Patents

Literature

2689 results about "Discharge efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Charge/Discharge efficiency is the ratio of the energy you can take out of a battery divided by the energy you put in. Example figures here... http://large.stanford.edu/course...

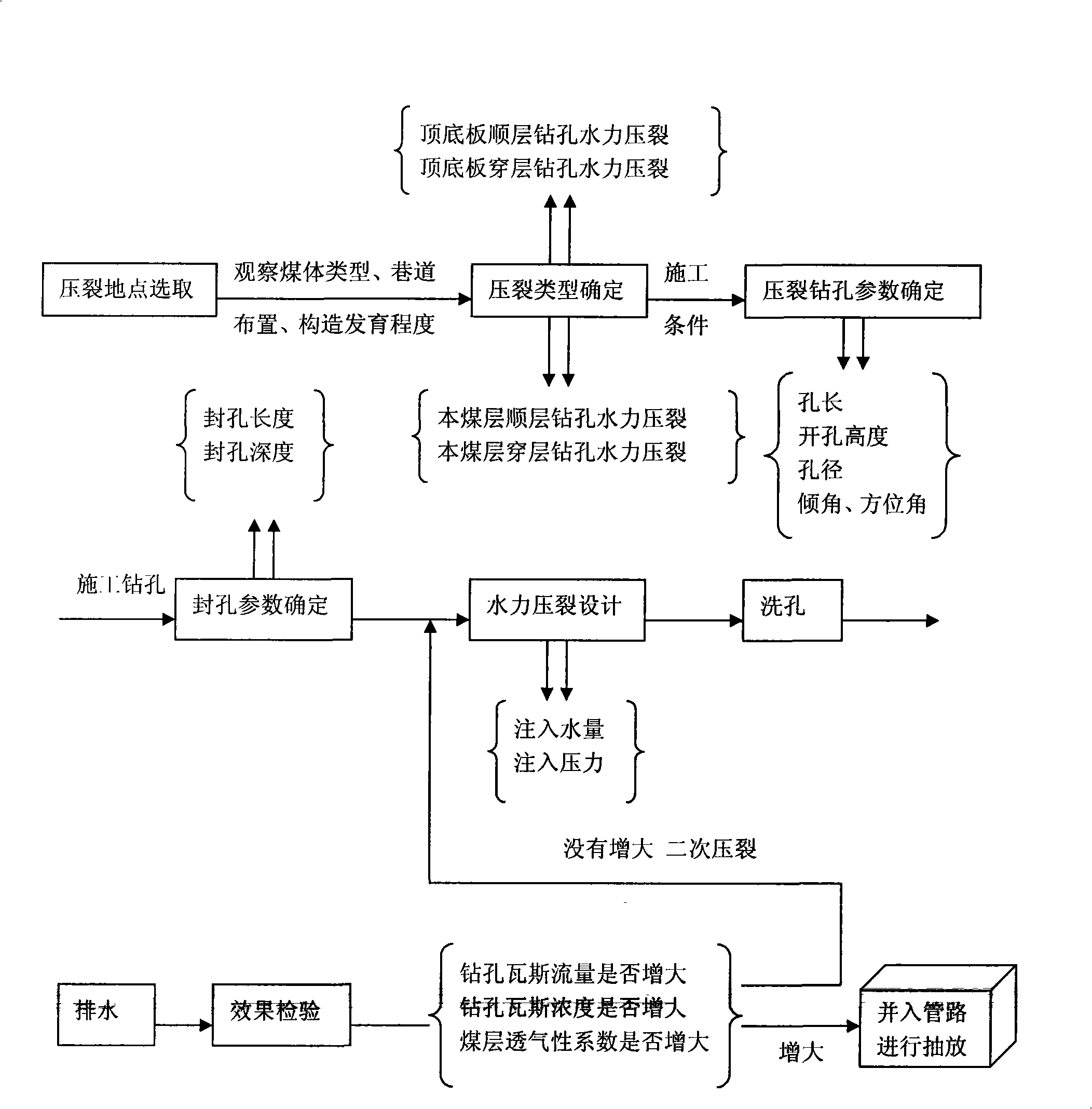

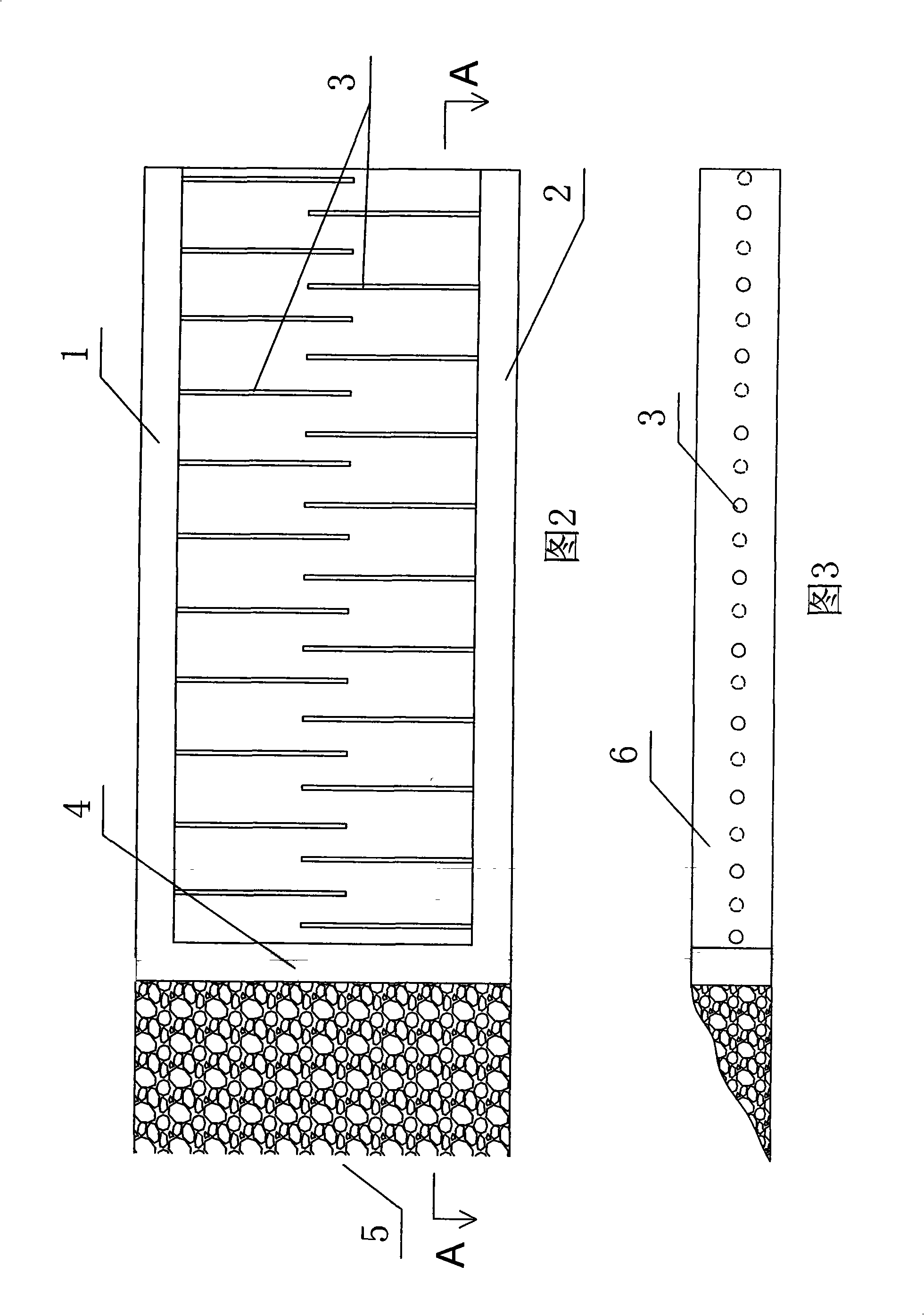

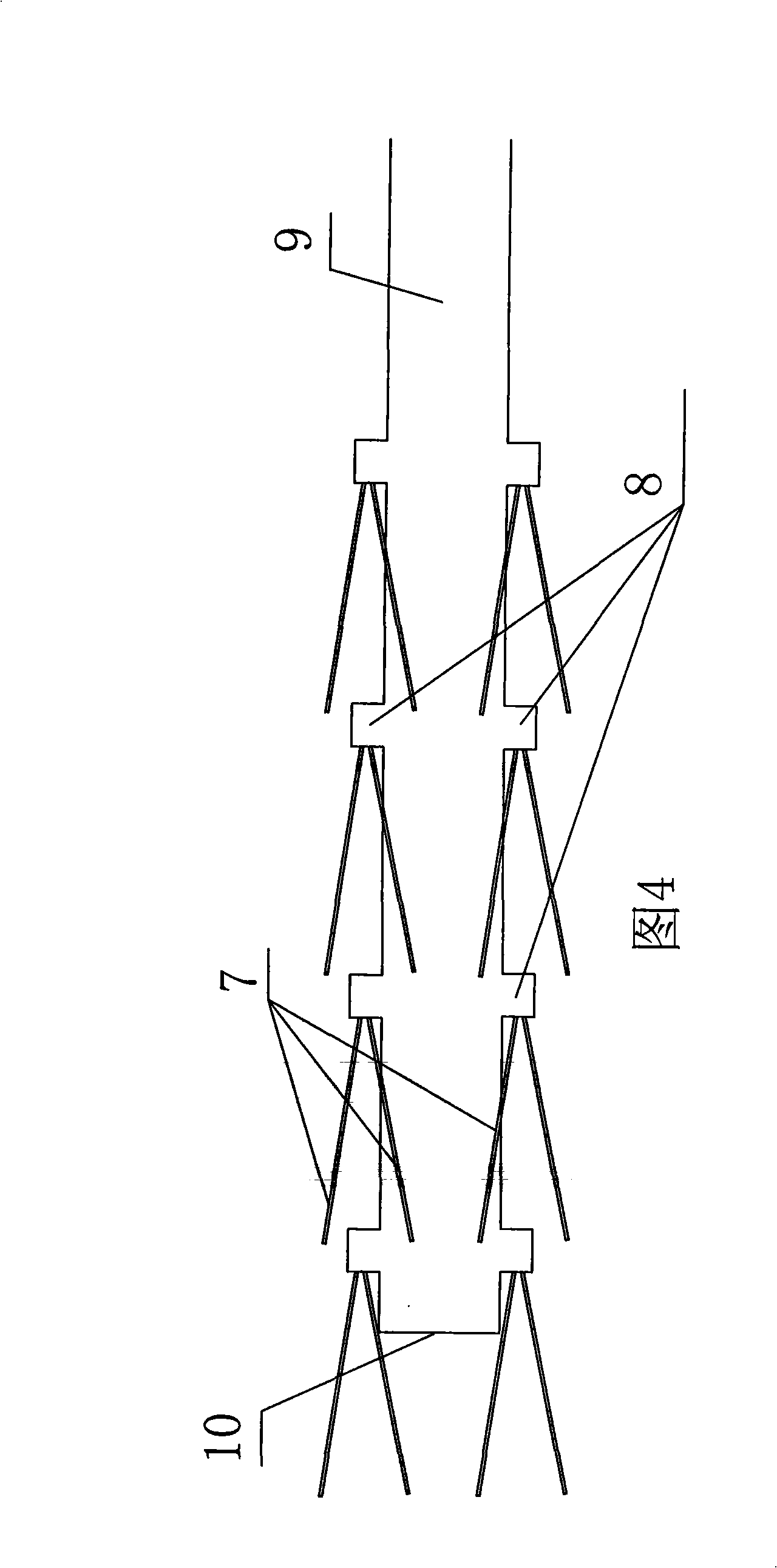

Coal mine down-hole drilling hydraulic fracturing anti-reflection mash gas extraction technique

ActiveCN101403314ALess gushEliminate disastersFluid removalGas removalDischarge efficiencyInjection pressure

The invention relates to a hydraulic fracturing anti-reflection technology for pumping and exploring gas by drilling a hole in a coal mine well, comprising the following steps sequentially: (1) selecting a fracturing location; (2) determining the pressure type according to observed coal type, laneway arrangement and construction development degree, and ways of top soleplate bedding plane borehole hydraulic fracturing, top soleplate translamellar borehole hydraulic fracturing, the coal bed bedding plane borehole hydraulic fracturing or the coal bed translamellar borehole hydraulic fracturing can be adopted; (3) determining borehole parameters for constructing drilling, wherein, the borehole parameters include borehole length, borehole height, aperture, obliquity angle and azimuth angle; (4) designing the hydraulic fracturing, including injected water volume and injection pressure; (5) borehole washing; (6) draining; (7) examining the fracturing effect, if the fracturing effect is in accordance with the requirement, the following step is carried out, if not, turning to step (4); and (8) entering a pipeline for pumping and discharging. The technology enhances the air permeability of the coal bed, reduces the gas emission rate of an excavation working face, and obviously promotes the pumping and exploring capability and the pumping and exploring effect of the single borehole. The pumping and discharging efficiency is improved, the pumping and discharging time is shortened and the damage of the gas is maximally eliminated.

Owner:HENAN POLYTECHNIC UNIV

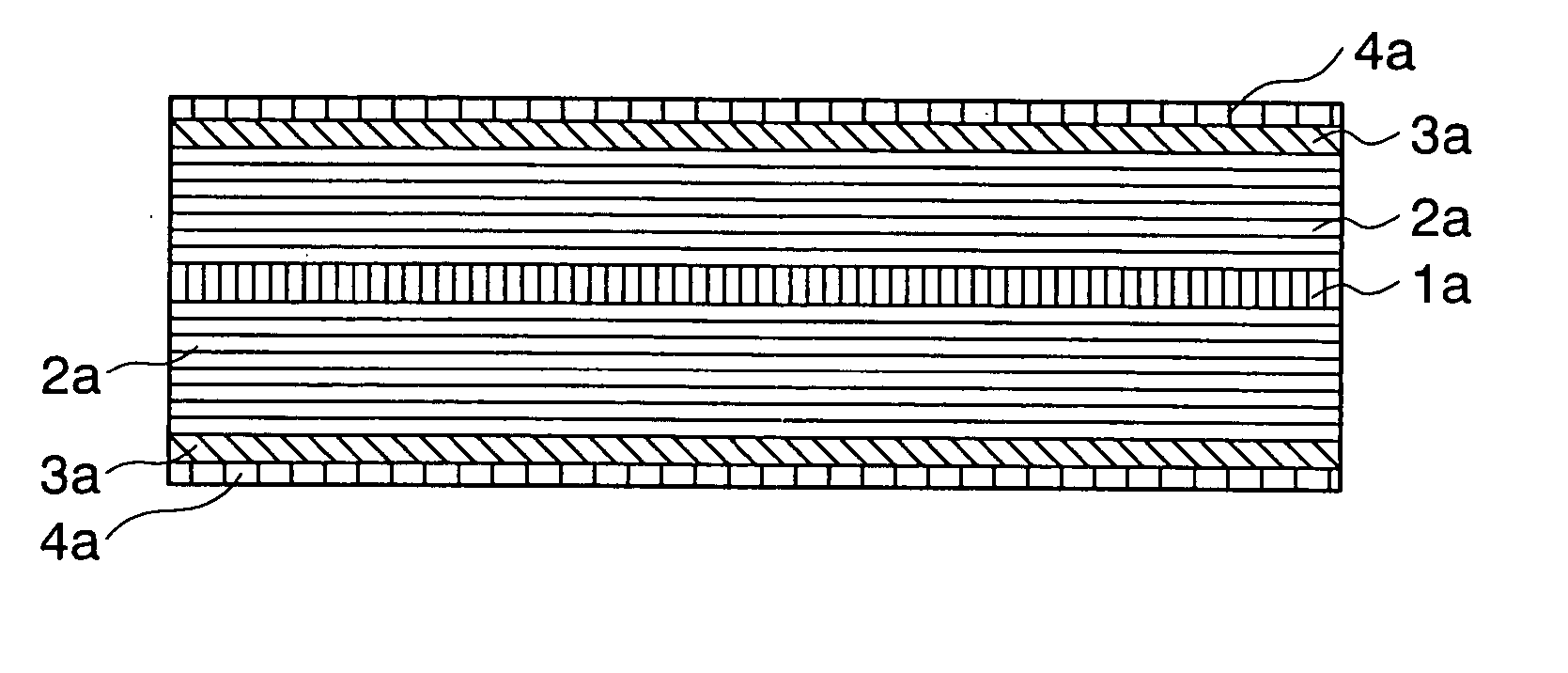

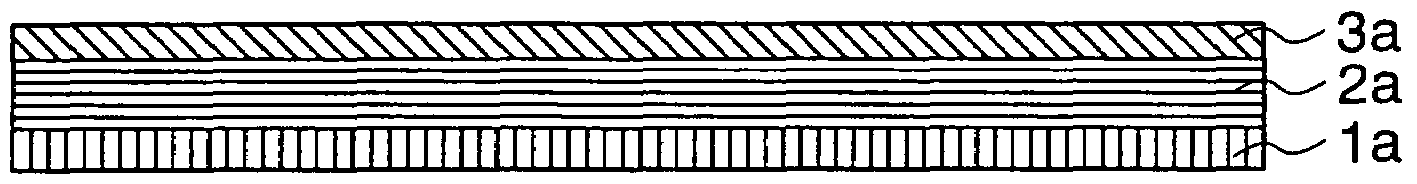

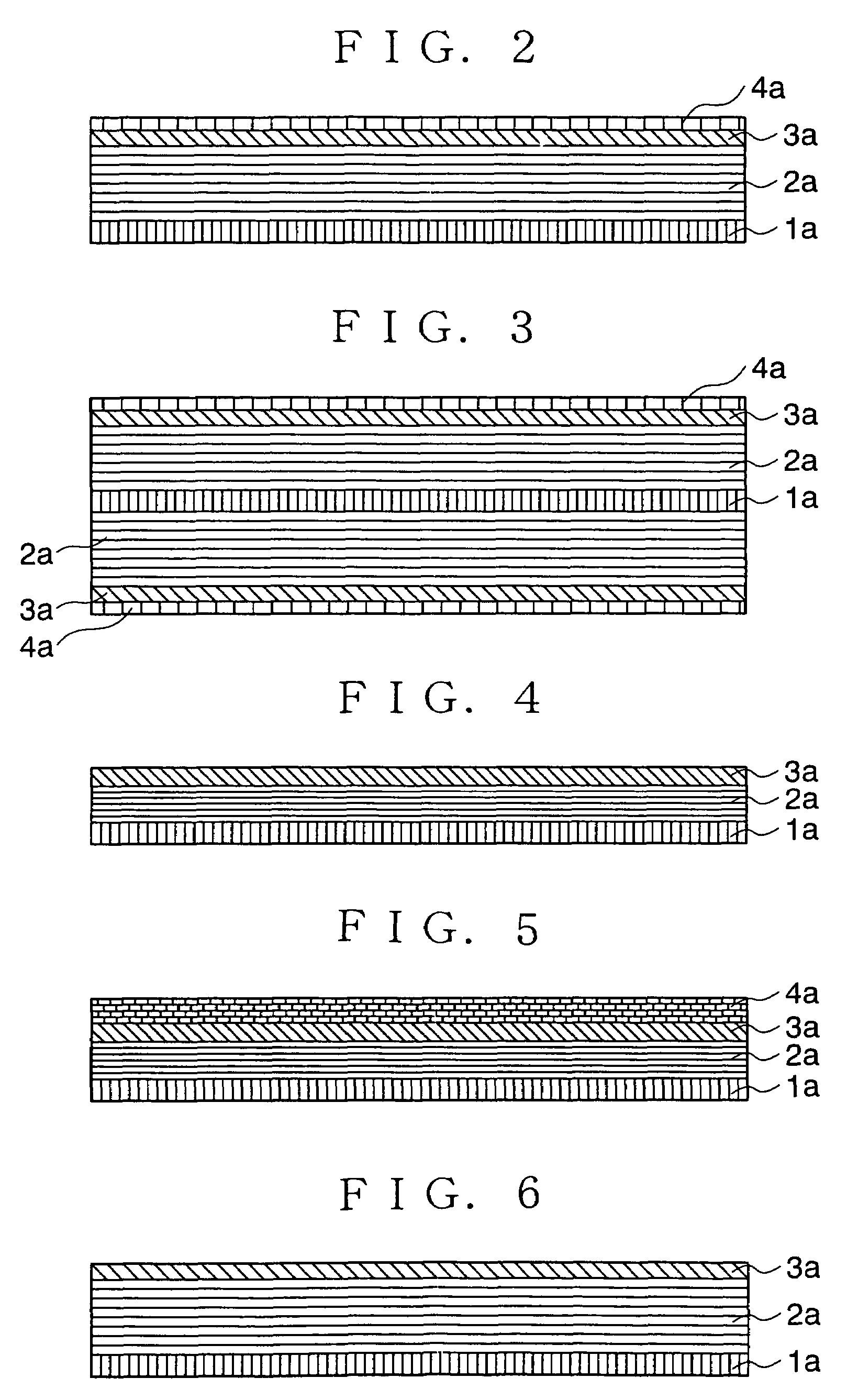

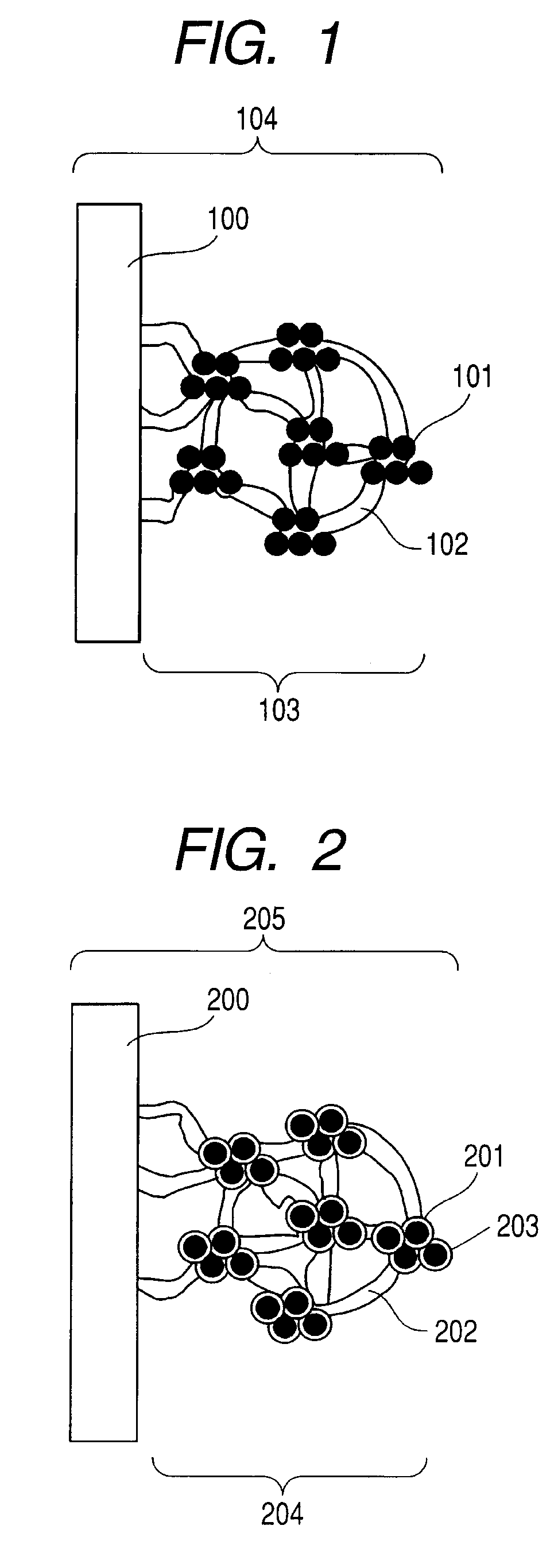

Negative pole for a secondary cell, secondary cell using the negative pole, and negative pole manufacturing method

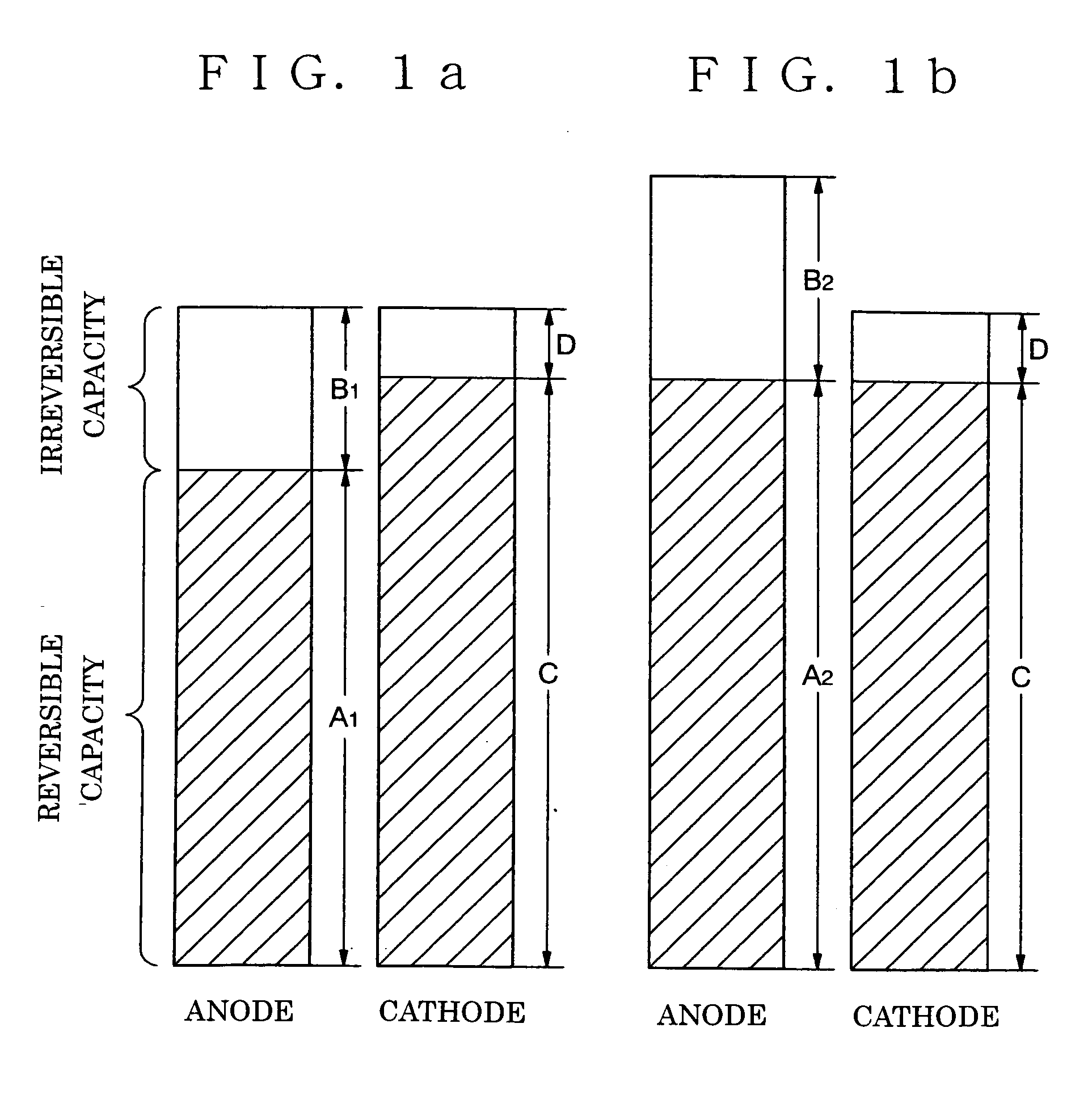

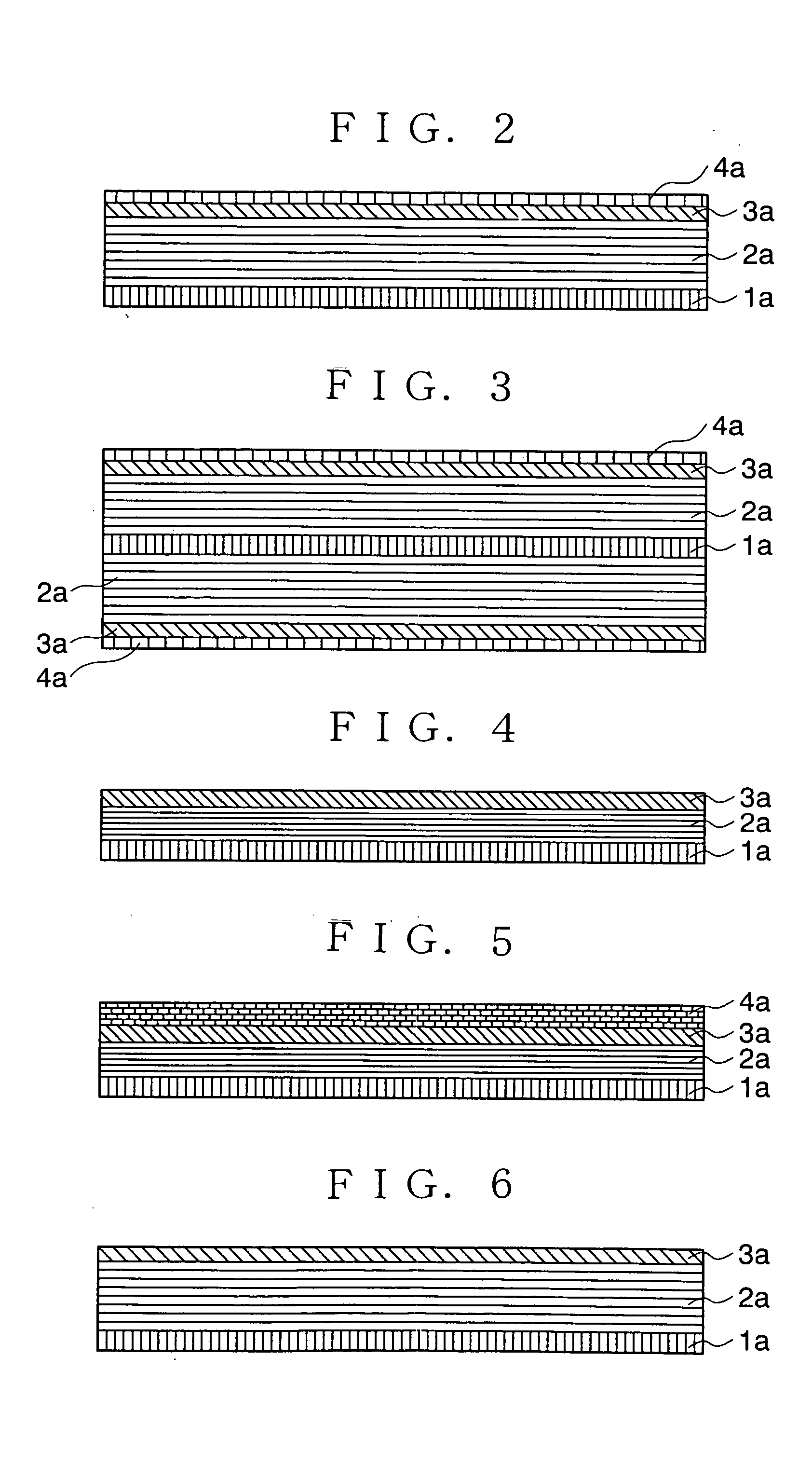

ActiveUS20040175621A1High reversible capacityImprove cycle performanceVacuum evaporation coatingSputtering coatingDischarge efficiencySodium-ion battery

