Patents

Literature

178results about How to "Reduced vacuum requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

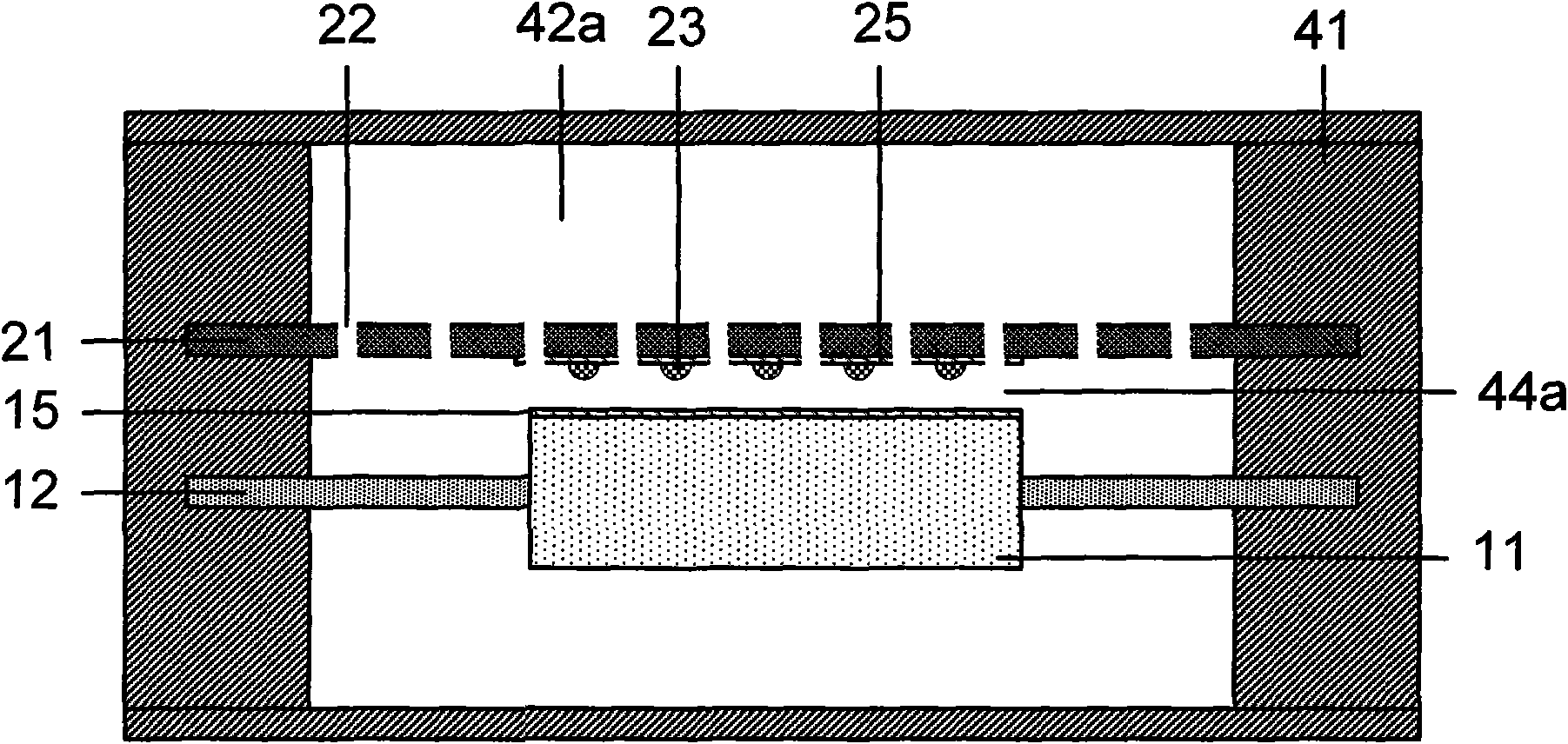

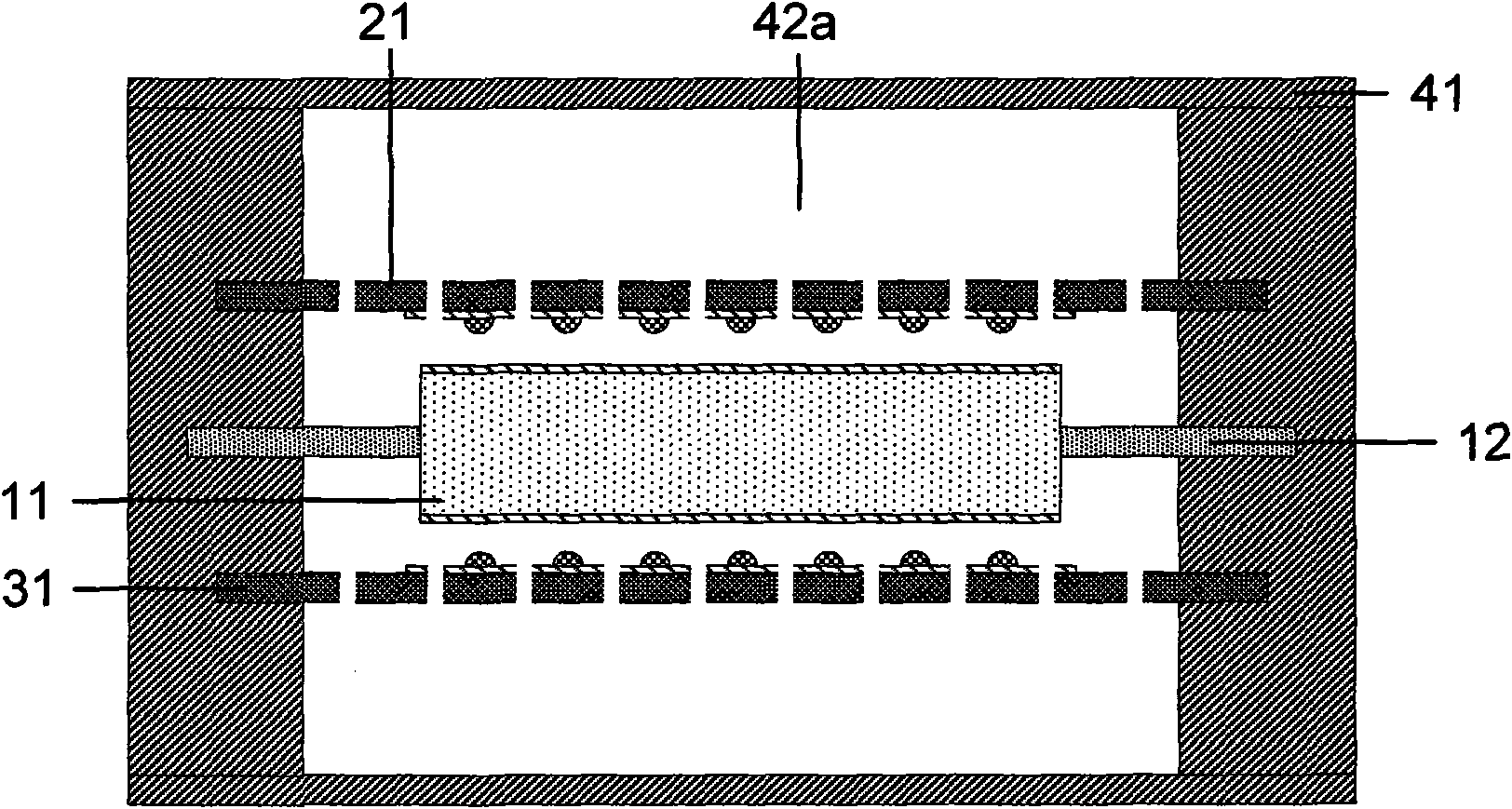

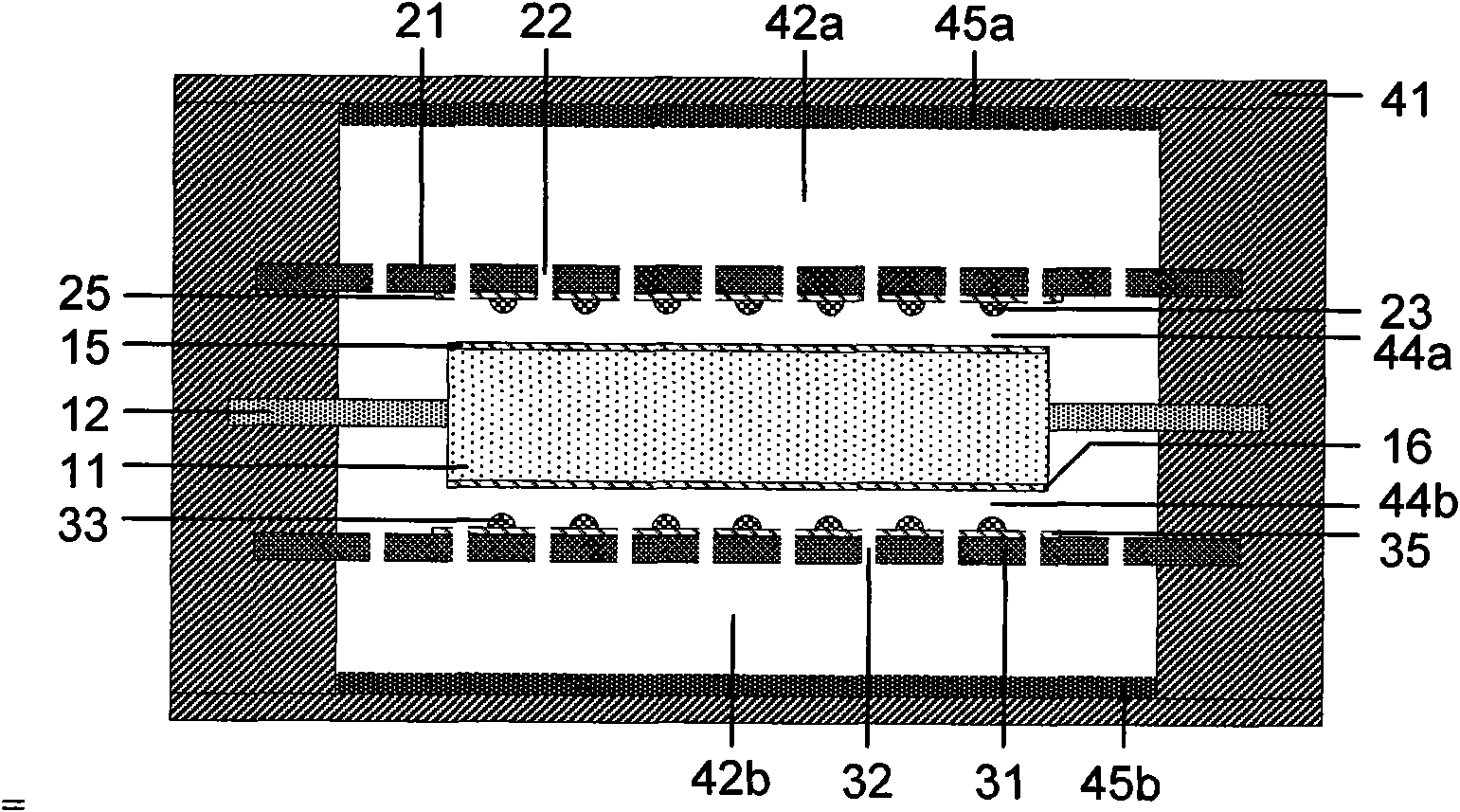

Capacitive acceleration sensor with acoustic cavity

InactiveCN101644718AReduced Cross-Axis Interference and Temperature Coefficient of SensitivitySmall dampingTelevision system detailsImpedence networksCapacitanceClassical mechanics

The invention provides a capacitive acceleration sensor with an acoustic cavity, comprising a sensor frame, an acceleration detection structure composed of a detection quality block and an elastic vibrating diaphragm, and a back plate with damping holes and limit embosses, wherein, the detection quality block is arranged at the center of the acceleration sensor and is connected with the sensor frame by the surrounding elastic vibrating diaphragm; the damping holes manufactured on the back plate are used for adjusting system damping, and the limit embosses are used for preventing adhesion or damage in the case of overload; the detection quality block is parallel to the back plate, and detection capacitances are respectively formed on the opposite surfaces of the detection quality block andthe back plate; and the fact that the sensor frame is internally provided with an acceleration detection structure and internally formed with the acoustic cavity after the back plate is closed can improve frequency response. The sensor structure of the invention has lower requirement on the vacuum degree of the acceleration sensor, and can adjust important parameters such as a quality factor Q andthe like which can adjust a system by changing density and size of the damping holes and volume of the acoustic cavity and the like, thus realizing larger flexibility on design and manufacture.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

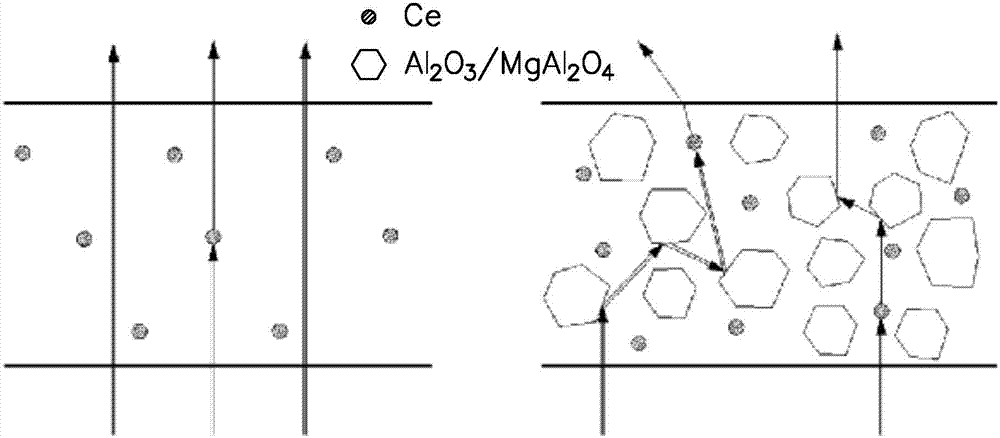

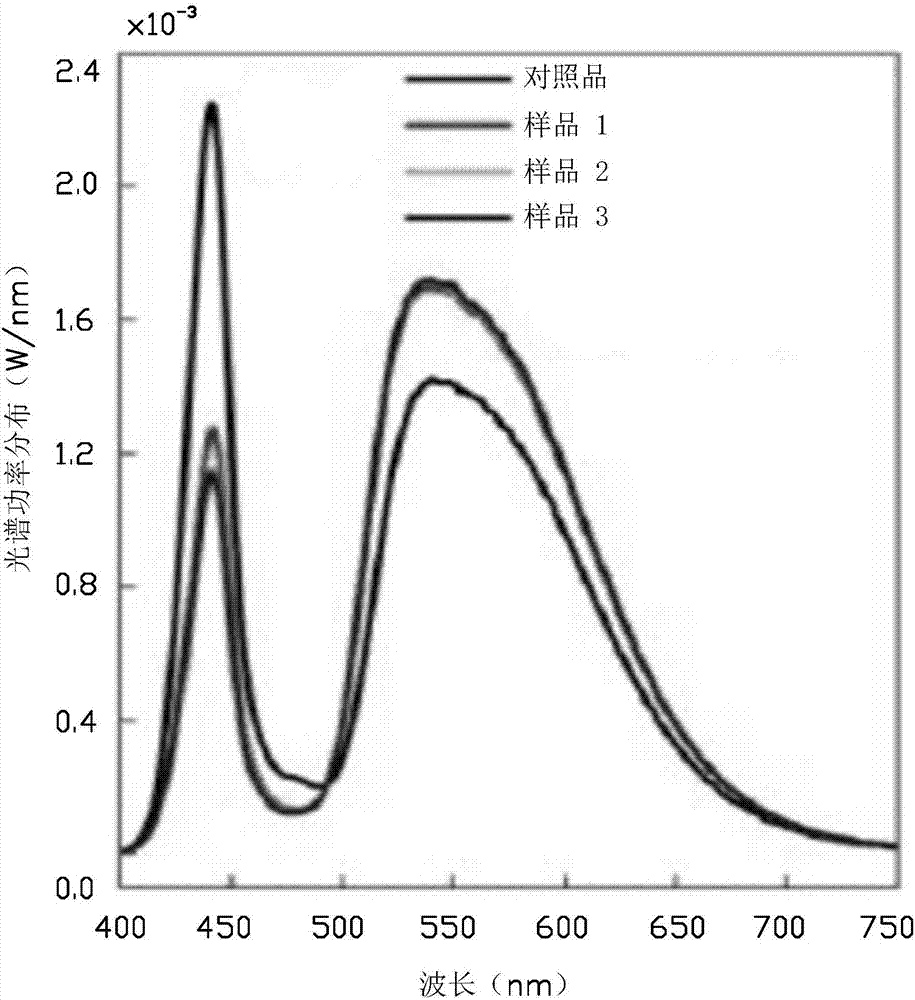

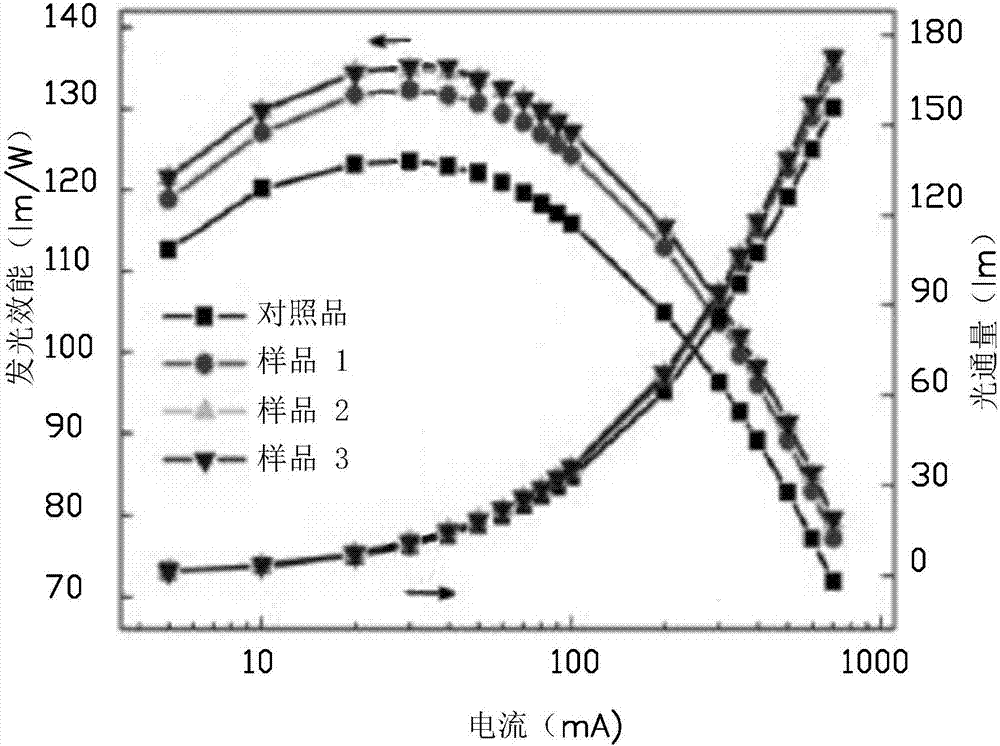

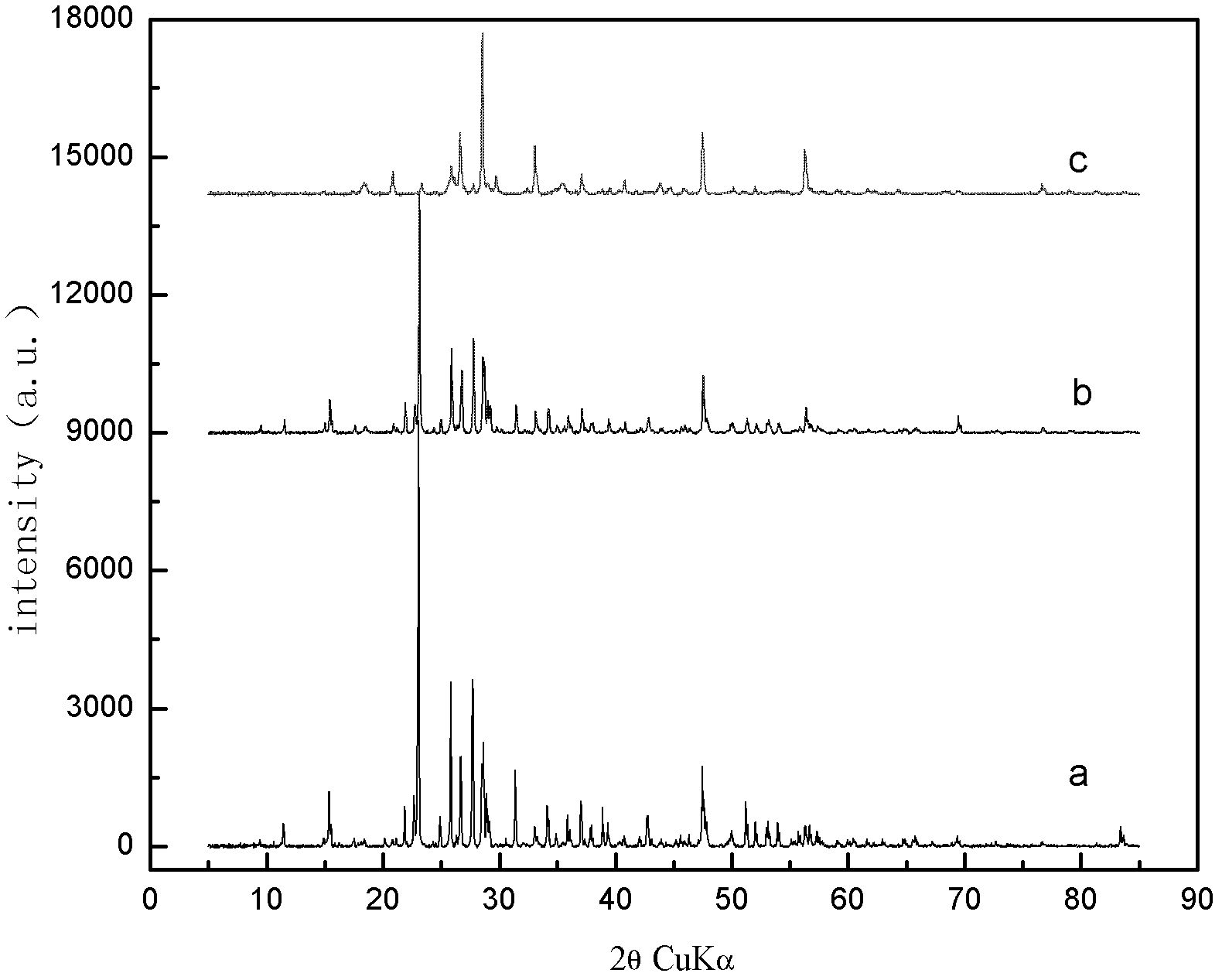

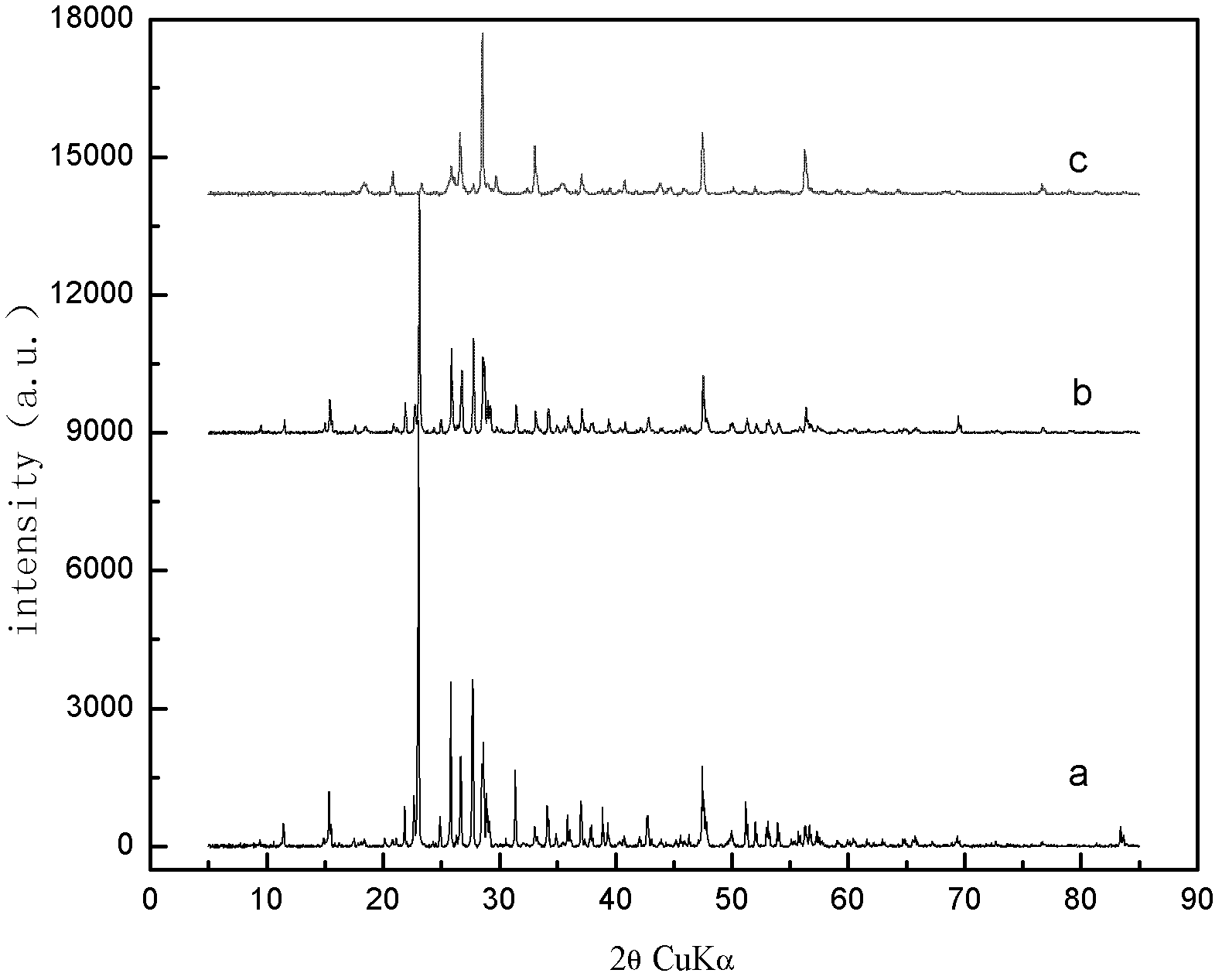

Method for preparing multiphase translucent fluorescent ceramic and LED module

ActiveCN107540368AOptimize the transmission routeImprove lighting efficiencyLight fasteningsSemiconductor devices for light sourcesFluorescenceCrystallite

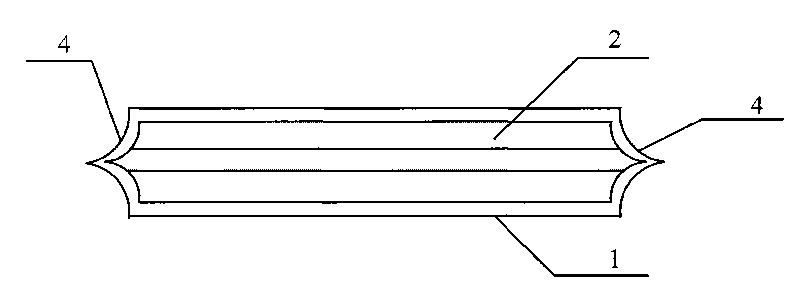

The invention provides a method for preparing multiphase translucent fluorescent ceramic. The method comprises providing raw materials comprising first phase phosphor and second phase ceramic raw material powder, wherein the first phase phosphor has the average crystal diameter (D50) of 1-10 micrometers and the second phase ceramic raw material powder has the average particle diameter (D50) of 0.5-5 micrometers, blending the second phase ceramic raw material powder and the first phase phosphor according to a mass ratio of 0.1-5, carrying out sintering pretreatment on the raw materials and carrying out sintering to obtain the multiphase translucent fluorescent ceramic. The method optimizes an excited blue light propagation route, improves the illumination efficiency, further reduces the usethickness of the fluorescent ceramic material and the phosphor concentration, acquires high-quality uniform white lights and has lower requirements on the light transmittance of the ceramic sheet, raw material purity and a sintering device vacuum degree. The invention also provides an LED module using the multiphase translucent fluorescent ceramic.

