Method for preparing graphene

A technology of graphene and ionic liquid, which is applied in the field of preparing graphene with carbon nanotubes as raw materials, can solve the problems of immature chemical vapor deposition, high corrosion, and low efficiency, and achieve high yield, mild reaction conditions, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

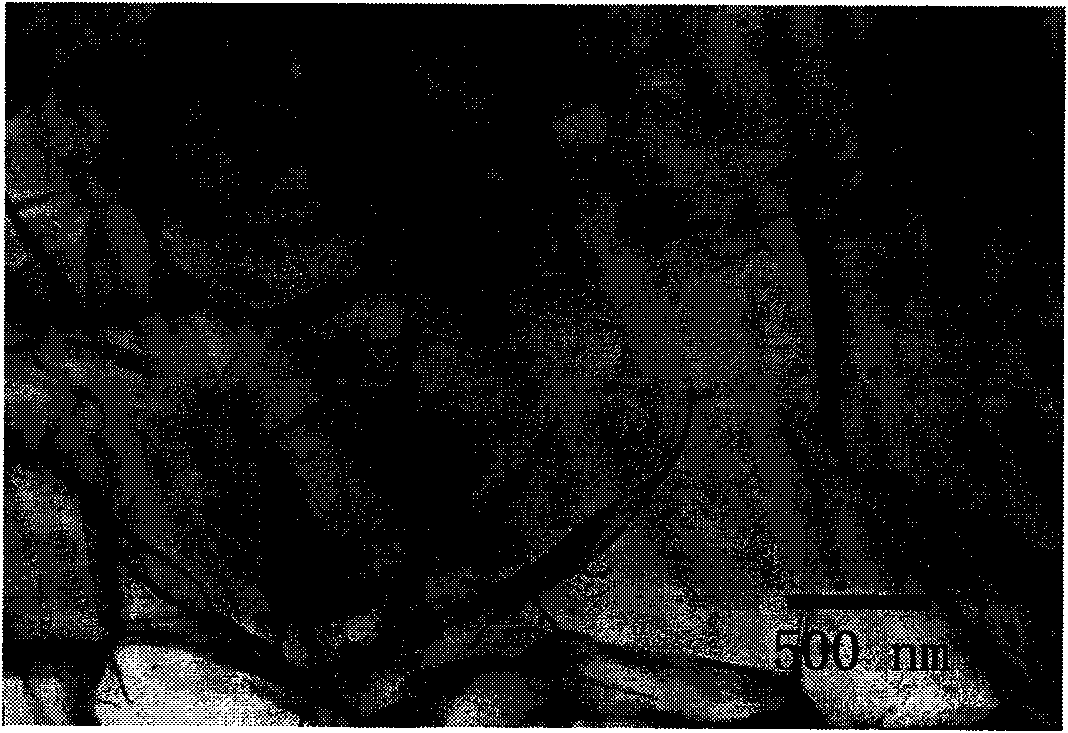

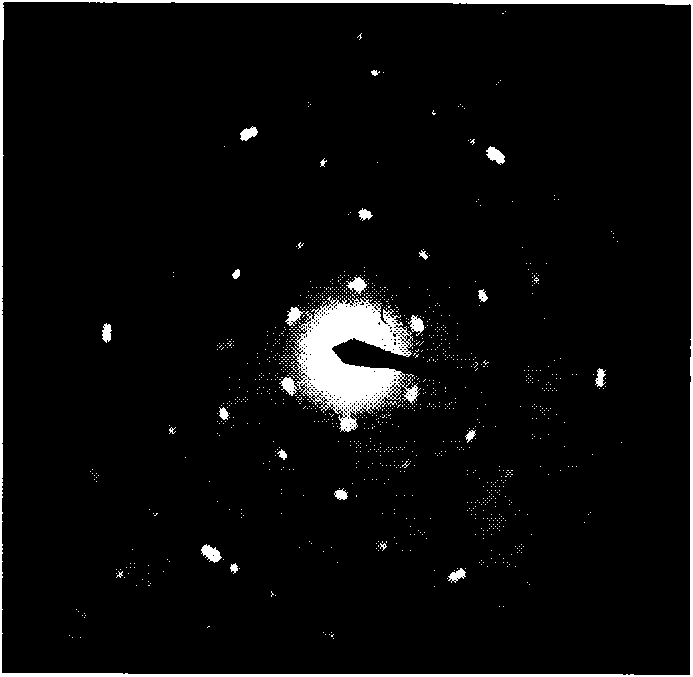

Image

Examples

Embodiment 1

[0022] Embodiment 1, the preparation of graphene

[0023] 20mg of carbon nanotubes were added in 200mg of 1-butyl-3-methylimidazolium tetrafluoroborate, ground in a mortar for 15 minutes to make the two evenly mixed, then 2ml of 6mol / L hydrochloric acid was added to the mixture, and After the temperature was stabilized at 50°C, 2ml of hydrogen peroxide was added and reacted for 0.1 hour. The black substance obtained was graphene.

[0024] After testing, the yield of graphene synthesized by the above method is about 85%.

Embodiment 2

[0025] Embodiment 2, the preparation of graphene

[0026] 2 mg of carbon nanotubes were added to 20 g of 1-butyl-3-methylimidazolium tetrafluoroborate, ground in a mortar for 15 minutes to mix the two evenly, then 5 ml of 6mol / L hydrochloric acid was added to the mixture, and After the temperature was stabilized at 60°C, 20 mg of potassium permanganate was added and reacted for 48 hours, and the obtained black substance was graphene.

[0027] After testing, the yield of graphene synthesized by the above method is about 90%.

Embodiment 3

[0028] Embodiment 3, the preparation of graphene

[0029] Add 2 mg of carbon nanotubes to 10 g of 1-ethyl-3-methylimidazolium trifluoromethanesulfonate, grind in a mortar for 30 minutes to mix the two evenly, and add 5 ml to the mixture after stabilizing the temperature at 50°C Concentrated nitric acid was reacted for 2 hours, and the obtained black substance was graphene.

[0030] After testing, the yield of graphene synthesized by the above method is about 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com