Patents

Literature

93 results about "Black substance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The black substance left behind as a result of burning wood and coal is called soot. This substance is classified as a mixture of impure carbon particles that result when hydrocarbons are improperly burned.

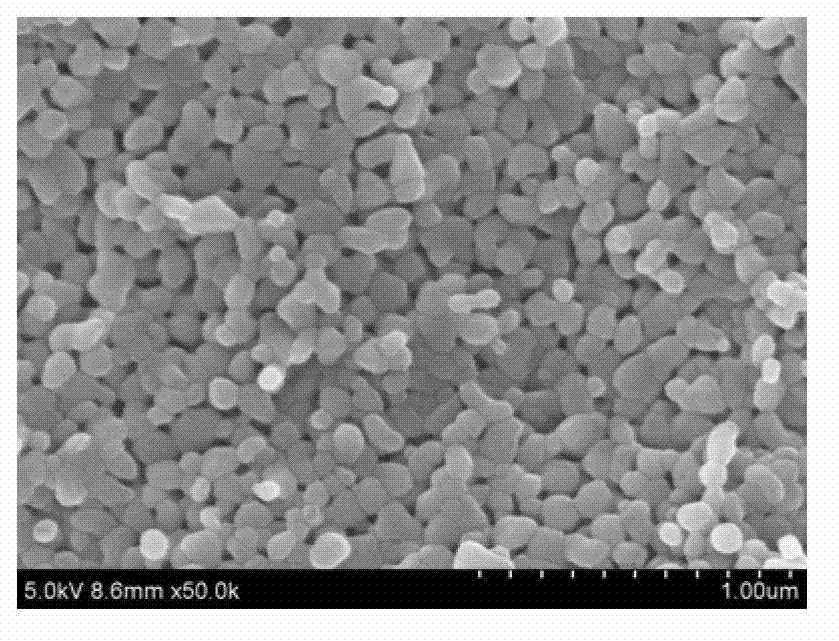

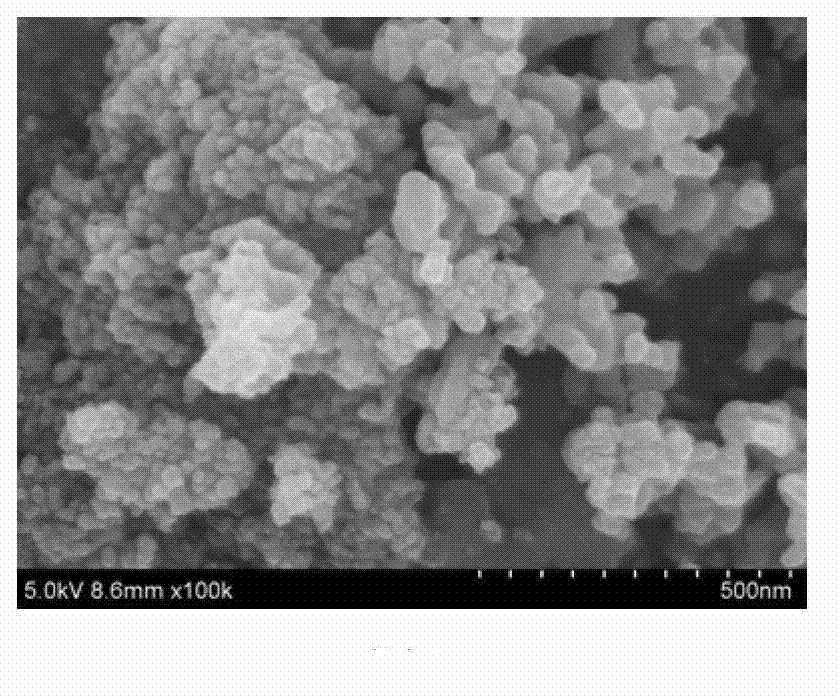

Method for preparing nano aluminum nitride powder

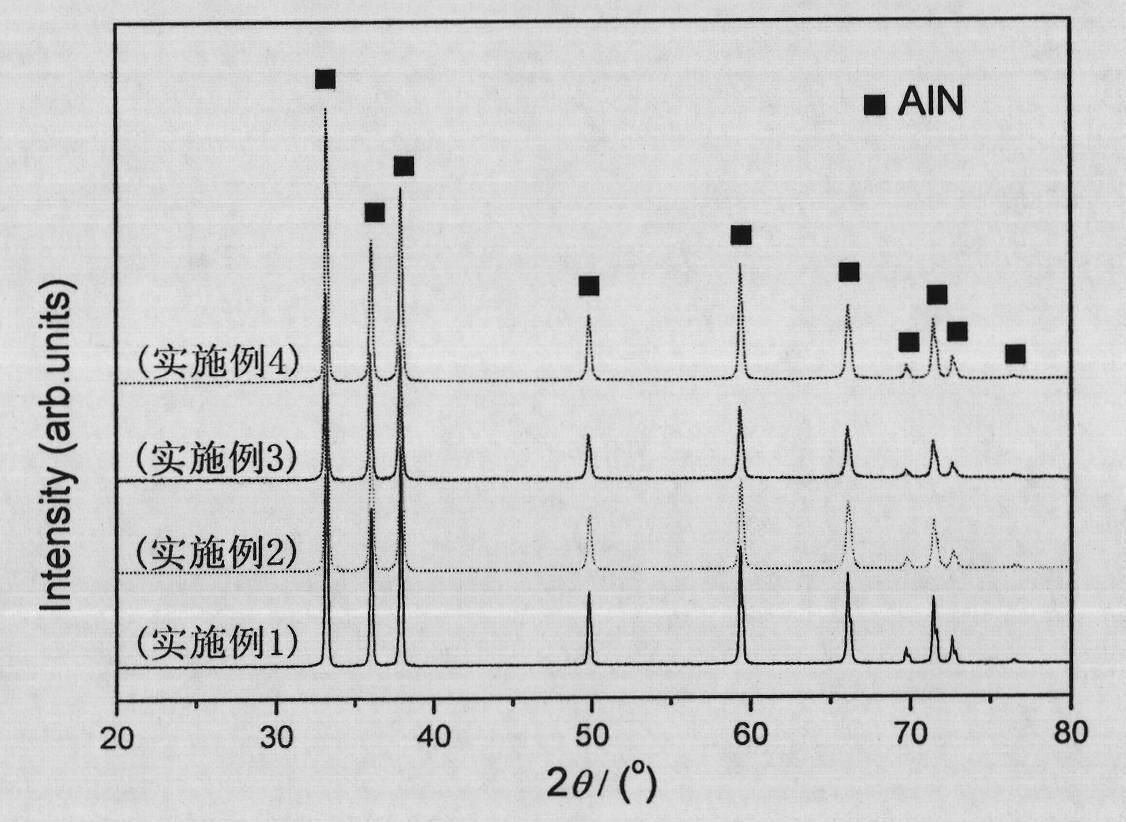

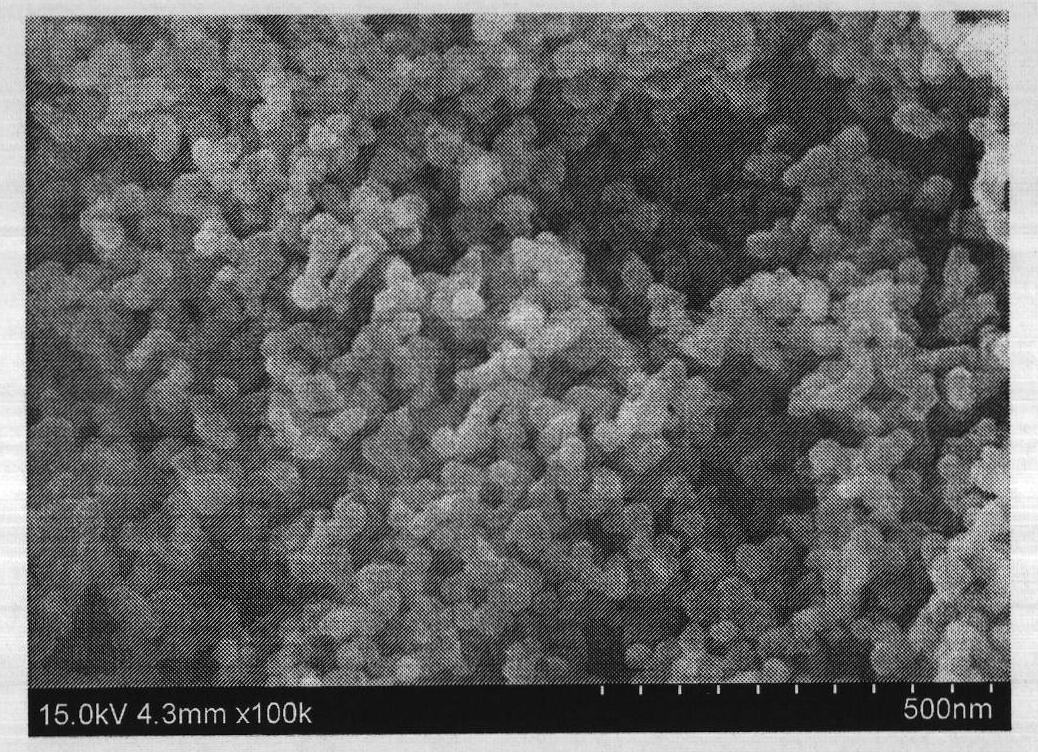

ActiveCN101973532ASmall particle sizeEvenly distributedNanostructure manufactureNitrogen compoundsAluminum IonMetallic aluminum

The invention discloses a method for preparing nano aluminum nitride powder. The method comprises the following steps of: dissolving an aluminum source and a carbon source in a solvent respectively, mixing the dissolved aluminum source and carbon source and glycol solution of citric acid; warming the mixed solution to 125 to 135 DEG C, and keeping the temperature for 2 to 4 hours; continuously warming to 180 to 220 DEG C, and keeping the temperature for 2 to 4 hours to obtain a crisp black substance; calcining the crisp substance at the temperature of between 800 and 1,200 DEG C in vacuum or in the atmosphere of nitrogen; cooling the calcined substance and grinding; and performing a carbothermal reduction reaction at the temperature of between 1,350 and 1,600 DEG C to obtain the nano aluminum nitride powder. Raw materials adopted by the method have a wide source range and are readily available, a preparation process is simple and controllable, and aluminum ions are uniformly distributed in the carbon source by using the complexing action of the citric acid on metallic aluminum ions and the bonding and steric hindrance actions of glycol on the metallic aluminum ions so as to finally obtain the nano aluminum nitride powder with small particle sizes and uniform particle distribution.

