Patents

Literature

310 results about "Primary standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A primary standard in metrology is a standard that is sufficiently accurate such that it is not calibrated by or subordinate to other standards. Primary standards are defined via other quantities like length, mass and time. Primary standards are used to calibrate other standards referred to as working standards. See Hierarchy of Standards.

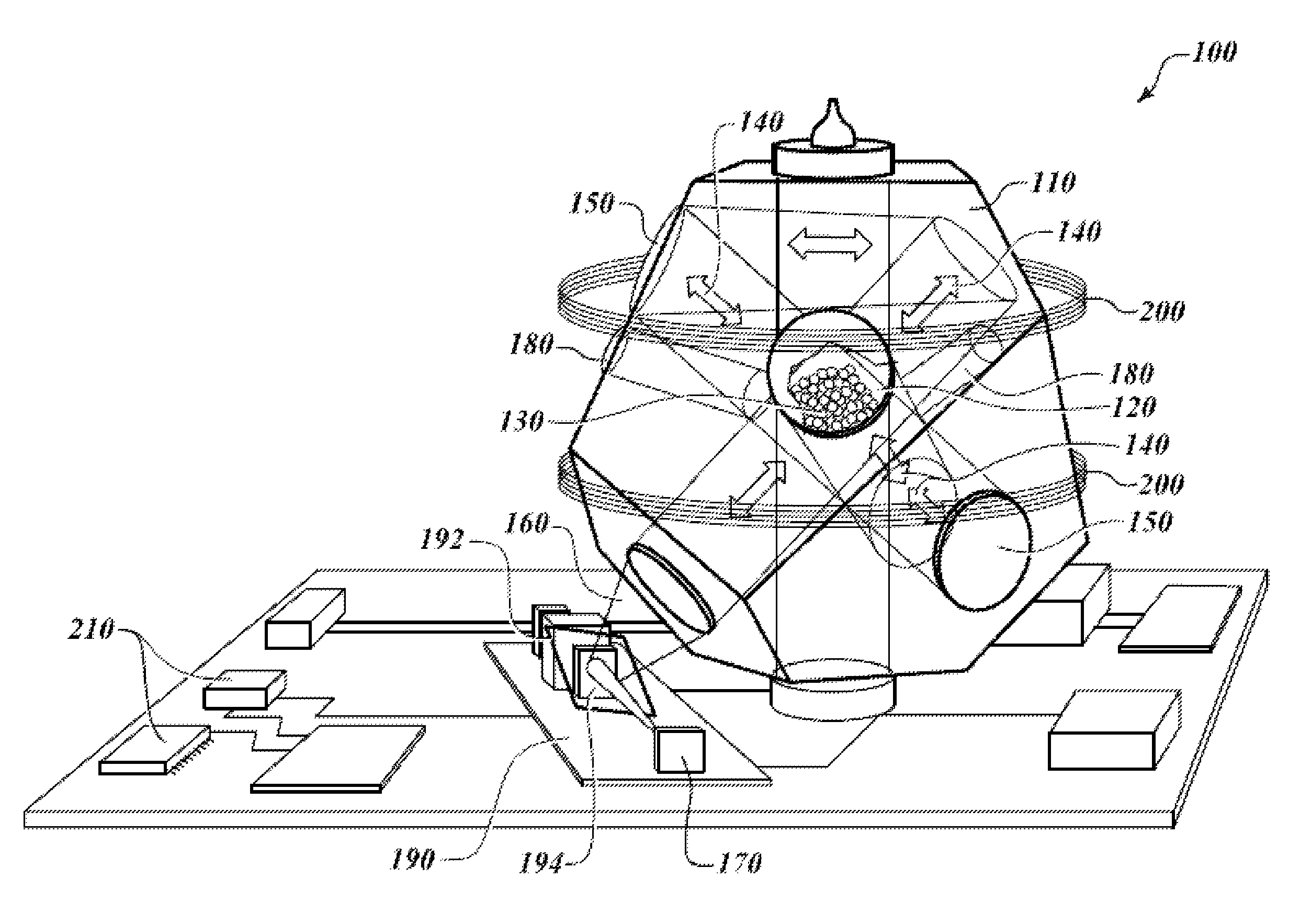

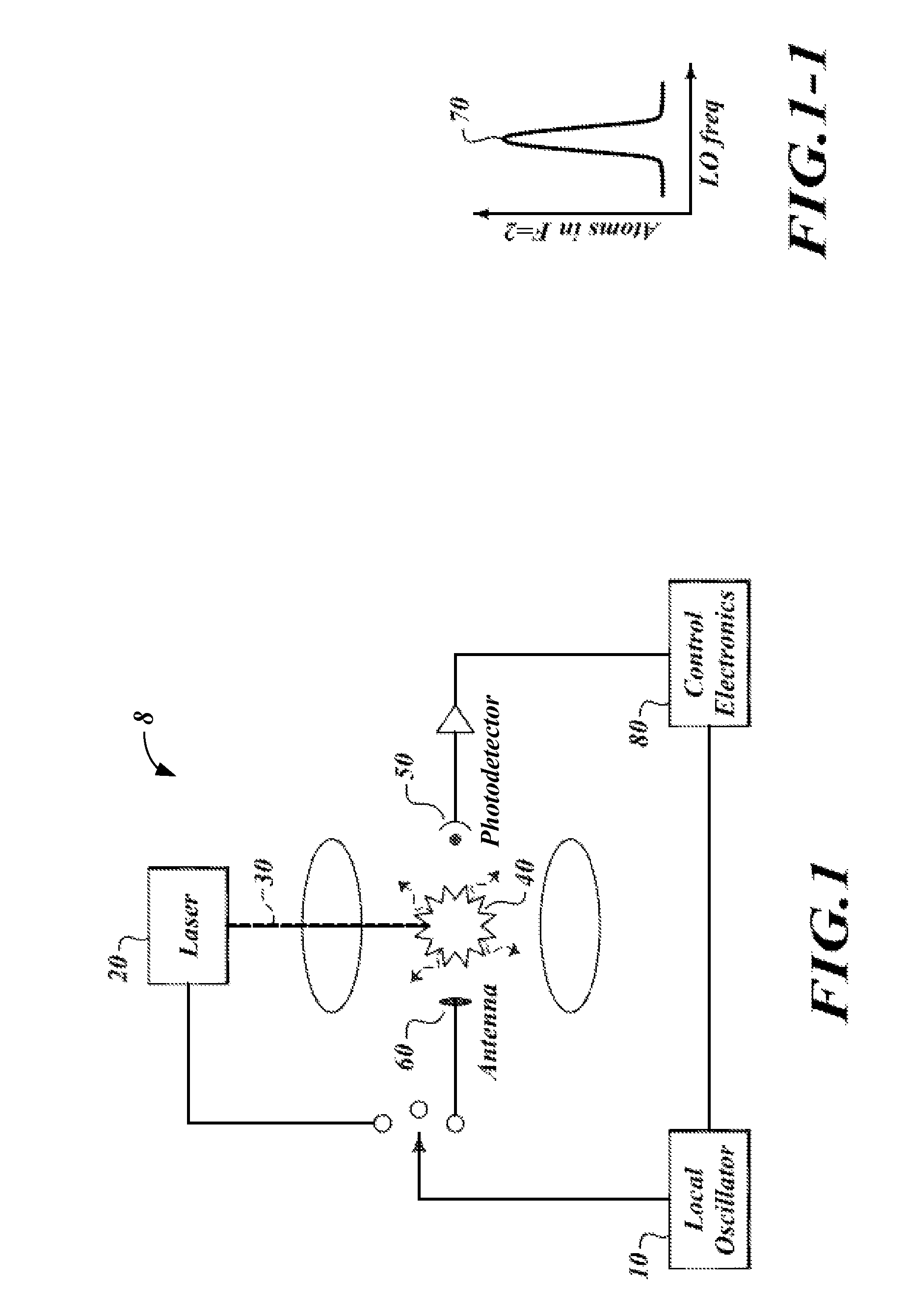

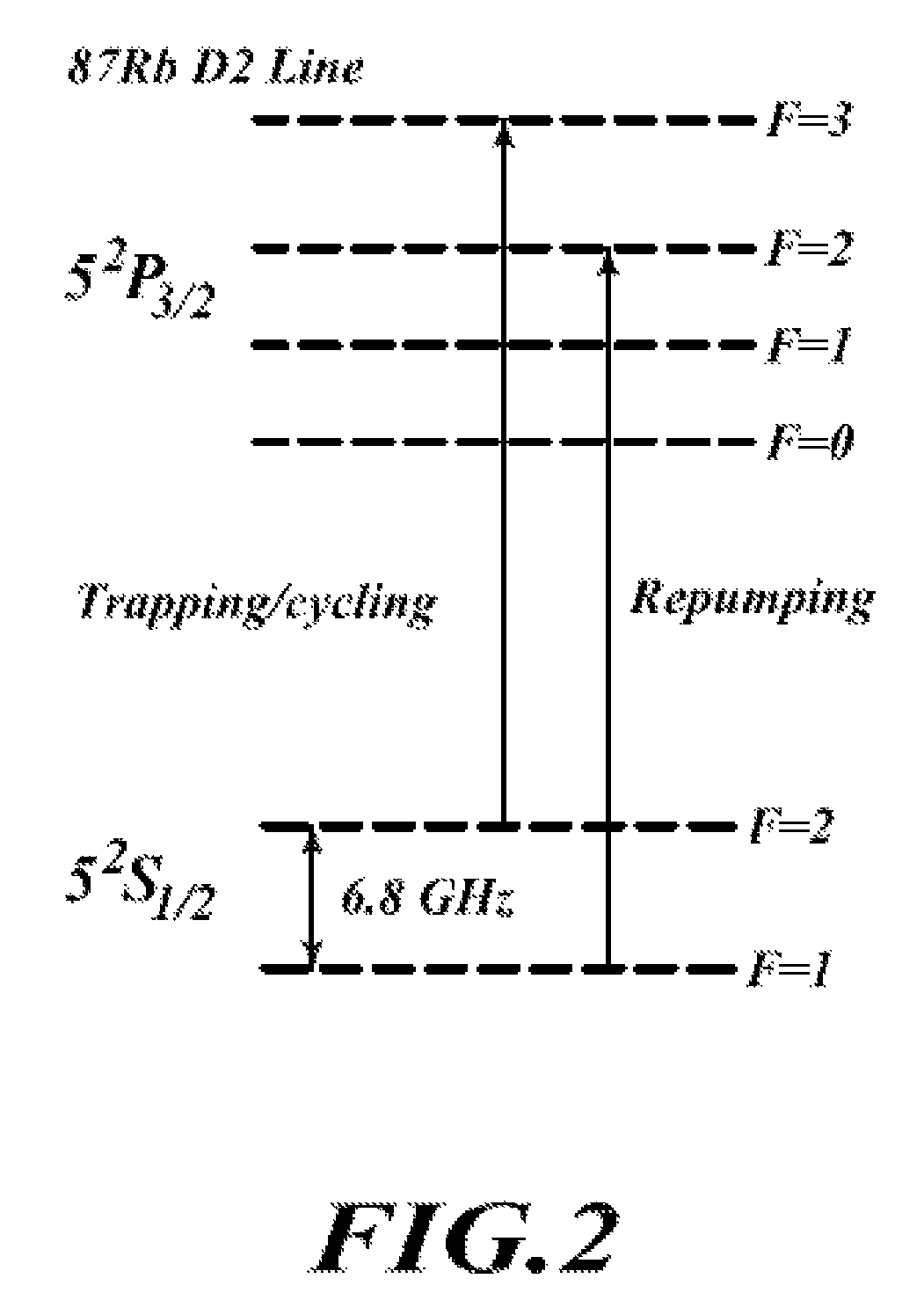

Cold atom micro primary standard

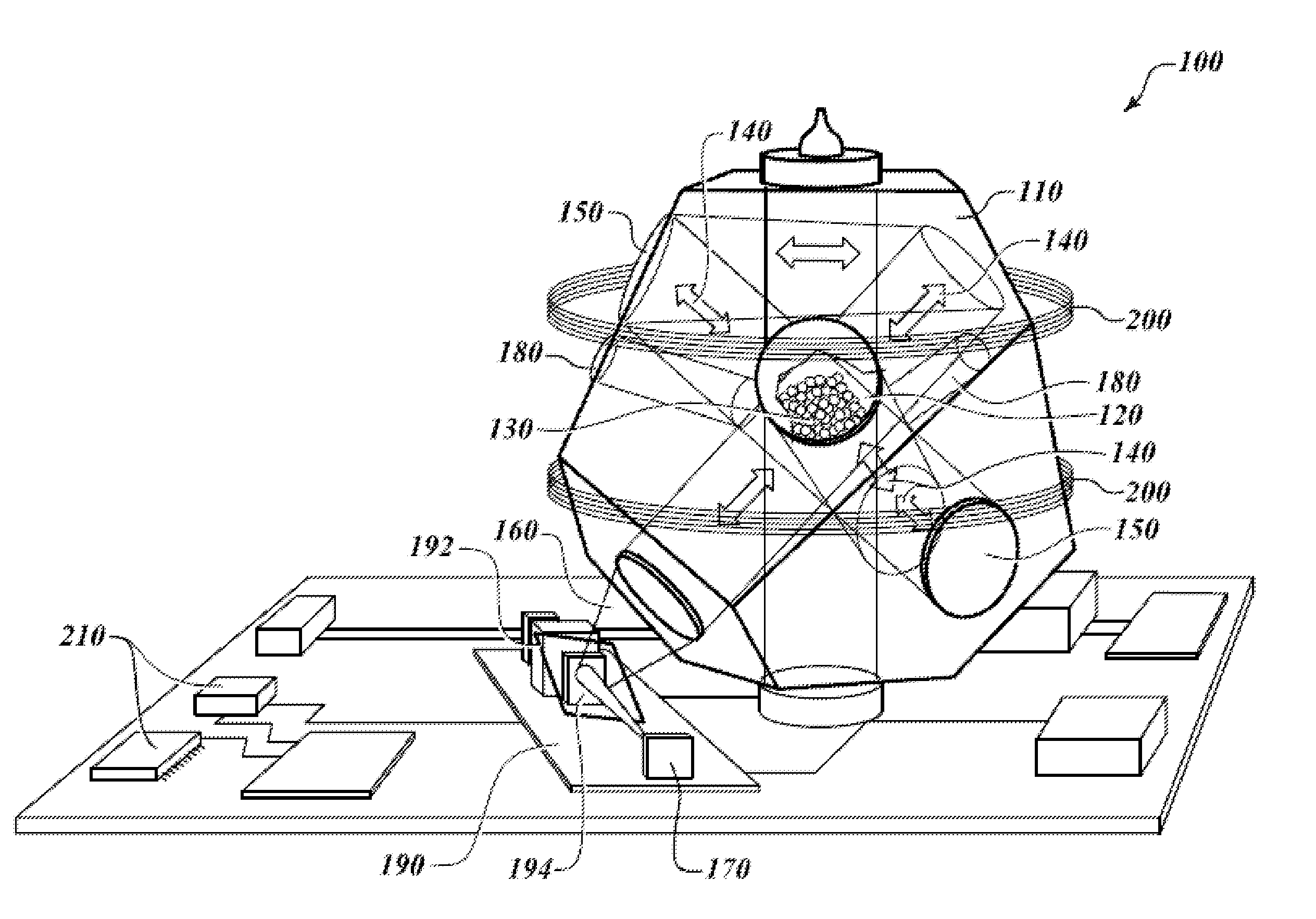

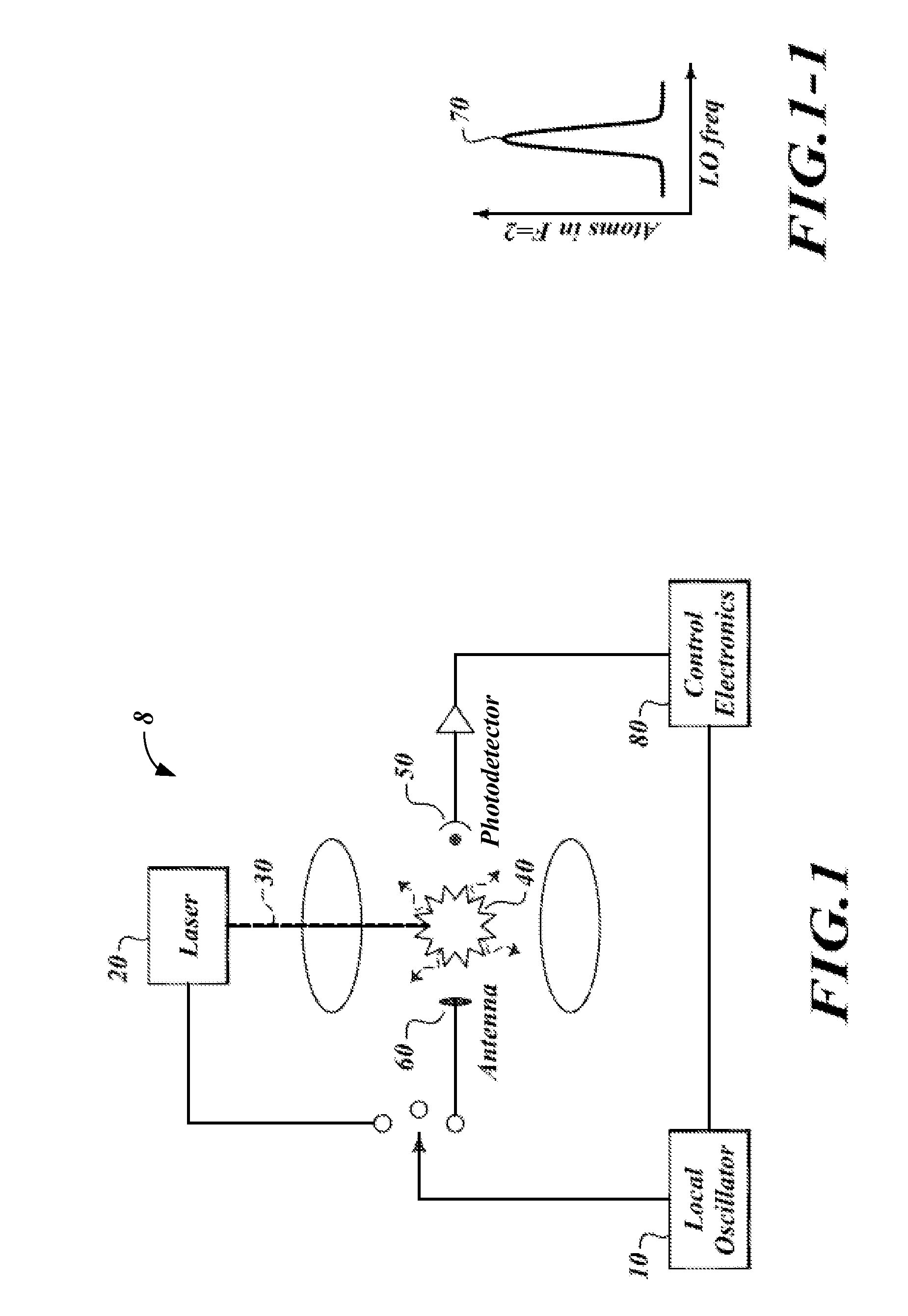

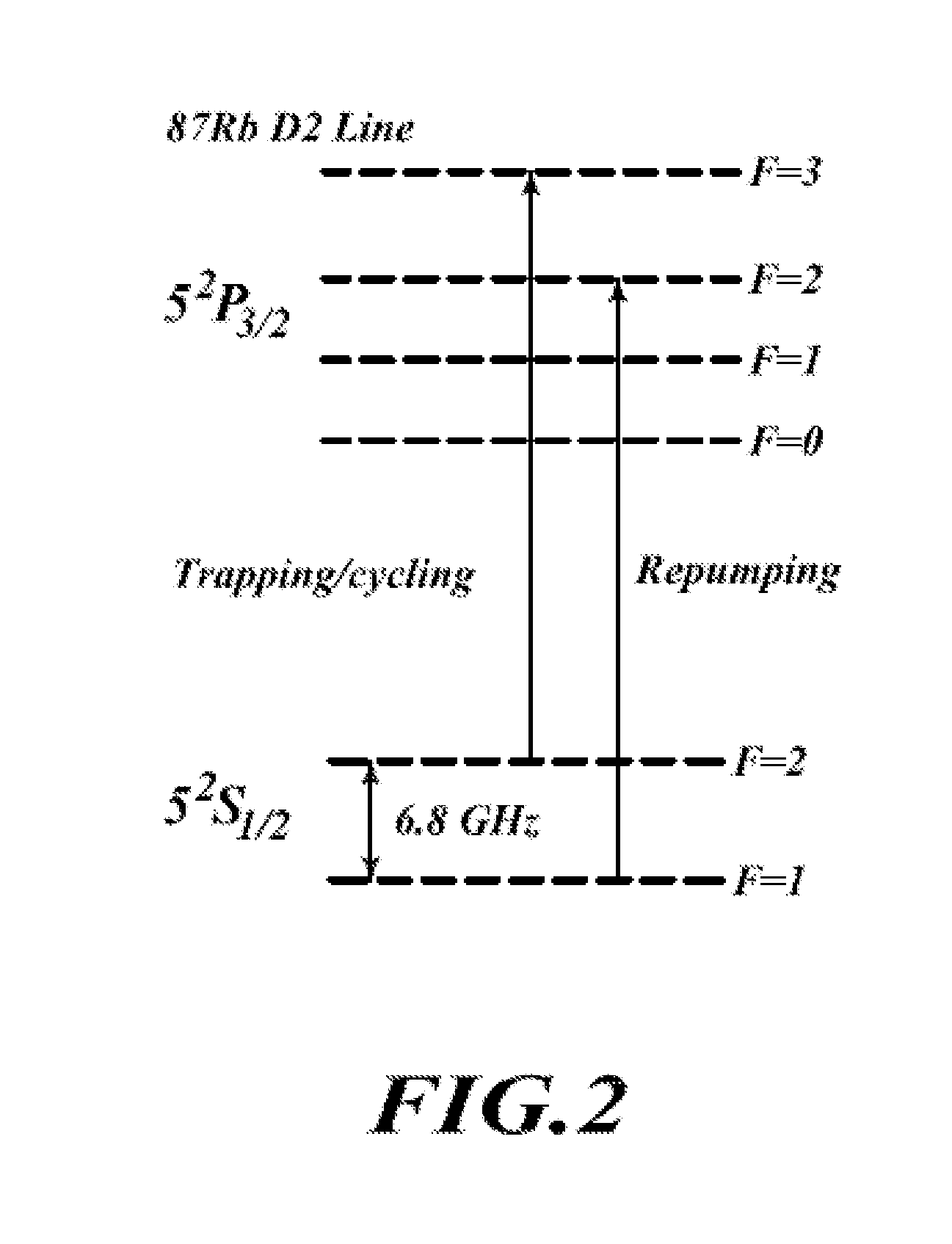

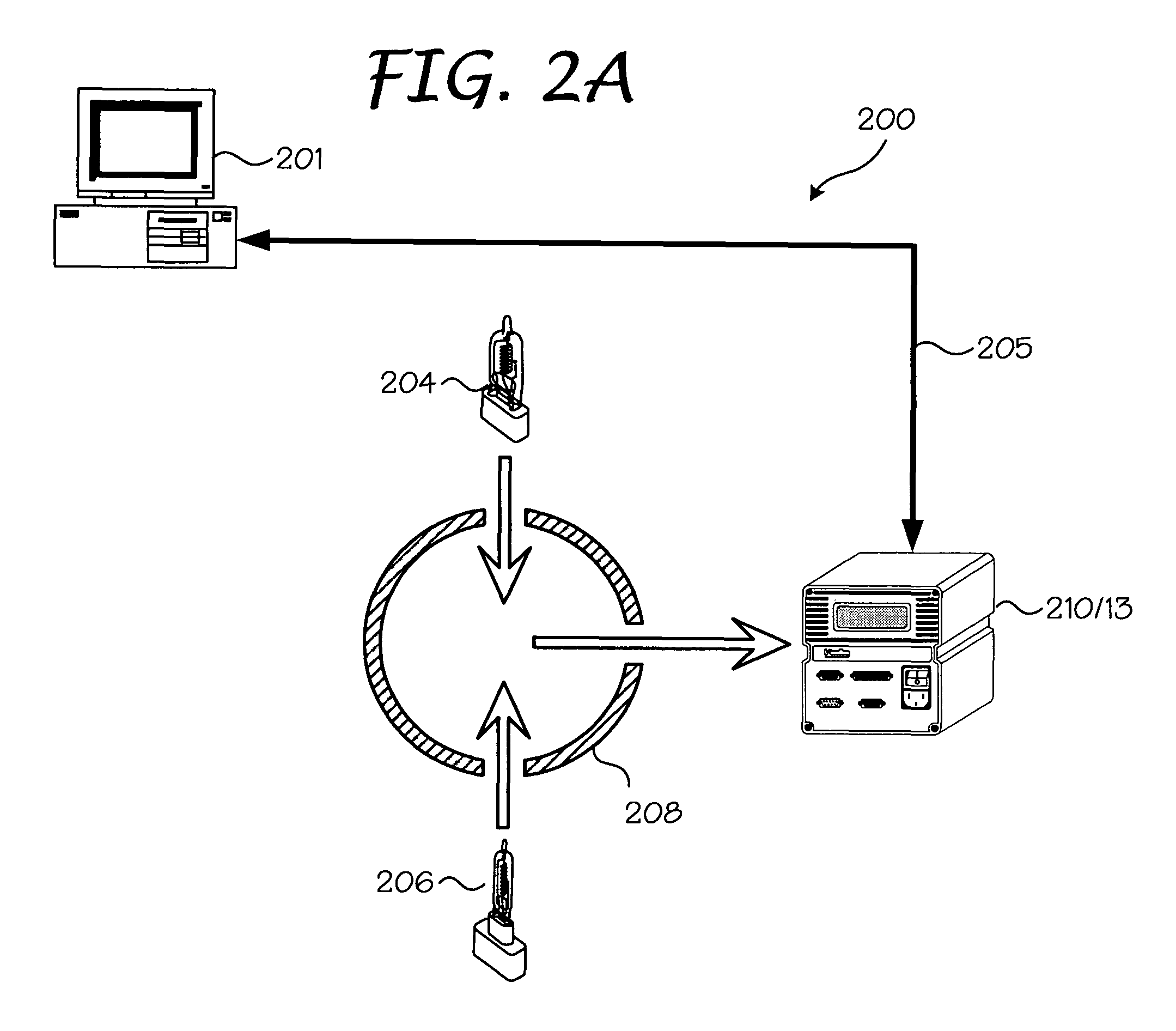

InactiveUS20100033256A1Maximizing numberLong life-timeLaser detailsApparatus using atomic clocksUltra-high vacuumTrapping

An atomic clock having a physics package that includes a vacuum chamber cavity that holds atoms of Rb-87 under high vacuum conditions, an optical bench having a single laser light source, a local oscillator, a plurality of magnetic field coils, an antenna, at least one photo-detector and integrated control electronics. The single laser light source has a fold-retro-reflected design to create three retro-reflected optical beams that cross at 90° angles relative to one another in the vacuum chamber cavity. This design allows the single laser light source to make the required six trapping beams needed to trap and cool the atoms of Rb-87. The foregoing design makes possible atomic clocks having reduced size and power consumption and capable of maintaining an ultra-high vacuum without active pumping.

