Patents

Literature

3703results about How to "Not corrosive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

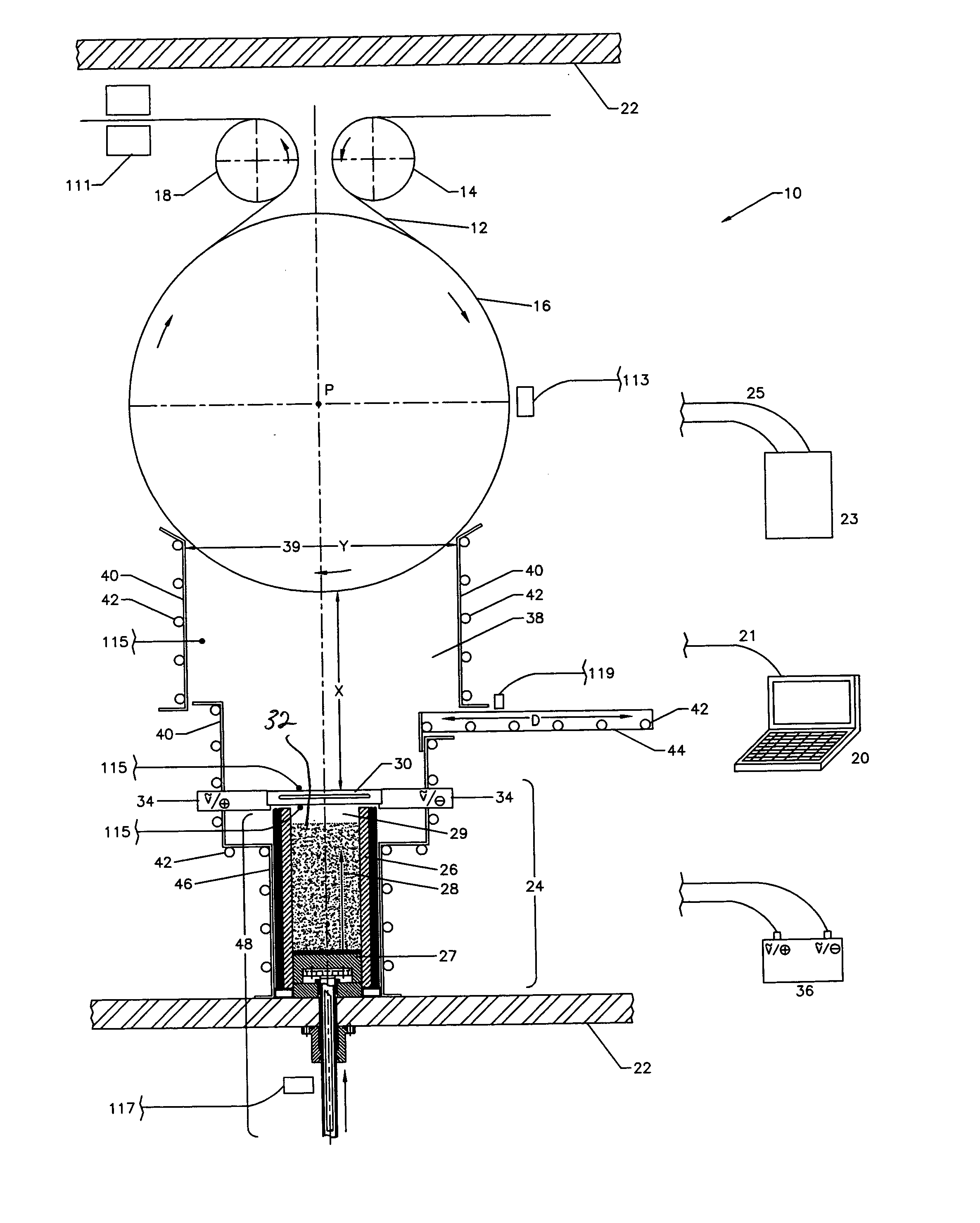

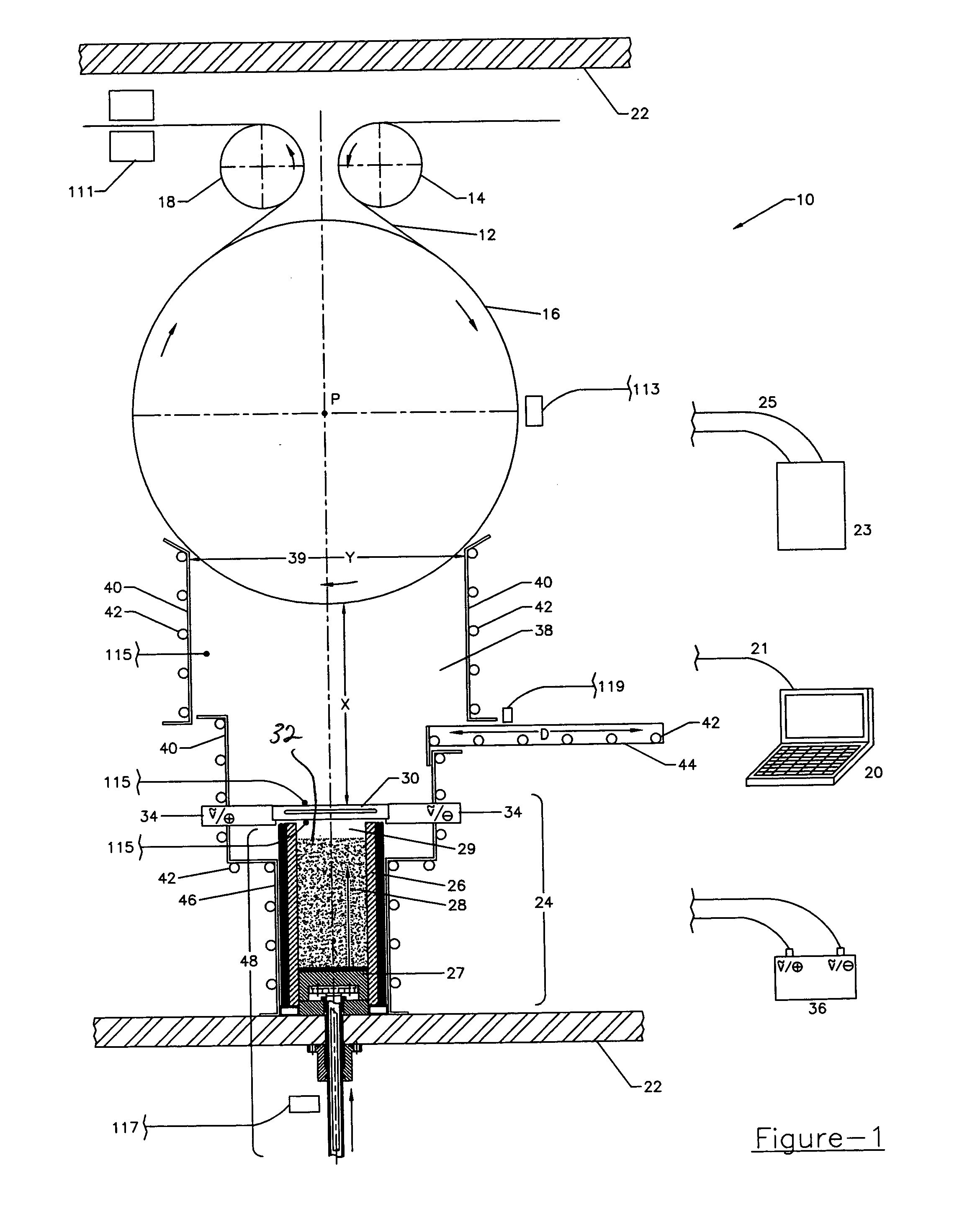

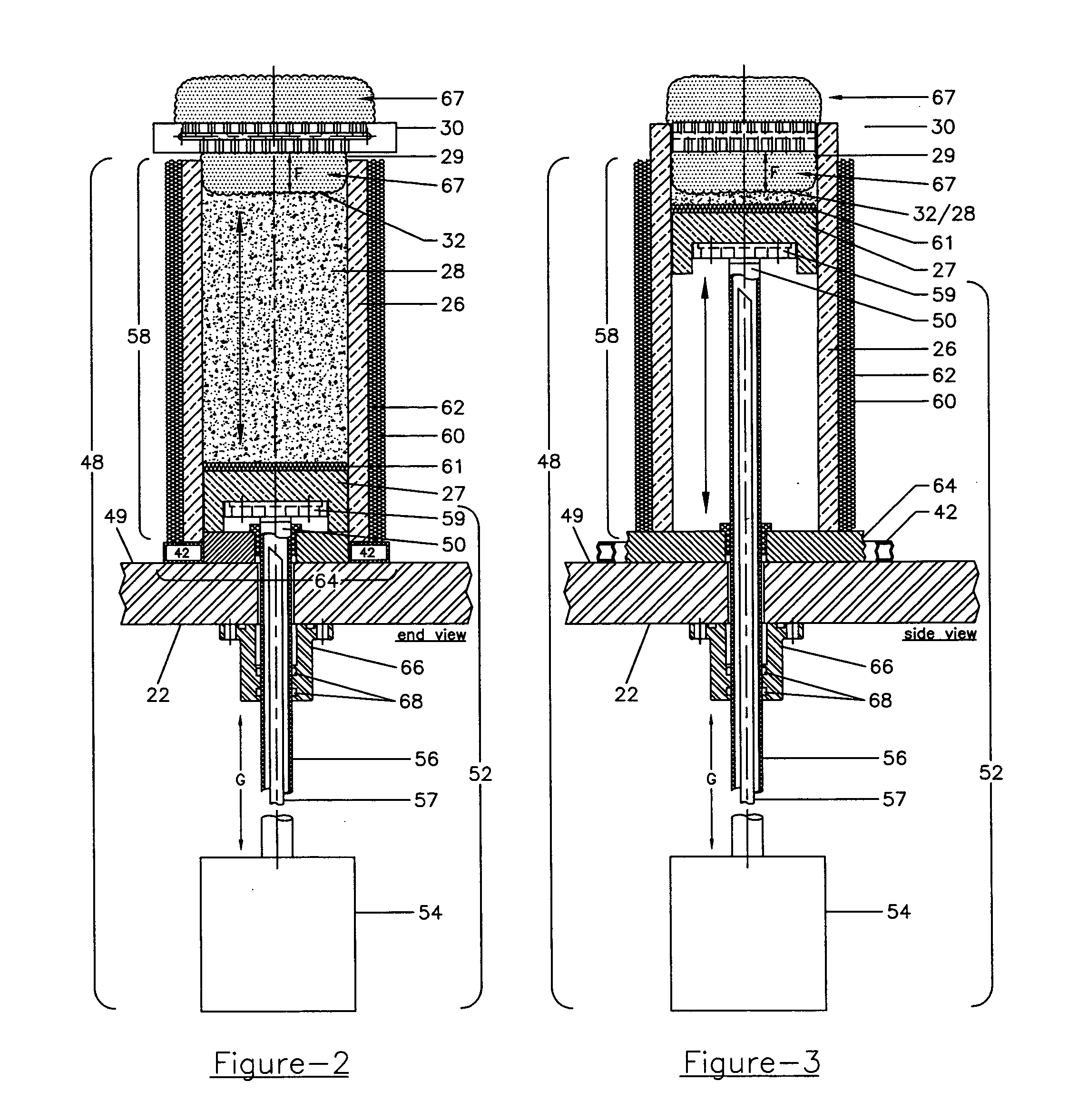

Multi-layered radiant thermal evaporator and method of use

InactiveUS20050072361A1Stable and reliableHigh quality usefulnessVacuum evaporation coatingSputtering coatingCrucibleVacuum chamber

The present invention provides a system and method for uniform coating of a substrate at high deposition rates by evaporating a coating material in a vacuum chamber. The system includes an evaporator having a heating crucible for containing a coating material to be evaporated and a generally planar heat source disposed so as to heat a surface of a coating material contained in the heating crucible. Preferably, the heat source is manufactured from a ceramic or intermetallic material and includes a first layer defining a first set of openings and a second layer defining a second set of openings wherein the second layer overlies the first layer and is spaced apart therefrom. The first and second sets of openings allow the evaporated coating material to pass therethrough for dispersion of the coating material in a deposition zone defined by a containment shield disposed above the heat source.

