Patents

Literature

71results about How to "Improve antistatic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

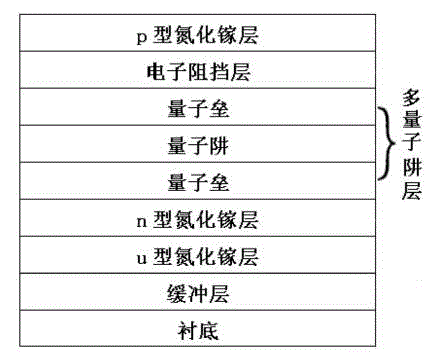

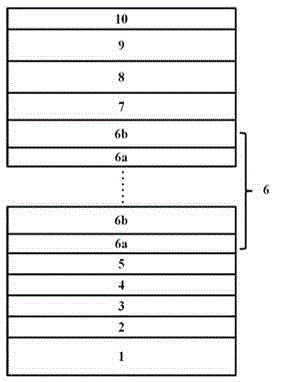

Nitride light-emitting diode (LED) epitaxial wafer and growing method thereof

InactiveCN102969416AStress reliefReduced polarizing electric fieldSemiconductor devicesPower flowHole injection layer

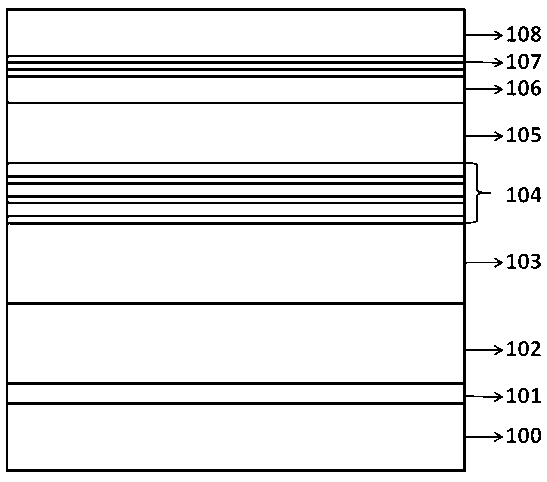

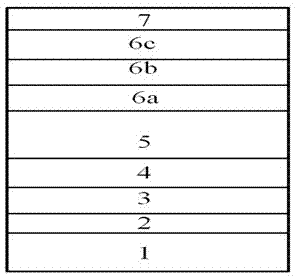

The invention provides a nitride light-emitting diode (LED) epitaxial wafer and a growing method thereof and relates to the technical field of semiconductor optoelectronics. The nitride LED epitaxial wafer structurally and sequentially comprises a substrate, a low-temperature buffer layer, an unintentionally doped GaN, an N-shaped electron-injection layer, an InGaN / GaN inserting layer, an active area, an electron blocking layer, a u-GaN / p-GaN superlattice and a p-GaN hole-injection layer from bottom to top. The InGaN / GaN inserting layer is grown between the N-shaped electron-injection layer and the active area so as to effective relieve stress of the active area, lower polarization electric fields, reduce limitation of stark effect through a quantum well, and improve luminance and anti-static properties. The u-GaN / p-GaN superlattice is inserted between the electron blocking layer and the P-shaped hole-injection layer so as to improve current expansion capacity and lower chip operating voltage.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

Coffee carbon multi-component fiber weaving fabric and preparation method thereof

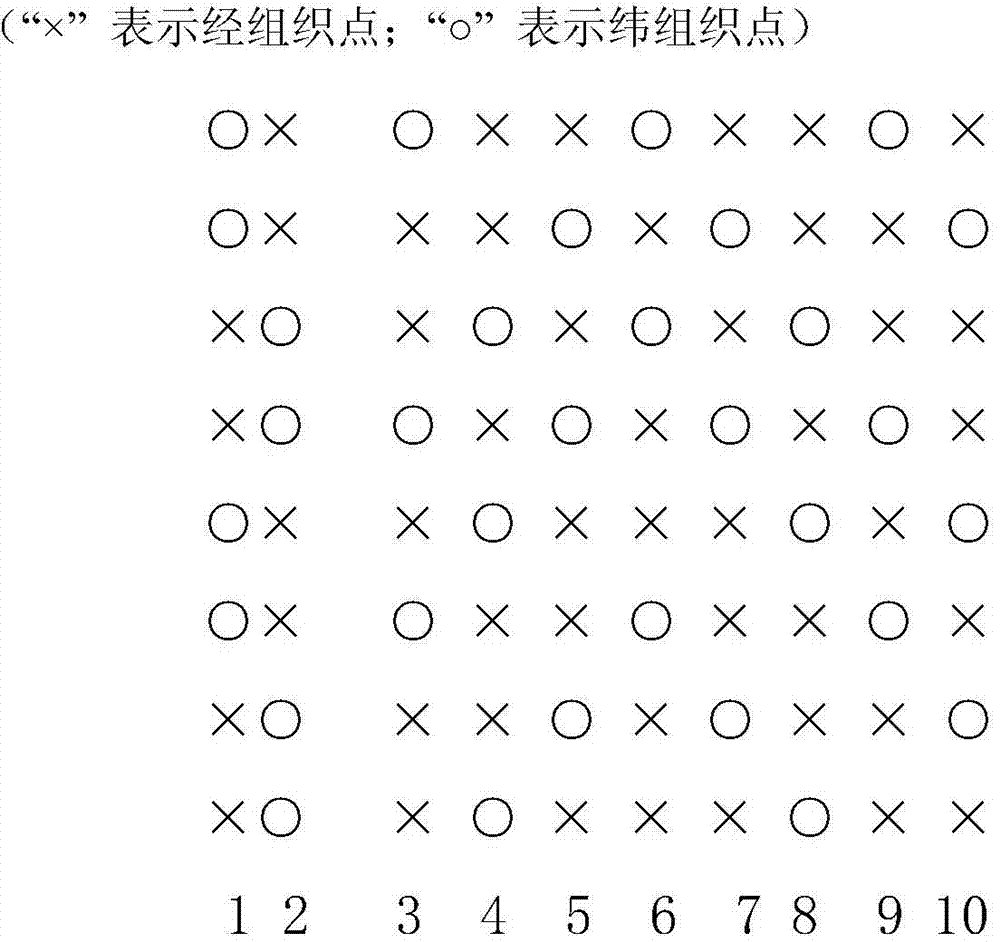

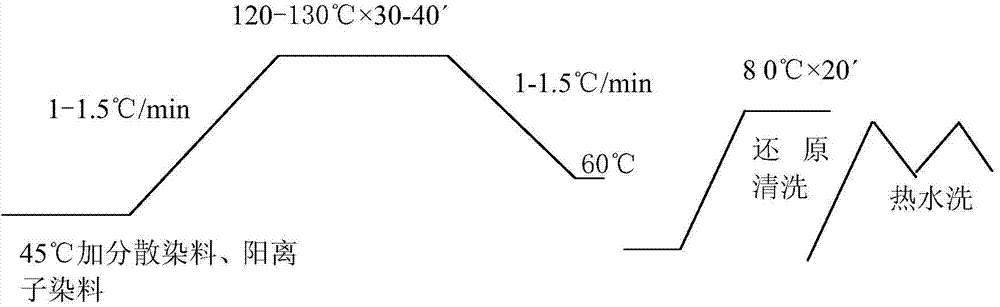

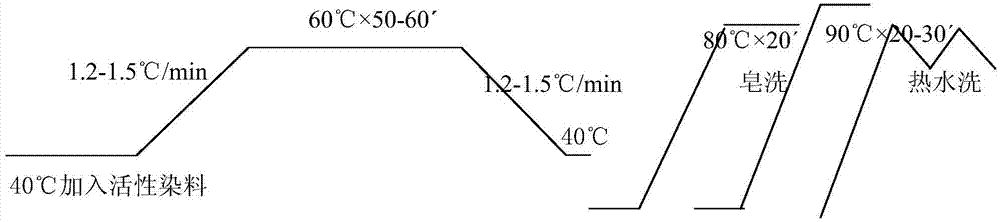

The invention belongs to the field of spinning, dyeing and finishing, and particularly relates to coffee carbon multi-component fiber weaving fabric and a preparation method of the coffee carbon multi-component fiber weaving fabric. The coffee carbon multi-component fiber weaving fabric is made of the following raw materials of warp direction yarns and weft direction filaments, wherein the warp direction yarns are formed by blending the following raw materials, by weight, 25-45% of coffee carbon fibers, 25-40% of bamboo fibers, 20-30% of cationic modified polyester fibers and 0.5-0.8% of conductive fibers, and the weft direction filaments are formed by alternately ranking 150D-160D coffee carbon fiber filaments and 100D-120D PTP fiber filaments at the ratio of 1 to 1. The coffee carbon multi-component fiber weaving fabric has the advantages that different characteristics of the coffee carbon fibers and the other fibers are exerted, comfort of the apparel fabric and the uvioresistant function and other protection functions are integrated, physicochemical indexes are good, dyefastness is high, and cost performance of the fabric is high. The preparation method is provided, the process is reasonable, and a new path is opened up for improving high performance and comfort of the coffee carbon multi-component fiber weaving fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

Antistatic polypropylene composite material and method for preparing same

The invention discloses an antistatic polypropylene composite material and a method for preparing the same and belongs to the technical field of modifying and processing polymers. The antistatic polypropylene composite material is prepared from the following raw materials in percentage by weight: 50 to 98 percent of polypropylene, 0 to 30 percent of inorganic filler, 0 to 20 percent of flexibilizer POE, 1 to 5 percent of antistatic agent, 0.1 to 1 percent of antioxidant and 0 to 1 percent of other auxiliary agents. The composite material and the method have the advantages that: 1, a proper amount of tin oxide is added in the composite material system, so that the prepared polypropylene composite material has better antistatic property; 2, under a condition of guaranteeing the antistatic property, the physical mechanical properties of the prepared polypropylene composite material are hardly affected; and 3, the method for improving the antistatic property of the polypropylene composite material is simple in preparation process and low in production cost.

Owner:SHANGHAI PRET COMPOSITES

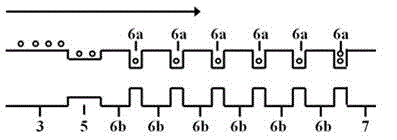

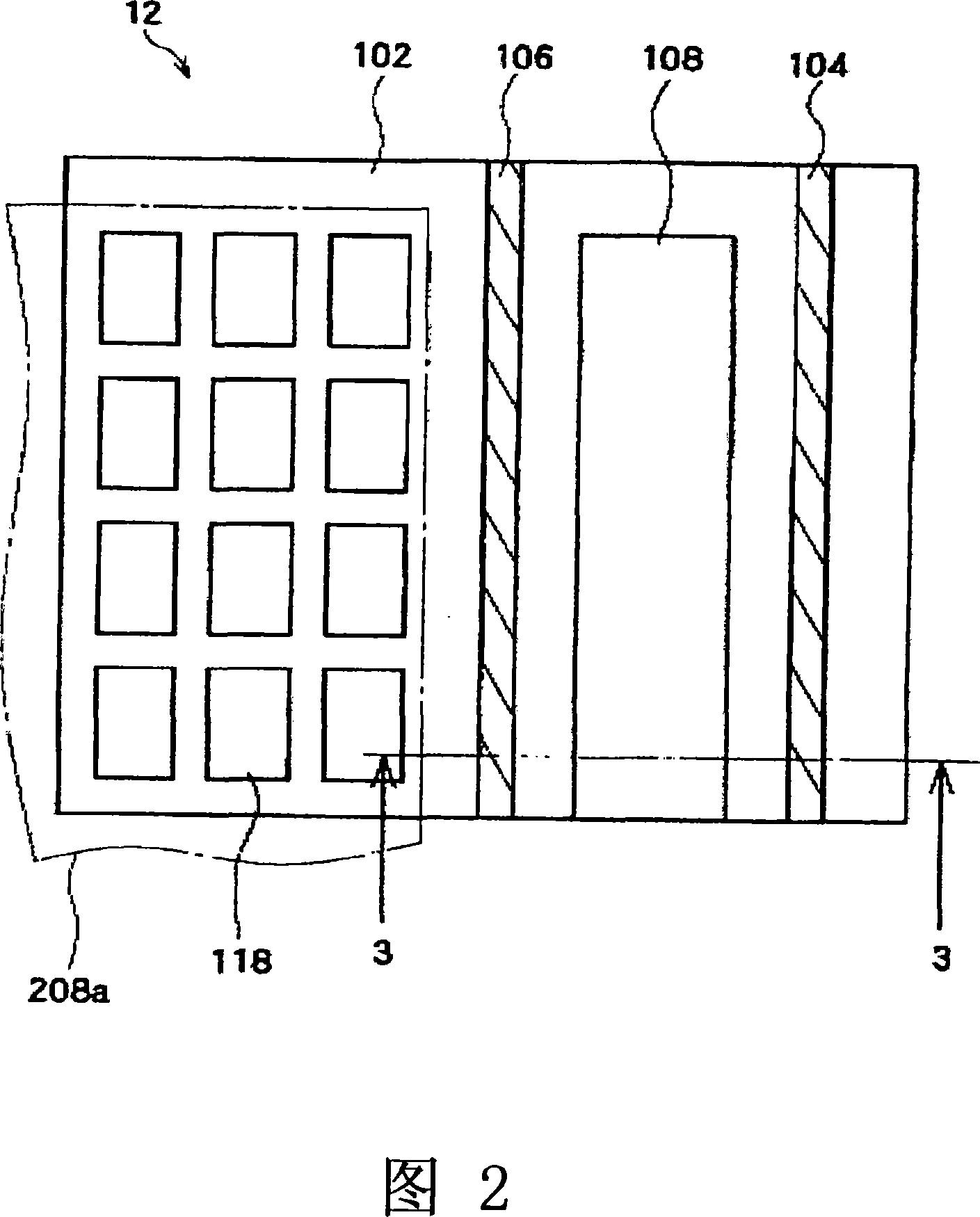

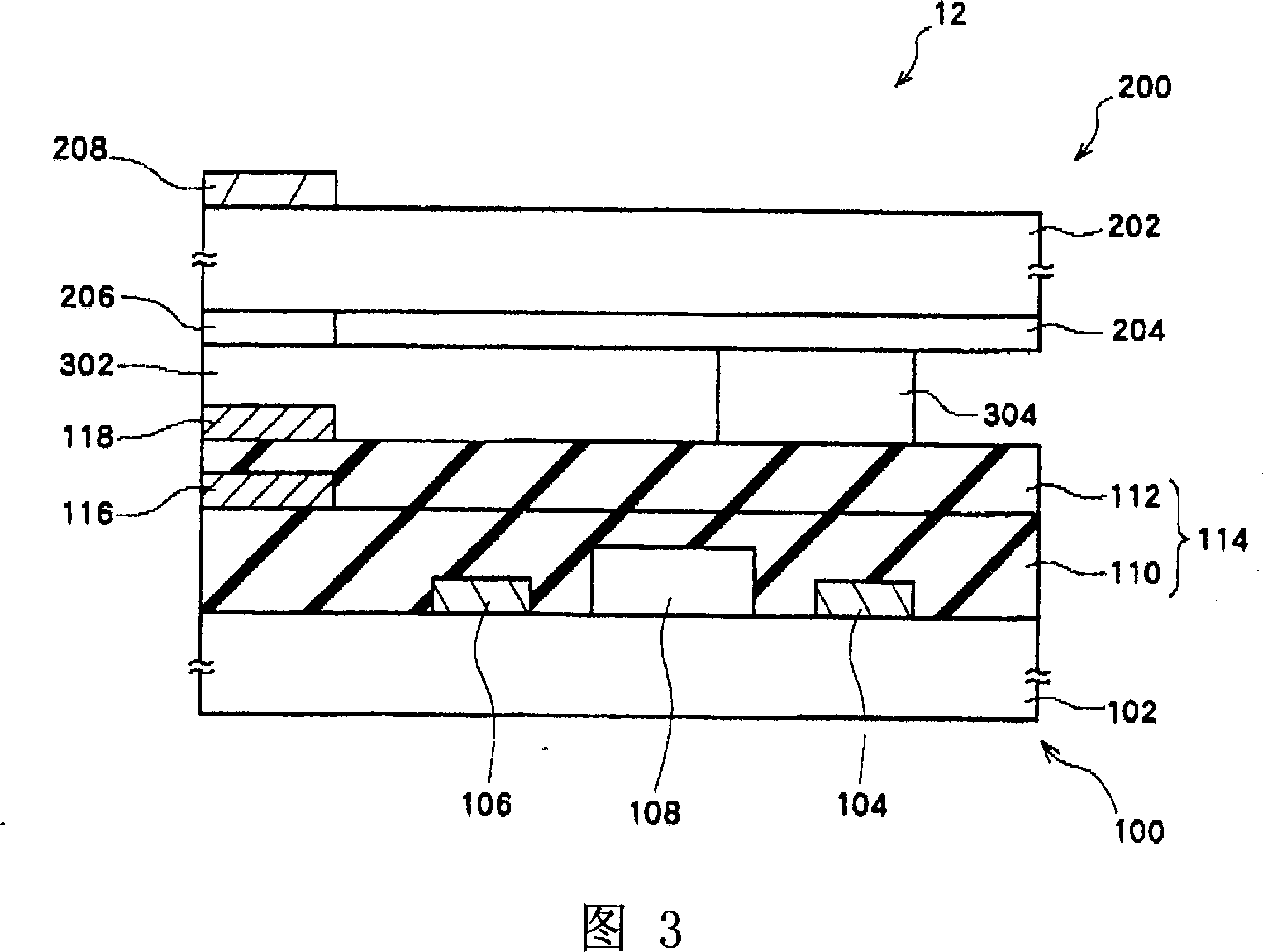

GaN-based light emitting diode epitaxial structure

InactiveCN105990478AImprove horizontal scalabilityImprove antistatic propertiesSemiconductor devicesElectron blocking layerPower flow

The invention provides a GaN-based light emitting diode epitaxial structure. From bottom to top, the structure successively comprises a substrate, a stress control layer, an n-type GaN layer, a stress buffer layer, a multi-quantum well active layer, an interval layer, an electron blocking layer, a p-type GaN layer and an ohmic contact layer. The light emitting diode epitaxial structure also comprises a current extension layer whose forbidden bandwidth is greater than the forbidden bandwidth of the n-type GaN and which is arranged below the multi-quantum well active layer. By using the epitaxial structure, electronic leakage in an active region when a light emitting diode works under a heavy current condition can be effectively reduced, radiation recombination efficiency of a hole-electron pair can be effectively increased and an antistatic characteristic of a LED is improved.

