Patents

Literature

82results about How to "Less gush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal seam pre-splitting method based on gas extraction

The invention relates to a coal seam pre-splitting method based on gas extraction, which adopts a 'CO2 gas extraction device' as a tool to blast and pre-split a pre-mined coal seam, so as to increase the crack of the coal seam, drive out gas absorbed on the coal seam and extract the gas. The method particularly comprises the following steps: drilling a hole on the working surface of a pre-mined coal seam, filling CO2 gas extraction device into the drilled hole, sealing the drilled hole, detonating the CO2 gas extraction device, releasing high-pressure CO2 gas for deep-hole impact and pre-splitting of the coal seam, taking out the CO2 gas extraction device, and connecting the drilled hole with a gas extraction system to extract gas. The pre-splitting method of the invention can greatly enhance the permeability of the coal seam, promote the gas dissociation in the coal seam, and improve the underground gas extraction efficiency of the coal mine.

Owner:山西锦浩诚科技有限公司

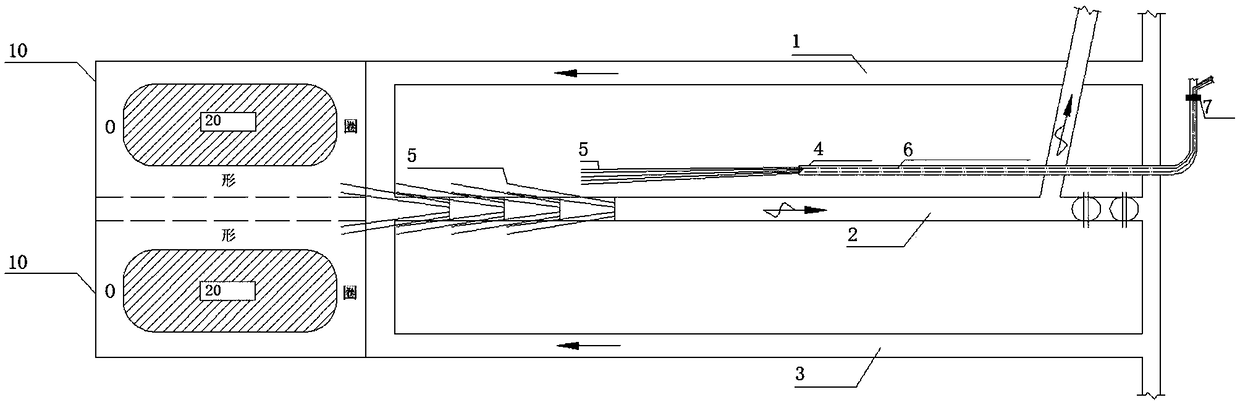

Method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on soft and high-outburst coal seam

InactiveCN102900460AIncrease the speed of excavationIncrease extraction concentrationGas removalStress distributionType fracture

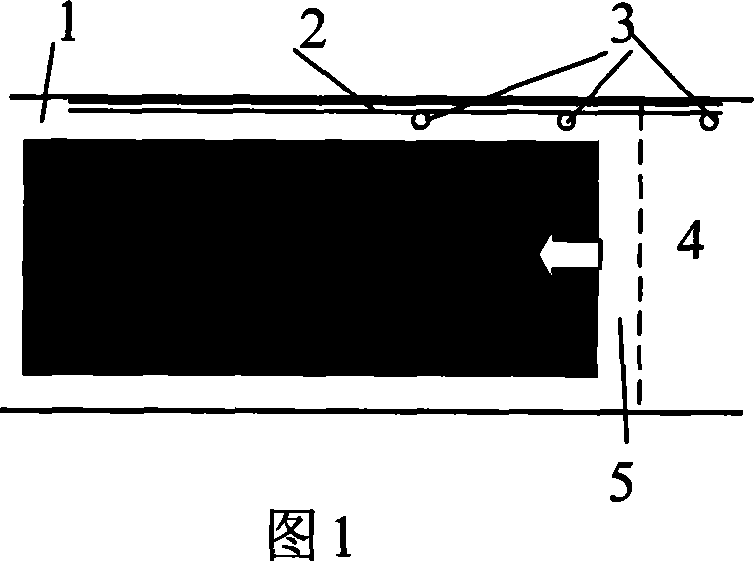

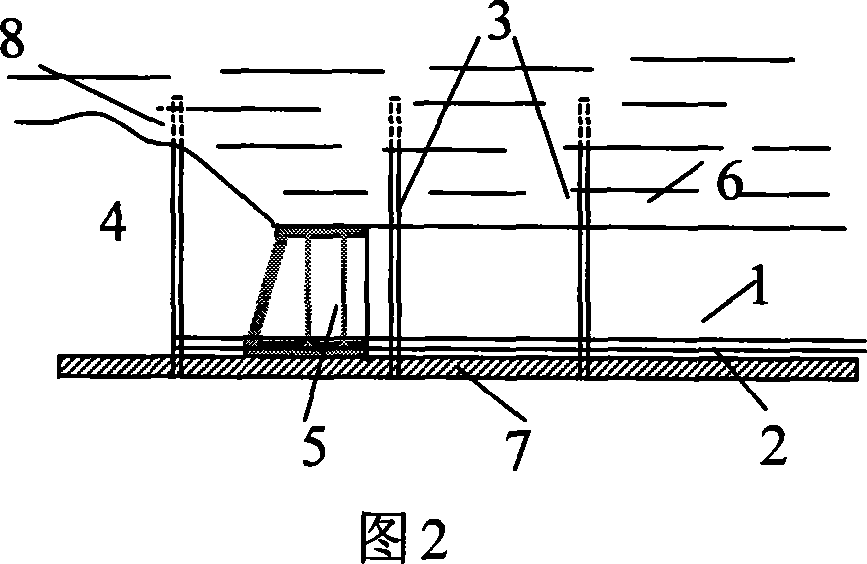

The invention discloses a method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on a soft and high-outburst coal seam, and in particular is applied to quick tunneling in a coal seam which is high in outburst danger and a laneway is difficult to support in a coal mine. The method comprises the following steps of: forming a network type fractured net by high-pressure jet flow seam cutting, pressure relief and permeability enhancement technologies, and enhancing an effect of extracting strip-type coal seam gas on a coal laneway subjected to through-going drilling and pre-extraction; and forming a network type filling region by pressing and injecting filling materials, so that the strength and stress distribution of a coal body are improved, the coal laneway is easy to maintain in the tunneling process, a phenomenon that the gas rushes out of a tunneled laneway is avoided, gas accidents are eliminated in the tunneling process, and an aim of safely and quickly tunneling the laneway is fulfilled.

Owner:CHINA UNIV OF MINING & TECH

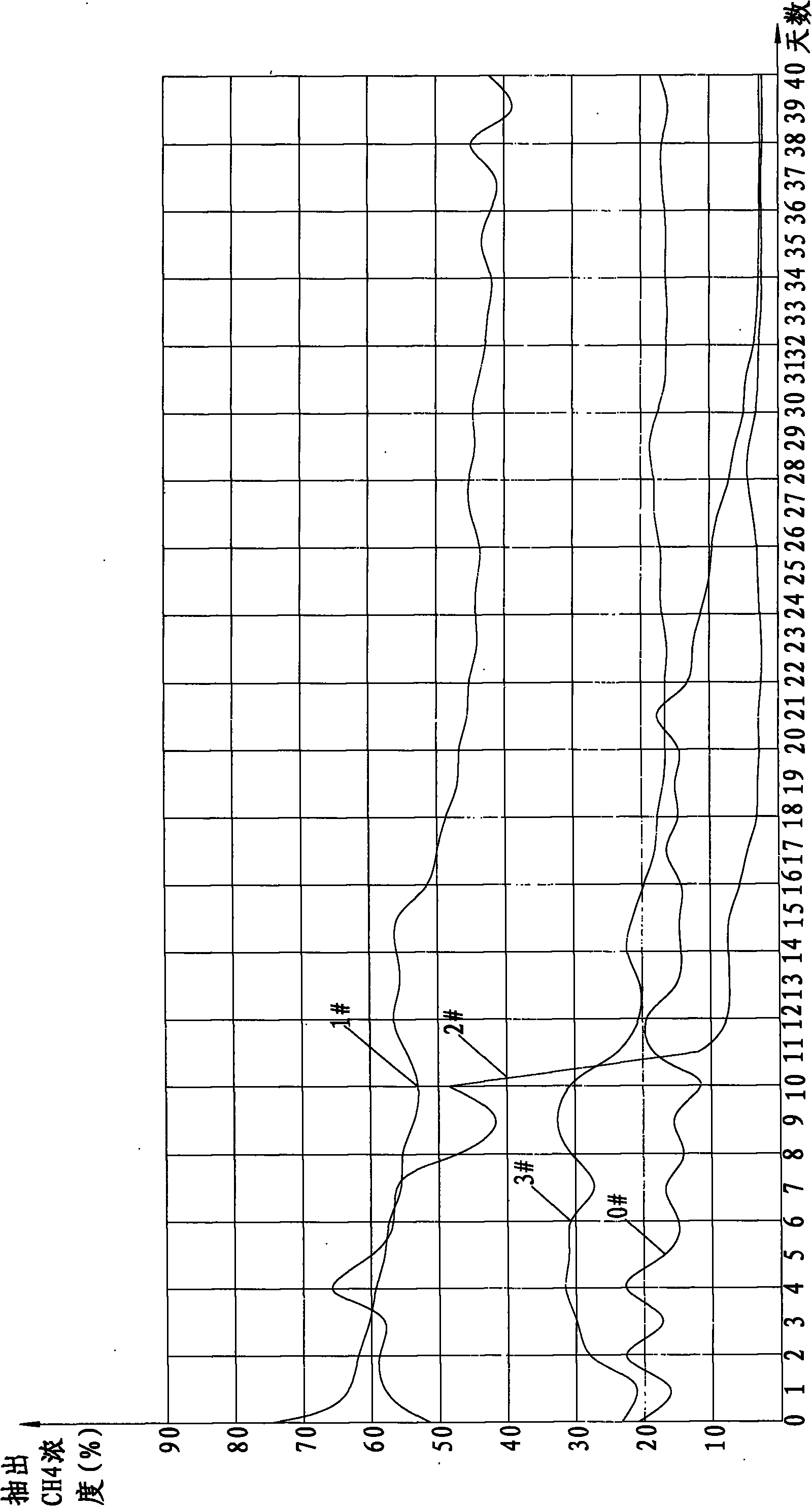

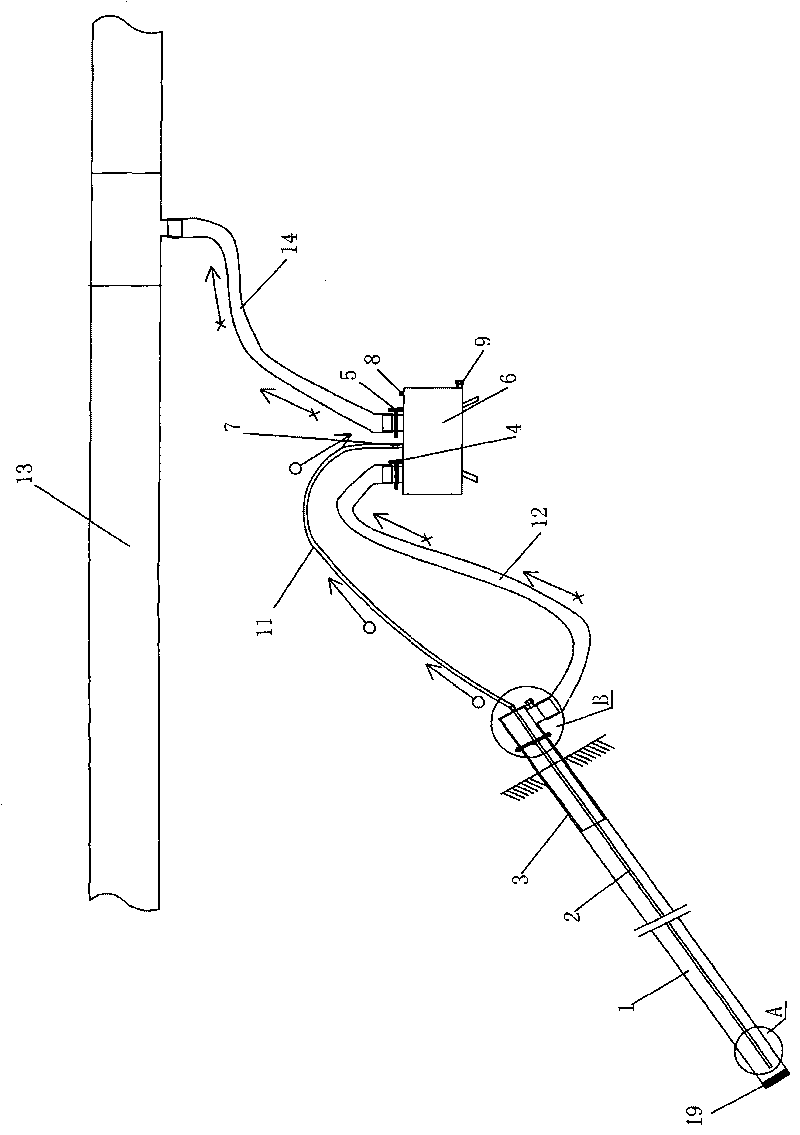

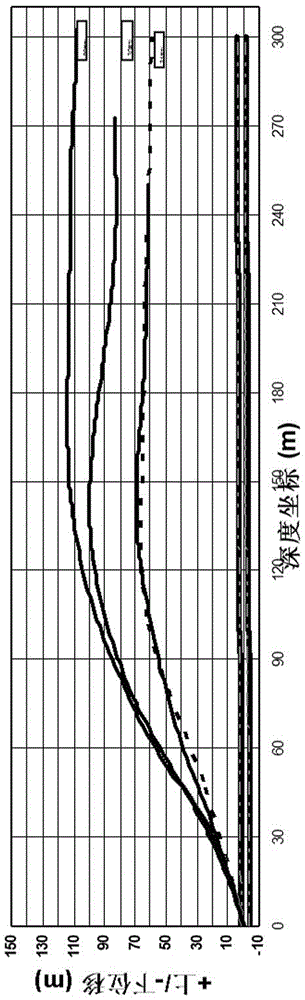

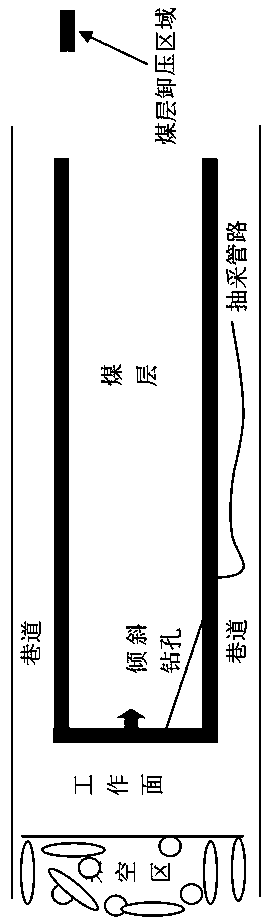

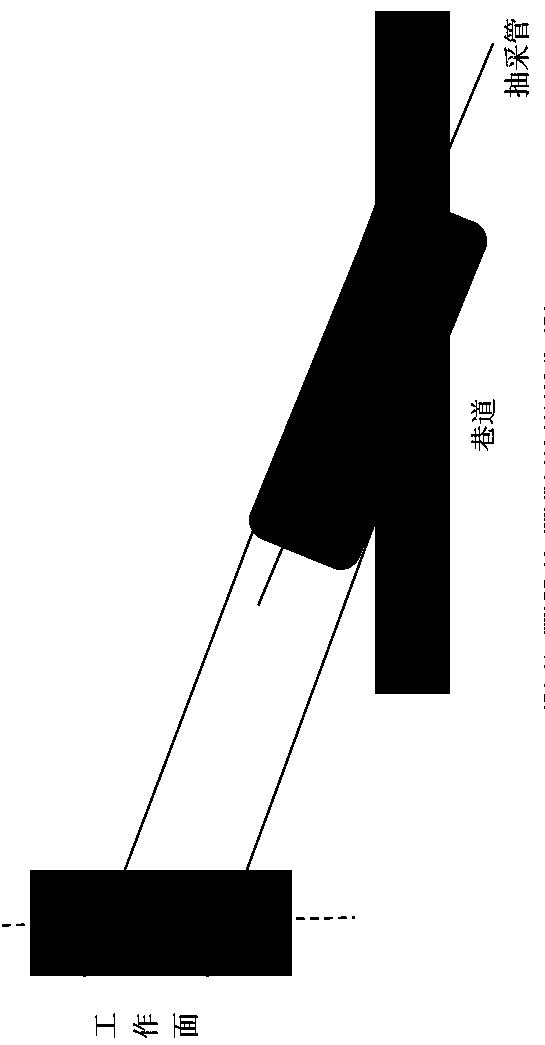

Method for extracting protruded coal-bed downward bedding long-borehole step-by-step covering area gas

InactiveCN101029575AReduce gas contentEliminate outstanding hazardsGas removalSealing/packingEngineeringGas concentration

This is a gas extraction method for a single burst coal bed of stable coal occurrence, angle less than 10o, and firm index over 0.5. Drill a hole from top working face downward along the coal bed from shallow bed to deep, from low gas concentration zone to high for pre-extraction to lower down the gas concentration.