Owner:DARLY CUSTOM TECH

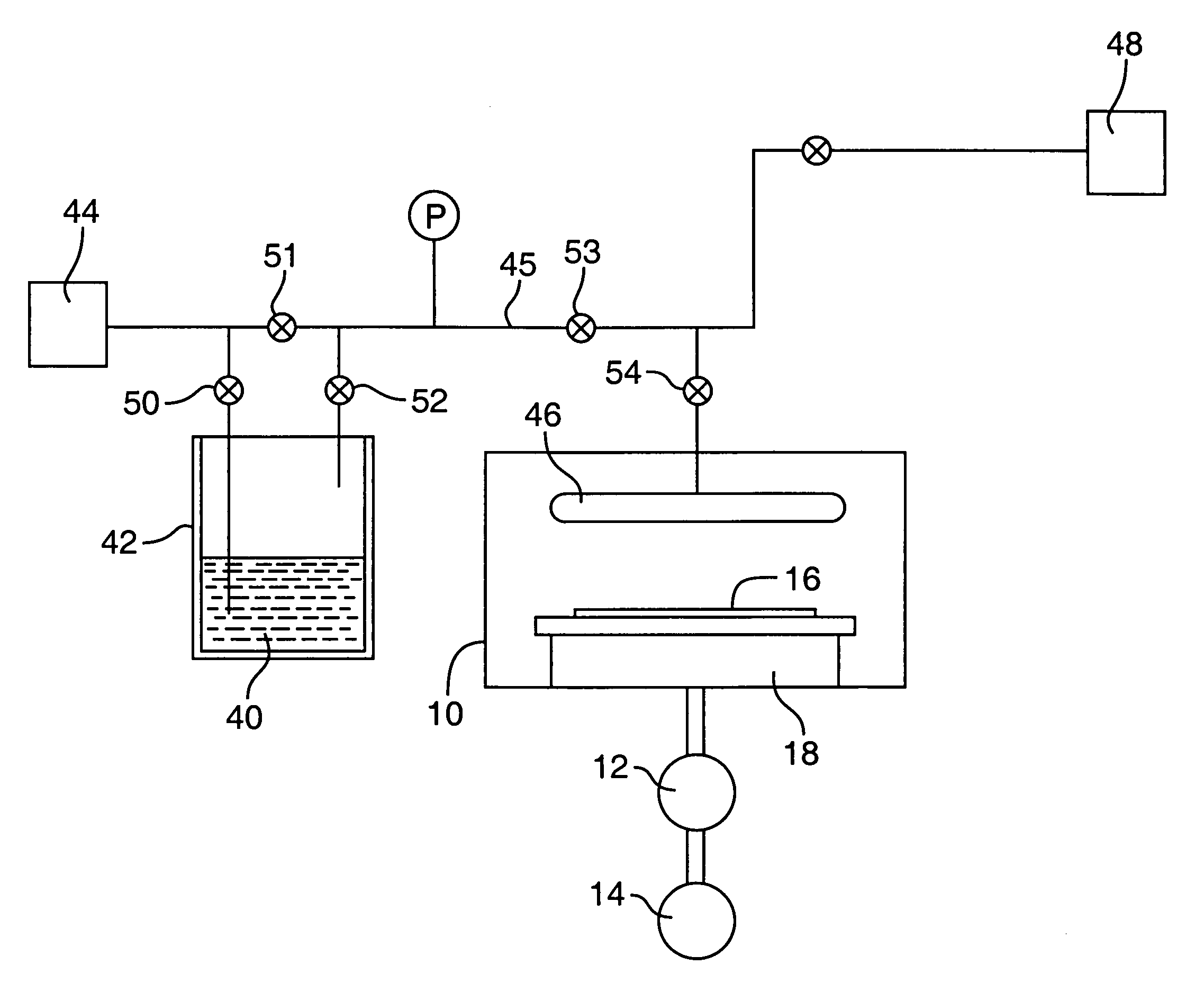

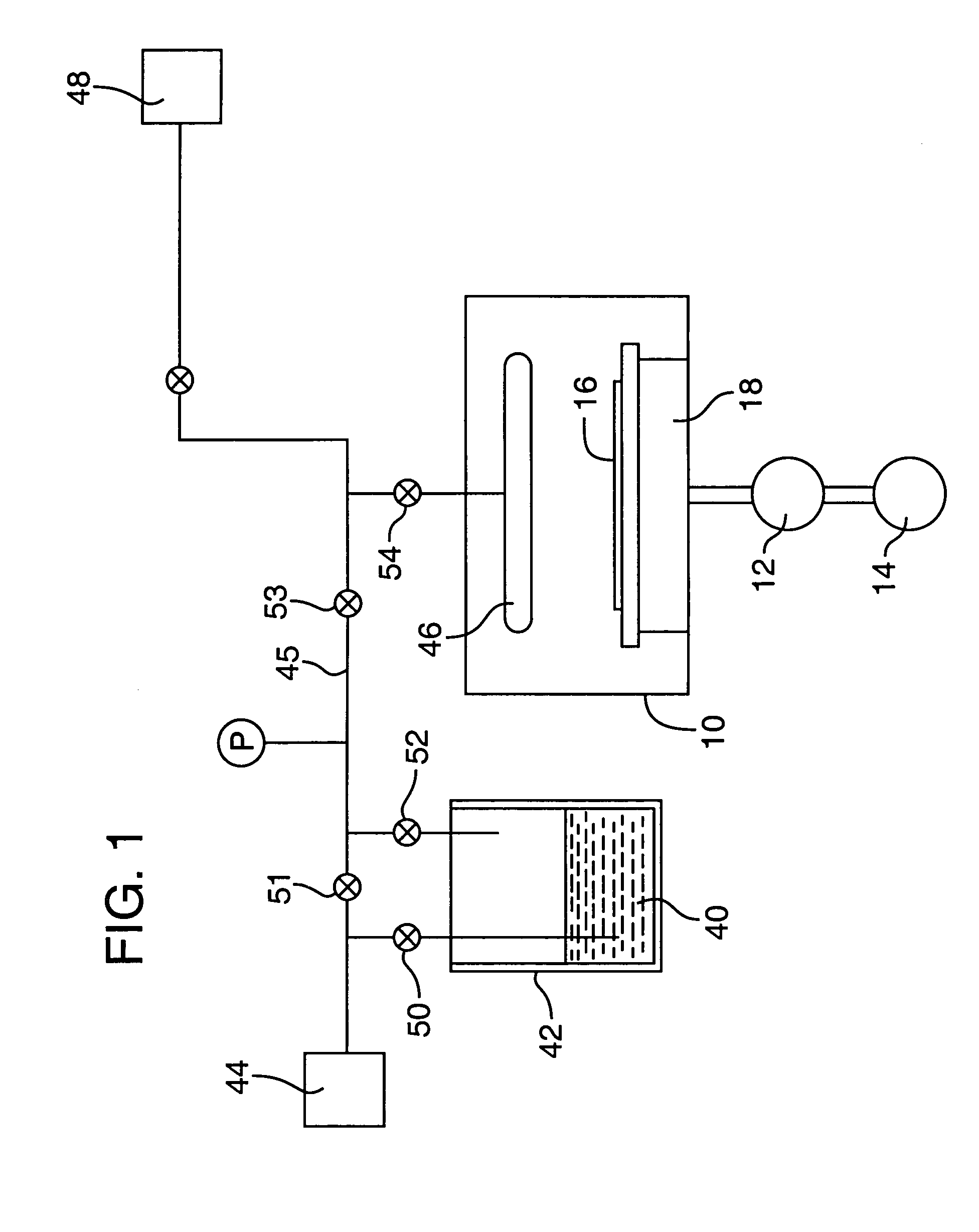

Equipment and method for extracting biologically active ingredients from subcritical fluid

InactiveCN101905091AKeep intactGuaranteed production costExtraction purification/separationSolid solvent extractionAutomatic controlSeparation technology

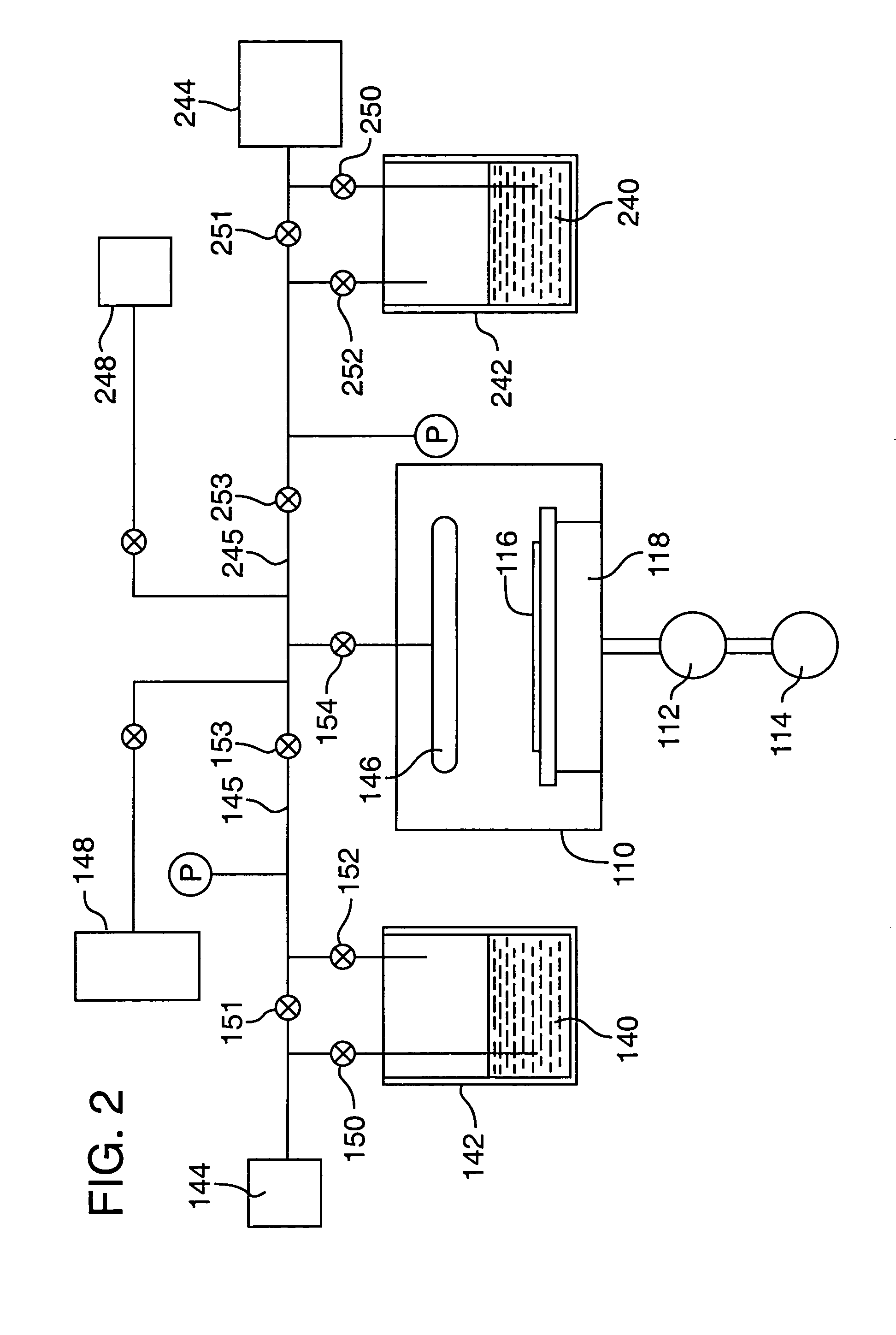

The invention discloses equipment and a method for extracting biologically active ingredients from subcritical fluid, aims to solve the problems of low extraction efficiency and the like existing in the aspects of biologically active ingredient separation technology in the prior art and provides a set of subcritical equipment which comprises an extracting agent supply system, an entrainer supply system, an extraction system, a separation system, a solvent recycling system, a desolvation system, a heat supply system, a computer control system and the like, has high automatic control degree and is used for extracting the biologically active ingredients. Simultaneously, the invention also provides a new technological method for extracting the biologically active ingredients by adopting a subcritical extraction process. The method has the advantage of relatively low cost on the conventional extraction of an organic solvent, and the equipment has the characteristics of no solvent residue, no pollution, high bioactivity and the like in a product obtained by supercritical CO2 extraction technology and has the advantages of low investment on production equipment, high production efficiency within unit time, low energy consumption, flexible operation, high degree of automation and the like.

Owner:XINJIANG UNIVERSITY +1

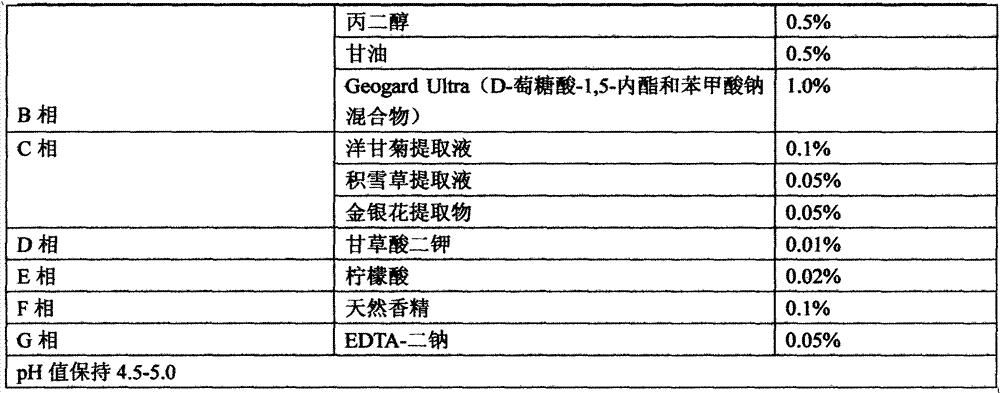

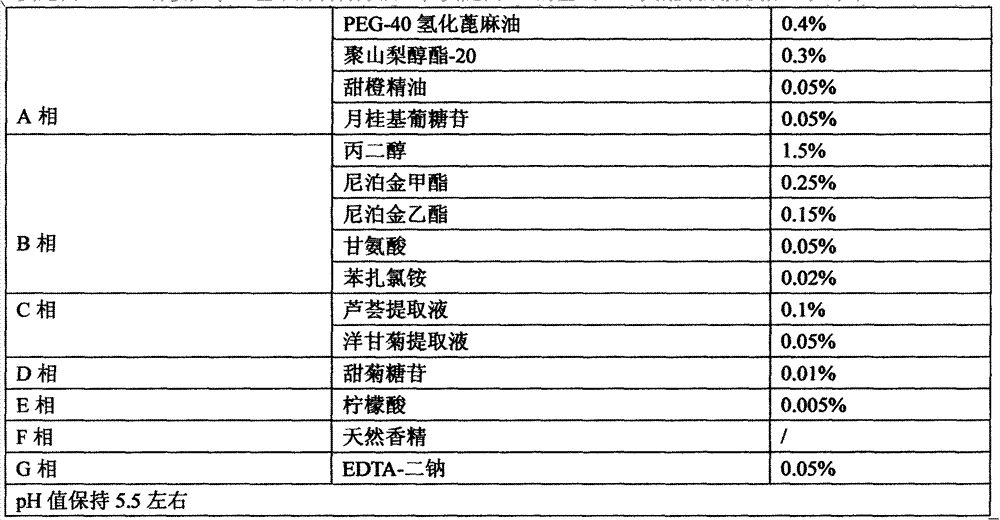

Hand-mouth baby wet tissue and preparation method thereof

InactiveCN103040688APromote secretionLower pHCosmetic preparationsToilet preparationsAdditive ingredientCleansing Agents

The invention relates to a hand-mouth baby wet tissue and a preparation method thereof. The hand-mouth baby wet tissue is composed of compound wet tissue liquid and non-woven fabrics for holding the compound wet tissue liquid, wherein every 100 parts of the compound wet tissue liquid comprises the following components in percent by weight: 0.01%-7.5% of a sweetening agent, 0.01-2.0% of a preservative, 0.01%-2.0% of a cleaning agent, 0.05%-5.0% of a solubilizer, 0-10.0% of a humectant, 0-5.0% of a skin care agent, 0-5.0% of an acidity regulator, 0-5.0% of essential oil, 0-5.0% of a stabilizer, 0-1.0% of natural essence, and the balance of pure water. The hand-mouth baby wet tissue has the advantages that edible sweetening agent is added into the compound wet tissue liquid to promote spittle secretion of babies, relieve the drop of pH value in the oral cavity and prevent the formation of decayed teeth. The product formula is stable and safe, and the material components are non-toxic. The formula is safe, non-irritant and non-corrosive, so that the allergic risks are reduced to be the lowest. The hand-mouth baby wet tissue can be used for cleaning the hands and mouths of an infant, infant tableware and other infant supplies and toys.

