Patents

Literature

13399 results about "Ammonium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium sulfate (American English and international scientific usage; ammonium sulphate in British English); (NH₄)₂SO₄, is an inorganic salt with a number of commercial uses. The most common use is as a soil fertilizer. It contains 21% nitrogen and 24% sulfur.

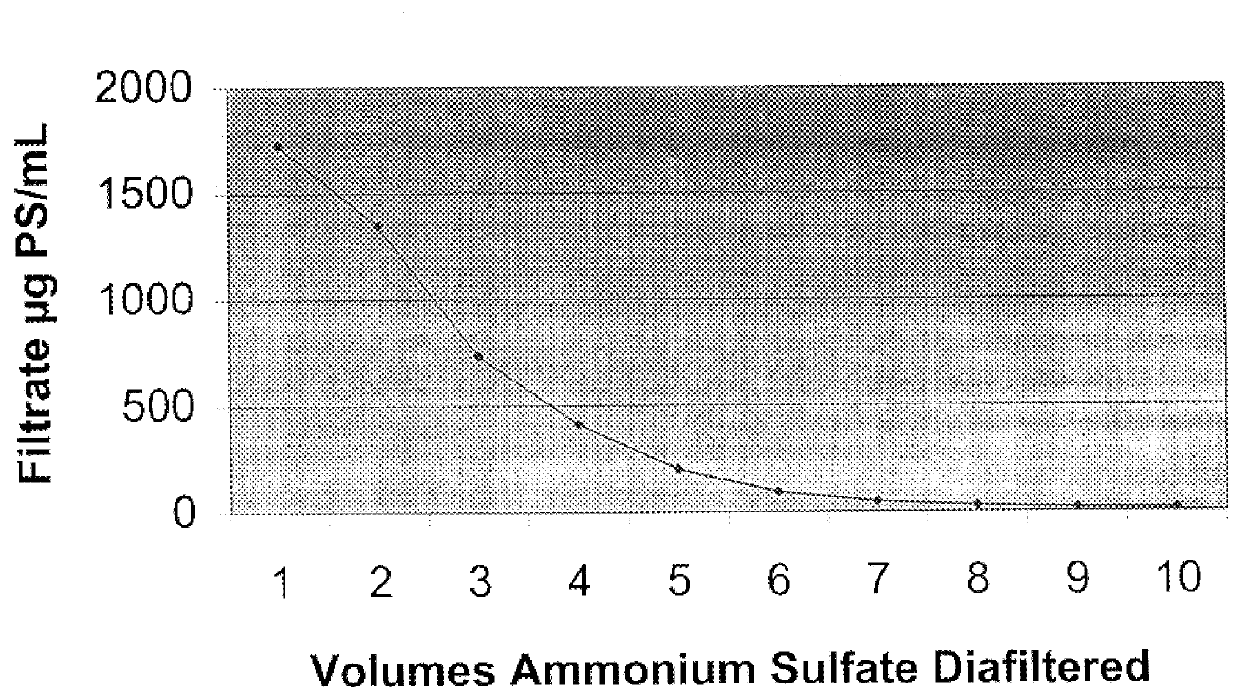

Purification of polysaccharide-protein conjugate vaccines by ultrafiltration with ammonium sulfate solutions

InactiveUS6146902AImprove scalabilityLevel of purityAntibacterial agentsSugar derivativesConjugate vaccineUltrafiltration

Disclosed and claimed are a method for the purification of polysaccharide-protein conjugate vaccines by ultrafiltration in a saturated solution of ammonium sulfate. The ultrafiltration method of the present invention provides an efficient, readily scalable method for removal of unbound polysaccharides from polysaccharide-protein vaccines, thereby improving the purity and consistency of the polysaccharide-protein vaccines.

Owner:AVENTIS PASTUER LTD

Preparation method for sodium alginate-acrylamide-based hydrogel

InactiveCN103396562AOvercome the shortcomings of generating air bubbles and forming uneven hydrogelsEasy to operateCross-linkPolyacrylamide Hydrogel

The invention discloses a preparation method for sodium alginate-acrylamide-based hydrogel. The preparation method comprises the following steps of: dissolving sodium alginate powder in deionized water; then sequentially adding an acrylamide monomer, a methylene diacrylamide cross-linking agent, ammonium persulfate and an N,N,N',N'-tetramethylethylenediamine catalyst; uniformly stirring the materials, pouring the mixture into a glass die, and heating the mixture to obtain a hydrogel; completely soaking the hydrogel in a 0.01-1 mol / L non-monovalent cation aqueous solution for 1-10 hours, wherein cations diffuse and enter in a hydrogel network structure, and induce sodium alginate to cross-link, so as to generate the high-strength and high-toughness sodium alginate-acrylamide-based hydrogel during the process. The hydrogel disclosed by the invention has the following performances: the highest tensile strength can achieve 1 MPa, and the highest tensile elasticity modulus can achieve 250 KPa; a loading-unloading test is performed on the hydrogel, and when the great tensile multiple before unloading is 8, the highest dissipated energy can achieve 2180 KJ / m<3>.

Owner:XI AN JIAOTONG UNIV

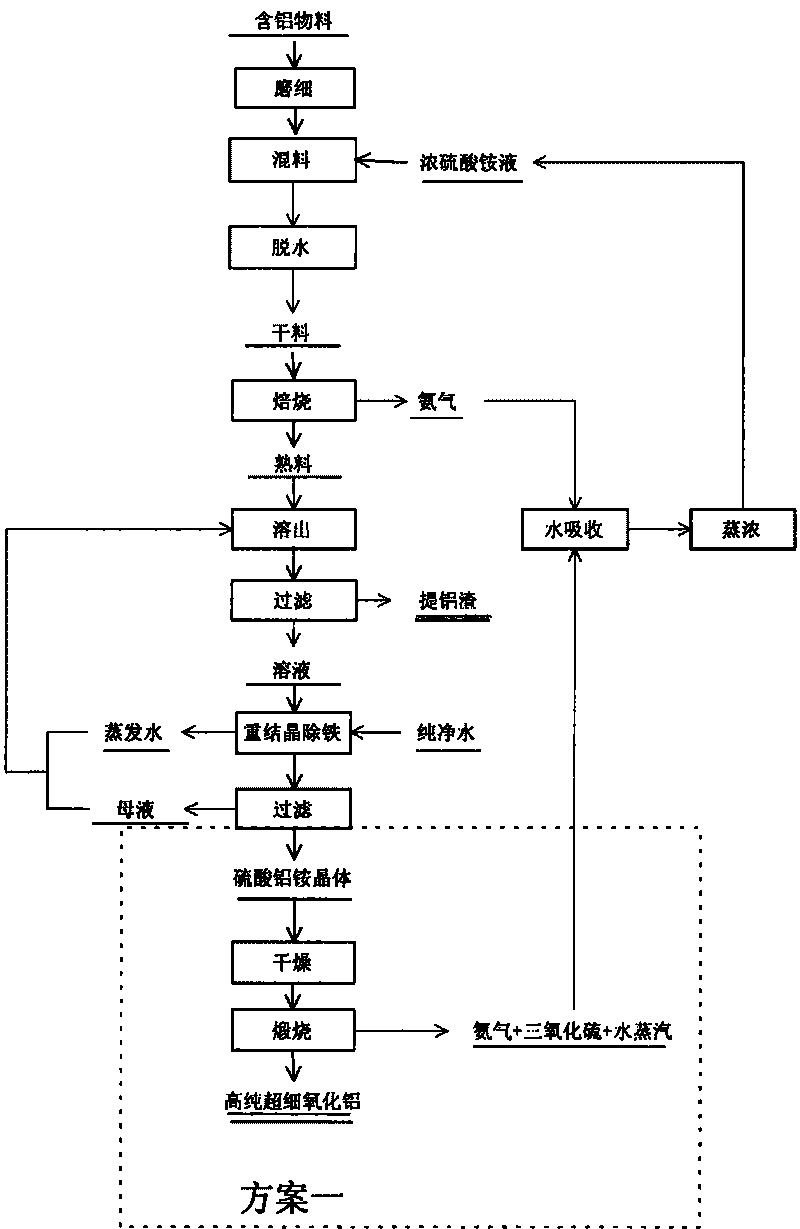

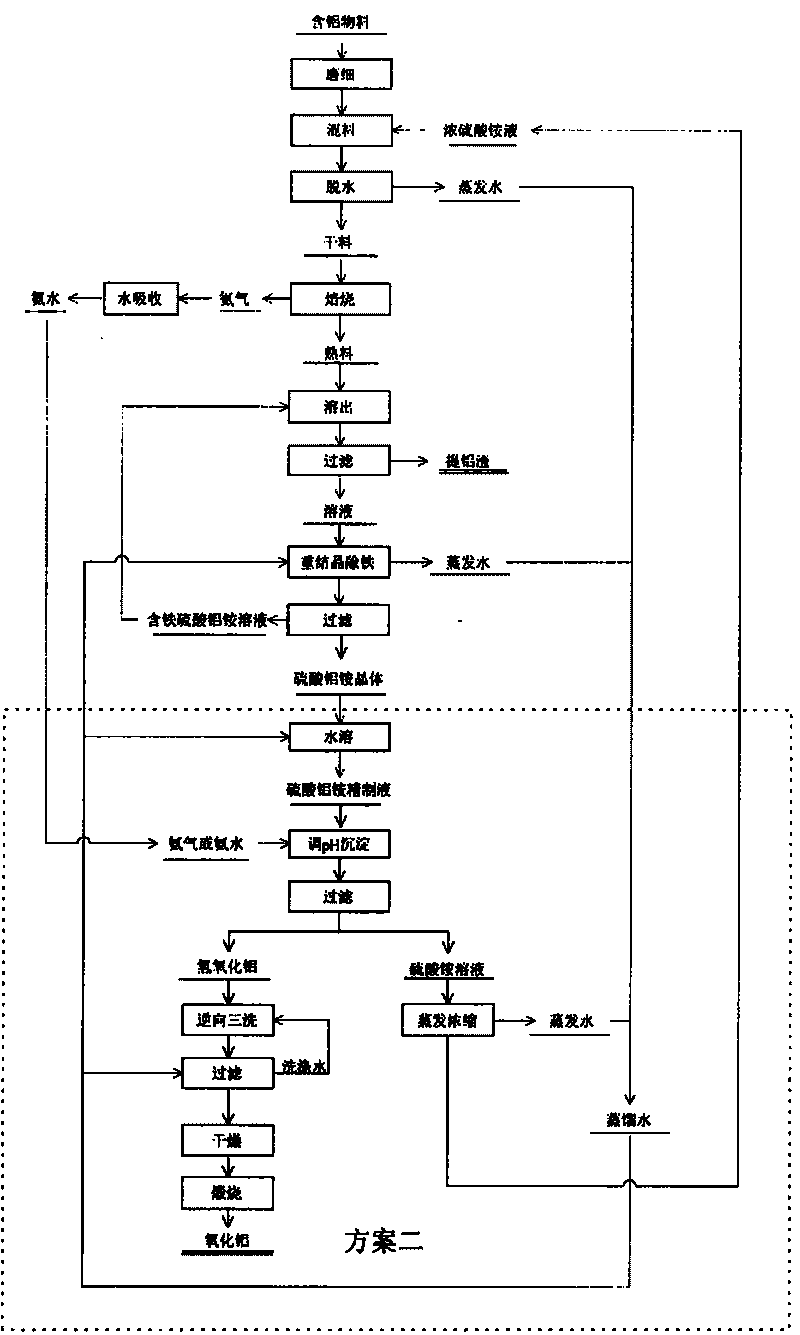

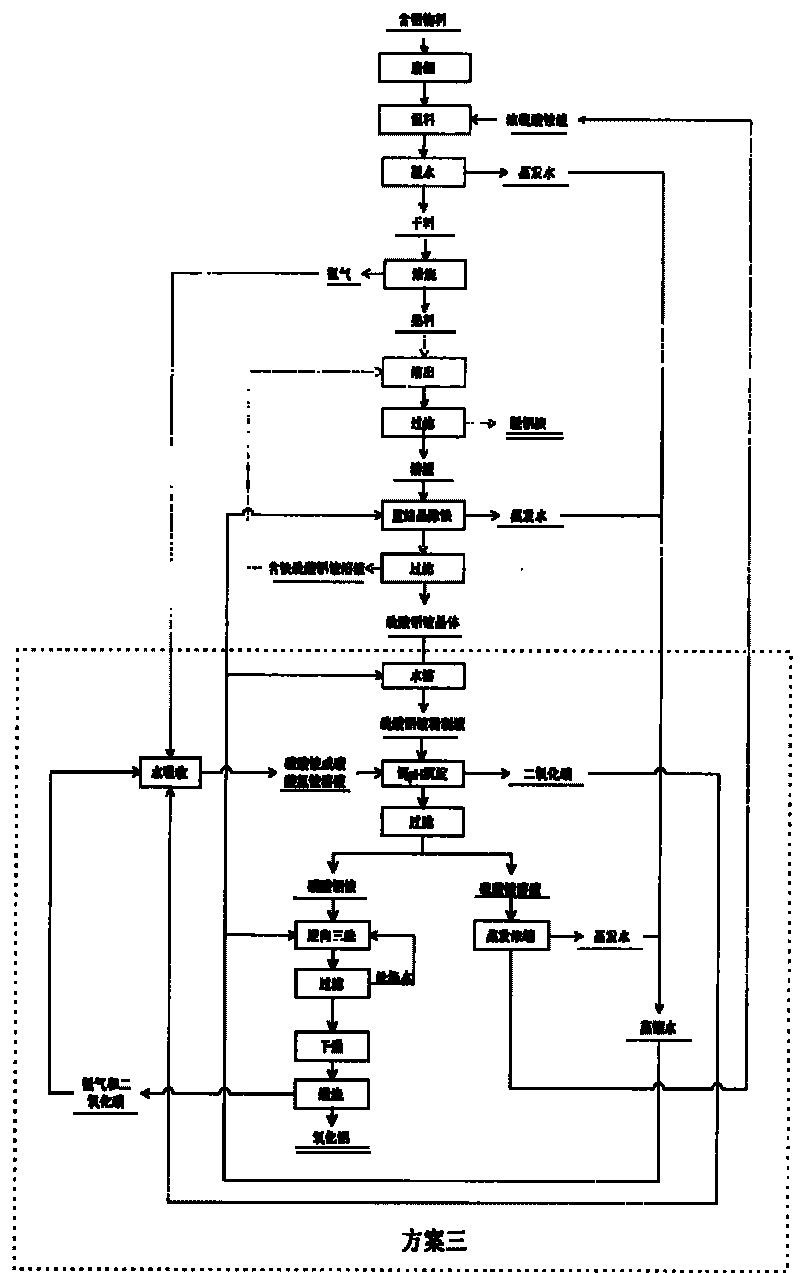

Method for preparing aluminum oxide from aluminiferous material

InactiveCN101734698AHigh value-added comprehensive utilizationCause secondary pollutionAluminium oxide/hydroxide preparationAluminium hydroxide preparationAluminum ammonium sulfateAlunite

The invention provides a method for preparing aluminum oxide and other products from aluminiferous materials such as bauxite, high iron bauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like. The method comprises the following steps: (1) crushing, grinding and mixing the aluminiferous materials with ammonium sulfate and then roasting; (2) dissolving the roasted product (clinker aggregate) in water, and filtering to obtain aluminum ammonium sulfate solution and filter residues; (3) carrying out deferrization, aluminum deposition or recrystallization on the aluminium ammonum sulfate solution with ammonia to prepare aluminum oxide, and meanwhile, recycling the ammonium sulfate; (4) preparing silicon dioxide from the filter residues, and taking the remaining residues containing ferrum as the raw material for ironmaking. The method is suitable for treating various aluminiferous materials, has the advantages of simple technical process, simple equipment, no emission of solid, liquid and gas wastes, and no secondary pollution, and realizes the high-added-value green complex utilization of the aluminiferous materials such as bauxite, high ironbauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like.

Owner:NORTHEASTERN UNIV

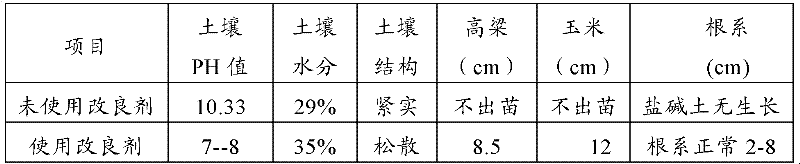

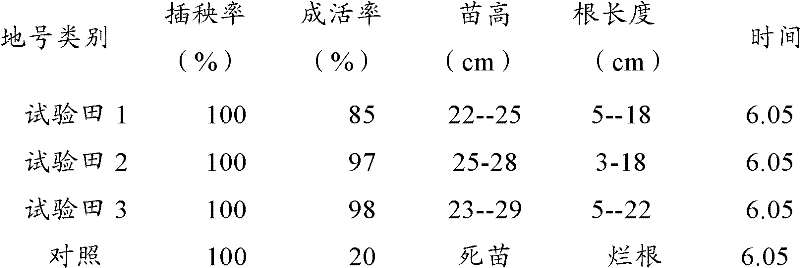

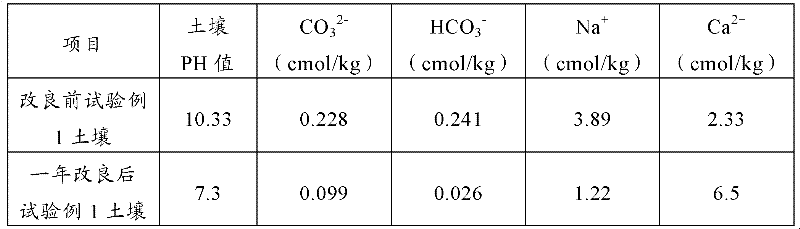

Saline-alkali soil improver

InactiveCN102517030ALower pHRaise the pHOther chemical processesOrganic fertilisersCis-Butenedioic AcidFatty alcohol

The invention relates to an improver for saline-alkali soil. The improver comprises a powder agent and a water agent, wherein the powder agent comprises the following components: organic matters, plant mycelium protein powder, active calcium, calcium superphosphate, aluminum sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, amino acid powder, bacillus subtilis and photosynthetic bacteria, and the water agent comprises the following components: citric acid, fulvic acid, humic acid, malic acid, maleic acid, fumaric acid, L-tartaric acid, pyrophosphoric acid, humic acid, lactic acid, oxalic acid, salicylic acid, sodium ion adsorbent, Tween-80 and water. The improver disclosed by the invention can improve the soil from multiple angles, namely soil structure, microorganism species, a chemical method and the like, obviously promote the release of iron and phosphorus in the soil, improve the soil structure, effectively reduce the content of sodium ions in the soil, reduce the pH value of the soil and restore land to a normal planting state after being used continuously for two years.

Owner:孙东军 +1

Anti-emulsification water-soluble metal washing agent

The invention relates to an anti-emulsification water-soluble metal washing agent. Every 100 parts of the anti-emulsification water-soluble metal washing agent include the following components according to parts by weight: 3-7 non-ionic surfactant, 3-7 bi-ion active agent, 1-5 chelator, 1-5 rust preventive, 5-10 inorganic builder and the balance water, wherein the non-ionic surfactant is any one of fatty amine polyoxypropylene ether, alkylphenol ether and fatty amine polyoxyethylene alkyl ether ammonium sulfate, the bi-ion active agent is any one of alkyl dimethylin acetic acid betaine, lauramidopropyl betaine and cocamidopropyl betaine, the chelator is any one of sodium citrate, ethylenediaminetetraacetic acid tetrasodium salt and nitrilotriacetic acid sodium salt, the rust preventive is any one of sodium borate, sodium nitrite, sodium benzoate and long carbon chain carboxylic acid amine, and the inorganic builder is any one of trisodium phosphate, sodium metasillcate, sodium carbonate, sodium bicarbonate and sodium hydroxide. The anti-emulsification water-soluble metal washing agent has the advantage of higher cleaning capacity and reutilization capacity.

