Patents

Literature

429results about "Cremation furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

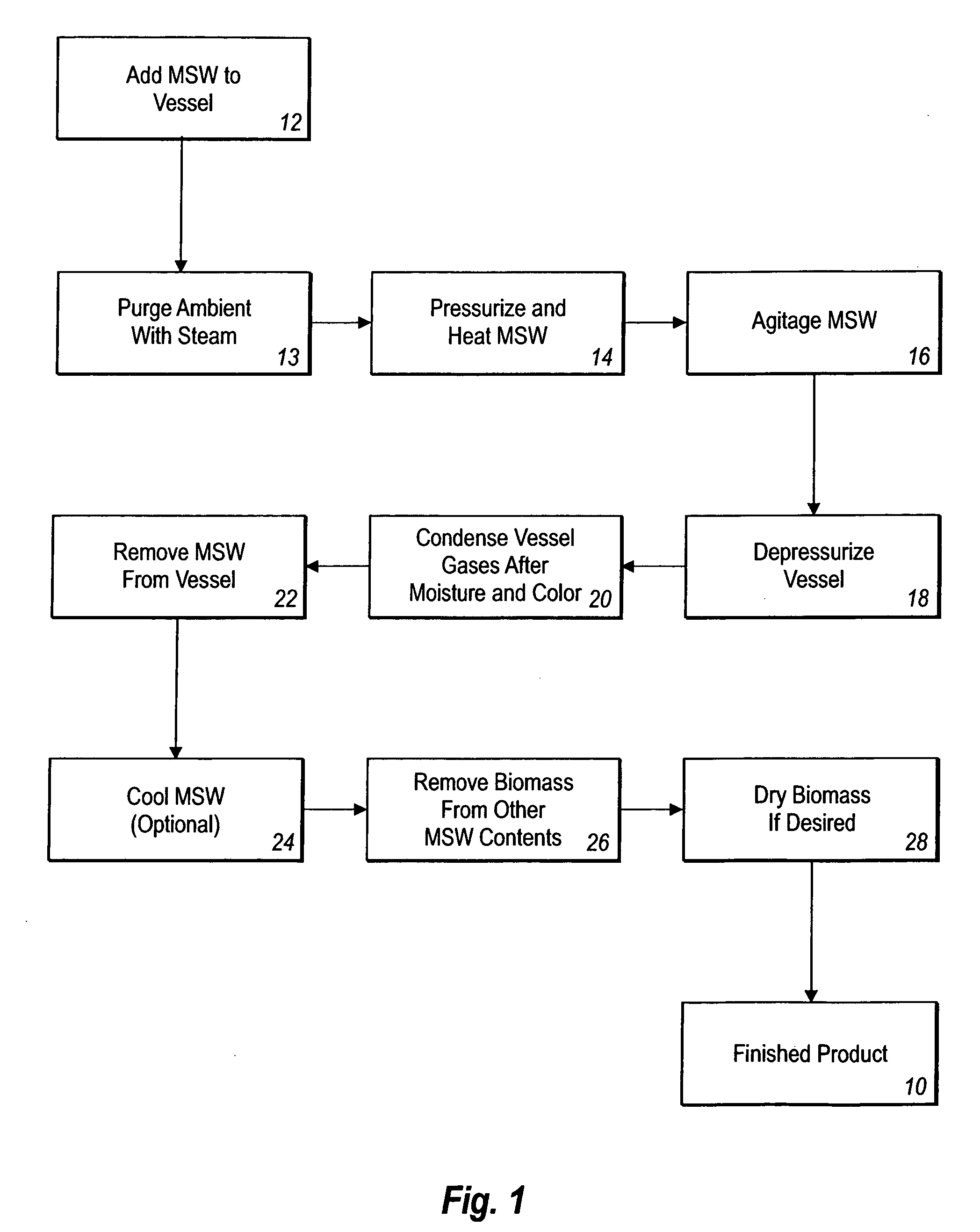

Biomass energy product and processing method

InactiveUS20060112616A1Increase concentrationCritical problemBiofuelsSolid fuelsEnergy productsProcess engineering

An energy product made from biomass, and a method of making an energy product from biomass. The energy product is made by processing biomass in a pressurizable reaction vessel with heat, pressure and agitation.

Owner:BIOMASS WORLDWIDE GROUP

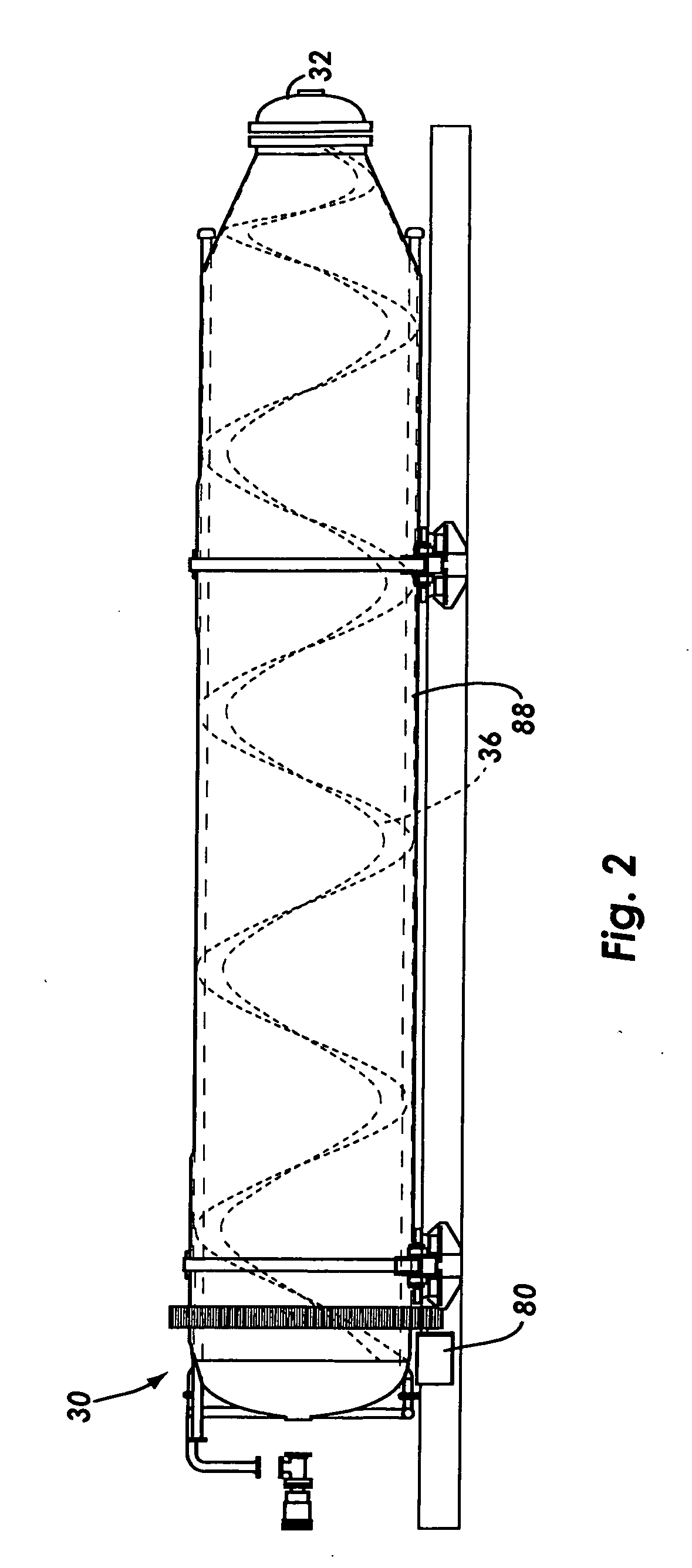

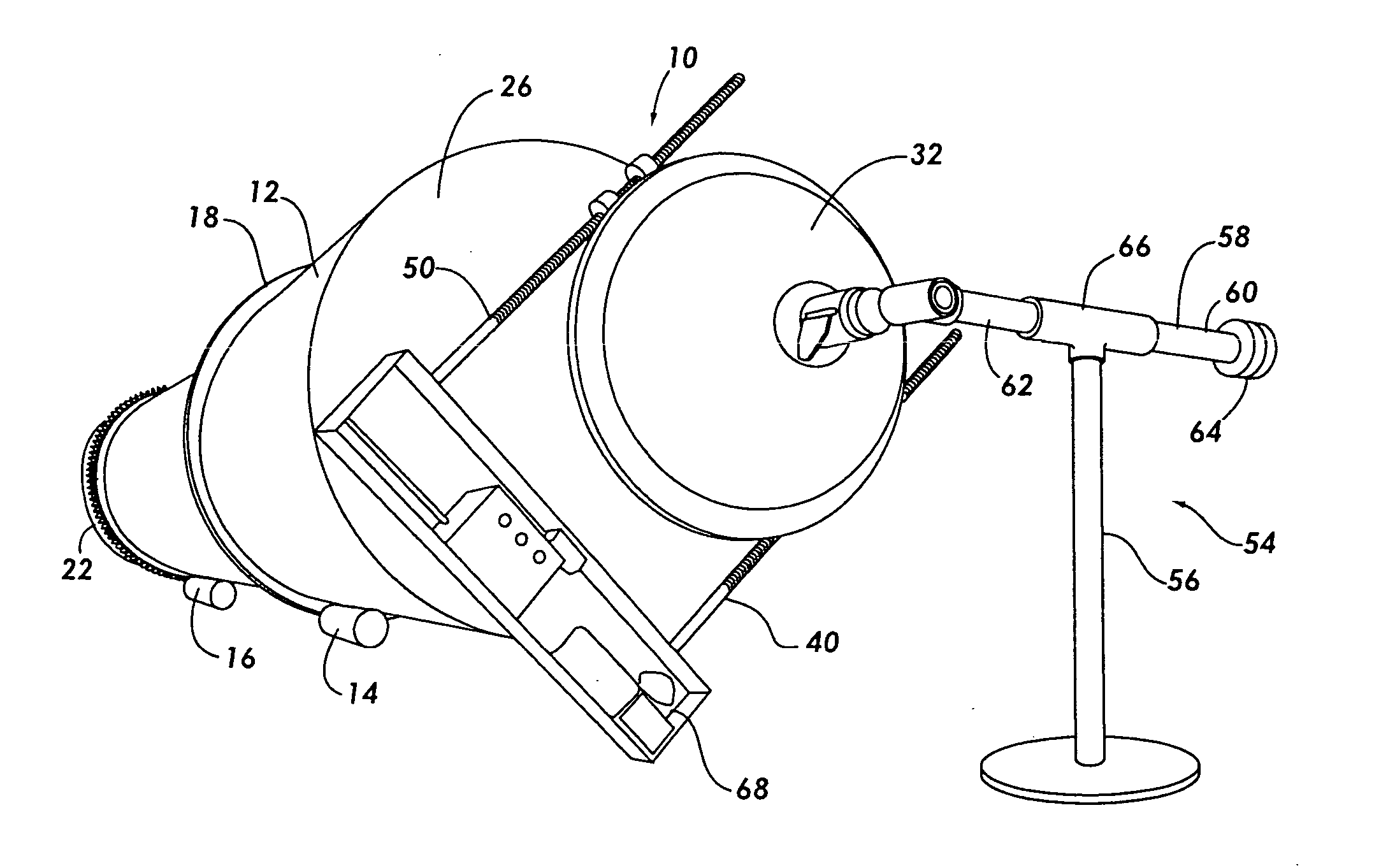

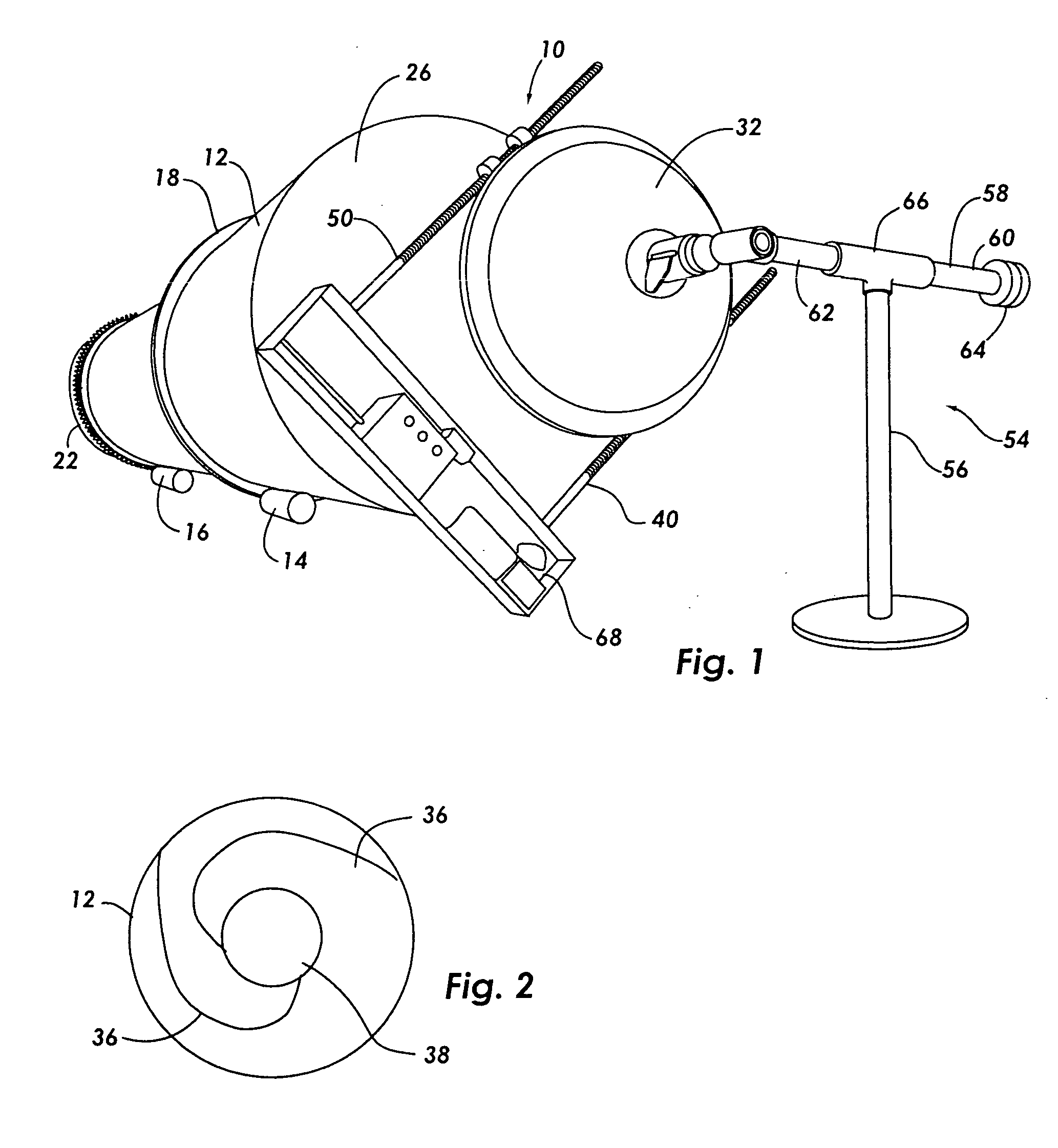

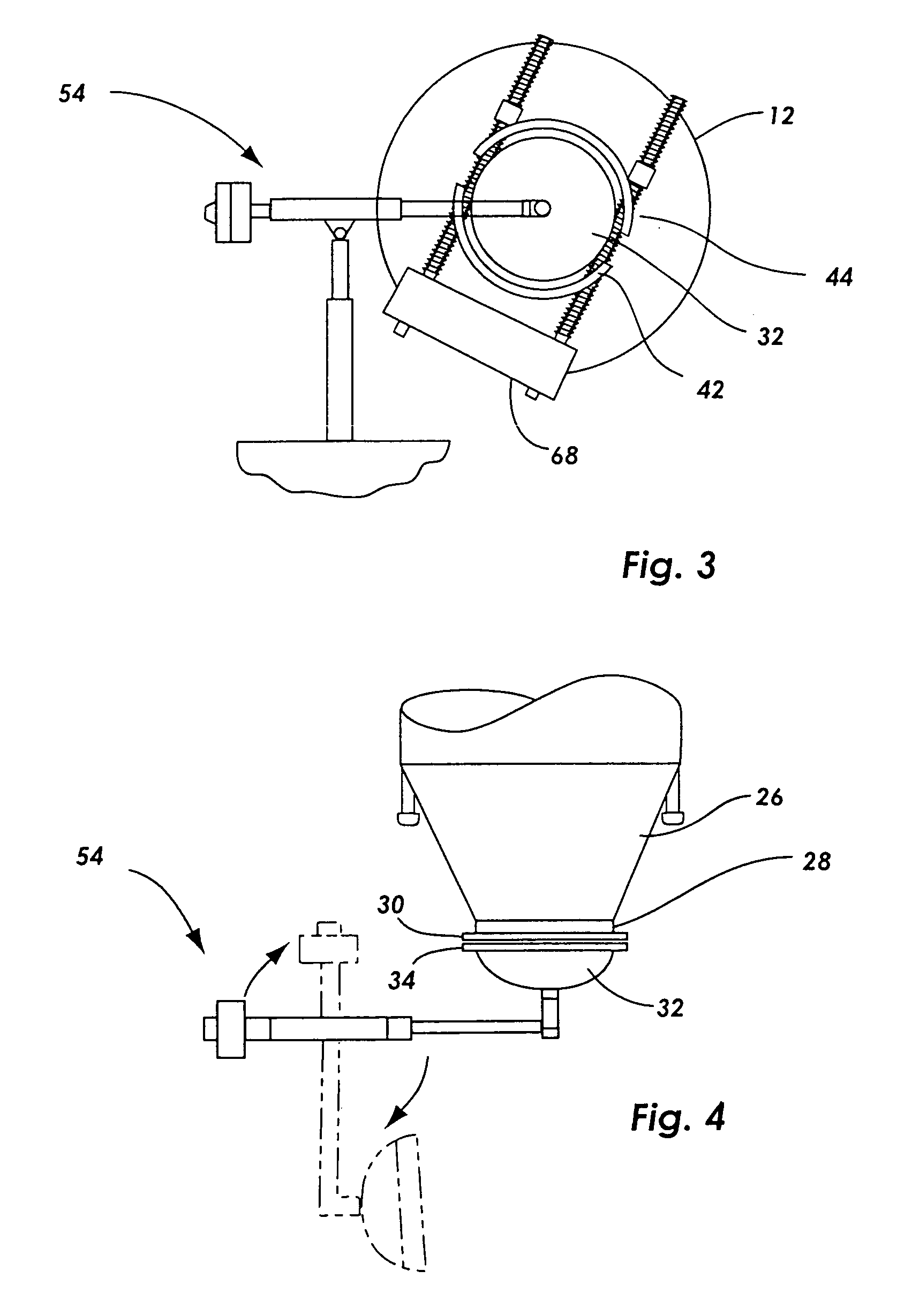

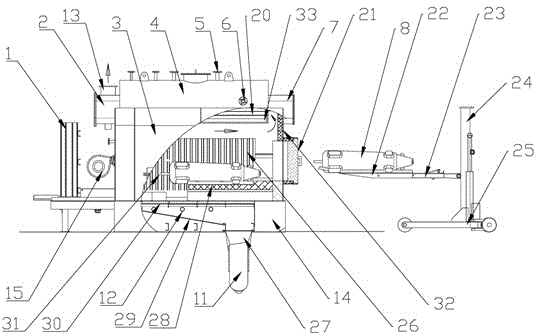

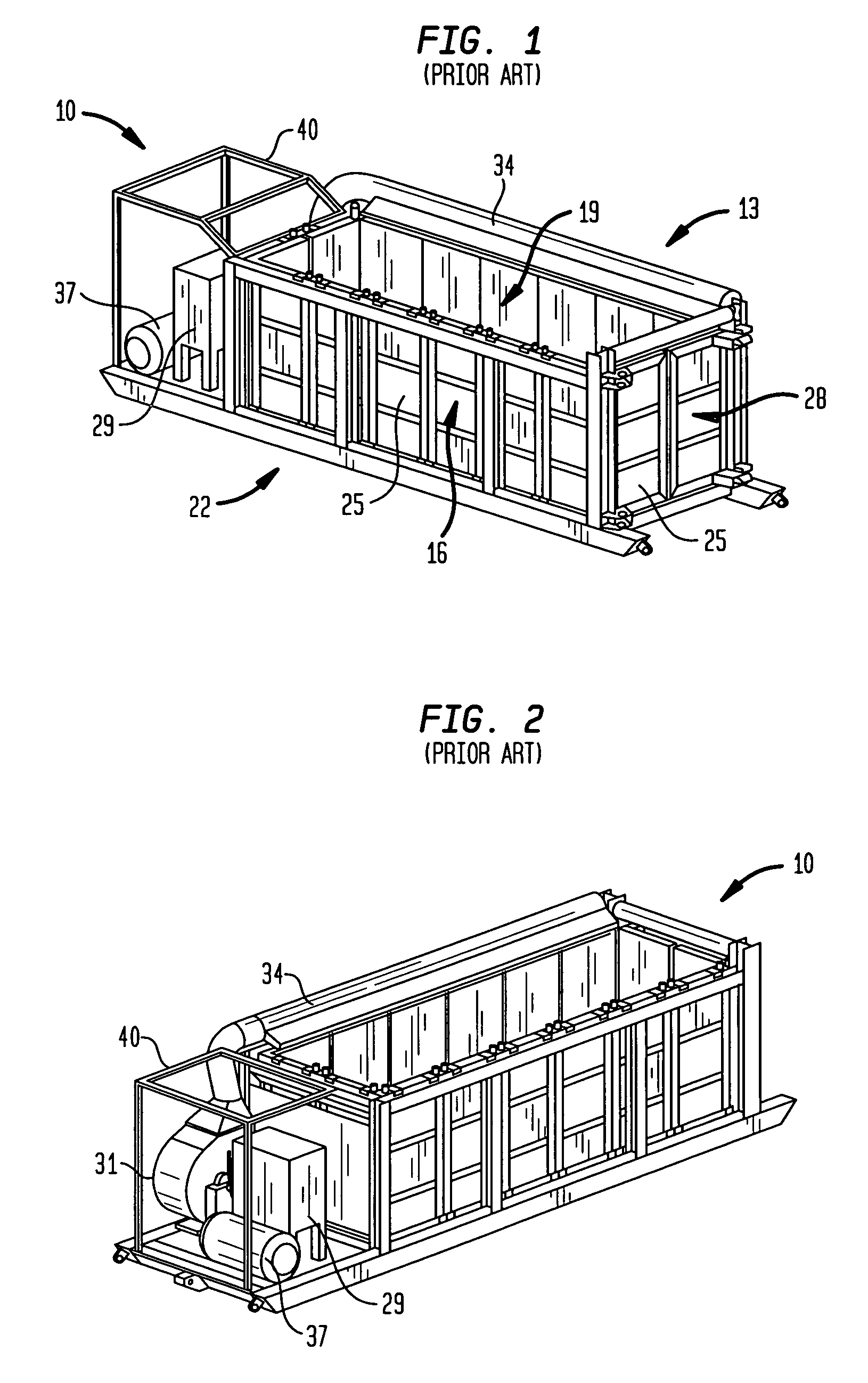

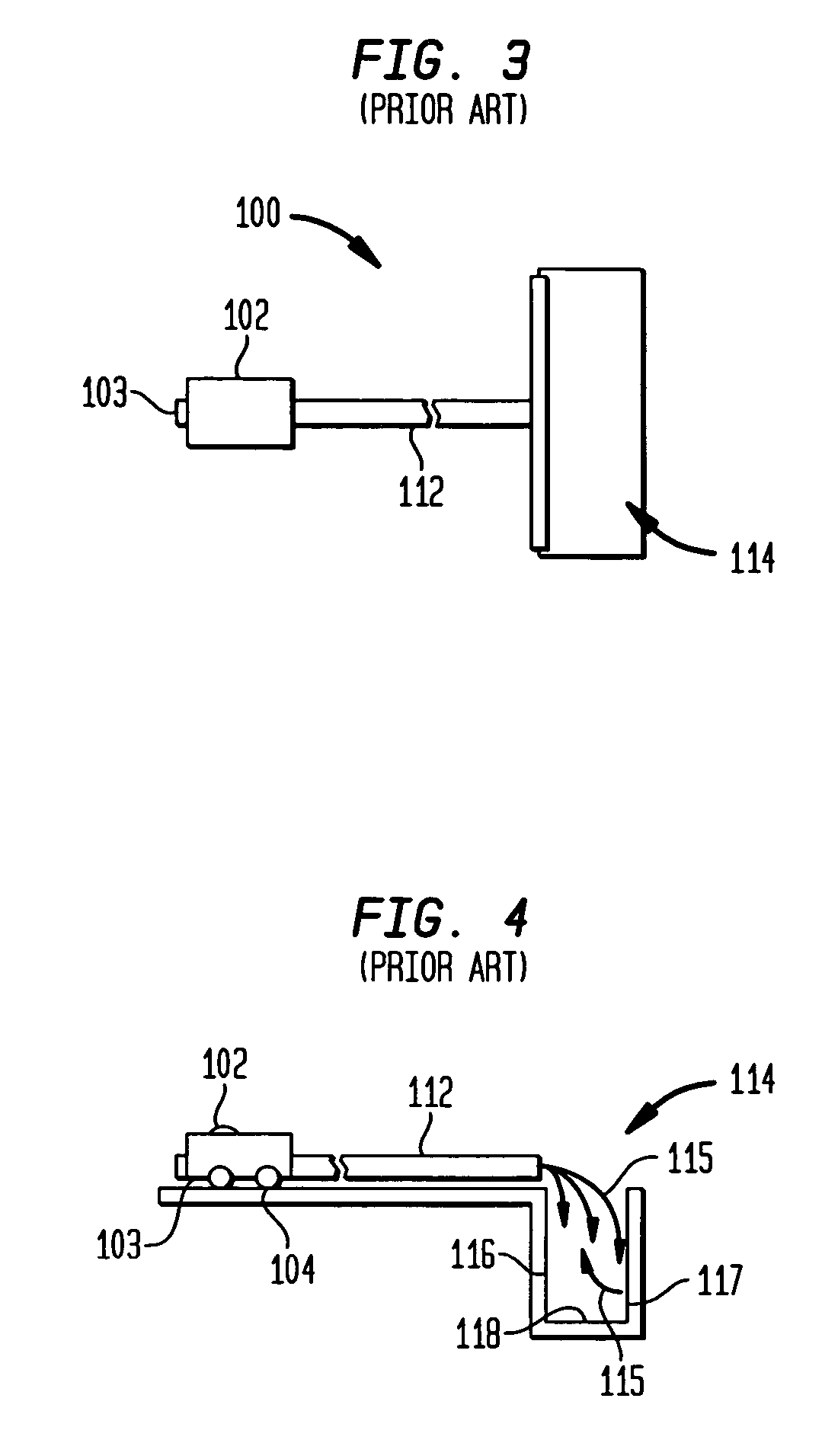

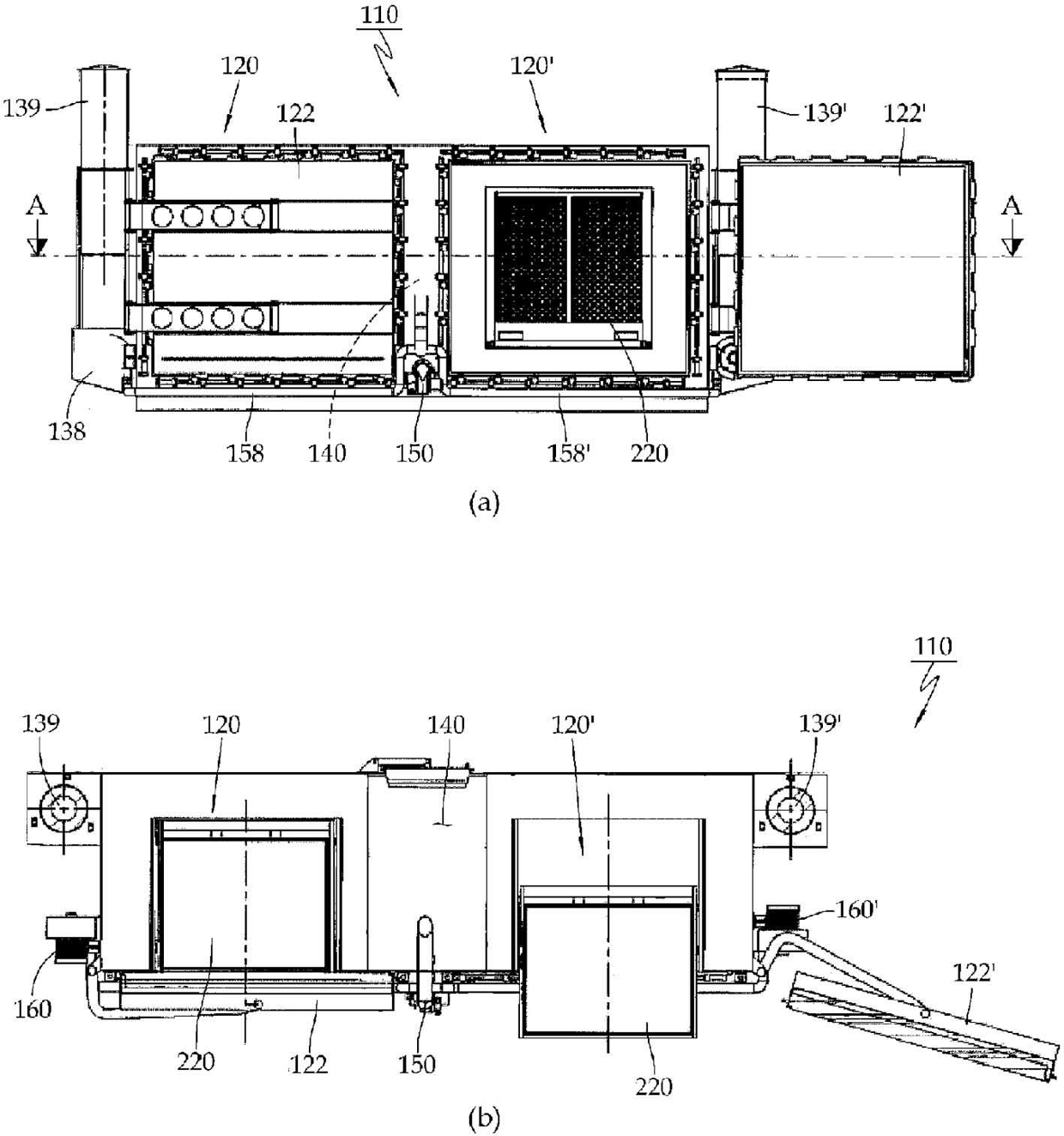

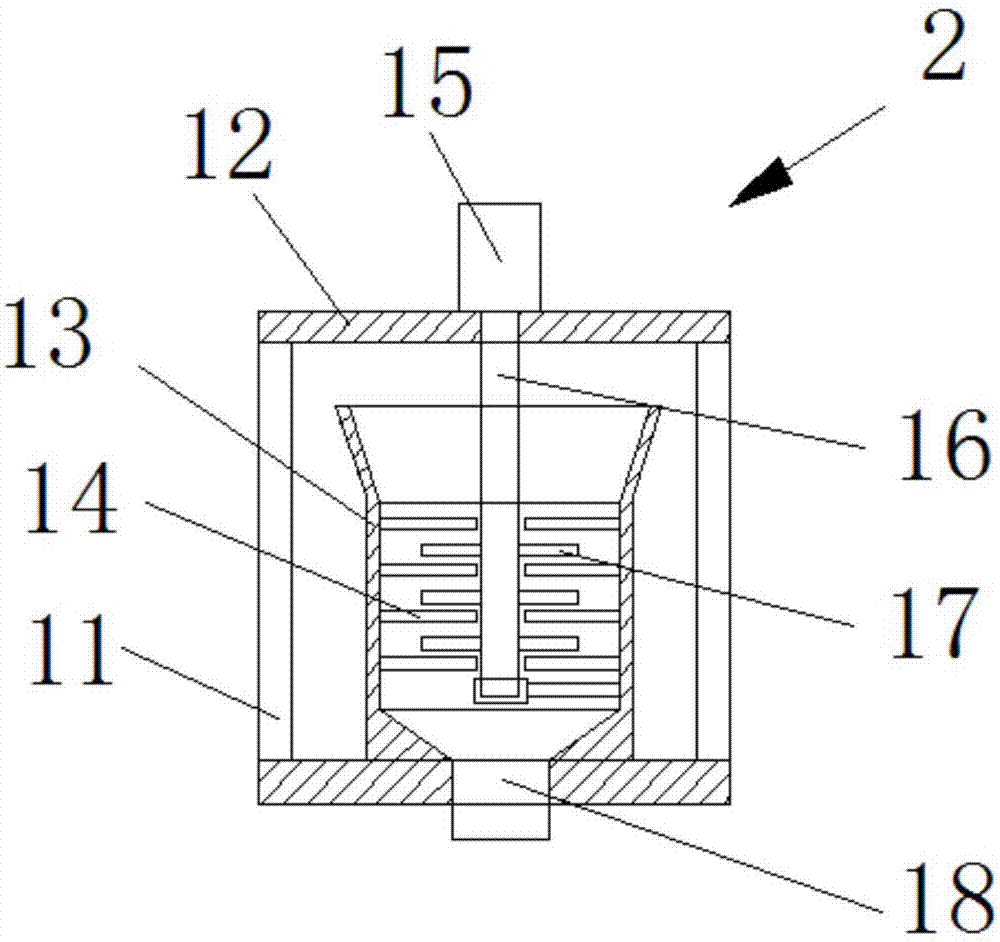

MSW processing vessel

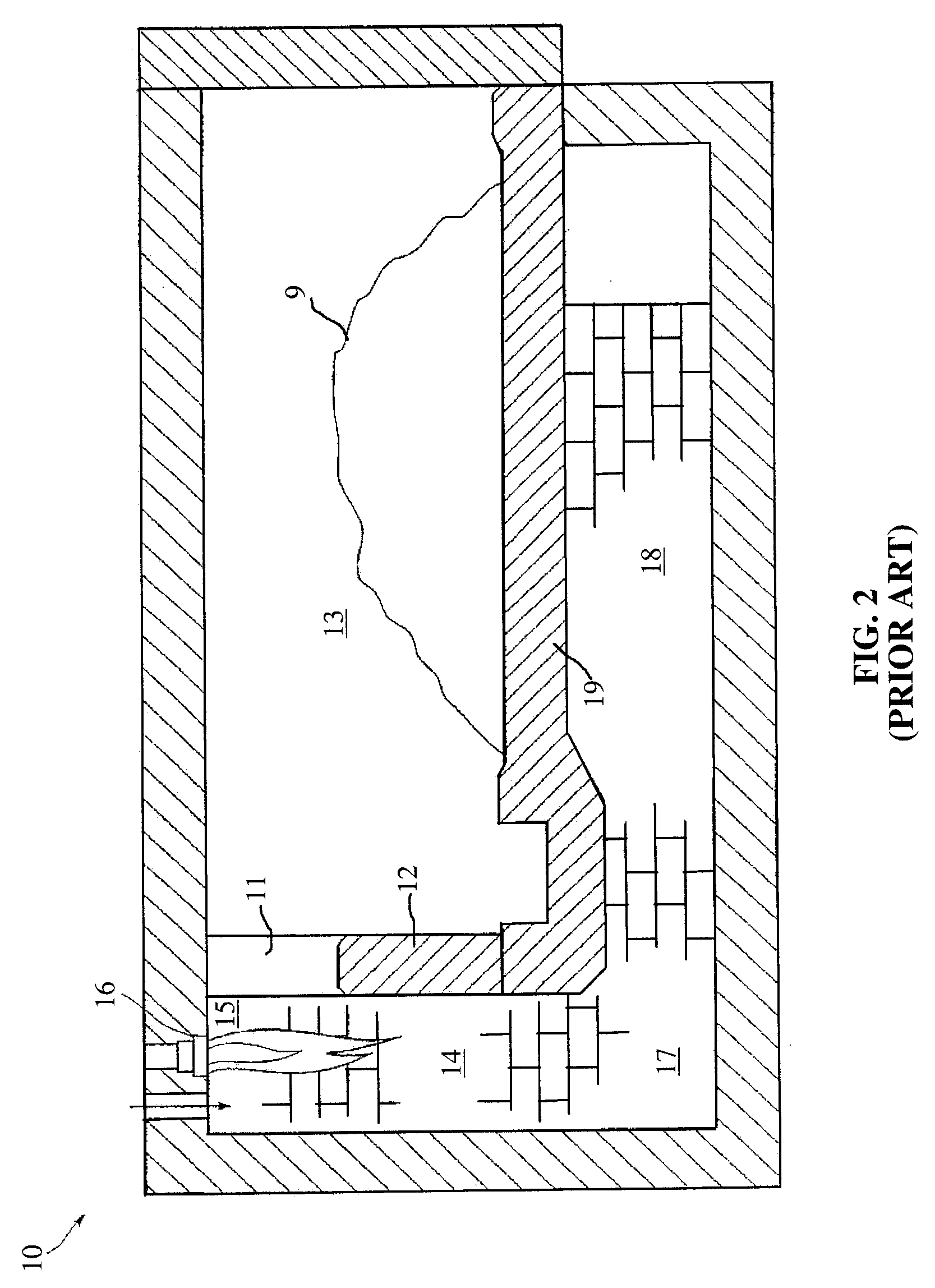

InactiveUS20050166812A1Improve automationCremation furnacesIncinerator apparatusMunicipal solid waste

