Patents

Literature

499results about How to "Improve anti-static performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet curing coating for preventing static on plastic surface and method for preparing the same

InactiveCN101423675ALight weightGood electrical conductivityElectrically-conductive paintsSolventPhotoinitiator

The invention relates to an ultraviolet photo-cured coating for the electrostatic prevention of the surface of plastic and a preparation method thereof, in particular to a photo-cured coating containing conductive powder of a metal oxide system or composite conductive powder. The coating comprises the following compositions in weight percent: 30 to 70 percent of oligomer, 25 to 65 percent of active thinner, 0.5 to 10 percent of light evocating agent, 5 to 40 percent of conductive powder, 0.2 to 8 percent of additive and 0 to 50 percent of solvent. As the added conductive powder of the metal oxide system and the composite conductive powder is white or light color, the prepared photo-cured has the characteristic of easy color modulation, has lasting antistatic property, high rigidity and wearing resistance, can be used for electrostatic prevention of the surface of electronic equipment, plastic vessel, shell of an electric appliance, office supplies, sports equipment and other plastic products.

Owner:SICHUAN UNIV

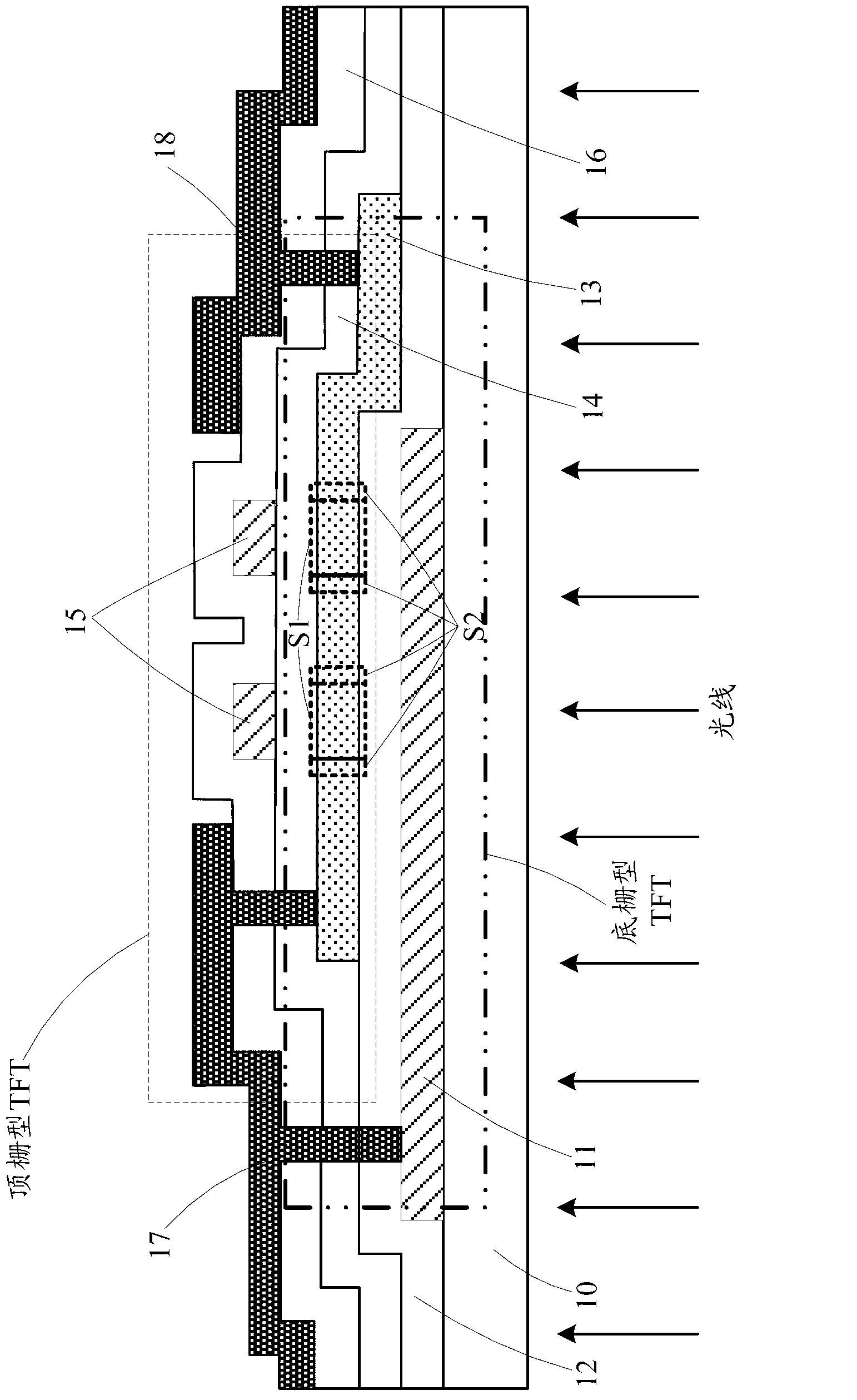

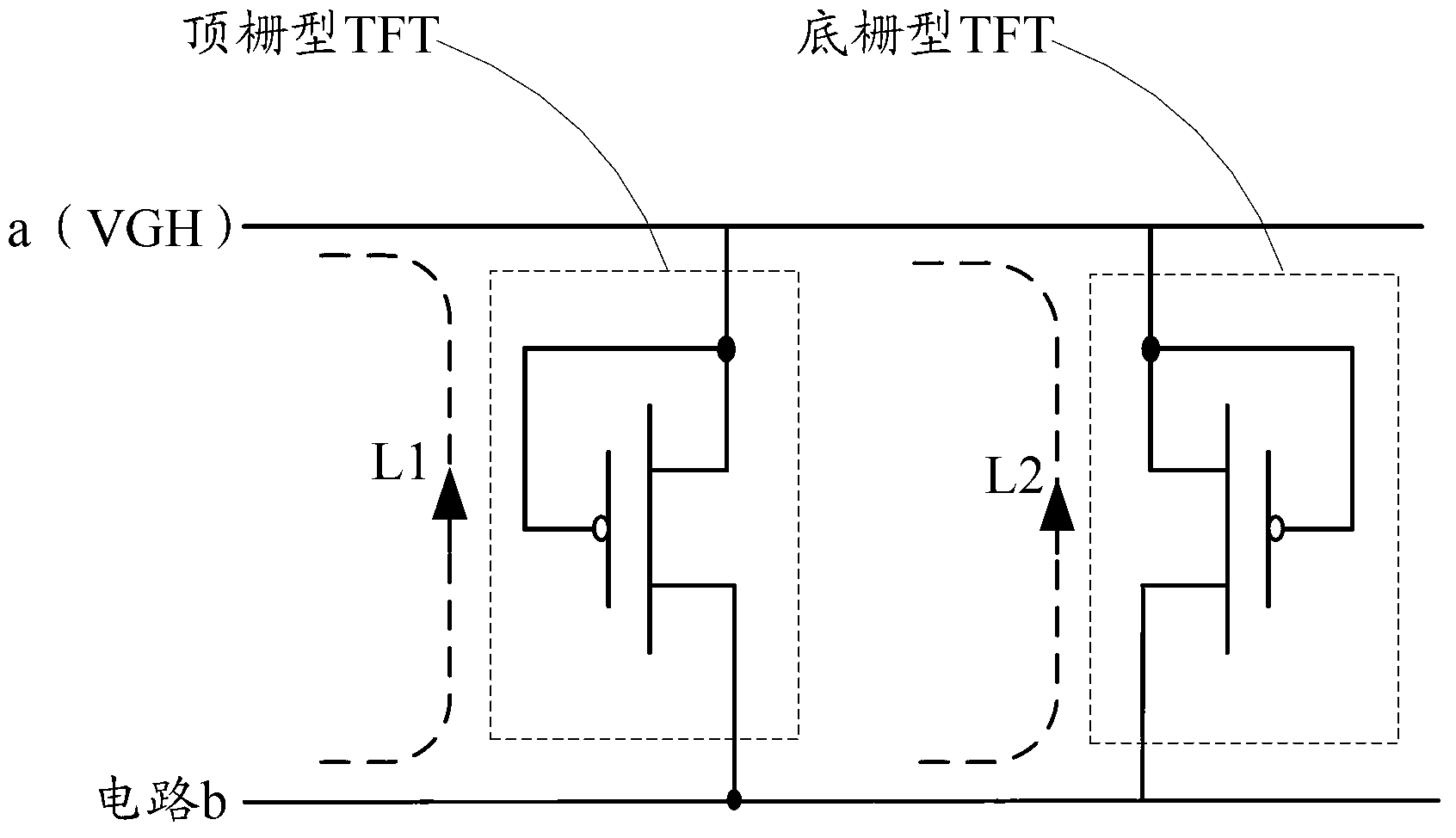

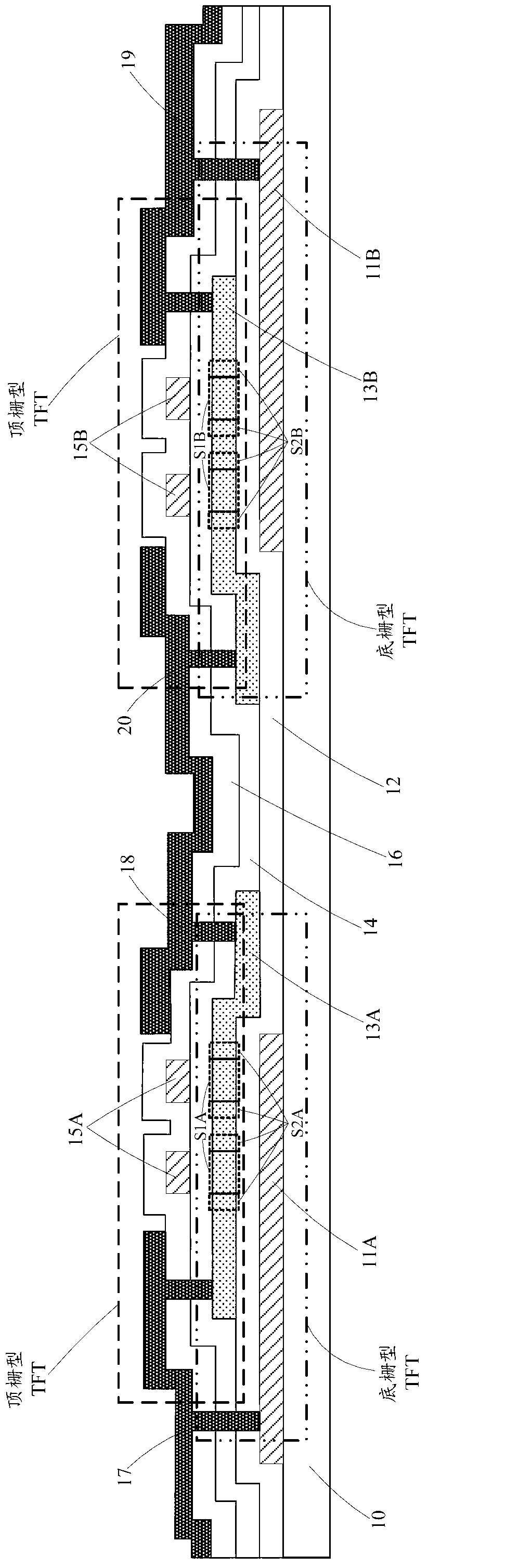

Electrostatic discharge protection circuit, display panel and display device

ActiveCN103268876AAdd release pathImprove anti-static performanceSolid-state devicesEmergency protective arrangements for limiting excess voltage/currentDisplay deviceBottom gate

The invention relates to the field of display devices, in particular to an electrostatic discharge protection circuit, a display panel and a display device. According to the embodiment of the invention, the electrostatic discharge protection circuit comprises at least one electrostatic protection element, and the electrostatic protection element comprises a bottom gate electrode, a first insulating layer, an active layer, a second insulating layer, top gate electrodes, a third insulating layer, a first electrode and a second electrode, wherein the bottom gate electrode is positioned on a substrate; the first insulating layer is positioned on the bottom gate electrode; the active layer is positioned on the first insulating layer, and corresponds to the bottom gate electrode; the second insulating layer is positioned on the active layer; the top gate electrodes are positioned on the second insulating layer, and correspond to the active layer; the third insulating layer is positioned on the top gate electrodes; the first and second electrodes are positioned on the two sides of the top gate electrodes on the third insulating layer respectively; the bottom gate electrode and the top gate electrodes are electrically connected with the first electrode and connected with a power cord or a circuit of a display area of the display panel; and the second electrode is electrically connected with the circuit of the display area or the power cord. According to the electrostatic discharge protection circuit, an electrostatic discharge path is added, so that the anti-electrostatic capability is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