Owner:NANJING KERUN LUBRICANTS

Stable multi-phased personal care composition

InactiveUS20060079418A1Increase depositionExcellent skin conditioningCosmetic preparationsHair cosmeticsPersonal careSodium laurate

A stable multi-phase personal care composition is described. The stable multi-phase composition comprises least two visually distinct phases; wherein at least one visually distinct phase comprises a cleansing phase comprising a surfactant component. The surfactant component comprises at least one anionic surfactant selected from the group consisting of ammonium lauryl sulfate, ammonium laureth sulfate, sodium lauryl sulfate, sodium laureth sulfate, sodium cocoyl sulfate, sodium laurate, sodium cocoyl isethionate, monomethyl branched surfactants and mixtures thereof. The visually distinct phases of the stable multi-phase personal care composition form a pattern.

Owner:THE PROCTER & GAMBLE COMPANY

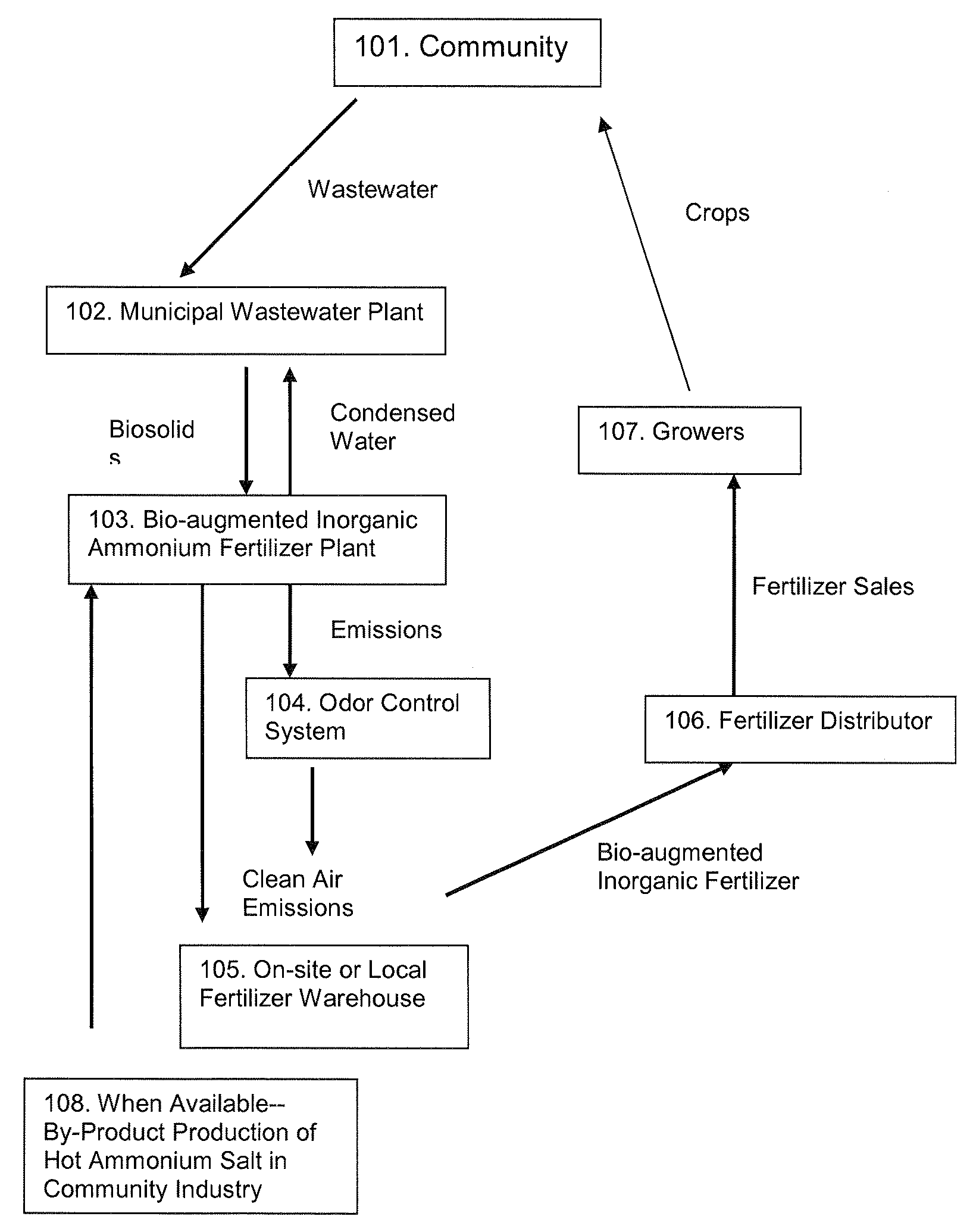

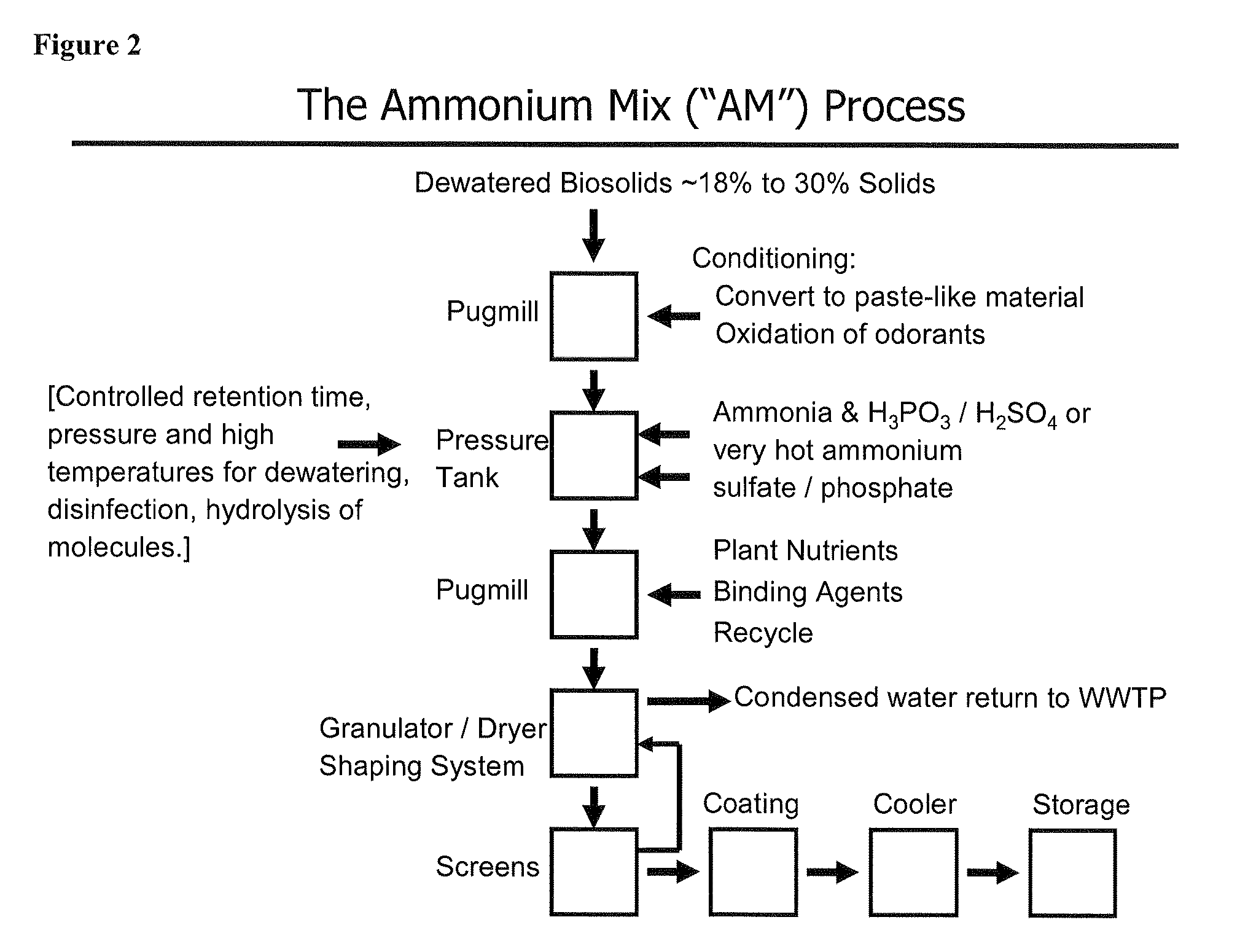

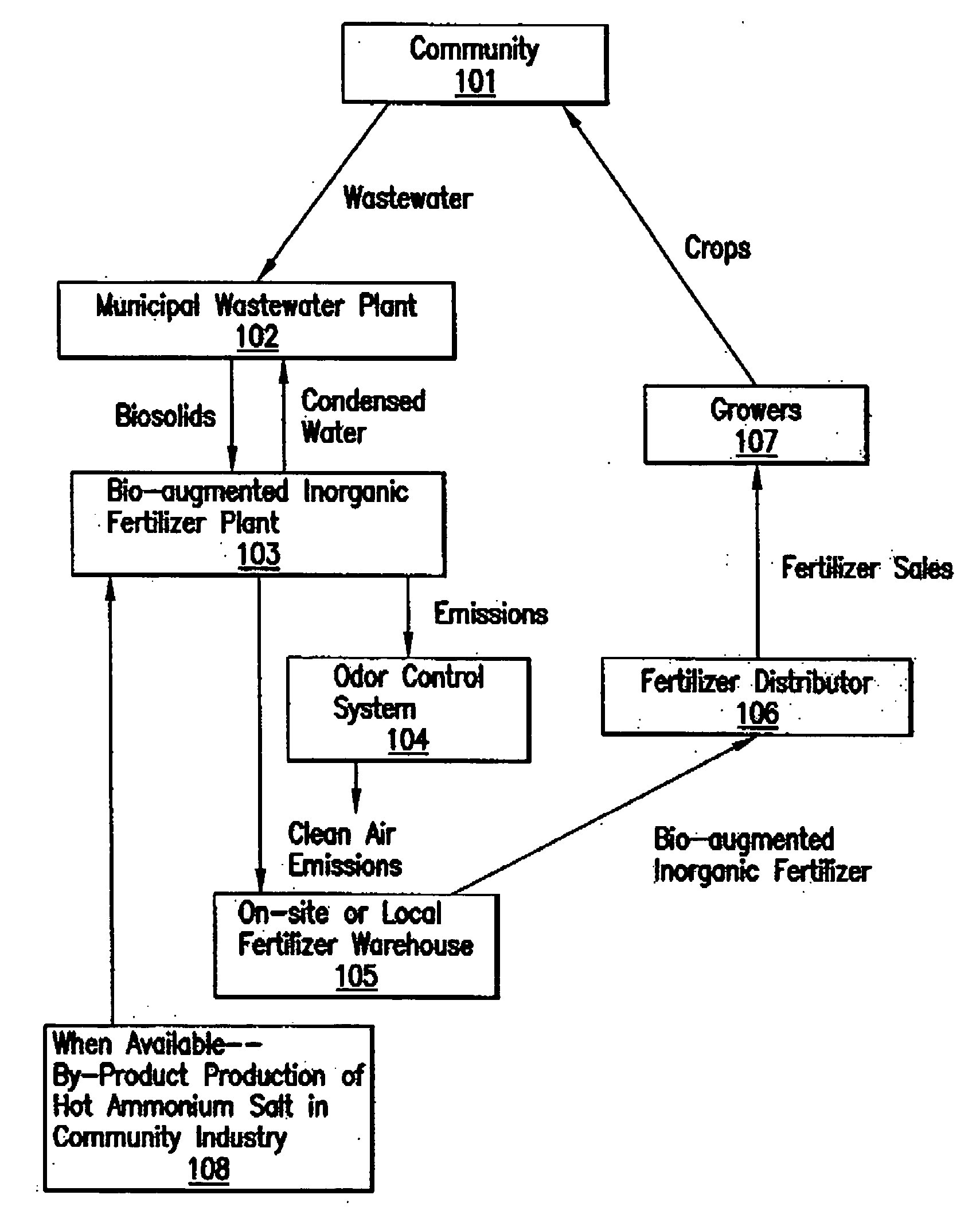

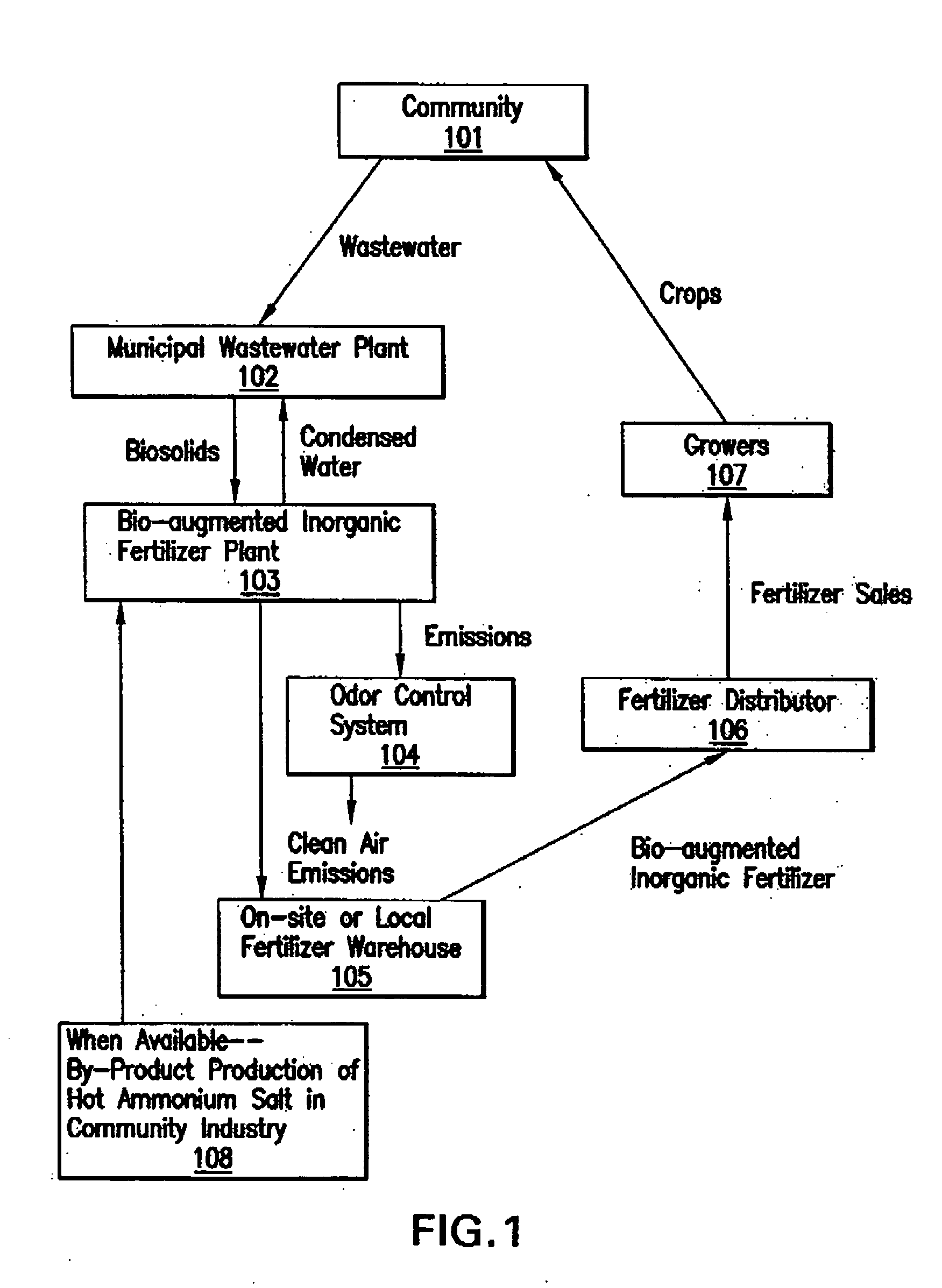

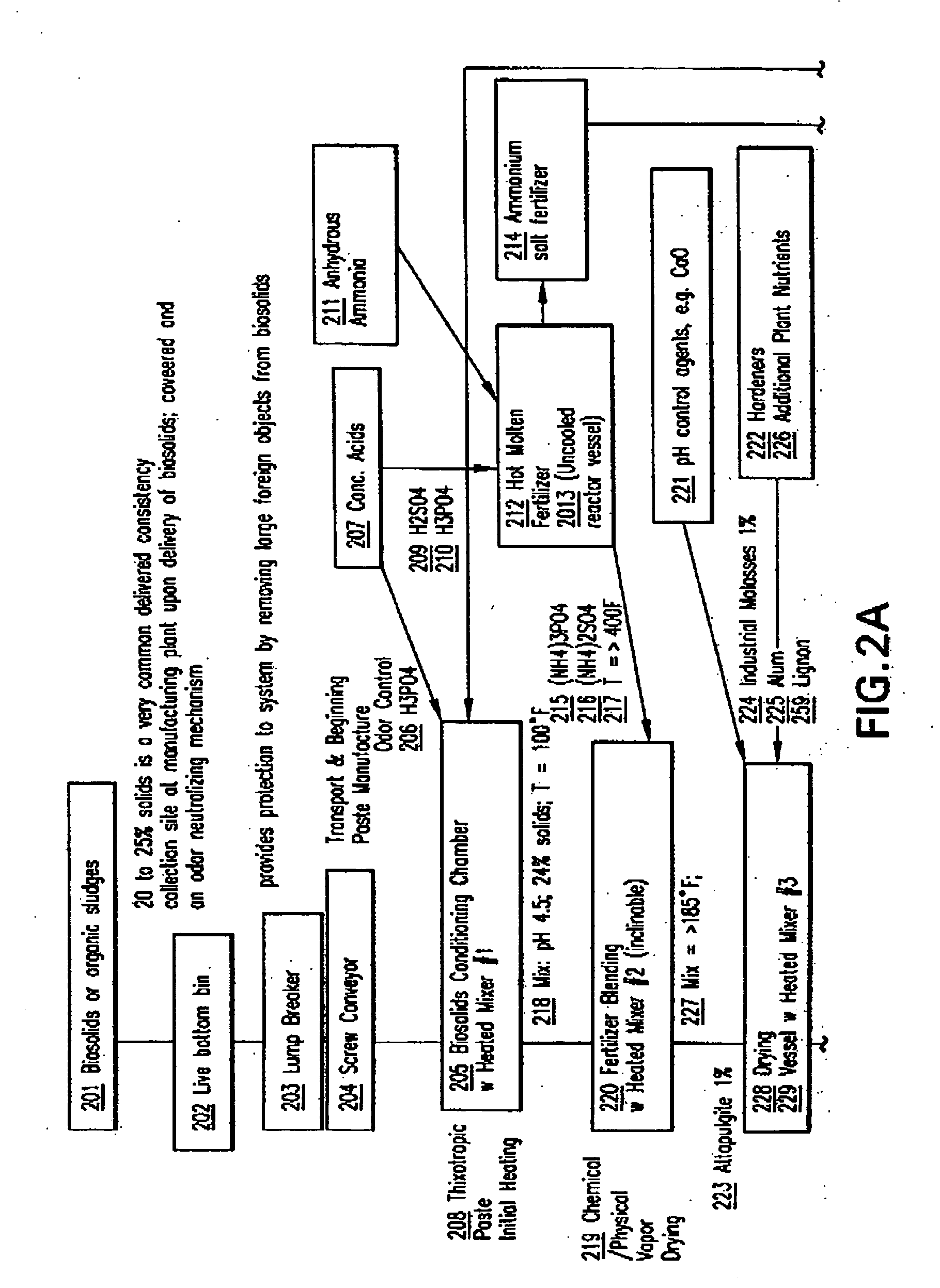

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS20080230484A1Reduce logisticsReduces liabilityByproduct vaporizationExcrement fertilisersPhosphateRetention time