Owner:JIANGSU LUOHUA NEW MATERIAL

Three-dimensional slab heat pipe with multi-layer microporous pipe arrays and processing technique thereof

ActiveCN101738118ANo need to reduce the distanceHigh efficiency of condensation heat releaseIndirect heat exchangersMetallic materialsEngineering

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

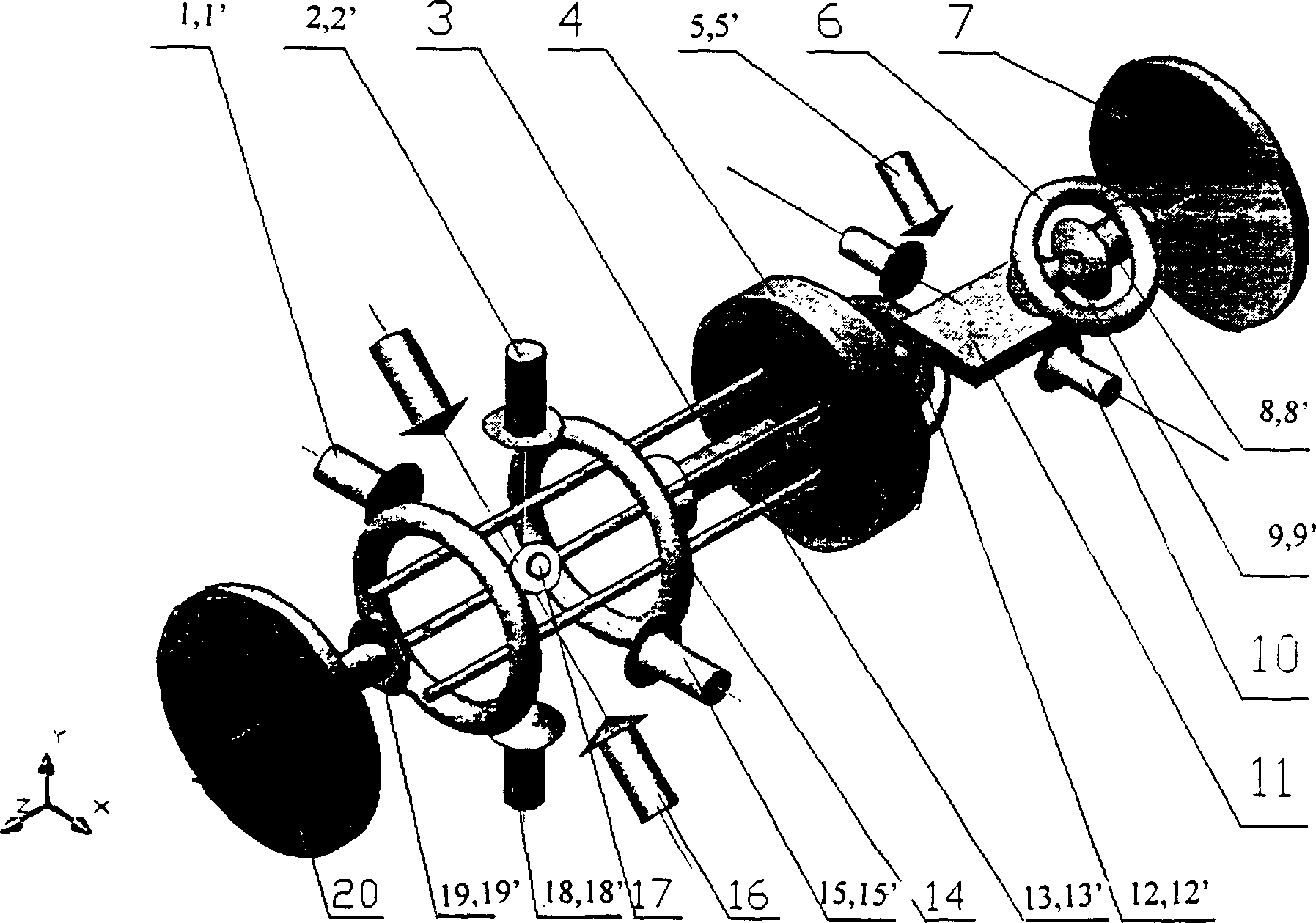

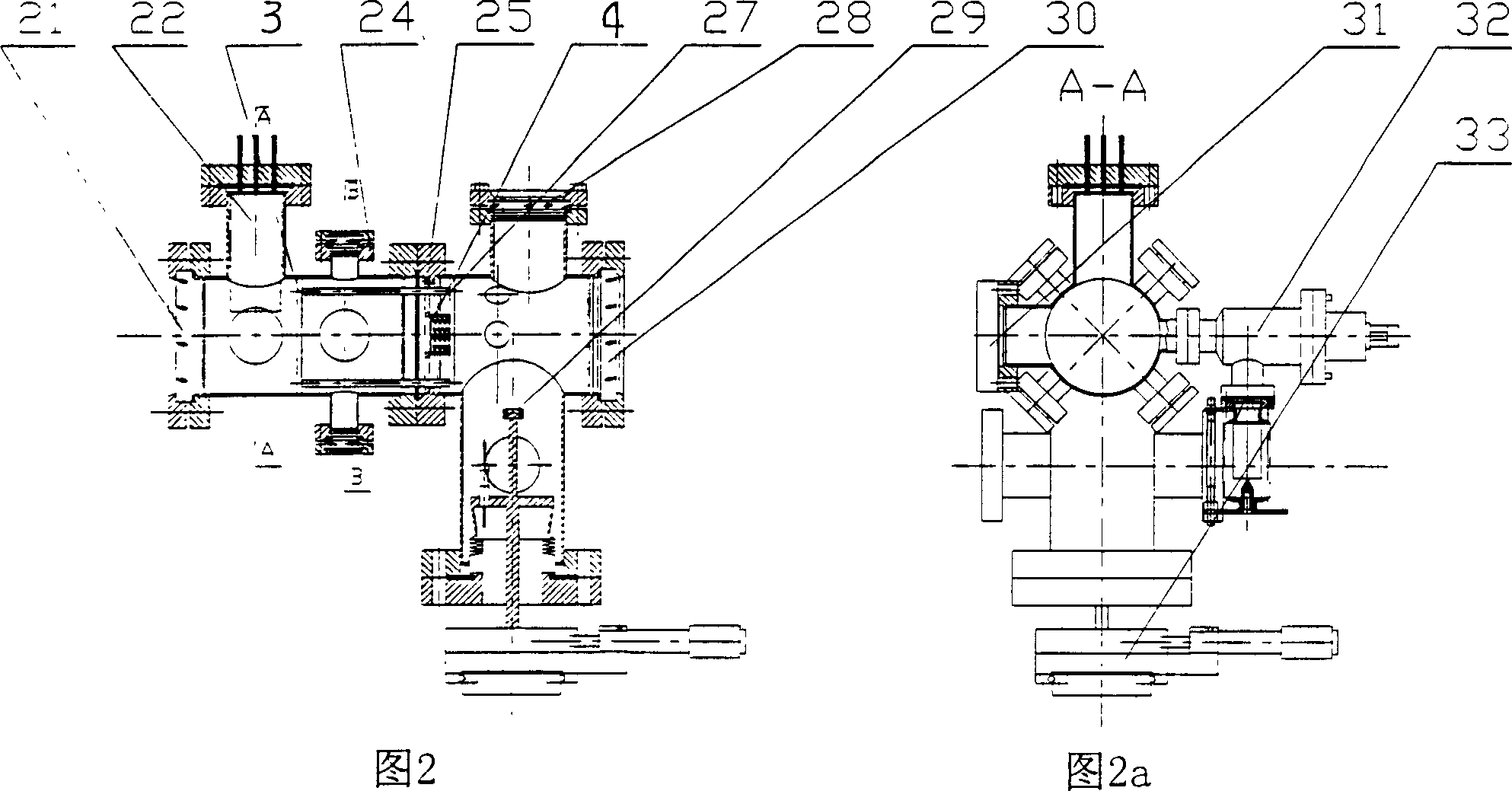

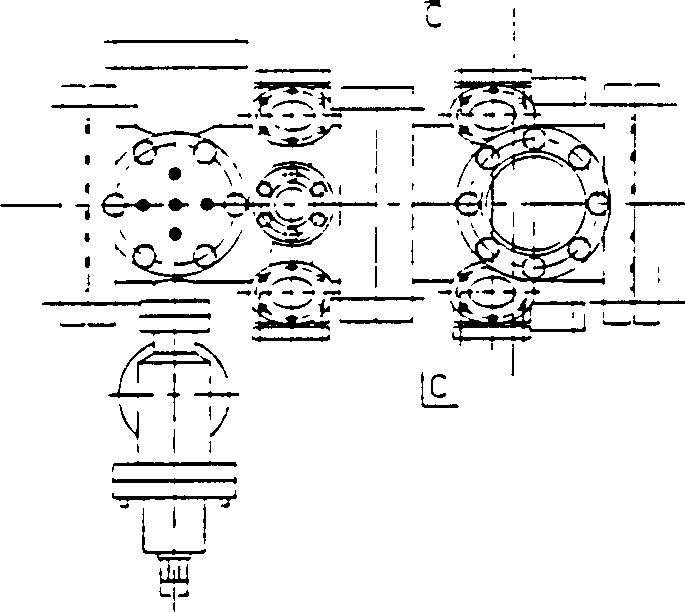

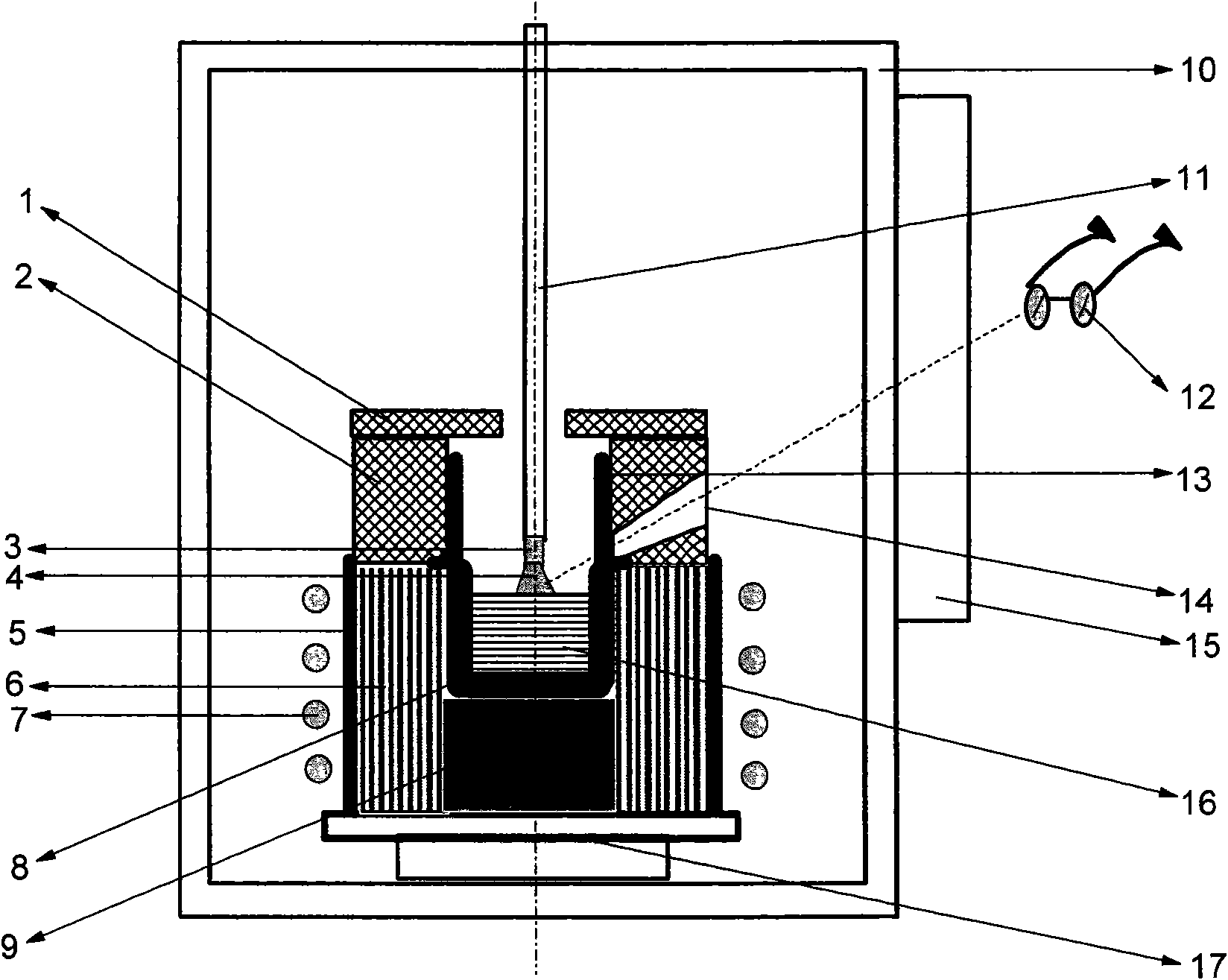

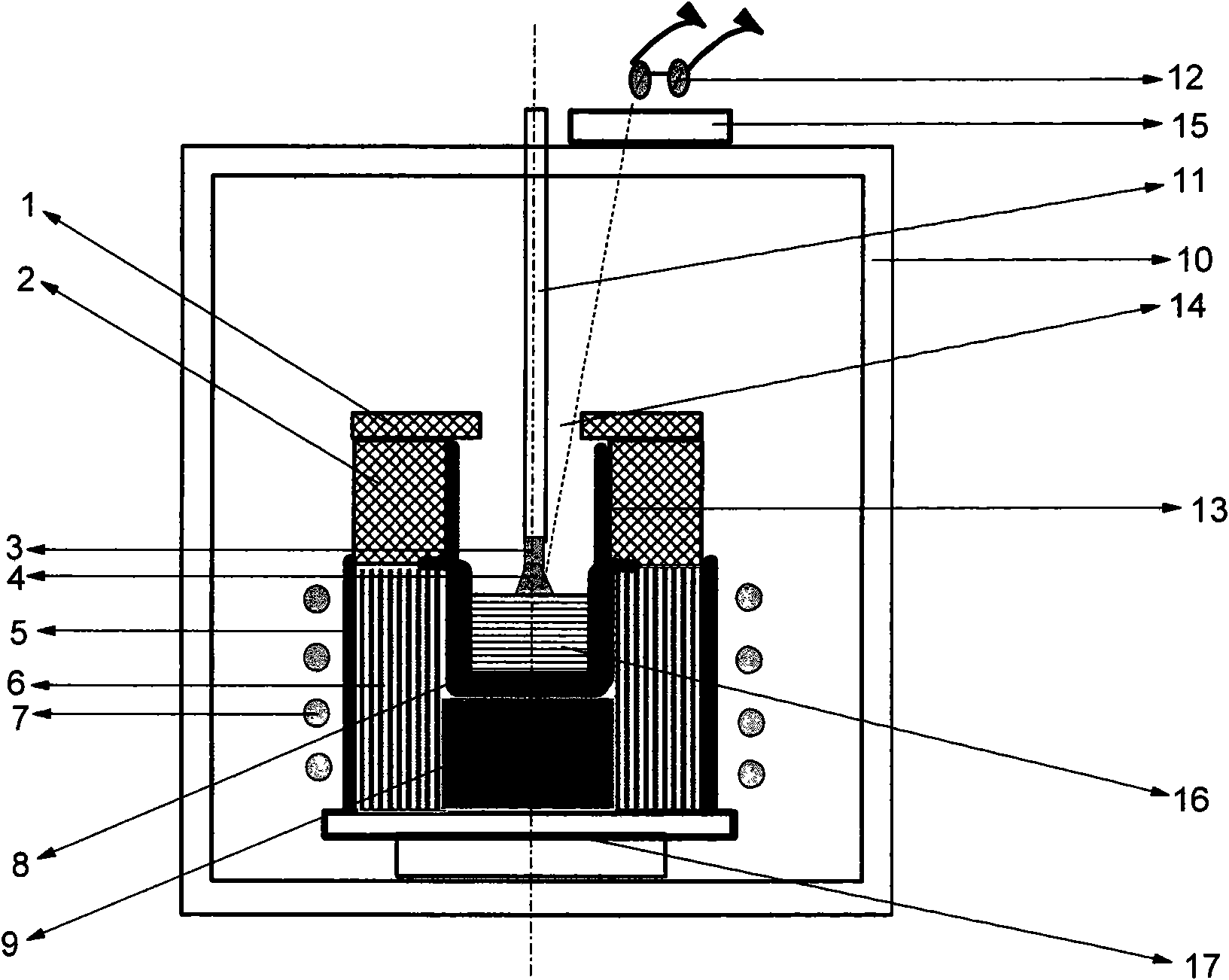

Atomic beam generation method and apparatus for atomic chipset

The invention relates to a method for generating the atom bean used in atom chip and relative device, wherein, the device comprises a vacuum room, an atom source, a two-dimensional micro adjusting platform, a magnetic iron and inner and outer light paths. The inner and outer light paths comprise a main laser and a re-pump laser; the vacuum room is mounted with a 1 / 4 wave plate reflector group with a hole in center and a direct-guide group; the magnetic light well uses the optical pump laser and the re-pump laser to prepare the atom into optimized weak field scanning state. The invention has small volume and simple structure, while it can supply the optimized weak field scanning state to the atom chip with the atom beam whose longitudinal speed is lower and uniform, transverse speed is nearly zero and density is high. The invention can be used in the guide, wave-division, interference and the Bose-Einstein Coagulation (BEC).

Owner:TSINGHUA UNIV

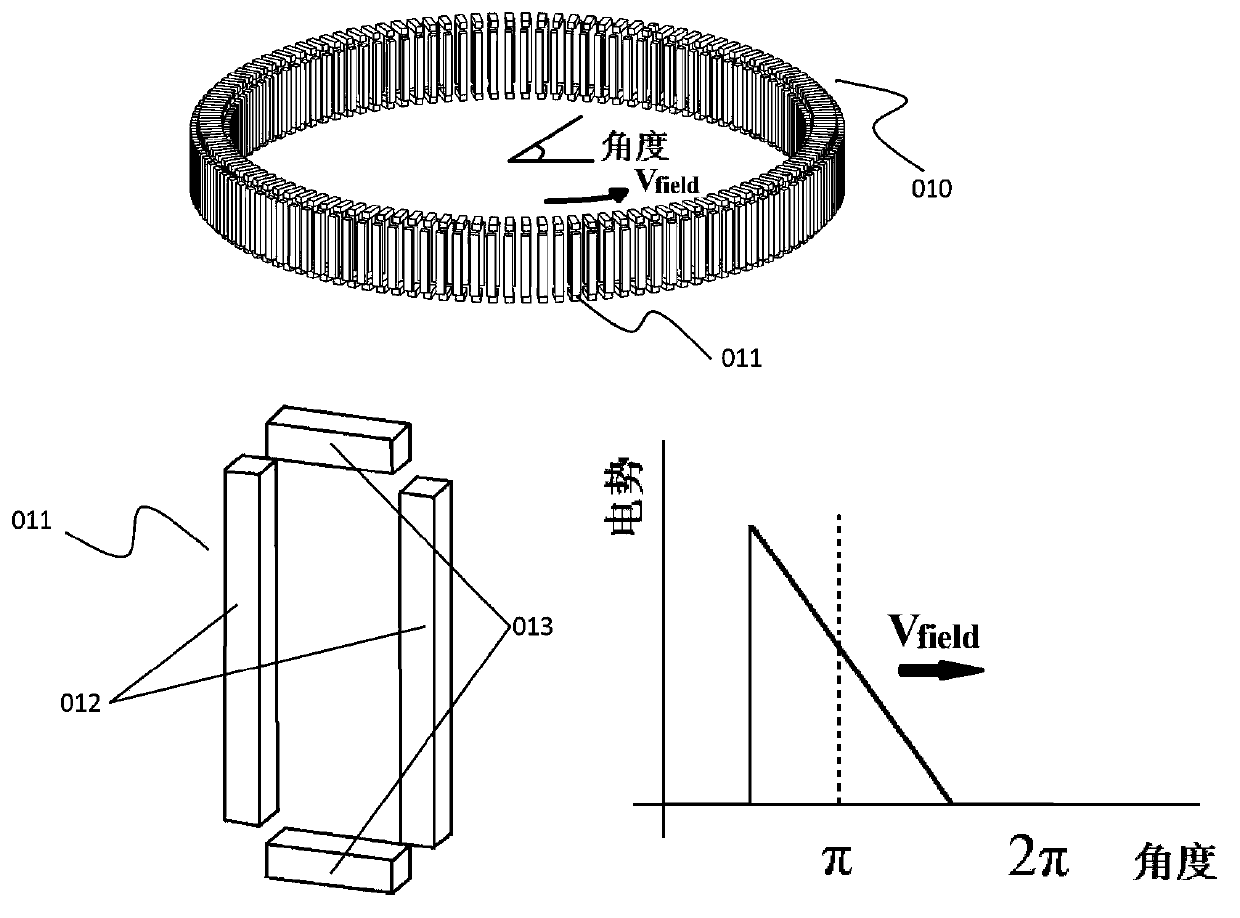

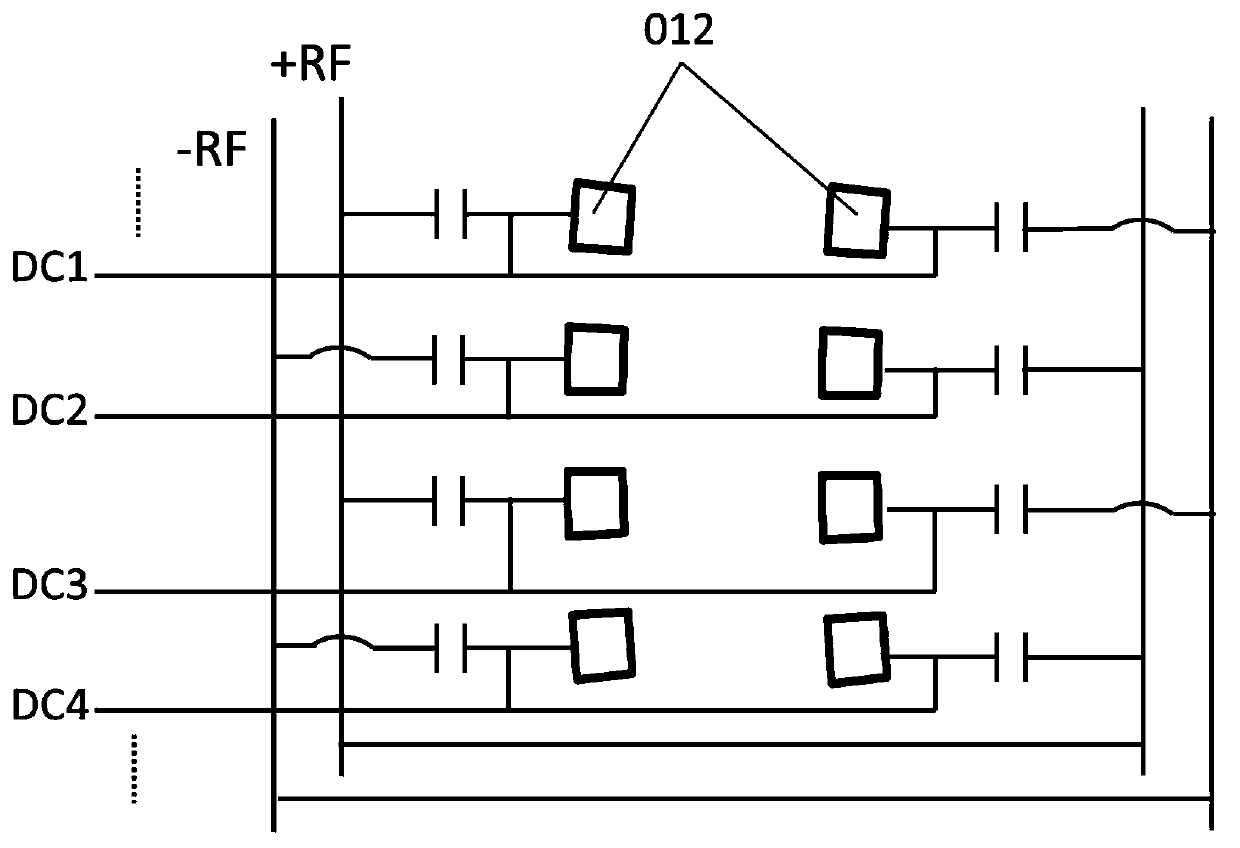

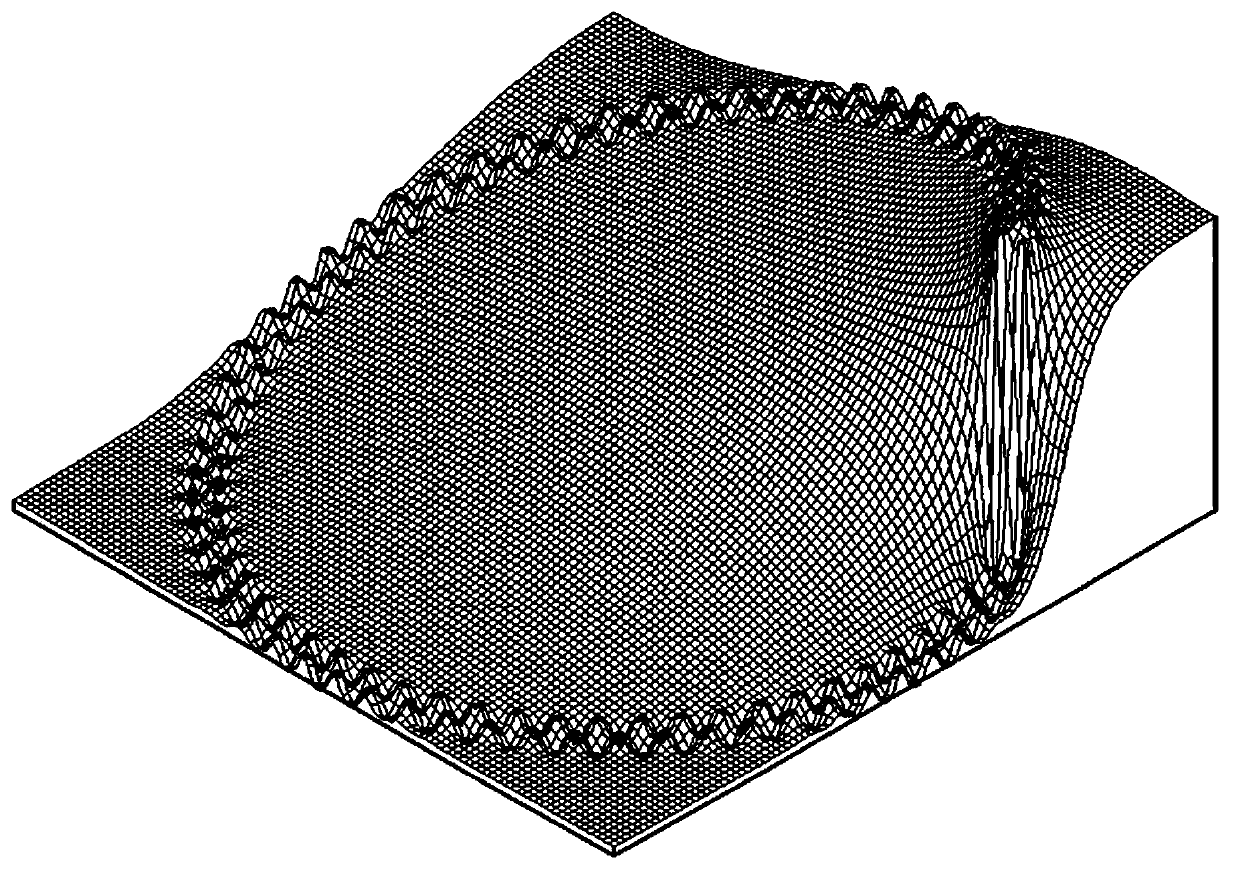

Ion mobility analyzer and combination unit thereof and ion mobility analysis method