Owner:深圳特新界面科技有限公司

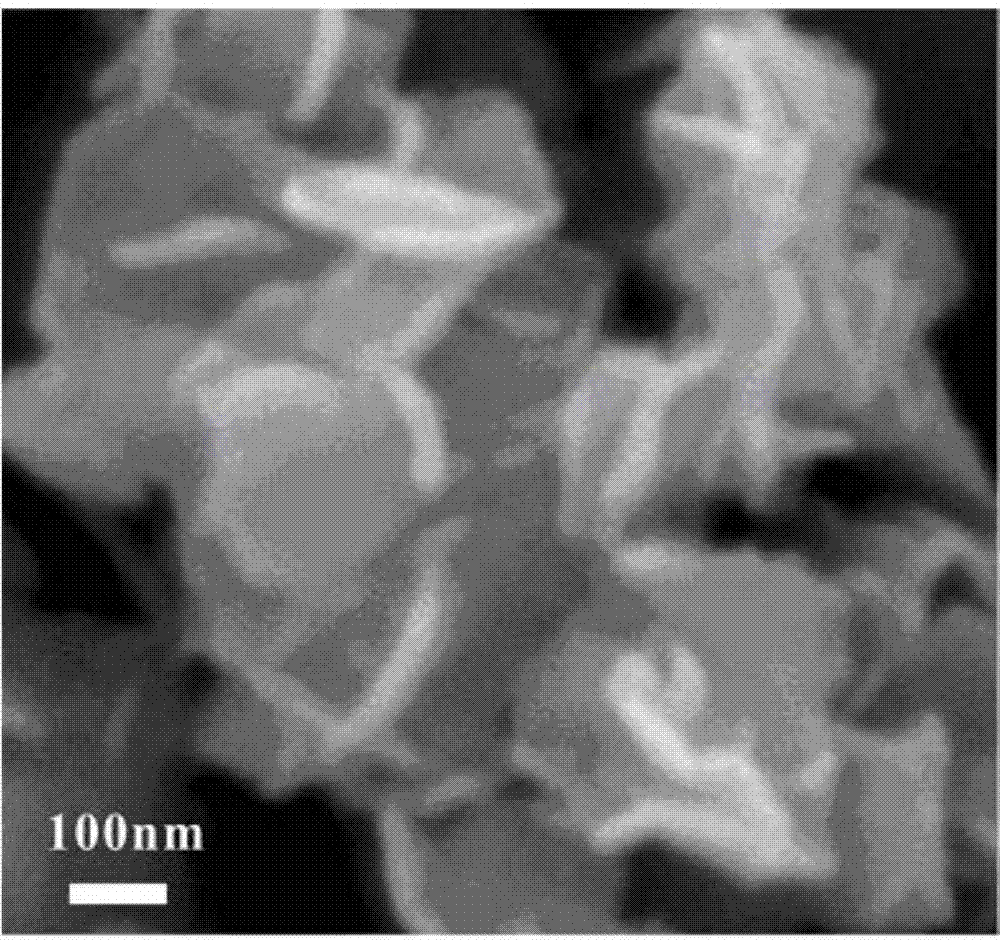

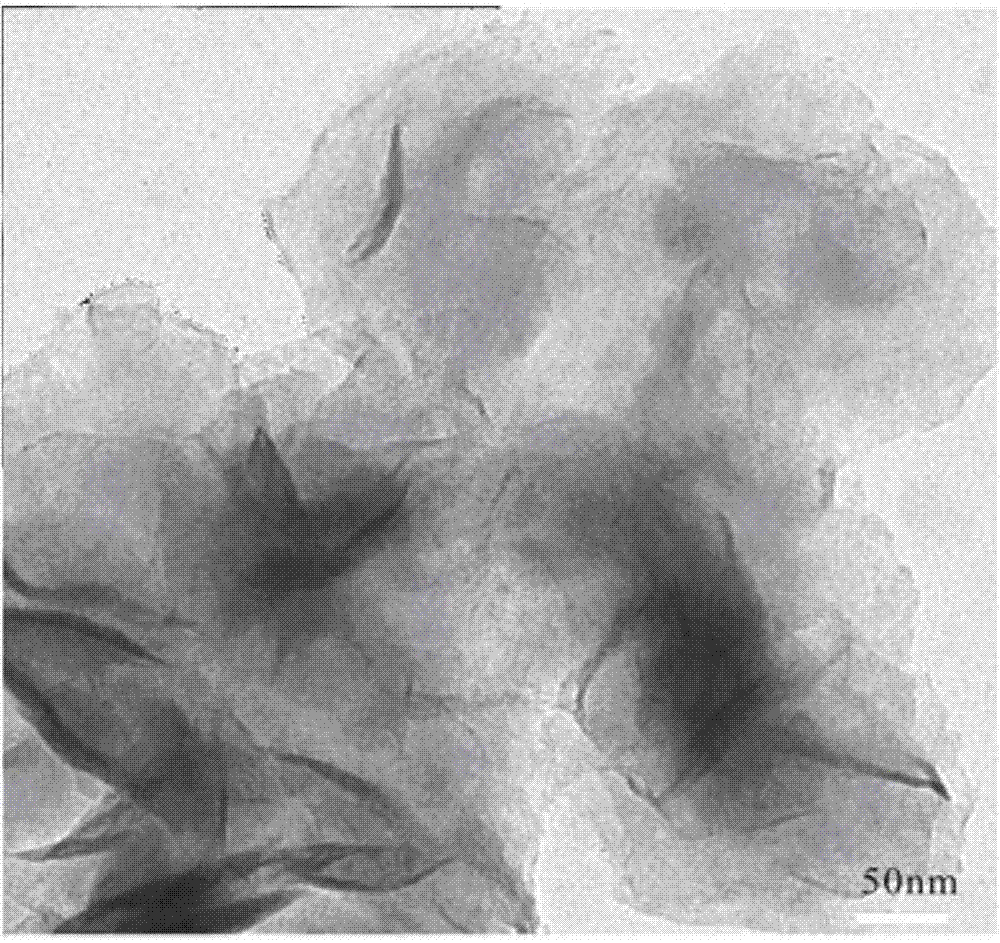

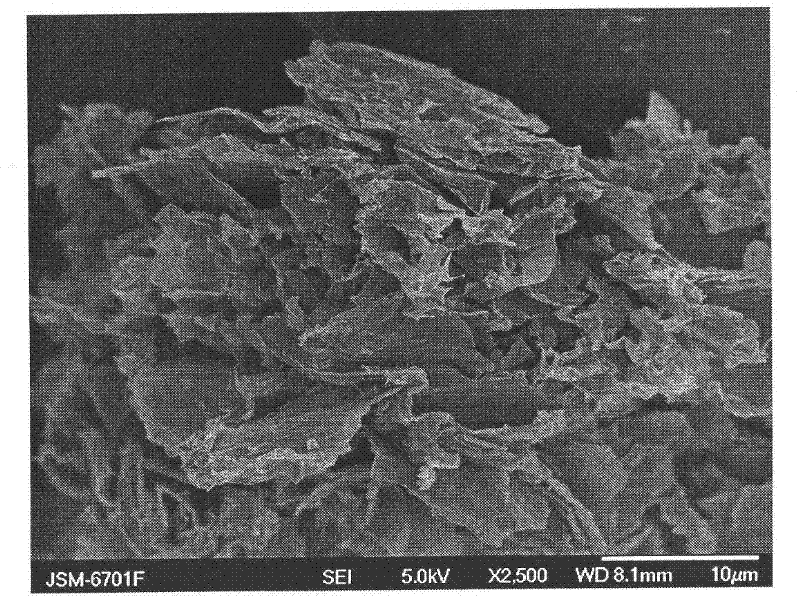

Preparation method of carbon-doped molybdenum disulfide nanometer material

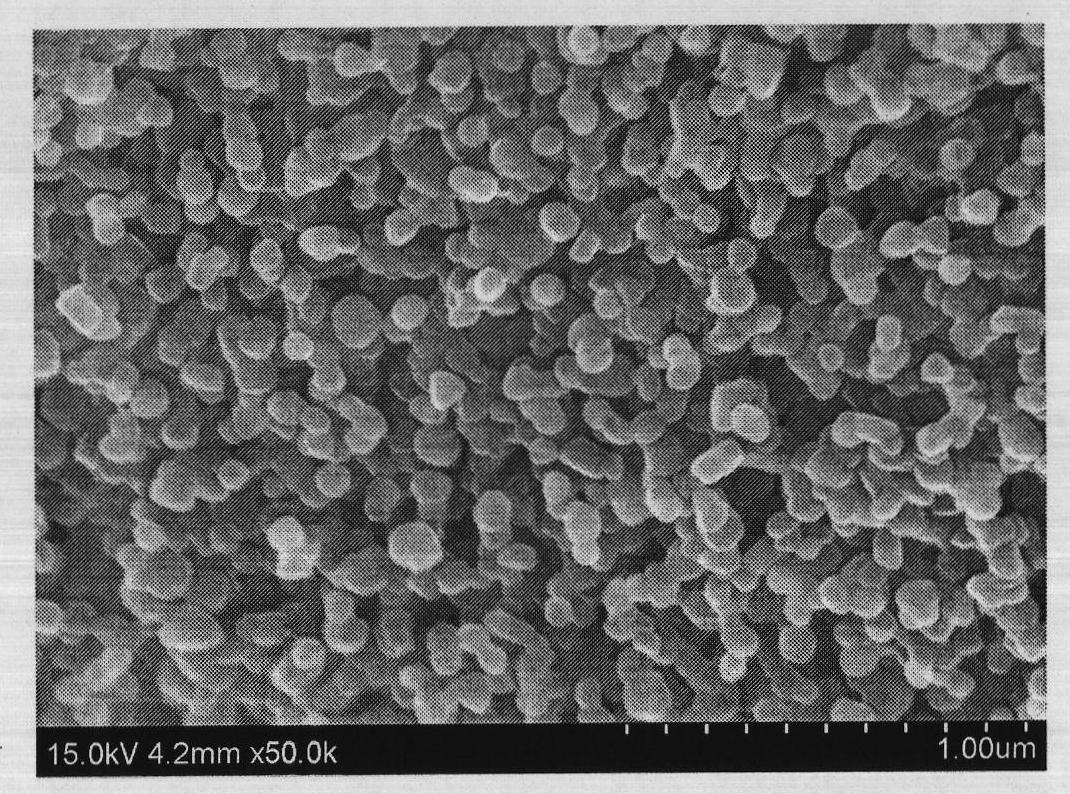

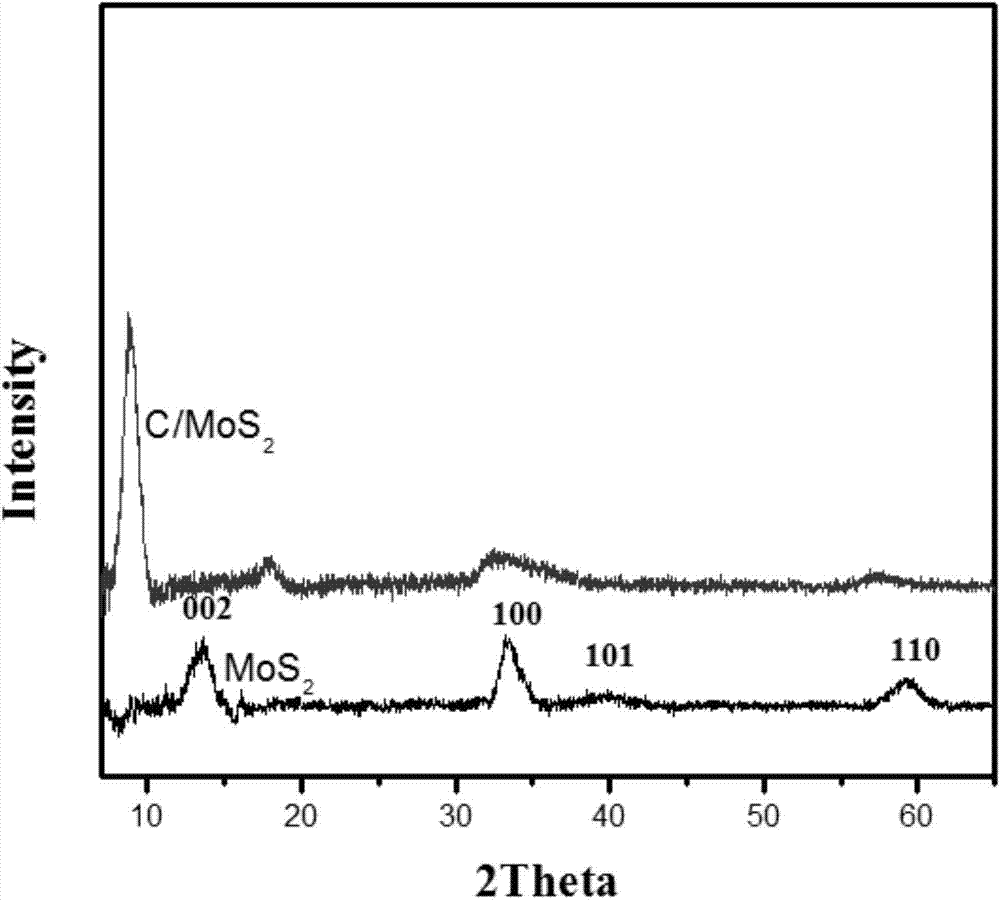

InactiveCN104495937AImprove cycle stabilityLittle change before and afterMaterial nanotechnologyMolybdenum sulfidesSodium acetateDispersity

The invention provides a preparation method of a carbon-doped molybdenum disulfide nanometer material. The method comprises the following steps: weighing sodium molybdate, ammonium molybdate or molybdenum oxide and thiourea, sodium sulphide, potassium rhodanate or dithiocyano sodium acetate to be firstly dissolved into an ethylene glycol solution, then dissolved into ultrapure water, and fully stirring, so as to prepare a mixed solution; adjusting the pH value of a mixed solution with ammonia water and hydrochloric acid; transferring the mixed solution into a reaction kettle, and carrying out solvothermal reaction; taking out the mixed solution after reaction, and naturally cooling to room temperature; sequentially washing with ultrapure water and ethyl alcohol, and collecting a black substance; and drying the black substance in a vacuum drying oven, so as to prepare the carbon-doped molybdenum disulfide nanometer material. According to the carbon-doped MoS2 nanometer material prepared by the method, the sheet is uniform in size, good in dispersity, small in pollution in preparation process, and free of harmful air; and the molybdenum disulfide nanometer material with good dispersity can be greatly prepared.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

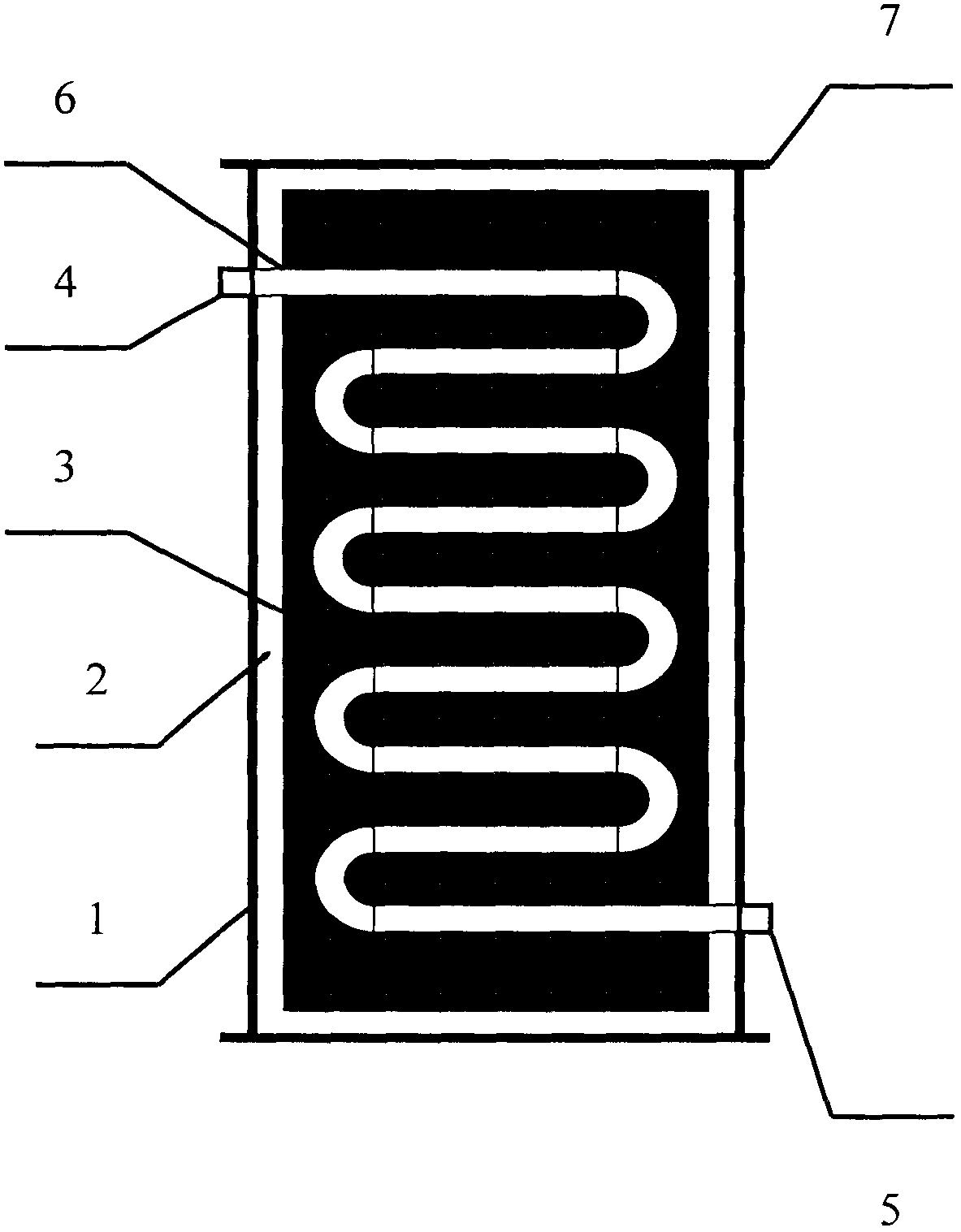

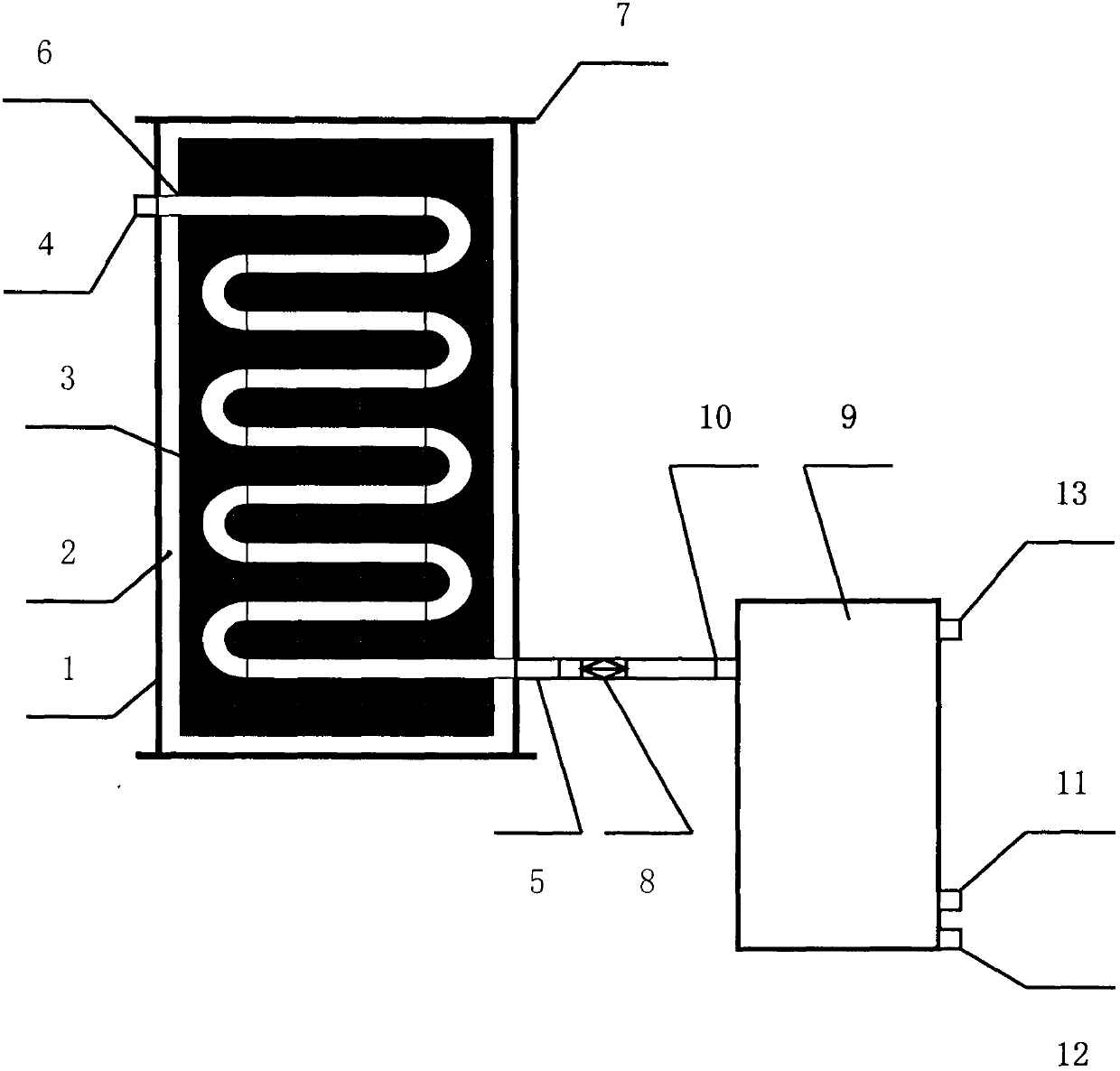

Novel black substance application and novel application method thereof

InactiveCN103134225AWide variety of sourcesSufficient supplySolar heat devicesEnergy industryUltrasound attenuationBuilding integration

The invention relates to a novel black substance application. The novel black substance application is characterized in that black substances are directly used as solar heat collection layers by the aid of excellent photo-thermal conversion characteristics of the black substances, and the black substances include vanadium extraction tailings, industrial black waste residues, natural black minerals, black compounds and black chemical products. A novel application method is characterized in that the black substances are directly used as the solar heat collection layers to construct a building-integrated solar air collector and a building-integrated solar water heater. Compared with the prior art, the novel black substance application and the novel application method have the advantages that construction cost is lowered greatly, service lives of the solar air collector and the solar water heater are prolonged greatly and can be as long as that of a building, the solar air collector and the solar water heater are high in heat collection efficiency, better in heat collection effect, less prone to attenuation after long-time use and quite simple to mount and maintain and can be integrated with the building, various potential safety hazards are eliminated, utilization rate of the solar water heater is increased, and the novel black substance application and the novel application method can be widely applied to the field of solar water heaters.