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

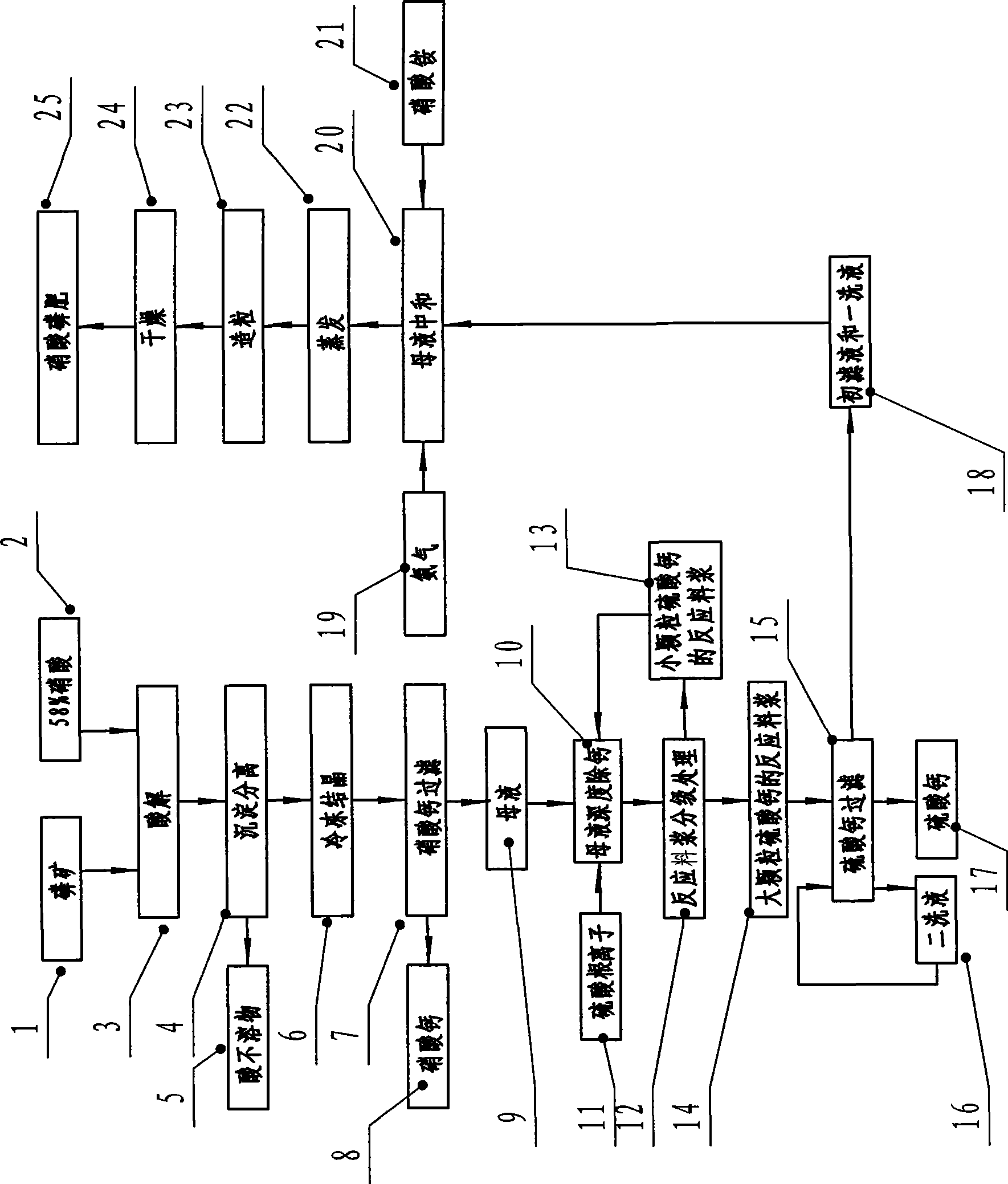

Technological process for producing high concentration nitric-phosphate fertilizer

The invention discloses a technique method for producing high-concentration nitric phosphate, which comprises the following steps of: adding nitric acid into phosphorus ore for acidolysis, depositing and separating acid non-soluble substance, freezing and crystallizing calcium nitrate, filtering the calcium nitrate, neutralizing the mother liquid, vaporization, pelleting and drying. The invention is characterized in that: a step of thoroughly removing the calcium of the mother liquid is arranged between the steps of filtering the calcium nitrate, and neutralizing the mother liquid. The steps comprise the following steps of: I) thoroughly removing the calcium of the mother liquid and adding sulfuric acid or ammonium sulfate; the calcium ions and the sulfate ions in the mother liquid generate dihydrate calcium sulfate crystal; II) the grading processing of reaction slurry: employing a grading device to carry out grading processing to the reaction slurry; returning the reaction slurry provided with small grain calcium sulfate to the mother liquid for thoroughly removing the calcium, and feeding the reaction slurry provided with large grain calcium sulfate to the calcium sulfate for filtering; and III) filtering and washing the filtering reaction slurry of calcium sulfate by a filter, feeding the primary filtrate and the primary lavage fluid into the working procedure of neutralizing, and returning the secondary lavage fluid to the filter. The invention has the advantage of using middle-low quality phosphorite to prepare the high-concentration nitric phosphate.

Owner:TIANJI COAL CHEM IND GROUP +1

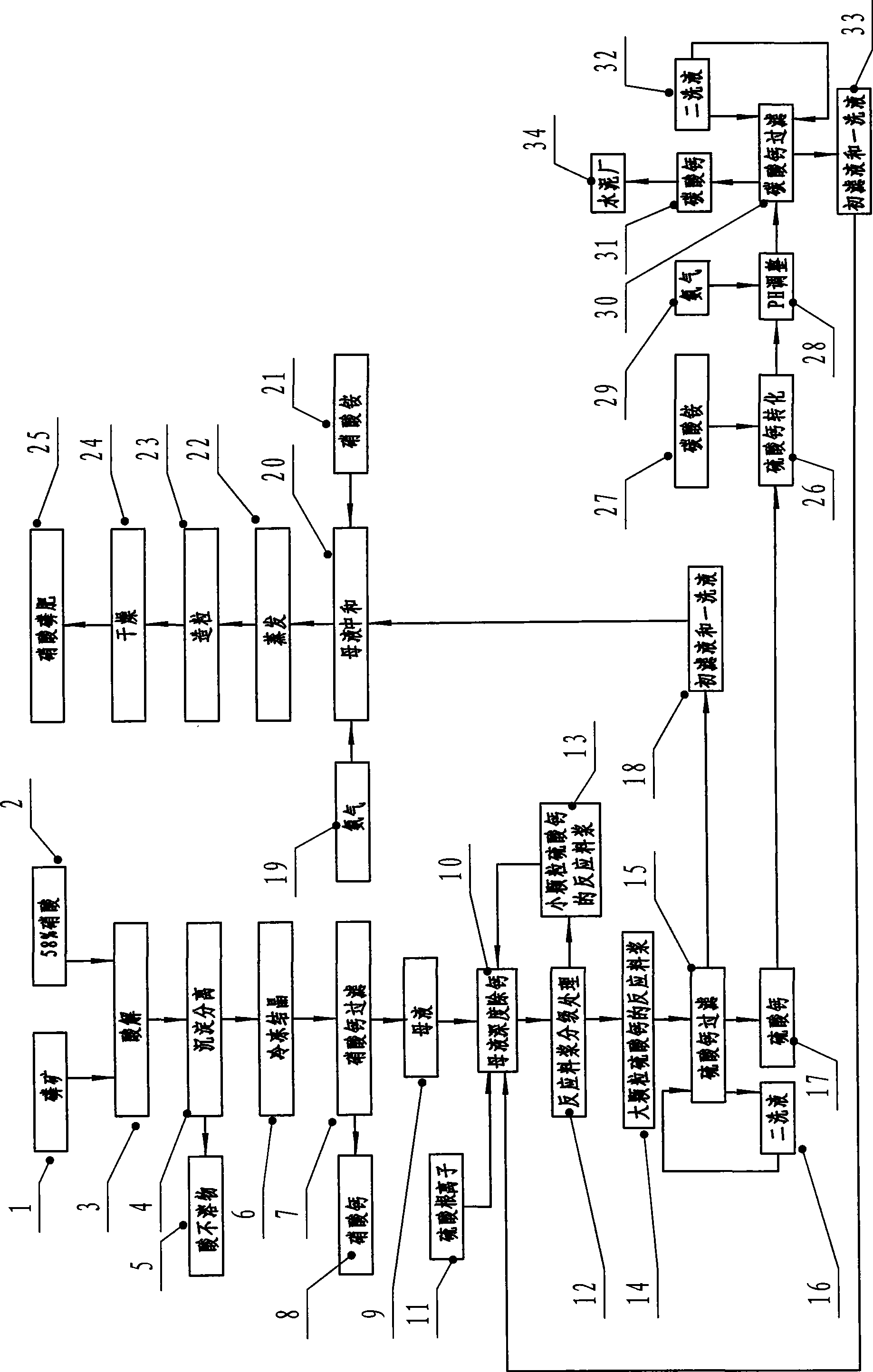

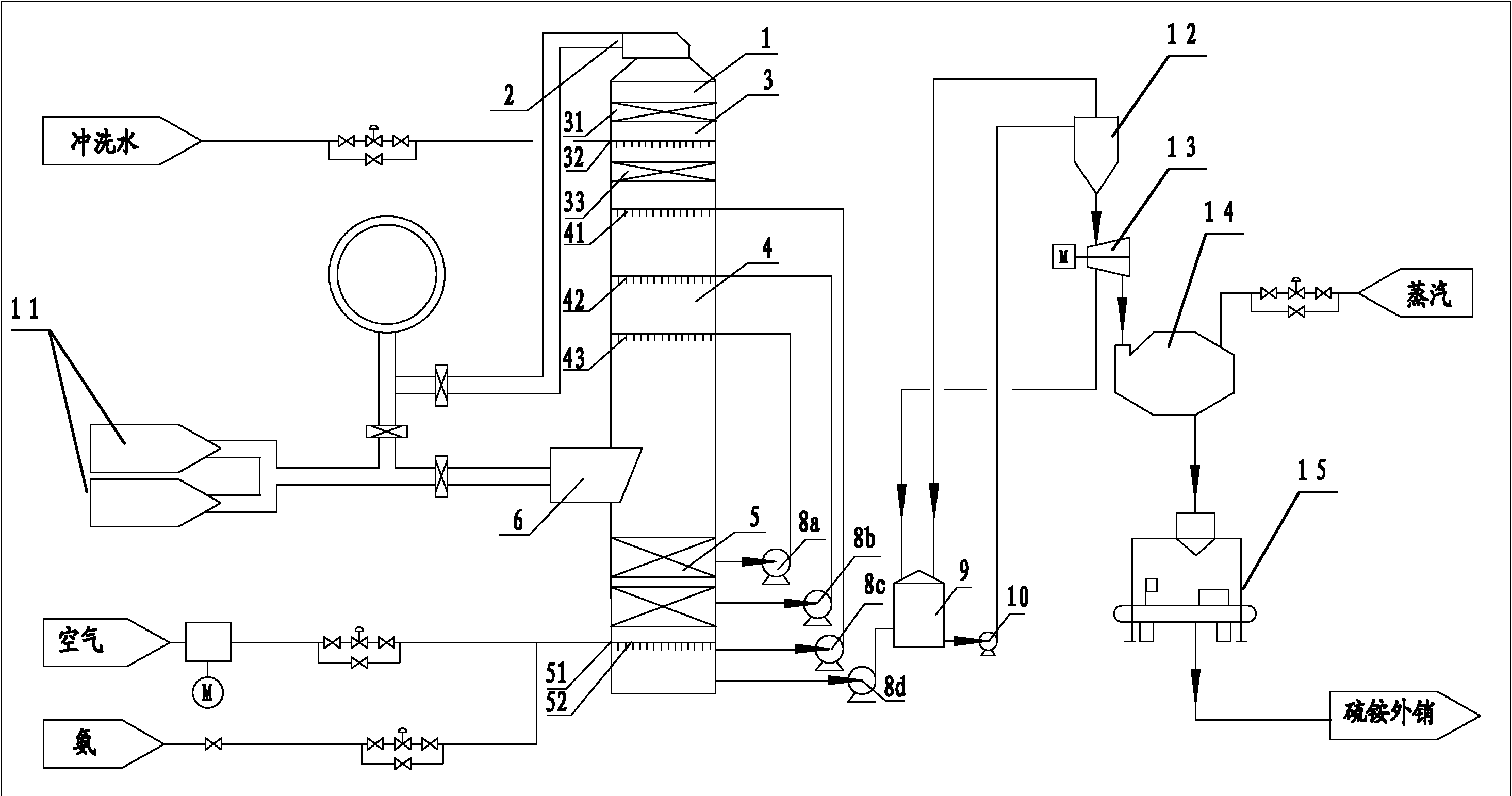

Method for desulfurizing and denitrating smoke simultaneously through ammonia method

ActiveCN101934191AIncrease profitReduce ammonia consumptionDispersed particle separationAmmonia compoundsAmmoniaAmmonium sulfate

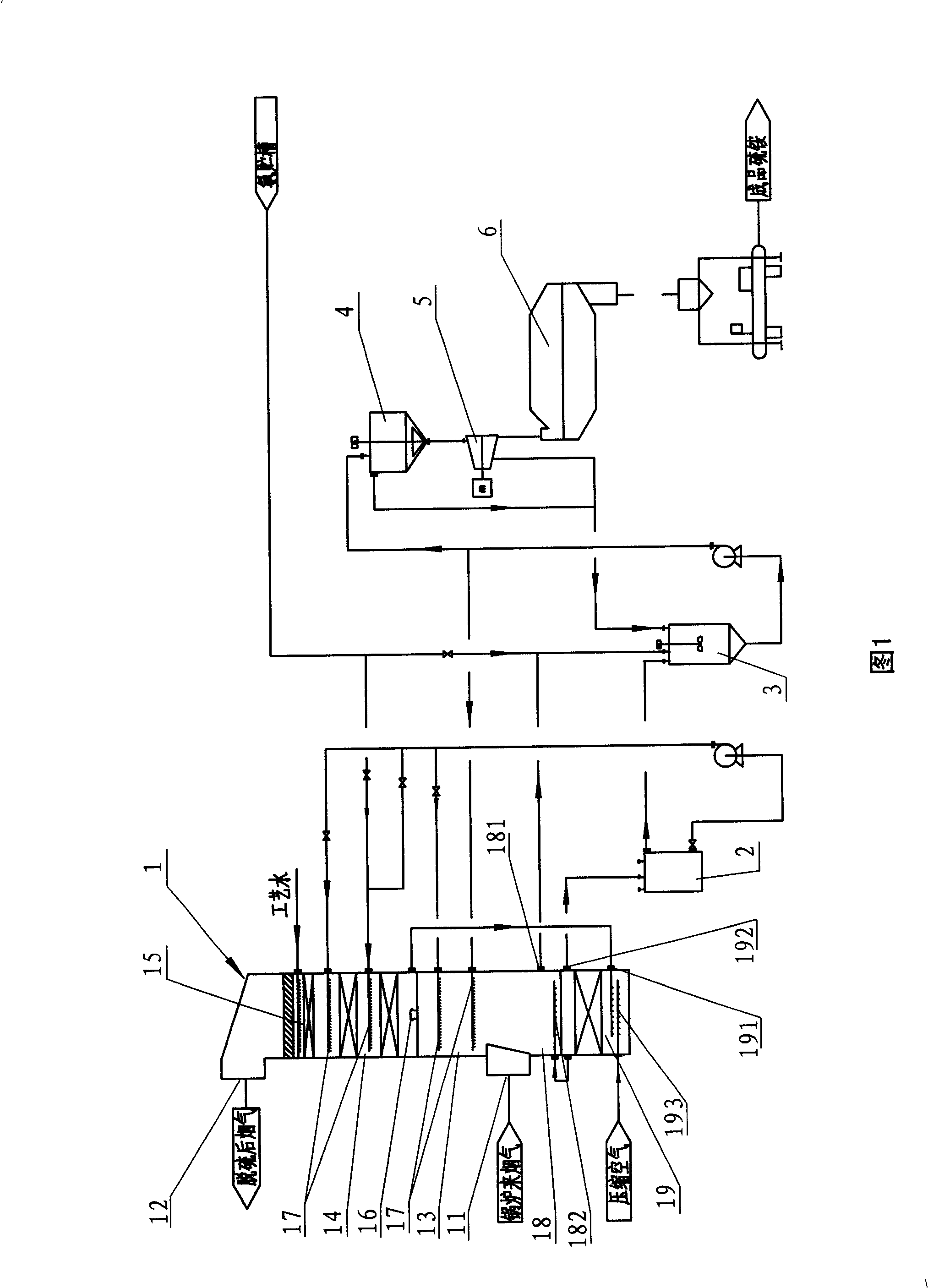

The invention relates to a method for desulfurizing and denitrating smoke simultaneously through an ammonia method, which is carried out in a desulfurizing and denitrating system. The desulfurizing and denitrating system comprises a desulfurizing and denitrating tower, the desulfurizing and denitrating tower is provided with a washing demisting segment, an absorption segment and an oxidation segment, wherein the absorption segment is provided with a first desulfurizing spray layer, a second desulfurizing spray layer and a denitrating spray layer from top to bottom; the oxidation segment is provided with a denitrating circulation layer, a desulfurizing circulation layer and an oxidation layer from top to bottom, wherein the denitrating circulation layer, the desulfurizing circulation layerand the oxidation layer are respectively communicated with the denitrating spray layer, the second desulfurizing spray layer and the first desulfurizing spray layer through circulating pipelines positioned outside the desulfurizing and denitrating tower; smoke enters from a smoke inlet, sequentially contacts with the absorption liquid of the denitrating spray layer, the second desulfurizing spraylayer and the first desulfurizing spray layer for denitration and desulfurization, then enters the washing demisting segment and then is exhausted; the absorption liquid of the spray layers descends to the oxidation segment and reacts on the oxidation layer to generate ammonium sulfate; and the absorption liquid of the denitrating circulation layer, the desulfurizing circulation layer and the oxidation layer is respectively delivered to the denitrating spray layer, the second desulfurizing spray layer and the first desulfurizing spray layer through the circulating pipelines positioned outsidethe desulfurizing and denitrating tower.

Owner:NANJING NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION CO LTD

Glass and method for producing glass

Glass having a small number of bubbles even without containing As2O3 or Sb2O3 and further without containing SO3 and a method for producing glass without using either As2O3 or Sb2O3 as a refiner, are provided. Glass having a reduction degree such that Fe2+ / (Fe2++Fe3+) is at least 0.61, as the reduction degree of glass is represented by a ratio of Fe ions. A method for producing glass, which comprises melting raw material to produce glass comprising, as represented by mass percentage, at least 40% of Si as SiO2, characterized in that the raw material contains an ammonium salt (except for ammonium sulfate and ammonium nitrate).

Owner:ASAHI GLASS CO LTD

Special organic-inorganic composite biological pesticide-fertilizer for flowers and preparation method thereof

The invention provides a special organic-inorganic composite biological pesticide-fertilizer for flowers. The special organic-inorganic composite biological pesticide-fertilizer for flowers comprises the following raw materials in parts by weight: 80-90 parts of municipal sludge, 10-20 parts of fruit peel, 10-20 parts of fallen leaves, 10-15 parts of poultry manure, 10-14 parts of bagasse, 20-30 parts of iron ore slag, 10-12 parts of animal feathers, 10-15 parts of tree ash, 10-15 parts of monoammonium phosphate, 20-25 parts of urea, 10-12 parts of ammonia sulfate, 8-10 parts of ammonium hydrogen carbonate, 8-10 parts of potassium chloride, 5-7 parts of carboxymethyl chitosan, 20-30 parts of modified bentonite, 5-8 parts of lignite, 2-4 parts of black dye tree, 9-11 parts of celastrus angulatus, 9-11 parts of common carpesium fruit, 9-11 parts of radix sophorae flavescentis, 4-6 parts of lilac daphne flower bud, 3-5 parts of coptis root, 10-12 parts of powder of root of stellera chamaejasme, 2-4 parts of vegetable oil, 1-3 parts of zinc sulfate, 3-4 parts of ferrous sulfate, 0.8-1.2 parts of borax, 20-26 parts of potassium fulvate and 0.3-0.4 part of EM (effective microorganism) strain. The pesticide-fertilizer disclosed by the invention has the advantages of scientific ratio of nitrogen, phosphorus and potassium, easiness in absorption by crops, obvious yield-increasing benefit and the like. By applying the pesticide-fertilizer, the nutrient absorption of plants can be balanced, the quality of flowers can be effectively improved, plants are green in leaves and bright in flower, and the flowering phase is also prolonged.

