Patents

Literature

706results about How to "Low gas consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

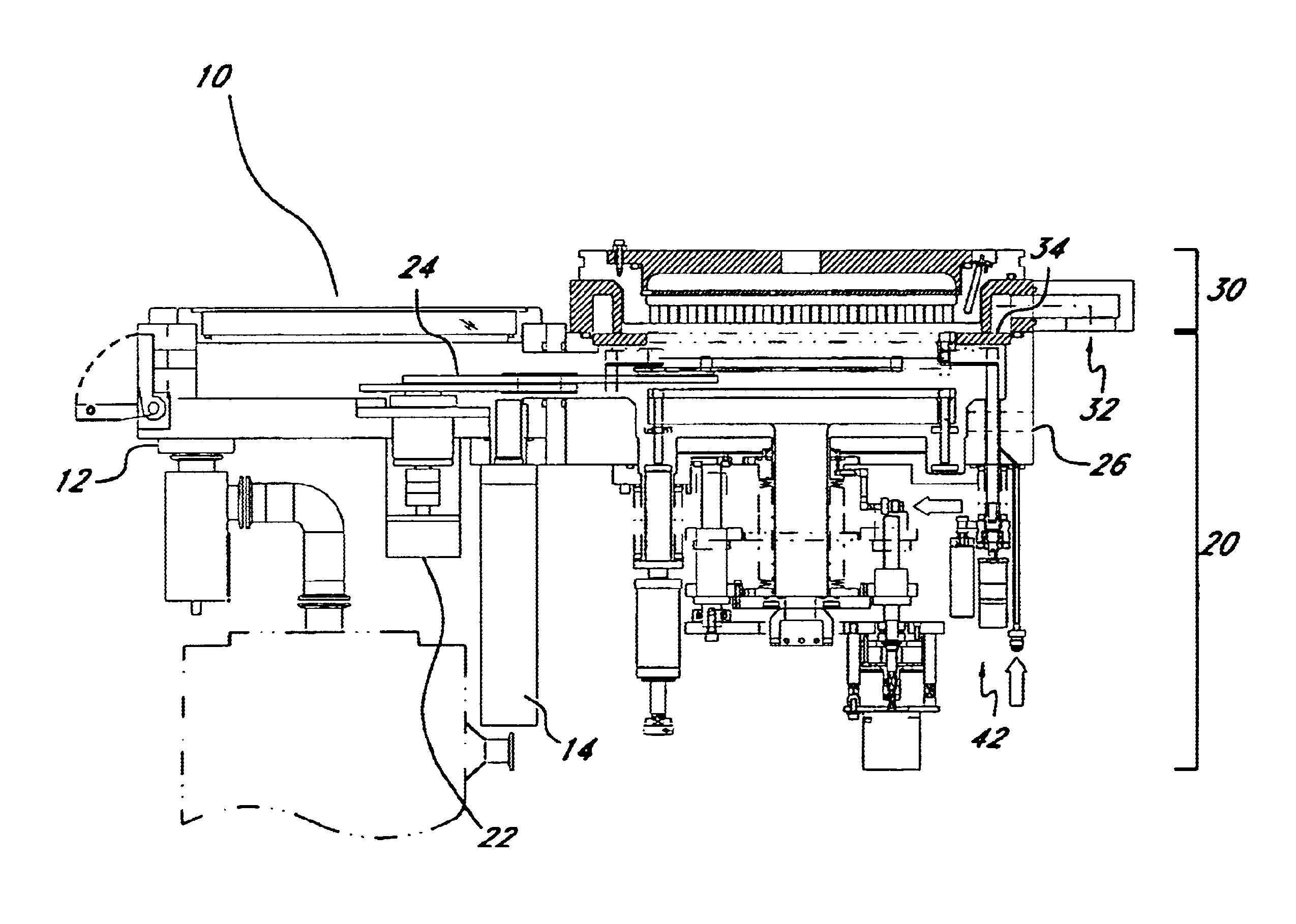

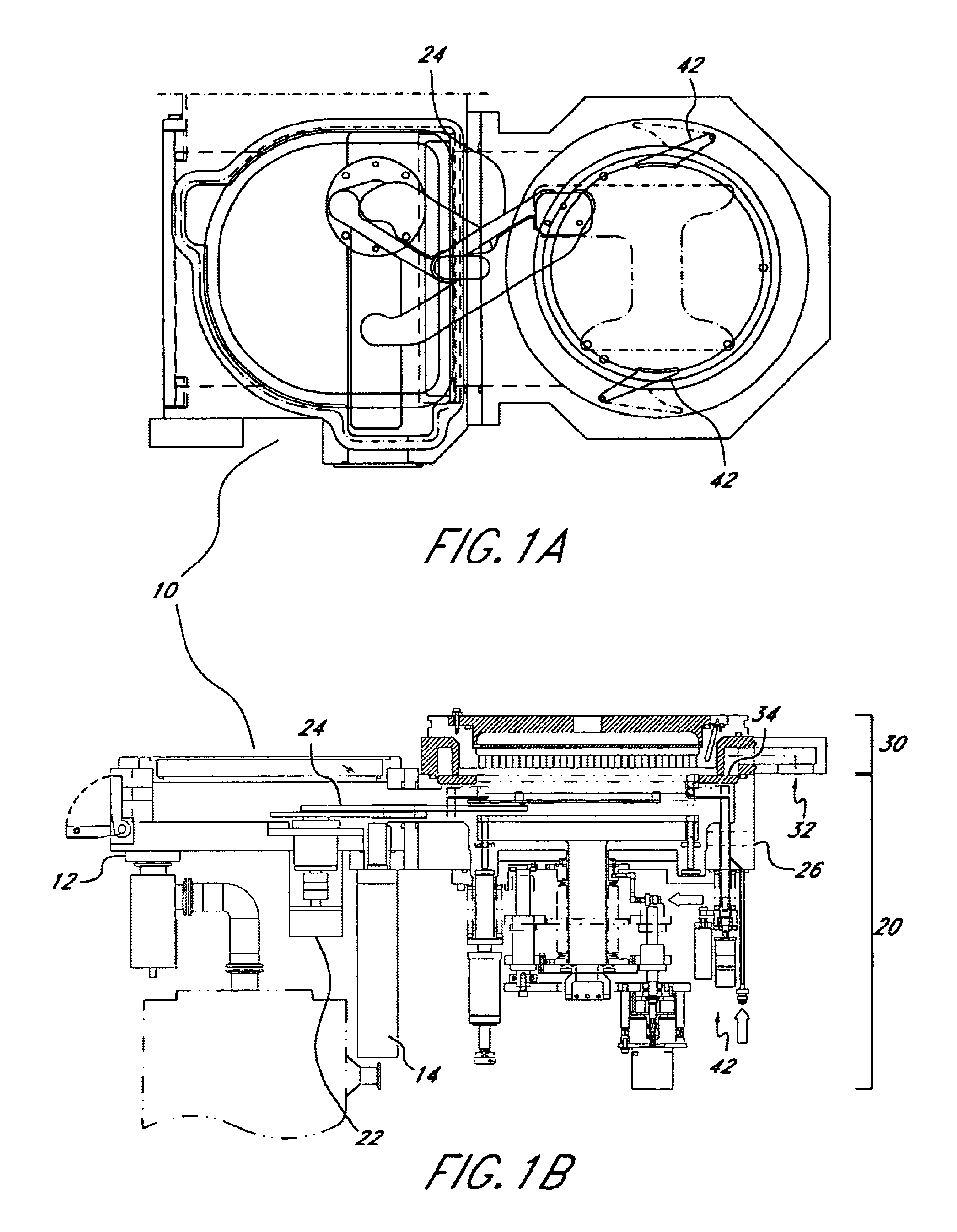

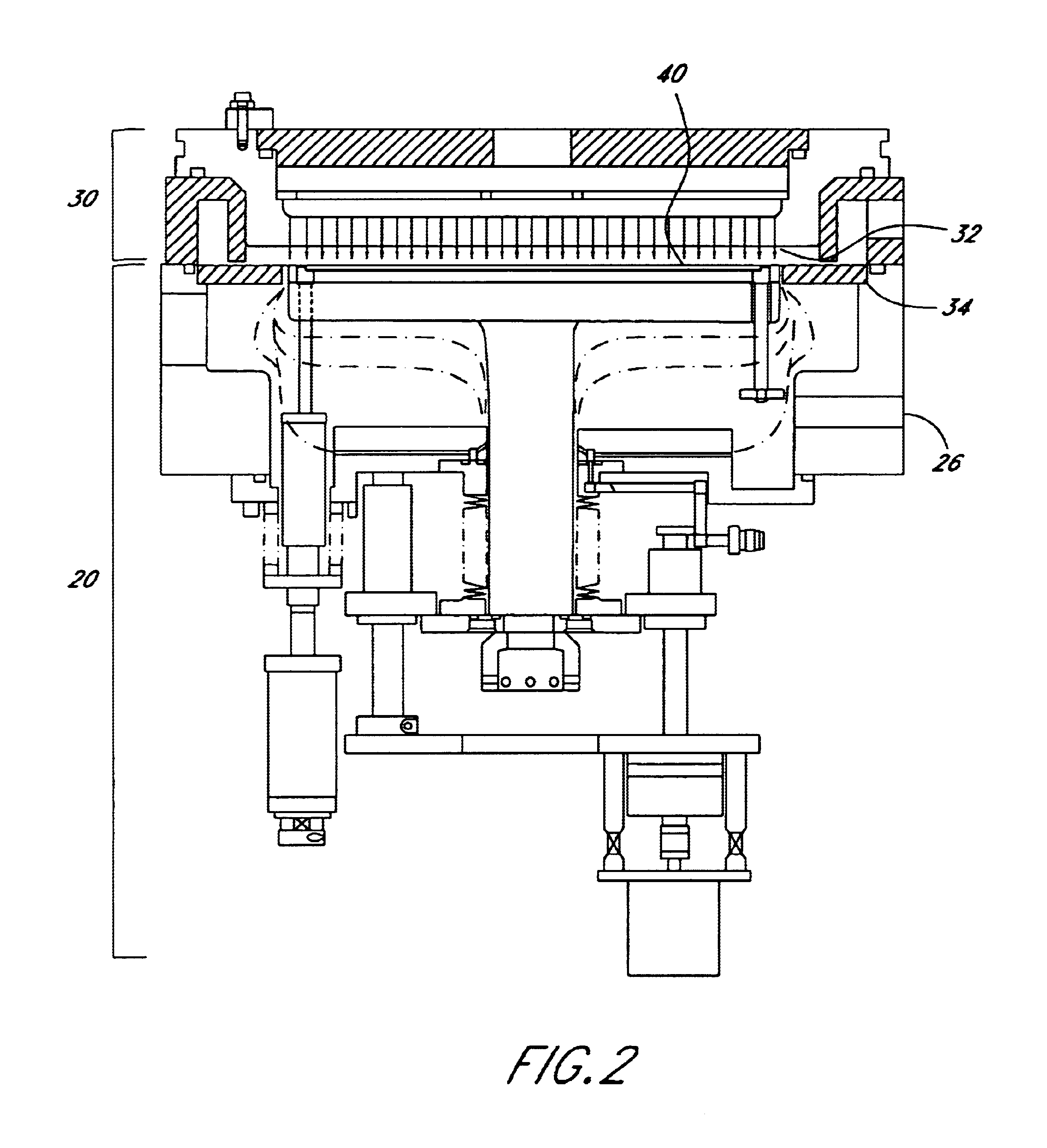

Semiconductor processing apparatus comprising chamber partitioned into reaction and transfer sections

InactiveUS6899507B2Reduce adhesionImprove efficiencySemiconductor/solid-state device manufacturingCharge manipulationEngineeringSemiconductor

Semiconductor processing equipment that has increased efficiency, throughput, and stability, as well as reduced operating cost, footprint, and faceprint is provided. Other than during deposition, the atmosphere of both the reaction chamber and the transfer chamber are evacuated using the transfer chamber exhaust port, which is located below the surface of the semiconductor wafer. This configuration prevents particles generated during wafer transfer or during deposition from adhering to the surface of the semiconductor wafer. Additionally, by introducing a purge gas into the transfer chamber during deposition, and by using an insulation separating plate 34, the atmospheres of the transfer and reaction chambers can be effectively isolated from each other, thereby preventing deposition on the walls and components of the transfer chamber. Finally, the configuration described herein permits a wafer buffer mechanism to be used with the semiconductor processing equipment, thereby further increasing throughput and efficiency.

Owner:ASM JAPAN

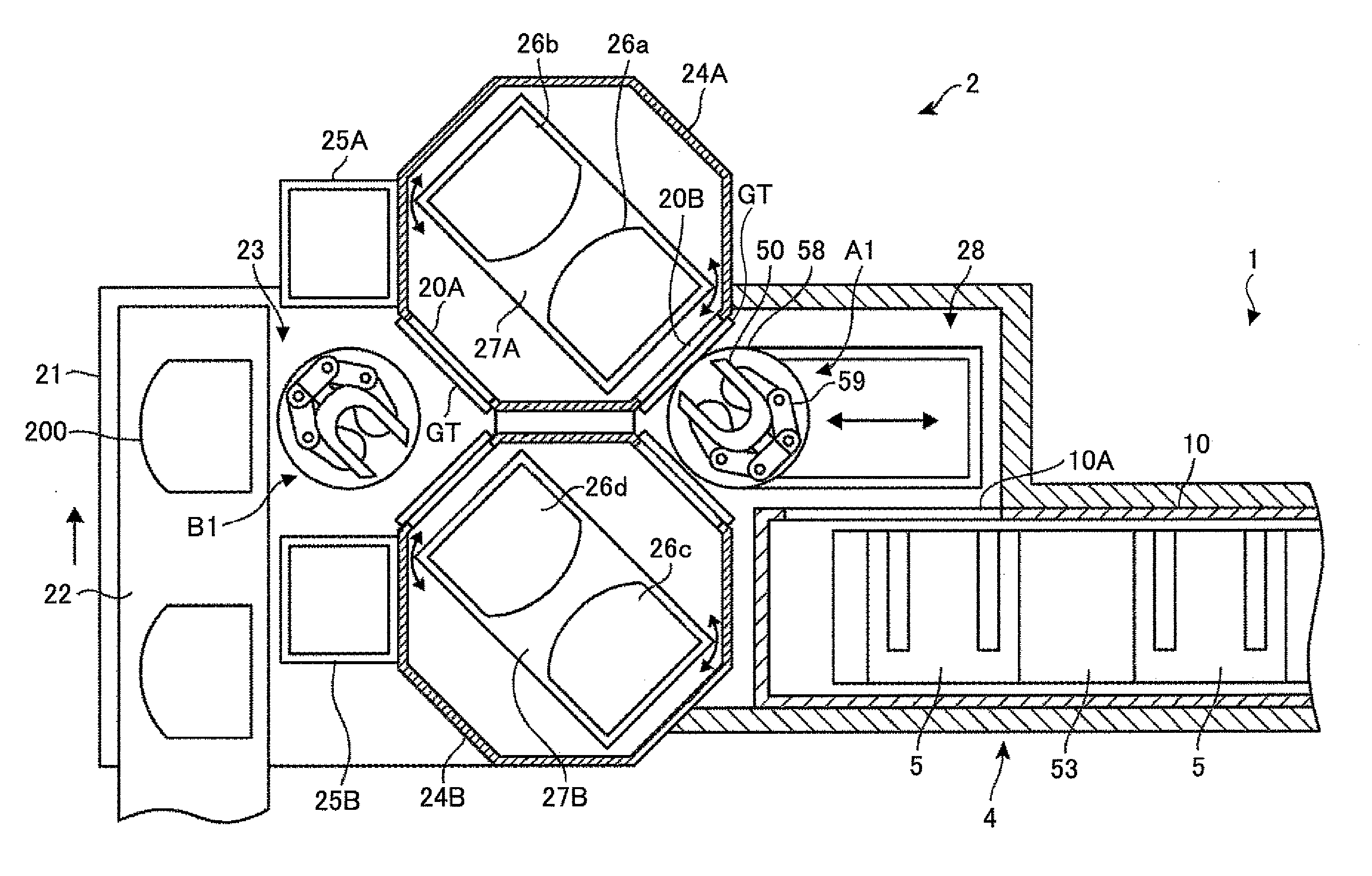

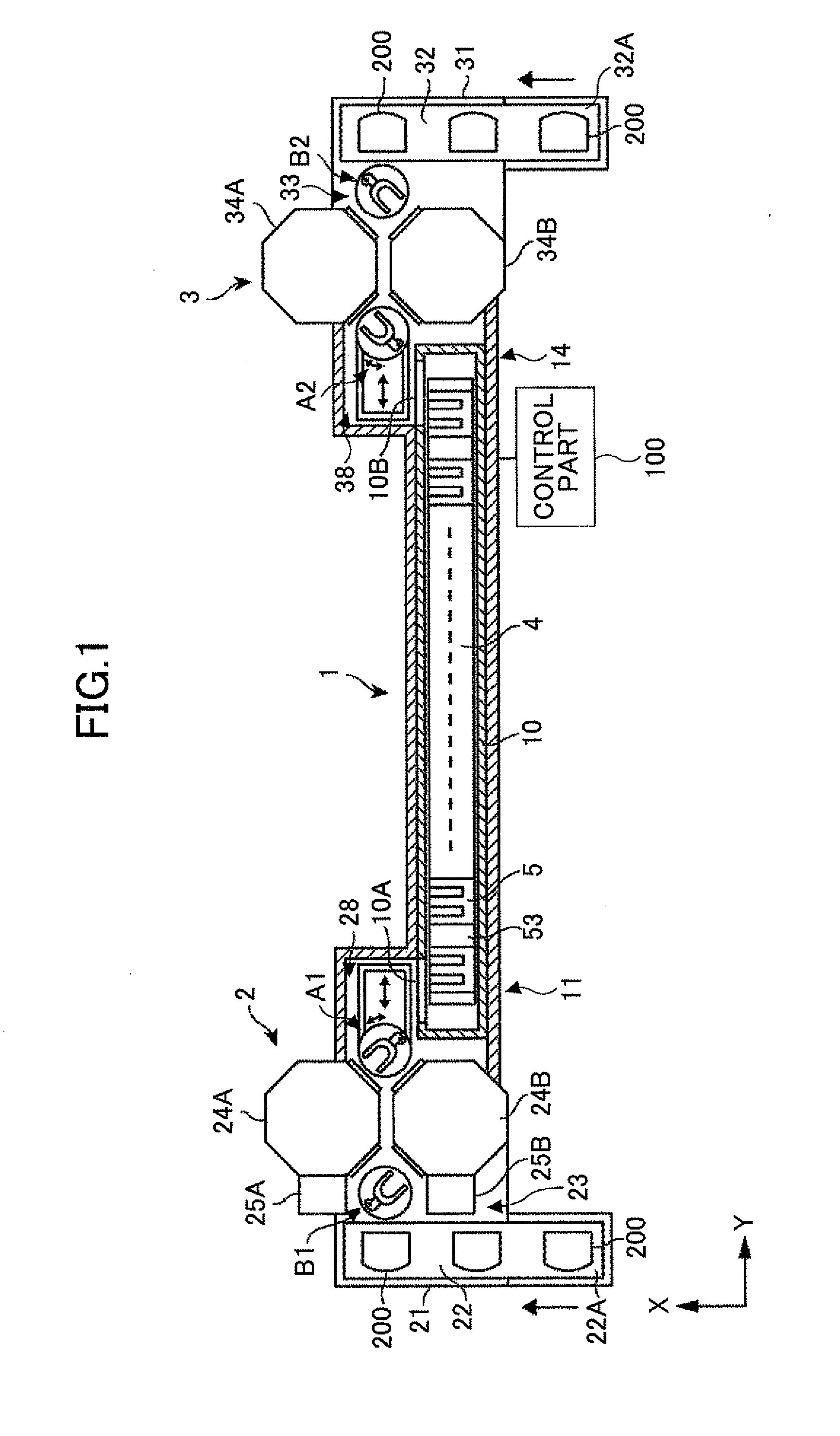

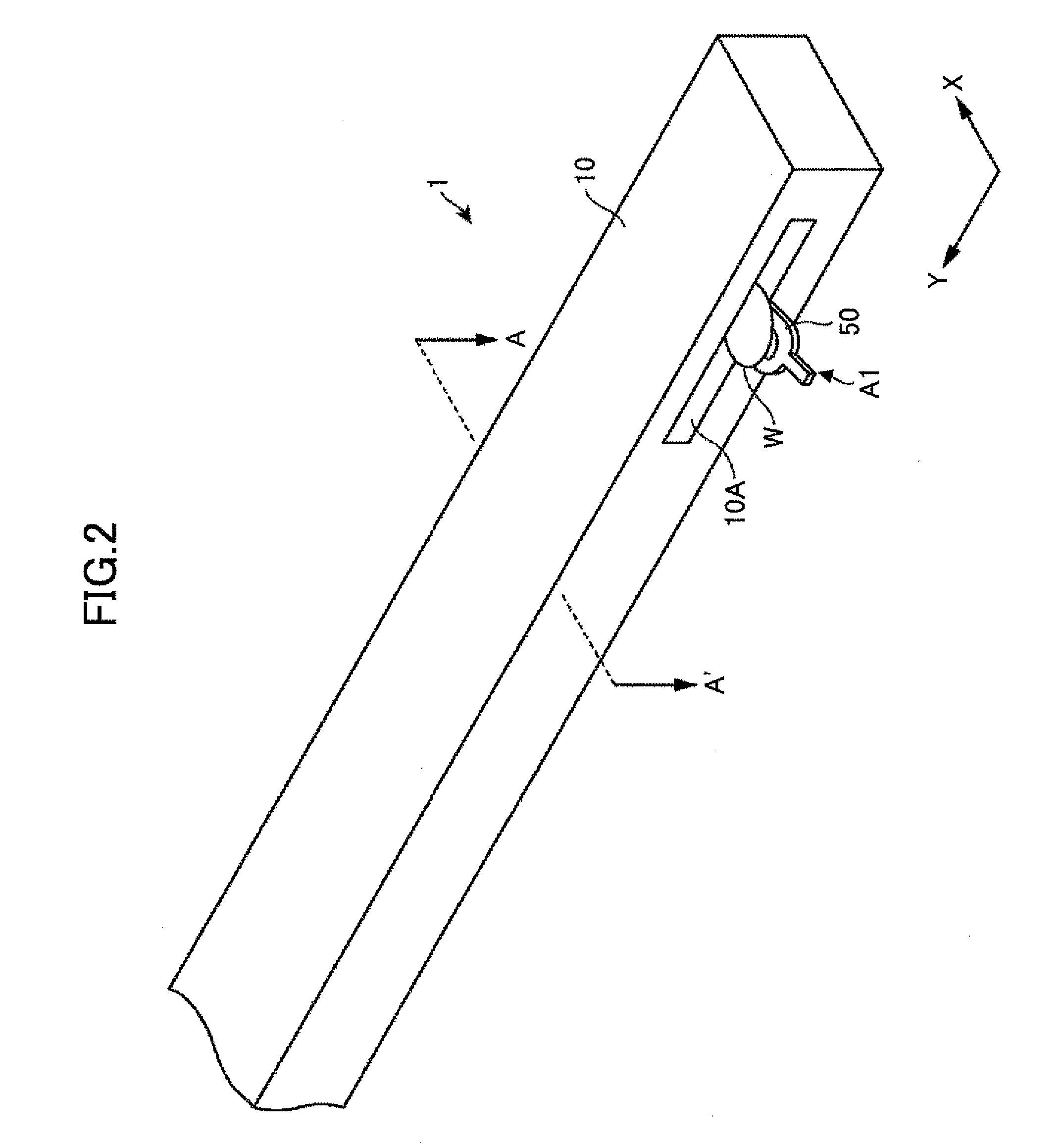

Film deposition device and substrate processing device

InactiveUS20110265725A1Improve throughputLow gas consumptionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReactive gasGas supply

A film deposition device includes a substrate transporting device arranged in a vacuum chamber to include a circulatory transport path in which substrate mounting parts arranged in a row are transported in a circulatory manner, the circulatory transport path including a linear transport path in which the substrate mounting parts are transported linearly. A first reactive gas supplying part is arranged along a transporting direction in which the substrate mounting parts are transported in the linear transport path, to supply a first reactive gas to the substrate mounting parts. A second reactive gas supplying part is arranged alternately with the first reactive gas supplying part along the transporting direction, to supply a second reactive gas to the substrate mounting parts. A separation gas supplying part is arranged to supply a separation gas to a space between the first reactive gas supplying part and the second reactive gas supplying part.