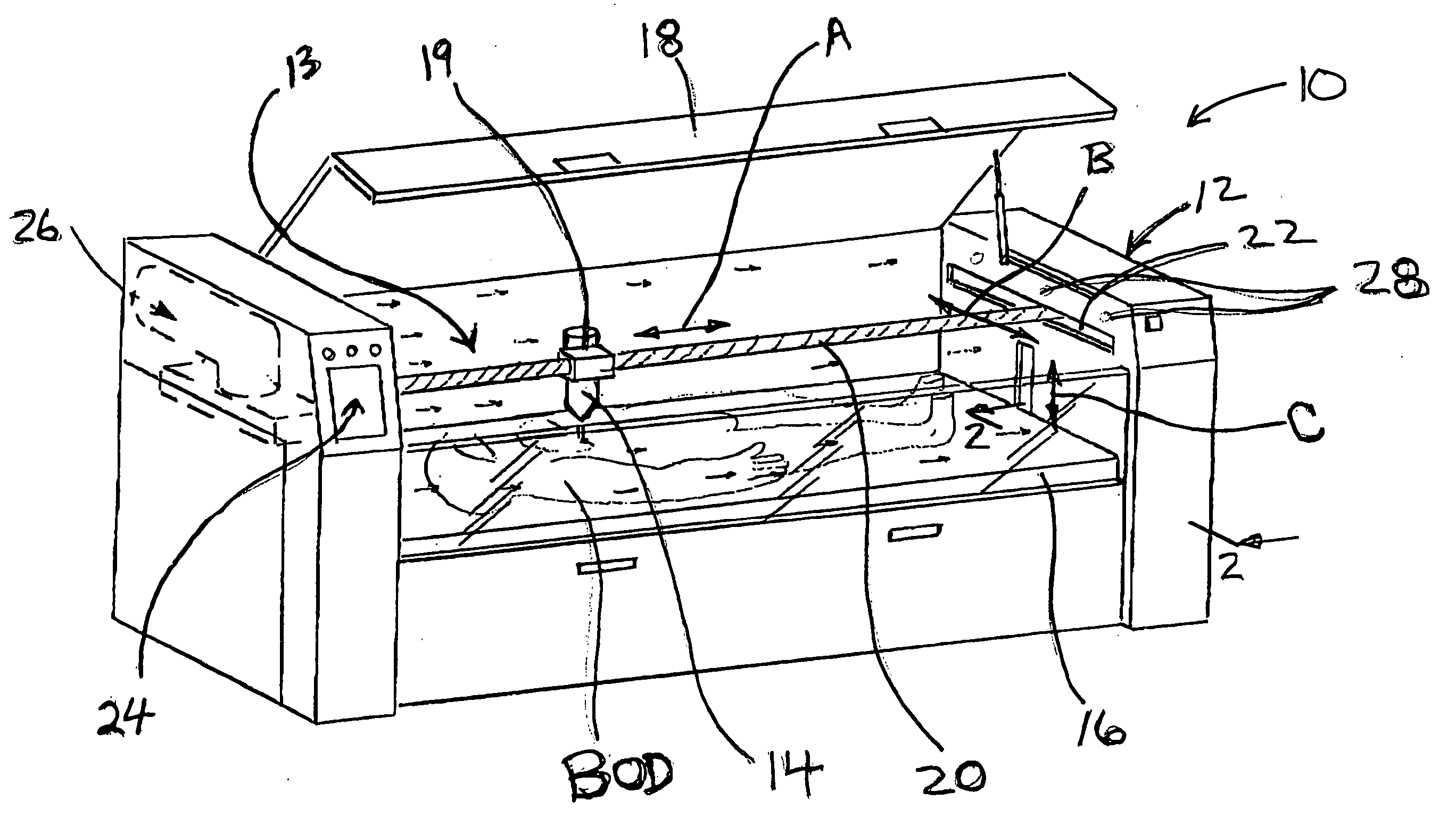

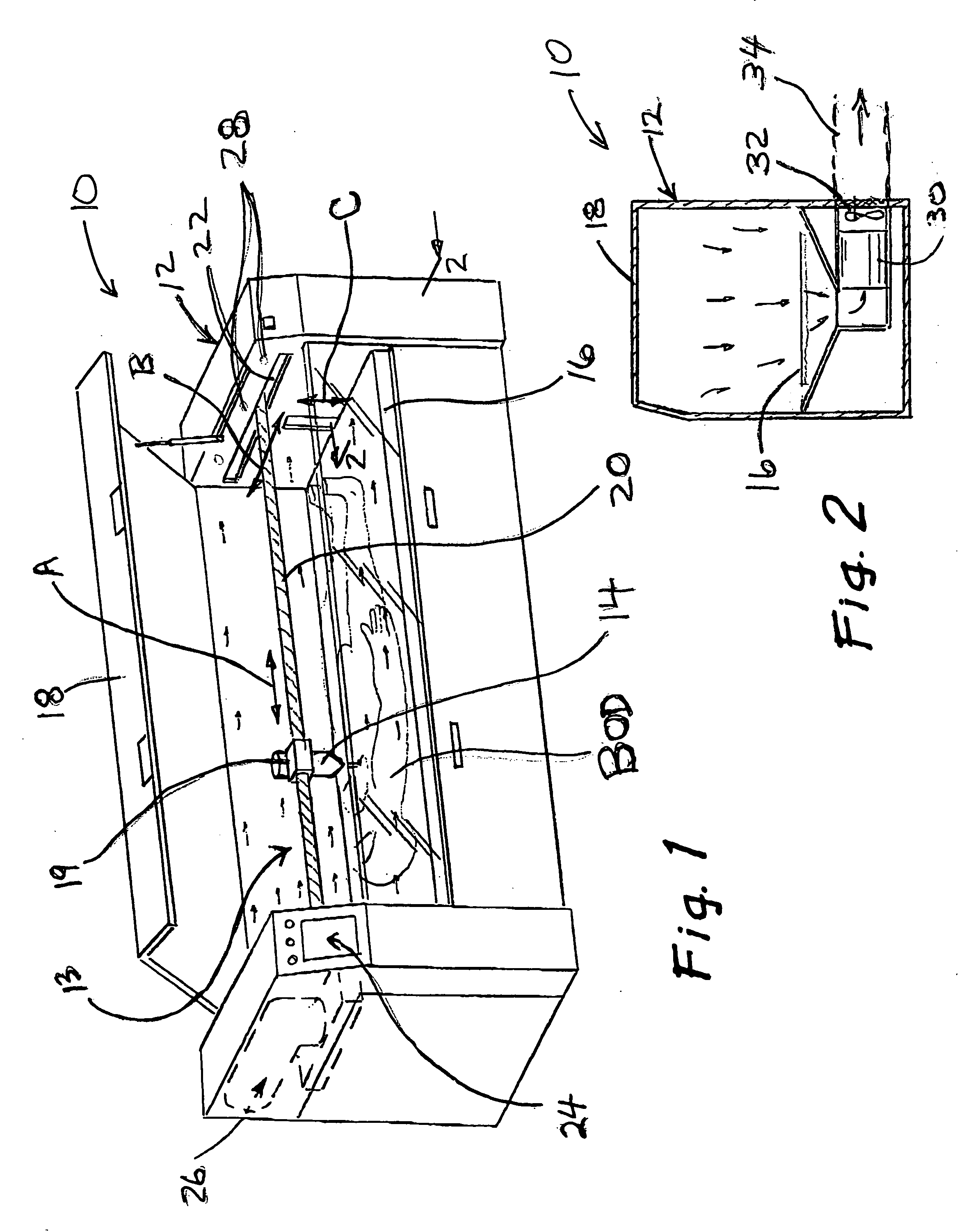

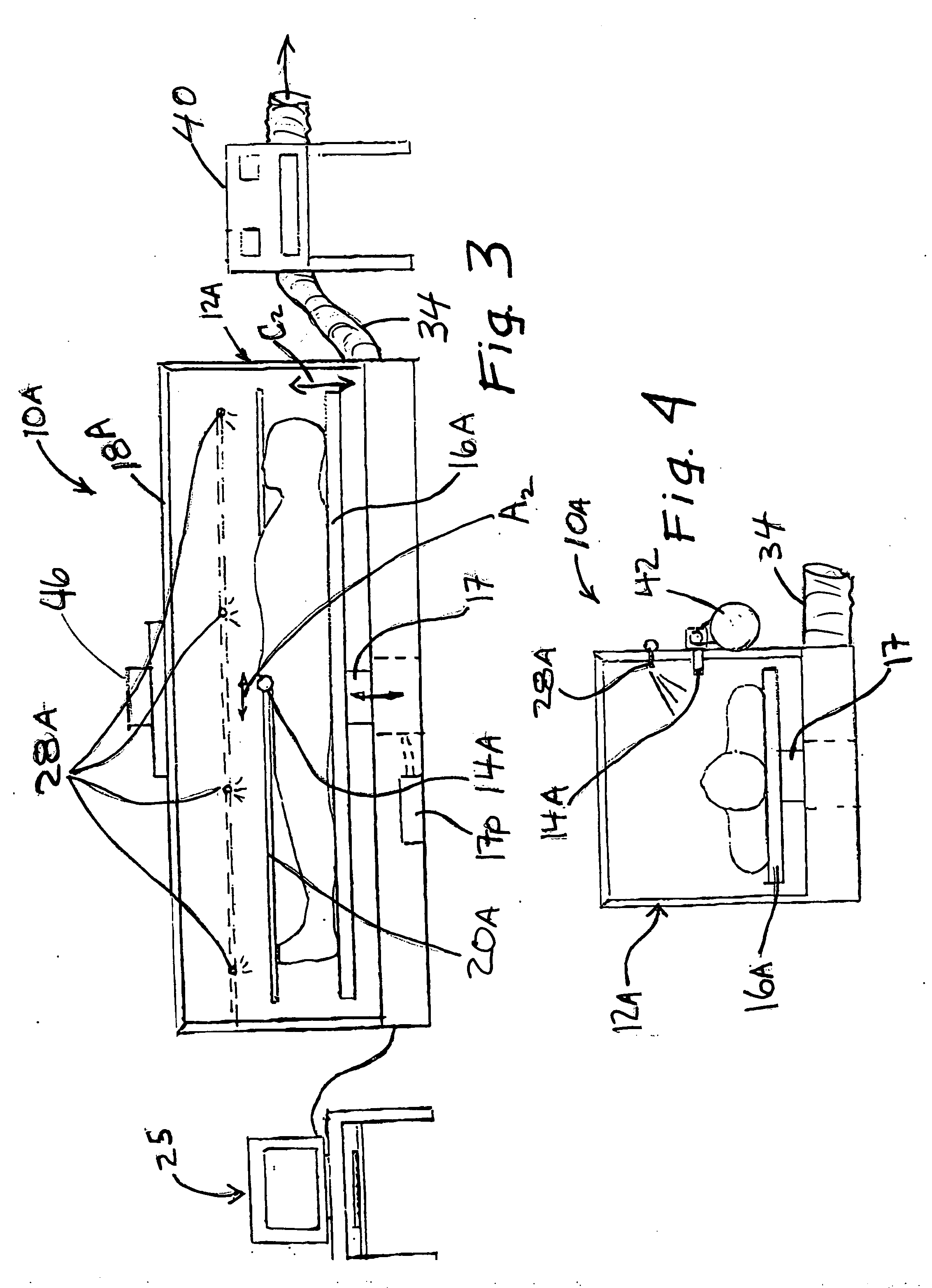

The present invention is an apparatus and a process for treating municipal solid waste (MSW). The apparatus includes a reaction vessel with helically arranged internal flights, a self-aligning door closure, and a swing-away door assembly. It also includes a novel structure for shredding MSW attached to the edges of the flights. This structure is number of projecting tooth like points.

Owner:NOLL ANTHONY P

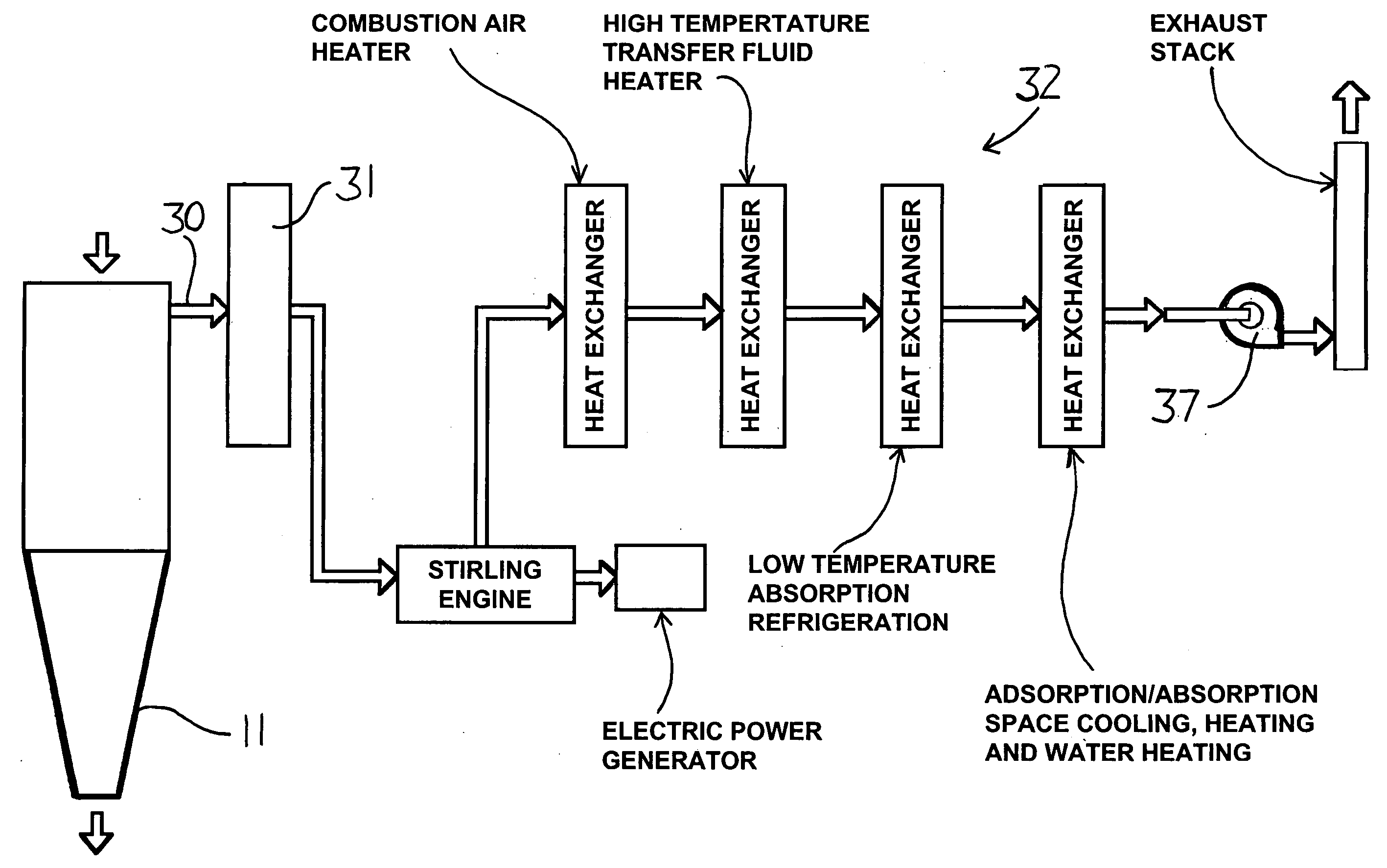

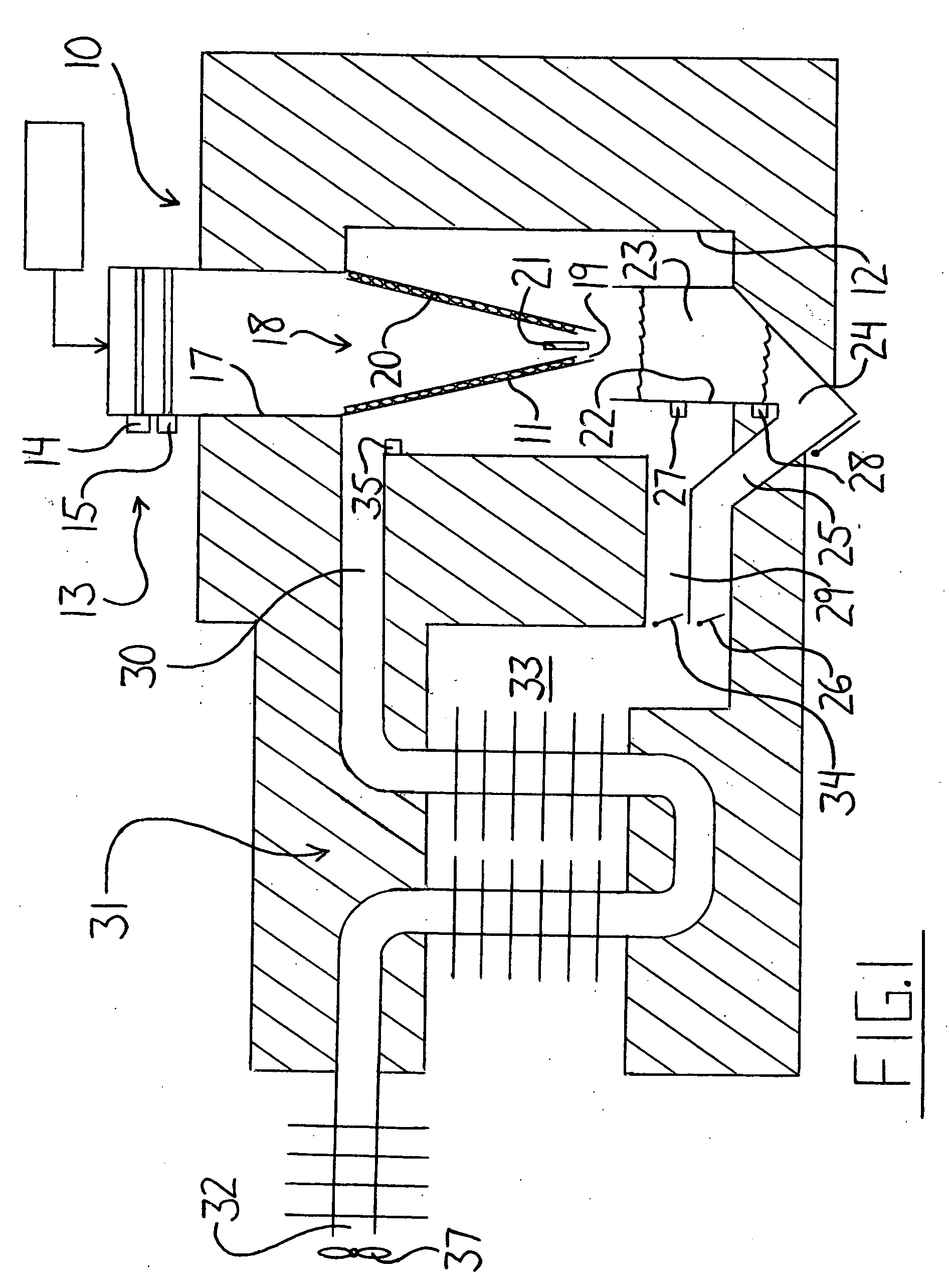

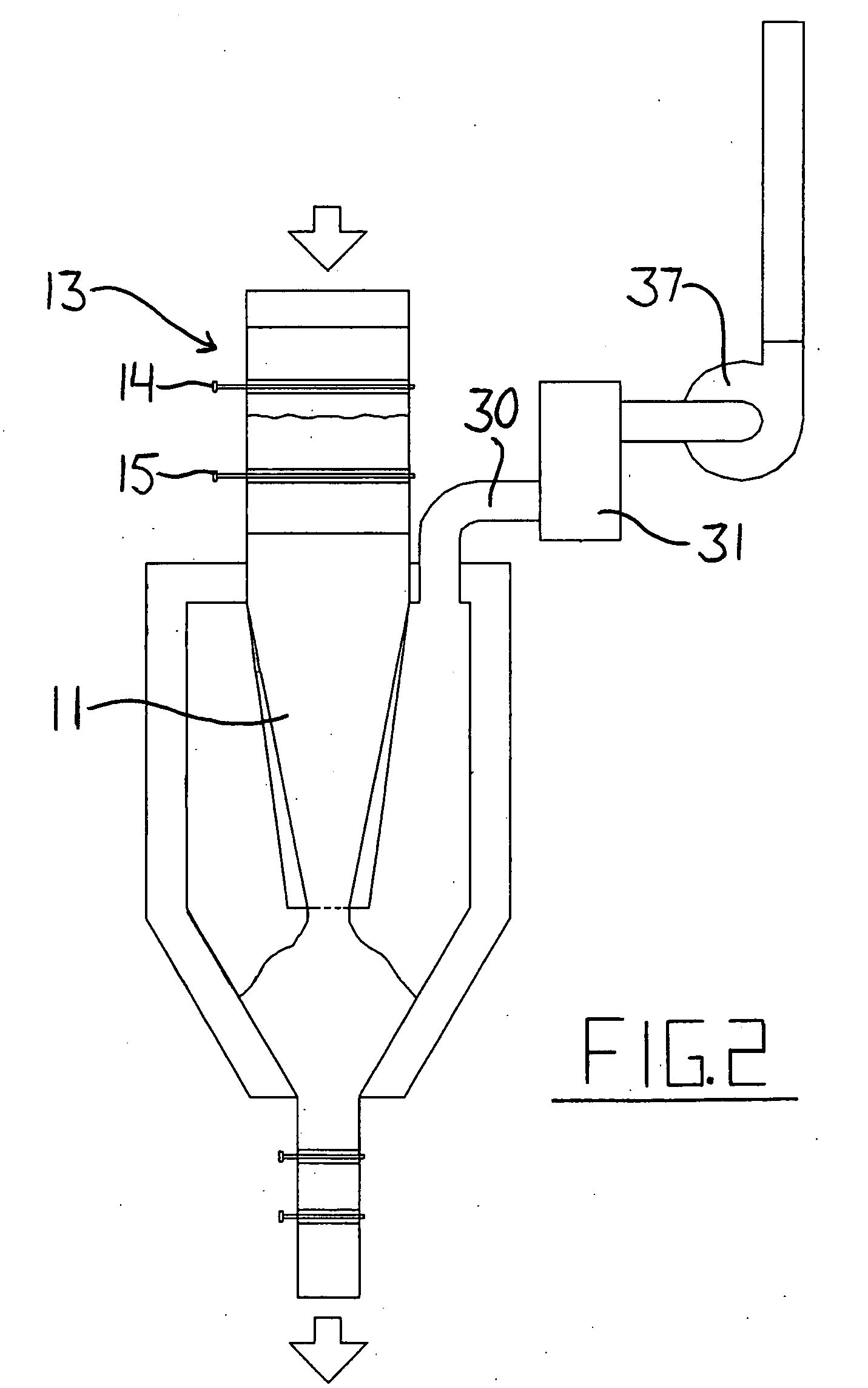

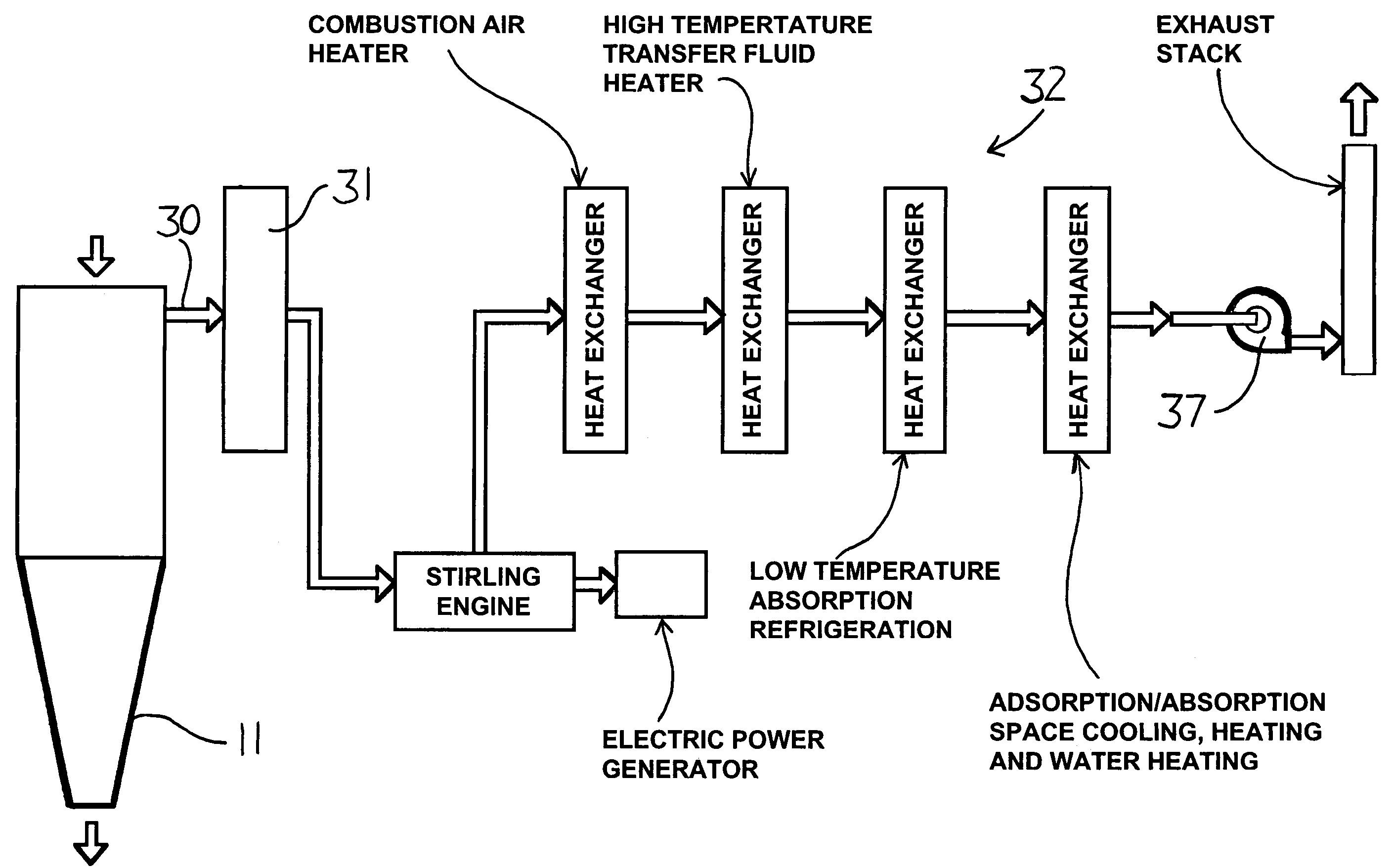

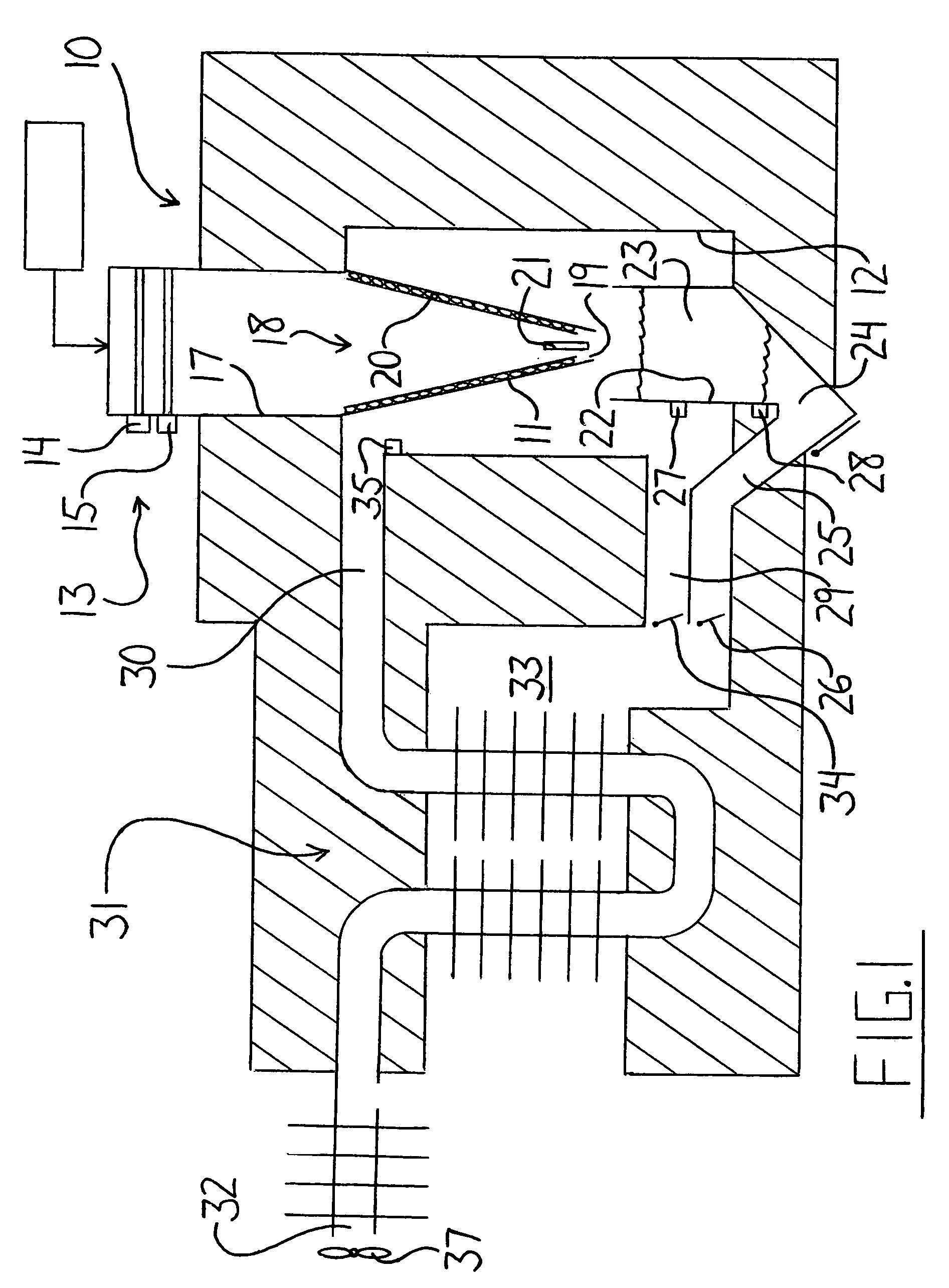

Biomass conversion by combustion

ActiveUS20060089516A1Eliminate requirementsHydrocarbon from carbon oxidesCell electrodesSupporting systemCombustion

Break down of waste materials such as animal parts is carried out by pyrolysis, gasification and combustion using a reactor vessel with a conical lower portion located within an exterior vessel. Feed material is deposited in continuous mode through an air lock at the top and falls by gravity alone into the lower cone portion. The cone geometry supports organic feedstocks, eliminating the requirement for grates or other combustion support systems. Organic material that may escape gasification and exit the bottom of the cone accumulates within the ash and carbon particle volume until burned. Carbon is sequestered from high energy feedstocks and is stored in a chamber below the gasification cone. This carbon supplements the energy output of lower energy feedstocks to maintain desired operating temperatures at all times.

