Water system chargeable sodium-ion battery

A sodium ion battery, sodium ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as uneven distribution and limited lithium reserves, and achieve the effects of wide range of uses, loose assembly environment, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation of positive / negative pole of the present invention and Na x m y Fe(CN) 6 -NaTi 2 (PO 4 ) 3 The general steps of the assembly of the system full battery are as follows:

[0020] (1) Na x m y Fe(CN) 6 Preparation of positive electrode

[0021] MCl n Prepare a solution with a certain concentration, drop Na 4 Fe(CN) 6 in aqueous solution and stirred for 24 h. The resulting precipitate was washed by centrifugation and dried in vacuum to prepare Na x m y Fe(CN) 6 Cathode material.

[0022] (2) NaTi 2 (PO 4 ) 3 Preparation of / C negative electrode

[0023] Take Na 2 CO 3 ,TiO 2 , NH 4 h 2 PO 4 As raw material, NaTi was prepared by solid phase method 2 (PO 4 ) 3 , and then use chemical vapor deposition (CVD) method for carbon coating, you can prepare NaTi 2 (PO 4 ) 3 / C negative pole.

[0024] (3) Na x m y Fe(CN) 6 -NaTi 2 (PO 4 ) 3 Assembly of system full battery

[0025] The cathode material is Na x m y Fe(CN) 6 , the ...

Embodiment 1

[0027] Example 1. Na 2 NiFe(CN) 6 -NaTi 2 (PO 4 ) 3 Assembly and performance of system full battery

[0028]Prepare positive / negative electrode material according to the method in embodiment 1, positive electrode material adopts Na 2 NiFe(CN) 6 , the negative electrode material is NaTi 2 (PO 4 ) 3 / C, according to the weight ratio of active material: carbon black: binder = 80:10:10, mix evenly, coat on the current collector, and after drying, press it into positive electrode film and negative electrode film respectively. Using glass fiber as the diaphragm, 5 mol / L NaNO 3 The aqueous solution is used as the electrolyte to assemble a full battery.

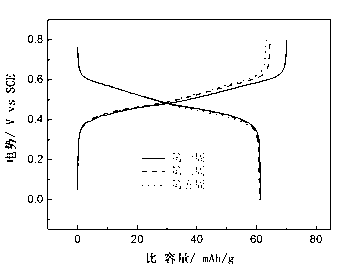

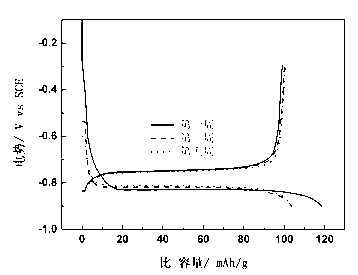

[0029] The performance of the positive electrode material: the positive electrode material is used as the working electrode, the saturated calomel electrode is used as the reference electrode, and the large-area Ni mesh is used as the counter electrode. In 1.0 mol / L NaNO 3 The electrochemical performance was tested in solu...

Embodiment 2

[0033] Example 2. Na 2 Cu 0.5 mn 0.5 Fe(CN) 6 - NaTi 2 (PO 4 ) 3 Assembly and performance of system full battery

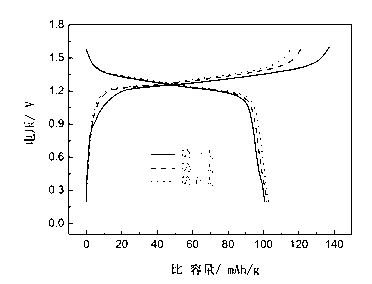

[0034] Prepare positive / negative electrode material according to the method in embodiment 1, positive electrode material adopts Na 2 Cu 0.5 mn 0.5 Fe(CN) 6 , the negative electrode material is NaTi 2 (PO 4 ) 3 / C, according to the weight ratio of active material: carbon black: binder = 85:10:5, mix evenly, coat on the current collector, and after drying, press it into positive electrode film and negative electrode film respectively. Using non-woven fabric as the diaphragm, the saturated Na 3 PO 4 The aqueous solution is used as the electrolyte to assemble a full battery. Such as Figure 4 As shown, the discharge specific capacity of the battery reaches 100 mAh / g at 2 C current density; at 5 C, 10 C, 20 C, 50 C and 80 C current densities, the discharge specific capacity is 93, 86, 82, 72, and 61 mAh / g; even at a current density as high as 100 C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com