Patents

Literature

434 results about "Chlorosulfuric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

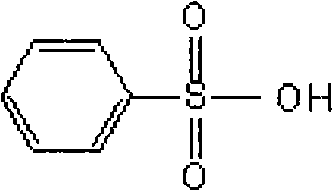

Chlorosulfuric acid (IUPAC name: sulfurochloridic acid) is the inorganic compound with the formula HSO₃Cl. It is also known as chlorosulfonic acid, being the sulfonic acid of chlorine. It is a distillable, colorless liquid which is hygroscopic and a powerful lachrymator.

Method for preparing bi-(sulfonyl fluoride) imine and (fluorinated alkyl sulfonyl fluorine sulfonyl) imine alkali metal salt

ActiveCN101747242AAvoid product agglomerationSimple and efficient operationSulfonic acid amide preparationSolventDecomposition

The invention discloses a method for preparing bi-(sulfonyl fluoride) imine and (fluorinated alkyl sulfonyl fluorine sulfonyl) imine alkali metal salt. The method comprises the following steps of: reacting sulfamide and thionyl chloride and chlorosulfonic acid to prepare bi-(sulfonyl chlorine) imine and (fluorinated alkyl sulfonyl chlorine sulfonyl) imine, reacting with antimony trifluoride and potassium carbonate (rubidium or caesium) to obtain corresponding high-purity bi-(sulfonyl fluoride) imine potassium (rubidium or caesium) salt or (fluorinated alkyl sulfonyl fluorine sulfonyl) imine potassium (rubidium or caesium) salt, performing double decomposition exchange reaction using the potassium (rubidium or caesium) salt with the lithium perchlorate (or sodium) or lithium tetrafluoroborate (or sodium) in the aprotic polar solvent to obtain corresponding lithium (or sodium) salt with high purity. The method in the invention has the characteristics of simple operating steps, easy separation and extraction of output, high purity and yield, no environmental pollution, and the like, and is suitable for mass industrial production.

Owner:武汉市瑞华新能源科技有限公司

Preparation method of lithium bis(fluorosulfonyl)amide

The present invention provides a preparation method of lithium bis(fluorosulfonyl)amide. The method comprises the following steps: A) reacting chlorosulfuric acid with ammonia in the presence of an organic base to obtain organic alkali salt of bis(fluorosulfonyl)amide; B) mixing the bis(fluorosulfonyl)amide obtained in the step A) with HF for a fluorinated reaction to obtain an organic alkali salt of bis(fluorosulfonyl)amide; C) mixing the organic alkali salt of bis(fluorosulfonyl)amide obtained in the step B) with an alkaline substance for a neutralization reaction to obtain a bis(fluorosulfonyl)amid metal salt crude product; D) purifying the bis(fluorosulfonyl)amid metal salt crude product obtained in the step C) to obtain bis(fluorosulfonyl)amid metal salt; and E) mixing the bis(fluorosulfonyl)amid metal salt obtained in the step D) with a lithium reagent for a replacement reaction, so as to obtain lithium bis(fluorosulfonyl)amide. The preparation method provided by the invention has the characteristics of low raw material cost, low impurity content in the product and high yield of lithium bis(fluorosulfonyl)amide.

Owner:湖南福邦新材料有限公司

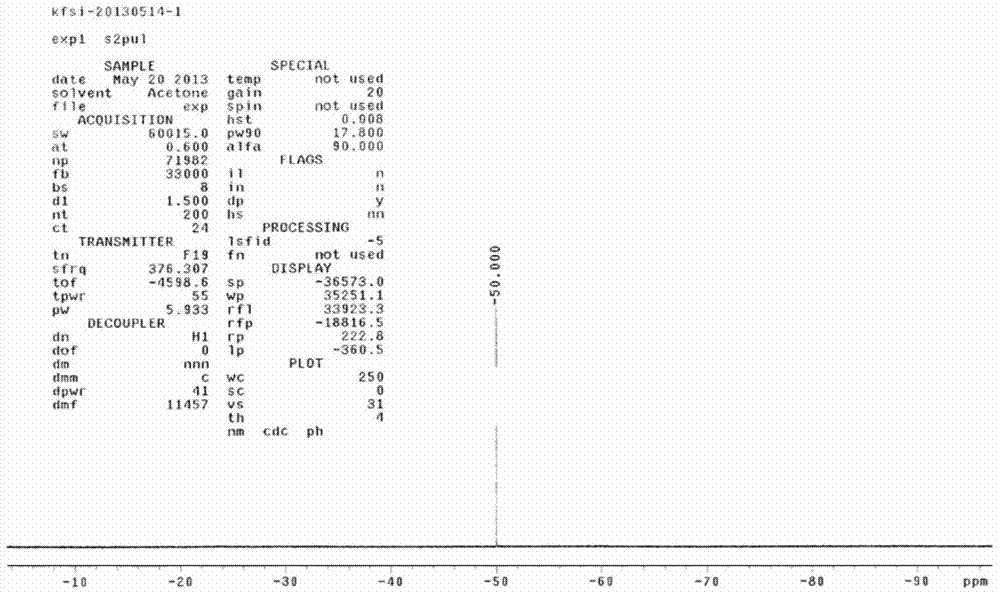

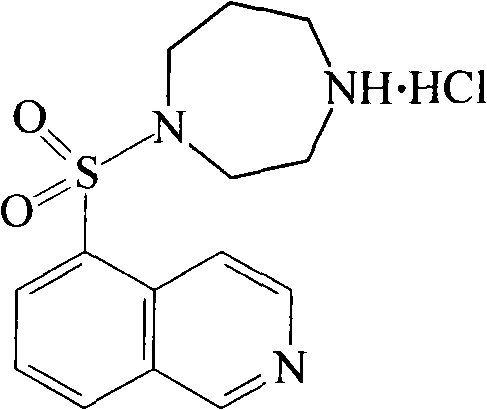

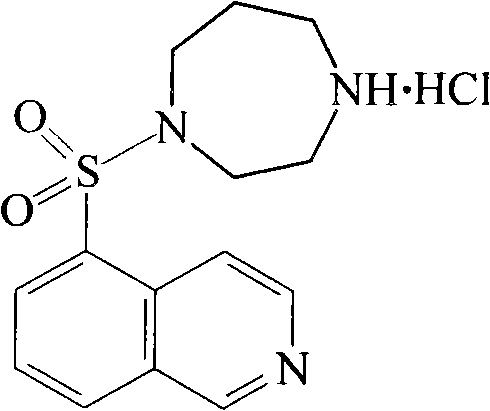

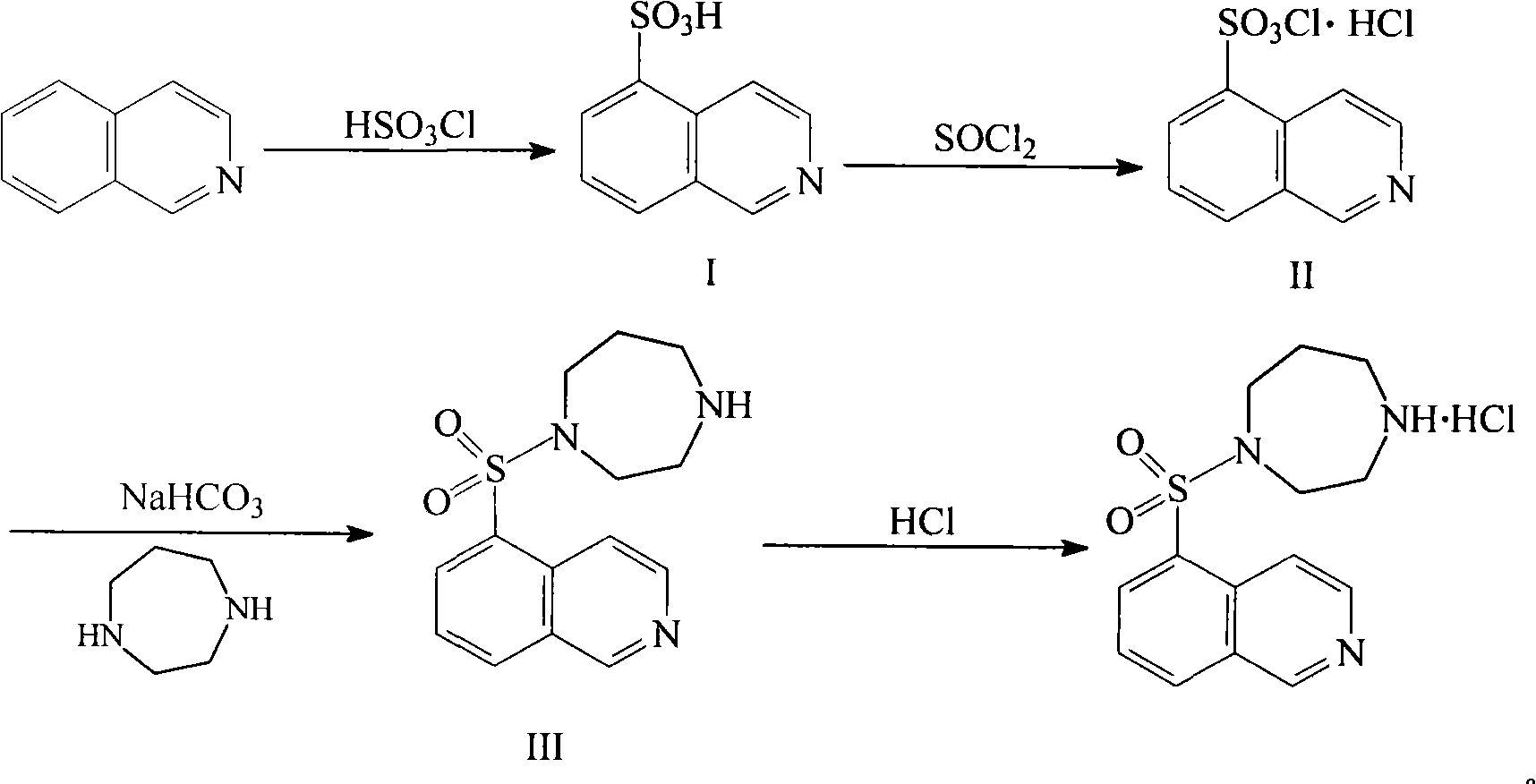

Fasudil hydrochloride compound and novel method thereof

InactiveCN101863880AImproved sulfonation reactionMild reaction conditionsOrganic chemistrySodium bicarbonateSulfonyl chloride

The invention relates to a fasudil hydrochloride compound and a novel method thereof. The method comprises the following steps of: in the presence of a solvent, performing sulfonation reaction on a chlorosulfonic acid serving as a sulfonating agent and isoquinoline to generate a 5-isoquinolinesulfonic acid; reacting the 5-isoquinolinesulfonic acid with thionyl chloride under a heating condition to generate isoquinoline-5-sulfonyl chloride hydrochloride; and dissolving the isoquinoline-5-sulfonyl chloride hydrochloride with ice water, adjusting the pH value of the solution with sodium bicarbonate, reacting the solution with homopiperazine, adjusting the pH value again with a hydrochloric acid, and concentrating under reduced pressure and recrystallizing to prepare the fasudil hydrochloride compound. The synthesis method of the invention has the advantages of mild reaction conditions, high yield and easy industrial production.

Owner:HAINAN LINGKANG PHARMA CO LTD

O-sulfated bacterial polysaccharides

InactiveUS6288044B1Interesting anti-angiogenetic and antiviral as well as anticoagulant activityPrevention of hair falling outOrganic active ingredientsBiocideBacteroidesChlorosulfuric acid

Process for the preparation of O-sulfated K4, K5 and K40 polysaccharides useful for the treatment of tumoral, HIV-1 and coagulation pathologies and in cosmetic preparations, wherein the K4, K5 or K40 polysaccharide in the form of sodium salt is suspended in an aprotic solvent and directly submitted to the reaction of O-sulfation with a pyridine-sulphur trioxide or trimetylamine-sulphur trioxide adduct or with chlorosulfonic acid.

Owner:INALCO SPA

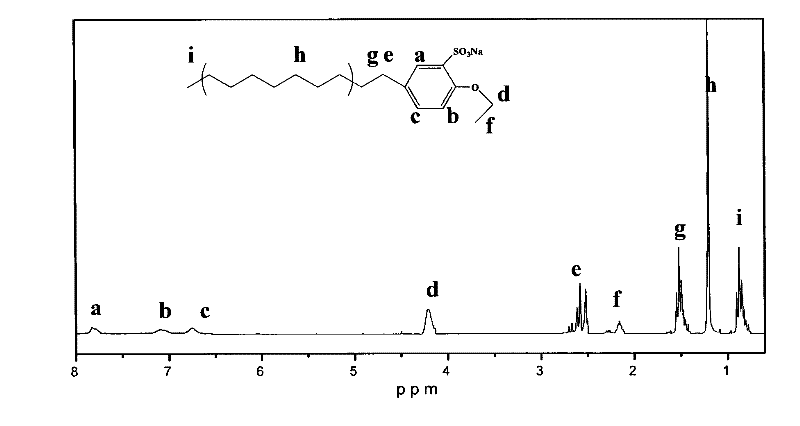

Alkylbenzene sulfonate Gemini surfactant and preparation method thereof

InactiveCN102452966ALow critical micelle concentrationReduce surface tensionTransportation and packagingSulfonic acids salts preparationAlkaneChlorosulfuric acid