Owner:DUNFORD HLDG INC

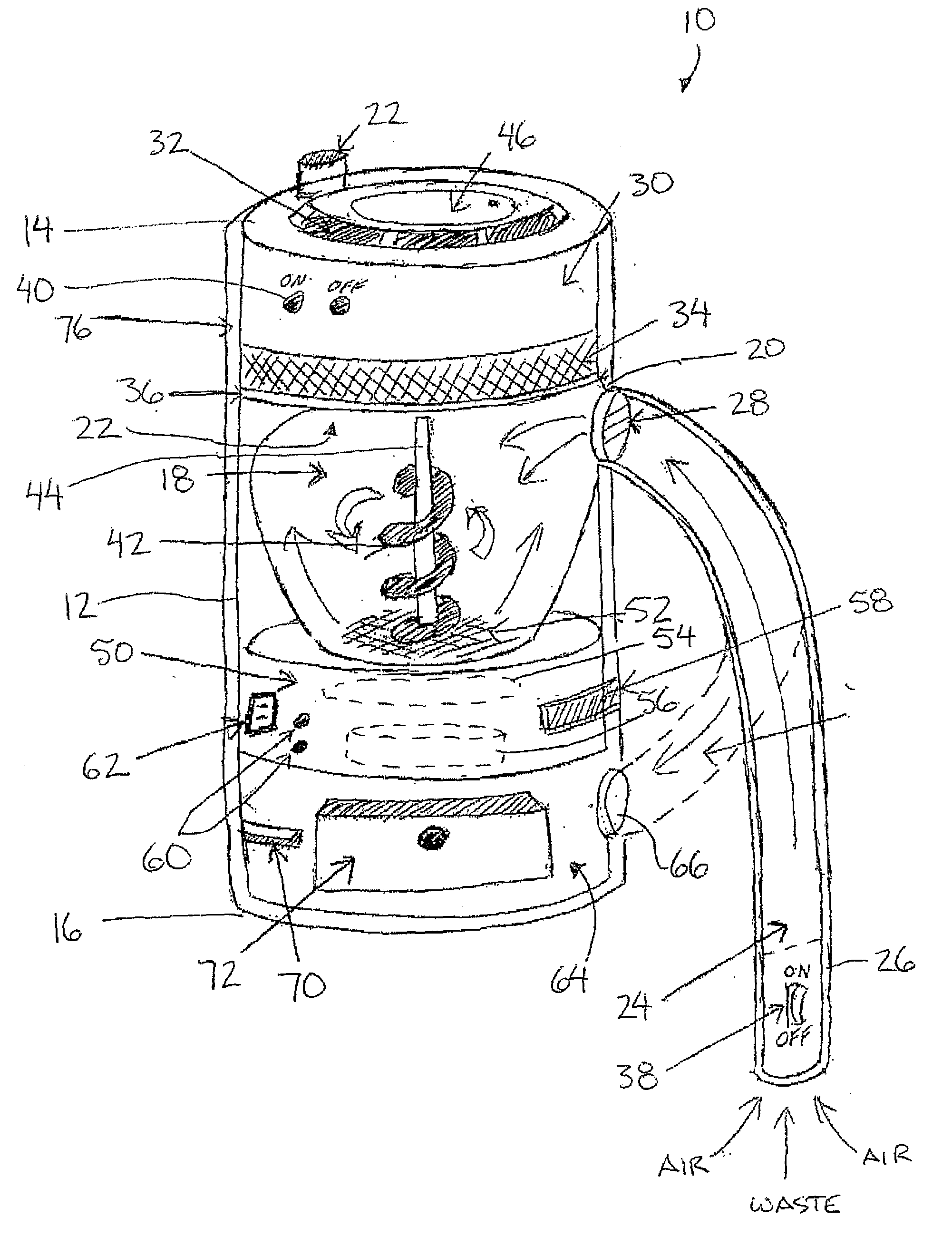

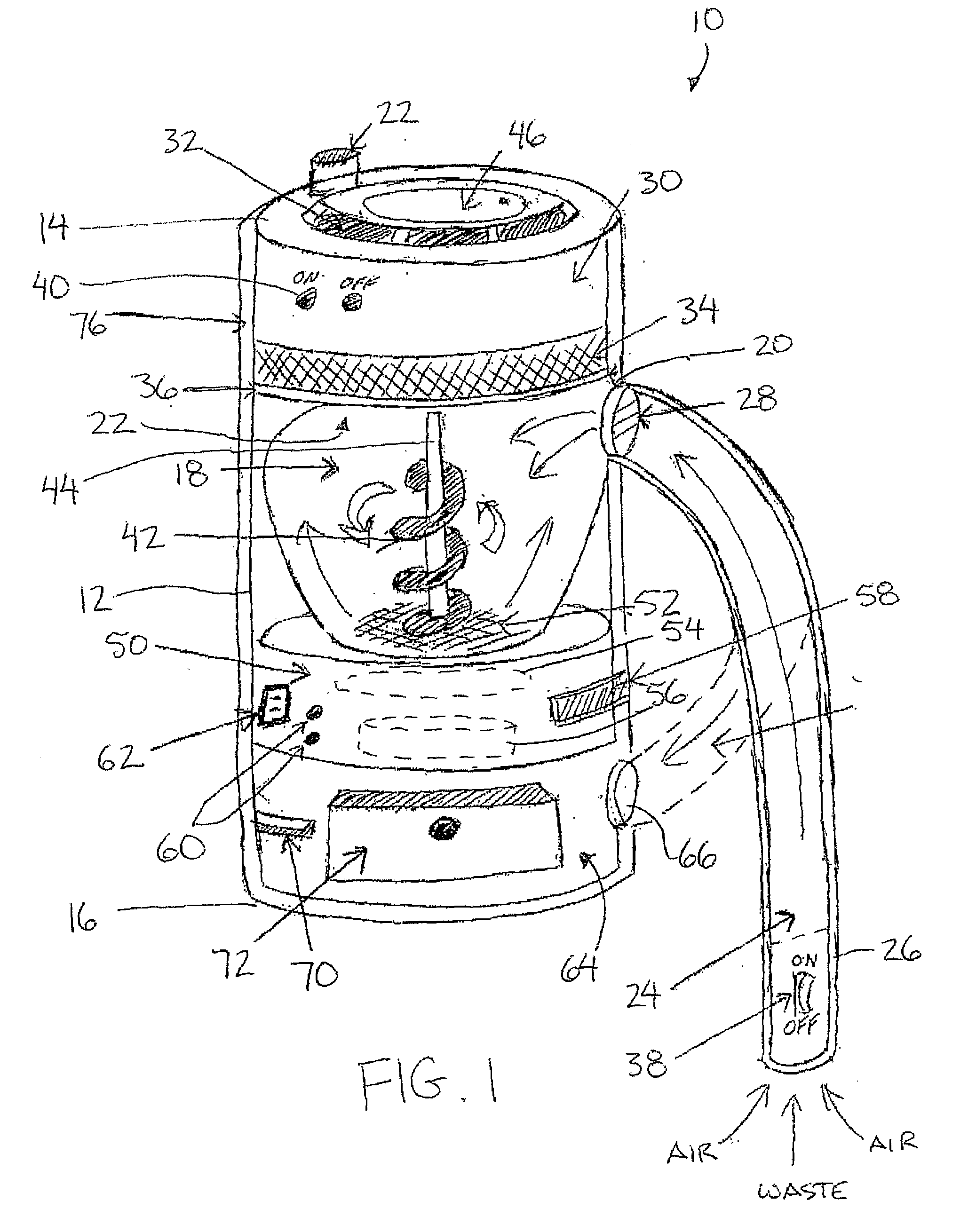

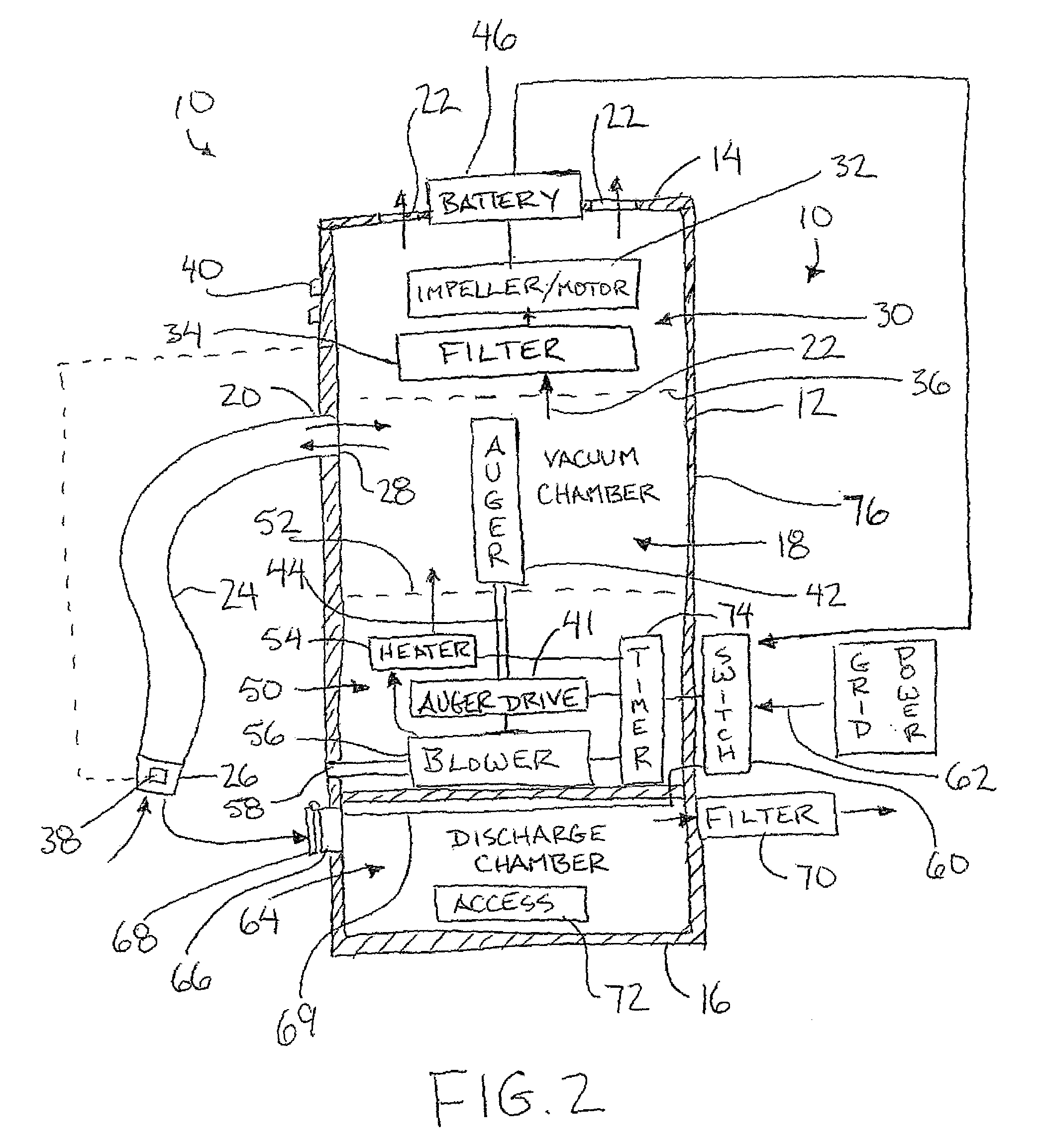

Waste Collecting Device

InactiveUS20100293741A1Easy to carrySuitable for collectionCleaning filter meansMechanical cleaningImpellerVacuum pressure

An animal waste collecting device comprises a vacuum chamber in communication with an impeller arranged to draw air from the vacuum chamber through the exhaust port to produce a vacuum pressure in the vacuum chamber and a pickup up nozzle in communication with the vacuum chamber to collect waste with air drawn therethrough into the vacuum chamber by the vacuum pressure. A heater is supported in communication with the vacuum chamber to heat waste collected in the vacuum chamber for drying and / or incinerating the waste. A blower permits the dried or incinerated waste to be redirected from the vacuum chamber to a separate discharge chamber for subsequent disposal.

Owner:FERRIS JOHN

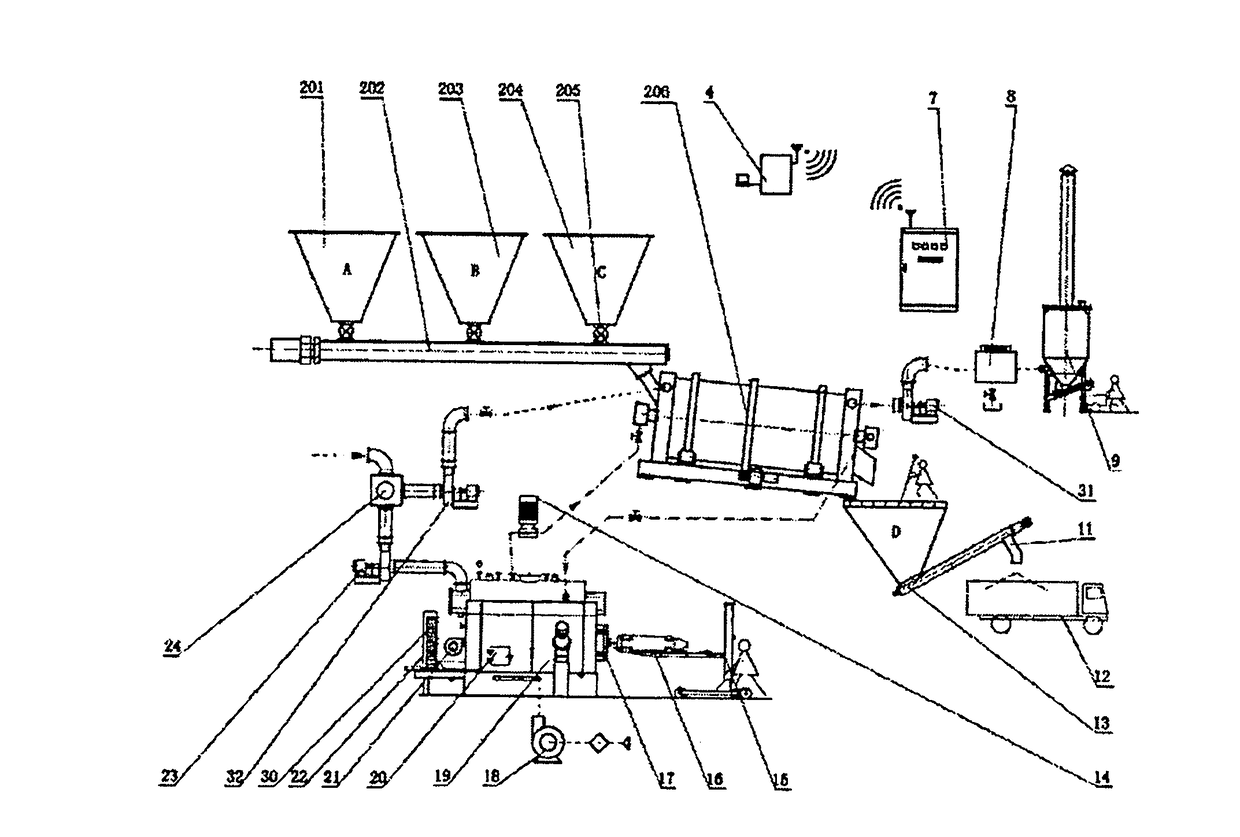

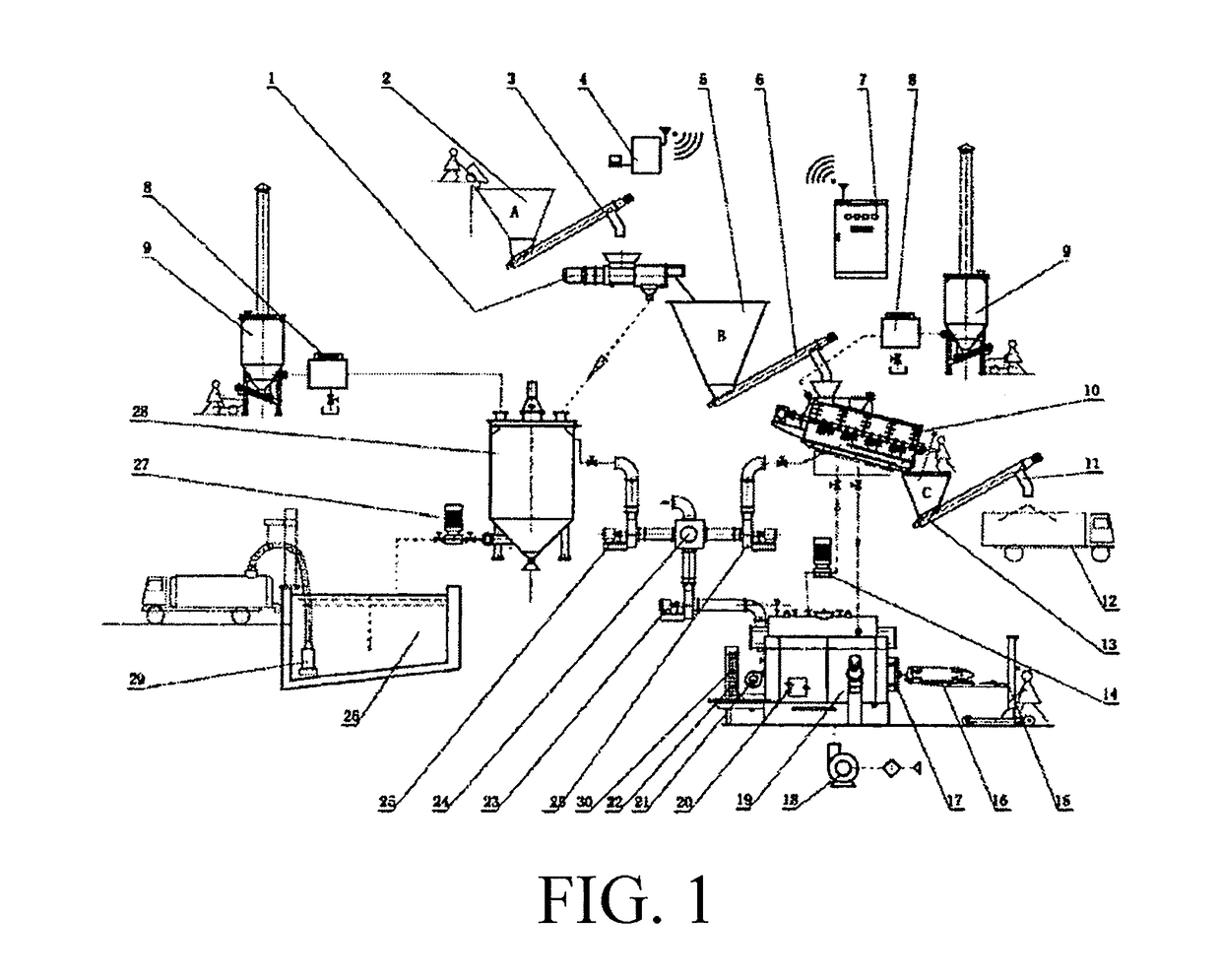

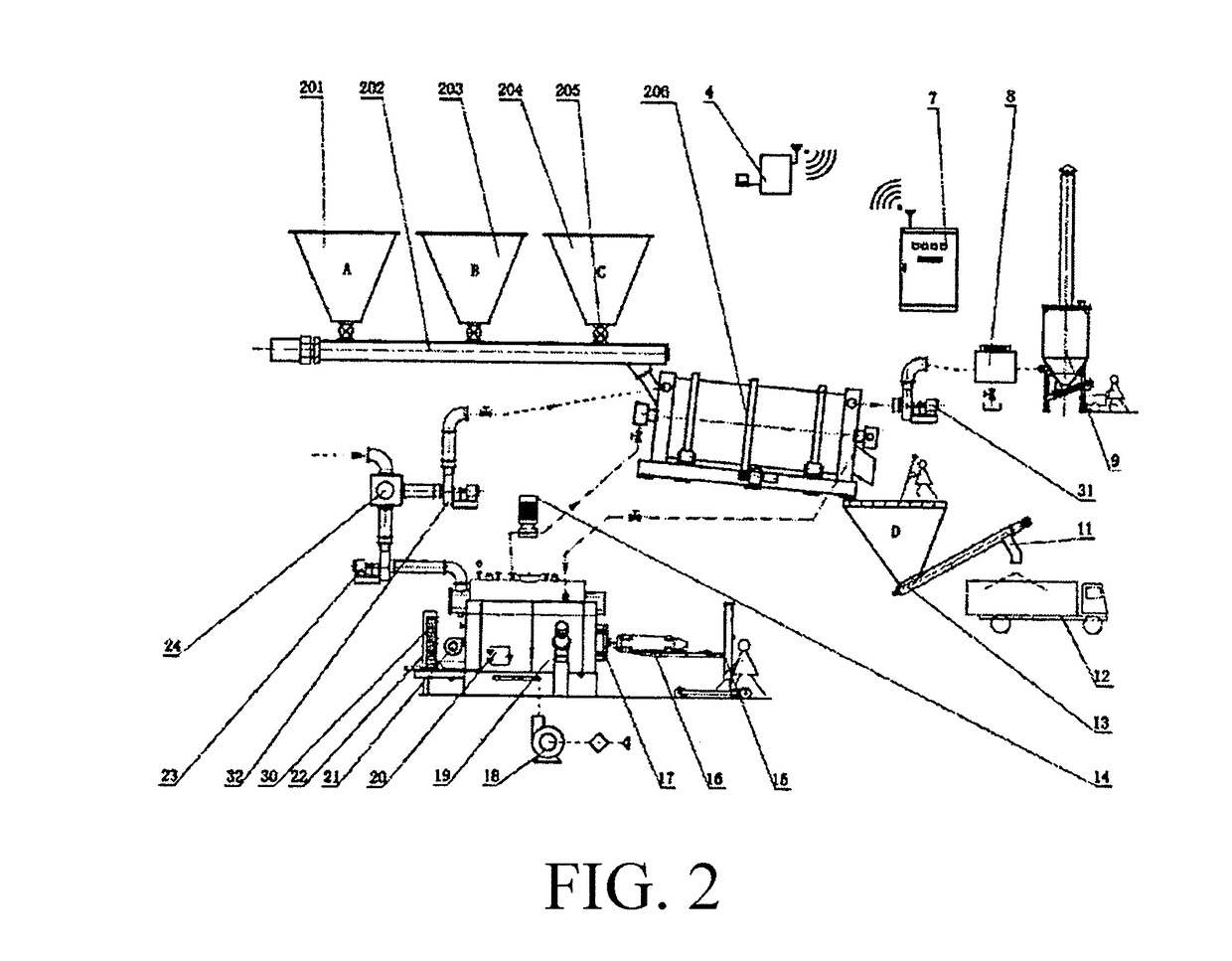

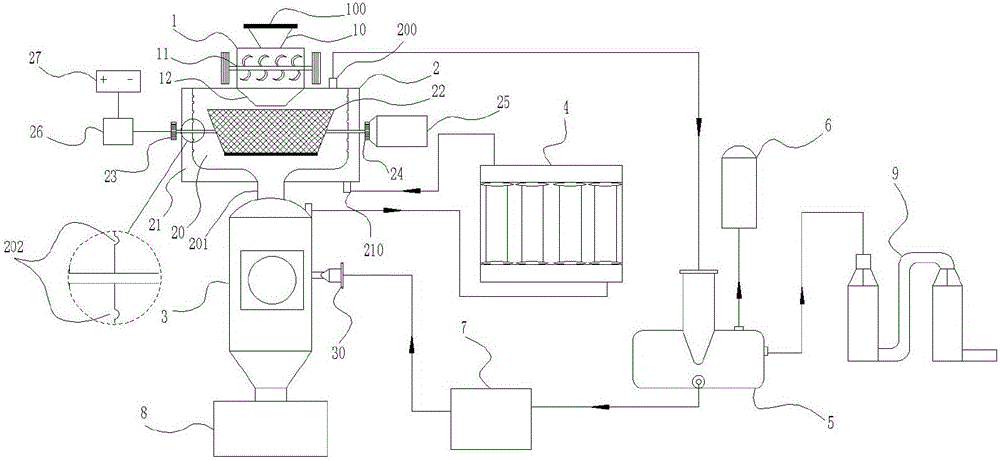

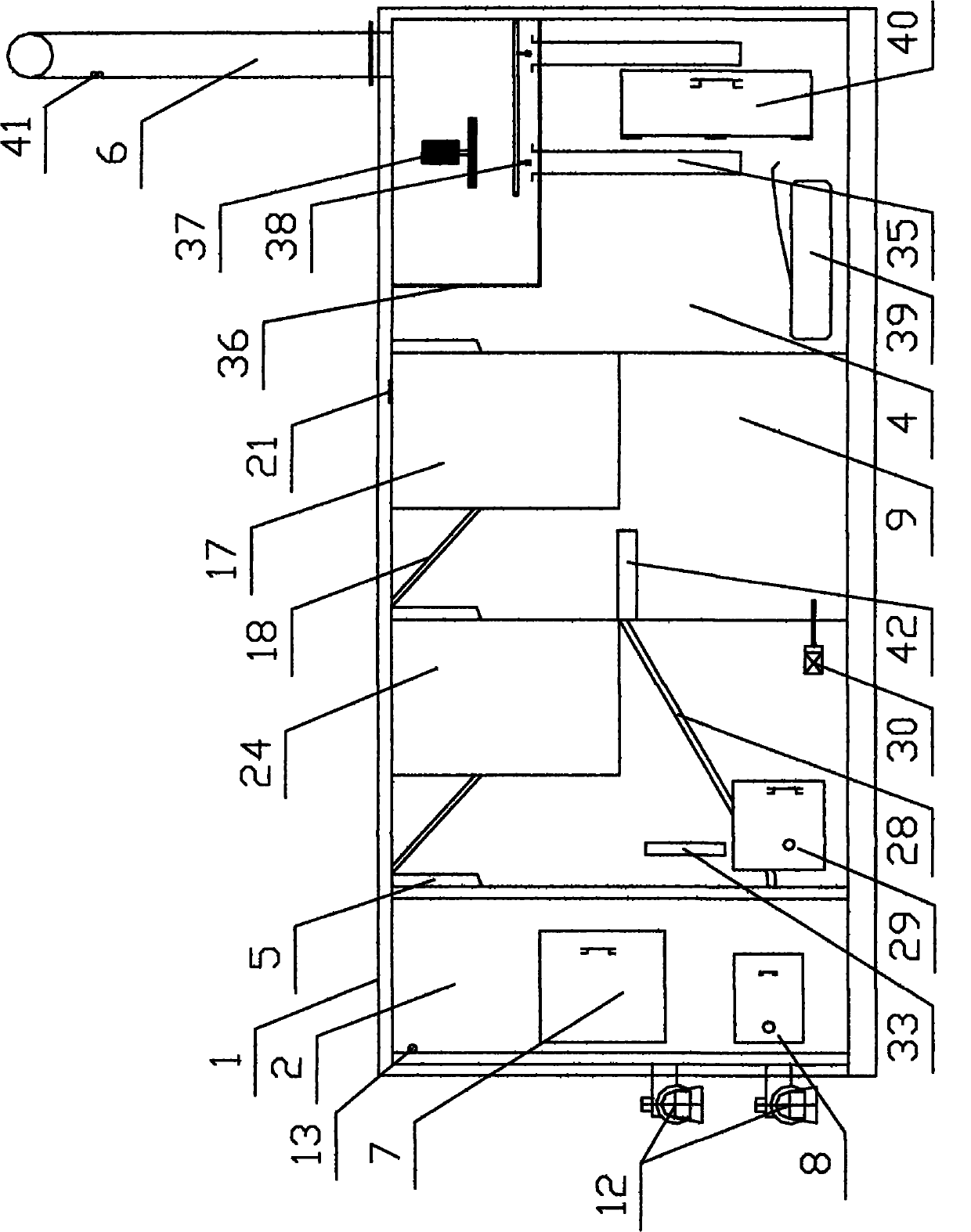

Rural bulk organic waste pollutant source comprehensive treatment system and method

ActiveUS20180148389A1Keep healthyProtect environmentBio-organic fraction processingSolid waste disposalOxygenFermentation

A rural bulk organic waste pollutant source comprehensive treatment system including a solid high-temperature aerobic fermentation reactor, a liquid high-temperature aerobic fermentation reactor and a multifunctional boiler is provided. A rural bulk organic waste pollutant source comprehensive treatment method. For excretion waste of a livestock farm adopting the technology of manure cleaning by urine submerging, a solid-liquid separation is firstly performed thereto, wherein solid is conveyed to the solid high-temperature aerobic fermentation reactor and fermented to produce solid organic fertilizers, and liquid is conveyed to the liquid high-temperature aerobic fermentation reactor and fermented to produce liquid organic fertilizers. For dry collection manure of a livestock and poultry farm, carbon-containing auxiliary materials, residues left after dead animals and household waste being incinerated by the multifunctional boiler, and ash generated by straw burning are added thereto, and then the mixture is conveyed to the solid high-temperature aerobic fermentation reactor and fermented to produce solid organic fertilizers. Exhaust fume and hot water produced by the multifunctional boiler pass through the solid high-temperature aerobic fermentation reactor and the liquid high-temperature aerobic fermentation reactor to heat the reactors and keep the reactors warm.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

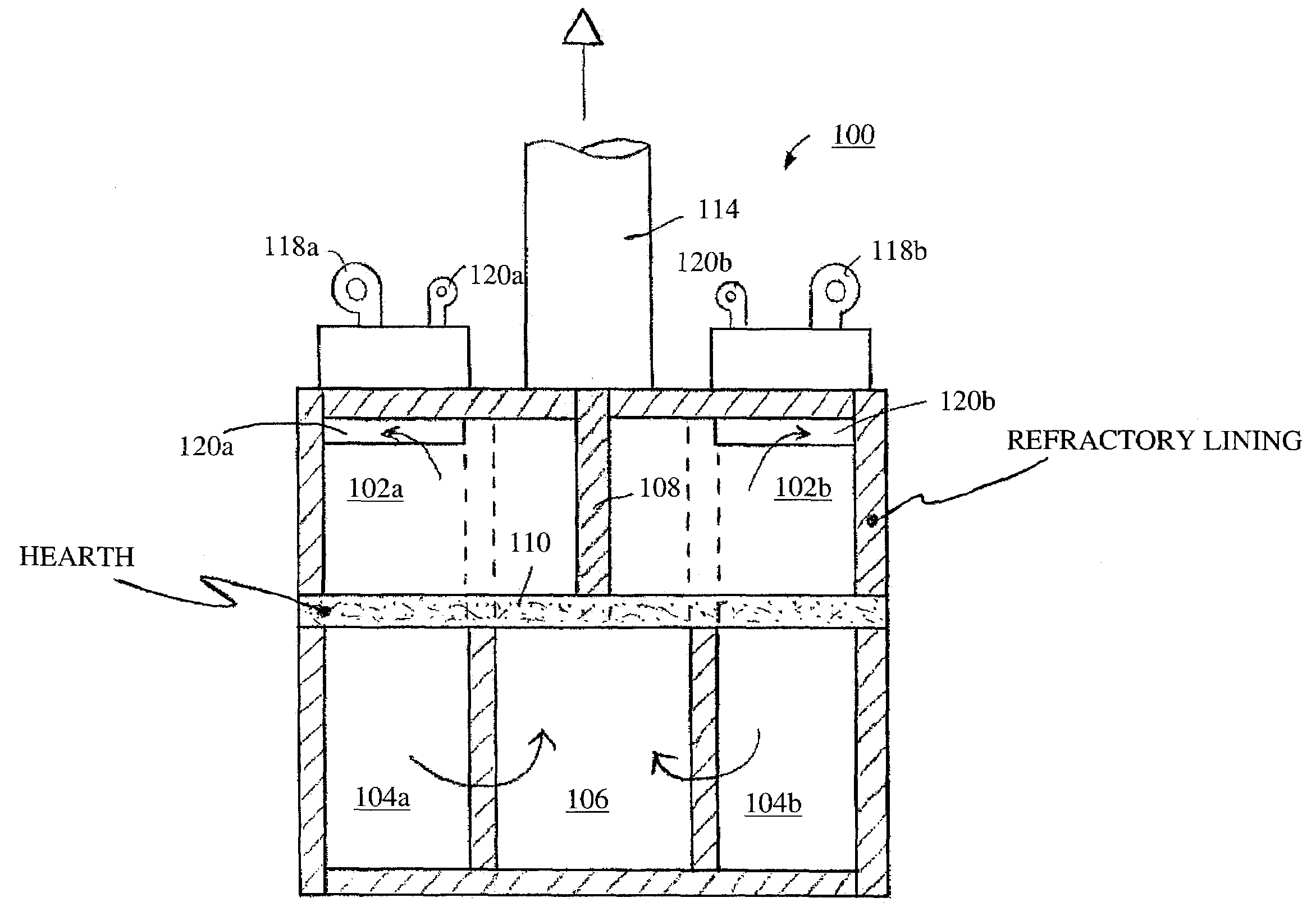

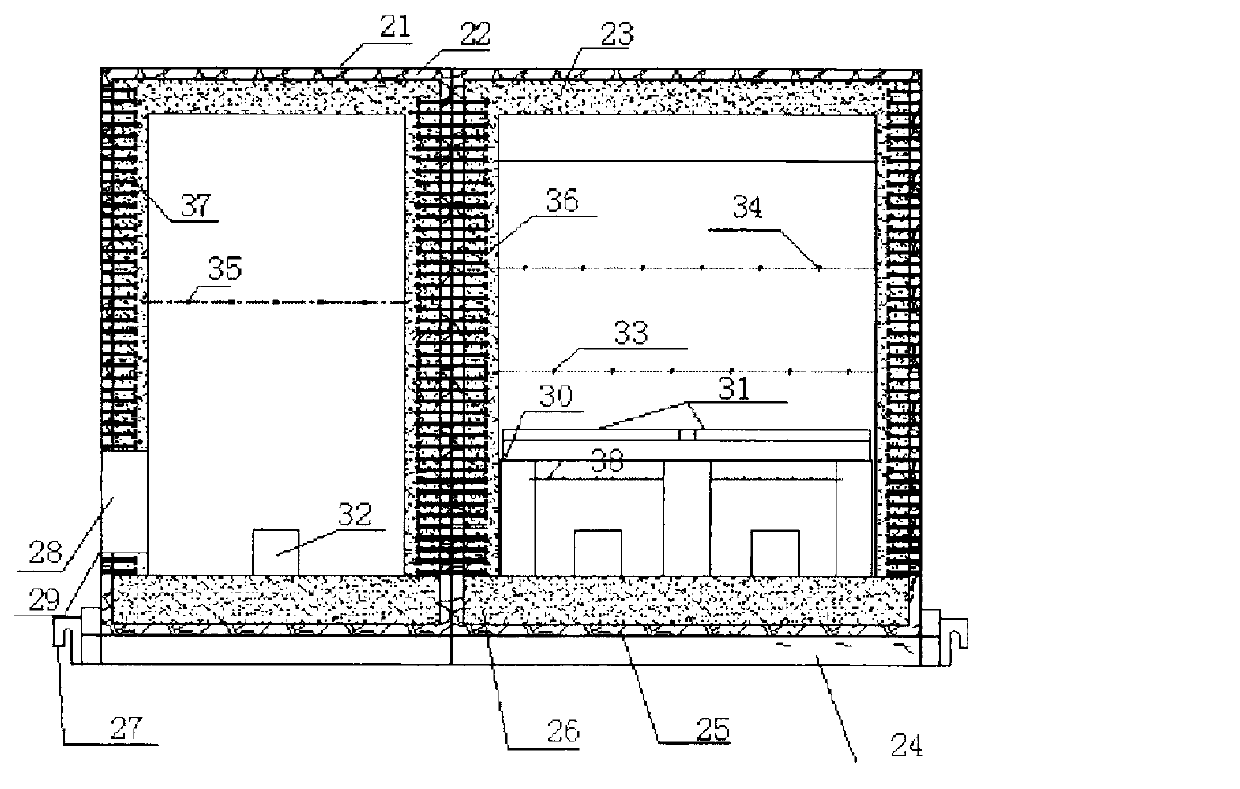

Dual Chamber System for Gasifying Biomass Waste

A device for gasifying biomass waste has two each of primary chambers, fume transfer vents, mixing chambers which accept fumes from the primary chamber, afterburner chambers in fluid communication with the mixing chambers, and an exhaust duct. Each secondary burner produces an initial heating flame within a vertical portion of the respective afterburner chamber, and secondary chambers are in fluid communication with the afterburner chambers. Heated gases from the afterburner chambers cause heating of the secondary chambers. A portion of each primary chamber has a heat conductive floor superimposed over the respective secondary chamber, and the partition between the primary chambers is heat conductive, so that conductive and convective heating of the primary chambers occurs.

