Patents

Literature

492results about How to "No adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet curing transfer adhesive

InactiveCN101942277AReduce consumptionImprove yieldOrganic non-macromolecular adhesivePolyesterOligomer

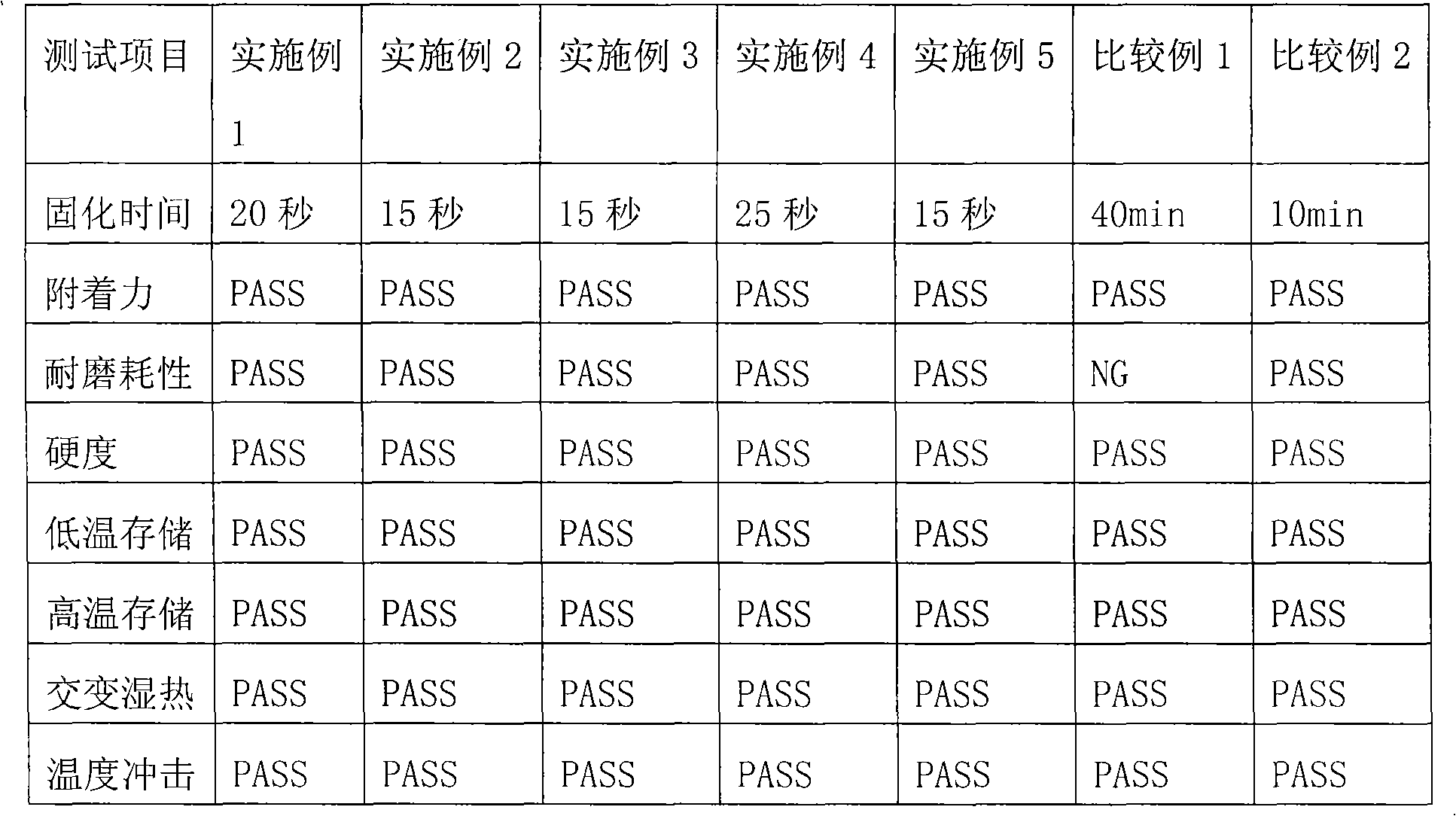

The invention discloses an ultraviolet curing transfer adhesive. The adhesive comprises the following components in percentage by weight: 45 to 67 percent of oligomer, 30 to 52 percent of activated monomer, 2 to 4 percent of free radical photoinitiator, and 1 to 3 percent of auxiliary, wherein the oligomer is one or more of epoxy acrylic ester, urethane acrylate and polyester acrylate; and the activated monomer is one of acrylic ester of a mono-functional group, a bifunctional group or a polyfunctional group. The ultraviolet curing transfer adhesive can form patterns with various shapes, can be cured at the room temperature in 20 seconds, can greatly reduce energy consumption, improve yield, is more suitable for continuous production, can improve the production efficiency, and has stable and reliable performance and high environmental protection property in the high-temperature high-dampness environment.

Owner:东莞市贝特利新材料有限公司

High oil absorption resin and synthetic method thereof

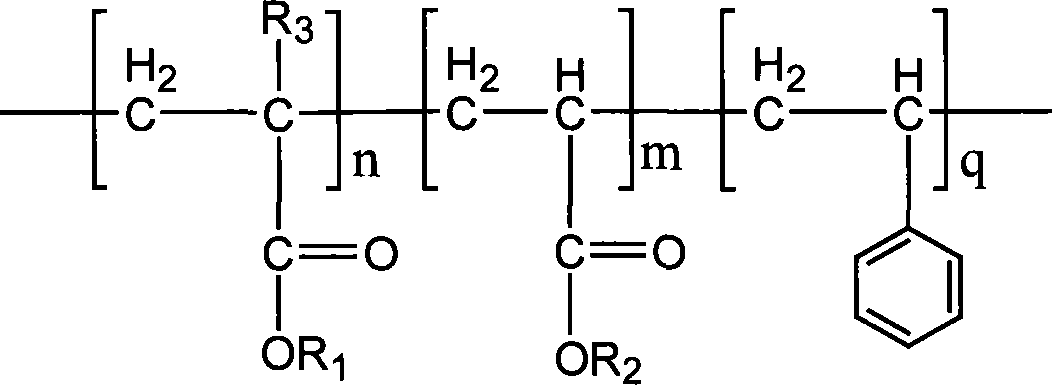

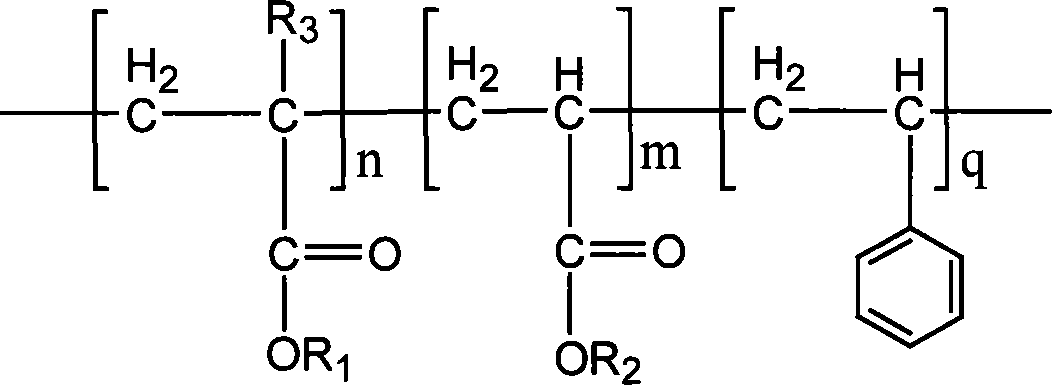

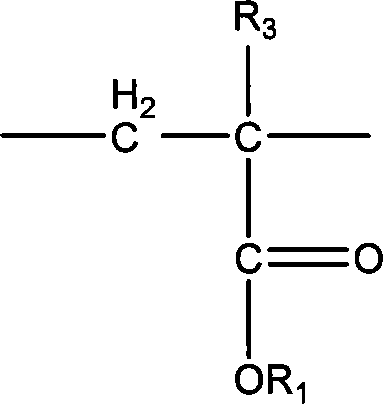

The invention discloses a high oil absorbing resin, and a process for preparation comprises utilizing short-chain ester of (metyl group) acrylic acid, long-chain ester of acrylic acid and styrene monomer to be monomers, adding dispersing agent and surface active agent, and getting through suspension polymerization and random copolymerization under the condition of the existence of cross linker and initiating agent. The process for synthesizing has lithe time consumption, which can be industrialized, and high oil absorbing resin which is got has high oil absorbing efficiency, fast oil absorbing speed, and which can be recycled to be repeatedly used.

Owner:SUZHOU TIMELYBLUE ENVIRONMENTAL TECH

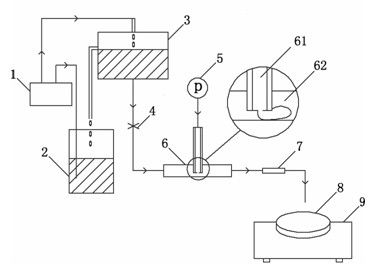

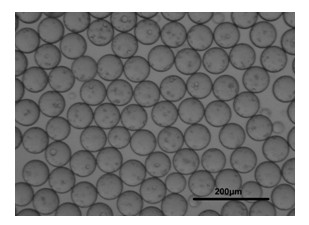

Detachable T-shaped microchannel device and method for preparing monodisperse polymer microspheres by same

InactiveCN102211008AEasy to unblockNarrow particle size distributionPharmaceutical non-active ingredientsChemical/physical/physico-chemical processesOrganic solventMicrosphere

The invention discloses a detachable T-shaped microchannel device and a method for preparing monodisperse polymer microspheres by the same. The method comprises the following steps of: performing heat treatment on a needle tube serving as a disperse phase flowing channel, and processing a duct with the same outer diameter as the needle tube on a pipeline serving as a continuous phase flowing channel to make the disperse phase needle tube and the continuous phase tube form a T-shaped channel; under the stable operating condition, making dispersed fluid form uniform micro liquid drops at a T-shaped tube orifice through the shearing force of continuous phase fluid to the disperse phase fluid; and under the action of a shaker, diffusing an organic solvent out of the liquid drops, and curing the liquid drops to form the polymer microspheres with uniform particle size. The T-shaped microchannel device is simple in equipment and can be detached, and pipelines are easy to dredge after being blocked; and the prepared polymer microspheres have uniform particle size, the particle size distribution coefficient of less than 15 percent, the minimum particle size distribution coefficient of 3 percent, and smooth surfaces without adhesion.

Owner:ZHEJIANG UNIV

Nanometer medicament microspheres

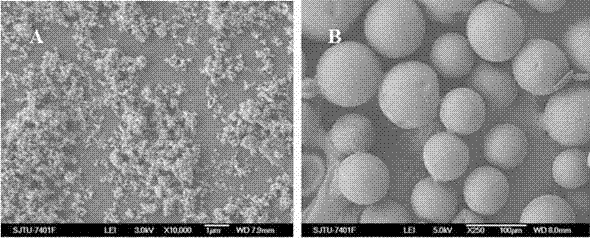

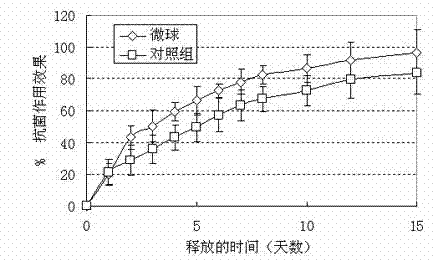

InactiveCN102885783AHigh encapsulation efficiencyImprove adhesionPharmaceutical non-active ingredientsGranular deliveryControlled releaseCell adhesion

The invention discloses nanometer medicament microspheres. The microspheres comprise a medicament, nanoparticles, a polymer and medicinal auxiliary materials. The invention further provides a preparation method of the nanometer medicament microspheres. The method comprises the following steps of: preparing a medicament and medicinal auxiliary materials into a nanometer medicament; adding the nanometer medicament into a polymer-containing organic solvent mixed solution for emulsifying; adding a nanometer medicament-in-oil mixed suspension into a water mixed suspension containing nanoparticles or containing nanoparticles and a surfactant for emulsifying to obtain an oil-in-nanoparticle mixed suspension-nanometer medicament-in-oil compound emulsion; and curing the obtained compound emulsion, and centrifugally collecting microspheres, wherein the obtained microspheres comprise the medicament, nanoparticles, the polymer and the medicinal auxiliary materials. An appropriate polymer material and an appropriate microsphere preparation method are selected, the prepared microspheres have high envelop rate, and a layer of self-assembled nanoparticles on the surfaces of the microspheres has the effects of improving cell adhesion and reducing inflammation and microencapsulation caused by local excessive acid and hydrophobic materials. The method disclosed by the invention can be applied to preparation of other medicament slow release or controlled release microspheres.

