Tower type earthworm and ecological filter for treating sewage

An ecological filter and domestic sewage technology, applied in the field of runoff pollution and domestic sewage, can solve the problems affecting the process of eutrophication treatment in key river basins and the process of sewage treatment in villages and towns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: A demonstration project of a tower-type earthworm ecological filter-constructed wetland combination system with a daily processing capacity of 12t.

[0032] Design treatment water volume: Q=12t / d.

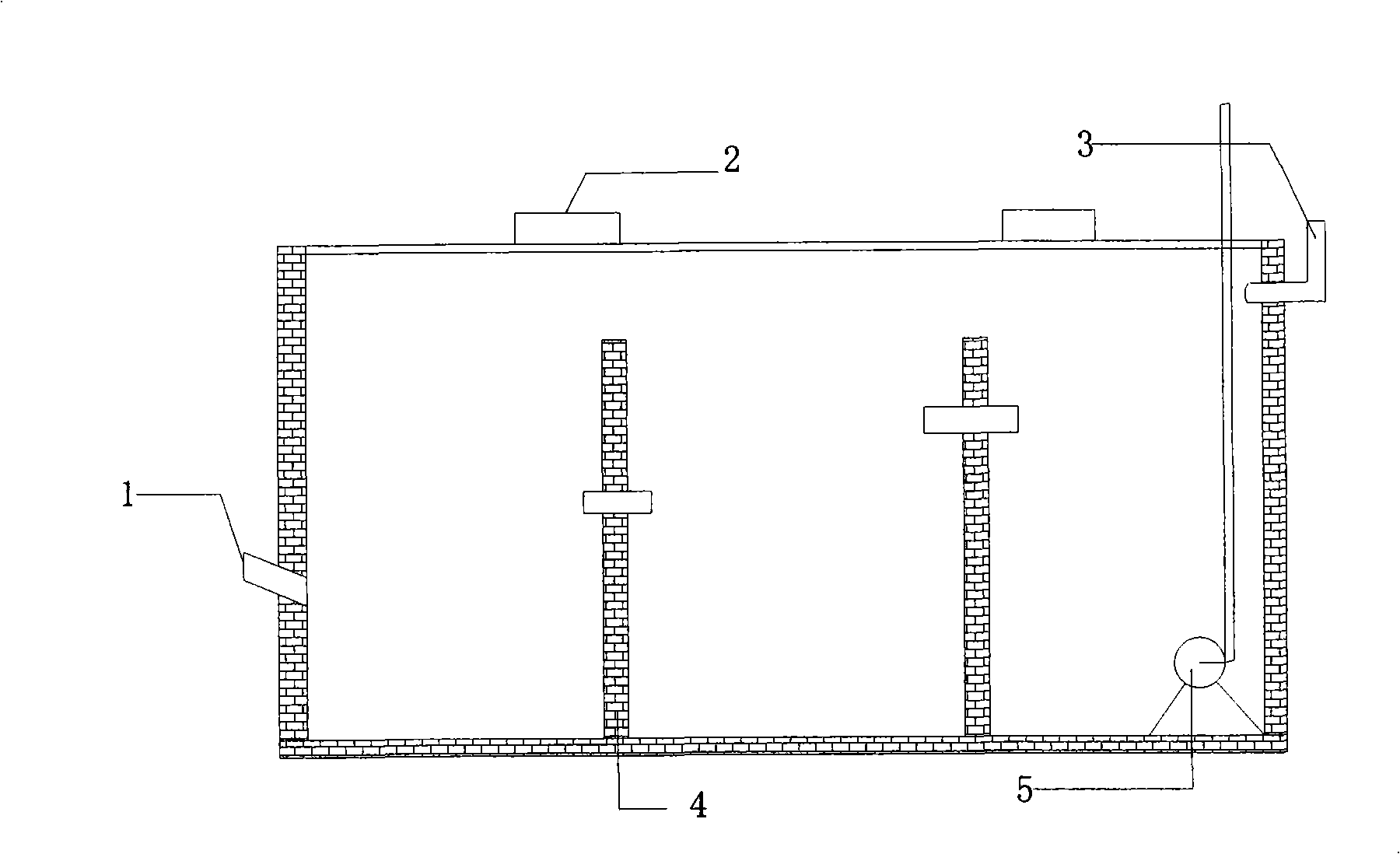

[0033] The hydrolytic acidification pool is buried underground, and the overall structure is brick-smeared.