Owner:ZEBREX ENVIRONMENTAL SYST

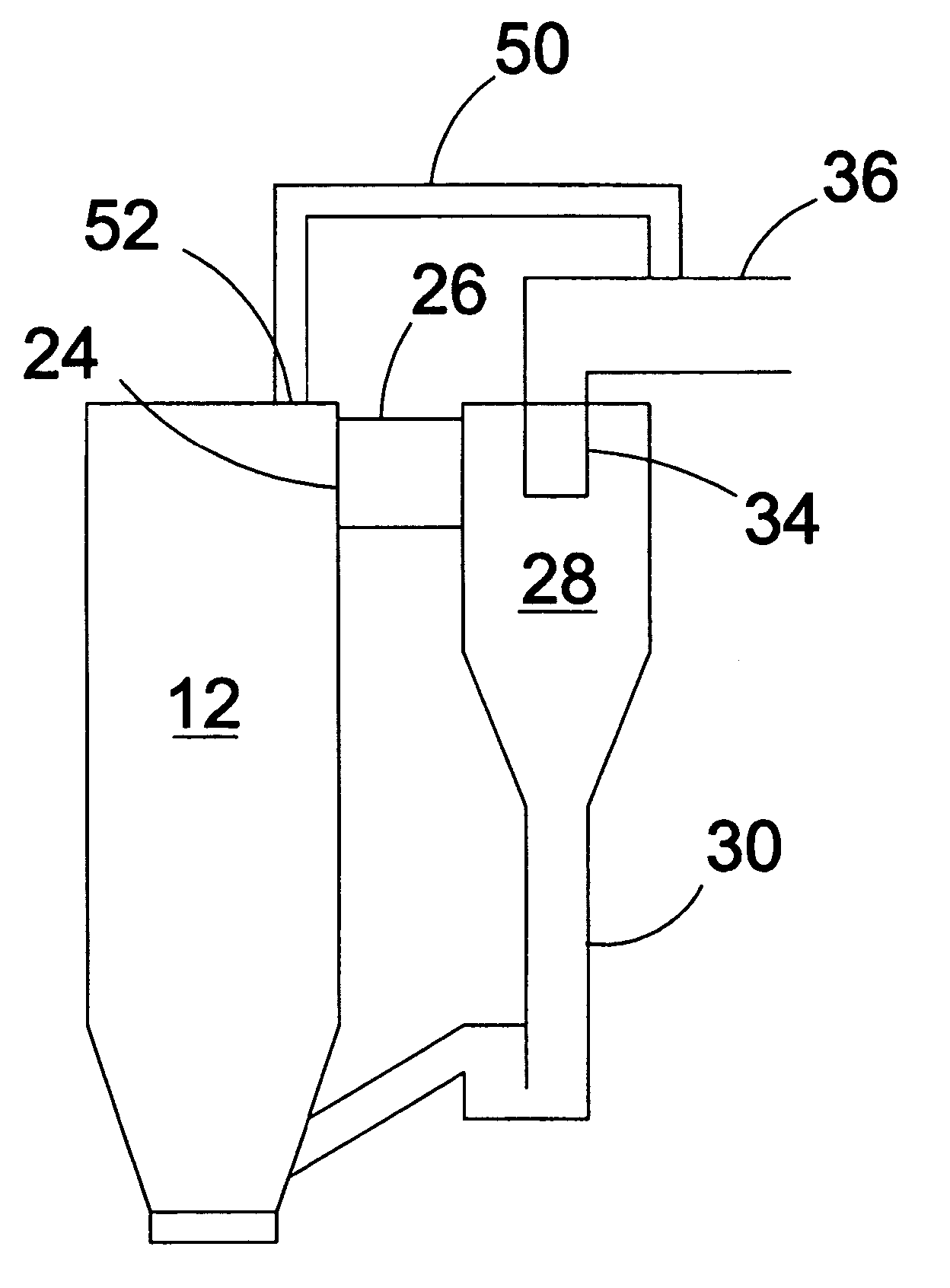

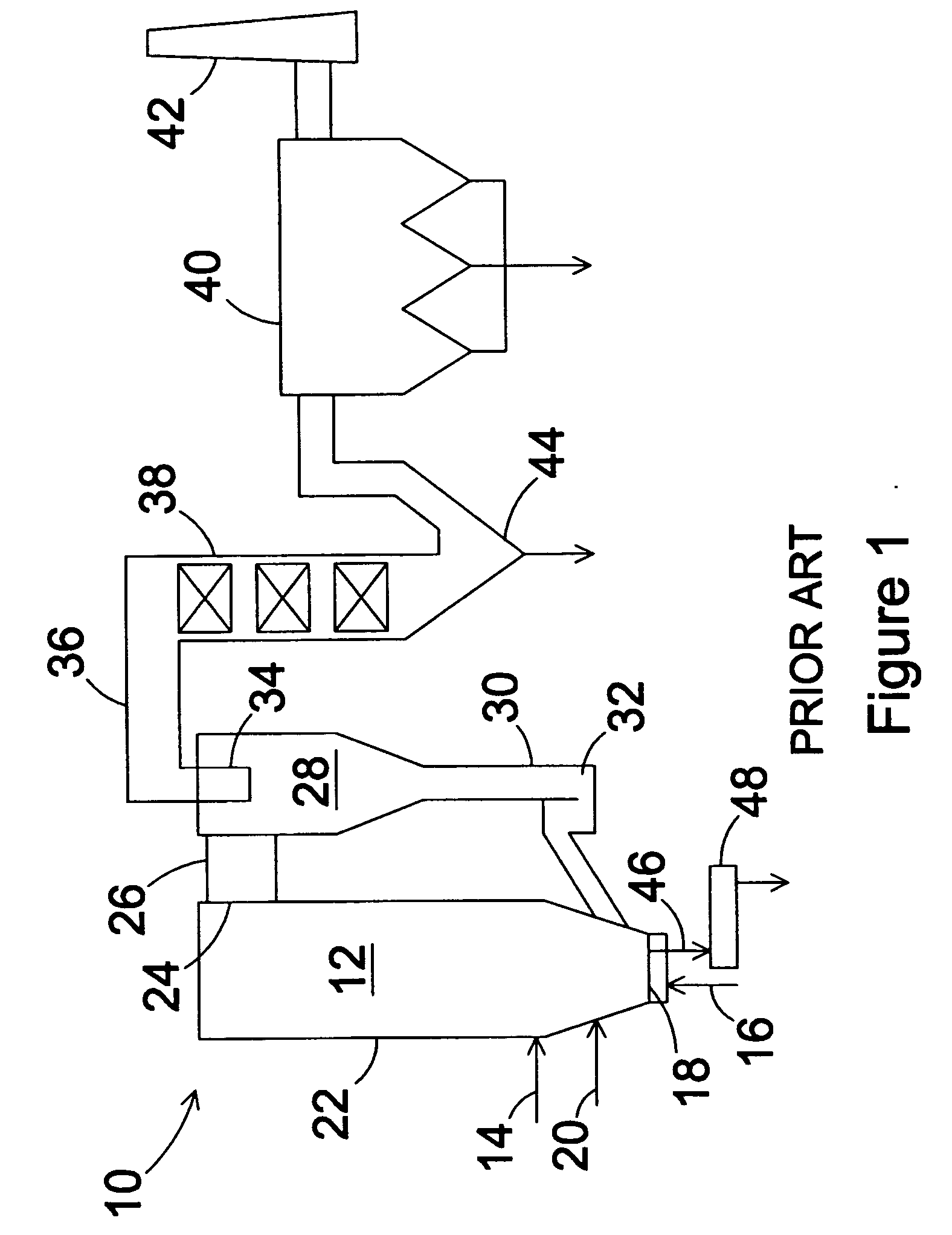

Biomass conversion by combustion

ActiveUS7906695B2Eliminate requirementsCell electrodesHydrogen productionSupporting systemCombustion

Break down of waste materials such as animal parts is carried out by pyrolysis, gasification and combustion using a reactor vessel with a conical lower portion located within an exterior vessel. Feed material is deposited in continuous mode through an air lock at the top and falls by gravity alone into the lower cone portion. The cone geometry supports organic feedstocks, eliminating the requirement for grates or other combustion support systems. Organic material that may escape gasification and exit the bottom of the cone accumulates within the ash and carbon particle volume until burned. Carbon is sequestered from high energy feedstocks and is stored in a chamber below the gasification cone. This carbon supplements the energy output of lower energy feedstocks to maintain desired operating temperatures at all times.

Owner:DUNFORD HLDG INC

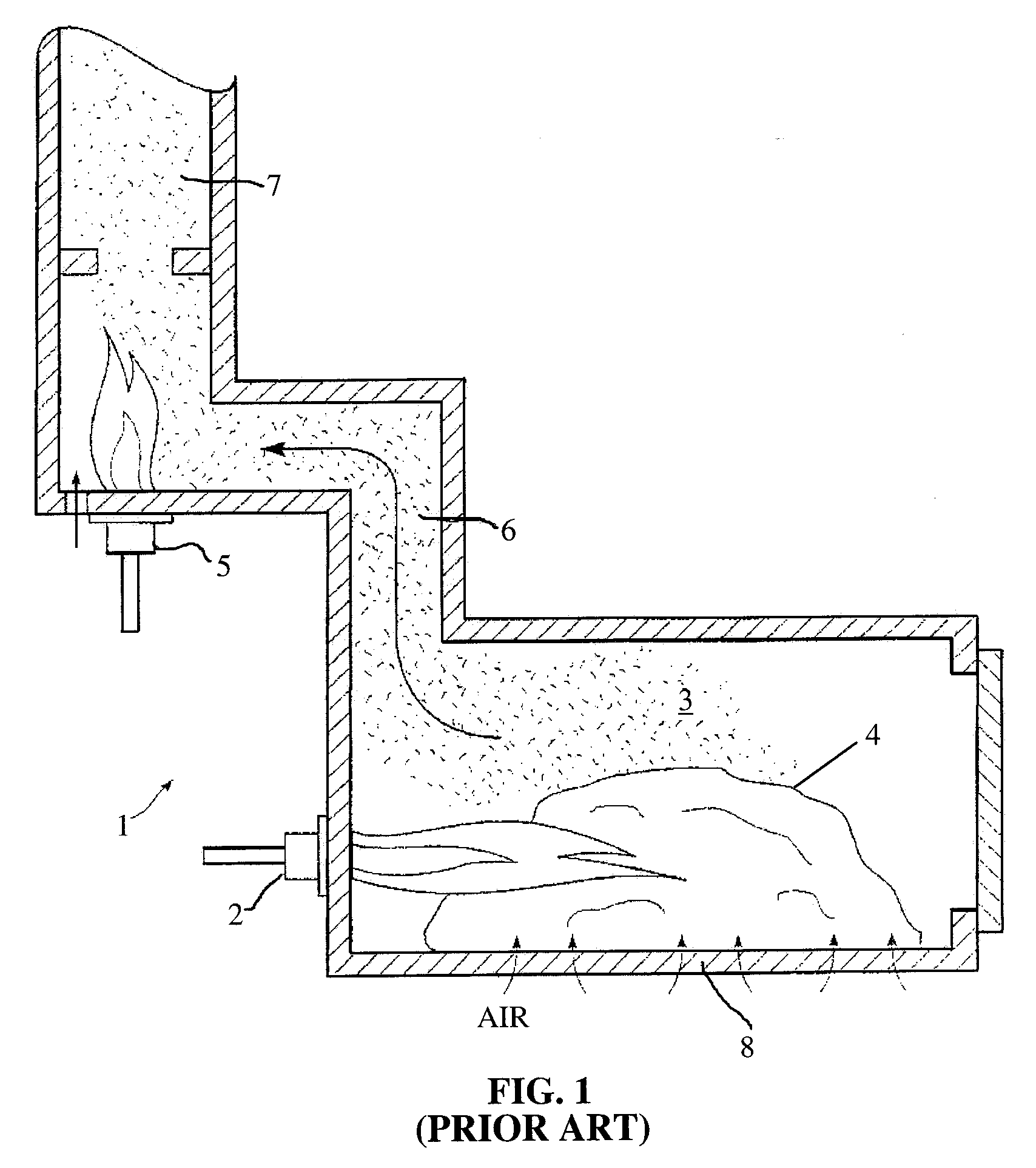

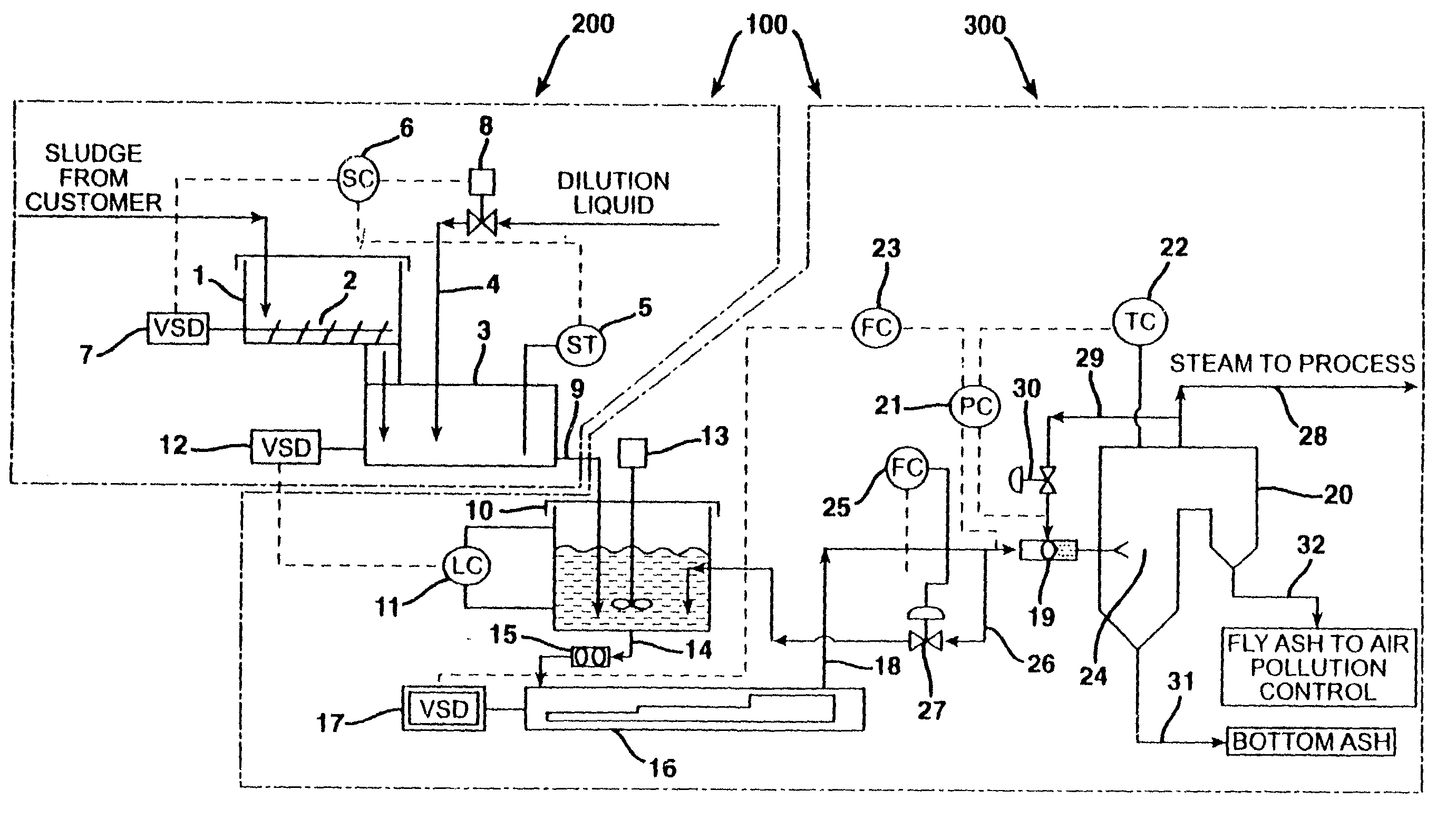

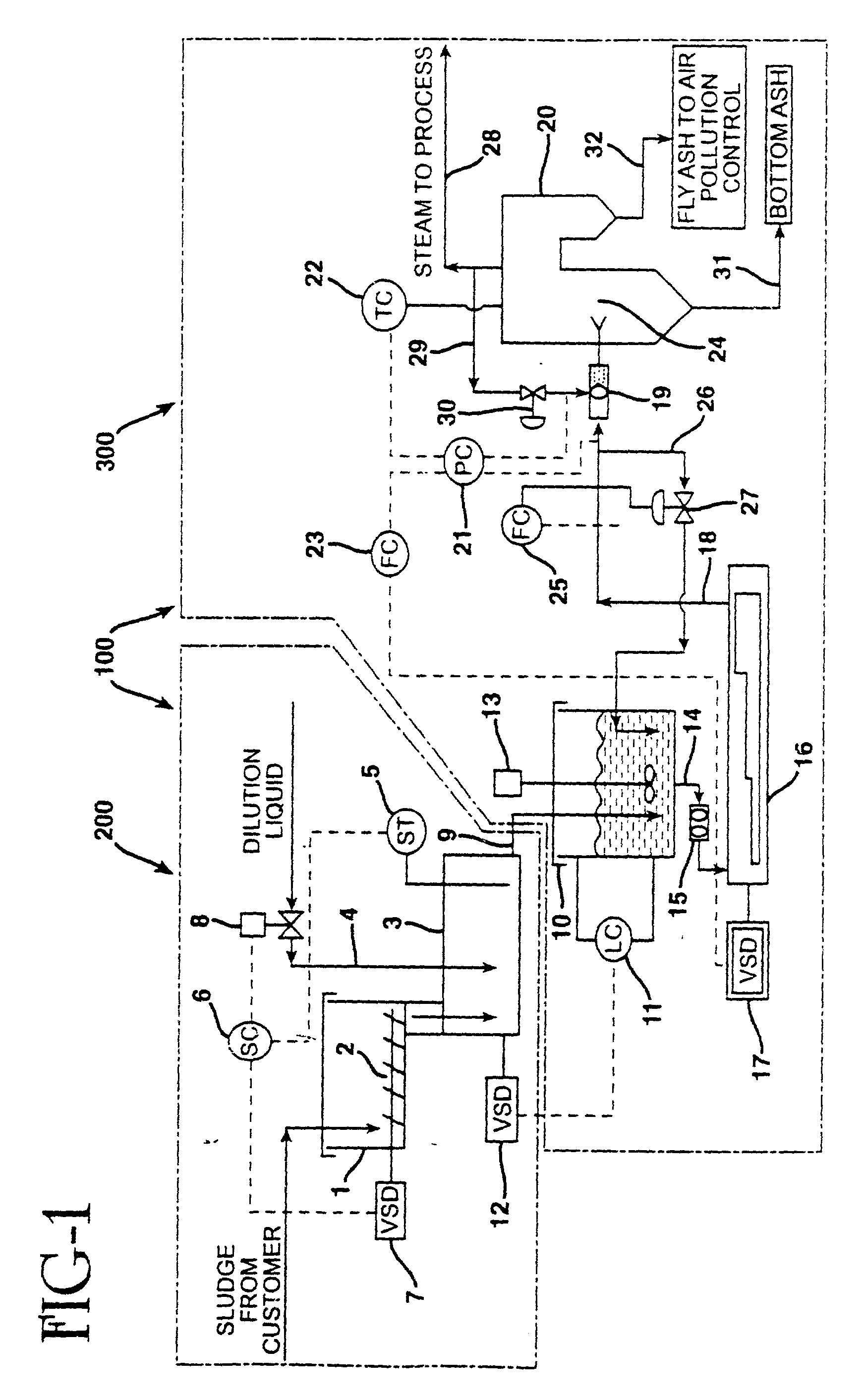

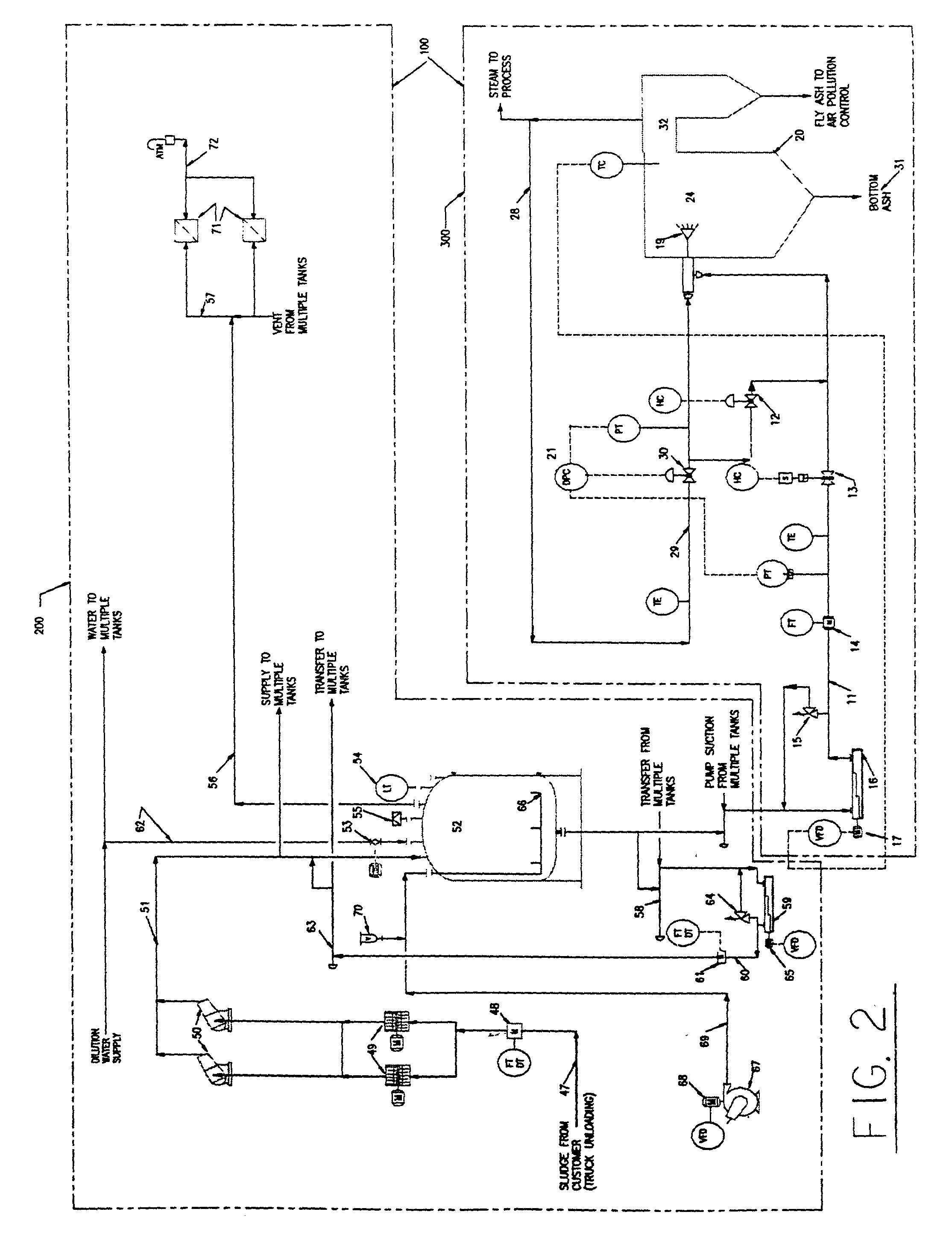

Co-combustion of waste sludge in municipal waste combustors and other furnaces

InactiveUS20020050236A1Maximize suspension burningEliminate needCremation furnacesSolid fuel combustionCombustorSludge

A system and method for treating, injecting and co-combusting sludge in a municipal waste or other solid fuel combustor. The system includes a sludge receiving and treatment module and a sludge injection and combustion module. The sludge is received and stored in one or more storage hoppers where its moisture content is monitored and varied to obtain a sludge having a desired moisture content. The treated sludge is then pumped to a furnace injection nozzle where it is preferably atomized with steam and sprayed into the combustion zone of the furnace. Improved odor control in sludge handling is also provided by a storage tank and a sludge tanker trailer each having an air diffuser for mixing and aerating the sludge and a filter system for filtering odors.