ActiveCN103871820AInterface Loss ReductionReduced vacuum requirementsMaterial analysis by electric/magnetic meansTube electrostatic deflectionMass analyzerIon migration

Owner:SHIMADZU SEISAKUSHO LTD

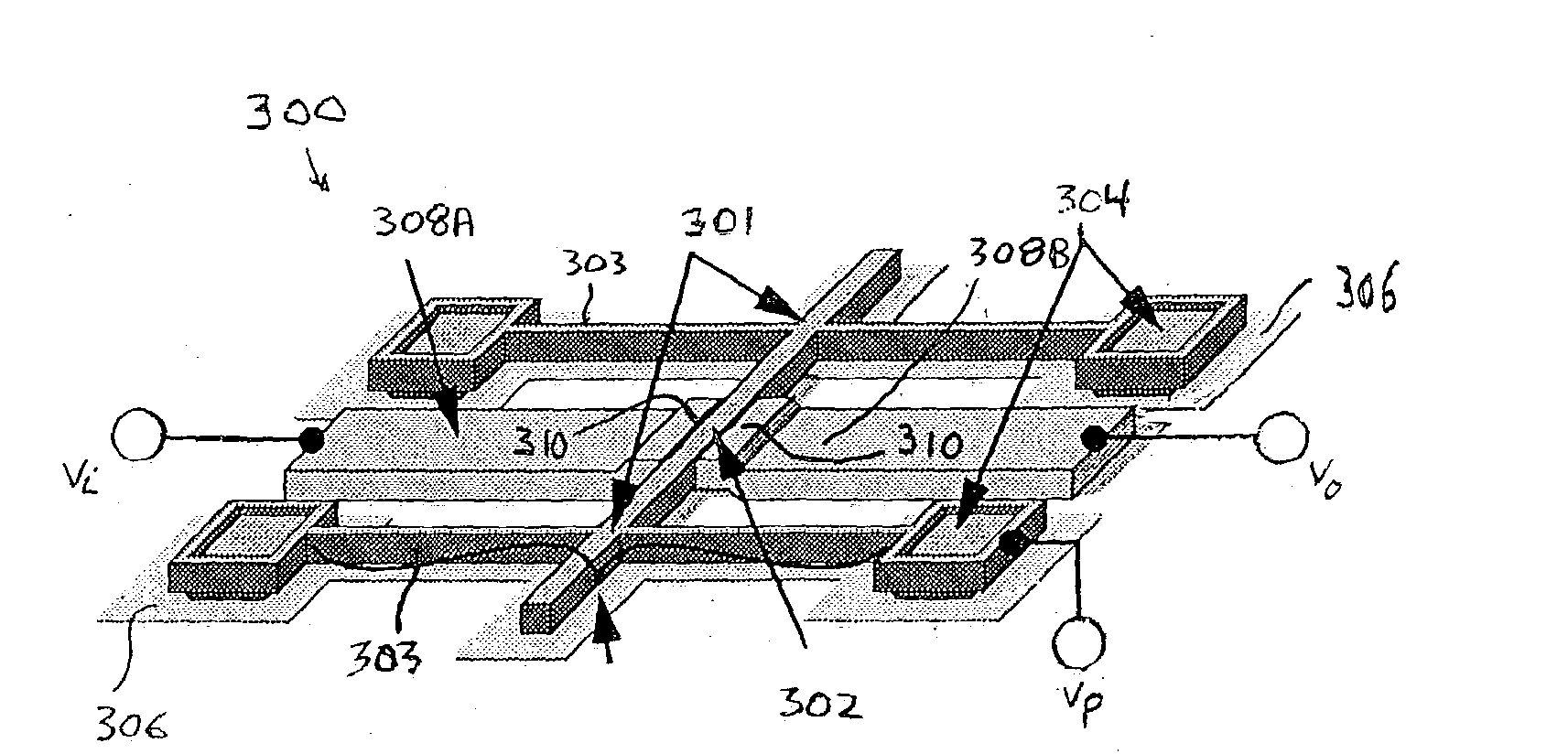

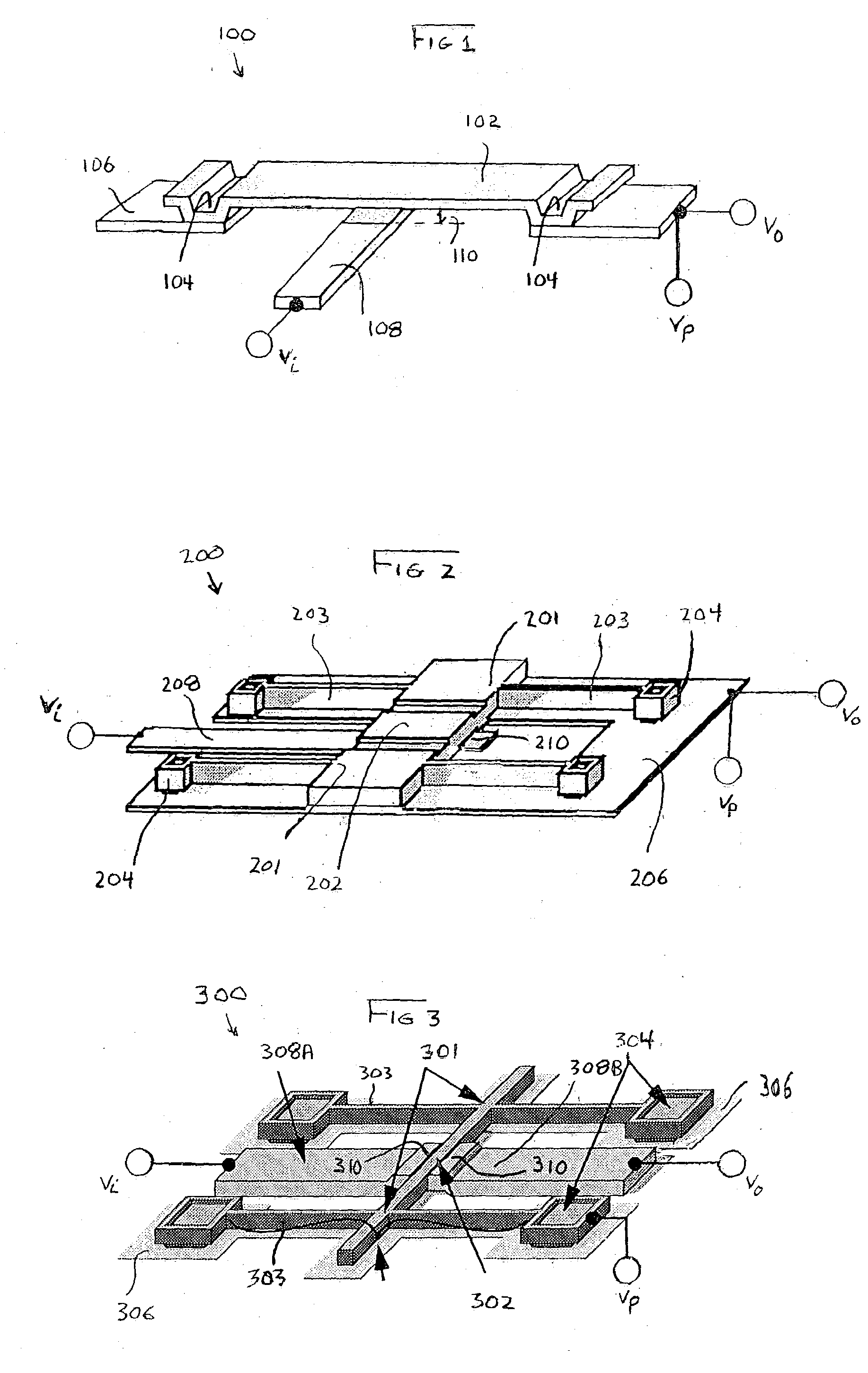

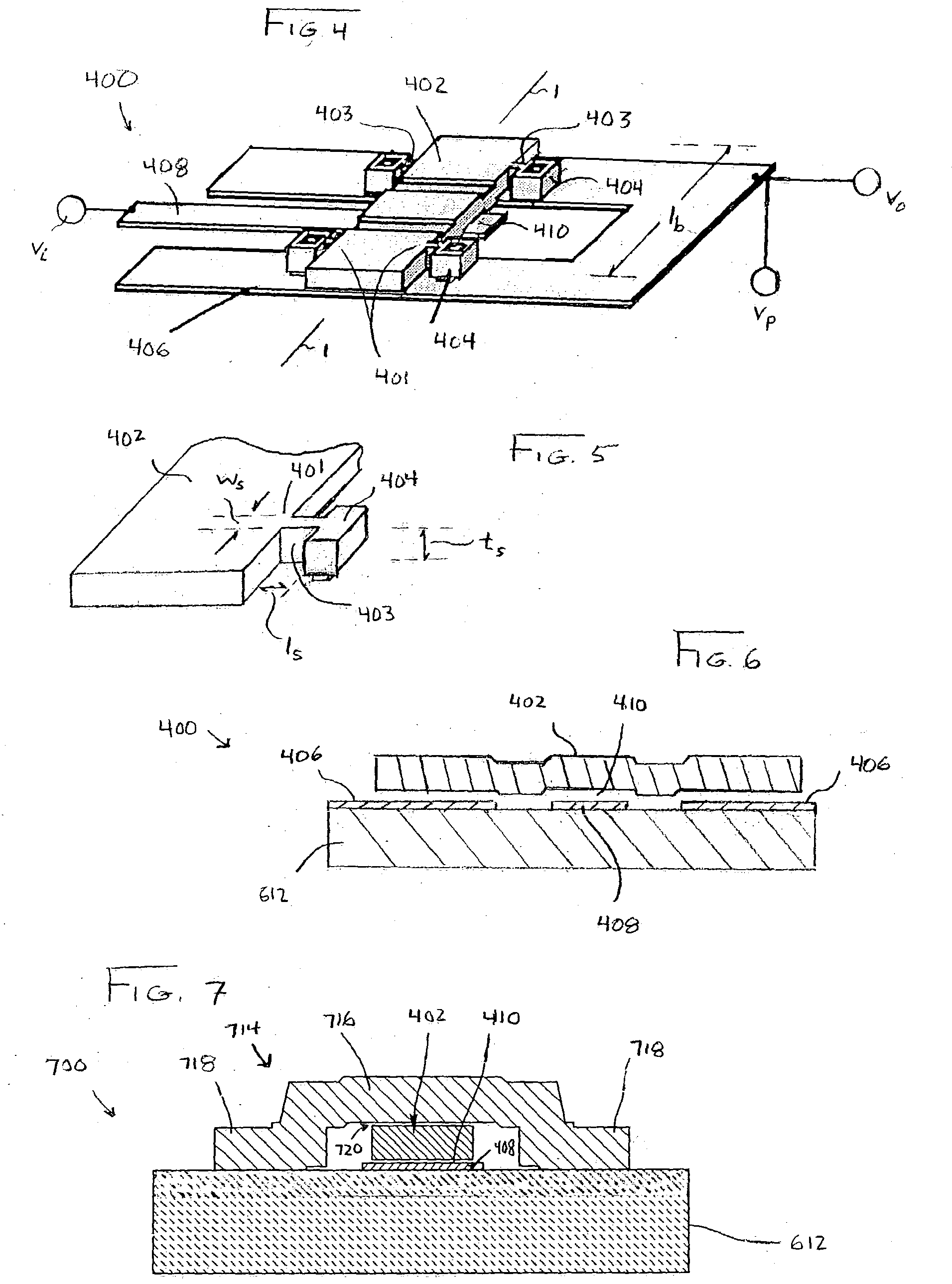

Apparatus comprising a micromechanical resonator

ActiveUS20050024165A1Decrease in electrical stiffnessIncrease temperaturePiezoelectric/electrostriction/magnetostriction machinesImpedence networksLight beamLength wave

The illustrative embodiment of the present invention is a vertical-mode, free-free beam resonator, and micromechanical circuits that include one or more such resonators. In accordance with the illustrative embodiment, the resonator comprises a movable beam that overlies a drive electrode. The movable beam is supported by a plurality of supports, the length of which is substantially less than one-quarter of a wavelength of the resonant frequency of the resonator.

Owner:MICREL

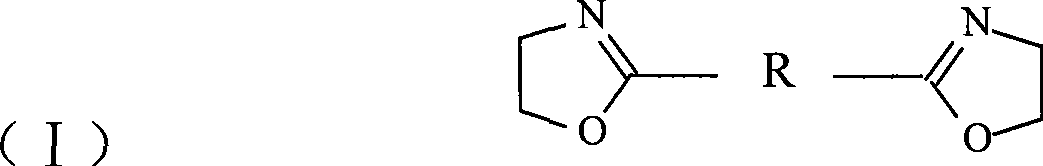

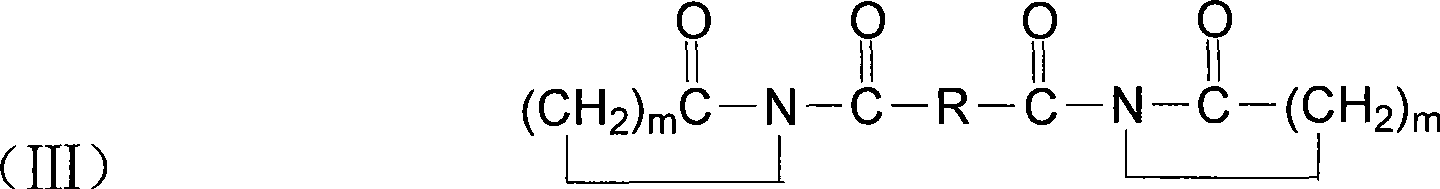

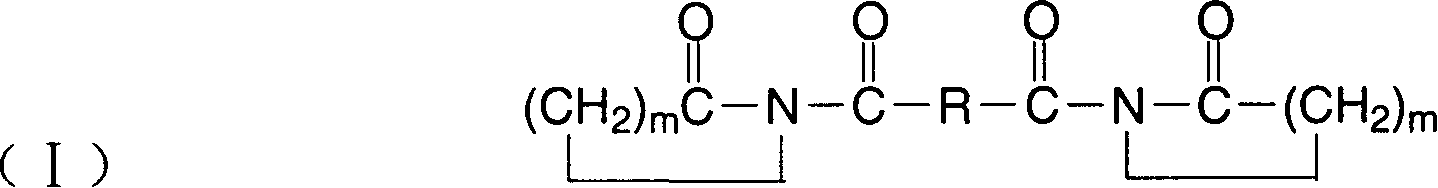

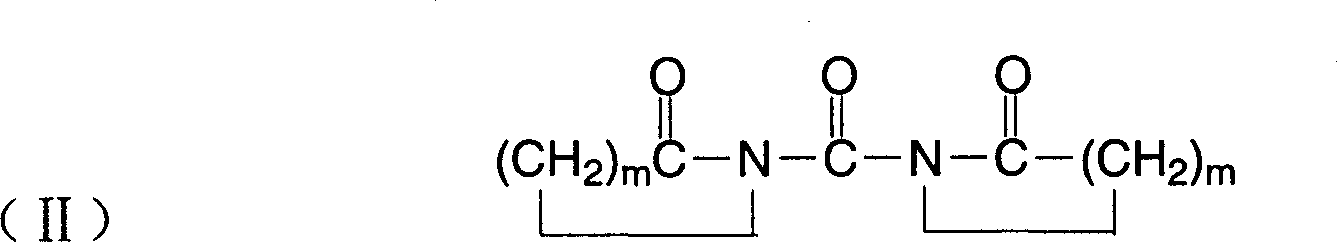

Method for preparing high molecular weight biodegradable polyester by combined chain extension

The invention relates to a method for preparing biodegradable polyester. Firstly, melt polycondensation is conducted through diol and dicarboxylic acid and a low molecular weight polyester prepolymer with number average molecular weight between 2, 000 and 20, 000 or intrinsic viscosity below 0.64dL / g is prepared; binary oxadiazoline and diacyl bis-caprolactamate are combined to extend chain, and chain extension is carried out at a certain temperature; and the biodegradable polyester is obtained. The number average molecular weight of polybutylene adipate (PBA) can reach up to 39, 000 and the intrinsic viscosity to 1.13dL / g. For poly (butylene succinate) (PBS) with relatively high melting point, the intrinsic viscosity after chain extension is up to 0.99dL / g.

Owner:BEIJING UNIV OF CHEM TECH

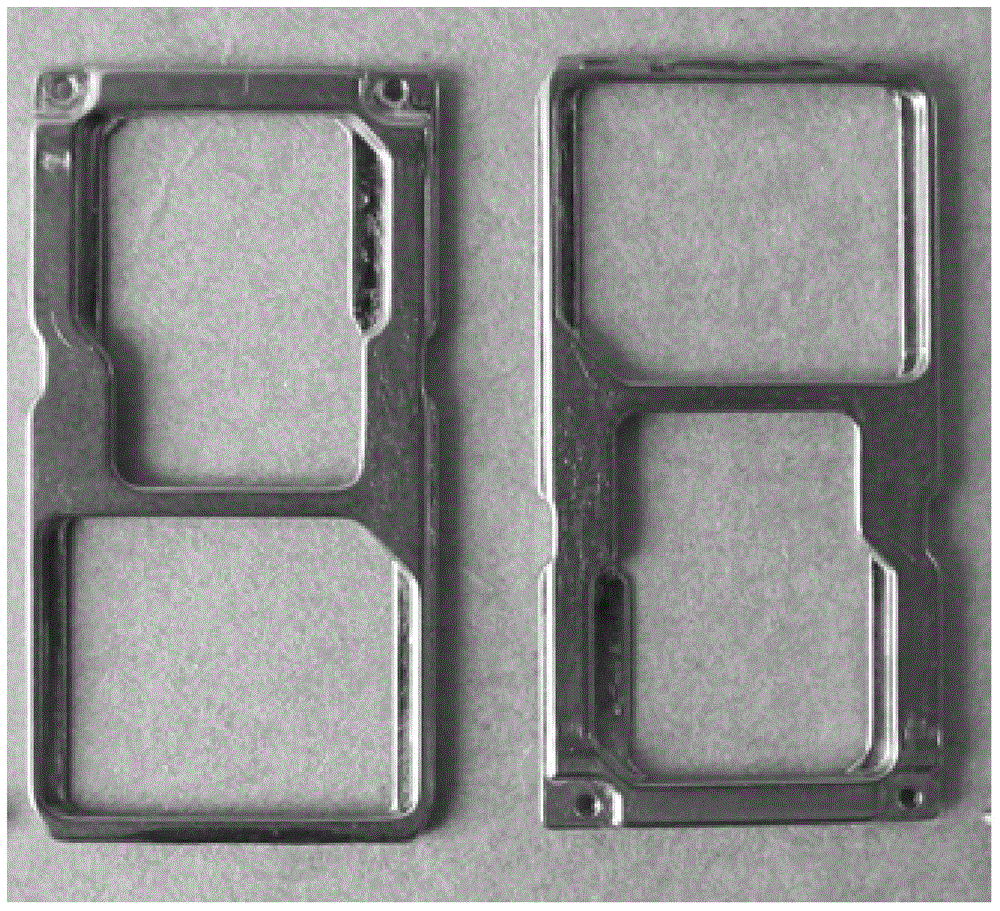

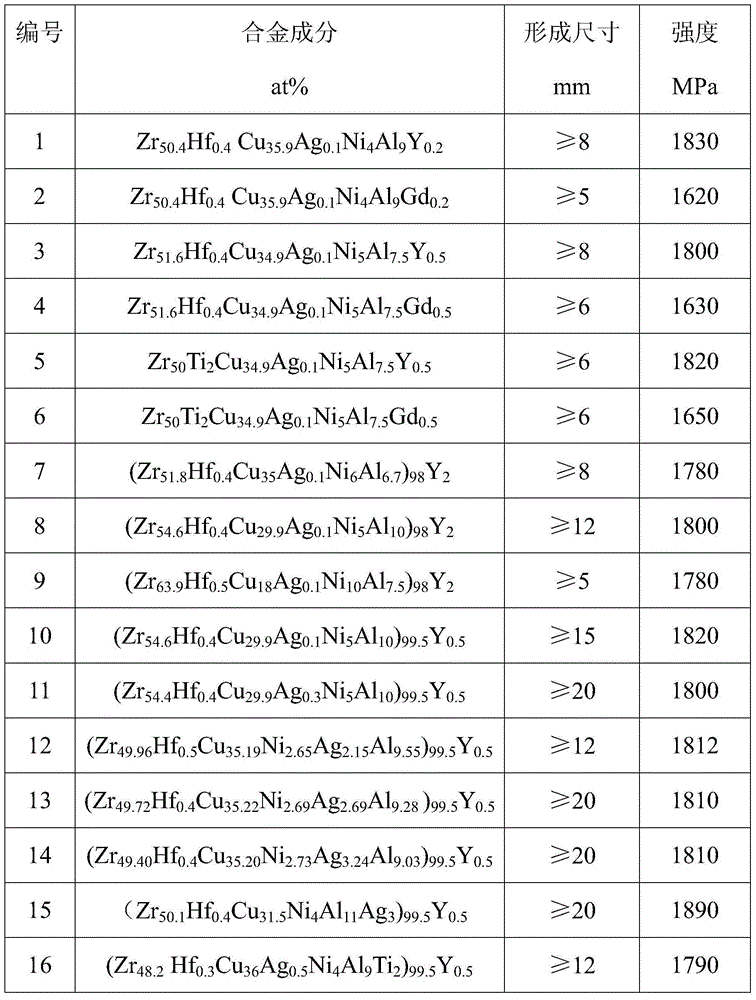

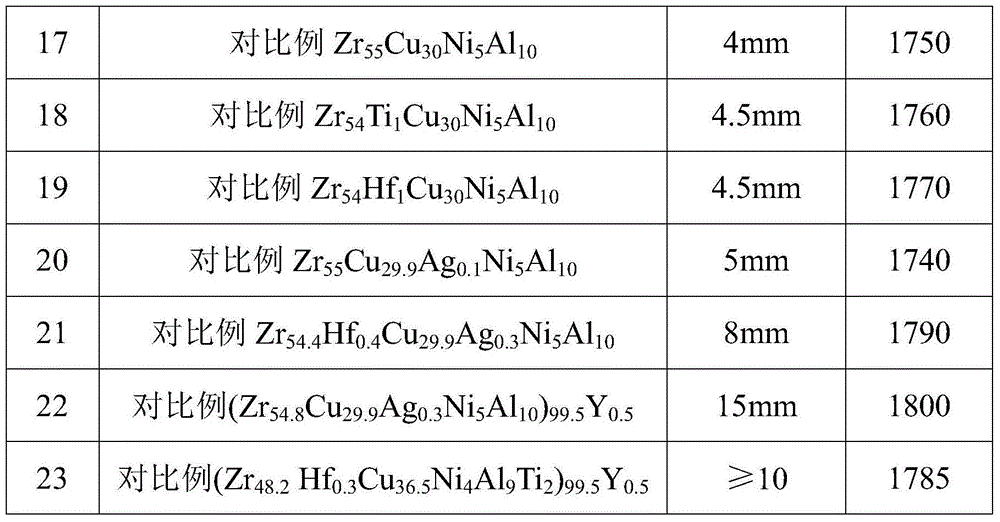

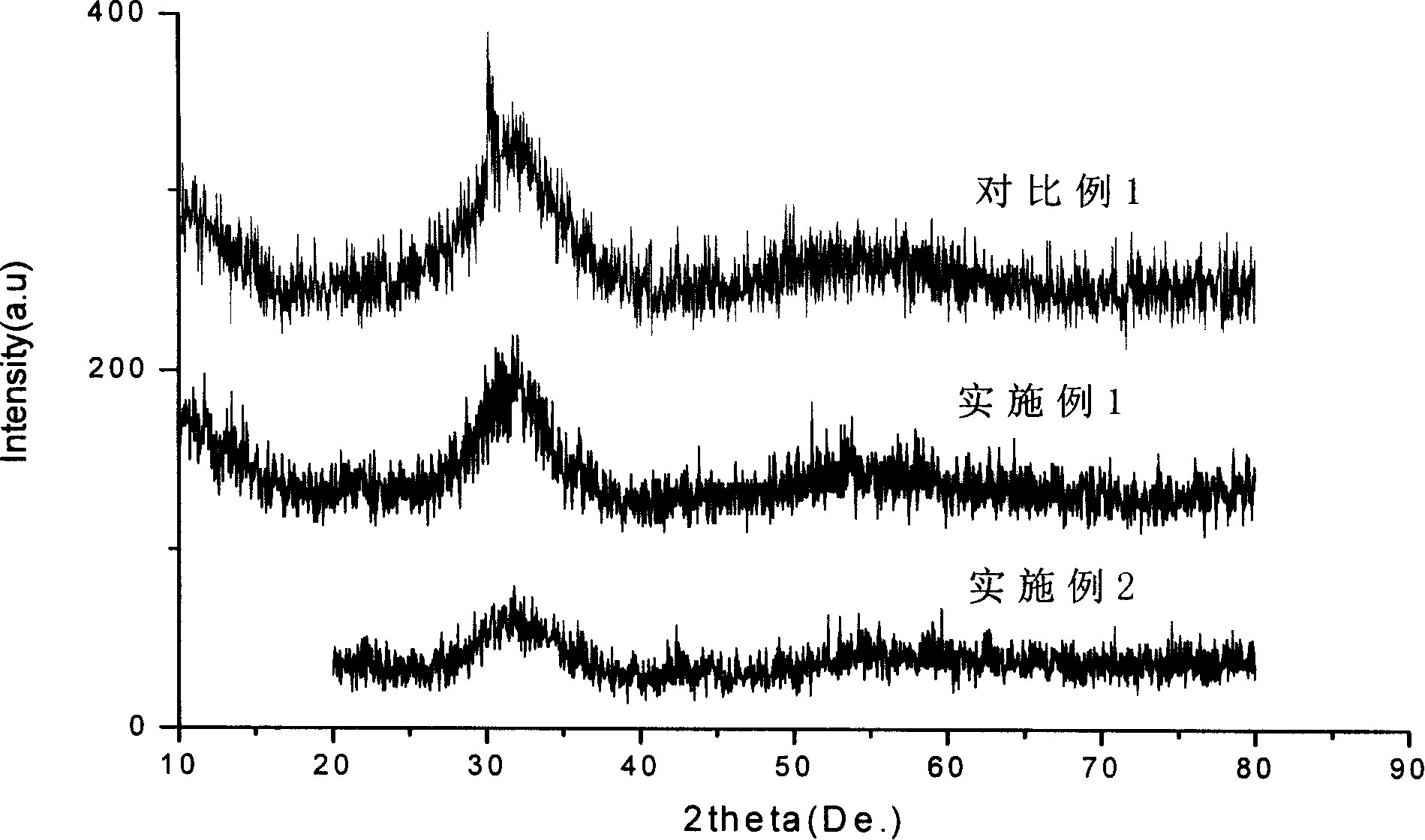

(ZrM)-(CuN)-Ni-Al-(Re) amorphous alloy, and preparation method and application thereof

ActiveCN104651756AImprove the ability to formImprove manufacturabilityRare-earth elementMechanical property

The invention discloses a (ZrM)-(CuN)-Ni-Al-(Re) amorphous alloy which comprises the following components in percentage by atom: 40-65% of Zr, 18-46% of Cu, 2-15% of Ni, 4-15% of Al, 0.1-3% of M(Hf, Ti or Hf+Ti), 0.05-3% of N (Ag) and 0.1-2% of rare-earth element RE (Y, Gd, Sc, Er or composition thereof). By adding small amounts of M, N and RE elements on the basis of the Zr-Al-Ni-Cu amorphous alloy, the alloy has the advantages of higher amorphous formation capacity, excellent manufacturability and favorable mold resistance, maintains the excellent mechanical properties of the Zr-Al-Ni-Cu amorphous alloy, and is an ideal material for preparing complex thin-wall parts in the fields of consumer electronics, medical care, automobiles and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for lifting crystal growth by induction heating in reducing atmosphere

