Patents

Literature

56 results about "AMMONIUM ALGINATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium Alginate is white or light yellow coarse or fibrous powder. It is odorless and tasteless, and can be slowly dissolved in water forming thick colloidal solution. Ammonium Alginate can not be dissolved by chloroform, diethyl ether and acid liquid with a pH value lower than 3.

Preparation method for sodium alginate-acrylamide-based hydrogel

InactiveCN103396562AOvercome the shortcomings of generating air bubbles and forming uneven hydrogelsEasy to operateCross-linkPolyacrylamide Hydrogel

The invention discloses a preparation method for sodium alginate-acrylamide-based hydrogel. The preparation method comprises the following steps of: dissolving sodium alginate powder in deionized water; then sequentially adding an acrylamide monomer, a methylene diacrylamide cross-linking agent, ammonium persulfate and an N,N,N',N'-tetramethylethylenediamine catalyst; uniformly stirring the materials, pouring the mixture into a glass die, and heating the mixture to obtain a hydrogel; completely soaking the hydrogel in a 0.01-1 mol / L non-monovalent cation aqueous solution for 1-10 hours, wherein cations diffuse and enter in a hydrogel network structure, and induce sodium alginate to cross-link, so as to generate the high-strength and high-toughness sodium alginate-acrylamide-based hydrogel during the process. The hydrogel disclosed by the invention has the following performances: the highest tensile strength can achieve 1 MPa, and the highest tensile elasticity modulus can achieve 250 KPa; a loading-unloading test is performed on the hydrogel, and when the great tensile multiple before unloading is 8, the highest dissipated energy can achieve 2180 KJ / m<3>.

Owner:XI AN JIAOTONG UNIV

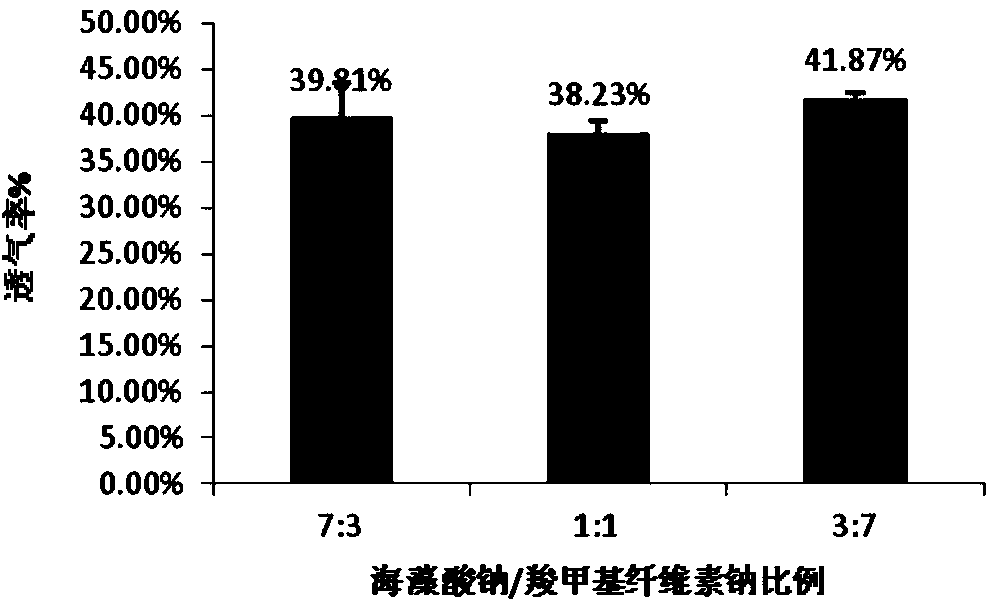

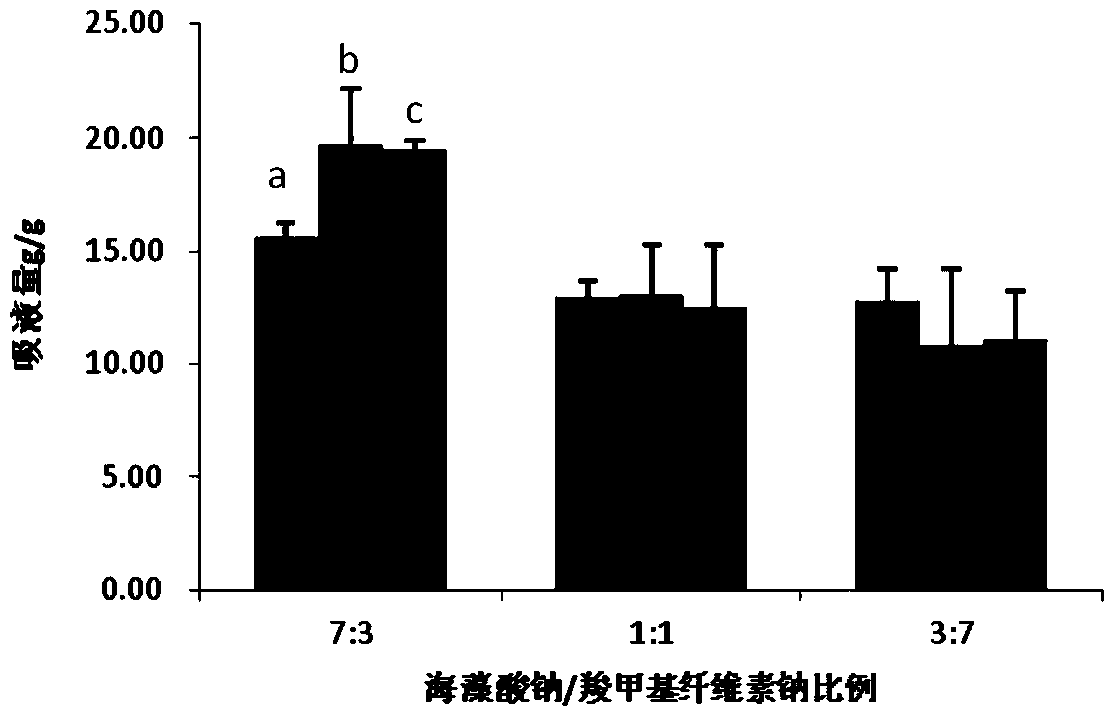

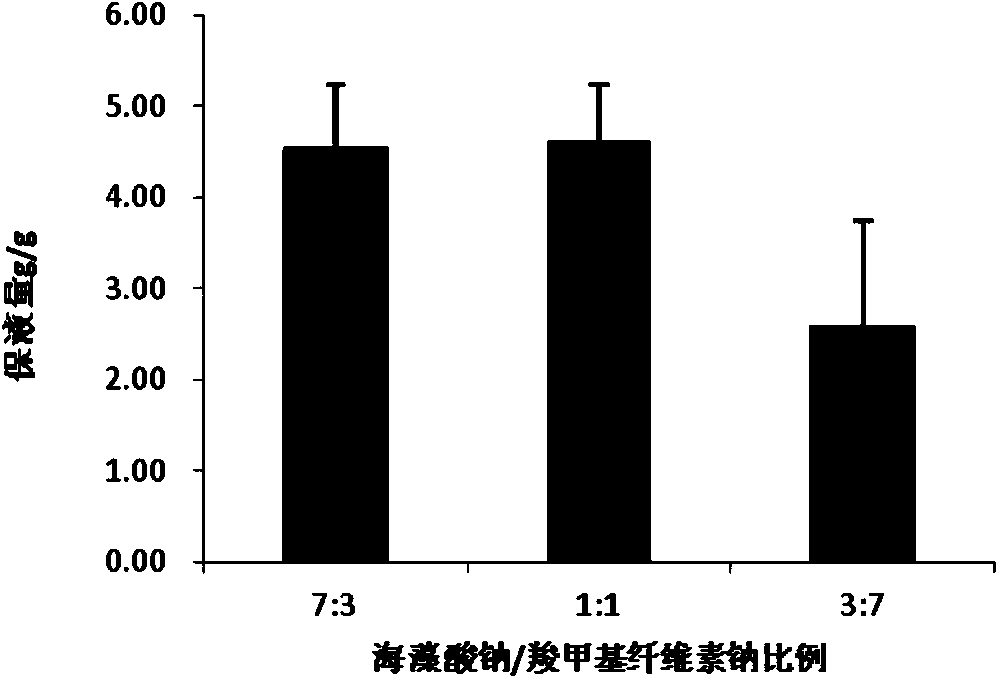

Sodium alginate-sodium carboxymethylcellulose-chitosan wound dressing and preparation method thereof

InactiveCN104069537APromote healingSimple preparation processAbsorbent padsBandagesAcetic acidAMMONIUM ALGINATE

The invention discloses a sodium alginate-sodium carboxymethylcellulose-chitosan wound dressing and a preparation method thereof, and relates to a dressing for human body skin wounds. The wound dressing is composed of 1%-1.4% of sodium alginate, 0.6%-1% of sodium carboxymethylcellulose, 0.3%-0.9% of chitosan, 6%-8% of glycerol and the balance of water. The preparation method comprises the following steps: adding sodium alginate and sodium carboxymethylcellulose into water, adding chitosan and acetic acid so as to obtain a uniform solution, and then pouring the uniform solution into a culture dish to perform first freeze drying; then putting the dried material into a CaCl2 solution and an NaOH solution in sequence to soak, performing second freeze drying, soaking in a glycerol aqueous solution, and performing a third freeze drying so as to obtain the product. The preparation technology is simple, the cost is low, the safety and the biocompatibility are better, the characteristics of being high in absorbability, capable of maintaining moist wound condition, low in adhesion, easy to replace and the like are achieved, and wound healing is facilitated.