Owner:JINSHAN HOSPITAL FUDAN UNIV

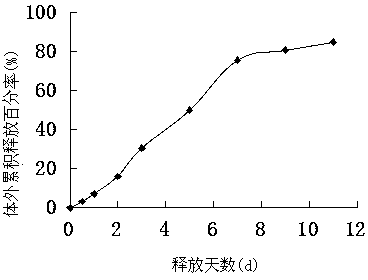

Polypeptide drug sustained-release microsphere preparation and preparation method thereof

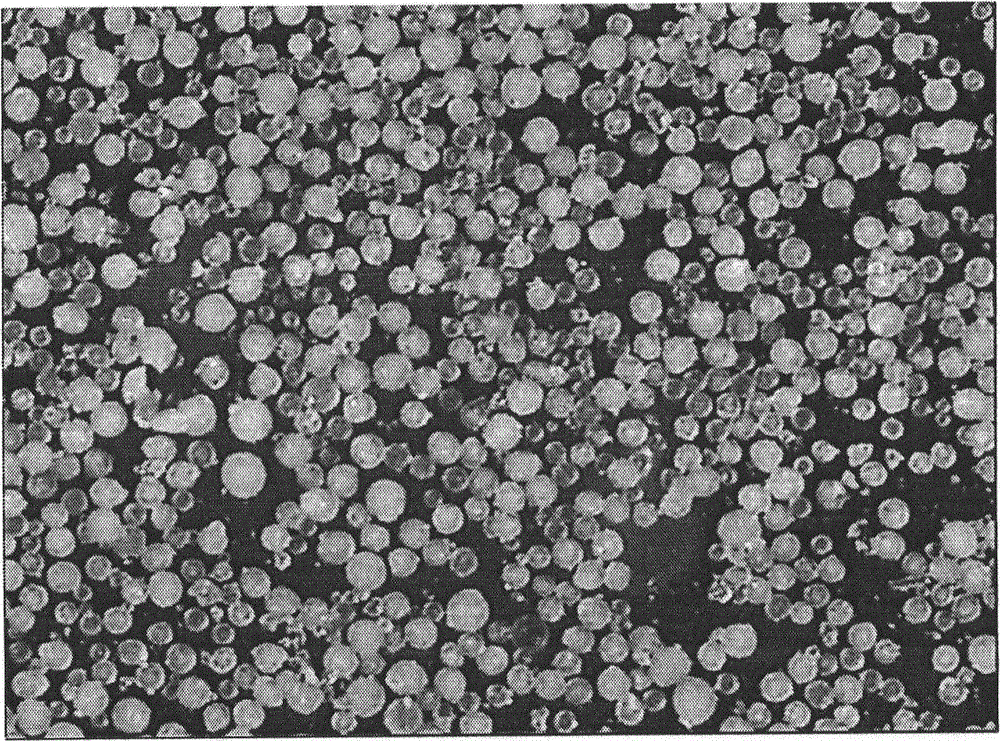

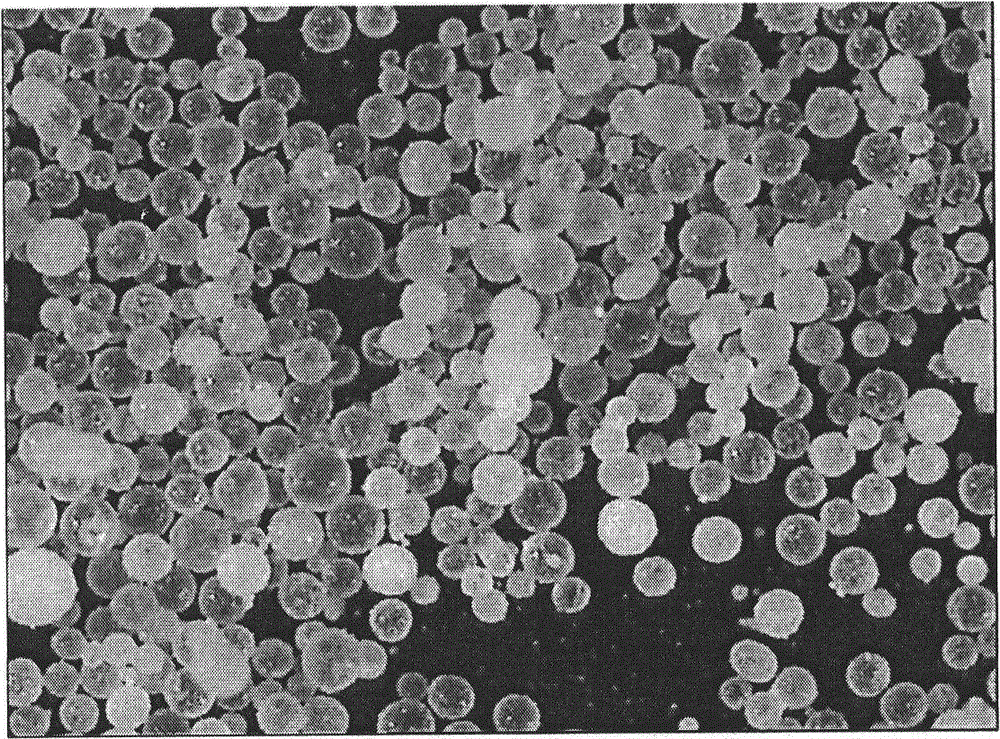

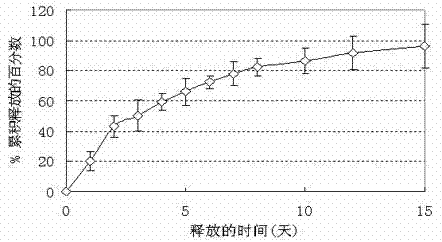

ActiveCN102688198AUniform particle sizeNarrow particle sizePeptide/protein ingredientsMetabolism disorderFreeze-dryingMicrosphere

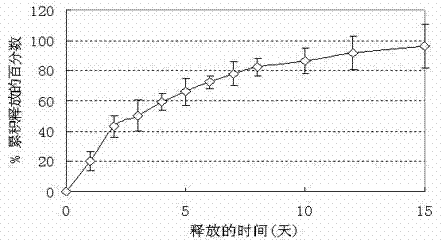

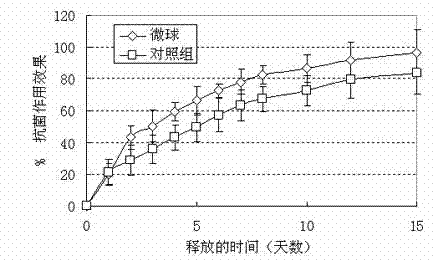

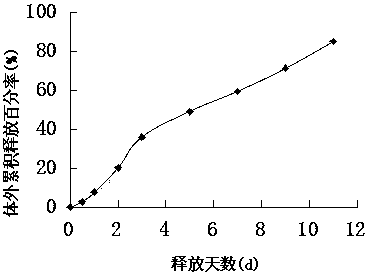

The invention discloses a polypeptide drug sustained-release microsphere preparation and a preparation method thereof. The method comprises the following steps of: dissolving the polylactic acid-glycollic acid copolymer or polylactic acid, a protective agent and a polypeptide drug in an organic solvent to form a completely uniform mixed solution; adding the mixed solution into an oil phase to form emulsion; removing the organic solvent; and performing centrifugal washing and freeze drying to obtain the polypeptide drug sustained-release microsphere. In the invention, an O / O method is adopted, the problem that the drug spreads toward the outer aqueous phase in the multiple-emulsion preparation method is solved, and the drug encapsulation efficiency is improved to 60-95%. The biological active polypeptide drug is degraded in the body and slowly released with the polymer material of the microsphere through the pores on the microsphere surface; the release time can be as long as several weeks and even several months; and the in-vitro release test indicates that the release conforms to similar zero-order release.

Owner:AC PHARMA CO LTD

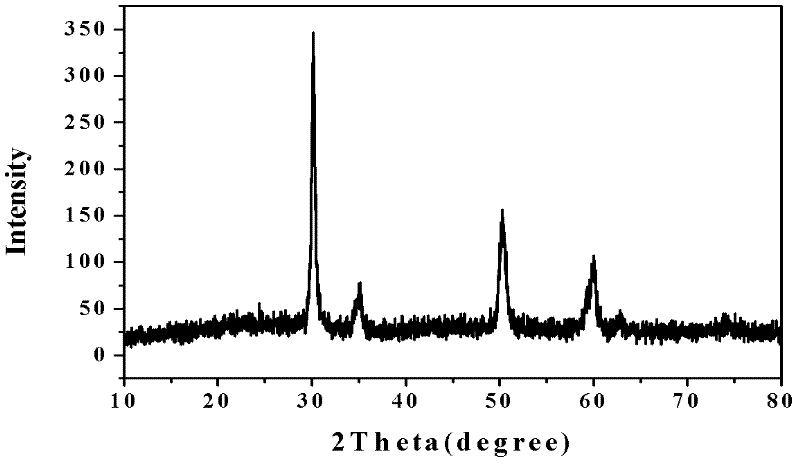

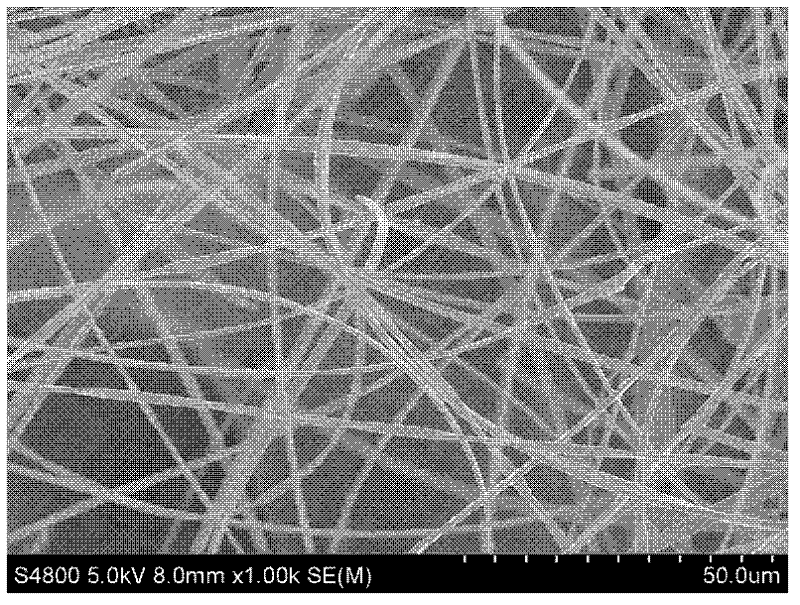

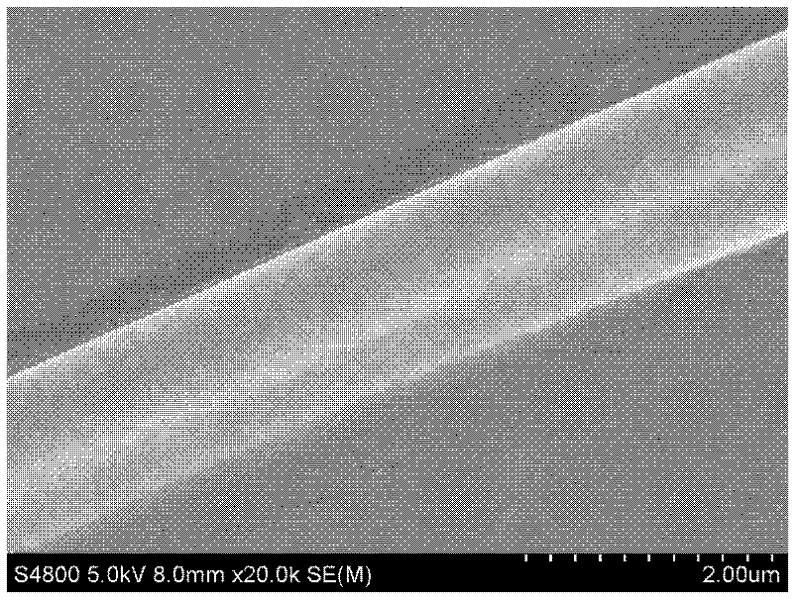

Flexible yttrium stable zirconium oxide ceramic fiber and preparation method thereof

The invention relates to a flexible yttrium stable zirconium oxide ceramic fiber and a preparation method thereof. The particle diameters of zirconium oxide particles constructing the ceramic fiber are 10-400 nanometers, the diameter of the ceramic fiber is 0.5-3 mum, and the fiber is uniform and continuous, is prevented from being broken easily and has high flexibility. A zirconium oxide gel fiber is prepared by combining a sol-gel method with an electrostatic spinning technology, and the yttrium stable zirconium oxide ceramic fiber is obtained by calcining the gel fiber. The obtained yttrium stable zirconium oxide ceramic fiber has high thermal stability and excellent mechanical property, can be taken as a high-temperature catalyst carrier, a high-temperature heat insulating material aswell as a battery membrane, and can be applied to high-temperature filtering and the like. A process disclosed by the invention has high operability, and is suitable for large-scale production.

Owner:SHANDONG UNIV

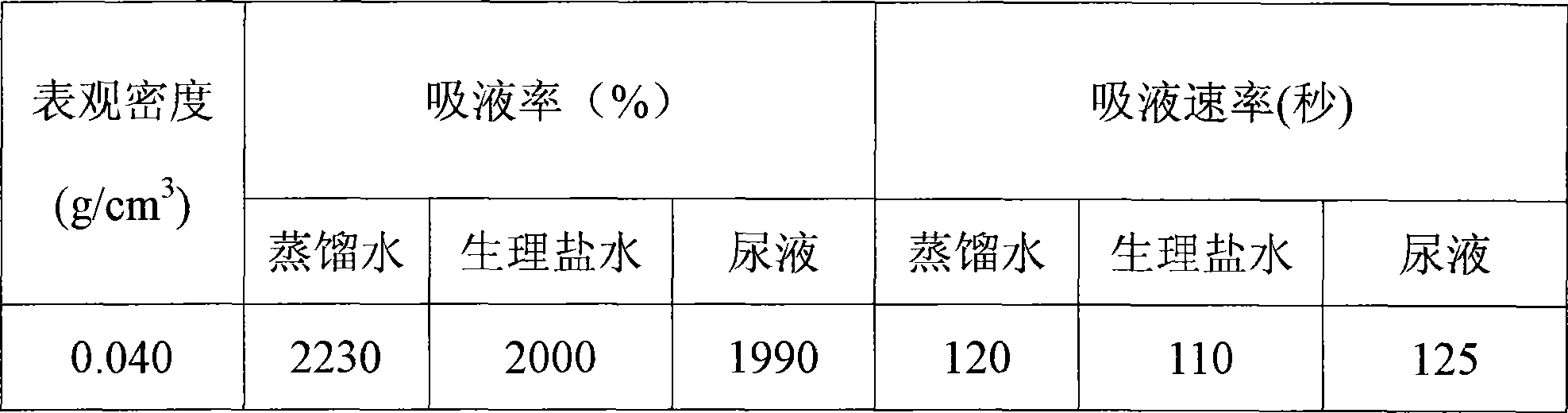

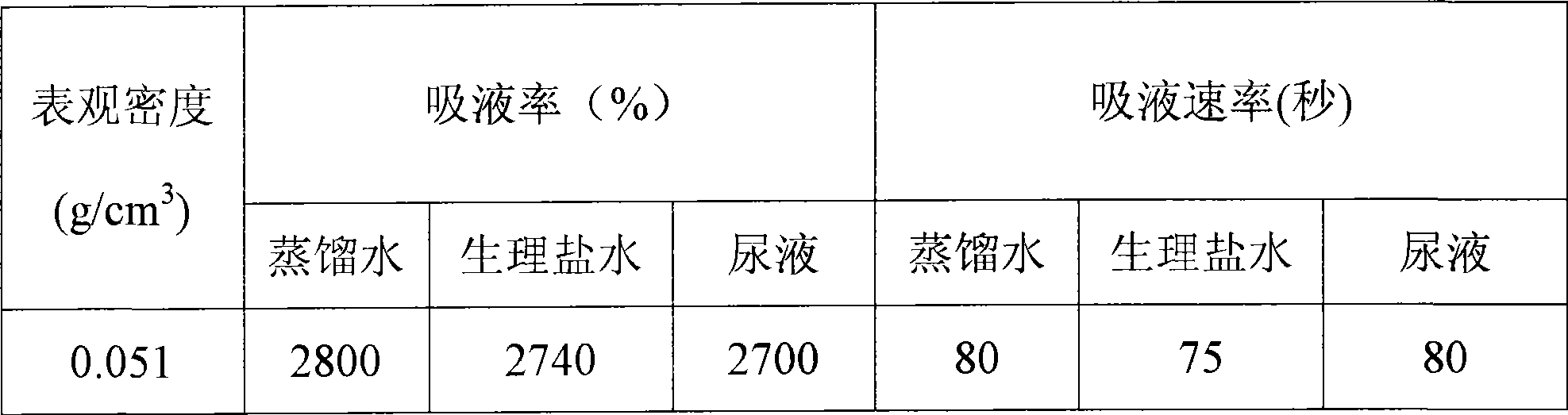

Preparation method of medical quick imbibition foam material

ActiveCN101507826ASimple preparation processProcess is easy to controlAbsorbent padsBandagesSaline waterChemistry

