Patents

Literature

23789results about "Sustainable biological treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing lignocellulosic material

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

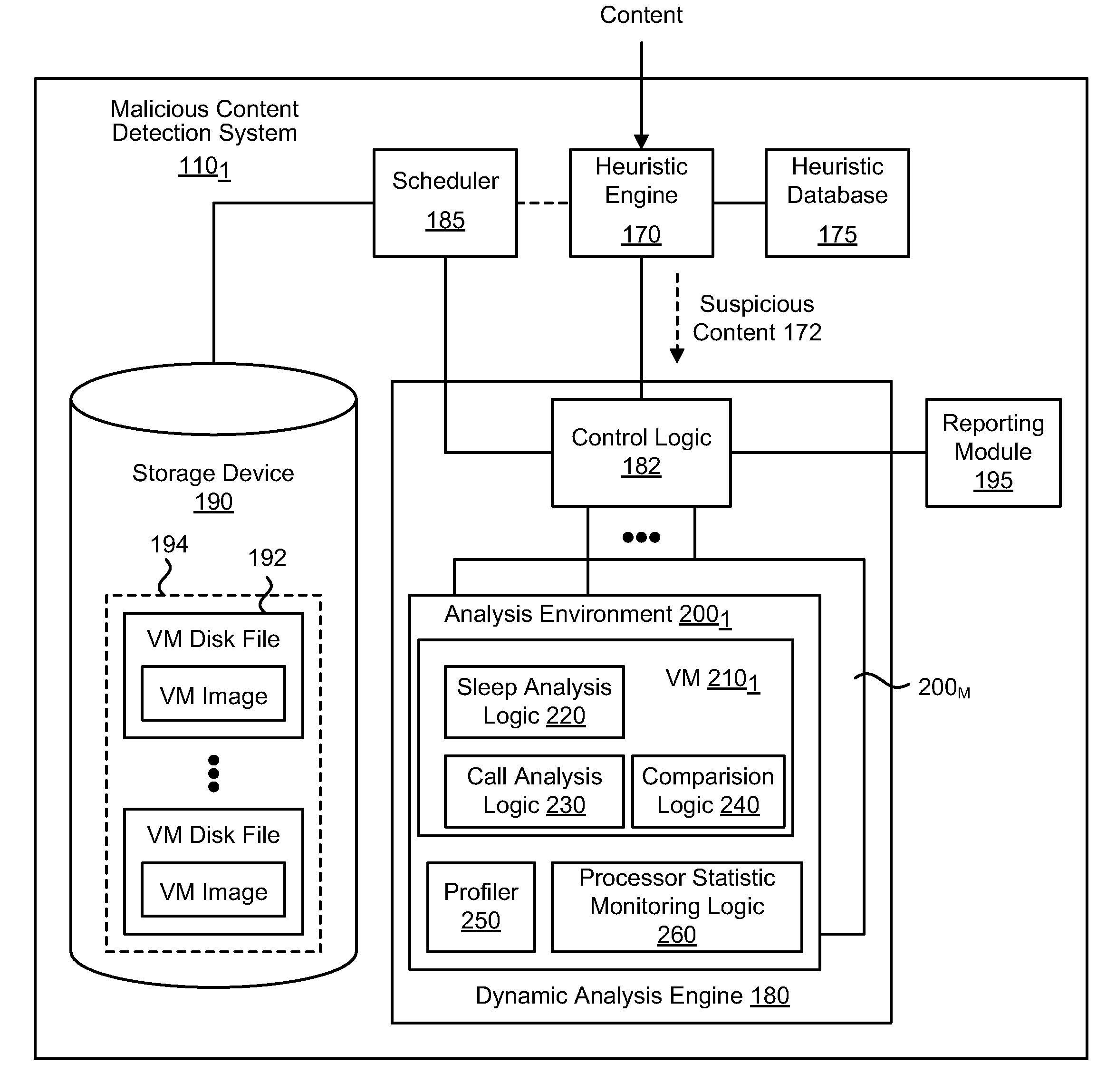

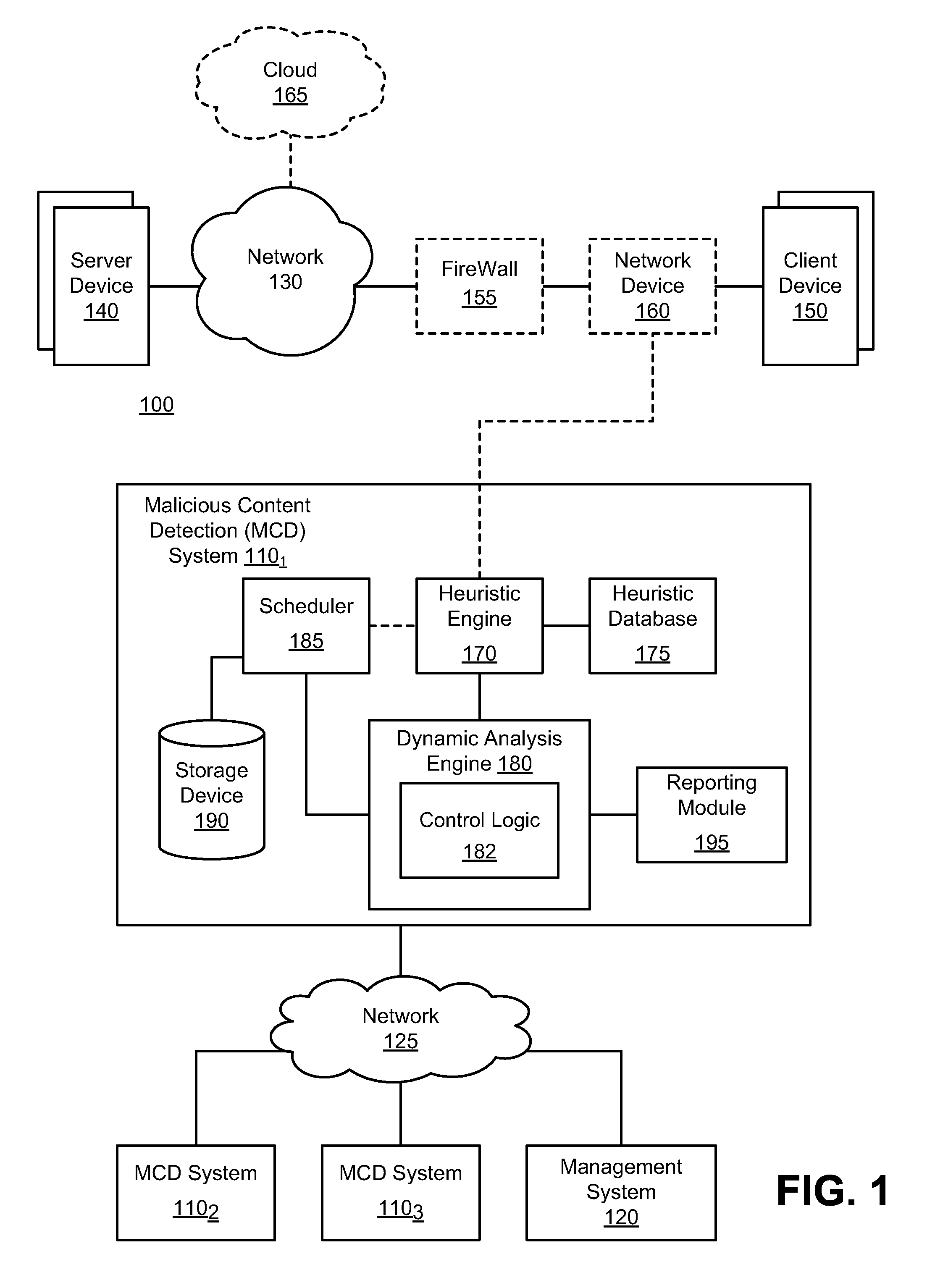

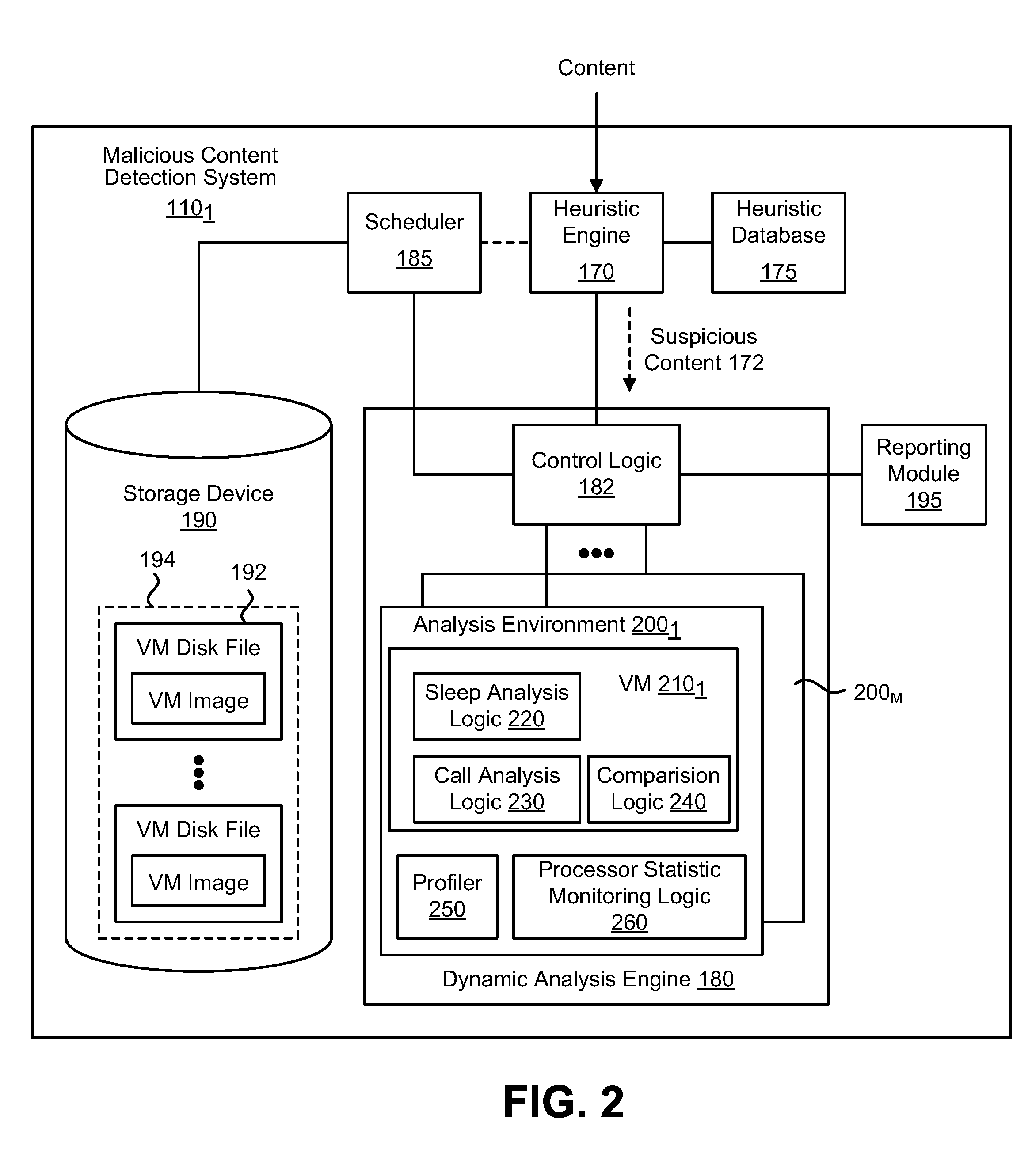

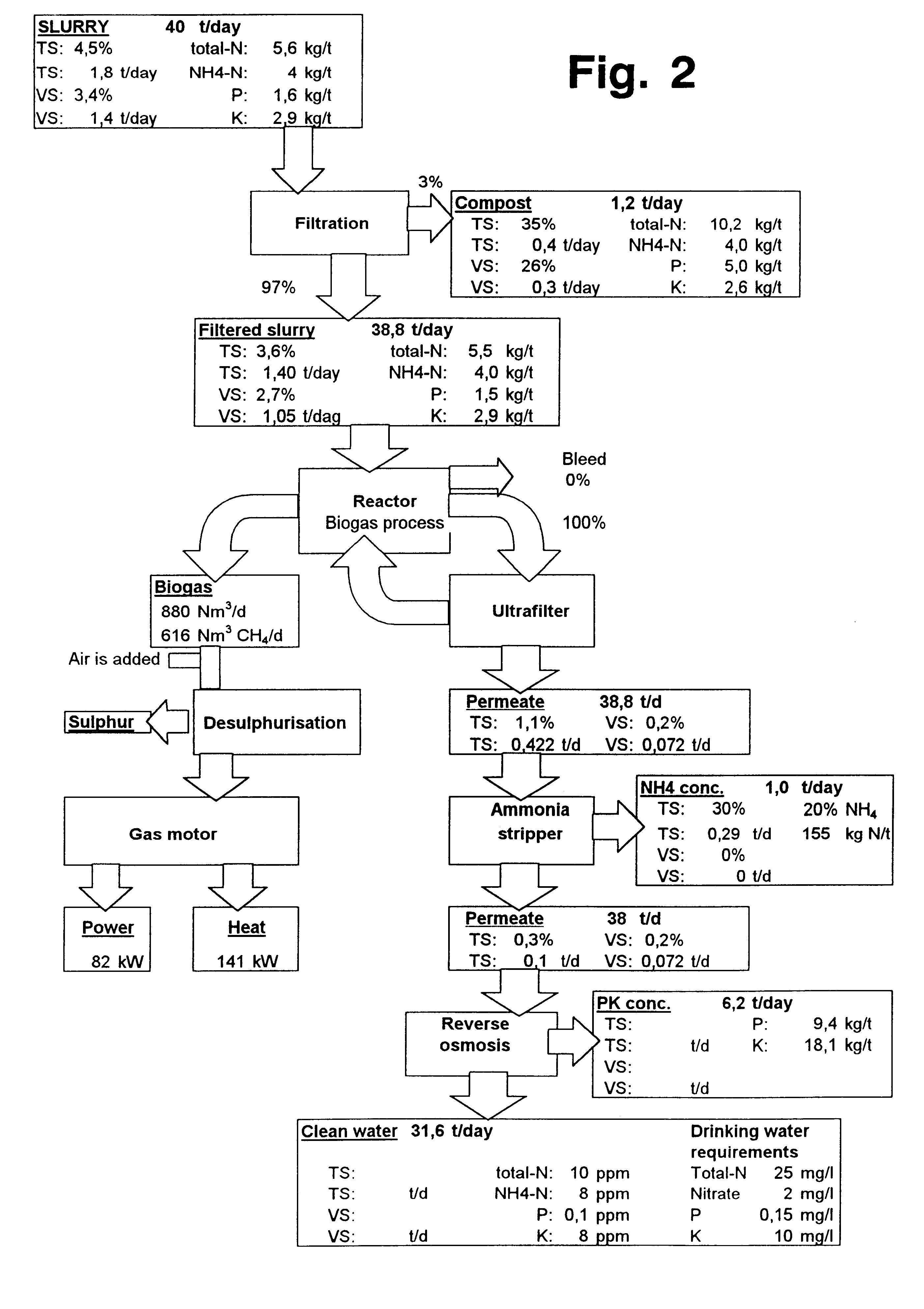

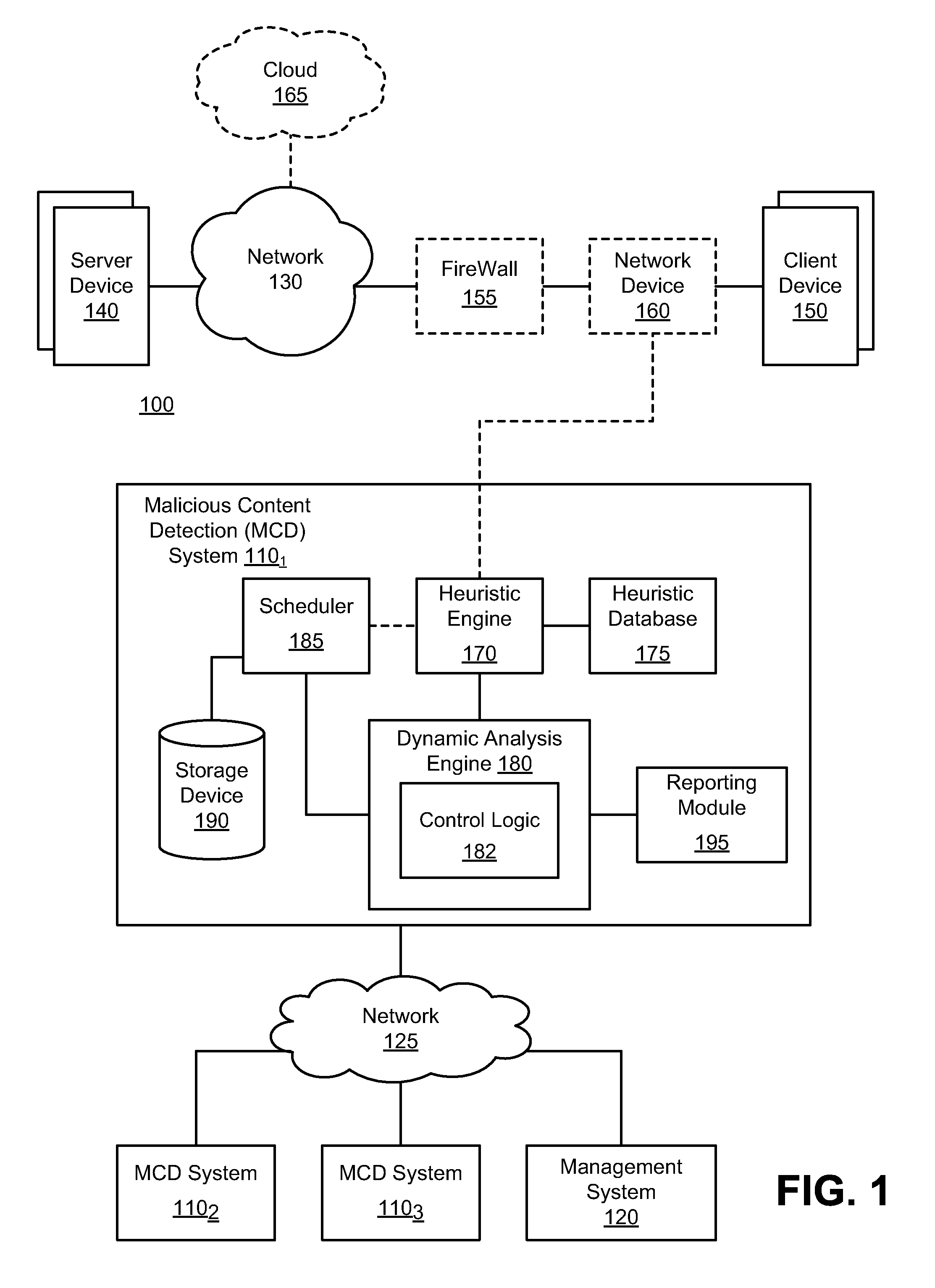

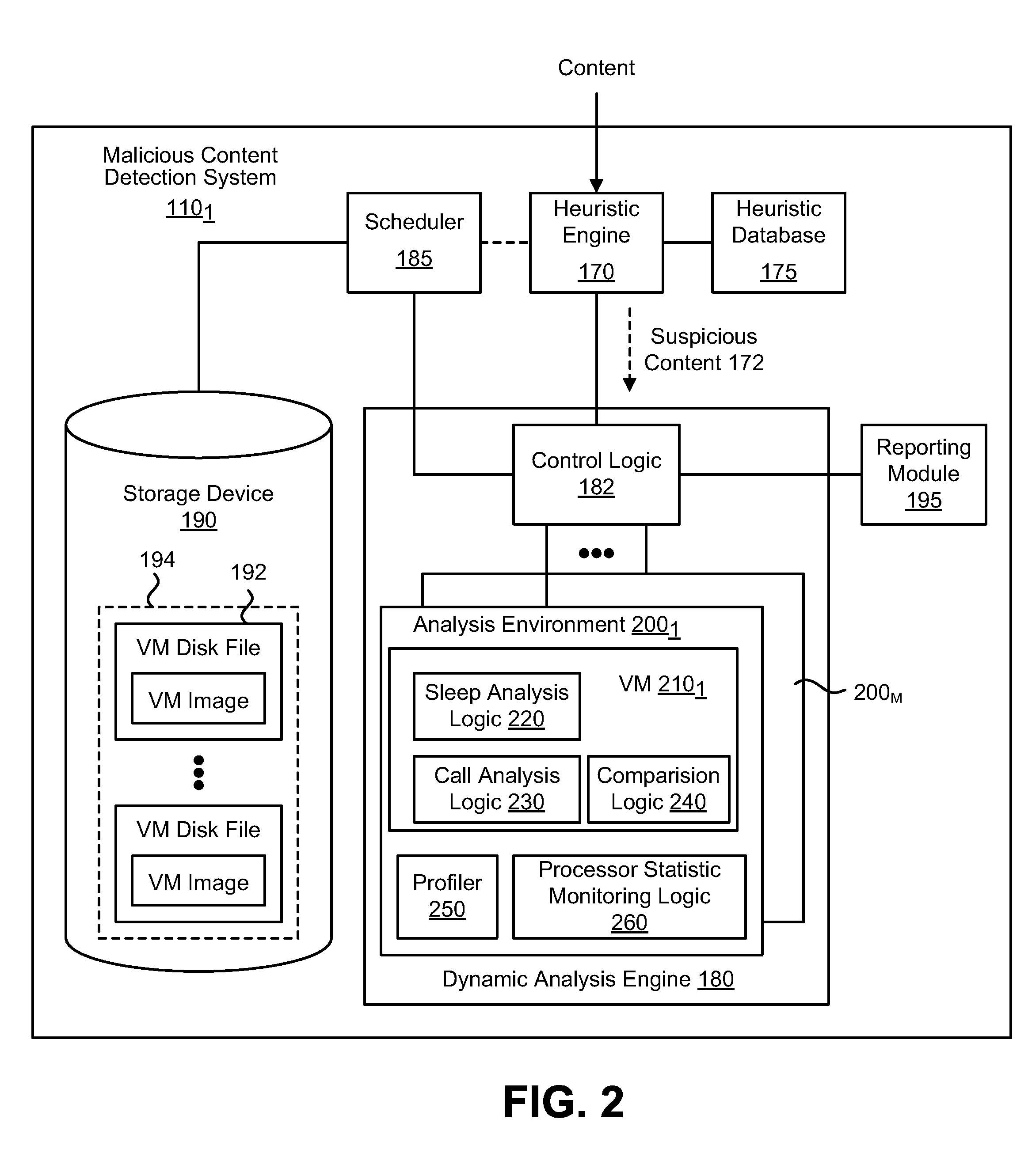

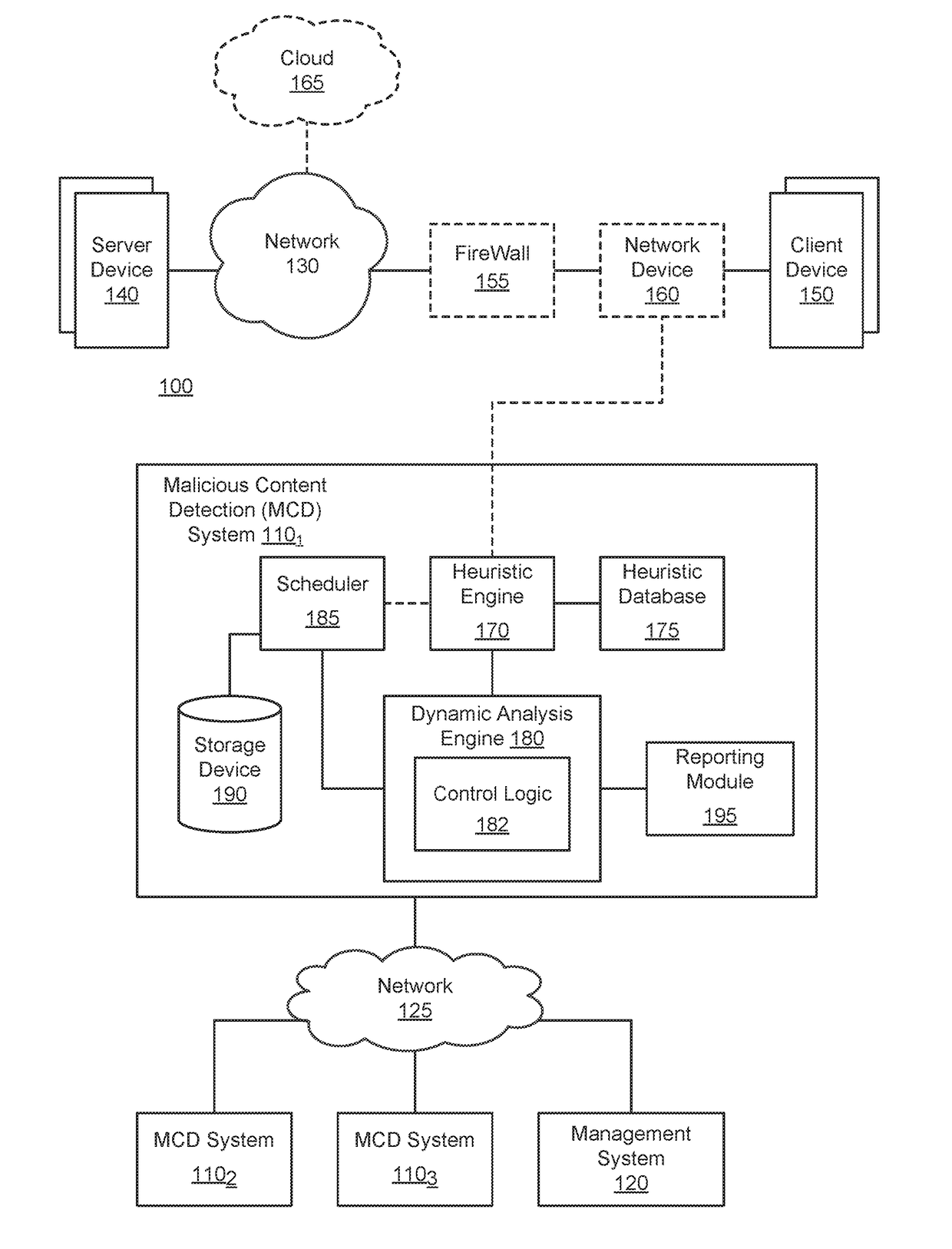

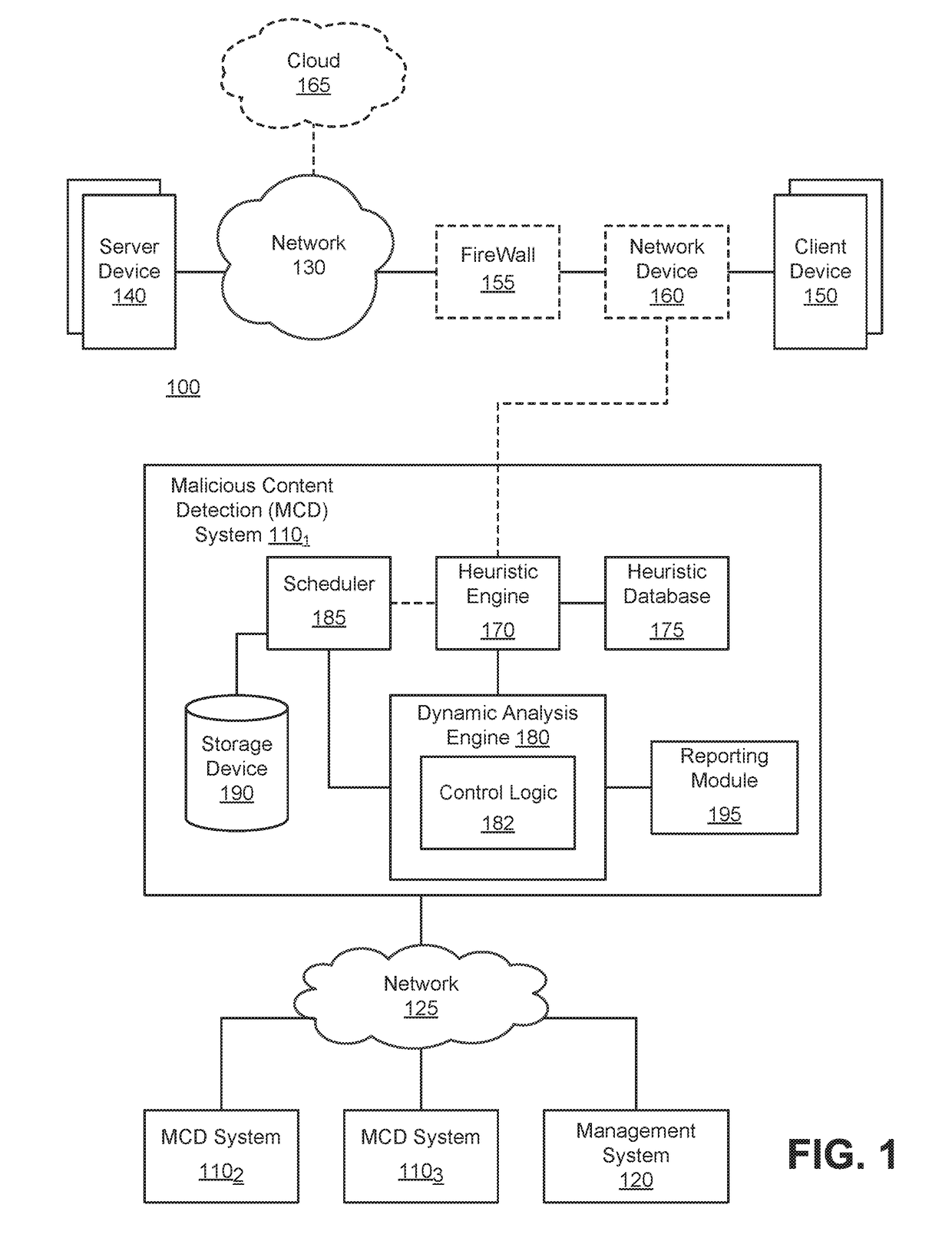

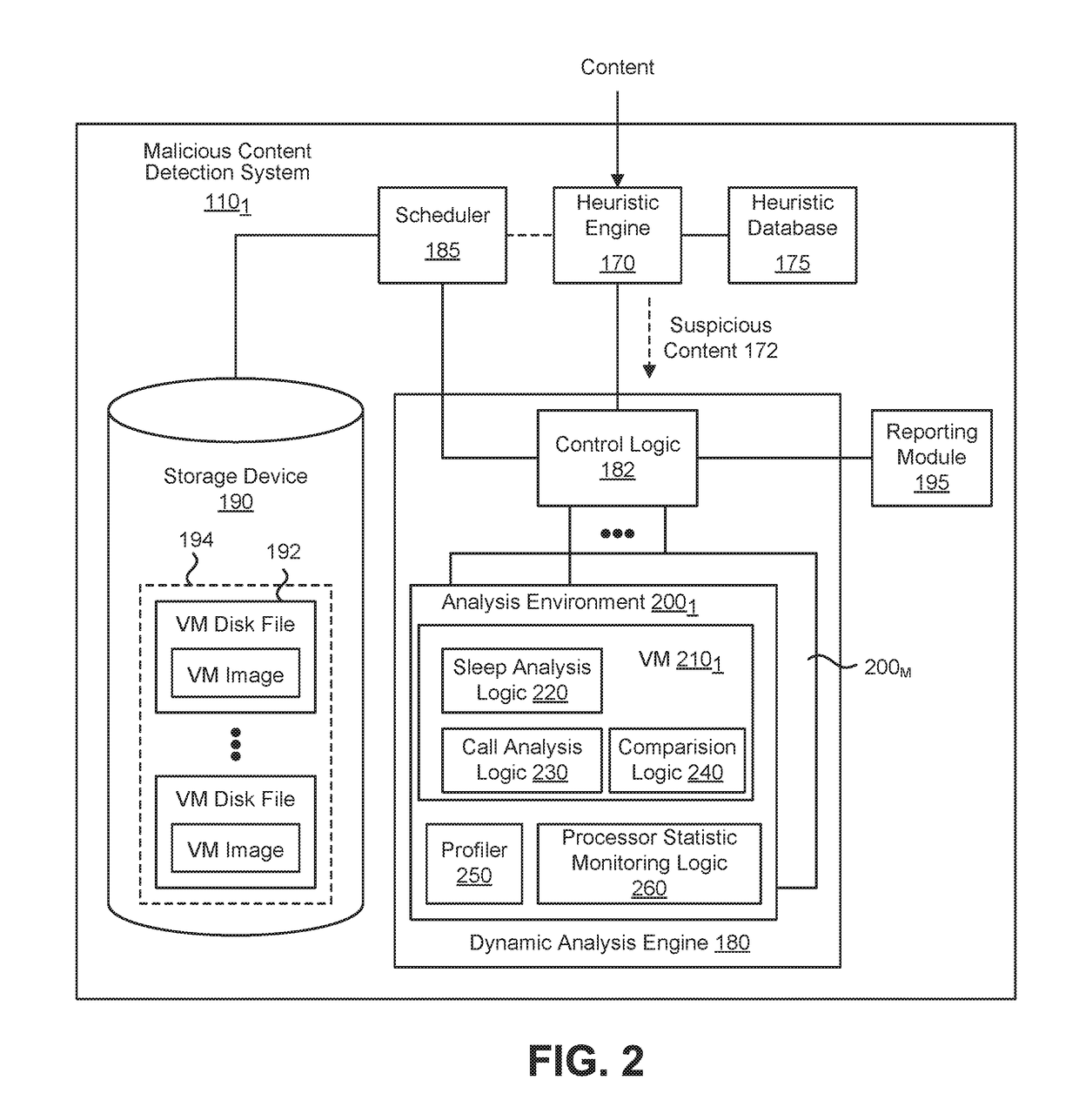

System and Method for Detecting Time-Bomb Malware

According to one embodiment, a system comprises one or more counters; comparison logic; and one or more hardware processors communicatively coupled to the one or more counters and the comparison logic. The one or more hardware processors are configured to instantiate one or more virtual machines that are adapted to analyze received content, where the one or more virtual machines are configured to monitor a delay caused by one or more events conducted during processing of the content and identify the content as including malware if the delay exceed a first time period.

