Method for preparing sulfonated polystyrene (strongly acid type) cation exchange resin

A technology of sulfonated polystyrene and cation exchange, which is applied in the field of preparation of sulfonated polystyrene strong-acid cation exchange resin, can solve the problems that heat preservation and transportation cannot meet the ideal requirements, and achieve high sulfonation degree, low reaction temperature, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

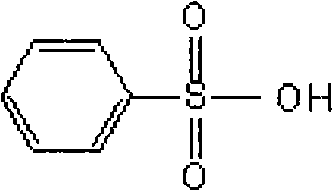

Image

Examples

Embodiment 1

[0016] Weigh 1.04g of reaction polymer containing benzene ring structure (average particle size: 220-260 μm, cross-linking degree 7%), in 10ml HCCl 3 After swelling in the medium for 3 hours, add 0.7ml of chlorosulfonic acid into the three-neck flask, and react at 60° C. for 25 minutes to obtain a sulfonated polystyrene resin with a sulfonation degree of 100%.

Embodiment 2

[0018] Weigh 1.04g of reaction polymer containing benzene ring structure (average particle size: 220-260 μm, cross-linking degree 15%), in 8ml CCl 4 After swelling in the medium for 6 hours, add 0.7ml of chlorosulfonic acid into the three-neck flask, and react at 30°C for 5 minutes to obtain a sulfonated polystyrene resin with a sulfonation degree of 45%.

Embodiment 3

[0020] Weigh 1.04g of reaction polymer containing benzene ring structure (average particle size: 0.01μm, cross-linking degree 0.1%), in 12ml CCl 4 Swell for 0.5 hour, add 0.7ml of chlorosulfonic acid into the three-neck flask, and react at 0°C for 30 minutes to obtain a sulfonated polystyrene resin with a sulfonation degree of 54%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com