Owner:TOKYO ELECTRON LTD

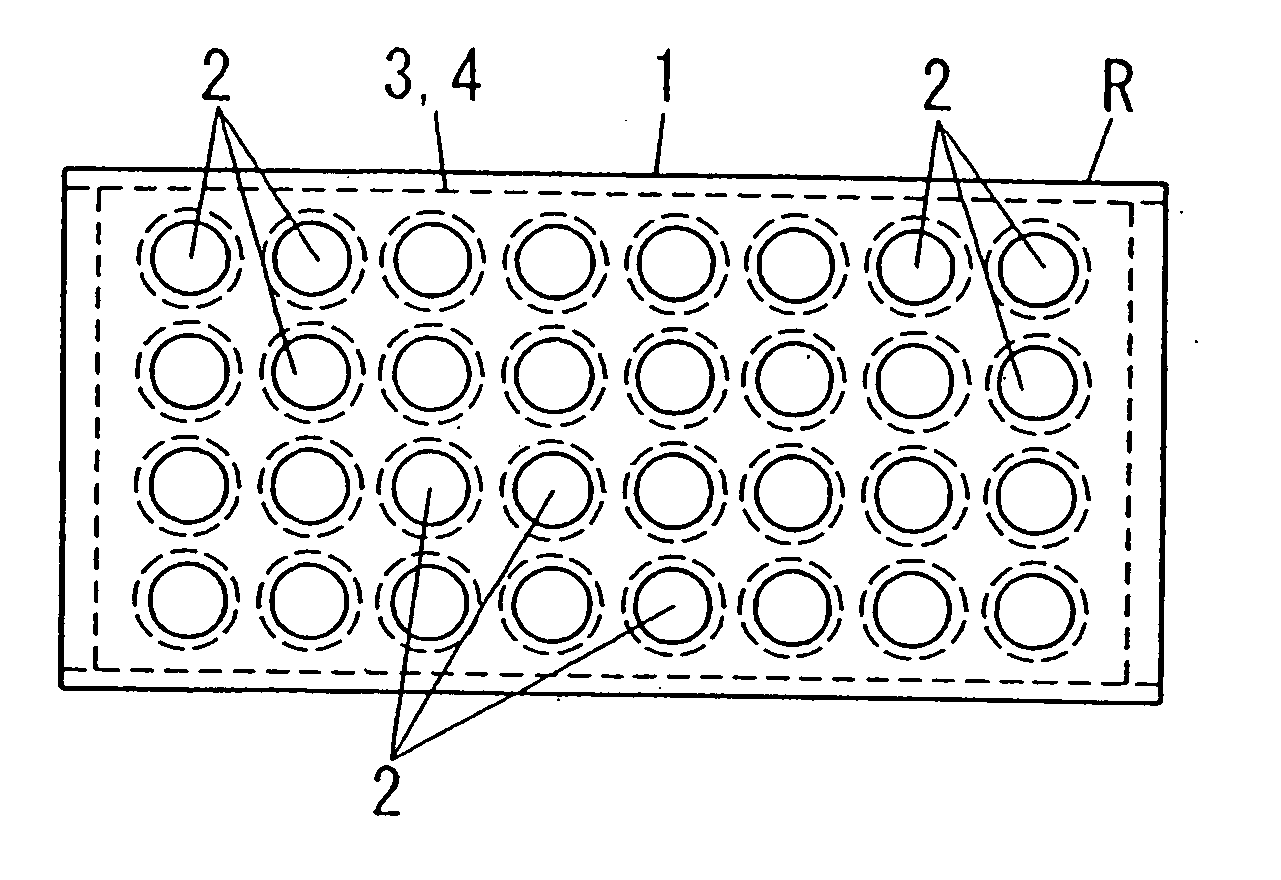

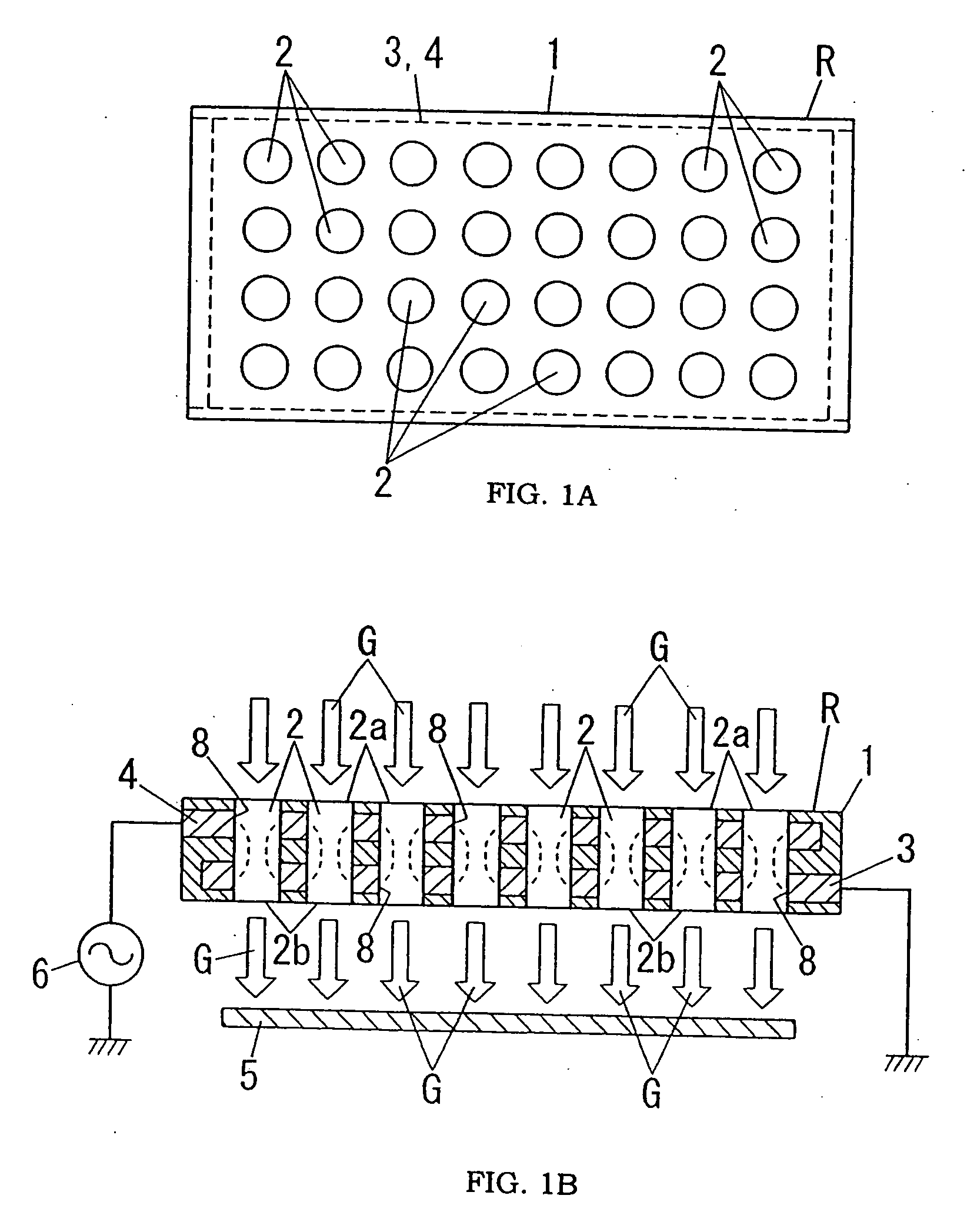

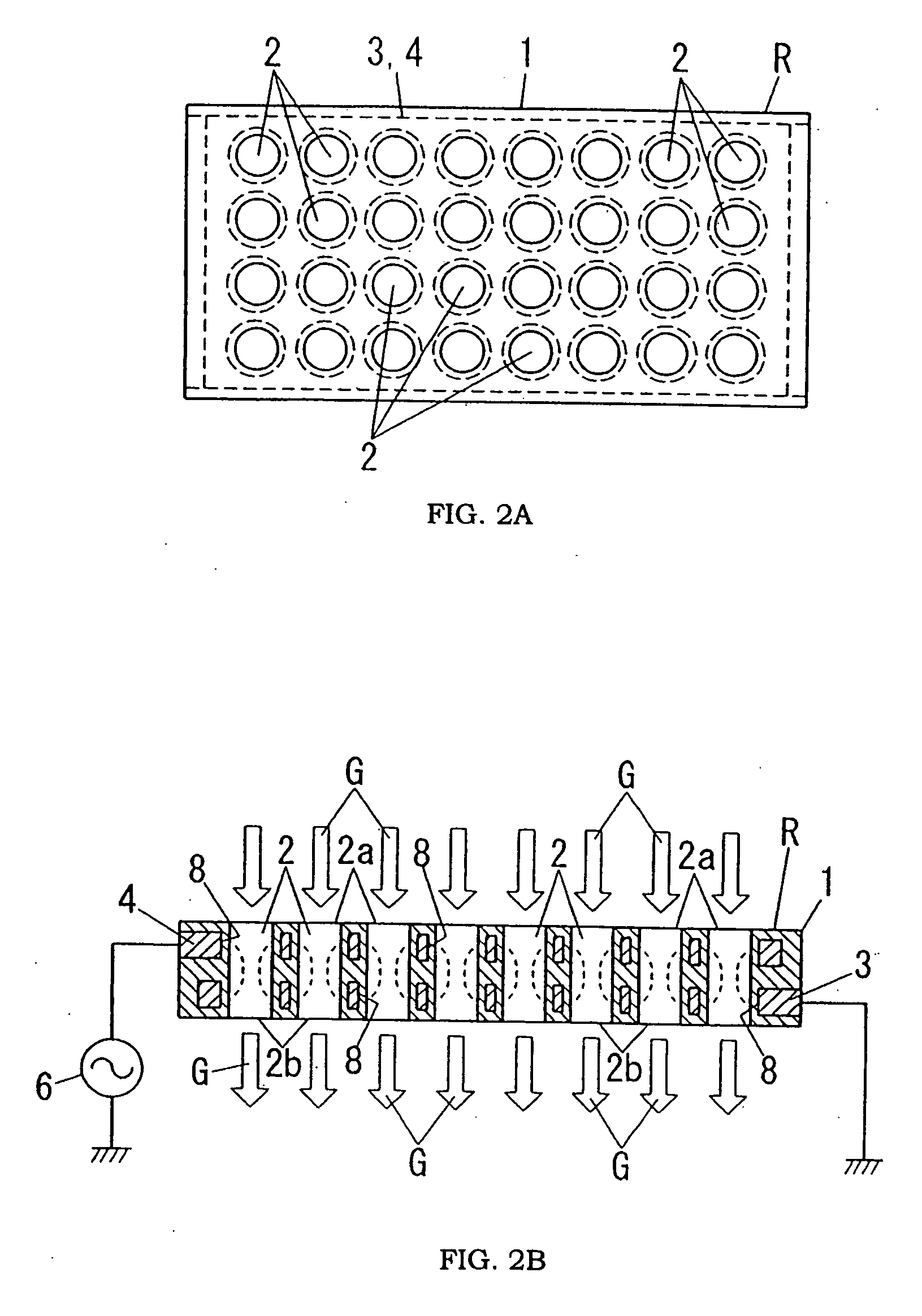

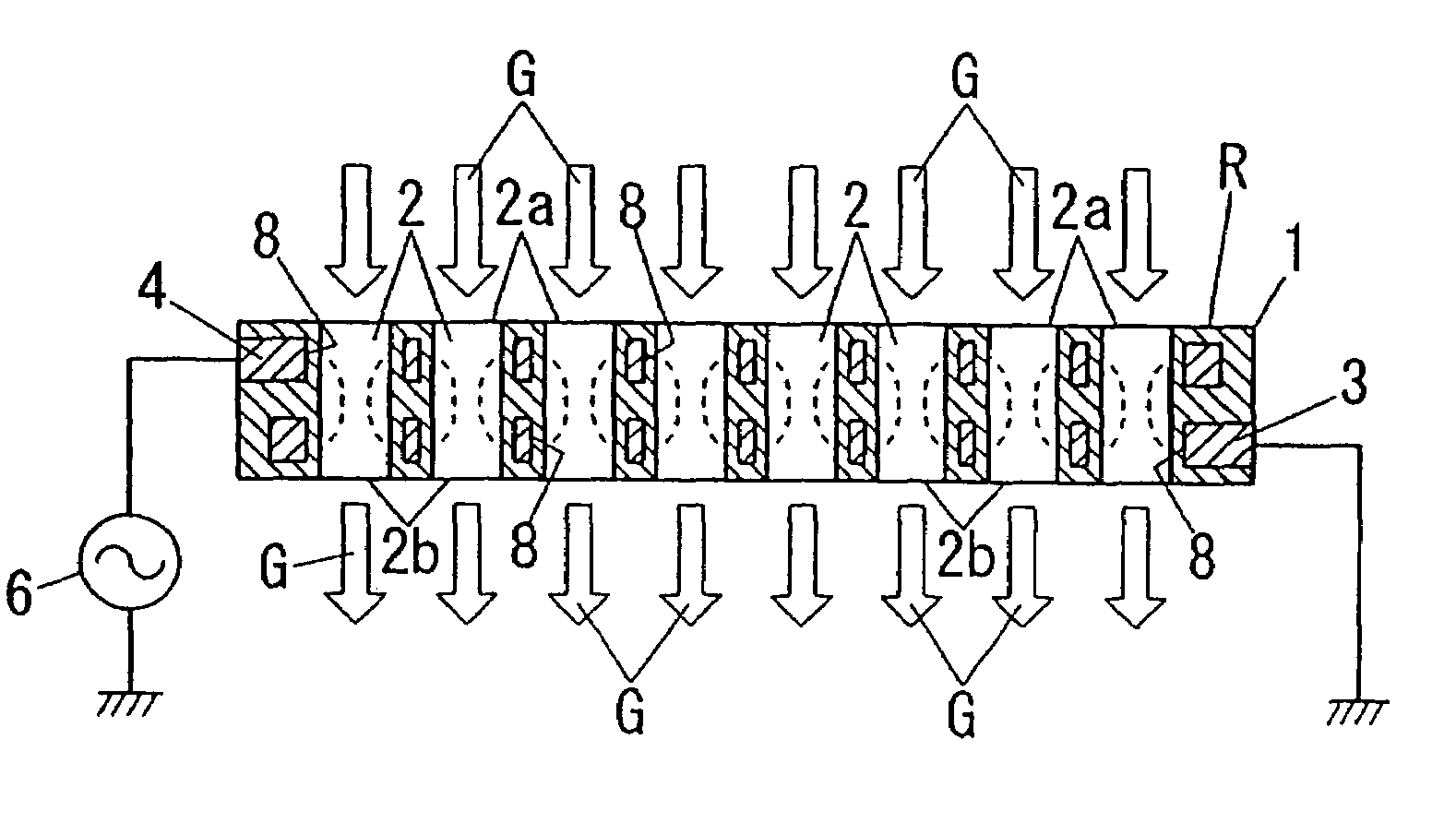

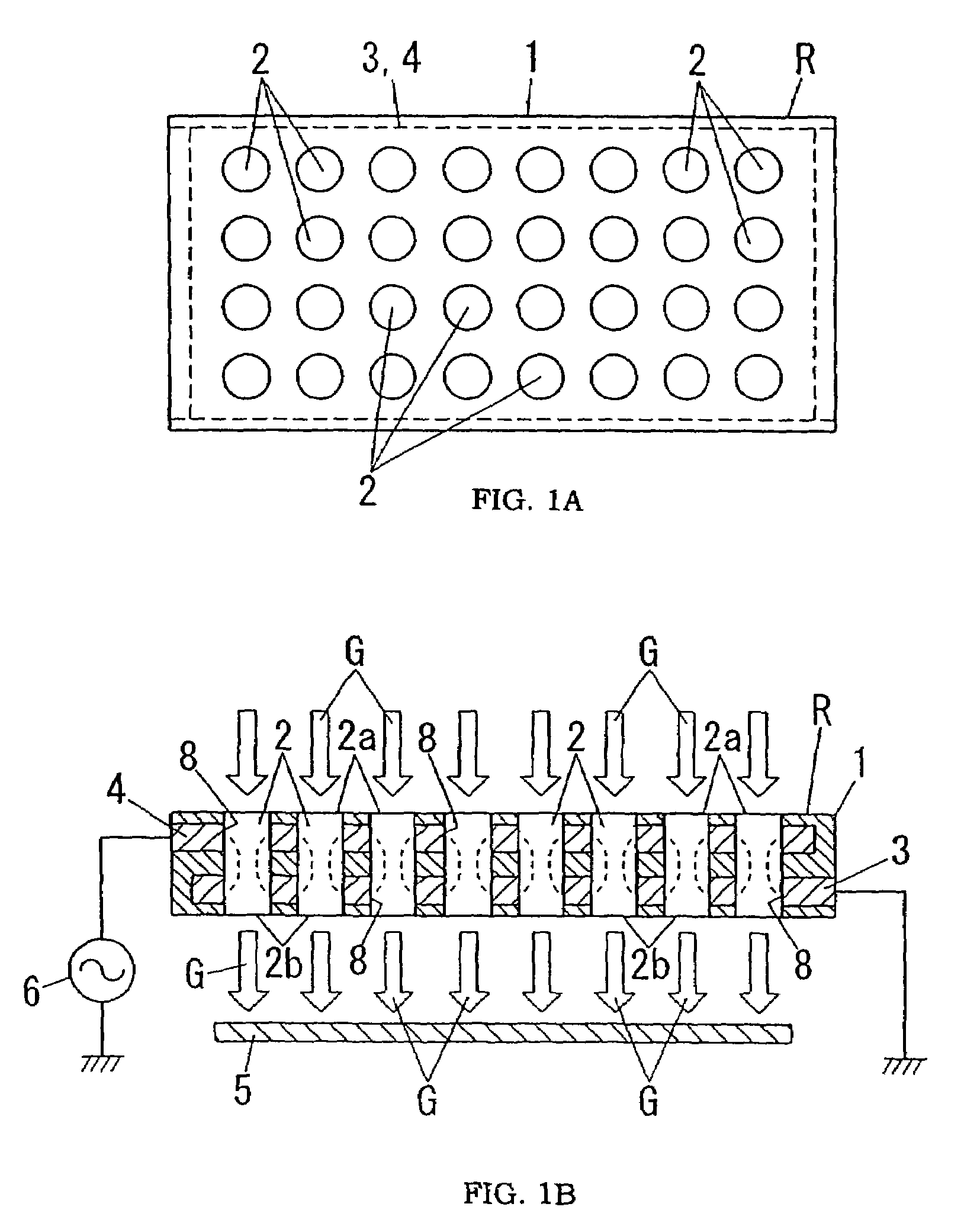

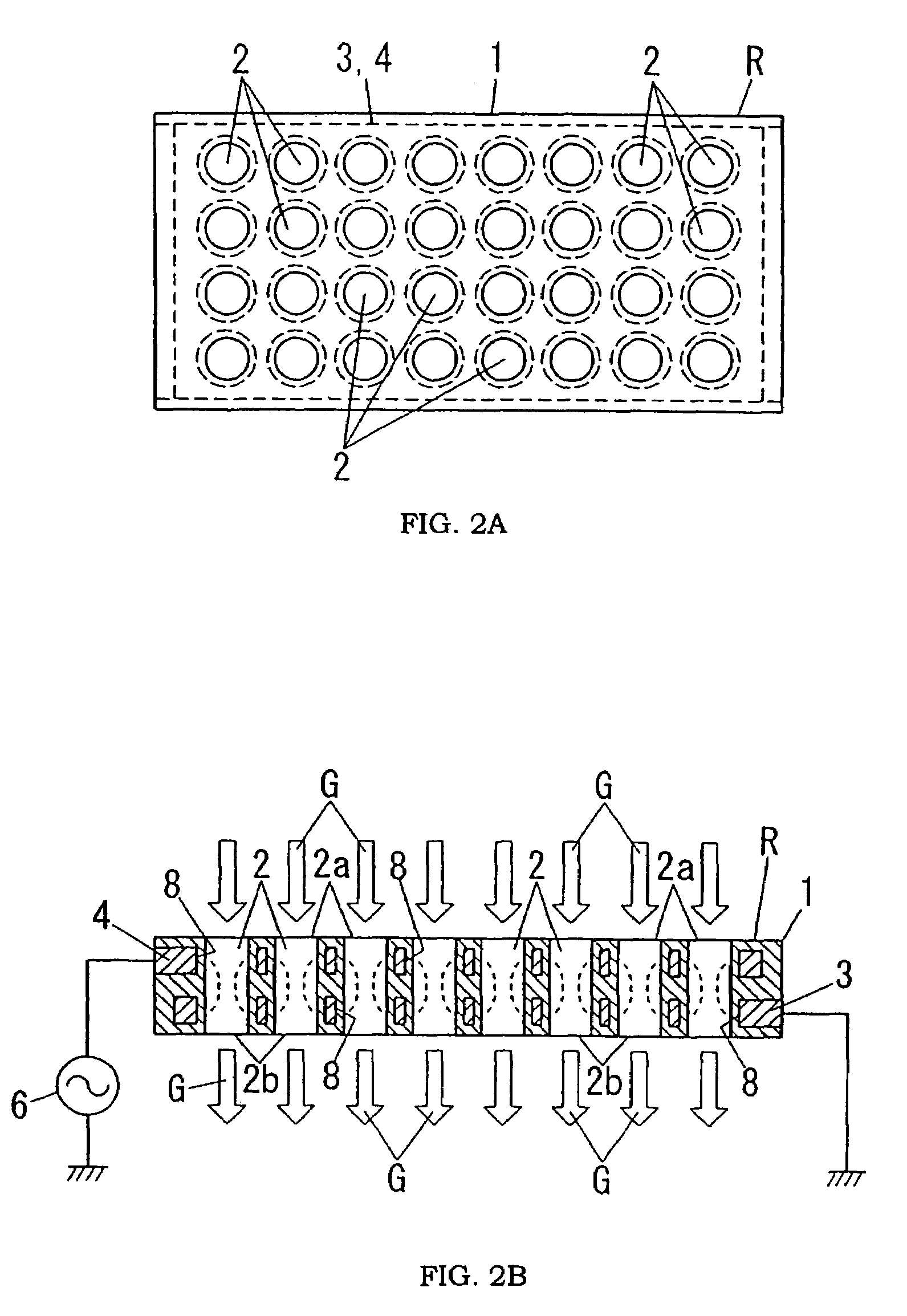

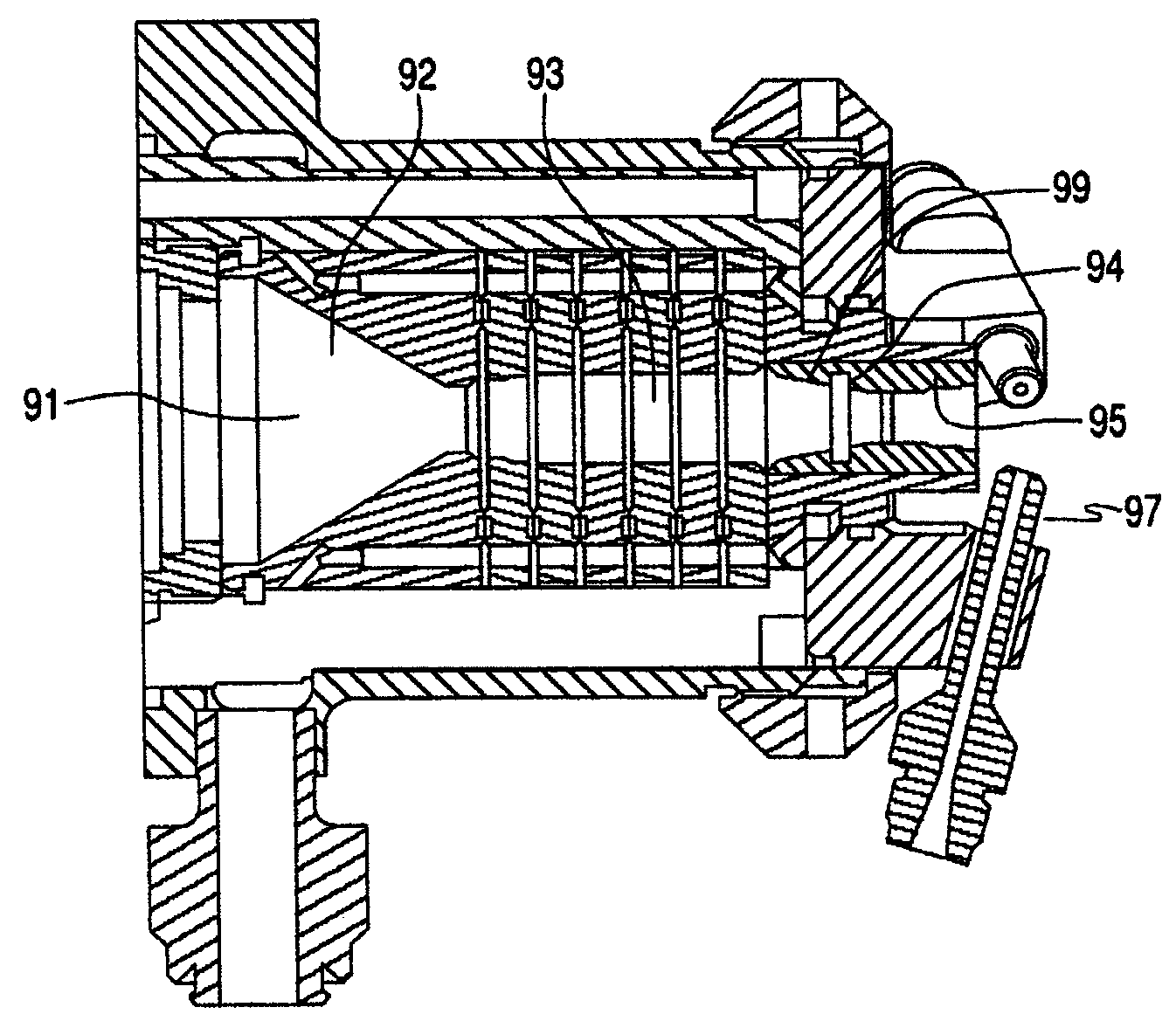

Plasma treatment apparatus, method of producing reaction vessel for plasma generation, and plasma treatment method

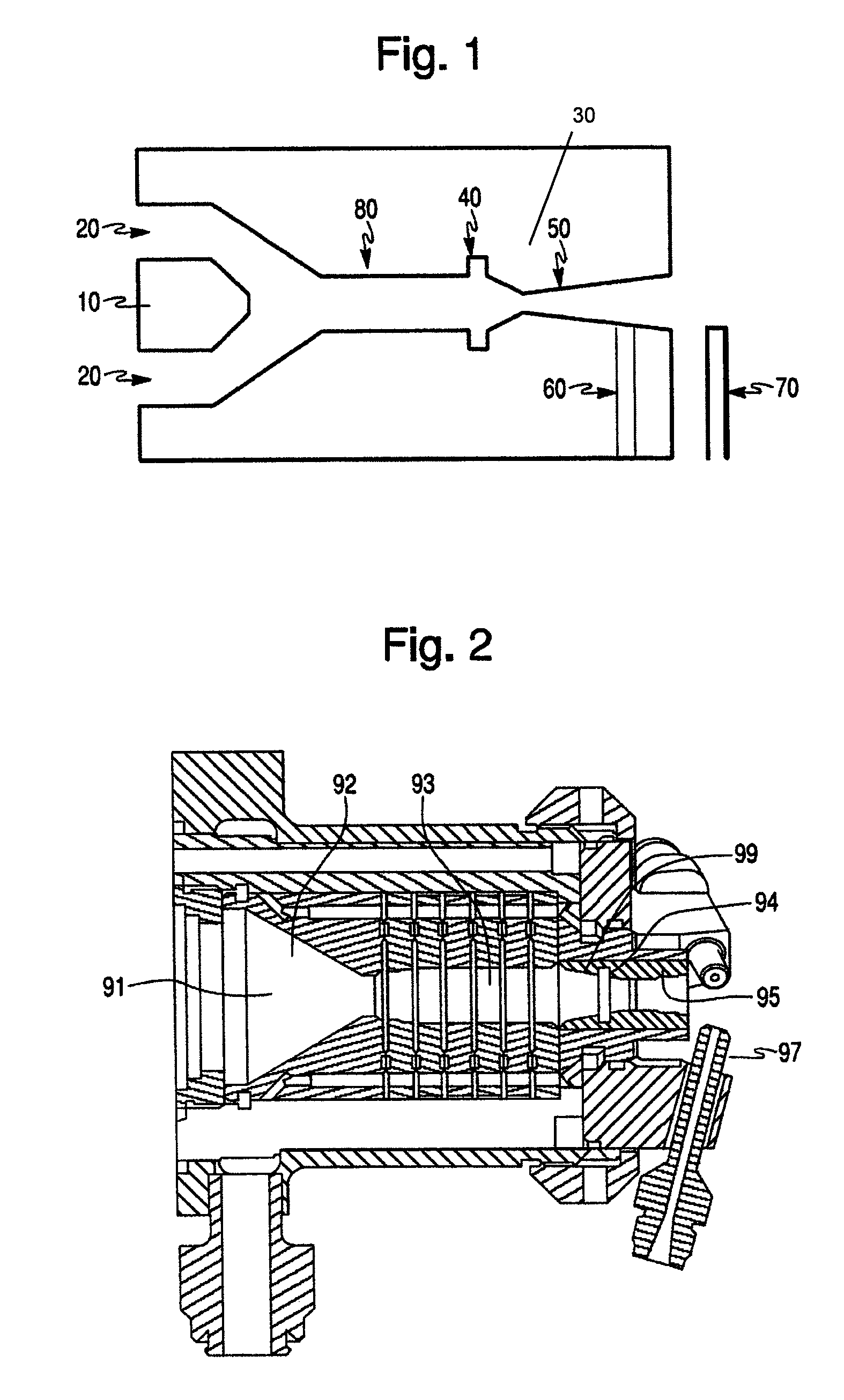

InactiveUS20060042545A1Large treatment areaLow gas consumptionMolten spray coatingElectric discharge tubesEngineeringVoltage

A plasma treatment apparatus is provided, which enables to increase a treatment area and provide good treatment uniformity. This apparatus comprises a pair of electrode plates having a plurality of through holes and an insulating plate having a plurality of through holes. The insulating plate is disposed between the electrode plates such that positions of the through holes of the electrode plates correspond to the positions of the through holes of the insulating plate. A plurality of discharge spaces are formed by the through holes of the electrode plates and the through holes of the insulating plate. By applying a voltage between the electrode plates, while supplying a plasma generation gas into the discharge spaces, plasmas are generated simultaneously in the discharge spaces, and sprayed on an object to efficiently perform a large-area, uniform plasma treatment.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Plasma processing apparatus, method for producing reaction vessel for plasma generation, and plasma processing method

InactiveUS7543546B2Large treatment areaLow gas consumptionMolten spray coatingElectric discharge tubesProcess regionEngineering

A plasma treatment apparatus is provided, which enables to increase a treatment area and provide good treatment uniformity. This apparatus comprises a pair of electrode plates having a plurality of through holes and an insulating plate having a plurality of through holes. The insulating plate is disposed between the electrode plates such that positions of the through holes of the electrode plates correspond to the positions of the through holes of the insulating plate. A plurality of discharge spaces are formed by the through holes of the electrode plates and the through holes of the insulating plate. By applying a voltage between the electrode plates, while supplying a plasma generation gas into the discharge spaces, plasmas are generated simultaneously in the discharge spaces, and sprayed on an object to efficiently perform a large-area, uniform plasma treatment.

