Patents

Literature

51results about "Liquid fuel impingement burners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

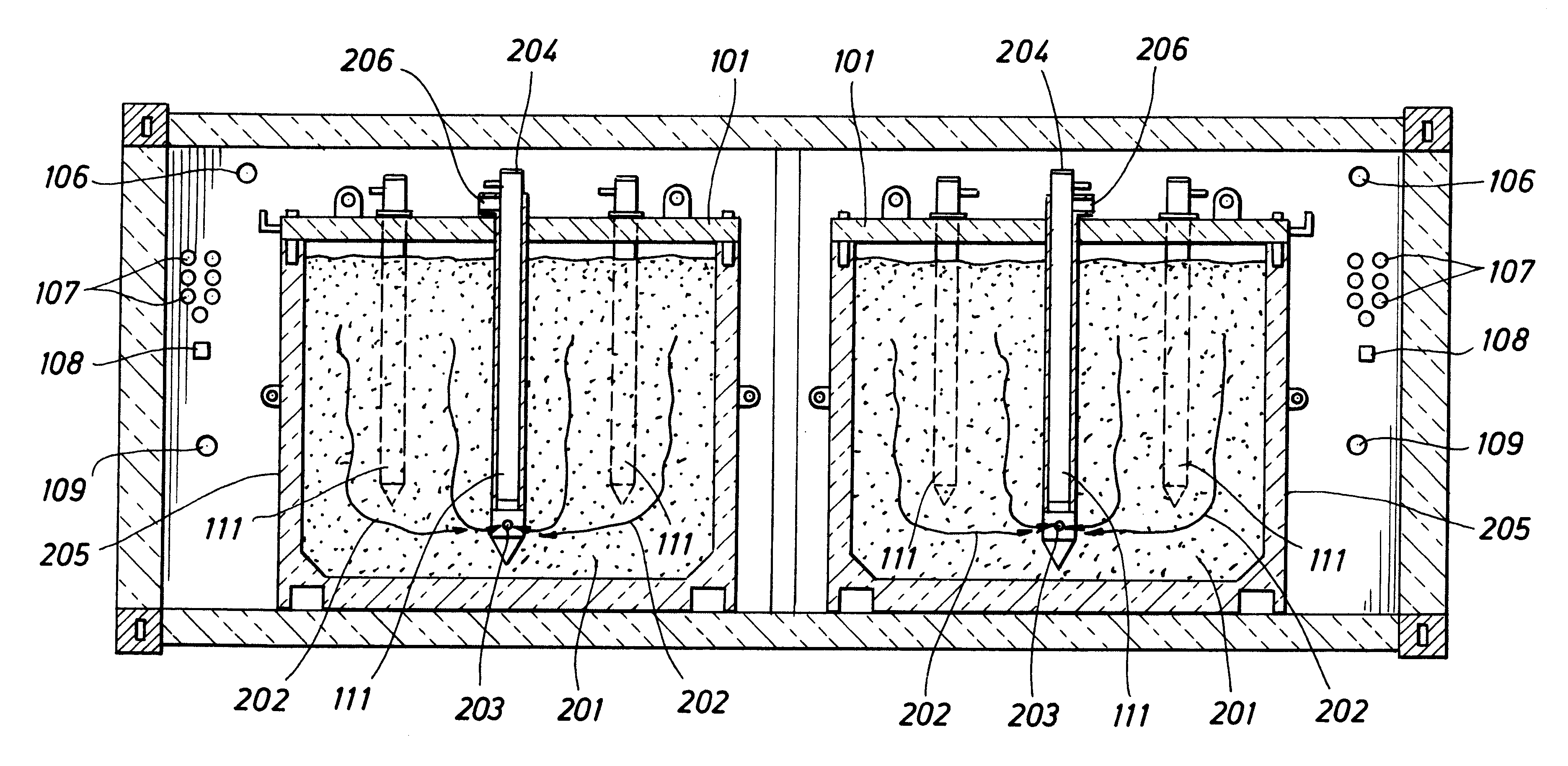

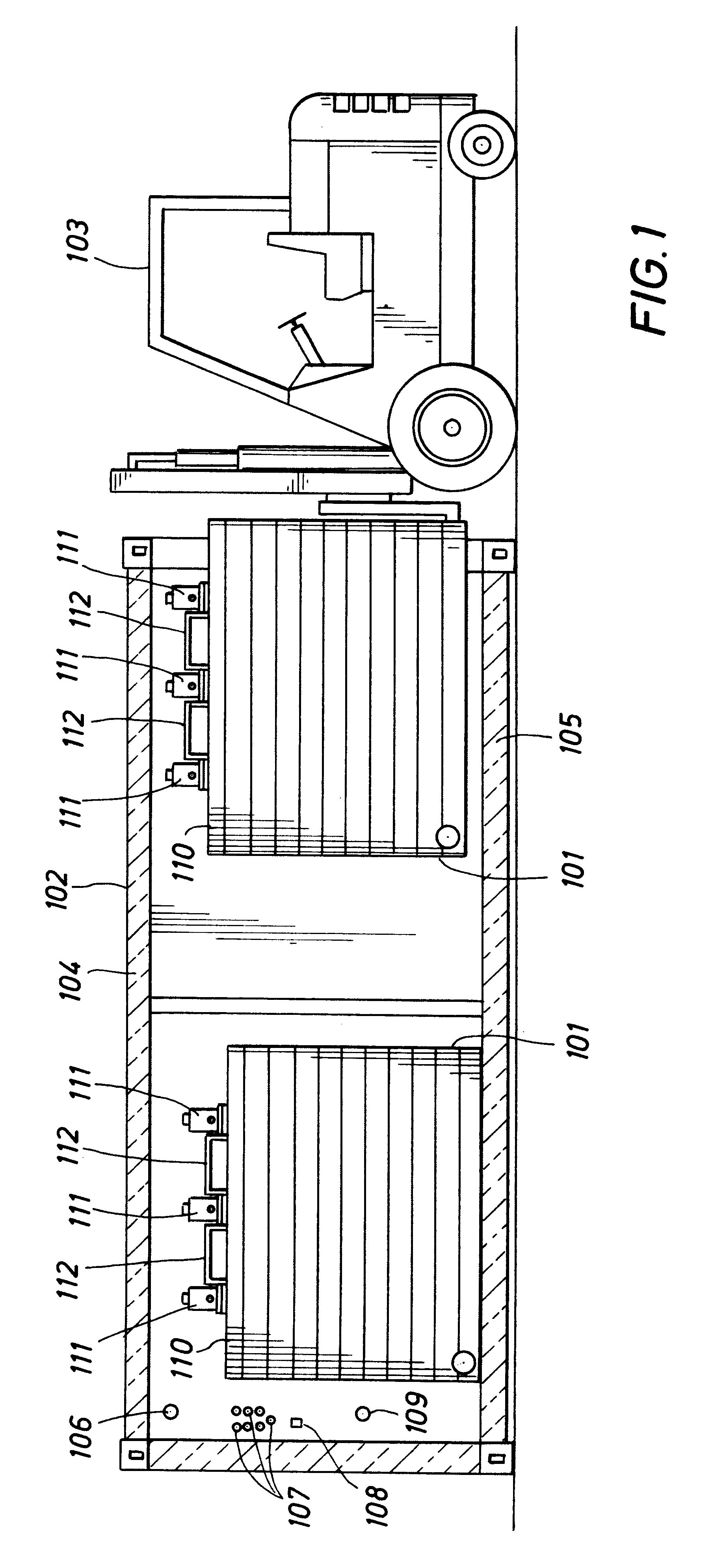

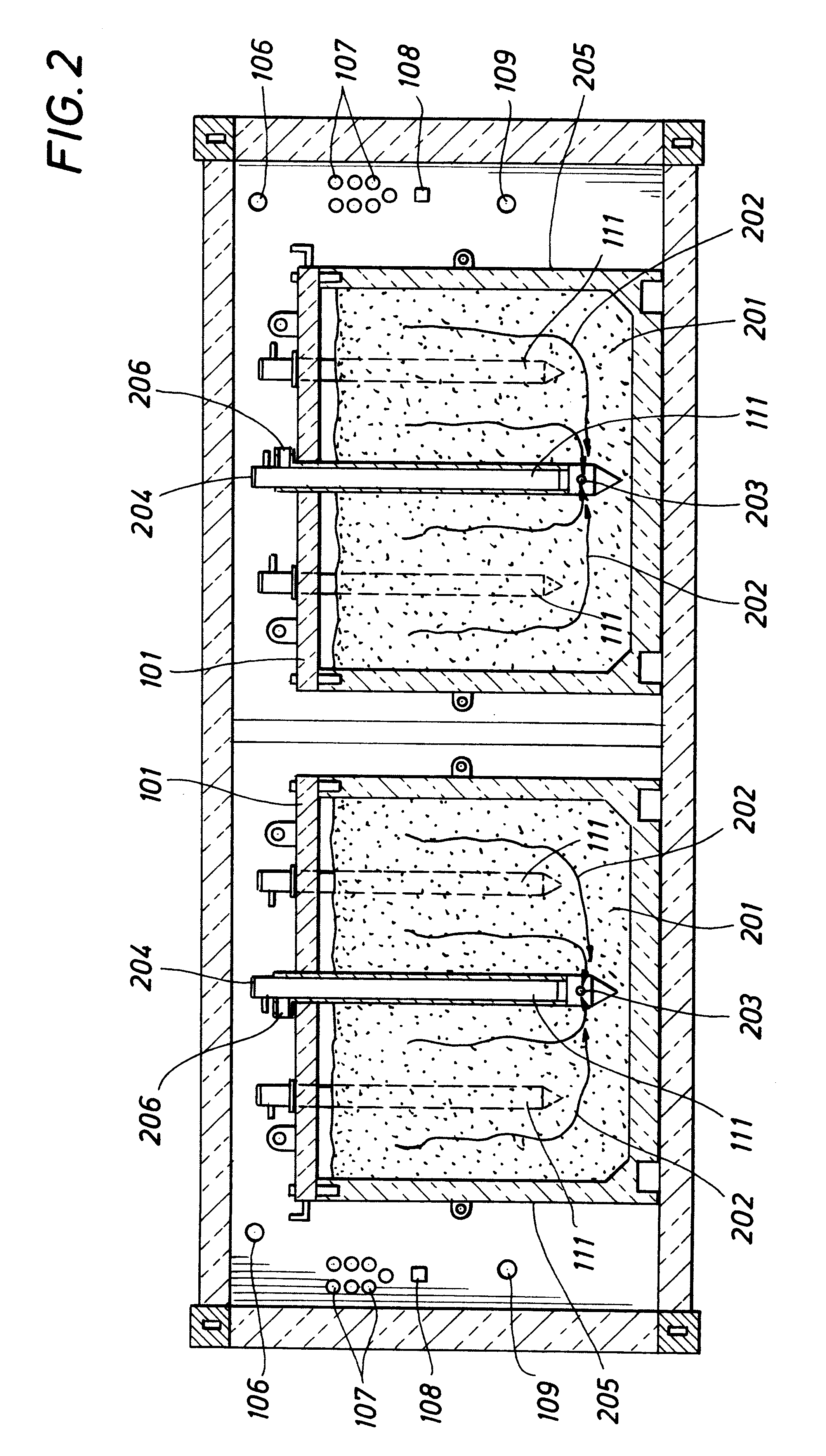

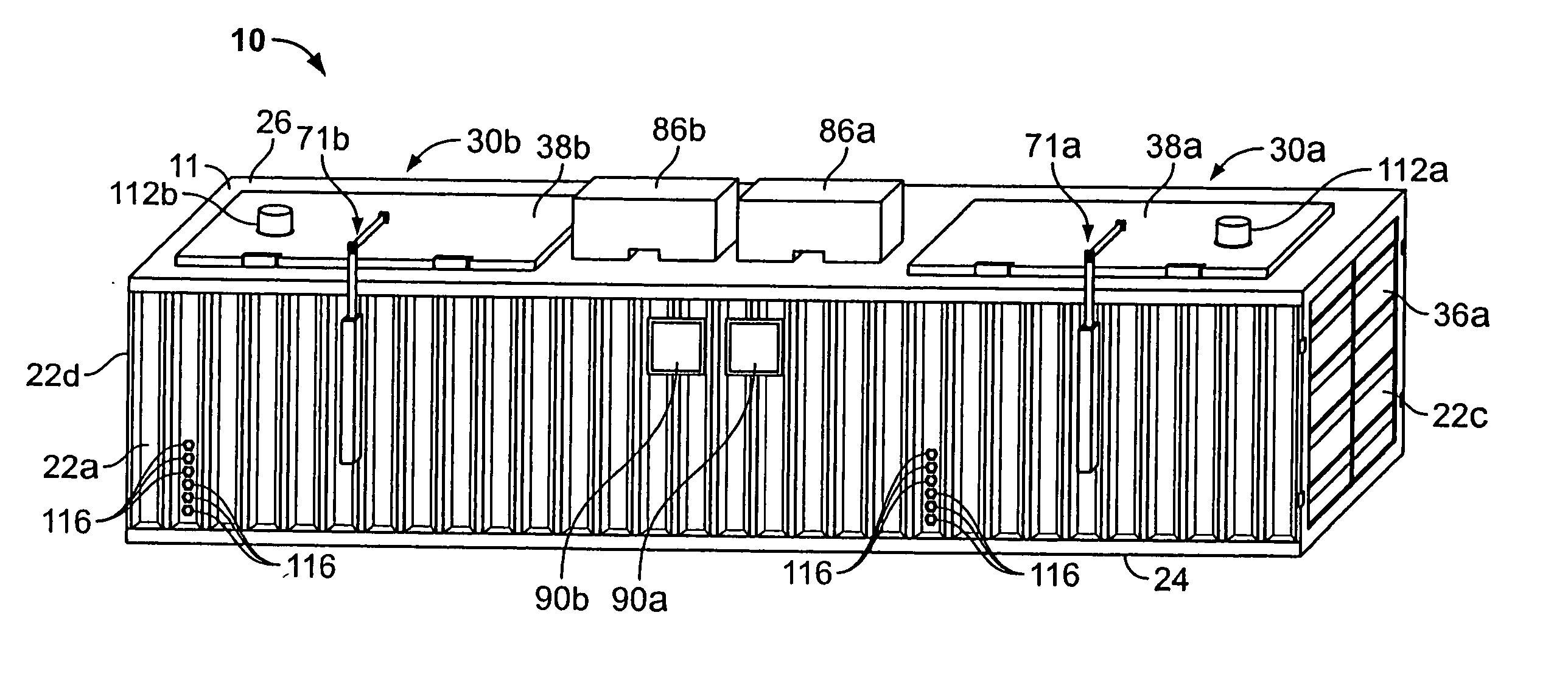

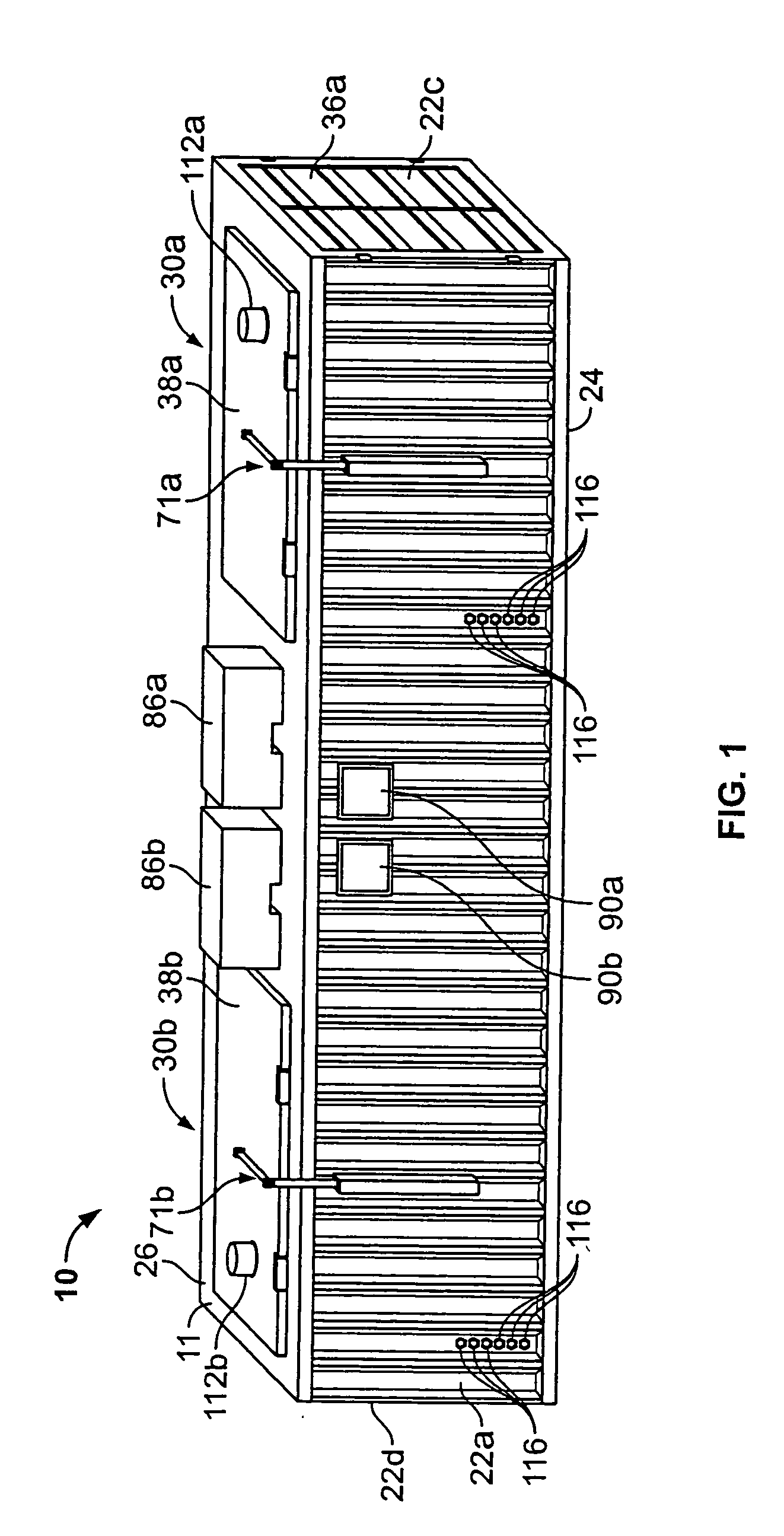

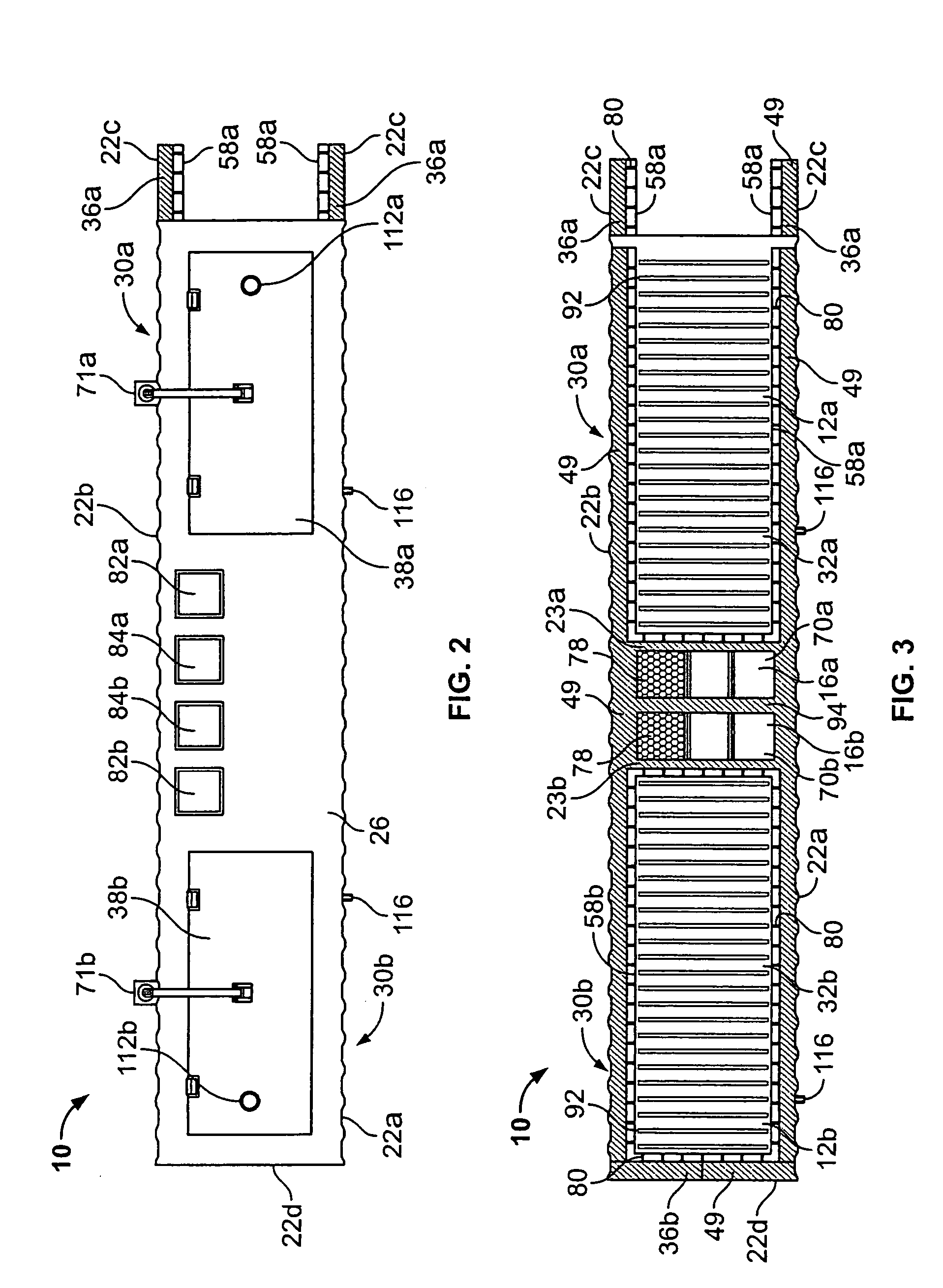

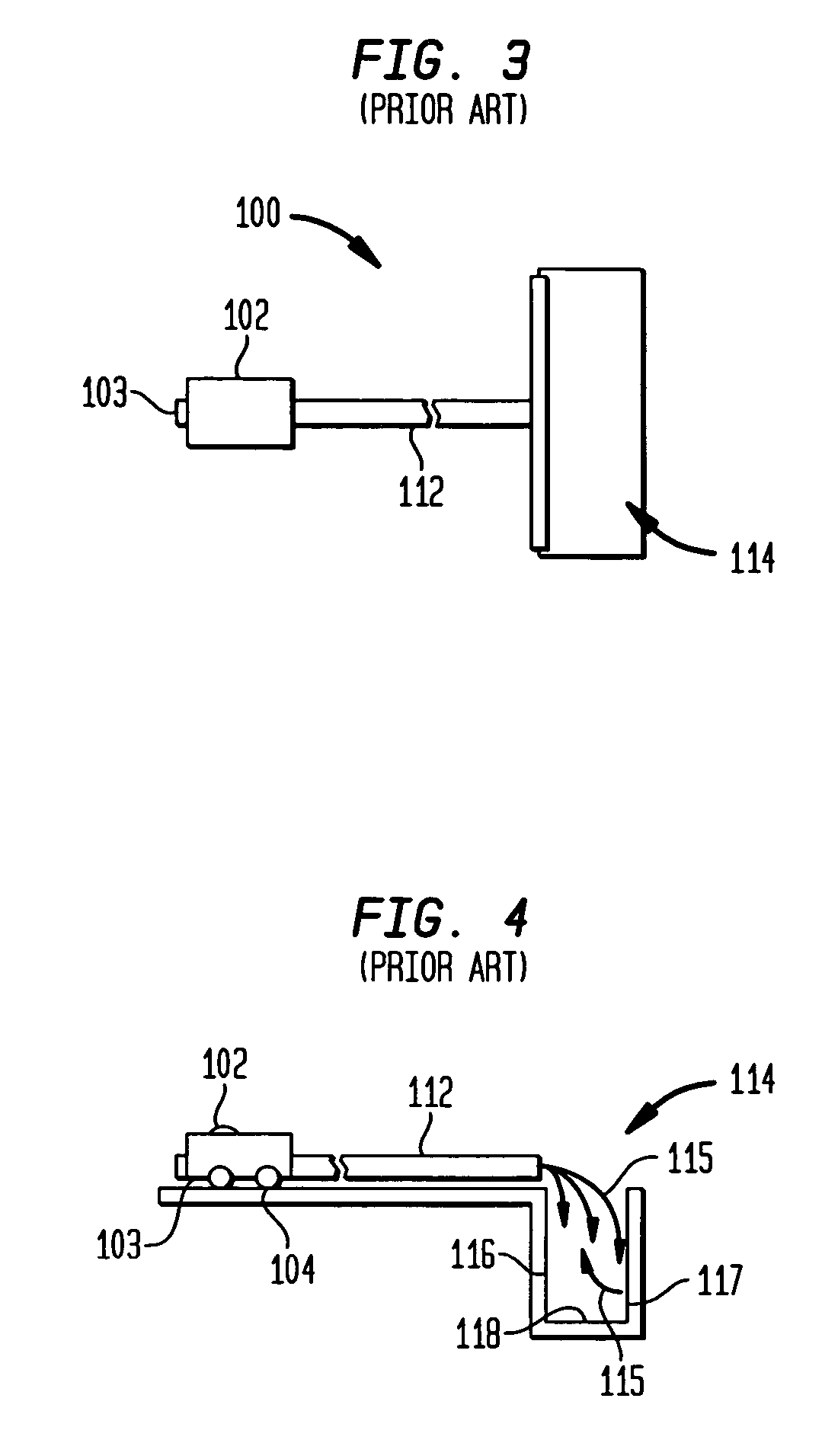

Apparatus for exsitu thermal remediation

InactiveUS6296815B1Solid waste disposalContaminated soil reclamationEngineeringMechanical engineering

An apparatus is disclosed for thermal desorption of contaminants from contaminated material, the apparatus including: a plurality of first insulated boxes, each insulated box, defining a volume effective for holding contaminated material, and each insulated box defining an opening at the top of the insulated box; at least one top effective to fit on the opening at the top of the insulated box and each top defining a pattern of heater orifices; a plurality of heaters, the heaters being insertable into the volume for holding contaminated material, through the heater orifices defined by the top; and a vapor extraction system effective to-remove vapors from within the volume for holding contaminated material.

Owner:SHELL OIL CO

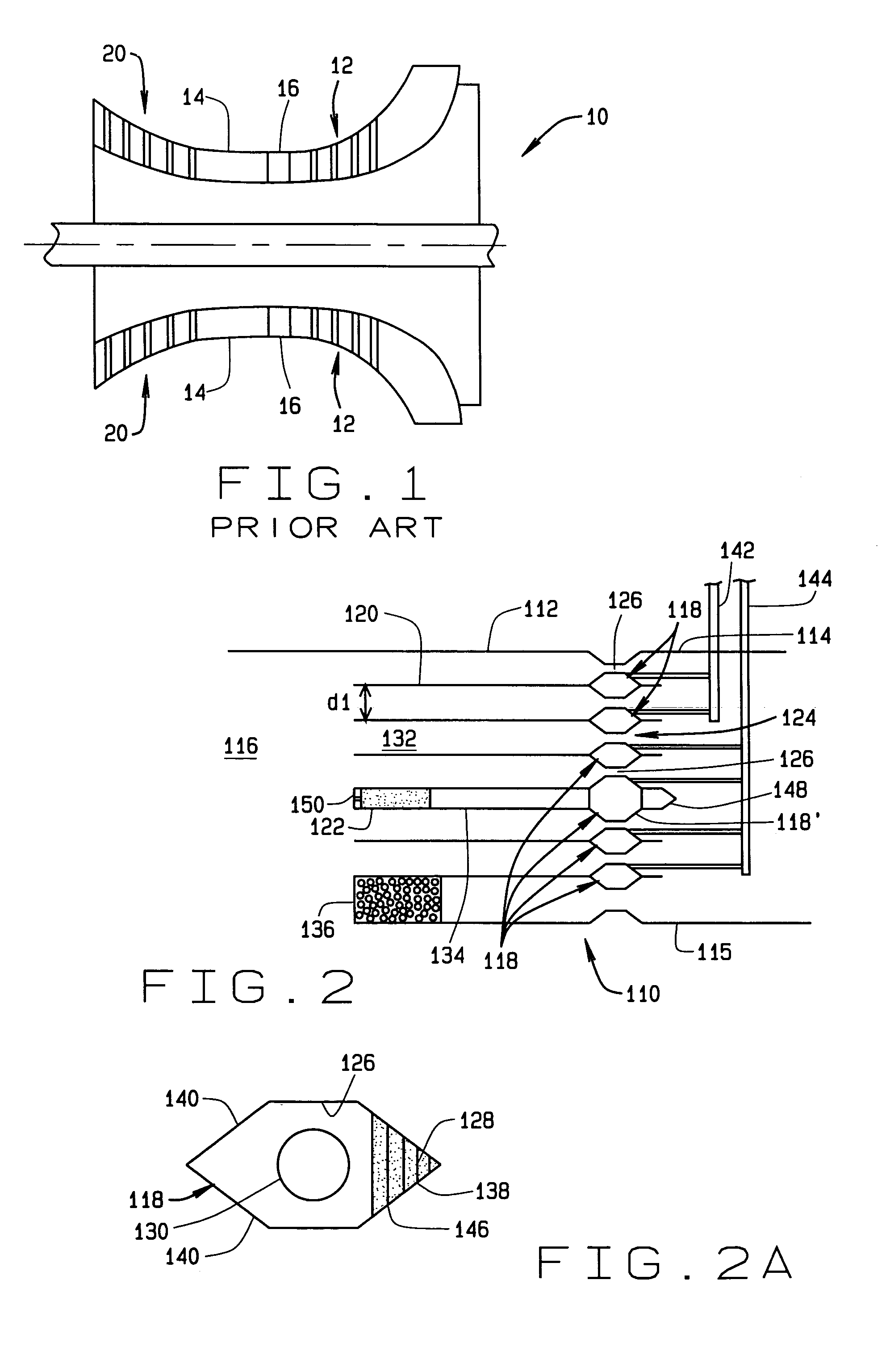

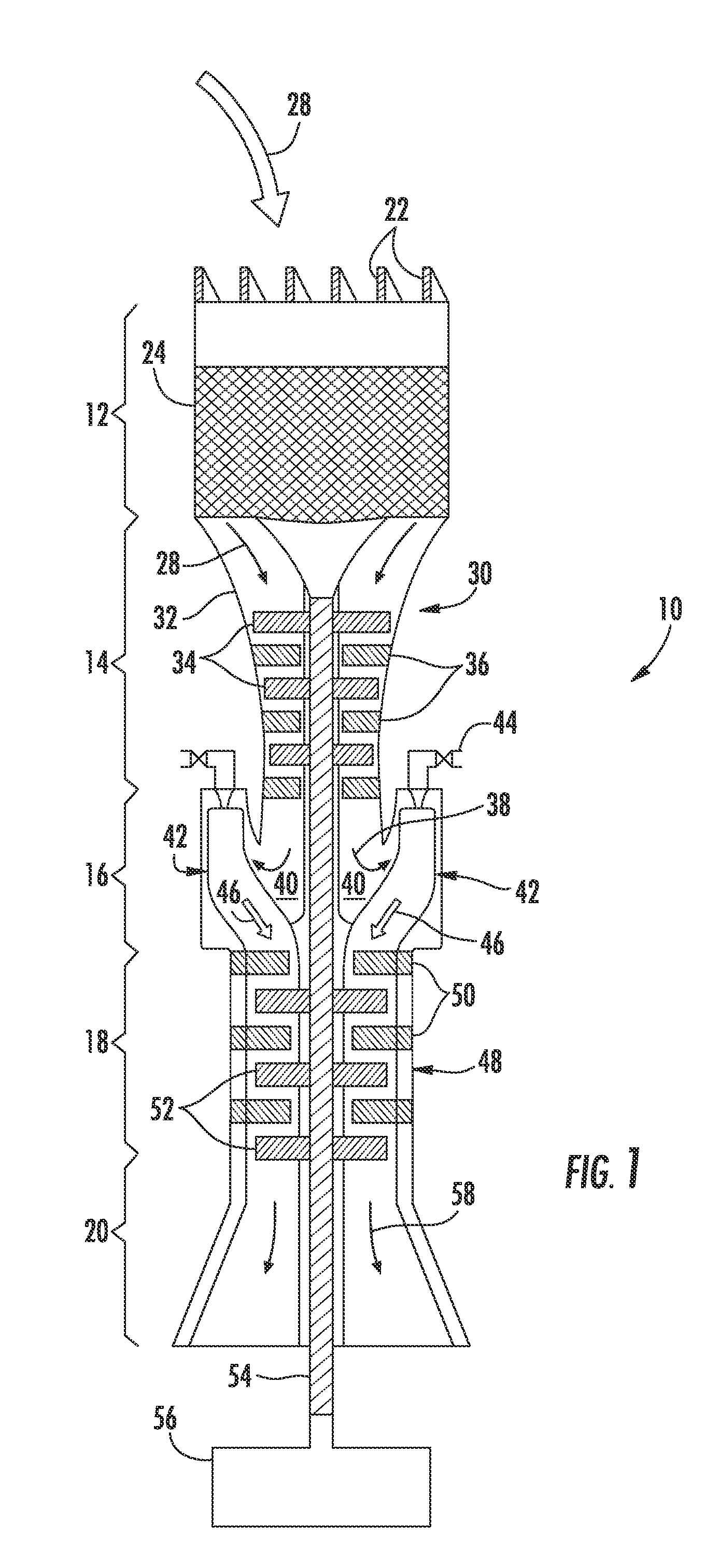

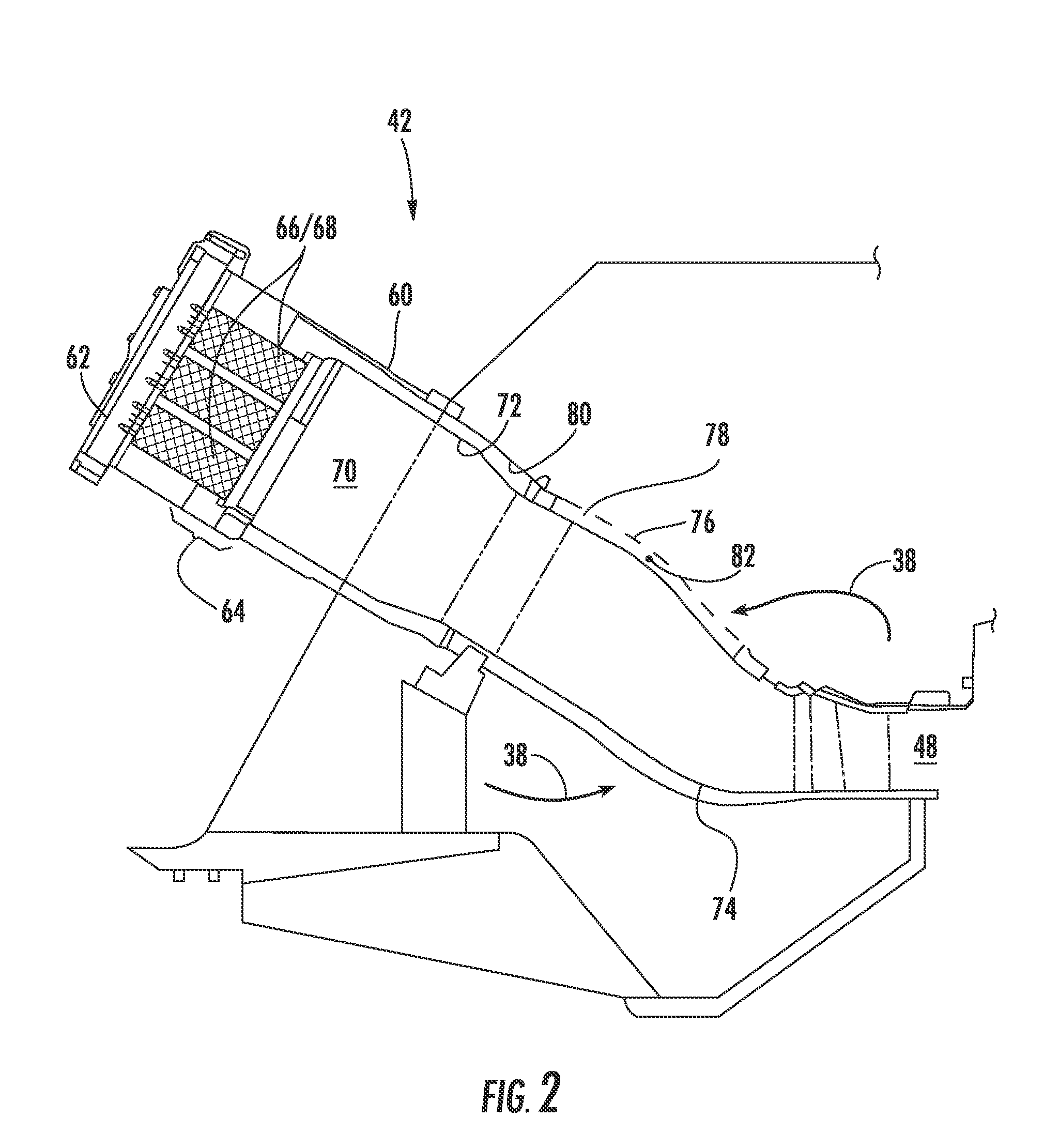

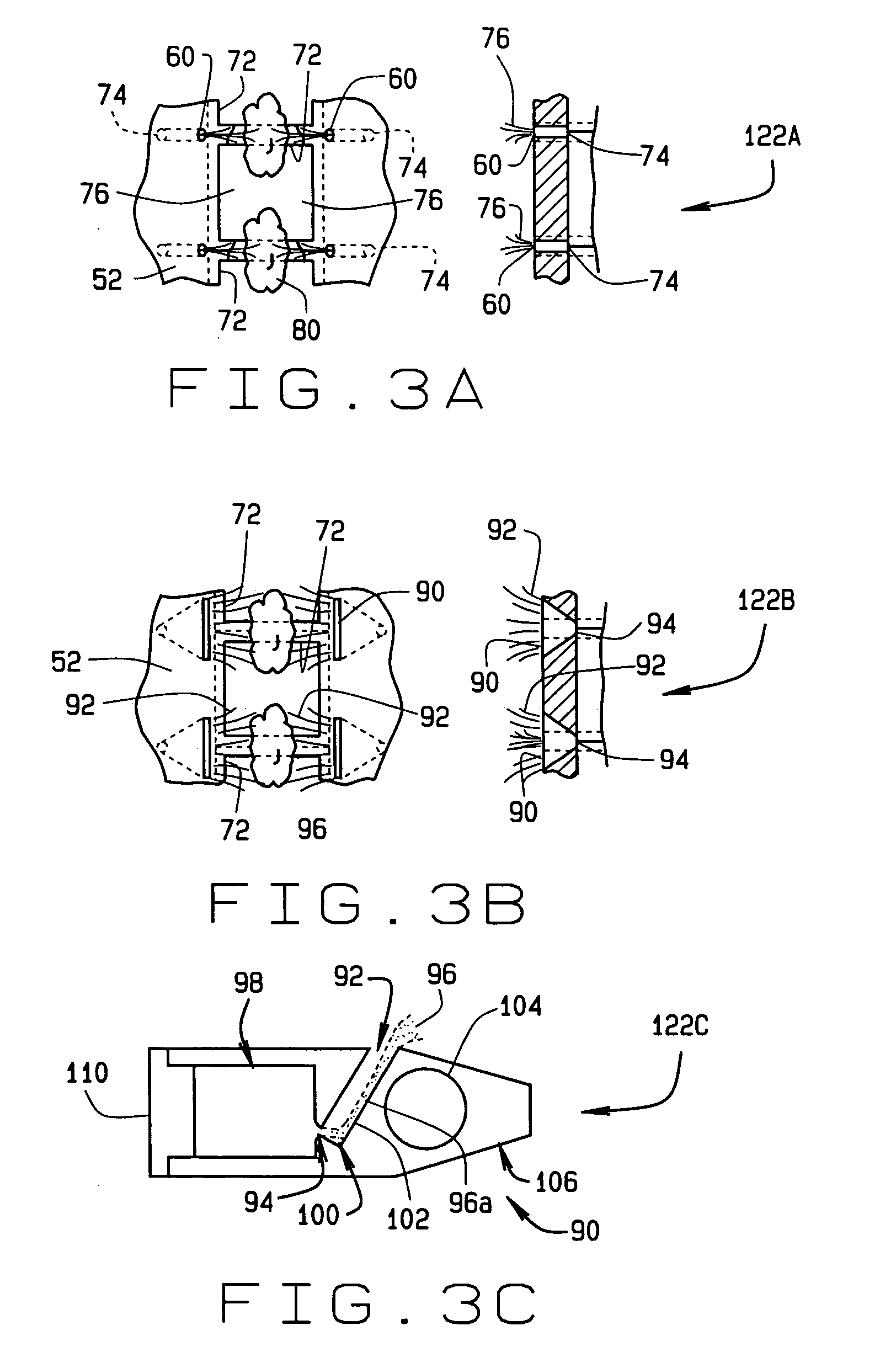

Non-swirl dry low NOx (DLN) combustor

ActiveUS7127899B2Reduce instabilityBurner safety arrangementsTurbine/propulsion fuel supply systemsCombustorGas turbines

