Patents

Literature

385results about How to "Improve flame retardant properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-nickel ternary lithium ion power battery electrolyte and high-nickel ternary lithium ion power battery

InactiveCN106058316AImprove transmission characteristicsImprove dynamic propertiesSecondary cellsBatteriesDifluorophosphatePower battery

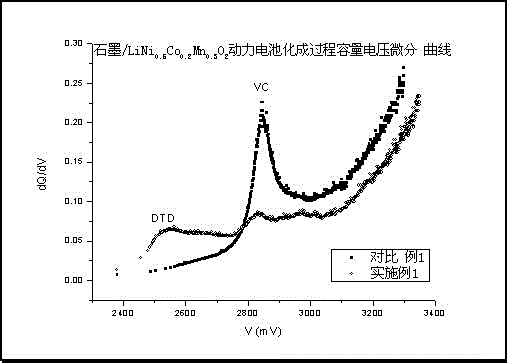

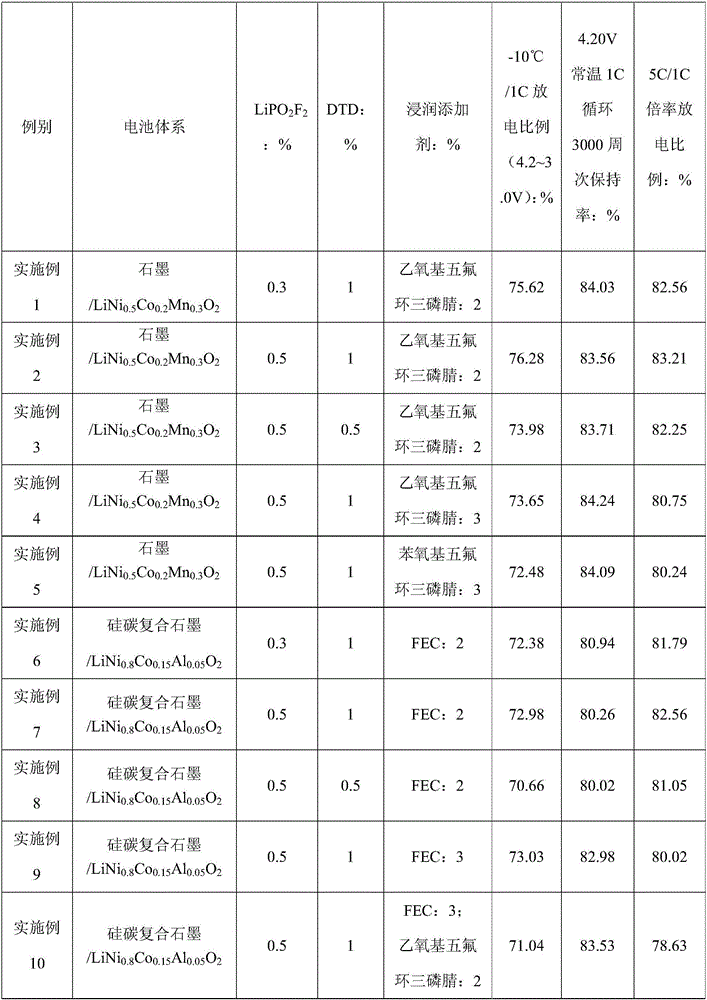

The invention discloses a high-nickel ternary lithium ion power battery electrolyte and a high-nickel ternary lithium ion power battery. The electrolyte includes a non-aqueous organic solvent, a lithium salt, a conductive additive, a film forming additive and an infiltration additive, wherein the conductive additive is lithium difluorophosphate, the film forming additive is ethylene sulfate, and the infiltration additive is at least one of fluorophosphazene and fluoroethylene carbonate; and synergism and mutual promotion of the three additives makes an excellent SEI film be formed on the surface of an electrode and effectively promotes all dynamic processes in the lithium ion battery. The power battery electrolyte has the advantages of good lithium ion transmission characteristic, good oxidation resistance, guaranteeing of high power characteristic and good cycle performances of the power battery, and high safety.

Owner:GUANGZHOU TINCI MATERIALS TECH

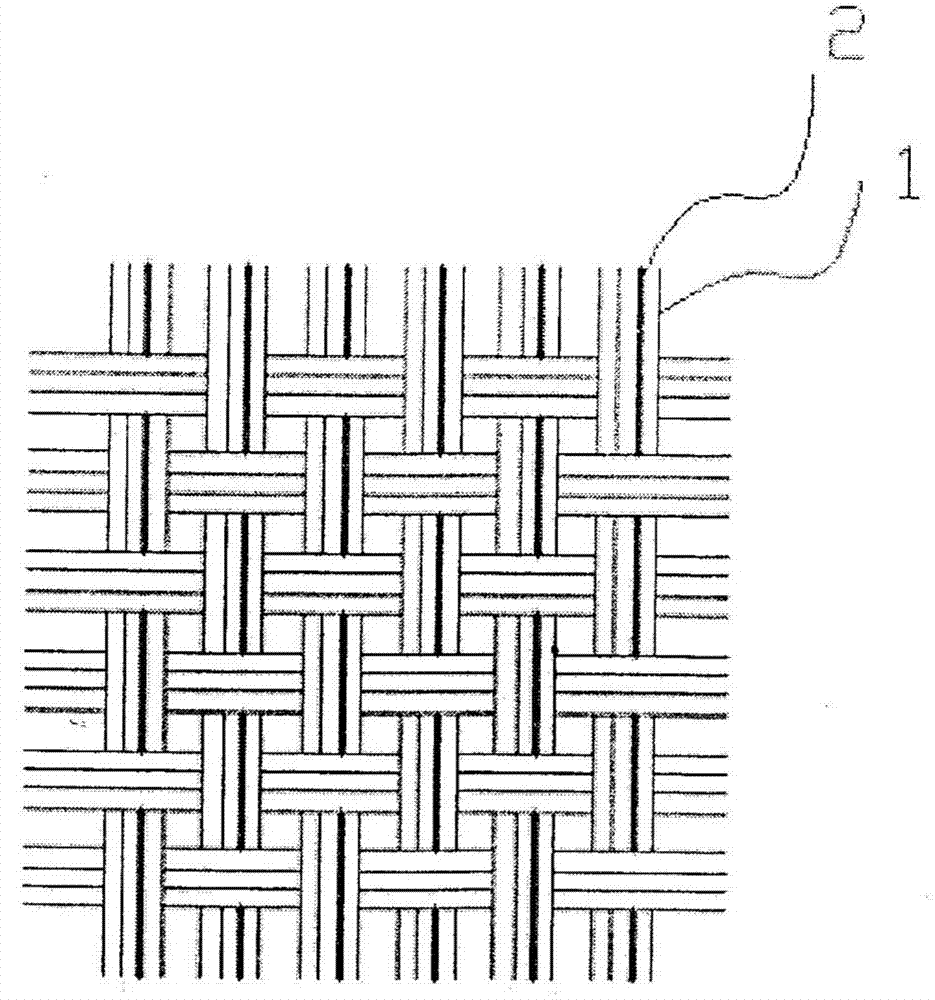

Permanent flame-retardant multifunctional fabric and making method thereof

ActiveCN104499161AImprove flame retardant propertiesReduce investmentWoven fabricsYarnPolymer scienceNatural fiber

The invention discloses permanent flame-retardant multifunctional fabric and a making method thereof and belongs to the technical field of protecting fabric and processing thereof. The permanent flame-retardant multifunctional fabric is formed by interweaving warp yarn and weft yarn. The permanent flame-retardant multifunctional fabric is characterized in that a raw material by which each of the warp yarn and the weft yarn is made is a mixture of high-temperature-resistant natural flame-retardant fibers and natural fibers or regenerated cellulose fibers, the high-temperature-resistant natural flame-retardant fibers account for 40-90% of the fabric, the natural fibers or the regenerated cellulose fibers account for 8-58% of the fabric, and antistatic filaments are woven in the warp yarn at intervals and account for 1-3% of the fabric. The permanent flame-retardant multifunctional fabric can permanently maintain ideal flame-retardant characteristics which do not decline with passage of time or increase of washing times, demonstrates high environment friendliness, breathability and wearing comfortability and has safety, and excellent antistatic performance can be guaranteed lastingly; processes are simplified, so that the above advantages of the fabric can be demonstrated comprehensively.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

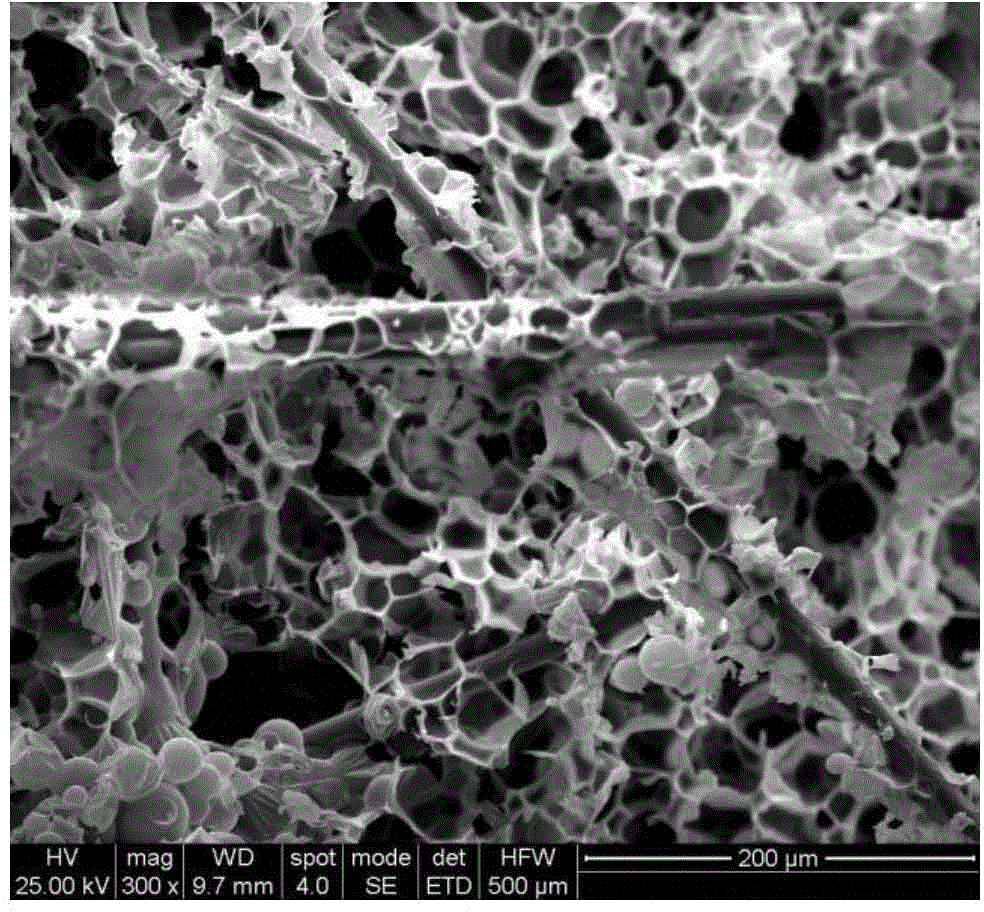

Active carbon fiber composite material and preparation method thereof

ActiveCN103334298AImprove adsorption capacityImproved performance characteristicsSilicaCarbon fibresFiberHigh absorption

The invention relates to an active carbon fiber composite material and a preparation method of the active carbon fiber composite material. The active carbon fiber composite material is formed by compounding an active carbon fiber layer and a silica gel layer covered outside the active carbon fiber layer, is large in specific surface area, light in gram weight and high in mechanical strength, not only maintains the high absorption property and flame-retardant property of the active carbon fiber, but also has the large specific surface area and very low heat conduction performance of silica aerogel, and has the characteristics of heat insulation, toxin prevention and flame-retardant property. The preparation method of the active carbon fiber composite material comprises the steps of: dipping the active carbon fiber layer into silica sol, then taking out the active carbon fiber layer, and drying to obtain the active carbon fiber composite material. The preparation method has the advantages of being simple and feasible as well as low in cost.

Owner:北京蓝星清洗有限公司

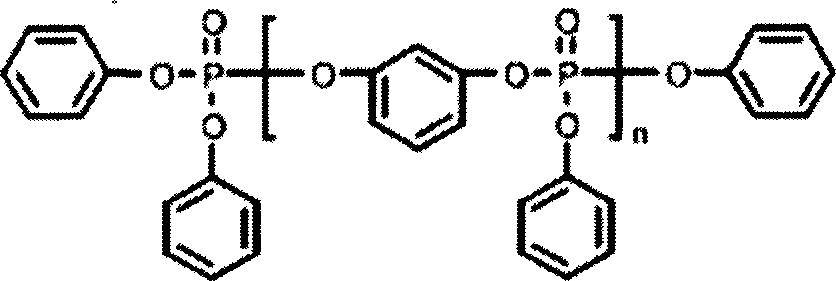

Antiflaming optical diffusion polycarbonate resin composition

InactiveCN101423655AExcellent optical propertiesImprove flame retardant propertiesPolycarbonatePolyresin

An objective of the invention is to provide a flame-proof light-diffusing polycarbonate resin composition which can simultaneously satisfy the excellent optical characteristic and high flame-proof characteristic of light-diffusing polycarbonate. According to the invention, the flame-proof light-diffusing polycarbonate resin composition is provided, wherein the resin composition comprises the following components: 100 weight parts of aromatic polycarbonate resin (A component); more than 0.005 weight parts of optical diffusing agent (B component) relatively to the aromatic polycarbonate resin; 0.001-20 weight parts of flame retardant (C component) relatively to aromatic polycarbonate resin; and 0.01-5 weight parts of polytetrafluoroethylene (D component) relatively to the aromatic polycarbonate resin, wherein the polytetrafluoroethylene has protofiber forming capability. Furthermore the total amount of B component and D component is 0.03-8 weight parts.

