Patents

Literature

77results about How to "Solving Governance Challenges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating coal gasification wastewater containing phenol and ammonia

InactiveCN101597124AEffective removal of fixed ammonia contentMeet the requirements of subsequent biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by degassingCoal gasification wastewaterHigh concentration

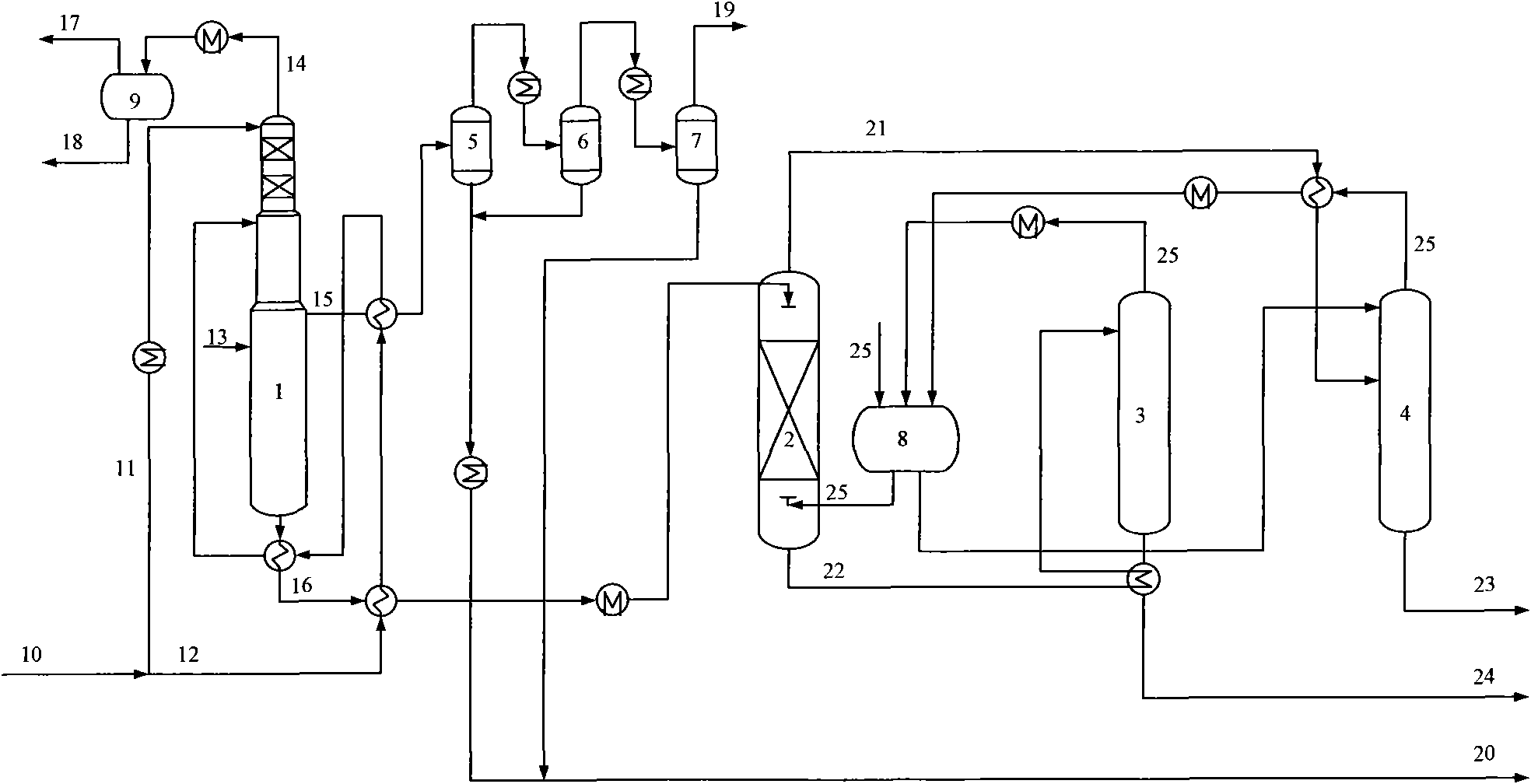

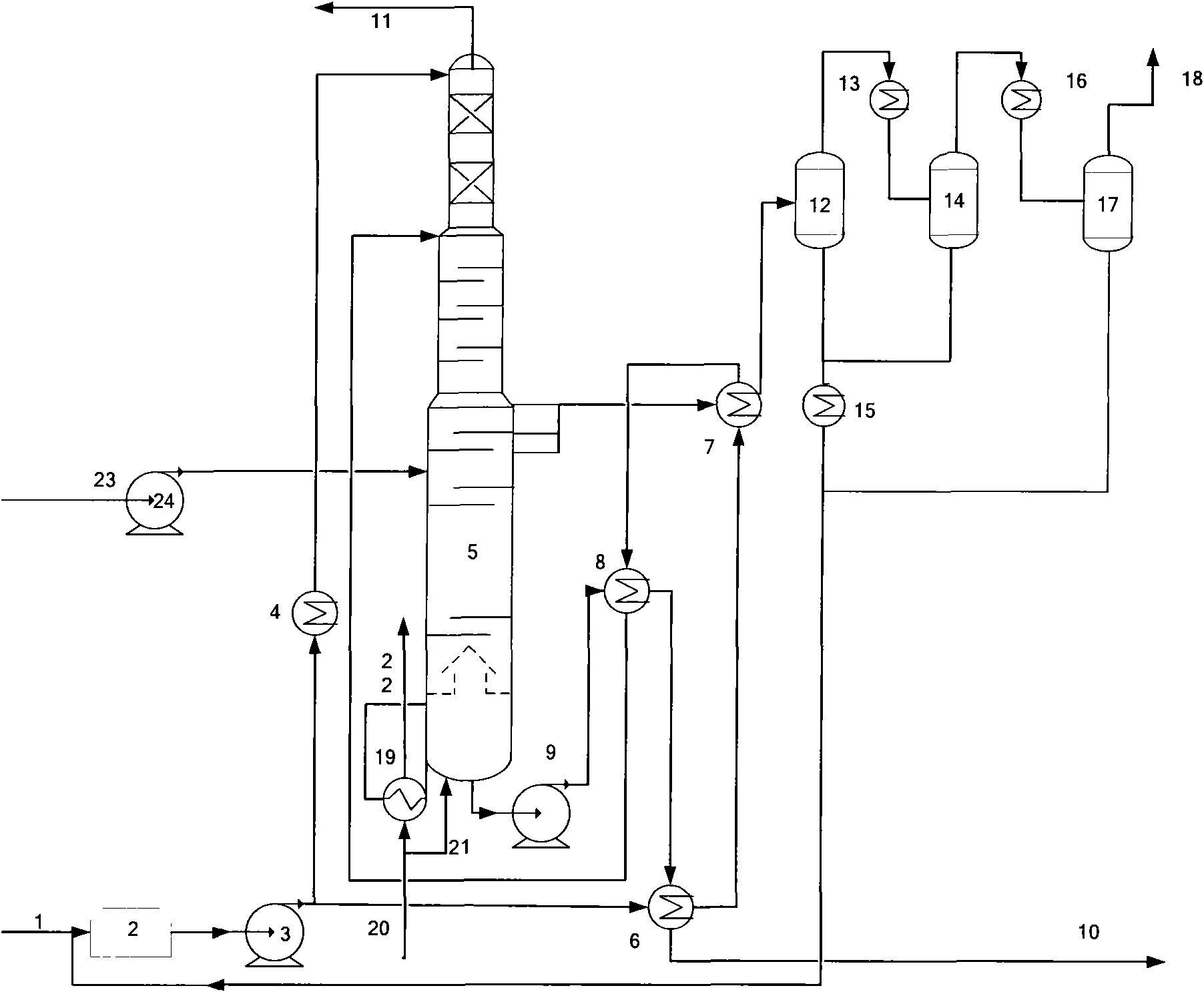

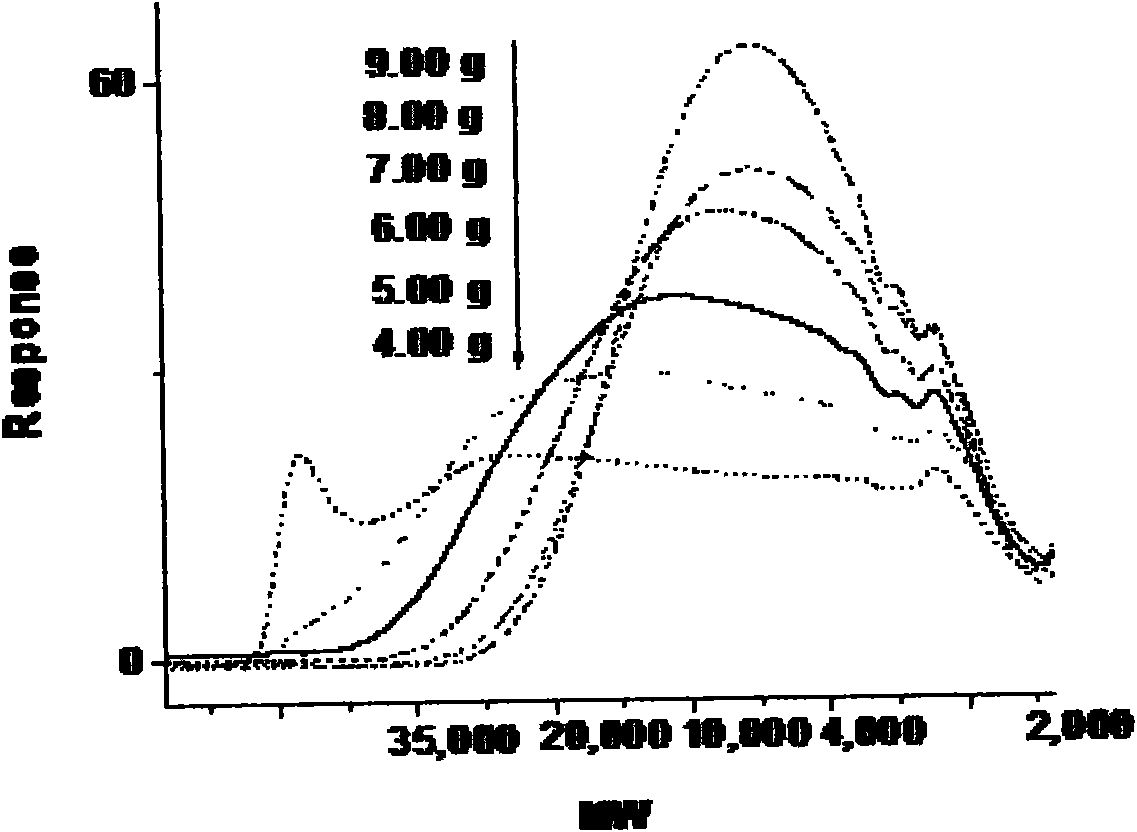

The invention relates to a method for treating coal gasification wastewater containing phenol and ammonia. The method comprises the following steps: single tower alkali injection and pressurization steam stripping removal of acidic gas and ammonia, three-level dephlegmation of lateral line tapped gas, extraction of phenol by diisopropyl ether and solvent recovery. The cold and hot coal gasification wastewater, according to a certain proportion, respectively enters a pressurization single tower from the upper part and middle upper part of a wastewater steam stripping tower, and acid gas is discharged from the tower top; the lateral line withdrawal mixed gas goes through three-level dephlegmation to obtain high-concentration ammonia, alkali is injected at the position below the lateral line to transform fixed ammonia into free ammonia which is to be removed; counter-current extraction is carried out on removed ammonia, residue of acid gas and diisopropyl ether to dephenolize; extraction solvent is recovered by a solvent recovery tower and a solvent steam stripping tower to obtain the byproduct, namely crude phenol. In the method of the invention, the process removing acid gas, free ammonia and fixed ammonia is carried out simultaneously on the coal gasification wastewater in the wastewater steam stripping single tower, as a result, high-concentration ammonia is obtained, the content of carbon dioxide, sulfureted hydrogen, free ammonia and fixed ammonia in tower kettle purified water is extremely low, encrustment is not prone to take place, and the purified coal gasification wastewater meets the requirement of follow-up biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH +2

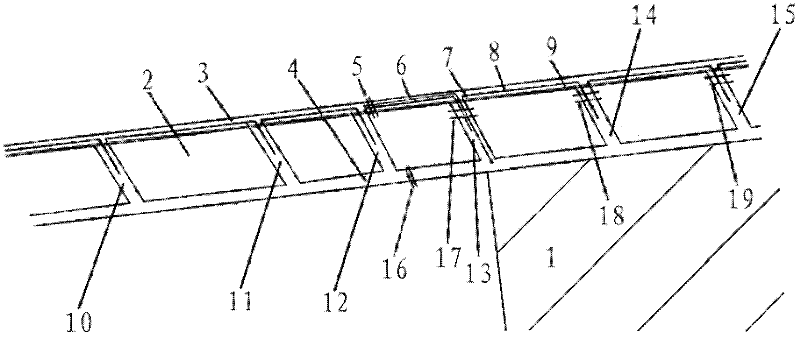

Laneway disposed by using large U to sleeve small u

InactiveCN101649741ARealize continuous excavationImprove governance effectUnderground miningTunnel/mines ventillationEngineeringCoal pillar

