Elevator nylon wheel machining process

A processing technology and nylon wheel technology, which is applied in the field of elevator nylon wheels, can solve problems such as long processing time, achieve the effects of improving mechanical strength, reducing friction coefficient and water absorption, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

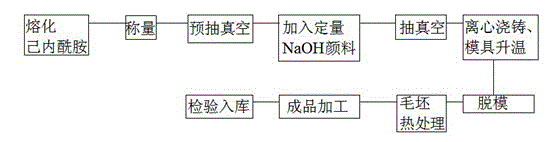

[0014] Such as figure 1 It is a structural schematic diagram of the present invention, a process for processing nylon wheels for elevators, and its processing flow is: melting caprolactam-weighing-pre-vacuumizing-adding quantitative NaOH pigment-vacuumizing-centrifugal casting, mold heating-demolding-blank heat treatment- Finished product processing - inspection and storage.

[0015] Among them, centrifugal casting, blank heat treatment, and finished product processing are the key steps of the present invention. The steps of melting caprolactam, weighing, pre-vacuumizing, adding quantitative NaOH pigment, vacuuming, mold heating, and demoulding are similar to traditional methods, so no longer repeat.

[0016] First, solid curing agent MSCP2013 is added during centrifugal casting, and the centrifugal casting time is 120s. The solid curing agent MSCP2013 is non-toxic, easy to measure and weigh, and the MC nylon wheel formed after polymerization is also non-toxic and has high m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com