Owner:TEIJIN KASEK KK

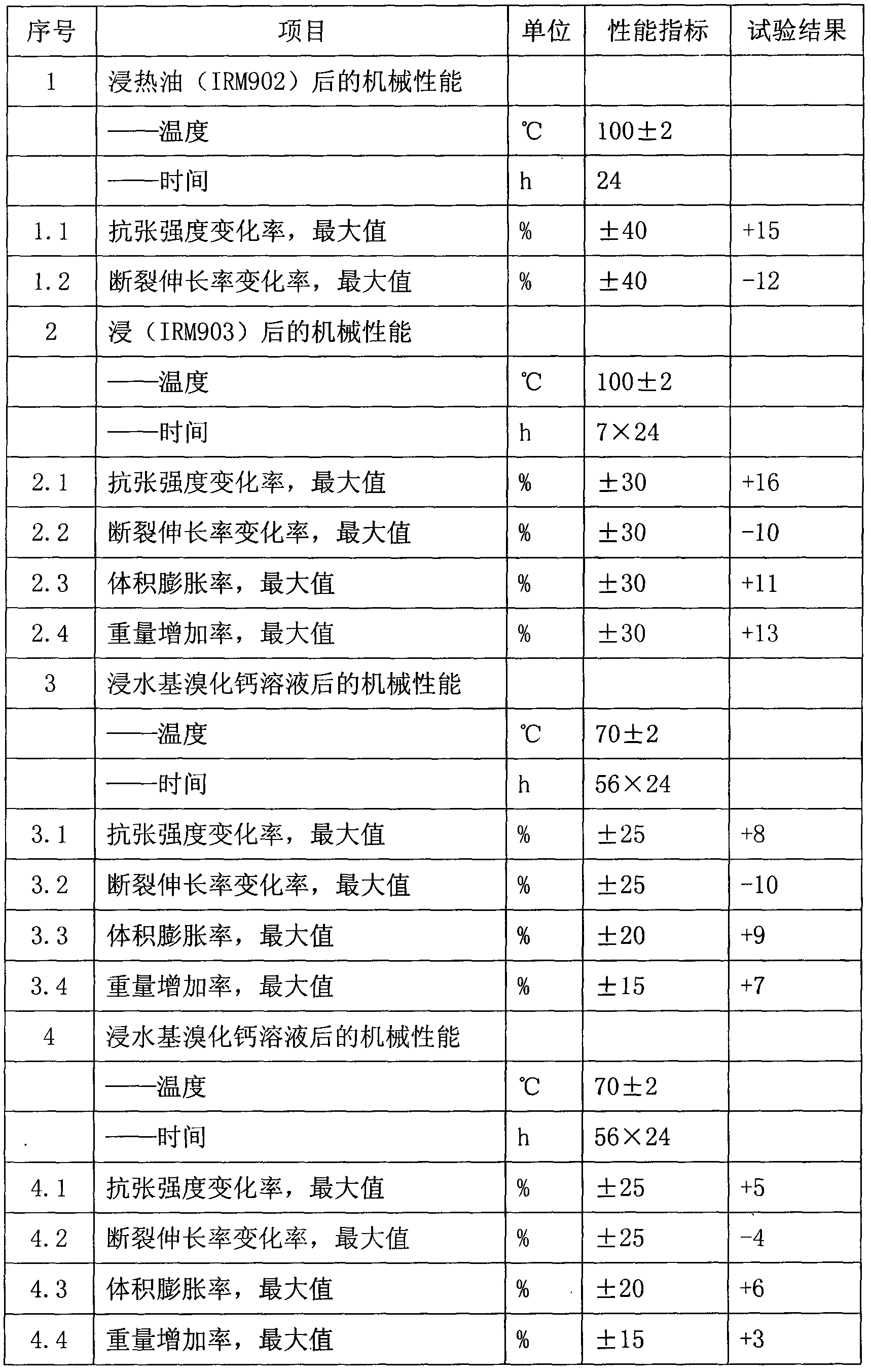

scable material for high-strength and ultra-soft oil-proof rubber elastic body, and preparation method thereof

InactiveCN101445630APromote environmental protectionGood softnessPlastic/resin/waxes insulatorsElastomerFuel oil

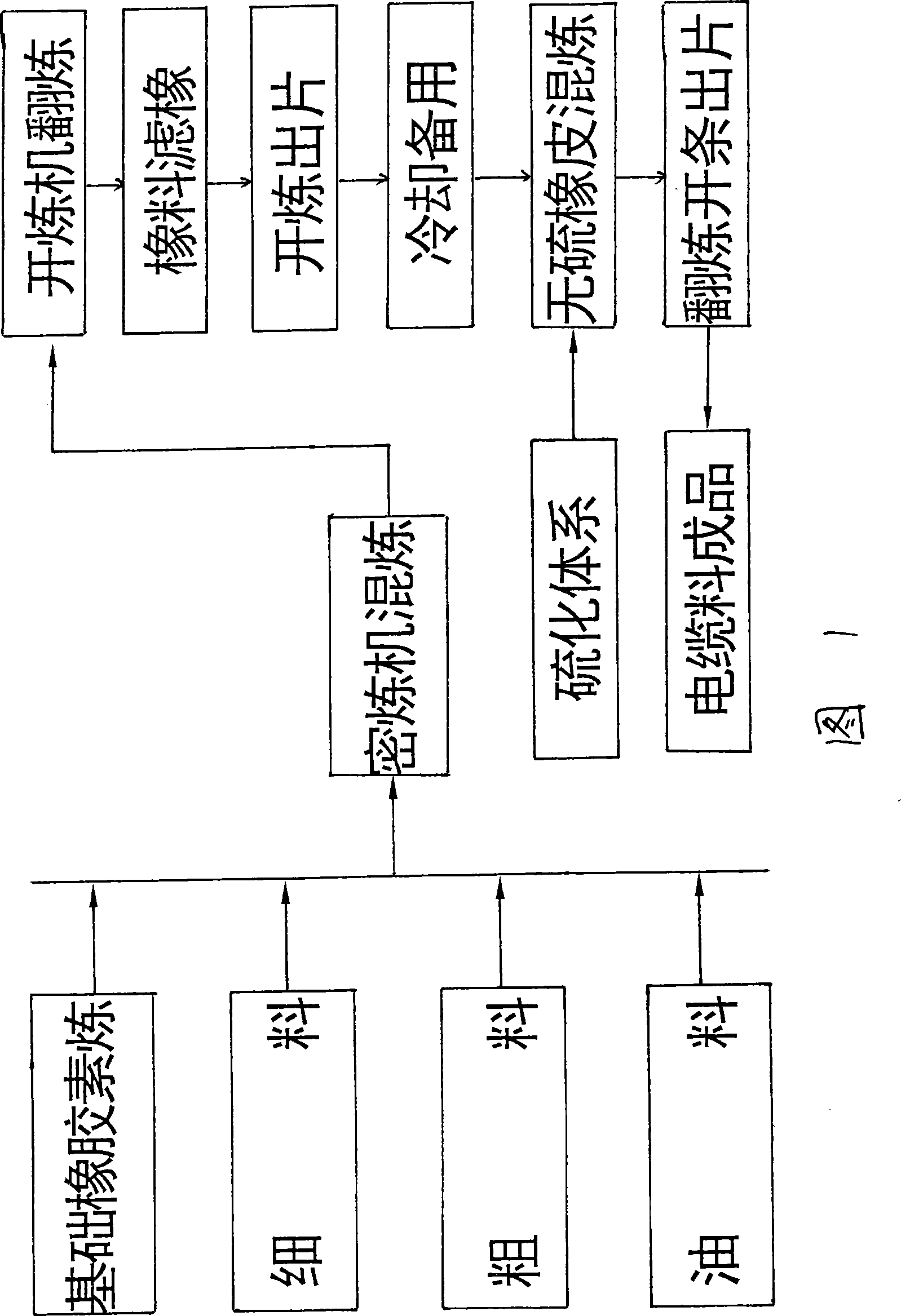

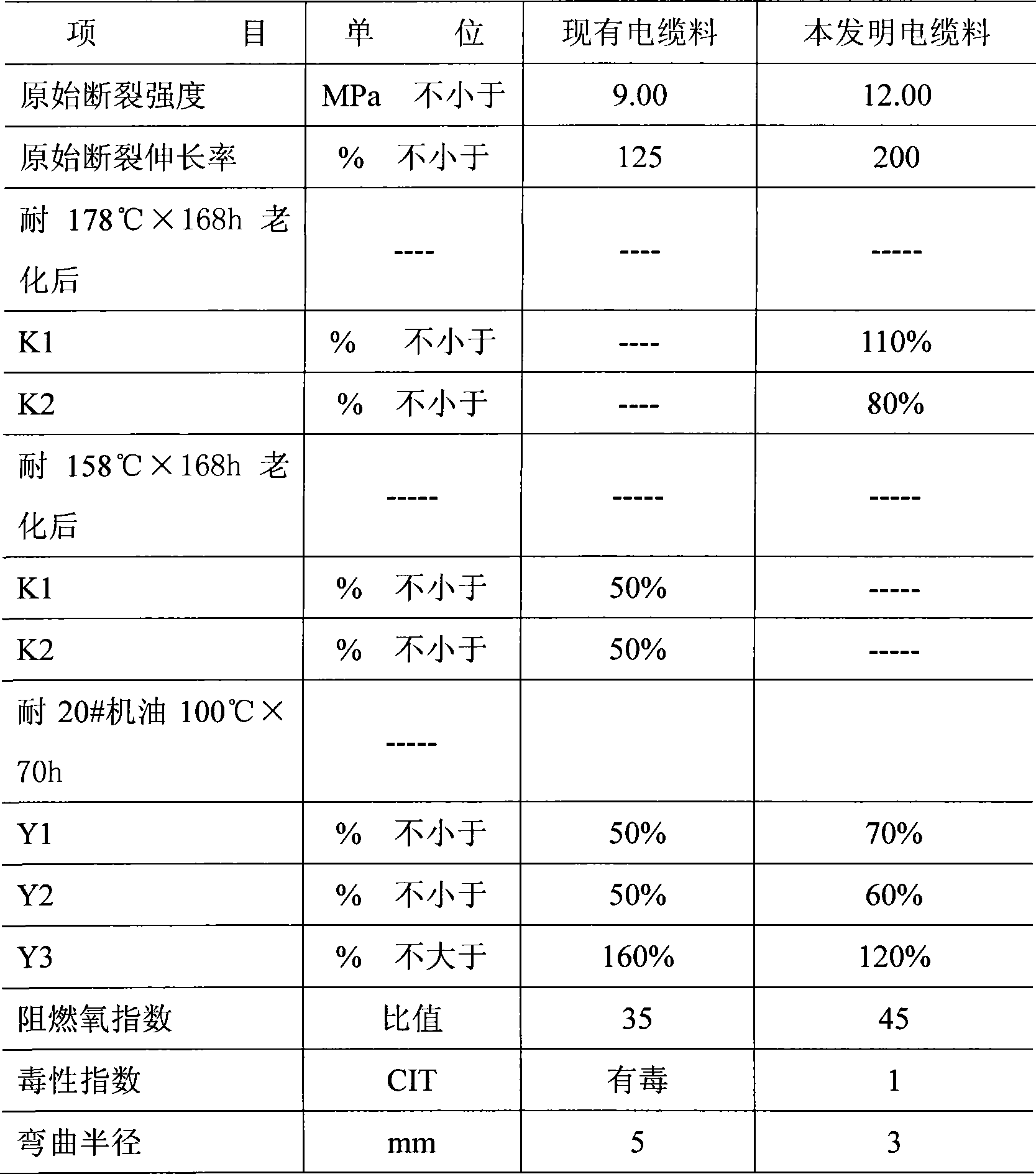

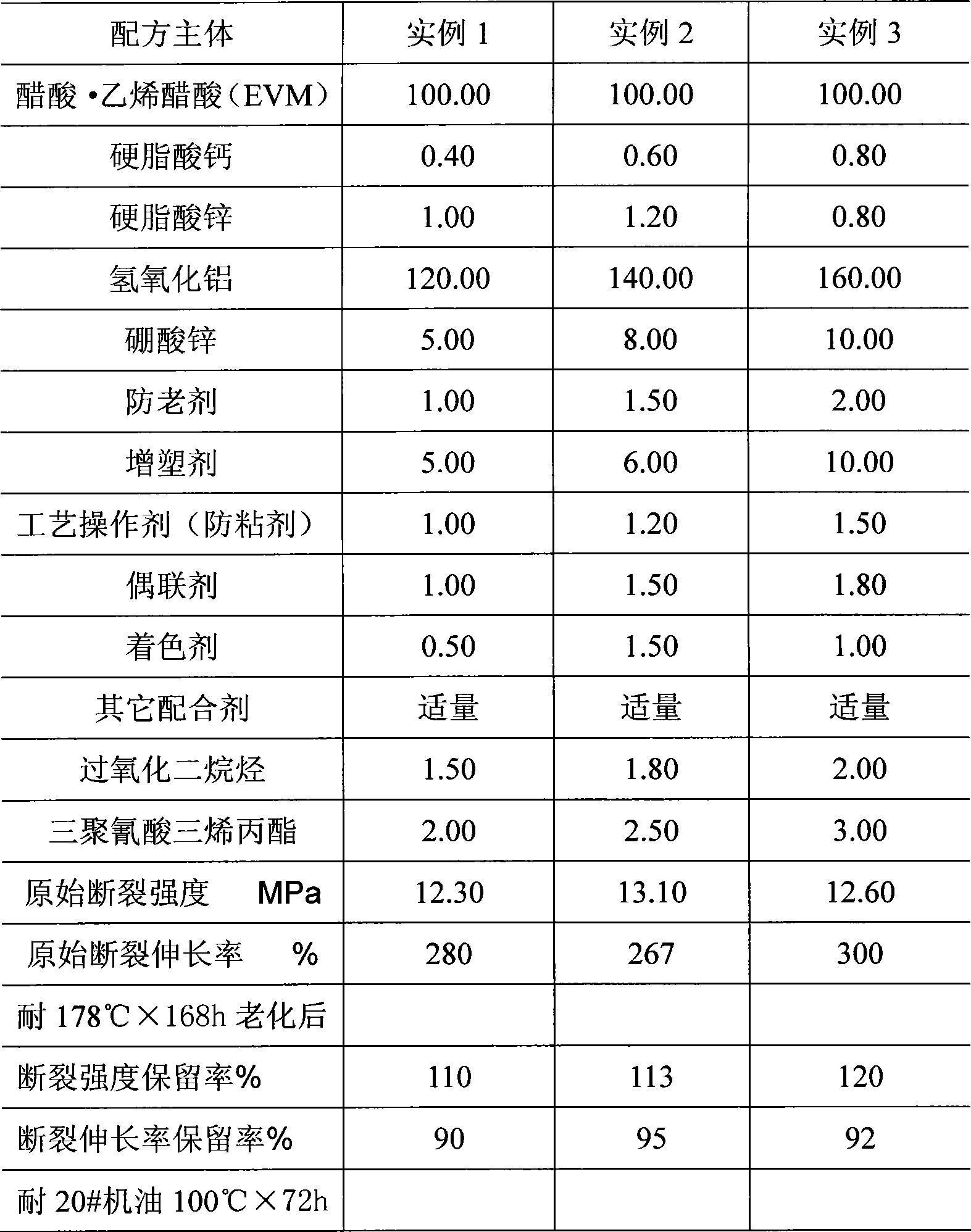

The invention provides a cable material for 140 DEG C high-temperature resistant, high-strength and ultra-soft oil-proof rubber elastic body, and a preparation method thereof. The invention is characterized in that the polar ethylene, the vinyl acetate (EVA) and the environmental-friendly high molecular material are taken as the foundational rubber formula, and the corresponding curing system is added with environmental-friendly aluminum hydroxide, boron-zinc flame retardant, calcium or zinc stabilizer, high-temperature resistant silicone oil plasticizer, and the like, therefore, the cable material for the rubber elastic body is formed. The cable material has the characteristics that the cable material is 140 DEG C high-temperature resistant and mineral oil and fuel oil resistant, and is ultra-soft, conforms to the requirement of the railway motor train cable and provides convenience for the users of the railway motor train cable.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

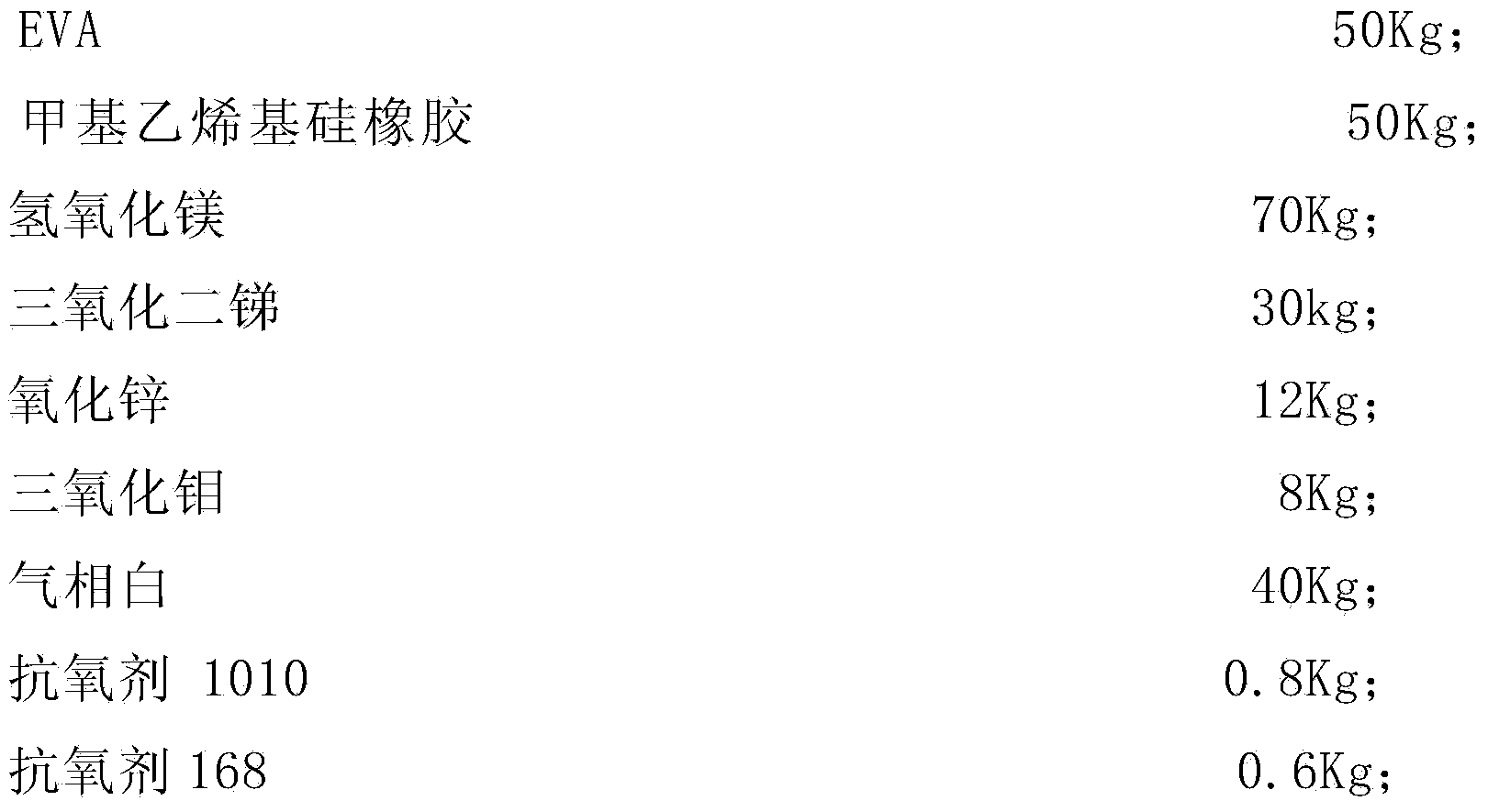

Low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material, preparation method thereof and cable