Owner:MATSUSHITA ELECTRIC WORKS LTD

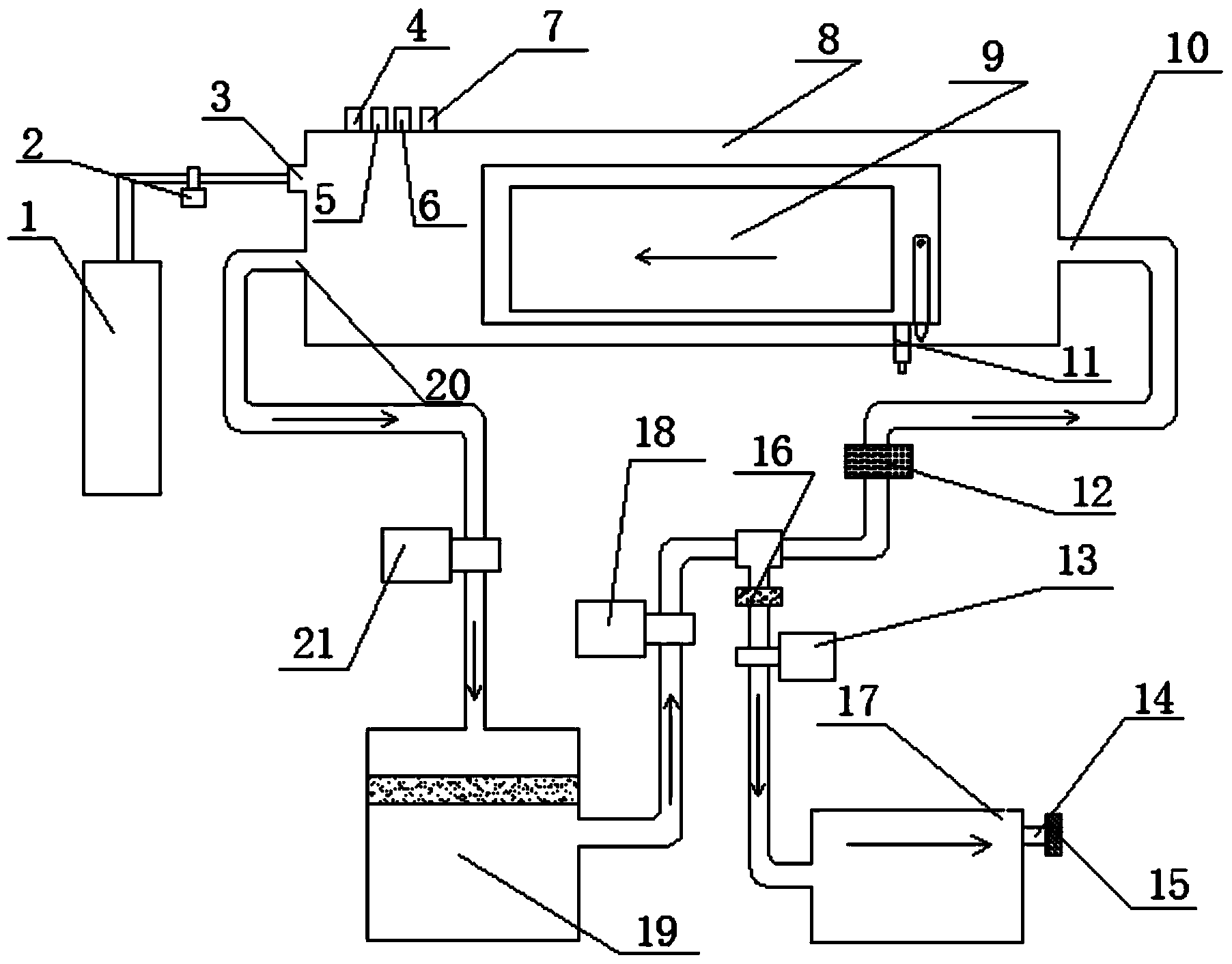

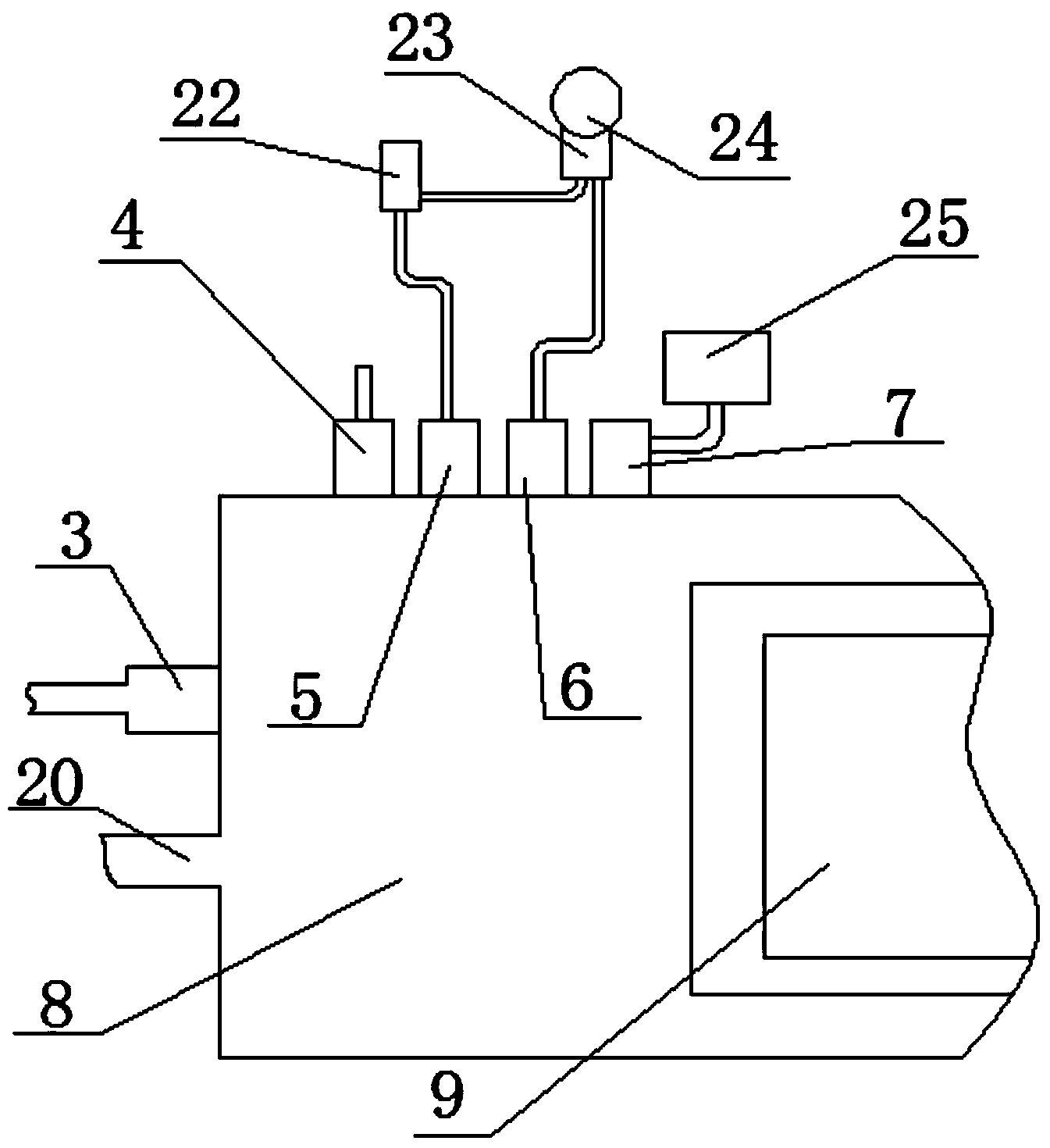

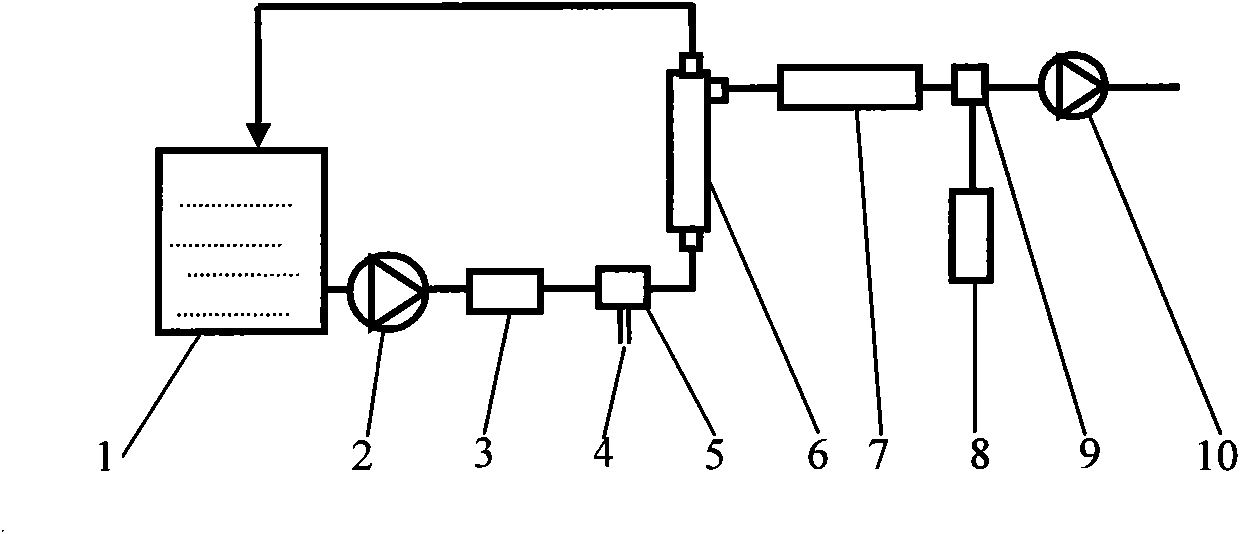

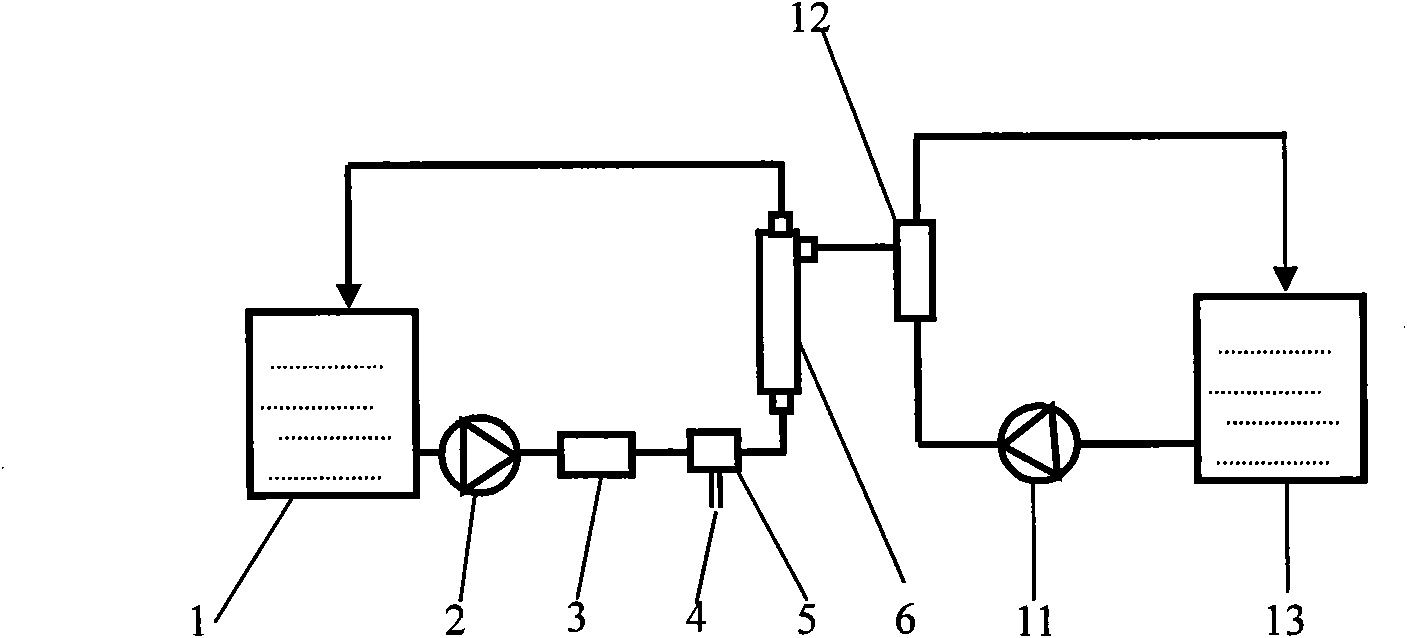

Method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for metal 3D printer

ActiveCN104353832ALow oxygenReduce usageAdditive manufacturingIncreasing energy efficiencyMolecular sieveSolenoid valve

The invention discloses a method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for a metal 3D printer. A gas inlet and a gas outlet are respectively formed in two ends of a forming chamber; the gas inlet and the gas outlet are mutually connected through a gas circulating pipeline; a first pneumatic butterfly valve, a dust purifier, a second pneumatic butterfly valve and a water removal drier are arranged on the gas circulating pipeline; a branch pipeline is arranged on the gas circulating pipeline between the second pneumatic butterfly valve and the water removal drier; the tail end of the branch pipeline is connected with a vacuum pump; a molecular sieve and a vacuum pipeline solenoid valve are arranged on the branch pipeline; the forming chamber is connected with an inert gas source. According to the method, firstly the oxygen content in the forming chamber is reduced to a required range before machining, and gas circulating purification is started during machining, so that gas purity degree in the forming chamber is kept; pressure detection and oxygen content detection are introduced, so that the oxygen content and pressure are within a reasonable range at all time during machining. The method and the equipment improve the forming efficiency and quality of the 3D printer, and guarantee the safety and the reliability of the machining process.

Owner:SOUTH CHINA UNIV OF TECH

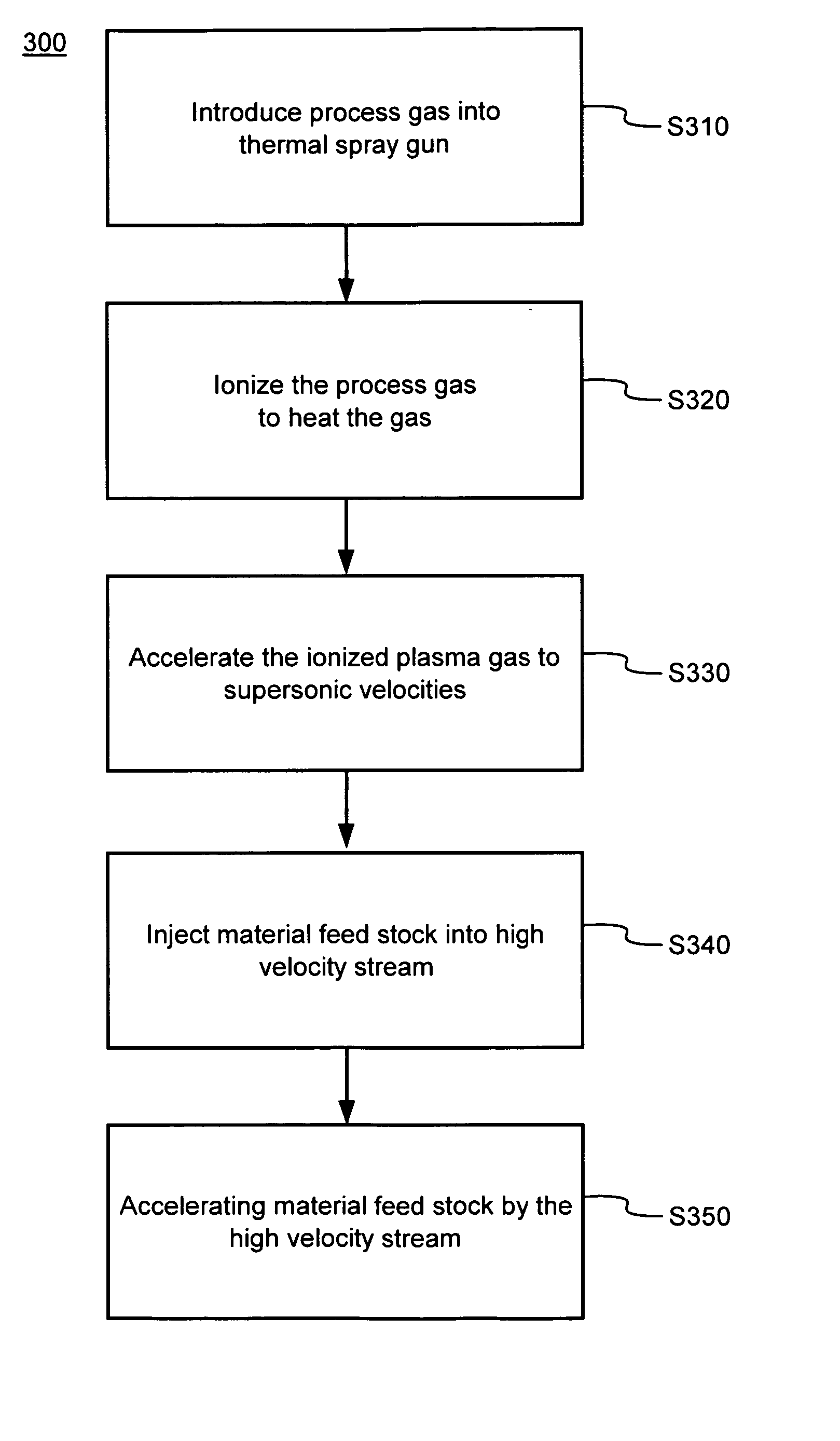

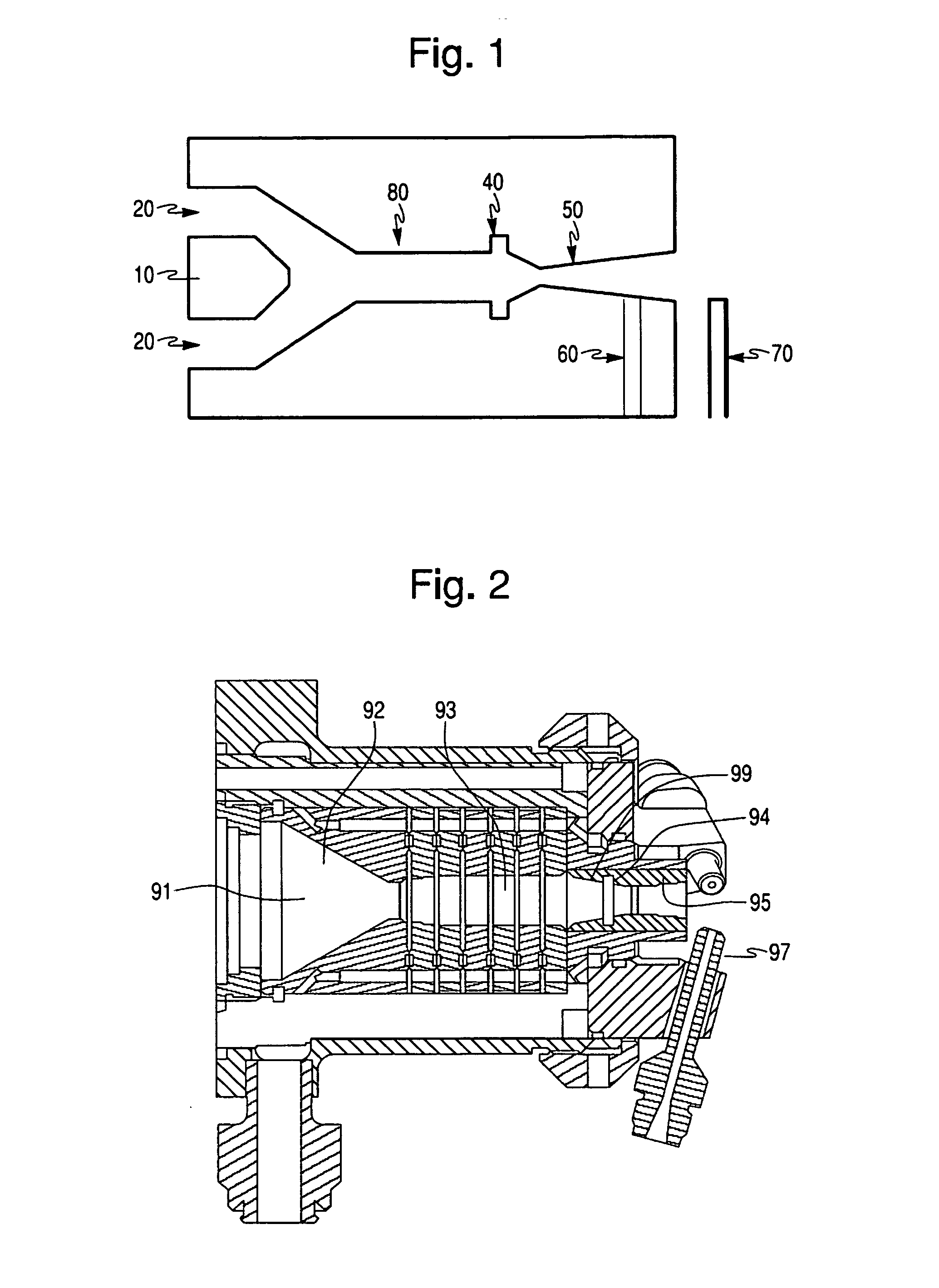

Hybrid plasma-cold spray method and apparatus

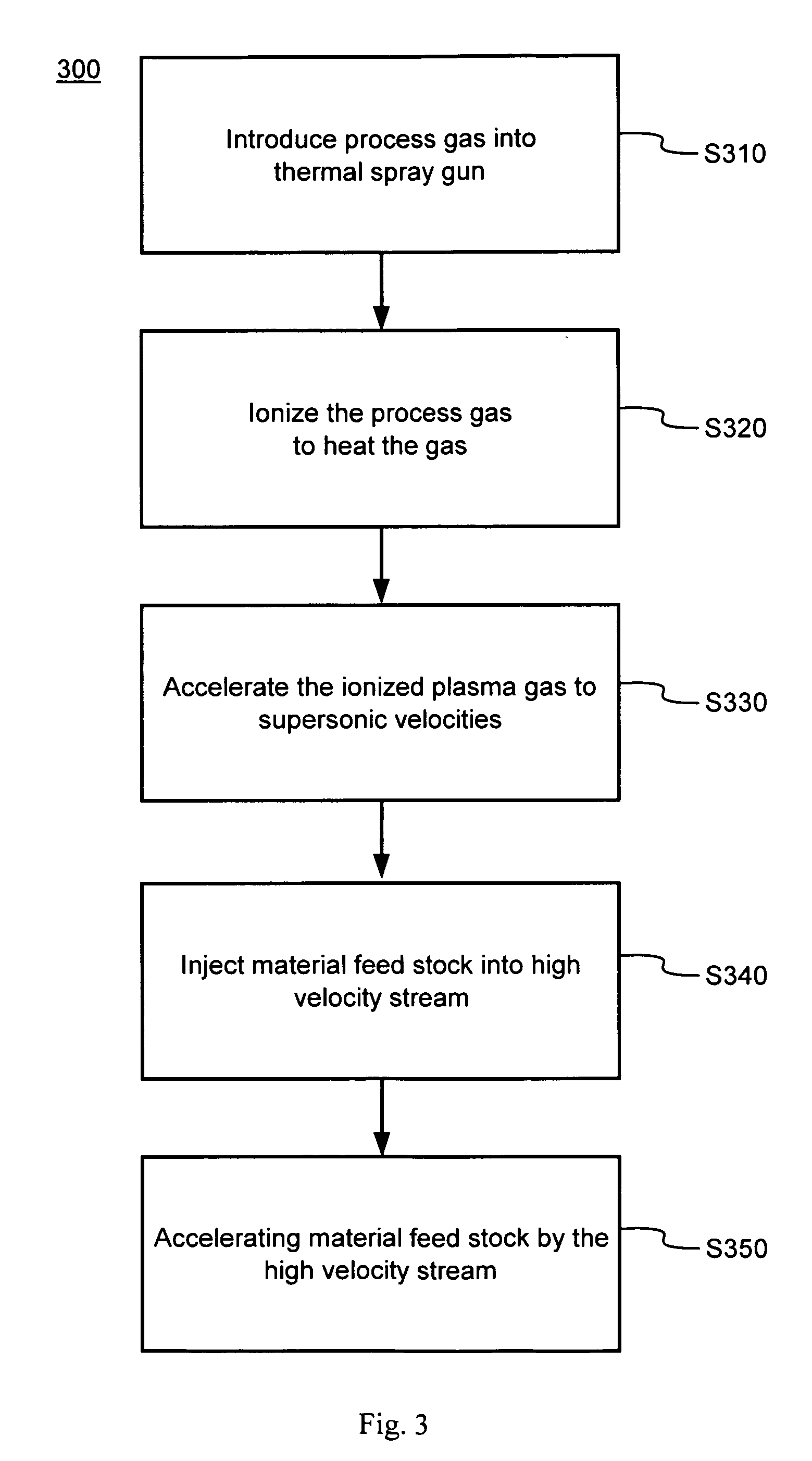

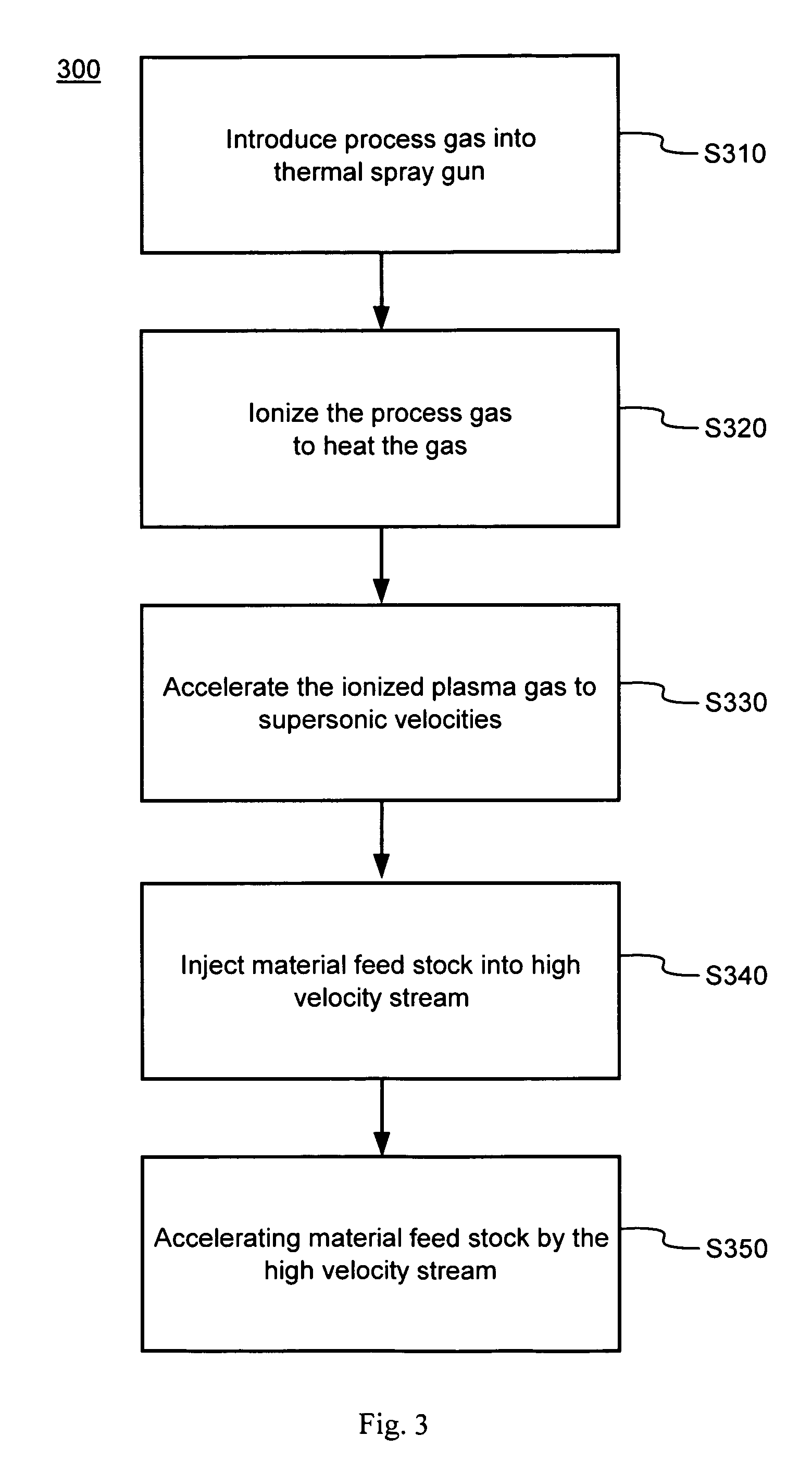

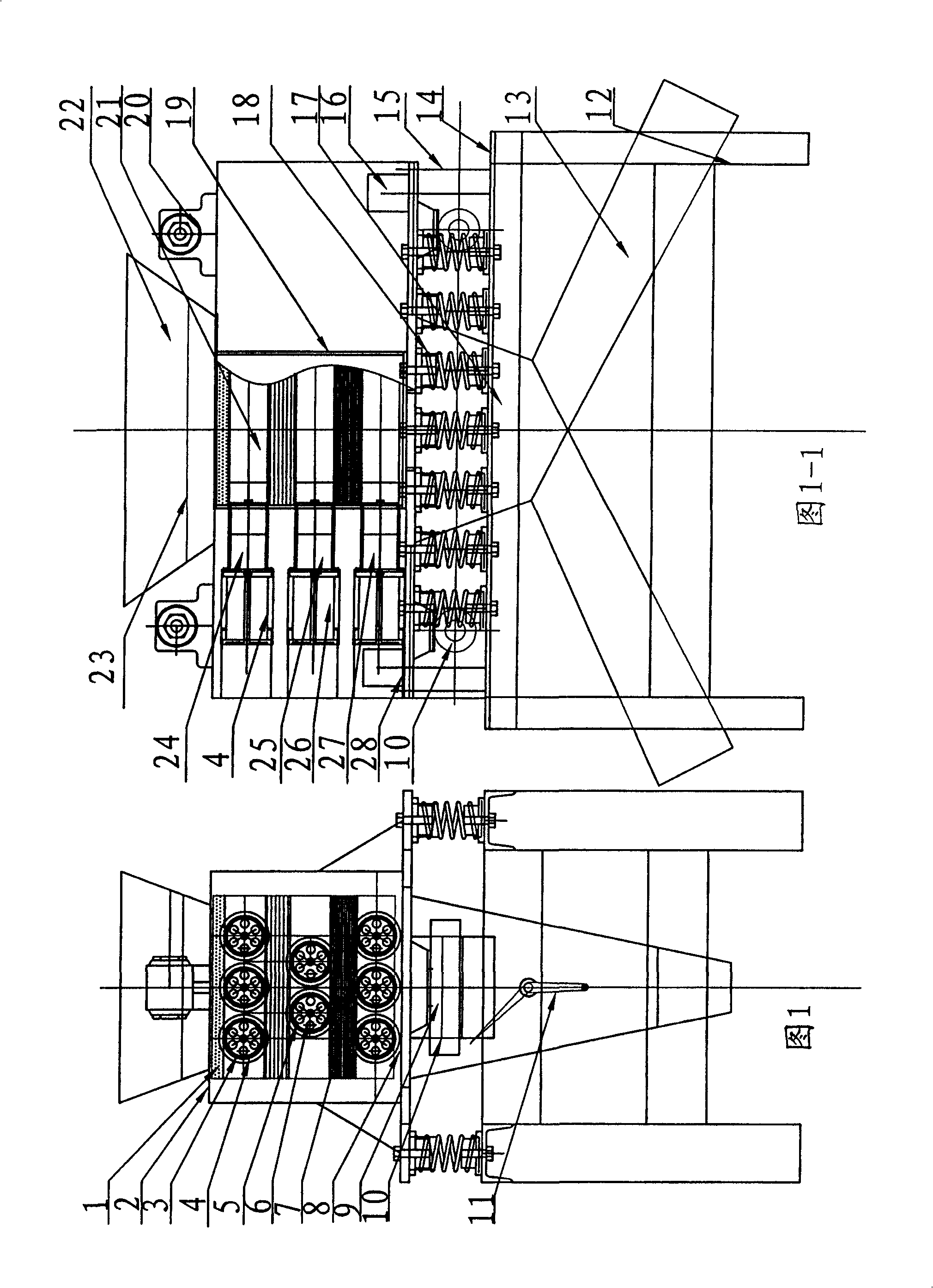

ActiveUS20070138147A1High processing efficiencyLow gas consumptionMolten spray coatingArc welding apparatusProcess engineeringSpray method

The present invention provides a method and apparatus of producing a dense coating with desirable stress conditions similar to coatings produced by a cold spray processes, but with higher process efficiencies and lower gas consumption. The inventive process combines features of a plasma process method of gas heating and a cold spray process to accelerate the gas, incorporating these elements into a single hybrid process.

Owner:SULZER METCO (US) INC

Process and machine for producing lightweight thermoplastic composite products in a continuous manner