Owner:FIREEYE SECURITY HLDG US LLC

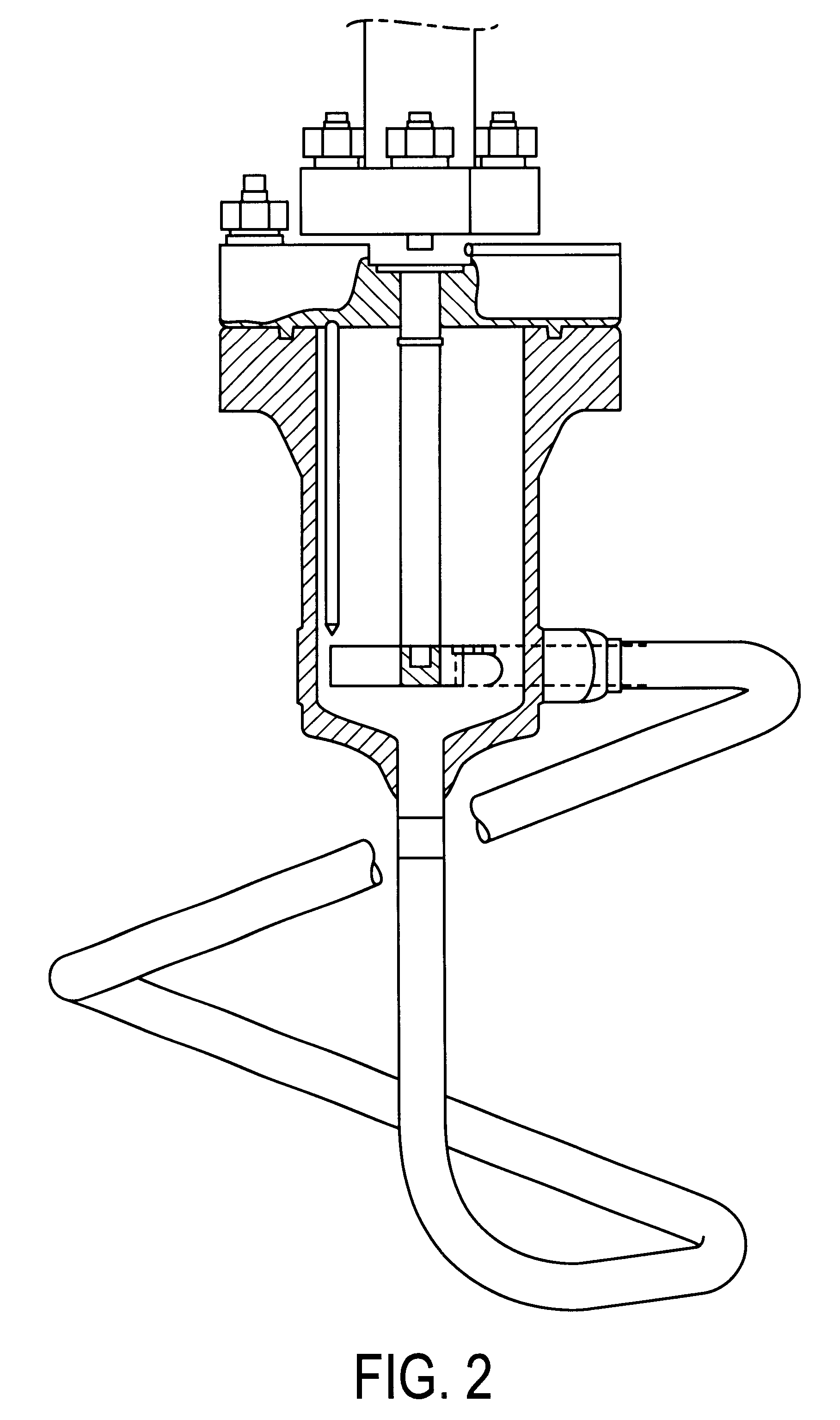

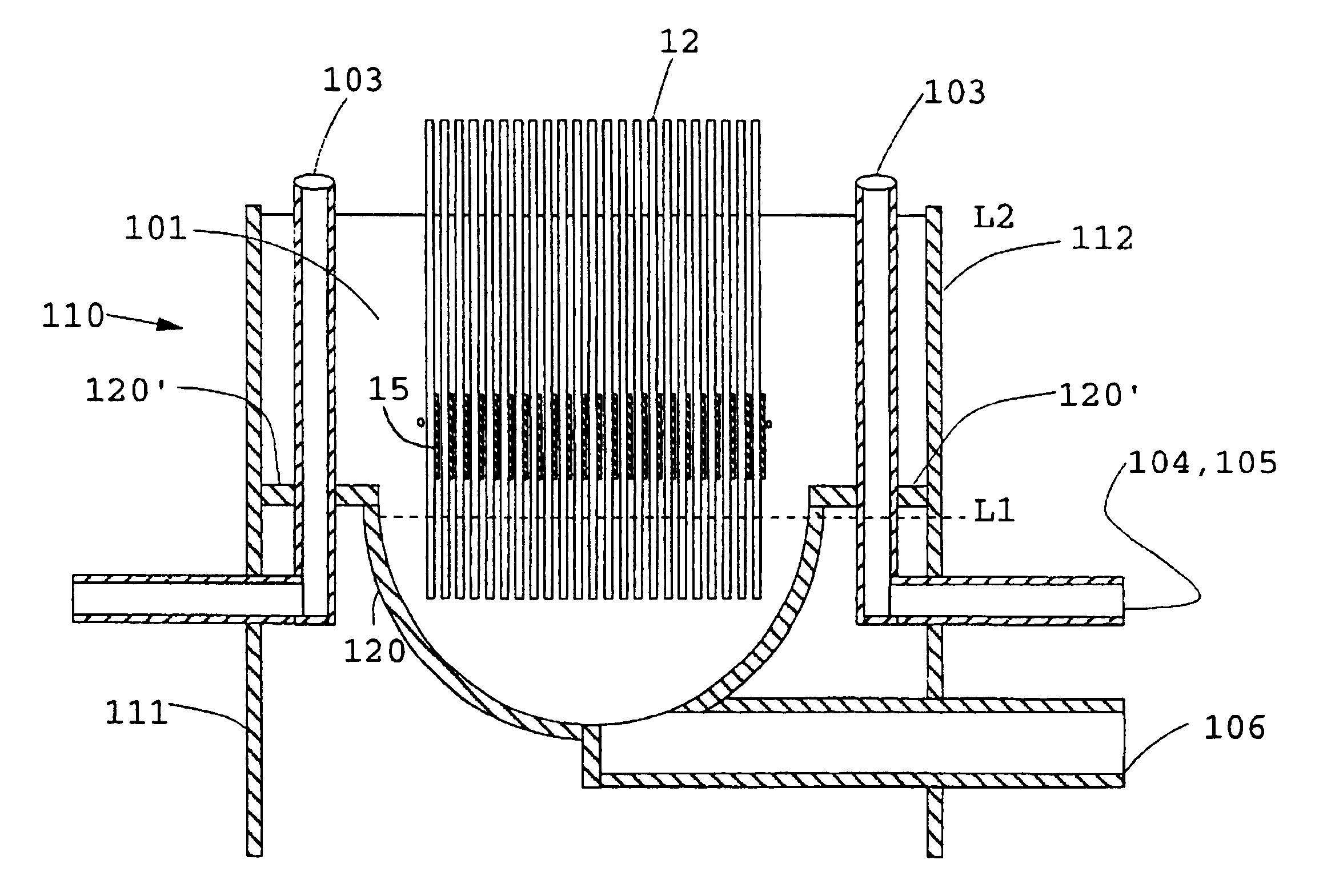

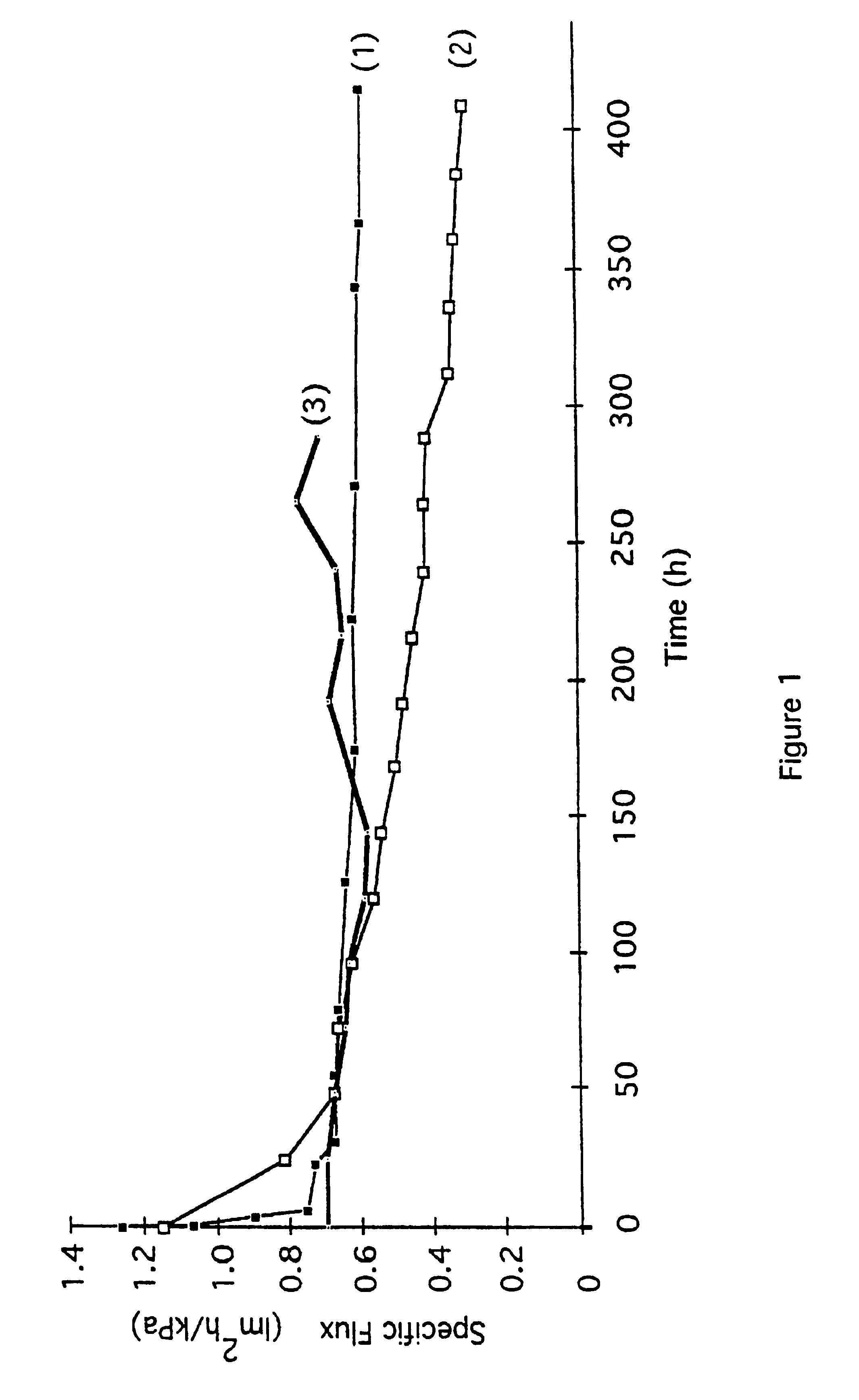

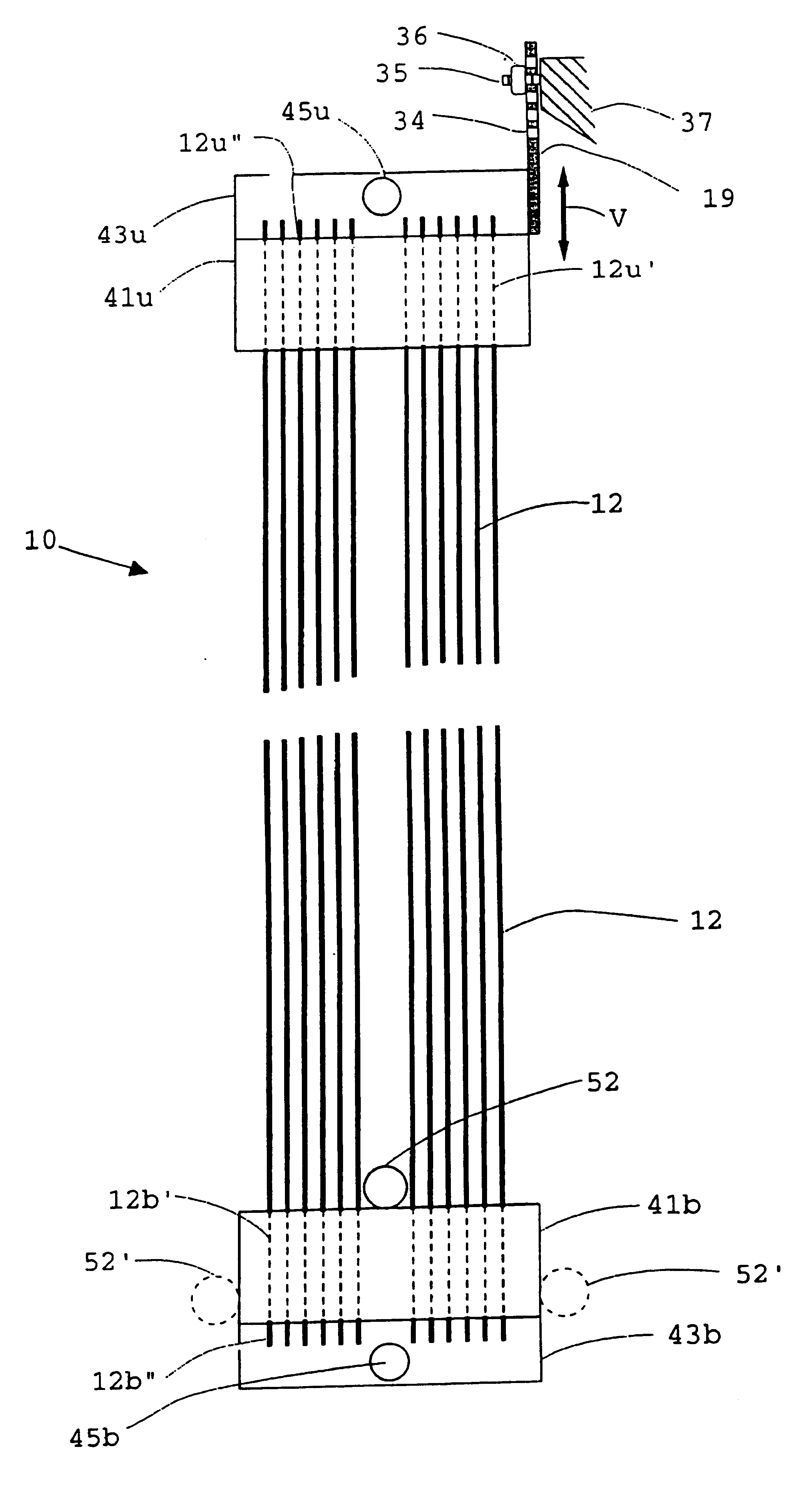

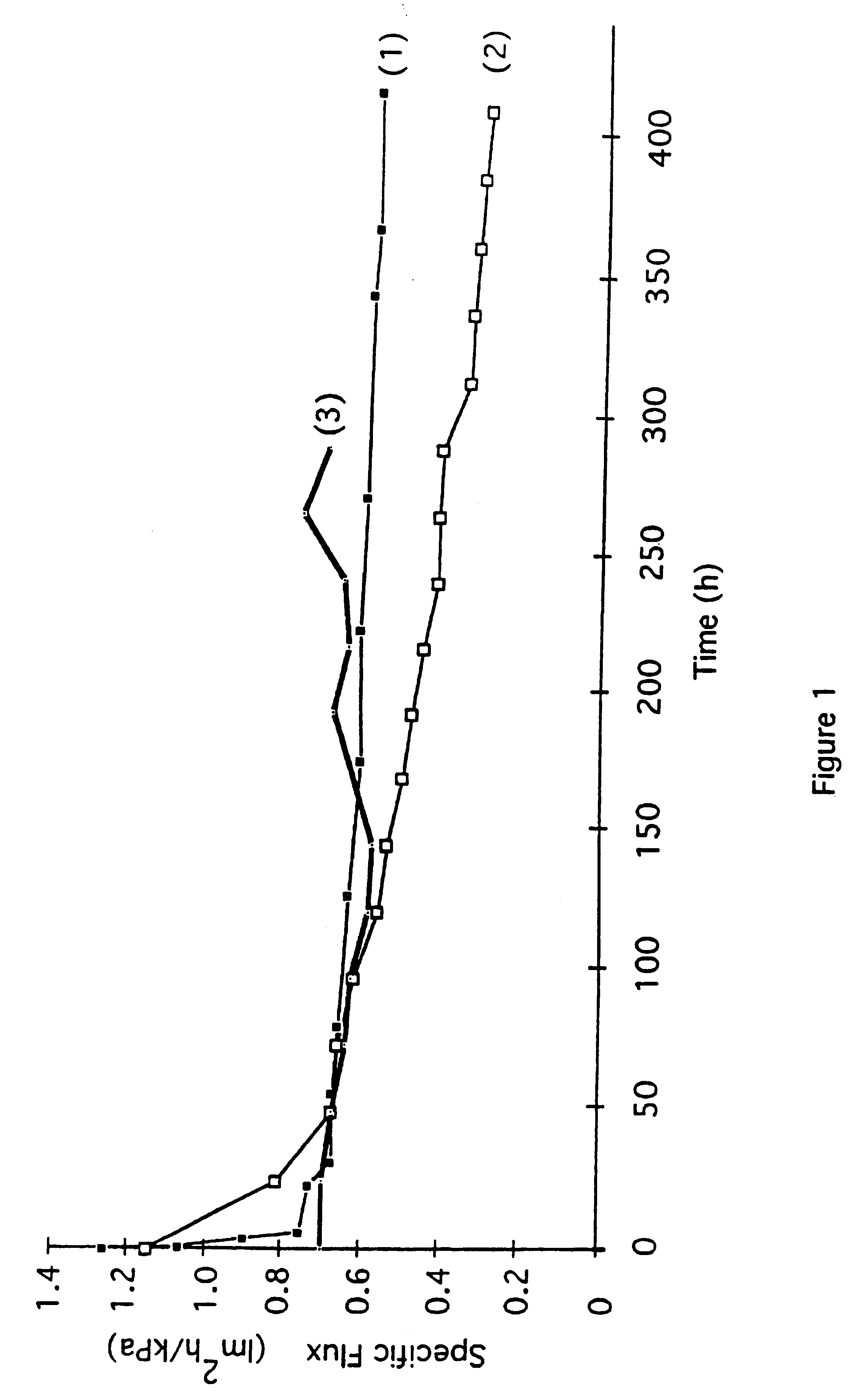

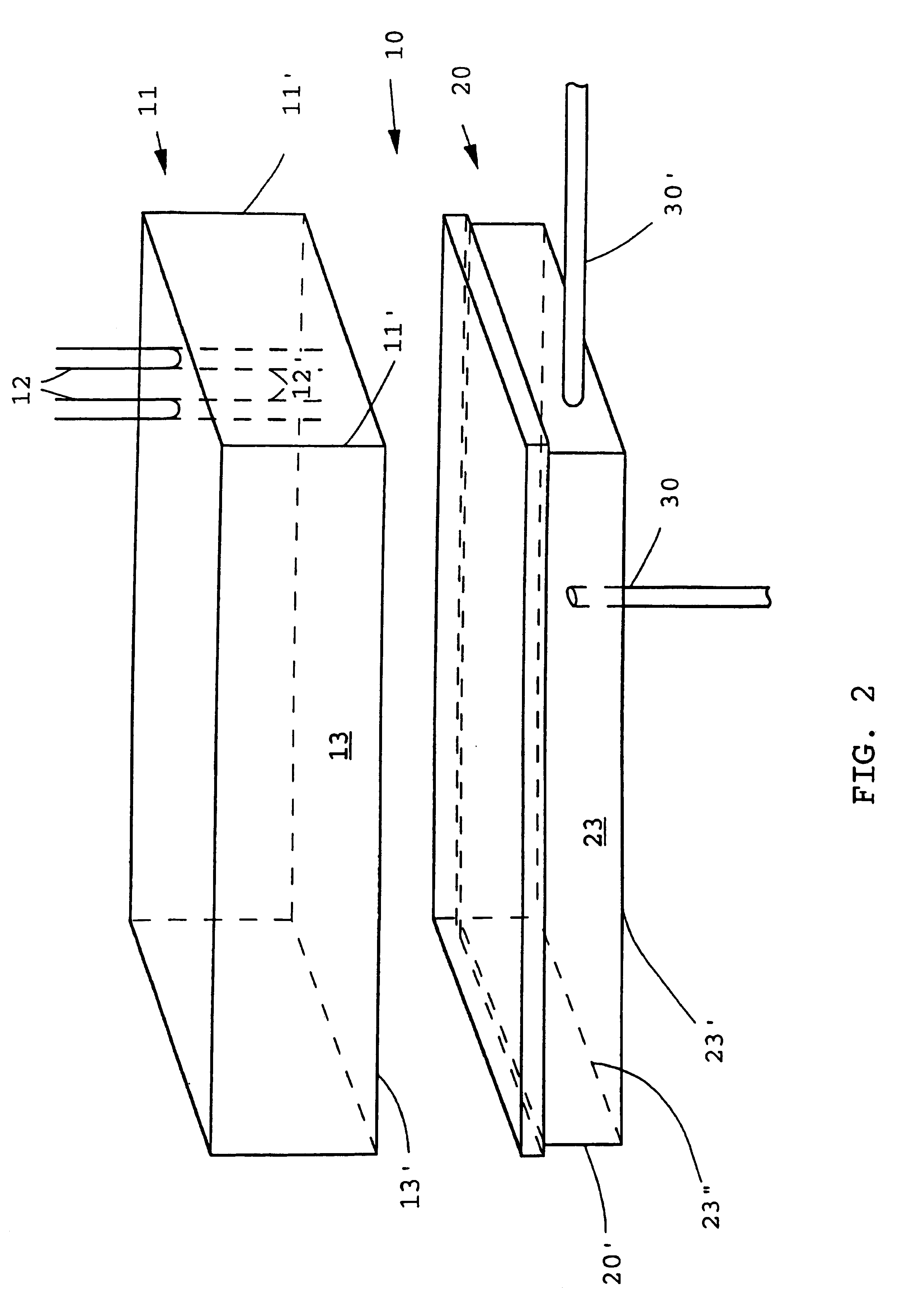

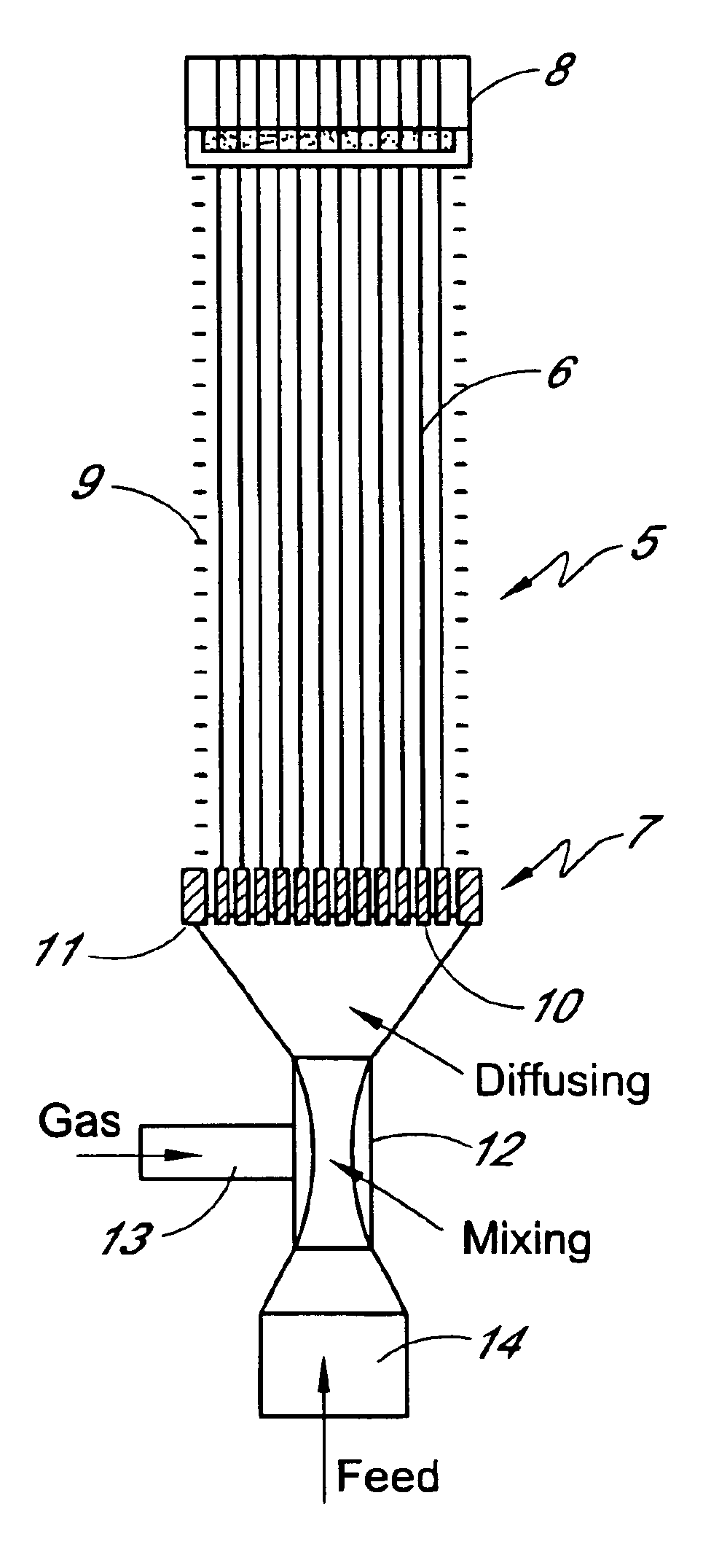

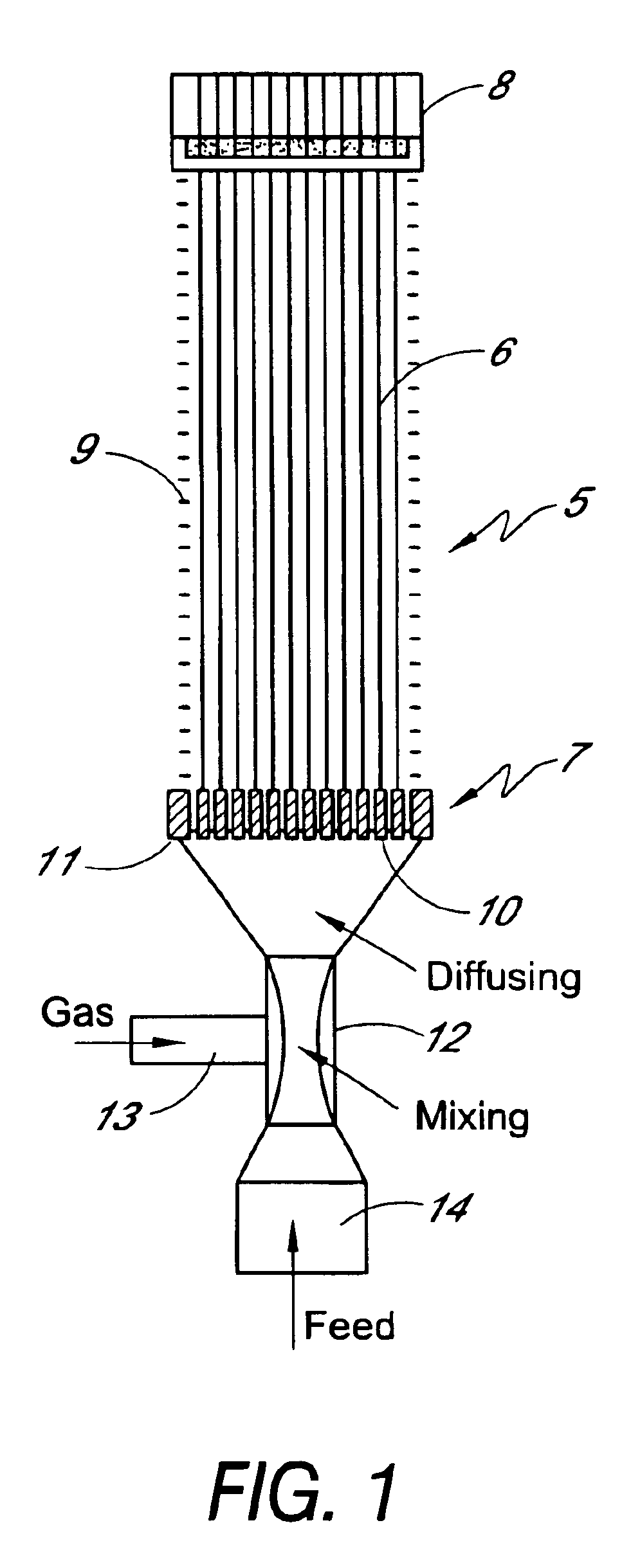

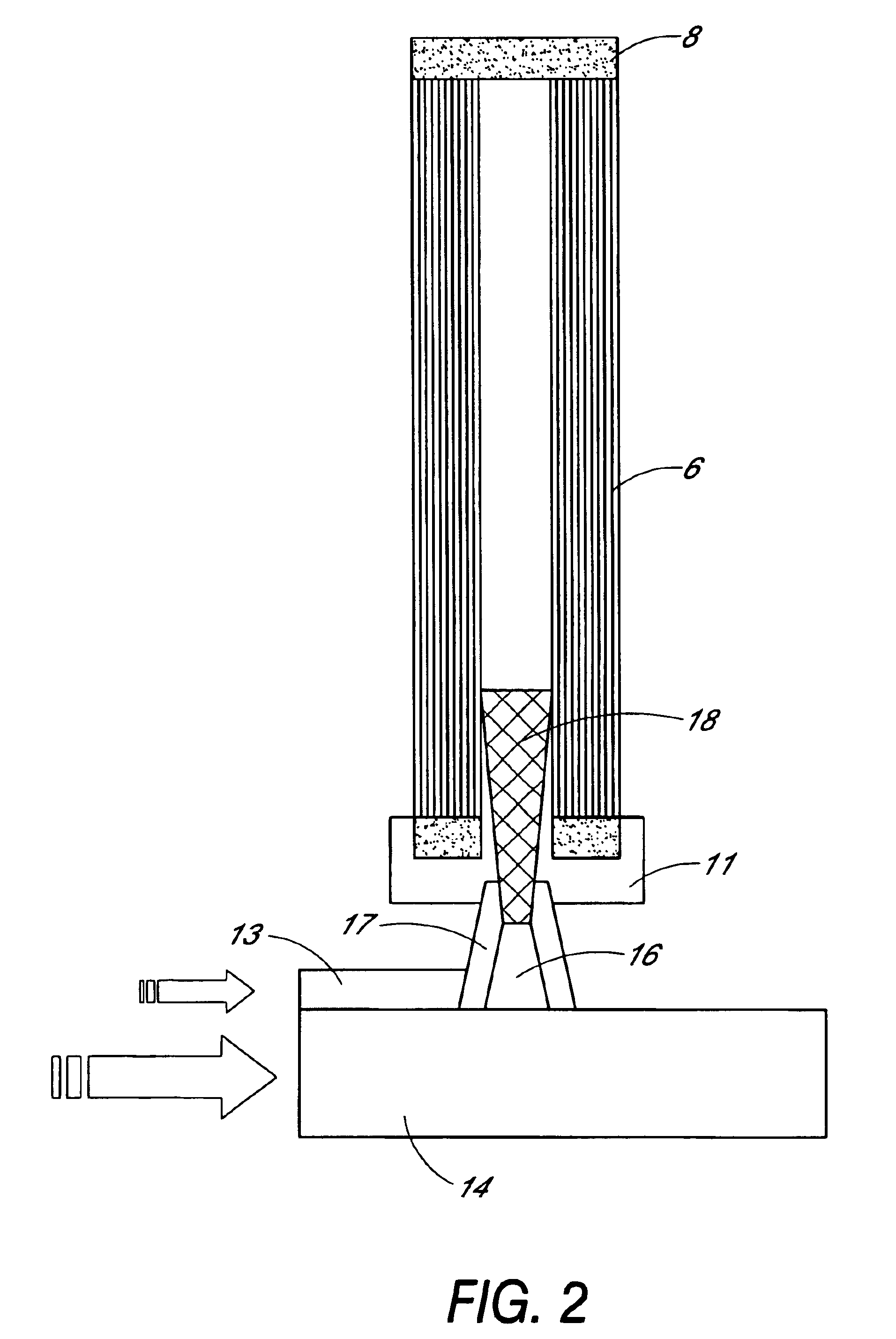

Vertical skein of hollow fiber membranes and method of maintaining clean fiber surfaces while filtering a substrate to withdraw a permeate

A vertical skein of "fibers", opposed terminal portions of which are held in headers unconfined in a modular shell, is aerated with a gas-distribution means which produces a mass of bubbles serving the function of a scrub-brash for the outer surfaces of the fibers. The membrane device is surprisingly effective with relatively little cleansing gas, the specific flux through the membranes reaching an essentially constant relatively high value because the vertical deployment of fibers allows bubbles to rise upwards along the outer surfaces of the fibers. Further, bubbles flowing along the outer surfaces of the fibers make the fibers surprisingly resistant to being fouled by build-up of deposits of inanimate particles or microorganisms in the substrate provided that the length of each fiber is only slightly greater than the direct center-to-center distance between opposed faces of the headers, preferably in the range from at least 0.1% to about 5% greater. For use in a large reservoir, a bank of skeins is used with a gas distributor means and each skein has fibers preferably >0.5 meter long, which together provide a surface area >10 m2. The terminal end portions of fibers in each header are kept free from fiber-to-fiber contact with a novel method of potting fibers.