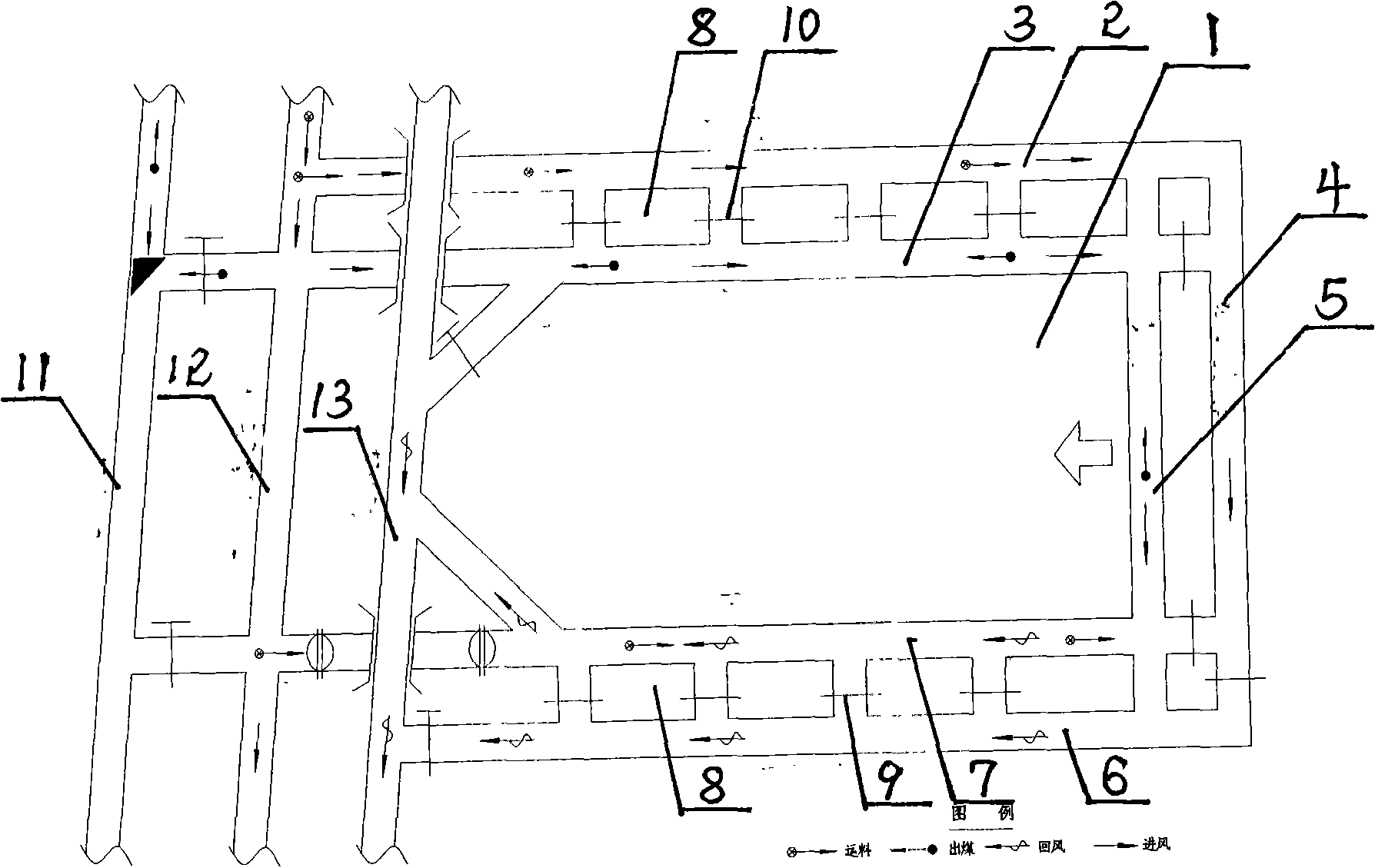

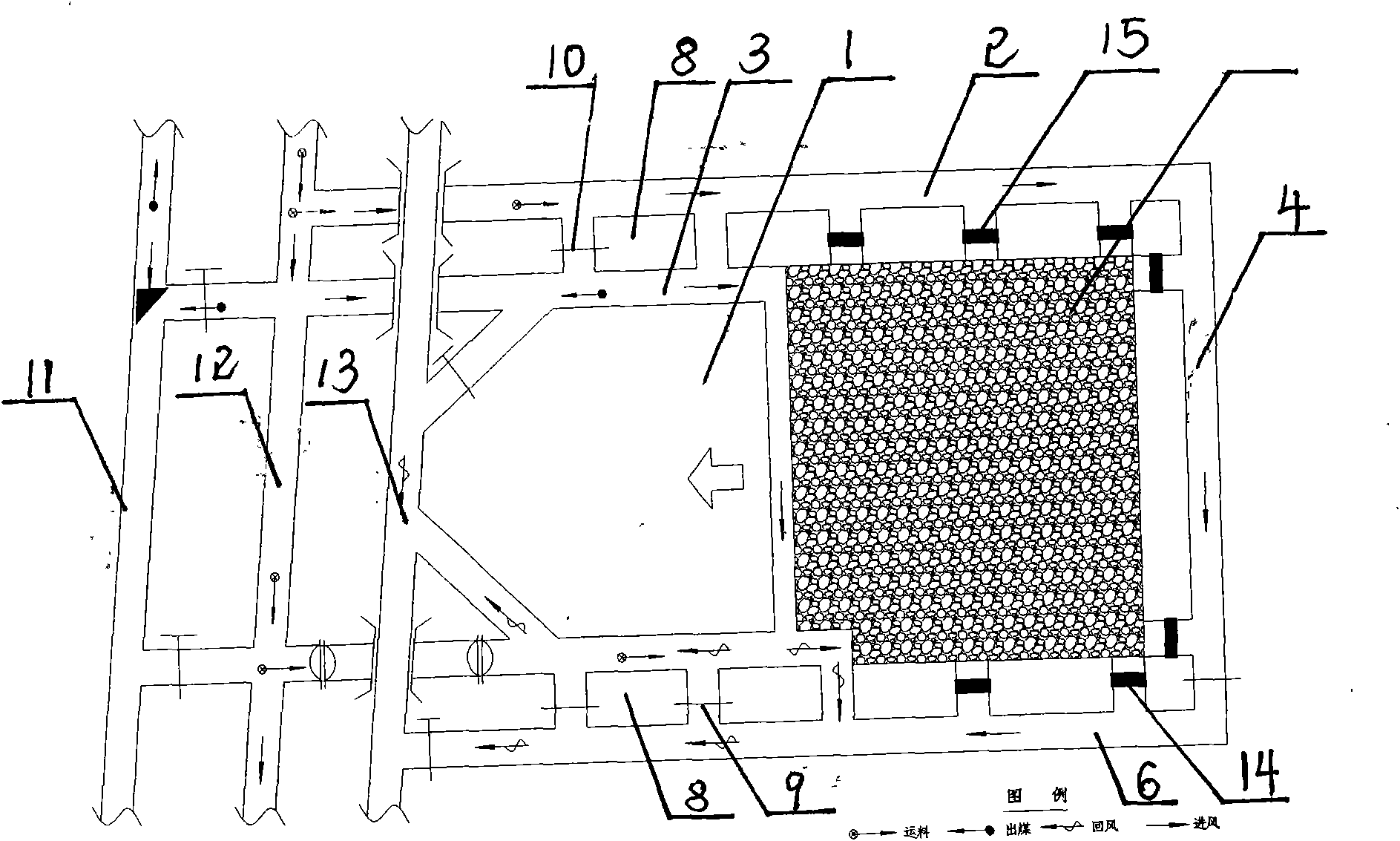

The invention relates to a laneway disposing shape of a coal mine, in particular to a laneway disposed by using large U to sleeve small u, which solves the problems of driving along a groove and gas control of a stope in the prior laneway disposing mode. The laneway comprises a stope, a small u-shaped laneway is arranged at the periphery of the stope, the small u-shaped laneway comprises a belt laneway and a return airway which are arranged on both sides of the stope, the front side of the stope is provided with a cutting hole, a large U-shaped laneway is arranged outside the small u-shaped laneway and comprises a head-to-tail connection device, a ventilation laneway, a ventilation connection laneway and a gas tail laneway, wherein the head-to-tail connection device and the ventilation laneway are positioned outside the belt laneway, the ventilation connection laneway is arranged outside the cutting hole, the gas tail laneway is positioned outside the return airway, and a plurality ofentity supporting coal pillars are arranged between the large U-shaped laneway and the small u-shaped laneway. The laneway disposing shape solves the problem of gas control of the stope and increaseswork efficiency.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Method for treating coal gasification wastewater by single tower alkali injection and pressurization steam stripping

InactiveCN101597092ALow investment costLow running costWater/sewage treatment by degassingAmmonia preparation/separationHigh concentrationCoal gasification wastewater

The invention discloses a method for treating coal gasification wastewater by single tower alkali injection and pressurization steam stripping, comprising the following steps: the cold and hot coal gasification wastewater respectively enters a single tower from the upper part and middle upper part of a wastewater steam stripping tower, gas ammonia is extracted from the lateral line of the single tower which goes through three-level dephlegmation to obtain high-concentration ammonia, condensate returns to a stock tank; alkali is injected at the position below the lateral line to transform fixed ammonia into ammonia which is to be removed; the mass percentage concentration of alkali liquor is 20-40%, the use level of the alkali liquor is not more than that of mol number of fixed ammonia in the wastewater, and residue is extracted from the tower bottom and is subjected to follow-up extraction and dephenolizing process of coal gasification wastewater. In the method of the invention, the process removing acid gas, free ammonia and fixed ammonia is carried out simultaneously on the coal gasification wastewater in the wastewater steam stripping single tower, as a result, high-concentration ammonia is obtained, the content of carbon dioxide, sulfureted hydrogen, free ammonia and fixed ammonia in tower kettle purified water is extremely low, encrustment is not prone to take place, pH value is reduced to around 6, as a result, fine extraction conditions are created for the follow-up solvent extraction dephenolizing of the coal gasification wastewater. The method of the invention is suitable for the coal gasification wastewater and overall treatment process thereof.

Owner:SOUTH CHINA UNIV OF TECH +2

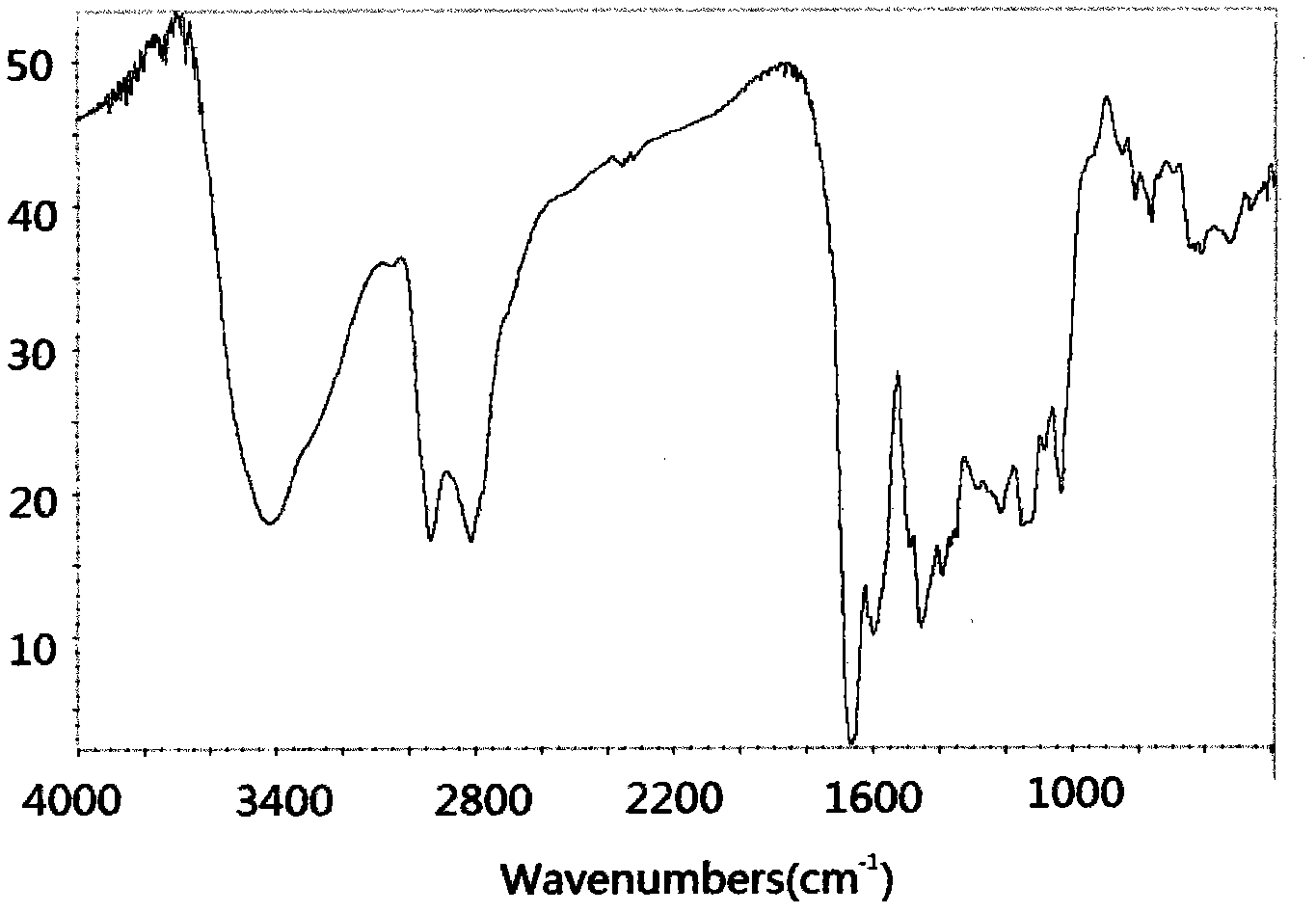

Preparation method of soil moisturizing bio-fertilizer

InactiveCN101712566APromote decompositionHigh organic contentOrganic fertilisersEcological environmentInsect pest

The invention provides a preparation method of soil moisturizing bio-fertilizer. The composite microorganism bactericide adopted in the invention comprises an A group bactericide and a B group bactericide, and fermentation preparation is completed by smashing straws, composting and secondary piling fermentation. Compared with the prior art, the invention has simple preparation technique without needing large mechanical equipment, simple and practical method, wide raw material source, and low cost, solves the difficulty in straw treatment, and realizes recycling of resources; the inventive soil moisturizing bio-fertilizer has strong water absorptivity which is increased by over ten times, good moisture retention property to soil, and can eliminate soil hardening and promote root system to grow, improve content of organic matter in soil by 1-1.5 times, reduce dosage of fertilizer by over 35% resulting in planting in the next season without applying fertilizer, adjust soil micro-ecological environment, and reduce occurrence of plant diseases and insect pests and has no putrefactive odor.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

Advance grouting transformation method of bottom plate combination directional holes of deeply-buried aquifers underground coal mine

ActiveCN110566118ASolving Governance ChallengesImprove governance efficiencyUnderground chambersDirectional drillingBlind zoneTherapeutic effect