Owner:黄锦熙

Method for preparing large size hollow ceramic plate and use products thereof

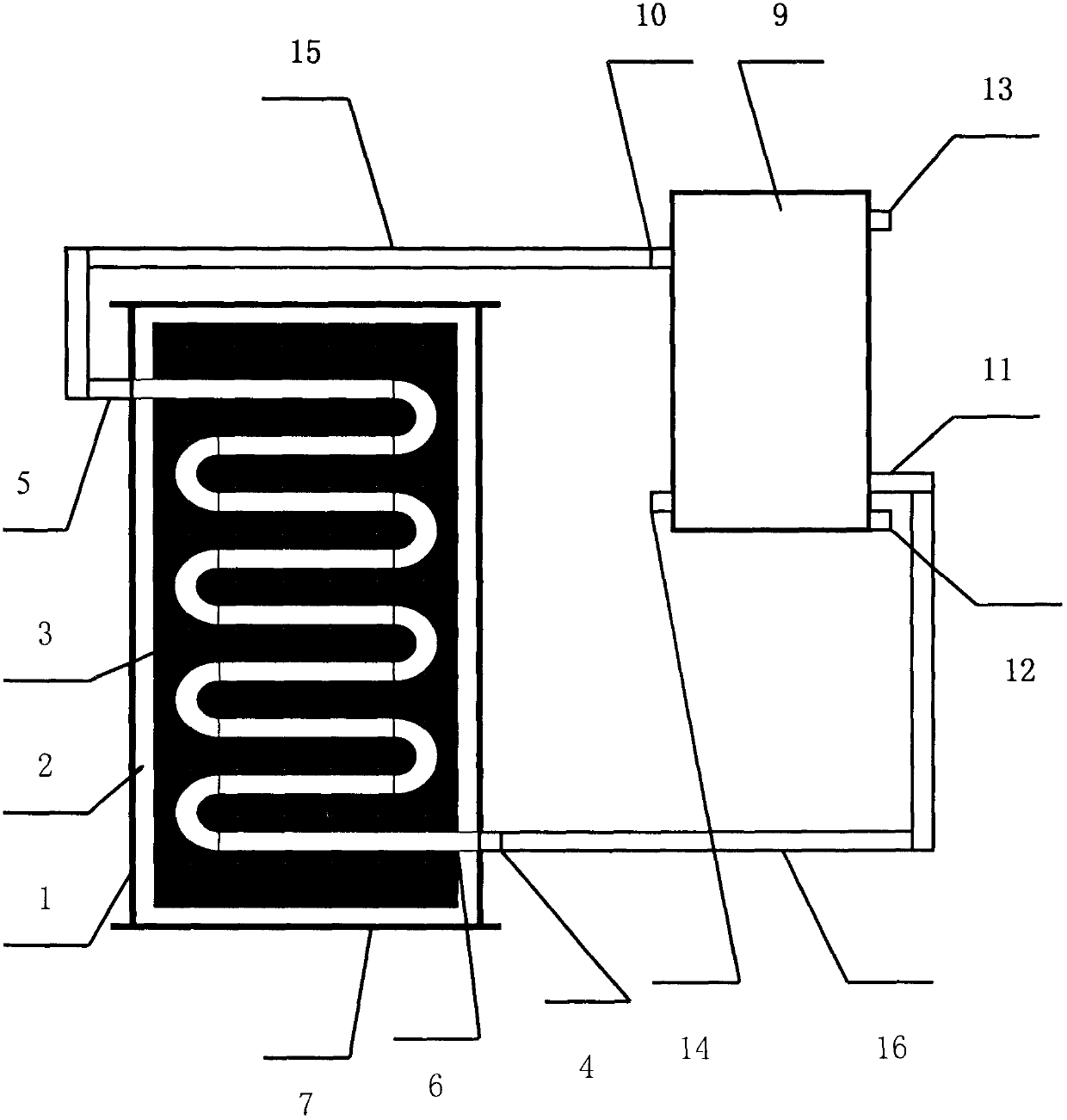

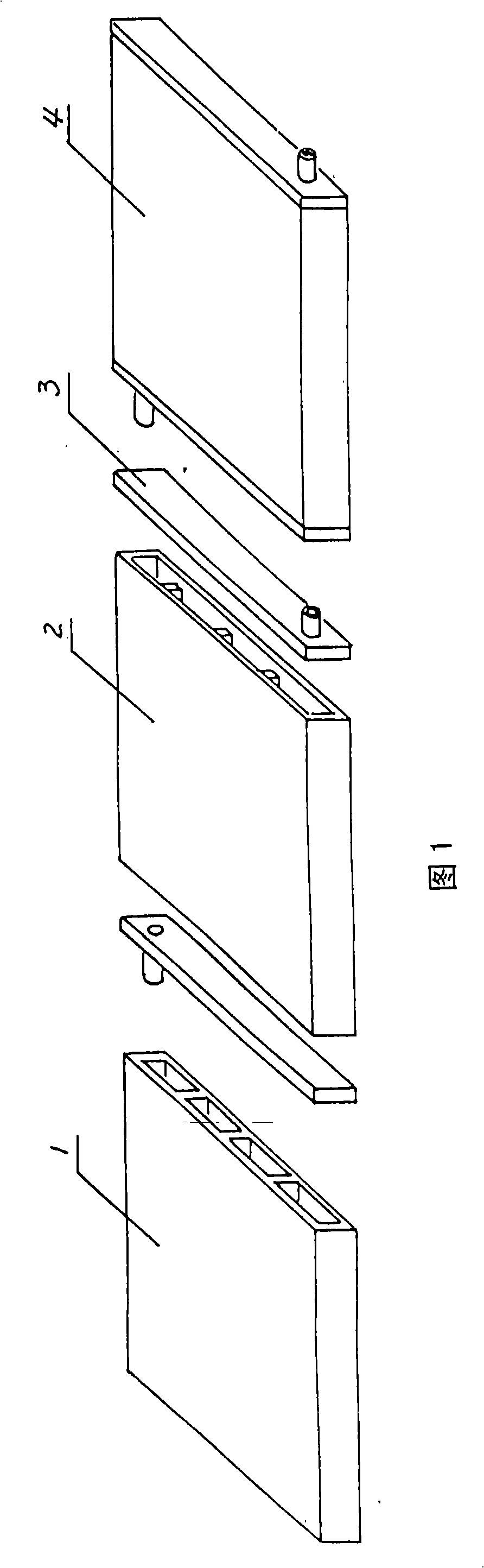

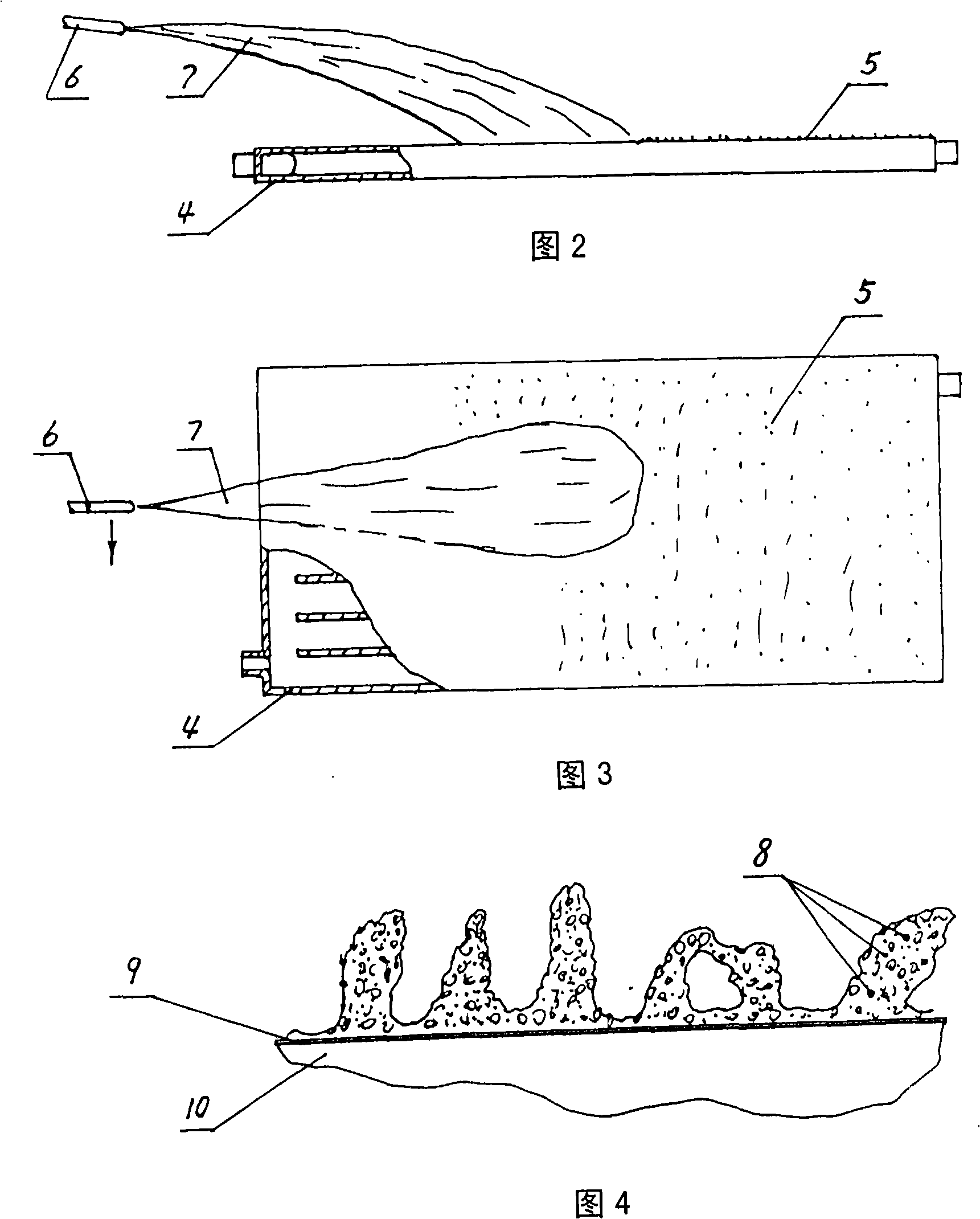

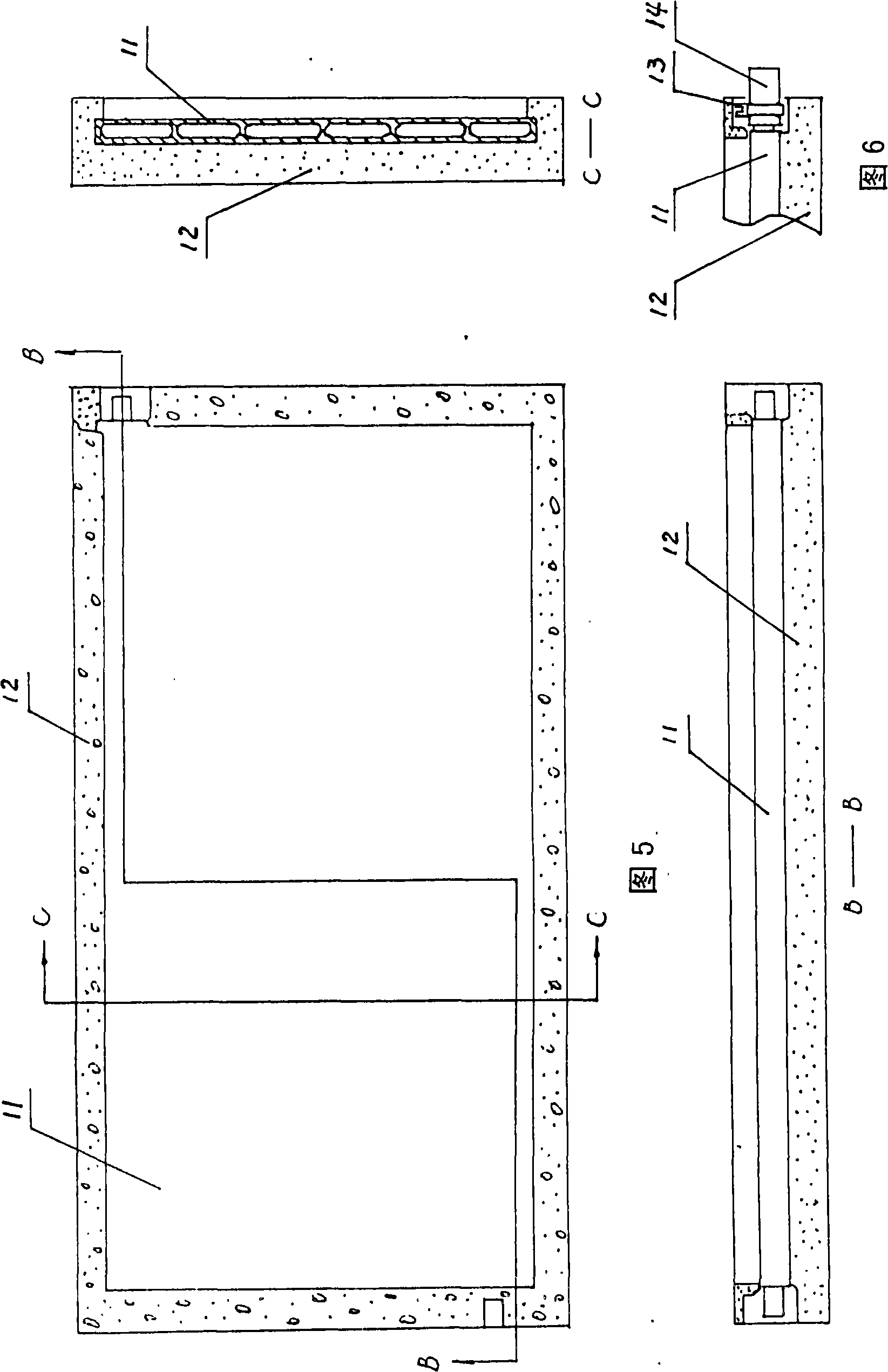

InactiveCN101311141AWide variety of sourcesLow costCeramic shaping apparatusLiquid fuel impingement burnersWhole bodySolar water

The invention relates to a production method for a big size hollow ceramic plate and a product thereof; common ceramic material and ceramic black substance that is rich in transition metals of fourth period such as natural minerals, industrial waste, and the like, and a extrusion molding method by a vacuum extruding machine are adopted to produce the big size hollow ceramic plate at low cost; the surface or the whole body of the big size hollow ceramic plate is black or dark, and the area of a single plate can be more than 0.5m<2>; a ceramic perforated plate, a ceramic through hole plate and an attachment of the big size hollow ceramic plate form a tandem of the big size hollow ceramic plate in the forms of glued joint and socket joint, or ceramic seal plates are connected in series to form the tandem of the big size hollow ceramic plate; the tandem of the big size hollow ceramic plate can be applied to a solar water heater for supplying hot water, to a solar roof and wall for providing refrigeration, warm air and hot water for the building, to a large-scale solar air course and a large-area solar heat collecting site for power generation, to far infrared drying for energy saving, to building radiator for realizing the purposes of saving energy, reducing indoor dust blowing and promoting health.