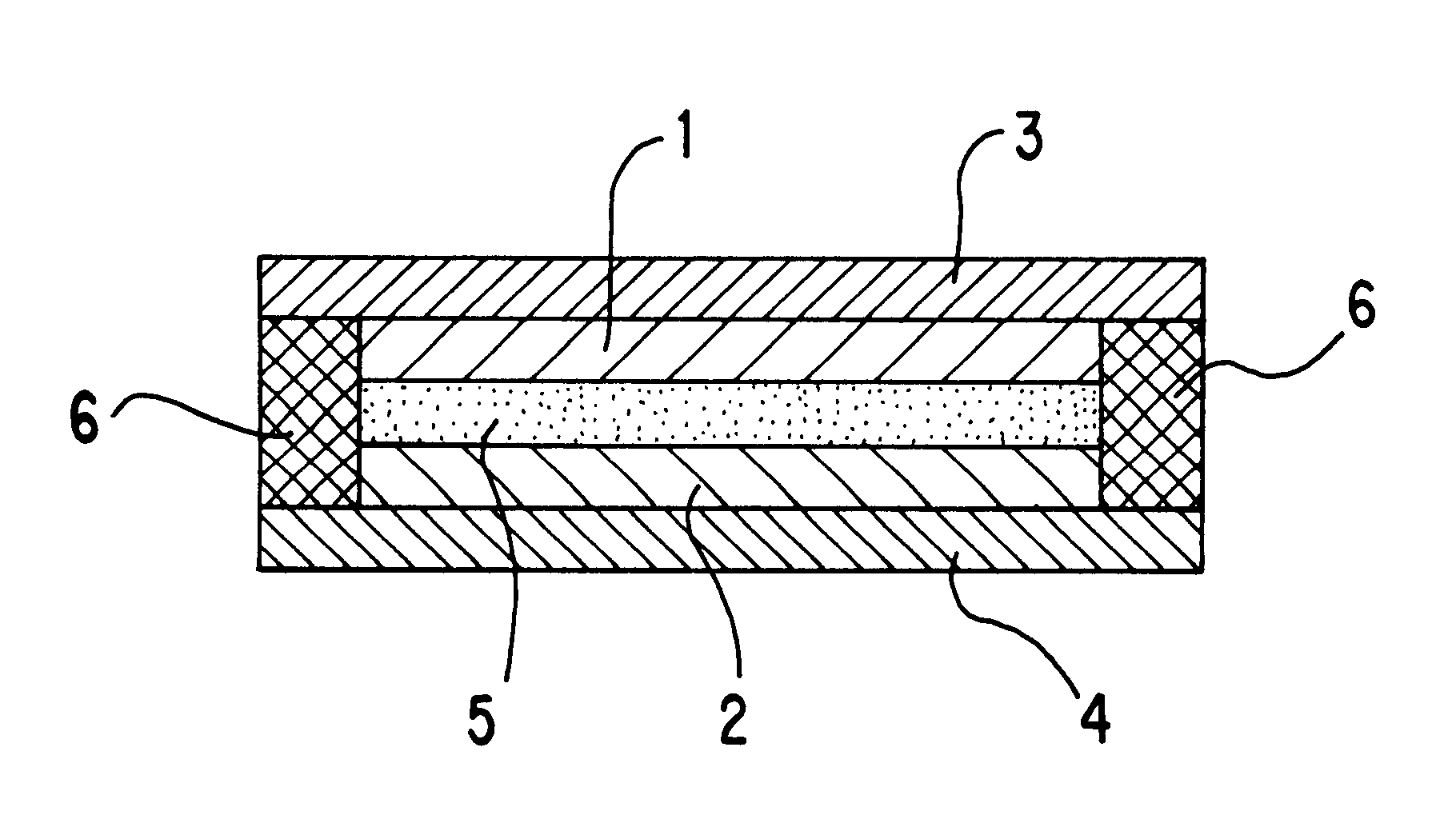

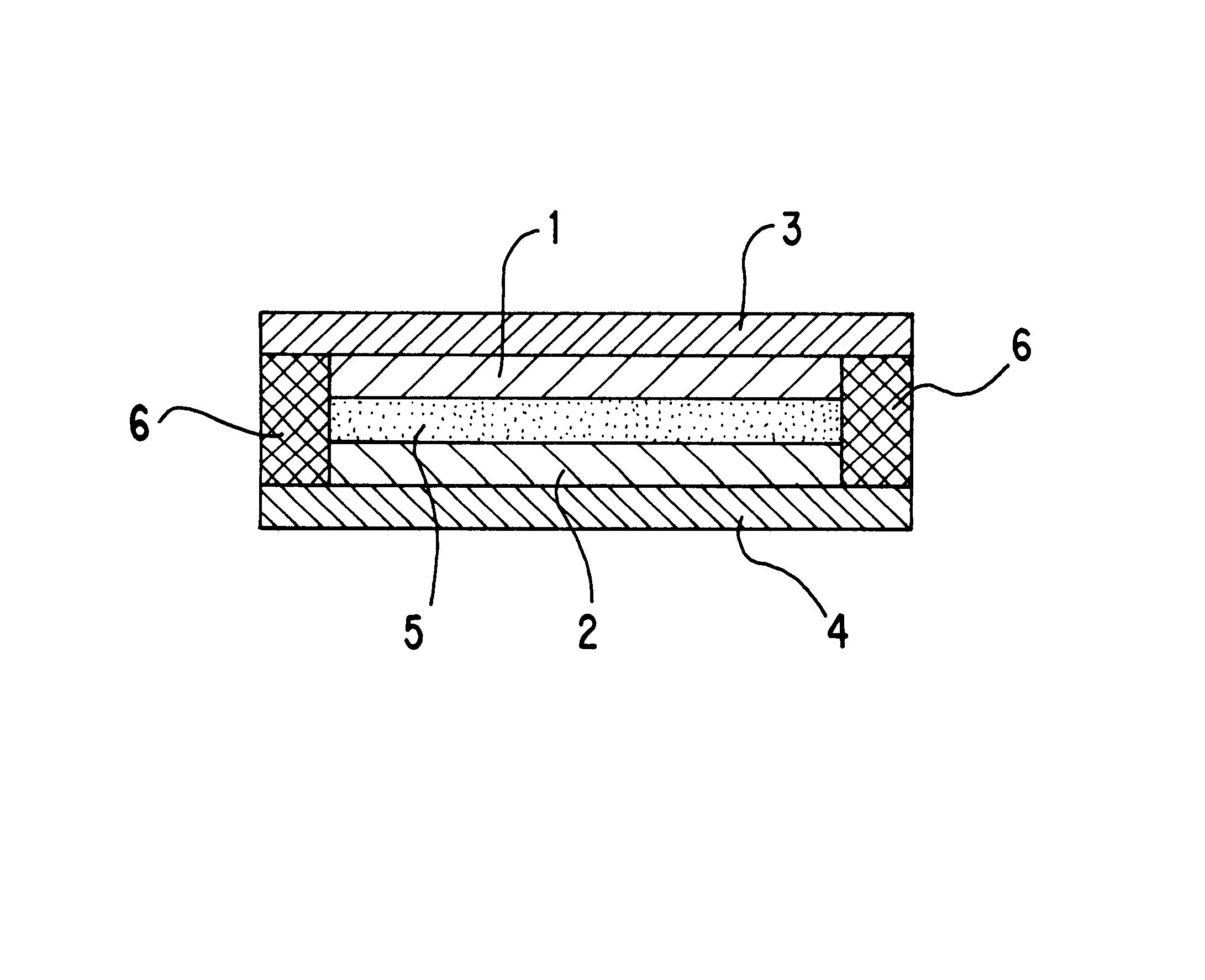

An anode for a secondary battery capable of inserting and extracting a lithium ion having a multi-layered structure including a first anode layer (2a) containing carbon as a main component; a second anode layer (3a) made of a film-like material through which a lithium component passes; and a third anode layer (4a) containing lithium and / or a lithium-containing compound as a main component. The battery capacity of the lithium ion battery is substantially increased while the higher charge-discharge efficiency and the stable cycle performance are maintained.

Owner:NEC CORP

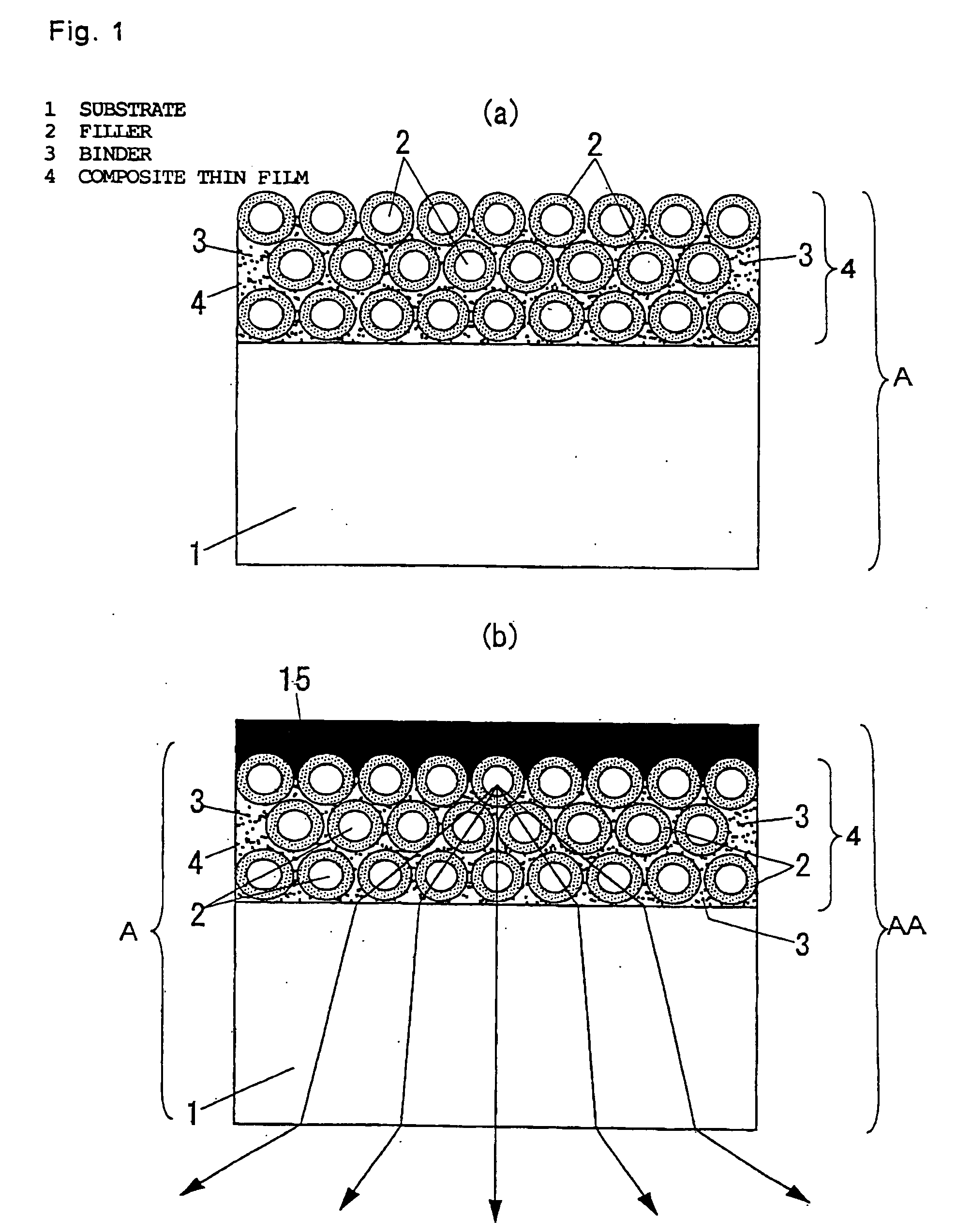

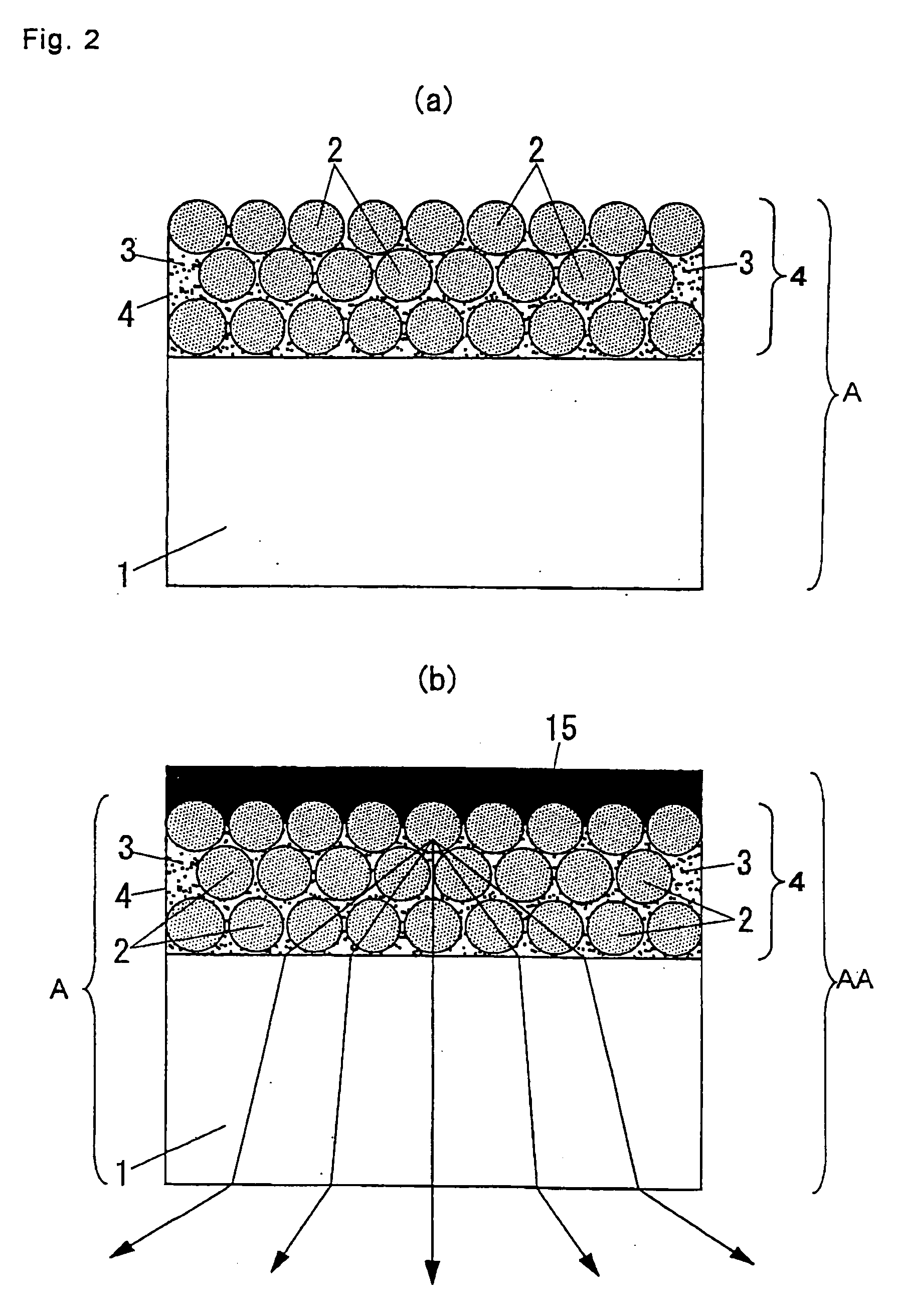

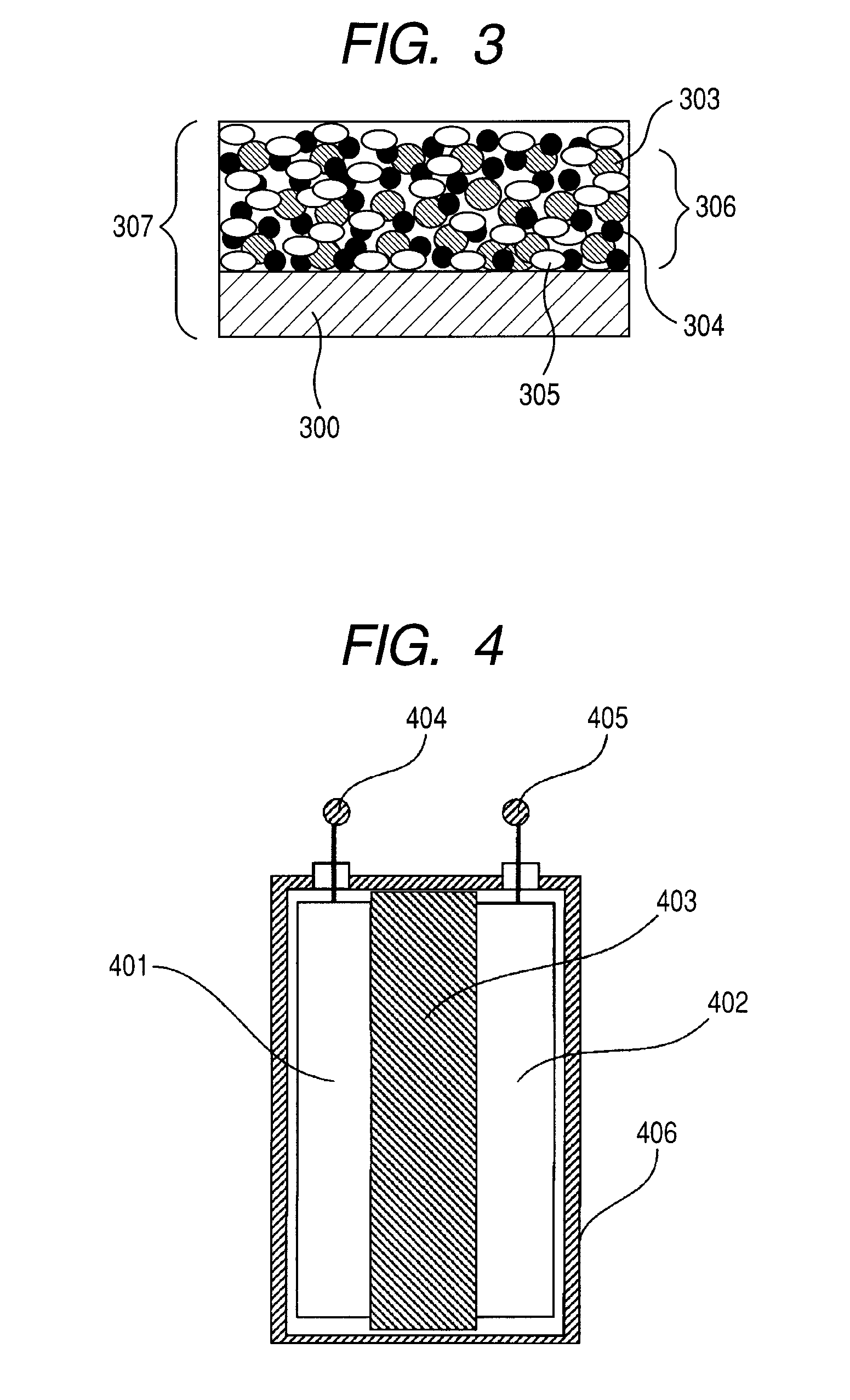

Composite thin film holding substrate, transparent conductive film holding substrate, and panel light emitting body

ActiveUS20040253427A1Improve efficiencyReduced strengthDiffusing elementsSolid-state devicesDischarge efficiencyComposite film

There is provided a composite thin film-holding substrate in which a composite thin film (4) comprising a filler (2) having a refractive index lower than that of a substrate (1) and a binder (3) having a refractive index higher than that of the filler (2) is formed on a surface of the substrate (1). Light is efficiently scattered when passing through the composite thin film (3) which comprises the filler (2) and the binder (3) having different refractive indexes from each other. In addition, the refractive index of a composite thin film (4) comprising a filler (2) having a low refractive index is low. As a result, the discharge efficiency of light which passes through the composite thin film (4) from the substrate (1) to the external is improved.

Owner:SAMSUNG DISPLAY CO LTD

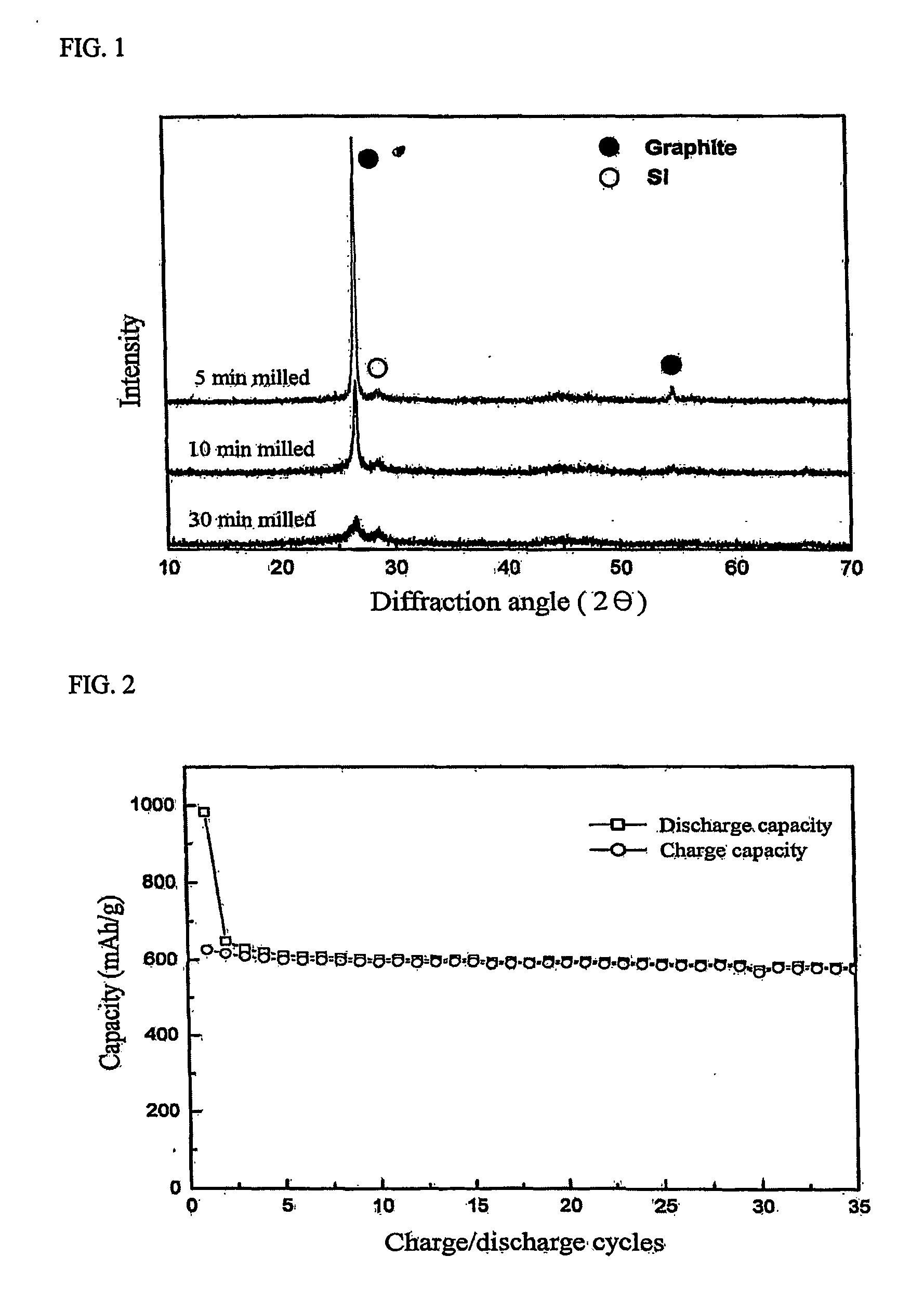

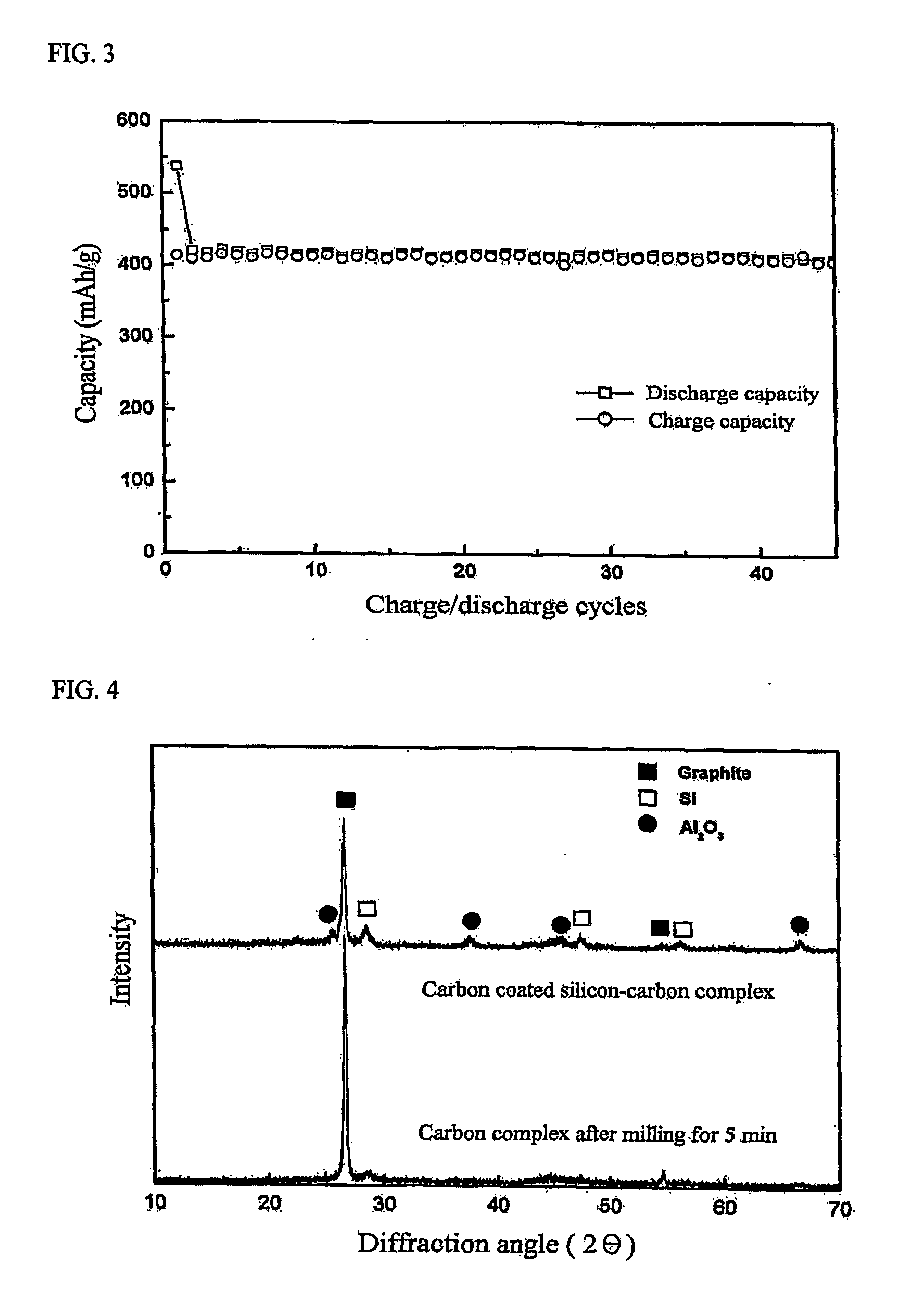

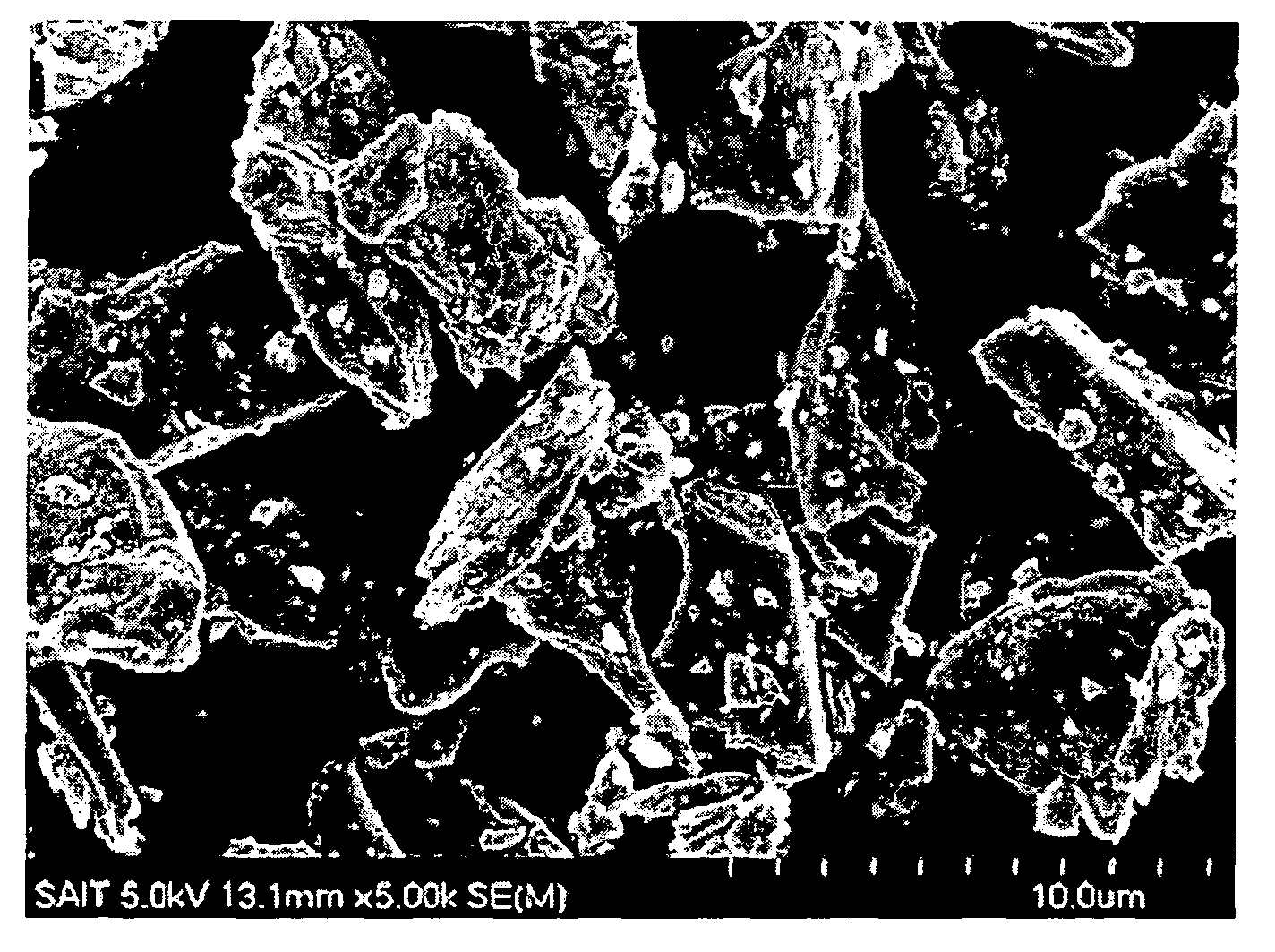

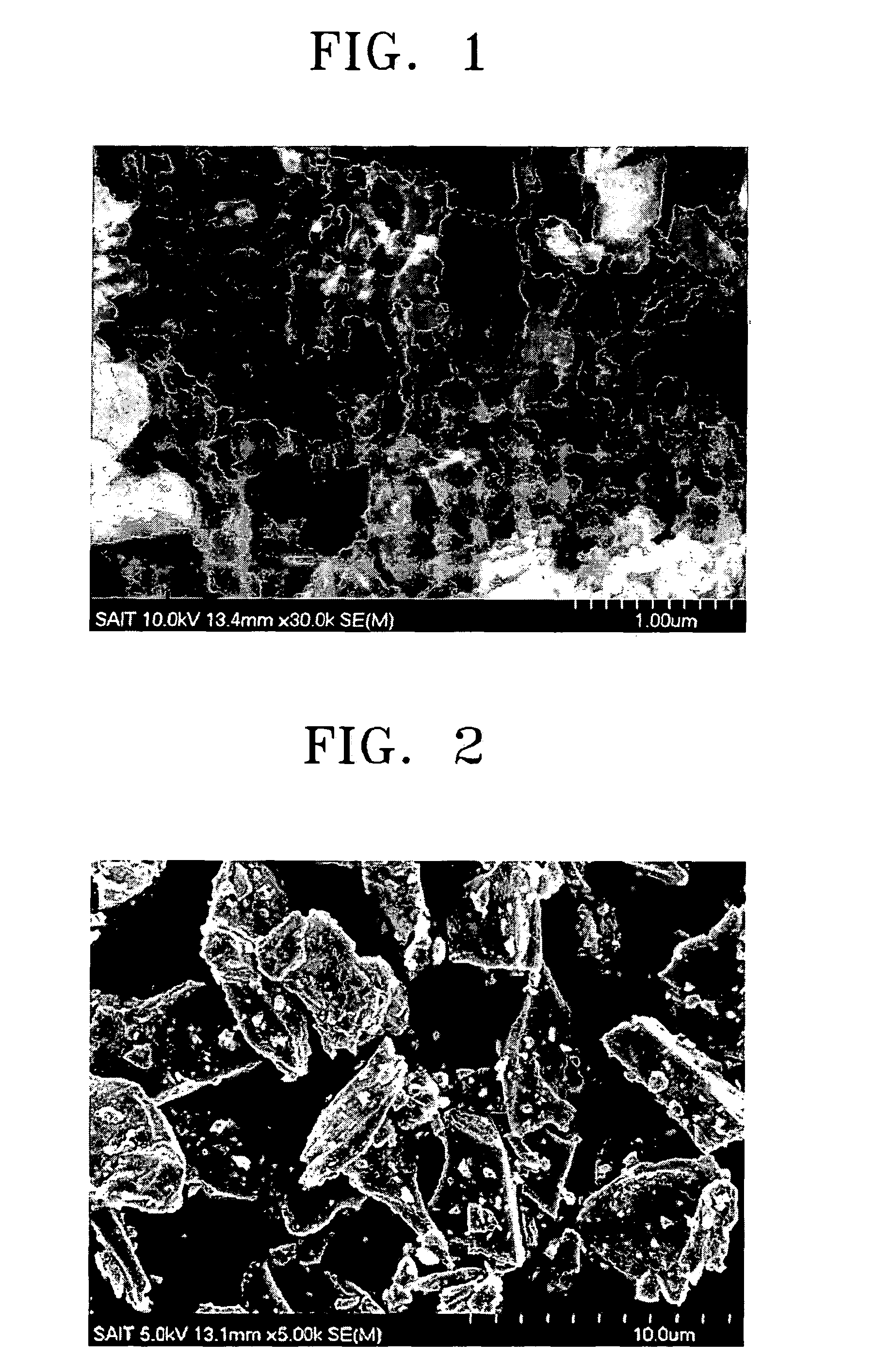

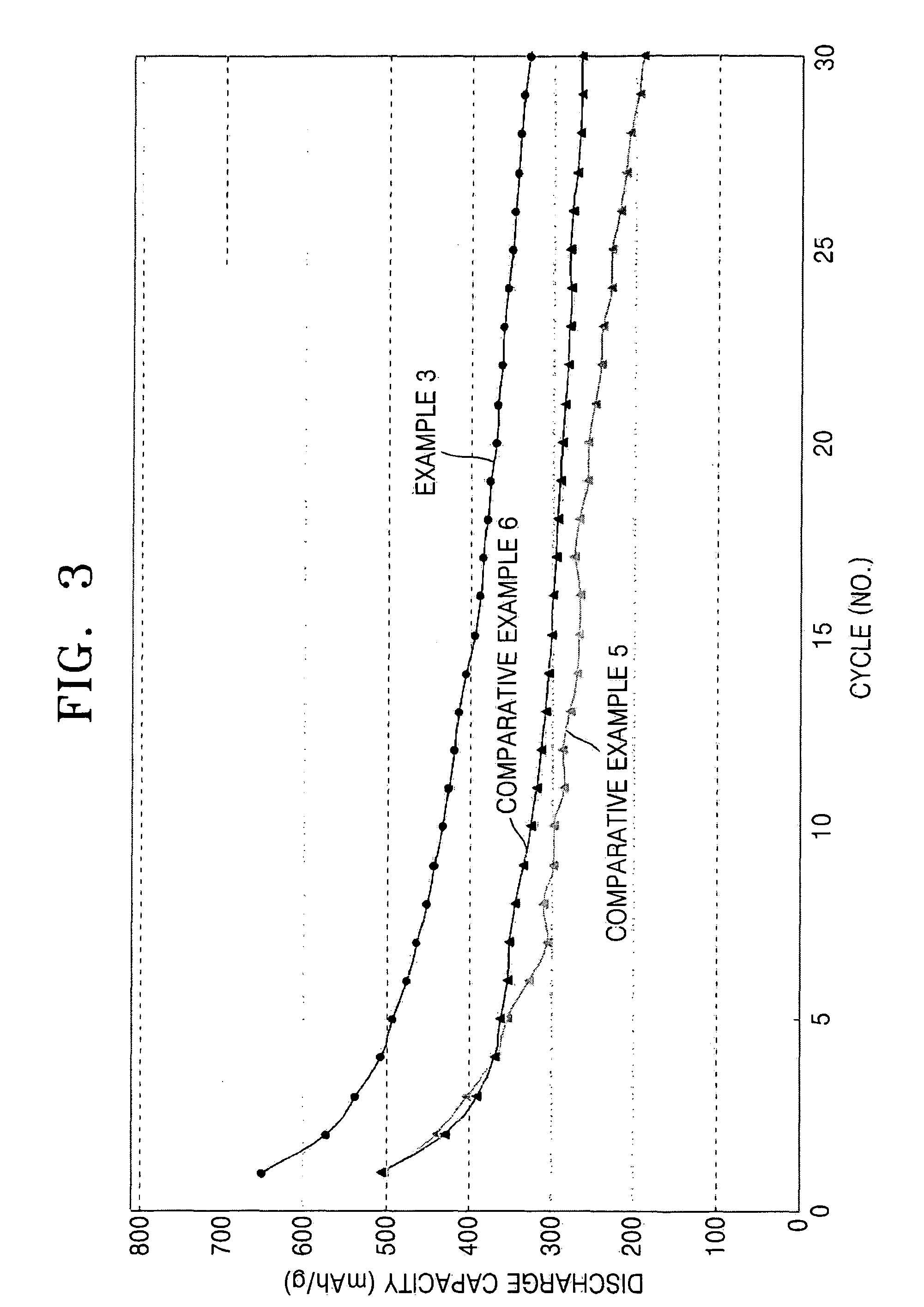

Negative active material for lithium secondary battery and method for preparating same