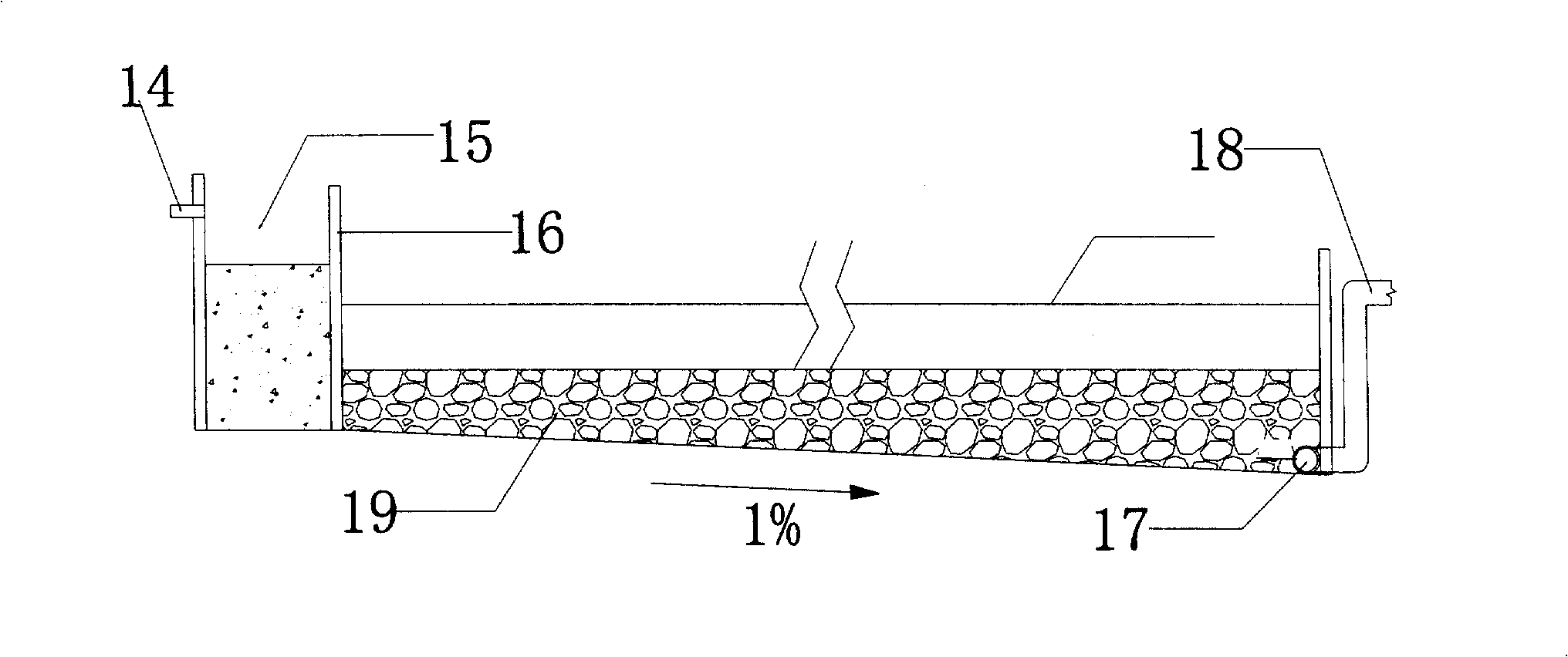

[0034] The acidification pool is 5 meters long, 3 meters wide, with an effective depth of 1.2m, a super height of 0.3m, and a total depth of 1.5m. The water inlet pipe is embedded at a height of 25cm from the base of the pool wall, and is downward at an angle of 40° with the pool wall. The effluent is fed into the high-level water distribution tank above the tower earthworm ecological filter through the submersible electric pump. The lower edge of the nozzle is flush with the inner wall of the pool wall. The embedding port is filled with fine stone concrete.