Owner:ZENON TECH PARTNERSHIP

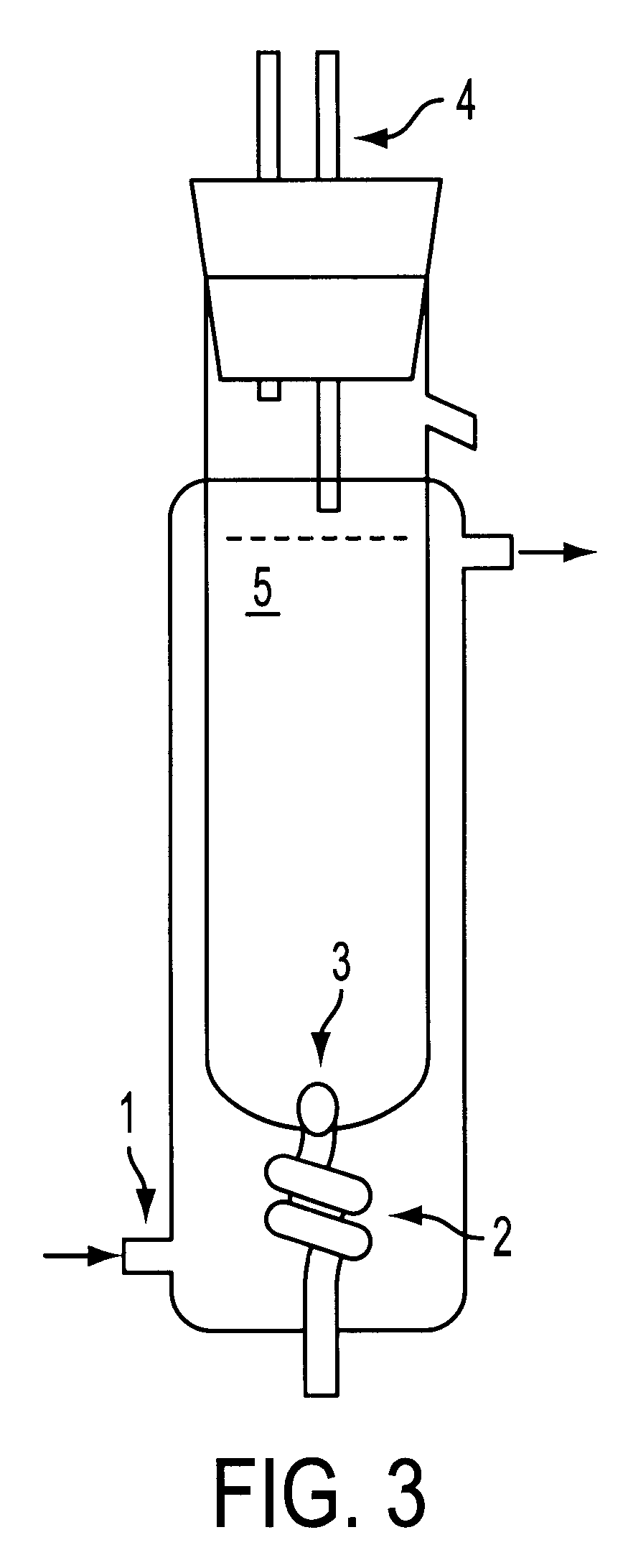

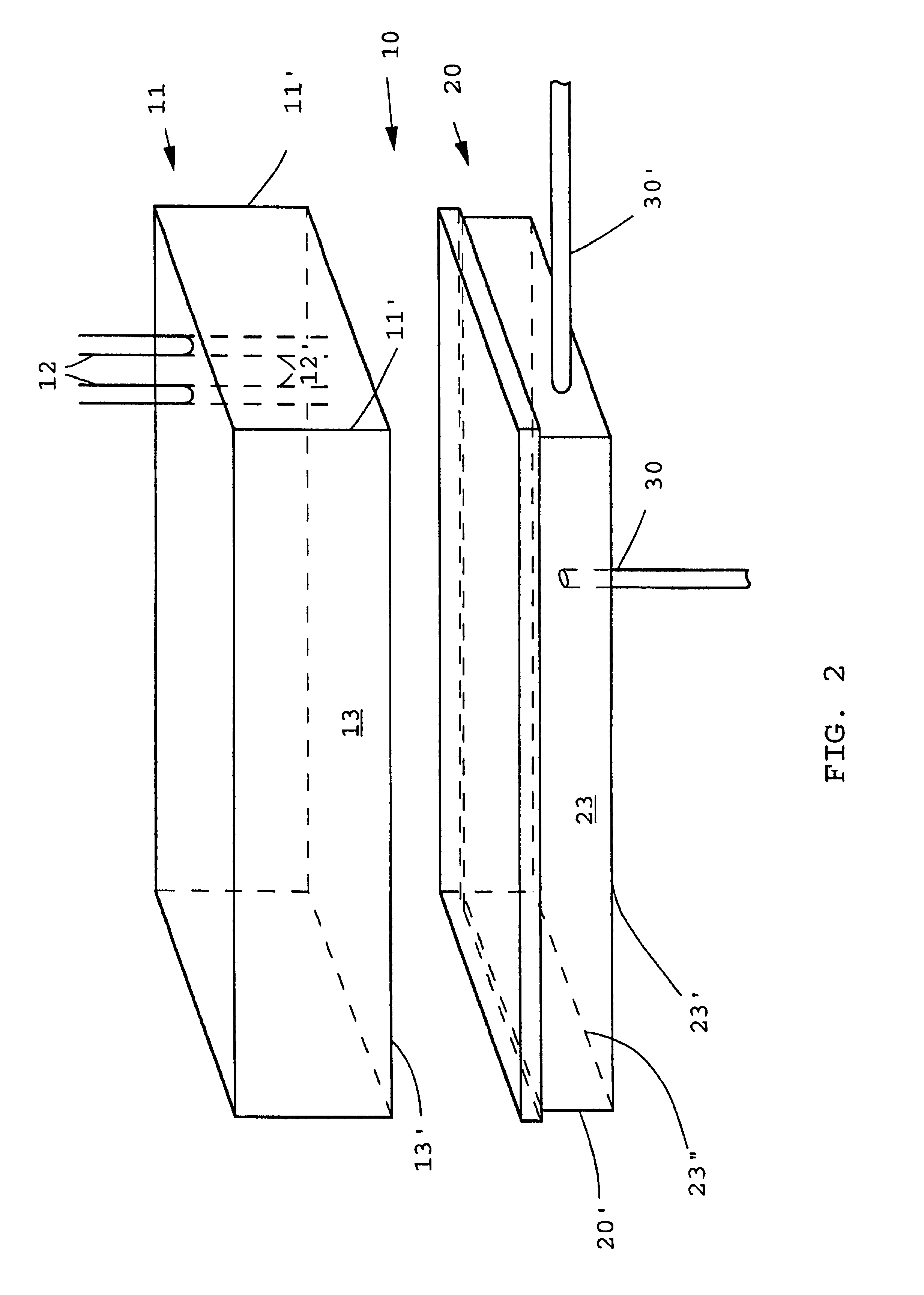

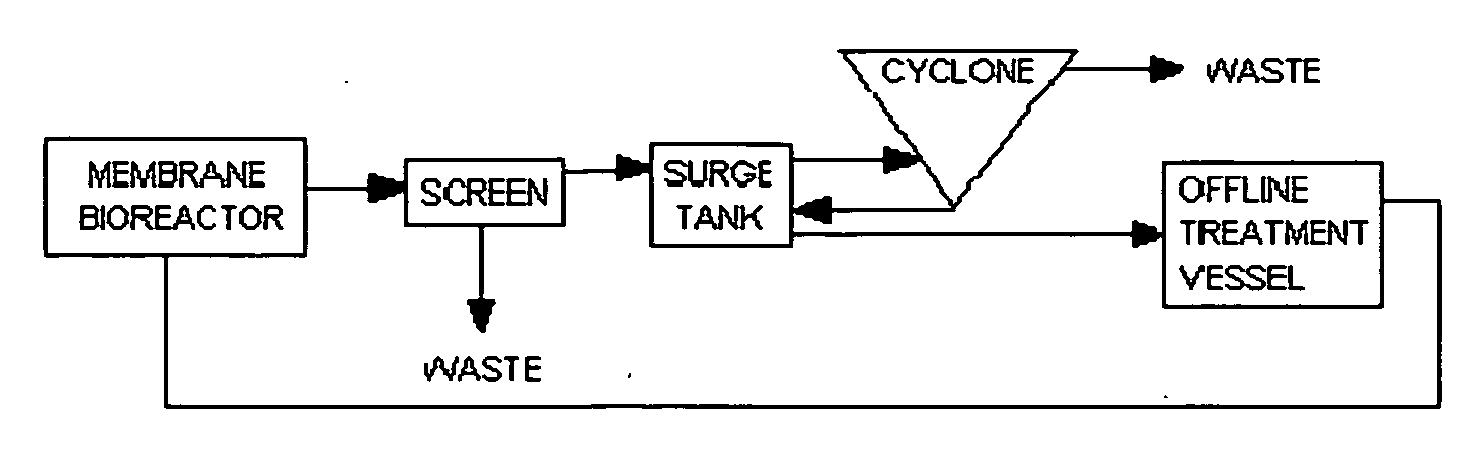

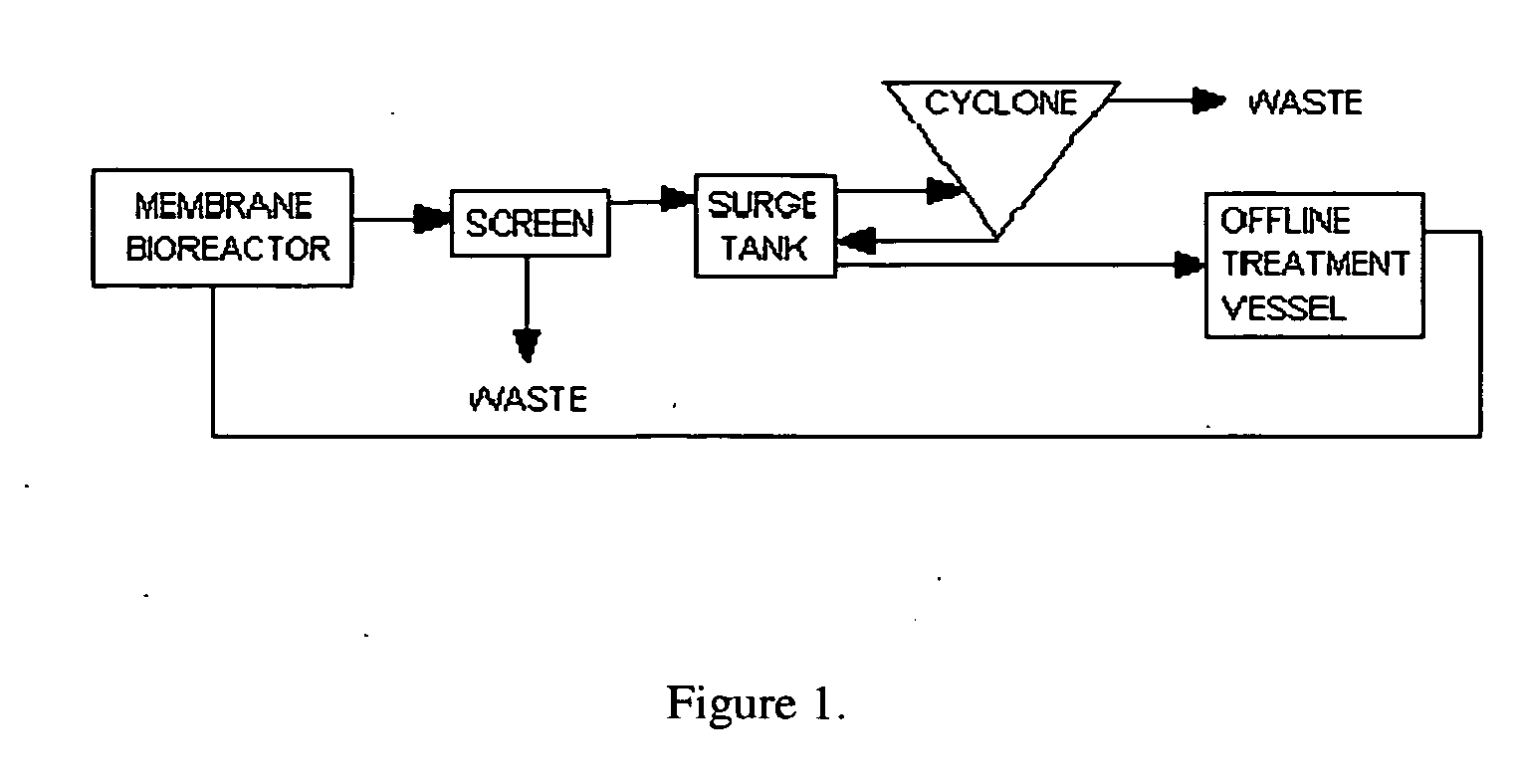

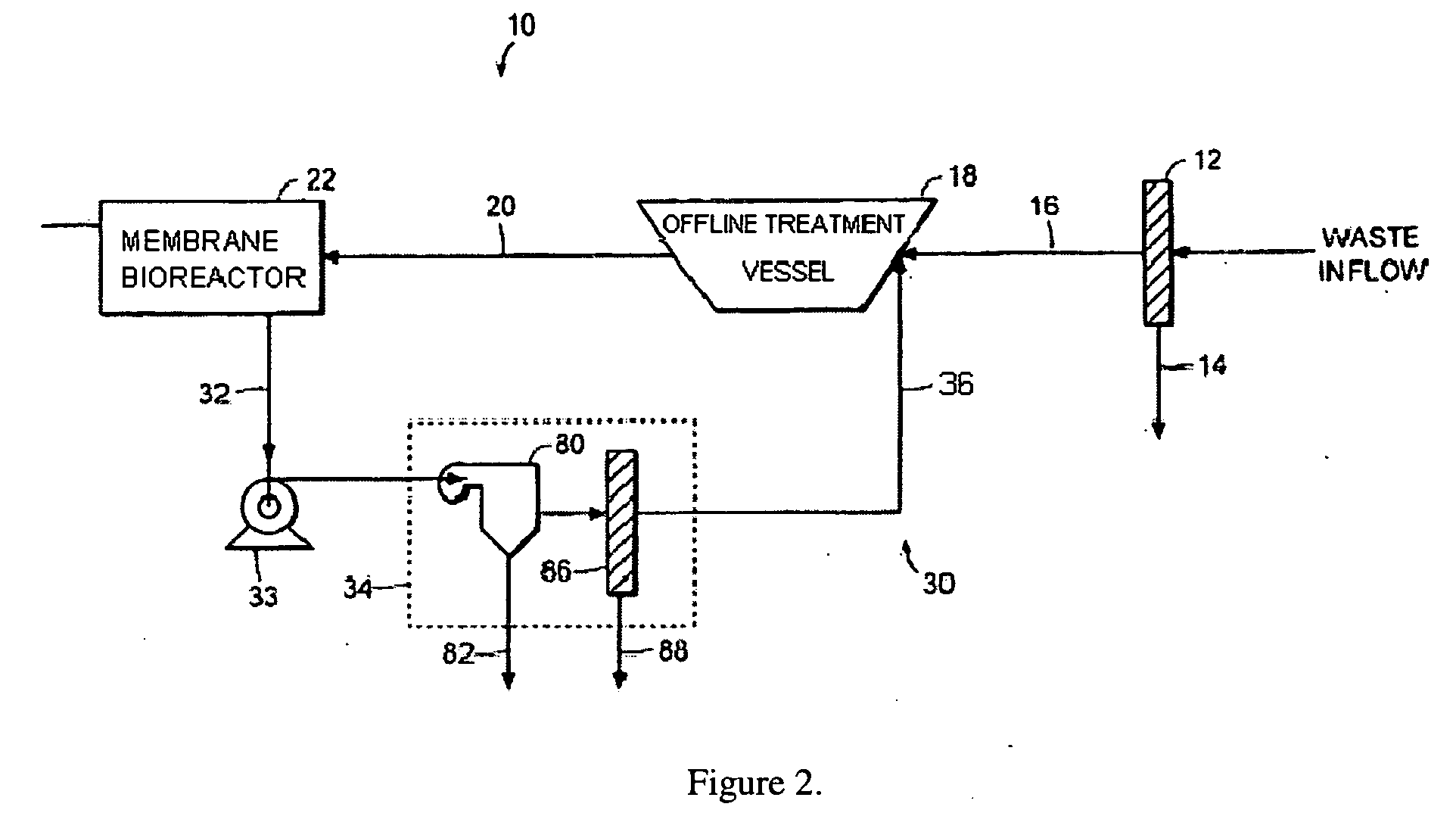

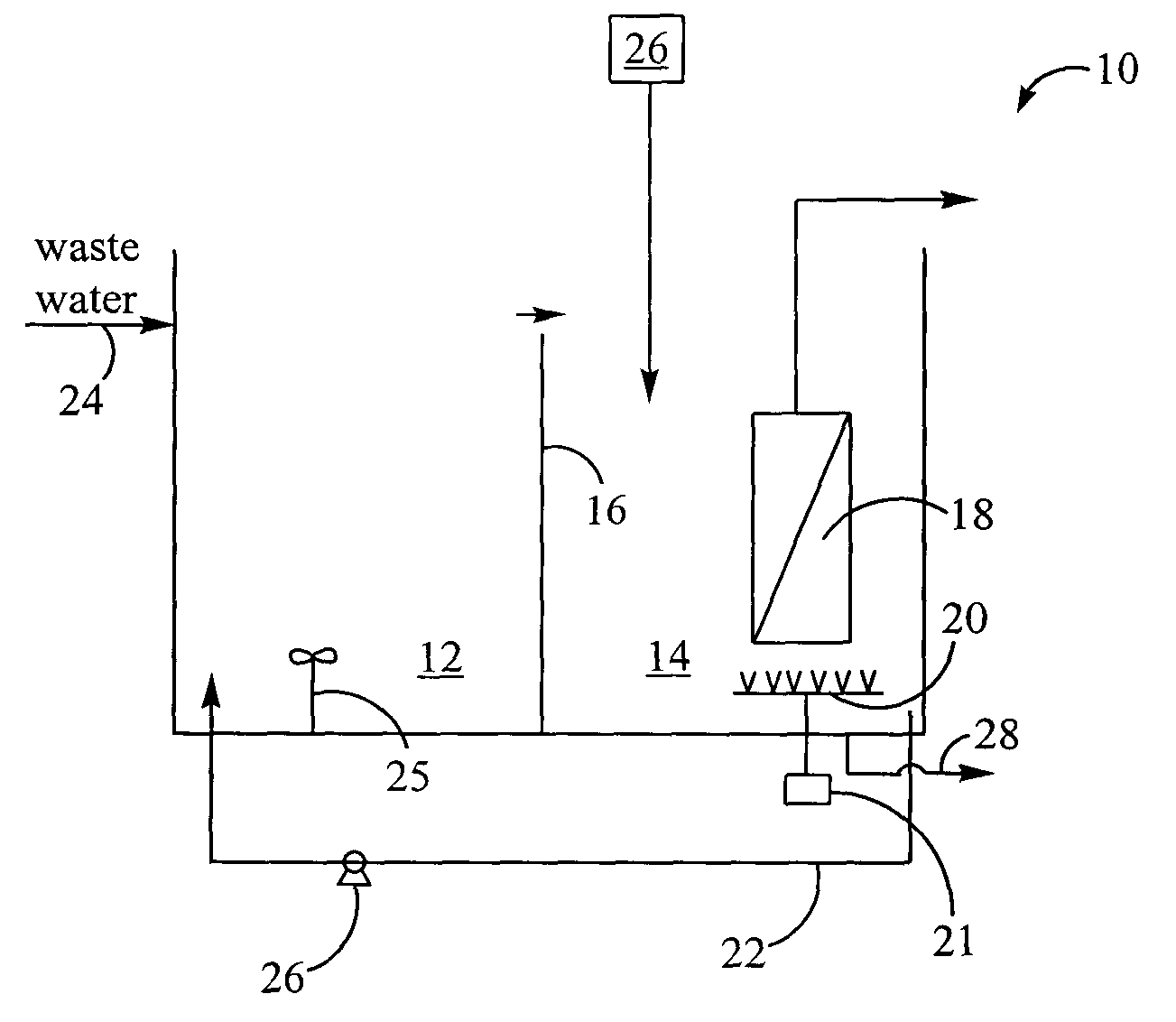

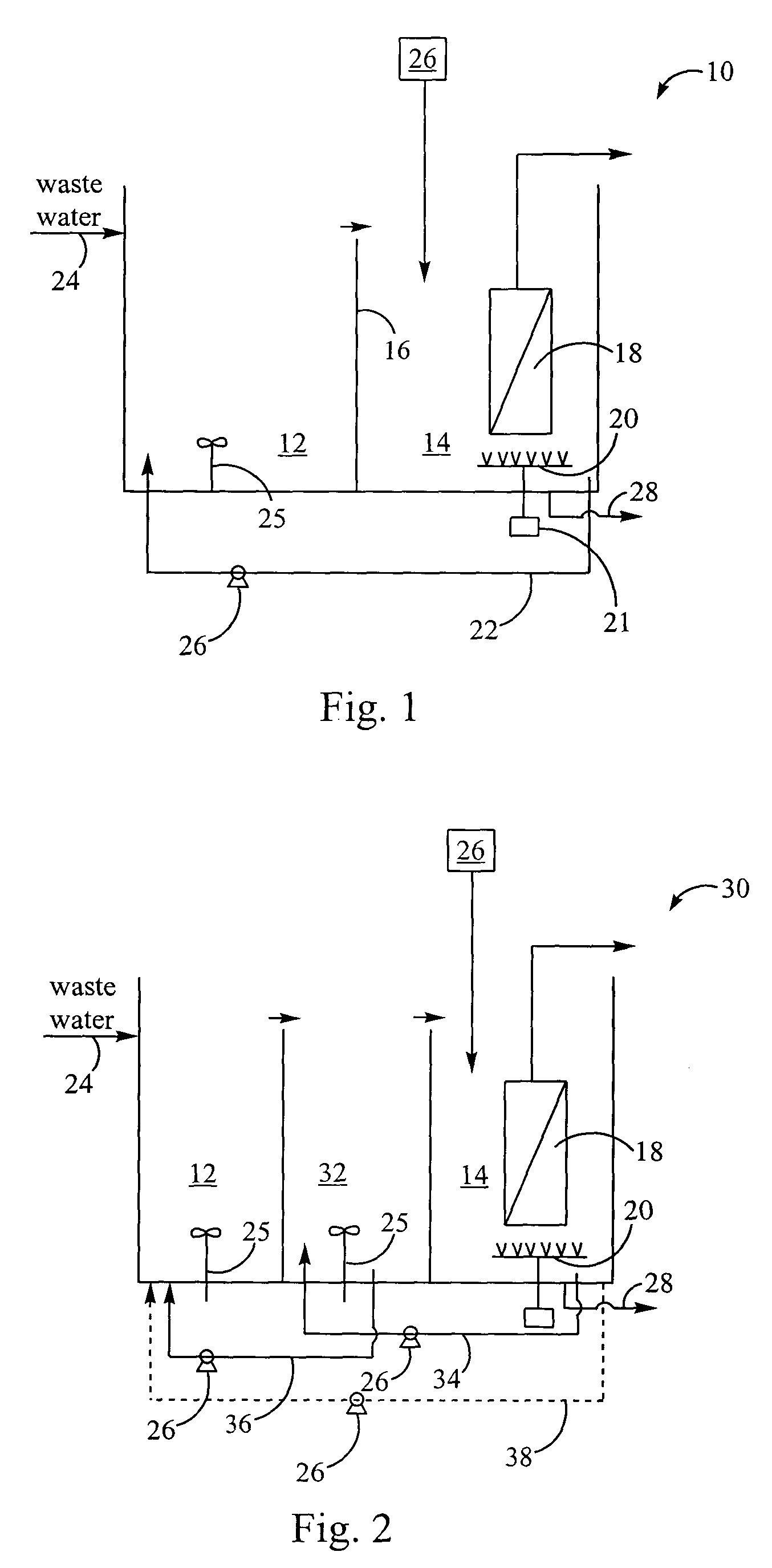

Filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS20060201876A1Low costReducing resourceWater/sewage treatment by centrifugal separationWater treatment parameter controlFiltrationMembrane bioreactor

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge.

Owner:EVOQUA WATER TECH LLC

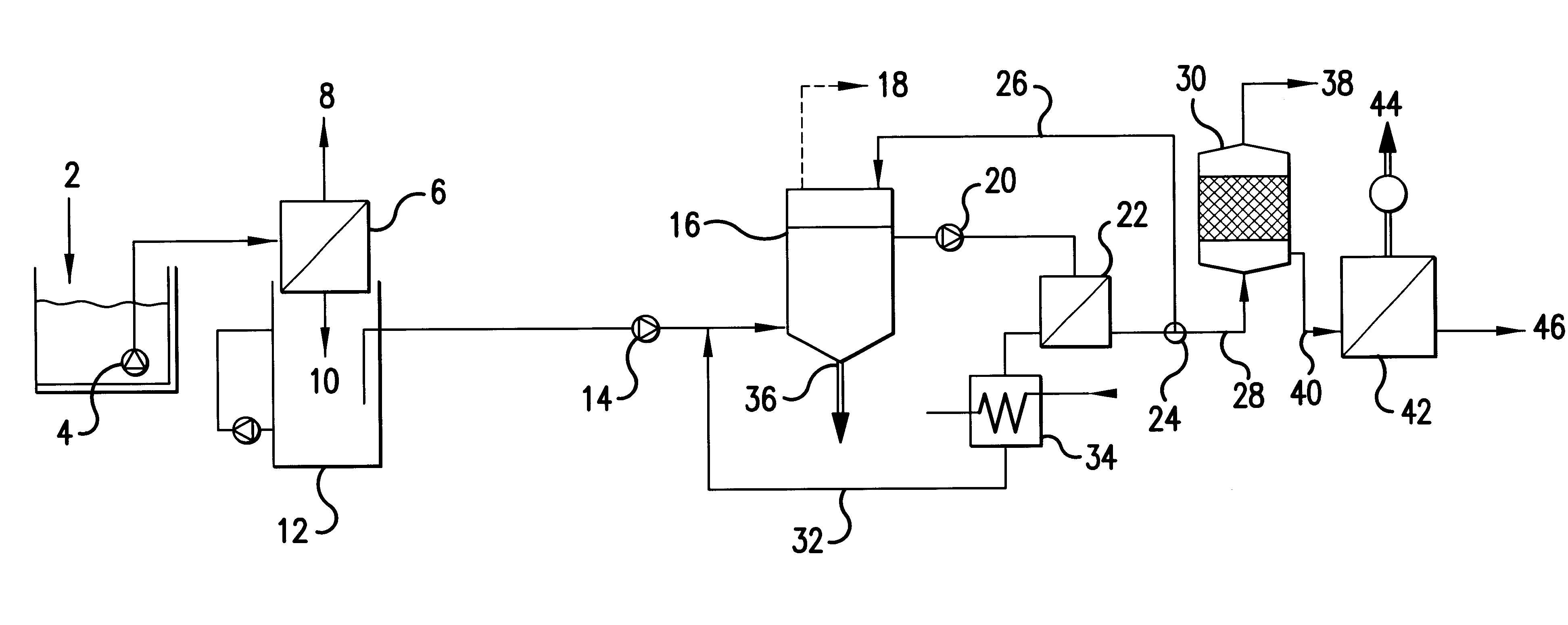

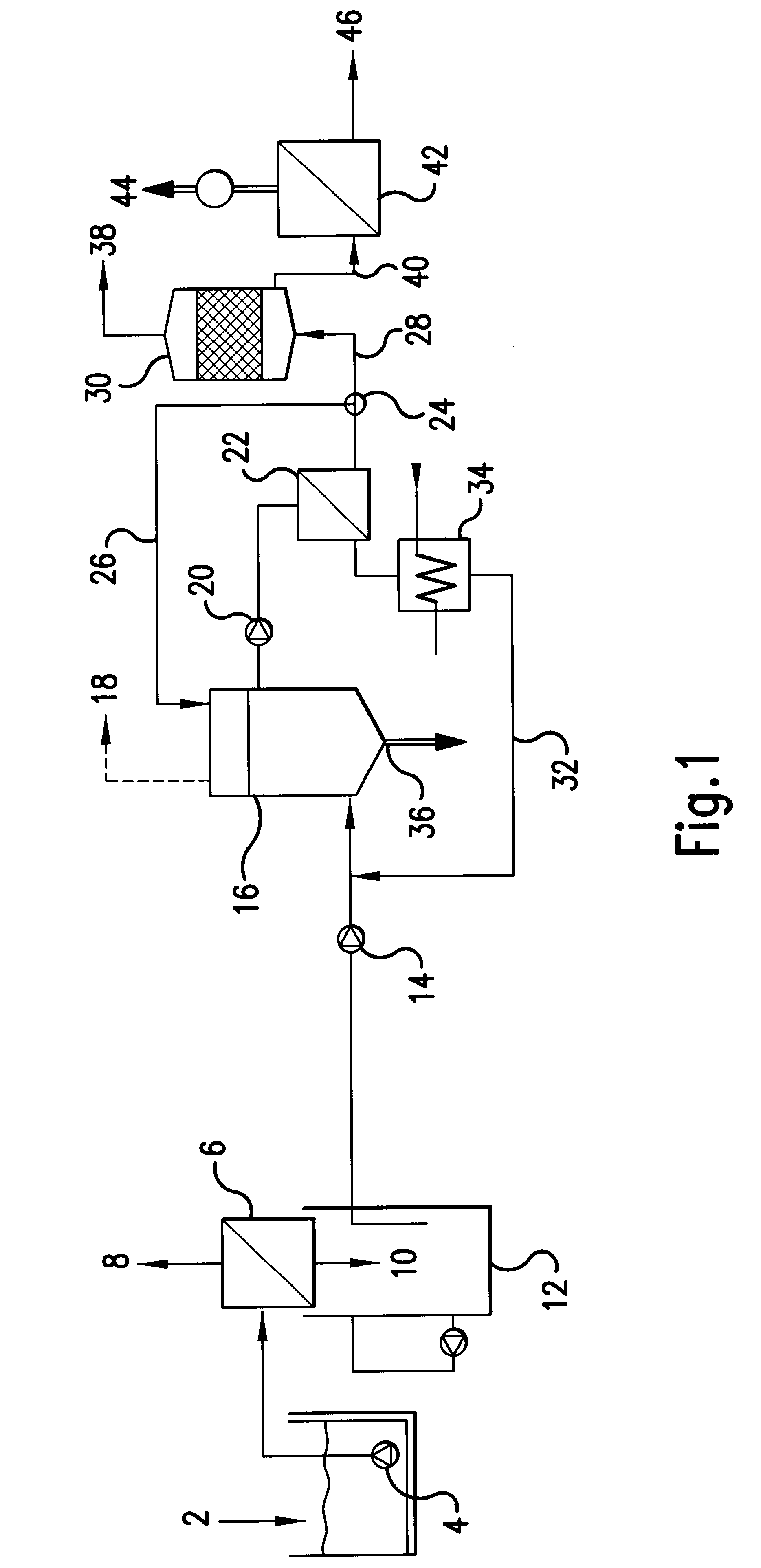

Method and plant for the treatment of liquid organic waste

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

System and method for detecting time-bomb malware

According to one embodiment, a system comprises one or more counters; comparison logic; and one or more hardware processors communicatively coupled to the one or more counters and the comparison logic. The one or more hardware processors are configured to instantiate one or more virtual machines that are adapted to analyze received content, where the one or more virtual machines are configured to monitor a delay caused by one or more events conducted during processing of the content and identify the content as including malware if the delay exceed a first time period.

Owner:FIREEYE SECURITY HLDG US LLC

Wastewater treatment system and method

ActiveUS20070209999A1Treatment using aerobic processesTreatment involving filtrationActivated carbonWater treatment system

The invention is directed to a method and apparatus for treating wastewater. The wastewater treatment system includes a bioreactor including activated carbon and a first biological population. The wastewater treatment system may also include a membrane bioreactor and / or a wet oxidation unit.

Owner:SIEMENS ENERGY INC

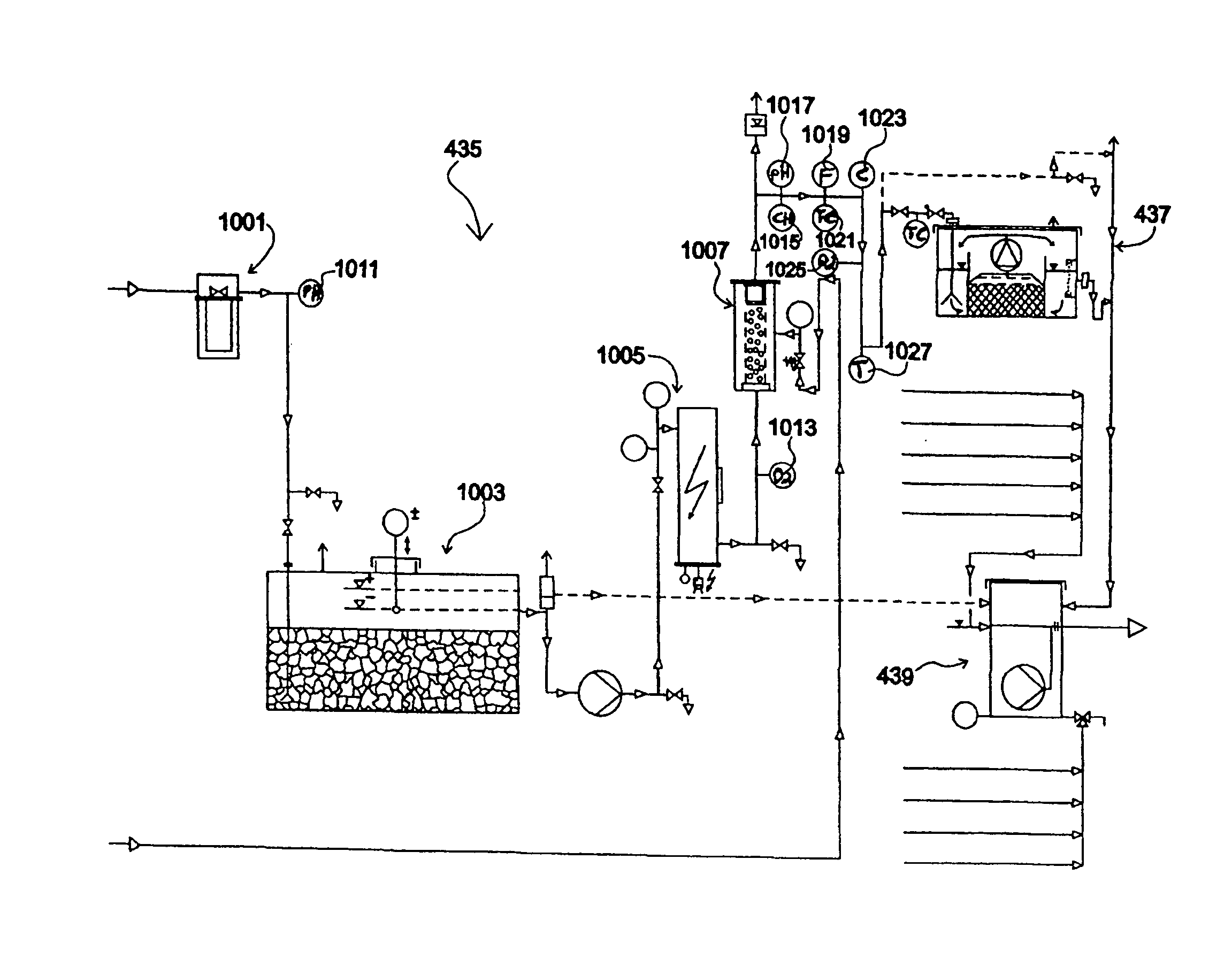

Integrated closed loop system for industrial water purification

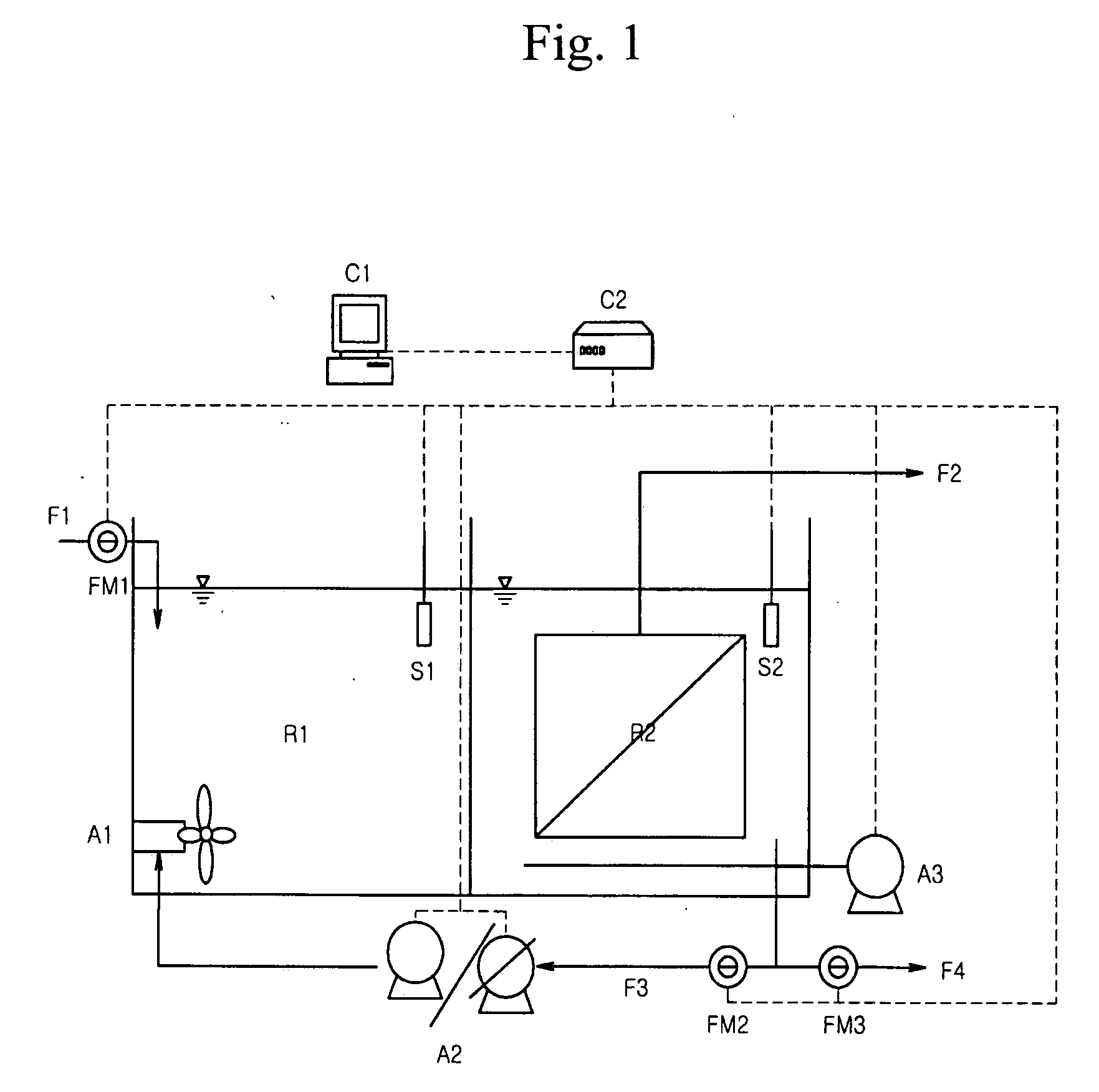

InactiveUS7001519B2Improve purification efficiencyTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

System and method for detecting time-bomb malware

Owner:FIREEYE SECURITY HLDG US LLC +1

Method for treating wastewater in a membrane bioreactor to produce a low phosphorus effluent

ActiveUS20050045557A1Minimizing space requirementMinimizing attendant costTreatment using aerobic processesOther chemical processesActivated sludgeMembrane bioreactor

Removal of biological nutrients from a wastewater yielding a low phosphorous (e.g., less than 0.25 mg / L) output includes providing a serial multistage bioreactor containing activated sludge having in hydraulic series an anaerobic zone and a downstream aerobic zone, with each zone having an upstream inlet and a downstream outlet. The wastewater is provided to the anaerobic zone inlet. A quantity of chemical sufficient to precipitate soluble and particulate phosphorous is added to the downstream aerobic zone in an amount sufficient to yield a low phosphorous output. Treated water is separated from the activated sludge and precipitated phosphorous and a return activated sludge separated from the treated water is recycled to the anaerobic zone.

Owner:CH2M HILL

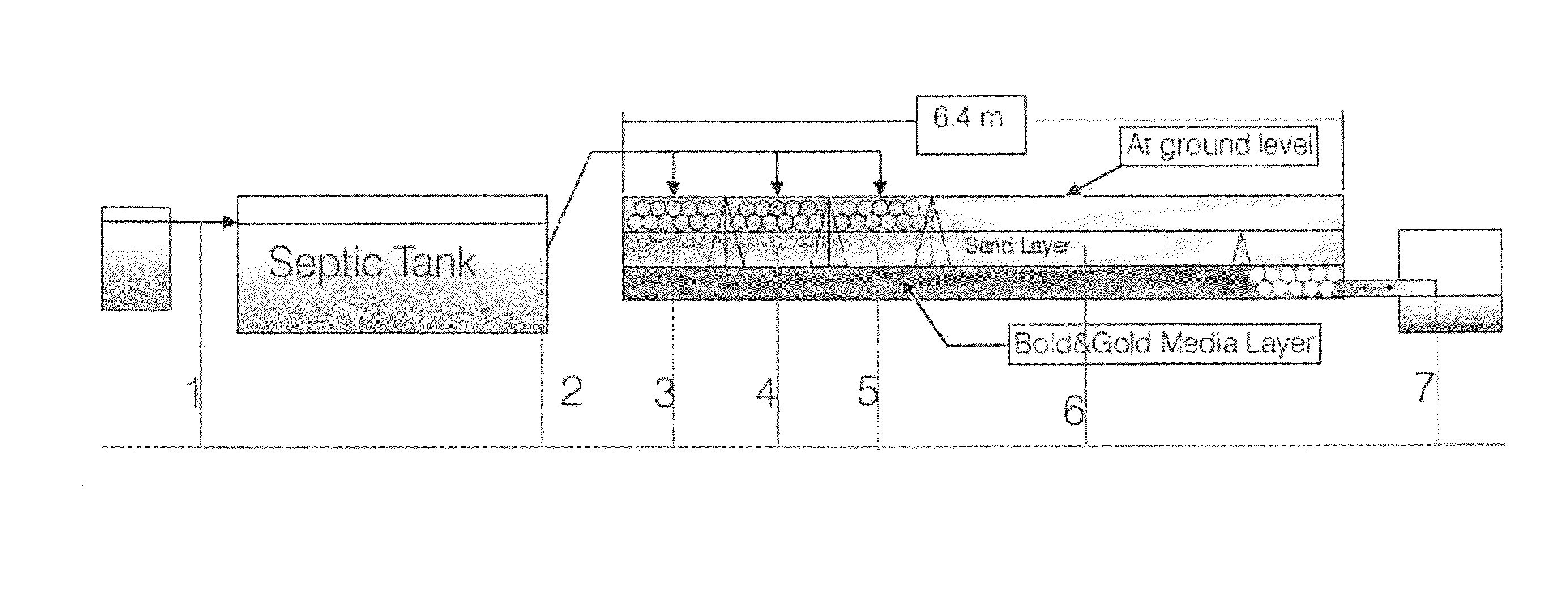

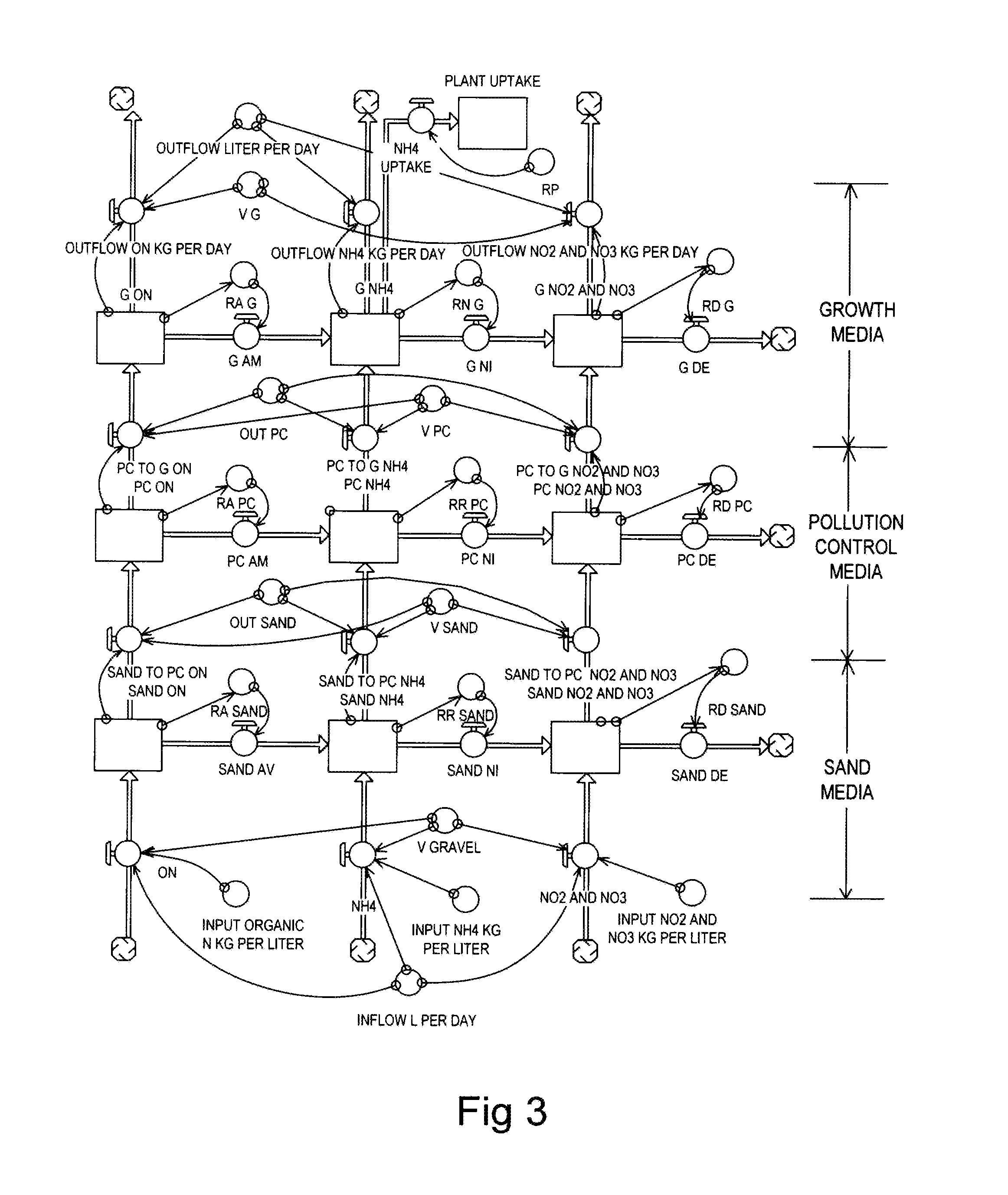

Subsurface upflow wetland system for nutrient and pathogen removal in wastewater treatment systems

ActiveUS8252182B1Low maintenance burdenHigh benefit cost ratioWater cleaningContaminated soil reclamationFecesTotal suspended solids

Methods and systems for a subsurface upflow wetland for wastewater treatment that includes a series of parallel treatment cells, each cell including from bottom to top, a layer of gravel, a layer of sand over the gravel to remove pathogens from a septic effluent, a pollution control medium above the sand layer to remove nutrients, total suspended solid, and biochemical oxygen demand and a growth media mixture layered on top of the pollution control media to grow plants, and a gravity distribution system to distribute effluent to the series of parallel treatment cells. The pollution control medium includes at least one recycled material and at least one naturally occurring material. In an embodiment it includes recycled tire crumb, sand and limestone or recycled tire crumb, compost, sand and limestone.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

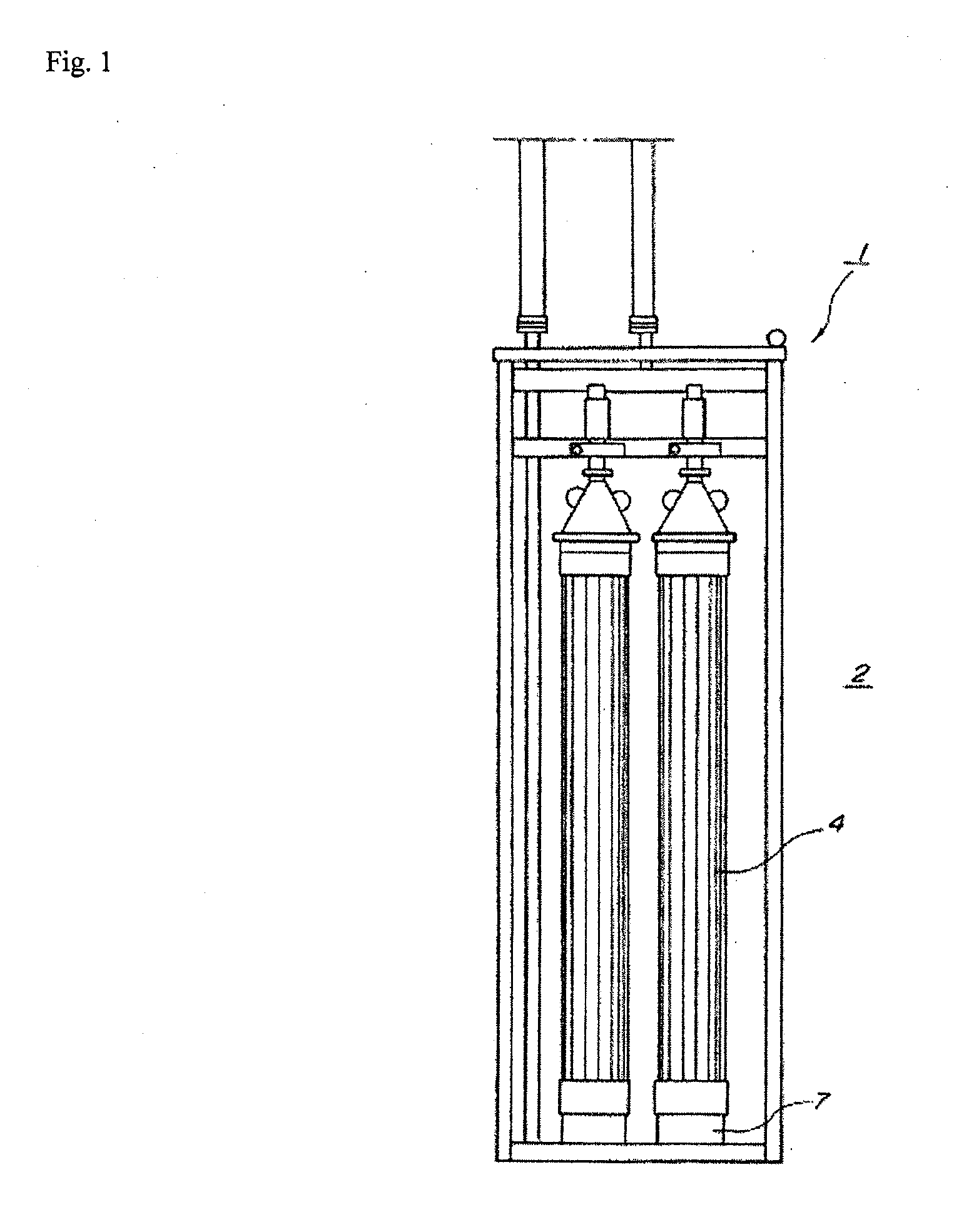

Apparatus for withdrawing permeate using an immersed vertical skein of hollow fibre membranes

An apparatus for treating a multi component liquid substrate while leaving particulate matter therein as a skein of hollow fiber filtering membranes immersed in the substrate which is contained in a non-pressurized reservoir. A pumping fluid communication with the lumens of the membranes draws a component of the substrate as permeate through the membranes by applying a section to the lumens of the membranes. In various embodiments, an aeration system as a gas distributor for discharging air directly into the substrate within the skein, upper and lower headers of the skein are spaced apart by a gas tube, and a gas distribution system has through passages through the lower header to discharge bubbles into the substrate above the lower header.