Owner:东至县神山化肥有限责任公司 +1

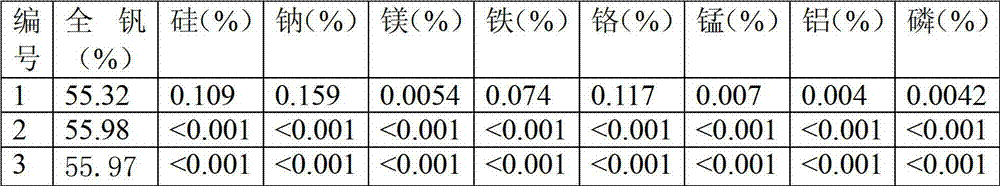

Preparation method of high-purity vanadium pentoxide

ActiveCN103194603AAffect the washing effectHigh purityProcess efficiency improvementVanadateImpurity

The invention discloses a preparation method of high-purity vanadium pentoxide. The method comprises the following steps of: a, grinding a vanadium-containing raw material, and removing iron; b, performing sodium roasting on the raw material treated in the step a, and leaching to obtain the vanadium-containing solution; c, removing cation impurities and anion impurities from the vanadium-containing solution obtained in the step b, and filtering to obtain the purified vanadium-containing solution; d, adding ammonium sulfate into the purified vanadium-containing solution to perform molybdenum precipitation treatment, filtering, washing and removing impurities to obtain vanadate precipitate; and e, pulping and filtering the vanadate precipitate, washing, further removing impurities in the vanadate precipitate, drying and roasting to obtain a vanadium pentoxide product. By virtue of the strict and effective impurity removal treatment, the purity of the vanadium pentoxide product can be increased, and can be over 99 percent.

Owner:攀枝花市阳润科技有限公司

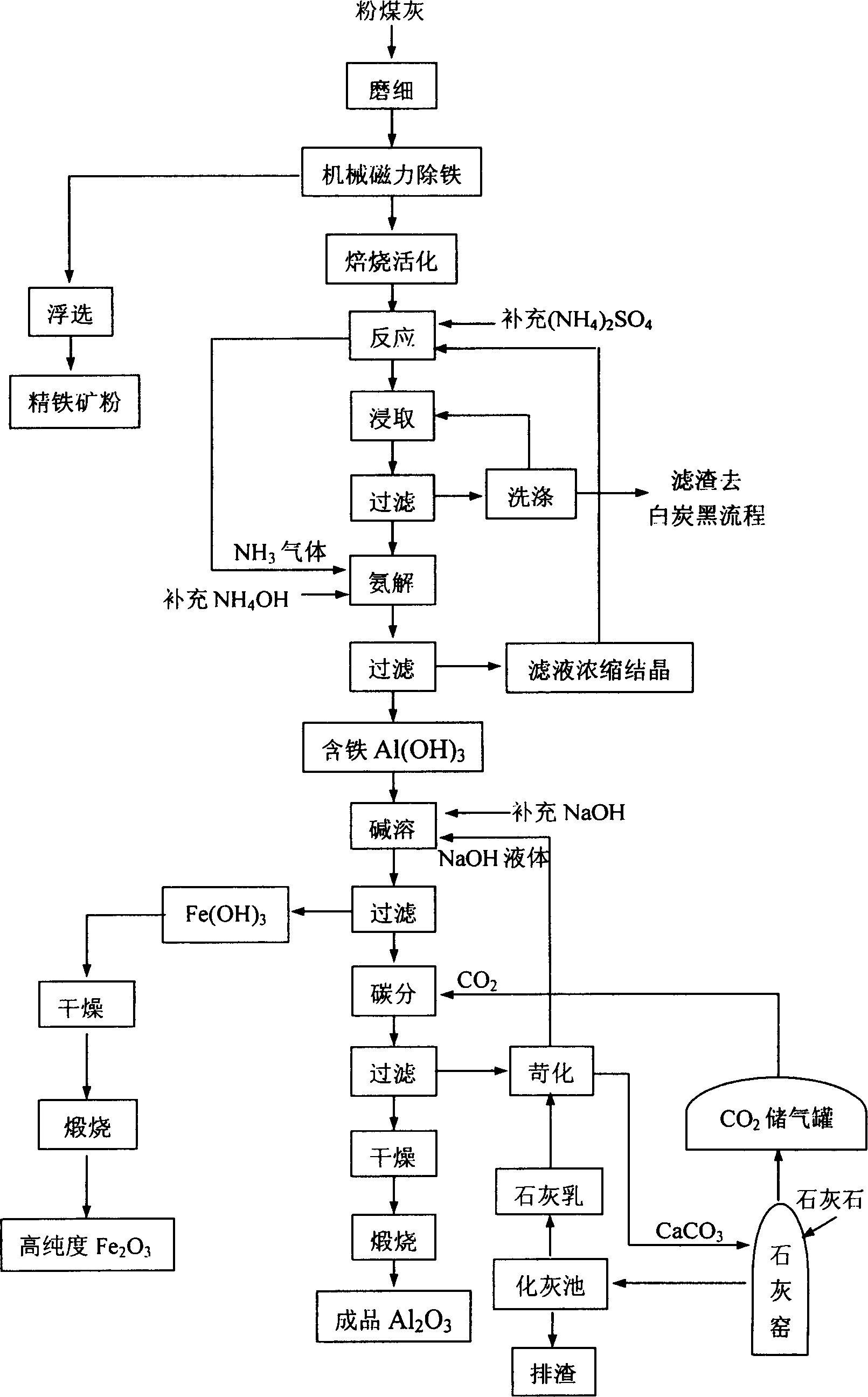

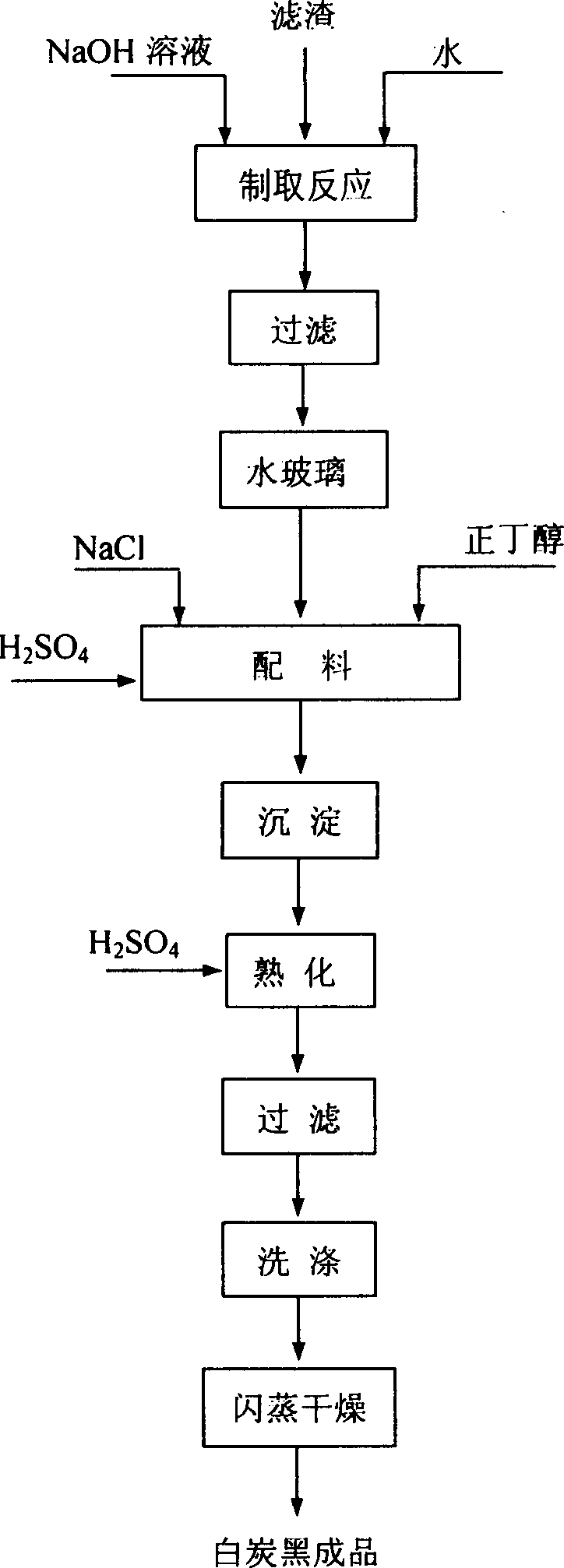

Method of extracting aluminium oxide from fly ash and simultaneously producing white carbon black

InactiveCN1868884AHigh activityUniform particle sizeSilicaAluminium oxides/hydroxidesAluminium hydroxideCoal

A process for extracting alumina from powdered coal ash while generating white carbon black includes such steps as grinding powdered coal ash, activating, adding ammonium sulfate, reacting, adding water, filtering, filling ammonia gas into the filtered liquid to obtain the deposited mixture of aluminum hydroxide and iron hydroxide, adding the solution of sodium hydroxide to dissolve the aluminum hydroxide deposit, adding carbon to obtain pure aluminum hydroxide, and calcining to obtain Al2O3.

Owner:NORTH UNITED POWER CO LTD

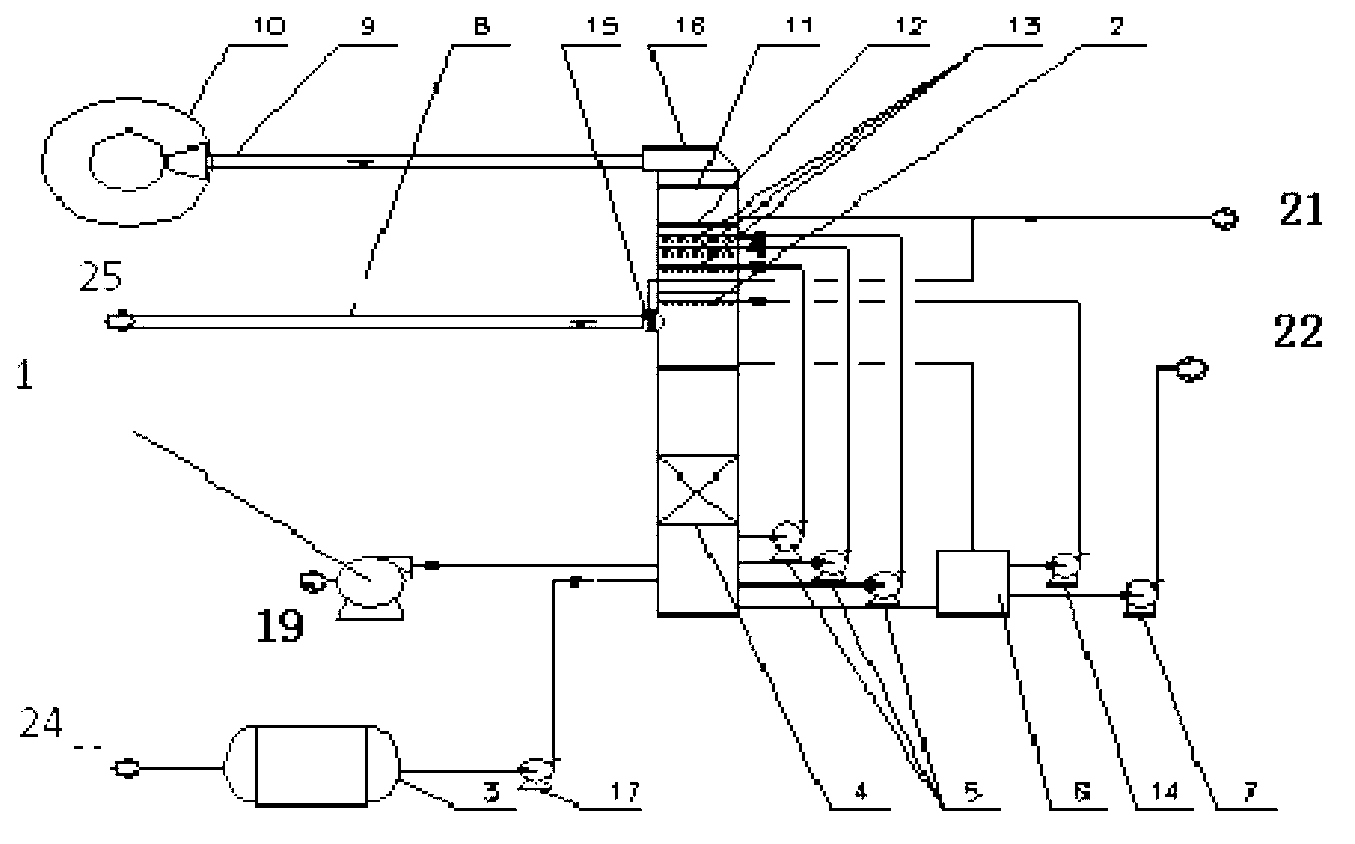

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Preparation method of high-purity vanadium pentoxide

InactiveCN102923775AEfficient removalReduce pollutionVanadium oxidesMetal impuritiesAmmonium metavanadate

The invention discloses a preparation method of high-purity vanadium pentoxide. The preparation method comprises the following steps of: returning and dissolving coarse vanadium in aqueous alkali, and filtering the solution to remove metal impurities, which are subjected to precipitation reaction with the aqueous alkali, in the coarse vanadium, thus obtaining a primary returned solution; slowly pouring the primary returned solution into a sulfuric acid solution, adjusting the pH value of the solution to be 1.0-2.0 to obtain a liquid-solid mixture, and performing solid-liquid separation on the liquid-solid mixture; filtering and washing precipitates obtained from the solid-liquid separation of the mixture, and returning and dissolving the mixture into the aqueous alkali, thus obtaining a secondary returned solution; adding ammonium sulfate into the secondary returned solution for precipitating vanadium, and filtering the solution to obtain ammonium metavanadate; and processing the ammonium metavanadate to obtain the high-purity vanadium pentoxide. The preparation method adopting multiple stages of returned dissolving can be used for effectively removing the metal canon impurities of the vanadium pentoxide, and further obtaining the high-purity vanadium pentoxide with the metal canon impurity contents of less than 0.001% and the vanadium pentoxide content of 99.99%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

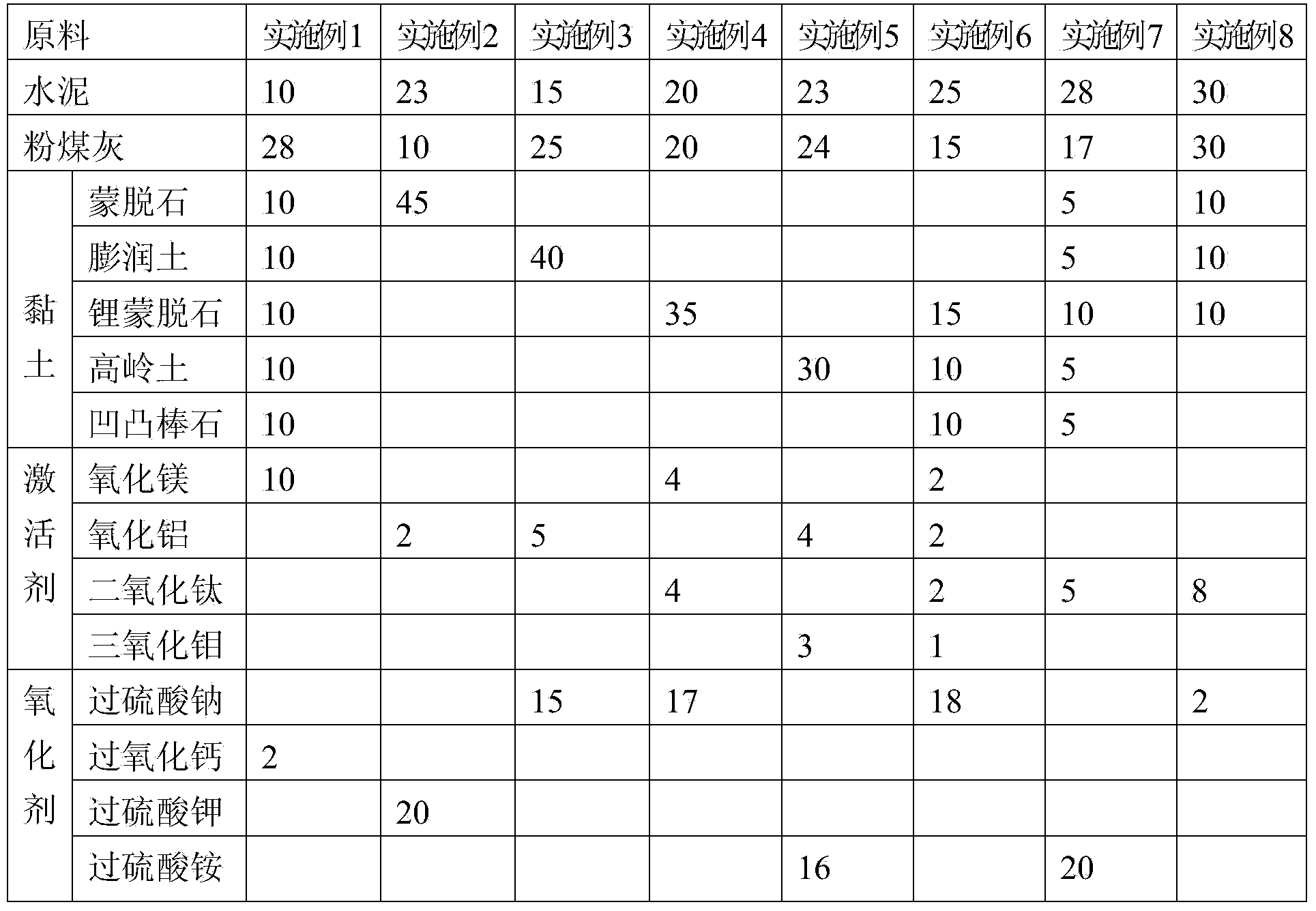

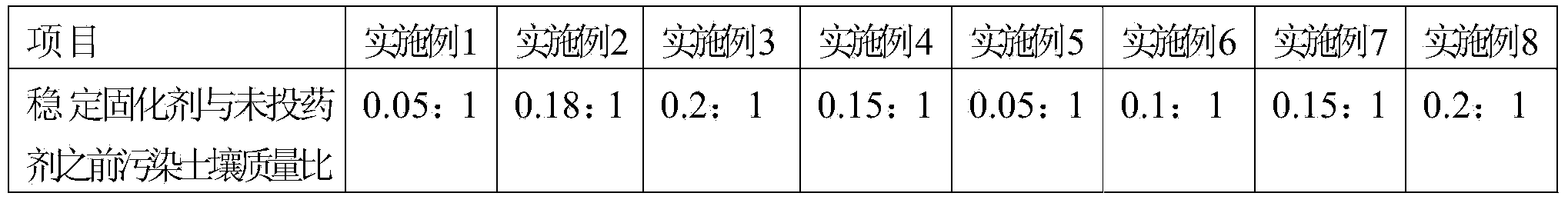

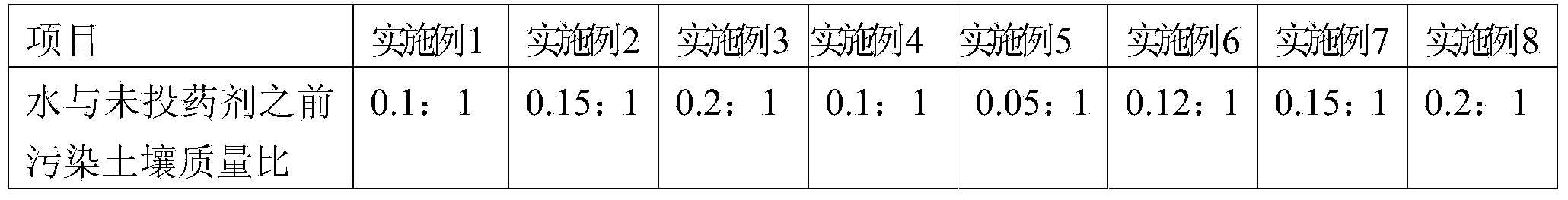

Stable curing agent of repairing heavy metal and toxic organic matter combined polluted soil and using method of curing agent