Owner:THE BOEING CO +1

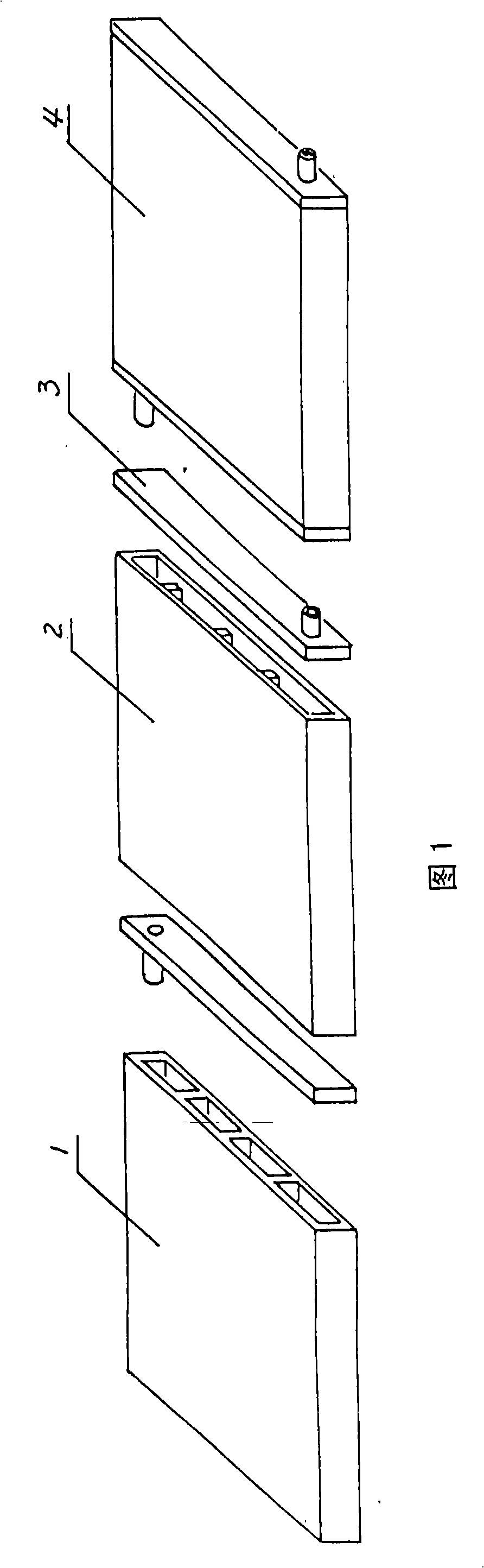

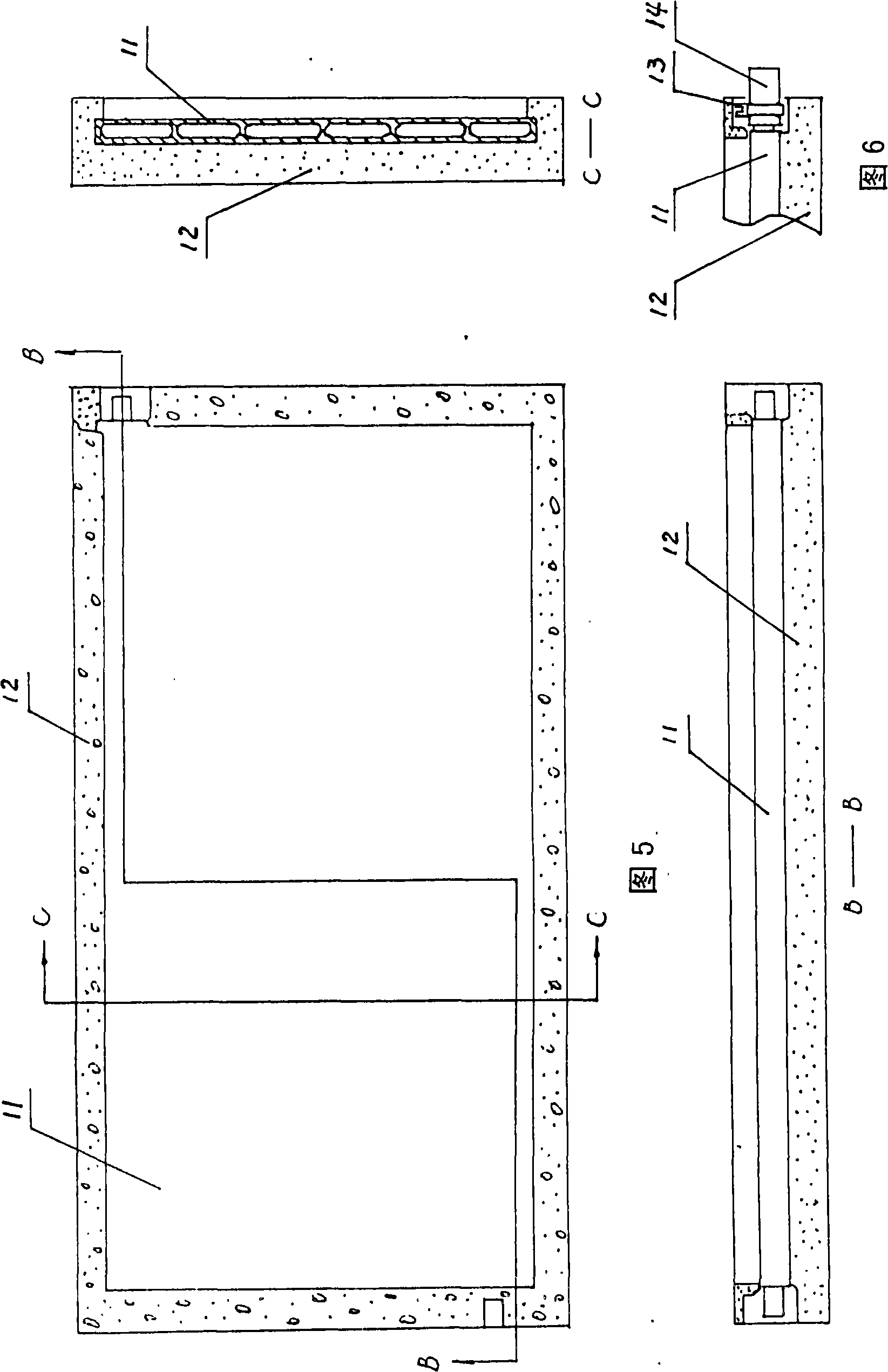

Method for preparing large size hollow ceramic plate and use products thereof

InactiveCN101311141AWide variety of sourcesLow costCeramic shaping apparatusLiquid fuel impingement burnersWhole bodySolar water

The invention relates to a production method for a big size hollow ceramic plate and a product thereof; common ceramic material and ceramic black substance that is rich in transition metals of fourth period such as natural minerals, industrial waste, and the like, and a extrusion molding method by a vacuum extruding machine are adopted to produce the big size hollow ceramic plate at low cost; the surface or the whole body of the big size hollow ceramic plate is black or dark, and the area of a single plate can be more than 0.5m<2>; a ceramic perforated plate, a ceramic through hole plate and an attachment of the big size hollow ceramic plate form a tandem of the big size hollow ceramic plate in the forms of glued joint and socket joint, or ceramic seal plates are connected in series to form the tandem of the big size hollow ceramic plate; the tandem of the big size hollow ceramic plate can be applied to a solar water heater for supplying hot water, to a solar roof and wall for providing refrigeration, warm air and hot water for the building, to a large-scale solar air course and a large-area solar heat collecting site for power generation, to far infrared drying for energy saving, to building radiator for realizing the purposes of saving energy, reducing indoor dust blowing and promoting health.

Owner:曹树梁

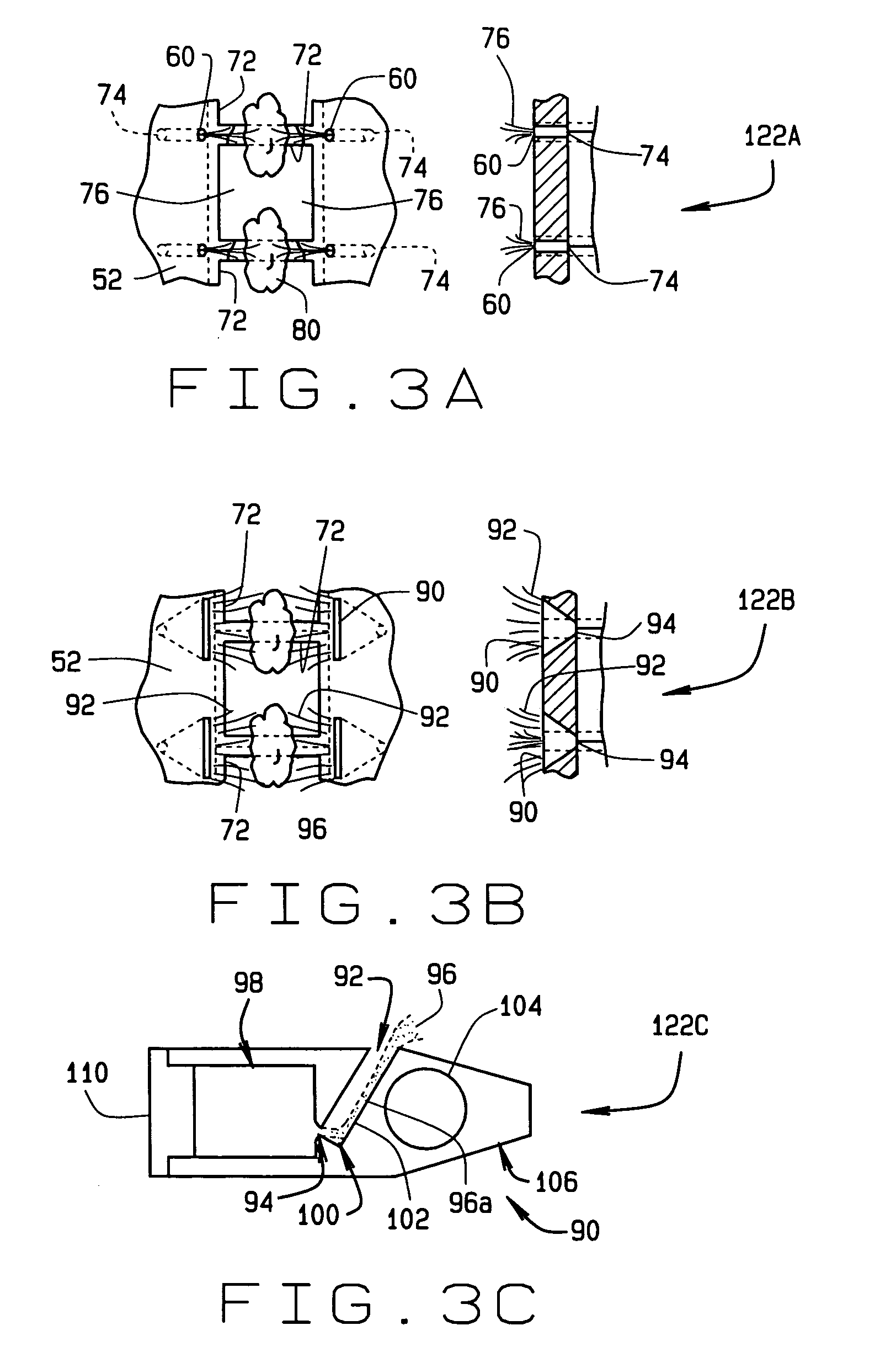

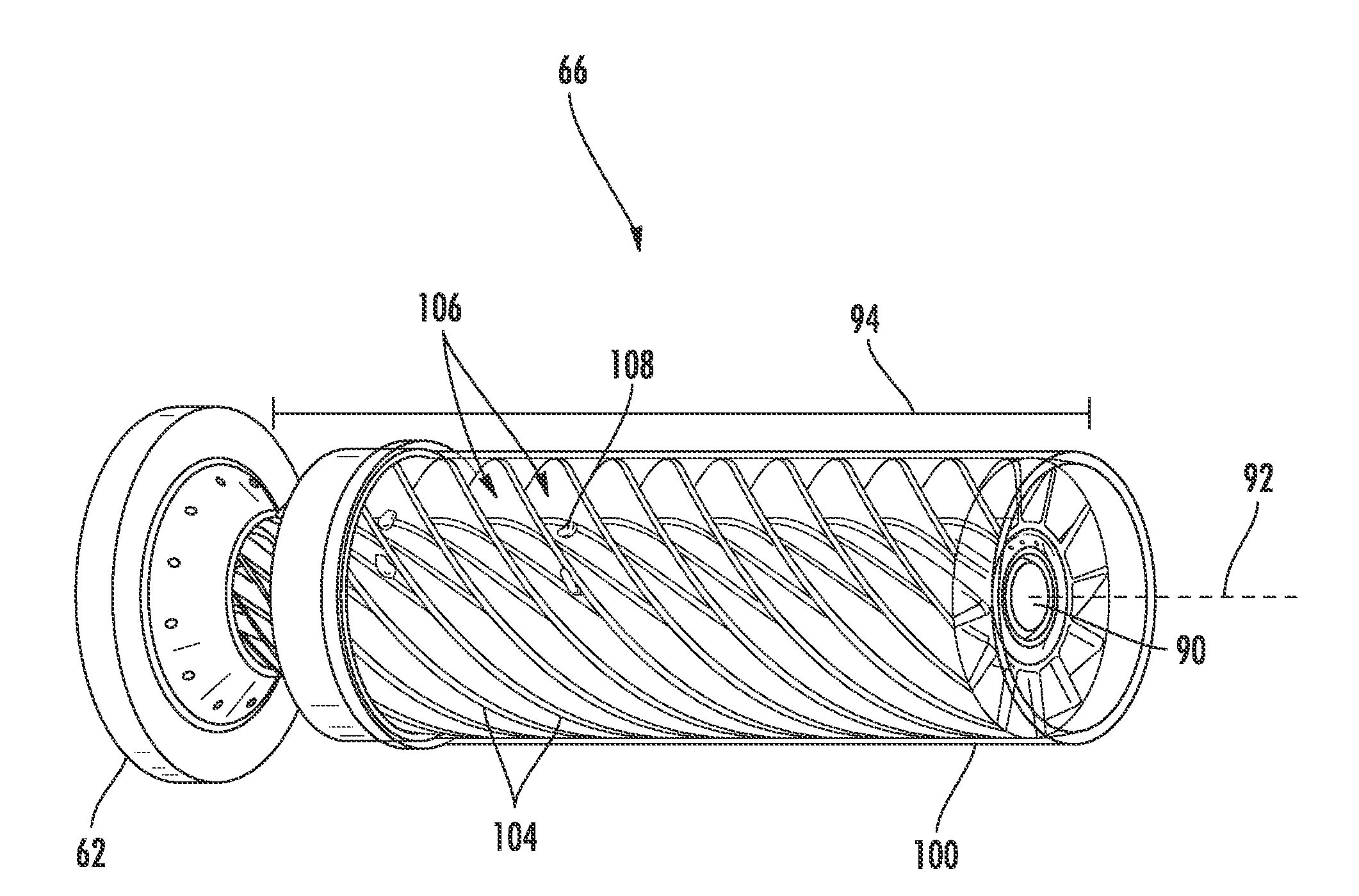

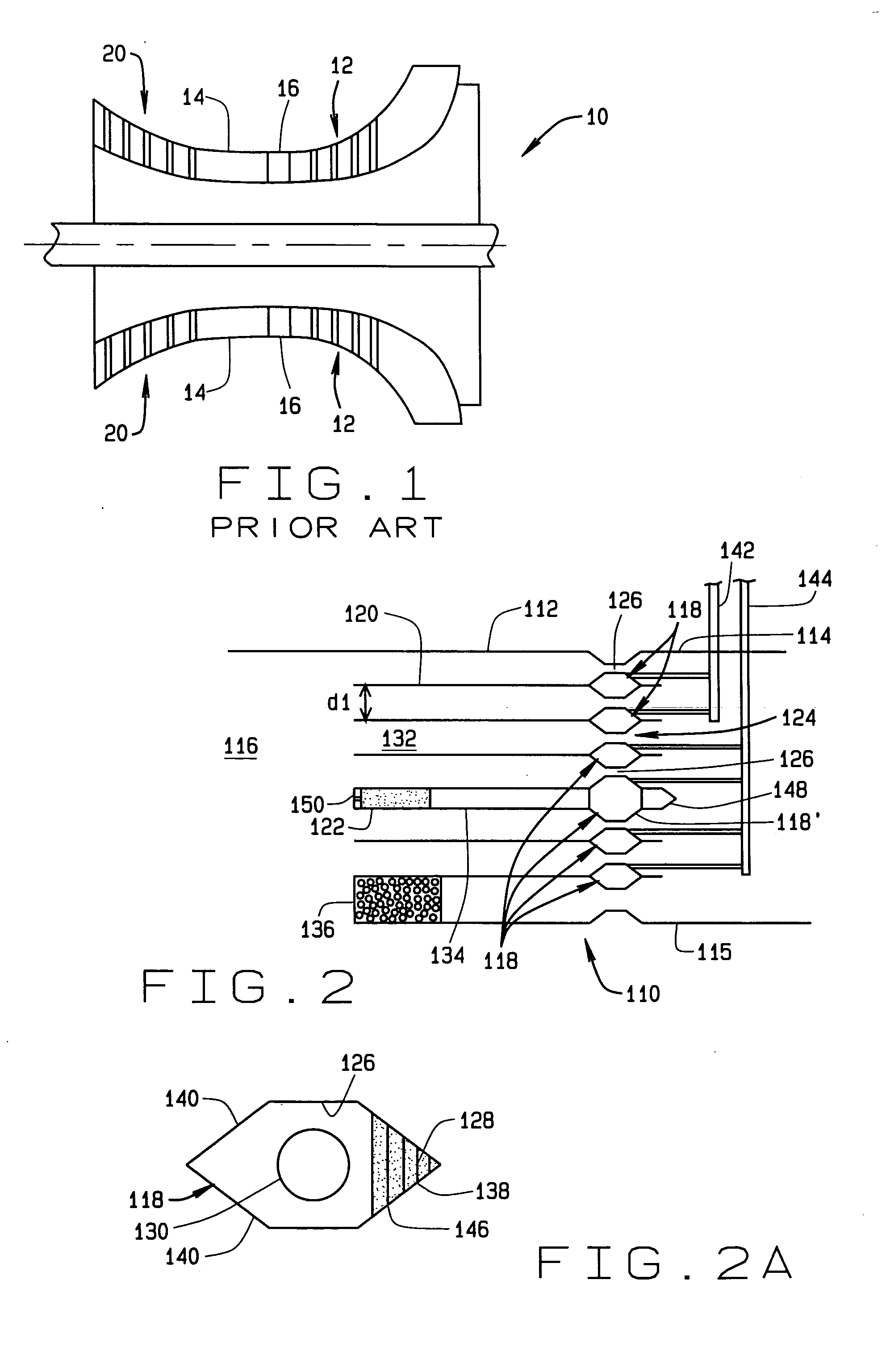

Fuel nozzle for reducing modal coupling of combustion dynamics

A fuel nozzle includes a center body that extends axially along an axial centerline for a length. A shroud circumferentially surrounds the center body for at least a portion of the length of the center body. A plurality of helical passages circumferentially surround the center body along at least a portion of the length of the center body, and a fuel port in each helical passage has a different convective time.

Owner:GENERAL ELECTRIC CO

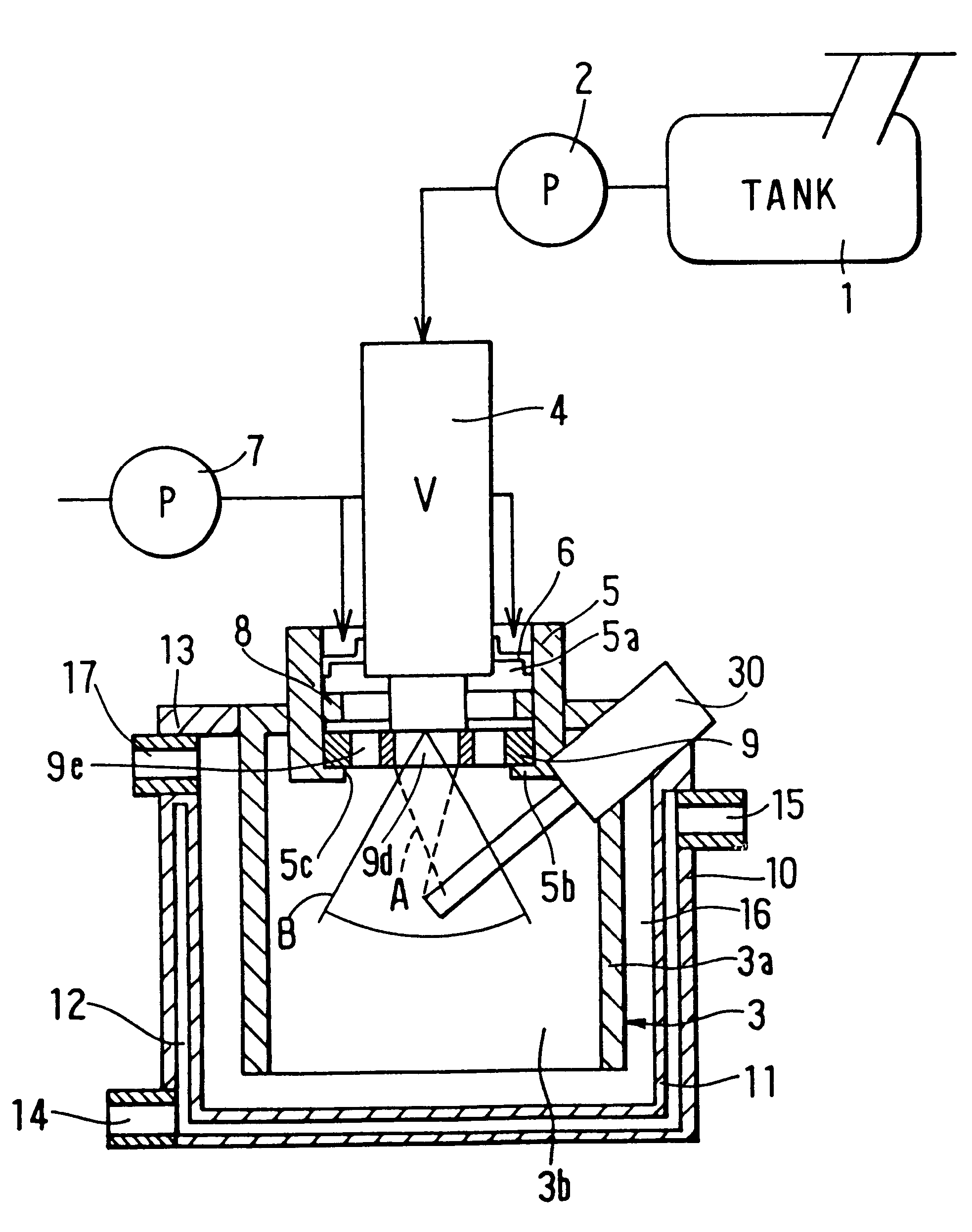

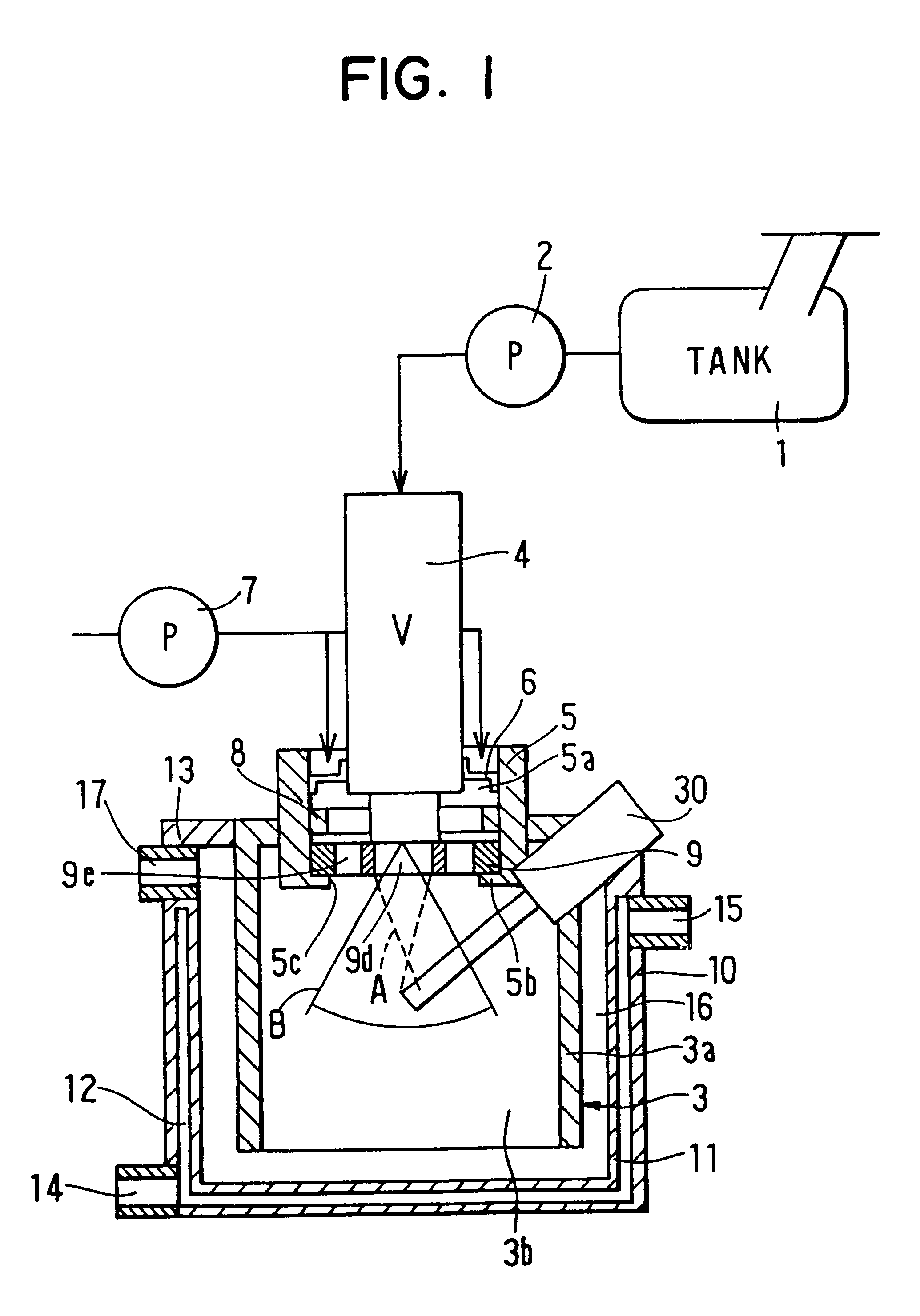

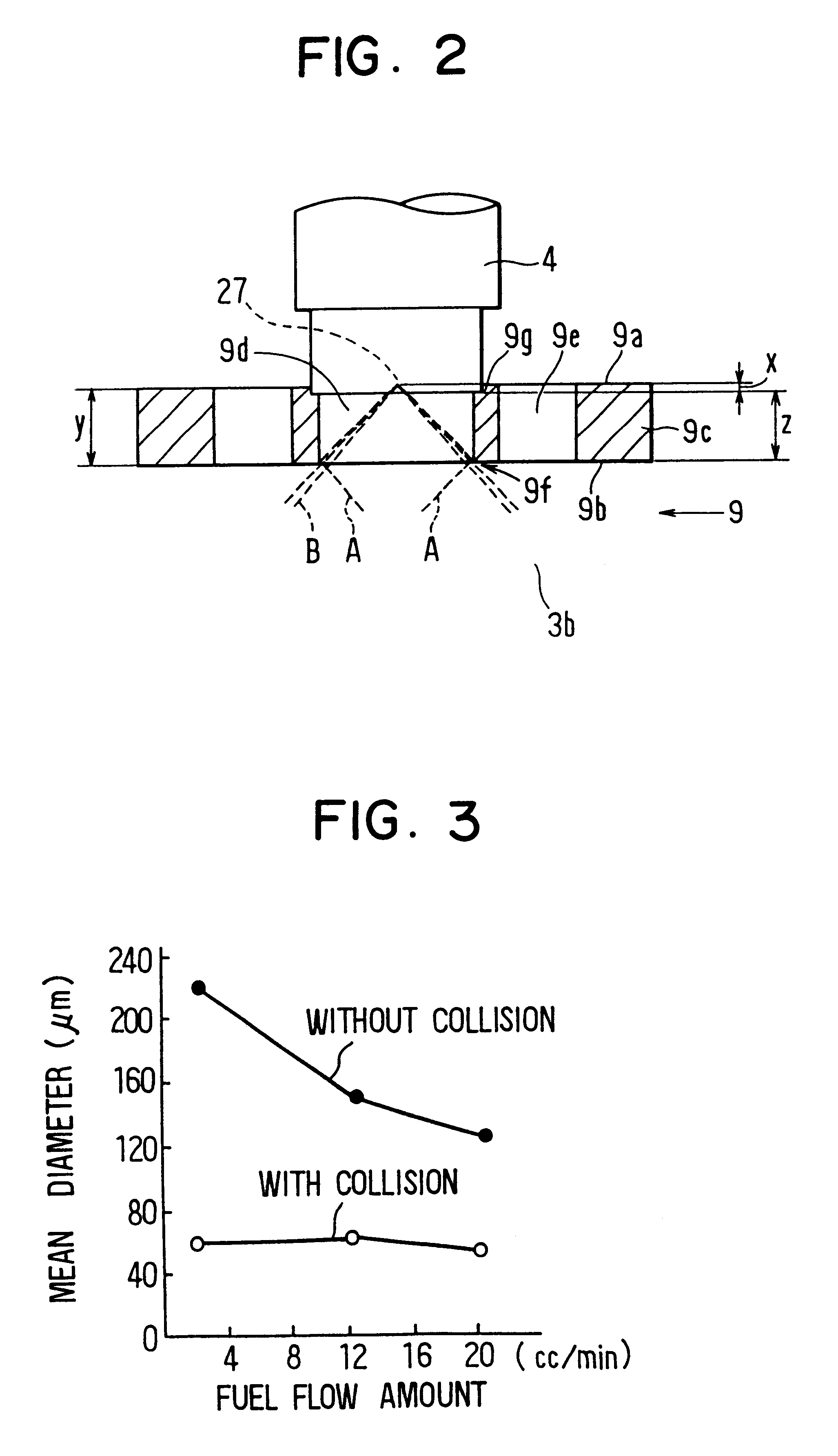

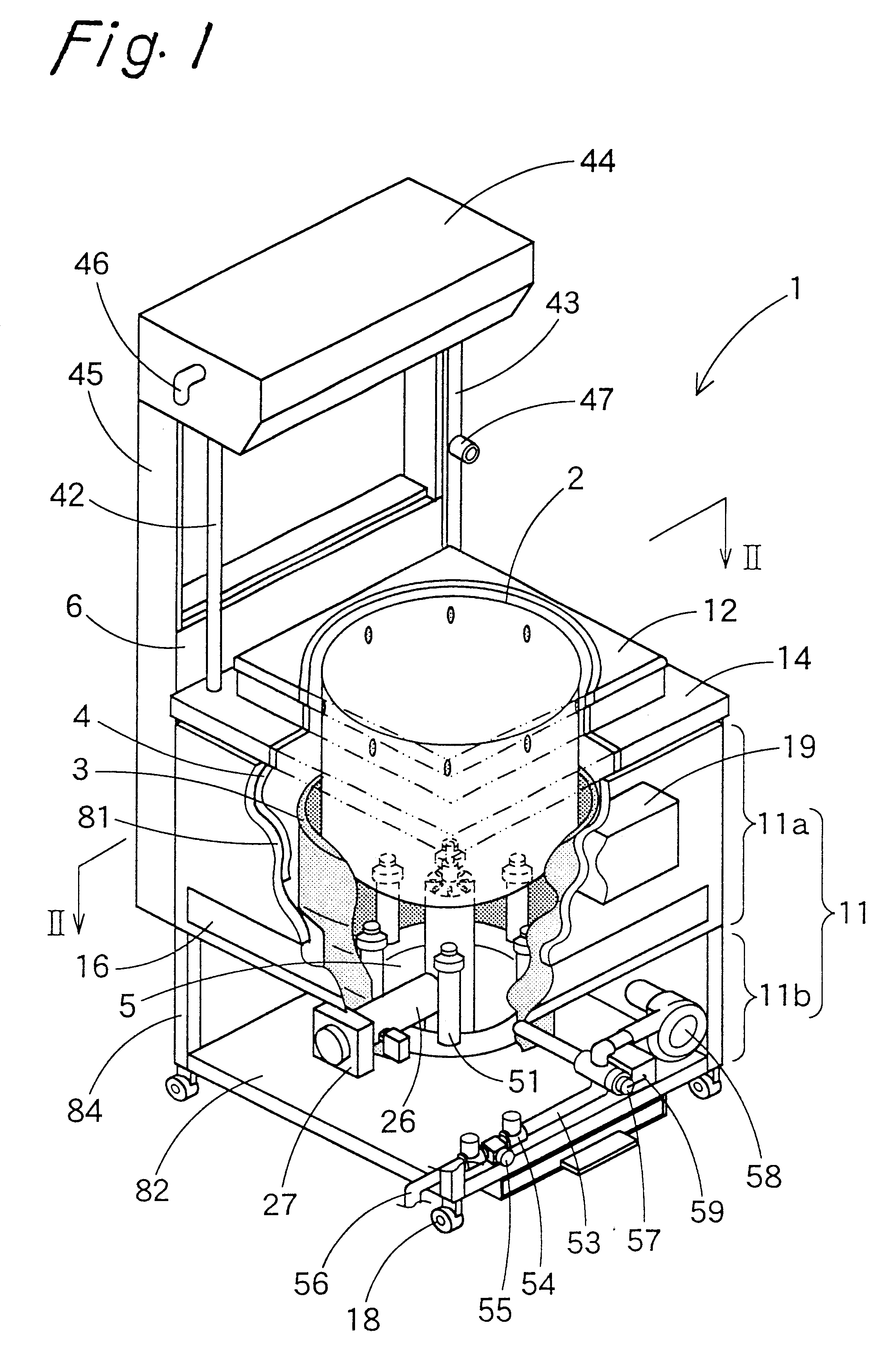

Combustion device

InactiveUS6402505B1Mixing performanceImprove performancePulsating combustionSpecial fuel supply arrangementsCombustion chamberFuel injection

In a combustion unit, a fuel collision member is disposed between a fuel injection valve and a combustion chamber. The fuel collision member is positioned so that, a part of fuel injected from said fuel injection valve is introduced into the combustion chamber while colliding with the fuel collision member, and the other part of fuel is directly introduced into the combustion chamber without colliding with the fuel collision member. Thus, fuel introduced into the combustion chamber is atomized while being introduced into the combustion chamber in a wide range.

Owner:DENSO CORP

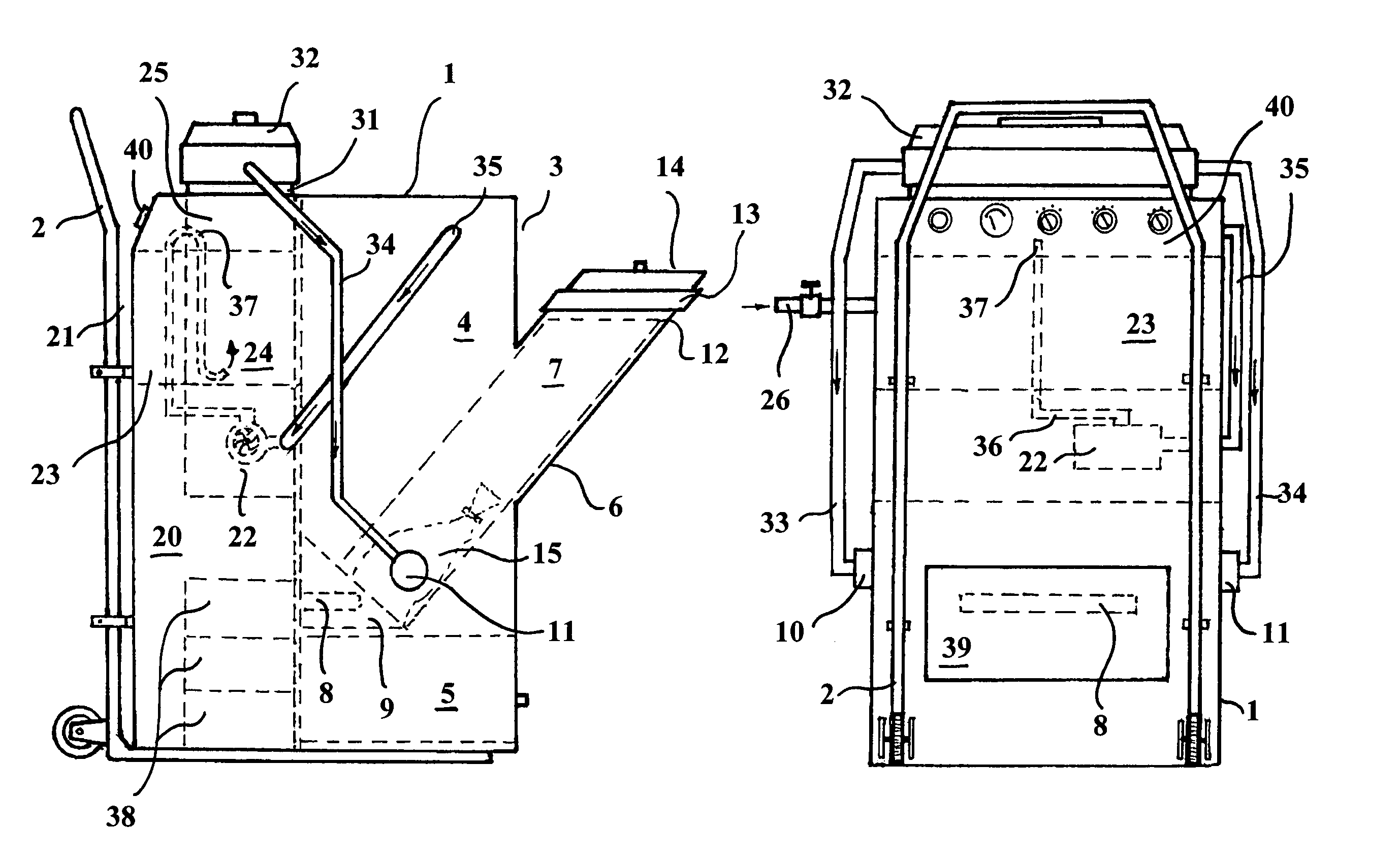

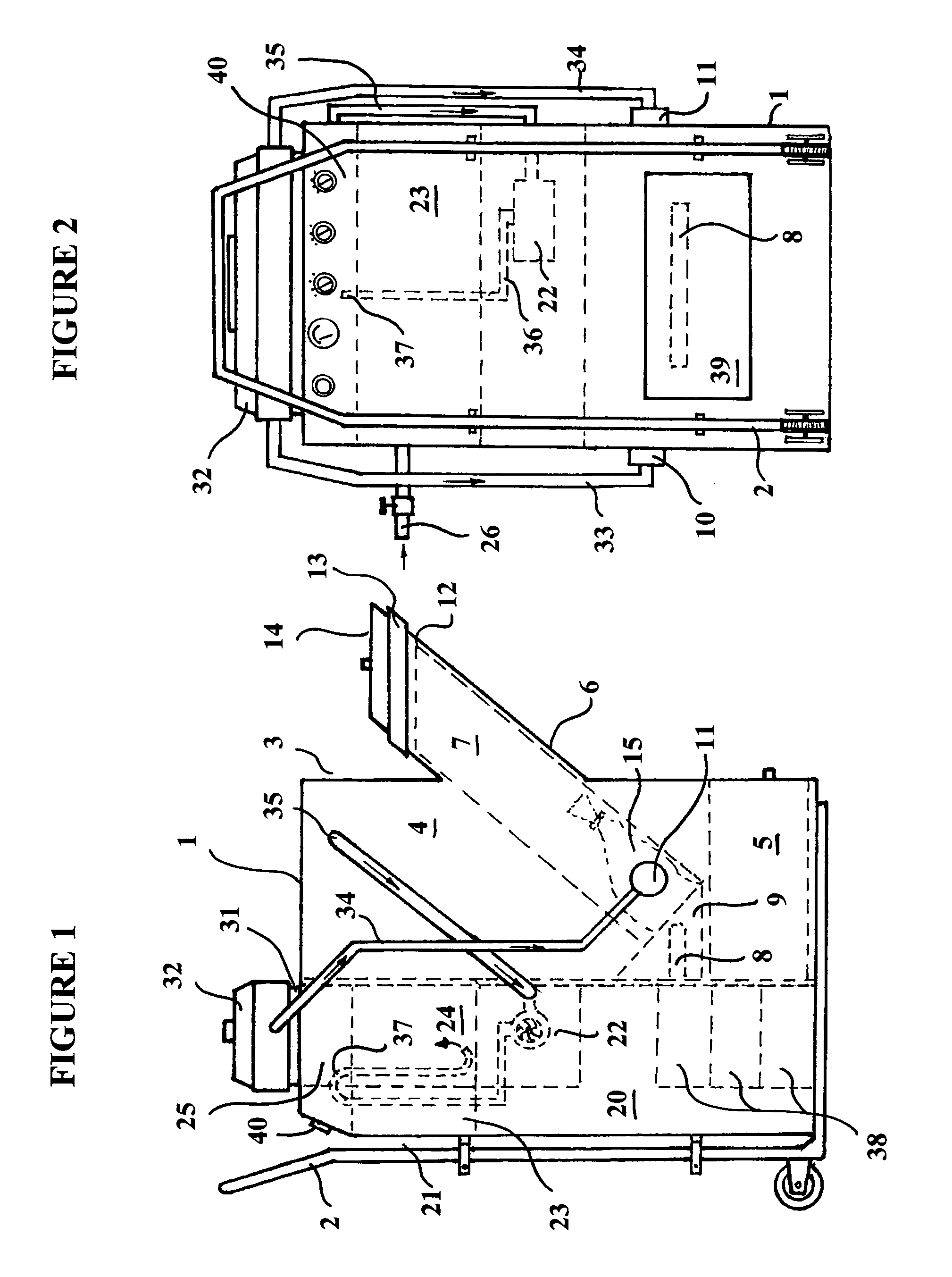

Miniature garbage incinerator and method for incineration

InactiveUS6945180B1Optimize locationEasy to useCapillary burnersLiquid fuel impingement burnersSpontaneous combustionFiltration

A portable miniature incinerator is described allowing easy disposal of household garbage for a single-family house or a small apartment building. The housing of the incinerator is mounted on a wheeled hand-truck assembly and contains an incineration block and a filtration block. The incineration block in turn comprises a furnace chamber equipped with an electric heater. The heater is adapted to bring the temperature of the air and therefore the temperature of the garbage up to the point of spontaneous combustion. During the process of heating up the garbage, it becomes dry as the fans of the device remove all water evaporation. Once ignited, the garbage is incinerated in the furnace chamber while all exhaust gases are directed to the filtration unit. The filtration unit has a first stage of filtration comprising a wire mesh separator submerged in water. Exhaust gases pass through the mesh separator and through the water so that the pollutants and exhaust particles are separated from the exhaust gases. Following that first filtration stage, the exhaust gases are sent toward the second cleaning stage, this stage being a fabric-filled gas filter, for complete separation of all impurities. The gases are then directed back towards the furnace chamber to re-circulate the flow of hot gases and save energy. That process continues until the incineration is complete.

