Patents

Literature

4608results about How to "Improve surface activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

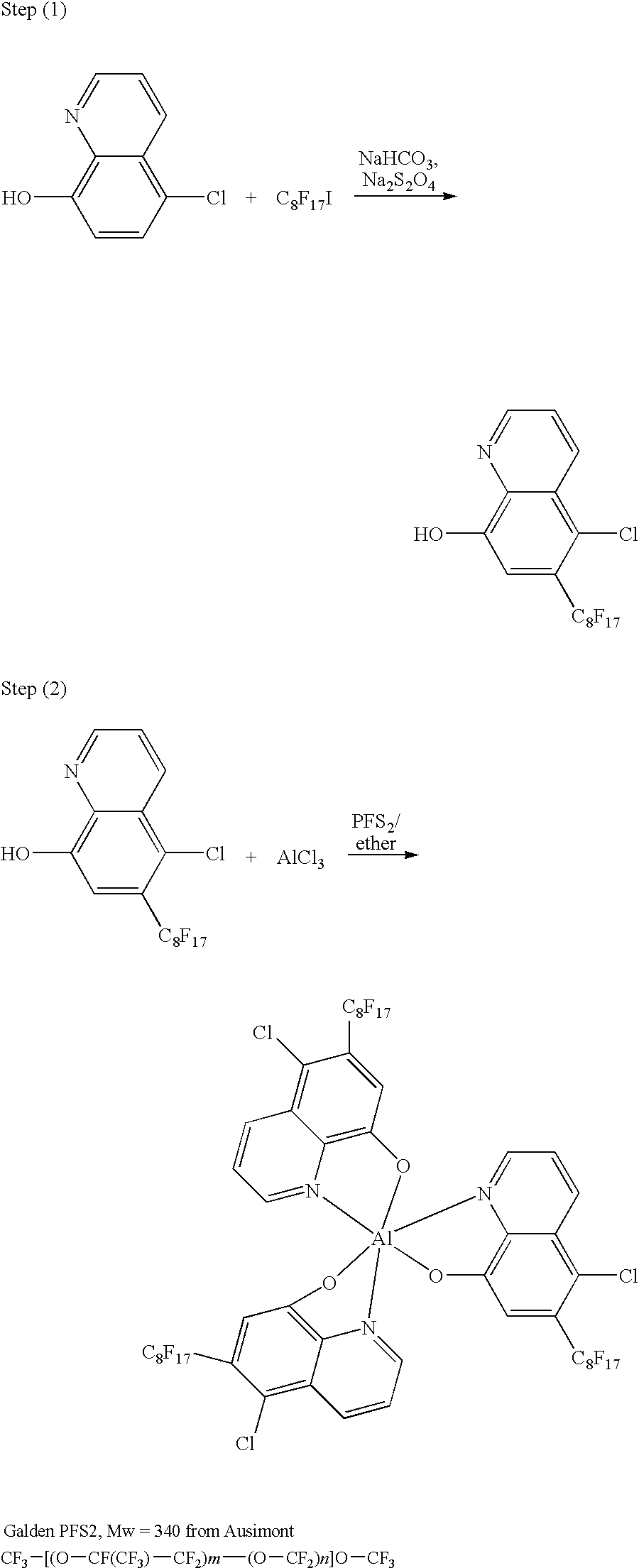

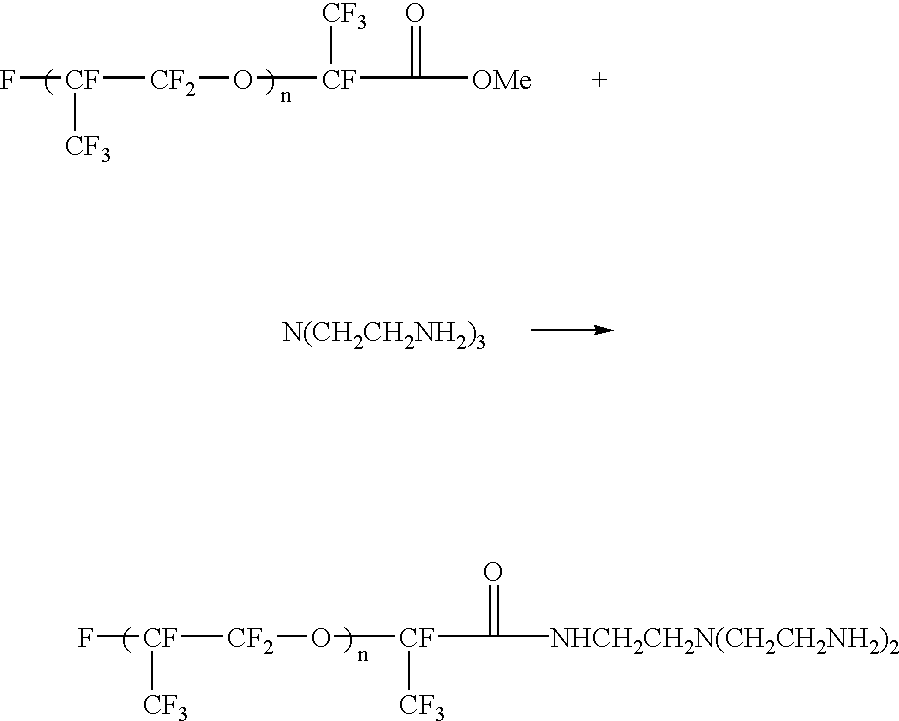

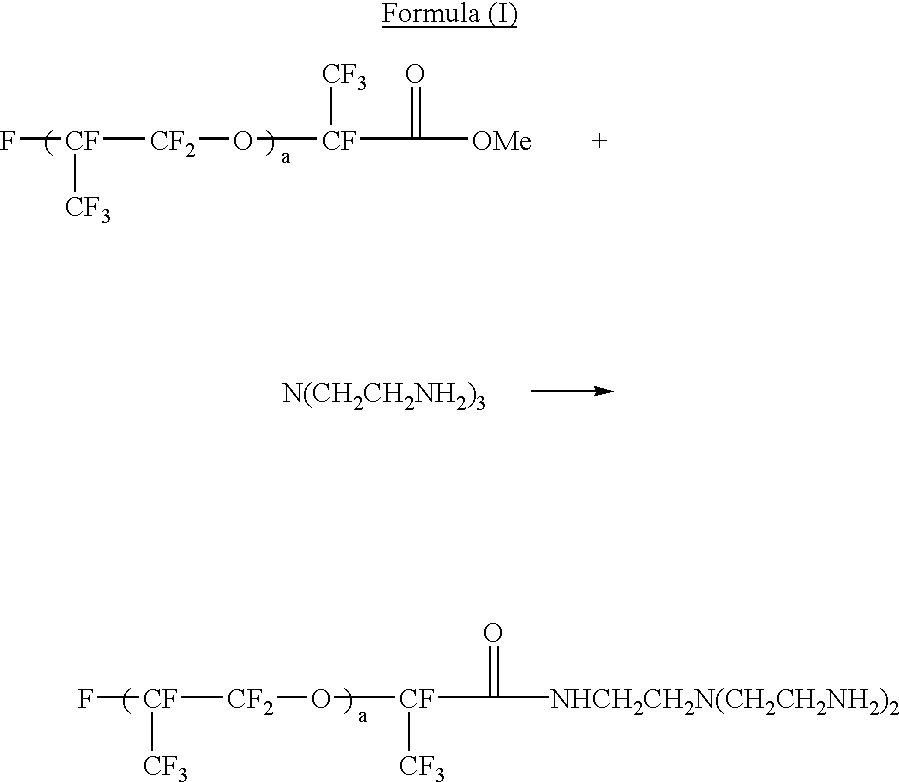

Electrophoretic dispersion with a fluorinated solvent and a charge controlling agent

ActiveUS7110162B2Improve adsorption capacityImprove surface activityStatic indicating devicesAzo dyesElectrophoresisCharge control

The invention relates to a novel electrophoretic dispersion comprising a fluorinated solvent as the continuous phase, charged pigment particles or pigment containing microcapsules as the dispersed phase, and the charge of the pigment particles is provided by a charge controlling agent comprising:(i) a soluble fluorinated electron accepting or proton donating compound or polymer in the continuous phase and an electron donating or proton accepting compound or polymer in the dispersed phase; or(ii) a soluble fluorinated electron donating or proton accepting compound or polymer in the continuous phase and an electron accepting or proton donating compound or polymer in the dispersed phase.

Owner:E INK CALIFORNIA

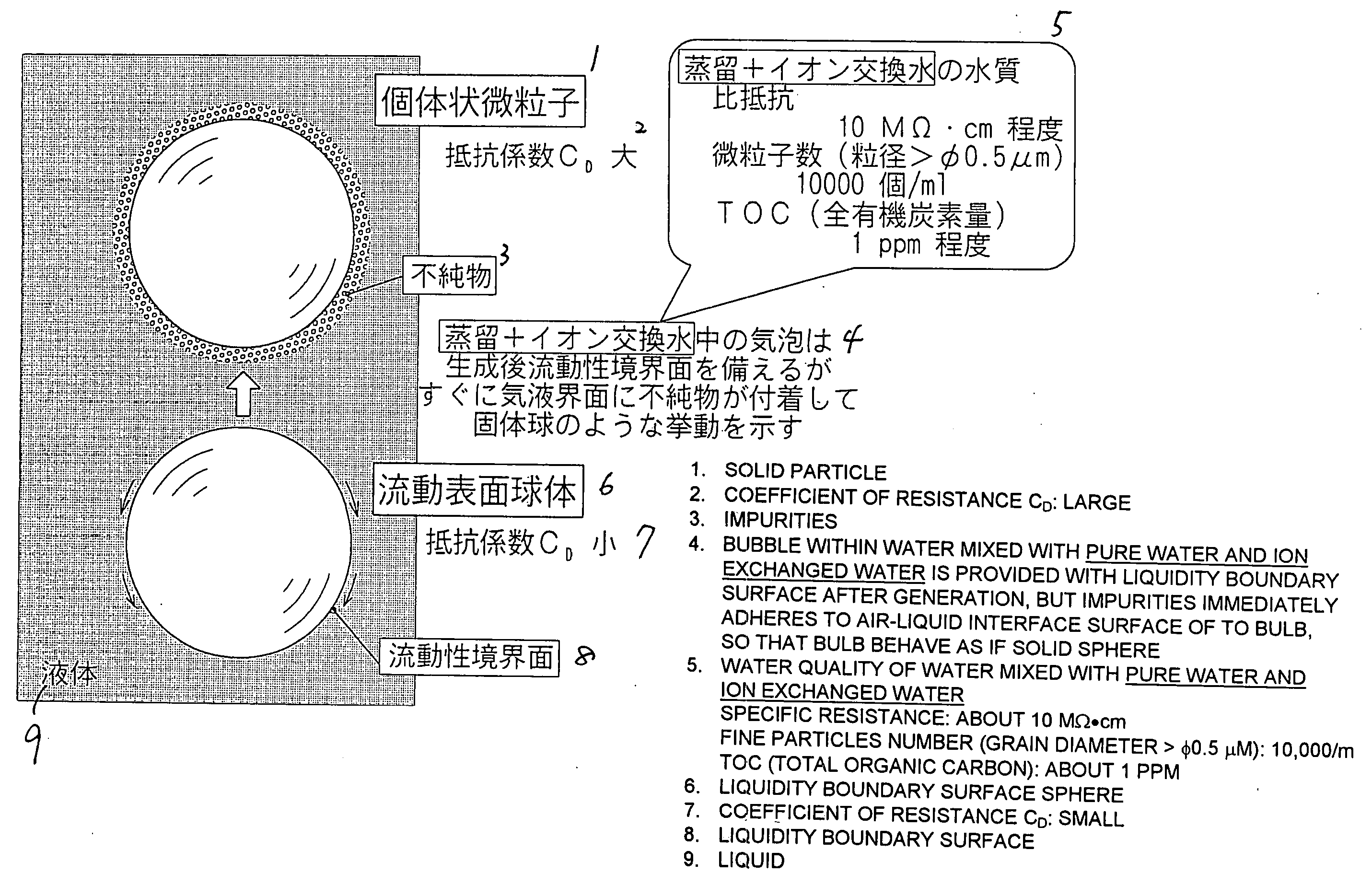

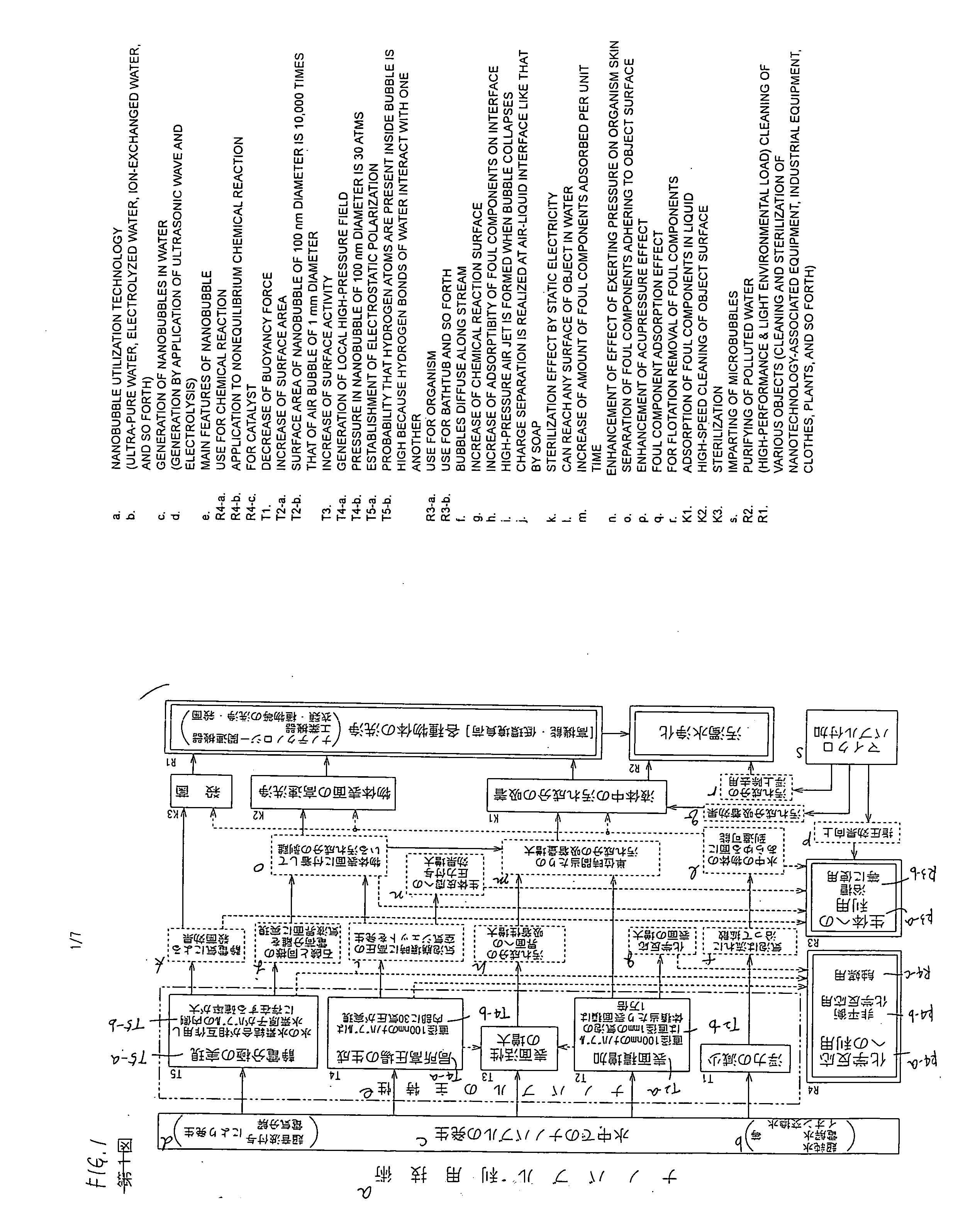

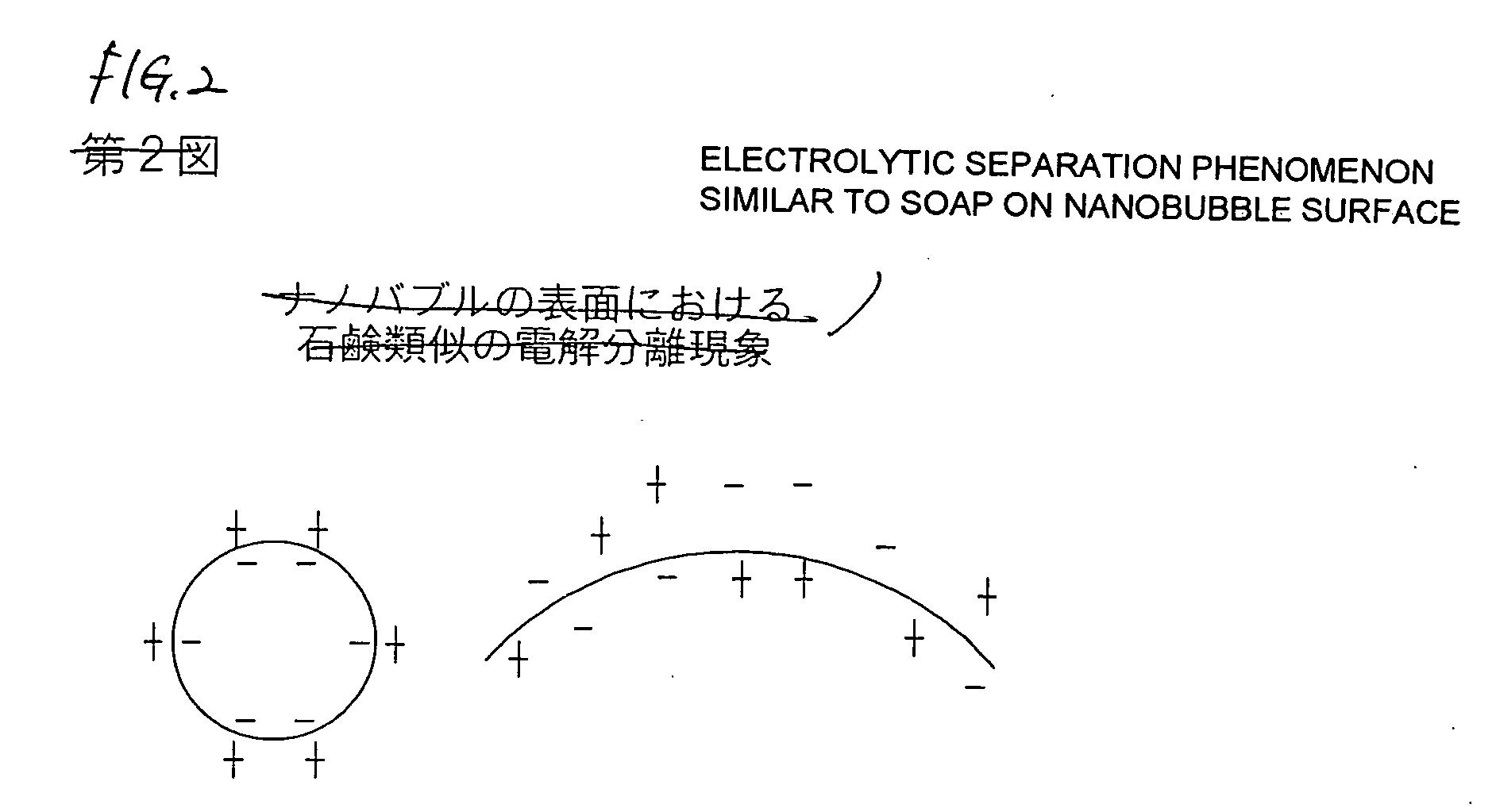

Nanobubble utilization method and device

InactiveUS20060054205A1Efficient use ofFast cleaningMaterial nanotechnologyVibration massageBiological bodyChemical reaction