Owner:淮北矿业股份有限公司祁南煤矿 +1

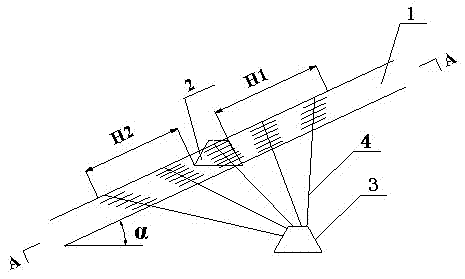

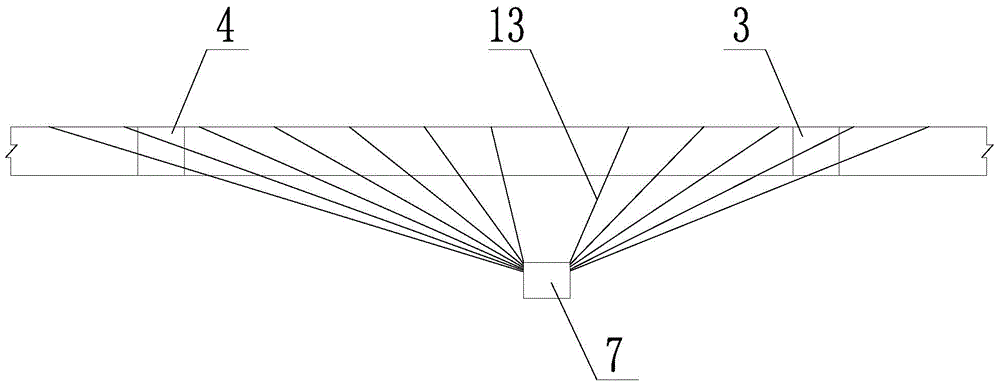

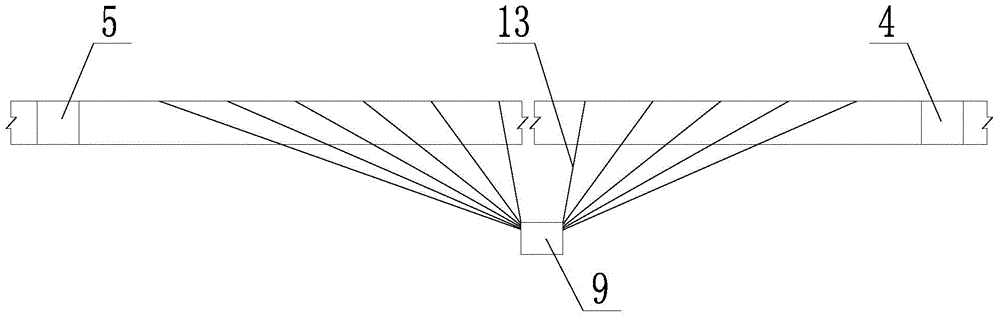

Method for extracting gas at corner on recovery working face in coal mine

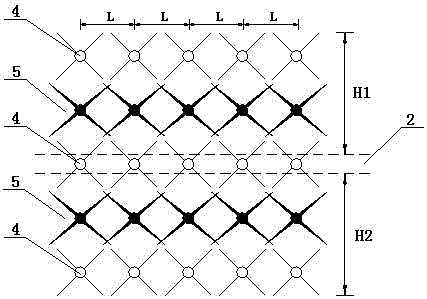

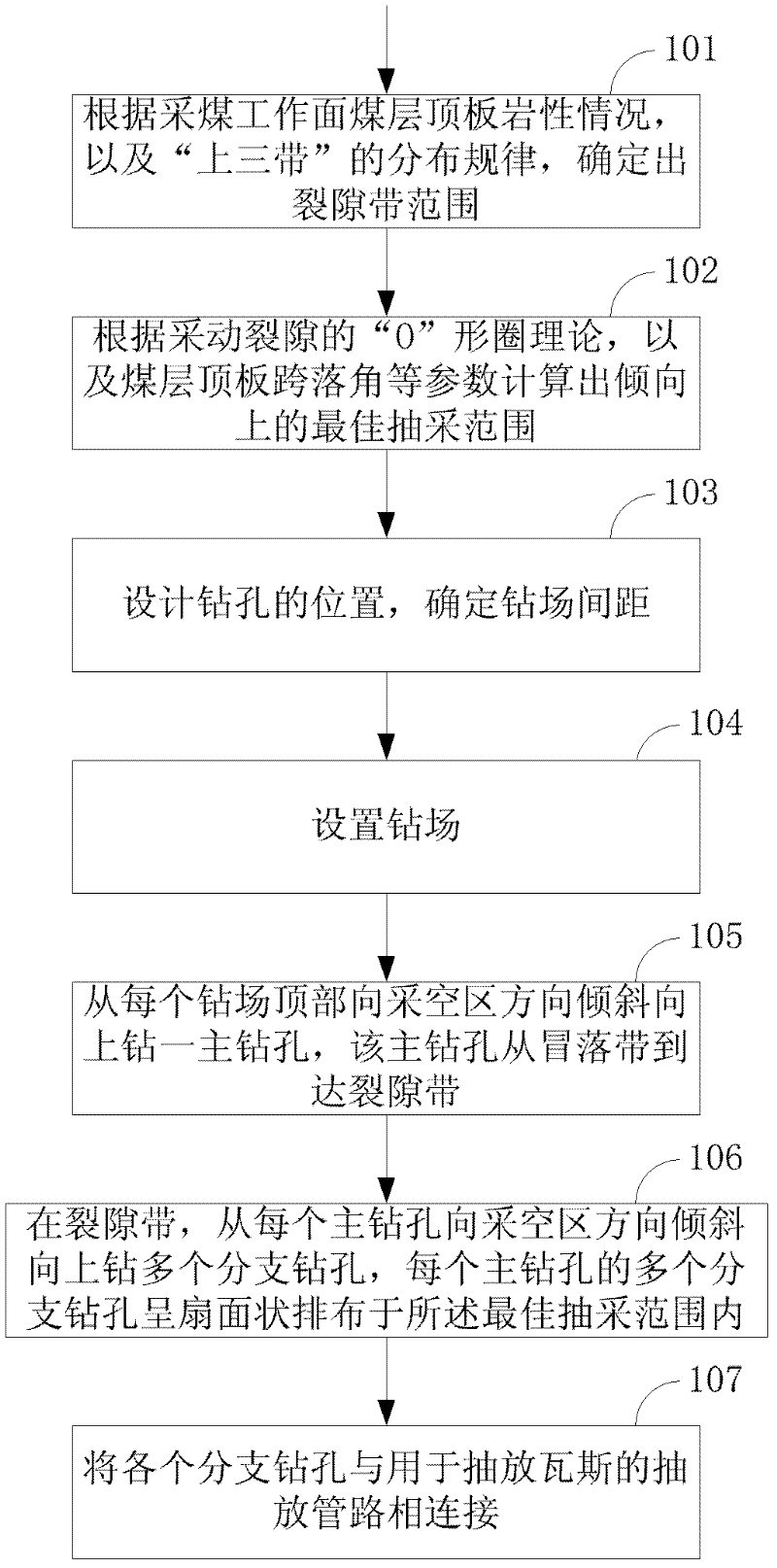

The invention discloses a method for extracting gas at a corner on a recovery working face in a coal mine, which comprises the steps of: A, predetermining the optimal extraction range and distance of drill sites; B, arranging the drill sites according to the distances of the drill sites; C, drilling a main drill hole upward from the top of each drill site toward a worked out section obliquely, wherein the main drill hole reaches a cracked zone from a caving zone; D, in the cracked zone, drilling a plurality of branch drill holes upwards from each main drill hole toward the worked out section obliquely, wherein the branch drill holes of each main drill hole are arranged in a fan shape in the optimal extraction range; and E, connecting the branch drill holes with extraction pipelines for extracting gas. By applying the method provided by the invention, when the mining work surface is advanced to the hole bottom, as the roof of a coal seam is carved automatically, the gas in the coal seam moves upward and adjacent coal seam is affected by the mining to release the pressure. The gas with pressure released moves toward a mined bed. Due to extraction negative pressure of the drill hole, the moving direction of gas is changed so that the gas is extracted to the extraction pipeline so as to reduce the gas amount pouring upward at the corner.

Owner:CHINA SHENHUA ENERGY CO LTD

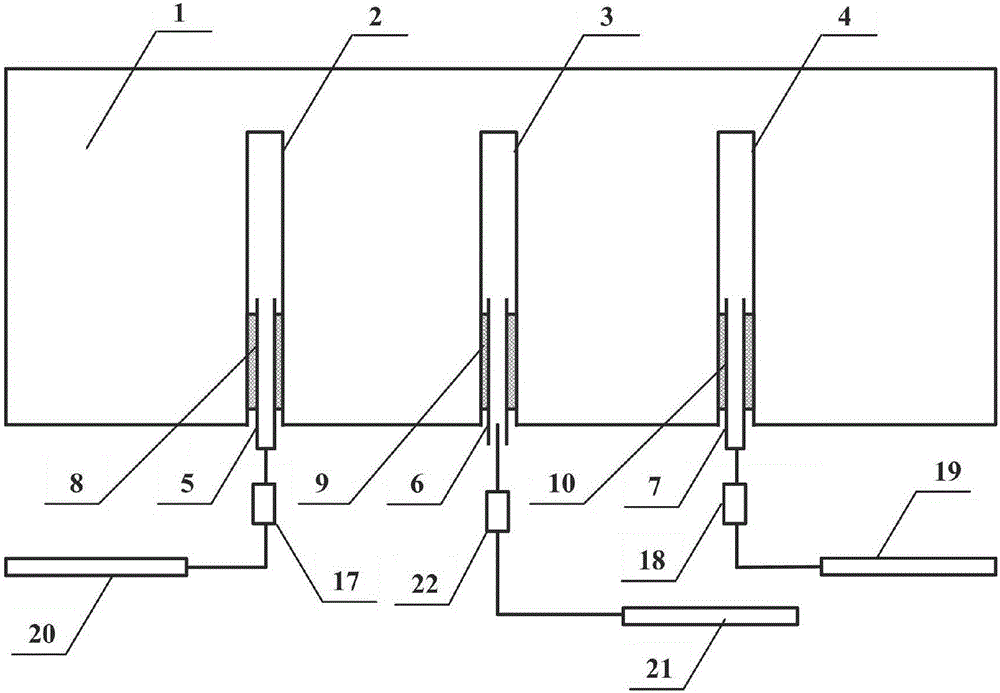

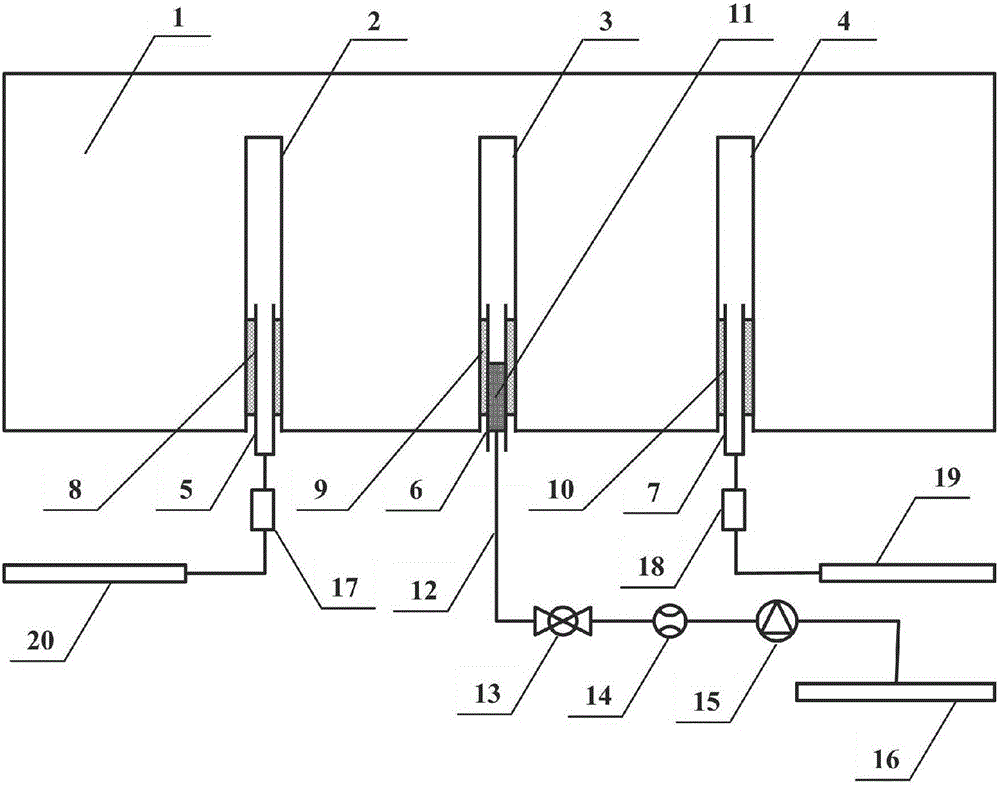

Method of using high-pressure water injection to prevent and treat gas coal dust

InactiveCN106703871AIncrease moisture contentLess gushSurveyDust removalWorking environmentHigh pressure water

The invention provides a method of using high-pressure water injection to prevent and treat gas coal dust, and relates to a method of using coal seam water injection to prevent and treat the gas coal dust. The method comprises the steps of constructing a bedding drainage borehole, inserting a drainage tube into the borehole, sealing a hole sealing section of the borehole, and beginning to conduct drainage of the gas in the coal seam; regarding a second borehole as a water injection hole, dismantling a second drainage pipeline and a second orifice plate flowmeter which are connected to the second drainage tube, and inserting an expansion hole packer into the second drainage tube; connecting the expansion hole packer with a high-pressure valve, a water injection flowmeter, a high-pressure water injection pump and an underground water supply pipe sequentially through a high-pressure rubber hose; utilizing the high-pressure water injection pump to inject water into a second borehole implement coal seam; turning off the high-pressure valve. According to the method, injection-drainage boreholes are utilized to alternately arrange and implement the coal seam water injection, the gas drainage amount of adjacent drainage boreholes can be increased, the gas gushing amount during digging is reduced, the water content of the coal seam is increased, the dust concentration during digging is reduced, the working environment of working staff is improved, and mine gas coal dust disasters are effectively prevented and treated.

Owner:NORTH CHINA INST OF SCI & TECH

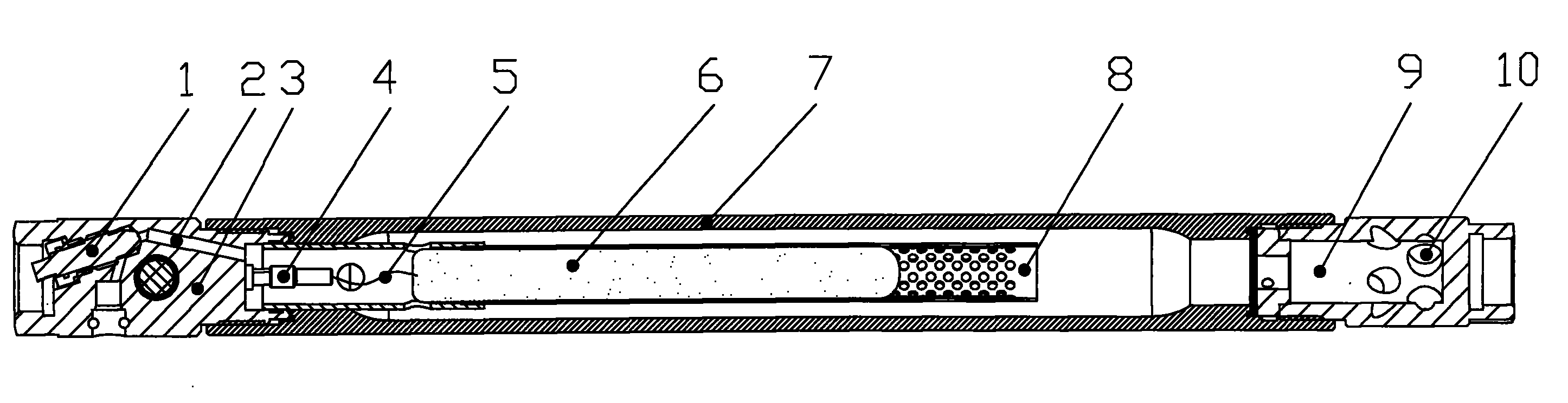

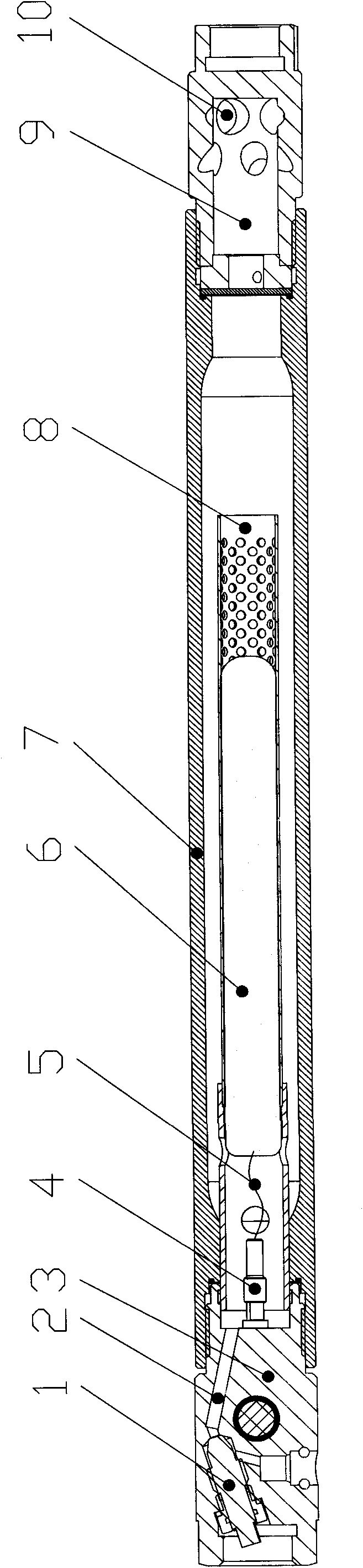

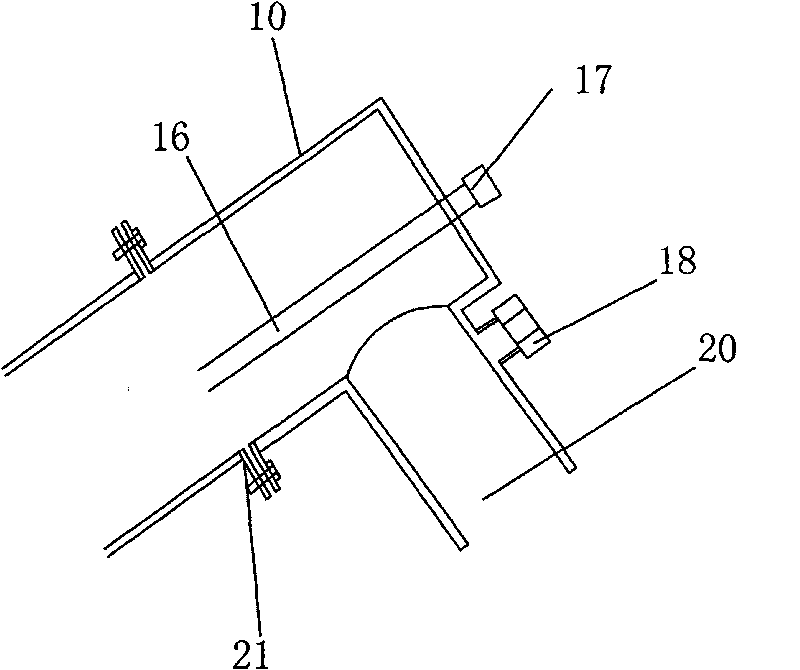

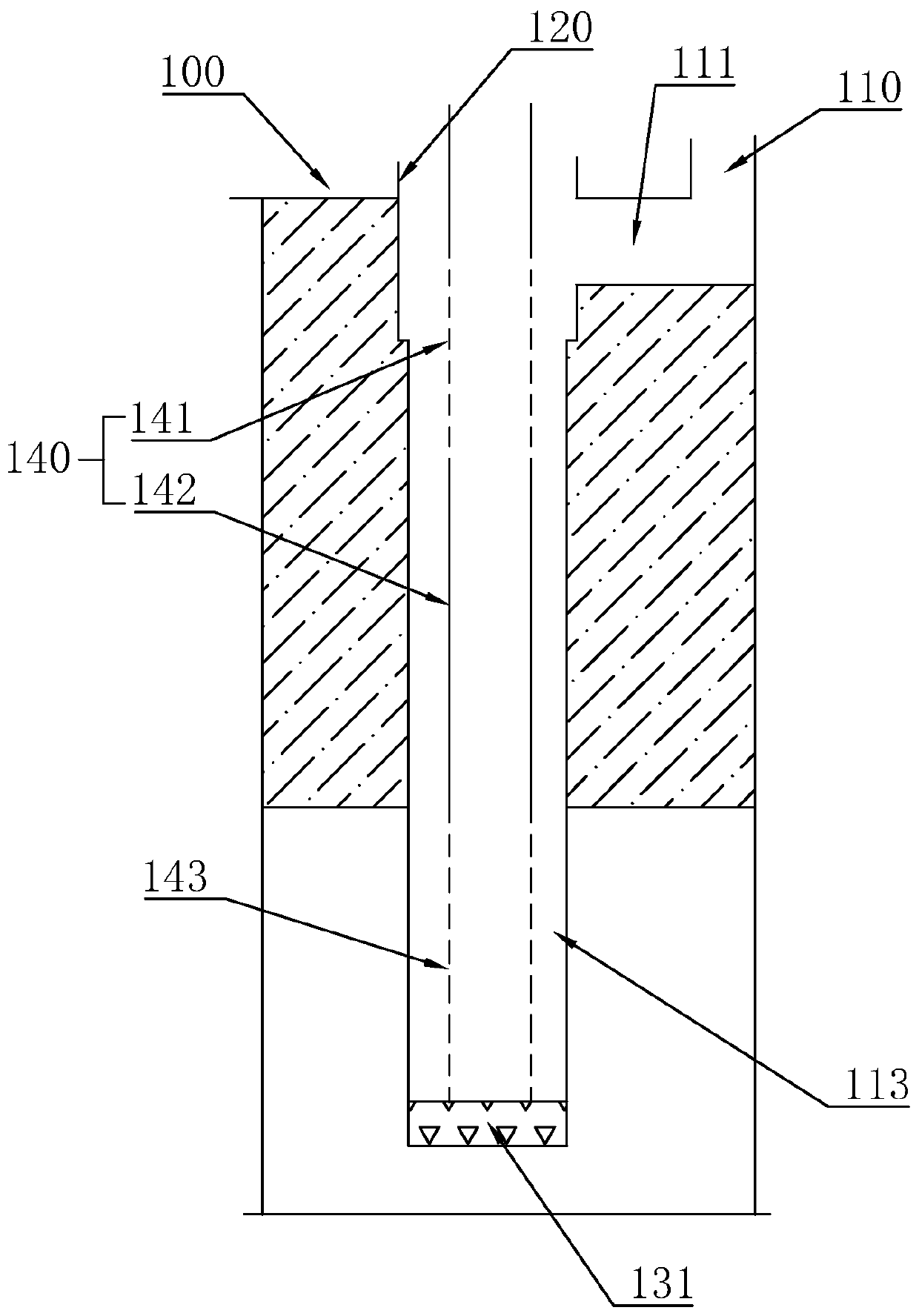

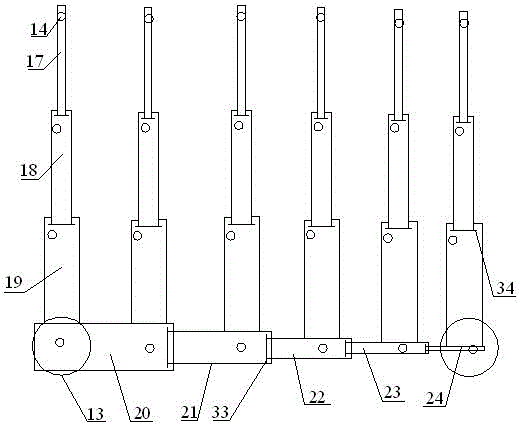

Device for pumping and draining water from downward hole of coal bed

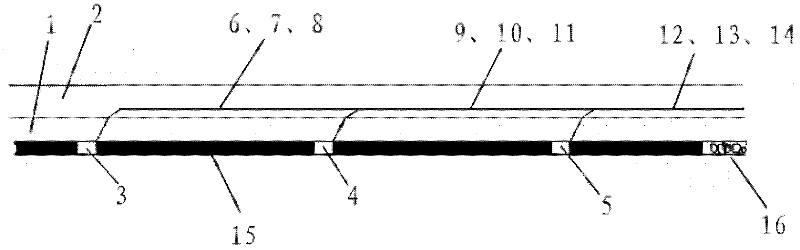

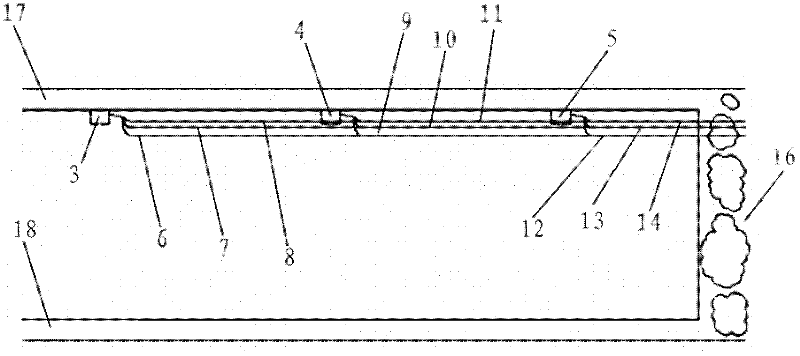

The invention relates to an auxiliary device for a drilling hole for gas drainage, in particular to a device for pumping and draining water from a downward hole of a coal bed, which solves the problems that the accumulated water in the downward hole of the coal bed cannot be drained out in time to influence the effect on gas drainage. The device comprises a liquid draining and pumping pipe, a drilling hole sealing device, and a drainage device provided with a first gate valve and a second gate valve, wherein the upper part of the drainage device is provided with a water inlet and a ventilation bolt of the drainage device, while the lower part is provided with a drainage bolt; the upper end of the drilling hole sealing device is connected with a hole connecting device; the upper end of the liquid draining and pumping pipe is extended in the hole connecting device, and a liquid guiding pipe is connected between the liquid draining and pumping pipe and the water inlet of the drainage device; and one side of the hole connecting device is provided with a first embedded wire pipe, and the second gate valve of the drainage device is connected with a second embedded wire pipe communicated with a gas drainage pipeline. The device can quickly and effectively drain out the accumulated water in the drilling hole to ensure the normal drainage and pumping of the drilling hole, improve the draining and pumping effect of the downward hole (or the drilling hole of a lower adjacent layer) of the coal bed, and reduce the gas content of the coal bed (or the lower adjacent layer) on a working surface; besides, the device has a simple structure and convenient connection and operation.