ActiveCN103627074AGood cold and oil resistanceImprove mechanical propertiesRubber insulatorsInsulated cablesAntioxidantCarvacryl acetate

The invention provides a low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material and a preparation method thereof. The low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material comprises the following components in parts by weight: 100 parts of basic material, 80-100 parts of flame retardant A, 10-20 parts of flame retardant B, 0.8-2 parts of antioxidant, 0.4-2 parts of lubricant, 0.8-3 parts of coupling agent, 25-40 parts of reinforcing agent and 0.4-0.6 parts of vulcanizing agent, wherein the basic material is a combination of ethylene-vinyl acetate (EVA) and methyl vinyl silicone rubber; the flame retardant A is a combination of magnesium hydroxide and antimony trioxide; the flame retardant B is a combination of zinc oxide and molybdenum trioxide; the antioxidant is a combination of pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate), (antioxidant 1010) and tri(2,4-di-tert-butylphenyl) phosphite (antioxidant 168); and the reinforcing agent is fumed silica. The low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material has the following characteristics of high abrasion resistance, high flame retardance, good oil resistance and chemical corrosion resistance, low temperature resistance, aging resistance, and excellent mechanical properties and the like. The invention further provides the preparation method of the low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material.

Owner:上海至正新材料有限公司

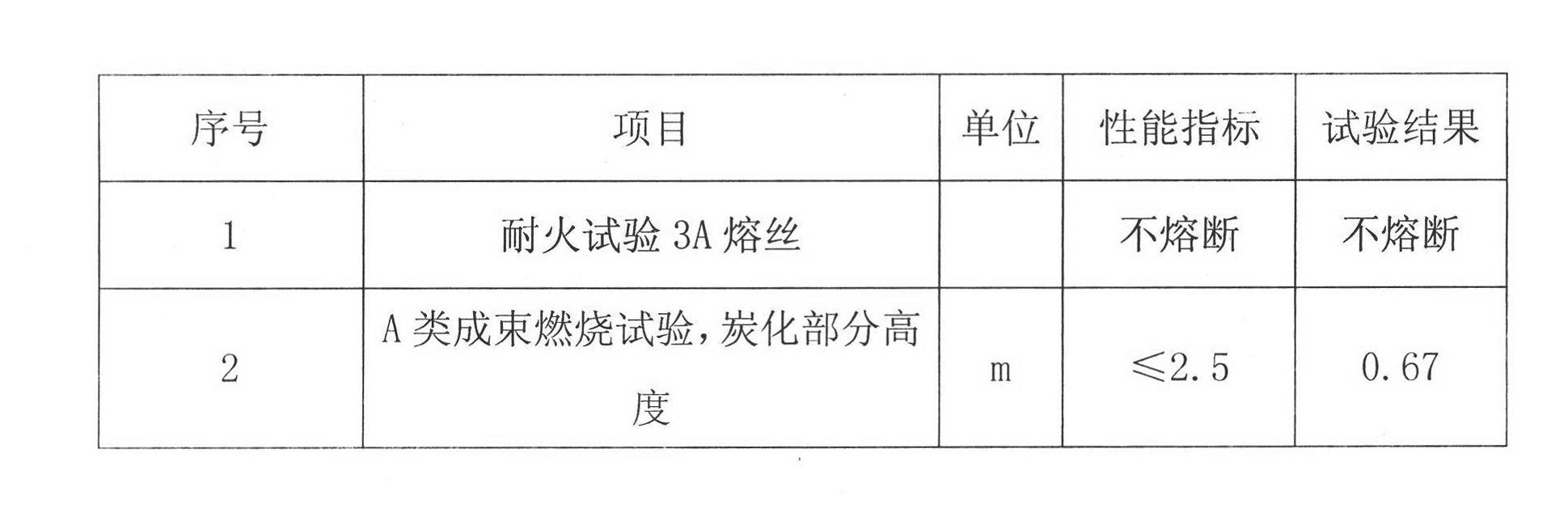

Flame-retardant electrical cable

ActiveUS20110240335A1Improve the immunityImprove thermo-pressure resistanceTransportation and packagingInsulated cablesElectrical conductorEthylene Homopolymers

A flame-retardant cable includes at least one conductor and at least one coating made from a flame-retardant composition. The flame-retardant composition includes: (a) at least one crystalline propylene homopolymer or copolymer; (b) at least one copolymer of ethylene with at least one C3-C12 alpha-olefin, having a density of from 0.860 to 0.904 g / cm3 and a Molecular Weight Distribution Index not higher than 5; (c) at least one ethylene homopolymer or copolymer of ethylene with at least one C3-C12 alpha-olefin having a density of from 0.905 to 0.970 g / cm3; and (d) at least one flame-retardant filler.

Owner:PRYSMIAN SPA

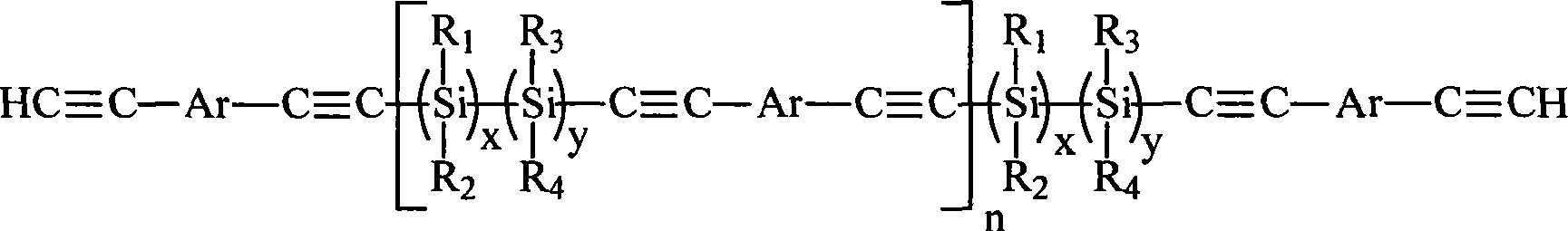

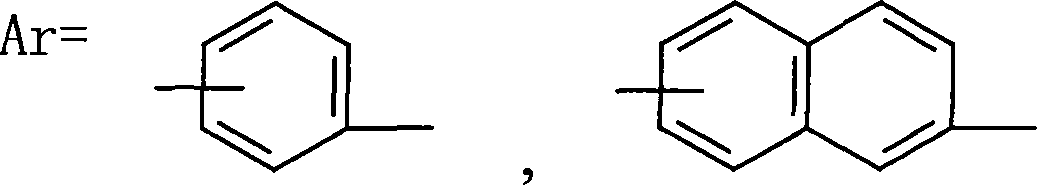

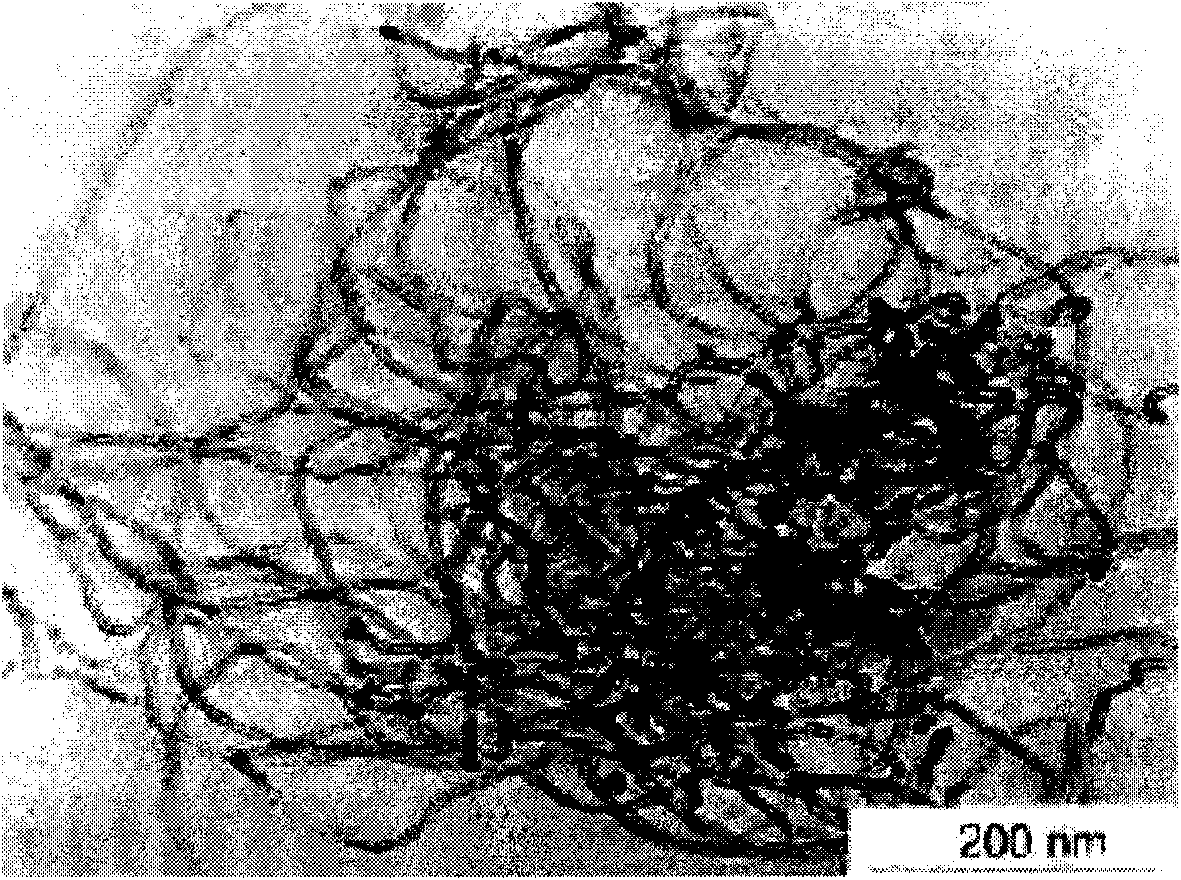

Aryne resin containing polysilicone and preparation method thereof

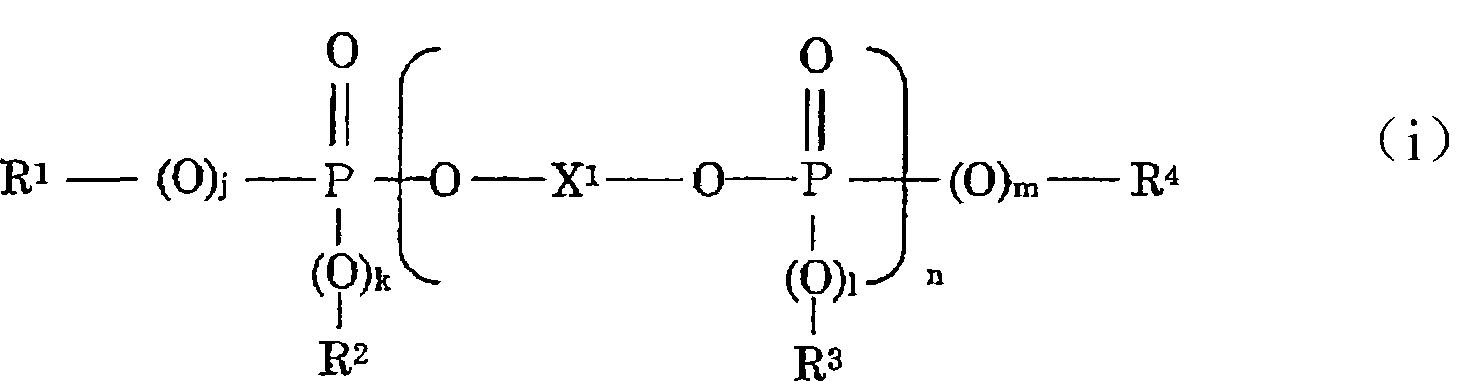

The invention relates to a polysilane-containing aryne resin represented as right, wherein n is 0-20, x and y are 0-20, R1, R2, R3 and R4 are CH3 and C6H5, or R1 is H, R2, R3 and R4 are CH3 and C6H5, or R1 and R3 are H, R2 and R4 are CH3 and C6H5. The preparation method of polysilane-containing aryne resin uses aryne Grignard reagent to be reacted with terminated chlorine polysilane, while terminated chlorine polysilane is prepared by chlorination process and sodium condensation method. The inventive polysilane-containing aryne resin has better processing character, mechnical character, heat endurance, oxidation resistance and fire-retardancy, which can form ceramic material in high temperature and own better cementation with reinforcing fiber, with wide application in resin substrate and ceramic boving precursor.

Owner:EAST CHINA UNIV OF SCI & TECH

High-flame-resistance high-strength high-reflection polycarbonate material as well as preparation method thereof and application thereof

ActiveCN105968771AImprove flame retardant propertiesGood light shading reflection functionMass ratioHigh intensity

The invention discloses a high-flame-resistance high-strength high-reflection polycarbonate material which is prepared from the following raw materials in percentage by mass: 10-75% of polycarbonate, 0.05-10% of a flame retardant, 0.1-0.8% of an anti-dropping agent, 25-75% of light-reflecting master batches, 1-10% of a toughening agent, 0.2-1% of an ultraviolet resistant agent, 0.2-1% of an antioxidant and 0.2-5% of a lubricant, wherein the light-reflecting master batches consist of a light reflecting agent, a coupling agent, polycarbonate and auxiliaries in a mass ratio being 40 to (7.5 to 17.5) to (37 to 57) to (0.1 to 5). The material has a good light shielding and reflecting function, high flame resistance, and good mechanical property. The invention further discloses a preparation method and application for the high-flame-resistance high-strength high-reflection polycarbonate material. The high-flame-resistance high-strength high-reflection polycarbonate material can be used for preparing a light reflecting piece, and is especially suitable for preparing an LED (light-emitting diode) lamp reflecting cover.