Owner:XIAMEN UNIV +1

Method of Preparation of Polysaccharide Fibres, Wound Covers that Contain Them, Method of Manufacturing of Wound Covers, and Apparatus for Preparation of Polysaccharide Fibres

InactiveUS20150119783A1Low areal weightEasy to useNon-adhesive dressingsSpinning head liquid feederFiberCarboxymethyl cellulose

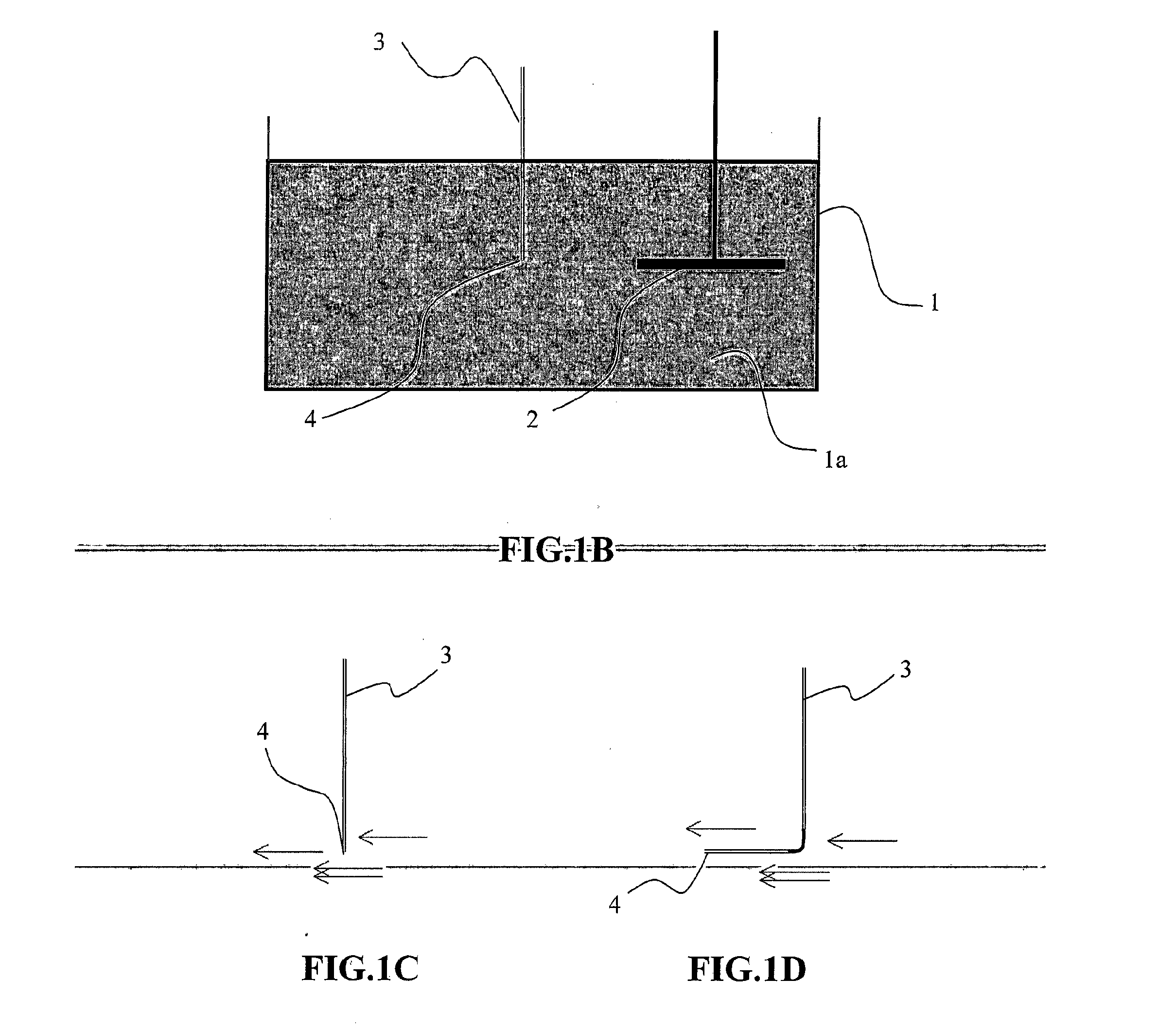

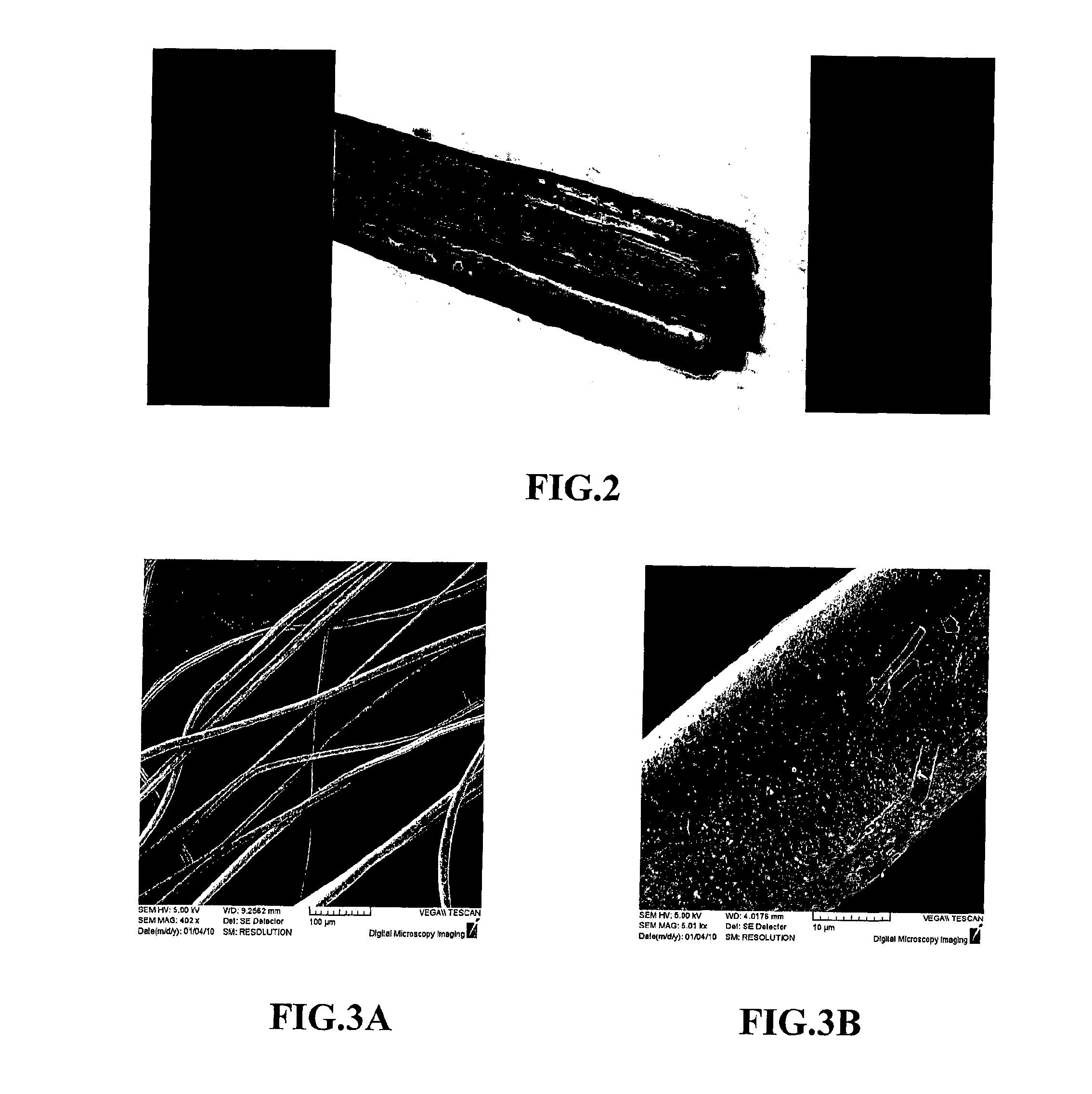

The invention relates to the method of the preparation of polysaccharide fibers based on hyaluronic acid, a compound comprising hyaluronic acid and metal ions, schizophylan, chitin / chitosan-glucan complex, a compound comprising chitin / chitosan-glucan complex and metal ions, internal mixture of chitin and chitosan, a compound comprising internal mixture of chitin and metal ions, sodium alginate, potassium alginate, ammonium alginate, xanthane, xanthane sodium salt, xanthane potassium salt, oxycellulose, oxycellulose sodium salt, oxycellulose potassium salt, carboxymethyl cellulose, carboxymethyl cellulose sodium salt, and carboxymethyl cellulose potassium salt, or a mixture of polysaccharides, in a non-stationary coagulation bath. Further the invention relates to covers of internal and external wounds and skin defects based on these fibers, and a method of production thereof, and the apparatus for the preparation of polysaccharide fibers.

