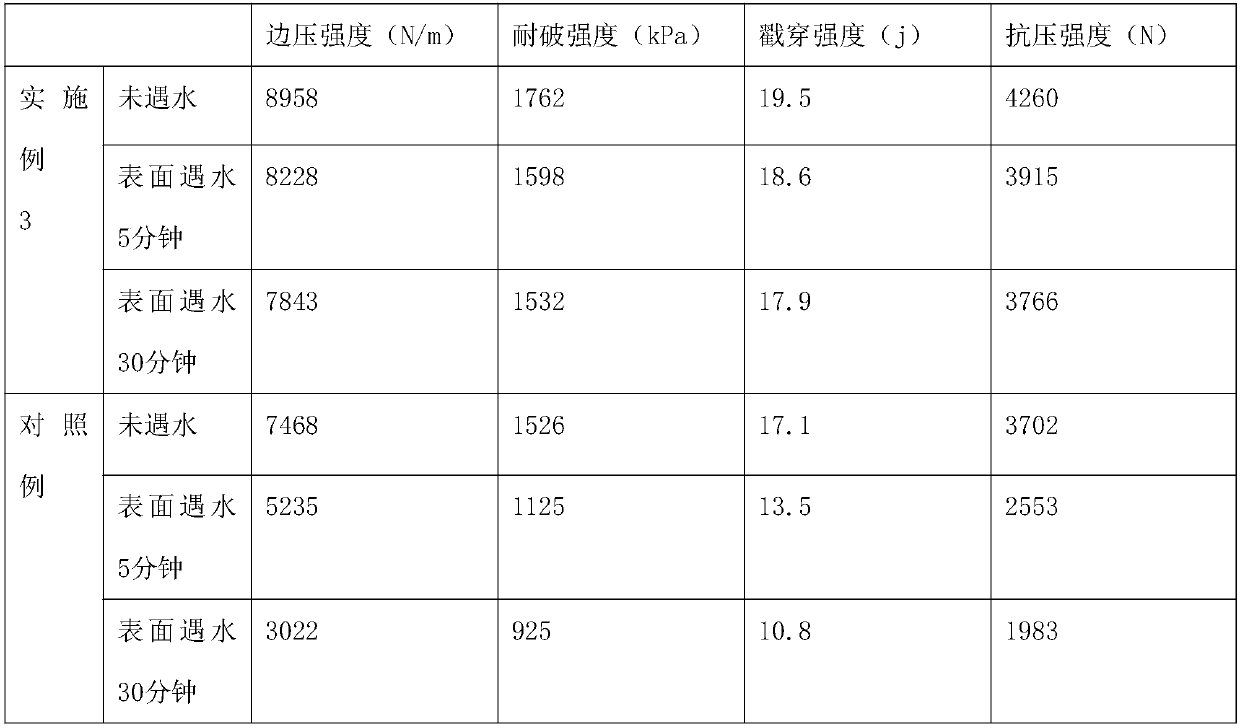

Corrugated cardboard core material

InactiveCN107892786AHigh strengthStrong service lifeNon-macromolecular adhesive additivesSpecial paperCarboxymethyl-chitosanBauxite

The invention discloses a corrugated cardboard core material which includes the raw materials in parts by weight: 50-80 parts of modified natural rubber, 15-30 parts of cis-1,4-polybutadiene rubber, 5-8 parts of nitrile rubber, 5-15 parts of a thermoplastic elastomer SIS, 5-8 parts of ethoxylated alkyl phenol ammonium sulfate, 3-5 parts of rosin based resin acid, 2-5 parts of polyether polyol, 12-20 parts of carbon black, 8-15 parts of C9 petroleum resin, 5-8 parts of tricaprate, 5-10 parts of polydiphenylmethane diisocyanate, 2-5 parts of carboxymethyl chitosan, 2-5 parts of zinc oxide, 2-6 parts of sodium based bentonite, 2-5 parts of bauxite, 1-2 parts of sepiolite fibers, 5-8 parts of a sericin solution, 3-5 parts of epoxidized soybean oil, 2-8 parts of stearic acid, 4-8 parts of a plasticizer, 2-5 parts of an accelerant, 6-12 parts of a softener, 2-5 parts of a toughening agent, and 10-15 parts of a vulcanizing agent. The core material adopts reasonable raw material and proportion, and all the components are complementary with each other and have synergistic effect, so that the prepared core material has the advantages of strong anti-aging property, high temperature resistanceand long service life.