Owner:HONEYWELL INT INC

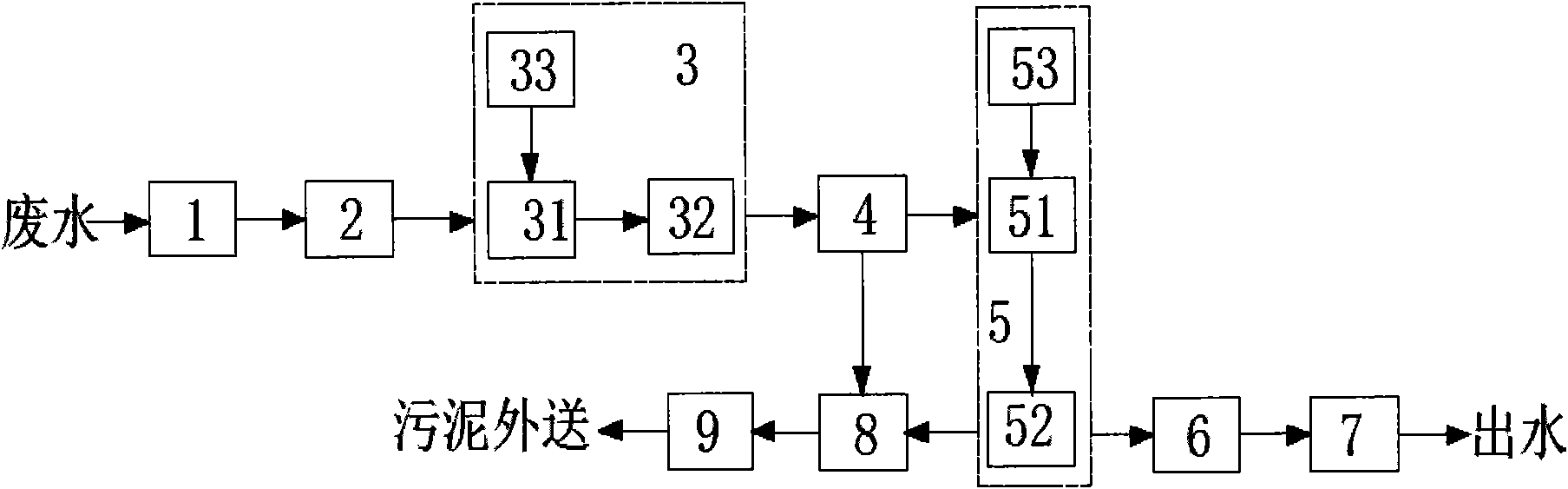

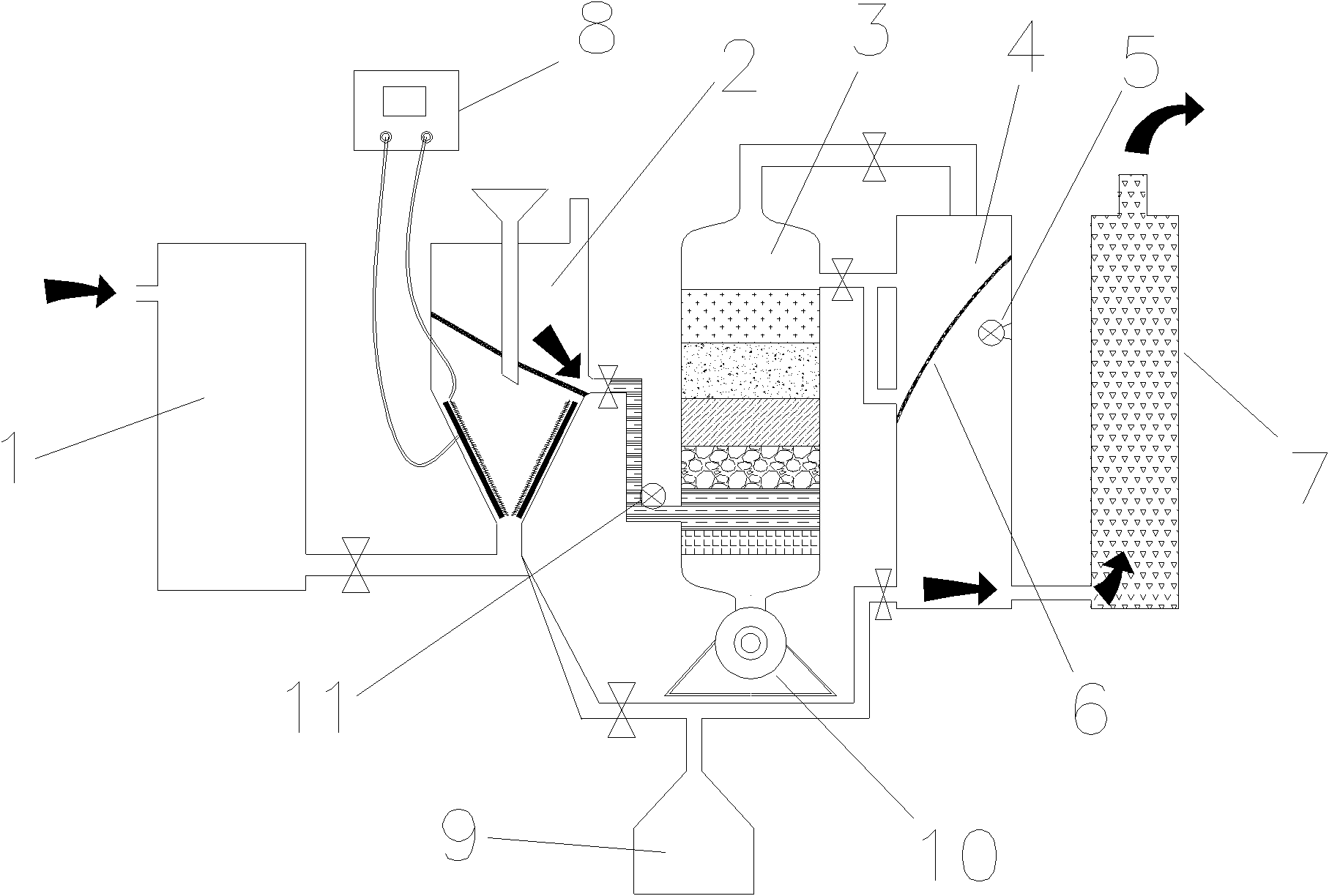

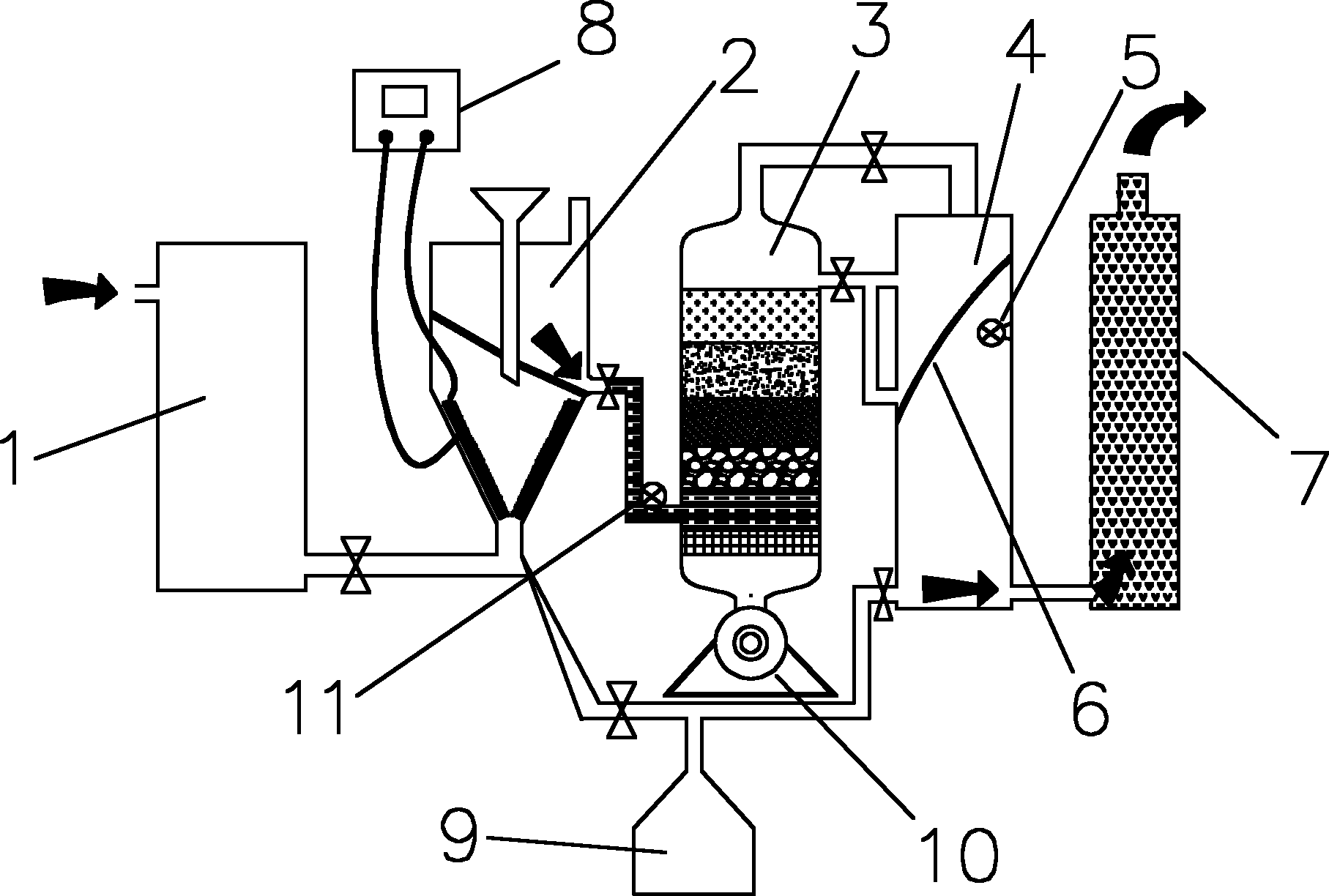

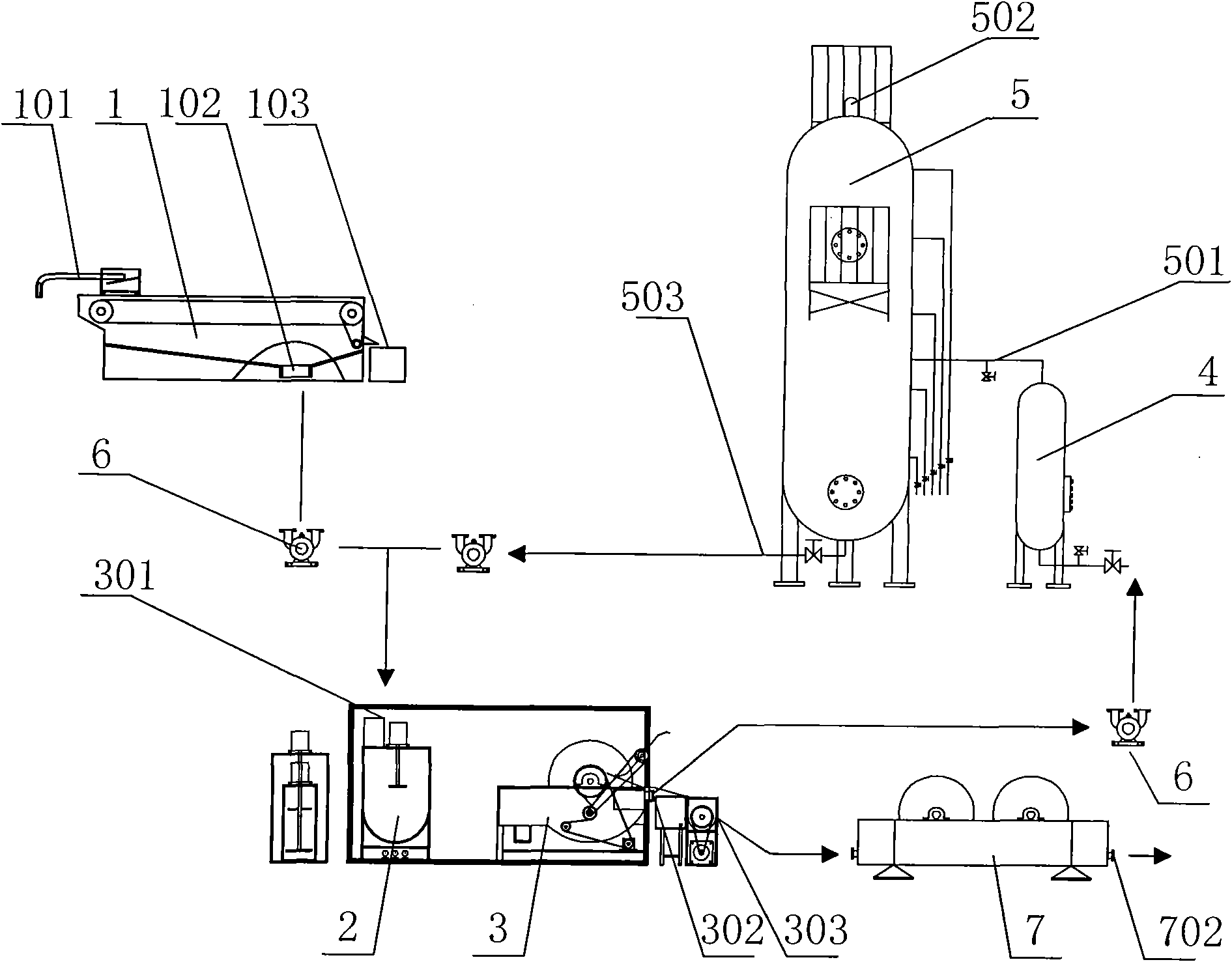

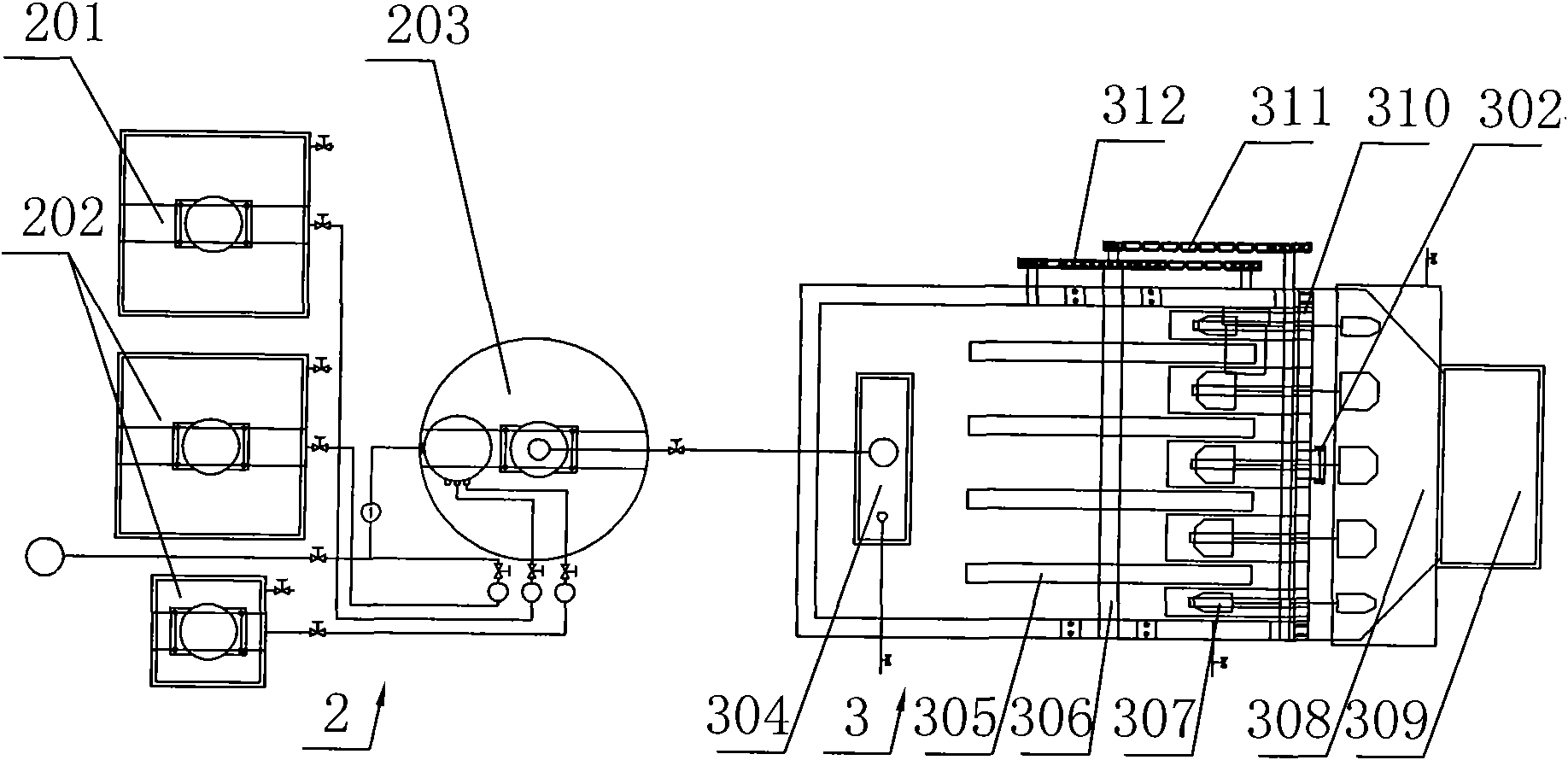

Printing and dyeing wastewater treatment system

InactiveCN101591123ACompact structureSmall footprintSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesSludgeWater quality

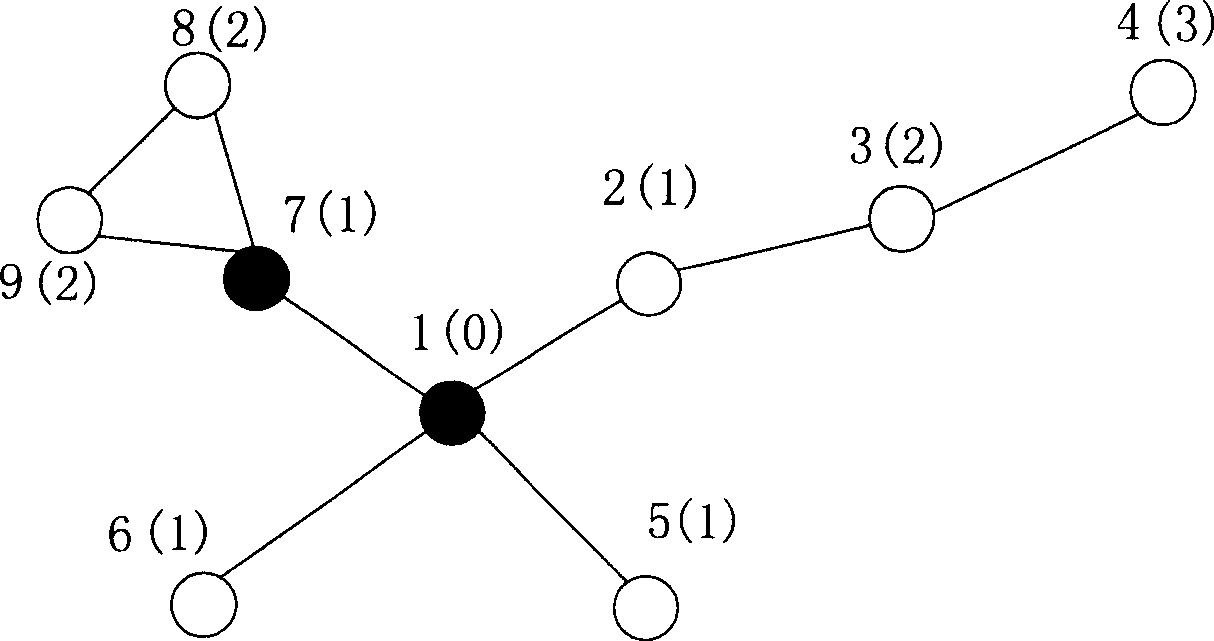

The invention relates to a printing and dyeing wastewater treatment system, and belongs to the technical field of printing and dyeing wastewater treatment. The system consists of nine parts, namely an adjusting tank 1, a lift pump 2, a coagulating system 3, a primary sedimentation tank 4, a contact oxidation sediment system 5, a sand filtering tank 6, an active carbon adsorbing tank 7, a sludge pump 8 and a sludge concentrating tank 9. The printing and dyeing wastewater treatment system adopts the combined process of coagulation, contact oxidation, sand filtration and active carbon adsorption, and adds the deep treatment processes of the sand filtration and the active carbon adsorption after the physical-chemical treatment coagulation process and the biochemical treatment contact oxidation process. The printing and dyeing wastewater treatment system can be designed and manufactured respectively according to the wastewater quantities of printing and dyeing enterprises, and has the advantages of good treatment effect of printing and dyeing wastewater, stable operation, high degree of automation, simple operation, convenient maintenance, good and stable outlet water quality, superior level to the national emission primary standard and the like. The system particularly has good treatment effect of the printing and dyeing wastewater with high density and high chromaticity.