The present inventors have found the presence of a nanobubble that has not been confirmed conventionally, and established a method for producing nanobubbles. The inventors have determined the theoretically expected characteristics of the produced nanobubbles, found new characteristics by analyzing data experimentally collected, and elucidated the relationship among the characters. Specifically, the inventors have found that a nanobubble has features such as decrease of the buoyant force, increase of the surface area, increase of the surface activity, generation of a local high-pressure field, interface activating action, and sterilizing action thanks to electrostatic polarization. By the association among the features, any of wide variety of objects can be cleaned with high performance and with light environmental load thanks to the function of adsorbing foul components, the function of cleaning the surface of an object quickly, and the sterilizing function, and polluted water can be purified. Nanobubbles can be applied to an organism to recover from fatigue and effectively used for chemical reactions.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method for producing methanol, dimethyl ether, derived synthetic hydrocarbons and their products from carbon dioxide and water (moisture) of the air as sole source material

InactiveUS7378561B2High activityImprove surface activityOrganic compound preparationOrganic chemistry methodsNano structuringWater source

A method for producing methanol and dimethyl ether using the air as the sole source of materials is disclosed. The invention relates to a method for separating the water (i.e., the moisture in the air) and carbon dioxide content of atmospheric air for their use in the subsequent production of methanol, dimethyl ether and derived synthetic hydrocarbons as products. The method includes the conversion of carbon dioxide and water under conditions sufficient to produce methanol and / or dimethyl ether. Methanol and / or dimethyl ether can be used as fuel or fuel additives or further converted to synthetic hydrocarbons and their products. Carbon dioxide is captured on a suitable absorbent, preferentially polyethyleneimine supported on nano-structured fumed silica. The process can also involve hydrogenation with hydrogen produced by electrolysis of water obtained from the air or from any other water source. Methanol can be dehydrated to produce dimethyl ether or further processed to produce synthetic hydrocarbons, polymers, and products derived from them by other known methods.

Owner:UNIV OF SOUTHERN CALIFORNIA

Method for producing methanol, dimethyl ether, derived synthetic hydrocarbons and their products from carbon dioxide and water (moisture) of the air as sole source material

InactiveUS20080039538A1High activityImprove surface activityOrganic compound preparationOrganic chemistry methodsSource materialMoisture

A method for producing methanol and dimethyl ether using the air as the sole source of materials is disclosed. The invention relates to a method for separating the water (i.e., the moisture in the air) and carbon dioxide content of atmospheric air for their use in the subsequent production of methanol, dimethyl ether and derived synthetic hydrocarbons as products. The method includes the conversion of carbon dioxide and water under conditions sufficient to produce methanol and / or dimethyl ether. Methanol and / or dimethyl ether can be used as fuel or fuel additives or further converted to synthetic hydrocarbons and their products. Carbon dioxide is captured on a suitable absorbent, preferentially polyethyleneimine supported on nano-structured fumed silica. The process can also involve hydrogenation with hydrogen produced by electrolysis of water obtained from the air or from any other water source. Methanol can be dehydrated to produce dimethyl ether or further processed to produce synthetic hydrocarbons, polymers, and products derived from them by other known methods.

Owner:UNIV OF SOUTHERN CALIFORNIA

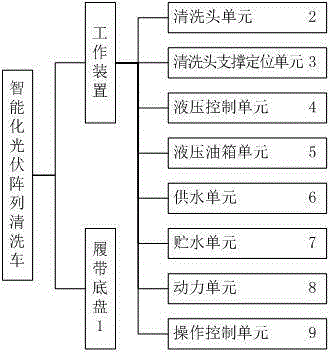

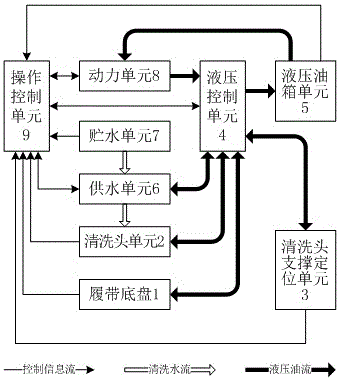

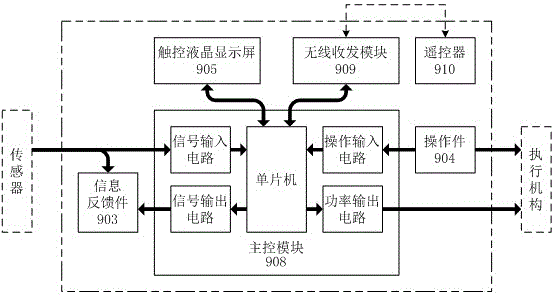

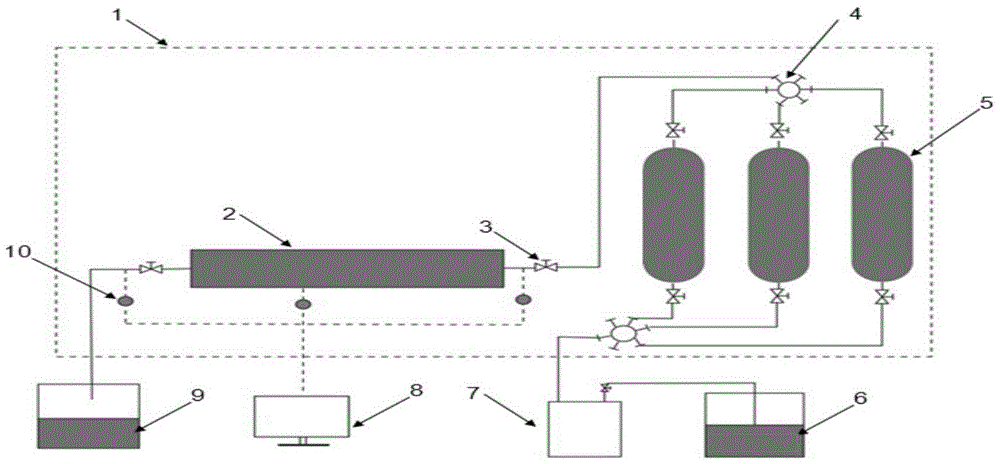

Intelligent photovoltaic array washing car

ActiveCN105107772AFunction increaseRegular shapeCleaning using toolsCleaning using liquidsWater storageHydraulic control unit

The invention provides an intelligent photovoltaic array washing car used for washing photovoltaic arrays of a large-scale ground photovoltaic power station. A washing head supporting and locating unit and a power unit are arranged on the head portion and the tail portion of a crawler base respectively, a water storage unit is arranged adjacent to the power unit, and a washing head unit is provided with range finder sensors used for measuring the distance between the washing head unit and solar cell panels; the washing head supporting and locating unit comprises a movable base capable of rotating and transversely moving and a working arm set provided with a main arm and an end arm, wherein the main arm and the end arm can pitch respectively; a water pump of a water supply unit is driven by a hydraulic motor; a computer is used as a control kernel of a main control module of an operation control unit; a pair of proportional directional valves of the hydraulic control unit controls two base crawler traveling motors, and other directional valves are electromagnetic directional valves controlled by the main control module. According to the intelligent photovoltaic array washing car, the position and the posture of the washing head unit relative to photovoltaic array panels and the position and the posture of a car body relative to the photovoltaic arrays can be automatically controlled, and the intelligent photovoltaic array washing car is intelligent, efficient, flexible in operation, high in adaptability, easy and convenient to operate, concise in structure and good in washing effect.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

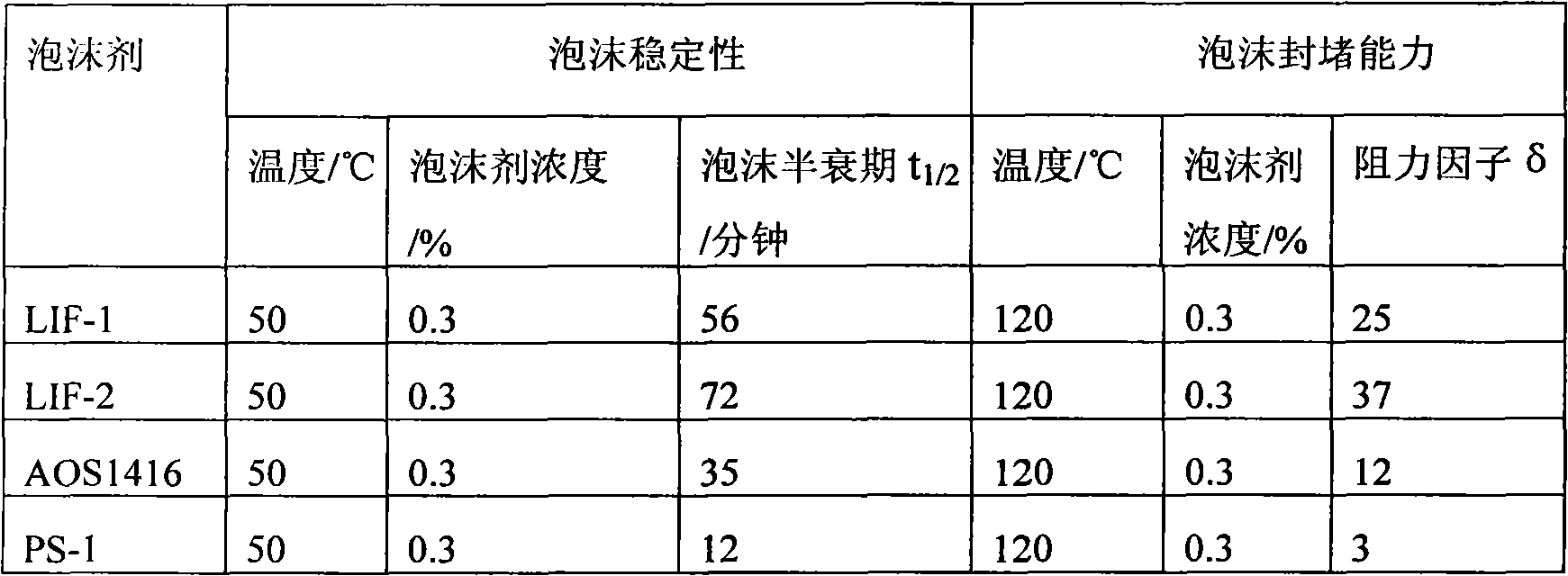

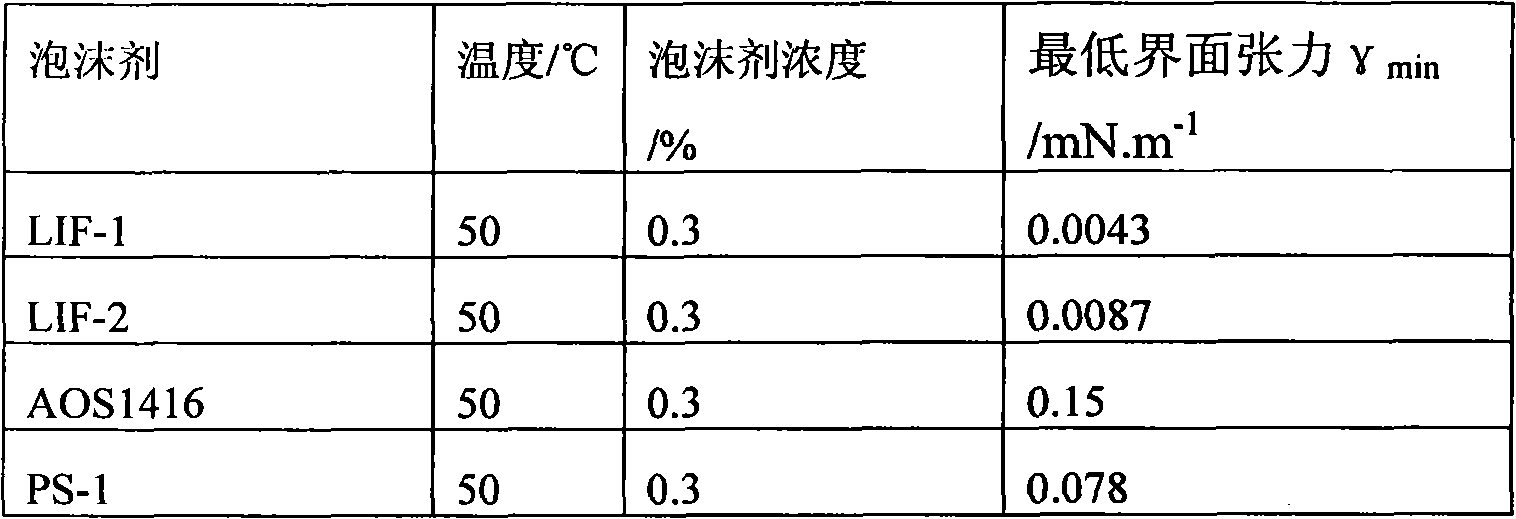

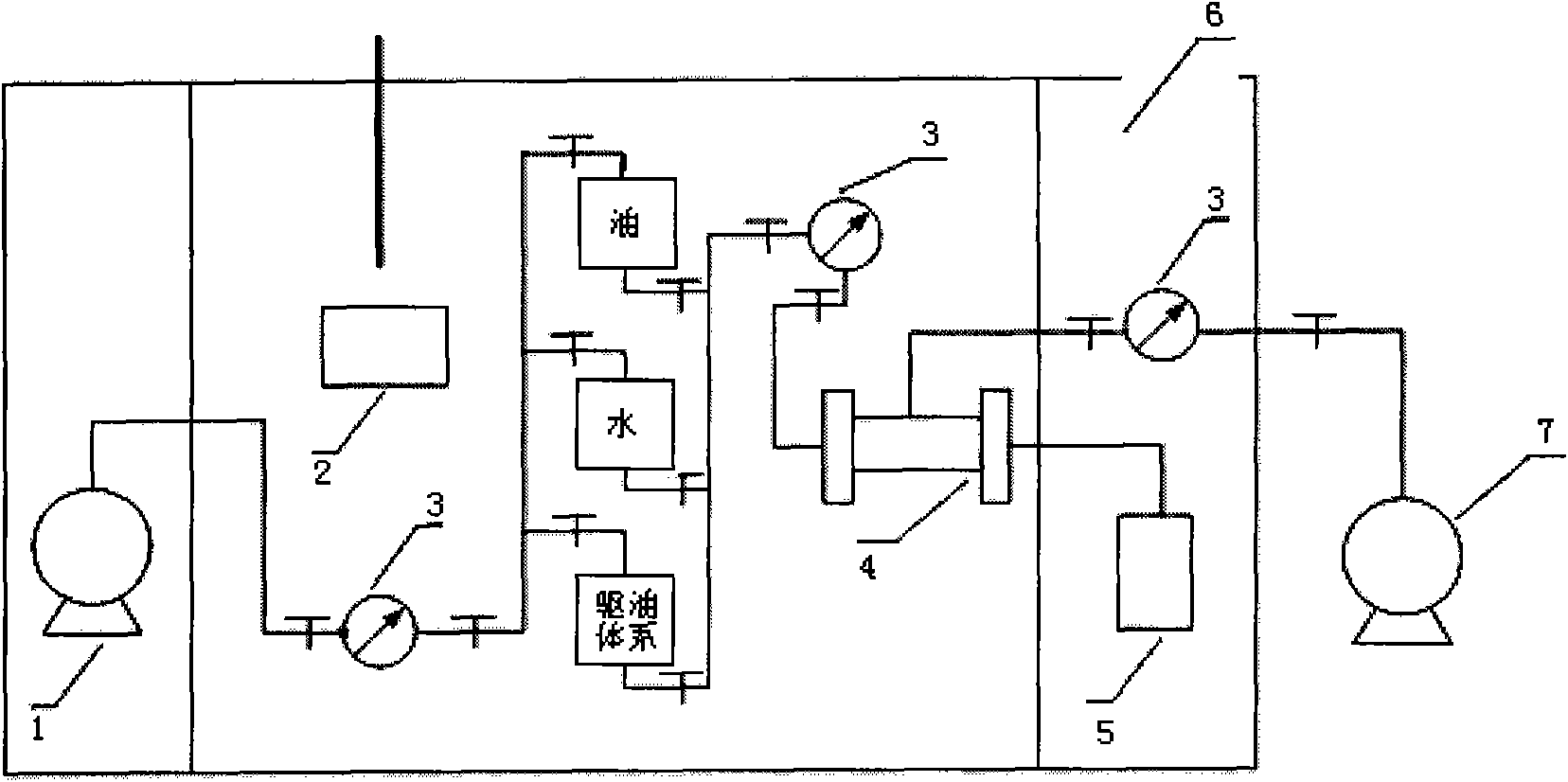

Temperature-resistant, salt-resistant and low-tension foam flooding agent and preparation method thereof

ActiveCN102020981AImprove stabilityReduce interfacial tensionFluid removalDrilling compositionFoaming agentActive agent

The invention relates to a temperature-resistant, salt-resistant and low-tension foam flooding agent and a preparation method thereof. The temperature-resistant, salt-resistant and low-tension foam flooding agent is prepared by continuously stirring alkanolamide, bipolar surfactant and water at 40-60DEG C until the alkanolamide, the bipolar surfactant and the water are completely dissolved. The temperature-resistant, salt-resistant and low-tension foam flooding agent provided by the invention is suitable for tertiary recovery under the conditions that the temperature is 50-120DEG C and the mineralization is 0-100000ppm. Compared with other common foam agents in the prior art, the oil-water interfacial tension is reduced from 10<-2>mN.m<-1> to 10<-3>mN.m<-1>; and compared with common interfacial active agents in the prior art, the half foam life period at 50DEG C is increased from 15 minutes to more than 40minutes, and the recovery ratio of an indoor model is increased by more than 15%.