ActiveCN103881727AImprove repair effectBioeffectiveAgriculture tools and machinesContaminated soil reclamationPotassium persulfateCoal

The invention relates to a stable curing agent of repairing heavy metal and toxic organic matter combined polluted soil. The stable curing agent comprises the following raw materials in percentage by weight: 10-30% of cement, 10-30% of coal ash, 20-50% of clays, 2-10% of an activating agent and 2-20% of an oxidizing agent, wherein the activating agent is a composition of one or more than two of magnesium oxide, aluminum oxide, titanium dioxide or molybdenum trioxide, and the oxidizing agent is a composition of one or more than two of sodium persulfate, calcium peroxide, potassium persulfate and ammonium persulfate. The raw materials are put into a grinder to be uniformly grinded and mixed to prepare the stable curing agent with the specific surface area of 400-800 / kg. The stable curing agent provided by the invention has the characteristics of low cost, good soil repairing effect and simplicity in construction.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

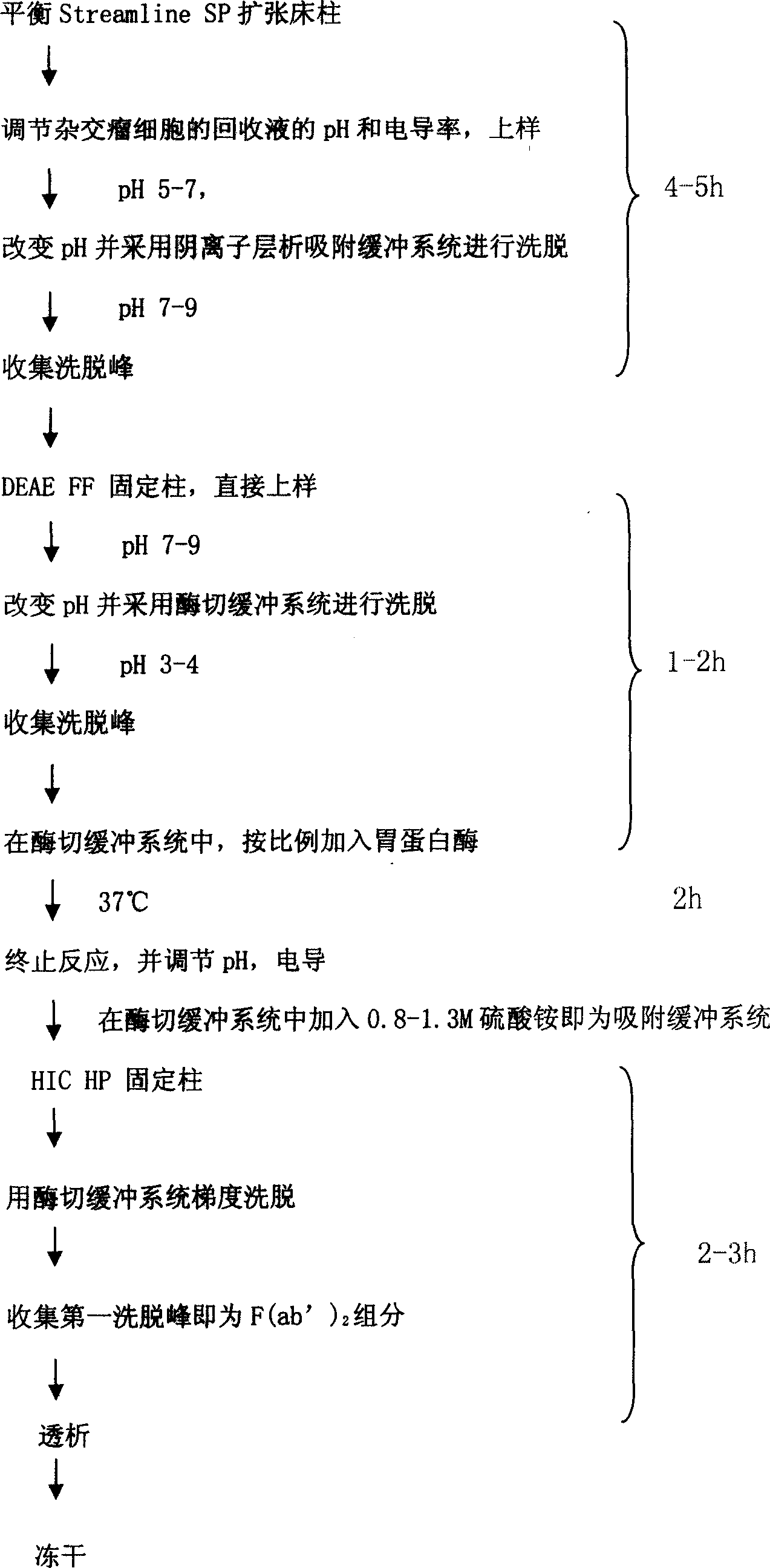

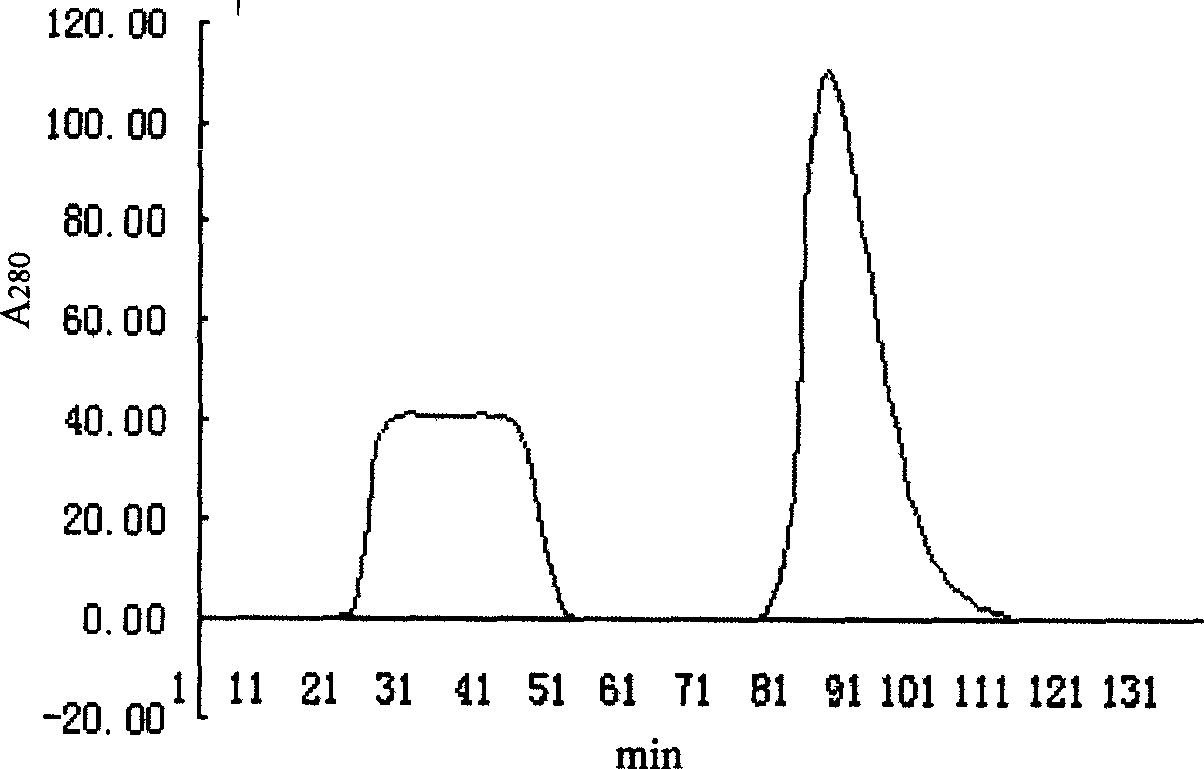

High performance quick purifying method for preparing piecewise antibody

ActiveCN1563090AReduce replacement stepsHigh purityImmunoglobulins against animals/humansPeptide preparation methodsPurification methodsEnrichment methods

The invention discloses a method for high-effectively quickly purifying and preparing fragment antibody from animal cell scale culture. Said method adopts the processes of dilatant column bed adsorption, anion chromatography concentration and hydrophobic chromatography purification, and includes the following steps: using dilatant column bed cation chromatography to adsorb antibody IgG from large-scale cell culture, changing pH value of buffer system to make elution, making collected elution peak be directly andergone the process of anion chromatography, using pepsinum to directly enzyme-out the fully-concentrated and purified antibody IgG to obtain fragment antibody, making hydrophobic chromatography and purification so as to obtain final fragment antibody whose purity is up to above 97%, and its whole purification process can be completed within 12 hr. Said invented method can be substituted for traditional ammonium sulfate precipitation, concentration method, and has the characteristics of high efficiency, rapid speed, high purity and stable operation and result, etc.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Manufacturing of bioorganic-augmented high nitrogen-containing inorganic fertilizer

The invention describes a new method for the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method creates a thixotropic paste-like material from the biosolids or organic sludge that is blended with hot or molten ammonium salts, especially a mixture of ammonium phosphate and ammonium sulfate. The invention can be an add-on to commercial production of ammonium salts or it can stand alone by manufacturing ammonium salts prior to their introduction to the conditioned biosolids. The invention is oriented to be tailored to production facilities for individual municipal waste treatment plants in order to keep manufacturing plants small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

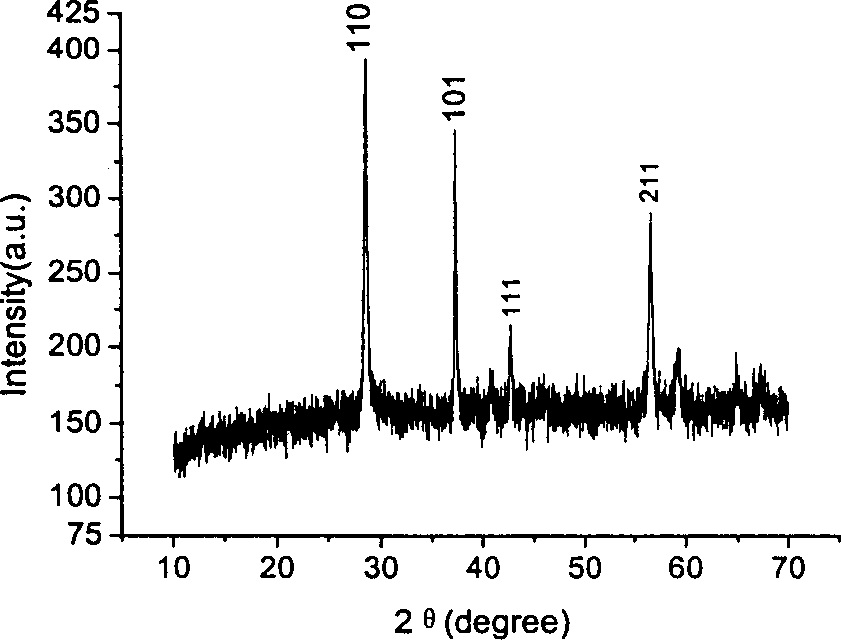

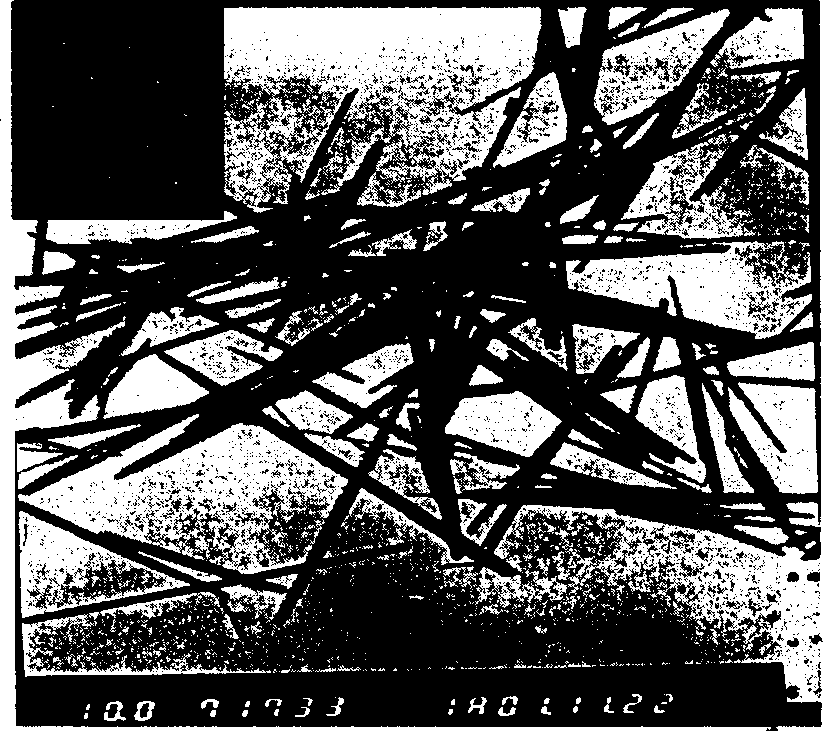

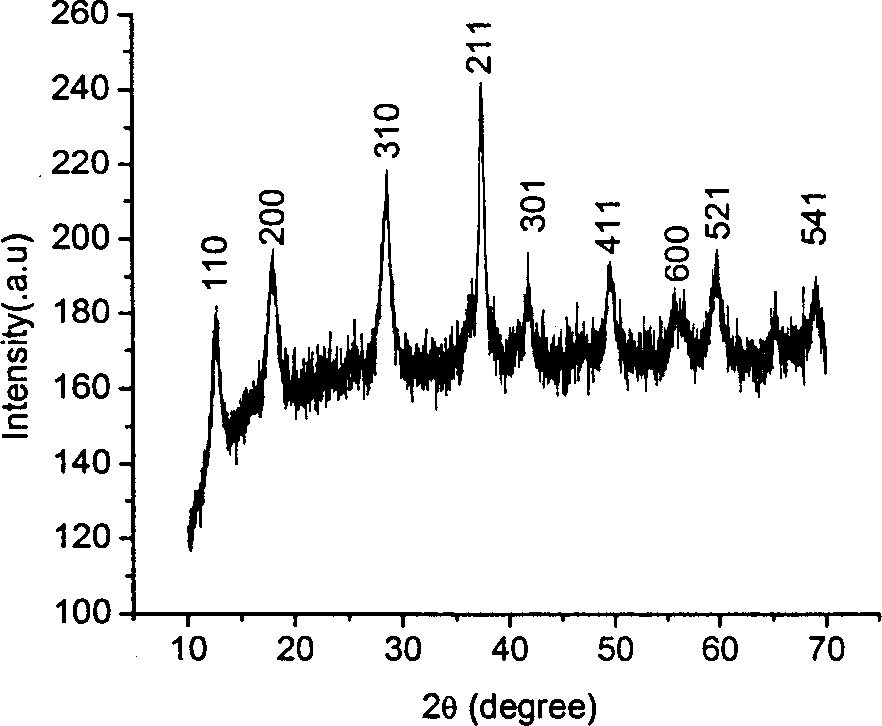

Process for synthesizing different crystal form one-dimensional single crystal mangnesium dioxide nano wire

InactiveCN1377832ALow costSimple processPolycrystalline material growthManganese oxides/hydroxidesNanowireManganese

The present invention relates to the preparation of nano material. One-dimensional monocrystalline nano manganese dioxide wire of different crystal form is synthesized selectively via controlling thetemperature, period and material control of the hydrothermal reaction of two-valent manganese salt and ammohnium persulfate as raw material and ammonium sulfate as additive at 100-220 deg.c inside one sealed reactor. The process may be widely used in basic theory research in lithium ion cell, molecular sieve and relevant fields.

Owner:TSINGHUA UNIV

Method for recovering rare earth from ionic type rare earth crude ore

ActiveCN102190325AReduce or eliminate pollutionSolve pollutionRare earth metal compoundsAmmonium sulfateCarbonic acid

The invention discloses a method for recovering rare earth from ionic type rare earth crude ore, which comprises the following steps of: leaching the ionic type rare earth crude ore by taking at least one of magnesium sulfate, magnesium chloride and calcium chloride, instead of most or all ammonium sulfate, ammonium chloride or sodium chloride, as an ore leaching agent to obtain rare earth leachate, performing neutralization and impurity removal, and precipitating rare earth by adopting solution of magnesium hydrogen carbonate or / and calcium bicarbonate to obtain a rare earth carbonate product. In the method, an ammonium bicarbonate precipitator and most or all ammonium sulfate, ammonium chloride and sodium chloride serving as ore leaching agents are eliminated, pollution of ammonia nitrogen wastewater and high-salinity sodium salt wastewater on environment and underground water is greatly reduced or eliminated, and the method is an environment-friendly ionic type rare earth ore mining process.