ActiveUS20070190413A1Reduce the amount of solutionImprove charge and discharge cycle lifeElectrode thermal treatmentActive material electrodesLithiumDischarge efficiency

Provided are an anode active material for a lithium secondary battery having high reversible capacity and excellent charge / discharge efficiency, comprising a complex composed of ultra-fine Si phase particles and an oxide surrounding the ultra-fine Si phase particles, and a carbon material; and a method for preparing the same. The present invention also provides a method for preparing an anode active material for a lithium secondary battery comprising producing a complex composed of ultra-fine Si particles and an oxide surrounding the ultra-fine Si particles by mixing a silicon oxide and a material having an absolute value of oxide formation enthalpy (ΔHfor) greater than that of the silicon oxide and negative oxide formation enthalpy by a mechanochemical process or subjecting them to a thermochemical reaction to reduce the silicon oxide; and mixing the Si phase-containing oxide complex and carbon material.

Owner:LG ENERGY SOLUTION LTD

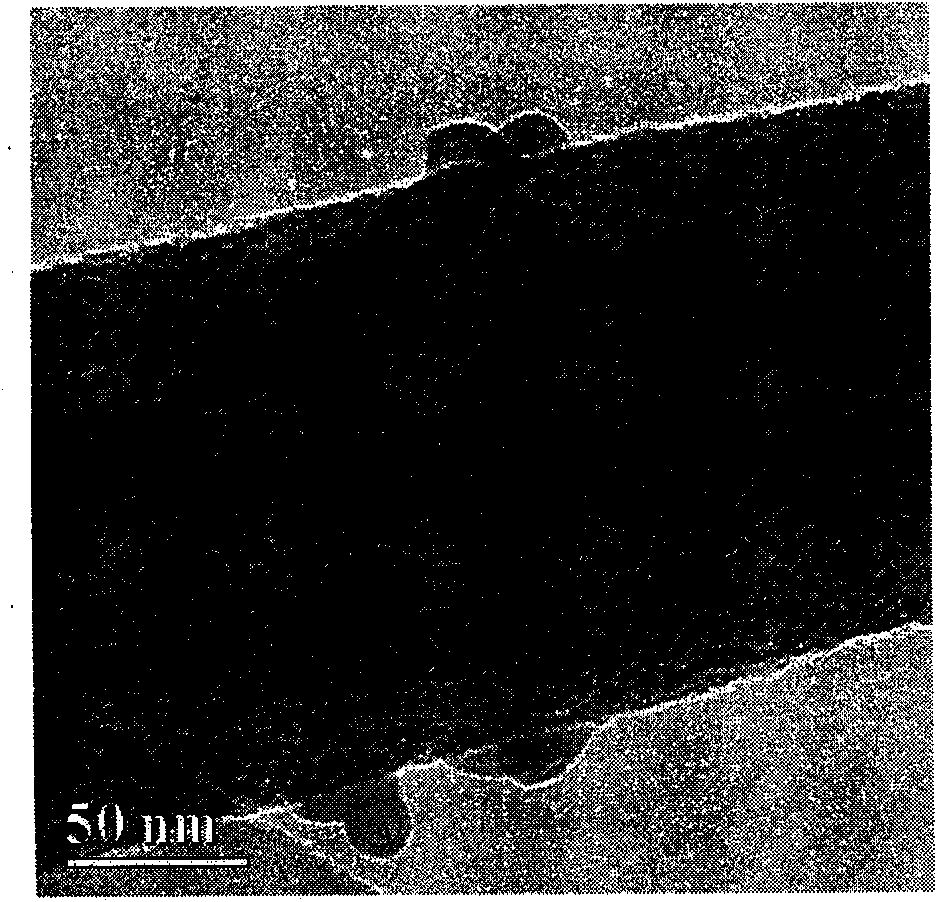

Negative electrode material for nonaqueous electrolyte secondary battery, making method and lithium ion secondary battery

InactiveUS20100288970A1High charge-discharge efficiencyImprove cycle performanceHybrid capacitor electrodesSecondary cellsDischarge efficiencyCarbon coating

A negative electrode material for nonaqueous electrolyte secondary batteries comprises composite particles which are prepared by coating surfaces of particles having silicon nano-particles dispersed in silicon oxide with a carbon coating, and etching the coated particles in an acidic atmosphere. The silicon nano-particles have a size of 1-100 nm. The composite particles contain oxygen and silicon in a molar ratio: O<O / Si<1.0. Using the negative electrode material, a lithium ion secondary battery can be fabricated which features a high 1st cycle charge / discharge efficiency, a high capacity, and improved cycle performance.

Owner:SHIN ETSU CHEM IND CO LTD

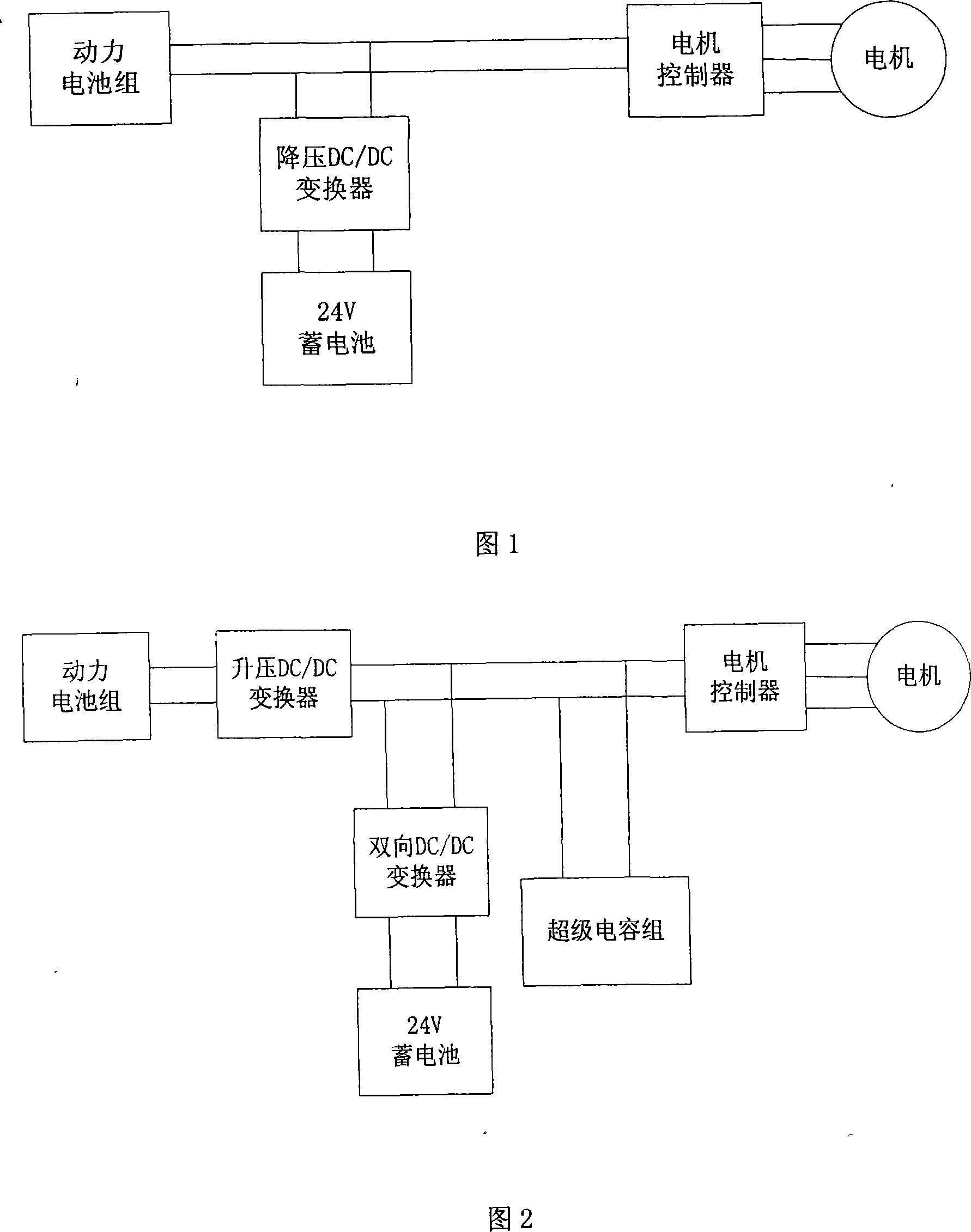

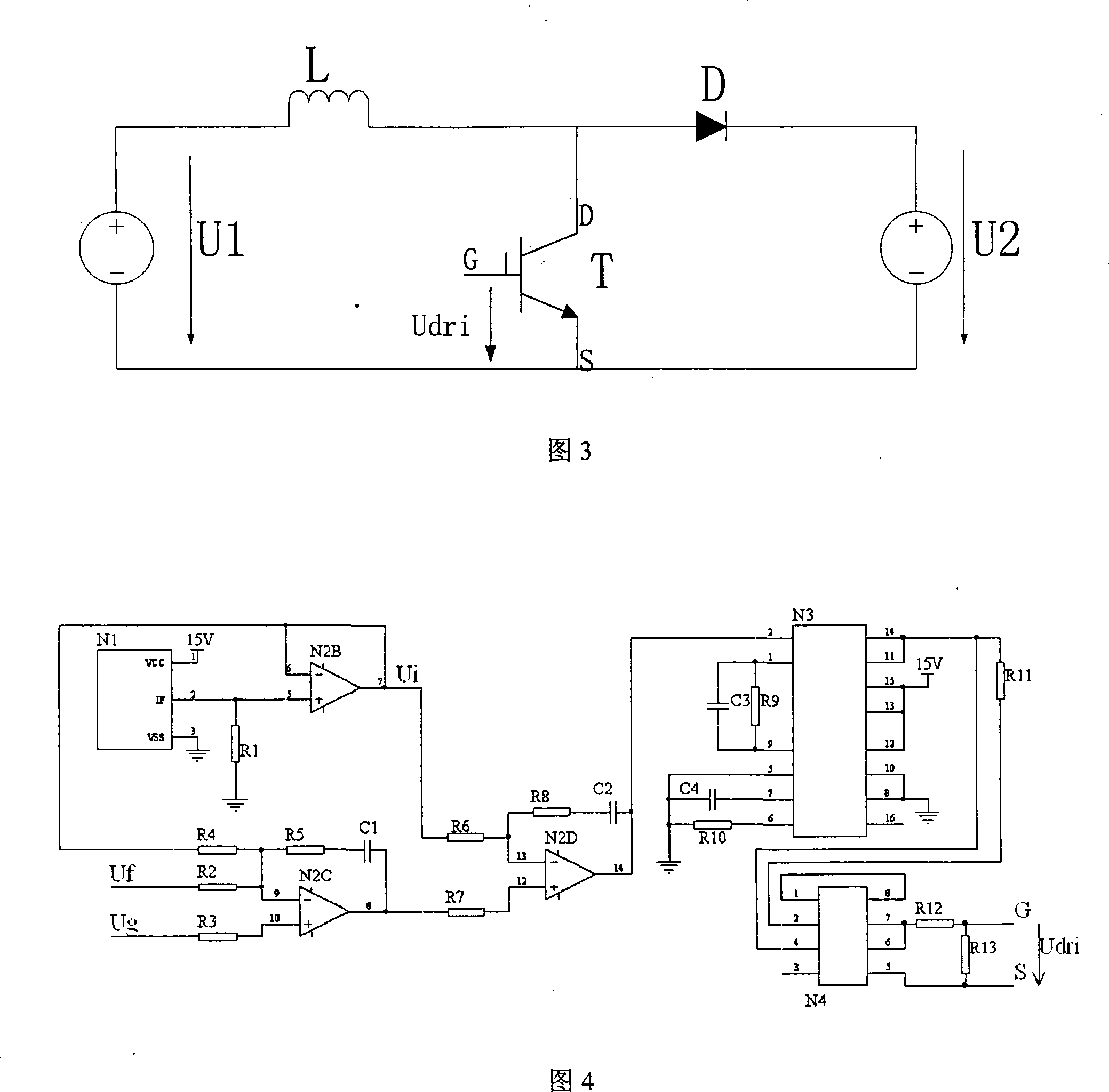

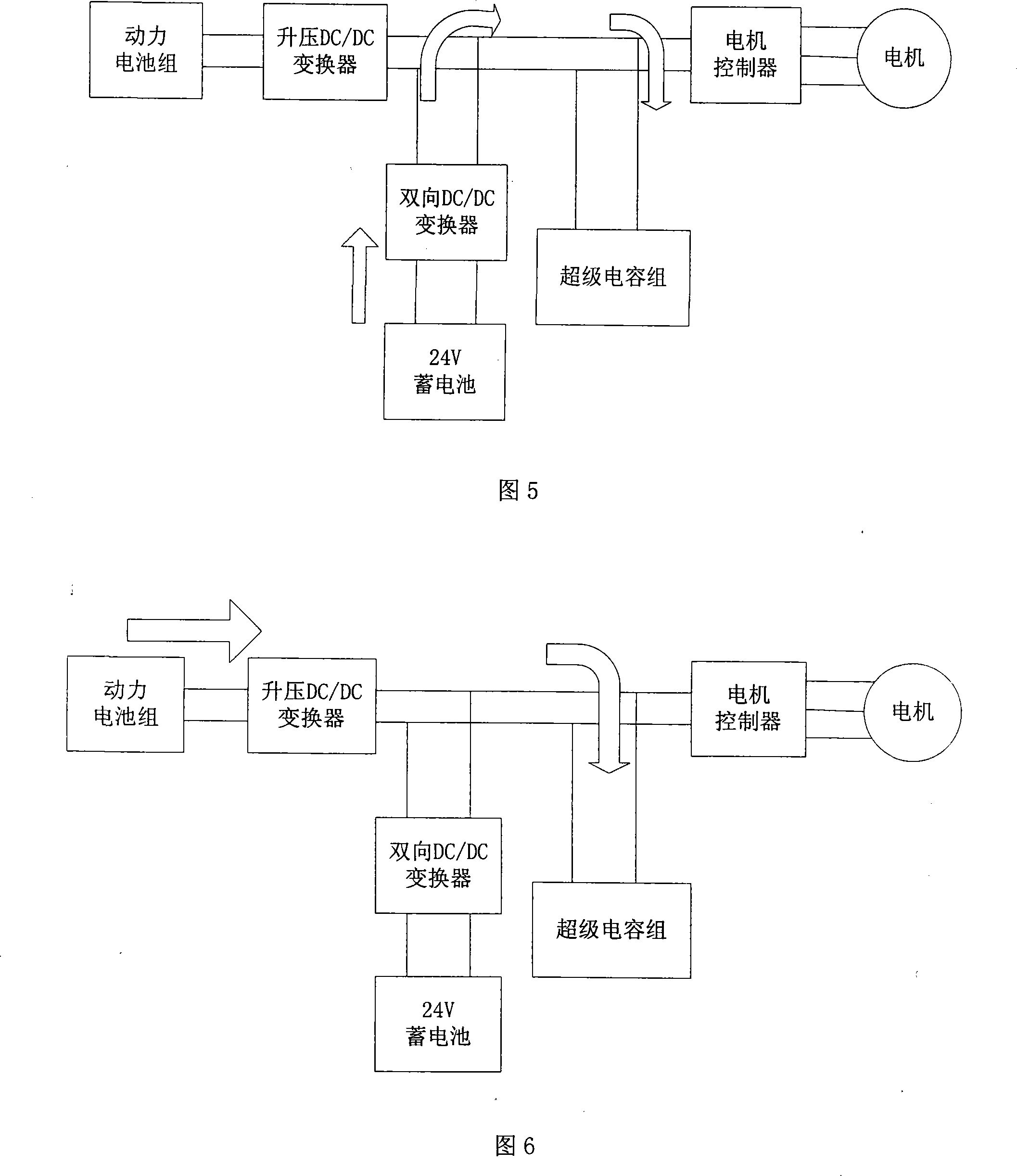

Dynamics battery-super capacitance mixed dynamic system for electric car

InactiveCN101237154AReduce peak discharge currentImprove energy efficiencyElectrical storage systemBatteries circuit arrangementsDischarge efficiencyCapacitance

The invention relates to a power battery-super capacitor hybrid power system for electric automobiles, belonging to the electric automobile technical field. The power battery-super capacitor hybrid power system for the electric automobiles comprises a power battery pack, a motor controller and a 24V storage battery, a boost DC / DC converter, a bi-directional DC / DC converter and a super capacitance group, wherein, the low voltage end of the boost DC / DC converter is connected with the output end of the power battery pack, the high voltage end of the boost DC / DC converter is connected with the motor controller; the super capacitance group and the high voltage end of the bi-directional DC / DC converter are directly hitched with the high voltage end of the boost DC / DC converter, and the low voltage end of the bi-directional DC / DC converter is connected with the 24V storage battery. The power battery of the power battery-super capacitor hybrid power system for the electric automobiles has smooth output current, small peak current, high discharge efficiency and long service life; when the battery pack SOC is lower, the hybrid system still ensures the normal power output capability; and the super capacitance can directly absorb the braking feedback energy and has high energy conversion efficiency.

Owner:TSINGHUA UNIV

Negative electrode material for nonaqueous electrolyte secondary battery, making method and lithium ion secondary battery

InactiveUS20100243951A1High charge-discharge efficiencyImprove cycle performanceMaterial nanotechnologyDecorative surface effectsDischarge efficiencyLithium

A negative electrode material comprising composite particles having silicon nano-particles dispersed in silicon oxide is suited for use in nonaqueous electrolyte secondary batteries. The silicon nano-particles have a size of 1-100 nm. The composite particles contain oxygen and silicon in a molar ratio: 0<O / Si<1.0. Using the negative electrode material, a lithium ion secondary battery can be fabricated which features high 1st cycle charge / discharge efficiency, capacity, and cycle performance.