Owner:SHANXI COKING COAL GROUP

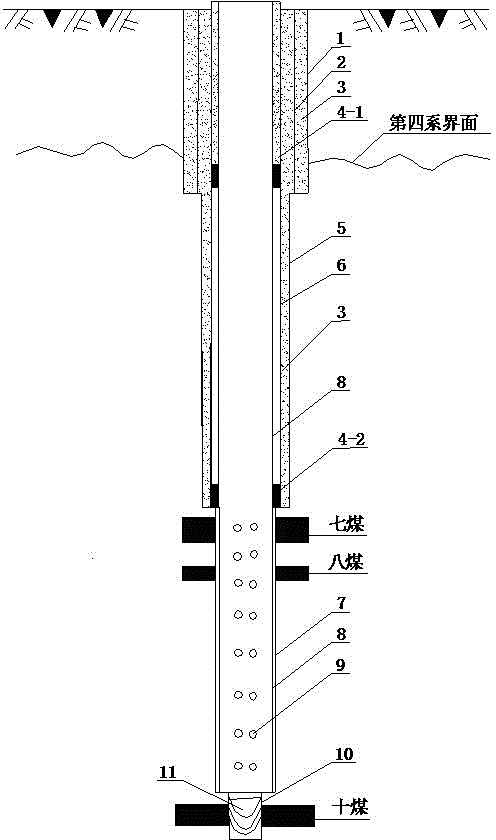

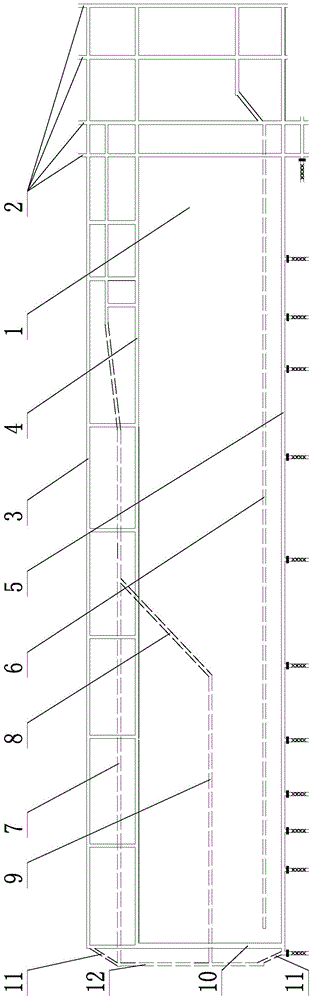

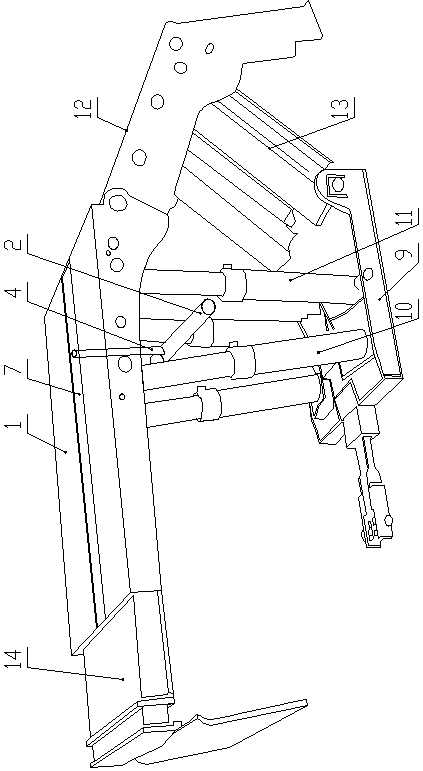

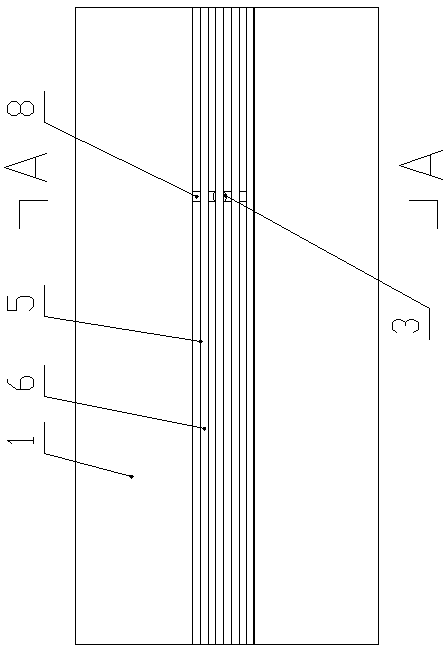

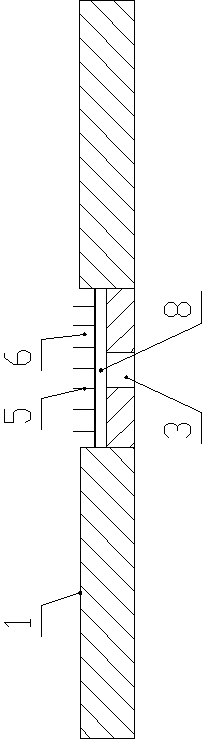

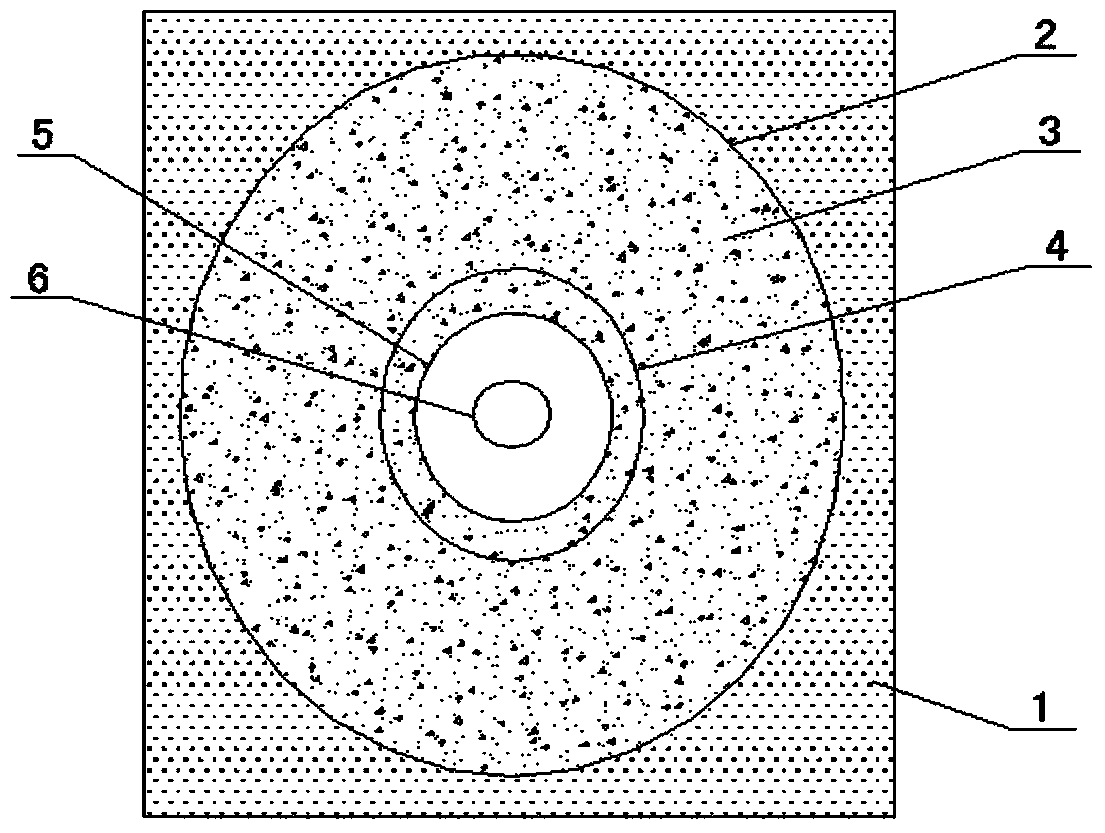

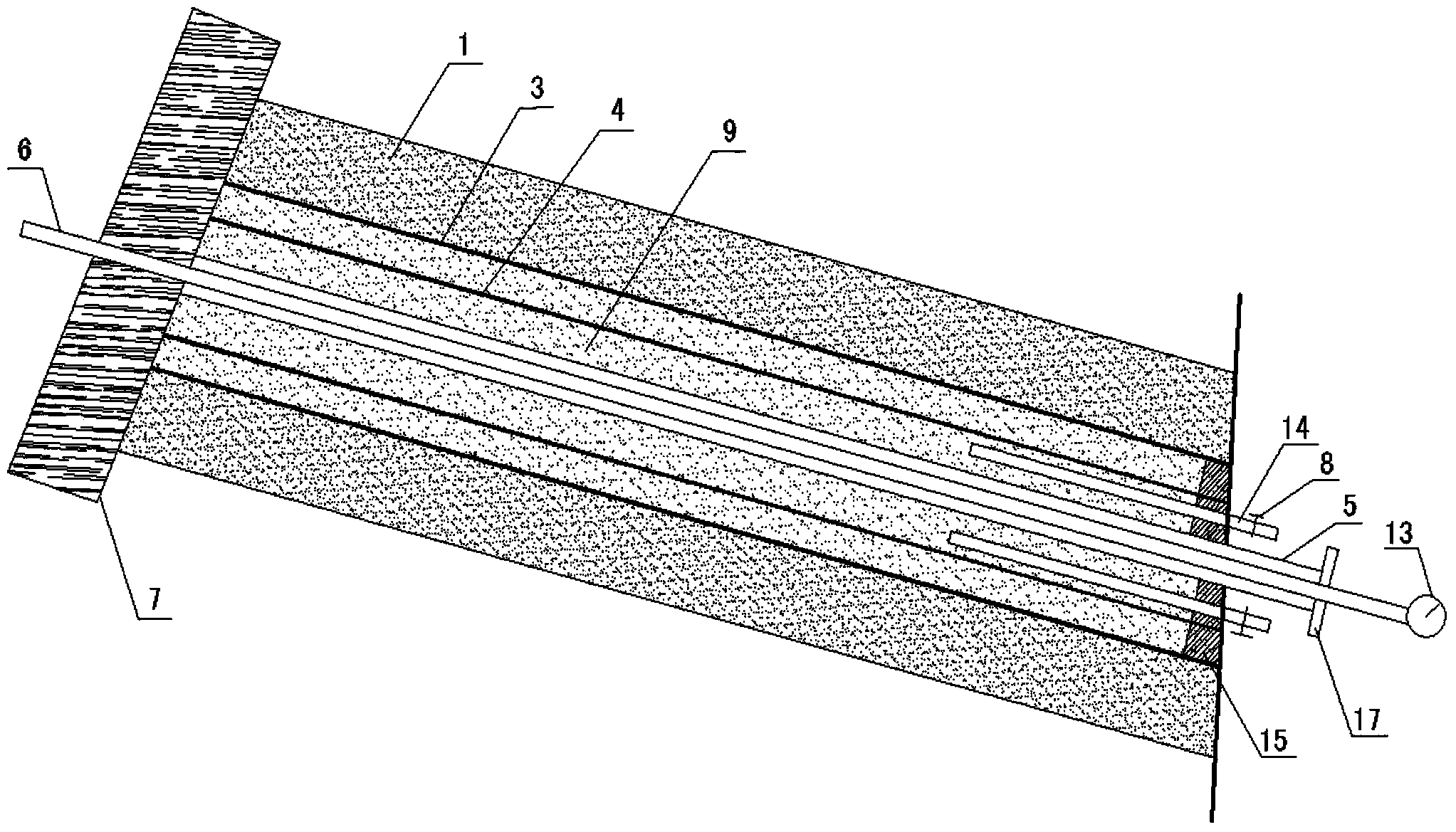

Upstream-blocking and downstream-seepage method for extracting gas in mining area

The invention discloses an upstream-blocking and downstream-seepage method for extracting gas in a mining area. The upstream-blocking and downstream-seepage method comprises the following steps of respectively drilling to a position which is 20-30m downward away from a fourth system interface, a position which is 5-6m upward away from a top plate of a seventh coal bed, a position which is 7-8m upward away from a top plate of a tenth coal bed and a position which is 3-5m downward away from a base plate of the tenth coal bed by using drill bits with different sizes and drilling to form a first drilling hole (1), a second drilling hole (5), a third drilling hole (7) and a fourth drilling hole (10); respectively driving a first casing pipe (2), a second casing pipe (6), a third casing pipe (8) and a cork (11); forming through holes (9) in the lower part of the third casing pipe (8), mounting expanding rubber between the second casing pipe and the third casing pipe and closing, then cleaning a well and extracting the gas. According to the upstream-blocking and downstream-seepage method disclosed by the invention, the problem that gas extraction is influenced due to the fact that a mining well seeps water can be effectively solved, the gas in the coal beds is released to the maximum extent and the extracting rate of the gas is increased; meanwhile, predominant threat of the seventh coal bed, the eighth coal bed and the ninth coal bed can be eliminated, the gas emission quantity of a mining face is reduced and the safety of mine production is ensured.

Owner:HUAIBEI MINING GRP EXPLORATION ENG +1

Combined spontaneous gas and coal combustion control method during roof cutting lane forming non-pillar mining

InactiveCN107725097ALess gushImprove recovery speedDust removalFire preventionCombustionLiquid carbon

The invention discloses a combined spontaneous gas and coal combustion control method during roof cutting lane forming non-pillar mining. A middle laneway left in a roof cutting lane forming non-pillar technology is fully used; in the combined spontaneous gas and coal combustion control method, an E-shaped working face ventilating system and a goaf stepping-type pipelaying and liquid carbon dioxide injection technology are used; the E-shaped working face ventilating system consists of two side laneways, a middle laneway, mining area downhill (uphill) lanes and contact lanes; the E-shaped working face ventilating system is used for controlling gas gushing from a current stoping working face; the goaf stepping-type pipelaying and liquid carbon dioxide injection technology is used for controlling spontaneous coal combustion in a goaf. By the combined spontaneous gas and coal combustion control method used in the stoping working face, the gushing amount of the gas during stoping of the working face is effectively reduced, dangers of gas over-limitation in the stoping working face and spontaneous coal combustion in the goaf are avoided, the stoping speed of the working face is increased, the coal recycling rate and the working face stoping connection speed are increased, and the safe production of the working face is guaranteed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Gas control method for large-mining-height working face of high gas coal seam

The invention provides a gas control method for a large-mining-height working face of a high gas coal seam, and belongs to the technical field of safety of mines. The gas control method comprises the steps of arranging a first bed extraction tunnel during excavating at the working face; upwards arranging a crossing hole through the first bed extraction tunnel to pre-extract gas; arranging and cutting holes in the bed extraction tunnel to pre-extract gas; arranging an inclined connection roadway to form a ventilation circuit; arranging a second bed extraction tunnel and a connection roadway; pre-extracting gas through the crossing hole which is upwards arranged through the first bed extraction tunnel; arranging a high extraction tunnel to reach a gob caving slit band; arranging the crossing hole in the high extraction tunnel; pumping gas at the high extraction tunnel. According to the gas control method for the large-mining-height working face of the high gas coal seam, gas pumping drilling holes are arranged in each tunnel, a gas treatment scheme under the combination of the bed extraction tunnel, the high extraction tunnel and the current coal seam extraction is created, and therefore, the gas emission rate in the excavating and recovery periods at the working face can be effectively reduced, the continuing speed of recovery at the working face is raised, the gas accumulated at the working face and upper corners and ultralimit of gas can be effectively avoided, and as a result, the safety in production at the working face can be ensured.

Owner:LIAONING TECHNICAL UNIVERSITY

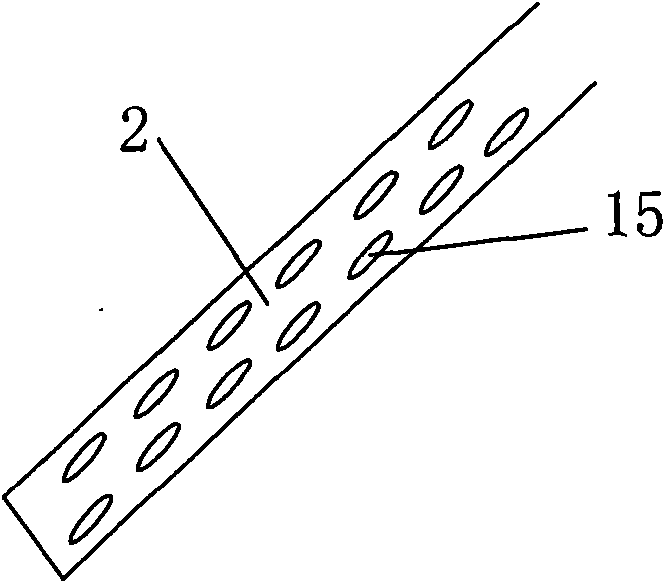

Long standpipe gas extraction in worked-out section

InactiveCN101029574AIncrease extraction concentrationThe extraction concentration is reducedUnderground miningSurface miningEngineeringGas concentration

This is a gas extraction method via a long vertical pipe at goaf zone. Two holes are made on the top and bottom board of the air gallery at the working face. Sectional metal pipes are linked together to form a long vertical pipe, with the top sealed and inserted into the hole on the top board, and the bottom inserted into the bottom board and concreted. Small holes distributes on the pipe wall and been wrapped with pack. The pipe is connected to the extraction network. With 5m of the pipe getting into the goaf zone, start extraction; with the previous pipe getting into the goaf zone at 30m, and the following one at 5m, shut the previous pipe and open the following one. So realize a continuous extraction and decrease the gas concentration at the solid angle. The gas concentration could be controlled under 0.6%.