Owner:中广核瑞胜发(厦门)新材料有限公司

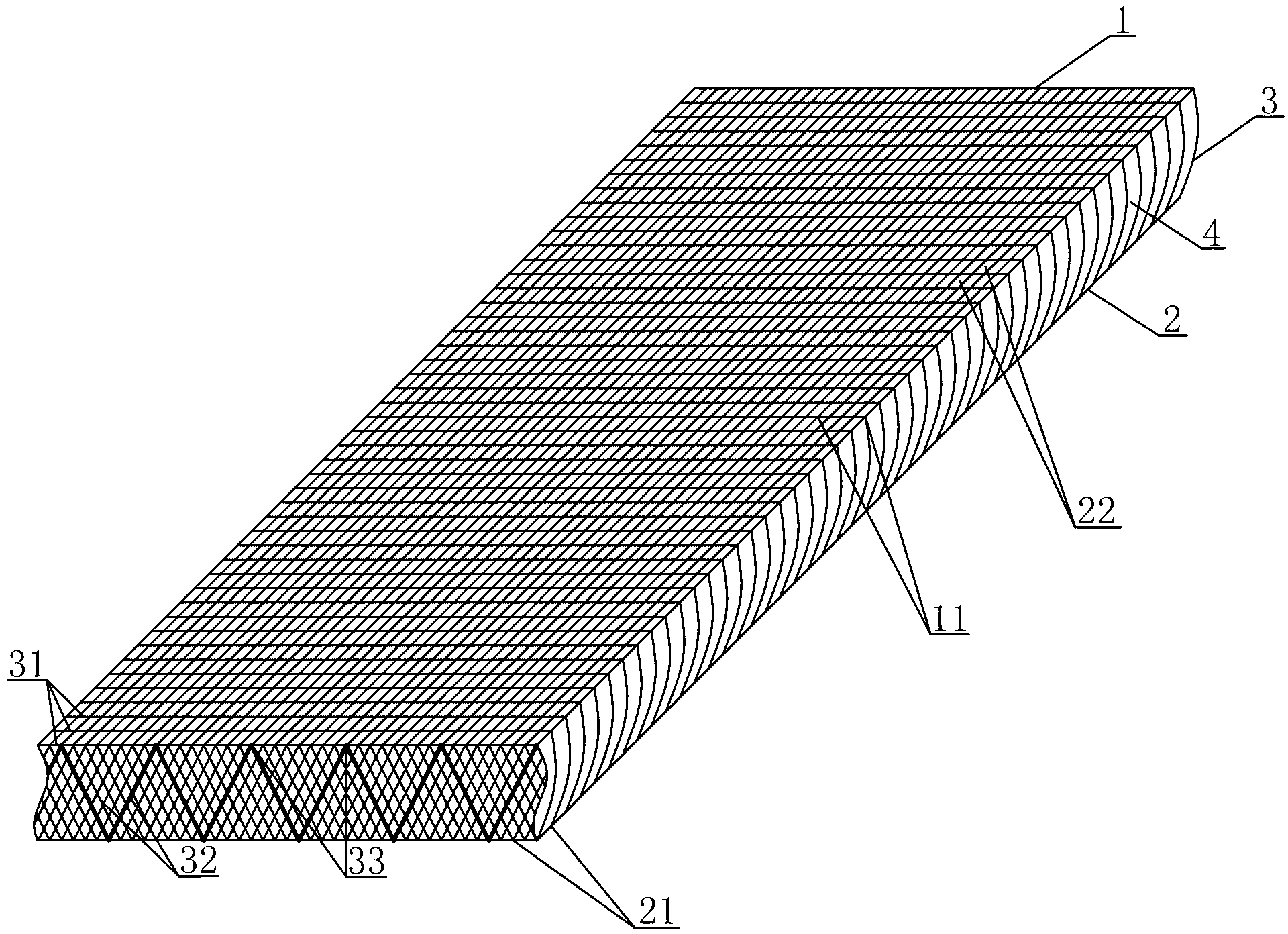

Multifunctional composite carpet and ditch construction technology thereof

The invention discloses a multifunctional composite carpet comprising three-dimensional warp knitting fabric composed of a top layer, a bottom layer and a connecting layer connecting the top layer and the bottom layer. The top layer, the bottom layer and the connecting layer enclose to form a cavity. The multifunctional composite carpet is characterized in that composite which can be solidified is filled in the cavity, the top layer is made of mesh fiber fabric, the bore diameter of each mesh of the mesh fiber fabric ranges from 0.02mm to 60mm, and the meshes in the top layer are in regular or irregular shapes. The multifunctional composite carpet and the ditch construction technology thereof have the advantages of good overall performance, environment friendliness, flexibility in application, convenience in using, mounting, demounting and transporting; the solidified composite can form special materials of mesh composite concrete layer with serialized functions and having certain thickness and hardness; the ditch construction technology is simple in technology, convenient to construct, high in efficiency, good in overall performance and attractive in appearance.

Owner:蔡晓民 +1

High-strength flame-retardant ablation-resistant coating and preparation method thereof

ActiveCN106467699AHigh heat resistanceImprove performanceFireproof paintsEpoxy resin coatingsFiberPolyamide

The invention relates to a high-strength flame-retardant ablation-resistant coating and a preparation method thereof. the coating comprises the following ingredients (by weight): 40-60 parts of high-temperature-resistant resin, 20-40 parts of an ablation-resistant filler, 5-15 parts of a flame-retardant filler, 15-35 parts of reinforced fiber, 0.5-2 parts of an auxiliary agent and 10-40 parts of a solvent. When the coating is used, 20-30 parts by weight of a polyamide curing agent and 0.3-2 parts by weight of a phenols curing agent promoter are added. Through a method of blade coating, roller painting and spraying for coating the surface of a device, a film is formed. In comparison with the prior art, the film formed by the coating can be resistant to instant high temperature of 1500 DEG C and above, has excellent flame-retardant effect and high bonding strength, and has been successfully applied to parts of guided missile launcher, etc. to effectively solve the thermal protection problem of the surface during missile launching, can be resistant to multiple times of ablation and scouring, and has repairability.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Oil-resistant and cold-resistant LSOH (Low Smoke Zero Halogen) cable material with high fire retardancy and preparation method thereof

ActiveCN104262773AMeet oil resistanceGuaranteed cold resistancePlastic/resin/waxes insulatorsLow smoke zero halogenProcedure Agents

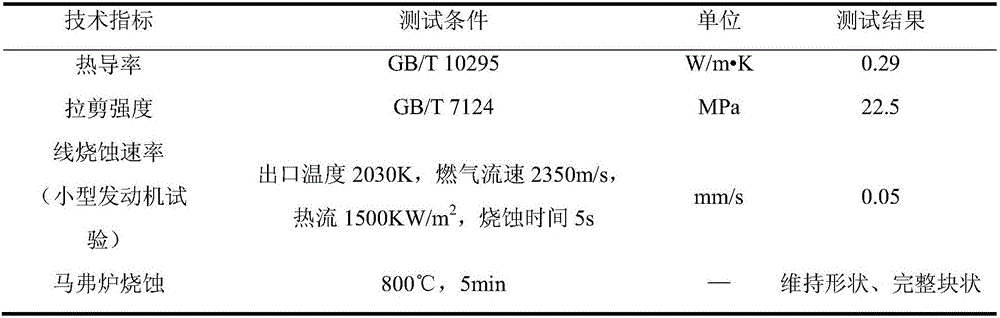

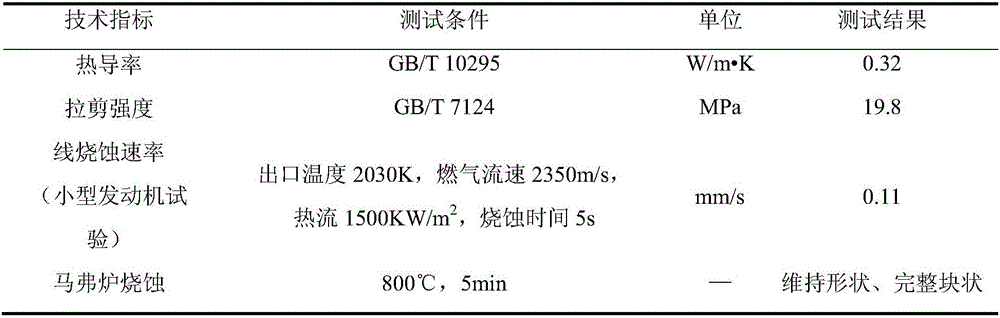

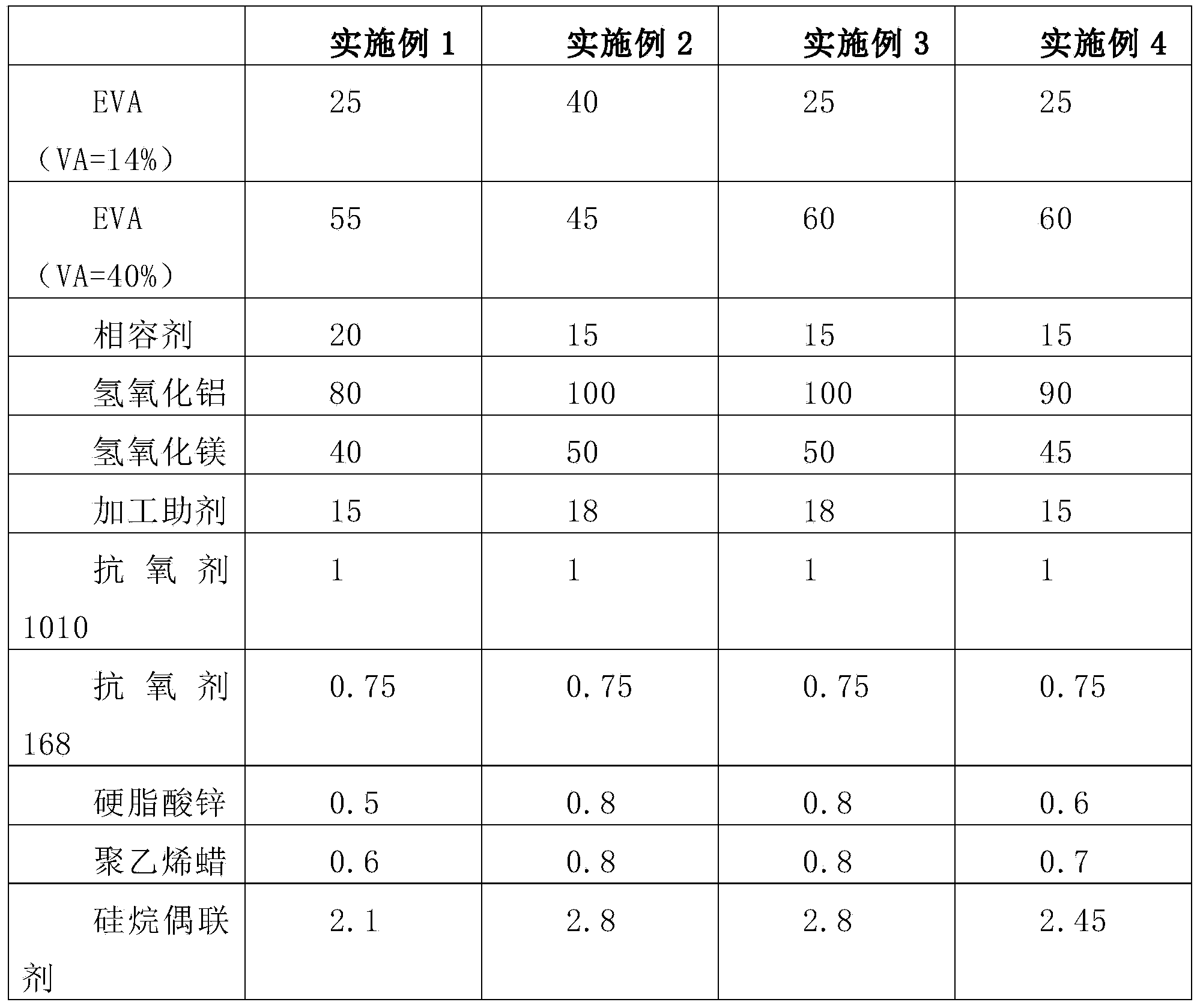

The invention provides an oil-resistant and cold-resistant LSOH (Low Smoke Zero Halogen) cable material with high fire retardancy. The cable material comprises the compounds in parts by weight: 80-85 parts of base resin, 15-20 parts of compatilizer, 120-150 parts of fire retardant, 0-18 parts of processing agent, 0-2 parts of antioxygen, 0-2 parts of lubricating agent and 1-3 parts of coupling agent. The base resin is formed through the combination of Ethylene-Vinyl-Acetate copolymers (EVA) with low VA (Vinyl-Acetate) content and Ethylene-Vinyl-Acetate copolymers (EVA) with high VA content in a weight compound ratio of (25-40): (45-60); the VA content of the Ethylene-Vinyl-Acetate copolymers (EVA) with low VA content is 14%-28% in the term of the total weight of the ethylene-vinyl-acetate copolymers with low VA content; the VA content of the Ethylene-Vinyl-Acetate copolymers (EVA) with high VA content is 35%-50% in the term of the ethylene-vinyl-acetate copolymers with high VA content. The cable material provided by the invention overcomes the disadvantages in the prior art, and the LSOH fire-retardant cable material is good in cold resistance and oil resistance, high in fire retardancy and excellent in mechanical property.

Owner:上海至正新材料有限公司

Floating body material and manufacturing technique thereof

The invention relates to a floating body material, in particular to a floating body material and a manufacturing technique thereof for an observation platform at the bottom of the sea. The floating body material comprises bisphenol A type epoxy resin, modified acrylonitrile-butadiene rubber latex, hollow glass microsphere, polyether amine, gamma-glycidoxypropyltrimethoxysilane, a silane coupling agent and polyvinyl alcohol fiber; and the floating body material comprises the following components in parts by weight: 100 parts of bisphenol A type epoxy resin, 0-10 parts of modified acrylonitrile-butadiene rubber latex, 12-18 parts of hollow glass microsphere, 15-20 parts of polyether amine, 2-3 parts of gamma-glycidoxypropyltrimethoxysilane, 1-2 parts of silane coupling agent and 2 parts of polyvinyl alcohol fiber. The invention provides the floating body material and the manufacturing technique thereof for the observation platform at the bottom of the sea; and the observation platform adopting the floating body material can be soaked in the seawater for use in a long term.