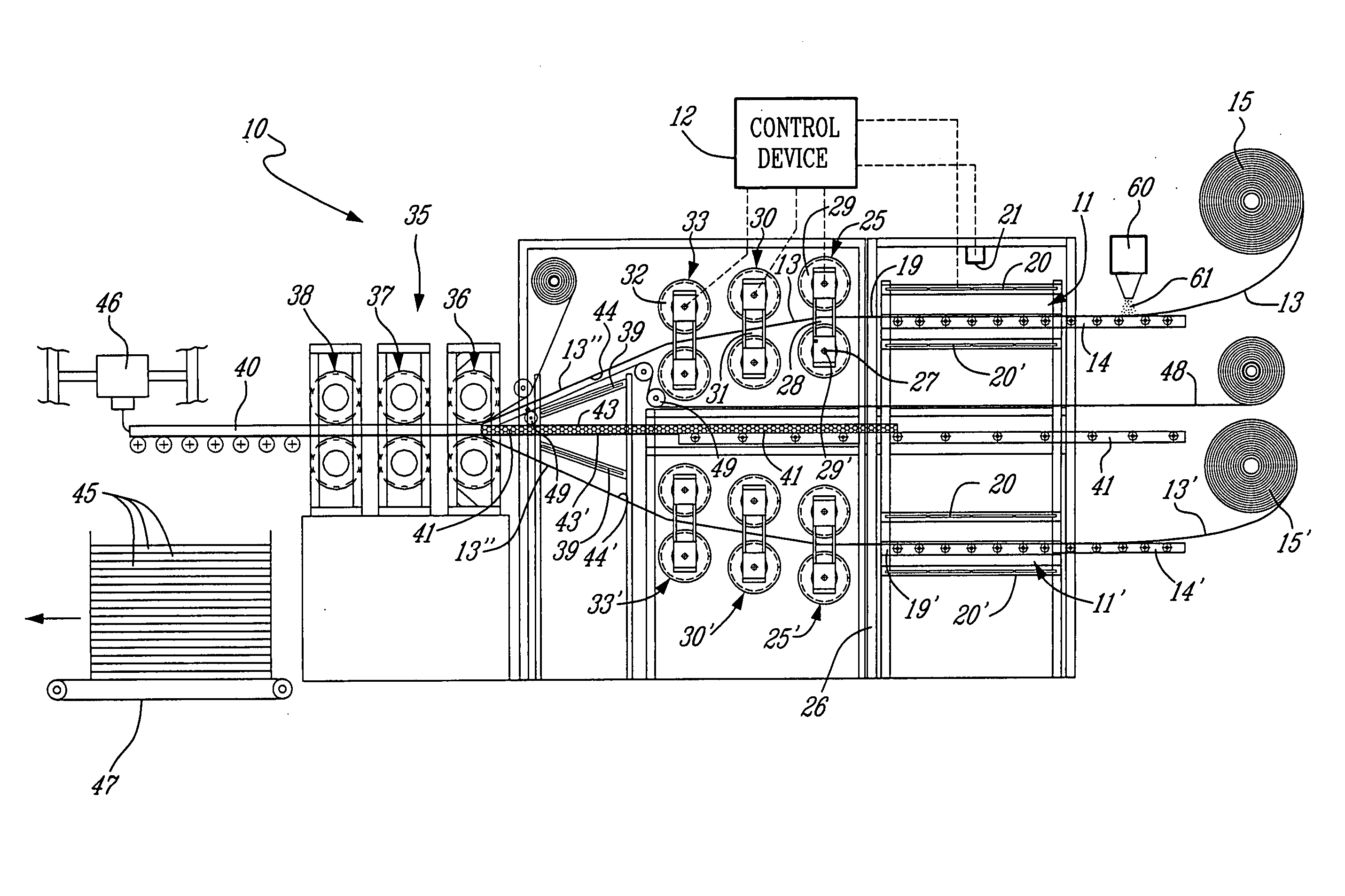

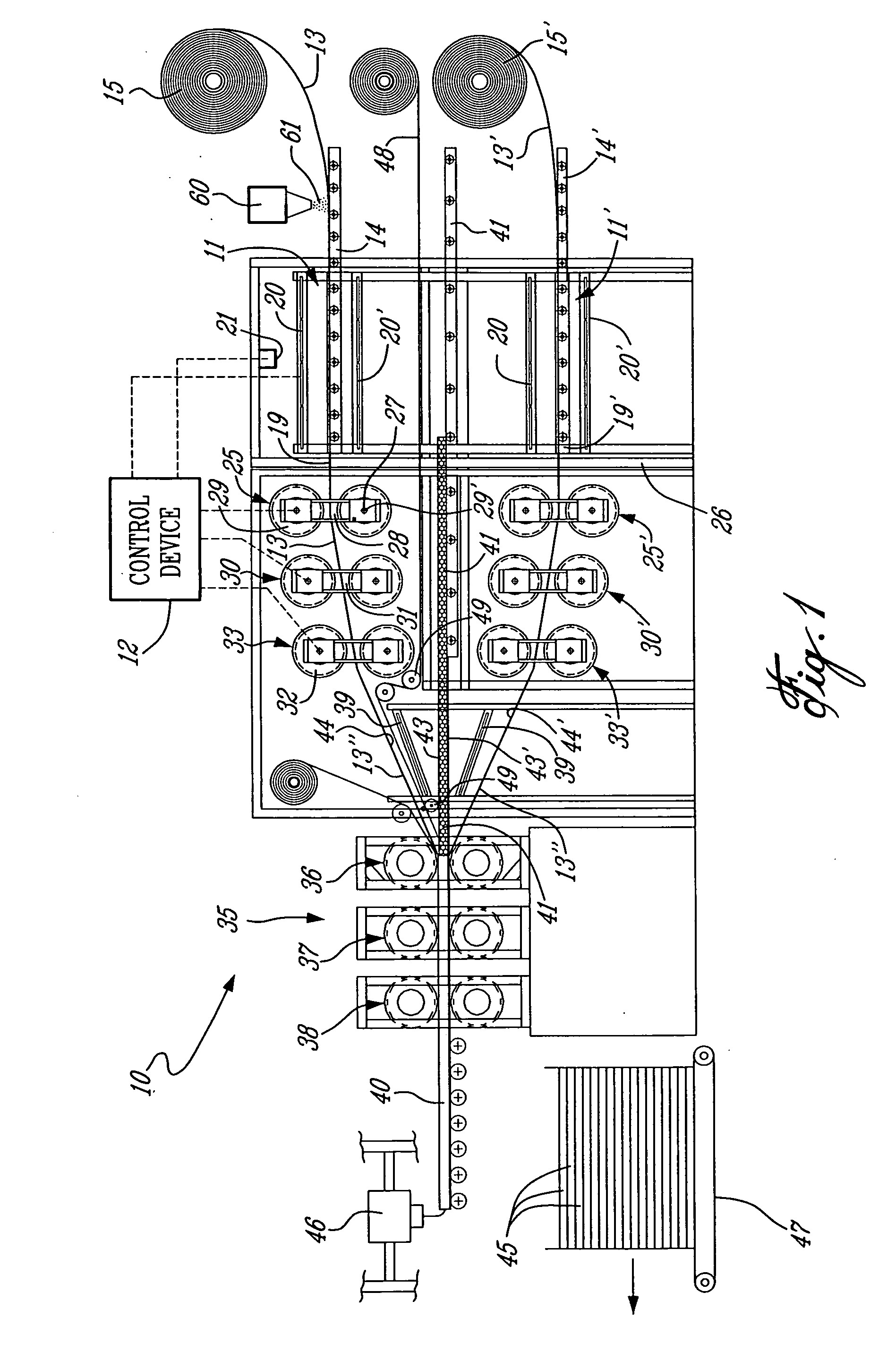

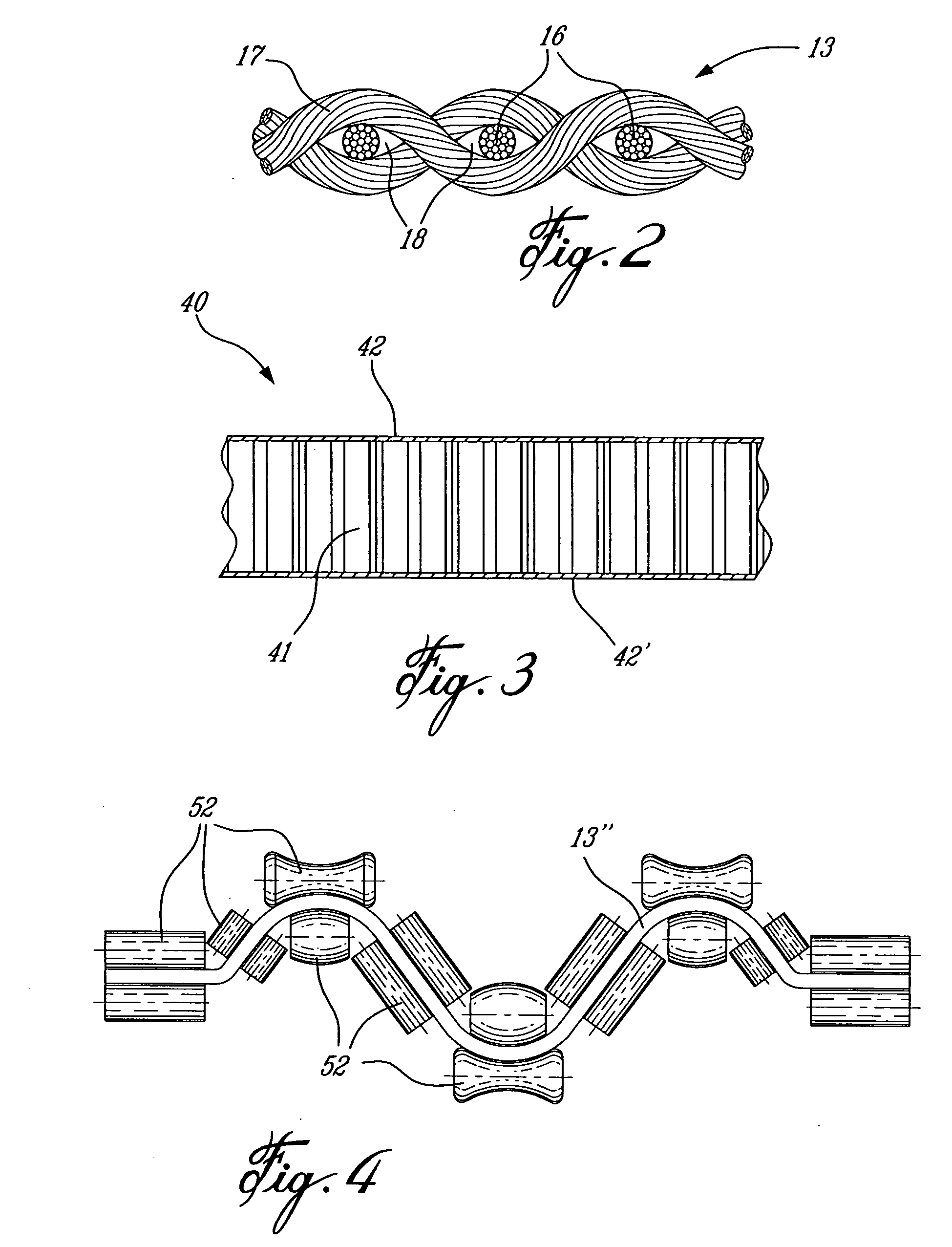

InactiveUS20060118238A1Eliminate physical restraintEasy to produceAdhesive processesVehicle componentsCarbon fibersThermoplastic composites

A machine and a process for producing lightweight thermoplastic composite products in a continuous manner is disclosed. An oven is provided for heating a dry unconsolidated fabric sheet of commingled fibers of thermoplastic and re-enforcing fibers or carbon fibers to a temperature sufficient to ensure melting and flow of the resin in the voids of the commingled fibers. The unconsolidated composite sheet is conveyed through the oven and then through a first pair of heated rollers at an outlet of the oven whereby to maintain the fabric sheet heated to prevent abrupt cooling at the surfaces while compressing it under pressure. A further pair of rollers at a further reduced temperature is provided whereby the heated sheet is gradually lowered in temperature and the pressure is maintained thereon during consolidation of the commingled fibers to ensure complete flow of the resin in the voids between the reinforcing fibers. The continuous composite consolidated sheet can then be processed to sheet form, or laminated in a sandwich, or profiled whereby to form a desired product.

Owner:BORAZGHI HOSSEIN

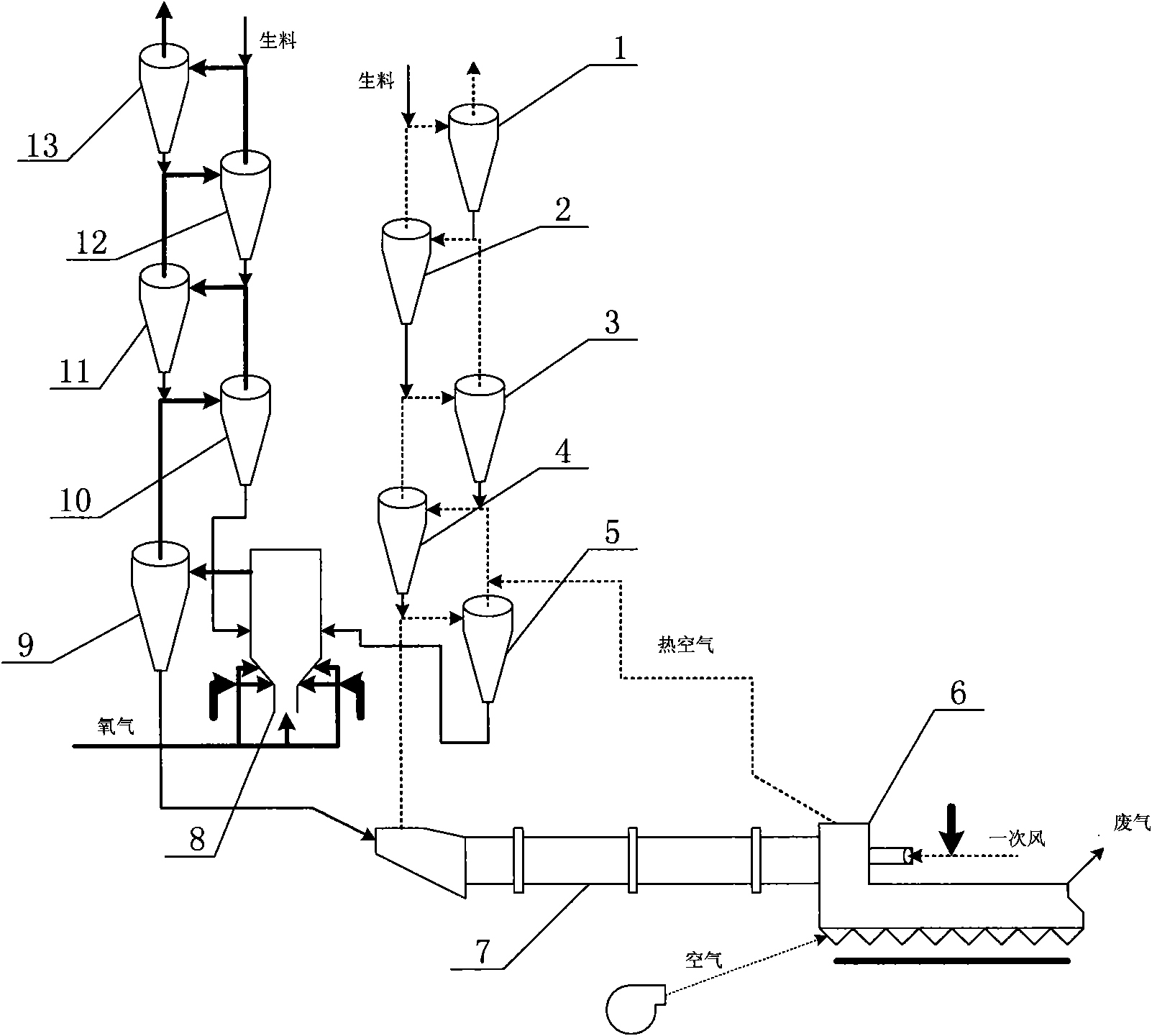

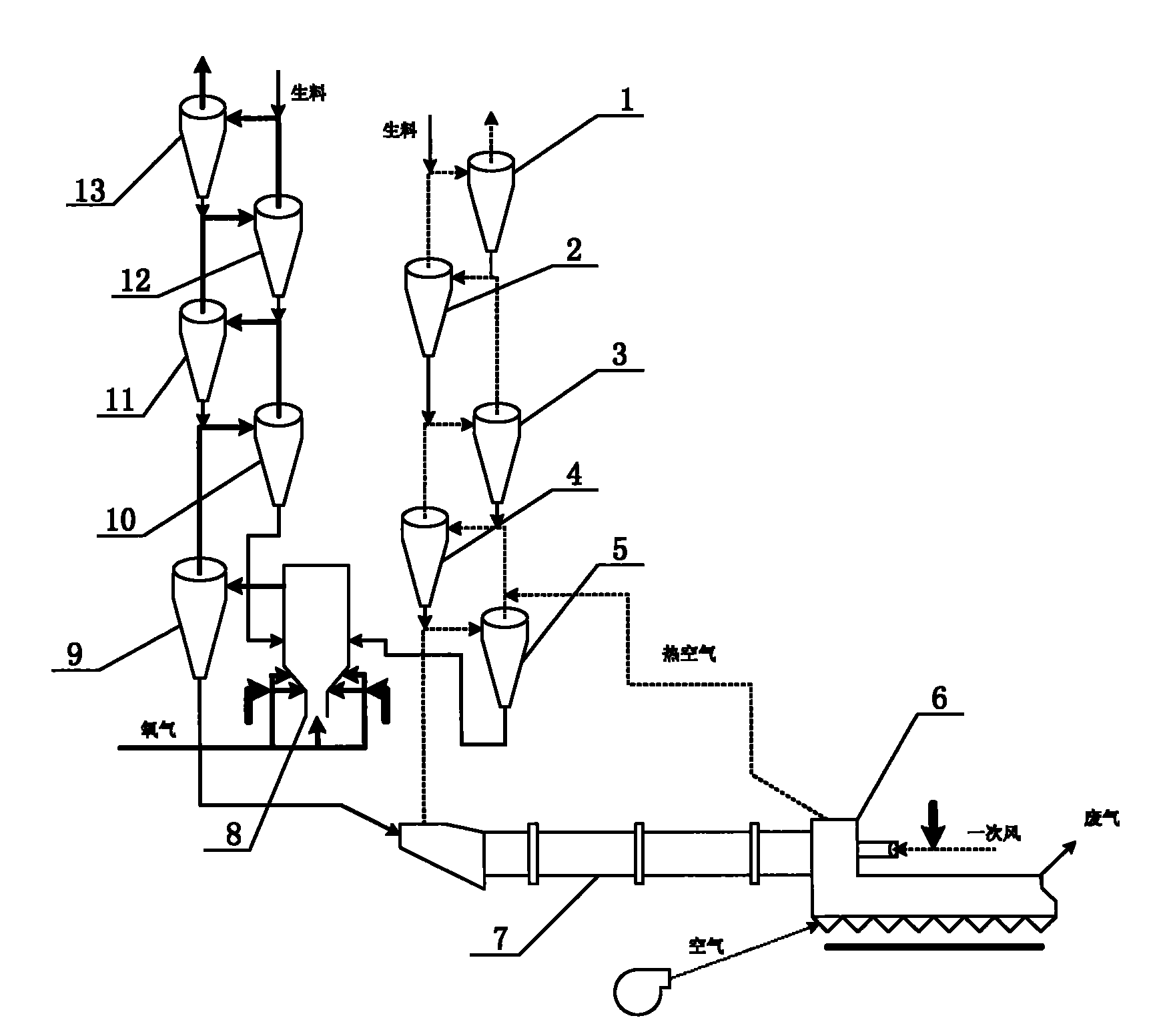

Method for producing partial full-oxygen type cement suitable for separation and collection of CO2

The invention discloses a method for producing partial full-oxygen type cement suitable for separation and collection of CO2, which is a cement production process combining a process of pre-decomposing cement raw materials by using full-oxygen combustion and a process of baking clinkers by using conventional heated air combustion and can effectively solve the problems of the separation and collection of the CO2 in the cement production process. The raw materials subjected to the decomposition of carbonate in a decomposing furnace are separated through a fifth-stage cyclone and enter a rotary kiln, and the combustion way of the rotary kiln is different from the conventional way; the other part of heated air is discharged by a grate cooler to serve as secondary air for combustion, wherein the temperature of the firing zone in the kiln reaches 1,800 DEG C; the heat from fuel combustion is transmitted to materials; the materials are calcined into clinkers; the clinkers from the rotary kiln enter the grate cooler and then enter a rear material receiving device after being cooled; smoke from the rotary kiln enters a right five-stage preheater and is mixed with the heated air from the grate cooler at the output of the five-stage preheater; and the mixed air enters a fourth-stage preheater, gradually rises and is discharged from the top of a first-stage preheater to an exhaust gas processing system.

Owner:SOUTHEAST UNIV

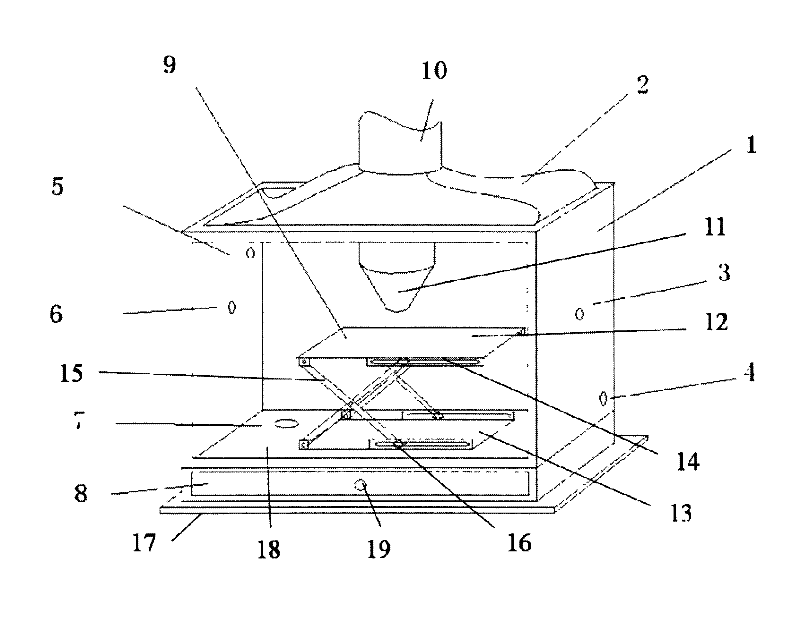

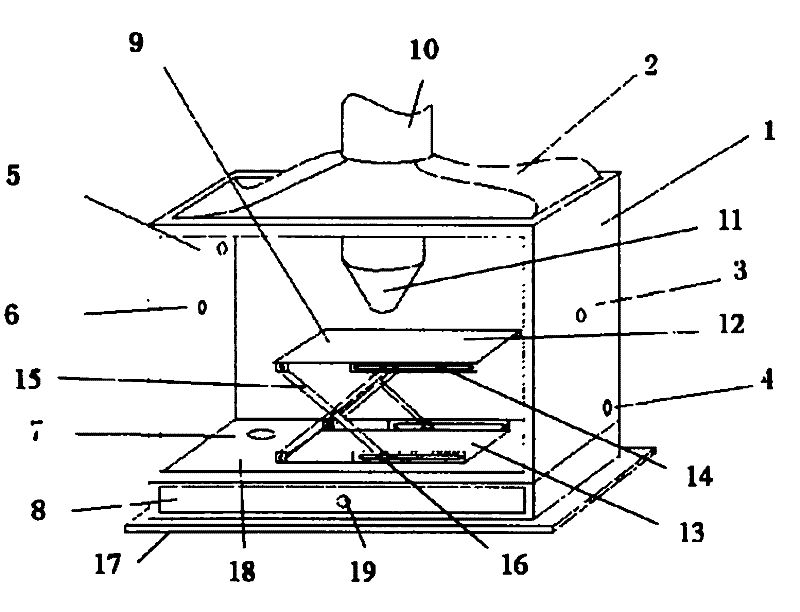

Multifunctional gas protection atmosphere case for laser cladding formation

InactiveCN102453906AEasy to observeEasy to carryMetallic material coating processesLaser beam welding apparatusLaser processingTemperature monitoring

A multifunctional gas protection atmosphere case for laser cladding formation. The case body mainly comprises two parts of a protection chamber and a powder collection chamber. The protection chamber is provided with a processing platform with an adjustable height. A processing chamber is enclosed by a front and a back baffle plate, a left side plate, a right side plate, an intermediate clapboard, and an upper sealing soft material. a gas outlet and a temperature monitoring hole are disposed on the left side plate, and a gas inlet and a pressure monitoring hole are disposed on the right side plate. Besides the processing platform, the intermediate clapboard is provided with a powder collection hole which can be opened or closed and is communicated with the power collection chamber at the lower layer. The invention is applicable to laser processing where the processing platform is fixed and a laser head freely moves with a robot, and especially applicable to the laser cladding and formation process of high-temperature easily-oxidized materials; as for powder feeding laser cladding formation, the invention also has the function of powder recovery, which saves experimental materials. Additionally, the case body has a small volume and a light weight, and has excellent characteristics of energy saving, environmental protection, and easy carrying.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Weak tumble rapid combustion system and gas engine

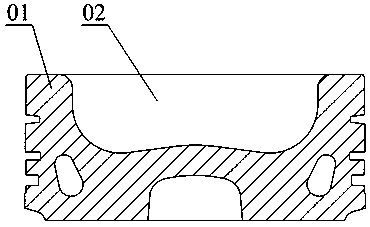

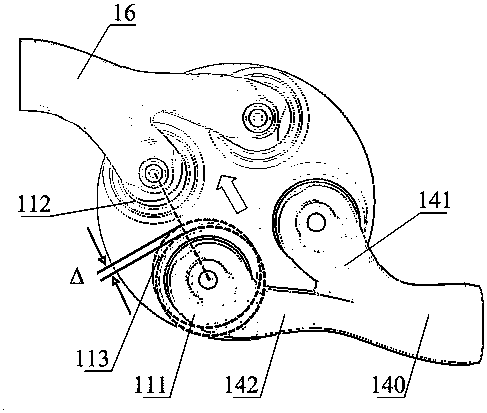

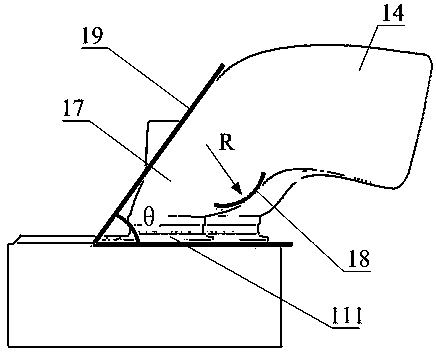

ActiveCN111287860AImprove gas utilizationHigh feasibilityInternal combustion piston enginesCylinder headsCombustion systemCombustion chamber

The invention discloses a weak tumble rapid combustion system and a gas engine. The weak tumble rapid combustion system comprises a piston, a cylinder cover, an air intake channel and an exhaust channel, a combustion chamber is formed between the top of the piston and the cylinder cover, the cylinder cover is provided with an air intake throat and an exhaust throat, the section, close to the air intake throat, of the air intake channel is a tumble guide air channel, the axis of the tumble guide air channel is obliquely arranged relative to the bottom face of the cylinder cover, the upper sideface of the tumble guide air channel is an undershoot guide face obliquely arranged relative to the bottom face of the cylinder cover, the lower side face of the tumble guide air channel is an arc-shaped guide face sunken towards the bottom face of the cylinder cover, an eccentric chamfer is arranged at the lower end of the air intake throat, and the eccentric direction of the eccentric chamfer deviates along the direction of a central connecting line from the air intake throat to the air outlet throat. According to the weak tumble rapid combustion system, during air suction, fuel gas forms large-scale weak tumble motion in the air cylinder and is broken into small-scale turbulent flow in the last stage of compression, so that the flame propagation speed is increased, and the fuel gas utilization rate and the engine heat efficiency are improved.

Owner:WEICHAI POWER CO LTD

Hybrid plasma-cold spray method and apparatus

ActiveUS7582846B2Wide range of operationsImprove processing effectivenessMolten spray coatingArc welding apparatusStress conditionsProcess engineering

The present invention provides a method and apparatus of producing a dense coating with desirable stress conditions similar to coatings produced by a cold spray processes, but with higher process efficiencies and lower gas consumption. The inventive process combines features of a plasma process method of gas heating and a cold spray process to accelerate the gas, incorporating these elements into a single hybrid process.

Owner:SULZER METCO (US) INC

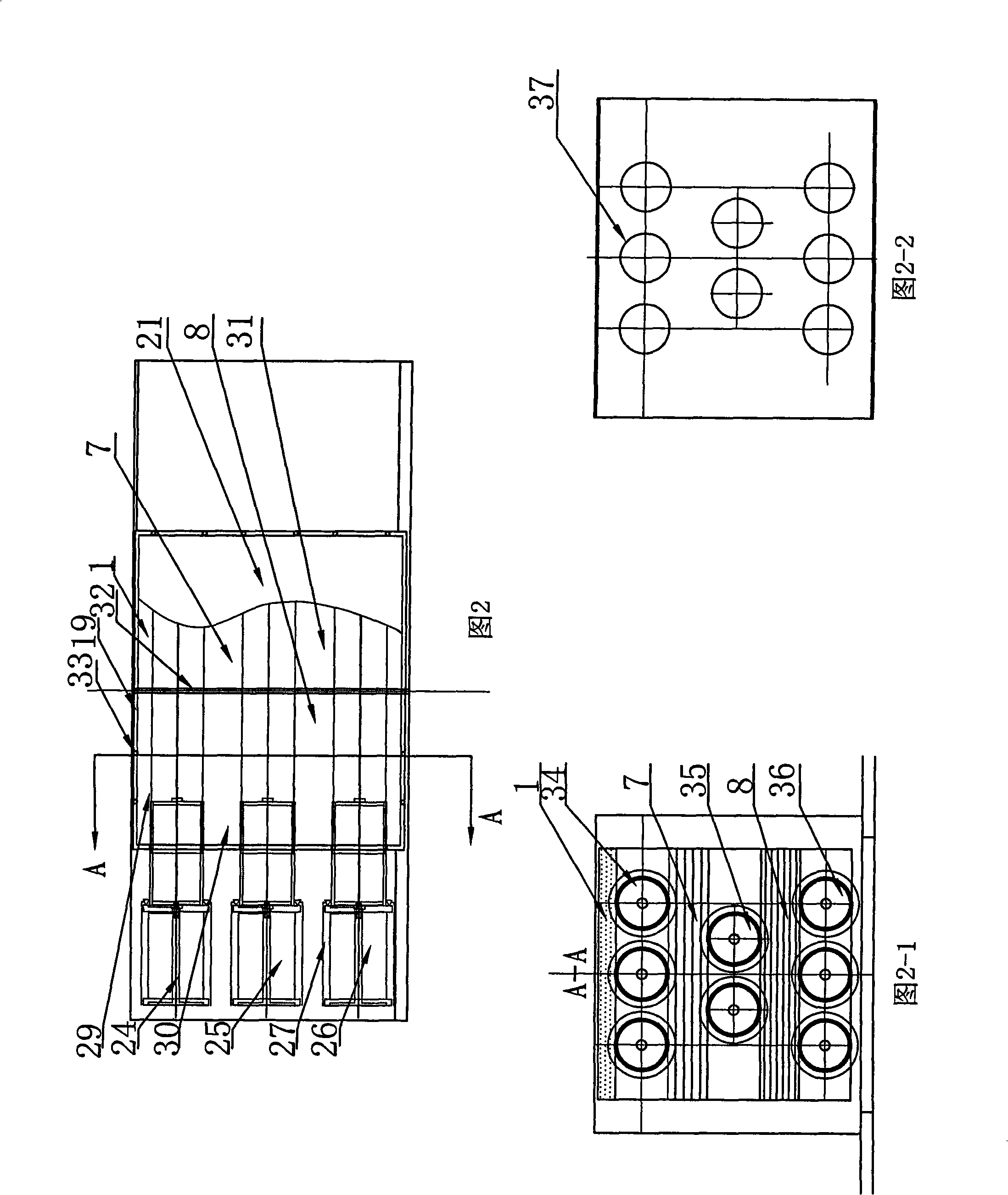

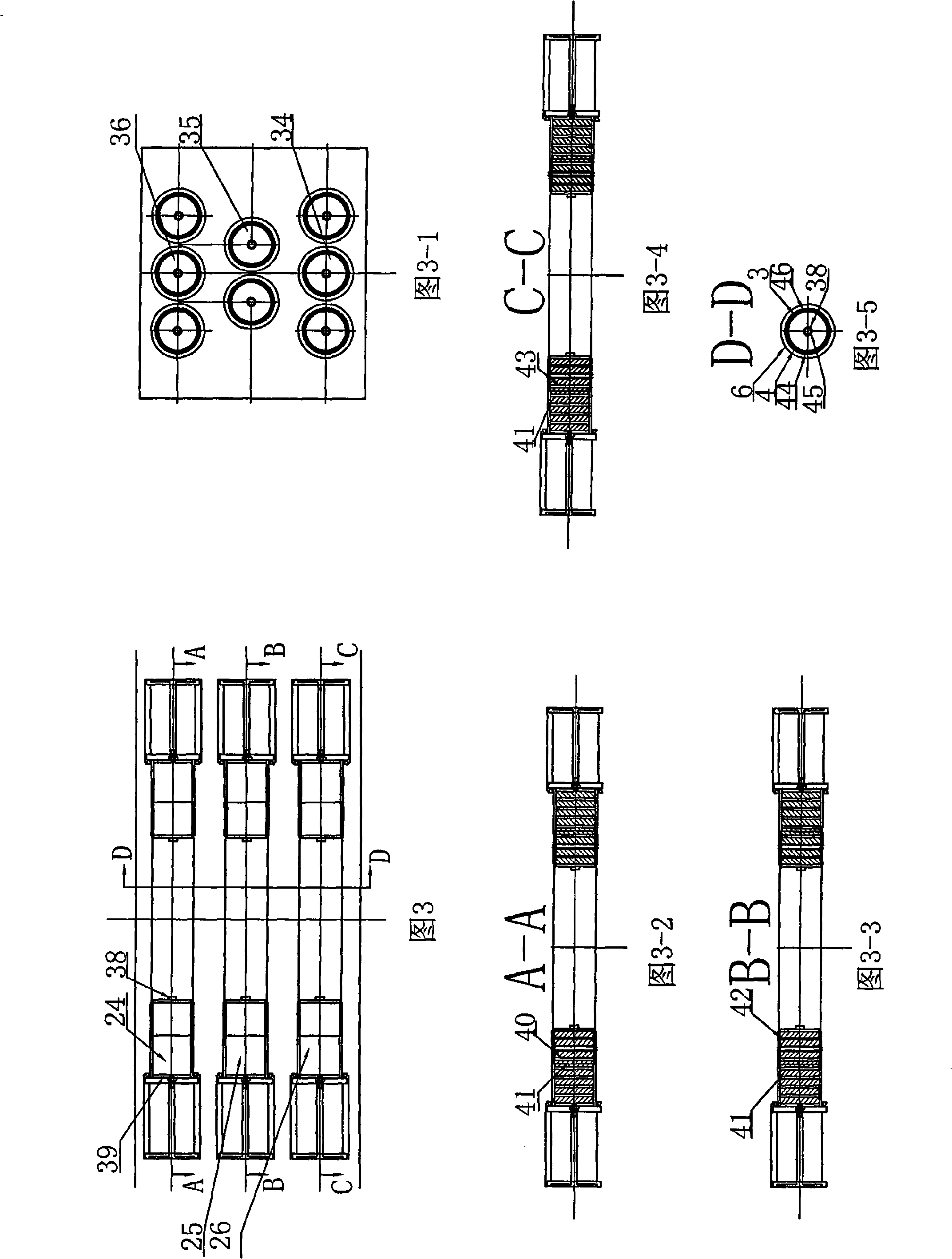

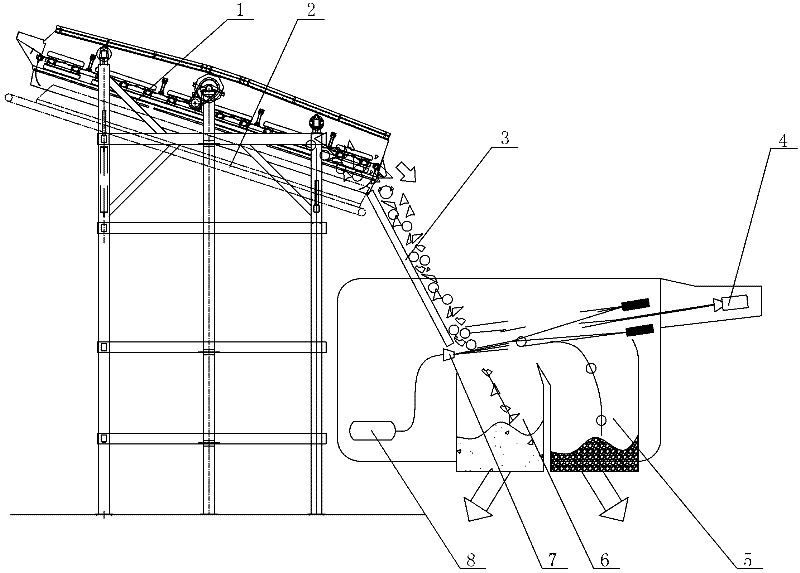

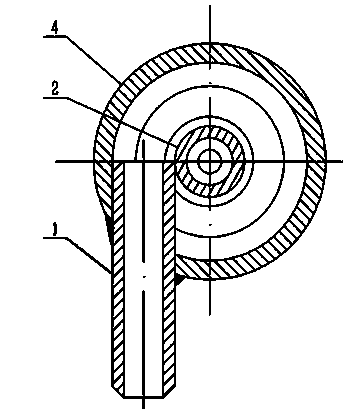

Split type multi-roller multi-component high-gradient vibration magnetic separator in permanent magnetism

InactiveCN101402069AHigh mechanical strengthEasy to replaceHigh gradient magnetic separatorsMagnetic separatorEngineering

The invention relates to a permanent magnetic midsplit type multi-roller multivariate high gradient vibration magnetic selector, which comprises a stander (12), a magnetic selection box body arranged above the stander (12) through a vibration reduction spring set (18), a plurality of permanent magnetic rollers arranged inside the magnetic selection box body, a feed hopper (22) positioned on the top of the magnetic selection box body and a feed discharging passage (17) positioned on the bottom of the magnetic selection box body. The vibration magnetic selector is characterized in that the permanent magnetic rollers are made from magnetic materials with different magnetic strengths; according to a two-dimensional matrix form, the plurality of the permanent magnetic rollers are arranged to construct a multivariate sorting magnetic field; the permanent magnetic rollers made from the magnetic material of the same type are positioned on the same plane; according to the magnetic strengths, the permanent magnetic rollers with different magnetisms are in deltaic alternate arrangement sequentially from top to bottom along the flowing direction of the materials; magnetic concentrating medium grooves with the same specification are arranged between the adjacent permanent magnetic roller layers in different layers and above the upper layer of the permanent magnetic roller layers; and the inside of each groove is provided with magnetic concentrating media with different types.