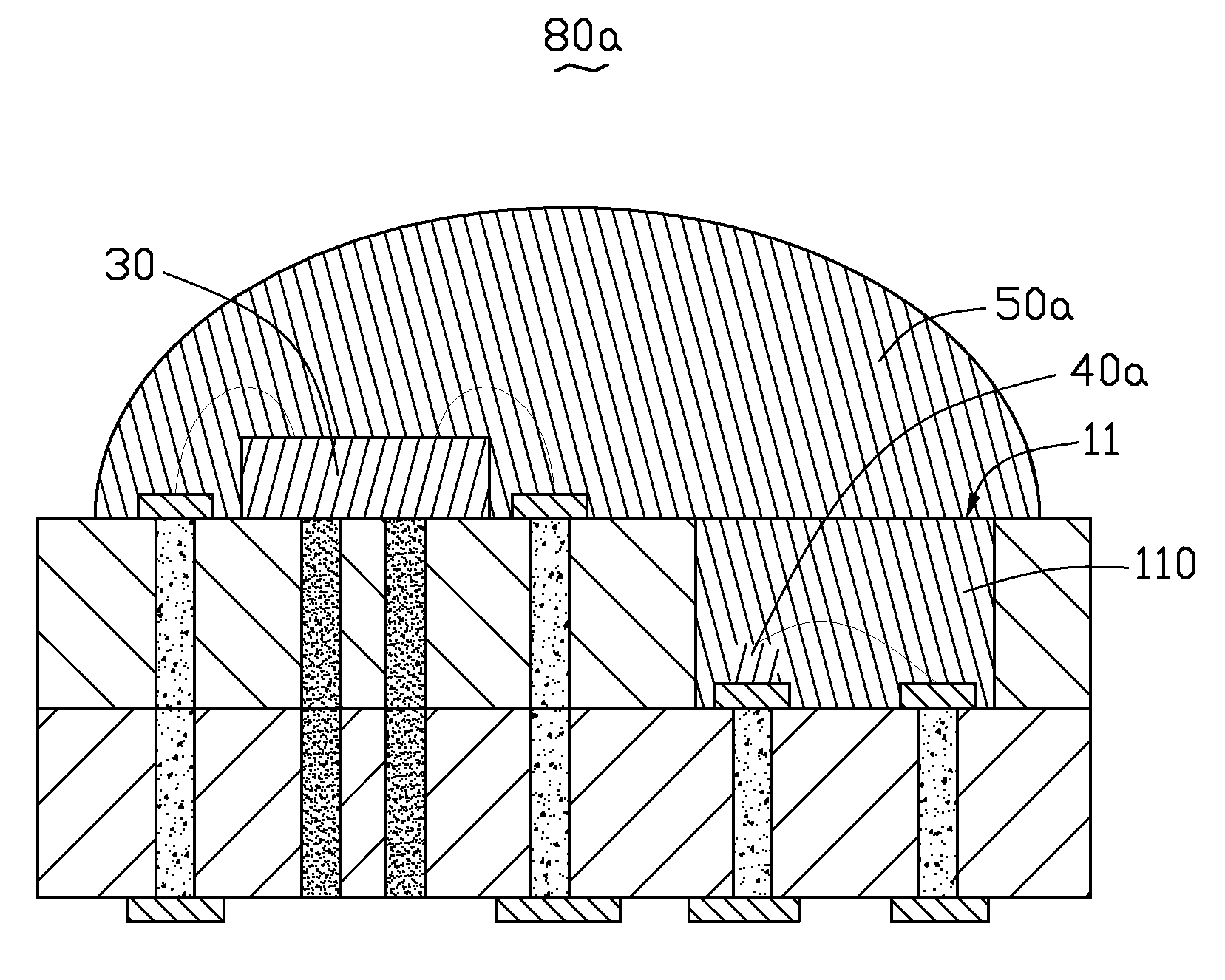

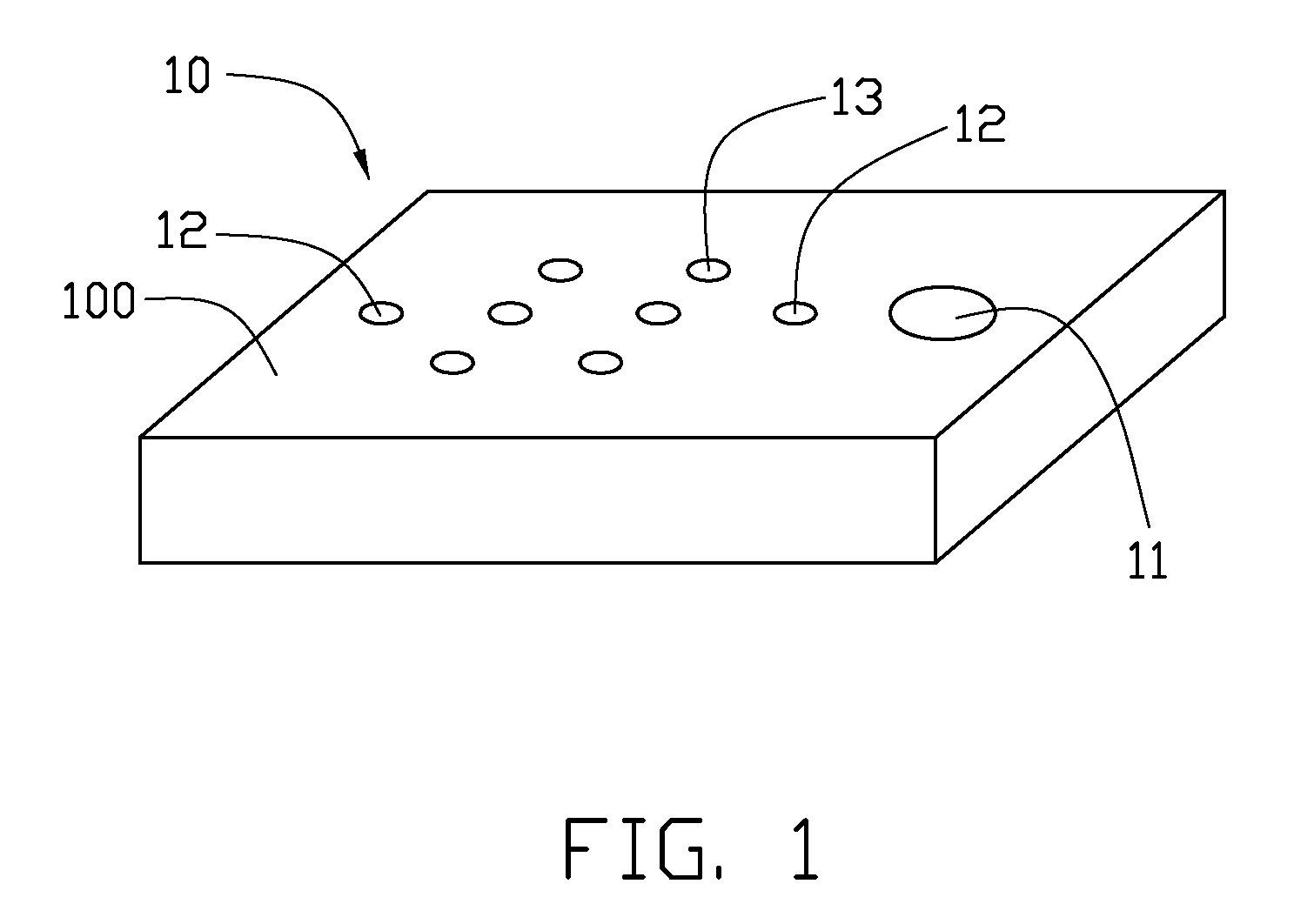

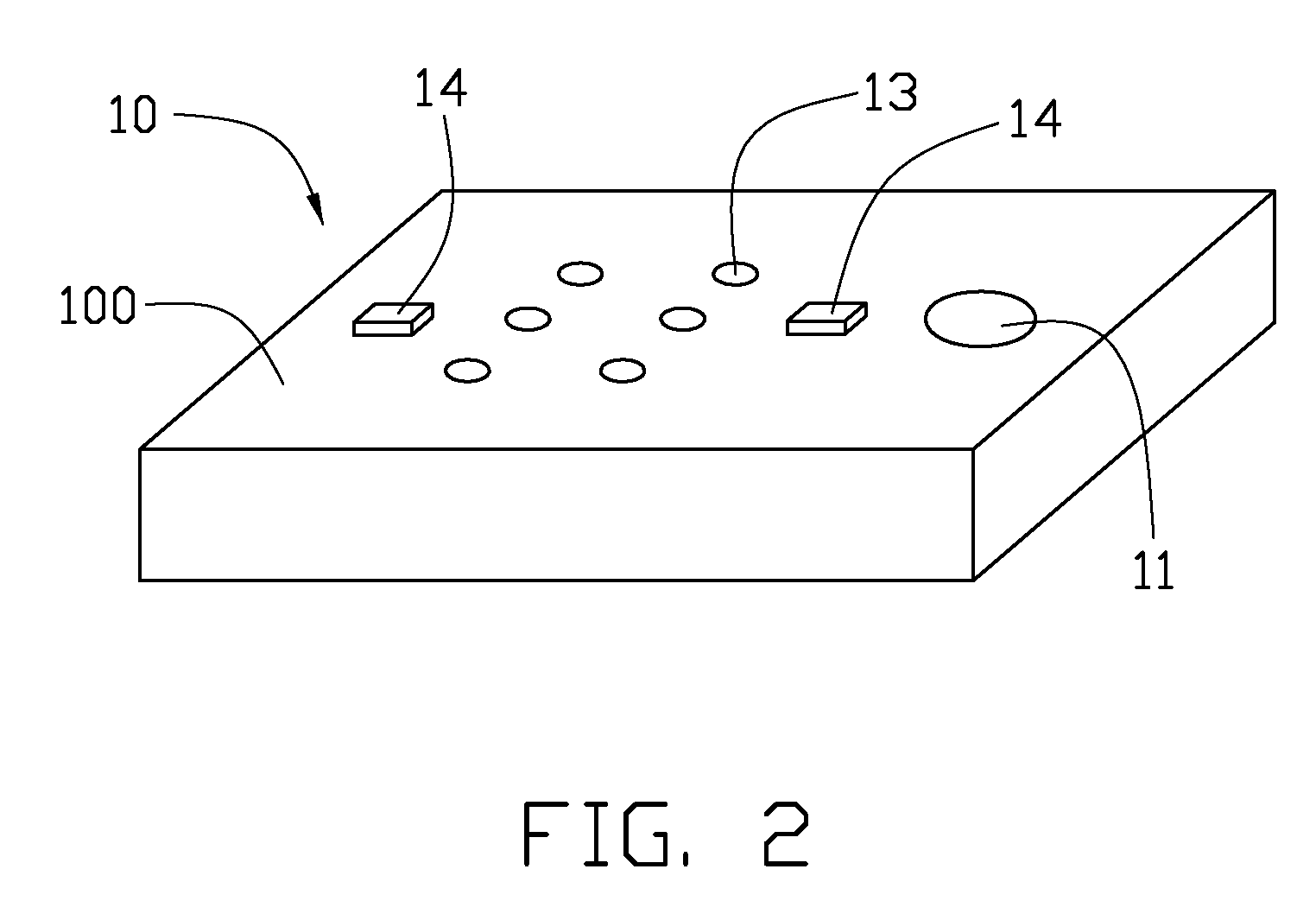

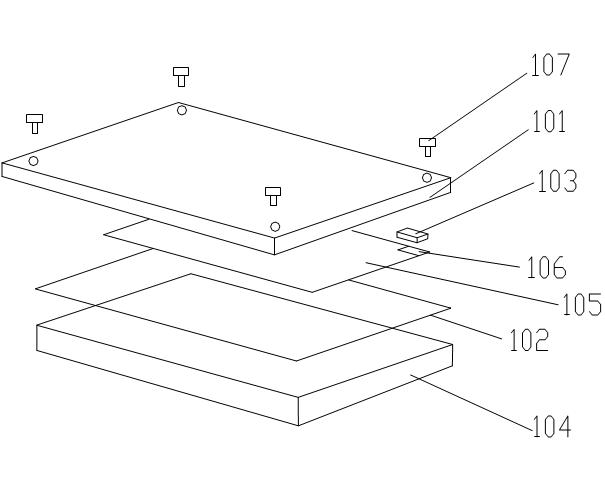

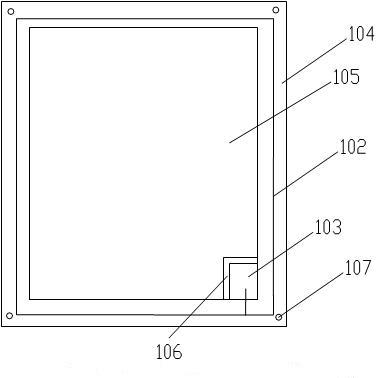

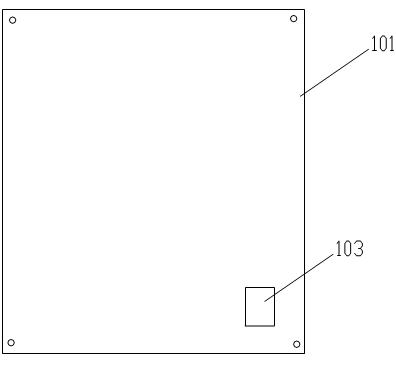

Solid state light emitting device

InactiveUS20090090926A1Improving reliability and practicabilityImprove anti-static performanceSemiconductor/solid-state device detailsSolid-state devicesLight emitting deviceElectron

A solid state light emitting device includes a laminated substrate structure (120), an LED chip (30), a transparent capsulation material (50) and an electric component (40). The laminated substrate structure includes a first substrate (10) and a second substrate (20) attached to each other by a sintering process. The first substrate has a mounting surface (100) and a receiving through hole (11) defined in the mounting surface thereof. The LED chip is mounted on the mounting surface of the first substrate. The transparent capsulation material envelops the LED chip therein. The electric component is received in the receiving hole and mounted on the second substrate. The electric component is located below the mounting surface of the first substrate.

Owner:FOXSEMICON INTEGRATED TECH INC

Glass cleaning agent

ActiveCN101434891AImprove film formationAvoid it happening againInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCross-linkAlcohol

A glass cleaning agent contains alcohol, a surfactant and water, as well as a solubilizer and a corrosion inhibitor which can be selectively contained, wherein, the cleaning agent further contains a siloxane / alkylene oxide cross-linked matter. The addition of the water-soluble siloxane / alkylene oxide cross-linked matter can enhance the film-forming performance of alcohol solvents, improve anti-static effect and effectively prevent glass from hanging fog at low temperature.

Owner:靖江市城中村投资建设有限公司

Anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and preparation method thereof

ActiveCN103173087ANovel structureImprove conductivityAnti-corrosive paintsElectrically-conductive paintsEpoxyEmulsion

The invention discloses an anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and a preparation method thereof and relates to the technical field of production of a coating. According to the invention, carbon nano tube is selected as an antistatic additive; and a film forming matter is waterborne acrylate grafted epoxy resin emulsion. The characteristics of the acrylate resin and epoxy resin can be effectively integrated into a whole; the prepared anti-corrosion antistatic coating is good in storage stability, good in construction property, fast to dry after being coated, smooth in dried film, and excellent in mechanical behavior, antistatic property, acid resistance, alkali resistance, salt water resistance and the like.

Owner:扬州市伊丽特高分子材料科技有限公司

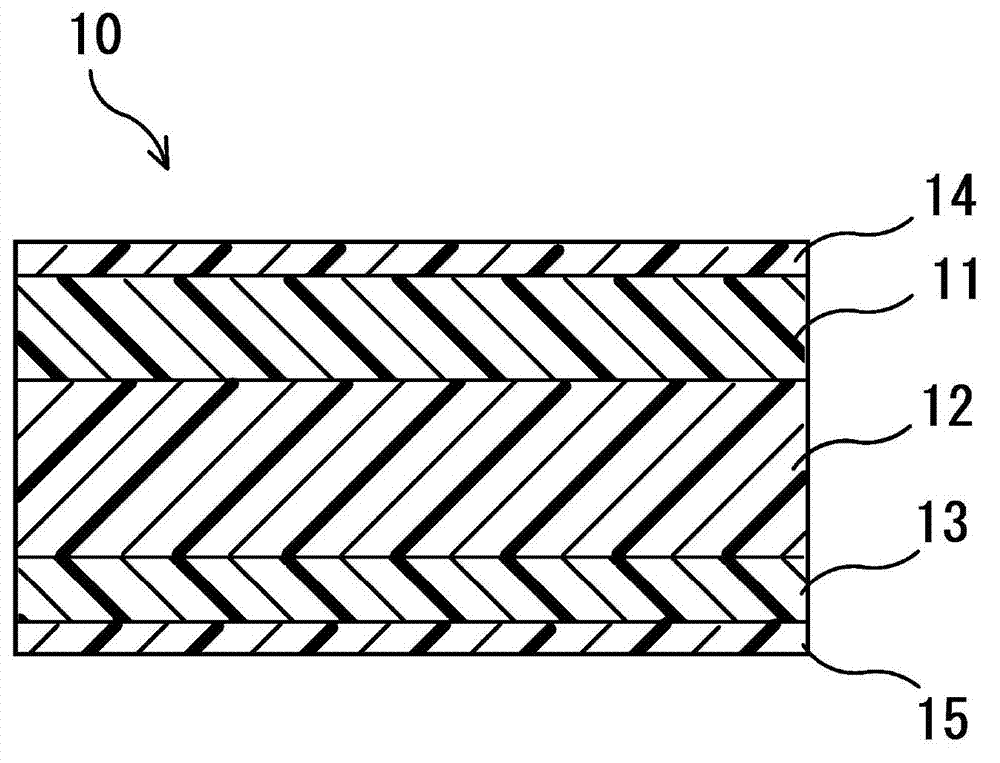

High-adherence anti-static release film

ActiveCN104210195AImprove anti-static effectExcellent adhesionSynthetic resin layered productsLaminationPlastic filmEthyl acetate

The invention relates to a high-adherence anti-static release film, belonging to the field of plastic thin films. The high-adherence anti-static release film comprises a base material layer, wherein the base material layer is coated with an anti-static layer; the anti-static layer is formed by coating anti-static liquid, and is coated with a release layer; the release layer is formed by coating a release agent; the release agent consists of the following components in percentage by mass: 5-30 percent of vinyl end group organic silicon resin, 0.3-5 percent of a bridging agent, 0.5-8 percent of a platinum catalyst, 5-50 percent of methylbenzene and 50-80 percent of ethyl acetate. The release film disclosed by the invention is high in anti-static property and high in adherence (the subsequent adhesion); the release force can meet requirements of some high-end electronic materials; the anti-static layer has an anti-static function and can enhance connection with the release layer, so that the anti-static layer is unlikely to fall; the film is high in firmness and durable; all the layers are tightly connected and are unlikely to separate; the manufacturing cost is low, and the technology is simple.