Owner:淮北矿业股份有限公司祁南煤矿 +1

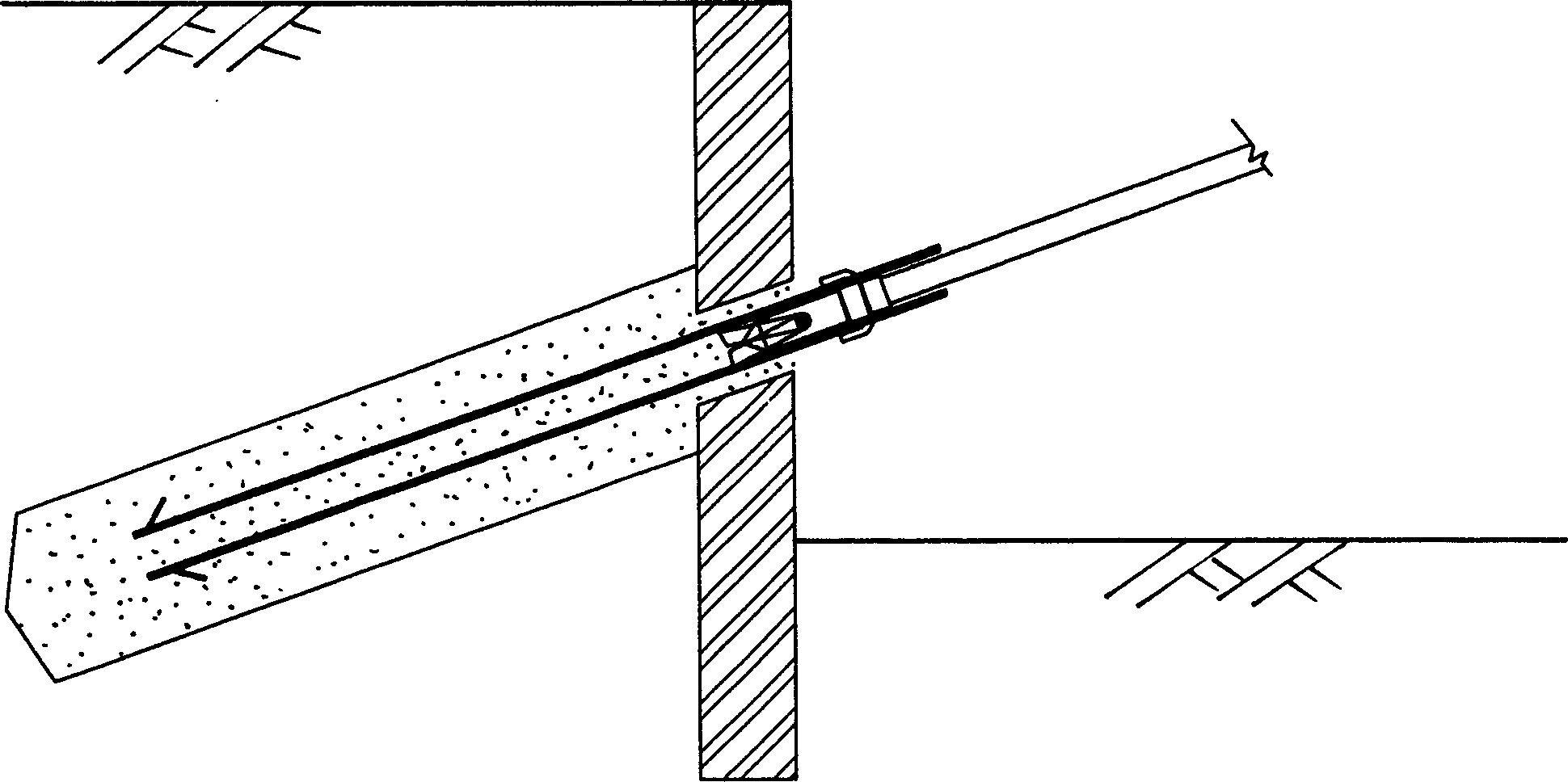

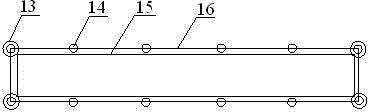

Roofbolt constructing method in civil engineering

InactiveCN1584245ALow costReduce construction proceduresBuilding reinforcementsCement slurryRock bolt

The present invention discloses an anchor rod construction method used in the civil engineering field. The described anchor rod construction is characterized by that the drill rod and drill bit are fixedly connected together, a movable hook is cover-mounted on the drill rod or drill bit, the movable hook and anchor bar are connected by adopting clasp joint mode. When the drill bit is forwards drilled, the anchar bar also can be driven and also forward advanced, then the solidifying materials of cement slurry, etc. are injected into the hole by means of drill rod, and after the solidifying materials are reached to predefined hole depth, the components, of drill rod and drill bit can be drawn out, the remained anchor bar and solidifying materials can be formed into anchor rod together.

Owner:GUANGDONG JINHUIHUA GROUP

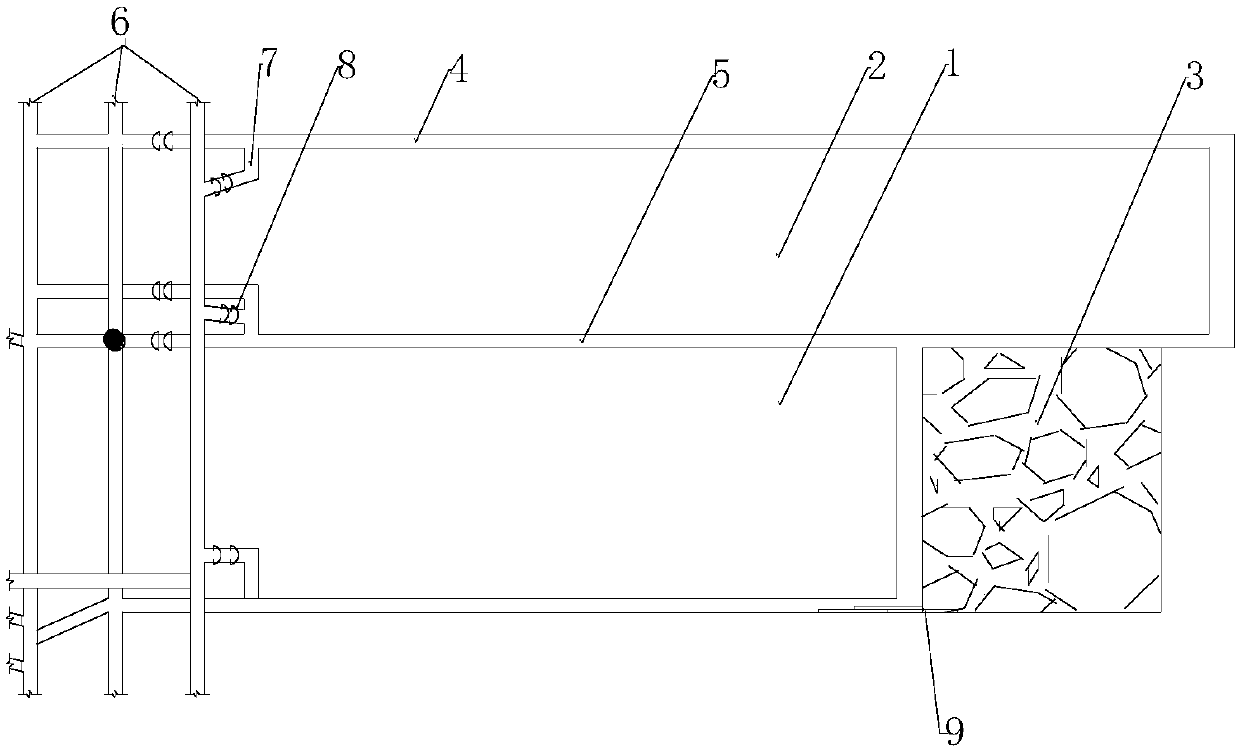

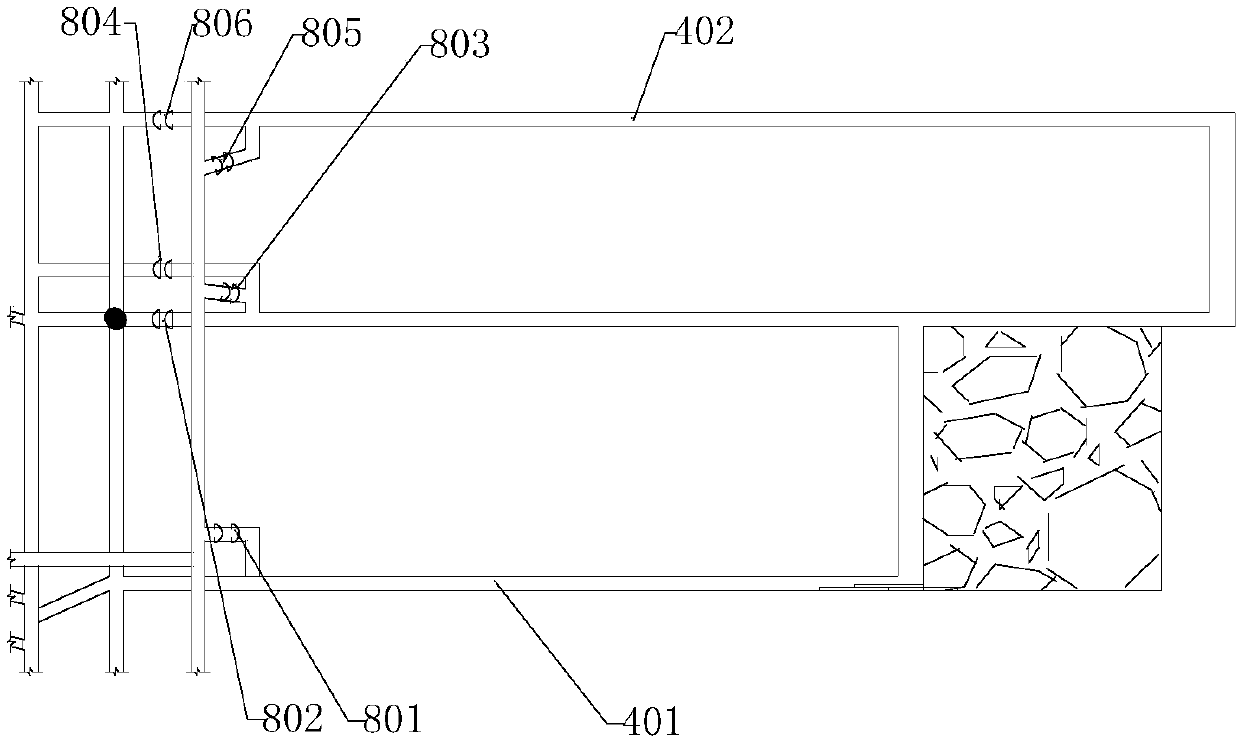

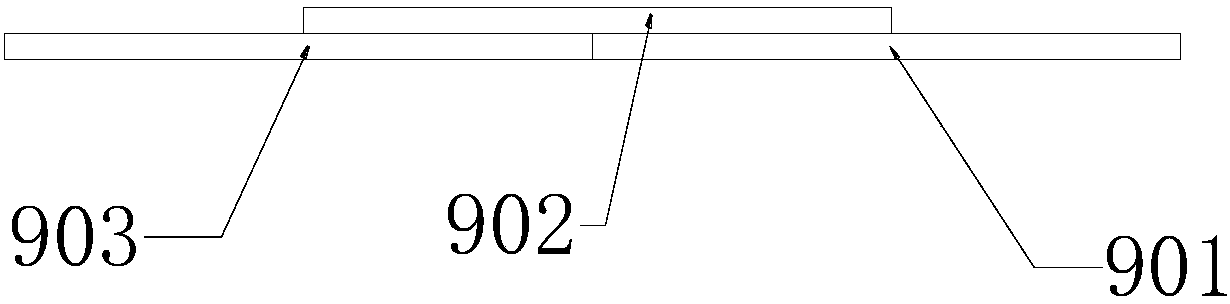

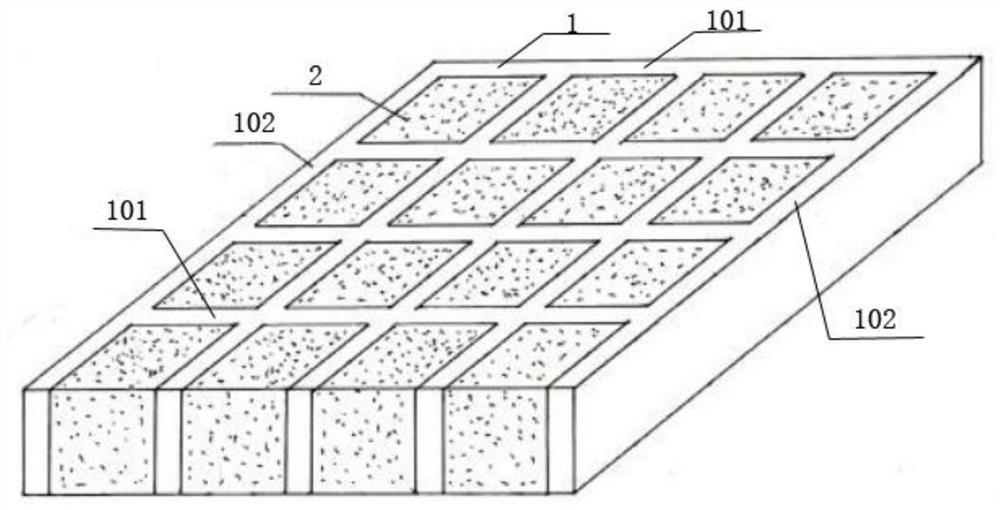

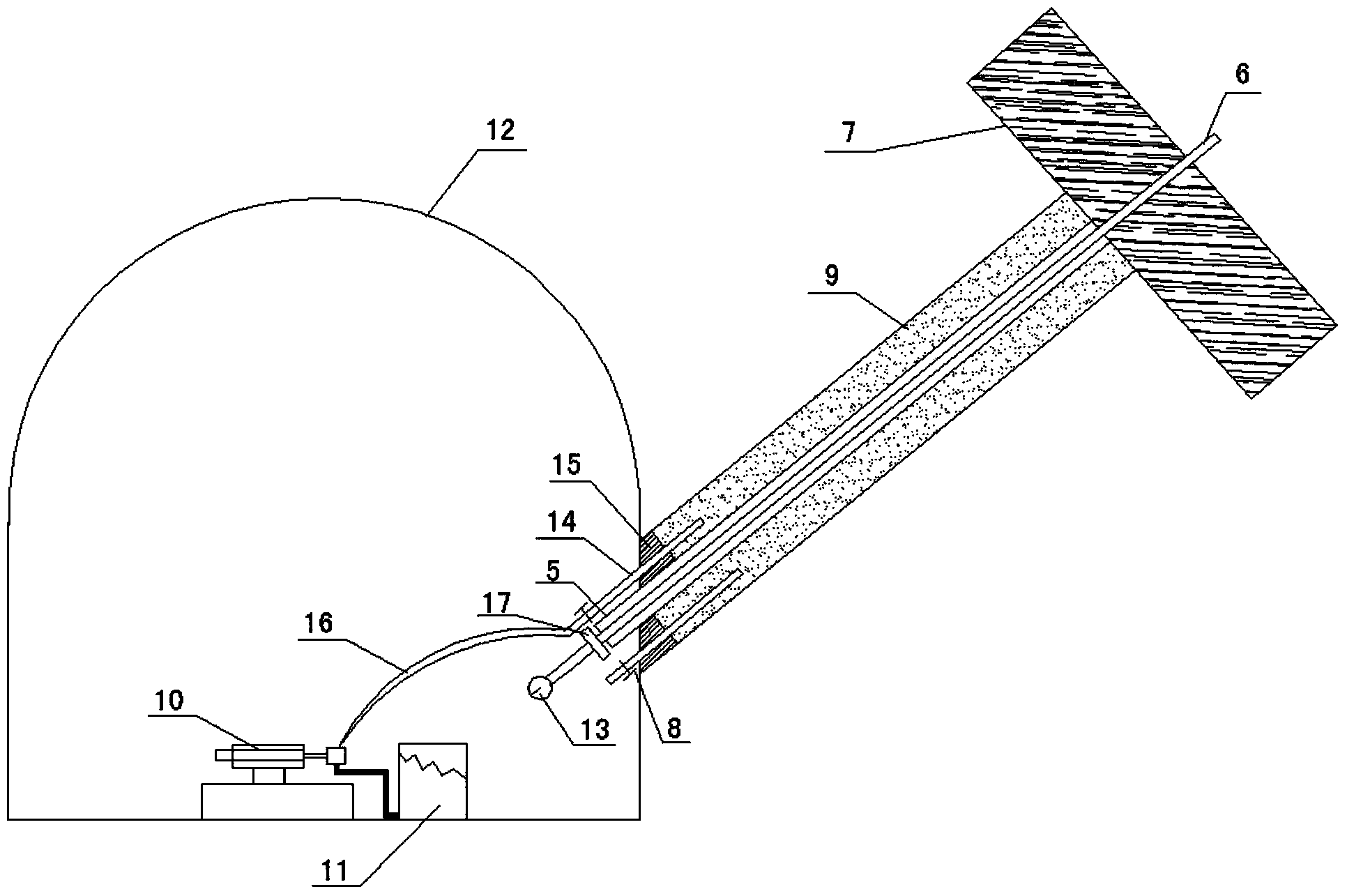

Fully mechanized caving face supporting top coal gas extraction system

A fully mechanized caving face supporting top coal gas extraction system comprises hydraulic supports. A top beam is arranged on the tops of the hydraulic supports, a groove is formed in the middle of the top beam in the length direction, a supporting main pipe is arranged below the top beam, an extraction hole communicated with the groove is formed in the top beam and connected with the supporting main pipe through a supporting branch pipe, the top beam is provided with at least one partition board in the length direction of the bottom surface of the groove, the partition board separates the groove to form extraction grooves, and ventilation groove holes enabling all the extraction grooves to be communicated are formed in the two sides of an upper end of the extraction hole of the top beam. According to the system, the fully mechanized caving face gas concentration can be reduced, the transfinite gas condition is reduced, the extraction rate and the yield of a working face are improved, the system has promotional value in national coal mine, fully mechanized caving face safety conditions are improved, the yield of coal is increased, and economic and social benefits are remarkable.

Owner:HENAN POLYTECHNIC UNIV

Double-roadway arrangement non-pillar mining method for high-gas-burst coal seam

InactiveCN108005655AReduce useless excavationLess gushUnderground miningSurface miningPeak valueUltimate tensile strength

The invention discloses a double-roadway arrangement non-pillar mining method for a high-gas-burst coal seam and belongs to the field of underground coal mine supporting and mining. The double-roadwayarrangement non-pillar mining method comprises the steps that an outer side roadway of a double-roadway tunneling working face is arranged outside a supporting pressure peak value area through a project analogy method or a stress monitoring method; during double-roadway tunneling, the length of a connection roadway between double roadways is 150-200 m, and thus the supporting cost is reduced; when the working face is stoped, gob-side entry retaining is conducted along the inner side roadway, air enters from two crossheading grooves of the working face, and the two crossheading grooves and theouter side roadway form a Y-shaped ventilation system; double-roadway tunneling of the next working face is also conducted through the method, and the air return roadway of the previous working faceis also turned into the air inlet roadway; and the steps are repeated, and high-gas-burst coal seam non-pillar mining of all the working faces is completed sequentially. By adopting the double-roadwayarrangement non-pillar mining method for the high-gas-burst coal seam, the roadway tunneling quantity can be decreased, the invalid roadway tunneling and outer side roadway supporting strength and cost are reduced, and non-pillar mining is achieved.