Owner:CONTIPRO BIOTECH

Water column forming method of spherical molecular sieve

ActiveCN104383967AImprove adhesionReduce production process stepsCatalyst carriersCatalyst activation/preparationNano al2o3Manganese

The invention relates to a water column forming method of a spherical molecular sieve. The water column forming method is characterized by comprising the following steps: 1, beating a molecular sieve, a binding agent and water uniformly; 2, adding an alginate solution, and stirring uniformly at high speed to prepare a suspended sizing agent; 3, dropping the suspended sizing agent to a polyvalent metal cation water solution to form gel particles; and 4, taking the gel particles out, drying and roasting to obtain the product, wherein the dry-basis mass rate of the molecular sieve to the binding agent in the step 1 is (0.2-3):1, and the binding agent is alumina hydrogel, nanometer aluminum oxide sol or silica sol; the soluble alginate in the step 2 is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, the content of alginate in the suspended sizing agent is 0.3-5w%, and total dry-basis content of the molecular sieve and the binding agent in the suspended sizing agent is 5-30w%; the polyvalent metal cation water solution in the step 3 is a saline solution containing aluminum, zinc, calcium, copper, ferrum, ferrous, cobalt, manganese or nickel ions, with the saturation concentration being 0.1mol / L.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Preparing method of spherical titanium-aluminum composite carrier

ActiveCN104353504AImprove adhesionReduce production process stepsCatalyst carriersAluminum IonNano al2o3

The invention relates to a preparing method of a spherical titanium-aluminum composite carrier. The preparing method is characterized by comprising the following steps: adding deionized water and titanium oxide into alumina gel and uniformly mixing; slowly adding an alginate solution, and stirring at high speed to prepare suspension slurry; dropping the suspension slurry into a multivalent metal cation solution to form spherical composite gel particles; and drying and roasting the gel particles to obtain the spherical titanium-aluminum composite carrier, wherein aluminum oxide hydrogel or nano aluminum oxide gel is adopted as the alumina gel; the adding amount of titanium oxide is 0.1-4 times the mass of alumina gel based on Al2O3, and the crystalline phase of titanium oxide is selected as anatase phase; the solid content of the suspension slurry is 5%-25%, and the content of alginate is 0.3%-5%; alginate is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate; the multivalent metal cation solution is saline solutions containing aluminum ions, zinc ions, calcium ions, copper ions, iron ions, ferrous ions, cobalt ions, manganese ions or nickel ions, with the saturation concentration being 0.1mol / L.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Preparation method of sodium alginate/chitosan hydrogel microspheres for heavy metal arsenic adsorption

InactiveCN108246261AGood environmental compatibilityAbundant resourcesOther chemical processesWater contaminantsFreeze-dryingVacuum drying

The invention relates to a preparation method of sodium alginate / chitosan hydrogel microspheres for heavy metal arsenic adsorption. The preparation method comprises the following steps of (a) selecting 1 to 5 percent of carboxymethyl chitosan solution and 1 to 5 percent of sodium alginate solution, and mixing according to the volume ratio of 1:(1 to 8) so as to obtain a mixed solution; (b) dropwise adding the mixed solution into 1 to 20 percent of CaCl2 solution, stirring with a rotation speed of 800 to 1200rpm for 20 min to 100 min at 30 to 80 DEG C, collecting small spheres, washing throughdistilled water for multiple times, and freeze drying or vacuum drying to obtain the hydrogel microspheres. The preparation method of the sodium alginate / chitosan hydrogel microspheres for heavy metalarsenic adsorption has the characteristics that the preparation process is simple, the raw material source is wide, harmful heavy metal in sewage can be adsorbed and conveniently removed, and the economic benefit and the social benefit of enterprises are improved.

Owner:ZHEJIANG OCEAN UNIV

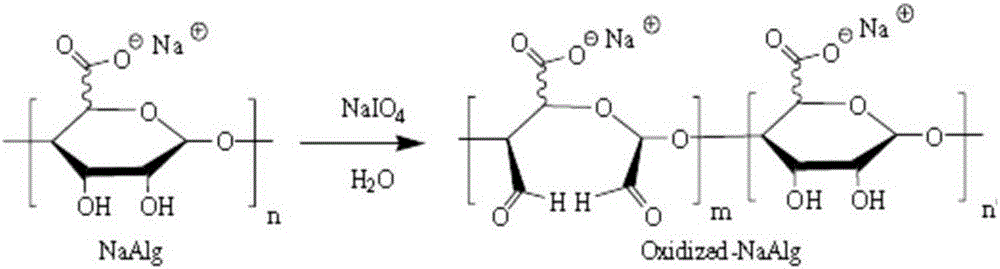

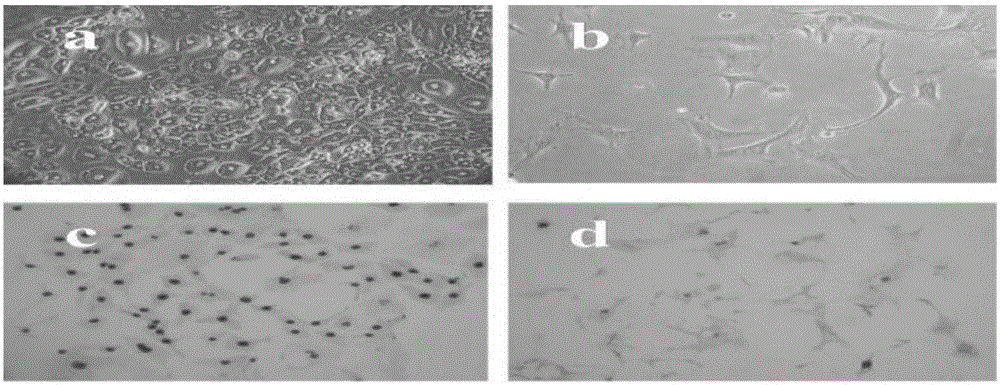

Preparation method for hydroxyethyl chitosan in-situ hydrogel

The invention belongs to the technical field of biomedicines and particularly relates to a preparation method for hydroxyethyl chitosan in-situ hydrogel. The preparation method comprises the following steps of firstly, dissolving sodium periodate powder into deionized water to obtain an aqueous solution of the sodium periodate; secondly, stirring an aqueous solution of sodium alginate and the aqueous solution of the sodium periodate to form a mixed solution; after the mixed solution is enabled to perform an oxidizing reaction, adding ethylene glycol to end the reaction; carrying out suction filtration on the mixed solution, carrying out dehydration precipitation on the mixed solution with absolute ethyl alcohol, and then carrying out low-temperature vacuum drying to obtain an oxidized sodium alginate crude product; dissolving the oxidized sodium alginate crude product into an aqueous solution of oxidized sodium alginate crude product with distilled water; carrying out complete dialysis on the aqueous solution of oxidized sodium alginate crude product, centrifuging, taking supernate for freeze drying to obtain oxidized sodium alginate; finally, mixing hydroxyethyl chitosan with the oxidized sodium alginate, carrying out cross-linking reaction on the mixed solution by a double-linkage syringe, and then pushing the reacted product into a test tube to obtain the hydroxyethyl chitosan in-situ hydrogel. The hydroxyethyl chitosan in-situ hydrogel is used for quickly coating and transplanting. The preparation method is simple in preparation process, safe and reliable in principle and low in preparation cost; the hydroxyethyl chitosan in-situ hydrogel has the advantages of good quality, safety and sanitation in use, and environment friendliness in a treatment environment.

Owner:QINGDAO UNIV

Method for preparing cigarette flaky carbonaceous heat source materials by calcium salt

The invention discloses a method for preparing cigarette flaky carbonaceous heat source materials by calcium salt. The method includes the steps of mixing sodium alginate, ammonium alginate or potassium alginate with carbon powder and water according to a mass ratio of the sodium alginate, ammonium alginate or potassium alginate to the carbon powder of 1:5-45, stirring to colloids, then extruding the colloid into flakes, and enabling the flakes to fully contact with calcium salt solution to obtain cured substances; and subjecting the cured substances to rinsing and drying to enable moisture content to reach 10-20% so as to obtain the cigarette flaky carbonaceous heat source materials. Harm caused by the fact that fiberglass is inhaled into a human body is reduced, and combustibility of carbonaceous heat sources is improved; and the method has the advantages of simplicity, short production cycle, low cost and the like.