Owner:HENAN POLYTECHNIC UNIV

Aluminum alloy material and production method of cast-rolling stock of decorative strip of same

The invention relates to a 3004 aluminum alloy material and a production method of a cast-rolling stock of a decorative strip of the 3004 aluminum alloy material. The compositions of the aluminum alloy material comprise smaller than or equal to 0.25 percent of Si, 0.20 to 0.60 percent of Fe, 0.10 to 0.15 percent of Cu, 1.0 to 1.20 percent of Mn, 0.85 to 1.25 percent of Mg, smaller than or equal to 0.05 percent of Ti, and the remaining amount of Al. The production method comprises the steps of smelting, refining, on-line degassing, grain refinement, filtration, cast rolling, and the like; during the smelting, 50 percent to 60 percent of electrolytic aluminum liquid and the rest of aluminum alloy waste materials are mixed and smelted; the compositions except Mg are added to the mixture; and after the steps of powder injection refining, slag skimming, magnesium ingot adding, furnace turning-down and refining are conducted, the stock of the strip is cast-rolled. A product of the production method has even and steady chemical compositions and can satisfy the mechanical property requirements of subsequent rolling, so that the yield of subsequent rolling is increased; by using the aluminum alloy waste materials as raw materials, the raw materials are saved; by directly adding the electrolytic aluminum liquid, gas loss in the melting process is reduced, and burning loss in the waste material melting process can also be decreased; and by using a cast-rolling manner to replace a hot-rolling manner, the process is simplified and the production cost is greatly reduced.

Owner:沁阳市鼎建建设发展有限公司

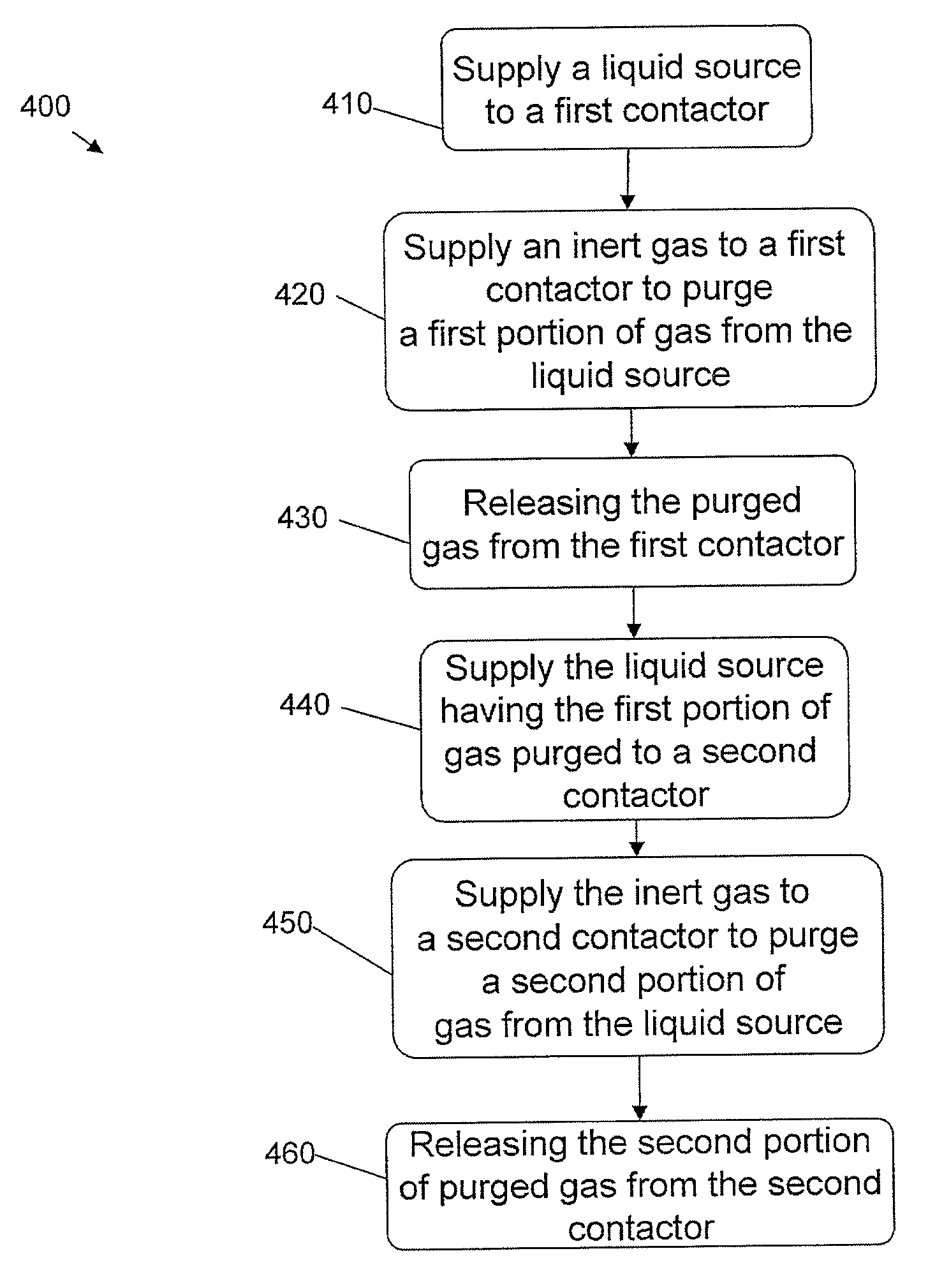

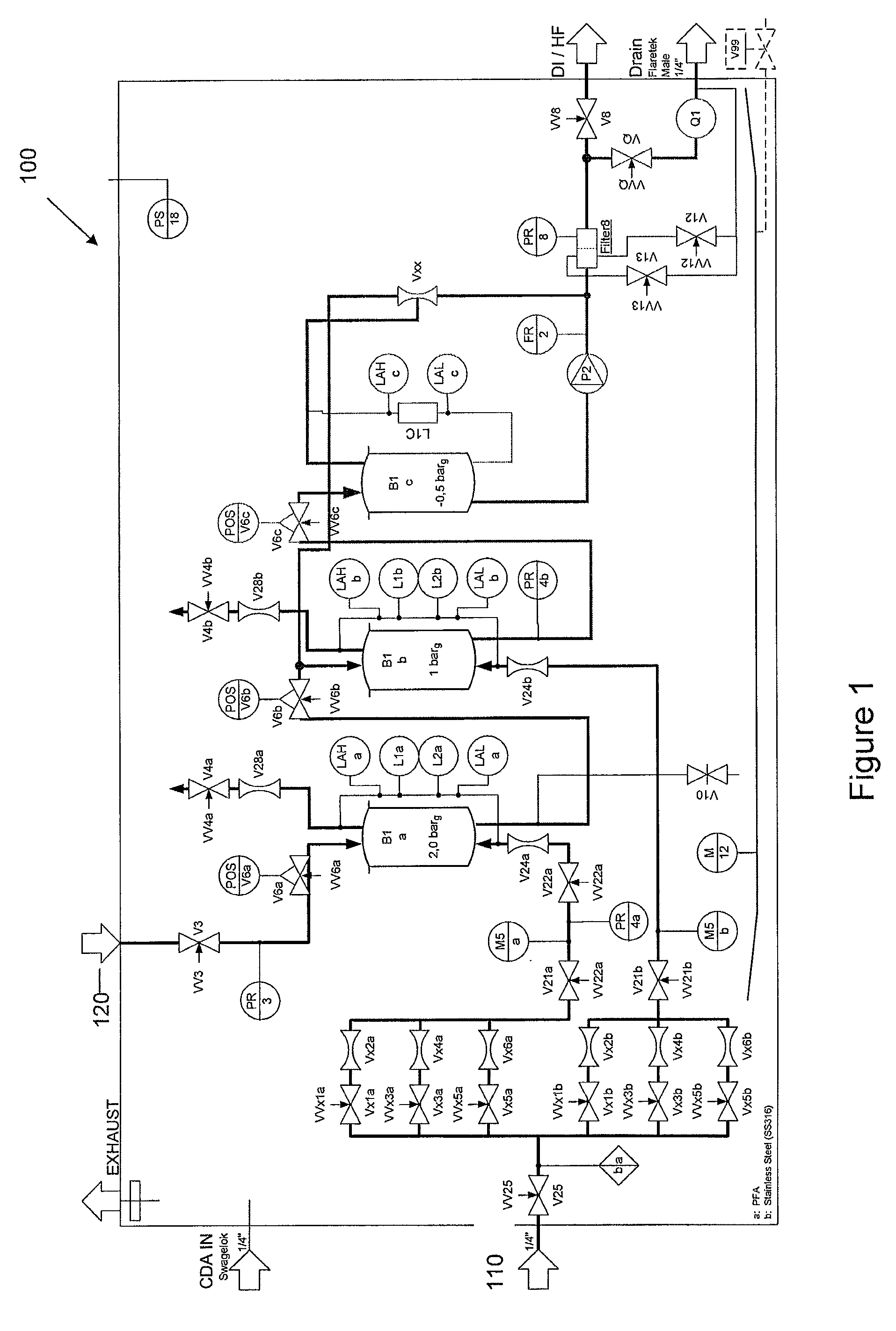

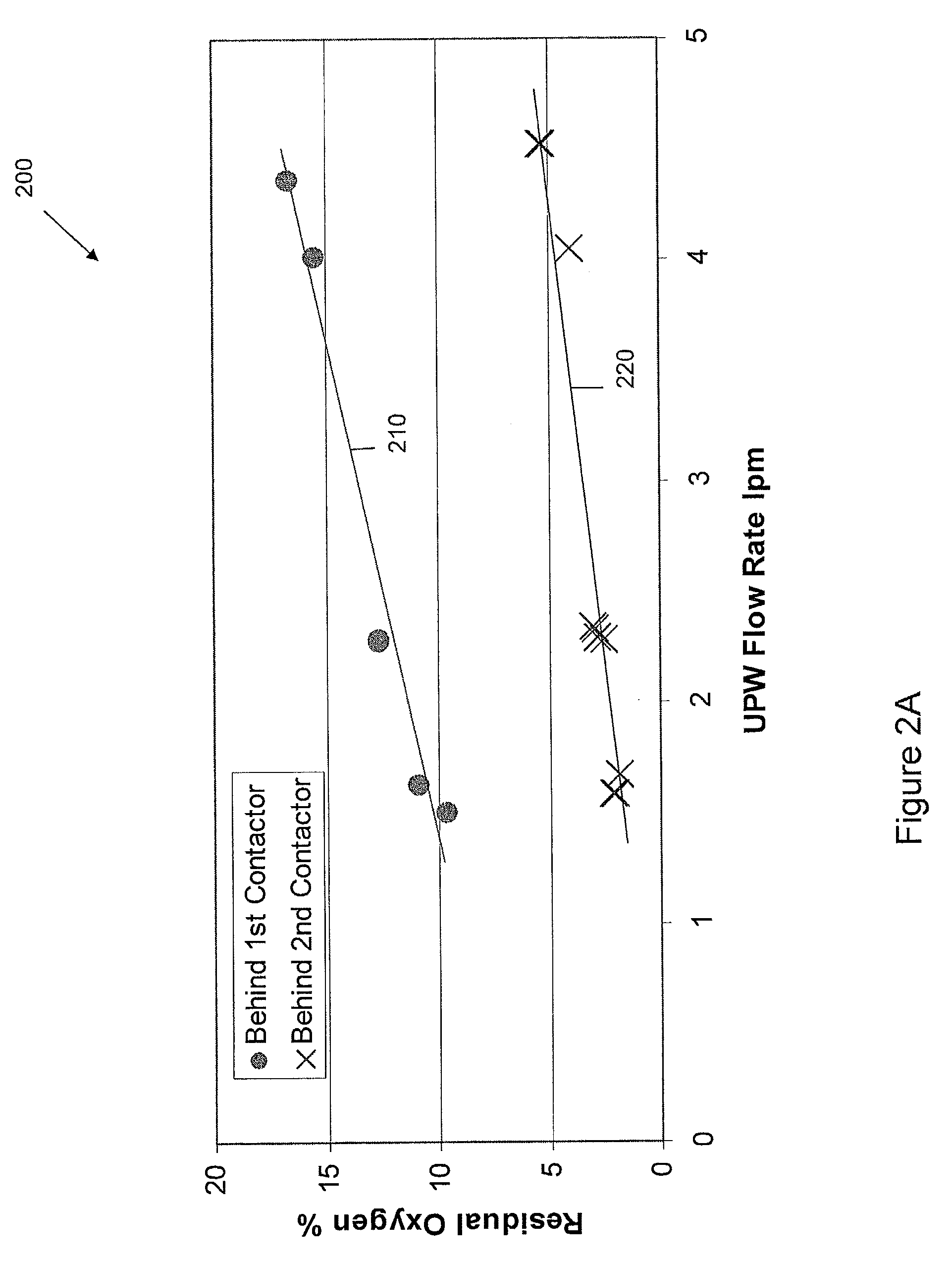

System to remove Dissolved Gases Selectively from Liquids

ActiveUS20120279396A1Reduce consumptionExtend your lifeLiquid degasification with auxillary substancesUsing liquid separation agentEnvironmental engineeringContactor

A system to purge dissolved gases selectively from liquids can include a first contactor having two first contactor inlets and two first contactor outlets. The first contactor can receive liquid from a liquid source at a first inlet of the first contactor and an inert gas source at a second inlet of the first contactor, the inert gas can purge a first portion of gas from the liquid source. The first portion of purged gas exits the first contactor at a first outlet of the first contactor. The second contactor can receive input from the second outlet of the first contactor and the inert gas, the inert gas purges a second portion of the gas from the liquid source. The second portion of purged gas can exit the second contactor at a first outlet of the second contactor.

Owner:MKS INSTR INC

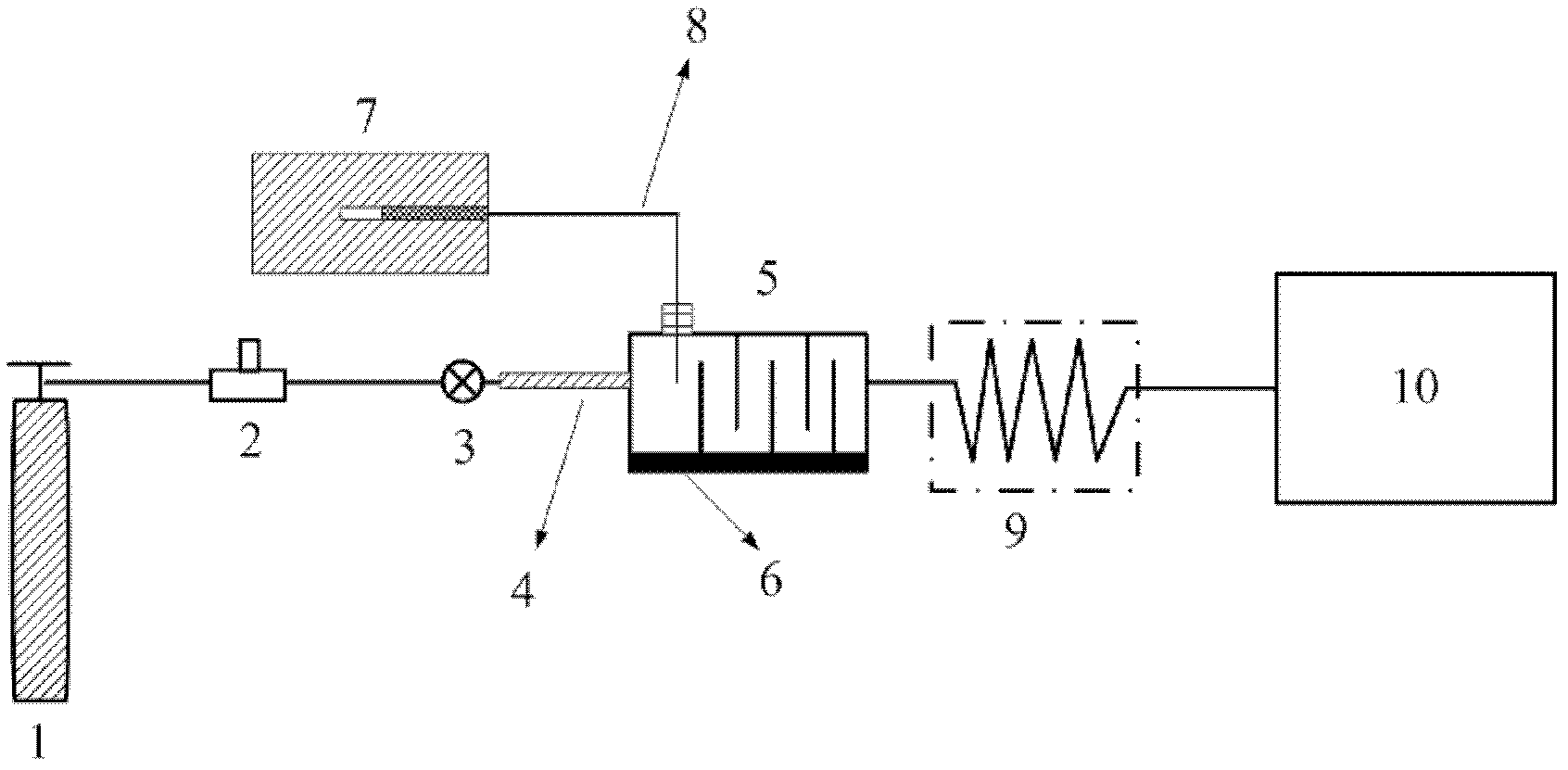

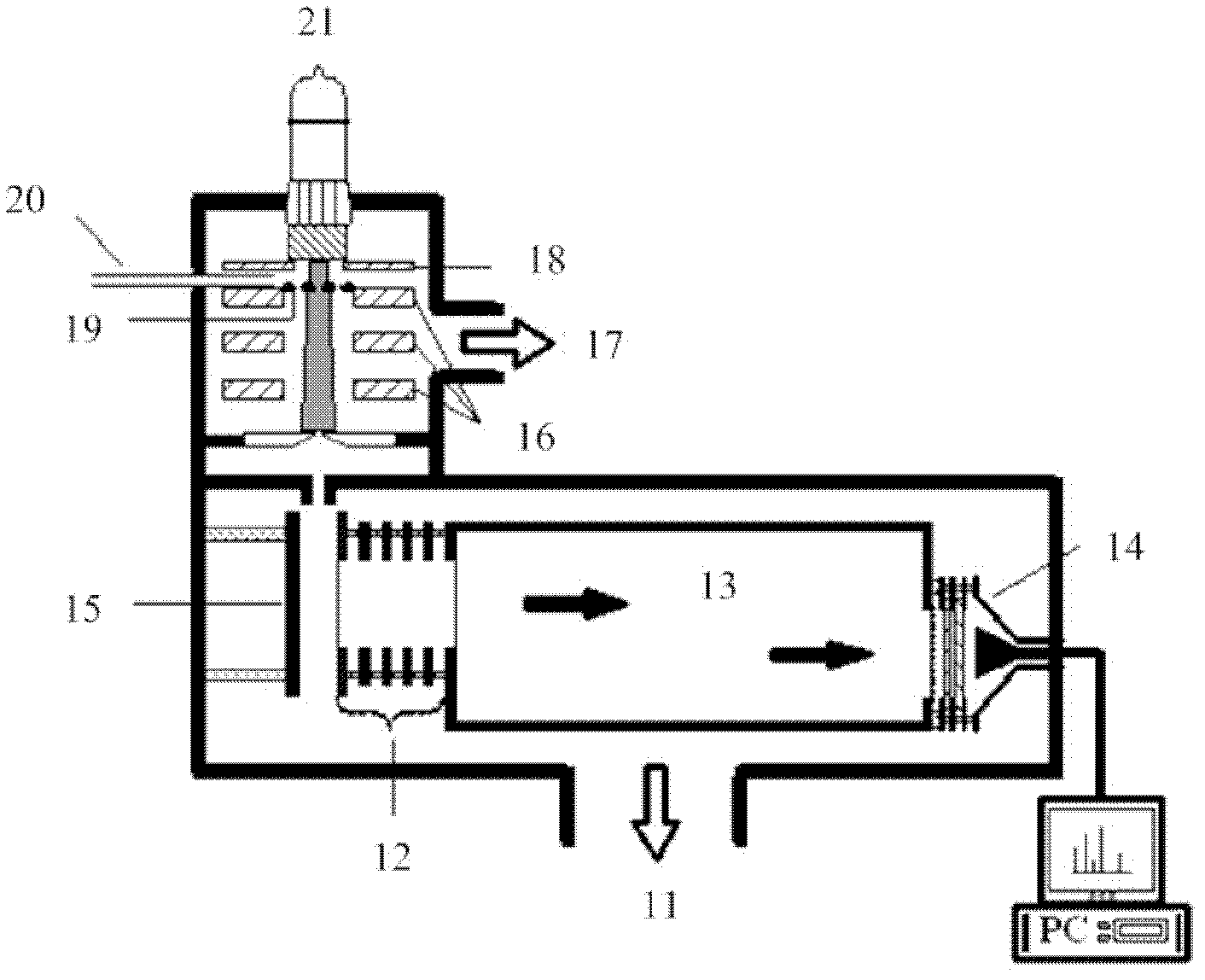

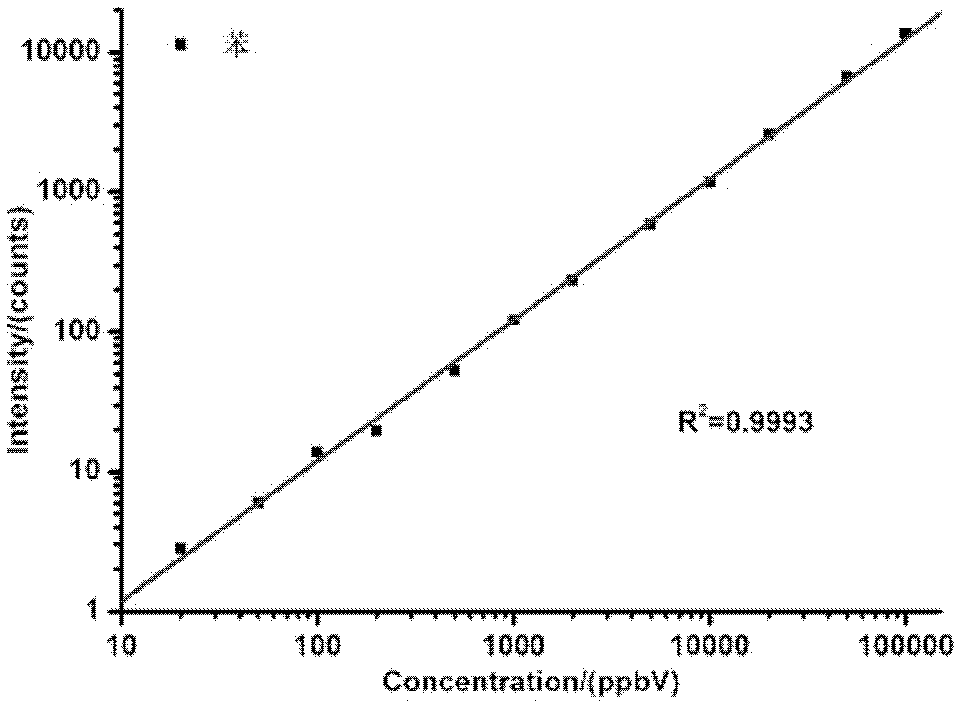

Solid phase and liquid phase compound dynamic gas preparation device and gas preparation method

InactiveCN103163007AEasy to operateShorten the timeComponent separationPreparing sample for investigationGas analysisFlow ratio

The invention provides a solid phase and liquid phase compound dynamic gas preparation device and a gas preparation method. The gas preparation system comprises a diluted gas supplying portion, a diluted gas preheating portion, a sample standard liquid micro-scale control sample injector, a gas mixing portion and a gas analysis device. According to the gas preparation method, diluted gas passes through the diluted preheating device and enters a liquid evaporating device in a certain flow, meanwhile sample standard liquid enters the liquid evaporating device to mix with the diluted gas, finally the mixed gas passes through the gas mixing portion for being mixed evenly, a part of gas enters the gas analysis device for analysis and other gas is exhausted as tail gas. The flow ratio of sample gas and the diluted gas can be effectively controlled due to change of flow of the micro-scale sample injector and flow of the diluted gas so that the mixed gas with different concentrations can be obtained without preparation of the sample standard liquid in all concentration points and preparation efficiency and accuracy of solid phase and liquid phase compound standard gas are improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

