Patents

Literature

63results about How to "Improve mechanical strength properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

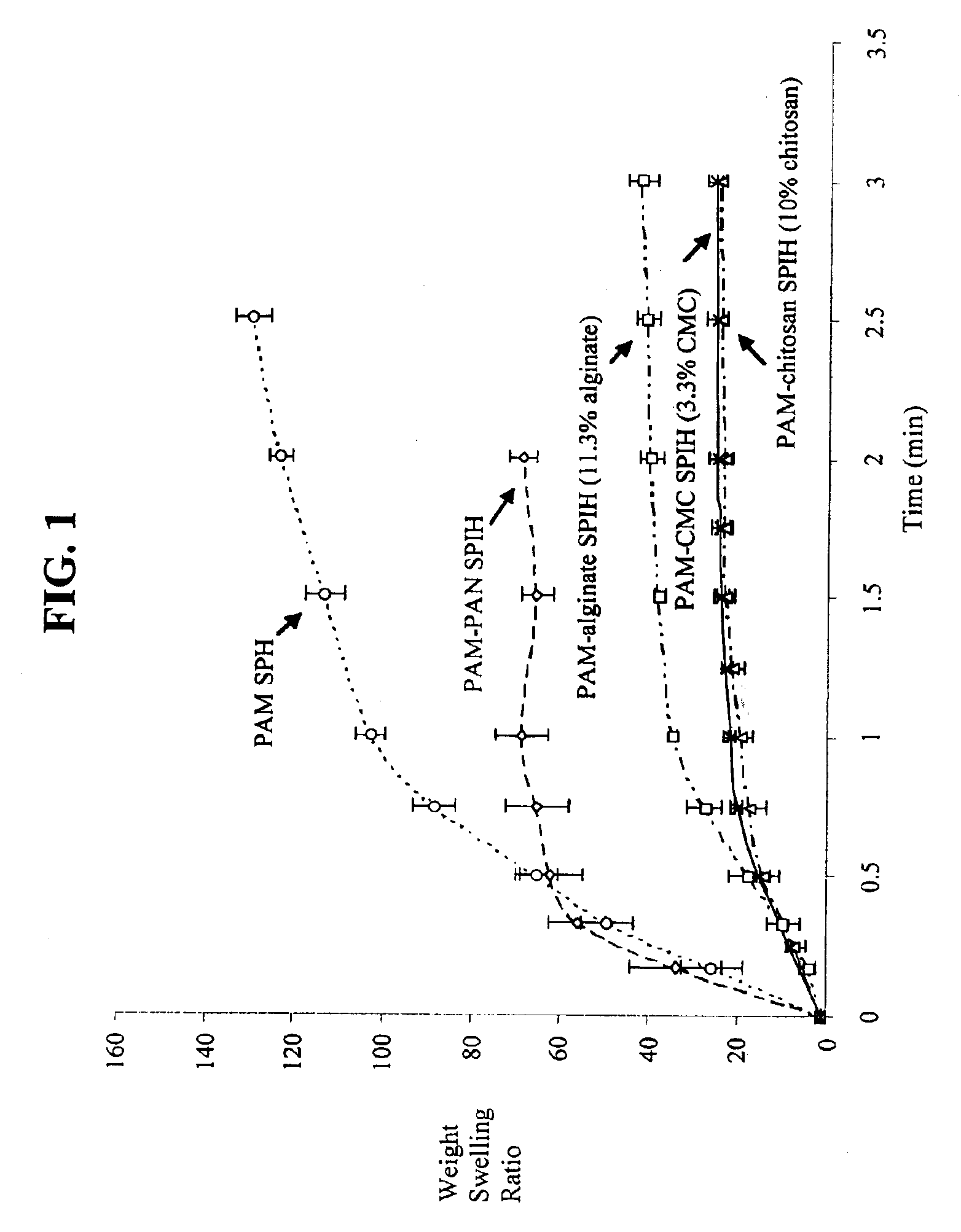

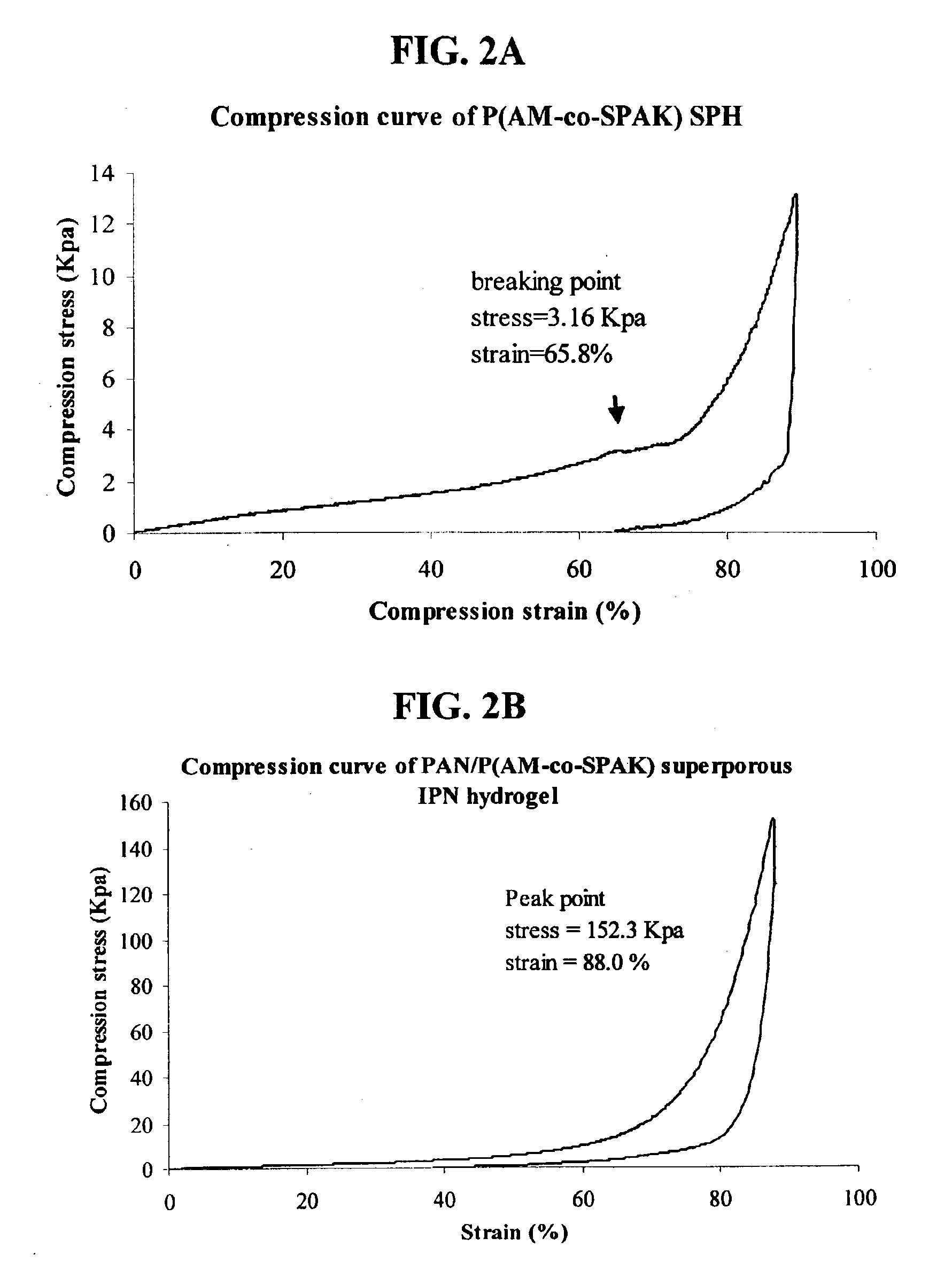

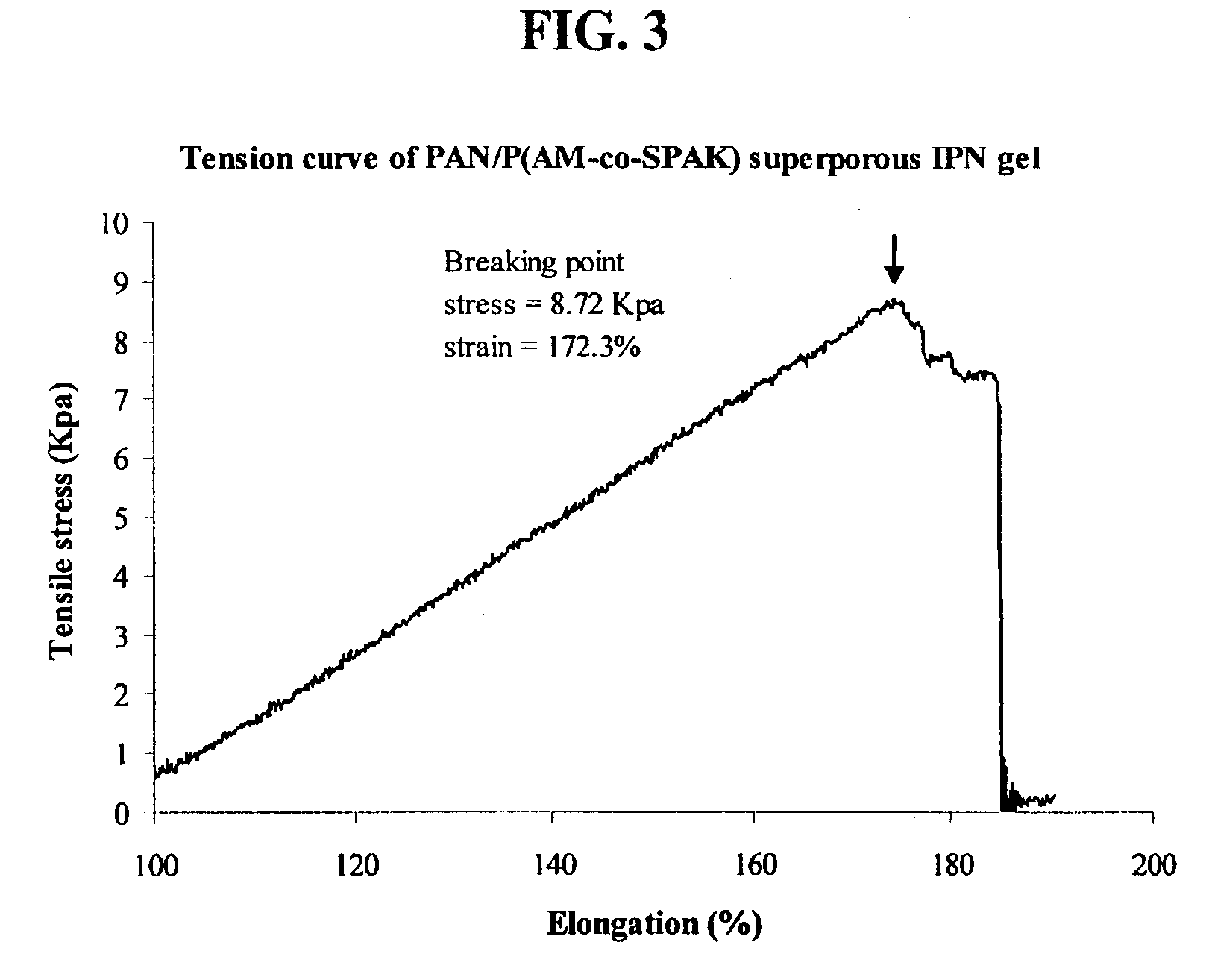

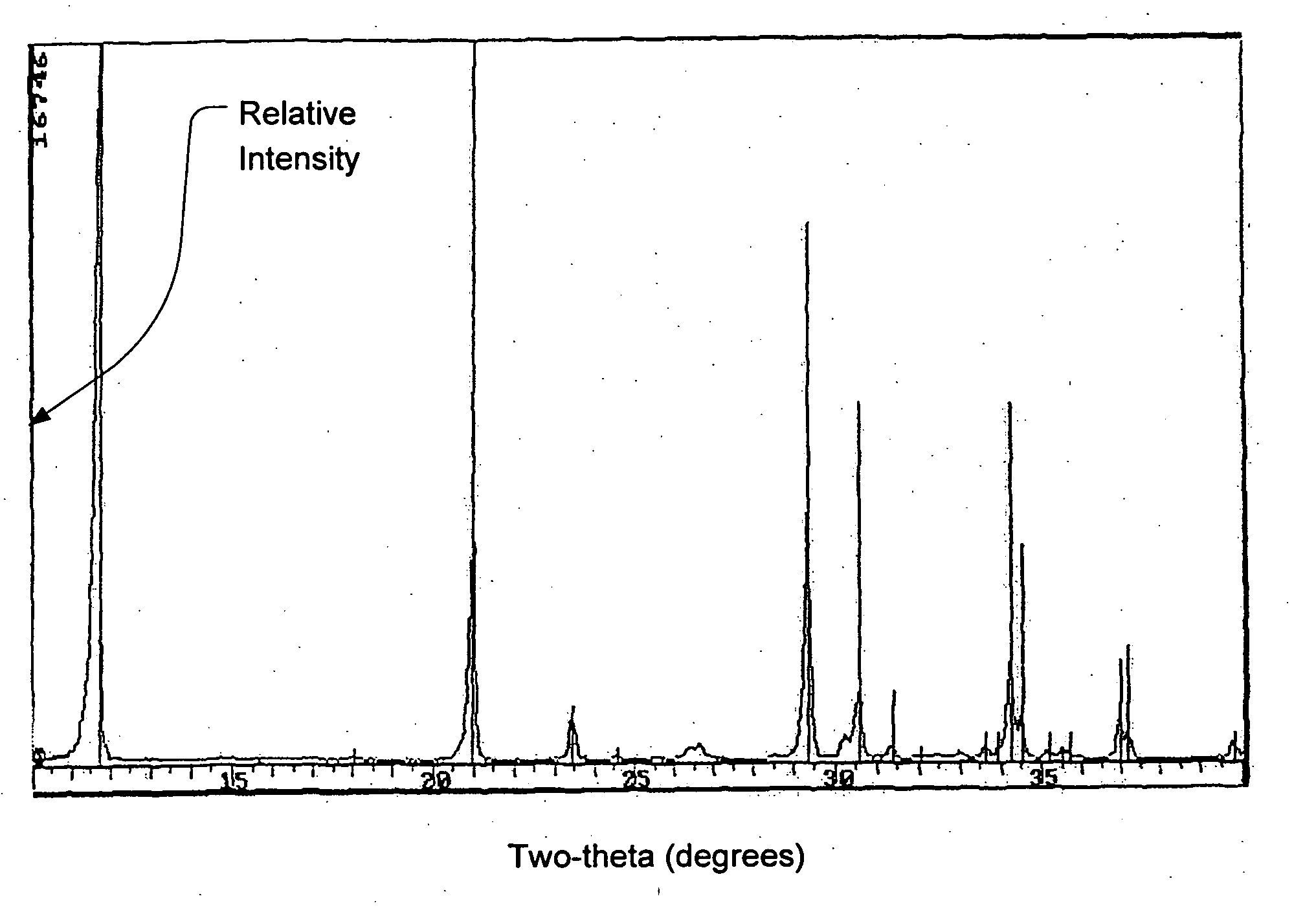

Hydrogels having enhanced elasticity and mechanical strength properties

InactiveUS6960617B2Great compression modulusEnhanced water absorbencePharmaceutical delivery mechanismAbsorbent padsPolyelectrolytePolymer science

Hydrogels having improved elasticity and mechanical strength properties are obtained by subjecting a hydrogel formulation containing a strengthening agent to chemical or physical crosslinking conditions subsequent to initial gel formation. Superporous hydrogels having improved elasticity and mechanical strength properties are similarly obtained whenever the hydrogel formulation is provided with a foaming agent. Interpenetrating networks of polymer chains comprised of primary polymer(s) and strengthening polymer(s) are thereby formed. The primary polymer affords capillary-based water sorption properties while the strengthening polymer imparts significantly enhanced mechanical strength and elasticity to the hydrogel or superporous hydrogel. Suitable strengthening agents can be natural or synthetic polymers, polyelectrolytes, or neutral, hydrophilic polymers.

Owner:PURDUE RES FOUND INC

Method for making toughening agent materials

ActiveUS20060057855A1Improve hydrophobicityImprove mechanical strength propertiesDecorative surface effectsSemiconductor/solid-state device manufacturingDielectricSilicate glass

A toughening agent composition for increasing the hydrophobicity of an organosilicate glass dielectric film when applied to said film. It includes a component capable of alkylating or arylating silanol moieties of the organosilicate glass dielectric film via silylation, and an activating agent selected from the group consisting of an amine, an onium compound and an alkali metal hydroxide.

Owner:HONEYWELL INT INC

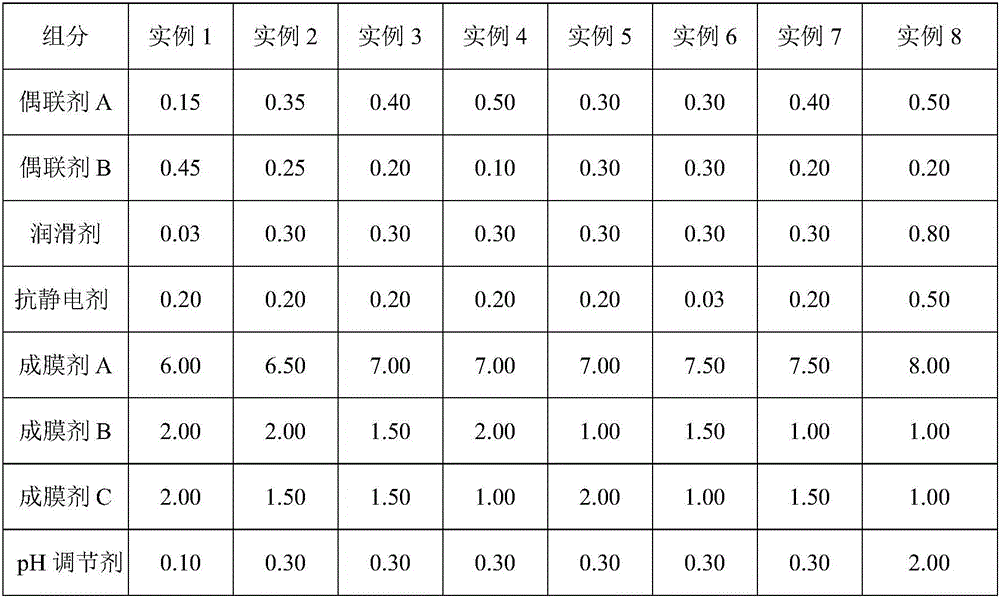

Chopped glass fiber sizing agent for bulk molding compounds (BMC) for reinforcing thermosetting resin

The invention discloses a chopped glass fiber sizing agent for reinforcing thermosetting resin, which is prepared by the components by weight percent: (1) 0.2-1.5% of coupling agent; (2) 3.0-20.0% of binding agent that is cross-linked polyurethane emulsion or the mixture of the cross-linked polyurethane emulsion and medium and high molecular weight epoxy emulsion, wherein the contents of the cross-linked polyurethane emulsion and the medium and high molecular weight elastic epoxy ester emulsion are based on the respective solid content; (3) 0.0-1.2% of lubricating agent; (4) 0.05-0.8% of antistatic agent; (5) 0.1-2% of pH value conditioning agent; and (6) the balance of deionized water, wherein the total weight of all the components is 100%. The chopped glass fiber sizing agent improves the bundling property of chopped glass fiber, reduces the broken filament, improves the mixing uniformity and the fluidity of the glass fiber and the BMC resin paste, and improves the mechanical strength and the appearance performance of BMC products.

Owner:JUSHI GRP CO

Method of improving mechanical strength of flexible polyurethane foams made from bio-based polyols, the polyol compositions utilized therein and the foams produced thereby

ActiveUS20120277338A1Improve rigidityReduce resiliency characteristicFatty acid esterificationOrganic compound preparationPolyesterPolyol

A method of improving the mechanical strength of polyurethane foams made from bio-based polyols, the polyol-containing compositions utilized in the method of the invention, and the polyurethane foams produced by the method of the invention are provided. The method of the invention involves the incorporation of aromatic polyester polyol in the polyol-containing composition used to manufacture the foams. In one embodiment, the aromatic polyester polyol is utilized in a polyol-containing composition which is employed in the manufacture of flexible polyurethane foam. In another embodiment, the aromatic polyester polyol transesterified with a natural oil-containing composition to form a transesterification reaction product that is utilized in a polyol-containing composition which is employed in the manufacture of flexible polyurethane foam. Flexible polyurethane foams of the invention exhibit substantial improvements in mechanical strength properties, such as tear strength, tensile strength and elongation relative to foams made from bio-based polyols such as soybean oil-based polyols.