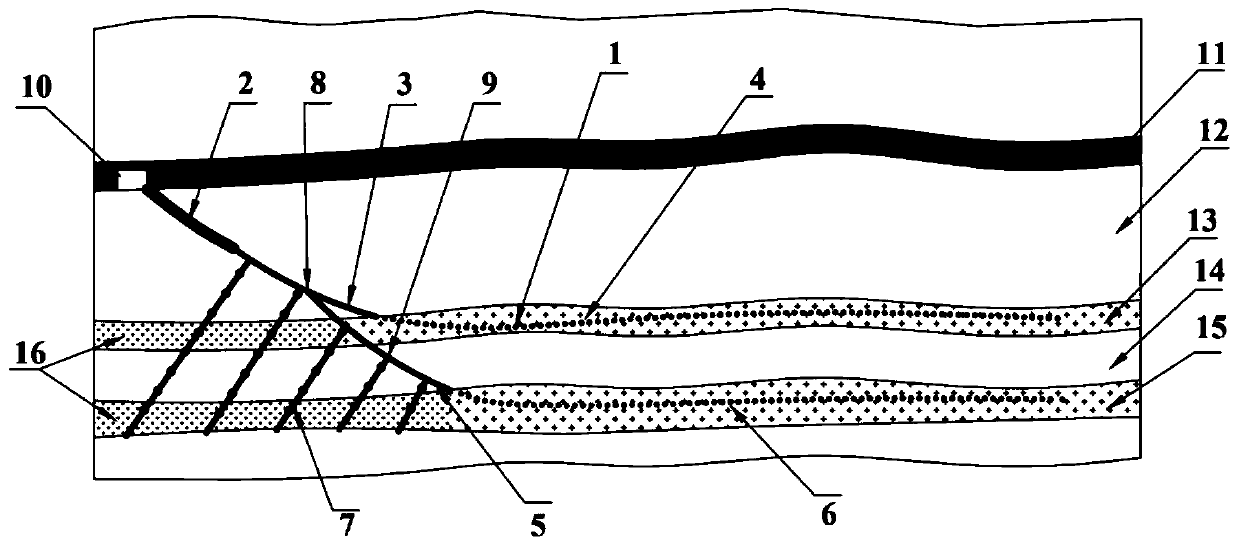

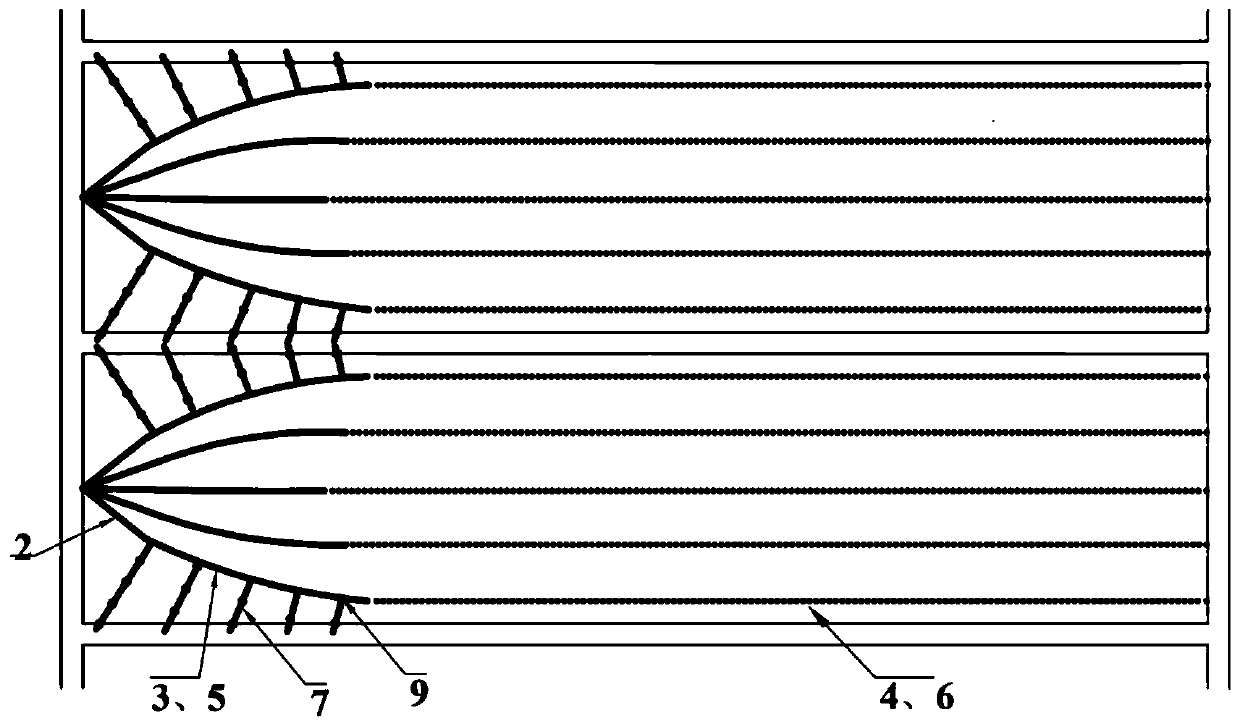

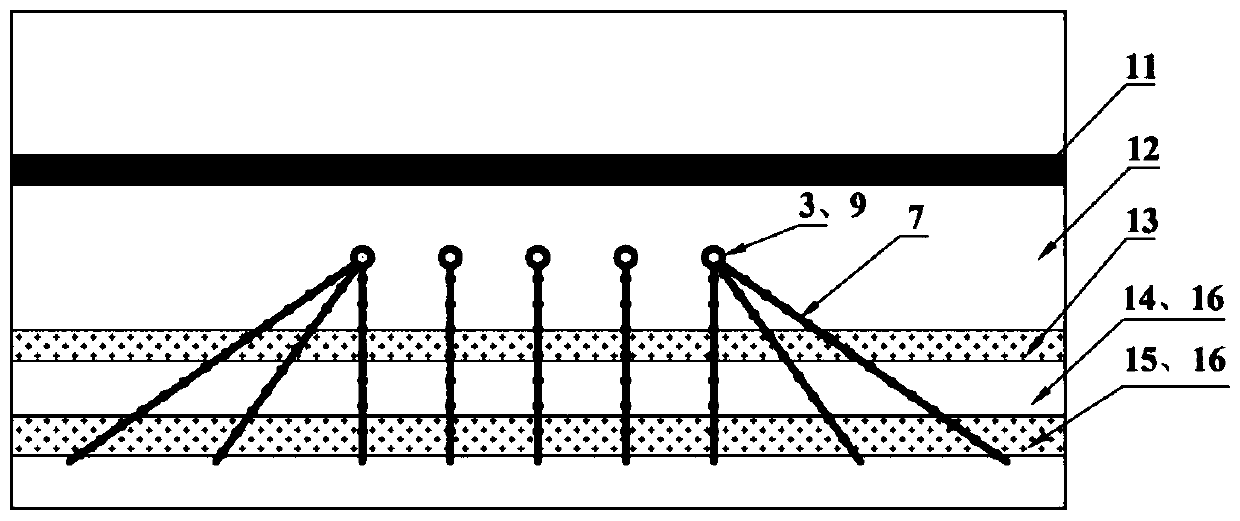

The invention relates to an advance grouting transformation method of bottom plate combination directional holes of deeply-buried aquifers underground a coal mine. The advance grouting transformationmethod includes the steps that the bottom plate combination directional holes are constructed, and comprise deflecting hole sections entering the aquifers from aquicludes and horizontal hole sectionsstarting from the deflecting hole sections and extending inside the aquifers; jet hole sections penetrating through one or more of the aquifers in an extending mode are constructed on the side walls of the deflecting hole sections at the preset interval, and the jet hole sections do not intersect with the horizontal hole sections in the aquifers and cover blind areas of the horizontal hole sections; and grouting is conducted on the horizontal hole sections and the jet hole sections to transform aquifer bottom plates into aquiclude bottom plates. According to the advance grouting transformationmethod, the problems that the distance from a coal seam is large, the number of the aquifers is large, the treatment effect of the coal seam bottom plates with the high water pressure is poor, the blind areas are prone to existing are solved, the advantages that the grouting covering area is wide, no blind area exists in treatment, and efficiency is high are achieved, advance area grouting transformation of the bottom plates of the multiple deeply-buried aquifers is achieved, and the technical guarantee is provided for safe stoping of a working face.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

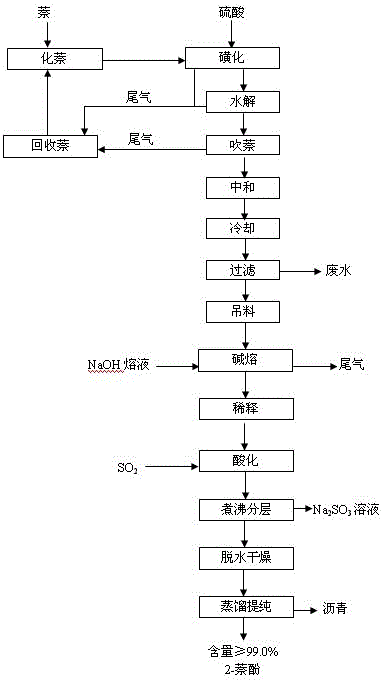

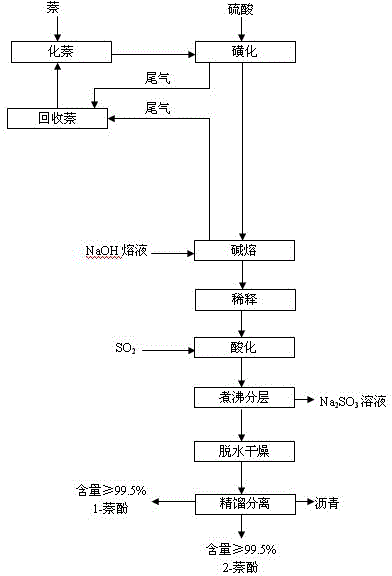

Method for cooperatively producing 1-naphthol and 2-naphthol from naphthalene sulfonation product by virtue of direct alkali fusion

ActiveCN104693009AAlkali fusion reaction goes wellReduce contentOrganic chemistryOrganic compound preparationMolten state2-Naphthol

The invention discloses a method for cooperatively producing 1-naphthol and 2-naphthol from a naphthalene sulfonation product by virtue of direct alkali fusion. The method comprises the following steps: performing multiple sulfonation reactions on naphthalene and concentrated sulfuric acid, directly performing an alkali fusion reaction on the obtained liquid sulfonation product and sodium hydroxide in a molten state, and then diluting, acidifying, boiling for layering, dehydrating and drying, rectifying and separating, thereby obtaining high-purity 1-naphthol and 2-naphthol simultaneously. The steps of hydrolyzing, naphthalene blowing, neutralization, cooling and crystallization and filtration of sulfonation products, and feeding for performing alkali fusion on a water-containing filter cake at a normal temperature in the existing process are avoided; no filtration wastewater difficult to treat is not generated anymore, the energy source and the resources are saved, the yield is increased and the operating environment is improved; as a result, the problems of three-waste treatment during naphthol production are thoroughly solved from the production process.

Owner:肖刚学

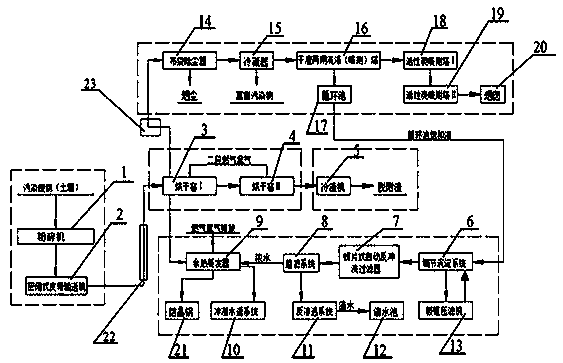

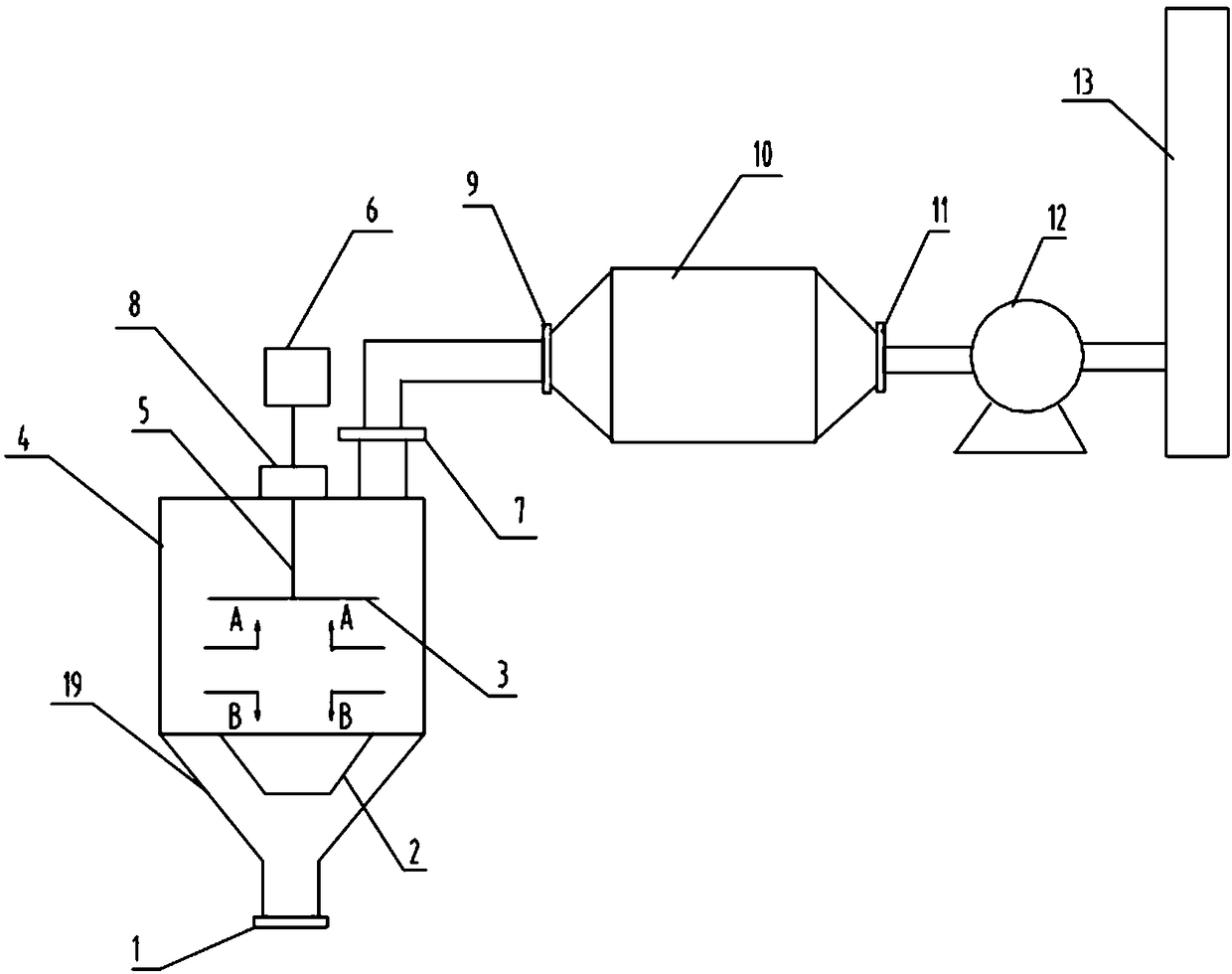

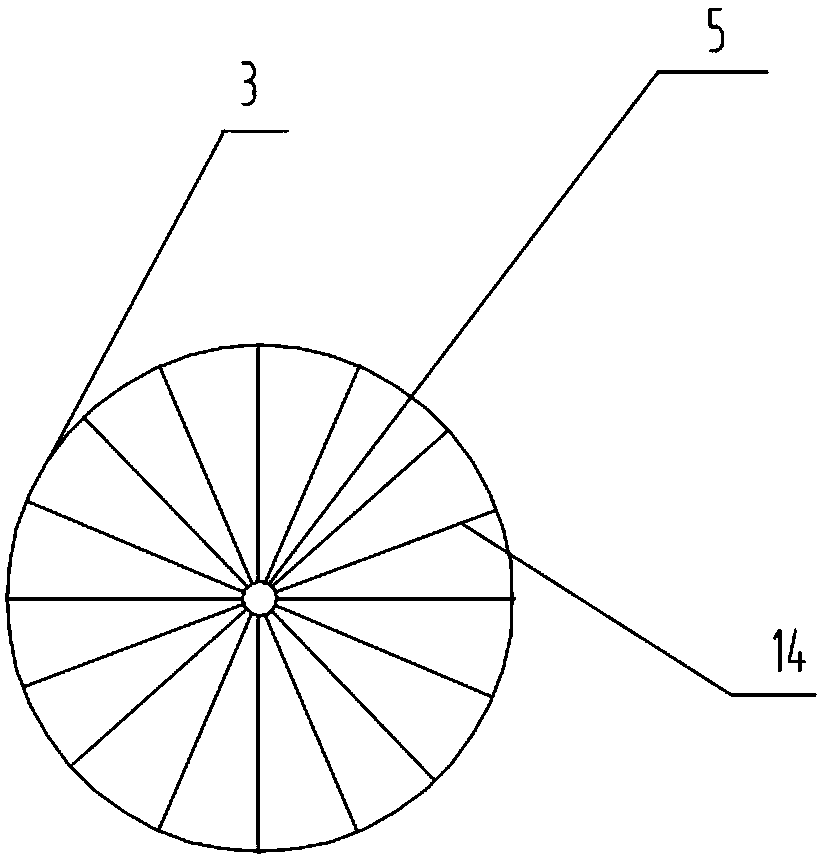

Movable type complete equipment for thermal desorption of polluted waste and method