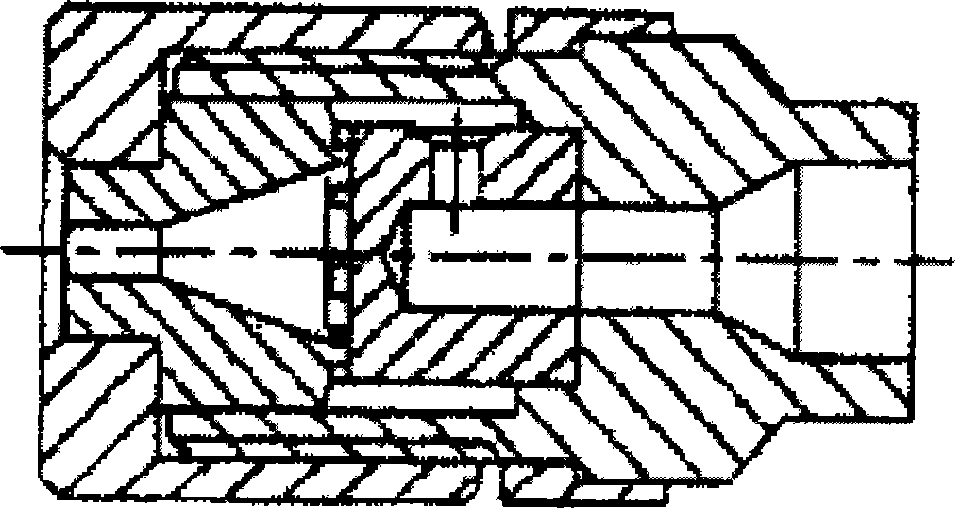

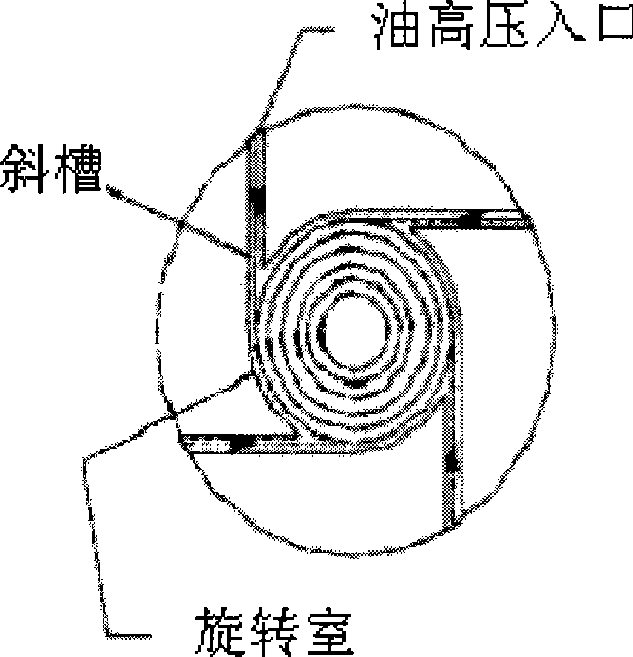

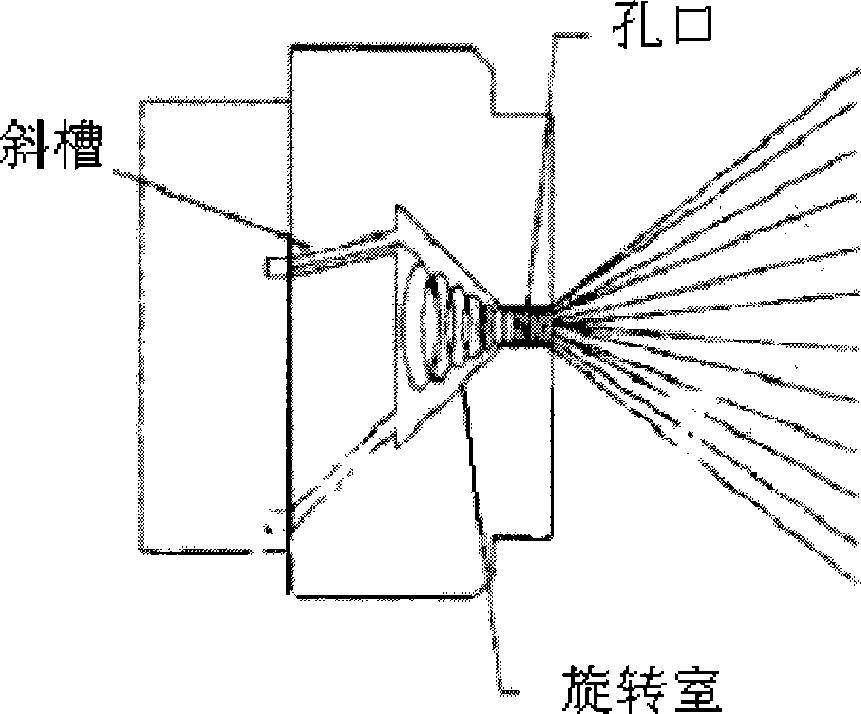

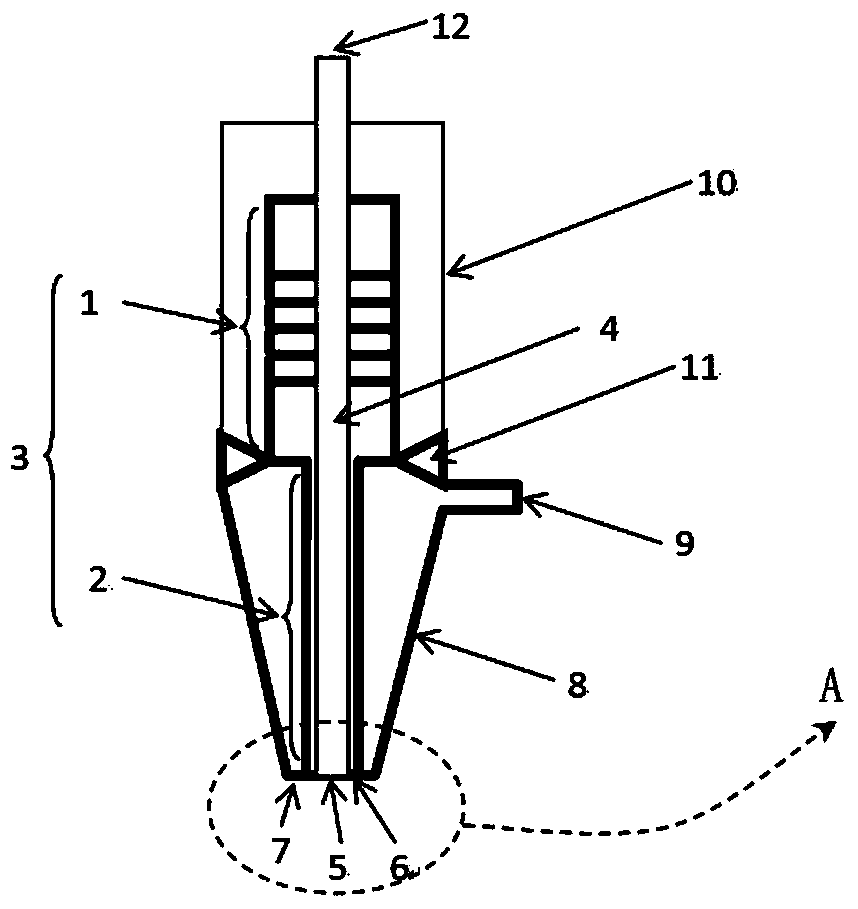

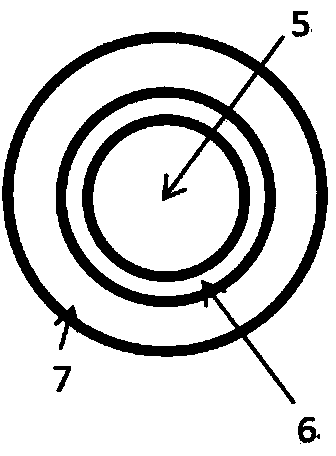

Self-absorption rotational flow pneumatic atomization nozzle device

InactiveCN101398186AGood fuel atomization qualityReasonable spatial distributionContinuous combustion chamberCombustion systemCombustion

The invention discloses a self-sucking swirl pneumatic atomizing nozzle device relating to a fuel atomizing evaporation mixing nozzle used for a full-automatic combustion engine and belongs to the field of industrial combustion systems. An atomizing sheet 2, a swirl sheet 3 and a stream guidance sheet 4 are compressed closely by a compression nut 1 and a fixing piece 5; the atomizing sheet 2 is an internal cone and the outlet of the atomizing sheet 2 is a spout 14; the swirl sheet 3 is provided with a tangential air hole 11; the outlet hole of the stream guidance sheet 4 is an oil hole 12 and the outlet of the stream guidance sheet 4 is a swirl chamber; the compression nut 1 is connected with the fixing piece 5 and a connecting piece 7; the outer surface of the upstream of the fixing piece 5 is provided with a seal ring 6; an oil inlet hole 8 is the inner hole of the connecting piece 7; an air inlet hole 9 is the connection hole of the connecting piece 7 along the radical and coaxial direction; compared with the existing centrifugal nozzle or pneumatic atomizing nozzle, the self-sucking swirl pneumatic atomizing nozzle device does not need an oil pump; has the advantages of improving the fuel atomizing evaporation mixing characteristic and the distribution uniformity of oil-gas space, improving the combustion performance, reducing contamination discharge, having no coking and plugging, and is an ideal nozzle for combusting the heavy oil and waste oil by the full-automatic combustion engine.

Owner:PEKING UNIV +1

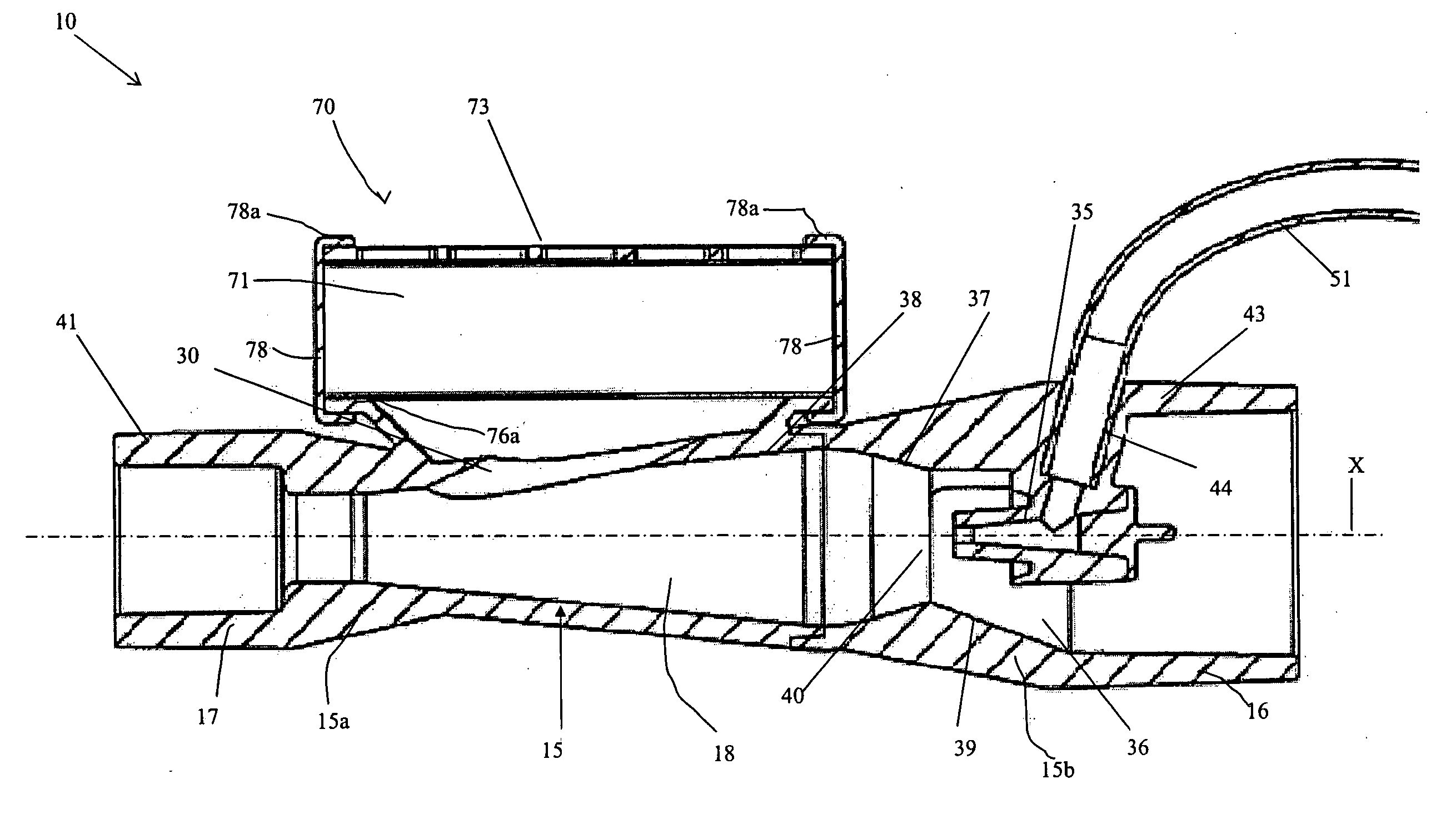

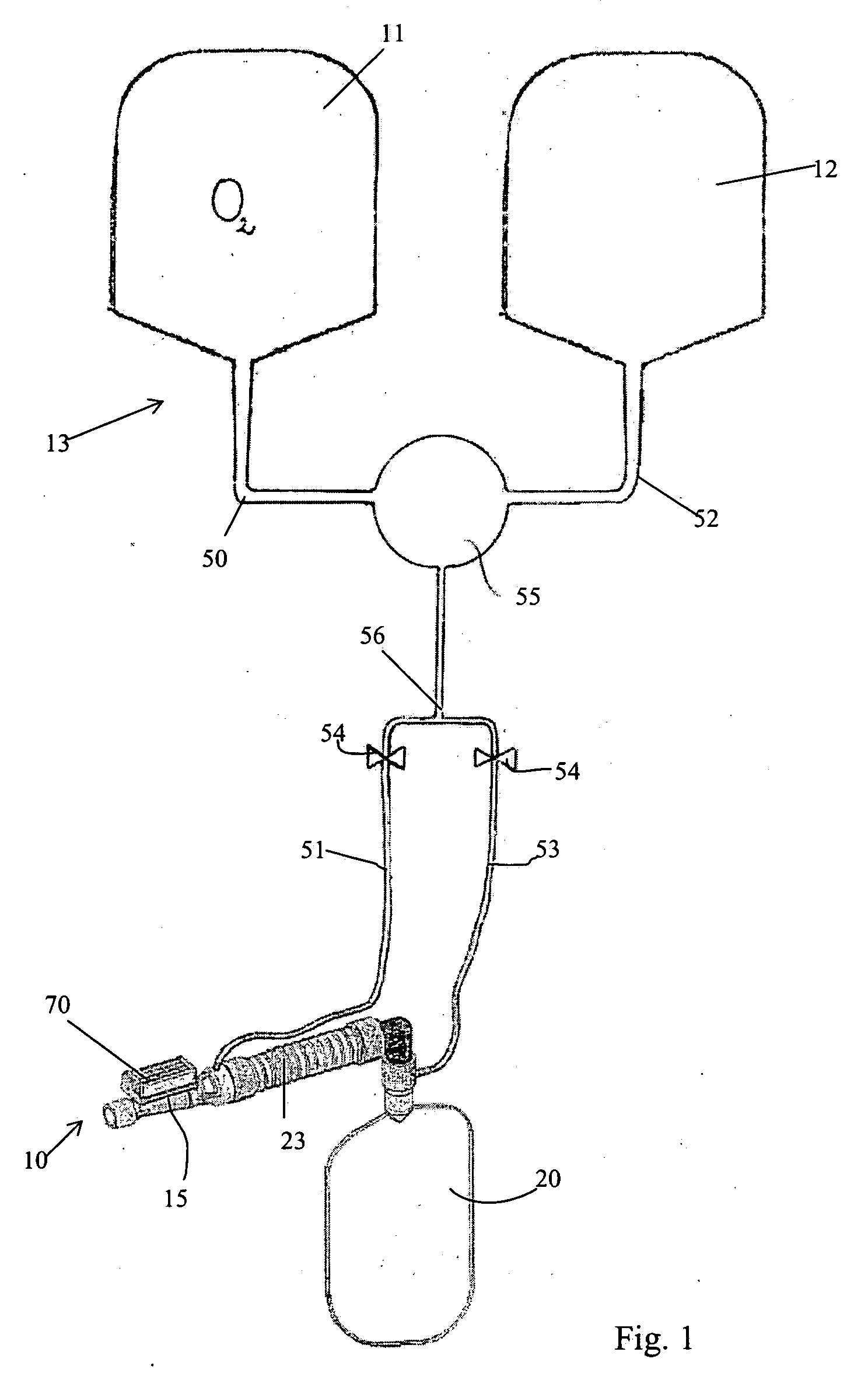

Medical device for a patient's ventilatory support

InactiveUS20070056587A1Easy to manufactureLow gas consumptionRespiratorsOperating means/releasing devices for valvesPositive pressureOxygen content

A ventilatory support device with administration of gas have a predetermined content of oxygen in continuously positive pressure. The device comprises a pipe extending between an intake fitting and a delivery fitting of the gas, wherein an inner portion of the pipe diverges towards the delivery fitting. The device also comprises a substantially tubular injector supported in the pipe and orientated towards the delivery opening, and suitable for being connected to a pressurised gas source having a predetermined oxygen content.

Owner:DEAS

Freeway optimization program

InactiveUS20070083322A1Minimize congestionMaximizing freeway capacityAnalogue computers for vehiclesAnalogue computers for trafficNatural gas consumptionEngineering

This invention enables freeways to carry the maximum amount of traffic they can safely carry during times of heavy use of the freeway system. The invention would maximize freeway capacity by restricting the inflows of traffic and facilitating the exits from the freeway. Freeway inflows would be restricted by extensive use of metering lights and restrictions on speeds on the freeway itself. Freeway exits would be facilitated by changing traffic lights, stop signs, and anything else that restricts exits from a freeway, to allow for the free flow of traffic off a freeway. An optimized freeway system would shorten commutes, lessen consumption of gas, lower pollution, and lessen the need to build or expand freeways. Thus, it would save several billions of dollars every year.

Owner:VAN EE JONATHAN HENDRIK

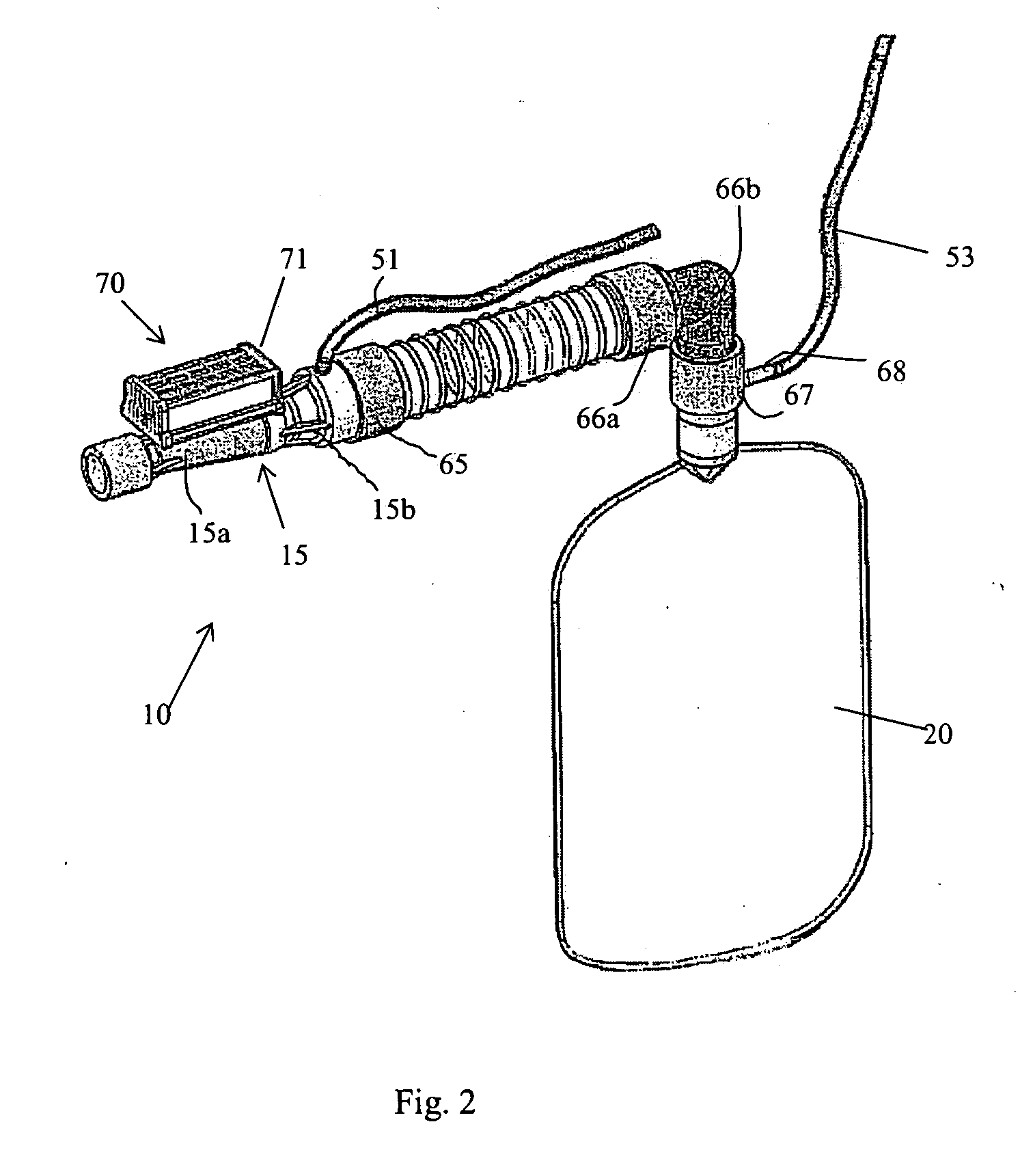

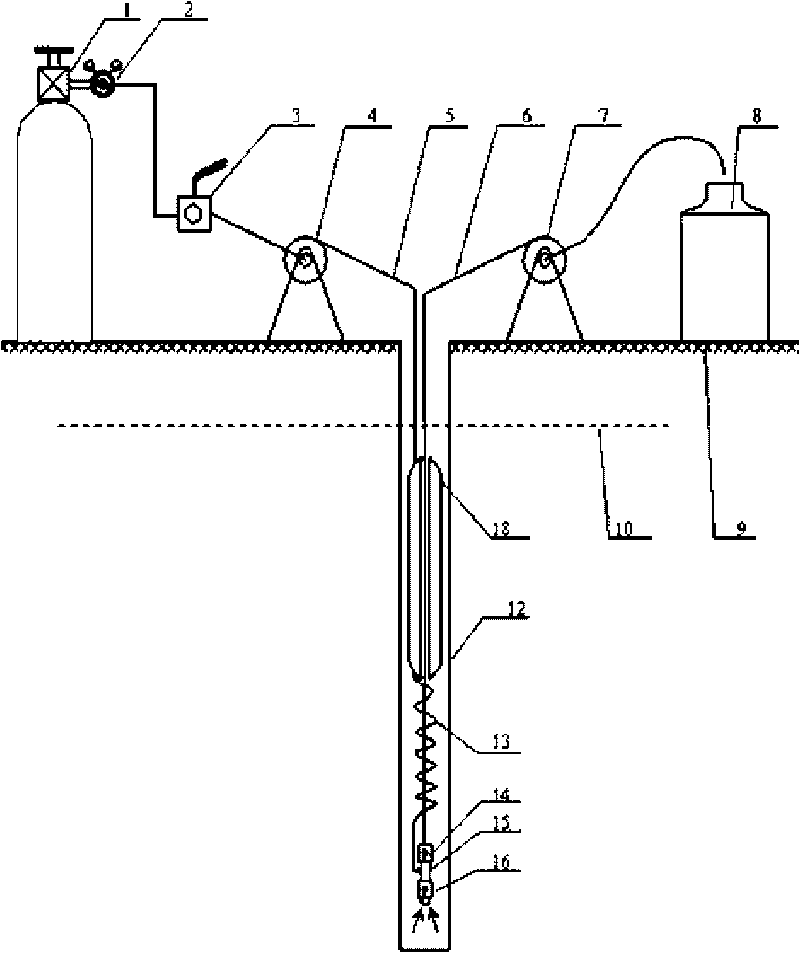

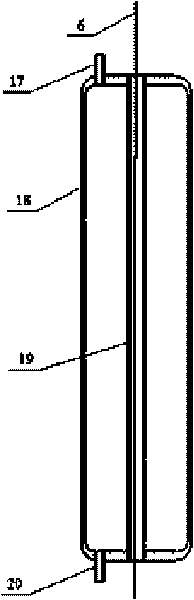

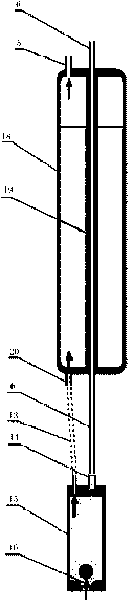

Split type gas displacement type underground water sampler

InactiveCN101718640AImprove sampling efficiencyRelieve pressureWithdrawing sample devicesLine tubingEngineering

The invention relates to a split type gas displacement type underground water sampler which comprises a sample containing pipe, an inflation and deflation unit and a water acquirement pipeline; the inflation and deflation unit comprises an air source, an air pipe and an air pressure controller, the upper end of the sample containing pipe is communicated with the inflation and deflation unit, and the water acquirement pipeline comprises a water outlet pipe. The underground water sampler also comprises a sampling unit, wherein the sampling unit comprises a water outlet non-return valve, a tee and a water inlet non-return valve which are sequentially communicated from top to bottom; the water acquirement pipeline also comprises a hose which is communicated with the lower end of the sample containing pipe and a middle outlet of the tee, and the water outlet non-return valve is communicated with the water outlet pipe. The invention solves the technical problems of large disturbance of underground water, existence of a gas spilling phenomenon and the like during sampling. The invention realizes the sampling of the underground water under the conditions of low air pressure and small gas quantity and has the advantage of high sampling efficiency.

Owner:NORTHWEST INST OF NUCLEAR TECH

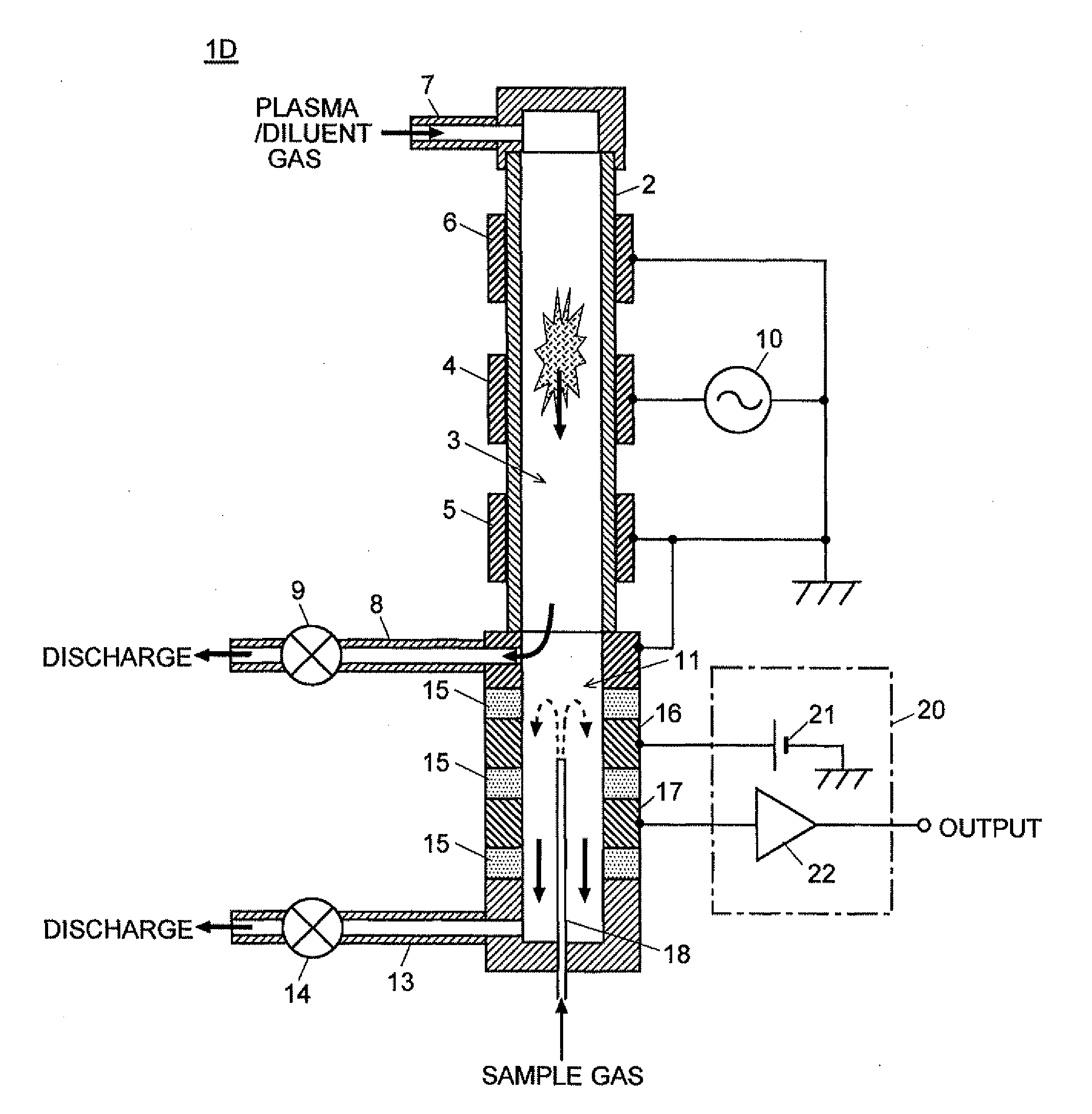

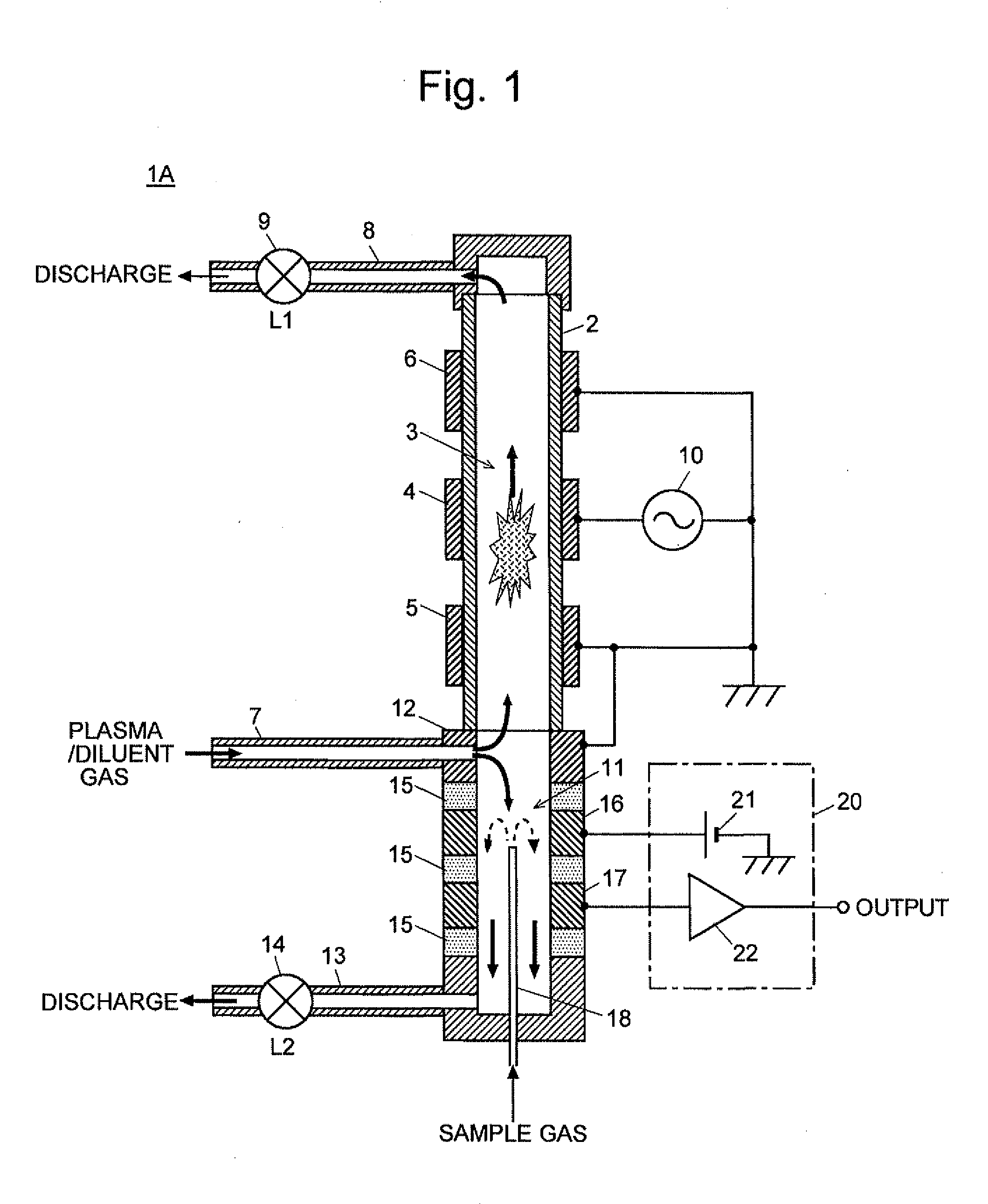

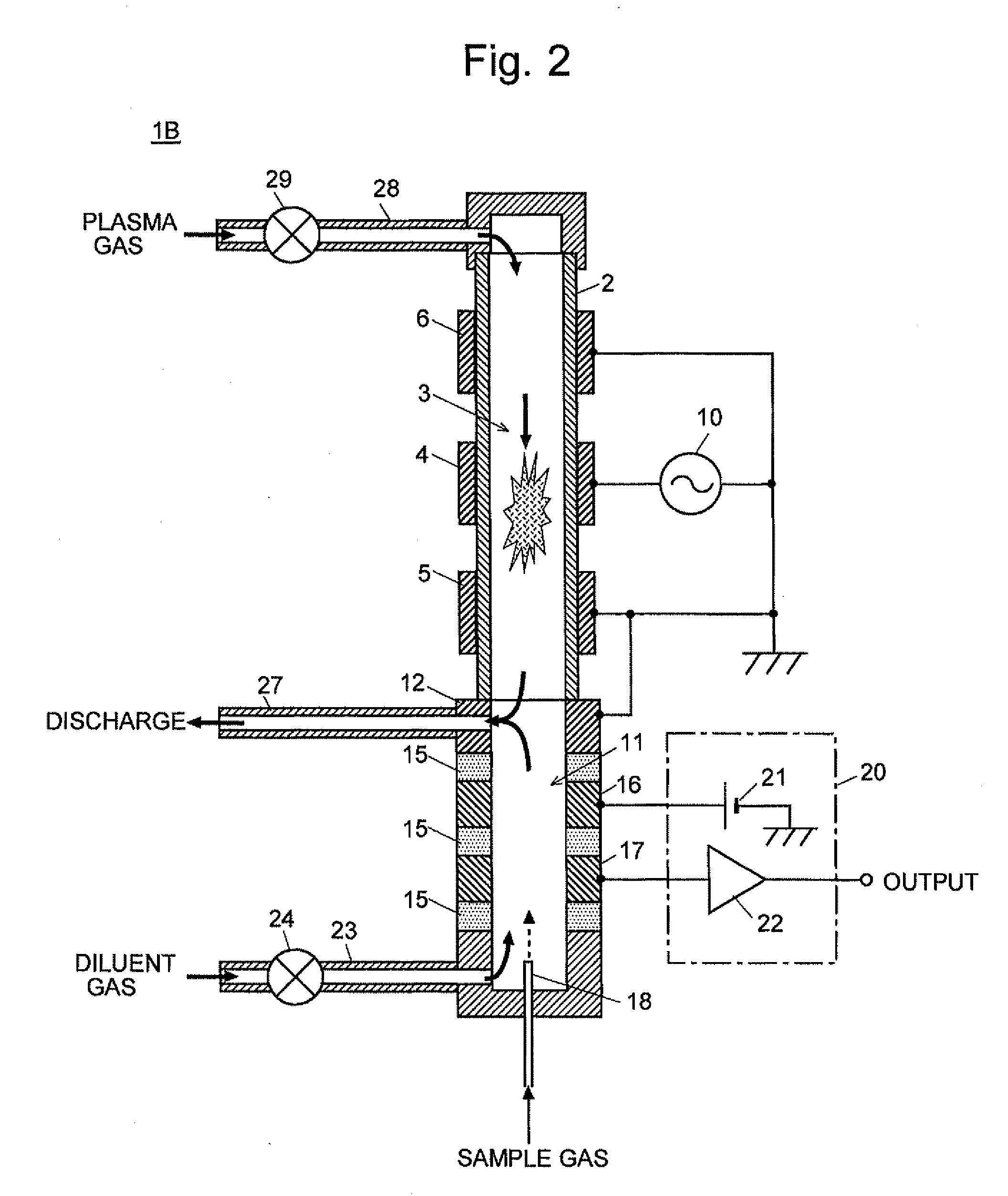

Discharge Ionization Current Detector

ActiveUS20110187379A1Enhance plasma 's stabilityImprove ionization efficiencyComponent separationMaterial analysis by electric/magnetic meansGas-discharge lampIonization current

A discharge ionization current detector capable of supplying plasma gas in large quantity to stabilize plasma simultaneously with lowering the sample dilution ratio to improve detection sensitivity is provided. A gas supply pipe 7 for supplying a plasma gas, which also functions as a dilution gas, is connected to a point near the connecting section of a first gas passage 3 having electrodes 4-6 for plasma generation and a second gas passage having electrodes 16 and 17 for ion detection. A first gas discharge pipe 8 is connected to the other end of the first gas passage 3, and a second gas discharge pipe 13 is connected to the other end of the second gas passage 11. Flow controllers 9 and 14 are provided in the gas discharge pipes 8 and 13, respectively. The flow rate of the gas passing through a plasma generation area and that of the gas passing through an ion current detection area can be independently regulated. Therefore, for example, it is possible to increase the former flow rate to stabilize the plasma and simultaneously decrease the latter flow rate to enhance the detection sensitivity for a low-concentration sample.