Owner:STEPAN COMPANY

Injectable calcium phosphate cement

ActiveUS20060225621A1Quick SetupLong-term shelf lifeSurgical adhesivesBone implantCalcium biphosphateSodium phosphates

Owner:HOWMEDICA OSTEONICS CORP

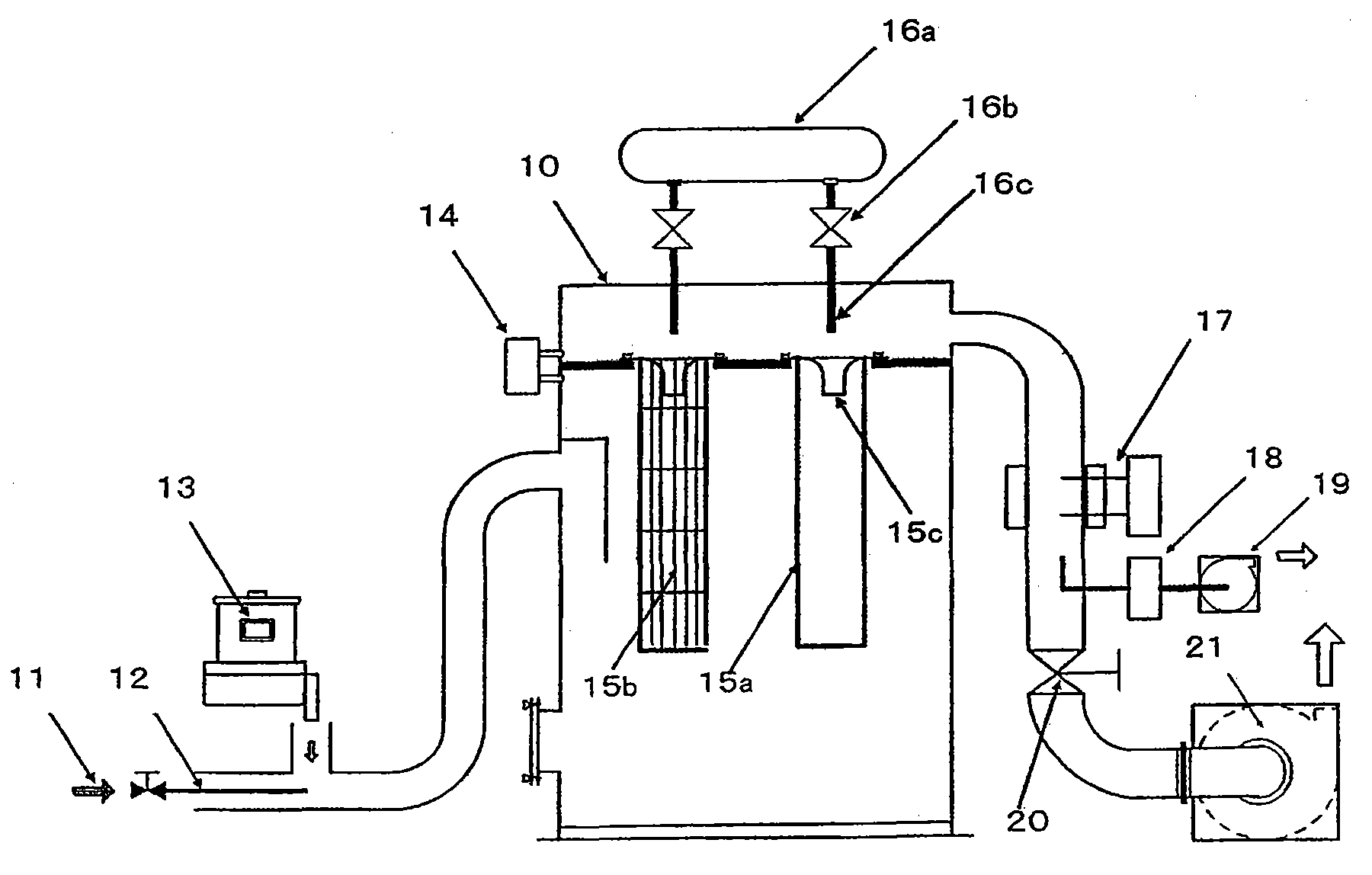

Antistatic filtering cloth in surface filtering mode for dust collector

InactiveCN101816856AIncreased durabilityImprove mechanical strength propertiesDispersed particle filtrationFiltration separationNanometreSurface filter

The invention provides an antistatic filtering cloth in the surface filtering mode for a dust collector. In a filtering cloth for a pulse blow swiping-off dust collector, the filtering cloth for the dust collector, which has numerous dust leakage after swiping off the dust, higher average outlet dust concentration, poor ventilation and dust swiping off performance and bad antistatic performance, is needed to be improved. The side of a soft material filtering surface made of fiber filtering cloth base materials such as non-woven fabric filtering cloth and the like used in the pulse blow swiping-off dust collector is laminated with a micro fine fibre layer formed by a nano carbon fiber with the conductivity, thereby the filtering cloth in the surface filtering mode for the pulse blow swiping-off dust collector, having excellent dust collecting performance and antistatic performance can be provided.

Owner:SINTOKOGIO LTD

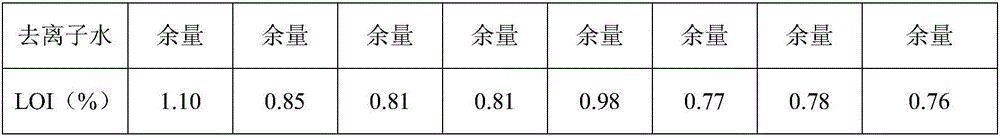

Glass fiber impregnating compound high in permeating speed and application thereof in producing twistless roving

The invention discloses a glass fiber impregnating compound which is prepared from, by weight, 0.02-3.00% of a coupling agent, 3.00-30.00% of a film forming agent, 0.02-2.00% of a lubricating agent, 0.02-0.80% of an antistatic agent, 0.01-2.00% of a pH adjusting agent and deionized water. The film forming agent is prepared by mixing nanosilicon dioxide modified polyester emulsion, PVAc emulsion and polyurethane modified epoxy emulsion, and the content of the nanosilicon dioxide modified polyester emulsion is not smaller than that of the polyurethane modified epoxy emulsion. The invention further provides application of the glass fiber impregnating compound in producing twistless roving. The twistless roving produced through the impregnating compound is high in permeating speed, good in choppability, good in production smoothness and good in compatibility with enhanced resin, production efficiency and the mechanical strength of a produced composite product are greatly improved, and the glass fiber impregnating compound is applicable to an injection process or a centrifugal casting molding process.

Owner:JUSHI GRP CO

Injectable calcium phosphate cement

ActiveUS7459018B2Quick SetupLong-term shelf lifeSurgical adhesivesInorganic phosphorous active ingredientsCalcium biphosphateMedicine

Owner:HOWMEDICA OSTEONICS CORP

Structure-enhanced SMC (Sheet Moulding Compound) glass fibre impregnating agent and application thereof in production of twistless roving

Owner:JUSHI GRP CO

Fire-retardant plastic and preparation method thereof

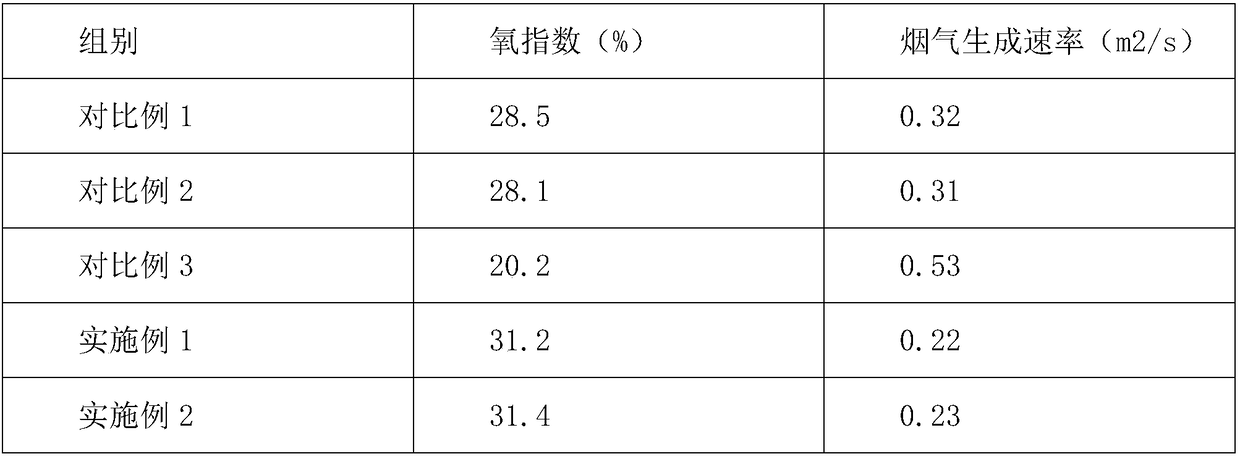

The invention discloses a fire-retardant plastic and relates to the technical field of high-polymer materials. The fire-retardant plastic solves the problem of influence of non-uniform dispersion of existing metal oxides on fire-retardant effects. The fire-retardant plastic is composed of raw materials including polyethylene, polypropylene, polyphenylene sulfide, modified mica powder, modified calcium carbonate, montmorillonite, diatomite, coupling agent, flexibilizer, ultraviolet absorber, sodium phytate and fire-retardant agent. The invention also discloses a preparation method of the fire-retardant plastic. The prepared fire-retardant plastic is high in oxygen index but low in smoke density; by means of the modified mica powder, the modified calcium carbonate, the diatomite and the coupling agent, the flexibilizer, the ultraviolet absorber and the fire-retardant agent can be uniformly dispersed into the fire-retardant plastic along with filling of the modified mica powder, the modified calcium carbonate and the diatomite to further improve the fire-retardant performance; the sodium phytate and the montmorillonite can achieve good synergistic effects, the sodium phytate can modify the montmorillonite to endow the montmorillonite with thermal stability and compressive strength. Therefore, the fire-retardant plastic has a good market prospect.

Owner:刘景章

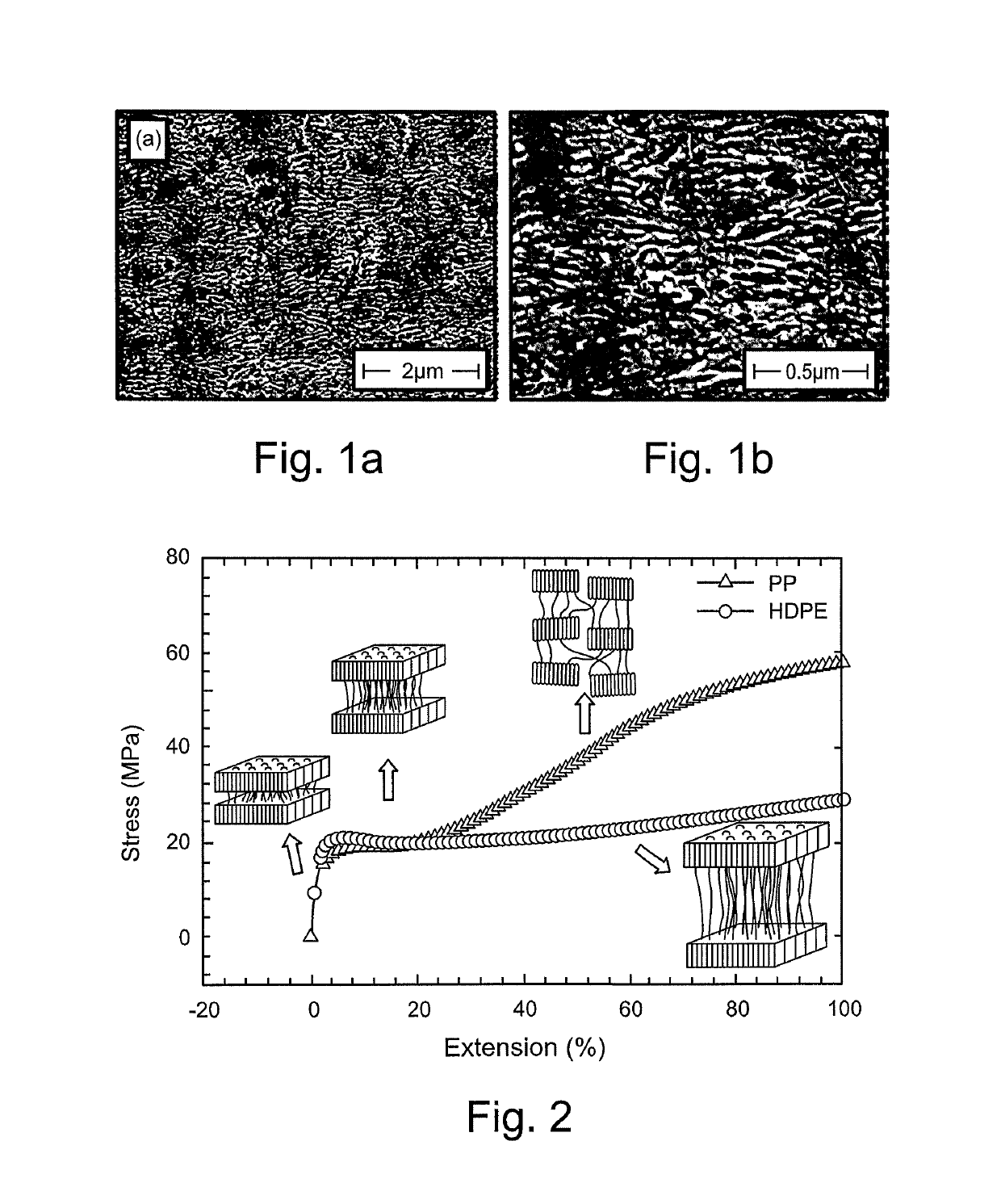

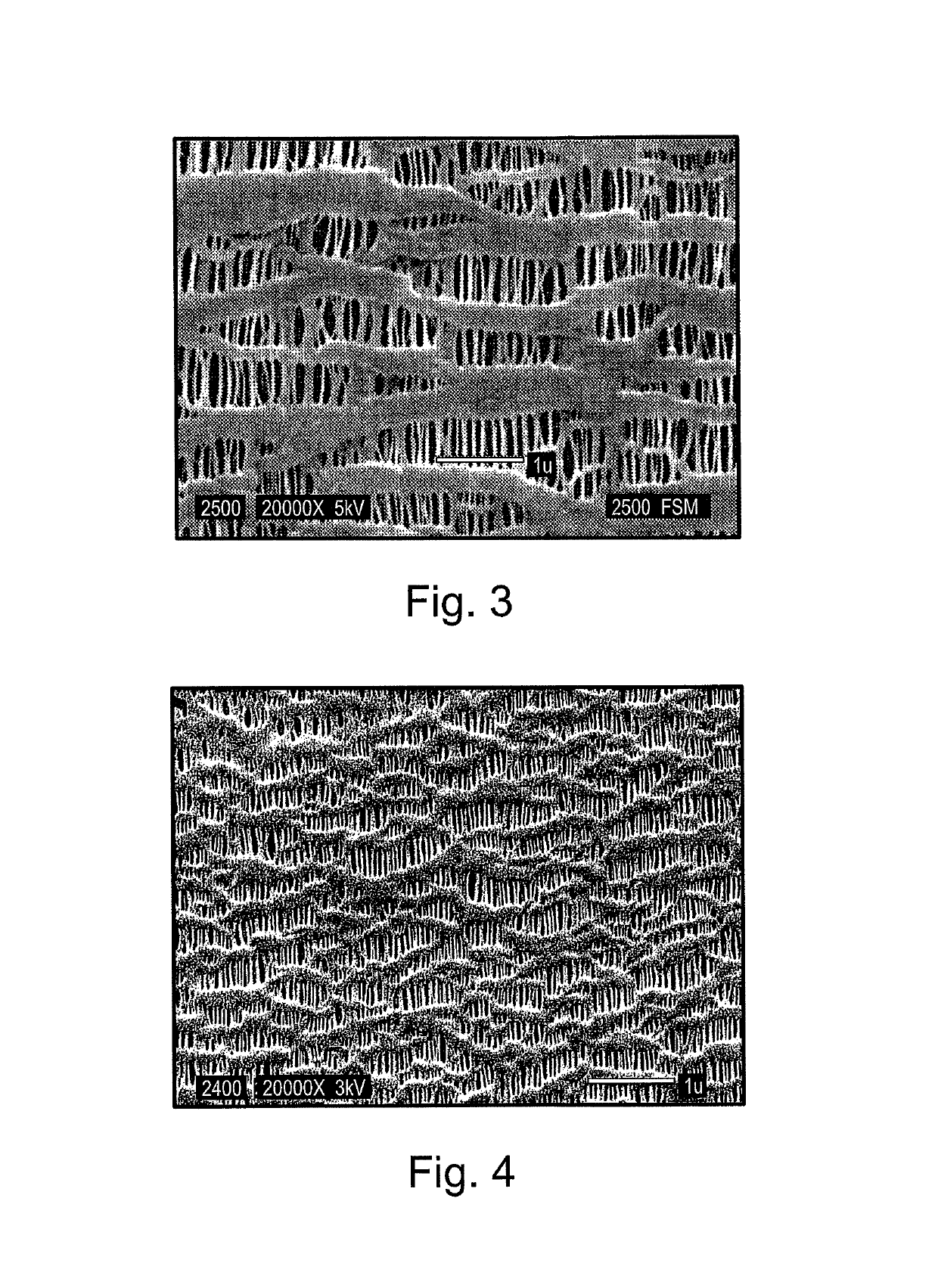

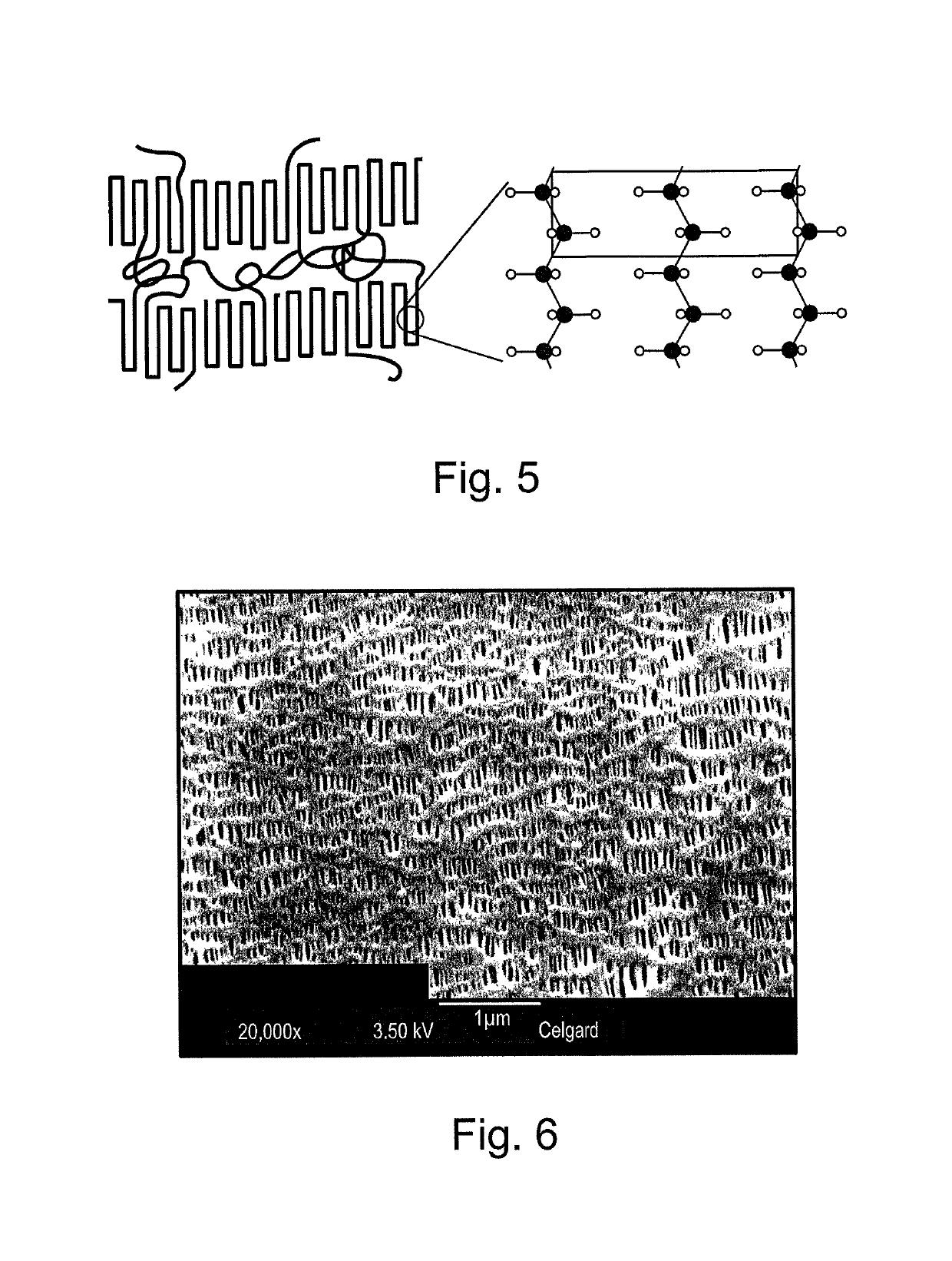

Multilayer microporous separators for lithium ion secondary batteries and related methods

ActiveUS20160149182A1Reduce decreaseHigh porosityFinal product manufactureSecondary cellsPhysical chemistryCharge rate

An improved multilayer laminated microporous battery separator for a lithium ion secondary battery, and / or a method of making or using this separator is provided. The preferred inventive dry process separator is a tri-layer laminated Polypropylene / Polyethylene / Polypropylene microporous membrane with a thickness range of 12 μm to 30 μm having improved puncture strength and low electrical resistance for improved cycling and charge performance in a lithium ion battery. In addition, the preferred inventive separator's or membrane's low Electrical Resistance and high porosity provides superior charge rate performance in a lithium battery for high power applications.