Owner:林建广

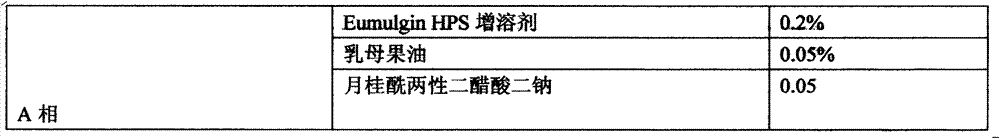

Metal deoiling agent and deoiling method thereof

InactiveCN102108321ASimple recipeLow costInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsMetallic materialsDicarboxylic acid

The invention provides a metal deoiling agent. The deoiling agent contains anionic surfactant, nonionic surfactants, solubilizer and corrosion inhibitor, wherein corrosion inhibitor contains monocarboxylic acid and dicarboxylic acid and the weight ratio of monocarboxylic acid to dicarboxylic acid is 10-1:1. The invention also provides a deoiling method. The deoiling method is as follows: soaking a metal material in the deoiling agent to perform ultrasonic deoiling for 1-3min, wherein the temperature of the deoiling agent is 50-80 DEG C and the metal deoiling agent is the metal deoiling agent in the claim 1. The deoiling agent of the invention can be used to effectively remove greasy dirts on the surface of metal in a short time can not corrode metal; and the deoiling agent has simple formula, low cost and stable performance.

Owner:CHANGSHA TOPWELLWEAR METAL MATERIAL SCI

Chemical vapor deposition methods utilizing ionic liquids

InactiveUS6998152B2Increase rangeWide temperature rangeChemical vapor deposition coatingPhysical chemistryThin membrane

The present invention provides methods and apparatus for vaporizing and transporting precursor molecules to a process chamber for deposition of thin films on a substrate. The methods and apparatus include CVD solvents that comprise ionic liquids. The ionic liquids comprise salt compounds that have substantially no measurable vapor pressure (i.e., less than about 1 Torr at about room temperature), exhibit a wide liquid temperature range (i.e., greater than about 100° C.), and have low melting points (i.e., less than about 250° C.). A desired precursor is dissolved in a selected CVD solvent comprising an ionic liquid. The solvent and precursor solution is heated to or near the precursor volatilization temperature of the precursor. A stream of carrier gas is directed over or is bubbled through the solvent and precursor solution to distill and transport precursor molecules in the vapor phase to a deposition chamber. Conventional deposition processes may be used to deposit the desired thin film on a substrate.

Owner:MICRON TECH INC

Collapsible carbine stock with spare magazine storage enclosure

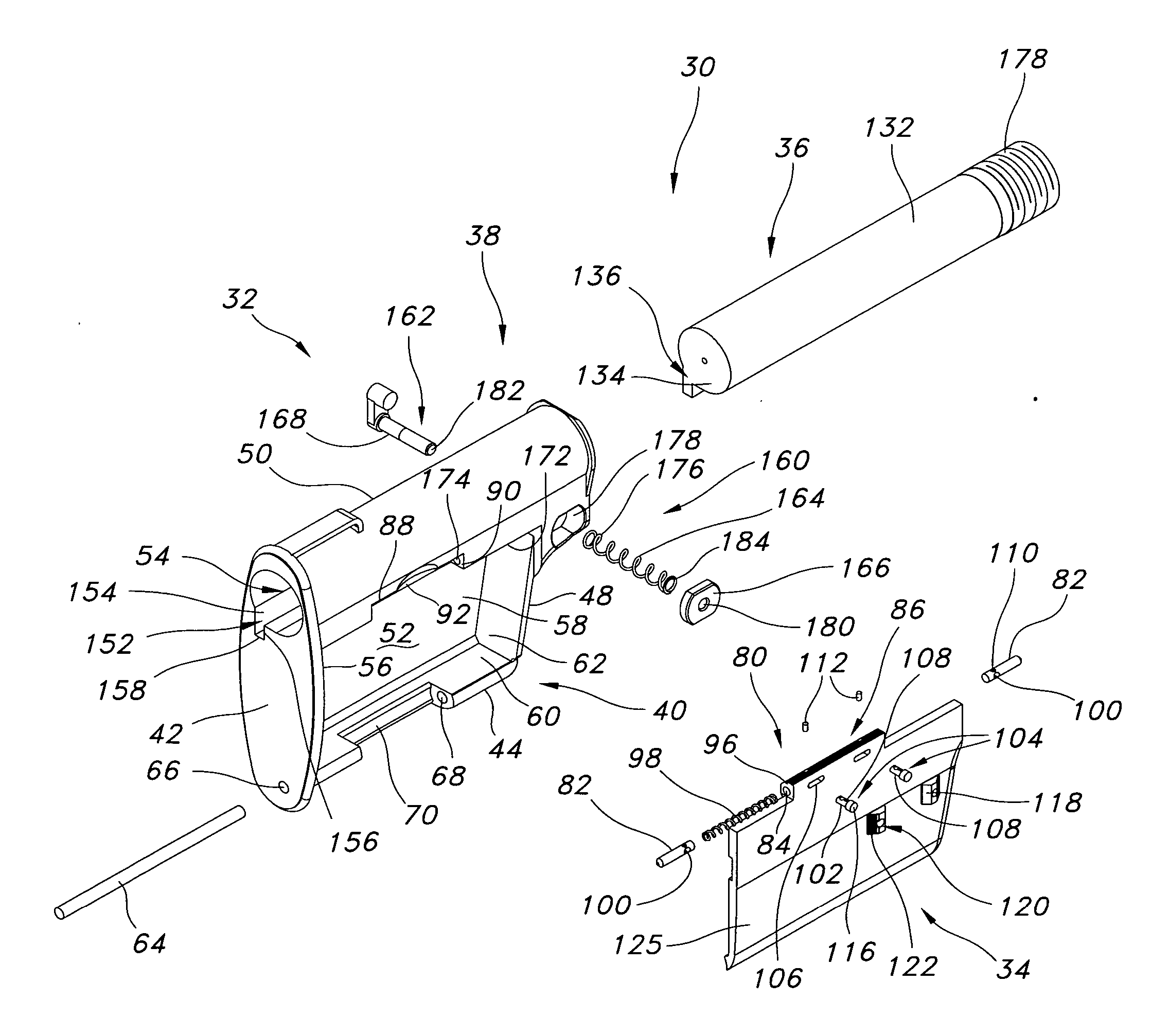

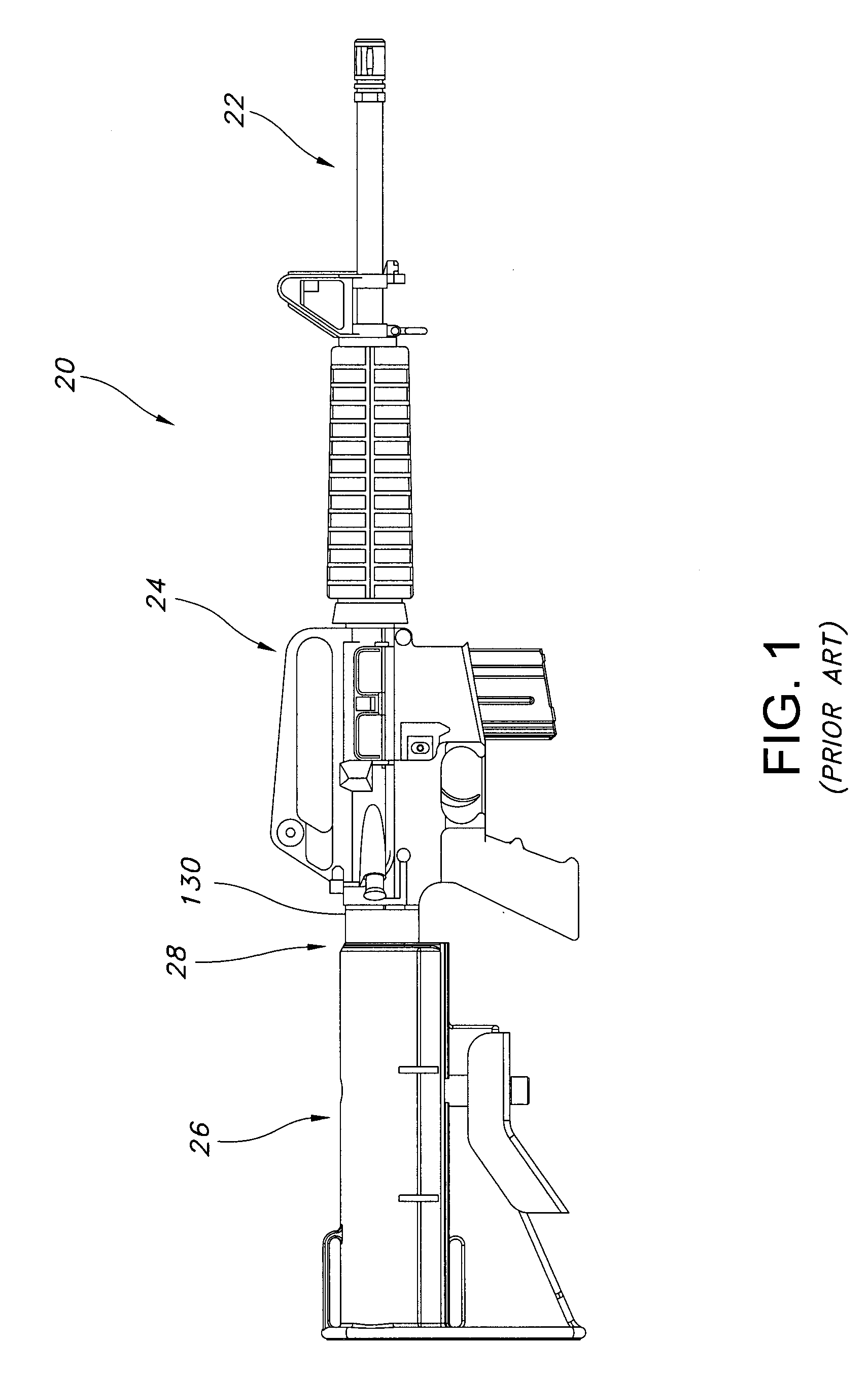

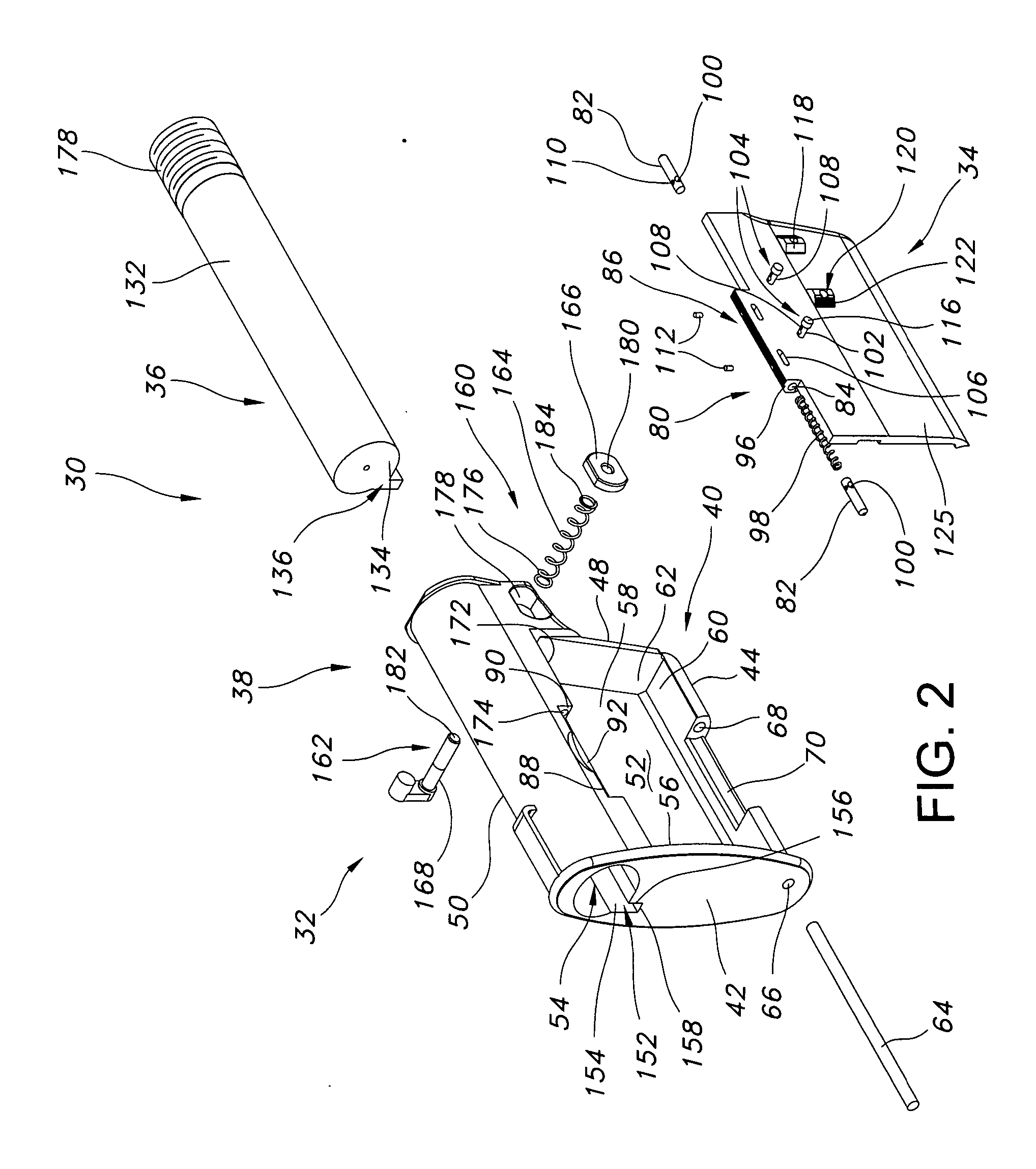

A collapsible buttstock which is adapted primarily for use with military and tactical carbines, is supported by an extension tube which is connectable to the receiver of a carbine on which the collapsible buttstock is to be mounted. A storage enclosure is formed in the body of the buttstock and is sized and dimensioned so that it can receive a clip or magazine, typically able to carry 20 rounds, that is usable with the carbine on which the collapsible buttstock is mounted. The enclosure is provided with an openable cover that is hingably attached to the buttstock body. An easily operable cover latch assembly is usable to secure the cover in a closed position while facilitating expeditious opening of the cover to afford access to the spare magazine storage enclosure.