Owner:LATTICE POWER CHANGZHOU

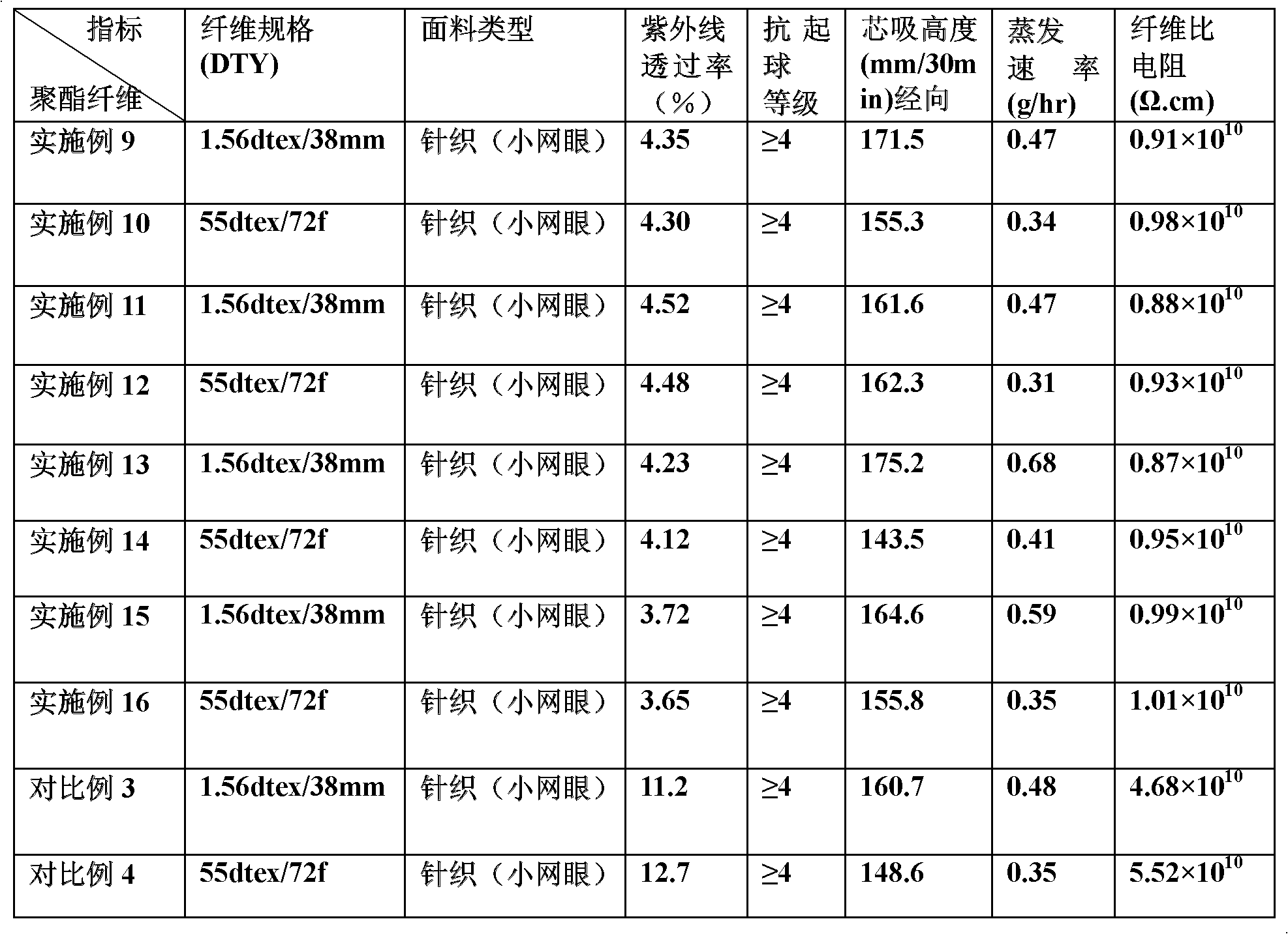

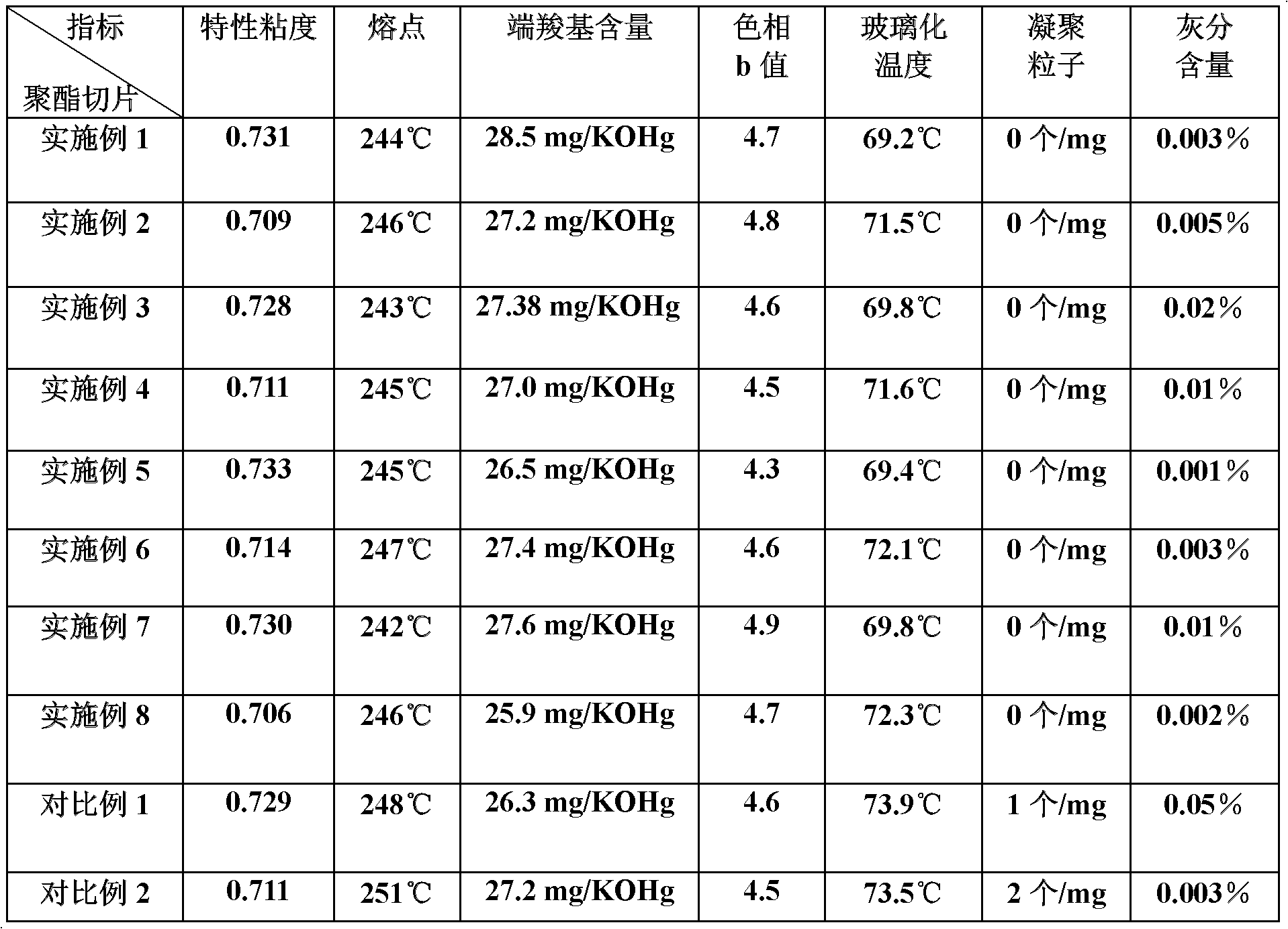

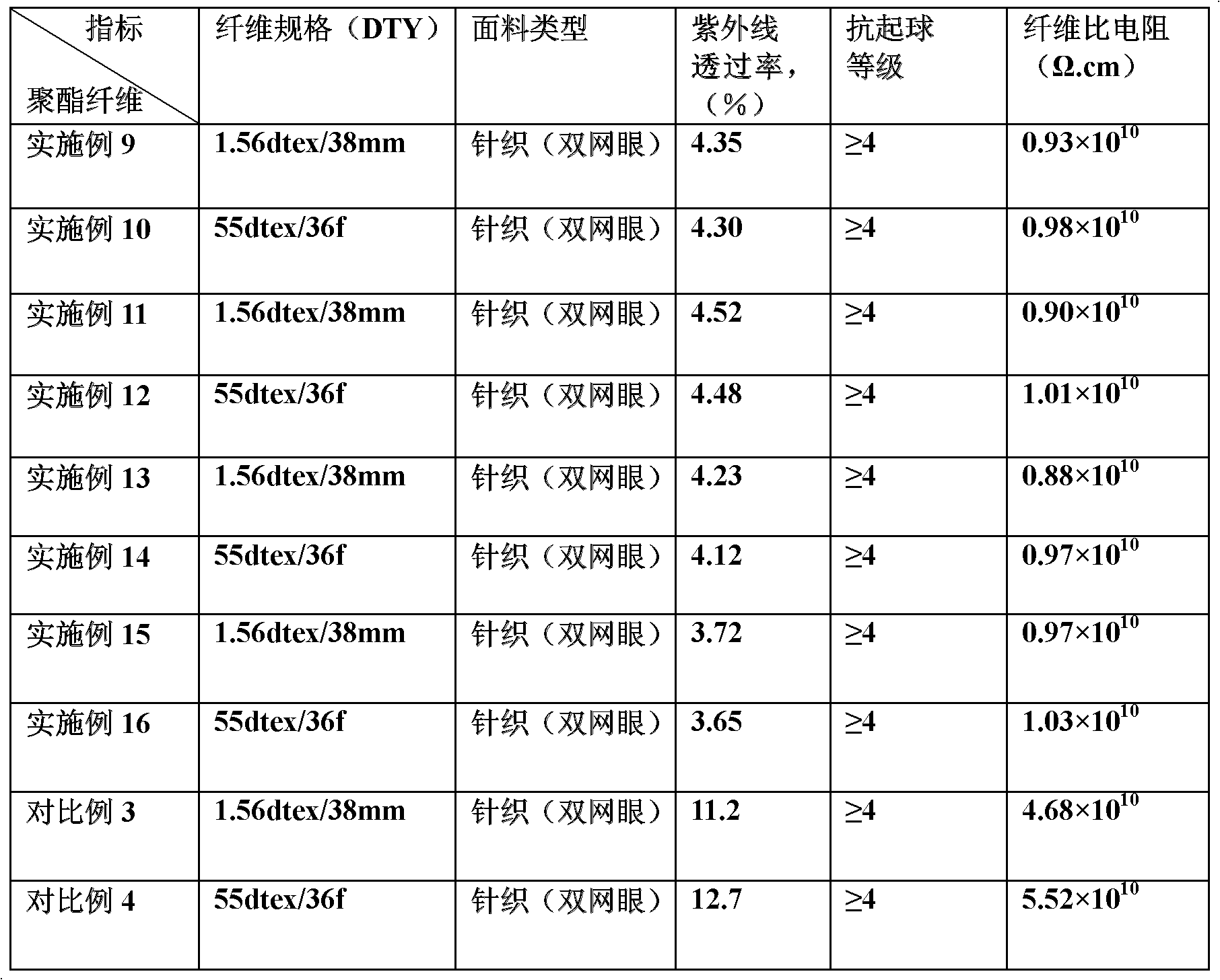

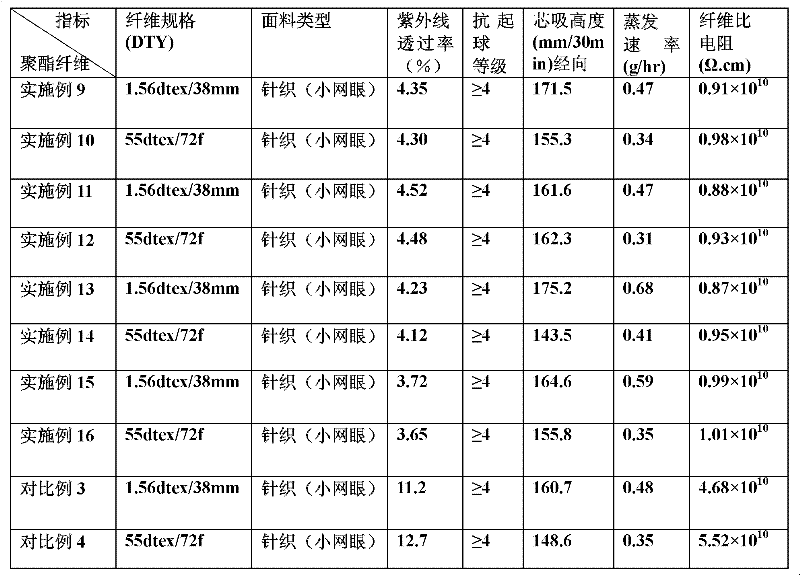

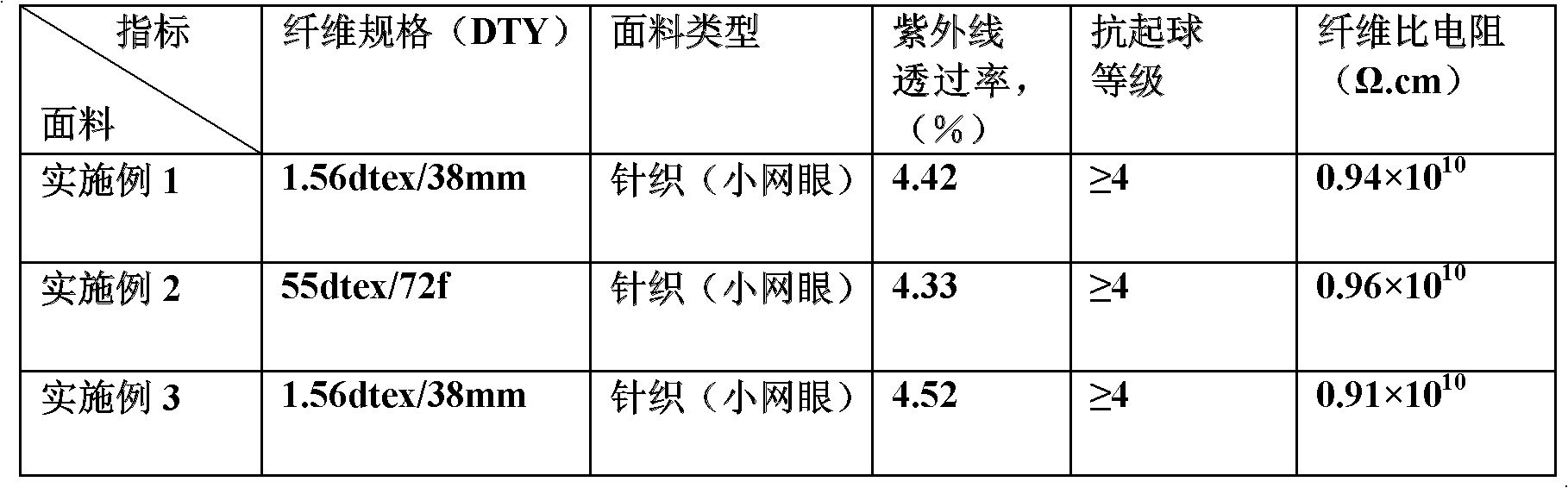

Method for preparing high-comfortable composite functional polyester fiber

ActiveCN102409429AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentSolventAntistatic agent

The invention relates to a method for preparing a high-comfortable composite functional polyester fiber, comprising the steps of: first esterification reaction section, secondary esterification reaction section, polymerization reaction process and spinning process, wherein aliphatic dicarboxylic acid and / or non-centrosymmetrically aromatic dicarboxylic acid is led into the first esterification reaction section to serve as a third monomer; flexible polyethylene glycol is led into the secondary esterification reaction section to serve as a fourth monomer; after finishing the esterification reactions, hindered amine light stabilizer and hindered phenolic antioxidant which are respectively prepared by taking acetic acid and ethylene glycol as solvents and hydroxyl silicone oil are added; after finishing pre-polymerization and before final polymerization of the polymerization reaction process, ultraviolet light absorber and antistatic agent are added; and before finishing the spinning process, polyester slices are performed pre-crystallization and drying; fibers with odd-shaped cross sections of three-leaf, cross, five-leaf and the like are prepared by melt spinning. The obtained polyester fiber is anti-ultraviolet light, antistatic, anti-pilling and has wet-absorbing quick-drying performance; and the fabric has high comfort.

Owner:JIANGSU ZHONGLU TECH DEV +1

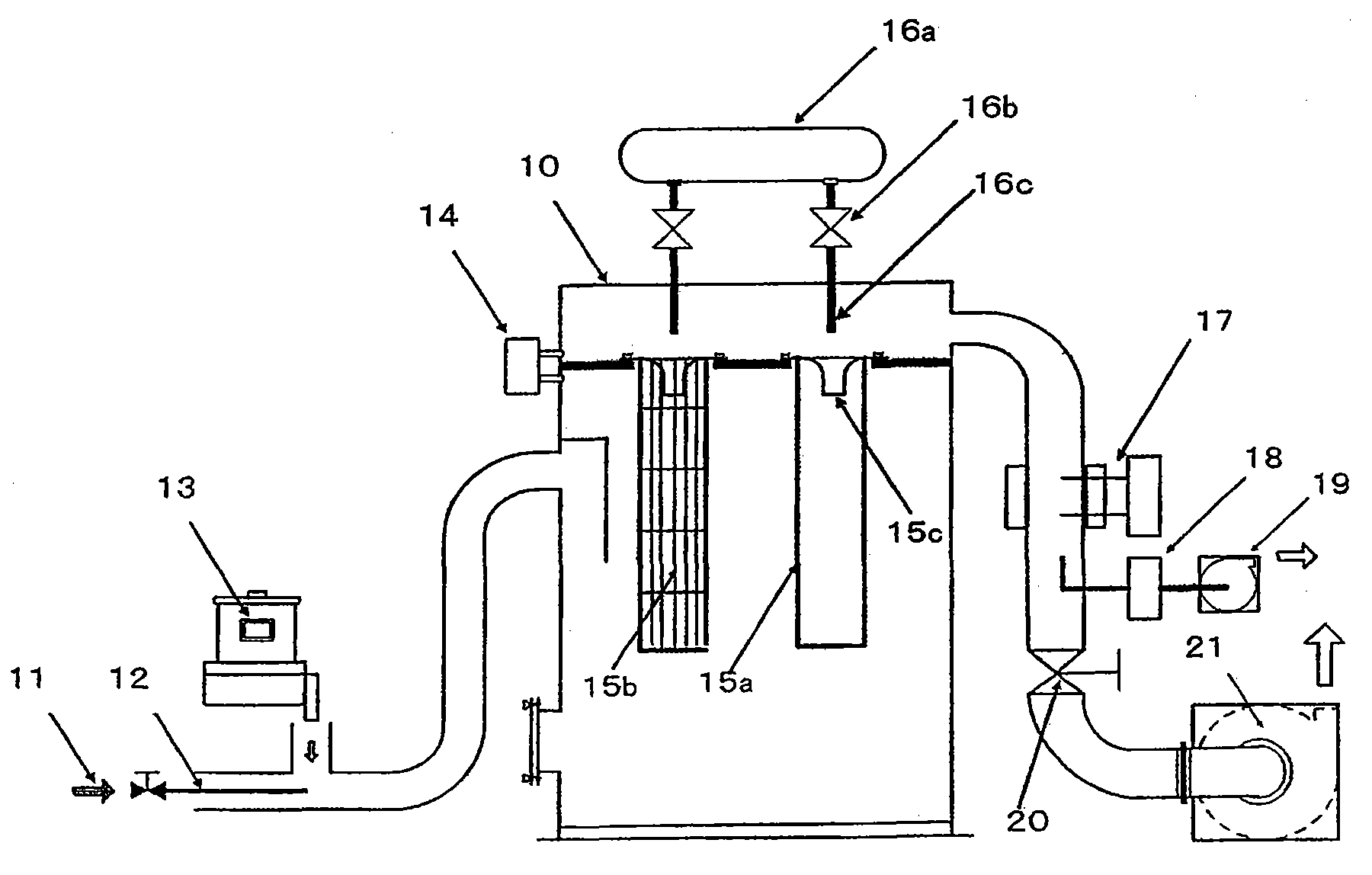

Antistatic filtering cloth in surface filtering mode for dust collector

InactiveCN101816856AIncreased durabilityImprove mechanical strength propertiesDispersed particle filtrationFiltration separationNanometreSurface filter

The invention provides an antistatic filtering cloth in the surface filtering mode for a dust collector. In a filtering cloth for a pulse blow swiping-off dust collector, the filtering cloth for the dust collector, which has numerous dust leakage after swiping off the dust, higher average outlet dust concentration, poor ventilation and dust swiping off performance and bad antistatic performance, is needed to be improved. The side of a soft material filtering surface made of fiber filtering cloth base materials such as non-woven fabric filtering cloth and the like used in the pulse blow swiping-off dust collector is laminated with a micro fine fibre layer formed by a nano carbon fiber with the conductivity, thereby the filtering cloth in the surface filtering mode for the pulse blow swiping-off dust collector, having excellent dust collecting performance and antistatic performance can be provided.