Owner:JIANGSU UNIV

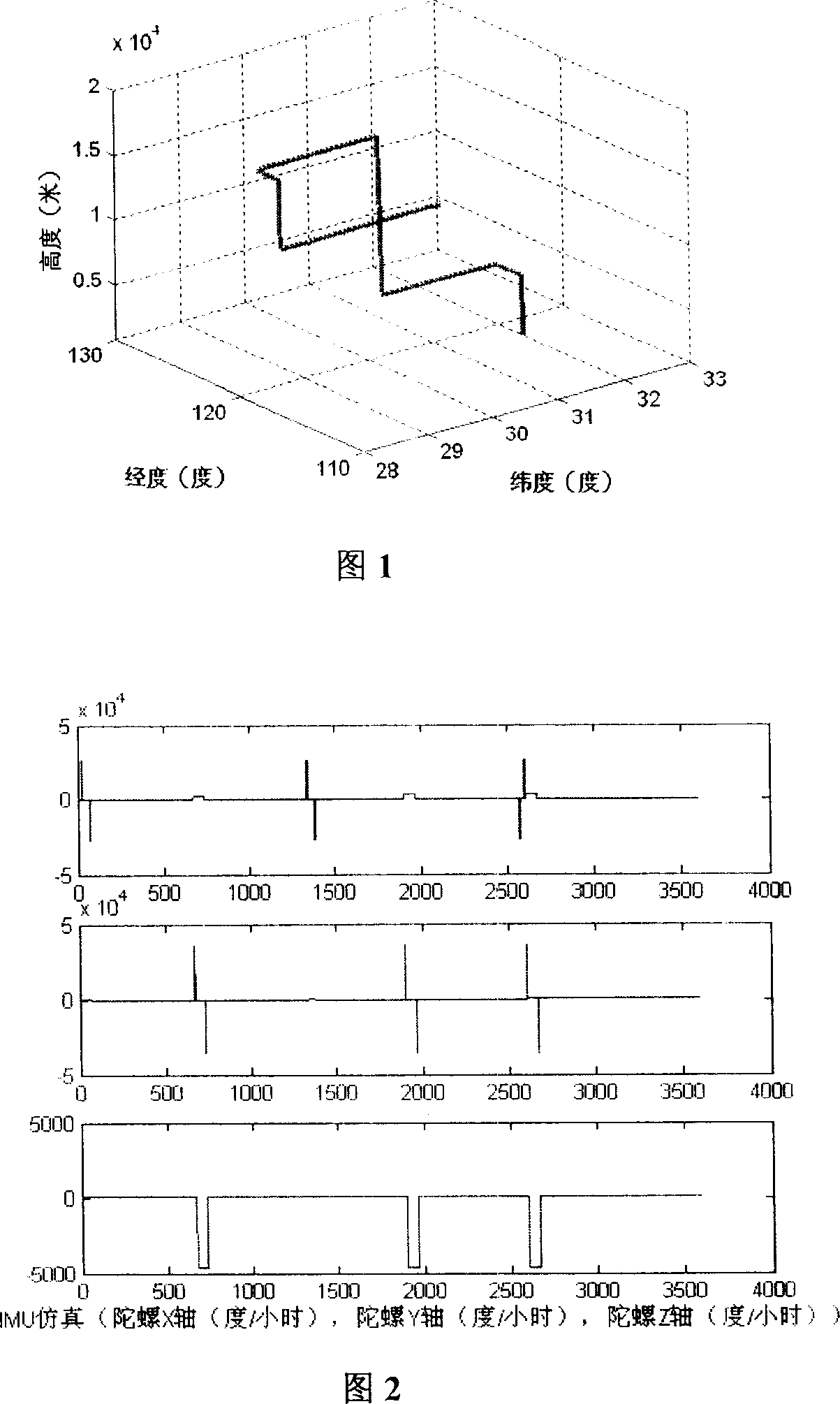

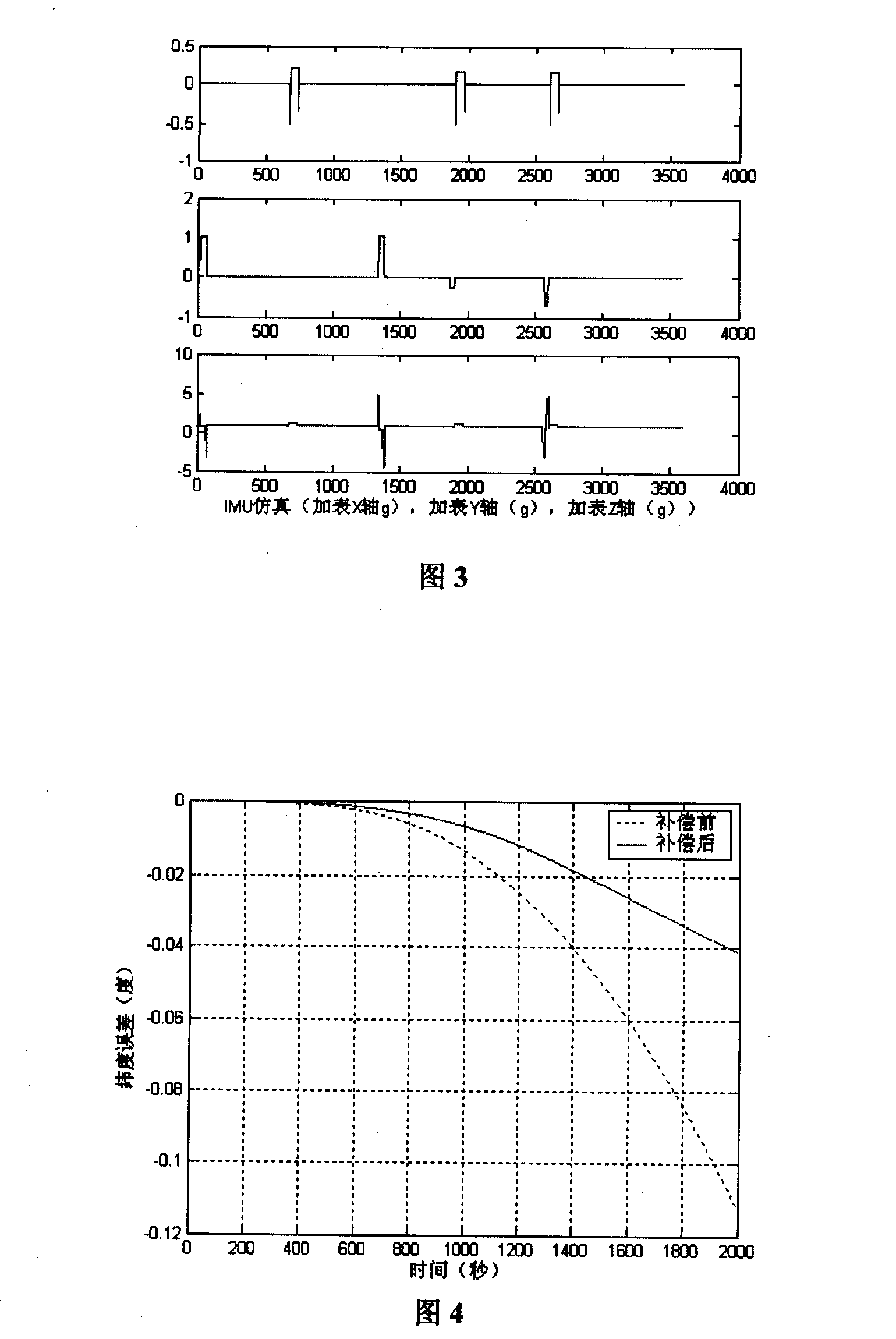

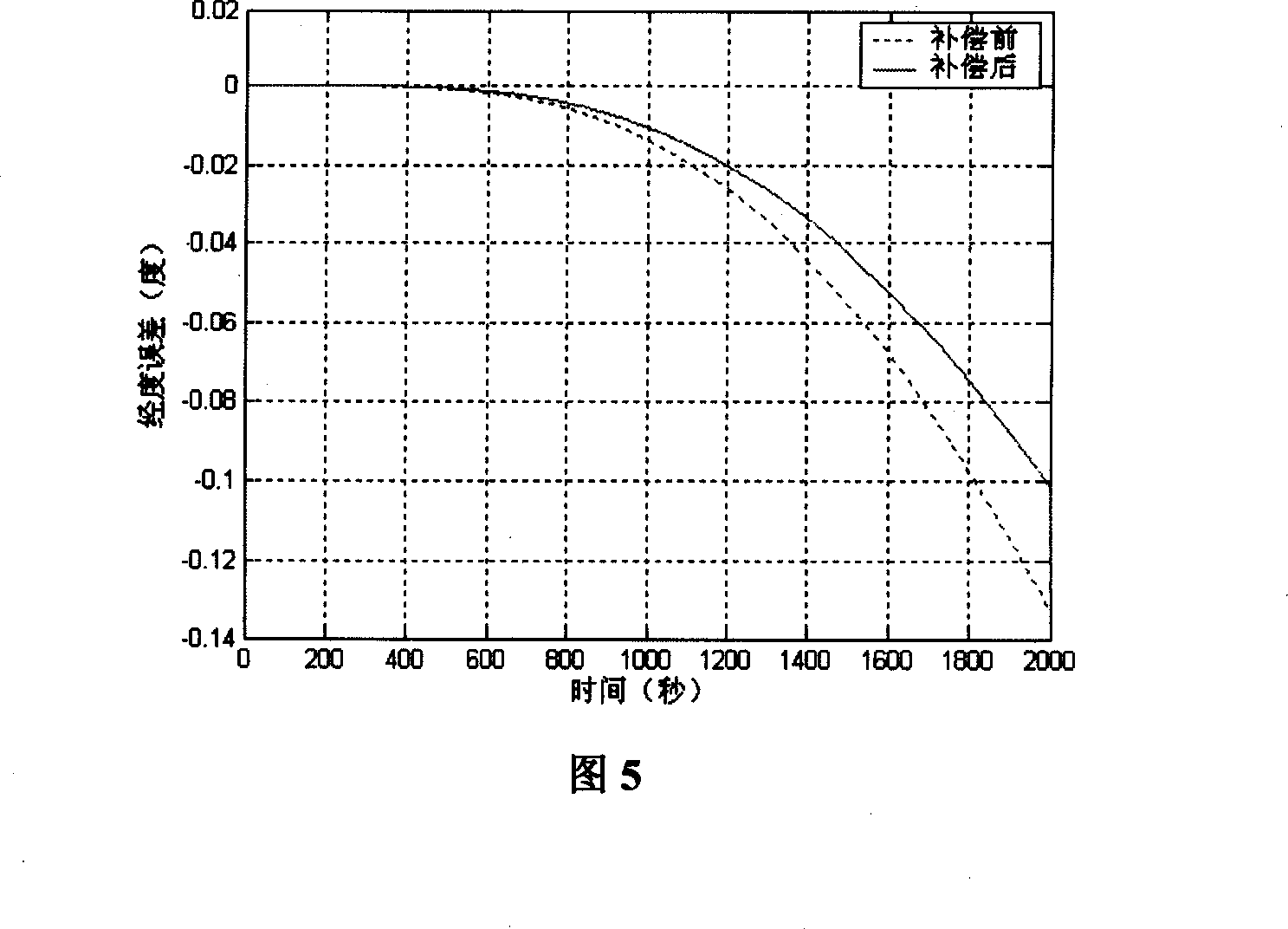

Inertial measuring system error model demonstration test method

InactiveCN101021879AHigh precisionImprove navigation accuracyNavigation by speed/acceleration measurementsSpecial data processing applicationsObservational errorPrimary standard

This invention relates to a test method for error model verification of an inertial measurement system, which sets up a multifunction software platform to simulate and argue the airliner load test plan directly including: designing specific flying trails based on the error model of an inertial sensor, in which, an aircraft flies along the designed flying trail and collects inertial sensor data of specific flight path points and transmits them to a master navigation computer, then the collected data are compared with the data output by a measurement primary standard device to get the measurement error of the sensor to compute and get the error parameters in the inertial navigation error model with an airborne inertial navigation space multi-position online demarcating method to understand the inertial navigation performance and is convenient for the compensation in navigation computation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

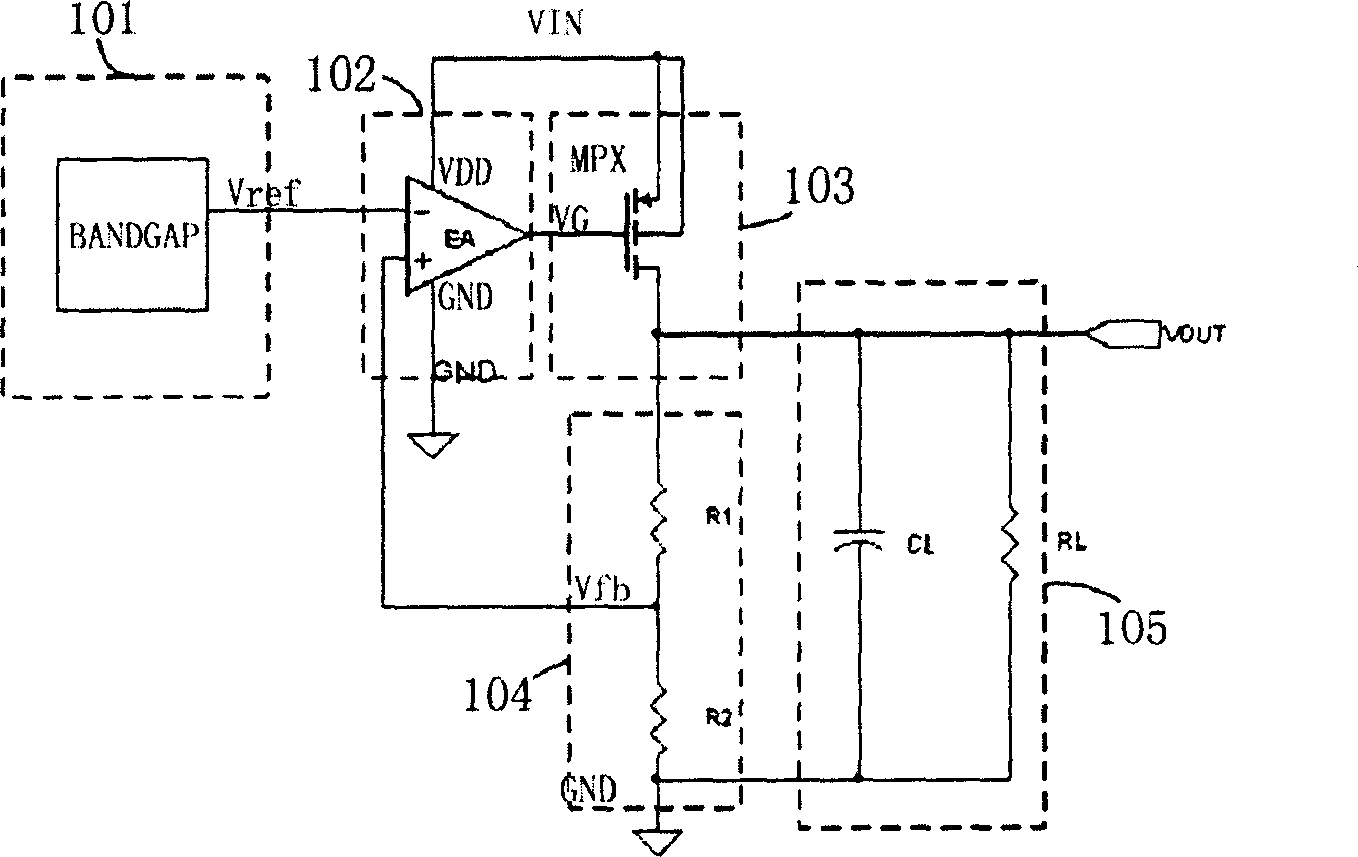

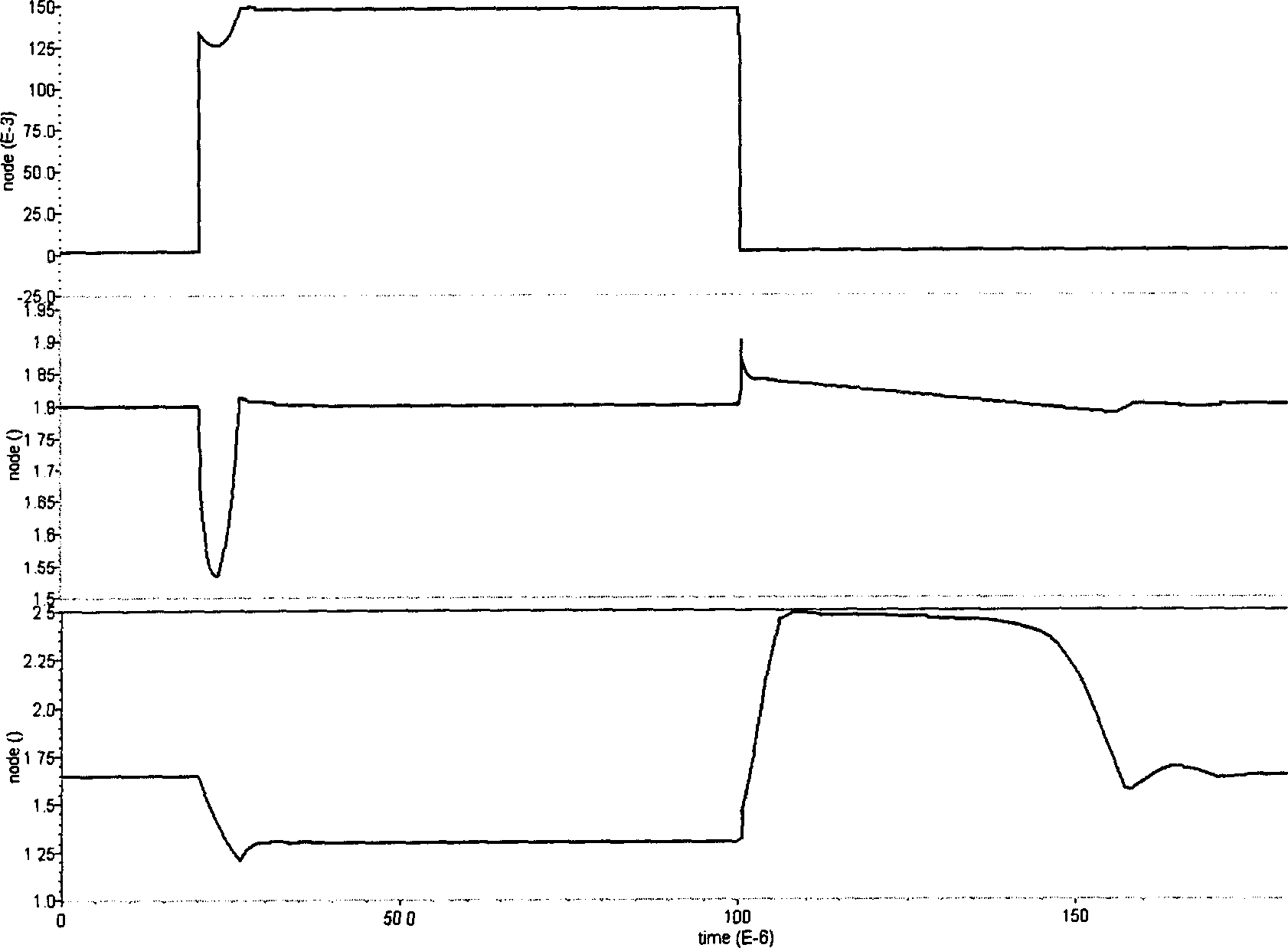

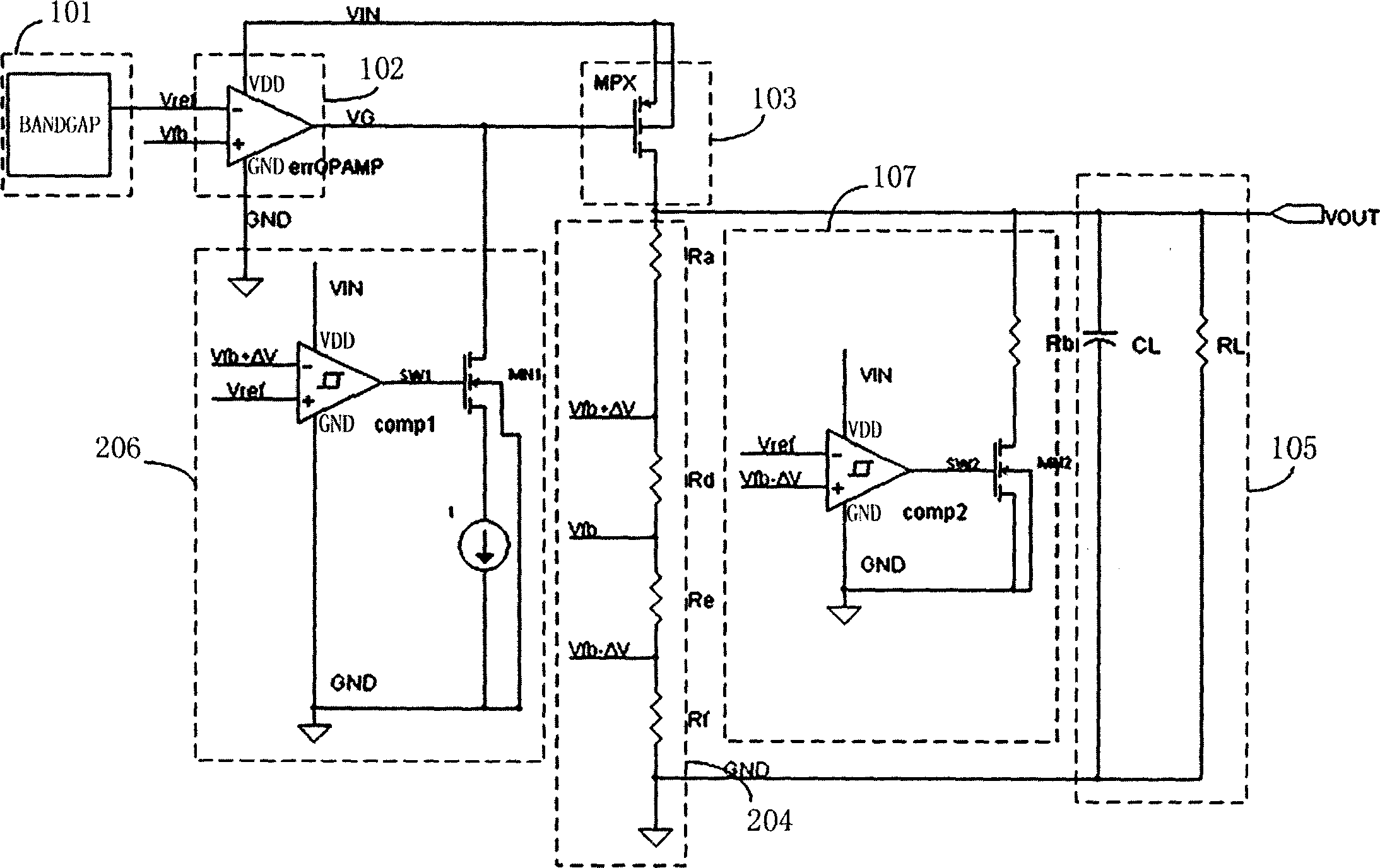

Circuit for speeding up stabilizing low voltage difference linear stabilizer output voltage

InactiveCN1821922AImprove transient responseApparatus without intermediate ac conversionElectric variable regulationCapacitanceLinear regulator

This invention relates to a circuit for speeding up the stabilized low voltage difference linear regulator output voltage based on a circuit composed of an output tube, an error amplifier, a primary standard voltage source, a resistor bleeder network and a load including reference voltage output by said primary voltage source and a feed back voltage output by the network characterizing that said resistor bleeder network is composed of four serial bleeder resistors used in providing three feed back voltages, namely, a first feed back voltage, a second voltage and a third feed back voltage, which utilizes the instant controlled current to speed up the discharge to the grating capacitance of the MPX and the discharge of the output capacitor so as to improve the instant response of LDO greatly.

Owner:CHIPHOMER TECH SHANGHAI

Calibration of a radiometric optical monitoring system used for fault detection and process monitoring

ActiveUS8125633B2Accurate measurementFacilitates quantitative comparisonsEmission spectroscopyRadiation pyrometryPrimary standardMonitoring system

Owner:VERITY INSTR

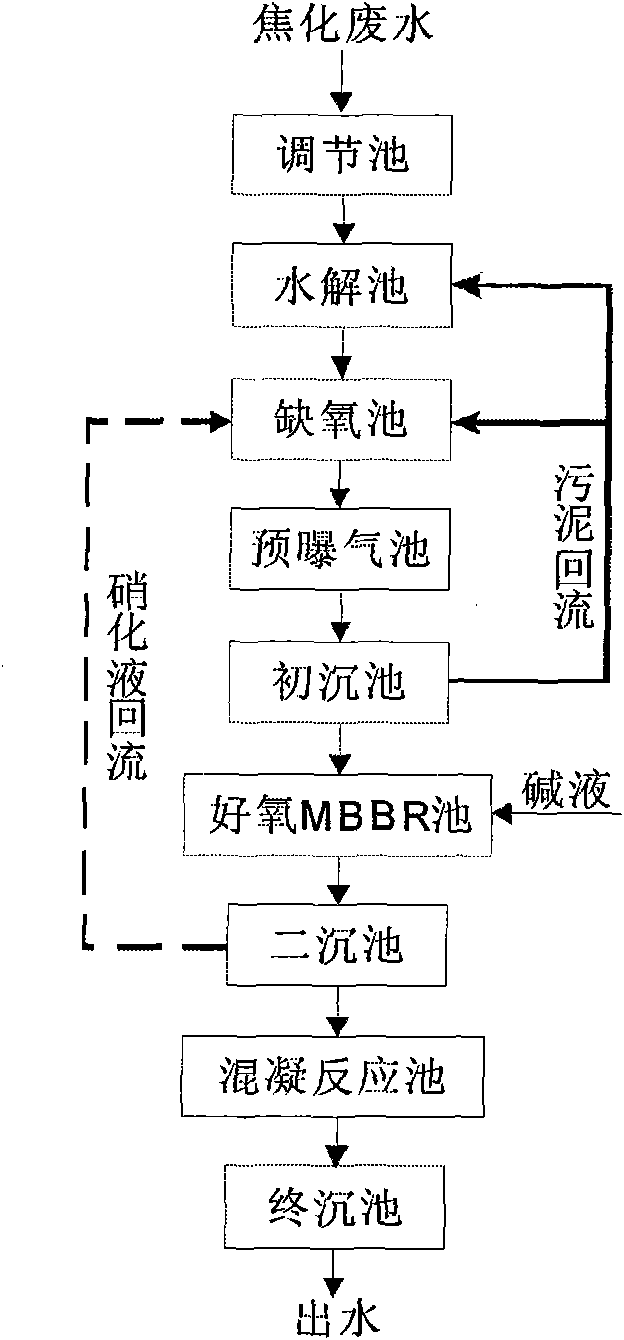

Method for treating coking wastewater

InactiveCN101602564AHigh activityNo reflow requiredTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationSludge

The invention discloses a method for treating coking wastewater, which belongs to the field of wastewater treatment. The method comprises the following steps that: wastewater of a coking plant enters a regulating reservoir for the adjustment of water quality and water amount, and orderly enters a hydrolytic tank, an anaerobic tank, a preaeration tank, a preliminary sedimentation tank, an aerobic tank, a secondary sedimentation tank and a coagulation reaction tank for treatment, wherein the hydrolytic tank and the preaeration tank are filled with a bio-cord filler; the sludge of the preliminary sedimentation tank refluxes into the hydrolytic tank and the anaerobic tank respectively; a clarifying solution of the secondary sedimentation tank refluxes into the anaerobic tank; and the aerobic tank adopts a moving bed bio-film reactor. The bio-cord filler adopted in the invention has short film formation time and high biomass, does not need repeated washing, and has strong shock resistance; and the moving bed bio-film reactor can fix a large amount of nitrobacteria with long generation time, and has no the problem of blocking. The method can remove high-concentration ammonia nitrogen and organic substances in the coking wastewater, and the COD and the ammonia nitrogen of treated effluent can synchronously achieve the primary standard of the national integrated wastewater discharge standard (GB9878-1996).