Owner:CELGARD LLC

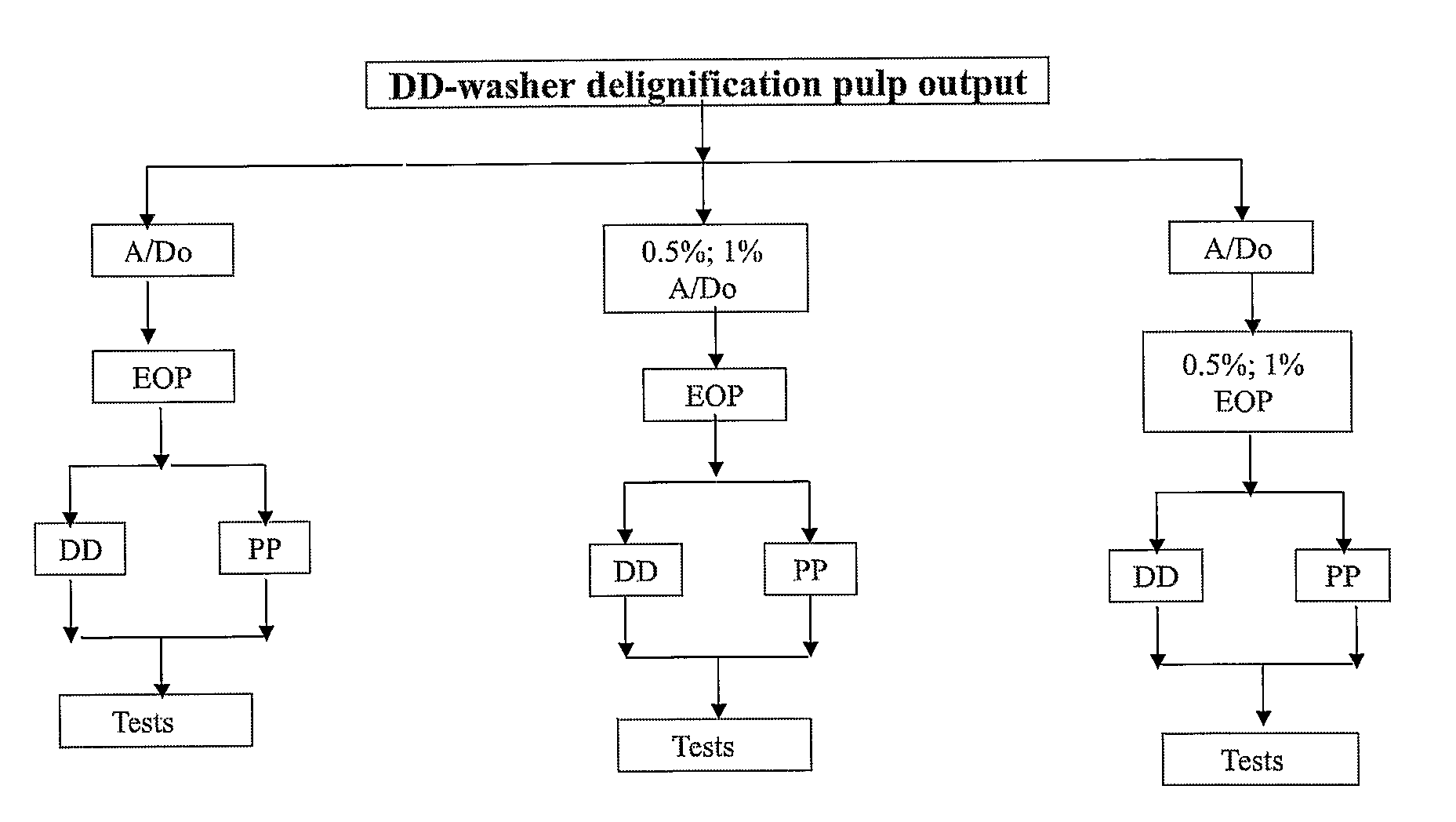

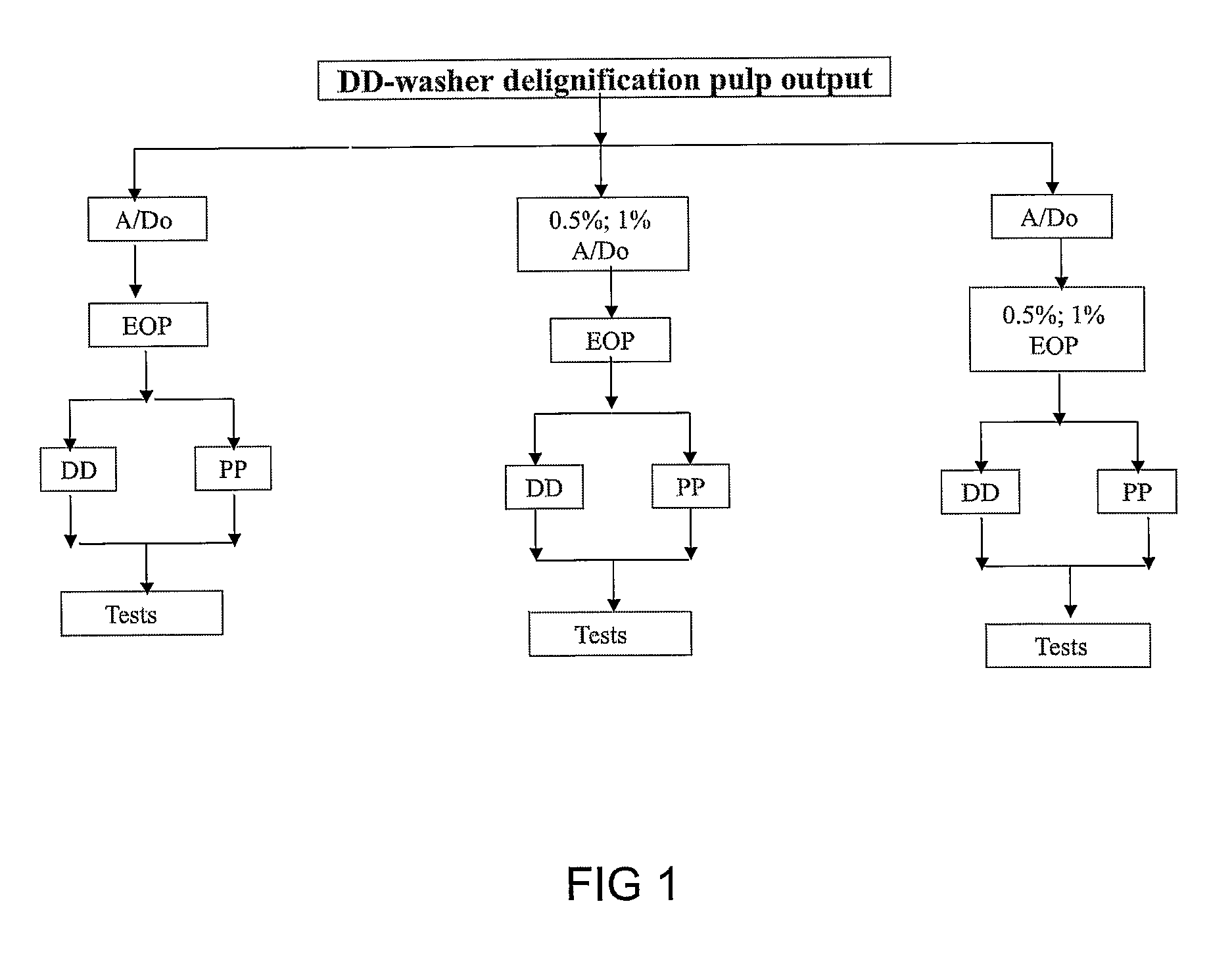

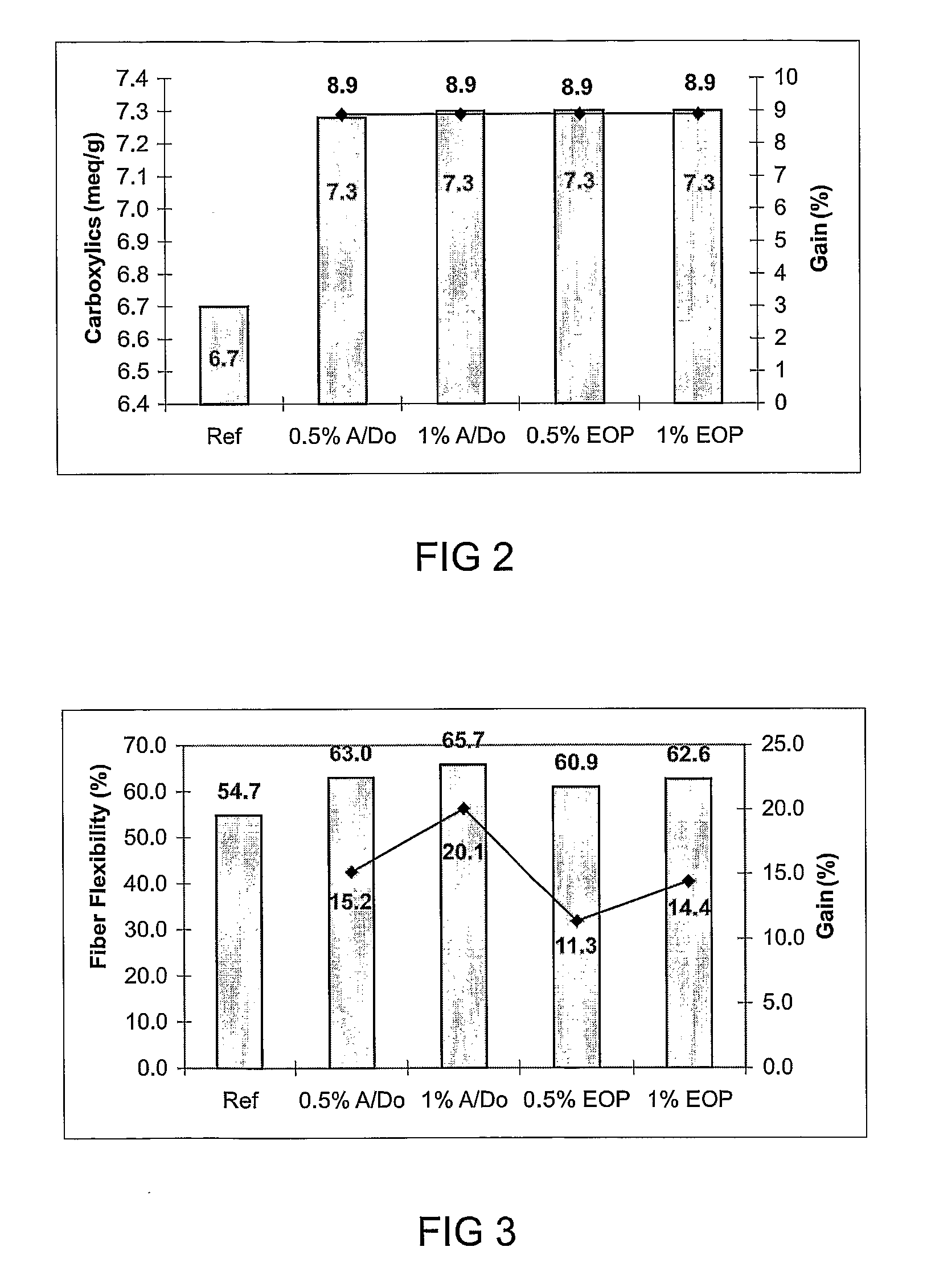

Process for treating cellulose pulp using carboxymethycelulose and pulp thus obtained

InactiveUS20100036113A1High mechanical strengthImprove mechanical strength propertiesCellulosic pulp after-treatmentImproved methodCellulose pulp

The present invention relates to an improved process for processing chemical cellulose pulp wherein carboxymethylcellulose (CMC) is added during the bleaching step of said pulp. The addition of CMC in this step of the bleaching process provides a pulp with improved physical, chemical and mechanical properties.

Owner:ARACRUZ CELULOSE

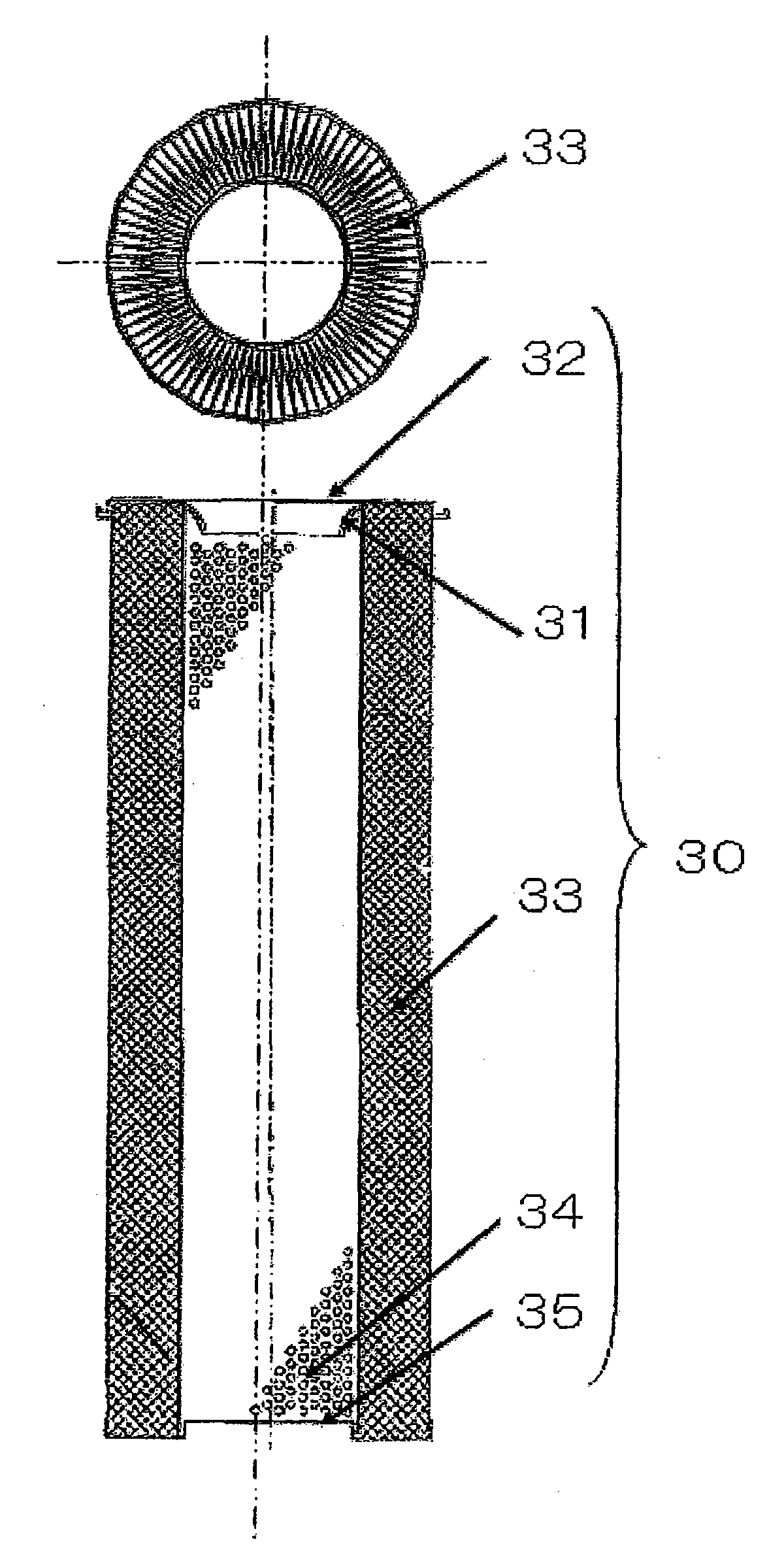

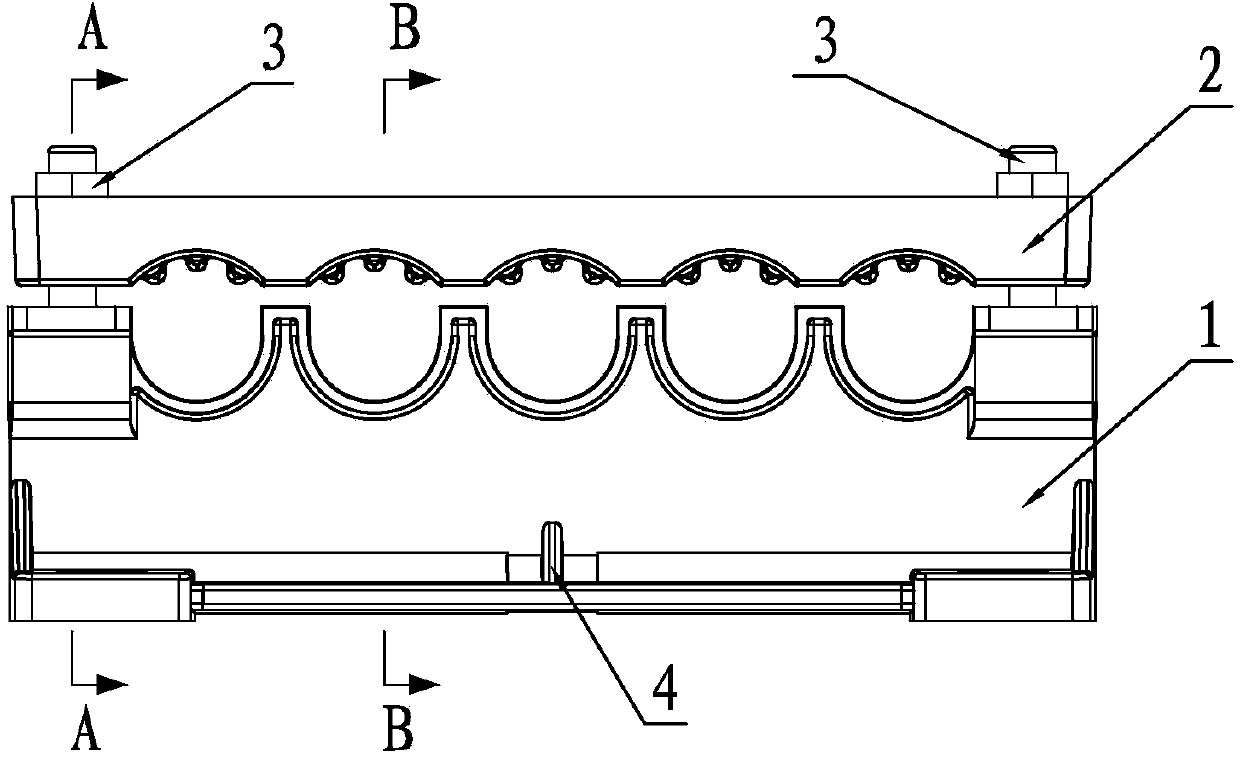

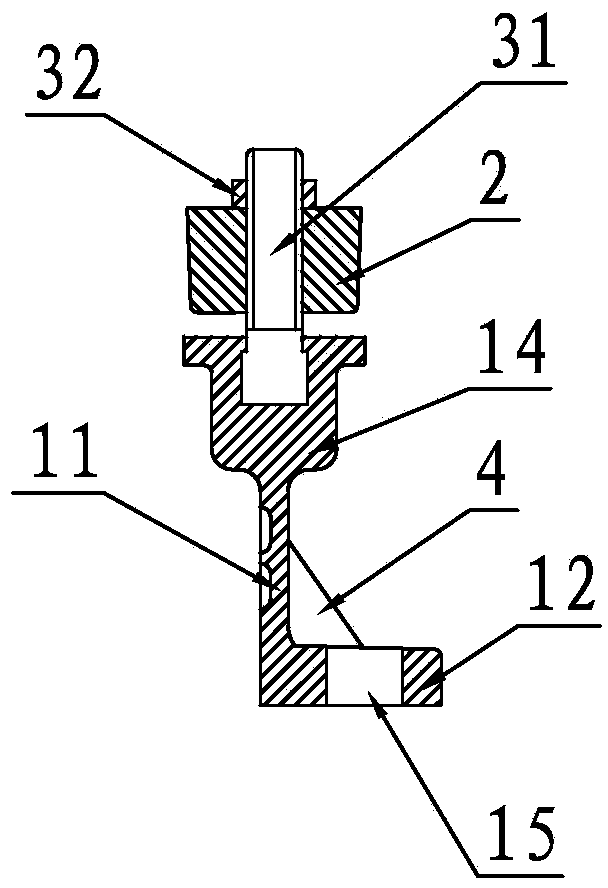

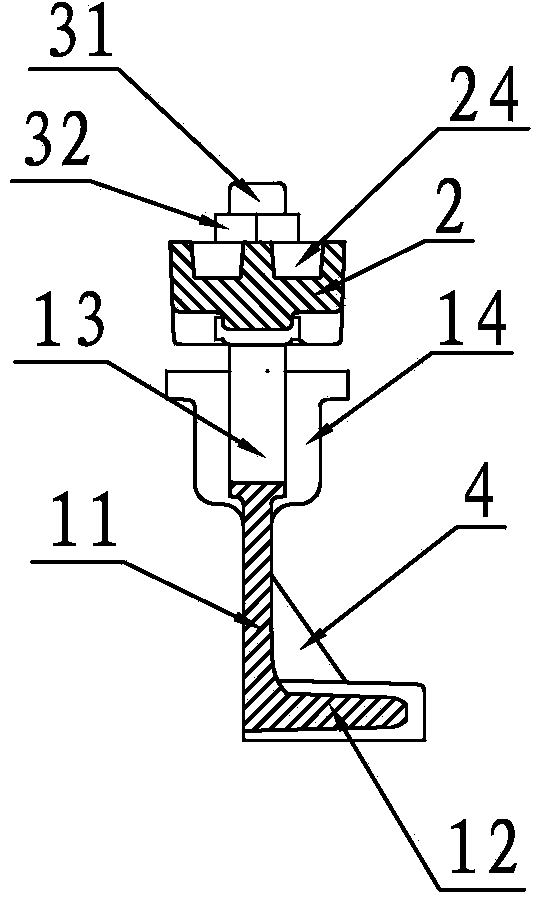

Pipe body flat clamp for spacing, limiting, fixing and clamping pipe body

InactiveCN104180075AEasy to installEasy to disassemblePipe supportsThermal stabilityUltimate tensile strength

The invention discloses a pipe body flat clamp for spacing, limiting, fixing and clamping a pipe body. The pipe body flat clamp comprises a pipe clamping seat and a pipe body pressing plate formed by adopting an SMC composite material through die pressing, wherein limiting grooves and fixing seats are arranged on the pipe-separating center plate of the pipe clamping seat at intervals; pipe bodies to be fixed are arranged among the limiting grooves and the pipe body pressing plate respectively; the pipe body pressing plate is connected with the pipe clamping seat through fastening components, so that the separated limiting and reliable pressing of the pipe bodies to be fixed are realized, and the virtual pressing of the pipe bodies are eradicated. According to the pipe body flat clamp, as the pipe clamping seat is designed into the support structure consisting of the pipe-separating center plate and a fixing baseplate, the limiting grooves for accommodating the pipe bodies to be fixed are formed in the pipe-separating center plate, fixing seats are arranged at the two ends of the pipe-separating center plate, fixing screws are embedded into the fixing seats, the fixing baseplate is fixed onto a wall, and the pipe body pressing plate is mounted on the screws in a sleeving manner and is tightened through nuts, the clamp adopting the structure is convenient to disassemble, and extremely convenient; moreover, as the pipe clamping seat and the pipe body pressing plate adopting the composite material are formed through the die pressing, the pipe body flat clamp is good in mechanical strength property, thermal stability property, corrosion resistance property and cold resistance property, and is long in service life.