Owner:SINTOKOGIO LTD

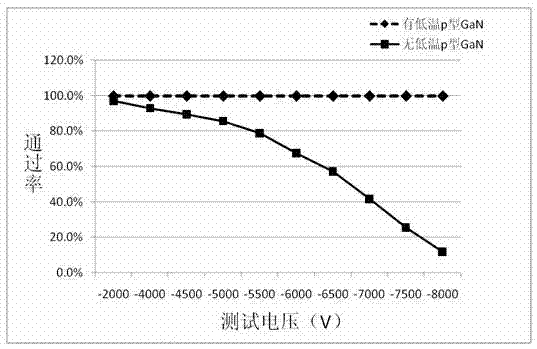

Epitaxial growth structure in GaN base green-light light emitting diode (LED) with P-type GaN

InactiveCN103199169AImprove luminous efficiencyExcellent luminous propertiesSemiconductor devicesMultiple quantumHole injection layer

The invention provides an epitaxial growth structure in a GaN base green-light light emitting diode (LED) with P-type GaN, and relates to the technical field of growth of the P-type GaN applied in a high-brightness GaN base green-light LED. The epitaxial growth structure in the GaN base green-light LED with the P-type GaN comprises a GaN nucleating layer, an un-doped GaN layer, an n-type GaN layer, an InGaN / GaN multiple-quantum-well active layer, the P-type GaN and an InGaN current tunneling layer, wherein the GaN nucleating layer, the un-doped GaN layer, the n-type GaN layer, the InGaN / GaN multiple-quantum-well active layer, the P-type GaN and the InGaN current tunneling layer sequentially grow on a substrate. The epitaxial growth structure in the GaN base green-light LED with the P-type GaN is characterized in that the P-type GaN is composed of a low-temperature P-type GaN hole injection layer, a P-type Al(In) GaN electron barrier layer and a P-type GaN hole activation layer. The P-type GaN with the structure is applied in the growth of the high-brightness GaN base green-light LED. The brightness of a 520 nm green-light chip with the size of 20mil*40mil reaches 75mw under a 120mA current in a COW. After the epitaxial growth structure is encapsulated, external quantum efficiency reaches 31 percent and reaches the domestic leading level. Meanwhile, anti-static performance of the green-light chip with the size of 20mil*40mil is improved to over 8000V.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

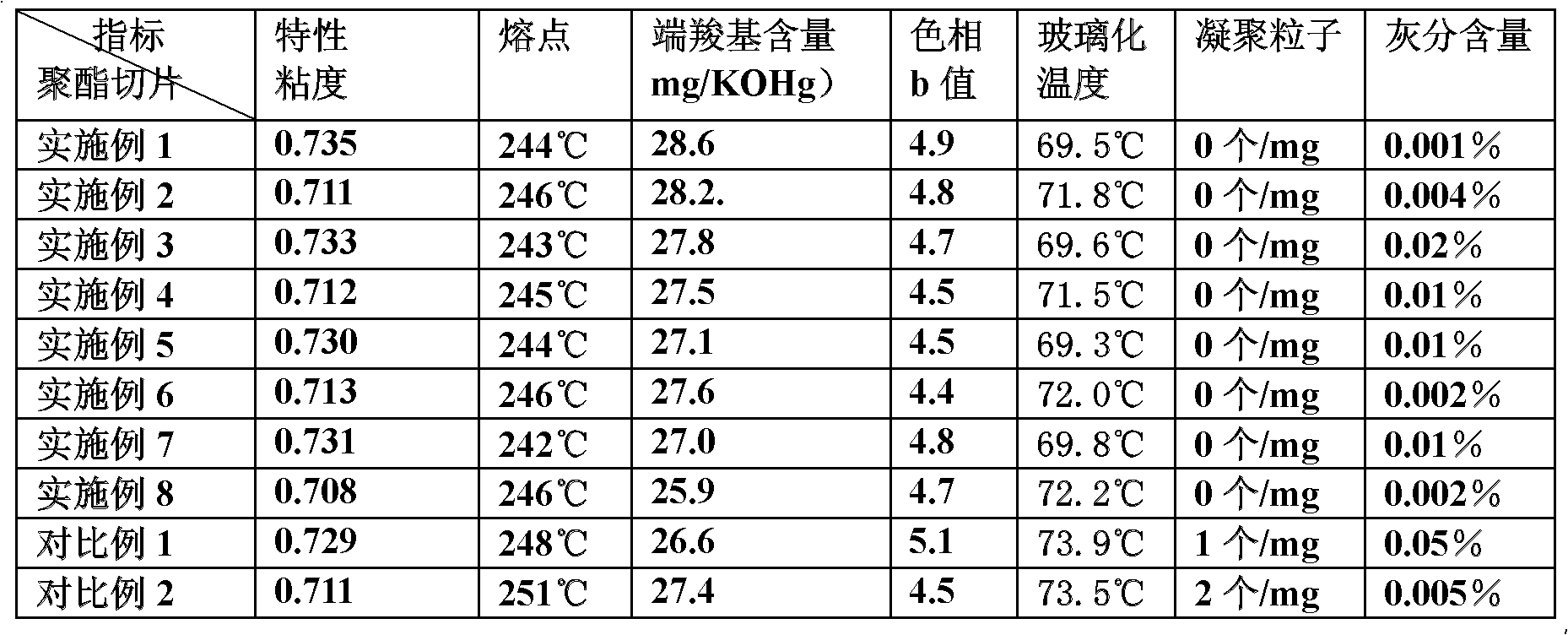

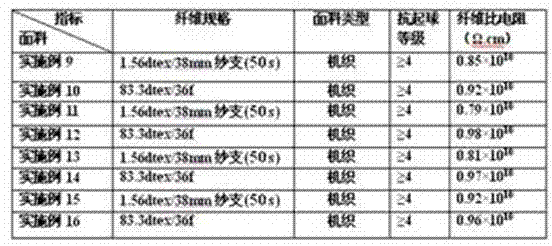

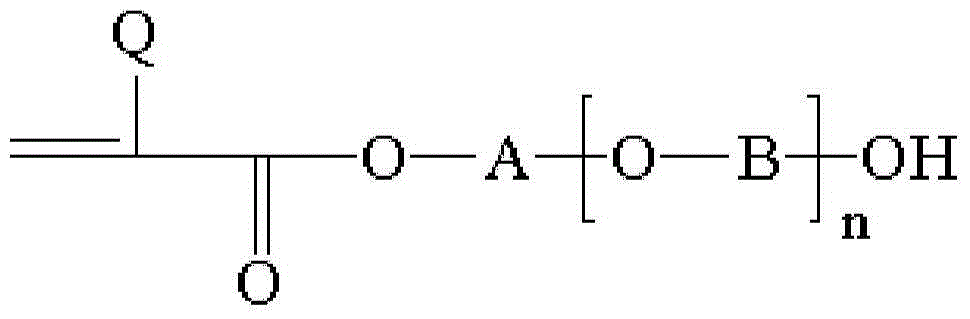

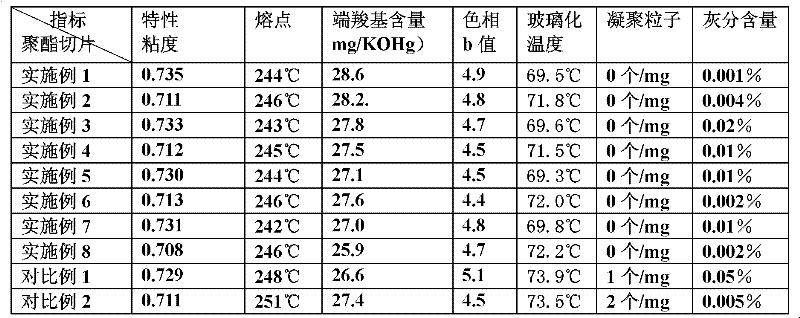

Preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cation dyeable compound functions

InactiveCN102391486AAvoid self-polymerizationEasy-to-stain function guaranteeMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cationic dyeable compound functions. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and an antistatic agent is added after the prepolymerization and before final polymerization. Fabric spun by the polyester fibers has high anti-static and anti-pilling properties; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

Preparation method for polyester fiber with composite ultraviolet, static electricity and pilling resisting functions

ActiveCN102409427AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureArtificial filament heat treatmentSolventTransmittance

The invention relates to a preparation method for a polyester fiber with a composite ultraviolet, static electricity and pilling resisting function. The preparation method comprises an esterification reaction procedure, a polymerization reaction procedure and a spinning procedure. The esterification reaction procedure comprises a primary esterification reaction stage and a secondary esterification reaction stage, flexible polyethylene glycol is introduced as a third monomer in the secondary esterification reaction stage, and after esterification is finished, a hindered amine light stabilizer,a hindered phenol anti-oxidant and hydroxyl silicone oil are added, wherein the hindered amine light stabilizer and the hindered phenol anti-oxidant are prepared by taking an acetic acid and ethyleneglycol as solvents. In the polymerization reaction procedure, after prepolymerization and before final polymerization, an ultraviolet absorbent and an antistatic agent are added. Before the spinning procedure, polyester is sliced for pre-crystallization and drying. The polyester fiber obtained by the method has the outstanding ultraviolet, static electricity and pilling resisting functions, and after being woven into knitted machine-made fabrics, is tested to have related technical indexes comprising the ultraviolet light transmittance of less than or equal to 5.0%, the pilling resistance of more than or equal to level 4 and the fiber volume specific resistance of less than or equal to 10*10<10> ohm.cm.

Owner:JIANGSU ZHONGLU TECH DEV +1

Halogen-free inflaming retarding permanent antistatic polypropylene composite material and preparation method

InactiveCN103131084AImprove flame retardant performanceImprove antistatic propertiesPolypropylene compositesLubricant

The invention relates to a halogen-free inflaming retarding permanent antistatic polypropylene composite material and a preparation method. The halogen-free inflaming retarding permanent antistatic polypropylene composite material is manufactured by the composite materials with the following weight preparation ratio: 40%-70% of polypropylene,5%-15% antistatic agents,1%-8% compatilizer, 5%-30% fire retardant, 0.1%-0.5% antioxygen, and 0.1%-0.5% lubricant. The preparation method comprises the following steps: weighing materials based on the weight preparation ratio; putting all the materials into a high-effective mixing machine to mix for 2-5 minutes and discharging the materials; and putting the uniformly blended materials in a double screw extruder and squeezing out prilling. Compared with the prior art, the halogen-free inflaming retarding permanent antistatic polypropylene composite material has an excellent inflaming retarding feature, 1.6 millimeters inflaming retarding V0 level, and permanent anti-static electricity. The surface resistance is 1010 omega. The halogen-free inflaming retarding permanent antistatic polypropylene composite material has the advantages of being good in mechanics performance, capable of satisfying product requirements and inflaming retarding performance, greatly improving the surface resistance of the composite material, and achieving a good antistatic level.

Owner:SHANGHAI SUNNY

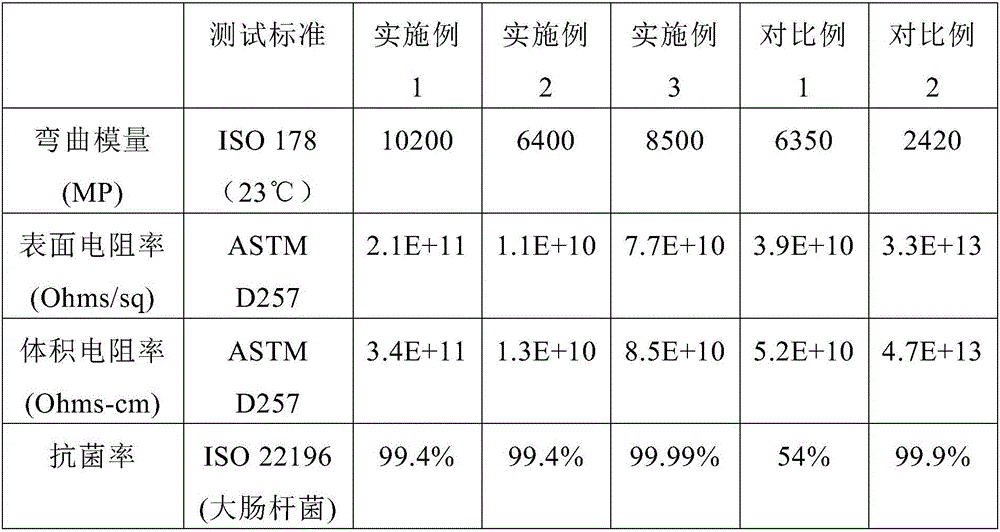

Antibacterial antistatic enhanced polycarbonate (PC) material and preparation method thereof

The invention relates to an antibacterial antistatic enhanced polycarbonate (PC) material and a preparation method thereof. The antibacterial antistatic enhanced PC material comprises the following components in parts by weight: 70-90 parts of PC resin, 5-20 parts of carbon fiber, 0.5-1 part of flame retardant and 5-10 parts of antibacterial agent. The preparation method comprises the following steps: adding the PC resin, antibacterial agent and flame retardant into a mixing stirrer, mixing, adding the mixture through a main feed inlet of a double screw extruder, adding the carbon fibers through a side feed inlet of the double screw extruder, and carrying out blend melting and extrusion granulation to obtain the product. Compared with the prior art, the antibacterial agent added in the PC resin enhances the antibacterial property of the PC material; the carbon fibers are compounded to improve the electric properties of the product; and thus, the material has the advantages of high rigidity, static resistance, bacterial resistance and flame retardancy, and can be widely used in various electronic product devices.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

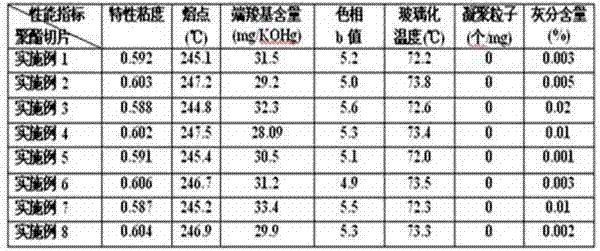

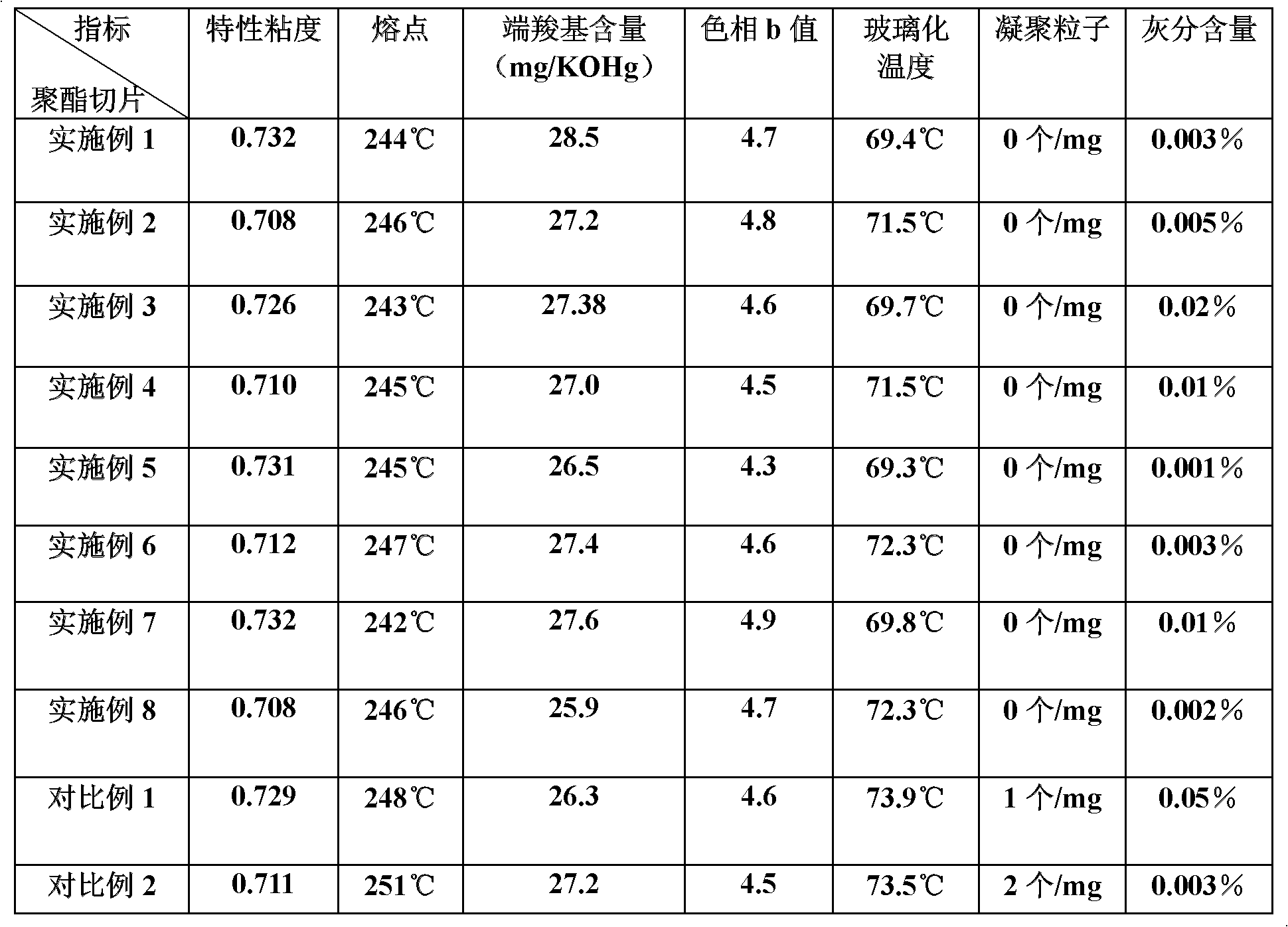

Preparation method of antistatic, anti-balling, and ordinary pressure cation dyeable polyester chip