Owner:SECOND INST OF OCEANOGRAPHY MNR

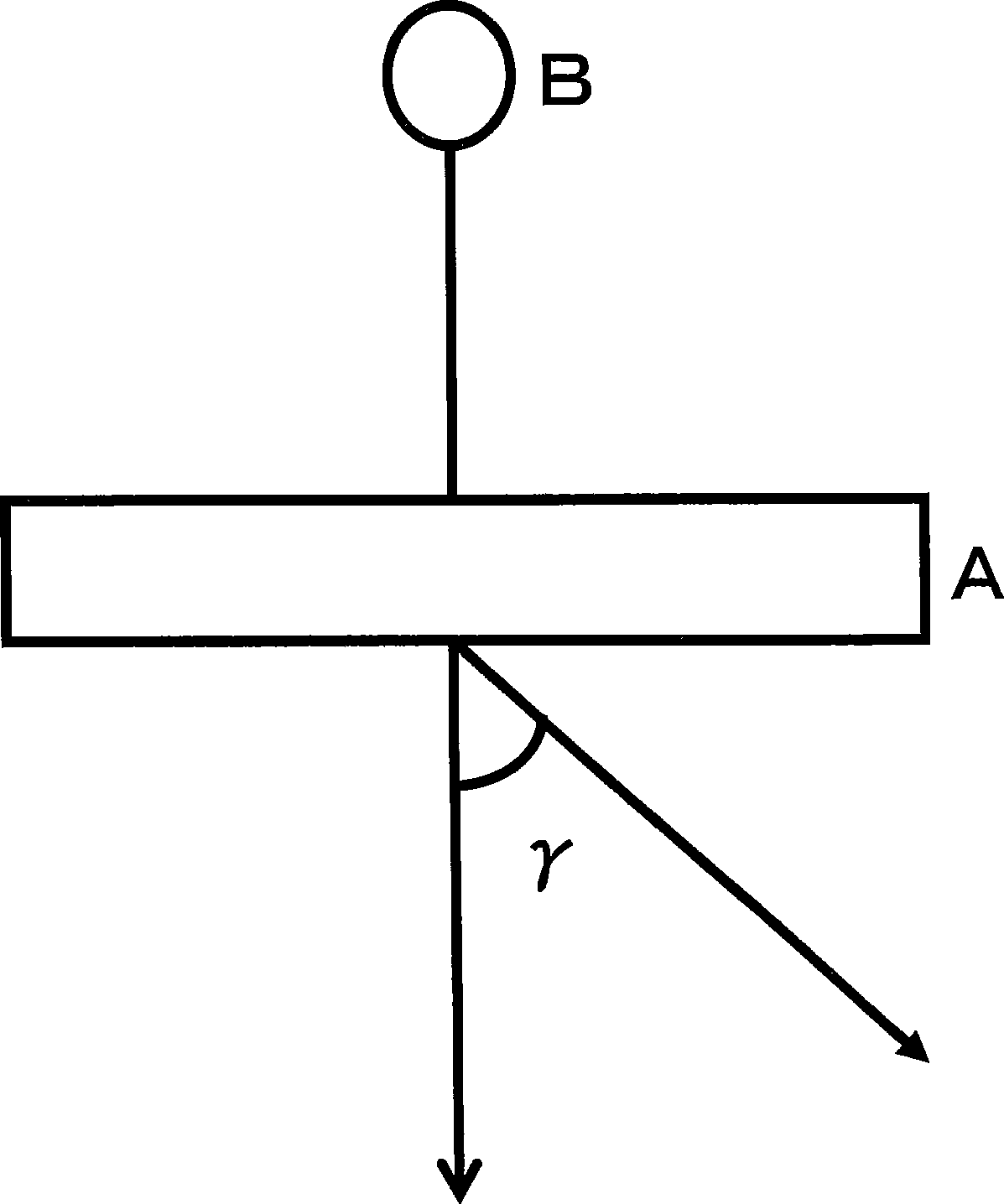

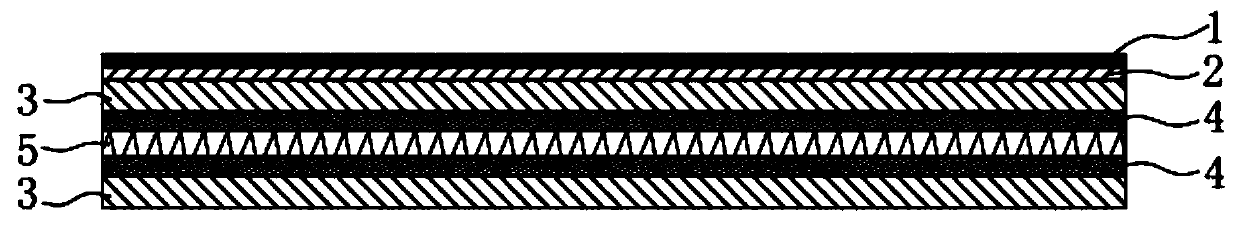

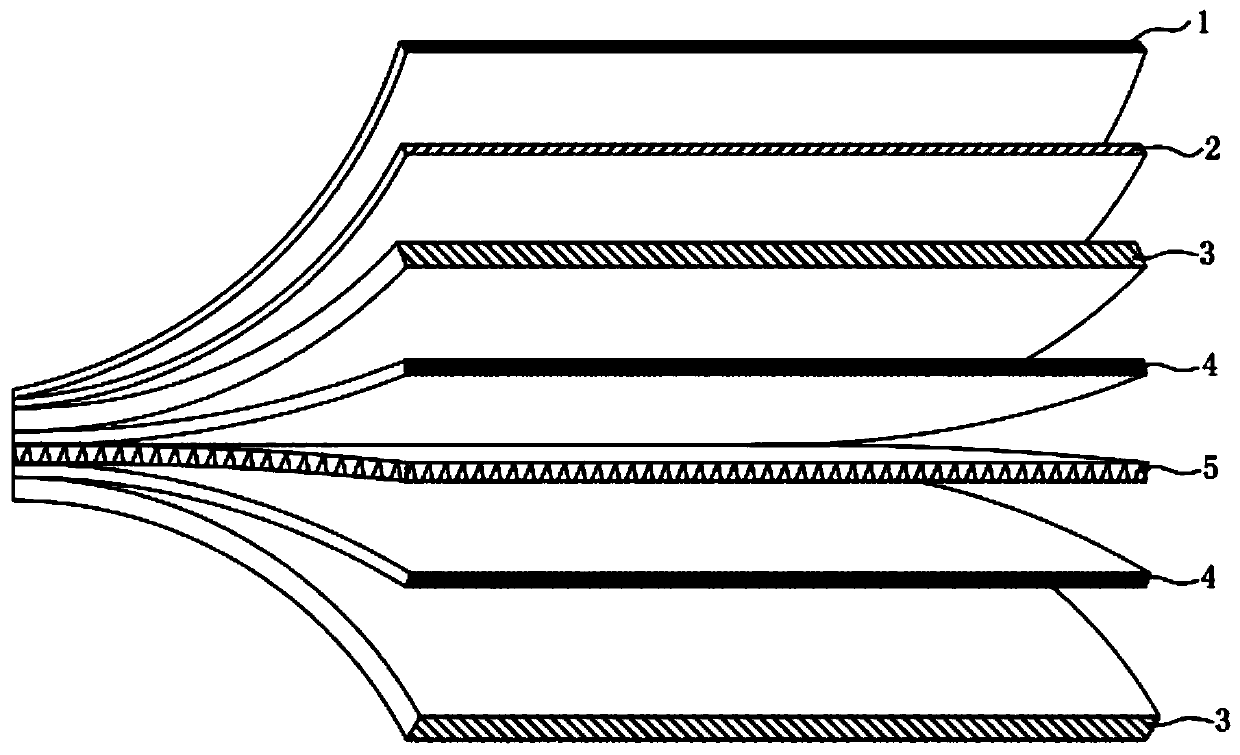

Method for preparing carbon nanometer paper flame resistant polymer matrix composite material

InactiveCN103317785AImprove flame retardant propertiesShorten ignition timeGlass/slag layered productsCarbon nanotubePeak value

The invention provides a method for preparing a carbon nanometer paper flame resistant polymer matrix composite material, which is intended to solve problems that: the current resin-based fiber reinforced composite materials exist unsafe factors of flammability, high combustion speed, difficult extinguishing, and environment pollution because of toxic gas generation; and addition of nano-materials like carbon nanotubes in a composite material can improves flame resistance of the composite material, but flame resistant and fireproof characteristics, and dispersibility and content of the nano-materials like carbon nanotubes affect integral mechanical properties of the composite material. The method comprises: adding at least one flame resistant material into a carbon nanometer paper structure, and then using the carbon nanometer paper structure as a flame resistant external layer of the composite material to form the carbon nanometer paper flame resistant polymer matrix composite material. The carbon nanometer paper flame resistant polymer matrix composite material has a good flame resistant characteristic, and a plurality of flame resistant materials is added into the carbon nanometer paper structure, thereby greatly raising flame resistant and fireproof characteristics of the composite material. Compared to a composite material without carbon nanometer paper, ignition time of the carbon nanometer paper flame resistant composite material can be reduced more than 10-30%, and a peak value of heat releasing speed can be reduced more than 15-45%, and a smoke releasing total amount can be reduced more than 10-30%.