Owner:BENGBU SHENHUI COLOR PRINTING & PACKAGING LIMITED

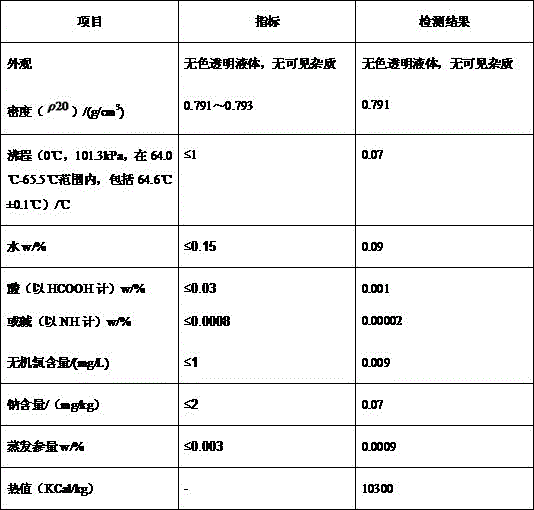

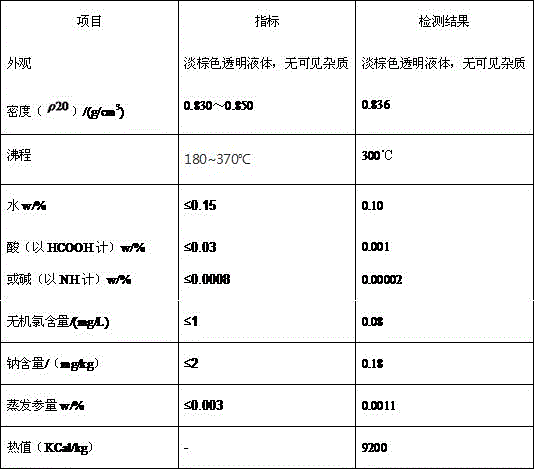

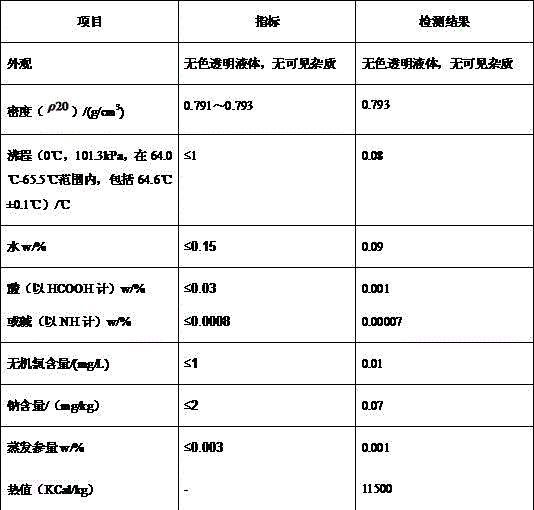

Novel multi-purpose environment-friendly methanol-based alternative fuel and preparing method thereof

InactiveCN106281482AIncrease the calorific value of combustionStable combustionLiquid carbonaceous fuelsFuel additivesAlternative fuelsAutomotive engine

The invention discloses a novel multi-purpose environment-friendly methanol-based alternative fuel and a preparing method thereof and belongs to the field of alcohol ether alternative fuel. The novel multi-purpose environment-friendly methanol-based alternative fuel is prepared from, by mass, 85-95 parts of methanol, 5-15 parts of a heat value regulator, 0-5 parts of a combustion stabilizing agent, 0-5 parts of a combustion improver, 0-5 parts of a thickening curing agent, 0-5 parts of a water-proof agent and 0-5 parts of a corrosion inhibitor. The novel multi-purpose environment-friendly methanol-based alternative fuel has the advantages of being large in methanol proportion, long in waterproof stable phase, and high in heat value and power performance; the cold staring performance, air resistance tolerance, low corrosion and rubber swelling prevention performance are superior to those of traditional methanol fuel, and the six existing problems hindering use and popularization of methanol gasoline for a long time are solved. The cost is low, and good economic benefits, social benefits and environmental benefits are achieved. The novel multi-purpose environment-friendly methanol-based alternative fuel is applied to boilers, automobile engines and other various occasions, and can be stably combusted for a long term, use equipment such as automobile engines does not need to be transformed, and the fuel can be directly used. The fuel is stored in a solid state, so that transportation is convenient, and use is safer.

Owner:刘前国

Lithium ion power battery and preparation method therefor

InactiveCN107706388AExcellent charge and discharge rateImprove cycle lifeMaterial nanotechnologyFinal product manufacturePower batteryCarbon nanotube

The invention discloses a lithium ion power battery and a preparation method therefor. A positive electrode plate of the lithium ion power battery consists of iron disulfide, carbon nanotubes, lithiumcobalt oxide, graphite and tin carbonate; and a negative electrode plate of the lithium ion power battery consists of lithium titanate, nanometer metal particles and a binder. The preparation methodprovided by the invention is simple and the prepared lithium ion power battery is excellent in rate charging and discharging, long in cycle life, and high in electrochemical performance and safety.