Owner:SHIN ETSU CHEM IND CO LTD

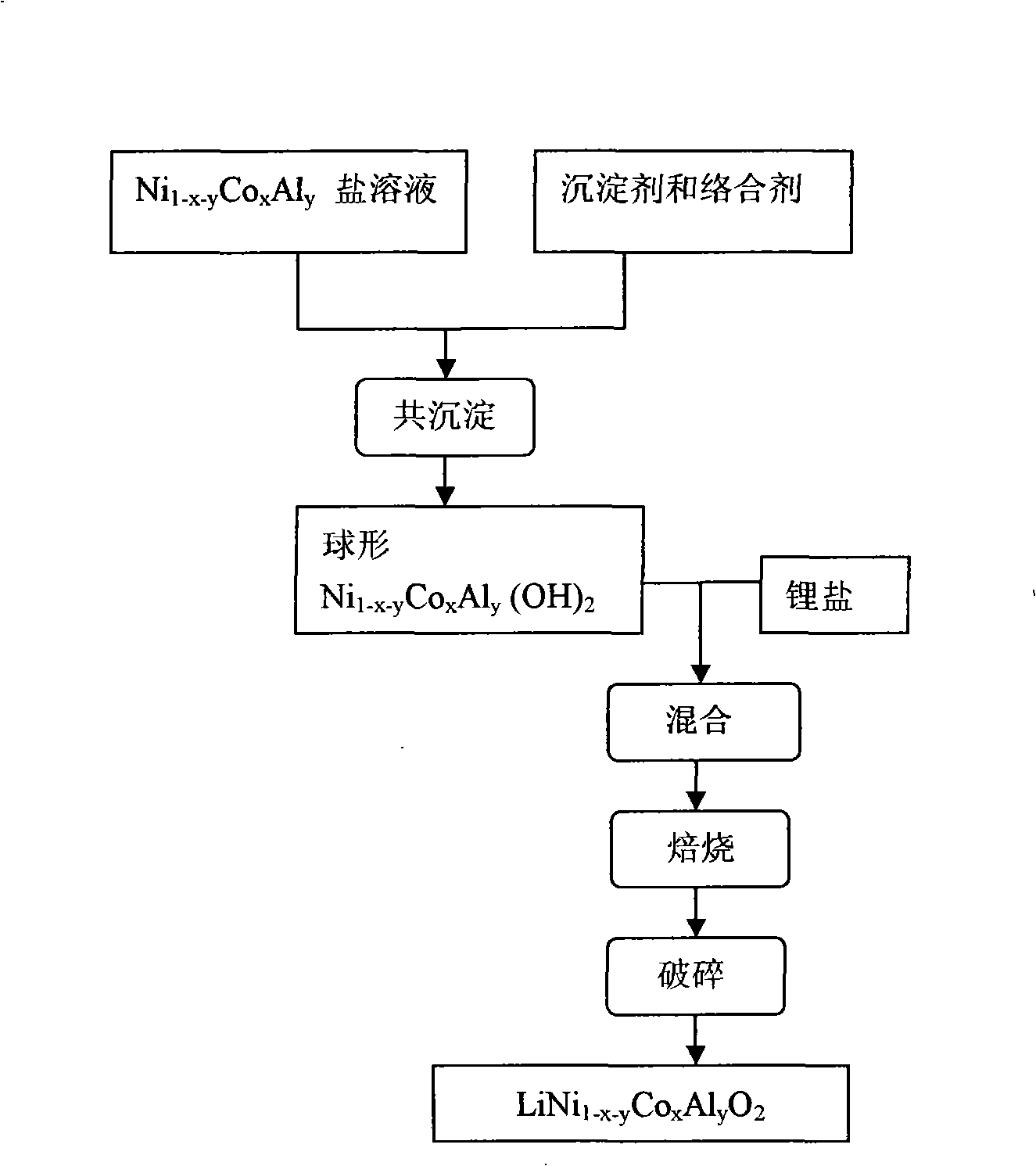

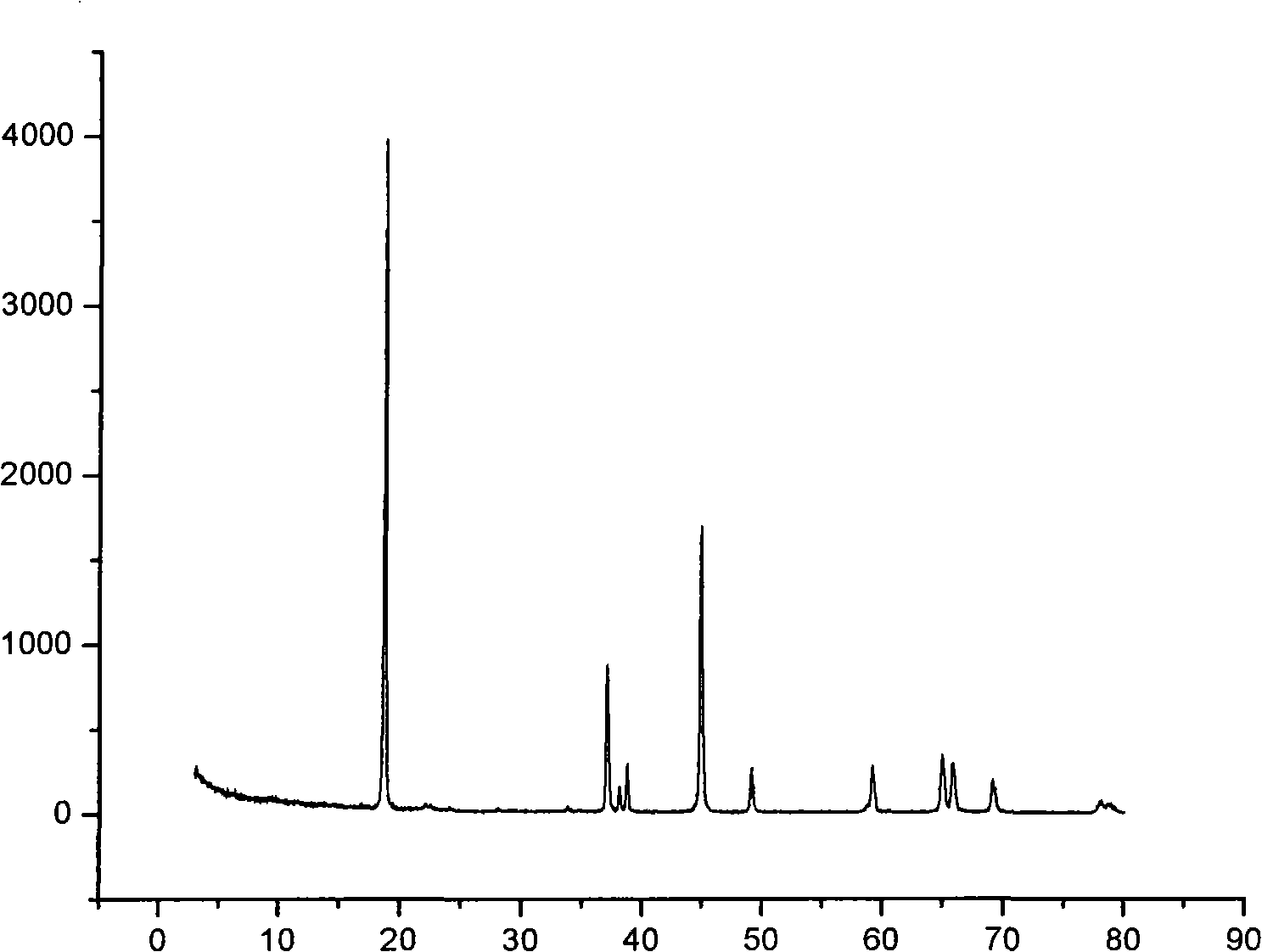

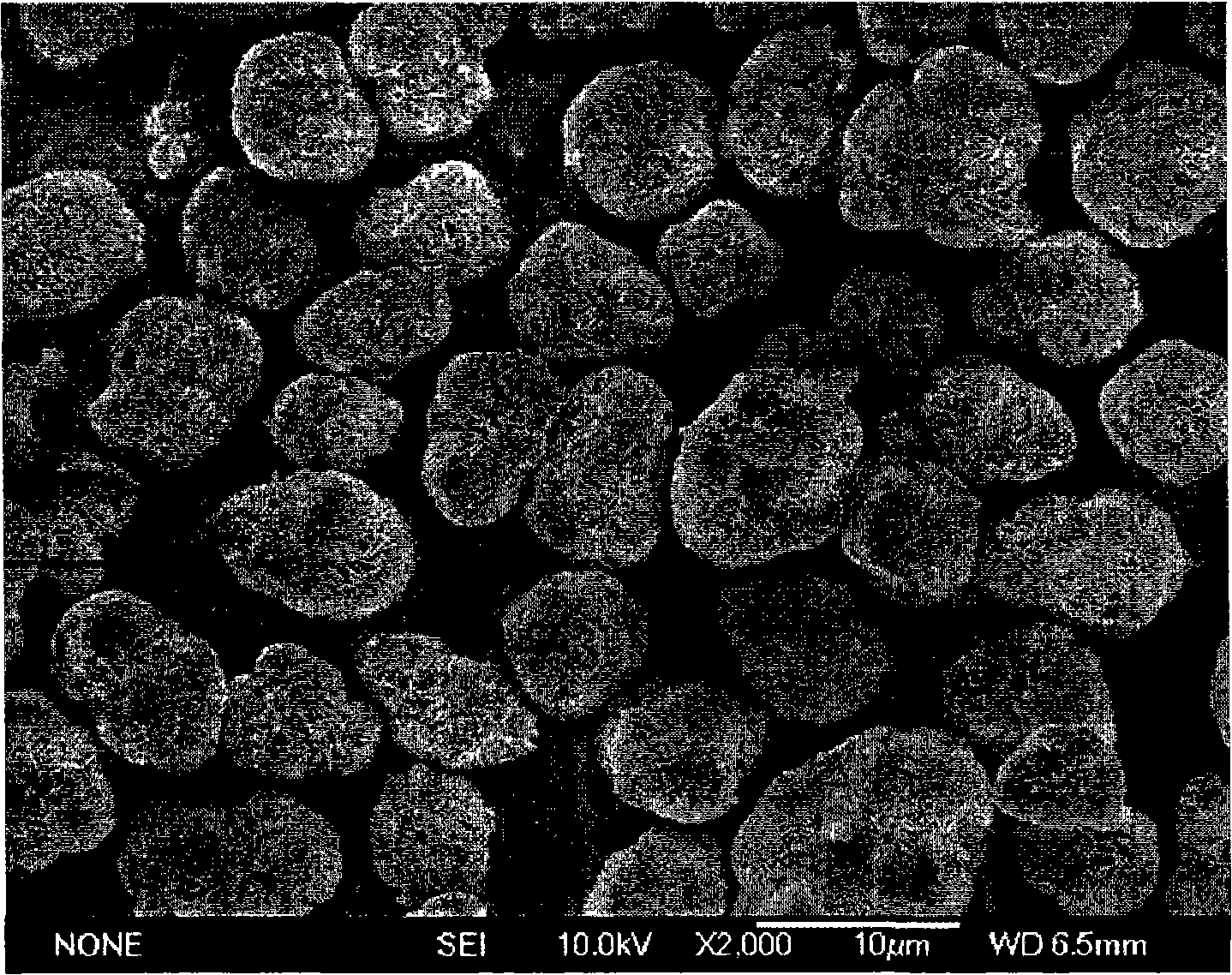

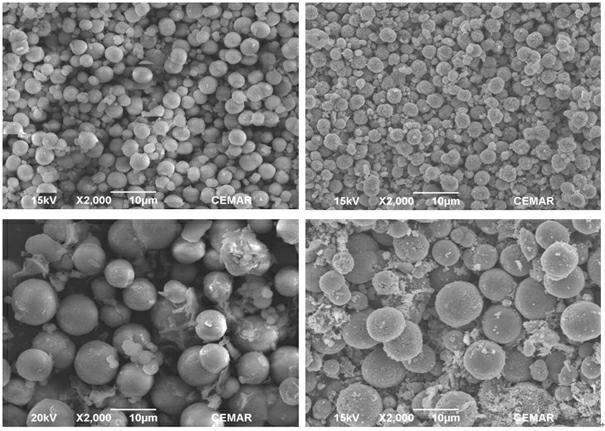

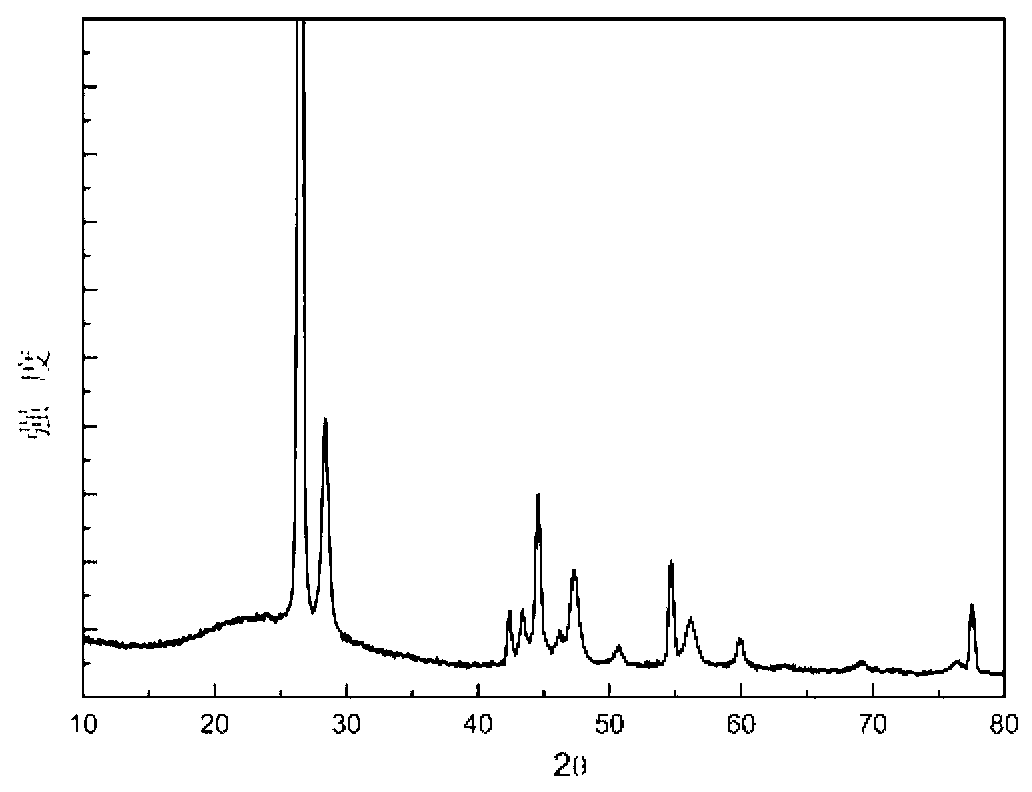

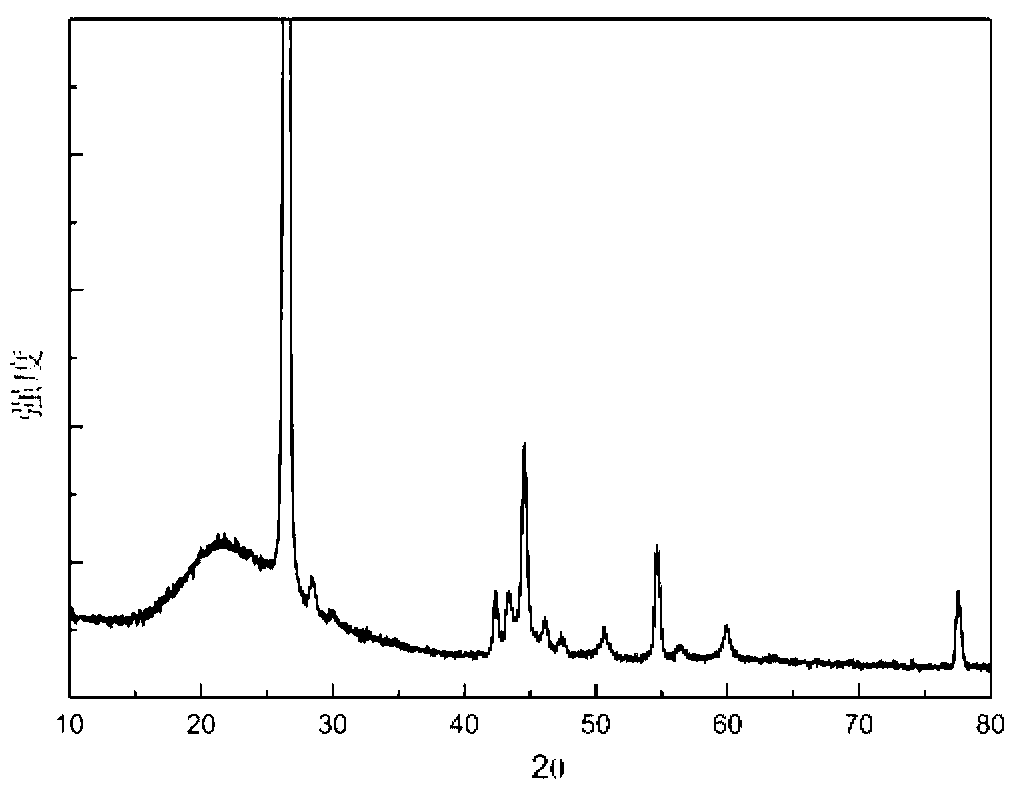

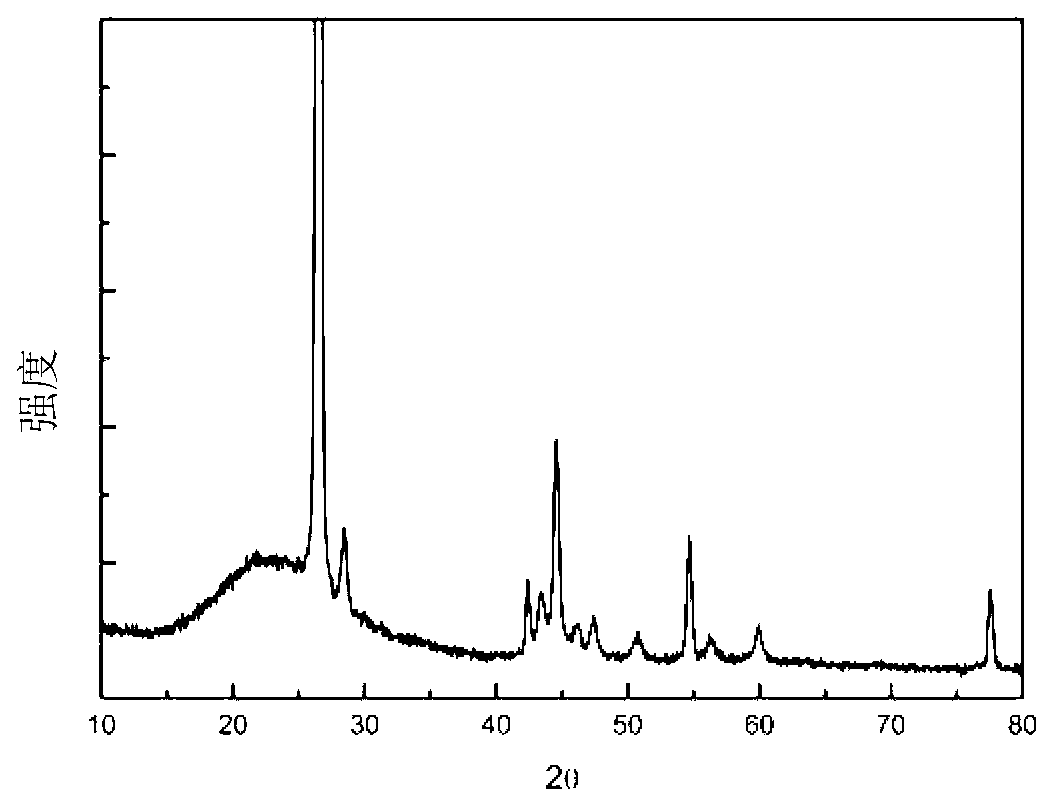

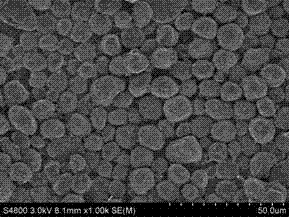

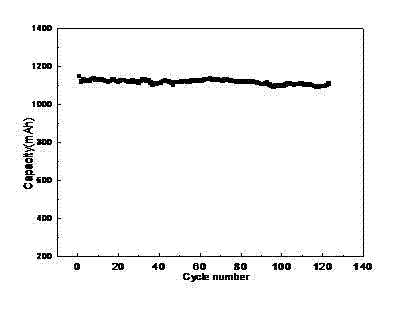

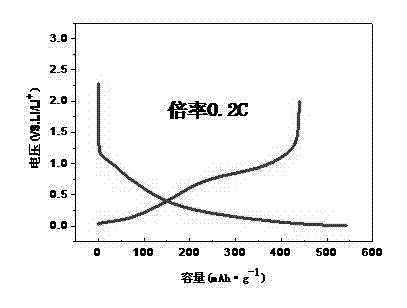

Spherical aluminum-doped nickel cobalt lithium for lithium ion battery and its making method

ActiveCN101262061AImprove liquidityImprove charge and discharge cycle stabilityElectrode manufacturing processesLithium compoundsDischarge efficiencyHigh rate

The invention discloses a preparation method of a spherical doped Al-Ni lithium cobalt oxide for lithium-ion battery. The preparation steps are that: first, sulfate, nitrate or chlorate of Al-Ni-Co react with strong alkali that is added with complex agent in liquid phase; the pH value, the temperature and the feeding speed of the reaction solution are controlled so as to produce a spherical precursor of Al-Ni-Co hydroxide; then the spherical precursor of Al-Ni-Co hydroxide is dried and evenly mixed with lithium hydroxide, lithium nitrate or lithium carbonate and dried; the obtained mixture is roasted into a spherical doped Al-Ni lithium cobalt oxide. The spherical doped Al-Ni lithium cobalt oxide has comparatively high tap density and remarkable cycle stability in the process of high-rate charge / discharge cycle, which improves over charge performance of Ni-Co substance and first obviously enhances charge / discharge efficiency; in addition, the preparation method of the spherical doped Al-Ni lithium cobalt oxide has the advantages of being simple, controllable and suitable for industrialized production with low energy consumption, high efficiency, short reaction time and low cost.

Owner:成都巴莫科技有限责任公司

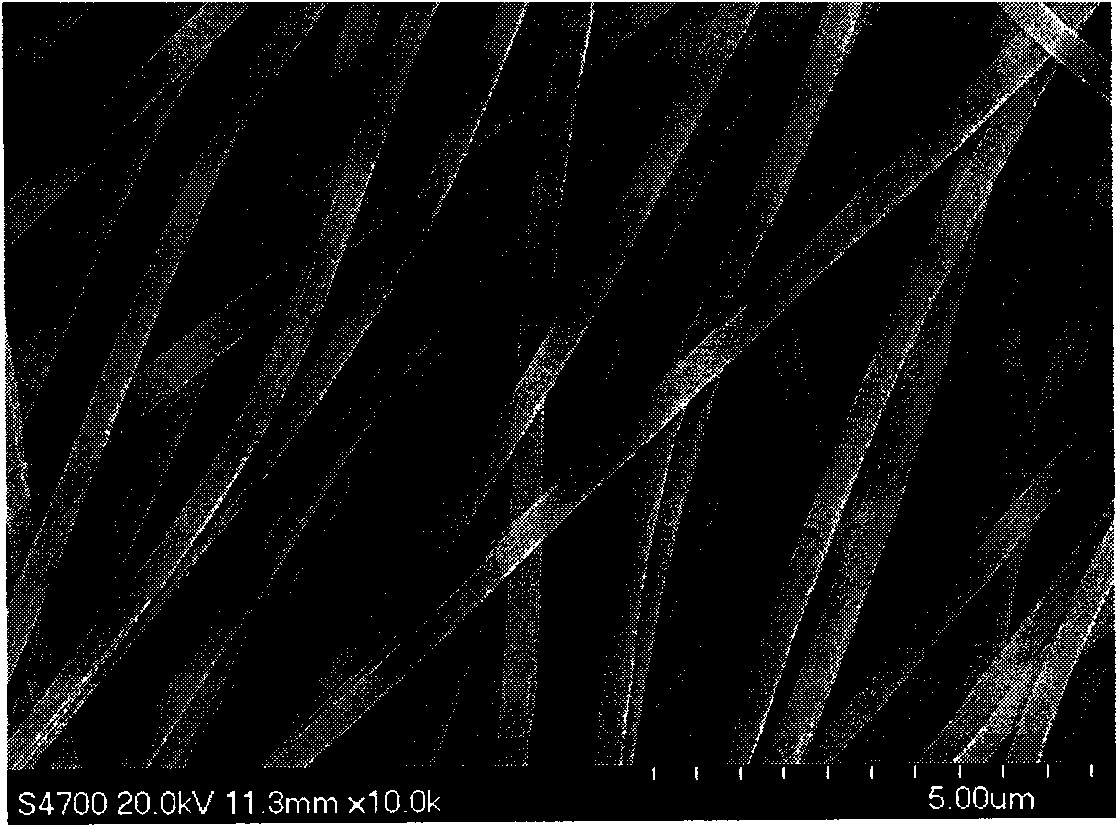

Stannum and carbon composite nano-fiber film negative-electrode material and preparation method thereof

ActiveCN101626075AExcellent discharge performance and charge-discharge cycle stabilitySimple configuration processElectrode manufacturing processesSolventCarbon composites

The invention relates to stannum / carbon nano-fiber composite film material used in the negative electrode of a lithium ion battery and a preparation method thereof and also provides an assembly method of the stannum / carbon nano-fiber composite film material generated according to the preparation method and used as the electrode of the lithium ion battery. The preparation method comprises the following steps: preparing an uniform spinning solution by mixing a stannum precursor compound, a solvent, a precursor polymer of carbon nano-fibers and an organic solvent together; obtaining a polymer nano-fiber film by electro spinning according to a suitable electrostatic spinning technology; and obtaining a stannum / carbon nano-fiber composite film used in the negative electrode of the lithium ion battery through final treatment technologies, such as preoxidation, carbonization, and the like, thereby effectively collaborating the electrochemical performance of stannum / carbon nano-fibers and improving the specific capacity, the first charge-discharge efficiency and the cycle performance of the lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

Non-aqueous electrolyte battery and charging method therefor

InactiveUS6316145B1Improve efficiencyLow efficiencyNegative electrodesSolid electrolyte cellsDischarge efficiencyTitanium oxide

In a non-aqueous electrolyte battery using titanium oxide or lithium titanate as a negative electrode material for negative electrode, polymeric electrolyte is interposed between the negative electrode and a positive electrode. If titanium oxide or lithium titanate is used as the negative electrode material for negative electrode and the polymeric electrolyte is interposed between the negative electrode and the positive electrode, the polymeric electrolyte is less liable to be decomposed by catalytic reduction induced by titanium oxide or lithium titanate. This prevents decline in the charge / discharge efficiency which occurs when a non-aqueous electrolyte solution is used. Thus, the non-aqueous electrolyte battery excellent in charge / discharge efficiency is provided.

Owner:SANYO ELECTRIC CO LTD

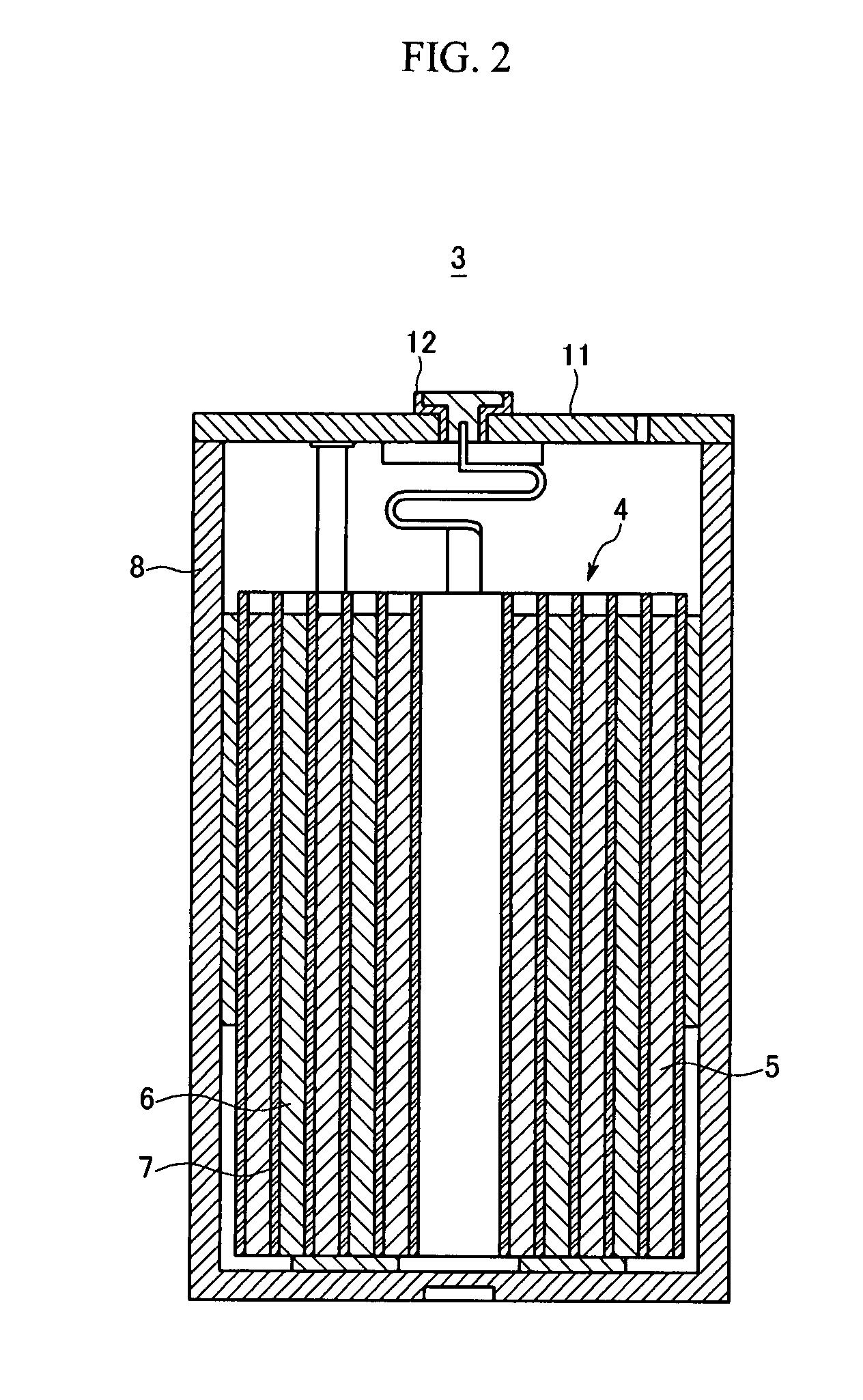

Anode and method of manufacturing the same, and secondary battery

ActiveUS20090111020A1Increase battery capacityExcellent cycle characteristicsAlkaline accumulatorsElectrode manufacturing processesDischarge efficiencySilicon

An anode and a secondary battery capable of improving the charge and discharge efficiency are provided. The anode includes an anode current collector, and an anode active material layer provided on the anode current collector. The anode active material layer has a plurality of anode active material particles containing at least one of a simple substance of silicon, a compound of silicon, a simple substance of tin and a compound of tin, and has a coat containing an oxo acid salt in at least part of the surface of the anode active material particles.

Owner:MURATA MFG CO LTD

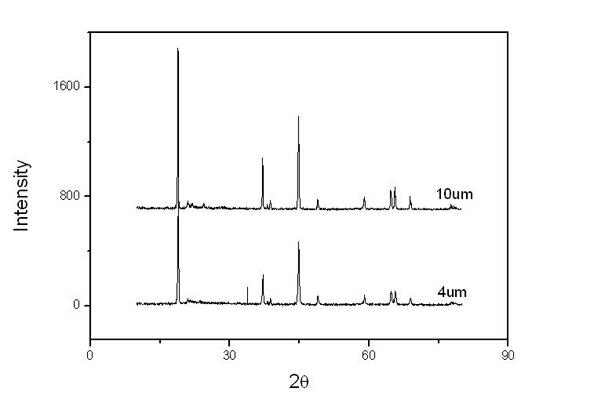

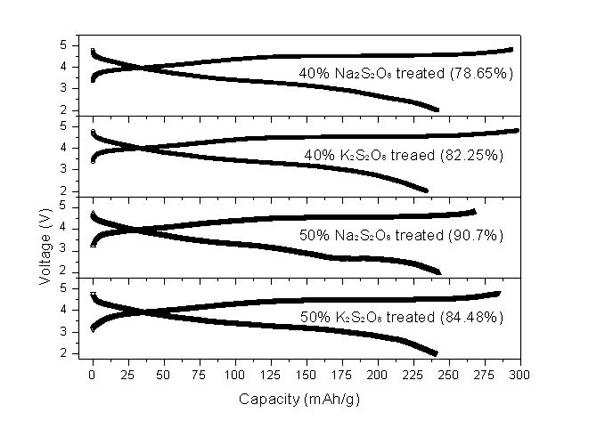

Synthesis and surface modification method of lithium excessive laminar oxide anode material

The invention relates to a synthesis and surface modification method of a lithium rich anode material Li1+xM1-xO2 (M is one or more of Ni, Co and Mn, and X is more than or equal to 0 and less than or equal to 1 / 3) for a lithium ion battery. The method comprises the following steps of: synthesizing a precursor by using a carbonate precipitation method, mixing the precursor and a lithium salt, and calcining for 2 to 20 hours at the temperature of between 800 and 1,100 EG C to obtain a lithium rich material, wherein the prepared lithium rich material has controllable particle size and higher reversible capacity; and dissolving persulfate or sulfate in an amount which is 5 to 80 mass percent of the lithium rich material into deionized water, adding the lithium rich material, stirring for 2 to 100 hours at the temperature of between 25 and 80 DEG C, heating the materials to the temperature of between 100 and 500 DEG C in a muffle furnace, calcining the materials for 2 to 20 hours, fully filtering the obtained materials, and washing off impurities to obtain the surface modified anode material Li1+x-yM1-xO2. The synthesized lithium rich material has controllable particle size; the first charge / discharge efficiency of the lithium rich material and the discharge specific capacity and the cyclical stability under high magnification can be improved; and the method is simple, low in cost, convenient for operation and suitable for industrialized production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

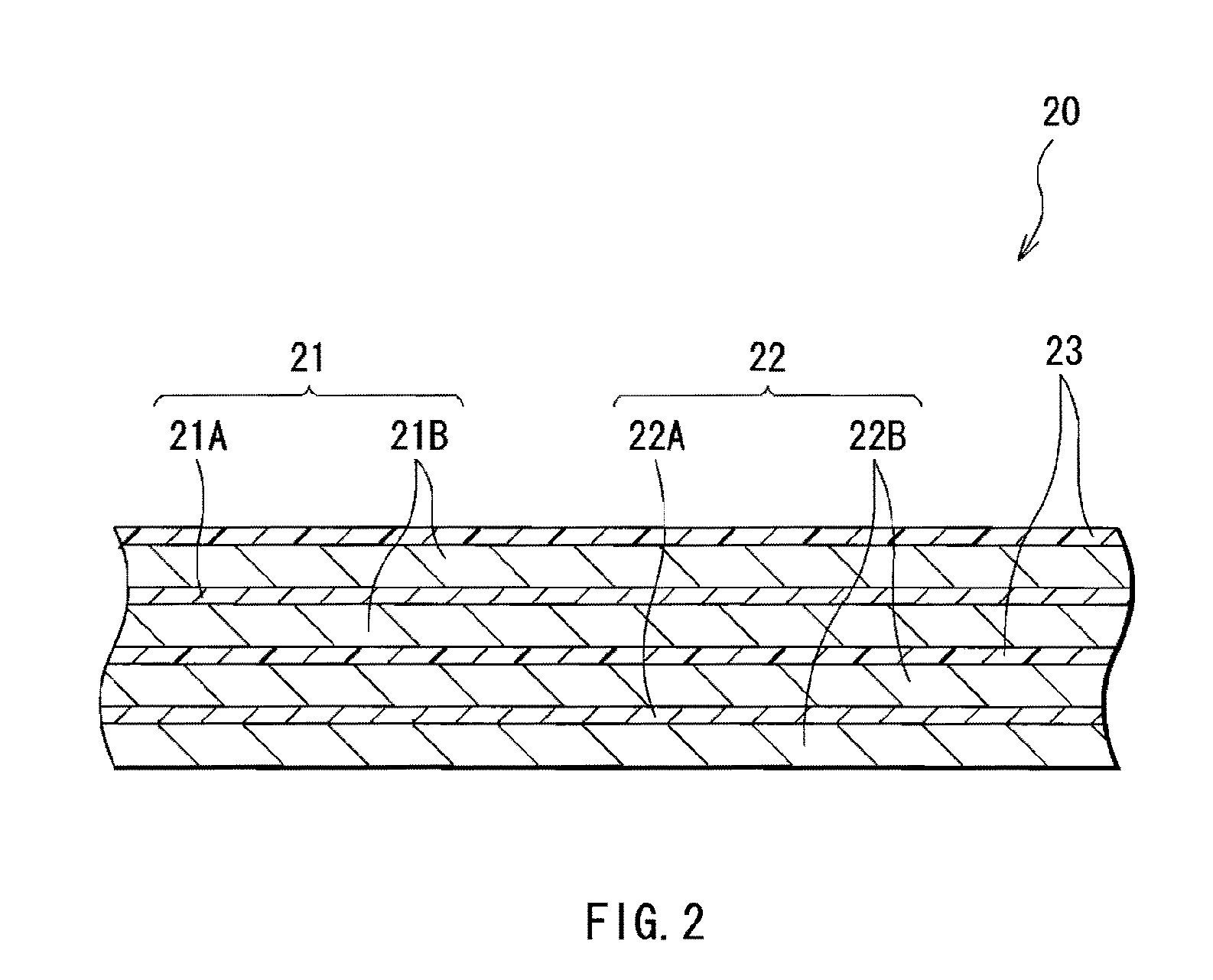

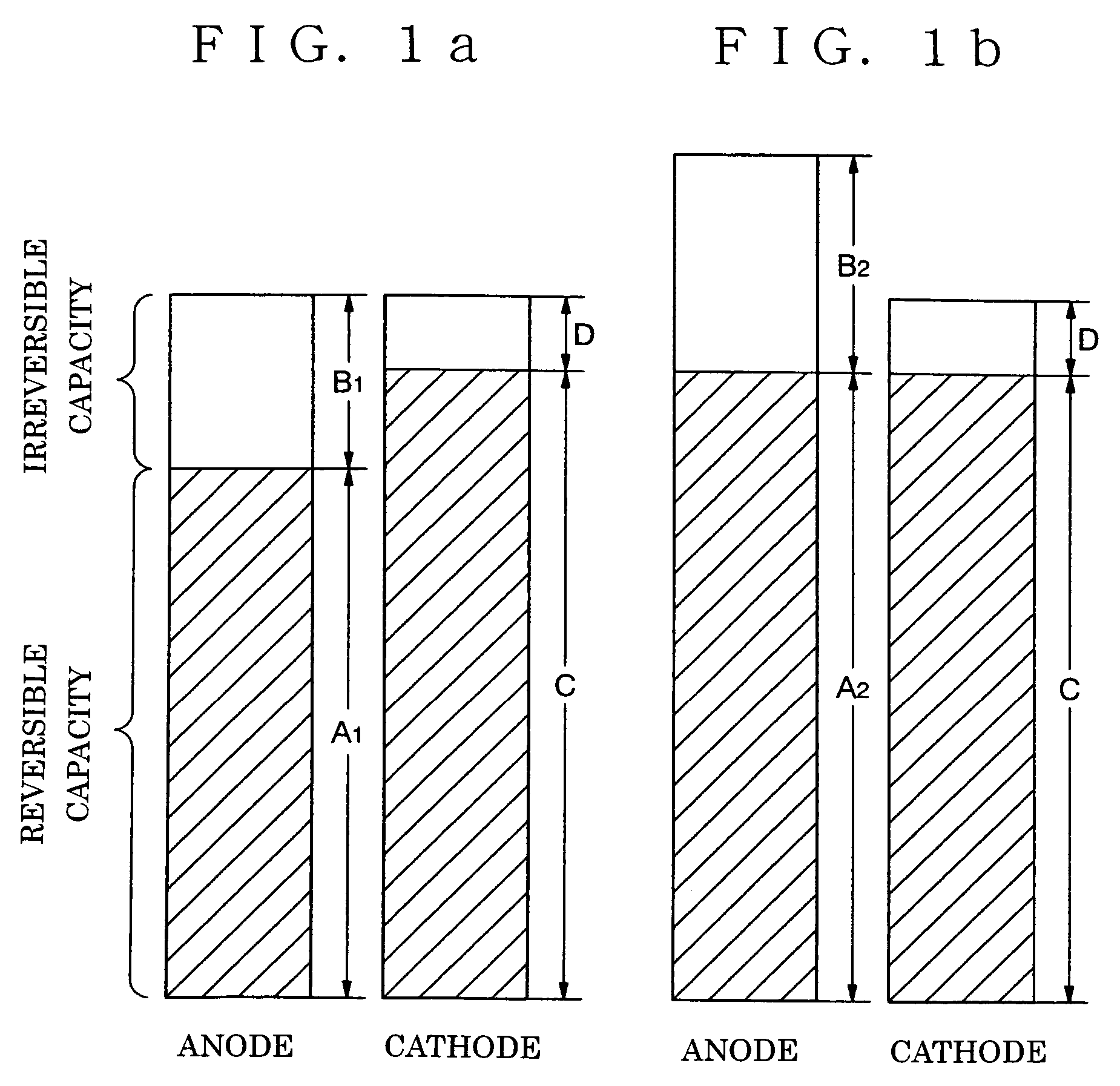

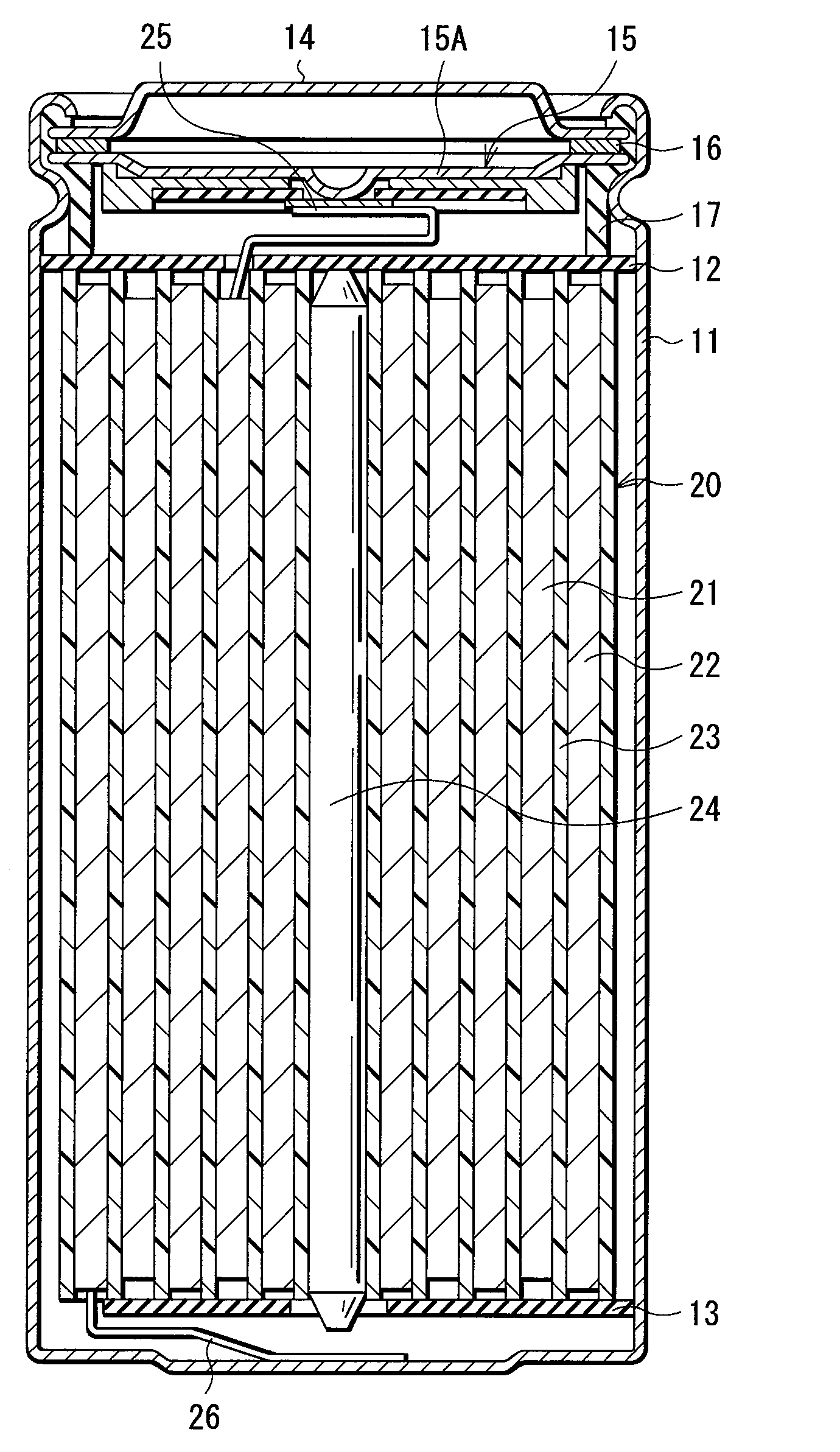

Anode for secondary battery, secondary battery using same and method for fabricating anode

InactiveUS7202000B2Efficiently irreversible capacityImprove breathabilityVacuum evaporation coatingSputtering coatingDischarge efficiencyCharge discharge

An anode for a secondary battery capable of inserting and extracting a lithium ion having a multi-layered structure including a first anode layer containing carbon as a main component; a second anode layer made of a film-like material through which a lithium component passes; and a third anode layer containing lithium and / or a lithium-containing compound as a main component. The battery capacity of the lithium ion battery is substantially increased while the higher charge-discharge efficiency and the stable cycle performance are maintained.

