Fabric one-bath deoiling agent

A degreaser and fabric technology, which is applied in the field of fabric degreaser in the same bath, can solve the problems of unsuitable degreasing and achieve good degreasing effect, good penetration and strong removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

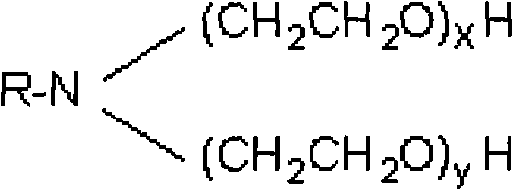

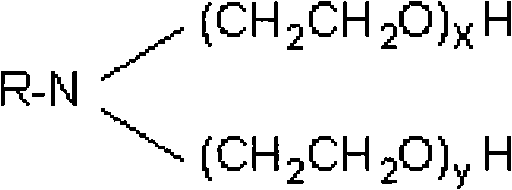

[0027] By mass percentage, the composition of the same-bath degreaser for fabrics is as follows:

[0028] Laurylamine Ethoxylate 50%

[0029] Sodium alpha-olefin sulfonate 10%

[0030] Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 10%

[0031] Sodium fatty alcohol polyoxyethylene ether phosphate 15%

[0032] water balance

[0033] The preparation method of the same-bath degreasing agent for fabric is as follows: Weigh laurylamine polyoxyethylene ether, α-olefin sulfonate sodium, fatty alcohol polyoxyethylene ether sodium sulfate and fatty alcohol polyoxyethylene ether phosphoric acid respectively by mass percentage Sodium ester, then all put into the reaction vessel, add water, raise the temperature to 50°C, stir well, and then the same-bath degreaser for fabrics is obtained.

Embodiment 2

[0035] By mass percentage, the composition of the same-bath degreaser for fabrics is as follows:

[0036] Oleylamine Ethoxylate 60%

[0037] Sodium dodecylbenzenesulfonate 5%

[0038] Sodium fatty alcohol sulfate 10%

[0039] Sodium fatty alcohol polyoxyethylene ether phosphate 15%

[0040] water balance

[0041] The preparation method is the same as in Example 1.

Embodiment 3

[0043] By mass percentage, the composition of fabric degreasing agent is as follows:

[0044] Cocamine Ethoxylate 60%

[0045] Sodium alpha-olefin sulfonate 10%

[0046] Sodium Lauryl Sulfate 10%

[0047] Sodium Laureth Phosphate 10%

[0048] water balance

[0049] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com