Owner:SHANDONG UNIV

Thermal-insulating external-wall coating of nano-composite water and its production

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

A biologic organic fertilizer, and preparation method

InactiveCN1872803APromote growthImprove the ecological environmentBio-organic fraction processingClimate change adaptationOil processingPotassium

This invention relates to a method for manufacturing bioorganic fertilizer. The bioorganic fertilizer is manufactured by: mixing sugar industry waste, breeding industry waste, oil-processing waste, phosphoric fertilizer, trace element fertilizer and silicon fertilizer, and performing aerobic fermentation and post fermentation. The effective components of the bioorganic fertilizer are: organic matters (greater than or equal to 30%), N, P and K (greater than or equal to 8%), beneficial microorganisms (greater than or equal to 200,000,000 / g), active silicone (greater than or equal to 5%), magnetic components (0.25%), and Fe, Zn and Mo (0.5-1%). The bioorganic fertilizer has abundant raw material sources, and is environmentally friendly.

Owner:成官文

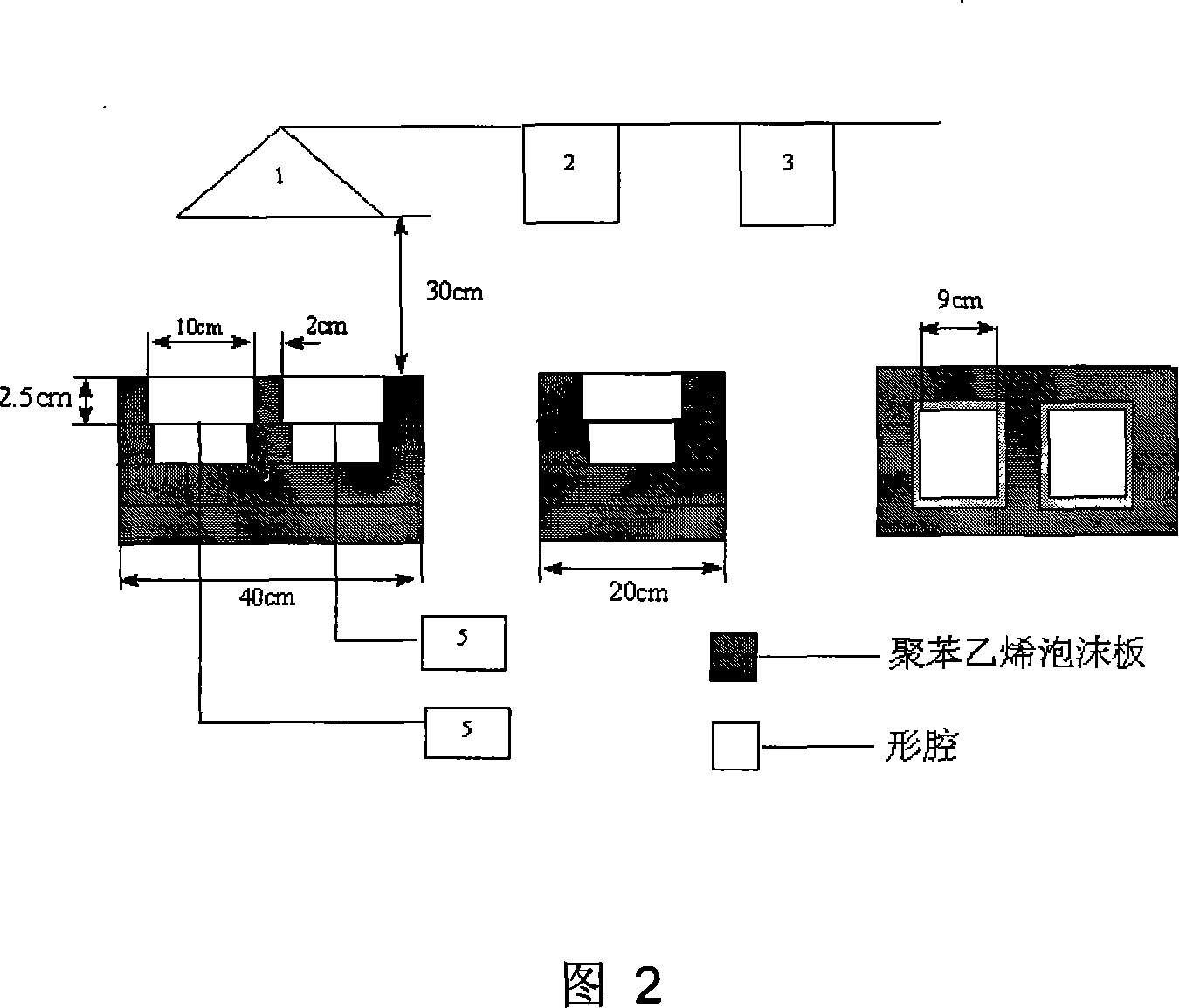

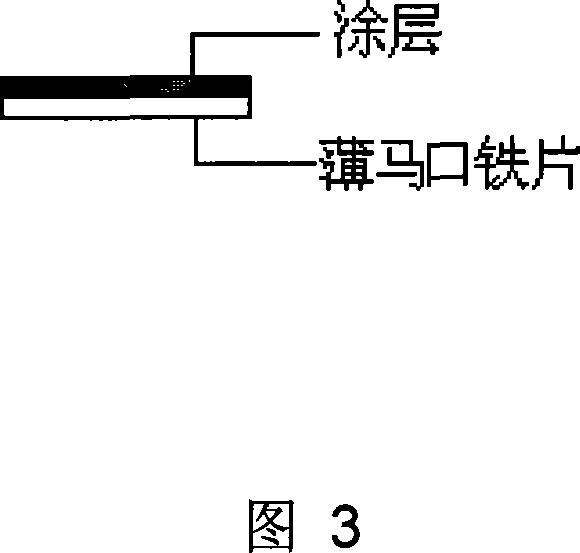

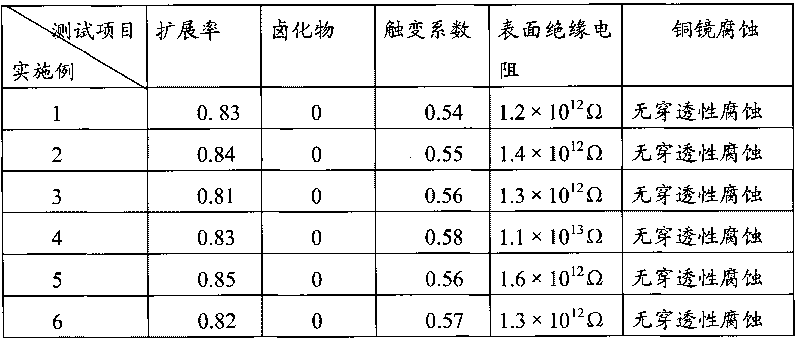

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

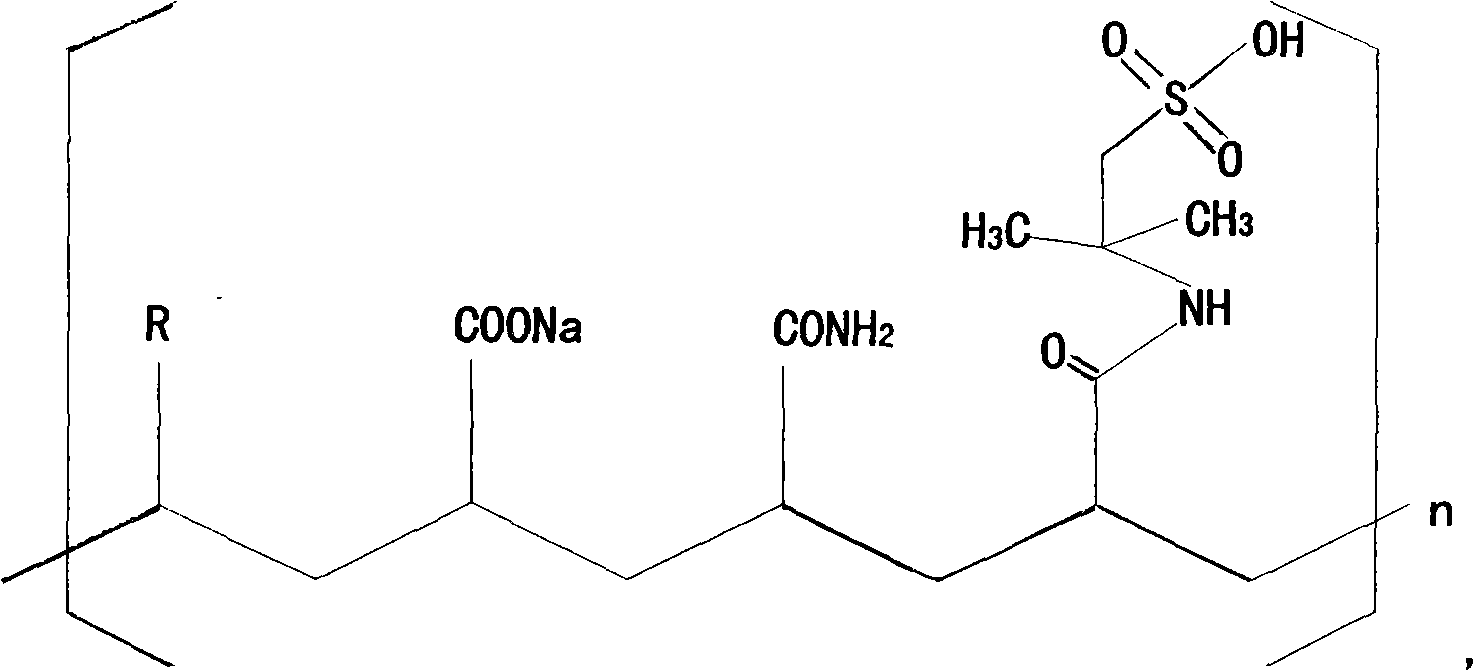

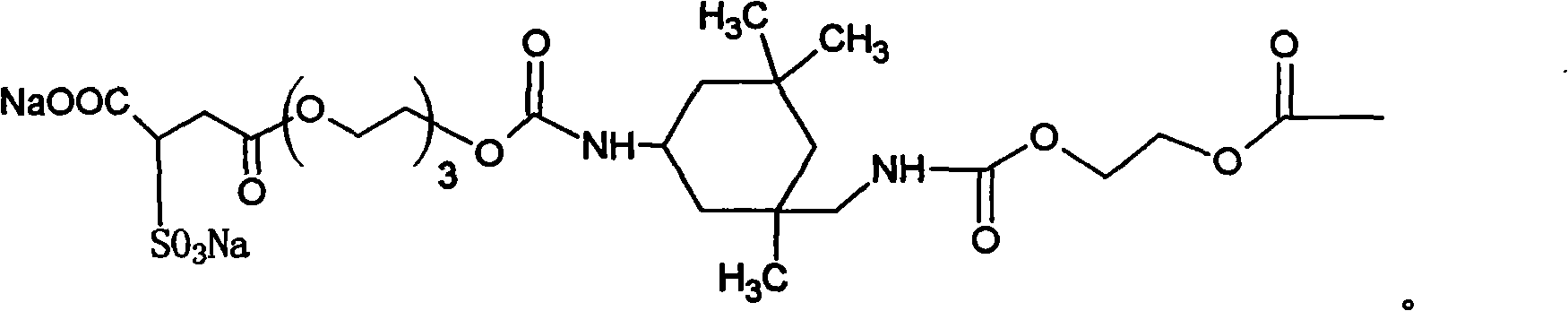

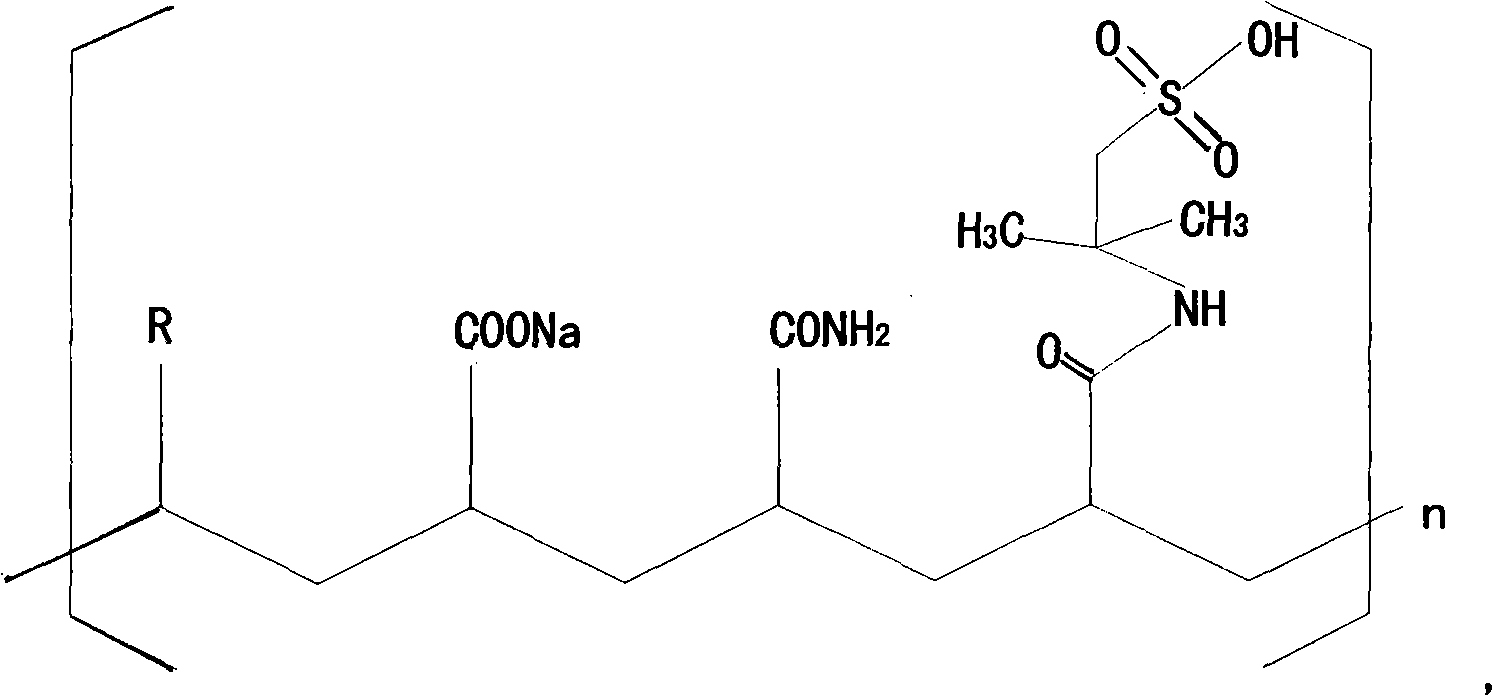

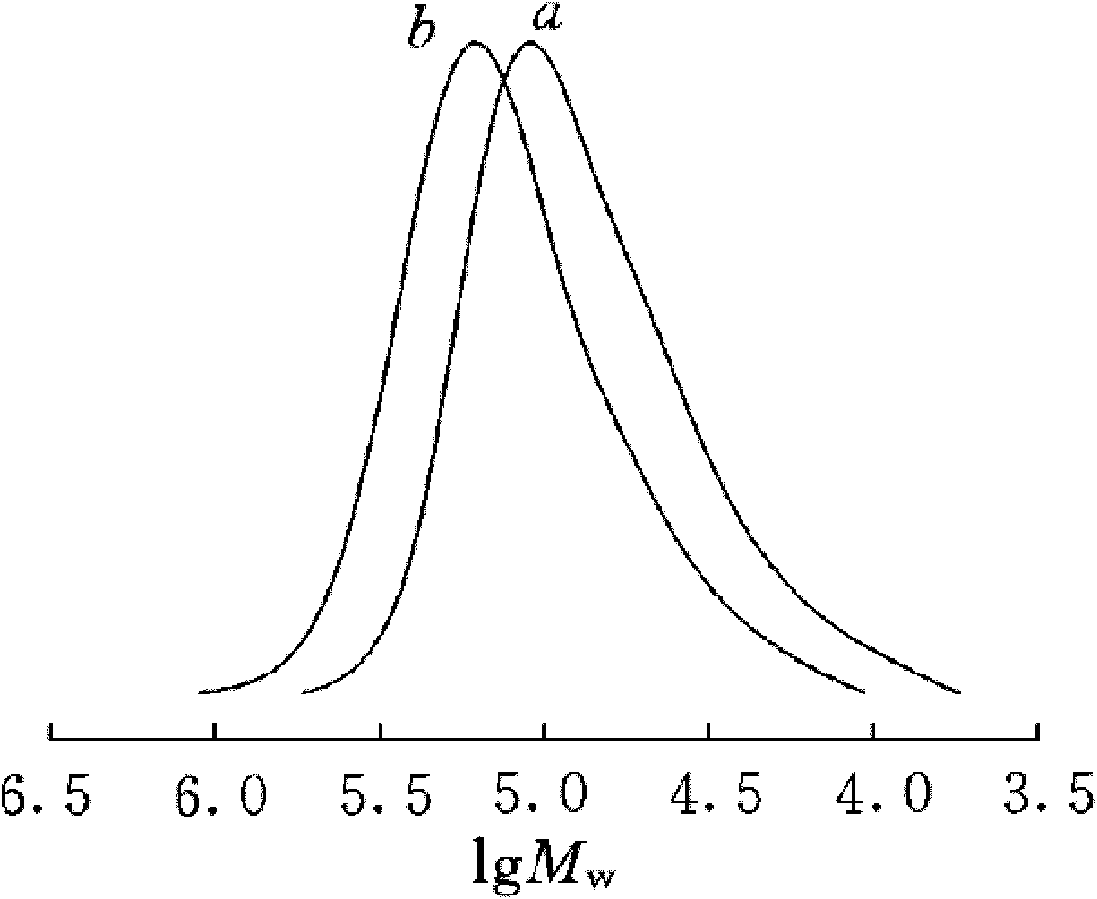

Comb-type structure activity polymer and its preparation technique and application

InactiveCN101260171AGood water solubilityHigh molecular weightDrilling compositionFunctional monomerHigh surface

The invention discloses a comb-type structural reactive polymer with the molecular weight ranging between 1x10<5> and 5x10<6>, wherein the main chain of the reactive polymer is obtained through the copolymerization of acrylamide monomer and functional monomers such as 2-acrylamido-2-methylpropanesulfonic acid and acrylic acid sodium salt, etc., which endues polymer aqueous solution with higher apparent viscosity and better temperature resistance and salt resistance; and the branched chain of the reactive polymer consists of unsaturated macromonomer molecule, which endues the polymer aqueous solution with higher surface activity. The invention also discloses a preparation method for the polymer, comprising the following steps: firstly, through process operation including esterification, prepolymerization and sulfonation, polyurethanes active macromonomer with a novel structure is prepared; then, under the action of oxidation reduction initiator, the copolymerization reaction of the active macromonomer and other functional micromolecule monomers is initiated quickly at low temperature. The comb-type structural reactive polymer can be used as oil displacement agent and has the advantages of high molecular weight and low surface tension, etc.