Owner:NANJING UNIV

High temperature acidified corrosion inhibitor for oil passageway containing Cr

The invention relates to a high-temperature acidizing inhibiter containing a Cr oil pipe. A main agent A comprises the following compositions by weight portion: 25 to 35 portions of quinoline quaternary ammonium salt or quinoline derivate quaternary ammonium salt, 5 to 10 portions of potassium iodide, and 40 to 60 portions of organic solvent methanol or formaldehyde. An addition agent B comprises the following compositions by weight portion: 30 to 50 portions of Mannich base, 15 to 35 portions of propiolic alcohol, 5 to 15 portions of chromic chloride, and 20 to 35 portions of formaldehyde. During use, the proportion of A to B is 2-1.5:1 according to the weight portions, in an environment of 15 percent HCl+3 percent HF mud acid and 20 percent hydrochloric acid, inhibitions to super 13Cr at 100 DEG C, 120 DEG C and 140 DEG C all accord with acidizing standard requirement; and according to SY / T5405-1996 acidizing inhibiter performance test method and evaluating indicator, corrosion velocity of the inhibiter is lower than 40g / m<2>h at 140 DEG C. The inhibiter achieves the requirement of primary standard, and solves the problem of acidizing corrosion of Cr-contained steel in a high-temperature oil well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

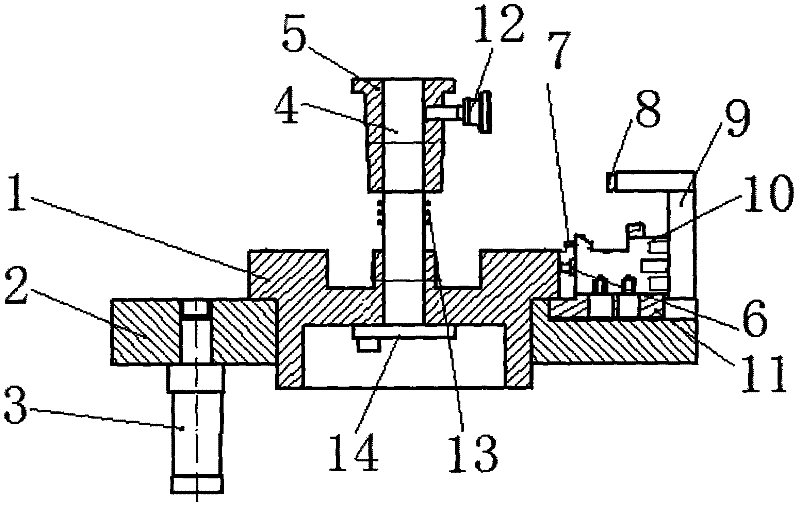

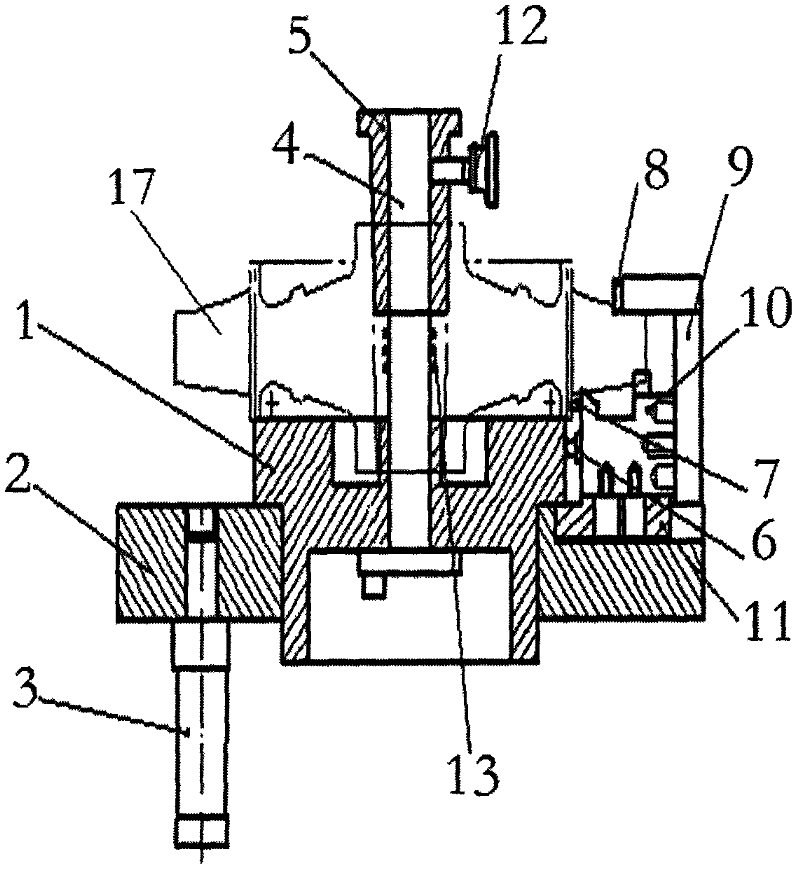

Manufacturing method and fixture of integral bladed-disk wax mold

ActiveCN102363199AImprove consistencyHigh dimensional accuracyFoundry moulding apparatusWaxPrimary standard

The invention discloses a manufacturing method and a fixture of an integral bladed-disk wax mold. According to the invention, an integral bladed-disk wax pattern is divided into single blades and a disk shaft. Processes of separated pressing, precise fixture positioning and wax mold welding assembling are adopted. The integral wax pattern is precisely cast. According to the invention, the disk shaft is fixed on an assembling fixture; the blades are sequentially positioned on positioning points on the fixture, and are welded onto the disk shaft. Blade bodies and channel inner walls with high precisions are adopted in the positioning of the blades, such that good consistency is provided for the blades. When the wax pattern is assembled, positioning points are positioned on the blade bodies;blade body positioning points are consistent with processing positioning points, primary standards of cold and hot processing are consistent, such that blade dimensional precision of the whole cast is optimally improved, throat areas between blades are ensured, and flow rate homogeneity is ensured. Positioning parts of the fixture can be adjusted according to measured dimensions of parts, such that the volume of flow rate can be changed according to directional positions of angles of the blades. Therefore, repairing or even rejecting risks caused by unqualified integral mold dimensions are avoided, production period is saved, and production cost is reduced. With the method provided by the invention, hard processes are turned easy, product precision is improved, and production efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

Cold atom micro primary standard

An atomic clock having a physics package that includes a vacuum chamber cavity that holds atoms of Rb-87 under high vacuum conditions, an optical bench having a single laser light source, a local oscillator, a plurality of magnetic field coils, an antenna, at least one photo-detector and integrated control electronics. The single laser light source has a fold-retro-reflected design to create three retro-reflected optical beams that cross at 90° angles relative to one another in the vacuum chamber cavity. This design allows the single laser light source to make the required six trapping beams needed to trap and cool the atoms of Rb-87. The foregoing design makes possible atomic clocks having reduced size and power consumption and capable of maintaining an ultra-high vacuum without active pumping.

Owner:HONEYWELL INT INC

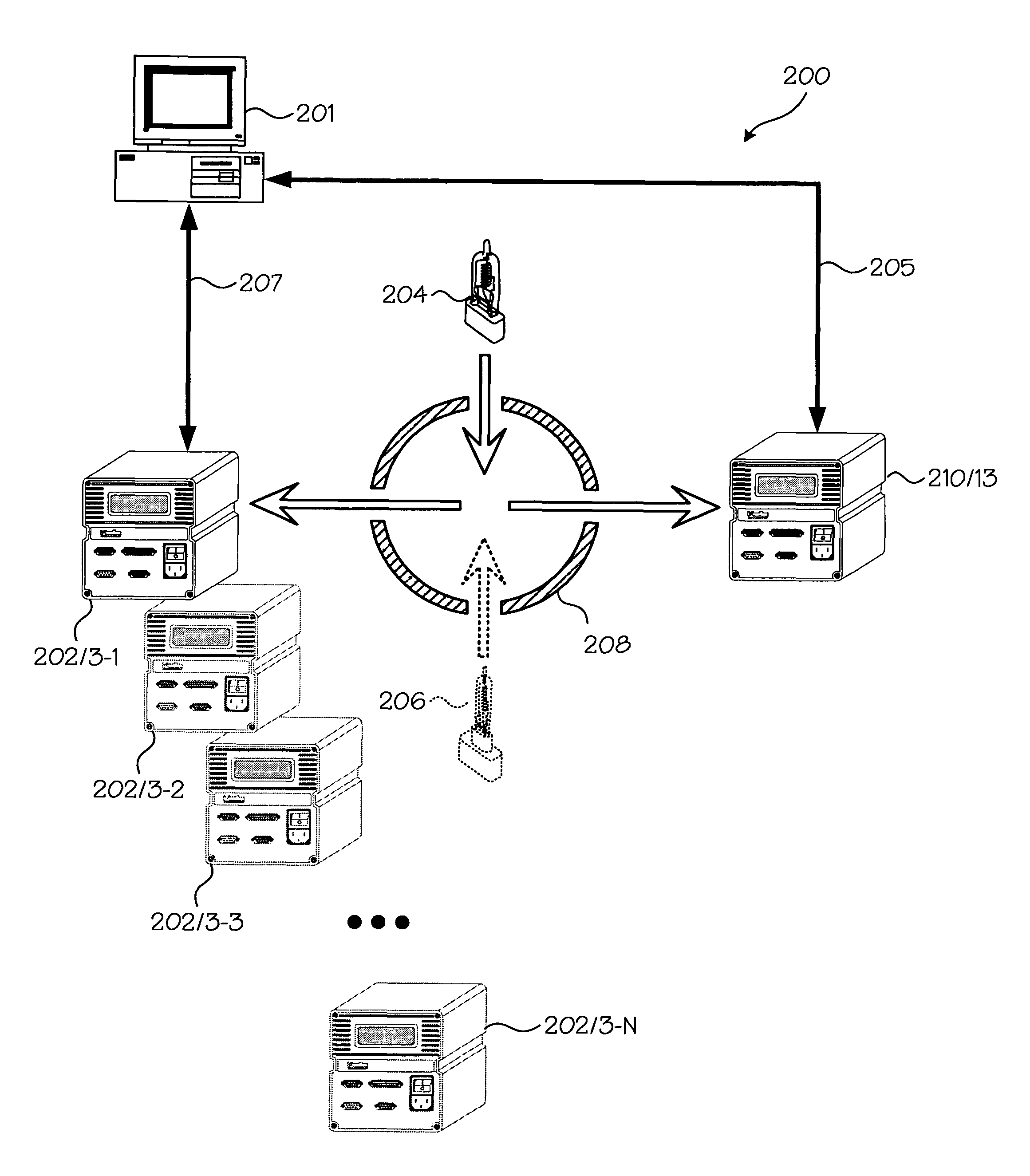

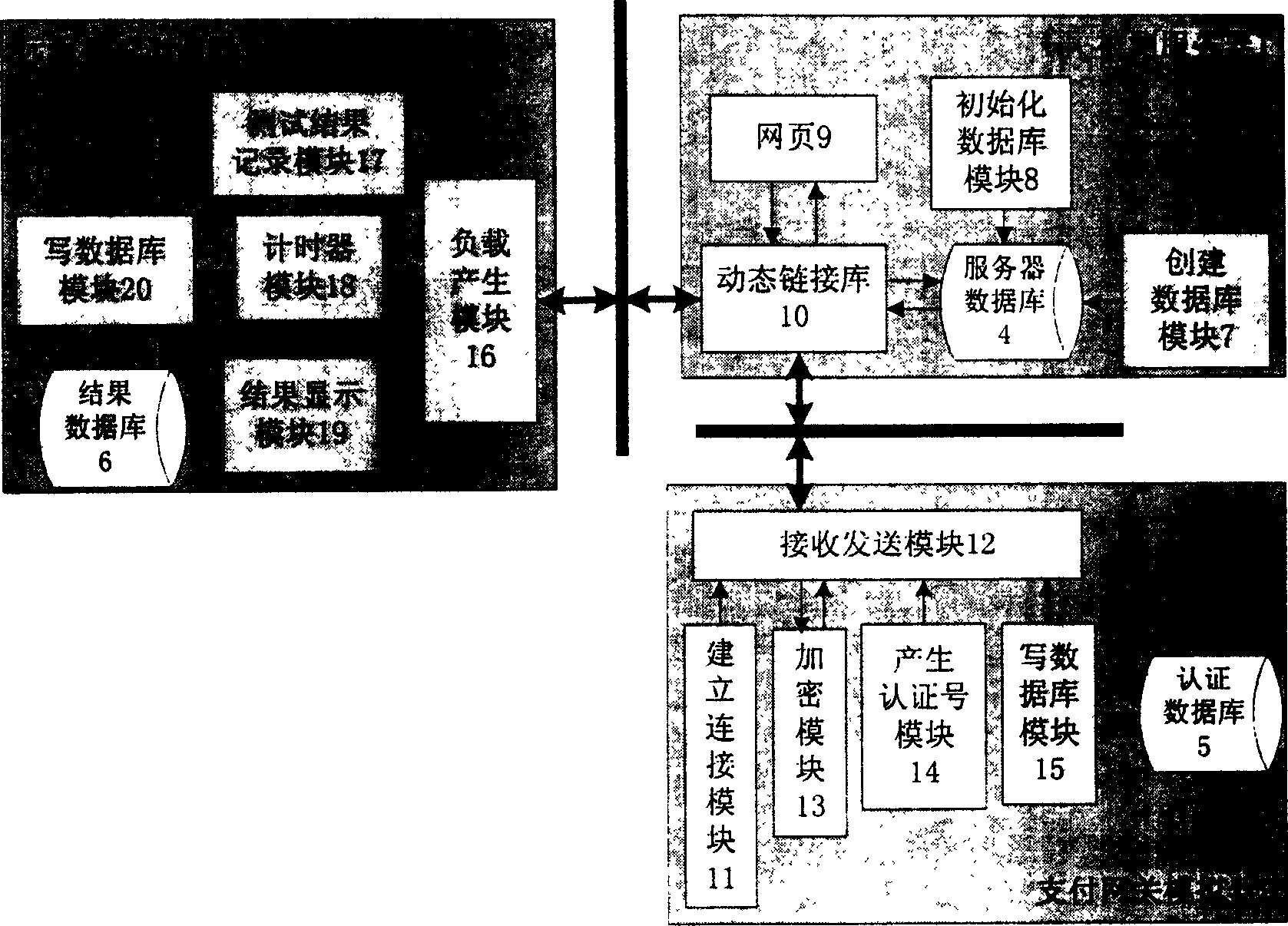

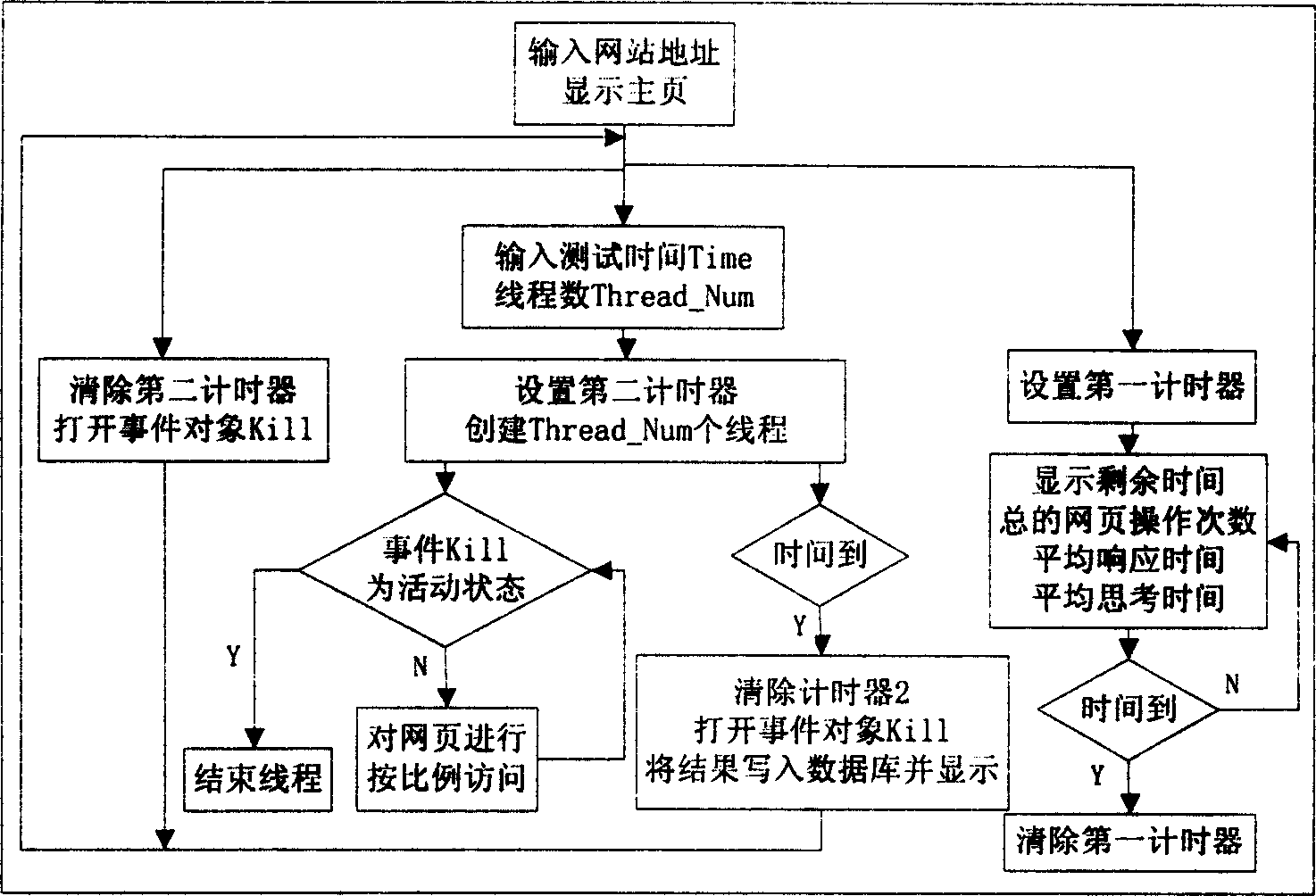

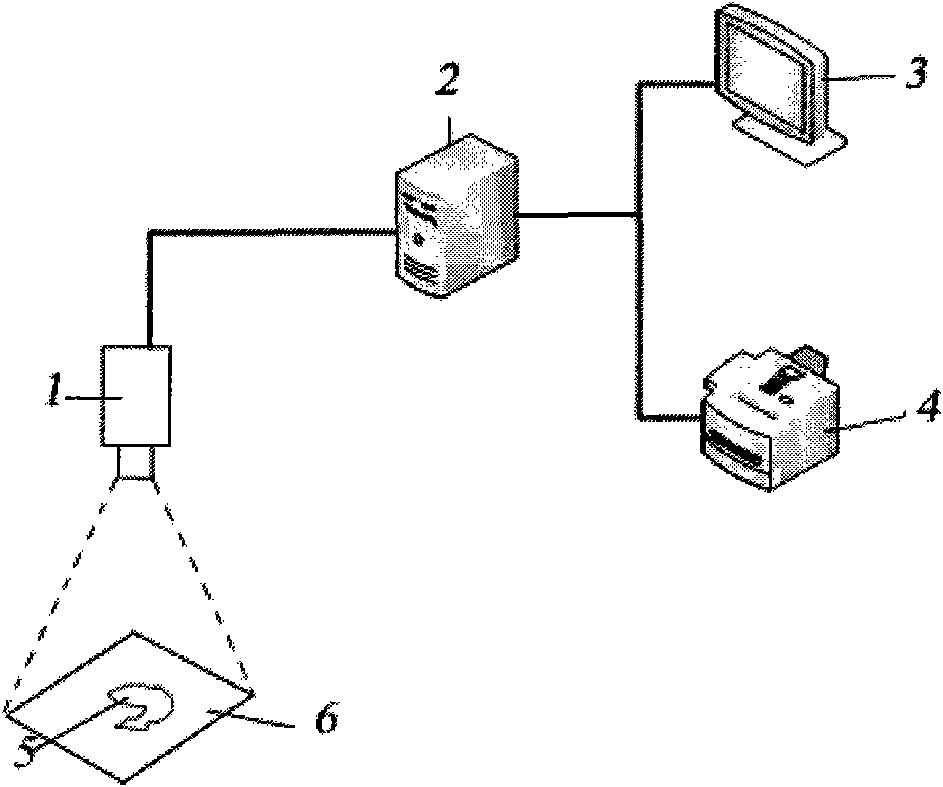

Network station server performance test system based on TPC-W benchmark

InactiveCN1561036ALow evaluation feeEasy to installData switching networksPrimary standardTested time

A network station server performance test system based on TPC-w primary standard applies a customer set / server system structure to utilize multiple customer sets to simulate multiple remote browsing customers and strictly obey the statistic property for user access to access it in stipulated test time and test its performance expressed under three test modes (WIPS, WIPSb an WIPSo), namely, the mean number for web-page operation in each second and mean response time of the server to users.

Owner:HUAZHONG UNIV OF SCI & TECH

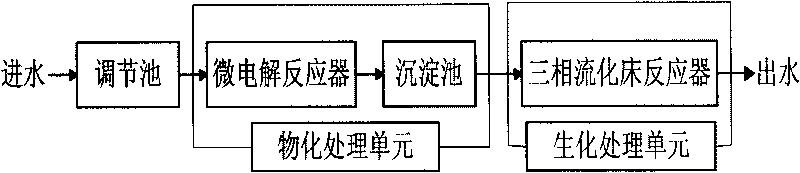

Process method for treating coking wastewater

InactiveCN101734826ALow densityReduce processing costsWaste water treatment from metallurgical processMultistage water/sewage treatmentVolatile phenolsActivated sludge

The invention discloses a process method for treating coking wastewater. The process method solves the technical problems that a micro-electrolysis method has hardening, channeling and narrow applicability of a pH range and a biochemical treatment process has long flow, large occupied area, poor impact load resistance and high expense. The method comprises a physical-chemical treatment unit consisting of a micro-electrolysis reactor and a settling tank; in the micro-electrolysis reactor, scrap iron, scrap copper and a lightweight blocky material are used as fillers; the pH of inlet water is between 2.0 and 6.0; the waterpower retention time is between 20 and 60 minutes; the method adopts air aeration; the method also comprises a filtering type inner circulating three-phase fluidized bed reactor biochemical treatment unit, and immobilized activated sludge balls are utilized to realize simultaneous denitrification and decarburization; the pH of inlet water is between 7.2 and 8.5; the concentration of dissolved oxygen is between 2 and 6mg / L; the temperature is between 28 and 32 DEG C; the waterpower retention time is between 20 and 40h; the COD of outlet water reaches secondary standard of integrated wastewater discharge standard; and volatile phenol, ammonia nitrogen and chroma reach primary standard of integrated wastewater discharge standard.