ActiveCN108704931AGas with low oxygen contentReduce the risk of explosionDispersed particle filtrationWaste processingHigh energyThermal desorption

The invention movable type complete equipment for thermal desorption of polluted waste and a method. The complete equipment comprises a feeding module, a hot phase separation module, a discharging module, a water treatment module and a waste gas treatment module. The complete equipment fills up a vacancy in domestic thermal desorption advanced technology. The problem of governing polluted waste (soil) containing mercury, arsenic, organic matters, organic pesticides and the like can be solved rapidly and efficiently by the complete equipment for thermal desorption. The complete equipment for thermal desorption has the beneficial effects that environmental safety is good, the application range of a material is wide, and the thermal desorption temperature is low. The manner of condensation isadopted in the waste gas treatment module to recycle the organic matters, arsenic and mercury in the polluted waste (soil); reutilization of resources is achieved; higher energy recycling efficiencyis achieved; circulation inside the equipment is achieved after waste water is treated; natural gas or light diesel is adopted as the fuel; and pollutant content in the discharged tail gas is little.The movable type complete equipment for thermal desorption of polluted waste is more environmentally friendly and has a wide application prospect.

Owner:云南省环境科学研究院(中国昆明高原湖泊国际研究中心)

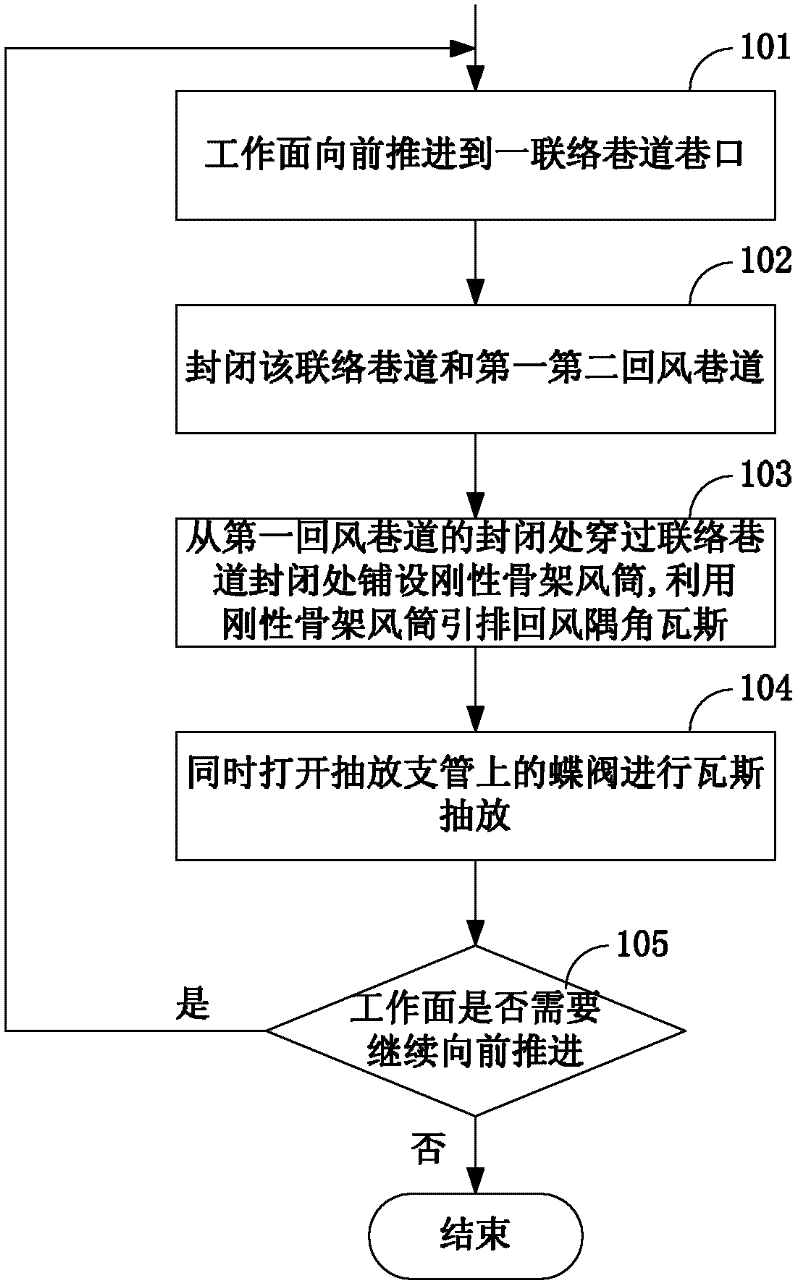

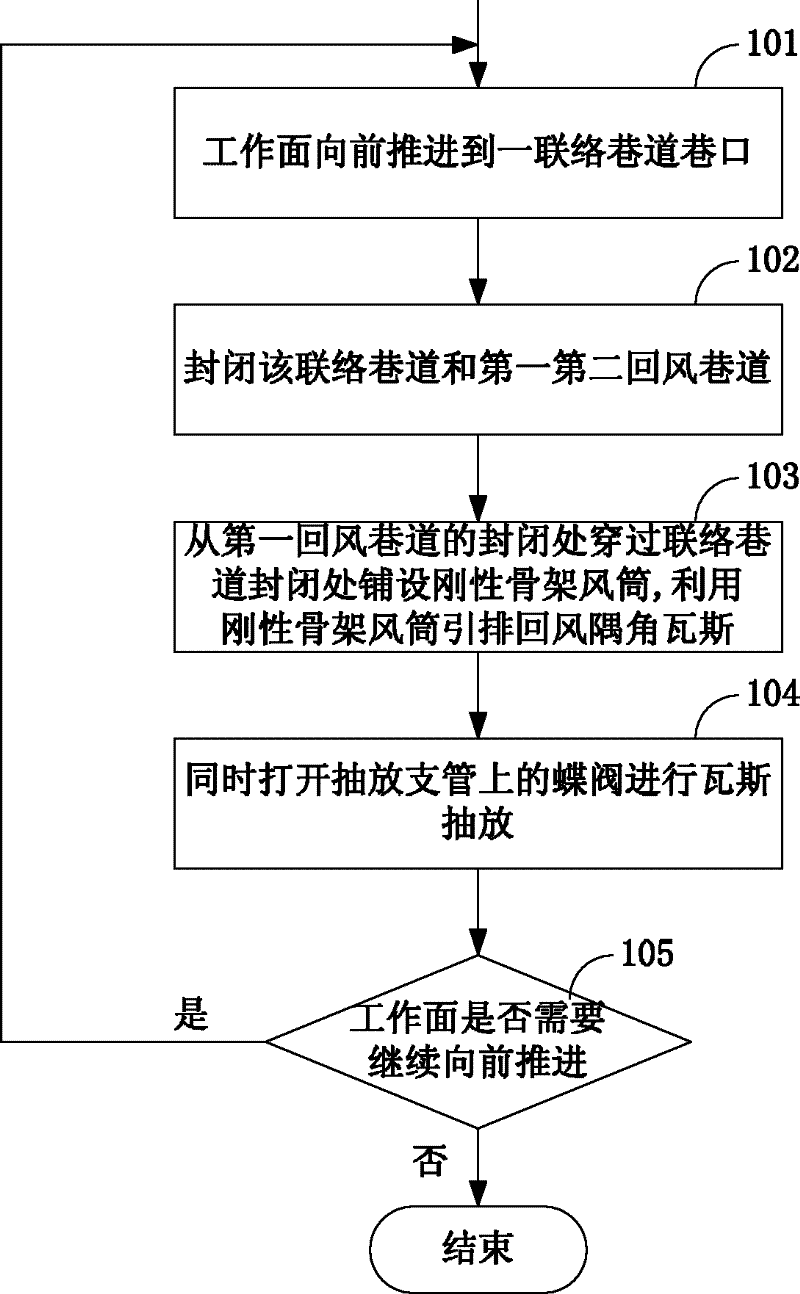

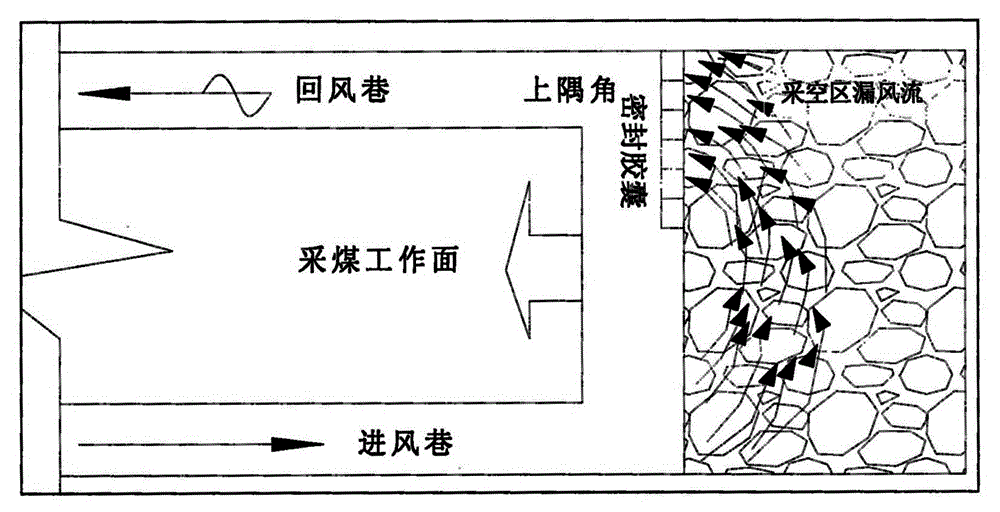

Gas control method for return airflow corner of coalmine coal working face

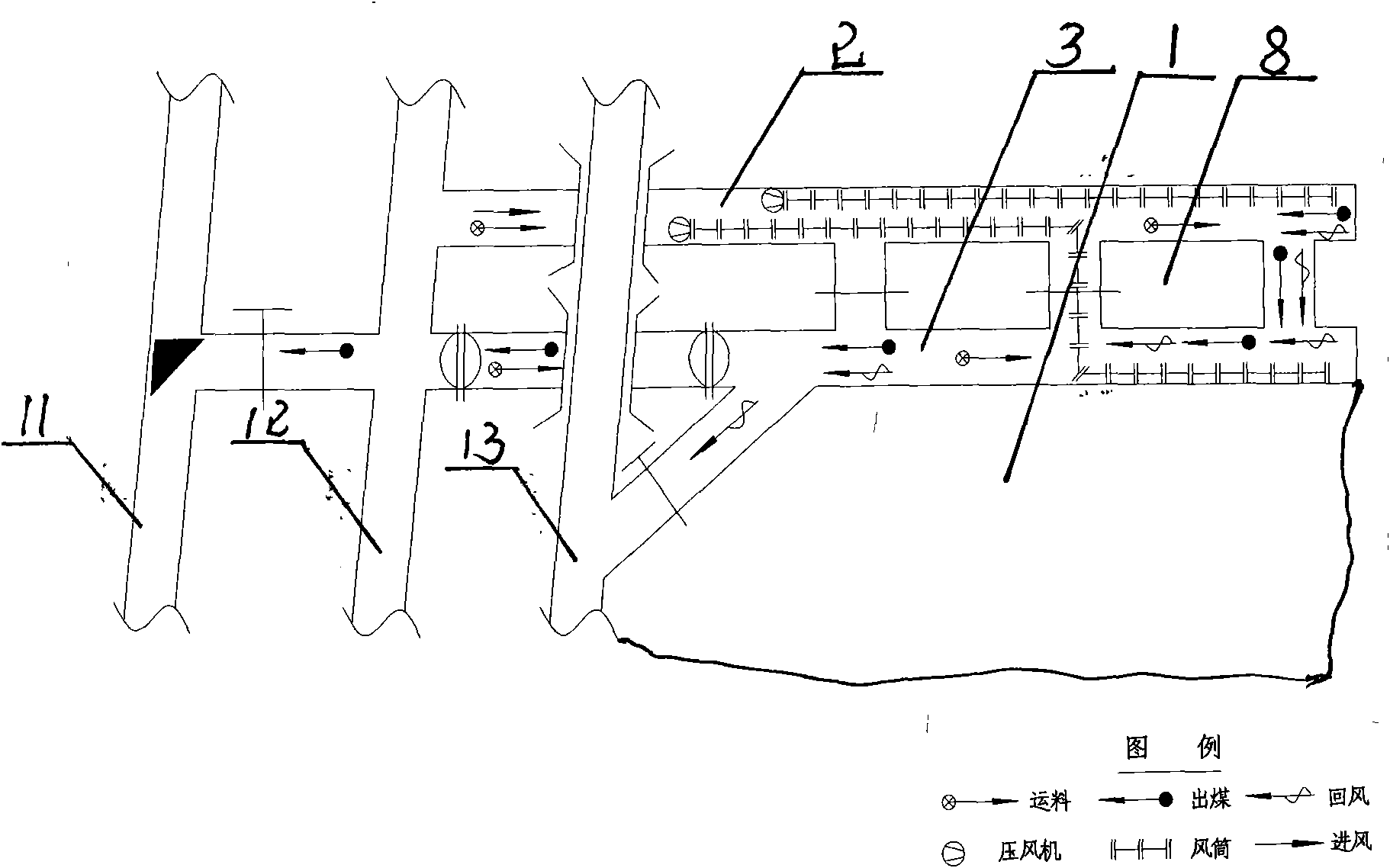

ActiveCN102410040AImprove a safe working environmentReduce concentrationGas removalEngineeringProcess engineering

The invention discloses a gas control method for a return airflow corner of a coalmine coal working face; the gas control method comprises the steps of laying a main drawing-out pipe in a return air roadway in advance and laying a drawing-out branch pipe with a butterfly valve, which corresponds to a connection roadway; the control process comprises the following steps of: A. closing the connection roadway and the return air roadway when the working face is pushed forward to an entrance of the connection roadway; B. laying a wind tunnel from a closing part of the return air roadway to a closing part of the connection roadway in a penetrating manner; and drawing out gas of the return airflow corner by using the wind tunnel; and C. opening a butterfly valve on a drawing-out branch pipe of a connection roadway previous to the connection roadway in the step A for drawing out gas. According to the gas control method, the gas concentration of the return airflow corner of the working face can be effectively reduced, the difficult problem of the gas control on the return airflow corner of the high-yield and high-efficiency working face is effectively solved, and the safety operating environment of the working face is greatly improved.