Owner:KHYMYCH VASYL

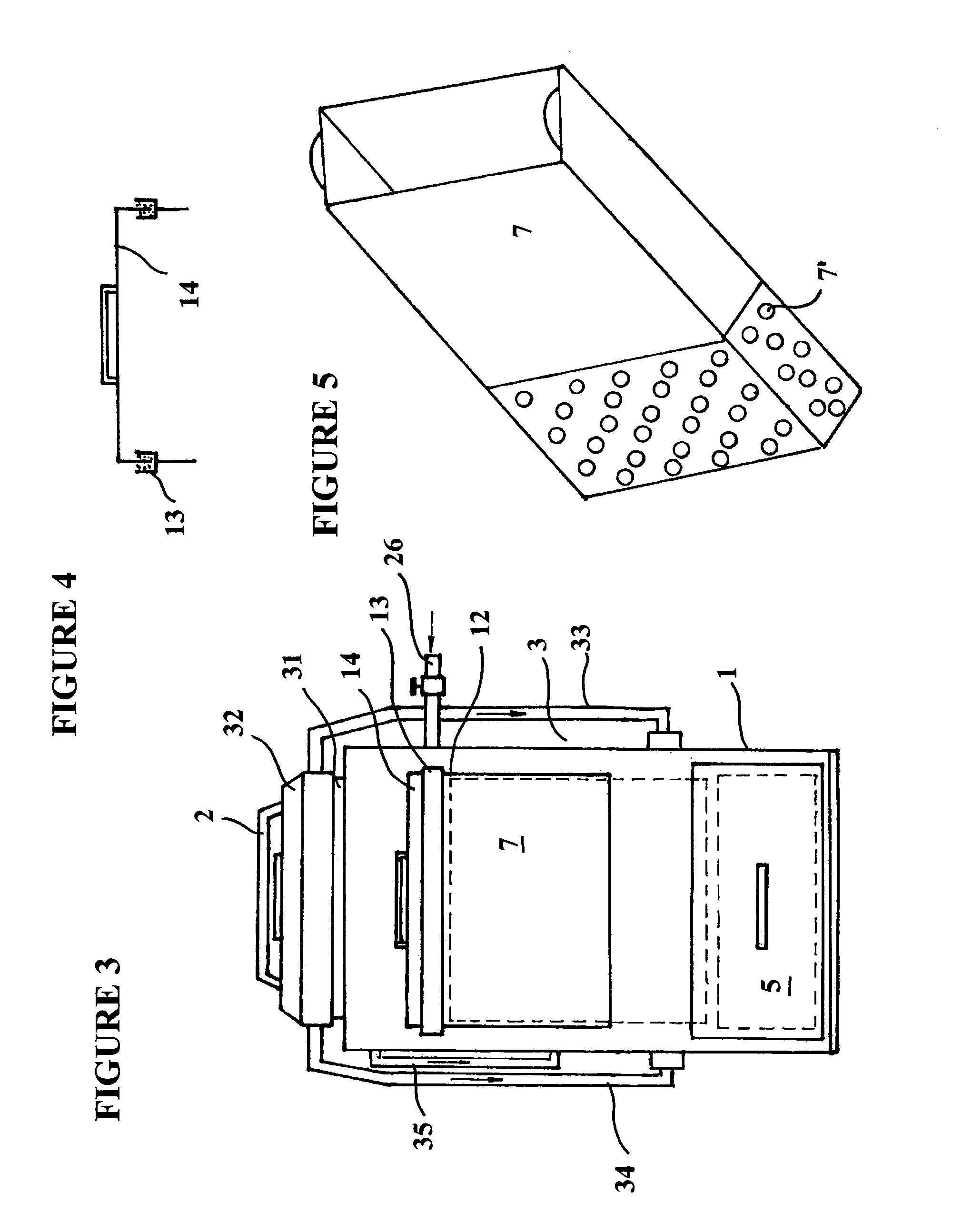

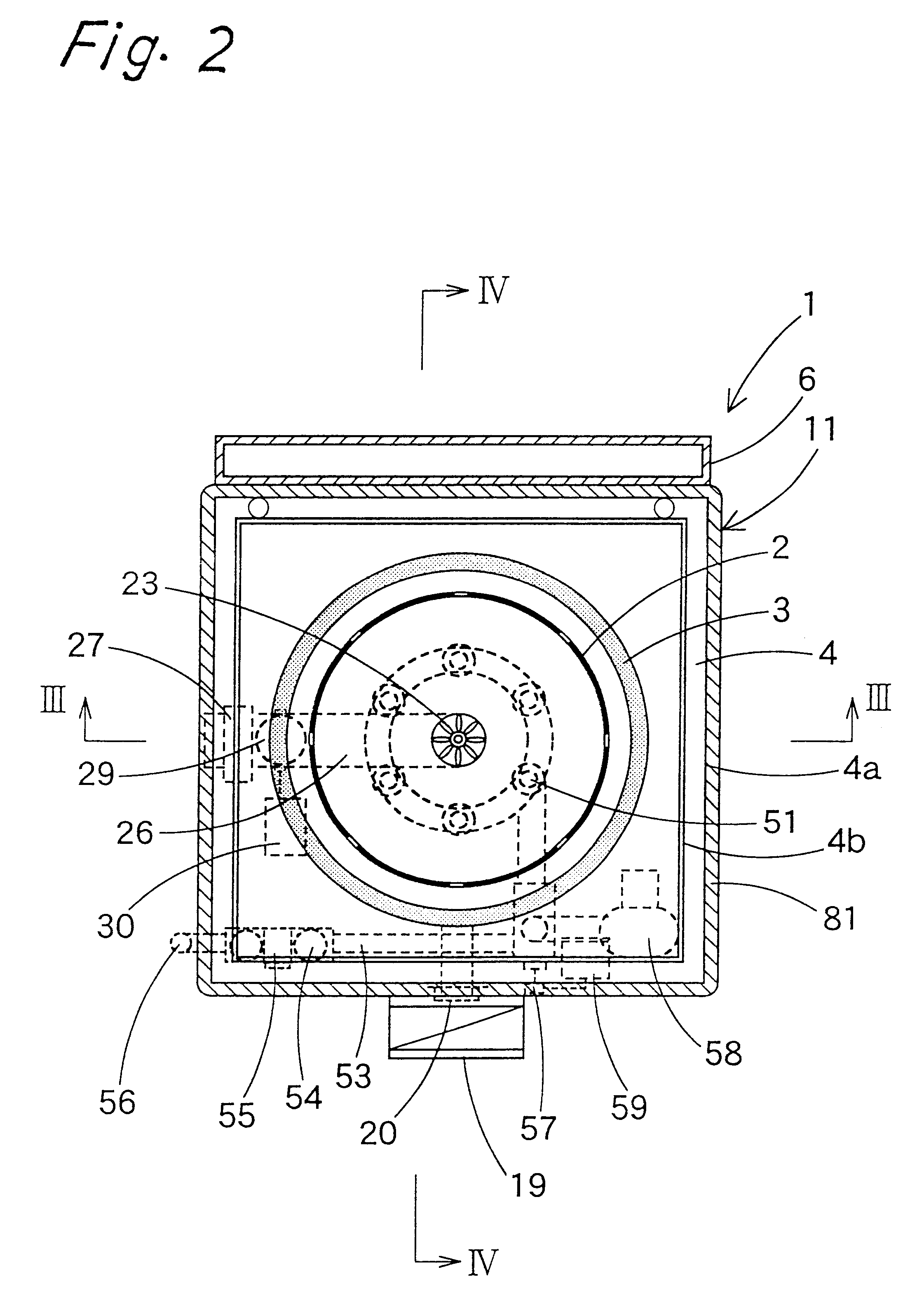

Waste incineration machine

InactiveUS6325000B1Reduce the temperatureAvoid high ambient temperatureCapillary burnersHand ironCombustion chamberPlate heat exchanger

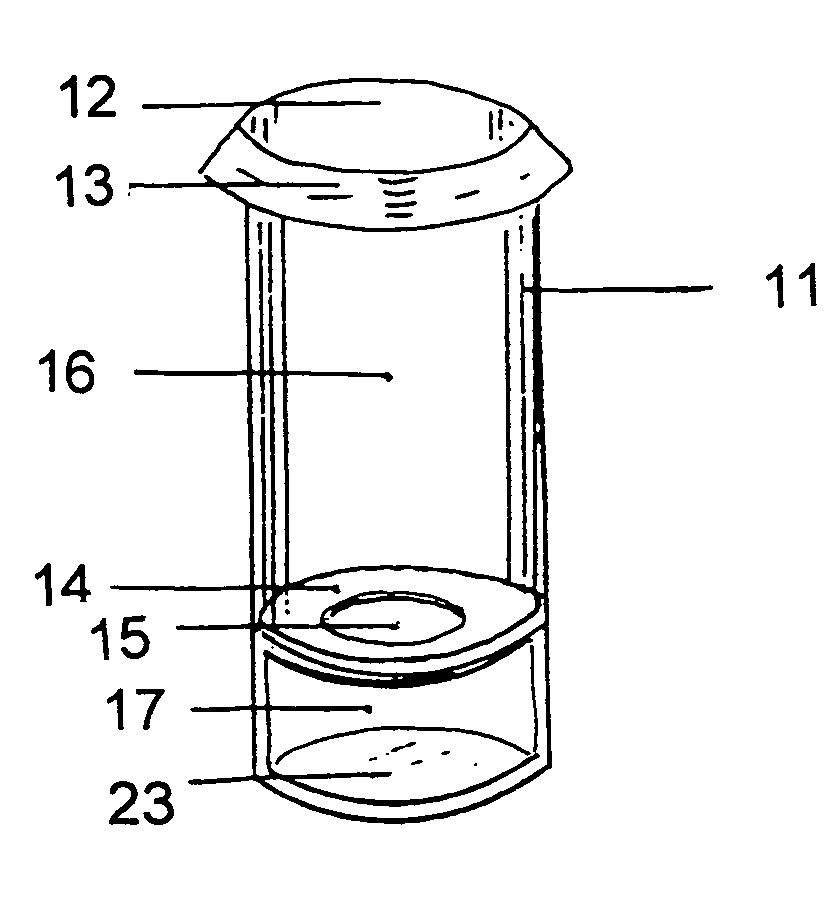

A waste incineration machine capable of rendering a waste gas occurring during the combustion of waste smokeless and odorless. A heat insulating wall to which a first far infrared ray radiator is fixed is provided so as to surround a combustion furnace and a combustion chamber, and a heat exchanger so as to surround the heat insulating wall. An inner flue is formed between the heat insulating wall and combustion furnace, and an outer flue serving as a waste gas convection chamber between the heat insulating wall and heat exchanger. An upper part of a communication portion between the inner and outer flues is covered with a heat insulating member constituting a second far infrared ray radiator so as to subject the waste gas to secondary heating using far infrared rays, and thereby to render the waste gas smokeless and odorless. Preferably, the heat insulating wall is formed into a substantially cylindrical shape, and the heat exchanger into a rectangular box-shape open at the top and the bottom, whereby the volume of the outer flue is increased to thereby lengthen the time for circulating the waste gas by convection.