Owner:NANJING UNIV OF SCI & TECH

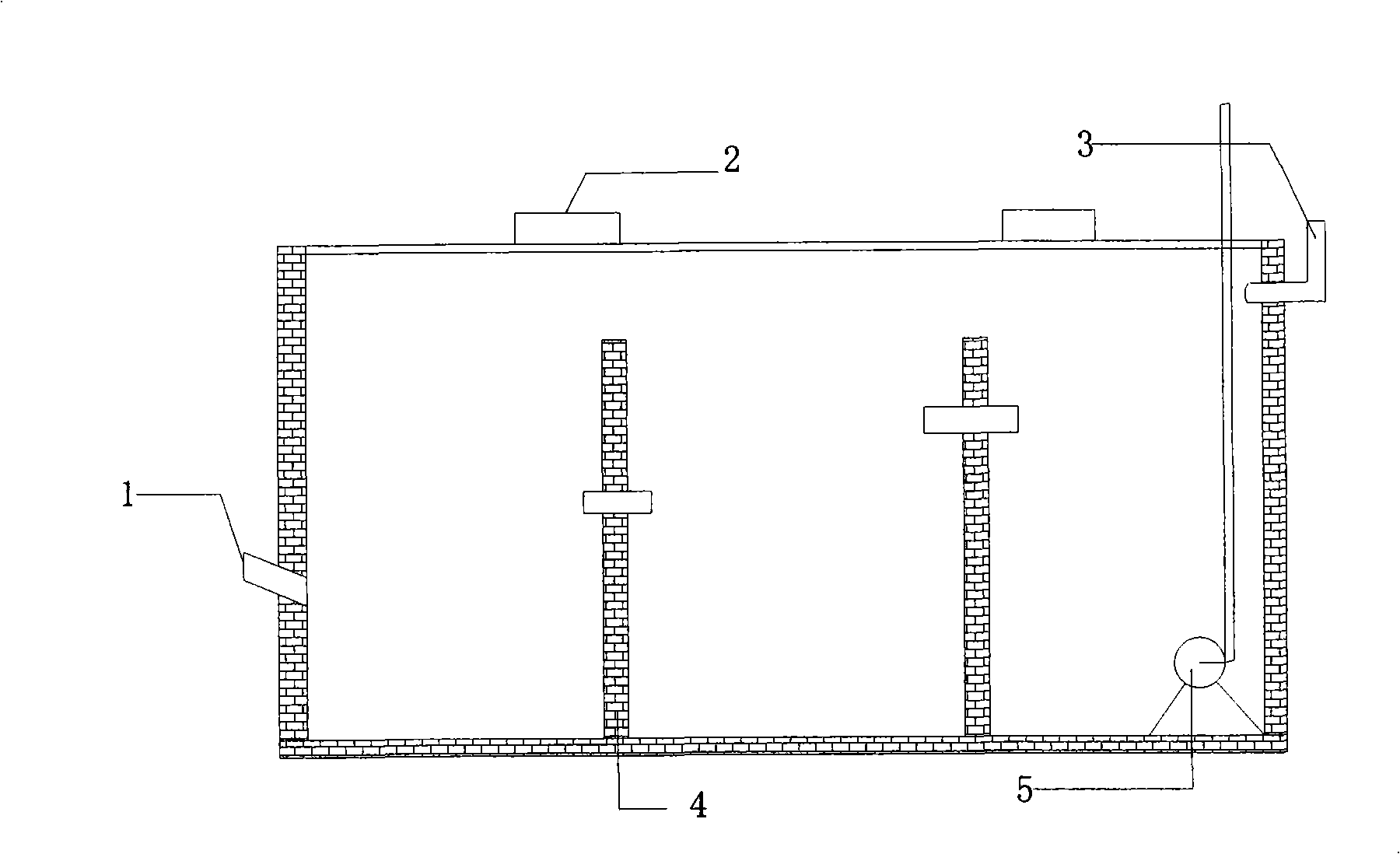

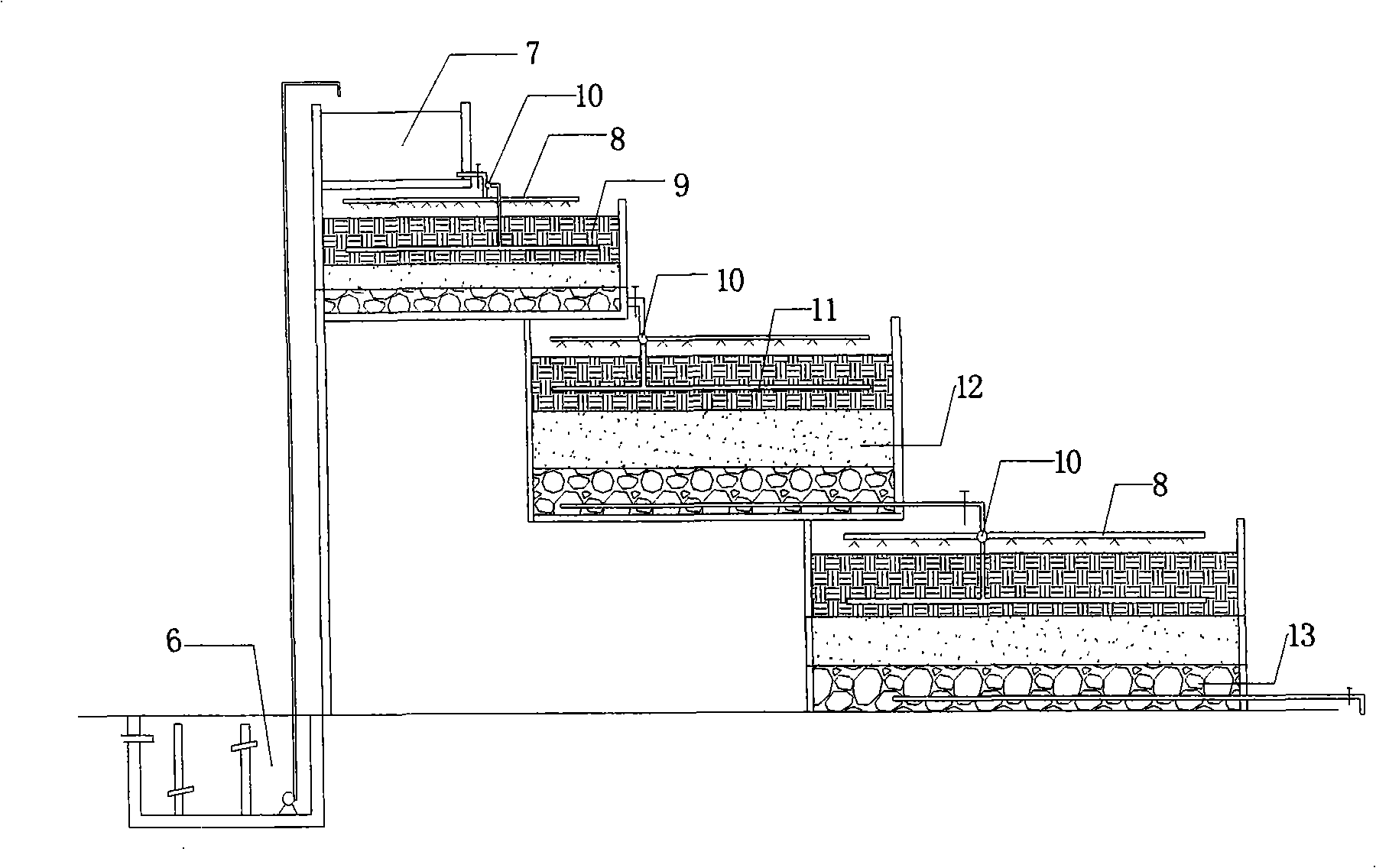

Tower type earthworm and ecological filter for treating sewage

InactiveCN101284705AReduce pollution loadSolve the problem of serious runoff pollutionMultistage water/sewage treatmentSustainable biological treatmentConstructed wetlandEmission standard

The invention provides a combined process of tower angleworm bio-filters and constructed wetlands for treating the domestic sewage. The combined process comprises the following steps: firstly, the sewage enters a hydrolysis-acidification pool and stabilizes after the action, and the water quantity is adjusted; secondly, the domestic sewage in the hydrolysis-acidification pool is distributed into a hydrolysis-acidification pool for removing COD, total nitrogen, nitrogen-nitrogen, total phosphorus and pathogeny microbes; and thirdly, the tail water in the second step enters a constructed wetland to be subjected to strengthening treatment, thereby building a suitable waterfront surroundings landscape, or the tail water is recycled by serving as reclaimed water. The combined process has the following advantages: firstly, the system hydraulic loading is high, and the surface hydraulic loading can reach 1m<3> / m<2>*d, thereby greatly saving land; and secondly, under the high hydraulic loading, the total nitrogen removal rate of the system can reach more than 85 percent; the removal rates of other materials in the system are all more than 90 percent, the effluent reaches the primary standard of the national sewage comprehensive emission standard (GB8978-1996), and reaches the miscellaneous domestic water quality standard of the PRC construction standard (CJ25.1-89), thereby being able to be recycled by serving as the reclaimed water.

Owner:NANJING UNIV

Device and method for processing restaurant wastewater

ActiveCN102145967AIncrease dissolved oxygenImprove the efficiency of degrading pollutantsMultistage water/sewage treatmentActivated sludgeElectrolysis

The invention discloses a device and a method for processing restaurant wastewater. A ferrallitic sheet is used as an anode and a graphite sheet is used as a cathode to carry out pulse direct current electrolysis on the restaurant wastewater so as to cause an electrocoagulation reaction; simultaneously ultrafine ozone bubbles are fed into an electrocoagulation reaction region to strengthen the electrocoagulation reaction, so that ferrous irons Fe2+ generated in the electrolysis process is rapidly converted into ferric irons Fe3+, the volume of flocculate becomes larger and the flocculate precipitates more efficiently to remove most of pollutants in the wastewater; sludge generated in the electrocoagulation process enters an activated sludge reactor and a sludge concentrating and extruding device; and clear water containing a little amount of organic matter enters an aeration-ozone-ultraviolet combined treatment degradation tank and a photocatalyst micro filtration membrane, and finally outflows through a fine porous sand filtering tank. The produced water can reach the primary standard in the industry. The processing method has high impact-load resistance. The outlet water quality is stable. In the engineering, consumables have long service life. Therefore, the processing cost of the restaurant wastewater can be greatly reduced.

Owner:TAIDEA TECH ZHONGSHAN

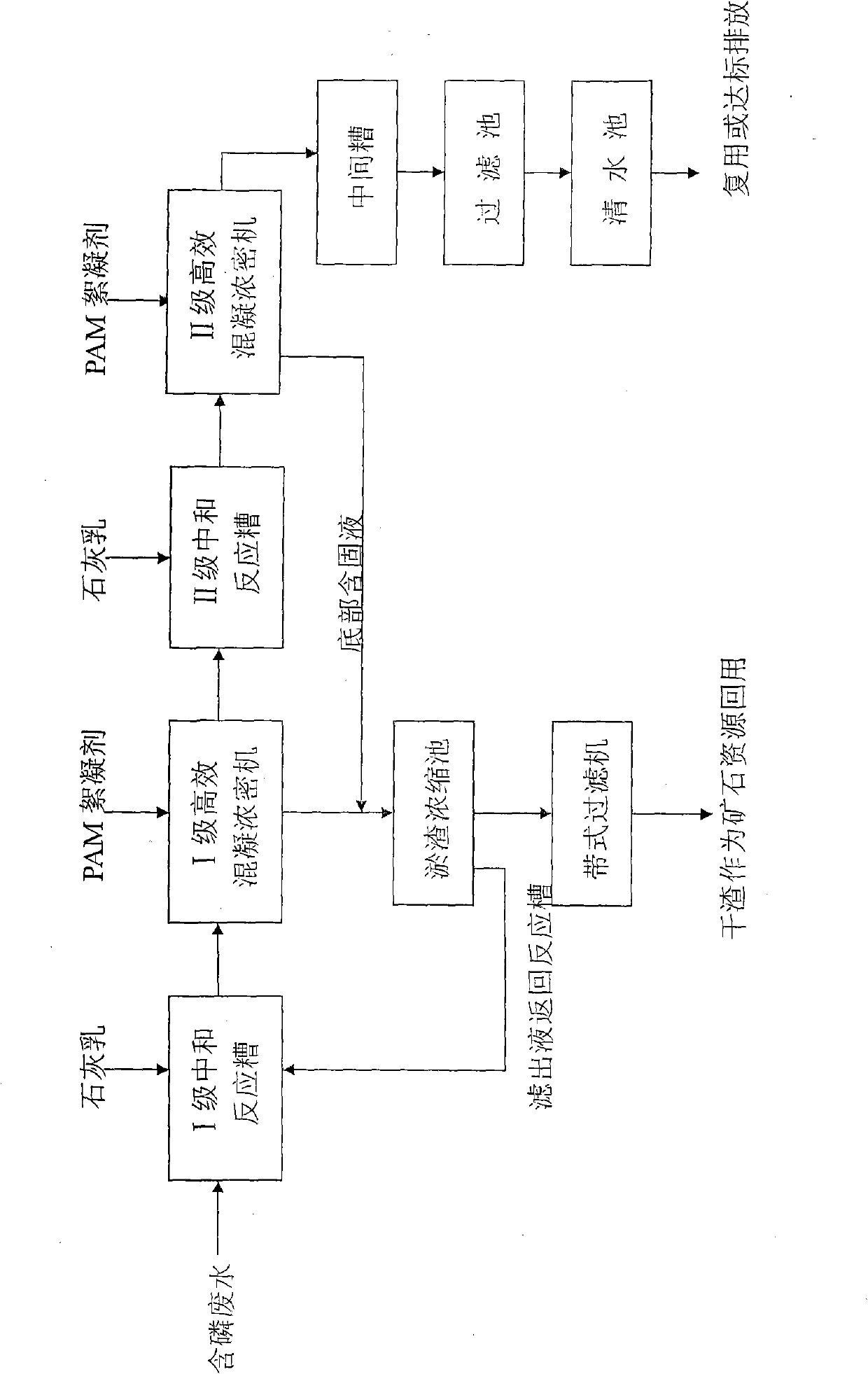

Treating method for phosphoric waste water and sludge generated in production process of phosphatic compound fertilizer

InactiveCN101905933AConform to energy savingEconomicalMultistage water/sewage treatmentWater/sewage treatment by neutralisationSludgeFiltration

The invention discloses a treating method for phosphoric waste water and sludge generated in the production process of a phosphatic compound fertilizer, which comprises the following steps: adding lime milk into the phosphoric waste water to be treated firstly, and controlling a pH value to be 5-6; carrying out neutralization reaction for the first time; adding a PAM flocculating agent for flocculation reaction and then carrying out separation of mud and water; adding the lime milk in the aqueous phase again, and controlling the pH value to be 10-11 for the neutralization reaction for the second time; and adding the PAM flocculating agent again for the flocculation reaction and then carrying out the separation of mud and water, wherein the aqueous phase reaches a effluent standard after filtration. The invention realizes the multiplexing or the standard-reaching discharge of the waste water, the zero release of the sludge, accords to the developing direction of the energy saving and emission reduction and circular economy. The clear liquid treated by the process of the invention contains 0.4-0.5mg / L of phosphate (calculated by being based on P2O5), 8-9mg / L of F and 60-80mg / L of COD, meets the primary standard emission requirement of GB8978-1996, the ultimate clear liquid can be returned to a phosphoric acid device for multiplexing, and also be directly discharged after reaching standards; and the sludge produced by the filtration comprises the following main components: calcium phosphate, calcium fluoride, calcium carbonate and calcium sulfate, which can be totally reused as phosphorite resources.

Owner:中化重庆涪陵化工有限公司

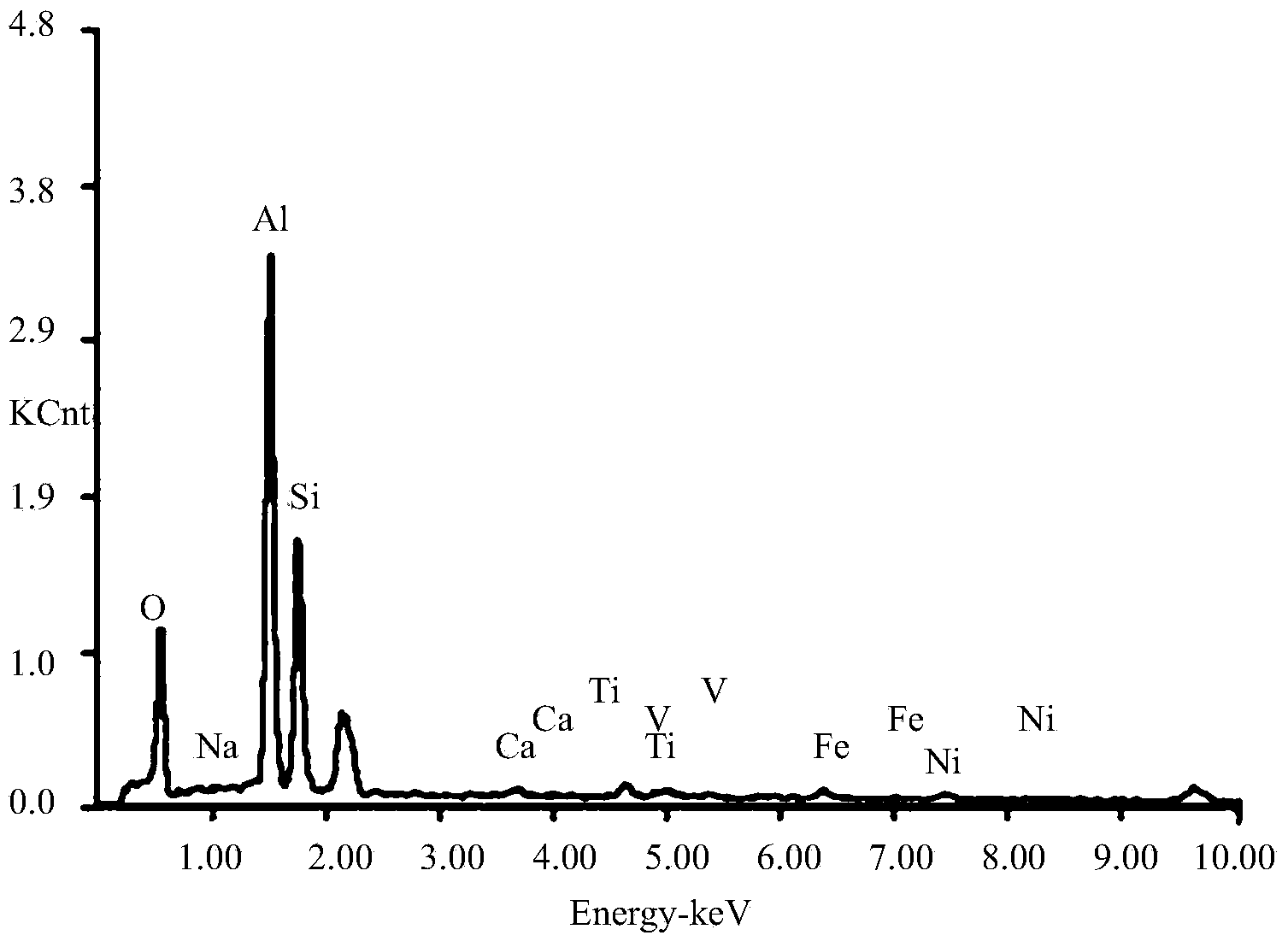

Method of preparing compact Ti3AlC2 ceramic by low-temperature non-pressure sintering

This invention relates to a low temperature pressless sintering preparation method for TiAL carbide ceramic, which takes pure Ti, Al and C as the raw materials to weigh and mix them in the mol ration of 3:1:2, then takes the mol volume of Al as the primary standard to add Sn, Si or Al powder of 0.3-0.6mol as the sinter aids, putting the mixed material in a ball mill kettle to be milled for 10-60h, in which, stainless steel balls or horniness alloy balls are applied in the kettle, the weight ratio of the ball material is 10:1-30:1, Ar or N inert gas is filled to the vacuumed kettle and the rate of the ball mill is 200-350rpm to get nanometer level super fine powder then to be ball-milled in ethanol medium for 3h to be dried and added with suitable PVB adhesive to granulate the powder and put into a steel model and pressed to an ingot on a cold equal static press to be sintered in vacuum, Ar or N protection atmosphere for 2-6h under 1250-1500deg.C to get a densed Ti3AlC2 ceramic.

Owner:SHANGHAI UNIV

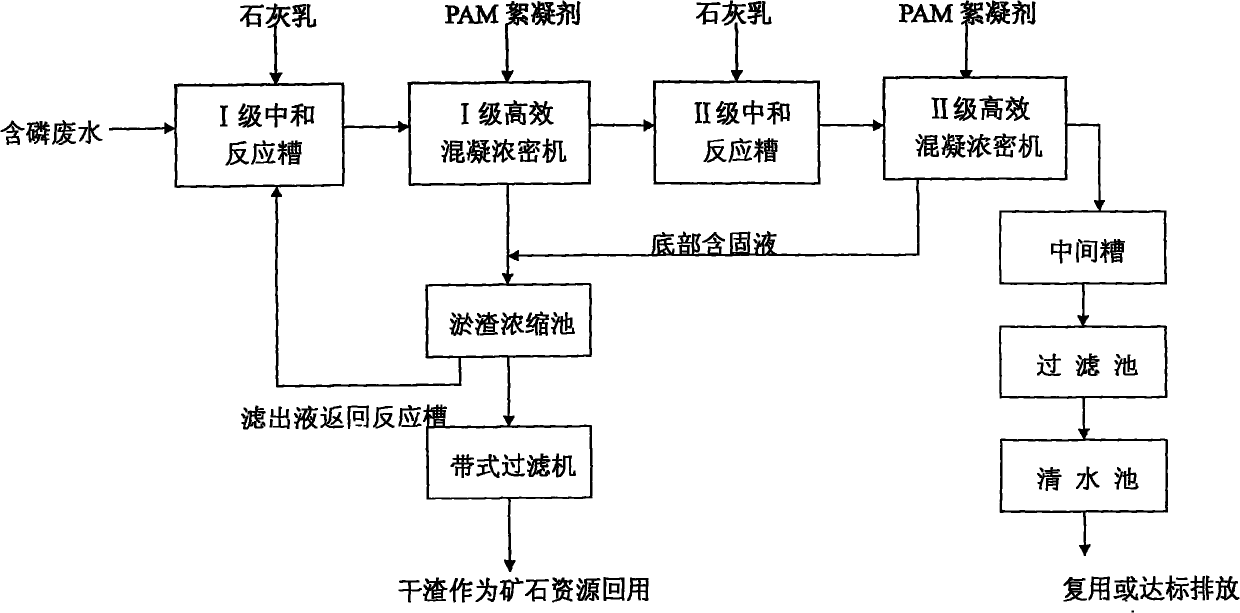

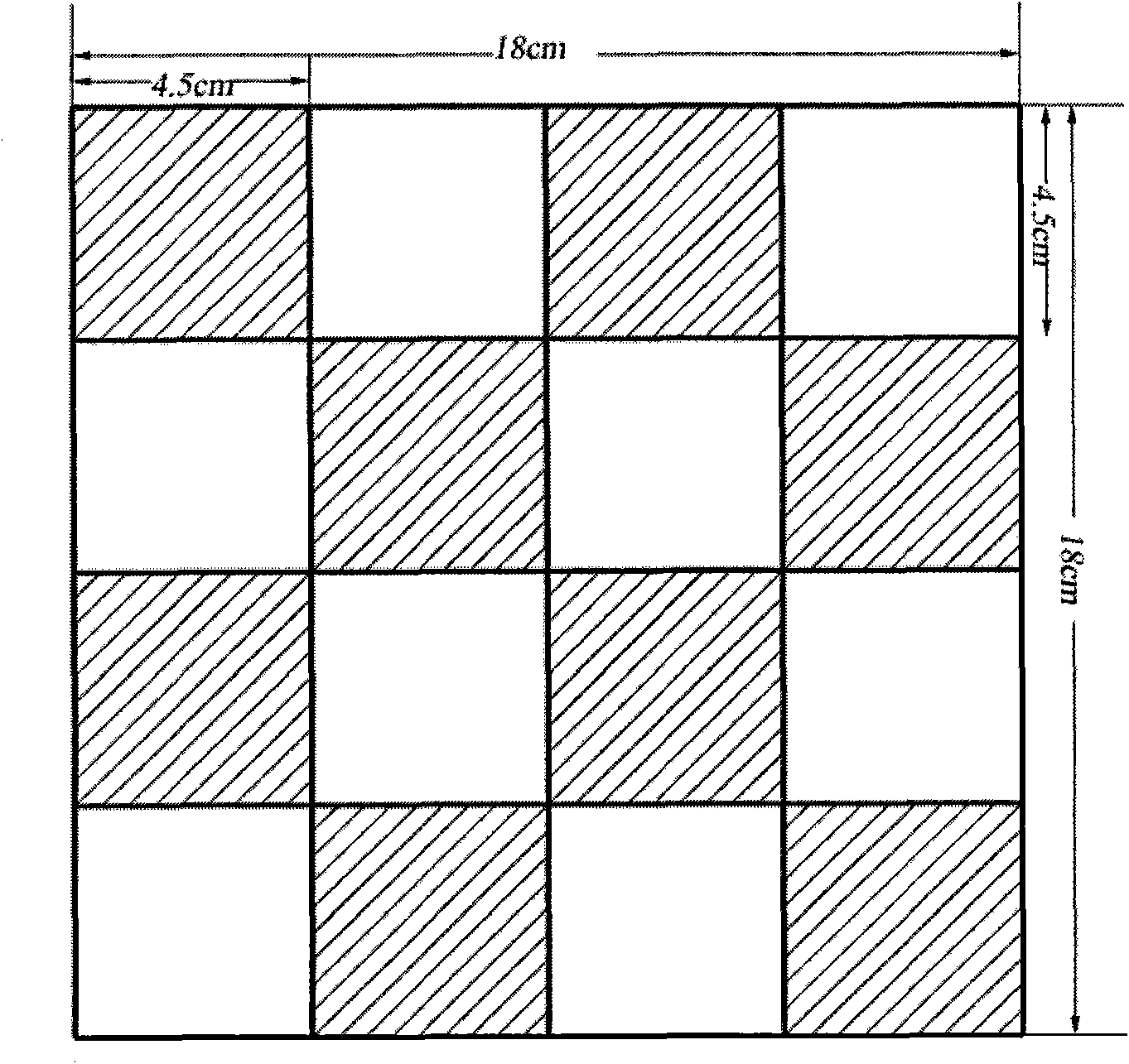

Plane area measuring method based on digital image technology

InactiveCN101865679AEasy and fast to readCorrection errorImage enhancementUsing optical meansPrimary standardImage correction

The invention discloses a plane area measuring method based on a digital image technology, which comprises the following steps: (1) carrying out parameter calibration to a pick-up device of a measuring system to obtain an internal parameter of the pick-up device; (2) utilizing the pick-up device to obtain an original image of background, and carrying out image correction and / or distortion correction and gray processing to the image to obtain a gray image of the background; (3) putting a plane primary standard substance with knew area in the background, imaging the plane primary standard substance by the pick-up device, carrying out the image correction and / or distortion correction, gray processing, difference operation and binarization processing to obtain a nonzero pixel of a binary image of the plane primary standard substance; (4) putting an object to be measured in the background, and obtaining a nonzero pixel of a binary image of the object to be measured according to the method of step (3) ; and (5) obtaining area of the object to be measured according to pixel equivalent of the measuring system and the nonzero pixel of the object to be measured.