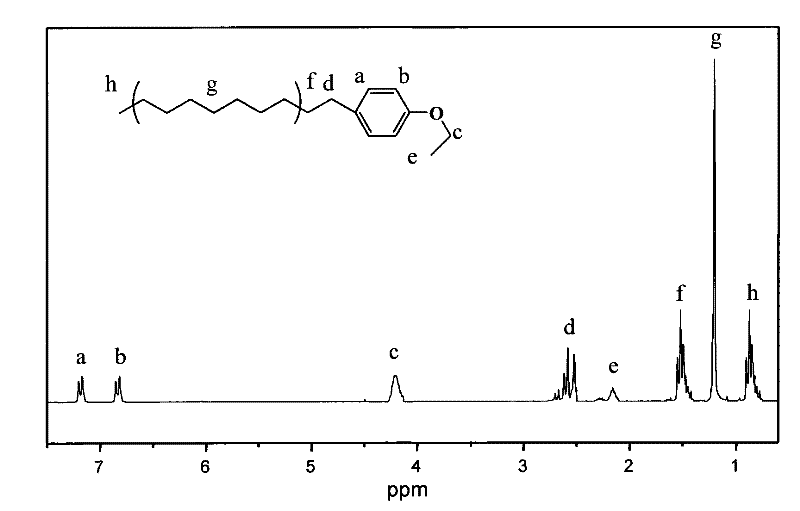

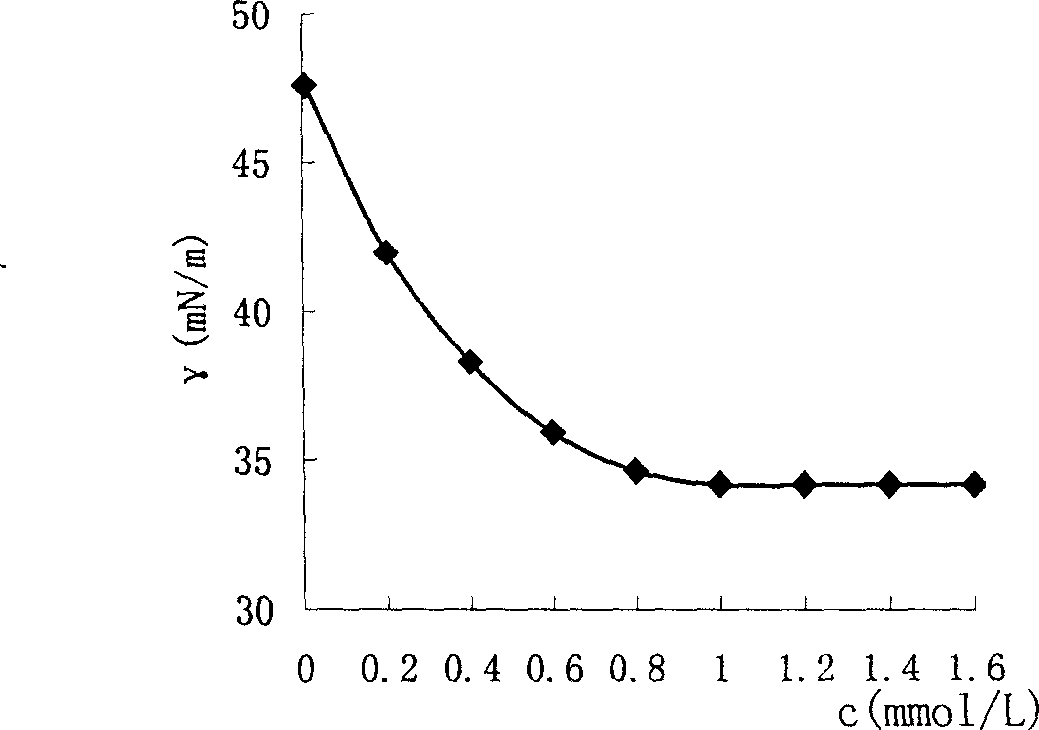

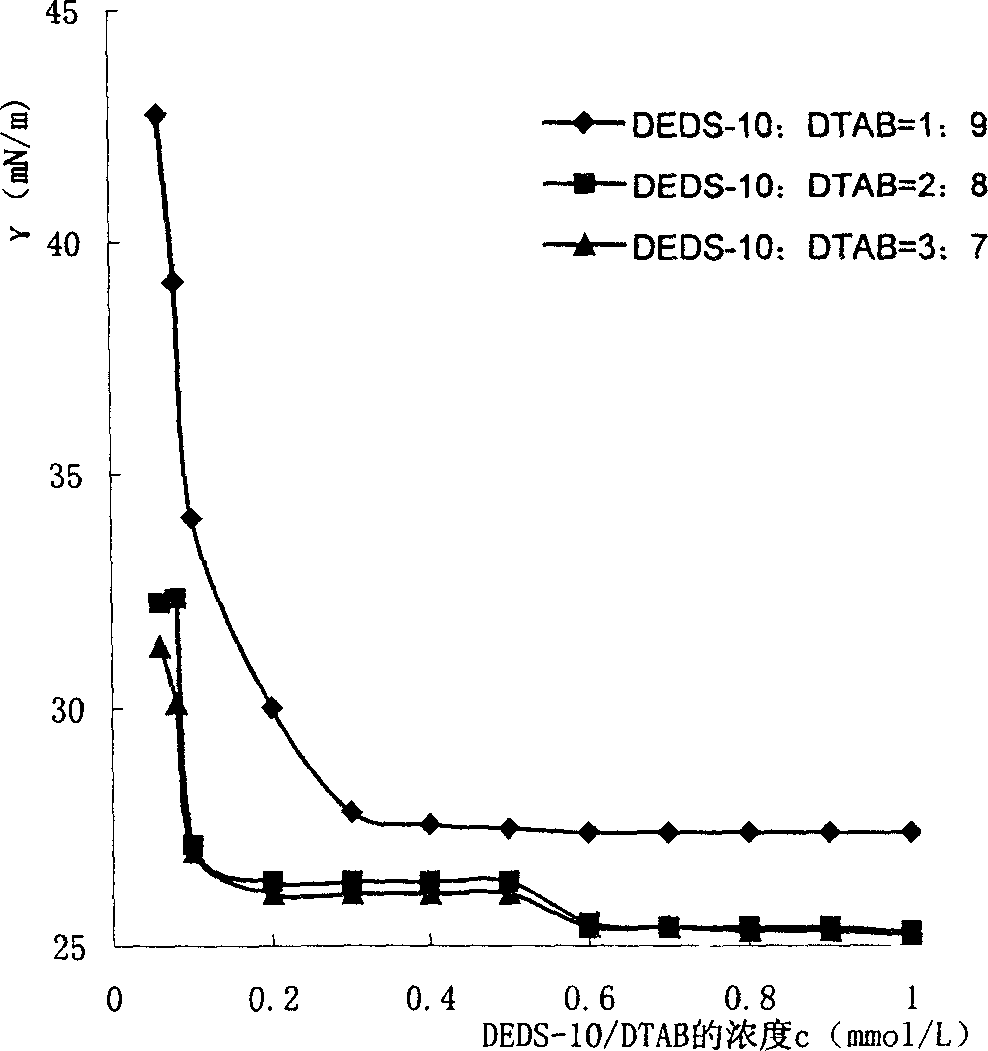

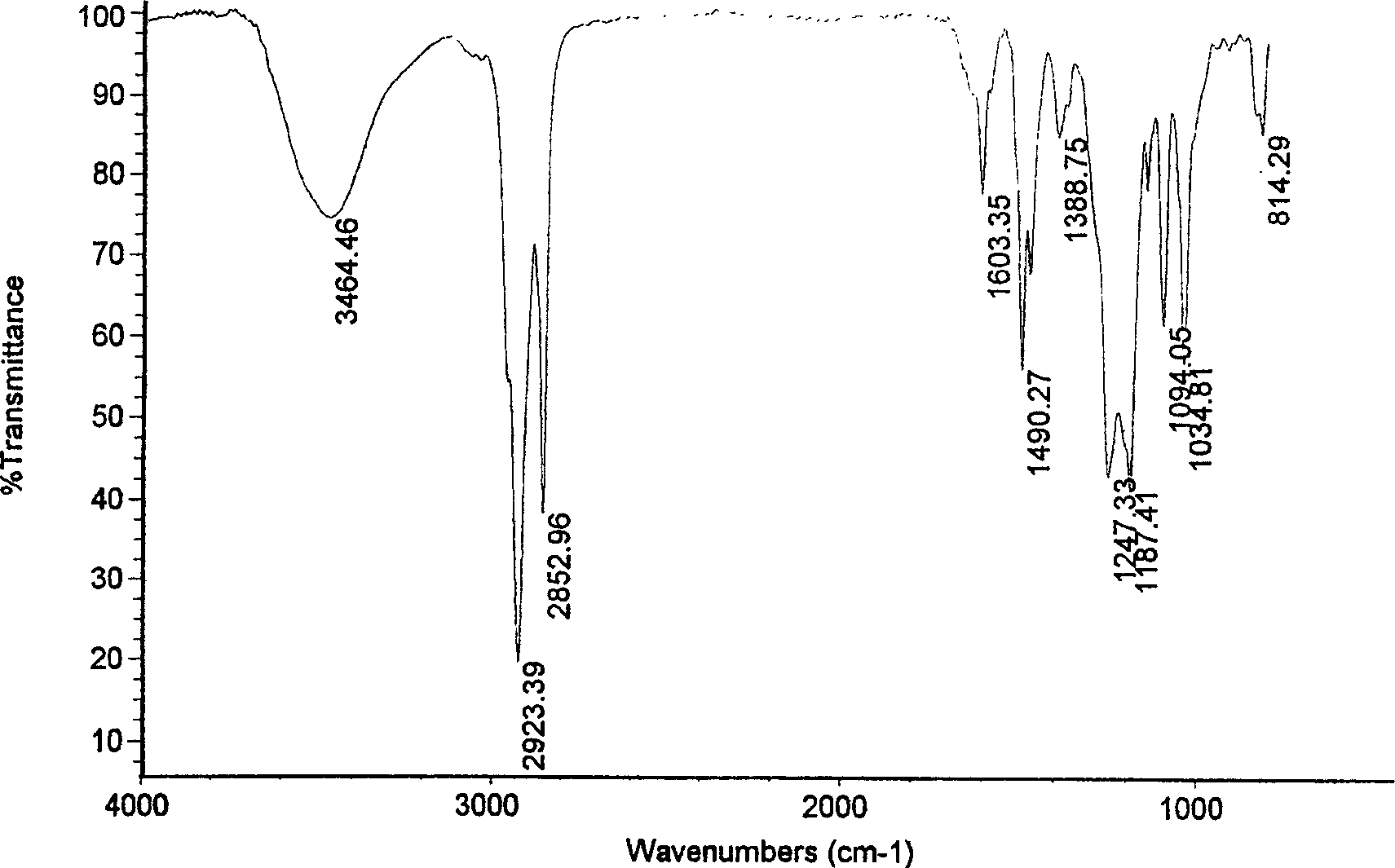

The invention relates to an alkylbenzene sulfonate Gemini surfactant and a preparation method thereof. The method comprises the following steps of: undergoing a substitution reaction: undergoing a substitutive etherification reaction at the temperature of 65-70 DEG C for 6 hours on phenol and dihalogenated alkane under the action of a phase transfer catalyst to generate bisether, wherein the molar ratio of the phenol to saturated dihalide is 1:3, the saturated dihalide is head-to-end dibromoalkane, the quantity of atoms C of the dibromoalkane is larger than 2, and the phase transfer catalyst is tetrabutylammonium bromide; performing Fourier alkylation: making the bis-ether react with an alkyl halide at the temperature of 80 DEG C and under the pressure of 0.3 MPa under the action of a Louis acid catalyst to generate dialkyl phenylate, wherein the molar ratio of the bis-ether to the alkyl halide is 1:2; undergoing a sulfonation reaction: undergoing a sulfonation reaction on the dialkyl phenylate and a chlorosulfonic acid in the molar ratio of 1:4 by taking dichloromethane as a solvent at the temperature of 0 DEG C; and undergoing a salt-forming reaction: adding an alkali to generate a target product. The alkylbenzene sulfonate Gemini surfactant has very high interfacial activity and a very low critical micelle concentration.

Owner:PETROCHINA CO LTD

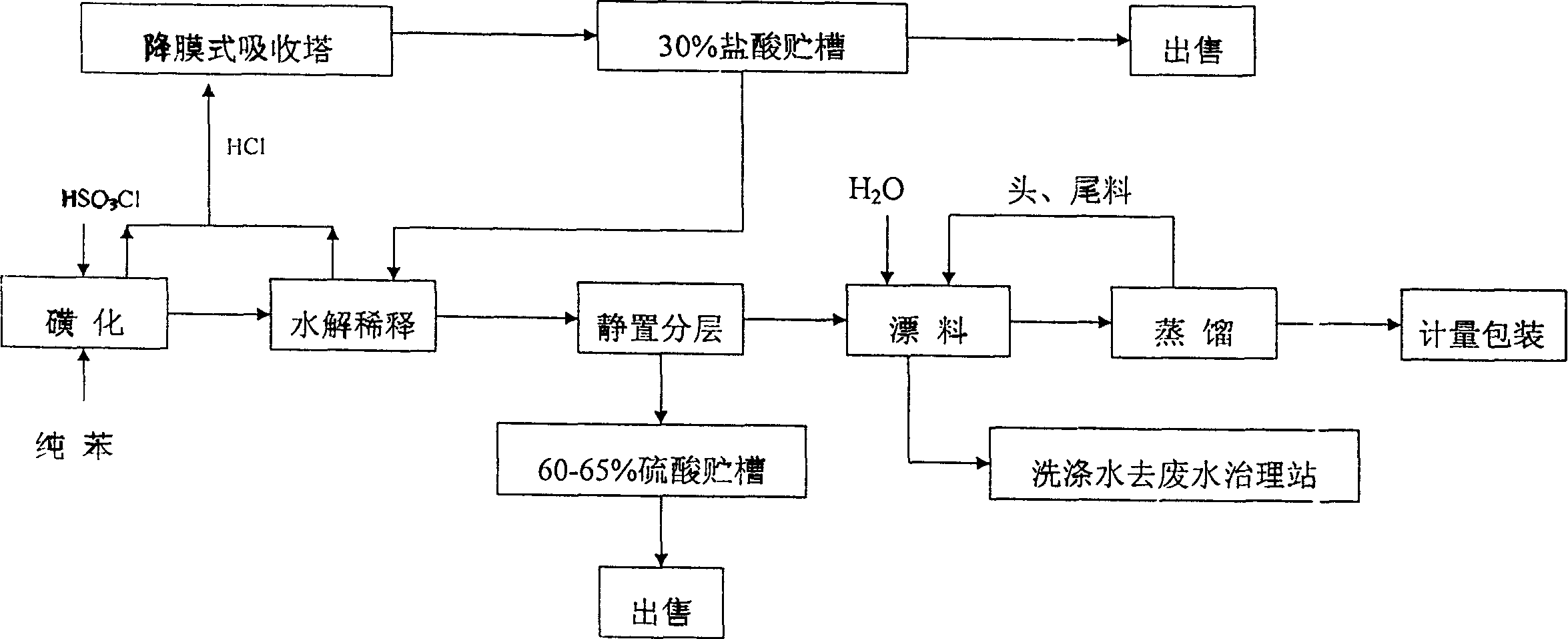

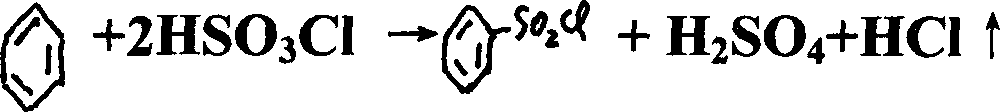

Production technology of phenyl sulfuryl chloride

The present invention provides a production method of benzenesulfonyl chloride. It is characterized by that said invention uses benzene and chlorosulfonic acid as raw material, and makes them undergo the processes of sulfonation reaction, hydrolytic dilution, standing still and layer separation and reduced pressure distillation so as to obtain the invented product. Said invention also provides the concrete steps of every process and its concrete requirements.

Owner:江苏康祥实业集团有限公司

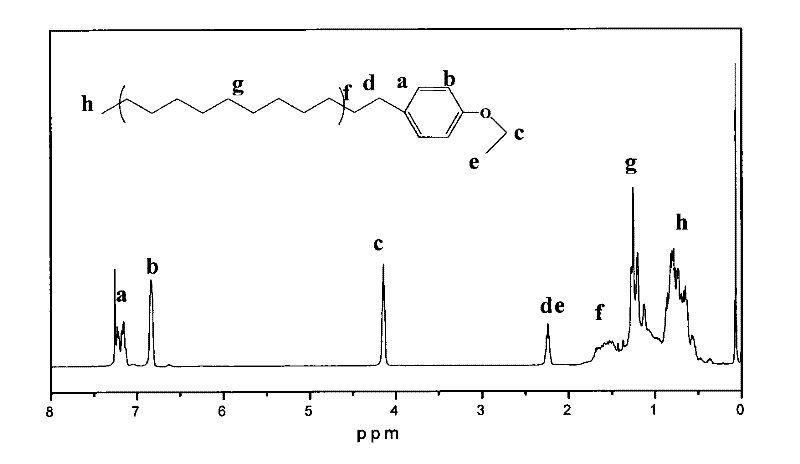

Surface activator with double-ether bisbensulfosalt and double molecule

InactiveCN1817430AMild reaction conditionsSimple and fast operationTransportation and packagingMixingChlorosulfuric acidHigh surface

A dual-component surfactant of biether biphenylsulfonate is 2.2-bis (4-alkoxy-3- sodium phenylsulfonate) propane. Its preparing process includes such steps as adding biphenol A and the aqueous solution of NaOH into reactor, reaction at 50-78 deg.C, sequentially adding absolute alcohol and long-chain alkyl bromine into reactor, reacting at 50-78 deg.C for 12-36 hr, evaporating alcohol, washing the resultant, recrystallizing, drying to obtain biether compound, adding it into reactor, using dichloromethane as solvent, dripping chlorosulfonic acid, reaction at 15-35 deg.C for 1-3 hr, neutralizing resultant, salting out, filtering and drying. Its advantages are high surface activity, and high foam stability.