Owner:KENGS FIREARMS SPECIALTY

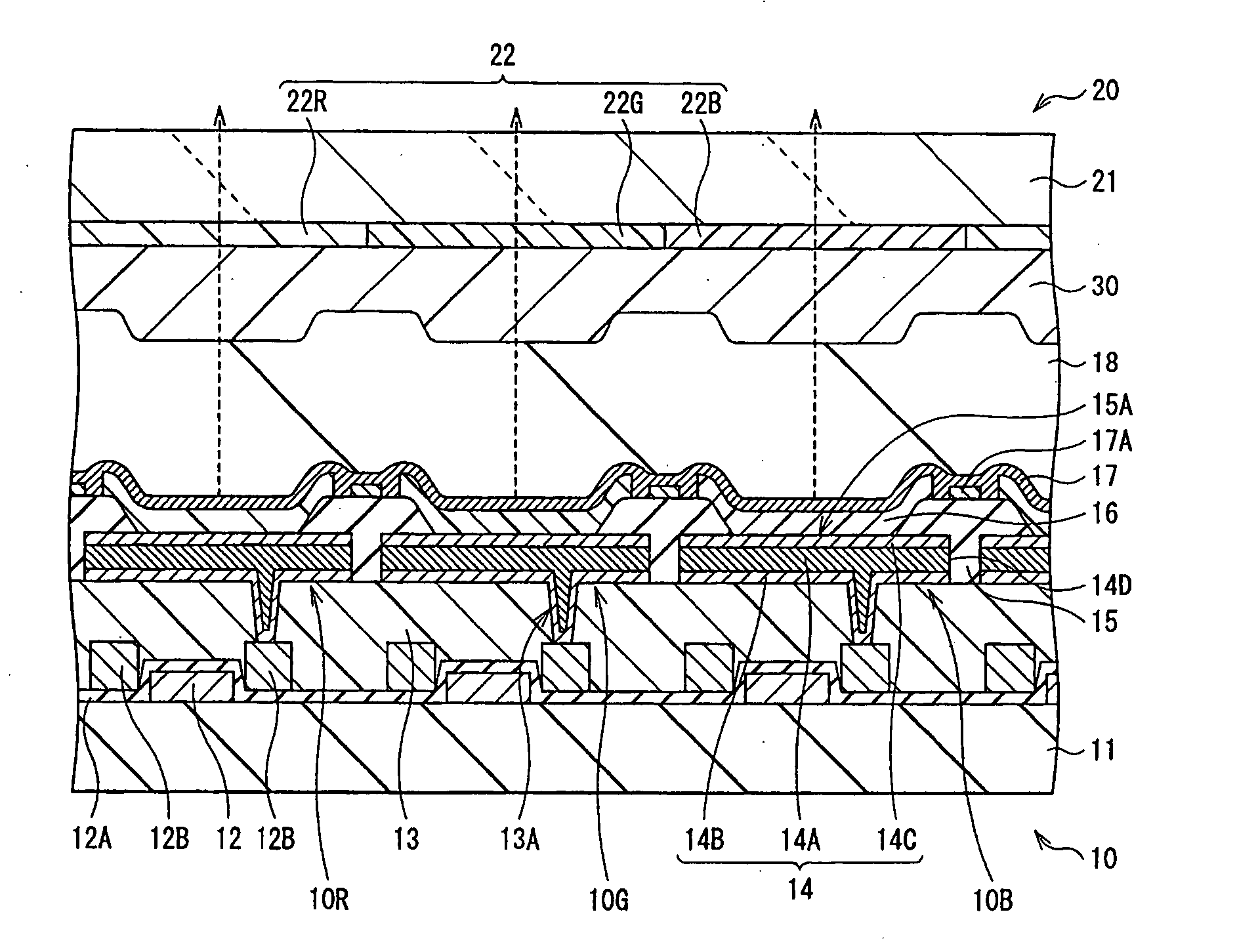

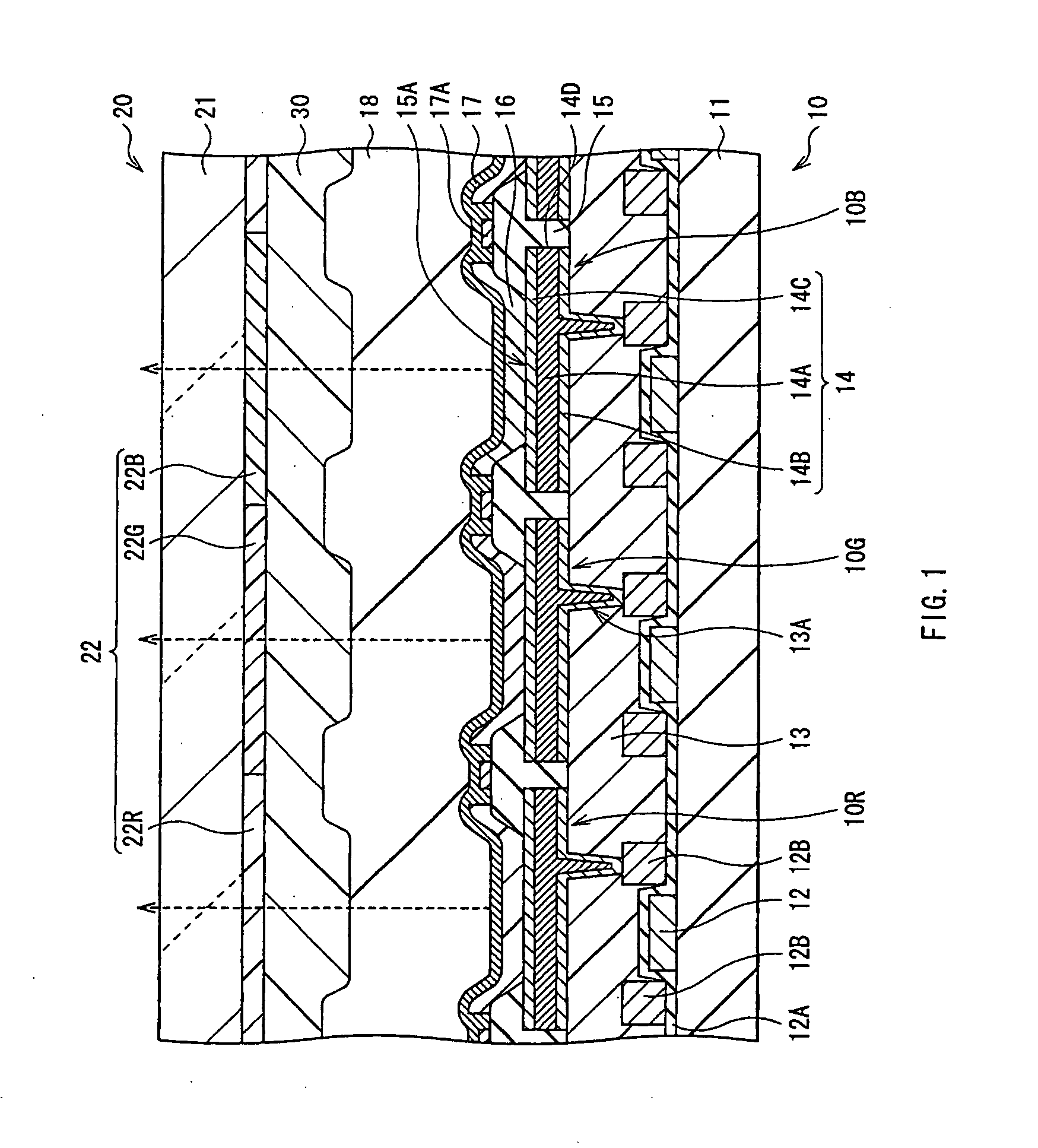

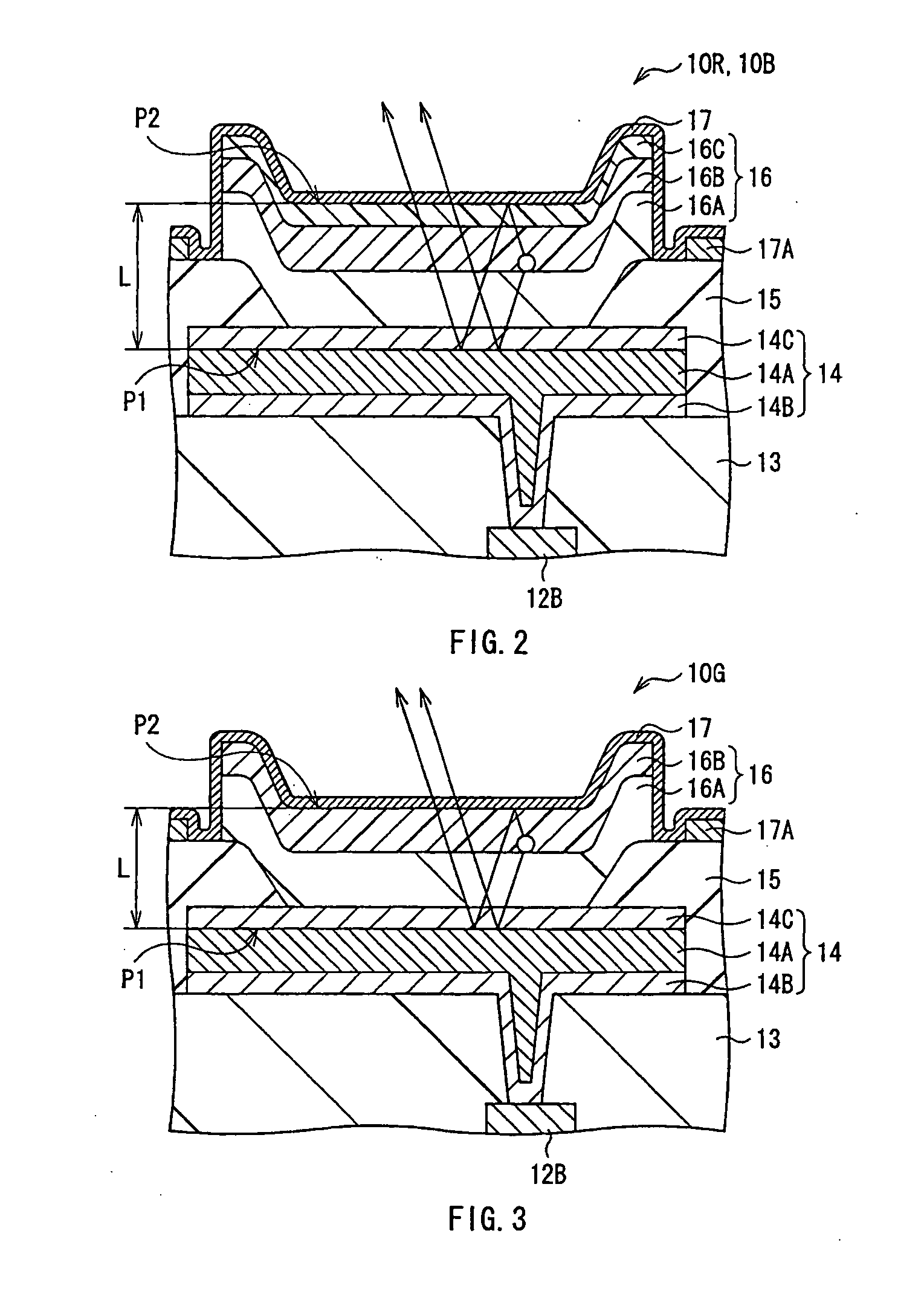

Method of manufacturing laminated structure, laminated structure, display device and display unit

InactiveUS20050007015A1Good body shapeReduce defectsDischarge tube luminescnet screensSemiconductor/solid-state device detailsEtchingLiquid-crystal display

A method of manufacturing a laminated structure capable of being patterned into a favorable shape by preventing side etching is provided. After an adhesive layer made of ITO or the like, a reflective layer made of silver or an alloy including silver, and a barrier layer made of ITO or the like are laminated in order on a substrate with a planarizing layer which is a base layer in between, a mask is formed on the barrier layer, and the adhesive layer, the reflective layer and the barrier layer are etched at once by using the mask to form a laminated structure. As an etching gas, for example, a gas including methane (CH4) is preferable. The laminated structure is used as an anode, and an insulating film, an organic layer including a light-emitting layer and a common electrode as a cathode are laminated in order on the laminated structure so as to form an organic light-emitting device. The laminated structure can be used as a reflective electrode, a reflective film or wiring of a liquid crystal display.

Owner:SONY CORP

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

Microencapsulation expansion type flame retardant and application in epoxy resin composite material thereof

The invention discloses a microencapsulation expansion type flame retardant and application in an epoxy resin composite material thereof. The microencapsulation expansion type flame retardant uses ammonium polyphosphate as a capsule core and uses a thermosetting resin melamine-formaldehyde resin as a capsule material. The microencapsulation expansion type flame retardant epoxy resin composite material consists of the epoxy resin, a curing agent, a curing accelerator, the microencapsulation expansion type flame retardant and a flame-retardant carbon-forming accelerator. The microencapsulation expansion type flame retardant and the application are economic, simple and convenient; the flame retardant has good flame-retardant synergistic effects; and under the condition of little flame retardant addition, the composite material can pass V-0 level of UL-94 test, and the oxygen index reaches over 30.0 percent.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Water diamond lapping liquid and its preparation method and use

InactiveCN101186804AEnvironmentally friendlyAccelerated corrosionPolishing machinesOther chemical processesAlloySuspending Agents

The invention provides aqueous diamond polishing liquid, process for preparation and purpose. The main components are diadust, dispersion stabilizer, suspending agent, pH modifying agent, antiseptic agent, organic solvent and deionized water. The preparing technique of the invention is that organic solvent, diadust, prior prepared suspending agent, deionized water and dispersion stabilizer are mixed, then the mixture is stirred or supersonically dispersed uniformly, finally pH modifying agent and antiseptic agent are added, and the preparation is accomplished after shaking up. The lapping liquid can be widely used in grinding and polishing in various departments and areas of optical instruments, glasses, ceramics, rigid alloy, diamonds, artificial lens, optical fiber, LED display, integrated circuit, semiconductor, hard disk and the like. The lapping liquid can be kept in uniform and stable state, generates no precipitation, delamination or invalidation.