The invention relates to a method for preparing a medical quick liquid-absorbing foam material. The method comprises the steps of well mixing polyvinyl alcohol aqueous solution, aldehyde and a pore-forming agent, adding acid to the mixture, continuing to stir the mixture, pouring the mixed solution into a die, curing and molding the mixed solution, washing and drying the obtained product and obtaining a target object. The material has abundant mutually communicated opening structures through a method of using mechanical foaming together with the pore-forming agent. The prepared material is good in biological compatibility and excellent in hydrophilcity, has the liquid-absorbing capability much higher than common cotton yarn and paper, has the capability of quickly absorbing a large amount of distilled water, physiological saline and urine, turns into soft tenacious elastic sponge after absorbing liquid, is resistant to heat and ultraviolet radiation, and can be disinfected in a plurality of ways. The prepared material is a rigid foam material in a dry state, is a spongy material in a wet state, has the apparent density of between 0.04 and 0.09 g / cm and the liquid-absorbing ratio of between 1,800 and 2,800 percent, and can be applied to medical operations.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Azithromycin for suspension and its preparing method

ActiveCN1813683AUniform sizeNarrow particle size distributionAntibacterial agentsOrganic active ingredientsAdhesiveDosage form

The present invention relates to a dried suspension preparation of medicinal azithromycin and its preparation method. Said dried suspension preparation includes (by wt%) 0.1-20% of azithromycin, 1-10% of lubricant flow aid, 0.1-10% of pH value regulating agent, 10-40% of high-molecular adhesive, 50-85% of sweetener and 0.5-15% of aromatic corrective.

Owner:HAINAN PULIN PHARMA +1

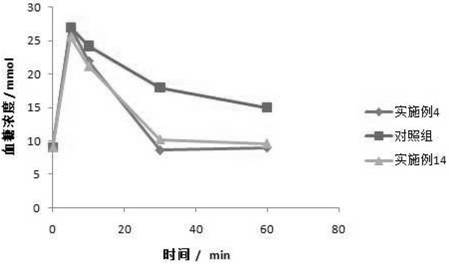

Liraglutide sustained-release microsphere preparation and preparation method thereof

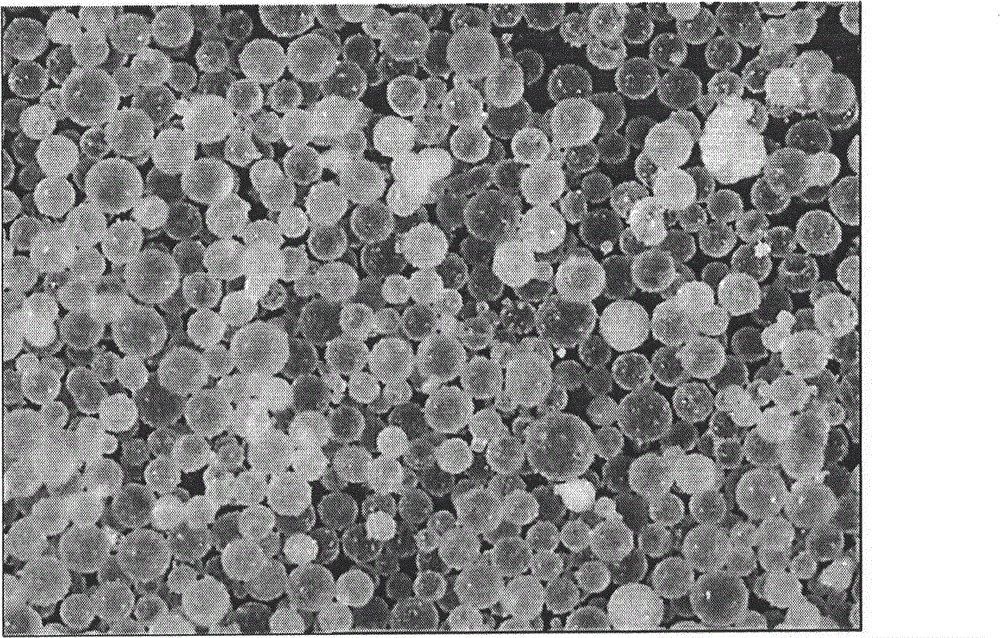

InactiveCN104382860AUniform particle sizeLow burst ratePeptide/protein ingredientsMetabolism disorderSucroseMicrosphere

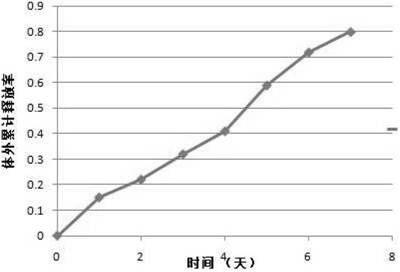

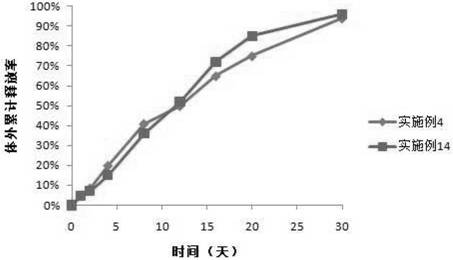

The invention relates to a liraglutide sustained-release micro sphere preparation and a preparation method thereof. The liraglutide sustained-release microsphere preparation comprises 5mg to 100mg of liraglutide, 0.5mg to 10mg of a protective agent and 50mg to 1000mg of a polylactic acid-glycolic acid copolymer, wherein the protective agent is one or a mixture of a plurality of sucrose, mycose, gelatin, mannitol, glycine, lysine and human serum albumin; the molecular weight of the polylactic acid-glycolic acid copolymer is 5000-20000 Daltons, and the ratio of polylactic acid to glycolic acid in the polylactic acid-glycolic acid copolymer is 1:3 to 3:1. According to the liraglutide sustained-release microsphere preparation disclosed by the invention, regular microspheres and medicines uniformly distributed in the microspheres can be obtained by just emulsifying and volatizing an organic solvent; processing procedures are simple; operation is simple; good repeatability is realized in preparation; the prepared liraglutide sustained-release microsphere preparations in batches have no remarkable difference; the obtained microspheres are uniform in grain size, narrow in distribution, controllable in grain size, round and orderly in surfaces and low in burst release rate.

Owner:浙江美华鼎昌医药科技有限公司 +1

Paper deacidification method

ActiveCN101538816ALow viscosityIncrease the diffusion coefficientOld paper after-treatmentOrganic solventPulp and paper industry

The invention discloses a paper deacidification method by using a supercritical fluid technology. The method comprises the following steps: placing paper (particularly ancient books) in a supercritical CO2 treatment device, extracting and purifying before adding a deacidification agent and an entrainer for treatment so that the paper approaches to neutral. The invention applies the supercritical fluid technology to the paper deacidification method to save time and labor and avoid organic solvent pollution, and the treated paper is not bent and deformed and has no phenomena, such as color diffusion, ink diffusion, conglutination, and the like.

Owner:GUANGDONG UNIV OF TECH +1

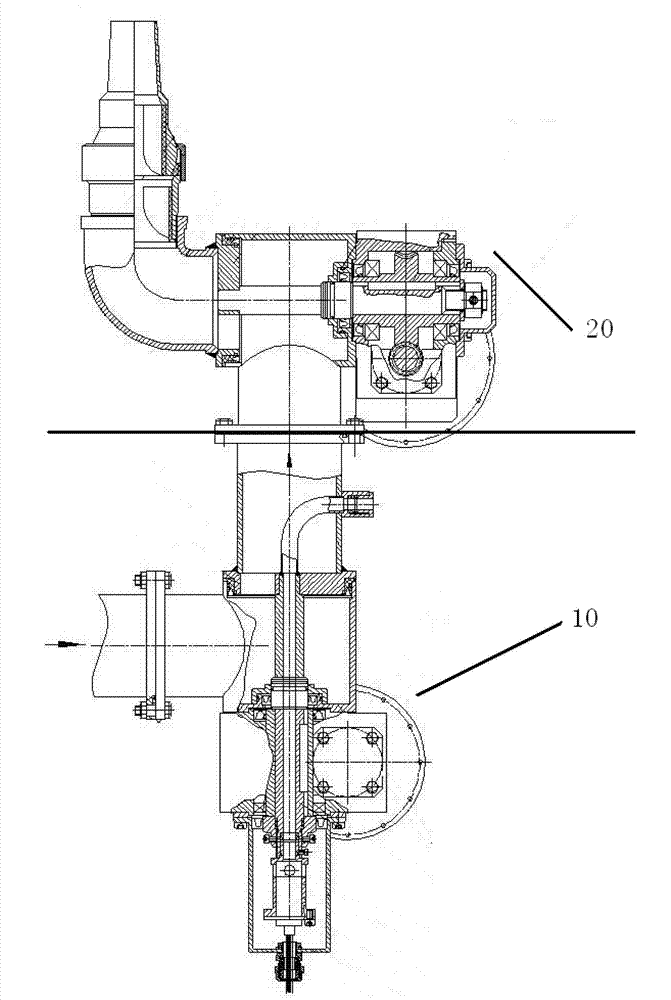

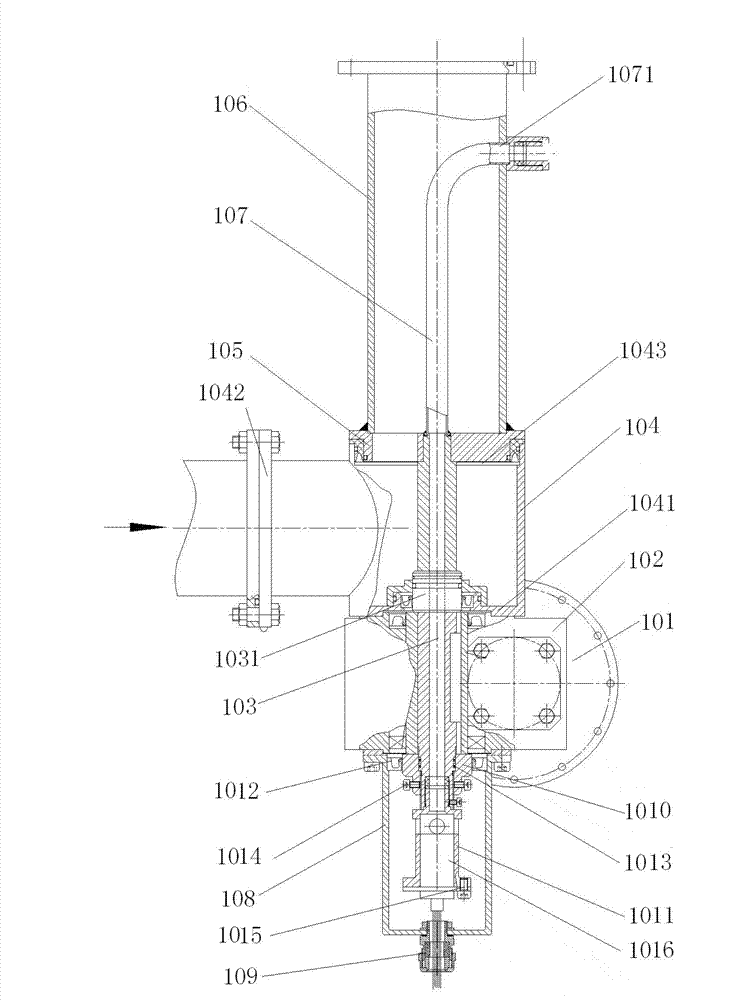

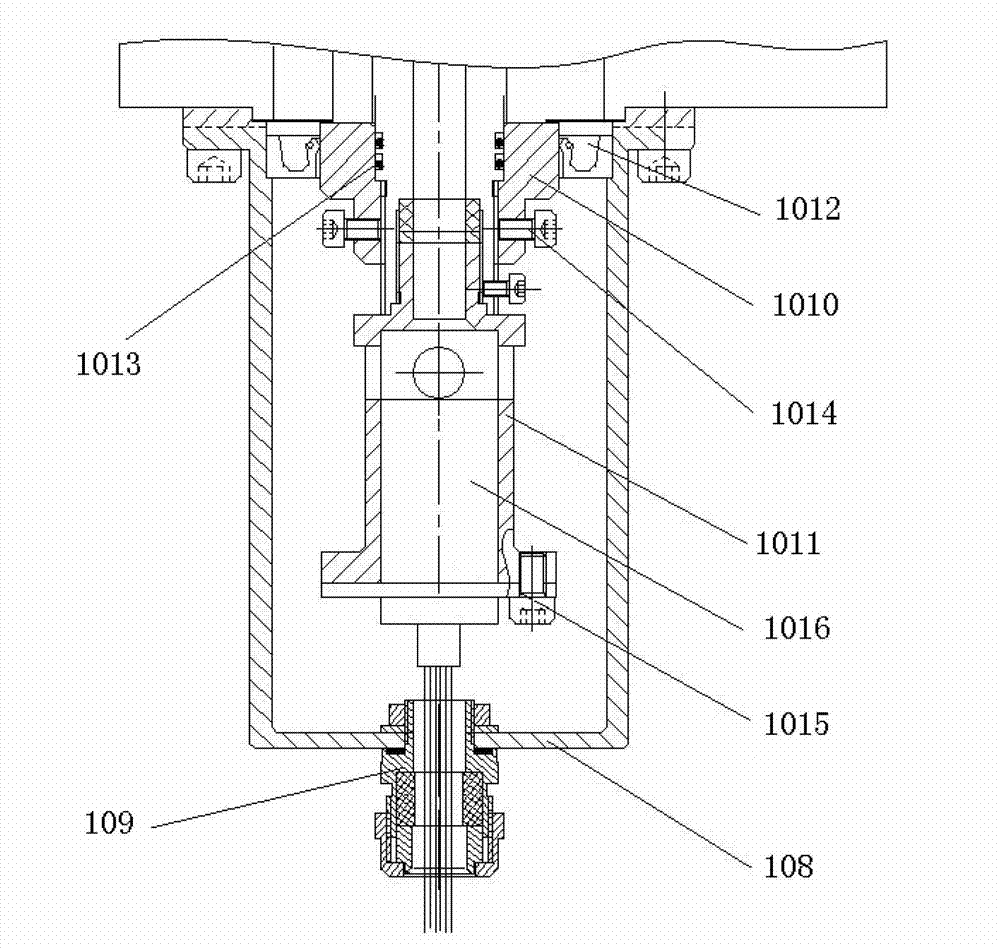

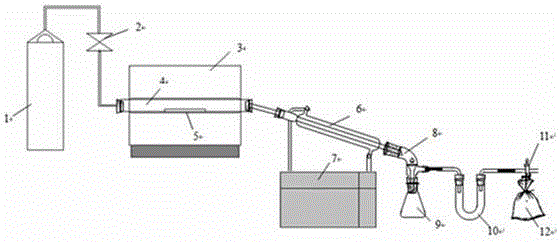

Two-dimension fountain device

ActiveCN102814255ASolve the entanglementSolve the problem of winding on the rotary transmission mechanismEngine sealsMovable spraying apparatusWater flowEngineering