Owner:SOUTHWEST PETROLEUM UNIV

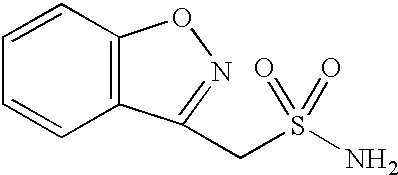

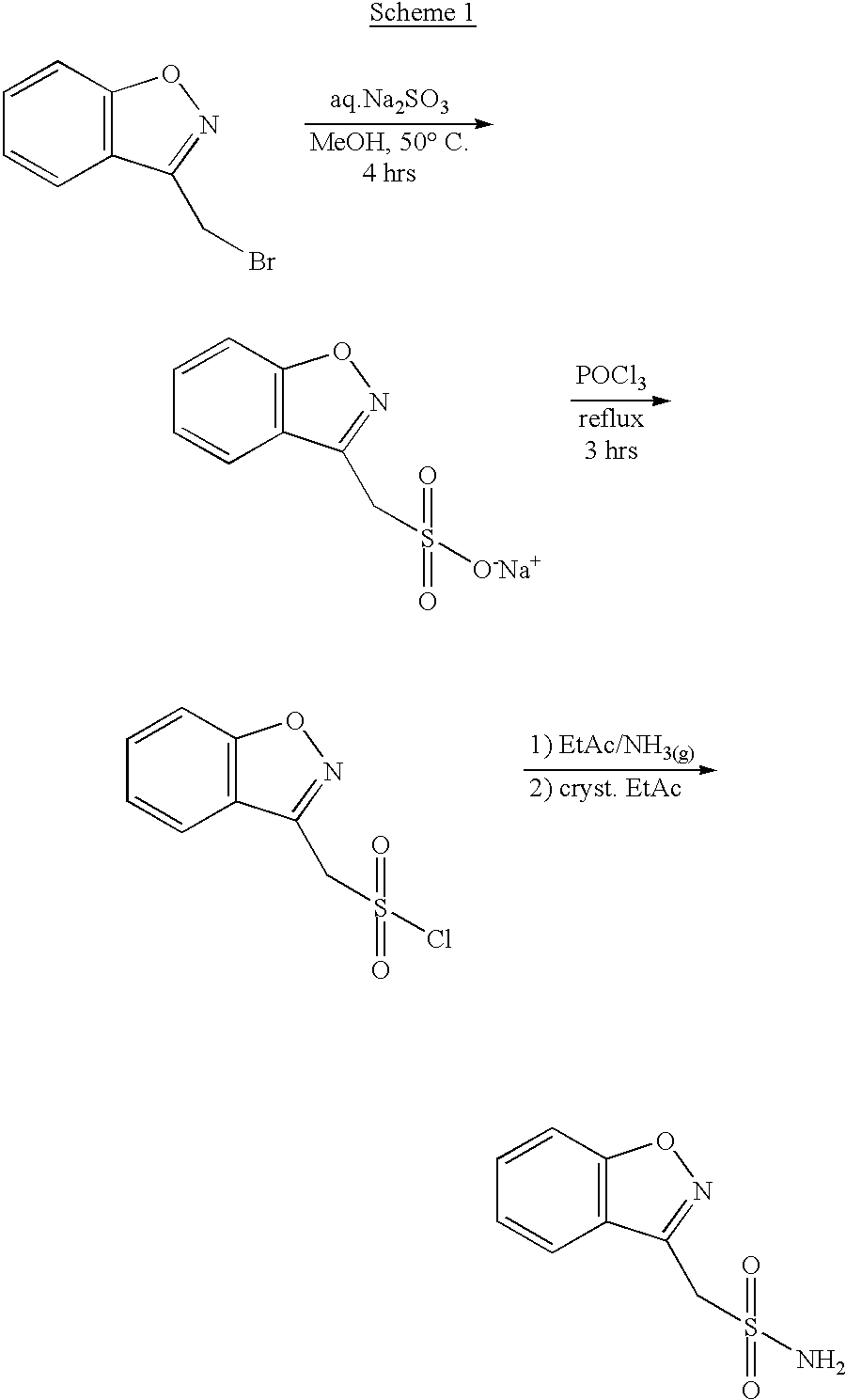

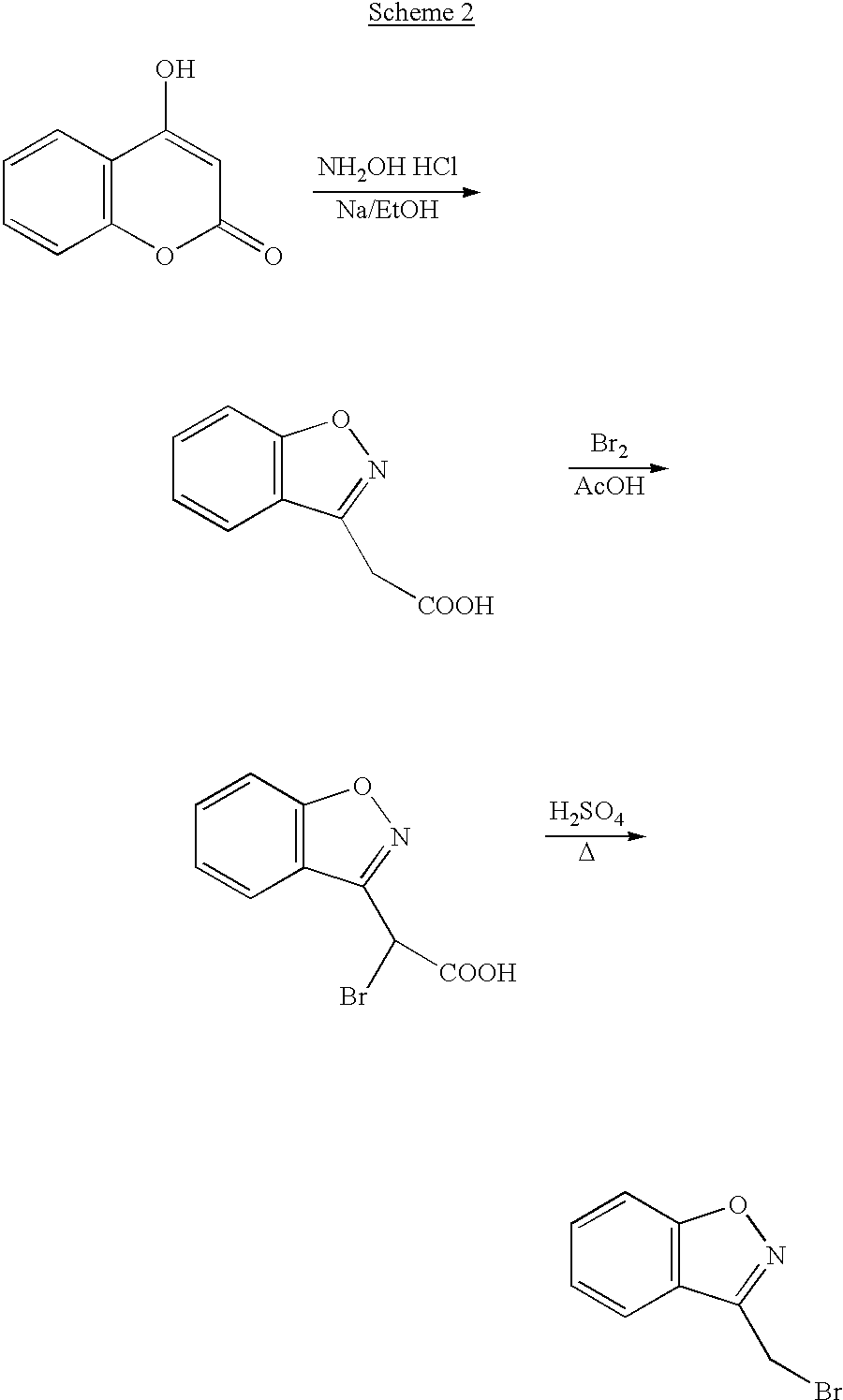

Process for the preparation of 1,2-benzisoxazole-3-acetic acid

InactiveUS20020183525A1High puritySpeed up the processOrganic chemistryAcetic acidMethane sulfonic acid

The present invention provides a process for preparing 1,2-benzisoxazole-3-acetic acid, comprising the step of reacting 4-hydroxy-coumarin with hydroxyl-amine in the presence of a base. The present invention further provides a process for preparing a salt of benzisoxazole methane sulfonic acid, comprising the steps of 1) sulfonating 1,2-benzisoxazole-3-acetic acid using chlorosulfonic acid in a solvent mixture comprising methylene chloride and sodium hydroxide; and 2) isolating the salt of benzisoxazole methane sulfonic acid.