A method for lifting crystal growth by induction heating in reducing atmosphere is characterized by placing a tungsten crucible or a molybdenum crucible on a hard graphite felt; wrapping a plurality of layers of soft graphite felt around the hard graphite felt and the crucible; sleeving the wrapped hard graphite felt and the crucible in a quartz cylinder; wholly putting the quartz cylinder in an induction coil inside a crystal-lifting furnace, especially on a tray at the bottom of hearth; charging materials to the crucible; arranging and covering a hard graphite felt insulation cover or a zirconia insulation cover above the crucible; closing the door of the furnace and carrying out vacuumization; injecting shielding gas till positive pressure is reached; carrying out crystal growth by using a conventional method; and carrying out anneal in the atmosphere of air, oxygen or other atmosphere after the crystal growth is finished. The method has the advantages of utilizing the graphite felt to provide the reducing atmosphere so as to be capable of adopting the low-cost tungsten crucible or molybdenum crucible and realize the growth of sapphire and lithium aluminate and other crystals with low cost, thus having better universality, requiring simple equipments and especially being suitable for production of large scale.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

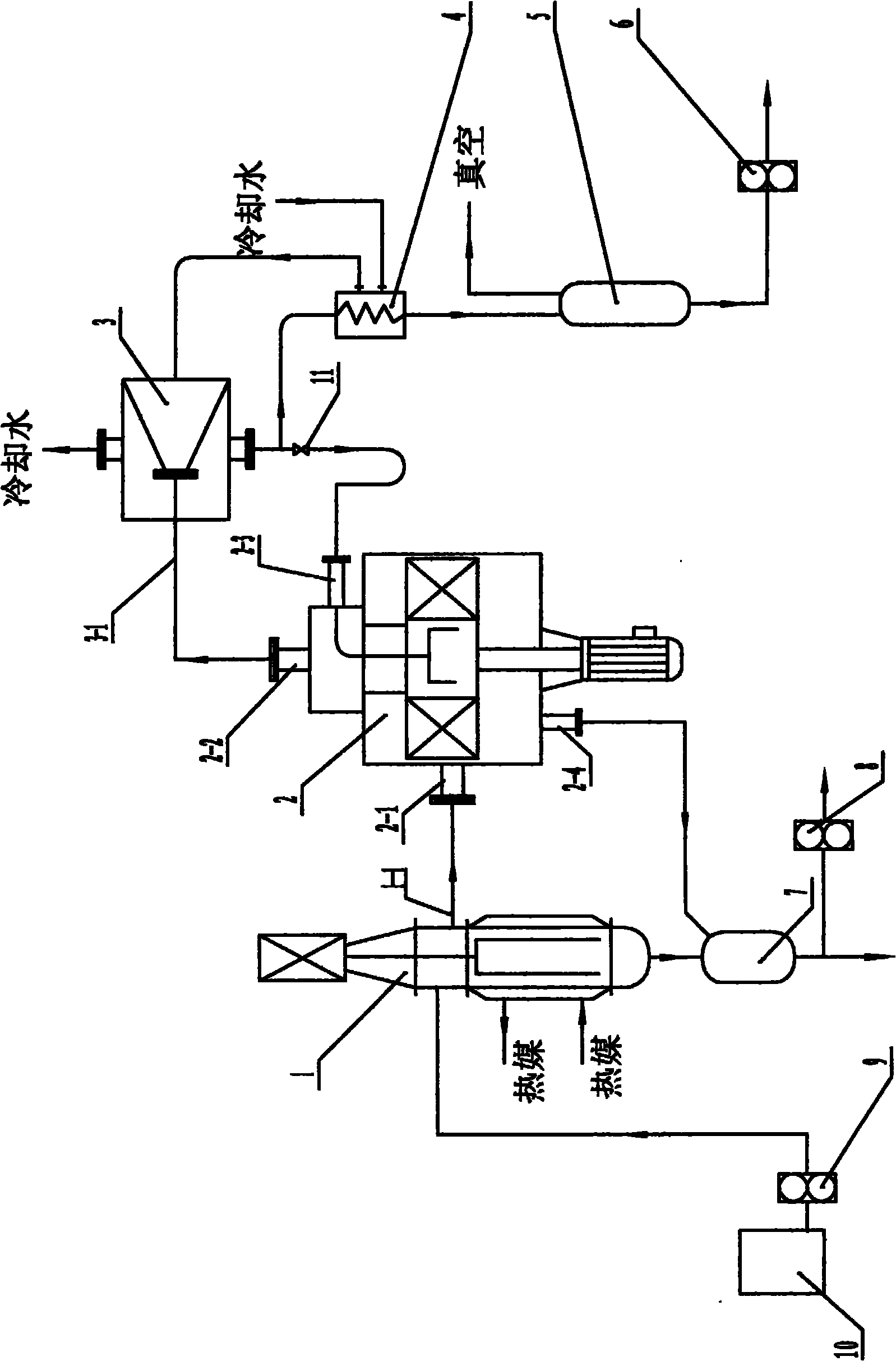

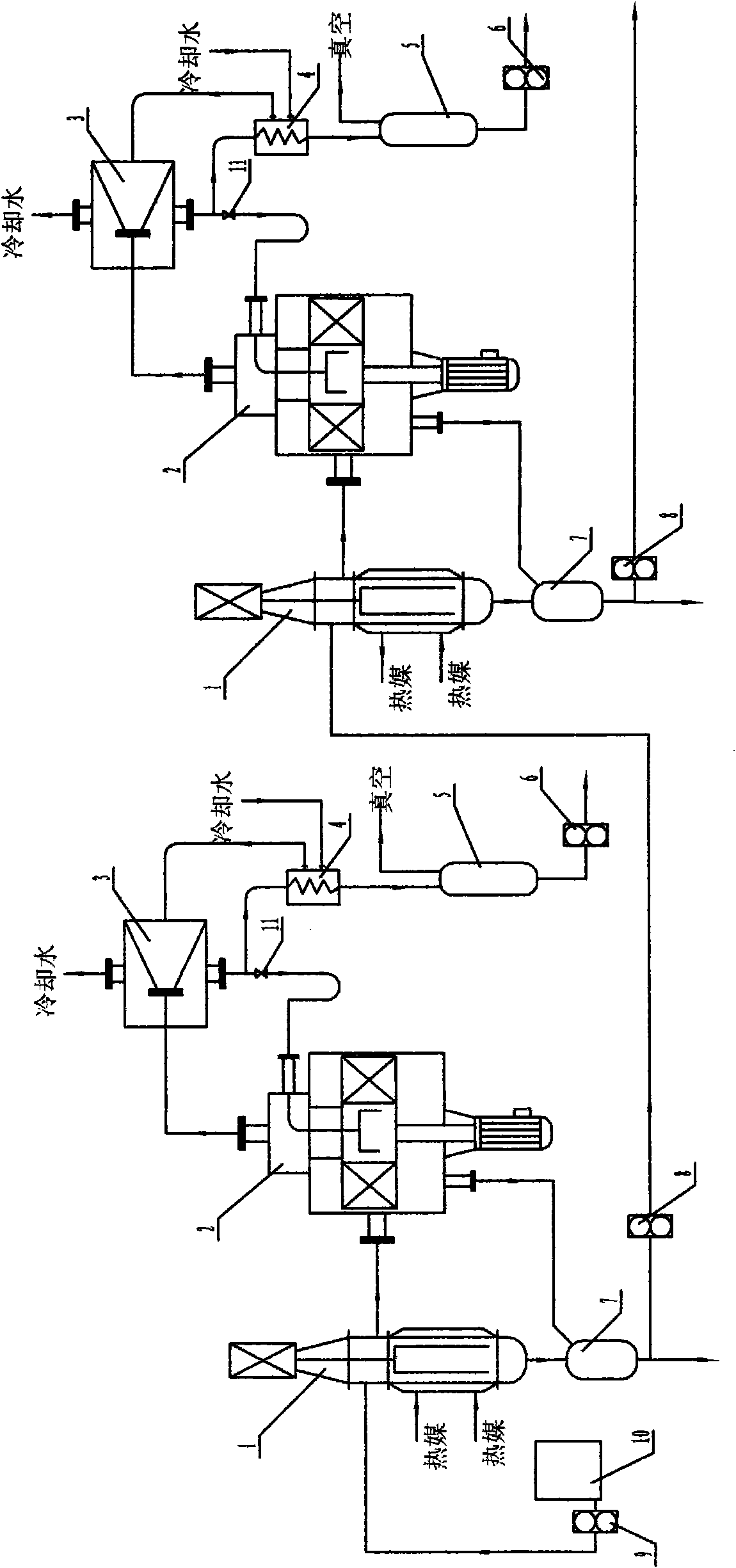

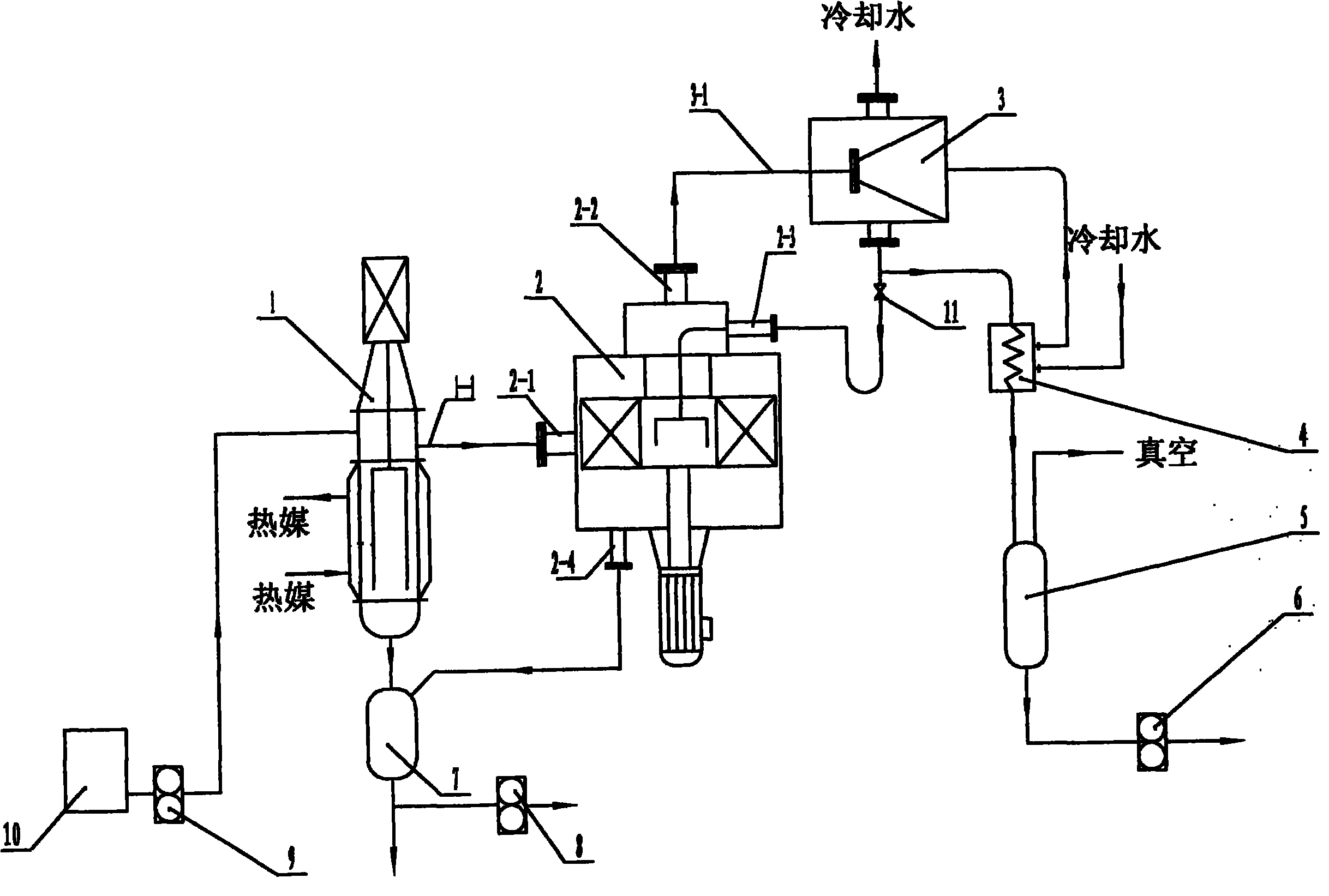

Method for separating and recovering product oil from waste lubricating oil and device thereof

ActiveCN101831348AImprove heating efficiencyShort heating timeLubricant compositionEvaporationEngineering

The invention relates to a method for separating and recovering product oil from waste lubricating oil and a device thereof, which relates to chemical production methods and devices. The method adopts the process that after preliminary treatment of dewatering, degassing and mechanical purity removal, multi-time intermittent rectification or multistage continuous rectification is carried out on the waste lubricating oil by thin-film evaporation and hypergravity revolving field. The device is a 1-4 time intermittent rectifying device or a 1-4 stage multistage continuous rectifying device comprising a raw material tank, a material pump and one to four thin-film evaporators, hypergravity revolving beds, condensers, coolers, finished product tanks, discharging pumps, heavy constituent receiving tanks, material pumps and reflux regulating valves. The method has high rectification speed, good product quality and high recovery rate, and meets the requirements of environmental protection; compared with short path distillation technology, the invention has smaller device volume and higher rectification efficiency and can further refine materials; the device for treating the materials with the same scale has lower requirements for field, less investment and relatively lower vacuum degree requirement.

Owner:HANDWAY TECH FOSHAN

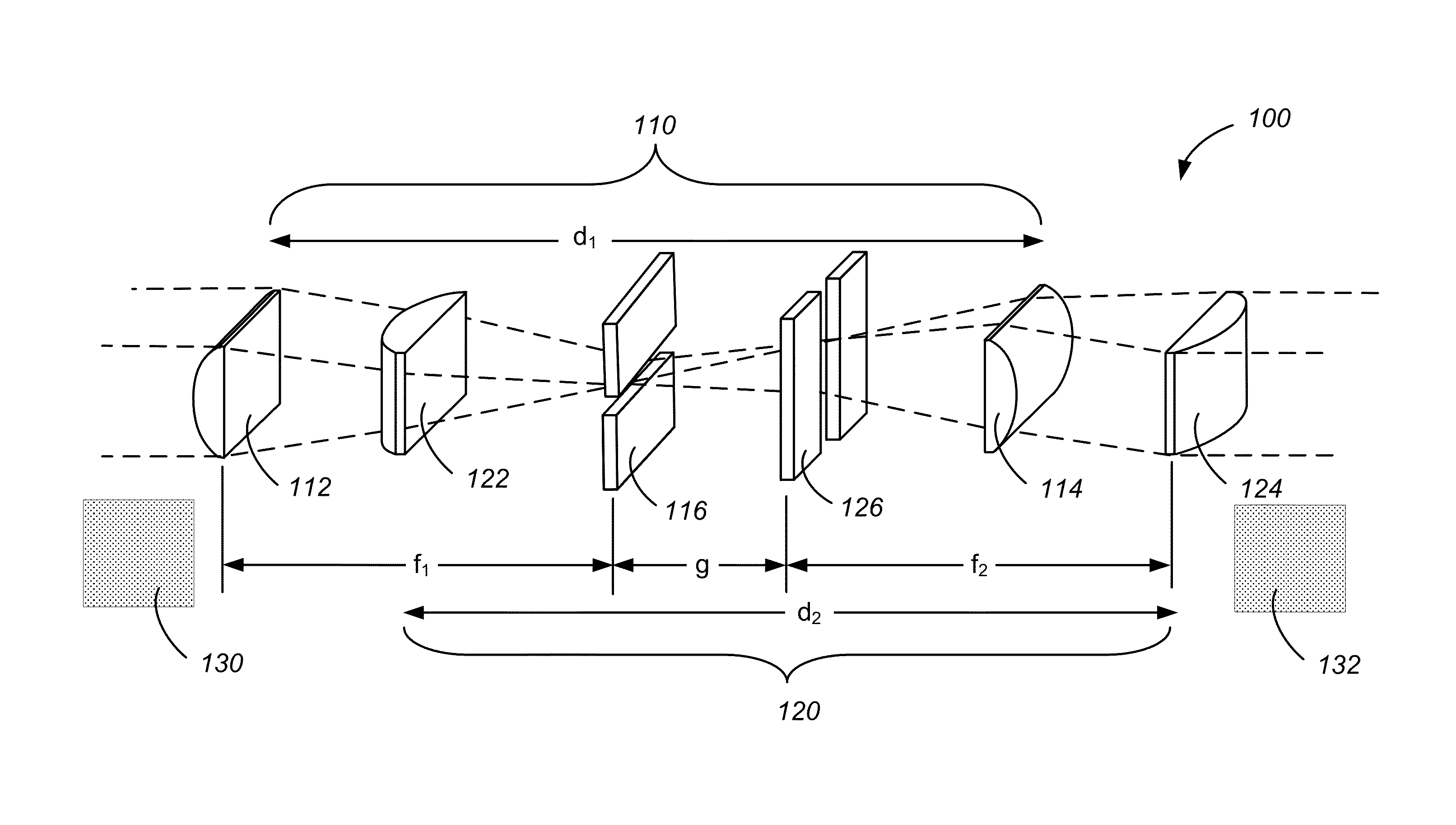

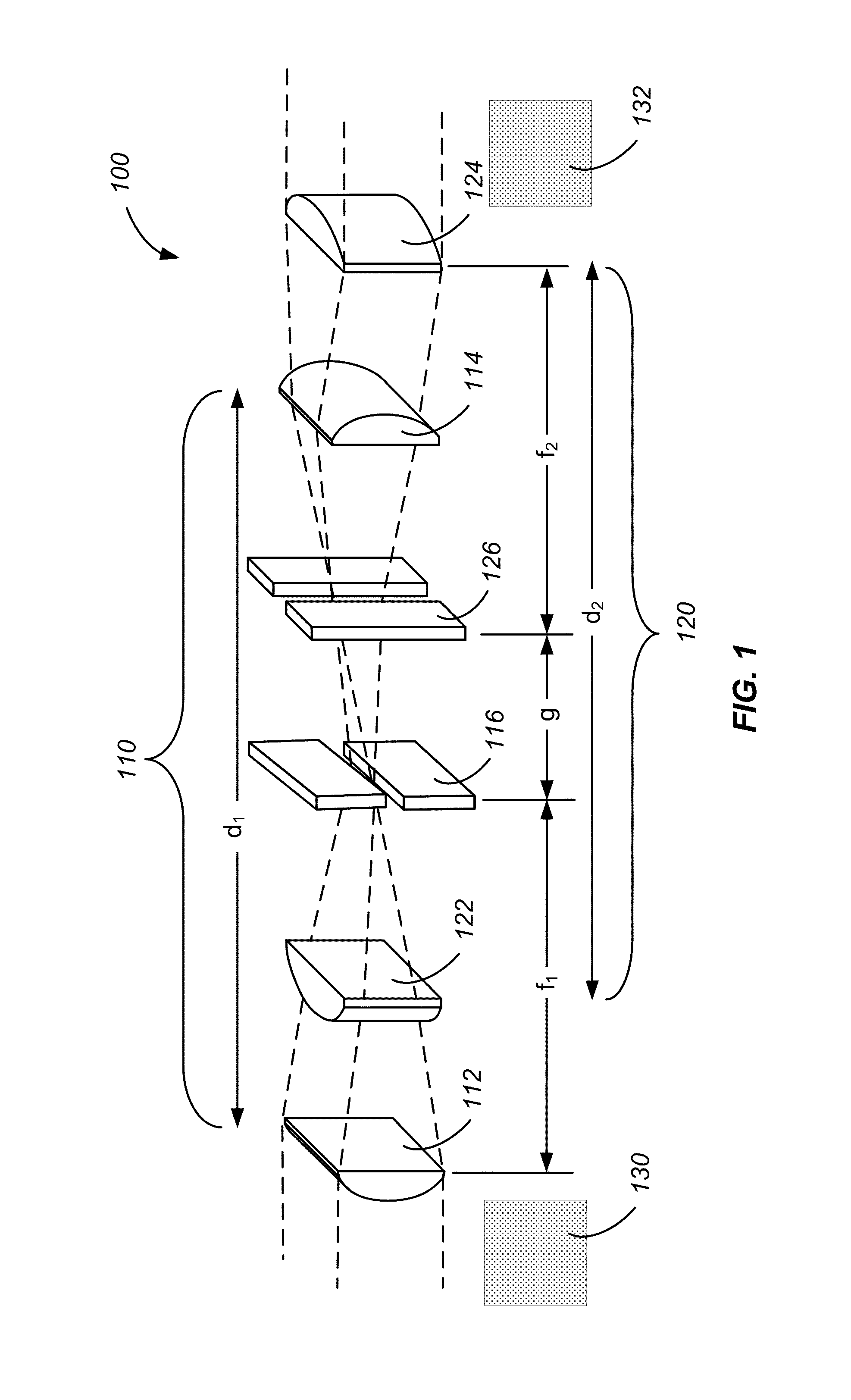

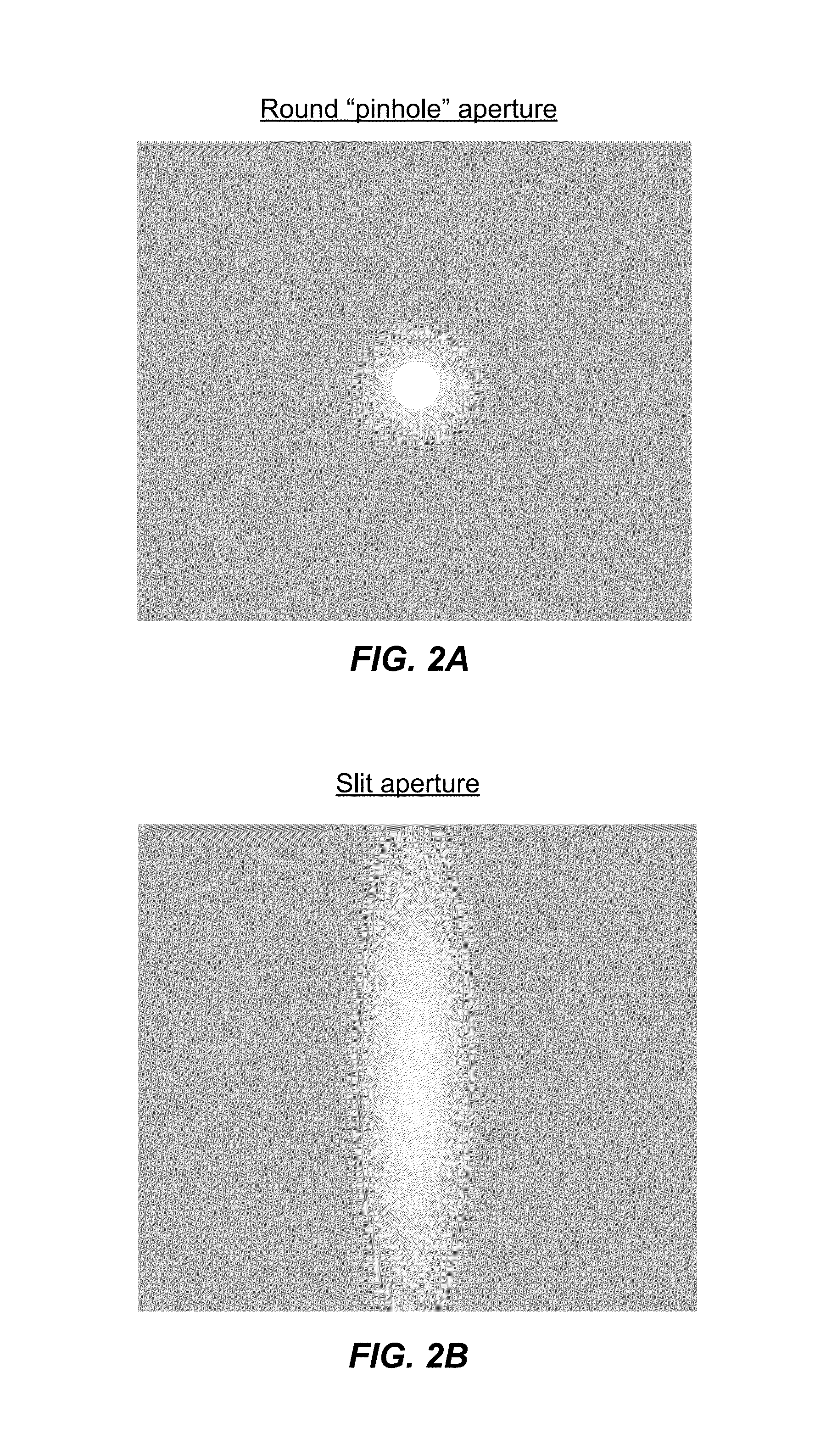

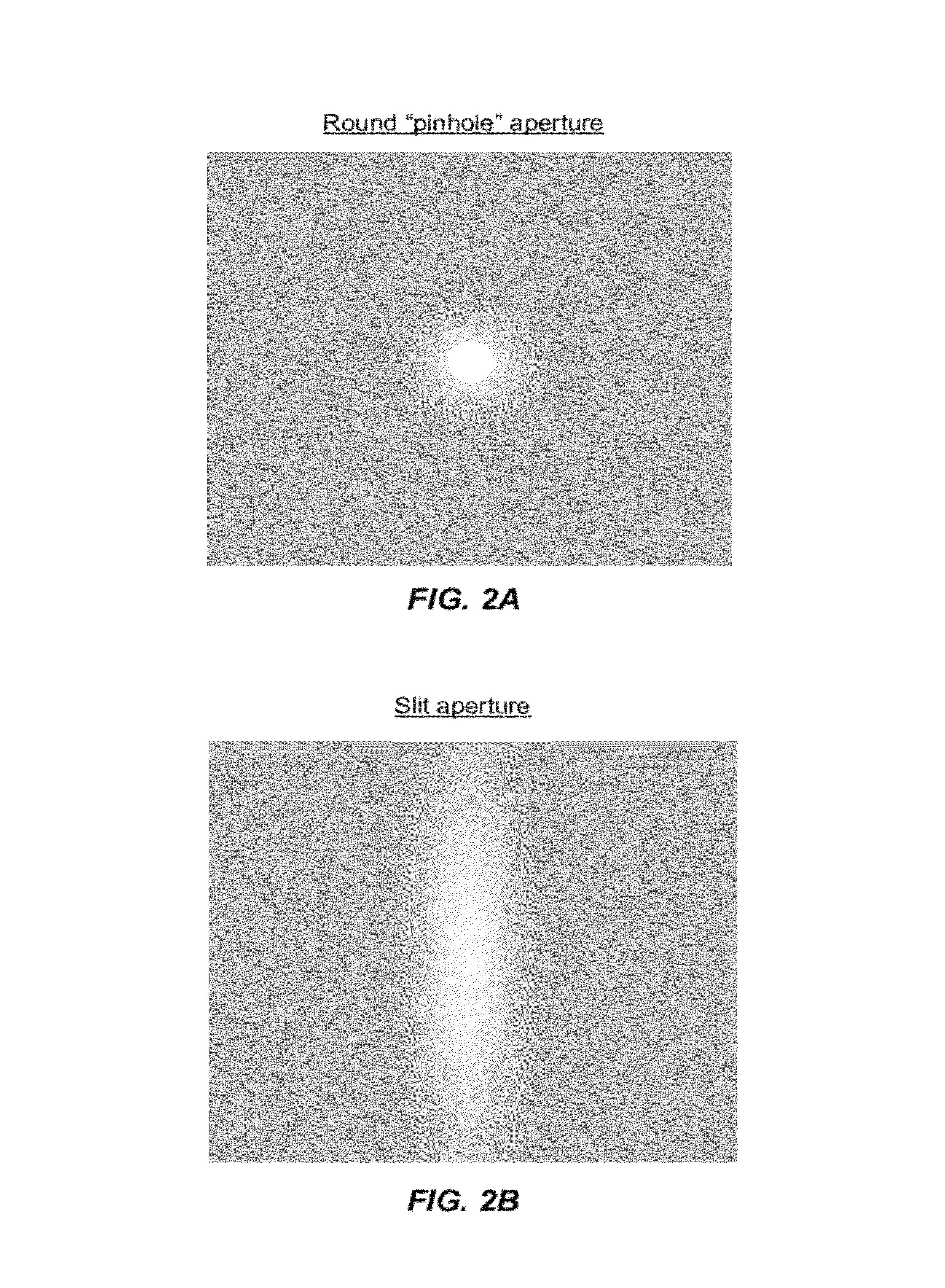

Spatial filters for high power lasers

ActiveUS8902497B2Reduced vacuum requirementsHigh repetition rateFibre transmissionActive medium shape and constructionHigh power lasersCylindrical lens

A spatial filter includes a first filter element and a second filter element overlapping with the first filter element. The first filter element includes a first pair of cylindrical lenses separated by a first distance. Each of the first pair of cylindrical lenses has a first focal length. The first filter element also includes a first longitudinal slit filter positioned between the first pair of cylindrical lenses. The second filter element includes a second pair of cylindrical lenses separated by a second distance. Each of the second pair of cylindrical lenses has a second focal length. The second filter element also includes a second longitudinal slit filter positioned between the second pair of cylindrical lenses.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

High-frequency-induction-heating ultrasonic-vibration-assisting preparing method of single-layer-diamond brazed grinding wheel

ActiveCN105414800AReduce manufacturing costReduce heat damageBonded abrasive wheelsWelding/cutting media/materialsUltrasonic assistedCarbide

The invention provides a high-frequency-induction-heating ultrasonic-vibration-assisting preparing method of a single-layer-diamond brazed grinding wheel. The preparing method includes the following steps that firstly, a grinding wheel base body and brazing filler metal are prepared; secondly, the brazing filler metal and diamond grinding particles are arranged; finally, high-frequency induction heating is assisted by ultrasonic waves to prepare the single-layer-diamond brazed grinding wheel in a brazed mode. Cu powder, Sn powder, Cr powder and Ni powder are mixed to prepare the Cu-based brazing filler metal with Cr as active elements, the proportion of the ingredients of the brazing filler metal is easy to control, and thin carbide layers are formed on the surfaces of the diamond grinding particles after brazing, and chemical metallurgical bonding of diamond and the steel base body is achieved. The preparing method is used for producing the grinding wheel and has the advantages that heat damage to the diamond grinding particles is small, and the preparing cost of the brazing filler metal is low. Due to assisting of the ultrasonic waves, even alloying of the elementary metal powder in the brazing process can be achieved, and the melting point of the brazing filler metal can be lowered.