Owner:曹树梁

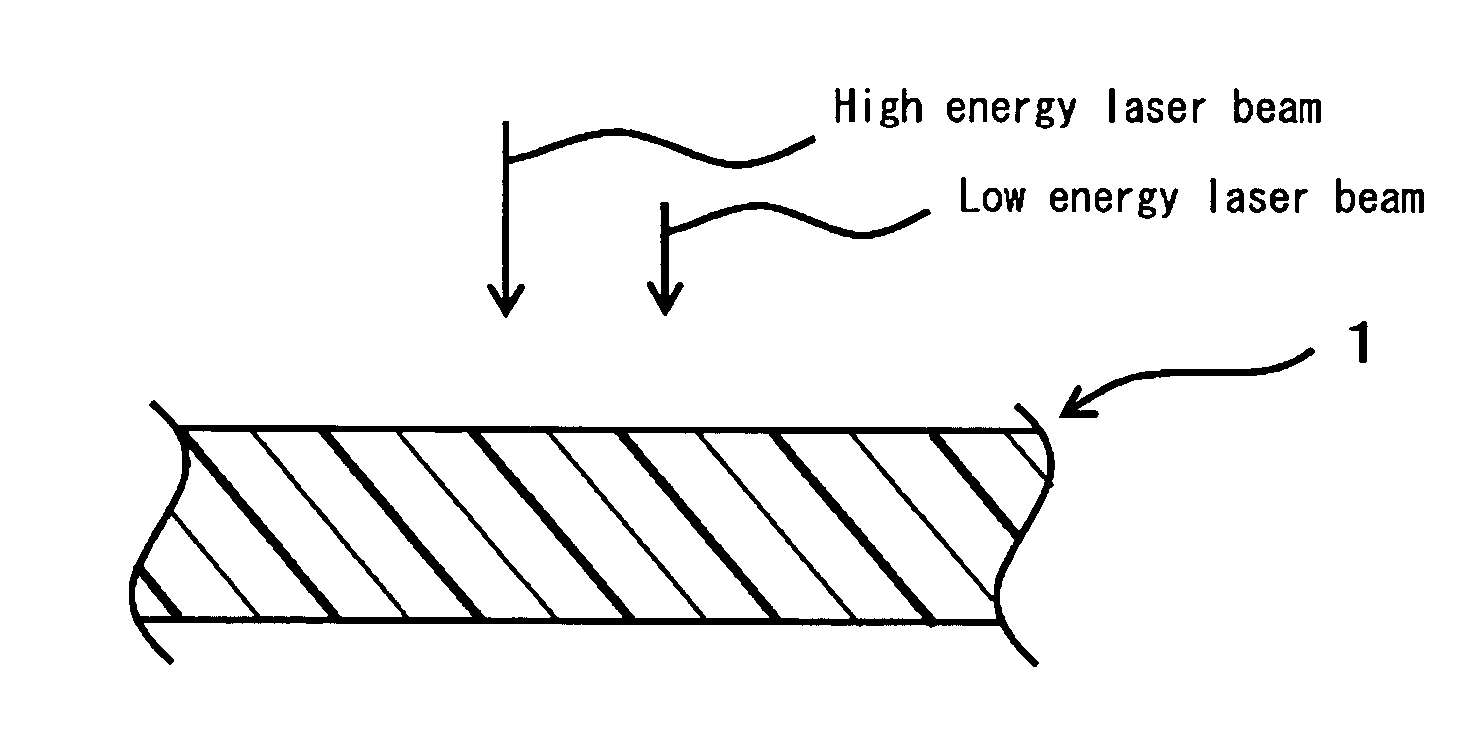

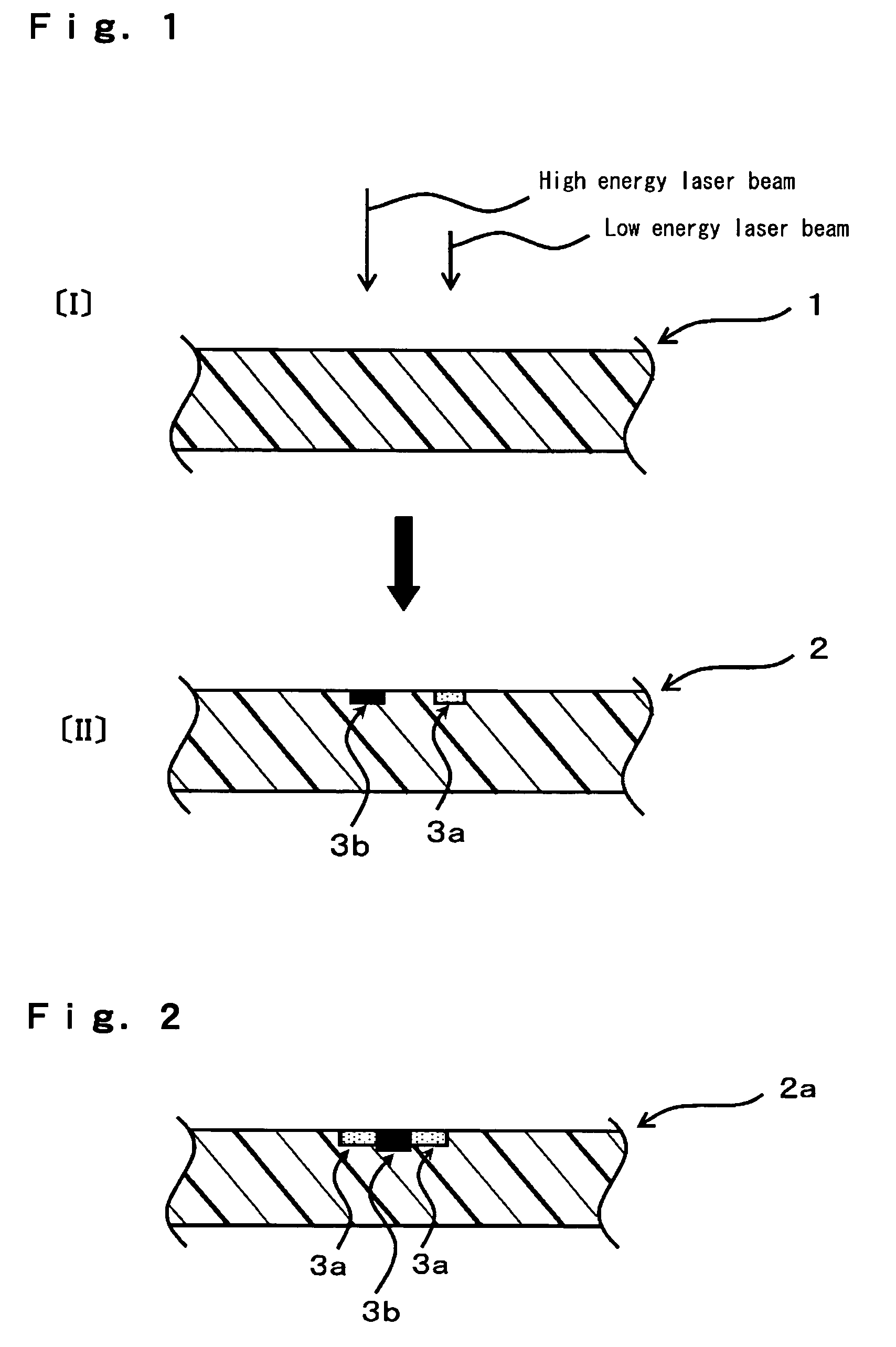

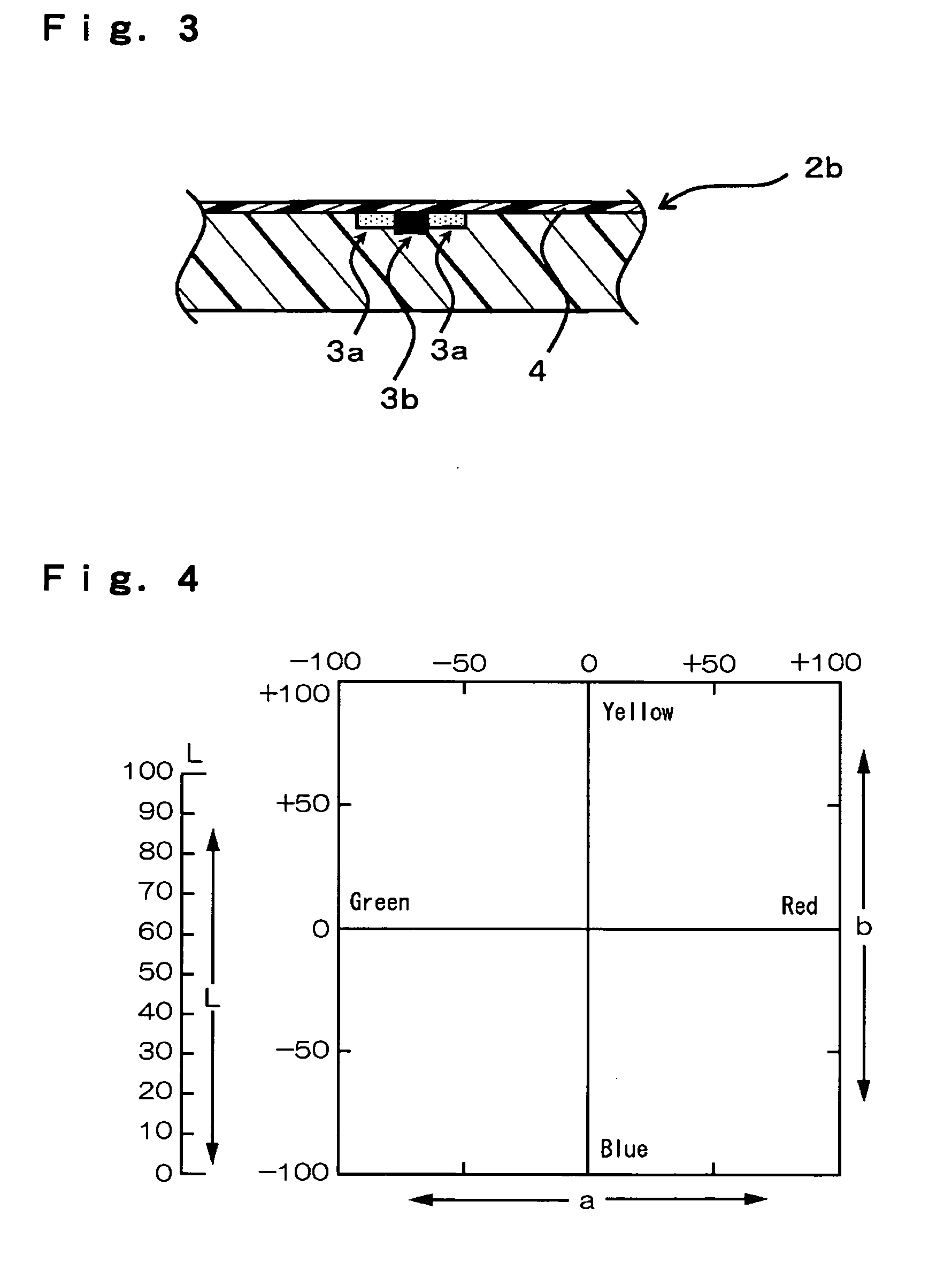

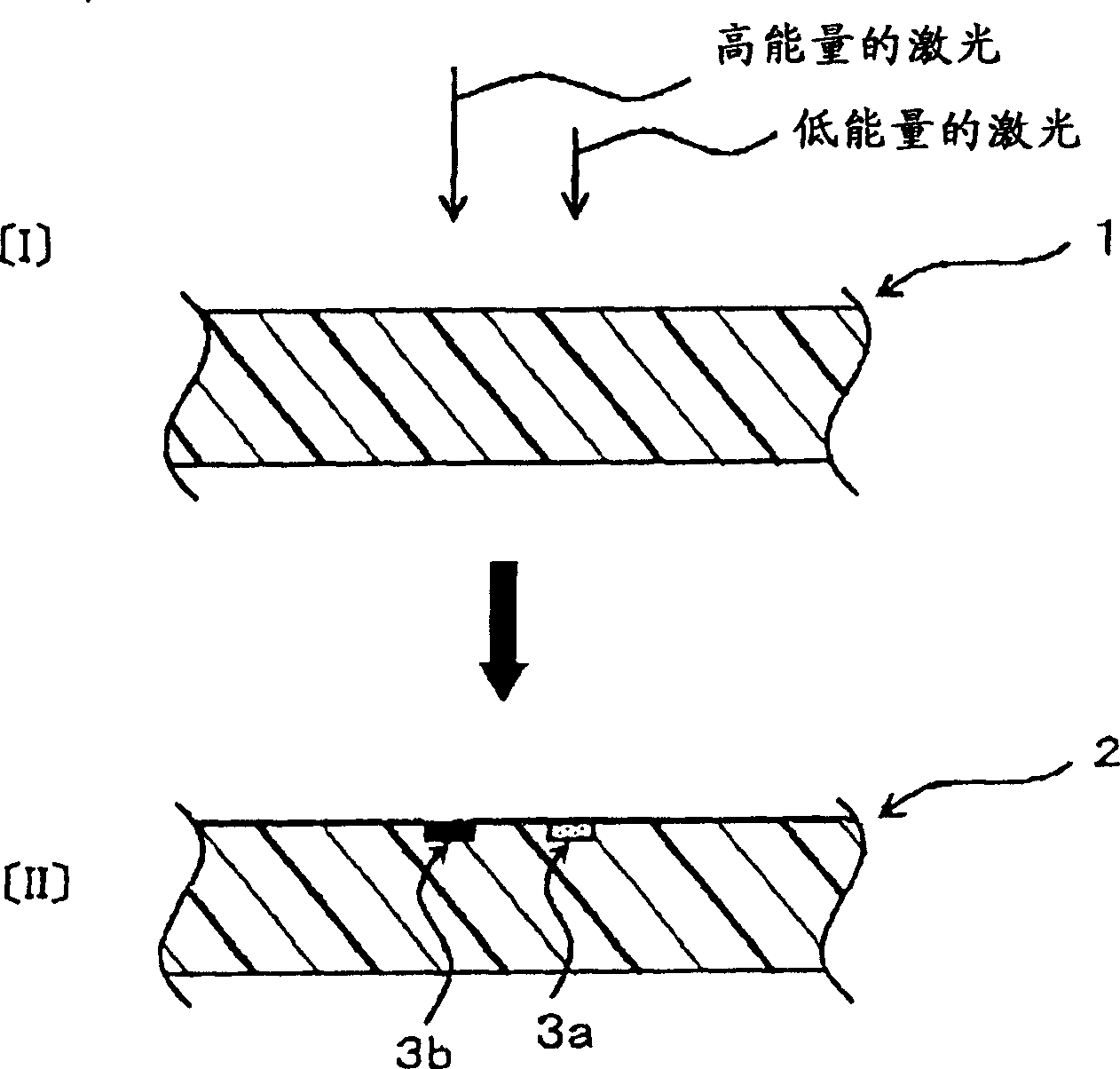

Multi-Color Coloring Laser Marking-Use Chromatic Color Colorant, Multi-Color Coloring Laser Marking-Use Composition And Molding Containing It, Multi-Color Making-Carrying Molding And Laser Marking Method

InactiveUS20080139707A1Conveniently and rapidly formedEasy to readDecorative surface effectsOrganic dyesDark colorBlack substance

The objective of the present invention is to provide a chromatic coloring agent for multicolor laser marking, capable of forming clear markings having two or more different color tones when two or more laser beams having different energy levels are irradiated onto different places of a molded article, a composition for multicolor laser marking, for example, capable of forming a chromatic marking derived from the chromatic coloring agent and a white marking on the surface of a molded article whose base color is black or dark-color based color, a laser marking method, a multicolor-marked molded article and the like. The present chromatic coloring agent has an exothermic peak in the range of 360° C. or higher and 590° C. or lower, as measured by differential thermal analysis. The present laser marking composition comprises a chromatic coloring agent, a black substance (carbon black or the like) which is itself depleted or discolored by receiving a laser beam, and a polymer, and the contents of the chromatic coloring agent and the black substance are respectively 0.001 to 3 parts by mass and 0.01 to 2 parts by mass with respect to 100 parts by mass of the polymer.

Owner:TECHNO POLYMER CO LTD

Multi-color coloring laser marking-use chromatic color colorant, multi-color coloring laser marking-use composition and molding containing it, multi-color marking-carrying molding and laser marking me

InactiveCN1910238AAvoid deformationLess prone to wearOrganic dyesThermographyColored whiteBlack substance

Owner:TECHNO POLYMER CO LTD

Preparation method of yttrium-stabilized nanometer zirconium dioxide powder

ActiveCN102923770AEvenly distributedSmall particle sizeMaterial nanotechnologyZirconium oxidesInorganic saltsSolvent

The invention discloses a preparation method of yttrium-stabilized nanometer zirconium dioxide powder. The preparation method comprises the following steps of: respectively dissolving inorganic salt of zirconium and inorganic salt of yttrium into a solvent, and then mixing with ethylene glycol solution of citric acid; heating mixed solution to 125-135 DEG C and thermally insulating for 2-4 hours, and heating the mixed solution to 180-220 DEG C and thermally insulating for 2-4 hours so as to obtain a crisp black substance; and burning the crisp substance at 600-1100 DEG C so as to obtain the nanometer zirconium dioxide powder with grain size of 30-120 nm, good particle dispersion and uniform yttrium element distribution. According to the invention, the source of feed is wide and easy to obtain, the preparation method is simple and controllable, through a complexing action of the citric acid on zirconium ions and yttrium ions, and bonding and steric hindrance actions of ethylene glycol on the zirconium ions and the yttrium ions, the yttrium ions can be uniformly distributed in a zirconium substrate material, so that the nanometer zirconium dioxide powder with the small grain size and the uniform distribution of the yttrium element can be finally obtained.

Owner:丽水亦众新材料科技有限公司

Laser cutting method for PCB plate

InactiveCN101402158AReduce short circuitEffective vaporizationLaser beam welding apparatusCarbideLaser cutting

The invention discloses a laser cutting method for a PCB, which comprises the following steps: (1) the PCB board is cut off, wherein laser is adopted to cut the PCB at the specified position of the PCB for at least one time until the PCB is cut off; and (2) the cross section of an incision is cleaned, wherein laser with different parameters are adopted to grind the cross section of the incision of the PCB according to the thickness of the PCB so as to ensure that a black substance at the cutting cross-section of the PCB is vaporized. A step of middle-high negative pressure smoke suction is also adopted when the PCB is cut off and the cross section of the incision is cleaned. The method can effectively vaporize carbide at the incision, reduce the short circuit of the PCB caused by the carbide, reduce production cost, and improve the rate of finished products.

Owner:HANS LASER TECH IND GRP CO LTD

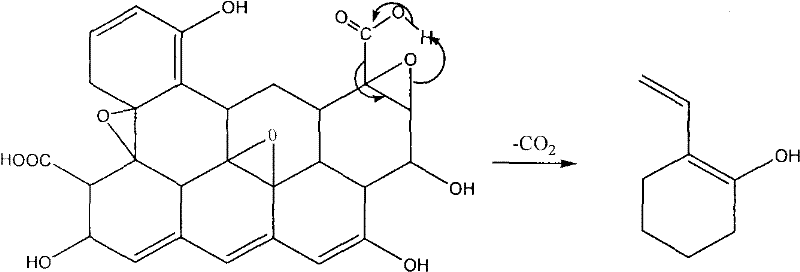

Graphene preparation method

The invention discloses a graphene preparation method. The method comprises dispersing graphene oxide in one or two of the following substances: water, ethanol, phenol and organic acid; carrying out normal-pressure reflux reaction in the presence of a reaction medium or not; stopping reaction until a black substance is not separated out; and separating and purifying the product to obtain graphene. The preparation method is green, safe, simple, energy-saving and so on, and can be applied in the fields of graphene and related products, such as transistor, touch screen, gene sequencing, fuel battery, and super capacitor.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

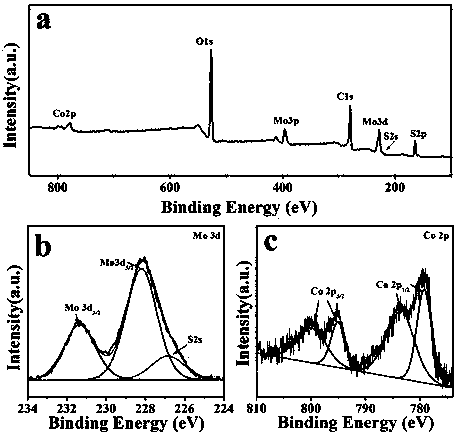

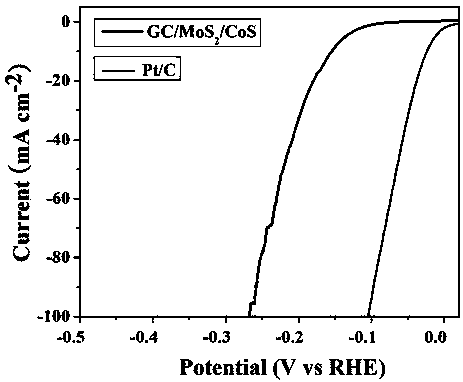

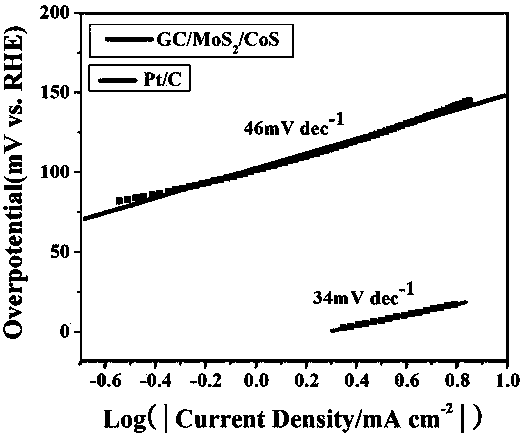

Three-dimensional graphene/ carbon nano tube based molybdenum disulfide/cobaltous sulfide composite material electrocatalyst as well as preparation method and application thereof

The invention belongs to the field of catalytic materials, and particularly relates to a three-dimensional graphene / carbon nano tube based molybdenum disulfide / cobaltous sulfide composite material electrocatalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: step I, treating a precursor: performing ultrasonic treatment on a certainamount of oxidized graphene and a modified carbon nano tube, adding ascorbic acid, thiourea and a metal ion precursor to be uniformly mixed, wherein the metal ion precursor is sodium molybdate and cobalt chloride; step II, performing a hydrothermal reaction process: transferring mixed composite into a reaction kettle, heating the composite to a temperature of 160-200 DEG C, reacting for 20-28 hours at the temperature, conducting cooling to the room temperature to obtain a gel-like black substance, and conducting washing and freeze-drying to obtain a cylindrical black solid. A graphene / carbonnano tube with a three-dimensional network structure provides a quick electron transfer path and an ion transport channel, and molybdenum disulfide / cobaltous sulfide with a nano structure is anchoredon three-dimensional structural carbon to expose more electro-active sites, so that electrochemical hydrogen evolution property is cooperatively improved.