Owner:SHANDONG UNIV

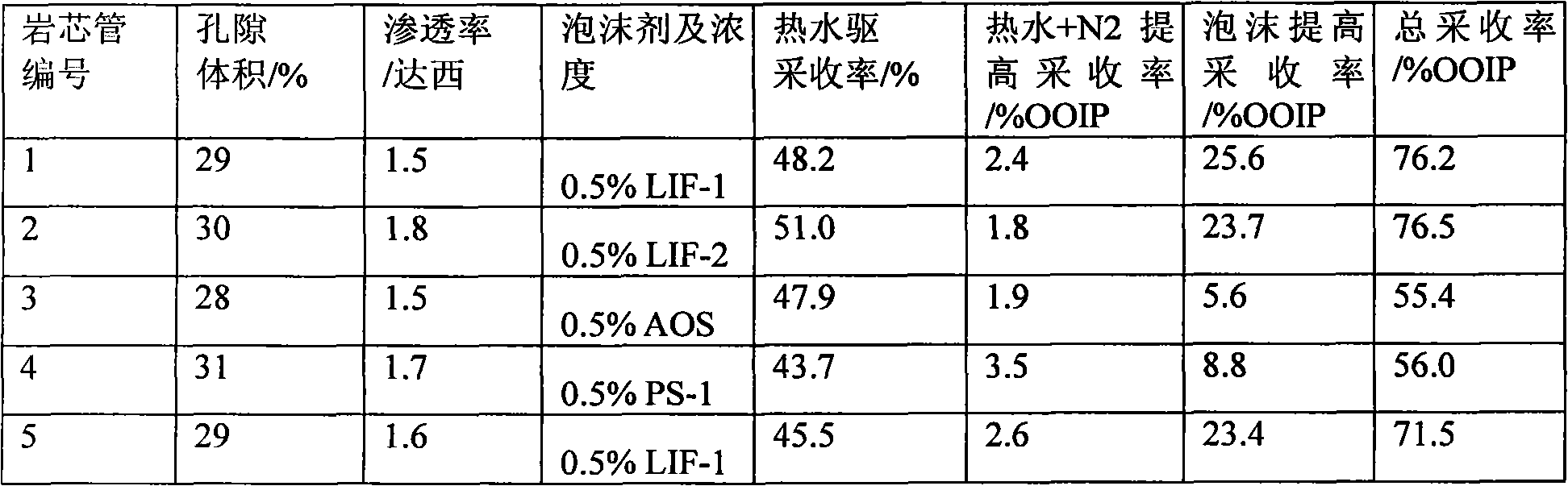

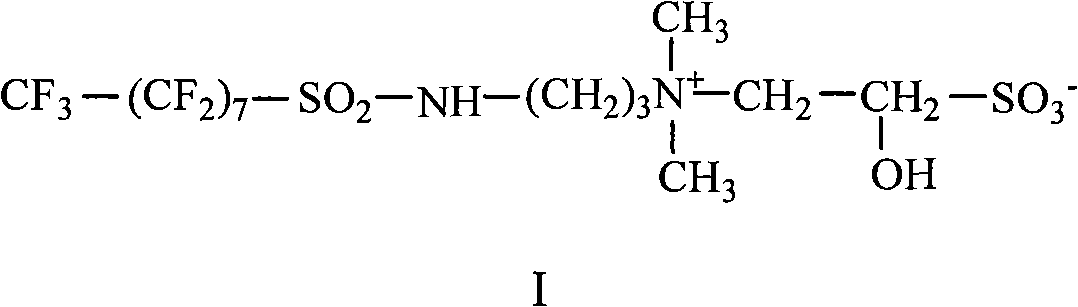

Fluorocarbon surfactant binary composite foam flooding system

ActiveCN102140338AImprove stabilityHigh apparent viscosityFluid removalDrilling compositionSulfonateFoaming agent

The invention relates to a fluorocarbon surfactant binary composite foam flooding system. The system is prepared by adopting fluorocarbon surfactant as a foaming agent, adopting a macromolecular compound as a foam stabilizer and adding water; the foaming agent is one or combination of sulphobetaine type fluorocarbon surfactant and amine oxide type fluorocarbon surfactant, or combination of alpha-alkenyl sulfonate and one of sulphobetaine type fluorocarbon surfactant and amine oxide type fluorocarbon surfactant; and the foam stabilizer is partially hydrolyzed polyacrylamide, polyvinyl pyrrolidone K30, polyvinyl pyrrolidone K90 or hydroxyethyl cellulose. An application method comprises that solution of the fluorocarbon surfactant binary composite foam flooding system and nitrogen are alternately injected into a stratum or a rock center so as to improve the recovery rate of crude oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

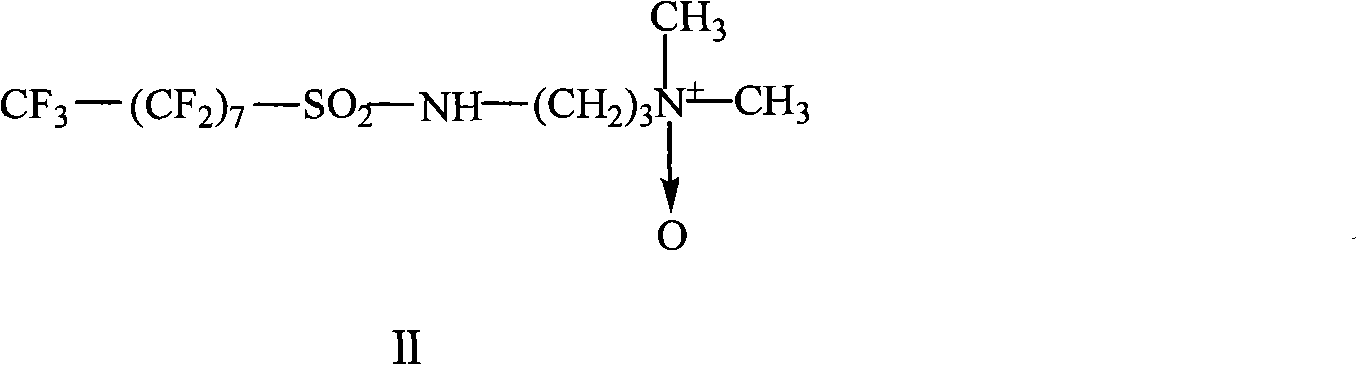

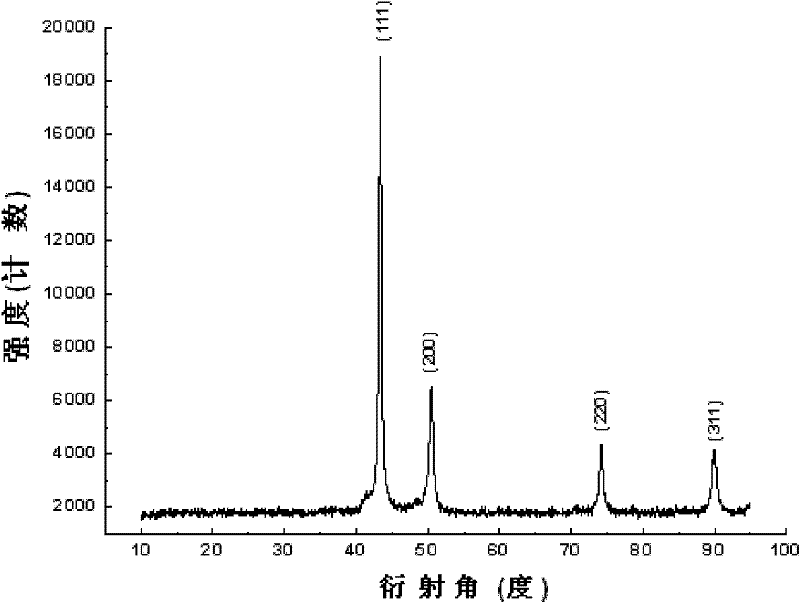

Method of preparing novel silver tin oxide silk electrical contact material

InactiveCN101202169AGranularity is easy to controlImprove surface activityContactsIntermediate frequencyElectric properties

The invention relates to a novel preparing method of a material used for a silver tin oxide wire electric contact. The invention has a process that the material prepared by silver, tin and additives according to a certain proportion is put into an intermediate frequency smelter for melting; a high pressure water atomizing device is adopted for high pressure alloy atomization; atomized alloy powder is dried and oxidated for modification; an isostatic pressing ingot is formed after isostatic pressing treatment; the ingot is agglomerated in a heating furnace; the agglomerated ingot is delivered into an extruding machine to extrude wires; the extruded wire is pulled and annealed to get a finished wire. The material property and electric property of the silver tin oxide wire electric contact material manufactured by the method can satisfy the use condition with high requirement.

Owner:FUDA ALLOY MATERIALS

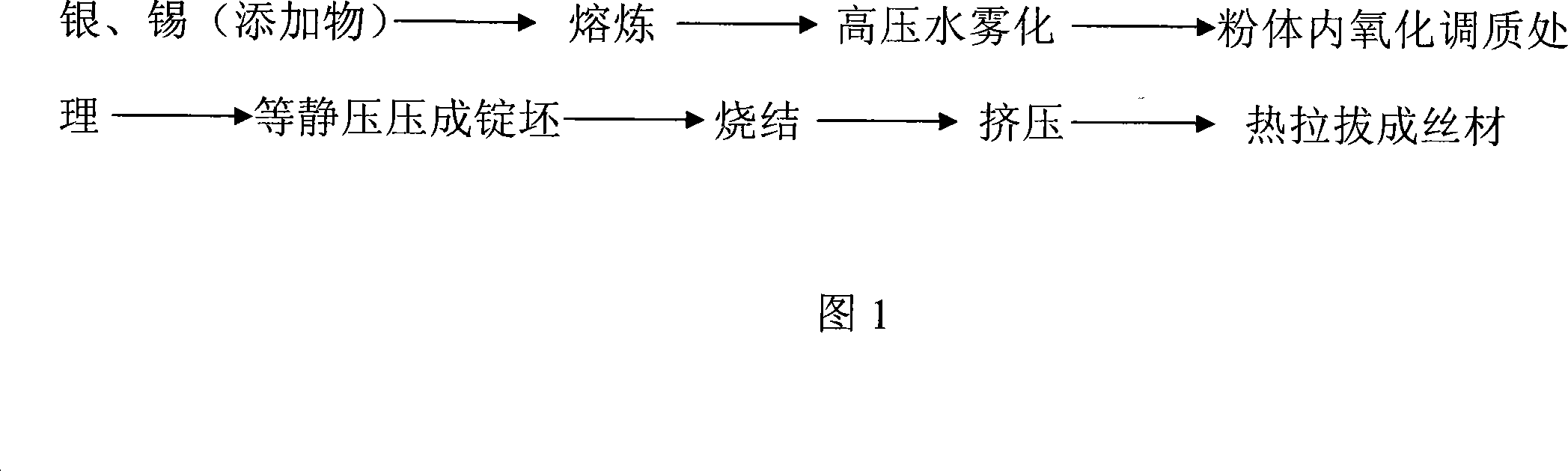

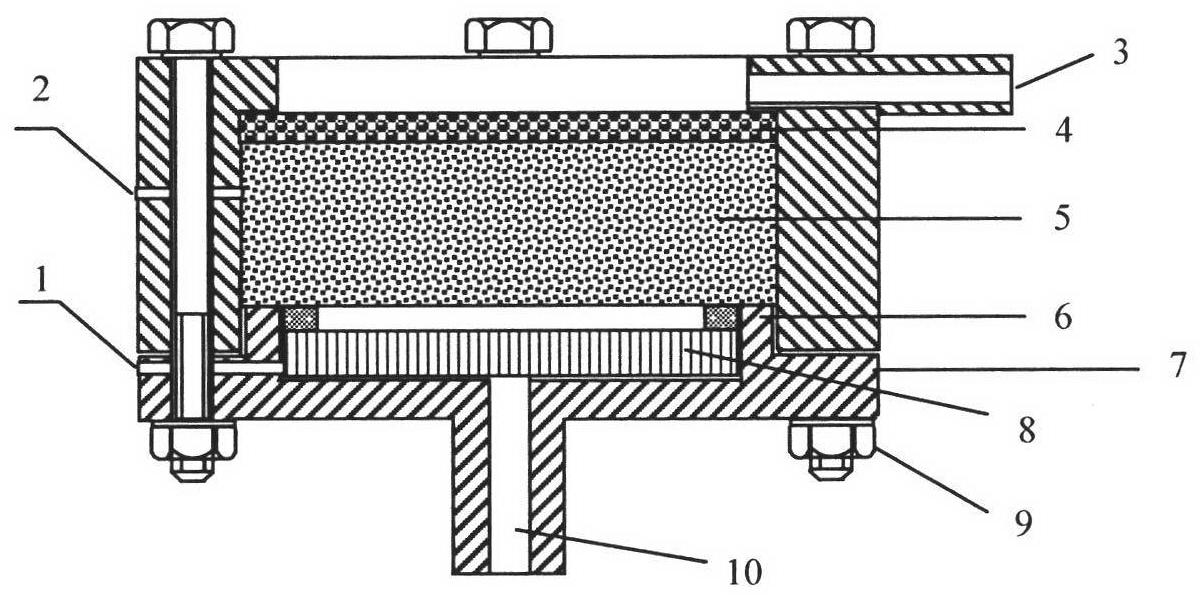

Organic wastewater treatment film reactor utilizing sunlight-assisted electro-catalysis

InactiveCN102603037AAccelerated adsorption/desorption rateThe actual user interface increasesWater/sewage treatment by irradiationEnergy based wastewater treatmentPhoto assistedPorous channel

The invention relates to an organic wastewater treatment film reactor utilizing solar energy photo-assisted electro-catalysis, which comprises a storage tank of water to be processed, a flow controllable constant flow pump, a photoelectric chemical reactor, a clear water storage tank and a solar battery component, wherein a photo anode and a cathode are correspondingly arranged in the reactor; the photo anode takes a porous metal membrane as a base body, and a TiO2 nano tube or a TiO2 mesoporous membrane is formed on the surface of a porous titanium membrane (net) by an electrochemical anisotropic etching technology; a porous channel film is used as the base body; a metal oxide coating electrode with high electrochemical catalytic activity and high electrical conductivity is prepared by a dipping film-forming method, simultaneously, by doping and modifying operations, the electrode material has photo catalytic activity and the reaction efficiency is improved. The reactor integrates electrochemistry, photocatalysis and film separation technologies; the three technologies are coupled to enhance a synergistic effect; the wastewater treatment efficiency can be improved; a solar component is adopted as a power supply; the clean solar energy is utilized to the maximal degree, and the organic wastewater treatment film reactor has social benefits of reducing environment load and economic benefits of reducing cost.