Owner:SUZHOU UNIV OF SCI & TECH

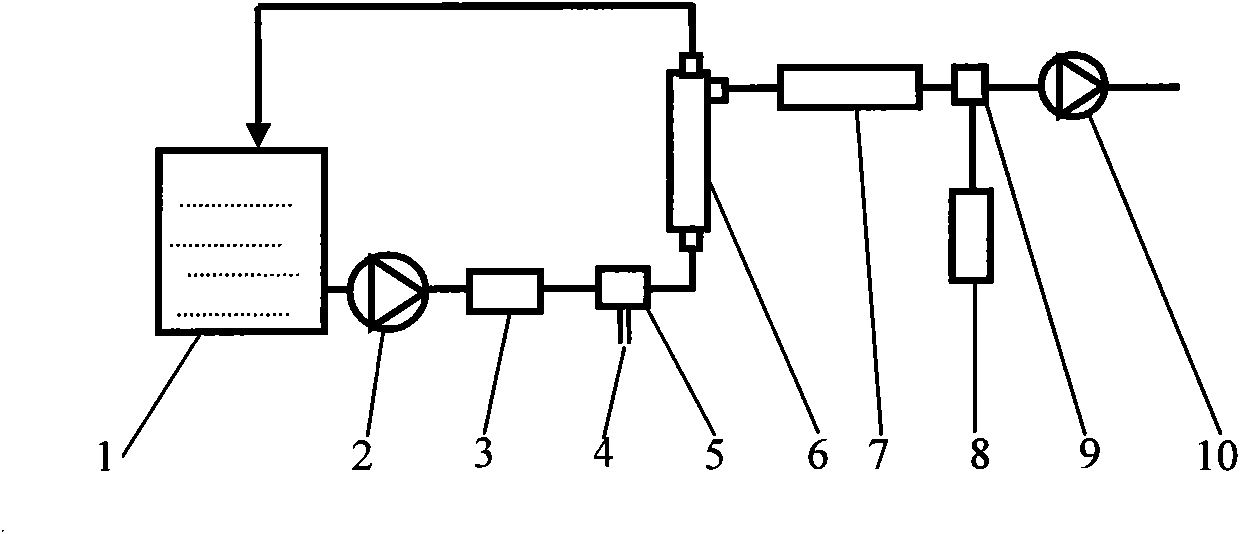

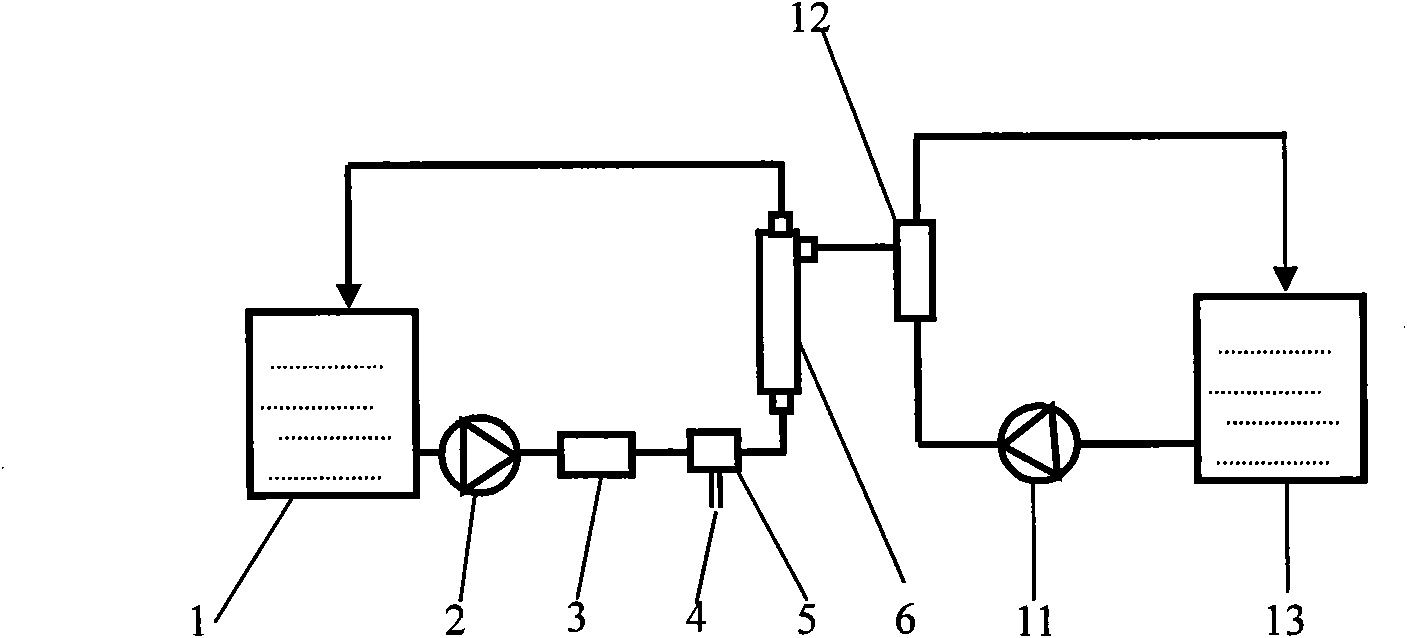

Device and method for air-blowing vacuum membrane distillation

InactiveCN101664642AReduced vacuum requirementsImprove mass transfer efficiencyDistillationForming gasWater vapor

The invention provides a device and a method for air-blowing vacuum membrane distillation. The device for air-blowing vacuum membrane distillation comprises the following sequentially-connected parts:a water tank arranged on the side of raw water; a water pump which is connected with the water tank and is used for pumping the raw water in the water tank; a compressed air inlet which is arranged on the downstream of the water pump and is used for blowing low-pressure compressed air to the raw water; a gas-liquid mixer used for mixing the compressed air and liquid to form gas-liquid mixed fluid; a hydrophobic membrane component used for processing the gas-liquid mixed fluid; and a vacuum generation device arranged on the effluent side of the hydrophobic membrane. In the device and the method, the compressed air is blown into the raw water side of the membrane when vacuum is generated on effluent side of the membrane. Under the suction action of the vacuum, water vapor and part of compressed air passes through the hydrophobic membrane together. As blowing and sweeping actions of the compressed air deliver the water vapor to the other side of the membrane, mass transfer efficiency isimproved. The requirements on the vacuum degree of the effluent side are reduced and equipment cost is reduced. Meanwhile, membrane pollution is effectively relieved.

Owner:TIANJIN POLYTECHNIC UNIV

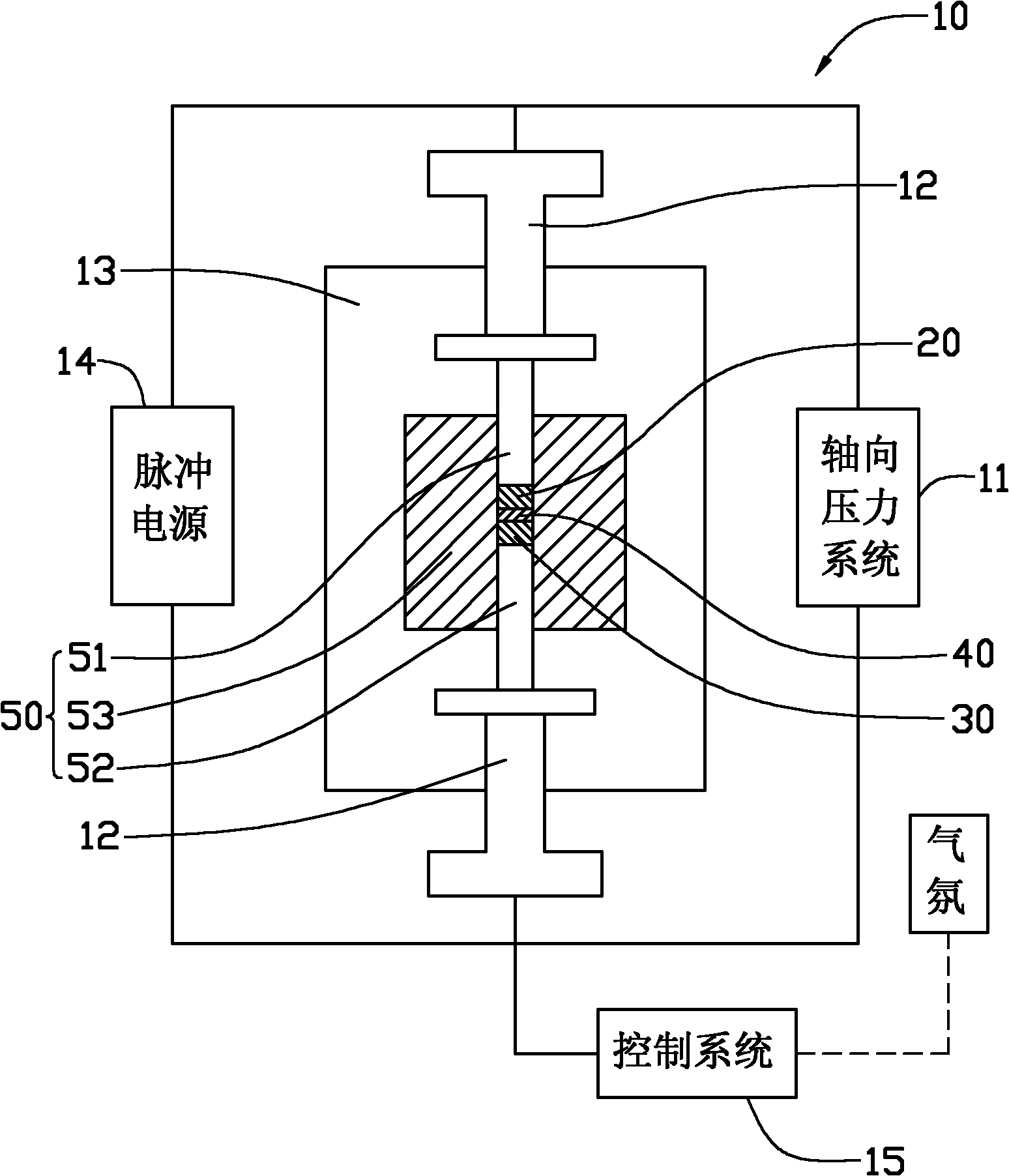

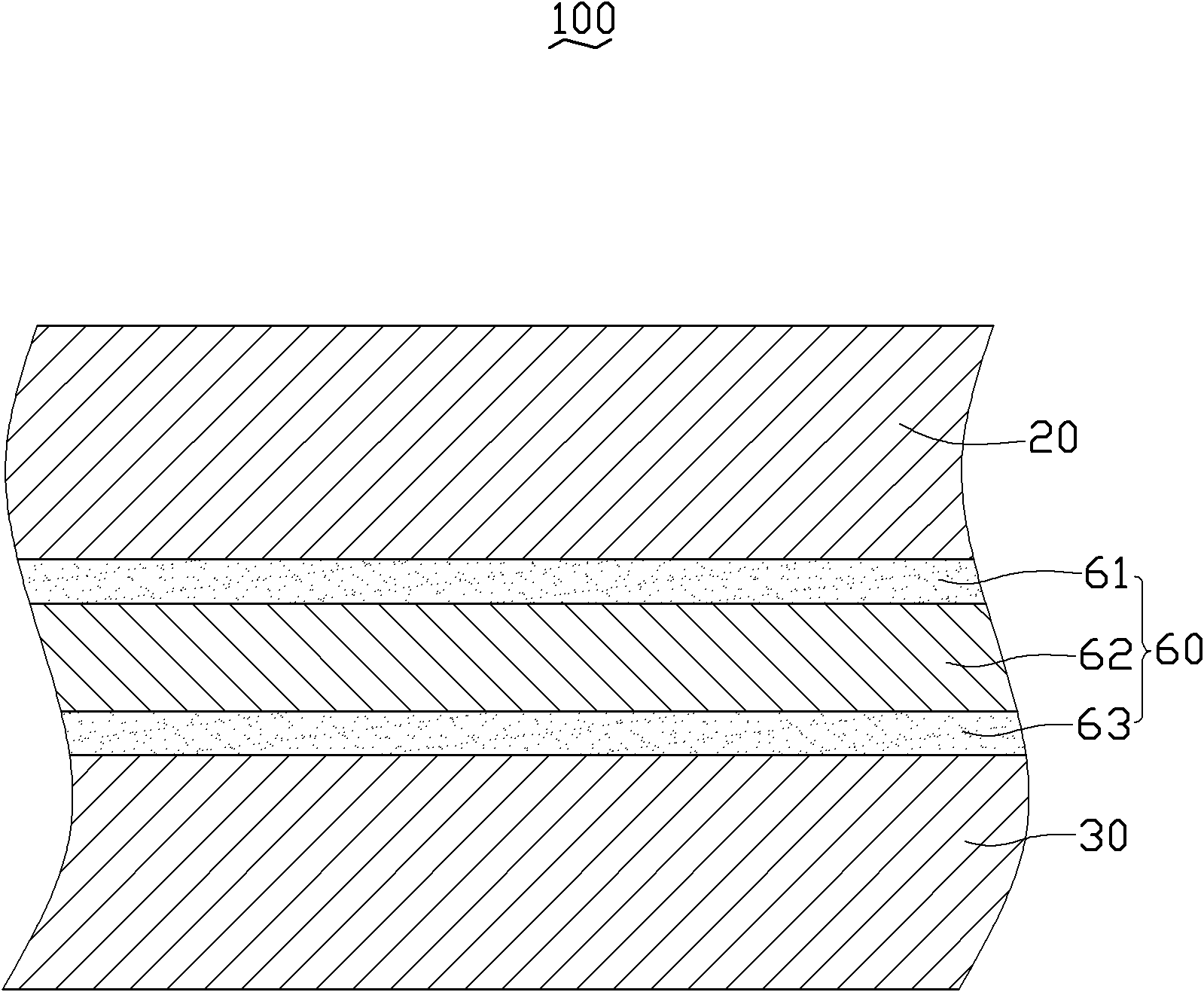

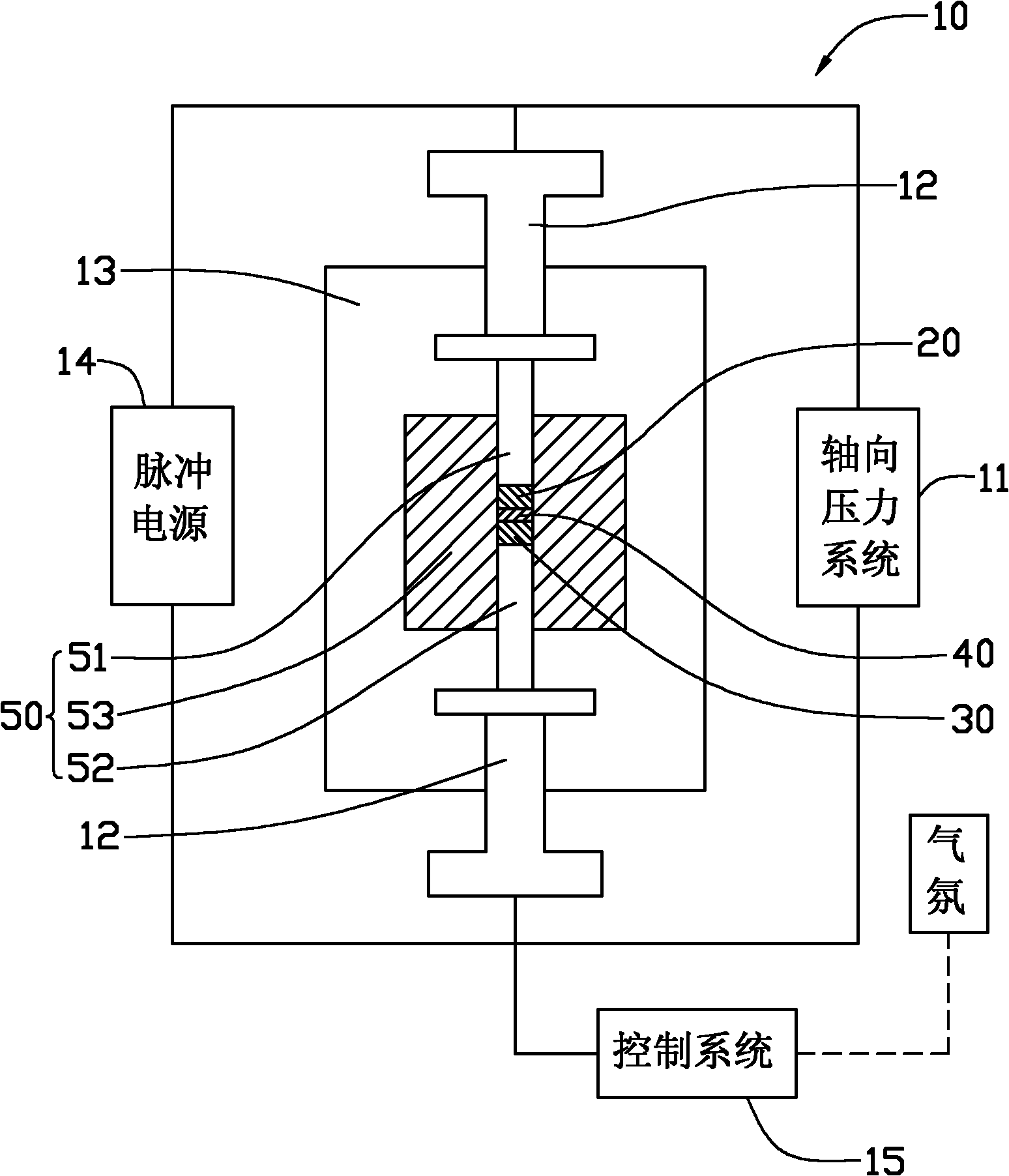

Connection method for carbon steel and zirconium oxide ceramic and connecting piece manufactured thereby

ActiveCN102335792AIncreased shear strengthShort holding timePlasma welding apparatusWelding/soldering/cutting articlesAxial pressureCarbon steel

Owner:深圳市伊比精密科技有限公司

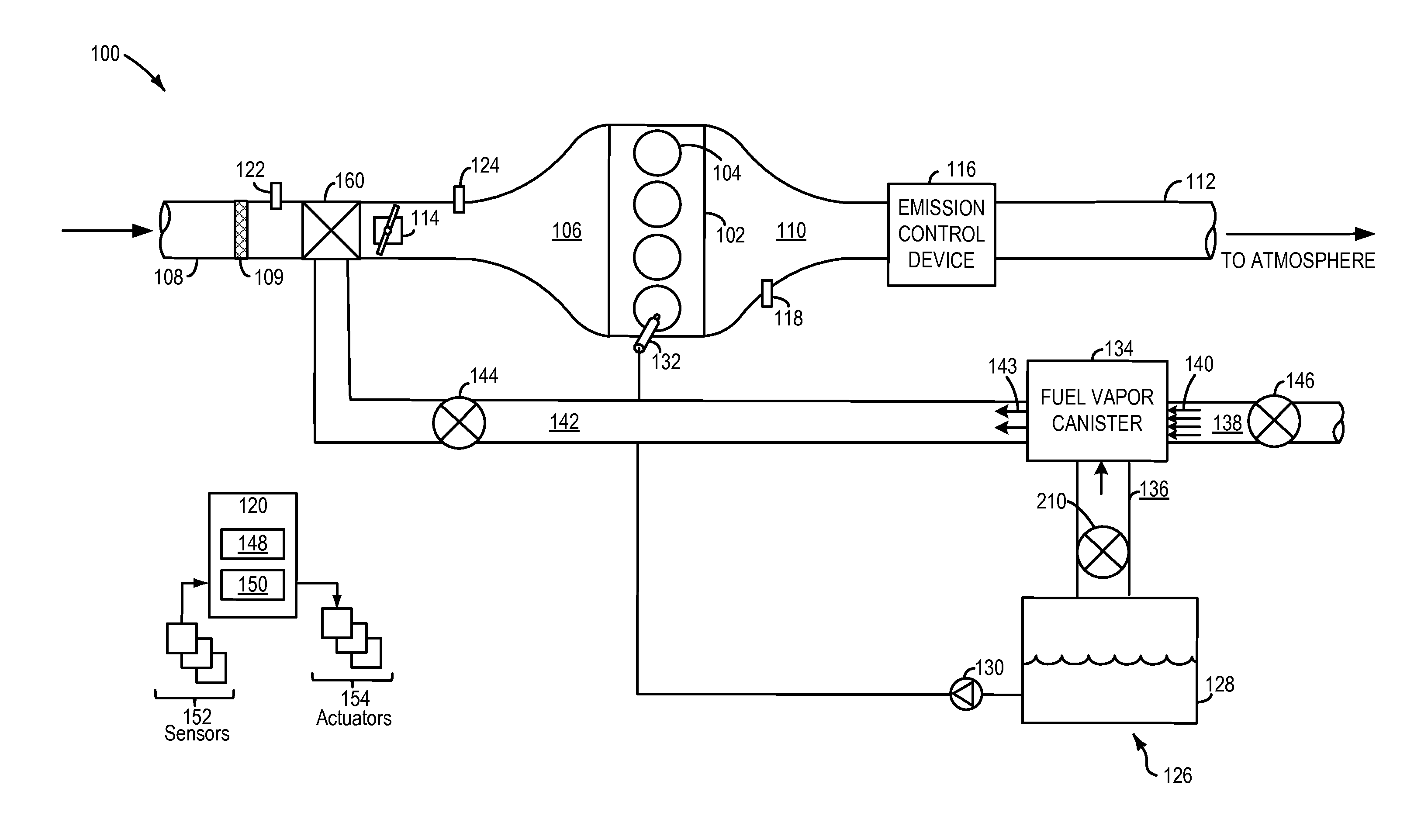

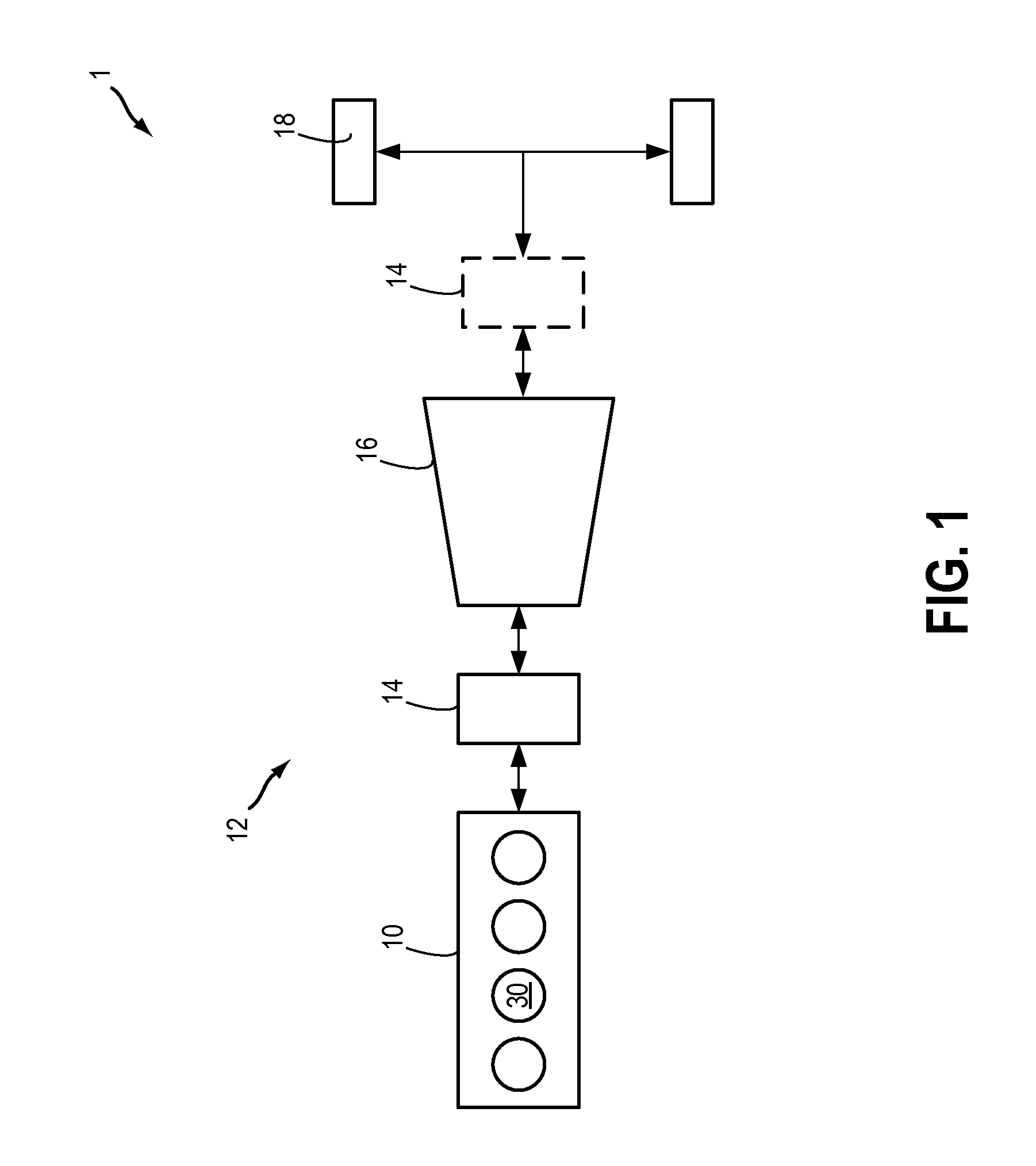

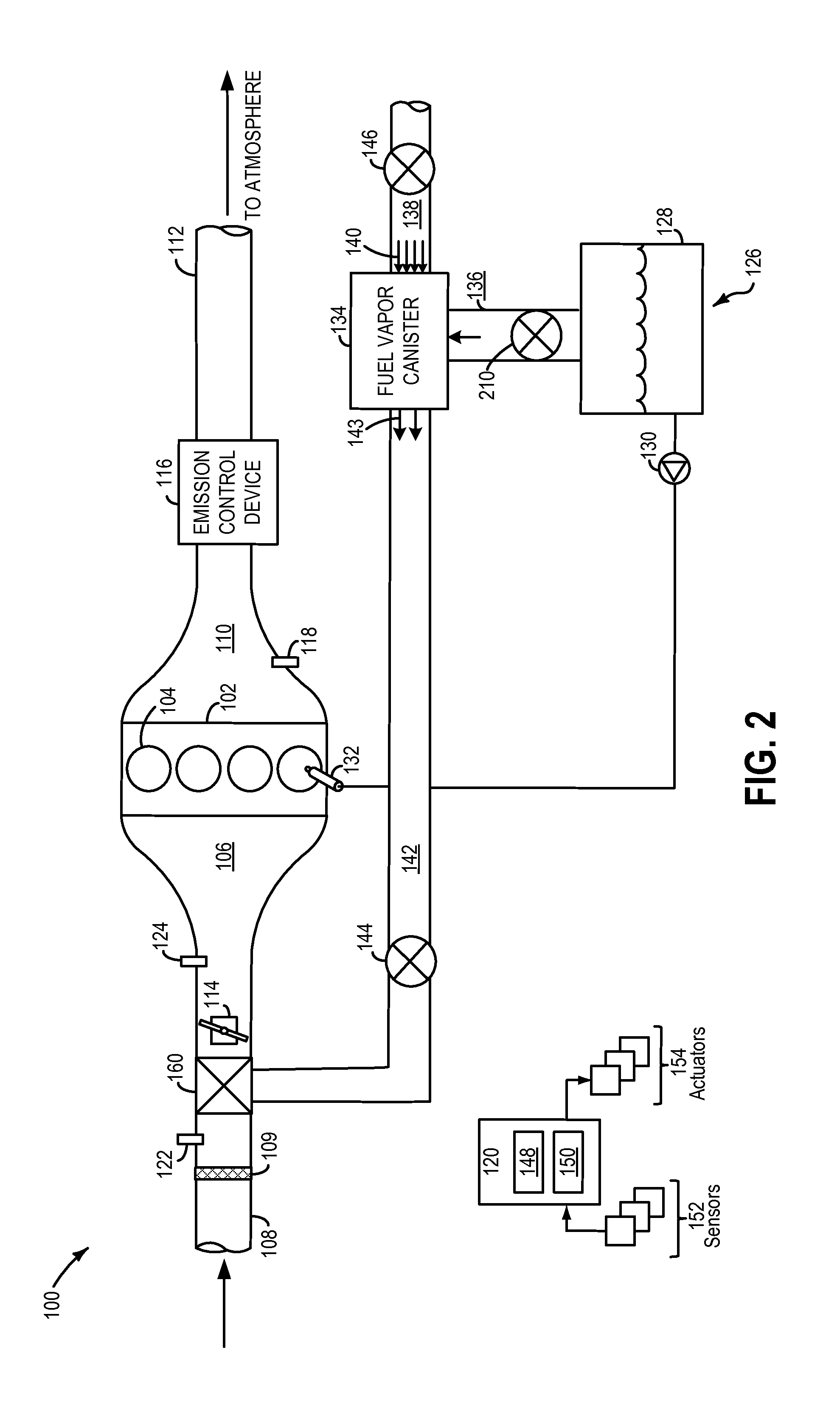

Evaporative emission control

ActiveUS20140123961A1Exhaust emission and emission compliance be improveTime requireElectrical controlNon-fuel substance addition to fuelAerospace engineeringThrottle