Owner:CHINA UNIV OF MINING & TECH

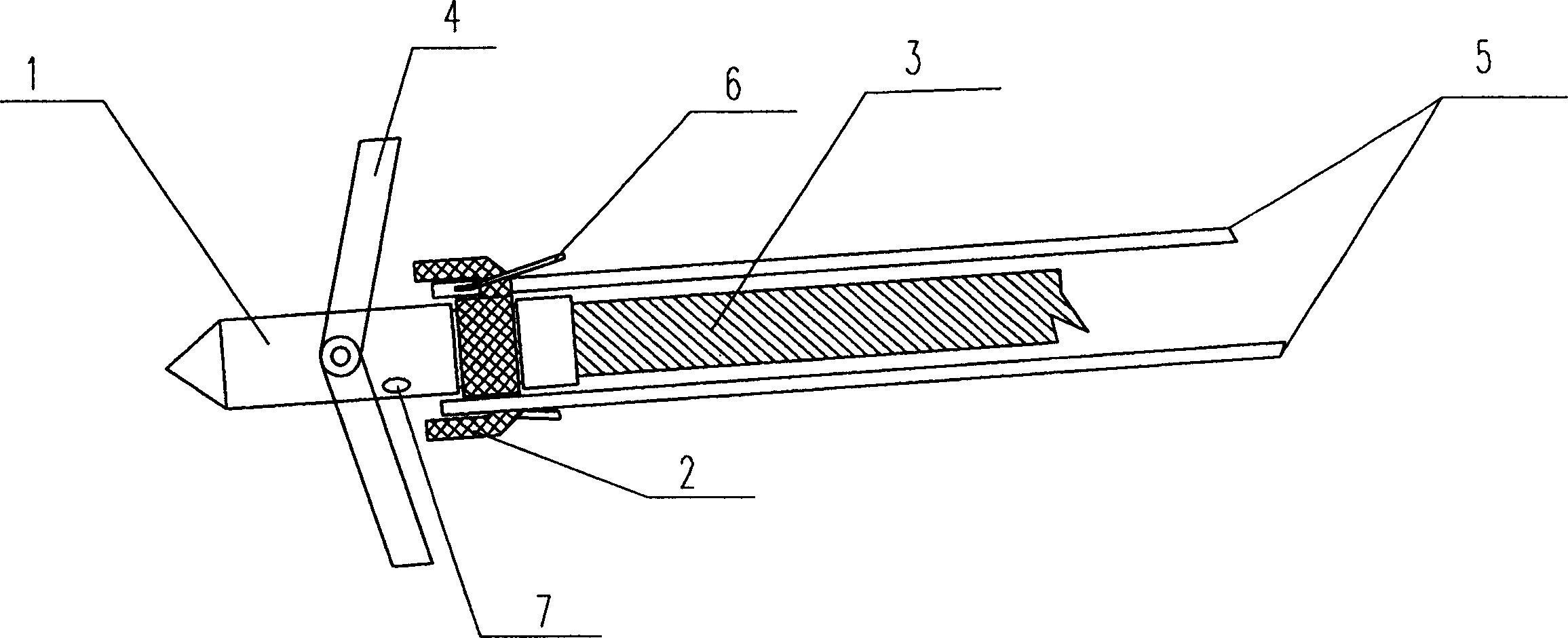

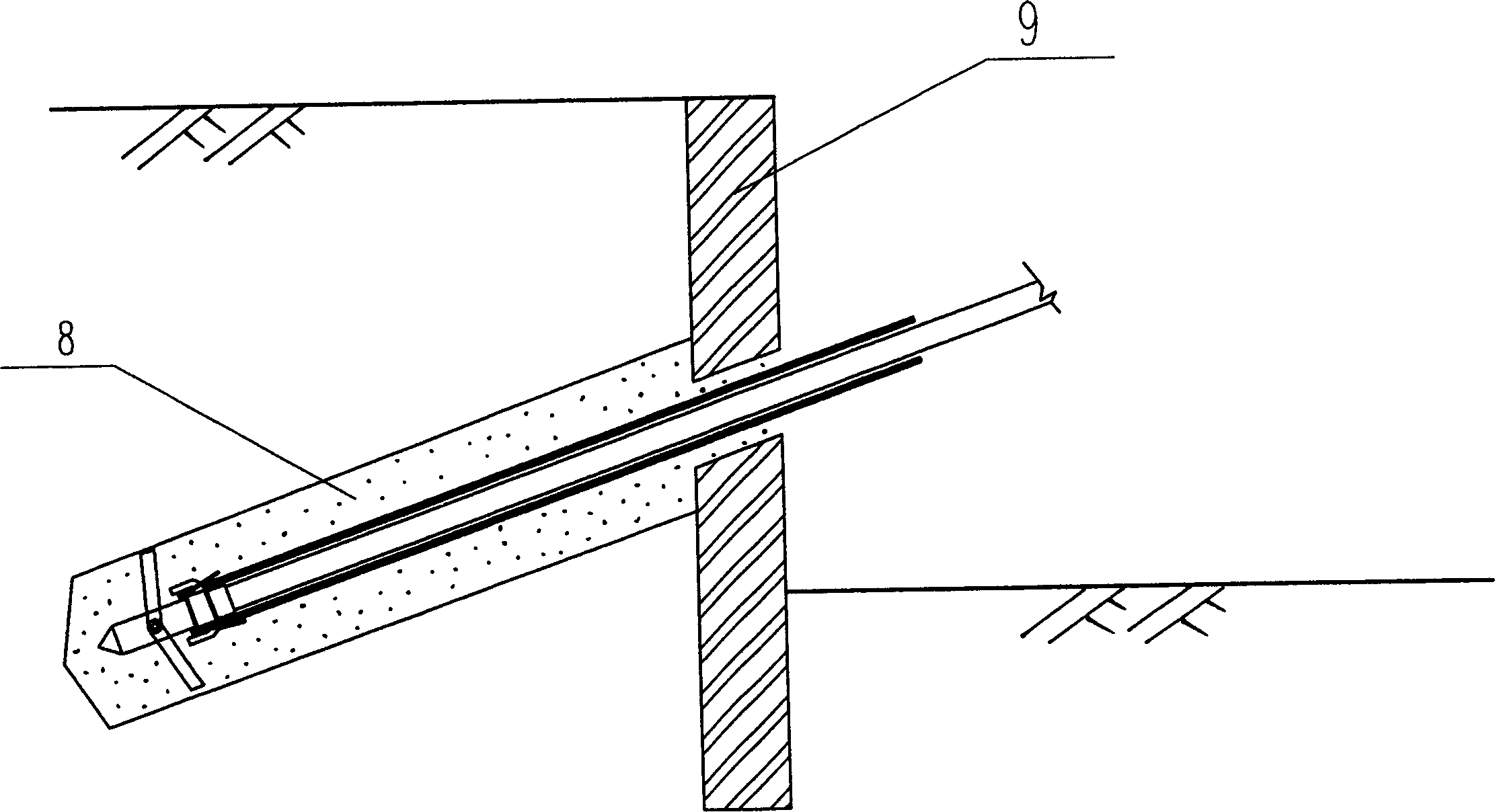

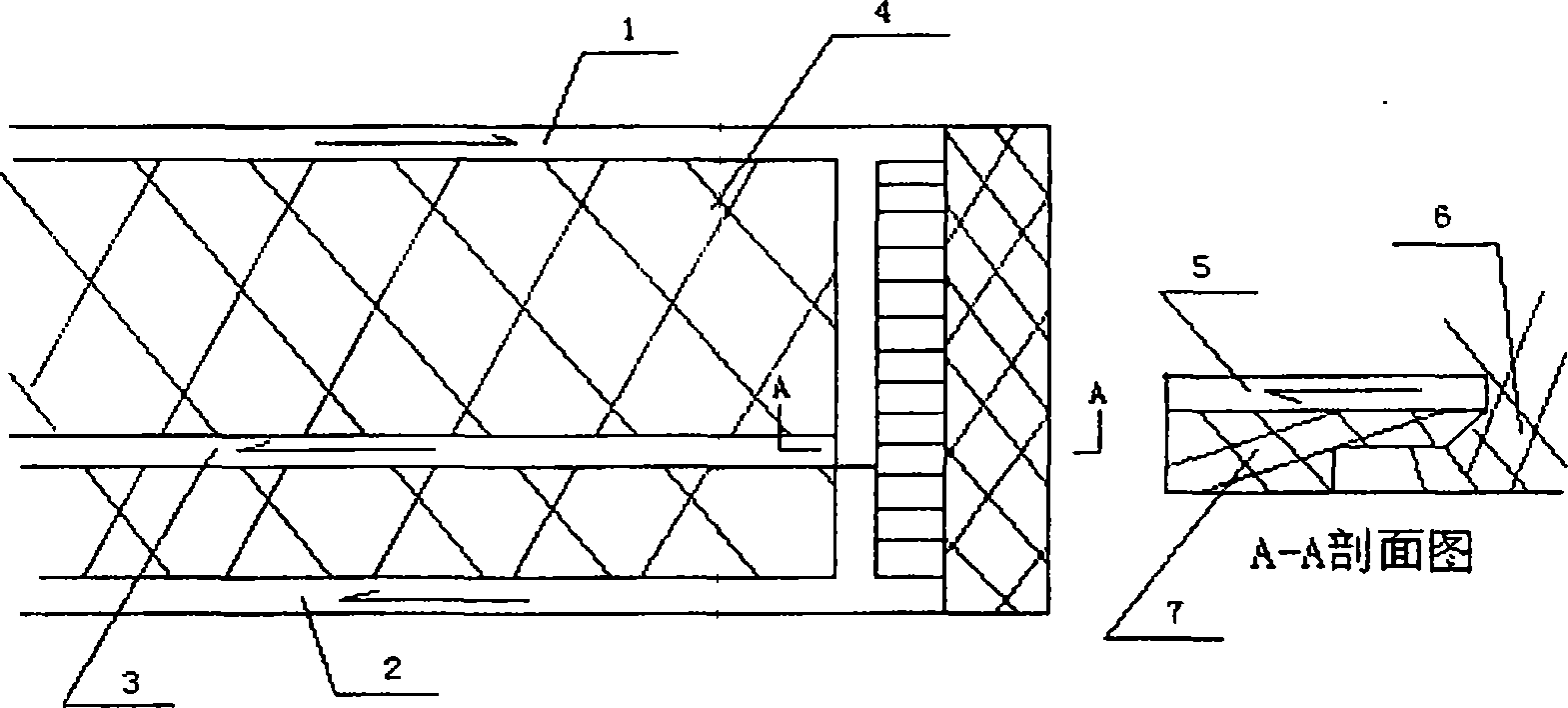

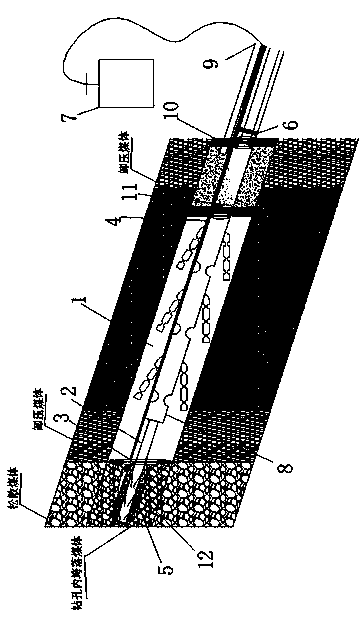

Filling and reinforcing method for floor roadway cross-layer pressure-relief borehole

The invention discloses a filling and reinforcing method of a floor roadway cross-layer pressure-relief bore hole, and is particularly adaptable to filling and reinforcing the cross-layer pressure-relief bore hole for pre-drainage of coal roadway strip gas in loose high-outburst coal seams. The method includes injecting a gas drainage pipe, a slurry injection pipe and a gas discharge pipe into the pressure-relief bore hole, and draining gas after slurring injecting and hole sealing; when gas draining flow is reduced to 0.5m3 / d, pressurizing and filling material slurry into the pressure-relief bore hole, and allowing the slurry to fill the pressure-relief bore hole and penetrate to surround coal through fracture networks. By the aid of the filling and reinforcing method, a reinforcing area can be formed in the coal, support and protect conditions of the coal roadway are improved, coal gas accidents are controlled effectively, speed of tunneling the coal roadway is increased greatly; the magnitude of two-side deformation of the coal roadway can be reduced to 40-60%, gas flowing-out amount is reduced to 30%, and the speed of tunneling the coal roadway is increased to 50%, and the filling and reinforcing method has excellent market promoting value.

Owner:CHINA UNIV OF MINING & TECH

Method for controlling gas of mountain angle and worked-out section by one-in one-out and alternate tail lane ventilation mode

InactiveCN101220749AIncrease ventilation pressureLow ventilation pressureTunnel/mines ventillationGas removalCoal mine methaneEngineering

The invention provides a method which disposes gases at corners and goaf by a one-intake one-return staggered tail tunnel ventilation type, which solves the problem that a plurality of gases are accumulated at the air return corners. The invention is characterized in that a working face air inlet tunnel and an air return tunnel are arranged along the soleplate of no. 15 coal; the staggered tail tunnel is arranged along the top plate of the no. 15 coal, which has the horizontal distance of 10-15m with the air return tunnel generally; a wind absorbing port extends at least more than 5m into a coal wall along the goaf direction, namely, the wind absorbing port is lagged by more than 5m compared with the stope air return port of the fully mechanised working face; the wind absorbing port is vertically higher than the soleplate of the stope space of the working face by nearly 5m, which is arranged at the upper wind side of the mechanised working face wind return corner and also at the top layer of the no. 15 coal layer; the wind inlet gateway and the wind return gateway are arranged along the soleplate of the coal layer and are supported by an iron shed, with the profile of 9m2; the staggered tail tunnel has 10m away from the wind return gateway horizontally, is arranged along the top plate of the no. 15 coal layer, and supported by anchors with the tunnel profile of 8m<2>; the invention has the advantages of convenient construction, safety and reliability, convenient management, low cost and obvious effect. The invention is especially suitable for gas disposal of coal mine.

Owner:山西华阳集团新能股份有限公司

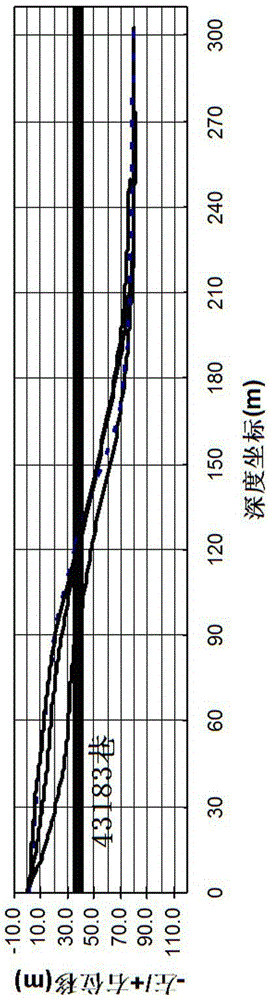

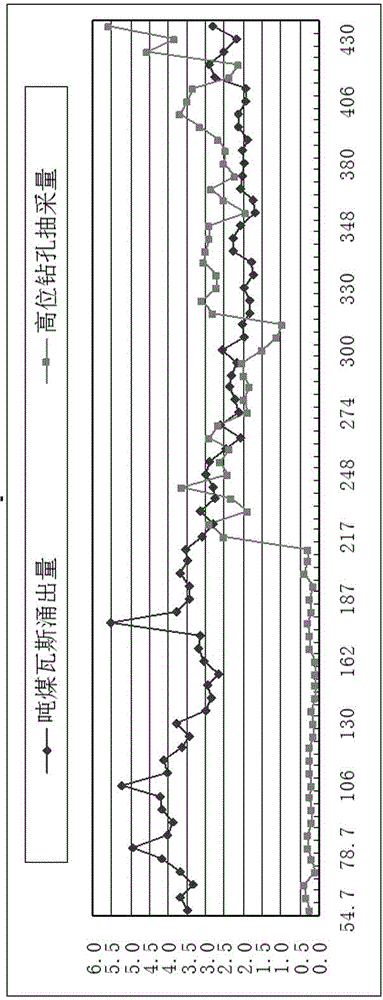

Goaf roof high-position directional borehole gas extraction technology

The invention relates to the gas extraction technology, and specifically relates to a goaf roof high-position directional borehole gas extraction technology, and solves problems that the goaf gas extraction is high in extraction cost and low in drivage efficiency and the like. The technical scheme is that a kilometer directional drilling machine is employed to construct high-position boreholes in a mining pressure field on the goaf, one high-position borehole is in the upper part, one high-position borehole is in the middle part, one high-position borehole is in the lower part, the goaf is divided into a coal pillar section and a goaf section, the coal pillar section is actual coal, the goaf high-position boreholes can be constructed in a caving zone and a fissure zone of the coal pillar section, after the boreholes come out from the coal pillar section and enter the goaf section, the boreholes need to be lifted to the fissure zone, and the lifting height is not less than 35 m. By researching the mine pressure rule of the coal working face, three zones of the goaf and the position of the gas enriched zone can be determined, by means of long-distance positioning capability of the directional drilling machine, directional boreholes are constructed in the gas enriched zone in the goaf overlying strata, goaf gas is extracted, and the aim of managing goaf gas is achieved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