Owner:ZHEJIANG UNIV CITY COLLEGE

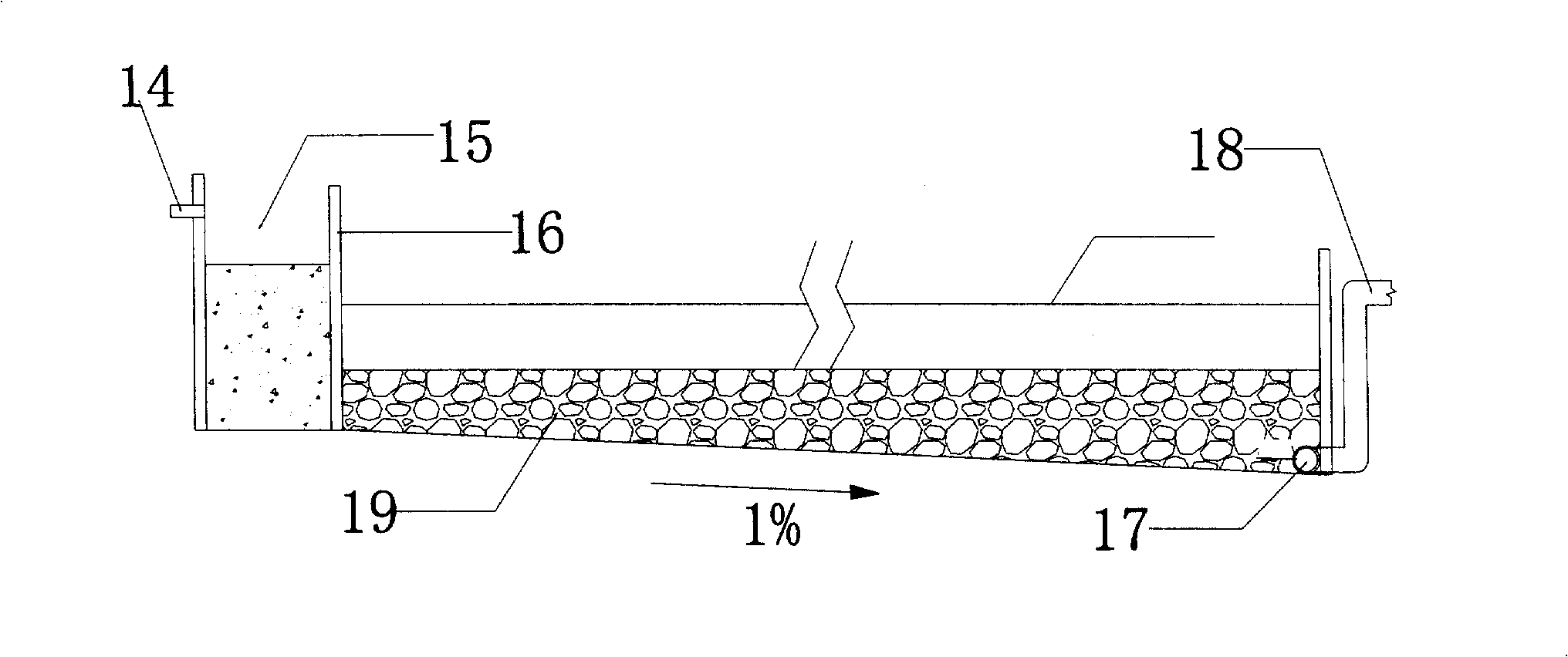

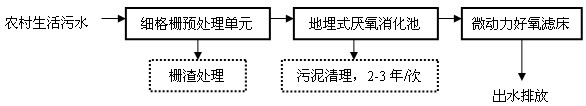

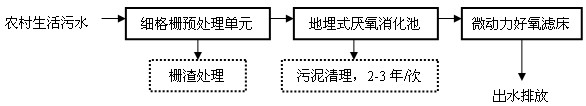

Rural domestic sewage treatment process

InactiveCN102145968AImprove retentionHigh degree of processingTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemical oxygen demandEmission standard

The invention discloses a rural domestic sewage treatment process. In the rural domestic sewage treatment process, a fine grid is used in a pretreatment process to remove large particle pollutants in sewage; an underground anaerobic digester is adopted to carry out hydrolysis acidification treatment so as to provide good conditions for a subsequent aerobic process; a micro power aerobic filter bed organically combines a solar energy micro power technology with an aerobic filter bed technology; a system is supplied with aeration power by solar energy; and a grading packing layer is arranged in the filter bed so as to realize low consumption and high efficiency treatment of the sewage. The rural domestic sewage treatment process particularly comprises the following procedures that after passing through the fine grid, the sewage enters the anaerobic digester; an elastic packing or a flexible packing is arranged in the anaerobic digester; and yielding water flowing out from the anaerobic digester enters the micro power aerobic filter bed system to be treated, wherein CODcr (Chemical Oxygen Demand), NH3-N (index of the ammonia nitrogen content in the sewage) and TP (total phosphorus) of the yielding water can reach the primary standard B of Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002). Due to the adoption of the rural domestic sewage treatment process, the treatment efficiency and the treatment degree of the domestic sewage can be improved. The rural domestic sewage treatment process is not limited by areas or air temperature and has small occupied area and low operation cost.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

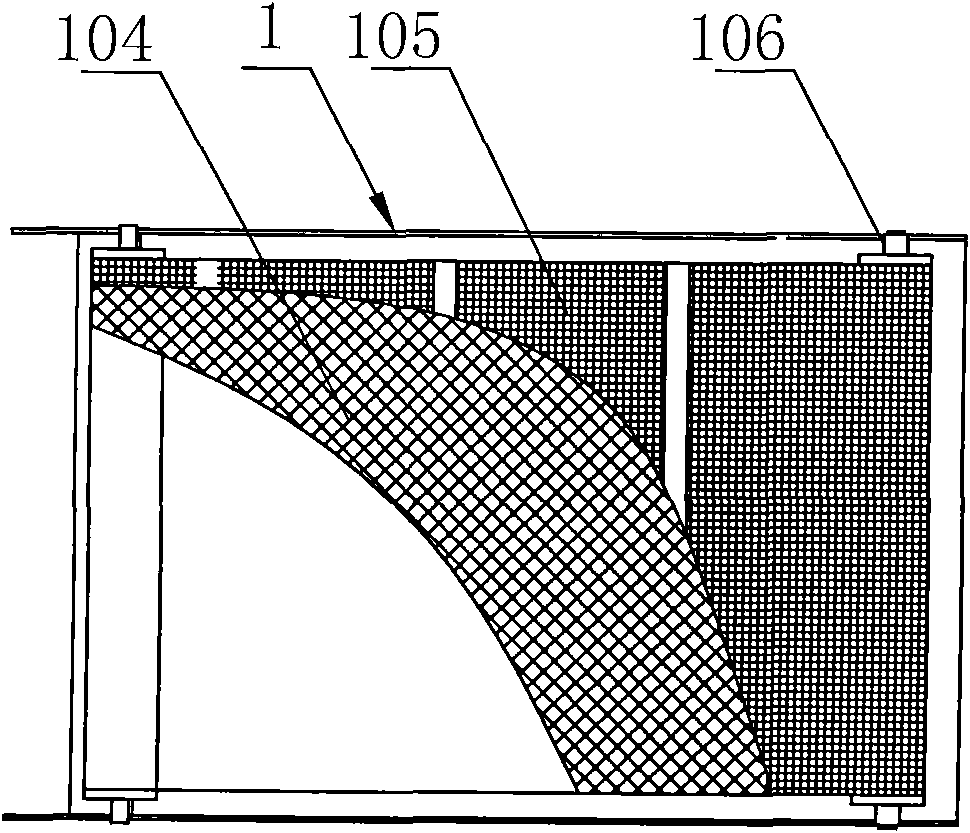

Zone division type display device and displaying method thereof

InactiveCN101021999AEffective brightnessEasy to useStatic indicating devicesPrimary standardDisplay device

This invention discloses a region segmentation display and its display method including at least a backlight module, a segmenting unit, a signal process unit and a variable unit, in which, the backlight module has several backlight regions and each backlight region includes a brightness unit with a primary standard brightness value, the segmentation unit segments the input picture signals into several output picture signals, the variable unit changes the primary standard brightness value to the output brightness value based on the regional signals matched to the corresponding primary standard value to present a brightness and a color, and the output brightness value matched with the corresponding output picture signal maintains the brightness and color approaching to the original one.

Owner:INNOLUX CORP

Ad hoc network TDMA slotted synchronous method

ActiveCN1719781AImprove securityEnsure safetySynchronisation arrangementData switching by path configurationTime division multiple accessPrimary standard

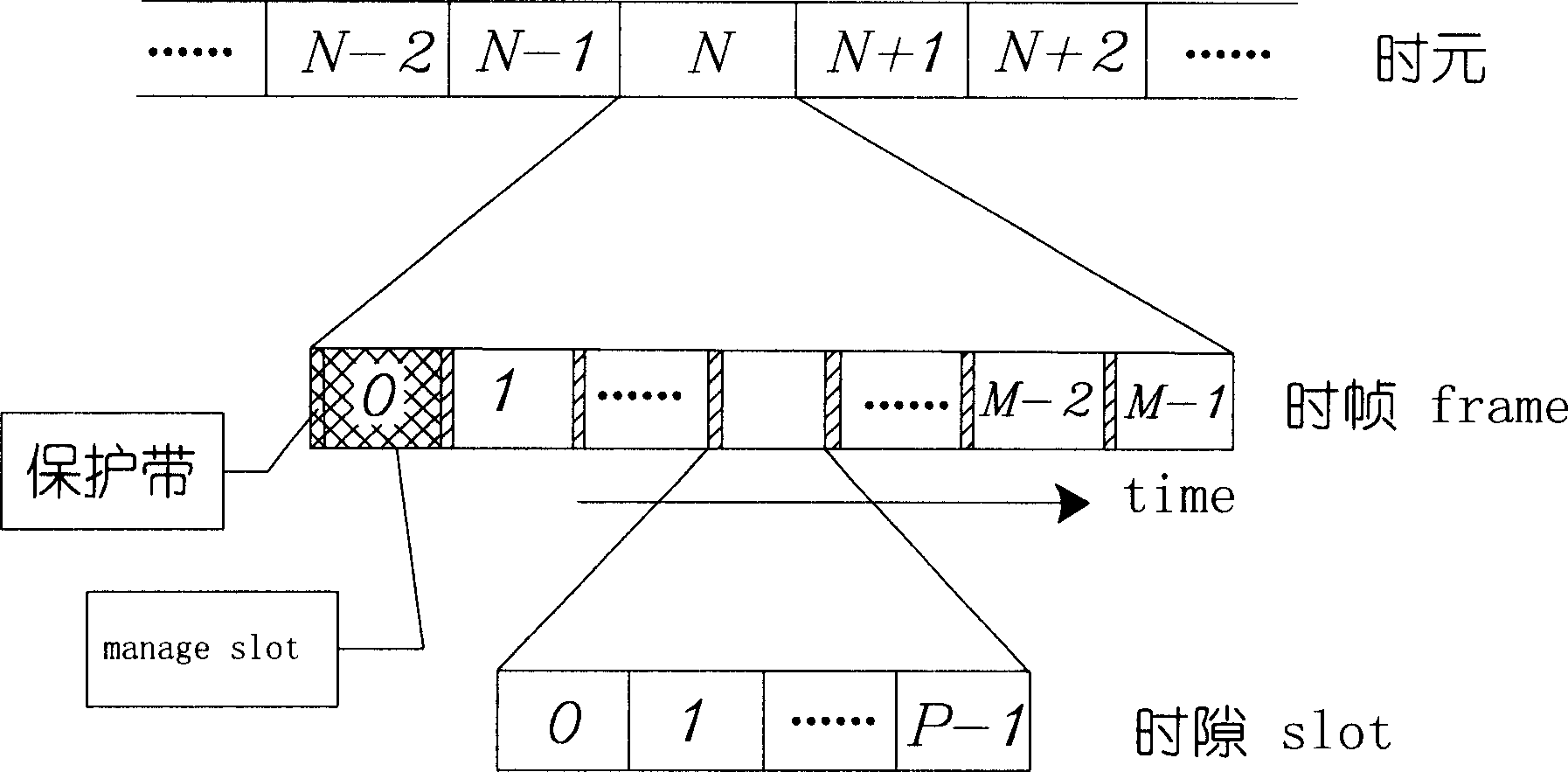

A TDMA time slot synchronous method for Ad hoc network includes the following: designing a first time slot of each time frame of time element in each node in the TDMA system as the management time slot for competition, generating a time master control node and a back up master control node by voting applying a FH digital transmission way between master control node and other sub-nodes to send time synchronous information and designing a frogging counter to realize a uniform frogging primary standard for the T / R two parties, adding a time slot counter and a time frame counter to realize the time synchronization among nodes and time refresh and the node time primary standards among nodes are basically the same.

Owner:GUANGZHOU HAIGE COMM GRP INC +1

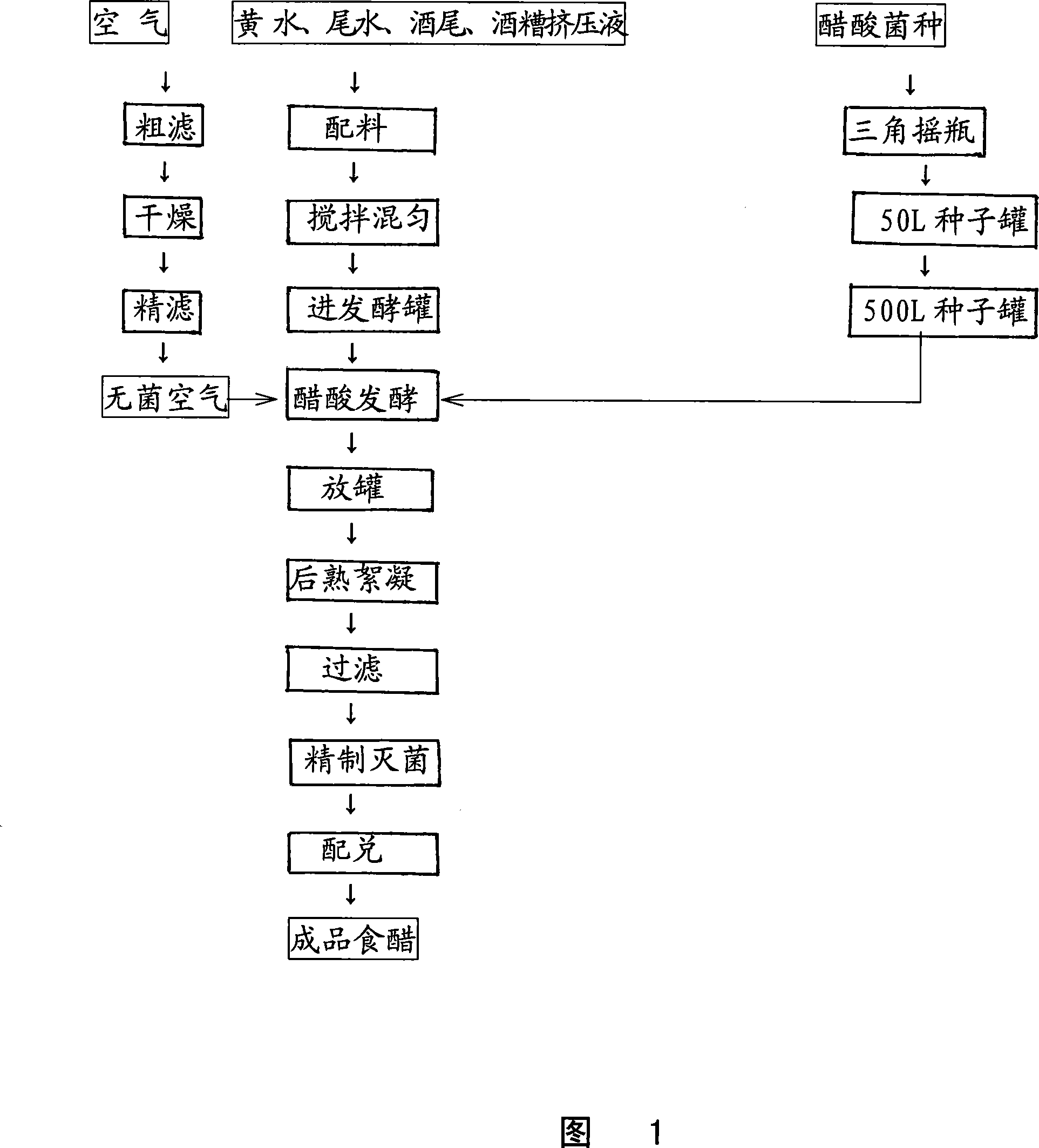

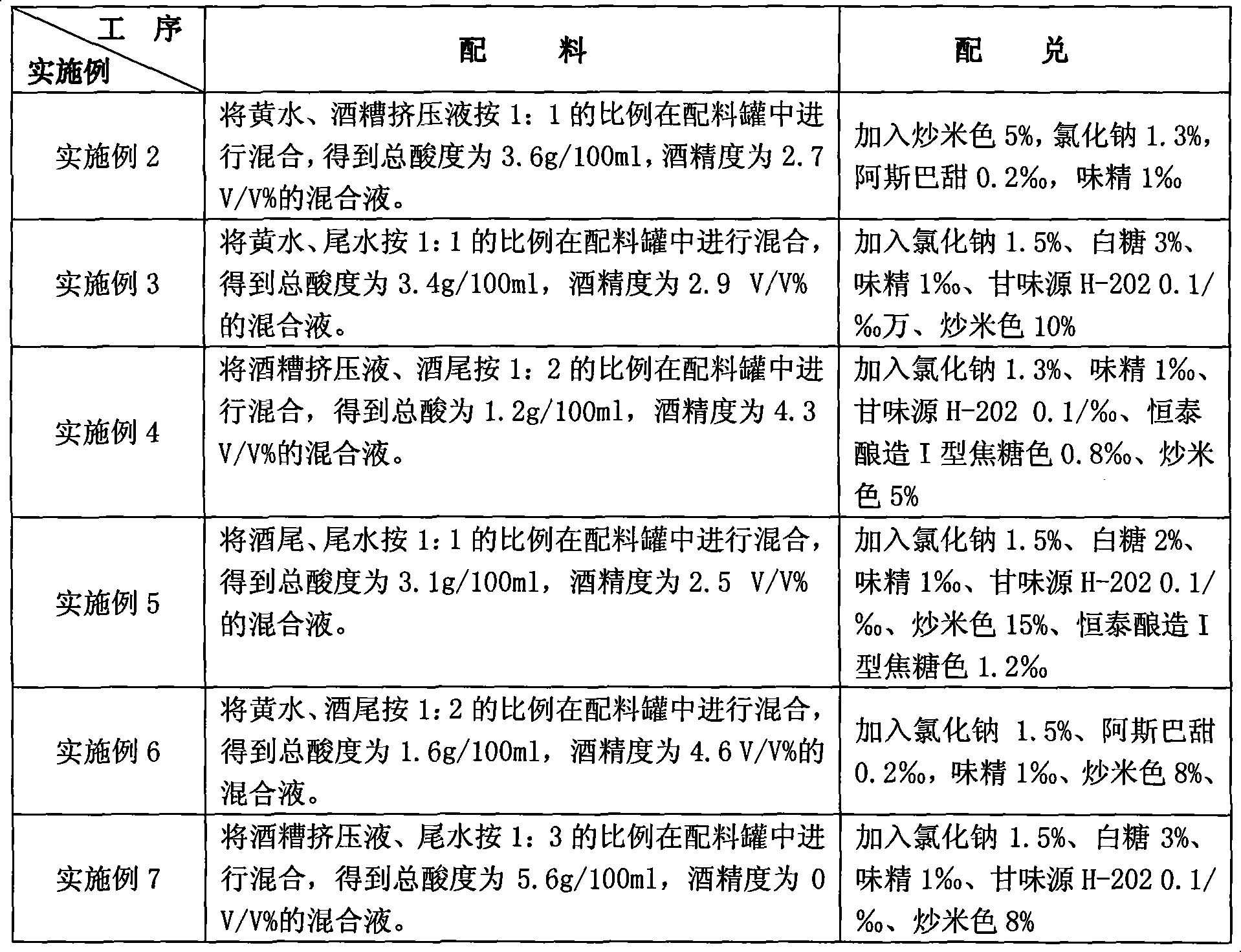

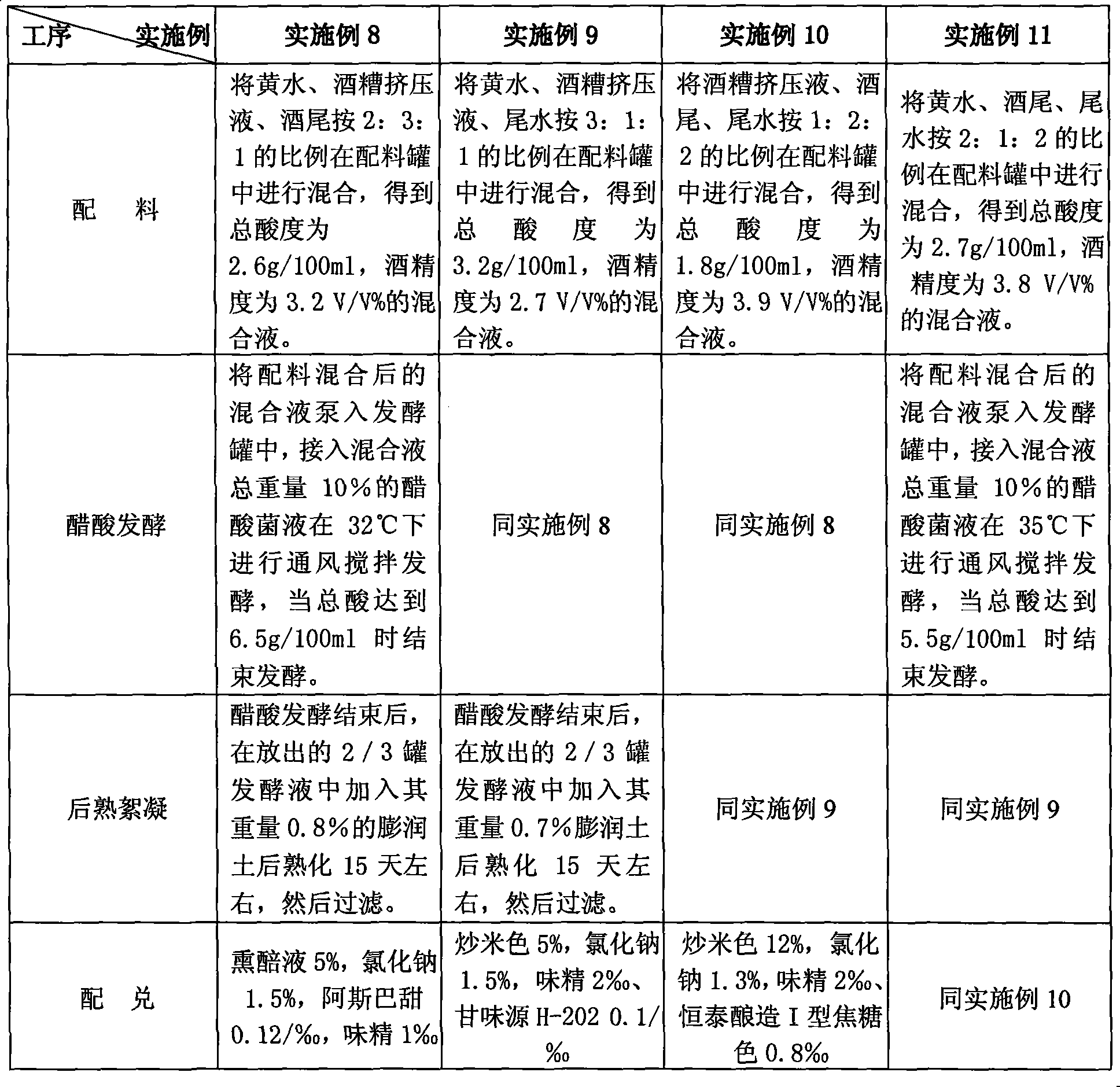

Zero grain consuming full liquid state method for producing vinegar with solid state fermentation flavor

ActiveCN101168715AGreat tasteHigh nutritional valueVinegar preparationNutritive valuesSodium Bentonite

The invention discloses a production method of table vinegar with zero grain consumption and complete liquid state and solid fermentation flavor. The method comprises a material blending process, an acetic fermentation process, a post maturation flocculation process, a refining sterilization process, and a mixing process, wherein, the material blending process adopts the steps that at least two of solid state liquor making concomitant flavoring liquid, grain stillage squeezed fluid, ending liquor, and ending water are blended, and the total acid content of acetometer in the mixed liquor is 0.48 to 6.5 g / 100 ml, and the alcohol content is 0 to 6.5 V / V percent; the acetic fermentation process adopts the steps that that the mixed liquor is accessed into acetic acid bacteria liquor, the weight of the mixed liquor is 10 percent of the weight of the acetic acid bacteria, and the mixed liquor is ventilated to be fermented at 32 to 36 DEG C, and the fermentation is finished when the total acid content of acetometer reaches 5.5 to 6.5 g / 100 ml; the post maturation flocculation process adopts the steps that that the fermentation liquor is accessed into aged bentonite abstracted filter liquor, and the weight of the fermentation liquor is 0.7 to 0.8 percent of the weight of the bentonite; then the vinegar is prepared according to the regular refining sterilization process and the mixing process. The invention has the advantages that the process period is short, the cost is low, the grain consumption is zero, the vinegar tastes good, the nutritive value is high, and the vinegar meets the the primary standard of the national value fermentation GB2719-2003. The effective constituents in the flavoring liquid, the grain stillage squeezed fluid, the ending liquor and the ending water can be fully used, the vinegar can effectively protect the environment from pollution, and the invention can be popularized in liquor manufacturing enterprises.