Owner:NEC CORP

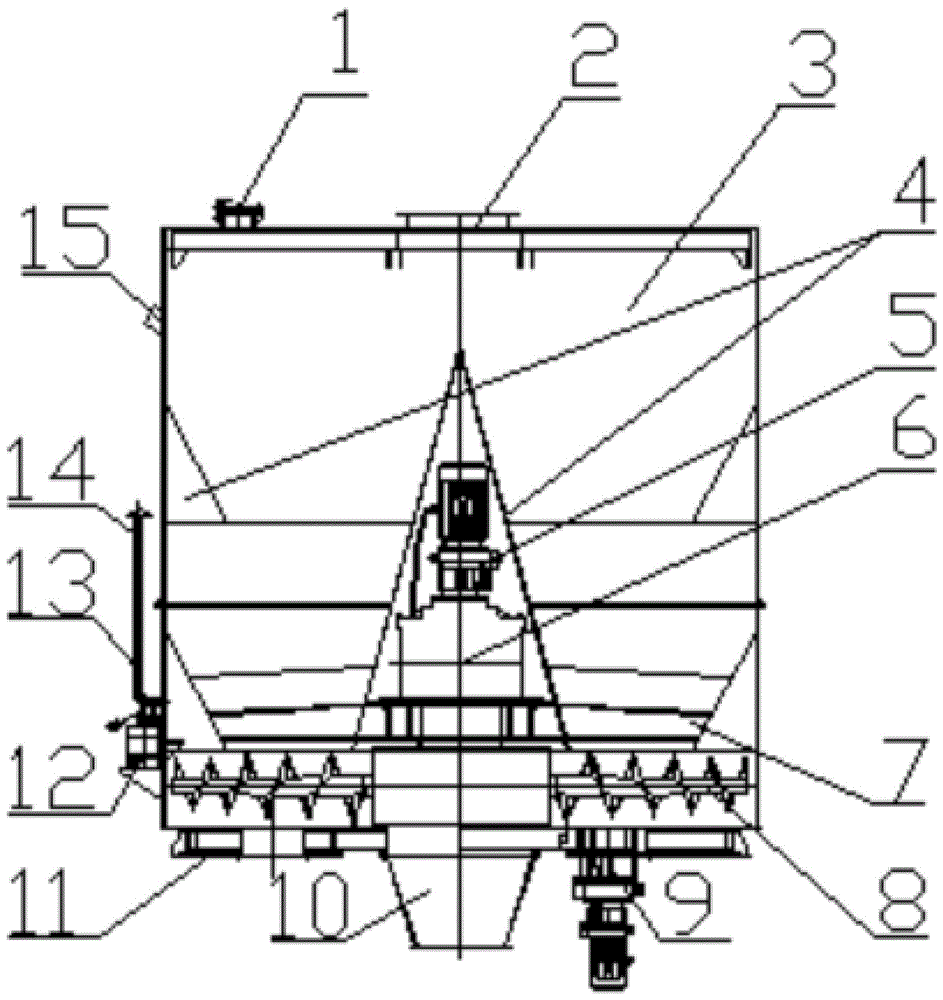

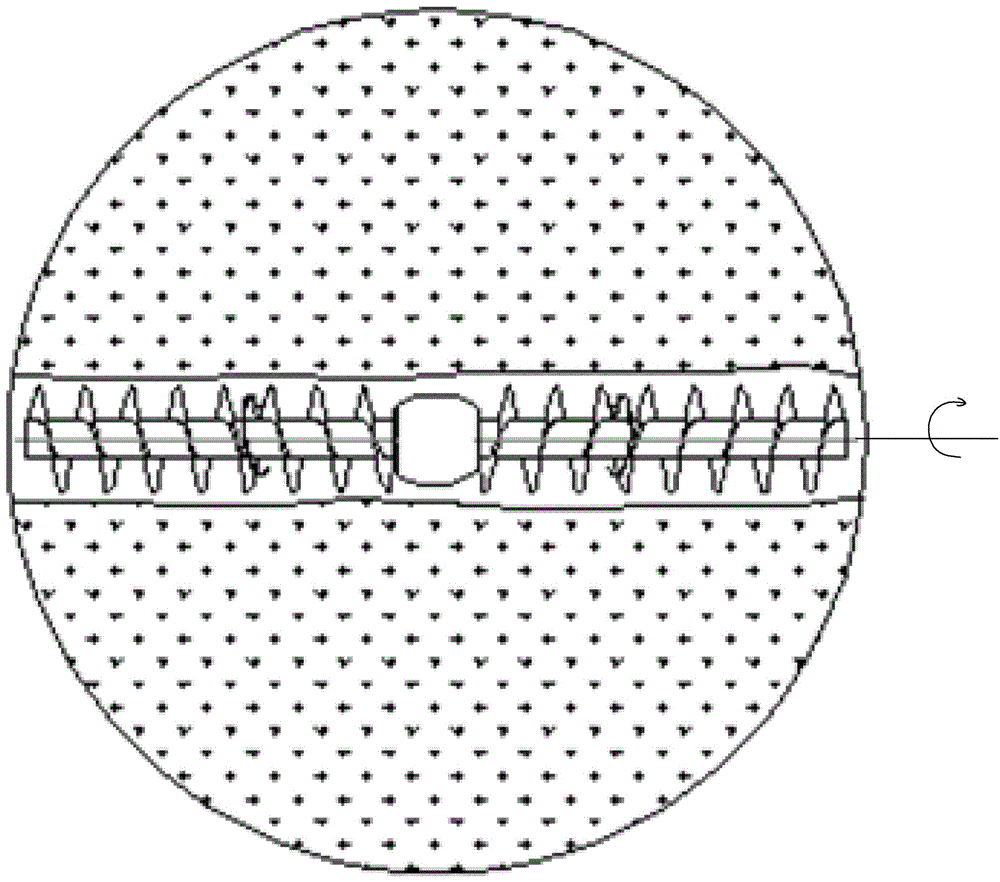

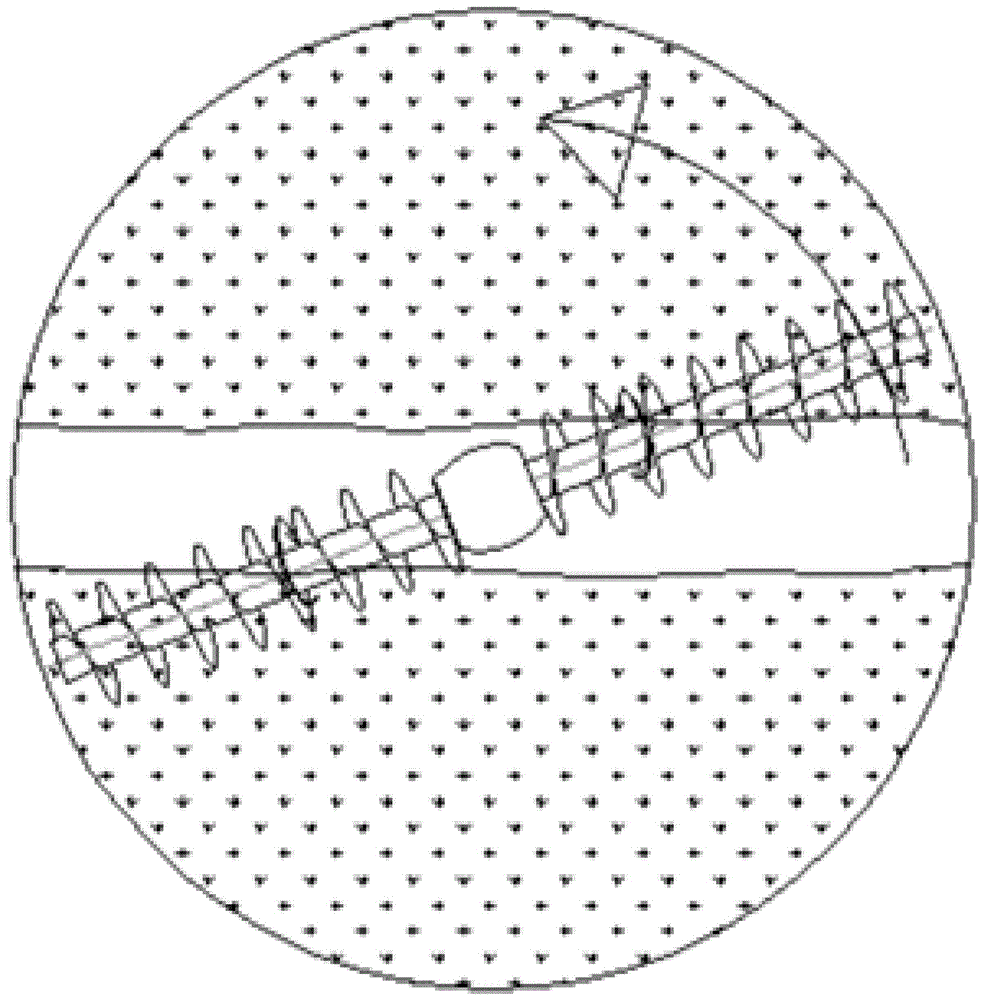

Traversing spiral discharge device for stock bin and discharging method

InactiveCN105883433ATraversal guaranteeGuaranteed uptimeLarge containersLoading/unloadingDischarge efficiencyEngineering

The invention relates to a traversing spiral discharge device for a stock bin and a discharging method. The traversing spiral discharge device comprises a round stock bin, wherein the round stock bin is fixed at the top of a mounting base; a feeding opening is formed in the center of the top of the round stock bin; an access door is arranged on a side edge of the feeding opening; a pressure relief cone cover is mounted inside the round stock bin; a primary rotating motor is mounted inside the pressure relief cone cover; the primary rotating motor and a transmission case are connected with each other and drive a spiral shaft to rotate along the axis of the spiral shaft; a discharging opening is formed in the bottom of the round stock bin; a rotational transmission system is fixedly mounted on a mounting base on the side edge of the discharging opening; the rotational transmission system drives the spiral shaft to conduct 360-degree rotational motion along the axis of the round stock bin. The traversing spiral discharge device is capable of facilitating material delivery, effectively preventing a charging basket from being blocked, boosting discharge efficiency, ensuring discharge safety and reducing the intensity of manual operation.

Owner:HUBEI YIDU YUNJI MEC & ELEC CO LTD

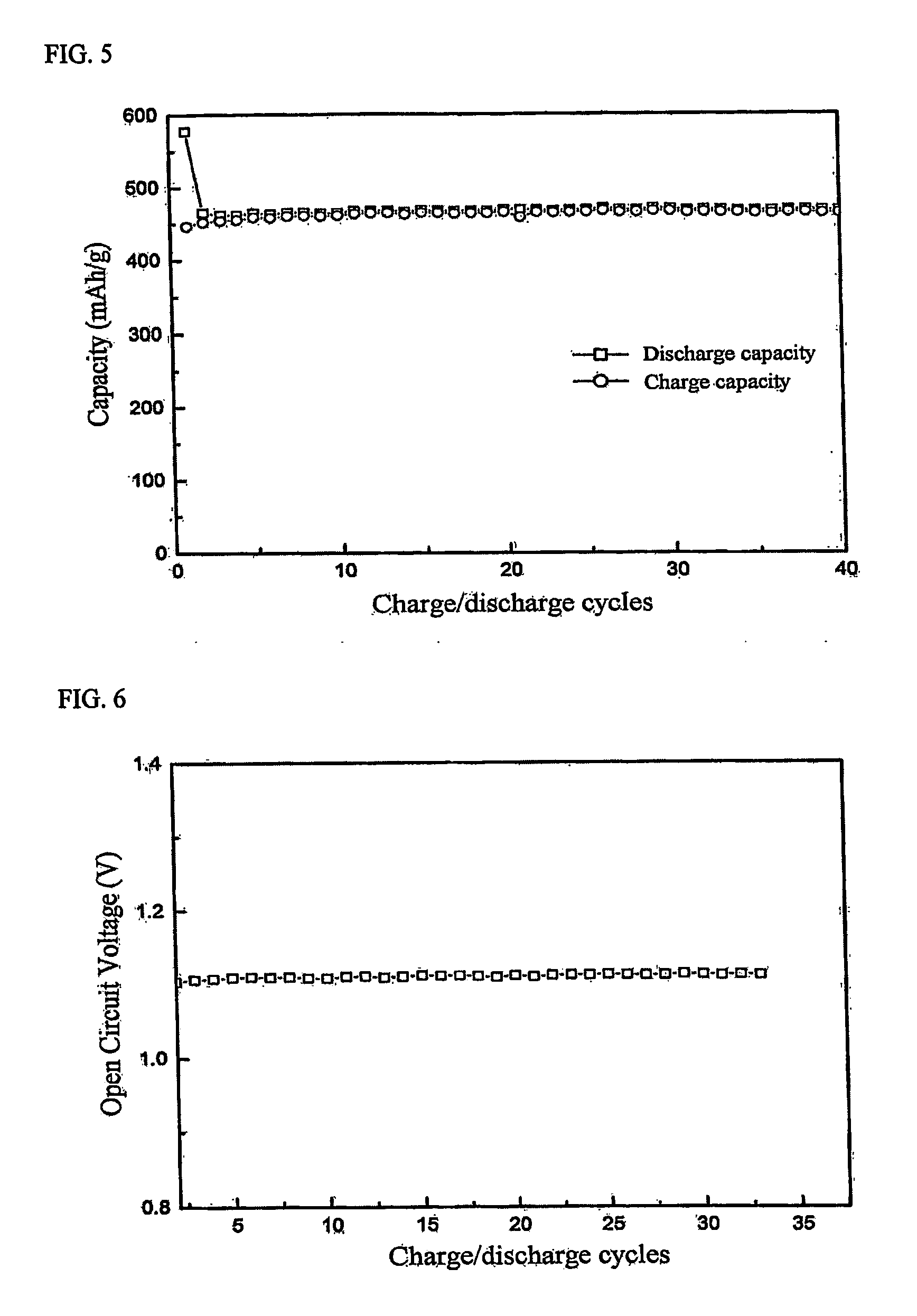

Preparation and application of lithium battery silicon-carbon composite material taking synthetic graphite as carrier

ActiveCN103346305AImprove integrity and compactnessSmall apertureCell electrodesCarbon sourceCarbon composites

The invention provides preparation and application of a lithium battery silicon-carbon composite material taking synthetic graphite as a carrier. The preparation method comprises the following steps of: dissolving nanometer silicon and synthetic graphite in a dispersant to obtain a uniform dispersion liquid, adding an organic carbon source, stirring uniformly to obtain a mixed liquid, feeding the mixed liquid into a closed circulation spray dryer to prepare composite precursor powder, pre-sintering for 3-10 hours at the temperature of 300-700 DEG C to obtain a silicon-carbon composite material subjected to primary carbon cladding; and further dissolving the silicon-carbon composite material subjected to primary carbon cladding with the organic carbon source in a dispersant, stirring to obtain a uniform mixed liquid, feeding the uniform mixed liquid into a second closed circulation spray dryer to prepare composite powder, and heating the powder for 6-18 hours at the temperature of 700-1000 DEG C, so as to obtain the lithium battery silicon-carbon composite material taking synthetic graphite as a carrier. The lithium battery silicon-carbon composite material prepared by the invention shows such excellent electrochemical properties as high first charge-discharge efficiency, high specific capacity and good cycle performance after being applied to a lithium battery.

Owner:中国有色桂林矿产地质研究院有限公司

Hard carbon negative electrode material of lithium ion battery, preparation method and application of hard carbon negative electrode material

InactiveCN102820455AIncrease capacityImprove the first Coulombic efficiencyCell electrodesDischarge efficiencyPhysical chemistry

The invention relates to a hard carbon negative electrode material of a lithium ion battery, and a preparation method and application of the hard carbon negative electrode material. The hard carbon negative electrode material is doped with silicon and phosphorus, wherein the mass ratio of silicon precursor, phosphorus precursor and hard carbon precursor is 1:(0.1 to 5):(5 to 30). Due to the addition of silicon / phosphorus, the hard carbon negative electrode material provided by the invention is remarkably improved in the first discharge capacity (up to 550.8mAh / g), the first charge / discharge efficiency (up to 80.9%) and the first coulombic efficiency by doping, is remarkably reduced in the irreversible capacity, and has the advantages of excellent cycle performance and rate capability, good PC (poly carbonate) consistency and high PC resistance, wherein the capacity retention ratio is above 95% after discharge cycle for 100 weeks at a high discharge rate of 10C.

Owner:天津市贝特瑞新能源科技有限公司

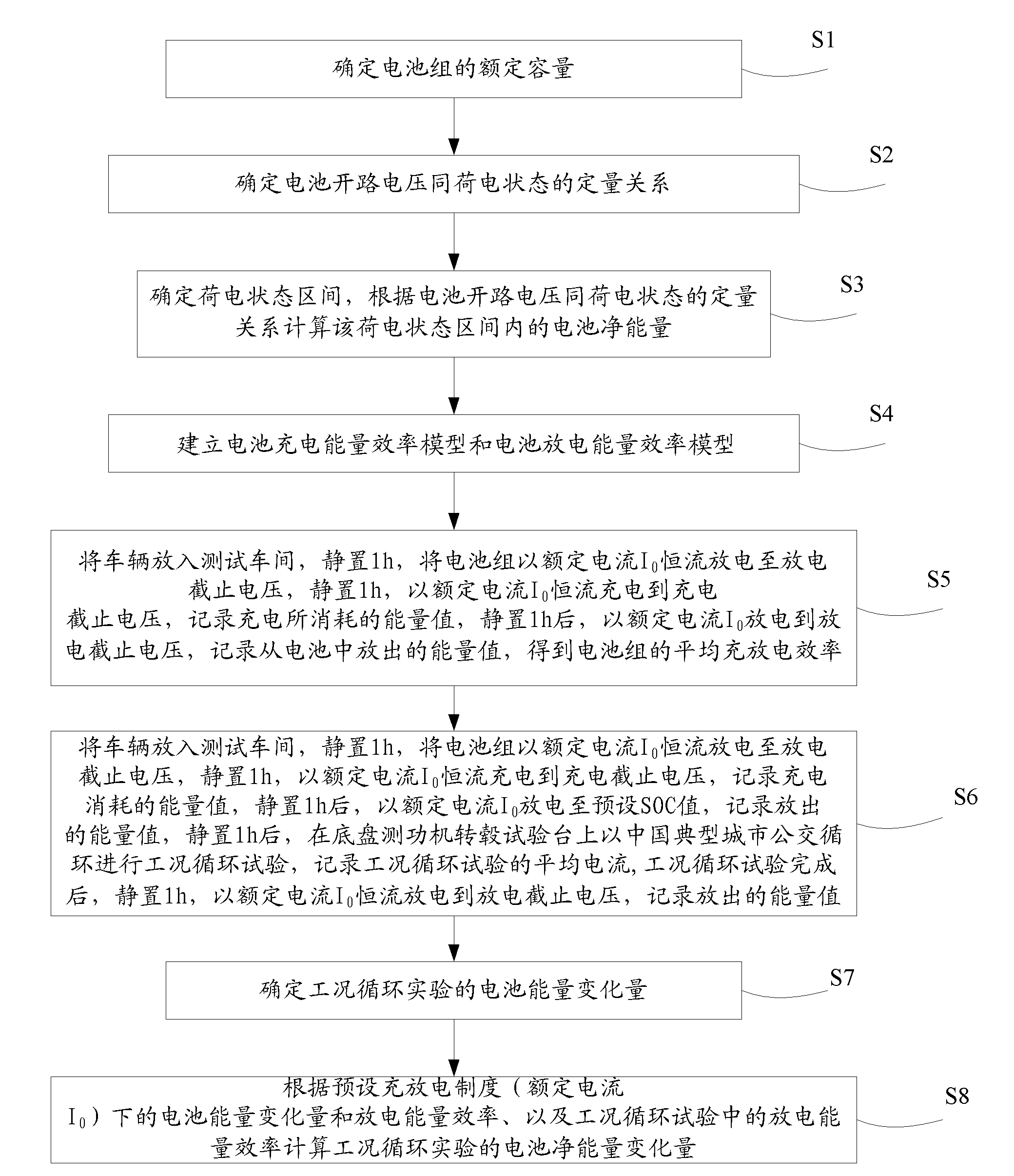

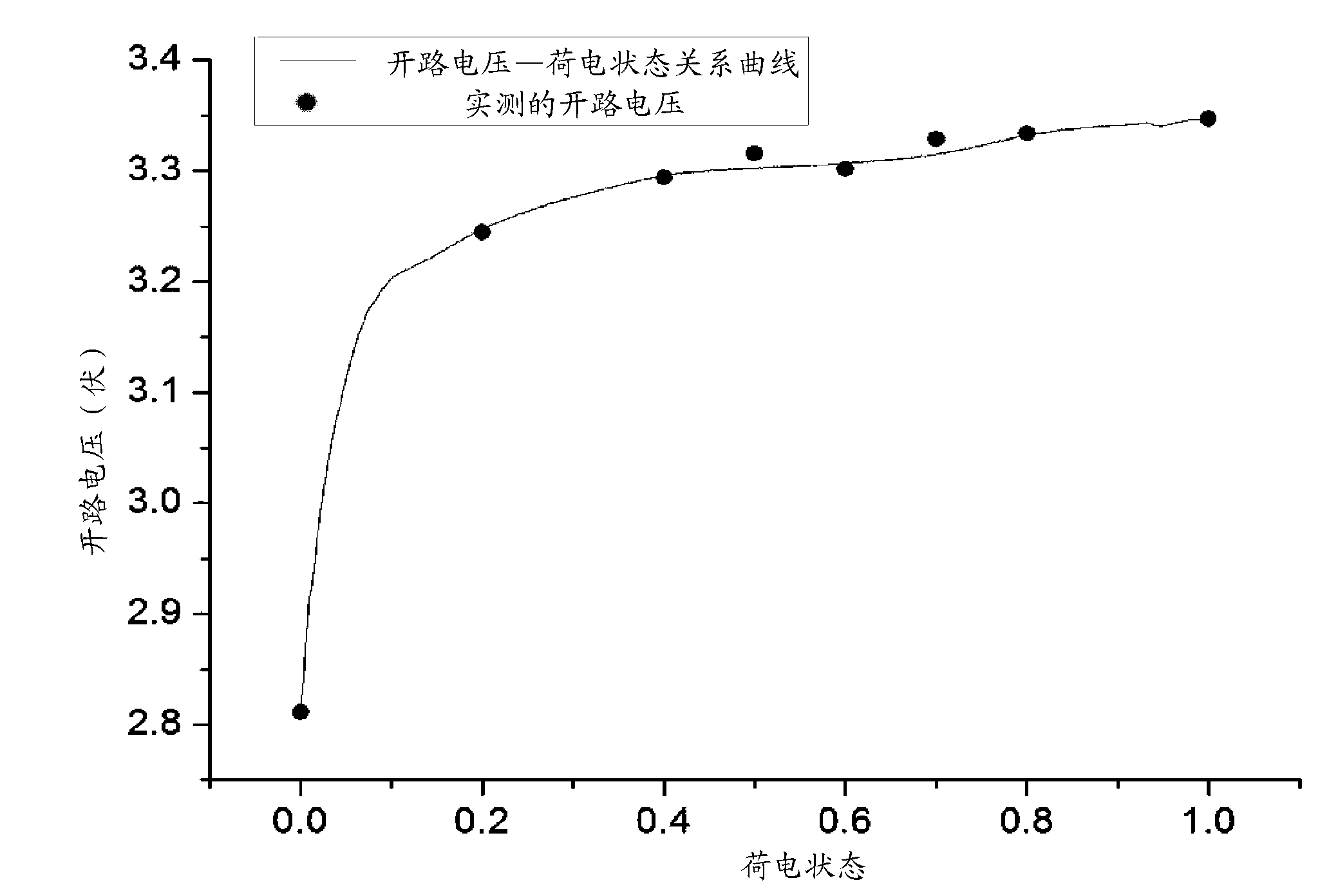

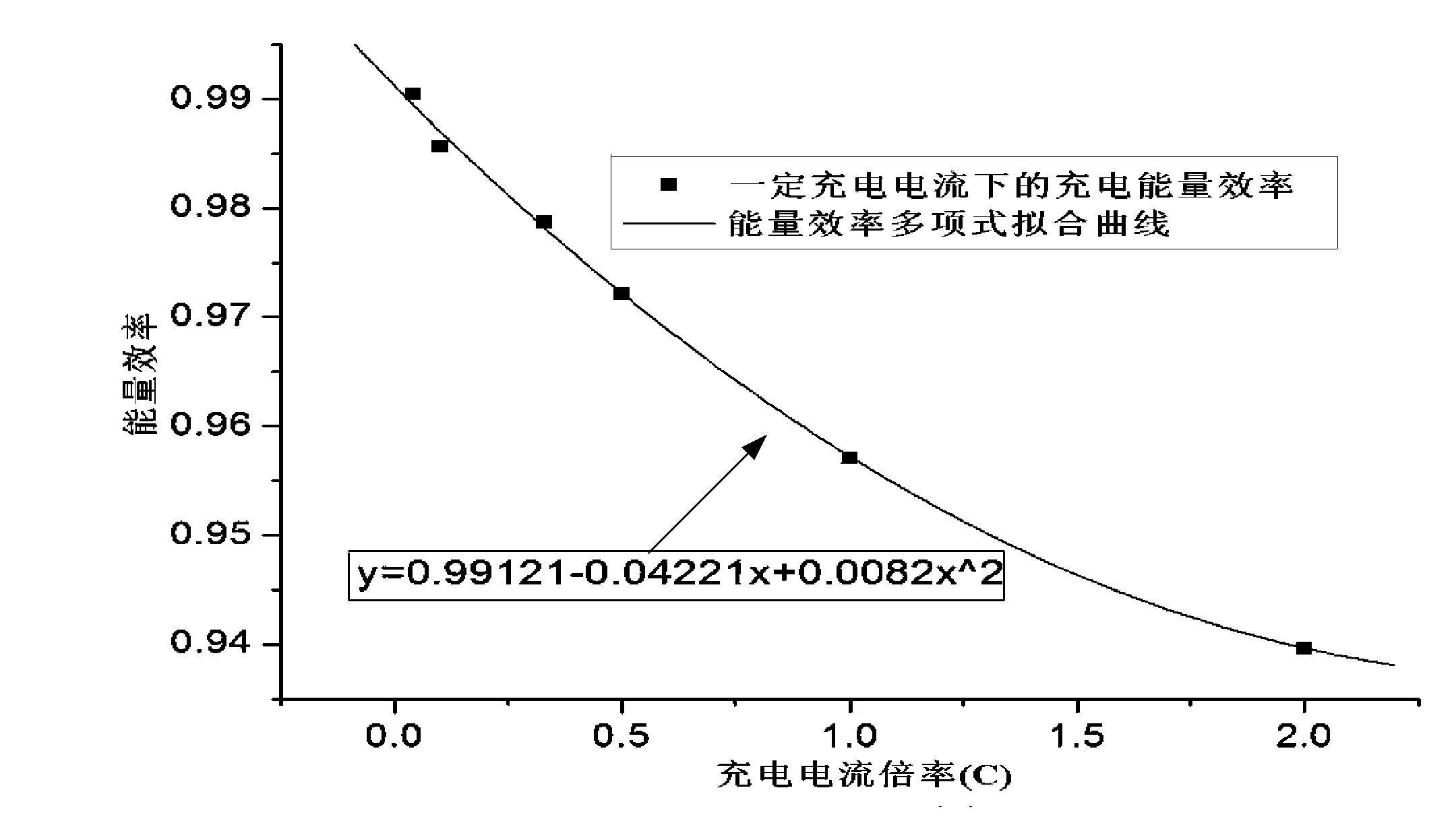

Method for testing net energy of electrical vehicle power battery

ActiveCN102121973AImprove accuracySimple test methodElectrical testingDischarge efficiencyEnergy variation

The invention discloses a method for testing net energy of an electrical vehicle power battery, which comprises the following steps of: charging a battery set in a state of discharging stop voltage to the state of charging stop voltage, recording the charged energy, discharging the battery set to a pre-set SOC by the stated current, recording the energy discharged at the first time, and then performing a working situation circulation test to the electrical vehicle, discharging the battery set to the discharging stop voltage by the stated current when the test is finished, recording the energy discharged at the second time, obtaining the energy change amount of the battery in the working situation circulation test according to the average charging and discharging efficiency of the battery set, correcting the energy change amount of the battery in the working situation circulation test according to the battery charging and discharging energy efficiency models, and obtaining the energy actually stored by the battery in the working situation circulation process, namely the battery net energy. The method considers the effect to battery net energy of charging and discharging efficiencies on one hand with high testing accuracy, and only tests the charging and discharging energies of the electrical vehicle before and after the test on the other hand, which is easy to be realized.

Owner:WUHAN UNIV OF TECH +1

Modified positive electrode material of lithium ion battery and preparation method of modified positive electrode material

InactiveCN102738451AImprove performanceImproved performance characteristicsCell electrodesDischarge efficiencyElectrical conductor

The invention discloses a modified positive electrode material of a lithium ion battery and a preparation method of the modified positive electrode material. The modified positive electrode material is characterized in that the modified positive electrode material is made of a lithium fast ion conductor and a positive electrode material of lithium ion battery at a molar ratio of n:1, wherein n is larger than 0 and not larger than 0.15. The invention also discloses the preparation method of the modified positive electrode material of the lithium ion battery. The modified positive electrode material provided by the invention is improved in conductivity property performance and surface properties, thereby enhancing the specific volume of the lithium ion battery, and improving the charging-discharging efficiency, rate capacity, cycling performance and temperature adaptability of the lithium ion battery.