Owner:ECO TECH LLC

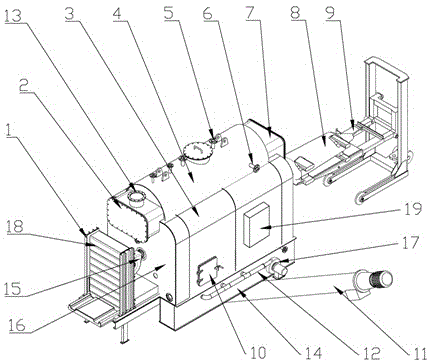

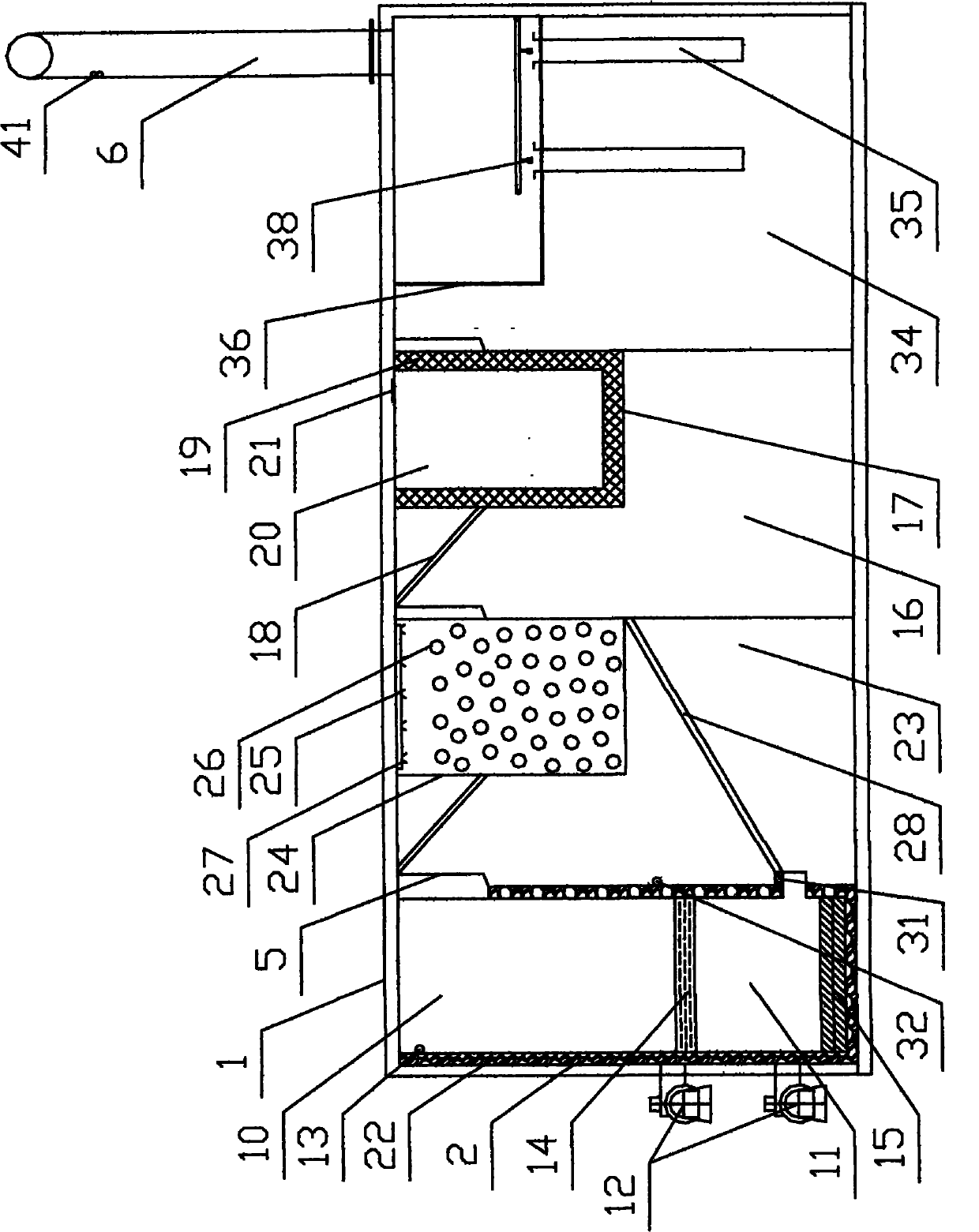

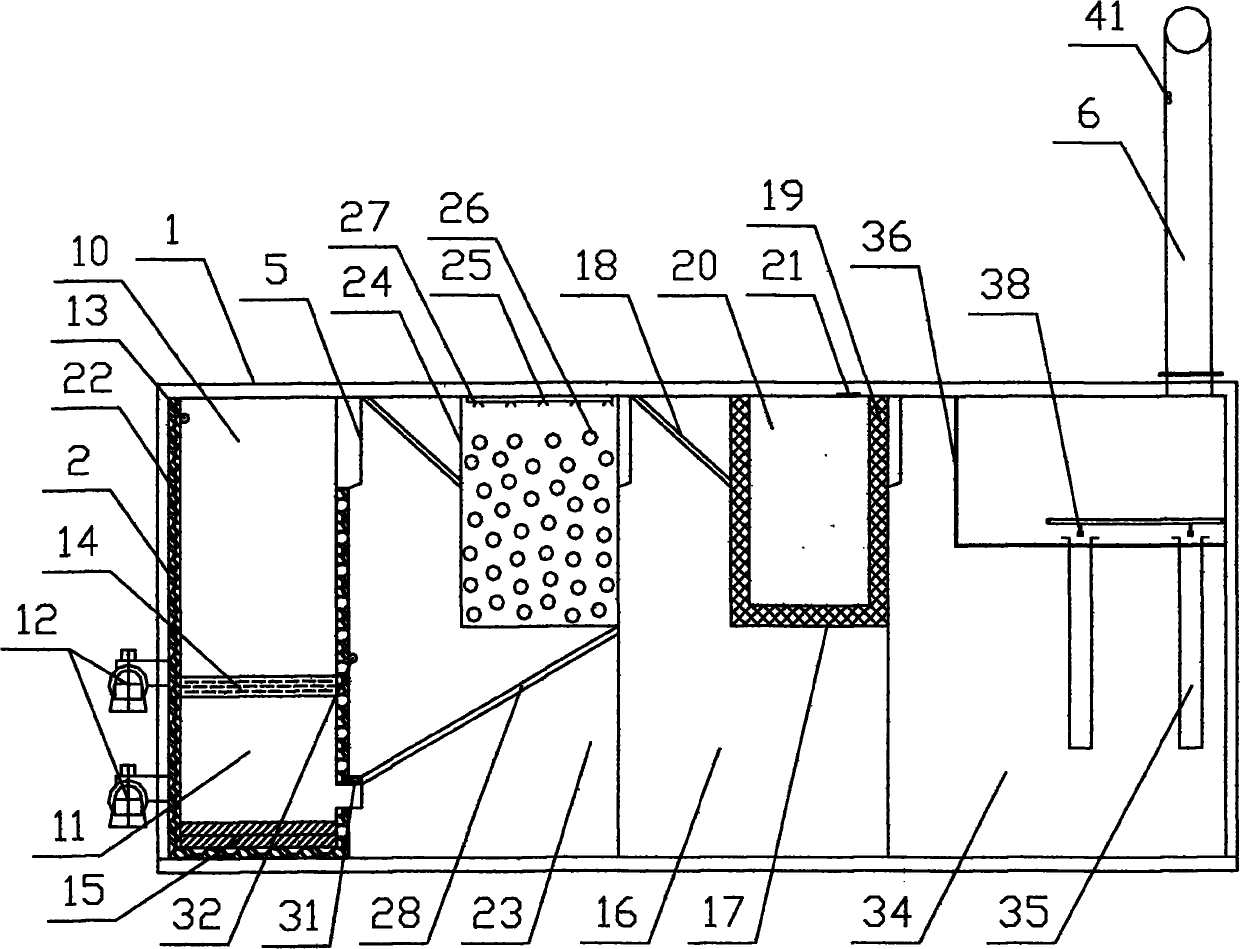

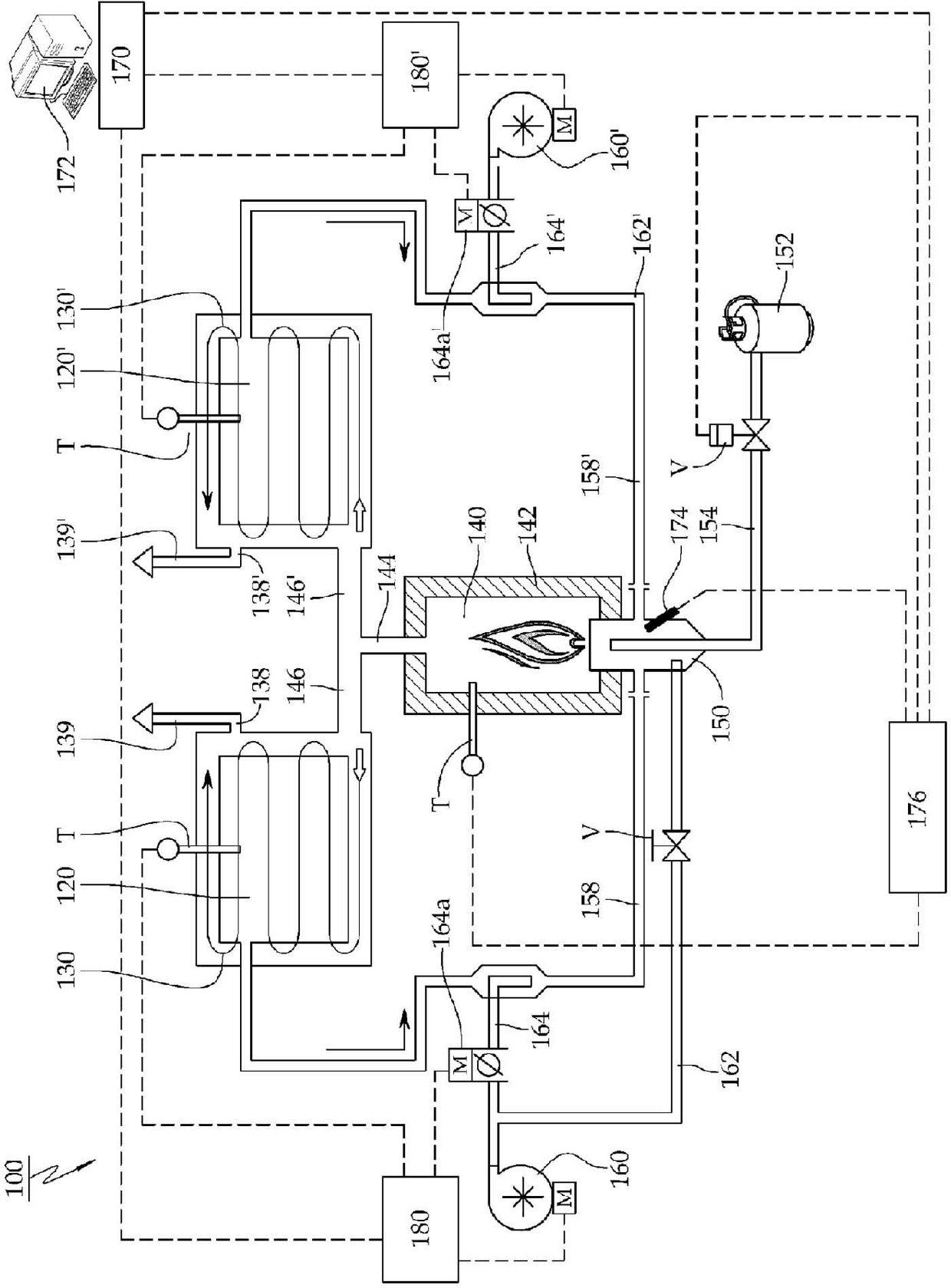

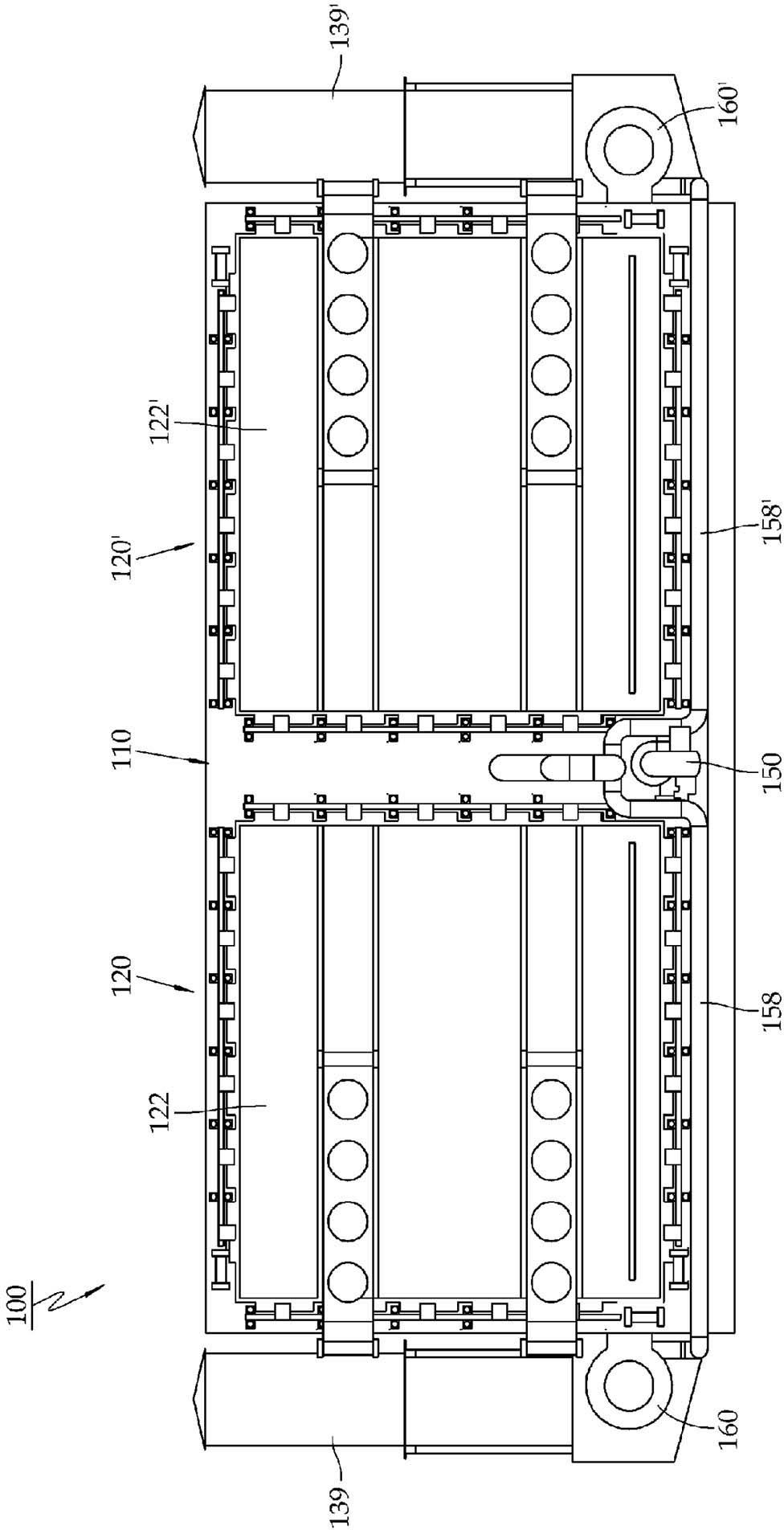

Constant pressure boiler for incinerating diseased livestock and poultry as well as garbage by straws to generate hot water and method thereof

ActiveCN104819468AEasy to storeEasy to transportCremation furnacesWater heatersCombustion systemControl system

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

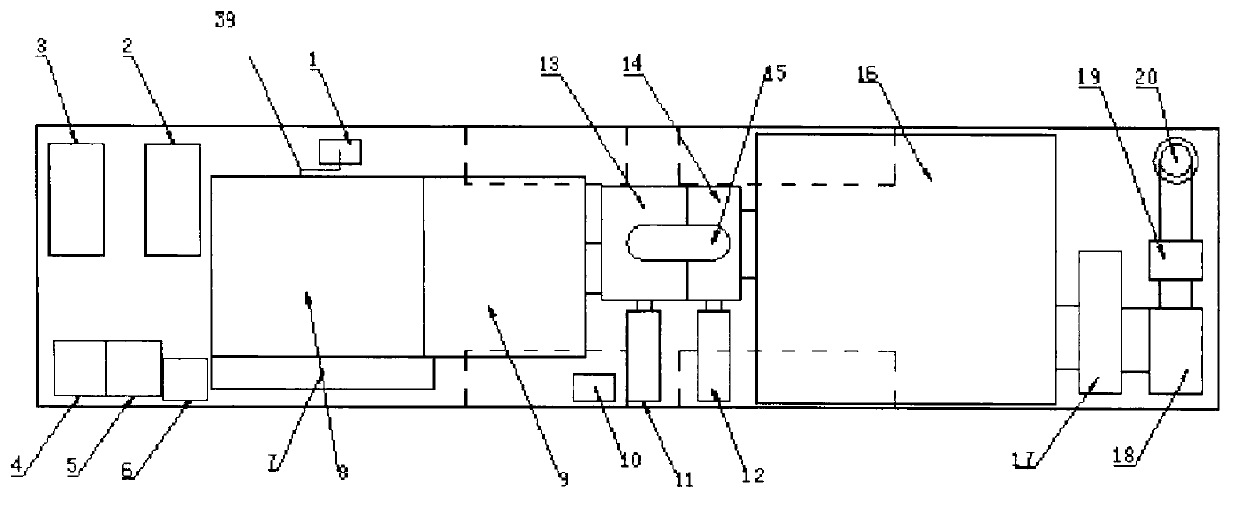

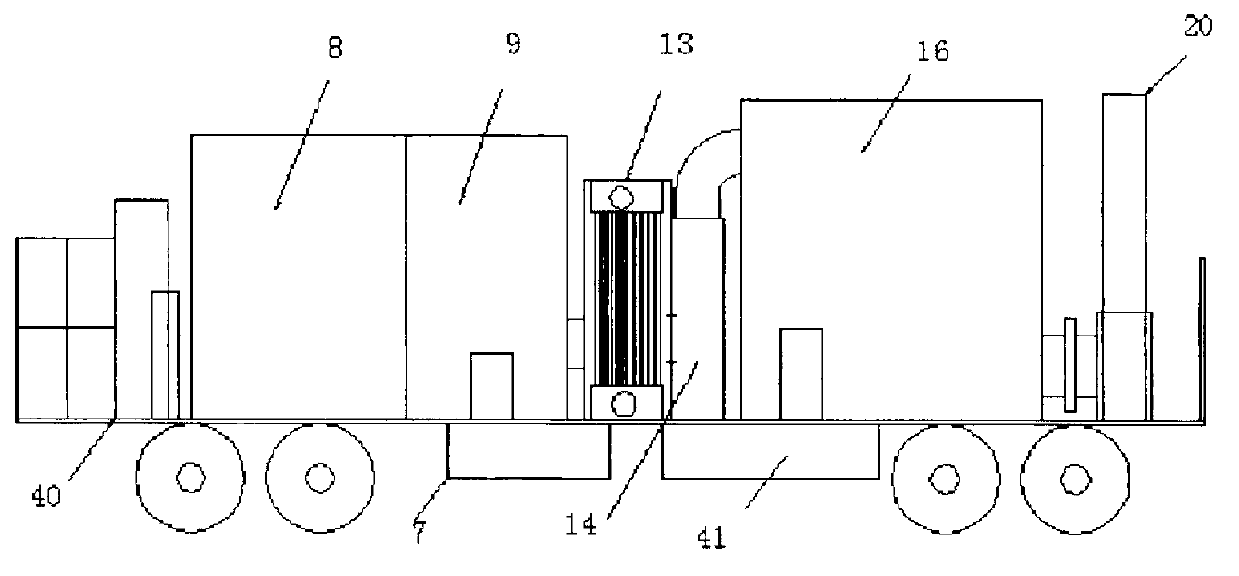

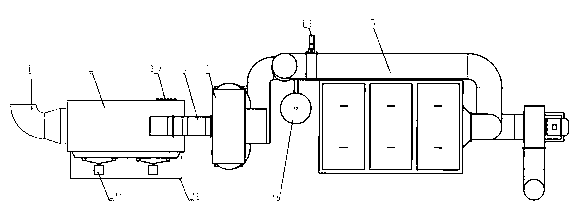

Movable incinerator

The invention provides a movable incinerator which is a vehicular incinerator. The movable incinerator comprises a box type vehicle with three sides capable of being opened, a main combustion chamber arranged in a box, a secondary combustion chamber, a heat exchanger, a smoke leaching and dust removing device, a water box, a generating unit and corollary equipment. Smoke channels of the main combustion chamber, the secondary combustion chamber, the heat exchanger, and the smoke leaching and dust removing device are communicated, and the main combustion chamber and the secondary combustion chamber are arranged in parallel. The movable incinerator has the advantages of being capable of solving the problems that a medical garbage bacterium device and the like in the prior art can not be moved as required, and an infected animal carcass and relevant waste can not be treated urgently on the spot, is convenient to use, capable of greatly reducing cost and occupied area of treatment of poisonous and harmful garbage, and small in affection on the environment.

Owner:上海凯鸿环保工程有限公司

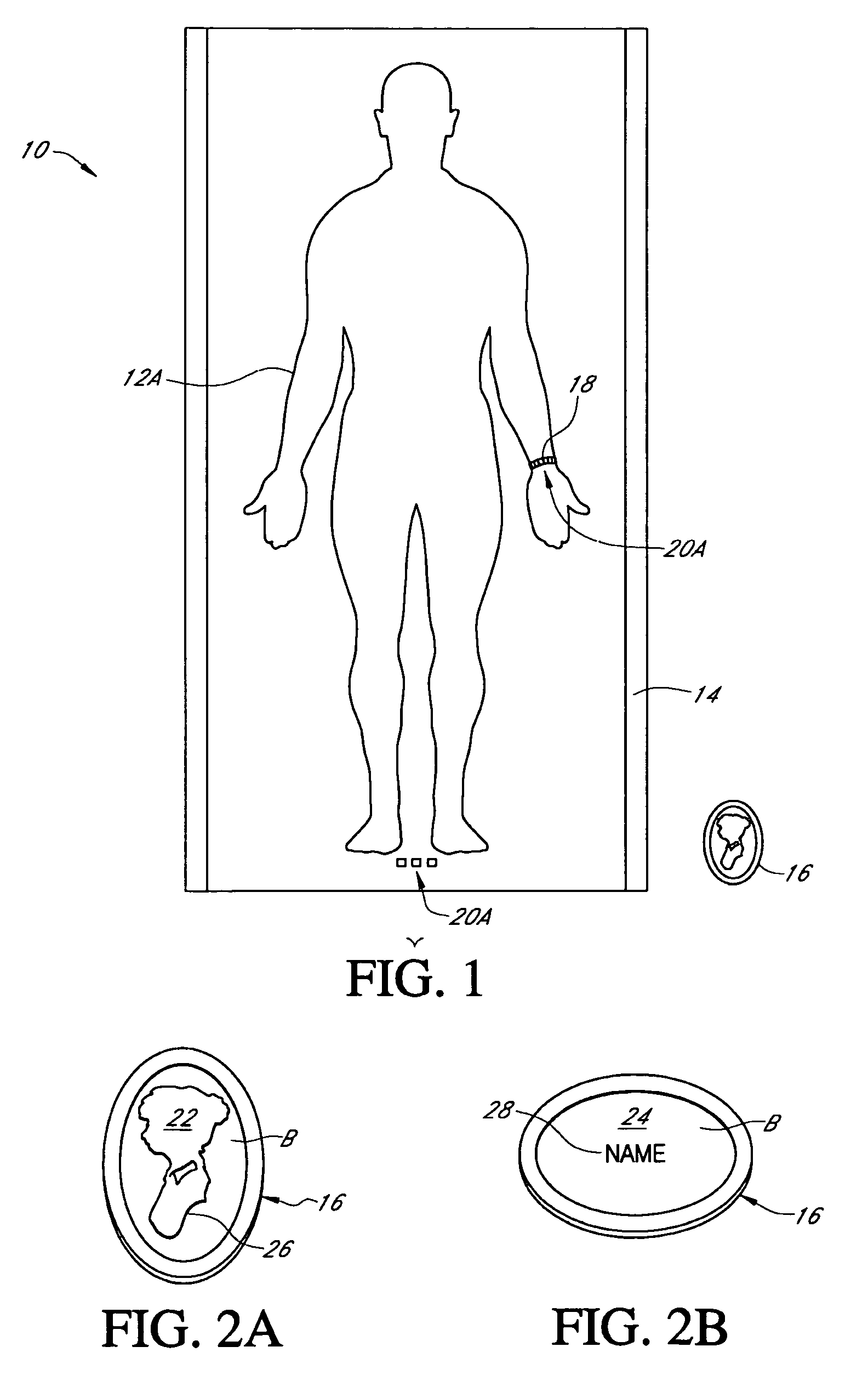

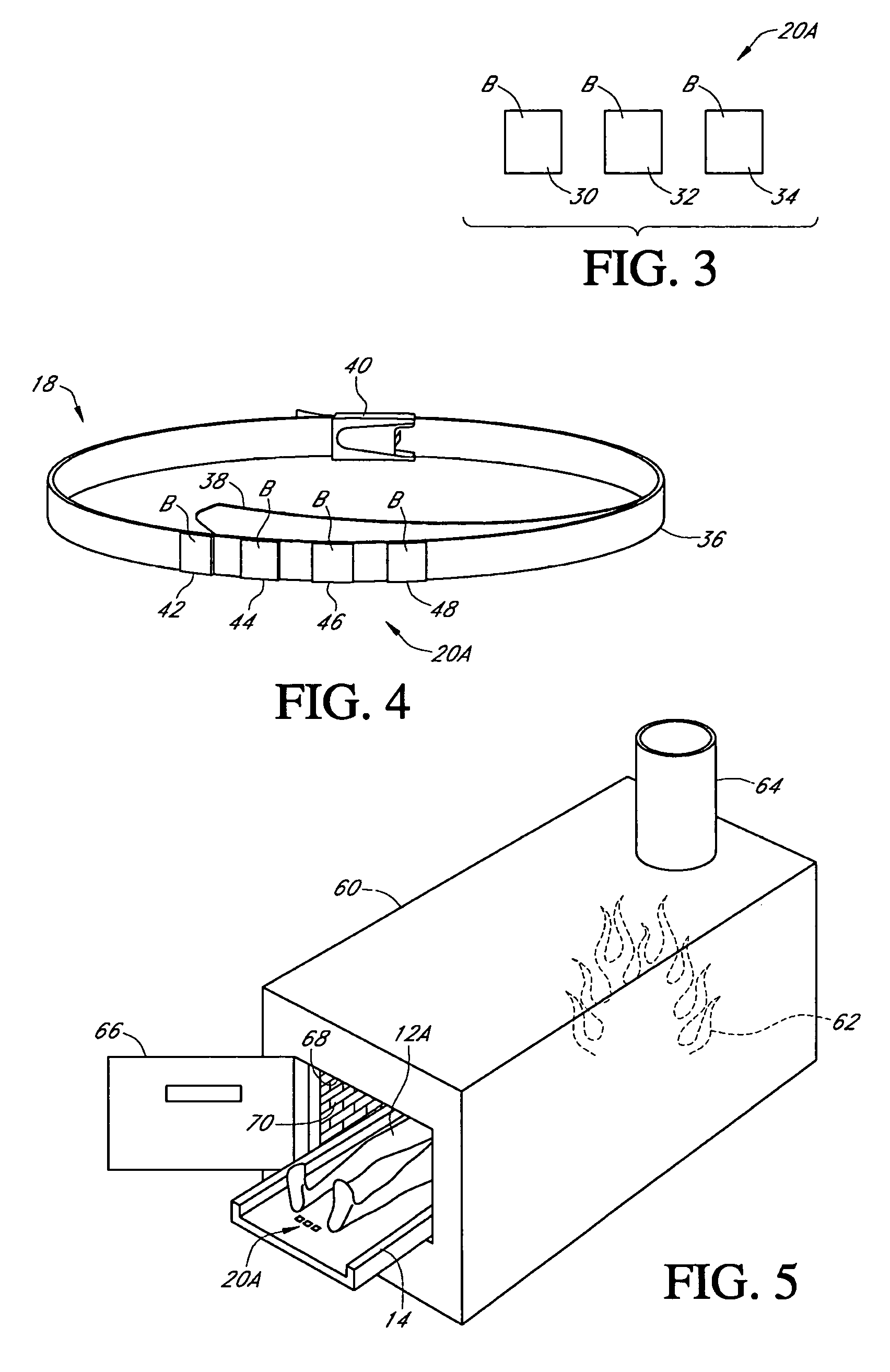

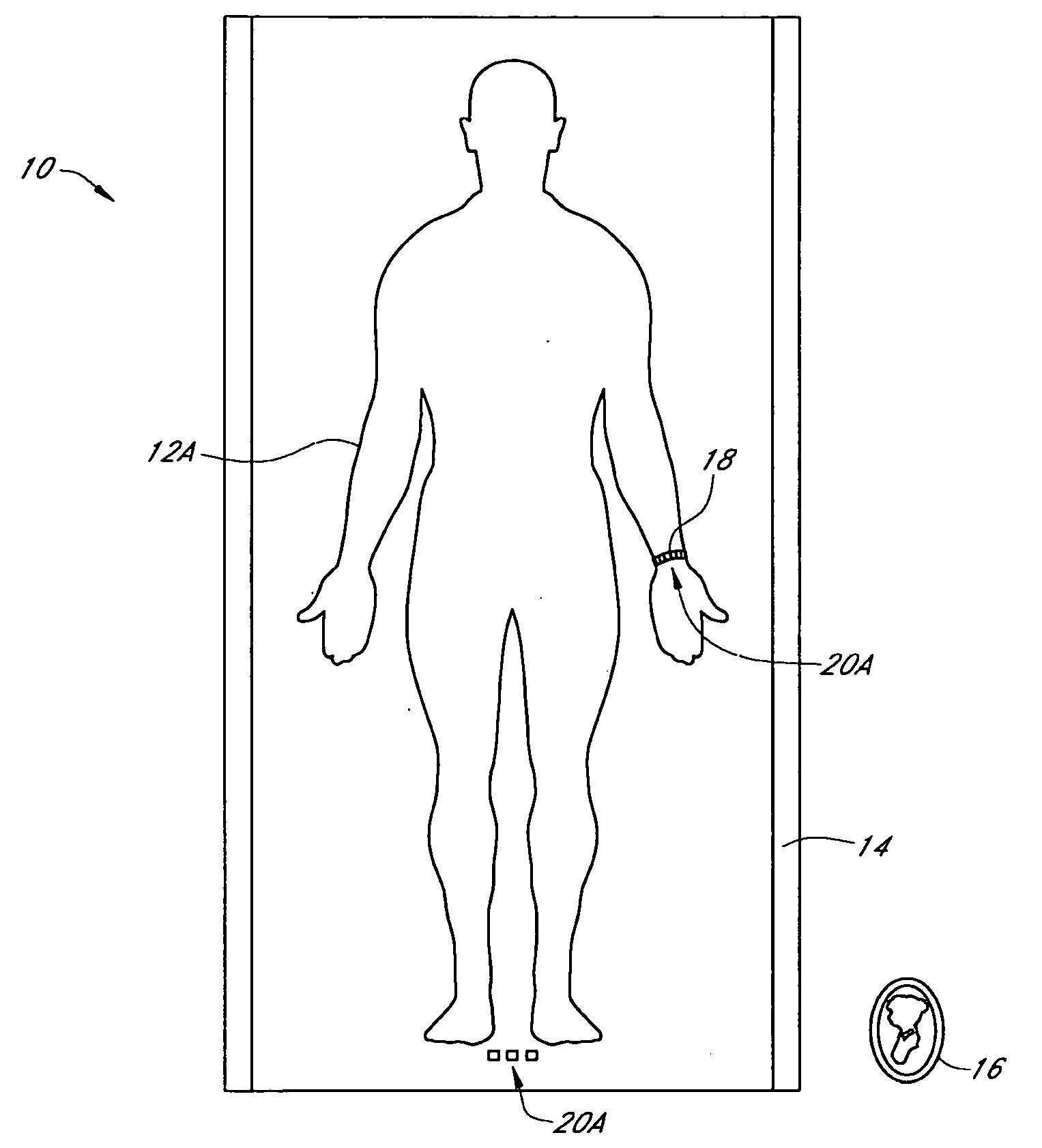

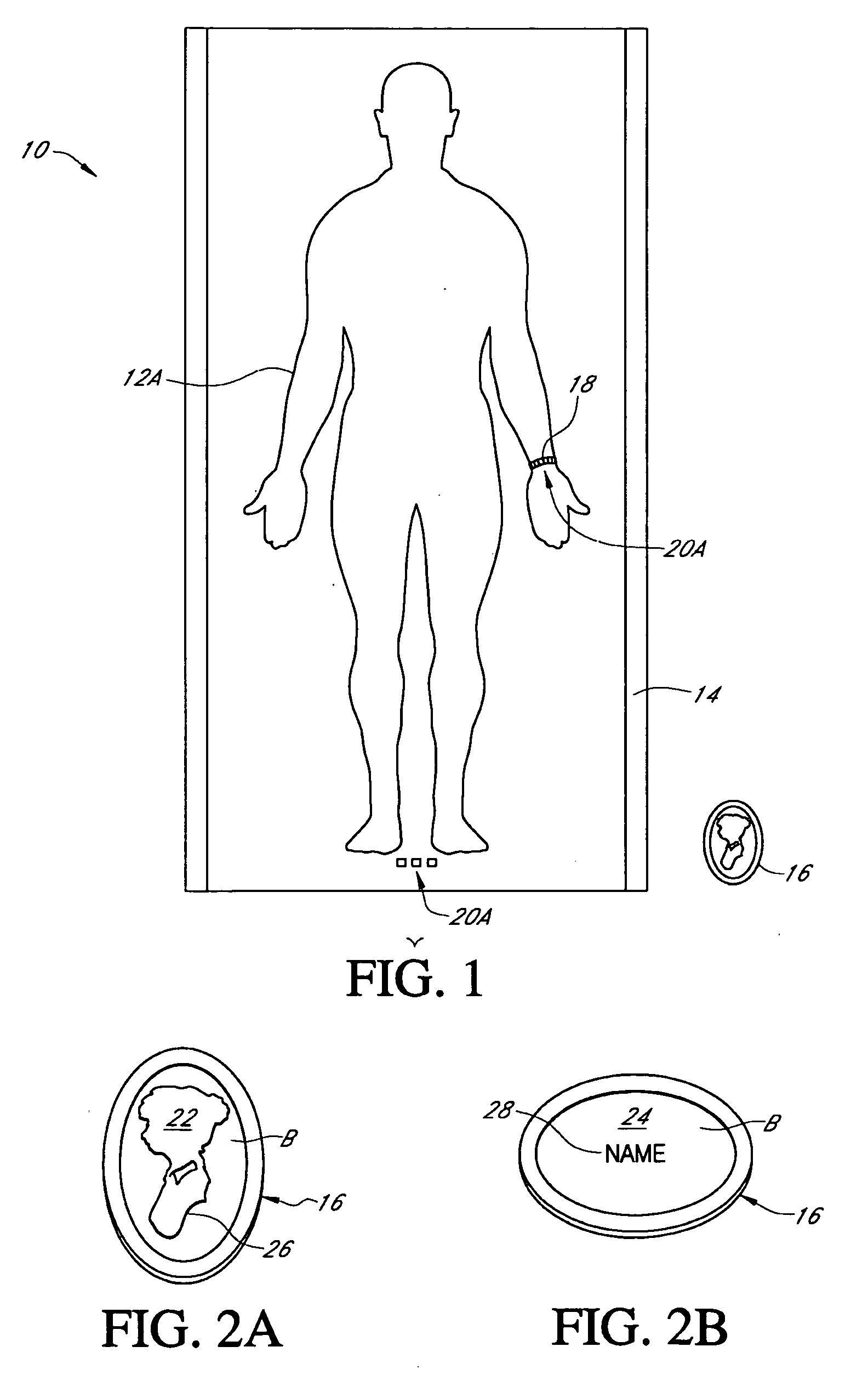

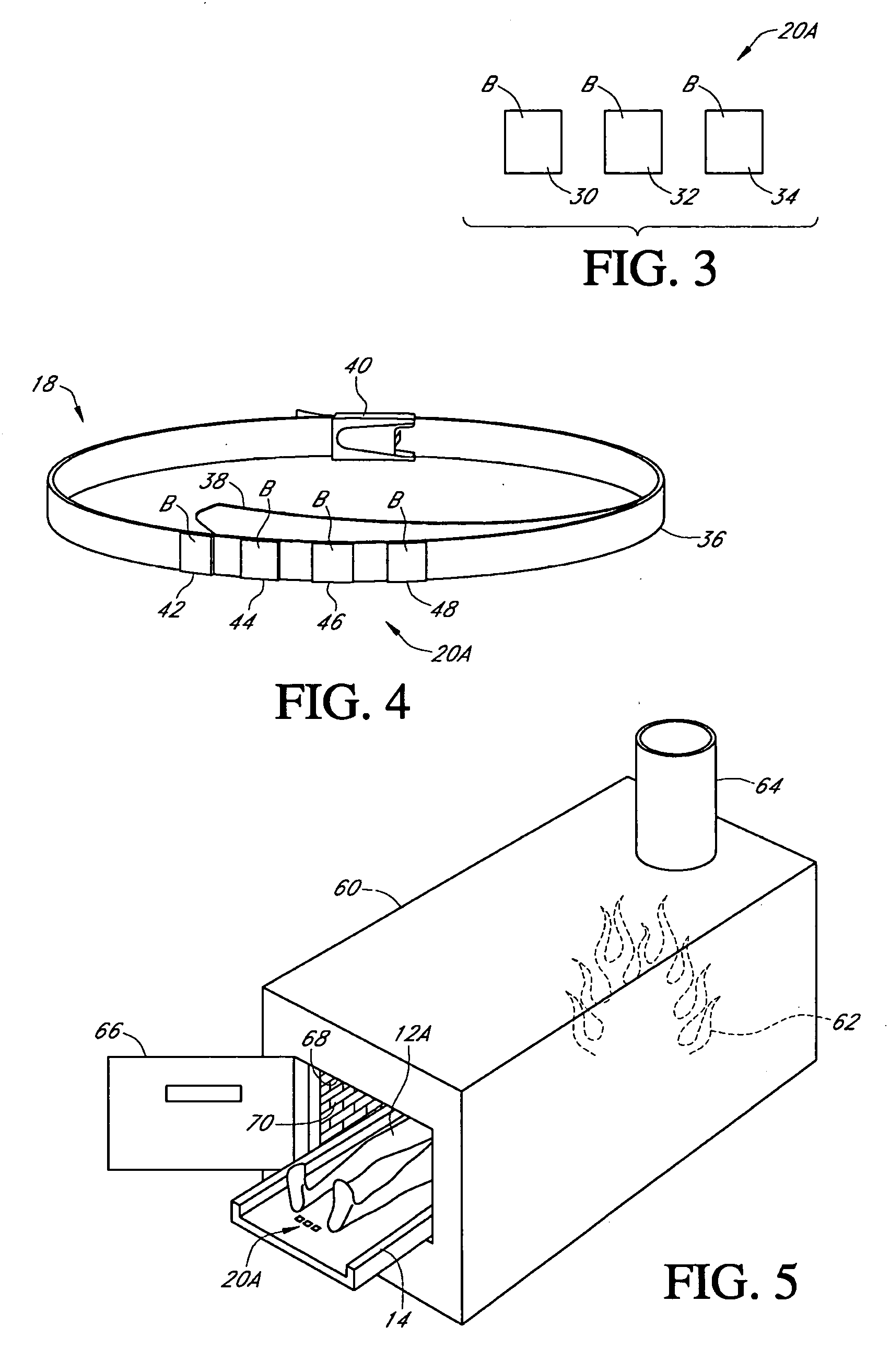

Synthetic biometric article and method for use of same

Owner:BILLS MICHAEL A

Synthetic biometric article and method for use of same

Owner:BILLS MICHAEL A

Cremation identification system and method for use of same

Owner:BILLS MICHAEL A

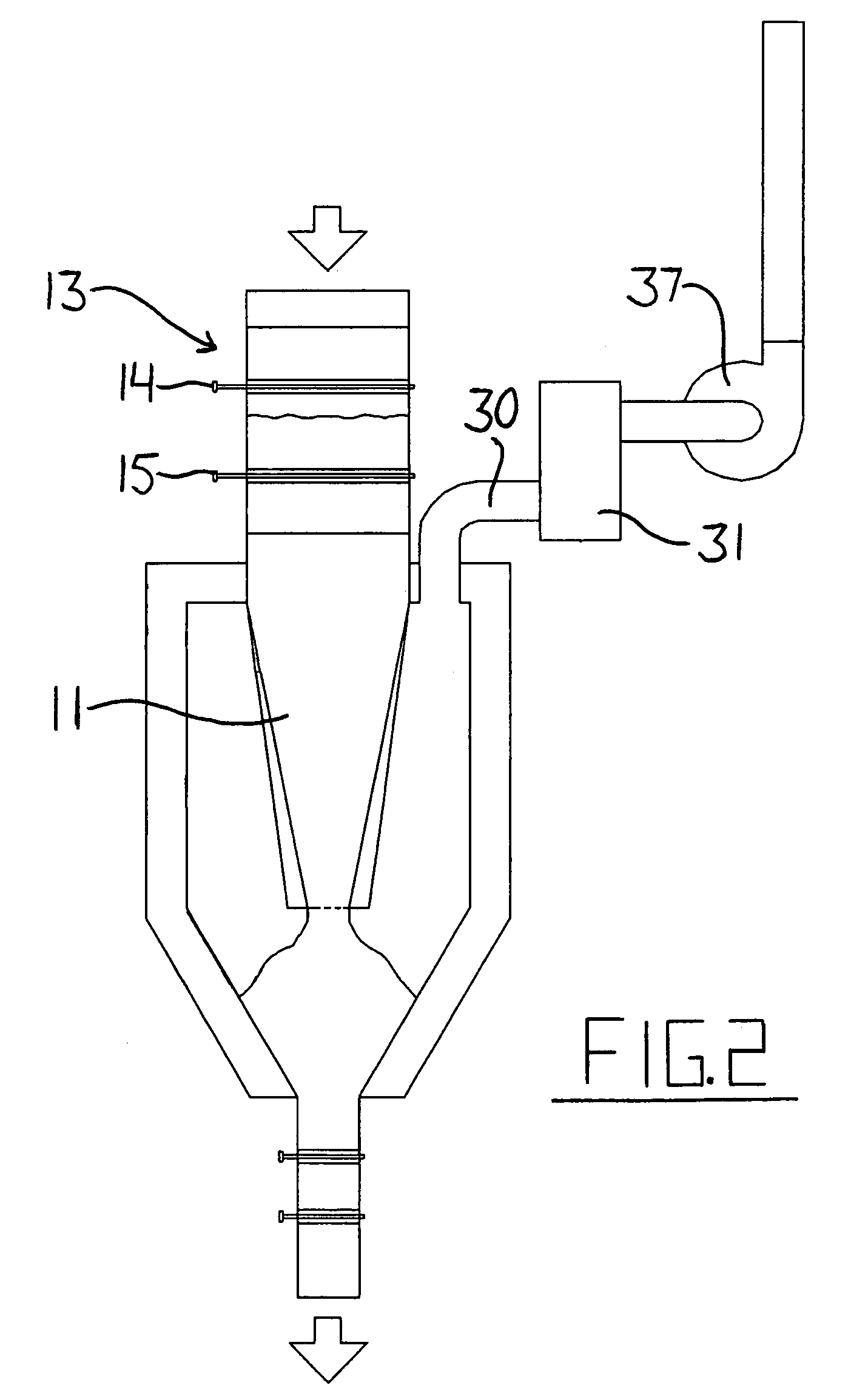

Cyclone bypass for a circulating fluidized bed reactor

InactiveUS20060075946A1Ingredients adjustableEasy to make changeFluidized bed combustionCremation furnacesFluidized bedExhaust fumes

A method of and an apparatus for operating a circulating fluidized bed reactor having a furnace with a discharge port for exhaust gas, and a particle separator having an inlet connected to the exhaust gas discharge port and an outlet duct for the exhaust gas and a return duct for separated solids. The method includes the steps of arranging a bypass duct bypassing the particle separator, and conducting a partial flow of exhaust gas along the duct for increasing the fly ash content in the exhaust gas after the separator. The bypass duct is advantageously provided with means for controlling the flow of exhaust gas in the bypass duct.