Owner:SHENYANG AEROSPACE UNIVERSITY

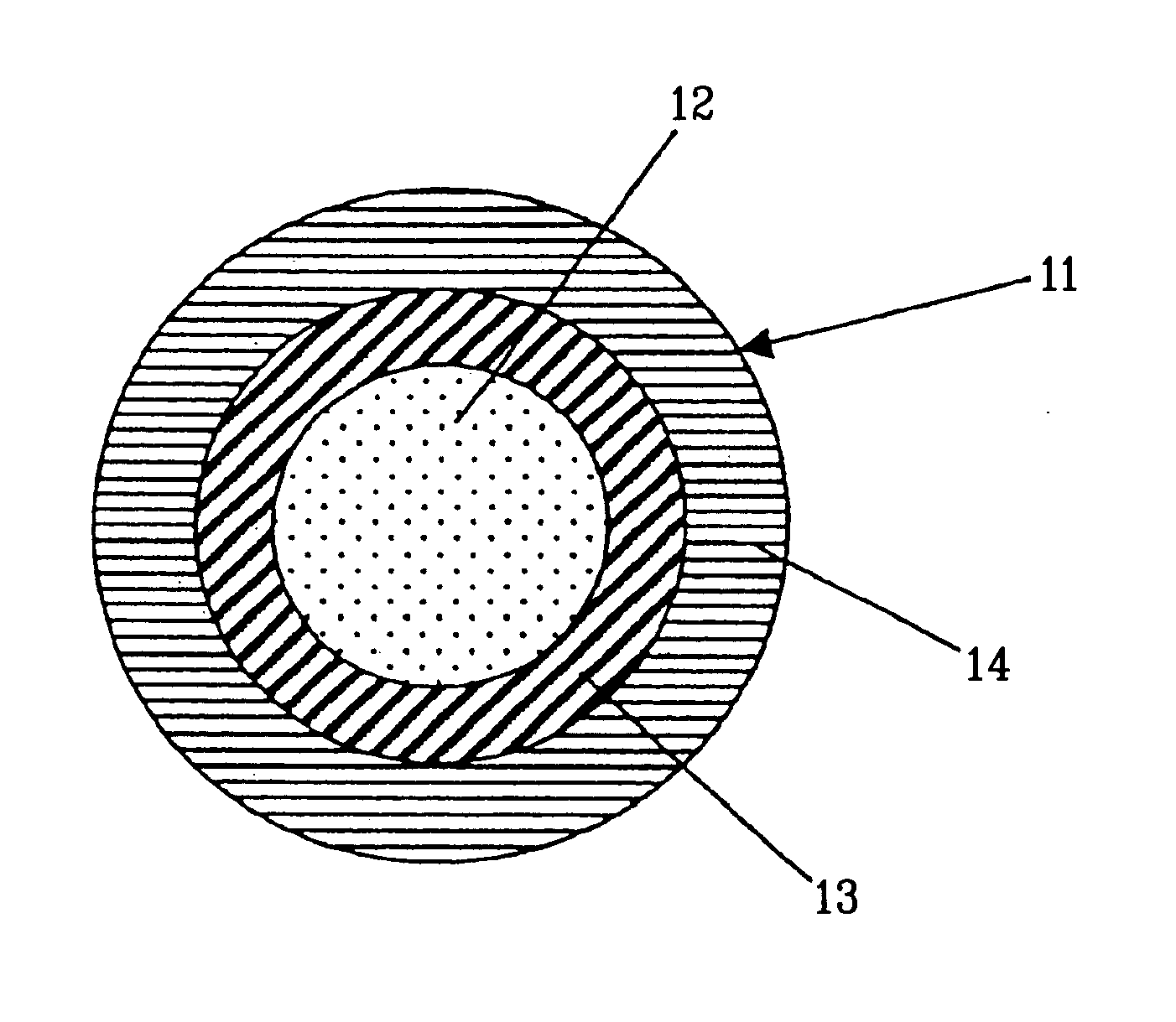

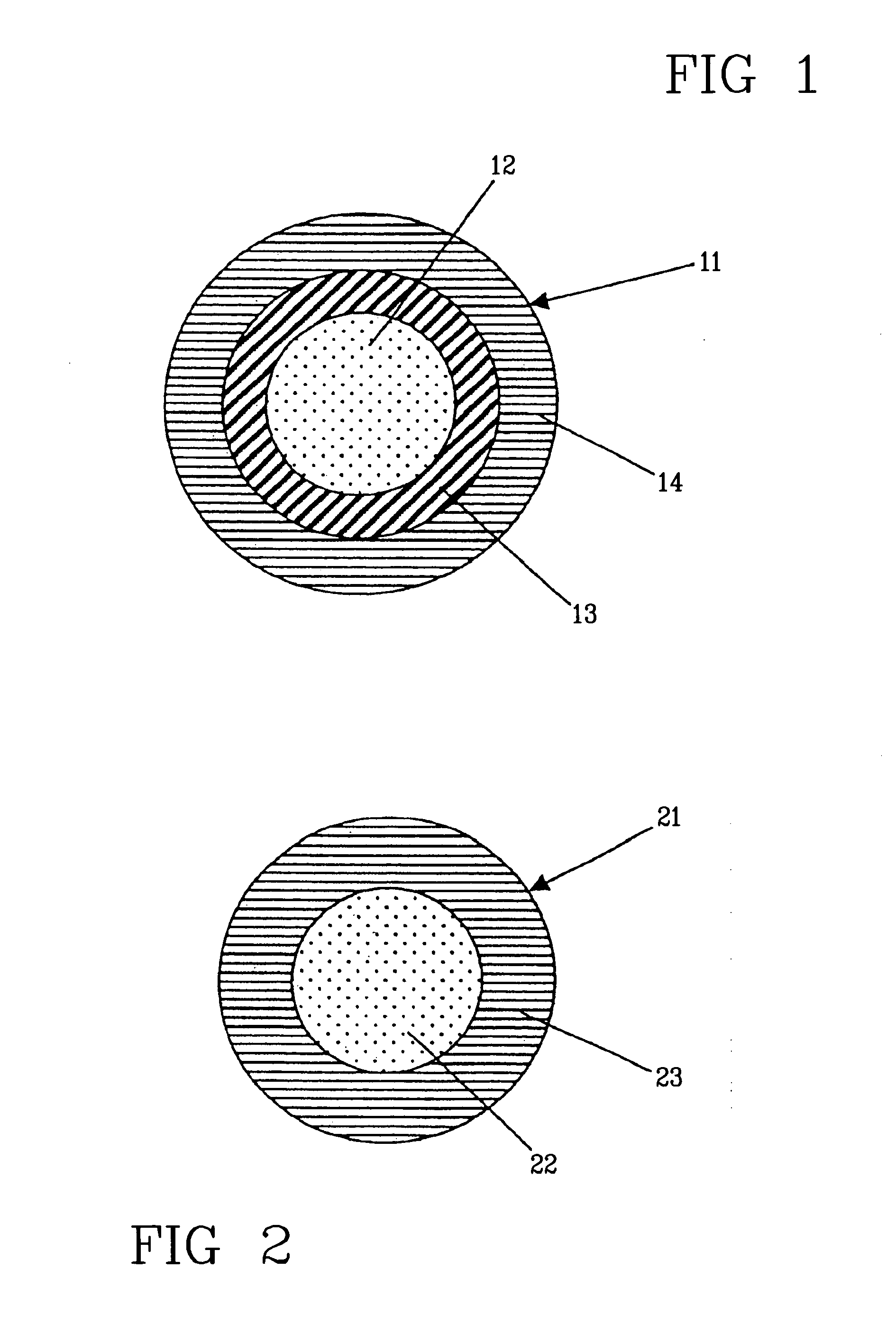

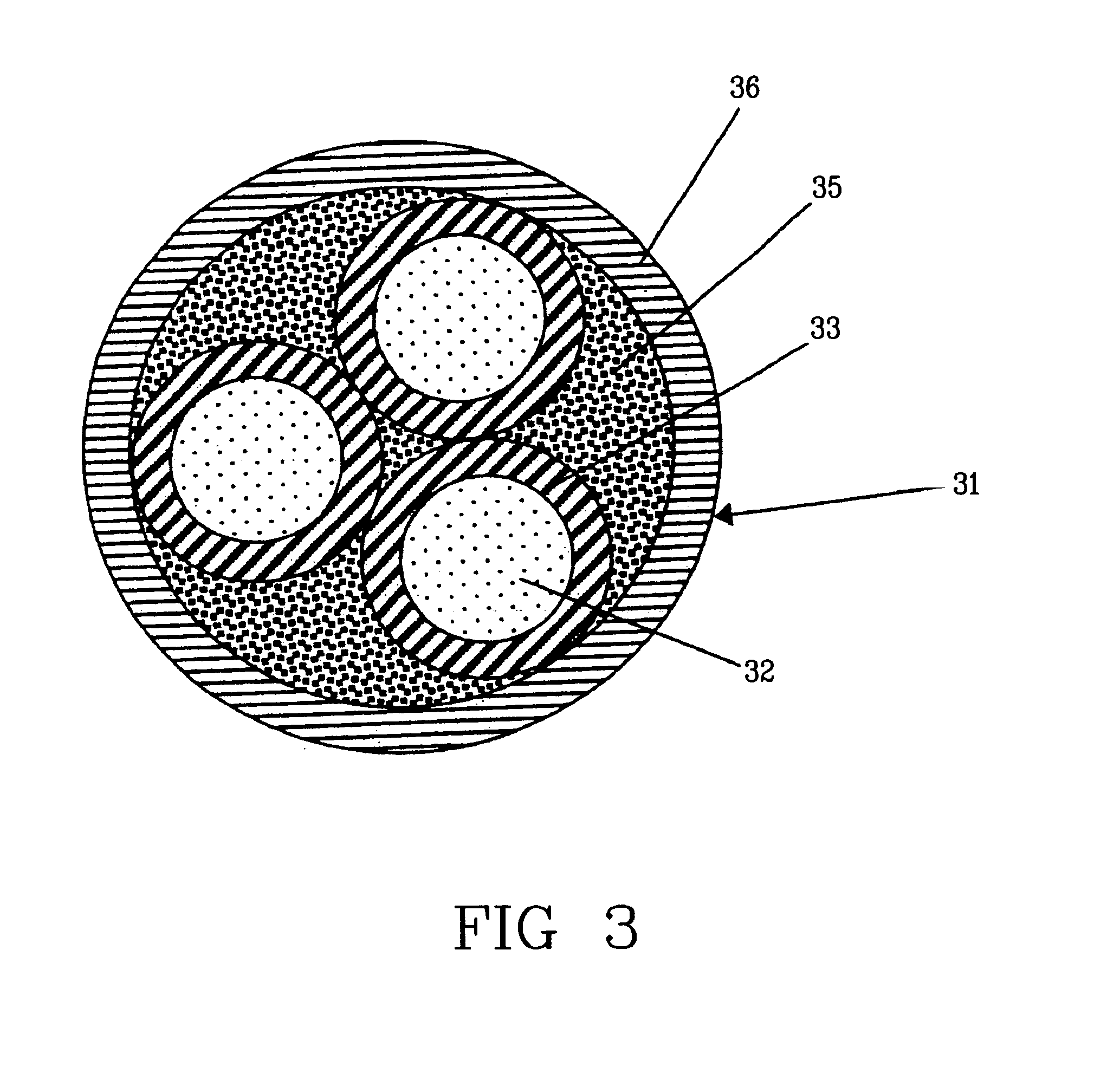

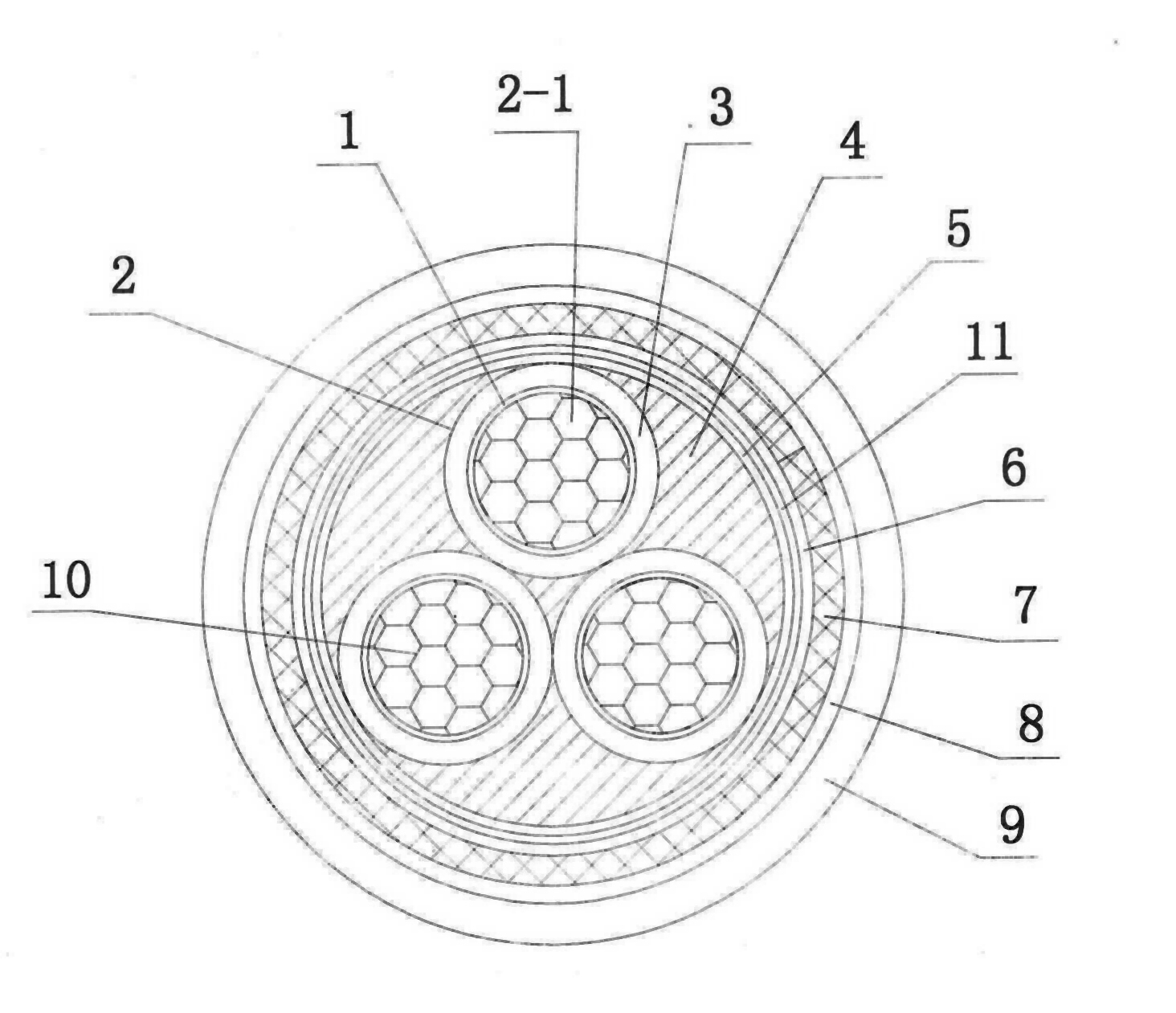

Cable for ocean engineering

InactiveCN102426883ASmall bending radiusSatisfy the use conditionFlexible cablesFlexible conductorsPolyesterElectrical conductor

The invention provides a cable for ocean engineering. The technical scheme is as follows: a plurality of conductor core wires coated by halogen-free ethylene propylene rubber insulating layers and high flame retardant filling materials form a cable through filling; the cable is lapped by a polyester belt; an oxygen barrier halogen-free inner sheath is extruded after an aluminium plastic belt is longitudinally wrapped and striated; a tinned copper wire total shielding layer is coated; a halogen-free glass fiber belt is lapped; and then an outer sheath is wrapped. The cable can be used for overcoming the following defects: the functions of the existing cables can not meet the requirements of the operation environment of ocean engineering equipment, thus serious corrosion and short service lives of the cables are caused and frequent maintenance and overhaul periods are brought for the operating engineering equipment so that the operation plans can not be accomplished on time, thus causing irreparable economic losses of users. The cable is suitable for serving as a cable for the ocean engineering environment, especially as a cable for power transfer in the severe environment of an ocean oil drilling platform and a cable for defence engineering.

Owner:湖南华菱线缆股份有限公司

Long-lasting anti-fouling membranous-structure composite canopy material

ActiveCN106003931AIncreased static contact angleNot easy to penetrateSynthetic resin layered productsCoatingsPolyesterFiber

The invention relates to a long-lasting anti-fouling membranous-structure composite canopy material comprising a base membrane, base cloth and a surface membrane which are arranged sequentially from bottom to top, wherein a polyvinylidene fluoride coating is arranged on the surface membrane and is subjected to mirror face embossing treatment; the surface membrane as well as the base membrane is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 50 to 70 parts of a dioctyl terephthalate plasticizer, 5 to 25 parts of calcium carbonate powder, 1 to 5 parts of a flame retardant, 1 to 4 parts of a smoke suppressant, 1 to 6 parts of a barium-zinc stabilizer and 1 to 5 parts of a titanium pigment; the base cloth is 1000D*1000D polyester fiber woven cloth. Raw materials such as PVC resin powder, the plasticizer, calcium carbonate, the stabilizer and the flame retardant are mixed, plasticizing and calendaring are carried out to obtain soft membranes, then the soft membranes are compounded with the 1000D*1000D polyester fiber woven cloth, and embossing is carried out after surface treatment of polyvinylidene fluoride, so that the long-lasting anti-fouling membranous-structure composite canopy material is a membranous-structure composite canopy material being long-lasting in fouling resistance, efficient in fire retardancy, and high in strength.

Owner:浙江明士达股份有限公司

Process for preparing polycarbonate /acrylonitirle-ternary ethyl propylene rubber-styrene resin / laminated silicate nano composite material

InactiveCN1900161AImprove flame retardant propertiesImproves strength and modulusHeat deflection temperaturePolycarbonate

The present invention discloses process of preparing polycarbonate / acrylonitrile-ternary ethyl propylene rubber-styrene resin / laminated silicate nanometer composite material. The preparation process includes pre-mixing polycarbonate 55-80 weight portions, acrylonitrile-ternary ethyl propylene rubber-styrene resin 10-30 weight portions, flame retardant 1-10 weight portions, laminated silicate 1-10 weight portions, drippage resisting agent 0.1-2 weight portions and antioxidant 0.1-1 weight portion in a high speed mixer; and subsequent melting and extruding in an extruder. The composite material with montmorillonite of 5 weight portions has an increase in strength, modulus and thermal deformation temperature of 7 %, 11.3 % and 18.6 % separately compared with that before modification. The composite material has balanced comprehensive performance and may be used in electric appliance, electronic equipment and other fields.

Owner:SHANGHAI JIAO TONG UNIV

Fiber-reinforced pure inorganic flame retardant foam composite and preparation method thereof

InactiveCN104876637AHigh temperature resistanceImprove flame retardant propertiesCeramicwarePhosphateAluminum silicate

The invention belongs to the technical field of composite preparation, and relates to a method for preparing a fiber-reinforced pure inorganic flame retardant foam composite. A glass fiber mat, a basalt fiber mat, an aluminum silicate fiber mat, an alumina fiber mat or a mullite fiber mat is used as a reinforcement, inorganic sol or solution, such as silica sol, alumina sol, water glass or an aluminum dihydrogen phosphate solution is used as an impregnating agent, and a microcapsule foaming method is used to prepare a low-density pure inorganic flame retardant foam composite plate. The method avoids the defects that the fiber content is low, the fiber dispersion is uneven, and the mechanical properties resulting therefrom are poor; the fiber in the composite is uniformly arranged, and the fiber mass content can reach 40-60%; the composite is good in mechanical property and formability; the density of the foam composite can be flexibly adjusted through adjusting the proportion of a microcapsule inflating agent added; the combustion level can reach the DIN5510 S5 grade.

Owner:AVIC COMPOSITES

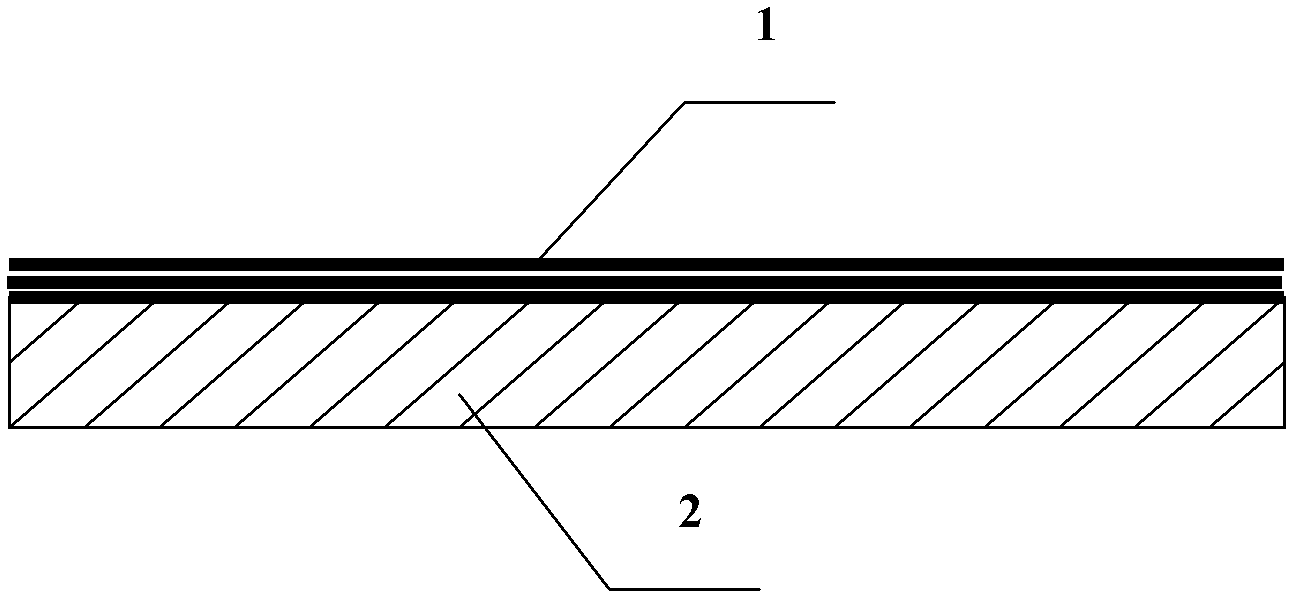

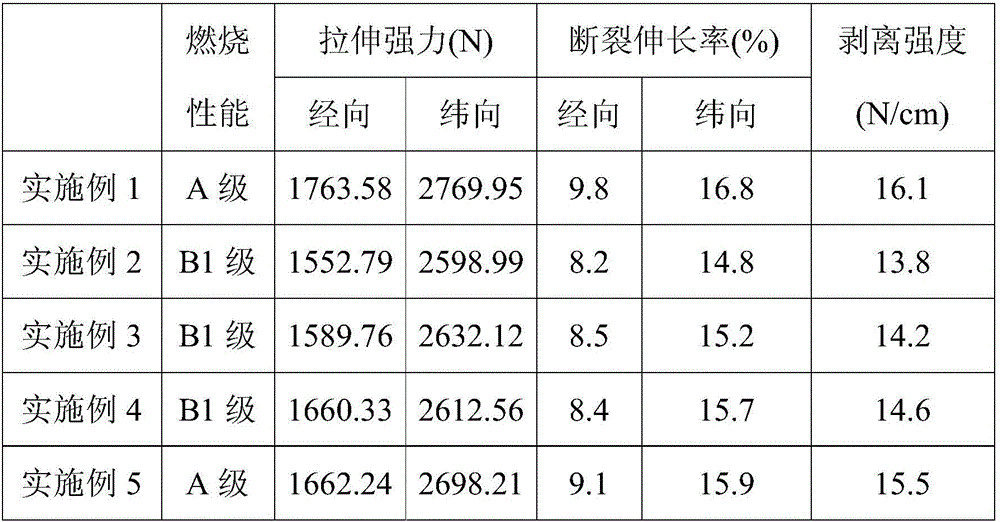

Coating composite material and preparation method thereof

InactiveCN110117911AImprove insulation performanceImprove flame retardant performanceCoatingsTextiles and paperFiberPolyester

The invention relates to a coating composite material, in particular to a coating composite material with high heat insulation and high peeling strength taking polyvinyl chloride and polyester fiber base cloth as main base materials and a preparation method of the material, and belongs to the technical field of new materials. The composite material comprises a polyester fiber fabric base materiallayer, wherein a coating surface layer and a back layer are respectively arranged on both sides of the base material layer; the back layer comprises a flame-retardant PVC primer layer and a flame-retardant PVC heat insulation layer from inside to outside; and the coating surface layer comprises a flame-retardant PVC primer layer, a flame-retardant PVC heat insulation layer, a PVC high reflection layer and an infrared reflection heat insulation transparent layer from inside to outside, and is prepared by adopting a specific preparation method. The coating composite material has good heat insulation, high peeling strength and wicking resistance characteristics, and has excellent flame resistance, weather resistance and ultraviolet resistance.

Owner:NINGBO XIANFENG NEW MATERIAL

Modified chloroprene rubber V band and method for preparing same

The invention discloses a modified chloroprene rubber V band and a method for preparing the same. The rubber matrix of the modified chloroprene rubber V band is prepared by mixing the following raw materials in portion by weight: 100 portions of chloroprene rubber, 20 to 50 portions of acid modification carbon nano-tube, 10 to 20 portions of carbon black, 2 to 10 portions of phosphorus oxide, 12 to 18 portions of sulfur, 0.3 to 5 portions of anti-aging agent, 1 to 5 portions of filler, 3 to 7 portions of softener, 2 to 10 portions of plasticizer, and 1 to 6 portions of promoter. The modified chloroprene rubber V band has good properties of heat resistance, oil corrosion resistance, static resistance and fire retardation, and can be widely applied to mechanical transmission systems under special operation environments in the industries such as coal mines, petroleum, chemical engineering, paper making and the like.