Owner:ZHEJIANG JIEMEI ELECTRONICS & TECH

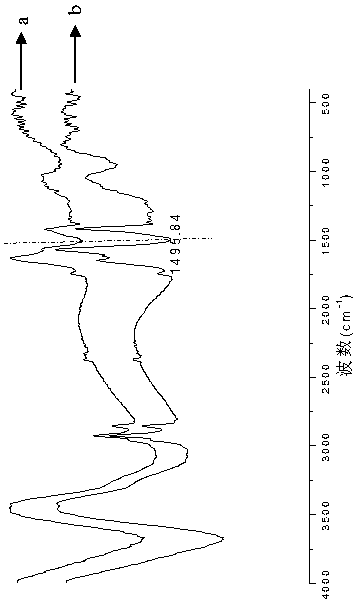

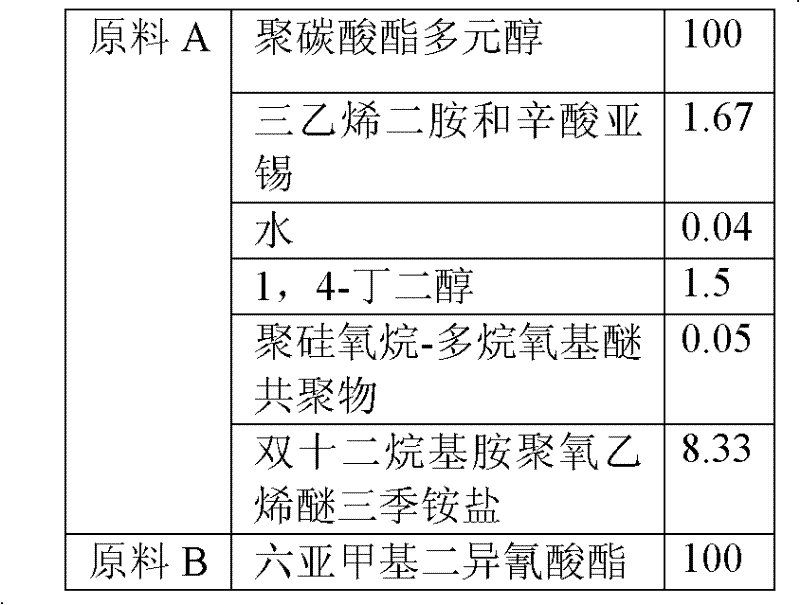

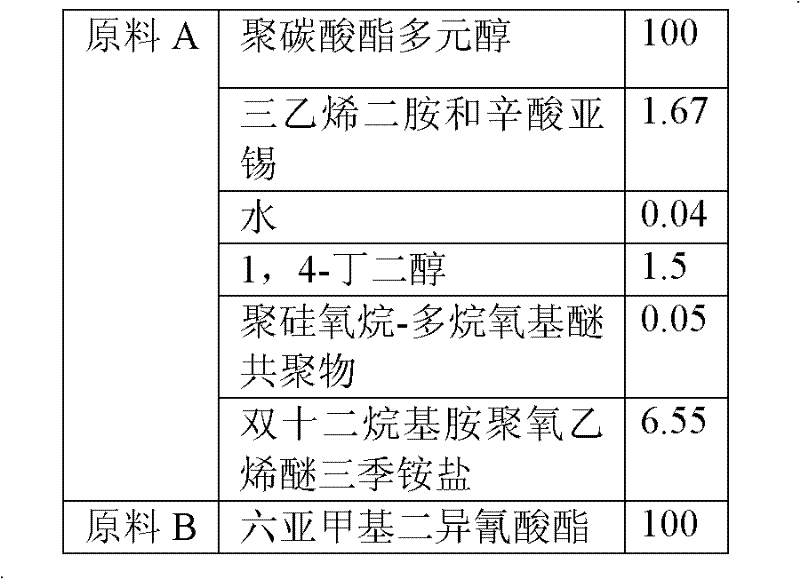

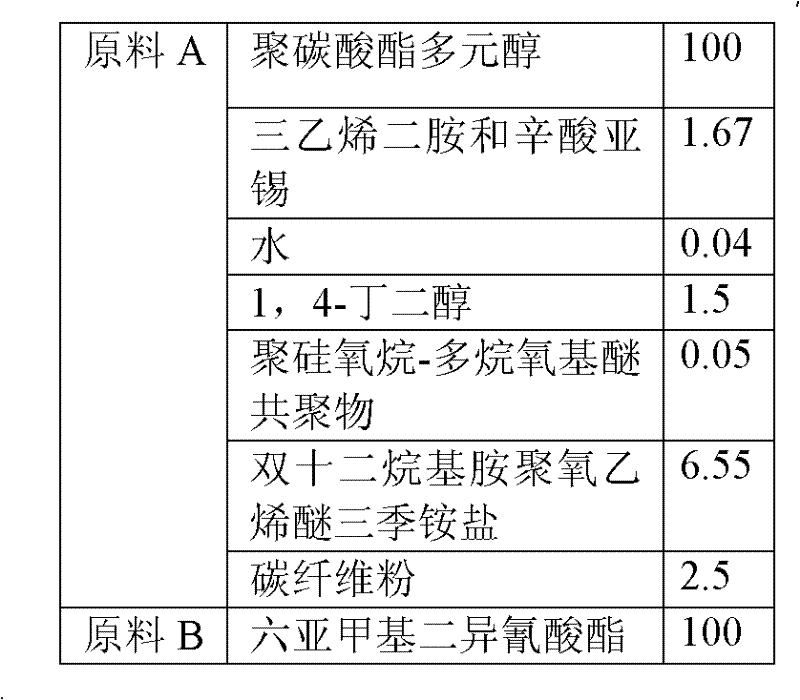

Anti-static polyurethane material for manufacturing shoe soles, shoe sole manufacturing method and manufacturing method of dual-density polyurethane safety shoe soles

ActiveCN102504519AImprove anti-static performanceGood anti-static performanceSolesDefoaming AgentsIsocyanate compound

The invention discloses an anti-static polyurethane material for manufacturing shoe soles, a shoe sole manufacturing method and a manufacturing method of dual-density polyurethane safety shoe soles. The anti-static polyurethane material consists of a component A and a component B which are mixed and poured, the component A includes polyatomic alcohol, catalyst, foaming agent, anti-static agent, carbon fiber powder, chain extender and defoaming agent; and the component B is isocyanate. The shoe sole manufacturing method includes steps of baking and drying the polyatomic alcohol and the isocyanate, mixing the rest compositions in the component A and the baked polyatomic alcohol uniformly to form material A, and mixing the material A with the isocyanate of the component B to obtain shoe soles made of anti-static polyurethane materials by pouring forming. The dual-density polyurethane safety shoe soles can be manufactured by secondary pouring by selecting foaming agents in different quantity. The polyurethane materials are high in anti-static performance, and the manufactured shoe soles are proper in hardness. Shoe soles manufactured by the manufacturing methods are fine in demouldingand high in production efficiency.

Owner:深圳市新纶超净科技有限公司

Adhesive composition, adhesive sheets and surface protecting film

ActiveCN1667071AAnti-static function hasImprove anti-static performanceNon-macromolecular adhesive additivesEster polymer adhesivesGlass transitionIonic liquid

The present invention provides a pressure-sensitive composition comprising an ionic liquid and a polymer having a glass transition temperature Tg of 0 DEG C or lower as a base polymer as a pressure-sensitive adhesive composition in which electrification of a pressure-sensitive adhesive sheet can be prevented upon peeling, and staining property on an adherend can be reduced, and an antistatic pressure-sensitive sheet and surface protecting film using the pressure-sensitive adhesive composition.

Owner:NITTO DENKO CORP

Conductive antistatic coating, coiled material, and preparation method of coiled material

InactiveCN105647339AImprove conductivityExcellent physical and chemical propertiesLayered productsEpoxy resin coatingsFiberEpoxy

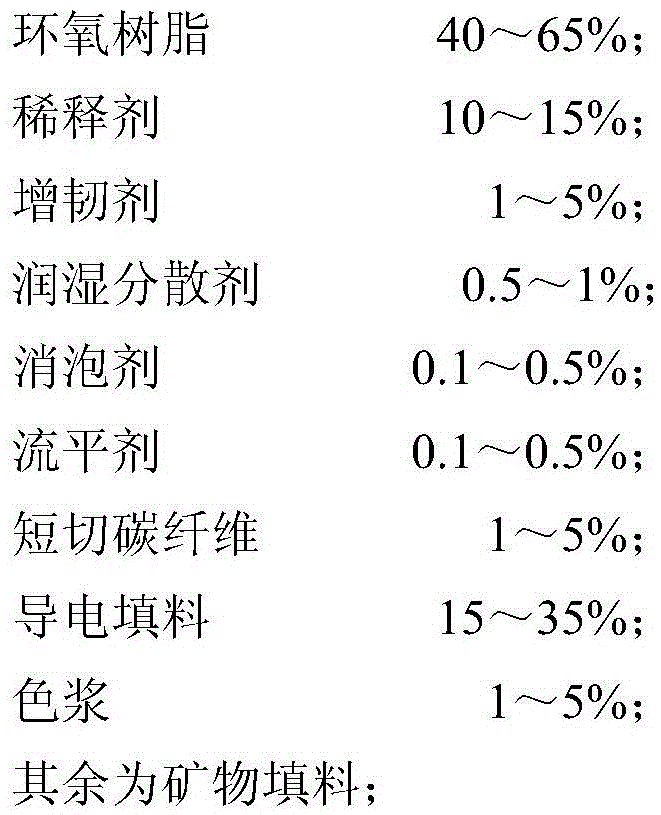

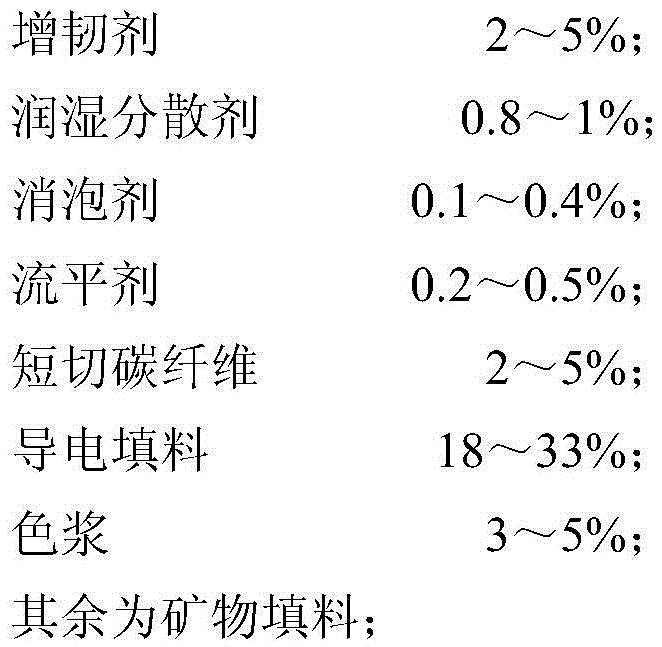

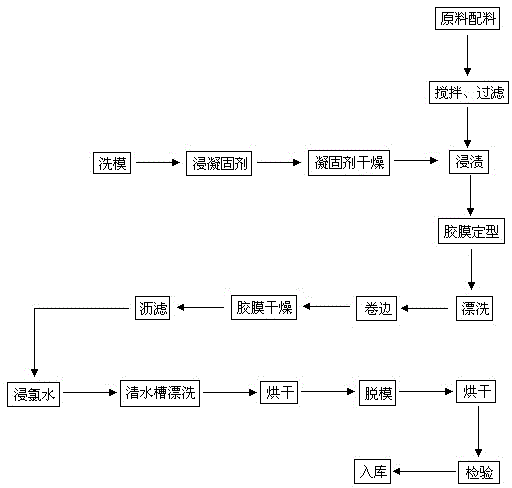

The invention discloses a conductive antistatic coating, a coiled material, and a preparation method of the coiled material. The coating comprises a component A and a component B according to a weight ratio of 10:2-5; the component A comprises, by mass, 40-65% of epoxy resin, 10-15% of a dilution agent, 1-5% of a flexibilizer, 0.5-1% of a wetting dispersant, 0.1-0.5% of an antifoaming agent, 0.1-0.5% of a leveling agent, 1-5% of short carbon fibers, 15-35% of a conductive filler, 1-5% of a color paste, and the balance of a mineral filler; and the component B comprises 91-98% of a curing agent, and the balance of a curing accelerator. The short carbon fibers and the conductive filler are added to the coating, so the conductivity of the coating is good; and a carbon fiber cloth, a carbon fiber felt and a carbon fiber surface felt are adopted as the conductive skeleton of the coiled material, so the resistance of the coiled material is reduced, the conductivity of the coiled material is guaranteed, and the mechanical performances of the coiled material are improved.

Owner:浙江港流高分子科技股份有限公司

Butyronitrile glove preventing static and production method thereof

InactiveCN104621800AImprove anti-static performanceImprove protectionGlovesCoatingsNitrile rubberPotassium hydroxide

The invention relates to a glove and a production method of the glove, in particular to a butyronitrile glove preventing static and a production method of the butyronitrile glove. The butyronitrile glove preventing static comprises 100 parts of nitrile rubber, 1 part of potassium hydroxide, 0.2 part of zinc dibutyl dithiocaarbamate, 0.15 part of defoaming agent, 0.3 part of anti-static fluid and 2.75 parts of auxiliary materials. The anti-static performance of the butyronitrile glove in the field of high-end electronic products is improved, and the skin is protected well. According to the production technology, automatic flow line production is adopted, in this way, mass production in quantity of the product is achieved, and the production efficiency and quality of the product are improved.

Owner:江苏东菱塑胶有限公司

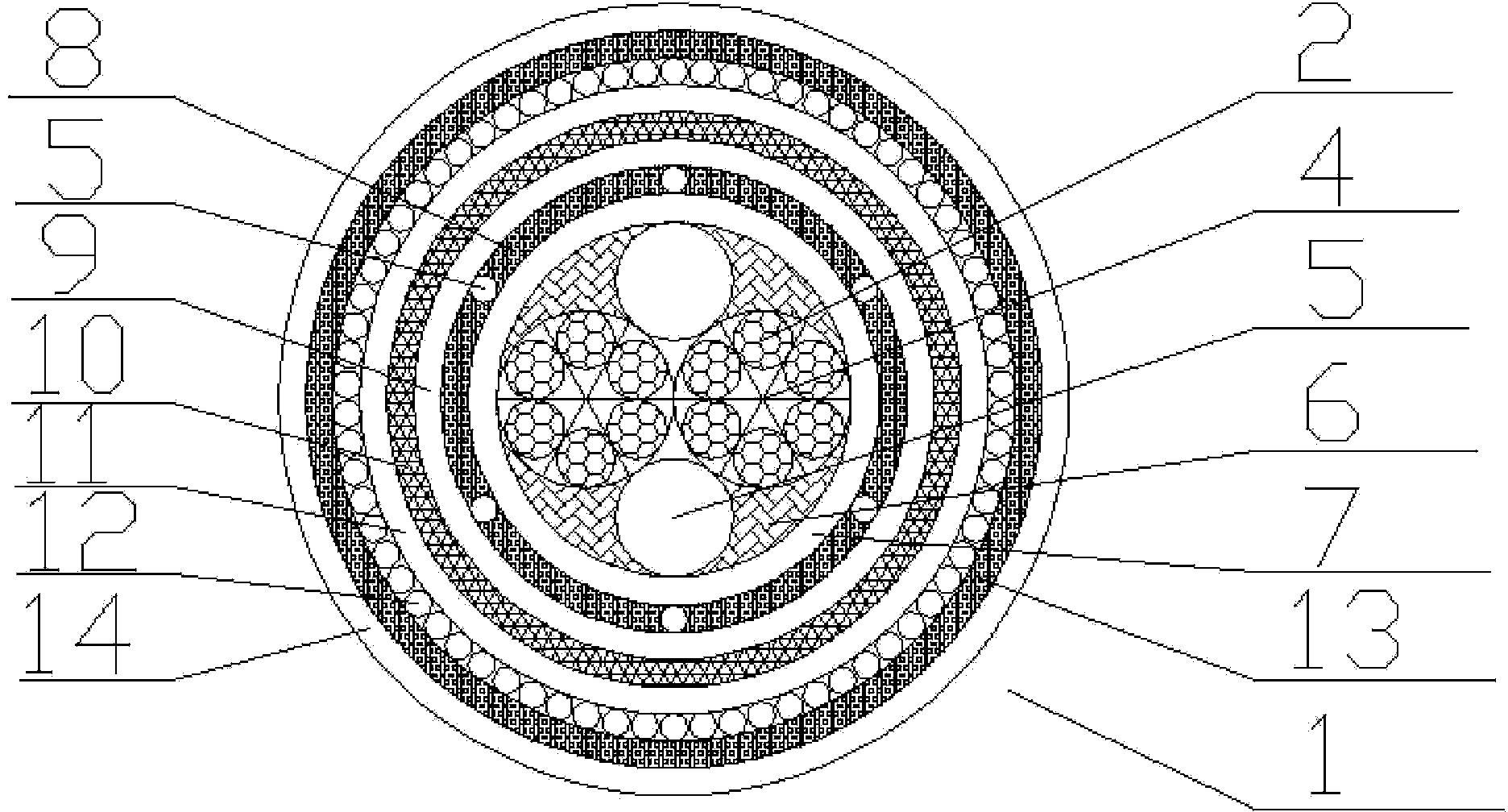

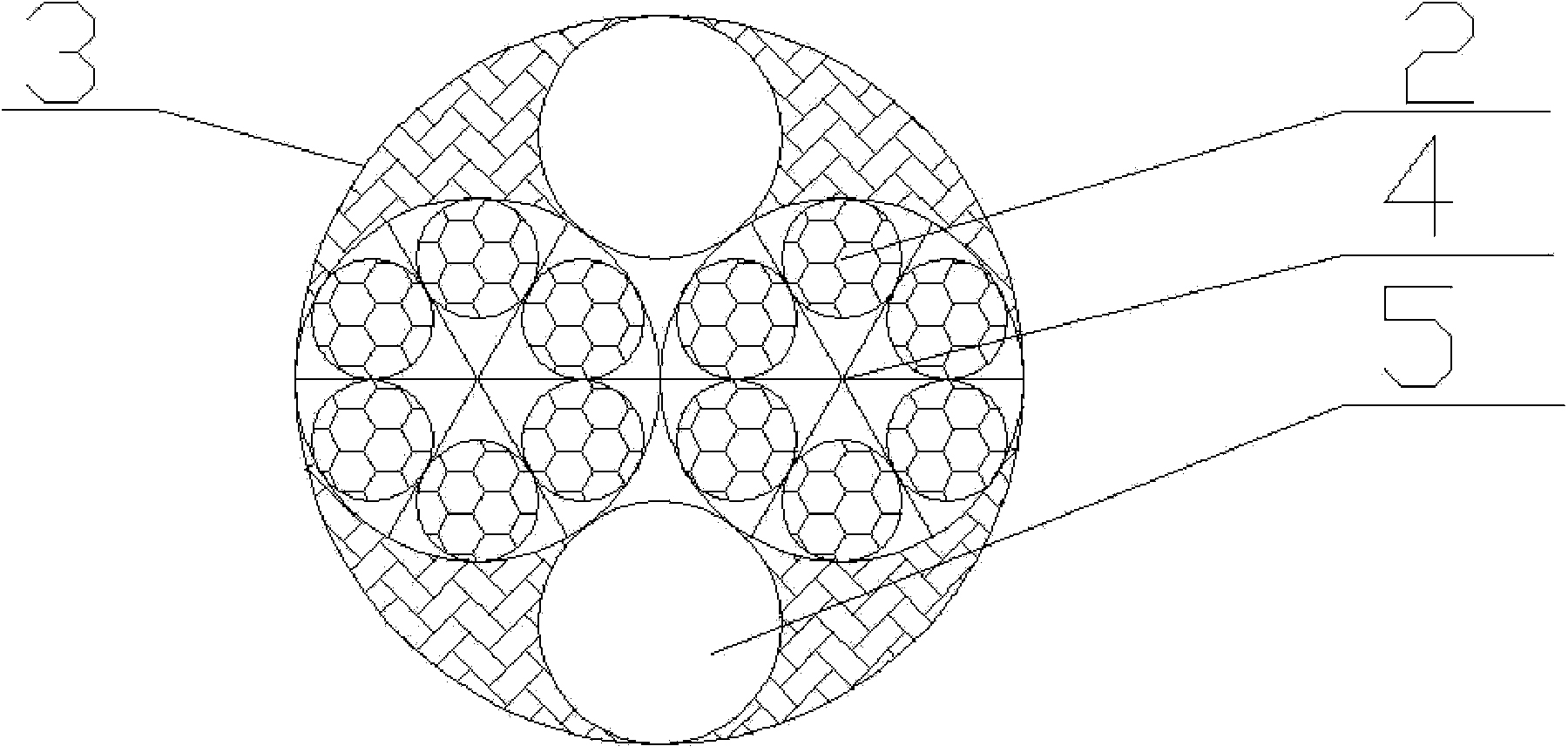

Anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable

InactiveCN104318986AReasonable structural designImprove anti-static abilityInsulated cablesInsulated conductorsGraphiteStatics