Owner:BEIJING GRISH HITECH

Preparation method of micro-emulsion absorption liquid used for processing organic exhaust gas

The invention relates to a preparation method of an organic exhaust gas micro-emulsion absorption liquid, and a method for applying the micro-emulsion absorption liquid for cleaning industrial organic exhaust gas comprising benzene, toluene, xylene, and the like. The invention belongs to the technical field of atmosphere pollution control. The absorption liquid is prepared from the components of, by mass, 80-90% of water, 0.5-3% of a surfactant, 7-19.5% of a coupling agent, and 0.02-0.06% of an auxiliary agent. The surfactant is sufficiently mixed with water, such that a surfactant solution is obtained; the auxiliary agent is dissolved in water, such that an auxiliary agent solution is obtained; the two solutions are combined and uniformly mixed; and the coupling agent is added, and the obtained solution is stirred, such that the organic exhaust gas micro-emulsion absorption liquid is obtained. The organic exhaust gas micro-emulsion absorption liquid is suitable to be used for controlling exhaust gas containing benzene-series volatiles, and has the advantages of convenient raw material source, low cost, mild and stable property, low toxicity, environment-friendliness, no absorption tower corrosion or blocking phenomena, no severe influence to human health, high removal rate to organic exhaust gas, no need of pretreatment upon exhaust gas, and low investment and running cost. Saturated absorption liquid and absorbed organics can be recycled, such that waste can be turned useful.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

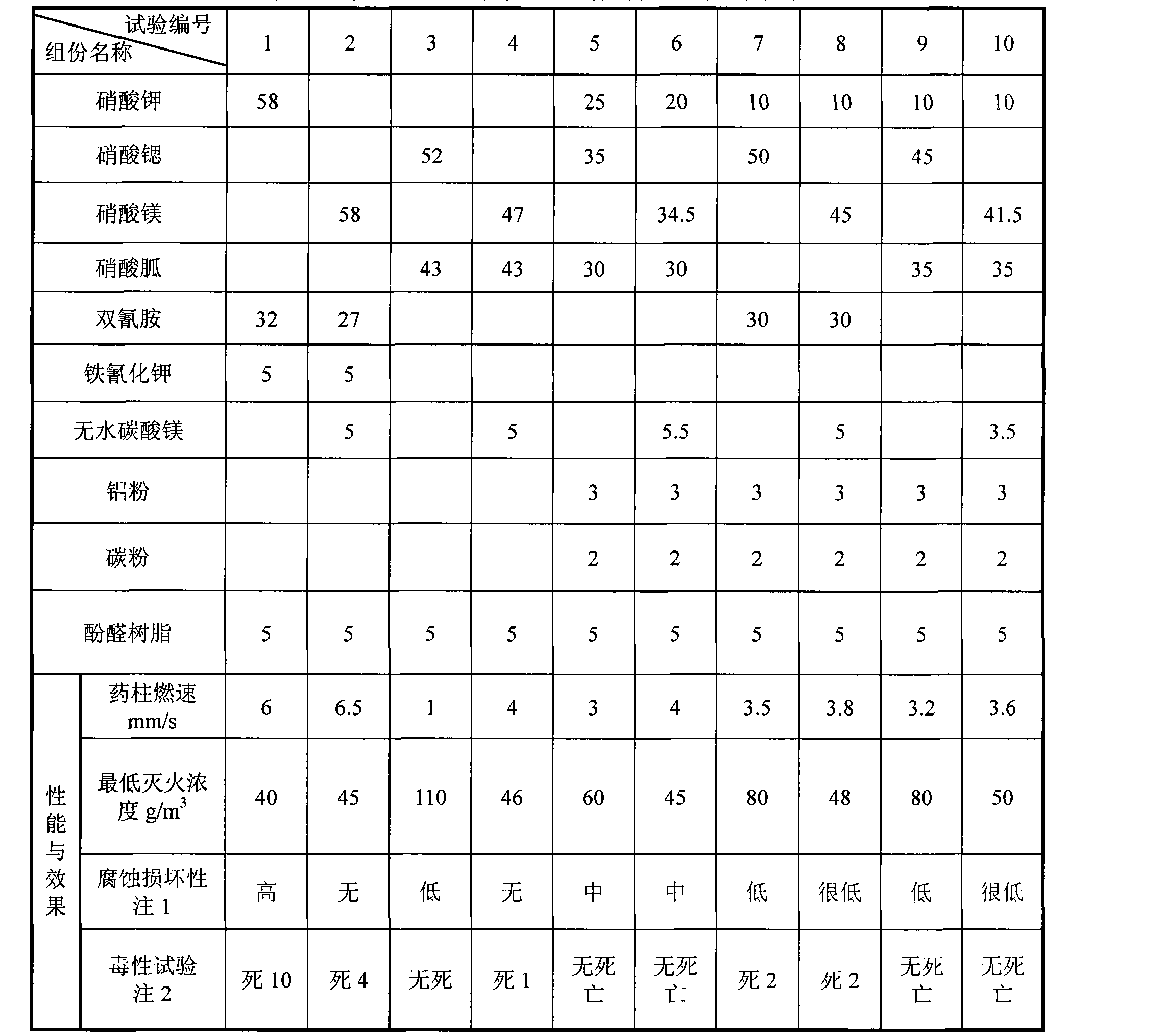

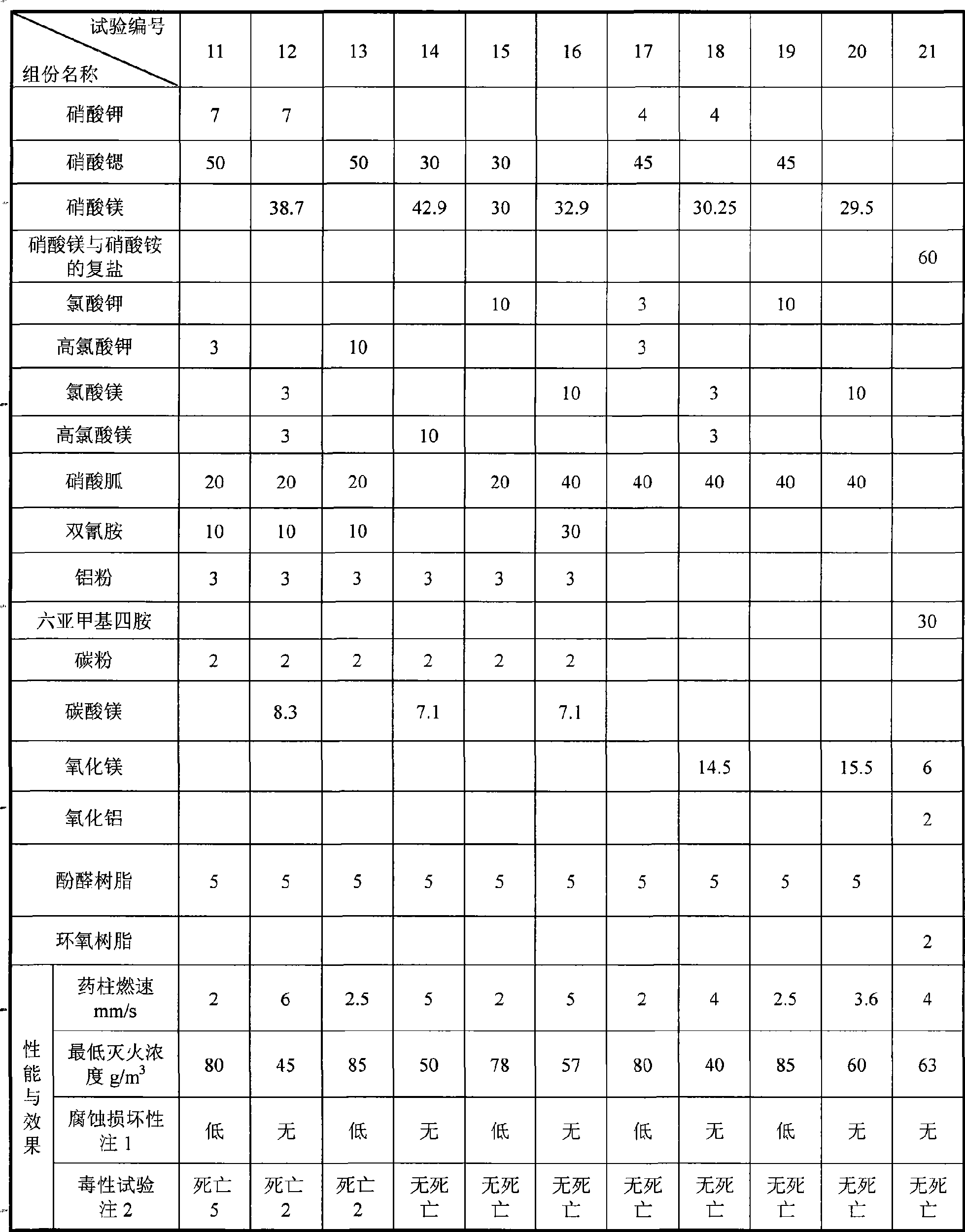

Extinguishment combination with hot gas sol

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

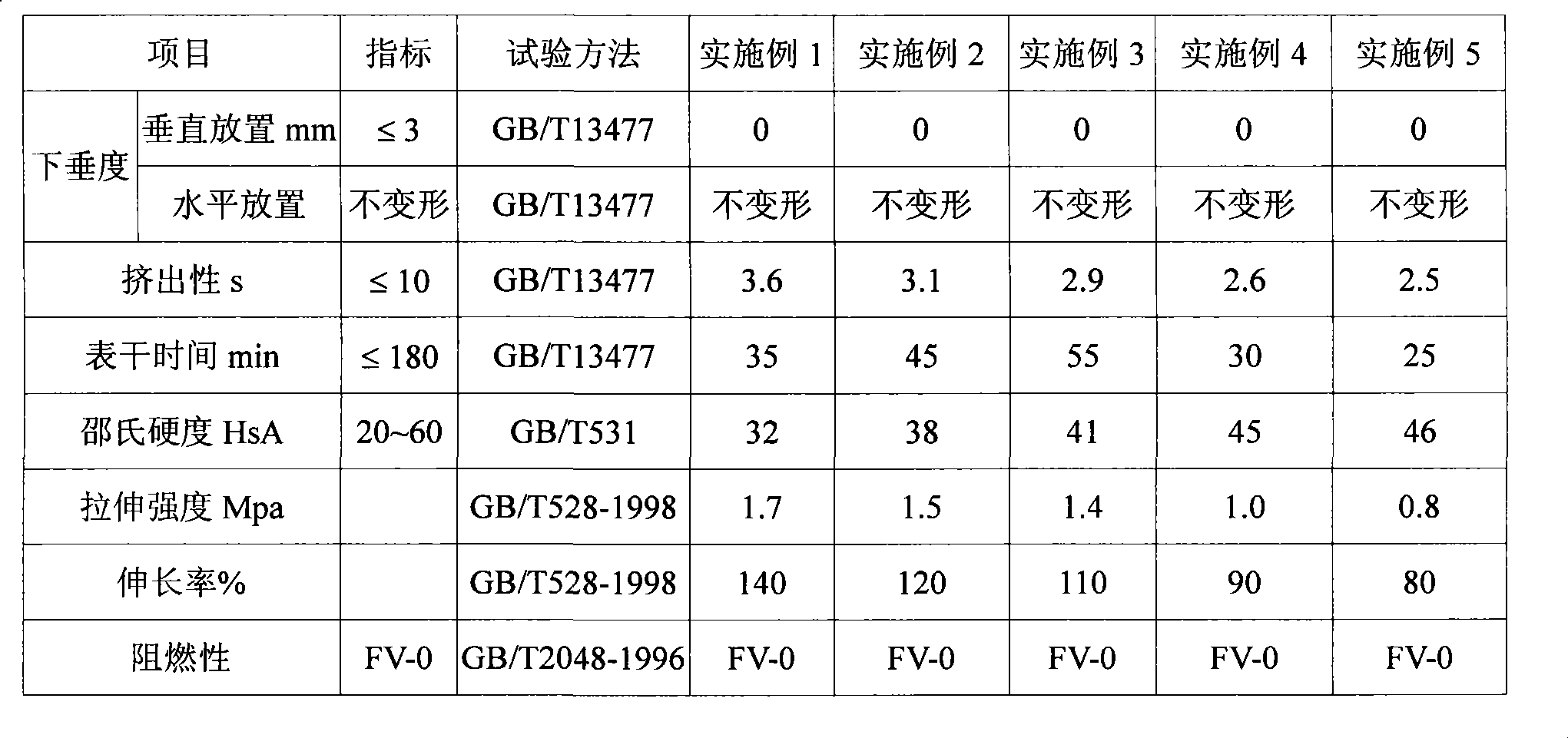

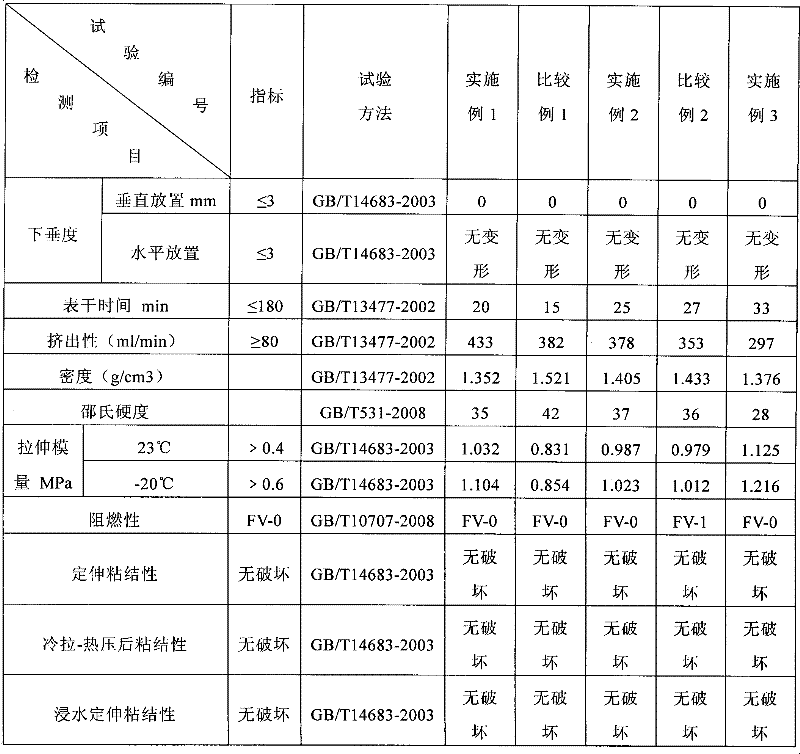

Expansion flame-proof organosilicon fluid sealant and method of producing the same

InactiveCN101368080AEnsure the safety of personnel and propertyGood fire performanceOther chemical processesAdhesivesOrganosiliconPlasticizer

The invention relates to an expansion flame retardant organosilicon sealant and a manufacturing method thereof. The sealant comprises the following components by weight portion: 100 portions of Alpha, Omega-dihydroxyl polysiloxane; 5 to 30 portions of plasticizer; 20 to 100 portions of filler; 50 to 150 portions of inorganic flame retardant; 5 to 30 portions of expansion fire retardant; 1 to 30 portions of cross-linking agent; 0.1 to 1 portion of catalyzer; 1 to 5 portions of viscosity increaser and 0.1 to 5 portions of inorganic pigment. The manufacturing method comprises the following steps: the Alpha, Omega-dihydroxyl polysiloxane, the filler, the inorganic flame retardant and the expansion fire retardant are dehydrated at 80 to 150 DEG C in a vacuum triple motion agitator, and are mixed for 0.5 to 2 hours before the mixture is cooled to the room temperature; the silane cross-linking agent, the viscosity increaser, the catalyzer and the plasticizer are added and mixed for 0.5 to 2 hours. The expansion flame retardant organosilicon sealant has excellent mechanical property, fire retardancy, adhesion and storage stability, which is primarily used as a sealant in devices that cables are threaded through on watercrafts as well as used for closing off various openings formed in the way that cables, air conduits, oil tubes and so on pass through walls, bulkheads, floor slabs, decks and so on in buildings or power supply systems.

