Patents

Literature

996 results about "Sodium dodecylbenzenesulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkylbenzene sulfonates are a class of anionic surfactants, consisting of a hydrophilic sulfonate head-group and a hydrophobic alkylbenzene tail-group. Along with sodium laureth sulfate they are one of the oldest and most widely used synthetic detergents and may be found in numerous personal-care products (soaps, shampoos, toothpaste etc.) and household-care products (laundry detergent, dishwashing liquid, spray cleaner etc.). They were first introduced in the 1930s in the form of branched alkylbenzene sulfonates (BAS) however following environmental concerns these were replaced with linear alkylbenzene sulfonates (LAS) during the 1960s. Since then production has increased significantly from about 1 million tons in 1980, to around 3.5 million tons in 2016, making them most produced anionic surfactant after soaps.

Trivalent-chromium blue-white passivator for zinc-plated permanent magnetic material and passivation method thereof

InactiveCN102041497AAvoid pollutionAvoid damageMetallic material coating processesRare-earth elementNickel salt

The invention provides a trivalent-chromium blue-white passivator for a zinc-plated permanent magnetic material and a passivation method thereof. The trivalent-chromium blue-white passivator contains a main film-forming agent, an auxiliary film-forming agent, a stabilizer, an oxidant and a surfactant, wherein the main film-forming agent is a soluble salt of trivalent chromium, the stabilizer is selected from at least one of fluoride, citric acid and oxalic acid, the auxiliary film-forming agent is selected from at least one of soluble cobalt salt, soluble nickel salt or soluble salts of rare-earth elements, the oxidant is nitrate ions or hydrogen peroxide, and the surfactant is NPE (Nonylphenol Polyoxyethylene Ether) or sodium dodecyl benzene sulfonate. The trivalent-chromium blue-white passivator provided by the invention has a low cost, does not pollute the environment, and also does not cause damage to the health of operators.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Chromium-free treating liquid for preparing erosion-resisting oxide film on aluminum alloy surface, treating and using method thereof

ActiveCN101054664AImprove corrosion resistanceGolden colorMetallic material coating processesSodium acetateChromium free

The present invention discloses a chromium-free treatment liquid for preparing corrosion resistant oxidation film at aluminium alloy surface as well as the processing and use method thereof, characterized in that said treatment fluid utilizes a cobalt (III) salt as a main salt and a hypermanganate and a nitrate as a composite oxidizing compound to prepare a composite Co-Mn oxidation film having favorable corrosion resistance performances at aluminium alloy surface. The formula for said treatment liquid is that each litre solution contains cobalt salt of 5 g / L(-1)-20 g / L(-1), kalii permangana of 1 g / L(-1)-4 g / L(-1), sodium nitrate of 1 g / L(-1)-4 g / L(-1), promotor (chlorides and fluorides) of 1 g / L(-1)-4 g / L(-1), sodium acetate of 20 g / L(-1)-50 g / L(-1) and wetting agents (sodium dodecylbenzene sulfonate, OP-10) of 0.5 g / L(-1)-1 g / L(-1). Saic processing and use method comprises (1)sanding the aluminium alloy until its surface is smooth and even; (2) pretreating the aluminium alloy surface; (3) performing a conversion processing by using the treatment fluid; (4) cleaning-up using water and atmospheric-drying naturally. Said treatment fluid in accordance with the present invention possesses the advantages of environmental protection due to its hexavalent chromium-free, fast film-forming speed, simple process, uniform rete, strong corrosion resistance, few environment pollution, and the like.

Owner:GUANGYA ALUMINUM

Neutral blockage removing agent composition used for oilfield mechanical recovery well and preparation method thereof

ActiveCN104194757AGood compatibilityGood miscibilityDrilling compositionSodium acetateActivated attapulgite

The invention relates to a neutral blockage removing agent composition used for a mechanical recovery well in an oilfield. The neutral blockage removing agent composition is prepared from the following components in parts by weight: 16-20 parts of polyepoxysuccinic acid amine, 7-12 parts of hydroxyethylidene dipllosphate sodium, 21-25 parts of divinyl pentaacetic acid amine, 20-25 parts of hydroxyl ammonium acetate, 12-16 parts of activated attapulgite, 21-25 parts of ammonium persulfate, 9-12 parts ofdicyclohexyl sulfobutanedioate sodium, 7-9 parts of butyl lactate, 0.2-0.3 part of vanadium pentoxide, 5-8 parts of straight chain sodium dodecylbenzenesulfonate, 10-14 parts of nitrilotriacetic acid sodium salt, 4-7 parts of urotropin and 0.1-0.3 part of glycerin fatty acid ester. The neutral blockage removing agent composition is suitable for scale removal and blockage removal of an oil pumping unit well and a screw pump well, can effectively control the reaction speed of the blockage removing agent and the scale of the oil pumping unit well and the scaled screw pump well, and prevent the falling-off of big scale residues to result in the secondary blockage of the mechanical recovery well and an oil recovery pump thereof, has high blockage removal speed, is neutral and is free of corrosion; the waste liquid for blockage removal does not need to be discharged onto the ground to be subjected to sewage treatment, the blockage removal time does not exceed 24 hours, and the effect of safe and corrosion-free blockage removal is achieved.

Owner:GANSU HEIMA PETROCHEM ENG

Spray washing method for removing heavy metal from domestic garbage compost

InactiveCN1962562AReduce contentSimple operation processSolid waste disposalClimate change adaptationBrickVolumetric Mass Density

The invention discloses a leaching method to remove heavy metal and restore living rubbish piling fertilizer, which allocates kinds of density of surface activator LAS, DL-malic acid, citrate single or composite leaching agent, wherein the leaching method comprises the following steps: (1) predisposing rubbish piling fertilizer; removing impurity such as plastic film, brick, stone and glass; (2) baking the fertilizer at 60-100 Deg C; removing water; drying for 2-8h; (3) placing rubbish piling fertilizer in the leakage device to collect leaching liquid; leaching the rubbish piling fertilizer; setting the weight of rubbish piling fertilizer and leaching agent at 1: 1-3; leaching for three times; collecting the leaching liquid.

Owner:TIANJIN NORMAL UNIVERSITY

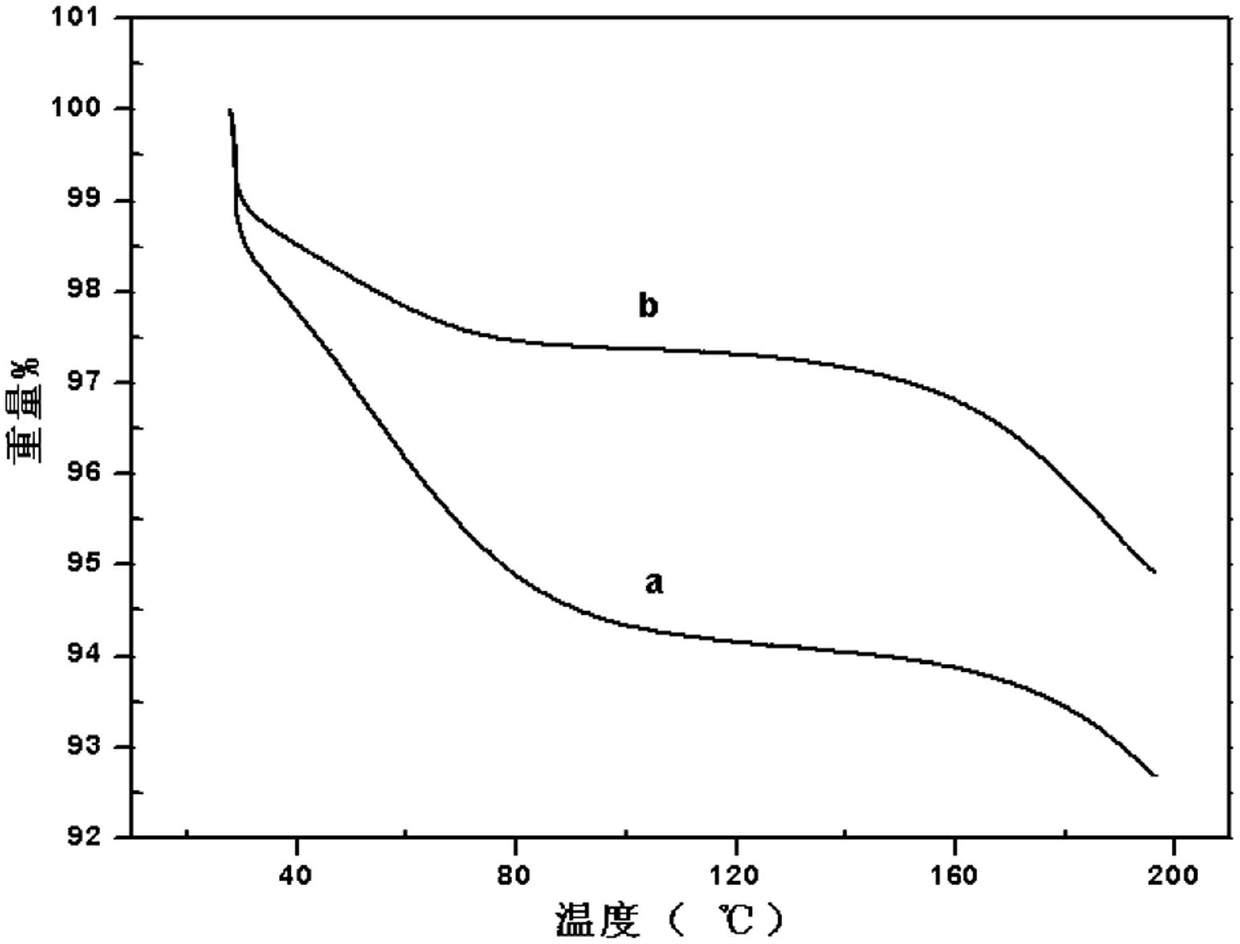

Gas hydrate generation accelerant and preparation method thereof

ActiveCN103663451AEnhance heat and mass transferShorten the timeCarbon compoundsGeneration processLiquid water

The invention belongs to the field of gas hydrate production and utilization and in particular relates to an accelerant capable of reinforcing gas hydrate generation and a preparation method thereof. The hydrate generation accelerant is a mixed water solution formed by compounding nano dispersed particles with a surfactant and dissolving the compound in water, wherein nano graphite powder is adopted as the nano dispersed particles; SDBS (sodium dodecylbenzenesulfonate) is adopted as the surfactant; based on the total amount of the mixed water solution, the mass fraction of the nano graphite powder is 0.05-1.5%, the mass fraction of SDBS is 0.02-0.08% and the balance is water. The accelerant has the obvious advantages that the mass and heat transfer processes of the hydrate can be greatly reinforced, the overall time of hydrate generation can be shortened and the synthetic efficiency of the hydrate can be improved by adopting the accelerant to reinforce the hydrate generation process; the graphite nano-particles can flow out along with liquid water and can be reused, thus saving the cost.