Owner:HUBEI CHINA TOBACCO IND +1

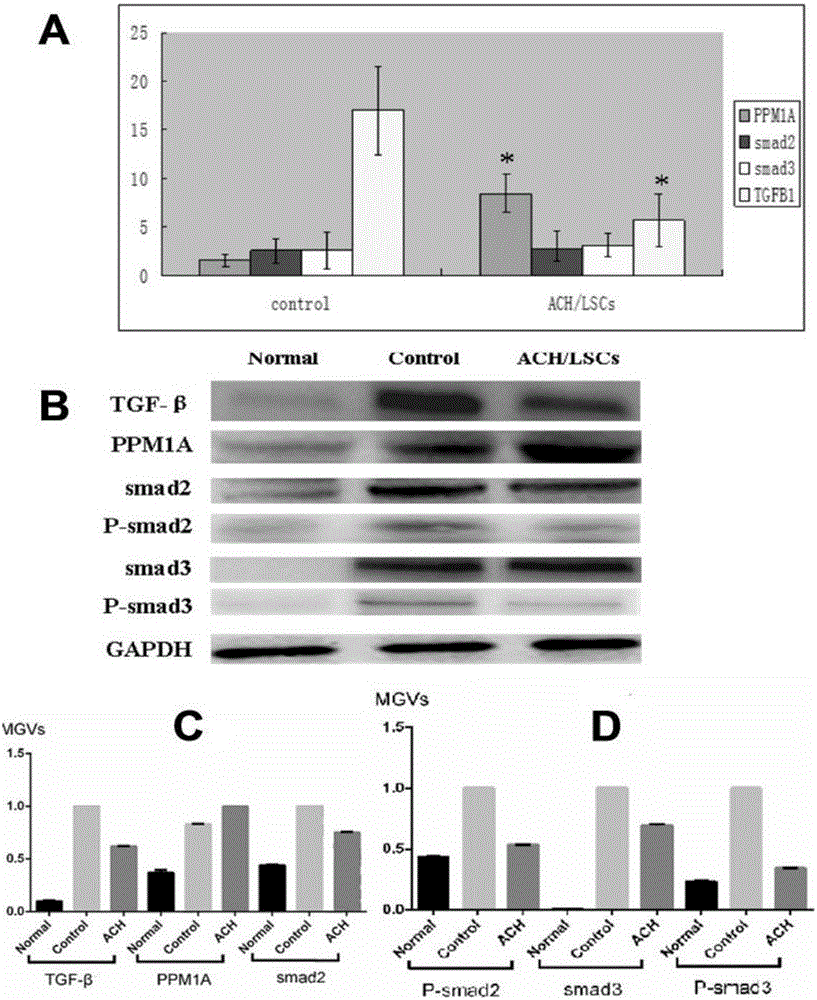

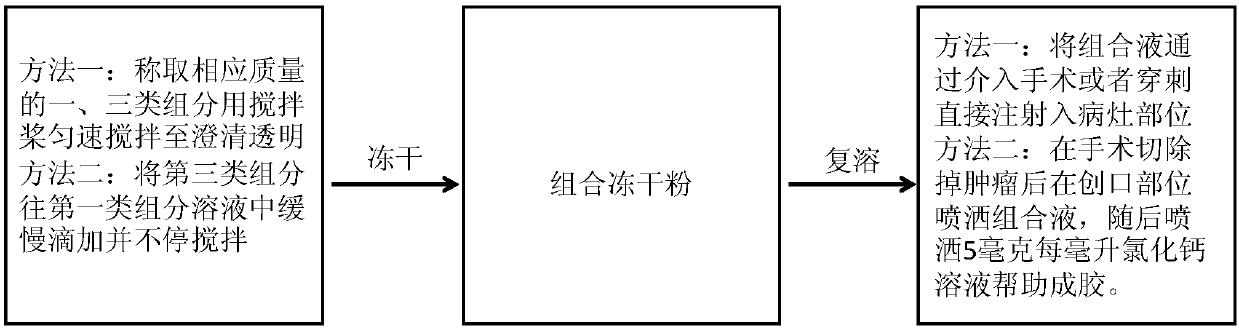

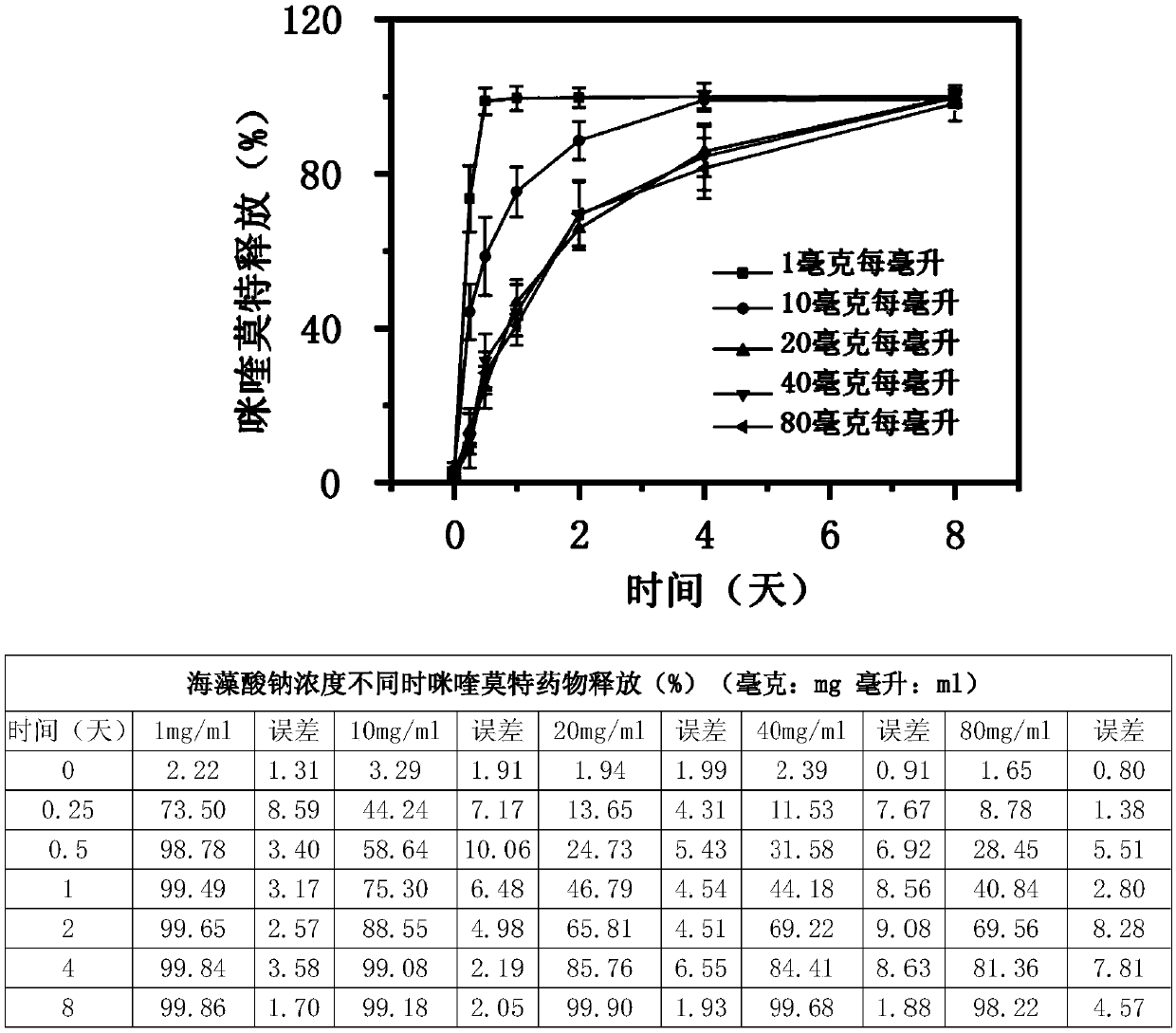

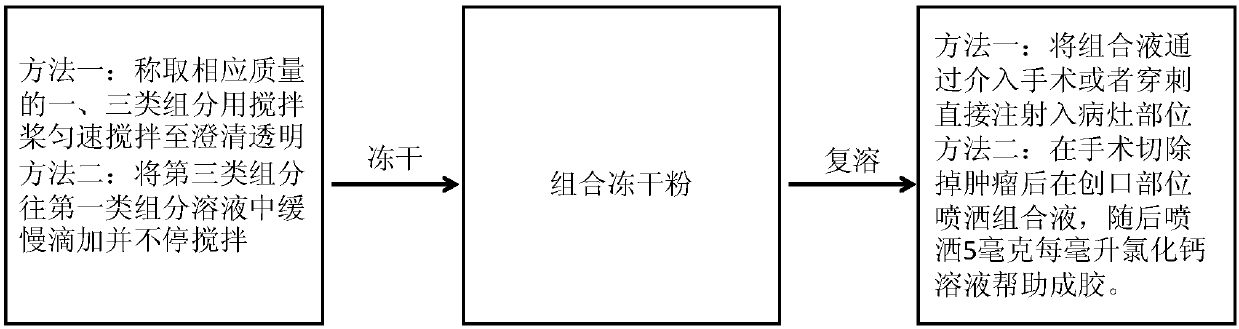

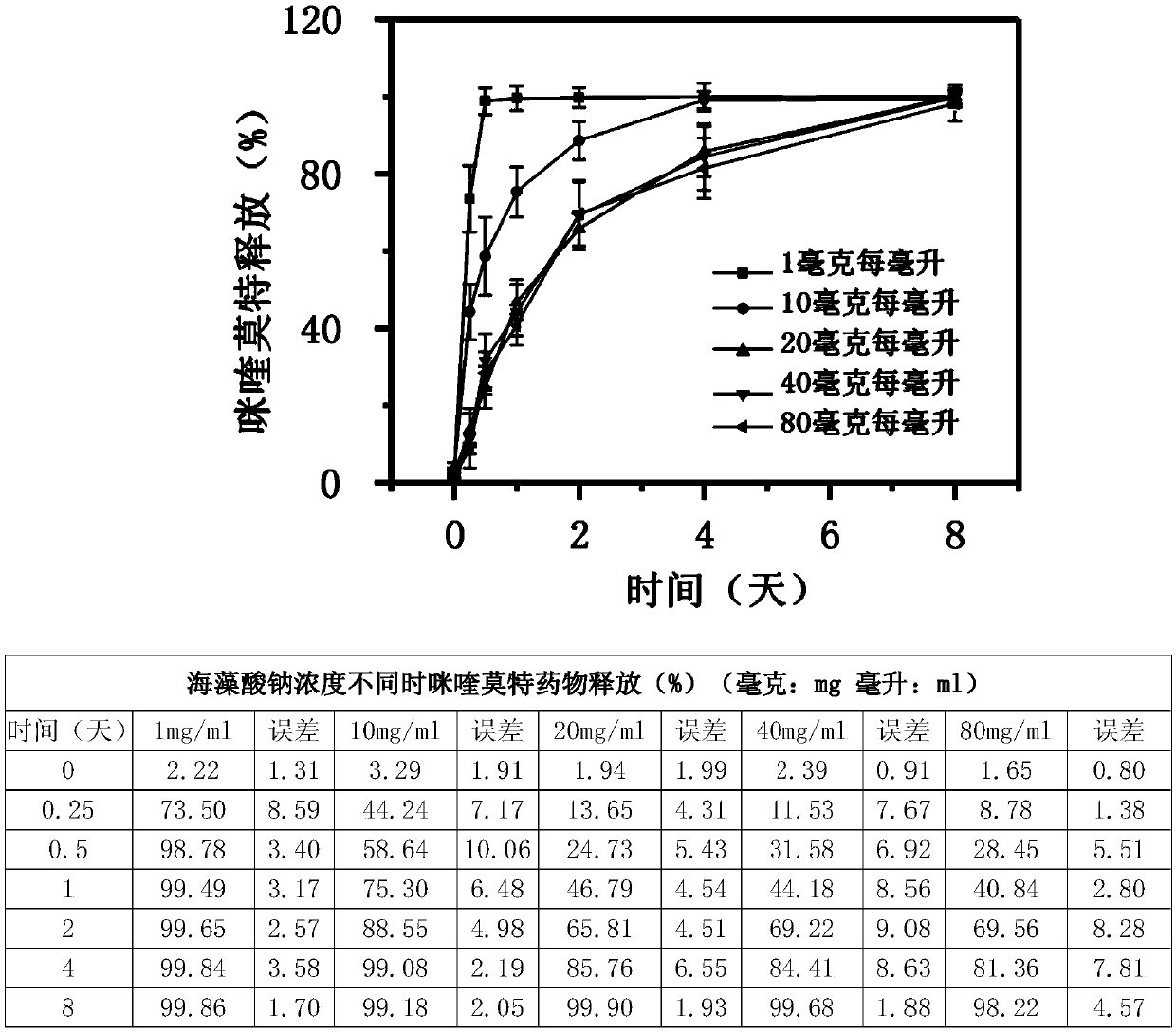

Pharmaceutical composition for chemotherapy and immunotherapy combined treatment

PendingCN111375064AGood biocompatibilityGood sustained release effectOrganic active ingredientsPharmaceutical delivery mechanismLymphatic SpreadCombined treatment

The invention discloses a pharmaceutical composition for chemotherapy and immunotherapy combined treatment. The pharmaceutical composition is prepared from: a first component alginate and a second component chemotherapeutic drug; the alginate can form a porous gel with calcium ions in a body, and the alginate is one or more of sodium alginate, potassium alginate and ammonium alginate; and the second component chemotherapeutic drug can cause immungentic cell death. The pharmaceutical composition belongs to an efficient tumor-specific immunotherapy program, the tumor in situ can be effectively killed, and the growth of distant metastatic tumors and the recurrence probability of tumor can be suppressed and reduced through immune response.

Owner:SUZHOU INNOVATIVE BIOMATERIALS & PHARM CO LTD

Preparation method of spherical silicon-aluminum composite carrier

ActiveCN104353503AImprove adhesionReduce production process stepsCatalyst carriersManganeseNano al2o3

The invention relates to a preparation method of a spherical silicon-aluminum composite carrier. The preparation method is characterized by comprising the following steps: adding silicon dioxide to an alumina gel, and uniformly mixing; slowly adding to an alginate solution, and uniformly stirring to prepare suspension slurry; dropping the suspension slurry into a multivalent metal cation solution to form a spherical composite gel granule; taking out the spherical composite gel granule, and drying and calcining to obtain the spherical silicon-aluminum composite carrier, wherein the alumina gel is an alumina hydrogel or a nano-alumina sol, the addition amount of the silicon dioxide is 0.1-0.3 time more than the weight of the alumina gel in terms of Al2O3, the suspension slurry contains 5%-25% by weight of solids and 0.3%-5% by weight of alginate, the soluble alginate is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, and the multivalent metal cation solution is an aluminum, zinc, calcium, copper, iron, ferrous iron, cobalt, manganese or nickel ion salt solution with the saturation concentration of 0.1 mol / L. The spherical silicon-aluminum composite carrier obtained through the preparation method disclosed by the invention has the advantages of high strength, large pore volume and low bulk density.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