Owner:BEIJING JUNXIU CONSULTATION CO LTD

Persimmon de-astringency method

The invention discloses a persimmon de-astringency method. The persimmon de-astringency method comprises the following steps: putting astringent persimmons into a container; adding mashed dropped persimmons and uniformly mixing the astringent persimmons with the mashed dropped persimmons; adding water until the water immerses the mixed persimmons; and immersing the mixed persimmons for 20-35 hours to finish de-astringency, wherein the weight ratio of the astringent persimmons to the mashed dropped persimmons is 100 to (30-40). According to the method, the dropped persimmons are used for carrying out the de-astringency on the astringent persimmons so that wastes are reutilized and resources are effectively saved; meanwhile, the adverse effects caused on a human body by the fact that people eat fruits subjected to de-astringency performed by a chemical reagent are avoided; the de-astringency time is short; the persimmons subjected to de-astringency are crispy as well as delicious and tasty, do not soften within the storage period of 6-8 days; the whole method is simple and easy to operate and low in cost.

Owner:唐飞

Preparation method of carbon-carbon composite material with high thermal conductivity

ActiveCN102504770BImprove stabilityImprove thermal conductivityHeat-exchange elementsCarbon compositesFiber

A preparation method of a carbon-carbon composite material with high thermal conductivity comprises the following steps: parallelly arranging mesophase asphalt-based carbon fibers in a flat plate, uniformly spreading a layer of condensed polynuclear aromatic hydrocarbon resin powder on the mesophase asphalt-based carbon fibers, heating the resin powder for fully melting so as to coat a resin film layer on the fiber surface, naturally cooling to obtain a carbon fiber preform; or dissolving the condensed polynuclear aromatic hydrocarbon resin by an organic solvent to prepare a solution, soaking the mesophase asphalt-based carbon fibers in the solution, completely volatilizing the solvent to form a resin layer on the fiber surface so as to obtain the carbon fiber preform; cutting the carbon fiber preform into thin sheets according to a desired dimension, orderly stacking the sheet-like carbon fiber preform in a mold, performing pressurization to 20-70 MPa, heating to 110-145 DEG C, performing depressurization, maintaining for 0.5-2 hours, heating again to 200-300 DEG C, curing for 1-6 hours, after curing, naturally cooling to room temperature for demolding, performing carbonization at 900 DEG C of the obtained cured sample, soaking the sample with asphalt at a soaking temperature of 340-400 DEG C for soaking time of 1-8 hours, repeating the carbonization-soaking cyclic process to increase the sample density to 1.5-1.7 g / cm3, and performing graphitization to prepare the carbon-carbon composite material with high thermal conductivity. The invention has the advantages of low energy consumption and high thermal conductivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A kind of 390mpa class polar hull structural steel with low temperature toughness and preparation method thereof

ActiveCN111155022BSimple production processImprove organizationProcess efficiency improvementHull structureMolten steel

Owner:CENT IRON & STEEL RES INST

Preparation method of double-faced transmission tooth-wedge belt

The invention discloses a preparation method of a double-faced transmission tooth-wedge belt. The preparation method is characterized in that double-faced transmission tooth-wedge belt is prepared from the following raw materials in parts by weight: 120 to 140 parts of ethylene-propylene rubber, 15 to 20 parts of non-cellulose fiber, 5 to 8 parts of staple fiber, 15 to 20 parts of chloroprene rubber, 15 to 20 parts of ultra-high molecular weight polyethylene, 3 to 5 parts of a binding agent, 1 to 3 parts of a vulcanizing agent, 1 to 3 parts of a crosslinking agent, 0.5 to 0.8 part of an auxiliary crosslinking agent, 1 to 5 parts of a reinforcing agent, 1 to 5 parts of a softening agent, 3 to 5 parts of an accelerant, 1 to 5 parts of a dispersant, 2 to 5 parts of a lubricant, 1 to 20 partsof organic filler, 1 to 20 parts of nano inorganic filler, 1.3 to 1.7 parts of a flame-retarding auxiliary agent, 1.3 to 1.7 parts of a flame-retarding synergist, 1 to 3 parts of a flame retardant, 1to 3 parts of a thermal stabilizer and 1 to 3 parts of carbon black. The preparation method of the double-faced transmission tooth-wedge belt has the advantages that components are reasonable, the method is simple, a wedge belt is produced by utilizing a mould and the method is simple and rapid, has good integrity and high yield and is suitable for popularization and application.

Owner:NINGBO GUL TZ RUBBER BELT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com