Owner:溧阳常大技术转移中心有限公司

Method for wetting hydrophobic porous polymeric membranes to improve water flux without alcohol treatment

A method is provided for substantially instantaneously wetting hydrophobic, porous polymeric membranes and for rendering hydrophobic membranes hydrophilic. The method involves treating the membrane with a non-alcoholic aqueous solution of a low molecular weight surfactant, and then drying the treated membrane. The low molecular weight surfactant exhibits high polymer affinity for the hydrophobic membrane substrate as well as high water solubility; a preferred surfactant is sodium dodecylbenzenesulfonate (SDBS). The method is particularly useful for treating hydrophobic membranes such as those made of polyolefins, fluorinated or chlorinated polymers, polysulfone, or polyethersulfone, preferably having a pore size of about 0.01 microns to about 1 micron. A wettable membrane is thus provided as the aqueous surfactant solution is absorbed into the hydrophobic membrane.

Owner:HYDRANAUTICS

Prepn process of RE nano oxide

Nano RE oxide is prepared through the process of: selecting single RE oxide R2O3, where R is La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y and Sc, or their mixture as raw material; dissolving in water solution of nitric acid or hydrochloric acid to reach a RE ion density of 0.1-0.4 mol / L; heating to 30-80 deg.c; adding dispersant sodium dodecyl benzenesulfonate, polyoxyethylenated alcohol, SPAN-80 or Tween-80 and precipitant to form RE carbonate precipitate; filtering, drying, and heating to 700-900 deg.c to obtain single or mixed nano RE oxide. The nano RE oxide has grain size smaller than 40 nm and specific surface area of 20-40 sq m / g.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

2, 4, 6-trichlorophenol adsorbing agent and application thereof

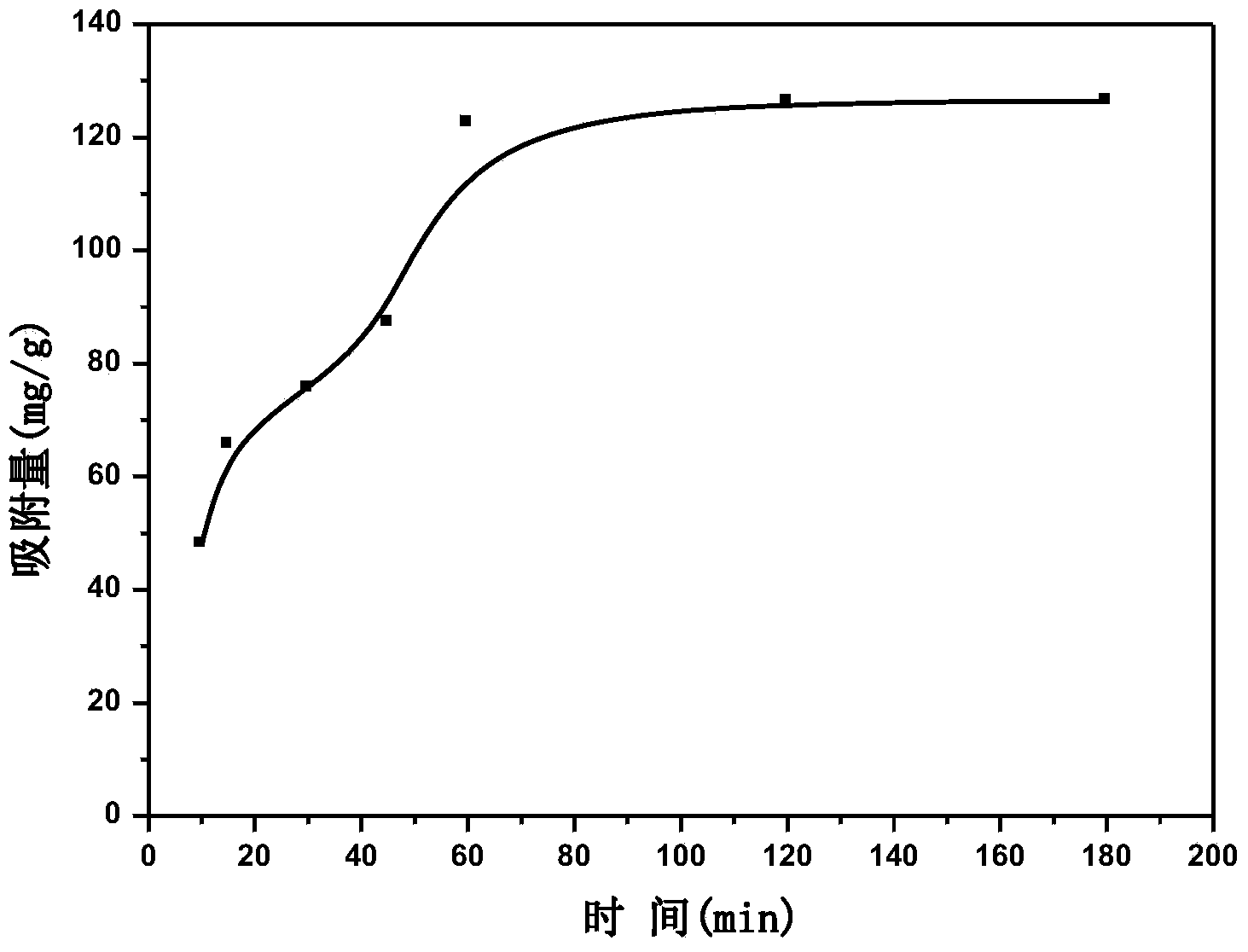

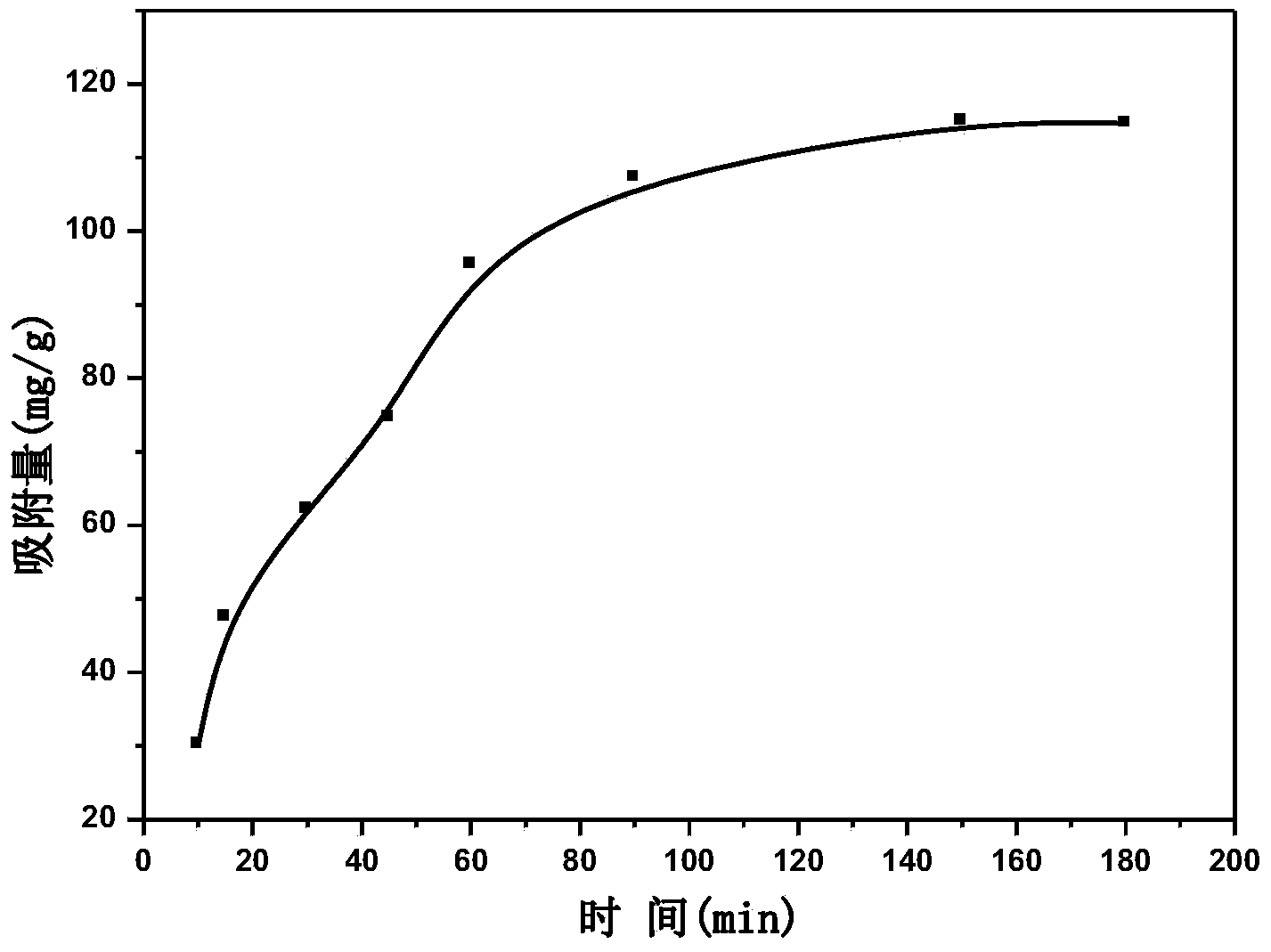

InactiveCN104289184AImprove adsorption capacityOptimizing Adsorption ConditionsOther chemical processesWater contaminantsSorbentHydrotalcite

The invention provides a purpose of modified hydrotalcite based on dodecyl benzene sulfonate and lauryl sulfate, and particularly relates to an adsorbing agent used for adsorbing 2, 4, 6-trichlorophenol in a wastewater solution. According to modified hydrotalcite, with sodium dodecyl benzene sulfonate (SDBS) and sodium dodecyl sulfate (SDS) as a modifying agent, modified Zn2Al-LDHs is prepared and obtained by a co-precipitation method, the adsorbing agent has larger laminated plate spacing compared with the adsorbing agent before modification, and the hydrophilic surface becomes hydrophobic after modified. The adsorbing agent adsorbs 2, 4, 6-trichlorophenol and reaches adsorbing balance after 2-3 hours under the conditions that the pH value is 3-5 and the temperature is 25-35 DEG C; the adsorbing capacity reaches 100-160mg / g, and the adsorption rate reaches 70-83%. The adsorbing agent is applicable to 30-300mg / L wastewater solution containing 2, 4, 6-trichlorophenol and has the characteristics that the price is low, the adsorbing capacity is large and the adsorbing process is simple and convenient and is easy to operate and the like.