Owner:GRIREM ADVANCED MATERIALS CO LTD

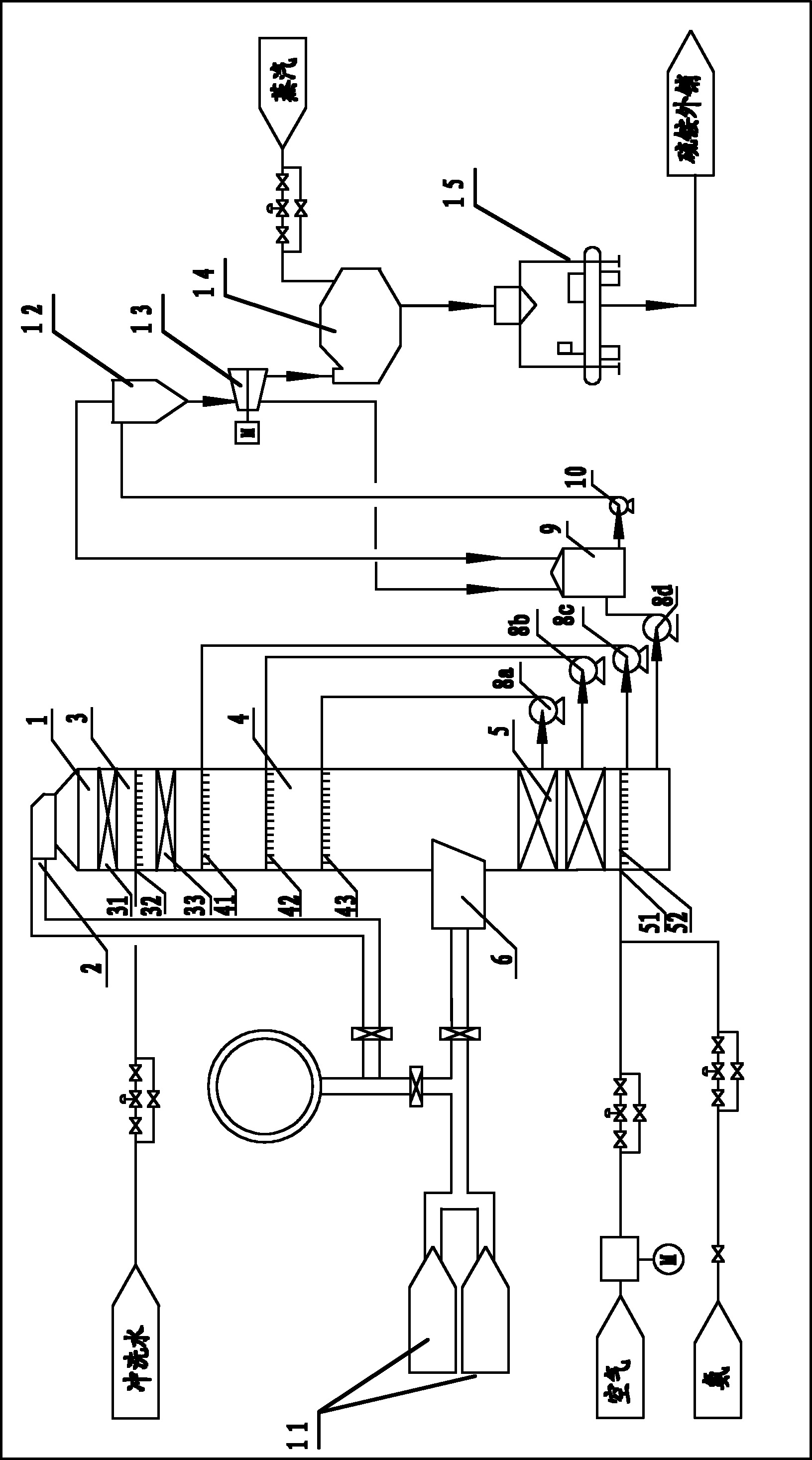

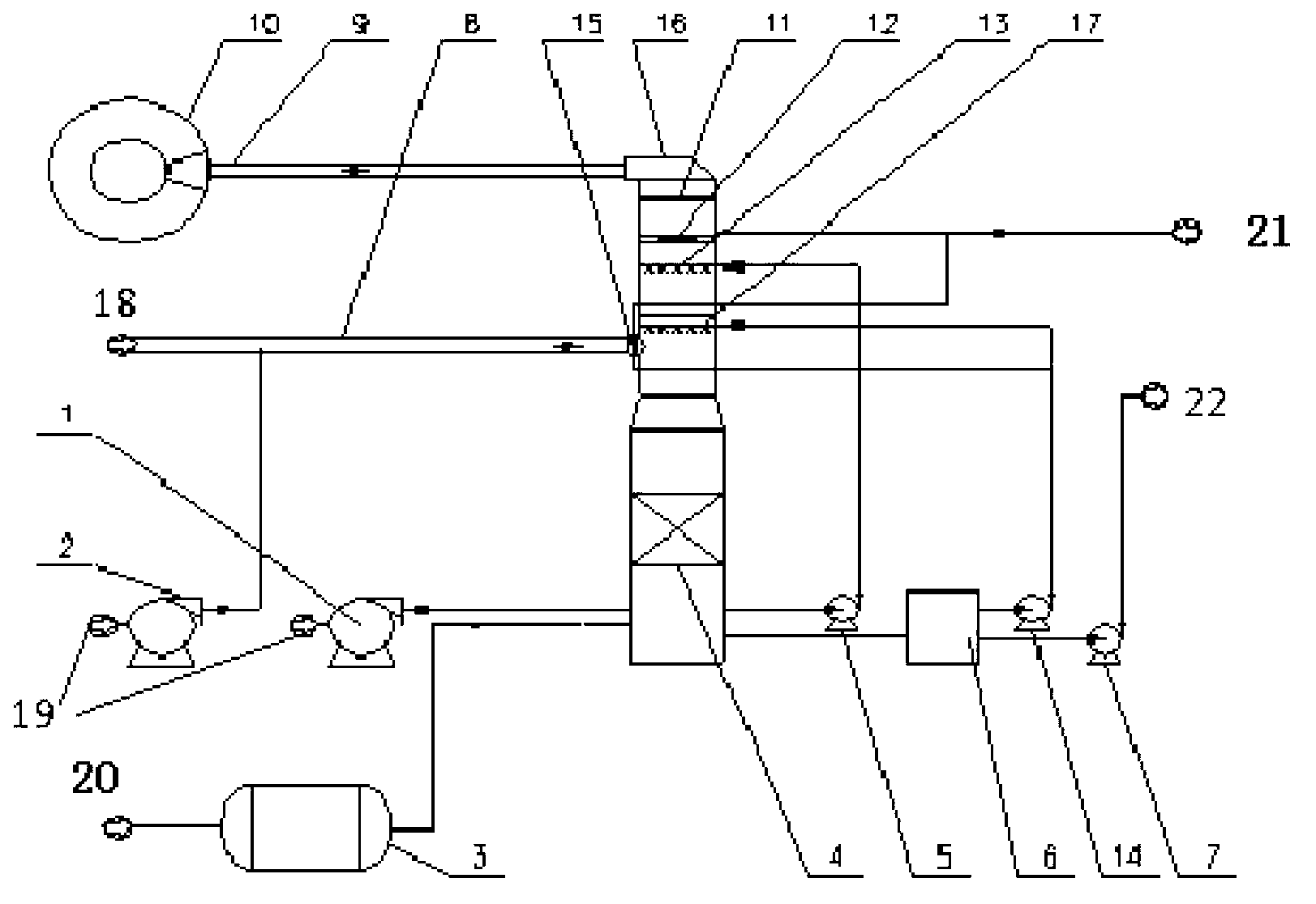

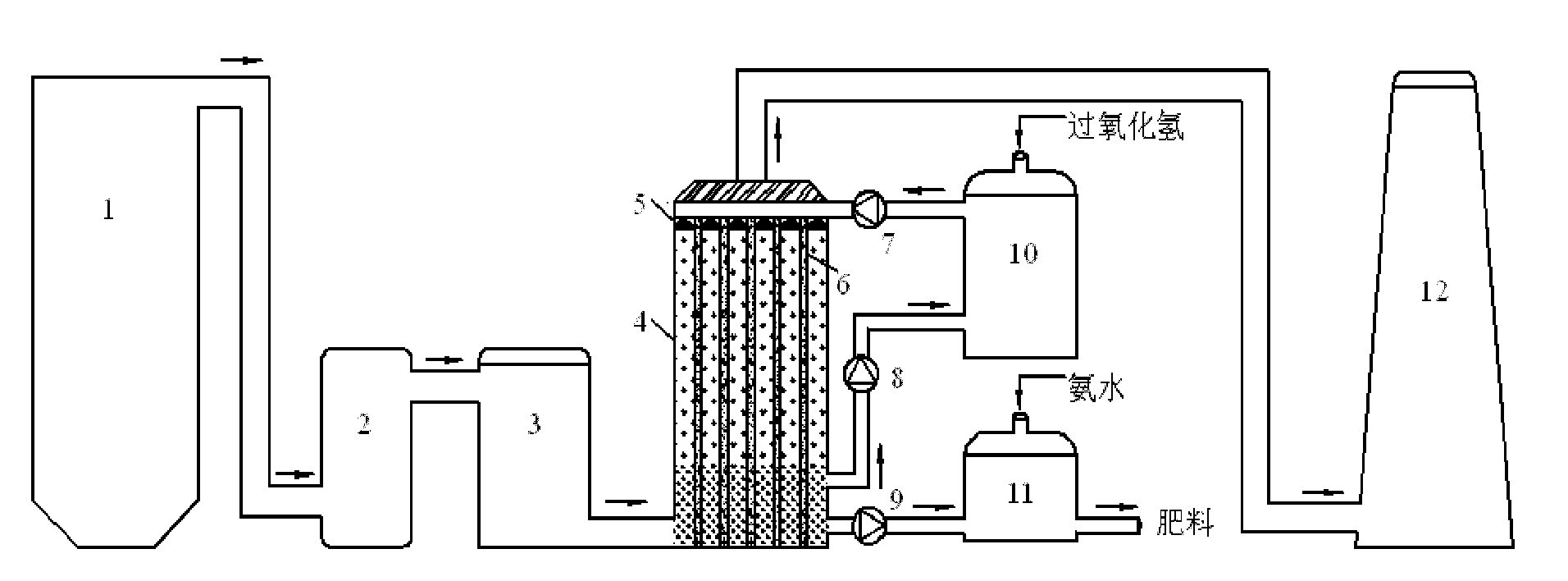

Photochemical advanced oxygenation-based simultaneous desulfuration and denitration system

InactiveCN101940871AThe process is simple and reliableSmall footprintDispersed particle separationAir quality improvementFertilizerAmmonium sulfate

The invention discloses a photochemical advanced oxygenation-based simultaneous desulfuration and denitration system. The system is provided with a burning and exhausting system consisting of a burner, an electrostatic dust collector, a heat exchanger, a spray tower, a liquid adding tower and a chimney, wherein fume generated by the burner enters the electrostatic dust collector, fume particles are removed from the fume by the electrostatic dust collector, the fume enters the heat exchanger and is cooled by the heat exchanger, and then the fume enters the spray tower; an UV light tube is arranged in the spray tower; hydrogen peroxide solution from the liquid adding tower is pumped by a circulating pump, sprayed into the spray tower through an atomizing nozzle and is activated by ultraviolet light to decompose hydrogen peroxide and then generate hydroxyl radicals (.OH) with strong oxidizing property; after being contacted with the fume in the spray tower, the hydroxyl radicals undergoes a gas-liquid absorption reaction with the fume to oxidize and remove NOx and SO2 in the fume; the fume, after being absorbed and washed, enters the chimney from the top of the spray tower and is exhausted; and sulfuric acid solution and salpeter solution generated in the spray tower are pumped into the separating column by the circulating pump and are reacted with added ammonia water to generate agricultural fertilizers including ammonium sulfate and ammonium nitrate.

Owner:SOUTHEAST UNIV

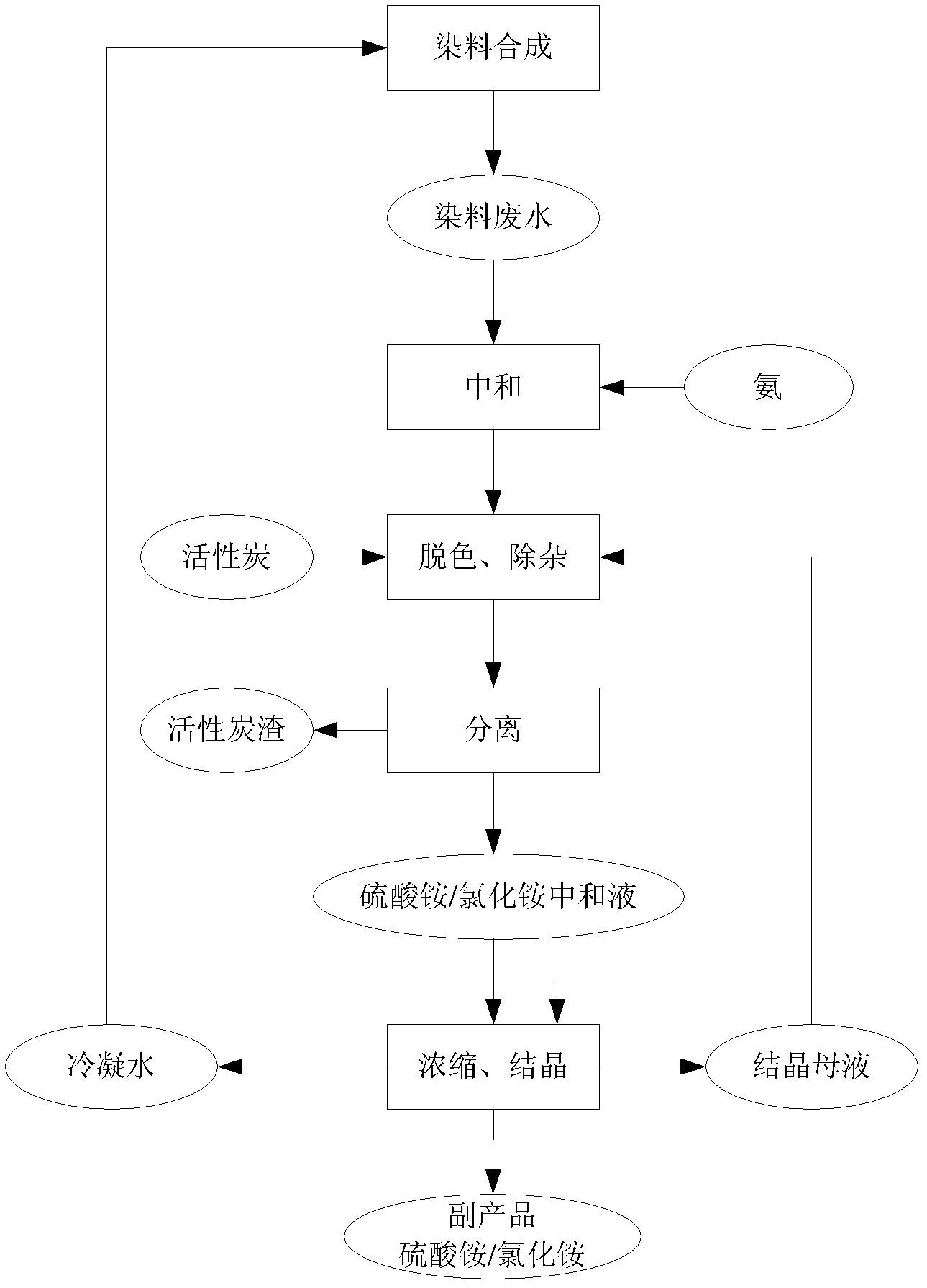

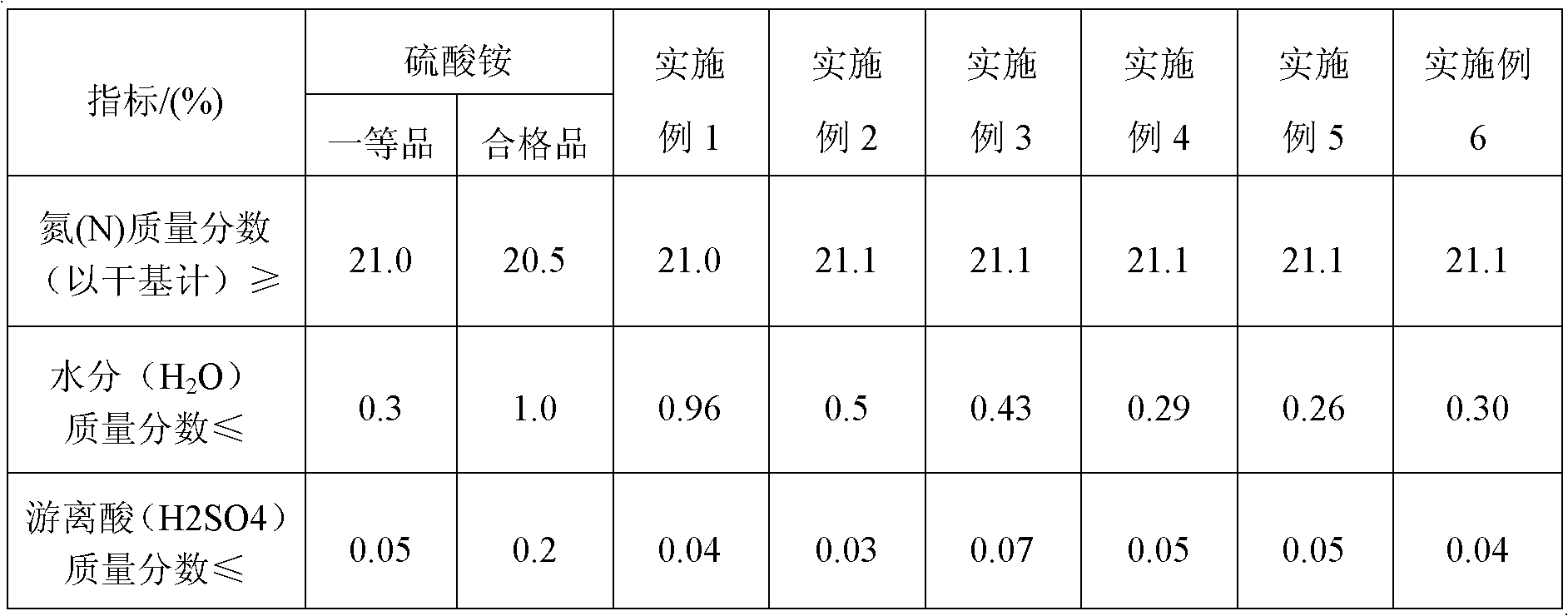

Cleaning treatment method of dying industrial acidic wastewater

ActiveCN102826673AAchieve recyclingAvoid it happening againAmmonium sulfatesMultistage water/sewage treatmentSulfateWastewater

The invention provides a cleaning treatment method of dying industrial acidic wastewater. After purified by measurements of neutralization, decolouring, oxidation, condensation, separation and the like, wastewater is reused as synthetic bottom water and dye filter cake washing water for dye production, thus avoiding discharge of a lot of colored wastewater with high COD value during a traditional dye production process. By a method of using a by-product ammonium sulfate or ammonium chloride, generation of calcium sulfate is avoided during neutralization of wastewater by the use of lime. Therefore, the dangerous solid waste calcium sulfate slug treatment problem is solved, and the cleaning production purposes of water saving, emission reduction and synergy are reflected.