The invention relates to a two-dimension fountain device, which comprises a lower dimension mechanism and an upper dimension mechanism. The lower dimension mechanism and the upper dimension mechanism respectively comprise a motor, a speed reducer, an output shaft, a three-way connector and an overflow support ring. The upper dimension mechanism also comprises a shower nozzle with an elbow pipe. In the lower dimension mechanism, an outlet at the lower end of the shell of the speed reducer is connected with a water-proof tube; the bottom part of the water-proof tube is provided with a cable input connector; the outer wall of the lower end of the output shaft in the water-proof tube is connected with a nut; the inner wall of the lower end of the output shaft in the water-proof tube is connected with a conducting ring seat; and the bottom part of the conducting ring seat is connected with an axial conducting ring inserted into the conducting ring seat. The first ports of the two three-way connectors and the outlet of the shell of the corresponding speed reducer as well as the corresponding input shaft are respectively and hermetically connected through two rubber seal rings, a skeleton seal ring, a seal stop bowl and a stainless steel snap ring. The third ports of the two three-way connectors and the corresponding overflow support ring are hermetically connected through a polytetrafluoroethylene ring. The two-dimension fountain device is good in sealing property under high-pressure water flow, can be used for enabling the shower nozzle to continuously and freely rotate for 360 degrees and can be widely applied to various fountain facilities.

Owner:北京中科恒业中自技术有限公司

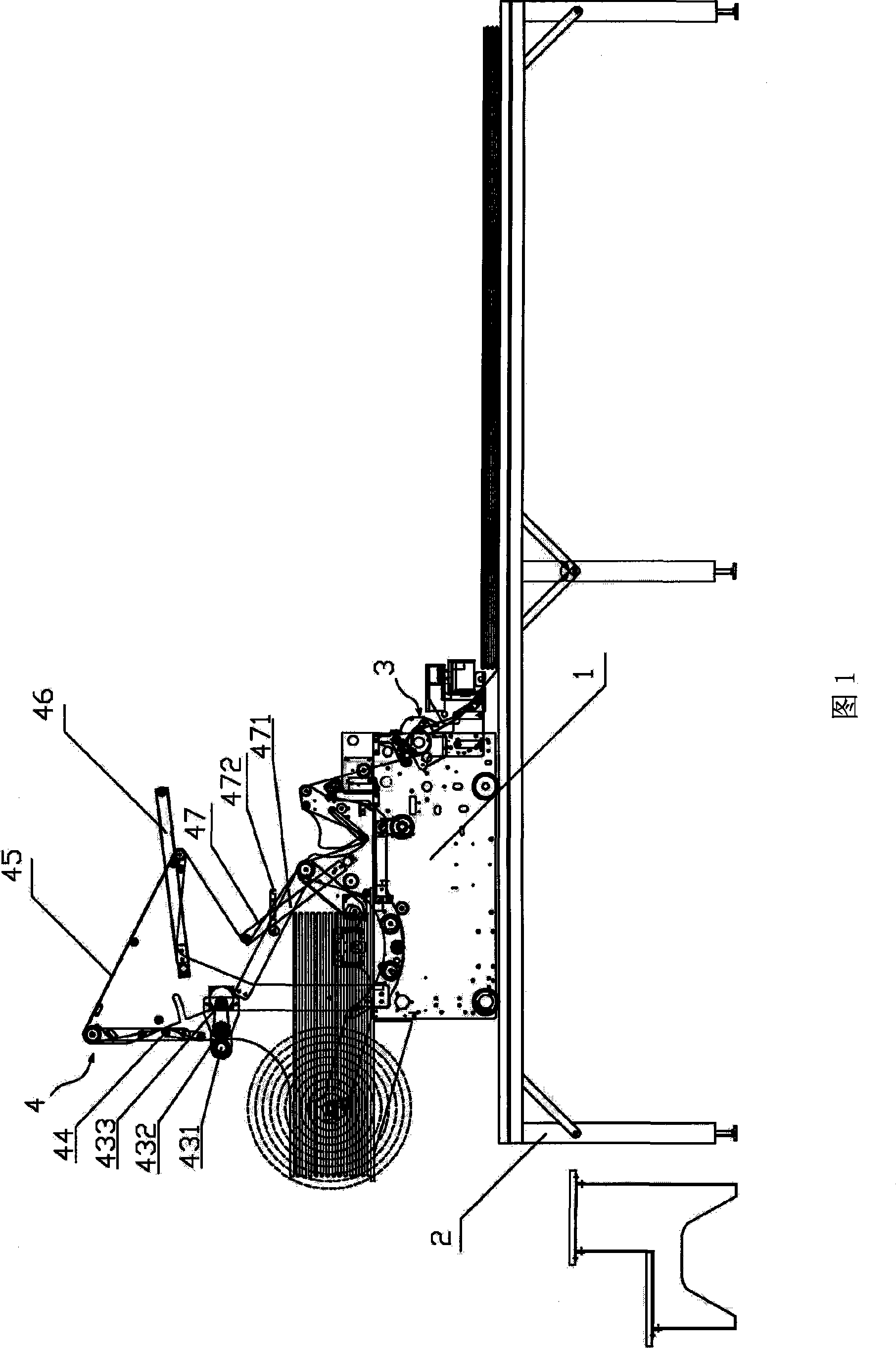

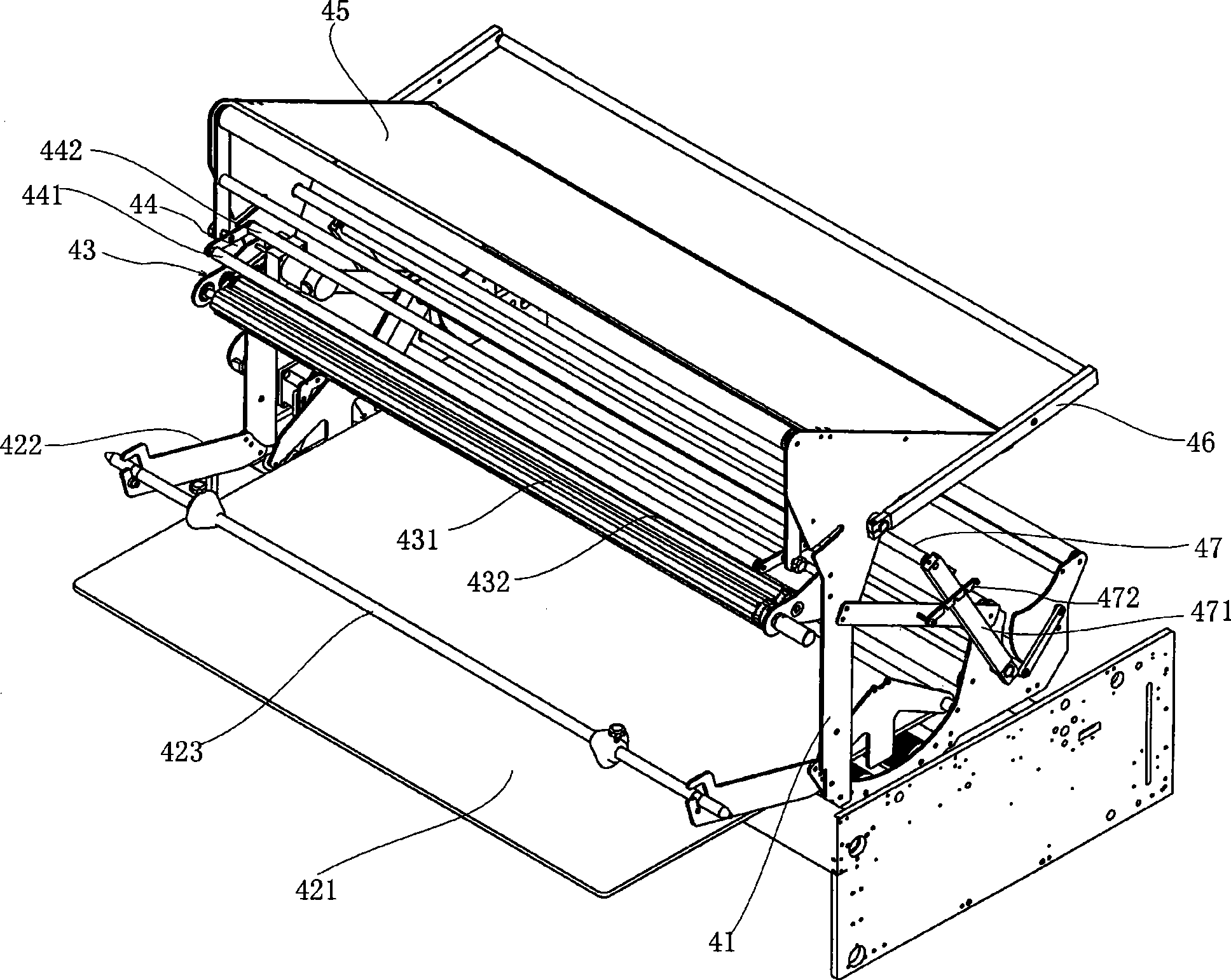

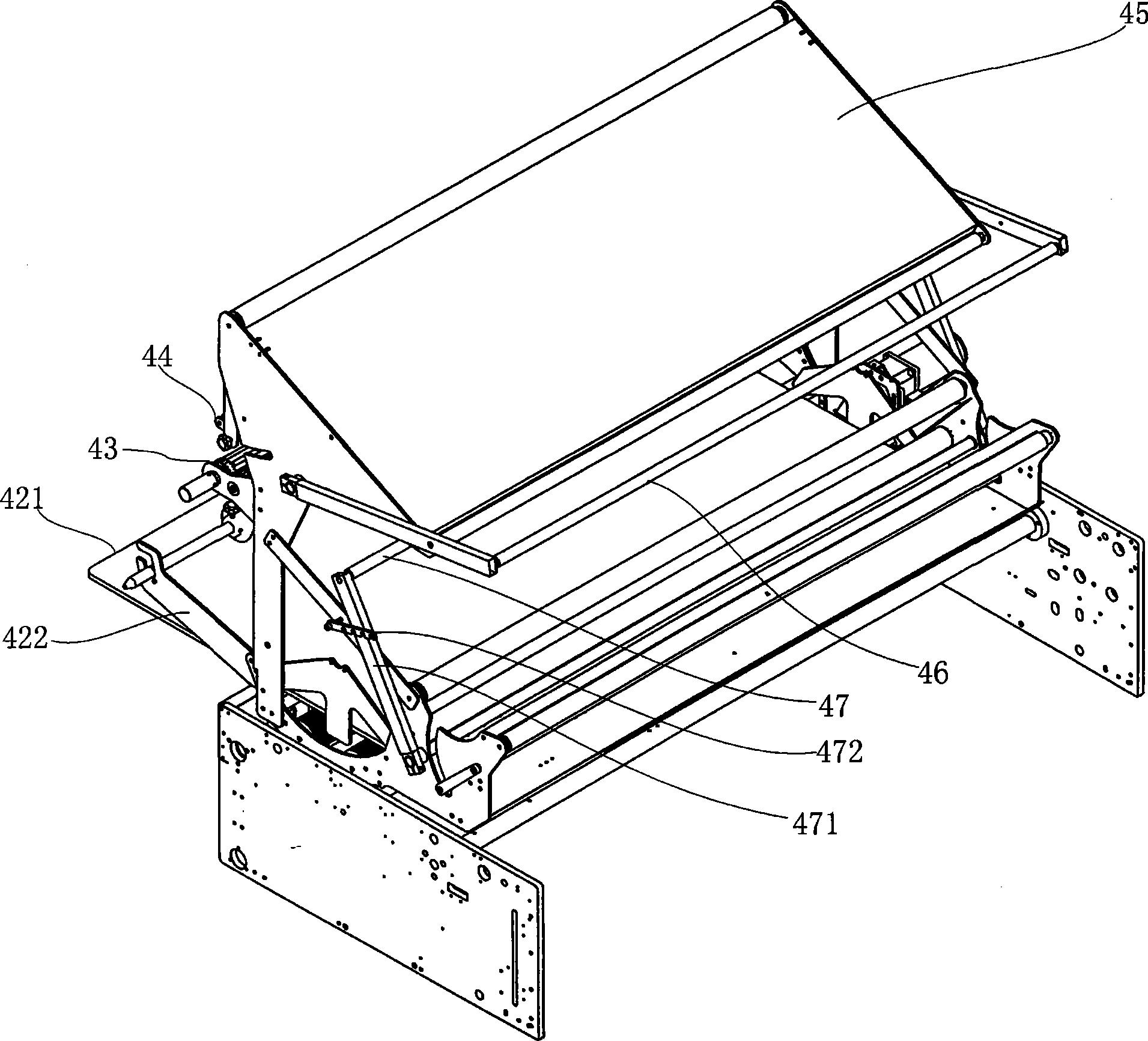

Gauze spreading machine

InactiveCN101446010ANo adhesionNo deformationSevering textilesStretchingMechanical engineeringEngineering

A gauze spreading machine comprises a body of the spreading machine which is arranged on a paving bed in a sliding way, and a cloth spreading mechanism arranged on the body of the spreading machine; the gauze spreading machine is characterized in that the body of the gauze spreading machine is also provided with a gauze special spreading mechanism which comprises a bracket, a cloth supporting mechanism arranged at one side of the bracket, a cloth removing device which is used for ripping away the cloth and is positioned above the cloth supporting mechanism on the bracket, a tension device that is used for tensioning the cloth and is arranged above the cloth removing device on the bracket, a light panel that is used for laying the cloth and arranged on the bracket, a turning roll wheel that is used for turning the cloth and is arranged under the light panel, and a cloth laying mechanism arranged below the turning roll wheel. When in work, winding cloth or piece goods can be placed on the cloth supporting mechanism, one end of the cloth passes in the middle of the a cloth removing roll wheel and then passes through the tension device upwards; then, the cloth is flatly laid by the light panel, passes through the cloth turning roll wheel, and is sequentially penetrated into the cloth laying mechanism; therefore, gauze spreading task can be carried out when the machine is actuated.