Owner:MEITO

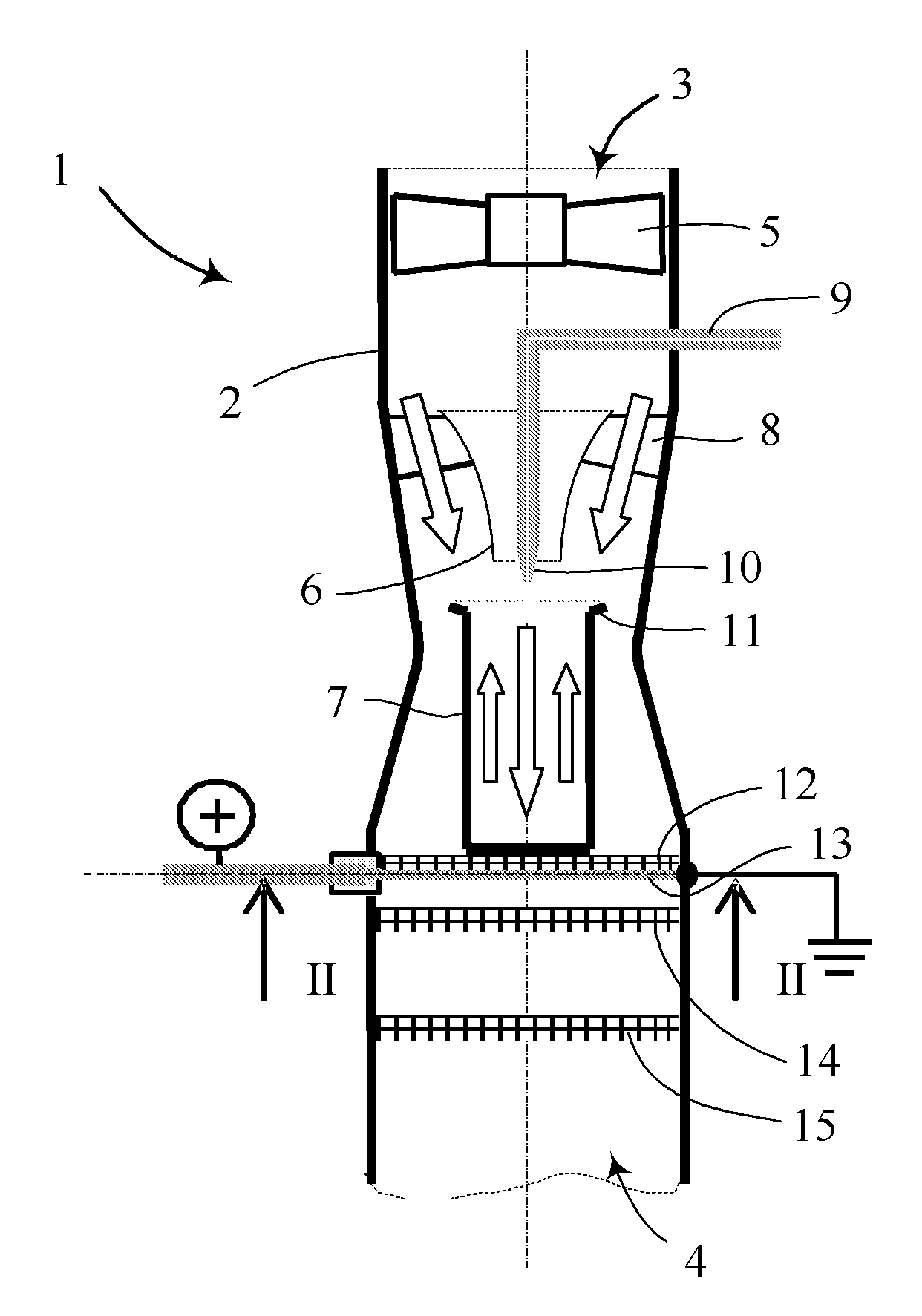

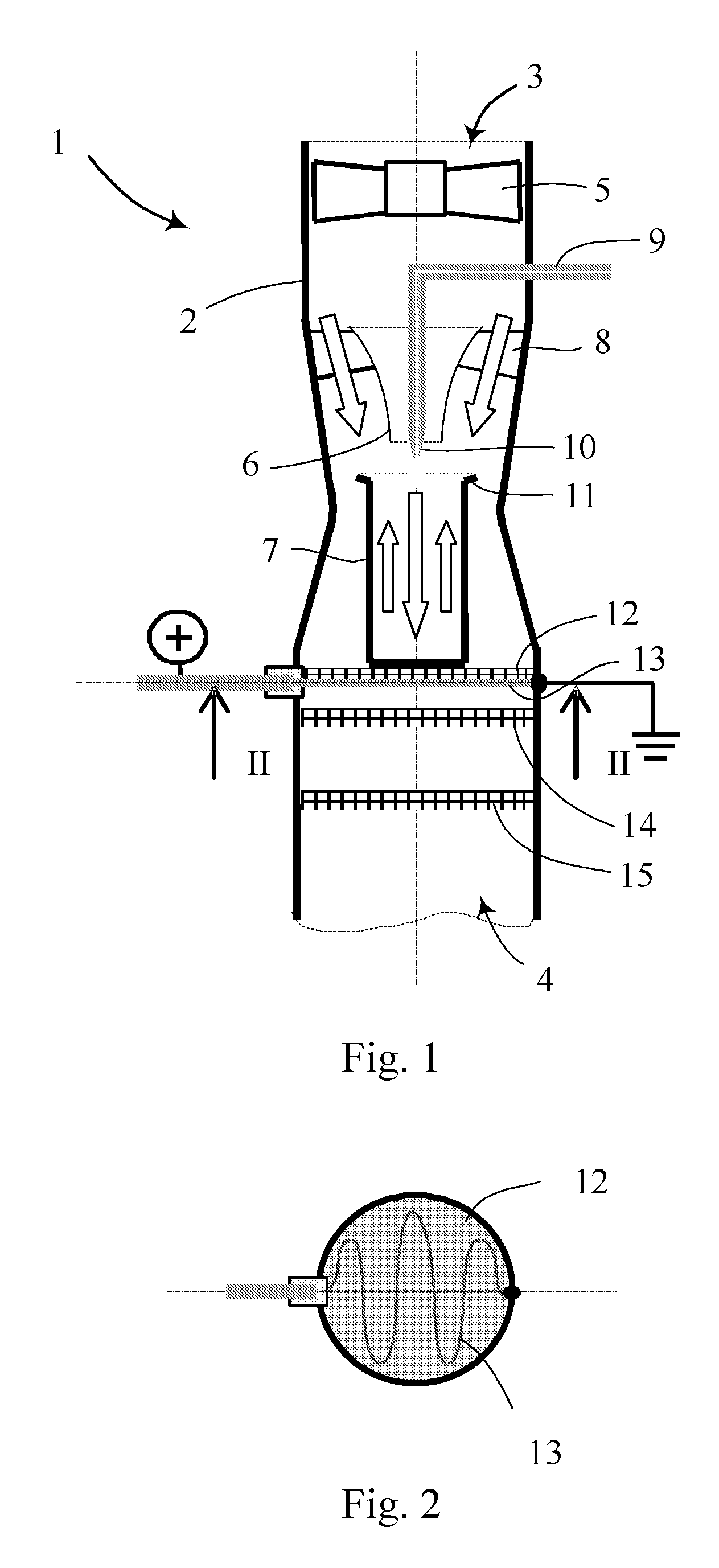

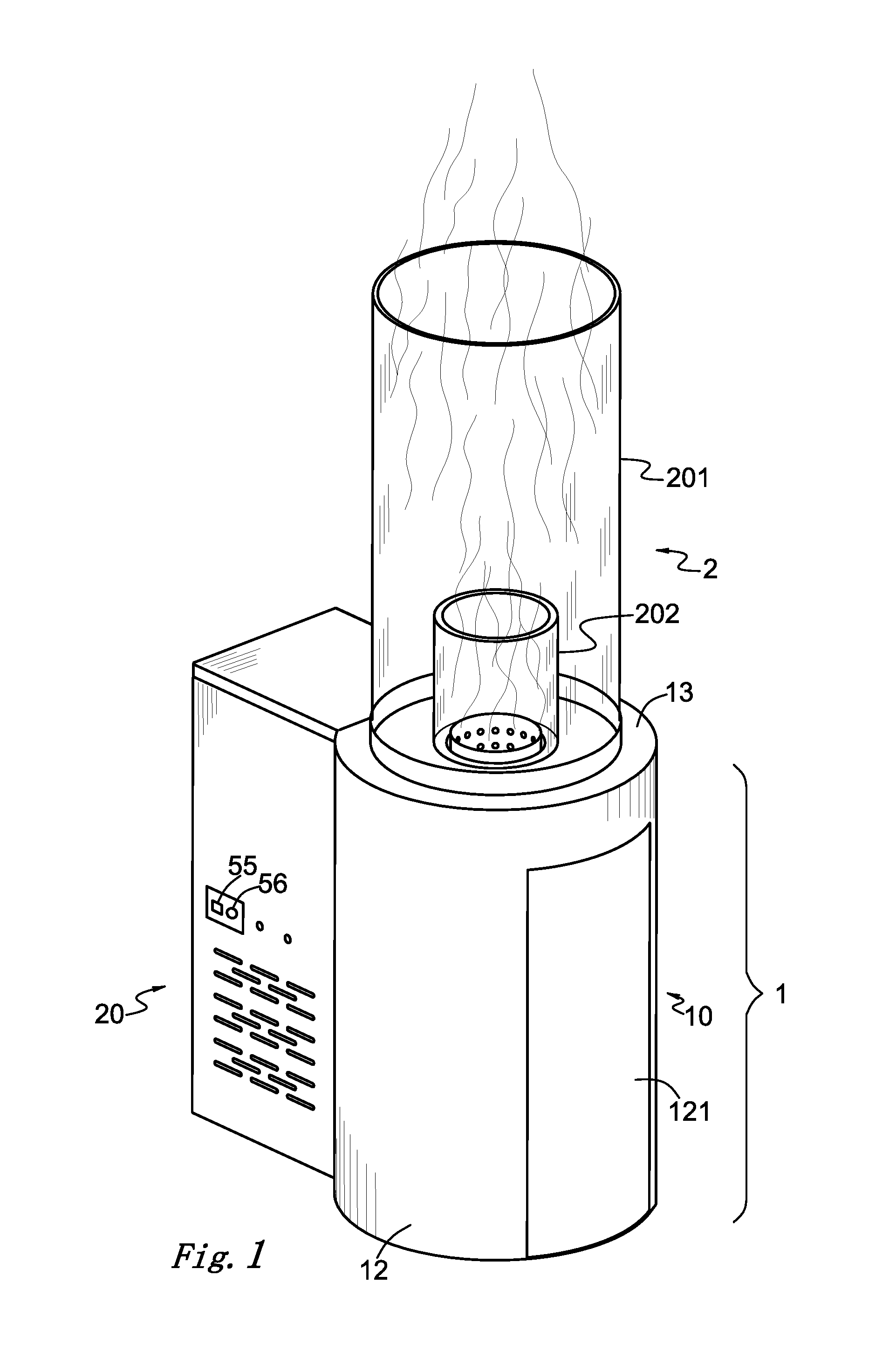

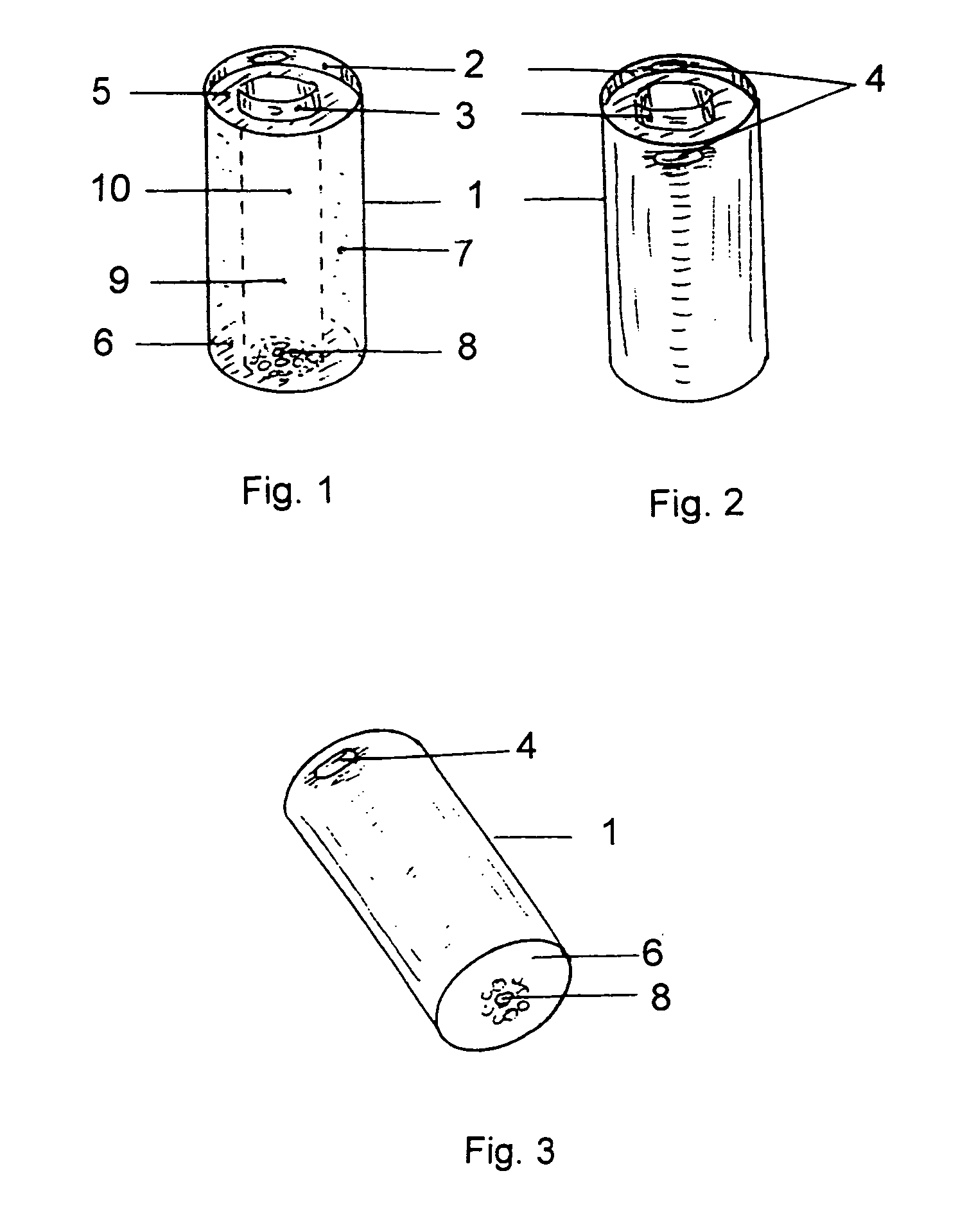

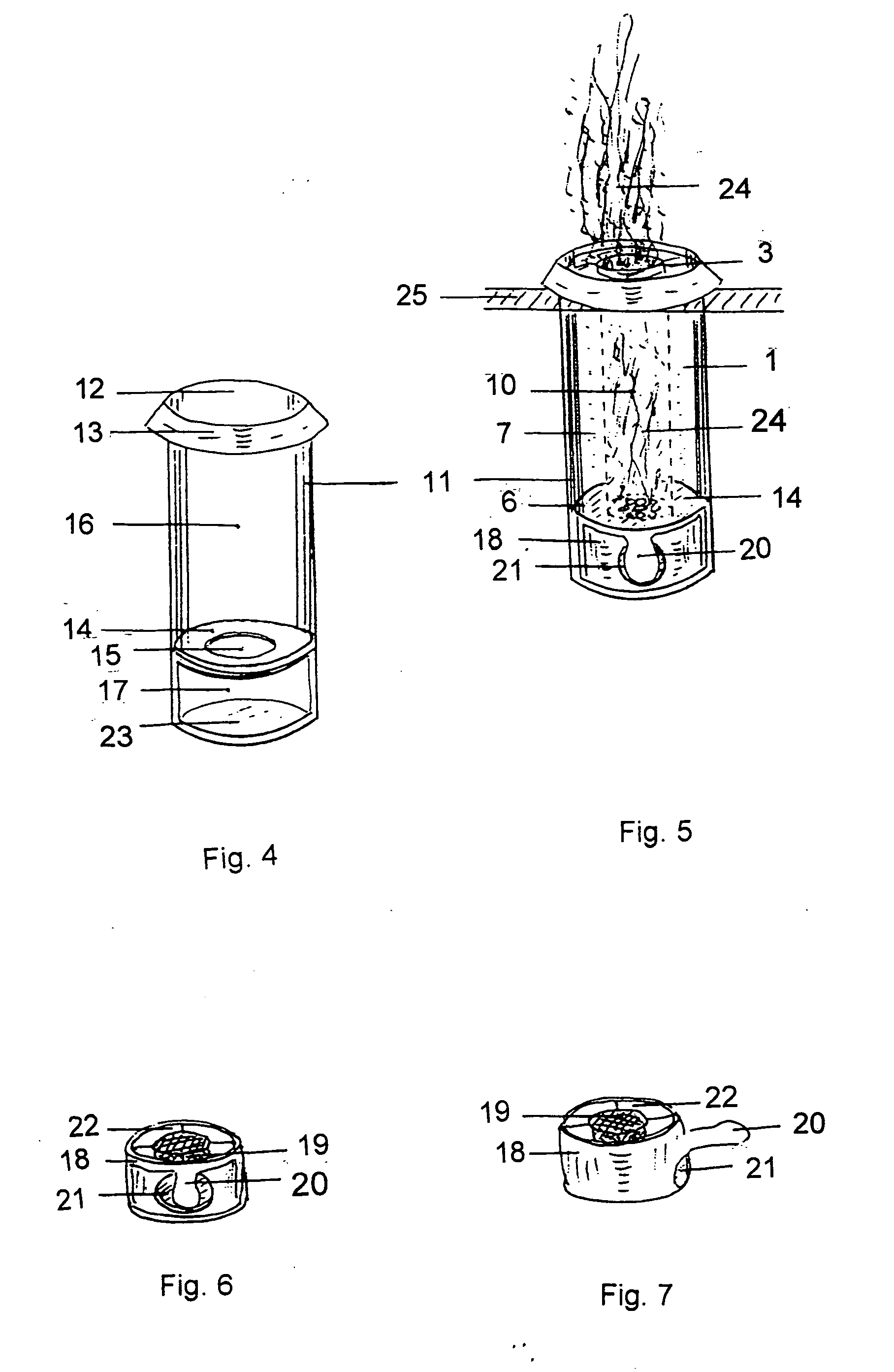

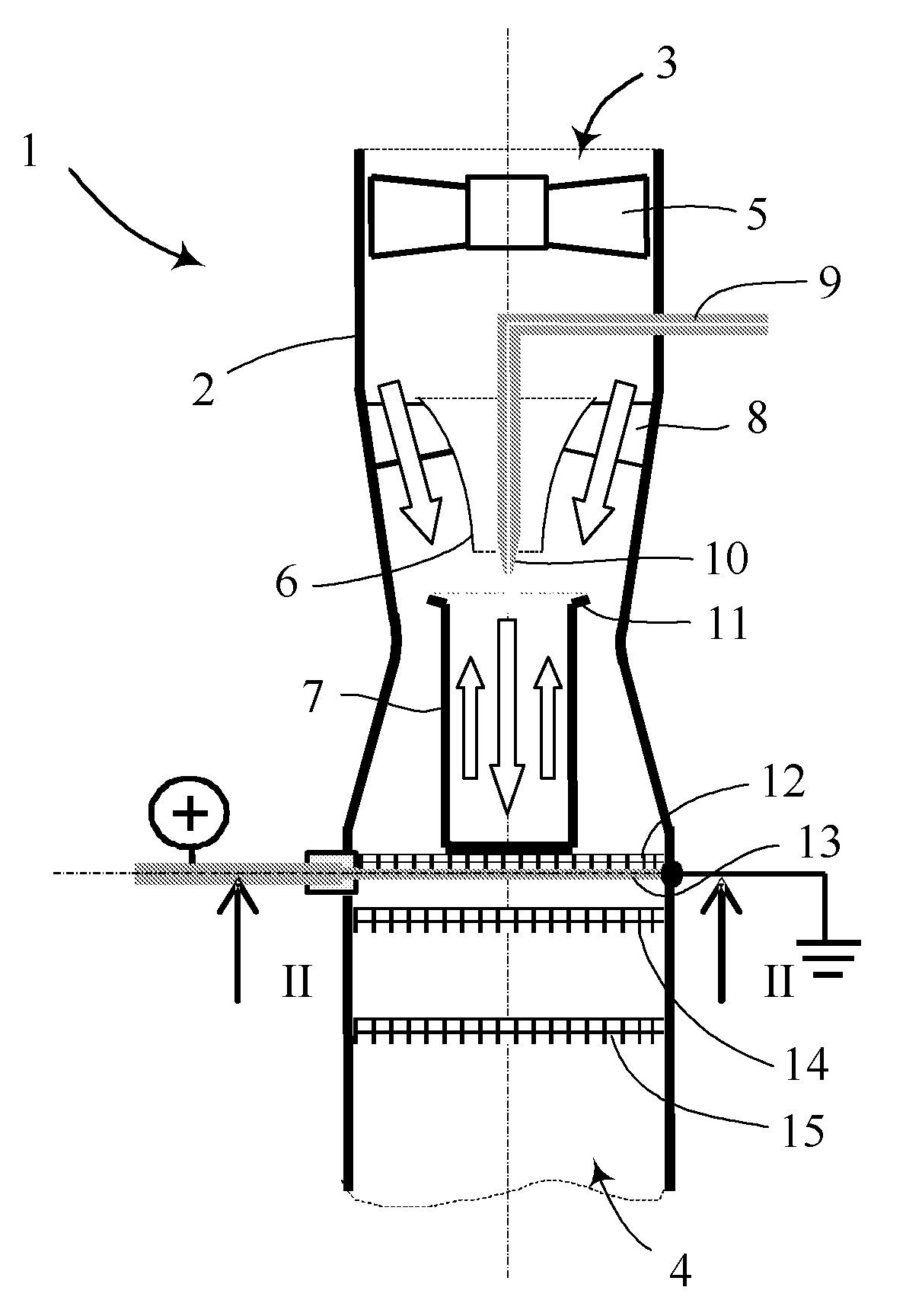

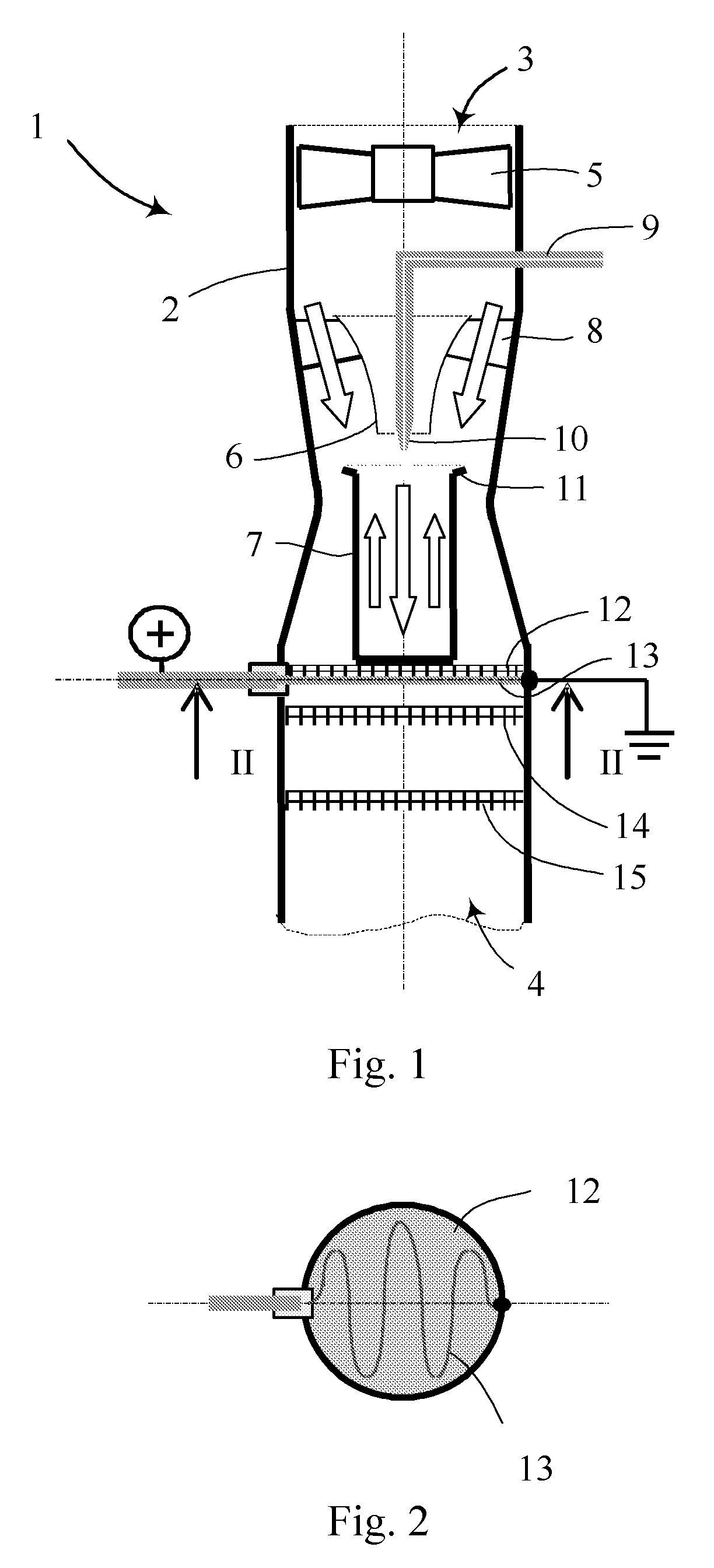

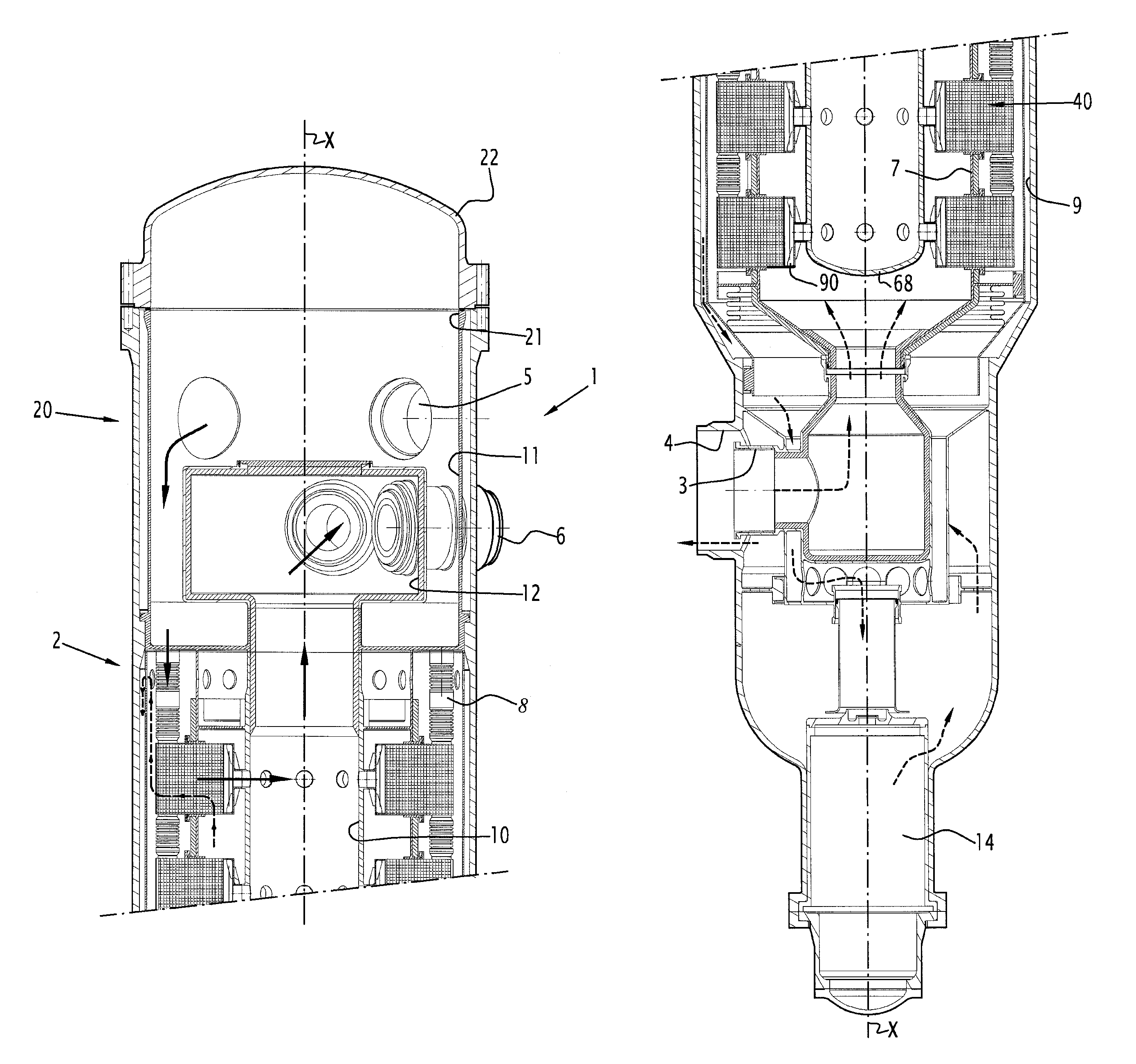

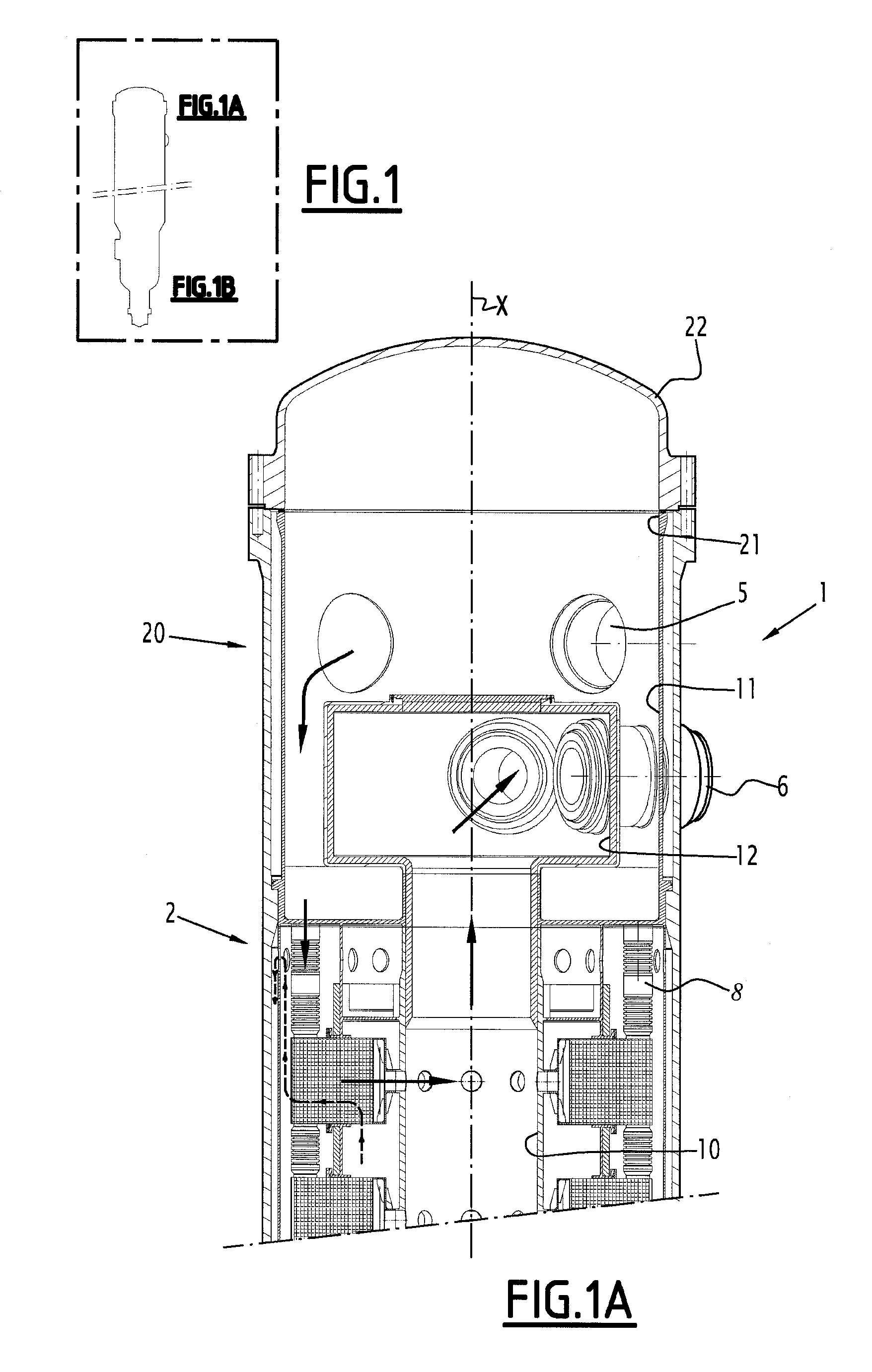

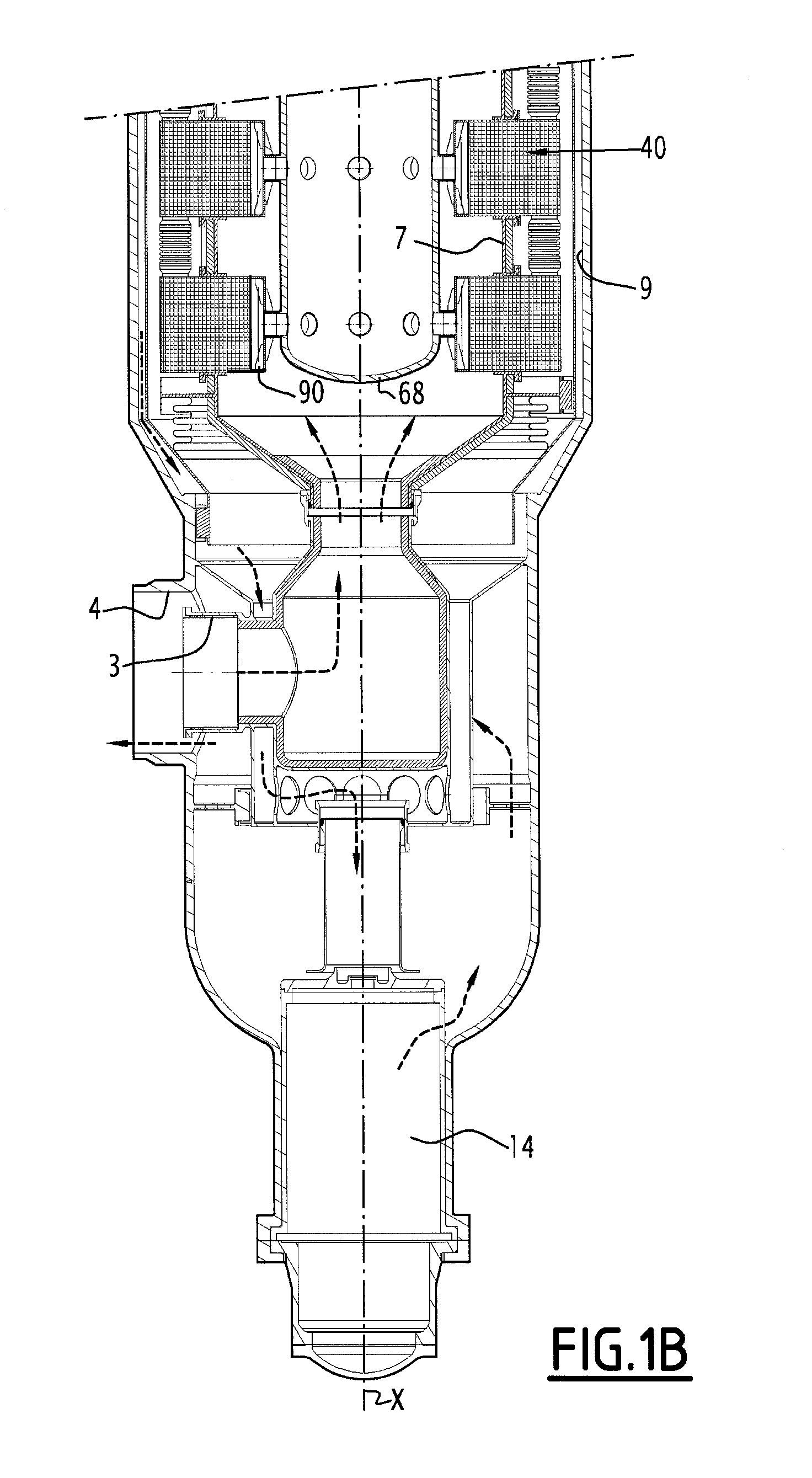

Catalytic Combustor And Method Thereof

A catalytic combustor (1) is provided for combustion of gaseous and liquid fuels, which combustor comprises a housing (2) having an inlet (3) and an outlet (4) through which an airflow is directed, and a fuel injector (10) for injecting fuel in the airflow. The combustor also comprises at least one catalytic element (12, 14, 15) for combusting the mixture of air and fuel. A fuel-evaporating device (7) is arranged for evaporating a liquid fuel, which device is heated by the catalytic element (12), either through combustion therein or by means of an electrical heating element (13) arranged adjacent thereto.

Owner:ZEMISSION

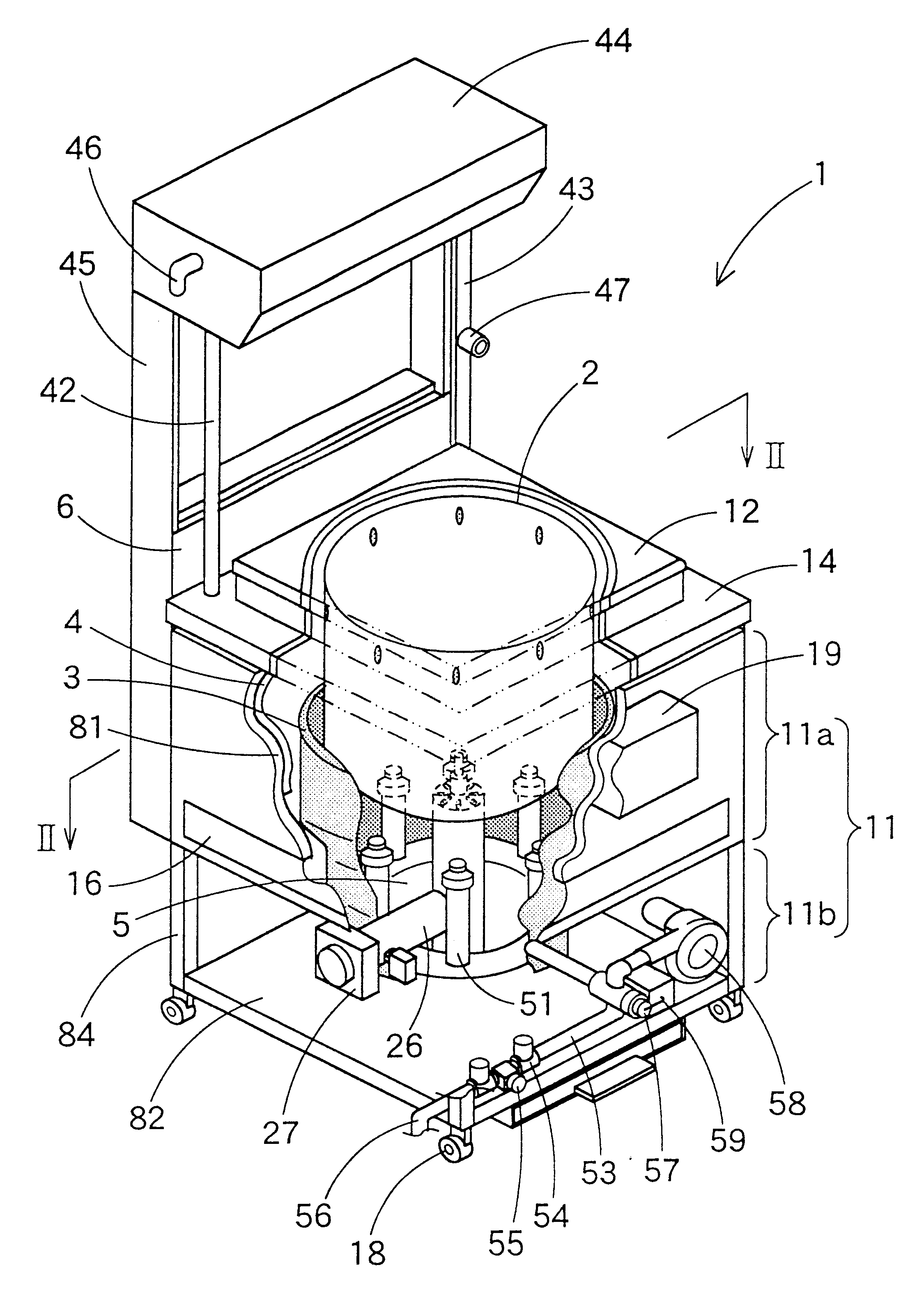

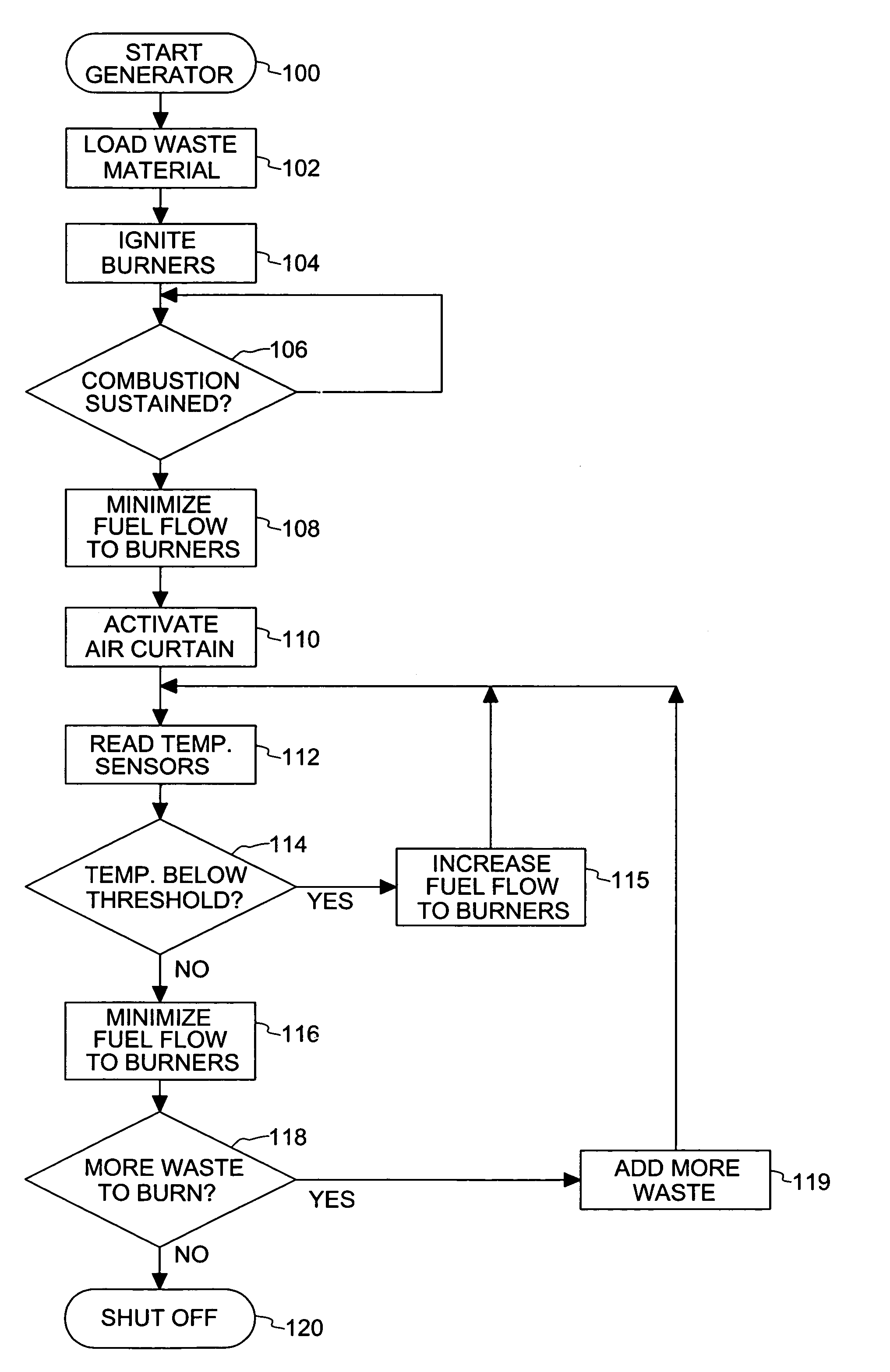

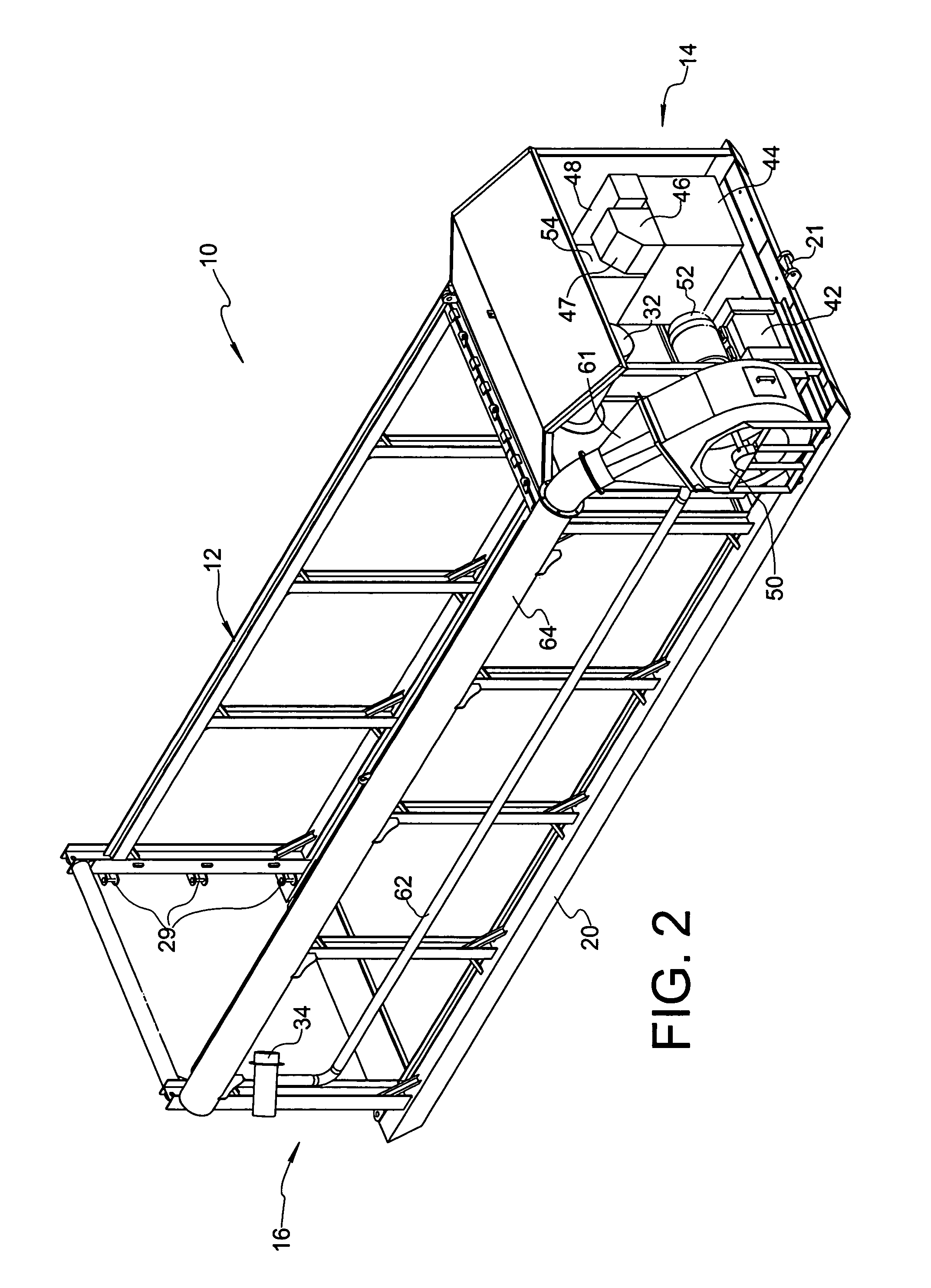

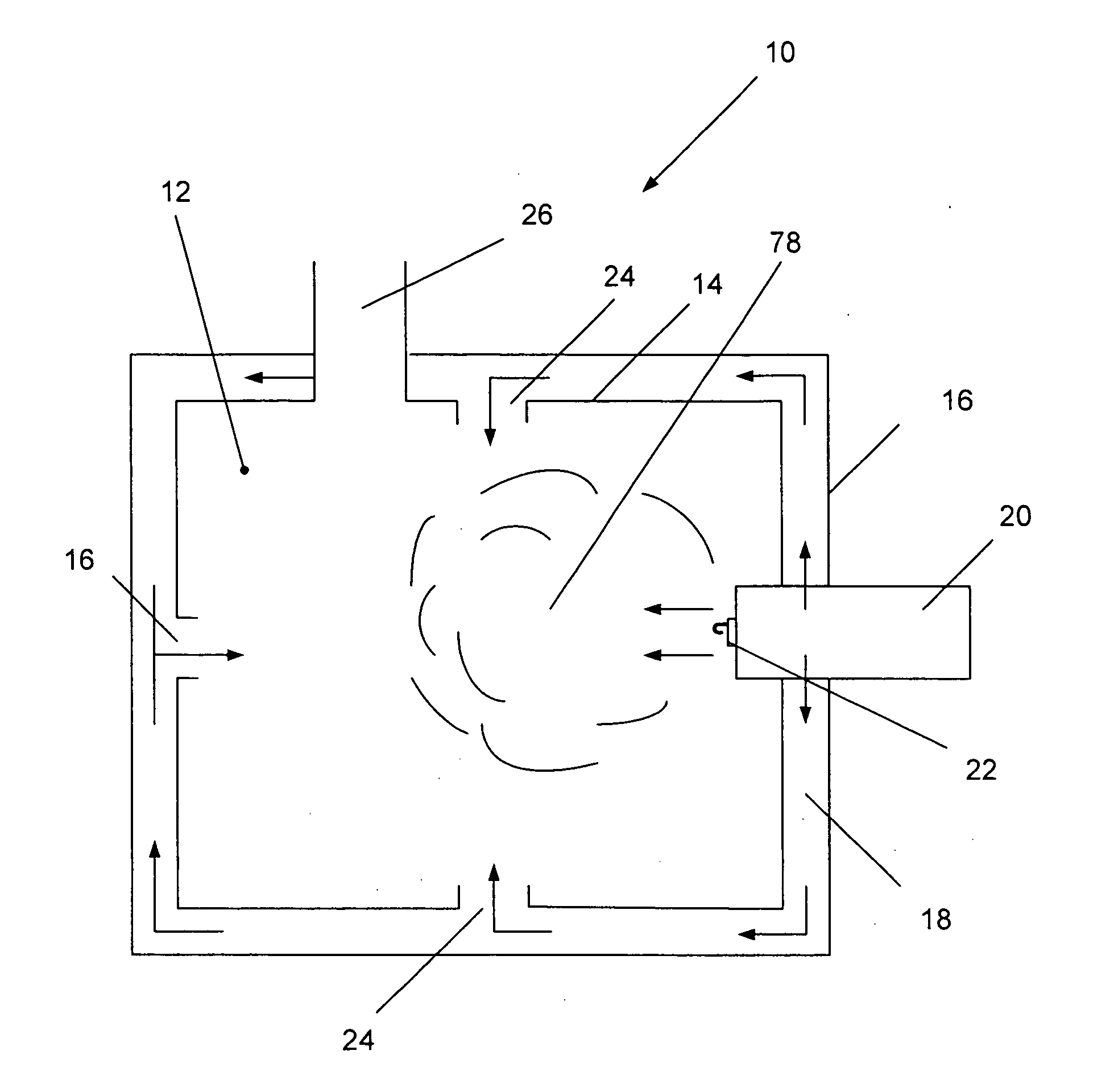

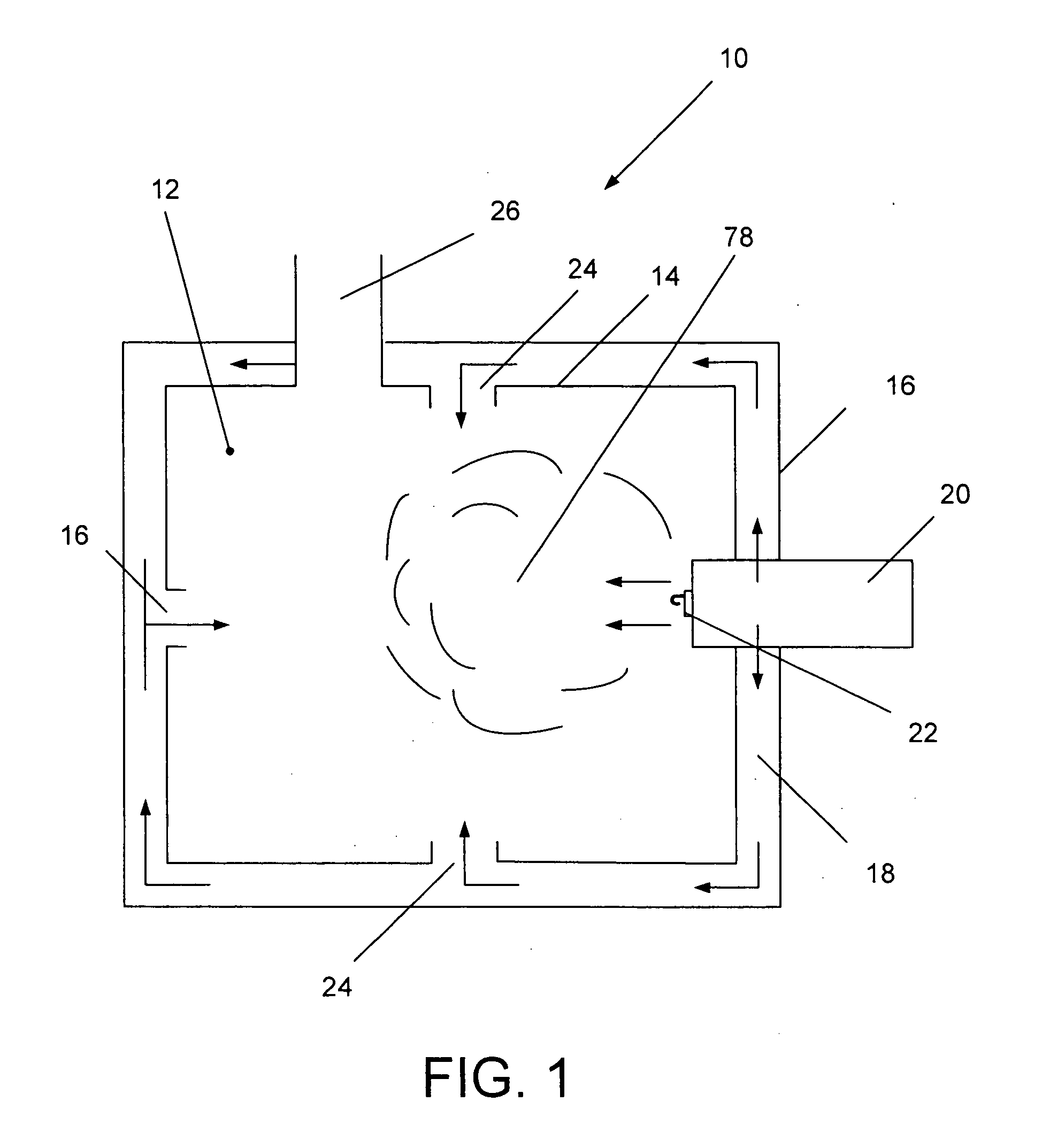

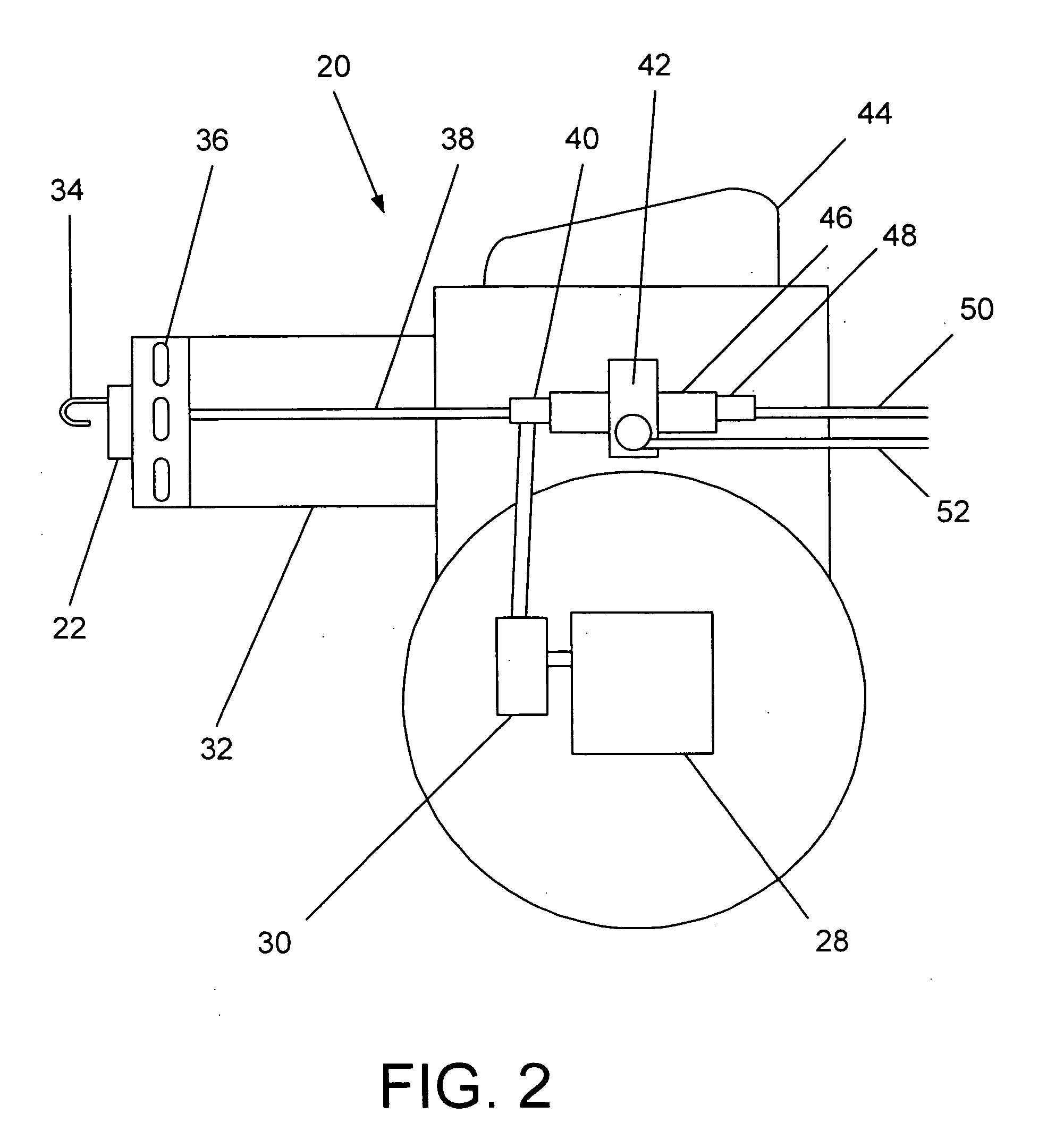

Air curtain incinerator

ActiveUS7063027B2Efficiently and cleanly burningLittle and set up timeSolid waste disposalCapillary burnersCombustorCombustion chamber

A self-contained, transportable air curtain incinerator for combustion of low calorific value waste comprises a transportable frame supporting a firebox, a fuel supply tank, a fuel-burning electric power generator in communication with the fuel supply tank, at least one fuel-burning burner unit in communication with the fuel supply tank for directing a flame into a combustion chamber defined by the firebox, and an air curtain blower powered by the generator for providing a sheet of high velocity air flow generally across an open top of the firebox.

Owner:AIR BURNERS

Bonfire oven

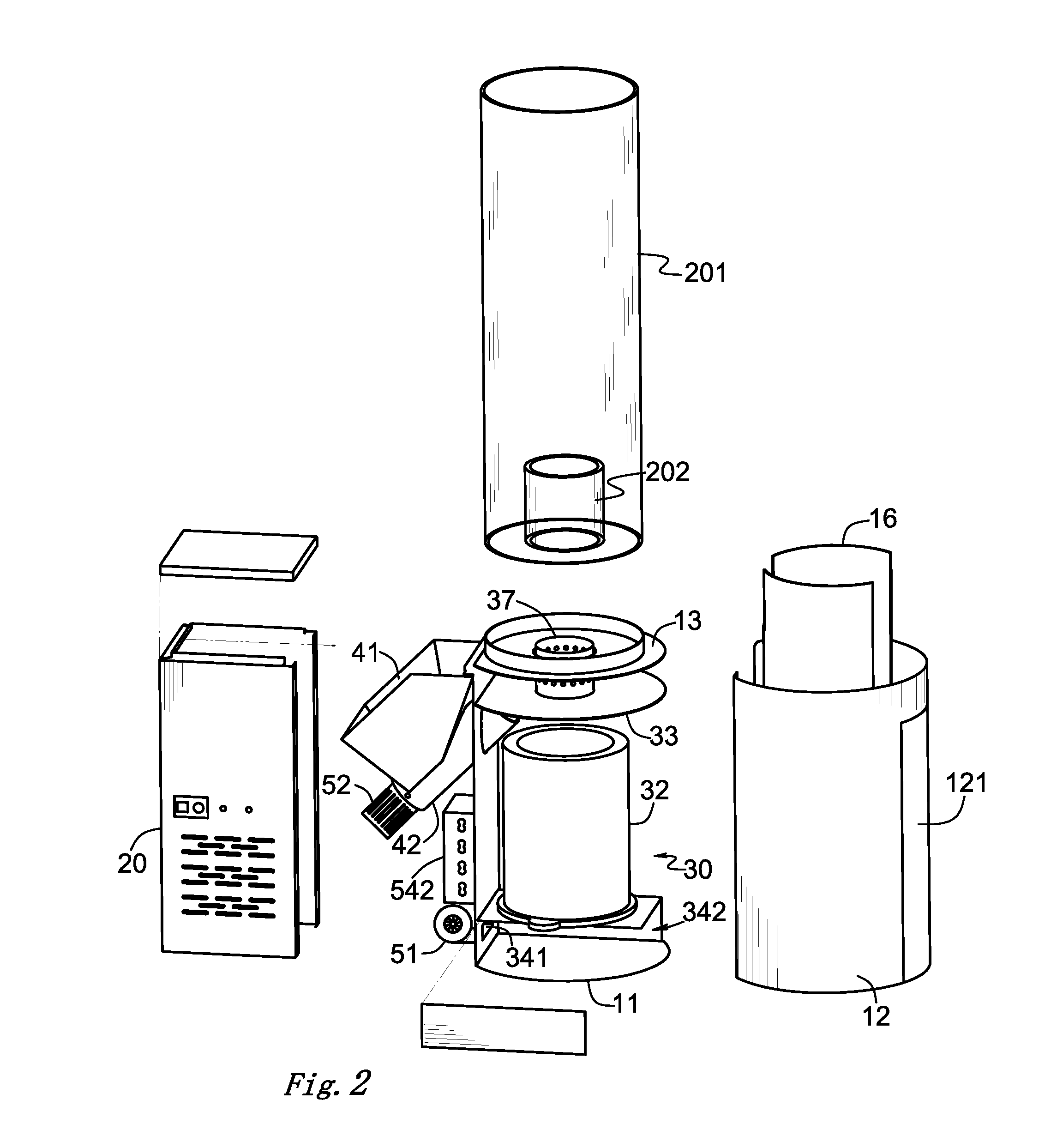

InactiveUS20140238282A1Easy to transportShort timeStoves/ranges with convection heatingCapillary burnersCombustorCombustion chamber

A bonfire oven has a body placeable on the ground. The body has a combustion cabinet and an auxiliary equipment cabinet. A burner contained in the combustion cabinet has a fire grate, a side plate extending upward from the fire grate, a top plate opposite to the fire grate, a blowing space beneath the fire grate, and a hearth defined by the fire grate and the side plate. A fuel supply mechanism, an electrical equipment and an air blower is contained in the auxiliary equipment cabinet. The bonfire oven further has a flame portion on the top which is a flame roaring space formed by at least one piece of high temperature resistant glass.

Owner:ZHU HONGFENG

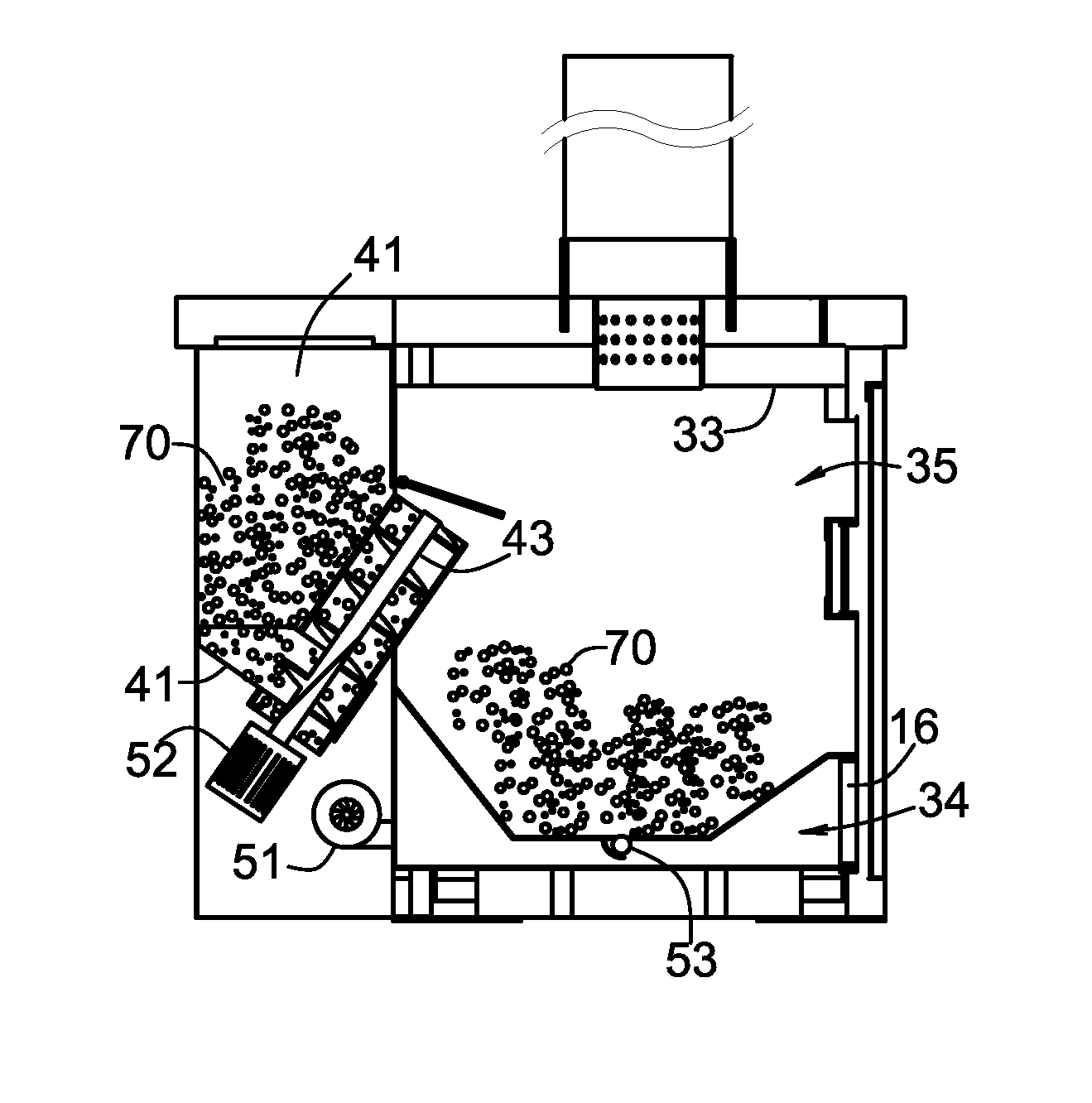

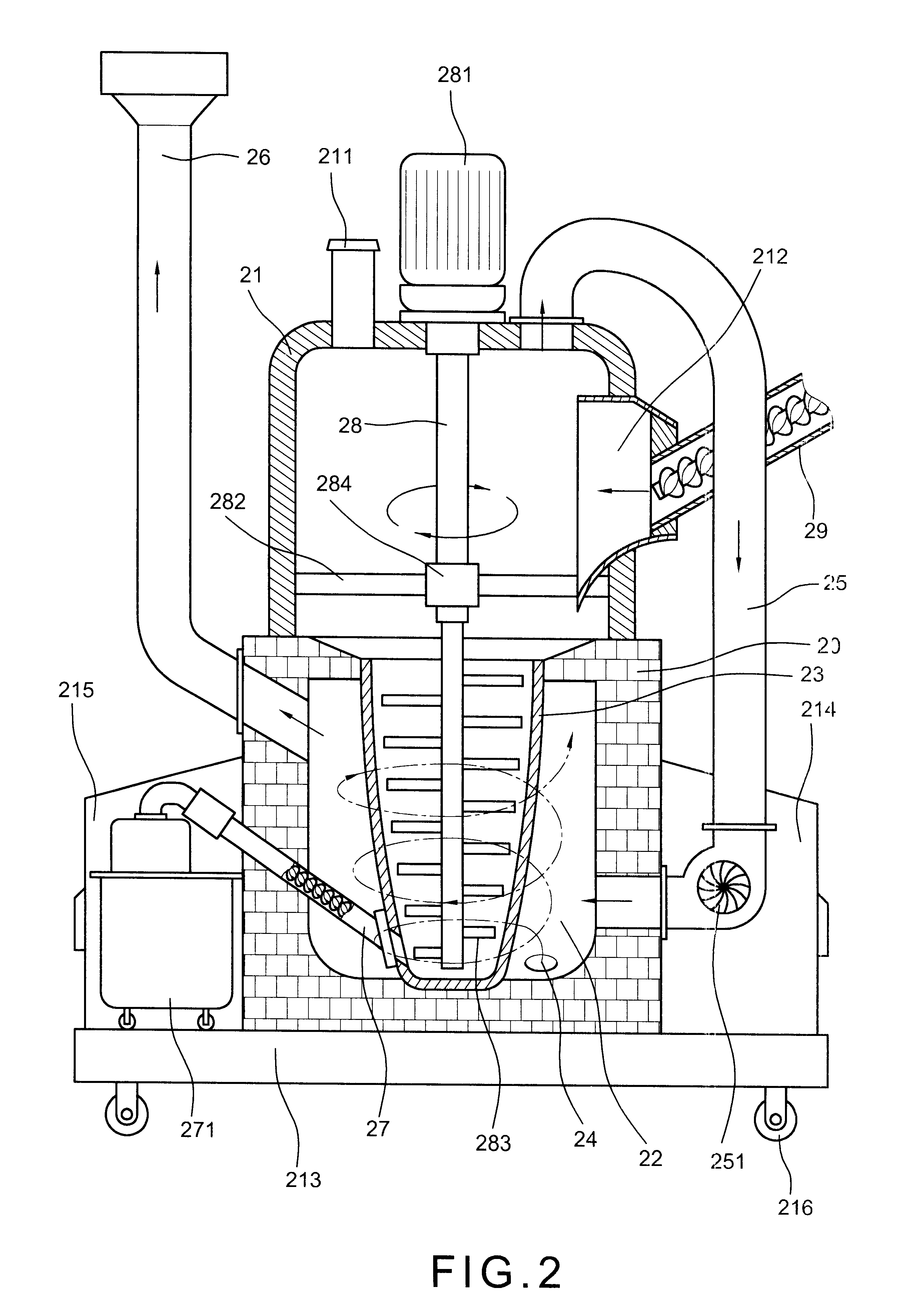

Miniature garbage incinerator

InactiveUS6425335B1Efficient combustionIncrease capacitySolid waste disposalCapillary burnersSludgeLitter

A miniature garbage incinerator includes a base, a cover on the base, a pot shaped furnace at the center of the base to define an revolving space therearound, a helical pipe connected to the air revolving space and heat source in the bottom of the base for providing whirlpool flame around the furnace, a motor on the central top of the cover to actuate a stirring rod inside the incinerator, an inlet including a spiral propeller tube in a side wall of the cover for feeding the garbage and filthy mud into the furnace, a heat revolving pipe including a blower connected between a top of the cover and a lateral wall of the base, a chimney connected to a lateral wall opposite to the heat revolving pipe, a pressure adjustment valve on a top of the cover and an ashes collector under the chimney connected to the bottom of the furnace through an ashes spiral propeller tube. The miniature garbage incinerator can be used individually or combined with a filthy mud furnace and a heat stove.