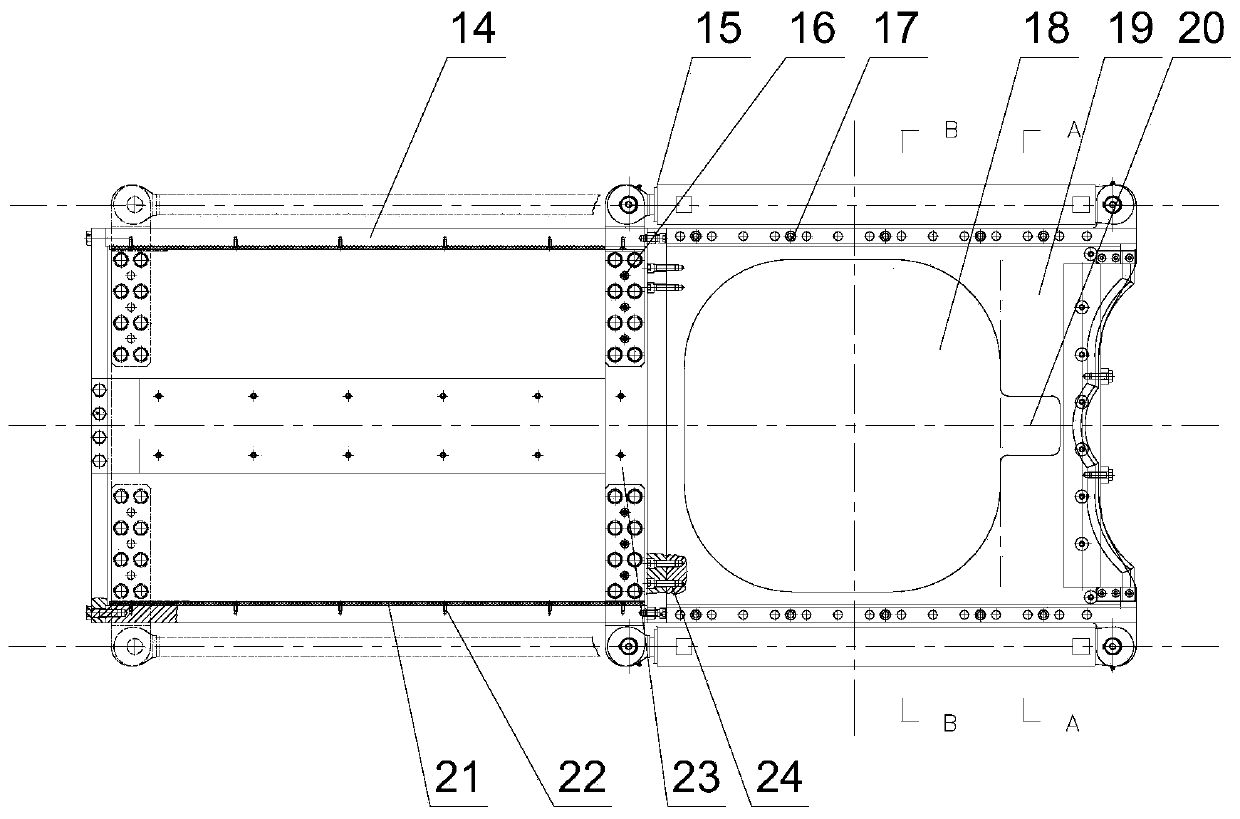

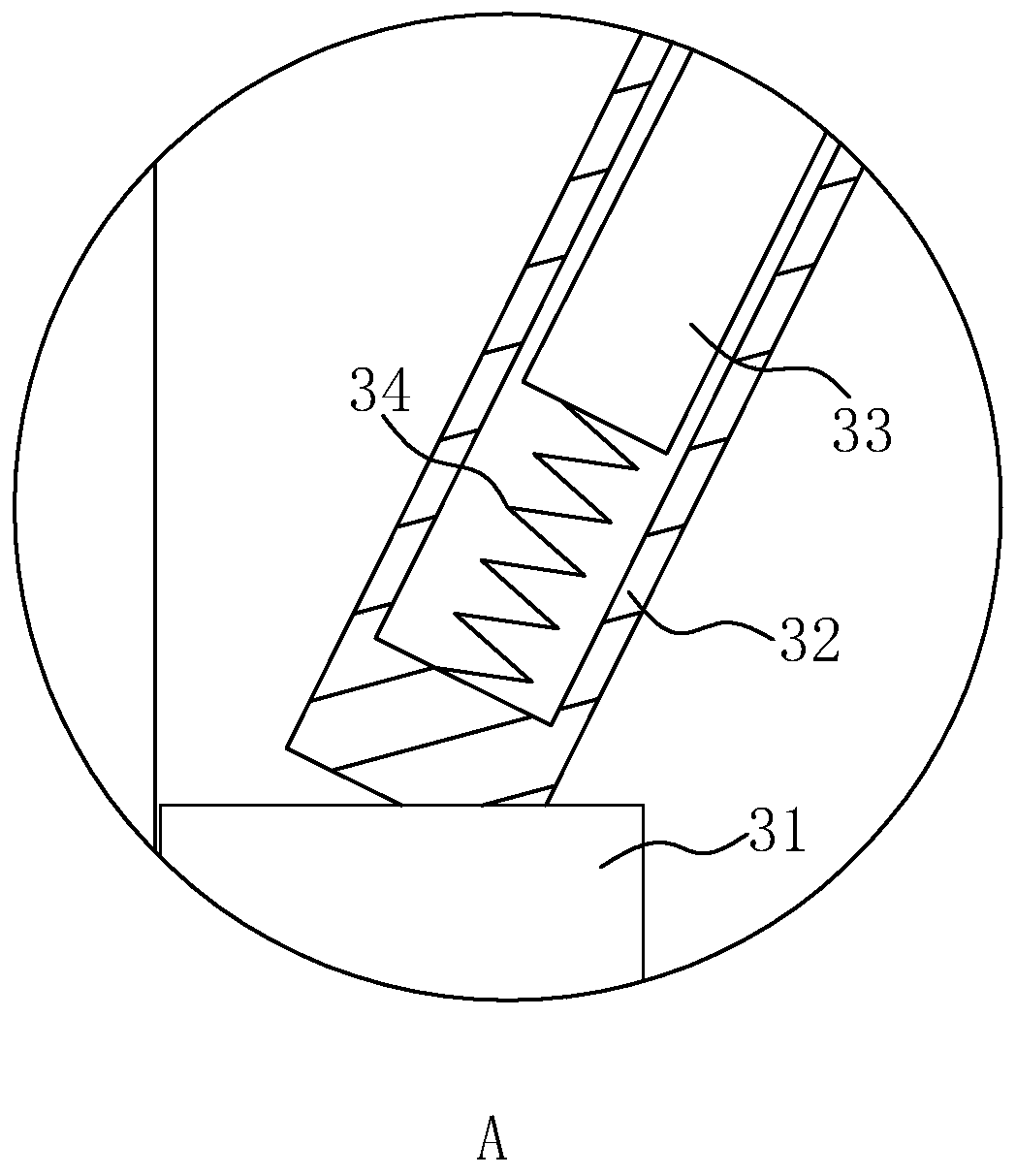

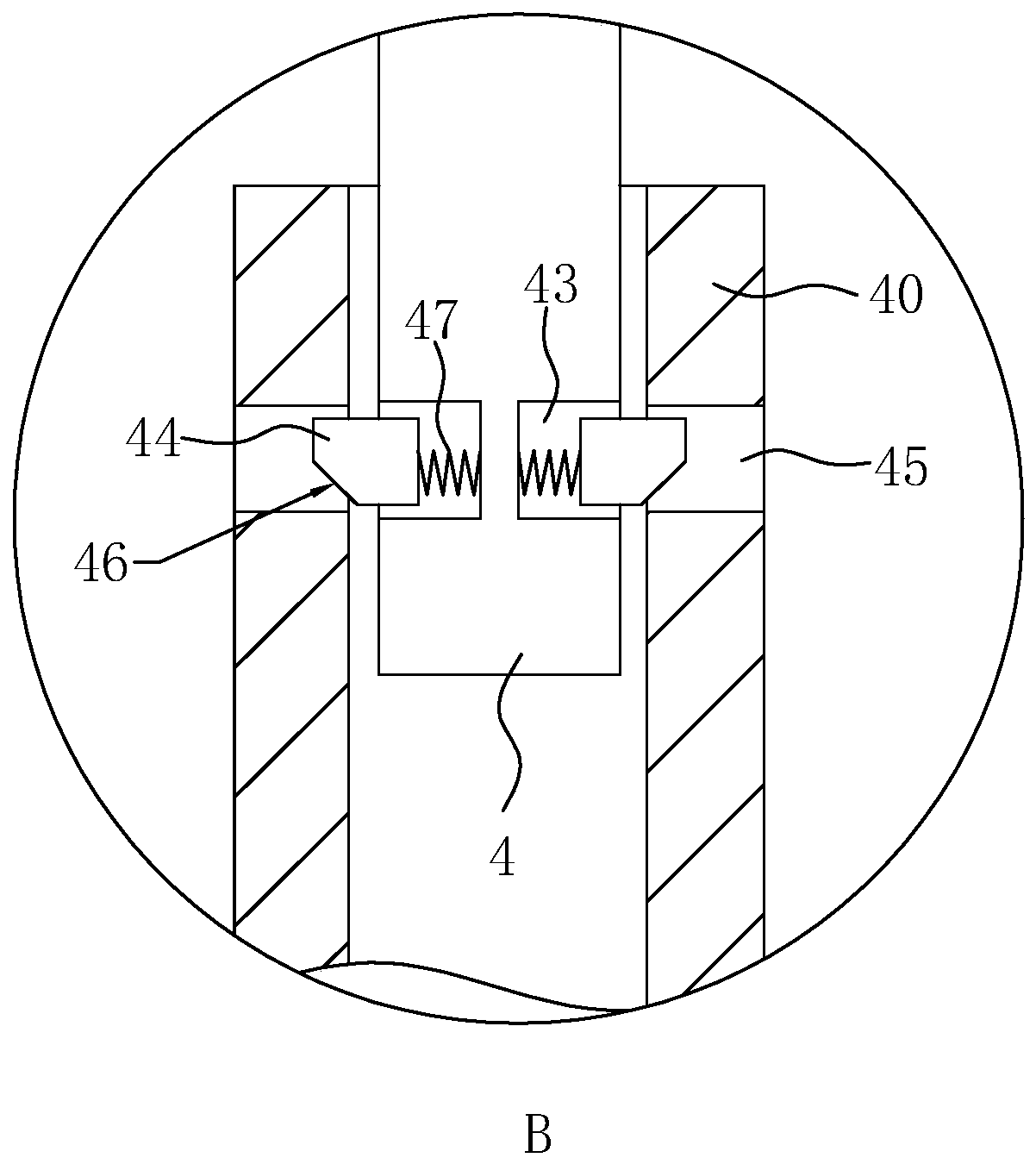

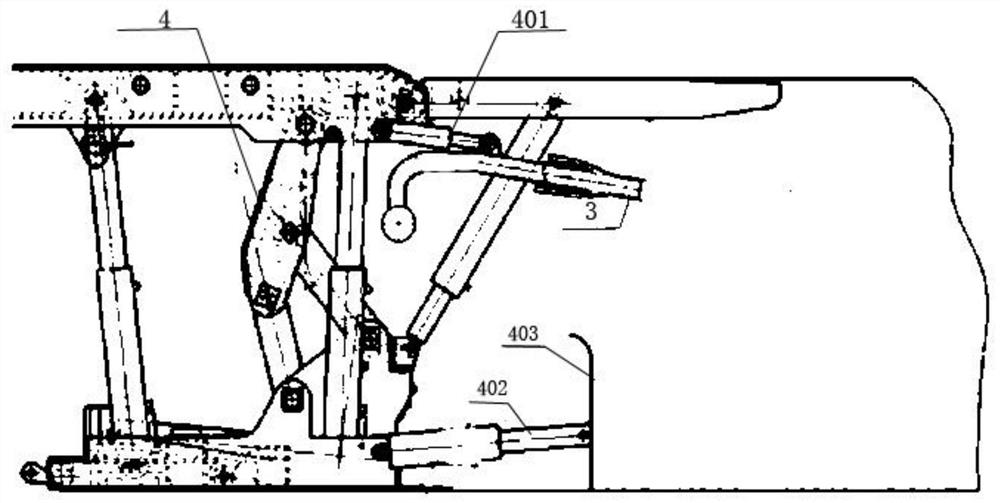

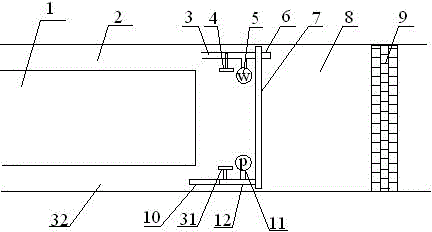

Earth pressure balance shield structure with gate anti-spewing structure and shield method

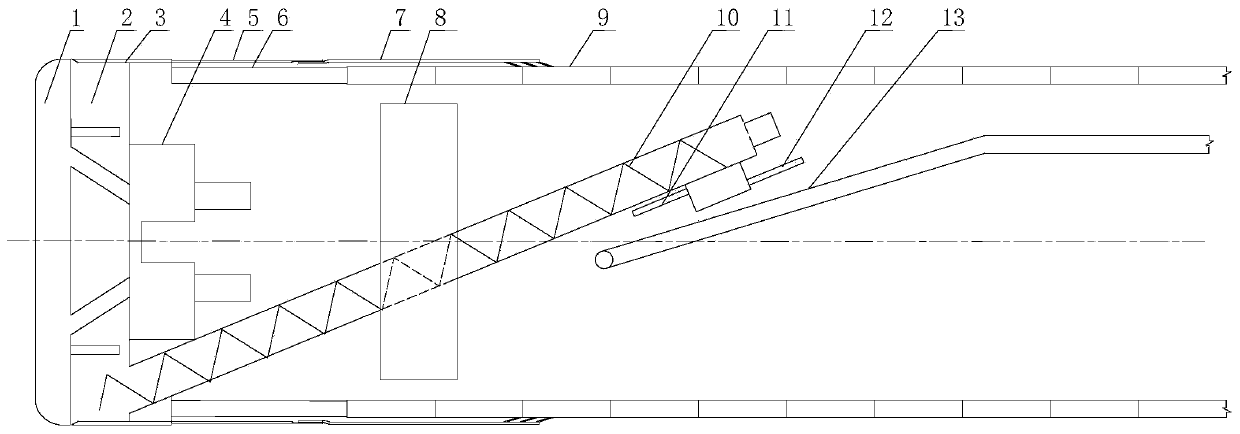

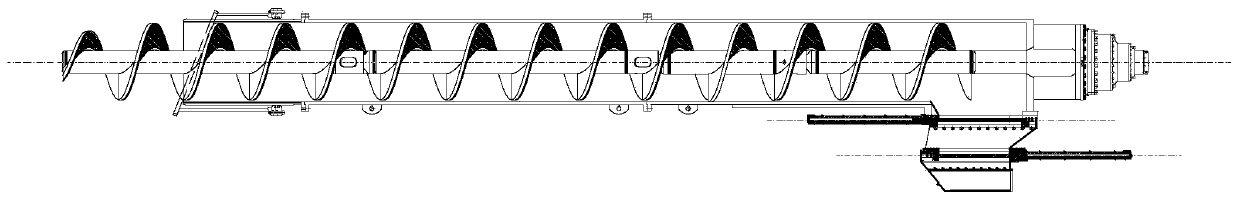

The invention discloses an earth pressure balance shield structure with a gate anti-spewing structure and a shield method. The structure comprises a cutterhead, a front shield, a main drive, a middleshield, a shield tail, a thrust cylinder and a spiral conveyor, wherein the thrust cylinder is propped against the front end surface of a tube piece; a soil cabin is arranged at the back of the cutterhead; the main drive is arranged at the back of the soil cabin; an opening is formed in the lower part of the soil cabin; a rotating shaft of the spiral conveyor is arranged at the lower part of the soil cabin; the spiral conveyor is arranged in an inclined manner; a slag falling opening of the spiral conveyor is provided with an upper gate mechanism and a lower gate mechanism; residue soil fallsonto a belt of a belt machine system through the upper gate mechanism and the lower gate mechanism; the upper gate mechanism is provided with an upper gate plate, a first slag falling opening and an anti-spewing slag falling opening; and the lower gate mechanism is provided with a lower gate plate and a second slag falling opening. The dilute slag passing area is small, the residue soil spewing amount is small, and the belt in operation can be effectively conveyed. The anti-spewing structure of an earth pressure balance spiral conveyor gate solves the spewing problem more directly and effectively, and has large popularization prospect.

Owner:POWERCHINA RAILWAY CONSTR +1

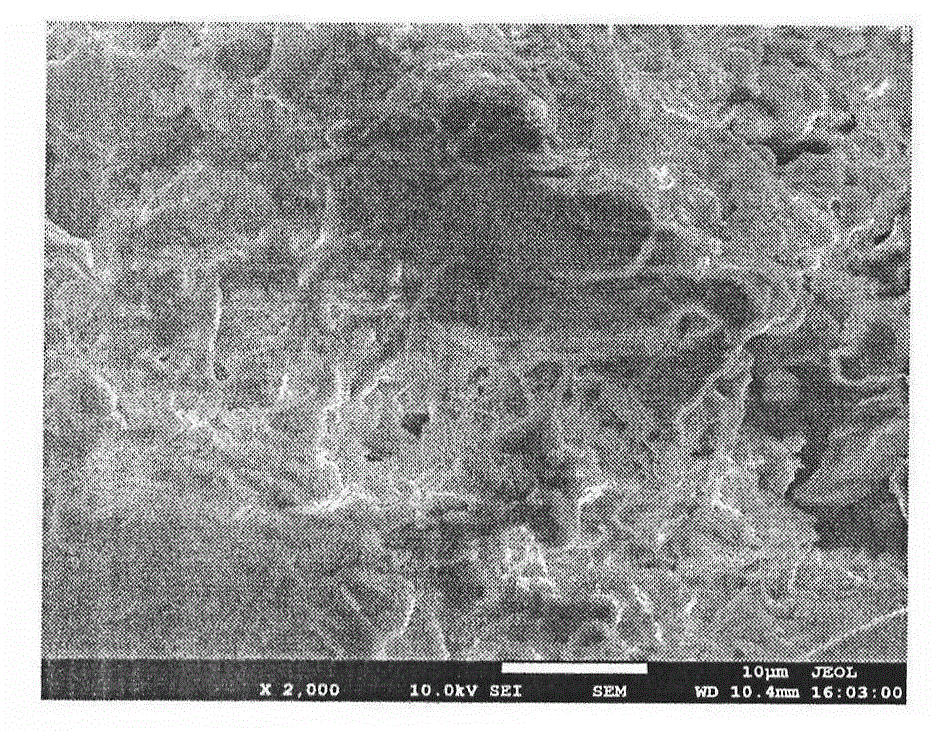

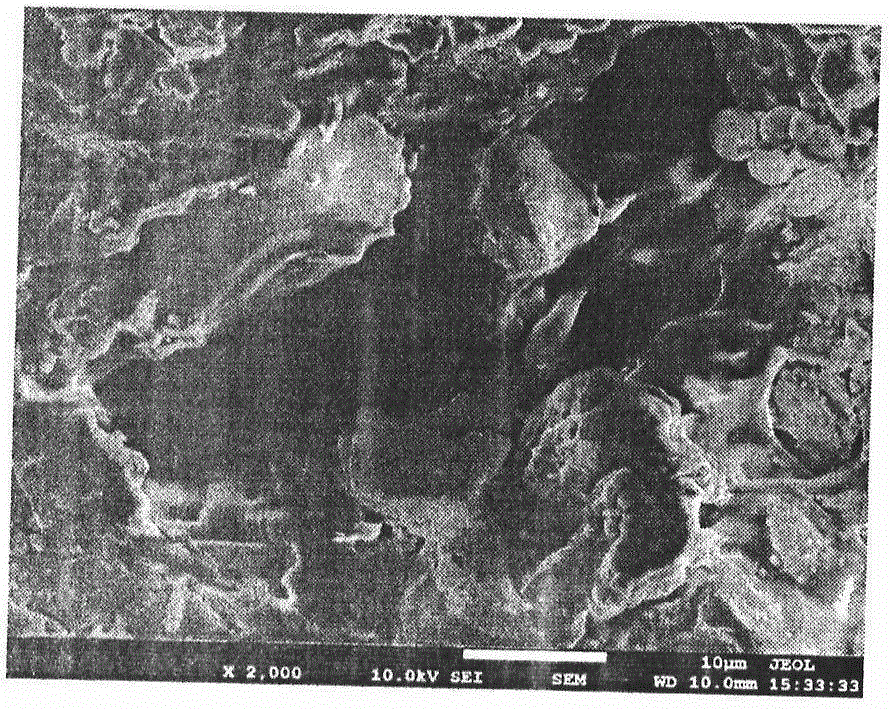

Gas plugging coating for wall surface of mine laneway

ActiveCN104650664ALess gushSlow down and stabilize gushFireproof paintsElectrically-conductive paintsSlagChlorinated paraffins

The invention relates to the technical field of coal mine safety, and particularly relates to a gas plugging coating for the wall surface of a mine laneway. The gas plugging coating is capable of reducing the concentration of gas inside the mine laneway, enabling the gas to uniformly effuse and reducing the cost. The gas plugging coating for the wall surface of the mine laneway comprises a liquid material and a powder material according to the mass percent of (40-55):100, wherein the liquid material is an elastic polymerized emulsion, the elastic polymerized emulsion is an anionic acrylate emulsion or a styrene-acrylate emulsion; the powder material comprises the following components in percentage by weight: 50%-80% of micropowder coal ash, 0%-30% of cement, 3%-5% of graphite, 0%-2% of carbon black, 7%-12% of chlorinated paraffin and 3%-8% of aluminum hydroxide; and the particle diameter of the micropowder coal ash is 1-10 micrometers, and the cement is 325# portland slag cement or higher-grade cement. The gas plugging coating disclosed by the invention is mainly applied to the aspect of coal mines.

Owner:SHANXI UNIV +1

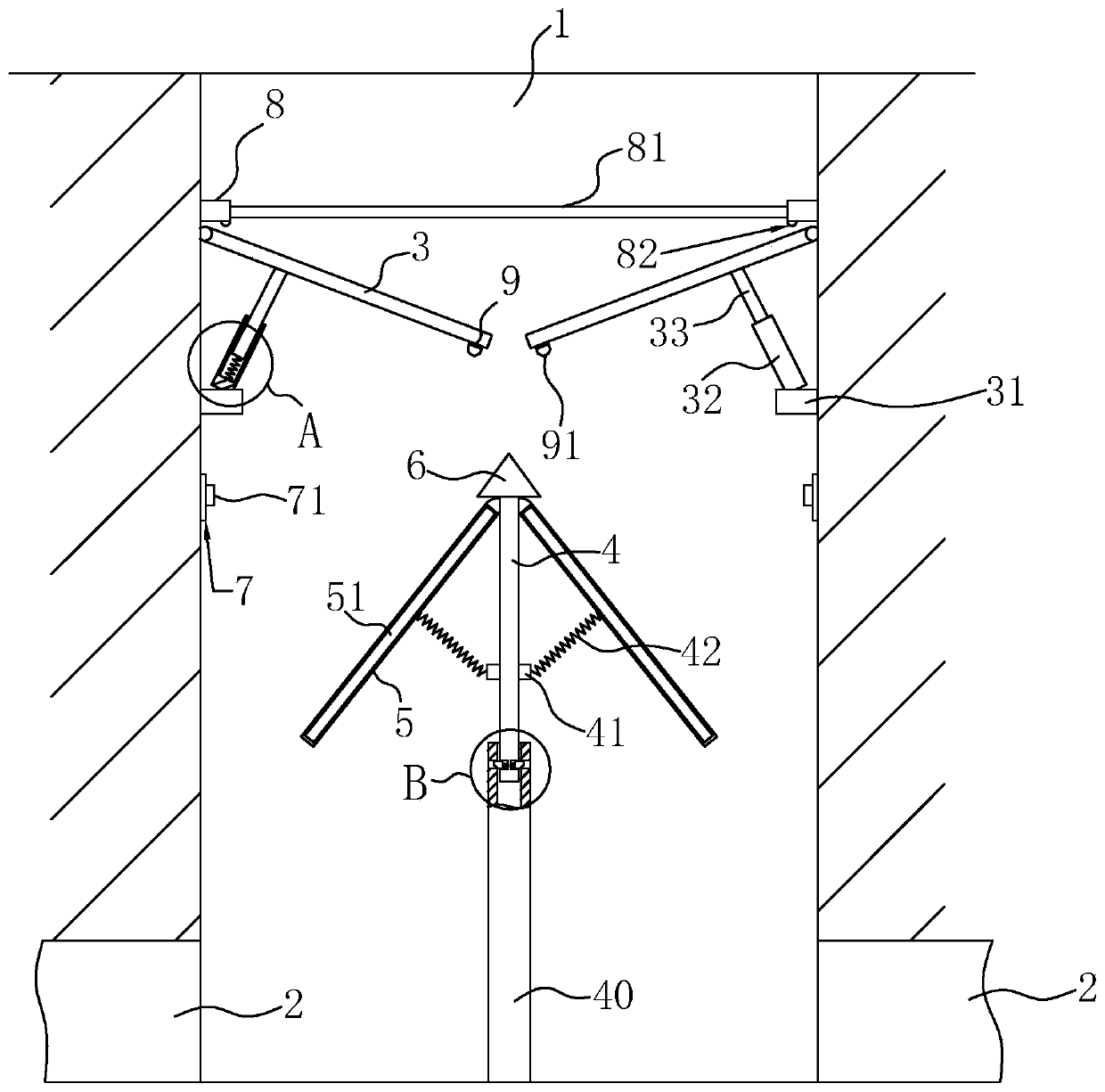

Drainage structure for municipal garden

ActiveCN111485619AReduce cloggingEasy to isolateSewerage structuresSewer pipelinesSewerageEngineering

The invention belongs to the technical field of municipal gardens, and relates to a drainage structure for a municipal garden. The drainage structure adopts the technical scheme that the drainage structure comprises a shaft well, a drainage pipeline, rotating plates, elastic supporting mechanisms, a vertical rod, a plurality of turning plates, elastic connecting pieces, and elastic adjusting mechanisms, wherein the drainage pipeline is connected between the bottom of the shaft well and a sewer; the rotating plates are hinged on the inner walls of the two sides of the shaft well and are symmetrical to each other; the elastic supporting mechanisms are arranged between the rotating plates and the inner walls of the shaft well and used to support the rotating plates; the vertical rod is vertically mounted at the bottom of the shaft well; the turning plates are hinged on the outer side of the top of the vertical rod; each elastic connecting piece is arranged between every two adjacent turning plates; when each turning plate is rotated to a horizontal position, the corresponding elastic connecting piece is extended, and the side of the turning plate far from the vertical rod is in contact with the corresponding inner wall of the shaft well to block sewage and impurities that pour upwards from the bottom of the shaft well; and the elastic adjusting mechanisms are arranged on the vertical rod and used to adjust the rotation angles of the turning plates. The drainage structure provided by the invention has the advantages that during use, the phenomenon that the sewage and the impurities reversely pour out of the shaft well in heavy rains can be effectively reduced, so that subsequent unnecessary troubles can be decreased.