Owner:ZHEJIANG LONGSHENG GROUP +1

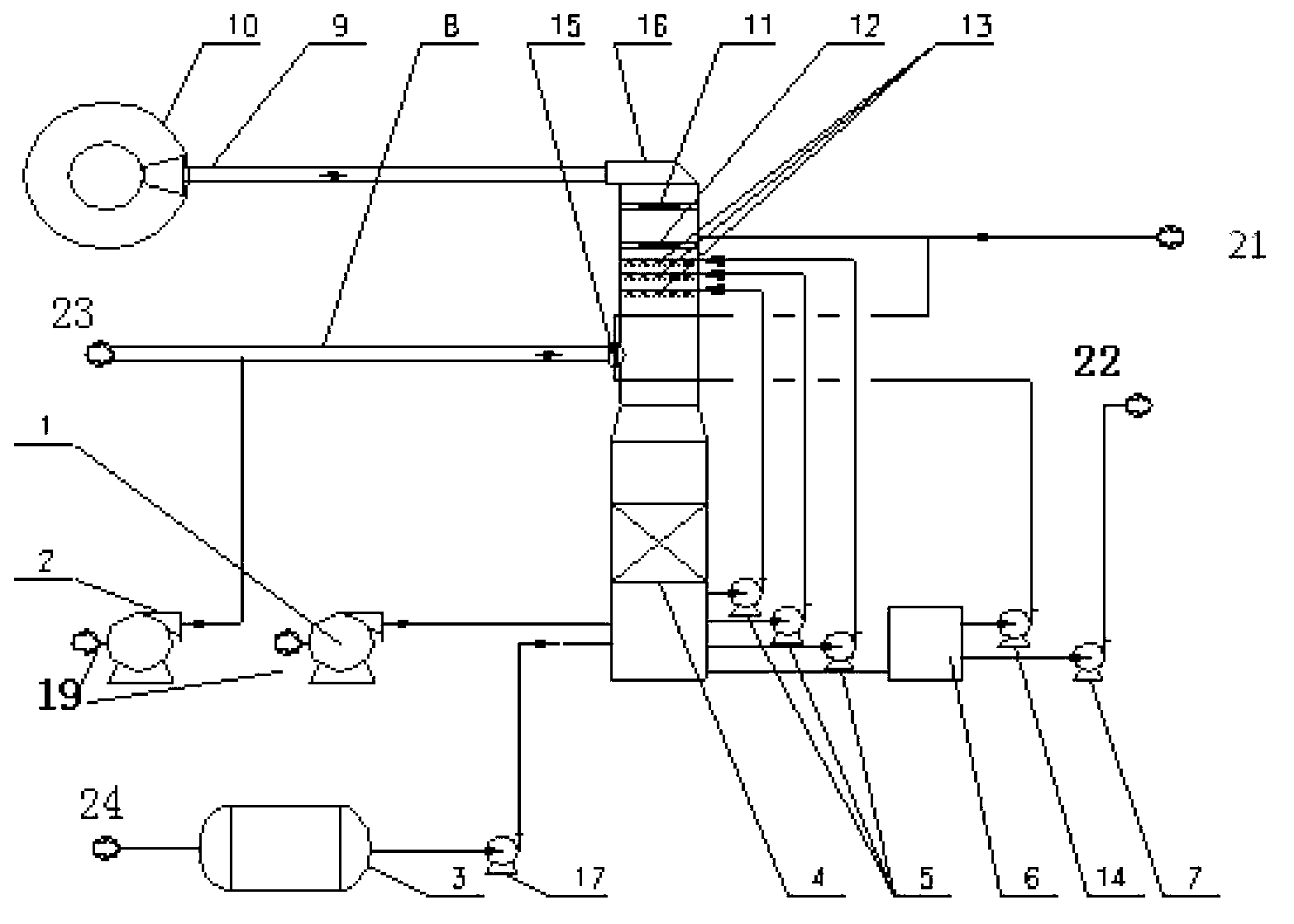

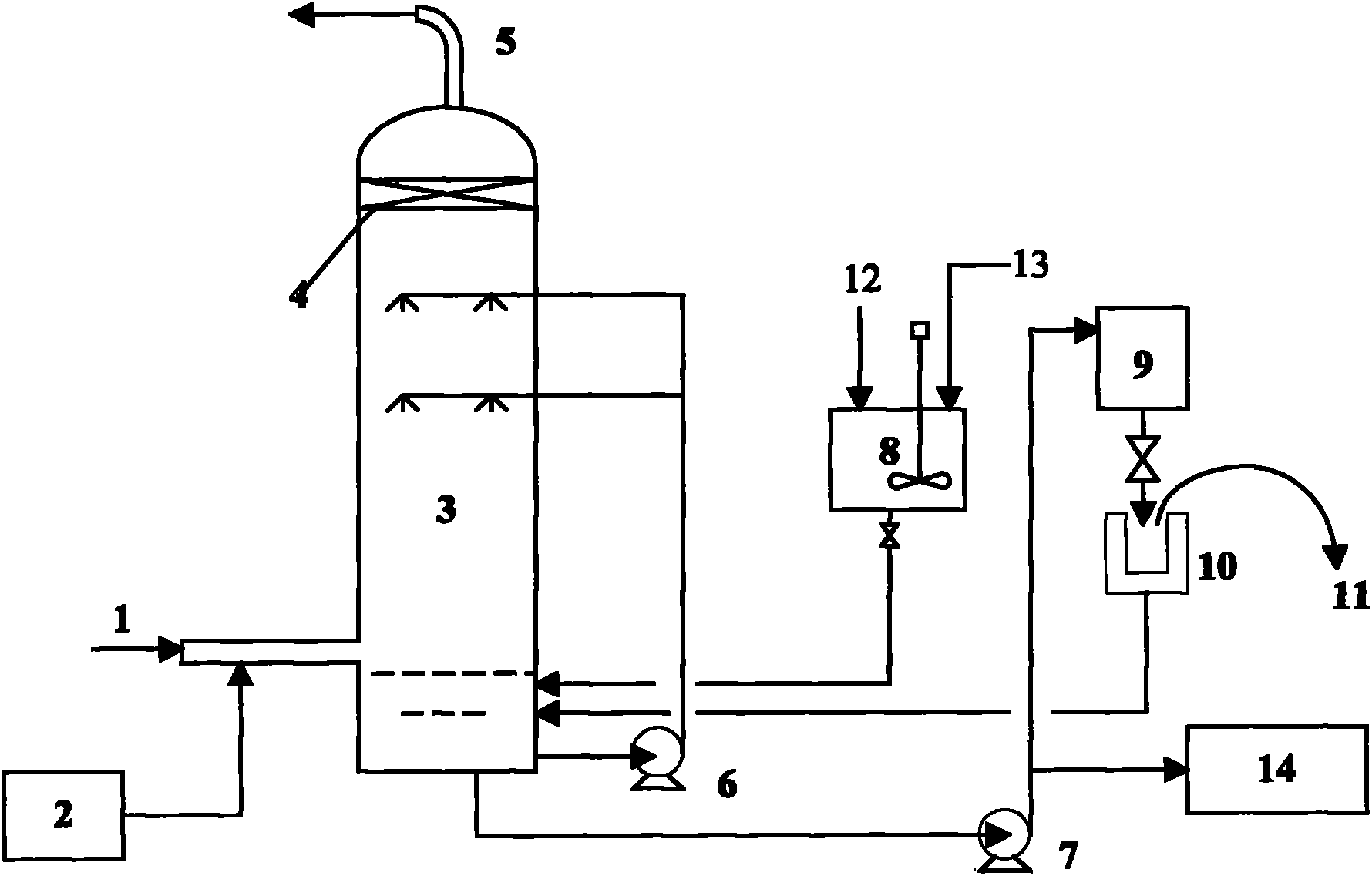

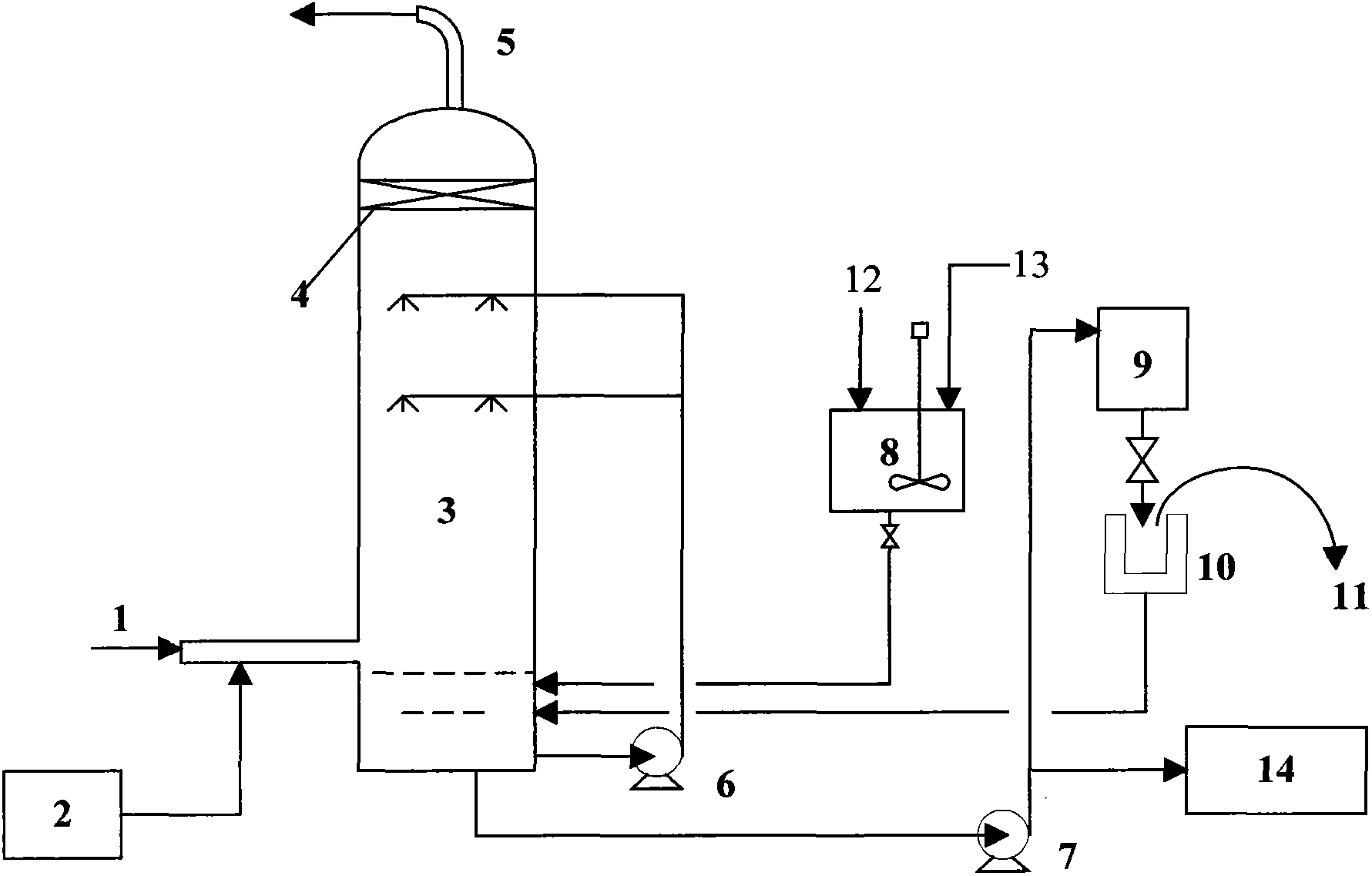

Ammonia desulfurizing process and apparatus with crystallization inside tower

The present invention belongs to the field of environment protection apparatus, and is especially crystallizing ammonia type desulfurizing process and apparatus for removing and recovering SO2 from fume. The apparatus includes one desulfurizing tower, one absorbing and circulating tank outside the tower, one concentrating and circulating tank, one ammonium sulfate thickener, one centrifuger and one drier. It features the crystallizing section and oxidizing section set below the fume inlet inside the desulfurizing tower, the connection of the crystallizing section with the concentrating and circulating tank, the connection of the oxidizing section outlet with the absorbing and circulating tank, and the successive connection of the other parts. The present invention has low cost and convenient apparatus maintenance and operation.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas

InactiveCN101816886APromote regenerationSolve pollutionDispersed particle separationAir quality improvementMass ratioSorbent

The invention provides a method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas. The method comprises the following steps: dedusting and cooling the coal-fired flue gas containing SO2, NOx and CO2; leading the gas into an adsorbent for saturated adsorption at the adsorption temperature of 50-100 DEG C and the adsorption pressure of 50-10000Pa; evacuating the coal-fired flue gas, desorbing the adsorbent by means of pressure reduction or temperature rise, and then repeatedly using; leading the desorbed gas into ammonia water for absorption treatment, wherein, the mass ratio of the ammonia water to the mixed gas containing SO2, NOx and CO2 is 2-6:1, the absorption temperature is 30-50 DEG C, and the absorption pressure is 5000-12000Pa; and recycling the gas to generate ammonium sulfate, ammonium nitrate and ammonium carbonate. The method can achieve simultaneouse desulfuration, denitration and decarbonization, and has small investment, low cost and low energy consumption; and the method can be widely applied to purification treatment of SO2, NOx and CO2 in the waste gas discharged from fixed fire coal sources such as thermal power plants, smelting plants, oil refinery, chemical plants and the like.

Owner:KUNMING UNIV OF SCI & TECH

Ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas

ActiveCN104941423ALess investmentLow running costUsing liquid separation agentEnergy inputNitric oxidePetroleum

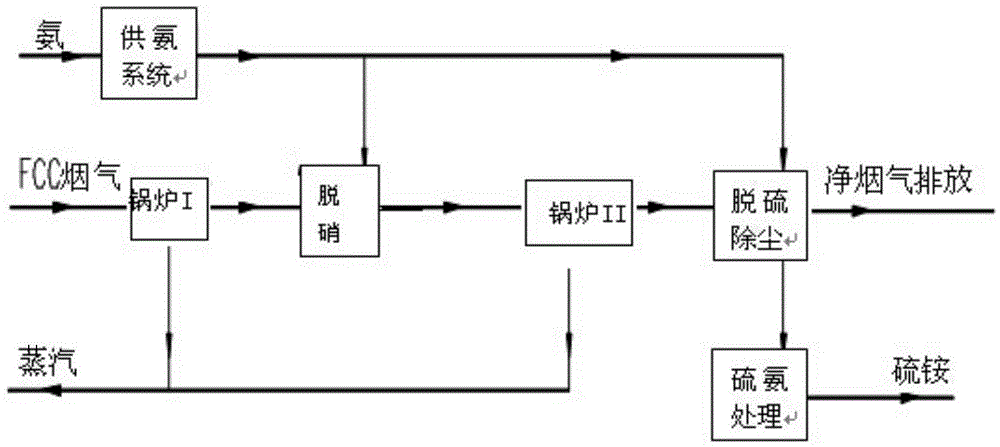

The invention relates to an ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas, comprising the following steps: enabling high-temperature catalyst regeneration flue gas coming from a catalytic cracking unit and containing catalyst dust to firstly enter a waste heat boiler I, reducing the temperature of the flue gas to 280-430 DEG C, wherein the heat of the flue gas is externally supplied by steam produced by the waste heat boiler I; enabling flue gas at temperature of 280-430 DEG C to enter a denitrification device for denitrification and enter a waste heat boiler II through an outlet flue after sufficiently reacting on the surface of a denitrification catalyst in a denitrification reactor; removing sulfur dioxide, nitric oxide and byproduct ammonium sulfate by taking ammonia as a reactant, and removing catalyst dust in the regeneration flue gas to achieve clean gas up-to-standard release; the three waste free release purifying method can be applied to catalytic cracking catalyst regeneration flue gas treatment in oil refining.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Method for producing amino acid tobacco-specific foliar fertilizer by using abandoned fur

InactiveCN102718605AWell developed root systemQuality improvementFertilizer mixturesDiseasePhosphate

The invention relates to a method for producing an amino acid tobacco-specific foliar fertilizer by using abandoned fur. The method comprises the following steps of: degreasing, drying and crushing various abandoned animal hair in slaughterhouses, hair in barber shops and various abandoned animal leather which are used as main raw materials; carrying out microbial fermentation, mainly Freund crack mould or other keratin decomposing bacteria fermentation; then decomposing and filtering to prepare a crude amino acid solution; and chelating the following components in parts by weight: 30-50 parts of crude amino acid solution, 15-18 parts of potassium sulfate, 15-25 parts of ammonium sulfate, 15-18 parts of potassium dihydrogen phosphate, 3-6 parts of humic acid potassium, 1.3-2 parts of trace elements, 0.3-0.5 part of surfactant, 0.5-1 part of chelating agent and 0.15-0.2 part of plant growth regulating agent. The tobacco-specific foliar fertilizer has the effects of promoting growth of tobacco roots, enhancing the absorption and utilization of tobacco on soil and the fertilizer, promoting lengthening, widening and thickening of tobacco, enhancing the ability of disease resistance, and improving the quality and yield of tobacco leaves.

Owner:HUNAN TOBACCO CHENZHOU

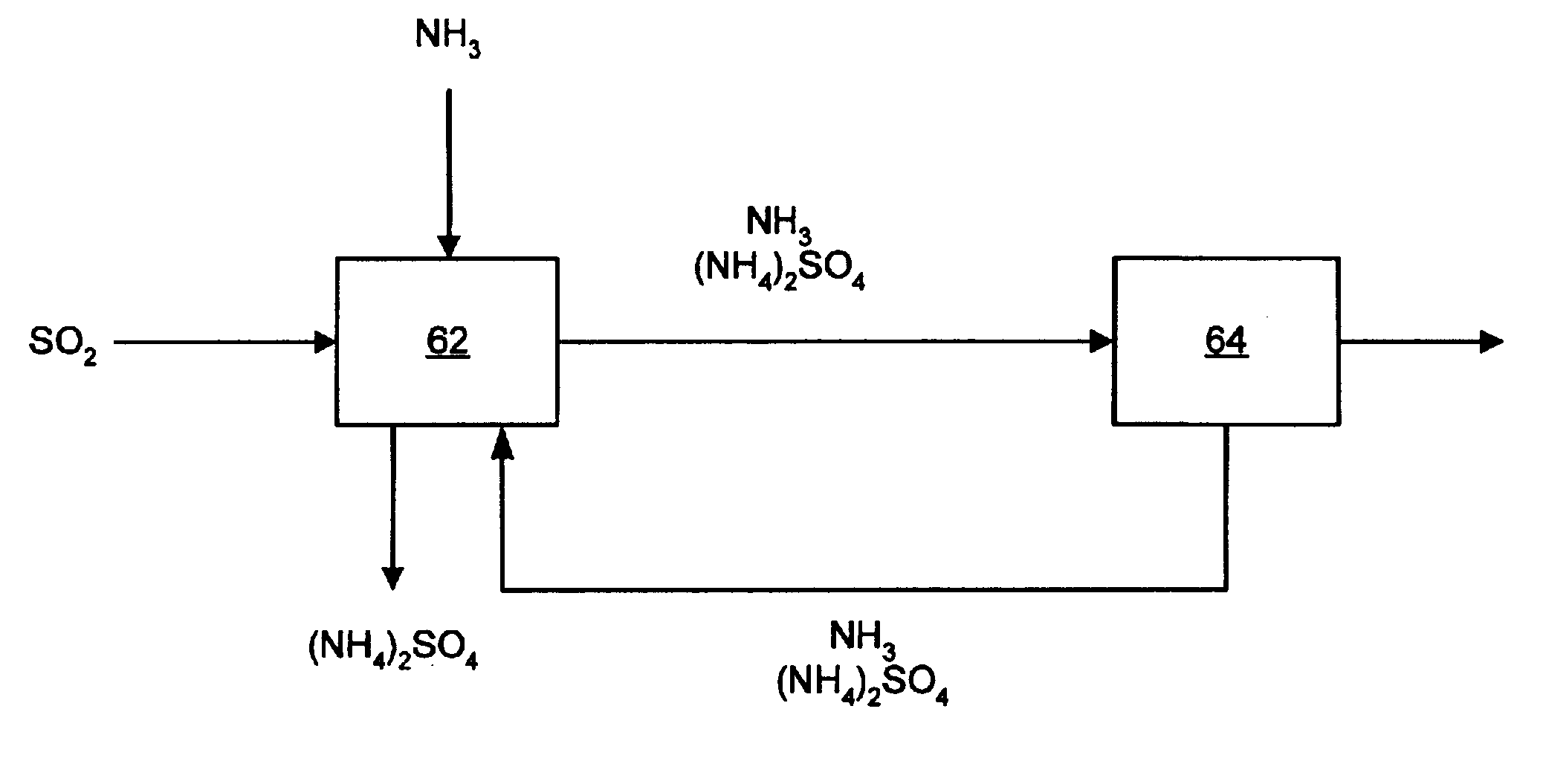

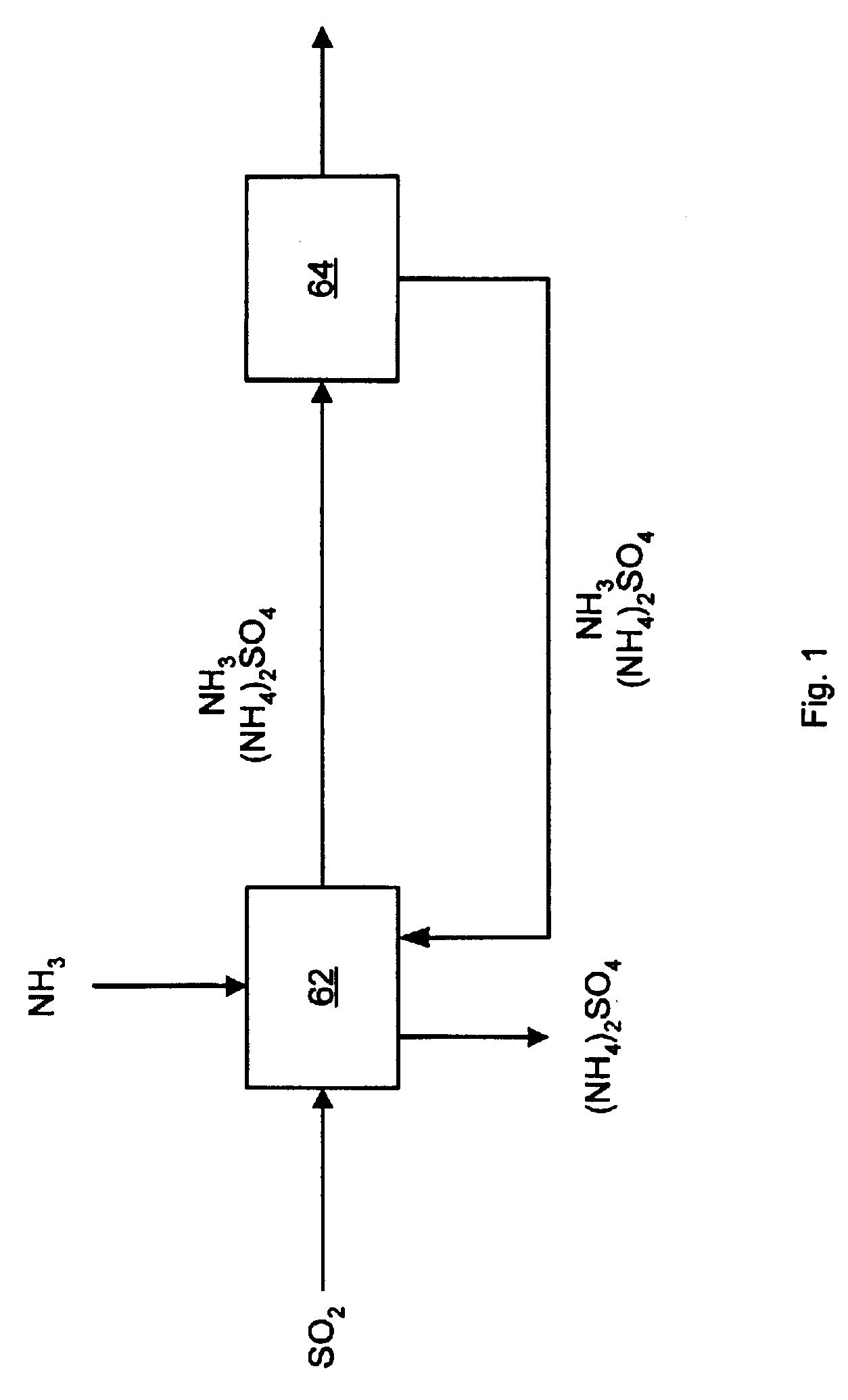

Desulphurization method for acid gas

InactiveCN101574614AEasy dischargeEmissions exceedingDispersed particle separationIncinerator apparatusCombustion chamberEmission standard

The invention provides a desulphurization method for acid gas, which comprises the following steps: firstly, carrying out heat combustion reaction on the acid gas and fuel in a combustion chamber; secondly, carrying out catalytic reduction reaction on the obtained combustion product; thirdly, combusting tail gas obtained by the catalytic reduction reaction; and fourthly, carrying out ammonia elution on sulfur dioxide in gas obtained after combustion to obtain ammonium sulphate. The desulphurization combined process for the acid gas has no strict requirement on the Claus combustion, does not need multistage Claus reaction, and even does not control the Claus reaction strictly; and wastewater subjected to ammonia washing in the acid gas containing ammonia is not discharged to a sewage treatment center of a factory, and a fussy device is not needed to add for ammonium refining and recovery. The method can balance the ammonia and the Clause reaction according to the yield of the ammonium sulphate, and does not have sewage discharge; heat required by the process can be balanced through by-product steam, so that the method greatly saves the investment and operation cost, and has short flow and simple operation; and the gas emission can be far lower than the national emission standard.