Owner:陈栋梁 +1

Expansion type fire retardant material

An expansion-type flame-retarding material is prepared through reaction between polyol and phosphorus compound containing hydroxy, adding melamine, reaction and modifying surface by high-molecular substance. Its advantages are high compatibility to polyethene and polypropyene, less consumption, high mechanical performance and flame-retarding effect, no poison and corrosion, and environment friendly.

Owner:EAST CHINA UNIV OF SCI & TECH

Glass cleaner and application thereof

InactiveCN102181326AEfficient removalImprove decontamination abilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEngineeringCleansing Agents

The invention provides a glass cleaner. The cleaner comprises a nonionic surfactant, an anionic surfactant, a corrosion inhibitor, an antifreezing film-forming agent, a lubricant and a solvent. The invention also provides application of the glass cleaner to the cleaning of front windshields of trains, in particular application of the glass cleaner to the cleaning of front windshields of motor trains. The cleaner has extremely strong decontamination capacity, and can quickly and effectively remove pollutants which appear on windshields of trains running at a high speed; the cleaner has higher ambient temperature adaptability, and can be used at the temperature of between minus 40 and 60 DEG C; the pH value is 6.8 to 7.2, and the cleaner has lower corrosivity; the cleaner has high lubricity and can prevent the windshields from being bruised; an antifreezing film-forming component is added and can achieve the effects of anti-icing and demisting; and the cleaner does not contain components which are toxic or irritant to human bodies such as methanol, ammonia water and the like.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

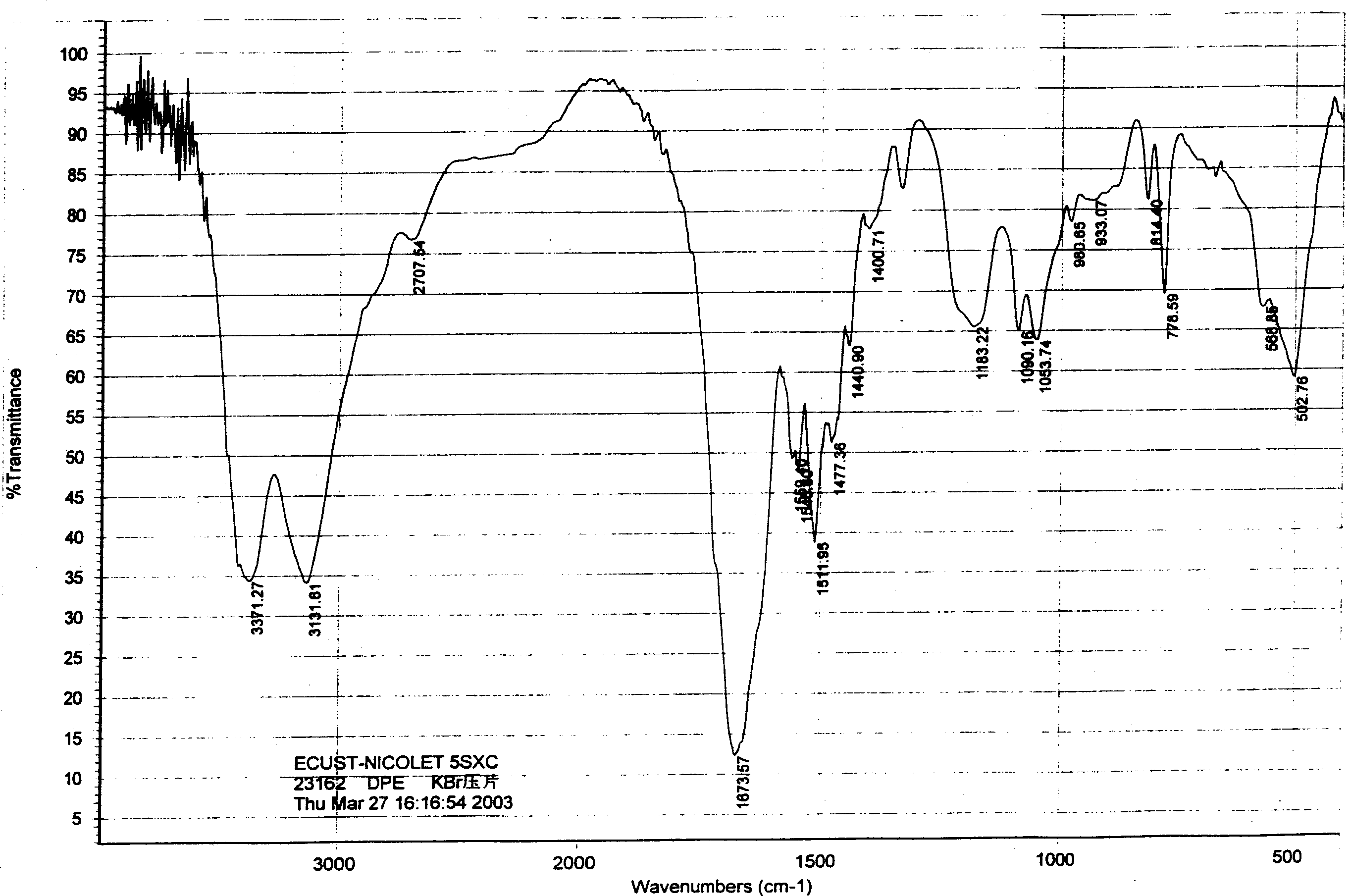

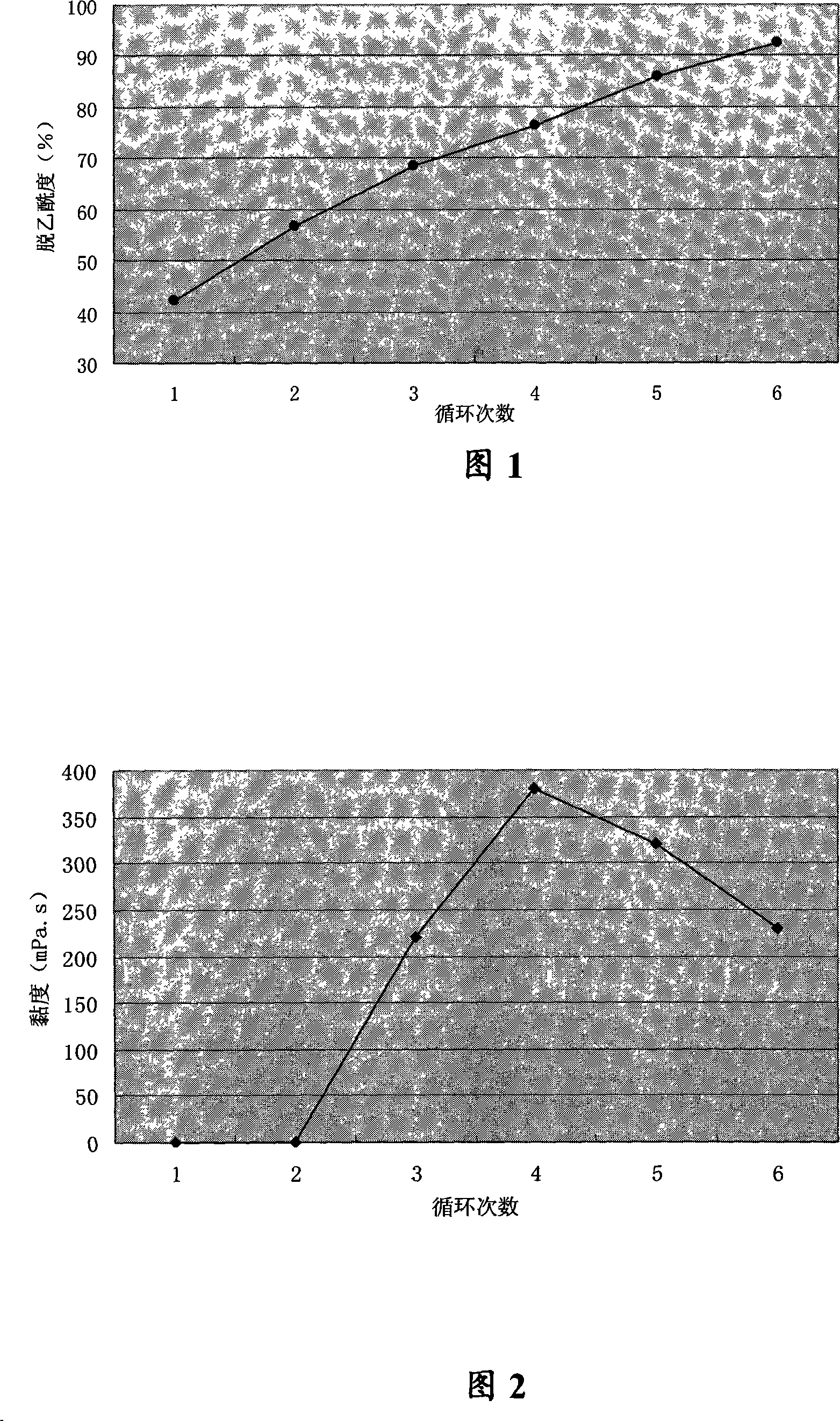

Method for preparing chitin and its chitosan and chitosan oligosaccharide

InactiveCN101144097ATake advantage ofImprove production conditionsMicroorganism based processesFermentationSolubilityBioreactor

The present invention relates to a method for preparing chitin and chitosan oligosac charide. The method comprises the steps that usual raw materials such as the crust of shrimp and crab, the insect crust or the fungal mycelia, etc. are micronized through the dry process or wet process; the carapace material of the obtained fine powder raw material is decalcified with the chemical process, and then is defatted and deproteinized with the method of micro-organism compound enzyme coarse enzyme liquid co-enzymolysis, and the insect and fungus fine powder thereof is directly defatted and deproteinized; a whole cell immobilizing bioreactor of a chitin deacetylase high-yield producing strain is prepared, to perform the circulatory deacetylation to the chitin and then obtain chitosan with corresponding degree of deacetylatoion; obligate anaerobic acid-producing bacterium and high-yield producing chitosan bacterium are utilized, the chitosan is submerged and fermented in the liquid, to obtain chitosan oligosaccharide with high water solubility. The present invention has the advantages that the method is helpful to fully utilize the resources, and makes the waste to the worth, at the same time, the default of the manufacturing process of the chemical process can be avoided, the production efficiency is improved, the energy is saved, the consumption is reduced, the byproduct with corresponding high value added can be produced, the comprehensive economic benefits of the relative secondary industry are obviously improved, the industrial development is promoted, and the multi-win effect is attained.

Owner:重庆百奥帝克微生态科技有限公司

Antimicrobial cidality formulations with residual efficacy, uses thereof, and the preparation thereof

InactiveUS20090074881A1Easy to manufactureEasy to prepareBiocidePeroxide active ingredientsMicroorganismDistilled water

The present invention is a quick-kill formulation that is able to kill organisms such as bacteria, viruses, fungi, mold, spore-forming bacteria and combinations thereof. In addition, the formulation contains a residual kill component that is effective for at least one day. The unique formulation is effective without being corrosive. This is an advantage that allows it to be used in a wide range of applications, one application being in the medical field for sterilizing instruments. Another improvement of this formulation over the prior art is that it is stabilized such that, unlike prior art formulations, tap water, as opposed to distilled water, may be used in its manufacture.

Owner:YCLEAN ENTERPRISES LLC

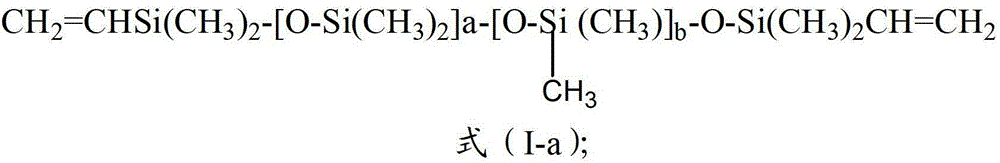

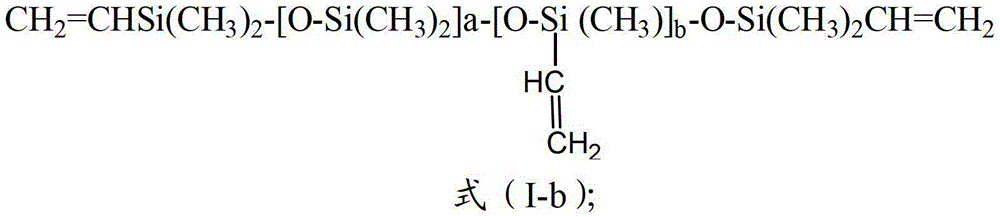

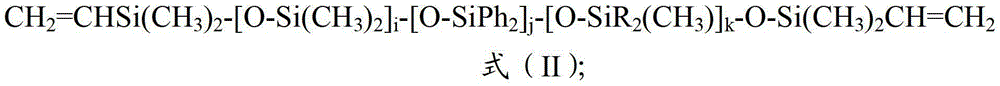

Single-component addition-type silicone rubber and preparation method thereof

The invention provides a single-component addition-type silicone rubber which is prepared by vulcanizing the following raw materials in parts by mass: 20-50 parts of vinyl polysiloxane, 3-18 parts of vinyl methyl phenyl polysiloxane, 4-20 parts of hydrogen-containing polysiloxane, 0.01-0.1 part of platinum catalyst, 0.3-2.5 parts of inhibitor, 40-60 parts of filler, 2.0-10 parts of additive and 0.5-3 parts of tackifier. The single-component addition-type silicone rubber comprises the heat-resistant additive and the filler, so that the single-component addition-type silicone rubber prepared by vulcanizing has good high temperature resistance and low temperature aging resistance. The single-component addition-type silicone rubber comprises the catalytic inhibitor, so that the single-component addition-type silicone rubber has a higher inhibitory effect, and the storage life of the single-component addition-type silicone rubber is prolonged. When the addition-type silicone rubber is vulcanized, small molecular substances are not produced, and packaging components are not corroded.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Glass cleaning agent composite for electronic industry

InactiveCN1482223AEasy to cleanRaw materials are easy to getInorganic non-surface-active detergent compositionsSodium bicarbonateSodium metasilicate

The electronic industrial glass cleaning agent composition belongs to the field of electronic industrial cleaning technology. The cleaning agent consists of sodium metasilicate, sodium hydroxide, sodium carbonate, sodium bicarbonate, Pluronic polyol, CMC, fluoric surfactant, complexing agent, defoaming agent and deionized water. It is used to clean substrate glass and coated conducting glass. During the cleaning, the cleaning agent in 1-5 % is compounded with deionized water in 95-99 % to compound the cleaning liquid for showering or ultrasonic cleaning to eliminate pollutant on glass fastcompletely. It is used to replace strong acid and strong alkali cleaning agent and has no damage to glass surface and no corrosion to ITO film. The cleaning agent has no bad smell, no toxicity and no corrosion, and is safe, reliable, environment friendly and low in cost.