Owner:TEVA PHARM USA INC

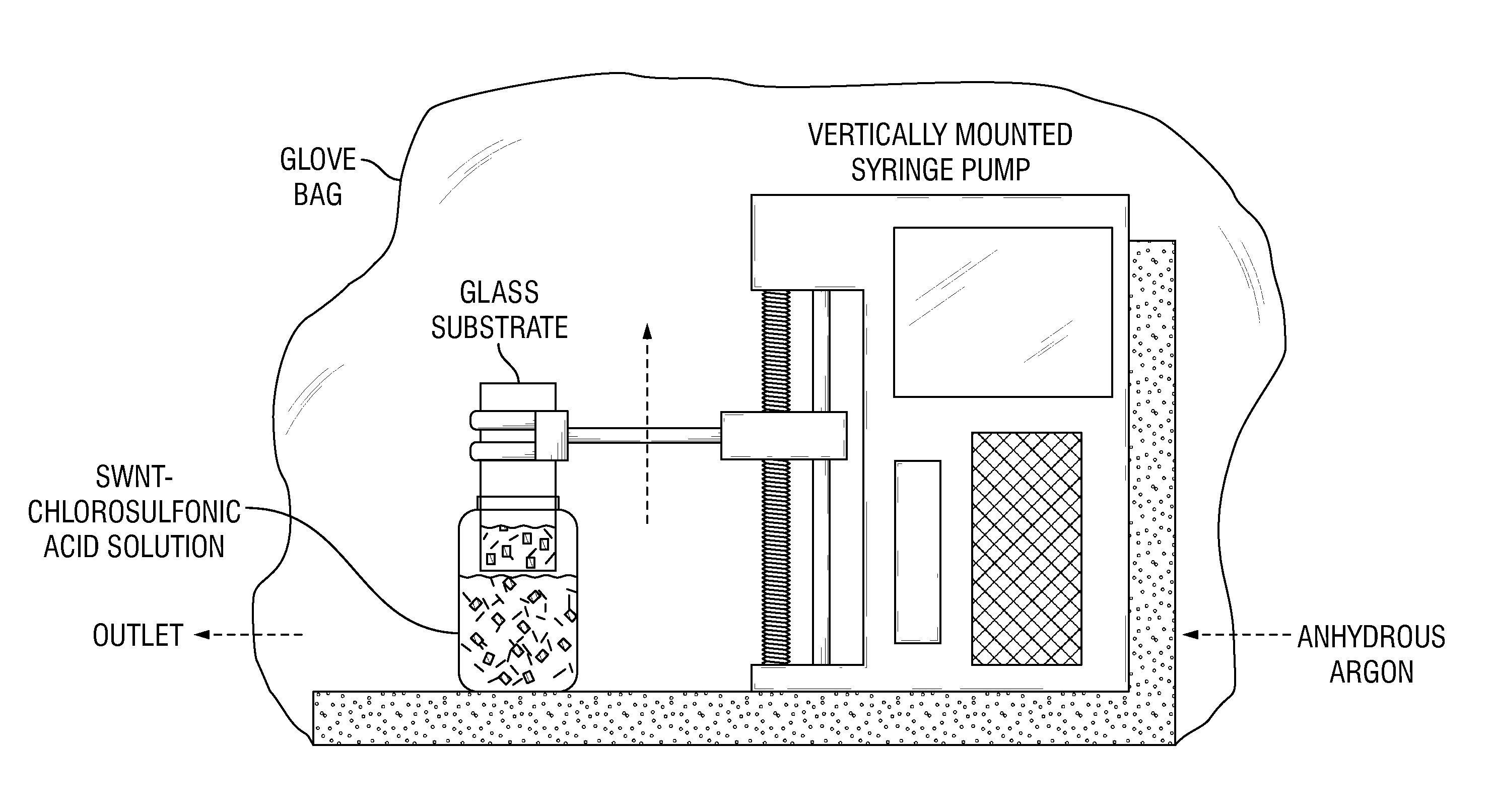

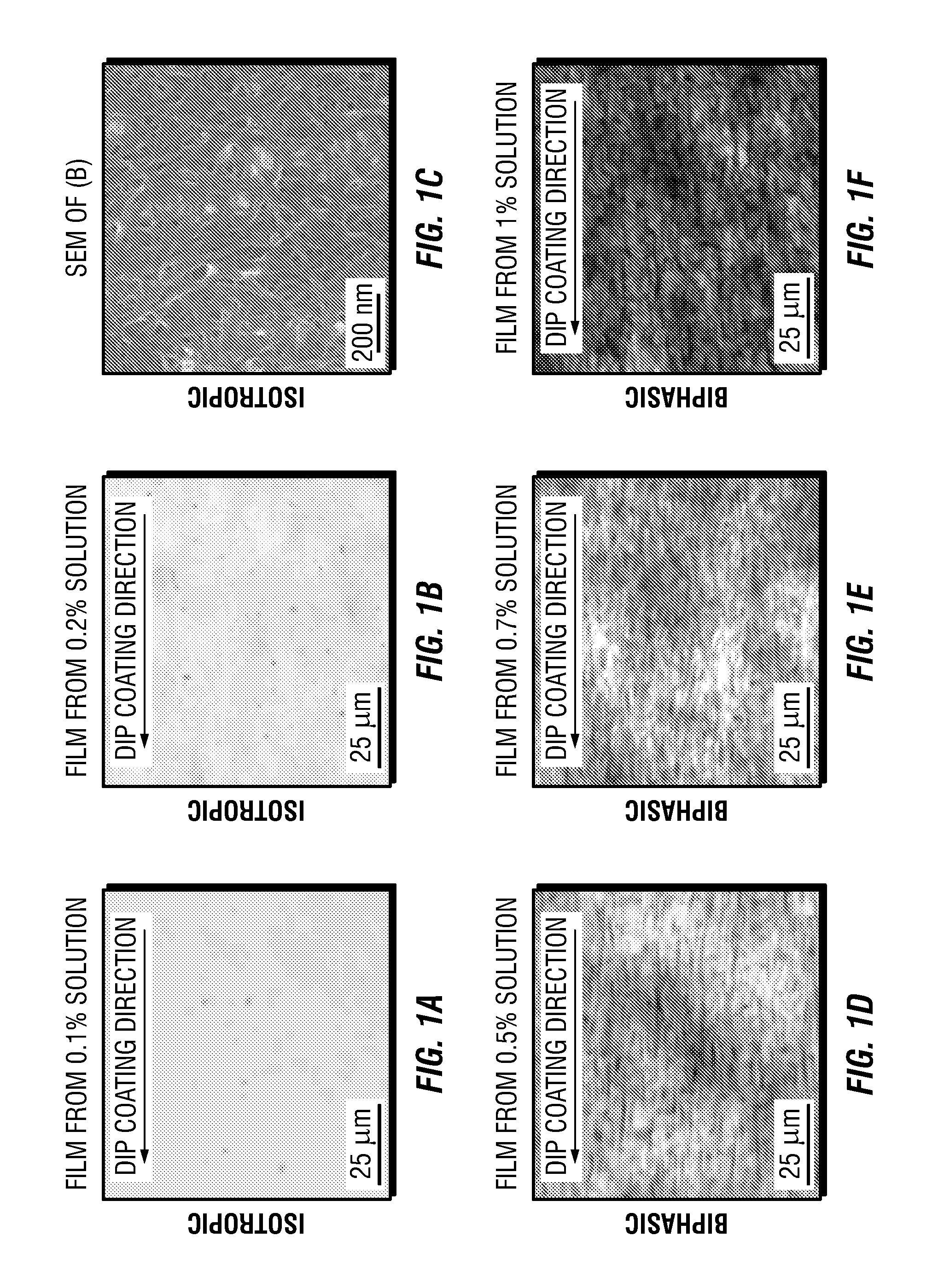

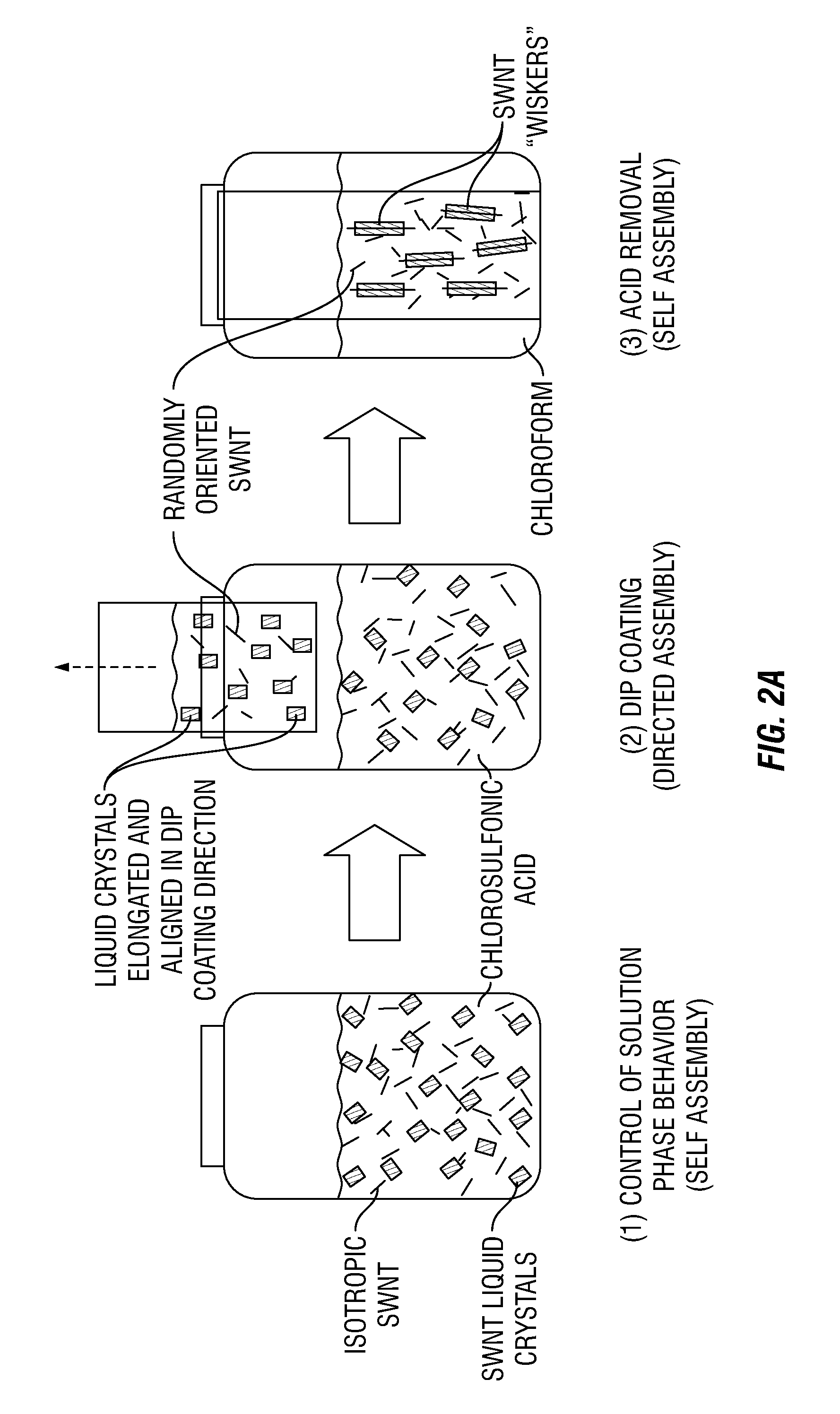

Carbon nanotube films processed from strong acid solutions and methods for production thereof

InactiveUS20150298164A1Material nanotechnologySynthetic resin layered productsStrong acidsCarbon nanotube

In some embodiments, the present disclosure provides methods for fabricating carbon nanotube films. Such methods generally comprise: (i) suspending carbon nanotubes in a superacid (e.g. chloro sulfonic acid) to form a dispersed carbon nanotube-superacid solution, wherein the carbon nanotubes have substantially exposed sidewalls in the carbon nanotube-superacid solution; (ii) applying the dispersed carbon nanotube-superacid solution onto a surface to form a carbon nanotube film; and (iii) removing the superacid. Desirably, such methods occur without the utilization of carbon nanotube wrapping molecules or sonication. Further embodiments of the present disclosure pertain to carbon nanotube films that are fabricated in accordance with the methods of the present disclosure. Such carbon nanotube films comprise a plurality of carbon nanotubes that are dispersed and individualized. Additional embodiments of the present disclosure pertain to macroscopic objects comprising the carbon nanotube films made in accordance with the methods of the present disclosure described supra.

Owner:RICE UNIV

Transition metal sulfonate complex thick oil water thermo-catalysis viscosity reducer and preparation method thereof

The invention relates to a viscosity reducer and a preparation method thereof. The preparation method for the transition metal sulfonate complex thick oil water thermo-catalysis viscosity reducer is characterized by comprising the following steps of: 1) adding fatty acid alkyl ester and dichloroethane into a container in a molar mass ratio of 1:2.0-3.0; 2) placing the container into an ice water bath, dripping chlorosulfonic acid in a molar mass ratio of the fatty acid alkyl ester to the chlorosulfonic acid of 1:1.3-2.0, performing sulfonation reaction, and performing ageing after the sulfonation is finished to obtain an intermediate product; and 3) adding a transition metal oxide into the intermediate product in a molar mass ratio of the fatty acid alkyl ester to the transition metal oxide of 1:0.17-0.25, performing complex reaction for 1 to 2 hours, standing and demixing after the reaction is finished, and removing the water of the upper layer, wherein the paste of the lower layer is the transition metal sulfonate complex thick oil water thermo-catalysis viscosity reducer. The viscosity reducer prepared by the method has good viscosity reducing effect at the temperature of 200 DEG C, and simultaneously has the characteristics of easily obtained raw materials and simple preparation process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

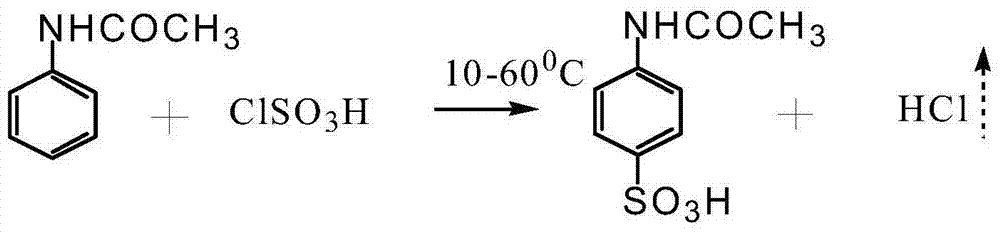

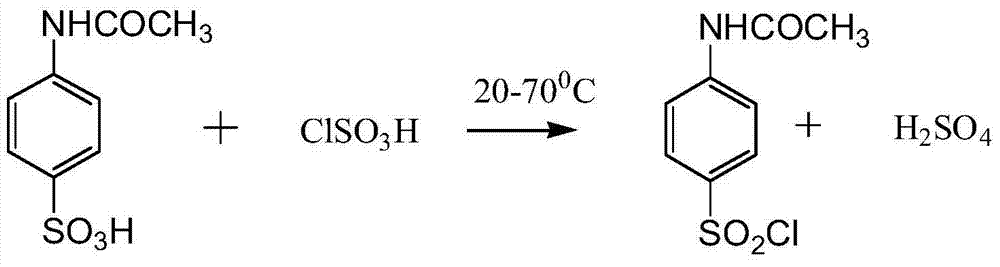

Method for synthesizing p-acetamido benzene sulfonyl chloride by phosphorus pentachloride

InactiveCN101613308AHigh yieldReduce dosageSulfonic acid preparationSulfonyl chlorideChlorosulfuric acid

The invention relates to a method for synthesizing p-acetamido benzene sulfonyl chloride by phosphorus pentachloride, relating to the preparation method for sterilization and mould inhibition midbody of sulfonamides. The invention takes acetanilide and chlorosulfonic acid as raw materials, uses phosphorus pentachloride as chlorinating agent; under the action of organic dissolvent, the raw materials are sulfonated, chloridized, separated, and washed to obtain the product. The invention has the effects of little chlorosulfonic acid usage, high product yield, few generated waste acid,, completely cycling dissolvent, recycled by-products, low manufacturing cost, being convenient to popularize and apply, and the like. The products prepared by the method can be widely applied to the preparation of the sterilization and mould inhibition of sulfonamides and industries such as coating, plastics, pesticides, etc.

Owner:CHONGQING UNIV

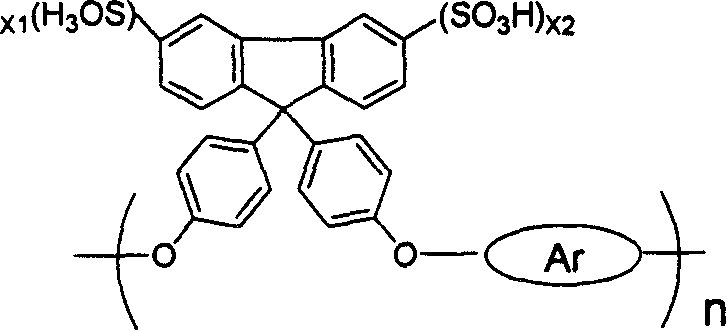

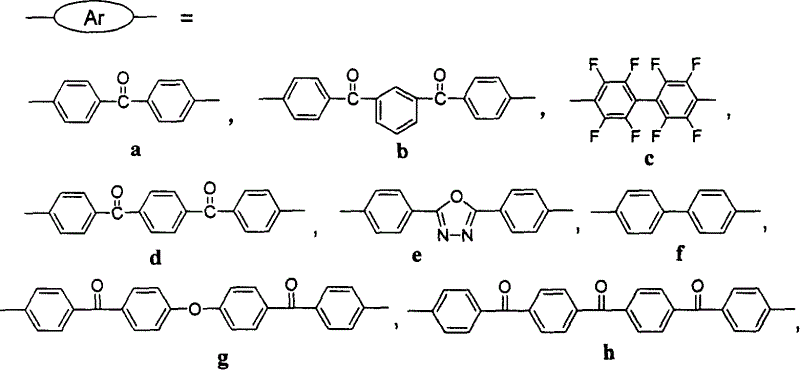

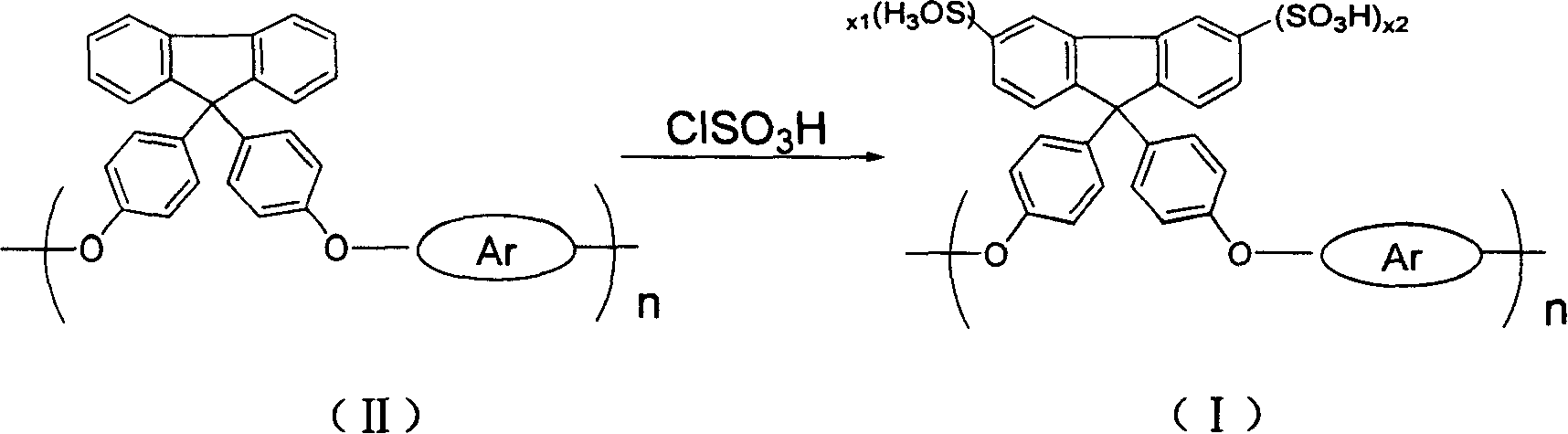

Sulfonated fluorine-containing poly-arylether (arone) and its preparing method and use

InactiveCN1621431ALow costLow priceChemical recyclingFuel cell detailsComposite filmChlorosulfuric acid

The present invention relates to one kind of sulfonated fluorene-containing polyaryl ether (ketone) and its application in preparing proton exchanging film. The sulfonated fluorine-containing polyaryl ether (ketone) may be prepared through polymerization of 9, 9-(4, 4-dihydroxyphenyl) fluorene and chloric or fluorous arone (arene) to form polyaryl ether (ketone); and the subsequent sulfonation with chlorosulfonic acid in the controlled consumption for controlled product sulfonation degree. The sulfonated fluorine-containing polyaryl ether (ketone) may be dissolved in different polar solvents before being cast to form single-component film, or be mixed with other polymer material for preparing composite film, or be mixed with heteropoly acid and other inorganic matter for preparing hetero film; and all these kinds of film have the advantages of low cost, high stability, high water absorption, small equivalent molecular weight, etc. and are expected to find use in fuel cell.

Owner:SUN YAT SEN UNIV

Preparation method of bromoamine acid

ActiveCN102617412AHigh purityQuality improvementSulfonic acid preparationAnthraquinonesChlorosulfuric acid

The invention relates to a preparation method of bromoamine acid, which comprises the following steps: (1) sulfonation reaction: by using 1-aminoanthraquinone as a raw material, dropwisely adding chlorosulfonic acid into an orthodichlorobenzene solvent to carry out sulfonation reaction so as to obtain the sulfonated material containing sulfonated product, wherein the weight ratio of the 1-aminoanthraquinone to the orthodichlorobenzene is 1:(5-7), and the temperature of the sulfonation reaction is 115-150 DEG C; (2) stratification by adding dilute sulfuric acid: after the sulfonation reaction reaches to the end, directly adding 55-60 wt% dilute sulfuric acid into the reaction system until the sulfonated material stratifies, wherein the upper stratum is an orthodichlorobenzene organic phase which can be used repeatedly, and the understratum is a sulfuric acid solution of 1-aminoanthraquinone-2-sulfonic acid; and (3) bromination reaction: adding water into the understratum material obtained in the step (2) until the acidity reaches to 8-10%, and directly dropwisely adding bromine to carry out bromination reaction, thereby obtaining the bromoamine acid crude product. The invention greatly lowers the energy consumption; and the quality and yield of the bromoamine acid product are obviously enhanced.