Owner:SPEEDFLY ZHEJIANG AUTOMATION TECH

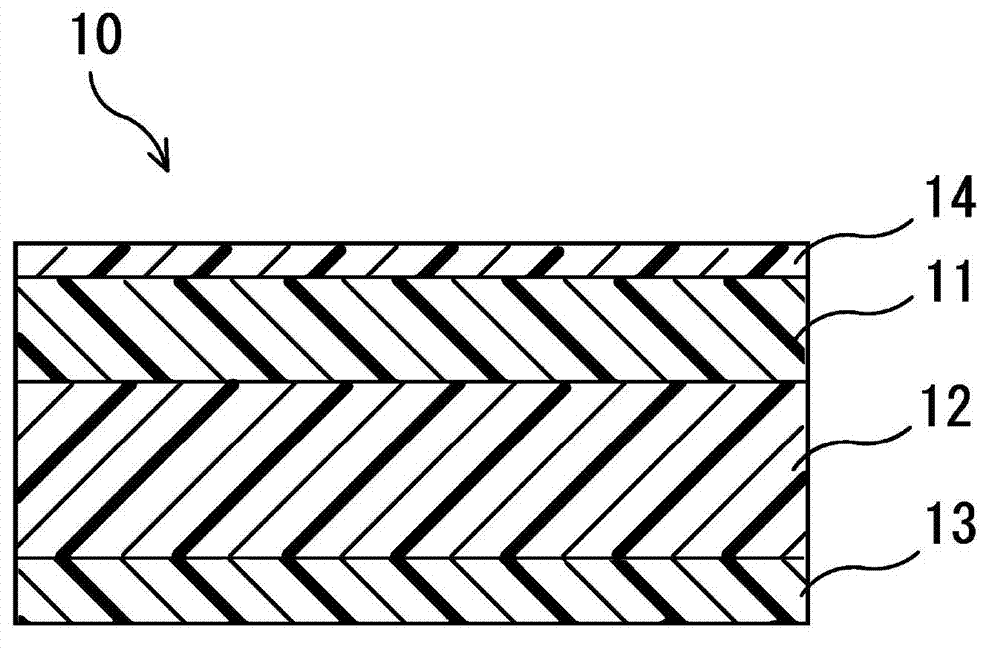

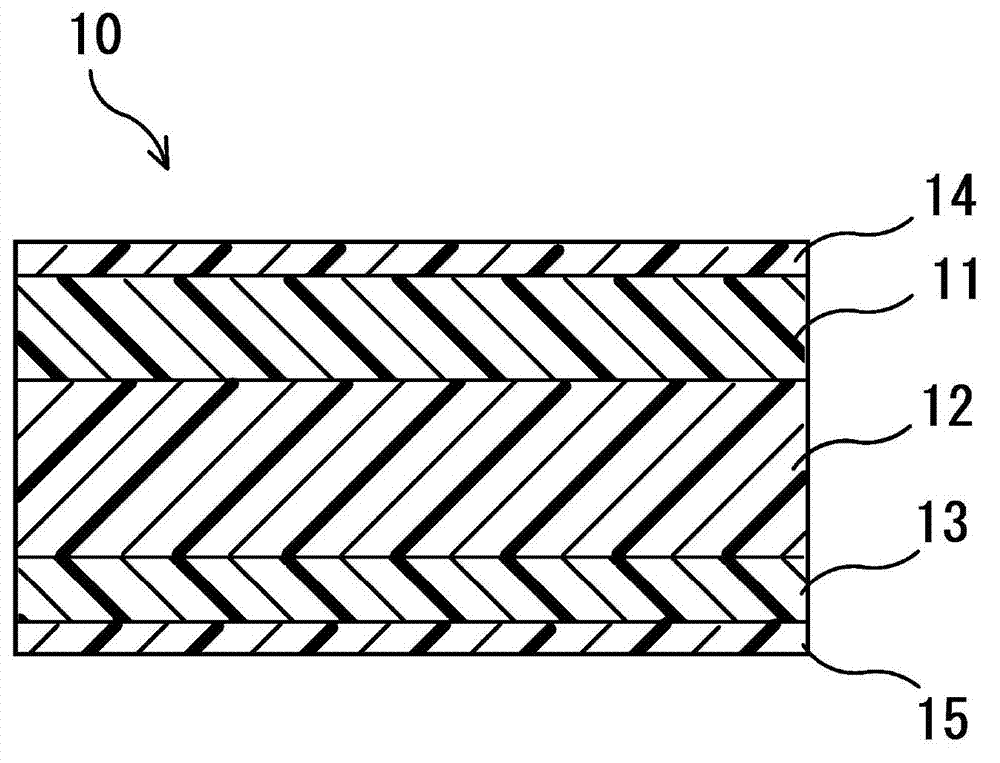

Polyester film with adhesion resisting function and preparation method of polyester film

ActiveCN102744945AGood thermal stabilityReduce environmental pollutionSynthetic resin layered productsChemistryPolyester

The invention discloses a polyester film with an adhesion resisting function. The polyester film is of a structure comprising a layer A, a layer B and a layer C, wherein the layer A and the layer C are surface layers; the layer B is a core layer; the layer A comprises the components of 65-80 percent of polyester slice for a general film and 20-30 percent of general adhesion resisting agent; the layer B comprises the components of 80-85 percent of master batch polyester slice for a functional film, 3-5 percent of general adhesion resisting master batch and 12-15 percent of high-performance adhesion resisting agent; and the layer C comprises the components of 50-65 percent of polyester slice for the general film and 35-50 percent of general adhesion resisting agent. The high heat resistance and excellent adhesion resistance are achieved by the steps of slicing, mixing, melting co-extrusion, longitudinal drawing, transverse drawing, drawing and trimming, coiling, splitting and forming a finished product. The products prepared by the preparation method disclosed by the invention is environment-friendly and can be directly recycled, so that the pollution to the environment is reduced; and the polyester film can be widely applied to packaging of cakes, seasonings, fast foods and candies and packaging of medical products.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

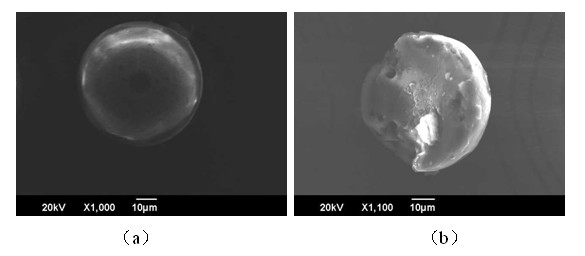

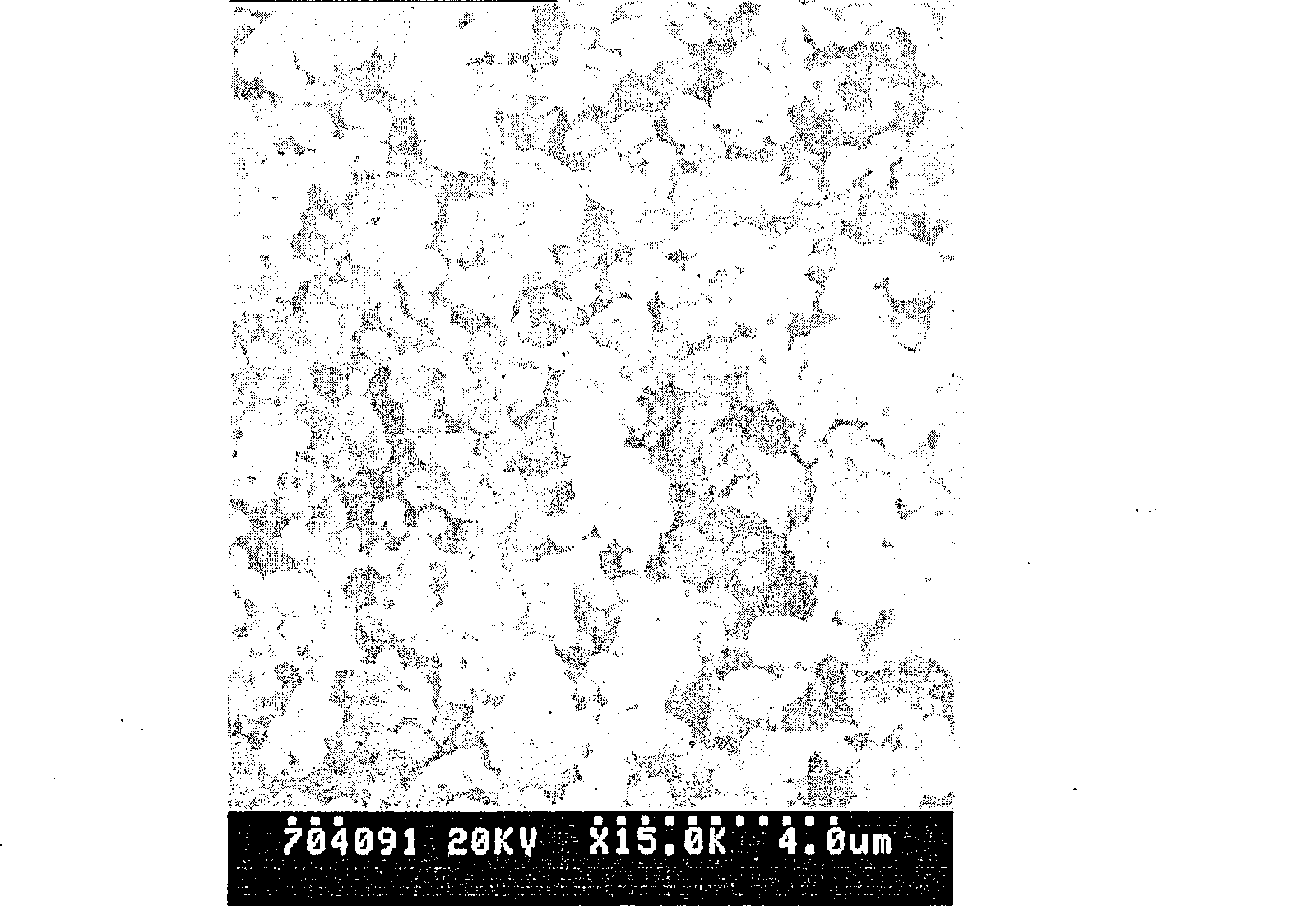

Sustained-release micro-spheres preparation containing recombined erythropoietin and preparation method and use thereof