The invention discloses an anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable. The anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable comprises a cable body. The cable body comprises cable cores, a cable core protective layer, an insulating layer, a shielding layer and an outer jacket. The cross section of the cable core protective layer is of a circular structure, and the multiple evenly-arranged cable cores are arranged in the cable core protective layer and separated through PVC plastic connecting rods; a plurality of current guide cores are arranged outside the cable core protective layer and are tangent with the cable core protective layer; the insulating layer is arranged outside the cable core protective layer; waterproof fillers are arranged in a gap between the insulating layer and the cable core protective layer; the shielding layer is tightly extruded on the insulating layer and internally provided with the multiple evenly-arranged current guide cores; a breakdown resistant layer, a steel core protective layer and a waterproof layer are sequentially extruded on the shielding layer from inside to outside; an armor layer is extruded outside the waterproof layer, the outer jacket is arranged outside the armor layer, and a graphite layer is arranged between the armor layer and the outer jacket. The anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable has the advantages of being reasonable in structural design, high in anti-static capacity, good in anti-corrosion performance and the like.

Owner:珠海长盛电缆有限公司

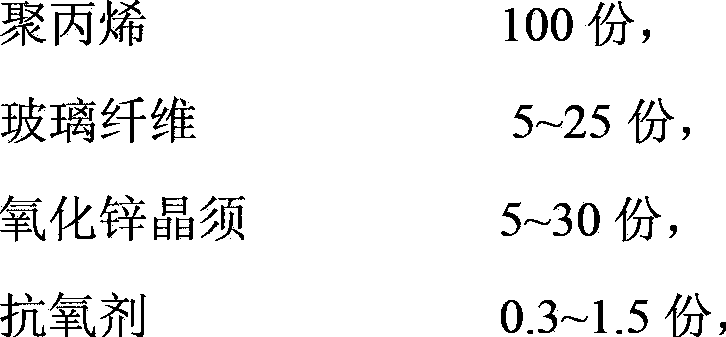

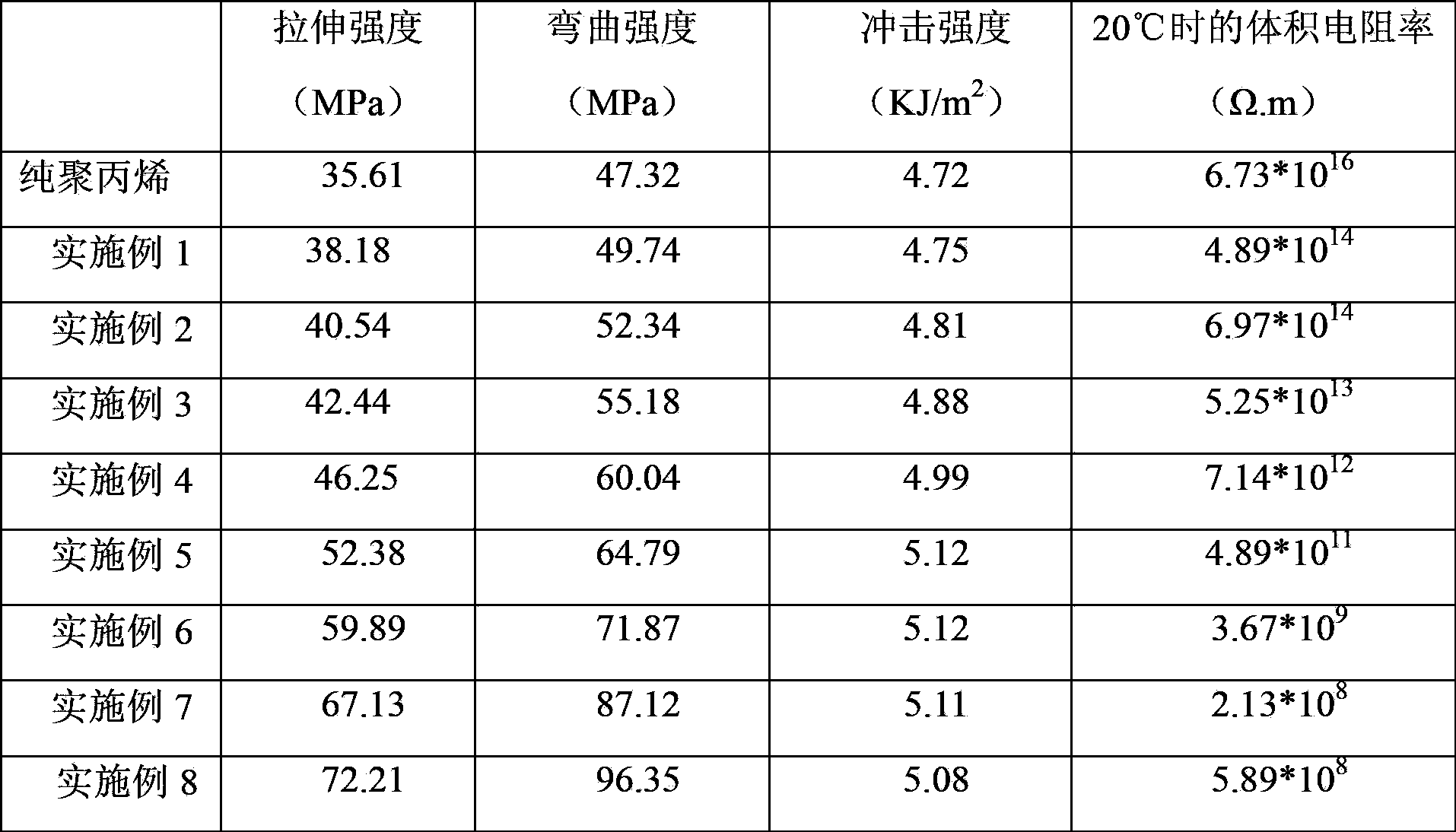

Enhanced antistatic polypropylene composite material and preparation method thereof

InactiveCN103849067AImprove mechanical propertiesImprove anti-static performanceSurface finishPolypropylene composites

The invention belongs to the technical field of high polymer materials and relates to a polypropylene composite material and a preparation method thereof. The material is prepared from the following components in parts by weight: 100 parts of polypropylene, 5-25 parts of glass fiber, 5-30 parts of zinc oxide whiskers, 0.3-1.5 parts of antioxidant, 0.2-1.5 parts of lubricating agent, 0.1-1 part of coupling agent and 0.1-1 part of nucleating agent. The zinc oxide whiskers and the glass fibers are compounded according to a certain ratio, so that the mechanical performance of the polypropylene is improved, and the antistatic performance of the polypropylene is enhanced. In addition, the zinc oxide whiskers are added into the system, so that the surface smoothness and dimensional stability of the products can be effectively improved, and the application range of the polypropylene modified material is widened. Moreover, by utilizing a simple preparation process, the polypropylene composite material with excellent mechanical performance and a certain antistatic performance is obtained.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

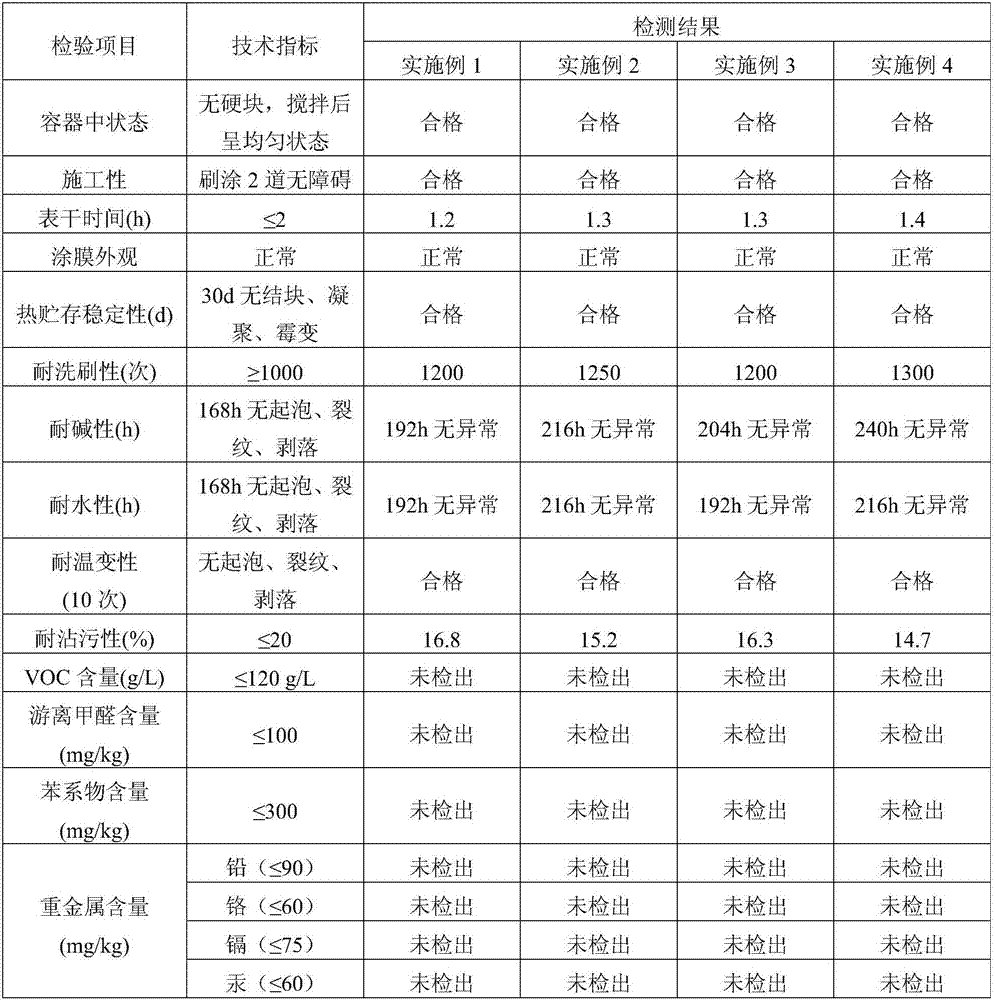

Novel environment-friendly waterborne inorganic paint and preparation method thereof

InactiveCN107266944AFire retardantAntibacterial and antifungalFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholFire resistance

The invention discloses novel environment-friendly waterborne inorganic paint and a preparation method thereof. The novel environment-friendly waterborne inorganic paint is prepared from, by weight, 55-65 parts of kaolin, 12-20 parts of sodium silicate, 20-30 parts of titanium dioxide, 1-5 parts of nano zinc oxide, 5-10 parts of ultrafine wollastonite powder, 1-10 parts of nano calcium carbonate, 1-5 parts of ultrafine white mica powder, 7-15 parts of polyvinyl alcohol, 1-4 parts of ultrafine molybdenum disulfide powder, 2-10 parts of nano silicon dioxide, 2-12 parts of nano magnesium oxide, 2-12 parts of nano aluminum oxide, 1-3 parts of magnesium chloride, 1-3 parts of a sodium silicate hardening accelerator, 2-5 parts of a pH value regulating agent, 1-8 parts of a waterproof agent, 6-10 parts of an antifoaming leveling agent, 1-3 parts of a thickening anti-settling agent and 280-310 parts of water. The novel environment-friendly waterborne inorganic paint which is environment-friendly waterborne inorganic paint for buildings is high in storage stability, excellent in water resistance and alkali resistance, strong in adhesion, high in fire resistance, high in strength and hardness, resistant to scratching and contamination, excellent in corrosion resistance and antibacterial property, free of formaldehyde, benzene compounds, VOC (volatile organic compounds) and heavy metal elements, completely environmental friendly and nontoxic, suitable for industrial production, easy for painting and convenient and quick in construction.

Owner:CHENGDU POLYTECHNIC

Water-based nano antistatic epoxy floor paint and preparation method thereof

InactiveCN108165076AImprove anti-static effectImprove performanceFireproof paintsEpoxy resin coatingsWater basedFiber

The invention discloses a water-based nano antistatic epoxy floor paint which comprises a component A and a component B. The component A includes the following components by the mass percentage: 85-90% of modified waterborne epoxy resin, and 10-15% of an epoxy active diluent; the component B includes the following components by the mass percentage: 45-50% of an epoxy resin curing agent, 2-3% of titanium dioxide, 5-8% of zinc oxide whiskers, 5-10% of alumina, 2-5% of nano zinc oxide, 2-5% of carbon fibers, 0.5-1% of a defoaming agent, 0.5-1% of a thickener, 0.5-1% of a dispersant, 0.5-1% of a pH regulator, and the balance water; the weight ratio of the component A to the component B is 1:3 to 1:5. The water-based nano antistatic epoxy floor paint has good compatibility of the components, small addition amount of an electrically conductive filler and good antistatic performance, has a certain flame retardancy, and has good application prospect.

Owner:百翼涂料(广州)股份有限公司

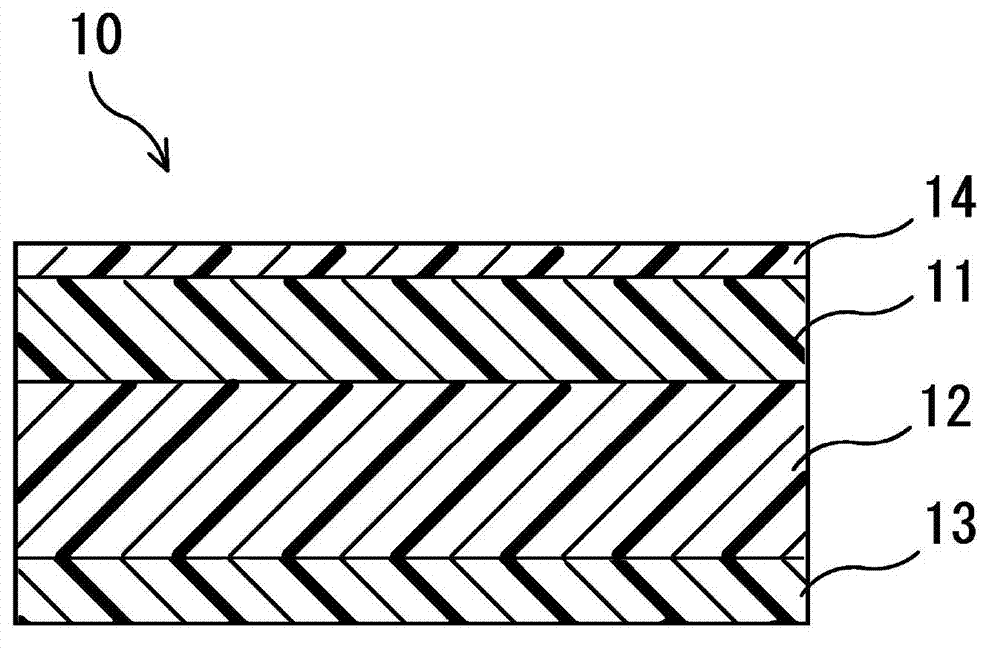

Cover tape

ActiveCN103043302ANo adhesionImprove anti-static performanceFilm/foil adhesivesAdhesive articlesWaxAntistatic agent

A cover tape having at least a base material layer, and an adhesive layer that is heat sealed by a resin carrier tape, the cover tape characterized in that: the base material layer has an antistatic layer on a surface thereof that is on the reverse side to the adhesive layer; the antistatic layer contains at least an inorganic antistatic agent and a wax having a particle diameter of 0.2-3.0 [mu]m; the inorganic antistatic agent is 40%-80% by mass and the wax content is 10%-50% by mass, relative to the total components forming the antistatic layer; and the surface resistivity of the base material layer side is no more than 1013Omega / - in a 23 DEG C 30% R.H. atmosphere.