InactiveCN102433605AAvoid self-polymerizationEasy-to-stain function guaranteeElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method of an antistatic, anti-balling, and ordinary pressure cation dyeable polyester chip, comprising the following steps: a primary esterification reaction step, an ester exchange reaction step, a secondary esterification reaction step, and a polymerization reaction step, wherein, a ternary-monomer is added in the ester exchange reaction step, hindered anime light stabilizers, hindered phenol antioxygens and hydroxyl silicone oil are added after the ester exchange reaction and before a prepolymerization reaction, and an antistatic agent is added after the prepolymerization of the polymerization reaction step and before a final polymerization. Fabrics prepared from polyester fibers produced by using the polyester chips disclosed herein have good antistatic behavior and good anti-balling behavior, and have unlimited dyeing possibilities by using the ordinary pressure cation dyeability, thus the uniform requirements of present high-grade spring and summer clothes for functionality and colors can be satisfied. The obtained fibers can be dyed with wool together, and the blending of the fibers with wool has good dress effect. The polyester chips and fibers disclosed herein are an important supplement of present cation dyeable polyester fiber market, and have a wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

Carbon nanotube/TiO2 modified UV resin coating with antistatic and antibacterial functions

InactiveCN106318134AGood compatibilityGood dispersionAntifouling/underwater paintsPaints with biocidesAcrylic resinCarbon nanotube

The invention discloses a carbon nanotube / TiO2 modified UV resin coating with antistatic and antibacterial functions. The carbon nanotube / TiO2 modified UV resin coating with antistatic and antibacterial functions is formed through compounding UV resin with a photoinitiator, an active diluent and various assistants; the resin is epoxy acrylic resin; and carbon nanotubes (CNTs) with the surface being grafted with methyl methacrylate (MMA) and nano-TiO2 with the surface being hydrophobically modified are added to the UV coating. The invention also discloses a production method of the carbon nanotube / TiO2 modified UV resin coating with antistatic and antibacterial functions. The method comprises the following steps: 1, purifying the CNTs, and grafting the surface of the CNTs with the MMA; 2, hydrophobically modifying the surface of the nano-TiO2; and 3, modifying an epoxy acrylic resin coating with the CNTs with the surface being grafted with the MMA and the nano-TiO2 with the surface being hydrophobically modified. The carbon nanotube / TiO2 modified UV resin coating has good antistatic and antibacterial functions.

Owner:TAIZHOU HUALI PLASTIC

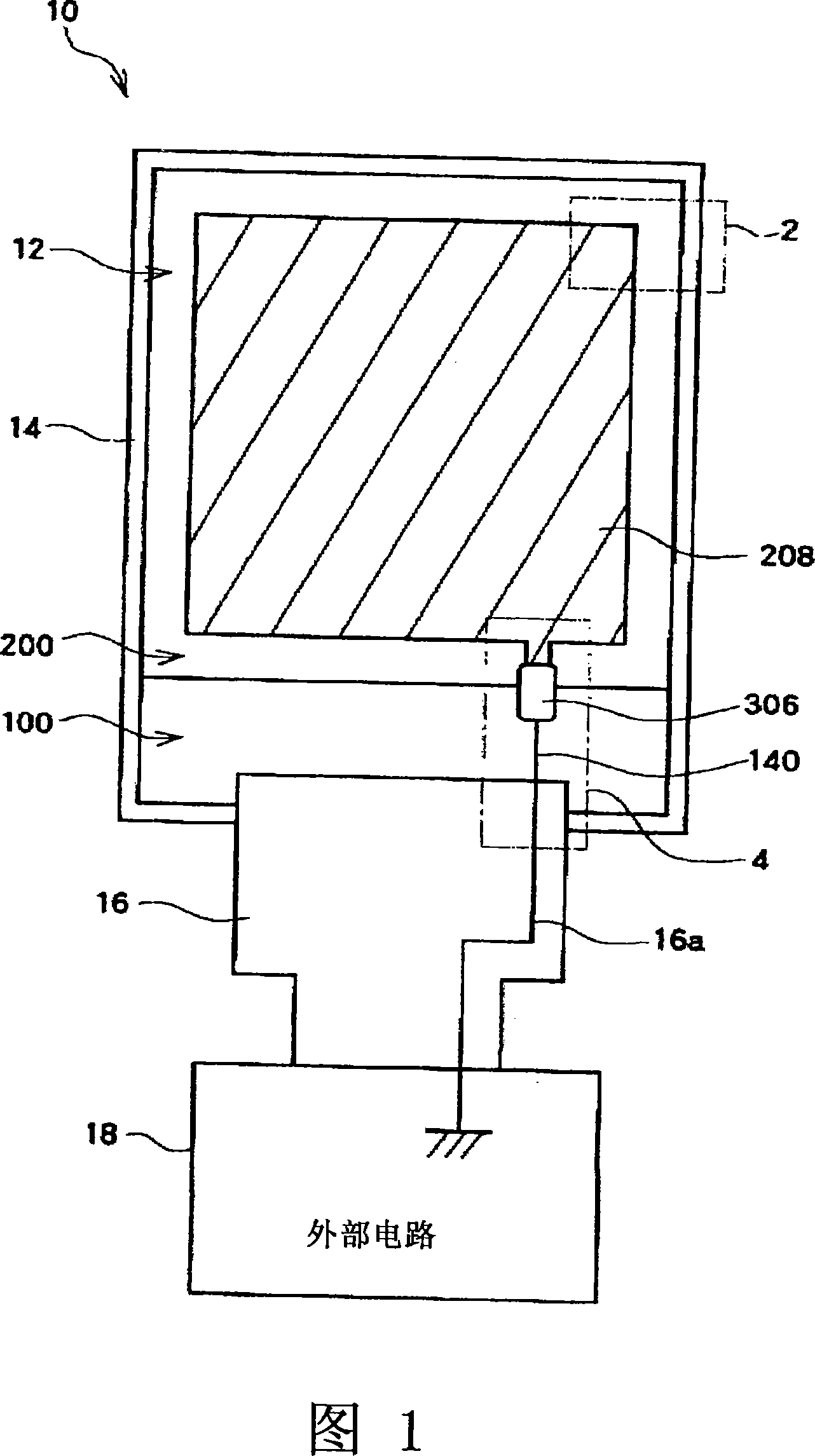

Liquid crystal display device

ActiveCN101211050AReduce intrusionImprove antistatic propertiesNon-linear opticsLiquid-crystal displayDisplay device

The present invention provides a liquid crystal display device, aiming at a liquid crystal display device in which a pixel electrode and a common electrode for driving a liquid crystal sandwiched between an opposing first substrate and a second substrate are arranged on the first substrate, Improves antistatic properties. The first substrate and the second substrate are arranged facing each other, and liquid crystal is sandwiched between the substrates. The pixel electrodes and common electrodes for driving liquid crystals are arranged on the first substrate. The first substrate includes circuit wiring arranged outside a pixel region where a plurality of pixels including pixel electrodes and common electrodes are arranged. The second substrate is provided with a light-transmitting conductive film disposed opposite to the pixel electrode and the common electrode and maintained at a predetermined potential on the side opposite to the liquid crystal, and the light-transmitting conductive film has a layer located on the second side of the second substrate than the outer edge of the second substrate. outer edge of the central side of the substrate.