Owner:SICHUAN TUOPAI SHEDE WINE

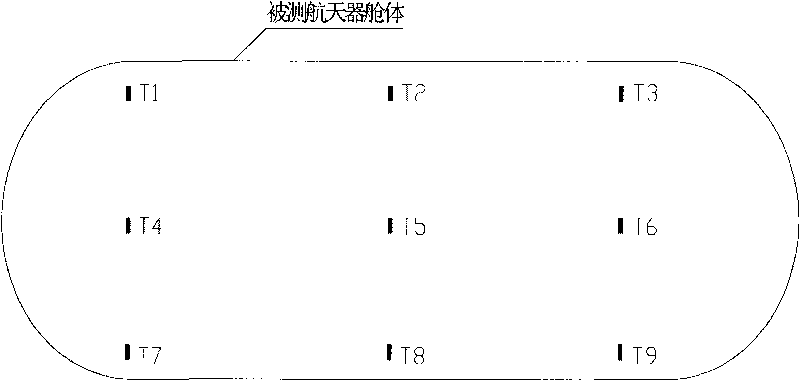

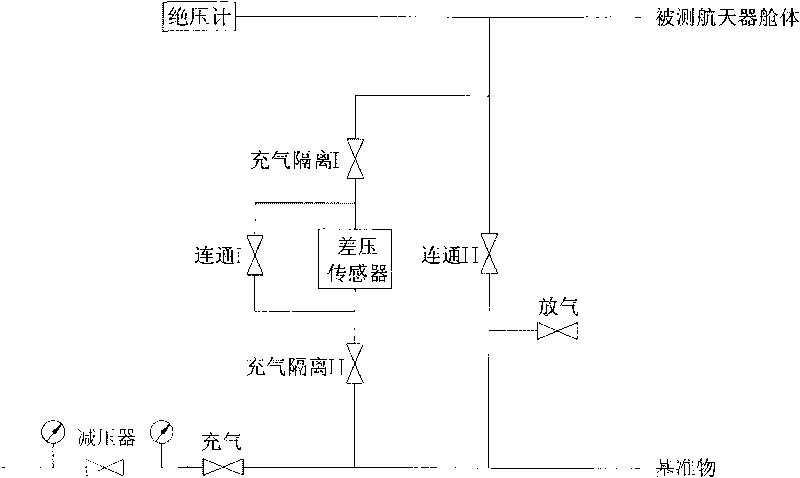

Method for detecting leakage of spacecraft cabin by differential pressure

InactiveCN101738296AReduce differential pressureAccurate leak rateMeasurement of fluid loss/gain ratePrimary standardDifferential pressure

The invention provides a method for detecting leakage of a spacecraft cabin by differential pressure. The method comprises the following processes: aerating, balancing, testing and gas deflating. In the method, a small-volume primary standard substance is put in a large-volume spacecraft cabin; standards and a temperature inside the measured cabin are measured when the differential pressure is measured; actually measured differential pressure is compensated by a temperature lagging for some time according to an ideal gas state equation; and finally integral leakage of the measured spacecraft cabin is acquired. In a gas path of the method, an aerating isolating valve is arranged on both sides of a differential pressure sensor respectively and used for avoiding an overrange phenomenon of the differential pressure sensor in the process of aerating or deflating.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

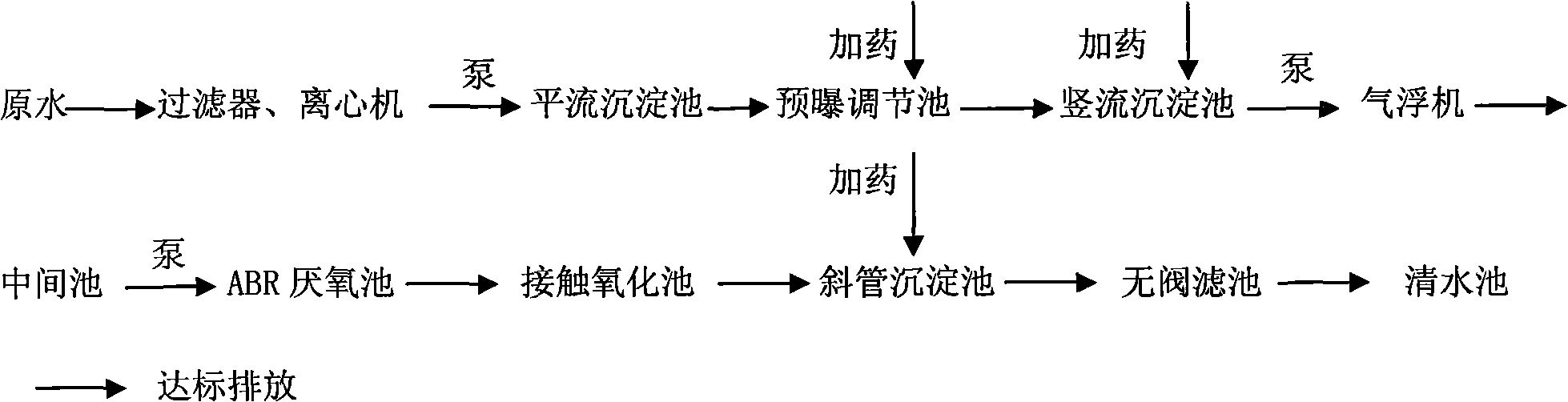

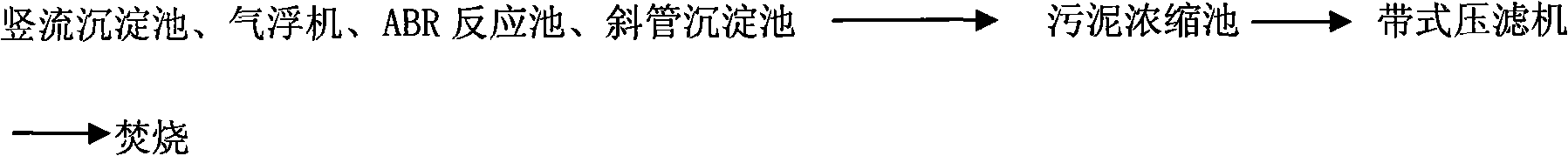

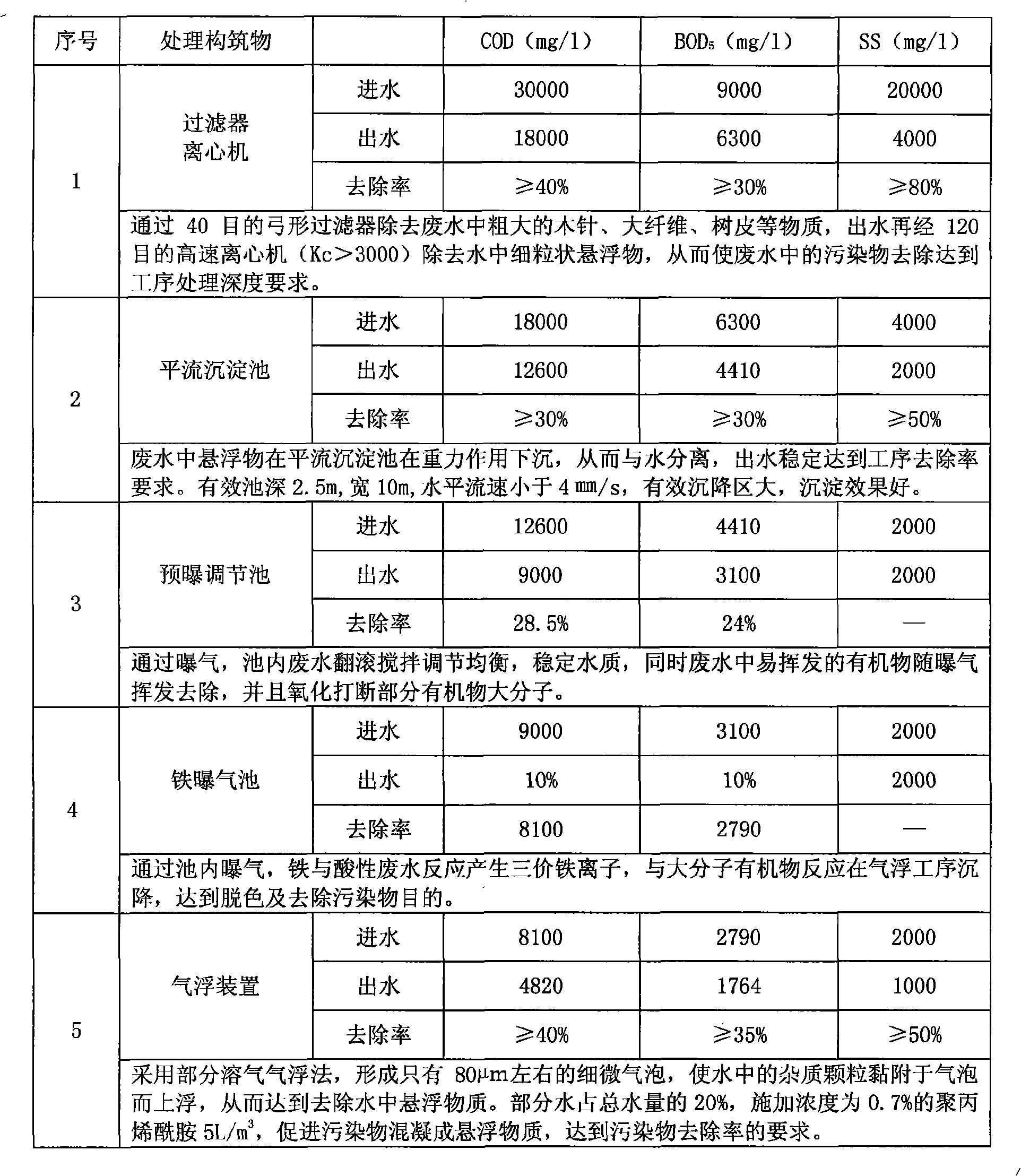

Method for treating wastewater of fibre-board plant

InactiveCN101575162AImprove removal efficiencyPromote recycling ratesTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentFiberSludge

The invention discloses a method for treating wastewater of a fibre-board plant. The method is characterized by including the combination of technical skills of the following three parts: a pretreatment system, a biochemical treatment system and an aftertreatment system; wastewater from production is respectively led into a filter and a centrifuger; after being processed by the step of slag removal, the wastewater flows into a horizontal sedimentation tank, a pre-aeration regulation tank and an iron aeration tank or a vertical sedimentation tank and then is processed by dissolved air flotation; the discharged water is respectively pumped into a turn-back flow anaerobic tank with filter materials and an oxidation tank and then flows into an inclined-tube sedimentation tank to settle; and after suspended substances in the wastewater are removed by a filtration tank, the wastewater is discharged while reaching standards. The method has the advantages that the efficiency of removing the suspended substances is high, water is circularly and repeatedly used, water consumption is reduced, the discharge amount of the wastewater can be reduced by more than 300 tons each day, the occupation of land of equipment is low, the operation is simple, and the running cost is low. Extruded wood slag and sludge can be used as energy to be led into an energy centre to combust, secondary pollution is not caused, and the treated wastewater can meet the requirement of primary standard in the Integrated Wastewater Discharge Standard GB8978-1996.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

Method for enhancing petroleum pollution removing effect of seawater

InactiveCN102432111AReduce concentrationReduce processing costsSeawater treatmentMicroorganism based processesMicrobial agentFreeze-drying

The invention belongs to the technical field of environmental pollution, in particular to a method for enhancing the petroleum pollution removing effect of seawater. The method comprises the following steps of: culturing high-yield biological surfactant bacteria and efficient petroleum degrading bacteria cultured and screened in a biological trickling filter in a mixed way by taking chitosan as a carrier, and performing freeze drying to obtain a microbial agent (bacterial powder); and treating petroleum pollution simulation seawater with the bacterial powder, wherein three days later, the initial concentration is 1,700 mg / L, the salinity is 3 percent, the removing rate of total petroleum hydrocarbon in the simulation seawater is over 95 percent, and the total petroleum hydrocarbon concentration in the seawater is lower than the primary standard in the Effluent Standards for Oil-Bearing Waste Water from Offshore Petroleum Development Industry. In the method, chitosan is taken as a carrier, so that microorganisms better float on the sea level and are tightly contacted with pollutants on the surface of seawater, and the petroleum removing rate is increased; moreover, the treatment cost of oil stains is reduced greatly; and the production process of the bacterial powder is safe, the application method is simple, and secondary environmental pollution is prevented.

Owner:FUDAN UNIV

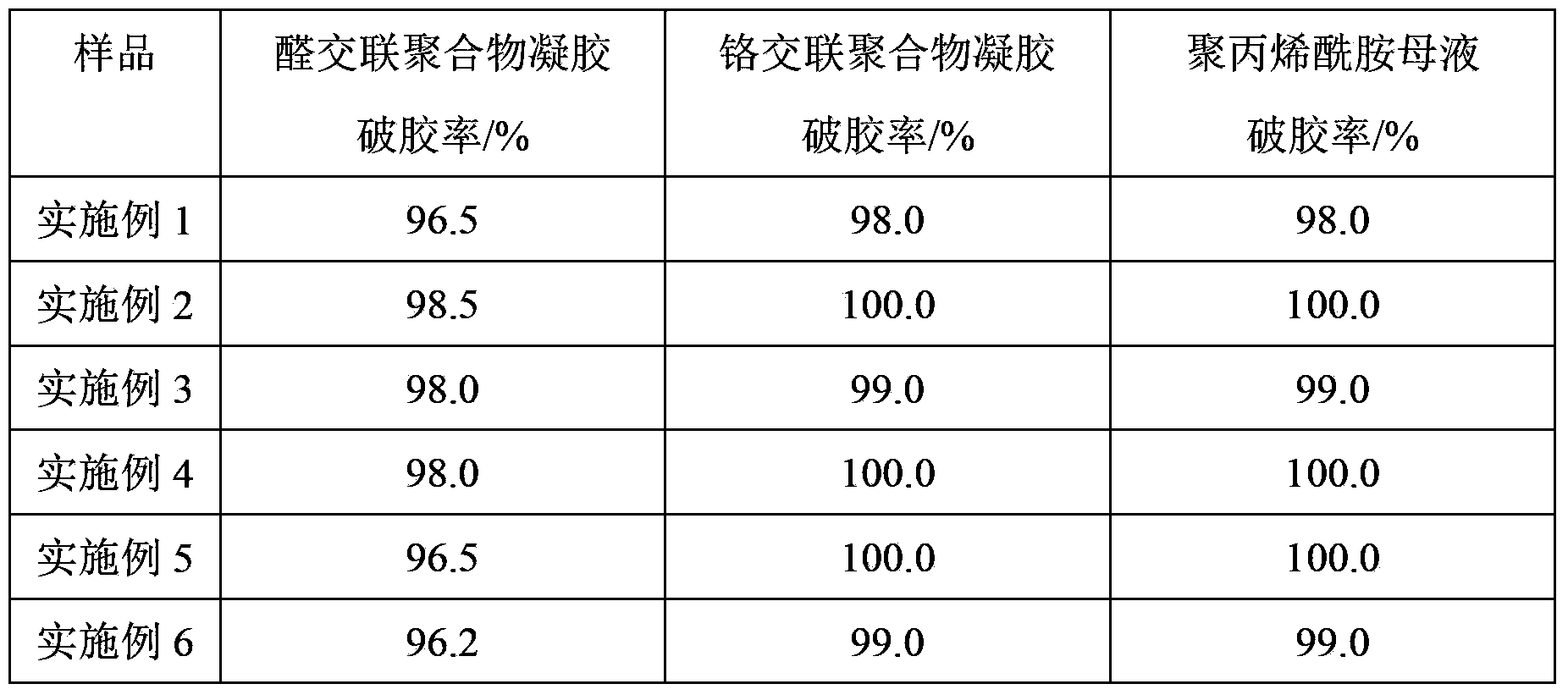

Oxidized gel breaker for polymer injection well and preparation method of oxidized gen breaker

ActiveCN103881673AOvercome the clogging defectEfficient release of blockageDrilling compositionCross-linkPolymer science

The invention discloses an oxidized gel breaker for a polymer injection well and a preparation method of the oxidized gel breaker, and belongs to the field of tertiary oil recovery. The oxidized gel breaker comprises the following components in percentage by weight: 12%-25% of persulfate oxidizing agents, 3.1%-8.5% of alkaline pH regulating agents, 0.5%-2% of corrosion inhibitors, 2%-5% of mutual solvents and the balance of water. The oxidized gel breaker for the polymer injection well has the characteristics of high oxidized gel breaking rate and low corrosivity, can efficiently remove the oxidized gel breaker formation plugging caused by aldehyde cross-linked polymer gelation, chromium cross-linked polymer gelation, a polyacrylamide high-molecular solution and the like, has the advantages of high technical adaptability, wide application range, high oxidative decomposition and gel breaking rate, good plugging-removing and injection-increasing effect, low corrosivity on steel equipment and high safety, meets the requirement for primary standard and can meet the requirement for large-dose extrusion injection plugging-removing construction of the polymer injection well and solve the technical problem of high corrosivity of an original oxidized gel breaker on the steel equipment and a down-hole pipe column.