Owner:BEIJING UNIV OF CHEM TECH

Water glass inorganic gel plugging agent as well as preparation and using methods thereof

The invention relates to a plugging agent and specifically relates to a water glass inorganic gel plugging agent as well as preparation and using methods thereof. The product comprises the following components in percentage by weight: 10-40% of water glass, 0.1-0.3% of polyacrylamide, 0.1-0.2% of sodium dodecyl benzene sulfonate, 0.1-0.3% of aluminum dihydrogen phosphate, 1-6% of N, N-dimethylformamide and the balance of water. The preparation method comprises the following steps: adding the water into a container, opening a stirring device, adding the polyacrylamide, curing for 10-15min, then sequentially adding the sodium dodecyl benzene sulfonate, the aluminum dihydrogen phosphate, the N, N-dimethylformamide and the water glass, stirring for 5-10min when one material is added, and continuously stirring for 10-15min after the end of adding of all the materials to obtain the water glass inorganic gel plugging agent. Compared with the prior art, the water glass inorganic gel plugging agent can be used for high-temperature and medium and low-permeability oil deposits, and has the characteristics of low initial viscosity and easiness in injection.

Owner:PETROCHINA CO LTD

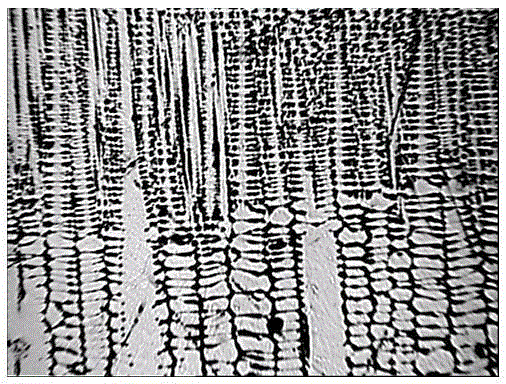

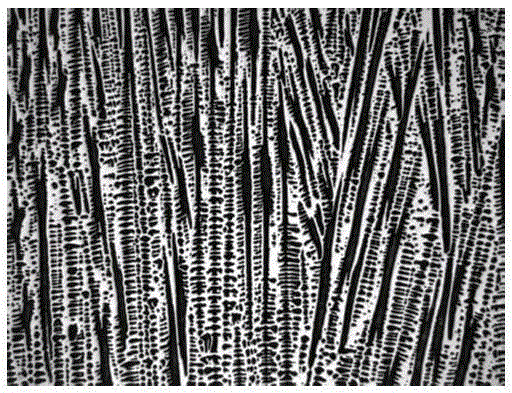

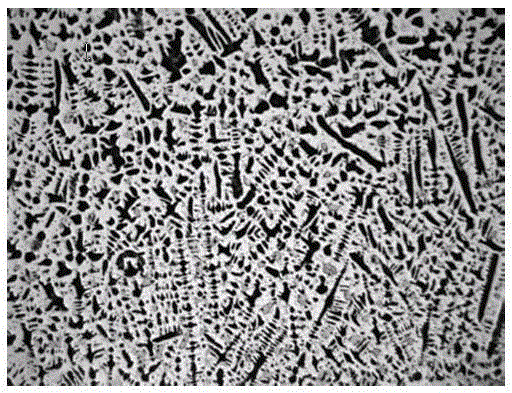

Erosion agent capable of displaying solidified dendritic structure of Fe-36 Ni invar alloy and erosion method of erosion agent

ActiveCN105386057AModerate erosion timeSimplify operating proceduresPreparing sample for investigationInvar alloyAlcohol

Disclosed are an erosion agent capable of displaying the solidified dendritic structure of a Fe-36 Ni invar alloy and an erosion method of the erosion agent. The erosion agent includes 1 g-2 g of picric acid, 0.5 g-1 g of anhydrous cupric chloride, 50 ml-60 ml of absolute ethyl alcohol, 0.5 ml-1 ml of hydrochloric acid and 1 g-2 g of sodium dodecylbenzene sulfonate. The erosion method of the erosion agent includes the steps that the prepared erosion agent is heated to the temperature of 50 DEG C-60 DEG C, a processed sample with the downward polishing face is suspended in the heated erosion agent to be eroded for 20 s-30 s, the eroded surface is wiped with ethyl alcohol firstly after erosion is completed, and then the sample is slightly polished at the one fourth radius position of a polishing machine for 4 s-6 s so that a copper film generated on the eroded surface can be removed. According to the method, the operating procedure is simple, the erosion effect is good, and the solidified dendritic structure of an invar alloy can be observed quickly and clearly, so that the solidification condition corresponding to continuous casting is obtained, and technical bases are provided for optimizing the continuous casting process technologies.

Owner:山西高义钢铁有限公司

Austenitic stainless steel cleaning and passivating agent

InactiveCN109487280AAccelerated corrosionLess corrosiveMetallic material coating processesPhosphoric acidYttrium

The invention discloses an austenitic stainless steel cleaning and passivating agent. The austenitic stainless steel cleaning and passivating agent is composed of, by mass, 30%-40% of citric acid, 0.1%-1% of ethylene diamine tetraacetic acid disodium, 1%-5% of 1-hydroxyethylidene-1,1-diphosphonic acid (HEDP), 3%-8% of glycollic acid, 3%-8% of phosphoric acid, 0.1%-2% of a non-ionic surface activeagent, 0.5%-3% of 322H, 0.5%-1% of sodium dodecylbenzenesulfonate, 0%-0.5% of yttrium nitrate, 0.1%-1% of corrosion inhibitor and the balance water. The prepared degreasing, rust removing and passivating agent has the characteristics of being environment-friendly, free of pungent smell and free of toxicity, harm to people and the environment can be remarkably reduced, and the production cost is effectively reduced.

Owner:安徽笃舜智能装备有限公司

Paint remover and method for removing paint from surface of plastic articles

InactiveCN1831052ACause damageHigh paint removal efficiencyChemical paints/ink removersCelluloseAccelerant

This invention relates to a paint remover composing and a method of using it to remove pain on plastic surface. It includes water, alcohols, solve accelerant agent and surface activator, the alcohols is at least one of methanol, ethanol, normal propyl alcohol, isopropyl alcohol, normal butyl alcohol, isobutyl alcohol, ethylene glycol. The alcohol can be replaced by cellulose solution, and the cellulose solution is at least one of methyl cellulose, ethyl cellulose or propyl cellulose. The solution accelerant is sodium hydroxide, and the surface activator is one of sodium dodecanesulphonate or sodium dodecyl sulfate. The method is that the paint remover is heated to 20-70 degrees centigrade, and the plastic is agitated in the paint remover for 5-20 minutes for fully contact to the agent. The remover in this invention has high paint removing efficiency, the cost is low, and less pollution to environment.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Metal polishing solution

The invention discloses metal polishing solution, which comprises the following components in percentage by weight: 15-20% of sodium oleate, 2-5% of citric acid, 5-7% of sodium tripolyphosphate, 3-4% of sodium dodecyl benzene sulfonate, 1-2% of 2-(heptadecene)-4,5-dihydro-1H-imidazole-1-ethanol, 8-10% of quartz sand and the balance of water. According to the metal polishing solution disclosed by the invention, greasy dirt and rust spots on the surface of a metal appliance, such as steel, iron, copper and aluminum can be effectively removed, and metallic luster of the appliance is kept and the appliance is bright as new, and the appliance is prevented from being rusted again for more than one year after cleaning one time.