Owner:ZENON TECH PARTNERSHIP

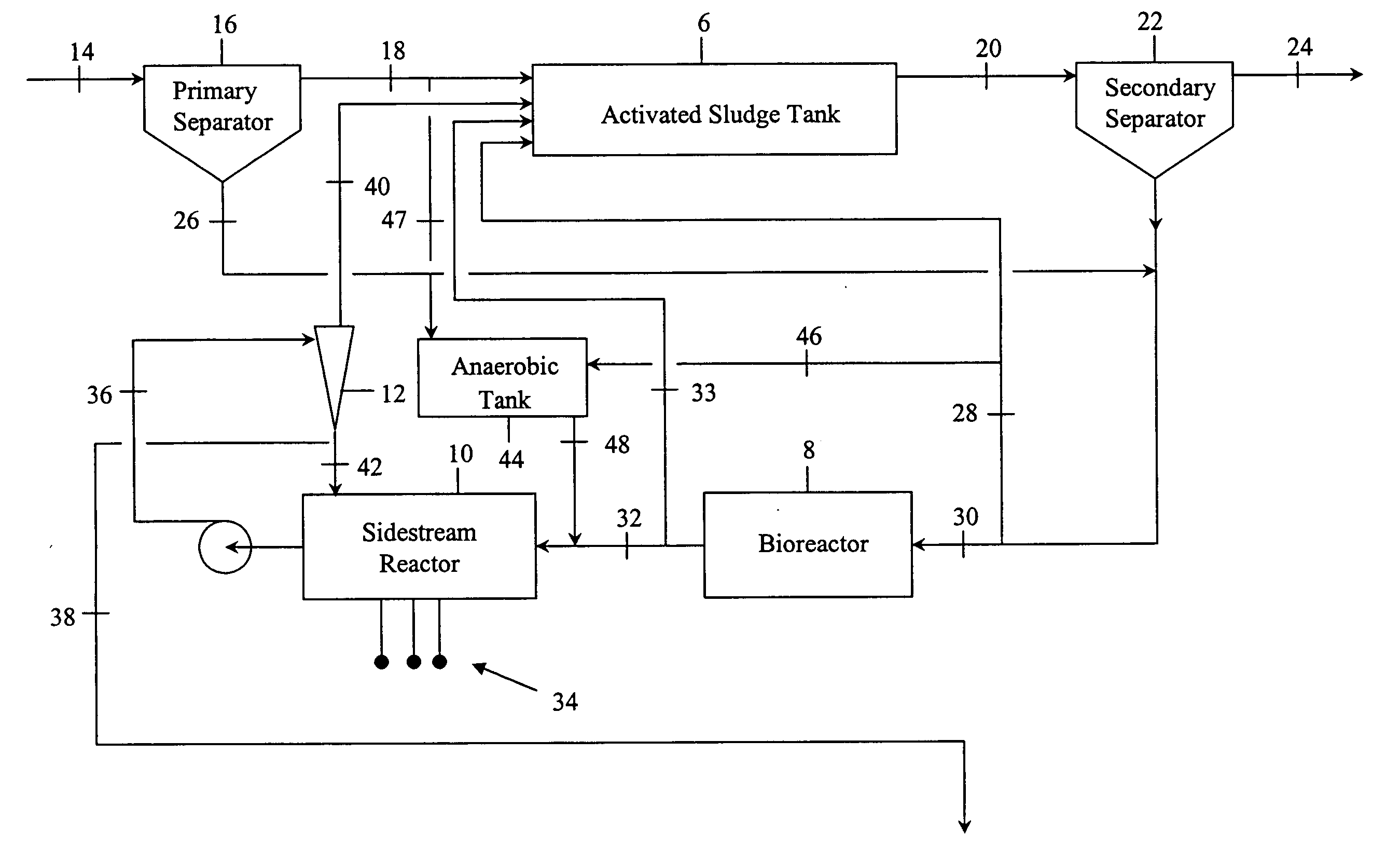

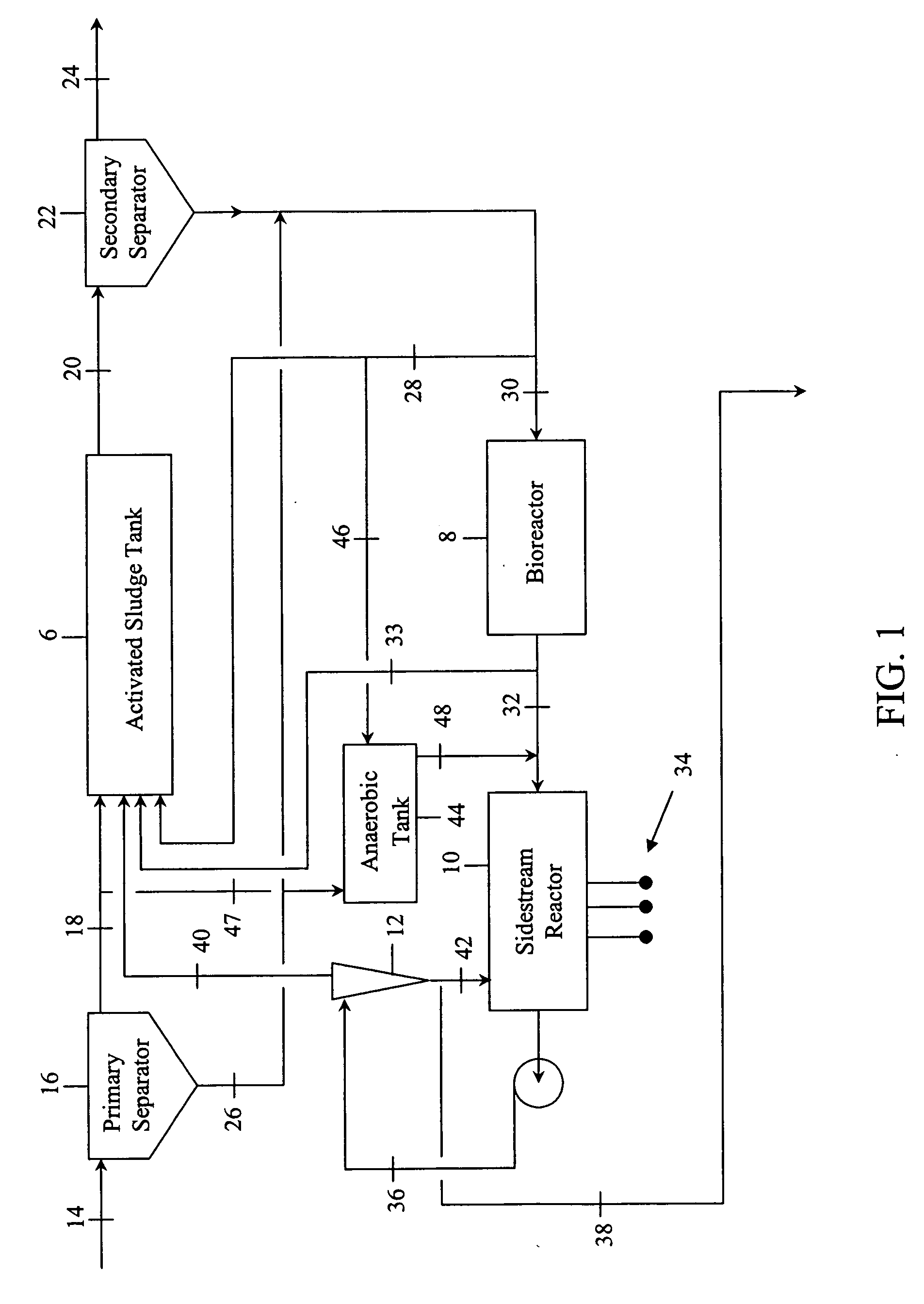

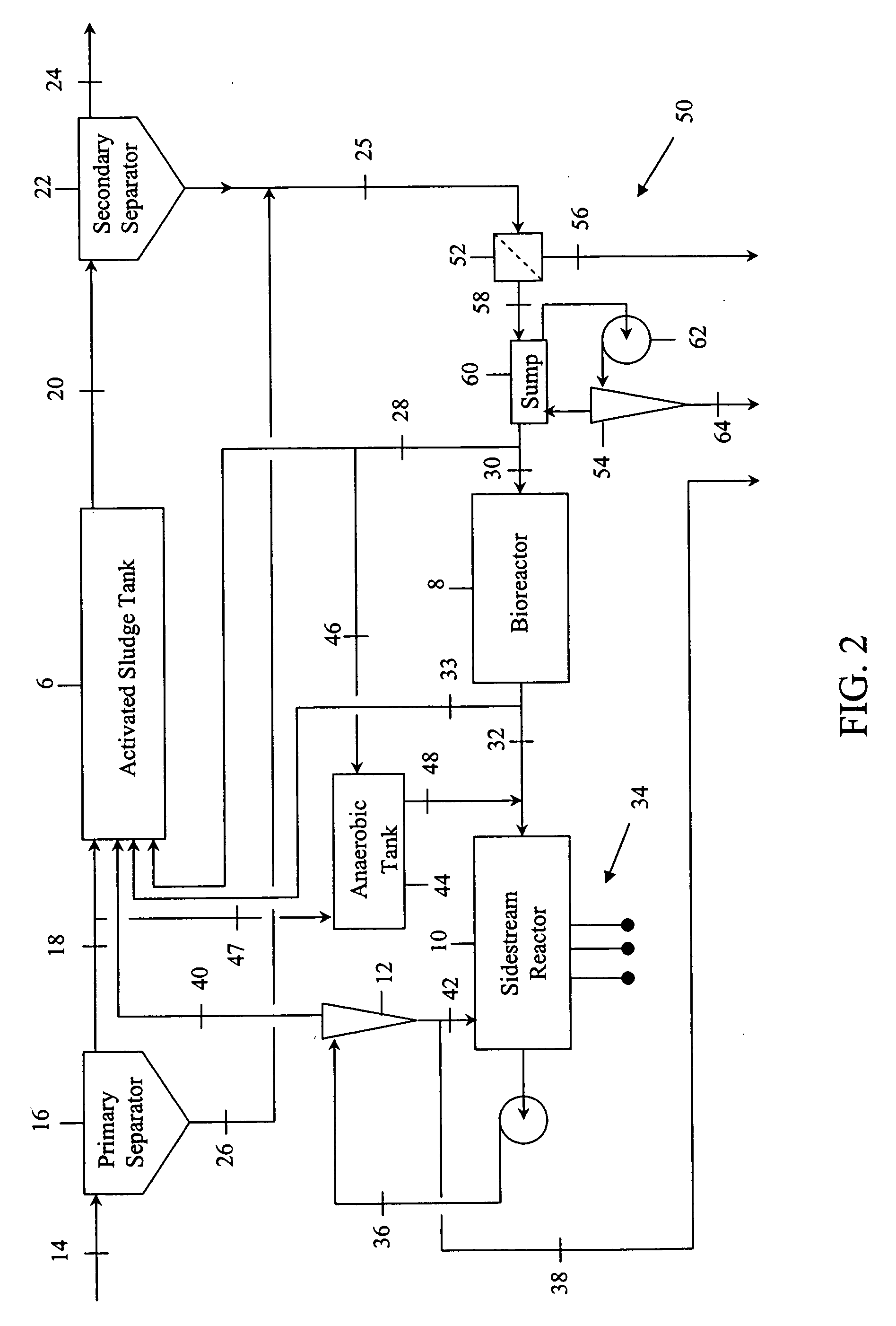

Process to enhance phosphorus removal for activated sludge wastewater treatment systems

InactiveUS20070000836A1Water/sewage treatment by centrifugal separationWater treatment parameter controlActivated sludgePhosphate

Contaminated wastewaters comprising biochemical oxygen demand (BOD), nitrogen and phosphorus are treated by an activated sludge process. The process utilizes an activated sludge tank, a solid-liquid separator, and a bioreactor to significantly reduce, or eliminate, waste activated sludge (WAS) within a sludge stream. A sidestream reactor is employed downstream from the bioreactor to remove soluble phosphates left in the sludge stream by the low WAS process. Within the sidestream reactor, a source of multivalent metal ions is added to a slightly alkaline sludge stream to precipitate the phosphates. The solid phosphates have a specific gravity higher than that of the organic matter in the sludge stream and may be separated from the sludge stream based upon differential settling velocity.

Owner:EVOQUA WATER TECH LLC

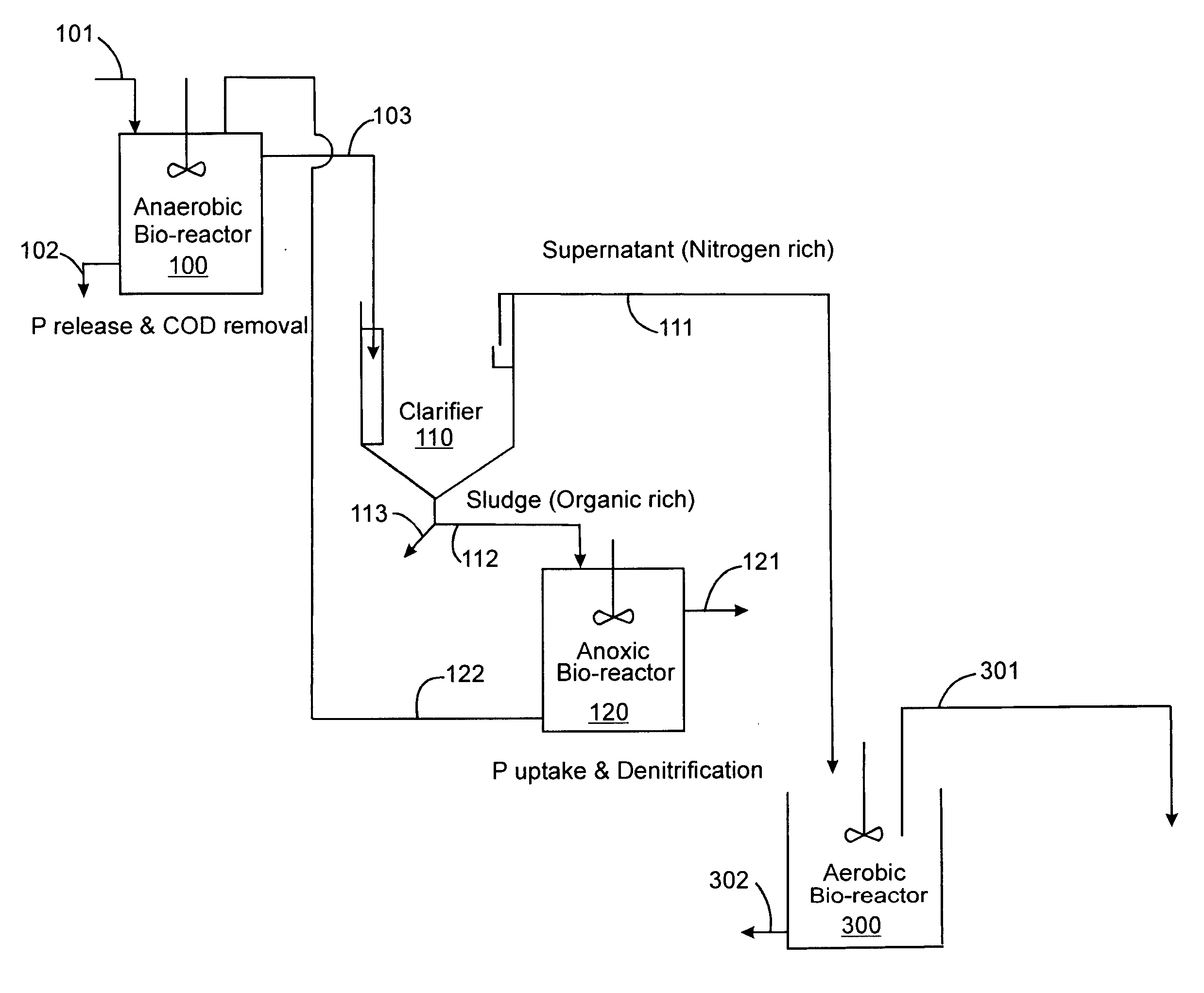

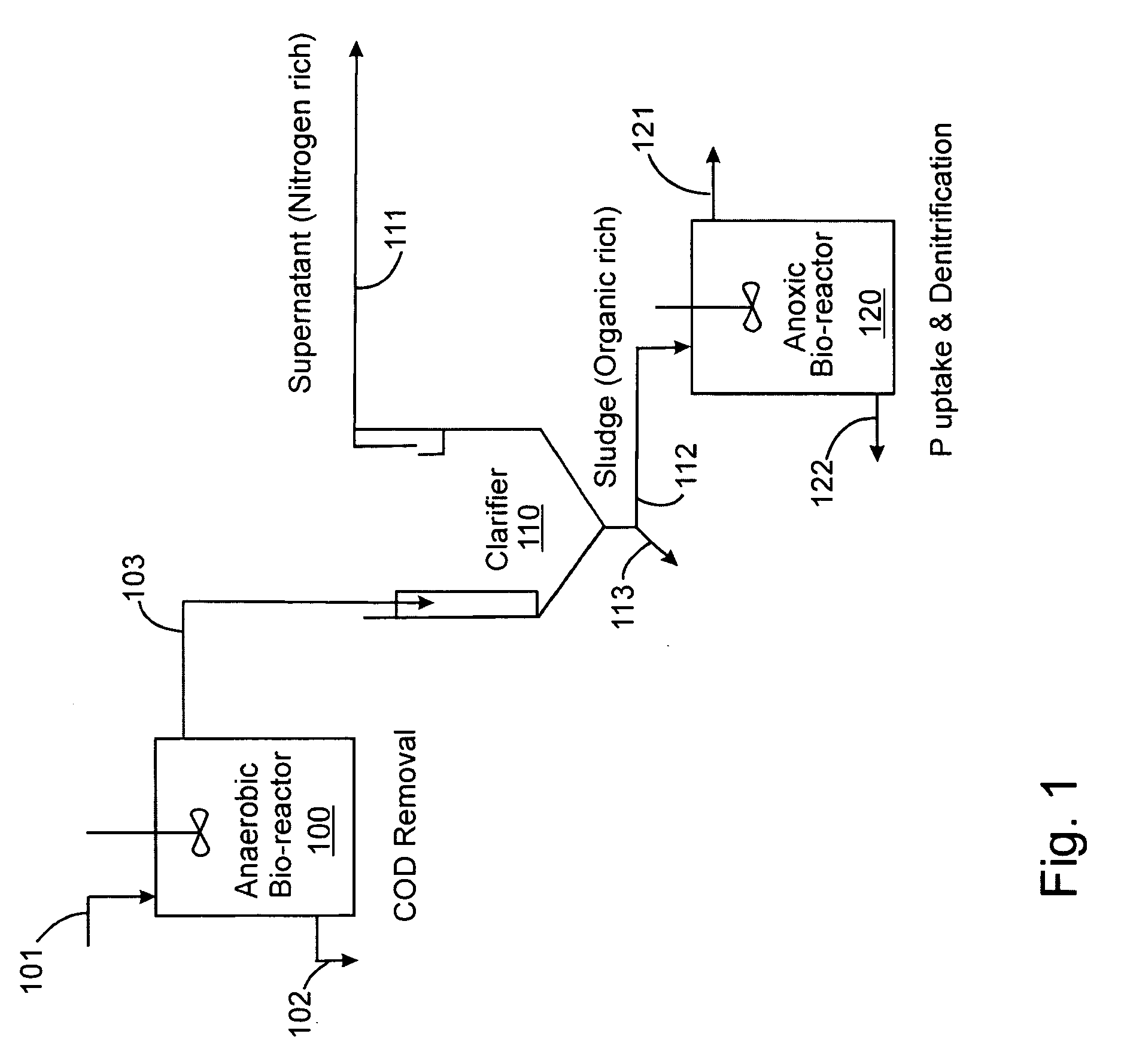

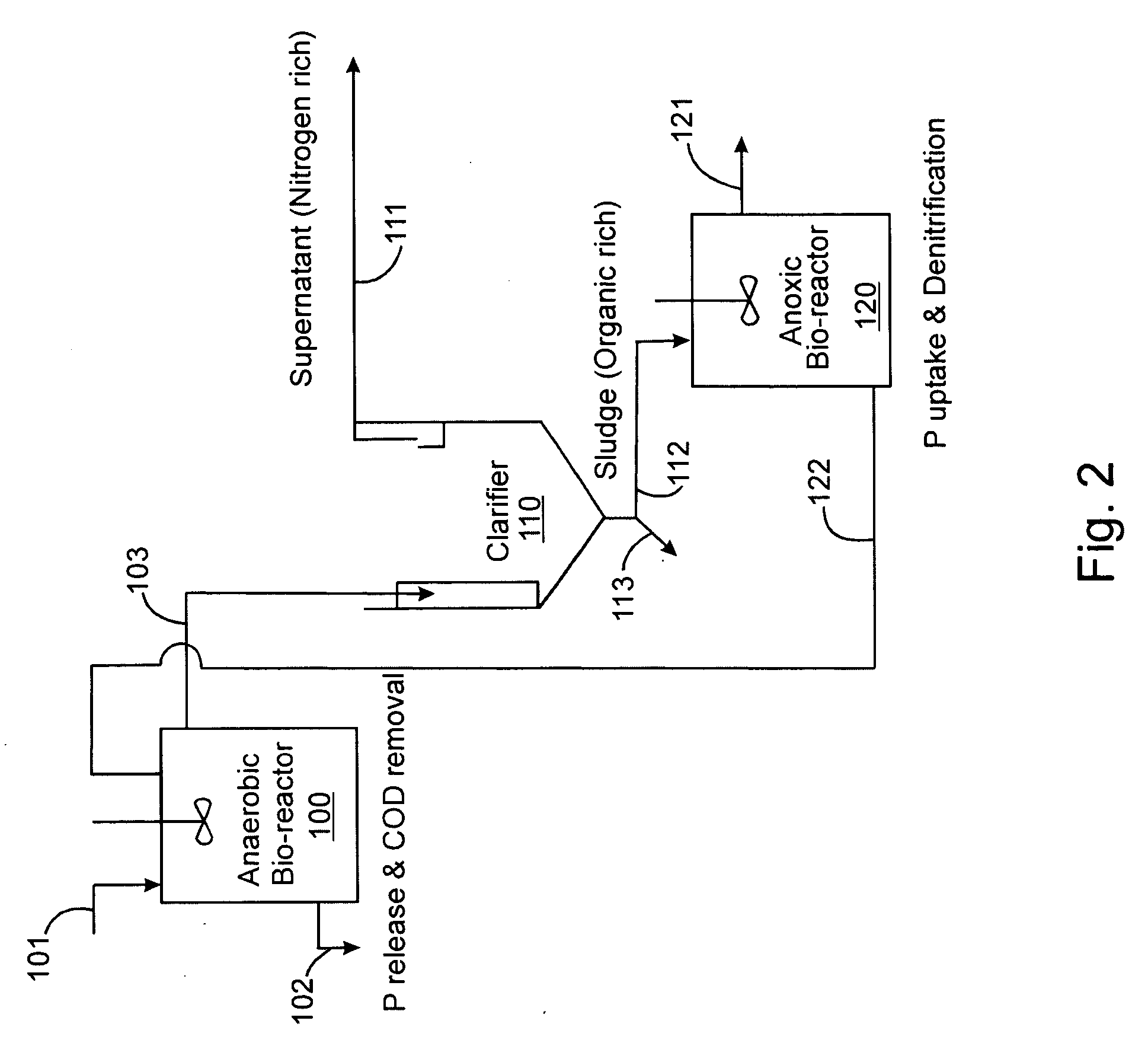

Treatment of wastewater containing phosphorous and nitrogen

InactiveUS20060249449A1Great extent of P releaseHigh P uptakeTreatment using aerobic processesSeparation devicesOxygenClarifier

A method and process for the treatment of wastewater containing phosphorous and nitrogen. The wastewater is first anaerobically treated to produce an anaerobic effluent from which insoluble organic carbon is separated to form a sludge rich in organic carbon that is used as a substrate during anoxic treatment of the wastewater by de-nitrifying phosphorous accumulating organisms (DPAO's) and ordinary de-nitrifying organisms. The separation of insoluble organic carbon is normally conducted using a clarifier located intermediate the anaerobic and anoxic bio-reactors. In one embodiment, the ammonia rich clarifier supernatant is directed to an aerobic reactor for nitrification and the nitrate produced is recycled to the anoxic bio-reactor. The final effluent may be membrane filtered to retain nitrifying biomass within the aerobic bio-reactor. The invention reduces overall hydraulic residence time and sludge volume, which results in a smaller, less expensive wastewater treatment system.

Owner:UNIV OF WESTERN ONTARIO

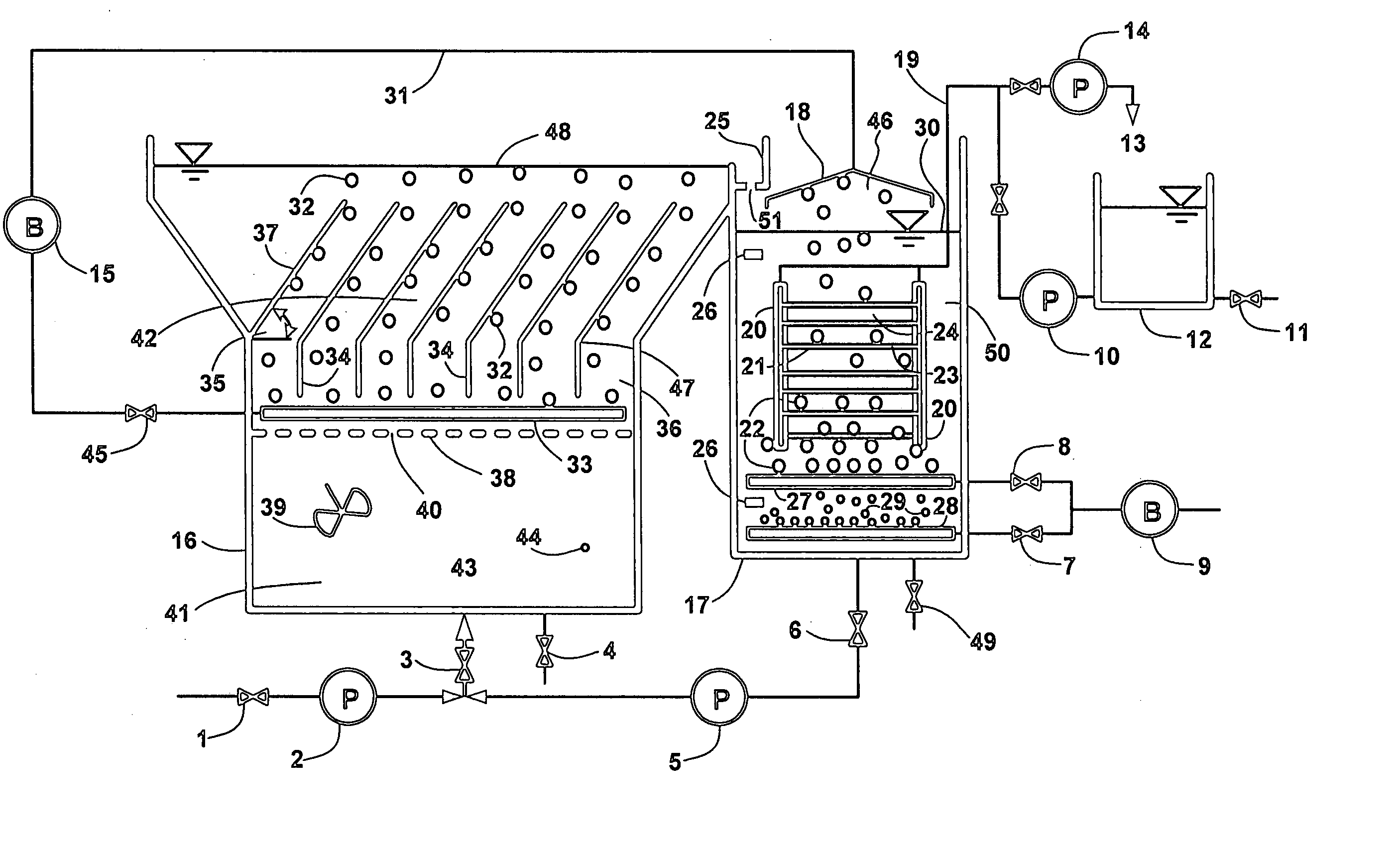

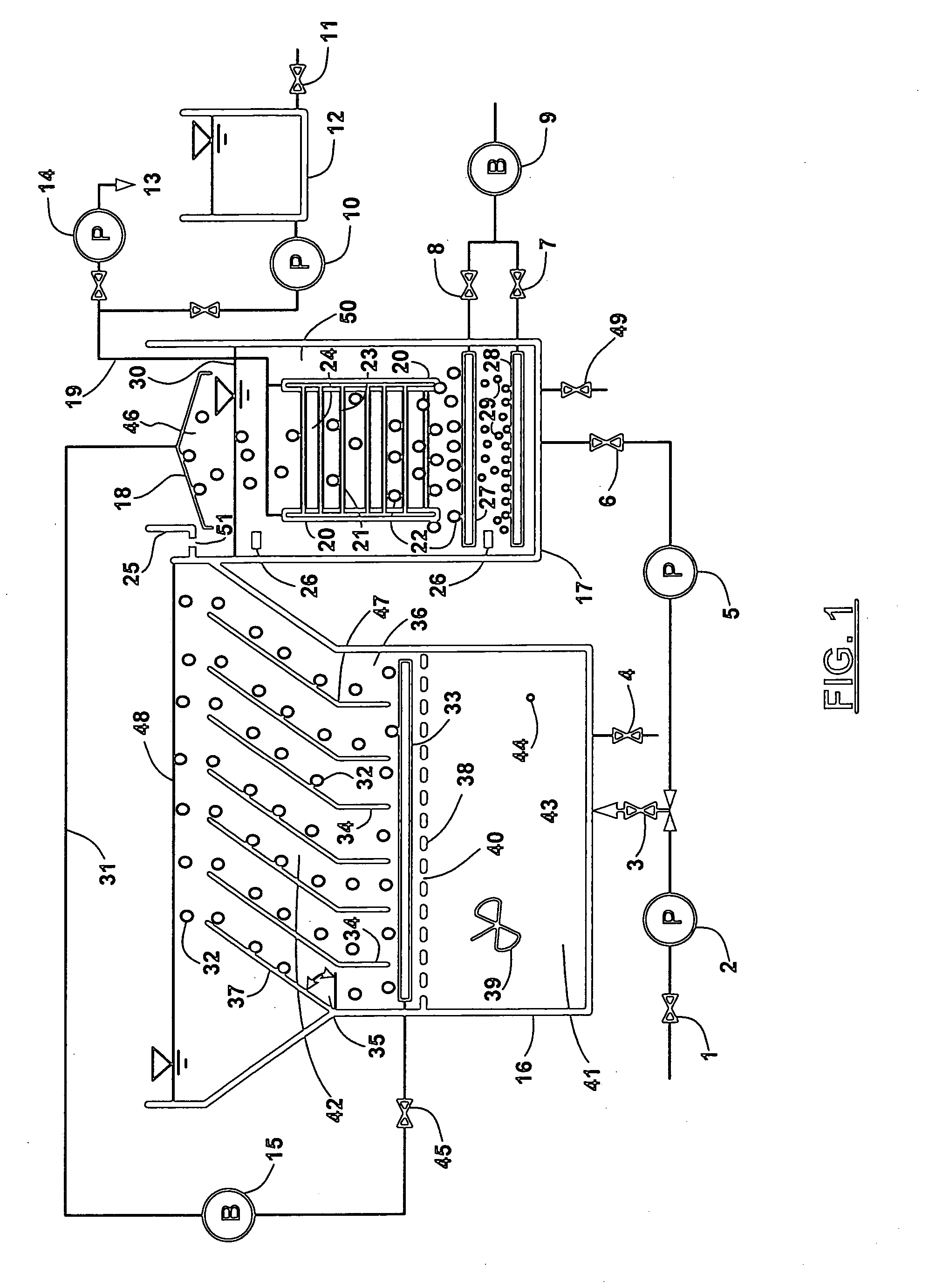

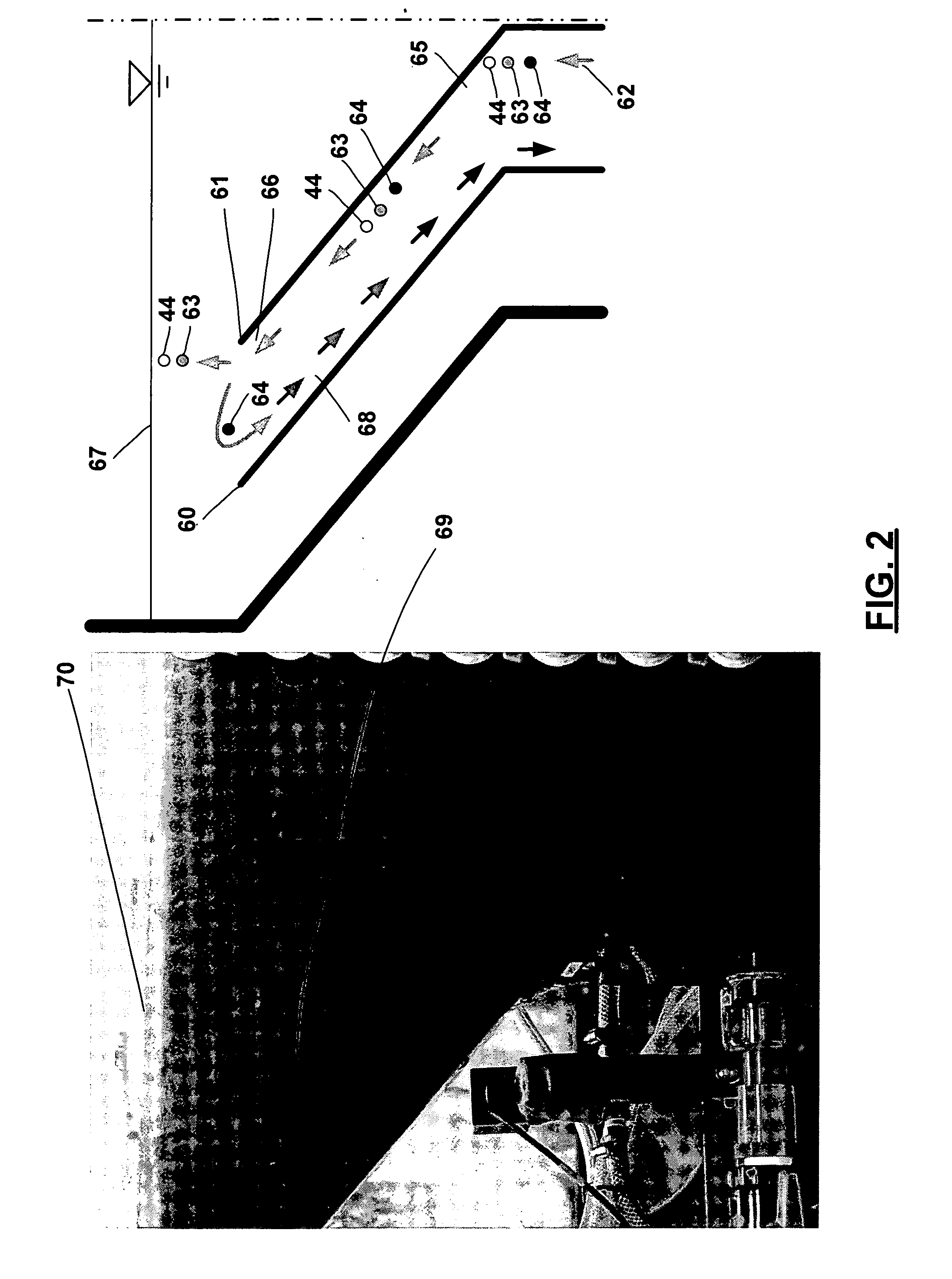

Zero excess sludge membrane bioreactor

InactiveUS20050194310A1High yieldAcceptable levelTreatment using aerobic processesDialysis systemsChemical oxygen demandTotal nitrogen

An inclined plate coupled membrane bioreactor for treating feed water having excessive level of nutrients in particular chemical oxygen demand and total nitrogen and suspended solids has an aerobic bioreactor for nitrification and aerobic biodegradation in which membranes are submerged for permeate extraction, and an anoxic bioreactor for denitrification within which the inclined plates are outfitted to confine as much anoxic sludge as possible. An air oxygenating and an air scouring are continuously provided to the aerobic bioreactor to maintain a desired aerobic environment and to mitigate membrane fouling while an intermittent air blowing is provided to the anoxic bioreactor to blow out gaseous content generated through denitrification and to rectify the uniformed flow along the inclined plates. The aerobic sludge is recycled to the lower compartment of anoxic bioreactor and the supernatant of anoxic bioreactor is collected as weir effluent and delivered to the downstream aerobic bioreactor. Permeate is intermittently extracted from the membranes by a suction pump. There is no excess sludge withdrawn from the inclined plate coupled membrane bioreactor throughout the experiment.