Owner:NANJING UNIV OF TECH

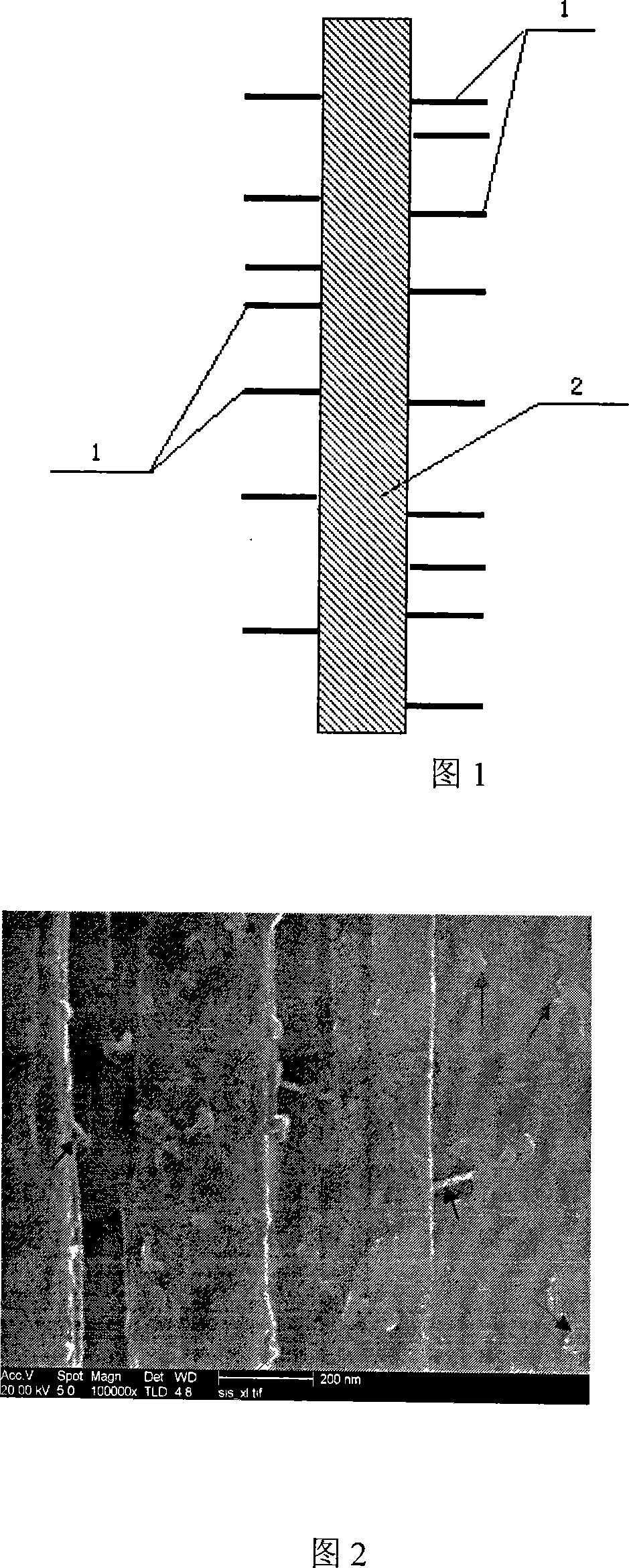

Carbon nano-tube connecting carbon fiber multi-scale reinforcing body and method for producing the same

InactiveCN101173386ATake full advantage of mechanical propertiesRealize chemical bond connectionFibre treatmentArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a multi-scale reinforcement body that carbon nano-tube is connected with carbon fiber and a preparation method aiming at solving the drawbacks of increasing rigidity at the interface, lowering toughness of material and not improving performance of resin base between the fibers and between carbon fiber plywoods after prior carbon fiber treatment is made. The multi-scale reinforcement body of carbon nano-tube connecting carbon fiber is made through combining between a carbon nano-tube decorated by 1, 6 hexamethylenediamine and carbon fiber with acyl chloride functional group on the surface. The preparation method comprises: the carbon nano-tube decorated by 1, 6 hexamethylenediamine and the carbon fiber with acyl chloride functional group on the surface are prepared before put into N,N-dimethylformamide for reaction, thereby getting the multi-scale reinforcement body of carbon nano-tube connecting carbon fiber. The invention has the advantages of big activity on the surface, a plurality of chemical activated functional groups, strong reactive activity, good cohesiveness with the base, improving shearing intensity at the interface for composite material by 127.5% to 144.7% and improving toughness for the base by 34.43% to 48.67%.

Owner:HARBIN INST OF TECH

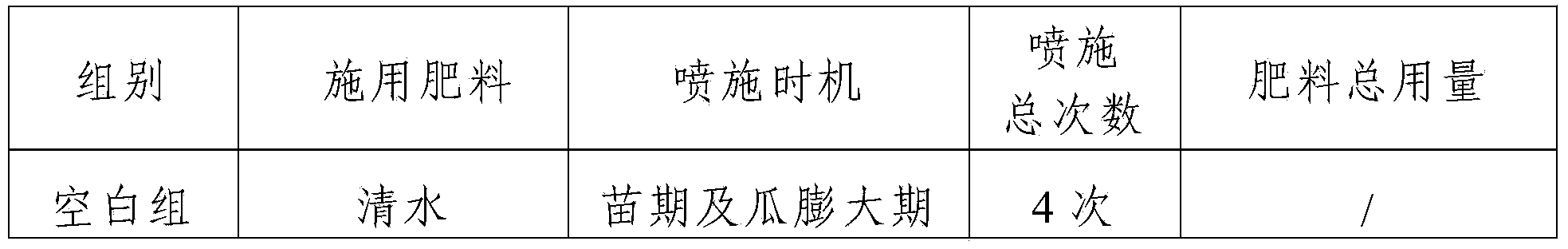

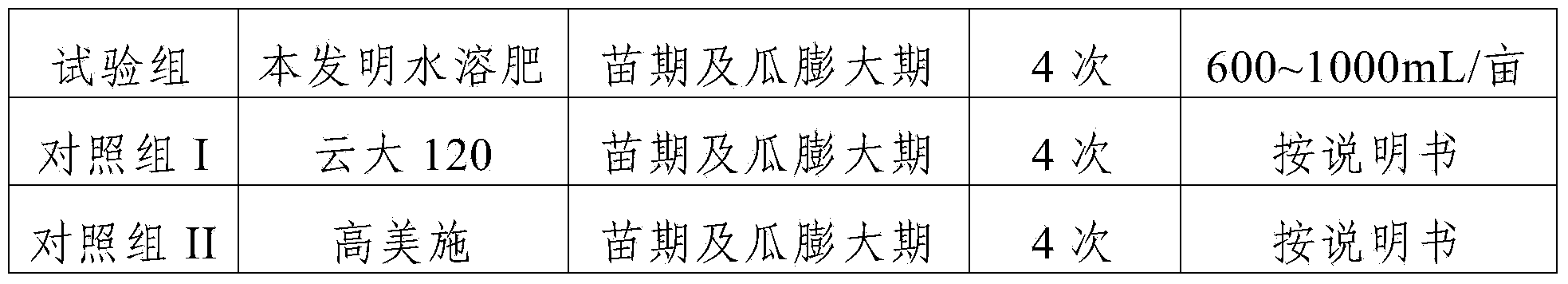

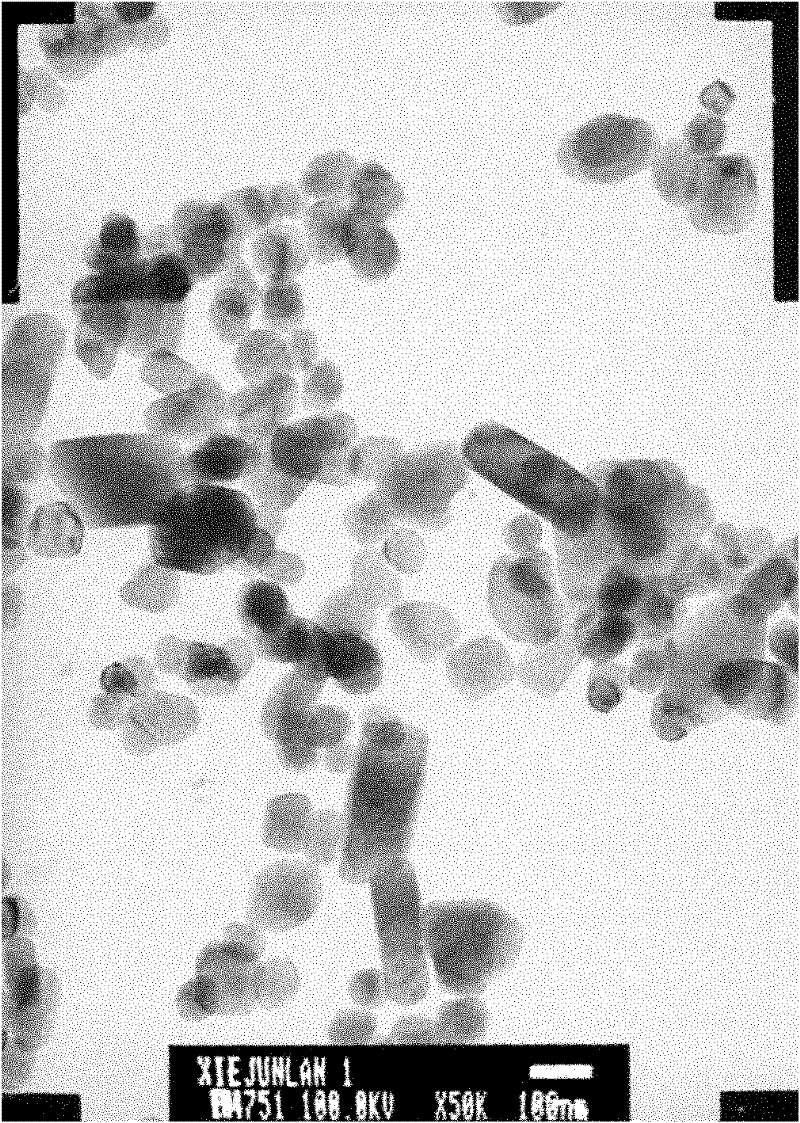

Water soluble fertilizer containing high-concentration humic acid and preparation method thereof

ActiveCN103408373AImprove buffering effectReduce heavy metal contentFertilizer mixturesDipotassium hydrogen phosphateHigh concentration

The invention provides a water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer comprises, by weight, 15-25 parts of a water soluble humic acid salt, 18-25 parts of urea, 9-15 parts of dipotassium hydrogen phosphate, 8-13 parts of potassium acetate, 0.5-2 parts of borax, 0.1-10 parts of polyglutamic acid, 1-5 parts of rhamnolipid, 5-10 parts of a hydroxymethyl cellulose aqueous solution and 30-40 parts of water. The water soluble fertilizer has humic acid content greater than or equal to 150g / L. The invention also provides a preparation method of the water soluble fertilizer containing high-concentration humic acid. The preparation method comprises the following steps of 1, carrying out heating stirring of the water soluble humic acid salt and water to obtain a humic acid salt solution, 2, adding dipotassium hydrogen phosphate, potassium acetate, borax, polyglutamic acid, rhamnolipid and urea into the humic acid salt solution, and carrying out heating stirring to obtain a mixed solution, and 3, carrying out emulsification of the hydroxymethyl cellulose aqueous solution and the mixed solution to obtain the water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer has obvious fertilizer efficiency, is environmentally friendly, stable and uniform and has a wide application range.

Owner:陕西鼎天济农腐殖酸制品有限公司

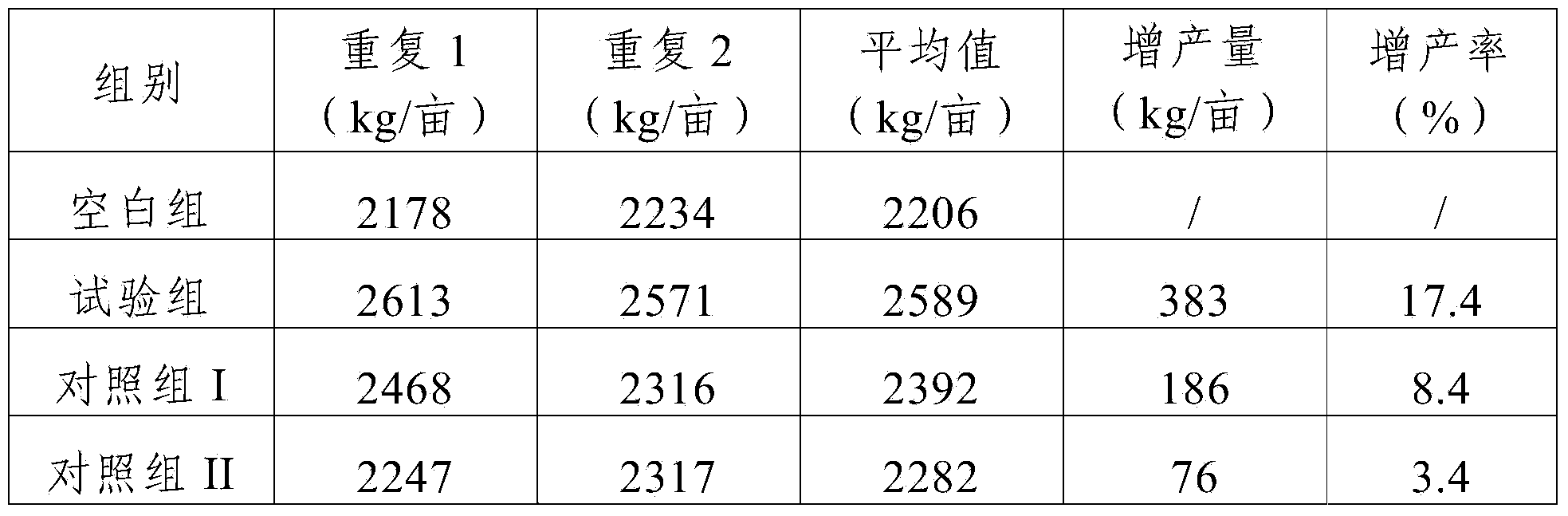

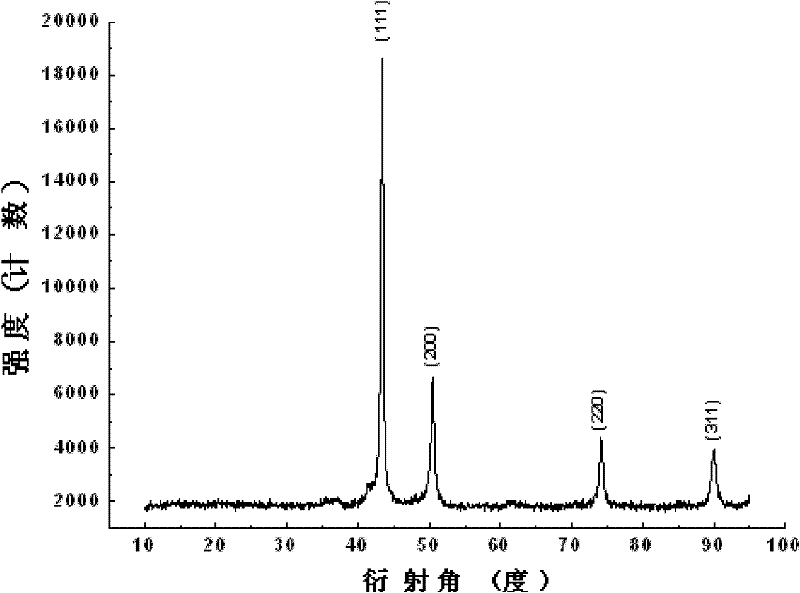

Nano copper powder for electronic paste and preparation process

InactiveCN102205422AUniform particle size distributionGranularity controllableHigh surfaceVacuum drying

The invention discloses nano copper powder for electronic paste and a preparation process. The process is characterized in that: nano copper powder is prepared through the reduction of a reducing agent under the condition of the temperature and the pressure which are produced by a hydrothemal method, and nano copper powder with different appearances and grain diameters can be prepared under the conditions of different temperatures, pressures, reducing agents and dispersing agents. The method comprises the following steps of: adding aqueous solution of a complexing agent into aqueous solution of water soluble copper salt to form the complex aqueous solution of copper; adding an appropriate amount of dispersing agent, stirring to uniformly disperse the mixture, adding an appropriate amount of reducing agent, and adding the finally-obtained mixed solution into a stainless steel high-temperature reaction kettle with a polytetrafluoroethylene lining; heating to a certain temperature; preserving heat for certain time; naturally reducing temperature to room temperature; filtering off precipitate; cleaning by using deionized water and ethanol for multiple times; and performing vacuum drying to finally obtain high-purity nano copper powder with high surface activity and controllable granularity.