Owner:SANLUX

Flame-retardant TPE material

The invention provides a flame-retardant TPE material which comprises the following ingredients, by weight, 10-40 parts of polypropylene, 20-100 parts of SEBS, 5-20 parts of polyurethane, 50-100 parts of white oil, 5-15 parts of calcium carbonate, 30-60 parts of a flame retardant, 0.5-5 parts of a compatilizer and 0.1-2 parts of an antioxidant. Based on conventional TPE components, the polyurethane material is added so as to further enhance properties of the TPE material, such as aging resistance, chemical resistance and the like, and prolong service life of the TPE material. The flame-retardant material has good flame retardancy, can be used to obviously raise flame retardancy of the TPE material, and is more applicable to be used in the field of flame-retardant materials. In addition, the flame-retardant TPE material accords with each environmental requirement, has low production cost and can be recycled and reused.

Owner:天津市杰欣利工贸有限公司

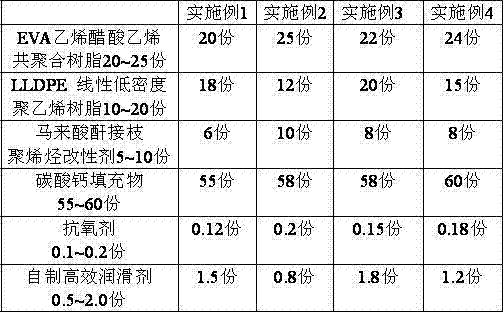

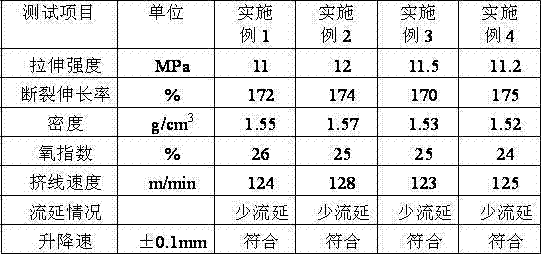

Polyolefin composite material for butterfly optical cable sheath and preparation method thereof

InactiveCN104774371ALow castIncrease extrusion speedPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a polyolefin composite material for a butterfly optical cable sheath and a preparation method thereof. The polyolefin composite material consists of the following components: 20-25 parts of EVA ethylene-vinyl acetate copolymer resin, 10-20 parts of LLDPE linear low density polyethylene resin, 5-10 parts of a maleic anhydride grafted polyolefin modifier, 55-60 parts of a calcium carbonate filler, 0.1-0.2 part of an antioxidant, and 0.5-2.0 parts of a self-made efficient lubricant. The EVA ethylene-vinyl acetate copolymer resin requires a VA content of 18-28% and an MI value of 1-8g / 10min; the LLDPE linear low density polyethylene resin has a density of 0.912g / cm<3> and an MI value of 1-3.5g / 10min; the grafting resin substrate of the maleic anhydride grafted polyolefin modifier is PE or PE / POE; and the calcium carbonate filler is light calcium carbonate or 2500-mesh heavy calcium carbonate. The polyolefin composite material provided by the invention has the advantage of low casting, fast extrusion speed and smooth appearance, and the finished product butterfly optical cable has good wrapping force, and the tensile strength and flame retardant properties are greatly improved.

Owner:中广核三角洲(苏州)高聚物有限公司

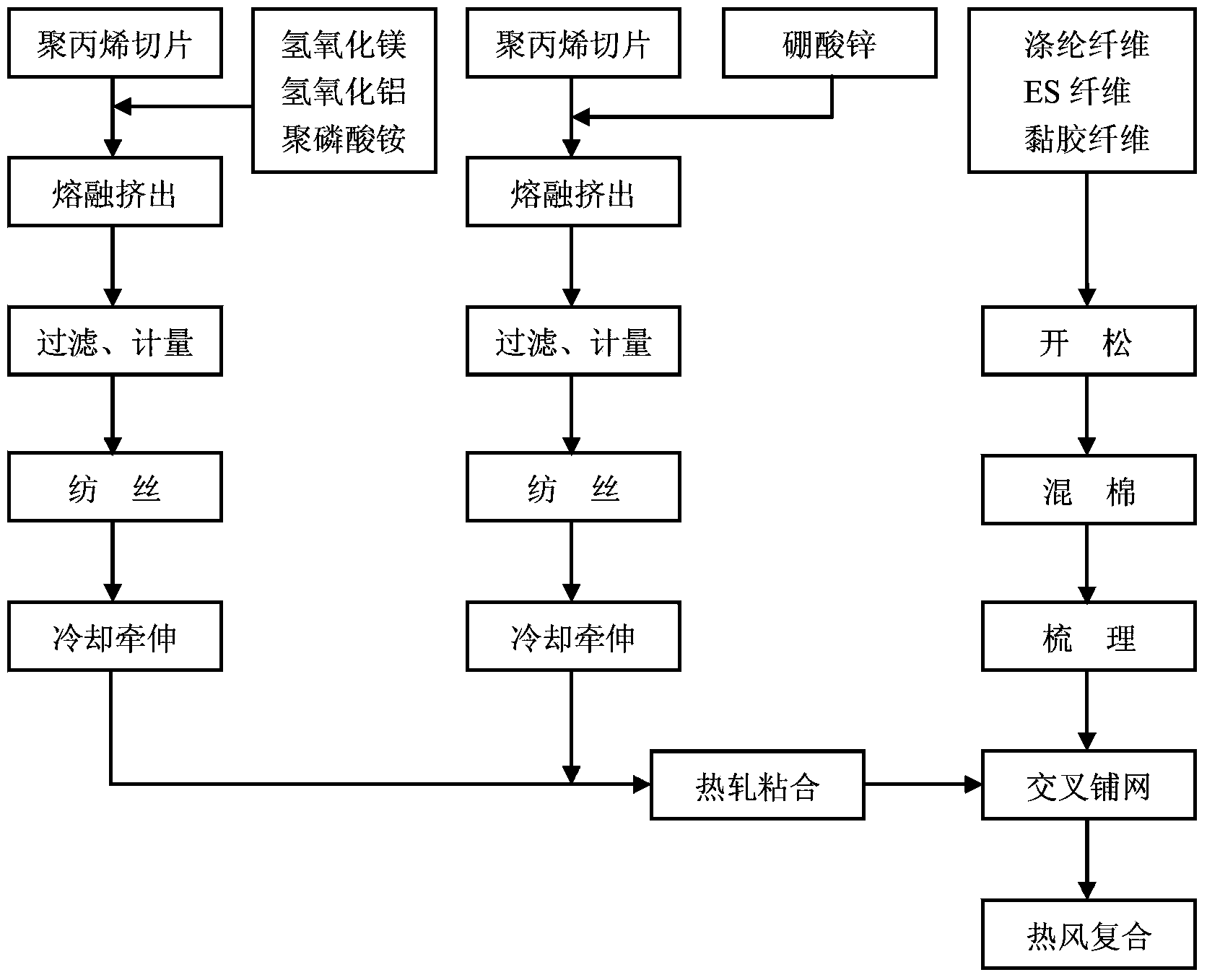

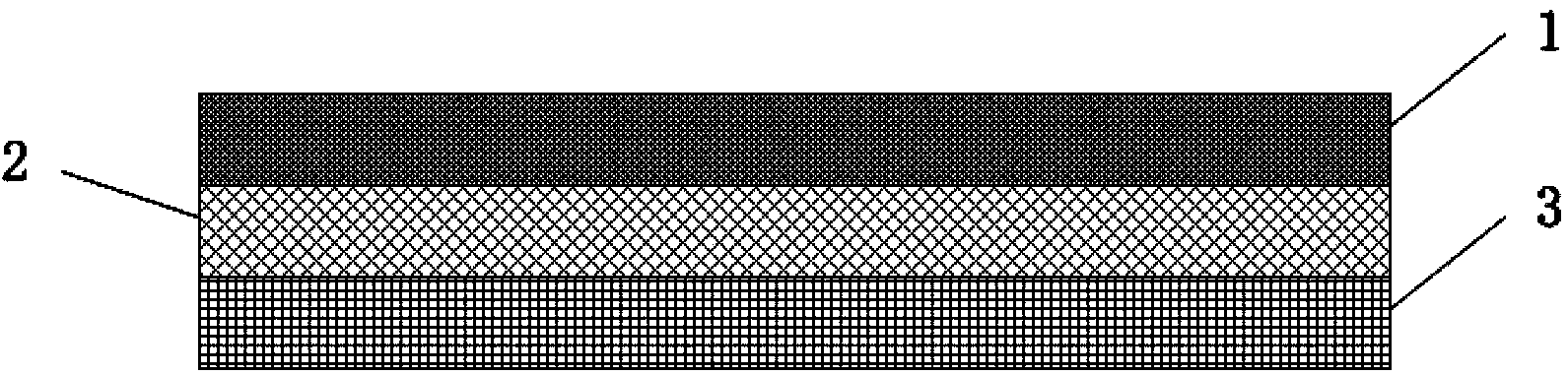

Industrial protection non-woven material and manufacturing method thereof

ActiveCN103526454AImprove breathabilityExcellent flame retardantFlame-proof filament manufactureNon-woven fabricsPolyesterEngineering

The invention discloses an industrial protection non-woven material and a manufacturing method of the industrial protection non-woven material. The industrial protection non-woven material comprises a PP spunbond non-woven fabric layer, an ES-mixed non-woven fabric layer and a PP melt-blown non-woven fabric layer sandwiched between the PP spunbond non-woven fabric layer and the ES-mixed non-woven fabric layer. Fire retardant mixtures of a first component are added to the PP spunbond non-woven fabric layer, and fire retardants of second components of different types are added to the PP melt-blown non-woven fabric layer. Mixed fibers of ES fibers, polyester fibers and viscose fibers are combed into a net to form the ES-mixed non-woven fabric layer. The industrial protection non-woven material has the moisture percentage similar to the moisture percentage of a human body, good gas permeability and soft and fluffy hand feelings, is comfortable to wear, has high tension stress and morphological stability in all directions, protects the structure of the melt-blown non-woven fabric layer and has the good inflaming retarding characteristic and the environment protection effect, and a guarantee is provided for the protection performance of the industrial protection non-woven material.

Owner:东营俊富净化科技有限公司

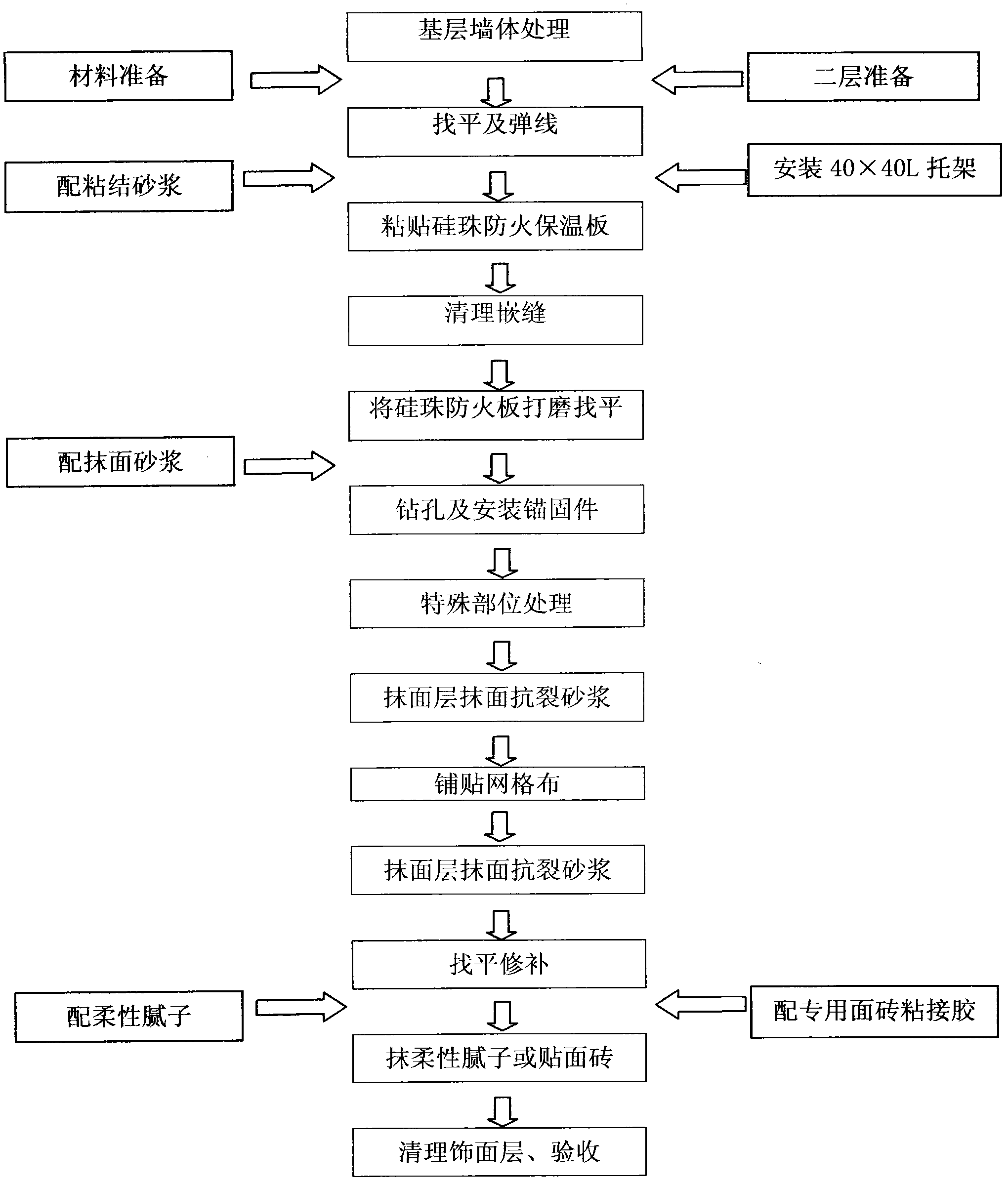

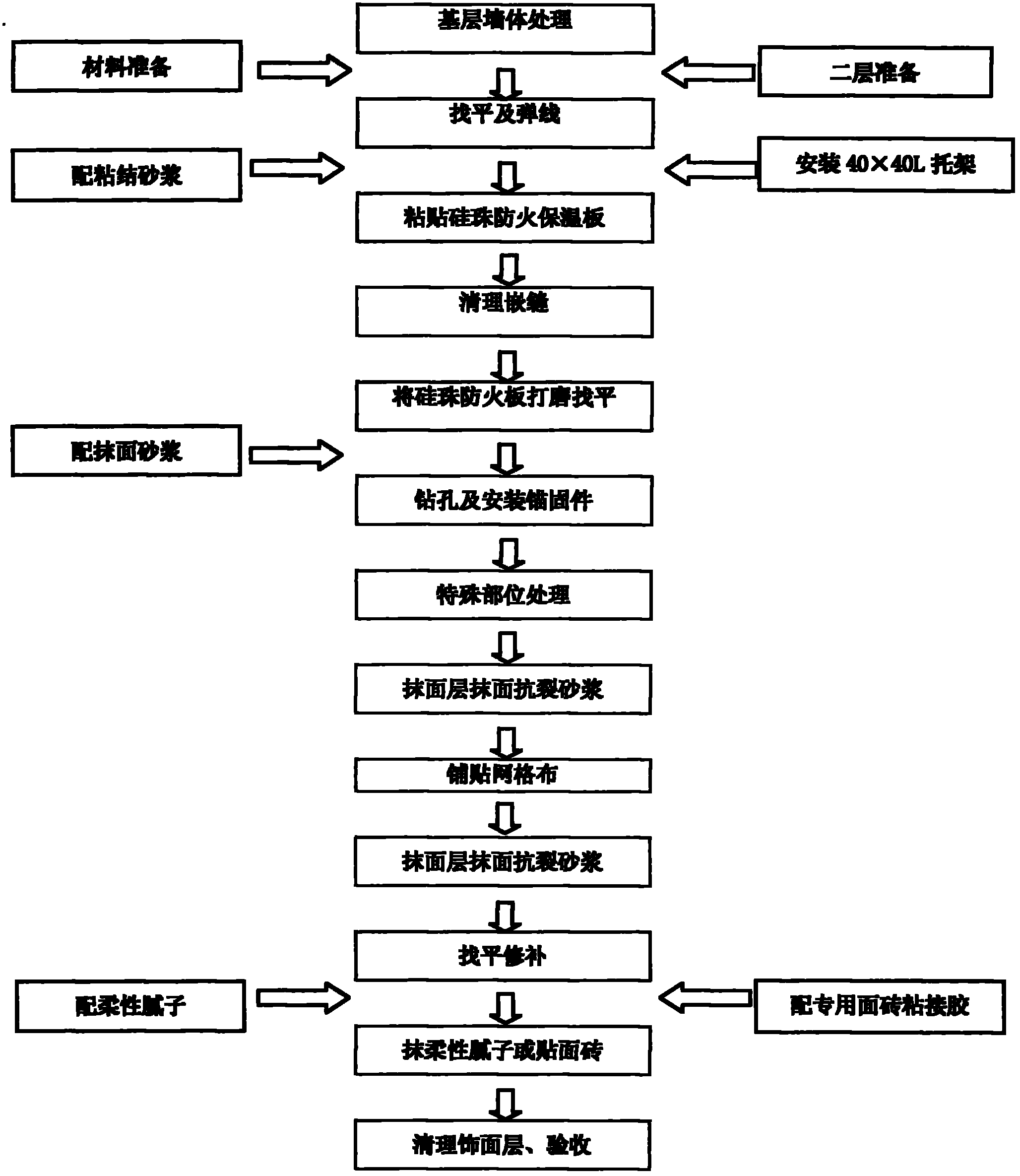

Inorganic heat-insulation fireproof plate

InactiveCN102619287ASolve easy pulverizationIncrease diversityHeat proofingBuilding material handlingPolymer scienceAging resistance