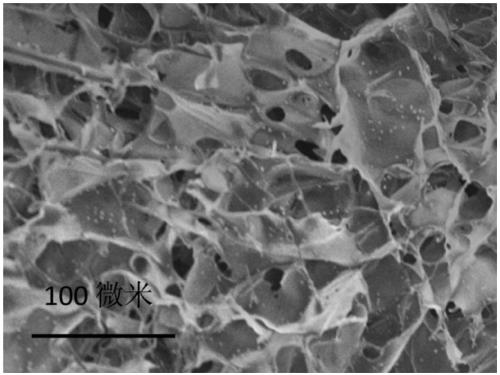

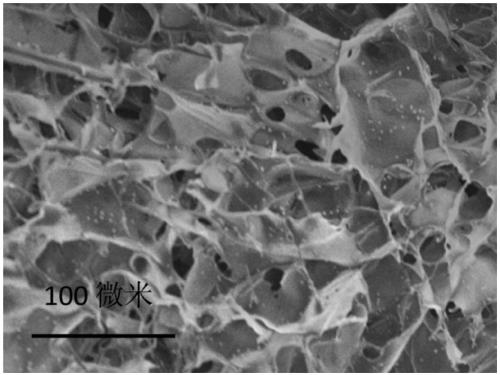

Biopolymer pharmaceutical composition used for tumor therapy

PendingCN111375065AGood biocompatibilityGood sustained release effectOrganic active ingredientsPharmaceutical delivery mechanismAMMONIUM ALGINATEBiopolymer

The invention discloses a biopolymer pharmaceutical composition for tumor therapy. The biopolymer pharmaceutical composition comprises a first component and a third component, wherein the first component is alginate; the alginate can form porous gel together with calcium ions in vivo, and the alginate is one or more of sodium alginate, potassium alginate and ammonium alginate; and the third component is an immune adjuvant. The biopolymer pharmaceutical composition can generate a synergistic anti-cancer effect, and reduces side effects, the cancer metastasis probability, and the cancer recurrence probability.

Owner:SUZHOU INNOVATIVE BIOMATERIALS & PHARM CO LTD

Preparation method of sodium alginate and cellulose hydrogel spheres

InactiveCN106732477AStable spherical structureOther chemical processesWater contaminantsAMMONIUM ALGINATECellulose

The invention relates to the technical field of functional materials and particularly relates to a preparation method of sodium alginate and cellulose hydrogel spheres. The preparation method comprises the following steps: stirring and dissolving NaOH, urea, water and natural bamboo fibers at -12 DEG C, so as to obtain a transparent cellulose solution, and stirring and dissolving sodium alginate and deionized water at room temperature, so as to obtain a sodium alginate solution; mixing the transparent cellulose solution with the sodium alginate solution to obtain a mixed solution, dropwise adding the mixed solution into an acidy regeneration solution prepared from trichloromethane by virtue of a 1mL disposable dropper, carrying out curing for 5 minutes, and taking out a gel sample; and flushing the gel sample with flowing deionized water, so as to obtain the sodium alginate and cellulose hydrogel spheres. When the mass fraction of sodium alginate is less than or equal to 50%, gel stays at a stable spherical structure and internally presents a threadlike crossed three-dimensional network porous structure; and sodium alginate and cellulose composite gel are combined together through physical aggregation.