Owner:CHEN YING TSUNG

Air curtain incinerator having waste heat power generation

A portable air curtain incinerator for burning biomass, such as cleared logs and vegetation, is equipped with heat recovery panels along at least one of the sidewalls of the incinerator's firebox, and a heat transfer medium is cycled through the heat recovery panels and expanded to its gaseous phase by heat released during incineration of the biomass. The gaseous medium is directed to drive the turbine of a generator to generate electricity. The heat transfer medium is condensed, preferably using a local source of cooling water, and the cycle is repeated. The air curtain incinerator may include its own generator, or multiple incinerators may be coupled to a single shared generator.

Owner:AIR BURNERS

Log cartridge burning system

A Log Cartridge Burning System is provided comprising a simple, convenient and manageable wood burning system which can easily be applied for use to cook and heat. The log cartridge is comprised of a flammable body of compressed material and a bore formed and sealed by the use of a protective outer paperboard tube and a protective inner paperboard tube together with a top and bottom paperboard cover which serve to hold and maintain the integrity of the entire cartridge without the use of any wax binders. The flammable body of compressed material may be made partly or entirely from natural combustible materials such as sawdust or wheat hulls. The burn pot is specially designed to accommodate the log cartridge of the present invention. The log cartridge burning system can easily be utilized in a variety of appliances such as a patio heater or fireplace, barbecue or grill, or other cooking and heating appliances.