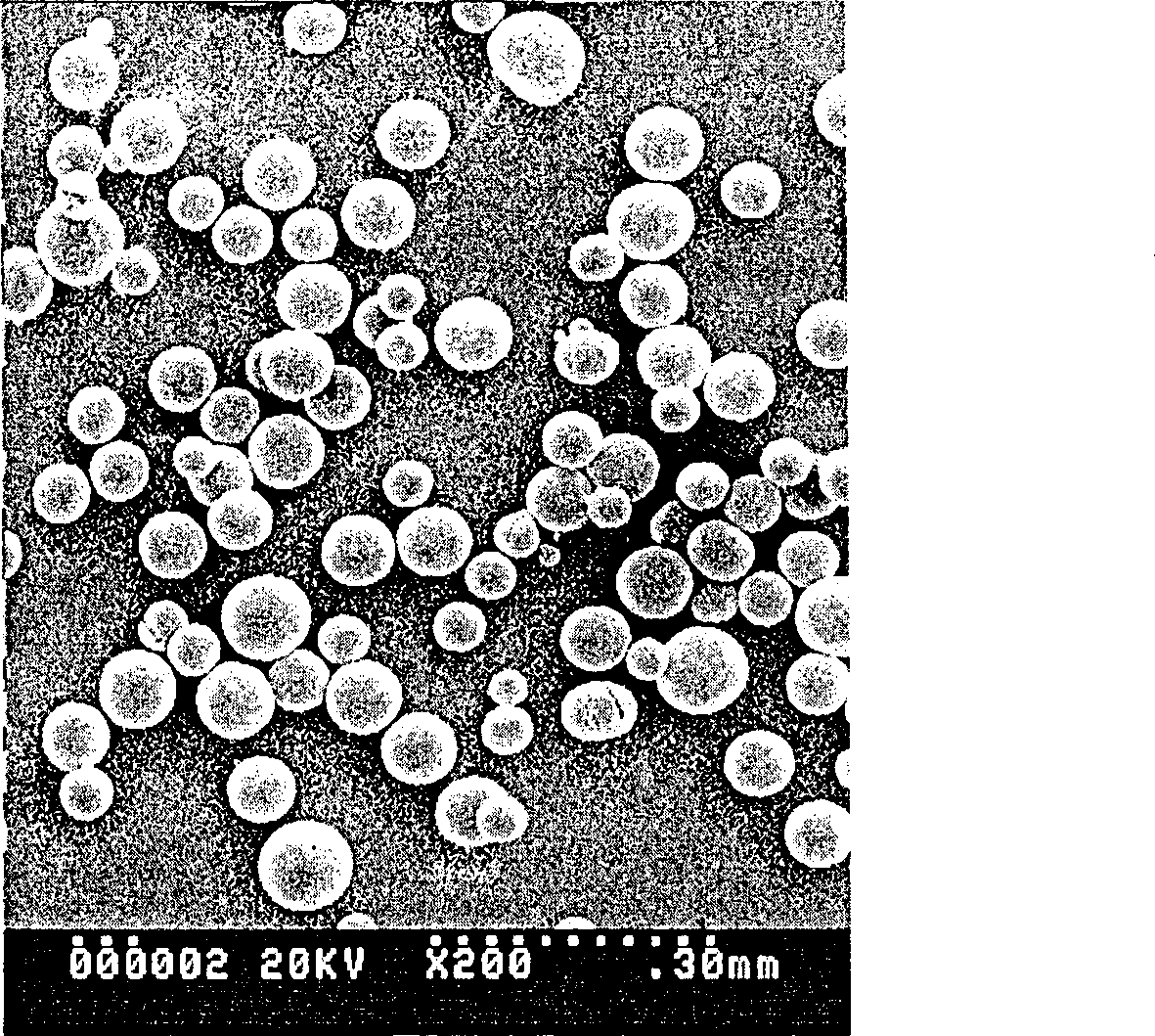

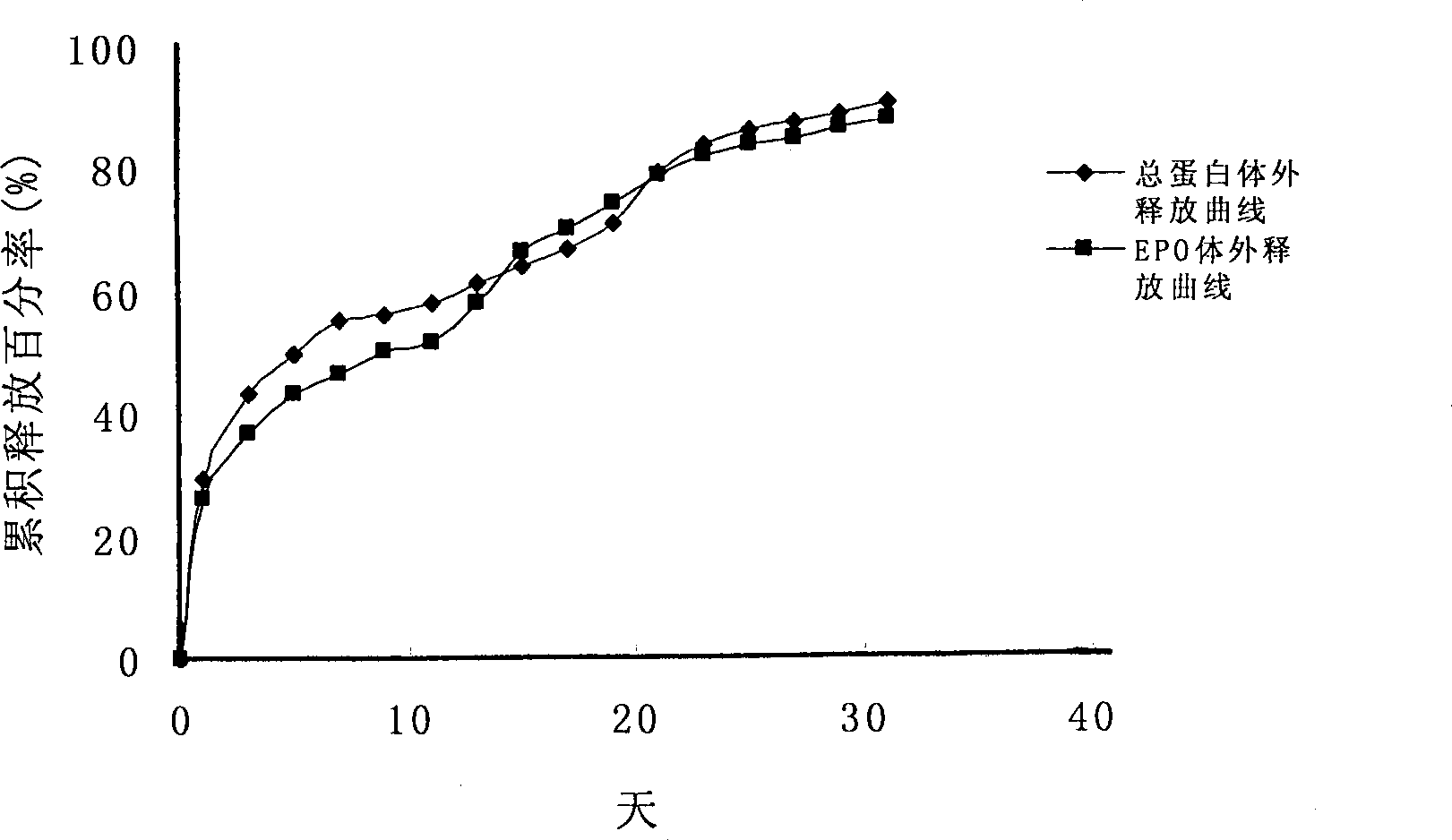

InactiveCN101507712AImprove stabilityFlat surfacePeptide/protein ingredientsGranular deliveryFreeze-dryingBiocompatibility Testing

The invention discloses a slow-release microsphere preparation containing a recombined human haemopoietin. The slow-release microsphere preparation is prepared by the S / O / W compound emulsion solvent volatilization method. The preparation method comprises that: firstly, by the freeze-drying method, a micro particle containing the human serum albumin and the recombined human haemopoietin is prepared; secondly, by using a biodegradable high molecular material of lactic acid-glycollic acid block copolymer as a carrier material, the micro particle containing the human serum albumin and the recombined human haemopoietin is encapsulated; and thirdly, the lactic acid-glycollic acid block copolymer slow-release microsphere preparation containing the recombined human haemopoietin is prepared. The microsphere of the invention has the advantages of smooth surface, uniform appearance, regular size and no adhesion, the average particle size is between 70 and 105mu m; moreover, the microsphere is high in drug-carrying quantity and encapsulating rate, and the in vitro slow release period is more than 30 days. The obtained slow-release microsphere preparation is good in biocompatibility and can be used for non-intravenous drug administration such as hypodermic drug administration and intramuscular drug administration, and when used as a drug preparation for treating renal anemia, the slow-release microsphere preparation can improve the hematocrit of a patient.

Owner:HEBEI NORMAL UNIV

Catalyst component and catalyst system for olefin polymerization, application of catalyst component and catalyst system, and olefin polymerization method

The invention provides a catalyst component for olefin polymerization and application of the catalyst component. The catalyst component contains a product obtained by reacting a magnesium halide adduct, a titanium compound and at least one optional internal electron donor compound, wherein the magnesium halide adduct is shown as MgX<1>Y-mEtOH-n(LB1)-k(LB2)-p(LB3). The invention also provides a catalyst system for olefin polymerization and application of the catalyst system. The catalyst system contains the catalyst component and one or more organic aluminum compounds. The invention also provides an olefin polymerization method. The method comprises the following step of: contacting one or more olefins and the catalyst system under the condition of olefin polymerization. The catalyst system has high hydrogen regulation sensitivity and stereospecificity in olefin polymerization, and good balance between the hydrogen regulation sensitivity and the stereospecificity of the catalyst system is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing microspheres by using oil-in-nanoparticle mixed suspension-nanometer medicament-in-oil

InactiveCN102885784AHigh encapsulation efficiencyImprove adhesionPharmaceutical non-active ingredientsGranular deliveryControlled releaseCell adhesion

The invention discloses a method for preparing microspheres by using oil-in-nanoparticle mixed suspension-nanometer medicament-in-oil. The method comprises the following steps of: preparing a medicament and medicinal auxiliary materials into a nanometer medicament; adding the nanometer medicament into a polymer-containing organic solvent mixed solution for emulsifying; adding a nanometer medicament-in-oil mixed suspension into a water mixed suspension containing nanoparticles or containing nanoparticles and a surfactant for emulsifying to obtain an oil-in-nanoparticle mixed suspension-nanometer medicament-in-oil compound emulsion; and curing the obtained compound emulsion, and centrifugally collecting microspheres, wherein the obtained microspheres comprise the medicament, nanoparticles, the polymer and the medicinal auxiliary materials. An appropriate polymer material and an appropriate microsphere preparation method are selected, the prepared microspheres have high envelop rate, and a layer of self-assembled nanoparticles on the surfaces of the microspheres has the effects of improving cell adhesion and reducing inflammation and microencapsulation caused by local excessive acid and hydrophobic materials. The method disclosed by the invention can be applied to preparation of other medicament slow release or controlled release microspheres.

Owner:JINSHAN HOSPITAL FUDAN UNIV

Coated polymeric film

InactiveCN101432379AImprove performanceReduce inventoryStampsFilm/foil adhesivesPolymer substrateIonomer

This invention relates to, in one aspect, a printable, two-side coated polymer film comprising a) a polymer substrate including a first side and a second side; b) a back-side coating on the second side of the substrate, the back-side coating comprising 1) an ionomer, and 2) particles of a colloidal mineral, a majority by weight of the colloidal mineral particles having an overall mean diameter of not greater than about 1.0 micron and preferably not greater than 0.1 micron; and c) a front-side coating on the first side of the substrate, wherein the front-side coating is printable.

Owner:JINDAL FILMS AMERICAS LLC

Pigment dyeing method for loose cotton fiber

InactiveCN101994249AShort processProcessing speedLiquid/gas/vapor removalDyeing processChemical activityCotton fibre

The invention relates to a pigment dyeing method for loose cotton fiber, in particular to a pigment dyeing method for subsequently performing physical and chemical pretreatment on the loose cotton fiber, and belongs to the field of textile printing and dyeing and processing. The loose cotton fiber needs to be subjected to the physical and chemical pretreatment; the physical treatment can improve the surface area and the chemical activity of the cotton fiber; and in the chemical treatment process, a direct bonding mode of a pigment and the cotton fiber in the conventional process is changed, the cotton fiber and the pigment are connected at two ends of gamma-epoxypropoxy propyltrimethoxysilicane through chemical condensation reaction, so that the mode of interfacial bonding is increased, the bonding force of the interface is improved, the single bonding mode of the pigment and the cotton fiber in the conventional process is changed and the color fastness is improved.