Owner:JAPAN DISPLAY INC

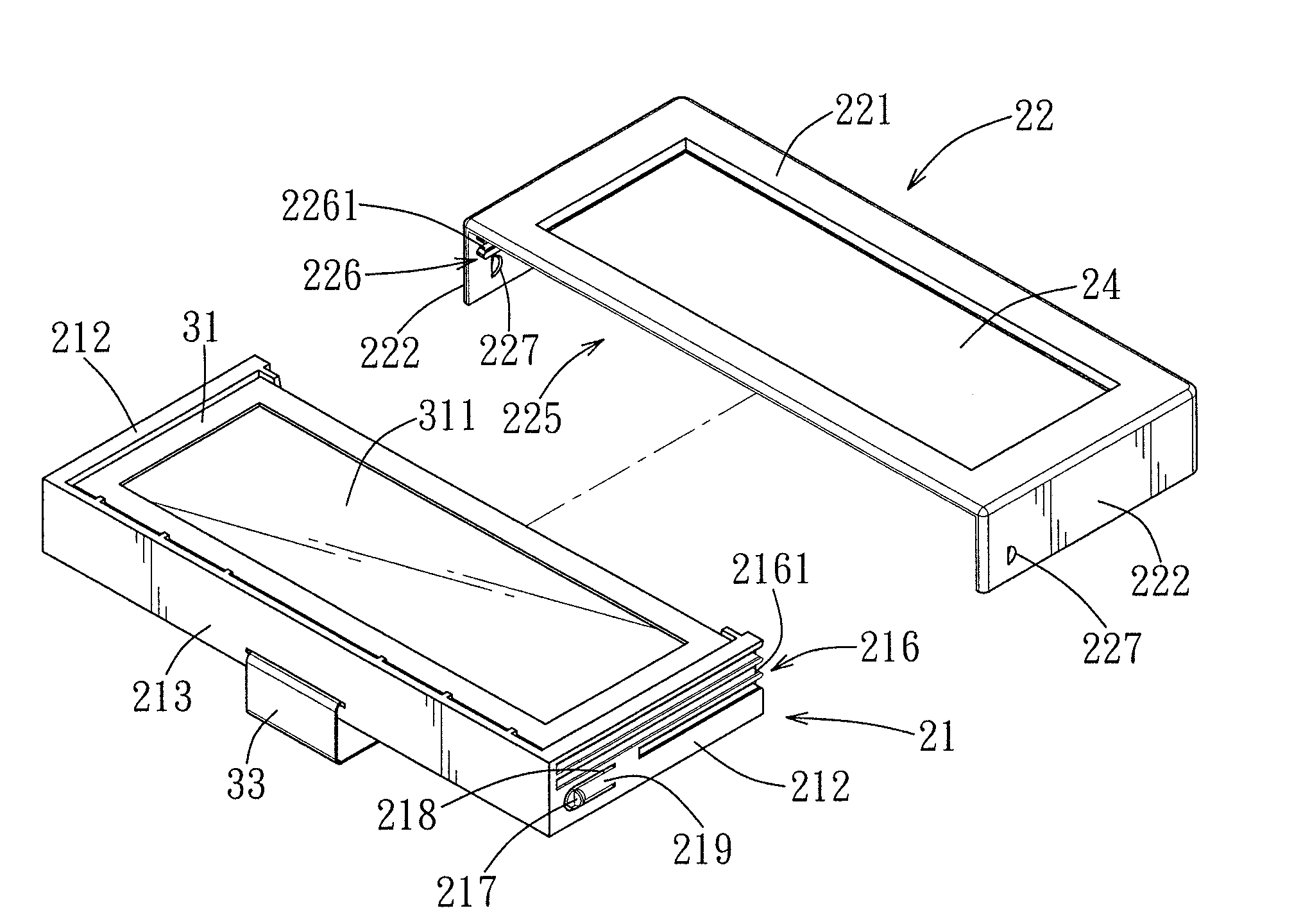

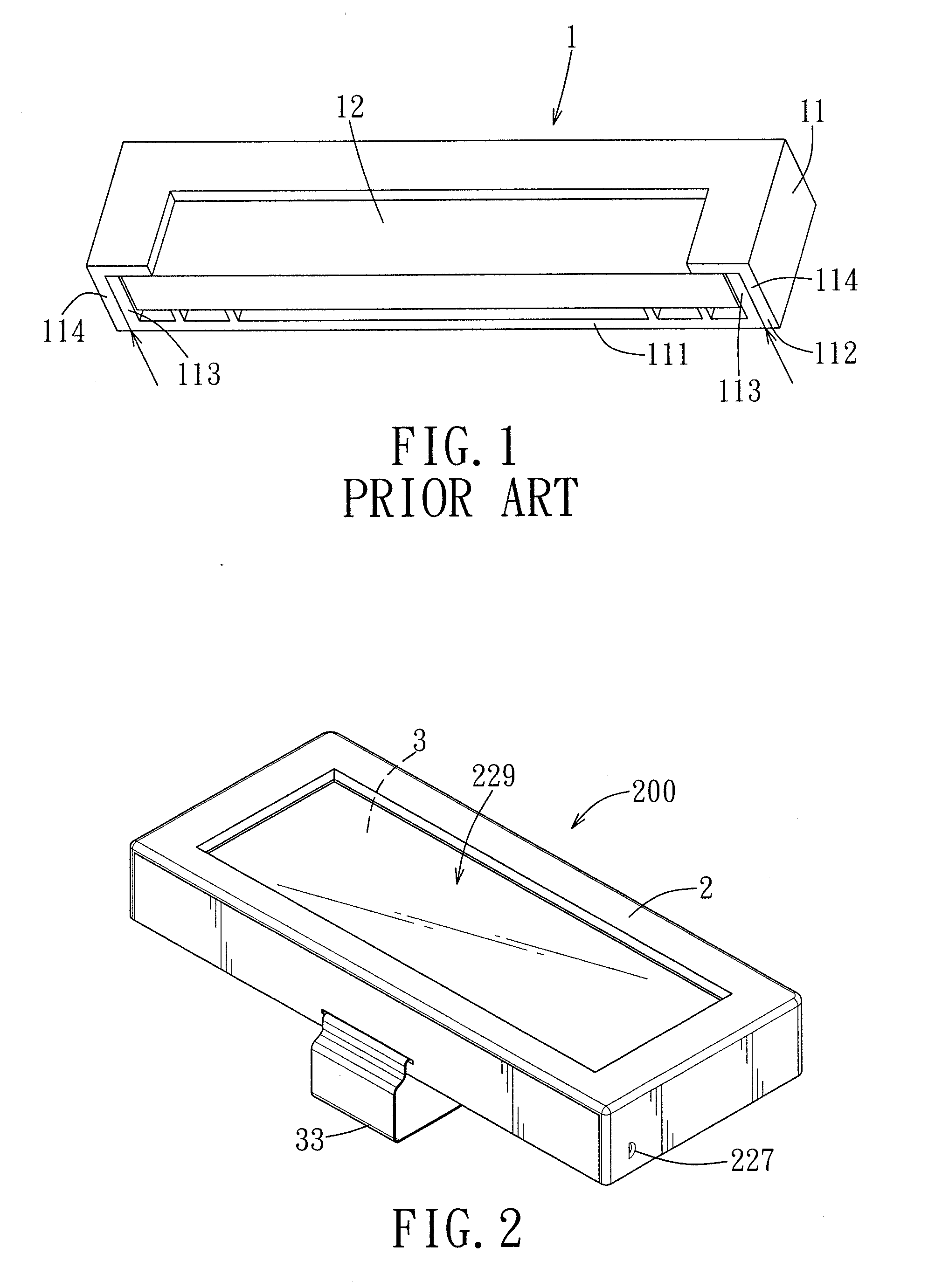

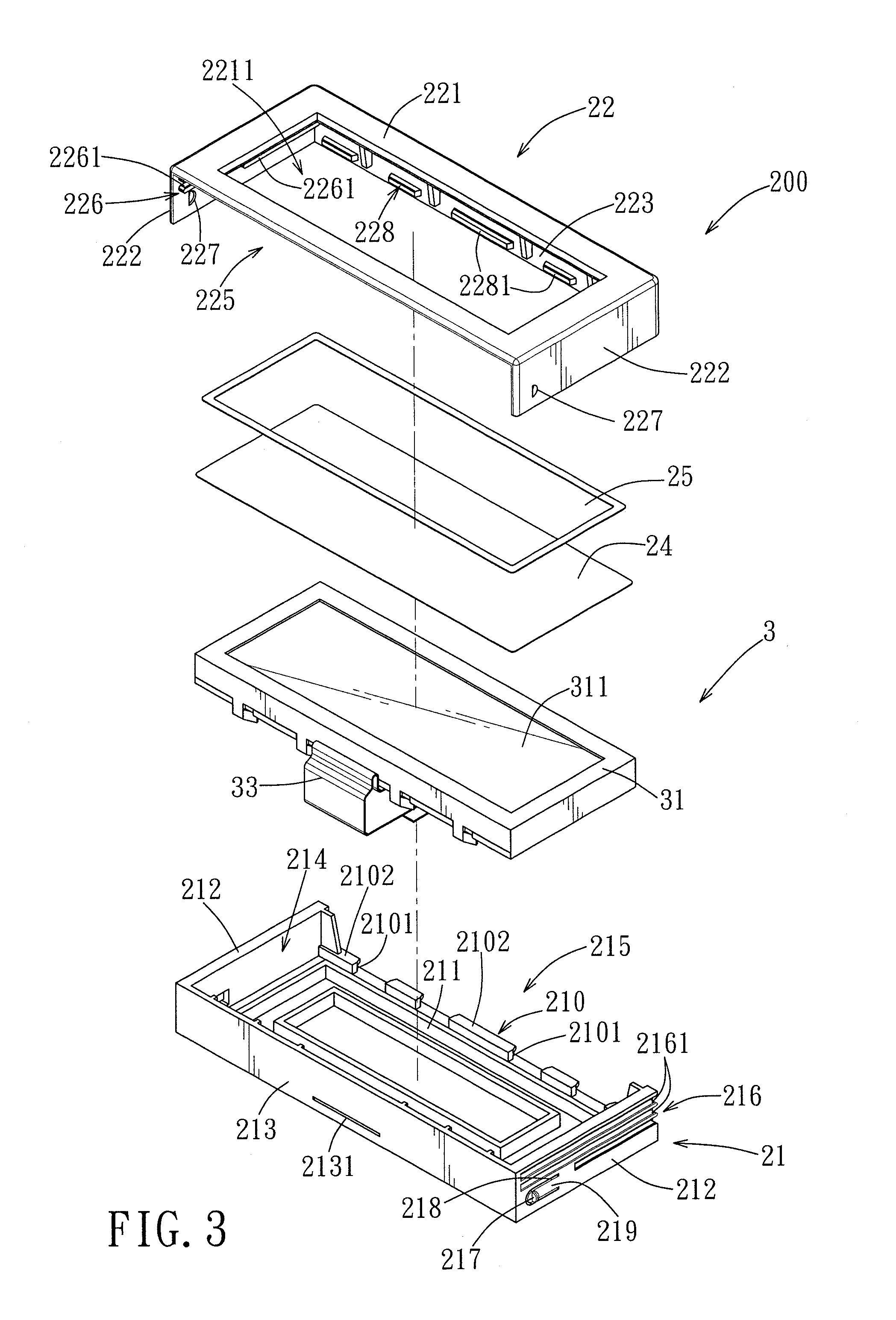

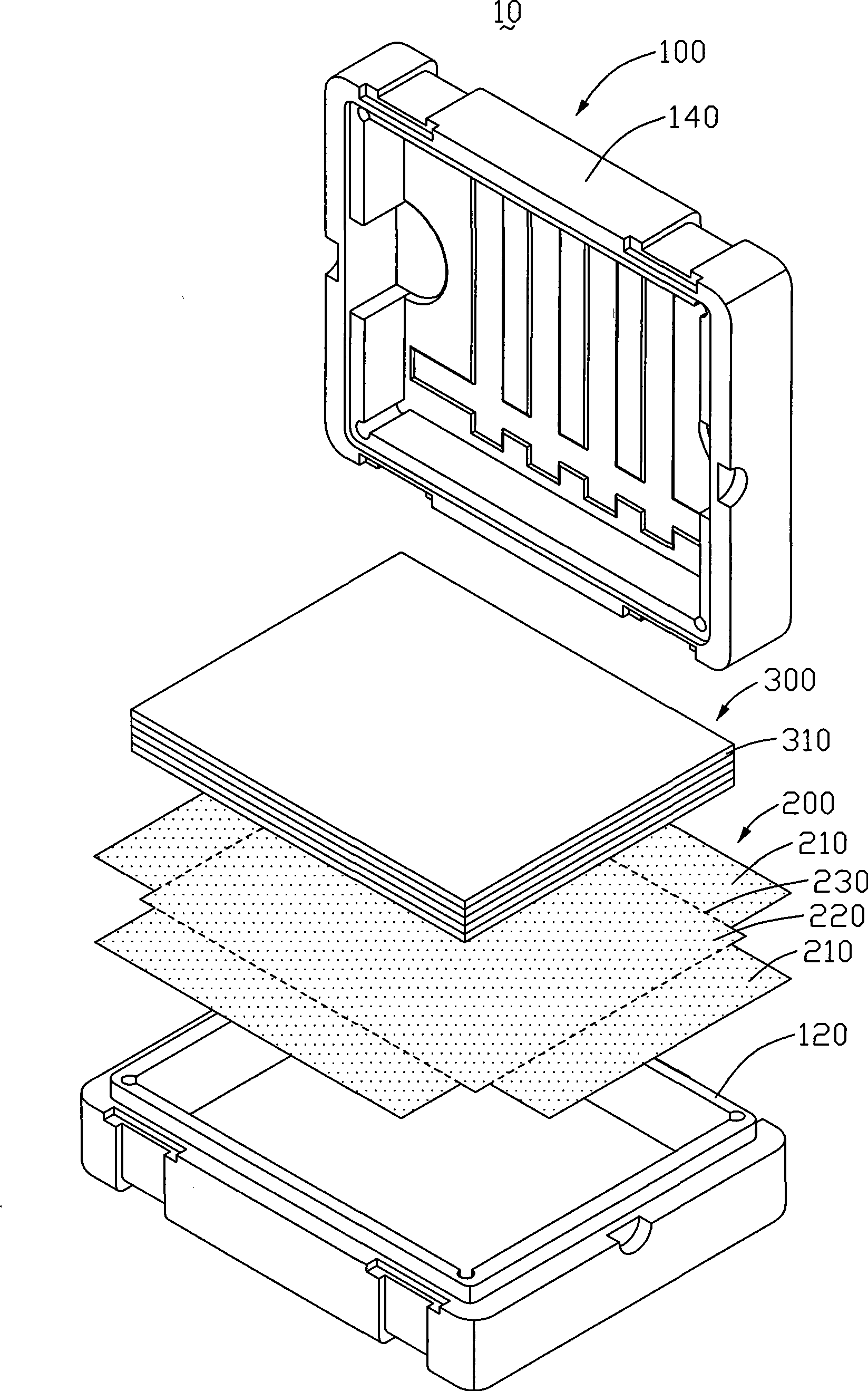

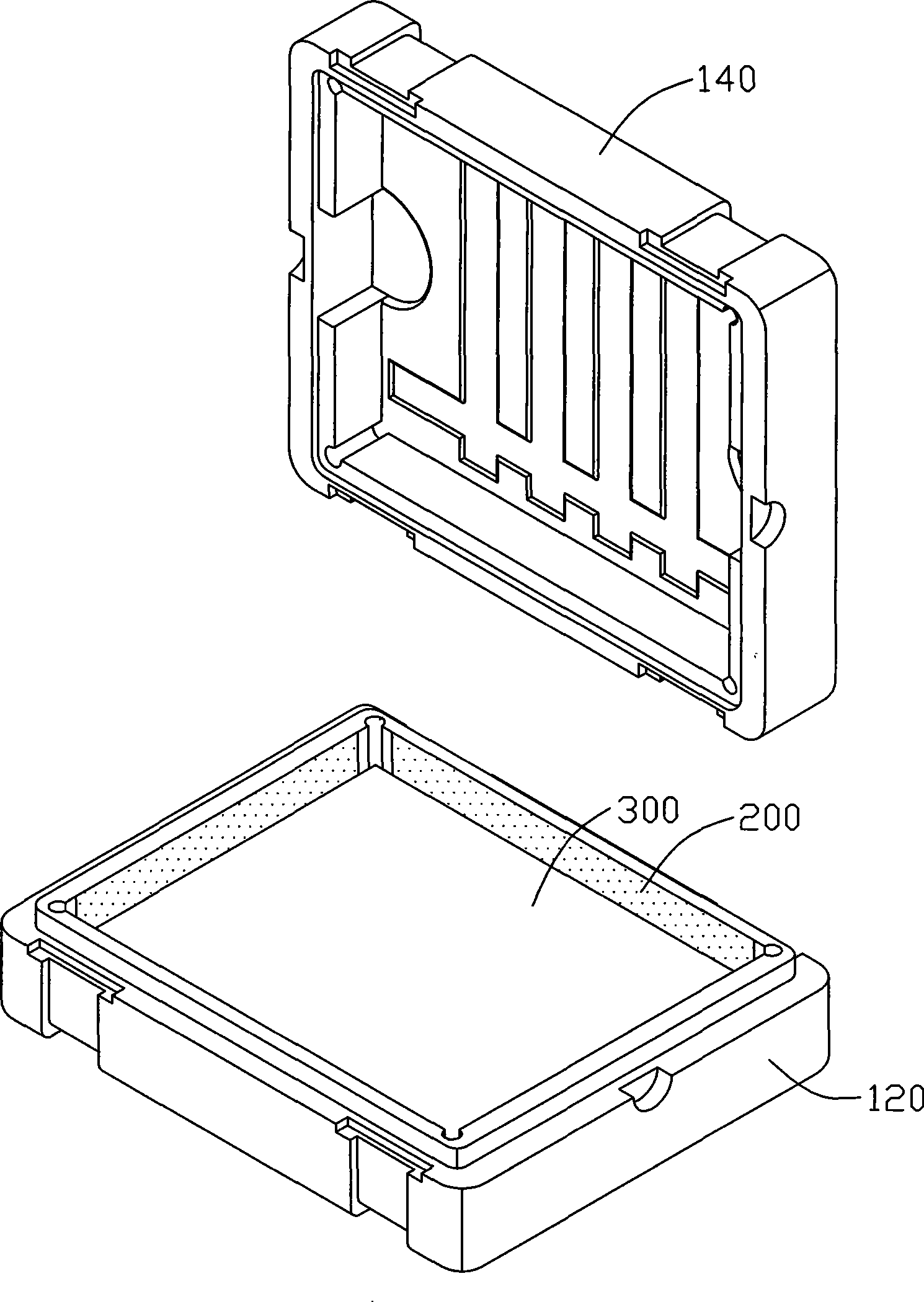

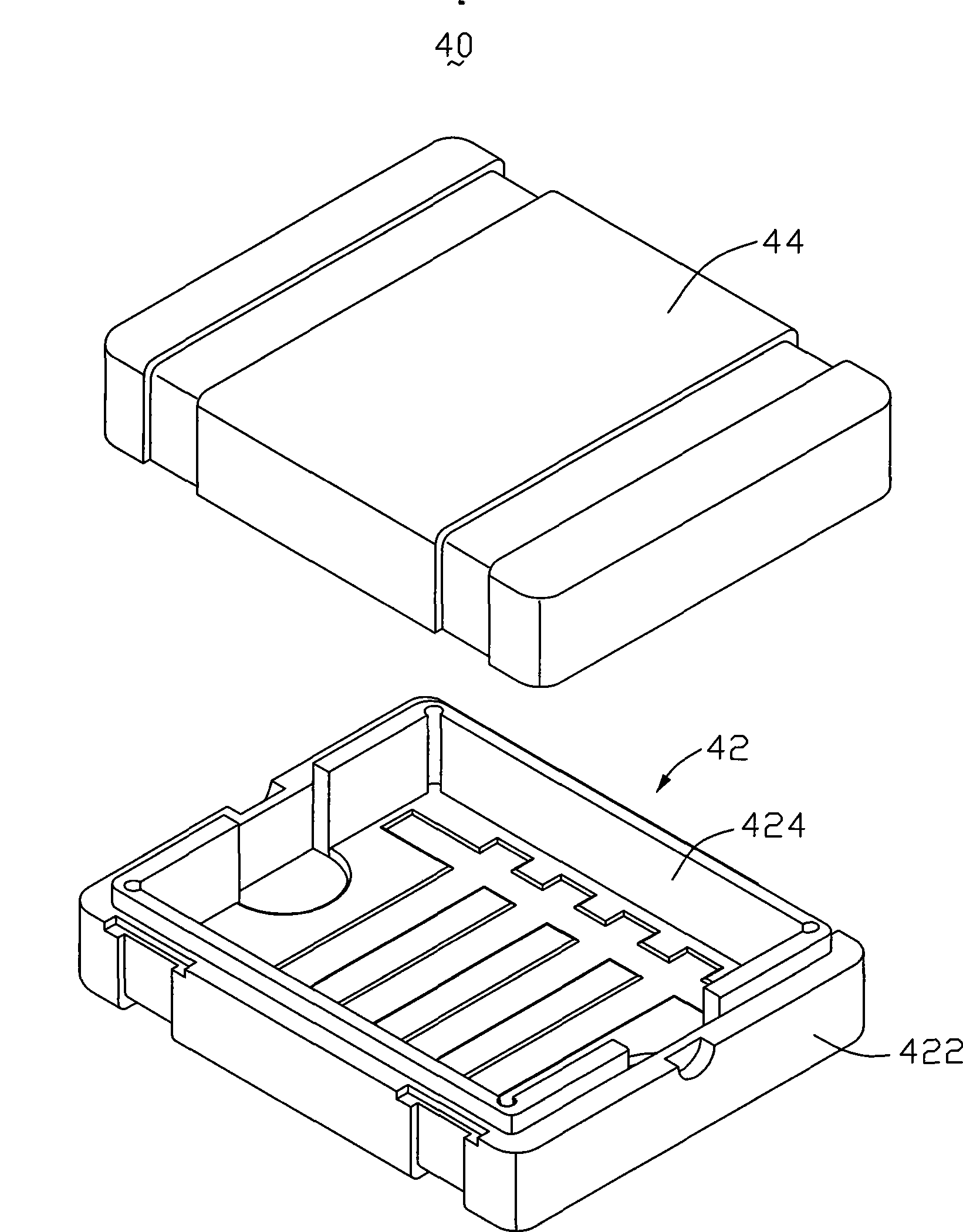

Anti-static housing and related display device assembly

ActiveUS20110075330A1Easy to assembleLower assembly costsCabinetsSubstation equipmentDisplay deviceEngineering

A display device assembly includes an anti-static housing and a displaying module contained therein. The anti-static housing has a first housing body, a second housing body and a plurality of anti-static dielectric layers. The first housing body and the second housing body respectively have a first rail-and-groove engaging structure and a second rail-and-groove engaging structure, and can be moved relative to each other such that the first rail-and-groove engaging structure engages the second rail-and-groove engaging structure. Due to dispositions of the first and second rail-and-groove engaging structures and the anti-static dielectric layers when the first and second housing bodies are coupled together, the anti-static housing has comparatively superior anti-static characteristics, and a manner of engagement between the first and second rail-and-groove engaging structures facilitates assembly of the anti-static housing and thus reduces assembly costs.

Owner:WISTRON CORP

Water antistatic synthetic leather and preparation method thereof

InactiveCN104562726AImprove mechanical propertiesHigh tensile strengthSynthetic resin layered productsTextiles and paperAntistatic agentSURFACTANT BLEND

The invention discloses water antistatic synthetic leather and a preparation method thereof. The synthetic leather is prepared from an antistatic sizing agent by adopting a rolling process, wherein the antistatic sizing agent is prepared by following components in parts by weight: 100 parts of water polyurethane resin, 5 to 10 parts of antistatic agent, 0.5 to 1 part of antifoaming agent, 0.5 to 1 part of flatting agent, 0.5 part of organic silicon dry sliding agent and 0.3 to 0.5 part of compatilizer, and the antistatic agent is a complex consisting of a quaternary ammonium cationic surfactant and a nonionic surfactant. The synthetic leather is not only relatively good in mechanical property and capable of improving tensile strength and impact strength of the product, realizing high filling and improving the processing rheological property, but also relatively excellent in antistatic characteristic.

Owner:JIANGSU GUOXIN SYNTHETIC LEATHER

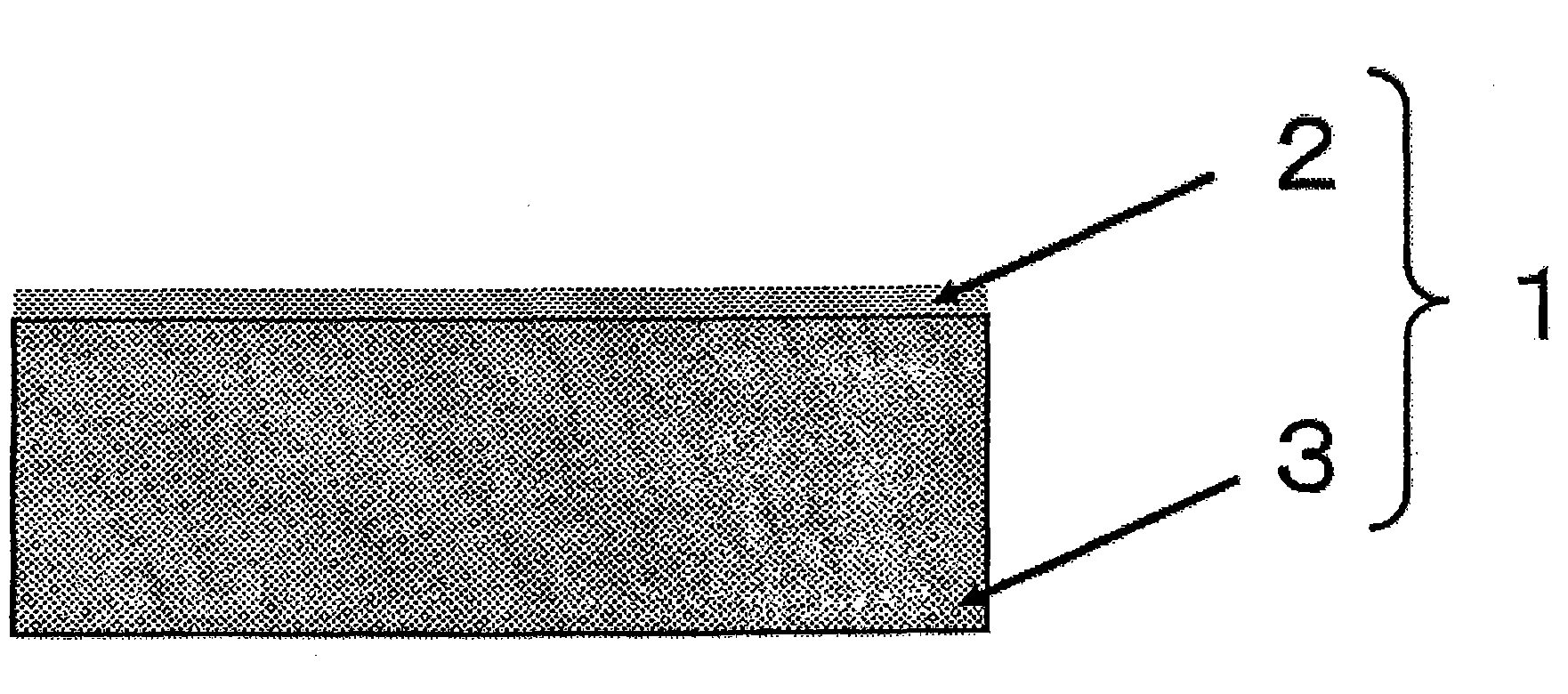

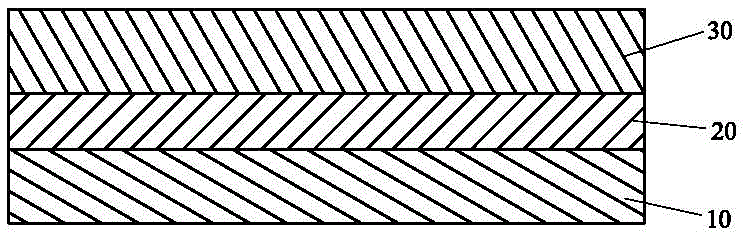

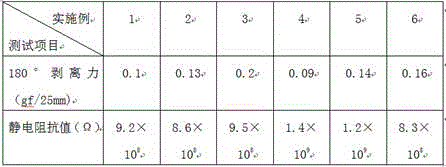

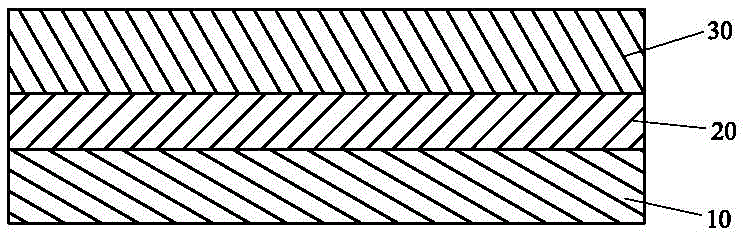

PET (polyethylene terephthalate) antistatic release film

InactiveCN105969238AHigh electrostatic resistance valueImprove antistatic propertiesFilm/foil adhesivesPolyureas/polyurethane adhesivesSolventPlasticizer

The invention disclose a PET (polyethylene terephthalate) antistatic release film, comprising a PET release layer, a PU (polyurethane) glue layer and a PET film face layer; the PET release layer, the PU glue layer and the PET film face layer are stacked together from bottom to top, and the PU glue layer is made from the following materials according to parts by weight: 65-80 parts of polyurethane resin, 5-8 parts of a solvent, 20-30 parts of a curing agent, 14-18 parts of an antistatic agent, 4-5 parts of a plasticizer, and 3-4 parts of an antioxidant agent. The PU glue layer prepared according to the formula of the invention has high electrostatic resistance, good antistatic feature, low peeling force, low adhesion and easiness of peeling and also has good self-gassing performance, easiness of attaching, good weatherability and zero post-peeling residue, the PET film face layer 30 is provided with holes in use, precision components are then disposed in the holes and adhered by the PU glue layer 20, and the film may be a replacement for circuit trays.