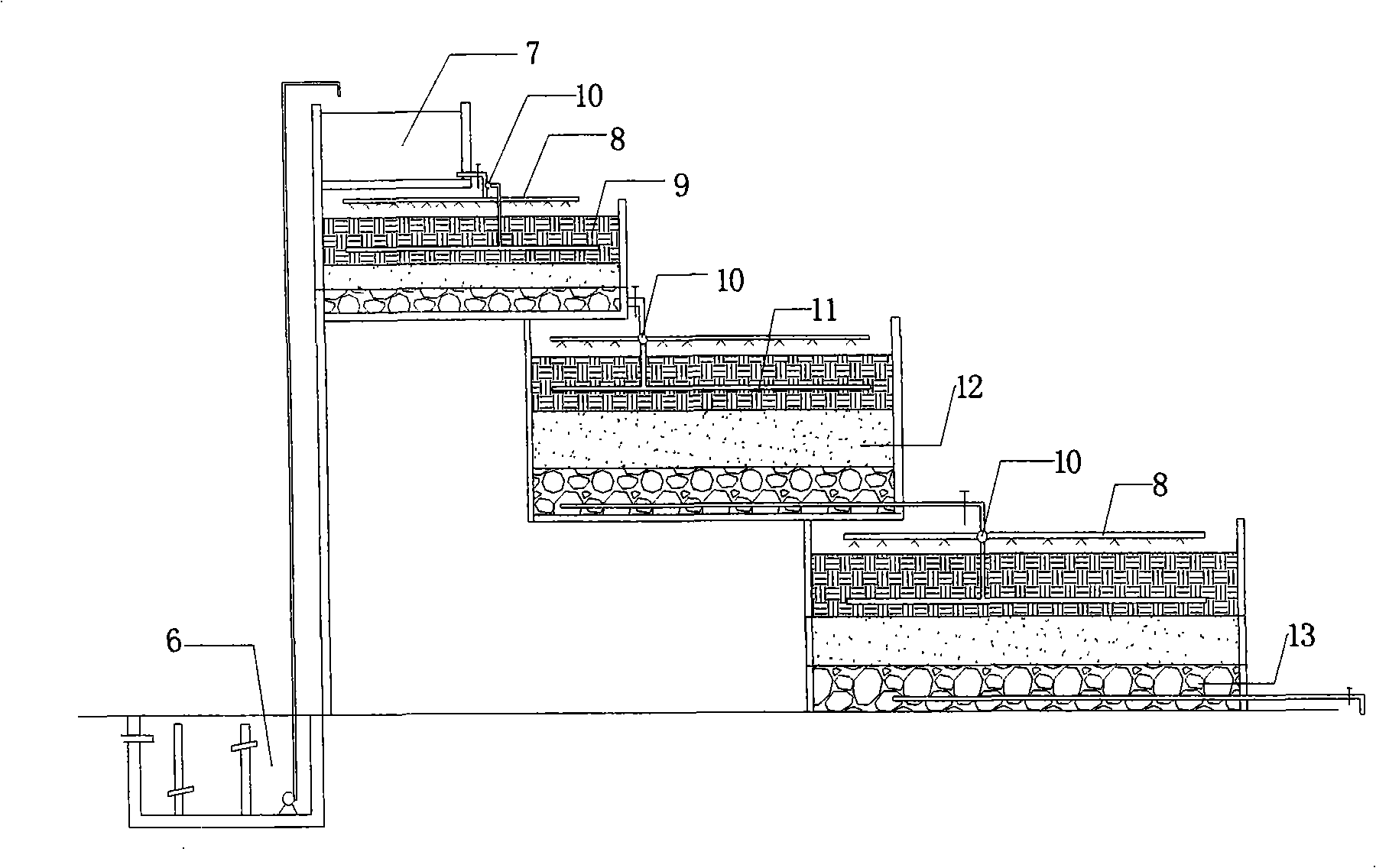

[0035] The total area of the tower earthworm ecological filter part is 45m 2 , the overall...

Embodiment 2

[0046] Example 2: A demonstration project of a tower-type earthworm ecological filter-constructed wetland combination system with a daily processing capacity of 9t.

[0047] Design treatment water volume: Q=9t / d.

[0048] The installation of the hydrolytic acidification tank adopts the buried type, and the tank body adopts a brick and plaster structure.

[0049] The effective depth of the hydrolytic acidification pool is 1.2m, the super height is 0.3m, and the total depth is 1.5m; the length H=4m, the width L=2m; The water inlet pipe is embedded at a height of 30cm from the base of the pool wall, and is downward at an angle of 30° with the pool wall. The effluent is fed into the high-level water distribution tank above the tower earthworm ecological filter through the submersible electric pump. The embedding port is filled with fine stone concrete. The pool is installed in the ground, and the pool body adopts a brick and plaster structure.

[0050] The total area of the ...

Embodiment 3

[0059] Example 3: The pollutant removal effect test of the tower-type earthworm ecological filter-constructed wetland combination system with a daily processing capacity of 12t.

[0060] When the ambient temperature was 25°C, the overall decontamination ability test of the combined process system was carried out. The test conditions were: the surface hydraulic load of the tower-type earthworm ecological filter was 0.8m / d, the dry-wet ratio was 4:1; the surface flow The hydraulic load of the constructed wetland is 0.5m / d, and the results are as follows:

[0061]

[0062] The natural hydraulic retention time of the tower-type earthworm ecological filter is about 175 minutes during operation; the total nitrogen removal capacity of the system has been greatly improved, reaching 87%, indicating that the denitrification capacity of the system has been well strengthened; The material removal rate is above 90%, showing a good removal effect.

[0063] The effluent has reached the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com