Vertical skein of hollow fiber membranes and method of maintaining clean fiber surfaces while filtering a substrate to withdraw a permeate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

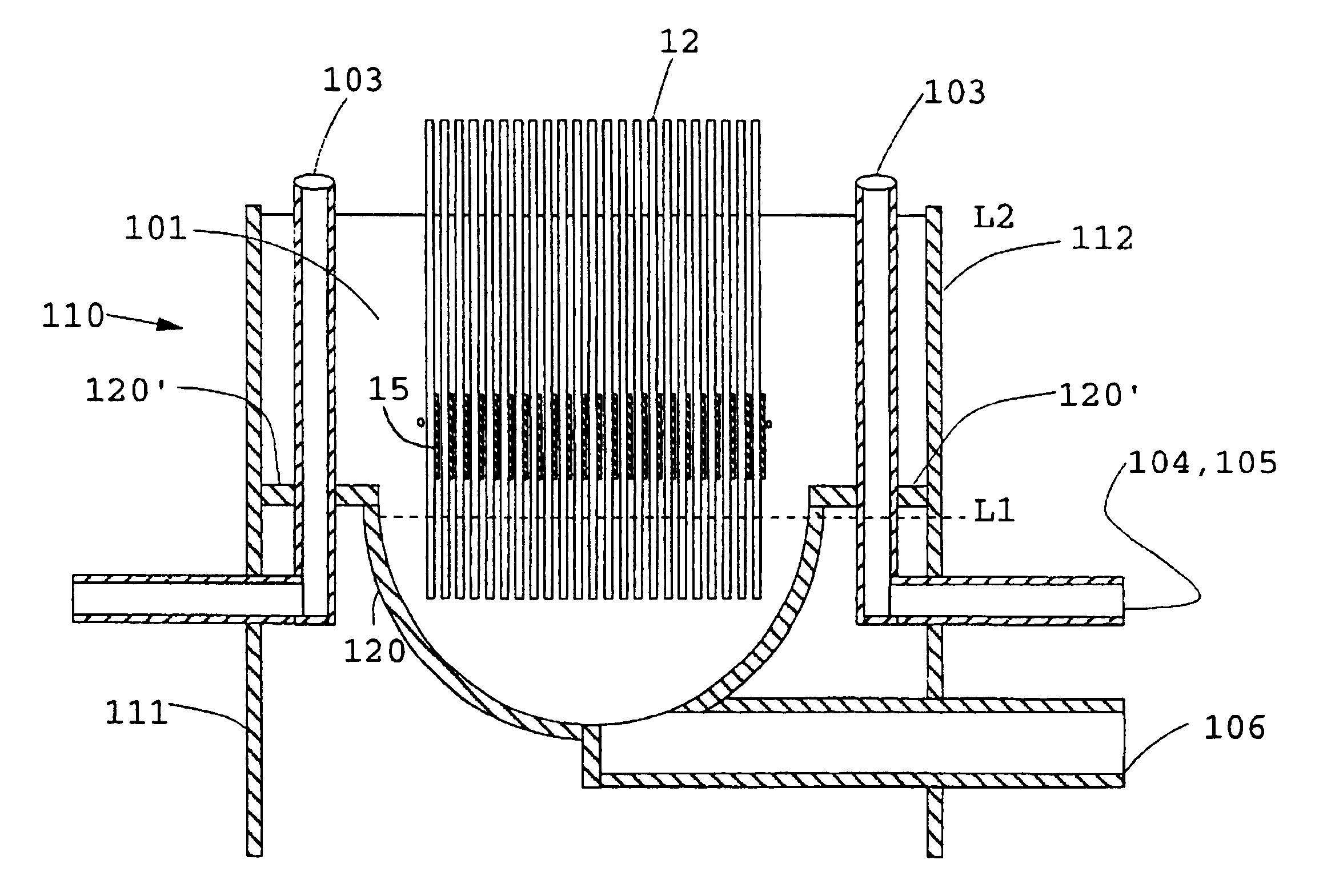

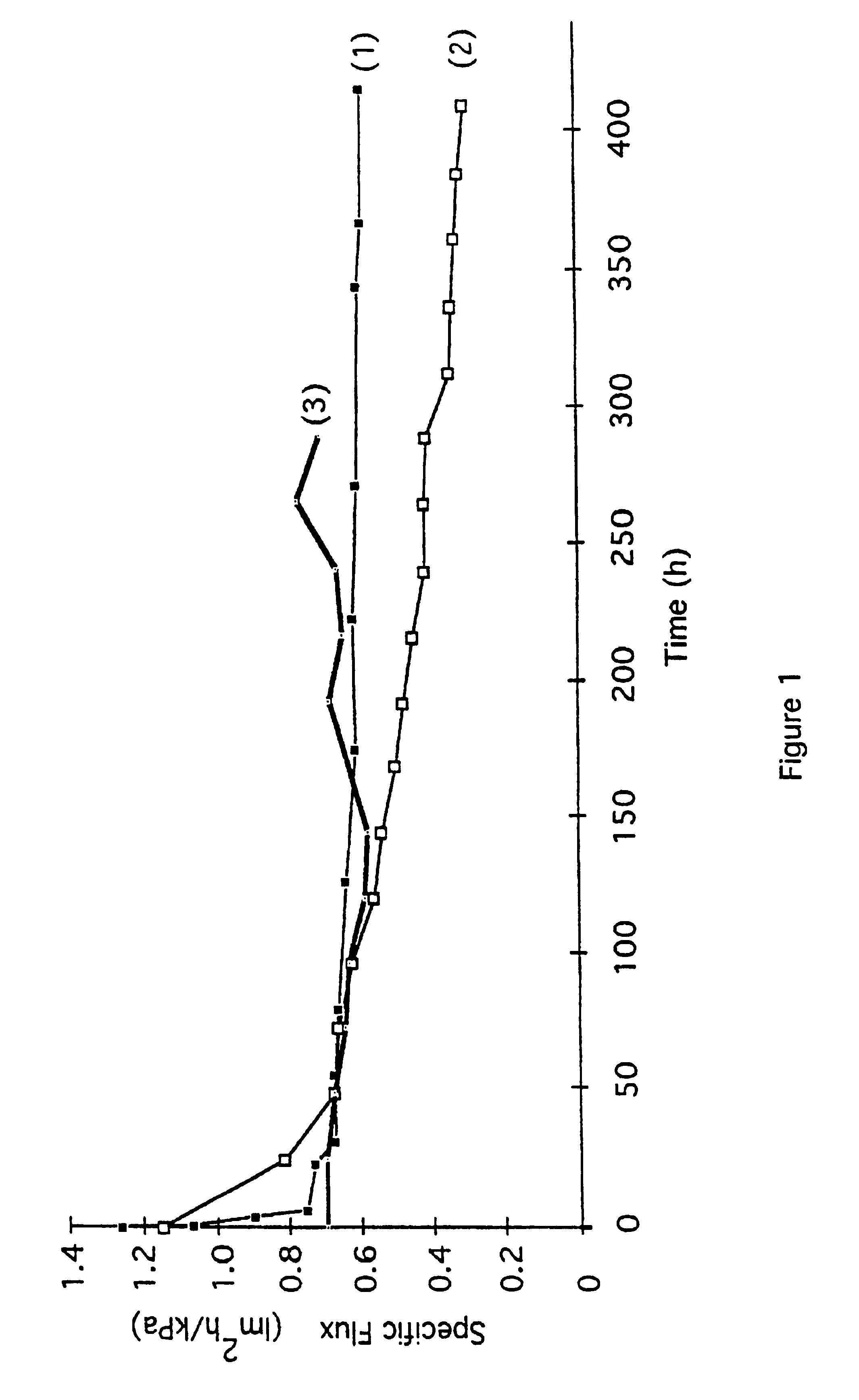

Microfiltration of an activated sludge at 30.degree. C. having a concentration of 25 g / L (2.5% TSS) is carried out with a skein of polysulfone fibers in a pilot plant tank. The fibers are "air scrubbed" at a flow rate of 12 CFM (0.34 m.sup.3 / min) with a coarse bubble diffuser generating bubbles in the range from about 5 mm to 25 mm, in nominal diameter. The air is sufficient not only for the oxidation requirements of the biomass but also for adequate scrubbing. The fibers have an outside diameter of 1.7 mm, a wall thickness of about 0.5 mm, and a surface porosity in the range from about 20% to 40% with pores about 0.2 .mu.m in diameter, both latter physical properties being determined by a molecular weight cut off at 200,000 Daltons. The skein which has 1440 fibers with a surface area of 12 m.sup.2, is wall-mounted in the tank, the vertical spaced apart distance of the headers being about 1% less than the length of a fiber in the skein. The opposed ends of the fibers are potted in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com