Owner:CHINA SHENHUA ENERGY CO LTD

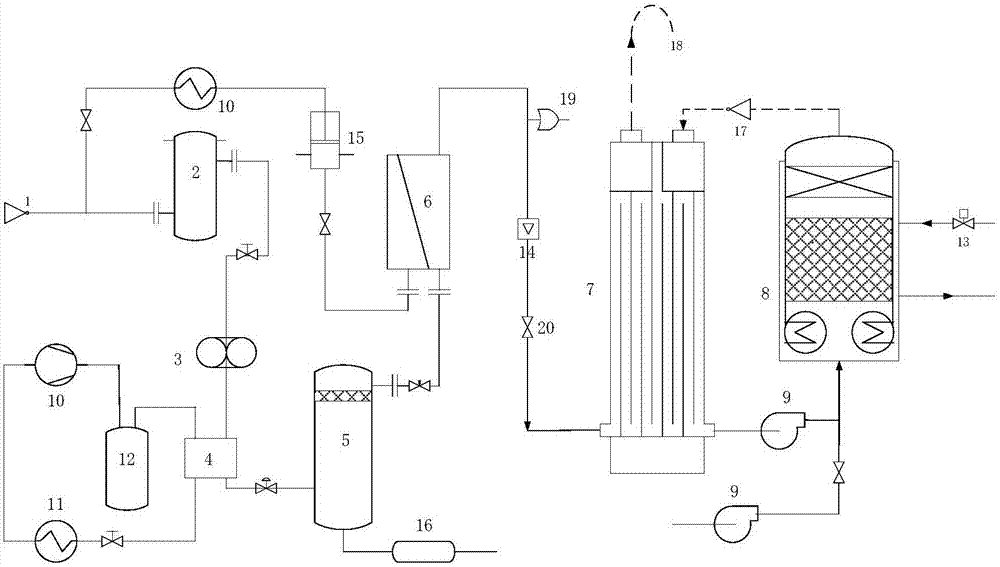

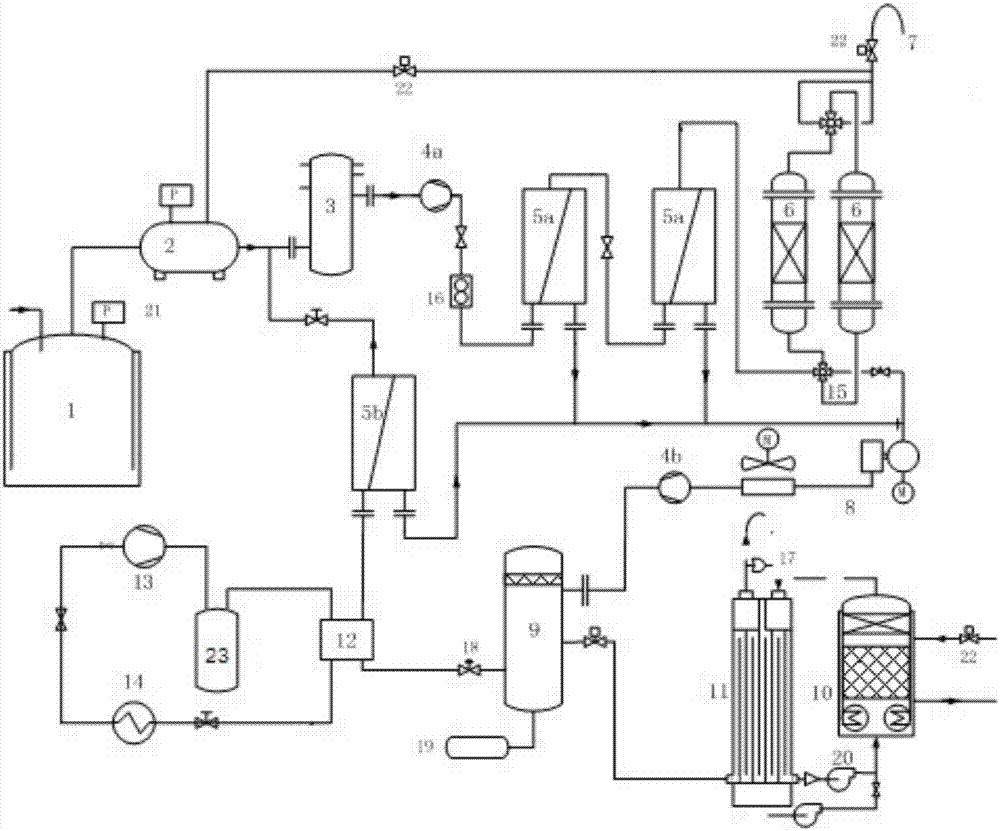

Process and complete-set apparatus for oil gas recovery and treatment

InactiveCN107297141AMeet emission targetsEfficient recyclingDispersed particle separationGas phaseCatalytic oxidation

The invention relates to a process and complete-set apparatus for oil gas recovery and treatment. The complete-set apparatus for oil gas recovery and treatment comprises an oil gas collection device, a buffer gas-mixing tank, a vacuum pump, membrane assembly, a compression and condensation unit, a gas-liquid separation tank, a tube array heat exchanger, and a catalytic oxidation reactor. The process comprises that oil gases successively enter the buffer gas-mixing tank, a compressor and the compression and condensation unit; the compressed and condensed oil gases enter the gas-liquid separation tank for gas-liquid separation, and a gas phase is subjected to membrane separation in the membrane assembly; gases located at the permeate side of the membrane assembly pass through the vacuum pump, and then is compressed and condensed again; the concentration of the oil gases in gases located at the retentate side of the membrane assembly is reduced, and discharging is directly performed after the oil gas concentration reaches a standard; and if the concentration of the oil gases in the gases located at the retentate side still exceeds the standard, the gases enter the tube array heat exchanger to exchange heat with oil gases which are subjected to catalytic oxidation in the catalytic oxidation reactor, and the gases subjected to heat exchange enter the catalytic oxidation reactor, catalytic oxidation is performed under the action of a catalyst for removing organic materials in the gases, and at last discharging is performed after the oil gas concentration reaches the standard. The process and complete-set apparatus for oil gas recovery and treatment realize the high-efficiency recovery and treatment of the oil gases, and have certain industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