Owner:王国平

Method of improving mechanical strength of flexible polyurethane foams made from bio-based polyols, the polyol compositions utilized therein and the foams produced thereby

ActiveUS9212250B2Improve rigidityReduce resiliency characteristicOrganic compound preparationCarboxylic compound preparationPolyesterPolyol

A method of improving the mechanical strength of polyurethane foams made from bio-based polyols, the polyol-containing compositions utilized in the method of the invention, and the polyurethane foams produced by the method of the invention are provided. The method of the invention involves the incorporation of aromatic polyester polyol in the polyol-containing composition used to manufacture the foams. In one embodiment, the aromatic polyester polyol is utilized in a polyol-containing composition which is employed in the manufacture of flexible polyurethane foam. In another embodiment, the aromatic polyester polyol transesterified with a natural oil-containing composition to form a transesterification reaction product that is utilized in a polyol-containing composition which is employed in the manufacture of flexible polyurethane foam. Flexible polyurethane foams of the invention exhibit substantial improvements in mechanical strength properties, such as tear strength, tensile strength and elongation relative to foams made from bio-based polyols such as soybean oil-based polyols.

Owner:STEPAN COMPANY

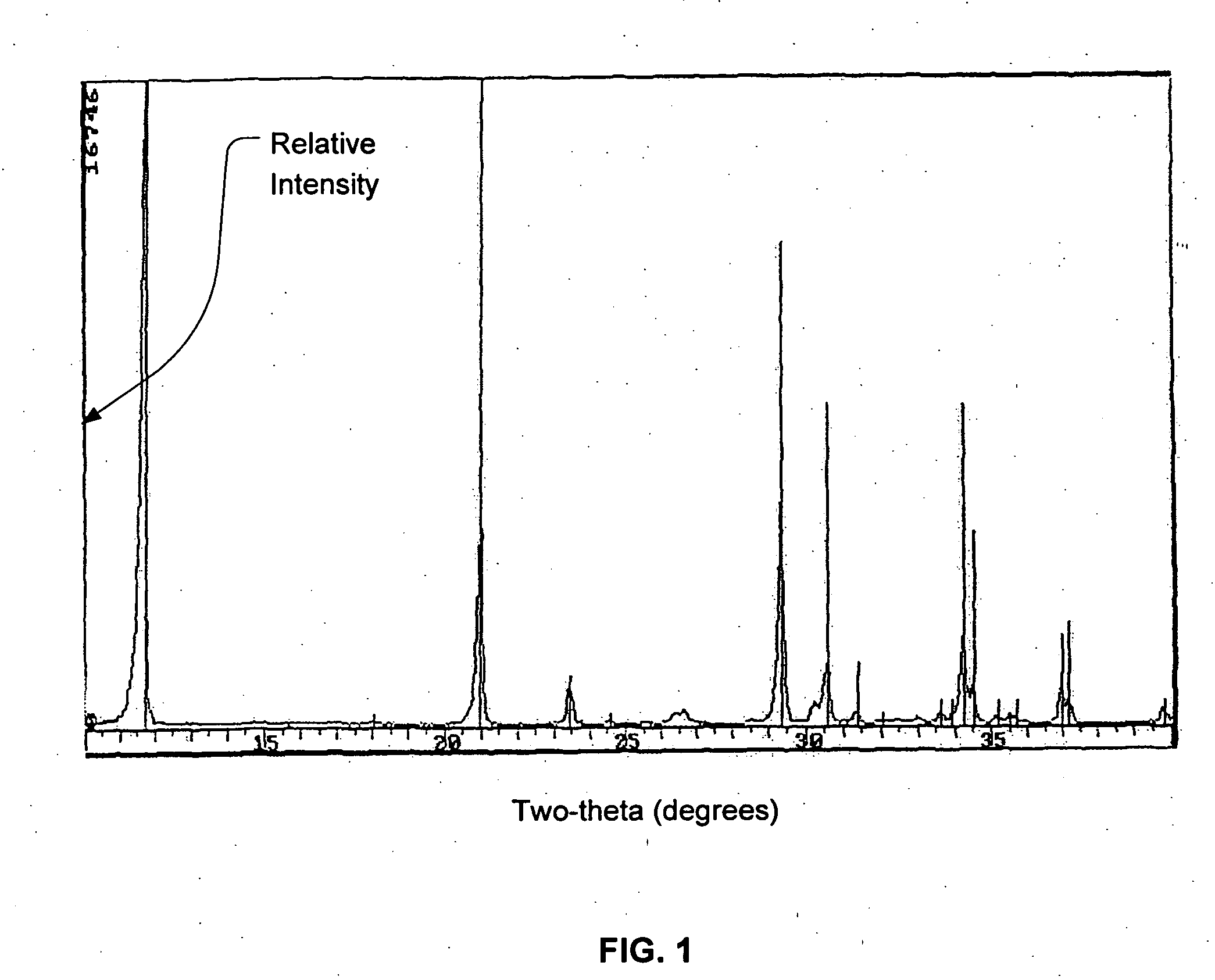

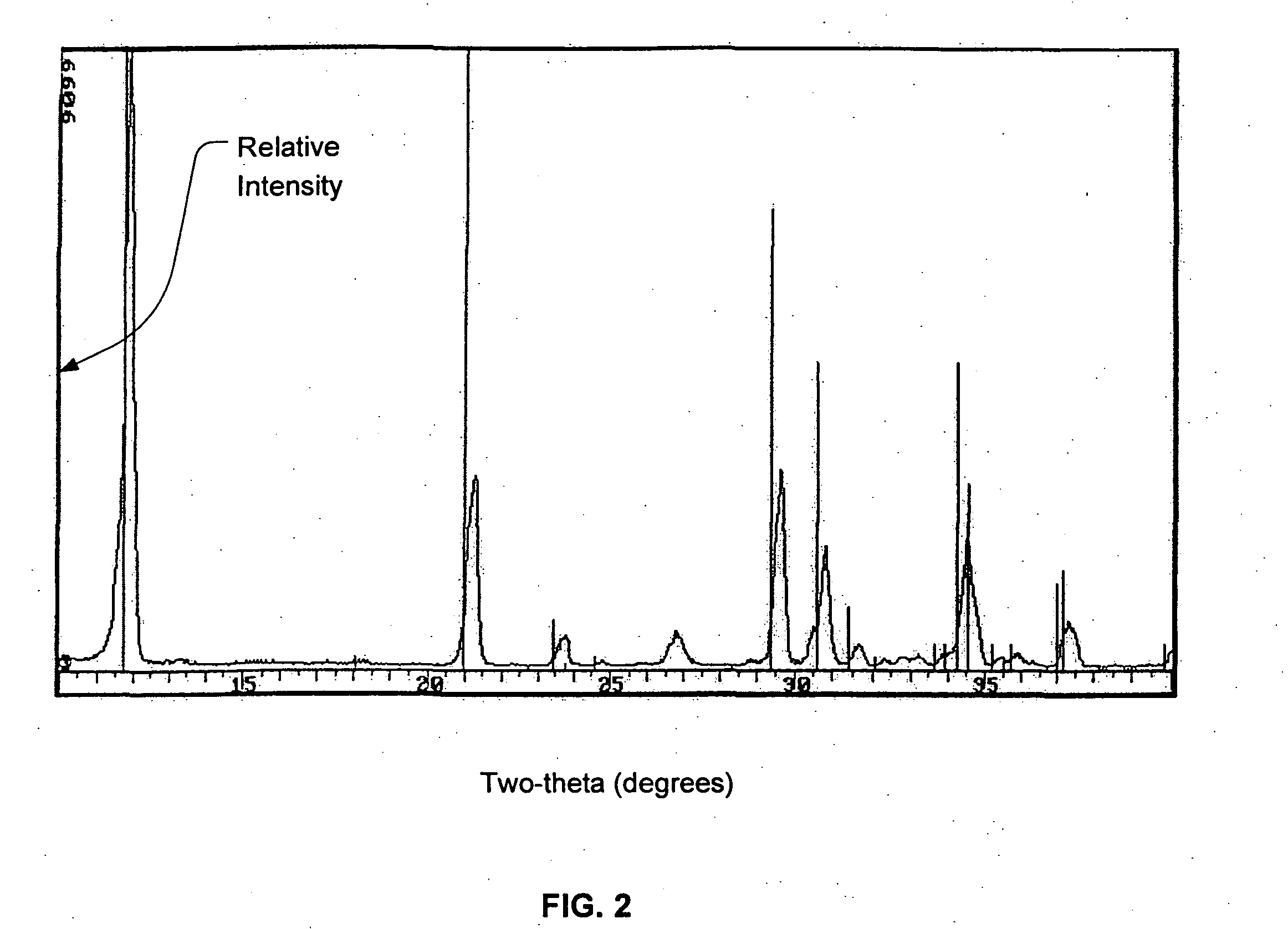

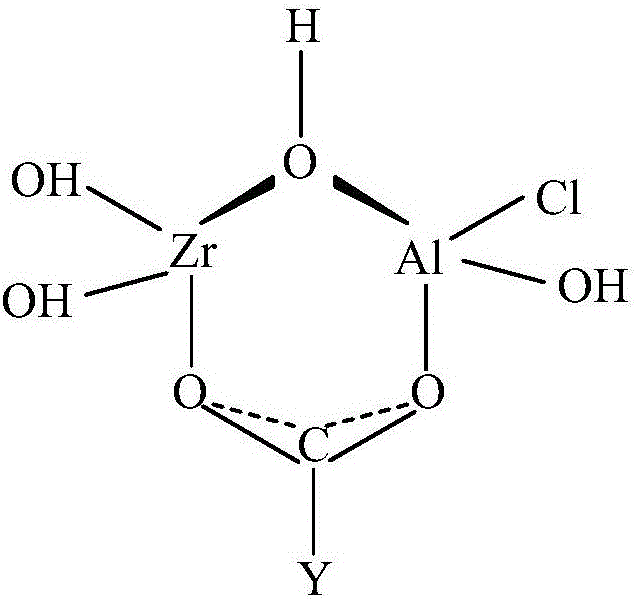

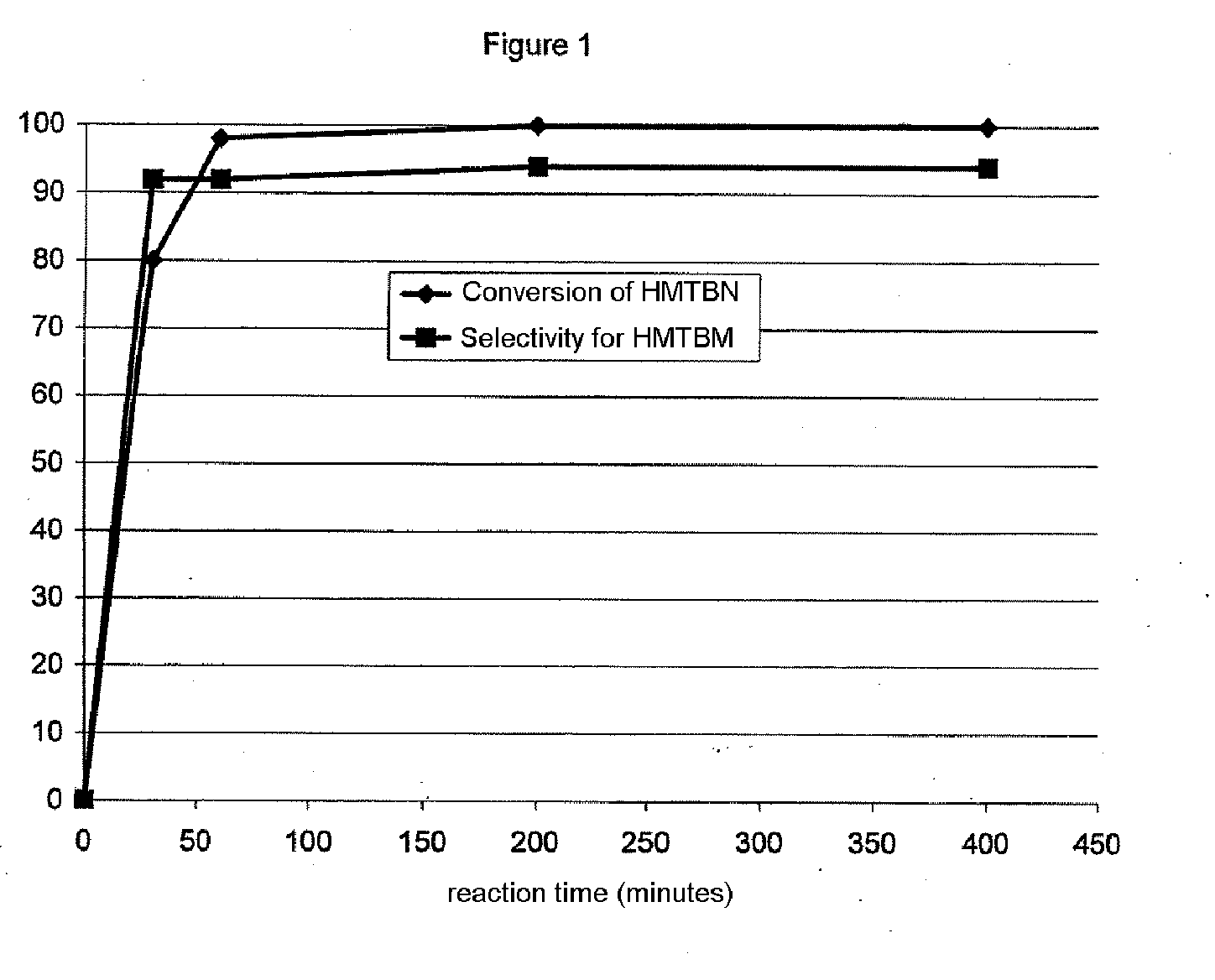

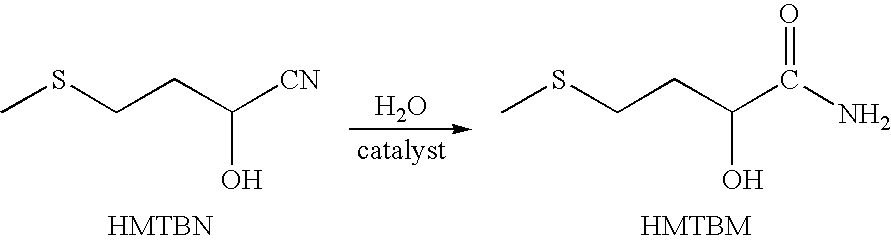

Method for the catalytic conversion of 2-hydroxy-4-methylthiobutanenitrile (HMTBN) into 2-hydroxy-4-methylthiobutanamide (HMTBM)

