Method for preparing graphene oxide/ silver antibacterial composite material through intermediate pneumatic plasma jet

A plasma and composite material technology, applied in the field of graphene oxide composite materials, can solve problems such as affecting biological safety, affecting bacteriostatic properties, and complicated steps, and achieve the effects of reducing the loss of precious metals, efficient preparation, and low vacuum requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, without any limitation to the present invention.

[0025] 1. Preparation of graphene oxide suspension: dissolving graphite oxide powder in deionized water, ultrasonic treatment for 8 hours to obtain brown graphene oxide suspension;

[0026] 2. Immersion silver precursor: Add 3 mmol / L silver nitrate solution to the obtained graphene oxide suspension while stirring, then place the resulting solution in a vacuum drying oven and dry at 80°C for 24 hours to obtain graphene oxide and silver precursor flake mixture;

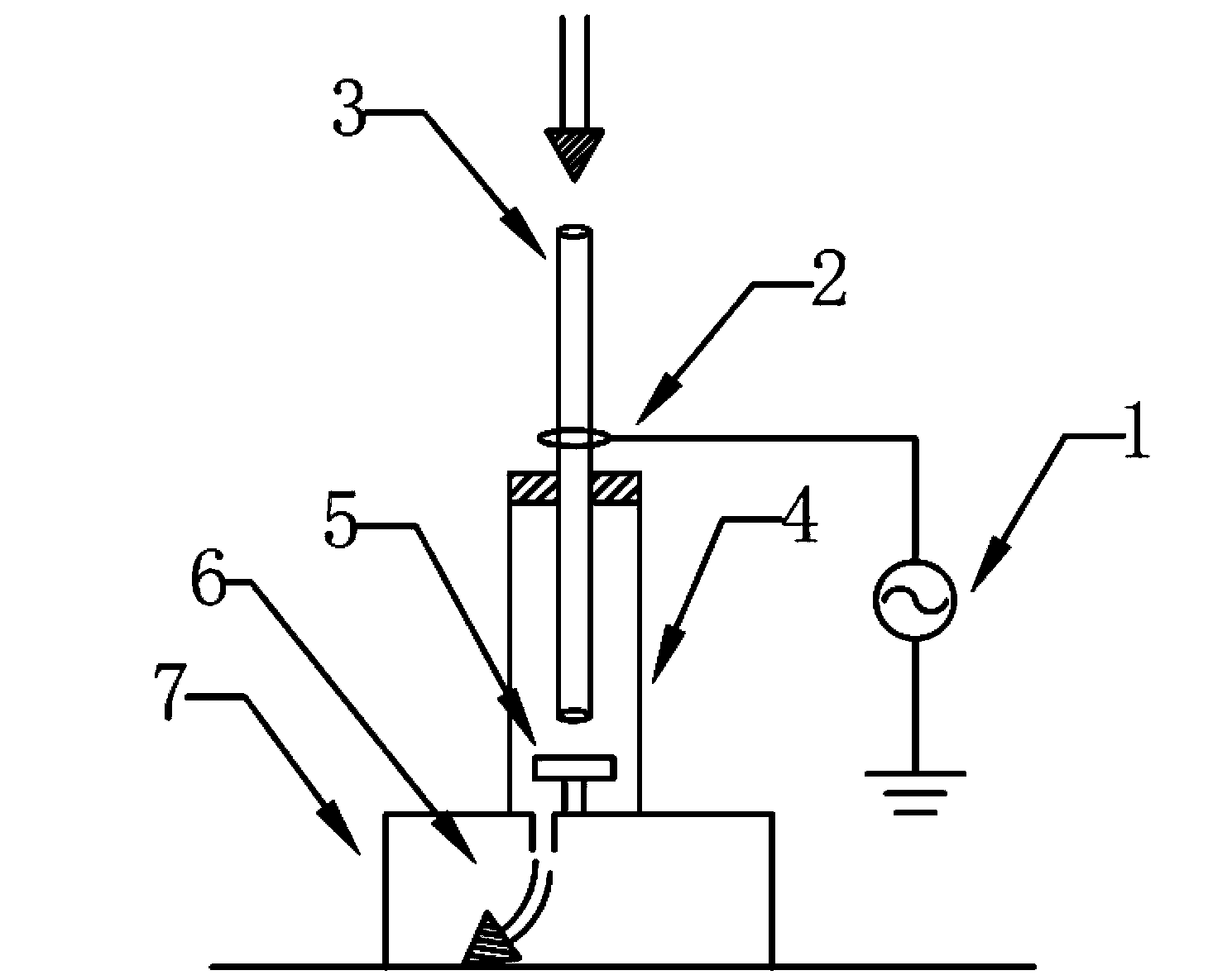

[0027] 3. Plasma reduction: put the flake mixture of graphene oxide and silver precursor into the jet plasma generator, turn on the vacuum pump to pump the air pressure in the device below 5 Pa; Pa, turn on the AC high-voltage power supply, adjust the peak voltage to 5000V, obtain a stable medium-pressure hydrogen-cooled plasma je...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com