Owner:WUHAN TEXTILE UNIV

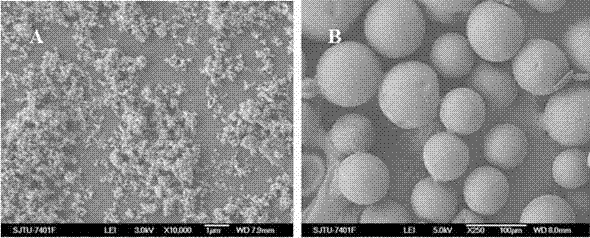

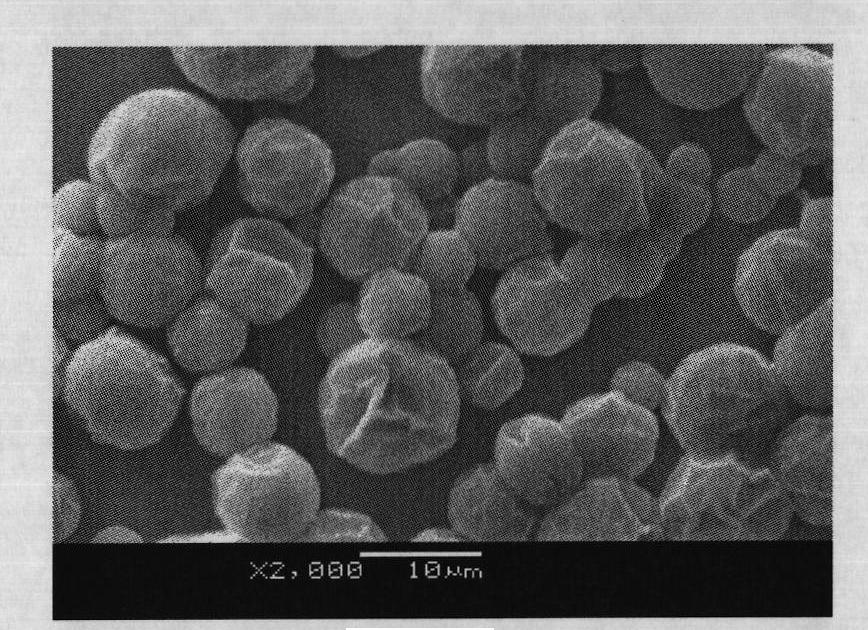

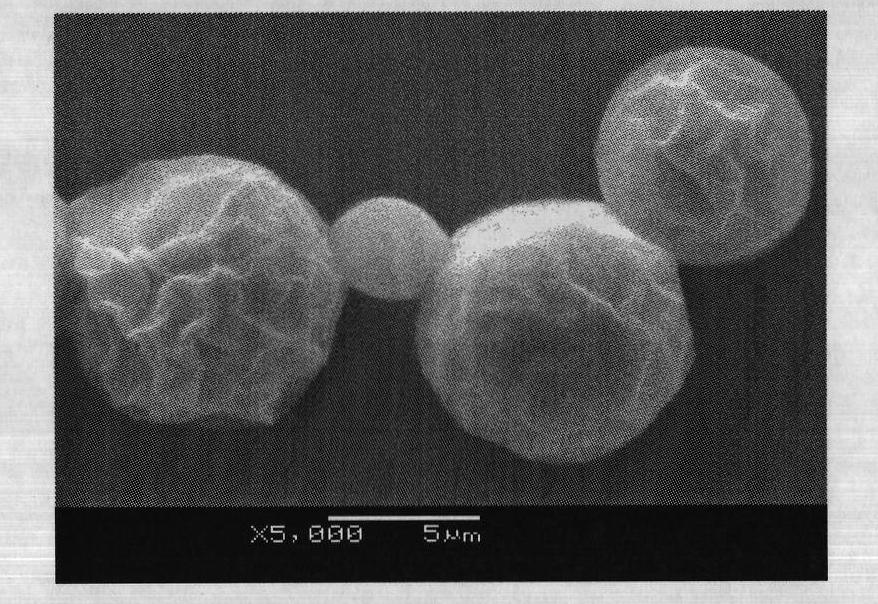

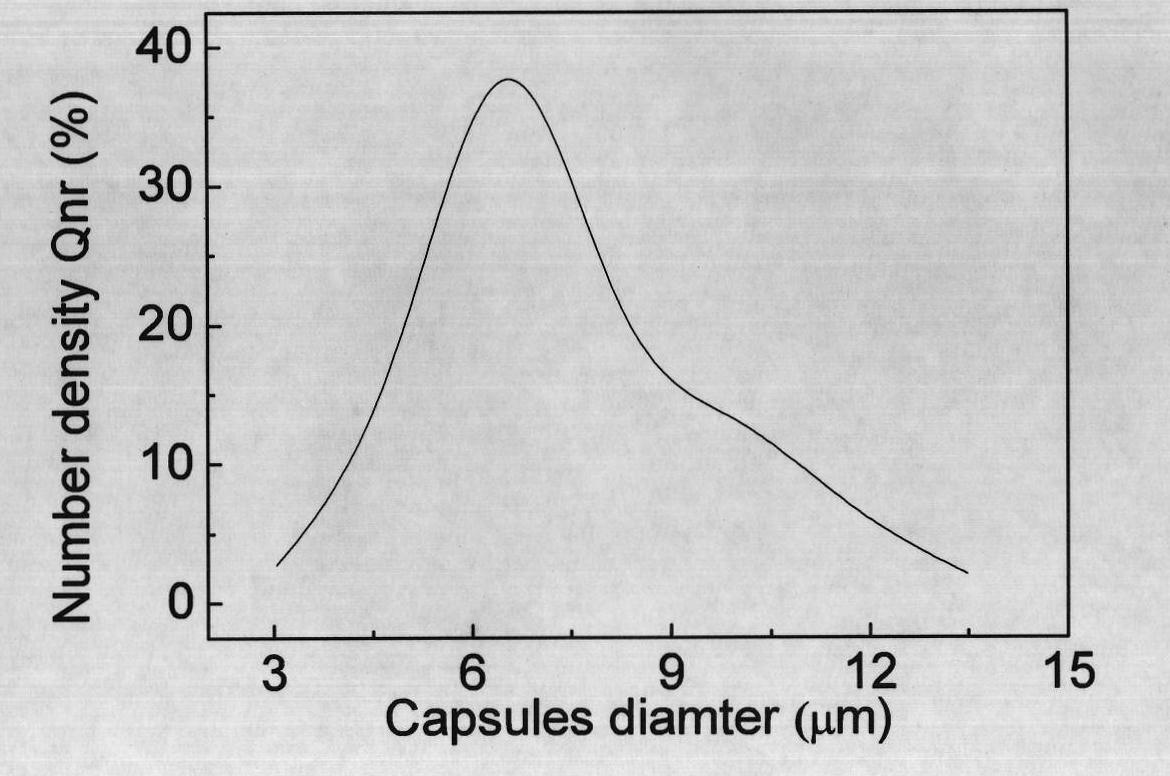

Preparation method of aromatic polyamide core-shell paraffin phase change microcapsule

InactiveCN101982231AReduce coverageReduce manufacturing costMicroballoon preparationMicrocapsule preparationFiberEthylene diamine

The invention relates to a preparation method of an aromatic polyamide core-shell paraffin phase change microcapsule, belonging to the field of preparation of the paraffin phase change microcapsule, and aiming to provide a preparation method of the paraffin phase change microcapsule of which the product has good heat resistance, chemical stability and compactness. In the method, trimesoyl chloride is adopted as an oil phase monomer, organic amine--ethylene diamine or piperazine is adopted as a water phase monomer, and the wall material of the prepared paraffin phase change microcapsule is cross-linking aromatic polyamide. The product microcapsule prepared by the technology of the invention does not contain autopolymer of a cyst wall material, the microcapsules do not adhere to each other, and a monodisperse state can be formed in a substrate easily. The coating ratio of the microcapsule is as high as 87.7%. The microcapsule prepared by the technology of the invention has no slow release, and the 5% thermo gravimetric temperature is 220 DEG C. The aromatic polyamide core-shell paraffin phase change microcapsule prepared by the technology of the invention can be applied to the fields of thermal-storage thermo-regulated fiber, solar energy and nuclear energy utilization, enhanced heat transfer, electronics, spaceflight and composite materials.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for processing purified konjac flour

A method for processing purified konjac flour comprises twelve steps of material selection, swelling, extraction, material placing in a low temperature oxygen-free room, grinding, dehydration, dehumidification drying, dry grinding, winnowing, sieving, checkout and homogeneous warehousing. The method for processing the purified konjac flour has the advantages that the swelling and the extraction can enable impurities in the konjac flour to be soluble in impregnation liquid and accordingly separated out, the activity of polyphenol oxidase can be restrained and brown stain can be prevented through processing in the low temperature oxygen-free room. Starch and the impurities attached to glucomannan particles can be further peeled off through the grinding, and then the impurities are removed through the dehydration. Heating can be avoided and brown stain, gelatinization and adhesion can be prevented through the dehumidification drying. By means of the grinding in the low temperature environment, the ragility of konjac particles can be improved, the impurities can be easily separated, and small particles can be obtained. Various levels of purified konjac flour meeting the national requirements is obtained after the sieving. Therefore, produced purified konjac flour does not contain sulfur, is free of brown stain, gelatinization and adhesion and is pure white, and the product quality is improved.

Owner:重庆天娇农业开发有限公司

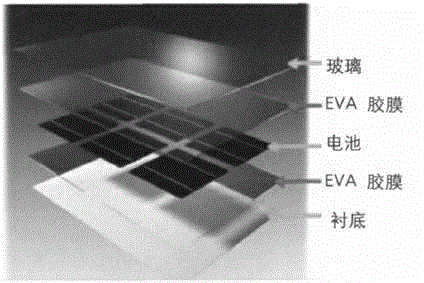

EVA heat treatment method of waste crystalline silicon solar cell module

ActiveCN103978010AEfficient separationEasy to sort and recycleWaste processingSolid waste disposalOrganosolvSilicon cell

The invention provides an EVA heat treatment technology of a waste crystalline silicon solar cell module, and can realize the effective separation of toughened glass, crystalline silicon cell pieces and a back plate of a waste crystalline silicon solar panel. The whole process has simple operation, no EVA residue in the heat treatment process, and the generated waste gas enters into an incinerator for incineration to avoid secondary pollution. The invention adopts the heat treatment process to effectively avoid environmental pollution caused by organic solvent volatilization in the process of EVA dissolution by an organic solvent, and also greatly shortens the processing cycle.

Owner:刘景洋

Water-soluble polyvinyl alcohol chopped fiber as well as preparation method and application thereof

ActiveCN102433599ALow water dissolution temperatureEmission reductionSpinnerette packsArtificial filament heat treatmentPolymer scienceSpinning

The invention discloses a water-soluble polyvinyl alcohol chopped fiber of which the water dissolving temperature is 65-75 DEG C. The water-soluble polyvinyl alcohol chopped fiber is prepared by performing spinning and spinning after-treatment on polyvinyl alcohol and water serving as raw materials, wherein the polymerization degree of the polyvinyl alcohol is 1,400+ / -200, the alcoholysis degree is 98.3-99.9 percent, and the mass percentage concentration is 21.0-23.0 percent. The water-soluble polyvinyl alcohol chopped fiber has low water dissolving temperature, and has particularly prominent application effects in the fields of soluble embroidery base cloth, water-soluble paper and the like in the industries of spinning and non-woven fabrics; the water-soluble polyvinyl alcohol chopped fiber is free from salt, so that fiber adhesion is prevented during drying after desalination in the production process; and meanwhile, the strength of the water-soluble polyvinyl alcohol chopped fiber is more than or equal to 3.2 cN / dtex, and the crispation number is more than or equal to 4 / 25 millimeters. The preparation method contributes to industrial mass production, the dissolving temperature of the prepared water-soluble polyvinyl alcohol chopped fiber is 65-75 DEG C, and grading, packaging and transportation are easy.

Owner:CHINA PETROCHEMICAL CORP +1

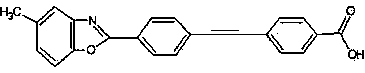

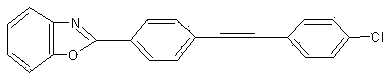

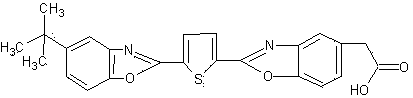

Fluorescent microsphere and preparation method and application thereof

ActiveCN104046350AWith fluorescent whitening effectGood ballMicroballoon preparationLuminescent compositionsColored whiteBright-white

The invention relates to a fluorescent microsphere and its preparation method. Particle size of the fluorescent microsphere is within the range of 0.1-10 micrometer. The fluorescent microsphere has good sphericity and narrow particle size distribution and also has fluorescent brightening groups. The fluorescent brightening groups are uniformly or randomly distributed in a polysiloxane microsphere or on the surface of the polysiloxane microsphere such that the polysiloxane microsphere has a fluorescent brightening effect, has high light fastness, has excellent heat resistance and high chemical stability, can absorb ultraviolet rays to prevent aging of a product, is especially suitable for an originally yellowish product, endows a product with bright white appearance, can make a colored product more dazzlingly beautiful when used in the colored product, and can enhance brightness of a product when used in a black product. The invention, on the other hand, provides a preparation method of the above fluorescent microsphere and a prepared photodiffusion material.

Owner:GUANGZHOU SHINE POLYMER TECH

Reactive polyolefin hot melt adhesive with low adhesion to uncoated aluminum tools and use thereof as a laminating hot melt

ActiveUS20150240135A1Low costAmeliorates or overcomesManual label dispensersSynthetic resin layered productsThermoplasticParaffin wax

A hot melt adhesive composition is provided which contains at least one silane group-containing thermoplastic poly-α-olefin which is solid at 25° C. and at least one paraffin wax. The hot melt adhesive composition has only low adhesion to uncoated aluminum tool surfaces, wherein at the same time they have high final strengths and thermal stabilities comparable to conventional adhesives, as well as good resistance to environmental influences. The hot melt adhesive is suitable as a laminating adhesive for laminating films made of thermoplastic olefins, which have sufficient stability for subsequent deep-draw lamination.