Owner:SHANDONG UNIV

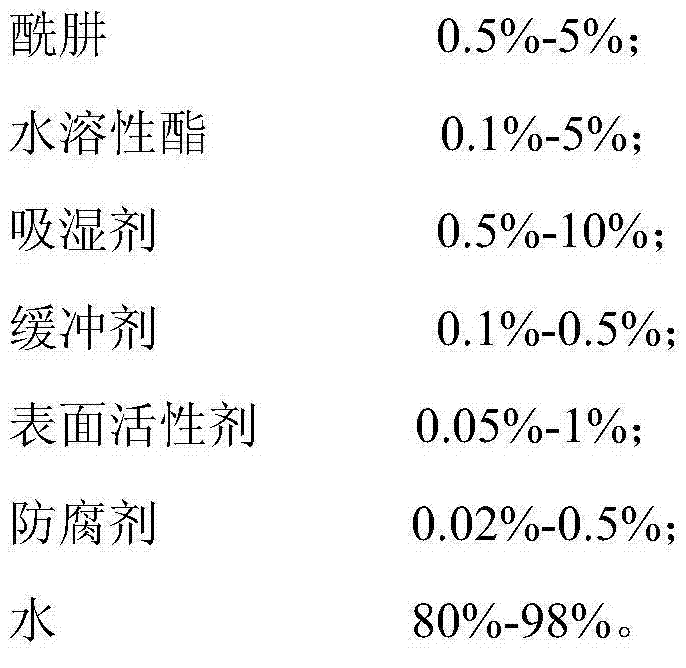

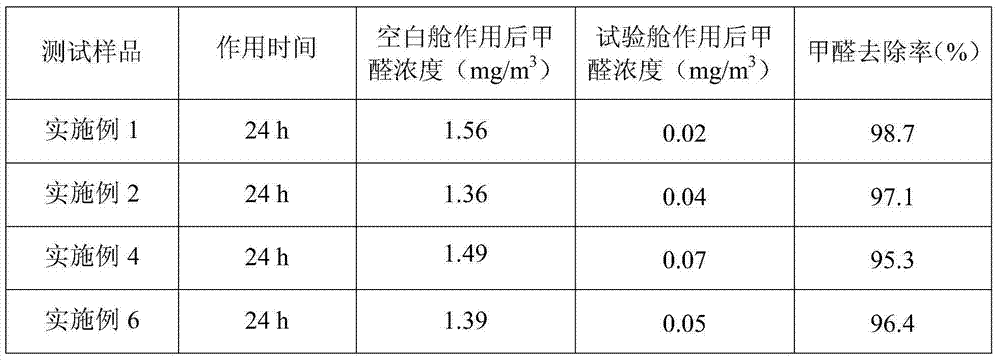

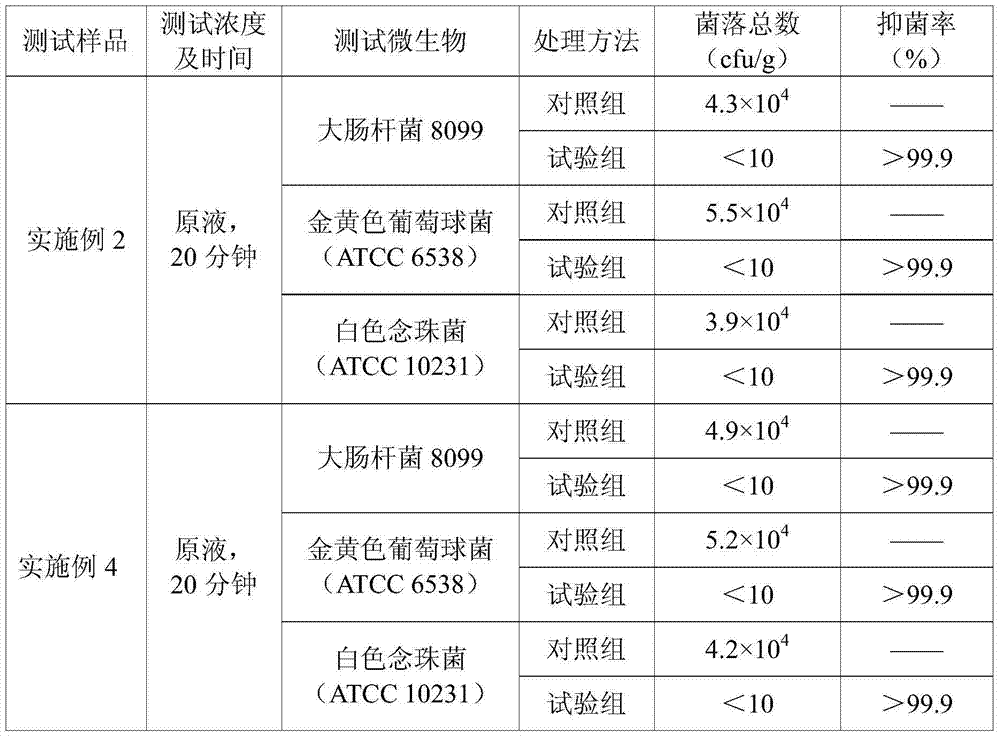

Efficient low-toxicity formaldehyde scavenger

ActiveCN104324583ANon-toxic or low toxicityNon-oxidizingDispersed particle separationScavengerPreservative

The invention discloses an efficient low-toxicity formaldehyde scavenger containing the following raw material components by weight: 0.5%-5% of hydrazide, 0.1%-5% of a water-soluble ester, 0.5%-10% of a moisture absorbent, 0.1%-0.5% and of a buffer, 0.05%-1% of a surface active agent, 0.02%-0.5% of a preservative and 80%-98% of water. The free hydrazine content in the efficient low-toxicity formaldehyde scavenger product is controlled in the range as low as possible by the manner of fine selection of the hydrazide raw material, control of free hydrazine content, adding of the water-soluble ester, adding of the buffer, and the like, and the efficient low-toxicity formaldehyde scavenger product has better security. The efficient low-toxicity formaldehyde scavenger product is good in formaldehyde removal effect, safe to people and objects, and simple in production process, and can be used for governance of the problem of formaldehyde exceeding the standard in new decorated residence or furniture.

Owner:广州超威生物科技有限公司

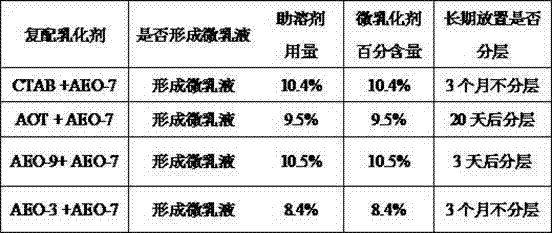

Micro-emulsion biodiesel and preparation method thereof

The invention discloses a micro-emulsion biodiesel and a preparation method thereof. The formula of the micro-emulsion biodiesel comprises the following components in mass percentages: 65-90% of biodiesel, 2-12% of complex emulsifier, 3-8% of cosolvent and 5-15% of water. The micro-emulsion biodiesel disclosed by the invention has reasonable proportion and has the characteristics of clearness, transparency, uniform dispersion, rather stable thermodynamics, storage and conveyance facilitation, no lamination and the like. The micro-emulsion biodiesel disclosed by the invention can exert the advantages of the biodiesel as a reproducible energy source, can also reduce the exhaust of harmful gas NOx and carbon smoke in the process of the combustion of the biodiesel, has low cost and can be stably stored and conveyed for a long time. The micro-emulsion biodiesel disclosed by the invention has a simple preparation method and does not cause pollution to the environment during preparation.

Owner:国家石油石化产品质量监督检验中心(广东)

Water-soluble insulating varnish and preparation method thereof

InactiveCN101270256AGood transparency and stabilityLong application periodPolyurea/polyurethane coatingsEmulsion paintsWater basedDiluent

The invention relates to water-soluble insulating varnish and a preparation method thereof. The water-soluble insulating varnish of the invention consists of water-soluble resin, water-borne curing agent, water-base defoamer, water-base flow agent, water-base catalyst and water; the proportion of the components is as below: 30 percent to 50 percent of water-soluble resin; 10 percent to 30 percent of water-base curing agent, 1 percent to 1.0 percent of water-base catalyst, 0 percent to 0.5 percent of water-base defoamer, 0 percent to 0.5 percent of water-base flow agent and 20 percent to 60 percent of water; the water-soluble insulating varnish has the advantages of environmental protection and safety; no harmful solvent released to the atmosphere; no inflammability and explosion, no corrosion; no transparent or translucent paint liquid, good stability, long application service life under normal temperature; simple solidifying process, good insulating performance of the paint film after solidification, high strength and strong toughness; technical indexes meeting or exceeding the technical indexes of the prior solvent-type insulating varnish; the most important is that the insulating varnish takes water as solvent or diluent, which does not bring pollution and reduces the cost.

Owner:SHANGHAI BAOQING TONGYONG ELECTRICAL

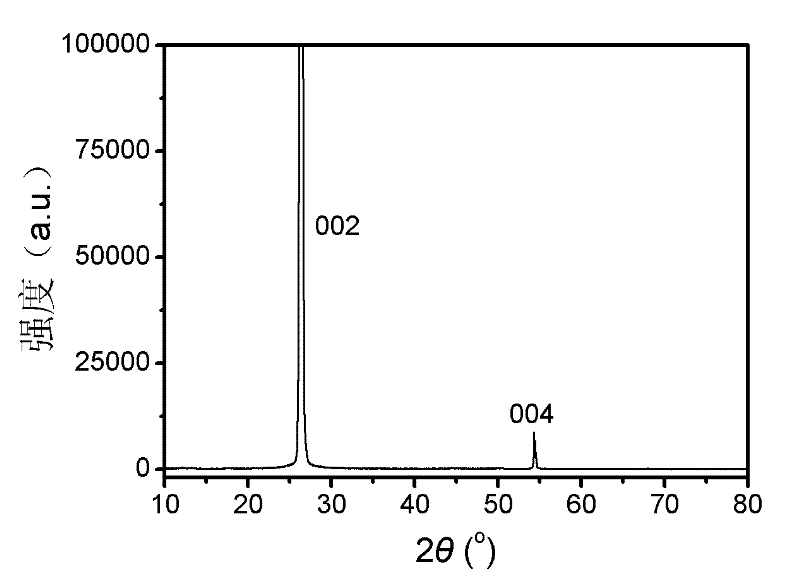

Carbon nano tube composite film and preparation method thereof

ActiveCN103435027AEvenly dispersedAvoid reunionMaterial nanotechnologyCarbon compoundsComposite filmCatecholamine

The invention discloses a preparation method for a carbon nano tube composite film. The method comprises the following steps: first, allowing a phenolic hydroxyl group, a quinonyl group and other functional groups to be introduced on the surface of a carbon nano tube through oxidation autopolymerization reaction of catecholamine under an alkalescence condition, so as to realize the modification for the surface of the carbon nano tube; then, using water-soluble polymers with amino groups or mercapto groups as raw materials to realize layer-by-layer self-assembly under the action of chemical bonds formed by Schiff base or Michael Addition reaction, thereby obtaining the carbon nano tube composite film. The method has the advantages of mild reaction condition, environmental protection, simplicity and feasibility, and is suitable for industrialized production. The carbon nano tube composite film prepared by the method has the advantages of excellent thermal and chemical stability, ductility, mechanical strength and transparency.

Owner:ZHEJIANG UNIV

Stainless steel weldless steel tube for ship and producing technique

InactiveCN101220443AHigh mechanical strengthGood extensibilityFurnace typesHeat treatment furnacesNo productionUltimate tensile strength

The invention relates to a stainless steel seamless pipe in metallurgical industry and the manufacturing process for the stainless steel seamless pipe; wherein, the steel pipe is made of 00Cr24Ni6Mo2N dual phase stainless steel; the manufacturing process for preparing the ship borne stainless steel seamless pipe comprises the following production steps of a. round steel preparation; b. heating; c. hot-puncturing process; d. end cropping; e. pickling; f. repair grinding; g. lubrication; h. cold rolling processing; i. degreasing; j. solution heat treatment; k. straightening; l. pipe cutting; m. pickling; n. inspection of finished products. The invention solves the problems of lower mechanical strength and extensibility, shorter service life and high prices in present 316L stainless steel pipes used in ship seawater channels and provides a novel ship borne dual phase stainless steel seamless pipe and the manufacturing process and has the advantages of no production of pitting corrosion and grain boundary corrosion of the steel pipes, higher mechanical strength and extensibility, longer service life as well as low price and low cost.

Owner:江苏长盈不锈钢管有限公司

Silicone fireproof sealant for construction and preparation method thereof

InactiveCN101747859ALess corrosiveHigh flame retardant efficiencyNon-macromolecular adhesive additivesOther chemical processesRoom temperatureNitrogen

The invention discloses a silicone fireproof sealant for construction and a preparation method thereof. The preparation comprises the steps of adding alpha, omega-dihydroxy polysiloxane, a filler, an inorganic flame retardant and a nitrogen system flame retardant into a kneading machine, carrying out dehydration at the temperature of 100-180 DEG C and the vacuum degree of 0.06-0.1MPa for 0.5-4 hours, cooling, and then preparing a base material. The base material, polydimethylsiloxane, an inorganic pigment, a crosslinking agent, a silane coupling agent and a catalyst are added into a planetary mixer at the room temperature, keeping the vacuum degree at 0.06-0.1MPa, stirring at the speed of 20-80 r / min, carrying out reaction under stirring for 0.5-6 hours, and preparing the silicone fireproof sealant for construction with no pollution to the base material, flame retardance and excellent adhesion and storage stability. The inorganic flame retardant and the nitrogen system flame retardant are in synergistic flame retardance, and the silicone fireproof sealant can effectively reduce the adding amount of the inorganic flame retardant and greatly improve the mechanical processing performance of a product under the situation of achieving the equivalent flame retardant grade FV-0.