Methods and systems are provided for purging a multi-port canister into an engine intake. Air is circulated through the canister and a resulting purge air is directed to an intake passage upstream of a throttle in engine configured with a throttle body. An amount of fresh intake air received at the intake passage is corresponding decreased.

Owner:FORD GLOBAL TECH LLC

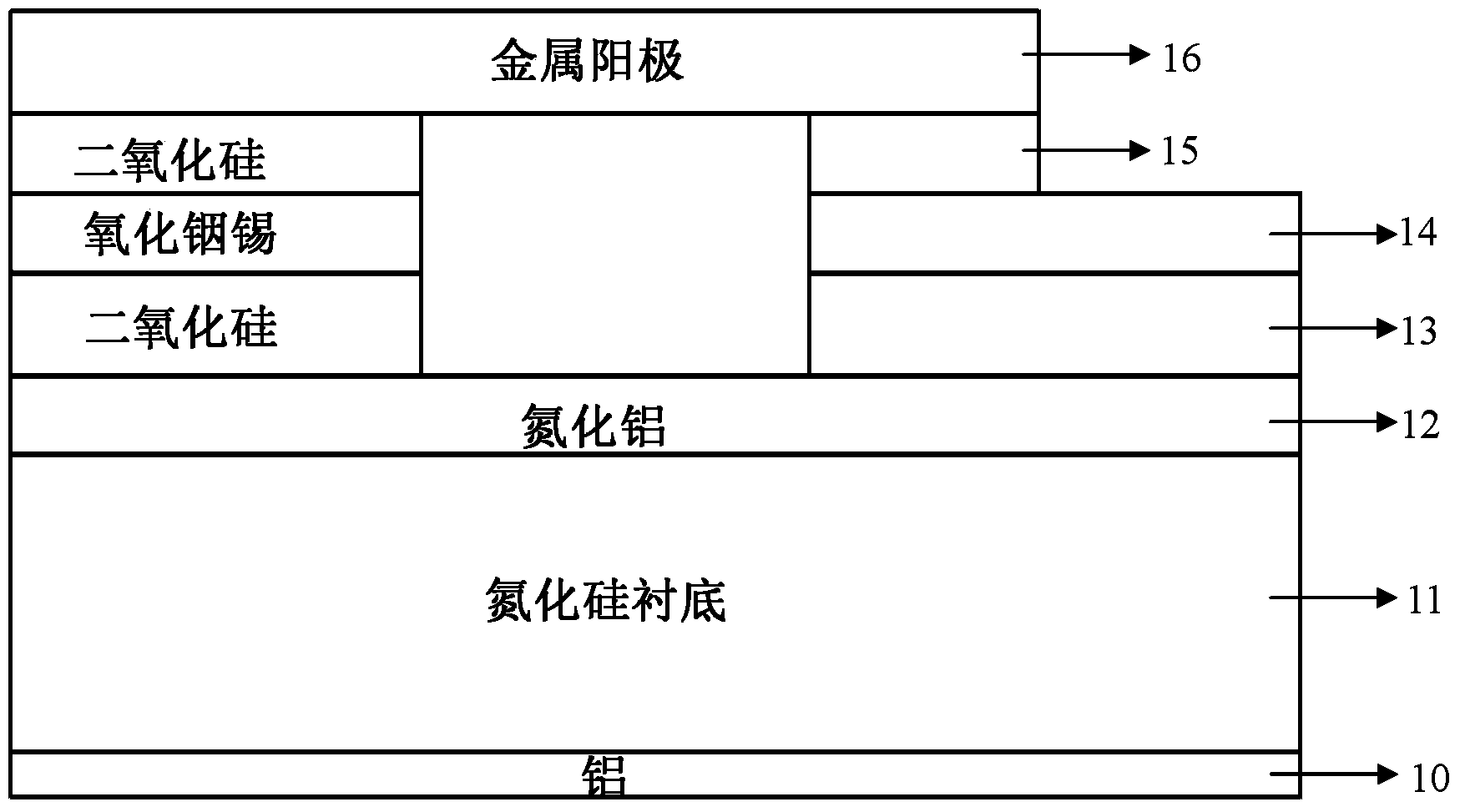

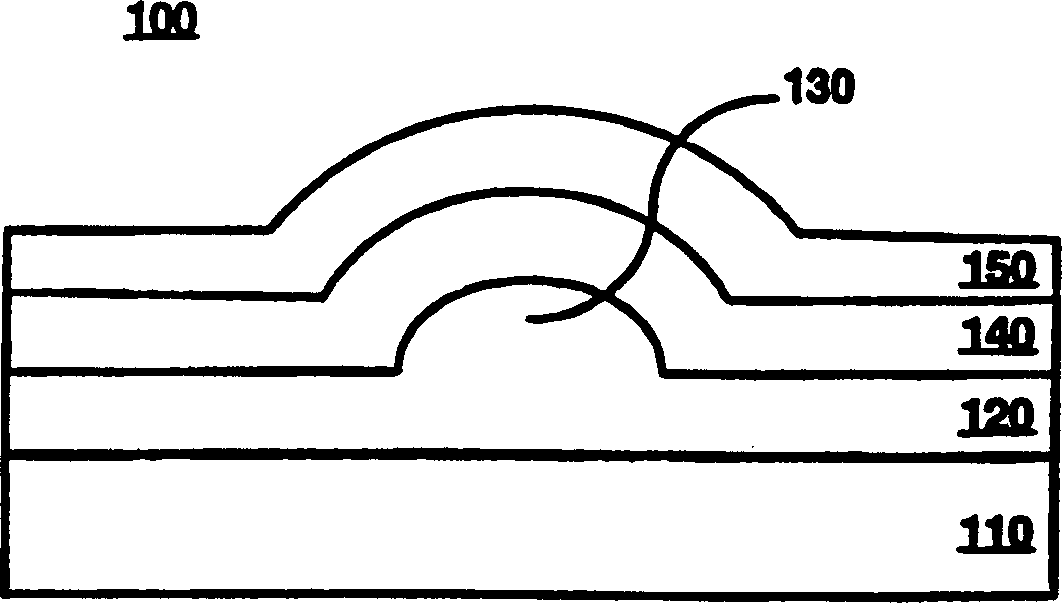

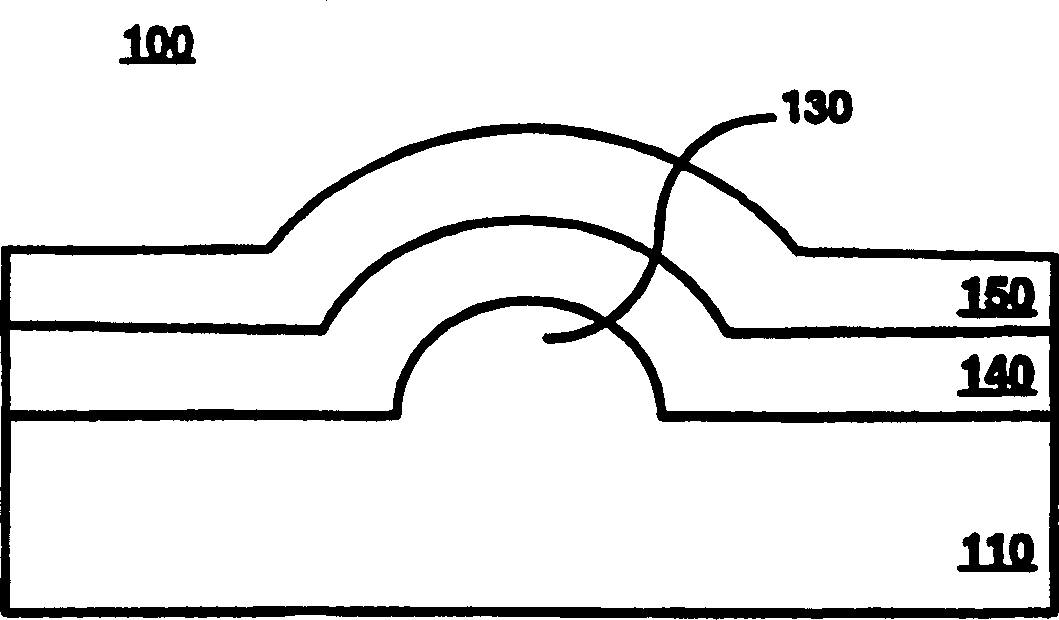

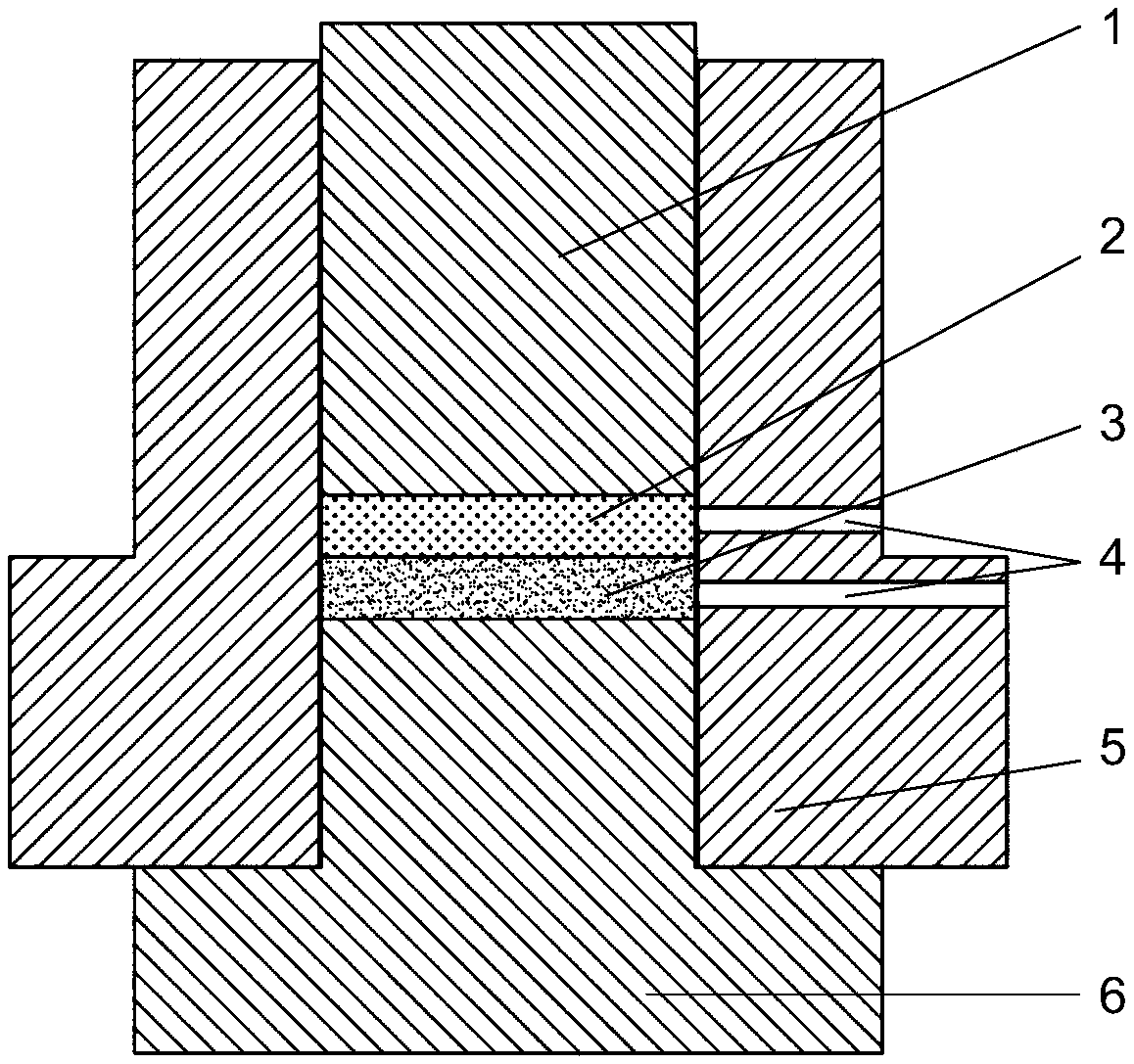

Nano vacuum triode with planar emitting cathode and manufacturing method thereof

ActiveCN104299988AReduced vacuum requirementsTransistorSemiconductor/solid-state device manufacturingInsulation layerIndium tin oxide

The invention provides a nano vacuum triode with a planar emitting cathode and a manufacturing method of the nano vacuum triode with the planar emitting cathode. The method comprises the steps that a substrate, a back electrode, the planar cold cathode, a first insulation layer, a grid layer, a second insulation layer, a small cylindrical hole, a grid layer step and an anode layer are included; the back electrode is manufactured on the back face of the substrate; the planar cold cathode is manufactured on the front face of the substrate; the first insulation layer is manufactured on the planer cold cathode; the grid layer is manufactured on the first insulation layer; the second insulation layer is manufactured on the indium tin oxide thin film grid layer; the small cylindrical hole penetrates through the first insulation layer, the grid layer and the second insulation layer; the grid layer step is formed by etching the second insulation layer to the grid layer; the anode layer is manufactured on the second insulation layer; the total thickness of the first insulation layer, the indium tin oxide thin film grid layer and the second insulation layer ranges from 10 nanometers to 100 manometers. The defect that the electron emitting density of a tip structure is uneven, and a tip is prone to being damaged is overcome, and meanwhile the defect that the planar cathode needs higher threshold electric field intensity is overcome through the negative electron affinity characteristic of aluminum nitride materials.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

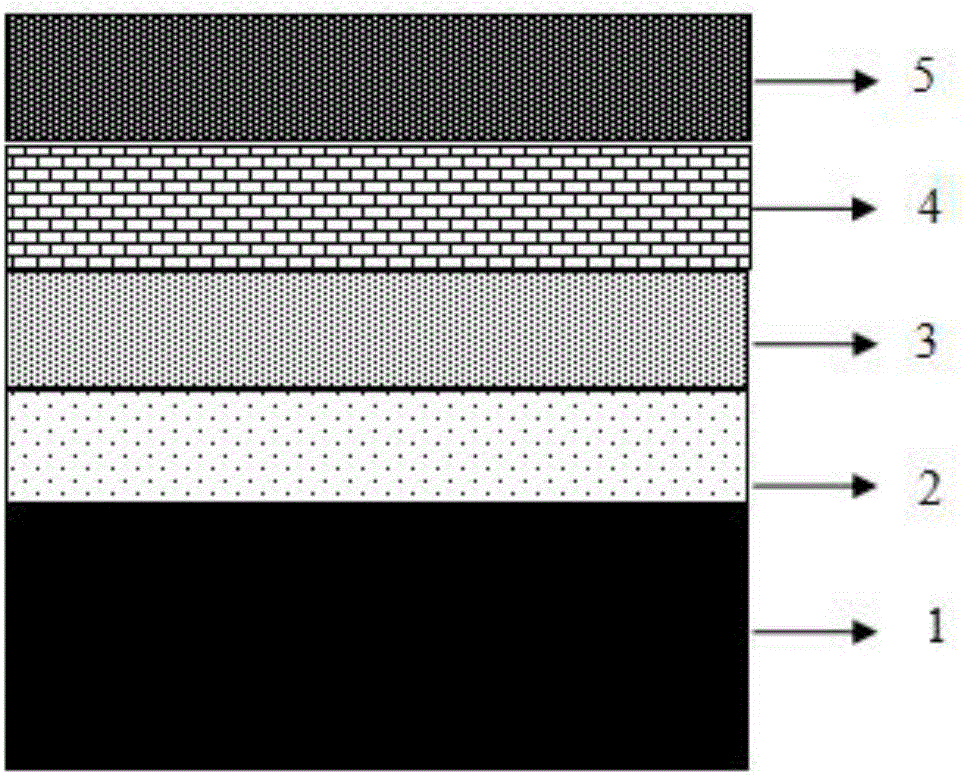

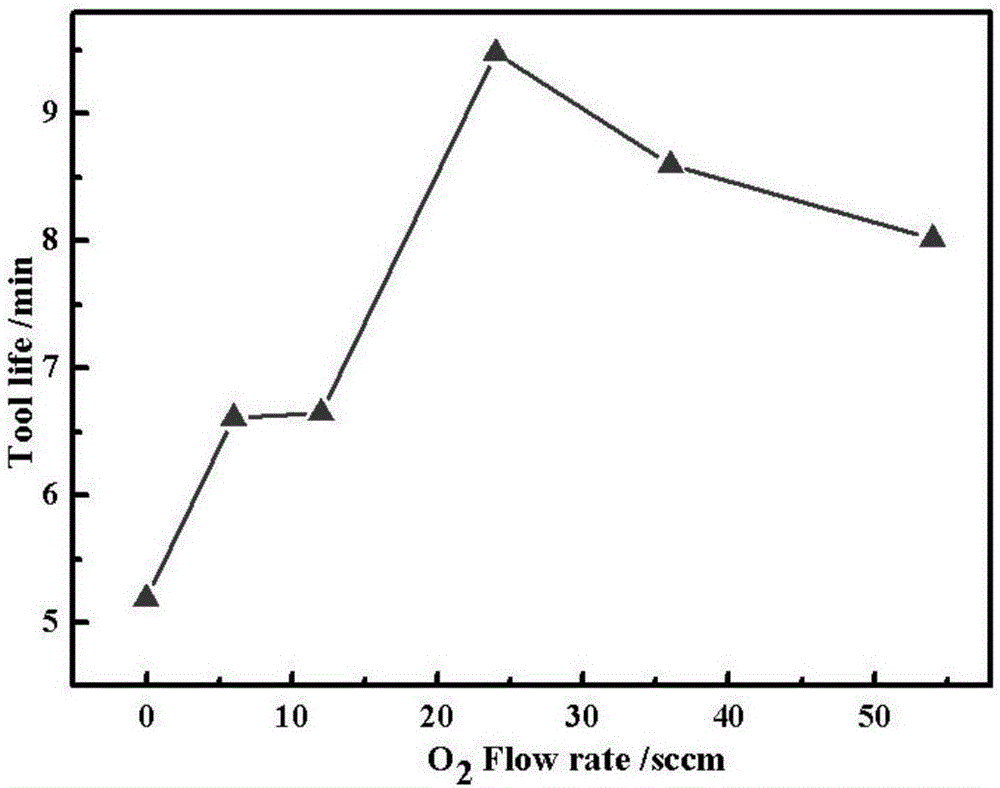

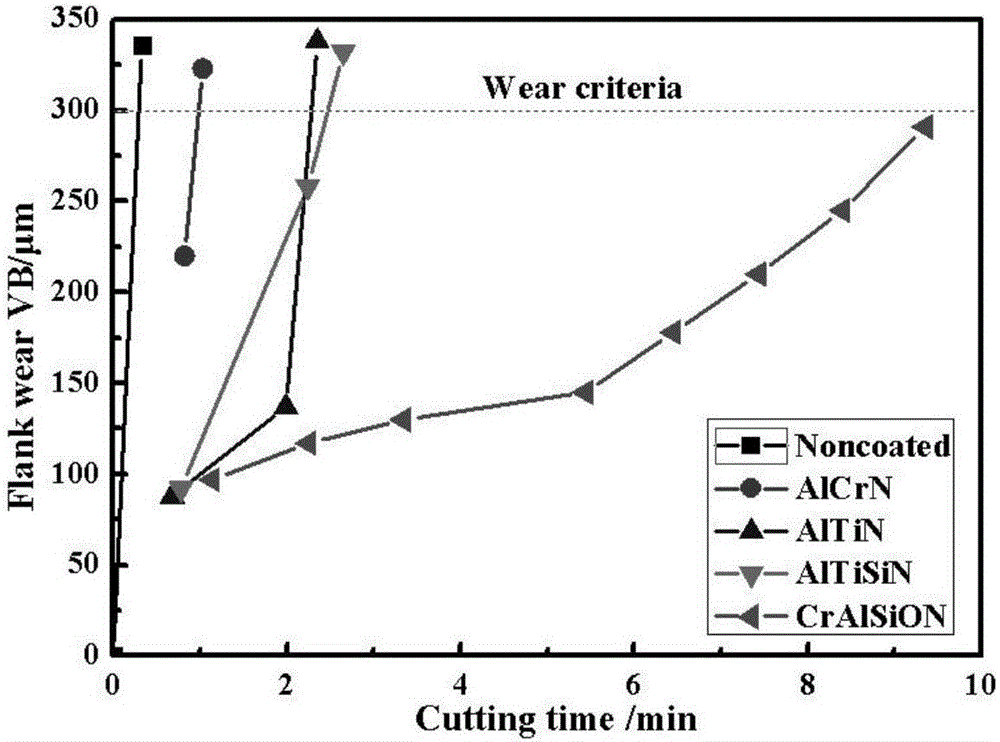

High-temperature abrasion-resistant CrAlSiON based nano-composite coating and preparation method and application thereof

ActiveCN106702331AReduce coefficient of frictionImprove bindingVacuum evaporation coatingSputtering coatingHardnessOxygen

The invention discloses a high-temperature abrasion-resistant CrAlSiON based nano-composite coating. The high-temperature abrasion-resistant CrAlSiON based nano-composite coating mainly comprises an AlTiN transition layer, a CrAlSiN supporting layer and a CrAlSiON functional layer. A multi-arc ion plating technology is adopted in the coating, and the CrAlSiON based nano-composite coating with different components can be obtained by changing technological parameters. An oxygen element is led into the CrAlSiON based nano-composite coating, the existence form of oxygen in the coating is controlled by changing the depositional condition, one or more sorts of oxide which is low in friction coefficient and resistant to abrasion can be pre-formed in the coating, and the binding force between coating bodies is increased; and meanwhile, the stress between the coating bodies and the friction coefficient under a high temperature condition are lowered, and friction resistance, abrasion resistance and thermal stability of the coating are improved, so that the coating is more suitable for a more demanding high-speed cutting and high-hardness environment, and the high-temperature abrasion-resistant CrAlSiON based nano-composite coating has great application prospects in the fields of cutters and surface protection.