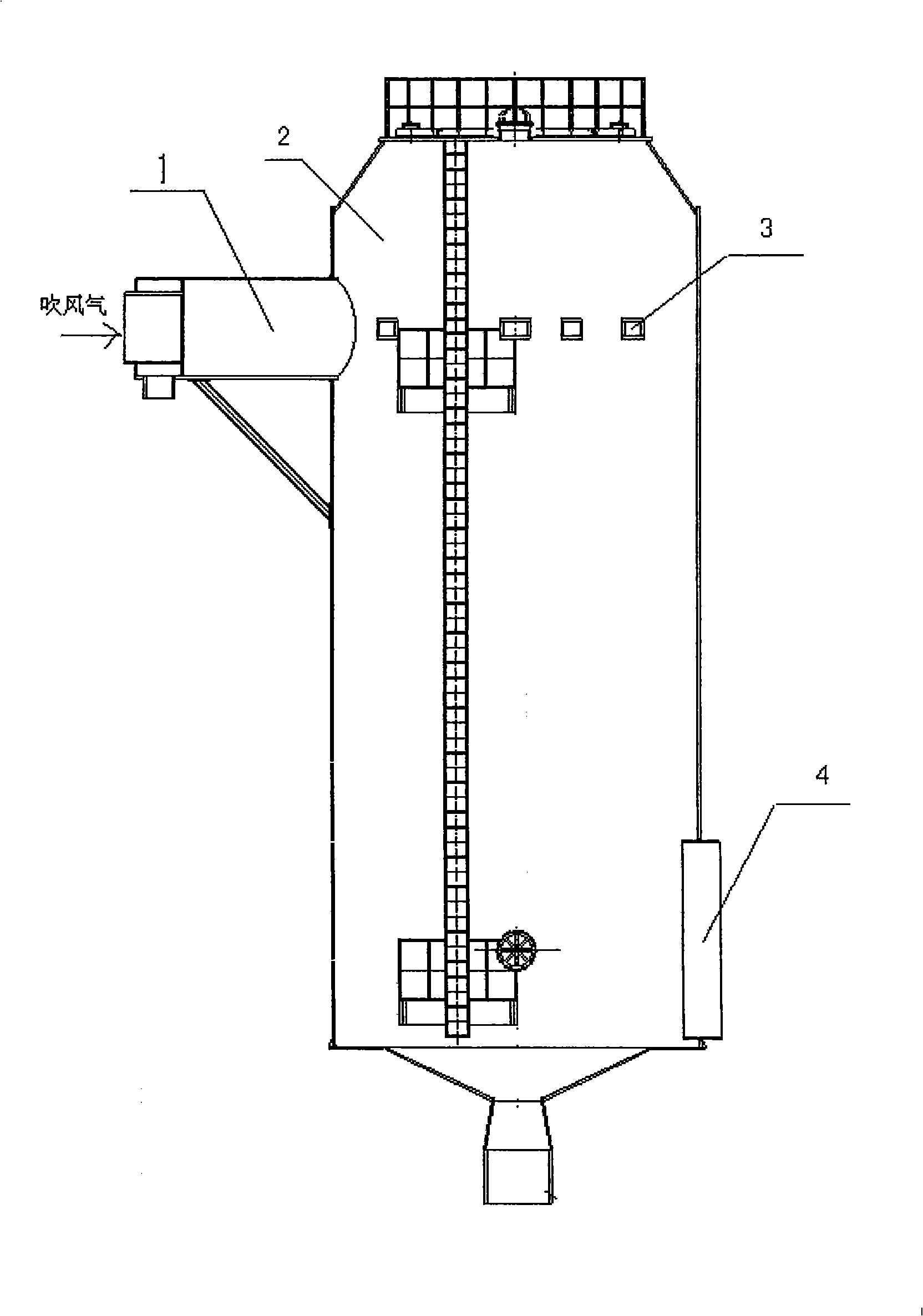

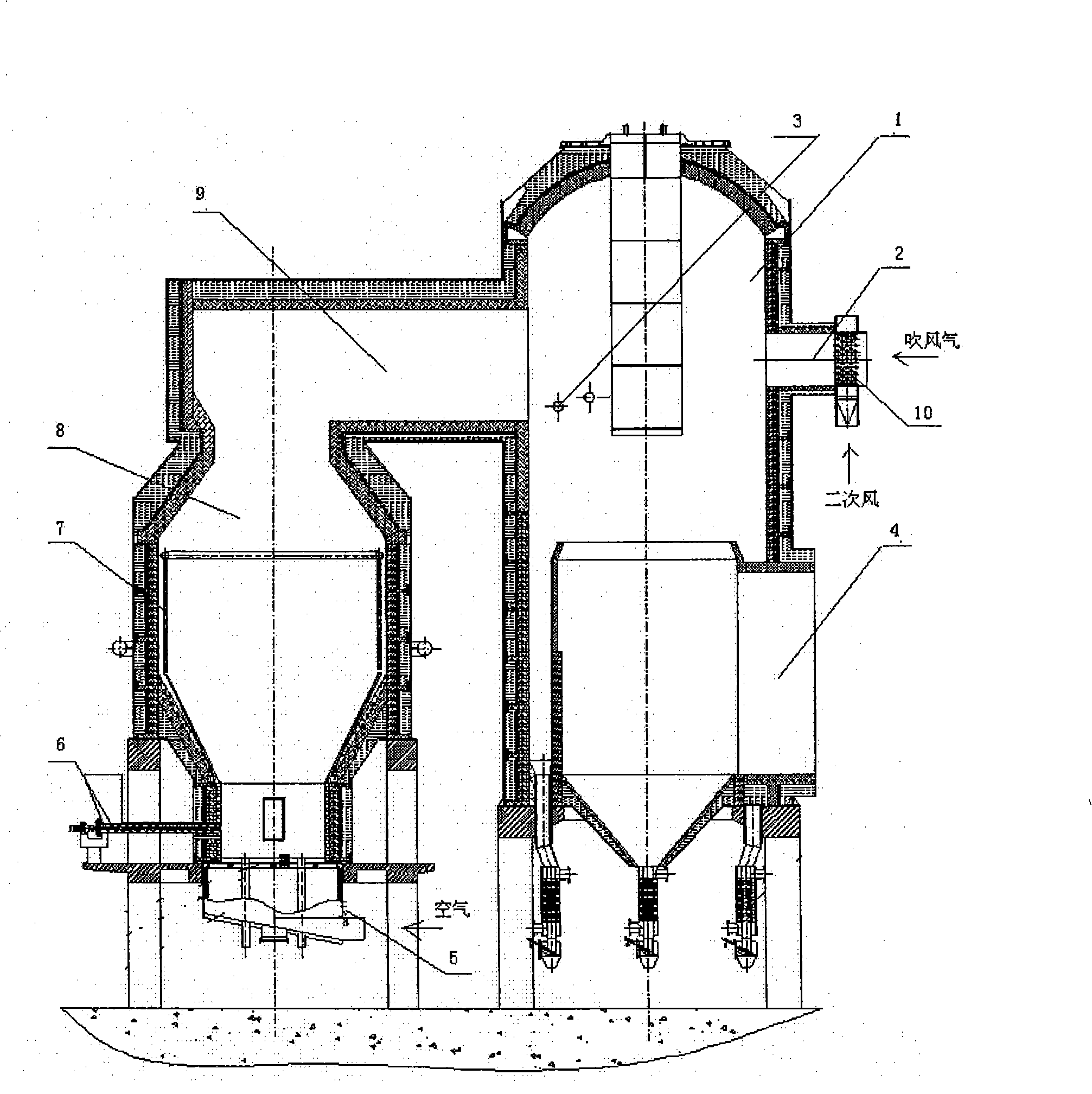

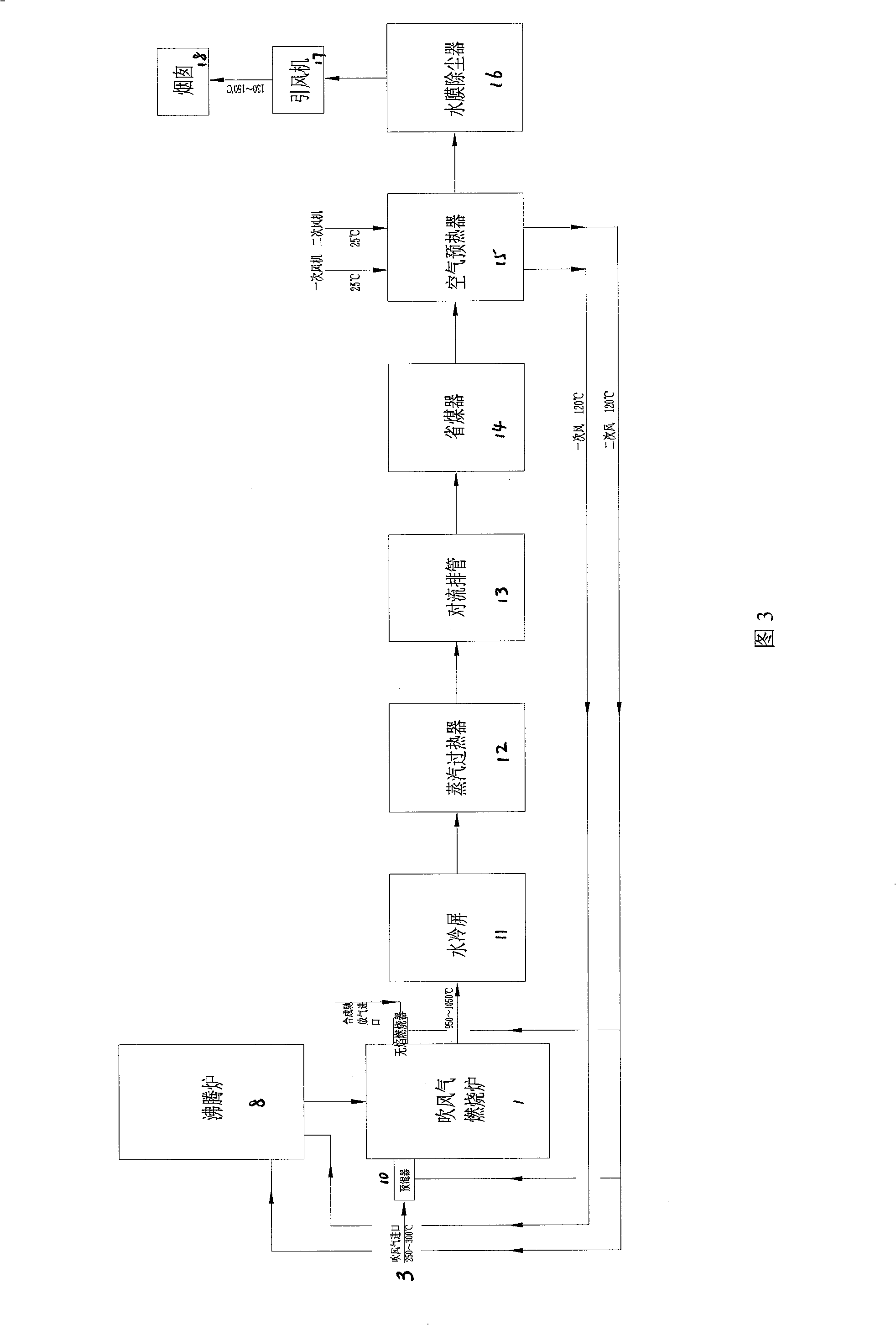

Coal gas waste gas, waste slag and waste ash comprehensive utilization process and apparatus

InactiveCN101348734ASave hydrogen and semi-water gasIncrease productionEnergy inputCombustible gas productionSlagExhaust fumes

The invention relates to a process for comprehensively utilizing waste gas, waste slag and waste ash of coal-making gas and a device thereof. The process combines a boiling furnace and a blowing gas residual heat reclaiming system of coal-making gas together; the boiling furnace utilizes the waste slag and waste ash after coal-making gas as fuel for secondary combustion; high-temperature flue gas is produced to ignite the blowing gas in a blowing gas combustion furnace; and flue gas produced after the blowing gas is combusted passes through the residual heat reclaiming system and is exhausted to atmosphere by a chimney. The device is combined into a whole by the boiling furnace and the blowing gas combustion furnace of the blowing gas residual heat reclaiming system of the coal-making gas.

Owner:邓立玮

Method for preparing chromium iron black from electroplated chromium-containing waste water in recycling mode

InactiveCN106277456ATake advantage ofIncrease economic value addedIron oxides/hydroxidesWater contaminantsIron BlackFerrochrome

The invention discloses a method for preparing chromium iron black from electroplated chromium-containing waste water in a recycling mode. The method comprises the following steps that 1, the total chromium, chromium (III) and chromium (VI) content in the electroplated chromium-containing waste water is measured, the pH of the waste water is adjusted to range from 8 to 11 with liquid caustic soda, and an oxidizing agent is added to oxidize chromium (III) into chromium (VI); 2, the pH of the oxidized waste water is adjusted to range from 3 to 4 with sulfuric acid, an iron-containing agent is added, stirring is carried out at normal temperature for reacting, and a reaction solution is obtained; 3, liquid caustic soda is added into the reaction solution obtained in the step 2, the pH is adjusted to range from 8 to 9, then an aeration reaction is carried out, filtering and separation are carried out, and a filter cake and filtrate are obtained, wherein the filtrate is waste water obtained after chromium removal and can be directly drained or used for the rinsing section in the step 4; the filter cake obtained in the step 3 is subjected to rinsing, drying, calcining and smashing, and the chromium iron black product is obtained. Chromium in the electroplated chromium-containing waste water is converted into chromium iron black pigments with high economic additional value through a simple process path, the problem about treatment of the electroplated chromium-containing waste water is solved, chromium resources are reutilized, and sustainable development of the resources is achieved.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

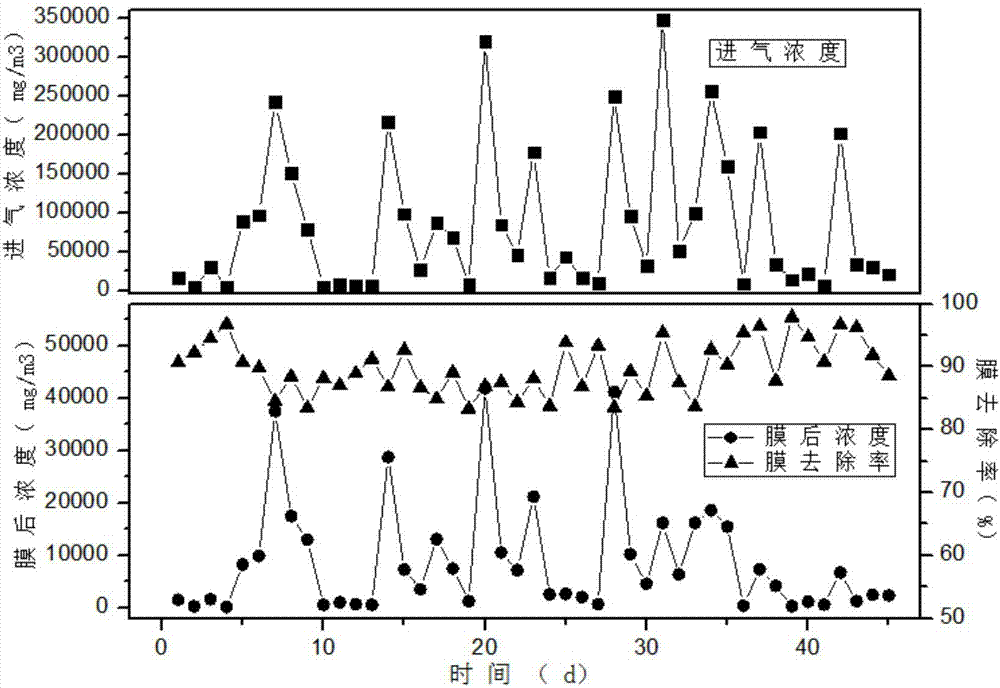

High-effective organic waste gas recovery processing method and complete equipment

ActiveCN107413173AHigh recovery rateHigh explosion-proof gradeGas treatmentDispersed particle separationHigh concentrationBuffer tank

The invention relates to a high-effective organic waste gas recovery processing method and complete equipment. The complete equipment includes: an organic waste gas collection apparatus, a gas storage tank, a buffer tank, a primary membrane unit, an active carbon adsorption unit, a vacuum pump, a gas-liquid separation tank, a compression condensing unit, a secondary membrane unit, a low temperature catalytic oxidizing reactor, and a tubular heat exchanger. Through the two-stage membrane as a core technology, advantages that a membrane process is high in efficient, is continuous, has high recover rate and high safety and is suitable for high-concentration organic waste gas are achieved, thus recovering the recoverable components in the waste gas; in addition, with the low temperature catalytic oxidization technology, an advantage of deep processing thereof is achieved, so that a problem of accumulation of light-hydrocarbon substances is overcome. The processing method and complete equipment not only high-effectively recover valuable organic substances, but also can perform deep processing to the organic waste gas with satisfaction of strict requirements on safety production in petrochemical enterprises. Through the deep processing to the organic waste gas, discharged organic waste gas can reach national emission standards.

Owner:CHINA PETROLEUM & CHEM CORP +1

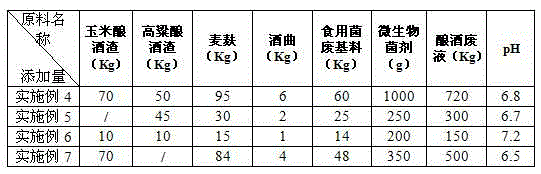

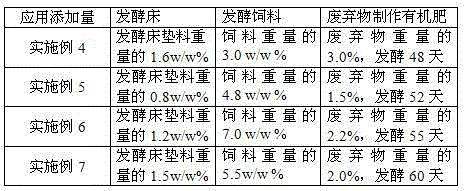

Preparing method and application of fermentation culture solution

A fermentation culture solution comprises, by weight, 10-15 parts of brewing waste residues, 7-12 parts of wheat bran, 0.5-0.8 part of yeast, 6-12 parts of edible mushroom waste base stock, 0.05-0.15 part of microbial agent and 70-100 parts of brewing waste liquid. The pH value of the fermentation culture solution is 6.0-7.5. The invention further discloses the preparing method and application of the fermentation culture solution. According to the fermentation culture solution, product waste materials are recycled, cost is low, preparation is easy, and fermentation effect is good when the fermentation culture solution is applied to a fermentation bed or fertilizer; the content of live bacteria in the culture solution is high, application is easy, and effect is good.

Owner:桃江县新星生物科技有限公司

Biological stalk pesticide and its prepn process

The present invention relates to biological stalk pesticide and its preparation process. The biological stalk pesticide is prepared through crushing stalk, gas explosion in a gas explosion chamber, adding water in the weight equal to the stalk, sterilizing in a high temperature steam treating chamber, microwave treating, cooling and spraying bacterial seed culture liquid, and solid fermentation in an aerobic fermenter to obtain the biological stalk pesticide. The biological stalk pesticide is used in killing termite, beetles and other pests in soil, and has the advantages of environment friendship, no residue, no pest's resistance, etc.

Owner:张培举

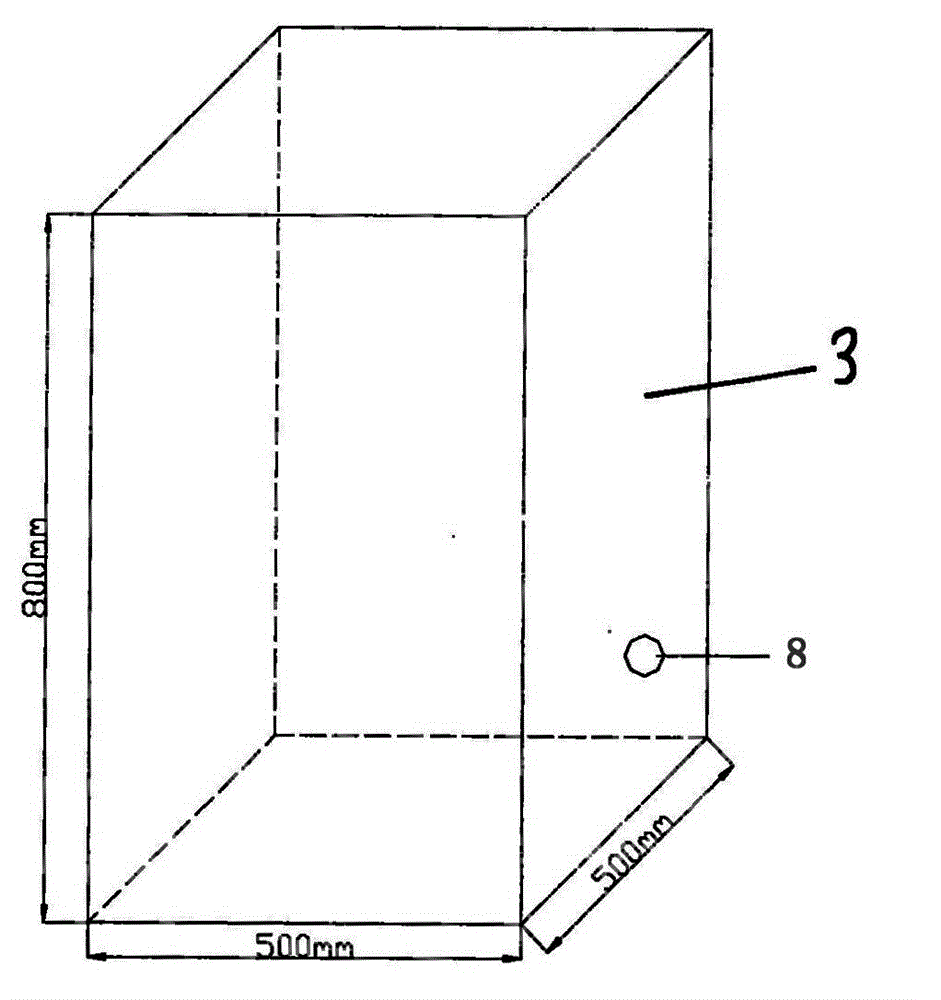

Sealing capsule and application thereof in coal mine

InactiveCN102979577AReduce the number of overrunsSolving Governance ChallengesMining devicesRubber materialWork cycle

The invention discloses a sealing capsule and application thereof in a coal mine. The sealing capsule is a rectangular cubic air bag made of an antistatic flame retardant rubber material, and an inflation and deflation valve is arranged on the rectangular cubic air bag. The application method of the sealing capsule in the coal mine comprises the steps that sealing capsules corresponding in quantity are chosen according to the size and the length of a working surface, and are arranged 10 cm before an upper corner of the working surface in a single-row and multi-layer arranging manner to form a sealing capsule wall. The specific operation steps are as follows: a), a position is chosen precisely, b), the capsules arranged at the bottom are placed levelly, c), the inflation of the capsules arranged at the bottom is completed, d), the capsules arranged on the upper layer are laid, and e), the inflation of the capsules arranged on the upper layer is completed; when the working surface is advanced, f), the capsules arranged at the upper part are deflated, g), the capsules are moved integrally, and h), the capsules arranged on the upper part are inflated; therefore, one working cycle is completed.