Owner:CHINA PETROLEUM & CHEM CORP +1

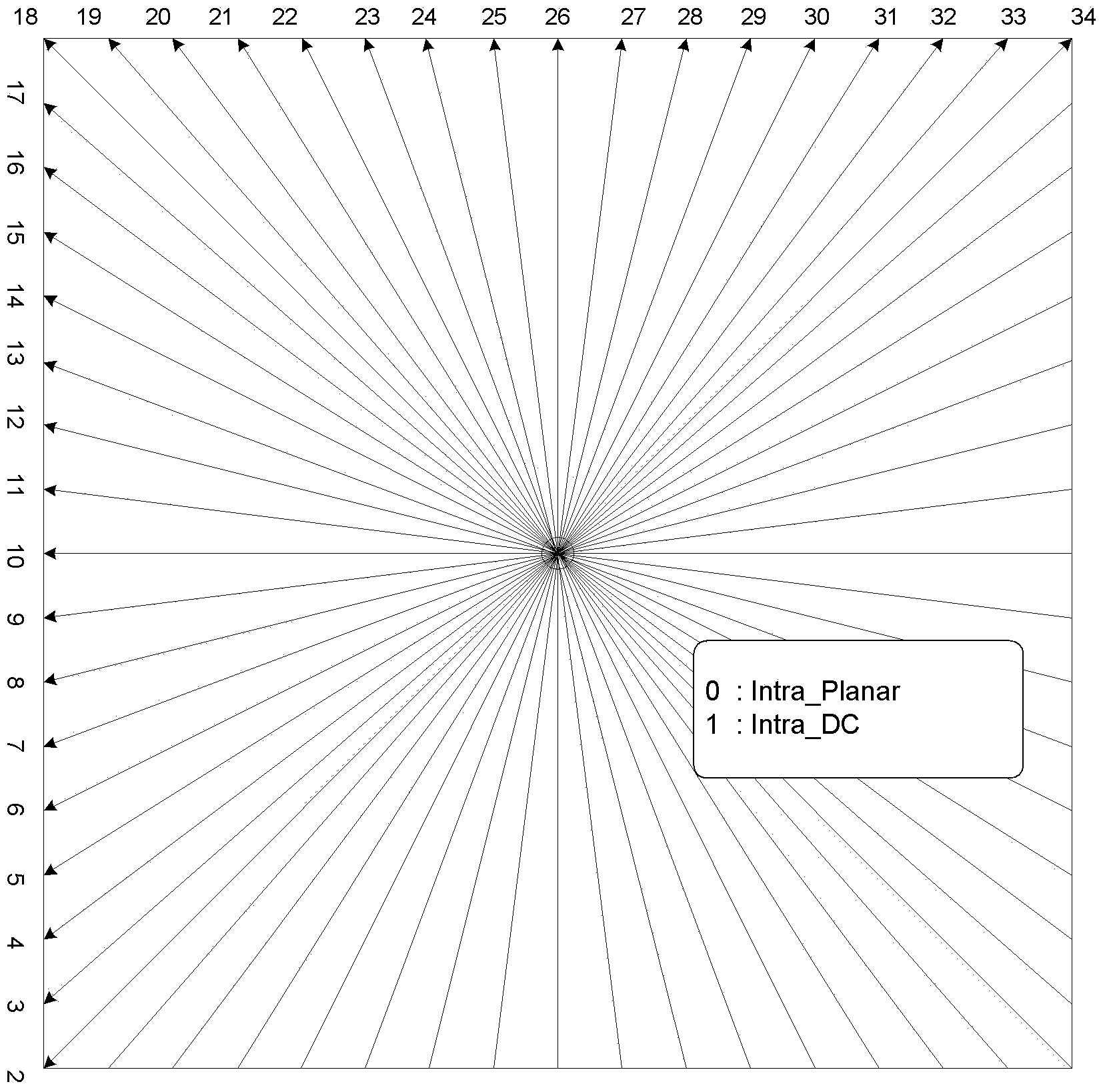

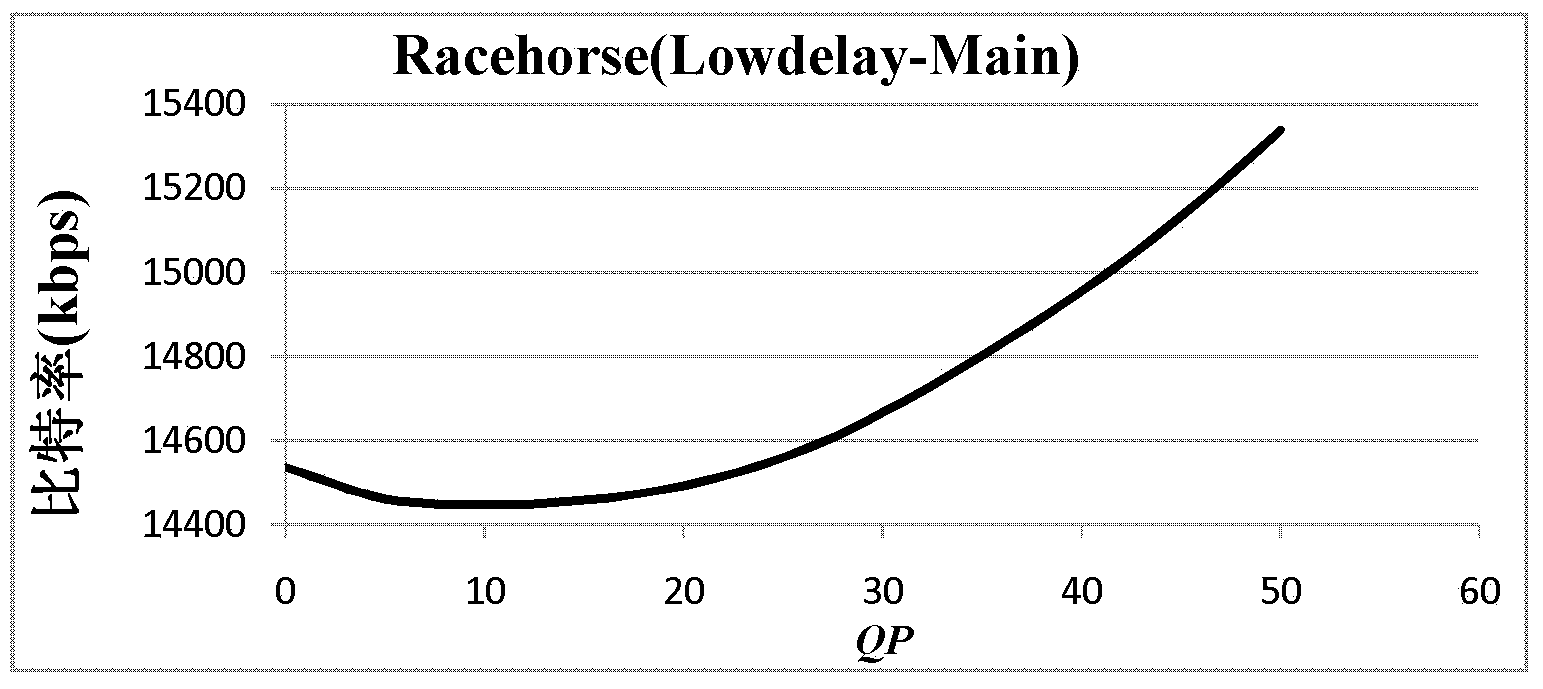

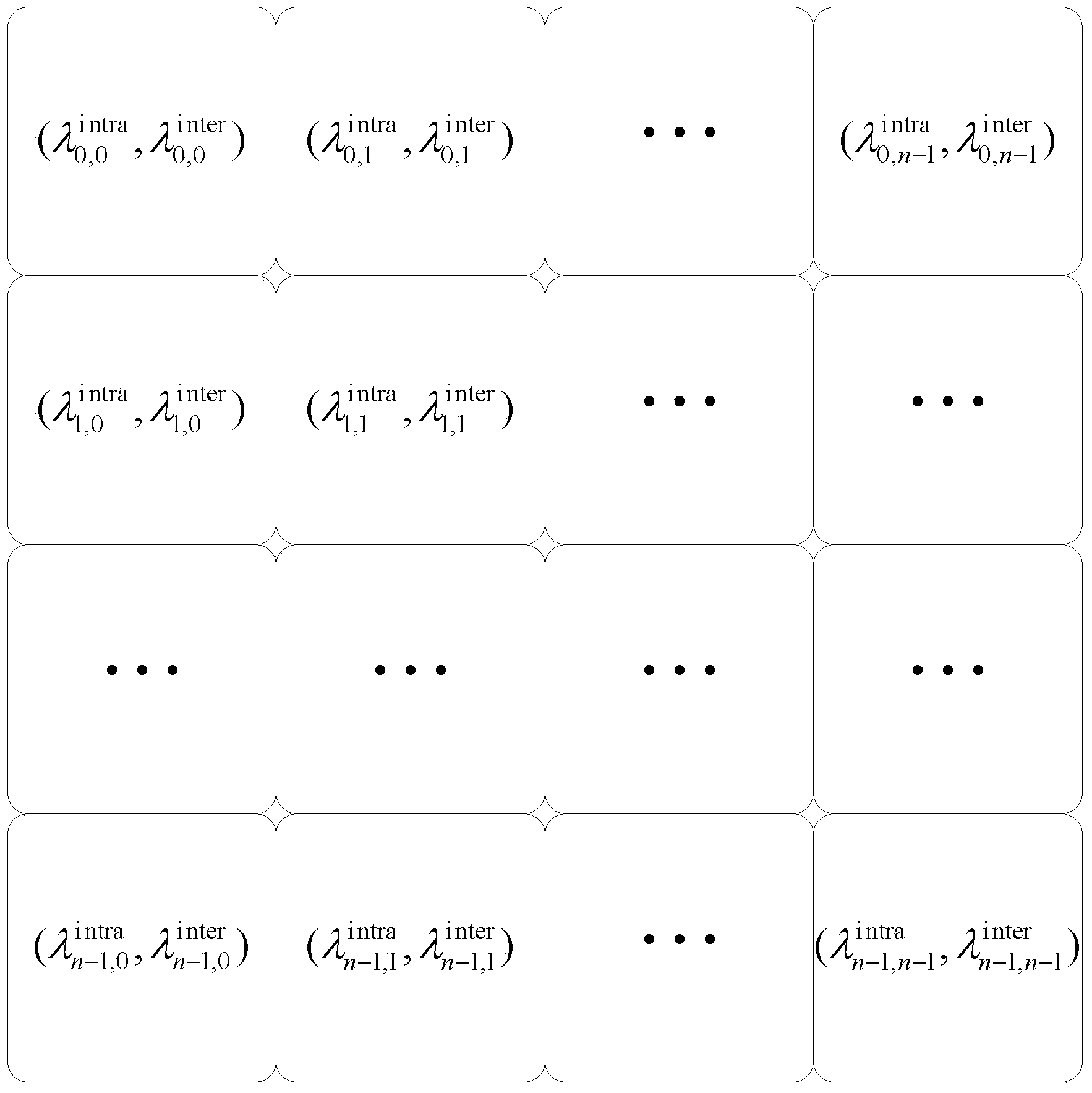

Method for selecting prediction mode of HEVC lossless video coding and corresponding coding method

ActiveCN104320657AMinor changesReduce encoding bitrateDigital video signal modificationPrimary standardVideo encoding

The invention provides a method for selecting a prediction mode of HEVC lossless video coding and a corresponding coding method. The method for selecting the prediction mode of the HEVC lossless video coding comprises the steps that firstly, the Lagrange multiplier, for RDO, of intra-frame prediction and the Lagrange multiplier, for RDO, of inter-frame prediction of each LCU of a video frame are initialized, intra-frame prediction and inter-frame prediction are conducted, an optimal mode is selected and used for coding, and the bit rate needed by coding of the frame is calculated and is used as a reference bit rate of initialization; secondly, the multipliers of the K LCUs of the frame are changed, the optimal mode is then selected and used for coding, the current bit rate is calculated, the difference value between the current bit rate and the reference bit rate is calculated, according to a preset rule, the changed multipliers are accepted or rejected, the current bit rate is used as the reference bit rate when the changed multipliers are accepted, whether the multipliers need to be changed again or not is judged, if not, the steps are ended, and if yes, the second step is executed again and iteration is conducted. According to the method for selecting the prediction mode of the HEVC lossless video coding, the original coding structure of the HEVC is changed slightly, the adverse influence of the QP in a primary standard on the lossless-mode coding efficiency is eliminated, and the coding bit rate is greatly reduced.

Owner:UNIV OF SCI & TECH OF CHINA

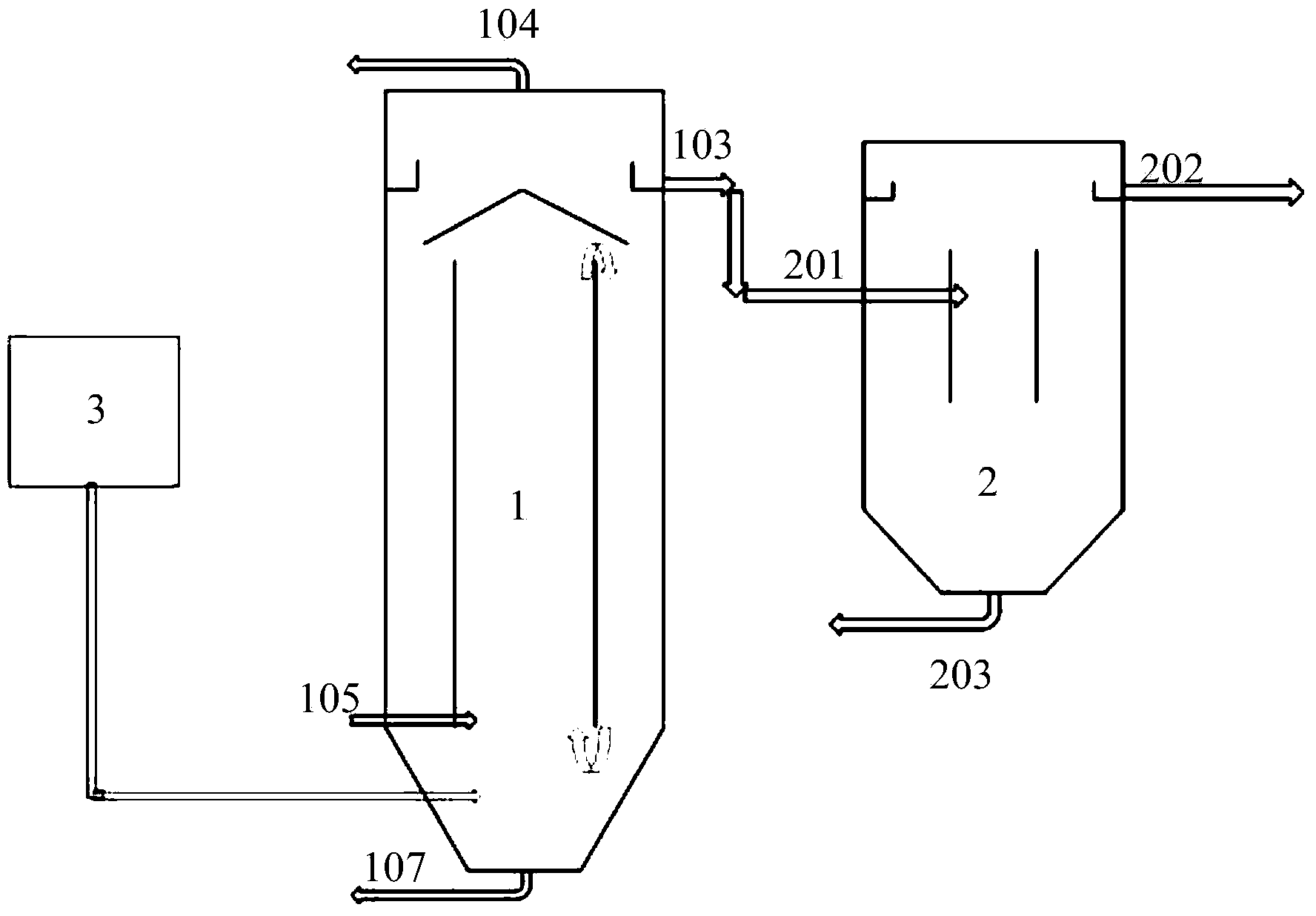

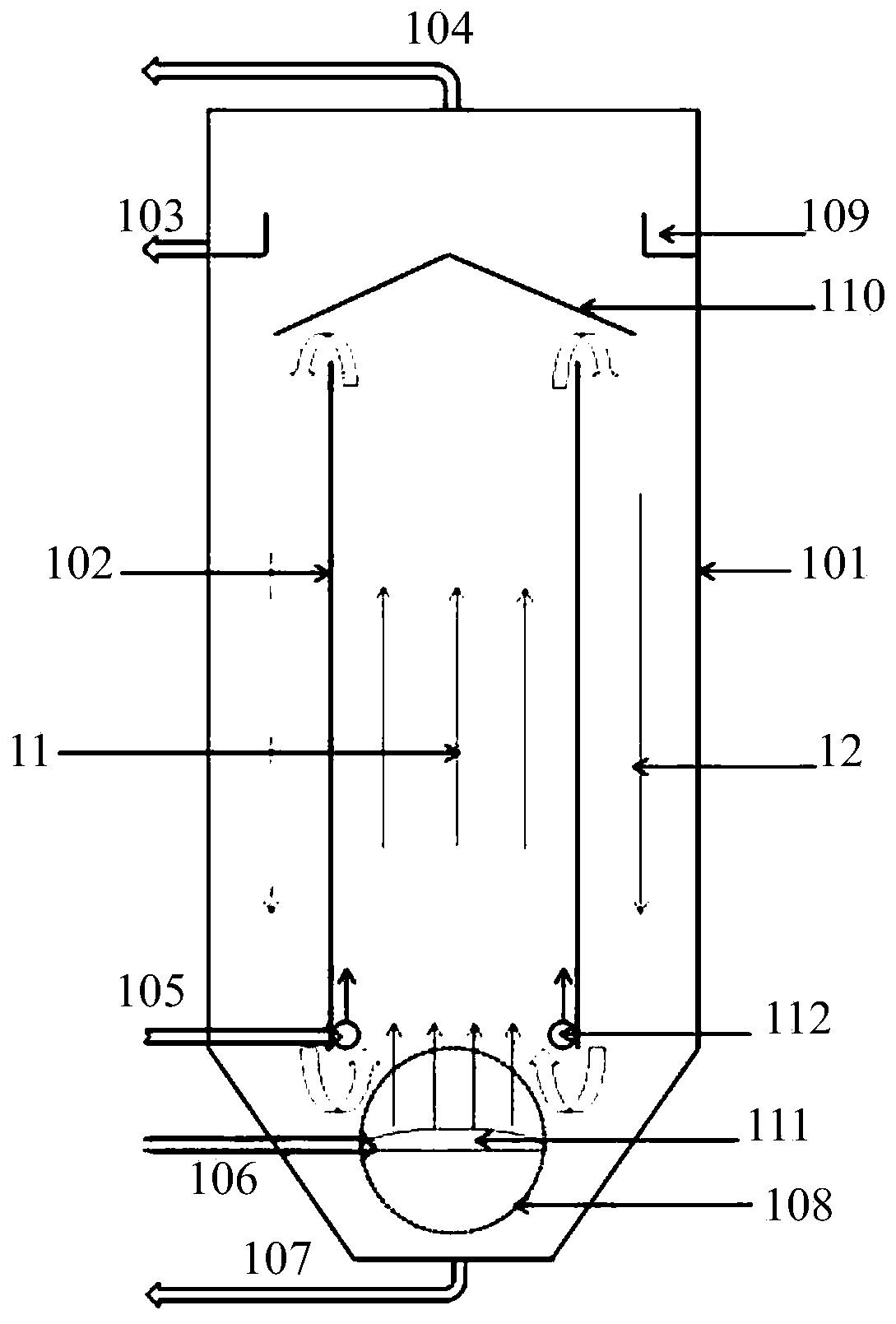

Method and device for treating oil refining salt-containing sewage by using oil refining waste catalyst and ozone

ActiveCN104370358AHigh value-added utilizationIncrease production capacityWater treatment compoundsWater/sewage treatment apparatusChemical oxygen demandPrimary standard

The invention provides a method and device for treating oil refining salt-containing sewage by using an oil refining waste catalyst and ozone. According to the method, the oil refining salt-containing sewage is subjected to catalytic oxidation treatment of internal circulation in a fluidized bed reactor by using ozone-containing gas and an activated oil refining waste catalyst, and the treated sewage flows through a vertical sedimentation basin and then is discharged outwards, wherein the CODcr (chemical oxygen demand) value of the effluent satisfies the primary standard A of Chinese Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB 18918-2002). The device is used for implementing the method, and at least comprises a fluidized bed reactor and a vertical sedimentation basin. According to the method and the device disclosed by the invention, the oil refining waste catalyst is used as a sewage ozone treatment cooperating catalyst, so that a utilization direction of 'waste control by waste' is provided for solid wastes of oil refining plants, and the problem of relatively high cost of a catalyst is solved; and the mass transfer effect among ozone, a catalyst and organic pollutants is strengthened by using a fluidization technology, and the problems that the utilization rate of ozone is relatively low and the catalyst is easy to scale are solved.

Owner:北京中实奥杰石油科技有限公司

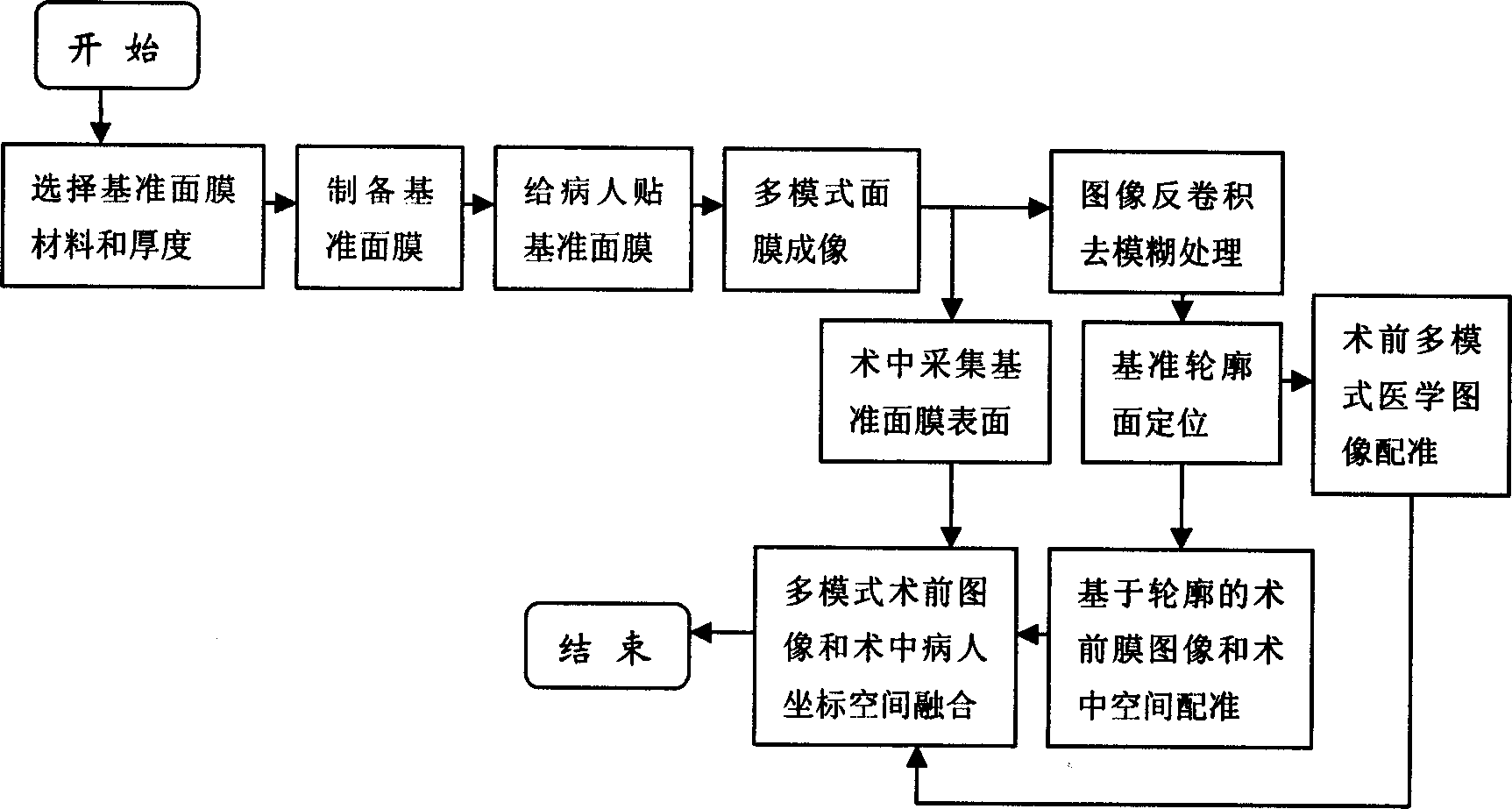

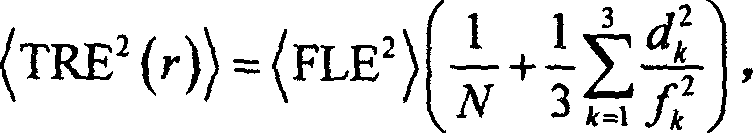

Multimodel type medical image registration method based on standard mask in operation guiding

InactiveCN1794301ALarge area attachment contact will not be stablePrecise registrationImage analysisSurgical navigation systemsPrimary standardSurface point

This invention relates to a configuring method for a multi-mode medical image based on a primary standard facial mask in surgery navigation including the following steps: 1, first of all preparing a multi-mode primary standard facial mask, 2, carrying out multi-mode image configuration before the surgery by the image recover method of the primary standard mask , 3, utilizing the collection method for the outer surface in the operation to collect the position information in the space of the outer surface points, 4, finally applying the real time configuration merge method before and in the surgery to get the configuration relation of the multimode image space before the operation and a coordinate space of the patient in the operation.

Owner:SHANGHAI JIAO TONG UNIV

Novel environmental protection and energy saving biological alcohol oil

InactiveCN102358853AHigh combustion valueAvoid situations where you mistakenly drink it for waterLiquid carbonaceous fuelsCombustionAlcohol

Relating to a biofuel, the invention provides novel environmental protection and energy saving biological alcohol oil, which is a biofuel with methanol as the main component. The novel environmental protection and energy saving biological alcohol oil of the invention is characterized by comprising, by weight percent: 75-95 parts of methanol, 0.2-1.0 part of an emulsifier, 0.01-0.5 part of ferrocene, and 5-25 parts of water. Characterized by complete combustion, high calorific value, stable performance, nonvolatility, low condensation point, difficult ignition, an ignition temperature higher than 200DEG C, no pressure, no explosion, and extinguishability by water in an accidental fire, the novel environmental protection and energy saving biological alcohol oil provided in the invention is nontoxic, odorless, smokeless and dust-free renewable green new energy, and has quality reaching the national primary standards of alcohol-based fuels.

Owner:刘一江

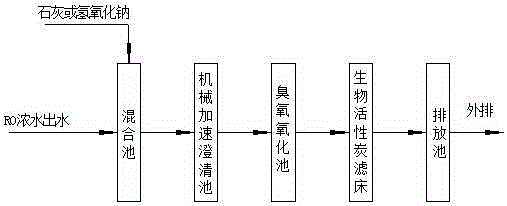

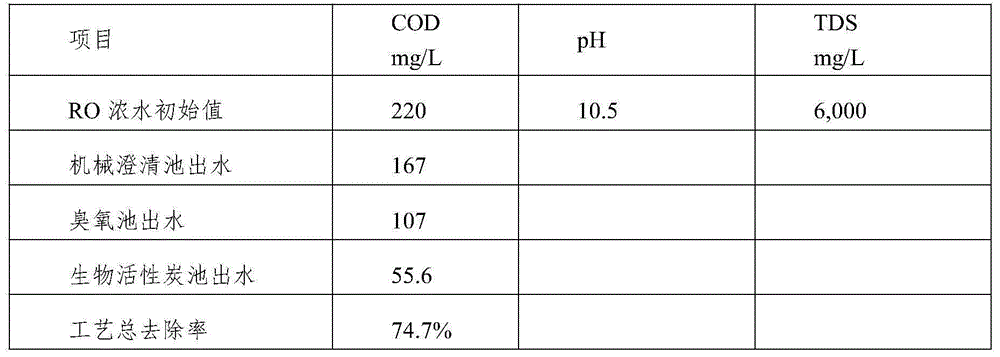

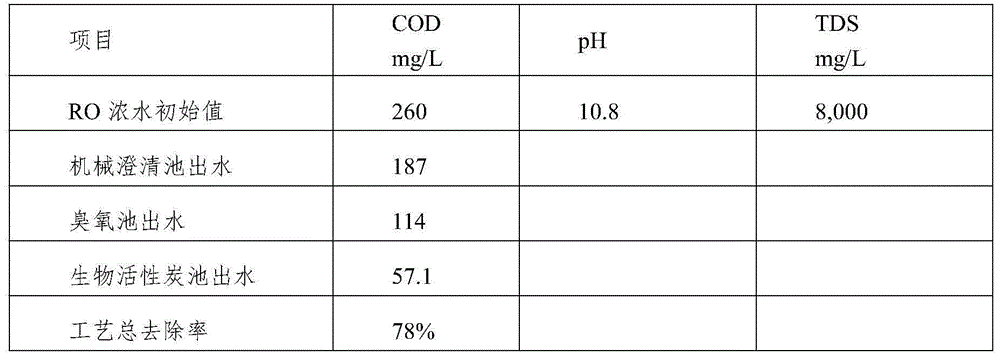

Treating technology for chemical RO concentrated water

InactiveCN105174641AGood processing effectIncrease dissolved oxygen contentMultistage water/sewage treatmentNature of treatment waterChemical industryUltrafiltration

The invention relates to a treating technology for reverse osmosis (RO) concentrated water after water reuse in a chemical membrane method. The technology comprises the steps that firstly, matter such as lime or sodium hydroxide which is alkaline in an aqueous solution is put in RO concentrated water effluent to enable the pH of the concentrated water to be about 10-11.5; secondly, flocculent precipitation is performed in a mechanical accelerating clarification tank to reduce the hardness of the wastewater and remove heavy metal and reducing metal ions; thirdly, the effluent directly enters an ozone reaction tank after the RO concentrated water passes through the mechanical accelerating clarification tank, and then ozone tank effluent enters a biological activated carbon filter bed device to further remove pollutants and turbidity in the RO concentrated water, so that the wastewater effluent can meet the national primary standard (the CODcr is smaller than or equal to 60 mg / L). According to the treating technology, further treatment is performed on the concentrated water generated after the water is reused through the front stage of biochemistry, ultrafiltration and reverse osmosis for the production wastewater in chemical industry to achieve the purpose of direct discharge, therefore, the pollution treatment ability of enterprises can be improved, the total pollutant discharge amount is reduced, and the effects of energy conservation and emission reduction, clean production and sustainable development are achieved.

Owner:博瑞德环境集团股份有限公司

Device and method for magnetic separation of underwater sludge

InactiveCN101798166AHigh outputImprove processing efficiencySludge treatment by de-watering/drying/thickeningSludge cakePrimary standard

The invention relates to a device and a method for magnetic separation of underwater sludge. The device comprises a roller screen, a magnetic separator, a reaction tank and a sludge separation tower which are connected in series by pipelines, wherein a water outlet of the previous stage treatment device is connected with an inlet of the next stage treatment device, and a sludge outlet of the sludge separation tower is connected to an inlet of the magnetic separator. The device has the characteristics of small floor area, low energy consumption, non-clogging continuous operation, large sludge yielding quantity and the like, has good removability and can be conveniently arranged at a sludge treatment site; the device not only reduces the natural drying time of a sludge stock dump and improves the sludge treatment efficiency, but also greatly reduces the desilting cost; and during an actual operation, the output quantity of sludge cakes is large, the yielding water of the separation tower completely reaches a primary standard in discharge indexes (GB18918-2002).

Owner:中国船舶重工集团公司第七〇二研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com