Owner:广东天濠建设工程有限公司

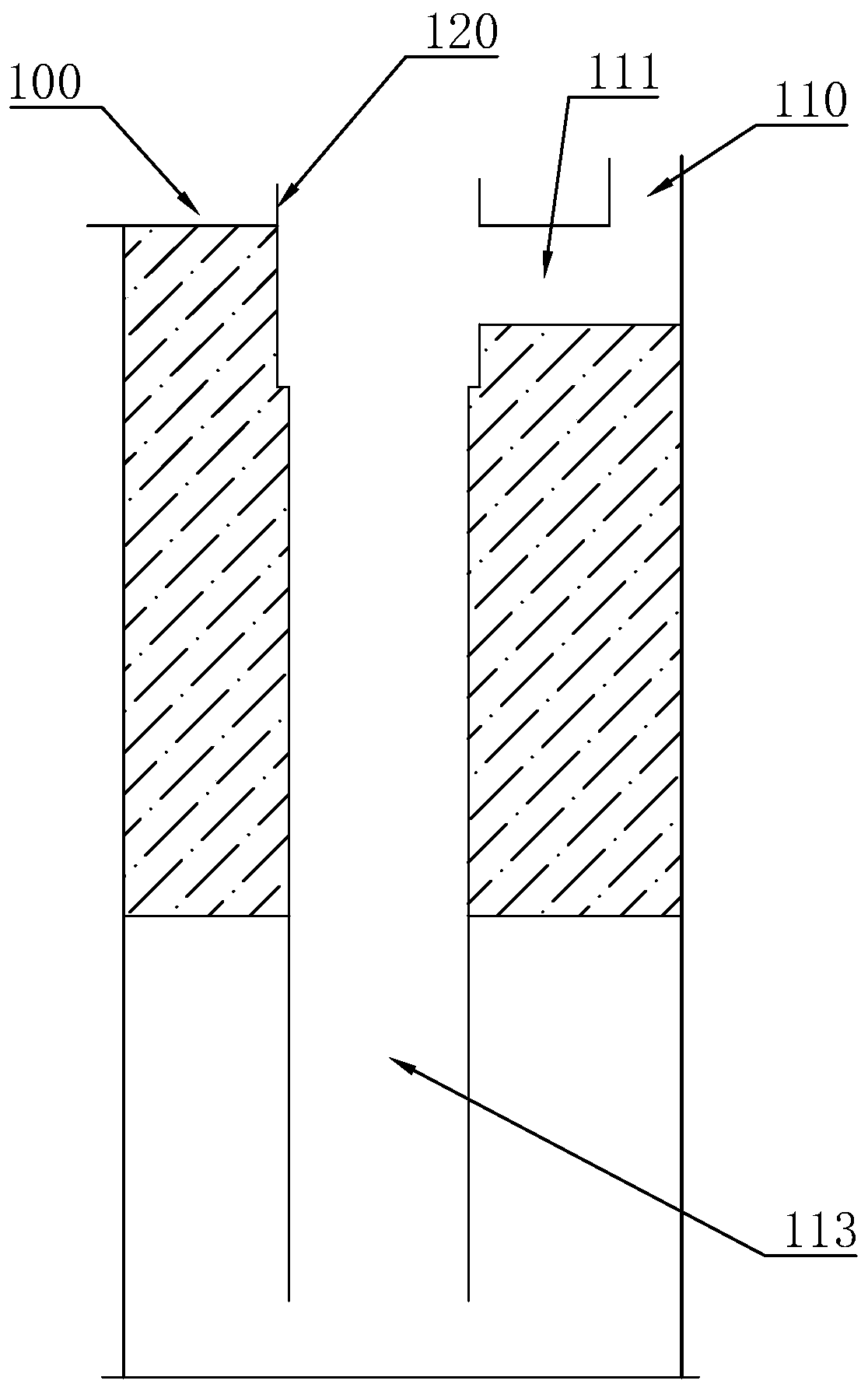

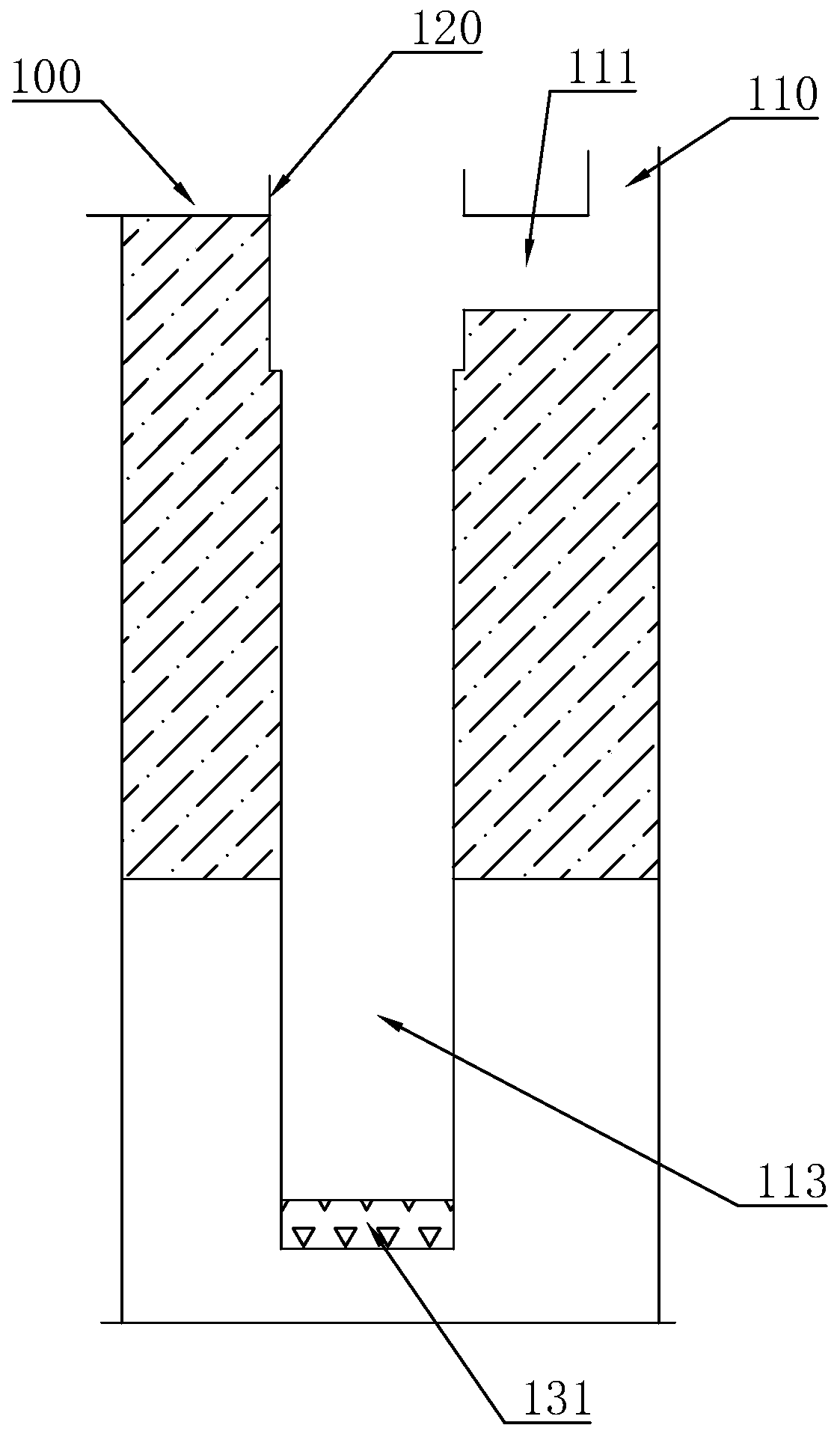

Construction method for carrying out pressure reduction water control treatment when confined groundwater bursting happens to deep foundation pit

InactiveCN110318410ALess gushImprove water control abilityFoundation engineeringControl treatmentWell drilling

The invention relates to the technical field of deep foundation pit construction, in particular to a construction method for carrying out pressure reduction water control treatment when confined groundwater bursting happens to a deep foundation pit. The method comprises the following steps that S1, well hole drilling is carried out and well drilling is carried out at the bursting position of the deep foundation pit; S2, a filter material bag is put in a hole, and the filter material bag is put into the well hole for bottom pressing; S3, a well tube is manufactured and hoisted, and the well tube is overall hoisted into the well hole; S4, the space between the hole well and the well wall is filled with materials; S5, a filter material bag is put into the well tube, water is drawn, the filtermaterial bag is put into the bottom of the well tube, then an immersible pump is lowered, and confined underground water in the well tube is drawn out; and S6, well sealing is carried out, the well hole is sealed, and foundation soil is subjected to grouting filling reinforcement treatment. The method has the following effects that the confined groundwater is temporarily stored in the well hole,the confined groundwater at the bursting point is controlled, after the confined groundwater is constantly drawn out, the well hole is closed, and therefore the confined groundwater bursting quantityunder the conditions of the high pressure and the large water quantity is reduced, and the water control effect is improved.

Owner:联建建设工程有限公司

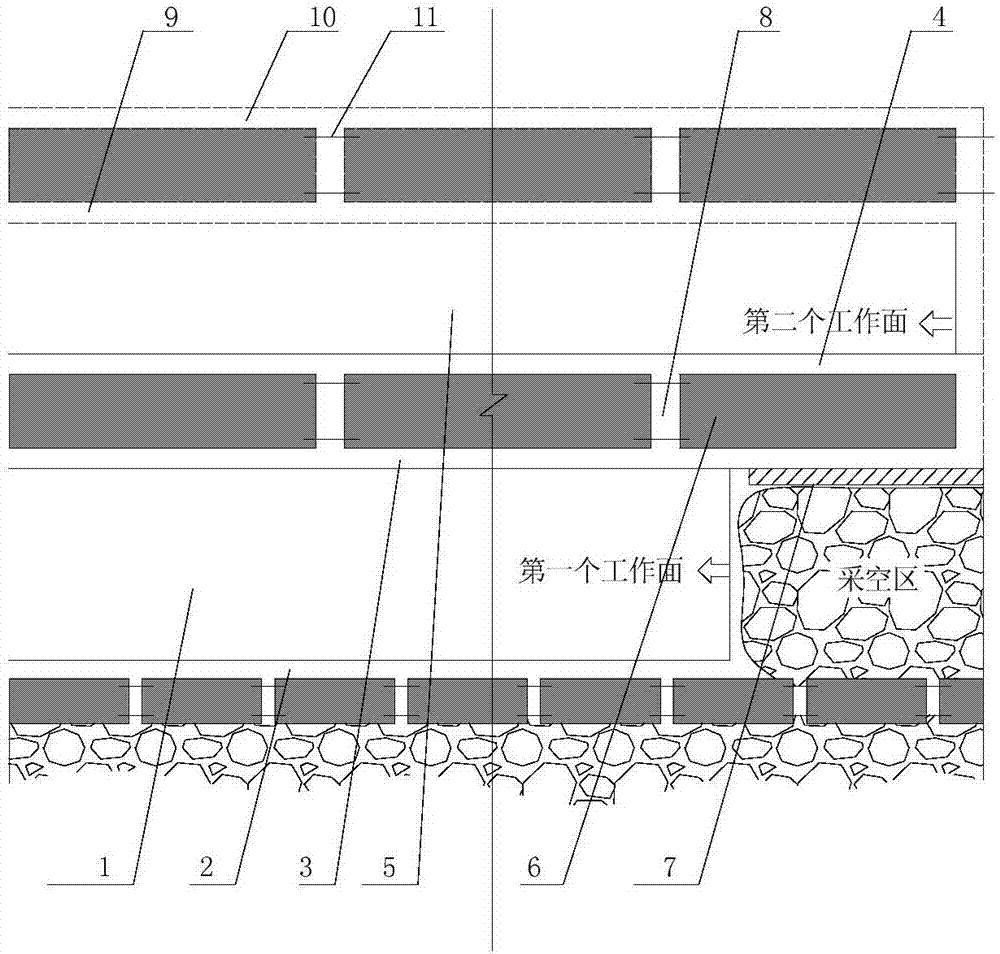

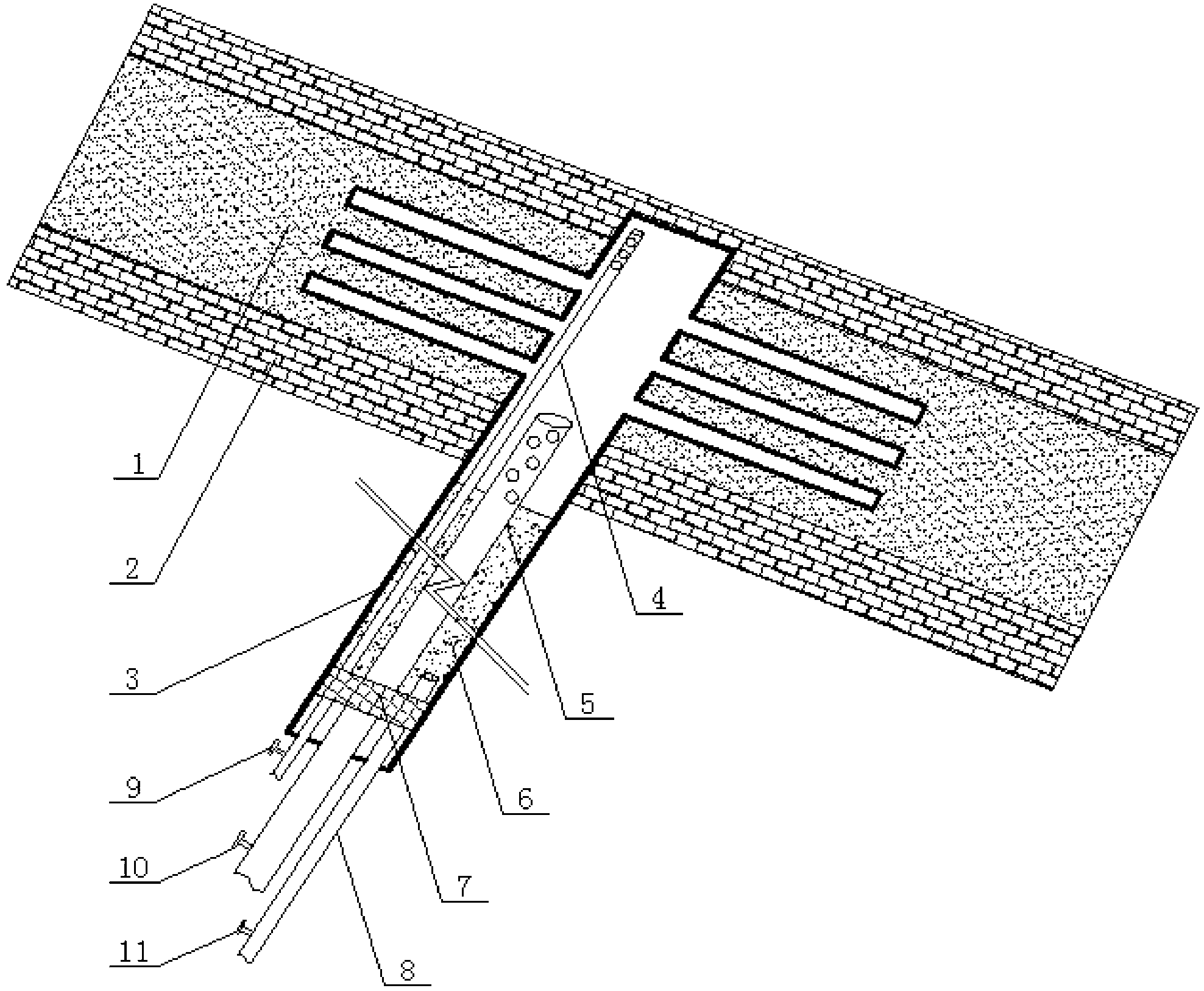

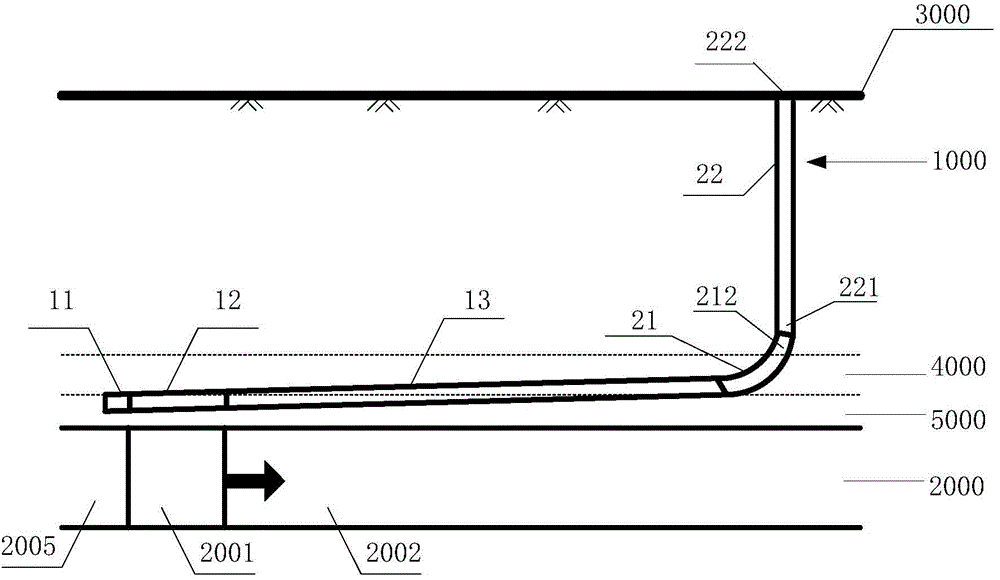

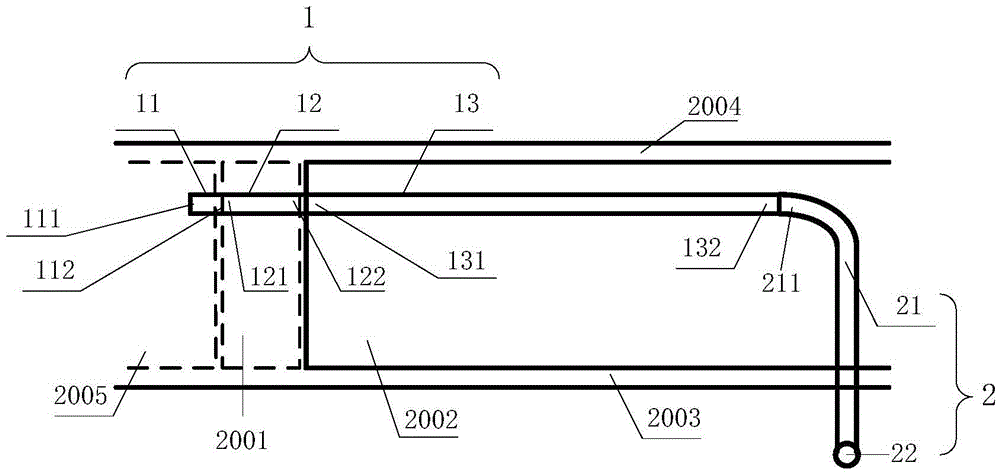

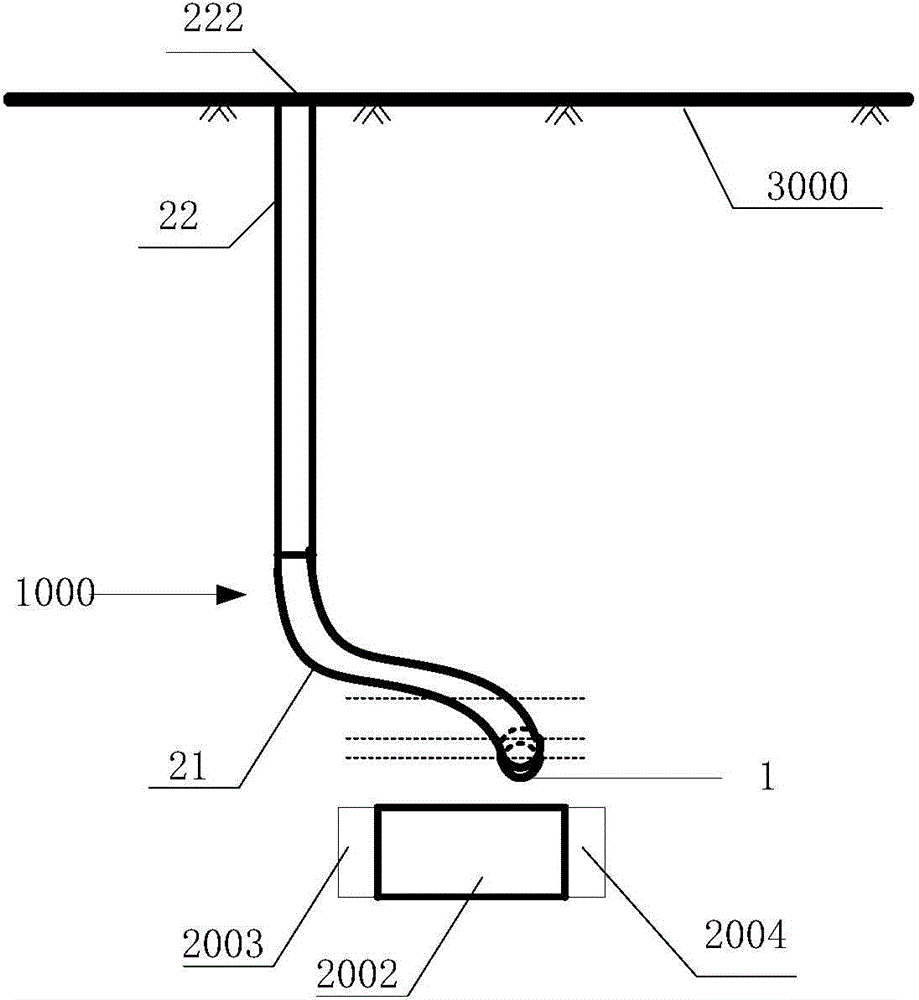

Ground composite L-shaped drilling well for gas control and gas control method

InactiveCN104594943ALess gushImprove securityFluid removalDirectional drillingProduction areaFissure

