Method for extracting gas at corner on recovery working face in coal mine

A technology for mining face and gas drainage, which can be used in gas emission, mining equipment, earth-moving drilling, etc., and can solve problems such as low drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

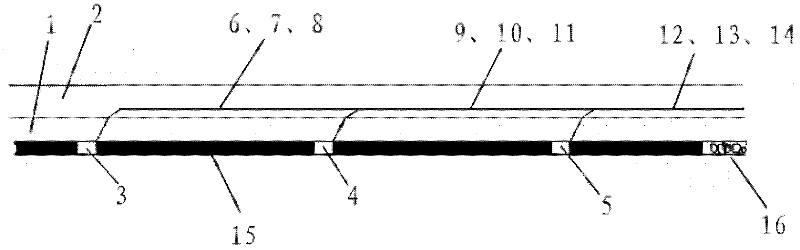

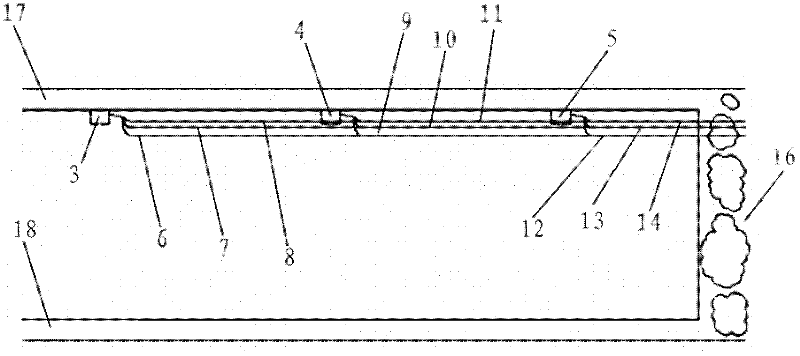

[0027] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

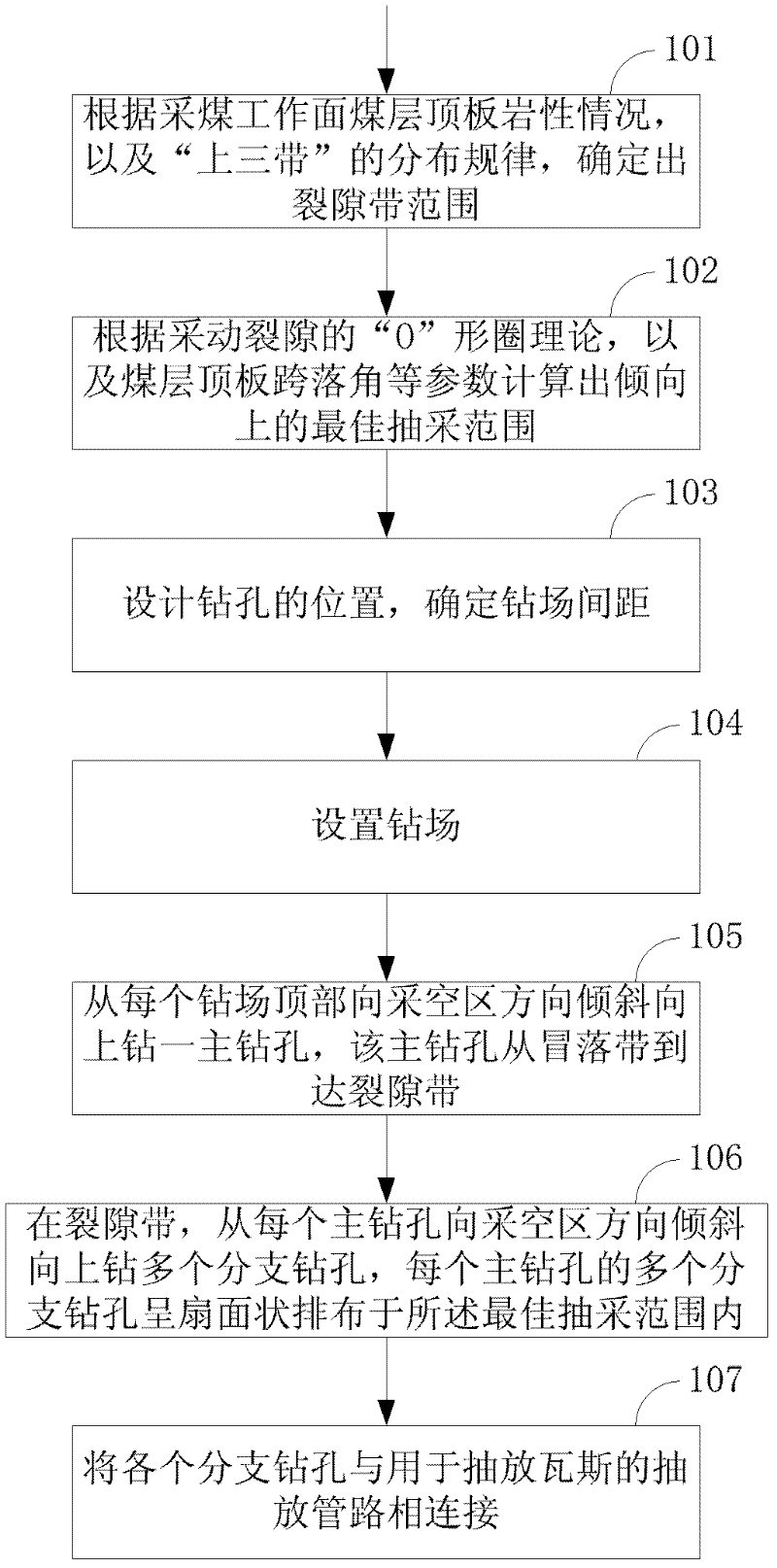

[0028] The specific implementation process of the gas drainage method at the upper corner of the coal mine mining face of the present invention is as follows: figure 1 shown, including the following steps:

[0029] Step 101: Determine the range of the fracture zone according to the lithology of the coal seam roof in the coal mining face and the distribution law of the "upper three zones".

[0030] The "upper three zones" in this step refer to the "caving zone", "fissure zone" and "curved subsidence zone" which are usually referred to from bottom to top.

[0031] Step 102: Calculate the optimal extraction range in the direction according to the "O" ring theory of mining fractures and parameters such as the roof spanning angle of the coal seam.

[0032] Both the method for determining the range of the fractured zone in step 101 and the method f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com