Owner:SHENZHEN SENLONT ELECTRONICS

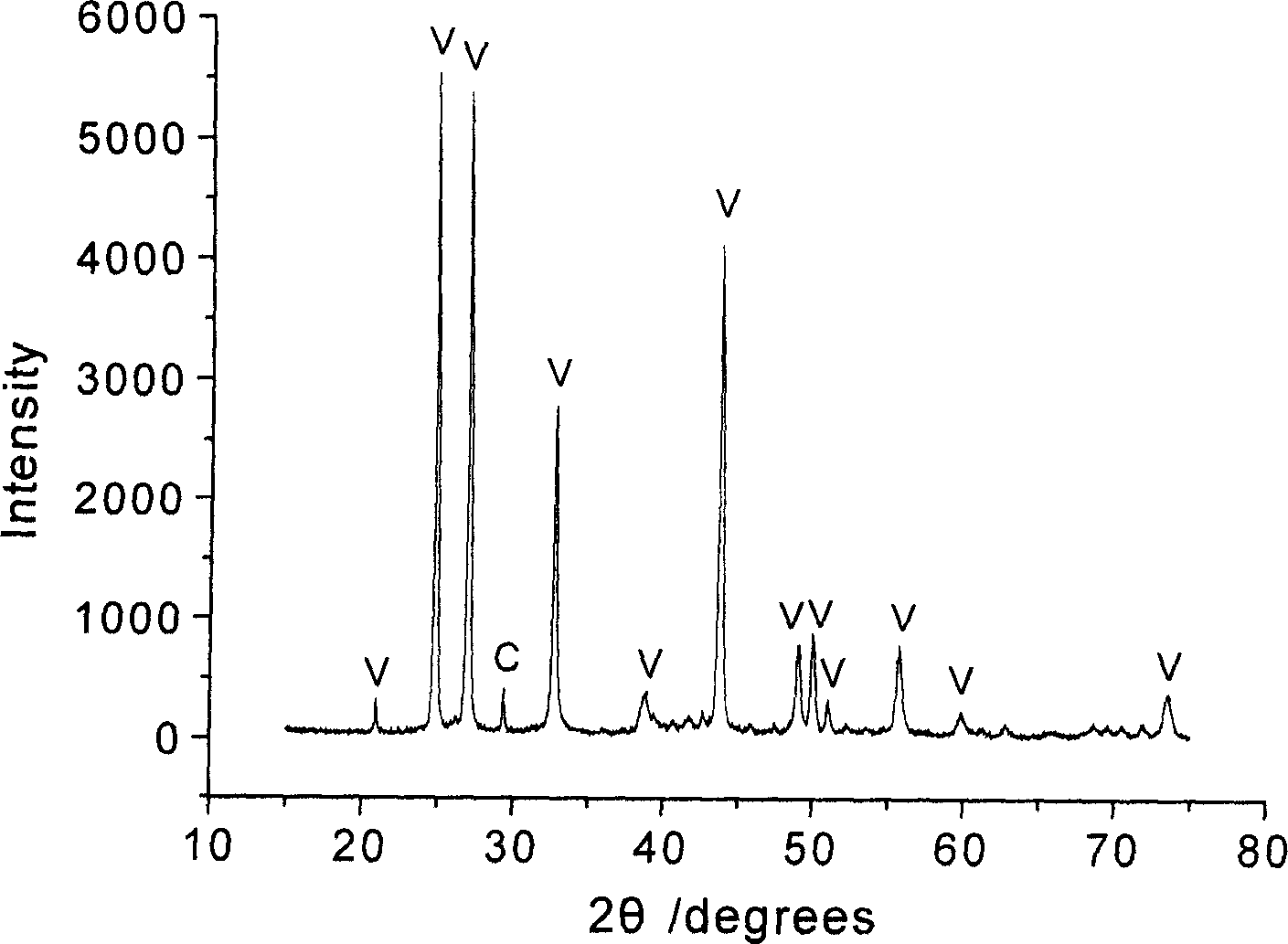

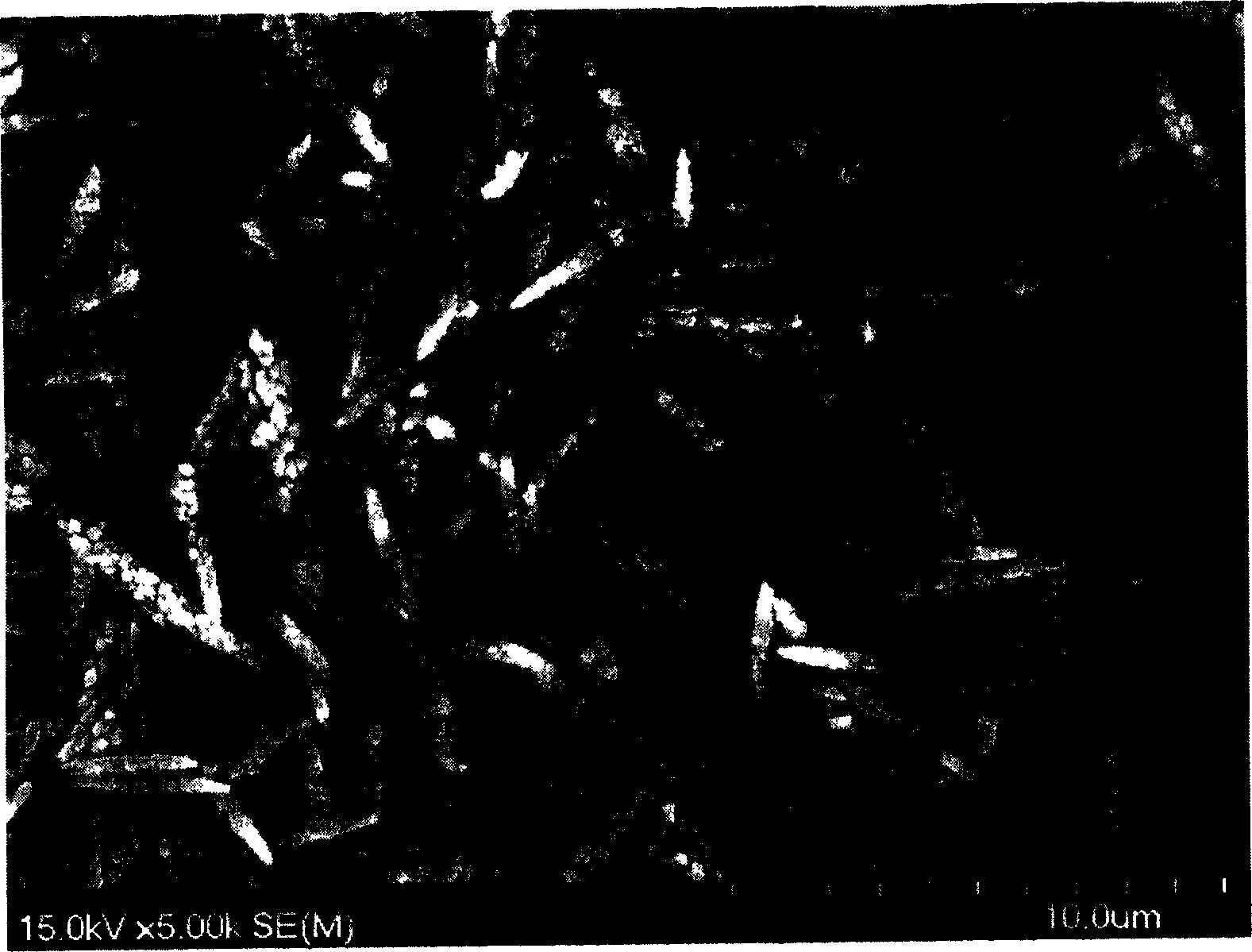

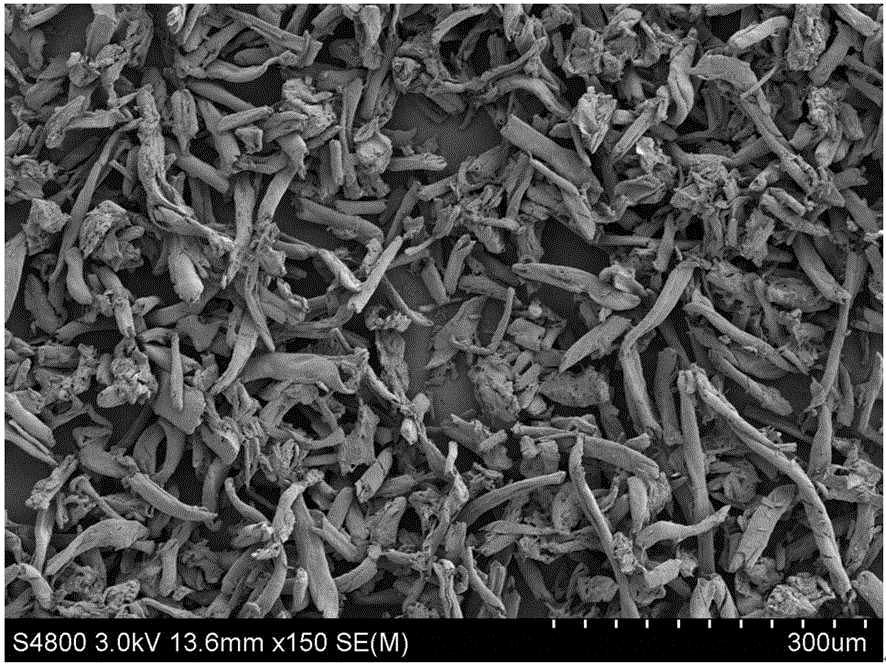

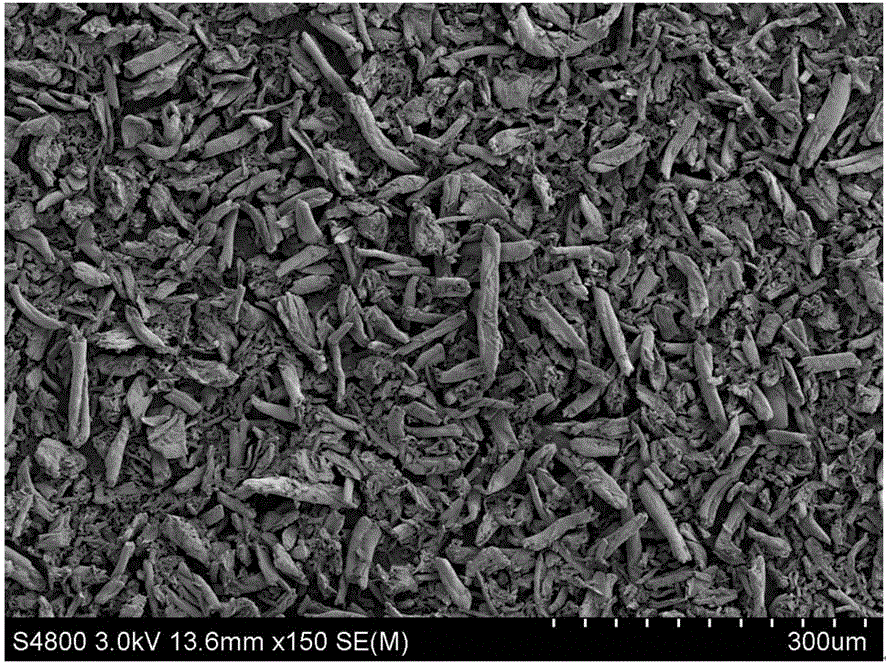

Single dispersing micron chopped fiber-like aragonite type calcium carbonate and preparation method thereof

InactiveCN1631792ASimple methodThe method is simple and controllableCalcium/strontium/barium carbonatesSolubilityPrinting ink

The invention relates to a single-distributive micron short fiber-typed vaterite calcium carbonate and its preparing method. The calcium carbonate crystal is needle short fiber-typed, its length is 2-8 micron and width is 0.3-1.5 micron, the ratio of length and diameter is 5-10, its content of vaterite calcium carbonate is larger than 90% with small particle on the surface of. The preparing method includes mix the aqueous solution of carbonate containing water soluble organic solvent with aqueous solution of calcium salt also containing that, make use of the different dissolubility of carbonate and calcium salt in water soluble organic solvent and water, and the different solvation to calcium ion, compound the product. The calcium carbonate has remarkable single distribution, large ratio of length and diameter, high activity of surface, suitable for coating on paper, filling plastic, coating, printing ink and paper, as well as the raw material for calcium preparations.

Owner:ZHEJIANG UNIV

Cellulose-based magnetic aerogel material and preparation method thereof

ActiveCN104479174AHigh activityHigh specific surface propertiesOrganic/organic-metallic materials magnetismCelluloseFreeze-drying

The invention discloses a cellulose-based magnetic aerogel material and a preparation method thereof. The method comprises the following steps: carrying out chemical modification, thereby obtaining high-activity amphoteric cellulose; firmly combining the amphoteric cellulose and a graphene oxide through electrostatic interaction and hydrogen bonding forces and the like to build a framework of the aerogel material. Disperse loading of a magnetic nano ferroferric oxide can be achieved by virtue of the advantages of high surface activity and super-large specific surface area; the structure uniformity and the stability of the magnetic aerogel of the amphoteric cellulose are ensured through the steps of cross-linking, freeze-drying and the like; the characteristics of high specific surface properties, good affinity, biodegradability and the like of the cellulose are kept by the magnetic aerogel; and the magnetic aerogel obtains high surface activity and superparamagnetic property, has the advantages of low cost, high strength, amphoteric characteristic, biocompatibility and the like, has the characteristics of high specific surface area, high loading capacity, high surface activity, intelligent positioning and the like, and has significant adsorption capacity on pollutants such as heavy metal ions and organic molecules.

Owner:HAIMEN ZHUOWEI TEXTILE CO LTD

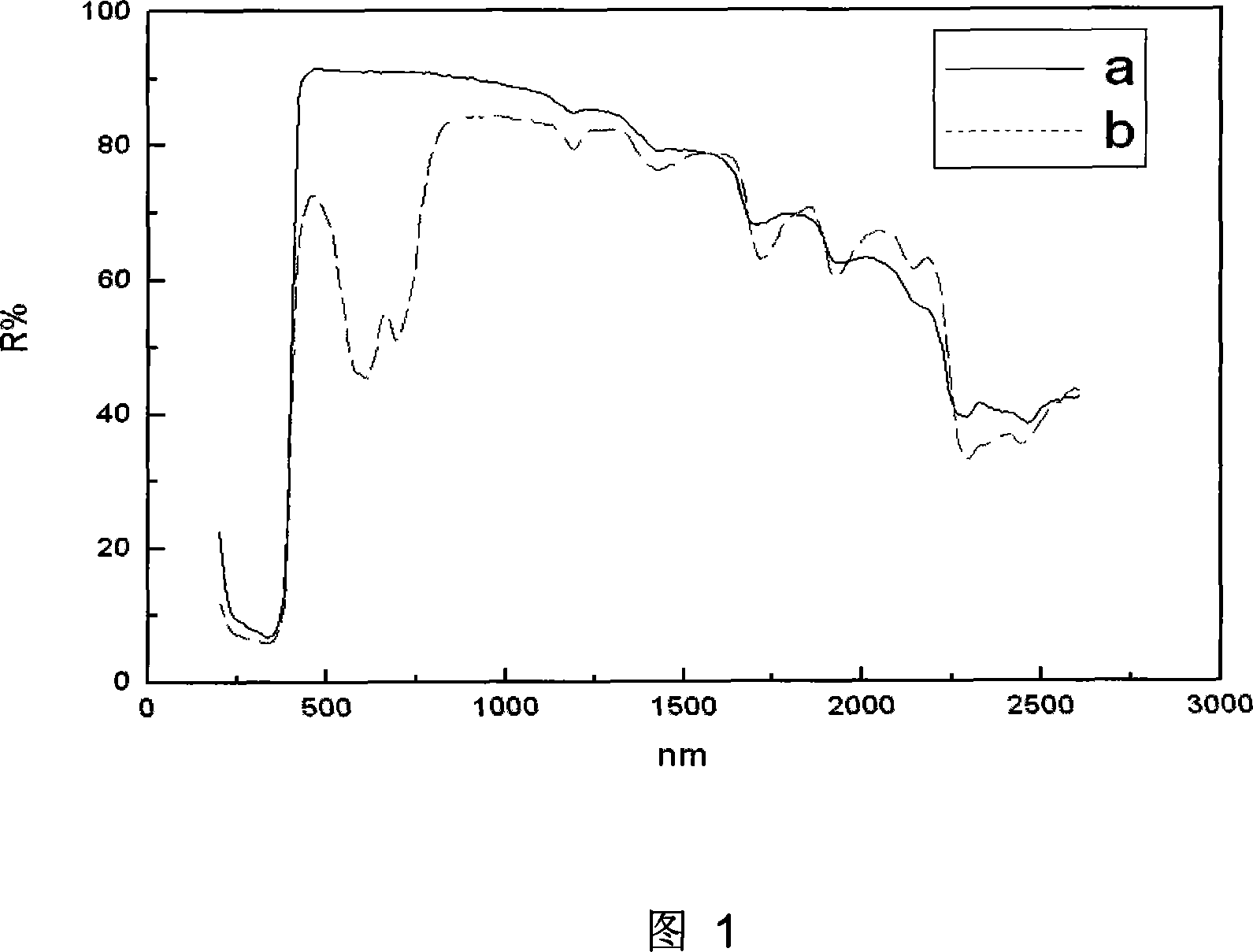

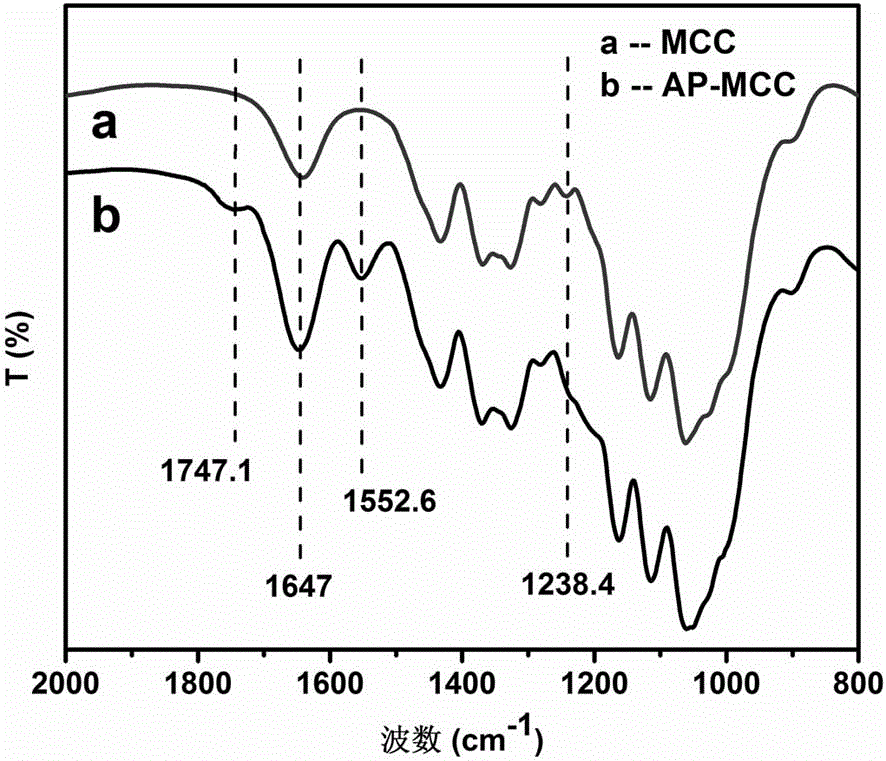

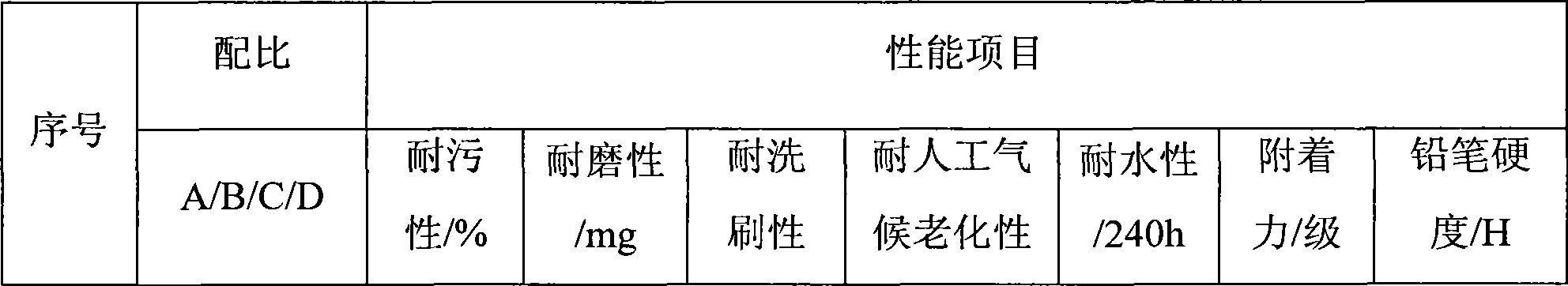

Silicon- and fluorine-containing epoxy (meth) acrylate UV-curing composite coating and preparation method thereof