Owner:深圳市永霖科技有限公司

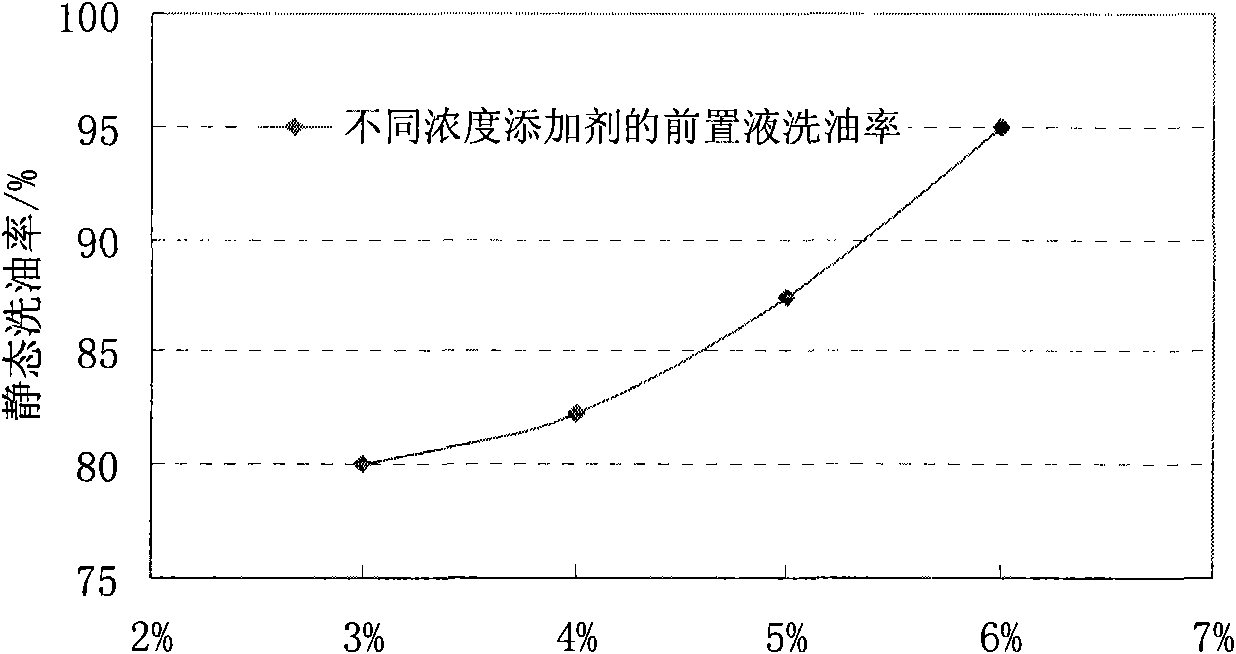

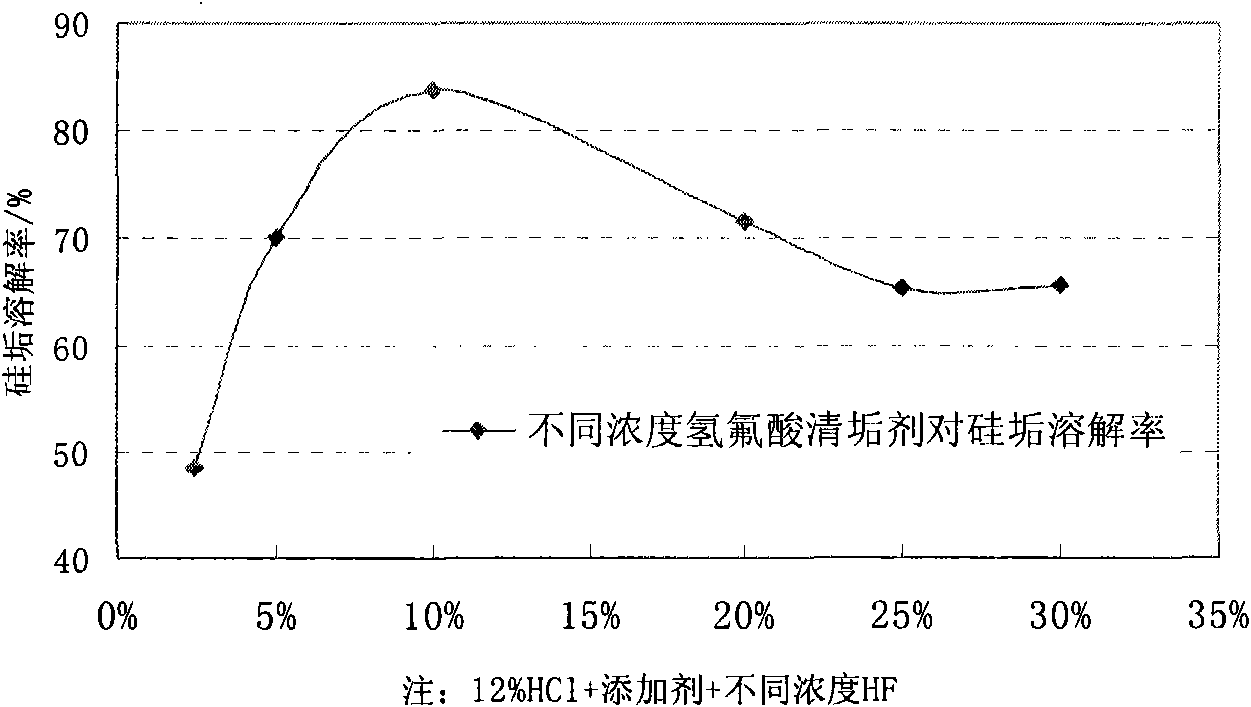

Silicate scale clearing agent for ternary combination flooding extraction well

The invention discloses a silicate scale clearing agent for a ternary combination flooding extraction well. The silicate scale clearing agent consists of prepad fluid and scale clearing main agent. The prepad fluid consists of 6% of additive (SYQ-II) and the balance of water. The additive (SYQ-II) consists of sodium dodecyl benzene sulfonate (ABS), nonyl phenol polyethenoxy ether (OP10) and ethylene glycol monobutyl ether with the ratio of 3:1:2. The scale clearing main agent consists of 12% of hydrochloric acid, 10% of hydrofluoric acid, 2% of glacial acetic acid, 0.2% of citric acid, 0.5% indoor-synthesized imidazoline type corrosion inhibitor (YC-II) and the balance of water. The scale clearing agent achieves a silicate scale clearing rate up to 80%, and can effectively clear silicate scale at an oil well pump cylinder, a rod pipe and other positions and prolong the pump examination period of the extraction well.