Owner:GUANGDONG UNIV OF TECH

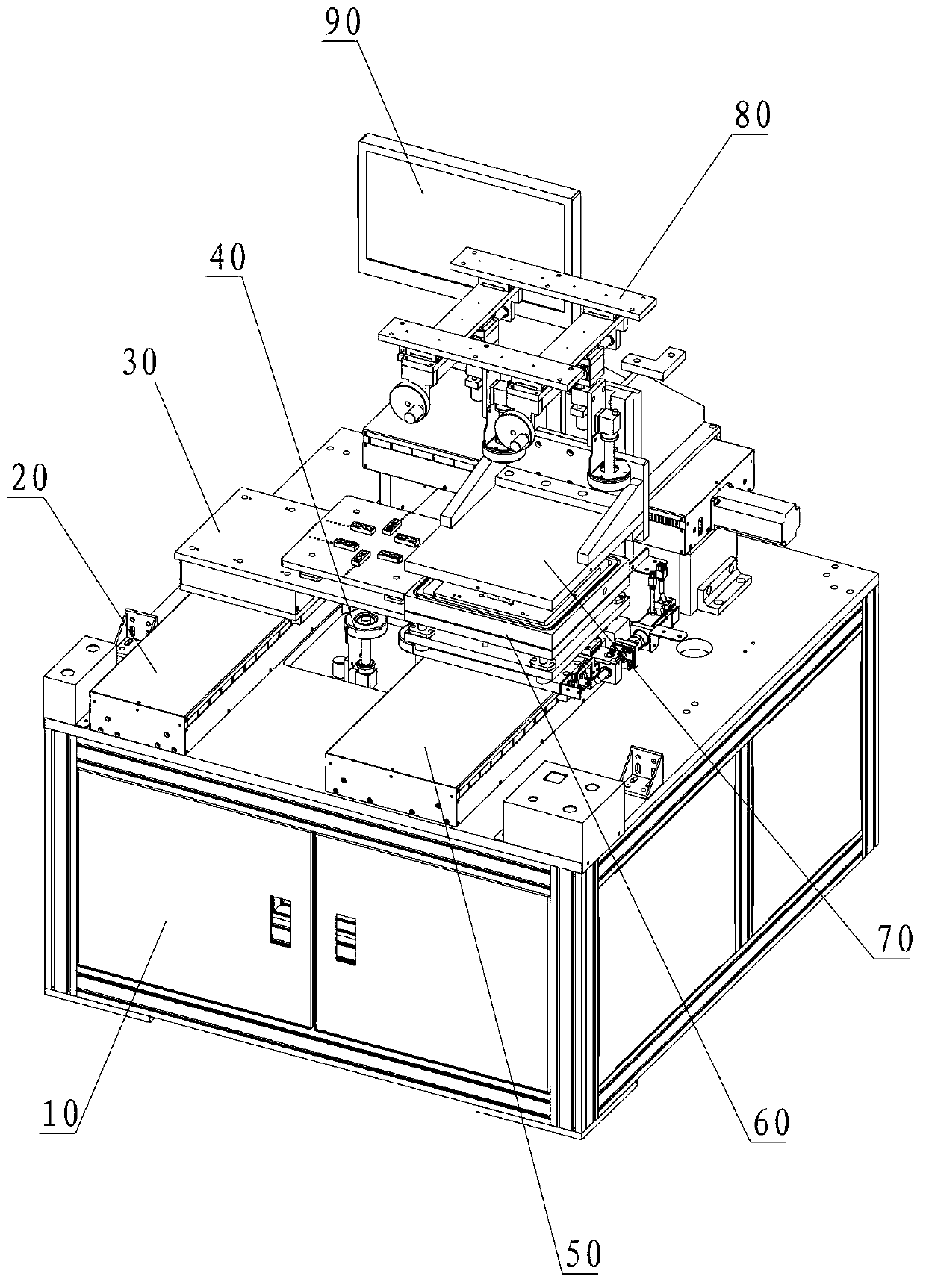

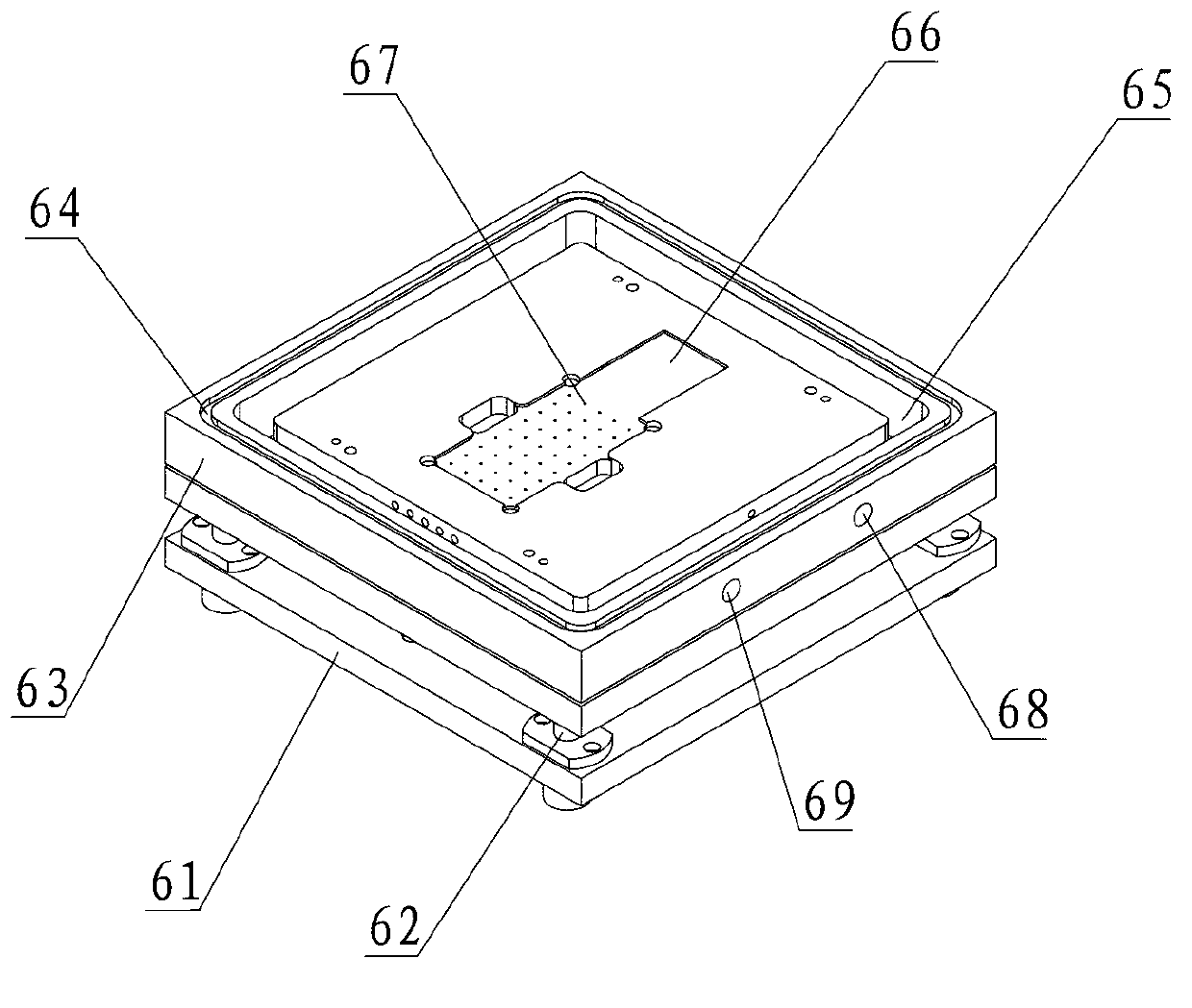

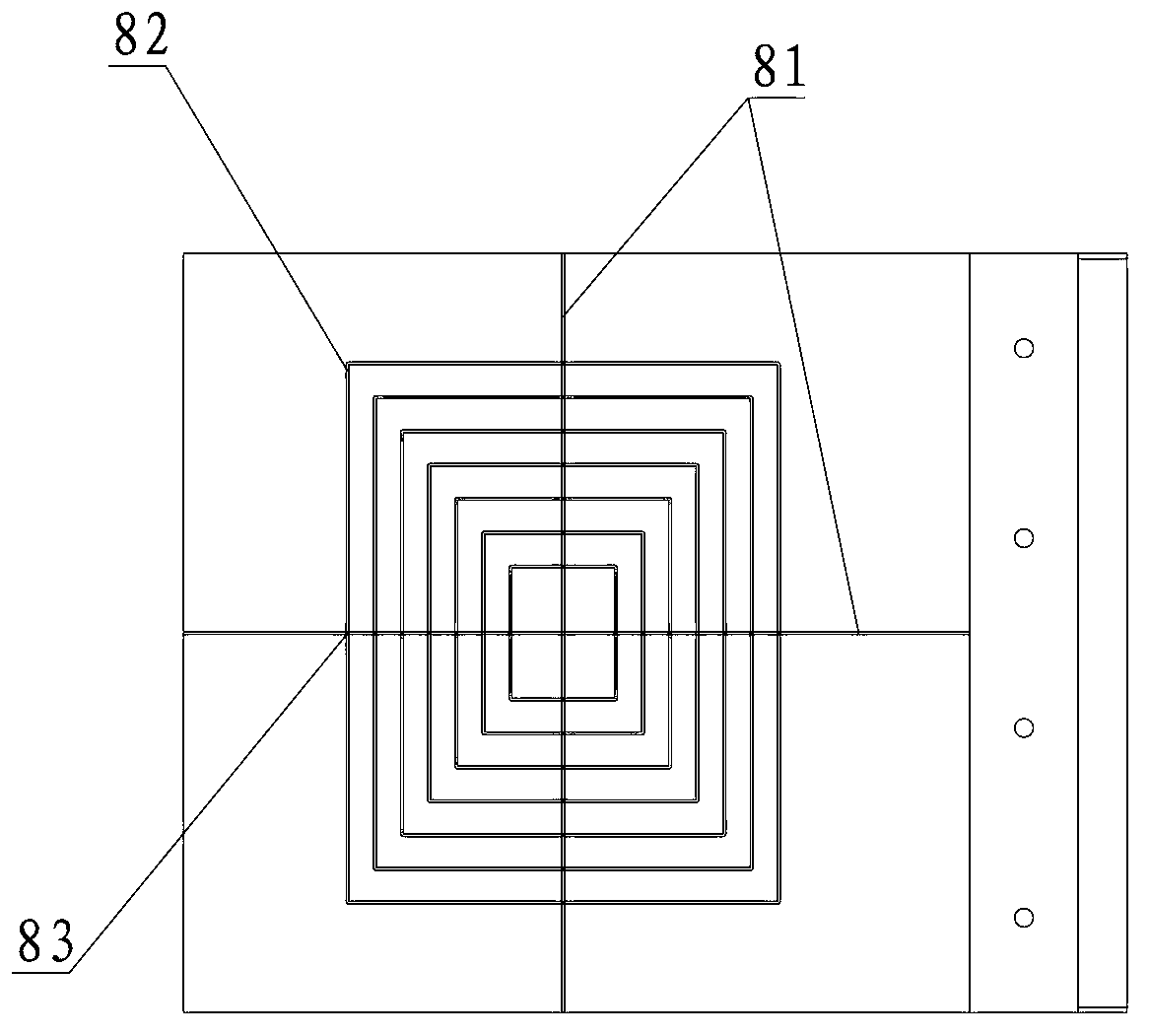

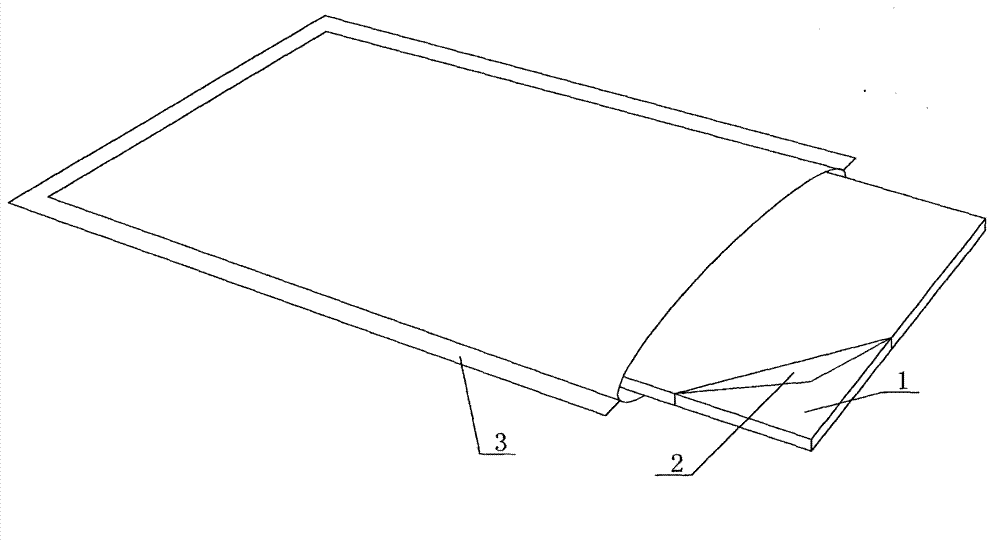

Precise OCA (optical clear adhesive) full-laminating machine and laminated production technology thereof

ActiveCN103273720ALow vacuum requirementEnergy savingLaminationLamination apparatusAdhesiveEngineering

The invention provides a precise OCA (optical clear adhesive) full-laminating machine and a laminated production technology thereof. The precise OCA full-laminating machine comprises a vacuum laminating mechanism and a suction plate mechanism, wherein the vacuum laminating mechanism is respectively used for loading two products to be adsorbed; and the vacuum laminating mechanism can be attached and sealed with the suction plate mechanism, so as to support the processes of firstly vacuumizing inside a stitching seal cavity before laminating and then aerating light gas. Thus, the vacuum degree requirements are reduced; and the light gas automatically ascends to remove air bubbles after the attached product is exposed in an atmospheric environment even if air bubbles are generated in the laminating process due to participation of the light gas. Therefore, an extra bubble removing step is not needed by adopting the technology; an energy source can be saved; and the laminating yield of the product can be greatly improved. In addition, the laminating registration accuracy can be greatly improved and achieve the range of + / -0.02mm by increasing image sensing recognition; the registration application range is wider; multi-purpose can be achieved; and the target of reducing the cost is achieved.

Owner:深圳市宝德自动化精密设备有限公司

Method for recovering sulfur from atmospheric-pressure oxygen-rich leached residues of lead-zinc ores

InactiveCN102633233AFast sublimation volatilizationHigh puritySulfur compoundsEnergy inputVacuum pumpSulfur containing

The invention discloses a method for recovering sulfur from atmospheric-pressure oxygen-rich leached residues of lead-zinc ores, and particularly relates to the recovery of sulfur in lead-zinc ore leached residues through vacuum distillation, belonging to the field of reclamation and reuse of solid waste resources. The method comprises the following steps of: placing atmospheric-pressure oxygen-rich leached residues, subjected to drying, milling and screening pretreatment, of lead-zinc ores into a vacuum distillation furnace, heating the residues to 200-400 DEG C, and controlling the pressure of the inside of the furnace to 600-10000 Pa, so that sulfur in the leached residues is sublimated and volatilized; pumping sulfur-containing vapor out of the distillation furnace by a vacuum pump; and cooling the sulfur-containing vapor so as to obtain a sulfur product. After the distillation is completed and the sulfur is completely volatilized, high-boiling-point residues are discharged out of the distillation furnace in a solid powder form. In the whole process, the furnace is internally sealed, thereby avoiding the oxidation and environmental pollution of elemental sulfur. The method is simple in technological process and equipment, high in sulfur recovery rate and product quality, low in energy consumption, strong in adaptability to raw materials and pollution-free, so that the method disclosed by the invention is an economic and efficient sulfur extraction method and can realize the zero discharge of waste smelting residues in a lead-zinc wet process, thus the method has broad application prospects.

Owner:CENT SOUTH UNIV

Amorphous powdered alloy and method for producing the same

The invention provides a non-crystal alloy powder, which comprises compounds which contain at least one or a plurality of the non-crystal alloy powder as Zr group, Cu group, Ti group, Ni group and Re group which contain rare-earth elements. Average particle diameters of powder are 50 micrometers-2000 micrometers. The invention also provides a process for preparing the non-crystal alloy powder, which comprises firstly, smelting the non-crystal alloy raw materials as Zr group, Cu group, Ti group, Ni group and Re group under protecting environment or a vacuum condition, and secondly, spraying melted metal into mist under the protecting environment and producing the non-crystal alloy powder with flash cold-settings, wherein the rare-earth elements are added in the first step to be smelted with the non-crystal alloy raw materials. The non-crystal alloy powder which is obtained through the invention has wide grain-size range, and the powder which is prepared can be used for addition agent of antifriction materials. The process for preparation has low requirements for preparing environment and pureness of raw materials, and is applied to productions with commercial scales.

Owner:BYD CO LTD

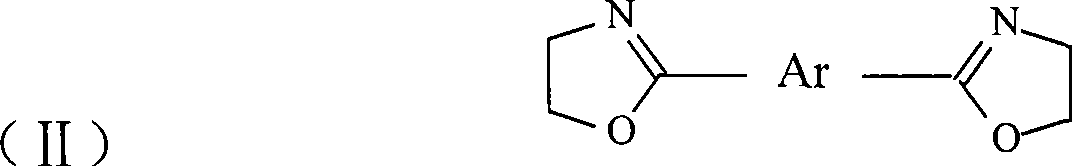

Process for preparing high-molecular aliphatic polyester

the invention discloses a preparing method of macromolecular aliphatic polyester, which is characterized by the following: proceeding melting polycondensation for diatomic alcohol and diacid; obtaining low-molecular hydroxy polyester prepolymer with even molecule at 2000-7000 or characteristic viscosity under 0.5; adopting aliphatic diacyl dilactone amide or aromatic diacyl dilactone amide to melt to expand chain; obtaining the product.

Owner:BEIJING UNIV OF CHEM TECH

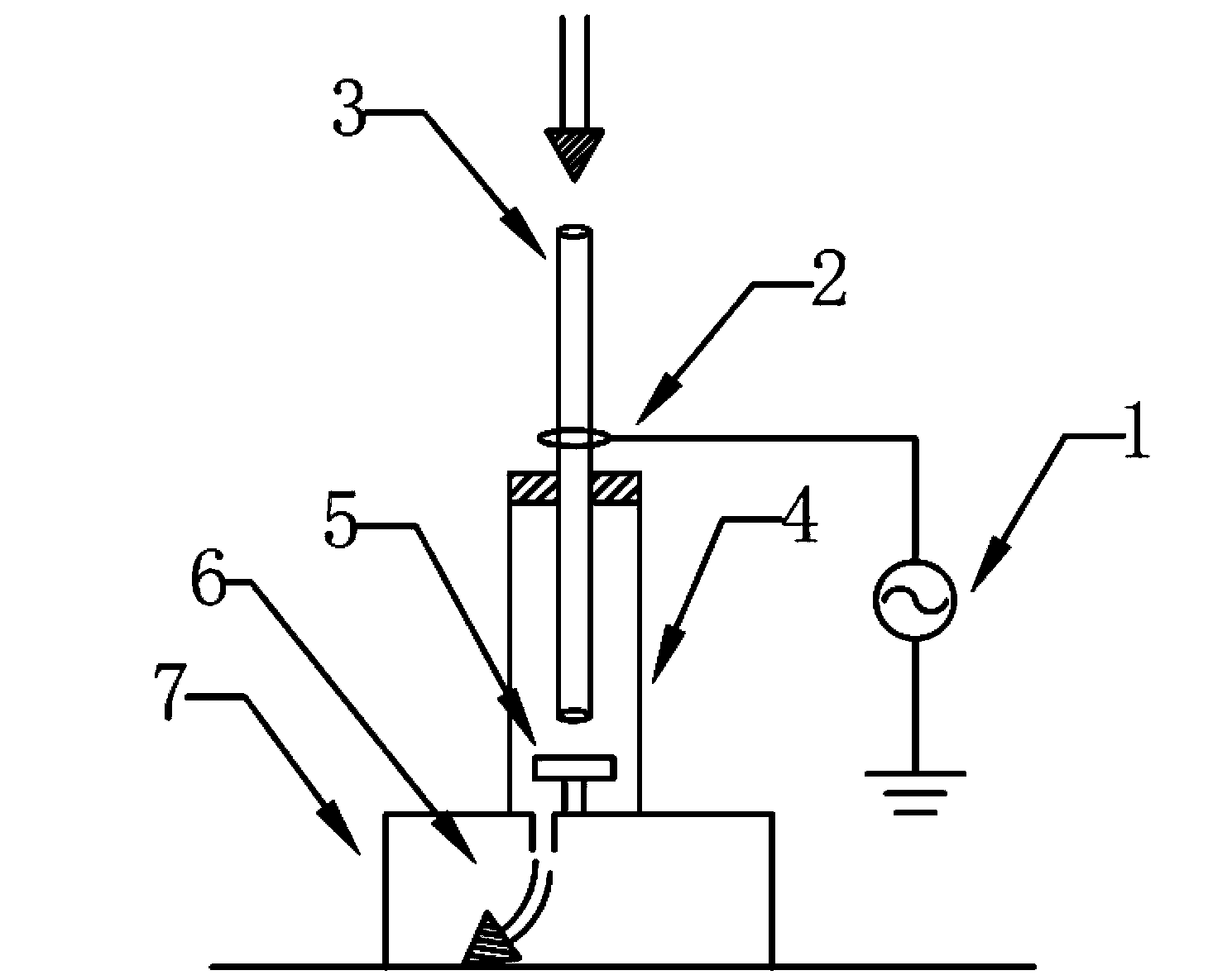

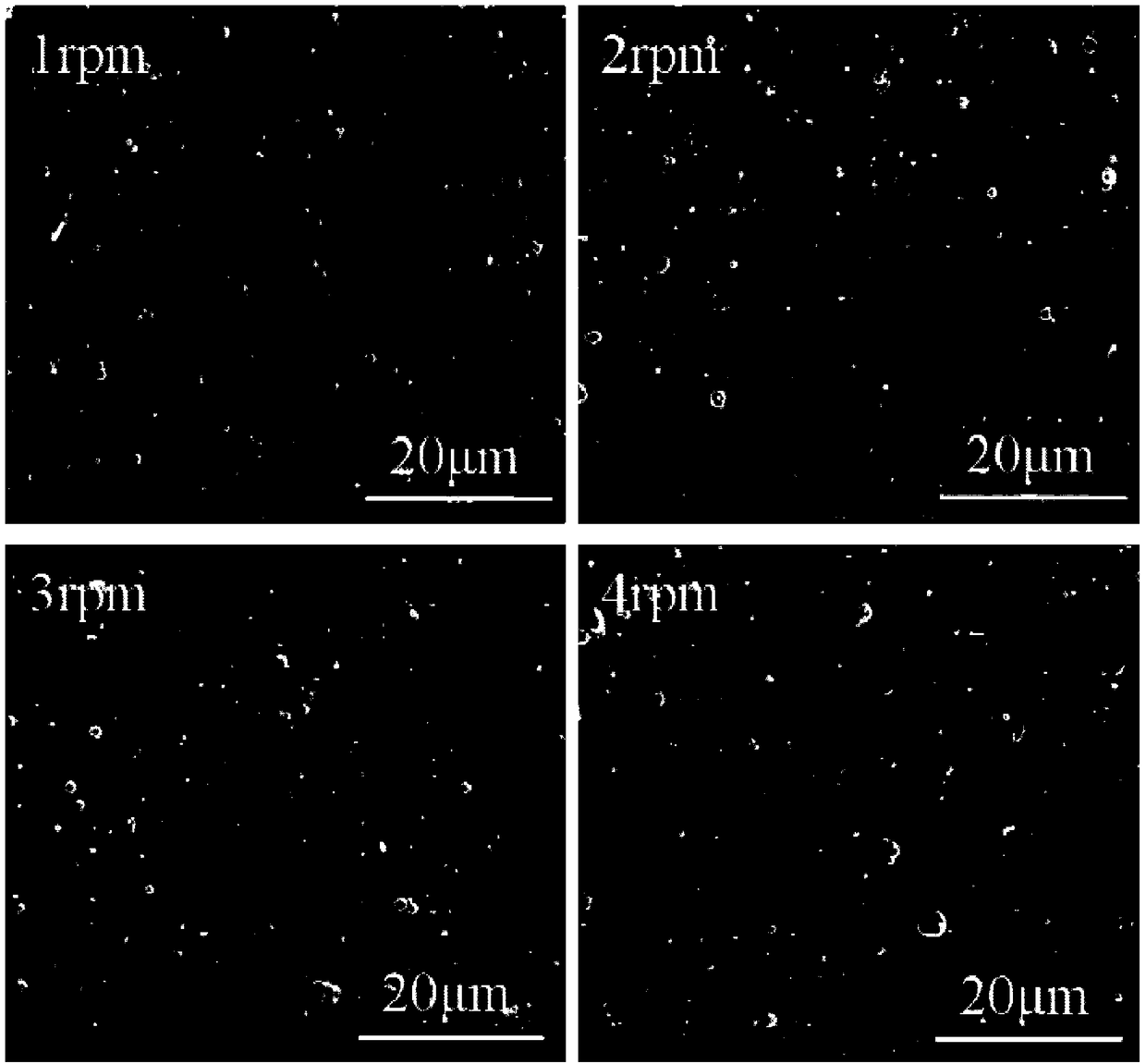

Method for preparing graphene oxide/ silver antibacterial composite material through intermediate pneumatic plasma jet

The invention discloses a method for preparing a graphene oxide / silver antibacterial composite material through intermediate atmosphere plasma jet. The method comprises the following steps of: dipping a silver precursor; loading silver ions on the surface of graphene oxide; treating through intermediate pneumatic hydrogen-cooling plasma jet under room temperature; and reducing the silver ions into silver nanoparticles to obtain the graphene oxide / silver composite material. According to the method, the precursor is reduced through plasma, so that a chemical agent bringing pollution to environment is avoided using; the reduction is performed in a dry state that the loss of precious metal is greatly reduced, and the graphene oxide / silver antibacterial composite material can be prepared efficiently. A sample transmission electron microscope image also shows that the silver nano ions are uniformly distributed on the surface of graphene oxide.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Sulfur slag vacuum volatilizing process for enriching noble metal

InactiveCN1986850AReduced vacuum requirementsLow temperature requirementProcess efficiency improvementSlagSulfur

The present invention relates to sulfur slag vacuum volatilizing process for enriching noble metal, and belongs to the field of vacuum fire metallurgy process. Sulfur slag material is distilled in a vacuum smelting furnace at pressure of 10-30 Pa and temperature of 250-400 deg.c for 50-120 min to volatilize sulfur and the sulfur vapor is cooled to form liquid and exhausted from the vacuum smelting furnace, so as to obtain metal sulfide powder with enriched Cu, Ni, Os, Ag, Au, etc. The process is simple, and has high noble metal enriching ratio, no environmental pollution, low power consumption and low production cost.