Owner:LEE HENRY K

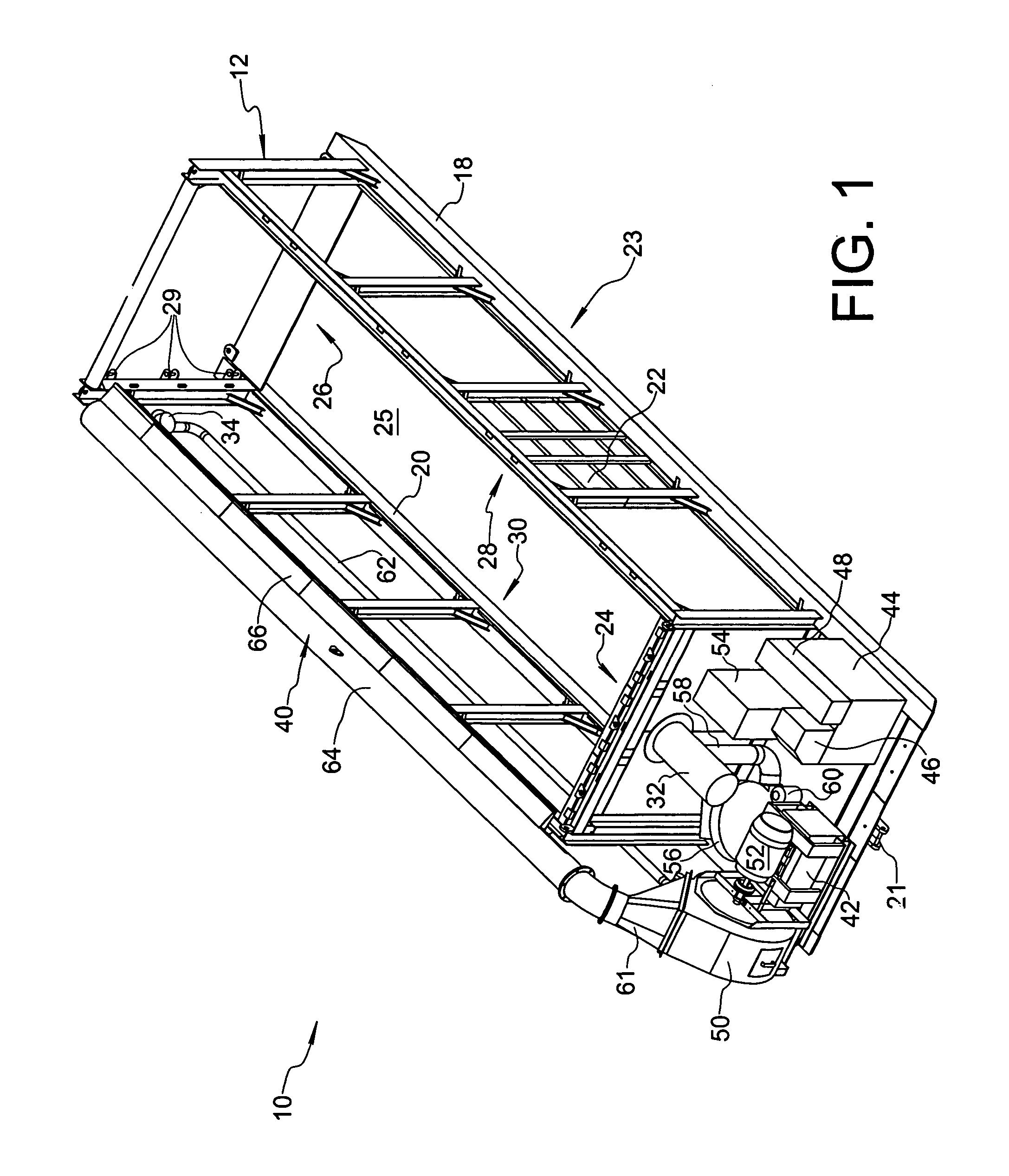

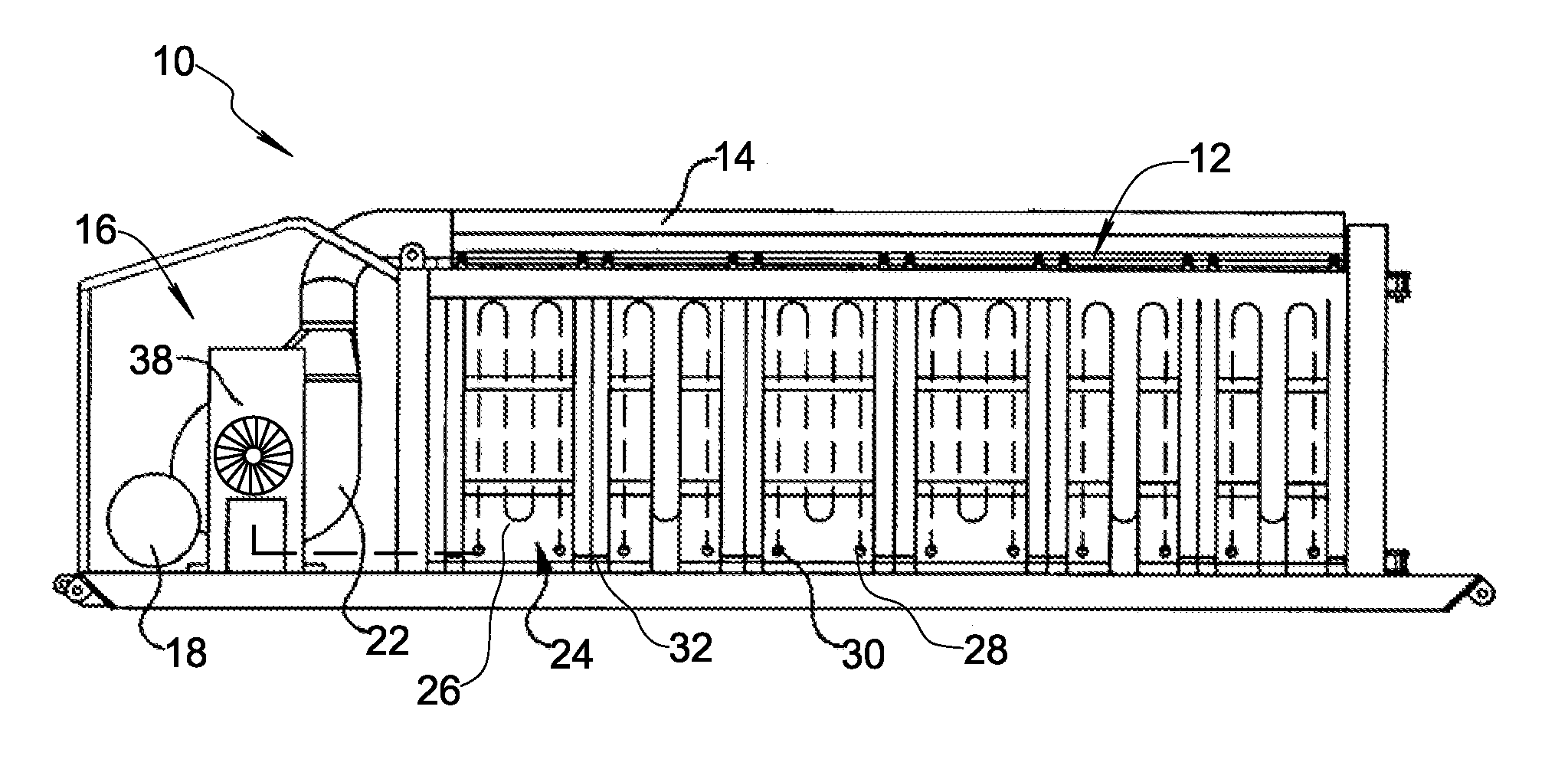

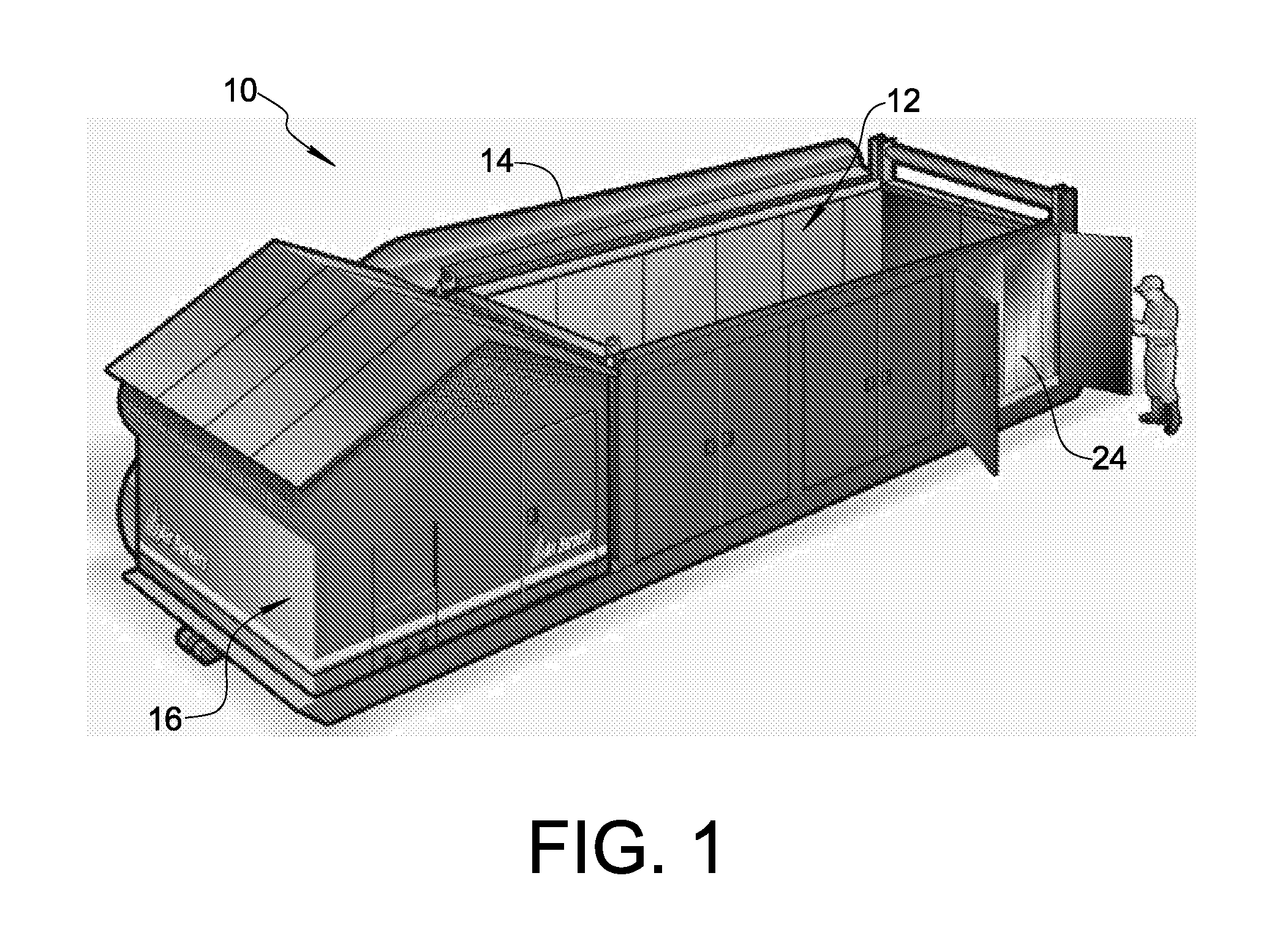

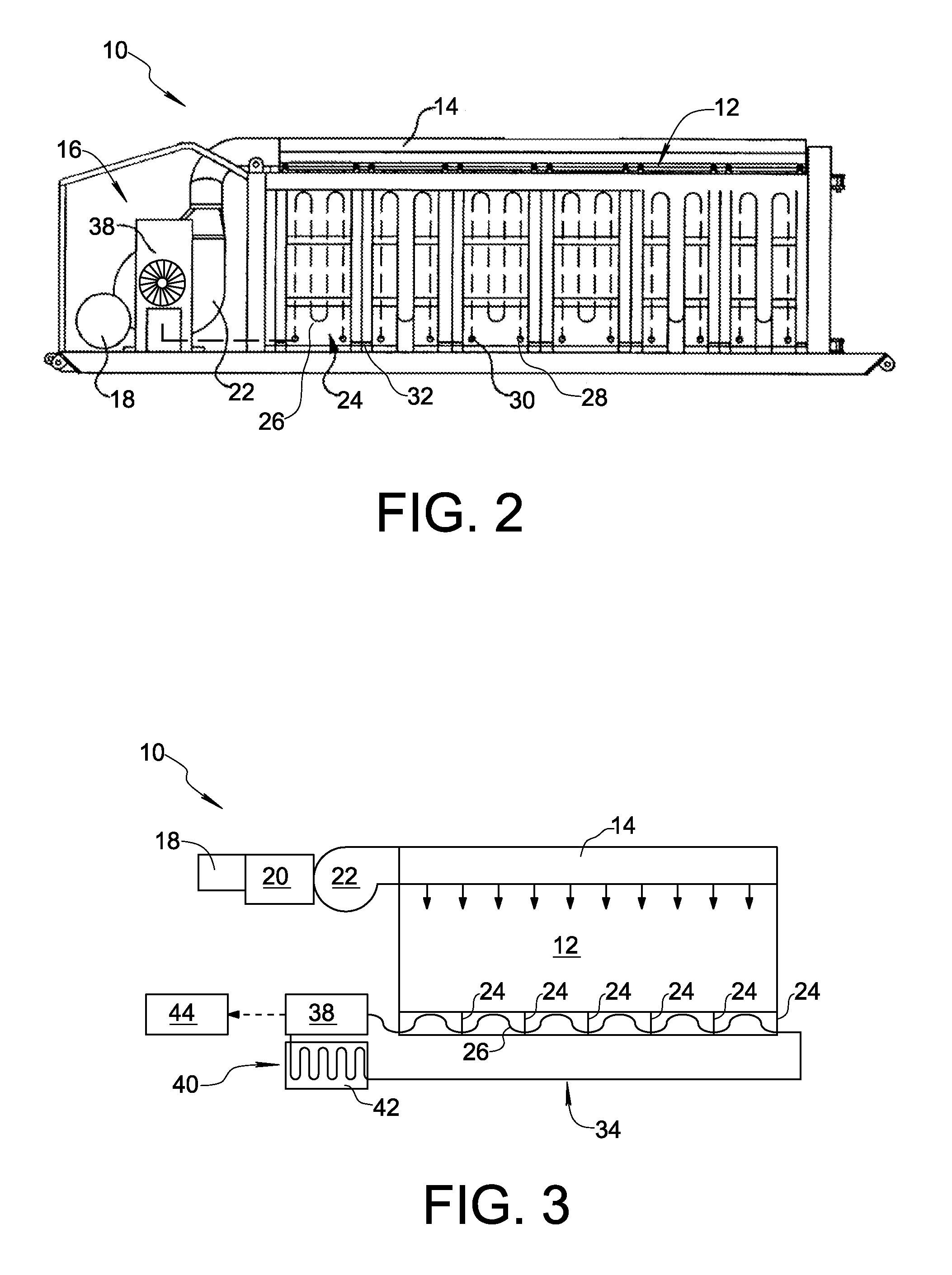

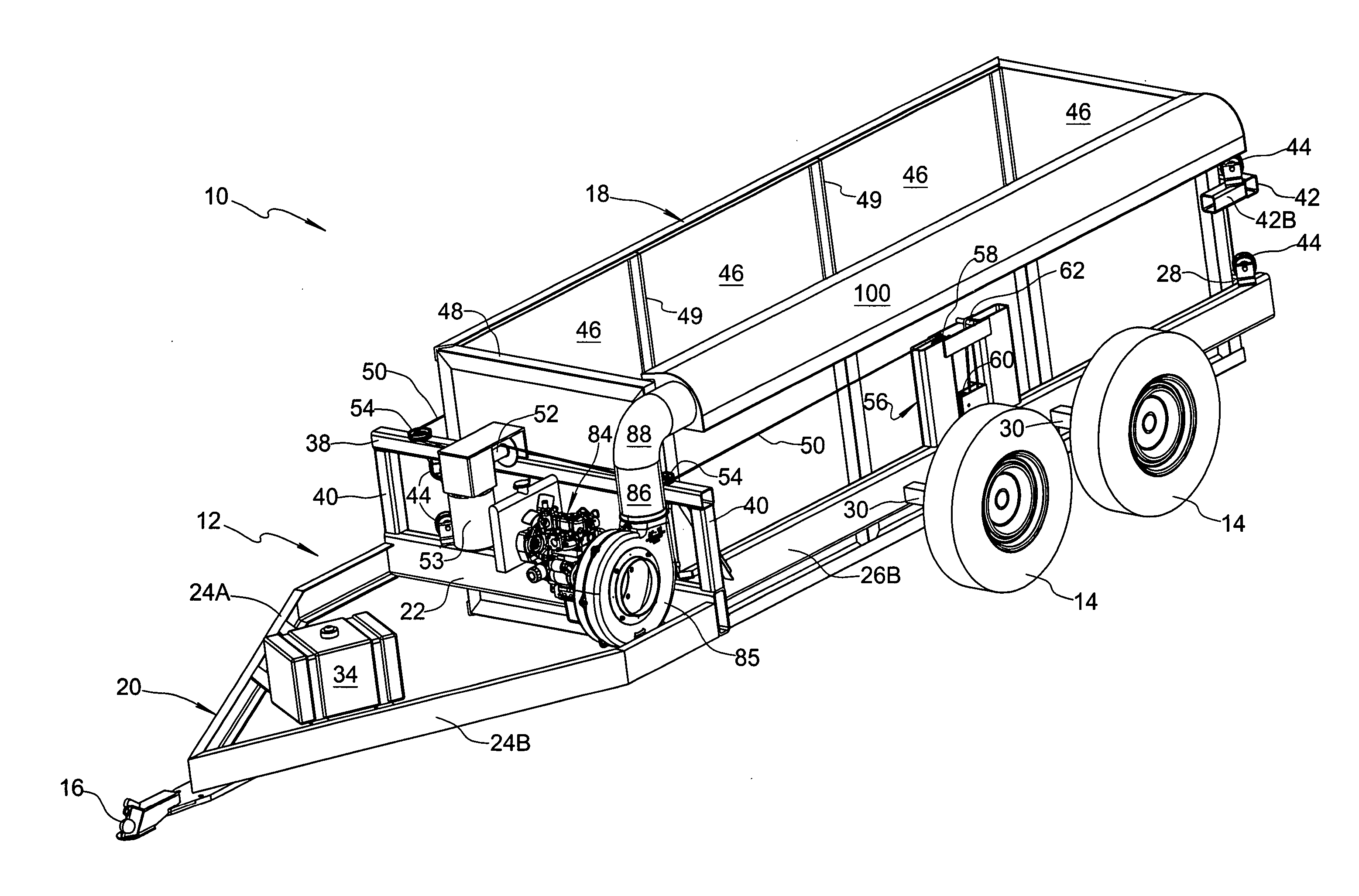

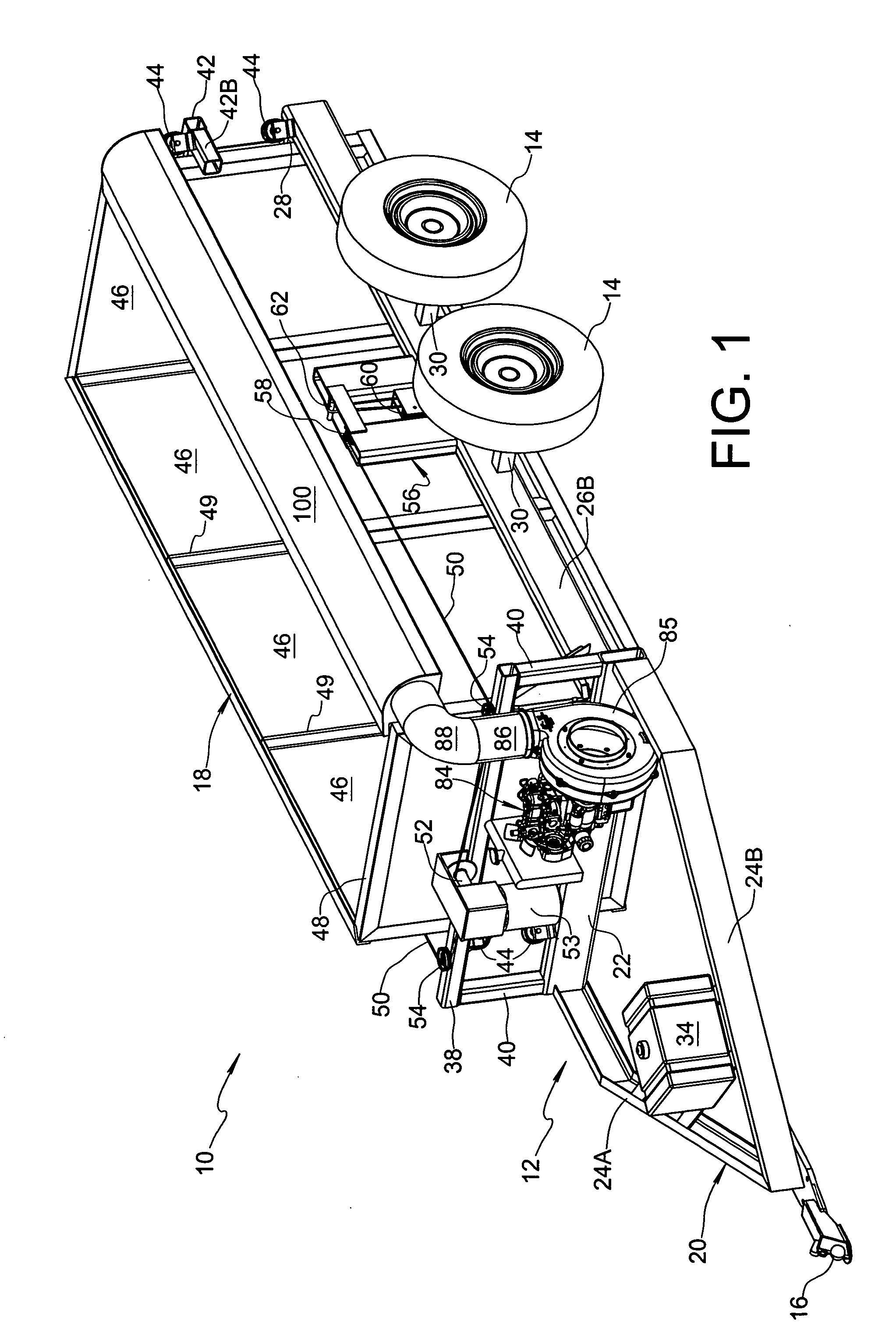

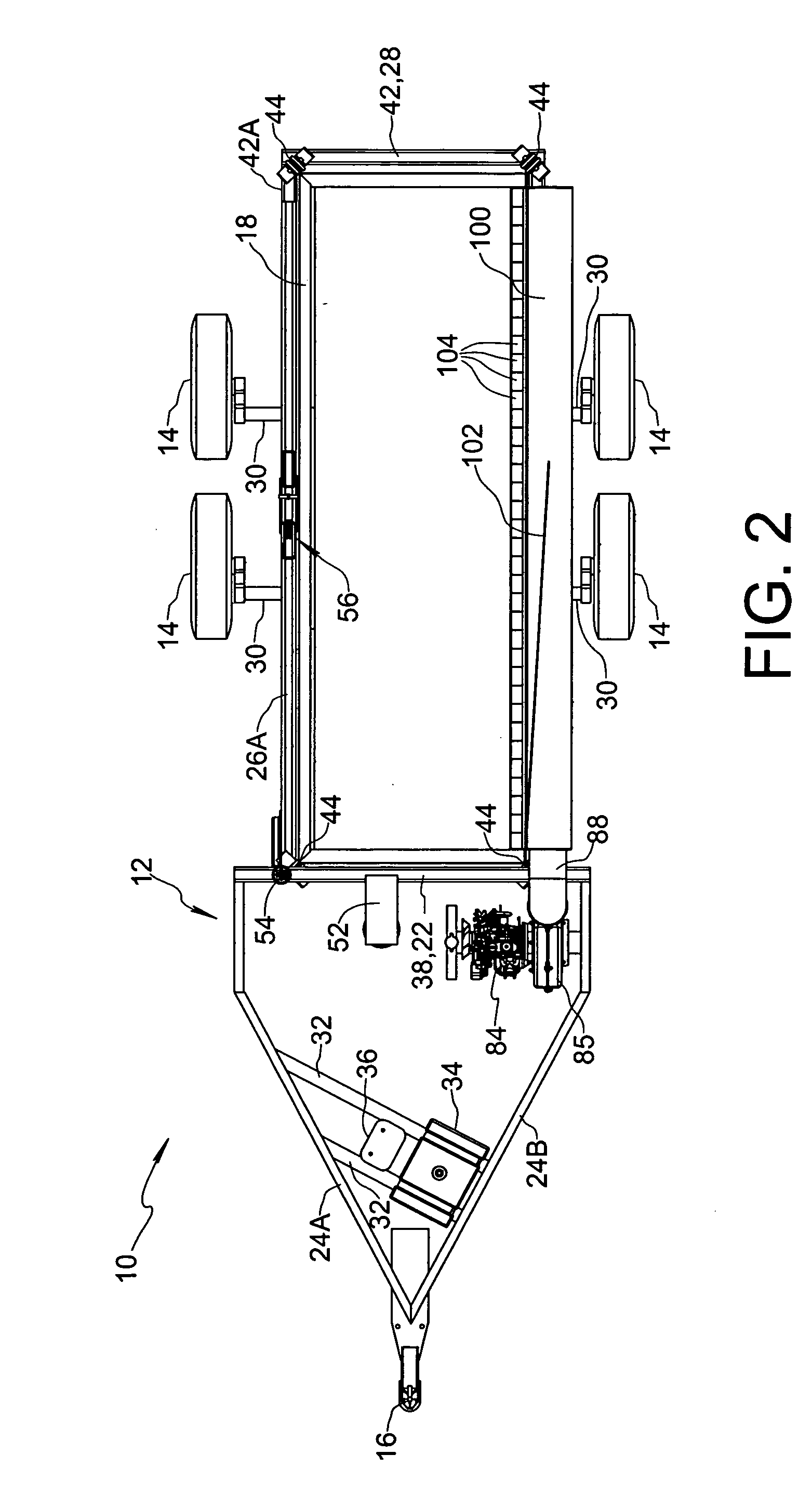

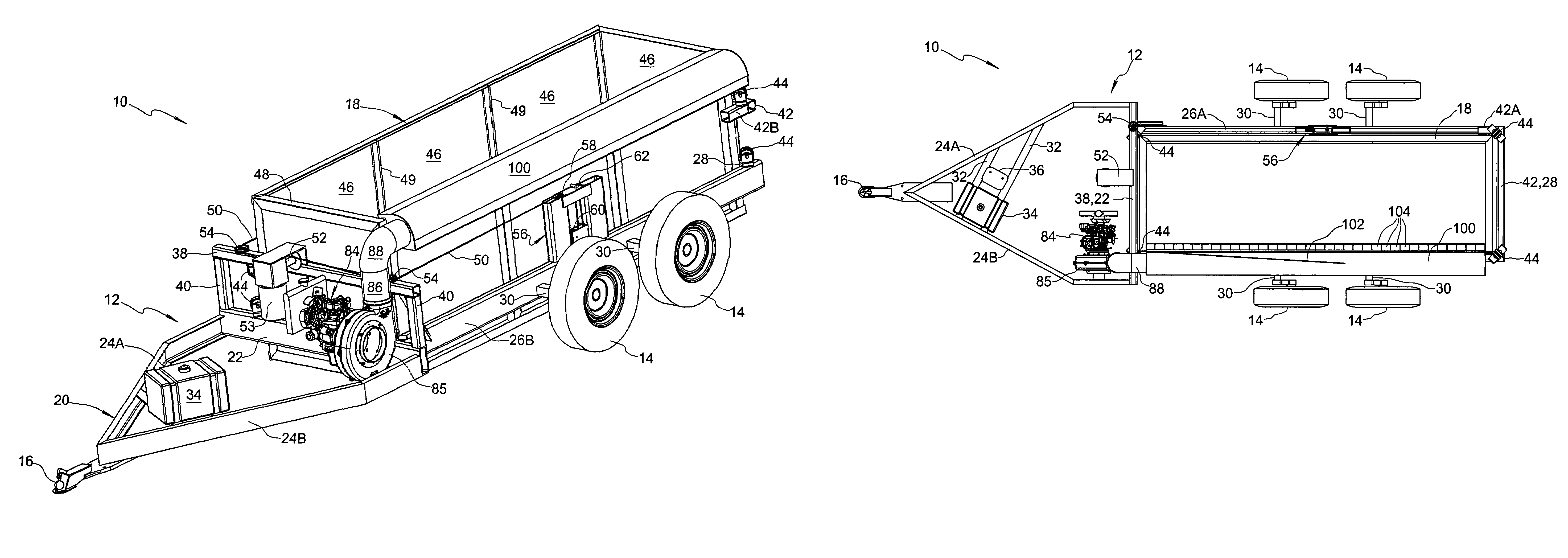

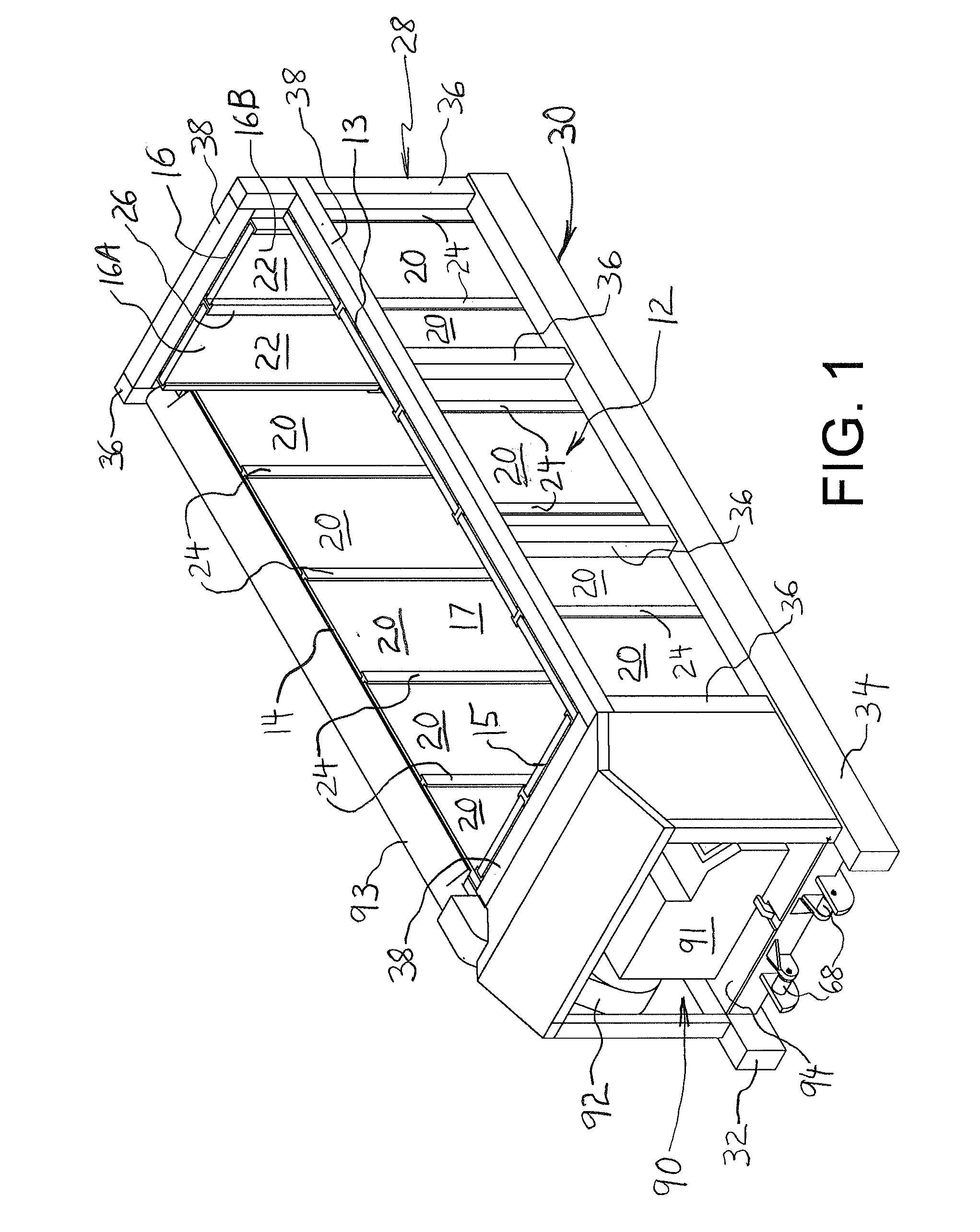

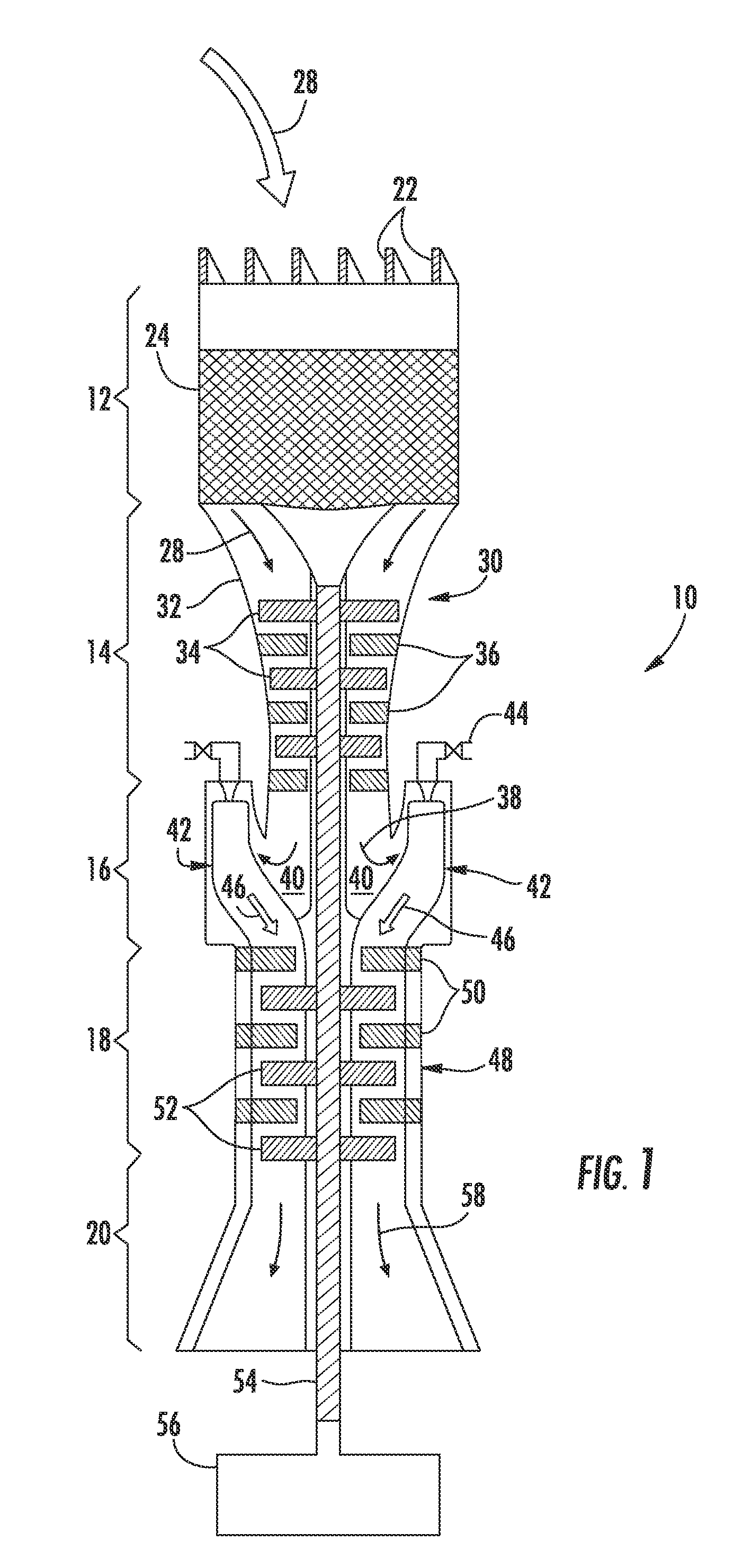

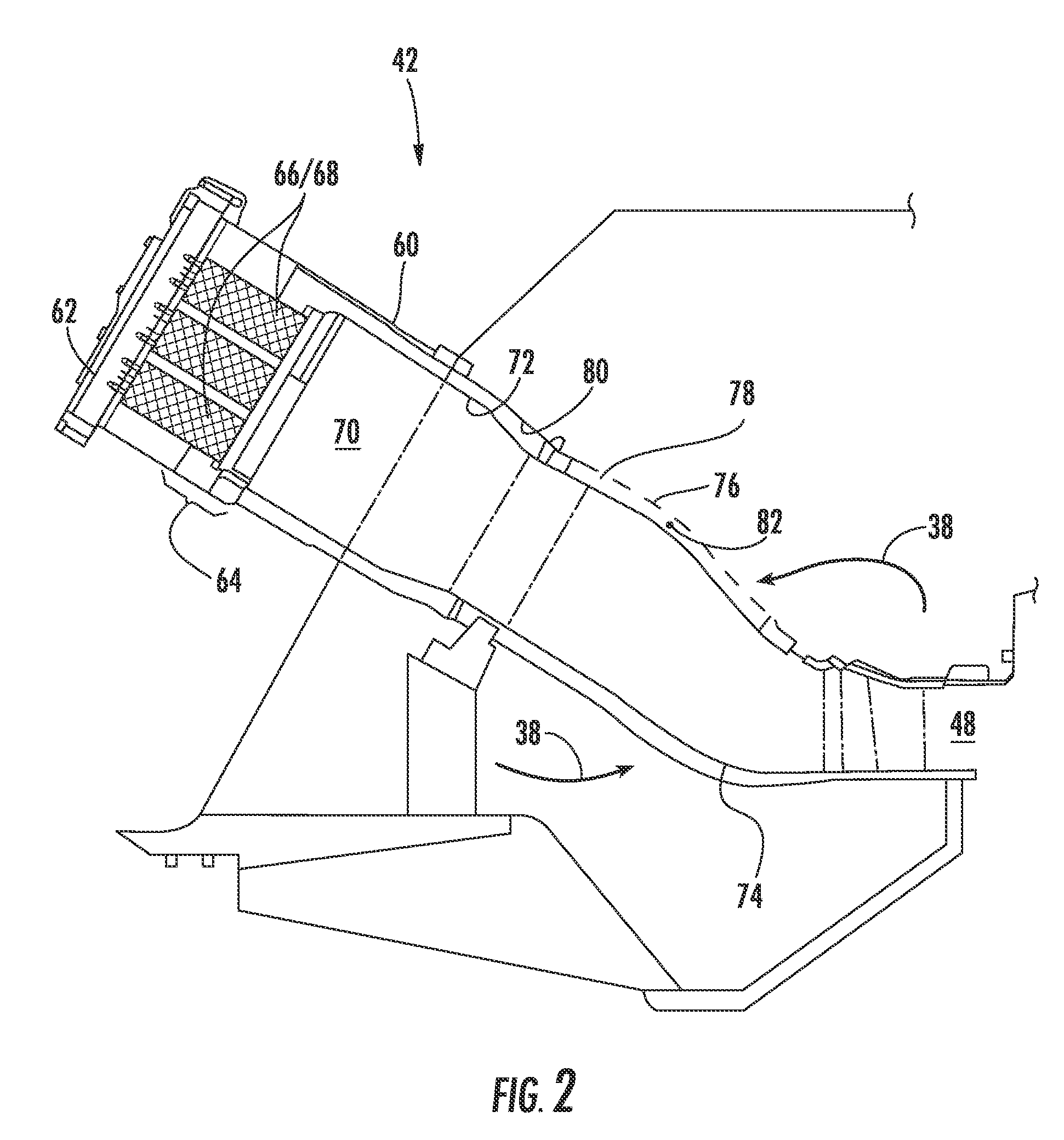

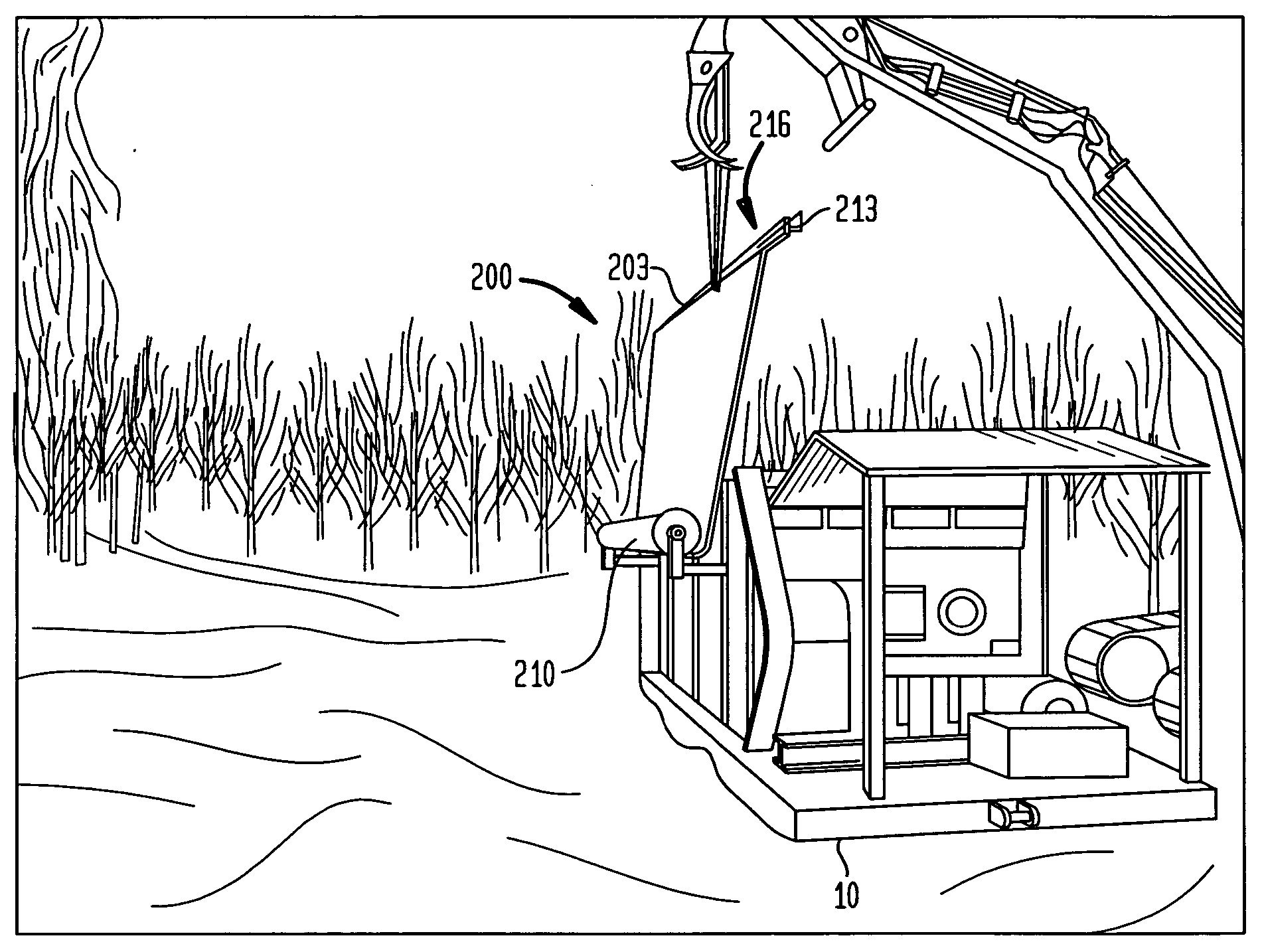

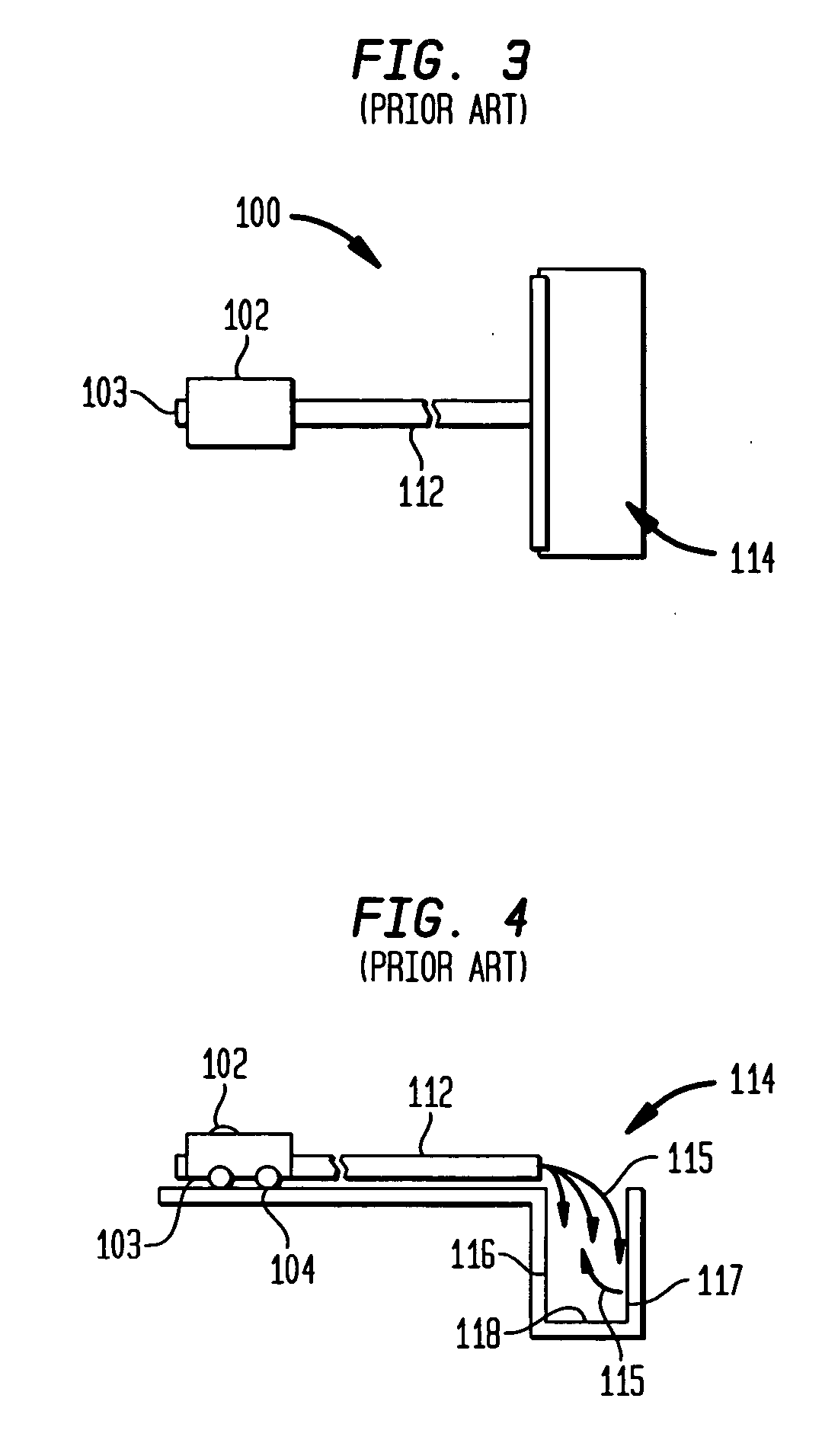

Transportable incineration apparatus and method

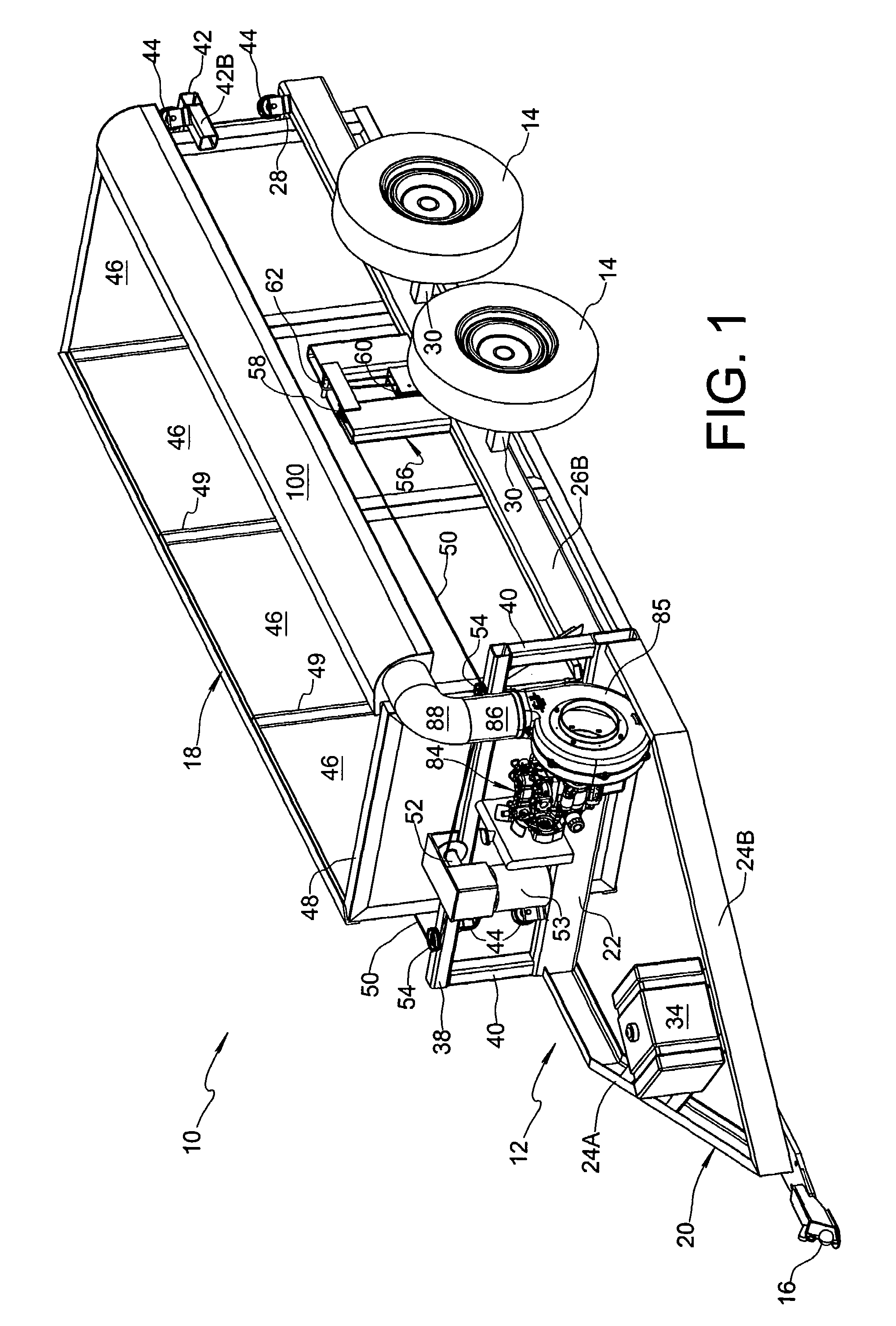

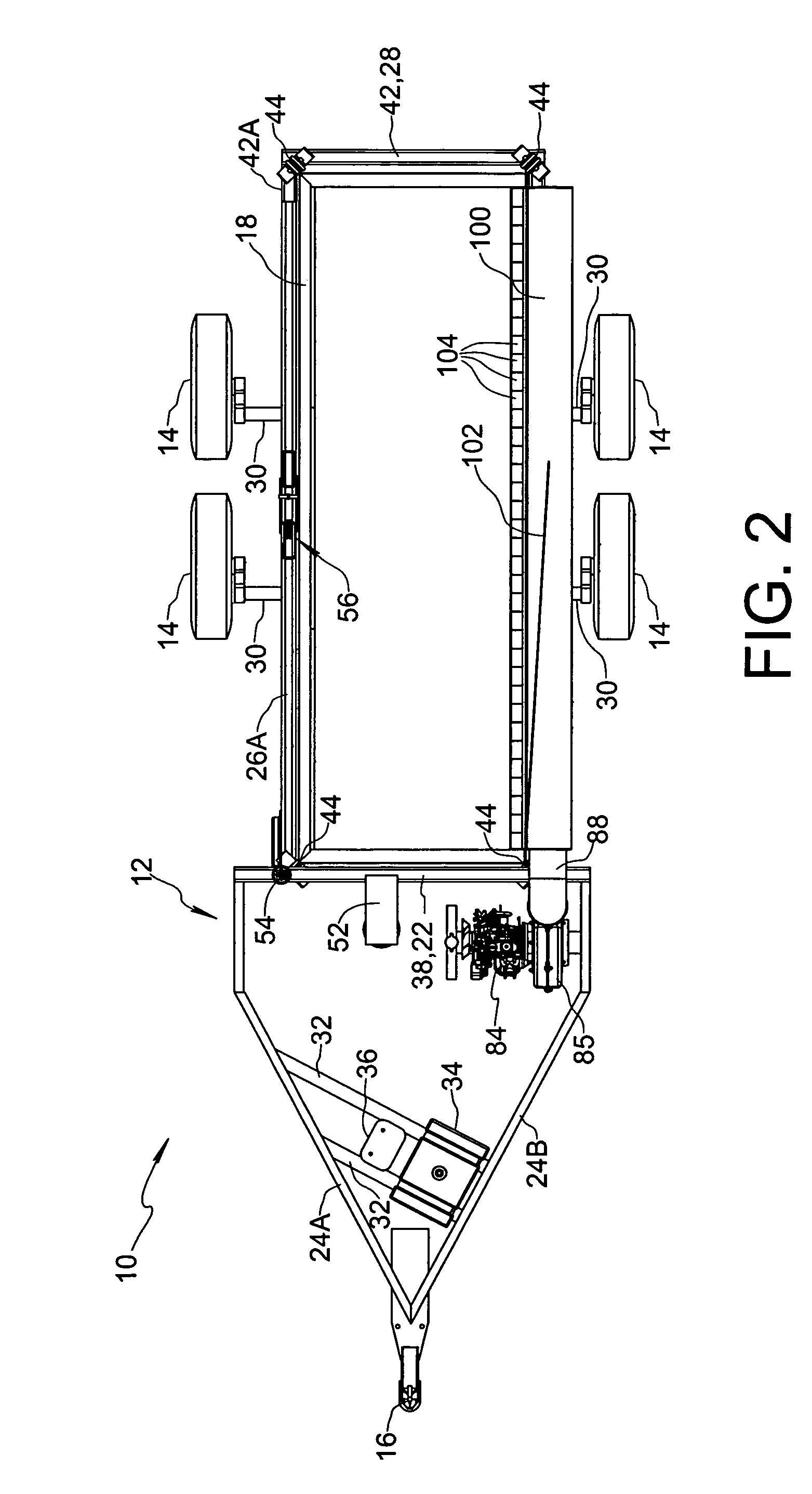

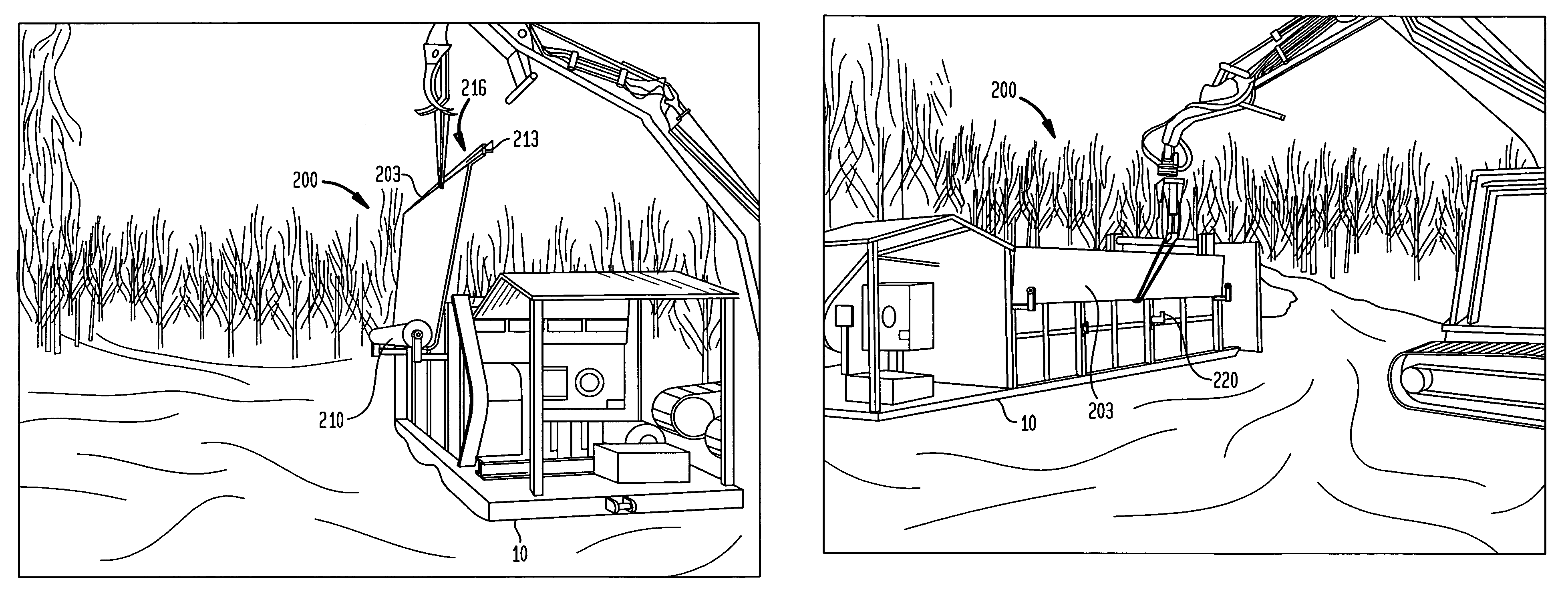

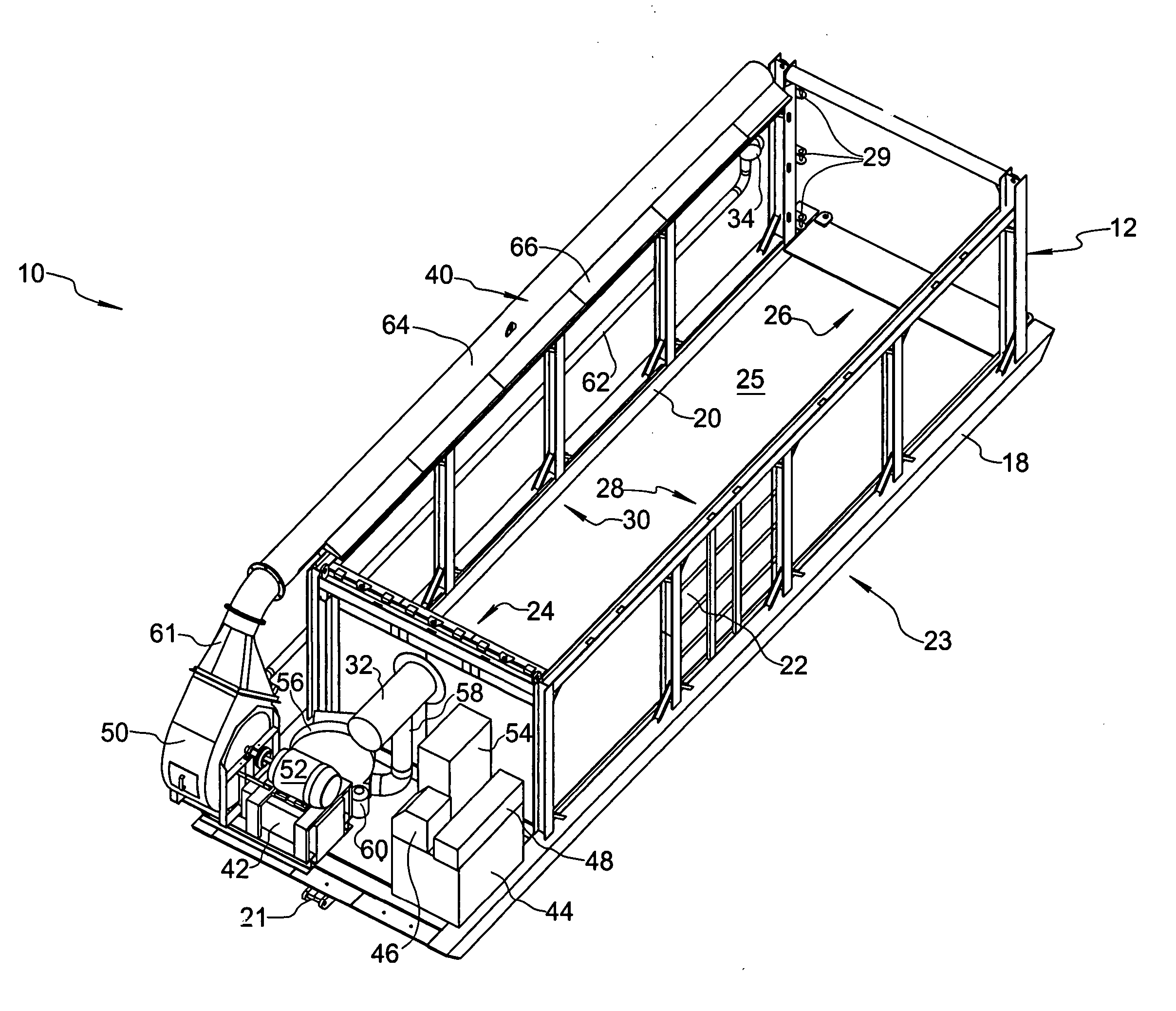

ActiveUS20070144412A1Reduce pollutionCapillary burnersLiquid fuel impingement burnersGreen wasteIncineration

A transportable incineration apparatus for burning wood and green waste comprises a trailer and a firebox mounted on the trailer by a suspension system operable to lift the firebox off of the ground for transport and to set the firebox onto the ground for incineration. The wheels of the trailer are mounted on independent torsion axles to increase the space available for the firebox. A system for generating an air curtain overtop the firebox reduces pollution resulting from incineration. The apparatus may be towed to an incineration location and used with minimal set up and take down time.

Owner:AIR BURNERS

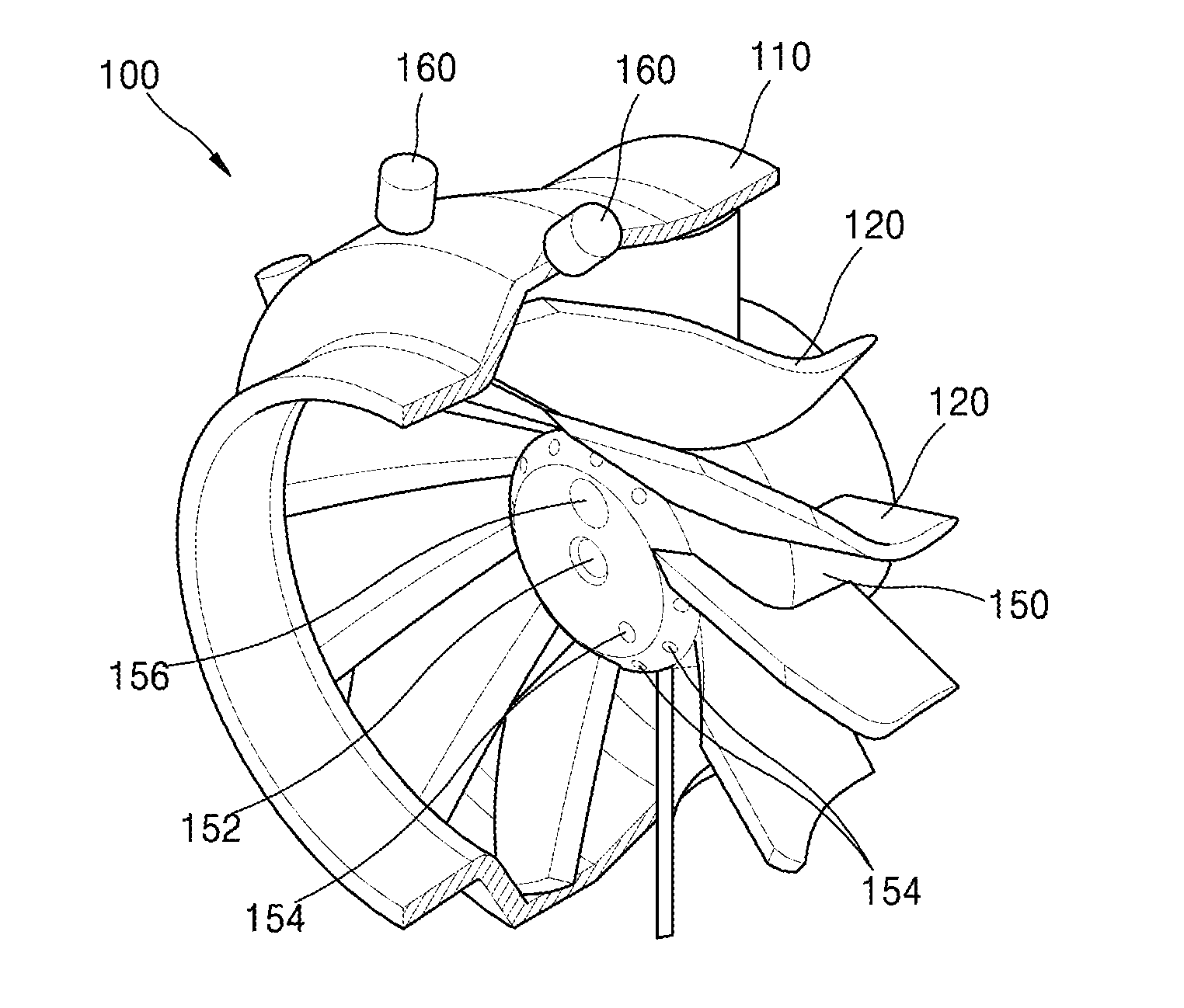

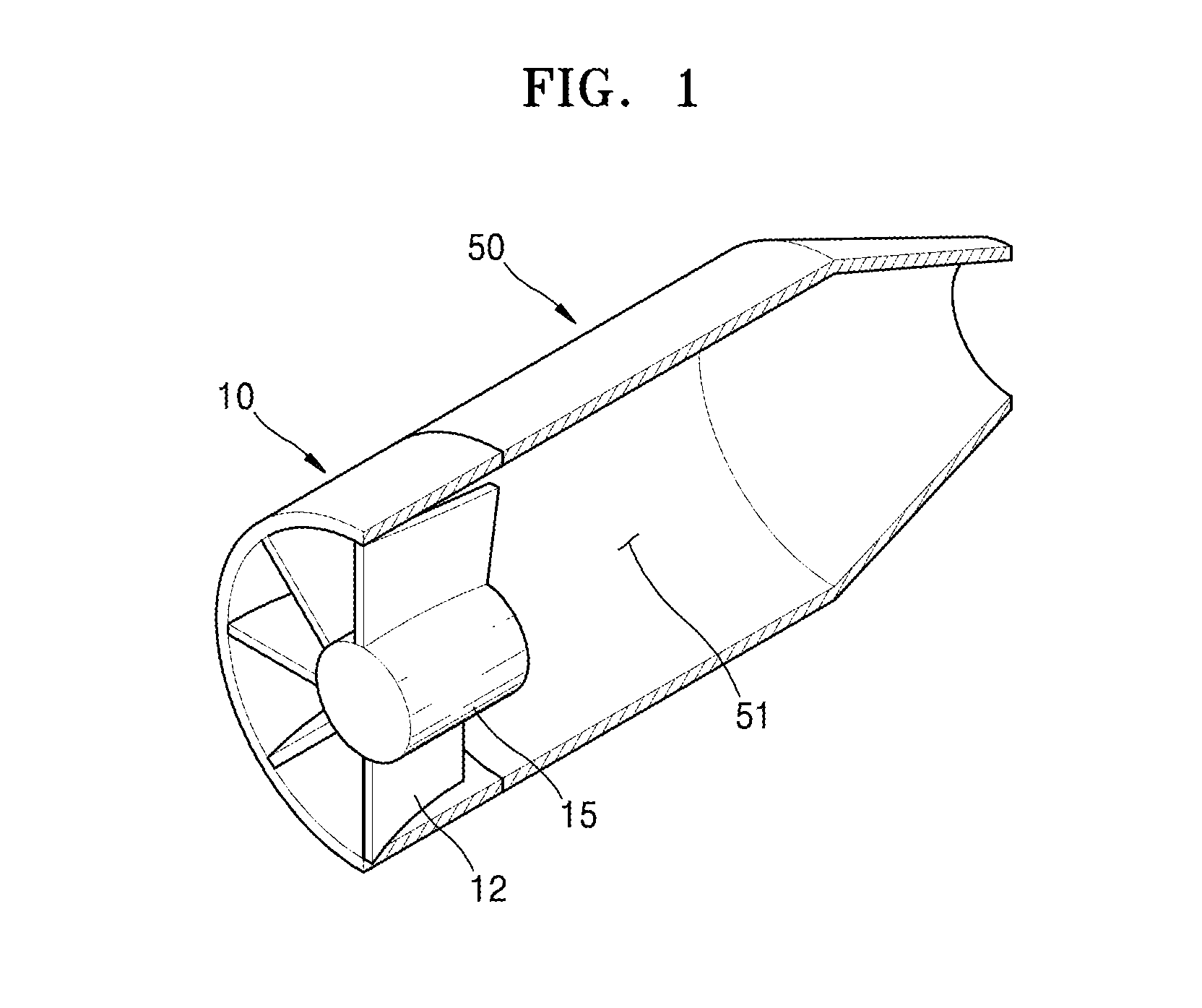

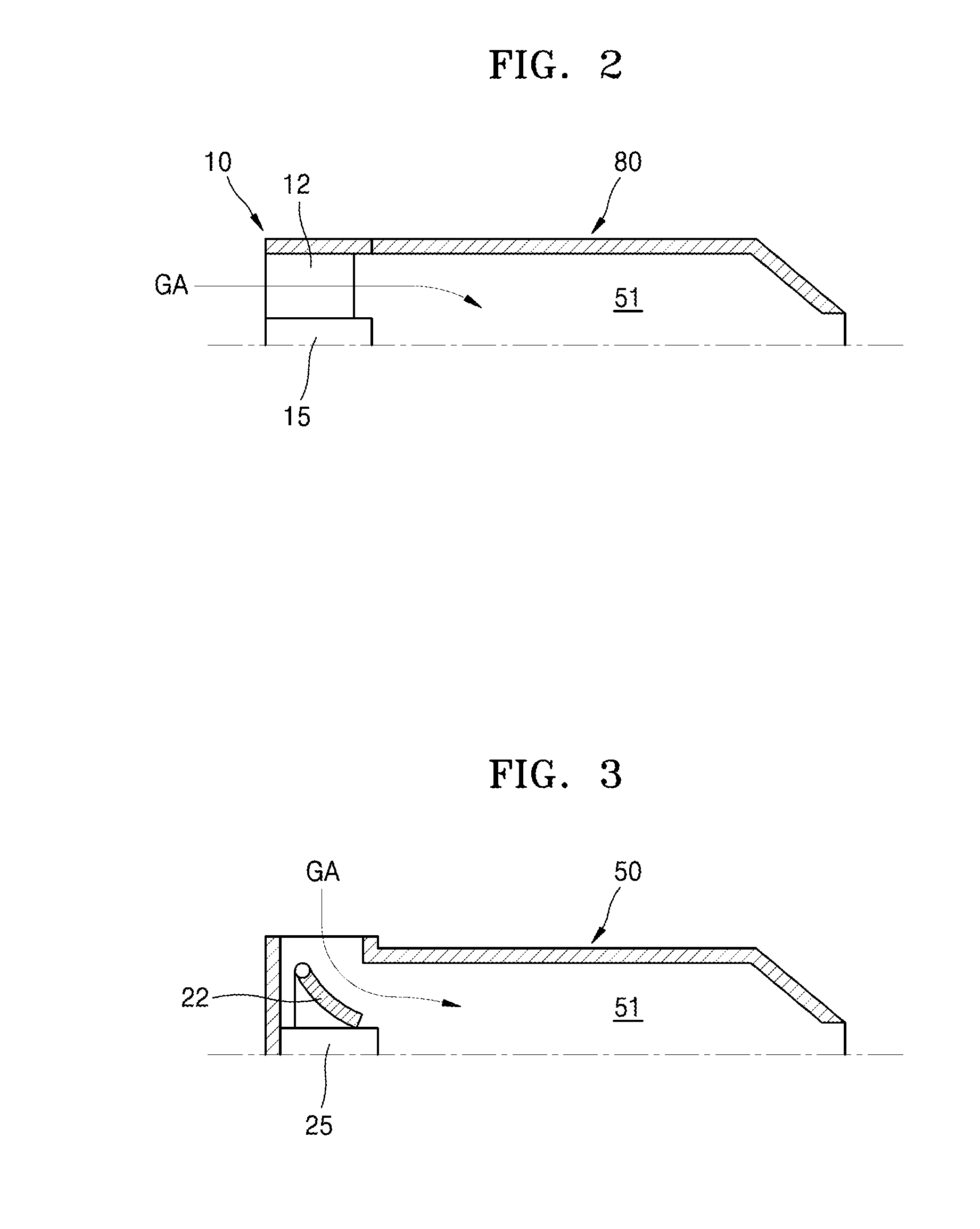

Swirler

ActiveUS20160195266A1Improve performanceLess pressure dropContinuous combustion chamberCapillary burnersEngineeringExtremity Part

The inventive concept relates to a swirler. According to an aspect of the inventive concept, there is provided a swirler including a casing, a pilot body disposed in the casing, and a plurality of vanes arranged along a circumference of the pilot body, wherein at least a part of the vane protrudes further to a downstream than an end portion of the pilot body.

Owner:HANWHA AEROSPACE CO LTD

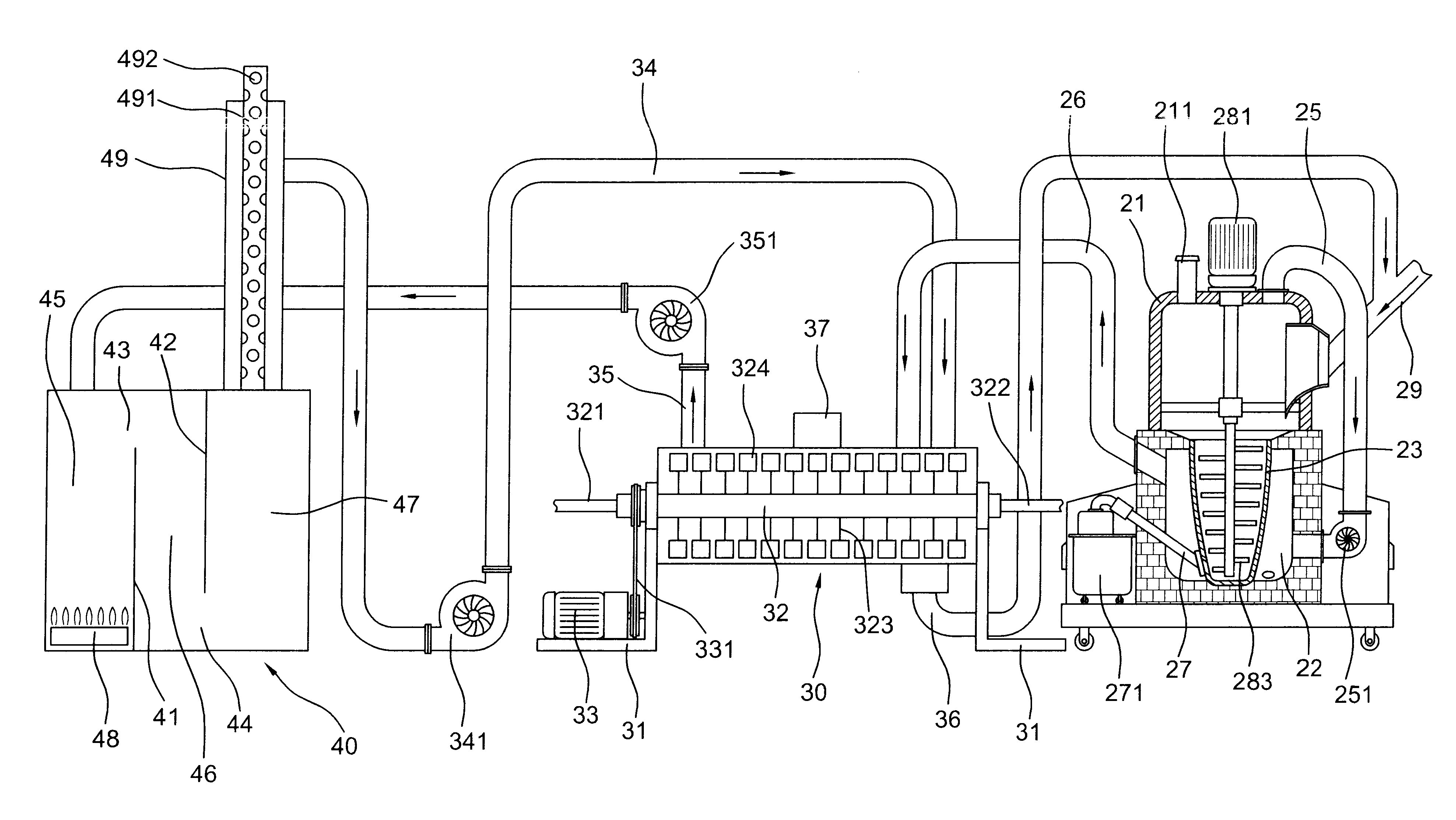

Mobile solid waste gasification unit

InactiveUS20050115478A1Easy to transportCapillary burnersLiquid fuel impingement burnersCombustion chamberExhaust fumes

A mobile waste gasification system comprised of a container, at least one gasification chamber, and a produced fuel gas combustion chamber, and may include a control room. Waste material is loaded into a suspended mesh liner that is offset away from the walls of the gasification chamber, thereby increasing the surface area of waste materials that are exposed to gasification conditions, and thus decreasing gasification temperature, time, and cooling period between subsequent gasification procedures. Process gas and supplemental flaring gases are preferably comprised of an oxygen or hydrogen rich gas. Produced fuel gases are withdrawn from the gasification chamber and into the produced fuel gas combustion chamber. The produced fuel gas combustion chamber may be comprised of a maze ignition chamber for the flaring of said fuel gases. Alternatively, the fuel chamber may be comprised of a gas accumulation tank that stores the produced fuel gas.

Owner:SENREQ

Transportable incineration apparatus and method

ActiveUS7503268B2Reduce pollutionCapillary burnersLiquid fuel impingement burnersCombustion chamberGreen waste

A transportable incineration apparatus for burning wood and green waste comprises a trailer and a firebox mounted on the trailer by a suspension system operable to lift the firebox off of the ground for transport and to set the firebox onto the ground for incineration. The wheels of the trailer are mounted on independent torsion axles to increase the space available for the firebox. A system for generating an air curtain overtop the firebox reduces pollution resulting from incineration. The apparatus may be towed to an incineration location and used with minimal set up and take down time.