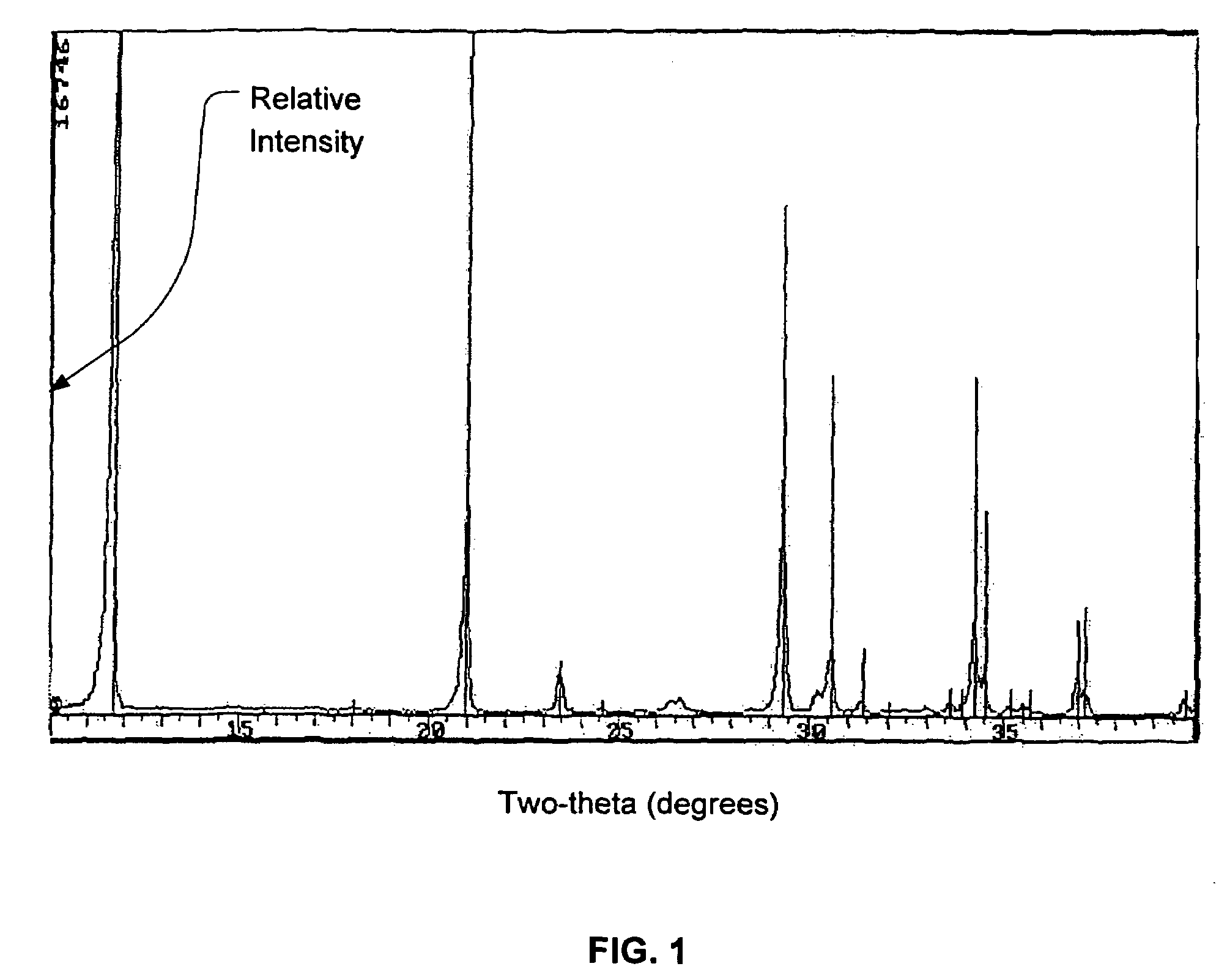

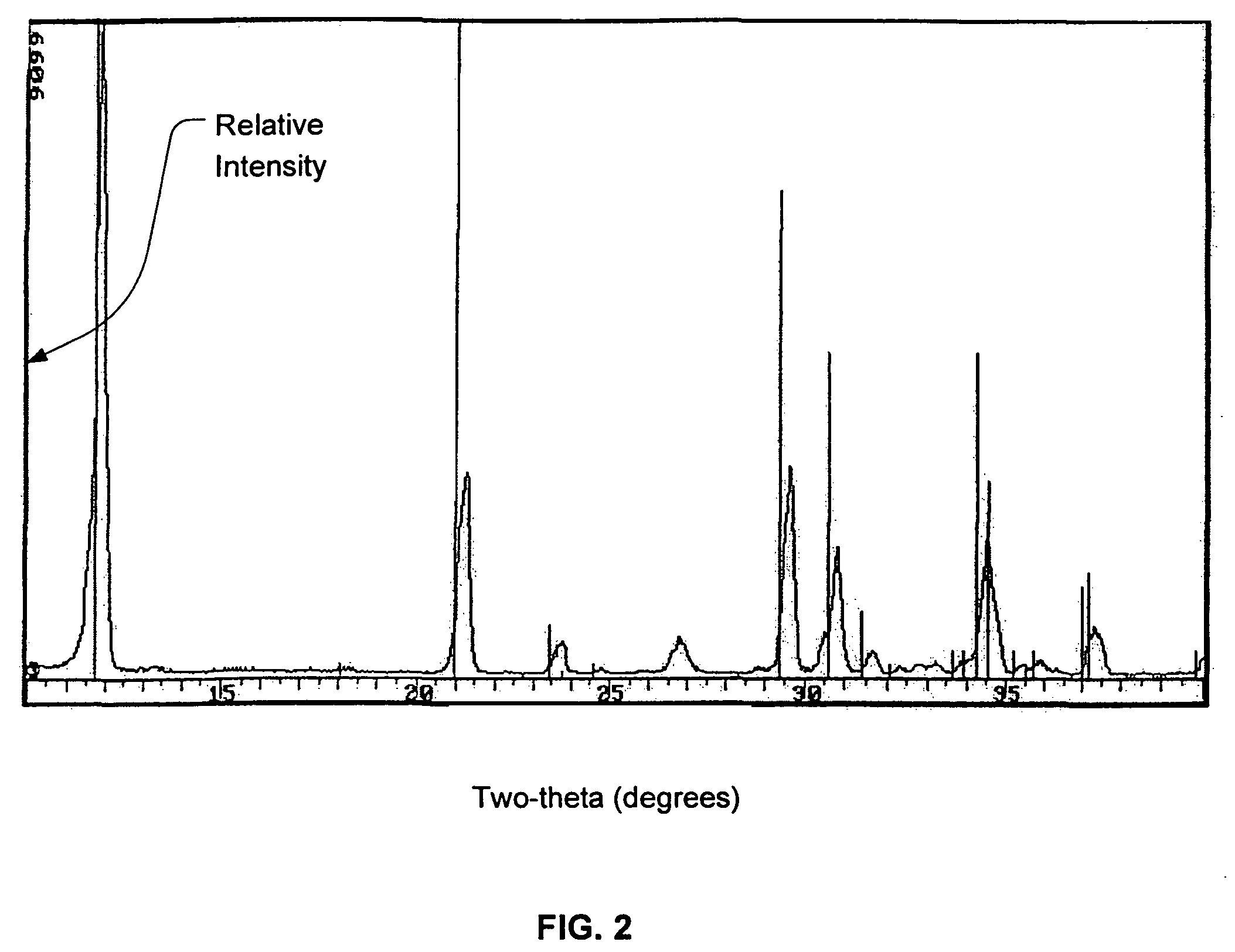

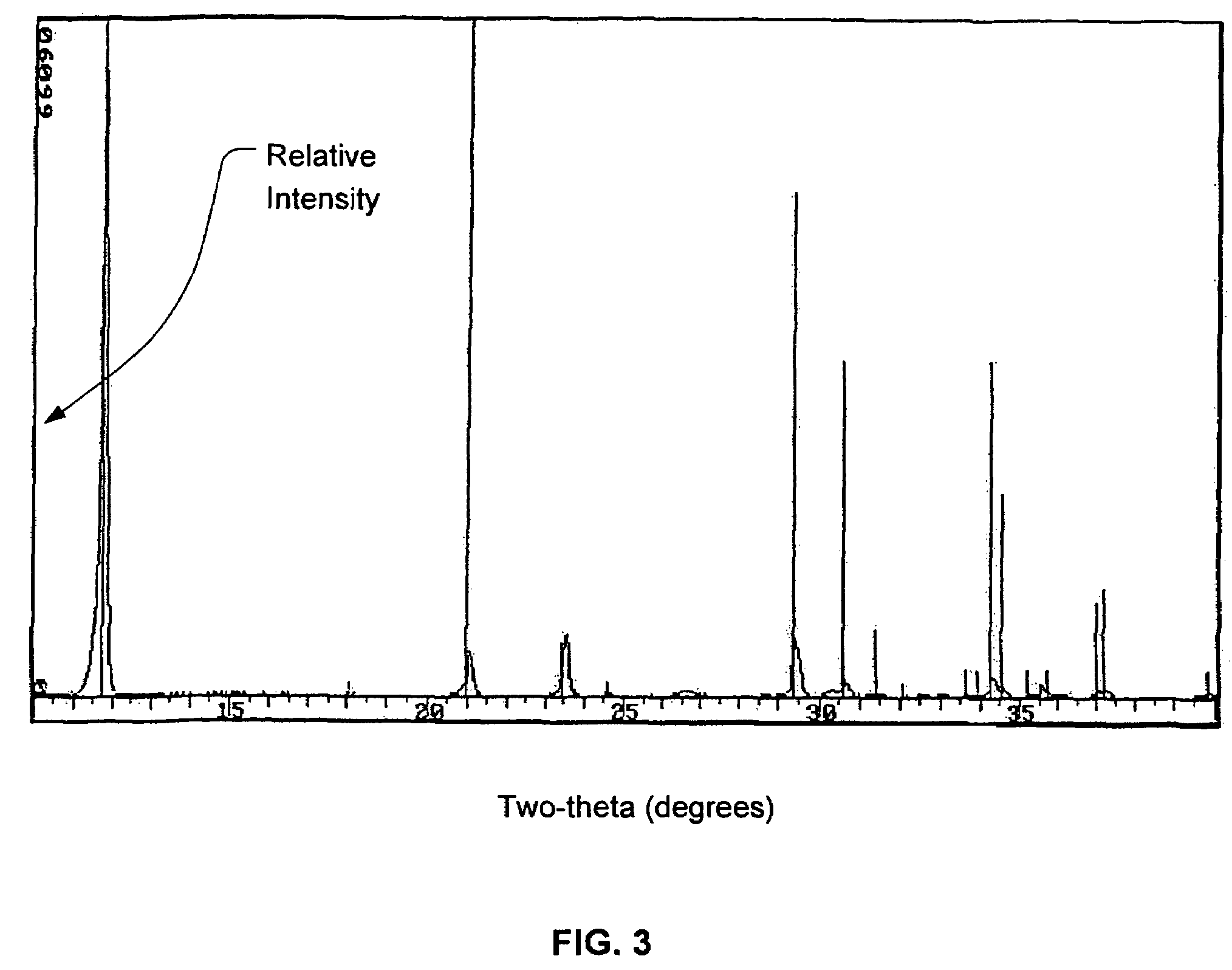

InactiveUS20100197965A1Resist formationNotOrganic compound preparationCatalyst activation/preparationActive phaseOrganic chemistry

This process is carried out in the presence of a solid catalyst comprising an active phase. The catalyst is formulated and the conversion is carried out in a medium essentially free of strong mineral acid.

Owner:ADISSEO IRELAND LTD

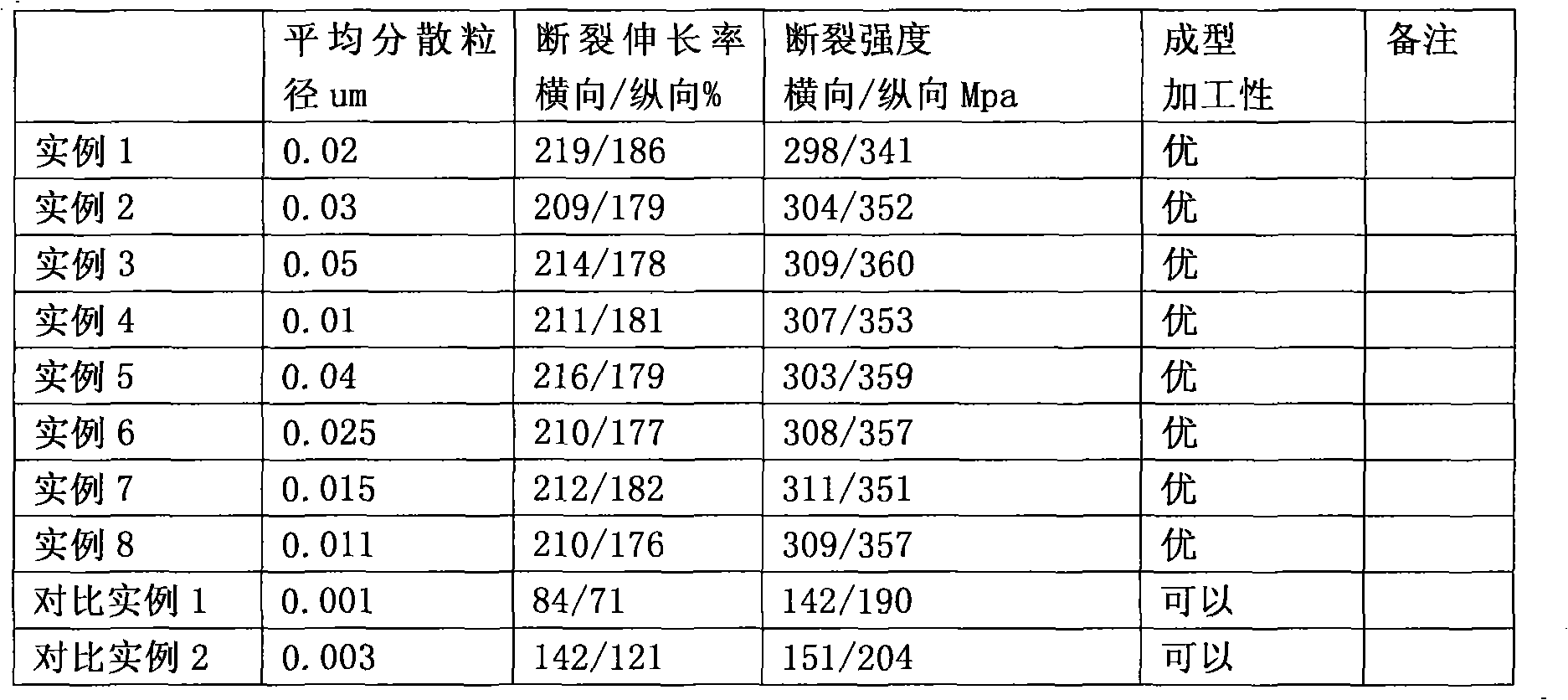

Method for manufacturing polyphenylene sulfide composite film

The invention discloses a method for manufacturing a polyphenylene sulfide composite film. The method comprises the following steps of: performing polycondensation under the action of an alkaline metal cosolvent by taking sodium sulfide and paradichlorobenzene as raw materials and N-methyl-2 pyrrolidone as a solvent so as to produce a polyphenylene sulfide resin, wherein the molar ratio of the sodium sulfide and the paradichlorobenzene is 1:1; and synthesizing polyphenylene sulfide under a certain condition, refining, purifying, washing and drying the polyphenylene sulfide to obtain the polyphenylene sulfide resin, adding a mixture comprising 1.5 to 0.9 percent of heat stabilizer, 8.5 to 4.1 percent of organic elastomer and the like into 90 to 95 percent of resin, extruding and pelletizing by a double-screw extruder, drying and performing a film preparation process so as to obtain a polyphenylene sulfide resin film. The film obtained by the method can be widely applied to fields such as electronic and electric products, war industry, space flight and aviation, machinery, chemical industry and the like.

Owner:陈逊

PVDF (Polyvinylidene Fluoride)/polyamide composite material used for 3D (Three-dimensional) printing, and preparation method and application thereof

InactiveCN106317861ALarge melting rangeTightly bondedAdditive manufacturing apparatusPolymer sciencePolyamide

The invention relates to a PVDF (Polyvinylidene Fluoride) / polyamide composite material used for 3D (Three-dimensional) printing, and a preparation method and application thereof. The PVDF / polyamide composite material is prepared from the following components in percentage by mass: 87 to 88 percent of polyamide powder, 10 to 11 percent of PVDF powder, 1.0 to 1.5 percent of flow promoting agent and 0.5 to 1.5 percent of antioxidant. The PVDF / polyamide composite material provided by the invention is higher in hardness, shear strength and bending strength, is good in corrosion resistance and acidic and alkali resistance, and can be well applied to 3D printing; meanwhile, the preparation method of the PVDF / polyamide composite material provided by the invention can adopt a physical doping mode, the damage to the PVDF / polyamide composite material caused by chemical doping is avoided, and the PVDF / polyamide composite material is environmental-friendly.

Owner:上海辰云信息科技有限公司

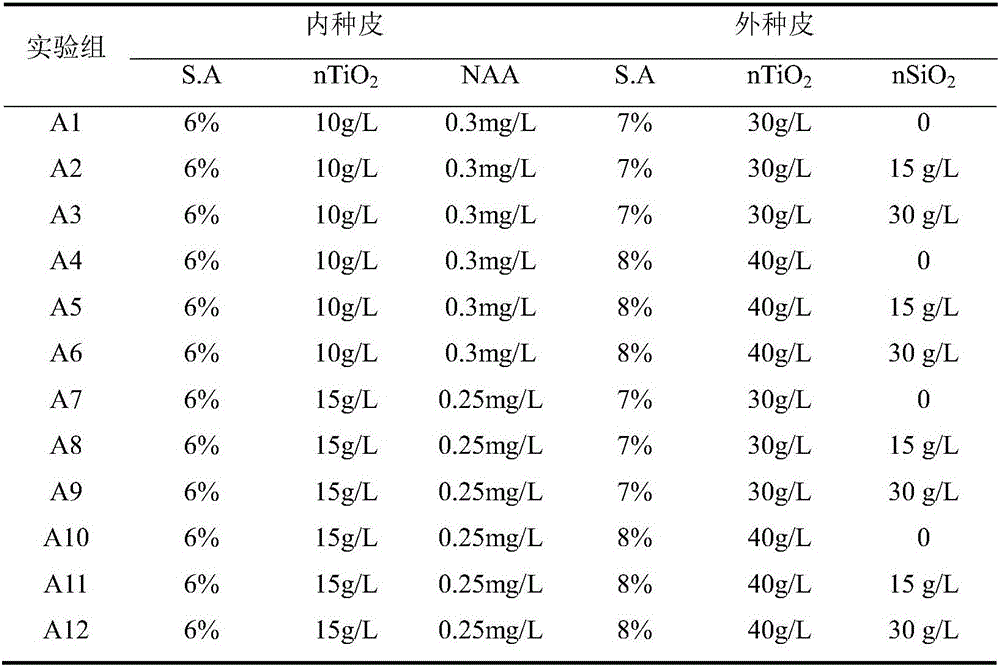

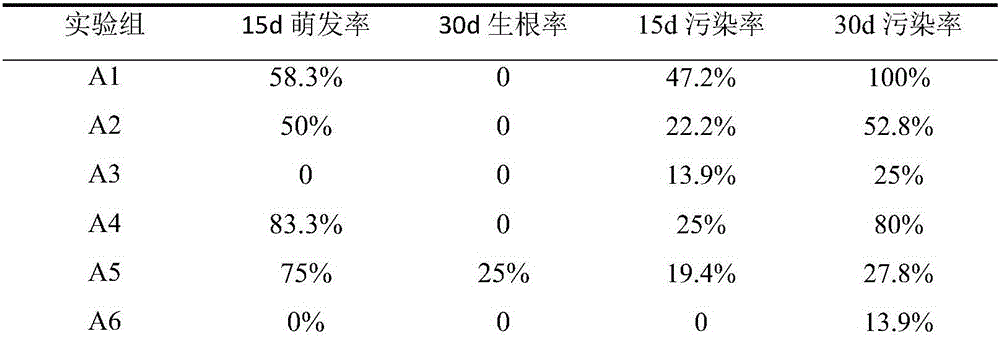

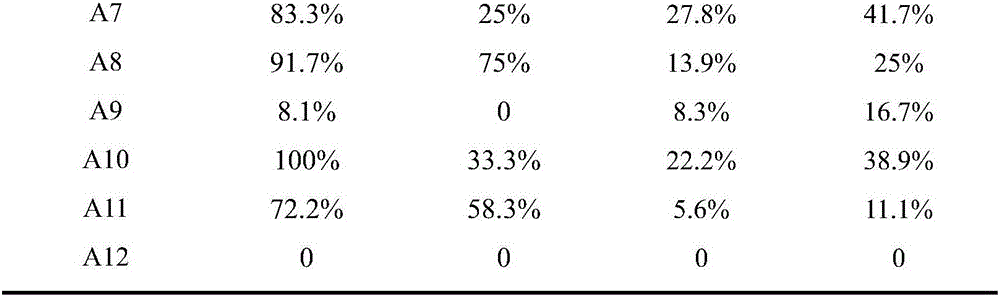

Making method of two-layer embedded artificial seeds of orychophragmus violaceus

ActiveCN106134995AGood antibacterial effectImprove germination and rooting ratesPlant tissue cultureHorticulture methodsNutrientBud

The invention discloses a making method of two-layer embedded artificial seeds of orychophragmus violaceus, and belongs to the field of biotechnology and agricultural engineering. The method comprises the steps of bud cluster inducing of the orychophragmus violaceus, bud propagation and cultivation and bud embedding and artificial seed capsule preparation; in the bud embedding and artificial seed capsule preparation process, an endopleura embedding solution is sodium alginate hydrosol which contains nano-titanium dioxide nTiO2, NAA, an MS medium and saccharose and has the mass concentration of 6%, and a testa embedding solution is a sodium alginate hydrosol which contains nano-titanium dioxide nTiO2 and nano-silicon dioxide nSiO2 and has the mass concentration of 7% or 8%. According to the made artificial seeds, a bactericide and nutrient substances can be separated through a two-layer embedding technology, and meanwhile the mechanical strength of endopleura and testa is adjusted; the artificial seeds have the advantages of being high in rooting and sprouting rate, low in contamination rate, low in toxic action on explants and the like in a bacterial environment; by means of the two-layer embedding technology, the making technology of the artificial seeds of the orychophragmus violaceus can be further pushed to practical production and application.