The invention discloses a silicon and fluorine-containing epoxy (meth) acrylate UV-curing composite coating, comprising the following ingredients of: epoxy (meth) acrylate, polyhedral iligomeric silsesquioxane, fluorine-containing (meth) acrylate, an active diluent monomer, a photoinitiator and an auxiliary agent. Such a composite coating, with excellent fouling resistance, corrosion resistance, weather resistance, abrasive resistance, water resistance, fouling resistance and dynamic performance, is an environmentally friendly coating which is suitable for building material, optical fiber wrapping and the coating of the surface of metal element.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

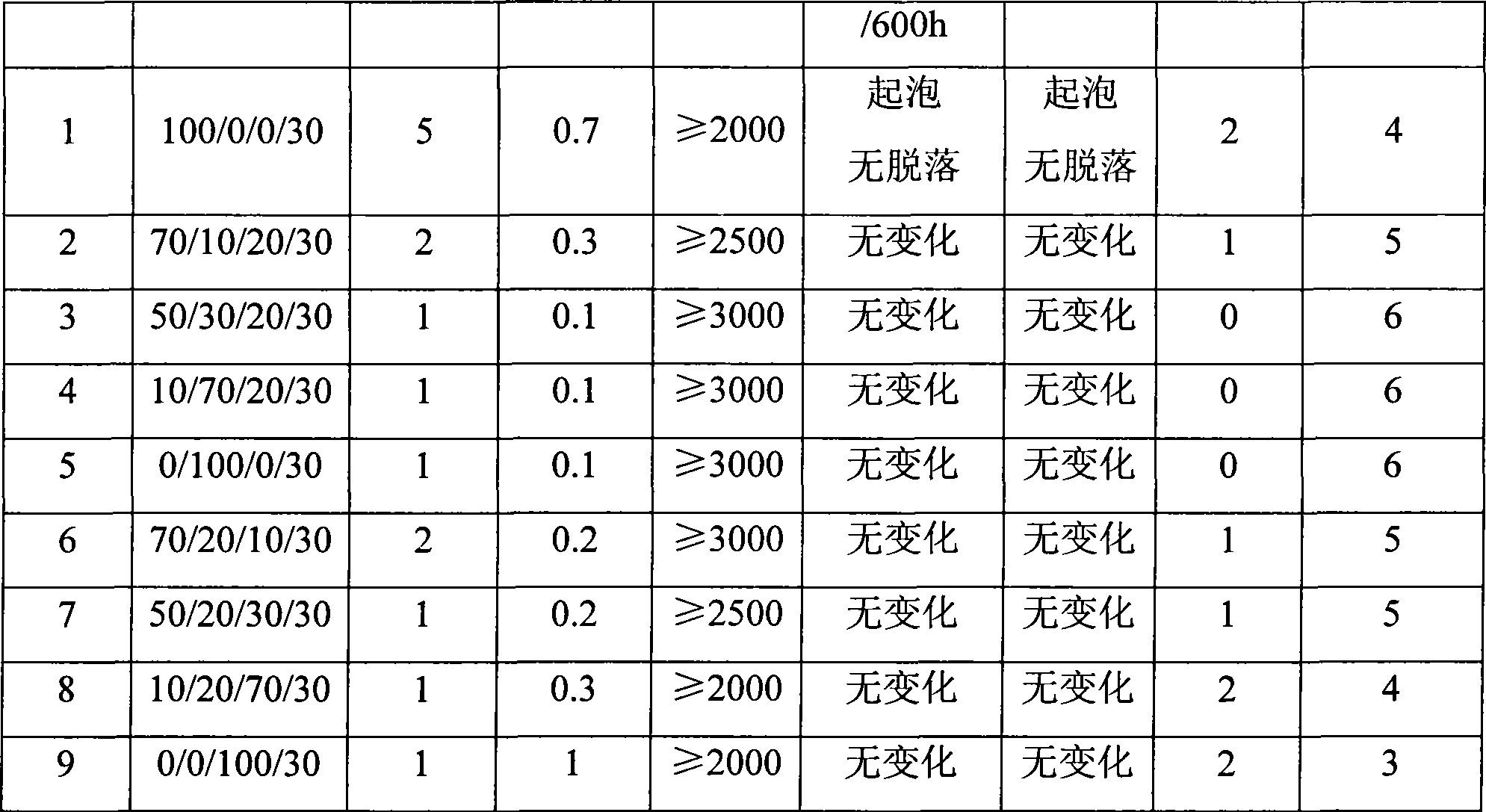

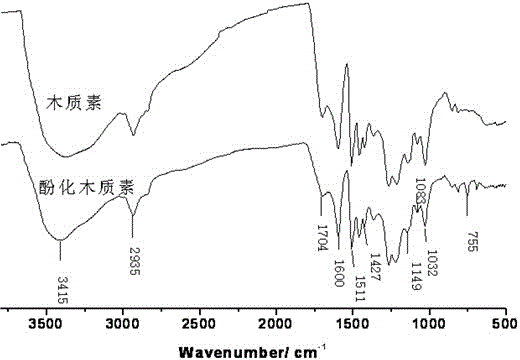

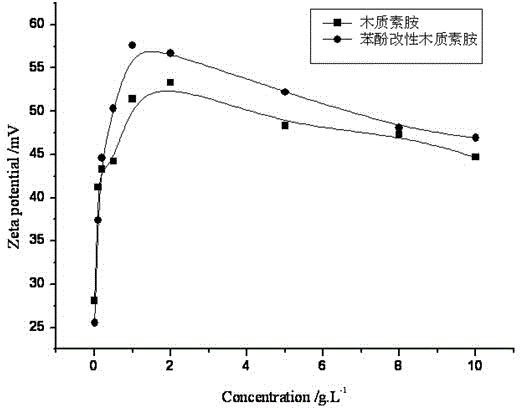

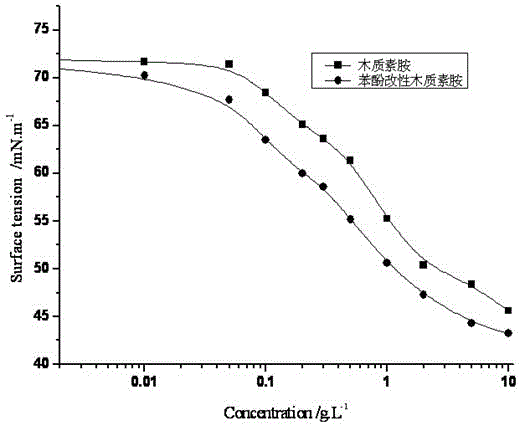

Preparation method of phenolated lignin amine cationic emulsifier

ActiveCN104592530AImprove surface activityImprove stabilityBuilding insulationsEmulsionRoad engineering

The invention discloses a preparation method of a phenolated lignin amine cationic emulsifier. The method comprises the following steps: heating an alkaline liquid of alkali lignin and a proper amount of phenol to 70-100 DEG C and reacting for 1-3h, then, acidizing a reaction liquid to realize pH=2.5 with 1 mol / L hydrochloric acid, performing suction filtration, washing with hot water at 80-100 DEG C until free phenol disappears completely, thus obtaining phenolated lignin; dissolving the phenolated lignin in a NaOH liquid with mass fraction of 10% and regulating pH to 10.5-12, then, further adding a mixed liquid of a certain amount of small molecule polyamine and 37% formaldehyde, reacting for 3-5h at 90 DEG C, then, introducing amine methyl hydrophilic groups into the phenolated lignin, thereby obtaining the cationic emulsifier which has positive electricity under the condition of diluted acid. In comparison with the cationic emulsifier modified by the lignin which is not phenolated, the emulsifier provided by the invention has higher surface activity, stronger Zeta potential and stronger emulsion stability, and can be widely used in the fields of road engineering, building waterproofing, material corrosion prevention, water conservancy construction, and so on.

Owner:GUANGXI UNIV FOR NATITIES

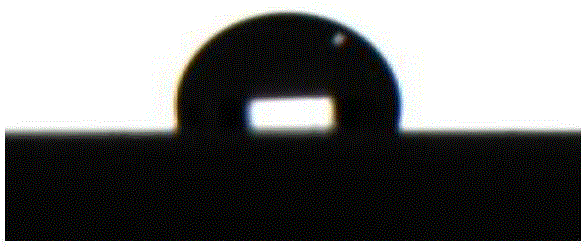

Strong gas-wetting nanosilicon dioxide water block removal agent, preparation method thereof and method for wetting transition of rock surface

ActiveCN104449631AReduce viscous resistanceImprove mobilityDrilling compositionPorous mediumWater block

The invention relates to a strong gas-wetting nanosilicon dioxide water block removal agent, a preparation method thereof and a method for wetting transition of rock surface. The modified nanosilicon dioxide water block removal agent comprises the following raw materials: 0.1-0.5% of modified nanosilicon dioxide, 0.5-1% of an emulsifying agent OP-10, 0.5-1% of lauryl sodium sulfate, 25-50% of ethyl alcohol and the balance of water; the nanosilicon dioxide modified treating fluid is 0.05-0.3% of a non-ionic fluorocarbon surfactant water solution. The invention further provides a preparation method and application of the modified nanosilicon dioxide water block removal agent. The modified nanosilicon dioxide material has a super-hydrophobic and super-oleophobic property, can be used for changing the liquid-wetting property of the rock surface into strong gas-wetting property, so as to reduce the viscous resistance of fluid flowing on the rock surface, improve the flowing status of fluid in a porous medium, remove water blocking damage, is used for low-permeability oil and gas field exploitation and increasing of the oil and gas recovery ratio.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

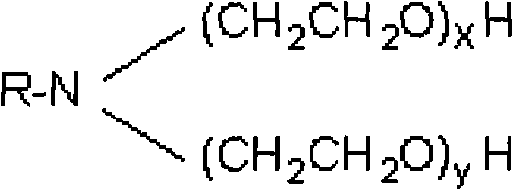

Fabric one-bath deoiling agent

ActiveCN101629130AHigh affinityGood emulsificationNon-ionic surface-active compoundsDry-cleaning apparatus for textilesFiberPolymer science

The invention relates to a fabric deoiling agent, in particular to a fabric one-bath deoiling agent not only suitable for the single deoiling treatment of fabrics, such as terylene, chinlon, cotton, and the like, but also particularly suitable for treating chemical fiber fabrics, such as the terylene, the chinlon, and the like by a deoiling dyeing one-bath method. The invention provides the fabric one-bath deoiling agent with favorable deoiling effect under acidic conditions and an application thereof. The fabric one-bath deoiling agent comprises the following ingredients in percentage by weight: 10-60 polyoxyethylene alkyl amine, 5-40 alkyl sulfonate, 10-50 sulfate surface active agent or / and phosphate salt surface active agent and the balance of water. The fabric one-bath deoiling agent can be used for treating the fabrics of the terylene, the chinlon, the cotton, and the like by the deoiling dyeing one-bath method.

Owner:福建省晋江新德美化工有限公司

Solid matter micro-encapsulated by an aminoplast and method for producing the same

InactiveUS6861145B2Minimal environmentMinimal strainLiquid surface applicatorsGlass/slag layered productsWater insolubleWastewater

This invention relates to micro-encapsulated particles of solid matter and a quasi-continuous method for producing the same, especially those having water-insoluble characteristics or a hydrophobic form, taking into careful consideration ecologically and economically favorable ways of recycling the media used, and the resulting smallest possible amount of waste products such as waste water and polymer residues, while simultaneously ensuring that even exposed parts of the solid bodies are coated, such as crystal tips and grooves, which are insufficiently coated using standard methods due to the hydrodynamic conditions on these areas.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Fluorine-contained surfactant and preparation method thereof

InactiveCN102172491AImprove surface activityHas a block structureTransportation and packagingMixingFluorine containingSURFACTANT BLEND

The invention discloses a fluorine-contained surfactant and a preparation method thereof. The fluorine-contained surfactant is characterized in that a fluorine-contained monomer and a non fluorine-contained monomer, such as acrylic ester are processed by an anion polymerization technology to obtain a segmented copolymer. Compared with the prior art, the fluorine-contained surfactant has a segmented structure, has the advantages of excellent surface activity, pure product, low polymerization temperature, high polymerization speed, wide application prospect and excellent efficacy in the field of leveling; and no active groups or catalysts are introduced in.

Owner:无锡市恒创嘉业纳米材料科技有限公司

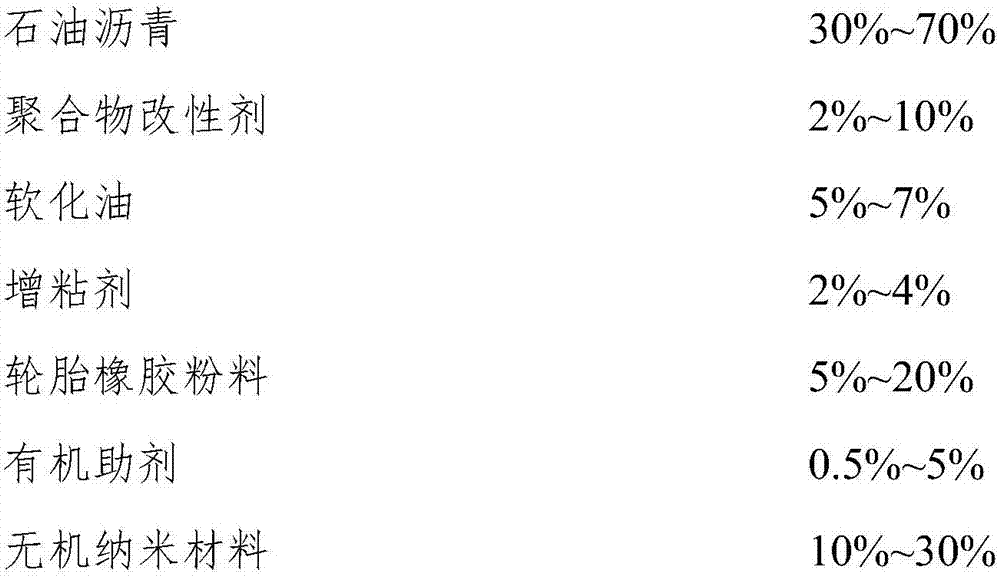

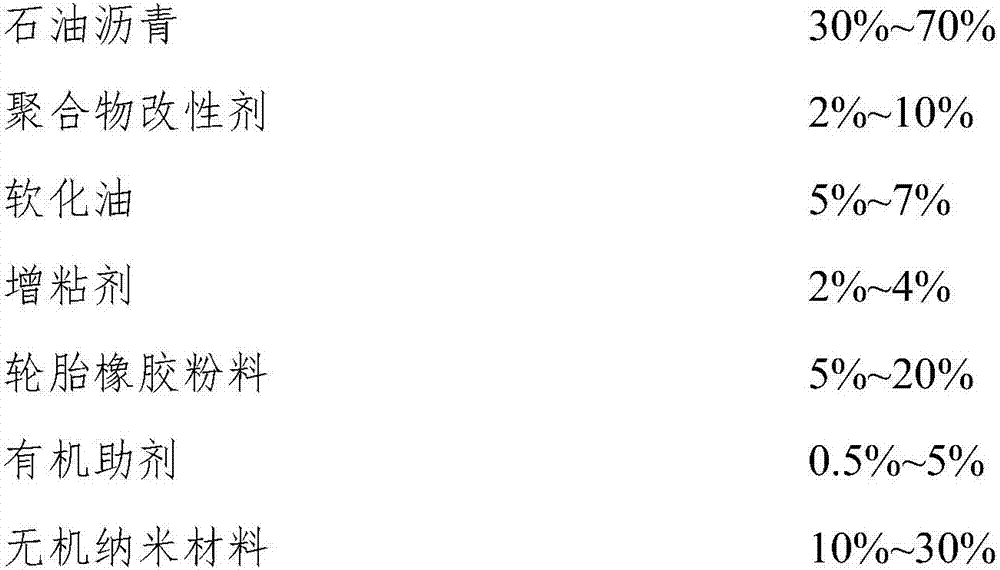

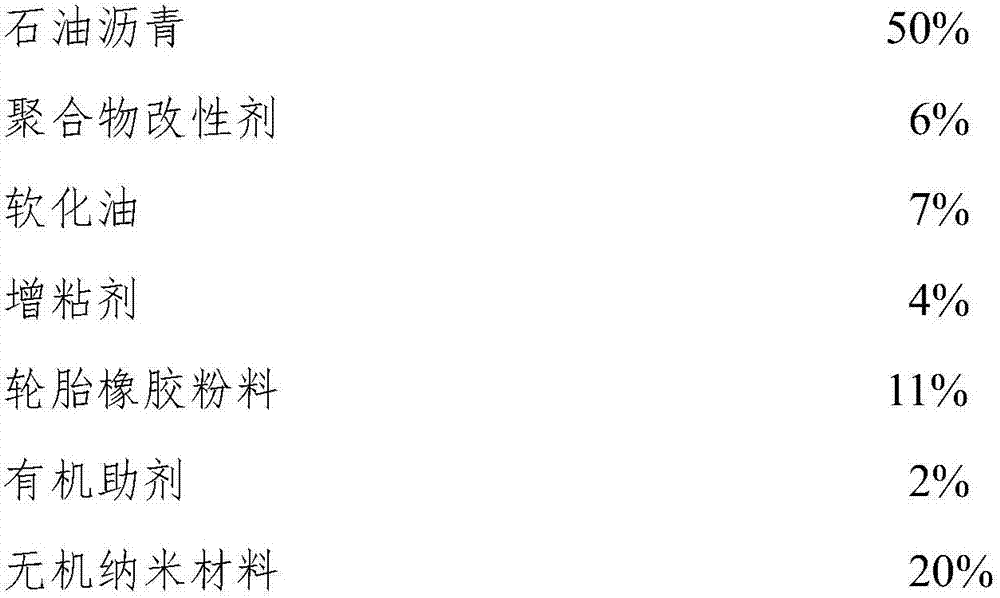

Polymer modified asphalt rubber material and preparation method thereof as well as waterproof coiled material

InactiveCN107286684AImprove high temperature performanceLarge chemical polarityBuilding insulationsBituminous coatingsBuilding materialPetroleum

The invention belongs to the technical field of building materials, and particularly relates to a polymer modified asphalt rubber material and a preparation method thereof as well as a waterproof coiled material. Aiming to solve the technical problems of poorer high temperature performance, low temperature performance and anti-aging performance of an existing modified asphalt rubber material, the polymer modified asphalt rubber material and the preparation method thereof are provided. A raw material formula the rubber material comprises petroleum asphalt, a polymer modifying agent, softening oil, a tackifier, tyre rubber powder, an organic additive and an inorganic nano-material. Meanwhile, the invention also discloses the preparation method of the polymer modified asphalt rubber material. The polymer modified asphalt rubber material provided by the invention has better high temperature performance and low temperature performance; moreover, according to the waterproof coiled material containing the polymer modified asphalt rubber material, the aging resistant performance is enhanced, and the service life of the waterproof coiled material is prolonged.