Owner:DONGGUAN HANGDA ELECTRONICS

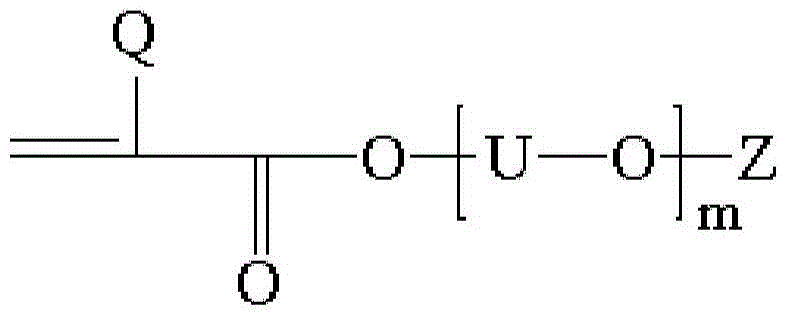

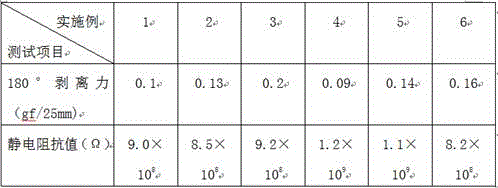

Adhesive composition

ActiveCN104640953AGood storage stabilityImprove protectionNon-macromolecular adhesive additivesFilm/foil adhesivesTectorial membraneDisplay device

The present application relates to an adhesive composition, a protection film, an optical device, and a display device. The adhesive composition of the present application has excellent storage stability, exhibits appropriate low-rate and high-rate peeling forces after the formation of a cross-linking structure, and is excellent in terms of quantum balance. Thus, when being applied to, for example, a protection film, the adhesive composition has an excellent protective effect, can be easily peeled at the time of high-rate peeling and thus favorable in terms of a high-rate process, and can exhibit an excellent anti-static property during the process.

Owner:LG CHEM LTD

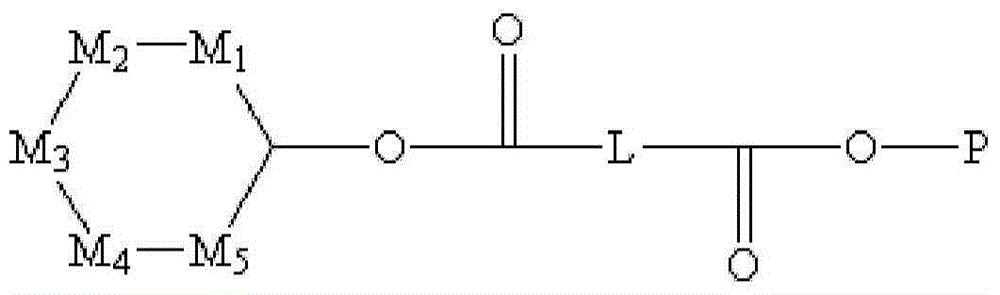

Preparation method of polyester chip with multiple functions

ActiveCN102443152AReduce harmImproves UV resistanceMonocomponent polyesters artificial filamentPolyethylene glycolSolvent

The invention relates to a preparation method of a polyester chip with multiple functions. The method comprises a first esterification reaction segment, a second esterification reaction segment and a polymerization operation. In the first esterification reaction segment, aliphatic dicarboxylic acid and / or non-para aryl dicarboxylic acid is introduced as a third monomer; in the second esterification reaction segment, flexible polyethylene glycol is introduced as a fourth monomer; after the esterification, hindered amine light stabilizer and hindered phenol anti-oxidant, which are respectively blended by solvents of acetic acid and glycol, and hydroxy silicone oil are added; and an ultraviolet ray absorber and an antistatic agent are added after prepolymerization and before final polymerization in the polymerization operation. The polyester chip of the present invention can be spun into polyester fibre by a routine spinning operation; the obtained polyester fibre has excellent ultraviolet resistance, static resistance, ageing resistance, pilling resistance, moisture absorption and quick drying performance, and fabric has high comfortableness.

Owner:JIANGSU GANGHONG FIBER CO LTD +1

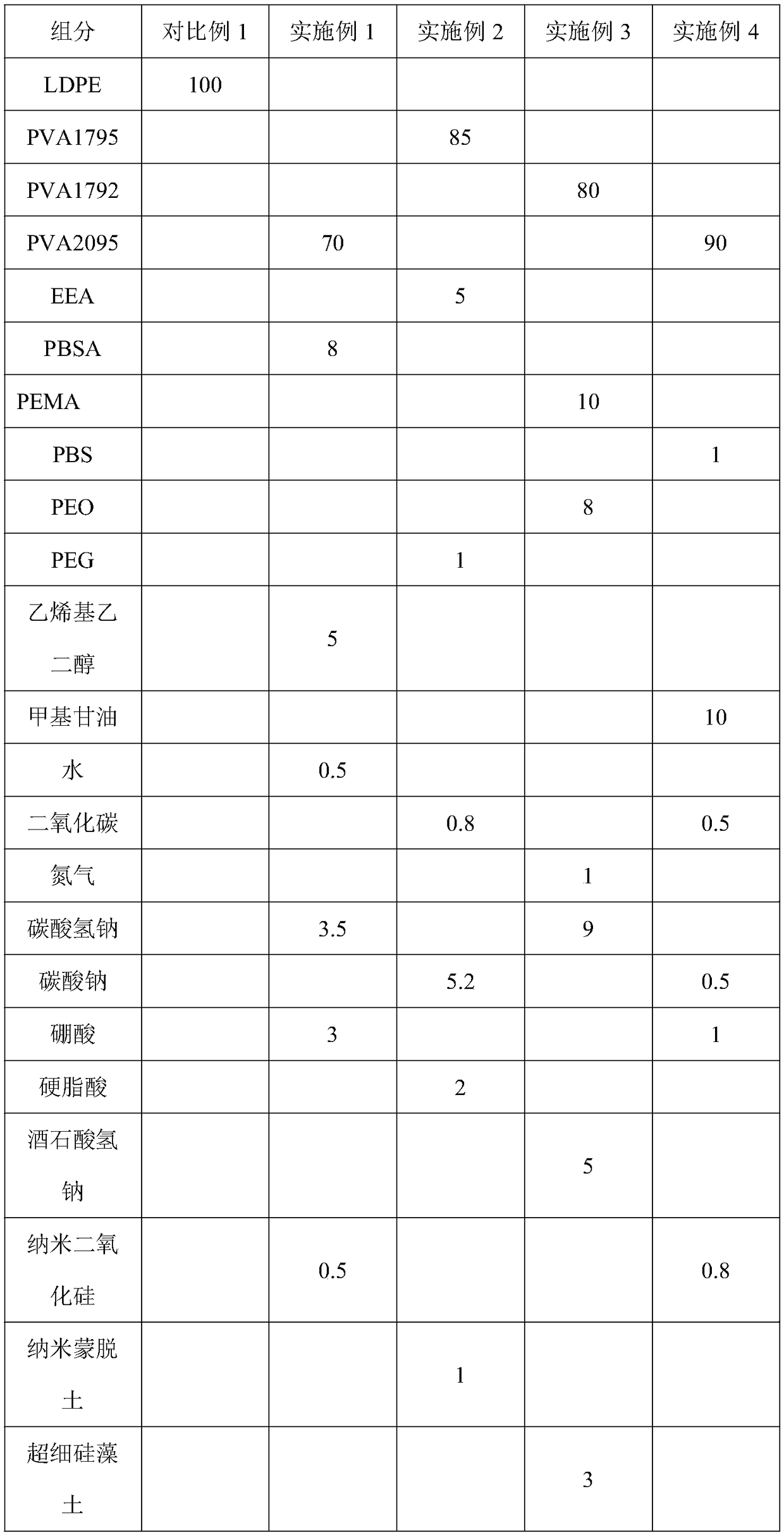

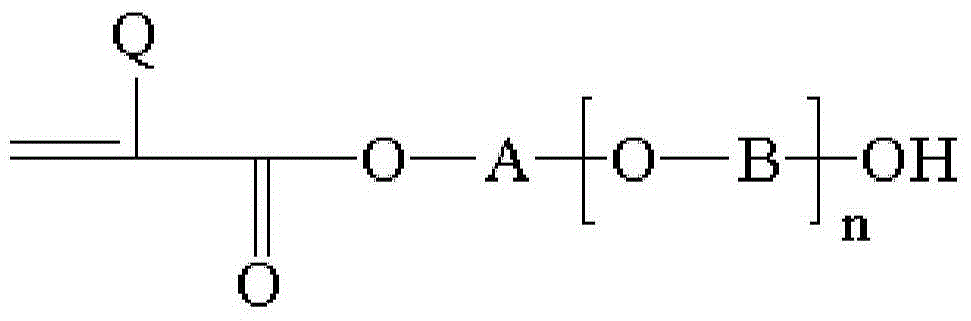

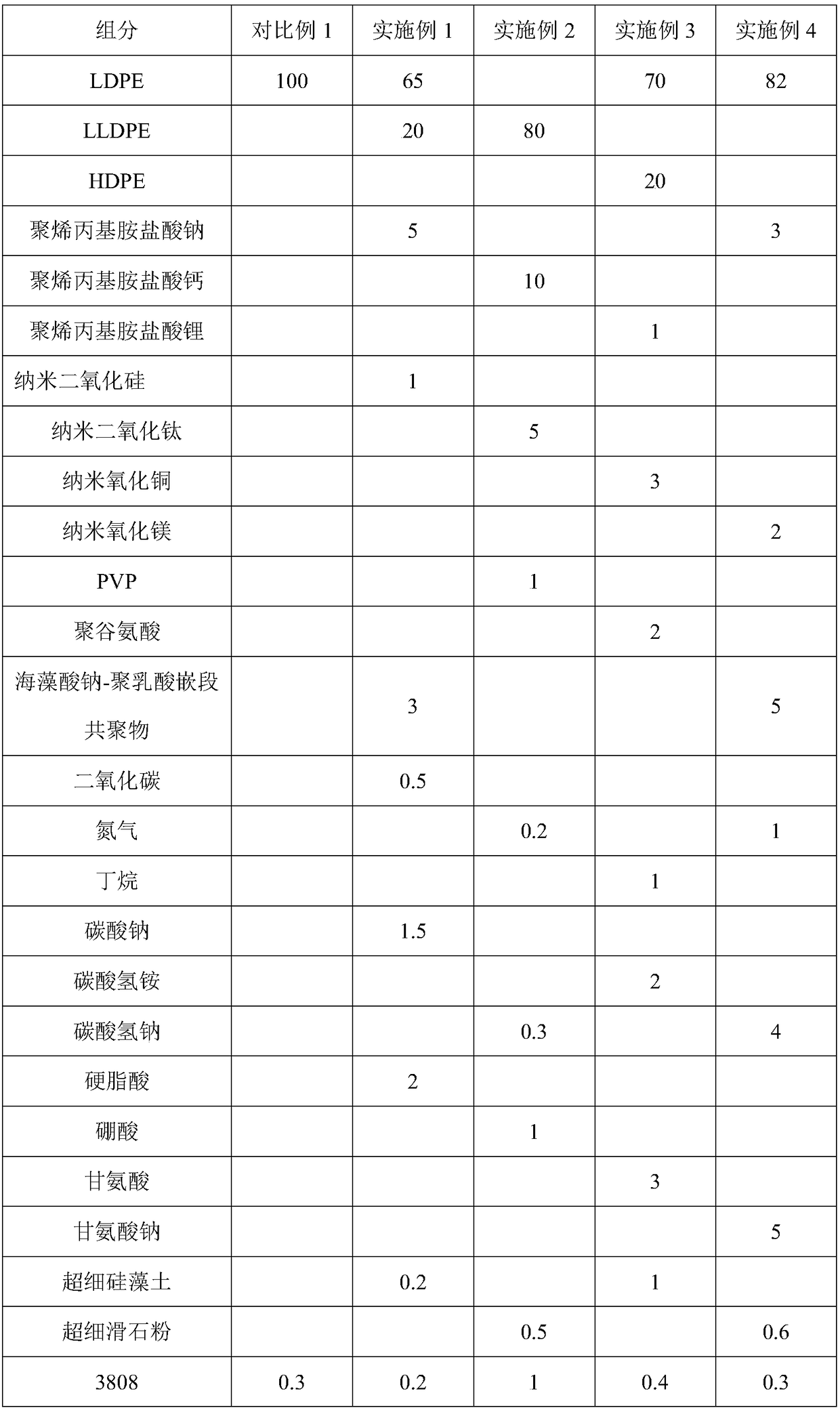

Microcellular foam film-coated packaging paper material and preparation method thereof

The invention relates to film-coated packaging paper and a preparation method thereof, in particular to a microcellular foam film-coated packaging paper material and a preparation method thereof. Thematerial is prepared from, by weight, 70-90 parts of polyvinyl alcohol, 1-10 parts of a melt reinforcing agent, 1-10 parts of a flow modifier, 1-10 parts of a foaming agent, 0.5-3 parts of an anti-adhesion agent, 1-5 parts of a foaming auxiliary agent and 0.5-2 parts of other auxiliary agents. The material is excellent in melt forming and stretching performance, small in foam hole diameter and high in cellular density, the foam film thickness can reach 20micron or below, and a product is light in weight, high in tensile strength and tear resistance and excellent in heat resistance and can be applied to the field of packaging with the requirement of high temperature of 80 DEG C or above; in addition, the product is environmentally friendly and biologically degradable; the product is excellent in oil substance barrier property; furthermore, due to high paper adhesiveness, a film surface aftertreatment process is avoided, and high productivity is realized.

Owner:NANJING JULONG SCI&TECH CO LTD

Pressure-sensitive adhesive composition

ActiveCN104662115AGood storage stabilityImprove protectionNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkDisplay device

A pressure-sensitive adhesive composition, a protective film, an optical element and a display device are provided. The pressure-sensitive adhesive composition has excellent storage stability, exhibits proper low-speed and high-speed peel strengths after formation of a cross-linked structure, and also has an excellent balance between the low-speed and high-speed peel strengths. Therefore, when the pressure-sensitive adhesive composition is applied to a protective film, the pressure-sensitive adhesive composition can have an excellent protective effect, and can also be advantageous to perform a high-speed process since the pressure-sensitive adhesive composition is easily peeled during a high-speed peeling process. In the high-speed peeling process, the pressure-sensitive adhesive composition can exhibit excellent antistatic characteristics.