Owner:东台海滨科技创业园管理有限公司

Polyfunctional compounds and uses as implant materials

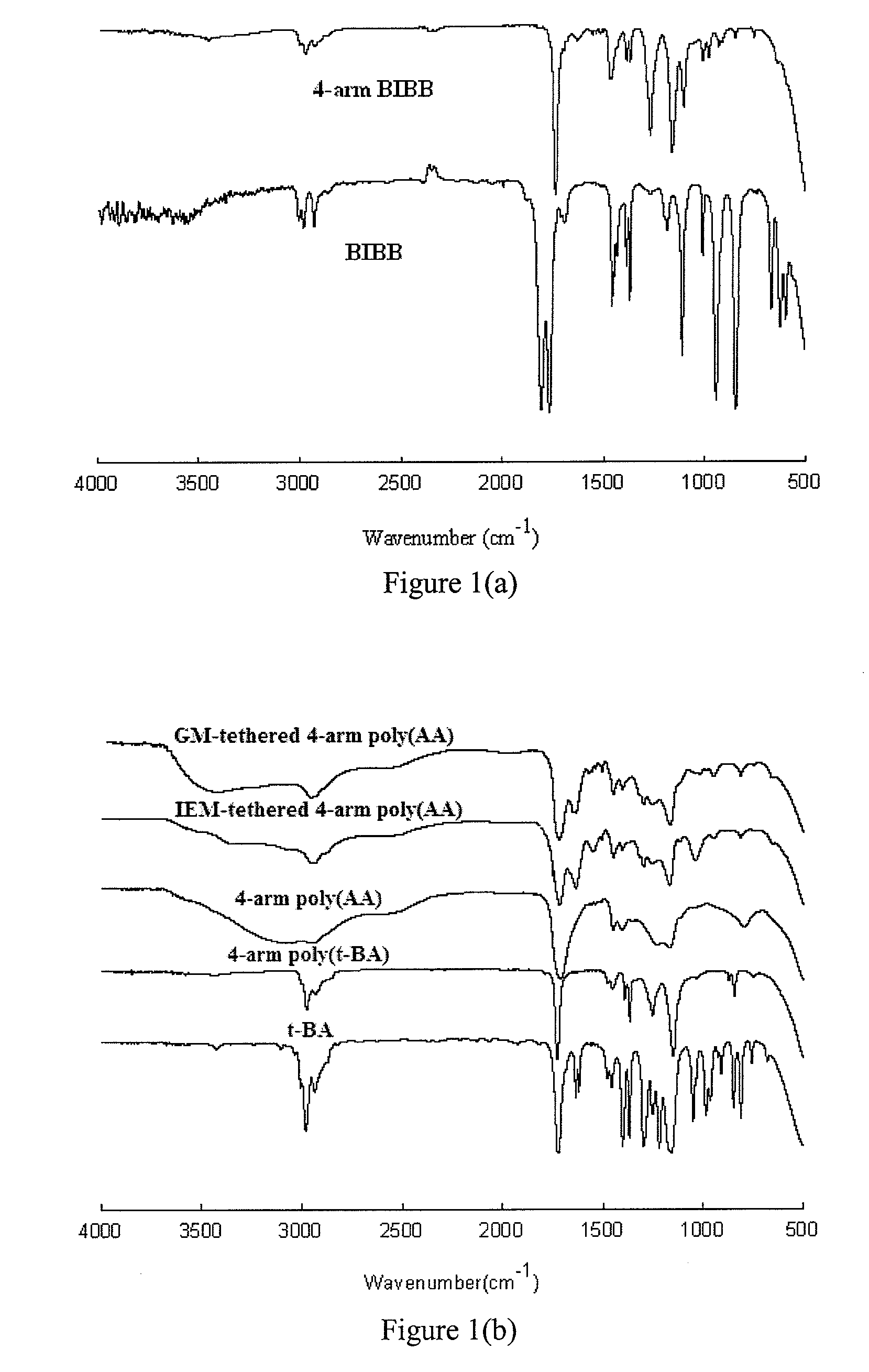

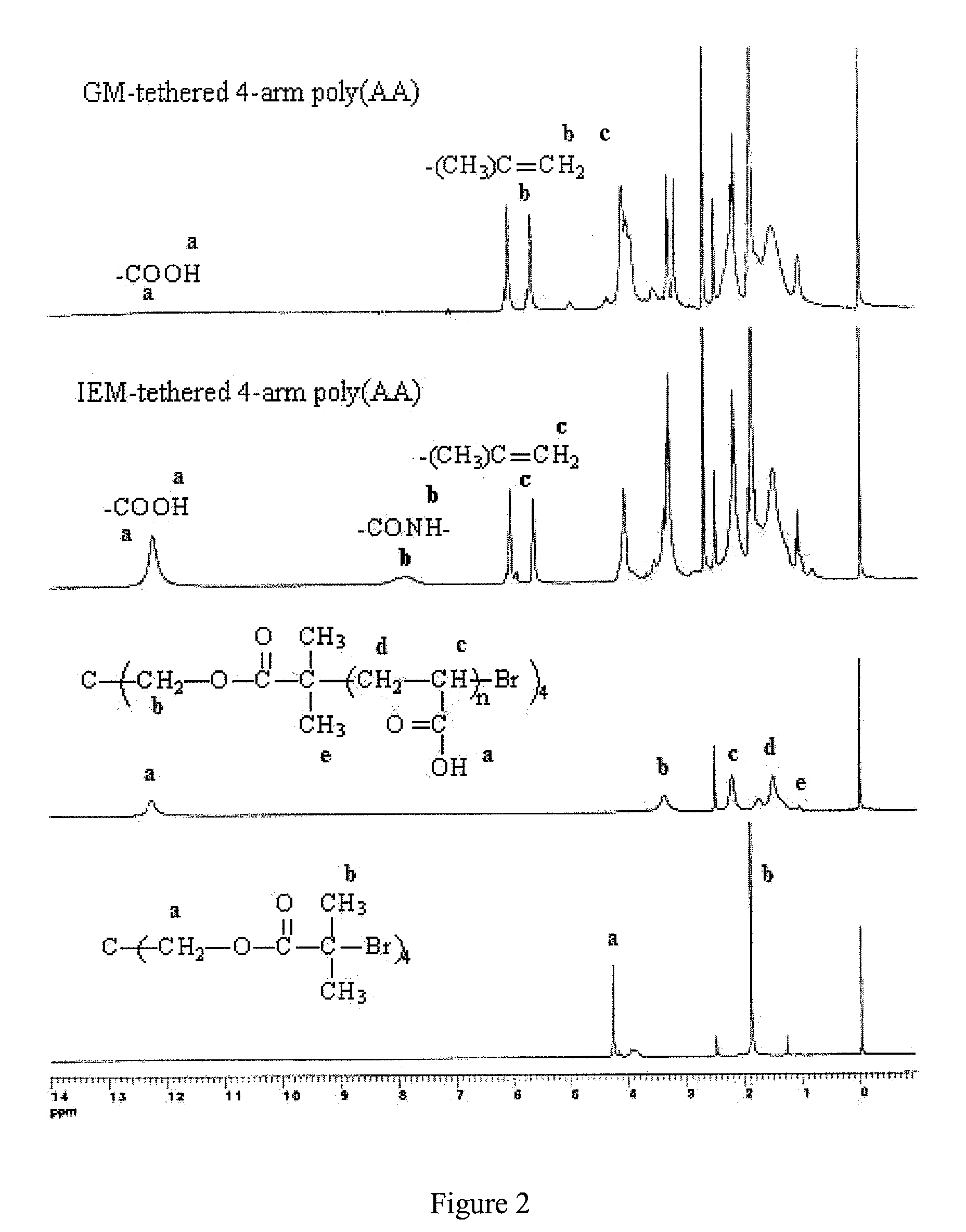

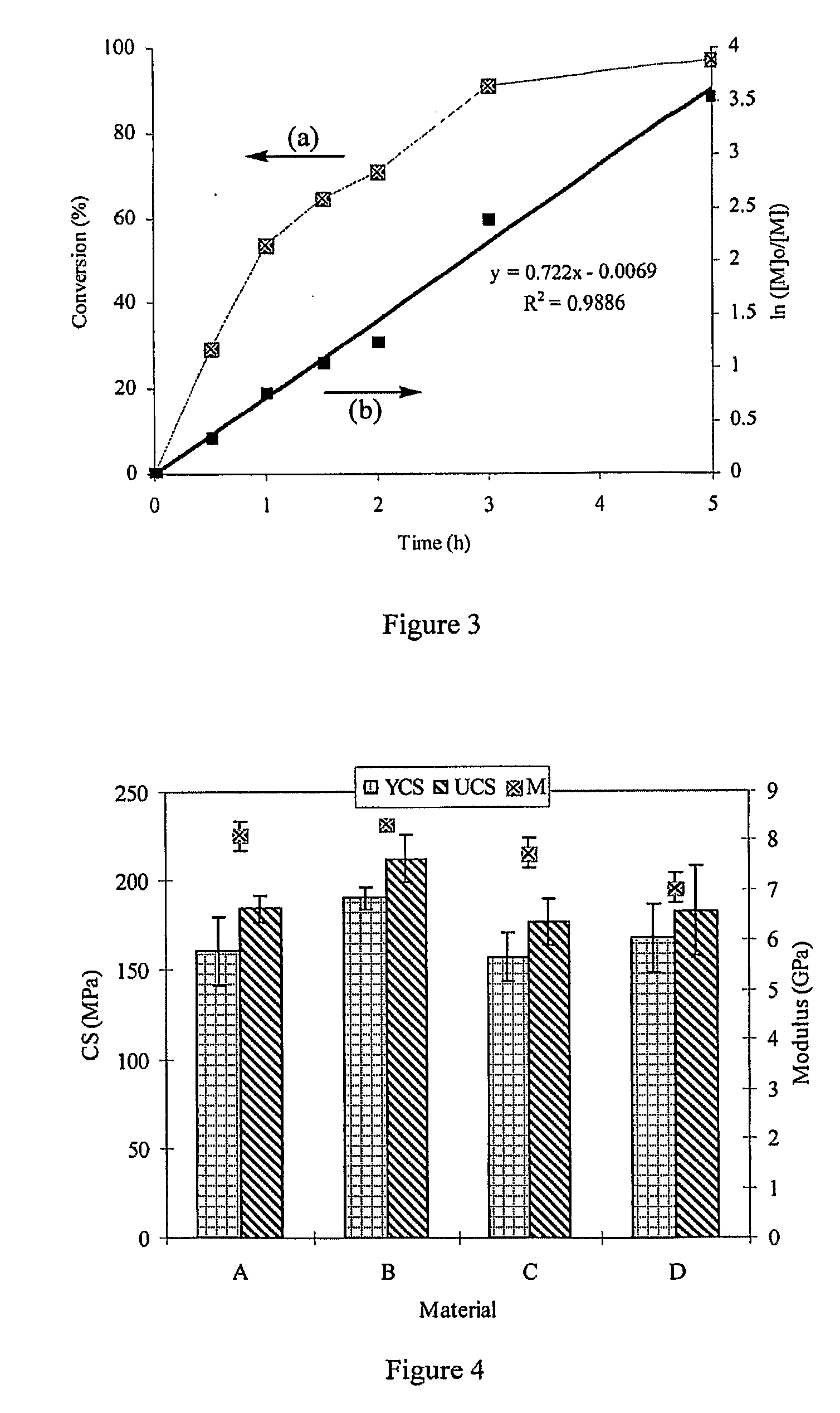

InactiveUS20090131551A1Improve mechanical strength propertiesLow solutionImpression capsOrganic chemistryPrepolymerImplant material

The synthesis and characterization of polymer core initiators are described herein. Polymer core initiators are used to prepare the polyfunctional prepolymers described herein, which may be optionally tethered. The polyfunctional prepolymers described herein are used to prepare cements, optionally with added co-monomers, for repairing and restoring tissues.

Owner:INDIANA UNIV RES & TECH CORP

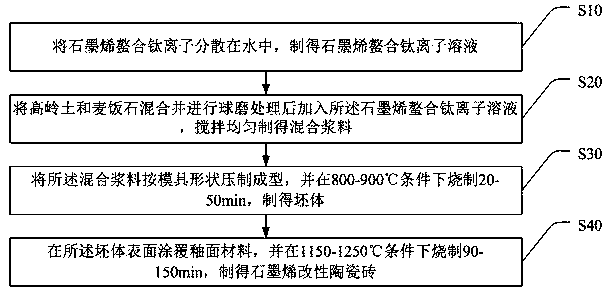

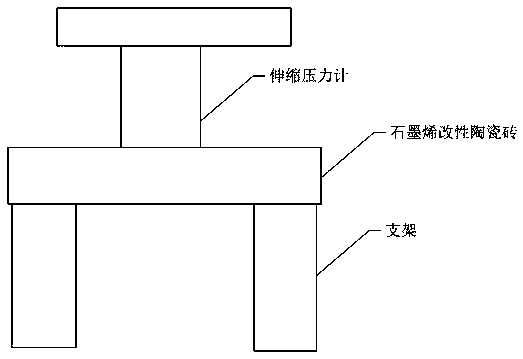

Graphene modified ceramic tile and preparation method thereof

The invention discloses a graphene modified ceramic tile and a preparation method thereof. The graphene modified ceramic tile comprises a green body and a glaze surface smeared on the outer surface ofthe green body, wherein the green body comprises 0.3 to 1 part by weight of graphene chelated titanium ions, 0.5 to 2 parts by weight of medical stone and 20 to 90 parts by weight of kaolin. By introducing the graphene chelated titanium ions into the ceramic tile, on the premise of not influencing the calcination whiteness of the ceramic tile, the mechanical strength property of the ceramic tilecan be effectively improved.

Owner:天元羲王控股有限公司

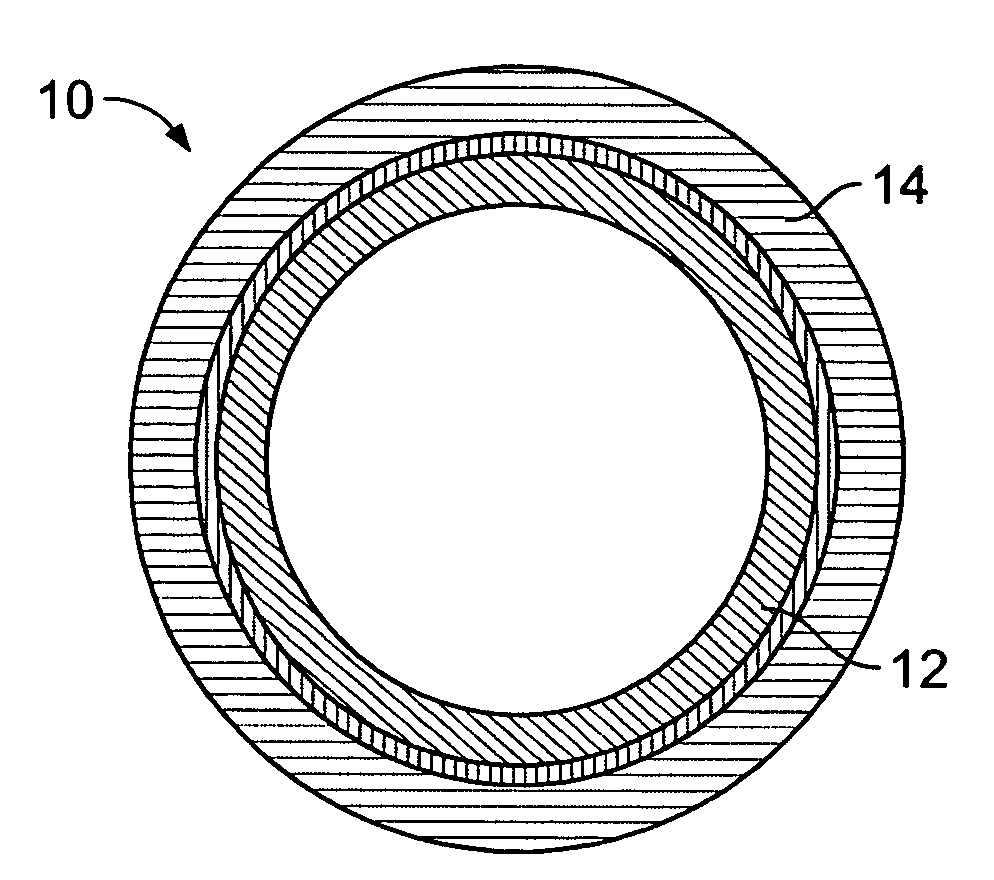

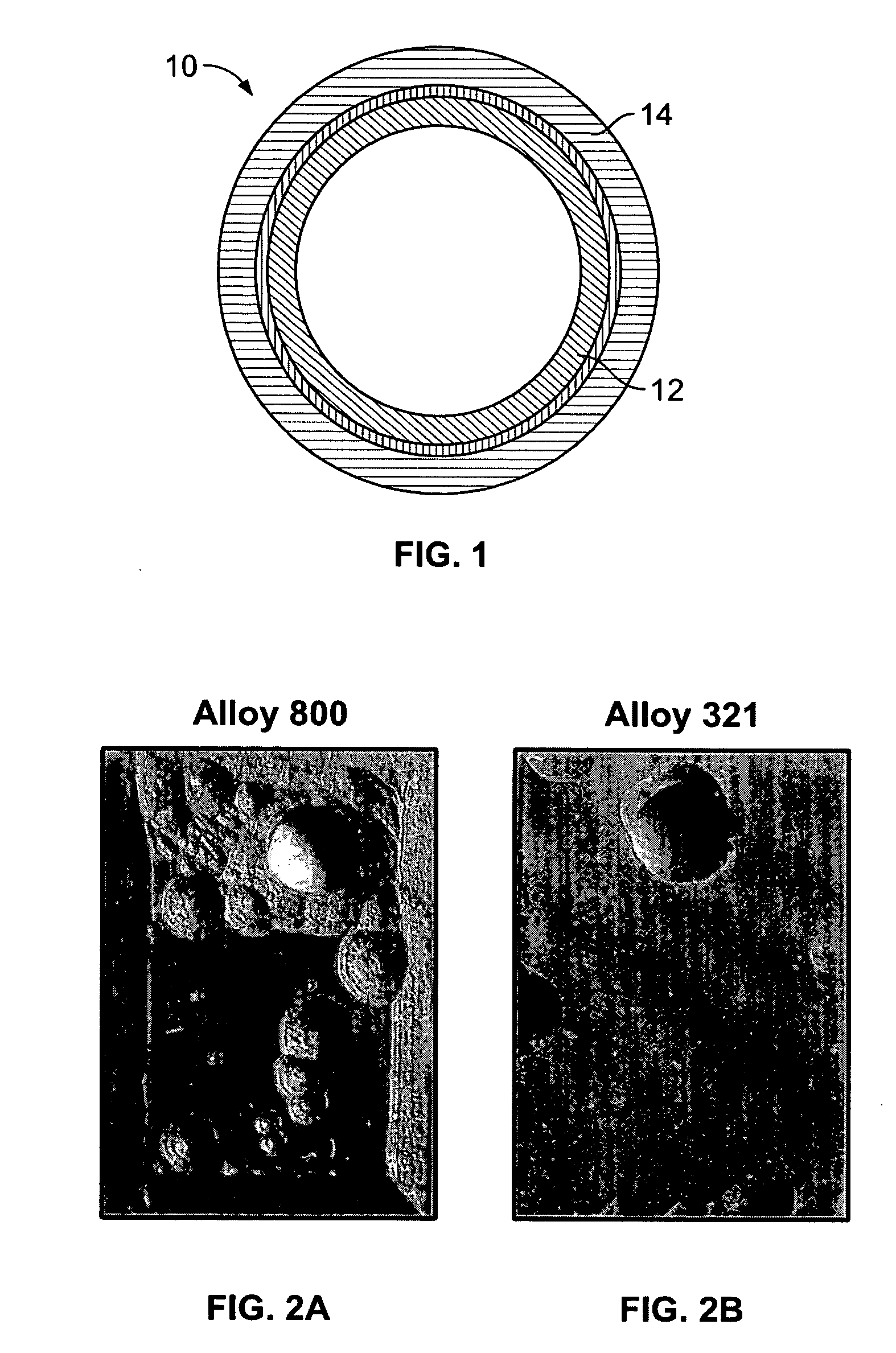

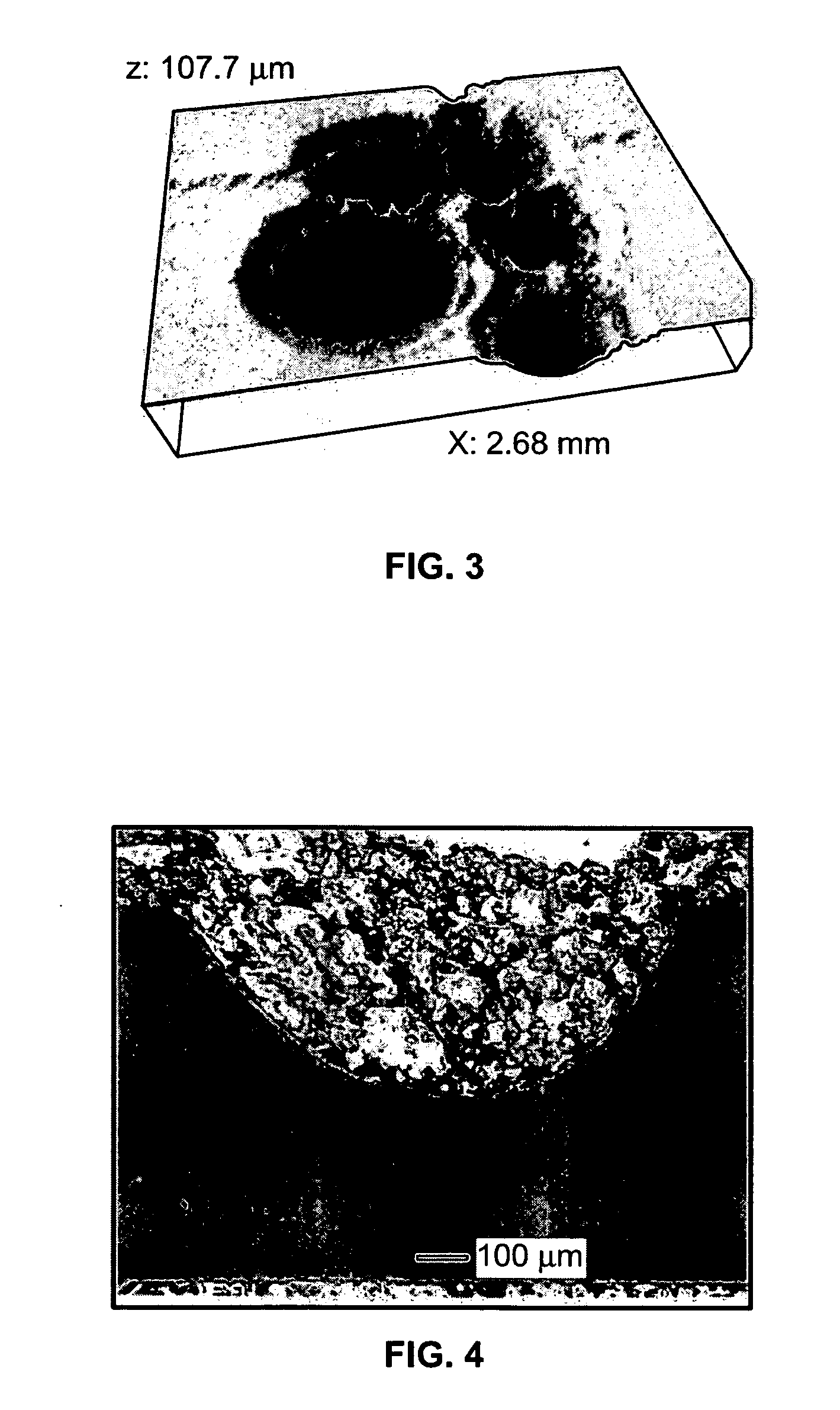

Nickel based alloys to prevent metal dusting degradation

InactiveUS20070104974A1Diffusion of in lowReduce solubilityBlade accessoriesMachines/enginesMetal dustingSpinel

An article of manufacture for reducing susceptibility of a metal pipe to metal dusting degradation. The article includes a multi-layer tubing having an alloy layer and a copper layer. The alloy layer can include a Ni based, an Al based and an Fe based alloy layer. In addition, layers of chrome oxide, spinel and aluminum oxide can be used.