Owner:SHAANXI SHENGMAI PETROLEUM

Preparation method of sodium alginate

The invention relates to a preparation method of sodium alginate and belongs to the field of preparation methods for food additives. The preparation method comprises the following steps of cleaning, drying and sectioning fresh kelp, putting the fresh kelp into a conversion tank, adding formaldehyde with the weight being 10% of the weight of dried kelp for soaking, adding an alkaline-containing solution into the conversion tank, stirring for reaction, so as to obtain pasty glue solution, adding water to dilute the pasty glue solution, foaming the diluted glue solution by a foaming machine, flowing the diluted glue solution into a floating sedimentation tank, collecting clear liquid at the middle-lower part to enter a decalcifying tank, simultaneously adding a diluted hydrochloric acid solution so that flocculent calcium alginate becomes insoluble alginic acid, crushing alginic acid, adding a pure-alkaline solution into a neutralizing machine with the alkaline-adding amount being 10-20% of the weight of alginic acid, and stirring for reaction so as to obtain a sodium alginate solution, and finally drying the sodium alginate solution in a drying machine to obtain the sodium alginate. The preparation method has the characteristics of simple process, strong operability and the like, and is suitable for industrial production and high stability of products. The viscosity of the prepared sodium alginate reaches more than 1500cps, and is generally more than 1.5 times higher than the viscosity 1000cps in the traditional preparation method.

Owner:西安莹朴生物科技股份有限公司

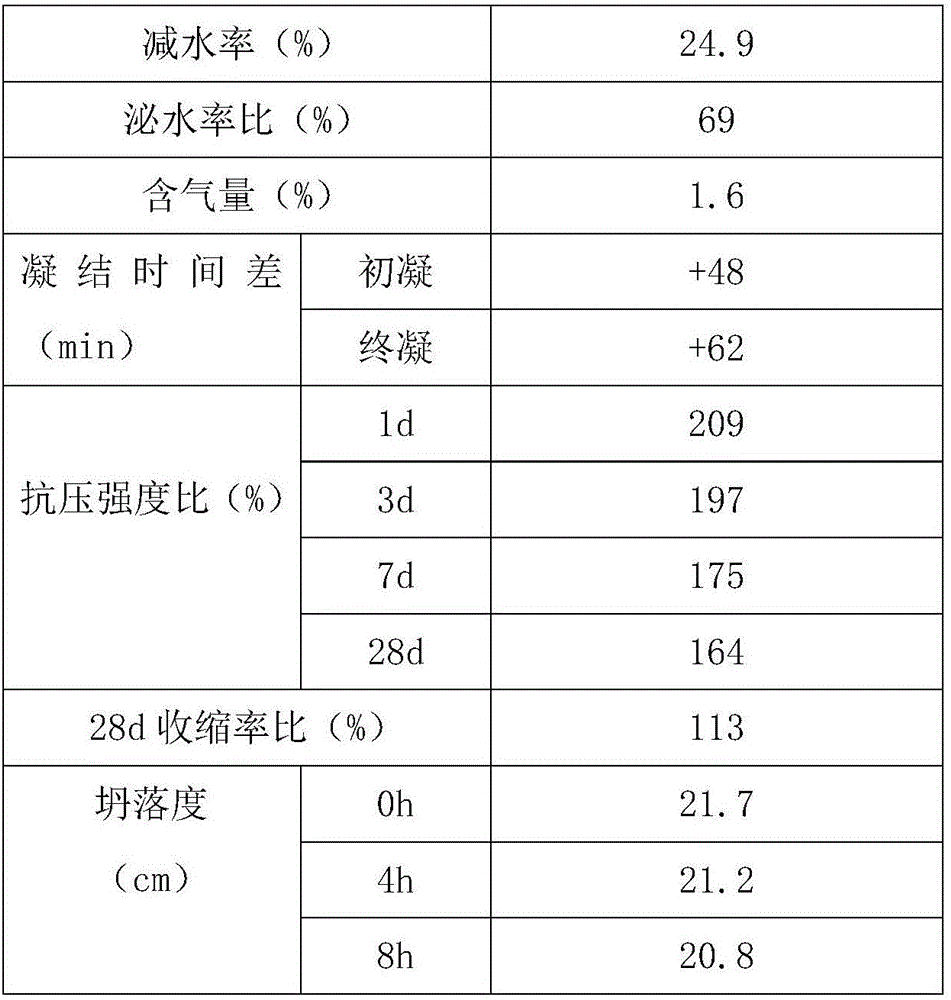

High slump loss resistant concrete water reducer and preparation method thereof

The invention discloses a high slump loss resistant concrete water reducer and a preparation method thereof. The water reducer is composed of the following raw materials in parts by weight: 9 to 14 parts of aliphatic hydroxyl sulfonate condensate, 7 to 11 parts of sodium beta-naphthalene sulfonate-formaldehyde condensate, 5 to 9 parts of sulfonated phenolic resin, 3 to 6 parts of casein, 6 to 10 parts of MPEGMA-MA-SMAS terpolymer, 4 to 8 parts of ammonium alginate, 8 to 12 parts of potassium humate, 4 to 7 parts of calcium chloride, 5 to 10 parts of sodium hydroxypropyl oxidized starch succinate, and 3 to 6 parts of sodium dodecyl benzene sulfonate. The water reducer prepared from aliphatic hydroxyl sulfonate condensate, sulfonated phenolic resin, MPEGMA-MA-SMAS terpolymer, and the like, has a strong slump retaining performance, overcomes the shortage that the slump loss of a high efficient water reducer is large, has the advantages of strong dispersion performance, high early strength, and good anti-permeability performance, and is especially suitable for preparing high slump loss resistant, high strength and durable concrete projects.

Owner:合肥永佳新材料科技有限公司

Adhesive Skin Patch

InactiveUS20100217170A1Simpler and more conciseCosmetic preparationsOrganic active ingredientsAMMONIUM ALGINATEPolyvinyl alcohol

A plaster including a pressure-sensitive adhesive layer containing a readily dissolvable agar and at least one additive selected from the group consisting of polyacrylamides, polyvinyl alcohols, polyvinyl pyrrolidones, sodium alginate, ammonium alginate, carboxymethylcelluloses, sodium carboxymethylcelluloses, methylcelluloses, gum arabics, tragacanth gums, and xanthene rubbers, is provided.

Owner:HISAMITSU PHARM CO INC

Method for coproduction of sodium alginate, mannitol and iodine by enzymolysis approach

InactiveCN103193897ASimple extraction processImprove qualityIodineHydroxy compound separation/purificationIon exchangeDigestion

The invention discloses a method for coproduction of sodium alginate, mannitol and iodine by enzymolysis approach. The method comprises the following steps of: taking brown seaweeds as the raw material, pretreating the raw material by a bio-enzymolysis approach, extracting iodine and mannitol from pretreated liquid, removing partial protein and the water soluble component seaweed residues for extraction and separation of sodium alginate, and finally, obtaining high-quality sodium alginate through a dilute alkali digestion process and by calcium solidification-ion exchange method. The method is characterized in that the seaweeds are pretreated by a biological enzyme, so that water soluble matters such as protein and the like therein are dissolved out in advance, which is advantageous for the subsequent extraction process of sodium alginate and the quality of the product and also for improving the product extraction ratio, and in such a way, the recycling of production water is realized finally; the process of extracting iodine and mannitol in the pretreated liquid is simple, and the production cost and the energy consumption are reduced; and compared with the existing industrial production process, more than 90% of water is saved, and the consumption of water resource and sewage drainage are greatly reduced so that environmental pollution is reduced.

Owner:QINGDAO BETTER BIO TECH

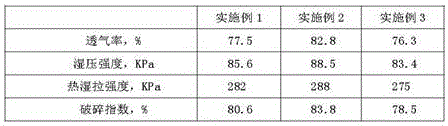

Core sand for automobile engine casting and preparation method of core sand

The invention discloses a core sand for automobile engine casting and a preparation method of the core sand. The core sand is prepared from the following raw materials in parts by weight: 170-180 parts of forsterite sand, 40-55 parts of graphite sand, 35-40 parts of high-magnesium phosphate tailing slag, 40-60 parts of skarn, 25-30 parts of waste foam concrete, 40-50 parts of knar clay, 15-18 parts of coal powder, 16-20 parts of coconut coir, 14-16 parts of blast furnace gas ash, 8-12 parts of high-aluminum fine powder, 10-15 parts of calcium zirconate, 15-17 parts of hollow silica nanospheres, 2-3 parts of sodium silicate, 3-5 parts of aluminum silicate, 3-4 parts of ammonium alginate, 4-6 parts of hydroxyethyl cellulose, 4-7 parts of beta-cyclodextrin and a proper amount of water. The core sand disclosed by the invention is good in performance; in the casting process, the amount of gas evolution is small, the drying time is short, the gas permeability is good, and the wet tensile strength is high; meanwhile, the demolding property of a sand mold can be improved, the sensibility to water during pouring can be lowered, and gas holes in a casting can be prevented; and bentonite and sodium water glass are adopted as binders, so that the mold drawing strength and the collapsibility of the core sand can be improved.