Owner:浙江凌志新材料有限公司

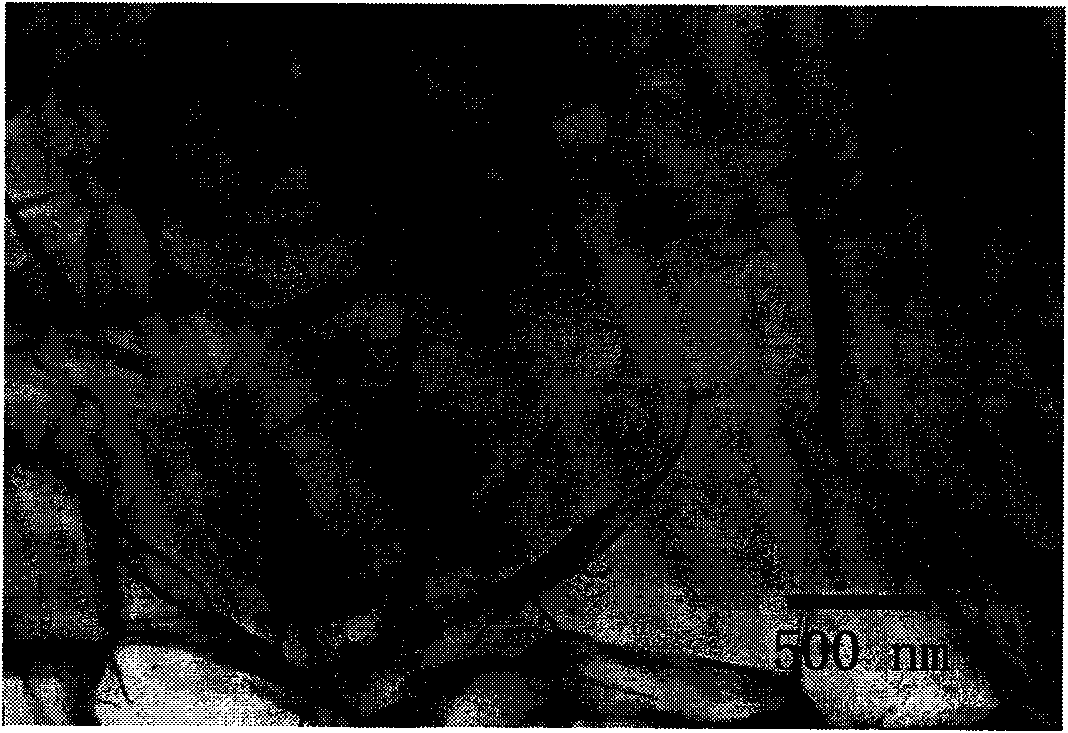

Preparation method of graphene uniform dispersion

The invention relates to a preparation method of graphene uniform dispersion, belonging to the technical field of new nano materials. The preparation method comprises the following steps of: (1) preparing aqueous surfactant solution with the concentration of 0.2-20g / L; (2) mixing raw graphite powder with the aqueous surfactant solution according to the concentration of 1-100g / L, forming suspension and adding the suspension into a high-pressure reactor with strirring; (3) adjusting the rotating speed of the high-pressure reactor to be 50-300rpm and the temperature in the reactor to be 100-300 DEG C, carrying out heat preservation treatment on the raw graphite powder for 5-24 hours and then taking out paste; (4) carrying out 1000-2000rpm centrifugation on the paste for 15-45 minutes, and obtaining supernatant solution which is the dispersion with one-layer and multilayer graphene. The preparation method has the advantages that the aqueous surfactant solution used in the preparation process can be recycled without exhaust emission; the used materials are non-corrosive, non-toxic, non-flammable and non-explosive products; the process can not cause large damage to the protogenic conjugated structure of the graphene; and the low cost can be realized, and the graphene dispersion with excellent dispersity and stability can be prepared.

Owner:常熟三爱富氟源新材料有限公司

Hollow glass bi-component organosilicone sealant and preparation method and application thereof

ActiveCN101831271AImprove adhesionNot corrosiveOther chemical processesAdhesivesSealantDimethyl siloxane

The invention relates to a hollow glass bi-component organosilicone sealant and a preparation method and application thereof. The hollow glass bi-component organosilicone sealant comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 100 parts of terminated polydimethylsiloxane, 10-30 parts of plasticizer and 100-400 parts of filler; and the component B comprises the following raw materials in parts by weight: 100 parts of plasticizer, 20-60 parts of carbon block, 30-70 parts of cross-linking agent, 20-60 parts of thickening agent and 0.2-2 parts of catalyst. The 100 percent tensile elongation modulus is 0.3-0.5MPa, the breaking elongation rate is 300-600 percent, the moisture transmissivity is 2.5-4.5g / m<2>.d, and the hollow gas bi-component organosilicone sealant has good adhesive force on a hollow glass base material and no corrosion on the base material. The preparation method has simple process and low equipment requirement; and a reaction by-product has no corrosion and can ensure the comprehensive implementation of technical effects of the bi-component low-permeability hollow glass bi-component organosilicone sealant. The invention is applied to a hollow glass frame and can play a role of ideal moisture obstruction.

Owner:西卡(江苏)工业材料有限公司

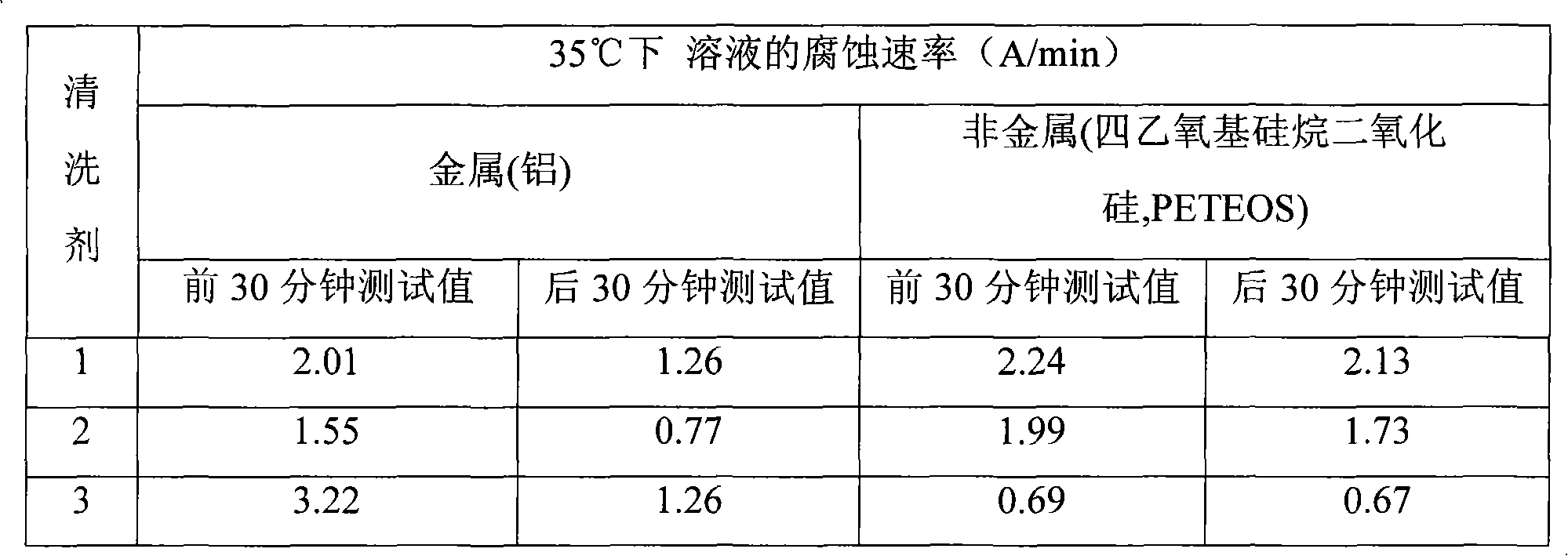

Cleaning fluid for cleaning plasma etching residue

InactiveCN101290482AImprove cleaning efficiencyEfficient and stable cleaning effectNon-surface-active detergent compositionsDetergent mixture composition preparationSilanesSolvent

The invention discloses washing liquid used in the semiconductor industry to wash plasma etching residues. The washing liquid contains citric acid / citrate buffer solution, fluorides, macromoledular corrosion inhibitor, anti-freeze agent and solvent. The washing liquid can effectively wash the plasma etching residues during the process of manufacturing a semiconductor, have low etching velocity on nonmetals and metal substrates such as Si, SiO2, tetraethoxy silane silicon dioxides (PETEOS), low-medium materials, Ti, Al, Cu and so on, is safe and harmless to the environment and the human body, and has good application prospect in the microelectronic field such as washing of semiconductor wafers and so on.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

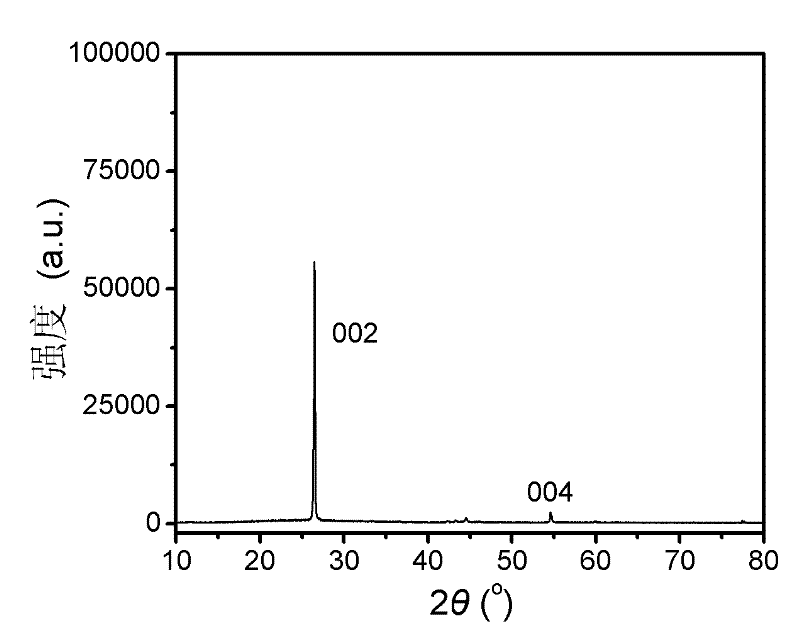

Method for synthesizing fine grain MCM-22 molecular sieve

InactiveCN1699170ALower synthesis costNot corrosiveCrystalline aluminosilicate zeolitesPolyethylene glycolSurface-active agents

Disclosed is a method for synthesizing fine grain MCM22 molecular sieve, wherein the templating agent employs the product yield of hexanolactam hydrogenation, and mainly comprises hexamethyleneimine, water, a small amount of byproduct and hexanolactam (reacted unconcompletely), the method comprises using silicon source, aluminium source, alkali source, templating agent and deionized water as reaction raw material, crystallizing for a finite period of time at 135-185 deg. C, untill completion of the reaction, obtaiting the needed molecular screen through hydrothermal synthesis, the invention is characterized in that organic additives can be charged into the reaction raw material, the organic additive can be sodium dodecylbenzene sulfonate, polyethylene glycol type surface active agent, or their mixture, the molecule ratio of the charged additive and the silicon dioxide in the reaction raw material is 0.01-2.5.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

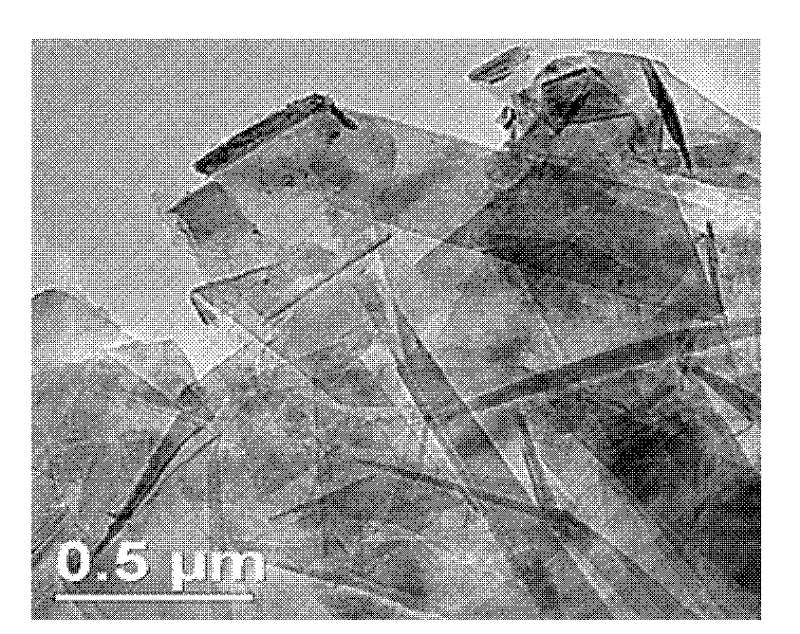

Method for preparing graphene

The invention discloses a method for preparing graphene, belonging to the technical field of material. The method prepares the graphene by the reaction of a carbon nano-tube and an oxidant in ionic liquid. Preferably, before reaction, the carbon nano-tube used as the reactive raw material is dispersed in the ionic liquid used as the reaction medium in a normal dispersion way (such as grinding, mixing, and the like.), subsequently the oxidant is added in the solution so as to carry out the reaction at certain reaction temperature and for a certain reaction time, thus obtaining the graphene. Preferably, the mass ratio of the carbon nano-tube to the ionic liquid is 1:10000-1:10; the reaction temperature is preferably within 0-300 DEG C; the reaction time preferably ranges from 0.1h to 48h; and the selection of the ionic liquid and the oxidant is wide. The method can be used for preparing the graphene and has the advantages of simple step, easy operation, suitable for large-scale industrial production, wide source of raw material, corrosion-free reaction medium, circular utilization of the medium, high yield, easy purification, moderate reaction condition, reaction at normal pressure and low energy consumption.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com