Owner:UCHICAGO ARGONNE LLC

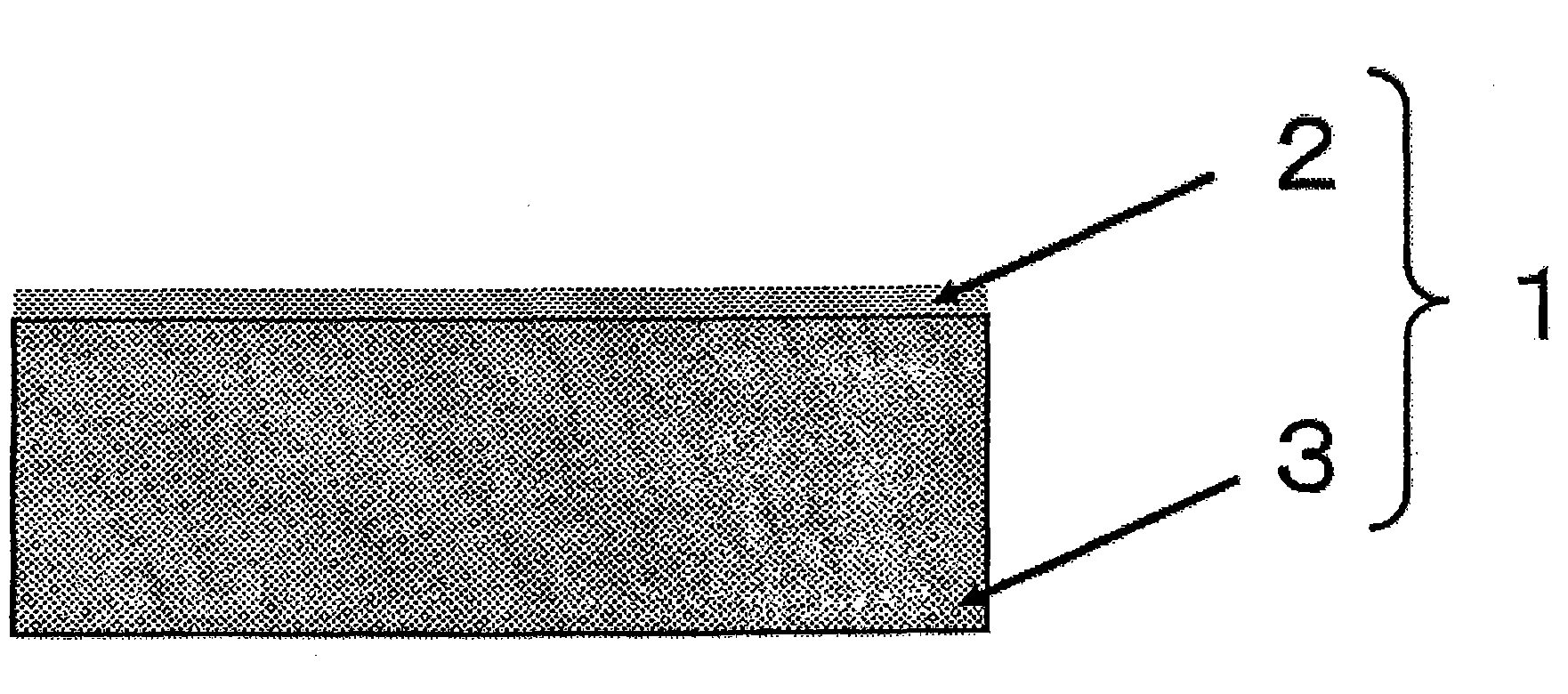

Dielectric structure that withstands compression

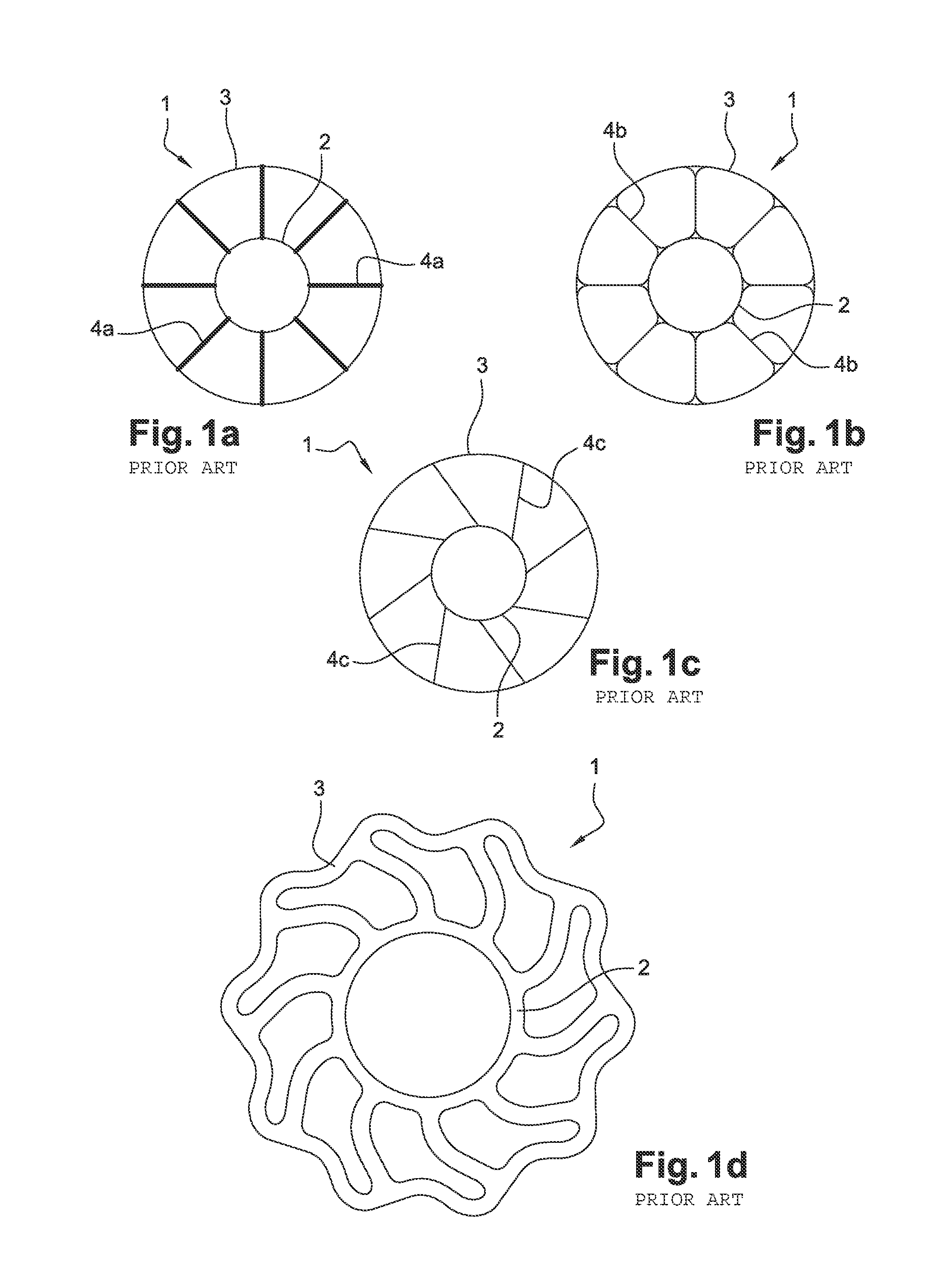

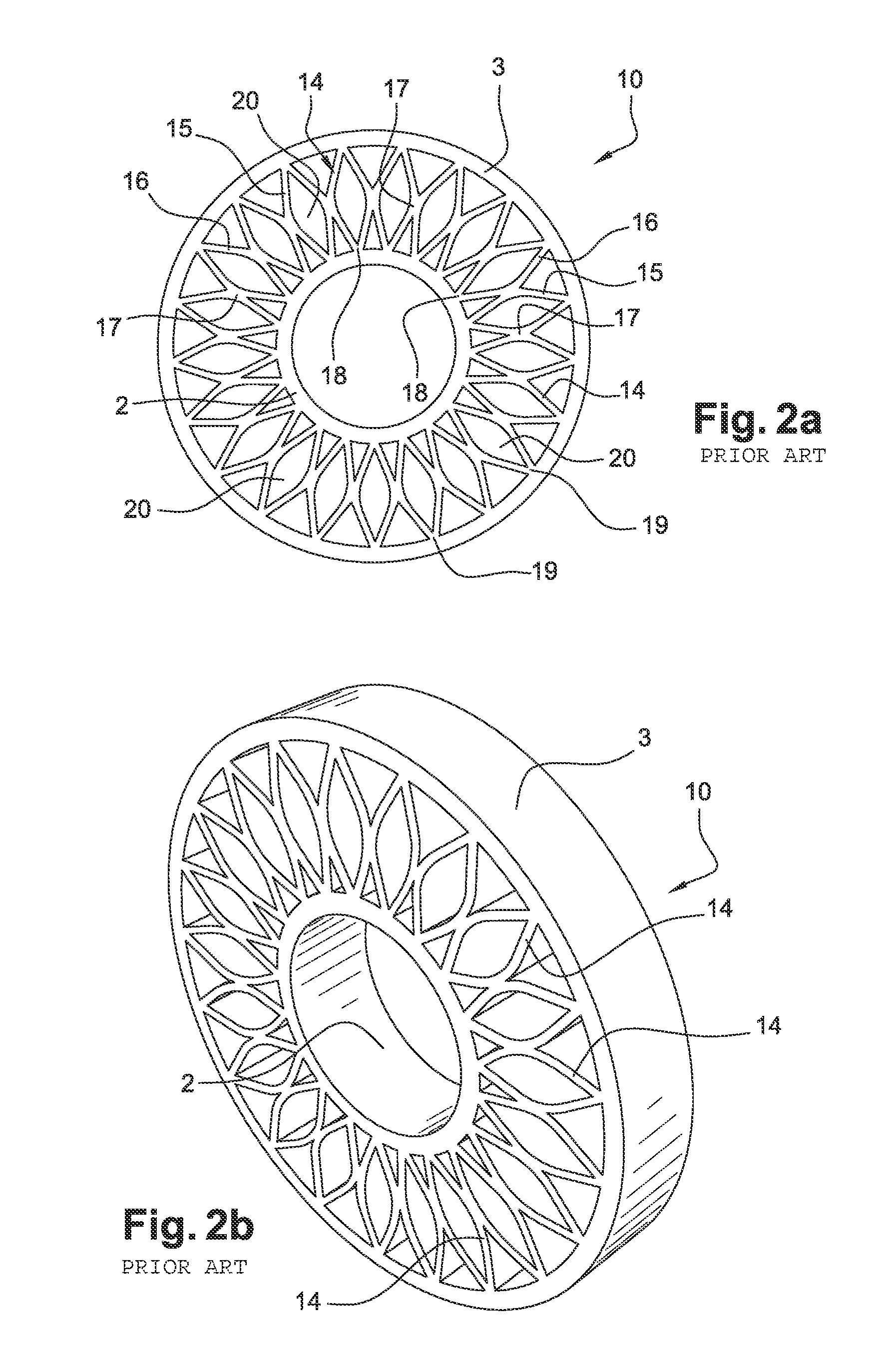

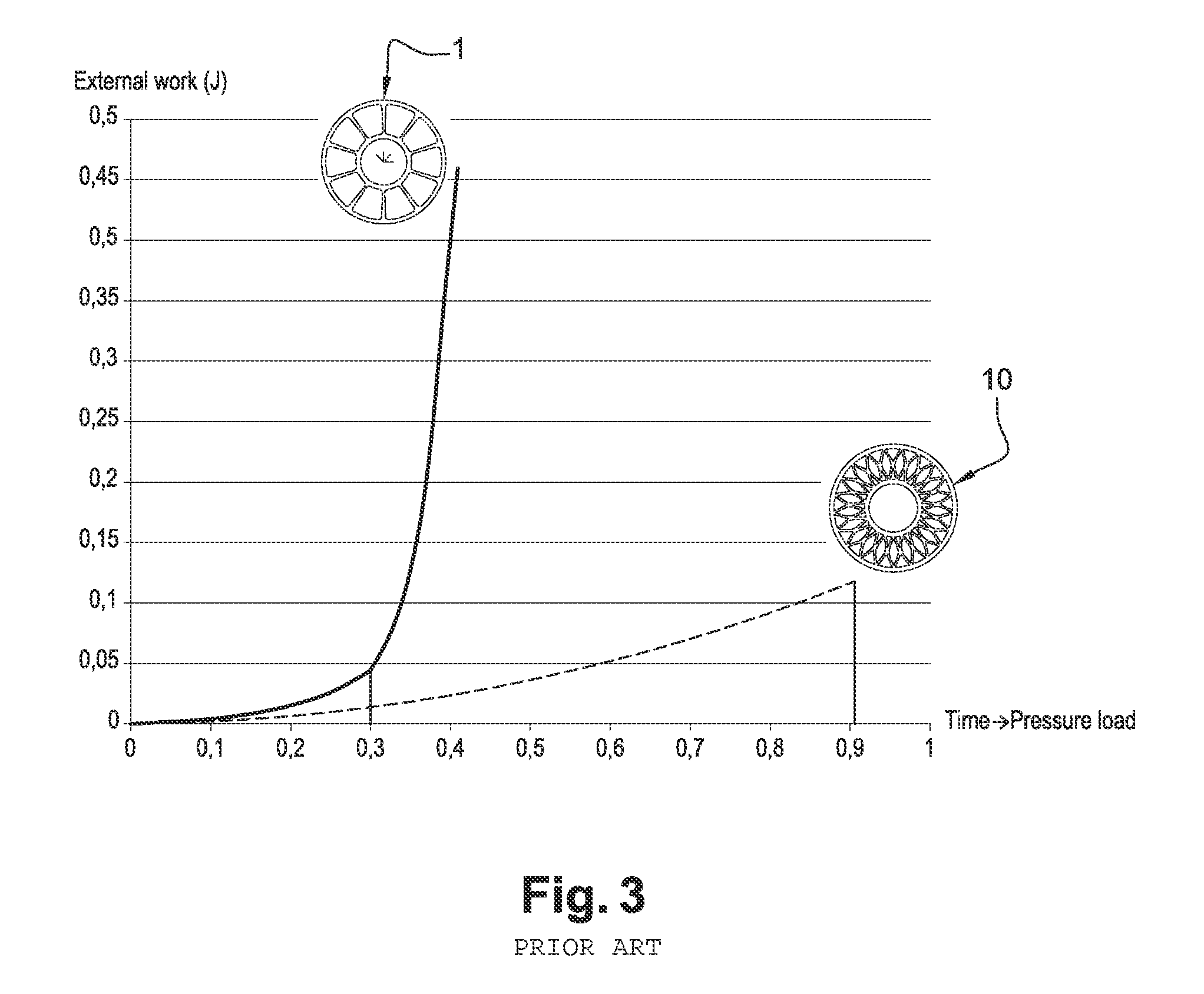

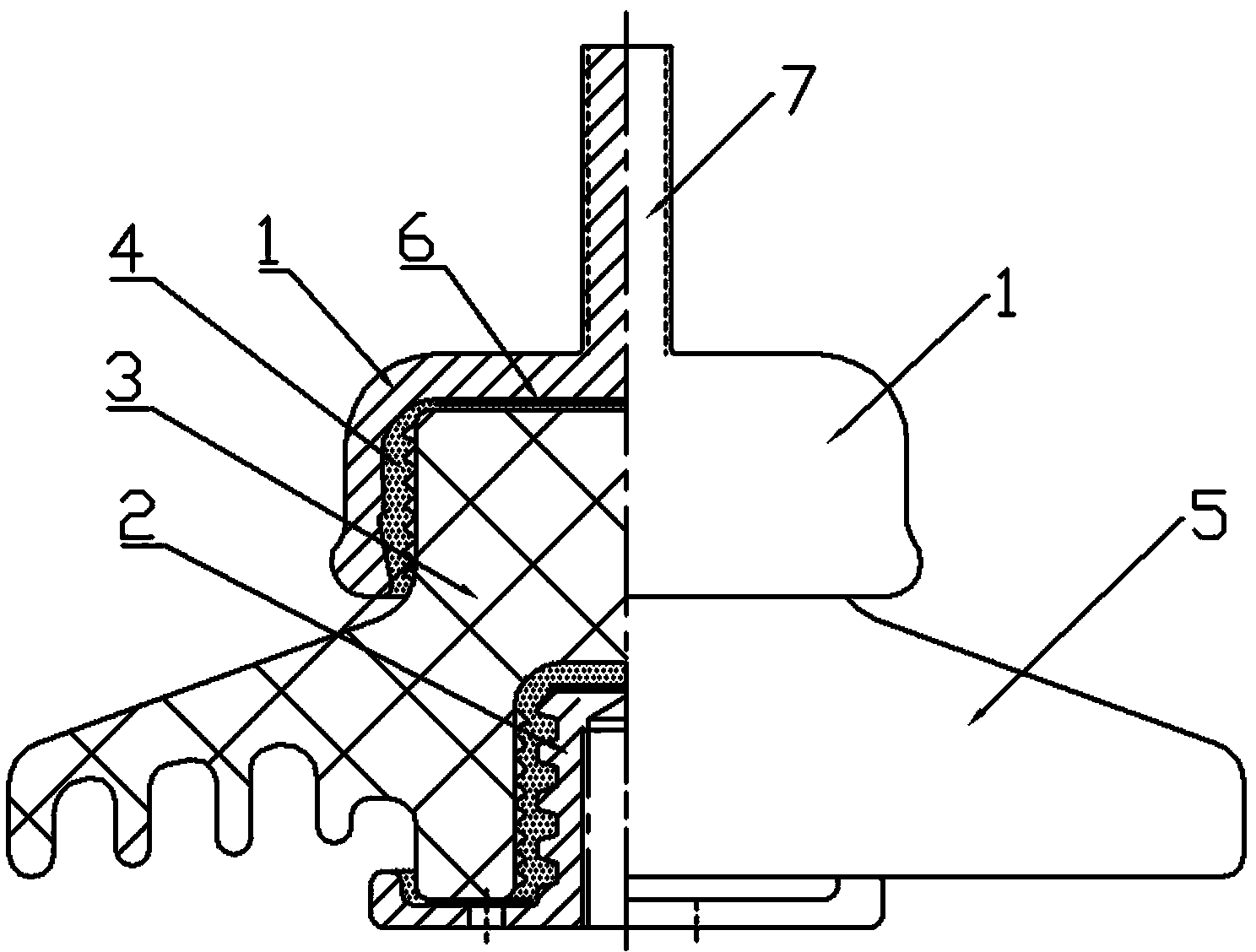

InactiveUS20120199235A1High mechanical strengthImprove mechanical strength propertiesInsulated cablesPipe elementsEngineeringRadial plane

A dielectric structure (10) for an electric wire or cable, presenting an inner hollow cylindrical body (2) and an outer hollow cylindrical body (3), said bodies (2, 3) being coaxial and being connected together by a plurality of spacers (4a, 4b, 4c, 14). The main characteristic of a dielectric structure is that each spacer (14) is constituted by a first curved wall (15) and by a second curved wail (16) that is curved in the opposite direction relative to a radial plane interconnecting the two bodies (2, 3), the walls (15, 16) having at least one intersection zone (17), two successive spacers (14) being in contact with each other.

Owner:NEXANS

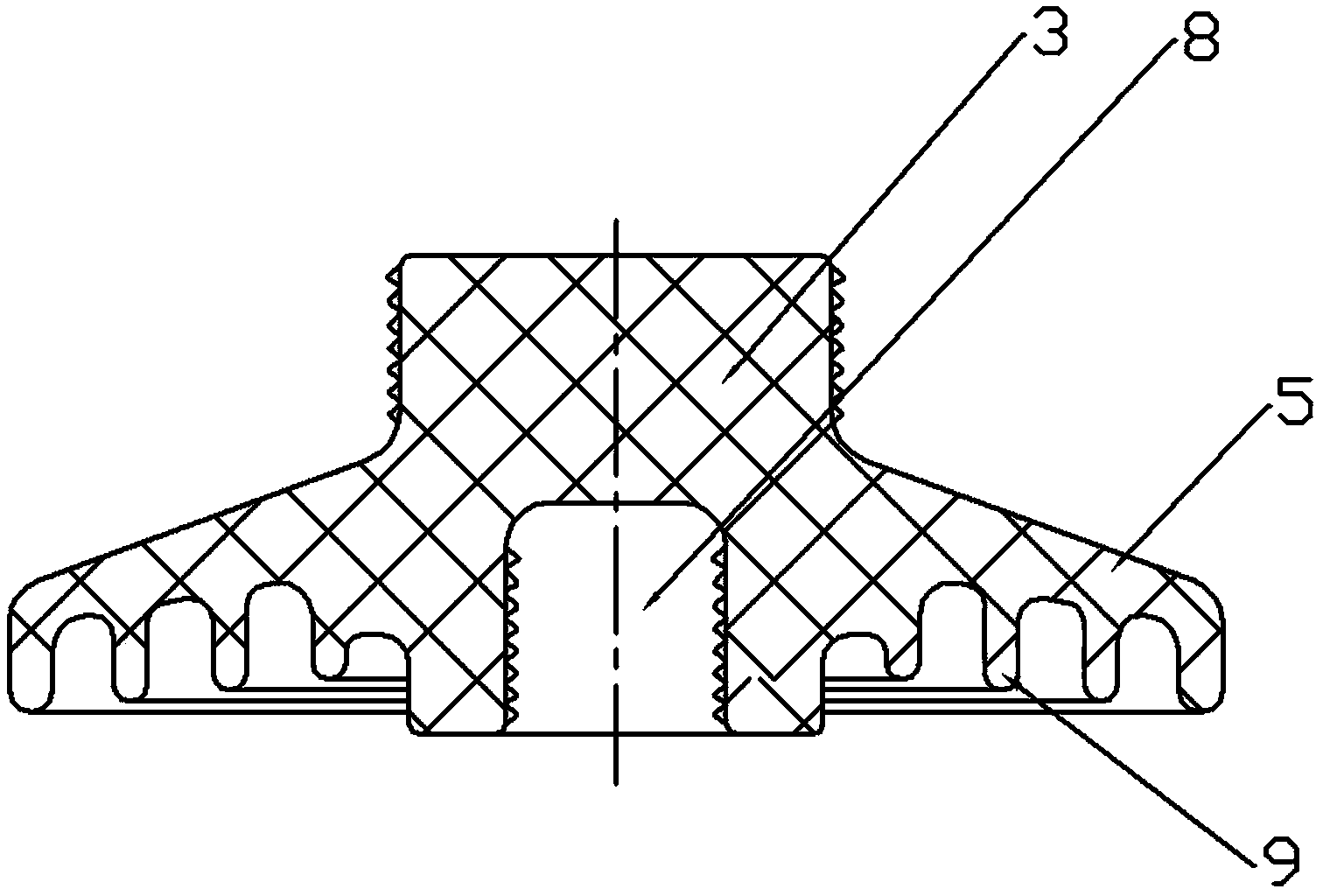

Stain-resistant burst-preventing rigid suspension insulator for urban mass transit metro contact network

InactiveCN104078169APrevent poppingImprove tensile propertiesSuspension/strain insulatorsContact networkStructural engineering

The invention relates to a high-voltage electric porcelain insulator, in particular to a stain-resistant burst-preventing rigid suspension insulator for an urban mass transit metro contact network. The insulator comprises an upper metal accessory, a lower metal accessory and an insulator porcelain body. The upper portion of the insulator porcelain body is a solid cylinder, the middle of the lower portion of the insulator porcelain body is of a hollow pit structure, and a canopy type umbrella skirt is arranged in the middle of the insulator porcelain body. The cementing face of the upper metal accessory is matched with the solid cylinder of the upper portion of the insulator porcelain body and is of a cap shape. The cementing face of the lower metal accessory is matched with a hollow pit in the middle of the lower end face of the insulator porcelain body. According to the stain-resistant burst-preventing rigid suspension insulator, the insulator porcelain body, the upper metal accessory and the lower metal accessory are cemented and combined into a whole through a cement adhesive layer, and the overall stretching resistance and the bend resistant mechanical property of the insulator are improved; meanwhile, the phenomenon that burst of the porcelain body of similar products due to inconsistency of expansion coefficients of the metal accessories and the porcelain body occurs easily can be avoided.