Disclosed is an inorganic heat-insulation fireproof plate, namely a silica bead fireproof heat-insulation plate. The fireproof plate is made of vitrified small balls and xonotlite, the weight ratio of the vitrified small balls to the xonotlite ranges from 1:2 to 1:5, in addition, waterproof materials with the weight ranging from 1% to 5% of the total weight of the fireproof plate and gel materials with the weight ranging from 8% to 10% of the total weight of the fireproof plate are added, and the fireproof plate is manufactured via working procedures including preparation, screening, pressure forming and drying. The vitrified small balls replace traditional common expanded perlite and traditional common polyphenyl particles to be used as lightweight aggregates of dry mixed heat-insulation mortar, shortcomings that the expanded perlite is high in water absorption and easy in pulverization and is high in volumetric shrinkage during slurry stirring, accordingly, low long-term strength, hollowing and cracking of a product are caused easily, and the like are overcome, defects of flammability, poor fireproof performance, harmful gas generation at a high temperature, low ageing resistance and weather fastness, high rebounding during construction and the like of the polyphenyl particles are also overcome, and comprehensive performances and construction property of the heat-insulation mortar are improved. In addition, the hydrophobic vitrified small balls cannot be degraded at a high temperature and are not easy to deform, and the flame retardant property of a polymer can be improved when the vitrified small balls are used as filling materials of the polymer.

Owner:QINGDAO FENGXIANG CHEM

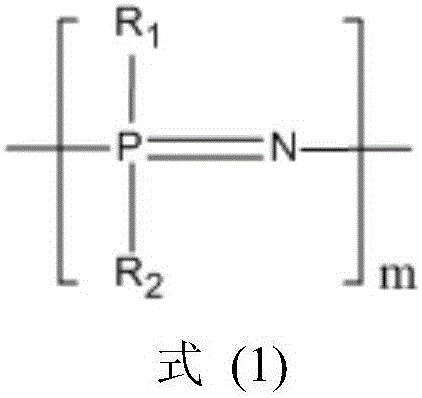

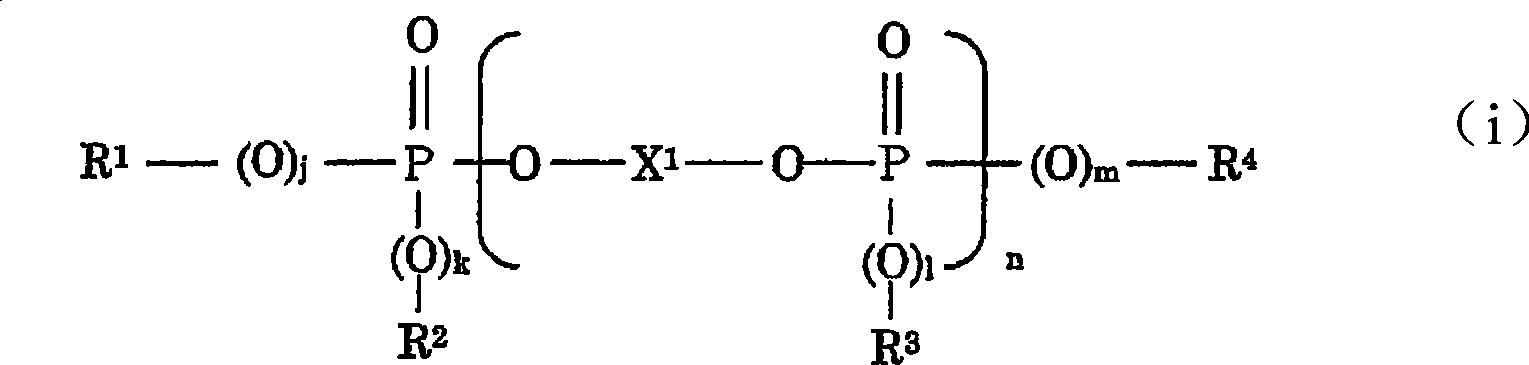

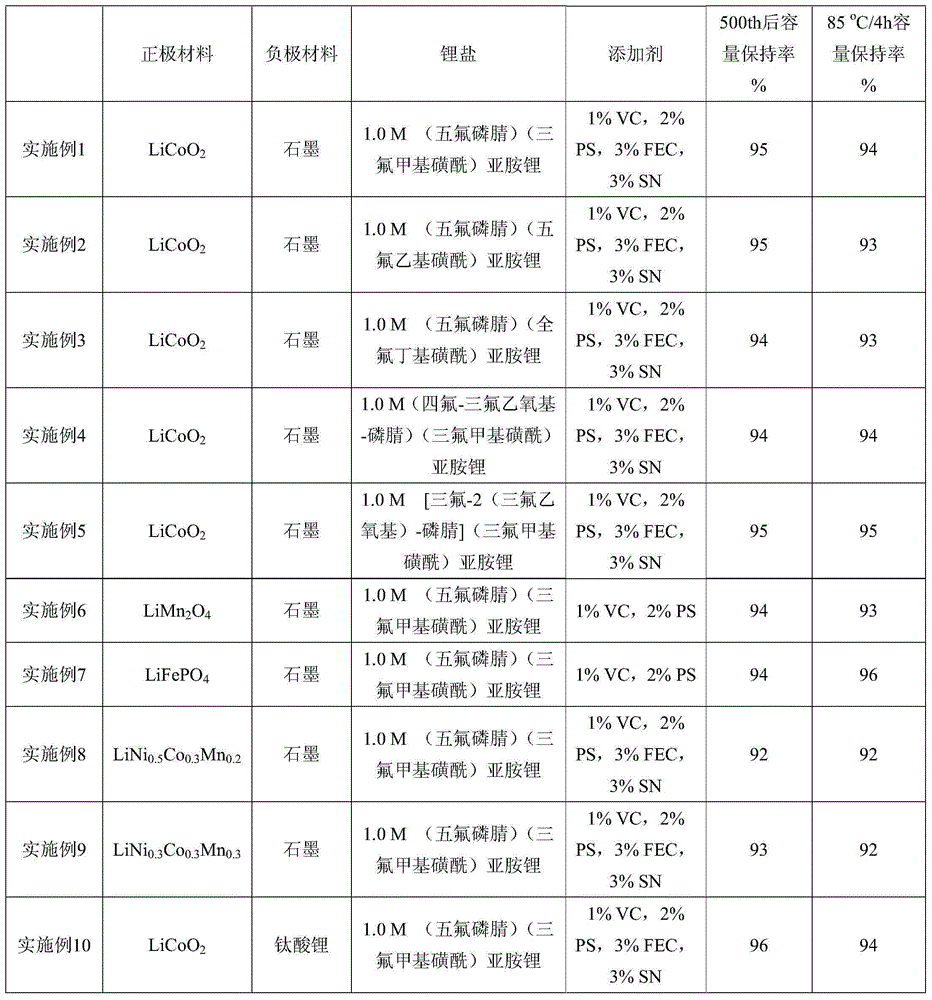

Phosphazene perfluoroalkanesulfonylimide lithium electrolyte and battery using electrolyte

ActiveCN105206873AImprove thermal stabilityImprove water resistanceSecondary cellsComposite electrolytesOrganic solventCarbonate ester

The invention provides a phosphazene perfluoroalkanesulfonylimide lithium electrolyte which includes a conductive lithium salt, a nonaqueous organic solvent and an additive, wherein the conductive lithium salt includes phosphazene perfluoroalkanesulfonylimide lithium with the structural formula being shown in the description. In the formula, M+ is Li, R1-5 = -OR7 or -M[NSO2-R6], R6 is fluorinated alkyl containing 1-8 carbon atoms, R7 is an alkanes group containing 1-10 carbon atoms. Phosphazene perfluoroalkanesulfonylimide lithium provided by the invention is good in thermal stability and hydrolysis resistance, has high electrical conductivity and oxidation potential in the traditional carbonate ester solution, and is good in compatibility with the extensively used electrode materials.

Owner:GUANGZHOU TINCI MATERIALS TECH

Silkworm silk flame retardant aid and flame retardation arrangement method

ActiveCN102660868AEfficient Flame RetardancyGood flame retardant propertiesAnimal fibresOligomerPhosphate

The invention provides a silkworm silk flame retardant aid which comprises the components of dibromoneopentyl glycol (DBNPG), a dibromoneopentyl glycol phosphate cyanamide salt, a hydroxy-containing non-polar phosphorus oligomer (HFPO), and 1,2-butanetetracarboxylic acid (BTCA), wherein the mass of the components of same mass or largest contents in the flame retardant aid does not exceed 10% of the mass of component of the lowest mass. The invention also provides a silkworm silk flame retardation arrangement method. The method comprises the following steps: 1, preparing or providing the flame retardation aid; 2, diluting by adding purified water having a weight two times the weight of the flame retardation aid, and uniformly stirring; 3, adding silkworm silk to be subjected to flame retardation arrangement to a flame retardation arrangement liquid prepared in last step, wherein the weight ratio of the silkworm silk to the flame retardation arrangement liquid does not exceed 0.9:1, and the error is equal to or less than 10%; and 4, drying the silkworm silk subjected to the flame retardation arrangement in step 3 with a dewaterer, and drying with a flat tender. The flame retardation aid provided in the invention is halogen-free and nontoxic. The silkworm silk flame retardation arrangement method provided in the invention, which effectively uses the flame retardation aid, is economic and reasonable.

Owner:ZHEJIANG GOOD LUCK GROUP

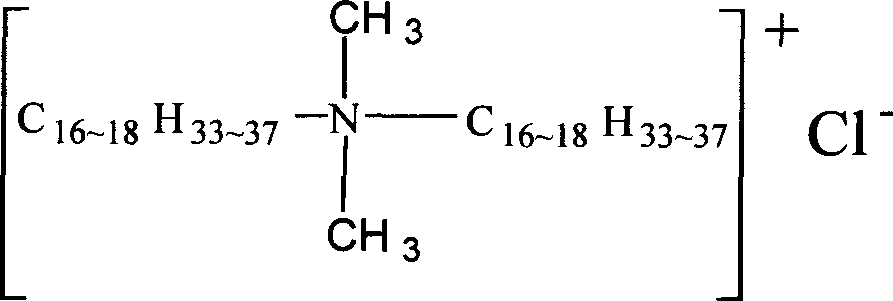

Halogen-free inflaming retarding permanent antistatic polypropylene composite material and preparation method

InactiveCN103131084AImprove flame retardant performanceImprove antistatic propertiesPolypropylene compositesLubricant

The invention relates to a halogen-free inflaming retarding permanent antistatic polypropylene composite material and a preparation method. The halogen-free inflaming retarding permanent antistatic polypropylene composite material is manufactured by the composite materials with the following weight preparation ratio: 40%-70% of polypropylene,5%-15% antistatic agents,1%-8% compatilizer, 5%-30% fire retardant, 0.1%-0.5% antioxygen, and 0.1%-0.5% lubricant. The preparation method comprises the following steps: weighing materials based on the weight preparation ratio; putting all the materials into a high-effective mixing machine to mix for 2-5 minutes and discharging the materials; and putting the uniformly blended materials in a double screw extruder and squeezing out prilling. Compared with the prior art, the halogen-free inflaming retarding permanent antistatic polypropylene composite material has an excellent inflaming retarding feature, 1.6 millimeters inflaming retarding V0 level, and permanent anti-static electricity. The surface resistance is 1010 omega. The halogen-free inflaming retarding permanent antistatic polypropylene composite material has the advantages of being good in mechanics performance, capable of satisfying product requirements and inflaming retarding performance, greatly improving the surface resistance of the composite material, and achieving a good antistatic level.

Owner:SHANGHAI SUNNY

Flame-retardant fiber reinforced nylon 6 material and preparation method thereof

ActiveCN110982254AImprove mechanical propertiesImprove flame retardant propertiesFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentGlass fiberNylon material

The invention relates to a flame-retardant fiber reinforced nylon 6 material and a preparation method thereof, and belongs to the technical field of flame-retardant nylon materials. The flame-retardant fiber reinforced nylon 6 material is prepared from the following components in percentage by weight: 11-78.8% of nylon 6, 10-60% of long fiber, 10-20% of an environment-friendly flame retardant, 1-5% of a flame-retardant synergist, 0.1-2% of a lubricant and 0.1-2% of an antioxidant. According to the invention, the composite fibers are used as a reinforcing material, the glass fibers in the composite fibers can effectively improve the mechanical properties of a nylon material, polyphenylene sulfide nanofibers with flame retardant properties are added, and polyphenylene sulfide belongs to a thermoplastic material and has good mechanical properties, so that the flame retardant properties of the nylon material can also be improved.

Owner:JIANGSU JICUI ADVANCED POLYMER MATERIAL RES INST CO LTD

Method for preparing inorganic nanoparticle/polyethylene copolymer composite material

InactiveCN106674705AHigh mechanical strengthImprove toughnessCarvacryl acetateCross-linked polyethylene

The invention discloses a method for preparing an inorganic nanoparticle / polyethylene copolymer composite material. The method comprises the following steps: performing oleophylic modification treatment on calcium carbonate, zinc oxide, aluminum oxide, titanium dioxide and silicon dioxide inorganic nanoparticles, performing blending dispersion on a copolymer of modified inorganic nanoparticles and an ethylene-vinyl acetate copolymer in an internal mixer at 100-130 DEG C, adding aids at 120-160 DEG C, performing melting and blending so as to cross-link polyethylene and inorganic nanoparticles / ethylene-vinyl acetate copolymer, granulating, and processing, thereby obtaining living or production articles. The oxygen index of the inorganic nanoparticle / polyethylene copolymer composite material disclosed by the invention is approximate to 30%. The inorganic / organic nano composite material disclosed by the invention is excellent in machinability, good in flame retardancy, good in antibacterial property, good in tensile and impact resistance and applicable to processing of tubes, films, daily articles and the like which are closely associated with living.

Owner:赵洪全

ABS (acrylonitrile butadiene styrene) halogen-free flame-retardant composite material and preparation method thereof

InactiveCN102367322AImprove flame retardant propertiesImprove mechanical properties and machining performanceAcrylonitrile butadiene styreneMaterials science

The invention relates to an ABS (acrylonitrile butadiene styrene) halogen-free flame-retardant composite material. The ABS halogen-free flame-retardant composite material comprises the following raw material components in parts by weight: 80-100 parts of acrylonitrile-butadiene-styrene copolymer, 40-55 parts of composite flame retardant, 5-12 parts of synergistic flame retardant, 1-5 parts of organic clay, 0.1-0.5 part of antioxidant, 1-3 parts of lubricating agent and 3-7 parts of compatilizer. The ABS halogen-free flame-retardant composite material prepared by the method provided by the invention has the characteristics of good flame retardance and excellent mechanical property and processing performance.

Owner:常熟市星源金属涂层厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com