Owner:WENZHOU UNIVERSITY

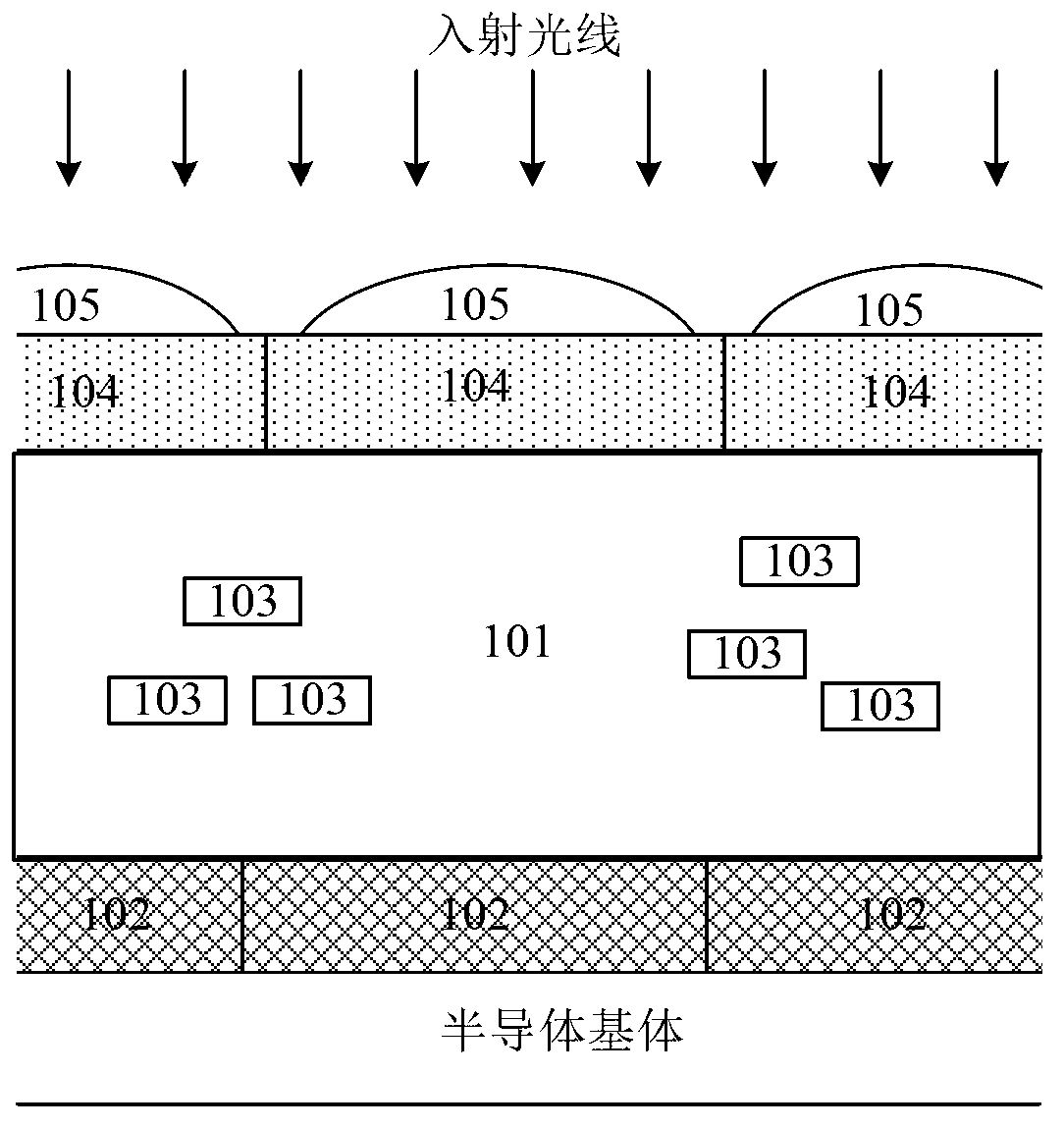

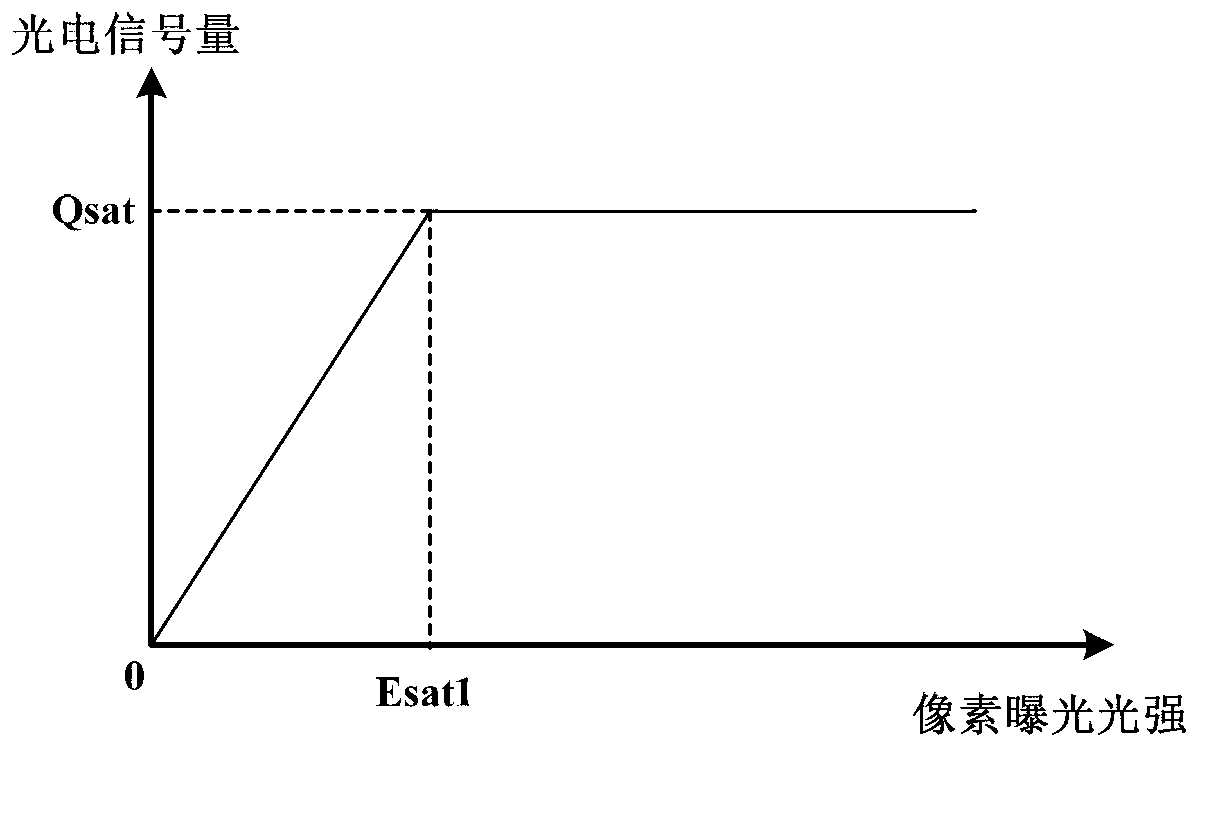

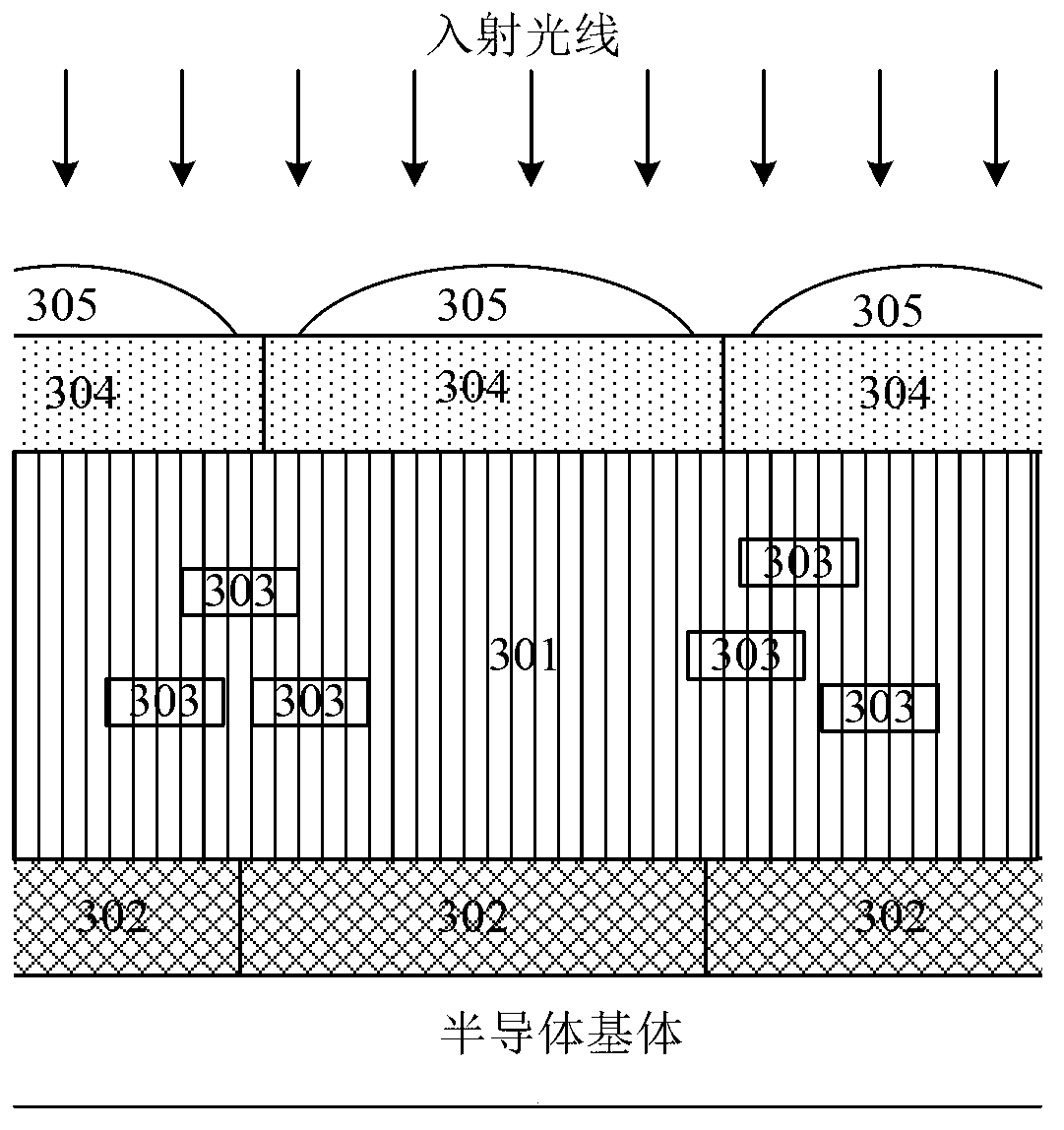

Image sensor with high dynamic range

ActiveCN103268881AImprove transmittanceReduce transmittanceRadiation controlled devicesImaging qualityColor gel

The invention discloses an image sensor with a high dynamic range. The image sensor mainly comprises a photosensitive device placed inside a semiconductor substrate, colorless and transparent insulating media above the photosensitive device, isolating metal embedded in the insulating media, colorized optical filters and micro lenses, wherein the colorized optical filters and the micro lenses are sequentially arranged above the insulating media. Photochromic materials and corresponding catalysts are evenly added in a pre-set region of one insulating medium. The photochromic materials are used for producing black substances in a decomposing mode under the effect of light. The catalysts are used for reducing the black substances which are produced in the decomposing mode into the photochromic materials. By the adoption of the image sensor, output image quality is improved.

Owner:BEIJING SUPERPIX MICRO TECHNOLOGY CO LTD

Preparation method of wormwood paint

ActiveCN105153908AEfficacy impactThe social response is goodAntifouling/underwater paintsPaints with biocidesWater basedSolvent

The invention discloses a preparation method of a wormwood paint, which comprises the following steps: (1) grinding dry wormwood into 150-mesh wormwood powder by using a plant grinding facility, and filtering dust and black substances out of the wormwood powder by using a negative pressure suction facility to obtain light yellow pure wormwood powder; and (2) stirring with a dry-wet separation dual stirrer, preparing 5-20 parts of wormwood powder, 30-60 parts of water-based polyurethane, 5-10 parts of filler and 2-7 parts of defoaming agent used as raw materials, putting the raw materials in an upper-layer dry material stirring system to perform primary stirring, putting in a lower-layer stirring system, adding 20-40 parts of solvent and 2-6 parts of film formation assistant, and carrying out wet stirring to promote the paint to be sufficiently mixed together. The paint prepared by the method has the disinfection function, contains natural plant pigments, is environment-friendly and pollution-free, and has the health-care effect on the human body.

Owner:NANYANG BAICAOTANG NATURAL WORMWOOD PROD

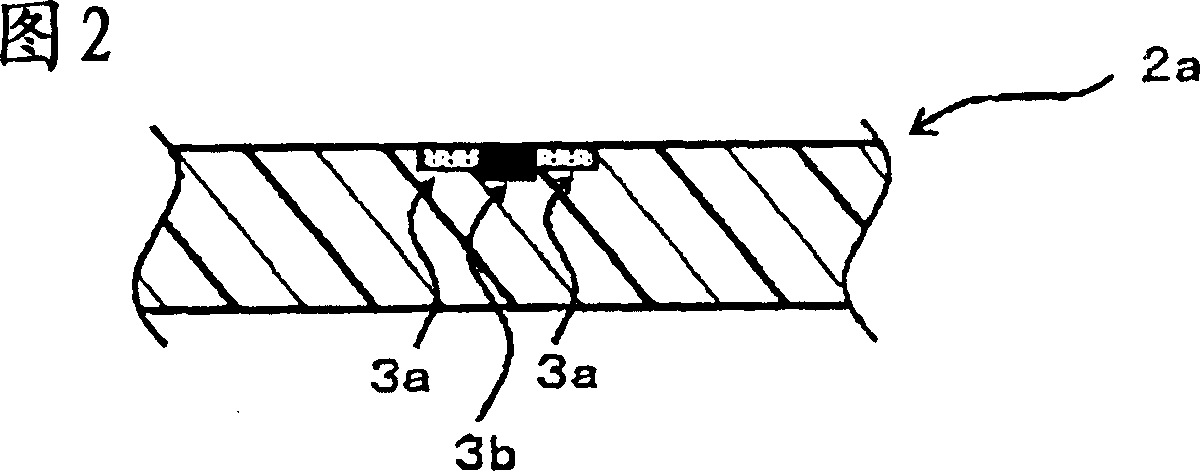

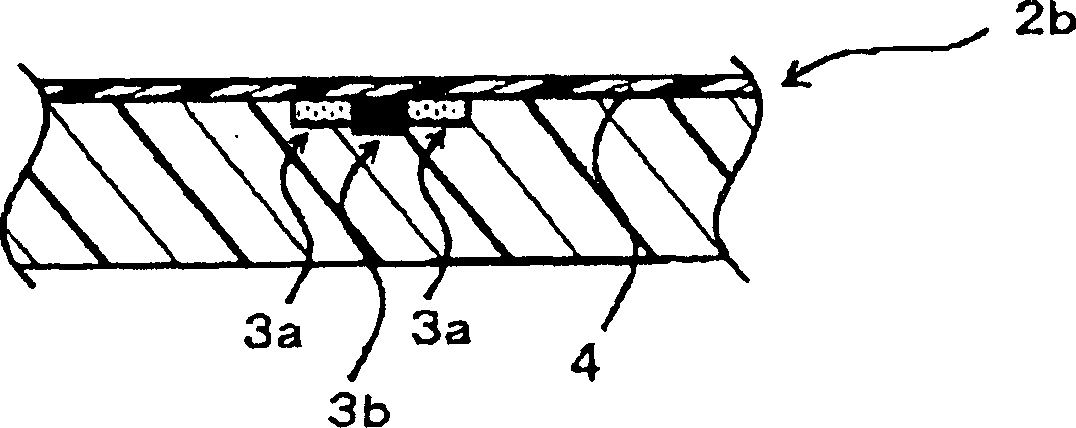

Cover membrane for printed circuit board

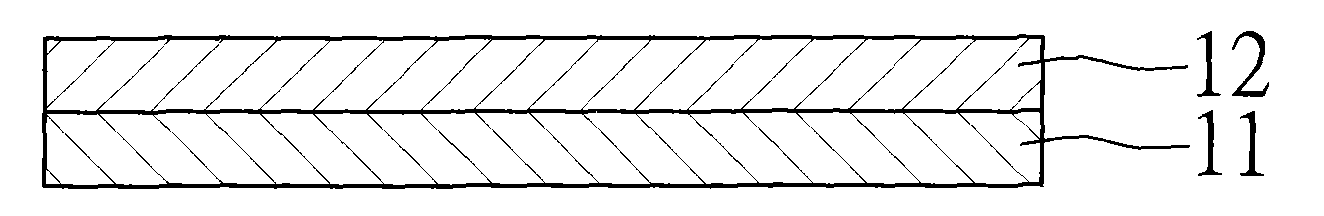

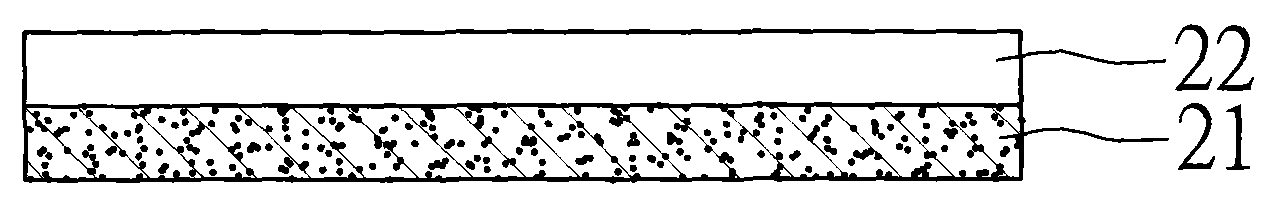

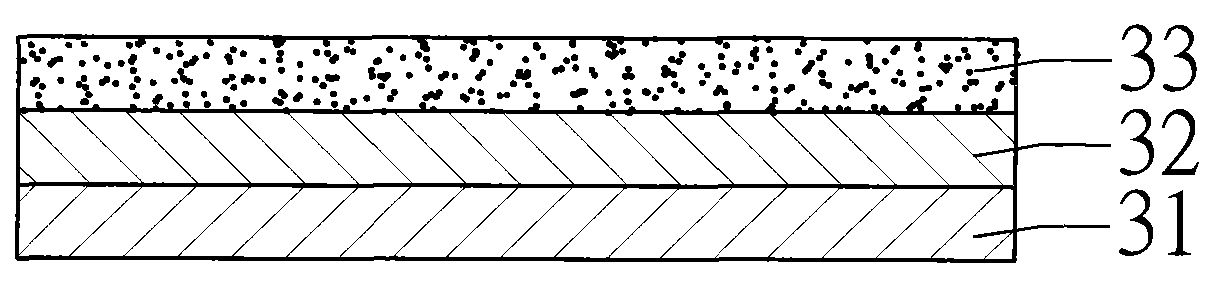

ActiveCN102083271ALow refractive indexHas matte propertiesPrinted circuit detailsSynthetic resin layered productsRefractive indexEngineering

The present invention discloses a cover membrane for a printed circuit board, comprising a center layer, a black composite material layer with a low refractive index, and an adhesive layer which is used to adhere the cover membrane to the printed circuit board. The center layer is fixedly clamped between the adhesive layer and the composite material layer, the composite material layer is formed by mixing resin, a black substance with an inorganic filling material and has low refractive index and black color, therefore, the cover membrane has misty characteristic on the outer surface thereof and is suitable for the printed circuit board in need of covering the circuit patterns. Besides, the cover membrane has excellent folding resistance, and is especially suitable for a flexible printed circuit board.

Owner:KUSN APLUS TEC CORP

Processing technique of vanilla

The invention discloses a processing technique of vanilla, which comprises the following steps: (1) adding 1 part by weight of vanilla into 2-10 parts by weight of 50-95% alcoholic solution, soaking for 5-10 days, and filtering to obtain a filtrate; (2) carrying out vacuum concentration on the filtrate in the step (1), boiling the concentrated solution, stopping heating when the volume of the filtrate is reduced to 15-20% of the original filtrate, and adjusting to normal pressure to obtain a paste liquid; (3) carrying out microwave drying on the paste liquid in the step (2) in vacuum until the weight percentage of the solvent in the paste is less than 5%; and (4) putting the paste dried in the step (3) into an extraction kettle, carrying out supercritical carbon dioxide extraction for 3-5hours, and separating the yellow oil liquid vanilla extract in the kettle, wherein the brownish black substance in the extraction kettle is vanilla oil resin. Since normal temperature and pressure extraction, vacuum concentration, microwave drying and supercritical carbon dioxide extraction are combined to extract the vanilla so as to simultaneously obtain the vanilla extract and vanilla oil resin, the extraction rate of odorous constituents in the vanilla extract can be enhanced, and the content of vanillin can also be enhanced.

Owner:海南兴科热带作物工程技术有限公司

Preparation method of straw-based magnetic charcoal

InactiveCN109759011AIncrease profitHigh crystallinityOther chemical processesBiofuelsLiquid productBlack substance

The invention provides a preparation method of straw-based magnetic charcoal. The method includes the following steps that (1) straw is cleaned, naturally air-dried, dried in a drying oven, smashed and sieved, and straw powder is obtained; (2) the straw powder is pre-carbonized in a muffle furnace, washed and dried, and a straw-based pre-carbonized product is obtained; (3) the straw-based pre-carbonized product is put in a tube furnace, argon is fed, pyrolysis is performed at the temperature of 400-500 DEG C for 2-3 hours, cooling is performed till the temperature reaches the room temperature,washing is performed till the product is neutral, drying and grinding are performed, then sieving is performed, and straw-based charcoal is obtained; and (4) the straw-based charcoal and oleylamine are put in a reaction kettle for uniform mixing and ultrasound treatment, ferric acetylacetonate is added into a mixed solution, the mixed solution is stirred uniformly, a liquid product is obtained, ablack substance is separated out after centrifugation is finished, and the straw-based magnetic charcoal is obtained. Compared with original charcoal, the prepared straw-based magnetic charcoal has the advantages of being better in thermal stability and larger in specific surface area, and medium and large pores in the pore structure of the straw-based magnetic charcoal prevail.

Owner:NANYANG NORMAL UNIV

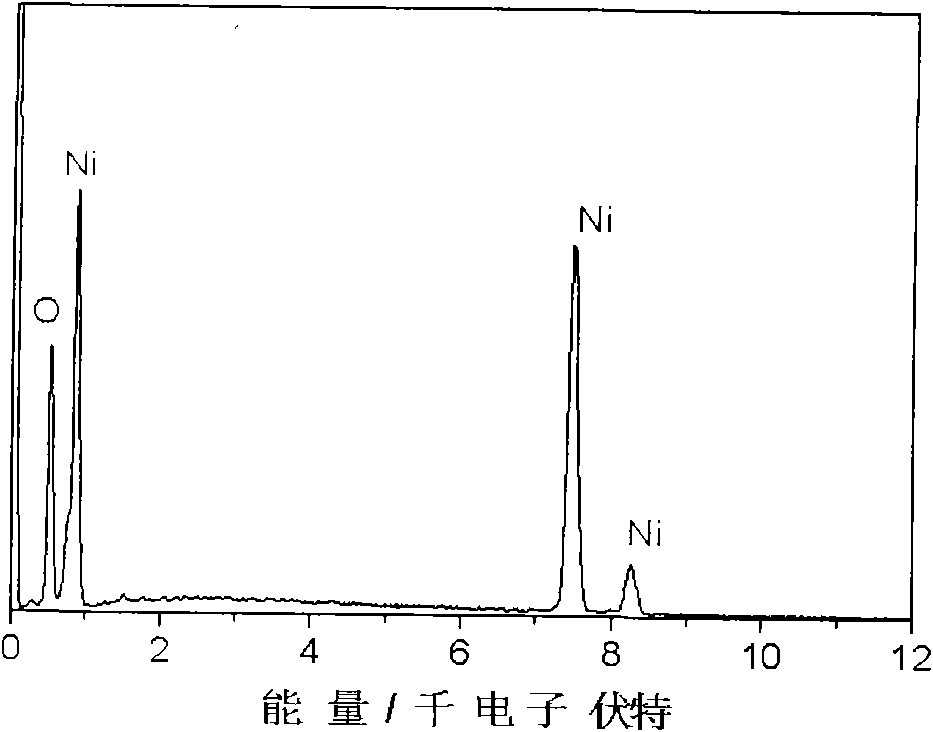

Preparation method of octahedron nickel nano micro-material

The invention relates to a preparation method of an octahedron nickel nano micro-material. The preparation method comprises the following steps of: adopting a thermal decomposition-reduction process, that is to say: putting nickelous nitrate as a raw material into a vessel and carrying out thermal decomposition reaction with the reaction time of 30min to 10h and the reaction temperature of 30 to 500 DEG C; washing, filtering and drying gray black substances generated by the reaction to obtain an octahedron nickel oxide nano micro-material; and reducing the octahedron nickel oxide nano micro-material by adopting reducing gas at 300 to 450 DEG C to obtain the octahedron nickel nano micro-material. The invention has simple preparation flows, unique forming mechanism, easy industrial application and popularization, unnecessary addition of any die or plate surfactant or structure guiding agent in the reaction process, low cost and high efficiency; and the synthesized material has high purity, excellent microwave absorption performance and chemical catalysis effect as well as remarkable economic and social benefits and is suitable for preparing a catalyst or a microwave absorption material.