Owner:YAMAMOTO KAZUO +1

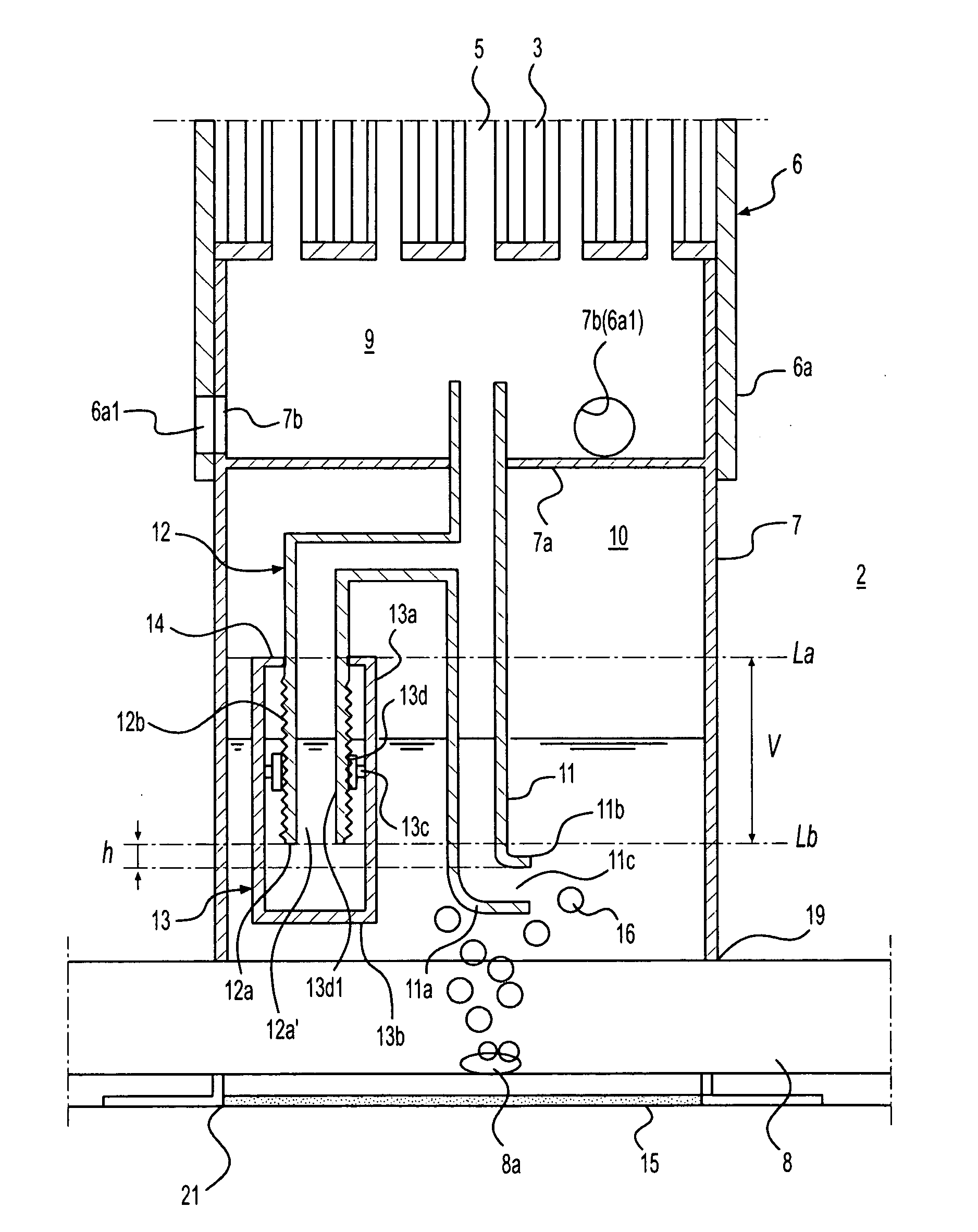

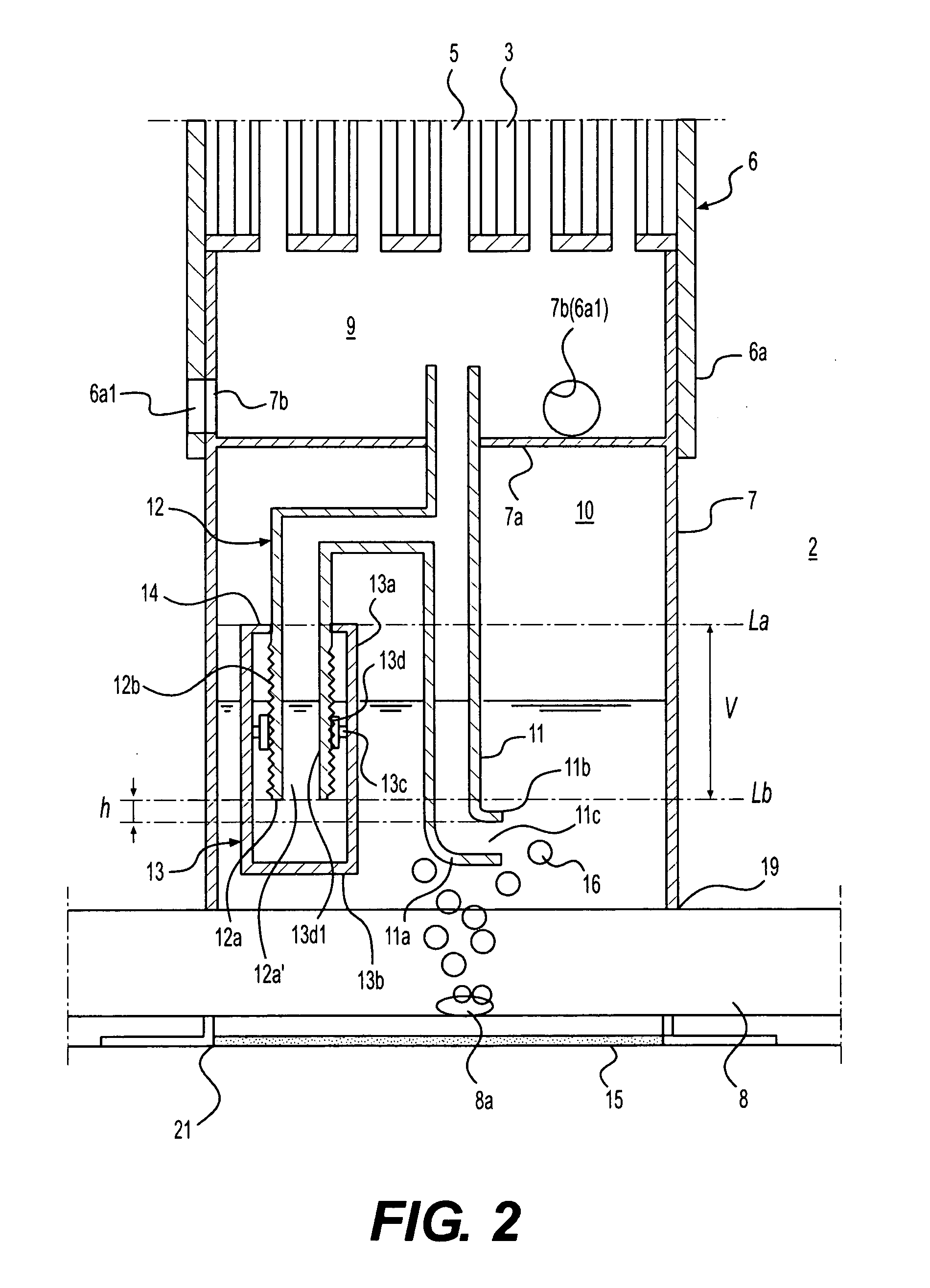

Intermittent gas flow apparatus and membrane separation apparatus

InactiveUS20090194477A1Easy constructionProlong lifeMembranesSpecific water treatment objectivesEngineeringGas chamber

Intermittent gas flow and membrane separation apparatus and methods of use including an internal gas chamber including an upper wall; at least one inlet for supplying gas to the internal gas chamber; a column pipe that extends above the upper wall of the internal gas chamber, the column pipe including a lower end portion including a lower end portion opening in the internal gas chamber, the column pipe linking the internal gas chamber to an area external to the internal gas chamber for fluid flow between the internal gas chamber and the external area; an auxiliary pipe including one end portion connected to the column pipe for fluid flow between the auxiliary pipe and the column pipe, and another end portion branched off from the column pipe, the another end portion including an opening located in the internal gas chamber at a position higher than the lower end portion opening of the column pipe by a predetermined height; and an auxiliary pipe external tubular member including a closed end, the auxiliary pipe external tubular member surrounding the another end portion of the auxiliary pipe with the closed end being positioned below the opening in the another end portion of the auxiliary pipe, and spaced from the another end portion by a predetermined distance permitting fluid flow into the space between the wall of the tubular member and the auxiliary pipe.

Owner:ASAHI KASEI CHEM CORP

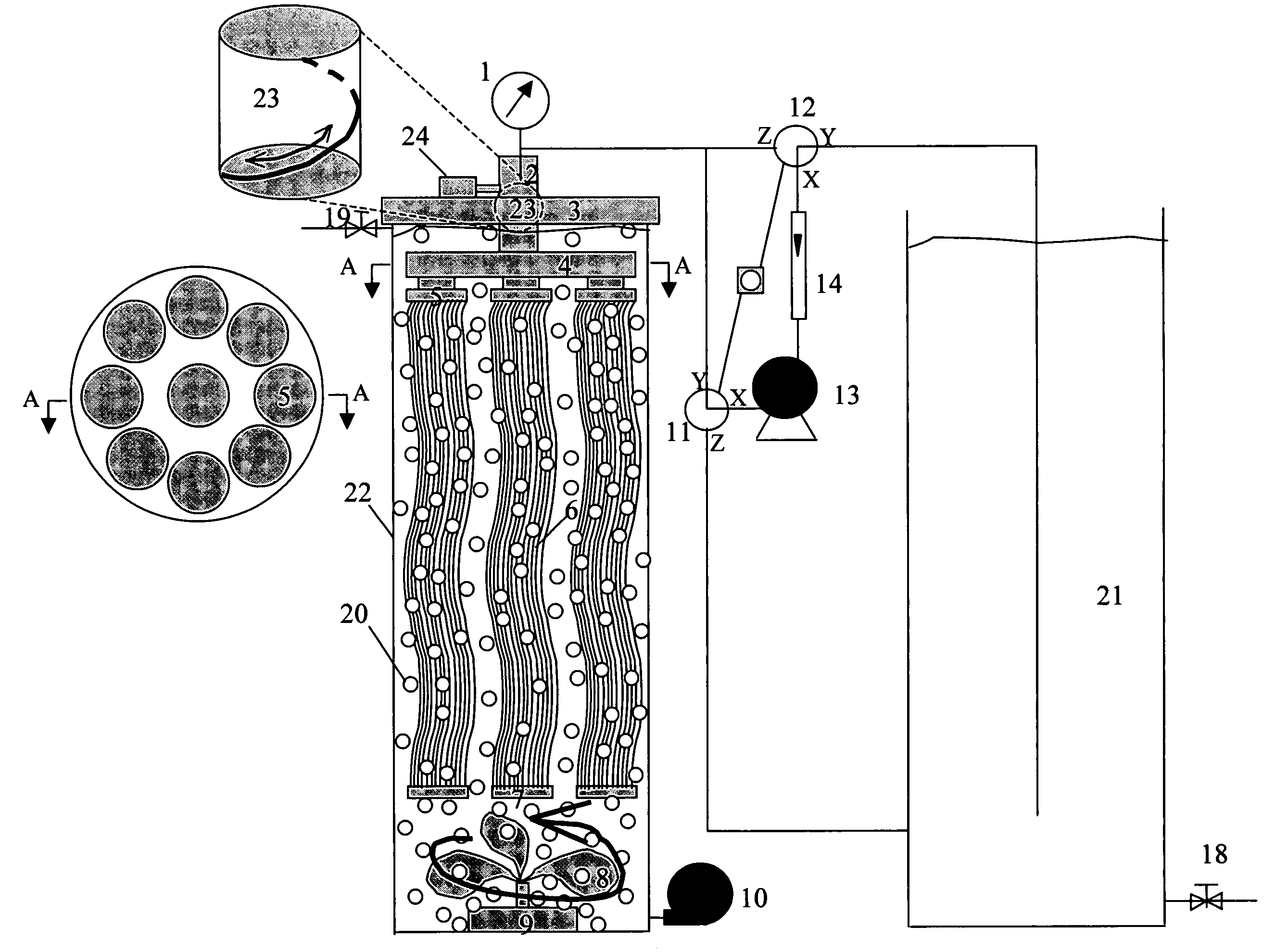

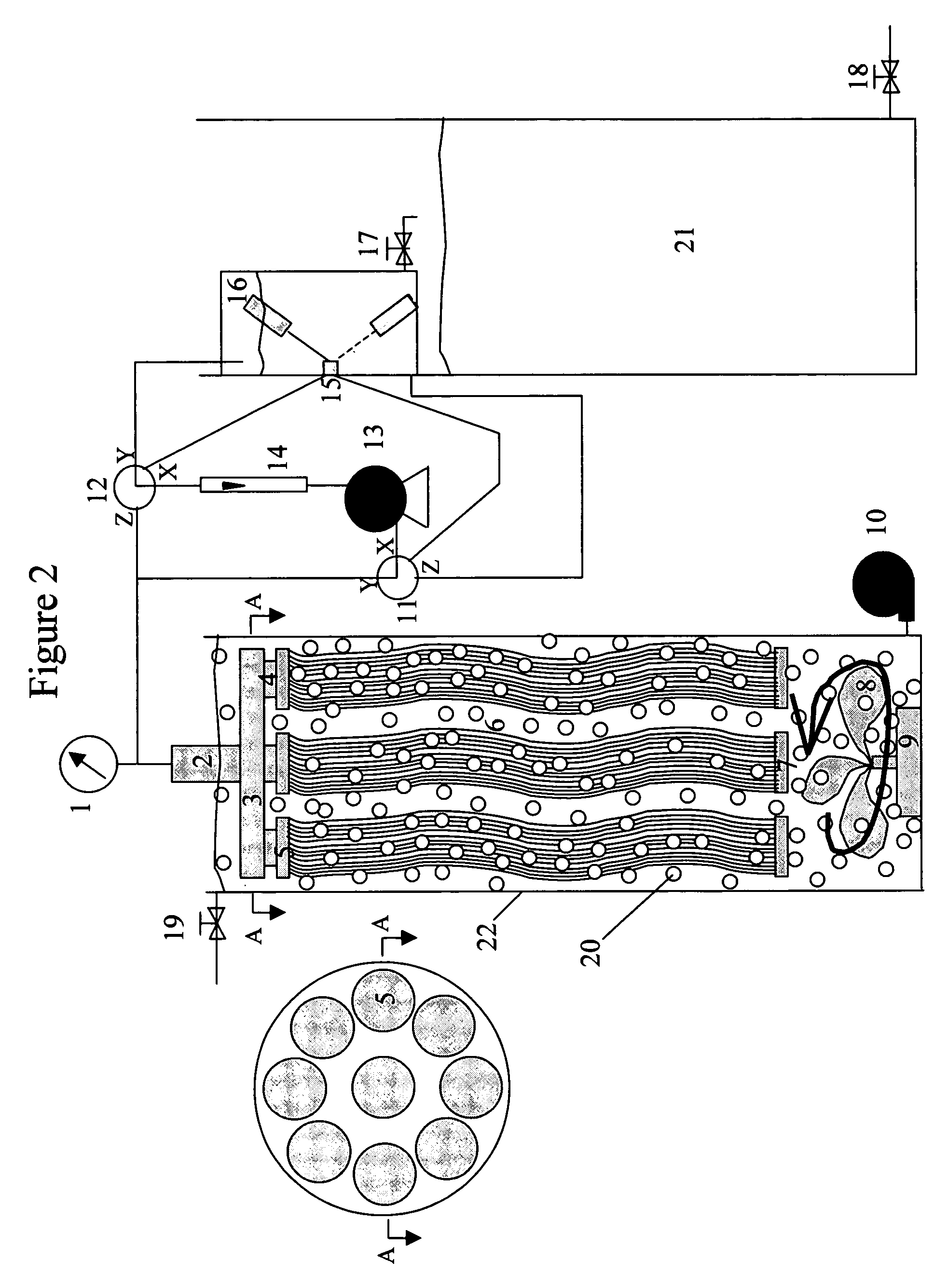

Advanced submerged membrane modules, systems and processes

Advanced submerged membrane systems are provided. Said submerged membrane systems have multiple membrane modules comprising of strips of flat sheet membrane, bundles of self-support hollow fiber membranes braided together for reinforcement, tubular membranes, and braid supported hollow fiber membranes. Said submerged membrane systems have alternating relay, or two-way floating switch or computer to control filtration and back flush / pulse cleaning. Said submerged membrane systems have an oscillating motor, and aerator which can generate liquid vortex (whirlpool) flow around membrane to keep membrane from fouling. The present invention provides advanced submerge membrane systems at very low cost for drinking water production, wastewater treatment and membrane bioreactors for biotech, pharmaceutical and other industries.

Owner:JI JIANG

Method for processing lignocellulosic material

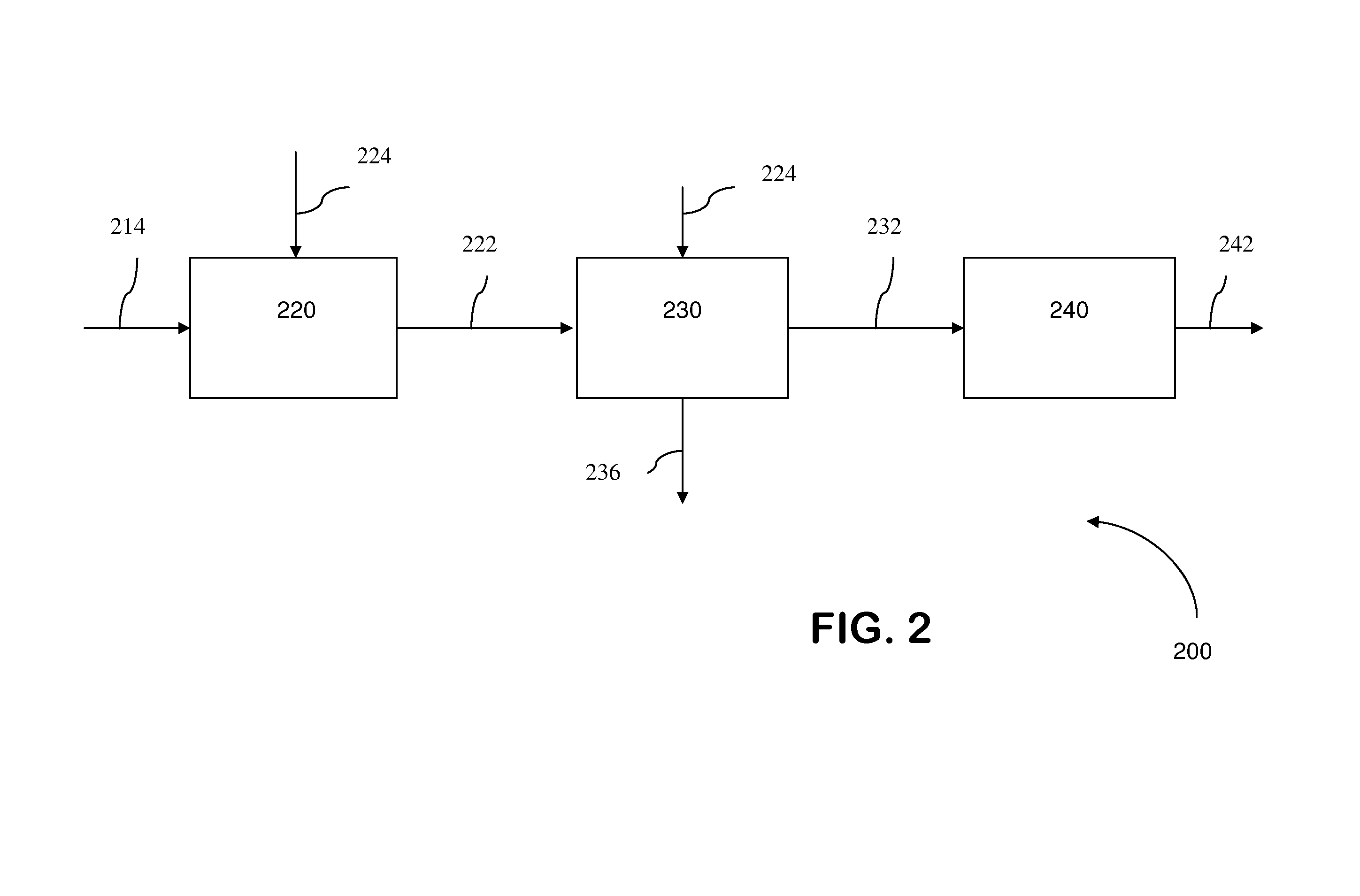

InactiveUS20020192774A1High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseEnvironmental engineering

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process. involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