Owner:LG CHEM LTD

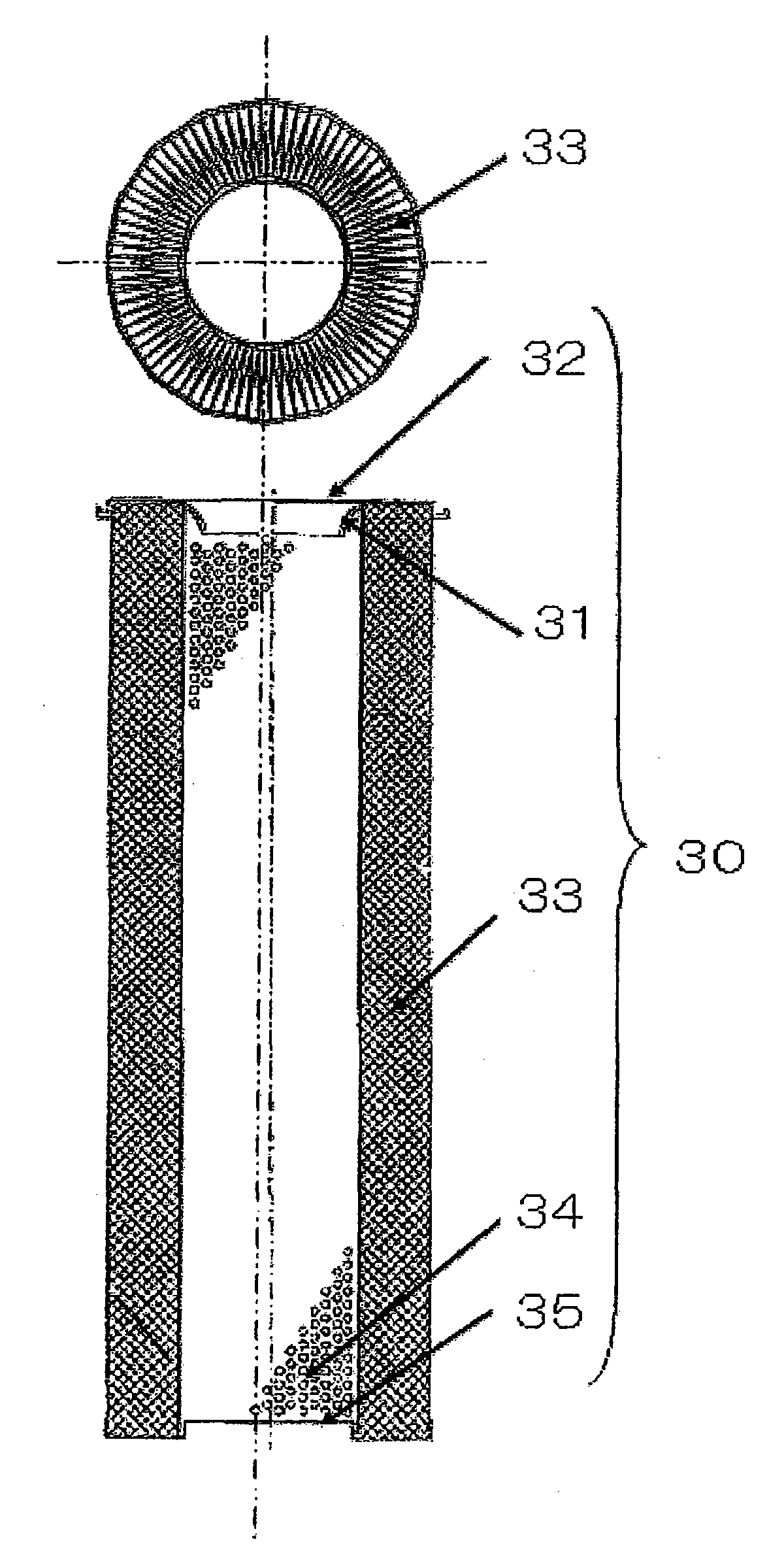

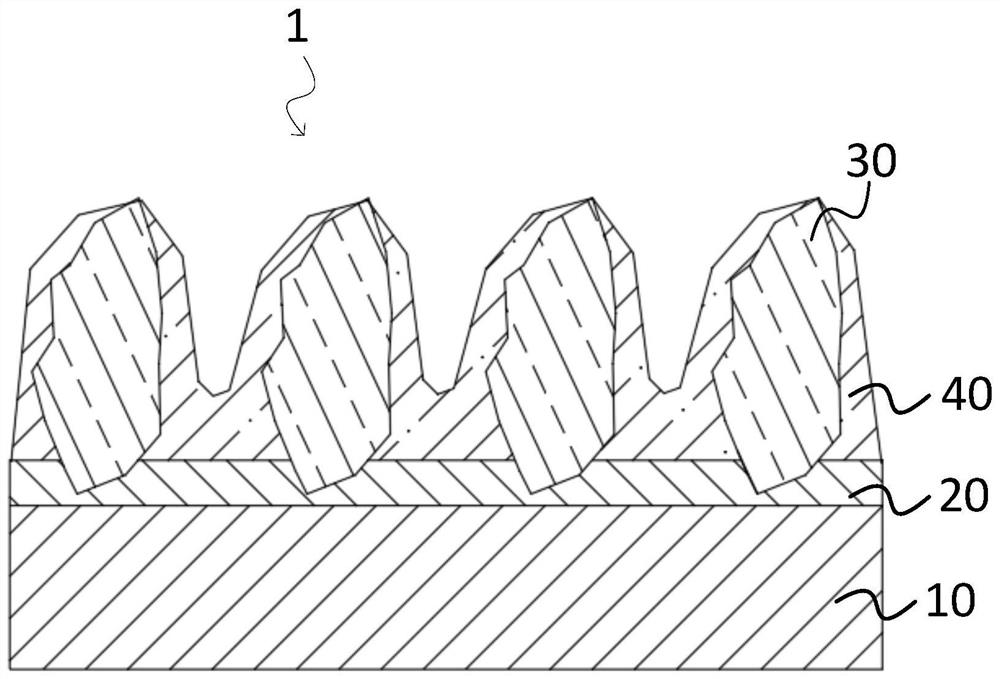

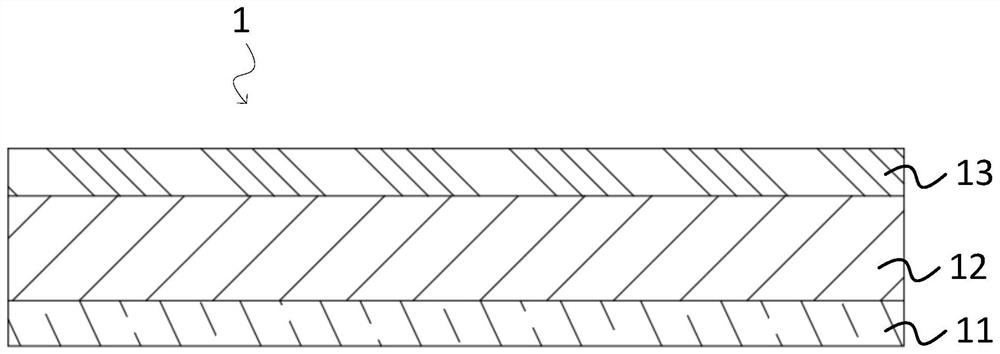

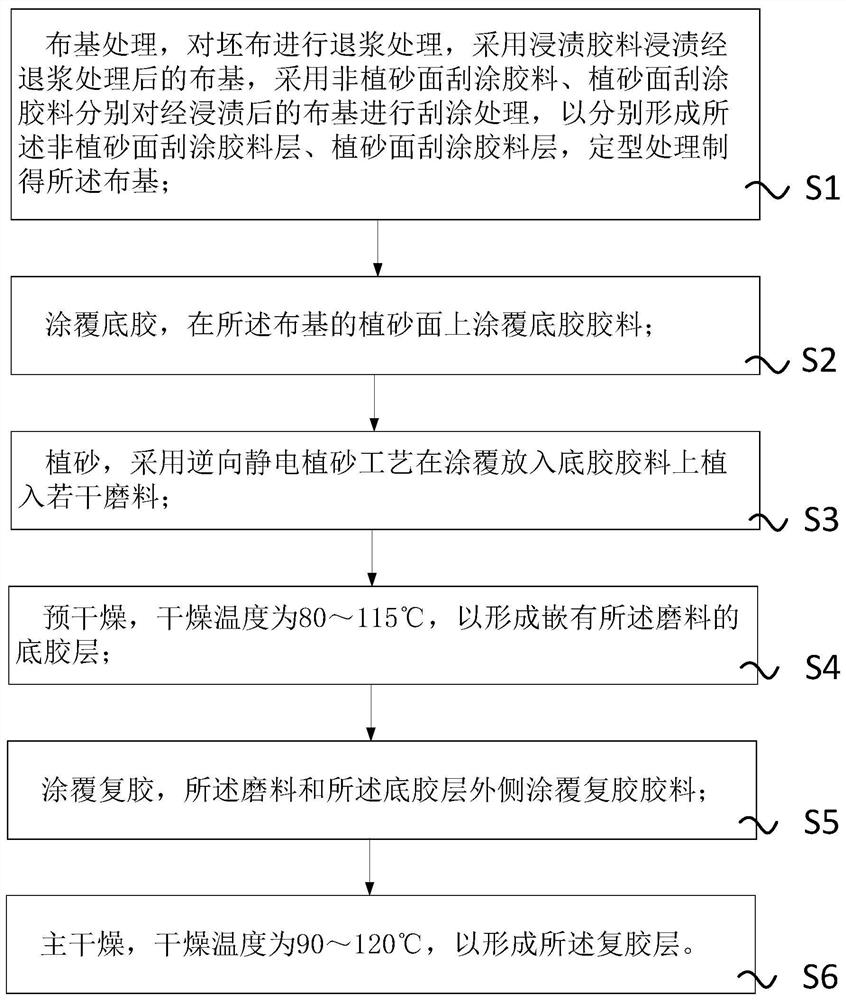

Antistatic cloth-based coated abrasive tool and manufacturing method

ActiveCN112720283ALower the resistance valueImprove antistatic performanceNon-macromolecular adhesive additivesFibre treatmentSizingAbrasive

The invention provides an antistatic cloth-based coated abrasive tool. The antistatic cloth-based coated abrasive tool sequentially comprises a cloth base, a primer layer, abrasive materials and a composite adhesive layer, the primer layer is adhered to the sand planting surface of the cloth base; the plurality of abrasive materials are uniformly and locally embedded into the primer layer; the composite adhesive layer is adhered to the outer sides of the abrasive materials and the primer layer; the cloth base sequentially comprises a non-sand-planting surface blade coating glue material layer, gray cloth and a sand-planting surface blade coating glue material layer; the gray cloth is impregnated with an antistatic impregnating sizing material; the non-sand-planting surface blade coating glue material layer and the sand-planting surface blade coating glue material layer are internally doped with a conductive material; conductive filler is doped in the primer layer and the composite adhesive layer; a conductive path in the abrasive tool body is formed by the non-sand-planting surface blade coating glue material layer, the impregnating sizing material in the gray cloth, the sand-planting surface blade coating glue material layer, the primer layer and the composite adhesive layer, so that the resistance value of the abrasive tool body is reduced. The invention further provides a manufacturing method. The cloth base, the primer layer and the composite adhesive layer of the abrasive tool body form the conductive path, the conductivity is improved, charges generated in the grinding process of the abrasive tool body are conducted to the ground, and the antistatic effect is achieved.

Owner:SUZHOU FAR EAST ABRASIVES

Easy-care micro-foam film packaging paper material and preparation method thereof

The invention relates to film packaging paper and a preparation method thereof, in particular to an easy-care micro-foam film packaging paper material and a preparation method thereof. The easy-care micro-foam film packaging paper material is made from, by weight, 80-90 parts of polyethylene, 1-10 parts of polyallyamine hydrochloride, 1-5 parts of nano oxides, 1-5 parts of an amphiphilic block copolymer, 0.5-5 parts of a foaming agent, 0.2-1 part of an anti-adhesion agent, 1-5 parts of a foaming aid, and 0.5-2 parts of other aids. The preparation method of the easy-care micro-foam film packaging paper material is also disclosed. The easy-care micro-foam film packaging paper material has the advantages of good melt forming tensile property, small foam cell diameter, high cell density, foamfilm thickness reaching 20 micrometers and below, light weight, high tensile strength, high tear resistance, and excellent heat resistance, and is applicable to the field of packaging having the requirement on the temperature of 80 DEG C and above; the easy-care micro-foam film packaging paper material is environmentally friendly and biodegradable, has excellent oil barrier property and has good adhesion with paper, and production efficiency is high as film surface post-treatment is omitted.

Owner:NANJING JULONG SCI&TECH CO LTD

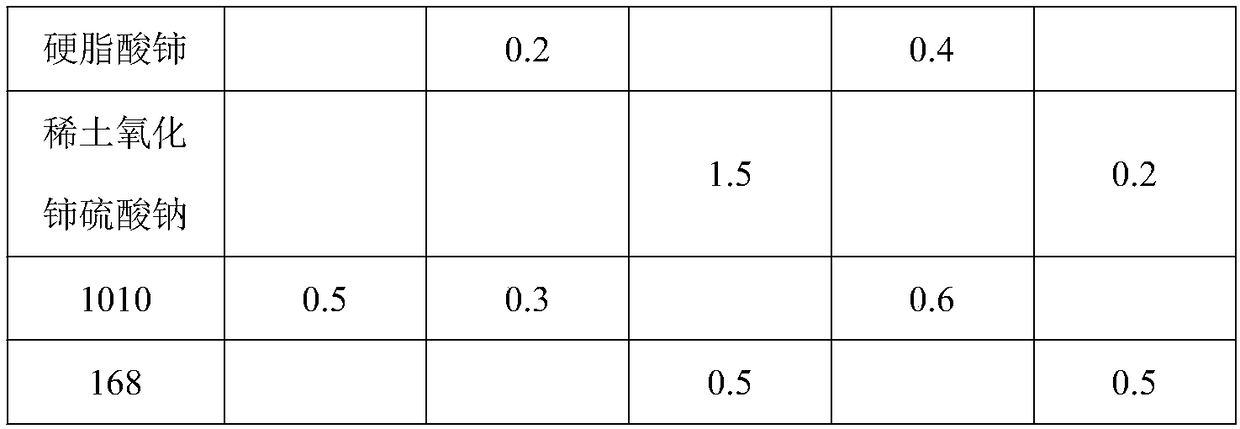

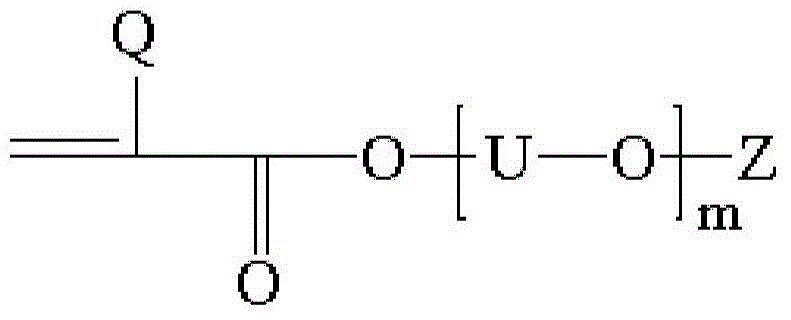

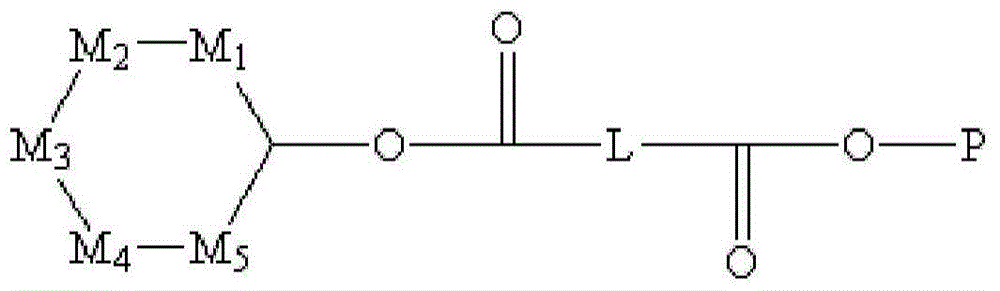

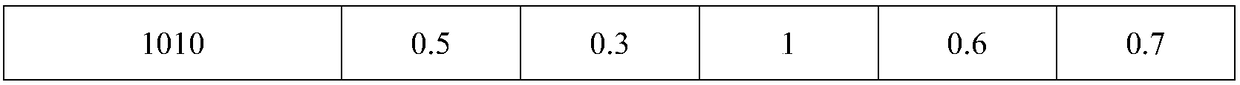

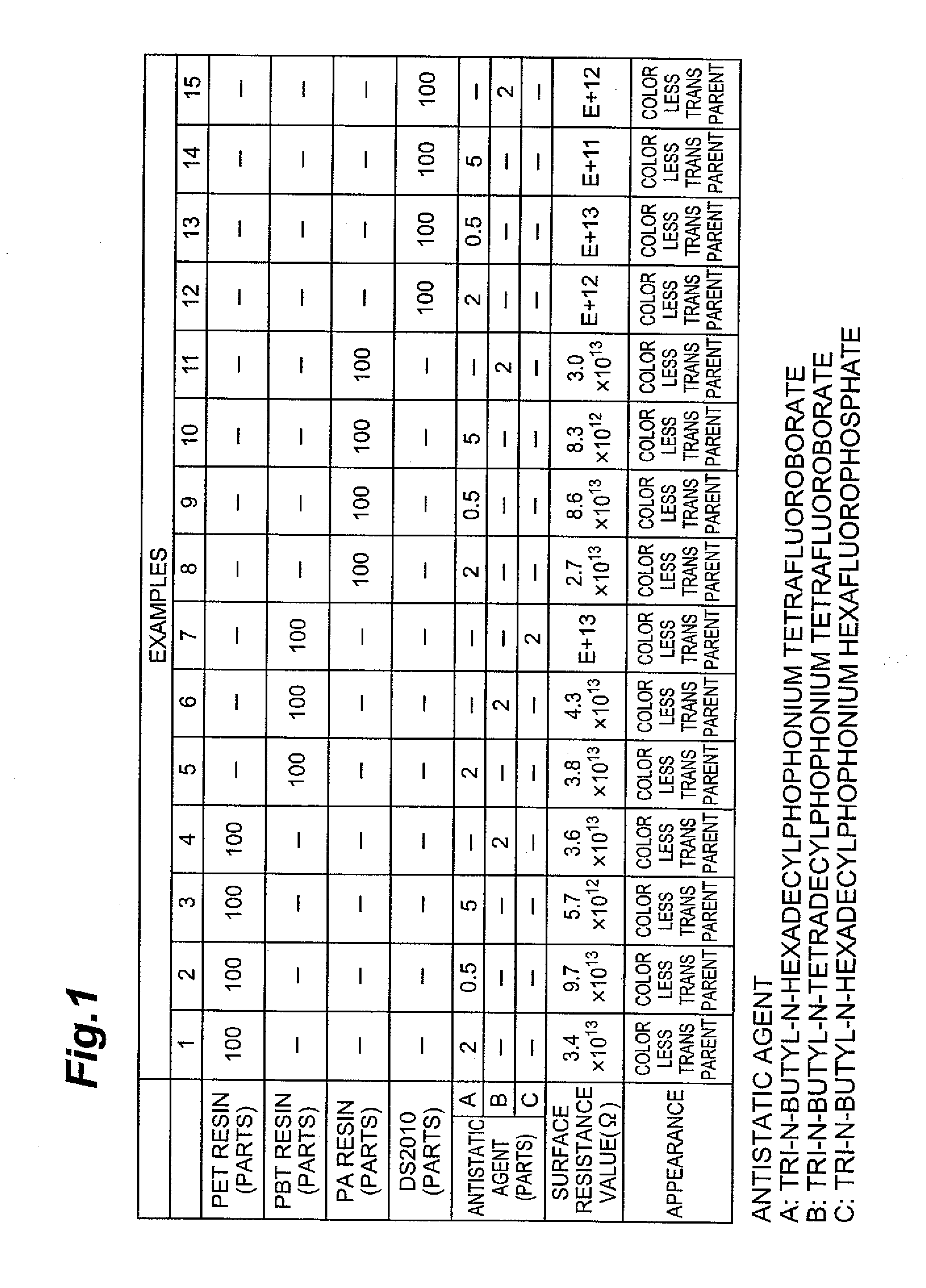

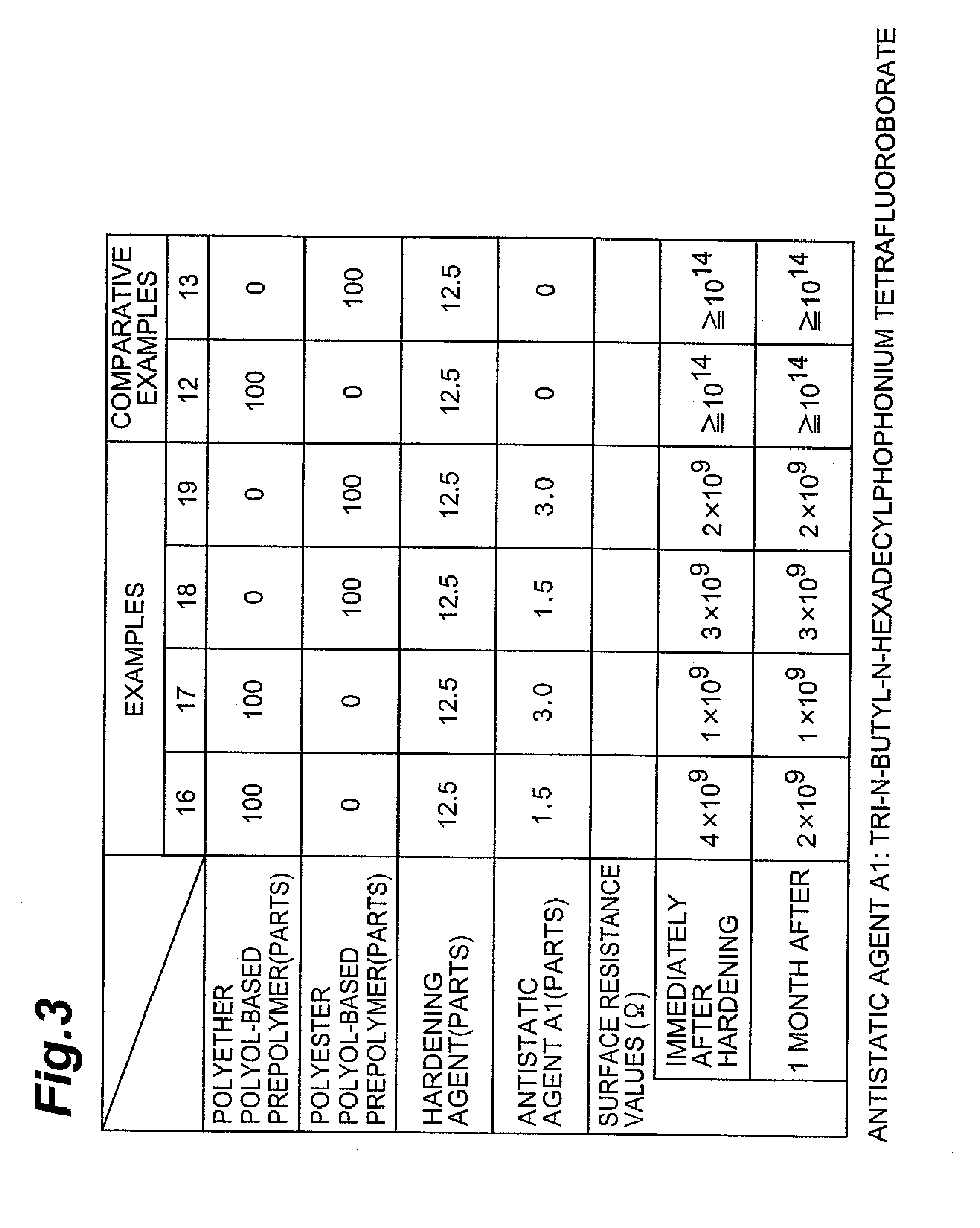

Antistatic agents for resins, antistatic resin compositions, and antistatic resin molded products