Owner:SHIMADZU CORP

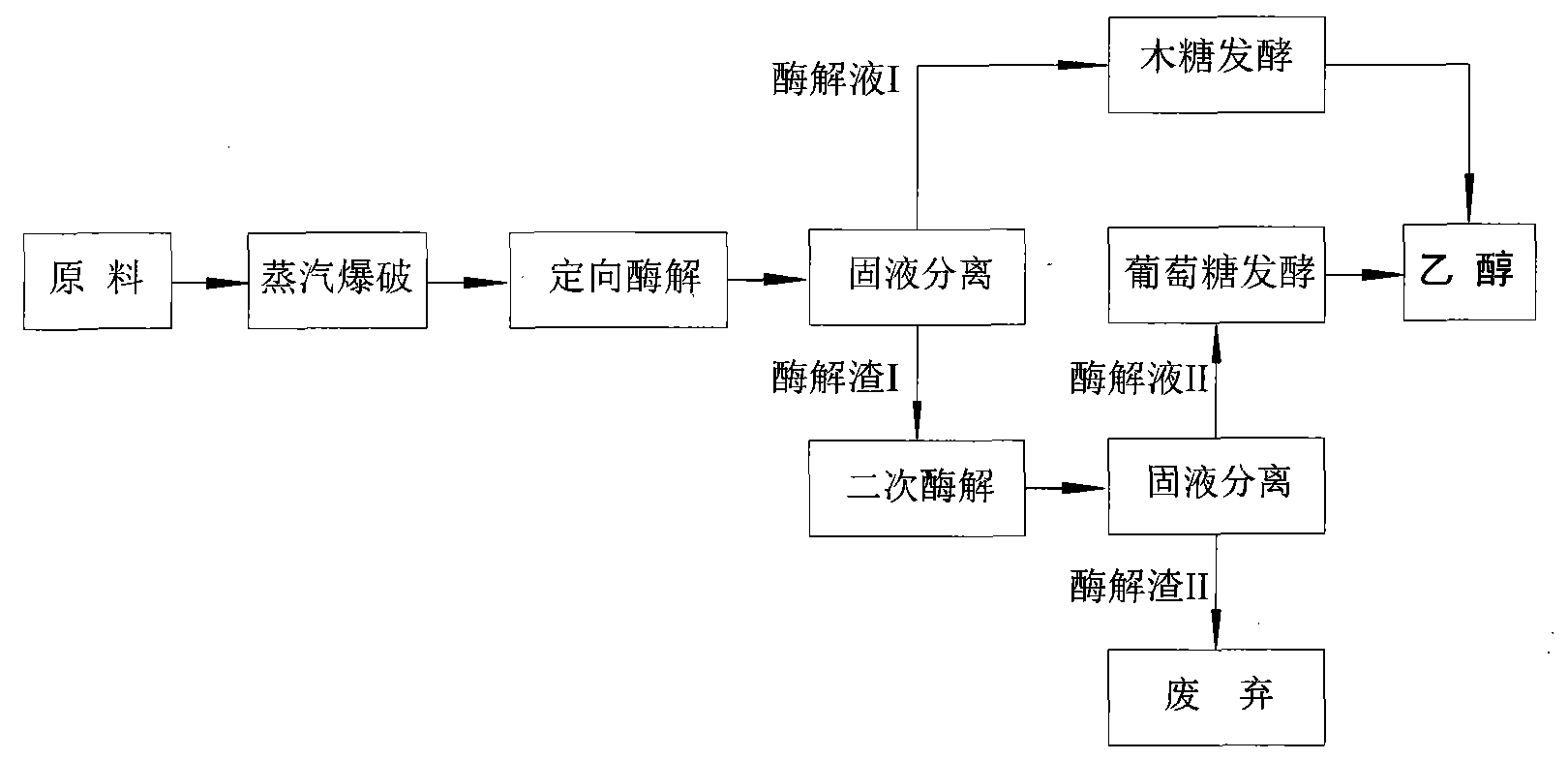

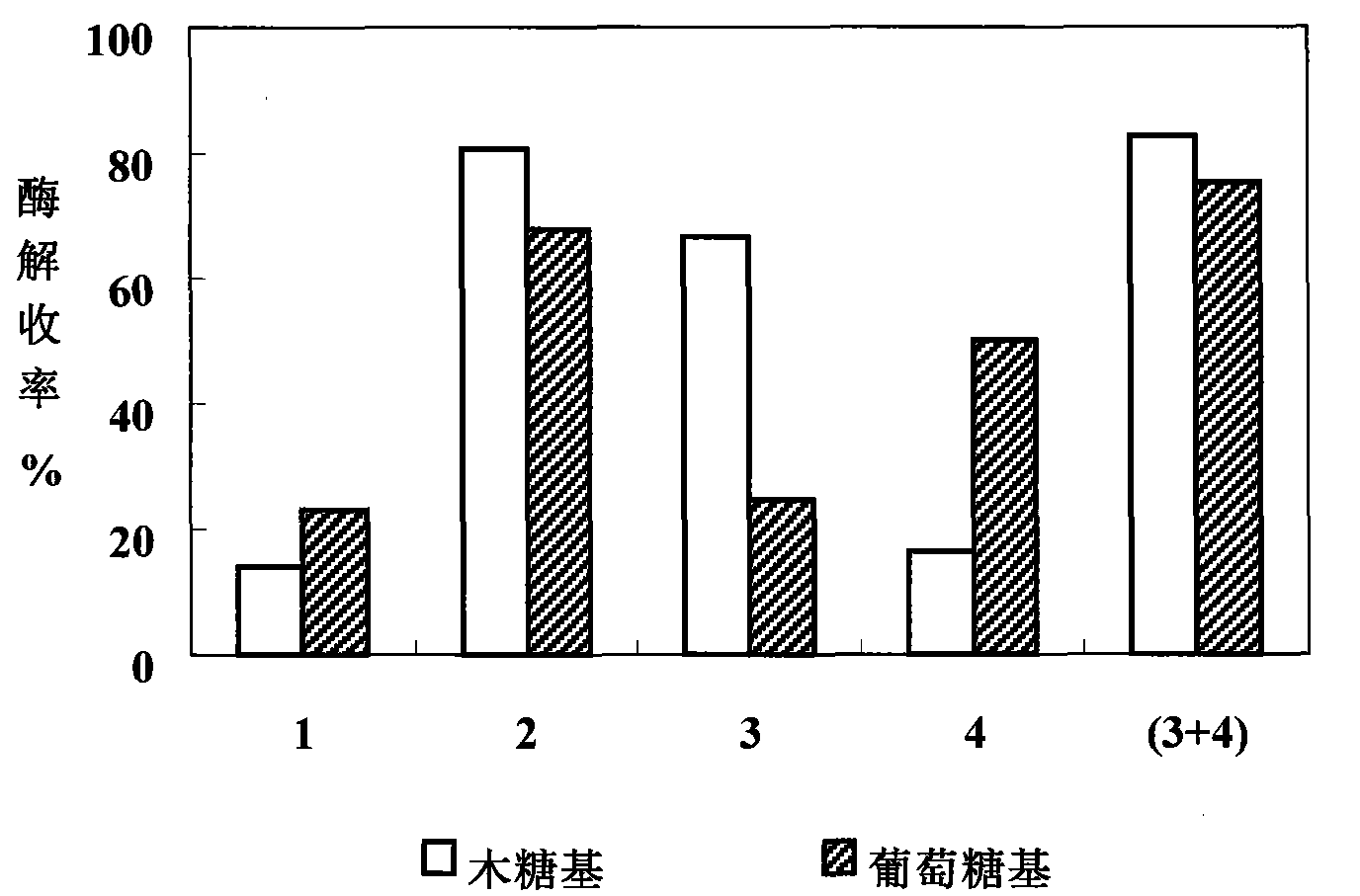

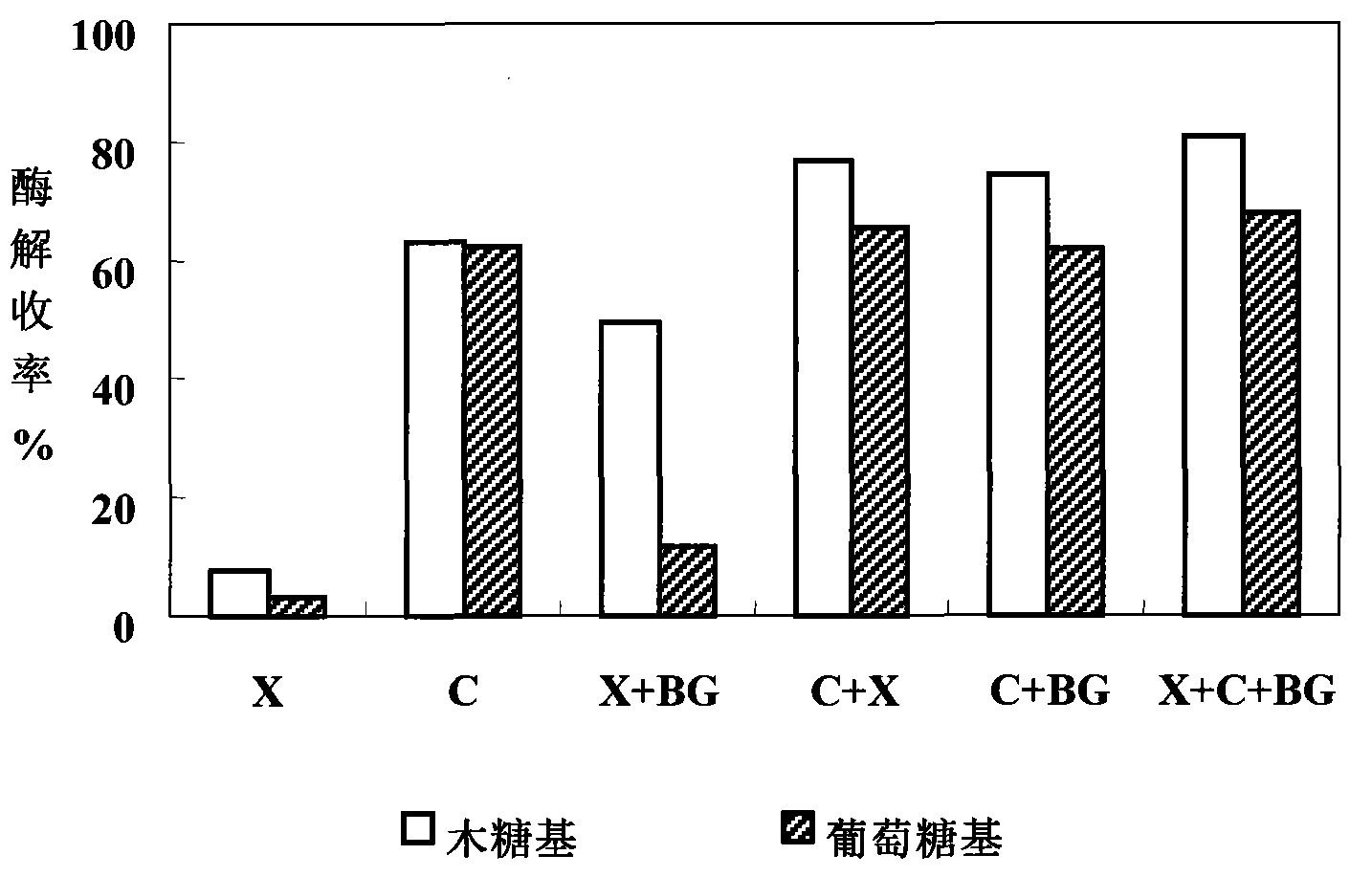

Method for performing steam explosion of wood fiber raw material, directional enzymatic dissociation and alcoholic fermentation

The invention relates to a method for performing steam explosion of wood fiber raw materials, directional enzymatic dissociation and alcoholic fermentation. The method is characterized in that steam explosion, directional enzymolysis of xylan, solid-liquid separation, extensive enzymolysis of cellulose, anaerobic alcoholic fermentation of xylose and anaerobic alcoholic fermentation of glucose areadopted. The new secondary enzymolysis technology is adopted and beta-glucosidase and little cellulose are introduced in xylanase so as to obviously improve the xylan directional enzymolysis and separation effect of raw materials. Therefore, the invention provides a new method for the effective separation of xylose and glucose in the wood fiber raw materials and the efficient alcoholic fermentation and significantly reduces the production cost for the fermentation of the ethanol in wood fiber raw materials.

Owner:NANJING FORESTRY UNIV

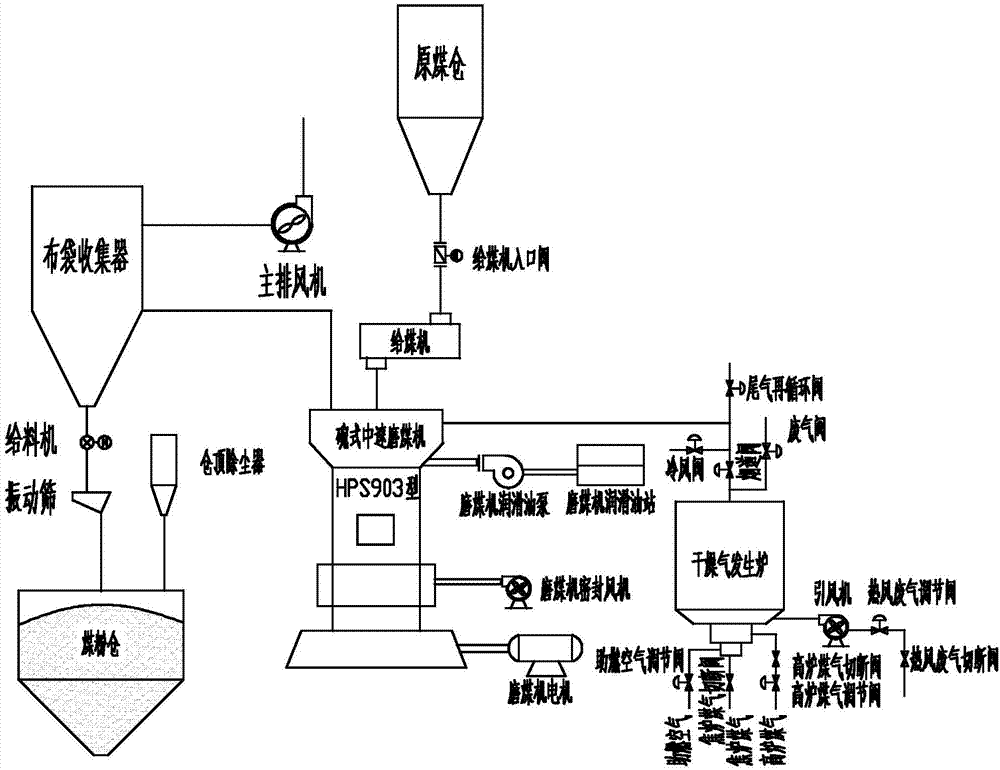

Full automatic control method and system for blast furnace pulverizing systems

ActiveCN103495488AReduce labor intensityReduce mental tensionBlast furnace componentsBlast furnace detailsAutomatic controlBunker

The invention discloses a full automatic control method and system for blast furnace pulverizing systems. Each blast furnace is provided with at least two pulverizing systems. All the pulverizing systems share the same pulverized coal bunker. The method comprises the following steps: preparing and starting, wherein starting judgments and starting control are included; operation adjustments; halt control. The method can realize uniform operation through program control, adjusts the number of started pulverizing systems according to actual conditions, and realizes full automatic control operation of the blast furnace pulverizing systems. The method greatly reduces labor intensity and thought tension degree of workers and improves working efficiency so as to eradicate manual operation errors and solve the problems that the equipment operation rate is high, running fluctuation is large, and index stability is poor when a manual operation system is used. Moreover, the method enables one person to monitor a plurality of pulverizing systems, improves the running efficiency of the systems, reduces operation cost, enables the systems to have more time to be maintained and repaired, and enables the whole pulverizing system to be in a virtuous circle.

Owner:JIANGSU JINHENG INFORMATION TECH CO LTD

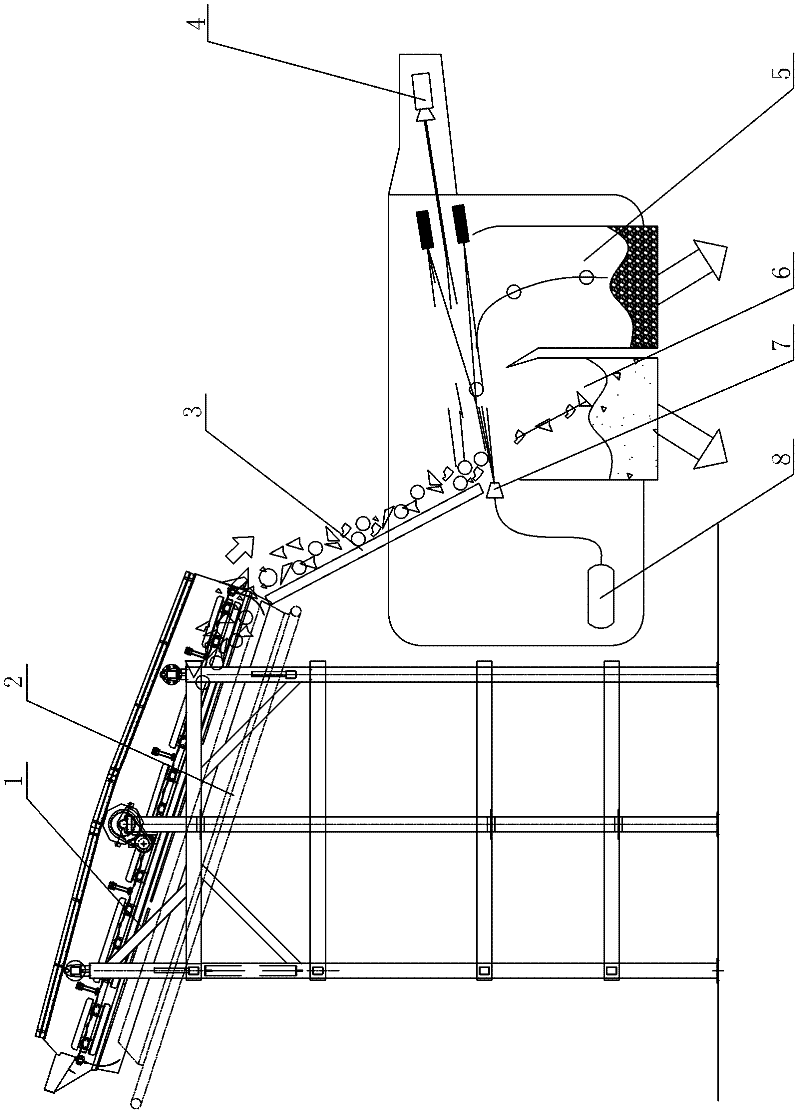

Process and system for sorting coal by discharging coal gangue through dry method

ActiveCN102416386ACompact structureSmall footprintSievingGas current separationCoal briquetteControl system

Owner:BIRTLEY TIANJIN IND EQUIP

Natural focusing type ultrasonic atomization nozzle

ActiveCN104324839AReduce volumeEvenly distributedLiquid spraying apparatusPrintingTransformerEngineering

Owner:千藤(南京)环保科技有限公司

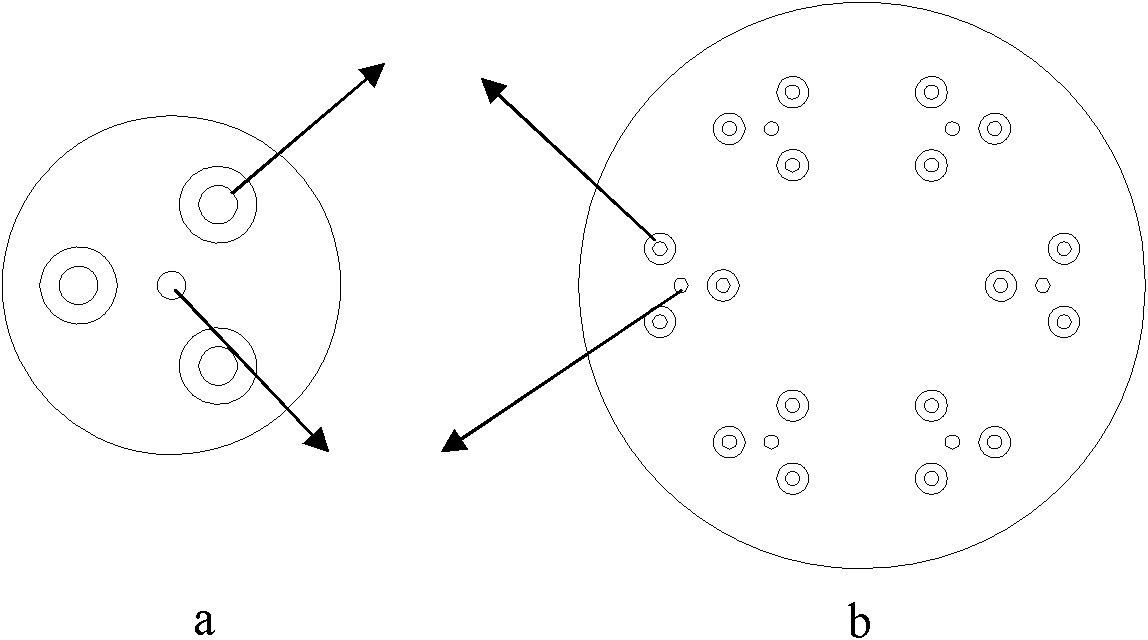

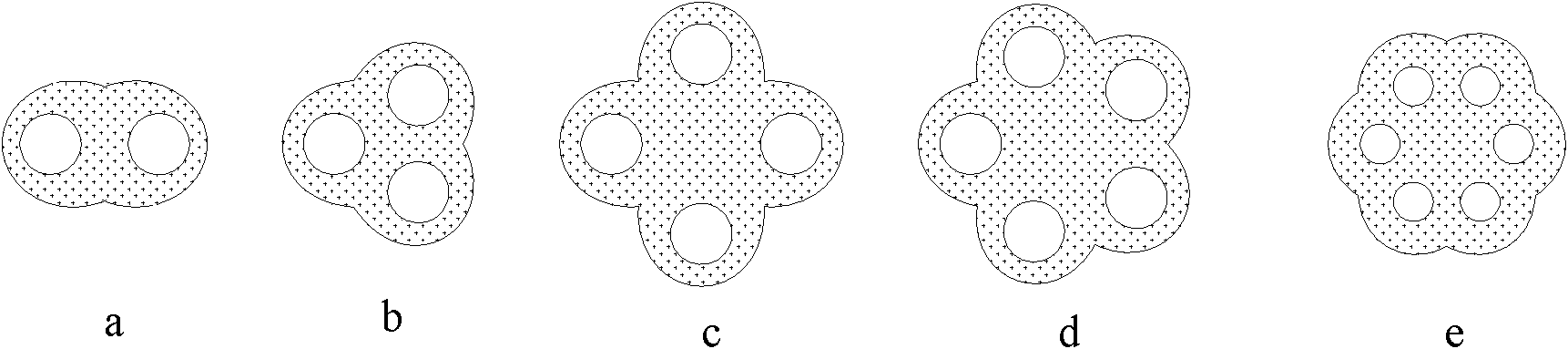

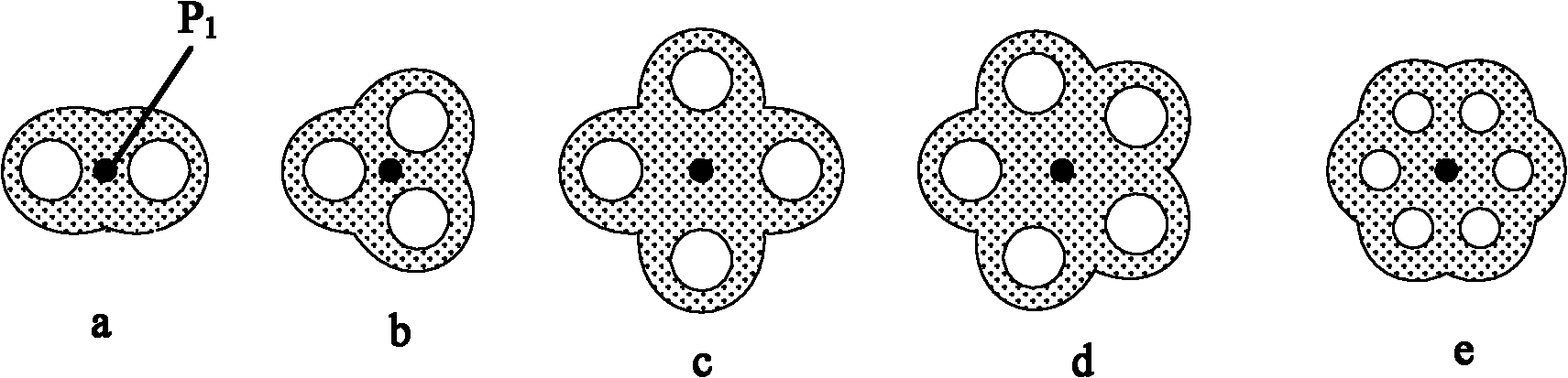

Multi-core hollow fiber porous membrane and preparation method thereof

InactiveCN102151489AAdjusting Cluster Fusion CircularityIncrease swingSemi-permeable membranesFiberNon solvent

The invention discloses a multi-core hollow fiber porous membrane and a preparation method thereof and relates to a polymer. The multi-core hollow fiber porous membrane is provided with at least two hollow fiber membrane bundles, the outer diameter of a single hollow fiber membrane is 0.2-3mm, the wall thickness of the single hollow fiber membrane is 0.05-1mm, the porosity is 50%-90%, the membrane separation pore size is 0.01-1 mu m, the rupture strength is 0.3-2MPa, the tension fracture tension of the hollow fiber membrane bundles is 0.2-10.0kg / bundle, and the pure water flux is 600-10000L / m2.h at 0.1MPa and 25 DEG C. The dry-wet non-solvent induced phase separation (NIPS) spinning process is adopted for enabling polymer casting solution and spinning core solution to simultaneously pass through a spinning spray head for forming nascent hollow fibers, and 2-8 single nascent hollow fibers are gathered into one bundle before entering into a coagulation bath water tank, and further enter into the coagulation bath water tank for forming the bundle-like hollow fiber membrane.