Owner:中油佳汇(广东)防水股份有限公司

Method for preparing silicate nano-clay/urea resin composite adhesive

ActiveCN101818036AGood dispersionHigh reactivityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesiveDeep processing

The invention provides a method for preparing a silicate nano-clay / urea resin composite adhesive, and belongs to the field of deep processing of non-metallic mine and high polymer materials. The technical scheme of the method comprises the following steps of: first, performing surface activating treatment on the silicate clay; then, inorganically and organically modifying the nano-clay by using soluble silicate solution and a silane coupling agent respectively; and finally, adding the modified nano-clay in a process of synthesizing the urea resin so as to prepare the silicate nano-clay / urea resin composite adhesive. The raw materials of the composite adhesive have rich sources and low price; and the method has a simple process, can effectively reduce the free formaldehyde content of the urea resin, and simultaneously improve the mechanical performance of the urea resin.

Owner:溧阳常大技术转移中心有限公司

Shale gas reservoir pre-fracture composite acid solution, preparation method and application thereof

InactiveCN105086989APrevent collapseCore dissolution rate maintenanceDrilling compositionAcetic acidHydrofluoric acid

The invention belongs to the field of petroleum engineering and relates to a shale gas reservoir pre-fracture composite acid solution and its preparation method and application. The composite acid solution comprises the following components: Component a) at least one component of hydrochloric acid, hydrofluoric acid, fluorboric acid, phosphoric acid, formic acid and acetic acid; and Component b) a corrosion inhibitor, a discharge aiding agent, a ferric iron stabilizer and a clay stabilizer. The composite acid solution containing different acids is selected for different reservoirs. Rock core corrosion ratio is 25-30%. A certain rock core corrosion ratio is maintained, and borehole wall collapse caused by too high corrosion ratio is also prevented. The corrosion inhibitor, the discharge aiding agent, the ferric iron stabilizer and the clay stabilizer which are used as additives have good compatibility with acid. The composite acid solution provided by the invention has advantages of fast dissolving speed, uniform mixing, high corrosion inhibition efficiency, high surface activity, good clay stabilizing effect and wide range. Applicable temperature of the composite acid solution is 20-180 DEG C. by the use of the composite acid solution, normal construction of large-scale fracturing of long horizontal-section shale gas wells can be guaranteed under the condition of existing equipment capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

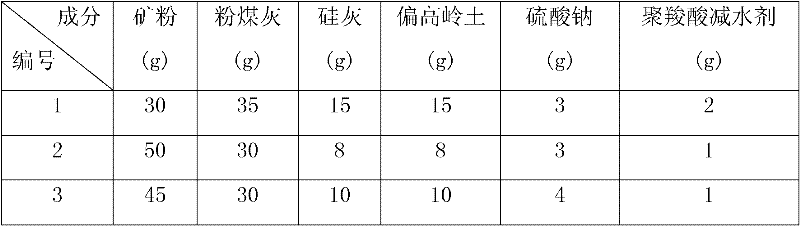

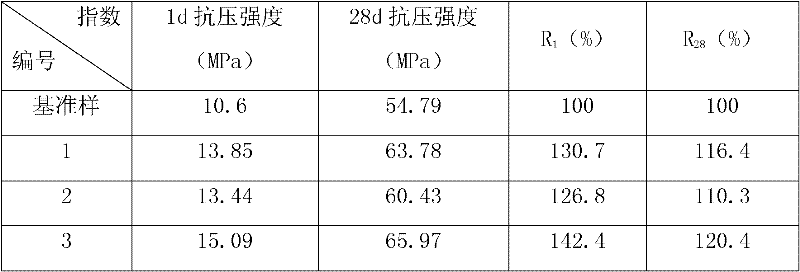

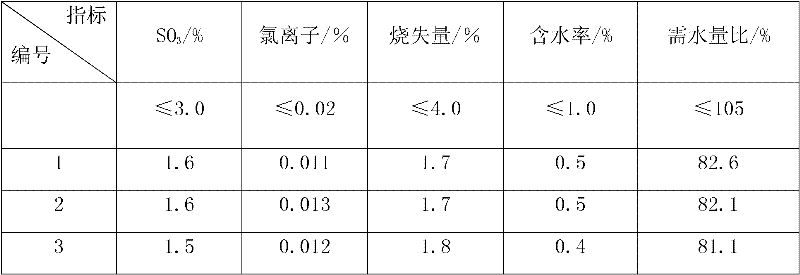

High-early-strength mineral additive for concrete

The invention relates to a high-early-strength mineral additive for concrete, which is characterized in that the high-early-strength mineral additive consists of the following ingredients which are mixed by mass percent: 30-50 percent of mineral powder, 20-35 percent of pulverized coal ash, 5-15 percent of silicon ash, 5-15 percent of metakaolin, 2-5 percent of sodium sulfate and 1-2 percent of polycarboxylate water reducing agent The high-early-strength mineral additive provided by the invention can be used for concrete prefabricated members, grouting materials, patching materials and the like. When 10 percent of high-early-strength mineral additive is added to replace cement to prepare the concrete, the water demand is small, the early activity index is high, the strength development situation is good, and compared with common cement and mineral additives, the dry shrinkage resistance is improved greatly.

Owner:赖斌

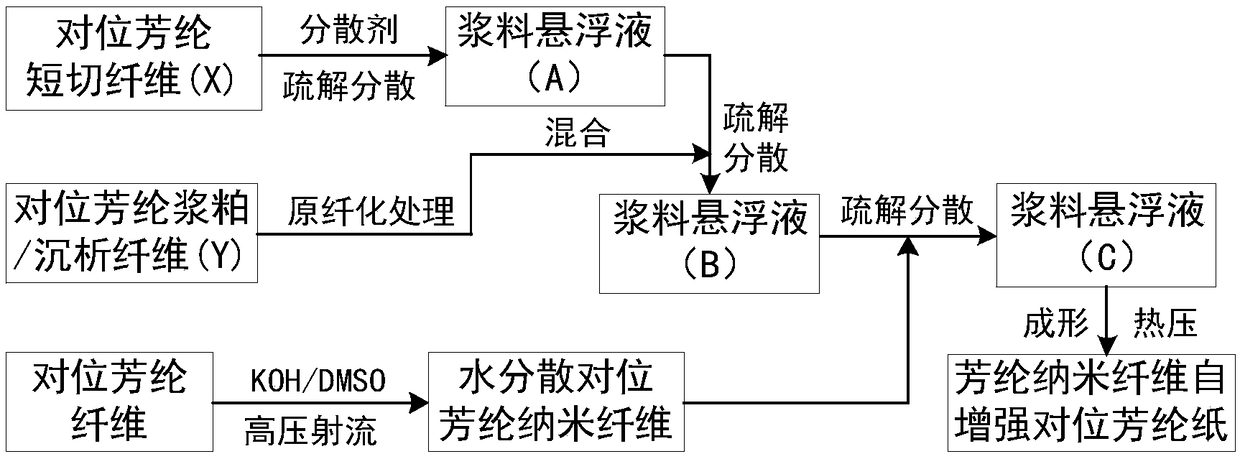

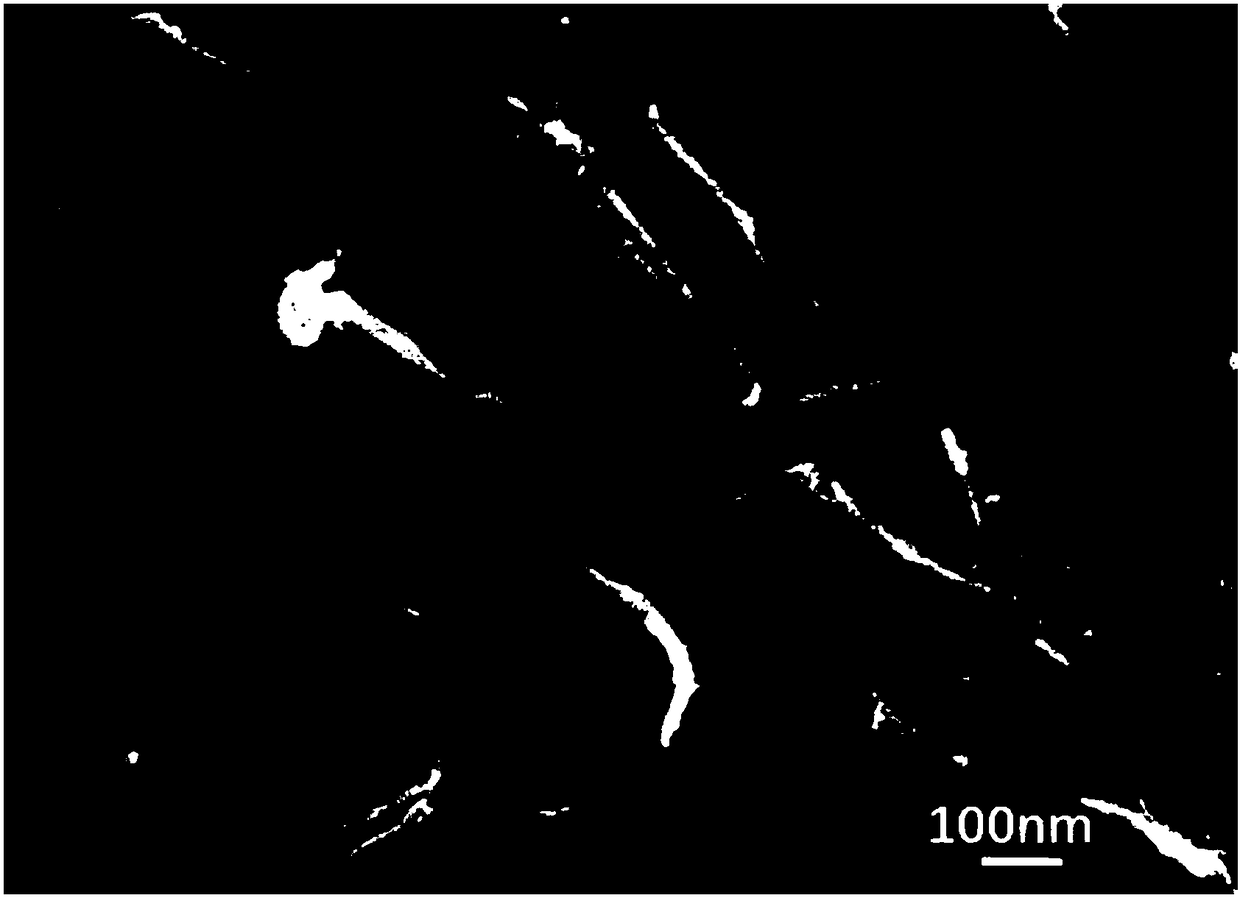

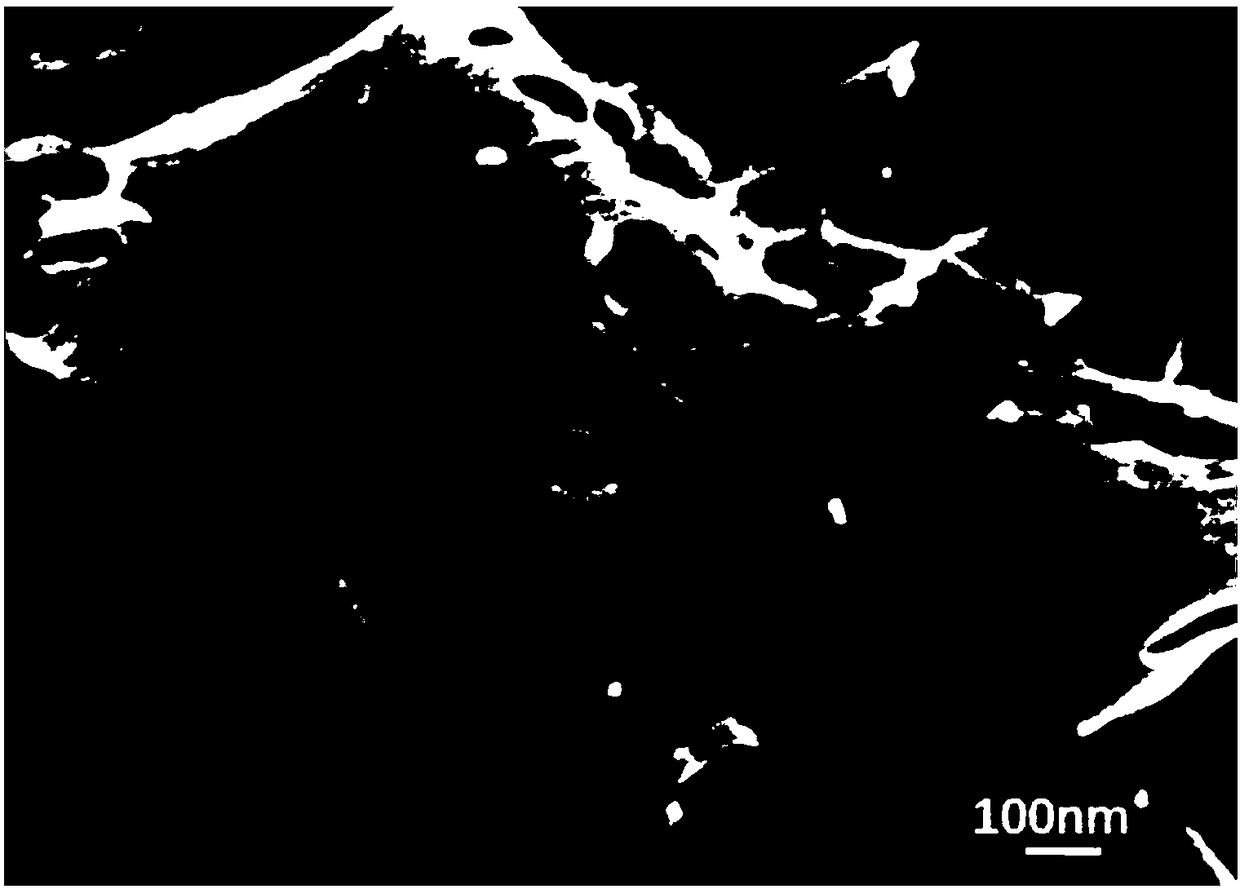

PPTA paper using aramid nanofiber for self-reinforcement and preparation method thereof

ActiveCN108265566AUnique nanoscale structureLarge aspect ratioSpecial paperPaper/cardboardNano structuringHigh surface

The invention discloses a PPTA paper using aramid nanofiber for self-reinforcement and a preparation method thereof. The preparation method includes: utilizing para-aramid paper nanofiber with the advantages of special nano-structure, small fiber diameter, large length-diameter ratio, high surface activity, excellent heat resistance and the like as the self-reinforcement material of para-aramid paper, conducting mixing, defibering and dispersion on aramid chopped fiber, pulp or fibrid and aramid nanofiber to make a uniform suspension, carrying out papermaking shaping, squeezing and drying, andfurther performing hot-pressing on a hot press to obtain aramid paper. The introduced aramid nanofiber enables nanoscale aramid fiber and an aramid nanofilm formed thereby to reach the good interfacefilling, coating and enhancement effects, provides more binding sites for the combination of components, at the same time reduces the pores and holes between components, significantly improves the bonding strength between the aramid paper components, and greatly enhances the mechanical and insulation properties.

Owner:SHAANXI UNIV OF SCI & TECH

Method for transferring graphene films

The invention provides a method for transferring graphene films, which comprises the steps of coating polymer on the graphene films and curing, forming a covalent binding between the polymer and the graphene films, and directly transferring the graphene films from a substrate. Compared with the traditional method, the method for transferring graphene films provided by the invention is simple and easy to operate, and the graphene films can be adhered to the substrate in the way of covalent binding, so that the graphene films are unlikely to fall off; and furthermore, the fresh surfaces of the graphene films can be taken as the constituent parts of the functional devices, so that the effect of the functional devices can be effectively improved and the method is suitable for industrialization.

Owner:许子寒

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com