Owner:HENAN NORMAL UNIV

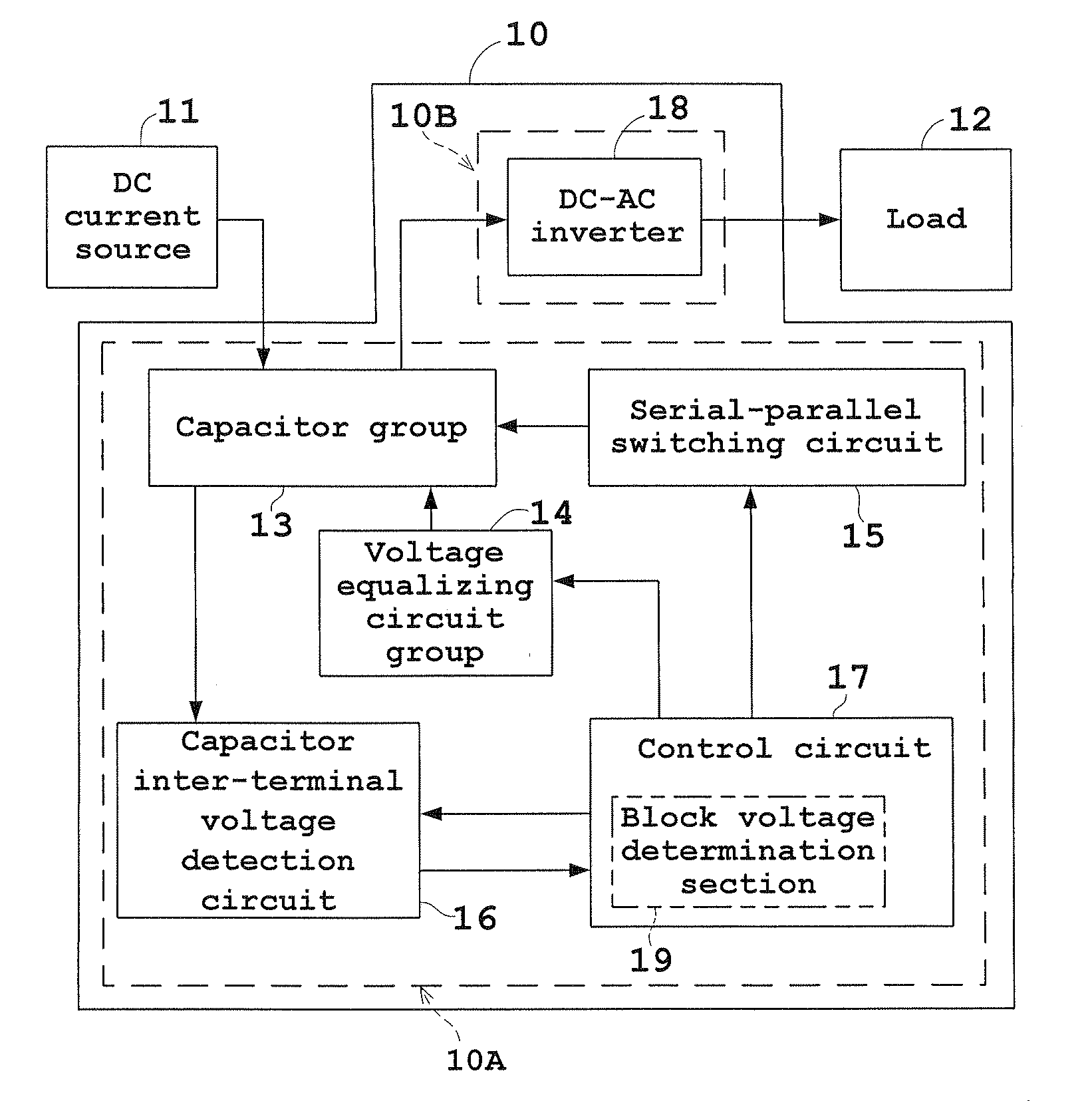

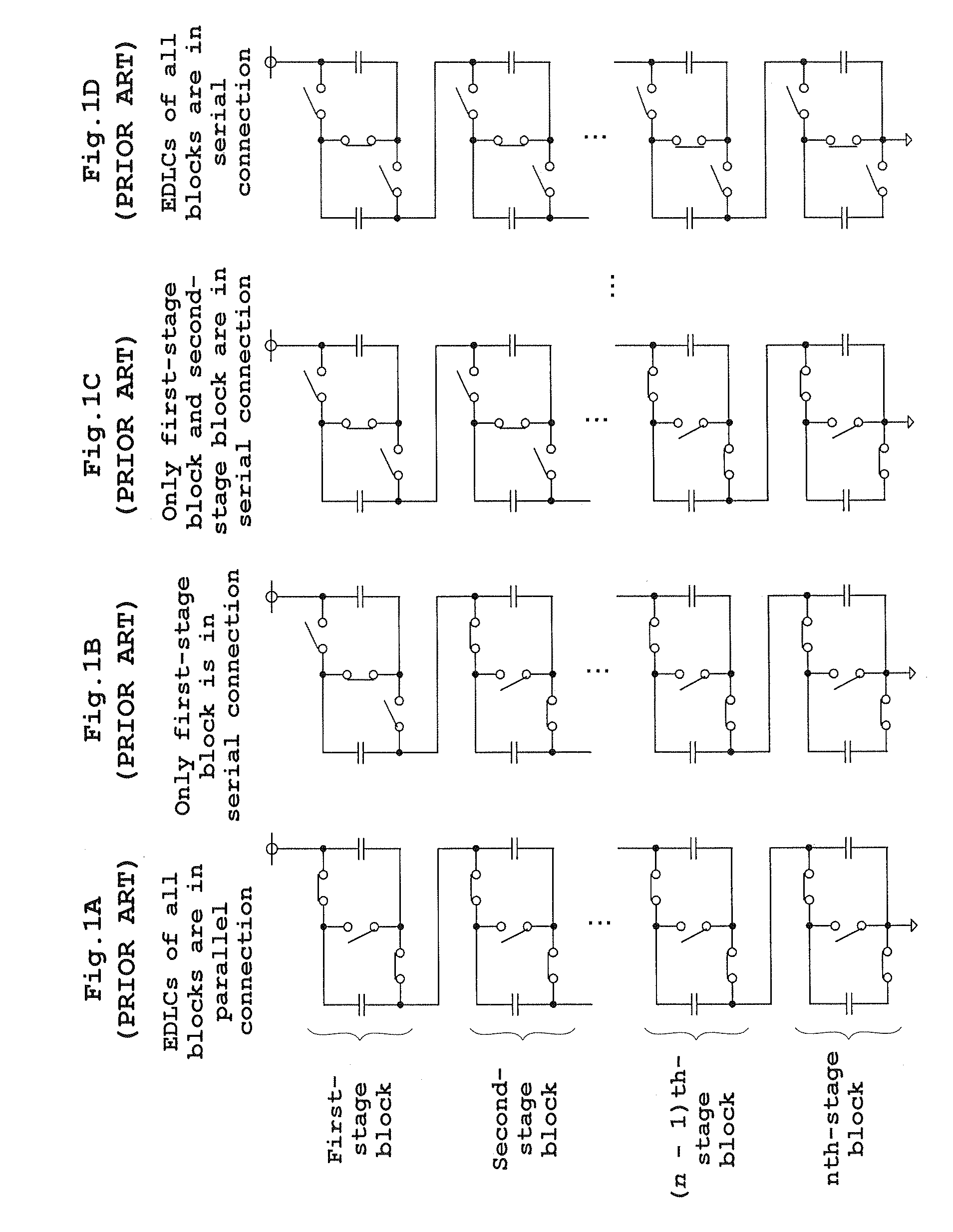

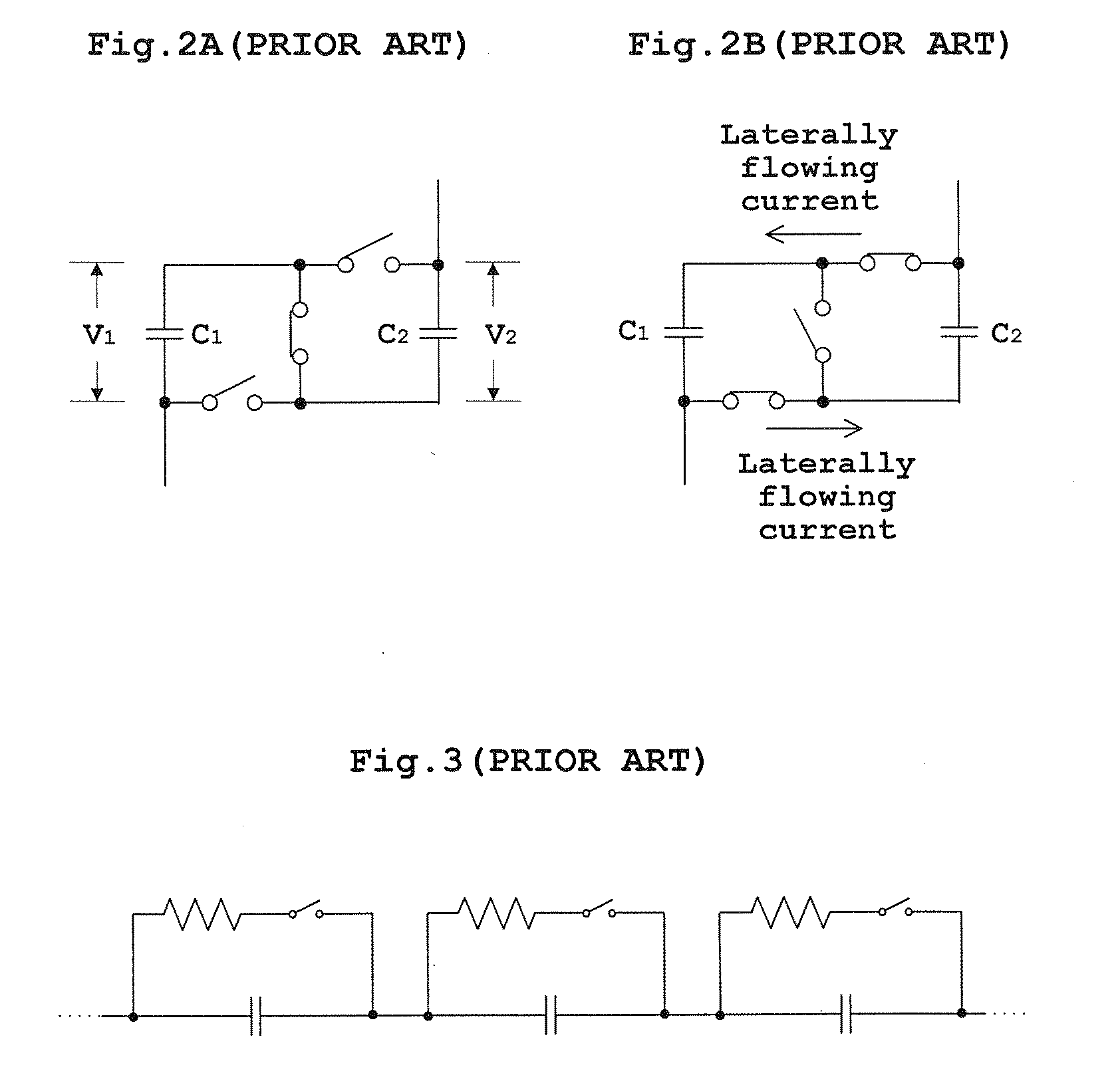

Electric power storage system using capacitors and control method thereof

InactiveUS20090134851A1High voltageSignificantly affecting the charging/discharging characteristicsHybrid capacitorsParallel/serial switchingDischarge efficiencyElectricity

In an electric power storage system according to the present invention, in the case of charging, a plurality of capacitors of each circuit block of the electric power storage system are switched to a serial connection to initiate the charging. When the output voltage of power storage means reaches the maximum input voltage of DC-AC conversion means, each capacitor of a number j of circuit blocks is switched to a parallel connection in order of higher block voltage. Also up to the time when the maximum input voltage is reached again, each capacitor of a number j of circuit blocks is switched to a parallel connection in order of higher block voltage. In the case of discharging, pluralities of capacitors of each circuit block of the electric power storage system are switched to a parallel connection to initiate the discharging. When the output voltage of power storage means reaches the minimum input voltage of DC-AC conversion means, each capacitor of a number k of circuit blocks is switched to a serial connection in order of higher block voltage. Also up to the time when the minimum input voltage is reached gain, each capacitor of a number k of circuit blocks is switched to a serial connection in order of higher block voltage. Accordingly, the electric power storage system is hardly affected by the capacitance error of the capacitors, and charging / discharging efficiency can be improved.

Owner:LIMITED COMPANY TM

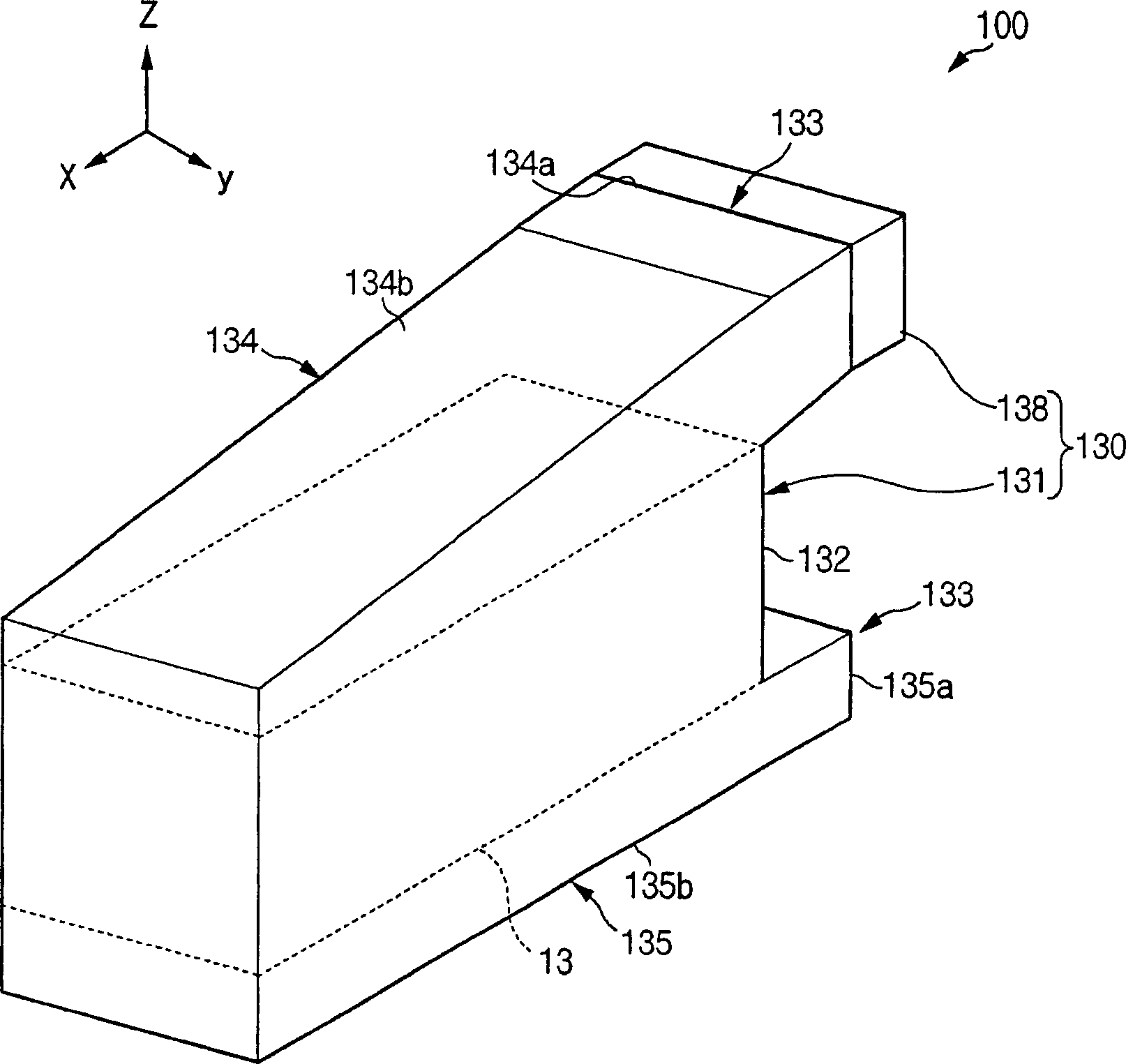

Rechargeable battery with nonaqueous electrolyte, its negative electrode, and its material

ActiveUS20090181304A1Improve discharge capacityHigh charge-discharge efficiencyVacuum evaporation coatingNegative electrodesDischarge efficiencyRechargeable cell

A negative electrode material for a nonaqueous electrolyte rechargeable battery that can stably and efficiently realize a high-performance nonaqueous electrolyte rechargeable battery in which a high discharge capacity, high charge / discharge efficiency at an initial stage and during charge / discharge cycles, and excellent charge / discharge cycle properties are provided as well as electrode expansion in volume after charge / discharge cycles is suppressed. The negative electrode material for a nonaqueous electrolyte rechargeable battery in the form of particles having, at least on the surface thereof, a compound of the phase in which an element Z is present in Si in a non-equilibrium state. The compound is expressed by the general formula SiZxMy, where Z represents C and / or N, M represents an element other than C and N, and when the concentration of the element Z in a compound SiaZp, where each of a and p is an integer, having a composition closest to that of Si and present in an equilibrium state is presumed to be 100 atomic percent, the concentration of the element Z in the compound SiZxMy is in the range of 10 to 95 atomic percent, and y is in the range of 0 to 0.5.

Owner:MITSUBISHI CHEM CORP

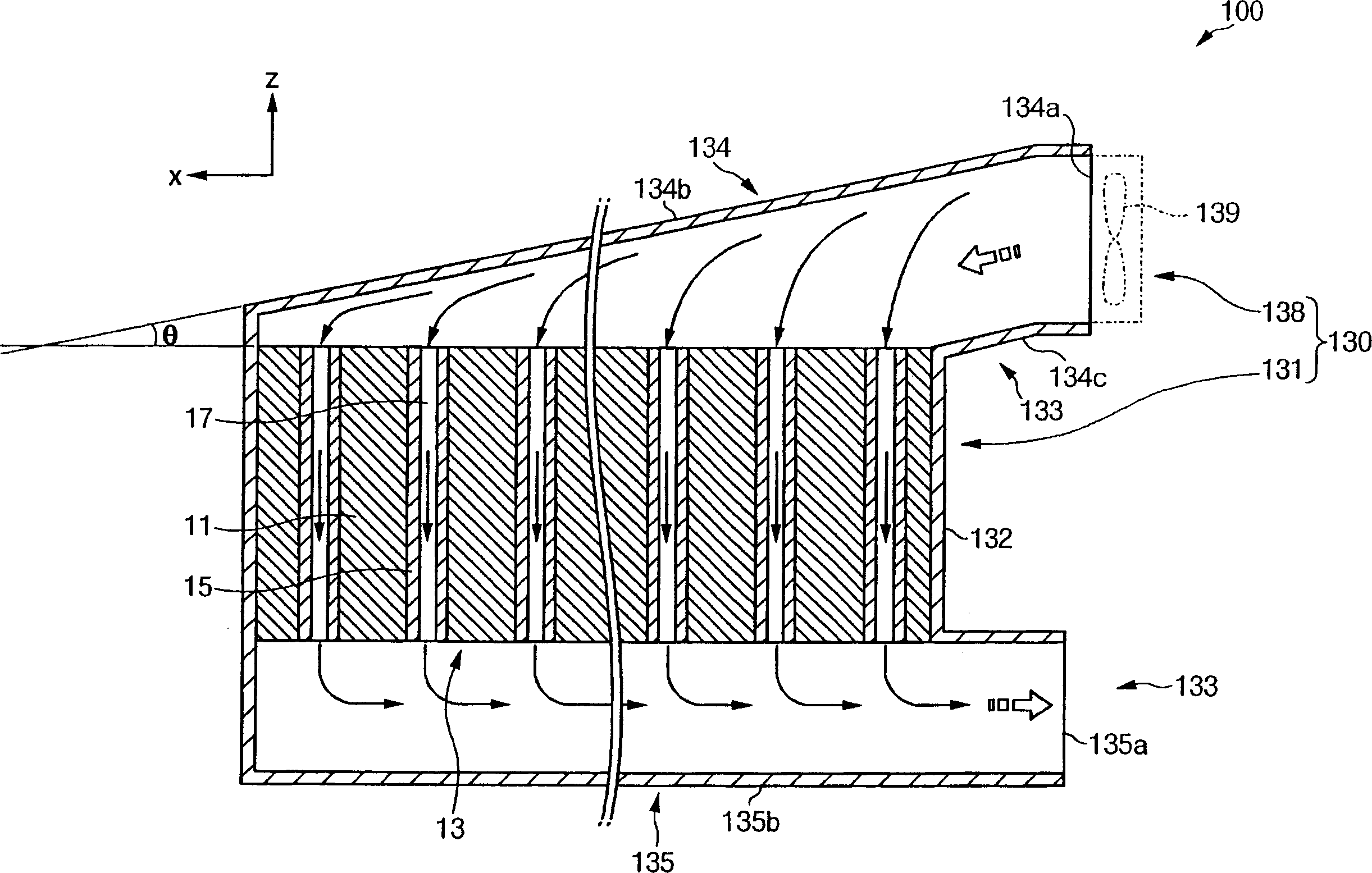

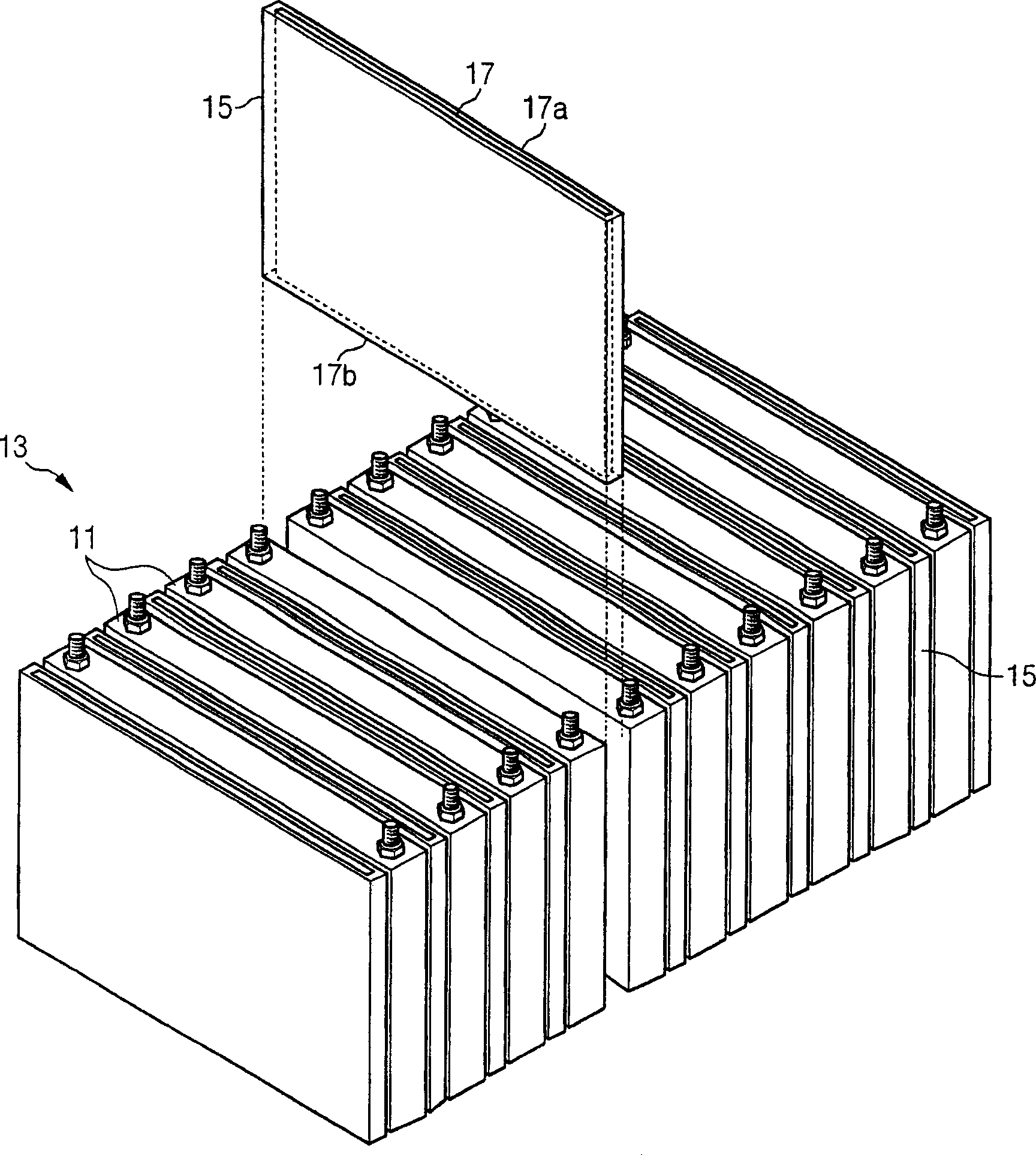

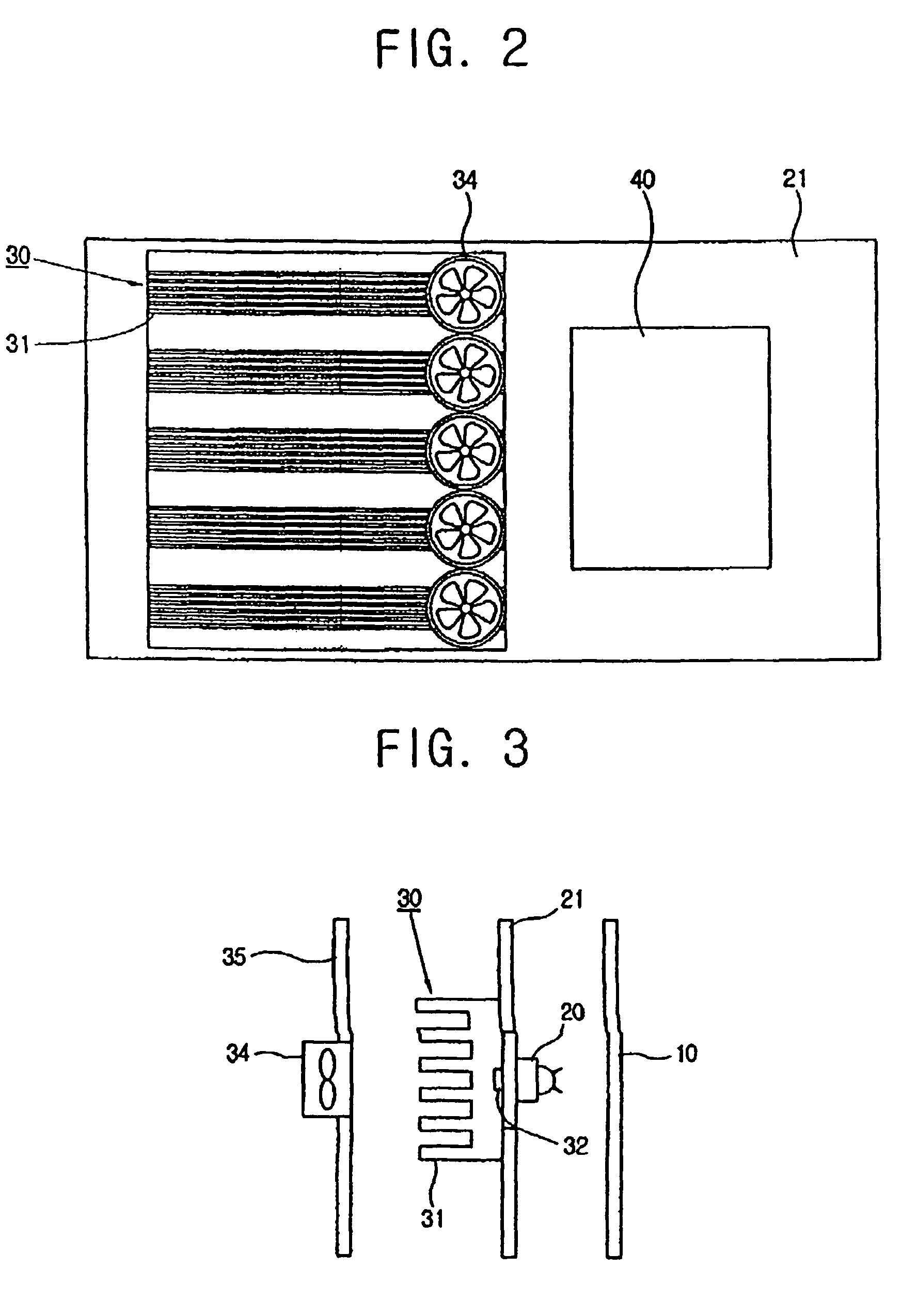

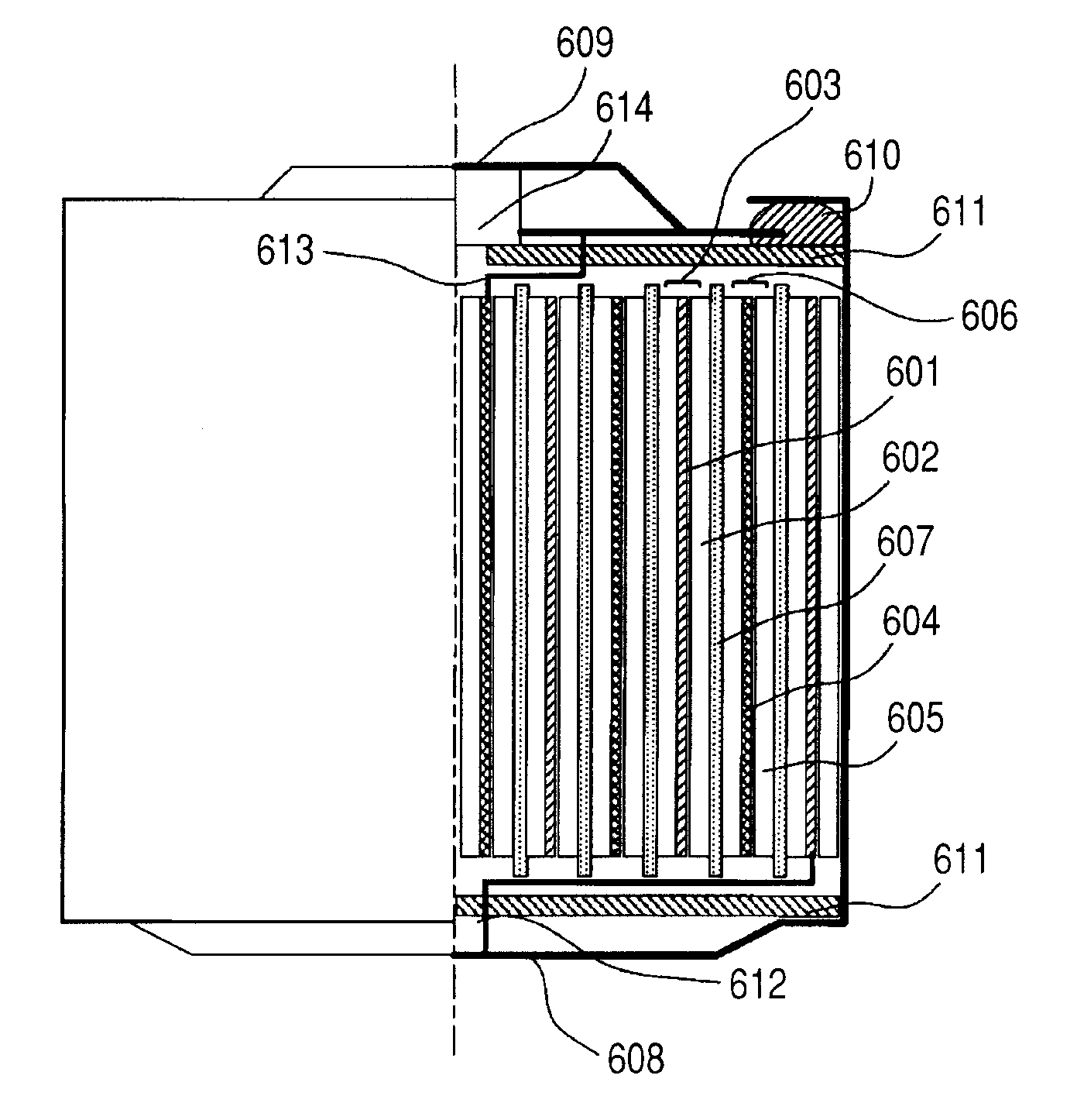

Battery module and cooling device for battery module

InactiveCN1812182AImproved air ventilation structureUniform temperature distributionFinal product manufactureSecondary cells manufactureDischarge efficiencyTemperature control

The invention discloses a battery module with a cooling system which enables the capacity of air which flows through each unit battery to be same. The battery module comprises a plurality of battery units which are separated mutually and a shell which is used to contain the battery units inside. The shell is provided with inclined inflow guiding sides which are vertical to the surfaces of a plurality of unit batteries, air inlets which are used to induce temperature control air and air outlets which are used to discharge the air which flows through the unit battery. Since the battery module of the invention is provided with an improved shell air ventilation structure, the capacity of air which is prearranged can be flowed through an air ventilation channel which is arranged between neighboring unit batteries, thereby the temperature on the whole region of unit battery components is distributed evenly, the cooling efficiency of the unit battery components can be optimum, and the charging and discharging efficiency of the battery module can be further increased.