Owner:PETROCHINA CO LTD +1

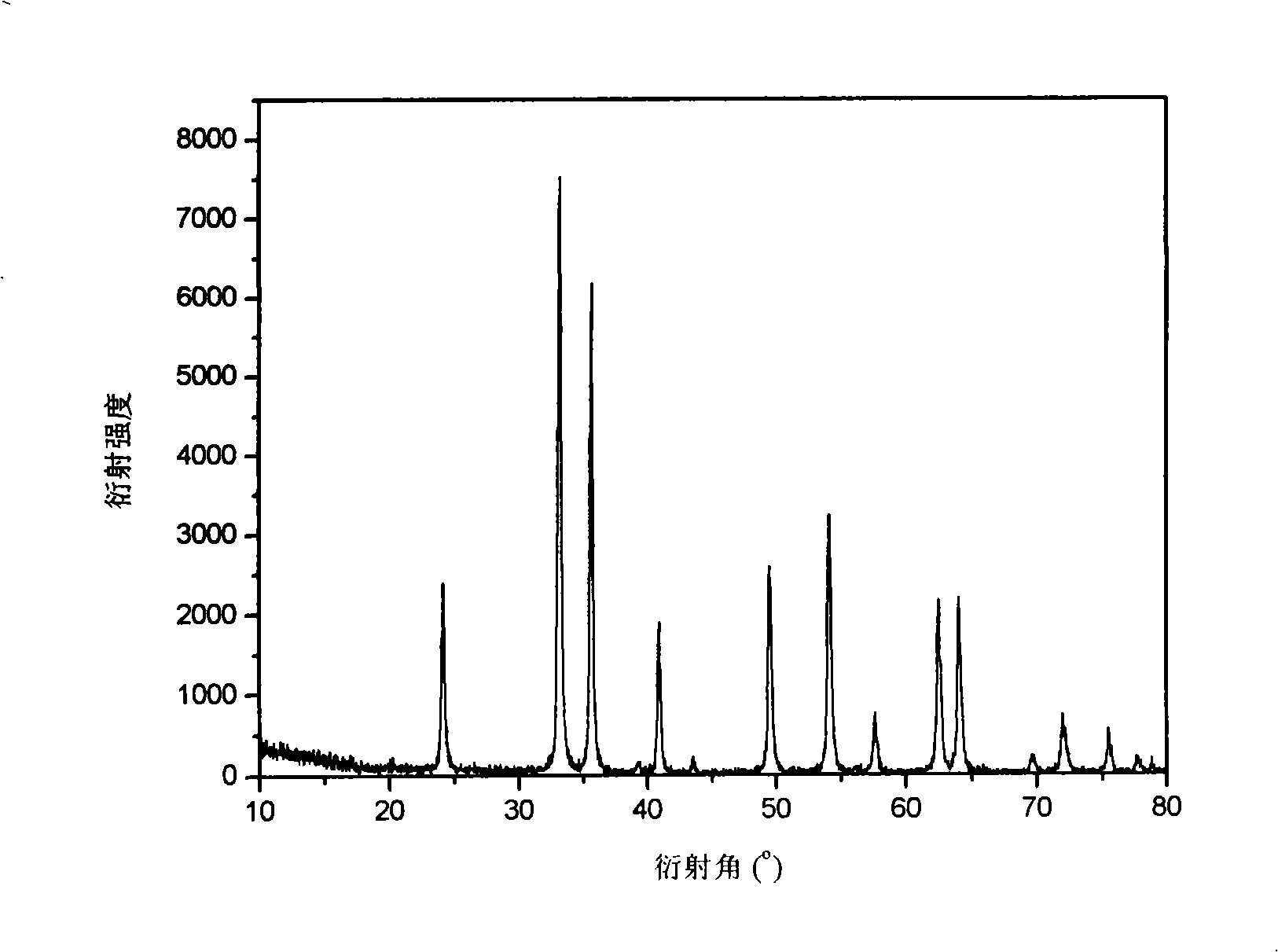

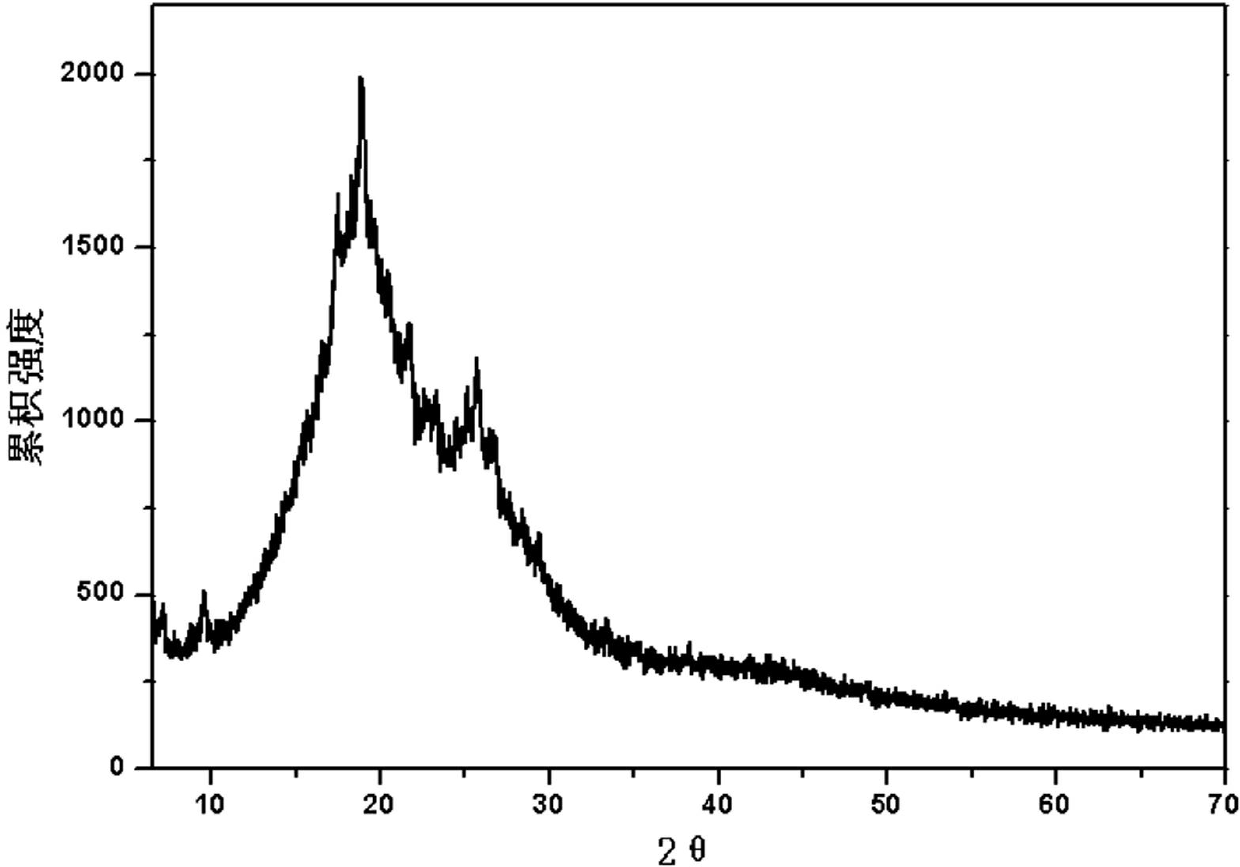

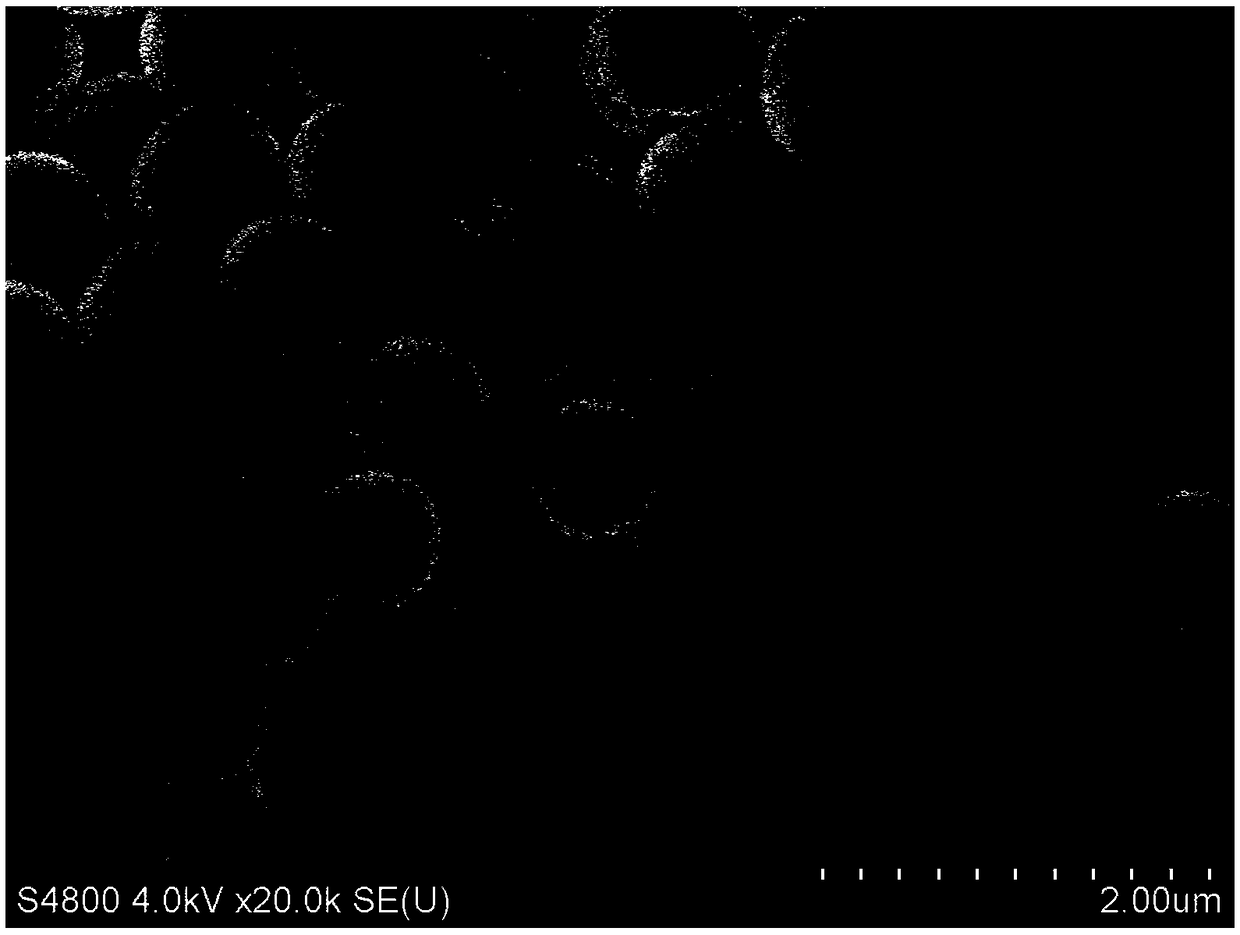

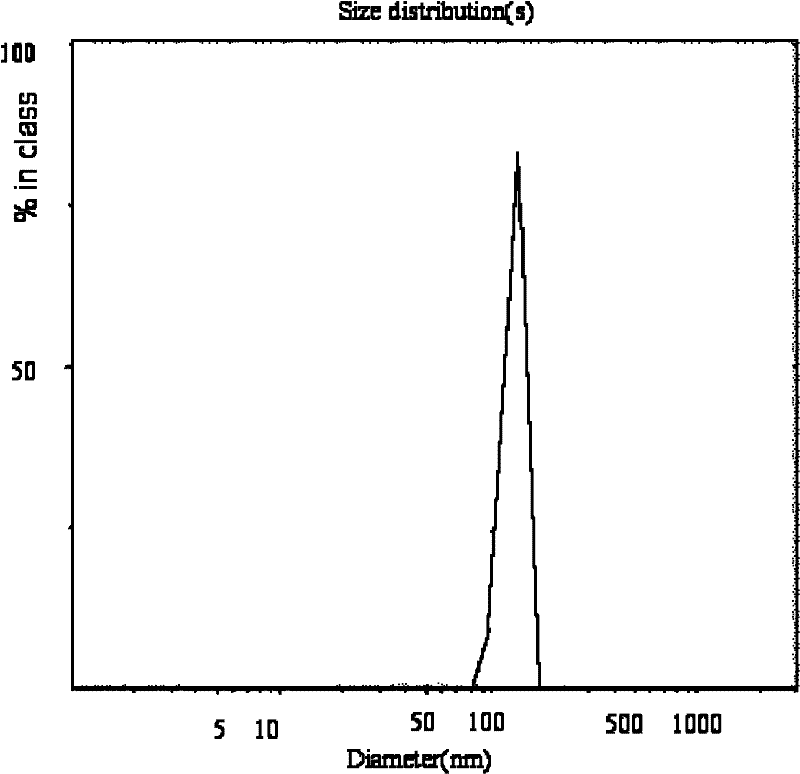

Method for preparing nano-gamma-Fe2O3 hollow magnetic microsphere

The invention discloses a method for preparing gamma-Fe2O3 nanometer hollow magnetic microspheres, which comprises the following steps that: a certain quantity of sodium dodecylbenzenesulfonate (DBS) is added into 100ml of water, then a certain quantity of FeCl3.6H2O and Fe2(SO4)3 are added into the mixed liquid and stirred for 20 to 60 minutes, then urea is added into the mixed liquid, the mixed liquid is refluxed for 2 to 5 hours at a temperature of between 95 and 105 DEG C, and a precipitate is centrifugated, washed for a plurality of times, and dried at a temperature of 100 DEG C after alcohol being washed to produce an alpha-FeOOH precursor. The precursor is subject to heat treatment for 0.5 to 3 hours under an air atmosphere of between 250 and 400 DEG C, then the obtained product is subject to heat treatment for 1 to 3 hours under an H2 atmosphere of between 300 and 450 DEG C, finally the temperature is slowly decreased to between 150 and 250 DEG C, the atmosphere is changed from H2 to O2, and a final product is prepared after 1 to 3 hours of heat treatment. The product prepared by the method has high purity, definite compositions and crystal forms, and homogeneous hollow spherical structures.