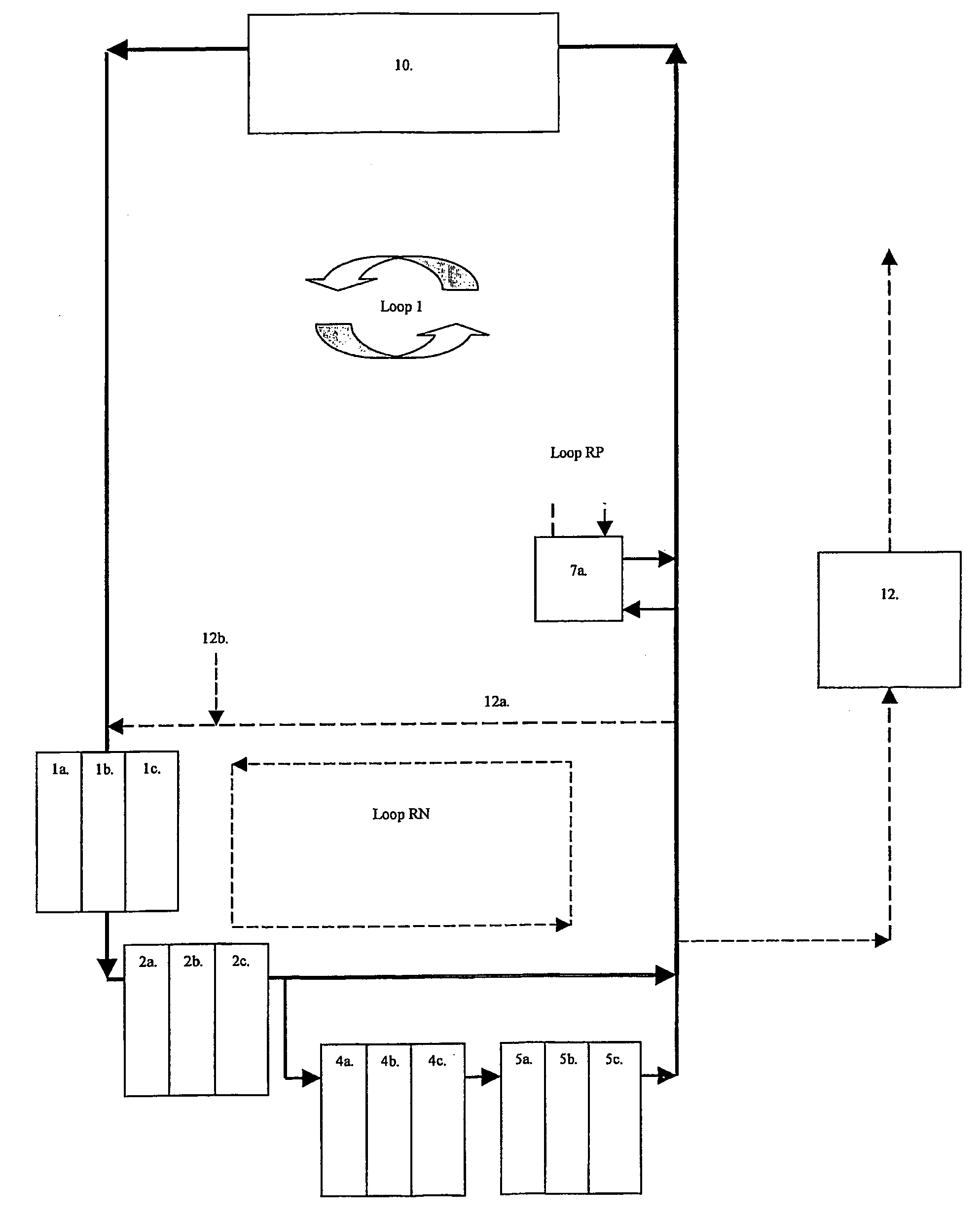

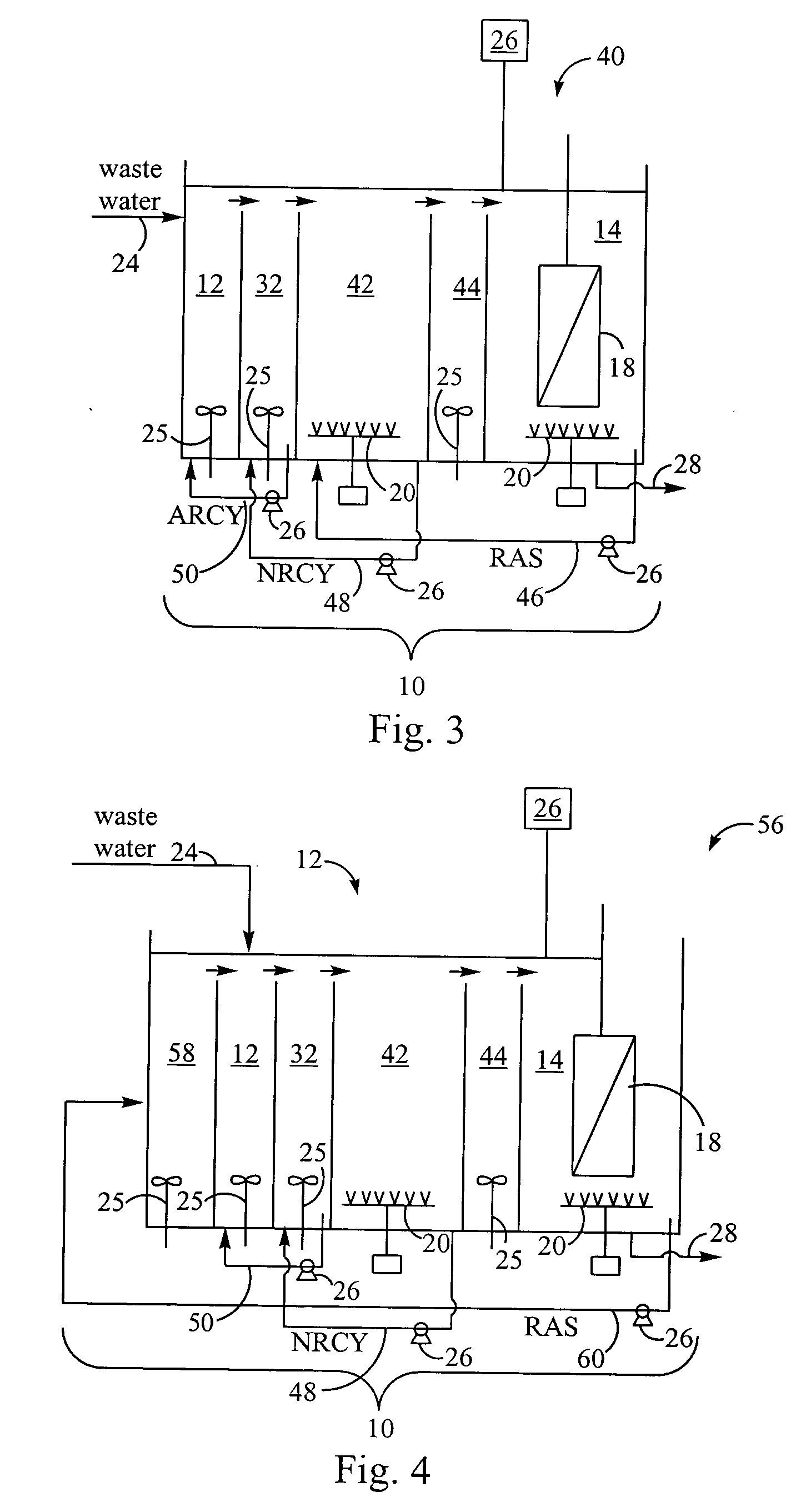

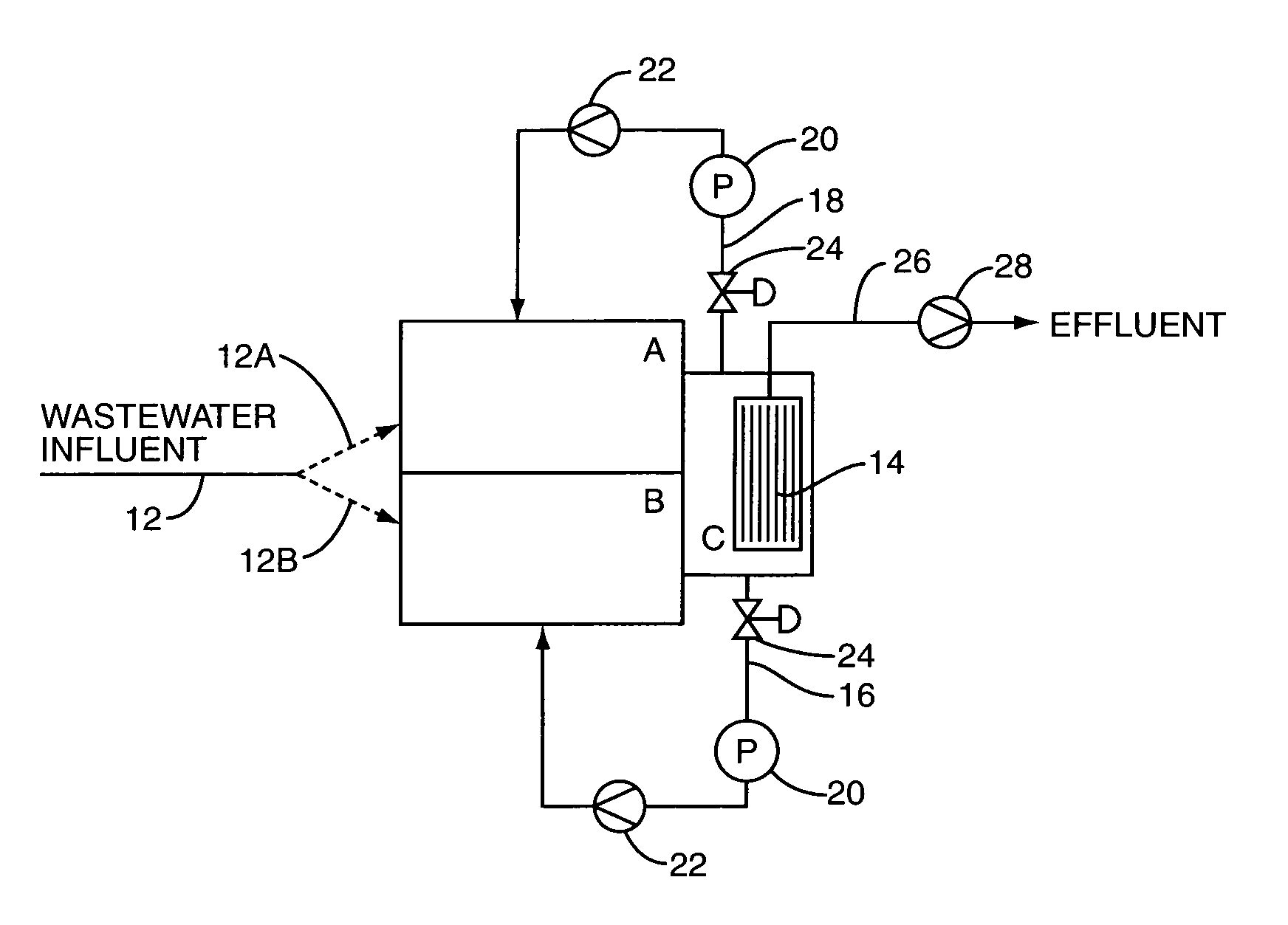

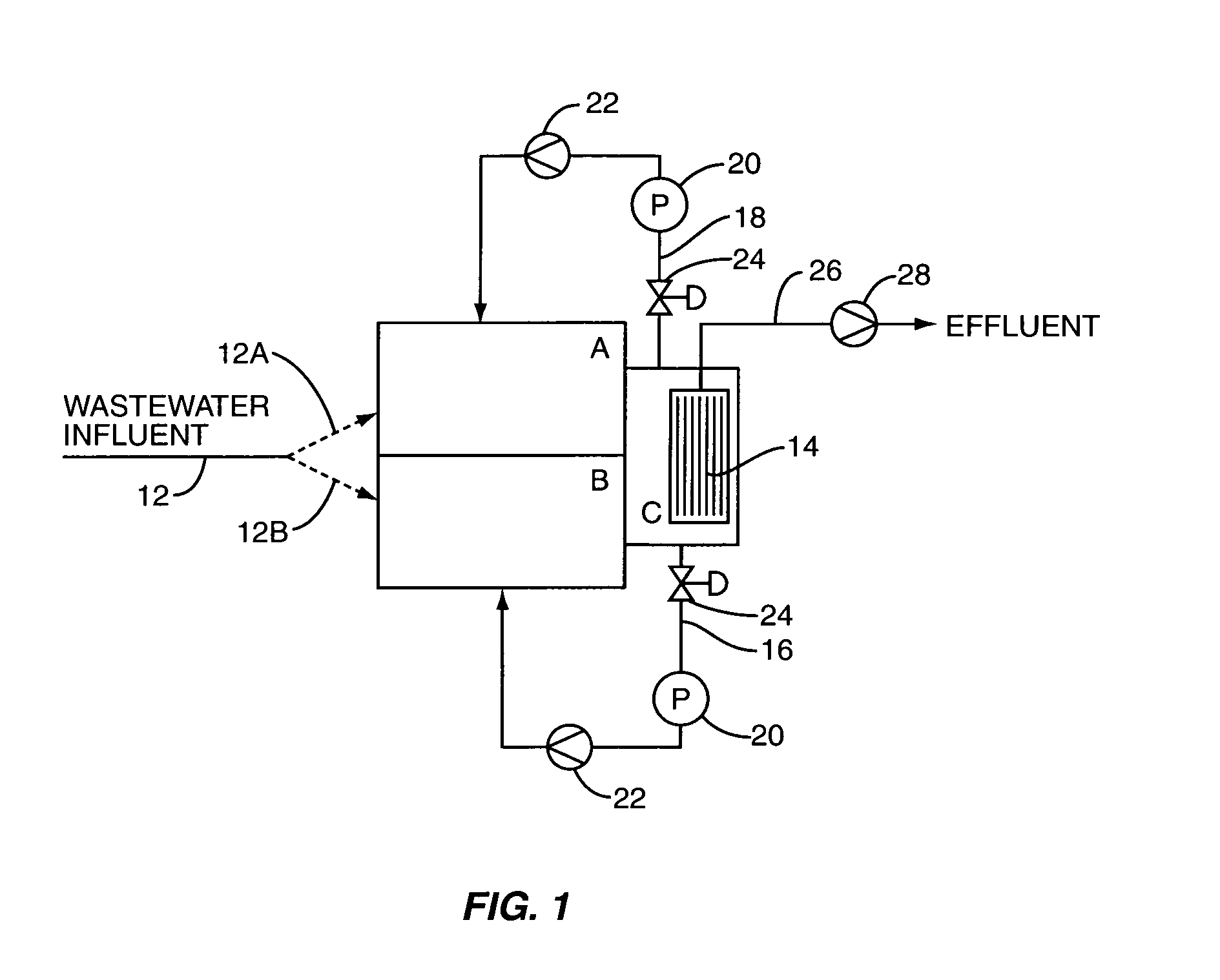

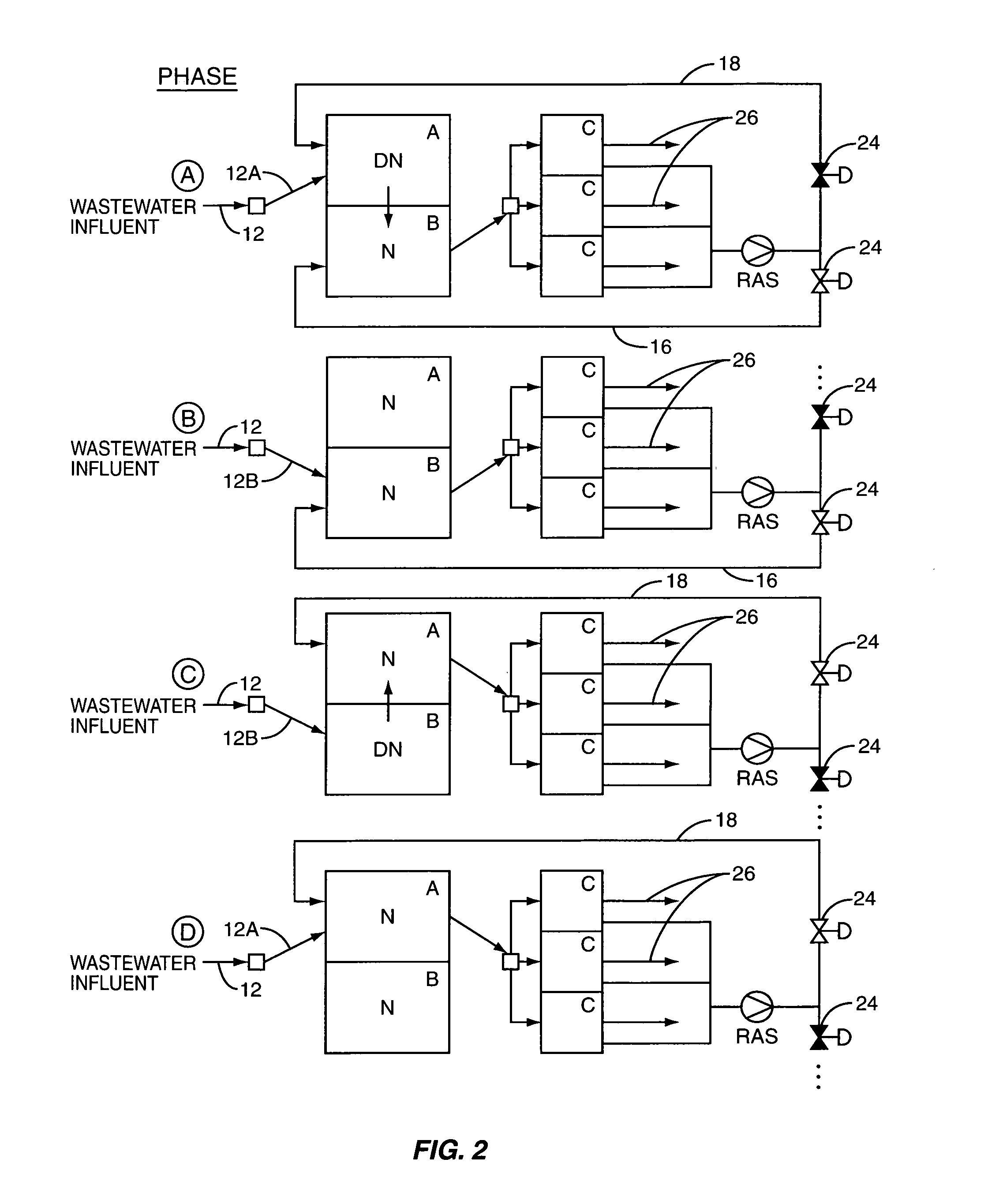

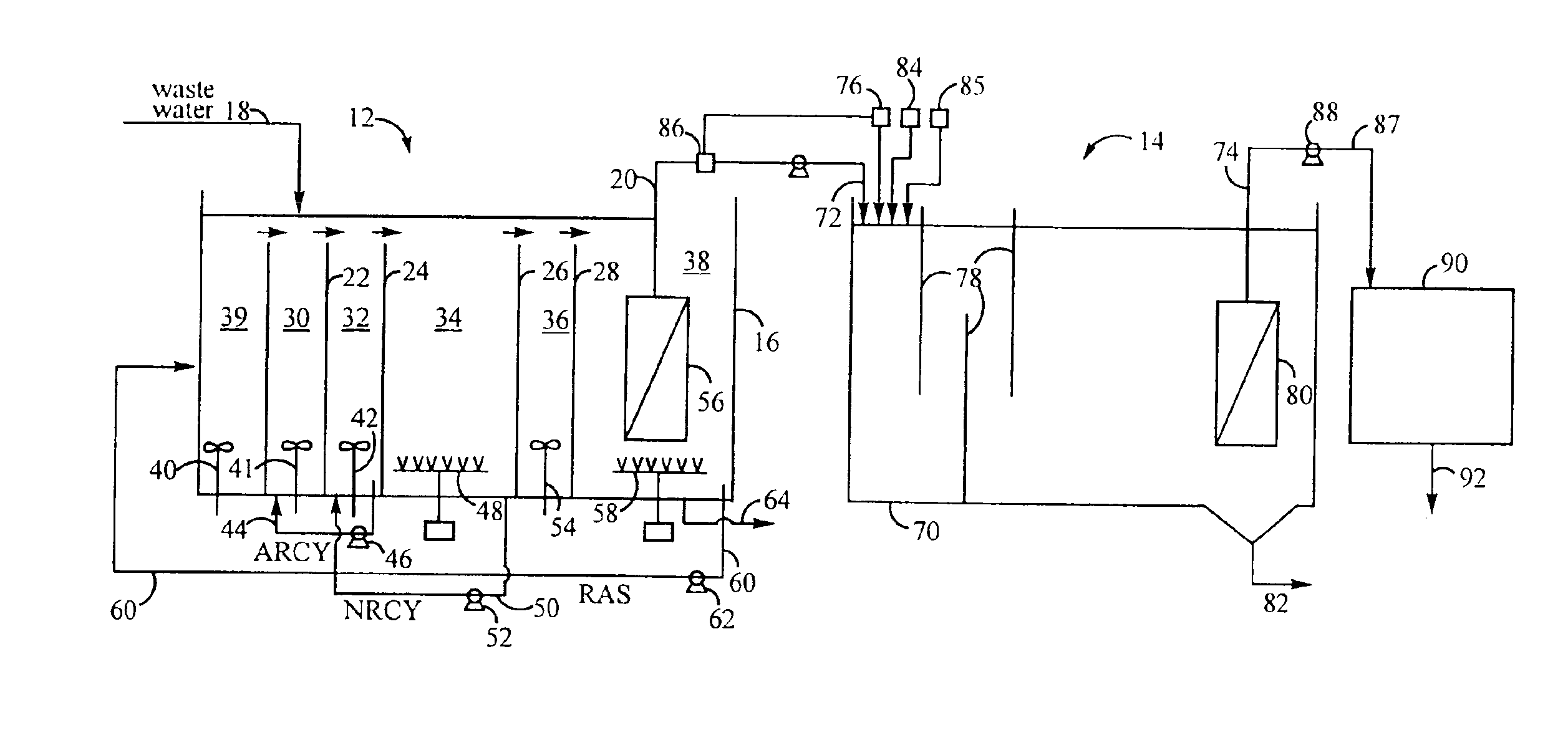

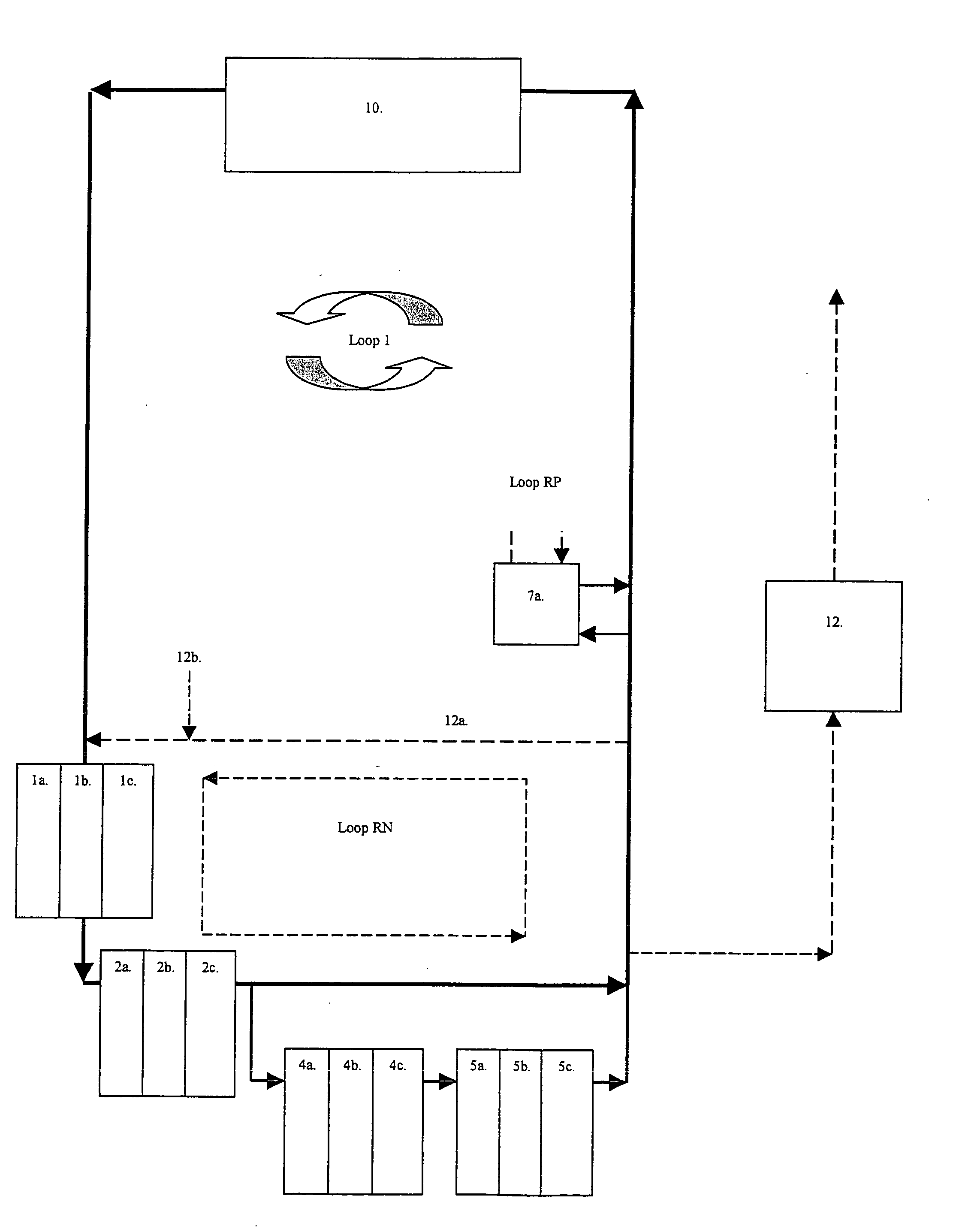

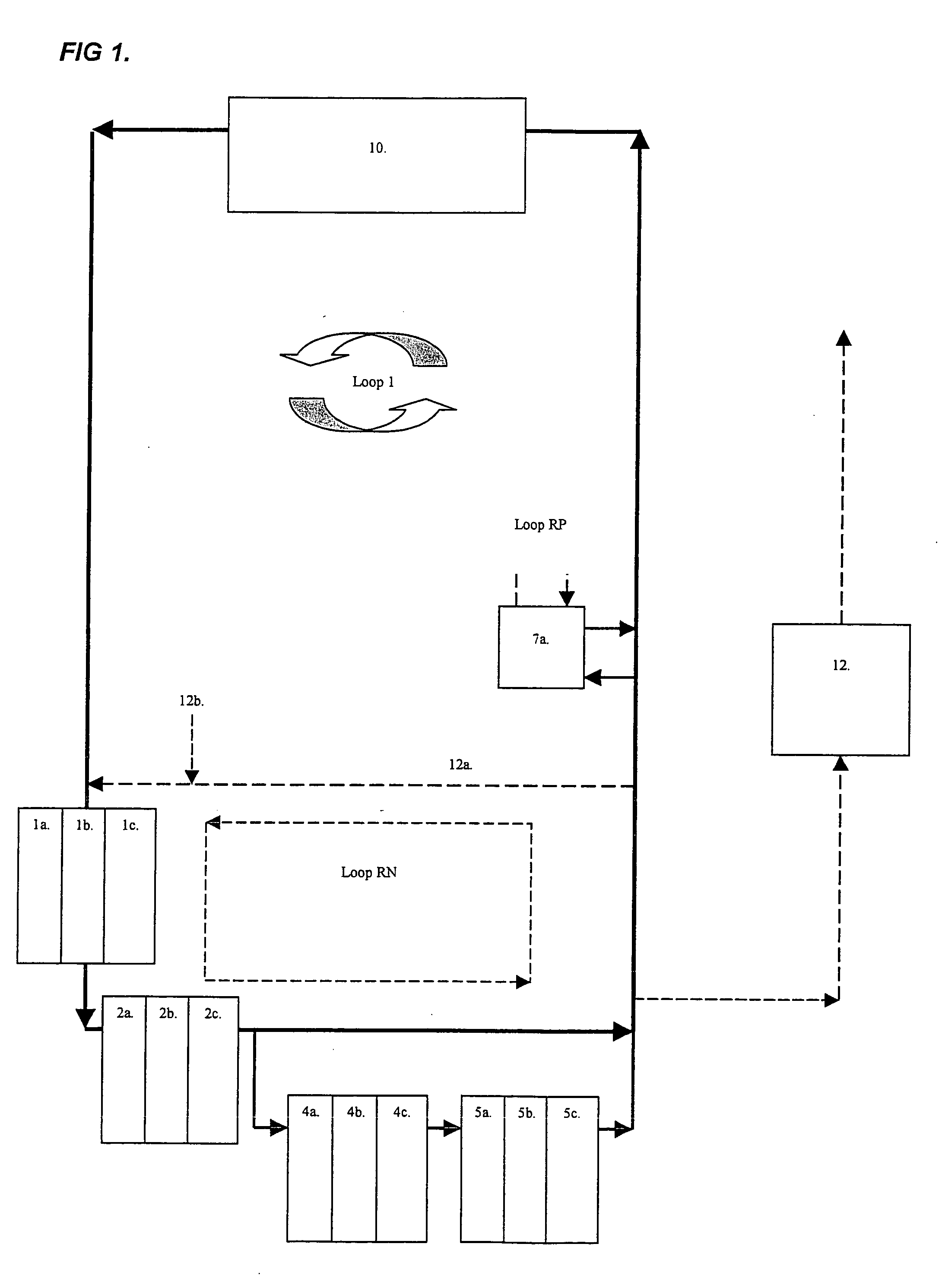

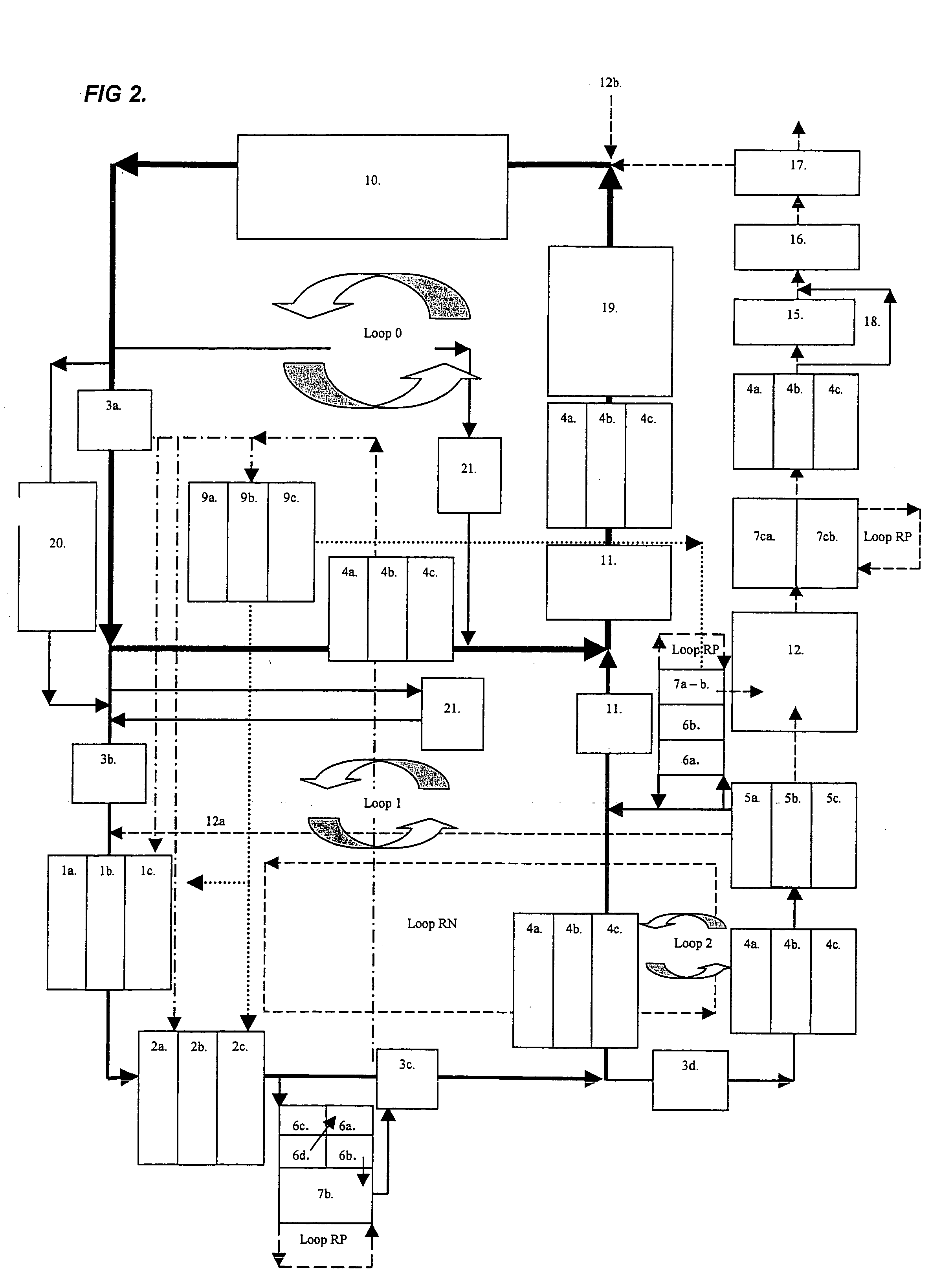

Method and system for nitrifying and denitrifying wastewater

ActiveUS7147778B1Reducing and minimizing dissolved oxygen concentrationReduces and minimizes dissolved oxygen concentrationTreatment using aerobic processesSeparation devicesActivated sludgeOxygen

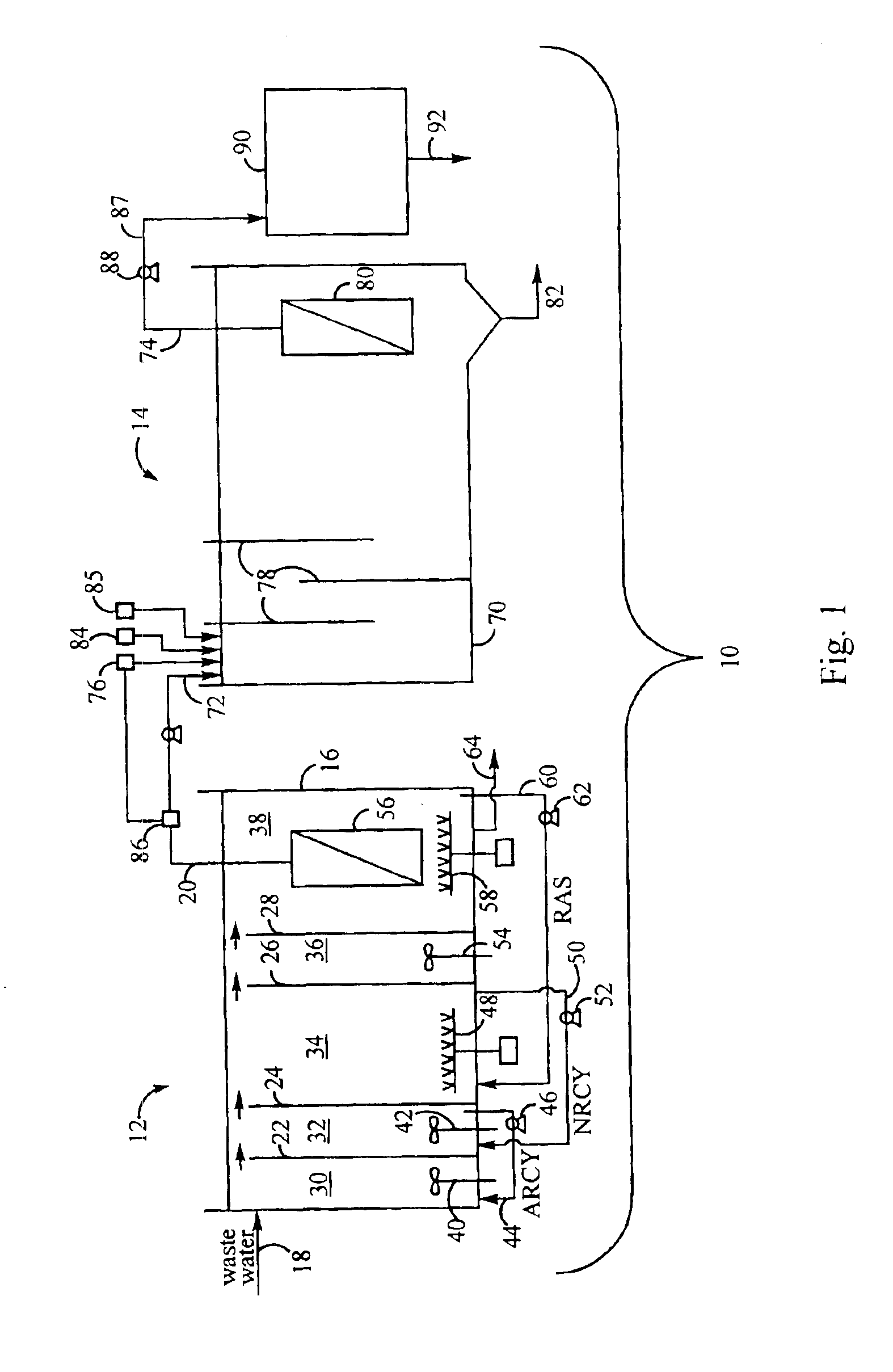

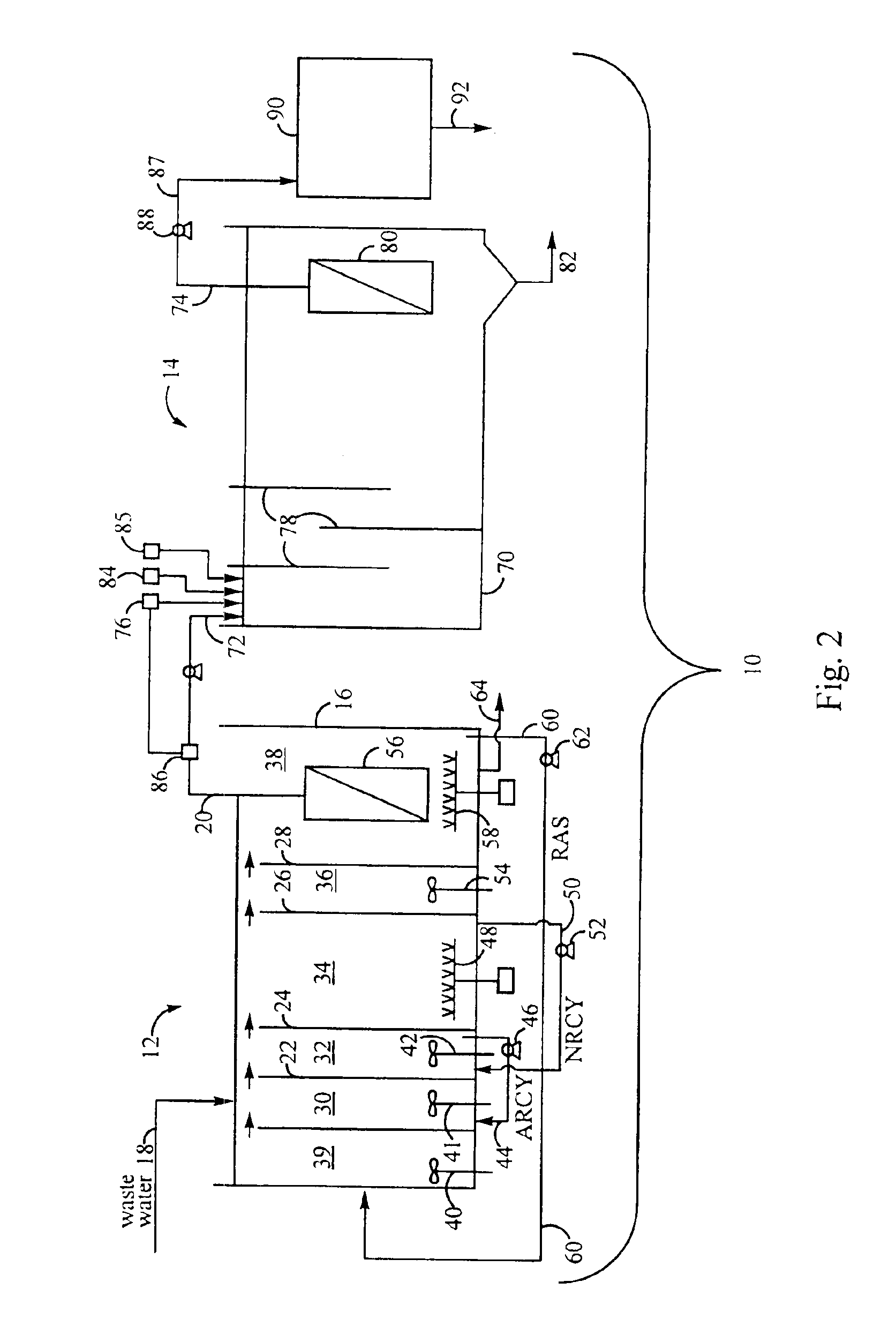

A wastewater treatment system is provided that includes first and second reactors, each operative to nitrify or denitrify wastewater contained therein. Downstream from the first and second reactors is a membrane reactor that operates under aerobic conditions and includes one or more submersed membranes for separating solids. Extending between the membrane reactor and each of the first and second reactors is a return activated sludge line with appropriate controls for permitting return activated sludge to be directed to one of the reactors at a time. To nitrify and denitrify wastewater, a wastewater influent stream is alternatively directed to the anoxic reactors which are alternatively operated under aerobic and anoxic conditions so as to nitrify or denitrify the wastewater contained therein. To reduce or minimize the dissolved oxygen return from the membrane reactor to the first and second reactors, the flow of return activated sludge is controlled such that generally return activated sludge is returned to the reactor operating under aerobic conditions.

Owner:KRUGER I INC

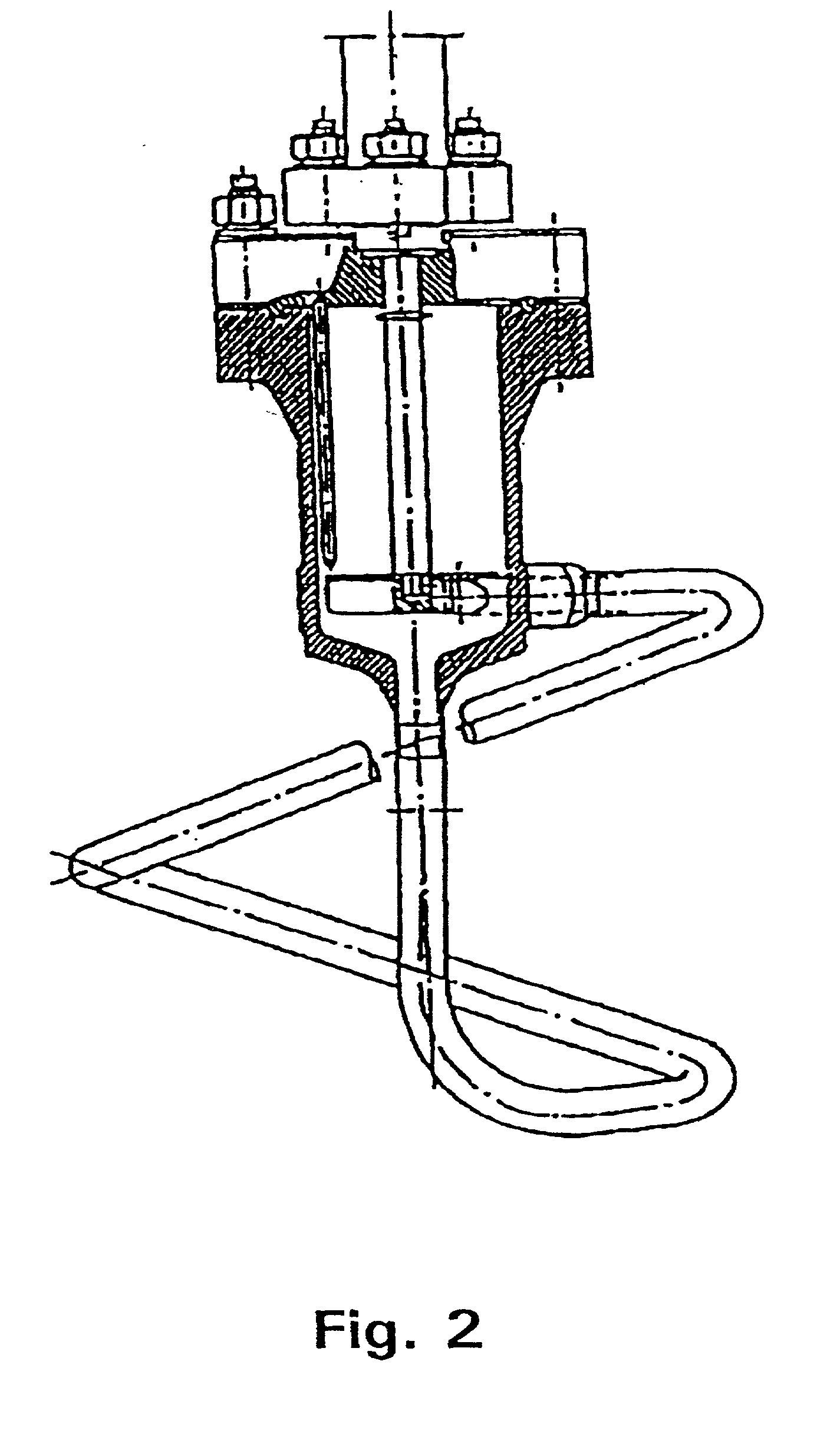

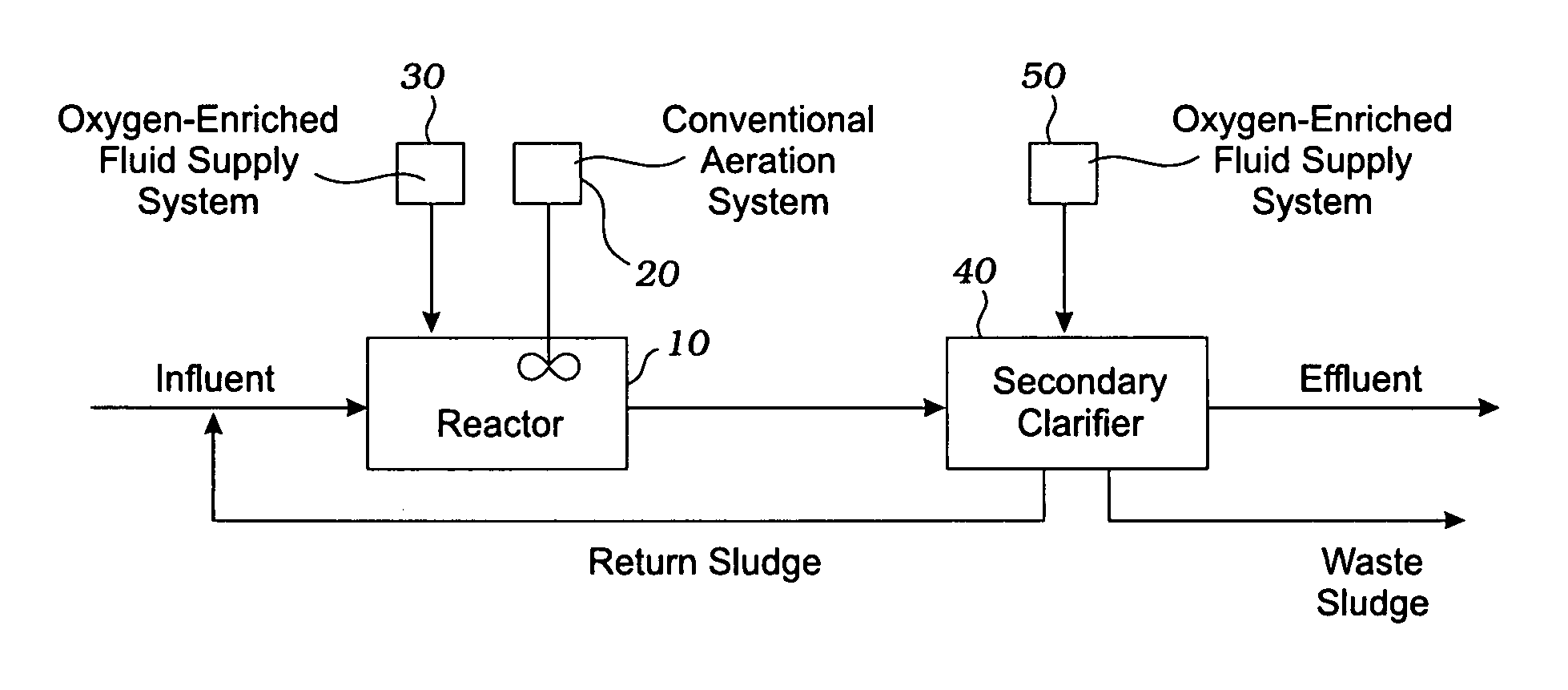

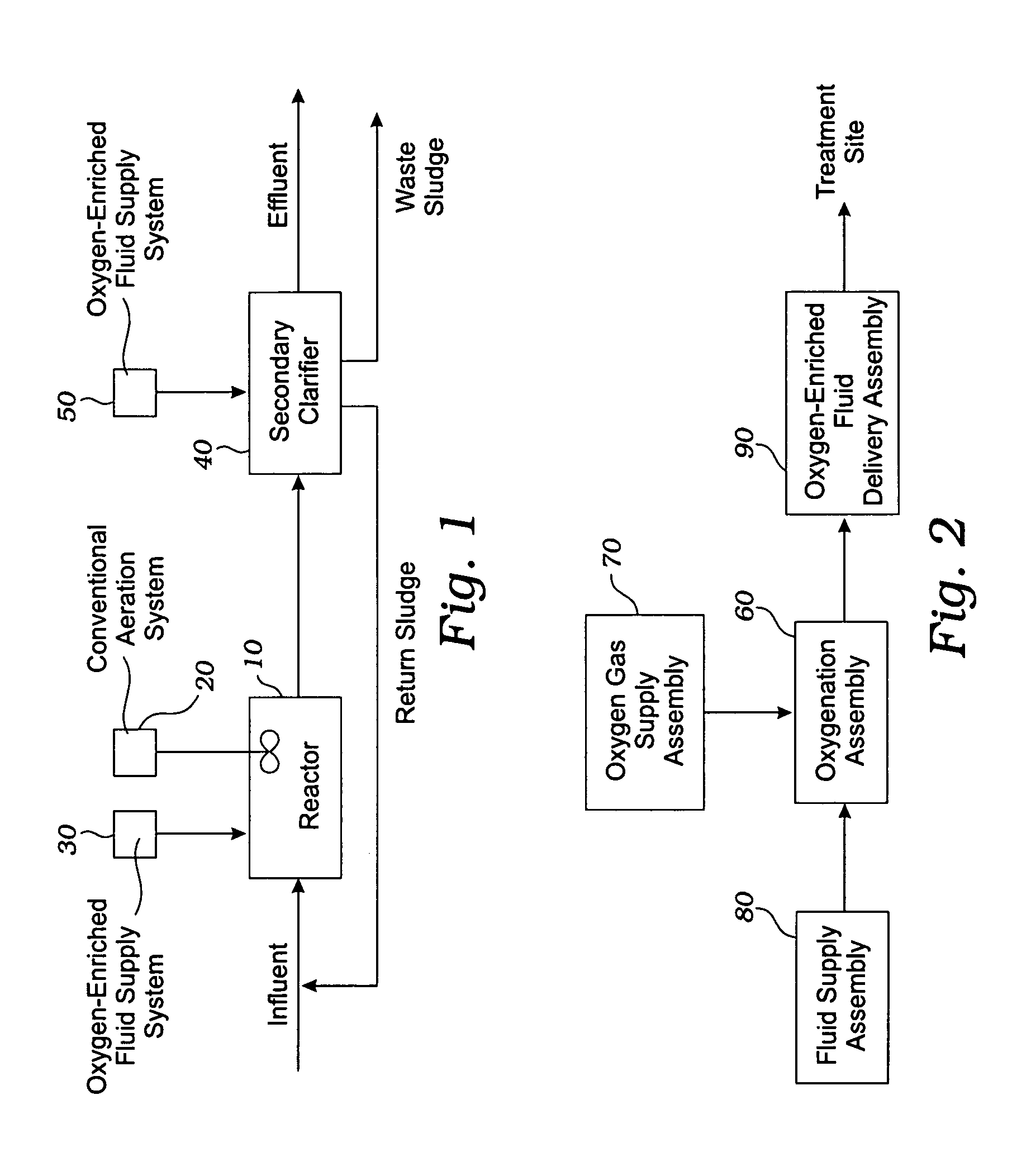

Apparatus for oxygenating wastewater

InactiveUS7008535B1Easy to assembleEasy to cleanTreatment using aerobic processesFlow mixersForming gasWastewater

A method and apparatus creates gas-enriched fluid that is used to treat wastewater. In one embodiment, the wastewater is withdrawn from a supply of wastewater to be treated, and the wastewater is delivered in an atomized manner to a vessel pressurized with gas to form gas-enriched wastewater. The gas-enriched wastewater is then delivered to the supply of wastewater to be treated.

Owner:WAYNE STATE UNIV +1

Magnetic biological carrier and preparation method thereof

InactiveCN102225806APromote recoveryRealize dynamic regenerationSustainable biological treatmentBiological water/sewage treatmentResource utilizationEngineering

The invention discloses a magnetic biological carrier and a preparation method thereof. The raw materials of the magnetic biological carrier comprise aggregate, iron oxide, a binder and a reducing agent. The preparation method of the magnetic biological carrier comprises the following steps of: mixing the aggregate, iron oxide and the reducing agent, crushing, screening with a 60-mesh sieve to obtain a mixed material, adding water which is 30-60% of the mixed material by weight to the binder, stirring for dissolving the binder to obtain a binder solution, then mixing the binder solution with the mixed material, uniformly stirring, granulating and shaping to obtain 2-10 mm granules, drying the granules till the water content of the granules is less than 10%, and calcining at the temperature of 350-1100 DEG C for 0.2-10 hours to obtain the magnetic biological carrier. The magnetic biological carrier provided by the invention can be applied to the deep treatment of secondary treatment water of domestic sewage, meets the requirements of landscape water replenishing and circulating cooling water treatment, and can be used for realizing the deep treatment and resource utilization of industrial wastewater.