Owner:KUNMING UNIV OF SCI & TECH

Al-Ni-Ce-La aluminum-based amorphous alloy and preparation method thereof

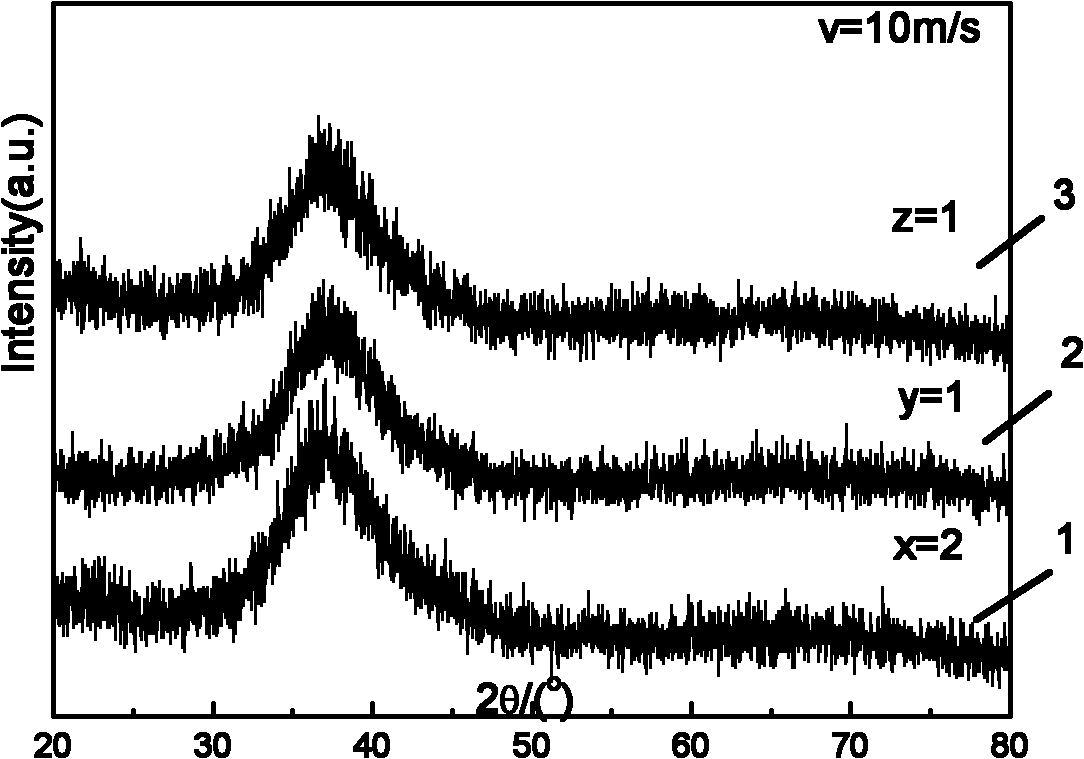

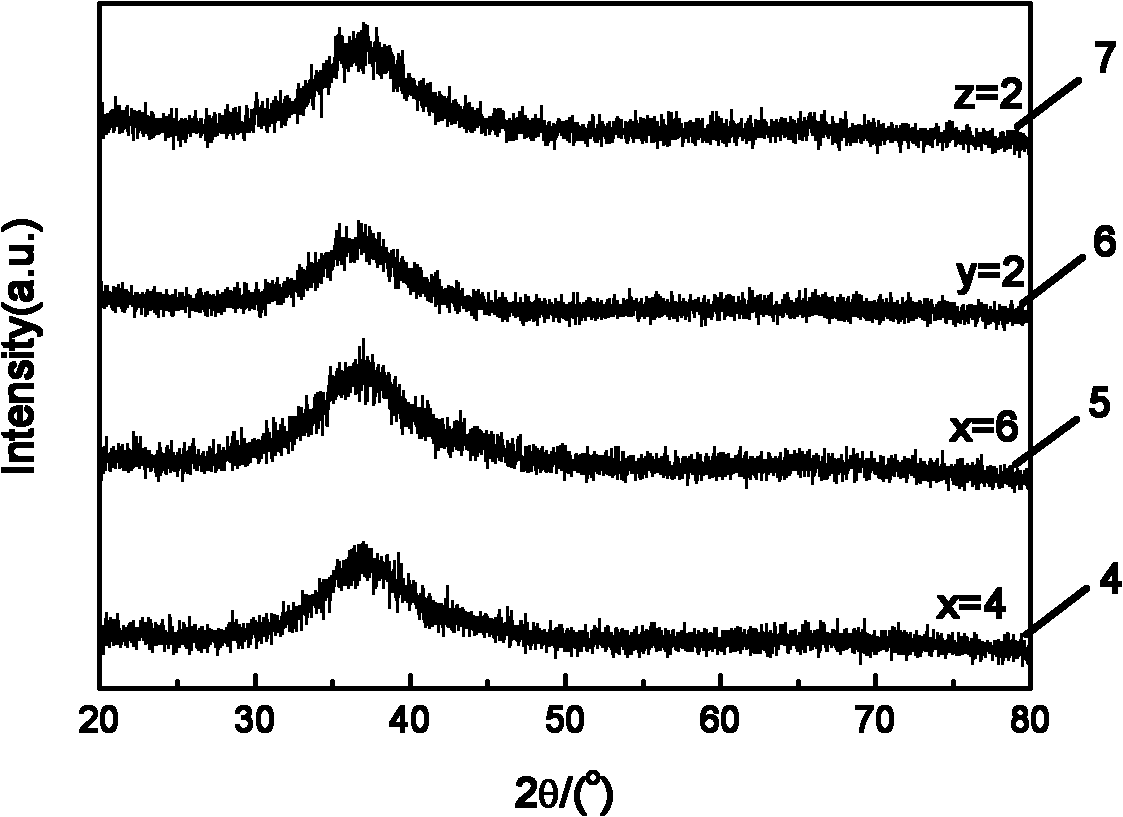

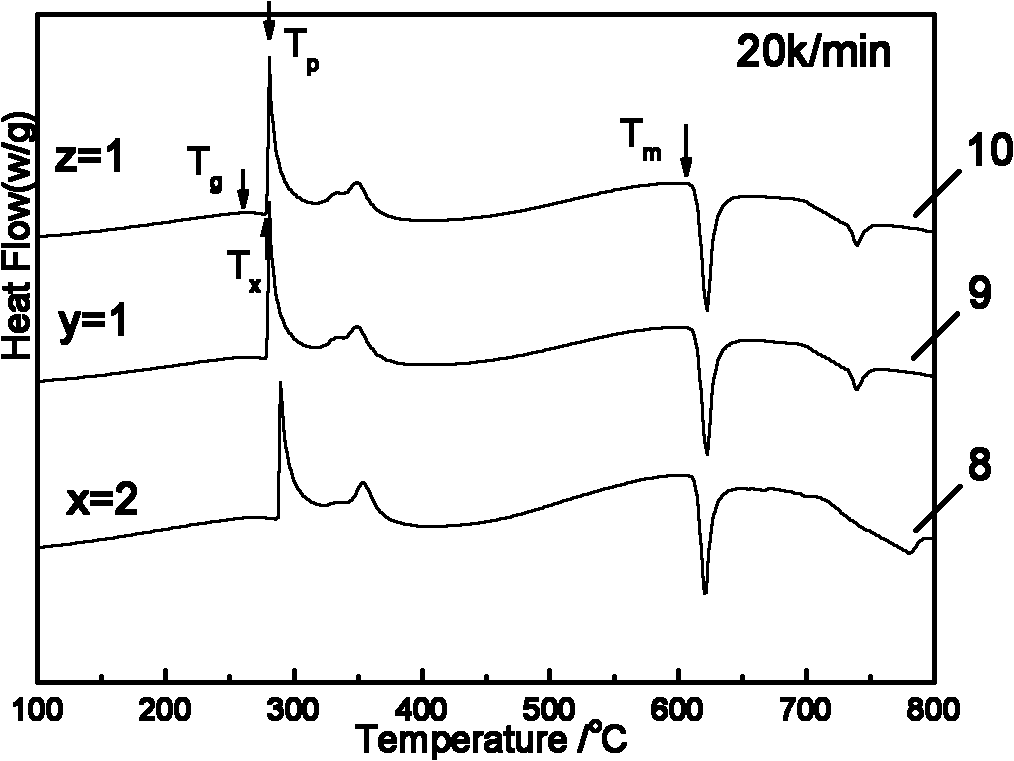

InactiveCN101838780AIncrease densityIncrease alloy viscosityVacuum induction meltingInjection pressure

The invention relates to an Al-Ni-Ce-La aluminum-based amorphous alloy which comprises the following components: Al84Ni10Ce(6-x)Lax(x=1 to 6, at.%), Al84Ni(10-y)Ce6Lay(y=1 to 3, at.%) and Al(84-z)Ni10Ce6Laz(z=1 to 3, at.%). A method for preparing the Al-Ni-Ce-La aluminum-based amorphous alloy comprises the following steps that: after preparing materials according to the nominal components of the alloy, under the protection of argon gas, a master alloy is prepared by vacuum arc melting or vacuum induction melting; and under the protection of Ar gas, an amorphous strip is prepared by spinning, the minimum linear speed of a copper roller when in spinning is 10m / s, the melt injection pressure is 0.07 to 0.08MPa, and the vacuum degree is 2 to 10-1Pa. The invention has the advantages of reasonable component ratio, strong amorphous forming capability, simple manufacturing method and low requirement on the vacuum degree.

Owner:CENT SOUTH UNIV

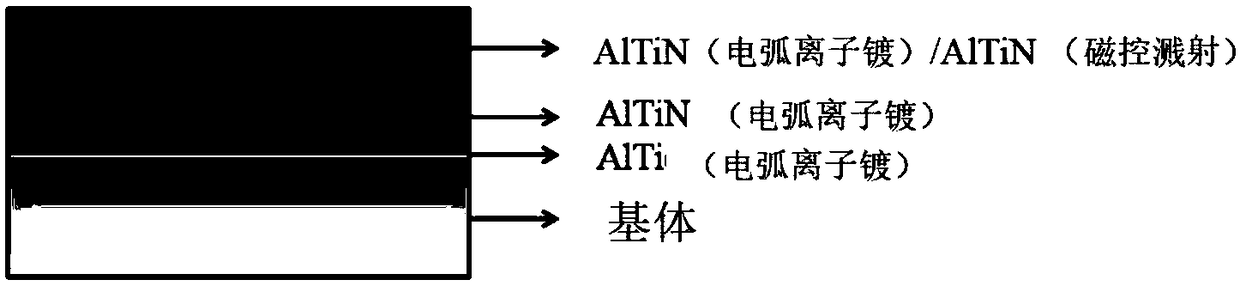

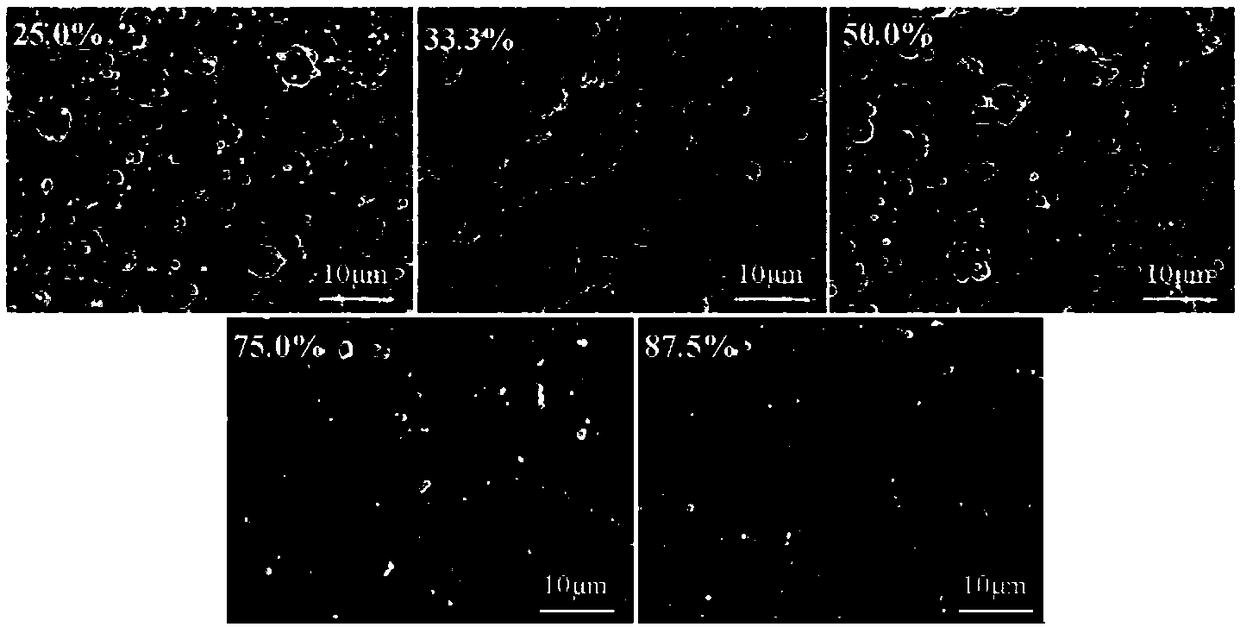

Arc ion plating-magnetron sputtering composite deposition high-temperature wear-resisting antifriction AlTiN nano multi-layer coating and preparing method and application thereof

ActiveCN108690956AIncrease ionization rateImprove mechanical propertiesVacuum evaporation coatingSputtering coatingFilm baseMicrometer

The invention belongs to the field of material coatings, and discloses an arc ion plating-magnetron sputtering composite deposition high-temperature wear-resisting antifriction AlTiN nano multi-layercoating and a preparing method and application thereof. An ion source is used for bombarding a cleaned base body surface, firstly, a metal AlTi combination layer is firstly deposited, base body and coating thermal expansion coefficient mismatching can be relieved, and the film-base combination strength is improved; the arc ions are used for sputter deposition of an AlTiN coating with the thicknessranging from 0.5 to 1 micrometer, the coating serves a transition layer, and support is provided for the nano multi-layer structure coating; finally, meanwhile, an arc AlTi target and a magnetic control AlTi target are opened to carry out composite deposition to prepare the AlTiN nano multi-layer function layer; through design of a combination layer, the transition layer and the composite deposition function layer and regulation of process parameters in the coating deposition process, the modulation period is changed, and the AlTiN nano multi-layer coating with the high combination force, lowfriction coefficient, small inner stress and stable performance is prepared on the hard alloy base body.

Owner:GUANGDONG UNIV OF TECH

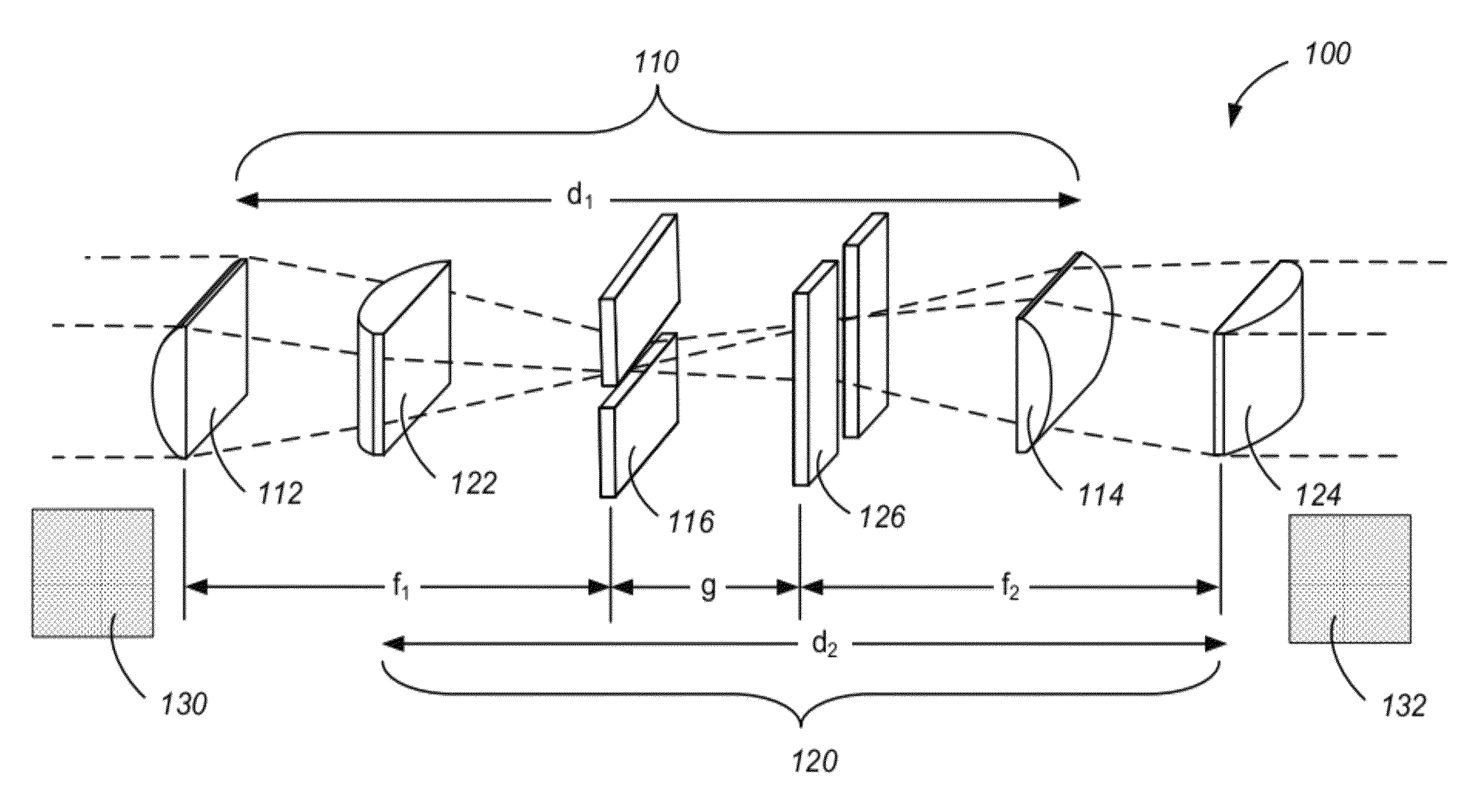

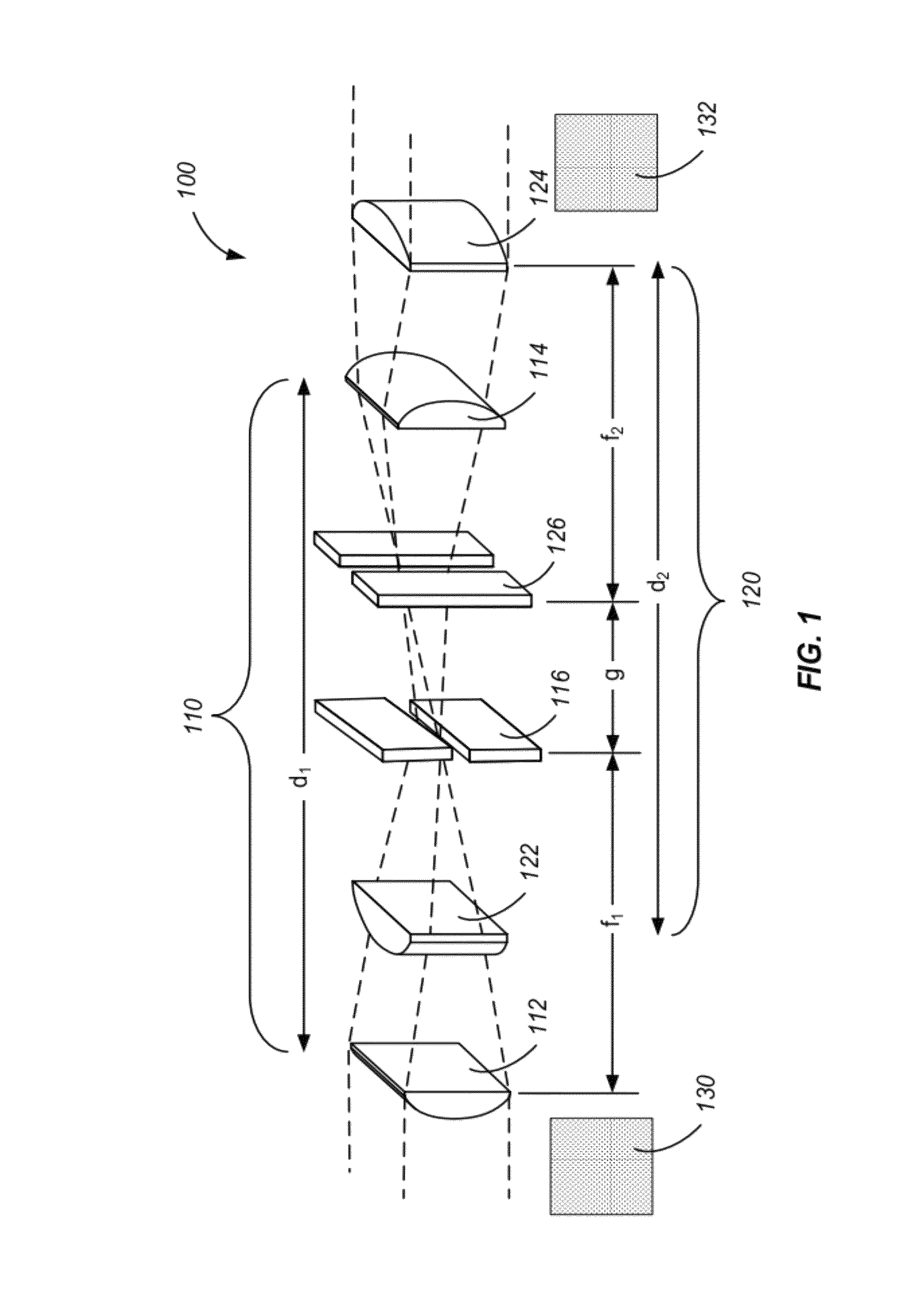

Spatial filters for high average power lasers

ActiveUS8320056B2Reduced vacuum requirementsHigh repetition rateOptical filtersOptical resonator shape and constructionCylindrical lensLaser

A spatial filter includes a first filter element and a second filter element overlapping with the first filter element. The first filter element includes a first pair of cylindrical lenses separated by a first distance. Each of the first pair of cylindrical lenses has a first focal length. The first filter element also includes a first slit filter positioned between the first pair of cylindrical lenses. The second filter element includes a second pair of cylindrical lenses separated by a second distance. Each of the second pair of cylindrical lenses has a second focal length. The second filter element also includes a second slit filter positioned between the second pair of cylindrical lenses.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

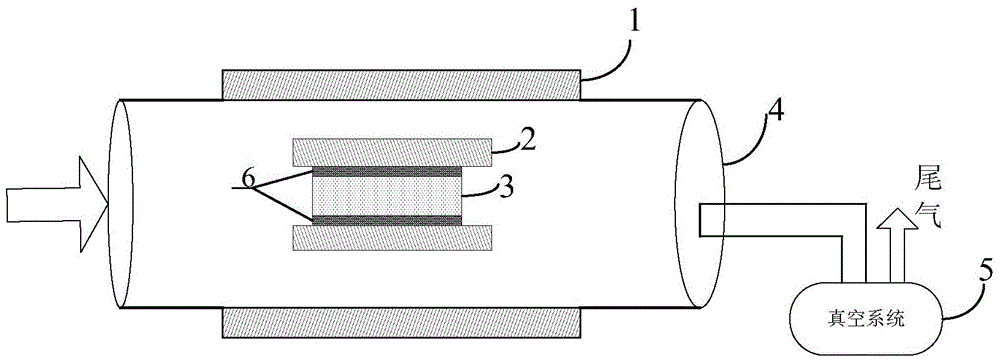

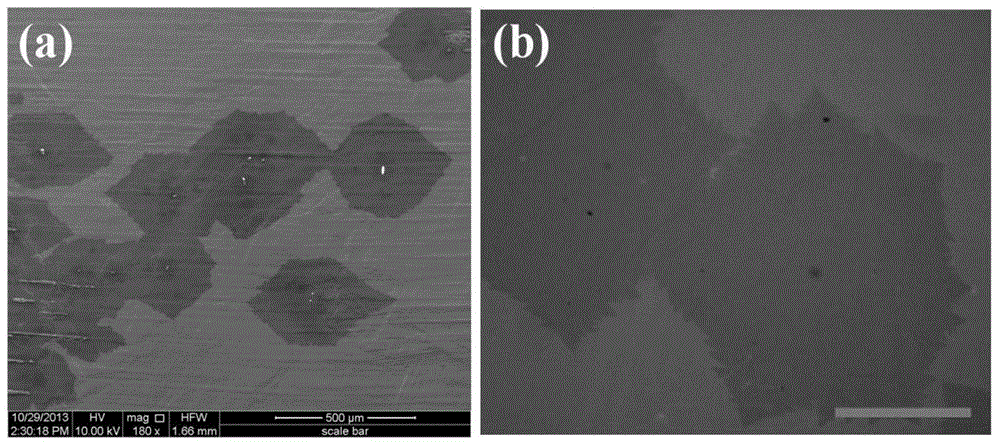

Method for preparing monocrystal graphene

ActiveCN105112999AFacilitates large area growthClose contactPolycrystalline material growthFrom chemically reactive gasesHydrogenMetal foil

The invention provides a method for preparing monocrystal graphene. Semiconductor layers are arranged on the upper surface and the lower surface of metal foil to obtain a semiconductor layer-metal foil-semiconductor layer stepped structure; the stepped structure is placed in a closed vessel of which air is emptied, the closed vessel is heated in the state that hydrogen and argon are introduced to enable the metal foil to be in a molten state, the metal foil can make contact with the semiconductor layers on the upper surface and the lower surface more closely, the contact area of the metal foil and methane is greatly decreased, therefore, the carbon source density of the surfaces of the metal foil is greatly reduced, and large-area growth of the monocrystal graphene can be facilitated. Due to the fact that the carbon source density of the surfaces of the metal foil can be greatly reduced by enabling the metal foil to closely make contact with the semiconductor layers on the upper surface and the lower surface, the vacuum degree requirement in the preparation method can be slightly lowered, the strictness for methane quantity control can be also lowered, and therefore the technology difficulty is lowered, so that the preparation process is implemented more easily.

Owner:NAT INST OF METROLOGY CHINA

Vacuum heat-preserving plate for light building

ActiveCN103206027ALightweight unitGood heat insulationClimate change adaptationInsulation improvementFiberSurface layer

The invention relates to a vacuum heat-preserving plate for a light building. The vacuum heat-preserving plate comprises a low-density micro-porous inorganic heat-preserving layer, a core plate enhanced wrapping layer and a low-permeability air resistance film surface layer, is characterized by consisting of the low-density micro-porous inorganic heat-preserving layer, the core plate enhanced wrapping layer and the low-permeability air resistance film surface layer, and has a structure that the low-density micro-porous inorganic heat-preserving layer, the core plate enhanced wrapping layer and the low-permeability air resistance film surface layer are sequentially arranged from inside to outside. The low-permeability air resistance film surface layer is internally vacuumized. The low-density micro-porous inorganic heat-preserving layer consists of plant ash, silicon dioxide and glass staple fibers. The thickness of the low-density micro-porous inorganic heat-preserving layer is 7 to 30mm. The core plate enhanced wrapping layer is made of a non-woven fabric material. The weight of the core plate enhanced wrapping layer is 40 to 70g per square meter. The low-permeability air resistance film surface layer has a five-layer aluminum plastic composite structure. The thickness of the low-permeability air resistance film surface layer is 0.2 to 0.5mm. The vacuum heat-preserving plate has the advantages of light weight, convenience in transportation, environment friendliness, high heat-preserving performance, long service life, incombustibility, and A-grade fire resistance. Materials are easily obtained and low in cost.

Owner:王明堂

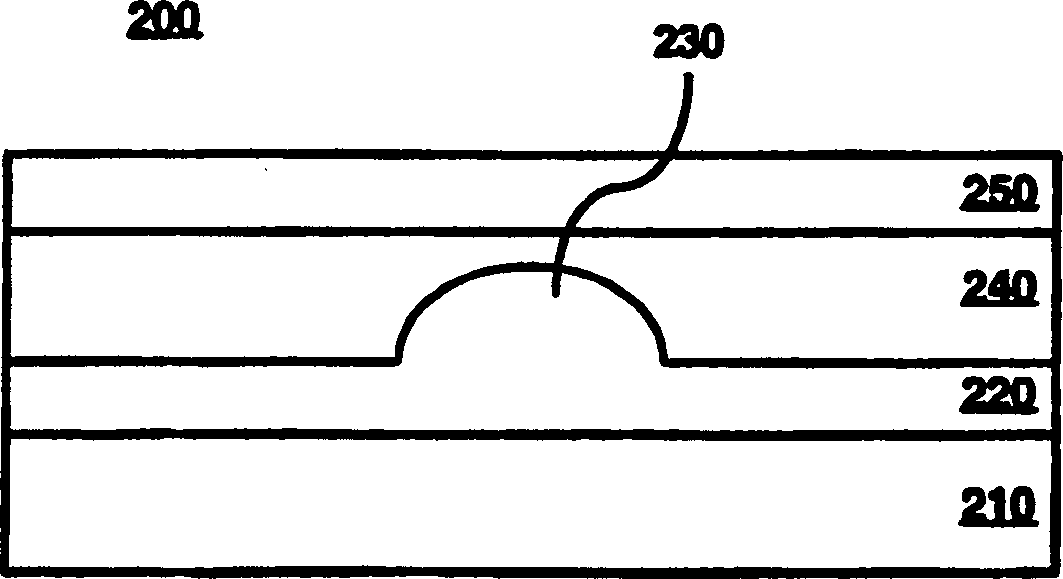

Field enhancement metal insulator-semiconductor/metal insulator-metal electronic emitter

InactiveCN1412804AExtend your lifeImprove efficiencyNanoinformaticsDischarge tube cold cathodesMetal-insulator-metalMetal insulator

In an electron emitter based on Metal-Insulator-Semiconductor or Metal-Insulator-Metal emitters, field emission structures are enclosed within the emitter structure. The electron emitter may include a conductive substrate and an electron supply layer formed on the conductive substrate. The electron supply layer, for example undoped polysilicon, has protrusions formed on its surface. The sharpness and density of protrusions may be controlled. Above the electron supply layer and the protrusions, an insulator may be formed thereby enclosing the protrusions. A top conductive layer may be formed above the insulator. The enclosed protrusions are relatively insensitive to vacuum contamination.

Owner:HEWLETT PACKARD CO

One-step method for preparing high-density WRe/TZM gradient composite material

The invention discloses a one-step method for preparing a high-density WRe / TZM gradient composite material. The method comprises the following steps that 5% WRe alloy powder and TZM alloy powder are taken as raw materials, the TZM alloy powder and the WRe alloy powder are loaded into a specially designed gradient mold according to the sequence that the TZM alloy powder is located at the lower partand the WRe alloy powder is located at the upper part, then SPS sintering connection is carried out, and the WRe / TZM gradient composite material is obtained at one time. The obtained WRe / TZM gradientcomposite material prepared by the method is high in density, uniform in connecting surface diffusion and excellent in hardness and shearing strength.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com