Owner:HENAN POLYTECHNIC UNIV

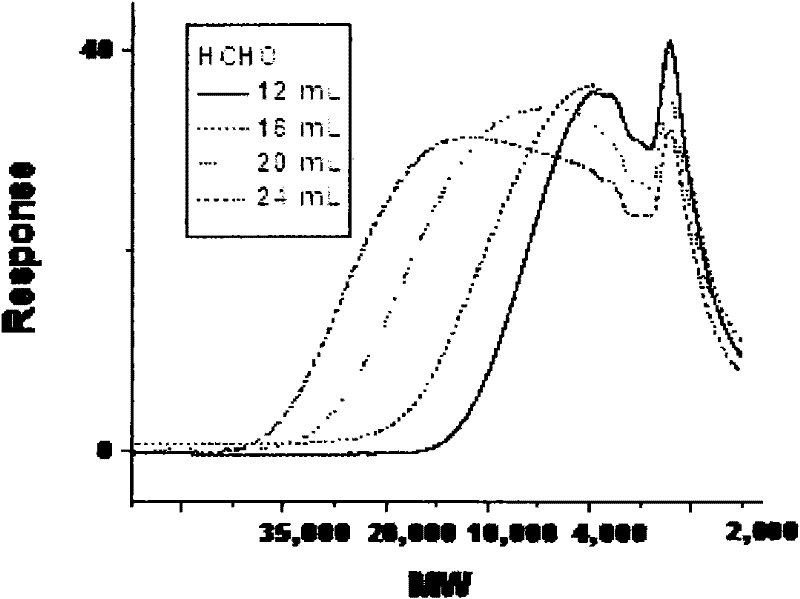

Method for preparing lignin amine from cyclohexanone wastewater

ActiveCN102838753ATake advantage ofSolve the emission problemTransportation and packagingMixingSocial benefitsCyclohexanone

The invention discloses a method for processing cyclohexanone wastewater, belonging to the technical field of comprehensive utilization of wastewater, comprising the following steps: weighing 60 weight parts of cyclohexanone wastewater with the pH value of 9-13, adding 10-20 weight parts of alkali lignin, and stirring for 10-15min for dissolving; adding 8-12 weight parts of aldehyde compound to the wastewater, stirring for 10-15min for dissolving; adding 15-25 weight parts of amine compound in the wastewater, stirring for 10-15min for dissolving; heating up to 75-90 DEG C, and reacting for 1-5 h to obtain a solution of high-molecular emulsifier lignin amine. According to the invention, by using the wastewater as a solvent and conducting high-molecular chemical reaction in the solvent to prepare the high-molecular emulsifier, the cost of processing the wastewater can be effectively reduced, the effective components in the wastewater can be fully utilized, thus the recycling of the wastewater is realized, and the method has obvious economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

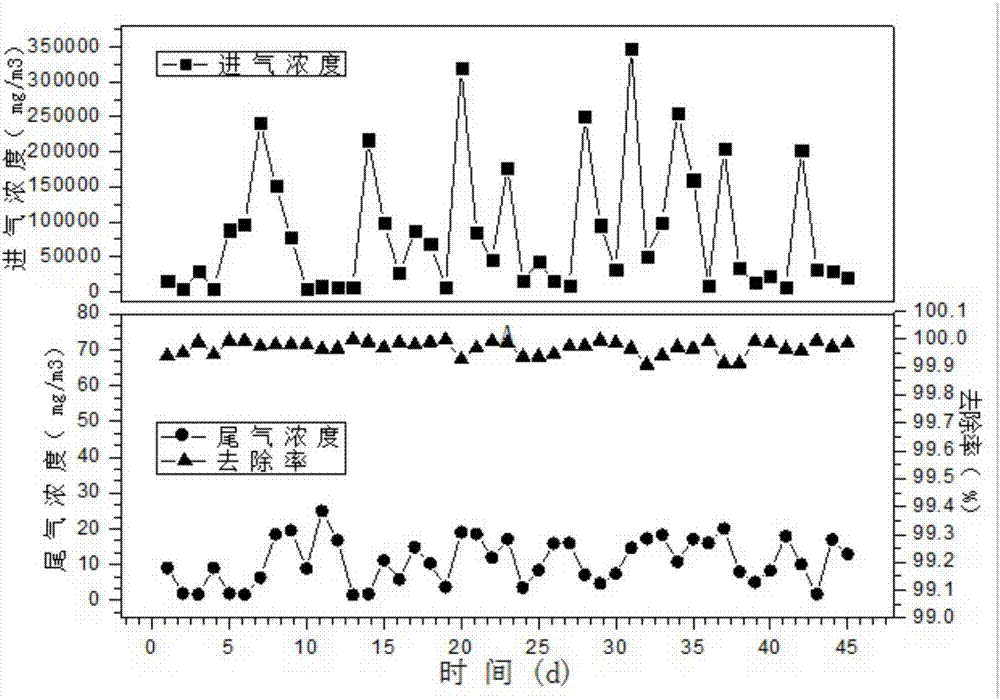

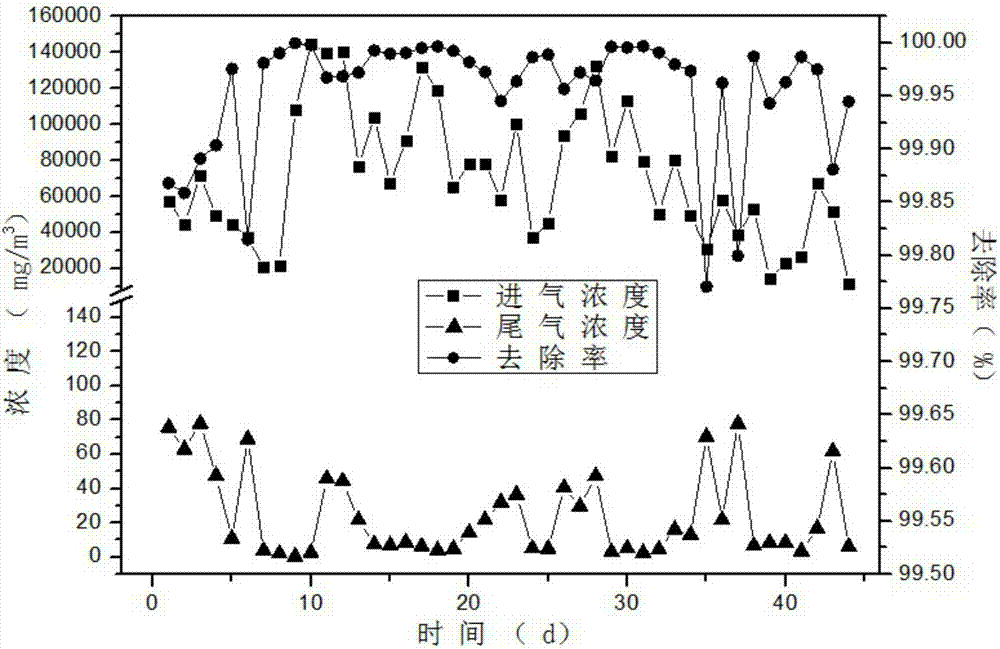

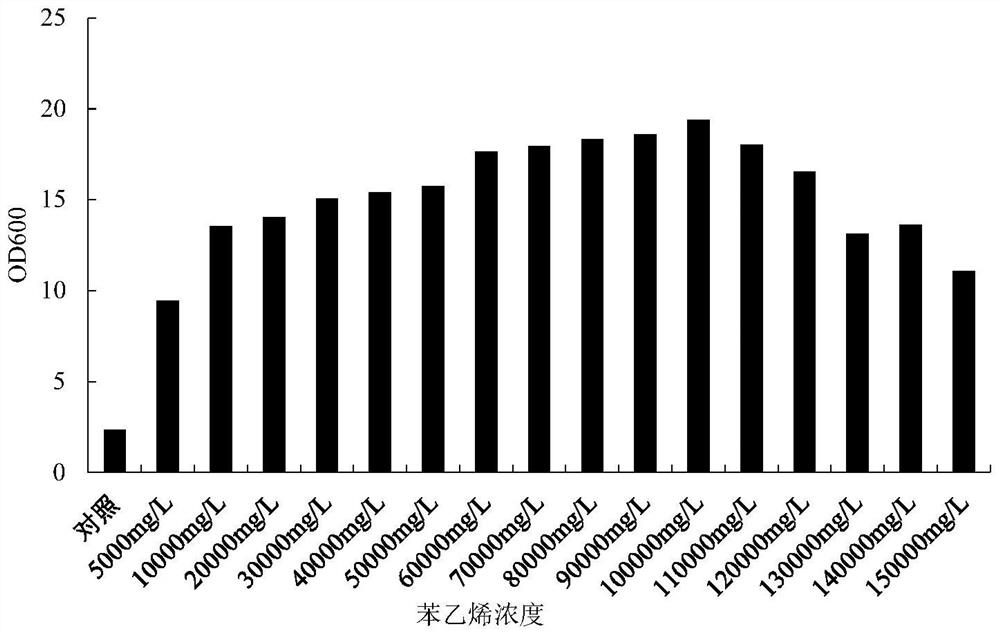

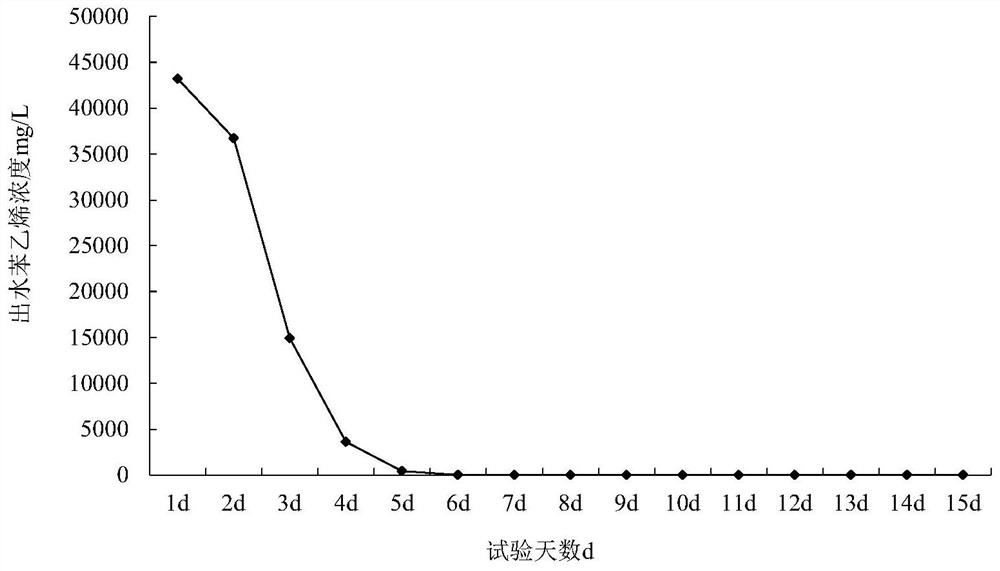

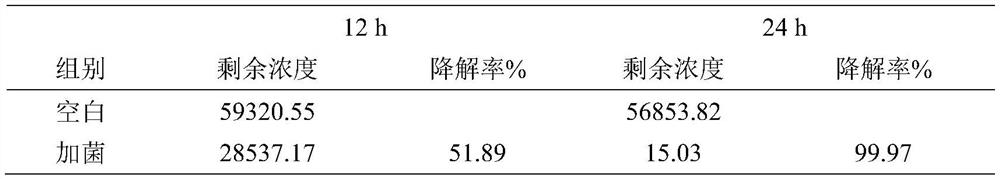

Styrene degrading bacterium and application thereof

ActiveCN114214233ASolving Governance ChallengesImprove biochemical treatment efficiencyBacteriaWater contaminantsStyrene degradationEngineering

The invention belongs to the technical field of bioengineering, and provides a styrene degrading bacterium and application thereof. According to the present invention, the styrene degrading bacterial agent is identified as Pseudomonas plecoglossa through 16S rDNA identification, the bacterial strain has been preserved in the China General Microbiological Culture Collection Center (CGMCC) in June 2021, and the preservation number is CGMCC No.22757. The invention further provides a preparation method of the styrene degrading bacterial agent, under the optimal condition, the degradation rate of the microbial inoculum to styrene with the initial concentration of 60000mg / L for 24h is 99.97%, and the maximum tolerance concentration to styrene reaches 100000mg / L. The styrene degrading bacterial agent provided by the invention can reduce the impact of styrene on a biochemical treatment system, improves the treatment efficiency of styrene-containing wastewater, and has remarkable economic and environment-friendly benefits. Meanwhile, the strain can be applied to the field of treatment of styrene polluted wastewater and soil or styrene-containing organic waste gas.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

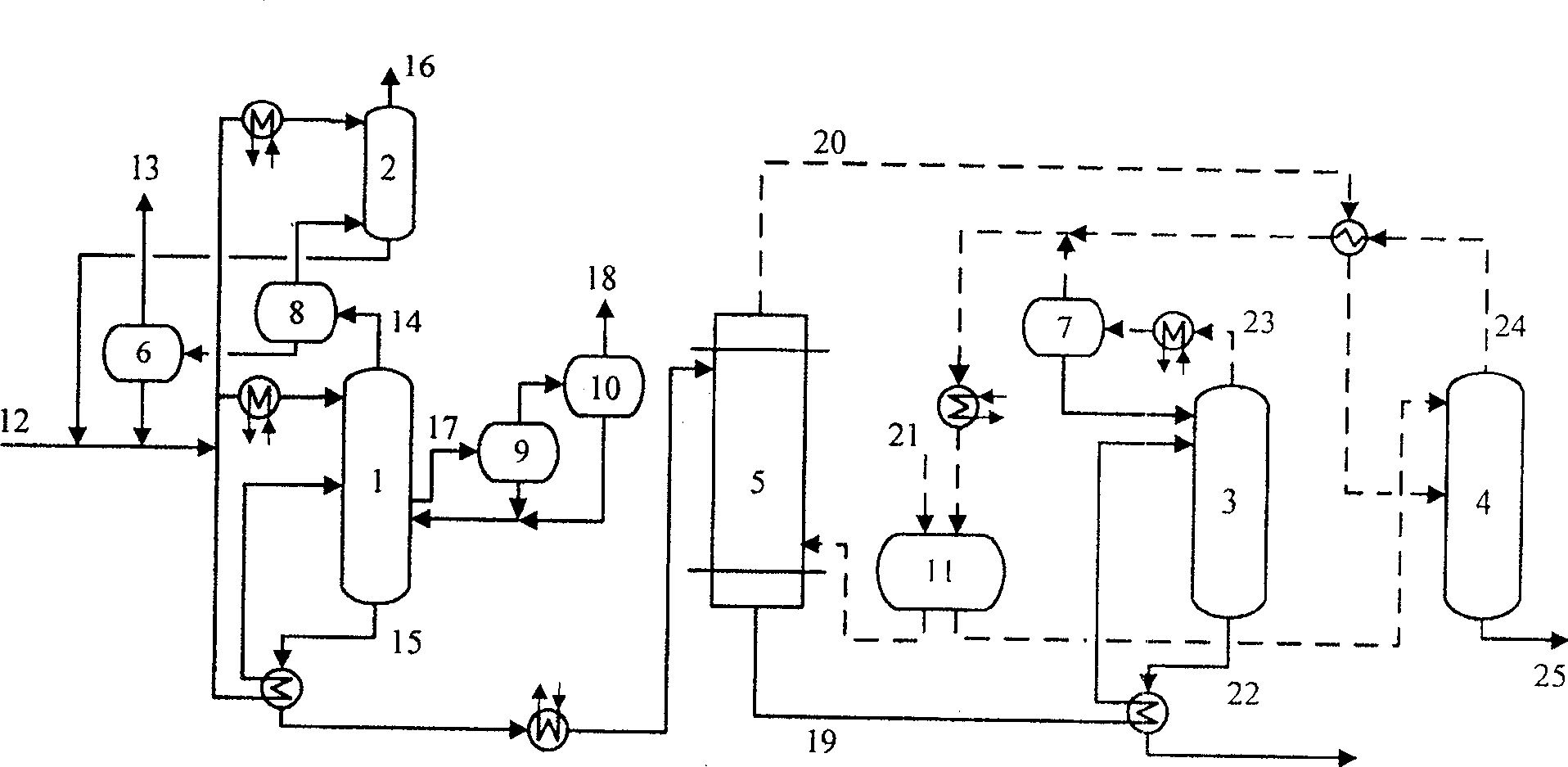

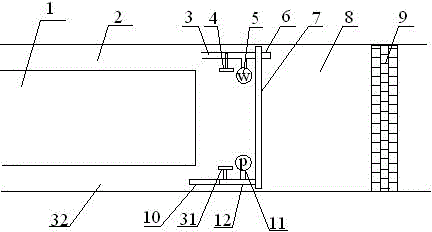

Method for treating coal gasification wastewater by single-tower pressurization stripping and device therefor