Owner:HEFEI UNIV OF TECH

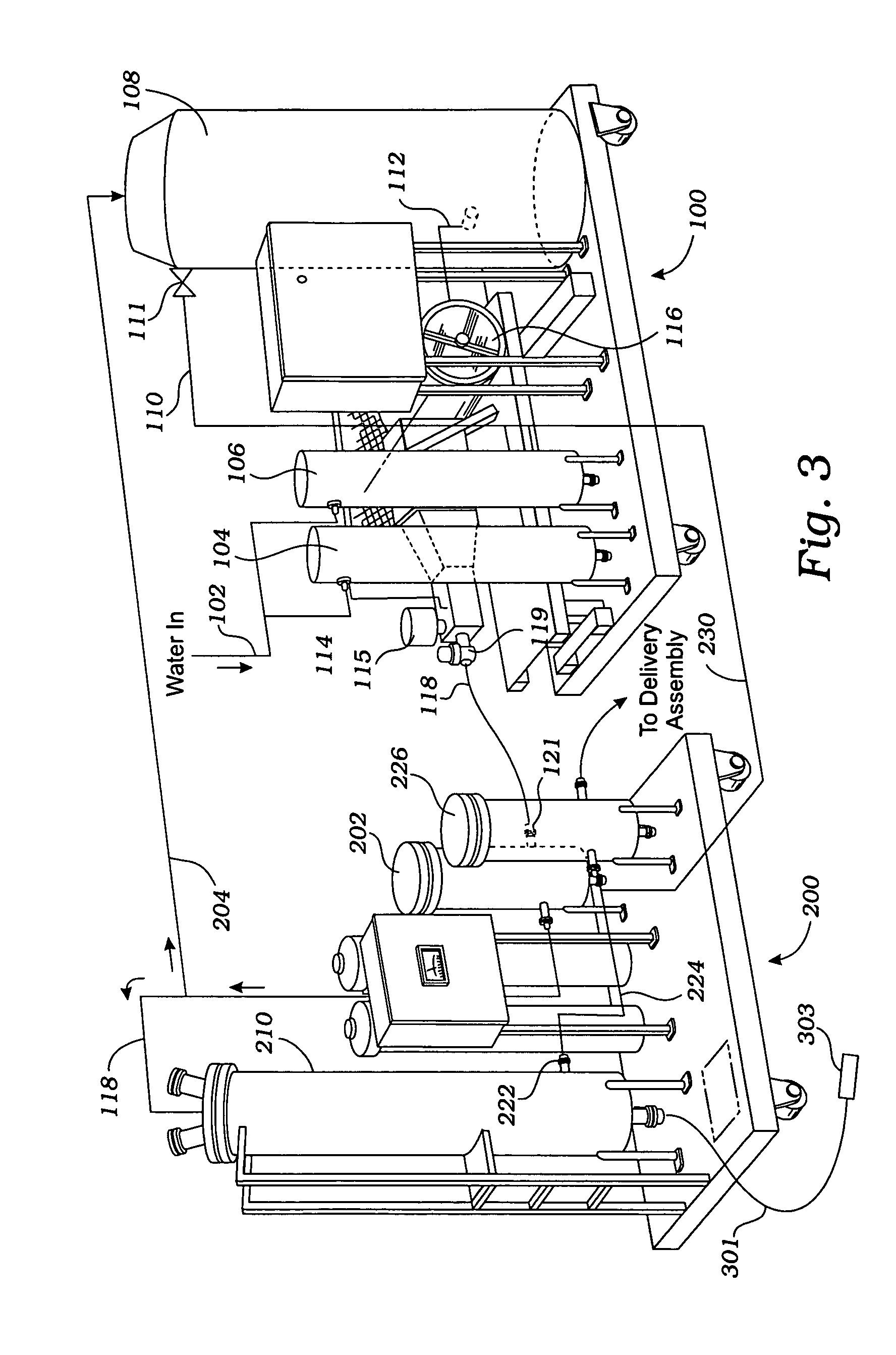

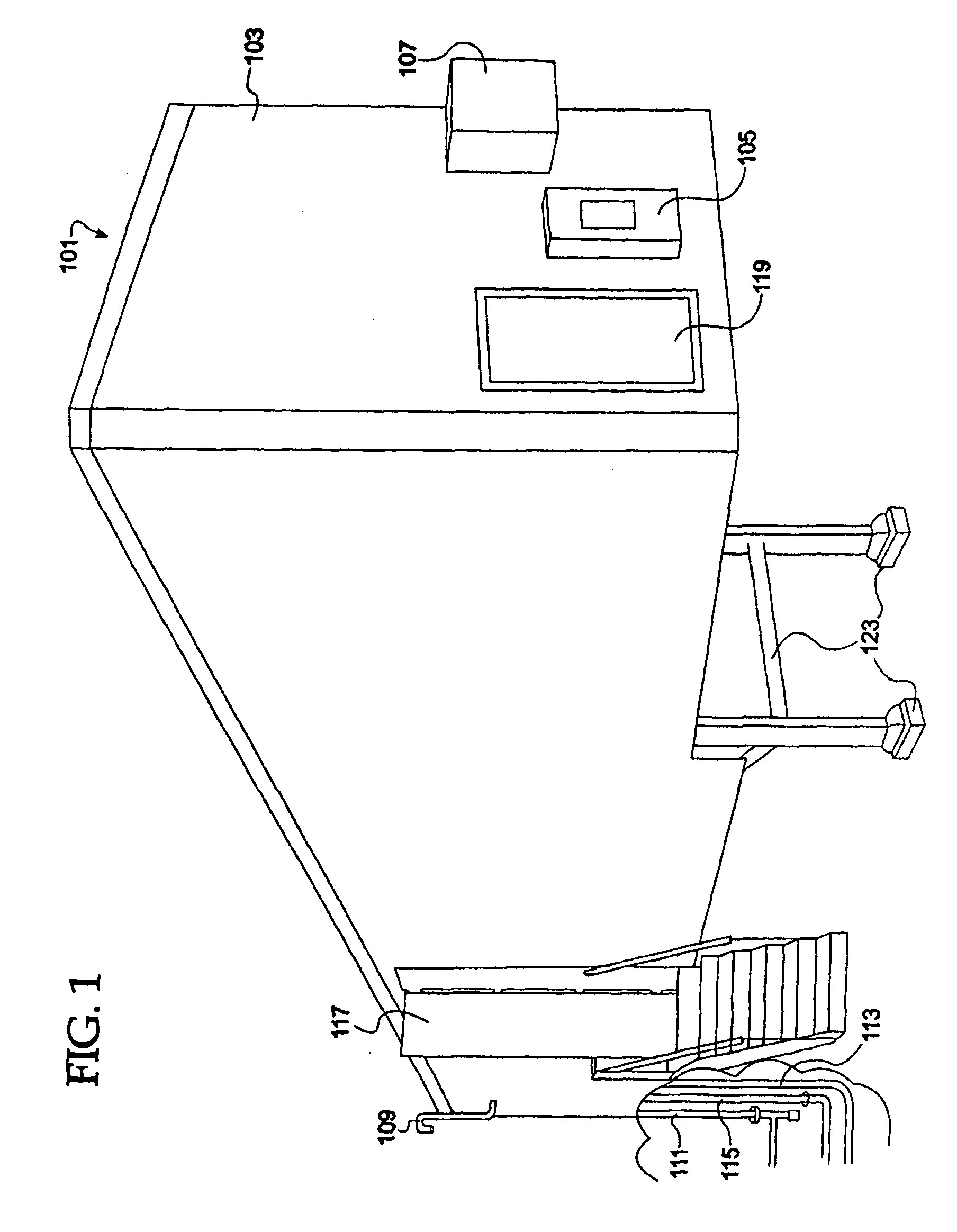

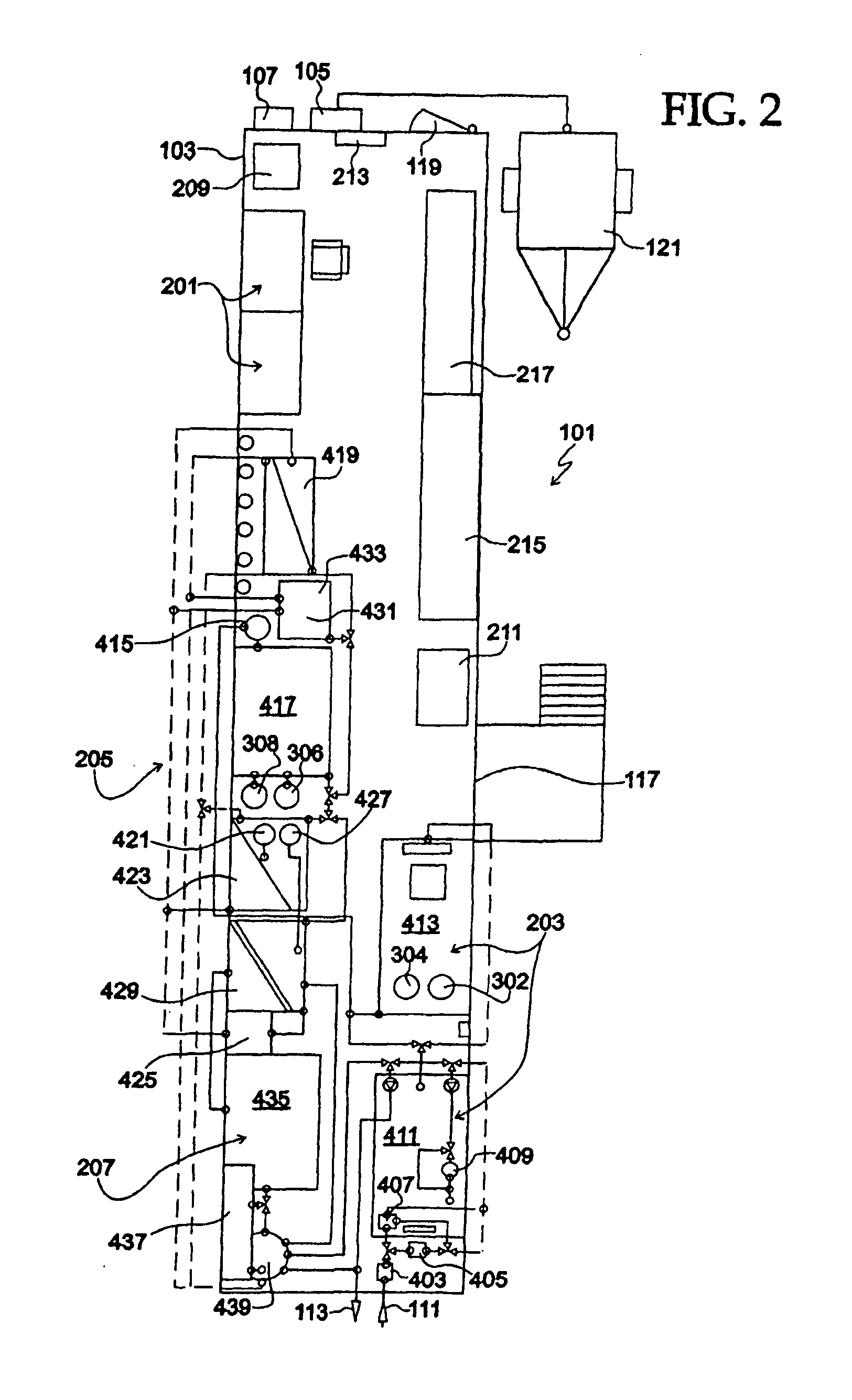

Mobile station and methods for diagnosing and modeling site specific full-scale effluent treatment facility requirements

InactiveUS20110257788A1Reduce financial riskHigh continuity of operationWater/sewage treatment by neutralisationSustainable biological treatmentInitial treatmentIon exchange

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus is housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies is also disclosed. The modeling methods include steps for analyzing raw effluent to be treated, providing a field of raw effluent condition entry values and a field of treated effluent condition goals entry values, and utilizing said fields to determine an initial treatment model including a selection of, and use parameters for, treatment technologies from the plurality of down-scaled treatment technologies at the facility, the model dynamically and continuously modifiable during treatment modeling.

Owner:ROCKWATER RESOURCE

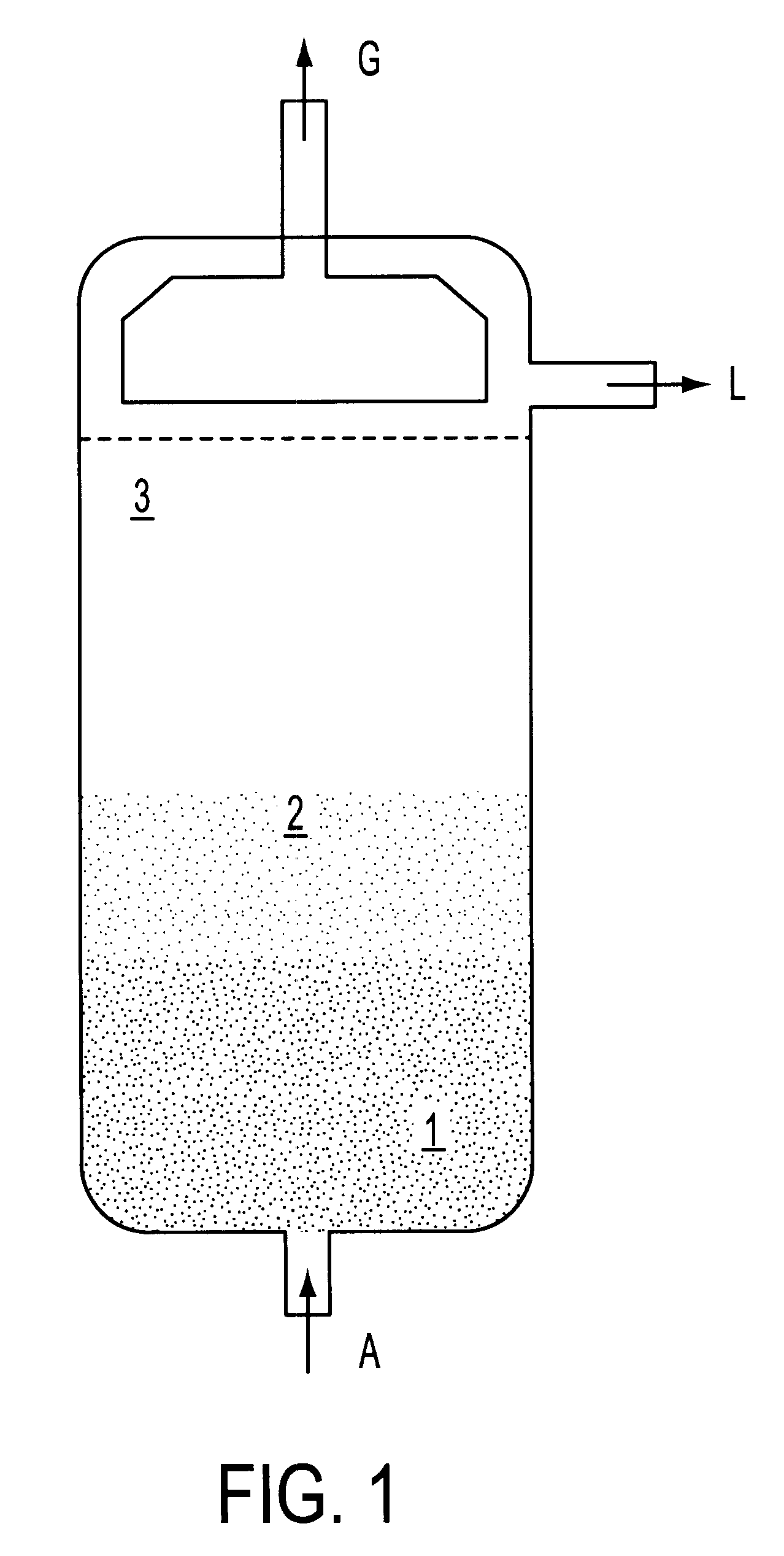

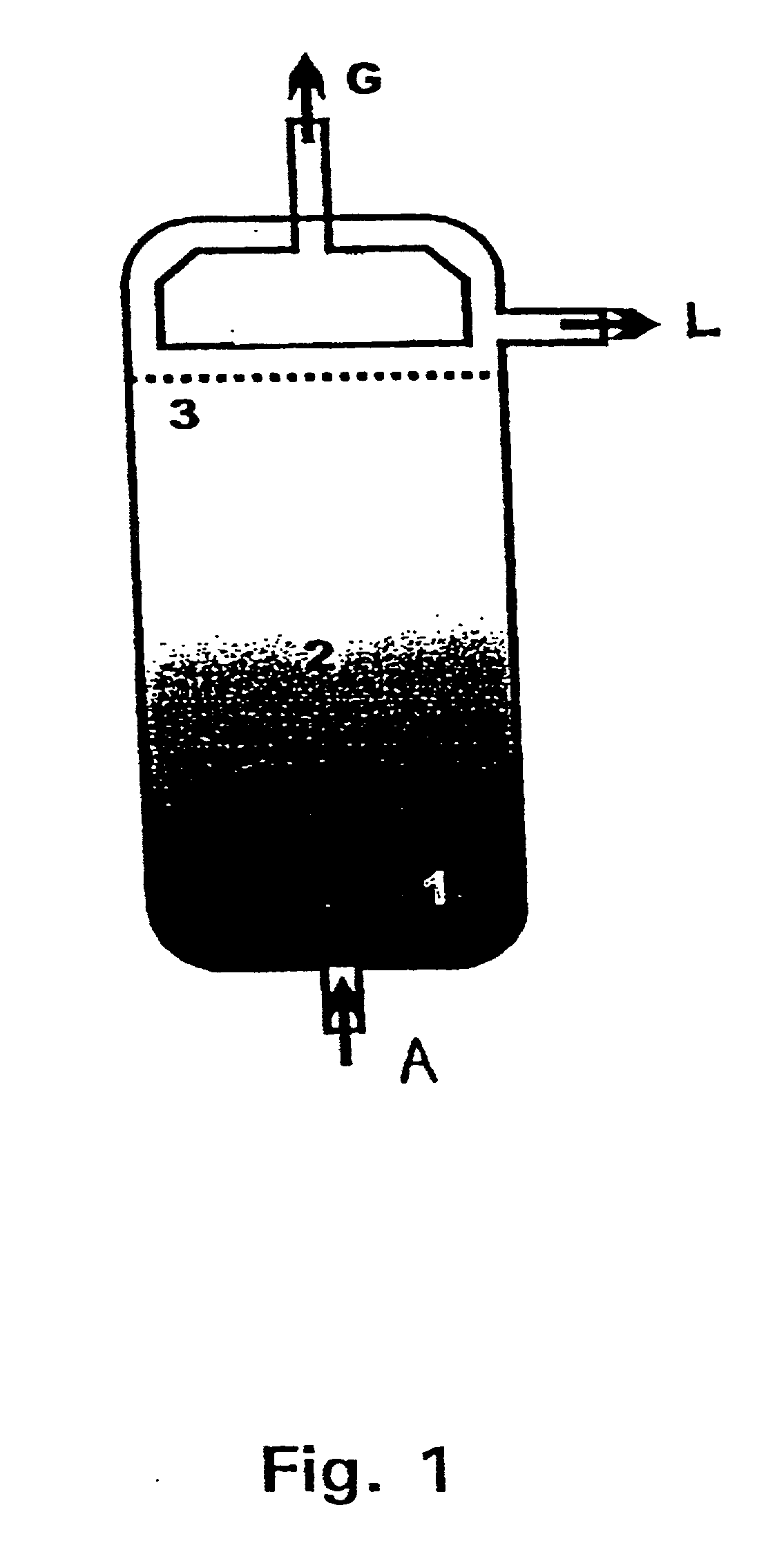

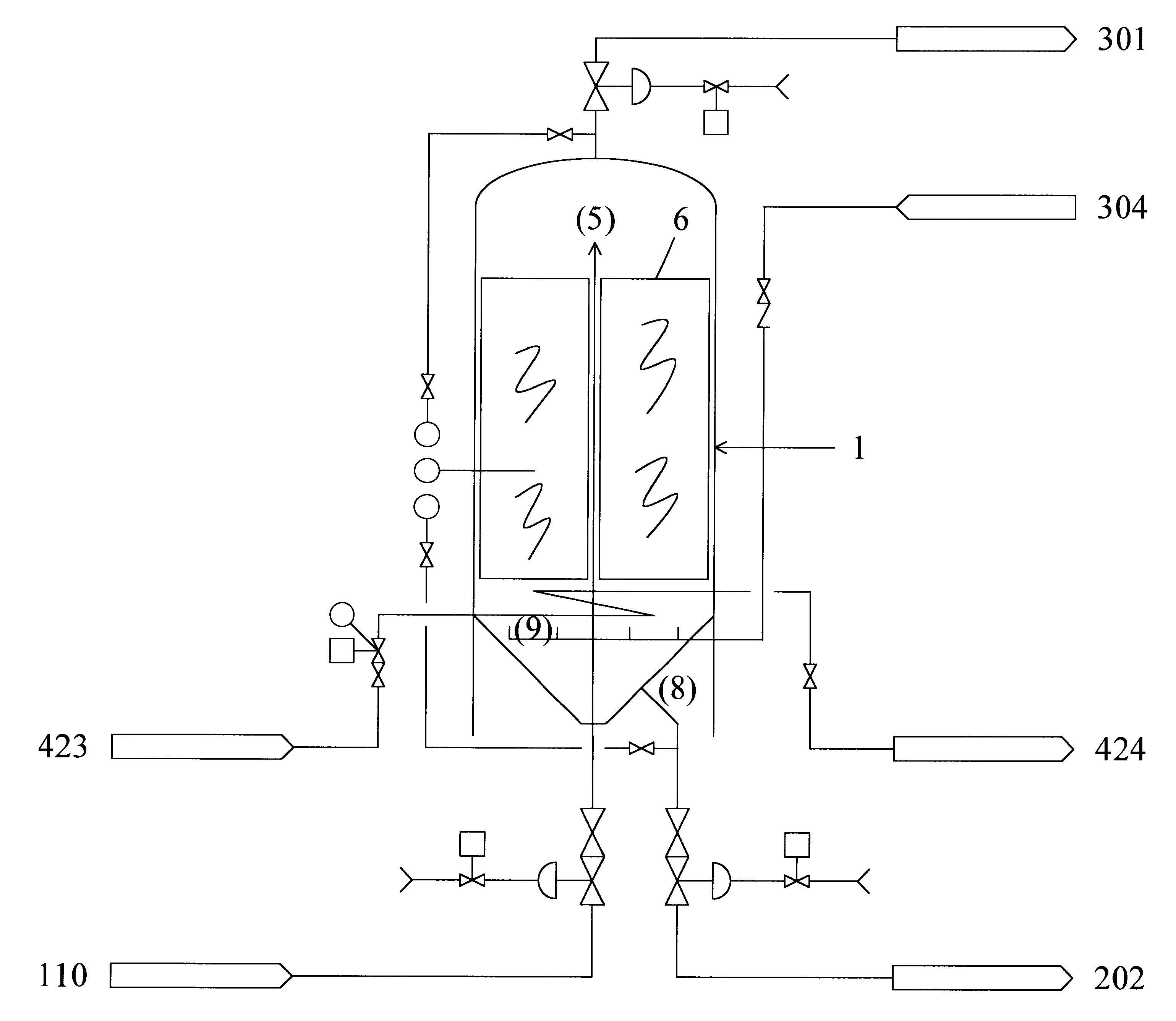

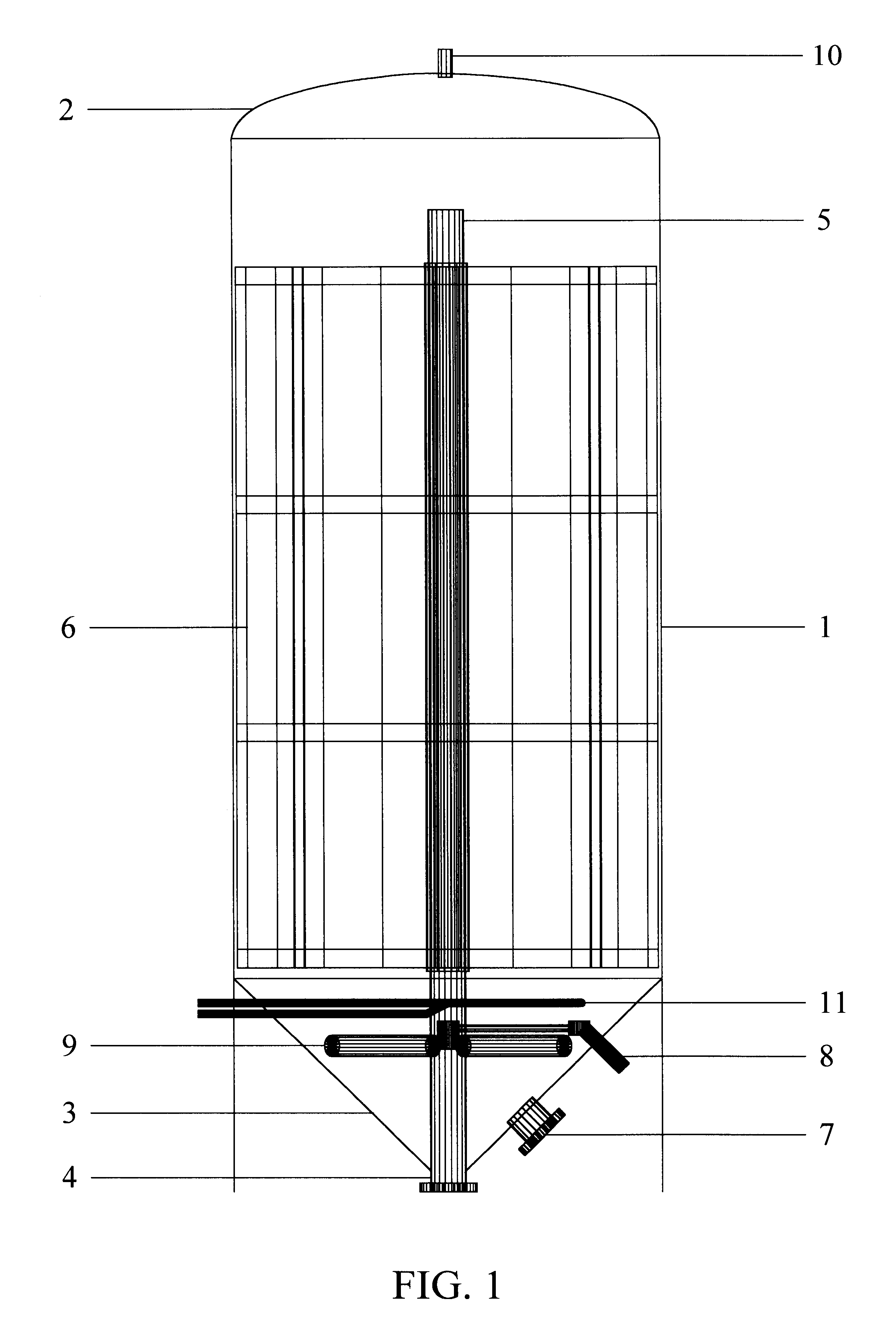

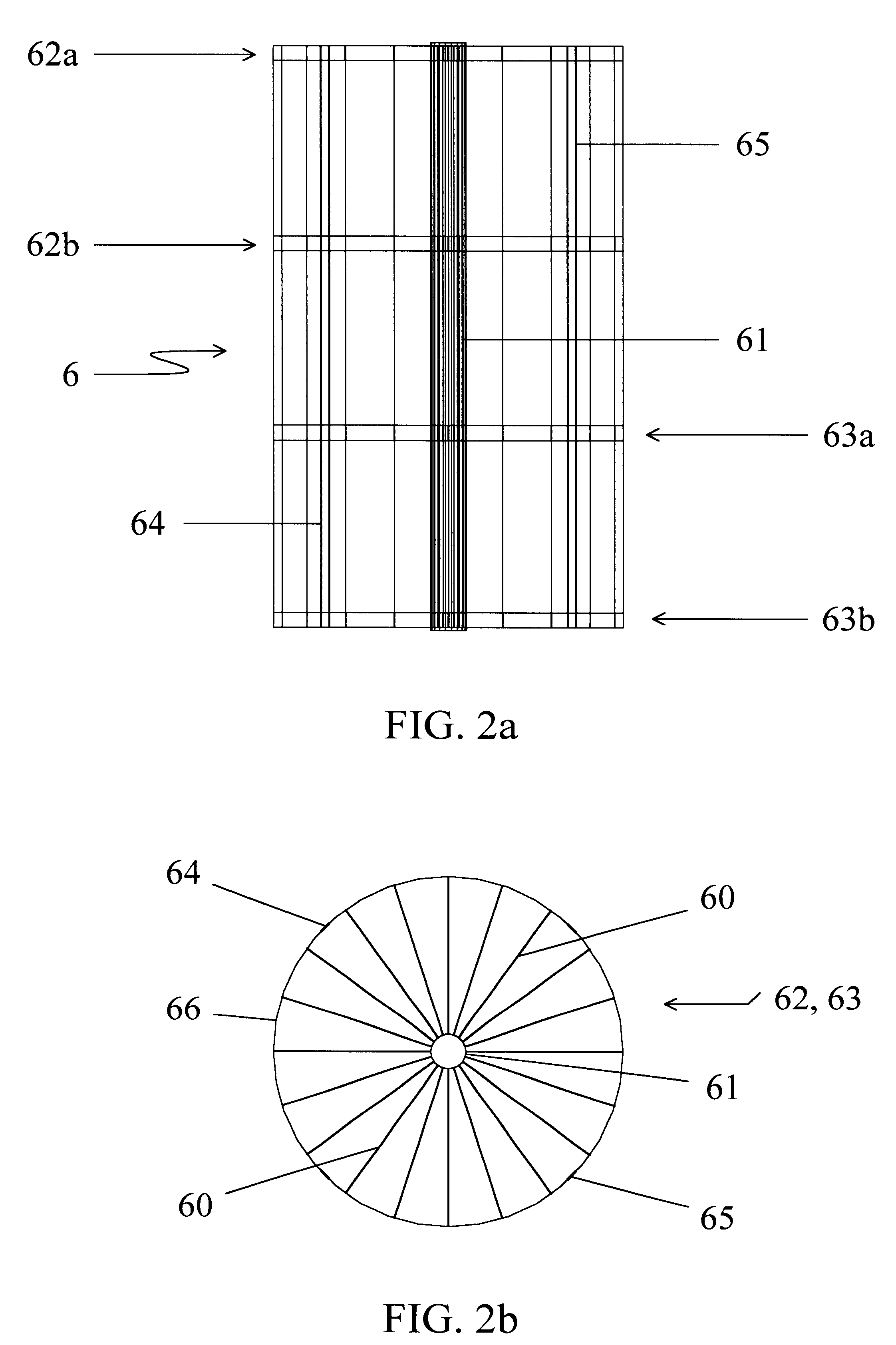

Anaerobic digester system and method

InactiveUS6254775B1High densityIncrease alkalinityGas production bioreactorsTreatment with aerobic and anaerobic processesSlurryMethane gas

An anaerobic digester system has a vertically upright vessel, a matrix arranged in the vessel supporting a microorganism biomass thereon, an input for supplying an input slurry of liquid and suspended solids at an upper portion of the vessel above the matrix, a gas output at the top of the vessel for withdrawing gas generated by anaerobic digestion of solids, and an effluent output at the bottom of the vessel for withdrawing liquid and remaining solids. The vessel has a preferred liquid height to diameter ratio of 2 to 1, and is constructed of inert fiberglass-reinforced plastic coated with a translucent blue gel pigment layer for filtering light at wavelengths that promote biomass cultivation. The matrix is formed as an array of panels mounted to a spindle with wheels fixed at spaced intervals along its vertical height, and the panel are made of a polyethylene grass matting providing a high surface area to volume ratio of at least 20 to 1. Gas from the top of the vessel is recycled to the bottom to generate bubbles for mixing the feedstock. The related method of anaerobic digestion includes comminuting input wastes with a slurry grinder into a pumpable slurry 8-10 % by weight solids, and providing as the biomass hydrolytic bacteria, and fermentative bacteria including acetogenic and methanogenic bacteria to produce a methane gas product. Other products include an organic soil additive, bacterial solids plant food, and a filtrate used as plant tonic.

Owner:RENERGY

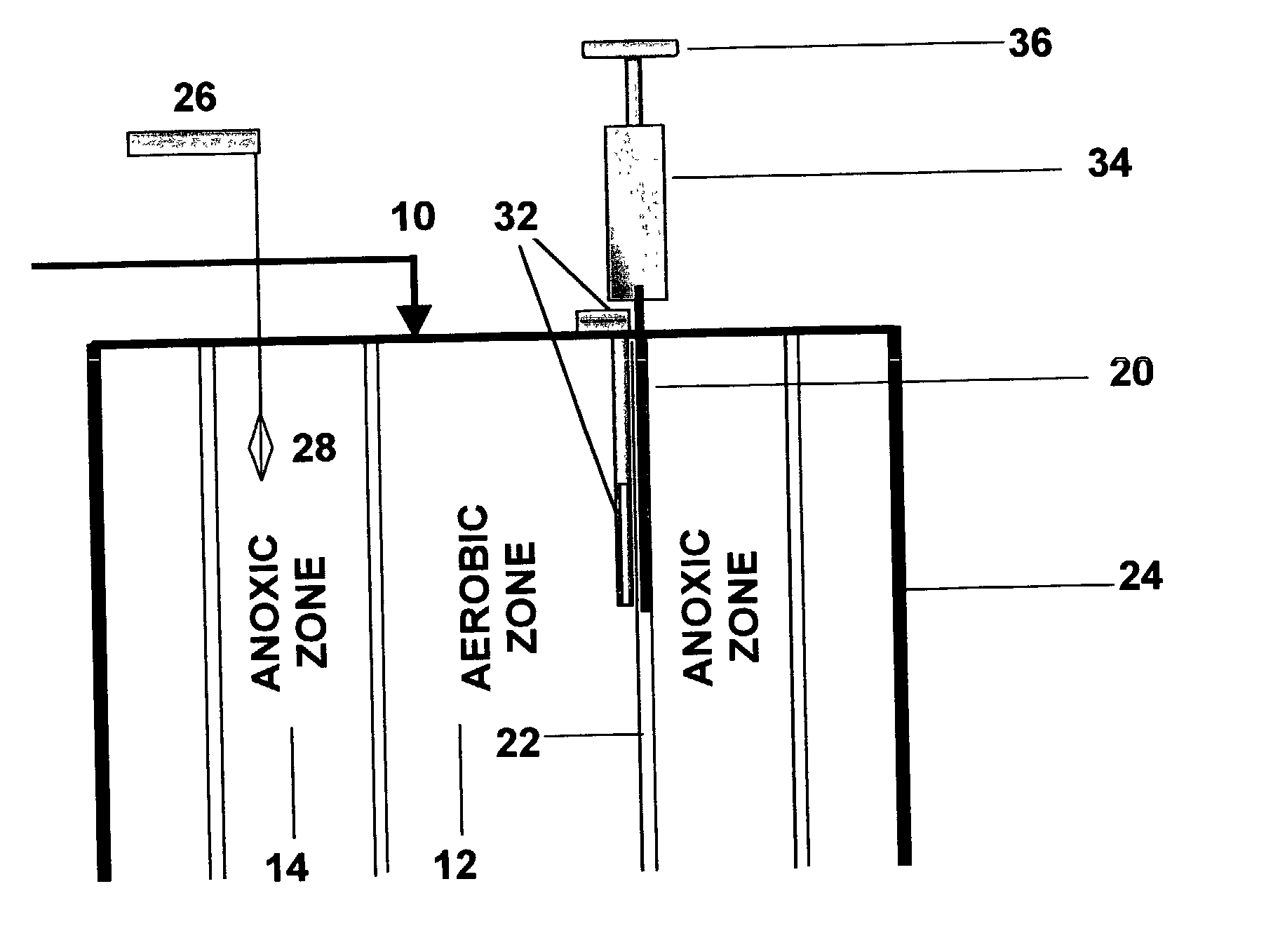

Method and apparatus for treating wastewater using membrane filters

InactiveUS6863818B2Good removal effectEfficient workTreatment using aerobic processesBiological treatment regulationActivated sludgeBioreactor

An apparatus using activated sludge for the removal of biological nutrients from a wastewater includes a bioreactor for containing a mixture of wastewater under treatment and activated sludge. The bioreactor is divided into a plurality of serially connected treatment zones and includes a wastewater inlet, a downstream aerobic zone and an upstream aerobic zone between the wastewater inlet and the downstream aerobic zone, the upstream and downstream aerobic zones being separated by an anoxic zone. A method for removal of nutrients from a wastewater includes providing a wastewater to an inlet of a serial, multi-zone, activated sludge bioreactor containing an activated sludge. The bioreactor has a downstream aerobic zone from which water is removed and an upstream aerobic zone between the wastewater inlet and the downstream aerobic zone, the upstream and downstream aerobic zones being separated by an anoxic zone.

Owner:CH2M HILL

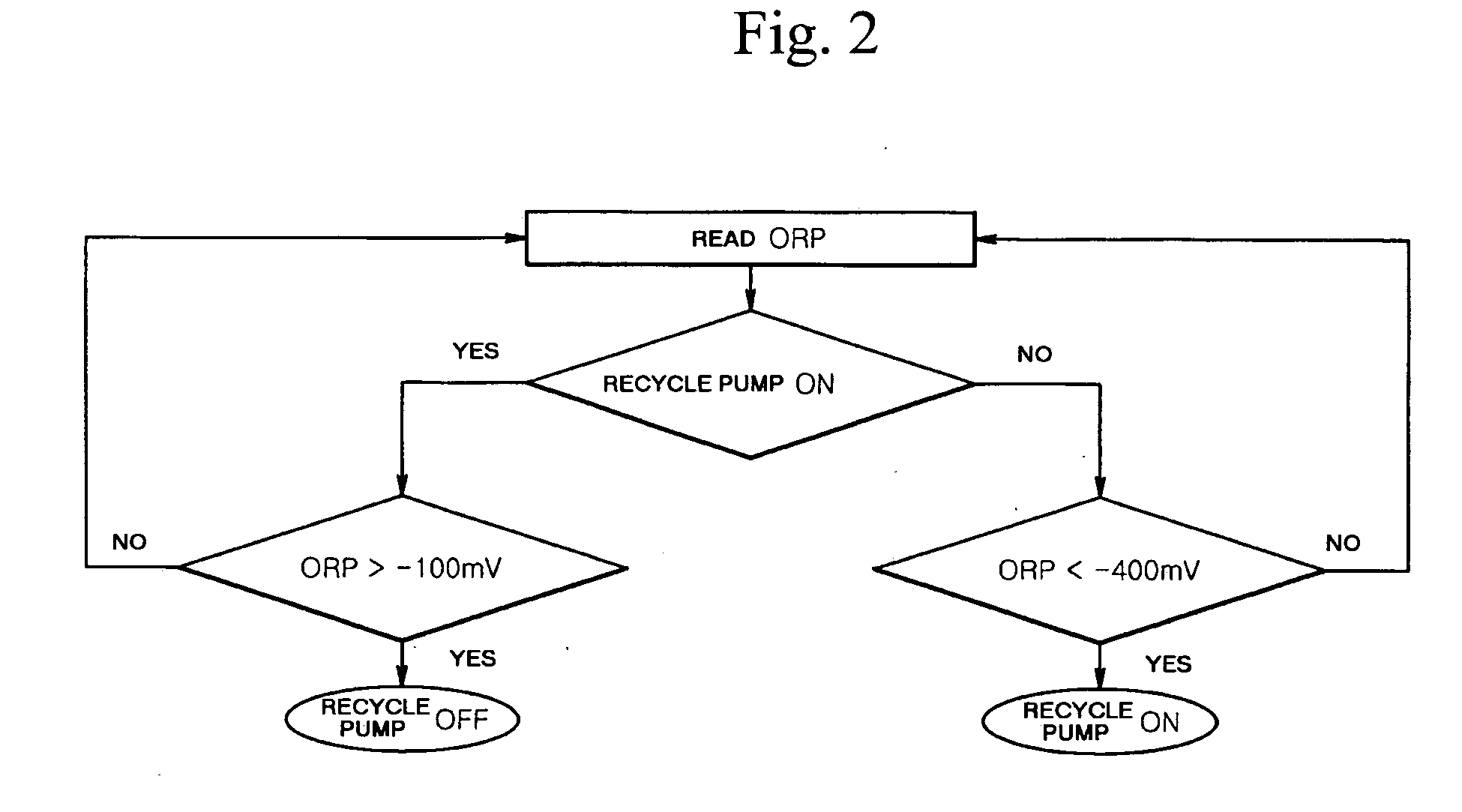

Membrane coupled activated sludge method and apparatus operating anoxic/anaerobic process alternately for removal of nitrogen and phosphorous

ActiveUS20070108125A1Quality improvementSimple processTreatment using aerobic processesMixing methodsActivated sludgeNitrogen

Disclosed are a membrane coupled activated sludge method and apparatus operating anoxic / anaerobic processes alternately for removal of nitrogen and phosporus, wherein nitrogen and phosphorous together with organics in the sewage, wastewater, filthy water etc. can be simultaneously removed with an economic and efficient manner, an operation thereof is easy and efficient, a capacity thereof is high and the method is economic due to the reduced operating costs with performing measurement and control of a recycle rate, a recycle time of alternate operation of the anoxic and anaerobic process, an amount of sludge, an amount of aeration and an operation of a blower for an intermittent membrane cleaning.