Owner:ZHEJIANG NORMAL UNIVERSITY

Antirust coating for automobile chassis

InactiveCN108300064AGood adhesionGood embroidery performanceAnti-corrosive paintsNano al2o3Chlorinated paraffins

The invention discloses an antirust coating for an automobile chassis, and relates to the technical field of coatings. The antirust coating is prepared from an acrylic emulsion, xanthan gum, a defoaming agent, a dispersant, a film forming additive, barium sulfate, modified zinc phosphate, a surfactant, isotridecyloxy propylamine, nano-alumina, talcum, tributyl phosphate, oxidized starch, sepiolitepowder and chlorinated paraffin. The antirust coating for the automobile chassis uses the acrylic emulsion as a basic film forming substance, contains general coating components, and also contains the modified zinc phosphate, and the modified zinc phosphate is chemically reacted with iron rusts to convert harmful iron rusts into harmless or protective substances, so the coating containing the modified zinc phosphate has a fast effect on the iron rusts, can be applied together with rusts, and can wet and infiltrate a loose and porous corrosion layer to convert the iron rusts into inert and non-corrosive black substances.

Owner:安徽喜宝高分子材料有限公司

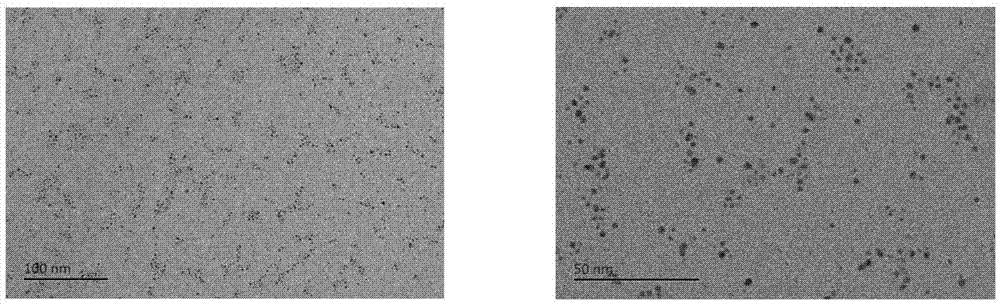

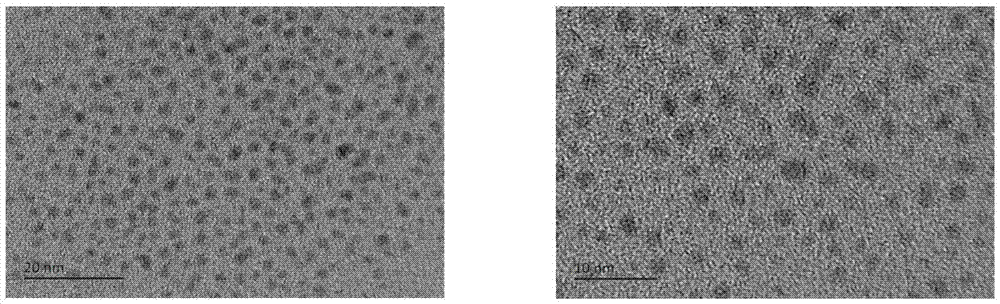

Preparation method of size controllable rhotanium nano particles

InactiveCN106862582ASmall sizeEvenly dispersedTransportation and packagingMetal-working apparatusOrganic solventThiol

The invention discloses a preparation method of size controllable rhotanium nano particles. The method can adjust and control the size of the nano particles through changing proportion of a ligand and comprises the following steps in specific: dissolving gold organic complex and palladium salt in an organic solvent, stirring, adding certain proportion of mercaptan ligand, stirring for a while until a large amount of saffron yellow sediment in the solvent, and adding sodium borohydride for reduction to generate black substance immediately; washing the black substance with a large amount of methyl alcohol, and removing mercaptan not reacting; and finally, extracting the nano particles with dichloromethane, and drying the nano particles in a vacuum drying box. Through adjusting the proportion of the mercaptan ligand, nano particles of different sizes are obtained, and the size distribution range comprises 1-1.5 nm, 1.7-2 nm, 2-2.5 nm and 3 nm. The preparation method, disclosed by the invention, is feasible and simple to operate; and nano particles of different sizes can be obtained through adjusting and controlling the proportion of the ligand.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing stevioside

InactiveCN105622683AAvoid generatingImprove leaching rateSugar derivativesChemical industryChlorogenic acidSimulated moving bed

The invention discloses a method for preparing stevioside. According to the method, oxidation reduction reaction of polyphenol oxidase and polyphenols in stevia rebaudiana leaves is inhibited by soaking and flocculating stevia rebaudiana leaves in a vacuum state, then generation of black substances can be prevented, the leaching rate of stevioside is increased, and the workload of removing pigment in a later procedure is greatly reduced. A simulated moving bed production process is adopted, continuous production is achieved, and the energy consumption is low; stevia rebaudiana leaf dregs generated after water extraction can be used as a raw material for extracting chlorogenic acid, so that relatively good economic benefits can be made, and relatively slight environment pollution can be caused; the method is short in whole production process route, low in energy consumption and small in pollution.

Owner:天津北洋百川生物技术有限公司

Method for preparing lithium manganate positive electrode material by using waste zinc-manganese dry battery

ActiveCN103746127AImprove resource utilizationEliminate secondary pollutionCell electrodesReclaiming serviceable partsResource utilizationManganese

The present invention relates to a method for preparing a lithium manganate positive electrode material by using a waste zinc-manganese dry battery. The method comprises: (1) taking a zinc-manganese dry battery black substance, and carrying out grinding, washing and drying to obtain a zinc-manganese raw material so as to be spare; (2) respectively determining zinc content and manganese content in the zinc-manganese raw material in the step (1); (3) mixing the zinc-manganese raw material and a lithium raw material, grinding, and drying to obtain a lithium-zinc-manganese mixture; and (4) carrying out heating calcinations on the lithium-zinc-manganese mixture obtained in the step (3) to carry out a high temperature solid phase reaction, cooling to a room temperature after completing the reaction, grinding, and screening to obtain the lithium manganate positive electrode material. According to the present invention, the method for preparing the lithium manganate positive electrode material by using the waste zinc-manganese dry battery is created, such that comprehensive recovery of the zinc element and the manganese element in the waste zinc-manganese dry battery is achieved, preparation of the doped LiMn2-xZnxO4 positive electrode material is achieved, the resource utilization rate is increased, and the secondary pollution is eliminated.

Owner:甘肃大象能源科技有限公司

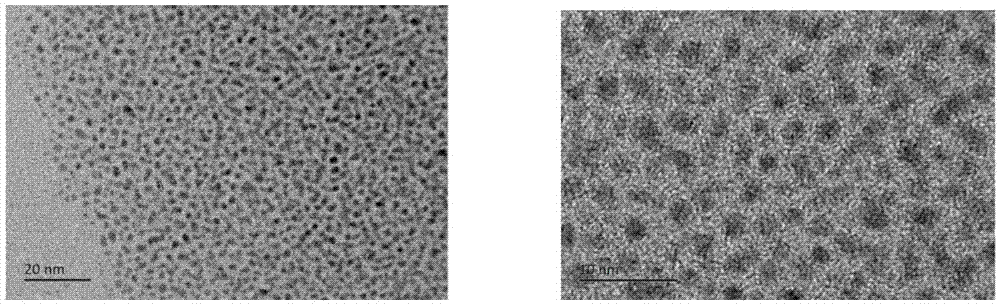

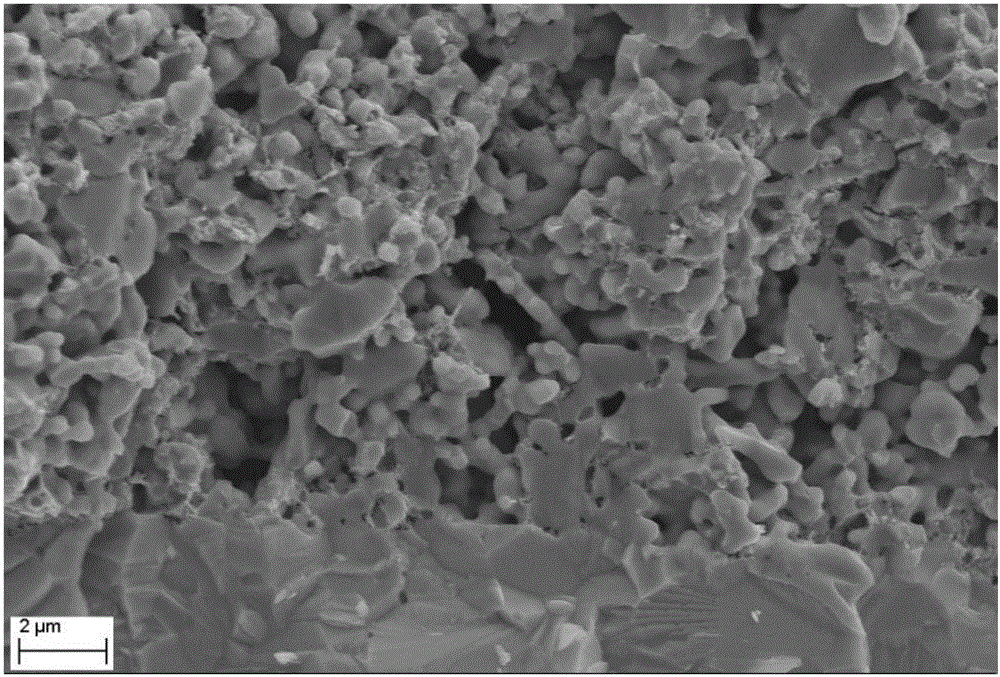

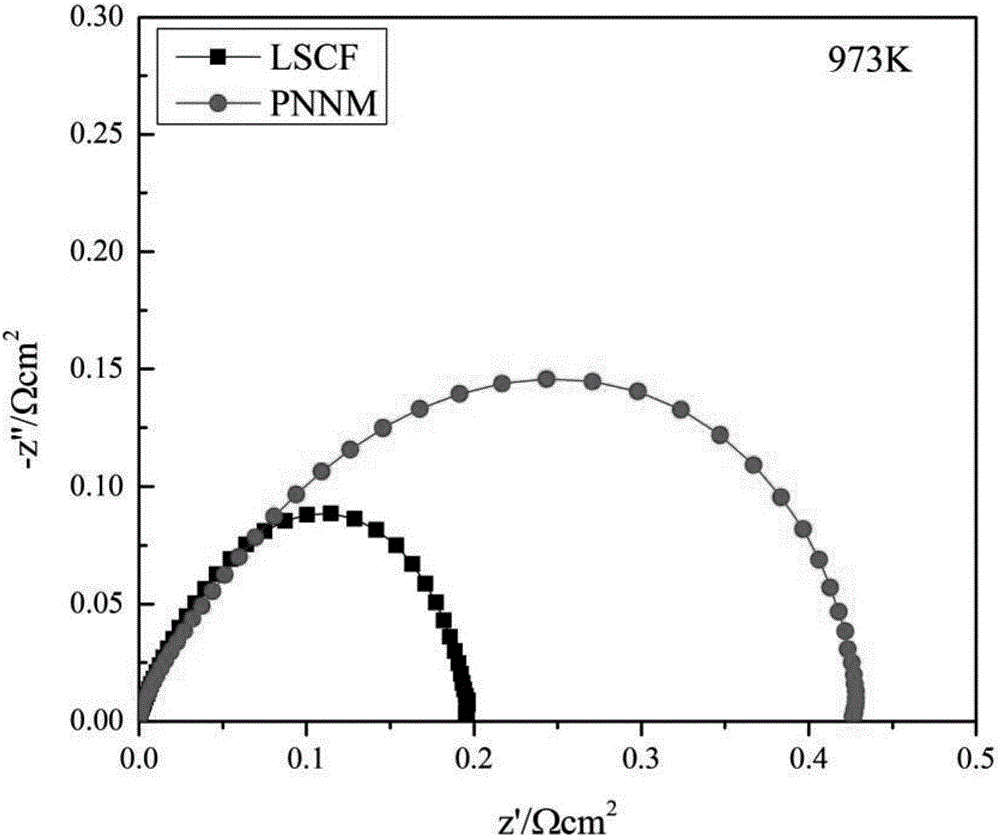

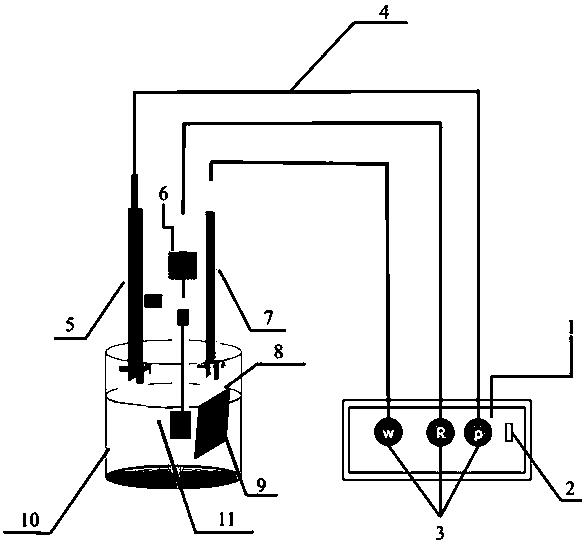

Catalyst for solid oxide fuel cell cathode and preparation method of catalytic cathode

ActiveCN106410245ALower operating temperatureLow running costCell electrodesSolid electrolyte fuel cellsFuel cellsBlack substance

The invention discloses a catalyst for a solid oxide fuel cell cathode and a preparation method of the catalytic cathode. The catalyst is Pr1.99Nd0.01Ni1-xMnxO4-delta (PNNM). The catalyst is prepared through enabling Pr(NO3)3.6H2O, Nd(NO3)3.6H2O, Ni(NO3)2.6H2O and Mn(NO3)2.4H2O to perform a complex reaction with citric acid sufficiently in absolute ethyl alcohol, and then calcining ground black substances obtained from a complexing solution through heating, evaporating, burning and grinding for two hours at the temperature of 800 DEG C. A porous LSCF (La0.6Sr04Co0.2Fe0.8O3-delta) cathode is soaked by the complexing solution of the catalyst, so that the catalytic LSCF cathode with PNNM is obtained. The catalyst can be used for strengthening the oxygen reduction performance of the catalytic LSCF cathode, and the polarization resistance of the cathode is reduced.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

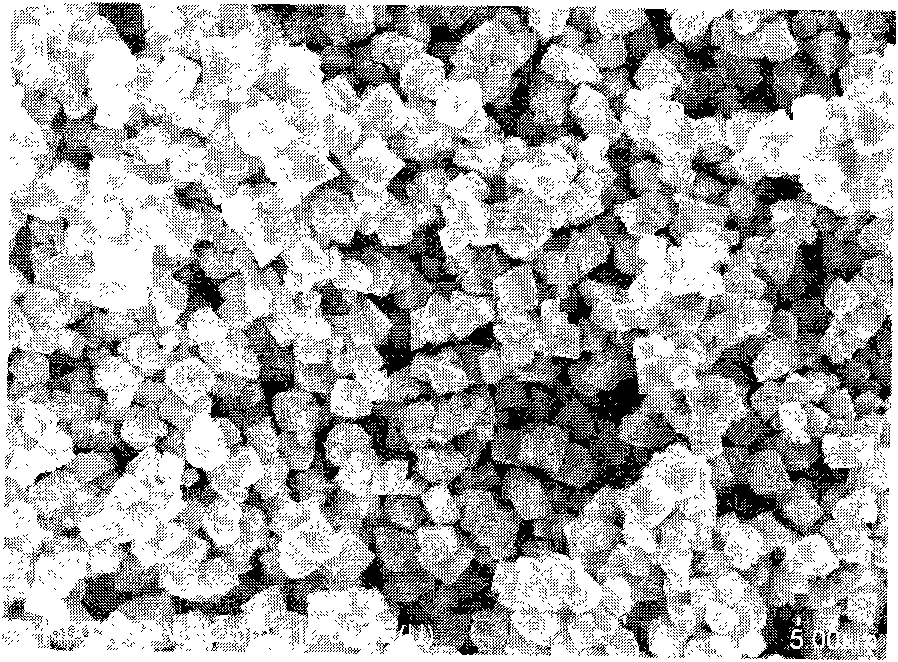

Method for preparing lithium ion imprinted membrane based on electrochemically switched ion exchange

InactiveCN110124631AImprove adsorption capacityCause secondary pollutionIon-exchange process apparatusElectrolysis componentsIon exchangeIon-exchange resin

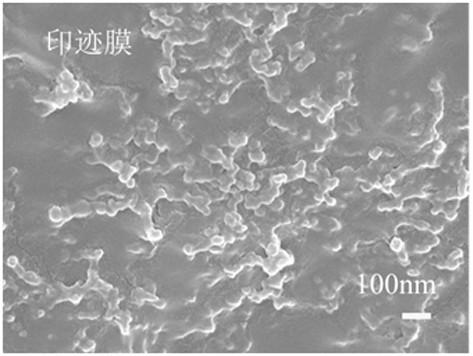

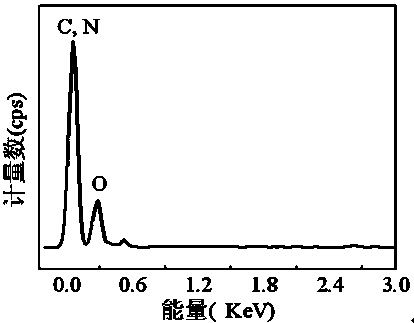

A method for preparing a lithium ion imprinted membrane based on electrochemically switched ion exchange belongs to the technical field of preparation and application of electroactive ion imprinted membranes. The problem that a traditional lithium extraction method might have low extraction efficiency and poor selectivity and is easily interfered with other metal objects in seawater and fly ash environments can be solved. The lithium ion imprinted membrane is synthesized by a unipolar pulse electrochemical method. The membrane has good adsorption of low-concentration lithium ions, and adsorption and elution are both carried out by a potentiostatic method. Therefore, secondary pollution to the environment is avoided. The membrane is an environmentally-friendly substance. The synthesized substance is a black substance polymerized on a platinum sheet, and the microstructure is a sphere-like substance. 2-hydroxymethyl-12-crown-4 is mixed in a pyrrole membrane, thus achieving good adsorption of low-concentration lithium ions in a solution. The method is an advanced ion imprinted material synthesis method.