Owner:FOSTER WHEELER ENERGY CORP

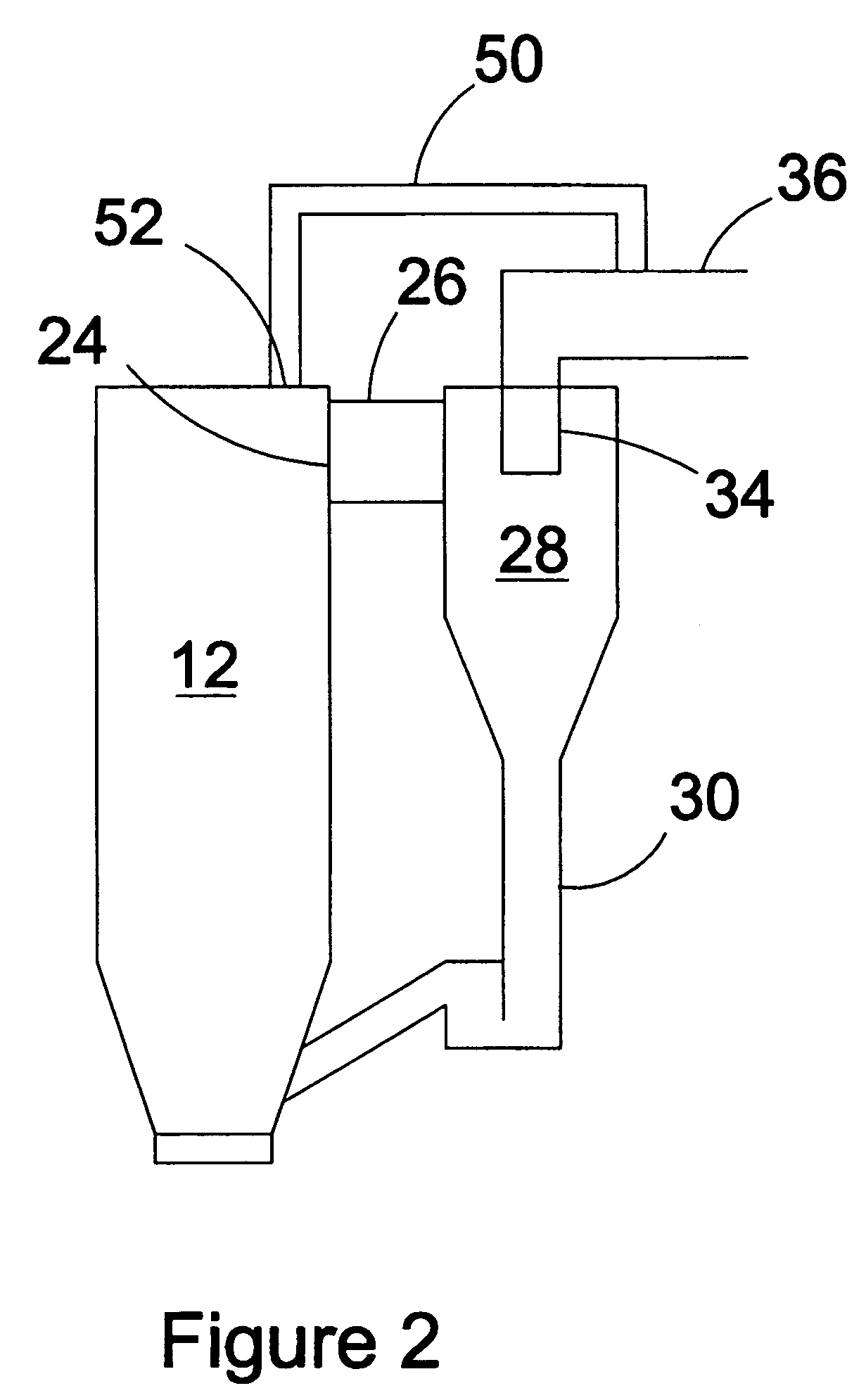

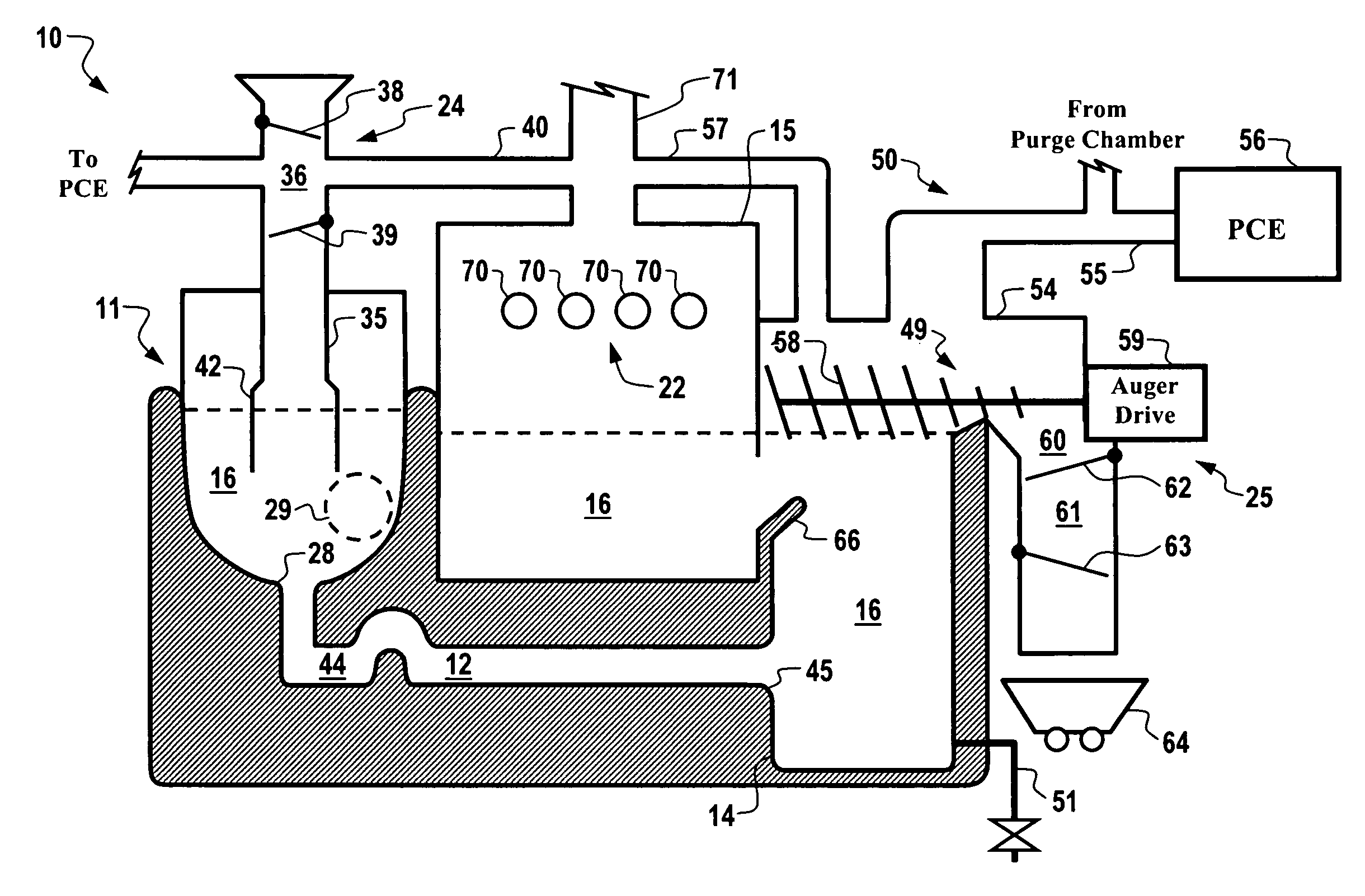

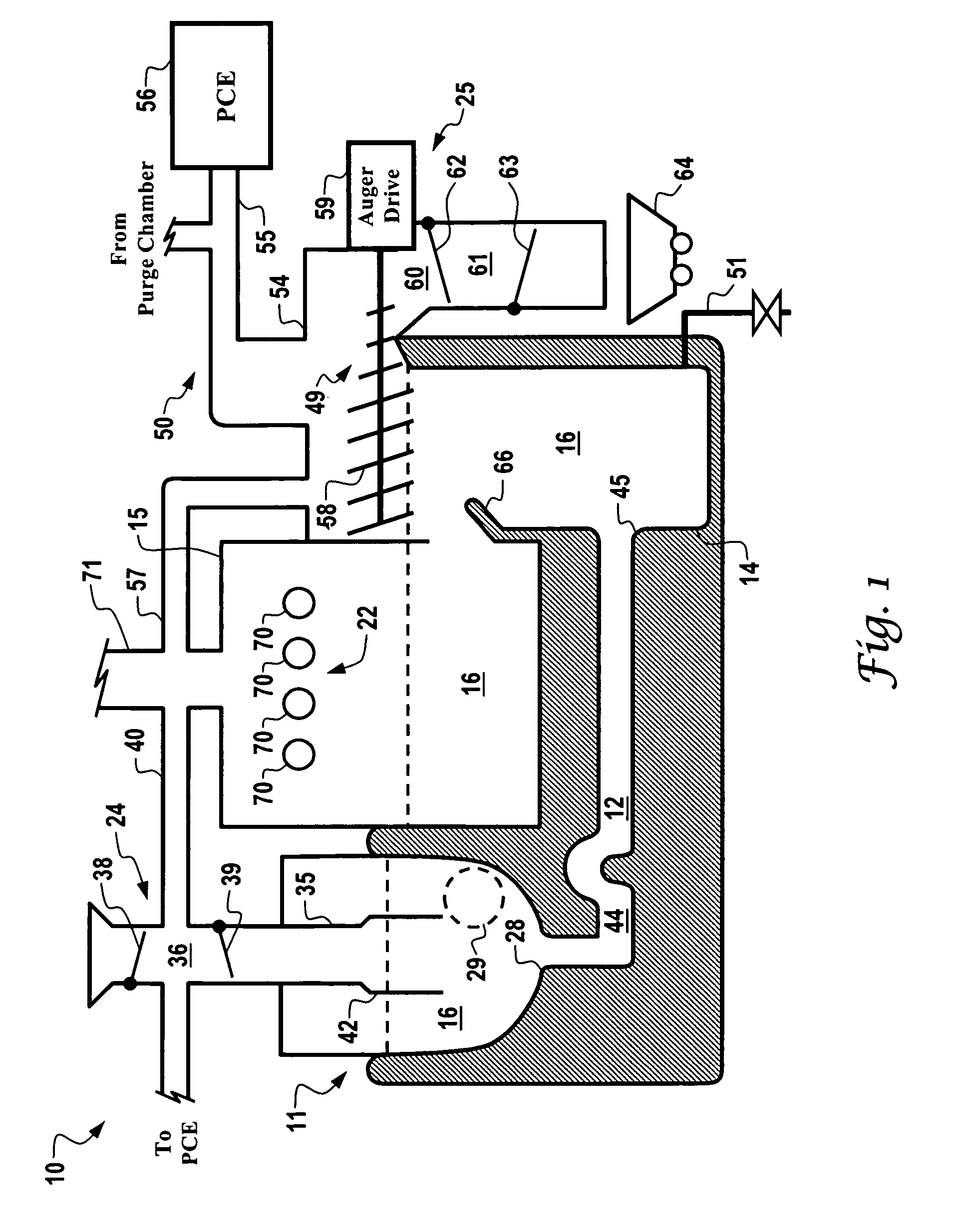

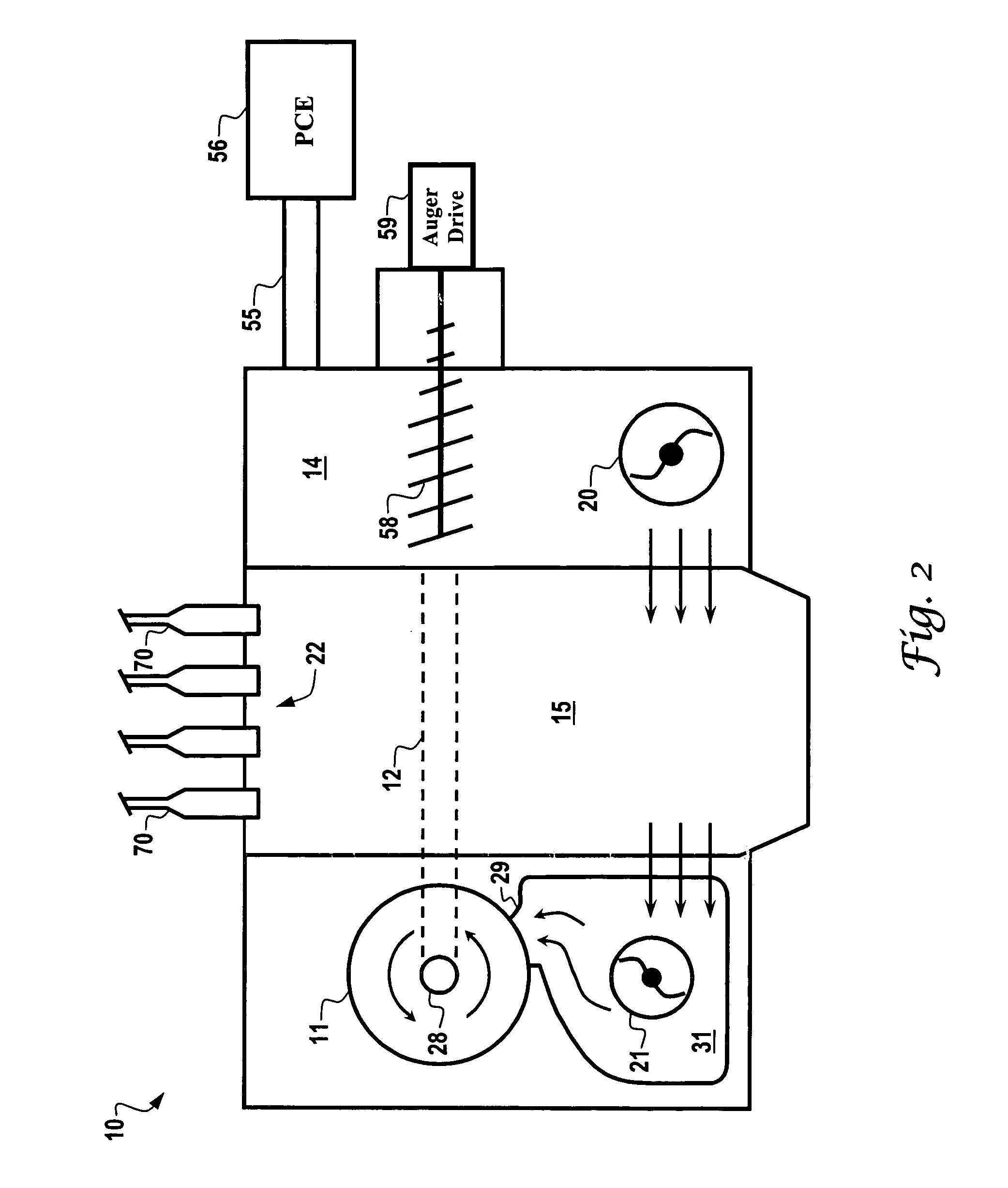

Molten metal reactor utilizing molten metal flow for feed material and reaction product entrapment

InactiveUS7449156B2Desired contactSpeed up the flowInorganic chemistryCremation furnacesPhysical chemistryMaterials science

A molten metal reactor (10) quickly entrains a feed material in the molten reactant metal (16) and provides the necessary contact between the molten reactant metal and the feed material to effect the desired chemical reduction of the feed material. The reactor (10) includes a unique feed structure (24) adapted to quickly entrain the feed material into the molten reactant metal (16) and then transfer the molten reactant metal, feed material, and initial reaction products into a treatment chamber (12). A majority of the desired reactions occur in the treatment chamber (12). Reaction products and unspent reactant metal are directed from the treatment chamber (12) to an output chamber (14) where reaction products are removed from the reactor. Unspent reactant metal (16) is then transferred to a heating chamber (15) where it is reheated for recycling through the system.

Owner:CLEAN TECH INT

Purification treatment device for incineration flue gas

ActiveCN102120132ABurn fullyExtended stayCombination devicesCremation furnacesActivated carbonCombustor

The invention discloses a purification treatment device for incineration flue gas. A condensate pipe is arranged in a cold and hot exchanger; a combustor is arranged on a flue gas combustion chamber; the flue gas combustion chamber is provided with an inlet and an outlet; the outlet of the flue gas combustion chamber is connected to the inlet of the cold and hot exchanger through a pipeline; the outlet of the cold and hot exchanger is connected to the inlet of a deacidification system through a pipeline; the outlet of the deacidification system is connected to the inlet of a dry-wet separatorthrough a pipeline; the outlet of the dry-wet separator is connected to the inlet of a mixing chamber through a pipeline; an activated carbon storage tank is arranged on the mixing chamber; the outlet of the mixing chamber is connected to the inlet of a bag-type dust collector through a pipeline; the outlet of the bag-type dust collector is provided with a draught fan; the outlet of a dosing device is connected to the deacidification system through a pipeline; a first outlet of a blowing device is connected to the deacidification system through a pipeline; and a second outlet of the blowing device is connected to the mixing chamber through a pipeline.

Owner:民政部一零一研究所

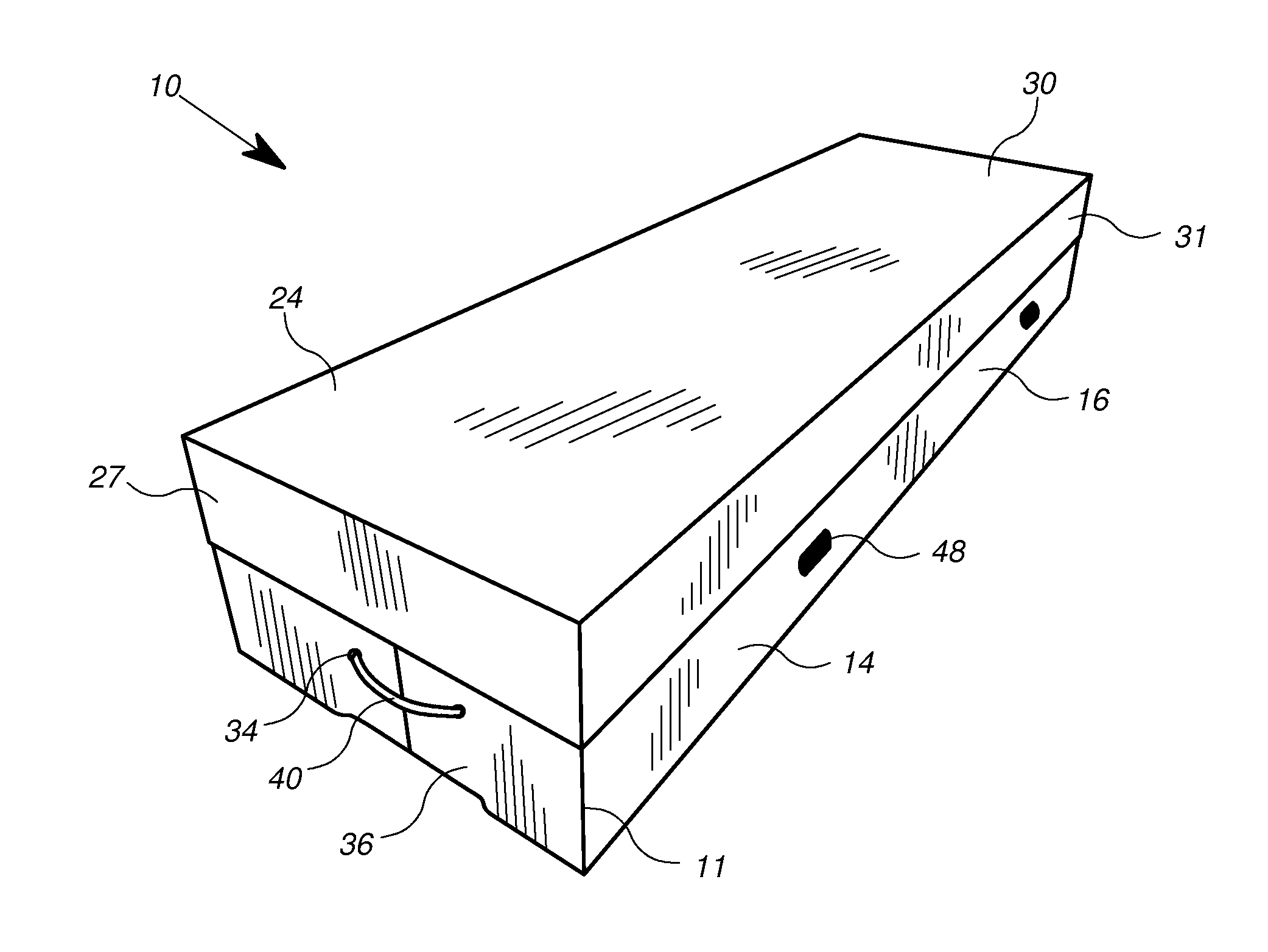

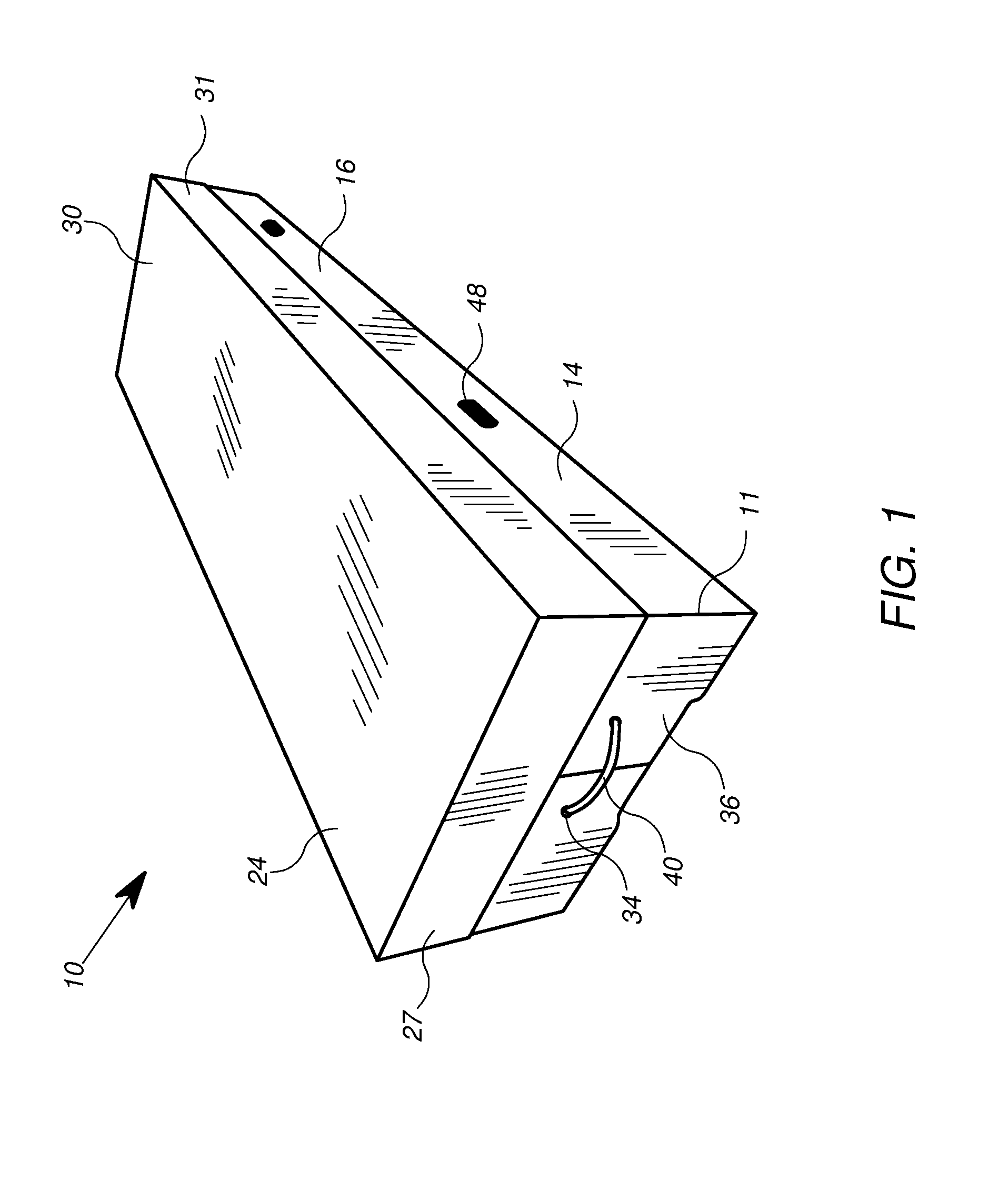

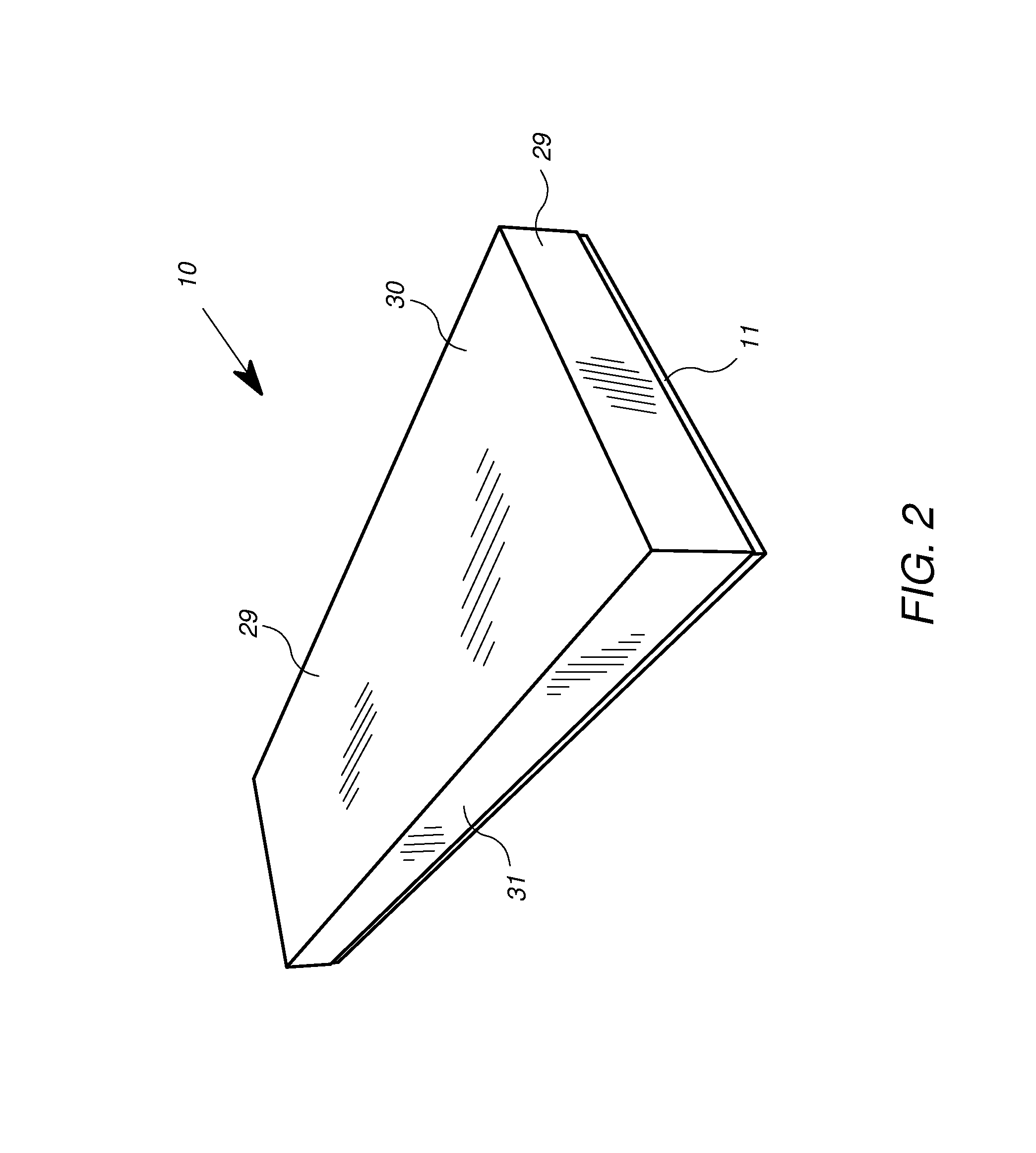

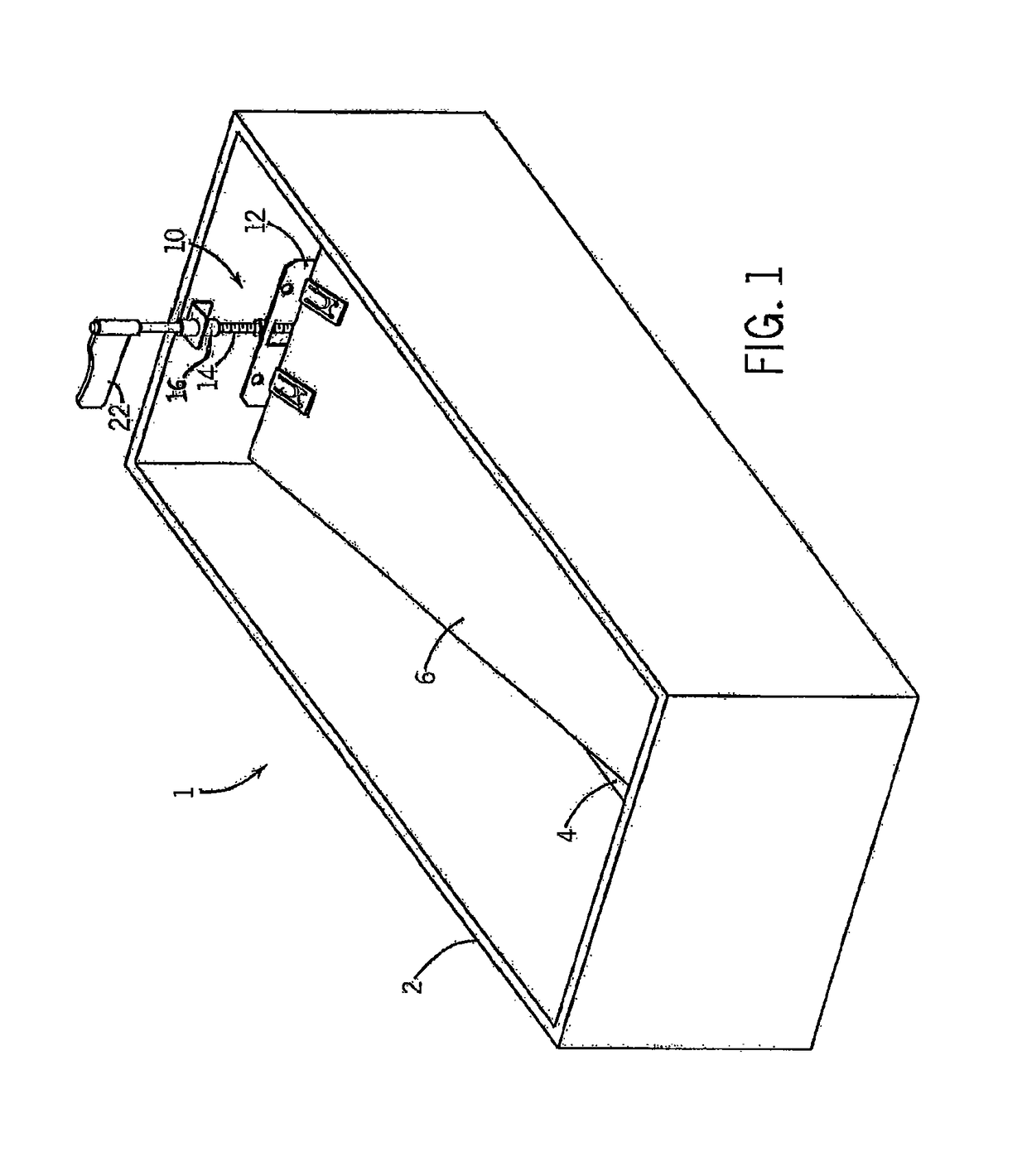

Lightweight casket having foldable features

A casket assembly includes a bottom panel, side panels, flaps and end panels. The bottom panel is formed of a pliable material. The side panels are formed intrinsically with the bottom panel. Each side panel includes a lower section and an upper section foldably attached thereto. The lower section extends vertically upward from the bottom panel. In a first configuration, the upper section extends upward from the lower section. In a second configuration, the upper section extends in a direction other than vertically upward from the lower section. The end panels are formed intrinsically with the bottom panel. The flaps extend laterally from each end of the upper section. The flaps in the first configuration extend upward from a first vertical level defined by the top portion of the lower section, and in the second configuration extend downward from the first vertical level

Owner:VANDOR CORP

Harmless treatment device of carcasses of animals died of diseases for livestock farm

InactiveCN107525076APrevent proliferationAvoid spreadingCremation furnacesIncinerator apparatusAgricultural scienceCarbonization

The invention discloses a harmless treatment device of carcasses of animals died of diseases for a livestock farm and belongs to the technical field of livestock breeding devices. The harmless treatment device of the carcasses of the animals died of diseases for the livestock farm mainly comprises a crusher, a high-voltage electric carbonization chamber, an incinerator, a dust collector, an oil-gas separating and recycling device, a gas collection tank, an oil collection tank, a bond meal collection box and an incineration tail gas purifying device. The crusher is connected to the position above the high-voltage electric carbonization chamber. An inner chamber and a flue are arranged in the high-voltage electric carbonization chamber. A high-voltage net rack is arranged in the indoor chamber. The incinerator and the bone meal collection tank are sequentially connected to the lower side in the high-voltage electric carbonization chamber. The dust collector is connected between a smoke outlet of and a flue of the incinerator. The oil-gas separating and recycling device is connected with the indoor chamber. The gas collection tank, the oil collection tank and the incineration tail gas purifying device are sequentially connected with the oil-gas separating and recycling device. To sum up, the harmless treatment device of the carcasses of the animals died of diseases of the livestock farm has the advantages of being environmentally friendly, safe, high in efficiency and the like.