Owner:DENKA CO LTD

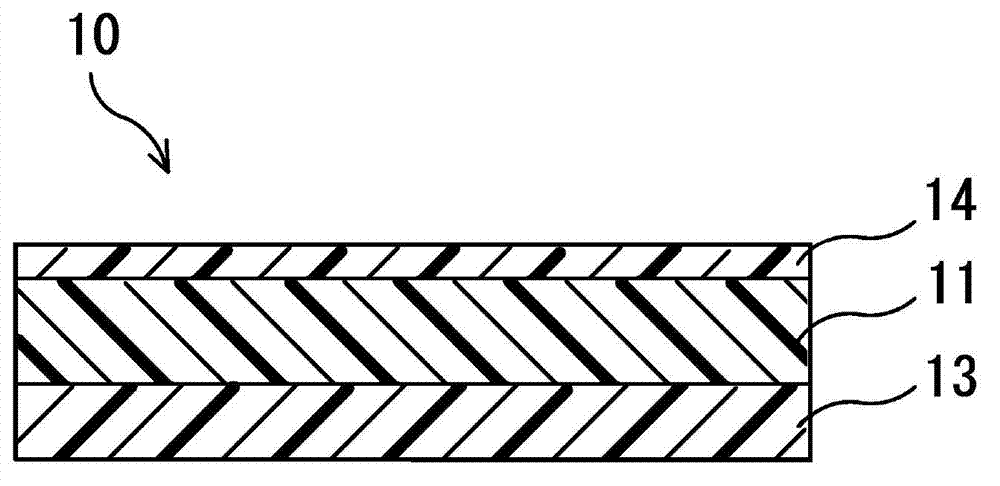

Anti-static self-exhaust protection adhesive tape and preparation method thereof

ActiveCN103589351AImprove antistatic performanceImprove thermal stabilityFilm/foil adhesivesPolyurea/polyurethane coatingsAdhesiveStatic performance

The invention provides an anti-static self-exhaust protection adhesive tape and a preparation method thereof. The anti-static self-exhaust protection adhesive tape successively comprises a base material (1), an adhesive layer (3) and a release film (4); and an anti-static layer (2) is arranged between the base material (1) and the adhesive layer (3). The anti-static self-exhaust protection adhesive tape possesses excellent anti-static performance, the anti-static performance also possesses excellent thermal stability, a defect of pollution caused by transference of ionic additives onto the surface of the anti-static self-exhaust protection adhesive tape is avoided, quick attachment can be realized when the anti-static self-exhaust protection adhesive tape is contacted with the surface of glass or a mirror plane, and the anti-static self-exhaust protection adhesive tape possesses self-exhaust performance.

Owner:SHENZHEN MOMA TECH CO LTD

Electrostatic discharge protection method and mobile terminal

ActiveCN102548173AImprove anti-static performanceTelephone set constructionsElectrostatic chargesEngineeringElectrostatic discharge protection

The invention discloses an electrostatic discharge protection method and a mobile terminal. The mobile terminal comprises a PCB and structural pieces, wherein the PCB is arranged in the structural pieces, and a gap is formed between the structural pieces. The mobile terminal is characterized by further comprising a conductive wire arranged in the gap between the structural pieces and connected with a main land on the PCB; as the main land area of the PCB is relatively larger, the PCB main land can not change greatly with the electrostatic impact; and a huge electric potential difference between functional modules on the PCB is avoided, thereby avoiding larger impact on the functional modules in the structural pieces, and greatly improving the electrostatic discharge protection performance of the mobile terminal.

Owner:SHANDONG LIANGSHAN TONGYA AUTOMOBILE MFG CO LTD

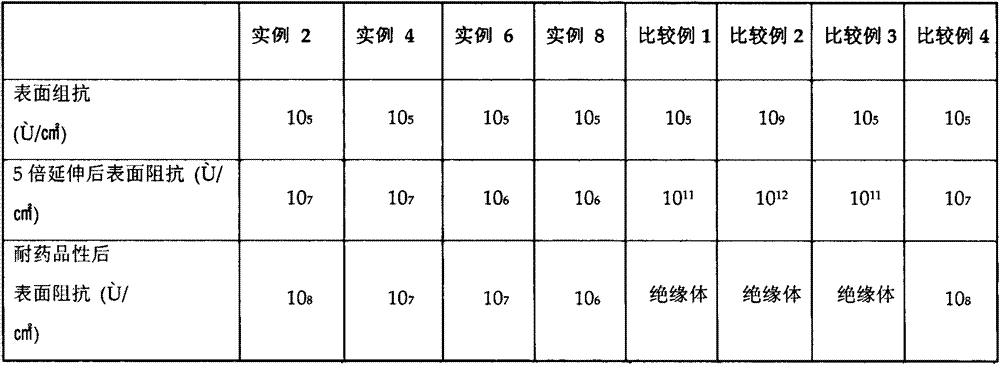

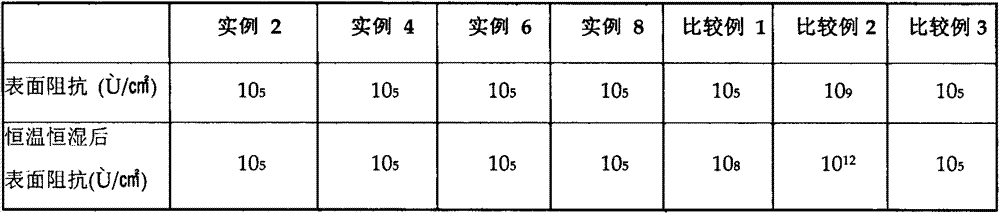

Processing method for producing anti-static sheet through continuous process

The invention relates to a processing method for producing an anti-static sheet through a continuous process. According to the processing method, in the process of extruding thermoplastic polymer resin of an insulator into the sheet through an extruder, an anti-static liquid is coated on at least one side of the sheet online to form an anti-static layer, wherein the anti-static liquid is kiss roll coating liquid which contains thermocuring resin and carbon nanotubes with the weight ratio of 100: (0.1-500), as well as the thermocuring resin and water or an organic solvent with the weight ratio of 100: (10-2000). The process of online kiss roll coating on at least one side simultaneously when the sheet is extruded refers to the continuous process [one-step (in-line)]. Compared with an off-line coating mode, the sheet extrusion mode through in-line kiss roll coating has the characteristics of relative corrosion resistance, strong extensibility, excellent anti-static performance of the sheet and the like.

Owner:恩斯盟防静电材料(镇江)有限公司

A material for preparing a dust collecting cloth bag

The invention discloses a material for preparing a dust collecting cloth bag, and relates to the technical field of dust collecting. The material includes polyphenylene sulfide, polytetrafluoroethylene, polyurethane resin, water-soluble polyester, graphene, polyvinylpyrrolidone, polypropylene-based carbon fibers, silicon fluoride, nanocrystal cellulose, citric acid, a flame retardant, a coupling agent, an adhesive, an antistatic agent and an antiager. Through a scientific ratio of the components of the material, the components are synergistic, temperature resistance, acid resistance, an antistatic property and stability of the dust collecting cloth bag are improved so that the dust collecting cloth bag can adapt to complex environments and has a wide application range. In addition, the silicon fluoride and the citric acid function comprehensively to improve the surface adhesive property of polytetrafluoroethylene, and adsorption effects are improved. The nanocrystal cellulose and the adhesive further improve adsorption effects of the dust collecting cloth bag, and improve dust collecting capability of the dust collecting cloth bag.

Owner:广西金邦泰科技有限公司

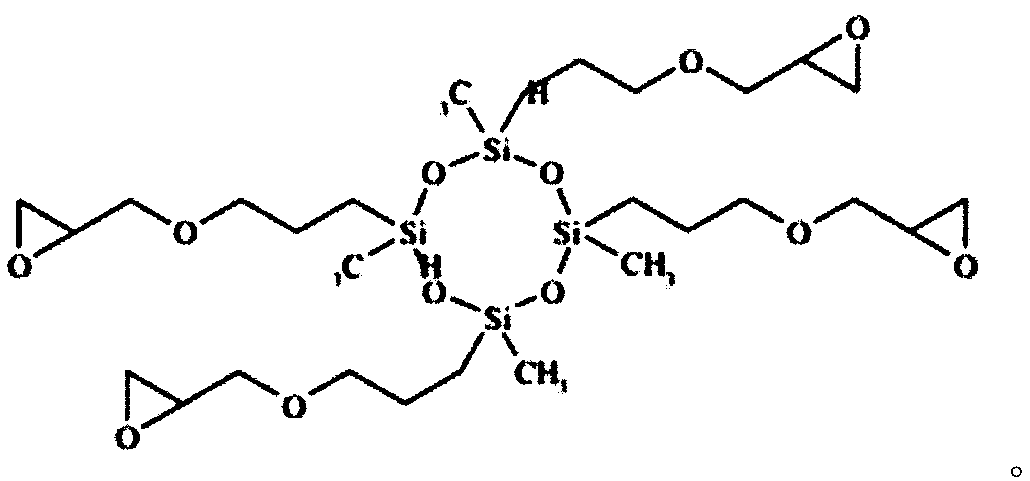

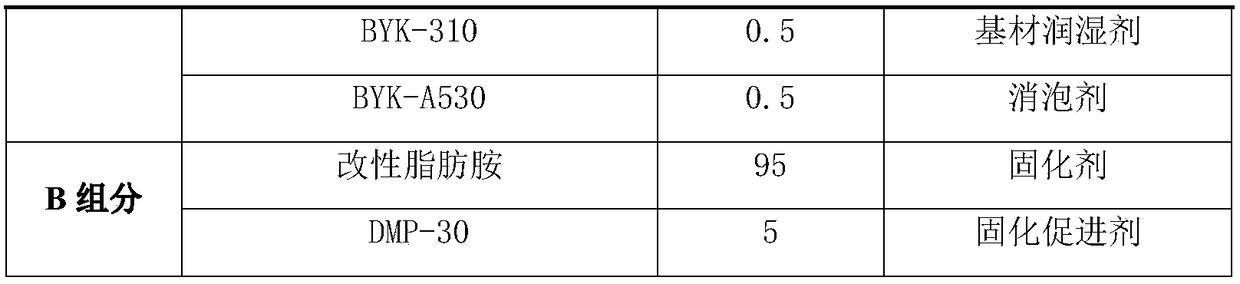

High performance antistatic self-leveling epoxy floor level coating compound

ActiveCN109294403AImprove performanceImprove overall performance, especially toughnessEpoxy resin coatingsElectrically-conductive paintsSolvent freeFirming agent

The invention discloses a high performance antistatic solvent-free self-leveling epoxy floor level coating compound. The compound comprises a component A and a component B. The component A comprises,by mass, 20 to 60 parts of epoxy resin, 0 to 20 parts of a reactive diluent, 2 to 10 parts of composite metal fiber slurry, 0.1 to 3 parts of an antistatic agent, 0.1 to 5 parts of a polyfunctional silicone modified epoxy compound, 30 to 60 parts of a filler, 2 to 10 parts of color paste and 0.1 to 3 parts of an aid. The component B comprises, by mass, 80 to 100 parts of a curing agent and 0 to 20parts of an accelerator. Through metal fibers and the long-acting antistatic agent, the problem of the conductive blind spot caused by the difficulty of overlapping the fibers due to the filter thickness increasing is solved and the uniform distribution of the resistance values is realized. The polyfunctional silicone modified epoxy compound can improve toughness, a drawing force, abrasion resistance, water resistance, pressure resistance and antistatic property.