Owner:苏州市罗森助剂有限公司

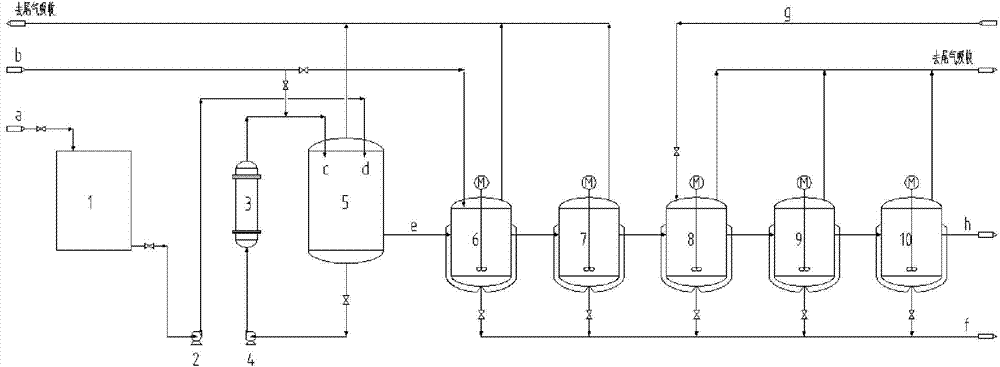

Continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate

ActiveCN104496866AImprove conversion rateThe reaction temperature is easy to controlSulfonic acid preparationMolten stateChlorosulfuric acid

The invention discloses a continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate. The process comprises the steps: performing reaction on chlorosulfonic acid and acetanilide which serve as raw materials; respectively atomizing chlorosulfonic acid and molten-state acetanilide and contacting with each other during feeding to perform reaction. According to the continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate, the molten-state acetanilide is used as a raw material, and the reaction on the acetanilide in an atomizing state and chlorosulfonic acid which is also in an atomizing state are carried out and the reaction temperature is easily controlled, so that the production of byproducts such as parachloroaniline is avoided, and the conversion rate of acetanilide serving as a raw material is high. The process is convenient to operate, short in production period, controllable in reaction process, less in labor demands, low in cost and easy for industrial production.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

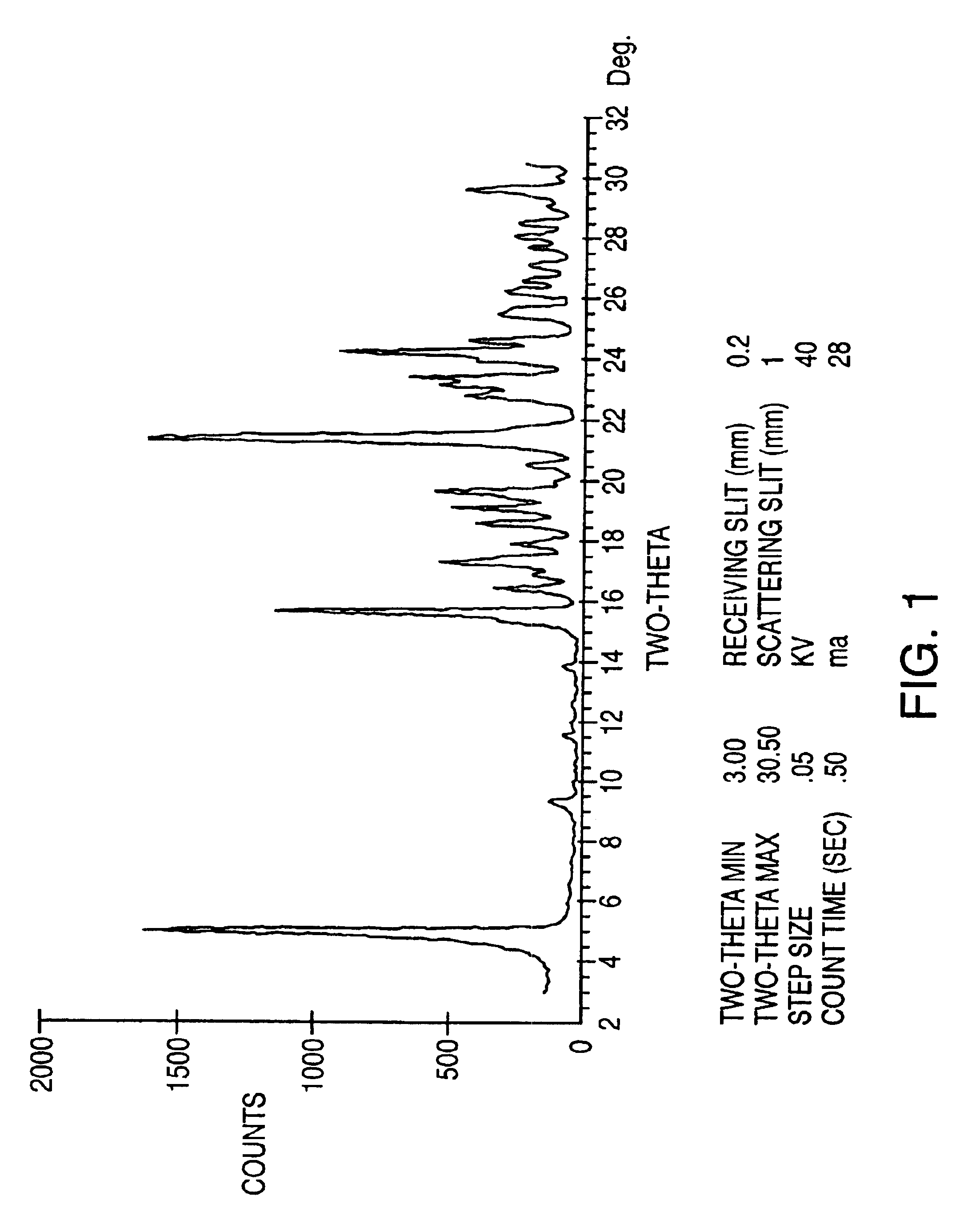

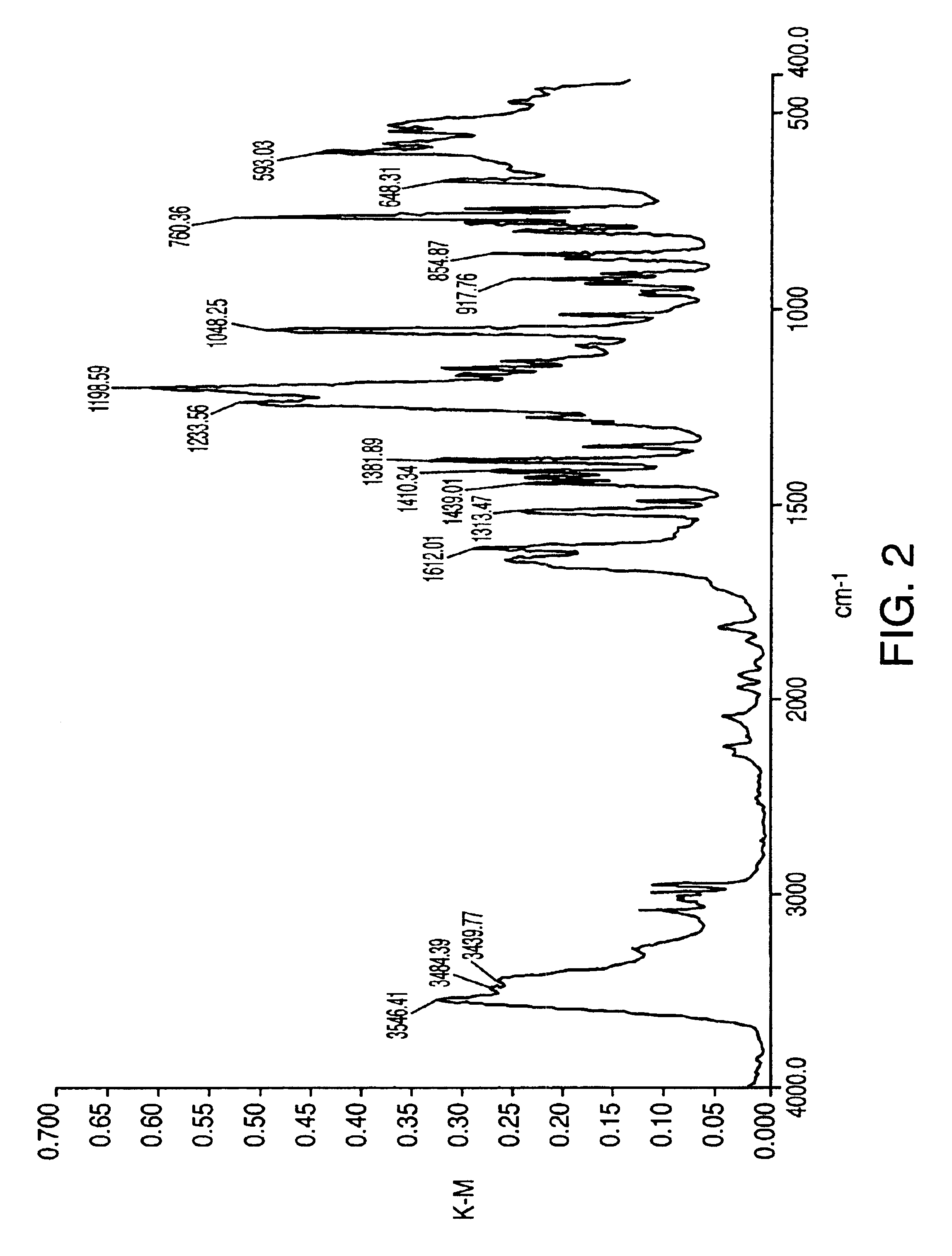

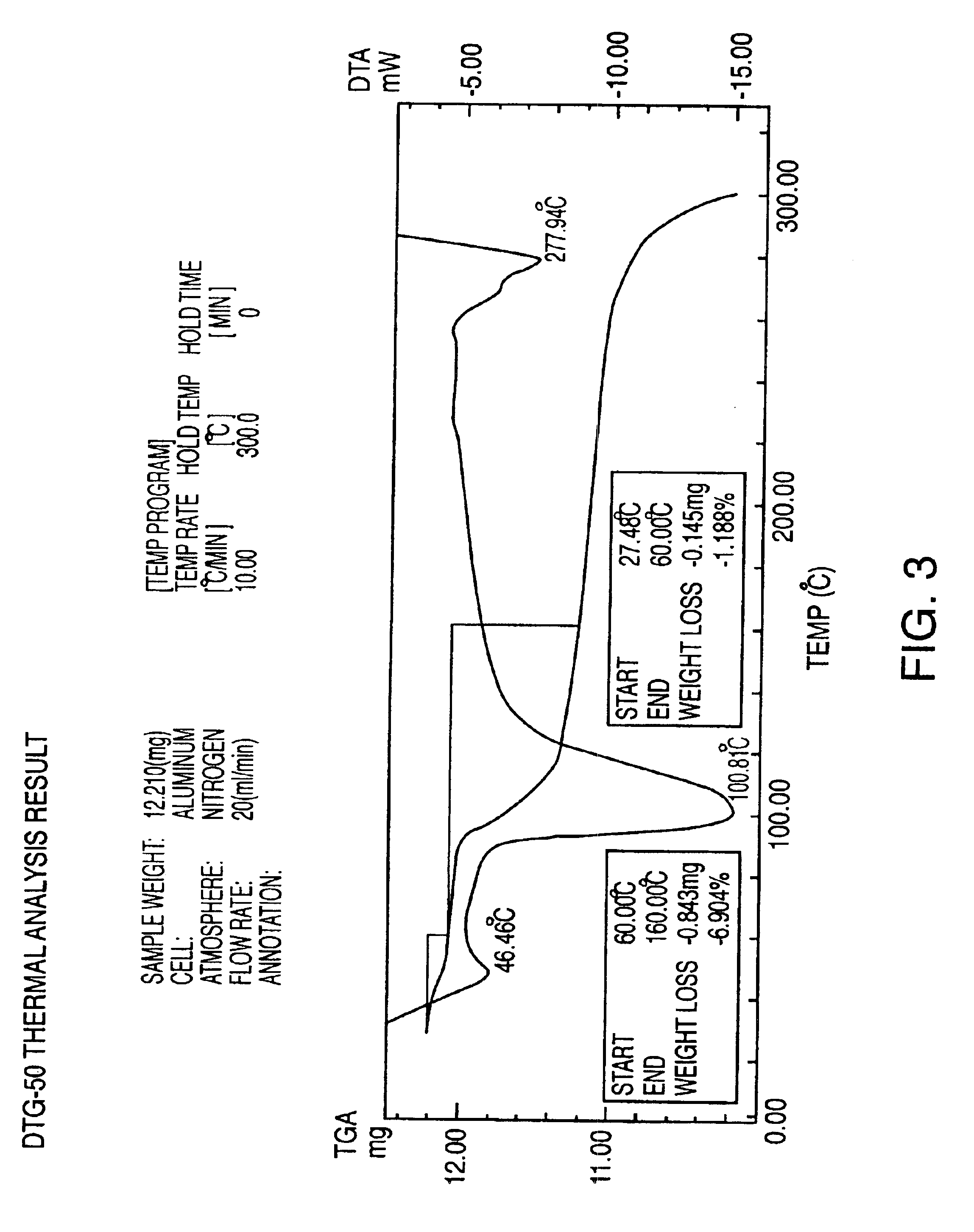

Sulfonation method for zonisamide intermediate in zonisamide synthesis and their novel crystal forms

The present invention relates to a novel sulfonation of an intermediate of zonisamide. The sulfonation processes using chlorosulfonic acid as well as acetic anhydride and sulfuric acid in an organic solvent are disclosed. Crystalline forms of benzisoxazole methane sulfonic acid (BOS-H) and its salts (BOS-Na, BOS-Ca, and BOS-Ba) and their novel preparation processes are disclosed.