Owner:SAMSUNG SDI CO LTD

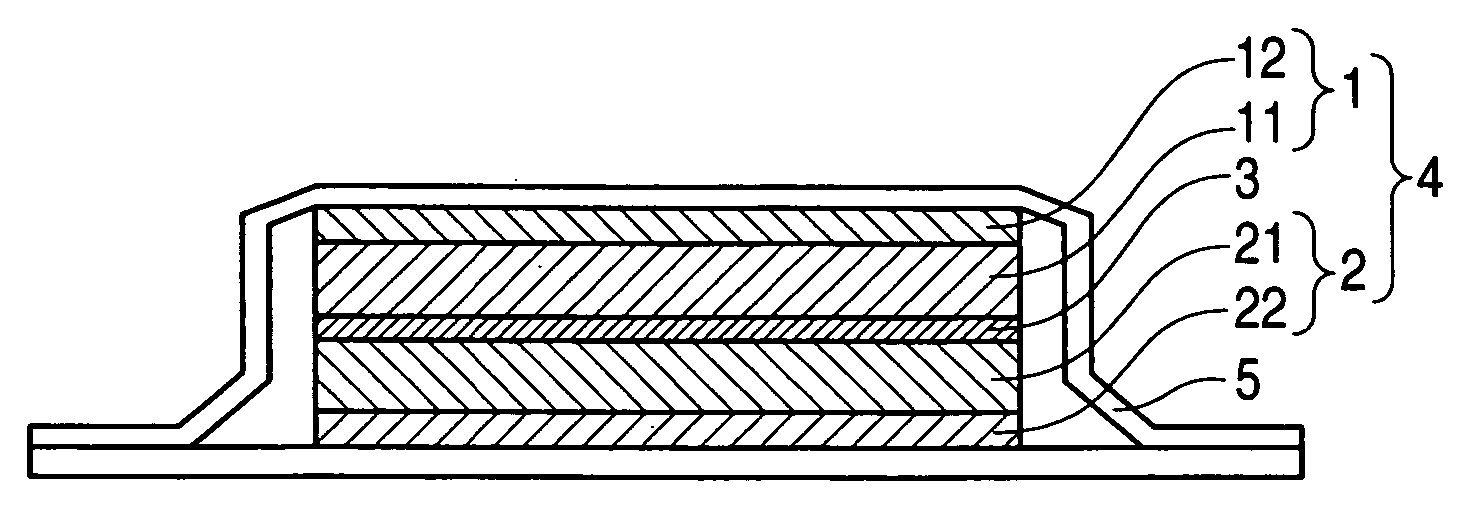

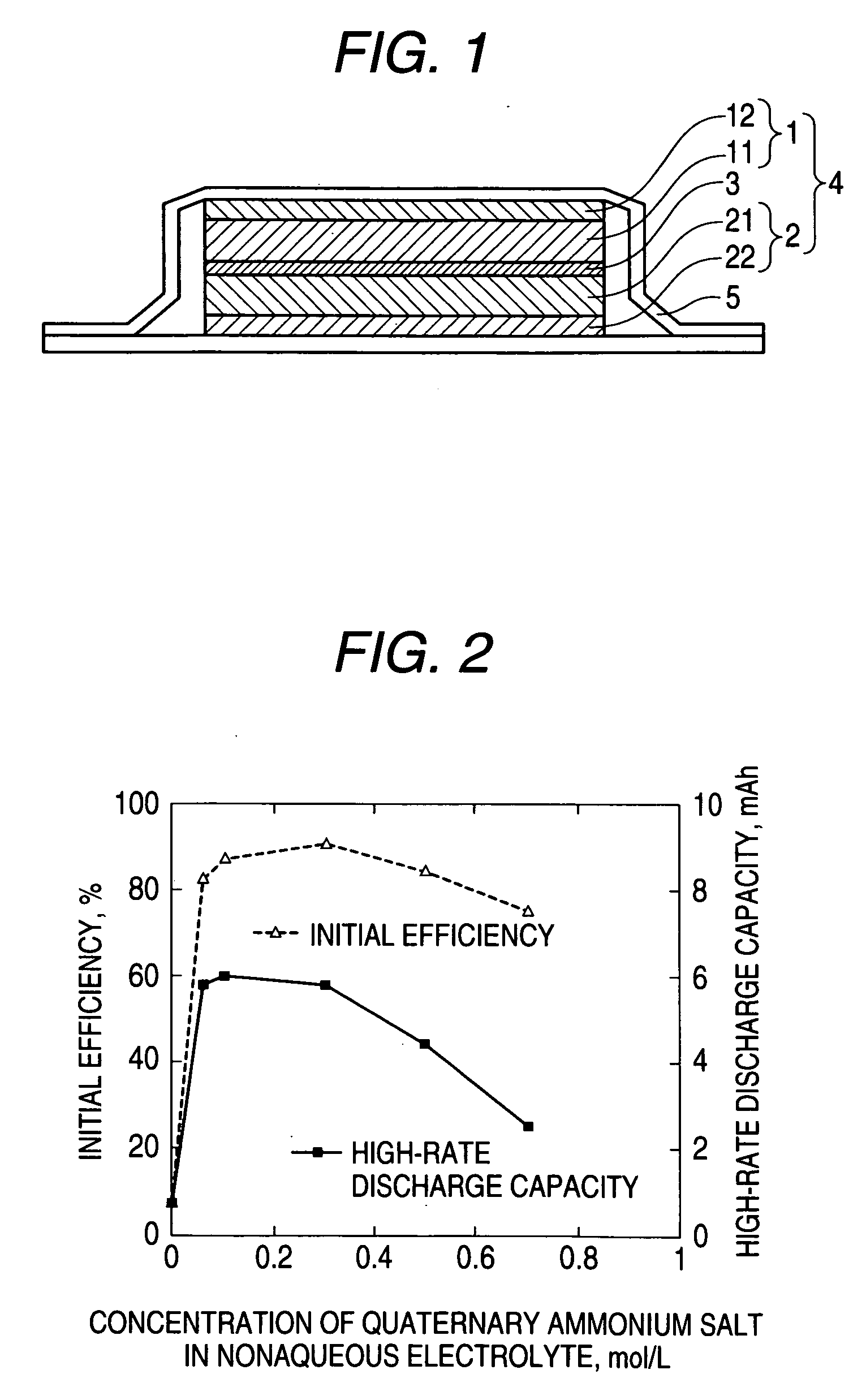

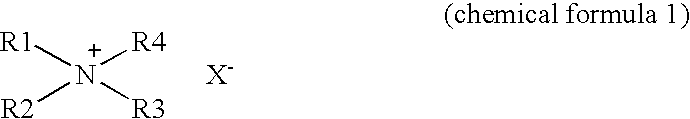

Nonaqueous electrolyte and nonaqueous-electrolyte battery

ActiveUS20060068296A1Avoid decompositionHigh rate discharge characteristicsHybrid capacitor electrolytesCell electrodesElectrode potentialDischarge efficiency

The object is to provide a nonaqueous-electrolyte battery having high charge / discharge efficiency and excellent high-rate performance. This subject is accomplished by using a nonaqueous electrolyte which comprises an organic solvent and a lithium salt dissolved therein and is characterized by containing at least one quaternary ammonium salt in an amount of 0.06 mol / L or larger and 0.5 mol / L or smaller. This effect is thought to be attributable to the following mechanism: in a relatively early stage (stage in which the negative-electrode potential is relatively noble) in a first charge step, a satisfactory protective coating film is formed on the negative electrode by the action of the quaternary ammonium salt and, hence, the organic solvent employed in the nonaqueous electrolyte is inhibited from decomposing.

Owner:GS YUASA INT LTD

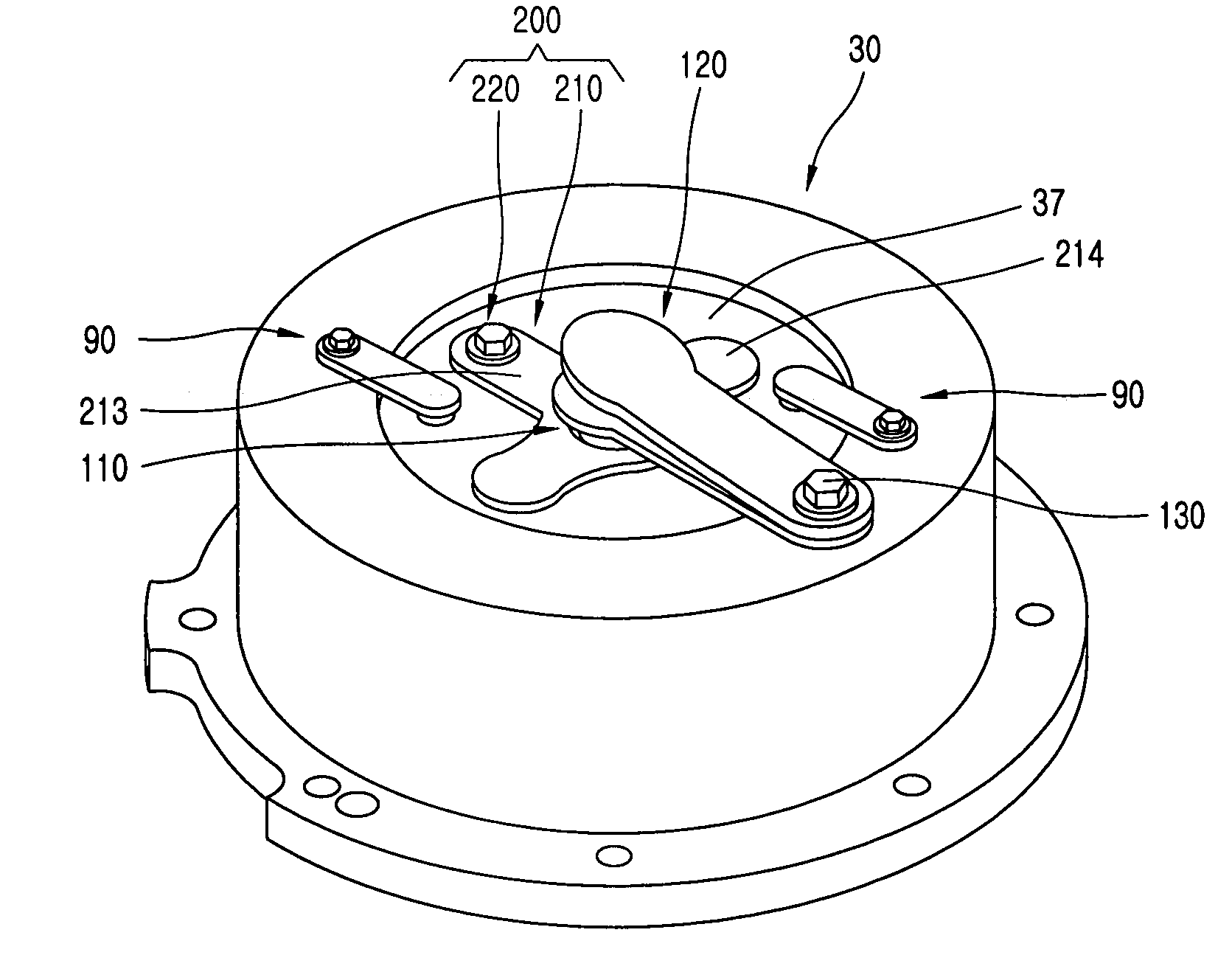

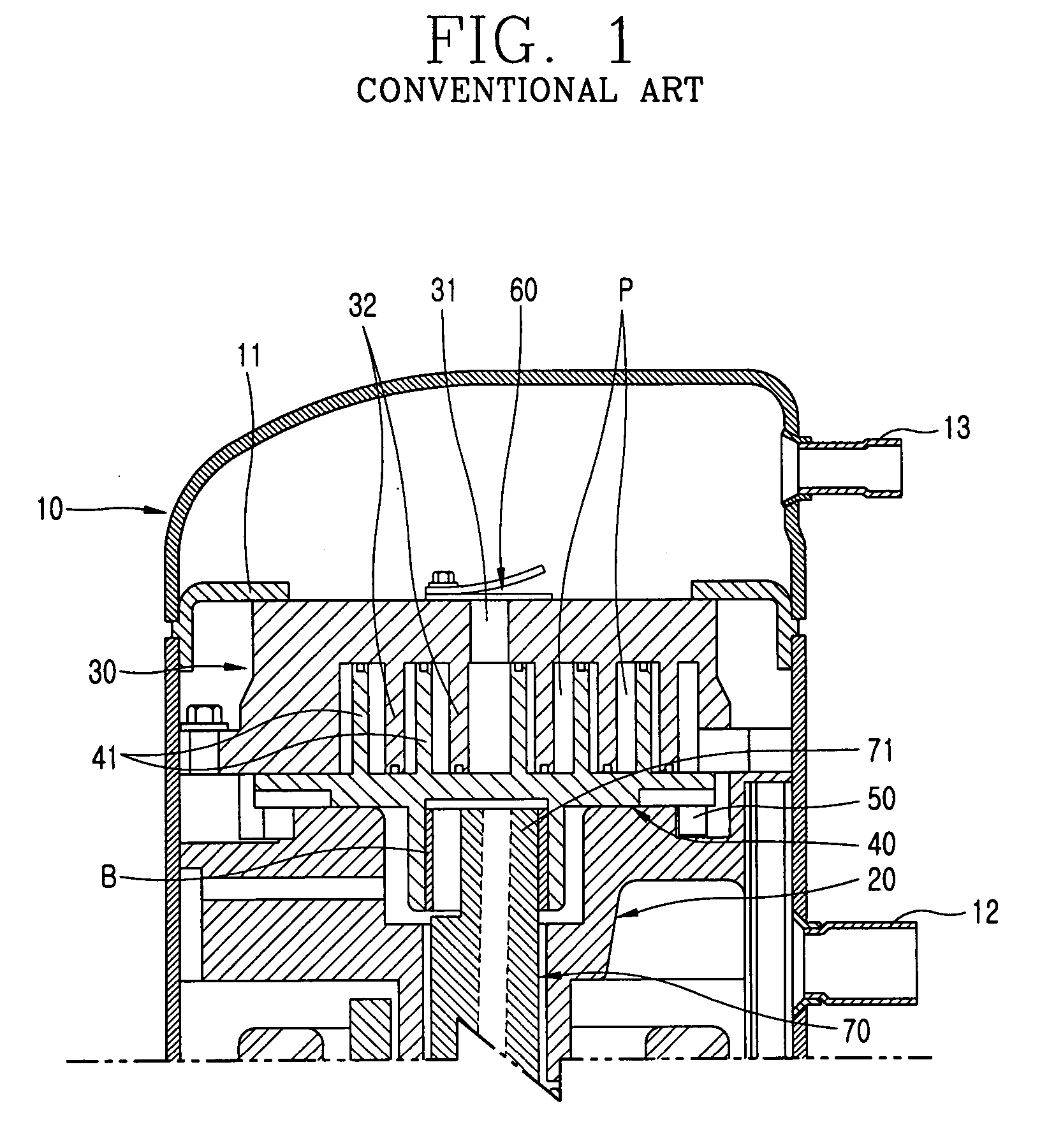

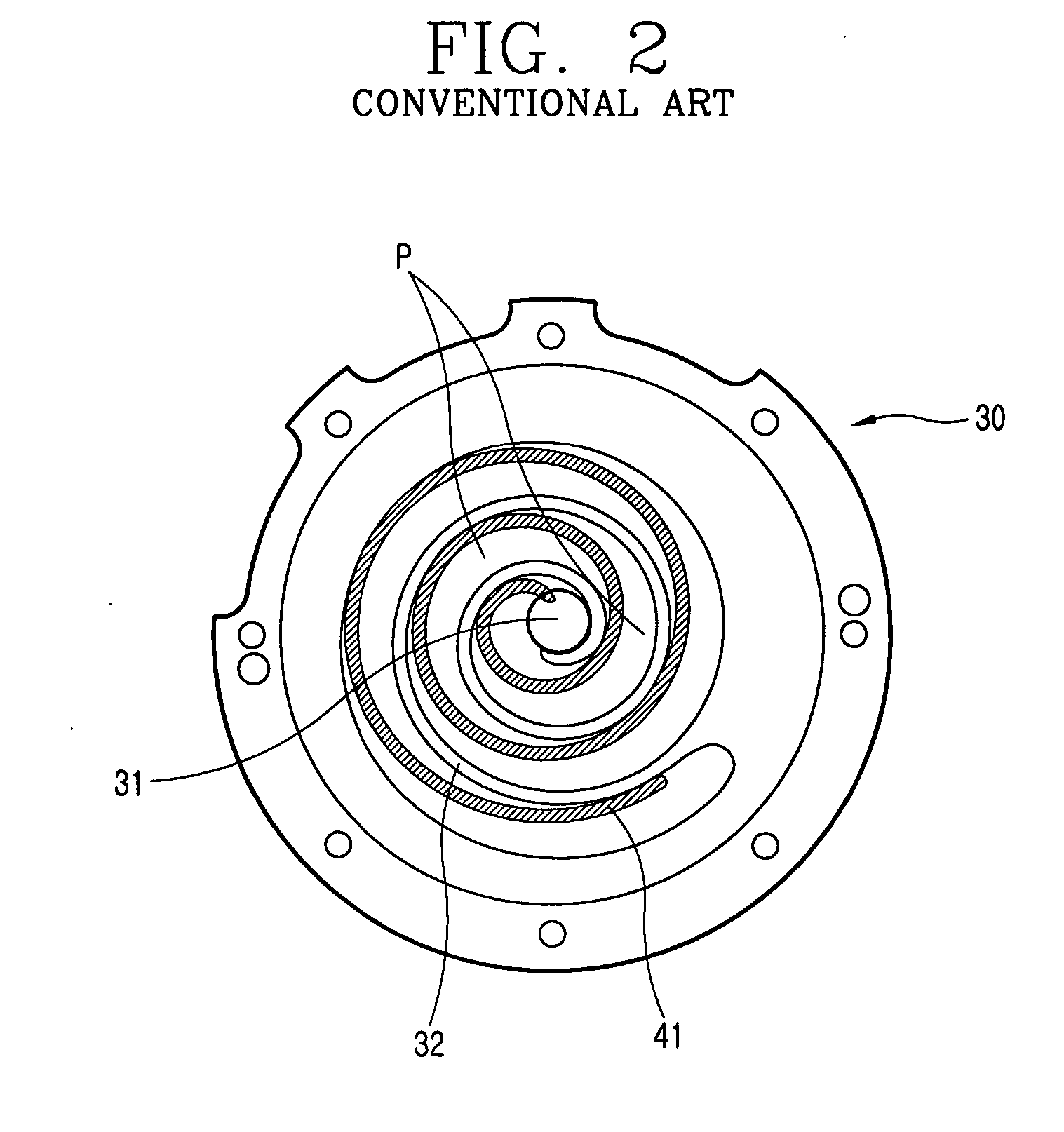

Discharge valve system of scroll compressor

ActiveUS20060099098A1Minimize the numberMaximize discharge amountEngine of arcuate-engagement typeOscillating piston enginesDischarge efficiencyProduction rate

A discharge valve system of a scroll compressor comprises: a fixed scroll having a discharge hole and discharge bypass holes; a discharge valve assembly mounted at the fixed scroll, for opening and closing the discharge hole by a pressure difference; and an integral bypass valve assembly mounted at the fixed scroll, for opening and closing the bypass holes and interworking the discharge valve assembly. According to this, a discharge amount of gas is maximized in a low pressure ration driving of the scroll compressor thereby to enhance a discharge efficiency. Also, the number of components is greatly reduced thus to reduce a fabrication cost. Also, the number of assembly processes is greatly reduced thereby to enhance an assembly productivity.

Owner:LG ELECTRONICS INC

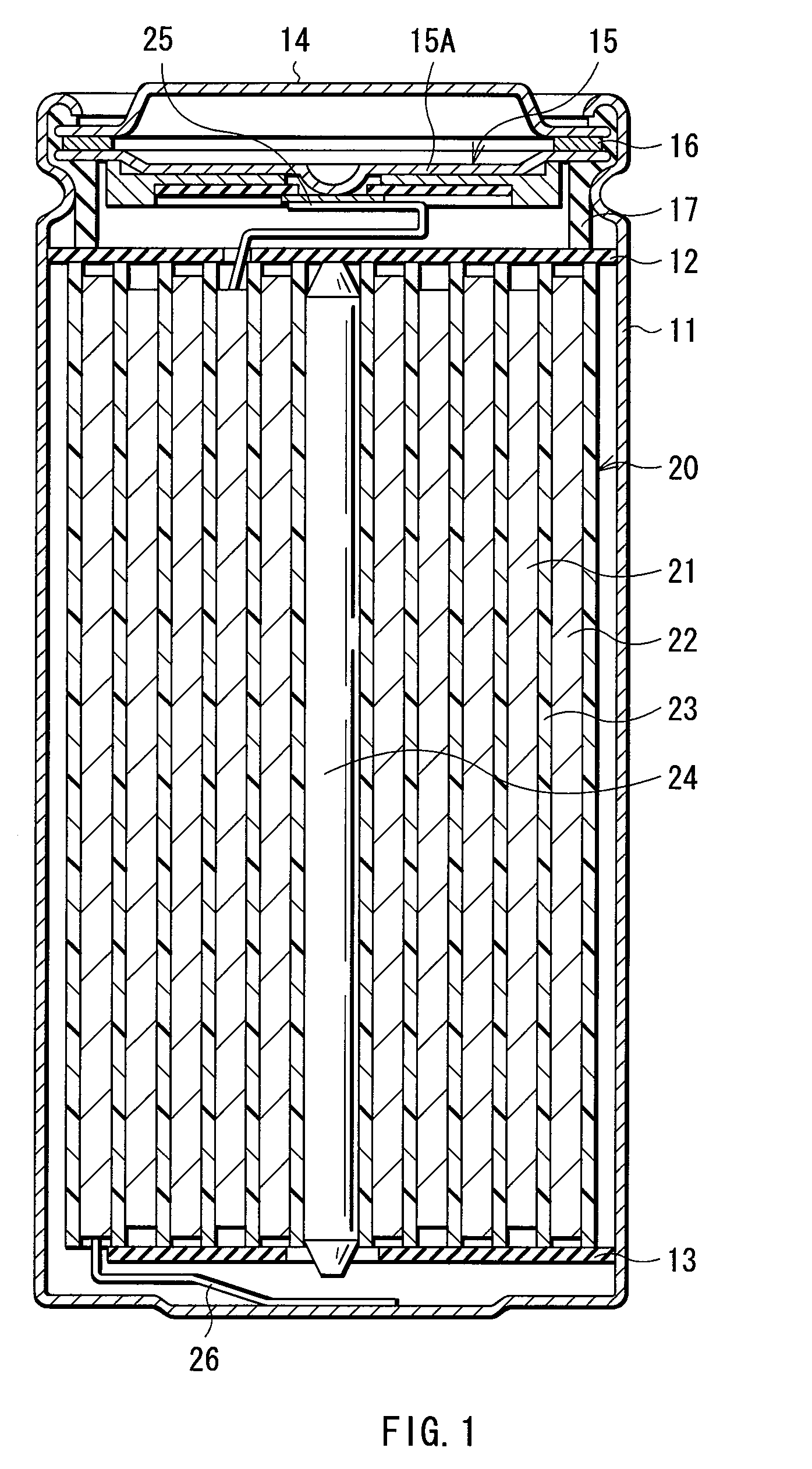

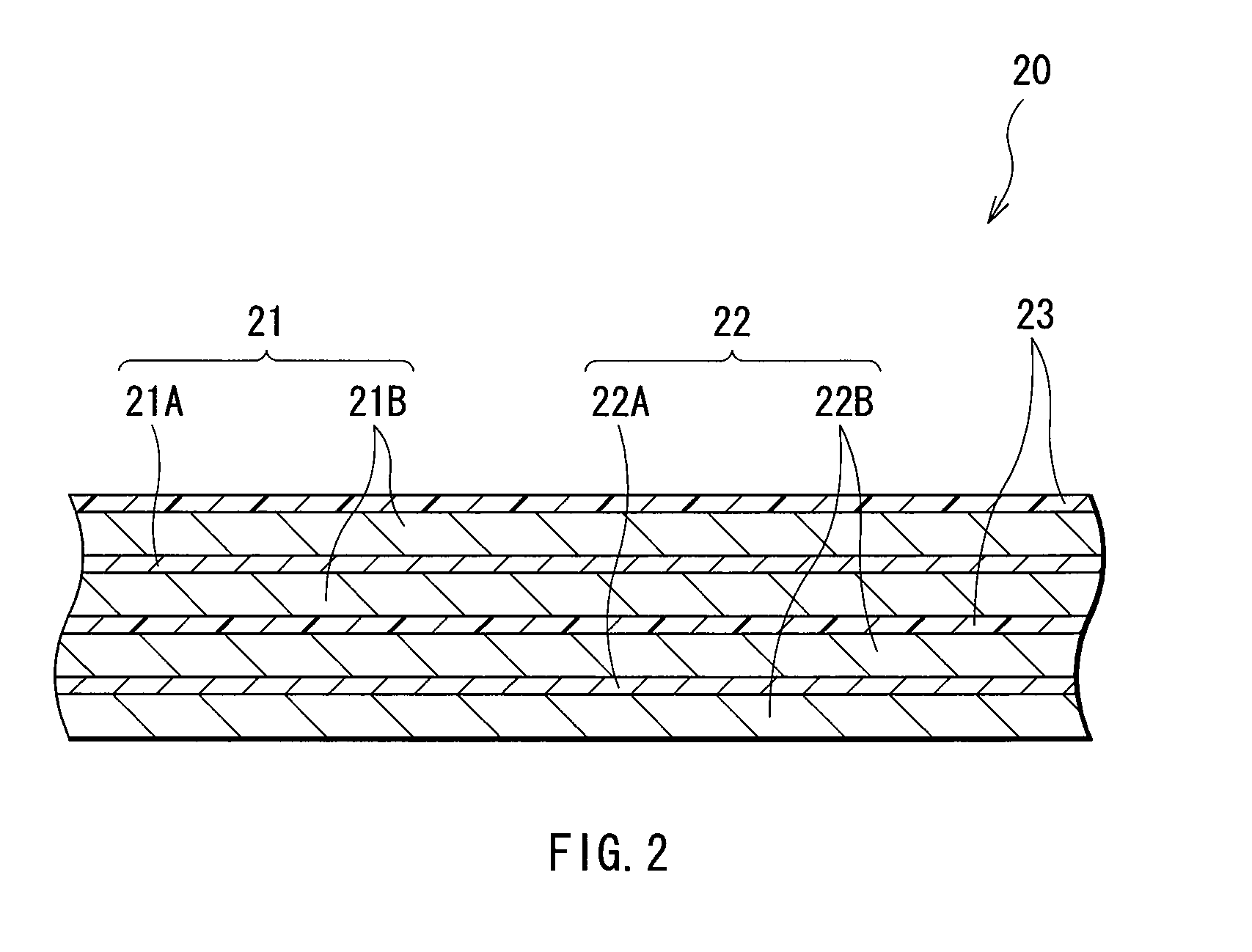

Anode and method of manufacturing the same, and battery and method of manufacturing the same

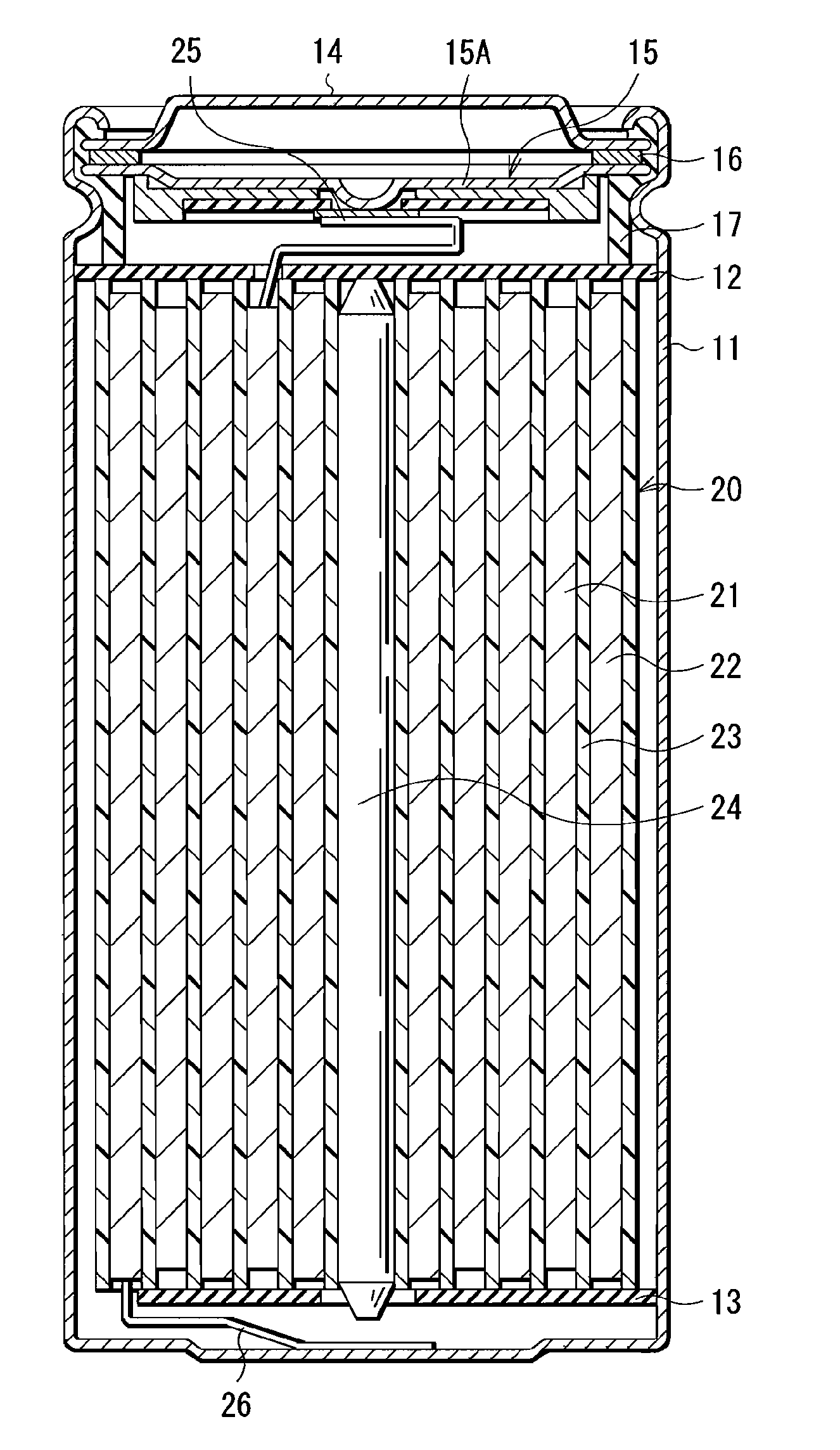

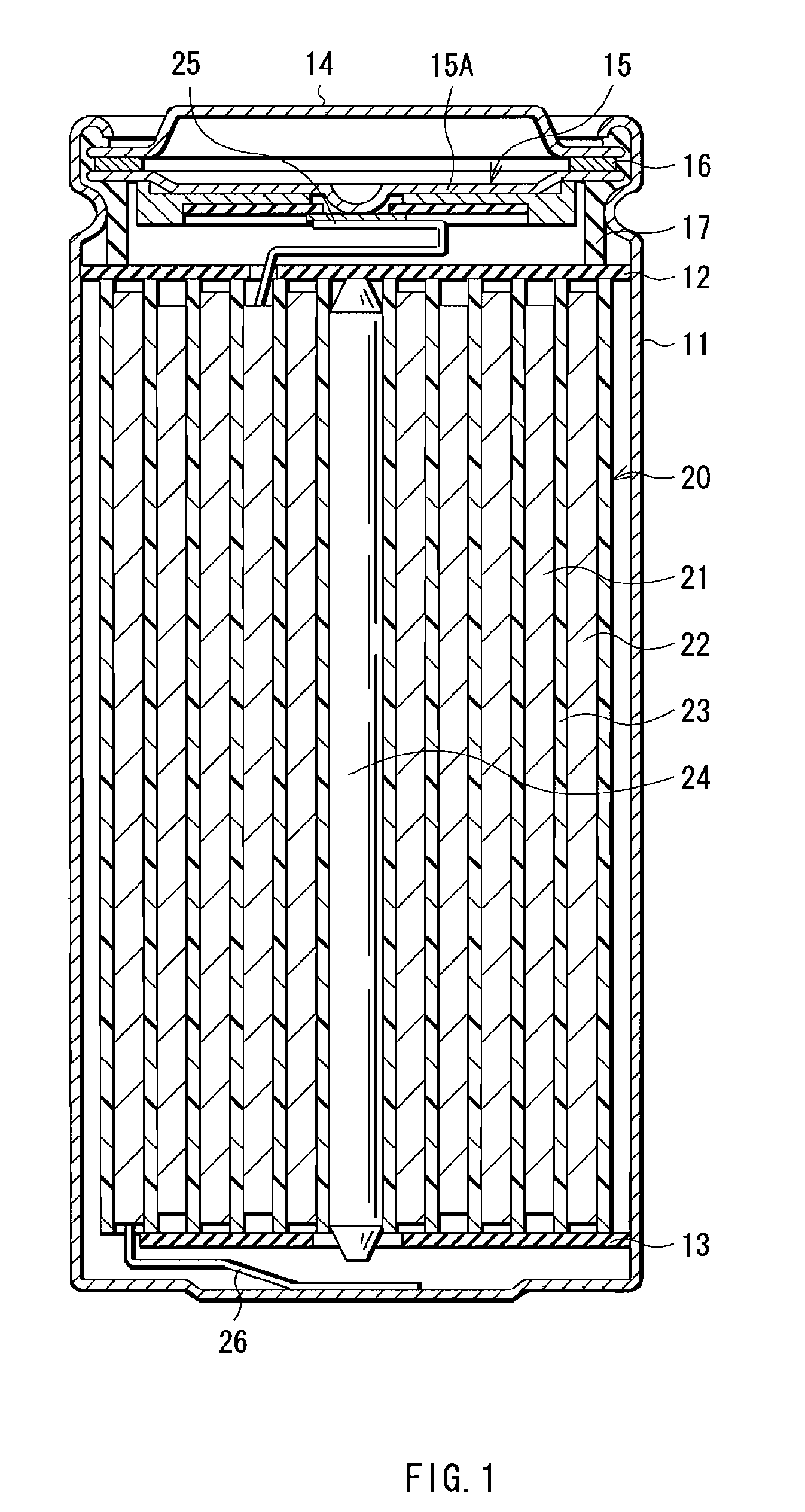

ActiveUS20090092892A1Good chemical stabilityCharge-discharge efficiency can be improvedLiquid separation by electricityElectrostatic separationDischarge efficiencyCharge discharge

An anode capable of improving charge-discharge efficiency, and a method of manufacturing the anode, and a battery using the anode are provided. An anode 22 has a configuration in which an anode active material layer 22B is arranged on an anode current collector 22A. The anode active material layer 22B includes anode active material particles made of an anode active material including at least one of silicon and tin as an element. An oxide-containing film including an oxide of at least one kind selected from the group consisting of silicon, germanium and tin is formed in a region in contact with an electrolytic solution of the surface of each anode active material particle by a liquid-phase method such as a liquid-phase deposition method. The region in contact with the electrolytic solution of the surface of each anode active material particle is covered with the oxide-containing film, thereby the chemical stability of the anode 22 is improved, and charge-discharge efficiency is improved. The thickness of the oxide-containing film is preferably within a range from 0.1 nm to 500 nm both inclusive.