Owner:河南省德立泰高压电瓷电器有限公司

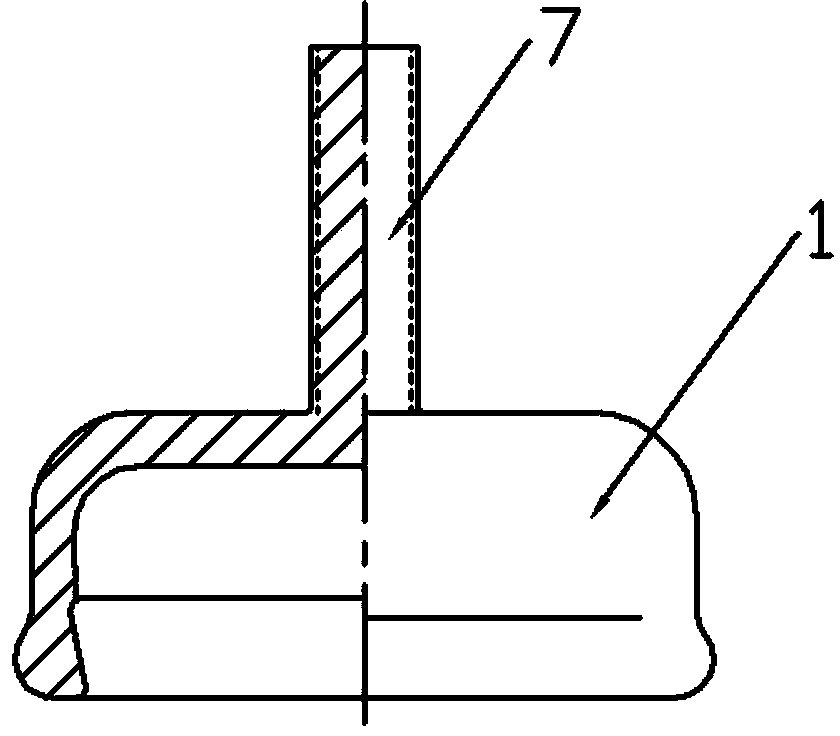

Post-treatment method for MC nylon composite material

InactiveCN109651637ACrystallization intactImprove mechanical strength propertiesPlastic materialsSlow cooling

The invention belongs to the technical field of plastic materials, and concretely relates to a post-treatment method for an MC nylon material. The temperature of a movable oven and the starting temperature of a slow cooling device are all designed in a range of 150-190 DEG C, and the temperature range is close to the maximum temperature of polymerization of MC nylon and the temperature required for crystallization, so an MC nylon blank material has a certain temperature condition to continuously complete the crystallization process; the crystallization process of the MC nylon blank material isa slow process from heat absorption to heat release, and a corresponding slow cooling condition must be set to crystallize the MC nylon blank material completely and make crystals regularized, and slow cooling is carried out for several hours to 100 DEG C or less to meet the condition, so the obtained MC nylon composite material has stable high mechanical strength and good toughness; and the lowly cooled MC nylon composite material can be aged for several days to ensure the stability of the finish size, so the processing precision of the product is ensured, and the production efficiency is guaranteed.

Owner:江苏易元新材料科技有限公司

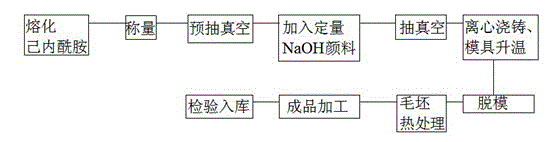

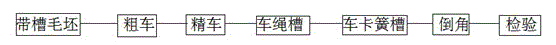

Elevator nylon wheel machining process

InactiveCN104590970AImprove mechanical strength propertiesHigh mechanical strengthElevatorsProduct inspectionMachining process

The invention relates to the technical field of elevator nylon wheels, in particular to an elevator nylon wheel machining process. The machining process comprises the machining flows of fusion of caprolactam-weighing-forvacuum-adding of quantitative NaOH pigment-vacuumizing-centrifugal casting and mold heating-mold release-blank heat treatment-machining of finished products-inspection and warehousing; in the centrifugal casting, a solid curing agent MSCP2013 is added; in the blank heat treatment process, cast nylon wheels are dipped in an oil-state medium; and the machining of finished products only comprises the steps of grooving of blanks-rough turning-finish turning-turning of rope slots-turning of snap spring grooves-chamfering-inspection. The elevator nylon wheel machining process replaces a traditional process; and the whole service performance of products is largely improved.

Owner:YANGZHOU MAISHANG PLASTIC

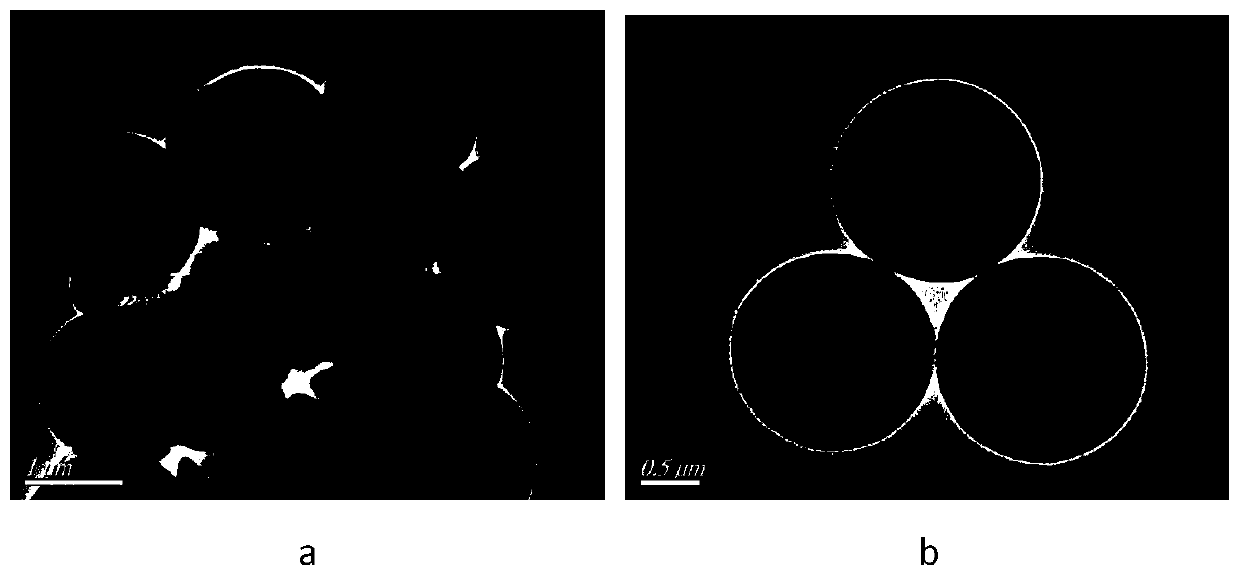

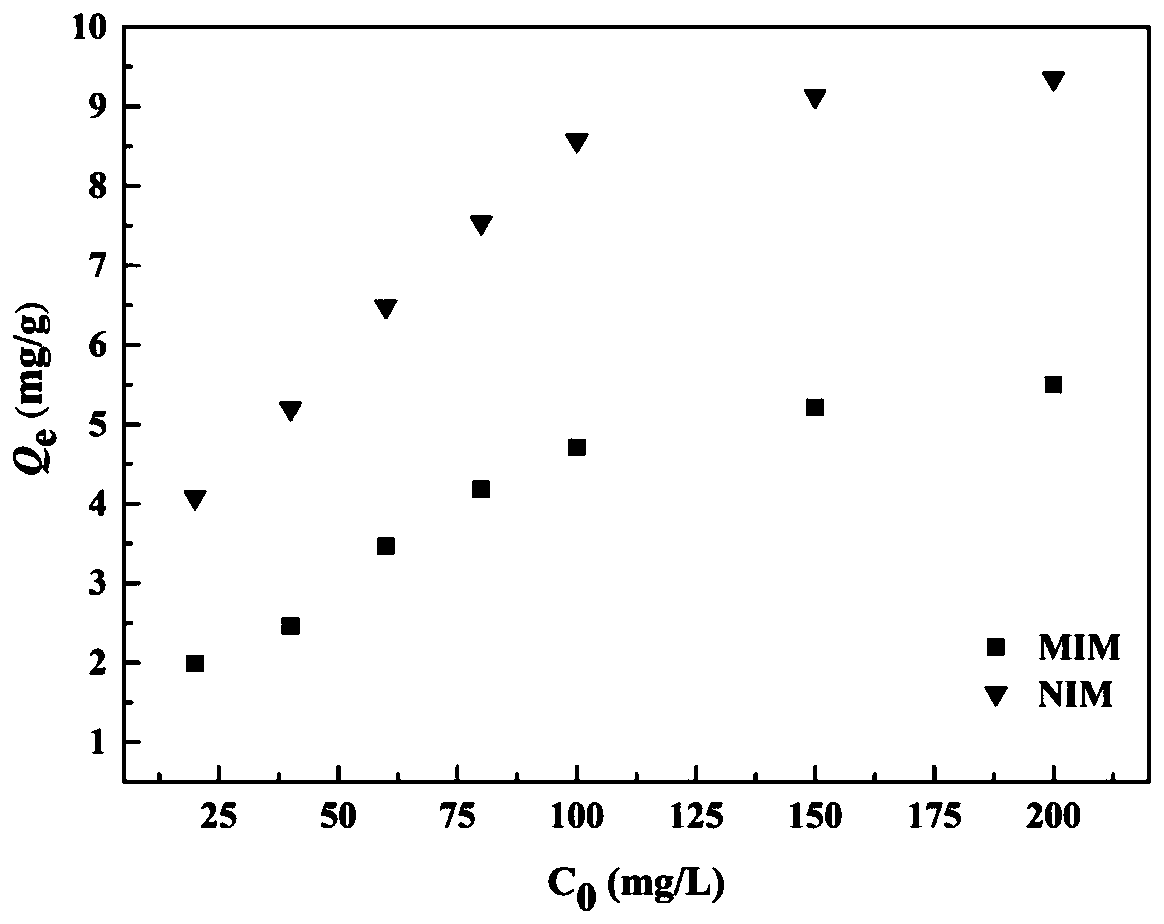

Preparation method and application of loofah-sponge-based imprinted membrane material with reinforced-concrete-like structure

ActiveCN110746538AImprove mechanical strength propertiesHigh blotting efficiencyOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceMolecular imprinting

The invention belongs to the technical field of material preparation and separation, and discloses a preparation method and application of a loofah-sponge-based imprinted membrane material of a reinforced-concrete-like structure. The preparation method comprises the following steps: step 1, preparing loofah sponge; step 2, modifying the loofah sponge with dopamine; step 3, preparing an artemisininmolecularly imprinted polymer; and step 4, preparing the loofah-sponge-based artemisinin molecularly imprinted membrane. The molecularly imprinted membrane prepared by using a loofah-sponge impregnation and permeation method can effectively overcome the defects that the molecularly imprinted polymer cannot be in full contact with target molecules, the mechanical strength and performance of the membrane are poor, and template molecules take much time to elute and even cannot be completely eluted, and has the advantages of simple synthesis, high selectivity efficiency and the like.

Owner:JIANGSU UNIV

Multilayer microporous separators for lithium ion secondary batteries and related methods

ActiveUS10333125B2Improve puncture strengthLower resistanceFinal product manufactureSecondary cellsPorosityPhysical chemistry

Owner:CELGARD LLC

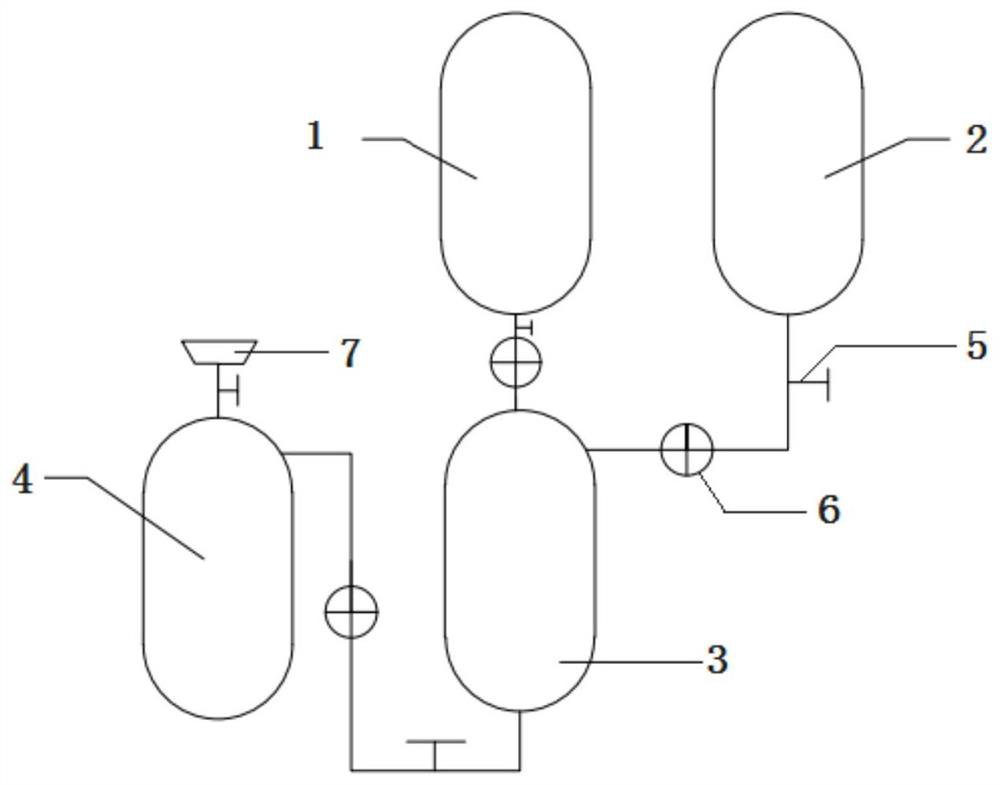

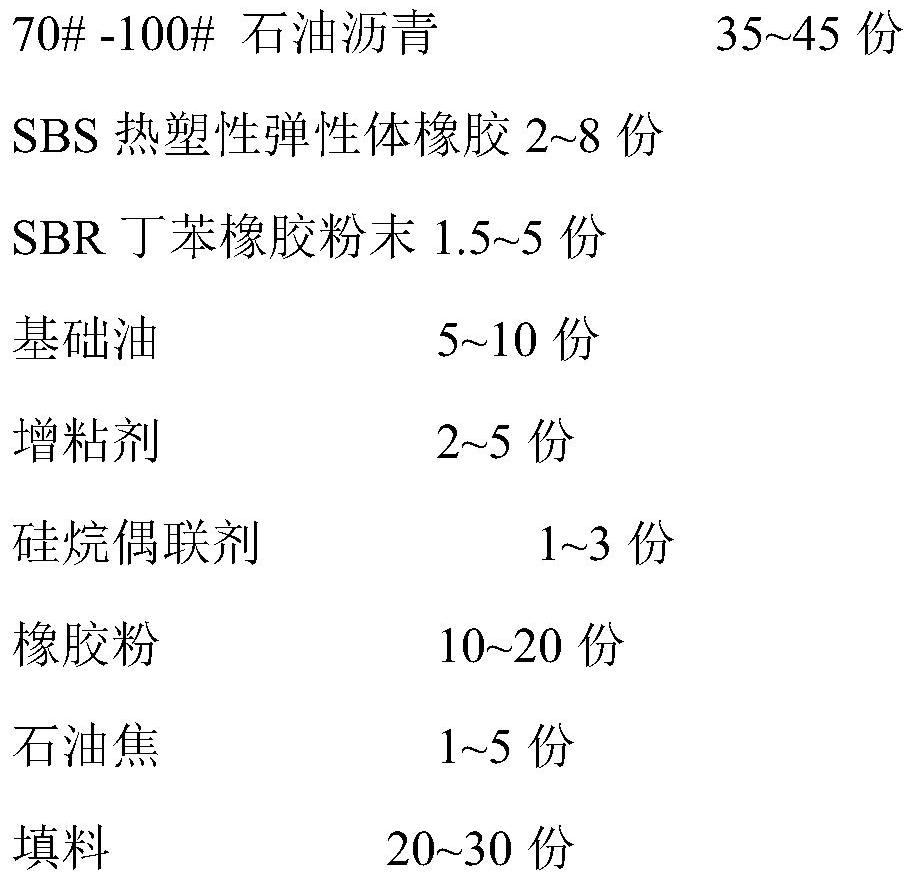

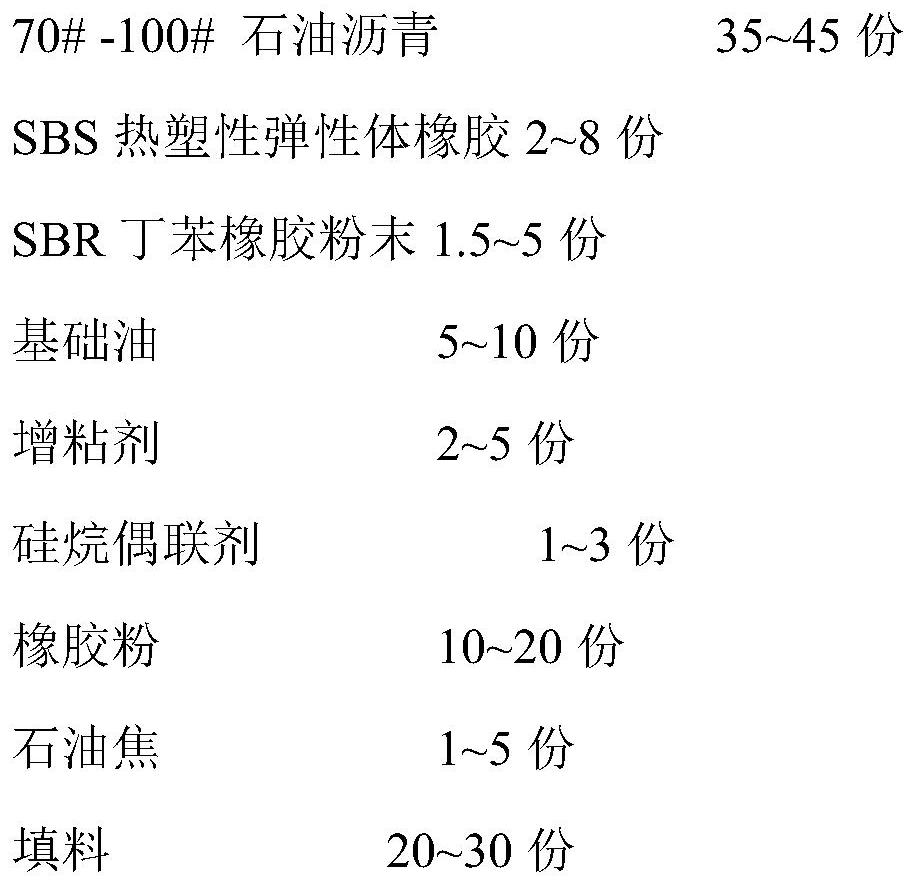

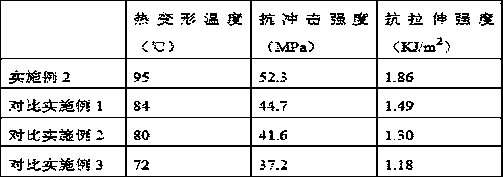

Petroleum coke high polymer modified asphalt waterproof coiled material and preparation method thereof

ActiveCN113136107AHigh tensile strengthGood extensibilityTextiles and paperBuilding insulationsElastomerBituminous waterproofing

The invention discloses an asphalt waterproof coiled material added with petroleum coke as a modifier. The asphalt waterproof coiled material comprises a tire base layer and self-adhesive coating layers arranged on the upper surface and the lower surface of the tire base layer, an upper surface covering layer is arranged above the self-adhesive coating layer on the upper surface of the tire base layer, and a lower surface covering layer is arranged below the self-adhesive coating layer on the lower surface of the tire base layer; wherein the self-adhesive coating layer is prepared from the following components in parts by weight: 35 to 45 parts of 70# to 100# petroleum asphalt; 2-8 parts of SBS thermoplastic elastomer rubber; 1.5-5 parts of SBR butadiene styrene rubber powder; 5-10 parts of base oil; 2-5 parts of a tackifier; 1-3 parts of a silane coupling agent; 10-20 parts of rubber powder; 1-5 parts of petroleum coke; and 20-30 parts of filler. Herein, the petroleum coke is used for partially replacing petroleum asphalt and also serves as an asphalt modifier and filler to improve the stability and weather resistance of the coiled material and improve the plasticity, wear resistance and mechanical strength performance of the coiled material, so that the prepared coiled material is good in tensile strength, high in extensibility and excellent in self-healing performance and waterproof performance. The invention also discloses a preparation method of the asphalt waterproof coiled material.

Owner:鞍山科顺建筑材料有限公司

Material for preparing degradable bionic fish bait

The invention discloses a material for preparing a degradable bionic fish bait. The material is prepared from the following raw materials: modified polylactic acid, a toughening agent, nano calcium carbonate, a phagostimulant, a pigment, an antioxidant, a ultraviolet ray absorber and a lubricating agent. According to the invention, various raw material components are reasonably combined, the enhancement and modification of material performances are effectively realized and the temperature tolerance, machinability and mechanical strength characteristics of the material are obviously promoted, so that the prolonging of the life span of the bionic fish bait and the enhancement of use quality are realized and the material has ultrahigh market competitiveness and popularization and applicationvalues.

Owner:界首市黑马渔具有限公司

Preparation method of filler for increasing strength of cable sheathing pipe

InactiveCN107936293AImprove surface activityImprove mechanical strength propertiesTemperature resistanceUltimate tensile strength

The invention discloses a preparation method of a filler for increasing the strength of a cable sheathing pipe. The method comprises the following steps: (1) preparation of raw materials, (2) pretreatment of the raw materials, (3) preparation of a modified treatment liquid, and (4) modification of the raw materials. The filler is specially prepared by the method, and the filler has very good surface activity, can effectively improve the mechanical strength characteristics in the preparation of the cable sheathing pipe, can enhance the corrosion resistance and temperature resistance of the cable sheathing pipe, and has good promotion and use value.

Owner:铜陵市远维线缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com