Owner:EAST CHINA UNIV OF SCI & TECH

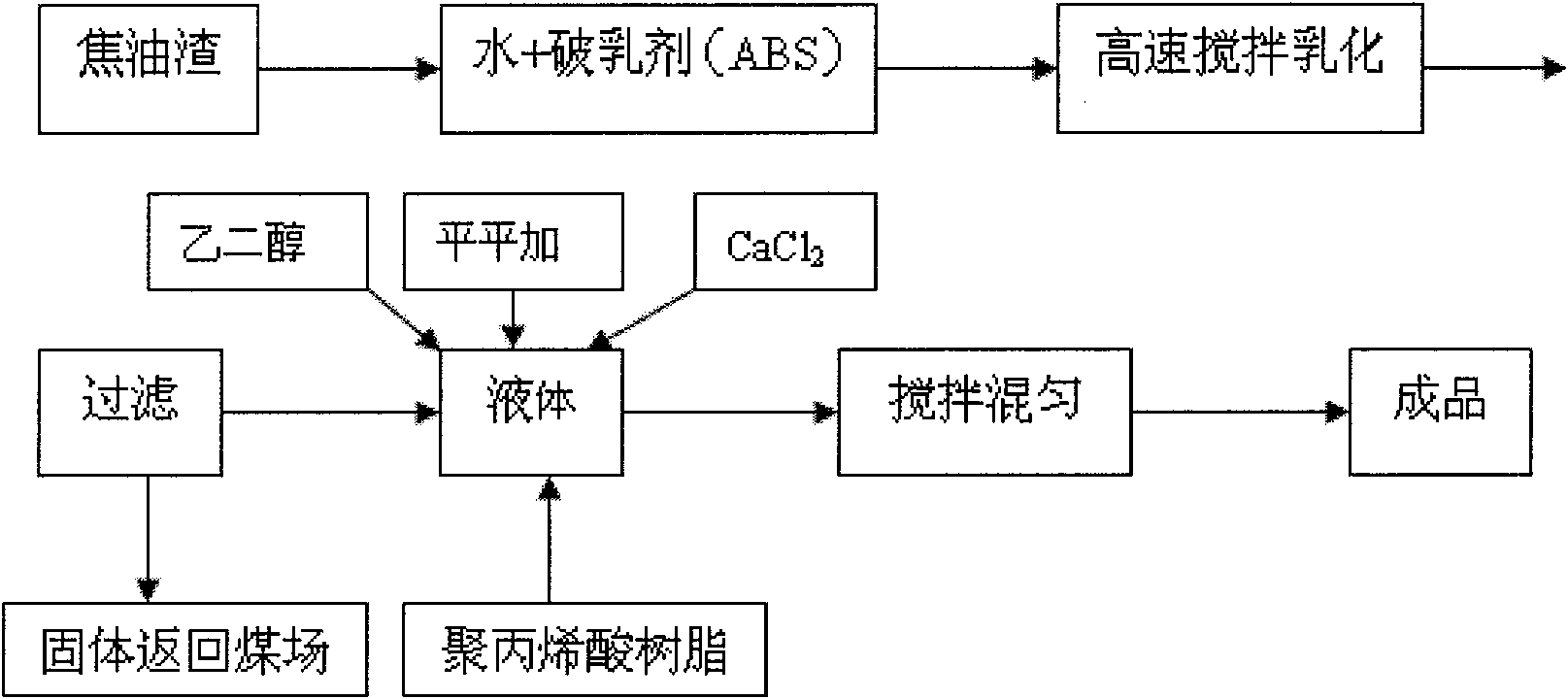

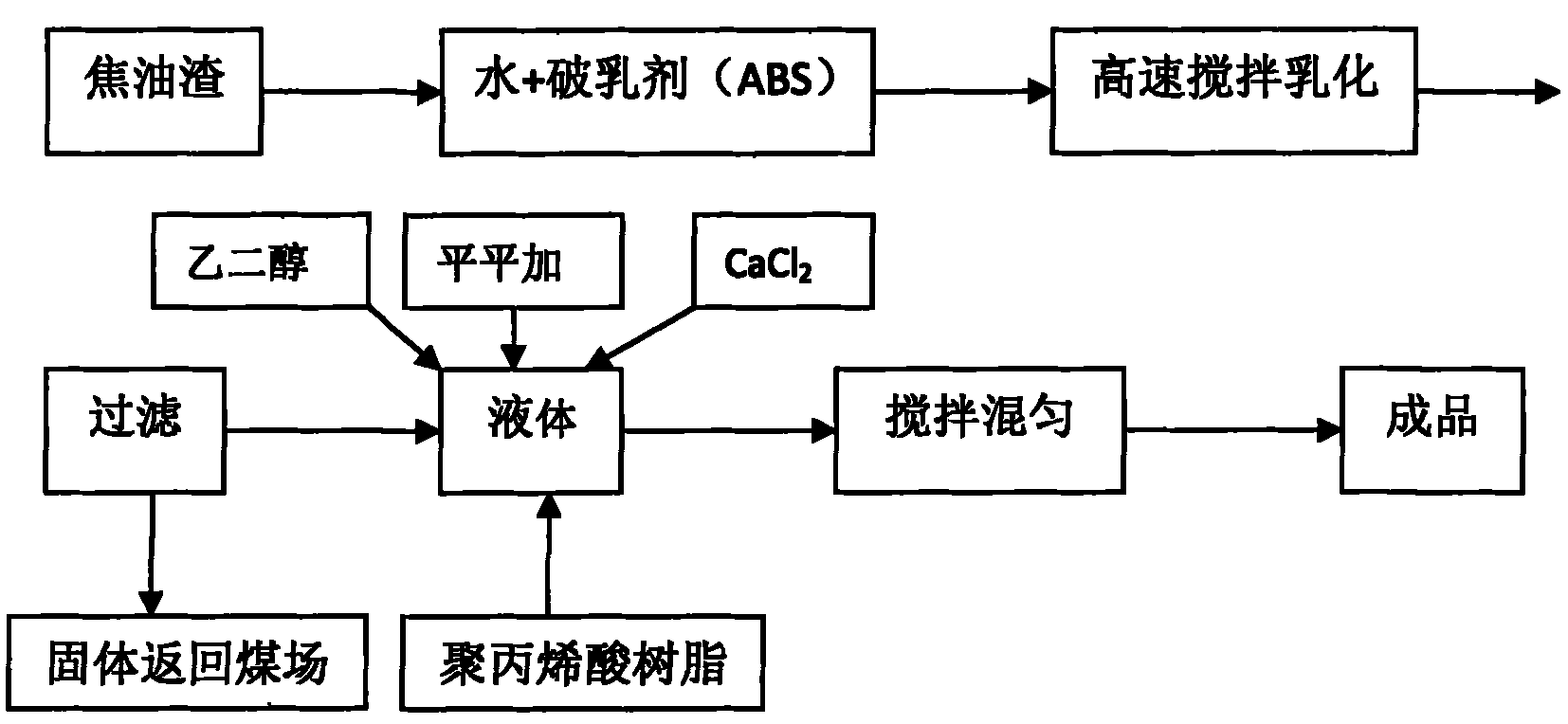

Dust inhibitor and preparation method thereof

The invention provides a dust inhibitor produced by tar residue, and a preparation method thereof, and belongs to the technical field of chemical materials. The dust inhibitor comprises the following components: 5% to 30% of polyacrylic resin, 0.5% to 2% of ethylene glycol, 20% to 30% of tar emulsion, 2% to 5% of SDBS, 0.5% to 1% of surfactant, 10% to 15% of hygroscopic matter, and reverse osmosis water. The preparation method comprises the following steps that: the tar residue is emulsified under the action of a demulsifier SDBS (ABS) and an emulsifier, and then the ethylene glycol, polyacrylic acid resin, the surfactant peregal and the hygroscopic matter calcium chloride are added to be evenly stirred to obtain the dust inhibitor. The invention has simple process and low cost, utilizes reverse osmosis concentrated wastewater, not only protects the environment, but also has good economic efficiency, and is a green circular economy project. The dust inhibitor provided by the invention has more than 90% of dust inhibition rate.

Owner:SHANDONG IRON & STEEL CO LTD

Tile mounting glue and preparation method thereof

InactiveCN102898975AIncrease the degree of emulsificationIncrease viscosityNon-macromolecular adhesive additivesStarch adhesivesStearic acidAdhesion strength

The present invention discloses a tile mounting glue and a preparation method thereof. Raw materials of the tile mounting glue comprise, by mass, 7-9 parts of a thickener, 80-100 parts of corn starch, 5-20 parts of sodium hydroxide, 1-5 parts of borax, 1-5 parts of a defoaming agent, 1 part of a surfactant, 5-10 parts of silica sol, 5-9 parts of heavy calcium carbonate, and 80-100 parts of water, wherein the thickener is carboxymethyl cellulose and / or polyacrylic acid and / or polypropylene, the defoaming agent is tributyl phosphate or polyether-modified organosilicon, and the surfactant is sodium dodecylbenzene sulfonate or stearic acid. According to the present invention, the thickener is added so as to increase emulsification degree and viscosity of the glue material, reduce precipitation of the starch and the heavy calcium, and improve drying speed and texture hardness of the finished product; and the silica sol is added, such that adhesion strength of the starch binder is significantly enhanced, and the produced corrugated paper has characteristics of stable performance and reliable product quality.

Owner:蚌埠市比优特包装印务有限责任公司

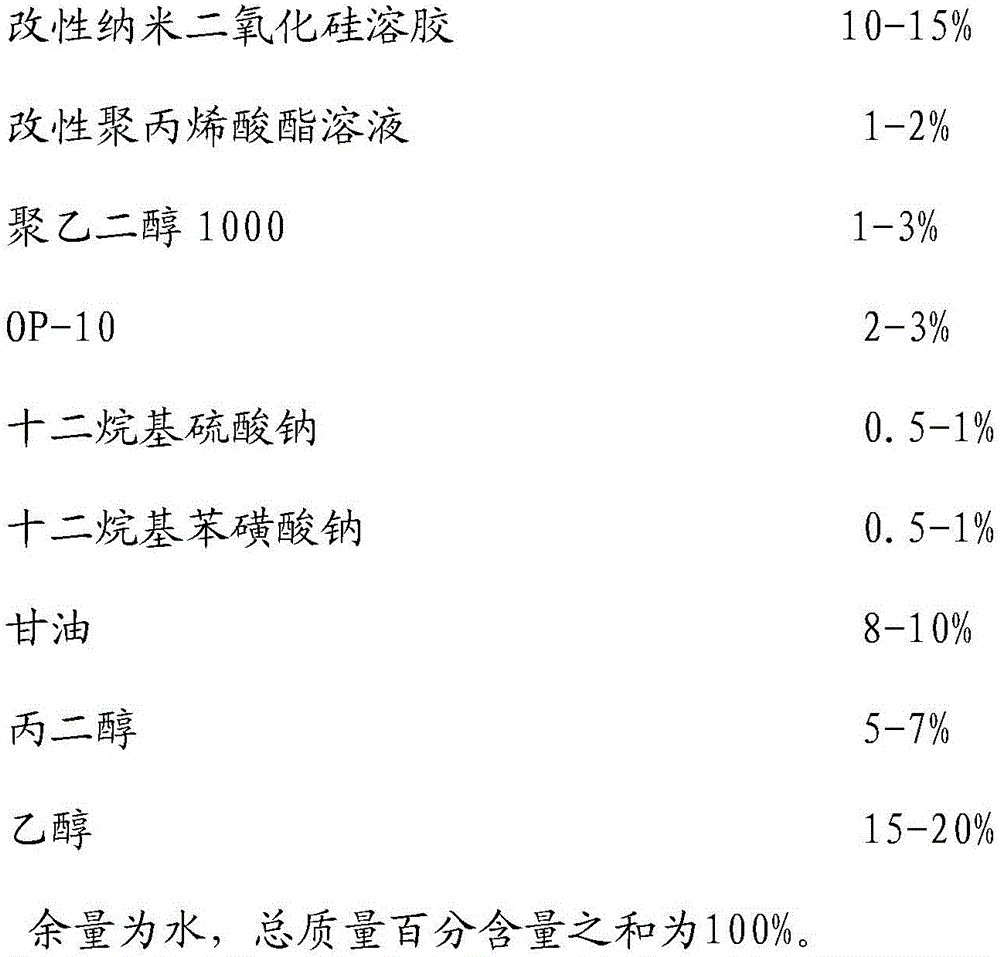

Long-acting anti-fog agent for automotive glass and preparation method of anti-fog agent