Owner:TEVA PHARM USA INC

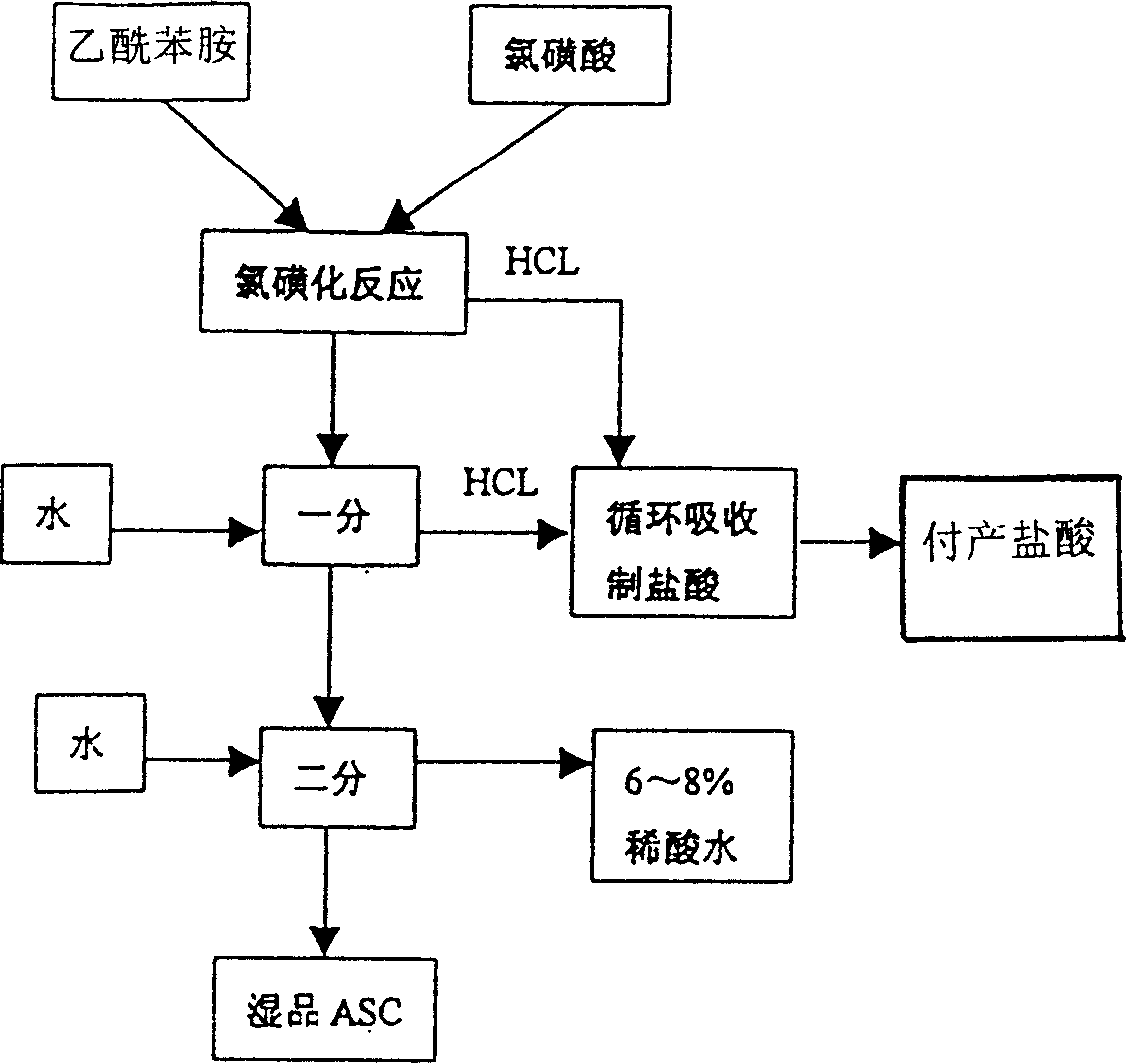

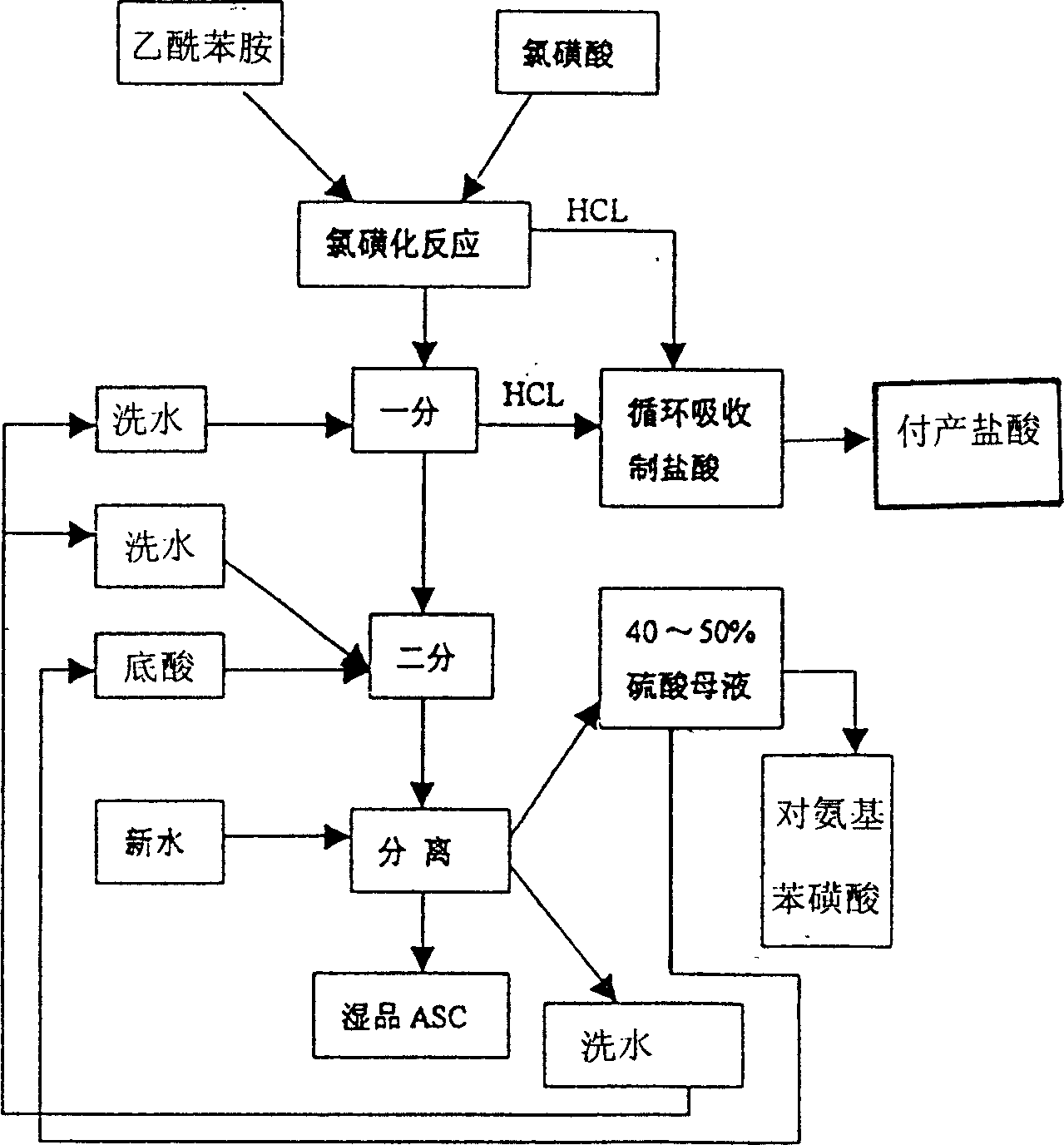

Process for producing sulfanilic amide medicine mother substance p-acetamido benzene sulfonyl chloride

InactiveCN1683331ATo achieve the goal of zero emissionsConserve waterSulfonic acid preparationSulfonyl chlorideChlorosulfuric acid

The production process of p-acetamido benzene sulfonyl chloride as intermediate for sulfanilamide medicine includes the following steps: chlorosulfonating acetylaminobenzene as main material with chlorosulfonic acid to produce sulfonated oil and absorbing hydrogen chloride gas to prepare hydrochloric acid; separating sulfonated oil, adding water and decomposing chlorosulfonic acid to obtain separated oil while absorbing produced hydrogen chloride gas; separating the separated oil and adding water to deposit out p-acetamido benzene sulfonyl chloride; further separating, eliminating p-acetamido benzene sulfonyl chloride mother liquid, water washing the crystal while side producing sulfuric acid; using the side produced sulfuric acid in recovering p-amido benzene sulfonic acid; and reusing crystal eliminating water in the separation. The present invention realizes the comprehensive utilization, protects environment and lowers the cost.

Owner:黄升

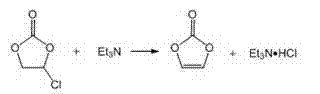

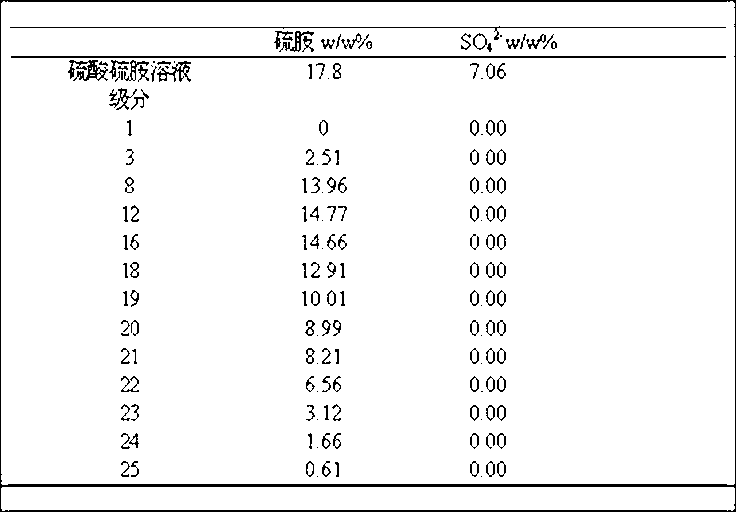

Method for continuously preparing vinylene carbonate by tubular reactor

ActiveCN104844556AIncrease production capacityAdapt to capacity needsOrganic chemistryChlorosulfuric acidEthyl Chloride

The invention provides a method for continuously preparing vinylene carbonate by a tubular reactor. The method includes using chlorosulfuric acid and ethylene carbonate as raw materials to be synthesized into chloroethylene carbonate in the tubular reactor under the action of initiator, rectifying the chloroethylene carbonate and subjecting the rectified chloroethylene carbonate to elimination reaction with trimethylamine in the tubular reactor with existence of organic solvent and generating the vinylene carbonate. By the method for continuously preparing vinylene carbonate by the tubular reactor, existing intermittent production methods are changed, reaction speed is greatly increased, reaction period is reduced, yield is increased and productivity can be effectively improved.

Owner:RONGCHENG QINGMU CHEM MATERIALS

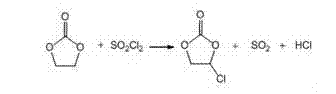

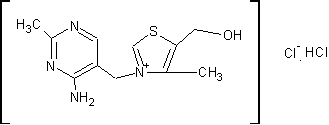

Novel method for synthesizing vitamin B1 hydrochloride

InactiveCN102952126AReduce usageSimple production processOrganic chemistryChlorosulfuric acidSulfate radicals

The invention provides a novel method for synthesizing a vitamin B1 hydrochloride. The method comprises the following steps of: treating a vitamin B1 sulfate aqueous solution by adopting an ion exchange resin; removing sulfate radicals; and concentrating and crystalizing to prepare the vitamin B1 hydrochloride. Due to the adoption of the method, the conventional process for producing a vitamin B1 hydrochloride by transforming from thiamine mononitrate is eliminated, residues of an organic solvent in a product are avoided since an organic solvent is not adopted, a process for preparing acid methanol from hydrochloric acid gas by using chlorosulfonic acid is eliminated simultaneously, and environmental pollution is lowered.

Owner:HUAZHONG PHARMA

Method for preparing sulfonated polystyrene (strongly acid type) cation exchange resin

InactiveCN102040694AWide range of usesEfficiently catalyzes the synthesis ofChlorosulfuric acidReaction temperature

The invention relates to a method for preparing sulfonated polystyrene (strongly acid type) cation exchange resin by taking chlorosulfonic acid as a sulfonating agent. The method has the following characteristics: 1. the advantages of low reaction temperature, short time, less dosage, high sulfonation degree, cost saving, environmental protection and the like can be achieved since chlorosulfonic acid is used as a sulfonating agent; and 2. the sulfonation degree of the resin prepared by using chlorosulfonic acid as a sulfonating agent is controllable in the range of 0.01-95%.

Owner:NANJING UNIV OF TECH

Method for preparing mononaphthalenesulfonic acid and sodium salt of mononaphthalenesulfonic acid

InactiveCN1958567APromote absorptionHigh selectivitySulfonic acids salts preparationSulfonic acid preparationChlorosulfuric acidSODIUM NAPHTHALENESULFONATE

This invention discloses a method for synthesizing 1-naphthalene sulfonic acid and / or sodium 1-naphthalene sulfonate. The method comprises: (1) dissolving naphthalene in solvent, adding appropriate 1-naphthalene sulfonic acid seed crystals, cooling to 0 minus or plus 5 deg.C, stirring, dropping chlorosulfonic acid within 1-2 h, and keeping at -2-8 deg.C for 1.5-3 h; (2) cooling to 0 minus or plus 2 deg.C, and filtering to obtain the filter cake of 1-naphthalene sulfonic acid; (3) washing the filtrate with water, phase-separating to obtain the solvent and water scrubbing acid (for producing high-performance naphthalene water reducer); (4) neutralizing 1-naphthalene sulfonic acid and the solvent with 5-15% NaOH, keeping at 90 minus or plus 5 deg.C for 10-30 min, phase-separating the neutralization solution to obtain sodium 1-naphthalene sulfonate aqueous solution, cooling to lower than 35 deg.C, crystallizing, filtering to obtain the filter cake of sodium 1-naphthalene sulfonate, and utilizing the filtrate to prepare NaOH solution. The method has such advantages as high sulfonation selectivity, low product isomer content, easy operation and no wastewater.

Owner:江苏华达化工集团有限公司

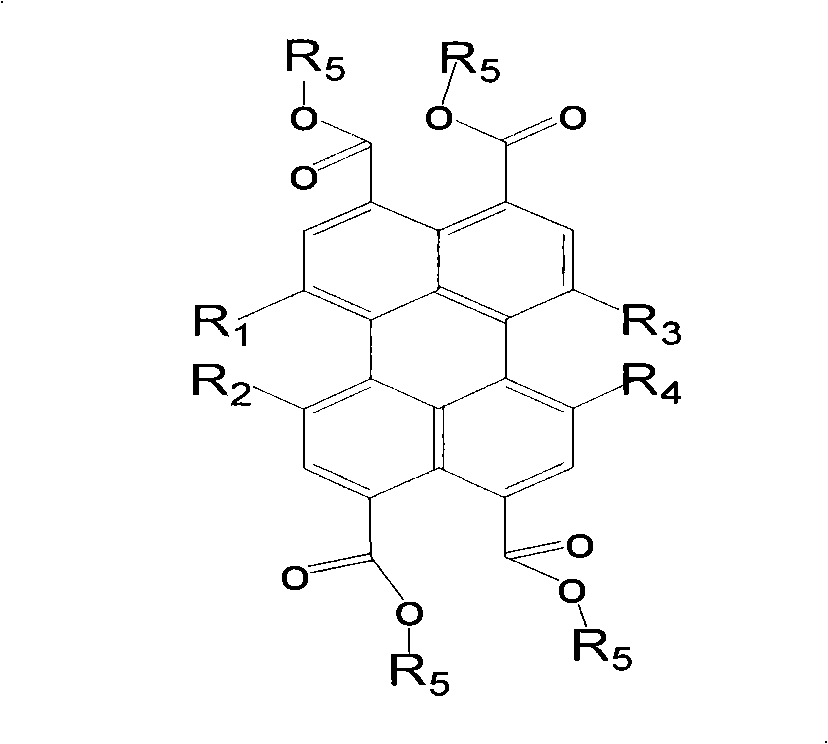

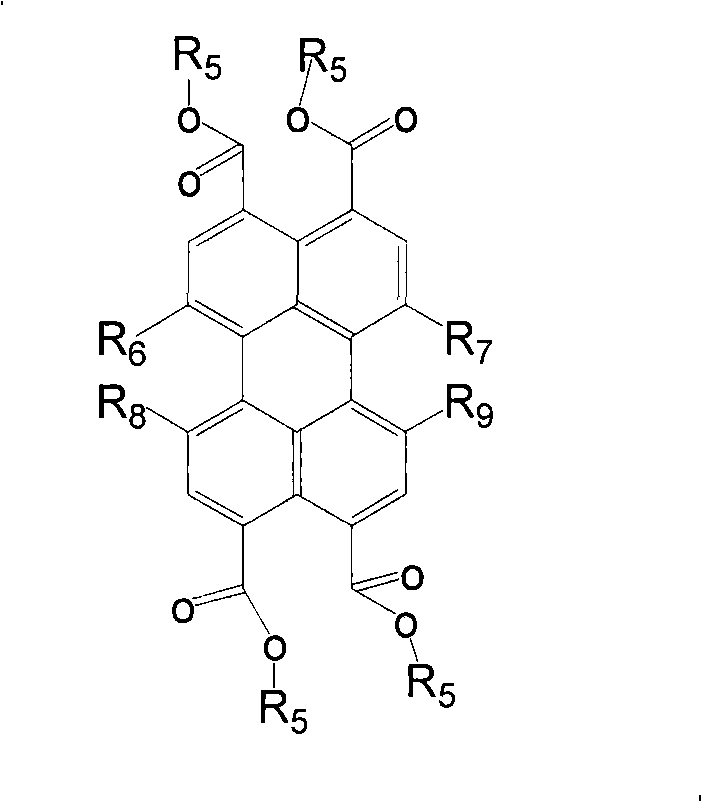

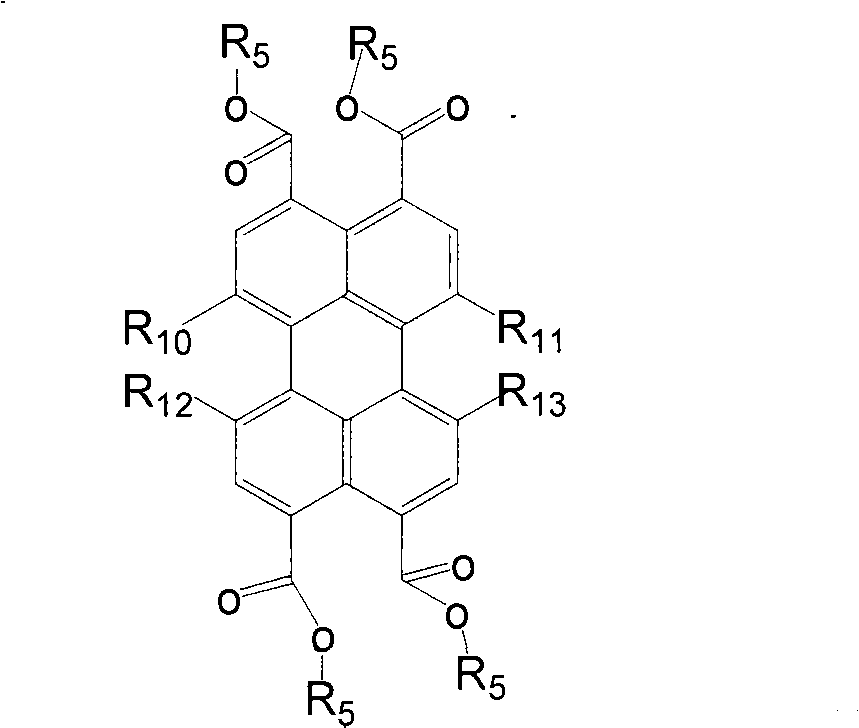

Trifluoromethyl substituted perylene bis diimines and preparation method thereof

The invention provides a category of perylene derivatives, that is perylene two-diimine replaced by trifluoromethyl and a preparation method thereof; wherein, the method comprises that perylene four-formate is used as the raw material to synthesize bromination perylene four-formate by brominating liquid bromine; the bromination perylene four-formate and perfluorinated iodoalkane are used as the raw materials to synthesize the perylene four-formate replaced by long chain perfluoroalkyl under the catalysis of copper powders or copper-tin alloy powder, and the bromination perylene four-formate and sodium trifluoroacetate are used as the raw materials to synthesize the perylene four-formate replaced by the trifluoromethyl under the catalysis of cuprous iodide; the long chain perfluoroalkyl or the perylene four-formate replaced by the trifluoromethyl is used as the raw material and hydrolyzed to synthesize the perylene four-formate or perylene four-formate anhydride replaced by the perfluoroalkyl under the function of inorganic alkali or chlorosulfonic acid; the perylene four-formate replaced by the trifluoroacetate and alkylamine or aniline are used as the raw material to synthesize the perylene two-diimine replaced by the trifluoromethyl .