Owner:王海森

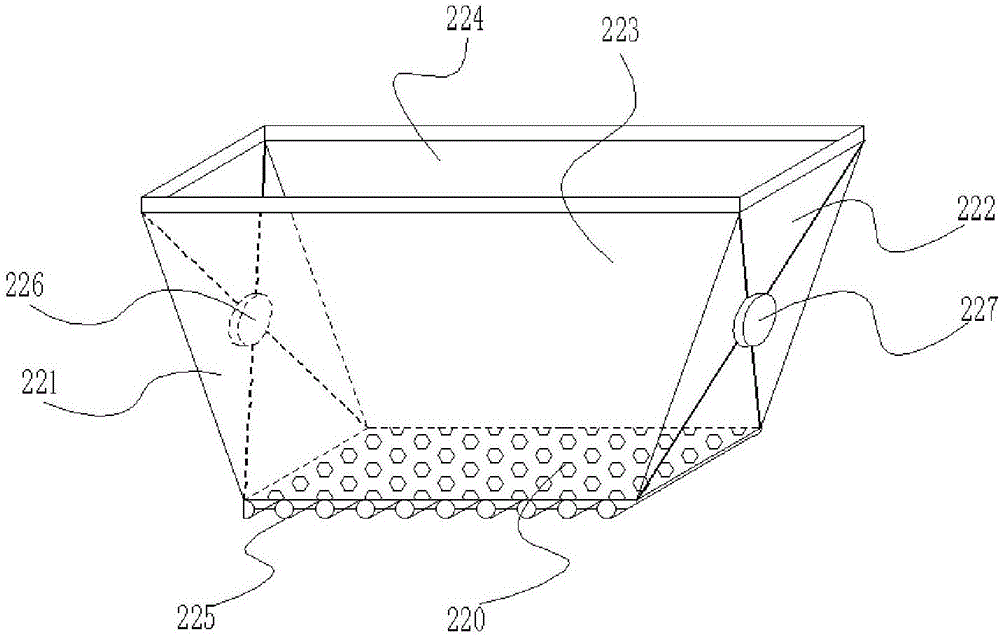

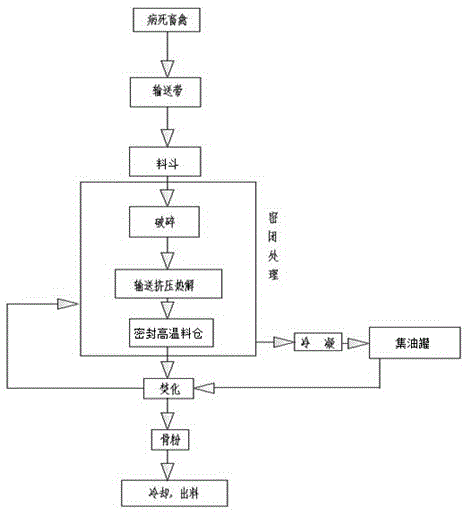

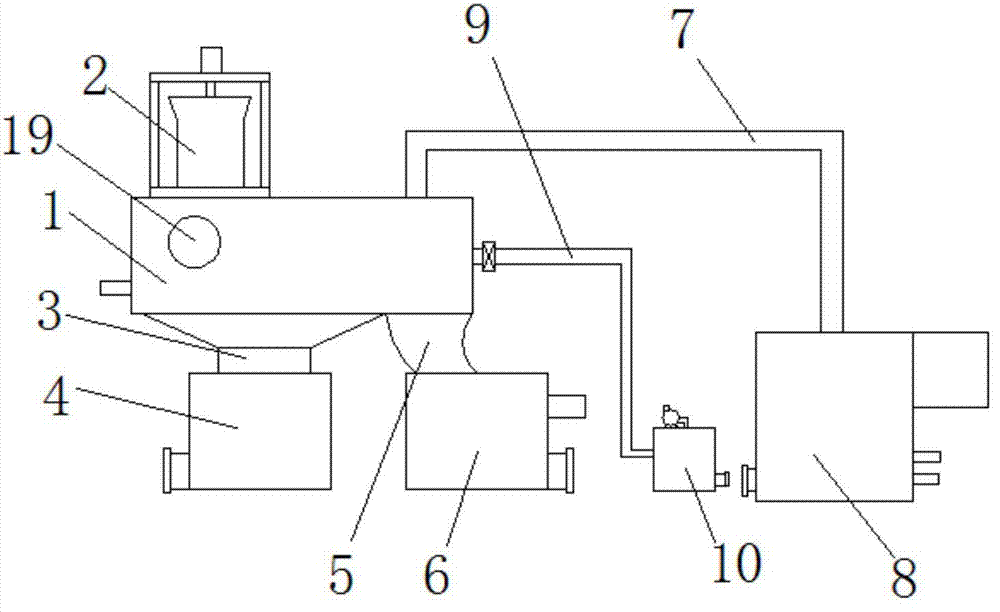

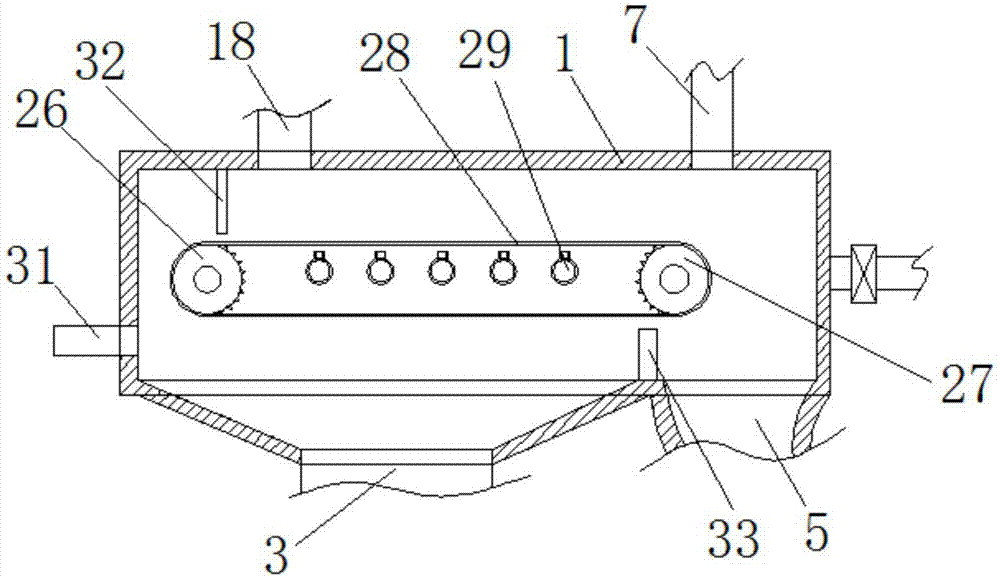

Pyrolyzing-incinerating harmless treatment device for livestock and poultry

ActiveCN104807014ARealize harmless treatmentImprove use valueCremation furnacesIncinerator apparatusCrusherHot Temperature

The invention relates to a pyrolyzing-incinerating harmless treatment device for livestock and poultry, comprising an incinerator, a material conveying mechanism, a crusher provided with a discharge port at the bottom and a heating cavity outside, a conveyer belt, a sealed pyrolyzing furnace, a sealed high-temperature stock bin and an oil-gas recovery unit; the crusher and the conveyer belt are arranged in the sealed pyrolyzing furnace; the lower part of the material feeding mechanism is embedded from a heating cavity and the top part of the sealed pyrolyzing furnace and is arranged above the brusher, and the bottom of the material feeding mechanism is provided with an outlet connected with the brusher; one end of the conveyer belt is installed below the outlet of the brusher, and the end part of the other end of the conveyer belt is located above the discharge port of the sealed pyrolyzing furnace; the sealed high-temperature stock bin is arranged below the heating cavity and the top part of the sealed high-temperature stock bin is connected with the discharge port through a communicating pipeline which penetrates through the heating cavity; the incinerator is arranged below the sealed high-temperature stock bin and is communicated with the sealed high-temperature stock bin; a high-temperature smoke gas outlet connected with the heating cavity by the pipeline is formed in the top part of the incinerator; an inlet in the top part of the oil-gas recovery unit is communicated with the sealed pyrolyzing furnace by the pipeline of the heating cavity. The pyrolyzing-incinerating harmless treatment device disclosed by the invention is high in efficiency, low in cost and harmless in treatment.

Owner:SOUTH CHINA AGRI UNIV

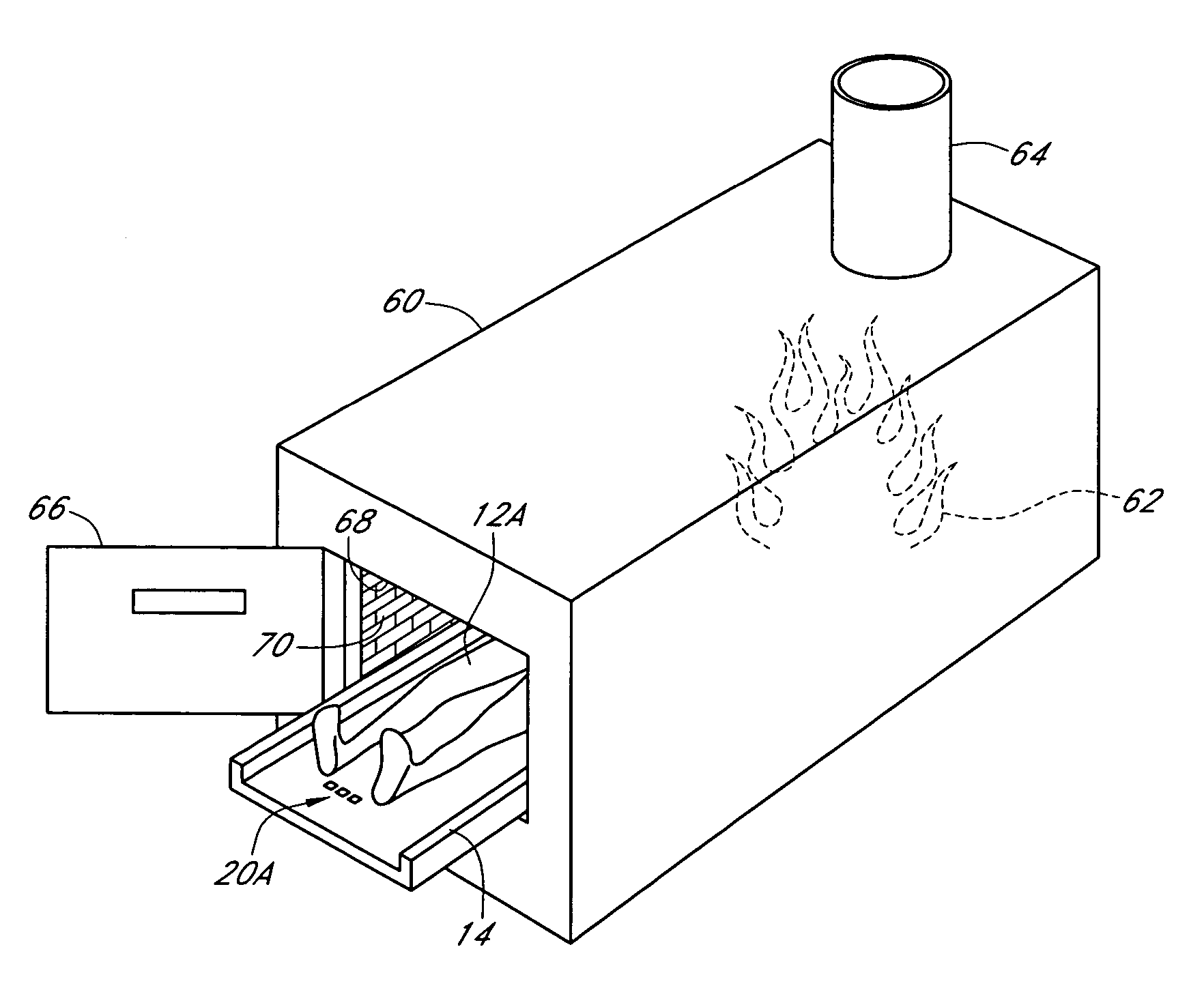

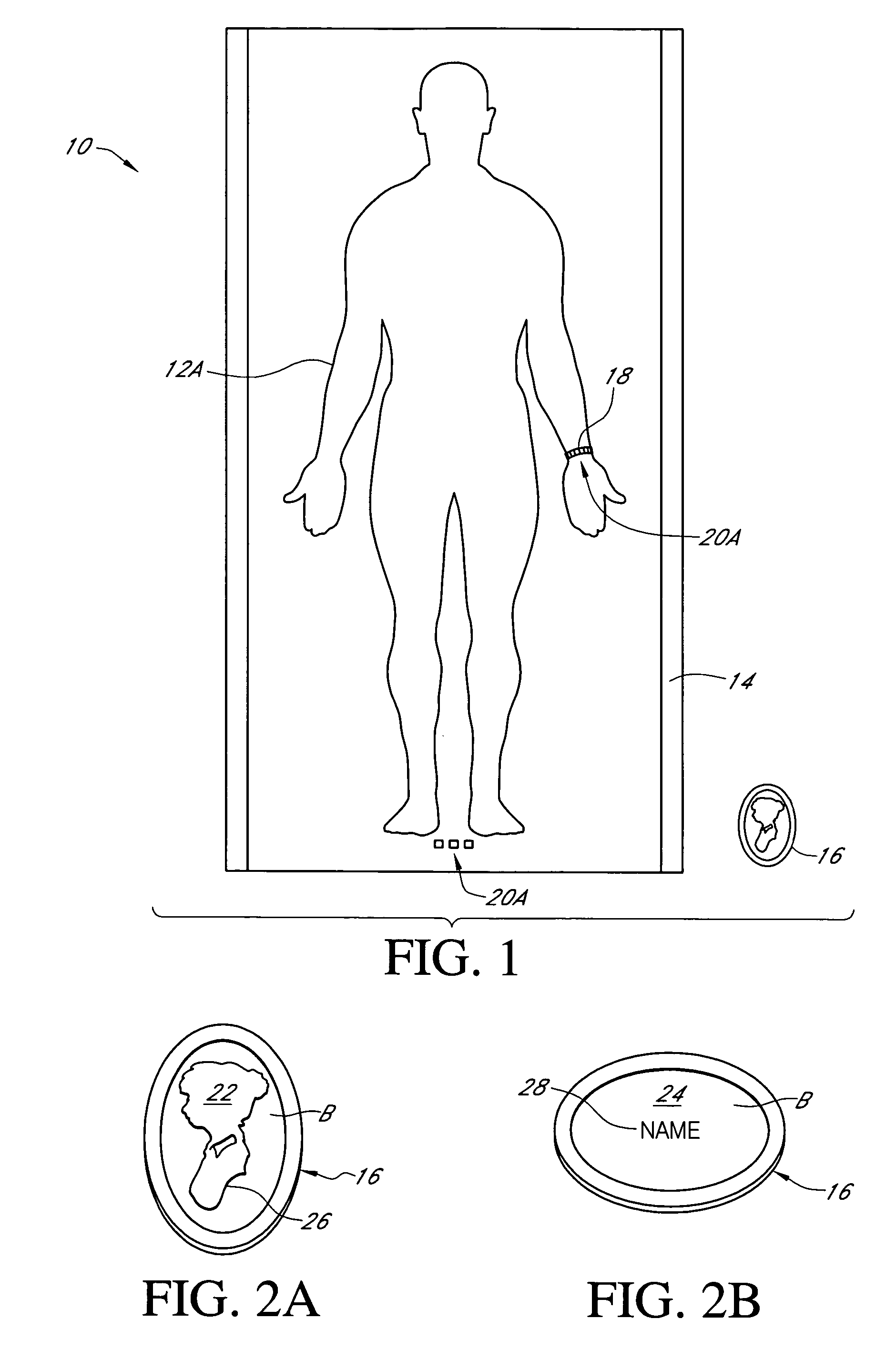

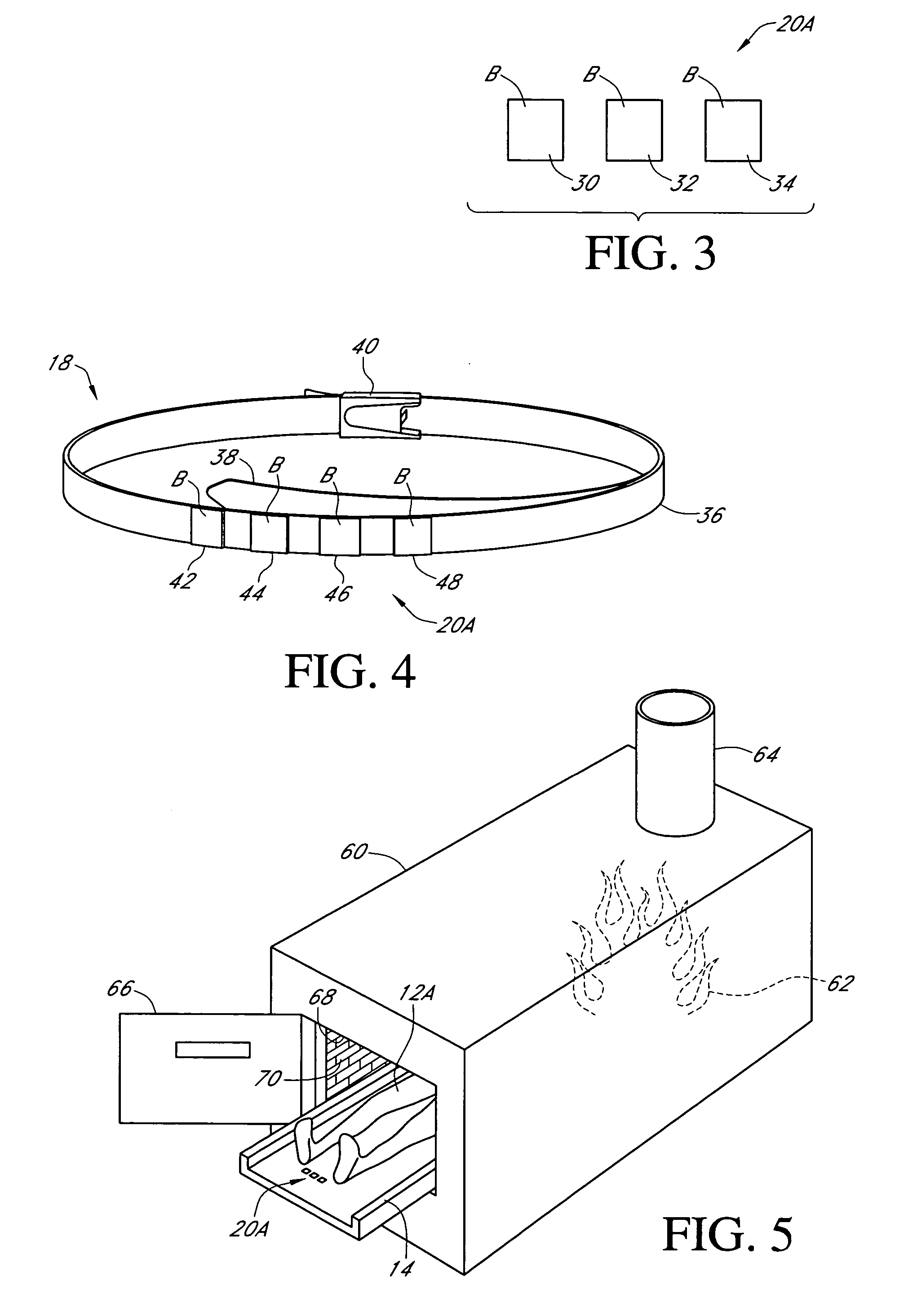

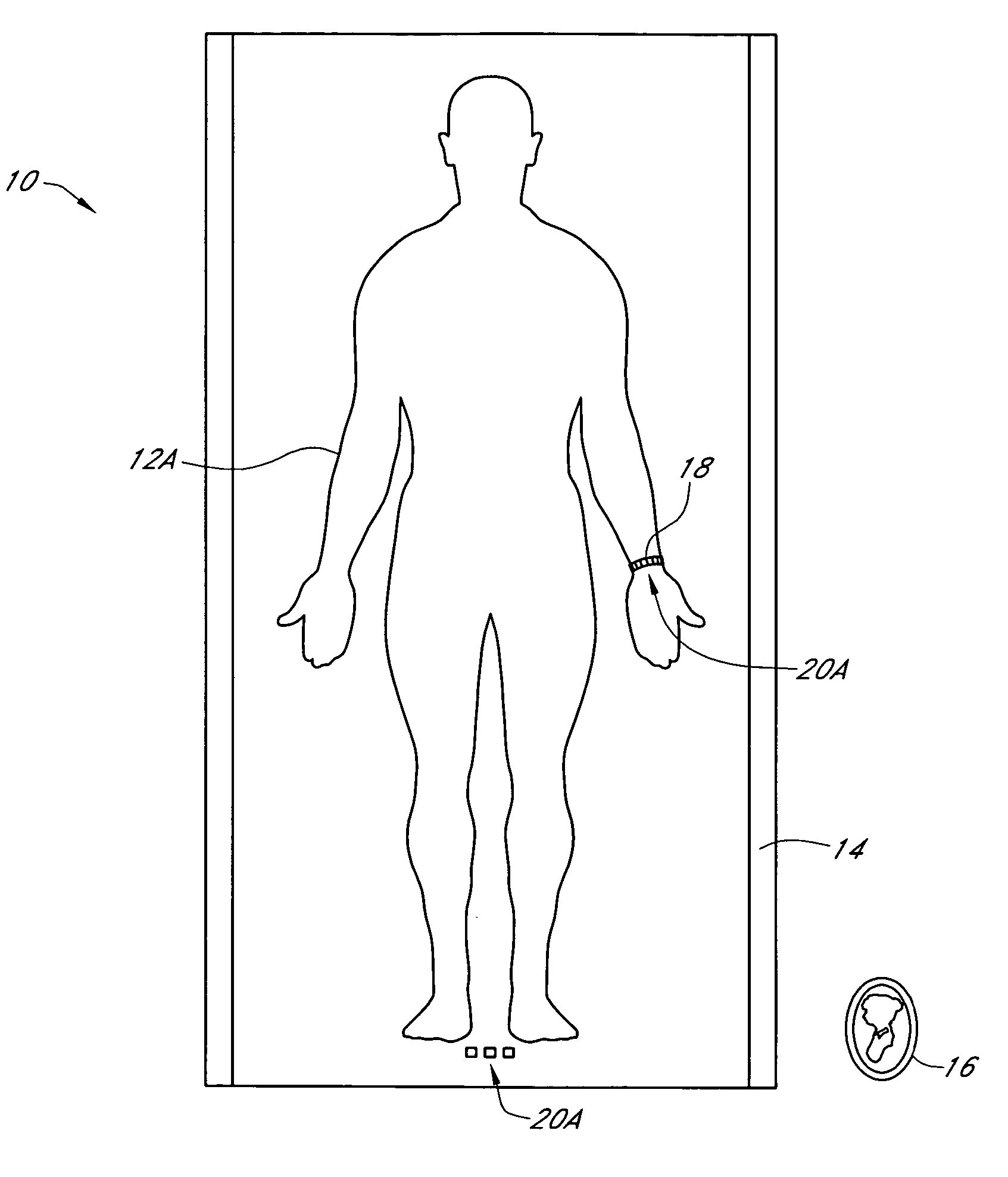

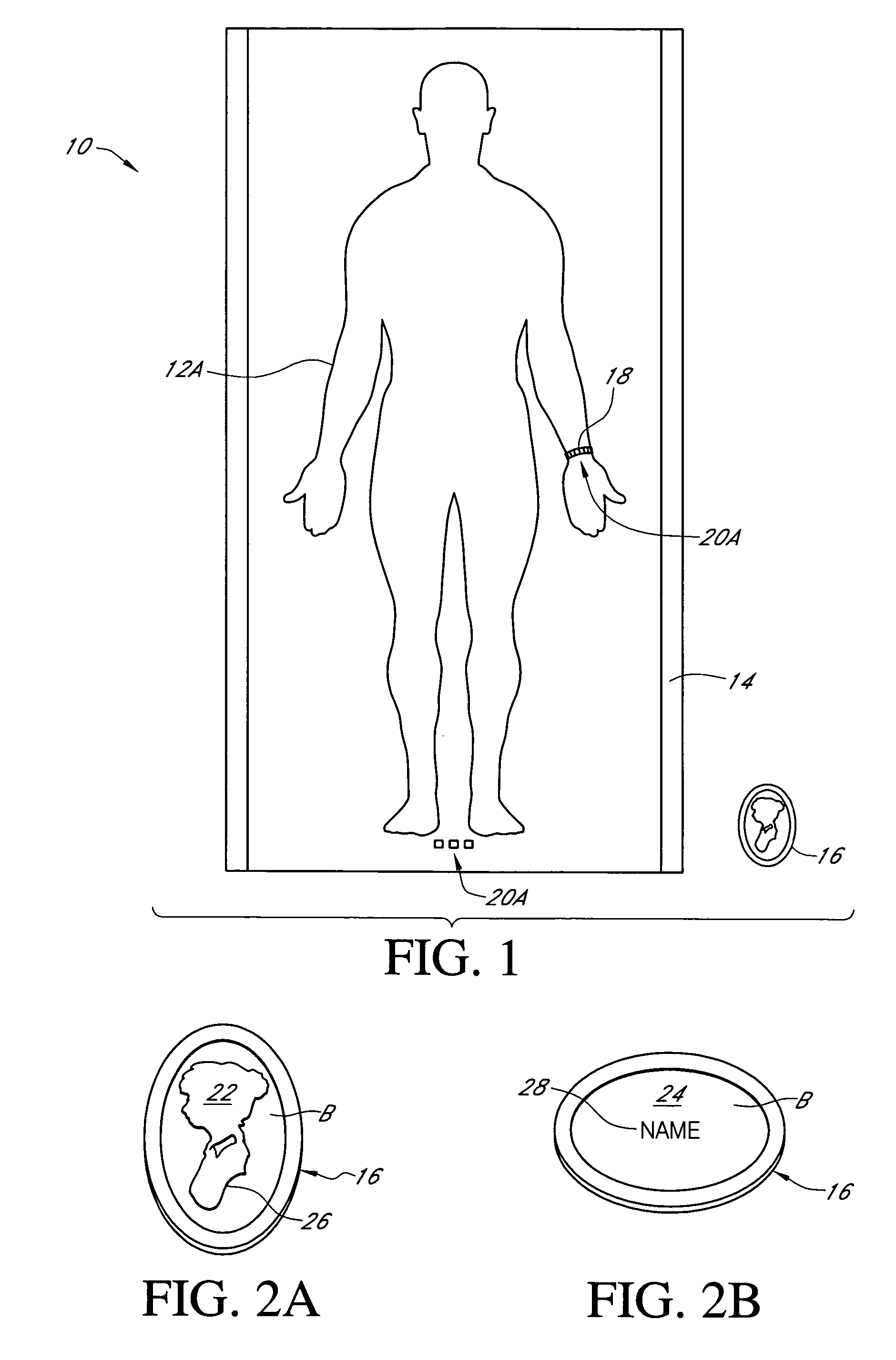

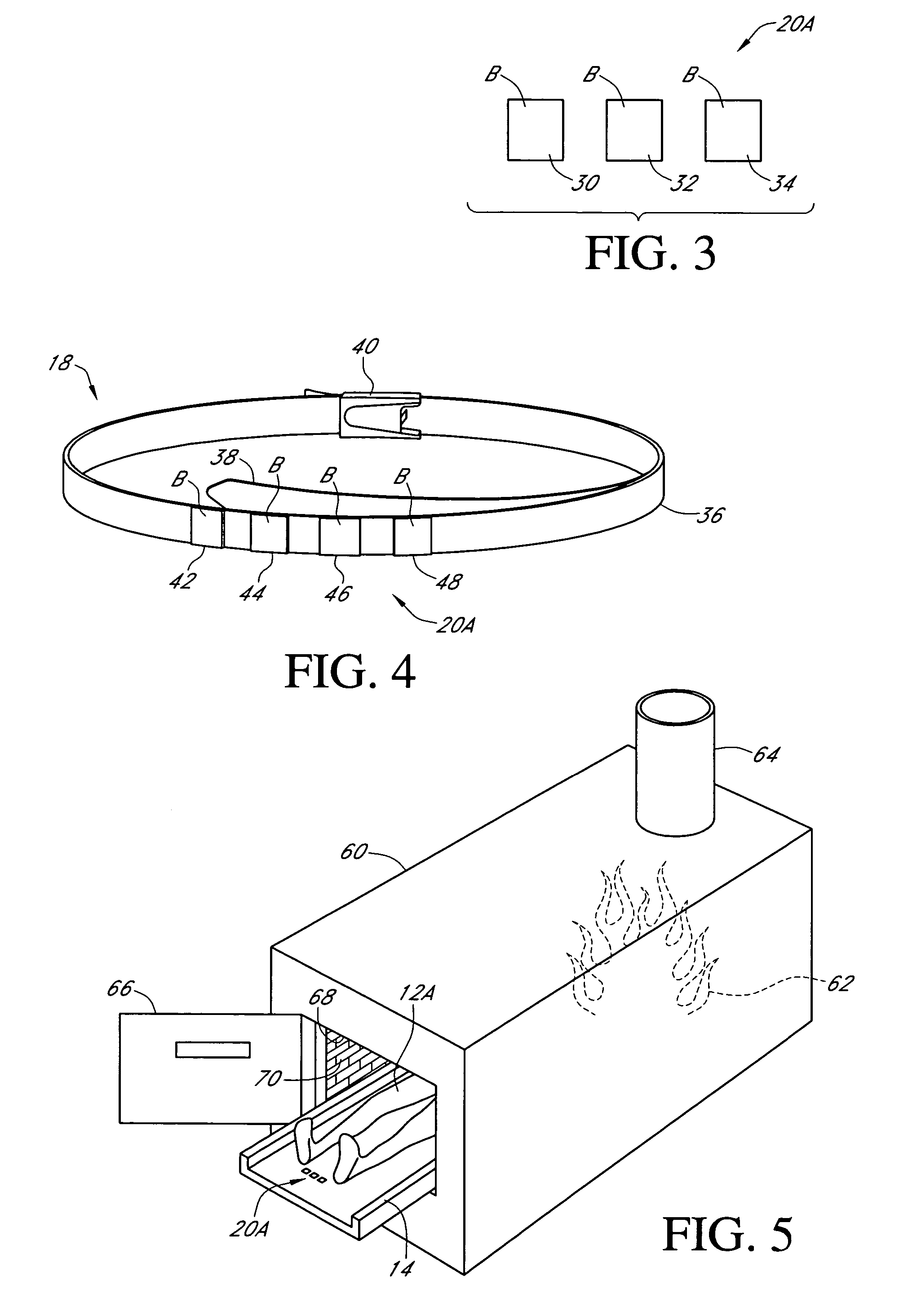

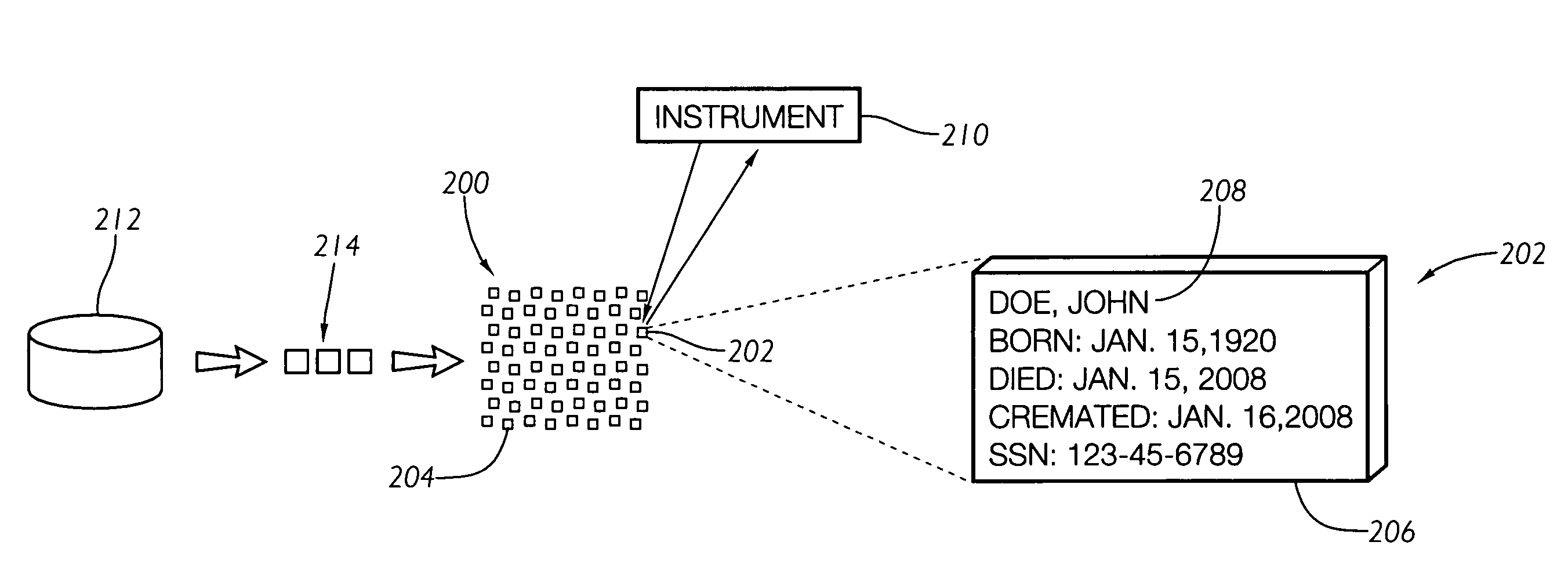

Cremation Identification System and Method for Use of Same

A synthetic biometric cremation identification system for use in cremation and burial processes of a deceased individual and method for use of the same are disclosed. In one embodiment, a plurality of synthetic biometric tokens include a cremation compatible material that is suitable for mechanical pulverization. A synthetic biometric identifier is integrated with each of the synthetic biometric tokens, which may be placed with the deceased individual at any stage during the cremation and burial process to provide, via instrumentation, continuous and integrated positive identification of the deceased individual, bone fragments, and / or granulated particles.