Owner:MURATA MFG CO LTD

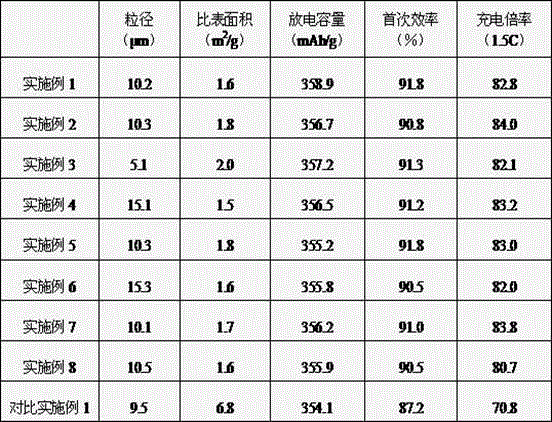

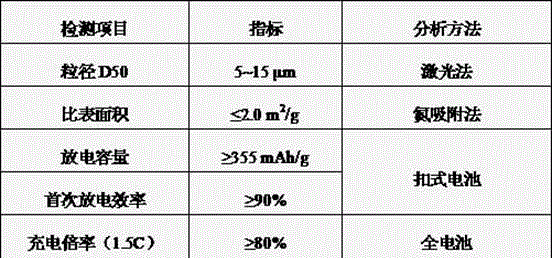

Negative electrode material for quickly rechargeable graphite lithium-ion battery and preparation method of negative electrode material

InactiveCN105024075ASmall specific surface areaIncrease charging rateCell electrodesSecondary cellsDischarge efficiencyElectrical battery

The invention discloses a negative electrode material for a quickly rechargeable graphite lithium-ion battery and a preparation method of the negative electrode material. The preparation method of the negative electrode material for the quickly rechargeable graphite lithium-ion battery comprises the following steps: (1) mixing a mixture containing a graphite precursor and bitumen and heating the mixture for kneading and crushing, wherein the mean grain size D50 of the graphite precursor ranges from 5 to 10 microns, and the mass ratio of the graphite precursor to the bitumen ranges from 50:50 to 90:10; (2) performing heat treatment at a temperature within the range of 300-700 DEG C under the protection of an inert gas; and (3) carrying out graphitizing. The mean grain size D50 of the negative electrode material prepared by use of the preparation method for the quickly rechargeable graphite lithium-ion battery is within the range of 5-15 microns and the specific surface area of the negative electrode material is below 2.0m2 / g; the first discharge capacity of a negative electrode, manufactured by use of the negative electrode material for the quickly rechargeable graphite lithium-ion battery, is more than 355mAh / g, and the initial charge-discharge efficiency of the battery is above 90%; if the battery is quickly charged (1.5C) for 45 minutes, the capacity of the battery can be above 80%; in short, the product is high in discharge capacity and charge / discharge efficiency, and good in rate capability. The invention also relates to a battery comprising the negative electrode material for the quickly rechargeable graphite lithium-ion battery.

Owner:SHANGHAI SHANSHAN TECH CO LTD

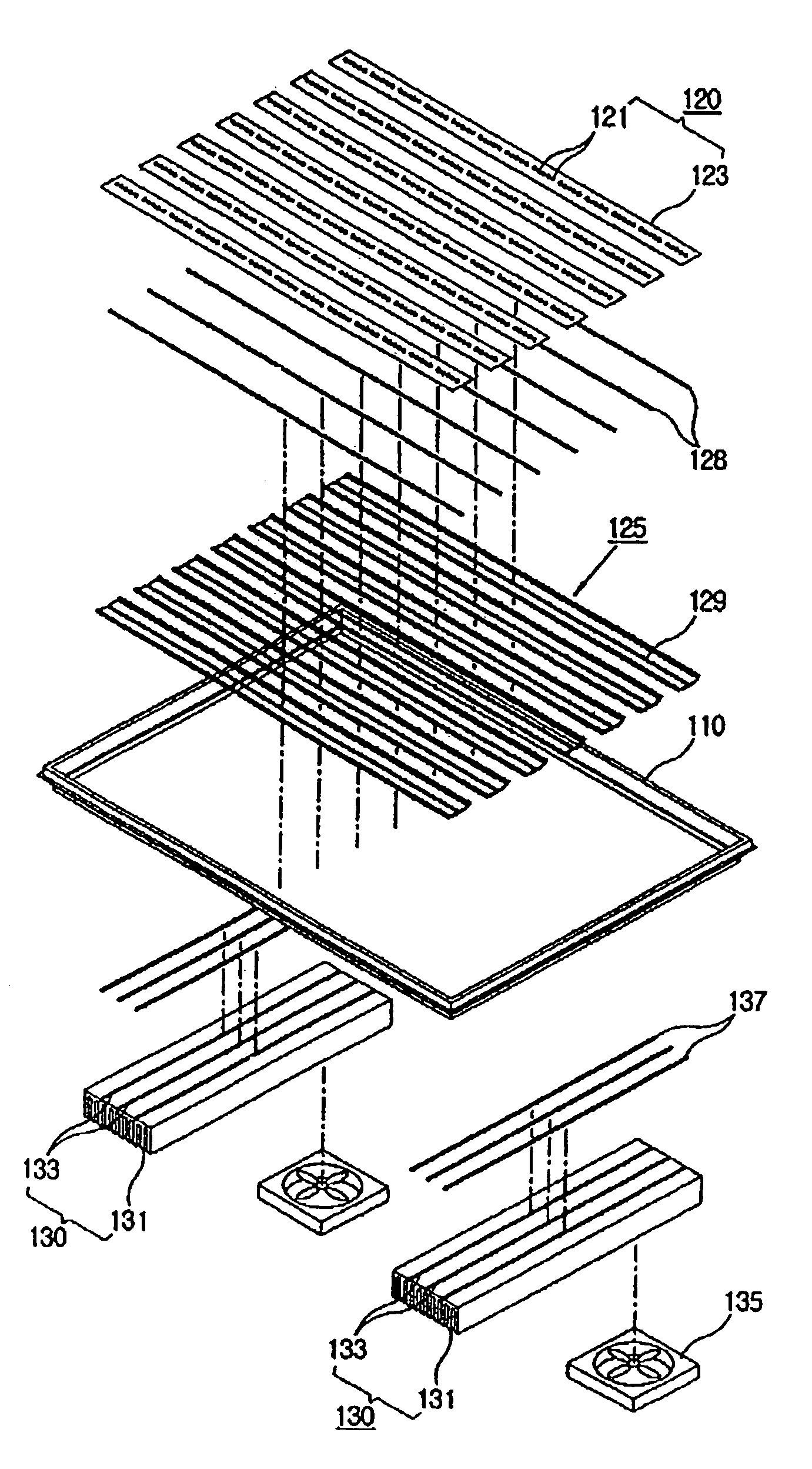

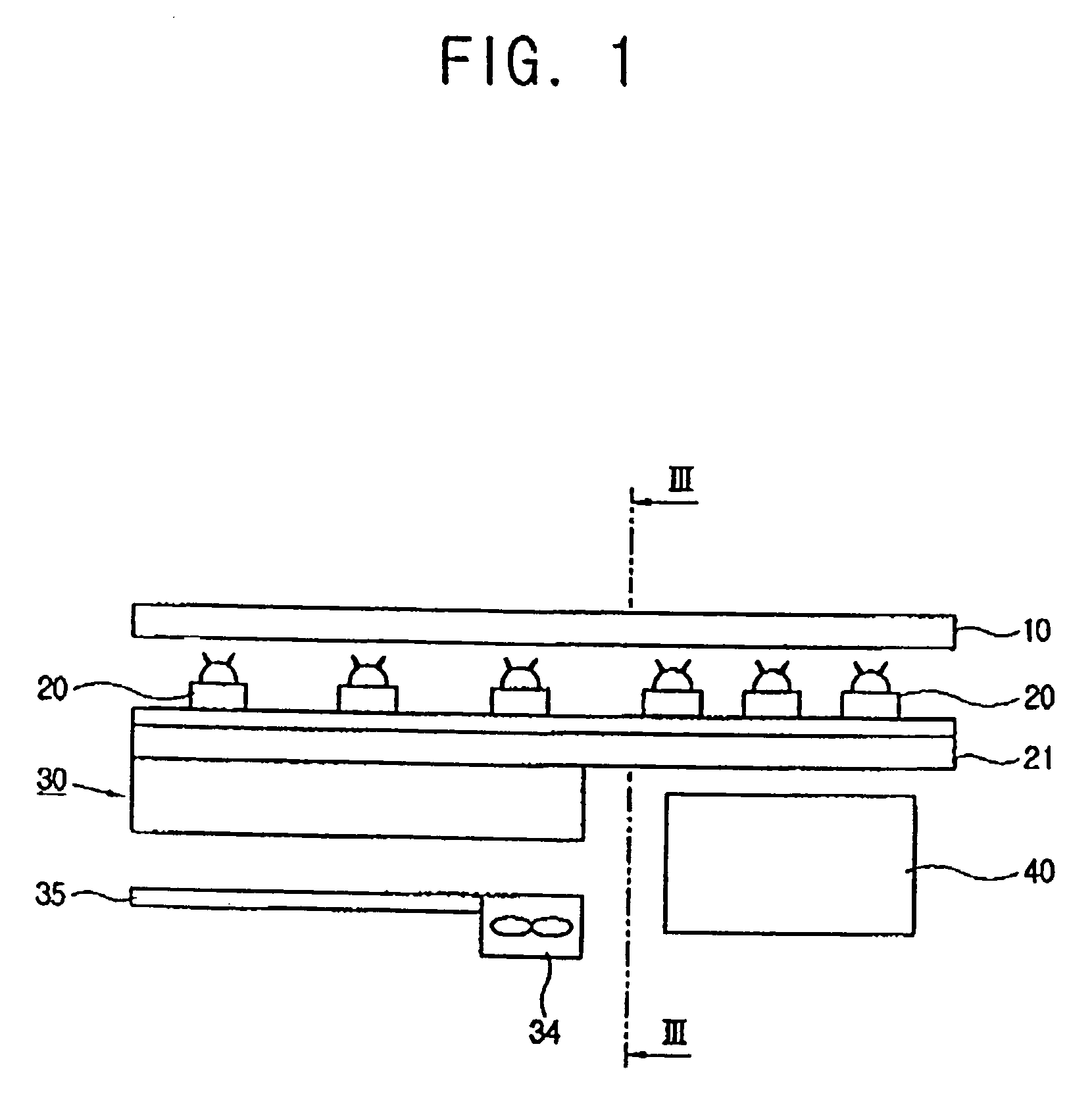

Backlight unit

InactiveUS7762707B2Thin appearanceImprove cooling efficiencyLighting heating/cooling arrangementsOptical signallingDischarge efficiencyEngineering

A backlight unit having light sources to illuminate light to a display panel includes a support plate to support the light sources, a printed circuit board provided on a first region of the support plate, and a heat discharging member provided on a second region of the support plate to discharge heat generated from the light sources. The backlight unit has a slim external appearance and an excellent heat discharging efficiency.

Owner:SAMSUNG ELECTRONICS CO LTD

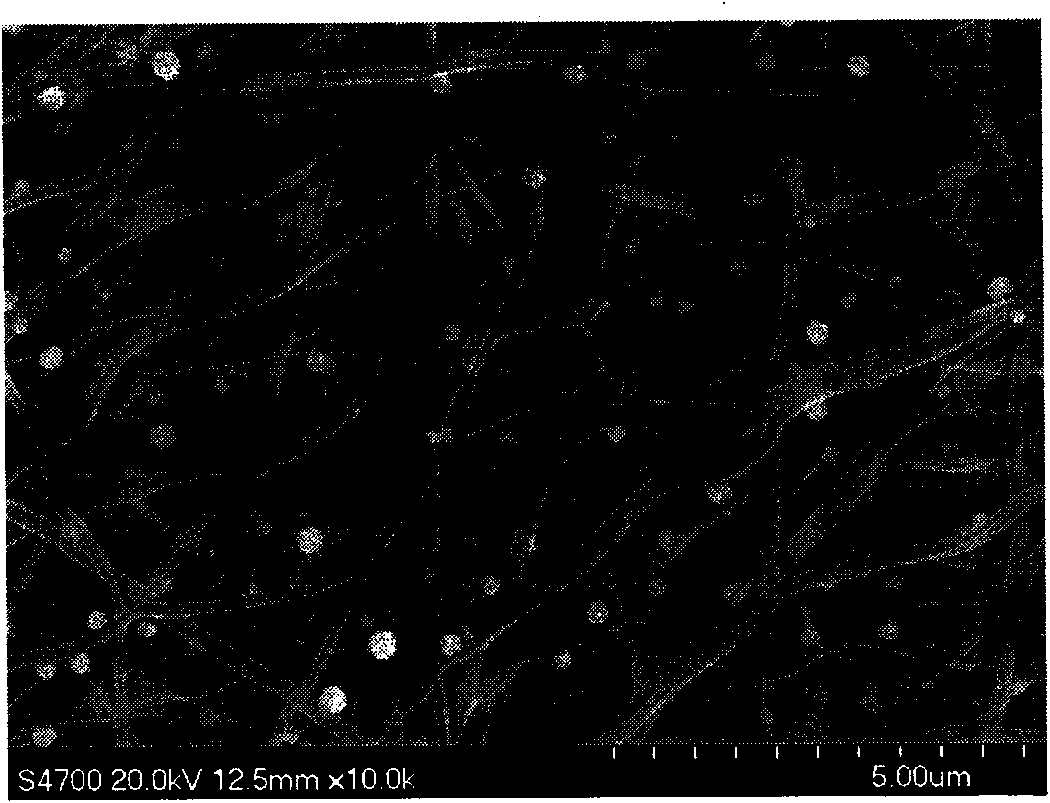

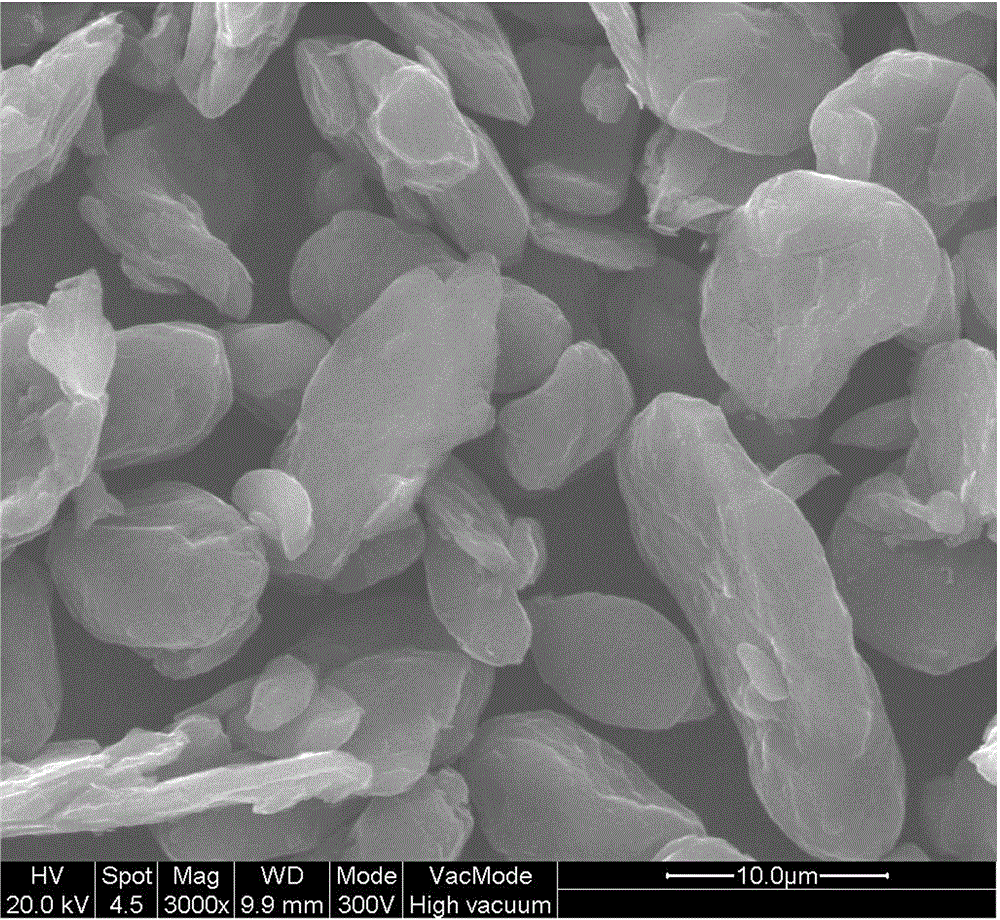

Anode active material, method of preparing the same, and anode and lithium battery containing the material

ActiveUS7767346B2Excellent initial charge/discharge efficiencyHigh charge and discharge capacityMaterial nanotechnologyElectrode manufacturing processesDischarge efficiencyNanowire

An anode active material comprises metal core particles, metal nano wires formed on the metal core particles, pores between the metal core particles and the metal nano wires, and a carbon-based coating layer formed on a surface of the metal core particles and metal nano wires. In the anode active material according to the present invention, the metal core particles and metal nano wires are combined to form a single body, and a carbon-based coating layer is formed on the surface of the metal nano wires and metal core particles. Thus, volume changes in the pulverized metal core particles can be effectively buffered during charging and discharging, and the metal core particles are electrically connected through the metal nano wires. As a result, volume changes in the anode active material and degradation of the electrode can be prevented, thereby providing excellent initial charge / discharge efficiency and enhanced charge / discharge capacity.

Owner:SAMSUNG SDI CO LTD

Electrode structure and electric energy storage device

InactiveUS20110052985A1Improve power densitySuperior in repetitive charge/discharge efficiencyHybrid capacitor electrodesNon-aqueous electrolyte accumulator electrodesDischarge efficiencyAlloy

Provided is an electrode structure having a high power density and being superior in repetitive charge / discharge efficiency and an electric energy storage device using the electrode structure. The electrode structure includes an electrode material layer including an electrode material including active material particles containing at least one of silicon, tin and alloys containing at least one of them, and a binder binding the active material particles, the binder has the following characteristics: tensile modulus: 2000 MPa or more, breaking strength: 100 MPa or more, break elongation: 20% to 120% and the ratio of breaking strength / break elongation >1.4 (MPa / %), and an average particle size of the particles is 0.5 μm or less, the electrode structure has a maximum thermal history temperature less than 350° C. and lower than the glass transition temperature of the binder. The electric energy storage device uses, as its negative electrode, the electrode structure.

Owner:CANON KK

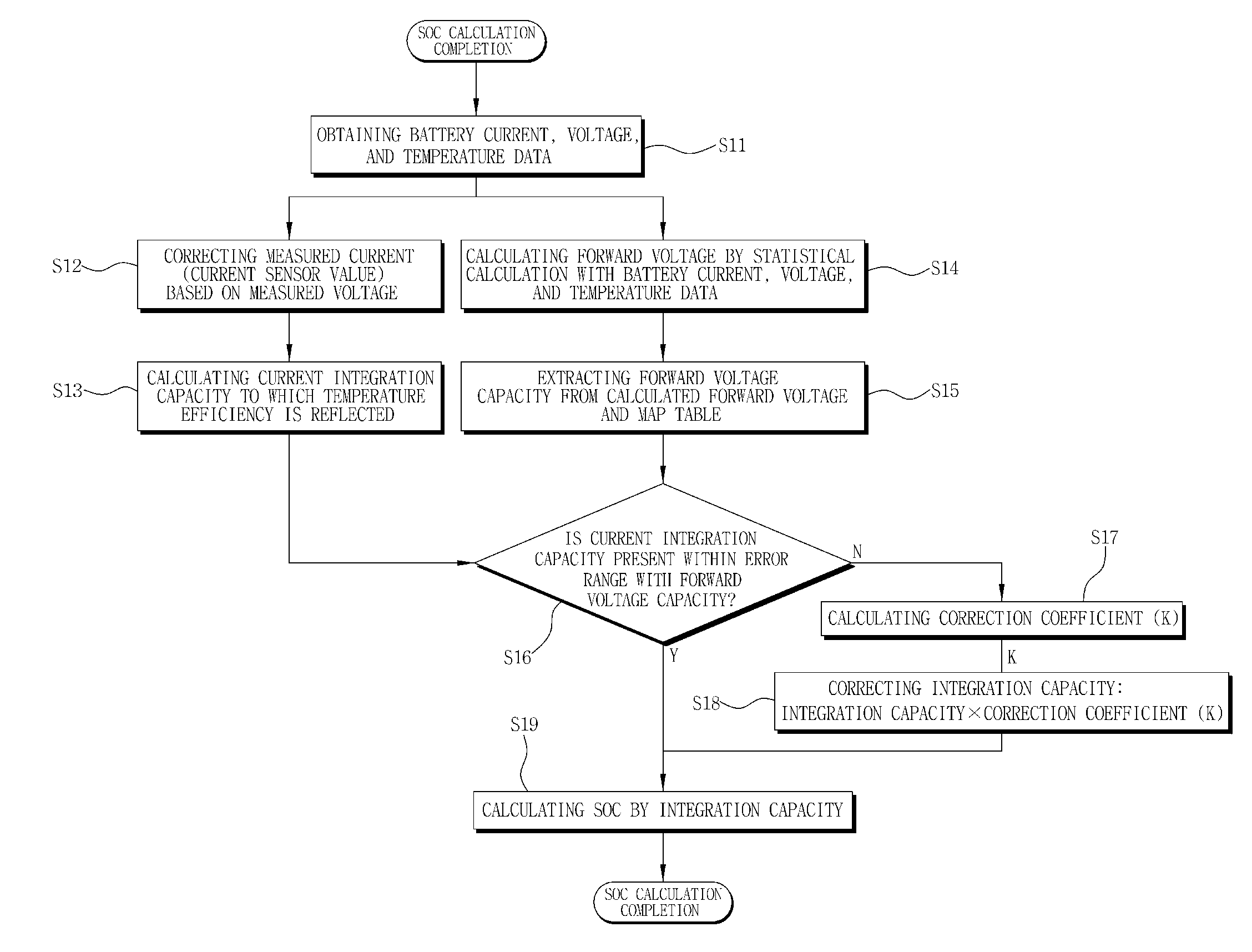

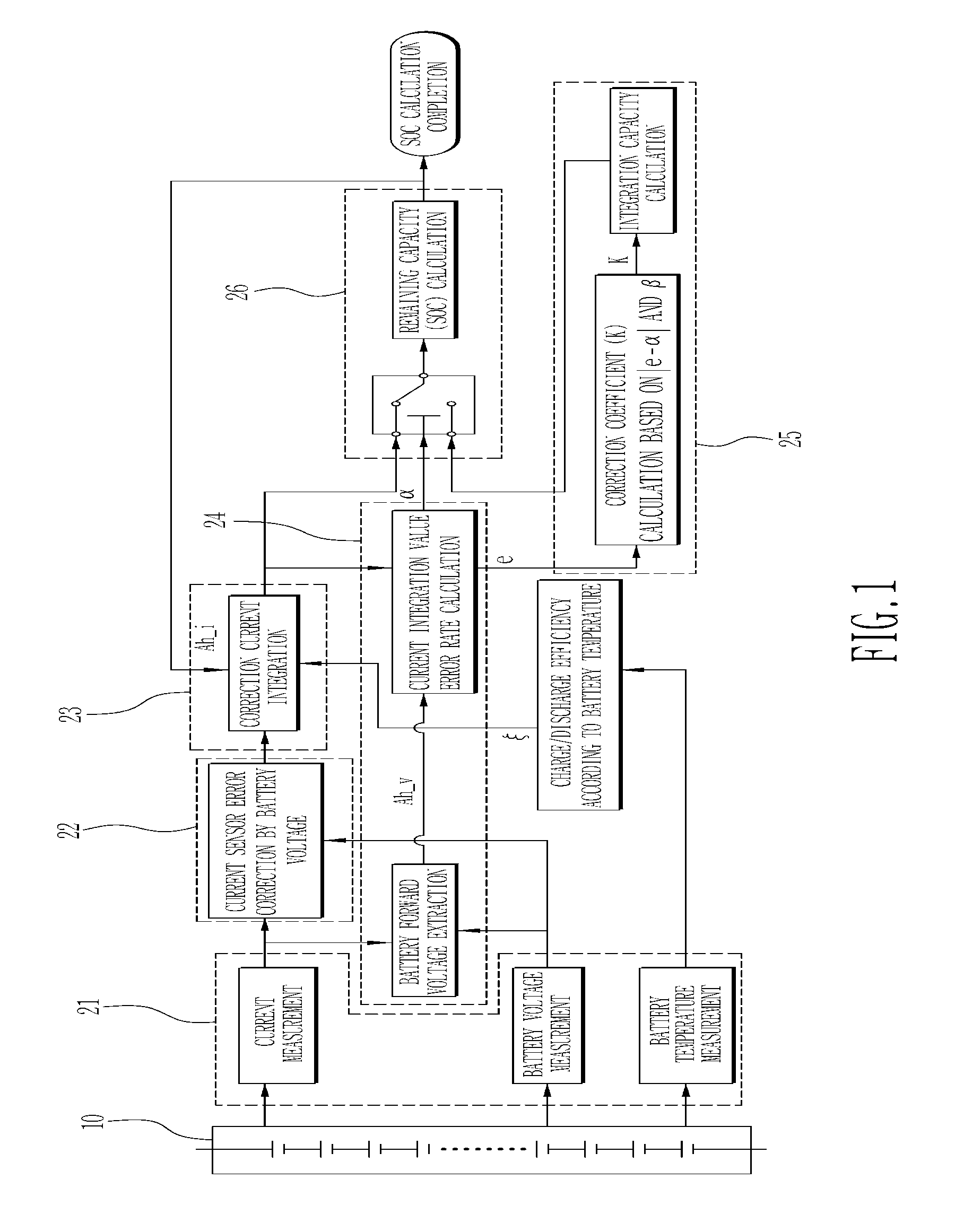

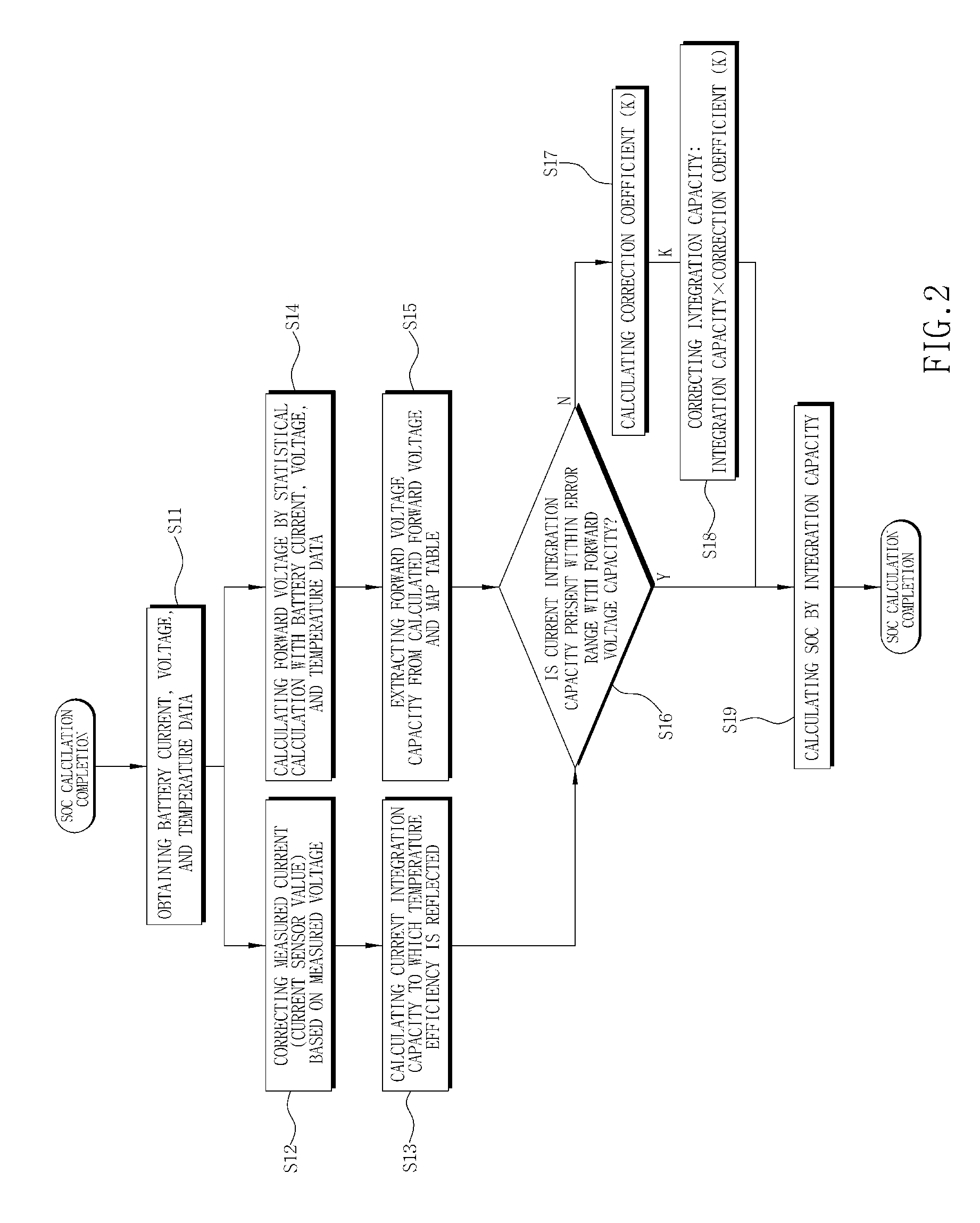

Method for estimating remaining capacity of battery

ActiveUS20090254290A1Batteries circuit arrangementsElectrical testingDischarge efficiencyEngineering

The present invention provides a method for estimating a remaining capacity of a battery. The method comprises: measuring a current value, a voltage value and temperature of the battery; correcting the current value based on the voltage value; calculating a current integration value by integrating the corrected current value and calculating a current integration capacity from the calculated current integration value by reflecting a charge / discharge efficiency; determining a battery forward voltage capacity from the measured current value, voltage value and temperature, and determining whether it is necessary to correct the current integration capacity based on the forward voltage capacity; converting the current integration capacity into a remaining capacity, if it is determined that it is not necessary to correct; and correcting, if it is determined that it is necessary to correct, the current integration capacity and converting the corrected current integration capacity into a remaining capacity. With the method, SOC of the battery can be more accurately calculated.

Owner:HYUNDAI MOTOR CO LTD +1

Negative active material for rechargeable lithium battery, method of preparing thereof, and rechargeable lithium battery including the same

ActiveUS20080118840A1Improve stabilityExcellent charge and discharge efficiency and cycle-lifeMaterial nanotechnologyMolybdeum compoundsDischarge efficiencyVanadium oxide

A negative active material for a rechargeable lithium battery of the present invention includes a lithium-vanadium oxide core material being capable of performing reversible electrochemical oxidation and reduction, and an inorganic oxide coating layer disposed on the surface of the core material. The negative active material can improve stability at the interface between a negative electrode and an electrolyte, charge and discharge efficiency, and cycle-life, and can be applied along with all kinds of aqueous and non-aqueous binders.

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com