Owner:凌雪萍 +1

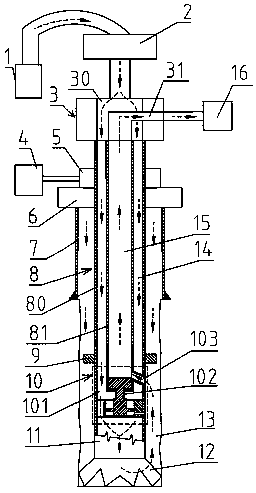

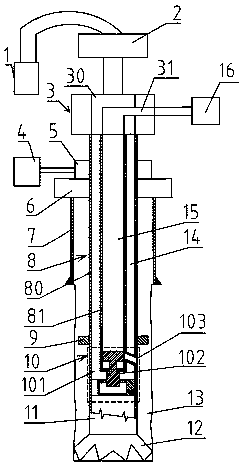

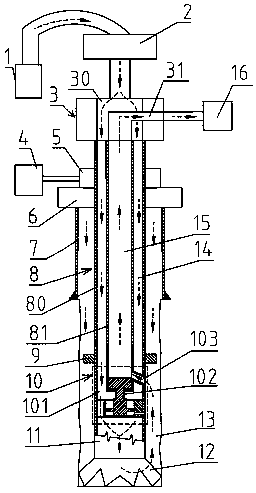

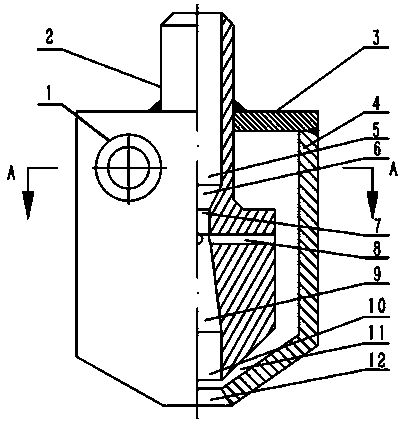

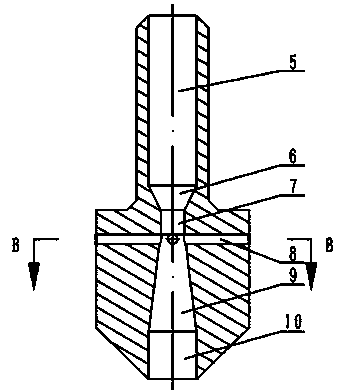

Gas reverse-circulation well-drilling method

ActiveCN110029938AReduce processing complexityLow gas consumptionConstructionsLiquid/gas jet drillingWell drillingDouble wall

The invention discloses a gas reverse-circulation well-drilling method. According to the gas reverse-circulation well-drilling method, a well-drilling system comprising a well-drilling pump set, a topdrive, a top drive adapter, a rotary blowout-preventing flow guiding device, a blowout preventer group, a casing, a double-wall drill pipe, a flow channel conversion device, a conventional drilling rig and a drill bit is used; and the gas reverse-circulation well-drilling method comprises the steps that during gas injection and well-drilling, one path of injected gas passes through the top drive,the top drive adapter, the double-wall drill pipe, the flow channel conversion device, the conventional drilling rig and the drill bit to enter a well bottom annular space, the other path of the injected gas enters the well bottom annular space through the rotary blowout-preventing flow guiding device; and the two paths of injected gas converge in the well bottom annular space and then passes through the flow channel conversion device, the double-wall drill pipe and the top drive adapter to return to a grit chamber. The gas reverse-circulation well-drilling method has the advantages that thegas using amount is small, the drilling speed is high, and low-cost well drilling can be achieved; and the gas reverse-circulation well-drilling method meets the well-drilling well control and well-drilling safety requirements in the field of oil drilling.

Owner:CHINA PETROCHEMICAL CORP +3

Multistage atomization gas-liquid two-phase large-caliber mist nozzle

InactiveCN103861753AImprove energy utilizationReduced gas consumptionLiquid spraying apparatusHollow cylinderAerosolize

The invention relates to a multistage atomization gas-liquid two-phase large-caliber mist nozzle. According to the technical scheme, the middle of a small cylinder body of a liquid inlet pipe (2) is fixedly connected with the center of a top cover (3), and a large cylinder body of the liquid inlet pipe (2) and a conical table of the liquid inlet pipe (2) are located in a rotational flow cylinder (4). The outer wall of the large cylinder body of the liquid inlet pipe (2) has a distance of 3-8 mm with the inner wall of a hollow cylinder body of the rotational flow cylinder (4). The minimum distance of a circular seam (11) formed between the outer wall of the conical table of the liquid inlet pipe (2) and the inner wall of a hollow conical table of the rotational flow cylinder (4) is 0.3-1 mm. The upper portion of the hollow cylinder body of the rotational flow cylinder (4) is horizontally provided with an air inlet pipe (1), and one end of the air inlet pipe (1) penetrates through a shell of the rotational flow cylinder (4) and is tangent with the outer wall of the small cylinder body of the liquid inlet pipe (2). The outer diameter of the air inlet pipe (1) is the difference between the inner diameter of the hollow cylinder body of the rotational flow cylinder (4) and the outer diameter of the small cylinder body of the liquid inlet pipe (2). The air inlet pipe (1) is located between the top cover (3) and the large cylinder body of the liquid inlet pipe (2). The multistage atomization gas-liquid two-phase large-caliber mist nozzle has the advantages that the structure is simple, mist drops are evenly distributed, and the nozzle cannot be blocked.

Owner:WUHAN UNIV OF SCI & TECH

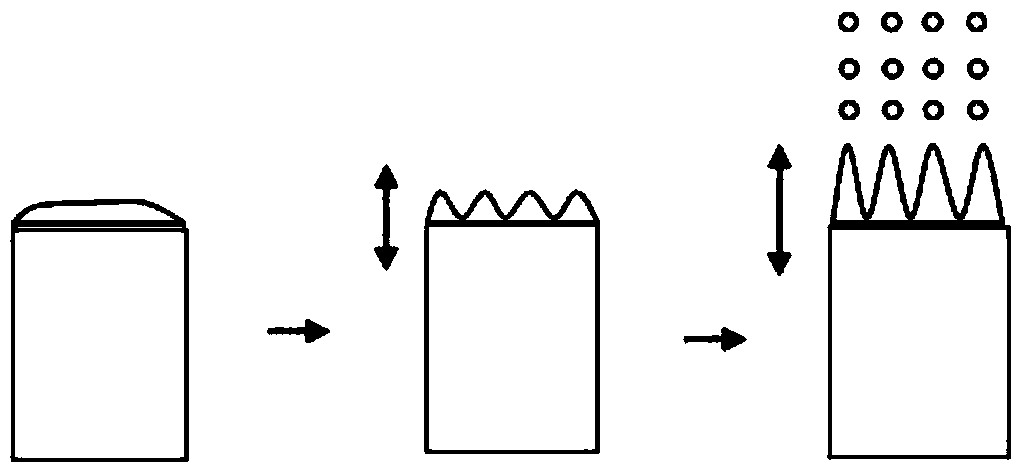

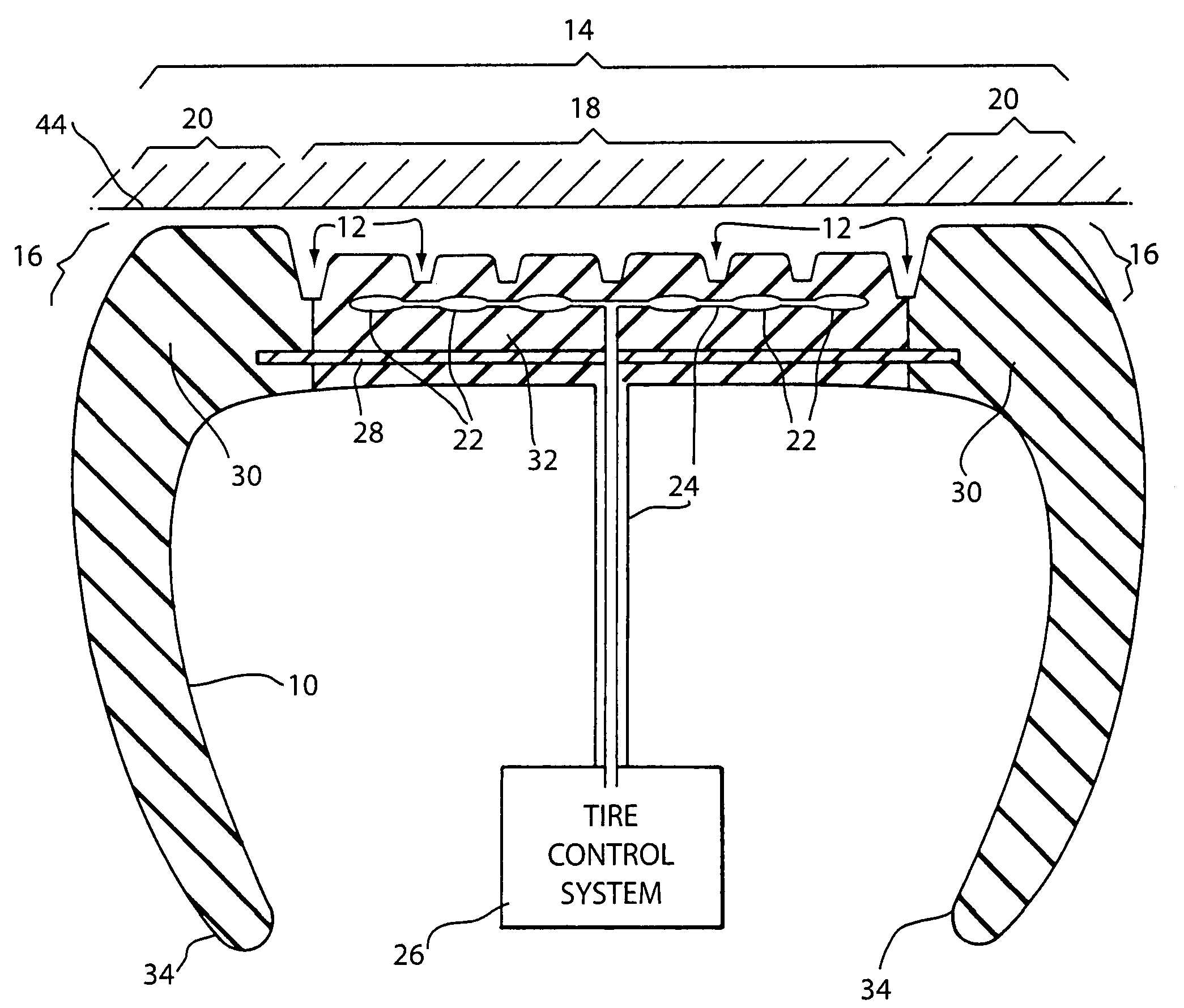

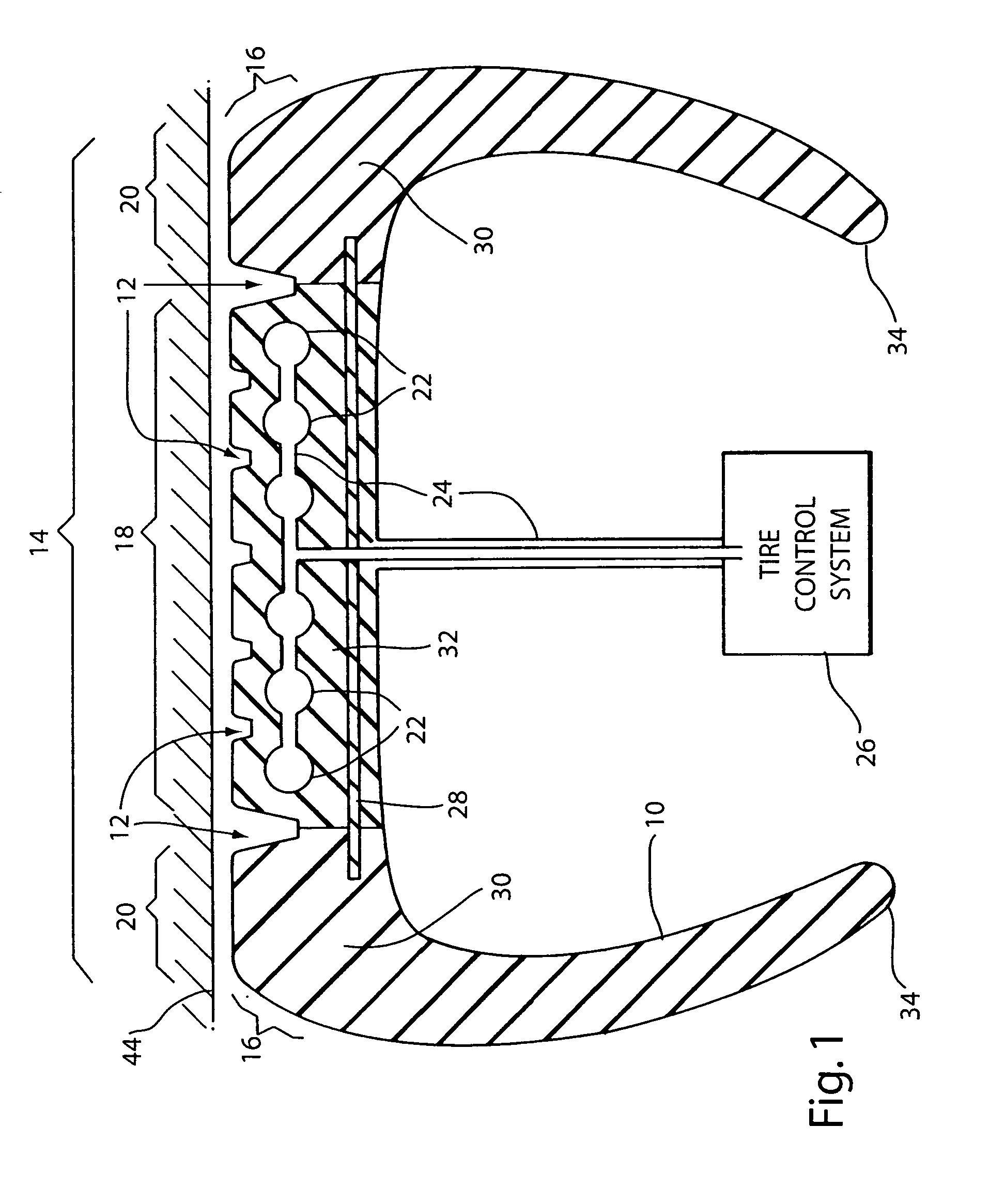

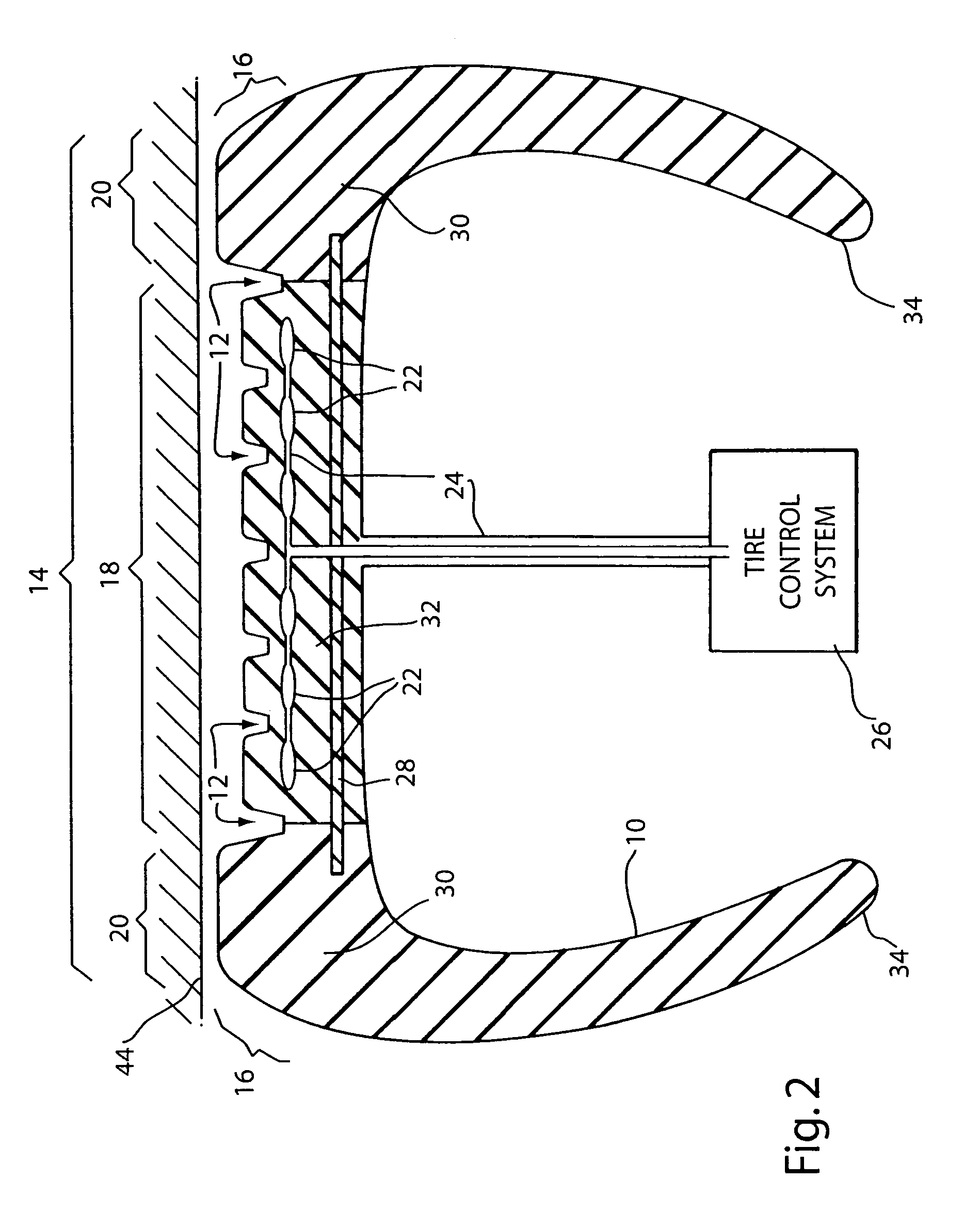

Fuel efficient vehicle tire having a variable footprint and low rolling resistance

InactiveUS7066226B1Low gas consumptionEffective dry tractionSpecial tyresTyre tread bands/patternsGround contactMicrocomputer

A tire for vehicles offering low rolling resistance wherein the ground-contact surface area is variable as a portion of the tread part can be retracted and / or extended using pneumatic, mechanical or hydraulic force to withdraw from, or come into contact with the road surface before, during or after operation permitting more efficient operation wherein the material used within the tread part that retains contact with the road may generally have a smaller internal friction loss than the material used in conventional tires and the rolling resistance is thereby reduced when the retractable portion of the tread is selectively withdrawn from contact with the road surface furthermore achieving a smaller ground-contact patch footprint. The achieved object of a tire with a lower rolling resistance yields improved fuel consumption efficiency. Improvements in exterior and interior noise levels and a reduced tendency to exhibit hydroplaning action are also attained with a variable groove volume to tread surface-contact ratio. Within one embodiment of the present invention, an automated microcomputer-based tire control system is disclosed useable to command the motion of the moveable tread portion of the said tire in response to various operational scenarios.

Owner:FIORE ROBERT ANGELO

Device and method for air-blowing vacuum membrane distillation

InactiveCN101664642AReduced vacuum requirementsImprove mass transfer efficiencyDistillationForming gasWater vapor

The invention provides a device and a method for air-blowing vacuum membrane distillation. The device for air-blowing vacuum membrane distillation comprises the following sequentially-connected parts:a water tank arranged on the side of raw water; a water pump which is connected with the water tank and is used for pumping the raw water in the water tank; a compressed air inlet which is arranged on the downstream of the water pump and is used for blowing low-pressure compressed air to the raw water; a gas-liquid mixer used for mixing the compressed air and liquid to form gas-liquid mixed fluid; a hydrophobic membrane component used for processing the gas-liquid mixed fluid; and a vacuum generation device arranged on the effluent side of the hydrophobic membrane. In the device and the method, the compressed air is blown into the raw water side of the membrane when vacuum is generated on effluent side of the membrane. Under the suction action of the vacuum, water vapor and part of compressed air passes through the hydrophobic membrane together. As blowing and sweeping actions of the compressed air deliver the water vapor to the other side of the membrane, mass transfer efficiency isimproved. The requirements on the vacuum degree of the effluent side are reduced and equipment cost is reduced. Meanwhile, membrane pollution is effectively relieved.

Owner:TIANJIN POLYTECHNIC UNIV

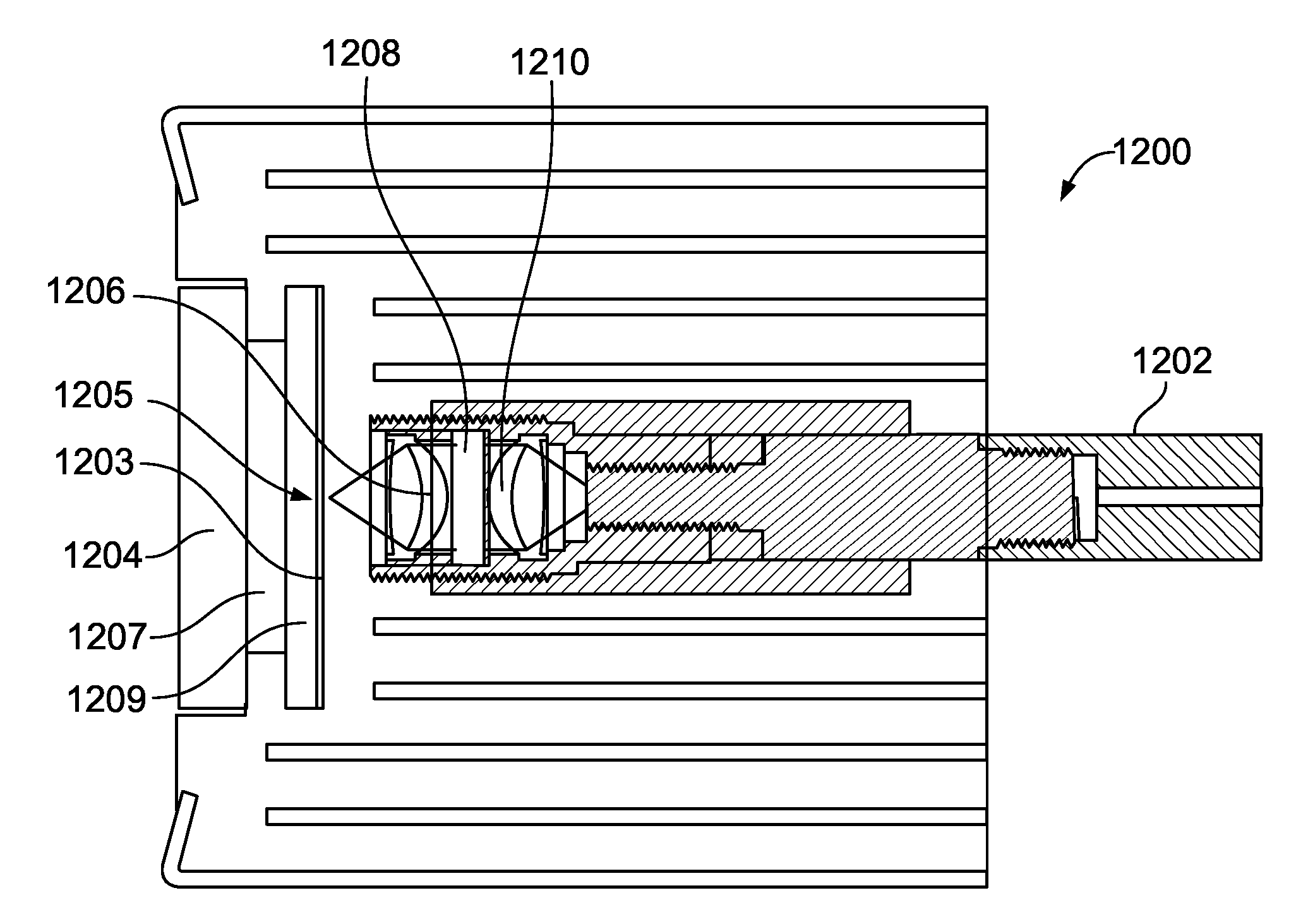

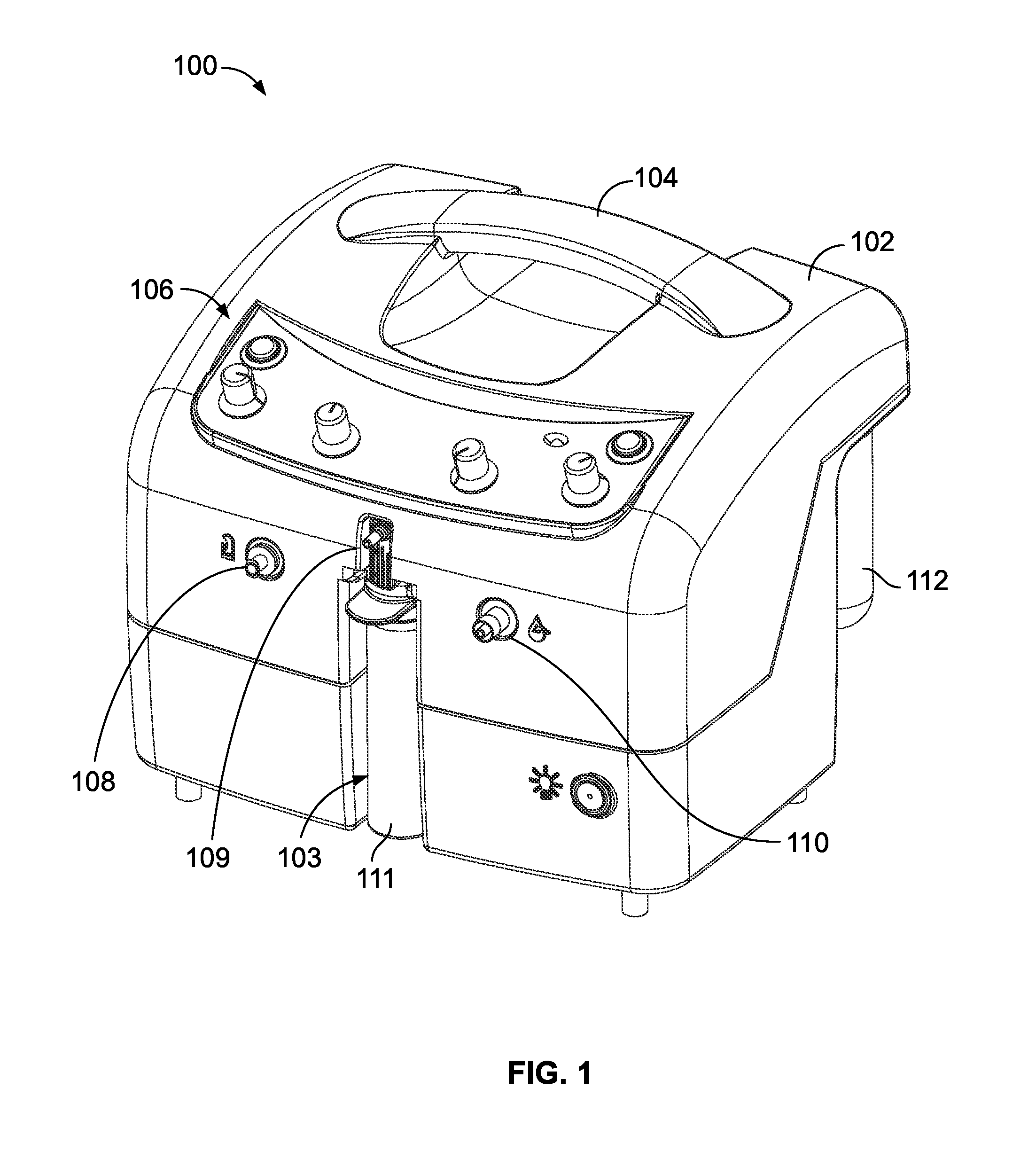

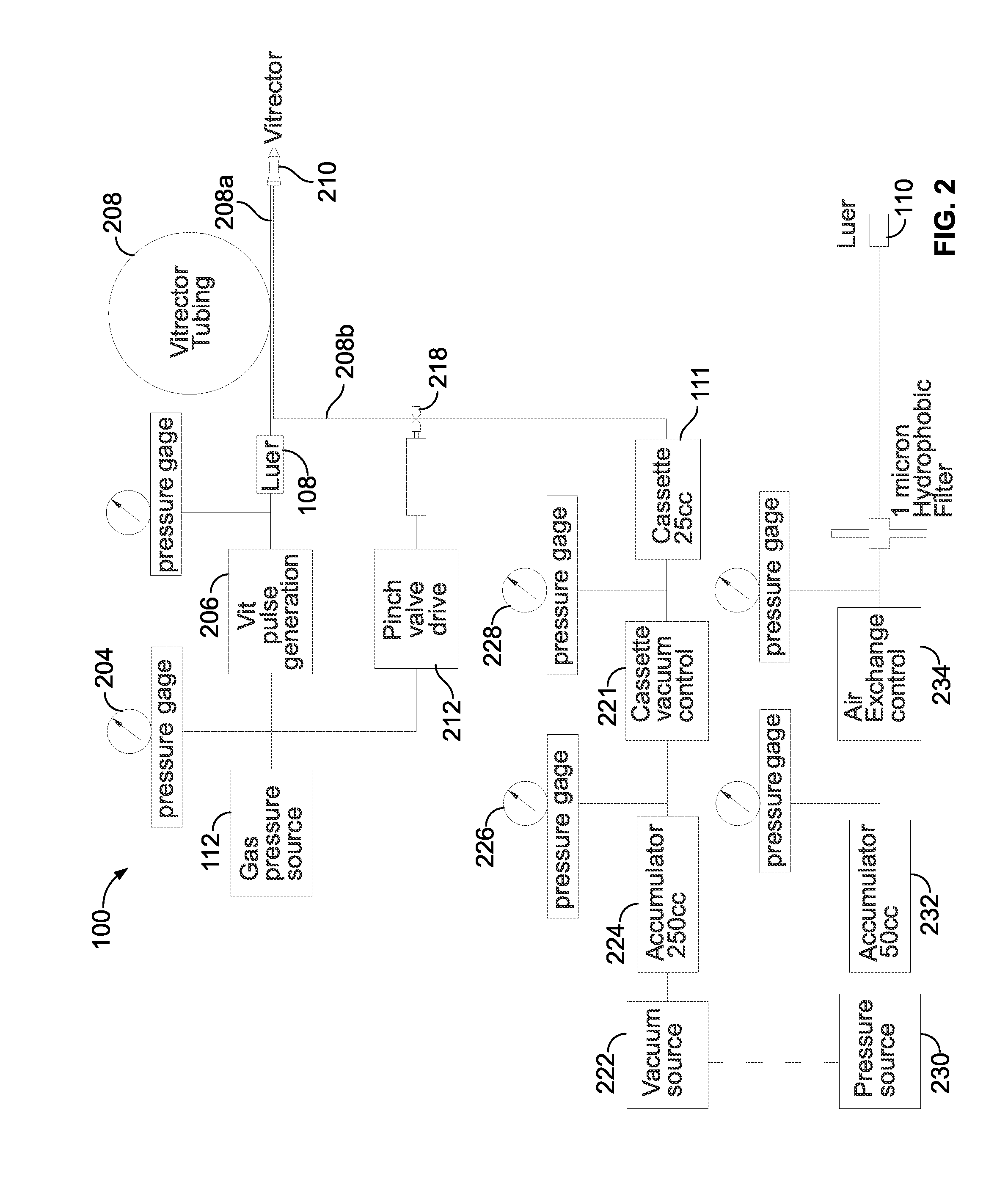

Systems and methods for vitrectomy

ActiveUS20120310146A1Reduce gas consumptionEfficiently useSurgical furnitureEye surgeryVitrectomyEngineering

A system for conducting a vitrectomy includes: a gas source; a vitrector including a cutting mechanism that opens and closes according to a pressure at the vitrector; and a pulse-generating system receiving gas from the gas source and generating pulses at the vitrector. The pulses cause the pressure at the vitrector to vary according to a cycle, and the varying pressure at the vitrector causes the cutting mechanism of the vitrector to open and close. At a first time in the cycle, the pulse-generating system, raises the pressure at the vitrector to a maximum pressure. At a second time in the cycle, the pulse-generating system reduces the pressure at the vitrector to a minimum pressure that is greater than ambient, the pressure at the vitrector being maintained at least at the minimum pressure. The difference between the maximum pressure and minimum pressure is minimized to reduce gas consumption.

Owner:SYNERGETICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com