Owner:DALIAN UNIV OF TECH

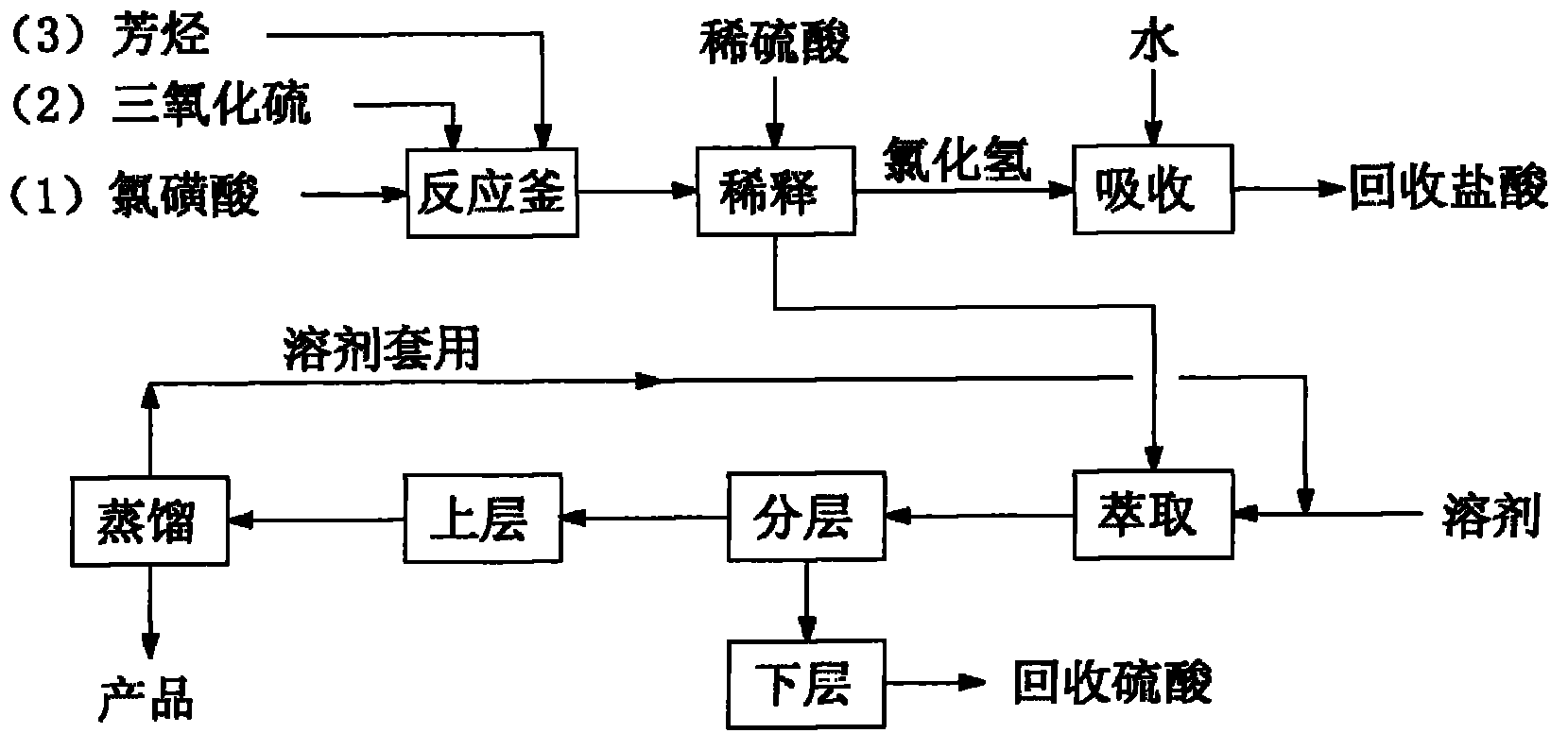

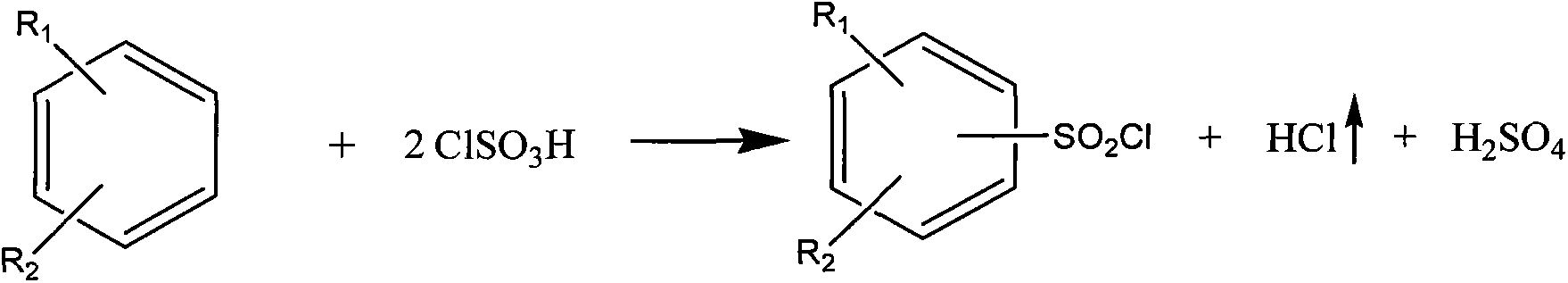

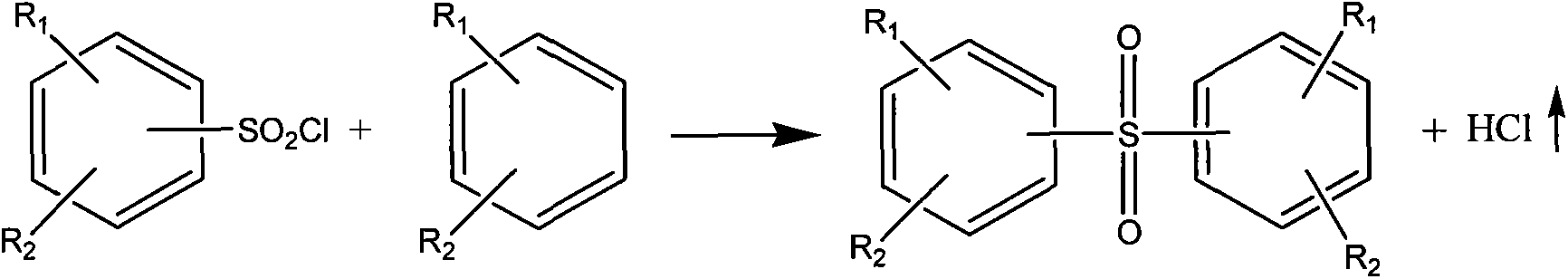

Preparation method of aromatic hydrocarbon sulfonyl chloride derivative

ActiveCN103304451AImprove use valueSmooth responseChlorine/hydrogen-chlorideSulfur-trioxide/sulfuric-acidSulfonyl chlorideChlorosulfuric acid

The invention discloses a preparation method of an aromatic hydrocarbon sulfonyl chloride derivative. The preparation method comprises the following steps of: (1) introducing sulfur trioxide gas into chlorosulfonic acid to prepare a chlorosulfonic acid solution of the sulfur trioxide, slowly adding an aromatic hydrocarbon, heating to 50-140 DEG C, performing heat preservation till the end of reaction, and then cooling to 25-35 DEG C; (2) controlling the temperature to be lower than 40 DEG C, and slowly dripping dilute sulfuric acid into the reaction solution, wherein generated hydrogen chloride gas can be recovered as a byproduct, namely hydrochloric acid after being absorbed by water; and (3) adding a solvent, stirring for 0.5-1h, and then standing for lamination, wherein the lower layer is sulfuric acid and can be recovered as a byproduct, and the upper layer can obtain a product, namely the aromatic hydrocarbon sulfonyl chloride derivative after removal of the solvent by distillation. The preparation method disclosed by the invention has the advantages of steady reaction, high yield, no generation of the hydrogen chloride gas during the reaction process, low energy consumption during the post-treatment process and high utilization value of the recovered sulfuric acid.

Owner:TAIZHOU QIANJIN CHEM CO LTD

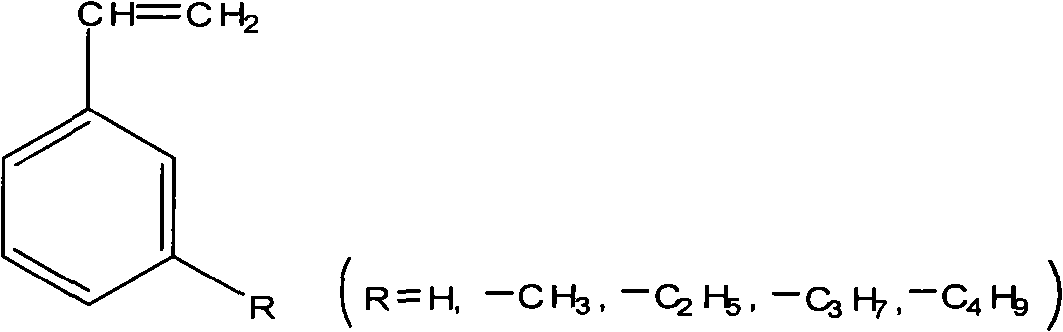

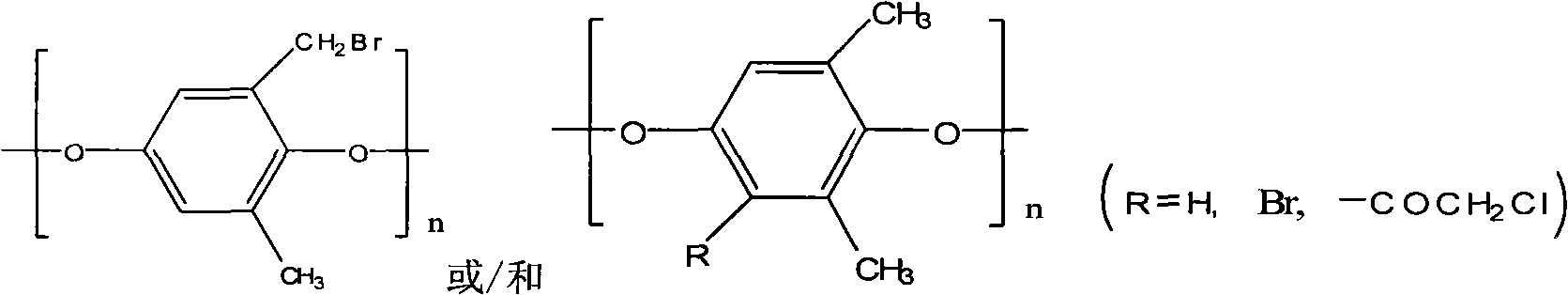

Homogeneous phase cation exchange film and preparation method thereof

ActiveCN101352657AHigh strengthGood compatibilitySemi-permeable membranesBenzoyl peroxideSolvent free

The invention relates to a homogeneous cation exchange membrane and a preparation method thereof, the homogeneous cation exchange membrane is characterized in that: cinnamene or / and alkyl cinnamene is taken as a monomer, divinylbenzene is taken as a crosslinking agent, benzoyl peroxide or / and azobisisobutyronitrile is taken as an initiator and bromomethyl or chloracetyl poly 1, 4-dimethyl-2, 6-phenylene oxide are taken as a polymer reinforcing agent to prepare even solution which is coated on a reinforced fabric for polymerization to obtain a base membrane which is then sulfonated in a mixture of concentrated sulphuric acid and chlorosufonic acid to obtain the homogeneous cation exchange membrane. Due to adopting aromatic polymer to produce a functional group by further sulfonation, the cation exchange membrane obtained has high exchange capacity, excellent electrochemical property and even structure. In addition, as the monomer used as the solvent can be polymerized, the preparation method is a green solvent-free technology. The cation exchange membrane series with different structures and functions can be obtained by regulating the content of polymer and crosslinking degree and changing the categories of supporters and the sulfonation condition.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

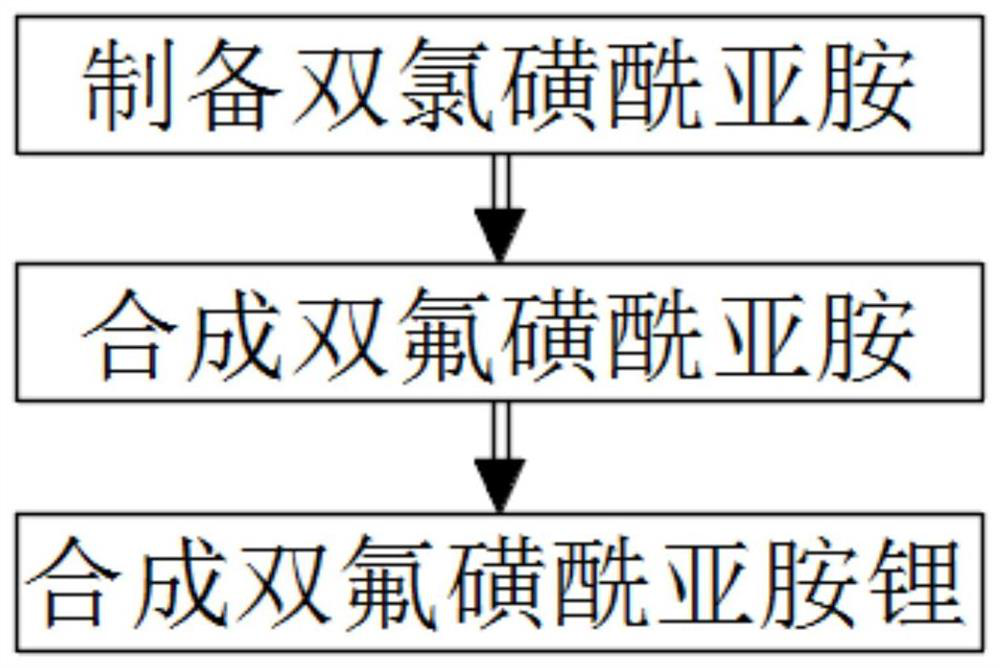

Preparation method of lithium bis (fluorosulfonyl) imide

The invention discloses a preparation method of lithium bis (fluorosulfonyl) imide. The preparation method comprises the steps of 1 by using chlorosulfonyl isocyanate and chlorosulfonic acid as reaction raw materials, dropwisely adding to react for 5 hours, and keeping the temperature to react for 10 hours to obtain bis (chlorosulfonyl) imide; 2 putting bis (chlorosulfonyl) imide serving as a reaction raw material into a tetrafluoro reaction bottle, reacting with anhydrous hydrogen fluoride under the action of a catalyst, and generating bis (fluorosulfonyl) imide after reacting for 20 hours; and 3 putting the bis (fluorosulfonyl) imide into a reaction bottle, and reacting with lithium hydroxide or lithium carbonate under the action of a catalyst to obtain a product containing lithium bis (fluorosulfonyl) imide. The preparation method disclosed by the invention is simple to operate, easy to control and small in environmental pollution, and meanwhile, inert gas is used as a reaction environment to remove water by low-temperature drying, so that the reaction of the bis (fluorosulfonyl) imide and the final product lithium bis (fluorosulfonyl) imide with water in air is avoided, the quality of the product is ensured, and the preparation method is suitable for industrial production of the lithium bis (fluorosulfonyl) imide.