Owner:BEIJING FUNGHAN ENG CONSULTING

Sulfur dioxide removal using ammonia

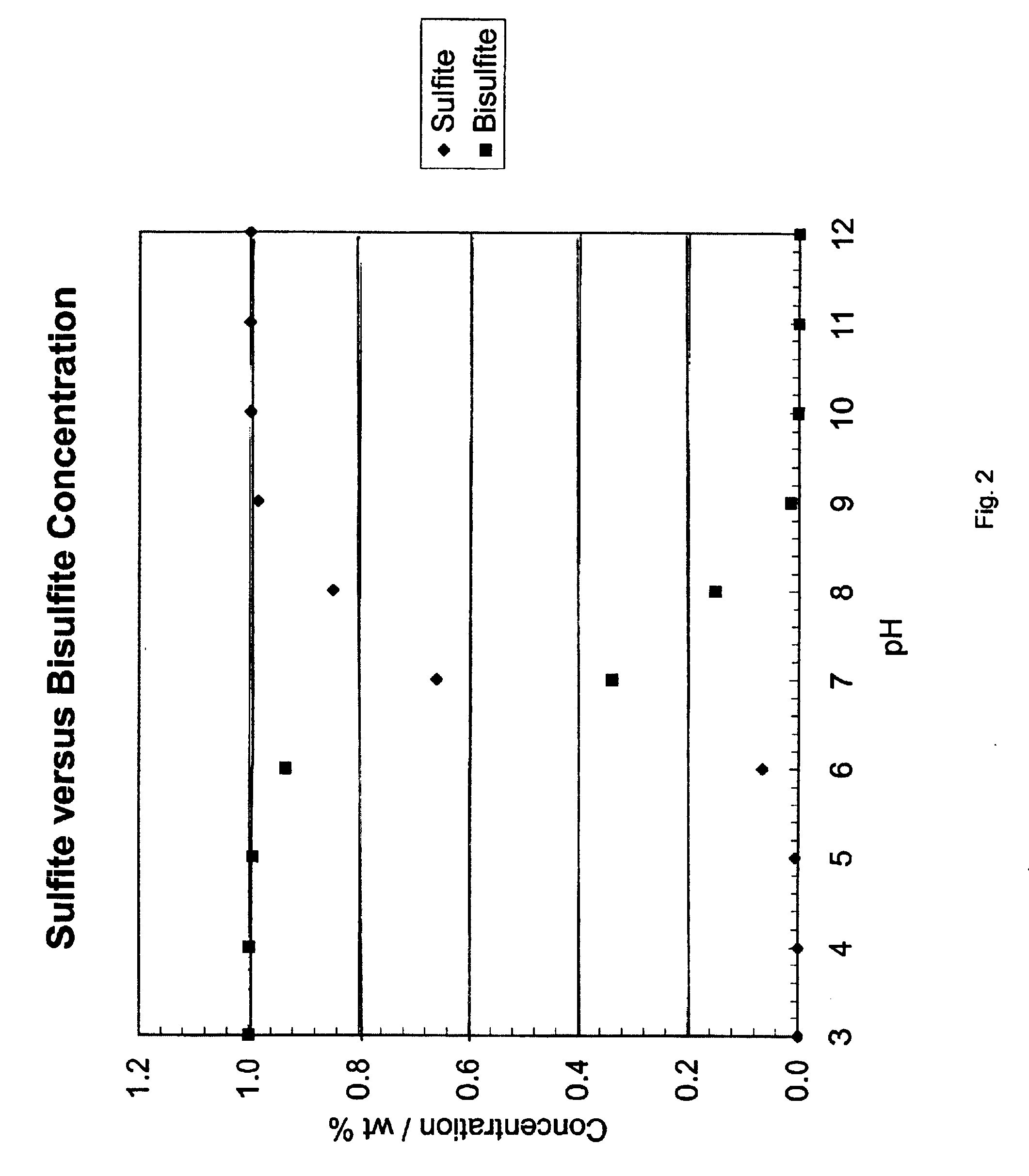

InactiveUS6605263B2Small sizeImprove efficiencyCombination devicesAmmonium sulfatesCorrosion resistant alloySulfite

Owner:POWERSPAN CORP

Device and method for simultaneously desulfurizing and denitrifying flue gas by ozone catalytic oxidation process

InactiveCN102247750AEfficient oxidationDispersed particle separationSulfur-trioxide/sulfuric-acidCatalytic oxidationAbsorption of water

The invention relates to a flue gas pollutant treatment process and aims to provide a device and method for simultaneously desulfurizing and denitrifying a flue gas by ozone catalytic oxidation process. The device comprises a desulfurization and denitrification tower, an ozone generator, absorption liquid circulating equipment and desulfurization and denitrification by-product post-treatment equipment. Ozone enters from a flue or the lower part of the desulfurization and denitrification tower, a catalyst is added to an absorption liquid, and the absorption liquid is injected in from the upper part of the desulfurization and denitrification tower, so that SO2 and NO in the flue gas are oxidized by ozone with high efficiency under the action of the catalyst, and in combination with the absorption of water or alkaline substances, SO2 and NOx in the flue gas are recovered in the form of high value-added sulfuric acid and nitric acid products, or ammonium sulfate / ammonium nitrate mixed nitrogen fertilizers, potassium sulfate / potassium nitrate mixed potassium fertilizers or ammonium / potassium compound fertilizers respectively, thereby achieving resource recovery and value maximization of the desulfurization and denitrification process. The desulfurization and denitrification process provided by the invention has the advantages of simple structure, low investment and low operation cost. The desulfurization rate and the denitrification rate of the desulfurization and denitrification process provided by the invention can reach more than 96% and more than 90% respectively.

Owner:EAST CHINA UNIV OF SCI & TECH

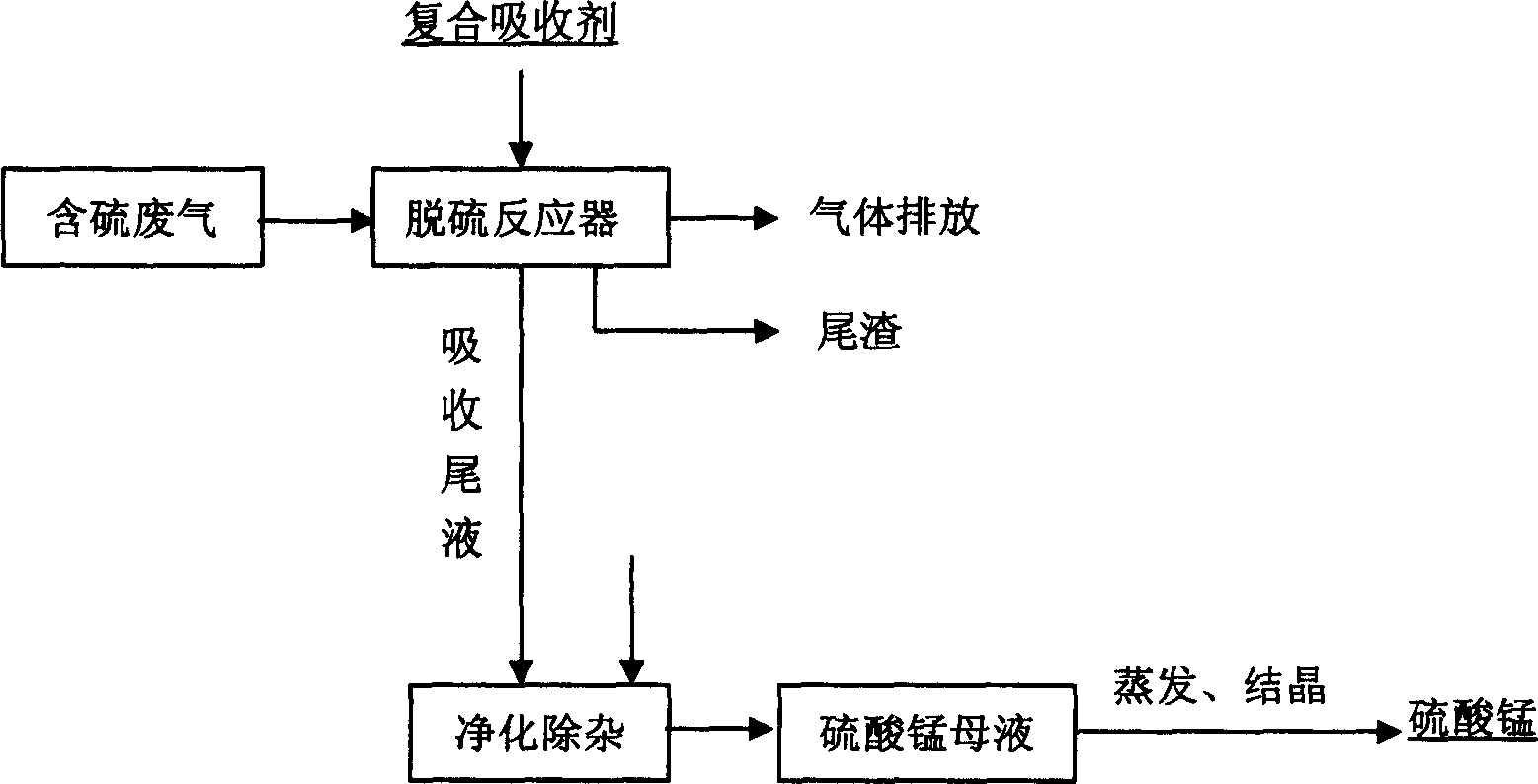

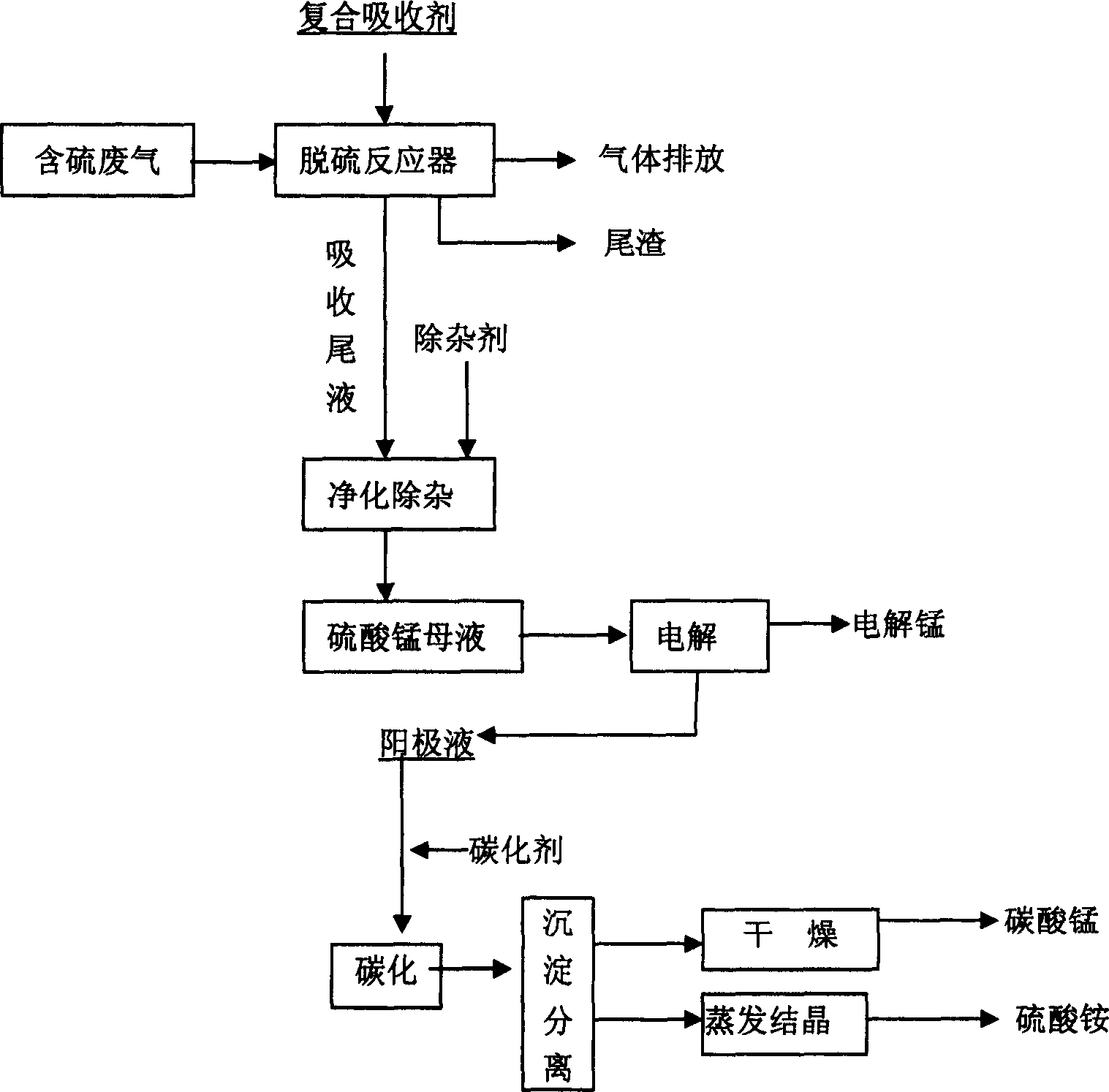

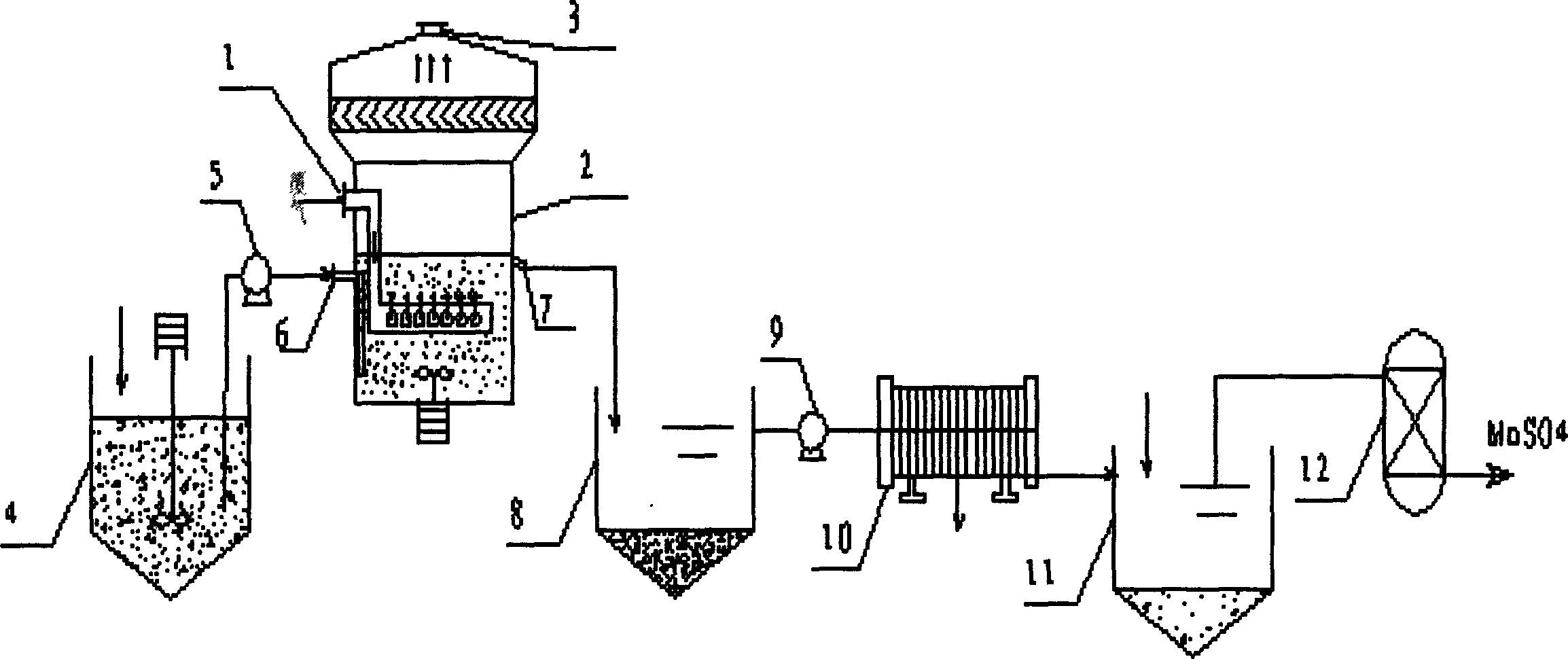

Waste gas desulfurizing method with composite absorbant comprising pyrolusite and pH buffering agent

ActiveCN1772345ARich reservesLow pricePhotography auxillary processesDispersed particle separationPyrolusiteElectrolysis

The present invention is method of comprehensively utilizing waste SO2 gas resource and pyrolusite, and the method includes utilizing the composite absorbent comprising pyrolusite slurry and pH buffering agent to produce oxidation-reduction and neutralizing reaction with waste SO2 gas to eliminate SO2 from the waste gas, purifying the absorbed tail liquid to obtain manganese sulfate product through direct evaporating crystallization or metal manganese product through DC electrolysis, and treating the anode liquid to obtain high purity manganese carbonate product and ammonium sulfate product. The present invention realizes treatment of waste with waste to recover sulfur resource and comprehensively utilize pyrolusite. The method of the present invention is reasonable and has no secondary pollution.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com