Owner:TAIYUAN UNIV OF TECH

Thermoplastic resin composition for laser mark

The present invention relates to a laser-marking thermoplastic resin composition, comprising: [A] a rubber-reinforced thermoplastic resin comprising a copolymer resin (A1) obtained by polymerizing a vinyl-based monomer (b) containing a (meth)acrylic acid ester in the presence of a rubber polymer (a), or a mixture of the copolymer resin (A1) and a (co)polymer (A2) of vinyl-based monomer(s), said rubber polymer (a), (meth)acrylic acid ester units (b1) and monomer units (b2) other than the (meth)acrylic ester units (b1) being contained in amounts of 5 to 40% by weight, 25 to 60% by weight and 0 to 70% by weight, respectively, with the proviso that a total content of the components (a), (b1) and (b2) is 100% by weight; [B] at least one material selected from the group consisting of an epoxy-containing polymer (B-1) and particles (B-2) having an average particle diameter of 0.05 to 150 mum, the component [B] being excluded from the component (A2); and [C] a black substance. The distinct mark is formed on the surface of the molding body through the laser irradiation.

Owner:TECHNO POLYMER CO LTD

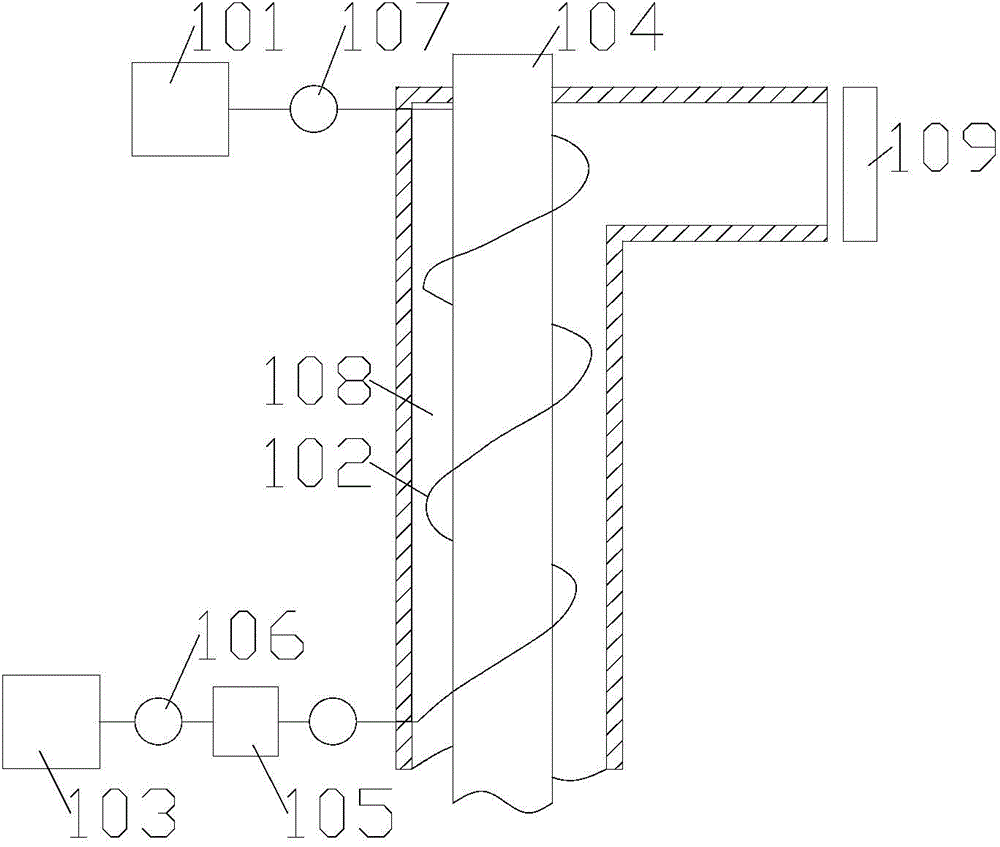

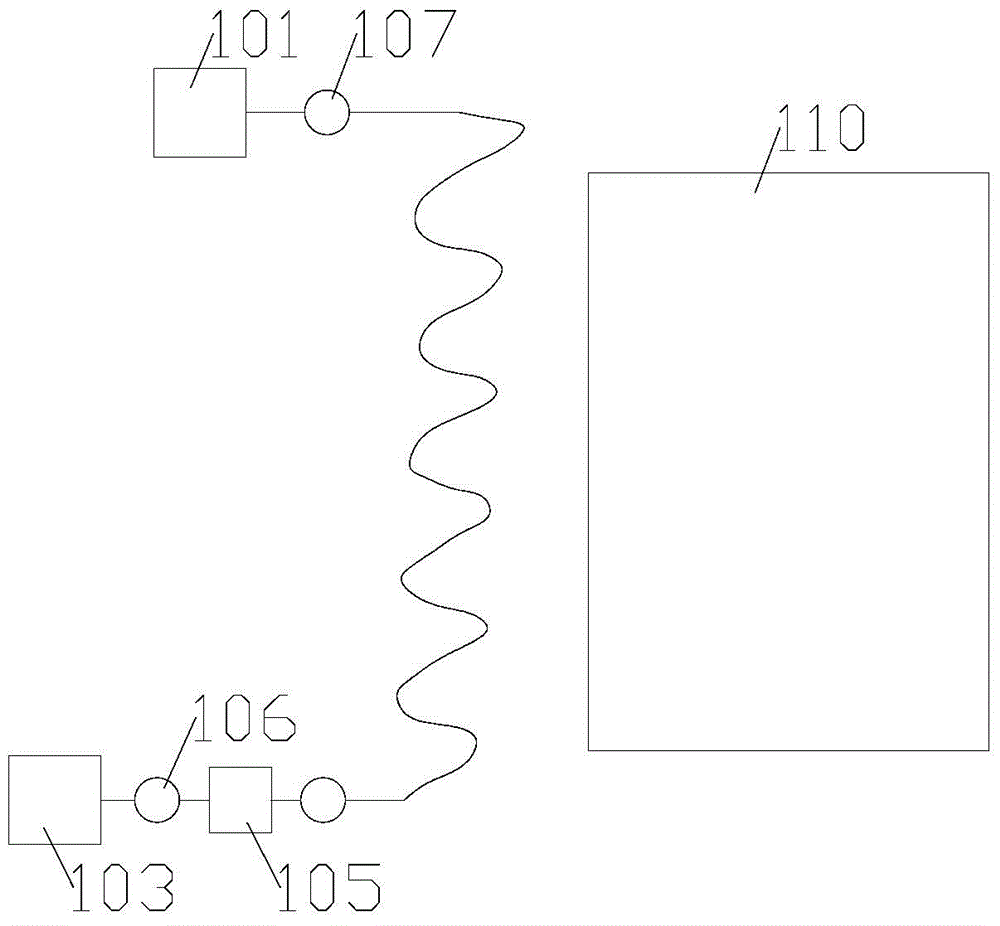

Fuel full combustion method and system

InactiveCN104895708AWon't burnGuaranteed service lifeInternal combustion piston enginesThermal treatment of fuelCombustionLiquid state

The invention provides a fuel full combustion method and system and belongs to the field of an internal combustion engine. Fuel in an oil tank enters an engine via a first oil conveying pipe for combustion; residual heat is discharged out of an exhausting flue; the first oil conveying pipe is arranged outside the exhausting flue; fuel in the first oil conveying pipe can be continuously heated by heat via the exhausting flue; during the heating, the fuel is converted from a liquid state to a gaseous state; fuel size is expanded after heating; then the fuel enters the engine and is fully mixed with air to release heat; and fuel in the first oil conveying pipe is continuously heated until the engine stops. The fuel is heated by the residual heat discharged by the exhausting flue expands after a conversion from the liquid state to the gaseous state; then the fuel is fully and evenly mixed with air, so the fuel can be fully burnt and release heat; with the above method, fuel utilization rate can be improved; obvious black material can be avoided in the inner wall of an exhausting port of the exhausting flue; and pollution to the environment can be reduced and the environment can be protected.

Owner:雷振

Preparation method for graphene

The invention discloses a preparation method for graphene. The preparation method for graphene comprises the following steps: uniformly mixing pyridine and formic acid according to a volume ratio of 1: 1 to 1: 5 so as to obtain a mixed solvent; dispersing graphite oxide in the mixed solvent so as to obtain a mixed solution, wherein the addition proportion of graphite oxide and the mixed solvent is 5 to 7 mg / ml; subjecting the mixed solution to ultrasonic dispersion for 30 to 40 min; adding 0.2 to 0.5 ml of methyl silicone oil, carrying out a normal-pressure reflux reaction and terminating the reflux reaction when a black substance is not precipitated any longer; subjecting products of the previous step to separation and purification so as to obtain pretreated graphene; coating a substrate with the pretreated graphene; and carrying out laser reduction on the substrate with the pretreated graphene so as to obtain finished graphene. According to the preparation method for graphene in the invention, graphite oxide is fully reduced by a reasonable reducing agent and related technological parameters, so the degree of reduction is improved, and the quality of the produced graphene is enhanced.

Owner:衡阳恒荣高纯半导体材料有限公司

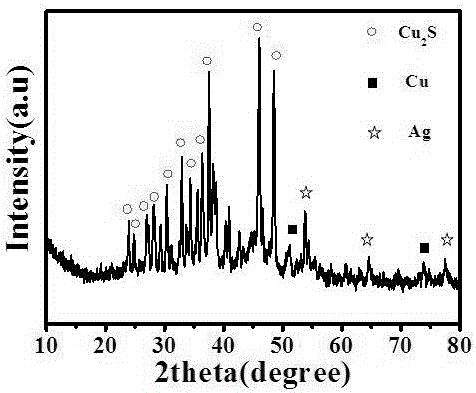

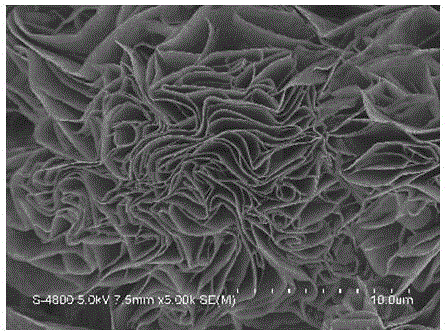

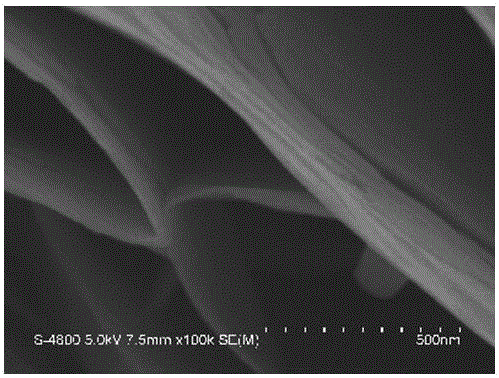

Preparation method of copper sulfide nano rose

InactiveCN106241855ANo pollution in the processReduce energy consumptionNanotechnologyCopper sulfidesSulfurCuprous sulfide

The invention provides a preparation method of copper sulfide nano rose. The preparation method comprises the following steps: cleaning treatment of a copper bar: the copper bar is washed with acetone, ethanol, 2 mol / L dilute hydrochloric acid and distilled water under an ultrasonic condition; (2) preparing of copper sulfide nano rose: monovalent silver salt and sulfur source are dissolved in the distilled water respectively and then stirred up; the cleaned copper bar is placed into a 5 mL test tube, a monovalent silver salt solution is dropped into the test tube by a dropper, then a sulfur source solution is dropped into the test tube, the test tube is shaken to enable the two solutions to be uniformly mixed and then sealed, the mixture is allowed to react for 10 min-12 h at normal temperature; after the reaction is ended, and the copper rod with black substance is washed with distilled water and allowed to naturally dry in the air. The preparation method disclosed by the invention is high in reproducibility, simple and convenient to operate, low in synthesis cost and suitable for industrial preparation; and the prepared nanometer rose is large in specific surface area and can be in full contact with an to-be-detected object as a sensor material.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

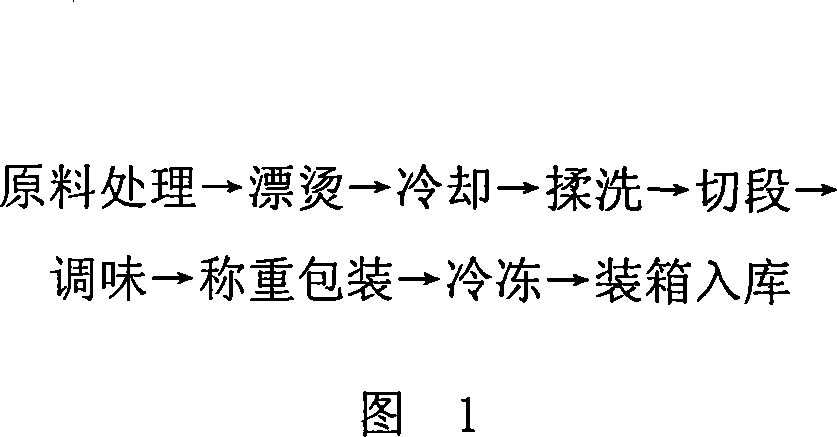

Method for preparing food with longsnout catfish skin as rough material

The invention relates to a preparation method of food. In the method, catfish skin is taken as the raw material. The method successively includes a step of the treatment of the raw material and a step of packaging. A step of washing is also included between the step of the treatment of the raw material and the step of packaging. The step of washing is essentially that: washing the catfish skin with 5-15 percent of acetic acid or 5-15 percent of white vinegar for 0.5-2 minutes and washing the skin with clear water. Compared with the prior art, the invention has the following advantage that: the method includes the step of using 5-15 percent of the acetic acid or 5-15 percent of the white vinegar for washing the catfish skin, and the step can clean the black materials in the catfish skin toremove the black color in the cooking liquor of the product, which can regulate the color of the cooking liquor and is beneficial to the beautiful appearance of the product.

Owner:德炎水产食品股份有限公司

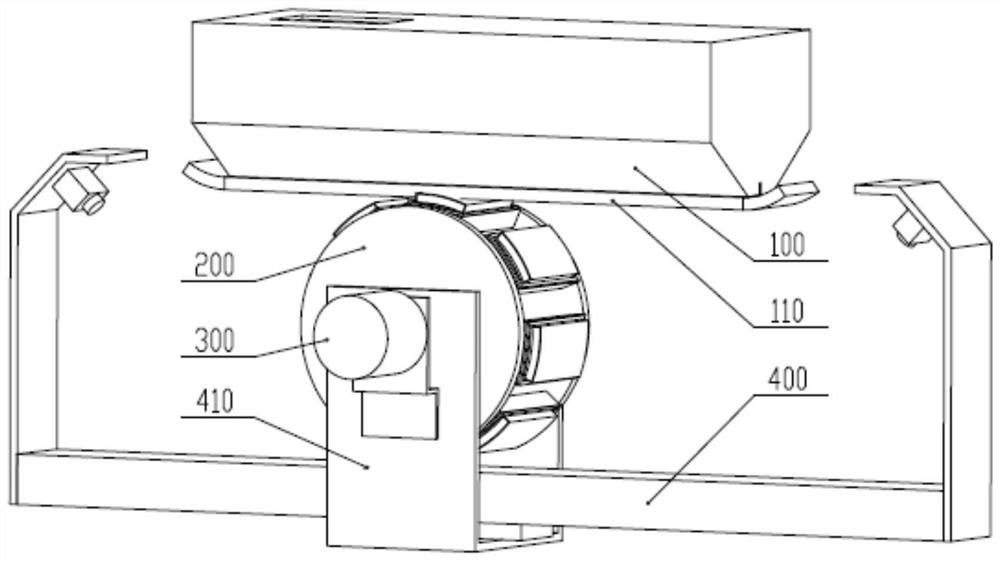

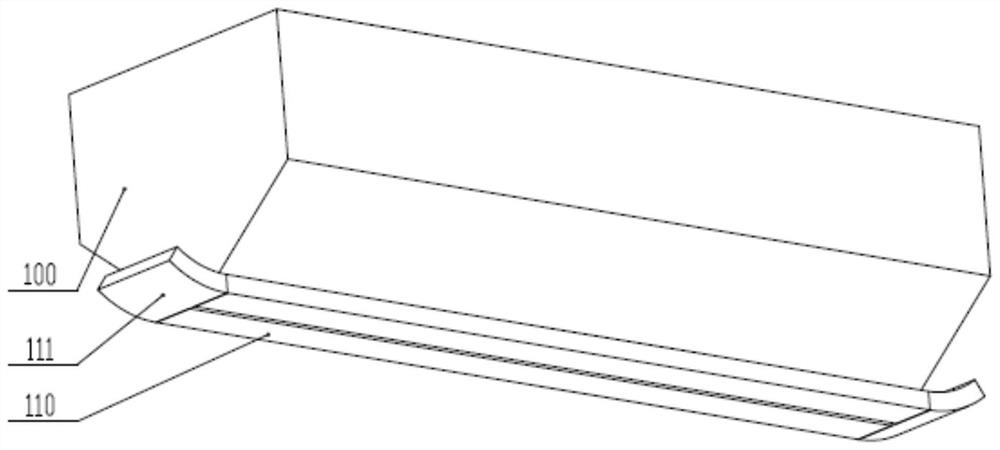

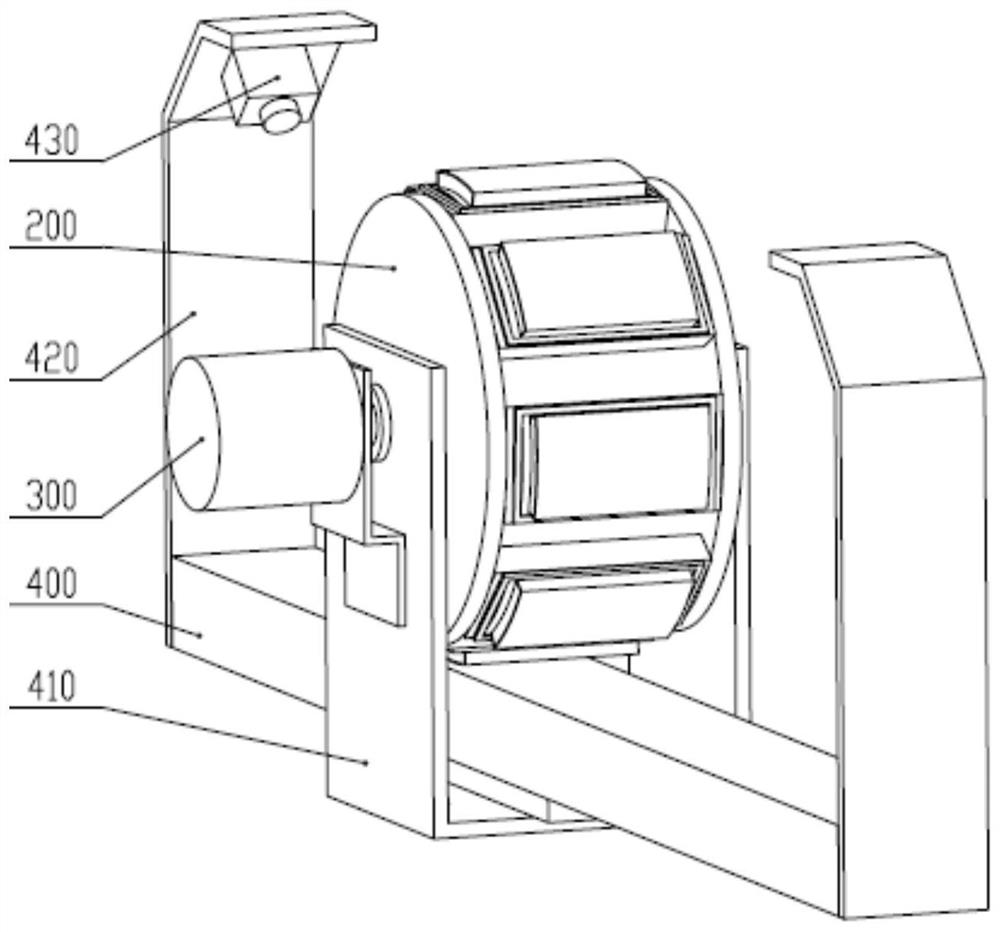

Cleaning device for sand scraping plate of sand paver

InactiveCN112122199AEfficient removalReduce contact areaAdditive manufacturing apparatusFoundry mouldsElectric machineComputer printing

The invention relates to the technical field of 3D printers, in particular to a cleaning device for a sand scraping plate of a sand paver of a sand mold 3D printer. The device comprises the sand paverwhich moves horizontally, wherein the sand scraping plate is fixedly arranged at the bottom of the sand paver, and the device further comprises a sweeping wheel, a driving electric motor and a linearmodule which are arranged below the sand paver, wherein the sweeping wheel is located between the sand scraping plate and the linear module, the driving electric motor is in driving connection to thesweeping wheel and is used for driving the sweeping wheel to rotate forwards or reversely, the linear module is parallel to the sand scraping plate, a support is arranged on the linear module in a sliding mode, the sweeping wheel is connected to the linear module in a sliding mode through the support, and a rotating direction of the sweeping wheel is opposite to a sliding direction of the sweeping wheel. The cleaning device for the sand scraping plate of the sand paver is provided and has the beneficial effects that black substances on the sand scraping plate can be effectively removed, and the phenomenon of sand pulling or local blocking of the sand paver is prevented.