Owner:泰兴华盛精细化工有限公司

Magnetic solid acid catalyst and application thereof to extracting saponin

ActiveCN109365004AHigh yieldHigh hydrolytic activity efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsSteroidsEthylenediamineChlorosulfuric acid

The invention discloses a magnetic solid acid catalyst which uses Fe3O4 as a magnetic core. Tetraethoxysilane and N-[3-(trimethoxysilyl)propyl]ethylenediamine are subjected to sol-to-gel reaction in water and ethanol solution separately, the surface of the magnetic core is coated with amino silica, and a sulfonic acid group is modified by the sulfonation reaction of chlorosulfonic acid, so that magnetic solid acid is obtained. The invention proposes that the magnetic solid acid catalyst is applied to the hydrolysis of dioscorea nipponica and the like to extract saponin for the first time, theobtained magnetic solid acid has high catalytic activity and environmental friendliness, the yield of saponin is effectively improved, and remarkable environmental and economic benefits are achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

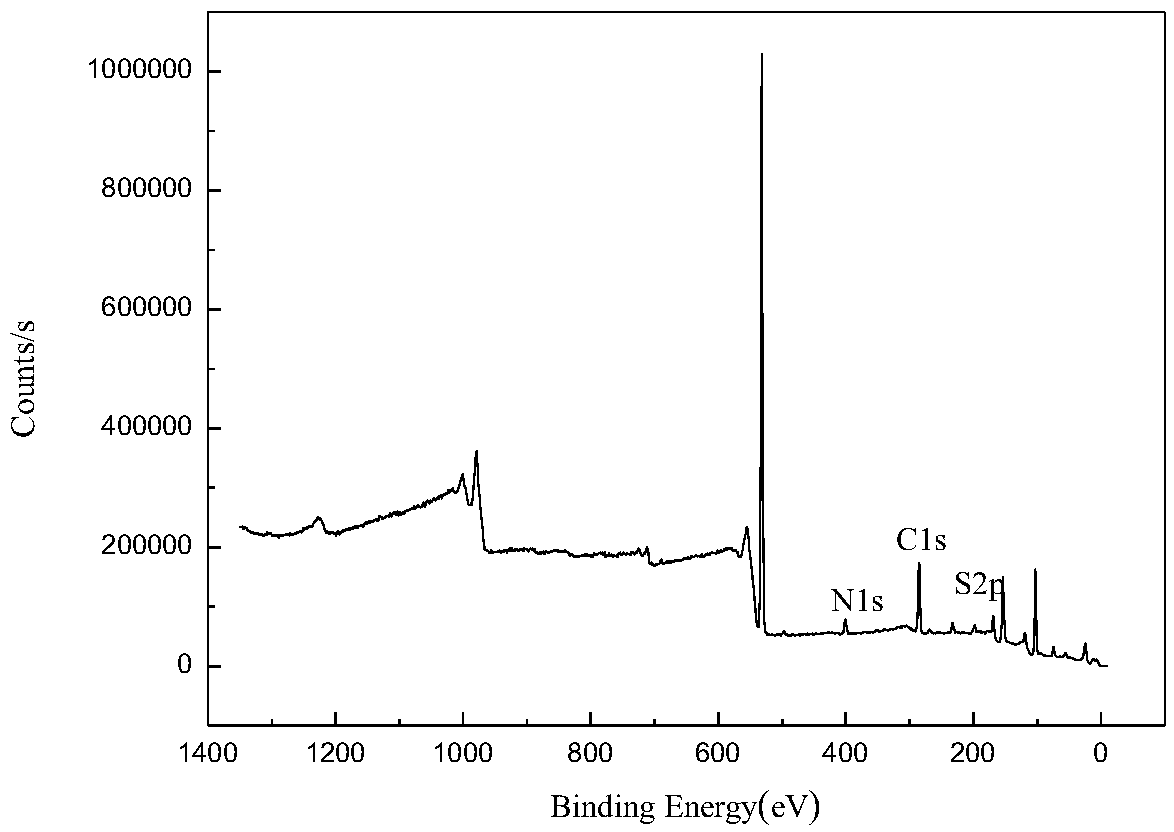

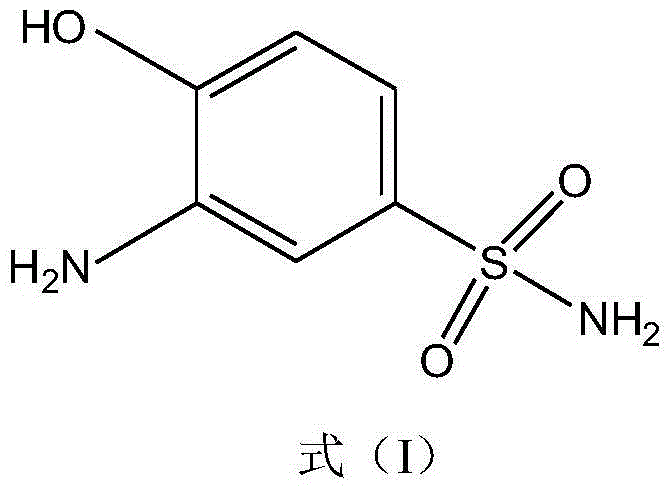

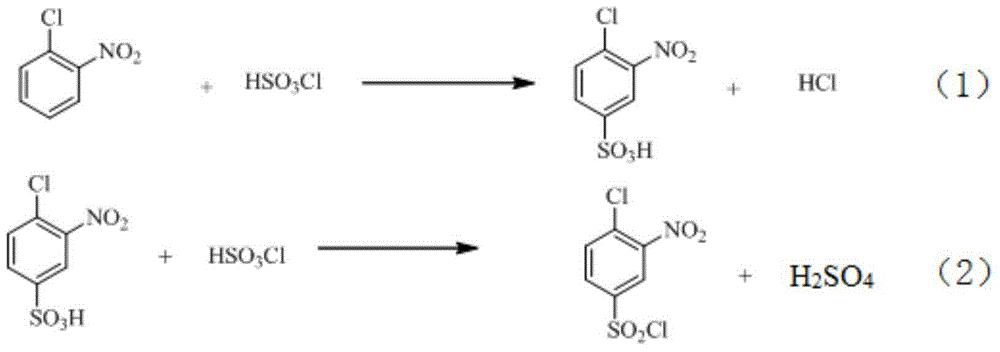

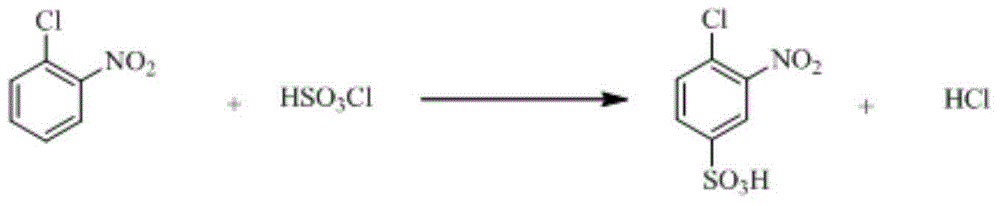

Synthetic method of 2-aminophenol-4-sulfonamide

InactiveCN104592064AReduce dosageReduce wasteOrganic compound preparationSulfonic acid amide preparationO-nitrochlorobenzeneChlorosulfuric acid

The invention relates to a synthetic method of 2-aminophenol-4-sulfonamide. The synthetic method comprises the steps of chlorosulfonation, ammoniation, hydrolysis, acidification and reduction, wherein the chlorosulfonation comprises the following two steps: (a) adding chlorosulfonic acid into p-nitrochlorobenzene which serves as a raw material, and carrying out sulfonation reaction to obtain 4-chloro-3-nitrobenzene sulfonic acid; and (b) adding sulfoxide chloride into 4-chloro-3-nitrobenzene sulfonic acid obtained in the step (a), and carrying out chlorination to obtain 4-chloro-3-nitrobenzenesulfonyl chloride. According to the synthetic method, a chlorosulfonation process is improved, and the chlorosulfonation is carried out in two steps, namely p-nitrochlorobenzene is taken as the raw material, is firstly sulfonated by chlorosulfonic acid and is then chloridized by sulfoxide chloride, so that the consumption of chlorosulfonic acid is reduced, the unnecessary wasting is reduced, the production cost is saved, and the yield of products is increased to reach up to 96.88%.

Owner:QINGDAO DOUBLE PEACH SPECIALTY CHEM GRP

Making process of strong acid ion exchange fiber

InactiveCN1608734AShort production processSimple processCation exchanger materialsStrong acidsSolid acid

The making process of strong acid ion exchange fiber includes the irradiation grafting step of setting PTFE fiber inside homogeneous mixed solution compounded with styrene in 10-70 vol% and dichloromethane in 30-90 vol%, introducing protecting nitrogen, and irradiating with Co-60 of dosage 15-30 KGy at room temperature for 24-80 hr, and washing to obtain grafted PTFE fiber; and the grafted PTFE fiber sulfonating step of setting the grafted PTFE fiber inside homogeneous mixed solution compounded with chlorosulfonic acid in 30-40 vol% and ethane tetrachloride in 60-70 vol% for sulfonation, cooling and washing to obtain the said strong acid ion exchange fiber. The production process of the present invention is simple and wide applicable and needs no special apparatus, and the product has high stability and strong acidity and may be used in ion exchange and solid acid catalysis.

Owner:NANKAI UNIV +1

Alkyl ester sulphonate complex viscosity depressant with hydrogen supply structure and preparation method thereof

InactiveCN102492411ARaw materials are easy to getSimple preparation processDrilling compositionChlorosulfuric acidEthane Dichloride

The invention relates to a viscosity depressant for aquathermolysis viscosity-reducing exploitation of thick oil and a preparation method thereof. The preparation method for the alkyl ester sulphonate complex viscosity depressant with the hydrogen supply structure is characterized by comprising the following steps: 1), performing esterification reaction in the molar mass ratio of natural fatty alcohol to formic acid of 1 to (5.0 -8.0); 2), adding the natural fatty alcohol and ethylidene dichloride in the molar mass ratio of 1 to (2.0-2.5); 3), dropping chlorosulfonic acid in the molar mass ratio of the natural fatty alcohol to the chlorosulfonic acid of 1 to (1.3-1.8) to perform sulfonation reaction for 0.5-1h, and then aging the mixture; and 4), adding the natural fatty alcohol and transition metal in the molar mass ratio of 1 to 0.12 or 1 to 0.17 to an intermediate product to perform a complex reaction for 1-2h; stewing and layering the mixture to remove the water of upper layer, and drying the mixture to obtain lower wax which is the alkyl ester sulphonate complex viscosity depressant with the hydrogen supply structure. The viscosity depressant prepared by the method has good viscosity-reducing effects at 200 DEG C, and simultaneously has the characteristics of easily acquired materials, and a simple preparation process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing composite reverse osmosis membrane

PendingCN108671755AIncrease water fluxImprove hydrophilicityGeneral water supply conservationReverse osmosisPhase conversionReverse osmosis

The invention discloses a method for preparing a composite reverse osmosis membrane. The composite reverse osmosis membrane comprises non-woven cloth, a porous support layer coated on the non-woven cloth, and a polyamide desalting layer coated on the porous support layer; the non-woven cloth is subjected to chlorosulfonic acid sulfonation treatment and is grafted with sulfonic acid groups; the porous support layer is a casting film liquid to be coated on the non-woven cloth and is prepared by using a phase conversion method; the polyamide desalting layer is prepared through an interface polymerization reaction of a water phase solution with two or more amino compounds and an oil phase solution with two or more acyl chloride compounds on the porous support layer. The prepared composite reverse osmosis membrane has a high water flux.

Owner:NANJING DELNAMEM TECH CO LTD

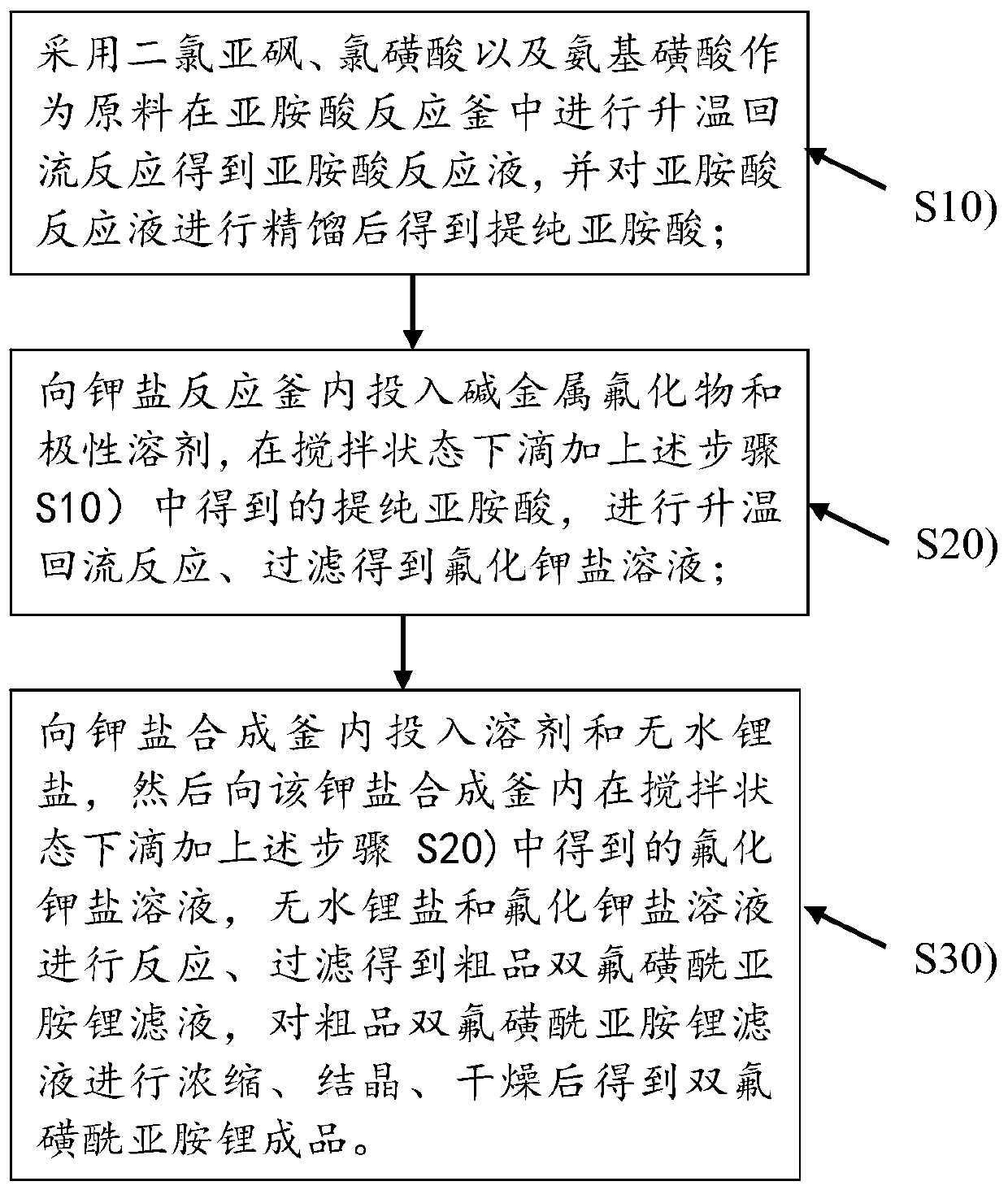

Preparation method of lithium bis (fluorosulfonyl) imide and lithium bis (fluorosulfonyl) imide

The invention discloses a preparation method of lithium bis (fluorosulfonyl) imide and the lithium bis (fluorosulfonyl) imide. Thionyl chloride, chlorosulfonic acid and sulfamic acid which are low inraw material cost and easy to obtain are used as raw materials; imidic acid is prepared under the condition of heating reflux reaction, potassium fluoride which is also used as a raw material and is low in cost and easy to obtain is used as a raw material to react with the imidic acid to obtain sylvite, potassium fluoride salt and anhydrous lithium salt react in a solvent to generate the lithium bis (fluorosulfonyl) imide, and the preparation process is low in energy consumption and has operation safety. And meanwhile, purification process treatment is carried out in each step, so that the high-purity and high-yield lithium bis (fluorosulfonyl) imide can be finally obtained, and the method is very suitable for being used as a process route for batch production of the lithium bis (fluorosulfonyl) imide.

Owner:CHANGSHU XINHUA CHEM

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com