Owner:SIKA TECH AG

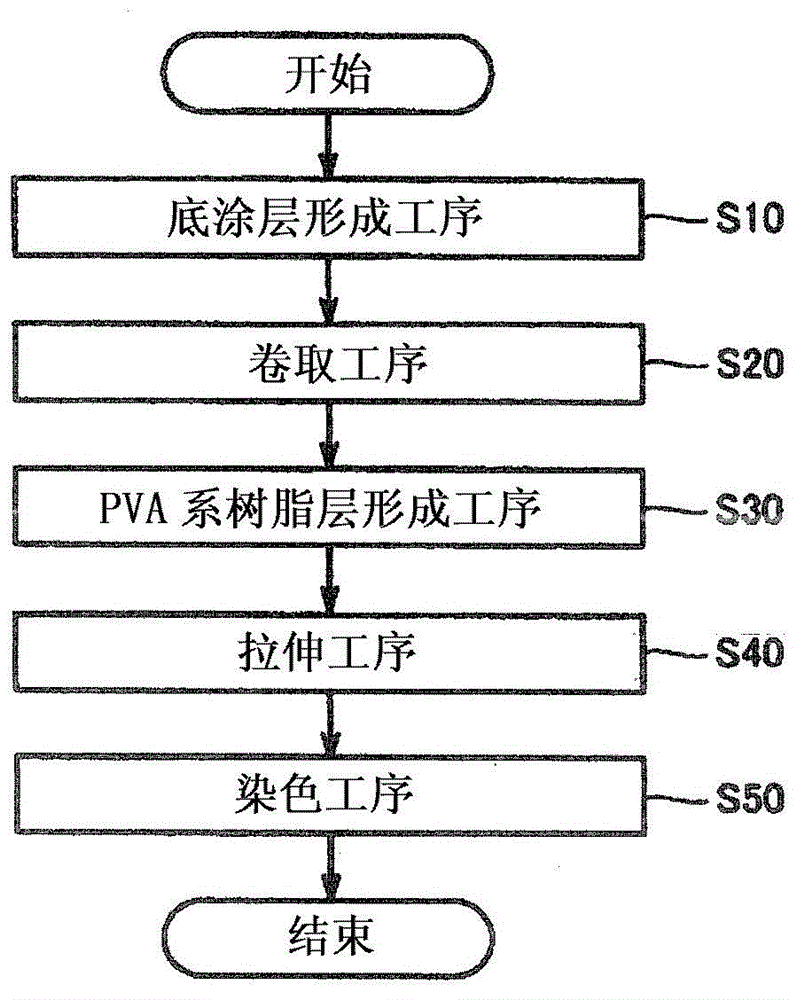

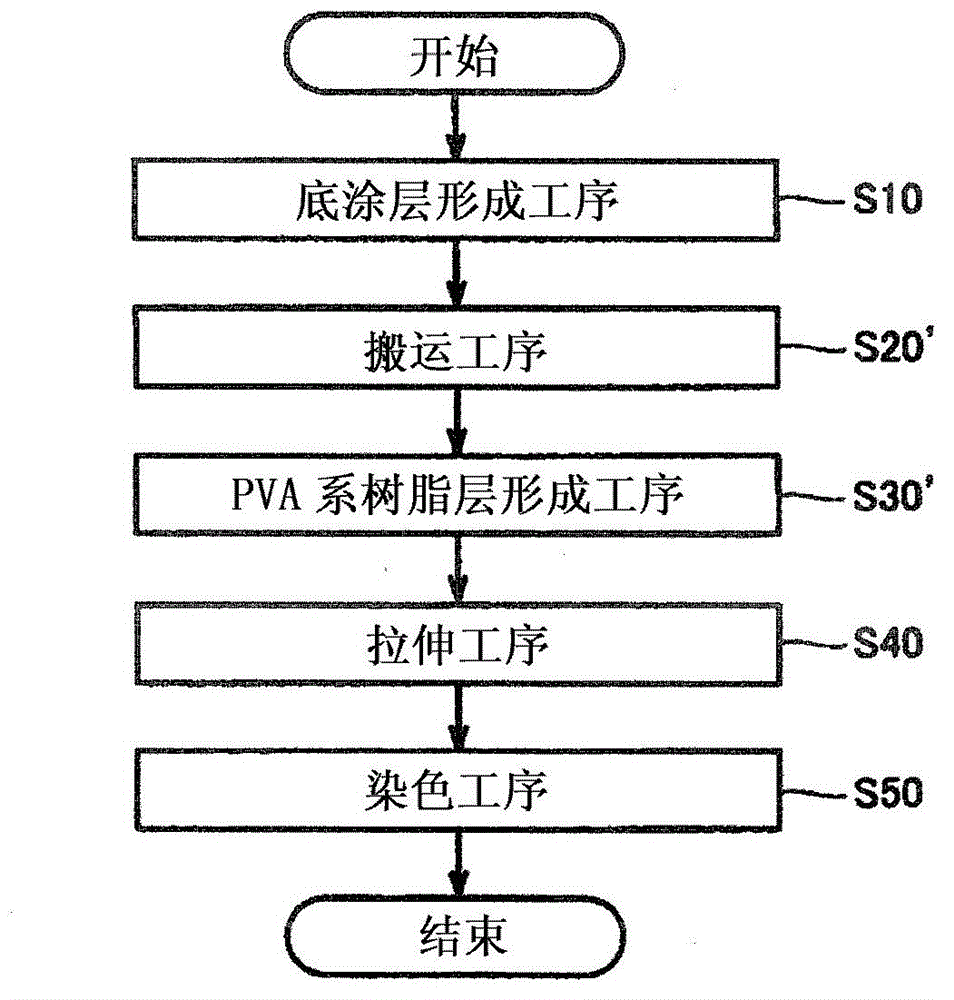

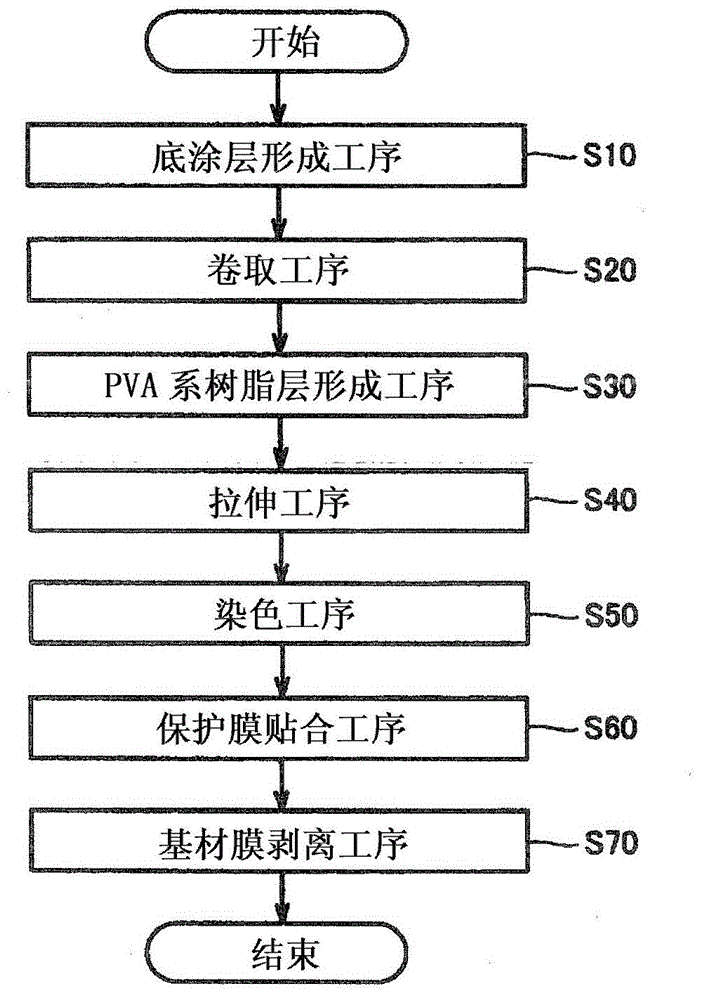

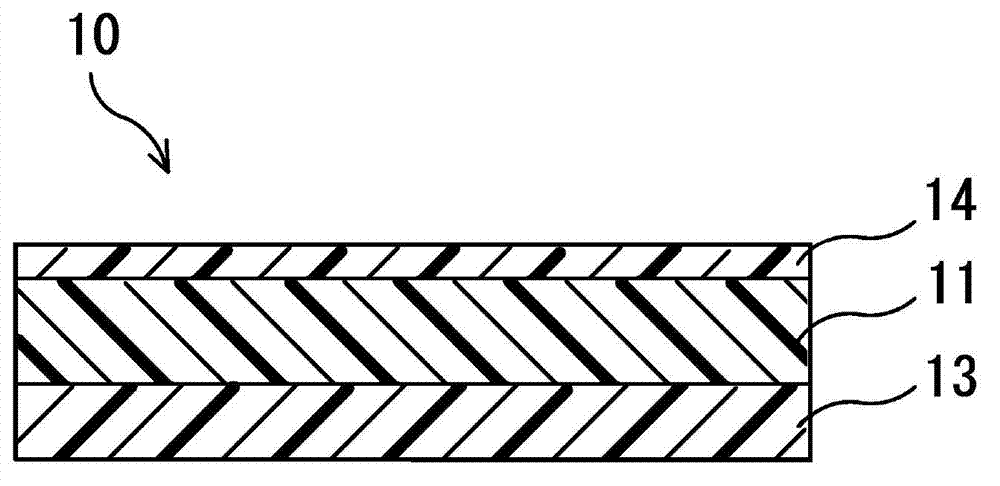

Methods for producing polarizing laminate film and polarizing plate

The present invention is a method for producing a polarizing laminate film that includes a base film, a primer layer, and a polarizer layer in this order, the method involving, in the following order: a step of forming a primer layer on one surface of a base film by coating a primer solution thereon; a step of forming a polyvinyl-alcohol-based resin layer on the primer layer and thereby preparing a laminate film that includes the base film, the primer layer, and the polyvinyl-alcohol-based resin layer in this order; a step of stretching the laminate film; and a step of dyeing the polyvinyl-alcohol-based resin layer of the laminate film with a dichroic dye and thereby making same into a polarizer layer. In said method, the concentration of epoxy-based cross-linking agent(s) in said primer solution is less than 0.1% by weight. The present invention can provide a polarizing-laminate-film production method that does not give rise to blocking even when the film is temporarily rolled up after forming the primer layer on the base film, does not cause the film to stick to conveyor rolls even in subsequent conveyance, and does not impair the adhesion between the base film and the polyvinyl-alcohol-based resin layer in the polarizing laminate film that has been produced.

Owner:SUMITOMO CHEM CO LTD

Washing method for spinneret plate

The invention relates to a washing method for a spinneret plate, and mainly solves the technical problems in the prior art that the spinneret plate cannot be cleanly washed, gel is adhered to the surface of the spinneret plate, a spinning solution at the outlet of a spinneret hole overflows, and polyacrylonitrile protofilament has more broken filaments and more thin filaments and is high in fiber breakage rate. The washing method for the spinneret plate comprises the following steps of disassembling the spinneret plate from a spinning assembly; immersing the spinneret plate in a solvent in a container; then immersing the container in water bath; washing by adopting a mode of combining temperature rising with ultrasound; taking out the spinneret plate after the washing is completed; blowing the surface of the spinneret plate by gas which is precisely filtered after the spinneret plate is dried; completing the washing. According to the technical scheme, the problems are well solved, and the washing method can be used in a device washing process after the spinning of the polyacrylonitrile protofilament.

Owner:CHINA PETROLEUM & CHEM CORP +1

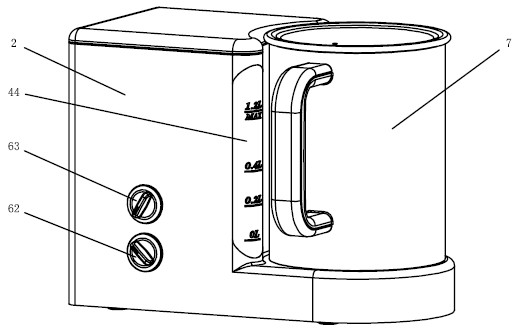

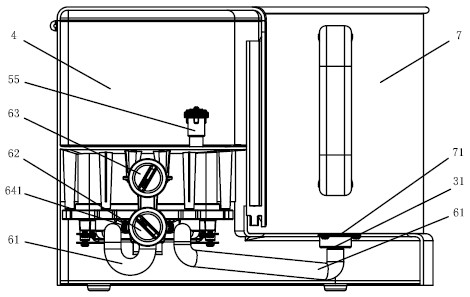

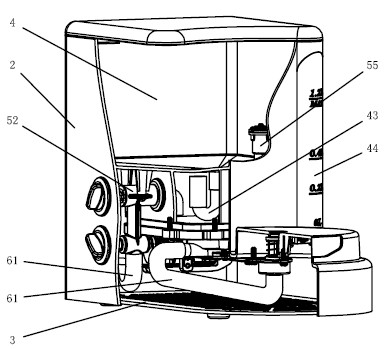

Apparatus and method for combining hot water and steam to cook food

InactiveCN102273917AEnergy controllableEasy to cleanSteam cooking vesselsWarming devicesCombined methodEngineering

The invention discloses an appliance for cooking foods by combining hot water and steam. The appliance comprises a body and a food container capable of being separated from the body, wherein the body comprises a machine body and a base; the machine body accommodates a water tank and a boiler positioned below the water tank; the base extends from the bottom end of the body laterally and is used for supporting the food container; fluid one-way communication is formed between the water tank and the boiler and between the boiler and the food container; and the boiler is used for receiving and heating water from the water tank and conveying generated hot water and steam into the food container. The invention also discloses a method for cooking foods by using the appliance. The food container can be separated from the body, namely separated from a heat source and a power source; the container is easy to clean; and by the method for cooking the foods by combining the hot water and the steam,the energy is easy to control, the cooking effect is good, and nutrient components of foods cannot be damaged.

Owner:申晓星

Cover tape

ActiveCN103043302ANo adhesionImprove anti-static performanceFilm/foil adhesivesAdhesive articlesWaxAntistatic agent

A cover tape having at least a base material layer, and an adhesive layer that is heat sealed by a resin carrier tape, the cover tape characterized in that: the base material layer has an antistatic layer on a surface thereof that is on the reverse side to the adhesive layer; the antistatic layer contains at least an inorganic antistatic agent and a wax having a particle diameter of 0.2-3.0 [mu]m; the inorganic antistatic agent is 40%-80% by mass and the wax content is 10%-50% by mass, relative to the total components forming the antistatic layer; and the surface resistivity of the base material layer side is no more than 1013Omega / - in a 23 DEG C 30% R.H. atmosphere.

Owner:DENKA CO LTD

Medicine ointment for treating burns and scalds and its prepn

InactiveCN1772145ANo adhesionIncrease elasticityOrganic active ingredientsAerosol deliveryHyperpigmentationChinese traditional medicine

The medicine ointment for treating burns and scalds is prepared with rhubarb, bletilla tuber, garden burnet, clove, frankincense and other nine kinds of Chinese medicinal materials, as well as streptomycin sulfate and medicinal vaseline in certain weight proportion. The Chinese medicinal materials have the functions of eliminating heat toxin, resisting bacteria, dissipating blood clots, eliminating swelling, relieving pain, etc., so that the medicine ointment of the present invention compounded based on Chinese medicine theory has the advantages of fast wound healing, elimination of skin grafting operation, less pain, no scar and pigmentation, no skin adhesion, etc.

Owner:黄绍恒

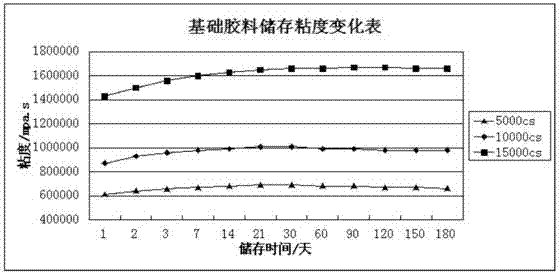

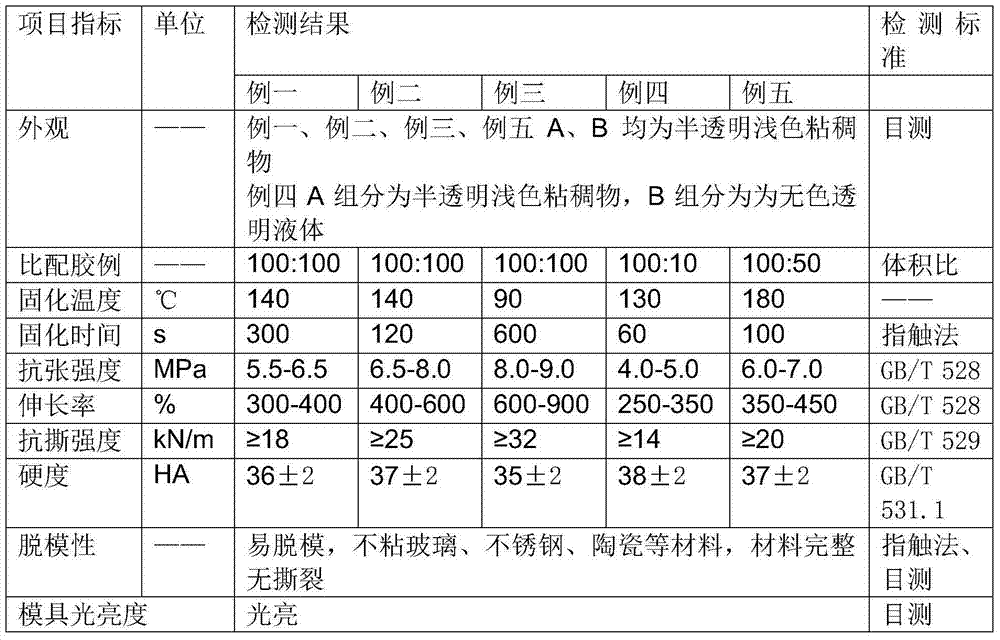

Bi-component addition type mold silicone rubber for injection molding

The invention discloses a bi-component addition type mold silicone rubber for injection molding. The silicone rubber is cured and molded by using A and B components, wherein the A component comprises the following components in parts by mass: 100 parts of base silica gel, 0.1-0.30 part of platinum complex catalyst, 0.1-2.0 part of polymerization inhibitor which is alkynol and vinyl ring-body compound, and 0-10 parts of vinyl silicone oil; the B component comprises the following components in parts by mass: 0-100 parts of vinyl silicone oil, 4-15 parts, preferably 5-10 parts of one or more hydrogen polysiloxanes, and 0-20 parts of vinyl silicone oil. The silicone rubber is used for preparing silicone rubber mold through injection molding and mainly suitable for fast injection molding, the obtained product is good in extrusion property, easy for demolding after being molded, good in mechanical property, free of volatile byproducts in the vulcanizing process, low in shrinkage percentage, internally and externally vulcanized at the same time, good in rebound resilience, wide in application, and can be applied to preparing various injection molded products such as artificial jewelry; the silicone rubber can be reused many times, the higher the reuse frequency is, the better the performance is.

Owner:CHENGDU TALY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com