Owner:NINGXIA KOCEL MOLD

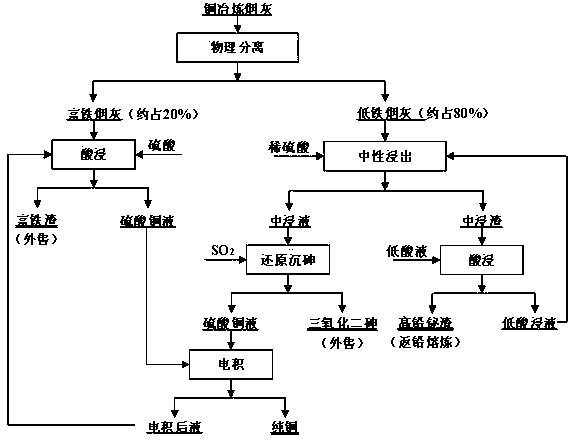

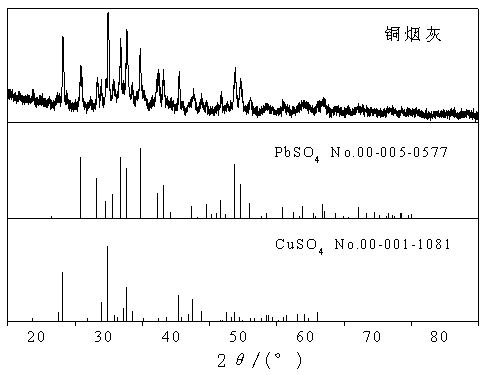

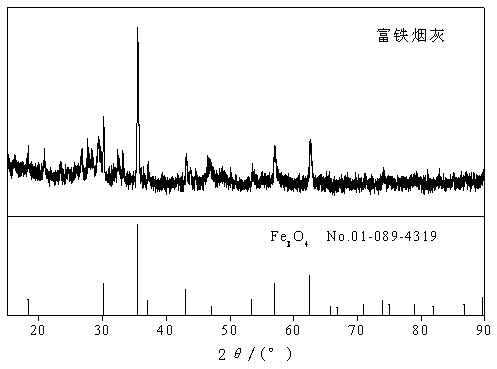

Method for comprehensively recovering valuable metal from copper smelting ash

ActiveCN108034830AReduce processingIncrease concentrationMagnetic separationProcess efficiency improvementPretreatment methodFiltration

The invention discloses a method for comprehensively recovering valuable metal from copper smelting ash. Firstly, a magnetic separation method is adopted to primarily separate the copper smelting ashto obtain iron-enriched ash and low-iron ash; the iron-enriched ash is leached by sulfuric acid to obtain iron-enriched slag and copper sulfate solution; the low-iron ash is neutrally leached to obtain neutral leaching slag and neutral leaching liquid; the neutral leaching slag is leached by low-acid liquid to obtain high-lead bismuth slag and acid leaching liquid; the acid leaching liquid is neutrally leached again; the neutral leaching liquid is reduced by SO2 to obtain As2O3 and copper sulfate solution; and the copper sulfate solution is electrodeposited to obtain pure copper. The magneticseparation pretreatment method is adopted to separate black substances which are about 20% of the total quantity of the ash and contain a lot of iron and less copper, so that the neutral leaching treatment quantity is reduced, the arsenic content of the neutral leaching liquid is increased, the SO2 reduction arsenic sinking is facilitated, meanwhile, the influence of iron on the acid leaching filtration is reduced, the acidity of acid leaching can be greatly improved, the arsenic content in the acid leaching slag is reduced, iron-enriched slag, high-lead bismuth slag and high-purity copper areobtained, and comprehensive recovery of the valuable metal is realized.

Owner:江西闪凝科技有限公司

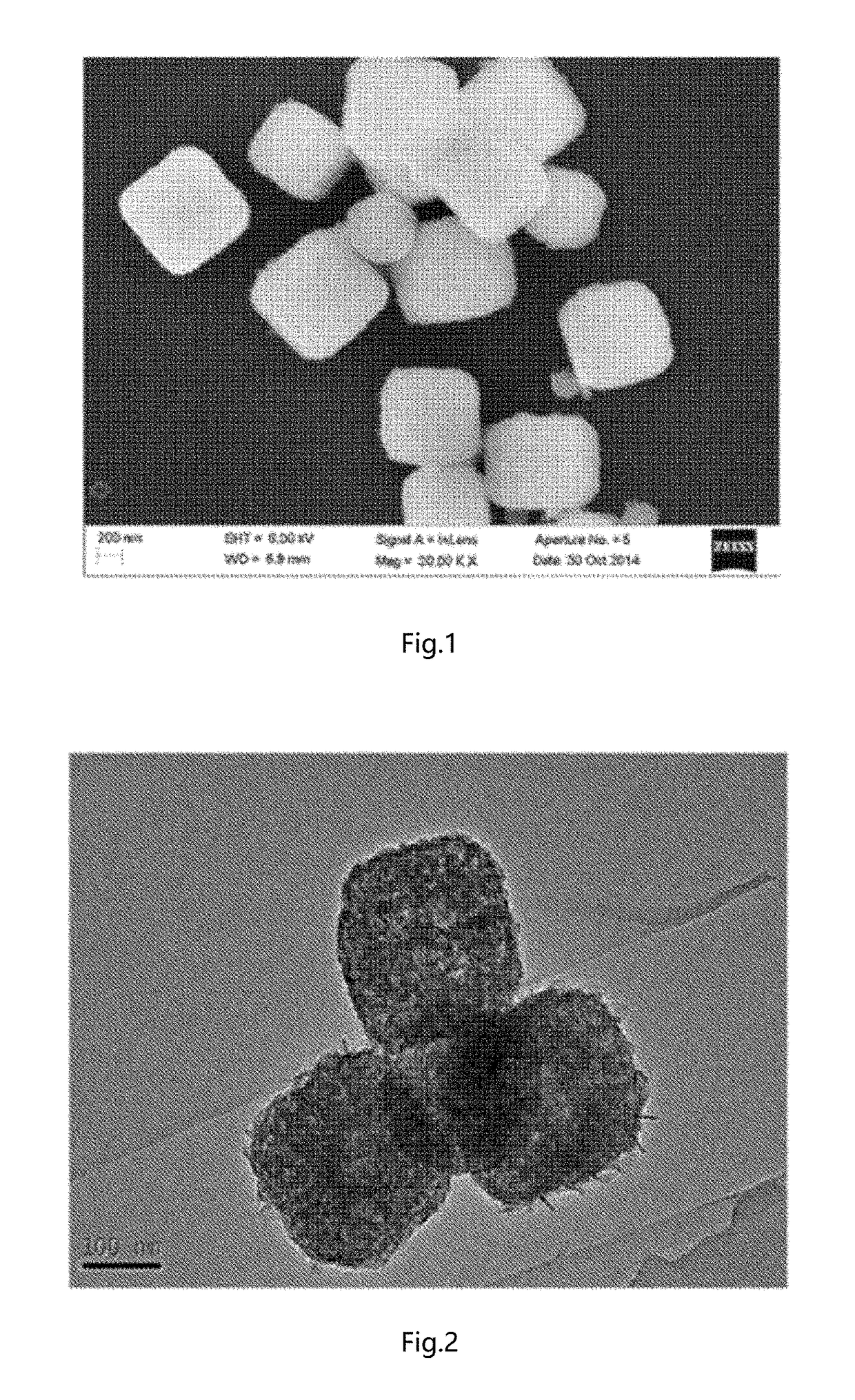

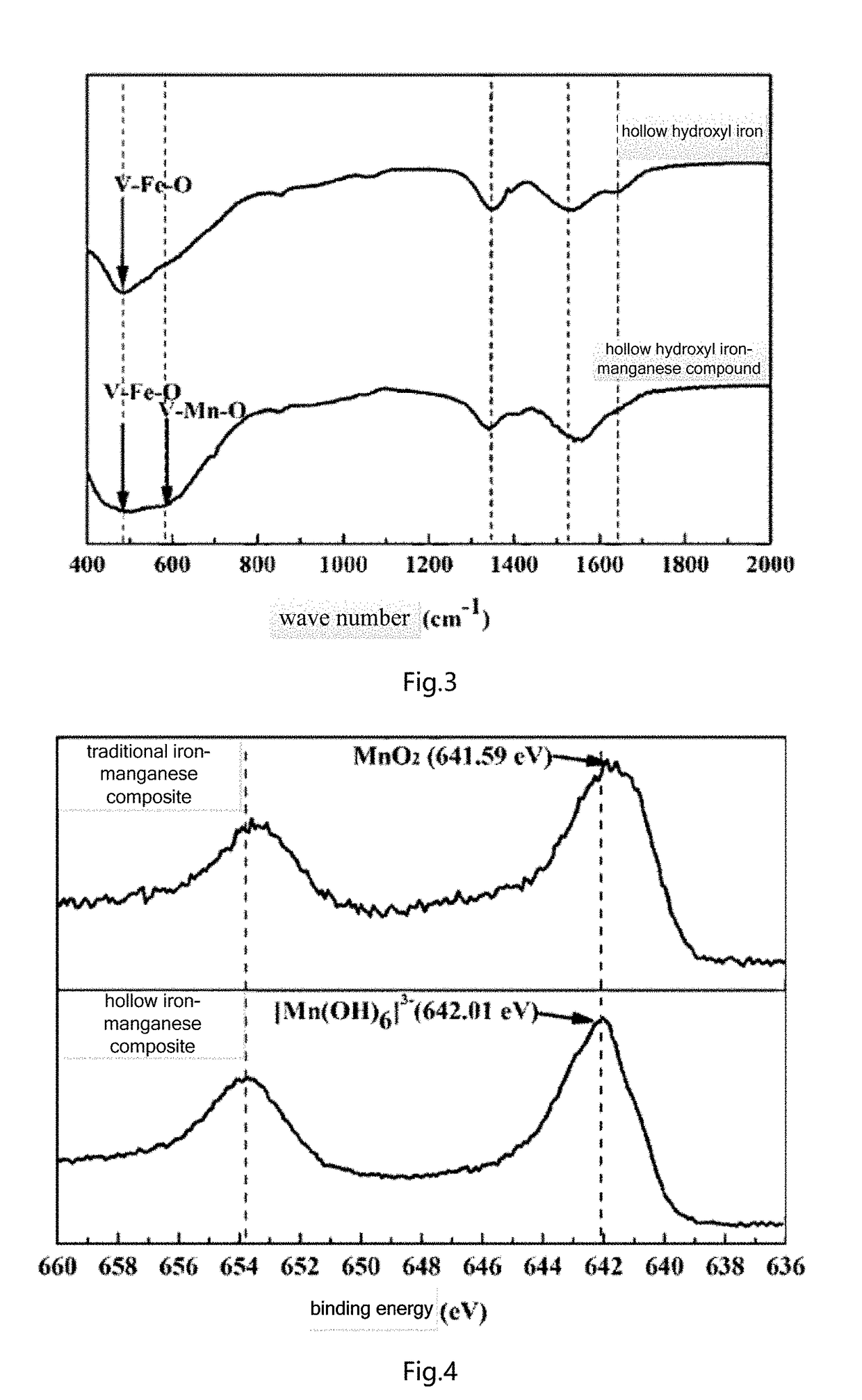

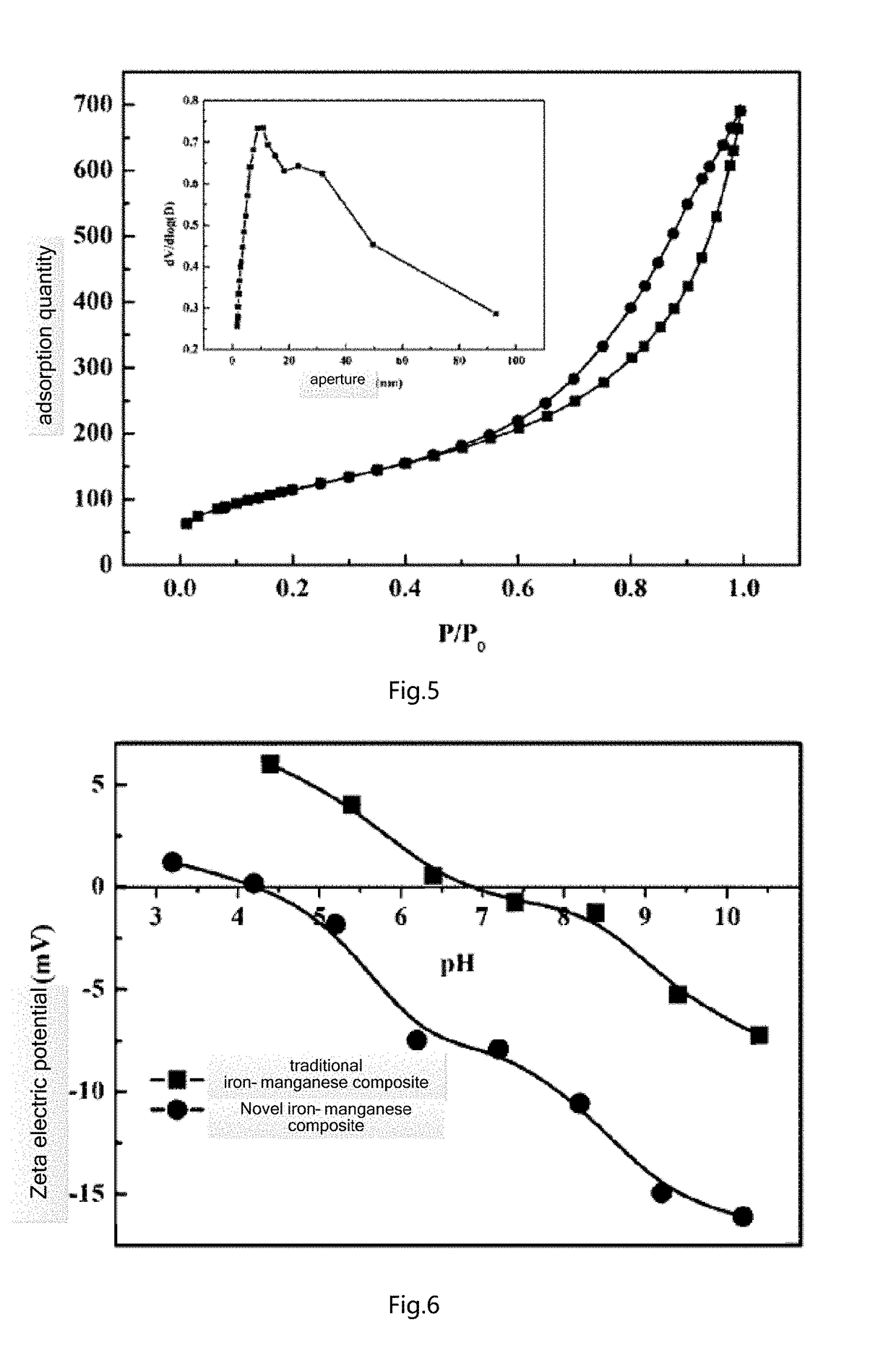

Hollow iron-manganese composite material prepared by etching template process and application thereof

ActiveUS20180056268A1Quality of waterTreatment cost and the treatment difficulty of the water body are reducedOther chemical processesWater contaminantsManganeseBottle

A method for preparing a hollow hydroxyl iron-manganese composite by employing a cubic structure template comprises: (1) preparation of a template: adding a certain mass of potassium permanganate to diluted hydrochloric acid, and dissolving and mixing evenly the same by magnetic stirring at room temperature; then adding polyvinylpyrrolidone thereto, and continuing to dissolve the same thoroughly by magnetic stirring; and finally adding a certain mass of potassium ferrocyanide and de-solubilizing the same for 10-60 minutes at room temperature, then transferring the above mixed solution into a sample bottle, and performing an isothermal reaction at 50-90° C. for 18-24 hours to obtain a blue-black deposit, namely a target iron-manganese composite template; and (2) preparation of a hollow iron-manganese composite: evenly dispersing the blue-black iron-manganese composite template obtained in the step (1) to a small amount of anhydrous ethanol, then adding a certain concentration of sodium hydroxide solution thereto, placing the same on a rotary shaker to react at room temperature for 6-12 hours, and then removing a supernatant liquid, so that a black substance remaining at a bottom of a centrifuge tube is a hollow hydroxyl iron-manganese composite having a cubic structure. Also provided are a hollow hydroxyl iron-manganese composite prepared by the above method, and an application thereof to adsorption and removal of heavy metal in water.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com