Owner:AIR BURNERS

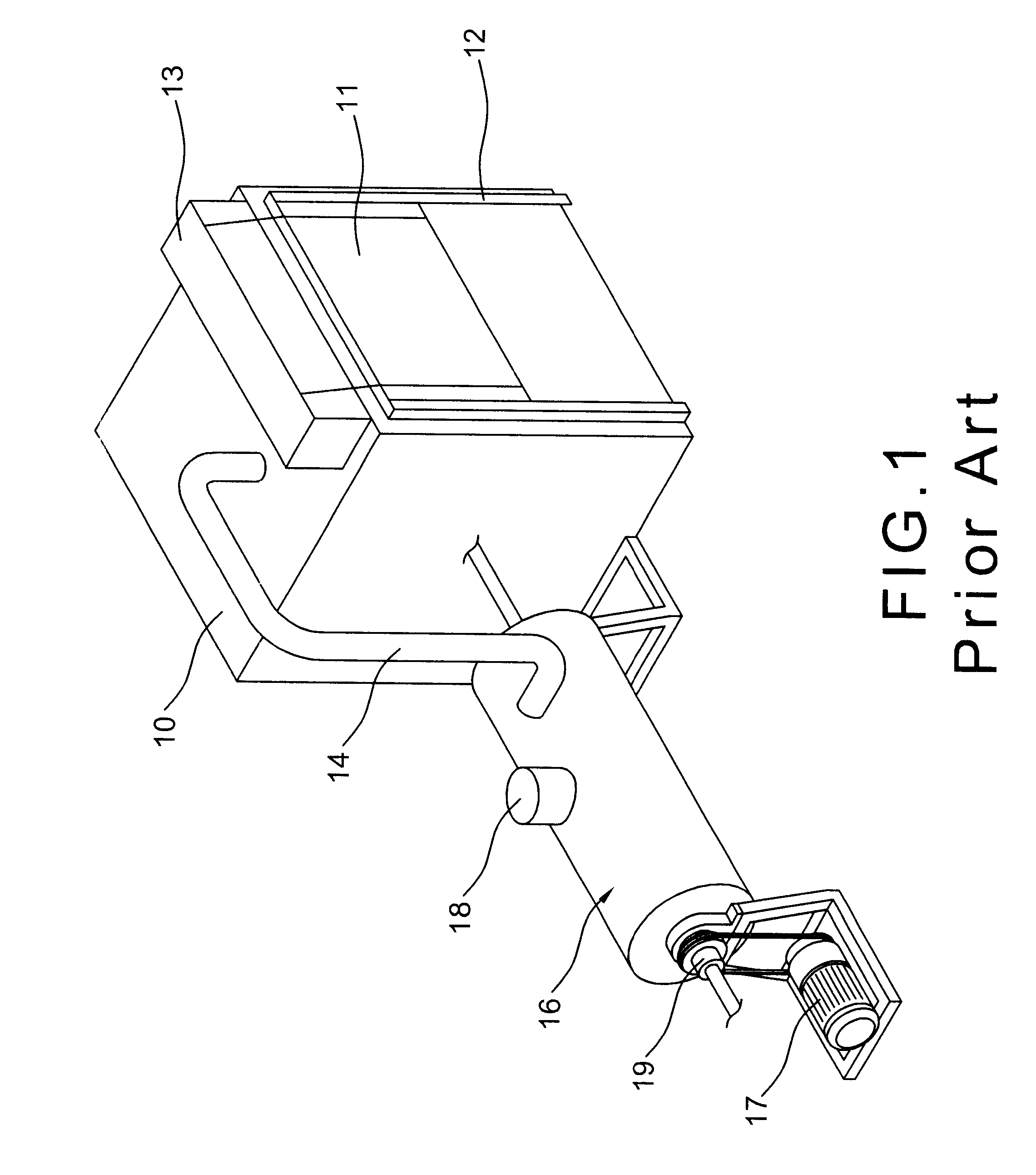

Protective device for incineration apparatus

A protective device may be attached to a portable incineration apparatus, or used over an open pit. The protection device may be a screen constructed of a stainless steel mesh. The screen is laid across the open top of the portable incineration apparatus or the top of the open pit. The screen forms a seal between the top portion of the walls of the incineration apparatus, or of the pit, and the portion of the screen that engages the top portion of the walls. Thereby, smoke, ashes and-embers are limited, or even prevented from escaping from the incineration apparatus or the open pit.

Owner:AIR BURNERS

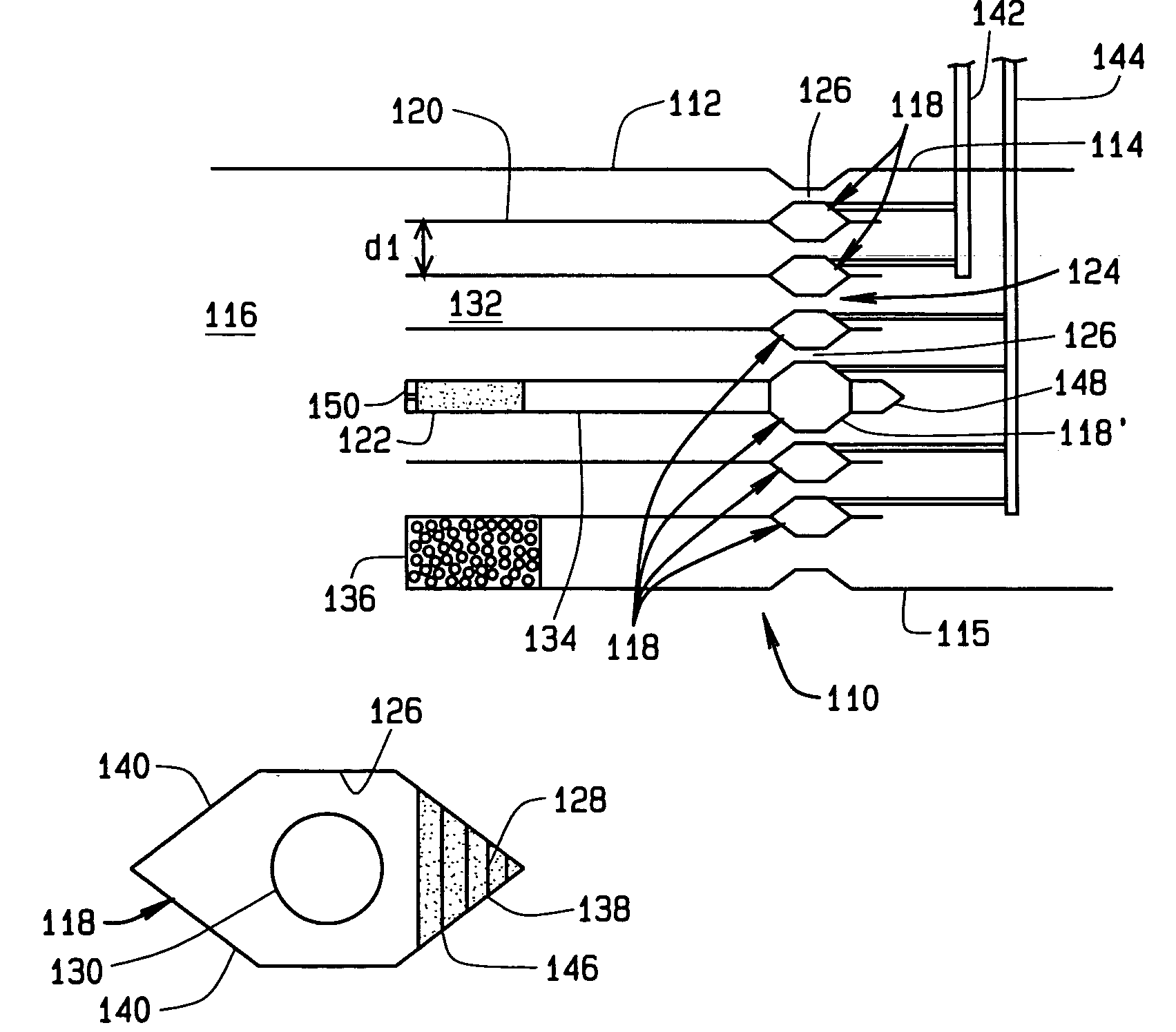

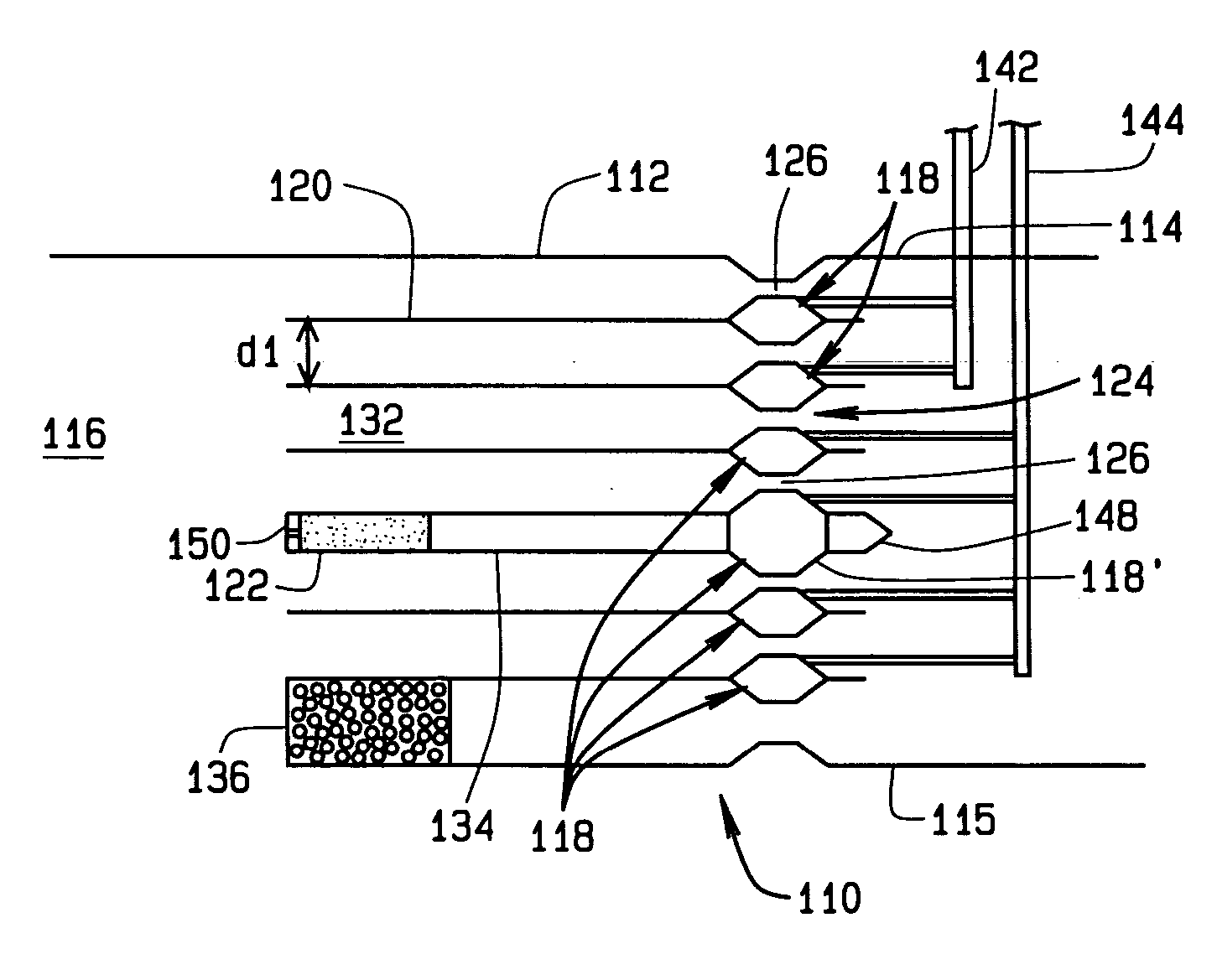

Non-swirl dry low NOX (DLN) combustor

ActiveUS20050188703A1Reduce instabilityLow turndown ratioBurner safety arrangementsTurbine/propulsion fuel supply systemsCombustorGas turbines

An air / fuel pre-mixer for a gas turbine combustor and a method of pre-mixing air and fuel for a combustor are provided. In one embodiment the pre-mixer includes a first annular premix fuel manifold disposed upstream of the combustor and an annular member concentric with the first premix fuel manifold. Together the annular premix fuel manifold and the annular member define a first venturi shaped air / fuel pre-mix volume between them that has a throat. At or upstream from the throat, the first premix fuel manifold has a plurality of pores whereby the fuel is injected from the first premix fuel manifold to mix with air in the first pre-mix volume. In another embodiment, the annular member is an outer wall, whereas in yet another embodiment, the annular member is a second premix fuel manifold.

Owner:THE BOEING CO +1

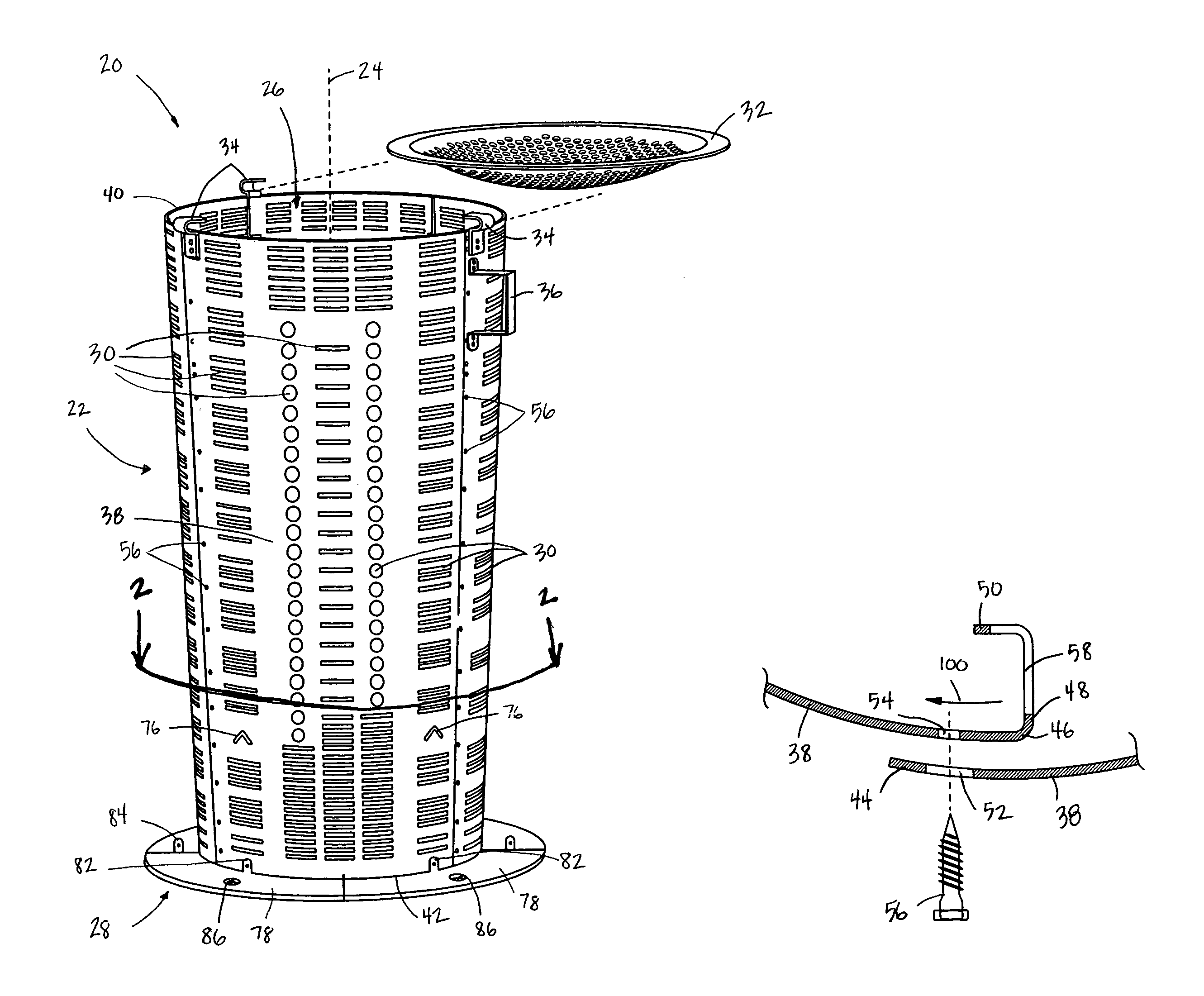

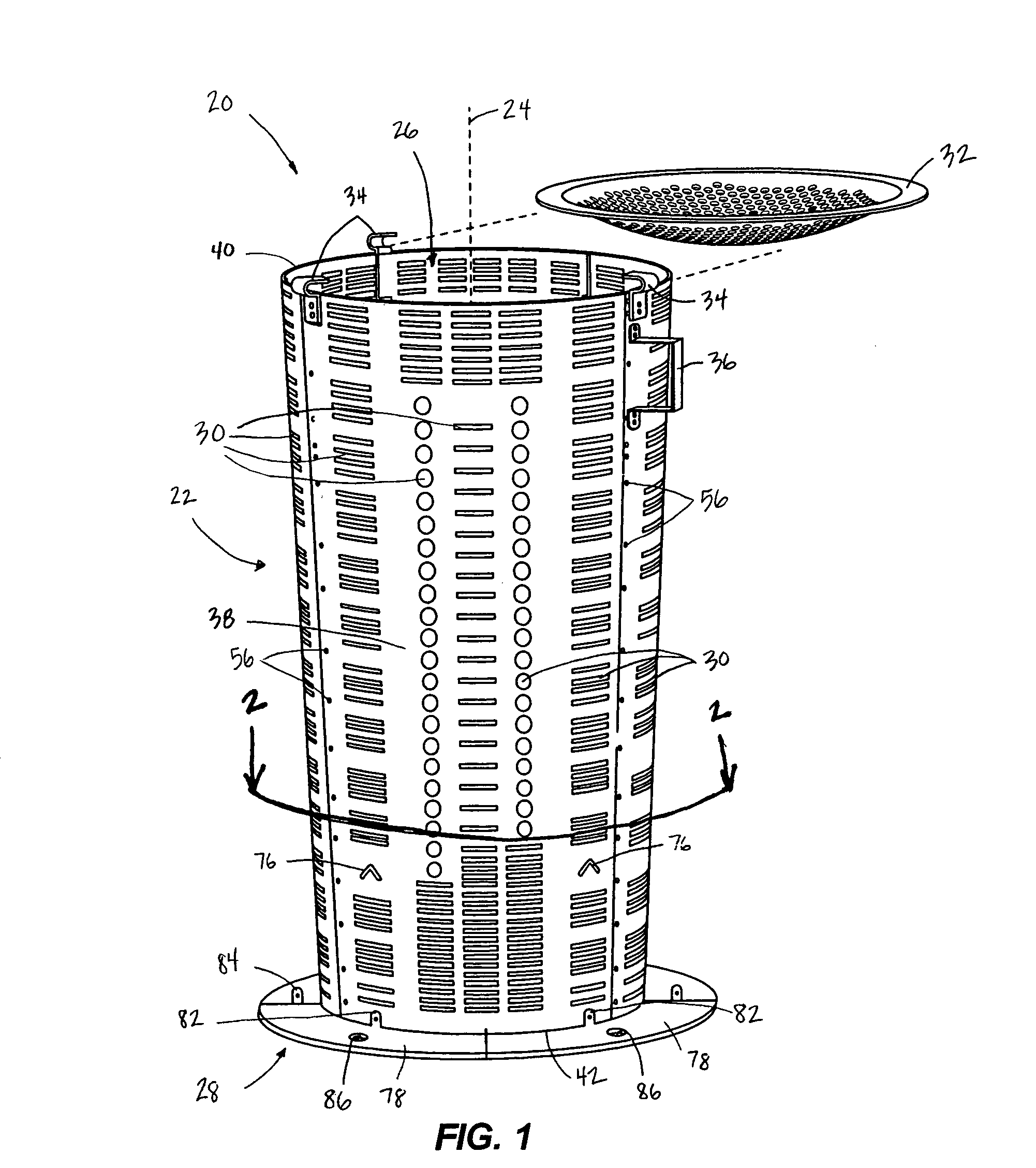

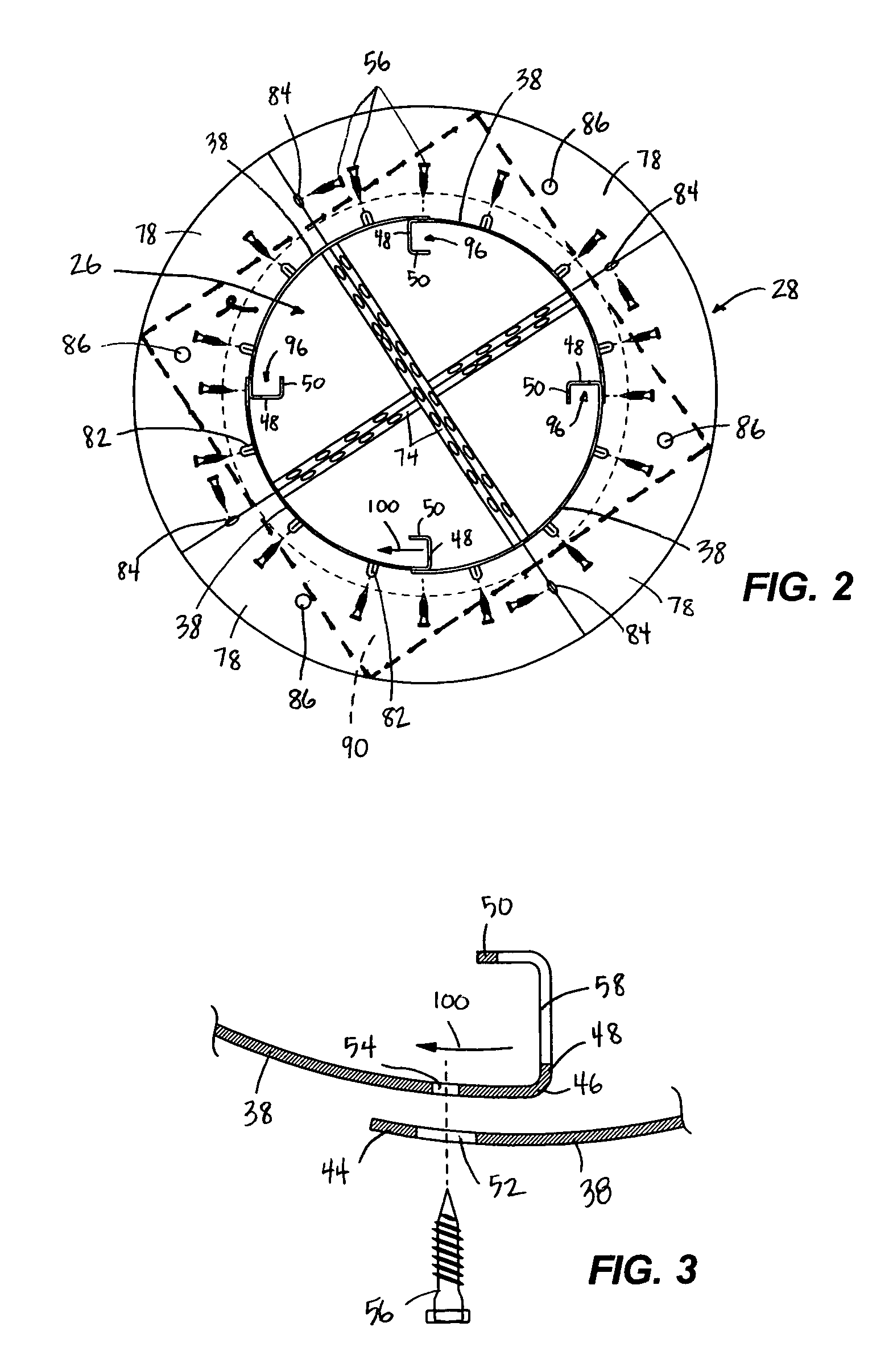

Burning container

A burning device includes a plurality of interconnected chamber walls defining a burning chamber and a central axis, each chamber wall also defining a plurality of chamber apertures. A plurality of flanges extend radially from the chamber walls and substantially parallel to the central axis, and a plurality of circumferentially extending lips extending from a respective flange. Each lip is radially spaced apart from an associated chamber wall and defines therebetween an air flow passageway communicating with the burning chamber and affording air flow into the burning chamber. Ventilation apertures are defined in at least one of the plurality of lips and the plurality of flanges, the ventilation apertures providing communication between the air flow passageways and the burning chamber. A cover is removably supported by the chamber walls and defines a plurality of apertures.

Owner:BURN RIGHT PROD

Air curtain incinerator

ActiveUS20060027150A1Efficiently and cleanly burningLittle and set up timeSolid waste disposalCapillary burnersCombustorCombustion chamber

A self-contained, transportable air curtain incinerator for combustion of low calorific value waste comprises a transportable frame supporting a firebox, a fuel supply tank, a fuel-burning electric power generator in communication with the fuel supply tank, at least one fuel-burning burner unit in communication with the fuel supply tank for directing a flame into a combustion chamber defined by the firebox, and an air curtain blower powered by the generator for providing a sheet of high velocity air flow generally across an open top of the firebox.