Owner:KOREA INST OF SCI & TECH

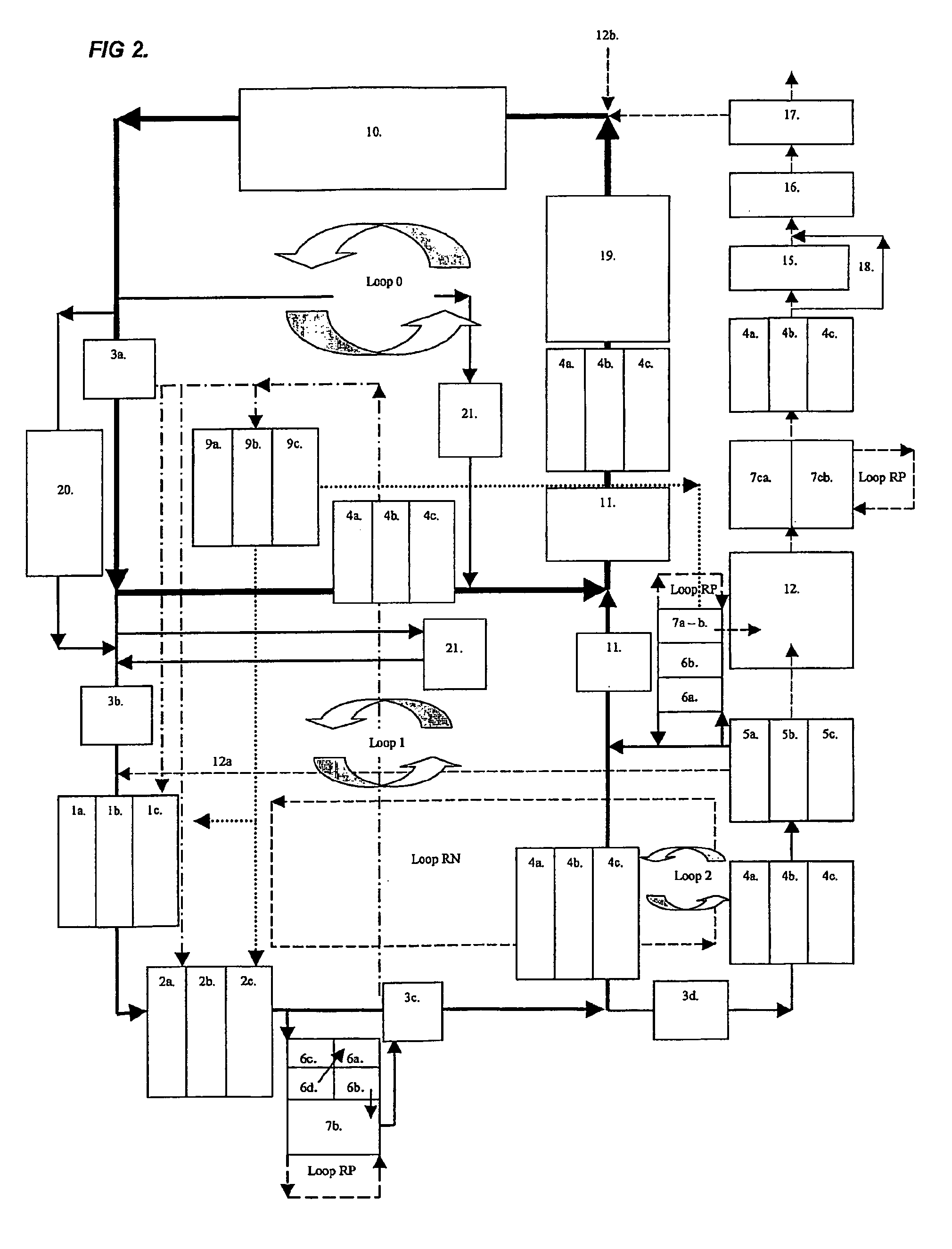

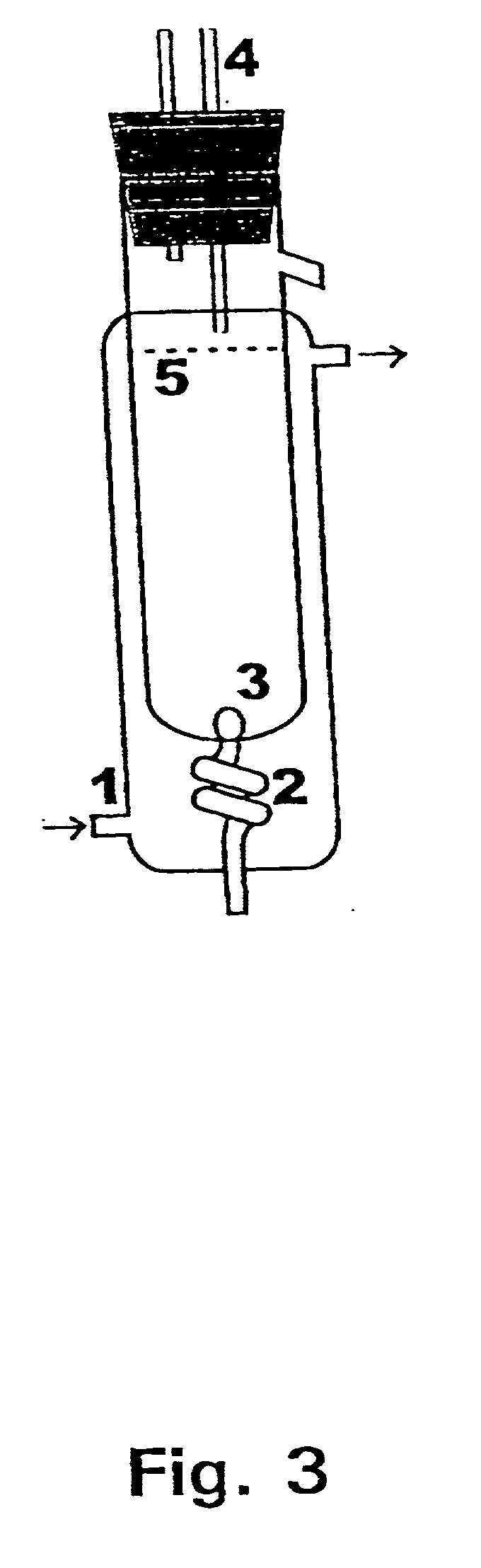

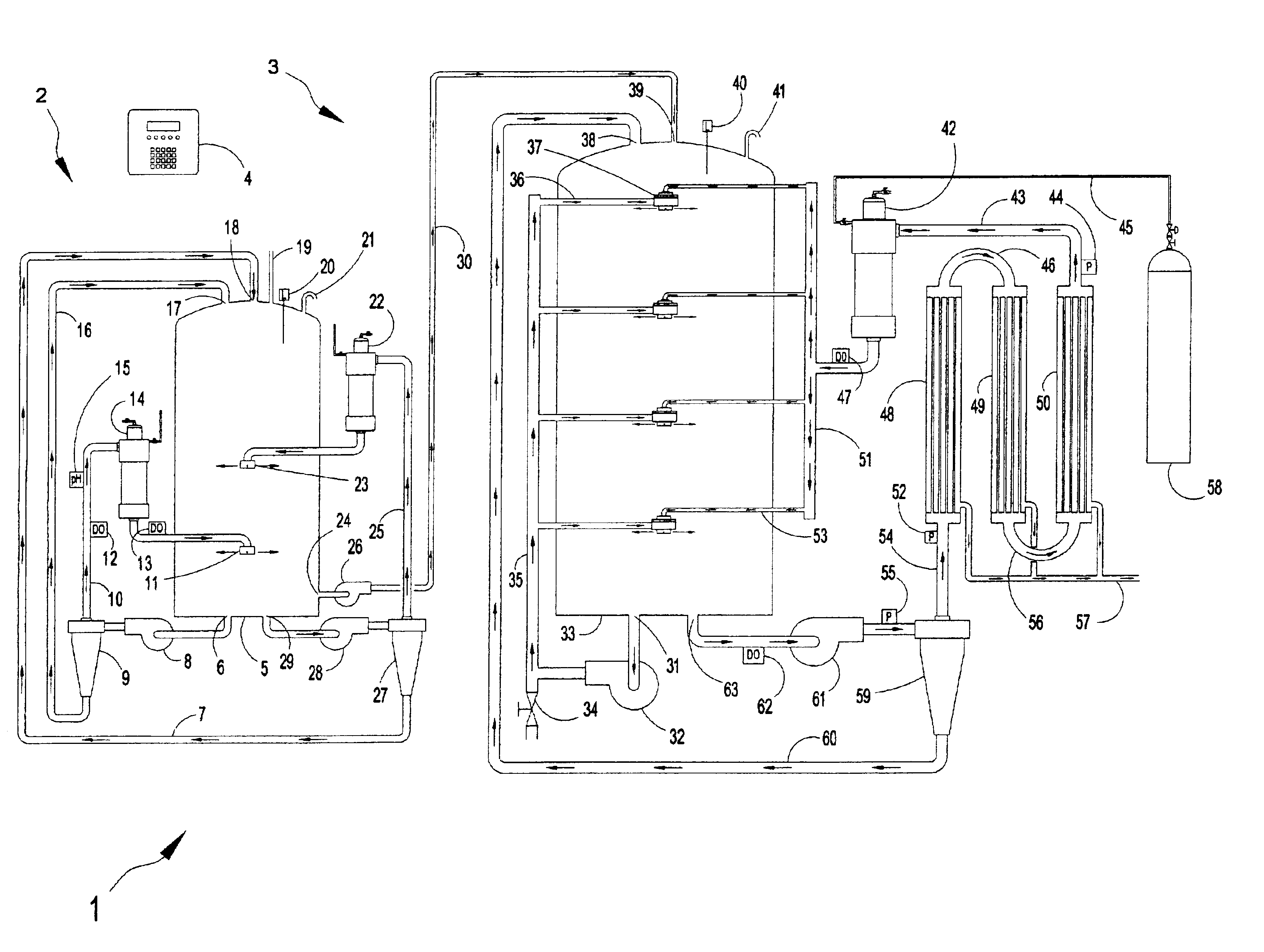

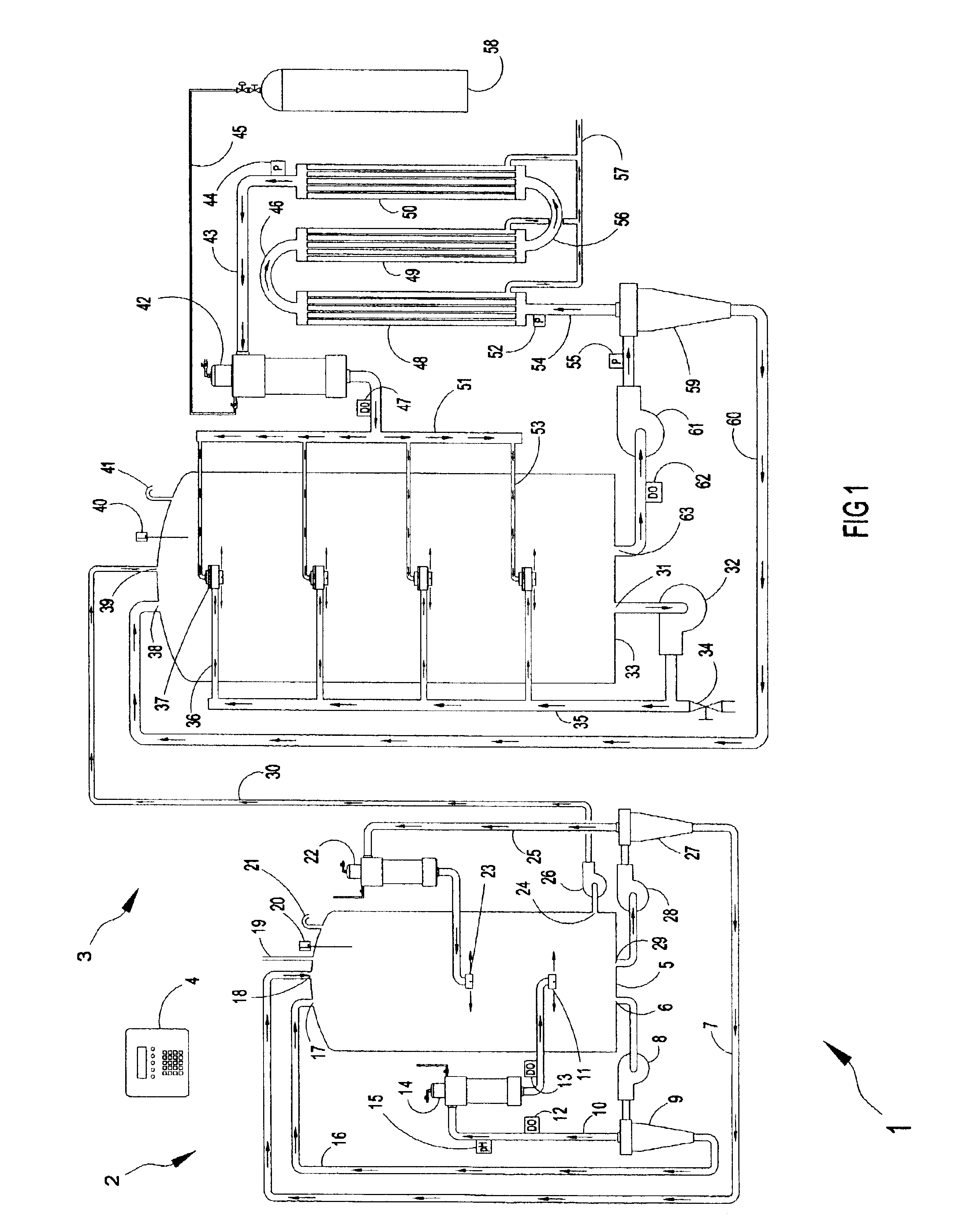

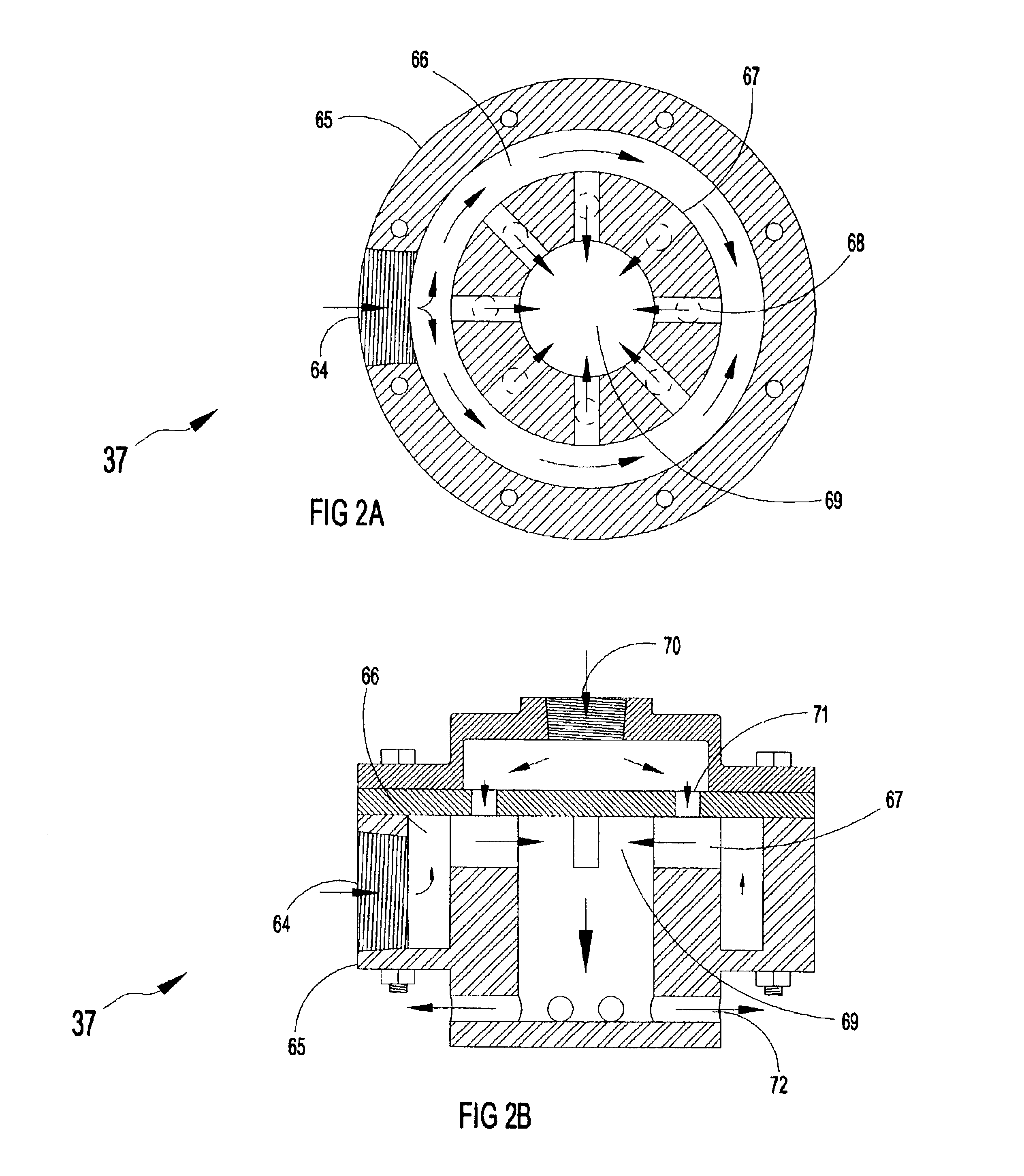

Method and apparatus for treatment of wastewater employing membrane bioreactors

InactiveUS6805806B2Accelerates the biodegradation processAvoid cloggingLiquid separation auxillary apparatusTreatment using aerobic processesAeration systemFiltration

Methods and apparatus employing membrane filtration in biodegradation processes for treatment of wastewater are described. A bioreactor system is described having an equalization system, a membrane bioreactor system, and a controller. Aeration systems for a membrane bioreactor, such as a mixer, and an ultrafilter subsystem are also described, as is a rotary membrane ultrafilter.

Owner:HYDROTREAT

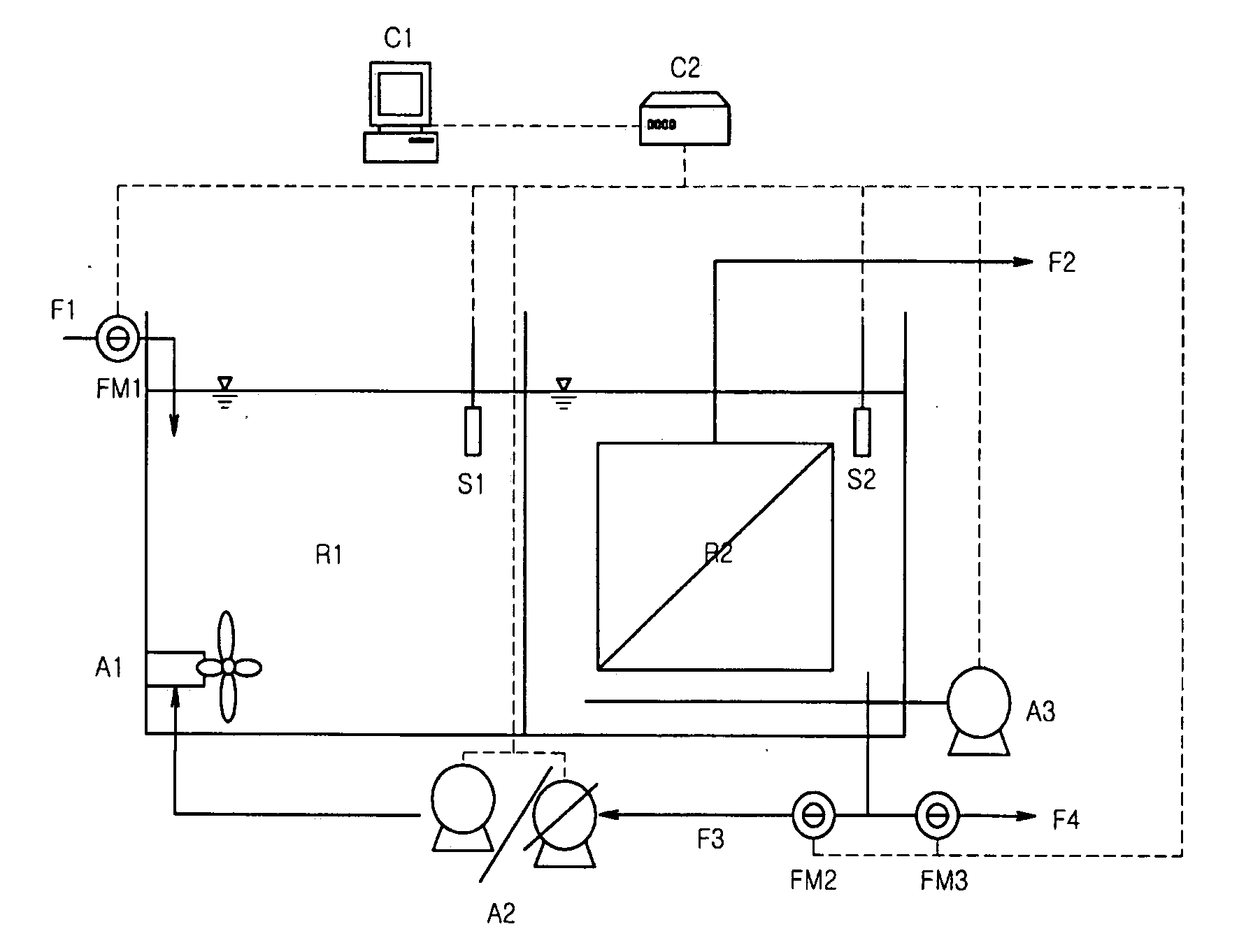

Integrated closed loop system for industrial water purification

InactiveUS20050061737A1Small surface areaIncreasing biofilm thicknessTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

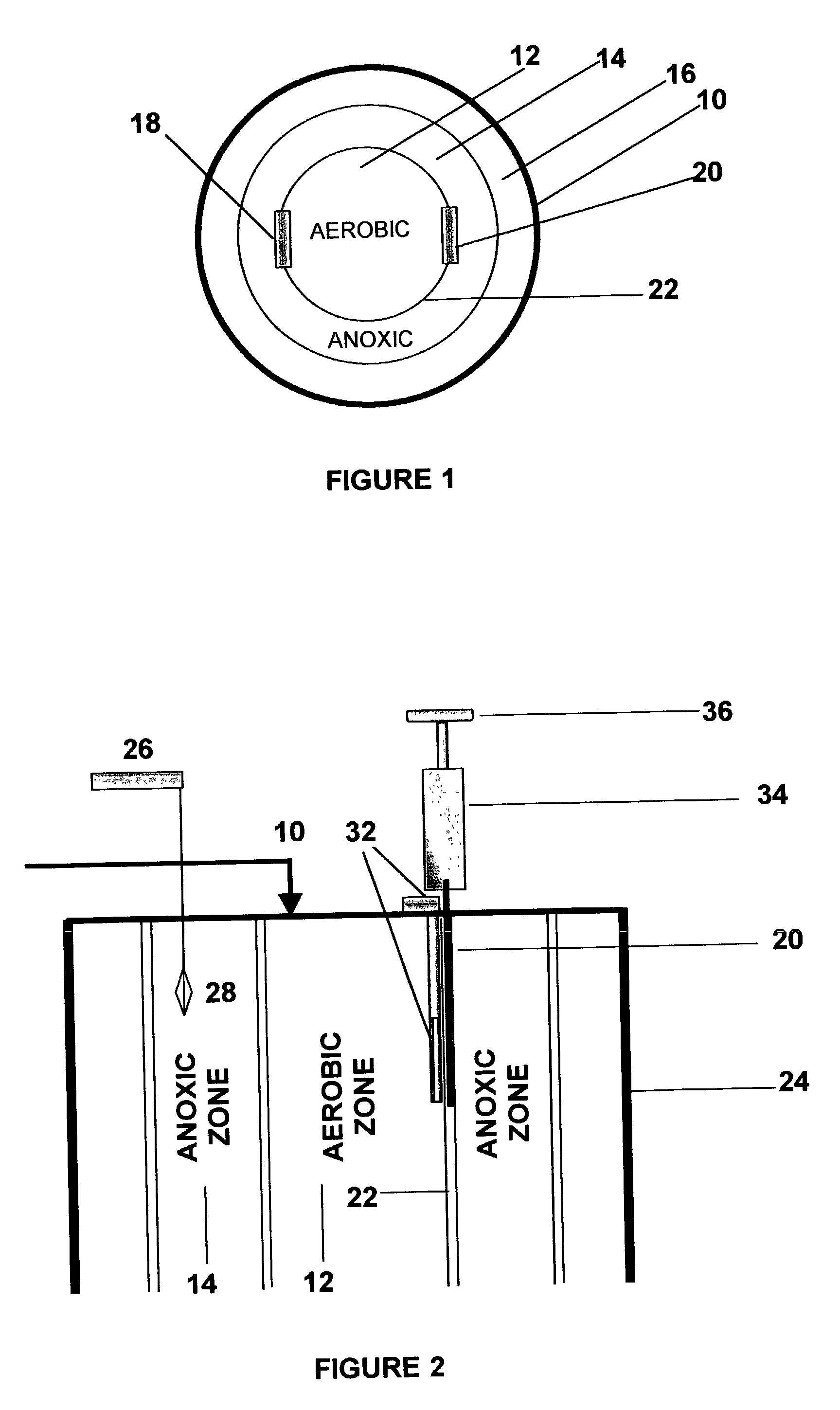

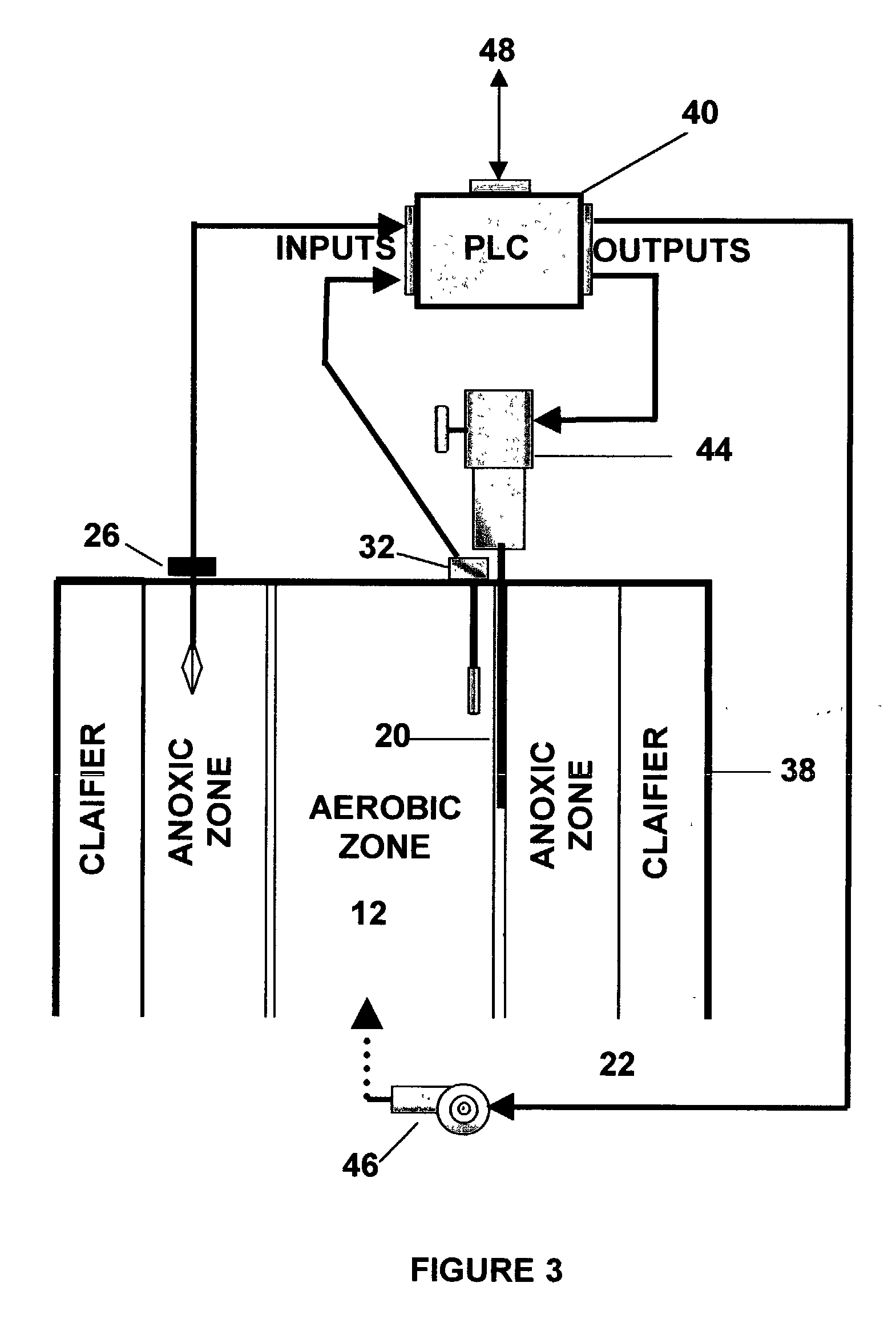

Dynamically responsive aerobic to anoxic inter-zone flow control system for single vessel multi-zone bioreactor wastewater treatment plants

InactiveUS20040035770A1Improve adaptabilityStable and fastLiquid separation auxillary apparatusWater treatment parameter controlProgram instructionProgrammable logic controller

An inter-zone aerobic to anoxic zone flow rate control system for single vessel multi-zone bioreactor plants for wastewater treatment is described herein. The system of the invention provides control of the relative treatment times of the mixed liquor in the horizontally disposed and adjacent aerobic and anoxic treatment zones of the bioreactor by providing one or more flow rate adjusting gates located between the aerobic and anoxic zones of the bioreactor. The opening of the gates is adjustable in accordance with sensed conditions in the treatment zones. An automated embodiment of the invention includes a programmable logic controller that provides control scripts for adjusting the opening of one or more flow control gates according to inputs from sensors and per programmed instructions. An automated and supervised embodiment of the invention includes a computer interfaced with a programmable automating controller. The computer provides status reports, commands to the programmable automating controller, storage and analysis of data, as well as a means of communicating to remote monitoring centers and networks.

Owner:ATARA ENVIRONMENTAL

Apparatus and method for cleaning membrane filtration modules

InactiveUS6841070B2Easy to cleanReduce concentrationSemi-permeable membranesMembranesFiltrationPorous membrane

A method and apparatus for cleaning a membrane module, the membrane module having a plurality of porous membranes, the membranes being arranged in close proximity to one another and mounted to prevent excessive movement therebetween and means for providing, from within the module, by means other than gas passing through the pores of the membranes, gas bubbles entrained in a liquid flow such that, in use, the liquid and bubbles entrained therein move past the surfaces of the membranes to dislodge fouling materials therefrom, the gas bubbles being entrained in the liquid by flowing the liquid past a source of gas to draw the gas into the liquid flow. The gas bubbles are preferably entrained into the liquid using a venturi type device. The membranes are preferably partitioned into discrete groups to assist cleaning while maintaining high packing density.

Owner:EVOQUA WATER TECH LLC

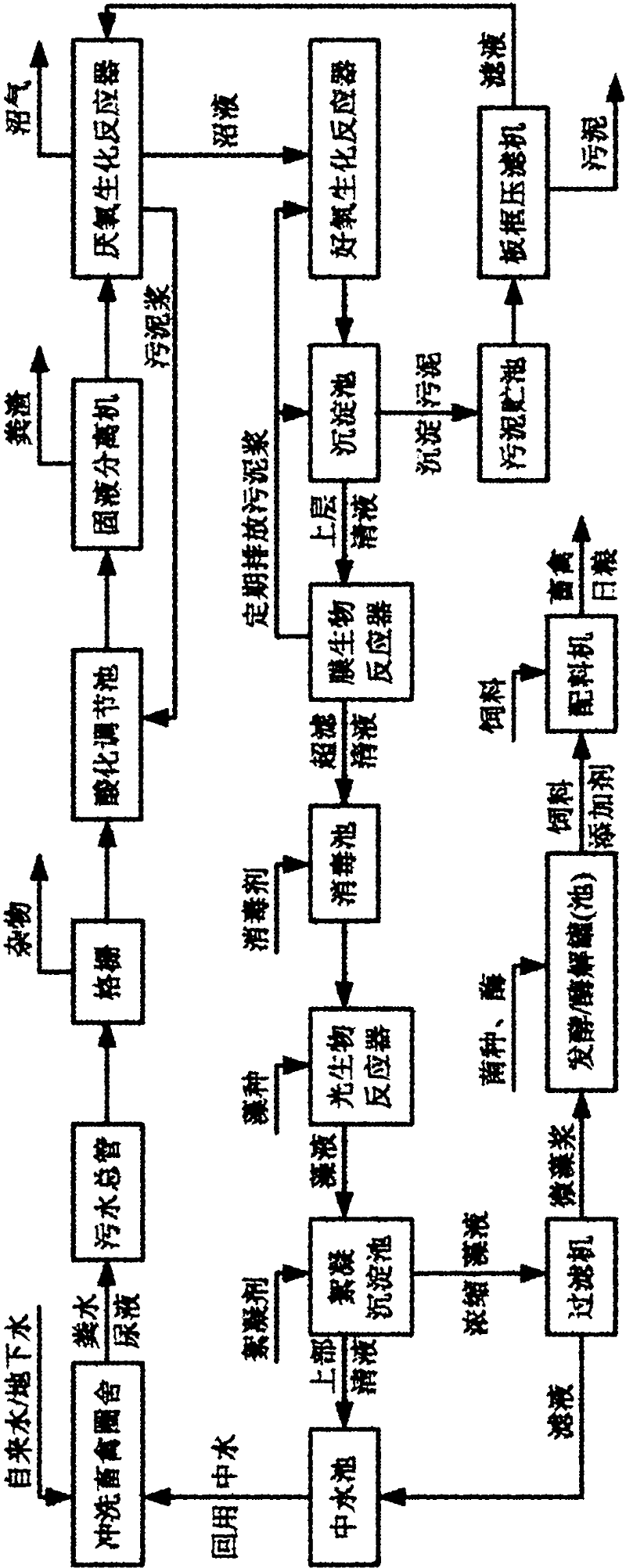

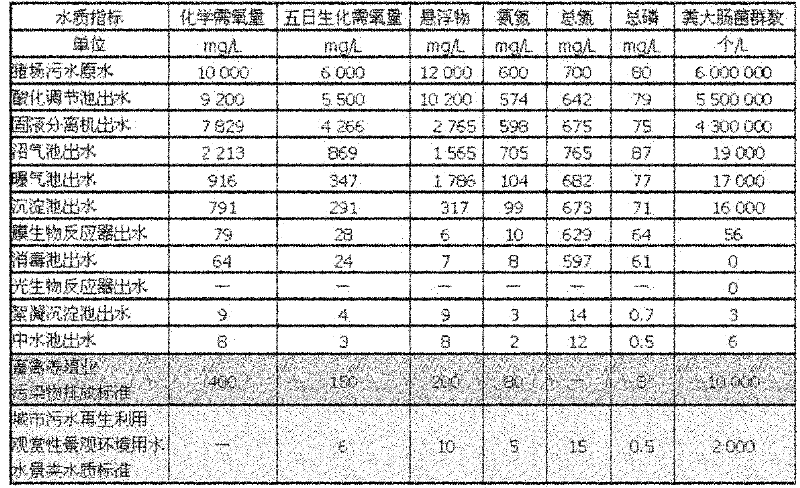

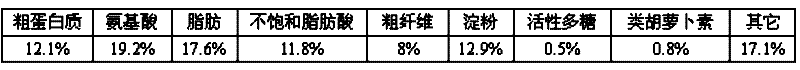

Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

InactiveCN102161550AReduce water consumptionAchieving zero emissionsWaste water treatment from animal husbandryAnimal feeding stuffUltrafiltrationSlurry

The invention relates to the fields of environmental technology and the breeding and processing of microalgae, in particular to a method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water. The method is characterized by comprising the following steps that: wastewater enters an acidification adjusting tank through a grille, and the acidified wastewater enters an anaerobic biochemical reactor for treatment and then enters an aerobic biochemical reactor; after the aerobic biochemical treatment, the obtained biogas slurry enters a settling tank for settling, the supernatant enters a membrane bioreactor for further aerobic treatment and is filtered by an ultrafiltration membrane, the generated ultrafiltration clear liquid is sterilized and neutralized and then enters a photobioreactor, algae are added into the photobioreactor to perform microalgae cultivation, and the algae liquid is discharged from the photobioreactor and then enters a flocculation and settling tank; and after flocculation and settling, the supernatant is used for water recycling, the concentrated algae liquid at the bottom enters a filter, and the separated microalgae slurry enters a fermentation / enzymolysis pot (tank) to perform fermentation / enzymolysis to be used as the feed additive. The invention has the advantages of high economic adaptability, zero discharge and the like.

Owner:蔡志武 +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com