Owner:MIANYANG HUILI EPOXY ENG

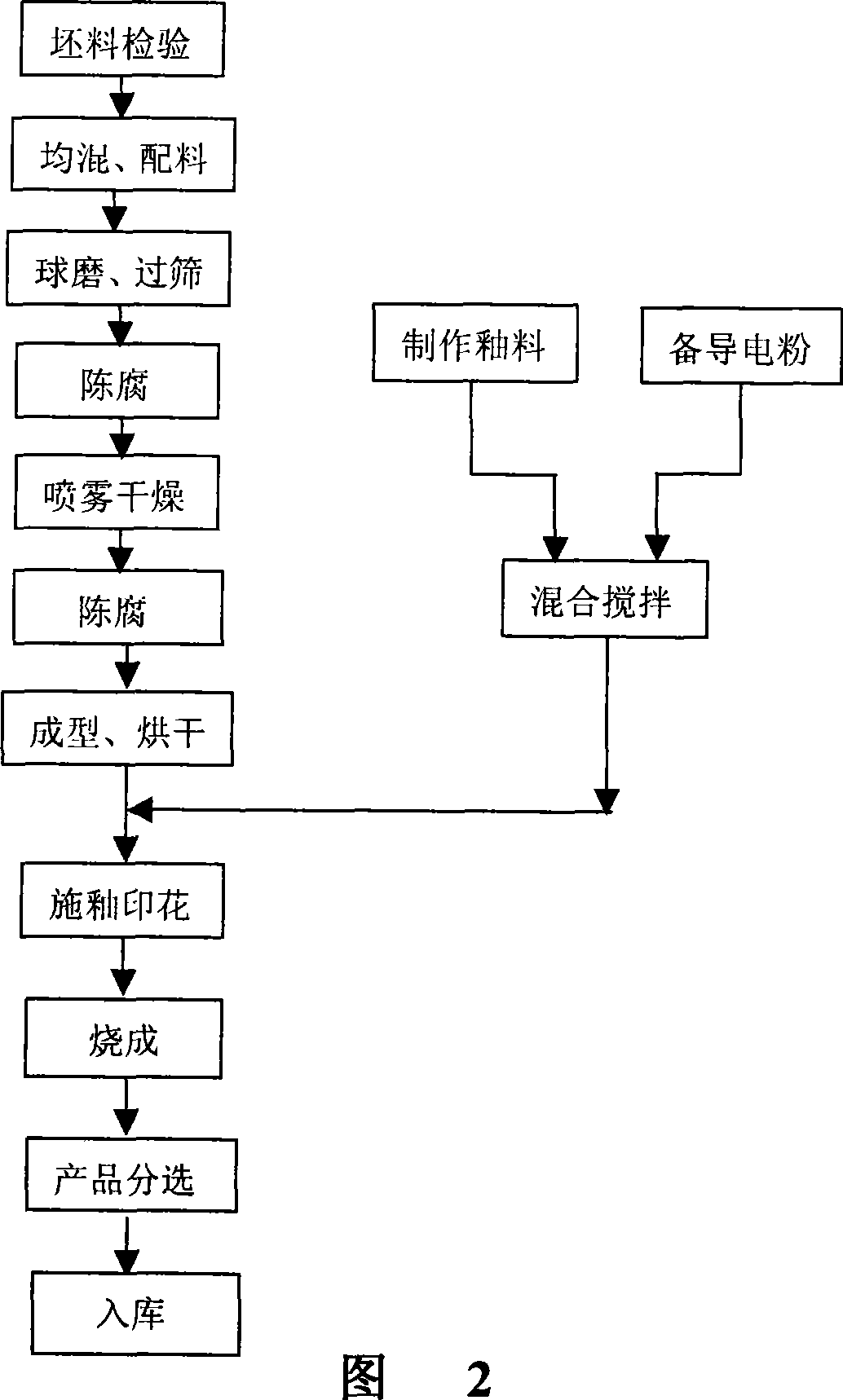

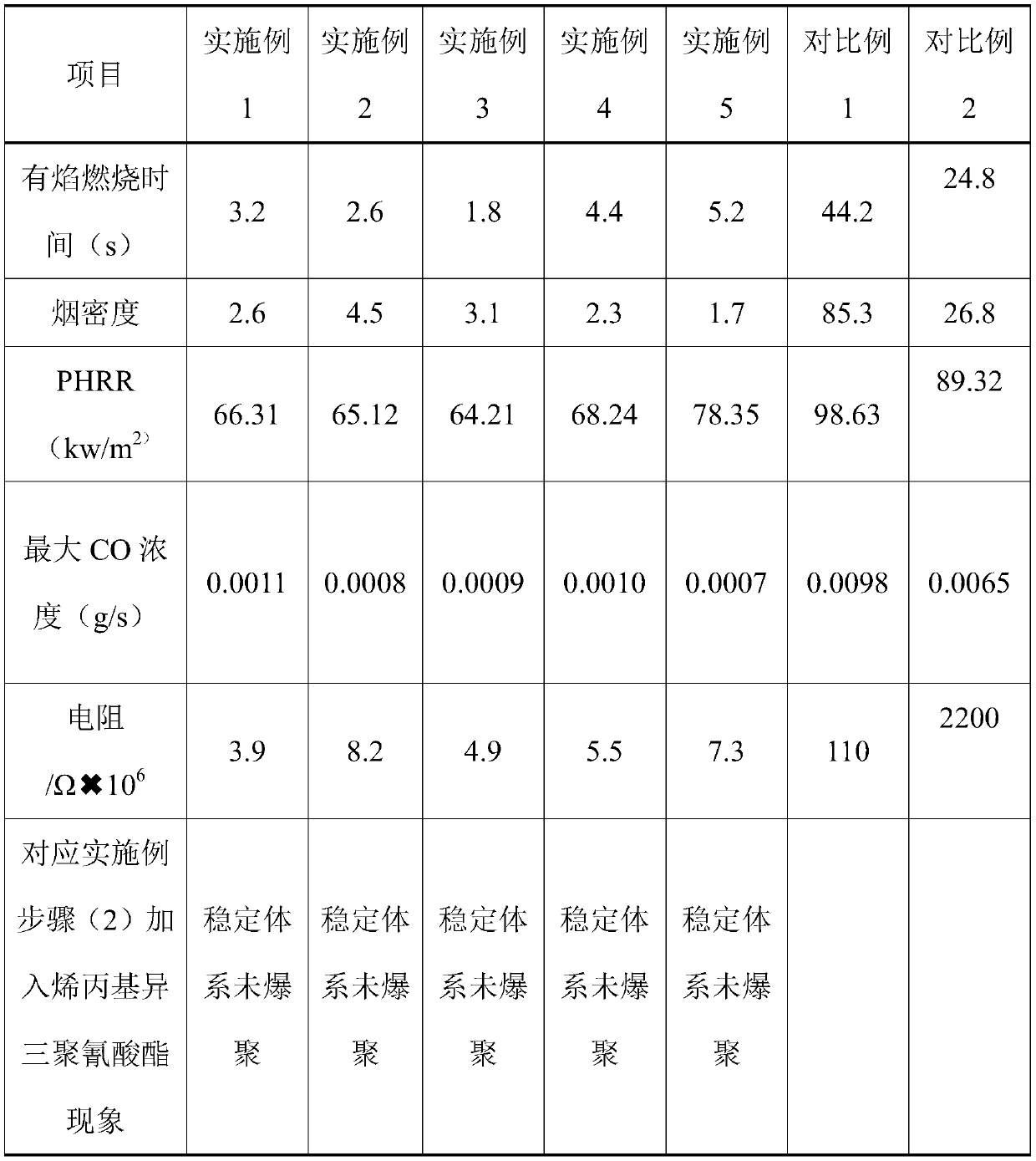

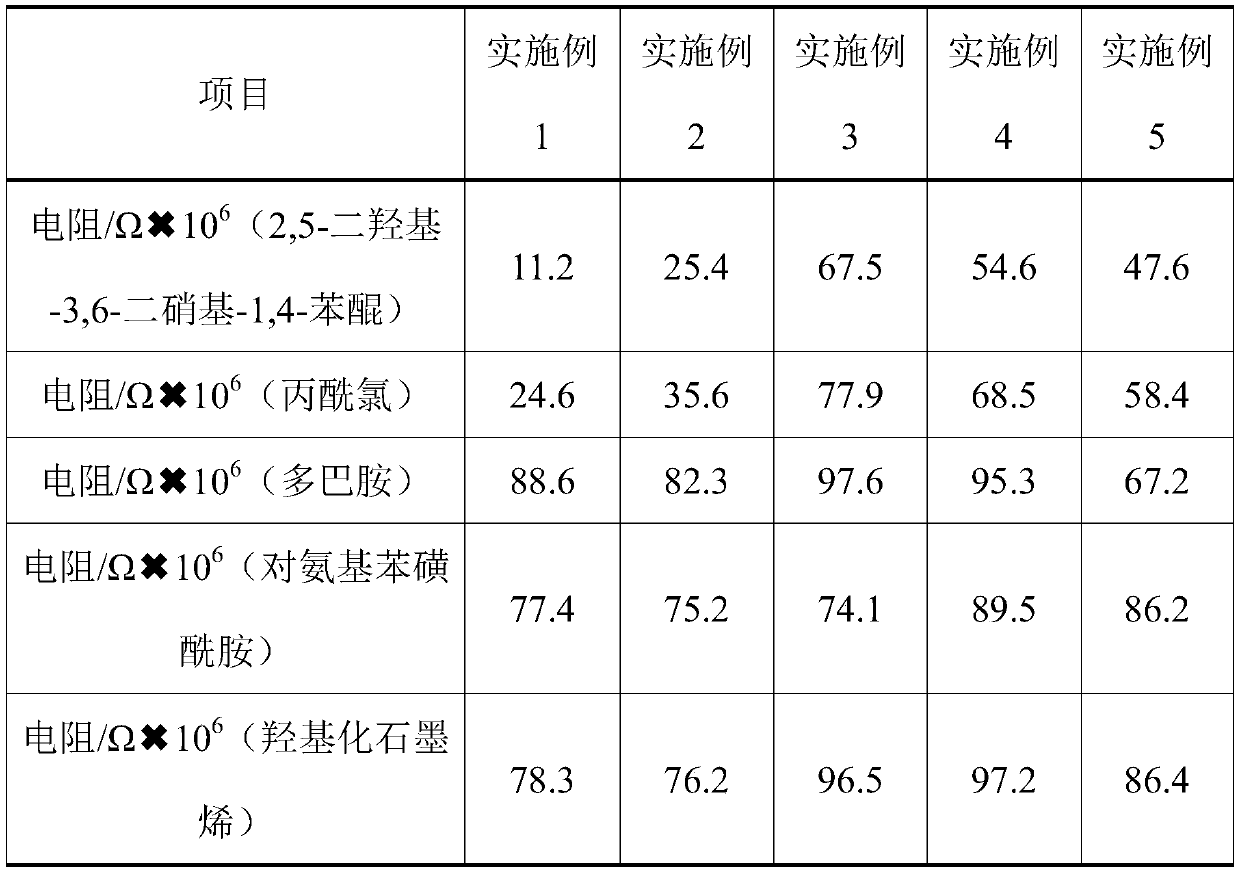

Antistatic ceramic floor and preparing method thereof

The invention discloses an anti-static ceramic floor and a preparation method thereof. The anti-static ceramic floor comprises a body of the ceramic floor, a surface layer of the ceramic floor is baked with a mixed layer of glaze and conductive powder, the conductive powder accounts for 20 to 40 percent of the material weight of the mixed layer, wherein the conductive powder comprises the following compositions in weight percentage: 55 to 90 percent of Sn, 5 to 25 percent of Zn, and 5 to 25 percent of Ti. The preparation method comprises the following steps: the glaze is produced first, and then the conductive powder is added according to the mixing proportion of the glaze and the conductive powder to mix and stir evenly; after a molding process of the ceramic floor is finished, a mixed material of the glaze and the conductive powder is coated on the surface layer of the ceramic floor according to the preset printing proposal; the baking and the separation to finished products are performed to obtain the qualified finished products.

Owner:BEIJING YUNHE INDAL & TRADE

Preparation method of graphene modified flame-retardant waterborne polyurethane coating and adhesive

ActiveCN111117467ALarge specific surface areaImprove flame retardant propertiesFireproof paintsNon-macromolecular adhesive additivesDibutyl tin dilaurateCyanate ester

The invention relates to a preparation method of a graphene modified flame-retardant waterborne polyurethane coating and adhesive. The preparation method comprises the following steps: preparing a flame-retardant MOFs compound from MOFs, preparing a flame-retardant MOFs dispersion liquid from the flame-retardant MOFs compound, and finally preparing the polyurethane coating and adhesive from polymer polyol, isocyanate, dibutyltin dilaurate and the flame-retardant MOFs dispersion liquid. The effect of improving the two important indexes of flame retardance and static prevention of the polyurethane coating and the adhesive is outstanding.