Owner:BILLS MICHAEL A

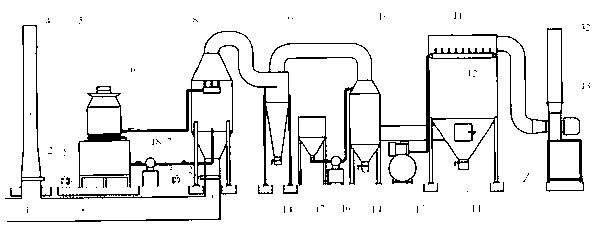

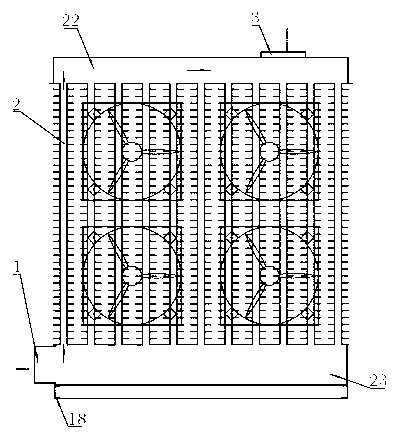

Incinerator for pollution-free disposal of animals

InactiveCN101995023AAvoid harmReasonable structureDispersed particle separationCremation furnacesToxic materialEngineering

The invention relates to an incinerator for pollution-free disposal of animals. The incinerator comprises a shell. An incinerator body, a temperature reducing purification device and a dedusting device are arranged in the shell in turn; the incinerator body is connected with the temperature reducing purification device through a flue; the dedusting device is connected with a chimney; a feed port is formed on the upper part of the incinerator body, and a discharge port is formed on the lower part of the incinerator body; and an active carbon adsorption device is arranged between the temperature reducing purification device and the dedusting device and is connected with the temperature reducing purification device and the dedusting device through the flue respectively. The invention has reasonable structure and ensures sufficient combustion, energy conservation and environmental protection. Large-particle dust of the exhaust gas produced by secondary combustion of animals is removed by the temperature reducing purification device, and then toxic substances, smelly components and odor molecules are removed by the active carbon adsorption device so as to thoroughly eliminate bacteria and viruses in the exhaust gas and prevent the environment from being damaged; and finally, dust is removed by the dedusting device so as to sufficiently purify the exhaust gas, and then the sufficiently purified exhaust gas is discharged to the atmosphere. Therefore, the invention ensures no secondary air pollution and thorough disinfection and sterilization.

Owner:青岛风顺环保科技有限公司

Protective device for incineration apparatus

A protective device may be attached to a portable incineration apparatus, or used over an open pit. The protection device may be a screen constructed of a stainless steel mesh. The screen is laid across the open top of the portable incineration apparatus or the top of the open pit. The screen forms a seal between the top portion of the walls of the incineration apparatus, or of the pit, and the portion of the screen that engages the top portion of the walls. Thereby, smoke, ashes and-embers are limited, or even prevented from escaping from the incineration apparatus or the open pit.

Owner:AIR BURNERS

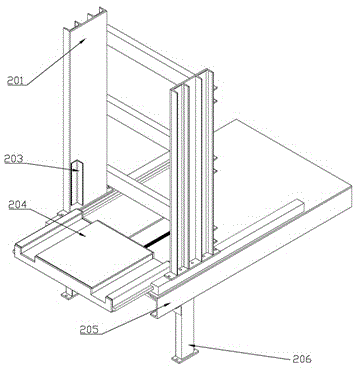

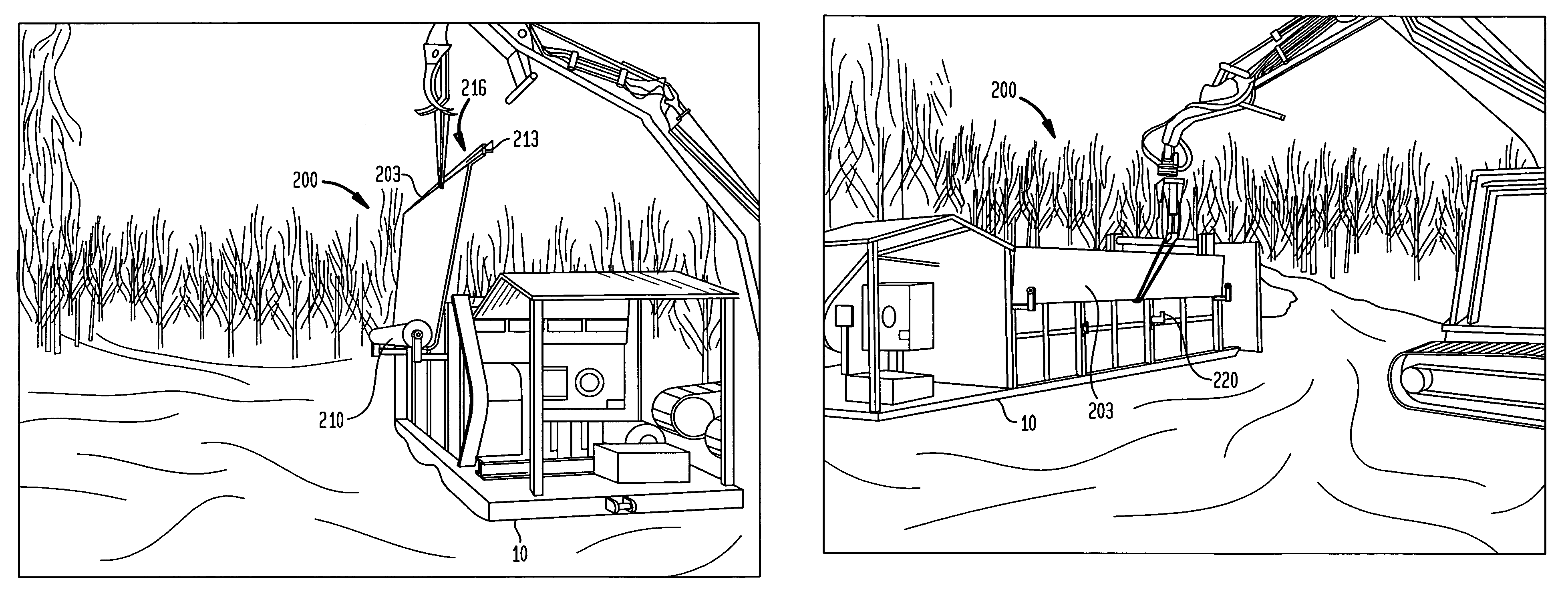

Indirect-heating-type carbonization treatment system for waste, and carbonization treatment vehicle using same

ActiveCN102667340AShorten carbonization timeRun automationCremation furnacesRefuse gatheringMedical wasteCarbonization

The present invention relates to an indirect-heating-type carbonization treatment system for waste, which disposes of organic industrial, livestock, and medical wastes generated by the industrial, livestock farming, and medical fields by collecting and effectively carbonizing the wastes, and to a carbonization treatment vehicle using same. According to the present invention, the waste generated by the industrial, livestock farming, and medical fields is carbonized at a location close to the location at which the waste is generated or is continuously disposed of while the vehicle is moving, in order to enable the complete carbonization of the waste and the effective protection of the surrounding environment.

Owner:株式会社福村

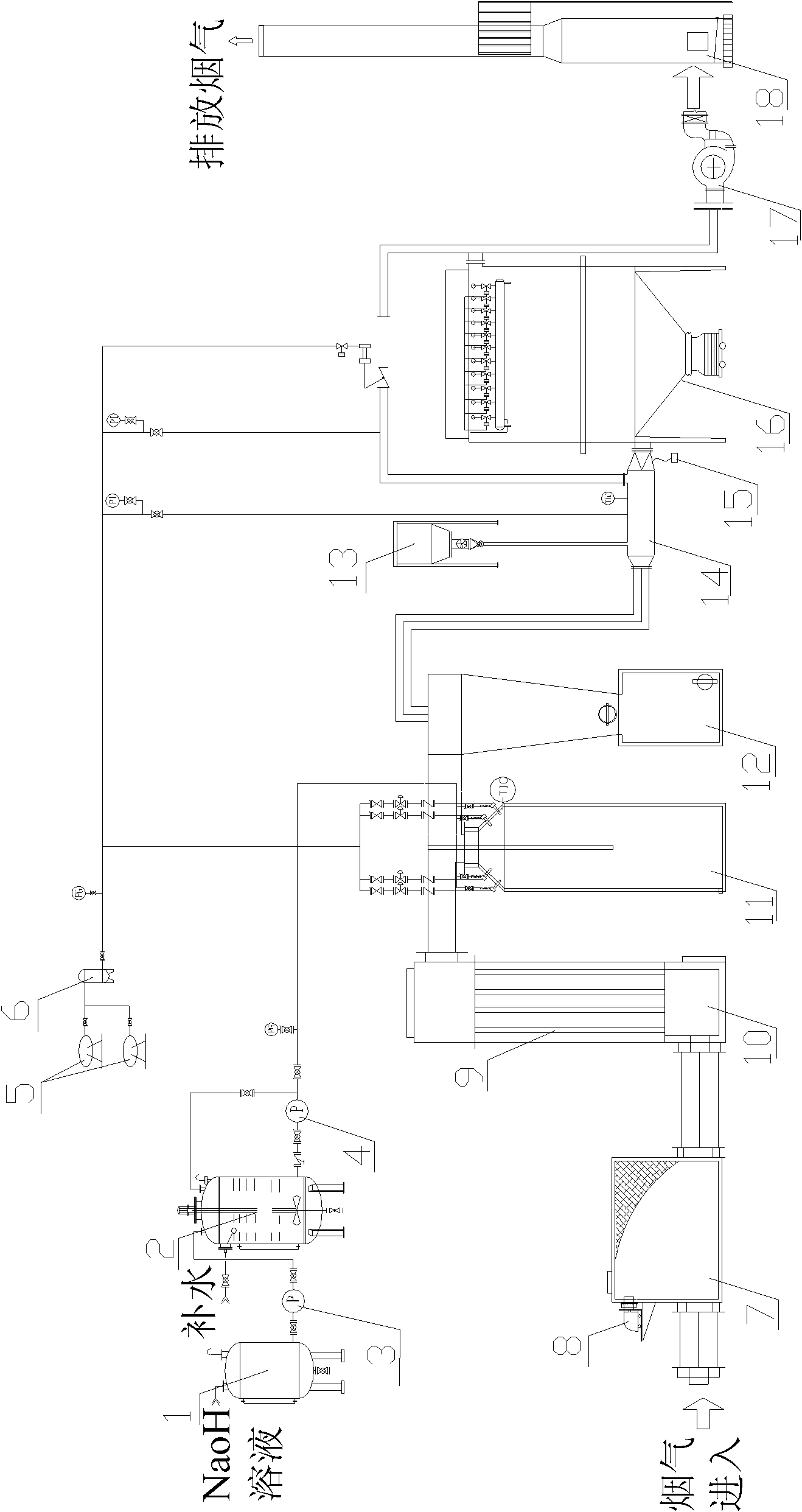

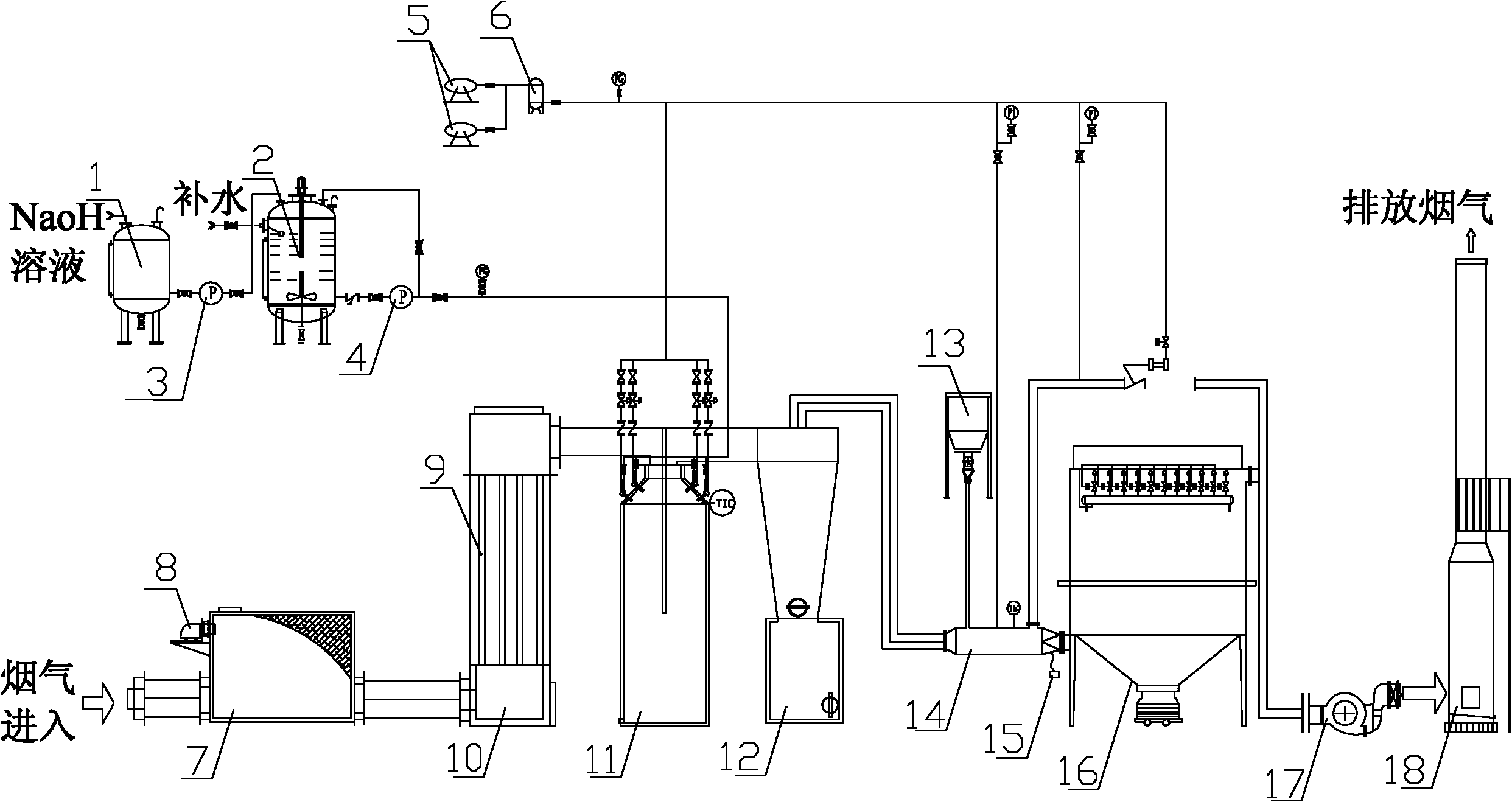

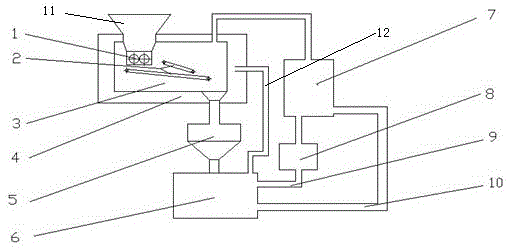

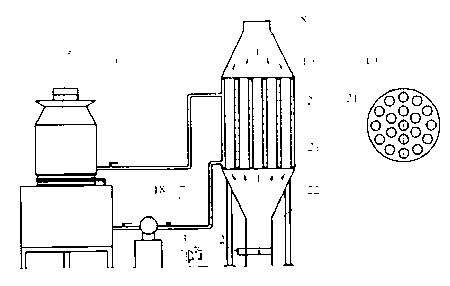

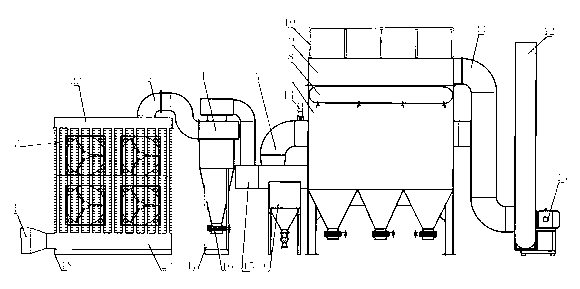

Tail gas purification treatment system of cremation machine

ActiveCN103047668AEfficient removalNovel structureCremation furnacesHazardous substanceExhaust fumes

The invention relates to the field of tail gas purification treatment, in particular to a tail gas purification treatment system of a cremation machine. The tail gas purification treatment system is provided with an emergency smoke exhausting system, a smoke cooling system, a spiral dust remover, a disacidify system and a bag-type dedusting system. By means of measures of fast cooling, spiral dedusting, desulfuration and deacidfication, bag-type dedusting and the like, toxic and harmful substances, particularly dioxin in the smoke can be effectively removed, and the aim of smoke purification can be achieved. The dedusting efficiency can reach 99.9%, the concentration of contained dust is smaller than 30mg / Nm<3> after the purification, the blackness of the smoke reaches ringelman 0 level, and the exhausted tail gas is lower than state standard of effluent discharge of waste gas. The tail gas purification treatment system has the advantages of being novel in structure, unique in design, high in dedusting efficiency, good in environment protection effect and the like.

Owner:山东金三宝环保设备有限公司

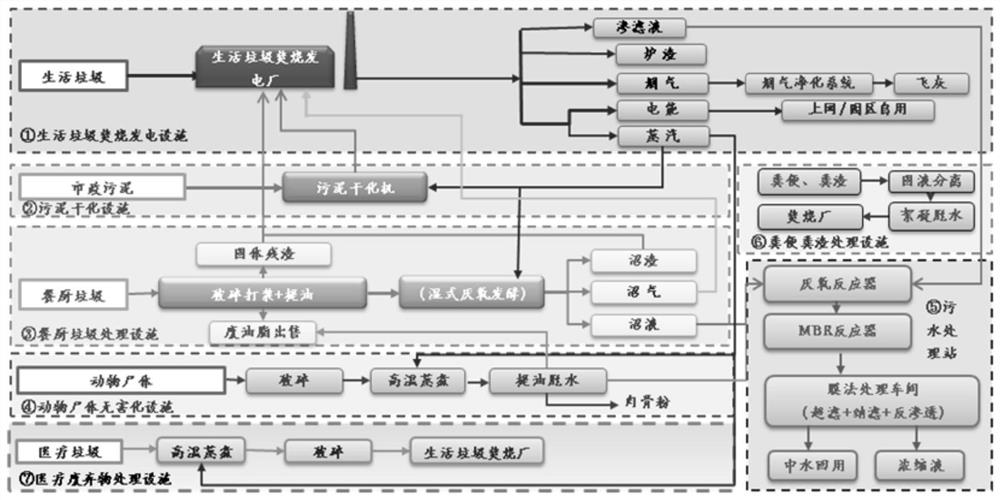

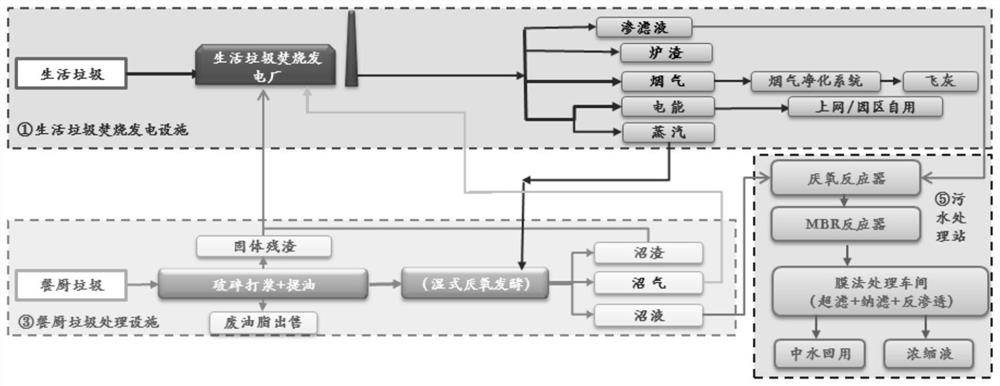

Venous industrial park system taking waste incineration power plant as core

PendingCN111750357AEfficient use ofReduce the impactSludge treatment by de-watering/drying/thickeningCremation furnacesElectric energyPower station

The invention discloses a venous industrial park system taking a waste incineration power plant as the core. The venous industrial park system is characterized in that electric energy and heat energywhich are generated by the waste incineration power plant are used for other solid waste disposal projects in a venous industrial park area, combustible residue or combustible odor generated in the disposal process of other solid waste is conveyed to a waste incinerator for incineration, and matter and the energy are recycled; and co-disposal of the other solid waste refers to co-disposal of municipal sludge, kitchen waste, medical waste, animal carcass and / or feces solid waste and is collaborative disposal of the one or more types of solid waste in the waste incineration power plant. The electric energy and the heat energy which are generated by the waste incineration power plant are used for the other projects of the industrial park area, the combustible residue generated by the other projects is conveyed to a waste furnace for incineration, the venous industrial park area taking household waste incineration power generation as the core is finally formed, the environmental problem issolved, and the matter and the energy are recycled.

Owner:SHANGHAI SUS ENVIRONMENT

Incineration device for processing poultry carcasses

InactiveCN107975802ABurn completelyEasy to handleCremation furnacesIncinerator apparatusFlue gasEngineering

The invention discloses an incineration device for processing poultry carcasses. A mesh screen is arranged in an inner cavity of a second material storing box; a first pipeline communicates with the top of an incineration oven; the incineration oven is inserted in a secondary combustion tank through a first pipeline; a third discharge opening is formed in the bottom of the left side of the secondary combustion tank; a flam spurting pipe which communicates with a second fuel gas inlet pipe is arranged at the bottom of the secondary combustion tank; a second baffle plate is arranged at the top of the right side of the secondary combustion tank; and first filter screens are arranged in an inner cavity of the second baffle plate. Through the adoption of the incineration device disclosed by theinvention, the poultry carcasses are smashed by a pulverizing device, so that the combustion of the poultry carcasses is more thorough and quicker; through the transmission of a conveying chain, continuous processing can be performed on the poultry carcasses; a second stirring rod is driven by a second motor to smash bones of the carcasses, so that residues of the carcasses are easier to process;and secondary combustion is performed on flue gas through the secondary combustion tank, so that waste gas is cleaner to process.

Owner:傅伟权

Method for obtaining a solid product comprising cremated ashes and a wax in a vessel, a product obtained by means of the method and a case containing said product

InactiveUS9700923B2Reduce the percentage of waxReduce weightSolid waste disposalTransportation and packagingWaxCentrifugation

The present invention reveals a method for obtaining a solid product comprising the cremated ashes of a human being or animal, inside a vessel, comprising the following steps: separating the ashes produced as a result of cremating a body, determining the ashes produced by the body itself and the ashes produced from other elements present during cremation; grinding the ashes produced from the separated human ashes; introducing the ashes and a wax composition into a vessel and closing the vessel with a lid; (iv) heating the vessel, subjecting it to centrifugation and cooling the vessel. It likewise discloses a solid product comprising cremated human or animal ashes inside a vessel, obtained as a result of the method and a case containing said solid product.

Owner:THE OMNEO UNIVERSAL GRP SL

Cremation machine tail gas purifying treatment system with air cooler

The invention relates to a cremation machine tail gas purifying treatment system with an air cooler. The cremation machine tail gas purifying treatment system comprises a smoke cooling system, a spiral dedusting system, a quicklime and active carbon jetting system and a bag dedusting system. Through measures such as air cooling, spiral dedusting, sulfur and odor removal to smoke, dioxin and other poisonous and harmful substances in the smoke are effectively removed, and smoke purifying treatment is achieved. Dioxin removal rate reaches above 95%, dust removal rate reaches 100%, and poisonousness equivalent of the dioxin in the smoke after purification is only 0.03 microgram / m<3> which is much lower than 0.5 microgram / m<3> specified in a national primary standard. The cremation machine tail gas purifying treatment system has the advantages of novel and special structure, high dedusting efficiency, low carbon generation, environment protection and the like.

Owner:WEIHAI LUYUAN ENVIRONMENTAL PROTECTION EQUIP SCI & TECH

Laser autopsy and cremation

Owner:HIERHOLZER LAWRENCE J

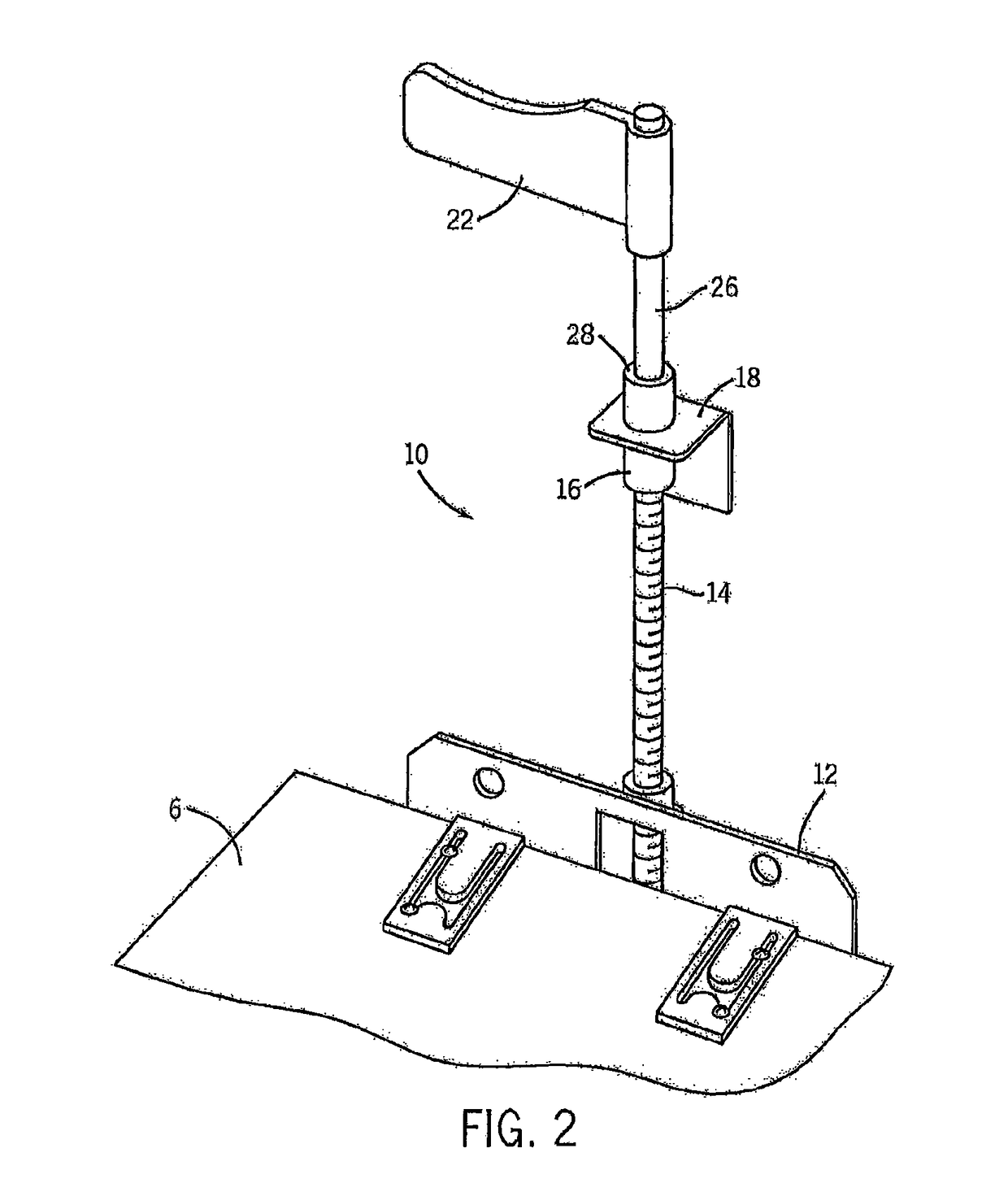

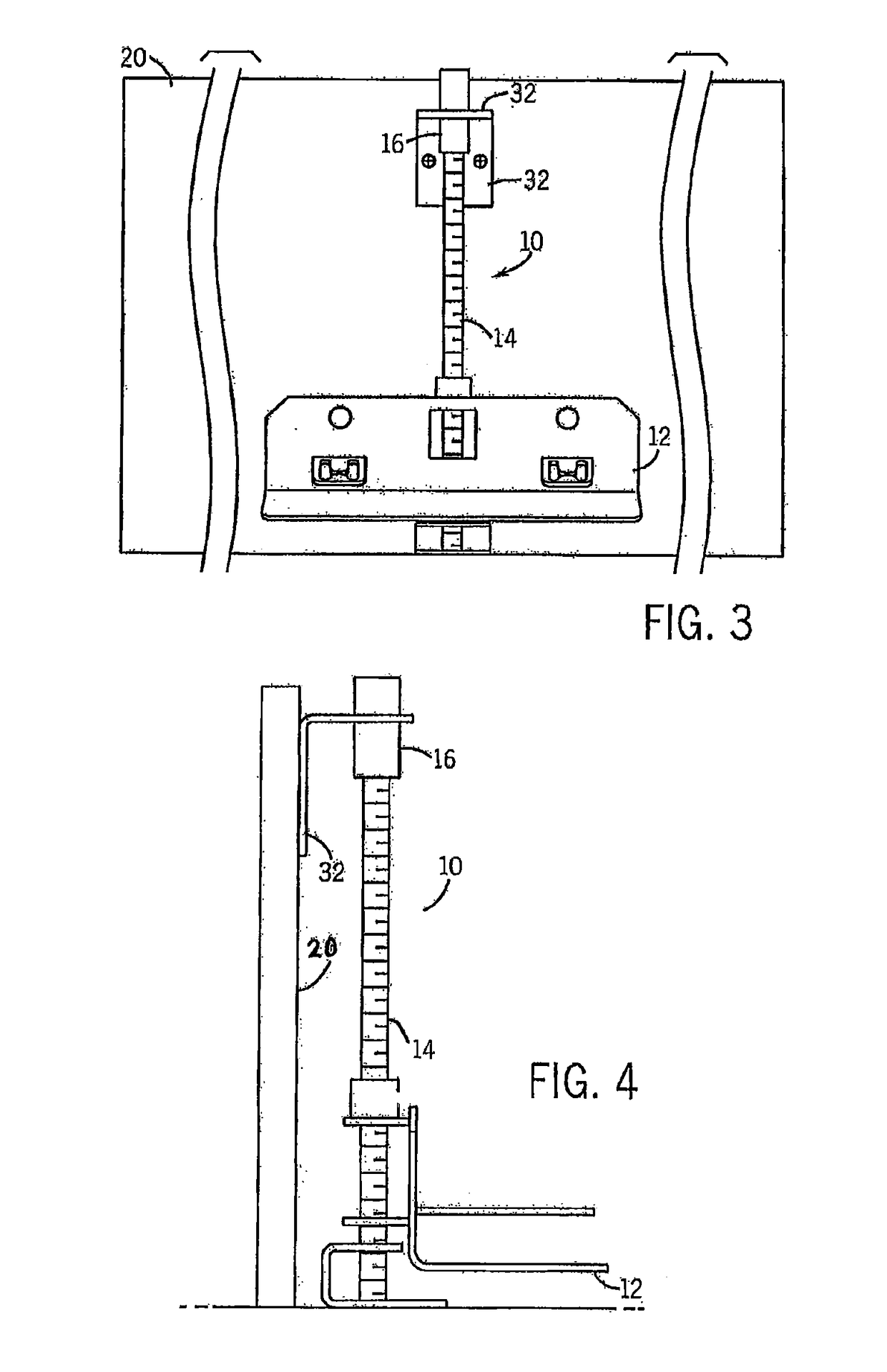

Adjustable temporary casket

A temporary casket made substantially from burnable material, having a positionable inclining mechanism inside a casket shell. The temporary casket may be inserted into a formal, traditional casket where the temporary casket shell protects the traditional casket. Inside the temporary casket, a plank is attached by a clamp or bracket to an adjusting mechanism for adjusting the tilt angle between the plank and the floor of the casket shell. The mechanism also includes a vertical threaded rod that engages the clamp, allowing the rod to be rotatable and move the clamp axially along the rod to lift or lower the plank. This allows a funeral director to easily adjust the deceased to achieve the most “restful” state, and without jostling or appearing disrespectful to the deceased. After a service, the deceased, along with the temporary casket and the mechanism itself, may be cremated.

Owner:STEINHAUS STEVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com