Owner:江阴联华铸造有限公司

Microcapsule type brightening eye cream

InactiveCN105213283ASmooth releaseFully absorbedCosmetic preparationsToilet preparationsGlycerolBatyl alcohol

The invention discloses a microcapsule type brightening eye cream which is a microcapsule with a core-shell structure. A capsule wall is prepared from the following materials: ammonium alginate, sodium polyacrylate and hyaluronic acid; a capsule core is prepared from the following materials: marten oil, squalane, lecithin, jojoba wax, glycerol, batyl alcohol, serine, corn porous starch, a mountain elm alcohol extract, an arabidopsis alcohol extract, bee milk, opoponax alcohol, a coenzyme Q10 and a surfactant. Through the microcapsule type brightening eye cream, the corn porous starch is used for adsorbing grease ingredients and active ingredients adsorbed in the materials of the capsule core, so that the microcapsule type brightening eye cream is capable of slowly and uniformly releasing the active ingredients and the grease adsorbed in the corn porous starch during use and is incapable of releasing a large quantity of the active ingredients and the grease in a short time and causing excessive nutrition and grease to the skin, thereby avoiding the generation of fat granules; the microcapsule type brightening eye cream also has the characteristic of excellent permeability.

Owner:CHONGQING PELLETS TECHN & TRADE

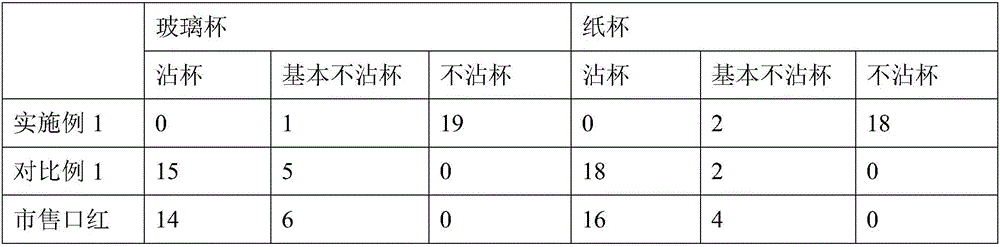

Cup-staining-free lipstick and preparation method thereof

InactiveCN106377441AImprove non-stick effectEasy to useCosmetic preparationsMake-upAdditive ingredientNuclear chemistry

The invention discloses a cup-staining-free lipstick, which is prepared from the following raw materials in parts by weight: 12-24 parts of wax ingredients, 20-50 parts of oil ingredients, 4-32 parts of pigment ingredients, 0-20 parts of additive ingredients, 2-12 parts of soluble salt alginate and 4-20 parts of soluble metal salt, wherein the soluble salt alginate is selected from sodium alginate tech grade, potassium alginate or ammonium alginate; the soluble metal salt is the soluble metal of aluminum, barium, calcium, copper, ferrum, lead, zinc or nickel. According to the lipstick, the soluble salt alginate and the soluble metal salt are matched to form various ingredients, the weight proportion of each component is reasonably designed, the cup-staining-free lipstick is designed and obtained, and the defects and the deficiencies of traditional lipsticks are overcome. Through tests, the lipstick disclosed by the invention has a good cup-staining-free effect, and the use method is simple and easy to accept.

Owner:SHANDONG UNIV

Method for preparing threadlike carbon heat source material for cigarettes by using calcium salt

ActiveCN103233295AHarm reductionEasy to coil processingArtificial filament chemical after-treatmentArtifical filament manufactureAMMONIUM ALGINATEGlass fiber

The invention discloses a method for preparing a threadlike carbon heat source material for cigarettes by using calcium salt, which comprises the following steps: mixing sodium alginate or ammonium alginate or potassium alginate with carbon powder and water, and stirring into a jelly, wherein the mass ratio of the sodium alginate or ammonium alginate or potassium alginate to the carbon powder is 1:(5-45); extruding the jelly into a thread, and sufficiently contacting the thread with a calcium salt solution to obtain a condensate; and rinsing the condensate, and drying until the water content reaches 10-20%, thereby obtaining the threadlike carbon heat source material for cigarettes. The invention lowers the hazard caused by glass fibers sucked into the human body, enhances the combustibility of the carbon heat source, and has the characteristics of simple method, short production cycle, low cost and the like.

Owner:HUBEI CHINA TOBACCO IND +1

Method for preparing cigarette filamentary carbon heat source material by ethanol

ActiveCN103205825AHarm reductionEasy to coil processingArtificial filament chemical after-treatmentArtifical filament manufactureGlass fiberAMMONIUM ALGINATE

The invention discloses a method for preparing a cigarette filamentary carbon heat source material by ethanol. The method comprises the following steps of mixing sodium alga acid or ammonium alginate or potassium alginate with carbon powder and water, and blending into jelly, wherein the mass ratio of the sodium alga acid or ammonium alginate or potassium alginate to the carbon powder is 1 to (5-45); then extruding the jelly into a filament, enabling the filament to fully contact ethanol of which the mass concentration is greater than or equal to 66% to obtain condensate; rinsing and drying the condensate, so that the moisture content achieves 10-20%, so as to obtain the cigarette filamentary carbon heat source material. By adopting the method, not only can the damage caused by a glass fiber absorbed into a human body be reduced, but also the combustibility of the carbon heat source is also improved; and the method has the characteristics that the method is simple in method, short in production period, low in cost and the like.

Owner:HUBEI CHINA TOBACCO IND +1

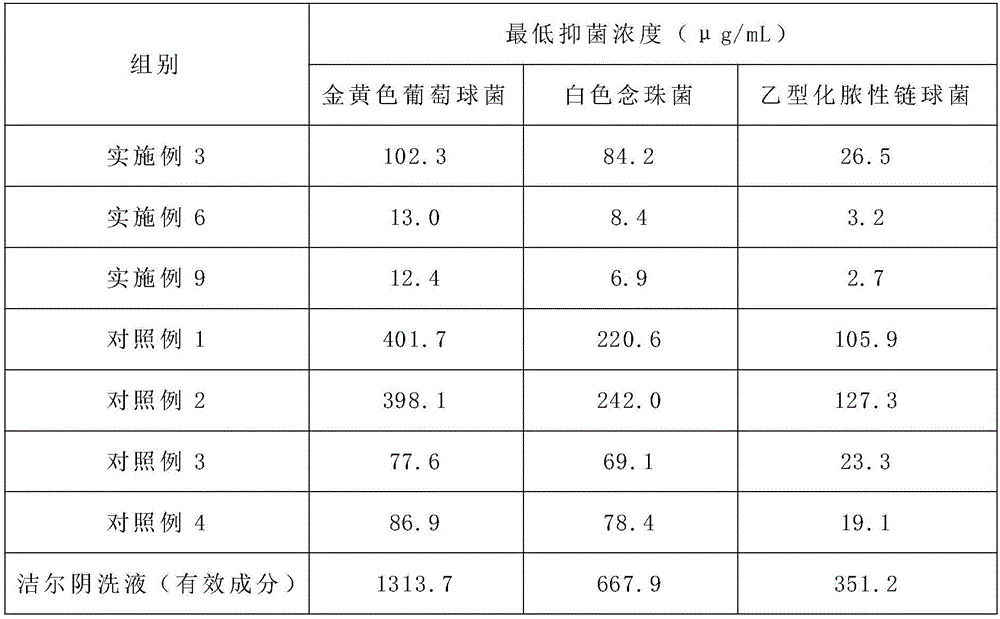

Vaginal antibacterial composition as well as preparation and preparation method thereof

InactiveCN105963340AImprove performanceLess irritatingAerosol deliveryAntisepticsAMMONIUM ALGINATEIrritation

The invention provides a vaginal antibacterial composition, which is mainly prepared from raw materials such as octoxynol, A.SAP antibacterial agent, Folium folium extract, ammonium alginate and the like. The vaginal antibacterial composition provided by the invention is less irritating, safe and efficient, can effectively inhibit various bacteria in the vagina, treat vaginal inflammation, and has daily cleaning, nursing, and disease prevention effects on the vagina and cervix, and can avoid the use of antibiotics Treatment of drug-resistant strains brought about by vaginal inflammation and further imbalance of vaginal flora.

Owner:北京好汉邦微商联盟电子商务有限公司

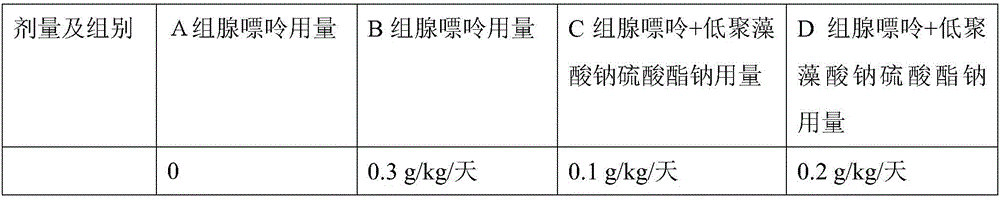

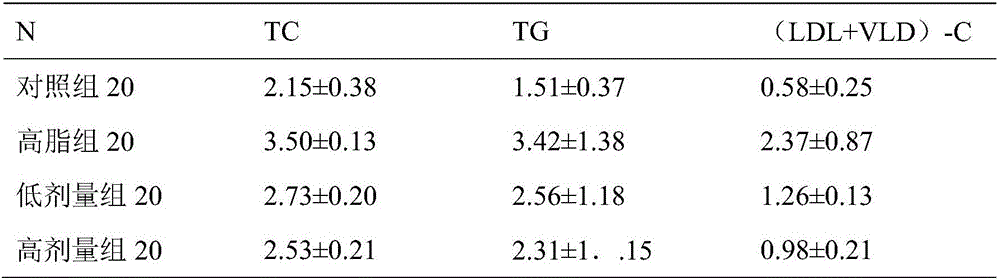

Preparation method and application of oligomeric sodium alginate sulfate salt

InactiveCN105820268APromote degradationSimple processOrganic active ingredientsMetabolism disorderChlorosulfuric acidSodium sulfate

The invention relates to a preparation method and application of an oligomeric alginate sulfate ester salt, belonging to the field of raw material preparation of chemicals. The preparation method of the oligomeric alginate sulfate provided by the invention is to add pyridine and chlorosulfonic acid after degradation, emulsification and washing to prepare oligomeric alginate sulfate, and use potassium ions, sodium ions or ammonia water to form a salt, Potassium oligomeric alginate sulfate, sodium oligomeric sodium alginate sulfate or ammonium oligomeric ammonium alginate sulfate are generated. The preparation method provided by the invention overcomes the problems of complex process in the prior art through direct sulfonation, and optimizes the degradation process of alginic acid.