Owner:中炬高新材料股份有限公司

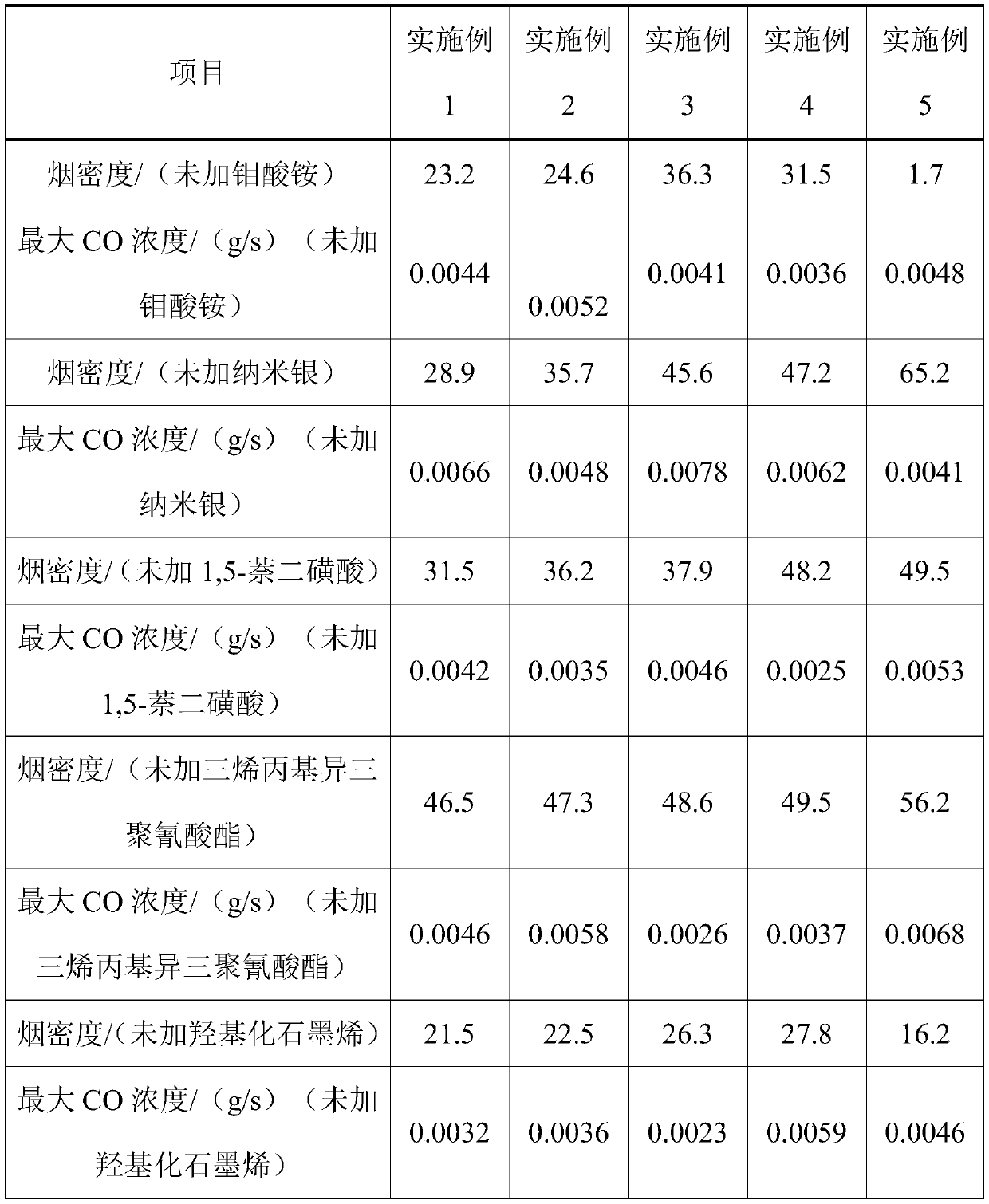

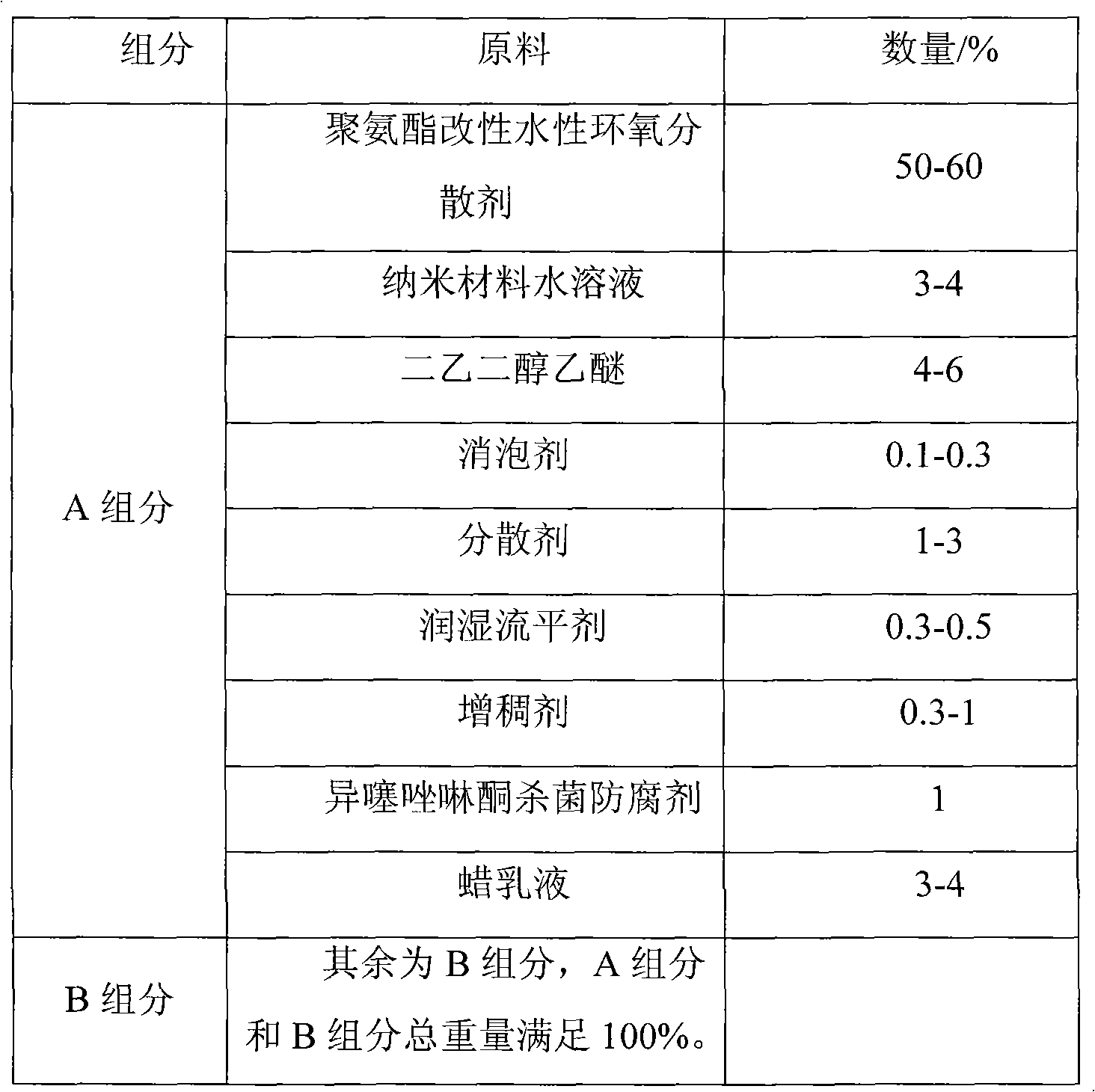

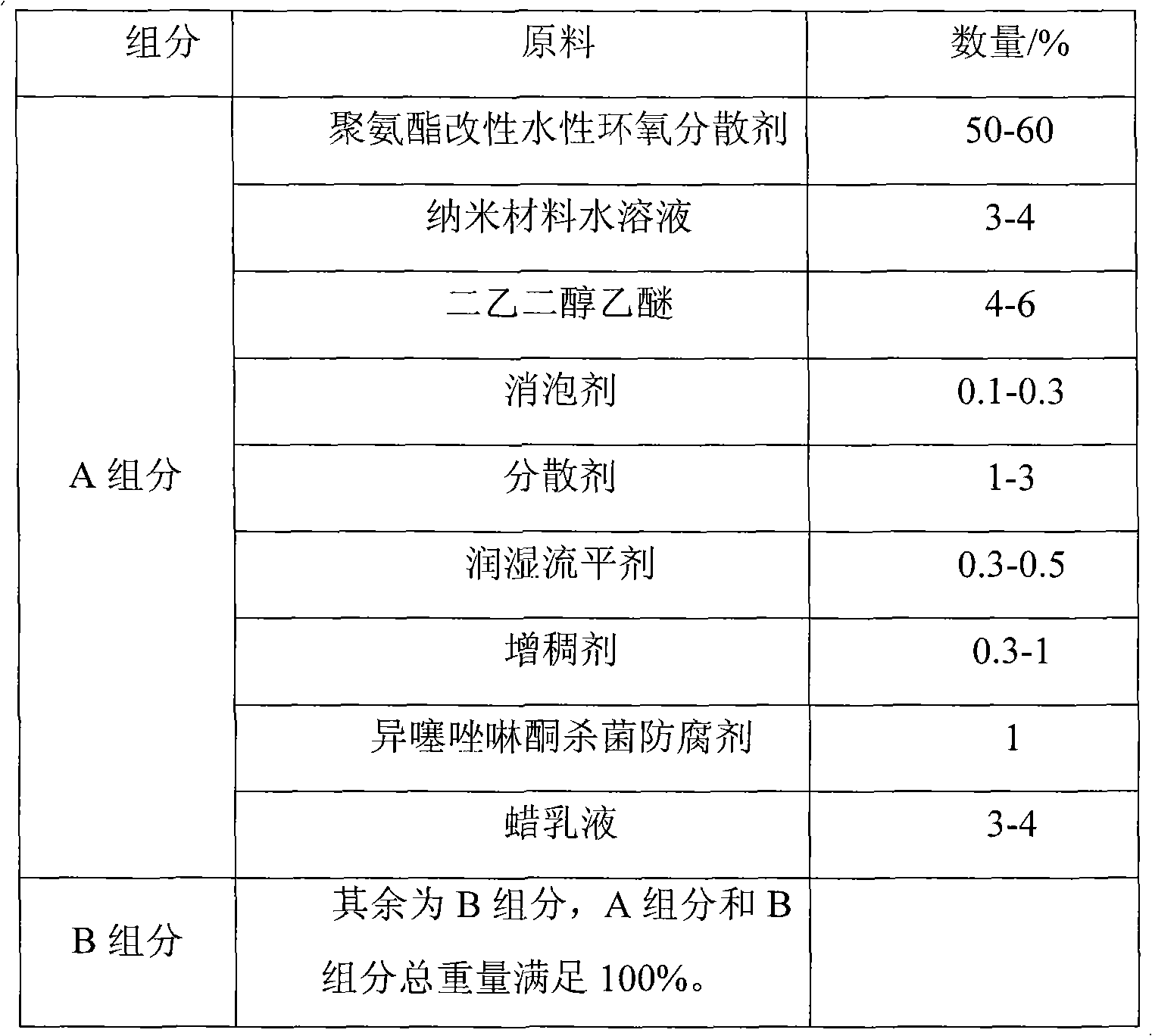

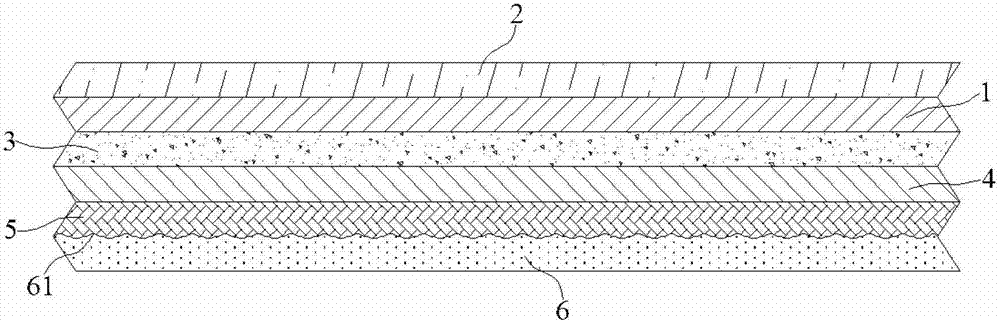

Preparation method of high abrasion water-borne wood coating

The invention belongs to the technical field of coating synthesis, in particular to a preparation method of a high abrasion water-borne wood coating, which comprises the following steps: firstly, using epoxy resin and polyamine to prepare a self-emulsifying water-borne epoxy resin curing agent; and then adding related additive and nano material water solution in polyurethane modified epoxy emulsion, and dispersing at high speed; and finally, blending the prepared curing agent and uniformly dispersed mixture to prepare the product. The invention fully utilizes and combines the advantages of epoxy resin, polyurethane, wax emulsion and inorganic nano-materials, and the obtained product achieves the standard through performance measurement; and the cost is substantially reduced in the experiment process, and the coating has no pollution to the environment, saves energy, and has greater application prospect in the filed of wood coatings.

Owner:TONGJI UNIV

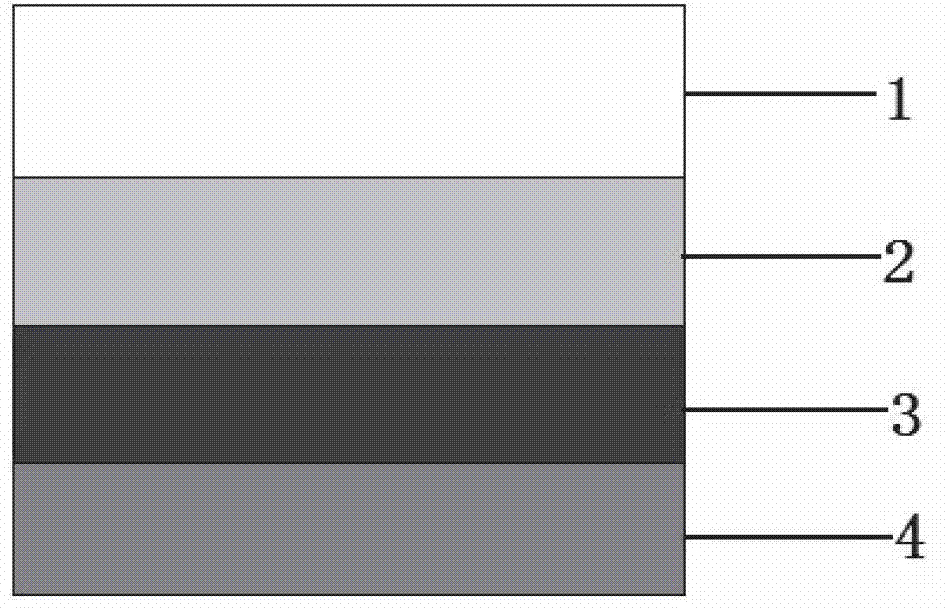

Anti-scuffing matt-surface antistatic release paper

ActiveCN103074819ALow wear resistanceImprove surface antistatic performanceNon-fibrous pulp additionSynthetic resin layered productsElectrostatic coatingPolyethylene glycol

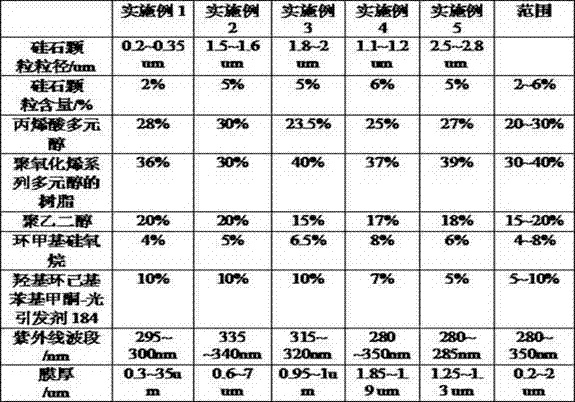

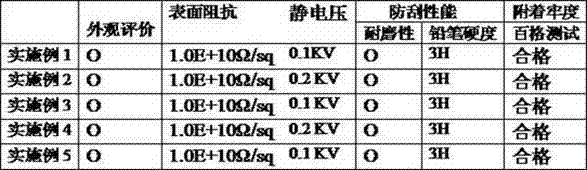

The invention discloses an anti-scuffing matt-surface antistatic release paper. The anti-scuffing matt-surface antistatic release paper comprises a release raw paper and a film layer. The other surface of the film layer is coated with a matt-surface antistatic layer having thickness of 0.2 to 2 micrometers. The other surface of the matt-surface antistatic layer is coated with a silicone oil layer. The surface of the matt-surface antistatic layer contacting with the silicone oil layer is provided with multiple concave and convex points. The matt-surface antistatic layer comprises 2 to 6% of silica particles, 20 to 30% of acrylic polyol having average molecular weight of 500 to 2000, 35 to 45% of polyoxyalkylene polyol having average molecular weight of 200 to 2500, 15 to 20% of polyethylene glycol, 4 to 8% of cyclomethyl siloxane, and 5 to 10% of 1-hydroxycyclohexylphenyl ketone-photoinitiator 184. The anti-scuffing matt-surface antistatic release paper solves the problem that the existing release paper has poor adhesion between a lamination layer and a release agent coating and unstable peel strength, improves antistatic performances of the film surface, and improves scuffing resistance.

Owner:斯迪克新型材料(江苏)有限公司

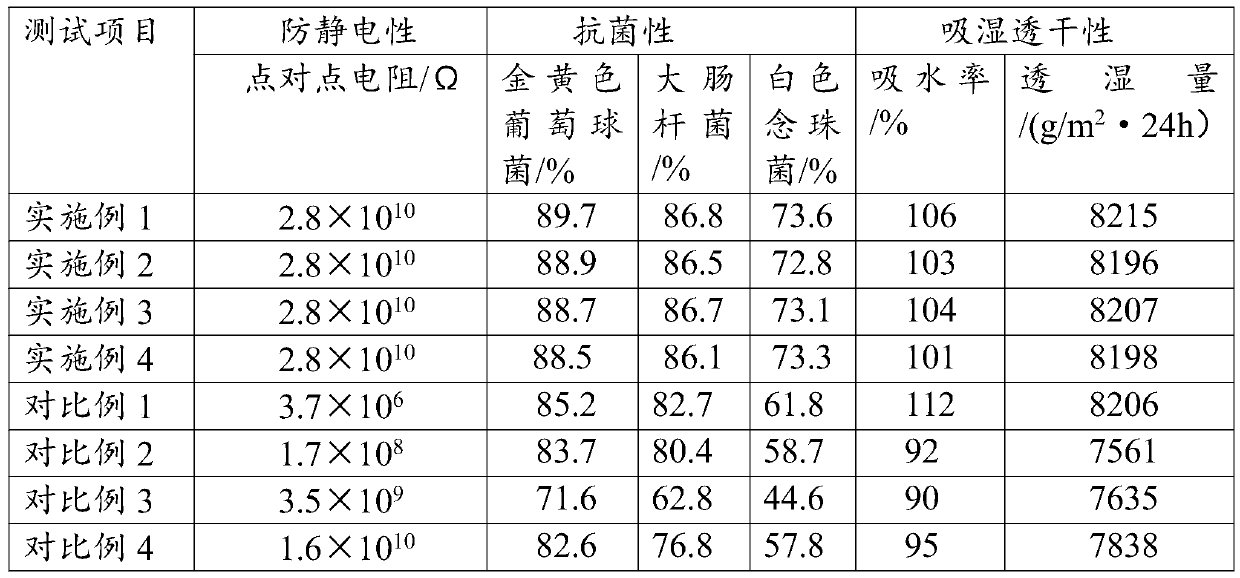

Production technology of anti-static fabric

ActiveCN110396753AImprove anti-static performanceIncreased durabilityBiochemical fibre treatmentSingeingPolyesterEscherichia coli

The invention discloses a production technology of an anti-static fabric. An electric conduction wire and a polyester cotton yarn are double-twisted to obtain a conductive yarn, the conductive yarn iswoven at intervals to obtain an anti-static gray fabric, and through singeing, shape setting and dyeing, the dyed gray fabric is obtained; through anti-static after-finishing of an anti-static finishing solution, two-time soaking and two-time rolling, the anti-static gray fabric is obtained; finally, through antibacterial anti-mite finishing of an antibacterial anti-mite finishing agent, two-timesoaking and two-time rolling, the anti-static fabric is obtained. The prepared anti-static fabric has good anti-static performance, can achieve moisture absorption and air permeation, has antibacterial and anti-mite performance and is good in comfort and particularly suitable for being used as a fabric of outdoor sports wear and climbing wear. The point-to-point resistance of the anti-static fabric reaches 2.8*1,010 omega, the rate of resisting staphylococcus aureus reaches 89.7%, the rate of resisting escherichia coli reaches 86.8%, the rate of resisting candida albicans reaches 73.6%, the water absorption rate reaches 106%, and the amount of water vapor transmission reaches 8,125 g / m<2>.24 h.

Owner:保定澳森制衣股份有限公司

Anti-static epoxy self-leveling coating material

InactiveCN104673051AImprove anti-static effectImprove anti-static performanceEpoxy resin coatingsElectrically-conductive paintsSlurryReactive diluent

The invention relates to an anti-static epoxy self-leveling coating material which comprises the following components in percentage by weight: 30-50 percent of bisphenol A epoxy resin, 1-5 percent of a reactive diluent, 5-20 percent of a conductive filler, 0.1-0.2 percent of a dispersing agent, 1-3 percent of a leveling agent, 0.1-0.5 percent of a defoaming agent, 5-10 percent of a curing agent and 20-50 percent of water. A preparation method of the anti-static epoxy self-leveling coating material comprises the following steps: (1) adding the reactive diluent into the bisphenol A epoxy resin, and stirring for 20min at a constant speed; (2) adding the conductive filler, the dispersing agent, the leveling agent and the defoaming agent into a mixture prepared in step (1), dispersing for 30min at a high speed, and grinding to obtain slurry; (3) mixing the curing agent and water, and stirring for 20 min at a constant speed to form a water solution; and (4) adding the slurry prepared by grinding into the curing agent water solution prepared in step (3), and mixing uniformly.

Owner:TIANJIN YUJIN COATING ENG

PU (Poly Urethane) sole antistatic agent

The invention discloses PU (Poly Urethane) sole antistatic agent. The PU sole antistatic agent comprises the following components in percentage by weight: 68%-88% of 1-ethyl-3-methyl imidazole ethyl sulfate, 12%-18% of a polyalcohol solvent, and 8%-12% of quaternary ammonium salt compounds containing silver or lithium ions. The preparation method of the PU sole antistatic agent comprises the following steps of: uniformly mixing the components according to the proportion; stirring for 2 hours-3hours at a high speed under the normal temperature; and stewing for 1-2 hours to obtain the product. The PU sole antistatic agent disclosed by the invention is scientific in formula, low in production cost, simple in preparation process and capable of strengthening the antistatic performances of the sole.