The invention provides a ground composite L-shaped drilling well for gas control and a gas control method. The ground composite L-shaped drilling well comprises a horizontal well section and an output well section, wherein the horizontal well section is positioned between a caving zone and a fissure zone above a first production layer, and comprises a first well passage, a second well passage and a third well passage, the first well passage is positioned above a goaf of the first production layer, the second well passage is positioned above a working surface of the first production layer, the third well passage is positioned above a to-be-produced mine body of the first production layer, the working surface is positioned at one side of the to-be-produced mine body, the goaf is positioned at one side, away from the to-be-produced mine body, of the working surface, the output well section comprises a first pipeline and a second pipeline, the second pipeline is positioned at the outer side of the first production layer, a first pipe opening of the first pipeline is communicated with a sixth opening end of the third well passage, and a fourth pipe opening of the second pipeline is connected with ground. The ground composite L-shaped drilling well is used for sucking and producing the gas enriched in the production area of the first production layer.

Owner:DATONG COAL MINE GRP +3

Goaf coal gangue supporting solid filling method

PendingCN112049682AReduce governance costsSave land acquisition costsMaterial fill-upUnderground transportCoal spontaneous combustionMining engineering

The invention discloses a goaf coal gangue compaction, roof contact, gridding and supporting solid filling method. Specifically, a high-strength coal gangue concrete filling material and a pure ganguenon-strength filling material are blended through a control system, and a net-shaped structure state combining a high-strength latticed supporting system and non-strength latticed inner filling is formed in a goaf by adopting a cross spraying operation mode of the two materials. The method has the beneficial effects that a gangue dump can be canceled; damage to a top plate and a bottom plate is reduced or eliminated, and water gushing of the top plate and the bottom plate is reduced; gas emission is reduced; the roadway retaining effect of two roadways is guaranteed, roadway retaining cost isreduced, coal pillar-free mining is achieved, the coal resource recovery rate is increased, the roadway tunneling amount is reduced, and mining continuing tension is relieved; the top and bottom plate approaching amount of the goaf is greatly reduced or eliminated, the top and bottom plate pressure is reduced, and good conditions are created for lower-layer mining; air circulation in the goaf iseffectively prevented, and coal gangue spontaneous combustion and residual coal spontaneous combustion are avoided; and great economic benefits are brought to enterprises.

Owner:孙嘉岐

Coal mine goaf management method

ActiveCN109578056ALess gushReduce hidden dangersDust removalFire preventionGas explosionCoal mine methane

The invention belongs to the field of coal mine gas treatment and particularly relates to a coal mine goaf management method. The coal mine goaf management method aims at solving the problem that high-concentration gas in a coal mine goaf is prone to flowing to a coal mining working face. The method comprises performing preventive firefighting treatment on the coal mine goaf, and then performing gas drainage on a coal mine overlaying goaf, a coal seam goaf and worked-out goafs neighboring to a coal seam. The coal mine goaf management method can to the maximum degree prevent gas stored in the closed space of the coal seam goaf and the overlaying goaf from flowing onto the working surface or roadways to avoid accidents such as spontaneous combustion or gas explosion. The coal mine goaf management method can effectively reduce gas overflow during mining to reduce gas accidents, thereby being a preventive measure ensuring safe mine production, achieving goaf managing effects, solving the problem of excessive gas on the working surface, ensuring coal recovery capacity and increasing the economic benefits.

Owner:DATONG COAL MINE GRP

Gas instant eliminating liquid preparing method and use method

InactiveCN103437800APromotes fast digestionQuick conversionDust removalFire preventionSodium bicarbonateSucrose

The invention relates to a gas instant eliminating liquid preparing method and a use method. Gas instant eliminating liquid comprises, by weight, 32% to 47% of carboxylic acid, 26%-33% of vegetable protein, 12%-18% of cane sugar, 7%-15% of alums, 7%-12% of sodium carbonate, 9%-15% of sodium bicarbonate, 4%-8% of glyodin and 5%-9% of calcium carbonate. The total weight ratio of all the mentioned components is 100%. The idea of passive prevention and treatment in the prior art is totally changed. The gas instant eliminating liquid preparing method and the use method belong to the scope of initiative prevention and treatment. Basically speaking, gas is treated before coal is exploited and drilling is carried out on the ground when a mine is constructed. The gas eliminating liquid can effectively decompose mine gas when a coal layer is in a primitive state, the concentration of the mine gas is reduced, the gas is treated to be within a safety range, and personal safety of exploiting workers is ensured.

Owner:刘正魁

Method for preparing coal mine gas instant eliminating liquid and method for using coal mine gas instant eliminating liquid

InactiveCN103437808APromotes fast digestionPromote rapid proliferationGas removalAcetic acidCoal mine methane

The invention provides a method for preparing coal mine gas instant eliminating liquid and a method for using the coal mine gas instant eliminating liquid. The coal mine gas instant eliminating liquid is prepared from the following components, by weight, 33-46% of beer, 31-41% of acetic acid, 16-22% of vegetable protein, 8-13% of cane sugar, 6-9% of apple green agents, 5-11% of alums and 4-13% of sodium carbonate. The sum of the ratios of the components by weight is 100%. The conception of passive prevention and treatment in the prior art is completely changed, the methods belong to the category of active prevention and treatment, basically, gas is treated before coal is mined, drilling can be conducted on the ground when mine construction is conducted, the gas eliminating liquid can effectively decompose coal mine gas when a coal bed is in the initial condition, therefore, the concentration of the coal mine gas is reduced, gas is treated to be within a safety range, and personal safety of digging workers is guaranteed.

Owner:刘正魁

Quick measurement method of coal seam gas pressure

InactiveCN104389587AReduce air leakageReduce borehole water gushingSurveySealing/packingDrill holePetrology

The invention discloses a quick measurement method of coal seam gas pressure. The method is characterized in that the measurement operation of measuring the drilling pressure is divided into two phases: the first phase is to perform the large-diameter drilling in the pressure measuring position, a bushing is put in the large-diameter drill hole, and slurry is injected in the bushing, the large-diameter drilling hole and a surrounding rock microfissure zone for compacting; and the second phase is to perform the drilling again in the bushing to form a pressure measuring hole penetrating in a coal seam, a drill rod is taken out, and the coal seam gas pressure is directly measured by an original bushing. The slurry is injected in a fissure group of a coal rock body surrounding the drilling hole, the drilling hole and the bushing under the effect of high pressure, so that the peripheral compactness of the drilling hole is improved, the emission of fissure water in a rock stratum is largely reduced, the air leakage and the water yield in the drilling hole are obviously reduced; and in particular, aiming at a soft coal measure strata, the coal seam gas pressure is quickly and accurately measured.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

Mobile type goaf gas quick blocking and extraction device and technology

InactiveCN104405431ASolving Governance ChallengesReduce aggregationSurveyMining devicesProcess engineeringCoal

The invention discloses a mobile type goaf gas quick blocking and extraction device and a mobile type goaf gas quick blocking and extraction technology. The device and the technology are easy and convenient to operate; furthermore, gas in a goaf can be quickly blocked, and the blocked gas can be quickly extracted, so that the difficulty in treating the gas in the goaf can be effectively solved, the gas content of the goaf is fundamentally reduced, the goaf gas gathering amount and the gas gush amount to a stopping working surface are reduced, the influence of the gas in the goaf on the concentration of the gas on the stopping working surface is reduced to the maximum extent, and great significance in reducing the mine ventilating difficulty and realizing safe and high-efficiency production of a coal mine is realized. Multiple stages of fixing devices are convenient for flexible gas pocket forming, and overlarge deformation of a local area of a flexible gas pocket can be avoided; the operation and the use are convenient and quick; the requirement on an underground narrow space can be met, and quick moving is facilitated; meanwhile, the device can be recycled, multi-frequency utilization is realized, and the treatment cost is lowered.

Owner:HENAN POLYTECHNIC UNIV

Extraction method for unloading gas in goaf bed separation zone of ultra-long working face

ActiveCN109026133ASolve overrunEasy to drawTunnel/mines ventillationGas removalHigh concentrationEngineering

The invention discloses an extraction method for unloading gas in a goaf bed separation zone of an ultra-long working face and treating top corner and goaf gas. The method comprises the following steps that an upper gate backstopping tunnel, a middle gate backstopping tunnel and a lower gate backstopping tunnel are arranged for the ultra-long working face to form a 'W'-shaped ventilation system ofupper gate air inlet, lower gate air inlet and middle gate air return; after a high-level extraction drill and a high-level drainage tunnel are arranged at the middle-upper portion in an 'O'-shaped circle of the upper portion of middle gate goaf zone cover rock, backstopping is carried out; the high-level extraction drill and the high-level drainage tunnel are connected to an extraction branch pipe, and the extraction branch pipe is merged into a mine gas extraction utilization system for extraction control. The extraction method can efficiently extract and utilize high-concentration gas in an unloading fissure zone of the goaf bed separation zone, reduce the gas emission amount in the goaf zone of the working face, eradicate working face air return, top corner gas exceeding and goaf zonegas explosion accidents, improve the working face production efficiency and safety and ensure mine safe backstopping.

Owner:SICHUAN HUAYINGSHAN LONGTAN COAL

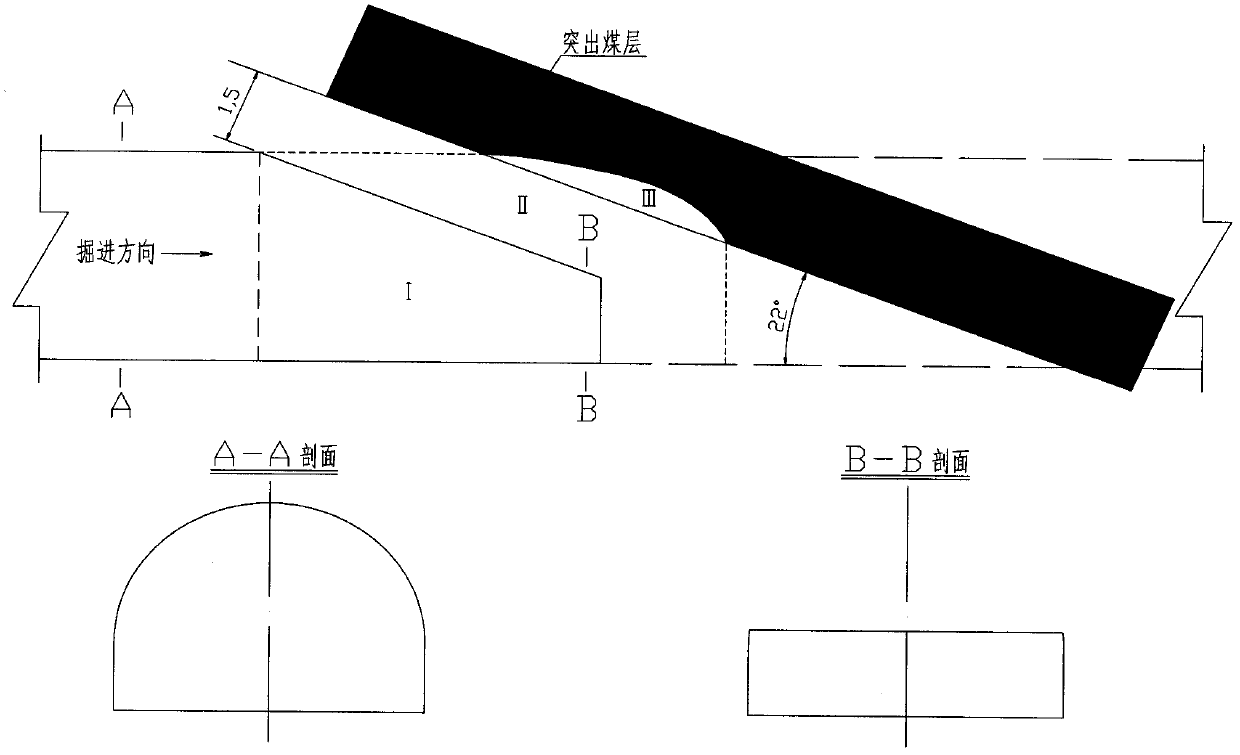

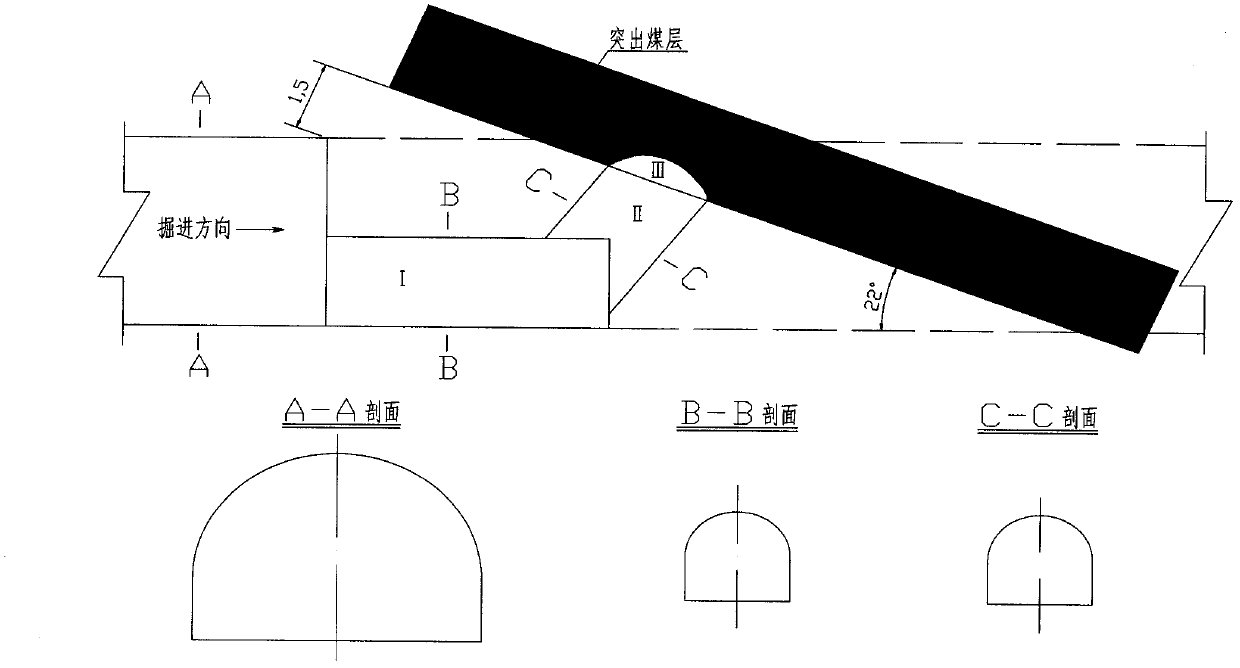

Pilot-tunneling method for coal uncovering

The invention relates to a pilot-tunneling method for coal uncovering, and belongs to the technical field of mine sinking and driving engineering. The method helps to solve problems that: when an uncovered outburst coal seam has a laneway sectional area more than 10m<2> or an inclined angle from the laneway to the coal seam less than 40 DEG, safe rock pillars for working face brush expension are difficult to control, shot holes are deep, explosive consumption is large, and vibration induced protrusion is easy to happen. Safe and effective coal uncovering is realized by that: the laneway sectional area is reduced, the angle of pilot-tunneling is changed, and technologies of smooth blasting, anchor-net temporary supporting and anchor-net permanent supporting etc. are employed. The method of the invention is especially suitable for coal uncovering when the laneway sectional area is large, surrounding rocks are broken, and the inclined angle is small. Advantages are that: working places need no finishing, the pilot-tunneling is flexible for operation, so that drilling by pneumatic drills is convenient, the safe rock pillars are easy to control, and operation is simple; uncovered sectional area is small, the number of working people is small, the number of blast hole is small, the amount of explosive is small, blasting disturbance is less, gas emission amount is small, and the safety is high; pilot-tunneling sectional area is small, operation technology is simple, speed is fast, and work efficiency is high.

Owner:CHONGQING JUNENG CONSTR GRP +1

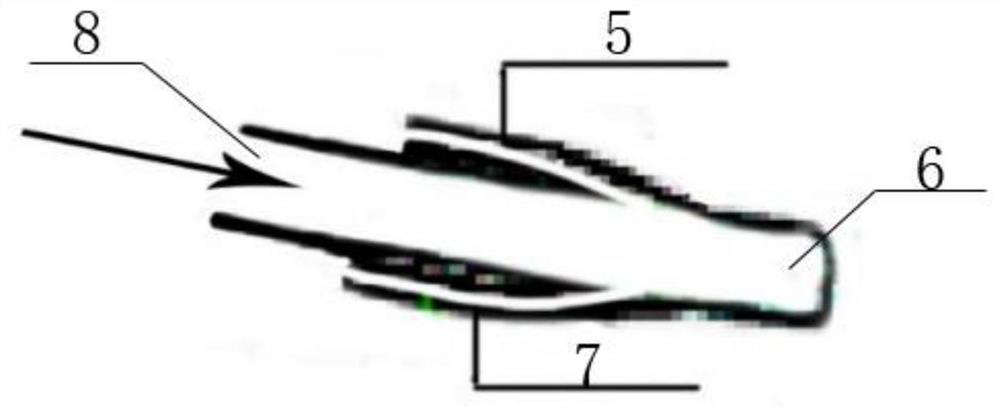

Front-injection back-extraction parallel coal seam inclined drilling gas control device and method

InactiveCN109838274ALess gushSolve the problem of uneven water injectionGas removalSealing/packingDesorptionEngineering

The invention provides a front-injection back-extraction parallel coal seam inclined drilling gas control device and method. The device comprises double hole sealing pipes, an air bag, a plastic pipeline, a sponge body, a clamp hoop, an inflating device, a grouting pipe, a fixed retainer ring and a sliding device; one hole reaches dual purposes; the front end is used for gas displacement through water injection, and the back end is used for gas extraction through negative pressure; through a blade-shaped iron sheet arranged on the inner wall of an inner pipe and a front-dense and back-sparse sponge body which is arranged at the front half part of a pressure relieving region and can be expended after meeting water, the problem of water injection nonuniformity due to broken degree of the loose coal body of the front half part of the pressure relieving region is solved; and excessive water solution can be prevented from flowing out from big pores of loose coal bodies. By using the front-injection back-extraction method, the air leakage from the pores and cracks of the loose coal bodies can be prevented; the coal seam gas extraction efficiency is improved; free gas of the loose coal body can be effectively expelled; the desorption of adsorption gas can be inhibited; and the gas gushing quantity during the working face stoping is reduced.

Owner:NORTH CHINA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com