InactiveUS20090069472A1Low transparencyImprove featuresMaterial nanotechnologyOther chemical processesAntistatic agentTetrafluoroborate

The antistatic agent for resins of the present invention contains phosphonium salts represented by the general formula (1) below:(wherein R1, R2, and R3 are each a straight-chain or branched alkyl group having 3 to 8 carbon atoms, and R4 is a straight-chain or branched alkyl group having 10 to 22 carbon atoms; each alkyl group may have substituted hydroxy group or alkoxy group; R1, R2, and R3 may be the same or different from each another; and X− is a tetrafluoroborate ion or a hexafluorophosphate ion).

Owner:NIPPON CHECMICAL IND CO LTD

Transparent PET antistatic release film

InactiveCN106010412AHigh electrostatic resistance valueImprove antistatic propertiesFilm/foil adhesivesPolyureas/polyurethane adhesivesWeather resistanceSurface layer

The invention discloses a transparent PET antistatic release film which comprises a PET release layer, a PU glue layer and a PET transparent film surface layer, wherein the PET release layer, the PU glue layer and the PET transparent film surface layer are sequentially overlapped from bottom to top; the PU glue layer consists of the following raw materials in parts by mass: 55-75 parts of polyurethane resin, 5-8 parts of solvent, 20-30 parts of curing agent, 11-15 parts of antistatic agent, 5-8 parts of high-temperature filler, 4-5 parts of plasticizer and 3-4 parts of antioxidant. The PU glue layer is prepared from the formula disclosed by the invention; the product has the advantages of high static resistance value, perfect antistatic property, low peel strength, relatively low viscosity and easiness in peeling; moreover, the product also has relatively good self-exhaust property and is easily pasted while the weather resistance is good and residue is avoided after peeling; and when in use, a hole is formed in the PET transparent film surface layer 30, and a precision component is put in the hole and stuck by the PU glue layer to replace a circuit board tray.

Owner:DONGGUAN HANGDA ELECTRONICS

Preparation method of anti-ultraviolet antistatic anti-pilling polyester chip

ActiveCN102408555AReduce harmImproves UV resistanceMonocomponent polyesters artificial filamentPolyesterPolyethylene glycol

The invention relates to a preparation method of an anti-ultraviolet, antistatic, and anti-pilling polyester chip, which comprises an esterification reaction procedure and a polymerization reaction procedure; the esterification reaction procedure comprises a primary esterification reaction phase and a secondary esterification reaction phase, and flexible polyethylene glycol is introduced into thesecondary esterification reaction phase as a third monomer; after the esterification is completed, a hindered amine light stabilizer and a hindered phenol antioxidant, which are respectively blended with solvents of acetic acid and glycol, as well as hydroxyl silicone oil are added; after the prepolymerization of the polymerization reaction procedure is finished and before the final polymerization, an ultraviolet absorbent and an antistatic agent are added. Polyester fibers spun by the polyester chip obtained by the method of the invention have excellent anti-ultraviolet, antistatic, and anti-pilling effect; when the polyester fibers are woven into knitted fabrics and woven fabrics, related technical indexes obtained by testing are that: the ultraviolet transmittance is not more than 5.0%; the anti-pilling performance is not less than grade 4; and the fiber volume specific resistance is not more than 10*1010 omega.cm.

Owner:JIANGSU ZHONGLU TECH DEV +1

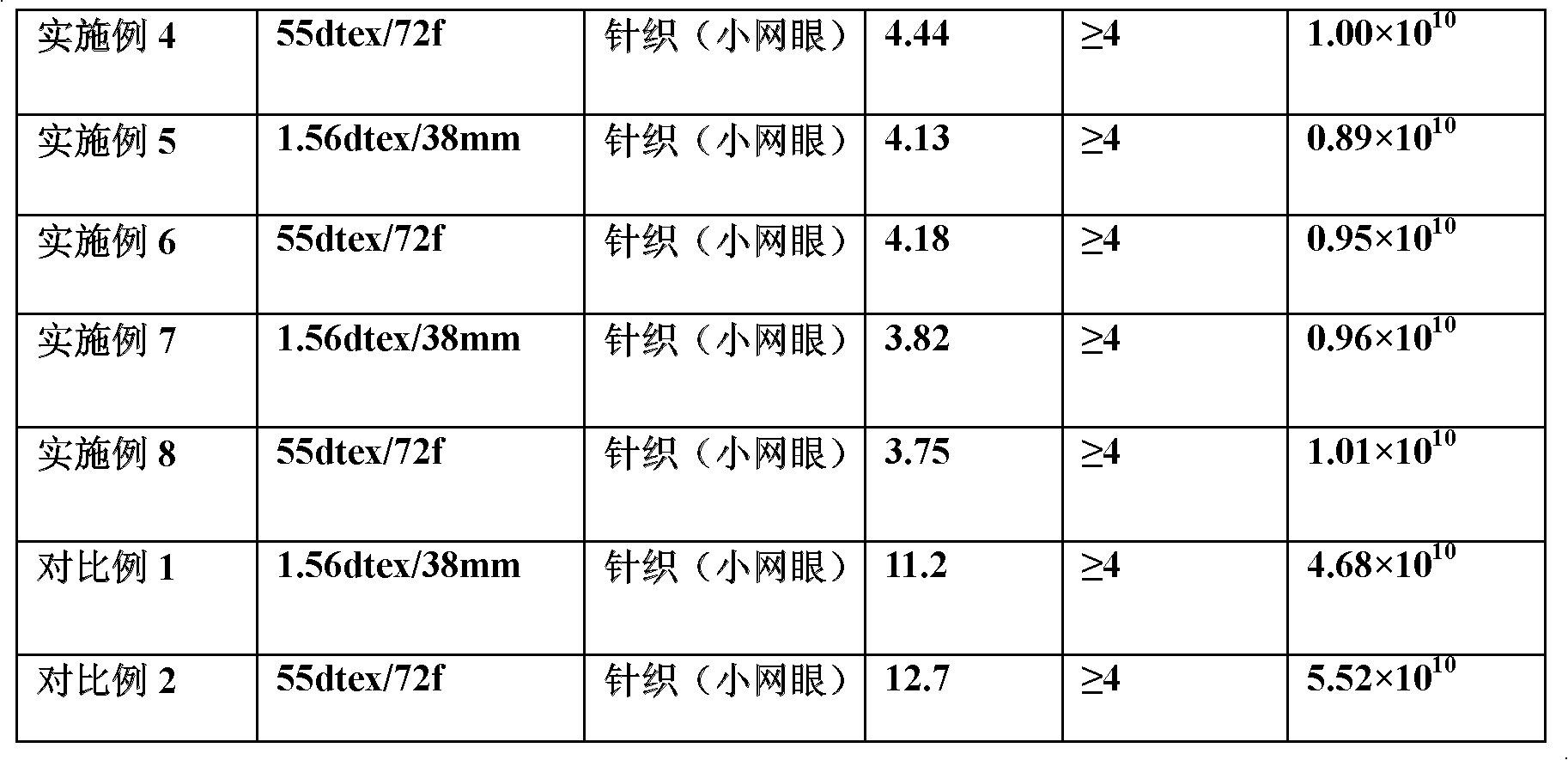

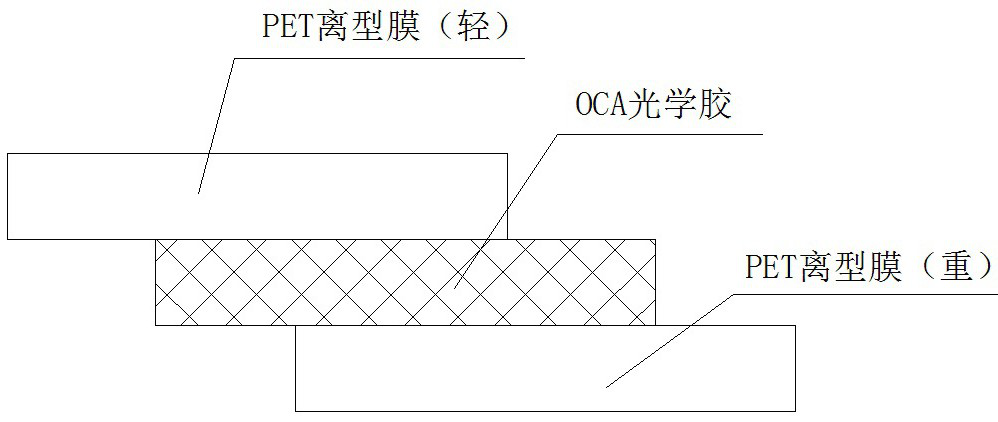

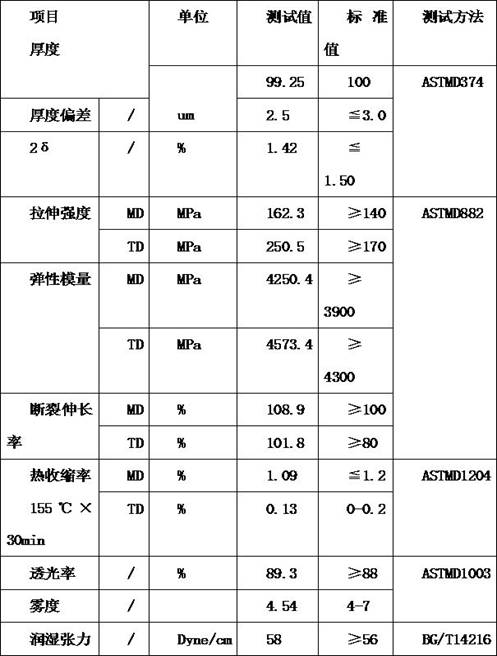

Preparation process of high-end release protection polyester base film for OCA

PendingCN112322208AReduce the impactImprove antistatic propertiesFilm/foil adhesivesFlat articlesPolyesterPolymer chemistry

The invention discloses a preparation process of a high-end release protection polyester base film for an OCA, which comprises the OCA. The OCA is produced by adopting an ABA three-layer structure, when the OCA is laminated, the thickness of a light release film is generally required to be 25-55 mum, the release force is 5-20 mm / g, and the thickness of a heavy release film is 50-100 mum, and the release force is 30-110 mm / g, the thickness of the adhesive layer is 45-100 mum, the shore hardness is 40-50 D, when a customer needs electrostatic treatment, the viscosity of one surface of the film before coating is about 5500 mps.s, and the solid content is about 95%, and by compounding and superposing the multiple adhesive layers, the obtained OCA has a better effect on the basis of ensuring complete curing of each adhesive layer, and has excellent optical apparent performance, excellent transparency and good haze, is free of crystal points, white points and other impurities and foreign matters, and can realize observation of bubbles, foreign matters and other defects in OCA under the condition of not removing the protective film.

Owner:SHANDONG SNTON OPTICAL MATERIALS TECH CO LTD

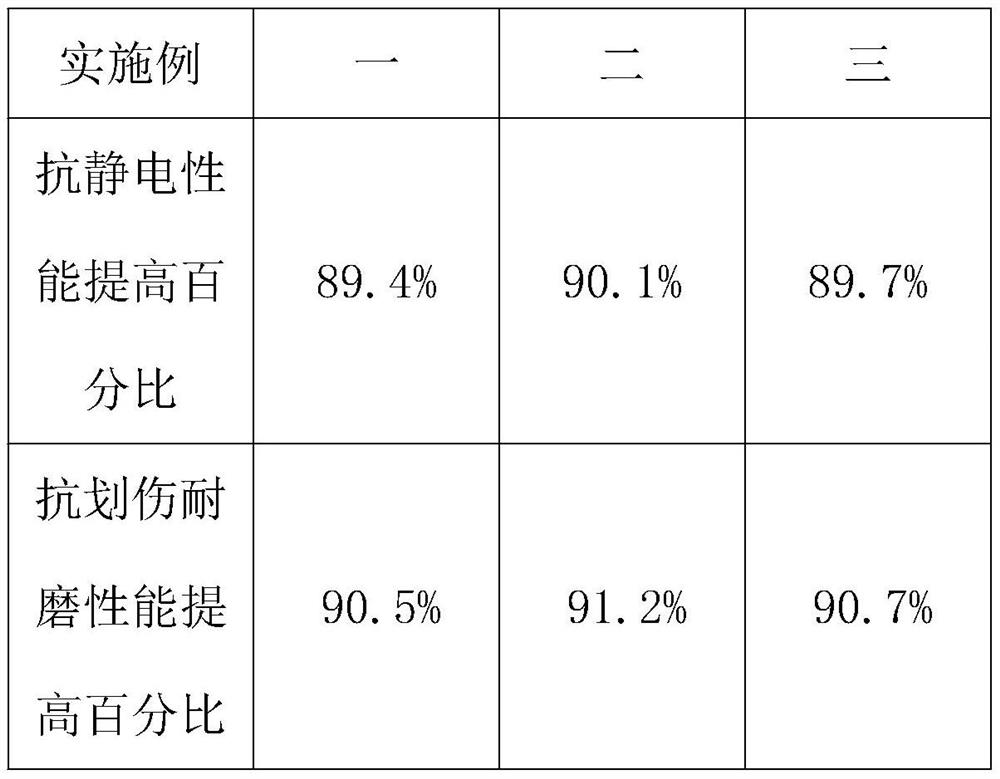

Antistatic color aluminum plate and production process thereof

InactiveCN111944406AImprove antistatic propertiesGood scratch resistance and wear resistanceWax coatingsPolyurea/polyurethane coatingsAcrylic resinFatty amine

The invention belongs to the field of aluminum plates, particularly relates to an antistatic color aluminum plate and a production process thereof, and provides the following scheme for solving the problems that an existing color aluminum plate is poor in antistatic property, scratch resistance and wear resistance. The antistatic color aluminum plate comprises the following raw materials in partsby weight: 30-50 parts of polyurethane resin, 15-20 parts of acrylic resin, 5-10 parts of titanium dioxide, 10-15 parts of polyvinyl acetate, 1-5 parts of ethoxylated alkylamide, 2-6 parts of polyether ester amide, 1-5 parts of dithiocarbamic acid, 3-7 parts of hydroxyethyl fatty amine, 5-10 parts of polypropylene wax, 1-5 parts of modified silicone oil, 1-5 parts of palm wax, 2-6 parts of calciumstearate, 1-5 parts of nanometer alumina, 1-5 parts of pigment, 5-10 parts of graphene and 1-5 parts of a color protecting agent. The antistatic color aluminum plate is excellent in antistatic property, scratch resistance and wear resistance, and the preparation method is simple.

Owner:山东沃丰新材料有限公司

Anti-static and flame-retardant composite PVC board

InactiveCN108724875AImprove antistatic propertiesImprove flame retardant performanceSynthetic resin layered productsElectrically-conductive paintsAntimony trioxideCvd graphene

The invention discloses an anti-static and flame-retardant composite PVC board. The composite PVC board adopts a multi-layer composite structure and comprises a base material, a PVC calendaring sheet,a patterned film, a transparent PVC wear plate and a UV coating from bottom to top, wherein the UV coating is an anti-static UV coating containing graphene, and the base material adopts a antimony trioxide flame retardant; the composite PVC board is characterized in that the UV coating contains graphene modified with a covalent bond modification method. The composite PVC board has better anti-static characteristics and higher structure strength and toughness.

Owner:陈红玲

Packing box for transporting glass base plate

InactiveCN101311077BGuarantee safety and reliabilityHigh foaming ratioContainers to prevent mechanical damageDamagable goods packagingThin membraneStructural engineering

The invention relates to a packing box used for transporting glass substrates. The packing box comprises a box body that comprises an outer-layer buffer material and an inner-layer buffer material; the outer-layer buffer material is arranged at the outside of the inner-layer buffer material which is enclosed into a holding space; the expansion ratio of the inner-layer buffer material are larger that of the outer-layer buffer material, and the inner-layer buffer material is adulterated with antistatic substances. In the packing box, by arranging the inner-layer buffer material with the expansion ratio larger than that of the outer-layer buffer material, the impact of an external force is effectively buffered; the antistatic characteristic is added to the inner-layer buffer material so as to effectively avoid the damage to the glass substrates caused by static accumulation and improve the safety and reliability of the glass substrates during transporting process. Meanwhile, the usage ofantistatic films is reduced, thus being convenient for packing.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com