Owner:SUZHOU JINGRO TECH

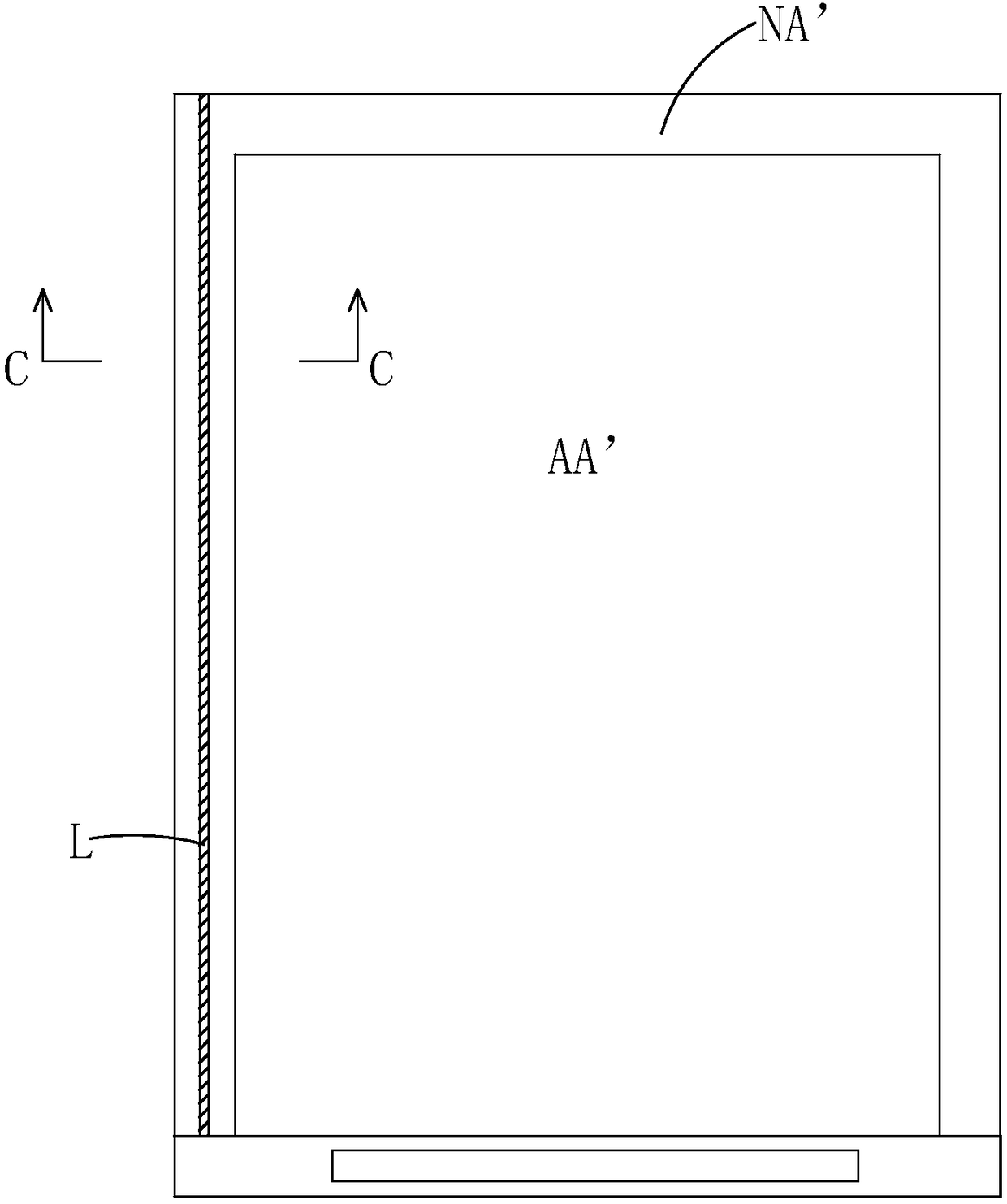

Liquid crystal display panel

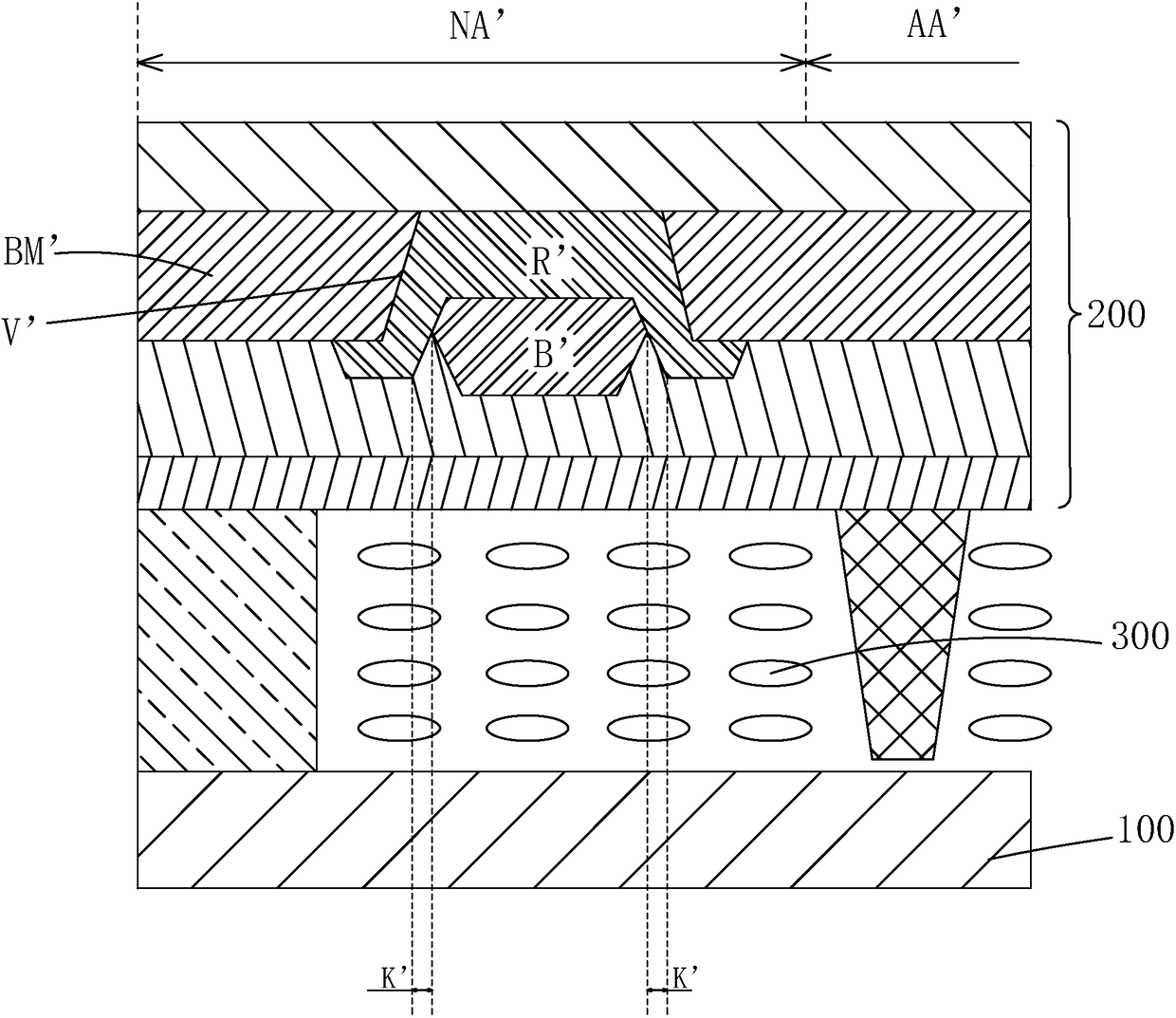

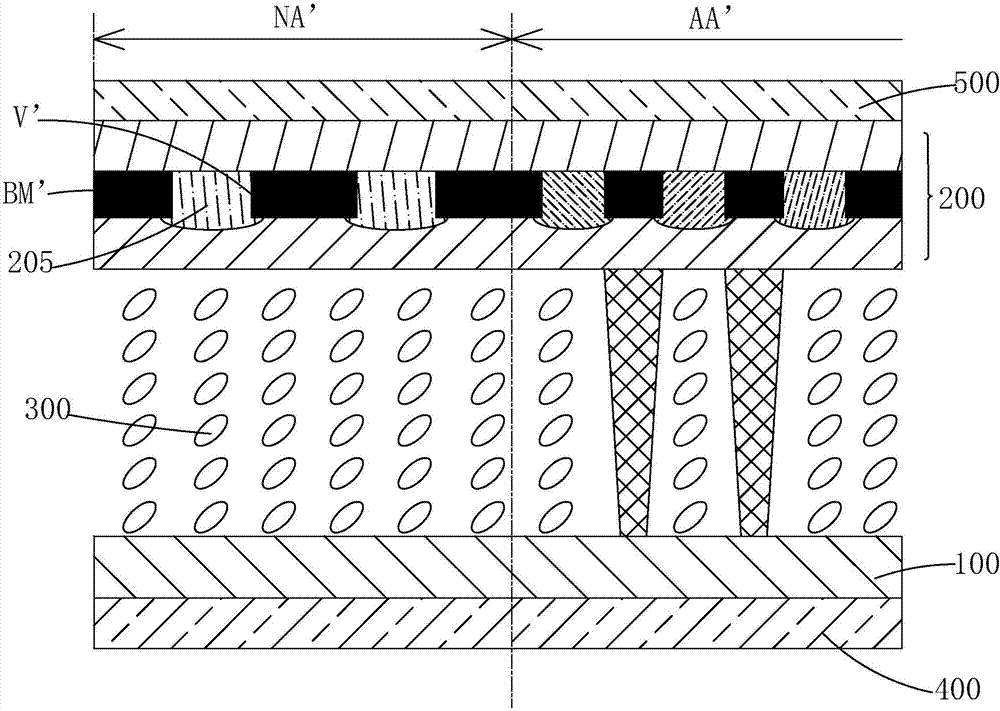

ActiveCN108153076AImprove display qualityImprove anti-static performanceNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel. A groove (V) penetrating a black matrix (BM) is dug in the black matrix (BM) positioned in a non-display area (NA), so that the black matrix (BM)can be stopped from conducting static electricity from the non-display area (NA) to a display area (AA), and anti-static capacity is enhanced. A light shield layer (4) is arranged on a thin film transistor array substrate (1), the width of the light shield layer (4) is larger than that of the groove (V), so that the light shield layer (4) shields backlight irradiating the groove (V), light leakage of the groove (V) of the black matrix (BM) can be effectively avoided, bright lines of the non-display area (NA) of the liquid crystal display panel are prevented, and the display quality of the liquid crystal display panel is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display panel

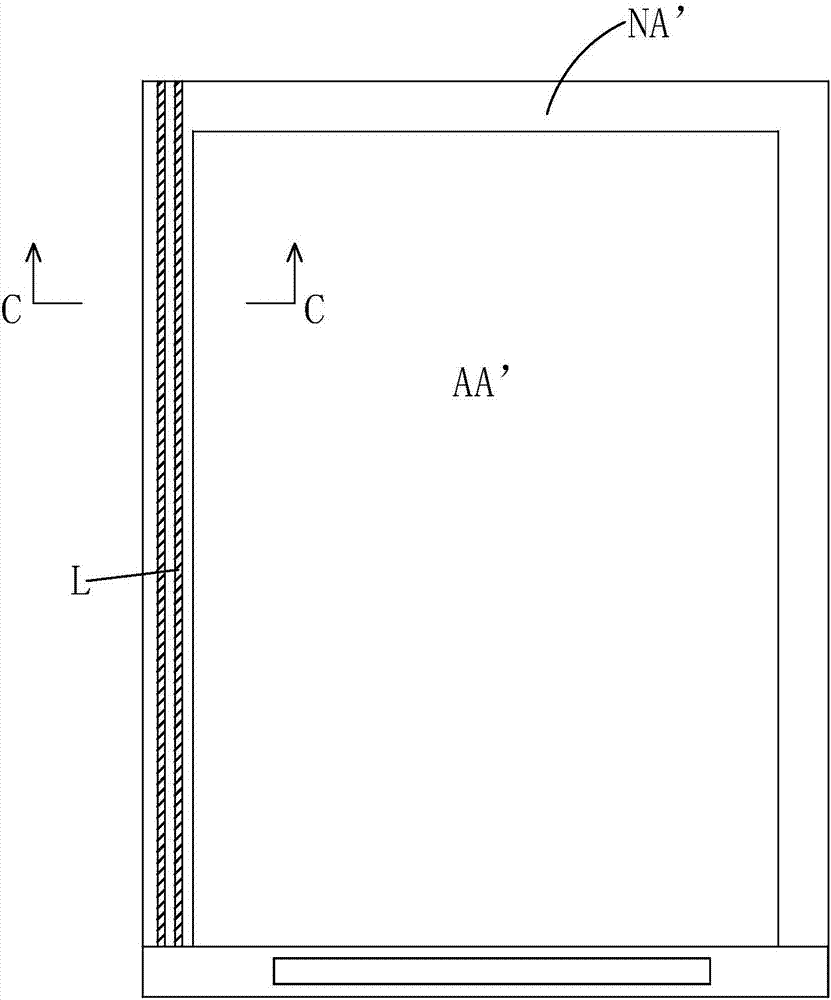

InactiveCN107991804AImprove display qualityImprove anti-static performanceNon-linear opticsTransistor arrayEngineering

The invention provides a liquid crystal display panel. Grooves (V) are formed in a black matrix (BM) in a non-display region (NA), so that the black matrix (BM) can be prevented from transmitting static electricity to a display region (AA) from the non-display region (NA), and therefore, anti-static ability is improved; occupying columns (7) which are as many as the grooves (V) are arranged between a film transistor array base plate (1) in the non-display region (NA) and a color light-filter plate base plate (2); one occupying column (7) is correspondingly positioned below one groove (V); theoccupying columns (7) are as high as a box thickness of a liquid crystal layer (3), so that a region below the grooves (V) is free of liquid crystal, and therefore, the grooves (V) of the black matrix(BM) can be effectively prevented from a light leaking phenomenon.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

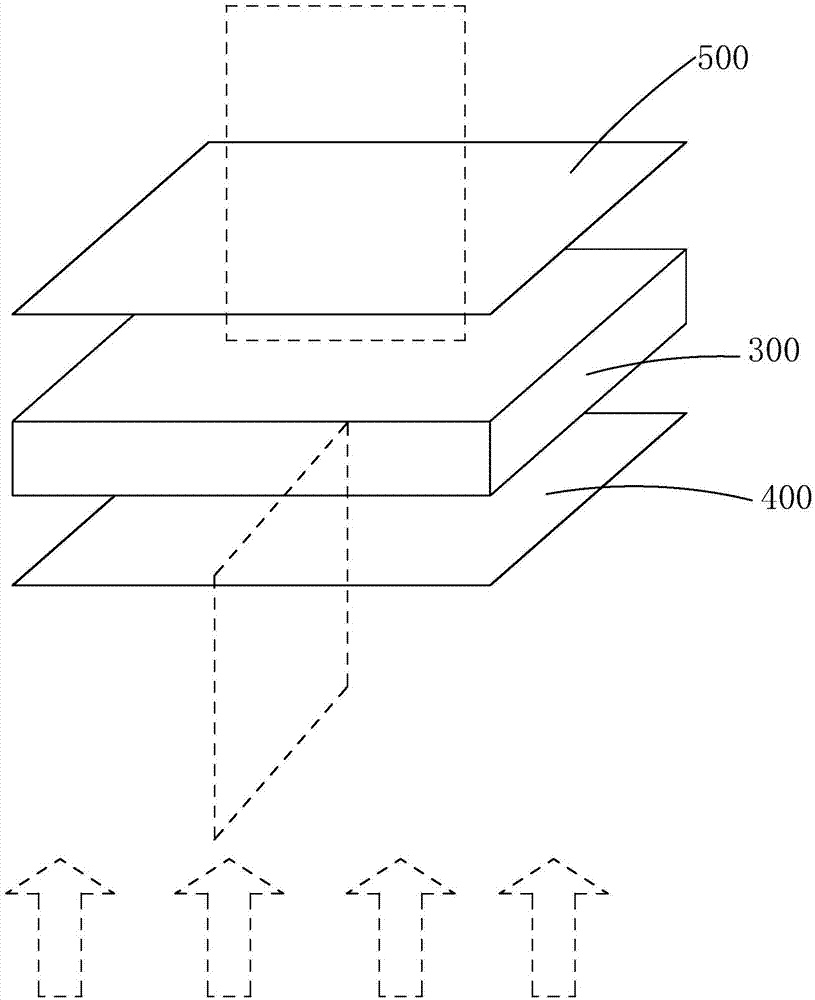

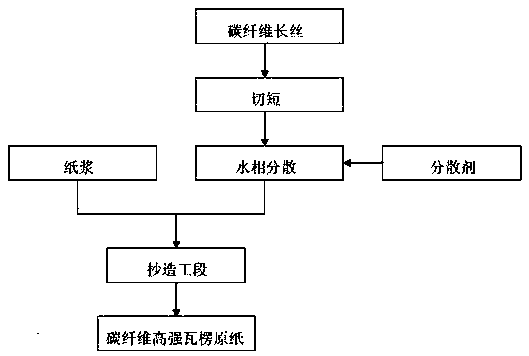

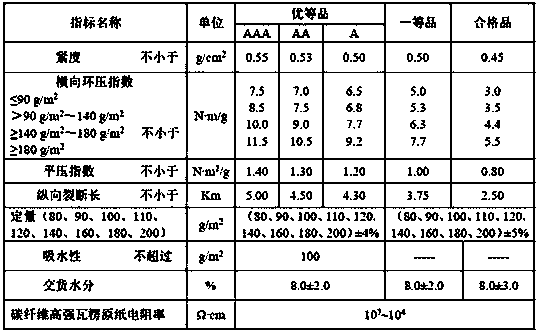

Carbon fiber high-strength corrugated raw board and preparing method thereof

ActiveCN103711022ASmall coefficient of thermal expansionReduce coefficient of frictionDefoamers additionWater-repelling agents additionCarbon fibersMaterials science

The invention discloses a carbon fiber high-strength corrugated raw board and a preparing method of the carbon fiber high-strength corrugated raw board and belongs to the field of paper technology. The carbon fiber high-strength corrugated raw board comprises, by weight, 78%-82% of waste paper, 3%-5% of carbon fibers, 6%-9% of starch, 0.5%-0.8% of assistant and 8%-9% of water. The assistant comprises rosin, alum, oxidized starch, sodium carbonate, a dispersing agent, non-ionic type polymeric flocculant, a surface sizing agent, a sterilizing agent, an antifoaming agent and retention aid. The carbon fiber adding amount of the high-strength corrugated raw board is small, the cost of the corrugated raw board is reduced to a great extent, the mechanical strength is high, the specific resistance is 107 omega cm-104 omega cm, and the electrostatic-resistant function is good. The main component of solid waste generated in the preparing process is fibers, the fibers can be used for preparing fiber boards, the utilization of the waste is achieved, and pollution of the environment is reduced.

Owner:SHANDONG TIANDIYUAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com