ActiveCN105713575ALong durationGood anti-fog performanceOther chemical processesPolyethylene glycolGlycerol

The invention belongs to the technical field of preparation of anti-fog agents for automotive glass and particularly discloses a long-acting anti-fog agent for automotive glass and a preparation method of the anti-fog agent. The anti-fog agent comprises raw materials in percentage by mass as follows: 10%-15% of modified nano-silica sol, 1%-2% of a modified polyacrylate solution, 1%-3% of polyethylene glycol 1000, 2%-3% of OP-10, 0.5%-1% of sodium dodecyl sulfate, 0.5%-1% of sodium dodecylbenzenesulfonate, 8%-10% of glycerin, 5%-7% of propylene glycol, 15%-20% of ethyl alcohol and the balance of water, and the sum of total mass percentage composition is 100%. The anti-fog effect of the anti-fog agent is greatly enhanced through adoption of modified super-hydrophilic nano-silica; with adoption of the modified polyacrylate solution with better adhesion performance, super-hydrophilic nanoparticles and surfactant components can adhere to the glass without falling, so that the durability of the anti-fog agent is enhanced, and the anti-fog effect can be kept for 3 months.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Method for preparing antiseptic soy protein adhesive

InactiveCN102086371AIncrease added valueHas industrial valueNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater bathsAdhesive

The invention relates to a method for preparing an antiseptic soy protein adhesive, comprising the following steps of: adding soy protein and water as a solvent to a reaction vessel, adding sodium dodecylbenzenesulfonate, heating in a constant-temperature water bath, setting the temperature at 60 DEG C, and starting to mix by a mixer, wherein the mixing speed is controlled within 60-80r / min to prevent the solved surfactant from foaming, and inner hydrophobic end of the soy protein modified by the sodium dodecylbenzenesulfonate turns outwards, thereby increasing the surface hydrophobicity of the proteins; adding polyphenyl polymethylene polyisocyanate to the reaction vessel to carry out a crosslinking reaction after the mixing process continues 2 hours; and adding a composite antiseptic tomix to prepare the antiseptic soy protein adhesive. After the adhesive prepared with the method provided by the invention is stored for 60 days at the room temperature, the appearance of the adhesiveis changeless, the comprehensive performance of the adhesive is better than that of the traditional similar products, the further processed products of the soy protein are obtained, and the added value of the soy protein is increased.

Owner:NANJING FORESTRY UNIV

Environmentally-friendly multifunctional metal surface treating fluid

The invention relates to treating fluid, and particularly relates to environmentally-friendly multifunctional metal surface treating fluid. The environmentally-friendly multifunctional metal surface treating fluid is mainly used for solving the technical problems in the prior art that when the treating fluid is used for treating metal surfaces, oil removal, dust removal and cleaning need to be carried out in advance, heating is also needed, operation working procedures are complicated, the conversion quality is low, the rust prevention capacity is low and the like. The treating fluid comprises the following components in percentage by mass: 25%-40% of phosphoric acid, 0.25%-0.32% of sheet zinc or zinc slab, zinc granules, 1%-1.5% of acid type manganese phosphate, 0.1%-0.15% of calcium nitrate, 0.8%-1% of tartaric acid, 0.2%-0.8% of phytic acid, 0.5%-0.7% of thiourea, 0.11%-0.16% of polyethylene glycol, 1.5%-2.5% of sodium dodecylbenzene sulfonate, 0.08%-0.12% of analytically pure ammonium molybdate and the balance of water.

Owner:杭州聚城环保科技有限公司

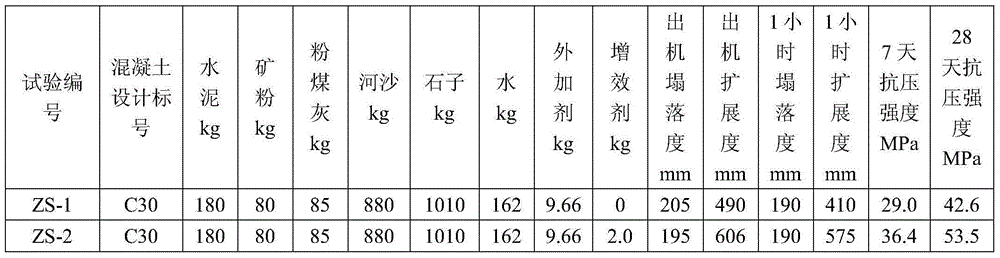

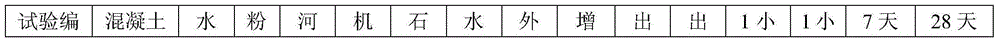

High-efficiency and energy-saving concrete synergistic agent and preparation method thereof

ActiveCN105198264ARaise the intensity levelIntensity level maintenanceWork performanceSodium dodecylbenzenesulfonate

The invention discloses a high-efficiency and energy-saving concrete synergistic agent and a preparation method thereof, and belongs to the concrete technical field. The concrete synergistic agent is prepared from the following raw materials in parts by weight: 10-25 parts of a UFD macromolecular copolymer, 10-15 parts of a water reducing agent mother liquor, 3-5 parts of sodium tripolyphosphate, 2-7 parts of sodium gluconate, 10-15 parts of a stabilizer, and 33-65 parts of water. The UFD macromolecular copolymer is prepared from urea, formaldehyde and sodium dodecylbenzenesulfonate. Through coordinative and promotion effects of the components, the high-efficiency and energy-saving concrete synergistic agent can increase the concrete strength grade, improve the working performance, or reduce the cement use amount under a condition of keeping the concrete working performance and the strength grade basically consistent, so as to achieve the purpose of reducing production cost of the concrete, and then achieve the purposes of saving energy, reducing consumption and reducing environmental pollution. The product production process is simple, and the product storage cycle is as long as one year.

Owner:SHANDONG ZHONGSEN TECH

Modified polyaniline adsorbent and application of modified polyaniline adsorbent in wastewater treatment

InactiveCN102513068AImprove adsorption capacityImprove stabilityOther chemical processesWater/sewage treatment by sorptionActive agentSurface-active agents

The invention provides a modified polyaniline adsorbent, and belongs to the technical field of polymer composite materials. According to the invention, an aniline monomer is modified by using sodium dodecylbenzene sulfonate and other surfactants containing a sulfonic group, and then is subjected to polymerization to obtain the adsorbent, wherein the polyaniline with unobvious adsorption performance is combined with the sodium dodecylbenzene sulfonate and other surfactants containing the sulfonic group, such that the polyaniline molecule chain is grafted with the sulfonic group with the cationadsorption performance, at the same time the surfactant exists, such that the internal pore structure of the polymer is changed so as to enhance the adsorption performance and the stability. The results of a plurality of experiments show that: the modified polyaniline adsorbent of the present invention provides good adsorption capacities for cationic dyes, heavy metal ions and phenol in wastewater. The adsorbent of the present invention has advantages of cheap and easily obtained raw materials, simple preparation process, low cost, good chemical stability, easy separation, capability of recycle, no secondary pollution on the environment, and the like, and is a potential sewage adsorption material.

Owner:NORTHWEST NORMAL UNIVERSITY

High solids latex for dry-bright floor polish compositions

InactiveUS20060205865A1High glossLow viscosityAqueous dispersionsPhosphorus organic compoundsPhosphatePolymer chemistry

A high solids emulsion polymer composition comprising styrene, an acrylate monomer, an acidic monomer, and an anionic surfactant. The emulsion polymer composition has a solids content of at least about 43 percent by weight. The anionic surfactant may be an alkyl benzene sulfonate, such as, for example, sodium dodecyl benzene sulfonate, or may be a co-surfactant system comprising an alkyl benzene sulfonate and an aliphatic phosphate ester. The high solids emulsion polymer composition is suitable as a component in a floor polish composition, and is particularly suitable for dry bright floor polish compositions.

Owner:OMNOVA SOLUTIONS INC

Solid chemical dredging agent for pipeline dredging and preparing method thereof

InactiveCN1488781AAchieve the purpose of dredgingImprove dredging effectCleaning using liquidsSodium dodecylbenzenesulfonateCleansing Agents

The present invention relates to a solid chemical pipe cleaning agent and its preparation method. It is characterized by that it is formed from 52-68% of granular sodium hydroxide, 11-19% of sodium carbonate, 15-21% of high test bleaching powder, 4-10% of sodium dodecyl benzene sulfonate and 0.02% of essence. Said invention has no need of adding metal aluminium, can obtain good cleaning effect, and can be used for killing pathogenic bacteria and insect eggs. Said invention also provides its preparation method and production steps.