Owner:天津中津药业股份有限公司

Adhesive skin patch

Disclosed is an adhesive skin patch which has an adhesive layer comprising a readily-soluble agar and at least one additive selected from the group consisting of polyacrylamide, polyvinyl alcohol, polyvinyl pyrrolidone, sodium alginate, ammonium alginate, carboxymethylcellulose, sodium carboxymethylcellulose, methylcellulose, gum arabic, tragacanth gum and xanthan gum.

Owner:HISAMITSU PHARM CO INC

Calcium titanate nanometer fiber-acrylic fiber pulp-reinforced thermal insulation mortar and preparation method thereof

InactiveCN106082897AHigh compressive strengthAccelerated corrosionSolid waste managementCalcium silicateSlag

The invention discloses calcium titanate nanometer fiber-acrylic fiber pulp-reinforced thermal insulation mortar and a preparation method thereof. The calcium titanate nanometer fiber-acrylic fiber pulp-reinforced thermal insulation mortar is prepared from 19-27 parts by weight of waste calcium silicate boards, 12-19 parts by weight of acrylic fiber pulp, 14-21 parts by weight of copper mine tailings, 10-15 parts by weight of calcite, 13-20 parts by weight of furnace cinder, 8-14 parts by weight of white mud, 10-15 parts by weight of calcium titanate nanometer fibers, 7-11 parts by weight of ammonium alginate, 16-22 parts by weight of basalt slag, 9-16 parts by weight of stone coal cinder, 5-10 parts by weight of fluorgypsum, 51-58 parts by weight of low-heat Portland blast furnace slag cement, 11-18 parts by weight of carbonized rice hull and 10-15 parts by weight of sodium polyacrylate. Through use of calcium titanate nanometer fibers and acrylic fiber pulp in thermal insulation mortar, good enhancement effects are obtained, thermal insulation mortar compressive strength is improved and corrosion resistance and high temperature resistance of the thermal insulation mortar are improved. The thermal insulation mortar has high compressive strength, good corrosion resistance, high temperature resistance, water resistance and aging resistance.

Owner:马鞍山市金韩防水保温工程股份有限公司

Method for using ethanol to prepare sheet carbonaceous heat sources for cigarettes

ActiveCN103222685AHarm reductionEasy to coil processingTobacco smoke filtersGlass fiberAMMONIUM ALGINATE

The invention discloses a method for using ethanol to prepare sheet carbonaceous heat sources for cigarettes. The method comprises the following steps: mixing sodium alginate or ammonium alginate or potassium alginate with carbon powder and water, and stirring the mixture into a jelly-like substance, wherein the weight ratio of the sodium alginate or the ammonium alginate or the potassium alginate to carbon powder is 1:(5-45); then extruding the jelly-like substance into thin sheets, and intensively mixing the thin sheets with ethanol with a mass concentration of more than or equal to 66% to obtain a solidified substance; and rinsing and drying the solidified substance until the moisture content of the solidified substance reaches 10-20% to obtain the sheet carbonaceous heat sources for cigarettes. The method provided by the invention not only reduces the harm caused by inhalation of glass fiber into a human body, but also improves the flammability of carbonaceous heat sources, and has the characteristics of simple method, short production period, low cost and the like.

Owner:HUBEI CHINA TOBACCO IND +1

A kind of preparation method of spherical silicon-alumina composite carrier

ActiveCN104353503BImprove adhesionReduce production process stepsCatalyst carriersManganeseNano al2o3

The invention relates to a preparation method of a spherical silicon-aluminum composite carrier. The preparation method is characterized by comprising the following steps: adding silicon dioxide to an alumina gel, and uniformly mixing; slowly adding to an alginate solution, and uniformly stirring to prepare suspension slurry; dropping the suspension slurry into a multivalent metal cation solution to form a spherical composite gel granule; taking out the spherical composite gel granule, and drying and calcining to obtain the spherical silicon-aluminum composite carrier, wherein the alumina gel is an alumina hydrogel or a nano-alumina sol, the addition amount of the silicon dioxide is 0.1-0.3 time more than the weight of the alumina gel in terms of Al2O3, the suspension slurry contains 5%-25% by weight of solids and 0.3%-5% by weight of alginate, the soluble alginate is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, and the multivalent metal cation solution is an aluminum, zinc, calcium, copper, iron, ferrous iron, cobalt, manganese or nickel ion salt solution with the saturation concentration of 0.1 mol / L. The spherical silicon-aluminum composite carrier obtained through the preparation method disclosed by the invention has the advantages of high strength, large pore volume and low bulk density.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Shampoo composition

A shampoo composition delivering consumer desired lather, cleaning and viscosity comprising from about 8 wt % to about 35 wt % of decyl glucoside having an average alkyl chain length of about C10; from about 0.25 wt % to about 1.0 wt % alkyl glucoside with an average alkyl chain of C12 and greater; from about 0.4% to 2.0% of a gum selected from non-ionic and anionic gums consisting of xanthan gum, sclerotium gum, guar gum, locust bean gum, tragacanth gum, acacia gum, agar gum, algin gum, gellan gum, carob gum, karaya gum biosacharide gum, calcium carrageenan, potassium carrageenan, sodium carrageenan, potassium alginate, ammonium alginate, calcium alginate and any combination thereof.

Owner:THE PROCTER & GAMBLE COMPANY

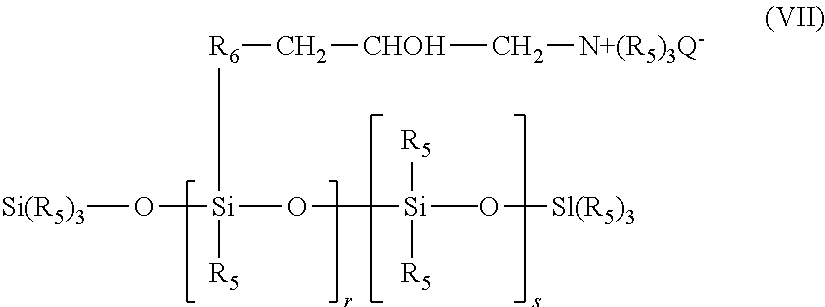

Preparation method of low-temperature-resistant car urea solution

InactiveCN108261922AHigh porosityImprove low temperature resistanceOther chemical processesExhaust apparatusPorosityIon

The invention relates to a preparation method of low-temperature-resistant car urea solution, and belongs to the technical field of a chemical process. High-temperature and high-pressure steam is used; through diffusion effect, condensed water in fiber cells fast evaporates and expands; the lignin coating effect and a cellulose crystallization structure are broken; the material porosity is obviously increased; then, the covalent bond is used for crosslinking free amino acid or amino groups of the soybean protein molecules with ammonium alginate to form a reticular space structure; under the basic condition, the soybean protein molecules swell so that the molecule structures loosen; peptide chains extend; hydrophobic groups are sufficiently exposed; through heating denaturation treatment, the materials are decomposed into pores of the materials; a viscous porous structure formed by multilayer micro fiber can be formed; the larger specific surface area and a great number of active sitescapable of being combined with metal ions are realized; the urea solution is purified; the prepared pure urea solution is mixed with ammonium acetate and ammonium chloride capable of lowering the water solution freezing point; the low-temperature-resistant performance of the urea solution is improved.

Owner:薛向东

Method for preparing threadlike carbon heat source material for cigarettes by using acid

ActiveCN103233294AHarm reductionEasy to coil processingArtificial filament chemical after-treatmentArtifical filament manufactureWater contentAMMONIUM ALGINATE

The invention discloses a method for preparing a threadlike carbon heat source material for cigarettes by using acid, which comprises the following steps: mixing sodium alginate or ammonium alginate or potassium alginate with carbon powder and water, and stirring into a jelly, wherein the mass ratio of the sodium alginate or ammonium alginate or potassium alginate to the carbon powder is 1:(5-45); extruding the jelly into a thread, and sufficiently contacting the thread with an acidic solution with the pH value of at most 3 to obtain a condensate; and rinsing the condensate, and drying until the water content reaches 10-20%, thereby obtaining the threadlike carbon heat source material for cigarettes. The invention lowers the hazard caused by glass fibers sucked into the human body, enhances the combustibility of the carbon heat source, and has the characteristics of simple method, short production cycle, low cost and the like.

Owner:HUBEI CHINA TOBACCO IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com