Owner:AIR BURNERS

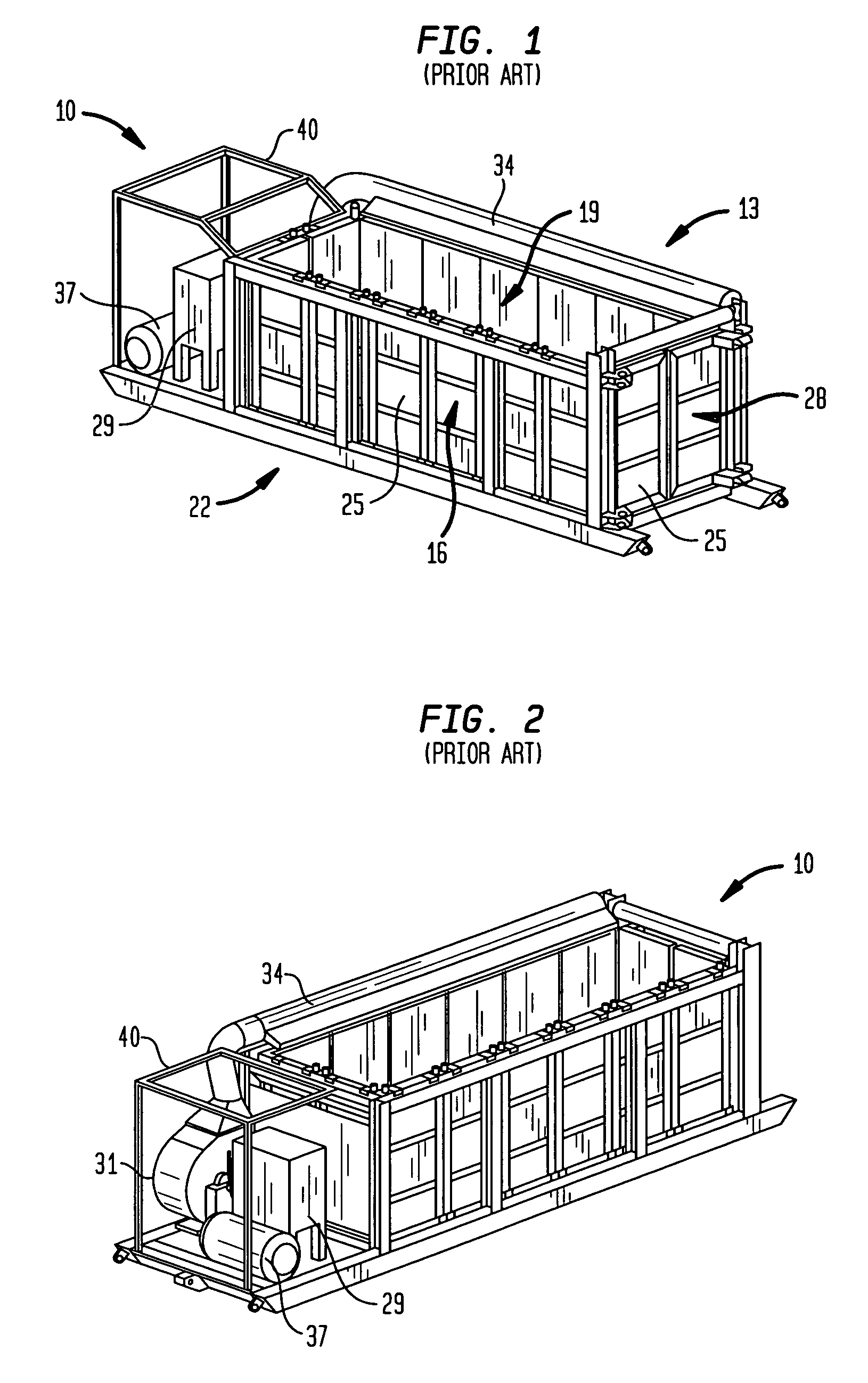

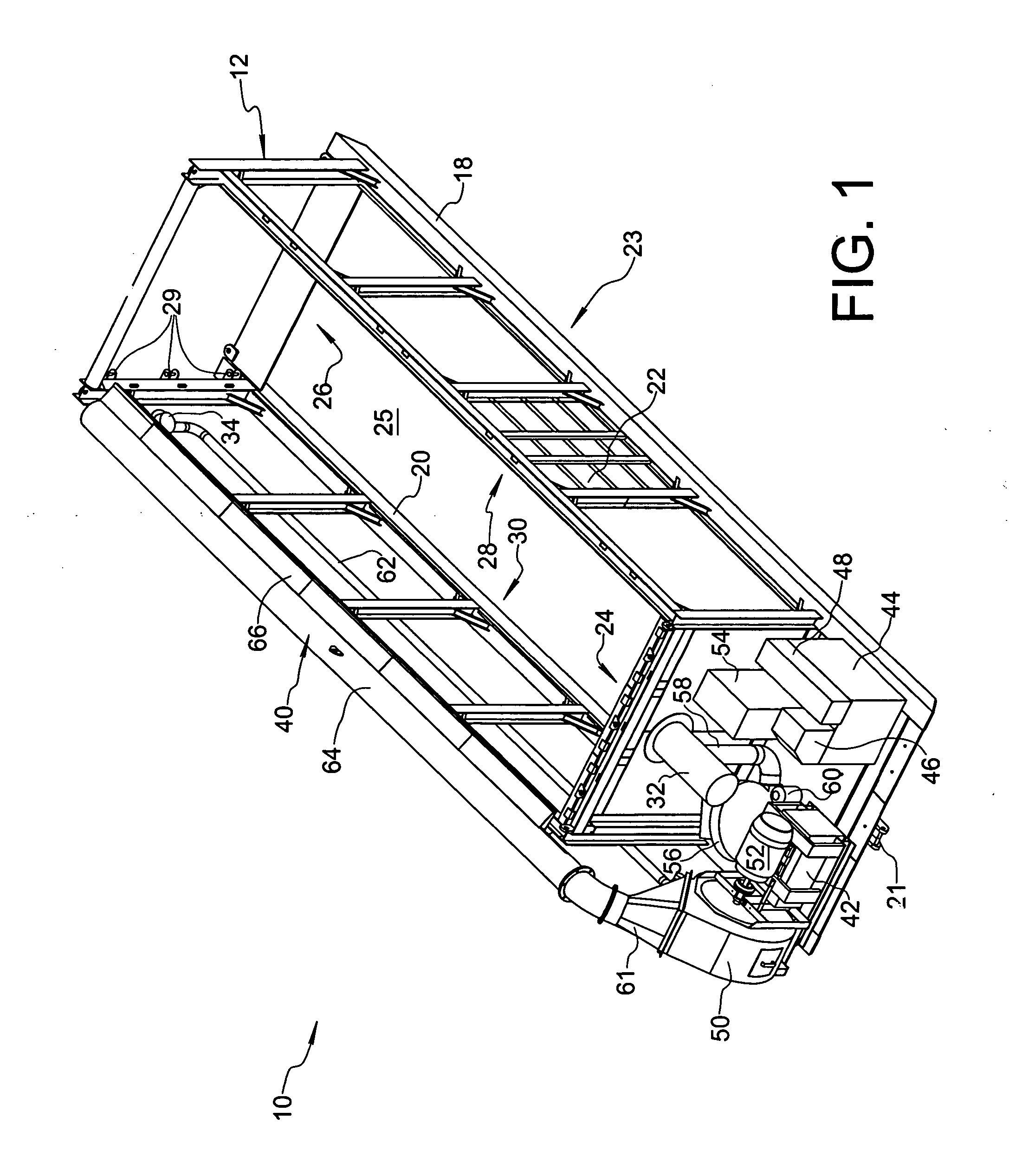

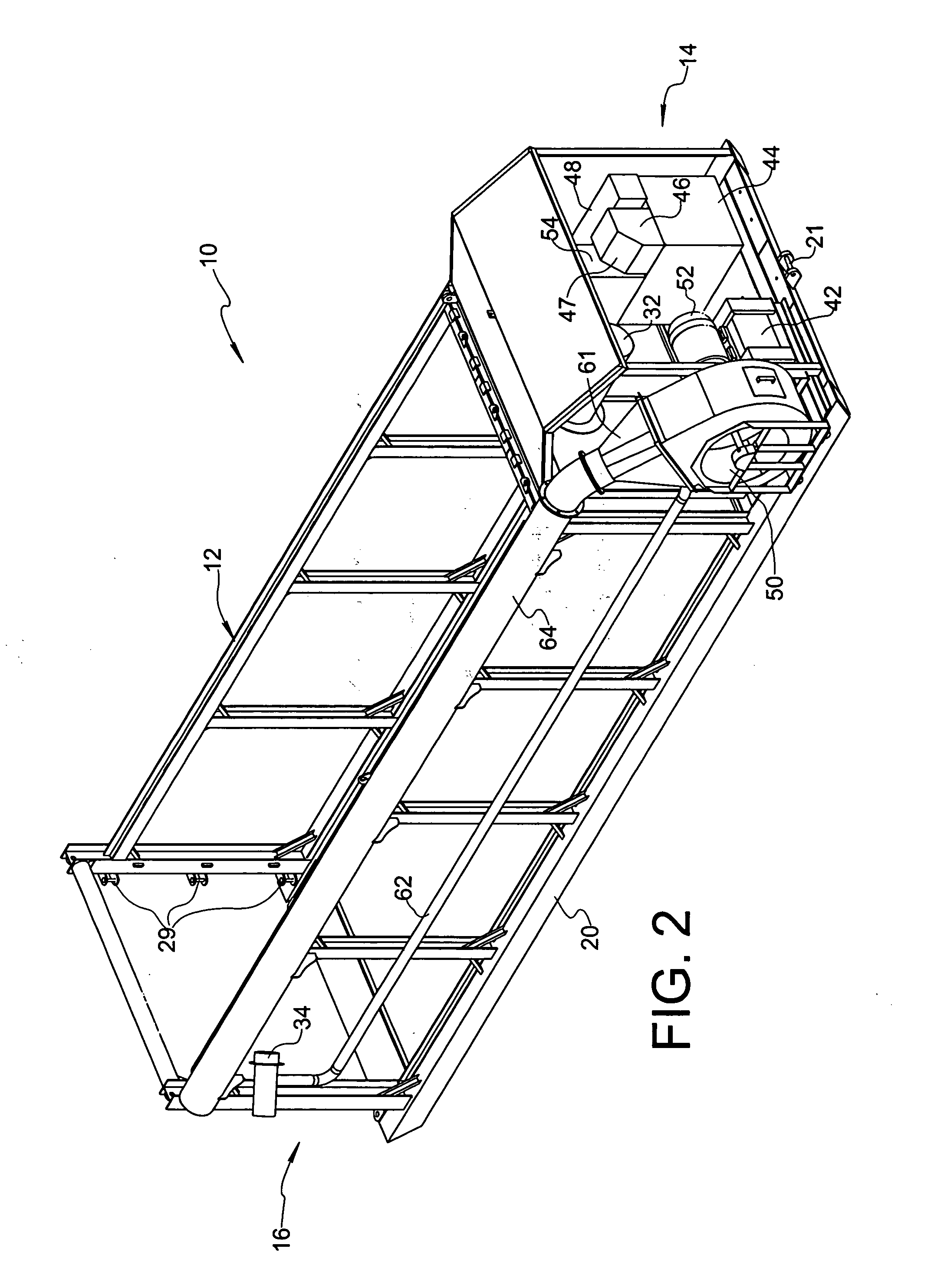

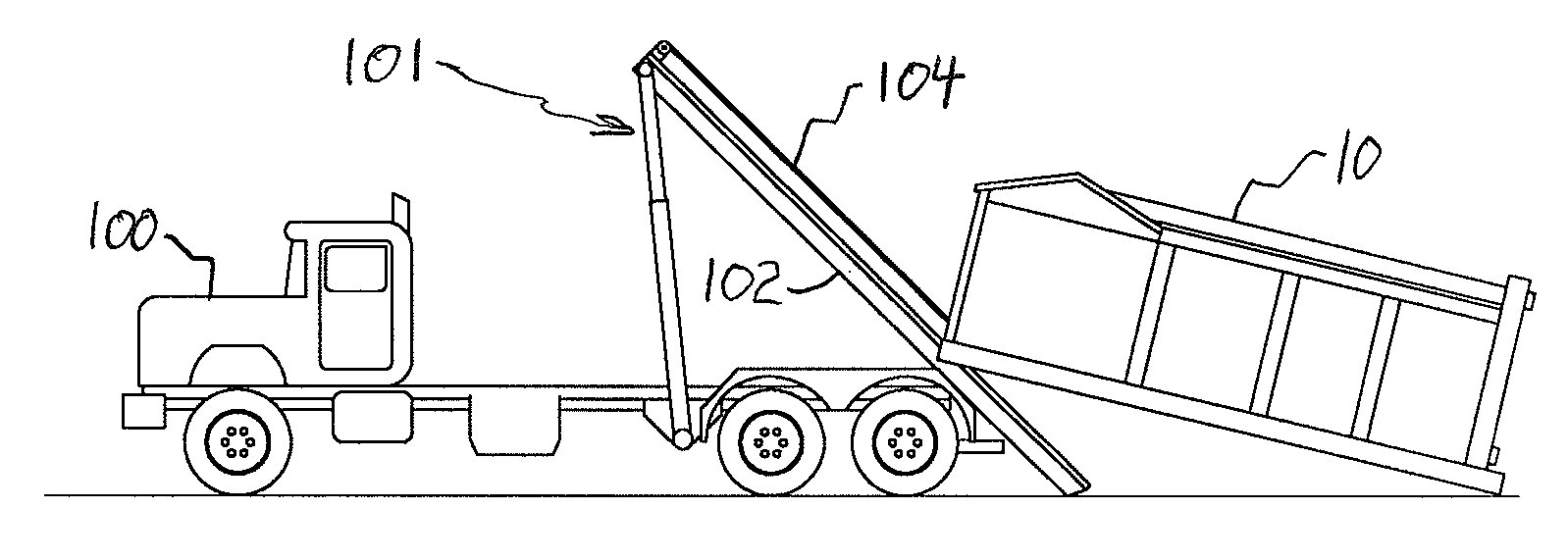

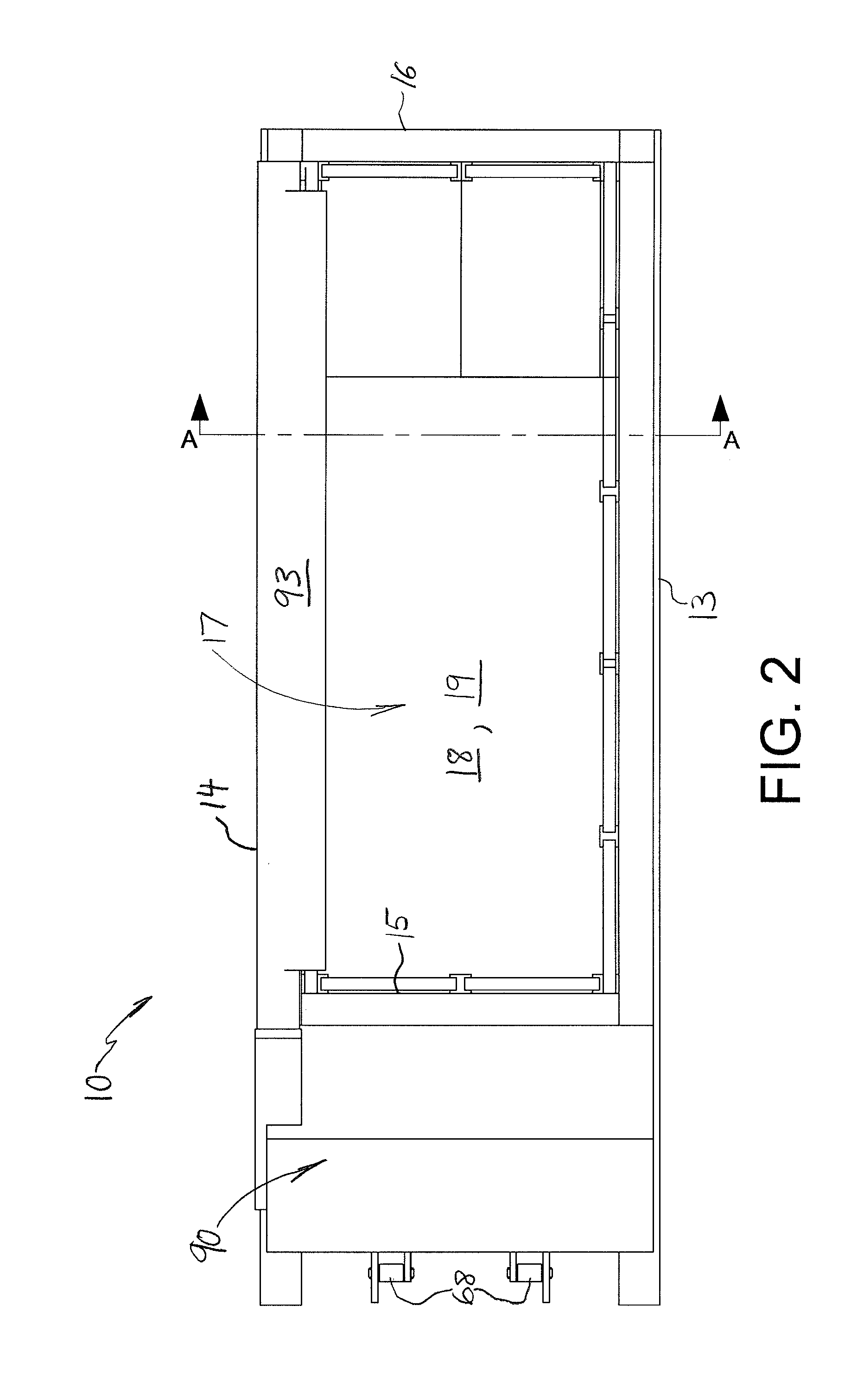

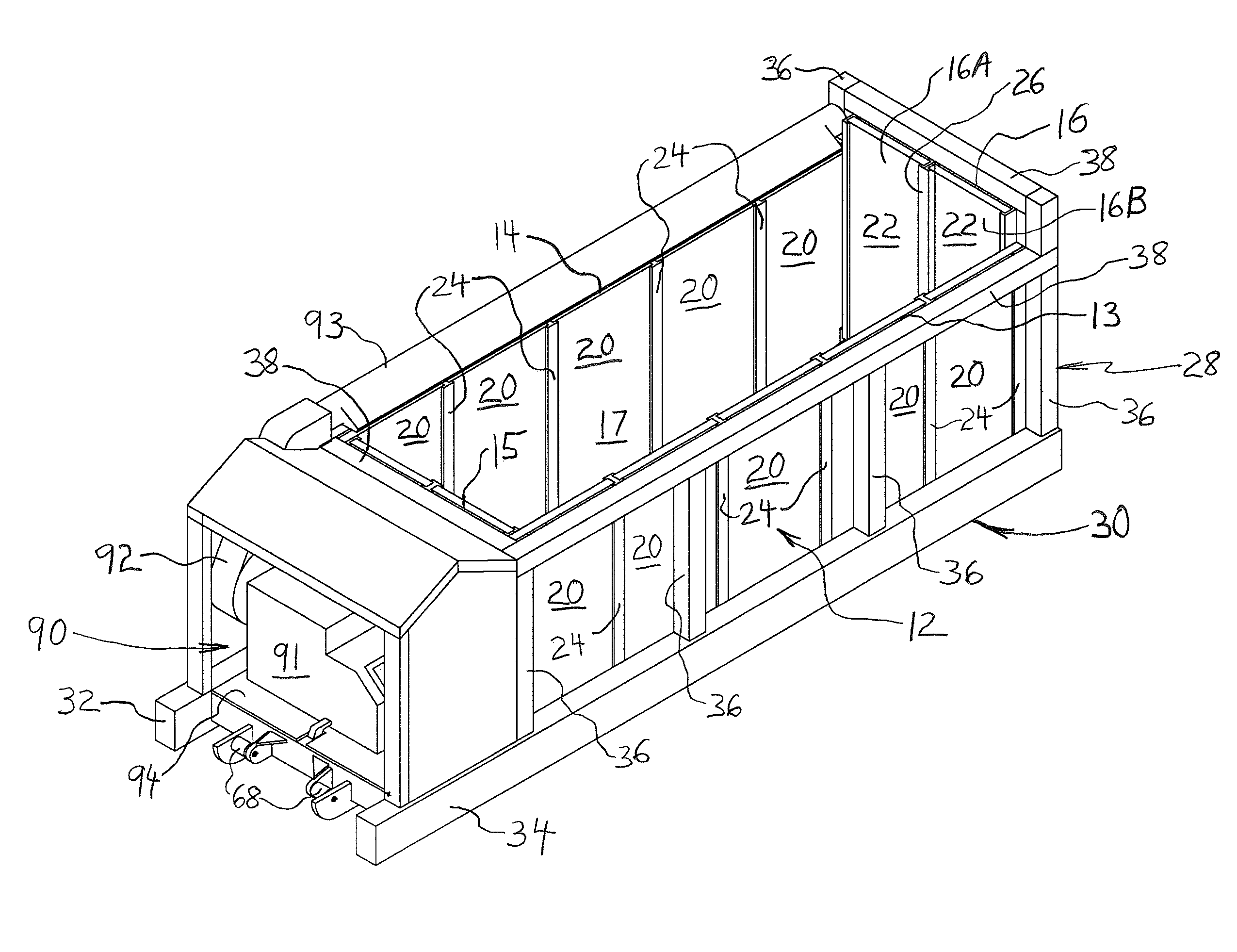

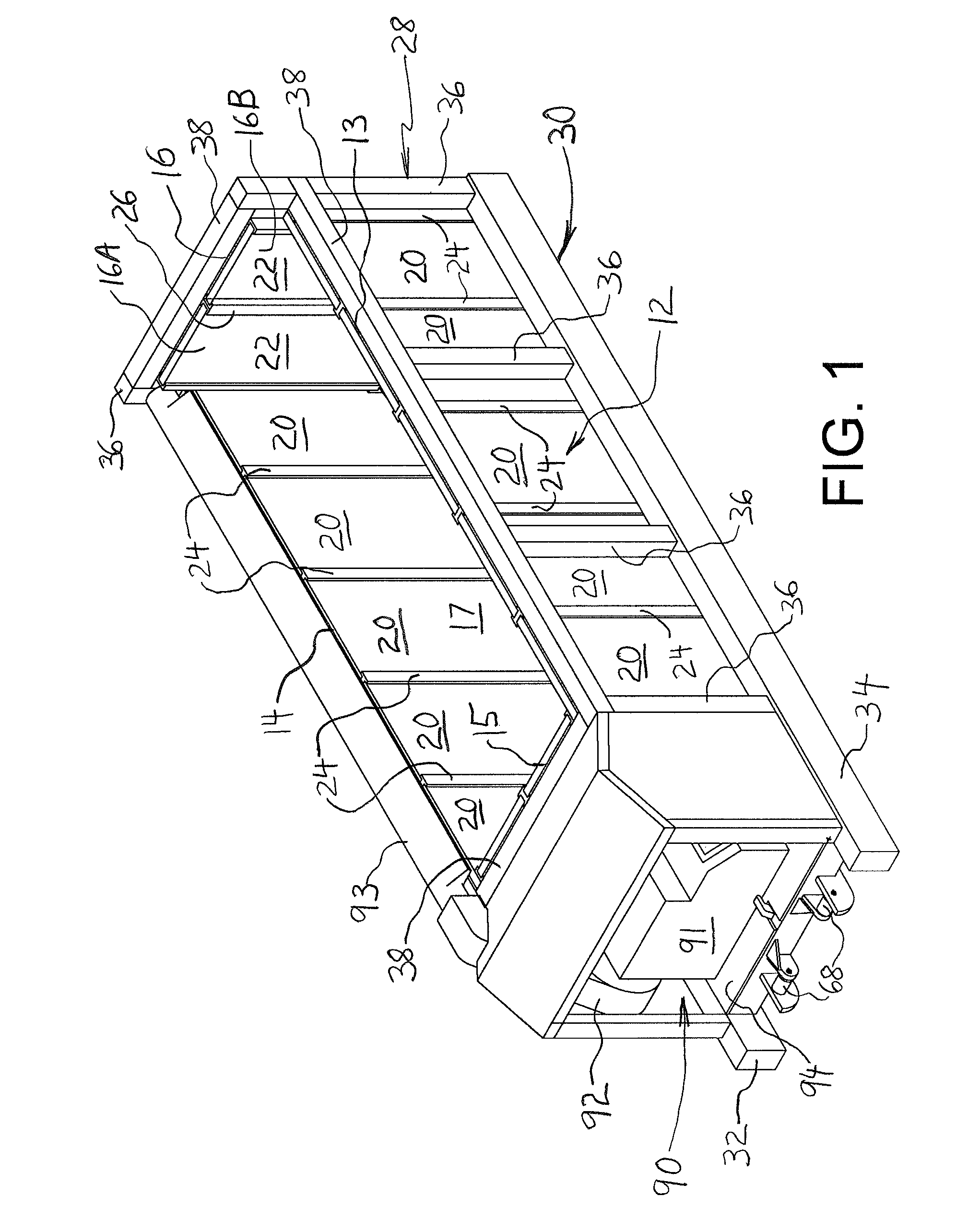

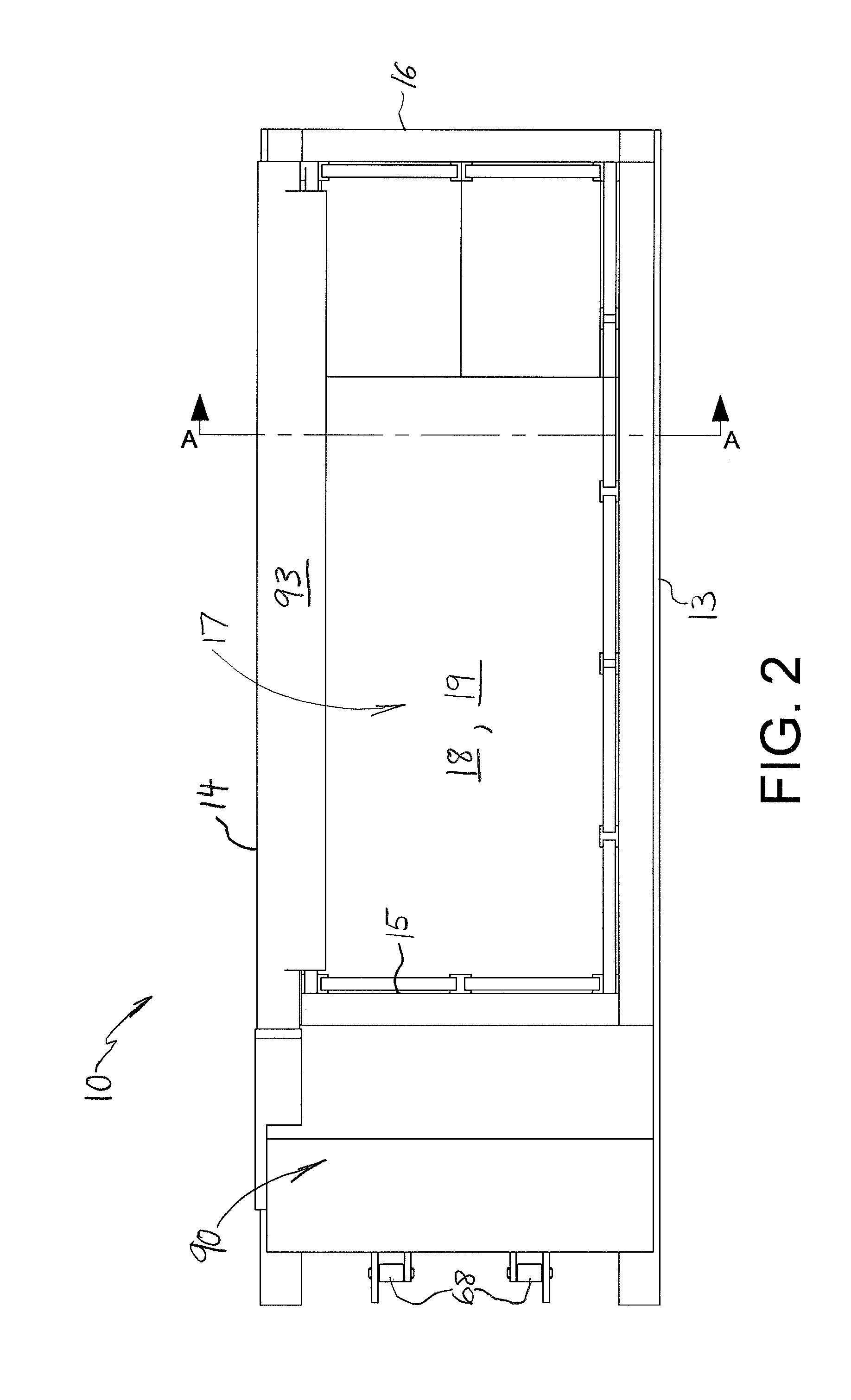

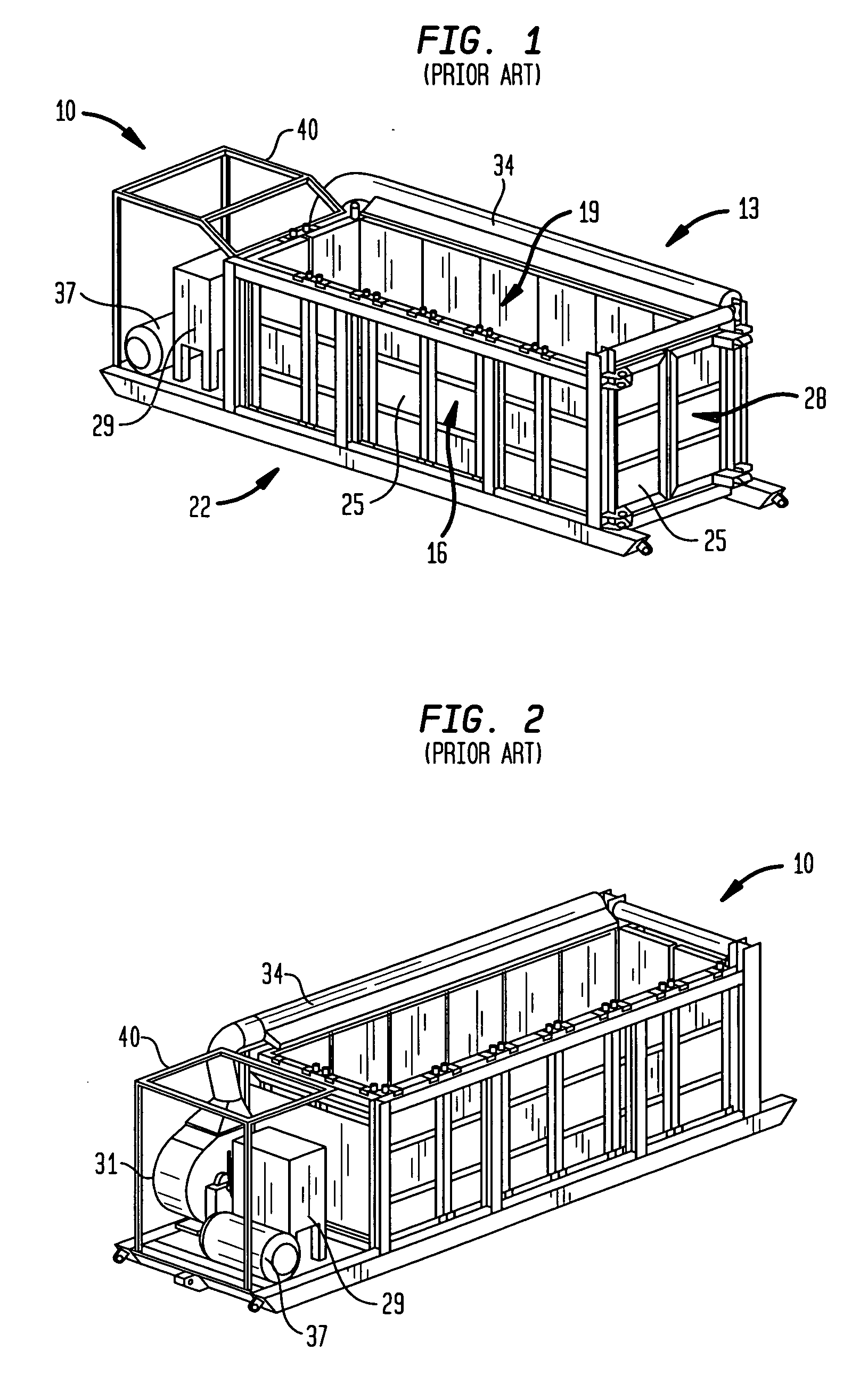

Roll-Off Firebox Apparatus

A firebox apparatus is adapted for transport on a vehicle having a roll-off hoist mechanism by providing parallel guides on the underside of a supporting skid assembly of the firebox apparatus for engaging siderails of a tiltable roll-off track of the hoist mechanism, and by providing reinforced front and rear portions connecting parallel longitudinal skid members to maintain an opening at the bottom of the firebox apparatus yet make the firebox apparatus sufficiently sturdy to withstand loads encountered during loading an unloading from the transport vehicle. The firebox apparatus includes an air curtain system for limiting pollution resulting from incineration of waste. The present invention enables easy installation and removal of the firebox apparatus in crowded environments, such as urban environments, to cleanly burn waste.

Owner:AIR BURNERS

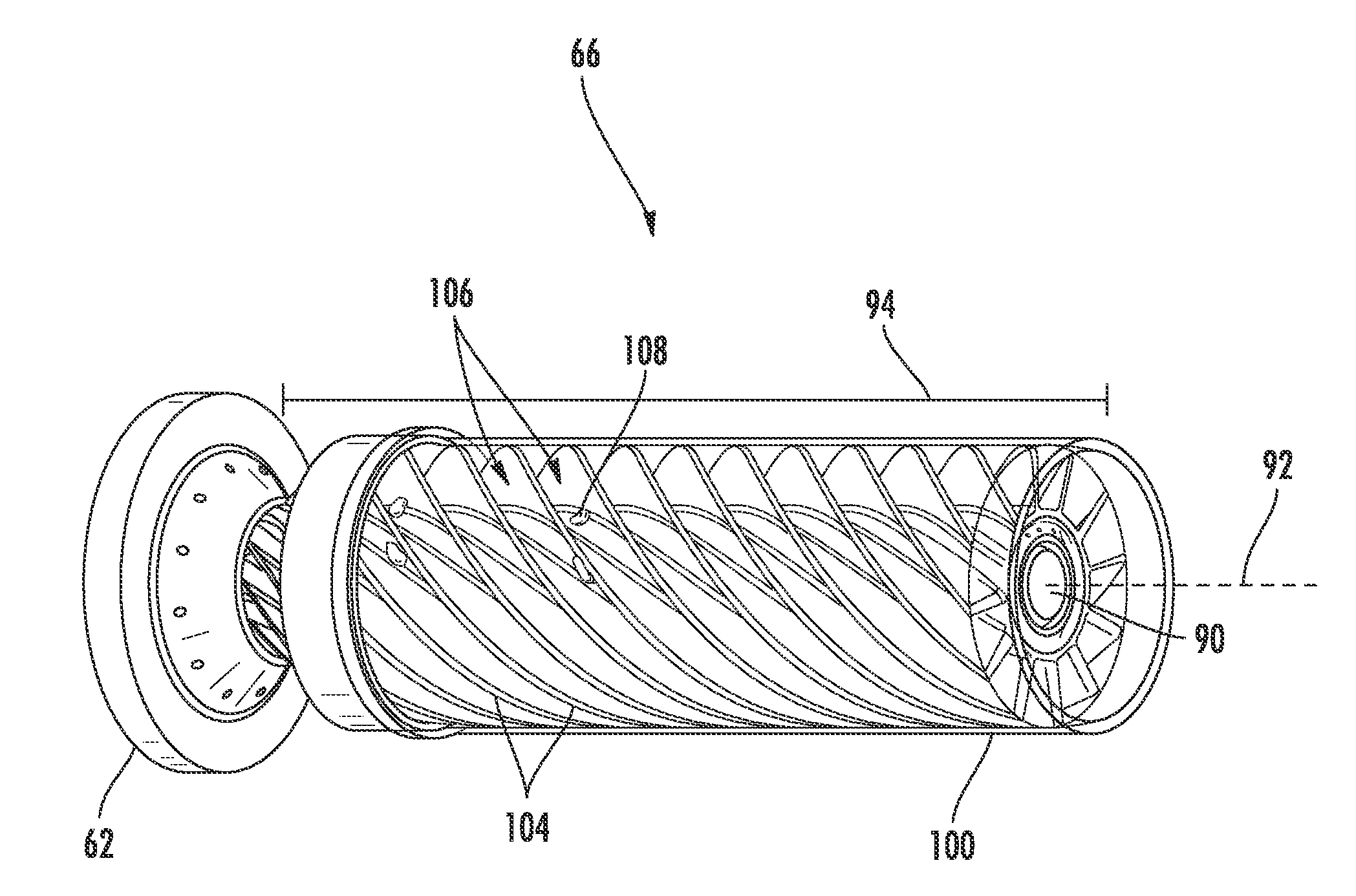

Fuel nozzle for reducing modal coupling of combustion dynamics

A fuel nozzle includes a center body that extends axially along an axial centerline for a length. A shroud circumferentially surrounds the center body for at least a portion of the length of the center body. A plurality of helical passages circumferentially surround the center body along at least a portion of the length of the center body, and a fuel port in each helical passage has a different convective time.

Owner:GENERAL ELECTRIC CO

Roll-off firebox apparatus

A firebox apparatus is adapted for transport on a vehicle having a roll-off hoist mechanism by providing parallel guides on the underside of a supporting skid assembly of the firebox apparatus for engaging siderails of a tiltable roll-off track of the hoist mechanism, and by providing reinforced front and rear portions connecting parallel longitudinal skid members to maintain an opening at the bottom of the firebox apparatus yet make the firebox apparatus sufficiently sturdy to withstand loads encountered during loading an unloading from the transport vehicle. The firebox apparatus includes an air curtain system for limiting pollution resulting from incineration of waste. The present invention enables easy installation and removal of the firebox apparatus in crowded environments, such as urban environments, to cleanly burn waste.

Owner:AIR BURNERS

Catalytic combustor and method thereof

Owner:ZEMISSION

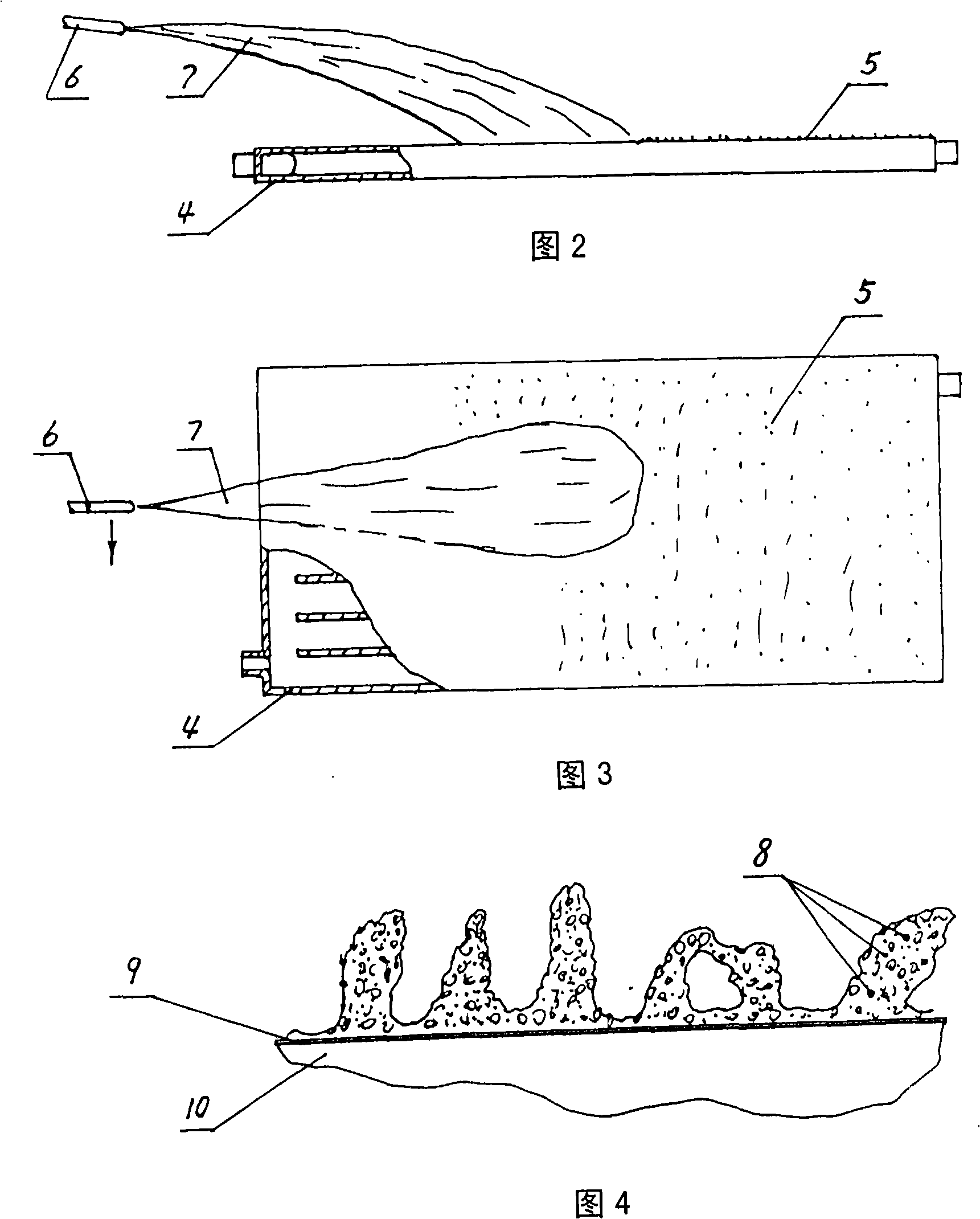

Glycerin burning system

InactiveUS20100233640A1Lower combustion speedShorten speedCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTarget surfaceCombustor

A glycerin burning system having a specialized atomizing burner capable of combusting a continuous feed of crude or pure glycerin. The burner preferably includes an impingement nozzle. The nozzle has an internal distributor which mixes two fluid feed streams (glycerin and air) and expels the fluid through an orifice. The distributor has channels which cause the air to swirl before mixing with the glycerin. An impingement pin is provided outside the orifice. The rapidly ejected glycerin / air mixture strikes a target surface on the impingement pin which transforms the mixture into a fine mist having a reduced velocity. The nozzle is located on the central axis of a turbulator which surrounds the atomized spray with rapidly revolving air. An outlet choke is provided on the combustion chamber to limit the speed of the flow so that steady combustion is maintained.

Owner:MASIN RADEK

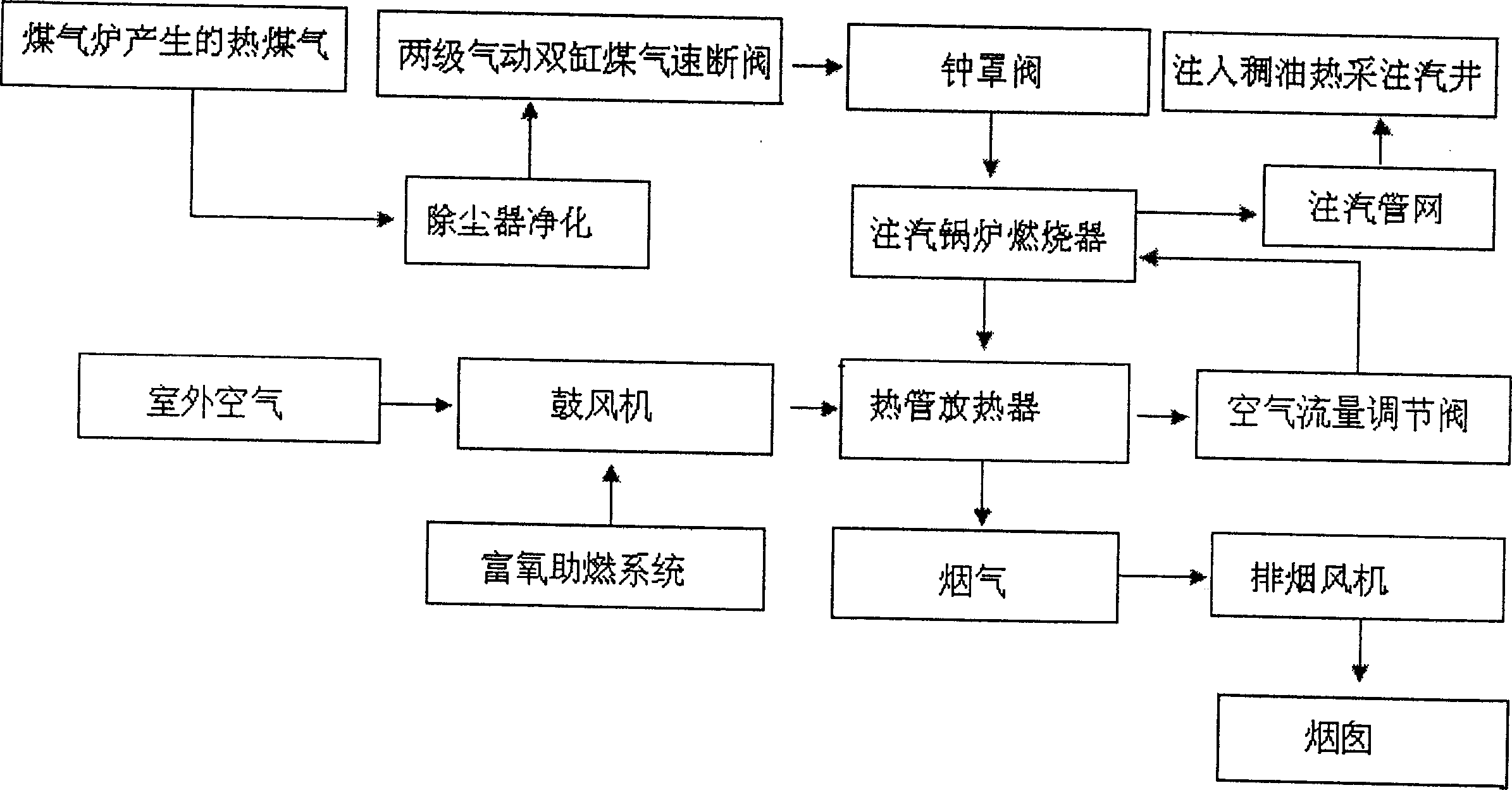

Process for using hot coal gas as viscous crude thermal recovery and gas injection boiler fuel

InactiveCN1945114AUniform deliveryImprove combustionFurnace-tube steam boilersFluid removalSupporting systemCombustor

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

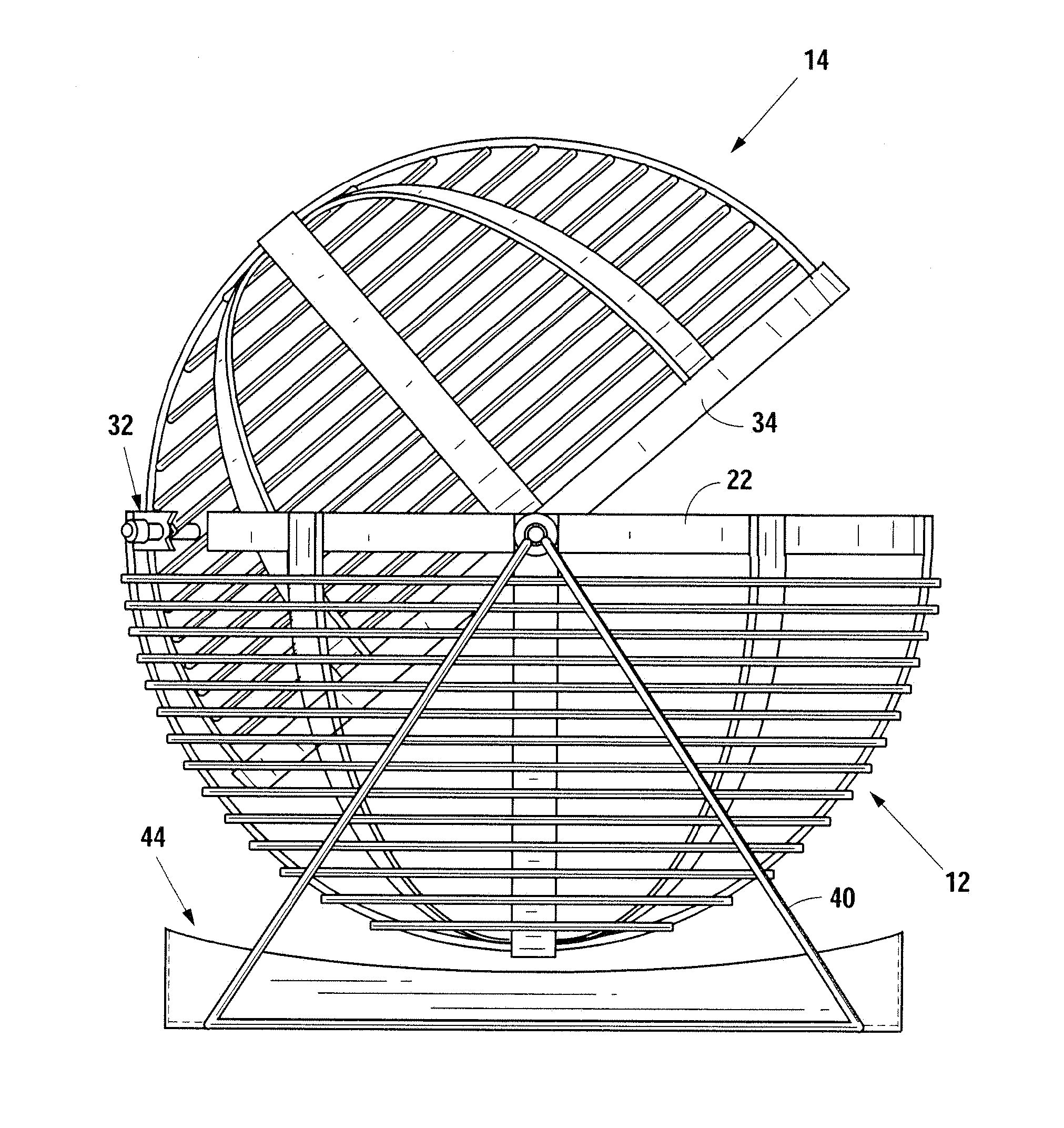

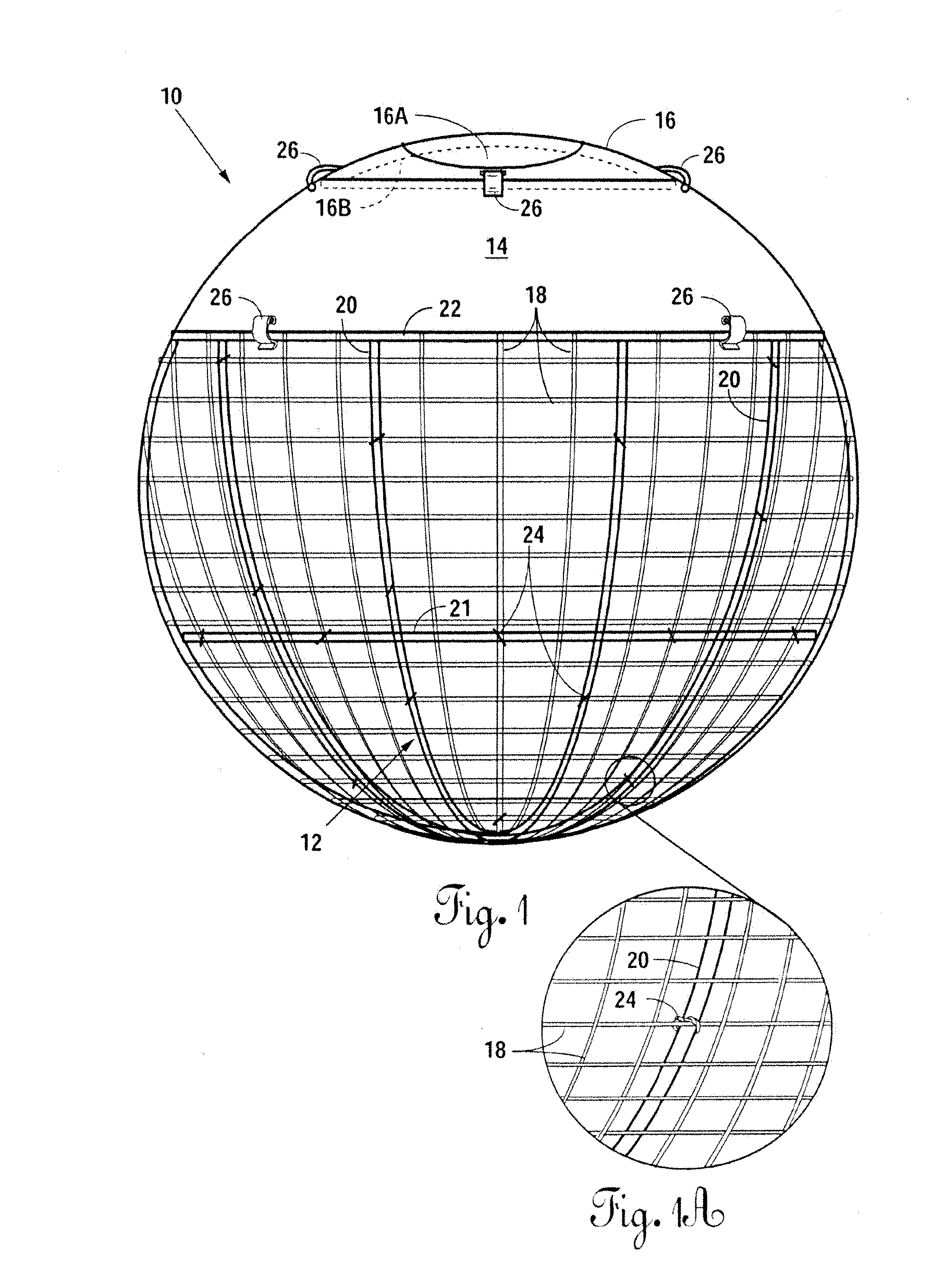

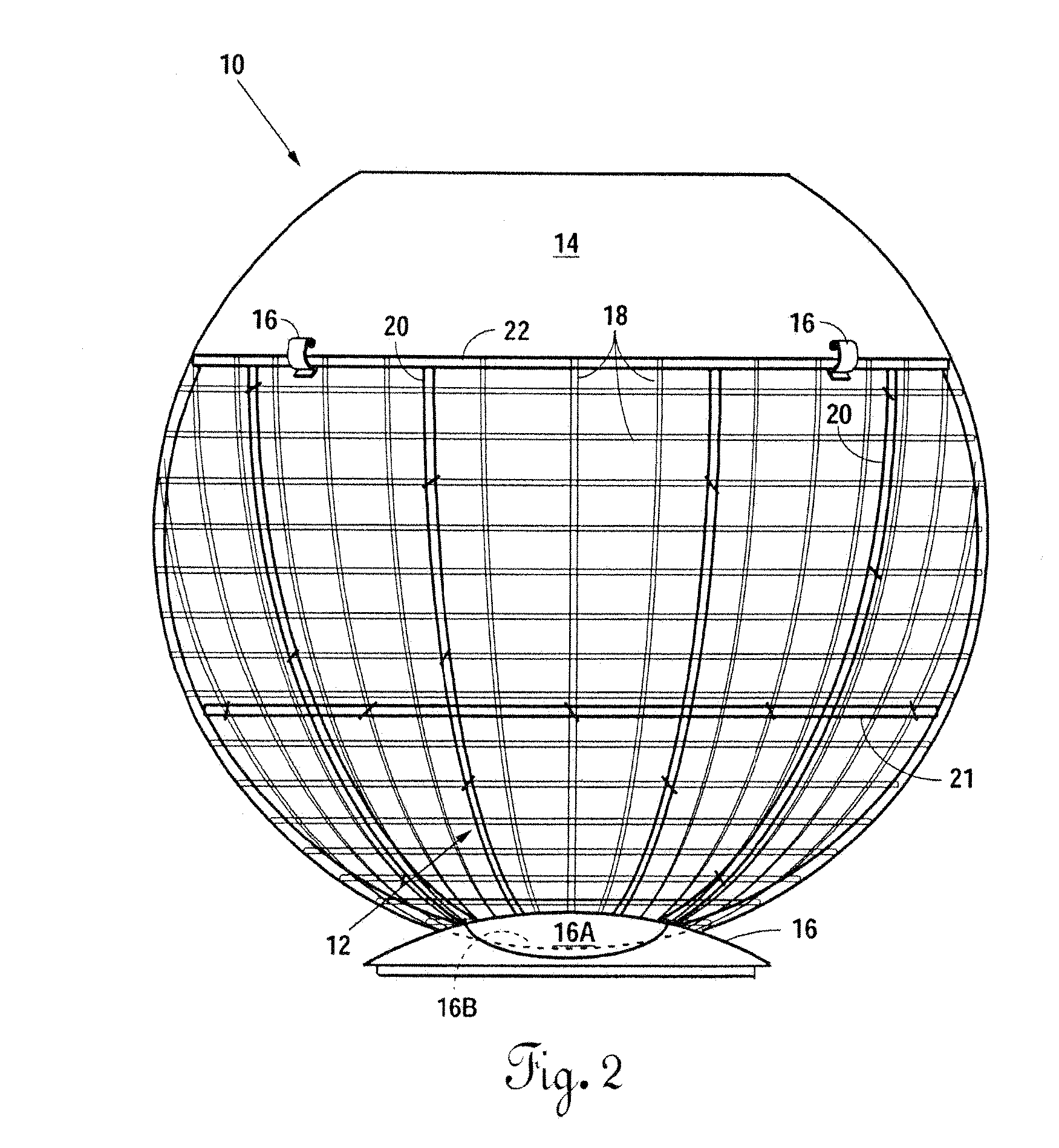

Substantially spherical yard waste container/incinerator

InactiveUS20120079972A1Simple equipmentHe collection, removal, and/or incinerationCapillary burnersLiquid fuel impingement burnersLitterSpherical shaped

A yard waste incinerator device is provided. The device includes an at least partially spherical outer member which is comprised of a truncated sphere. The outer member is usually comprised of a multiplicity of frame members that are spaced apart, but intersect with one another so they look much like latitudinal and longitudinal lines of a globe. Thus, they define a fairly open structure. A partially spherical cover is provided that will moveably engage the frame of the spherical outer member. The cover may be removed to allow debris and the like to be placed in the interior of the at least partially spherical outer member. By placing the cover back in a closed position, the yard ball can be rolled from one place to another rather easily. This is the result of the cover being generally spherically shaped, similar to the outer member so that, when the cover is in place, the yard ball has a spherical or ball shape. When the cover is moved, yard debris may be placed into the device.

Owner:SMITH JEFFREY S

Method for manufacturing a bundle of plates for a heat exchanger

InactiveUS9140498B2Compactness is limitedReduce in quantityMetal sawing devicesStationary conduit assembliesEngineeringMechanical engineering

Owner:ALFA LAVAL VICARB +3

Protective device for incineration apparatus

A protective device may be attached to a portable incineration apparatus, or used over an open pit. The protection device may be a screen constructed of a stainless steel mesh. The screen is laid across the open top of the portable incineration apparatus or the top of the open pit. The screen forms a seal between the top portion of the walls of the incineration apparatus, or of the pit, and the portion of the screen that engages the top portion of the walls. Thereby, smoke, ashes and-embers are limited, or even prevented from escaping from the incineration apparatus or the open pit.

Owner:AIR BURNERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com