Owner:汪立强

Vanadium tetrasulfide electrode material and preparation method and application thereof

ActiveCN108862381ASimple processStrong implementationMaterial nanotechnologyNegative electrodesElectrolysisInterface impedance

The invention provides a preparation method of a vanadium tetrasulfide electrode material. The preparation method comprises the following steps: a) mixing a vanadium source, a sulfur source and a surfactant in a solvent to obtain a mixed solution, wherein the surfactant is selected from one or more of polyvinylpyrrolidone, sodium dodecylbenzenesulfonate and cetyltrimethylammonium bromide; b) carrying out solvothermal reaction of the mixed solution obtained in the step a), collecting solid products, and sequentially washing and drying to obtain the vanadium tetrasulfide electrode material. Thepreparation method realizes the nanocrystallization and shape design of the VS4 electrode material, and the electrode material has the special morphology of nanosheet hollow sphere, nanosphere, nanoparticle, nanosheet hollow tube or nano flower, so that the contact area between the electrode material and electrolytic media is increased, the interface impedance is reduced, and the rate performanceof a battery is improved. At the same time, a larger active interface can alleviate the volume change of the material during charging and discharging, so as to improve the charge and discharge performance and cycle performance of the material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

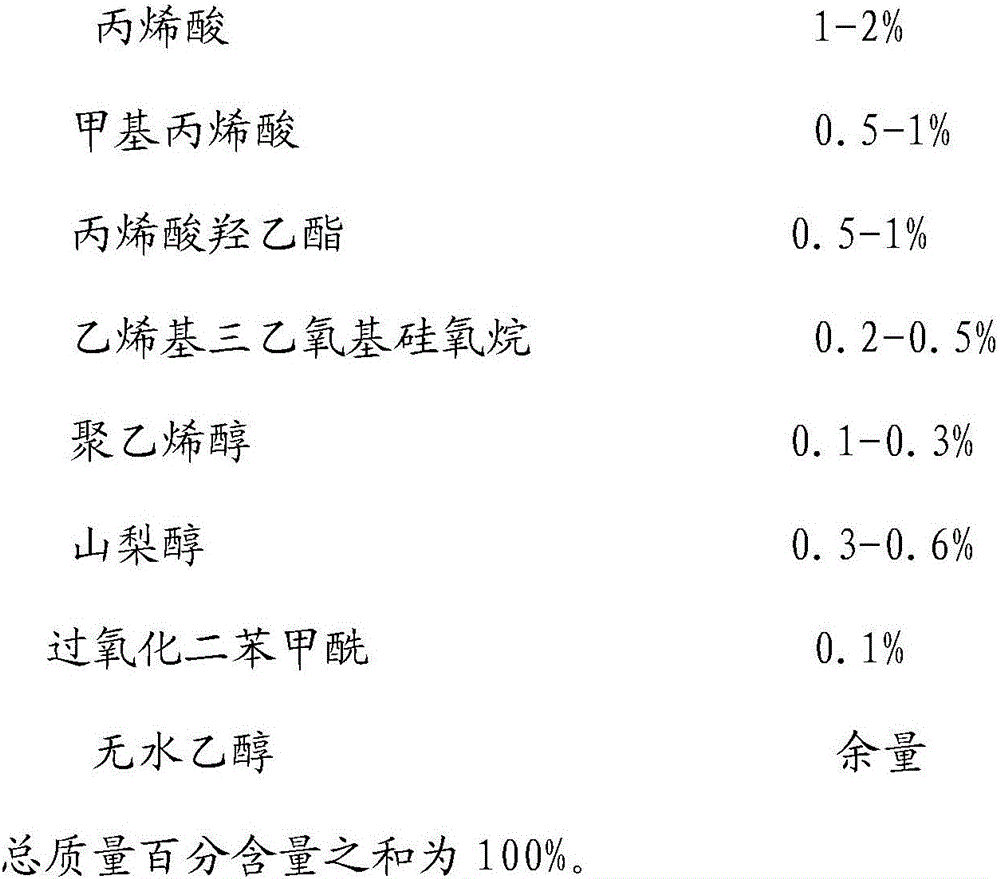

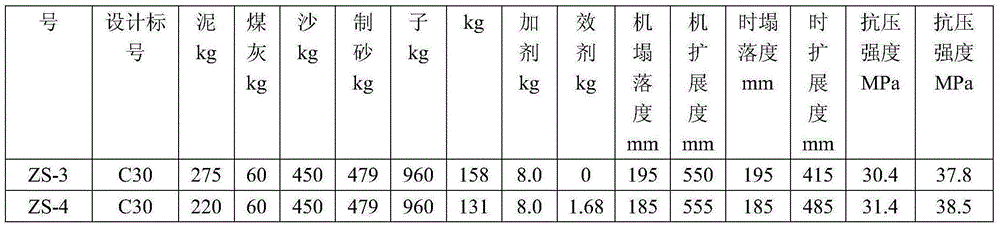

A kind of polymer type optical lens antifogging agent and preparation method thereof

InactiveCN102260482ADoes not affect light transmissionNot corrosiveOther chemical processesAnhydrous ethanolDistilled water

The invention relates to the field of material chemistry and mainly provides a polymer type antifogging agent for an optical lens and a preparation method thereof. The technical scheme in the invention comprises the following steps: mixing 1-2 parts by weight of colorless transparent secoctylphenol polyoxyethylene ether liquid which is abbreviated to TX-10, 8-12 parts by weight of isopropanol, 28-32 parts by weight of anhydrous ethanol and 45-50 parts by weight of double distilled water so as to form 100mL of basic liquid; and then adding about 100 parts by weight of double distilled water in 2-6 parts by weight of weighed white sodium dodecyl benzene sulfonate solid powder which is abbreviated to SDBS so as to prepare a 4.0% aqueous solution serving as an additive, and evenly mixing the additive with the basic liquid in a volume ratio of 1:1 (100mL:100mL), so that the antifogging agent is obtained.

Owner:中南大学肝胆肠外科研究中心 +1

Low-temperature-resistant high-power coalmine-permitted water-gel explosive and manufacturing method thereof

InactiveCN103319290ALow crystallization pointCrystal form controlExplosivesMethylamine nitrateFormamide

The invention relates to a low-temperature-resistant high-power coalmine-permitted water-gel explosive and a manufacturing method thereof. The explosive is composed of a methylamine nitrate solution, water, ammonium nitrate, sodium nitrate, formamide, urea, sodium dodecylbenzenesulfonate, sesbania powder, fine atomized aluminum powder, a composite alkali metal halide flame inhibitor, expanded perlite powder, a foam stabilizer and a crosslinking agent. According to the invention, sodium nitrate and sesbania powder are first well mixed; ammonium nitrate is dissolved in water, such that an ammonium nitrate solution is prepared; formamide is dissolved in the methylamine nitrate solution; the three are mixed in an agent mixing tank; the composite alkali metal halide flame inhibitor, the fine atomized aluminum powder, the expanded perlite powder, the foam stabilizer and the crosslinking agent are sequentially added; and the mixture is well mixed and is packaged into sticks. The explosive has high explosion power, and can be normally initiated and detonated under an experimental temperature of 0 DEG C to -20 DEG C. The explosive does not contain toxic component, and does not pollute the environment. The process is simple, and continuous production can be realized.

Owner:安徽理工大学爆破工程与器材研究所

Environmentally-friendly metal polishing agent and preparation method thereof

ActiveCN103451658AImprove antioxidant capacityImprove corrosion resistanceVegetable oilPolyethylene glycol

The invention relates to an environmentally-friendly metal polishing agent and a preparation method thereof, belonging to the technical field of metal surface treatment. The environmentally-friendly metal polishing agent comprises the following raw materials in parts by weight: 2-10 parts of vegetable oleic acid, 5-8 parts of coconut oil-based glucoside, 5-10 parts of sodium dodecylbenzene sulfonate, 20-30 parts of mineral oil, 8-13 parts of imidazoline quaternary ammonium salt, 2-5 parts of oleic acid triethanolamine, 50-80 parts of silicon micro-powder, 5-10 parts of polyethylene glycol, 15-20 parts of crystalline layered sodium disilicate and 80-100 parts of deionized water. The environmentally-friendly metal polishing agent can be used for effectively clearing away oil stains and rusty spots on the surfaces of metals, so that the surfaces of the metals are kept glossy and bright; and the raw materials do not comprise fluorine-containing or phosphorus-containing compounds, so that the environmentally-friendly metal polishing agent is safe and has environmentally-friendly effect; and meanwhile, as the raw materials comprise the mineral oil and the imidazoline quaternary ammonium salt, the surface smoothness of the metals can be effectively improved, and a layer of protective film is formed on the surfaces of the metals and has strong covering power, so that the oxidation resistance and the corrosion resistance of the metals are greatly improved.

Owner:江苏悠谷未来科技有限公司

Strip steel surface cleaning agent, preparation method and use method thereof

The invention discloses a strip steel surface cleaning agent, a preparation method and a use method thereof, wherein the strip steel surface cleaning agent comprises 20-25% of sodium hydroxide, 5-10% of sodium carbonate, 3-5% of sodium gluconate, 3.5-15% of an anionic surfactant, 0.5-10% of a nonionic surfactant, 5-10% of a chelating agent, and 20-63% of water, wherein the chelating agent is an ethylenediaminetetraacetic acid tetrasodium tetrahydrate, the anionic surfactant is one or more than one selected from sodium dodecylbenzene sulfonate and sodium dodecyl sulfate, and the nonionic surfactant is one or more than one selected from alkyl polyoxyethylene ether and polyethylene glycol octyl phenyl ether. According to the present invention, with the application of the cleaning agent in the degreasing treatment of cold-rolled plates, galvanized plates and other metal materials, no pollutant is generated during the strip steel cleaning, the cleaning effect is increased, and the coat is reduced; the cleaning agent uses the ethylenediaminetetraacetic acid tetrasodium tetrahydrate to replace the traditional phosphate so as to be used as the chelating agent, such that the advantages of safety and environmental protection are provided; and with the cleaning agent, the cleaning effect on the galvanized substrate can be achieved, the influence of the strip steel surface pollutant on the subsequent galvanizing process can be reduced, and the quality of the galvanized product is improved.

Owner:ANSTEEL BEIJING RES INST

Cleaning medicine and method for cleaning metallic surface using same

InactiveCN101265583AGood effectLow costInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium metasilicateAlkylphenol

The invention discloses a cleaning drug and a method of using the cleaning drug to clean metal work surfaces and remove the impurities on the metal work surfaces. The cleaning drug contains compositions in the following weight percentages: sodium hydroxide 27%-30%,sodium polyphosphate 6%-9%, sodium metasilicate 48%-51%, sodium dodecyl benzene sulfonate 2%-5%, sodium carbonate 48%-51% and alkylphenol polyoxyethylene 1%-4%. The method of using the cleaning drug to clean metal work surfaces includes the following steps: putting the metal work in a scouring reservoir with the aqueous solution containing the cleaning drug by concentration of 3%-5% for soaking; taking the metal work which undergoes surface derusting and cleaning out from the scouring reservoir, putting in pure water for water washing; and carrying out dry processing to the water washed metal work.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com