InactiveCN100484894CHigh removal rateReduce crystallizationFatty/oily/floating substances removal devicesMultistage water/sewage treatmentCoal gasification wastewaterSolvent

The invention discloses a gasification wastewater disposing method and device through single-tower pressurizing stripping, which comprises the following steps: entering the extracted of acid gas or ammonia gas of cold and hot coal gasification wastewater from band lateral line in the stripping tower from top and upper top; blending gas; dividing phases; washing; separating light oil and acid gas; preparing liquid ammonia through two-grade concreting and refining; separating crude phenol and organic solvent from bottom of tower through inversed-extracting autoclave liquid and organic solvent; recycling organic solvent through stripping. The gasification disposing device contains oil acid gas / ammonia stripping tower, extracting tower, acid gas washing tower, solvent stripping tower, solvent recycling tower, oil-water separator, dephlegmator, pump and reservoir.

Owner:SOUTH CHINA UNIV OF TECH

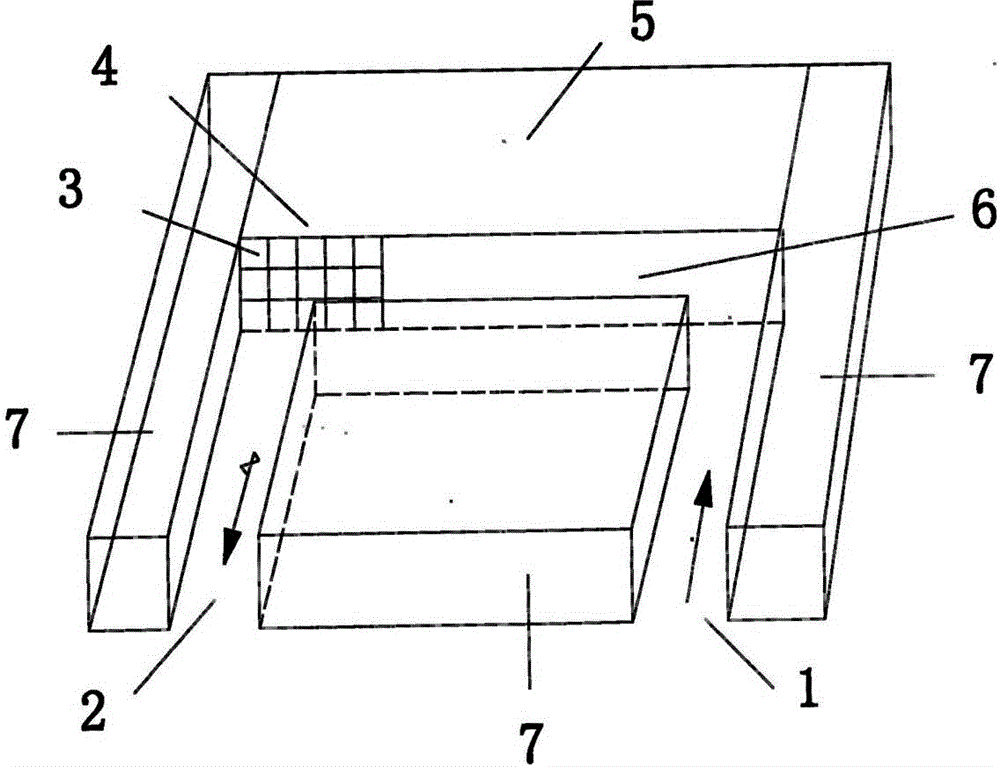

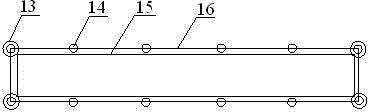

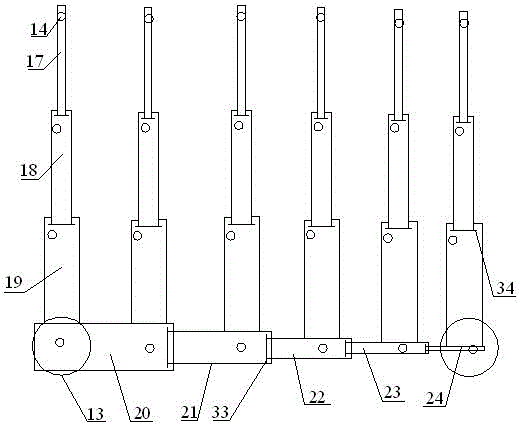

Mobile type goaf gas quick blocking and extraction device and technology

InactiveCN104405431ASolving Governance ChallengesReduce aggregationSurveyMining devicesProcess engineeringCoal

The invention discloses a mobile type goaf gas quick blocking and extraction device and a mobile type goaf gas quick blocking and extraction technology. The device and the technology are easy and convenient to operate; furthermore, gas in a goaf can be quickly blocked, and the blocked gas can be quickly extracted, so that the difficulty in treating the gas in the goaf can be effectively solved, the gas content of the goaf is fundamentally reduced, the goaf gas gathering amount and the gas gush amount to a stopping working surface are reduced, the influence of the gas in the goaf on the concentration of the gas on the stopping working surface is reduced to the maximum extent, and great significance in reducing the mine ventilating difficulty and realizing safe and high-efficiency production of a coal mine is realized. Multiple stages of fixing devices are convenient for flexible gas pocket forming, and overlarge deformation of a local area of a flexible gas pocket can be avoided; the operation and the use are convenient and quick; the requirement on an underground narrow space can be met, and quick moving is facilitated; meanwhile, the device can be recycled, multi-frequency utilization is realized, and the treatment cost is lowered.

Owner:HENAN POLYTECHNIC UNIV

Method for treating nitrobenzene waste water

ActiveCN102417249ALow costSolve the emission problemWater contaminantsMultistage water/sewage treatmentCoal waterEmulsion polymerization

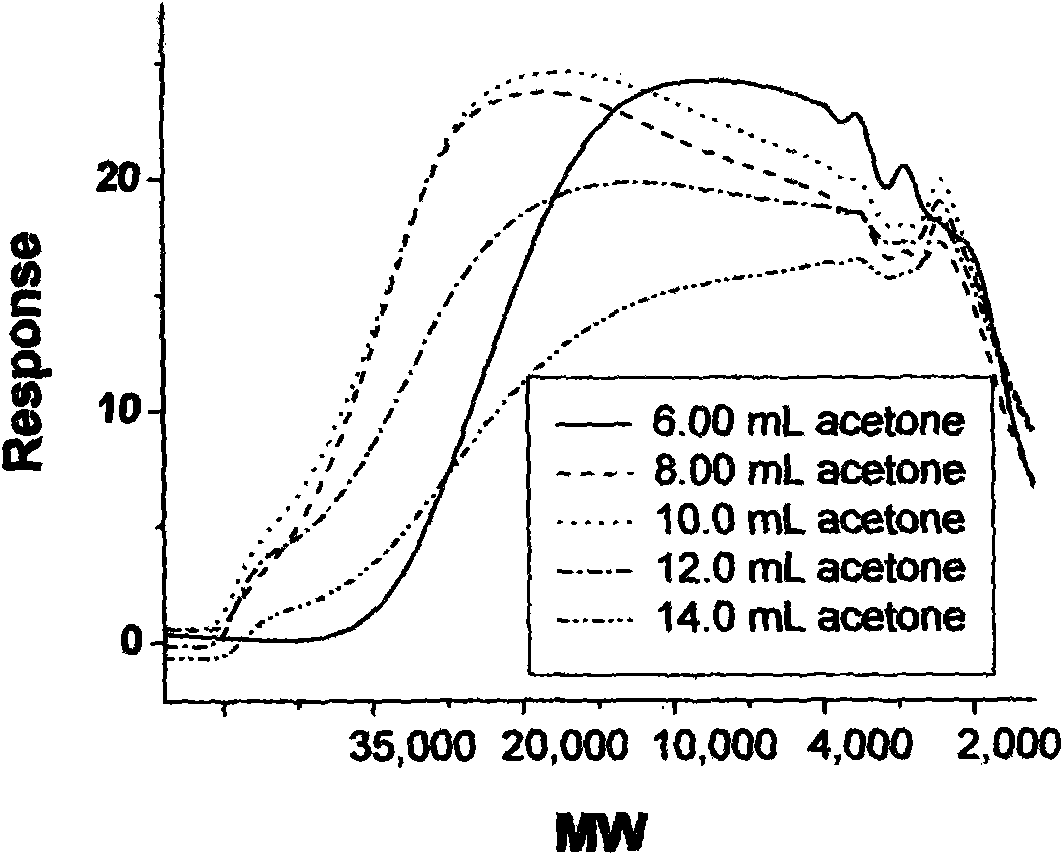

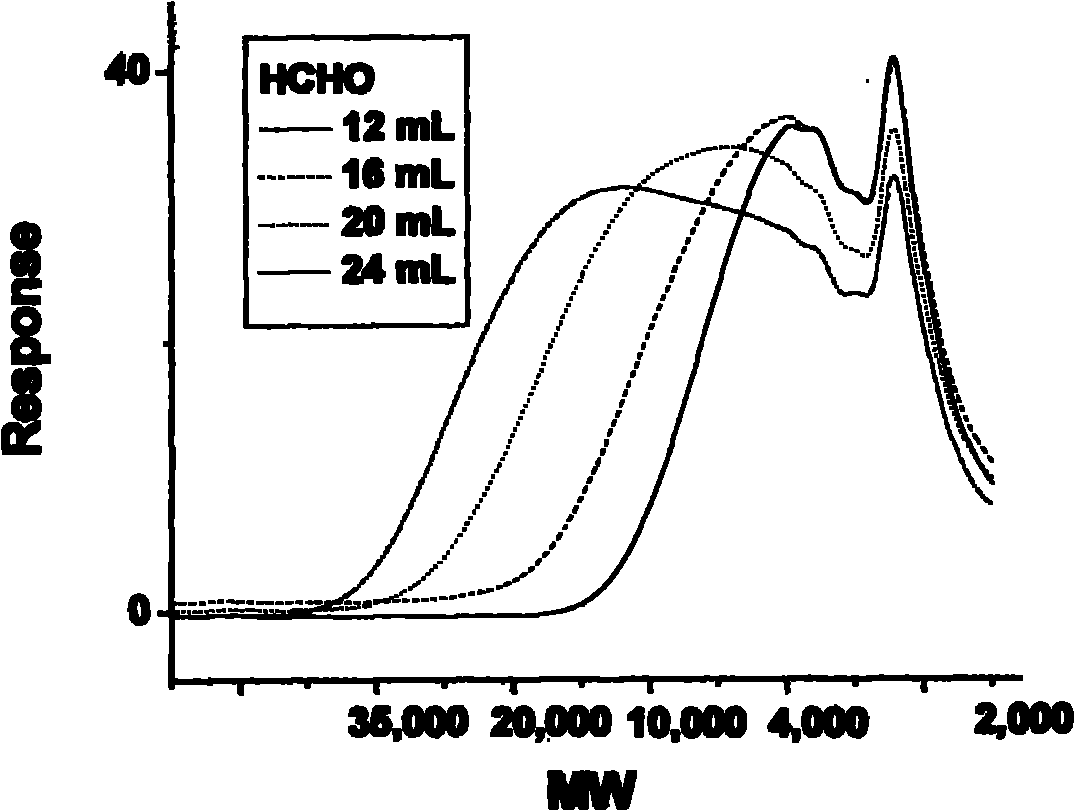

The invention relates to a method for treating nitrobenzene waste water. The method comprises steps of: step 1. according to a molar ratio, taking 50 parts of nitrobenzene waste water with a pH of 9-13 and adding 0.2-0.4 parts of sulfonating agent; step 2. adding 1-2 parts of ketone compound or acrylic acid compound into the nitrobenzene waste water for acetone sulfonation reaction; step 3. adding 2-4 parts of aldehyde compound or oxirane into nitrobenzene waste water for condensation polymerization; step 4. adding 450-950 parts of nitrobenzene waste water, continuing the condensation polymerization in step 3. for 0.5-1.0 h, thereby preparing a coal water slurry additive with an effective concentration of 0.5-1%. According to the method for treating nitrobenzene waste water of the invention, the coal water slurry additive is prepared in the waste water phase through solution polymerization, so as to avoid environmental pollution caused by discharge of nitrobenzene waste water and realize reuse of nitrobenzene waste water.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method for treating waste lye of cyclohexanone plant

ActiveCN102295965ARealize resourcesLow costLiquid carbonaceous fuelsMultistage water/sewage treatmentCyclohexanoneChemical treatment

The invention relates to a method for treating waste alkali liquor of a cyclohexanone device. The method comprises the following steps of: 1, adding 0.2-0.4 part of sulfonating agent into 50 parts of waste alkali liquor of the cyclohexanone device with pH of 9-13 in molar ratio; 2, adding 1-2 parts of acetone or acrylic acid compound into the waste alkali liquor of the cyclohexanone device to perform acetone sulfonation reaction; 3, adding 2-4 parts of aldehyde compound or ethylene oxide into the waste alkali liquor of the cyclohexanone device to perform condensation polymerization reaction; and 4, then adding 450-950 parts of the waste alkali liquor of the cyclohexanone device and continuously performing the condensation polymerization reaction of the step 3 to prepare a composite coal water slurry additive at effective concentration of 0.5-1 percent. By adopting the method, the coal water slurry additive and coal water slurry are obtained by using an organic synthesis method after the waste alkali liquor of the cyclohexanone device is properly and chemically treated, so that the environment is prevented from being polluted by discharge of the waste alkali liquor of the cyclohexanone device, the cost of the coal water slurry additive is effectively reduced, and recycling of the waste alkali liquor of the cyclohexanone device is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

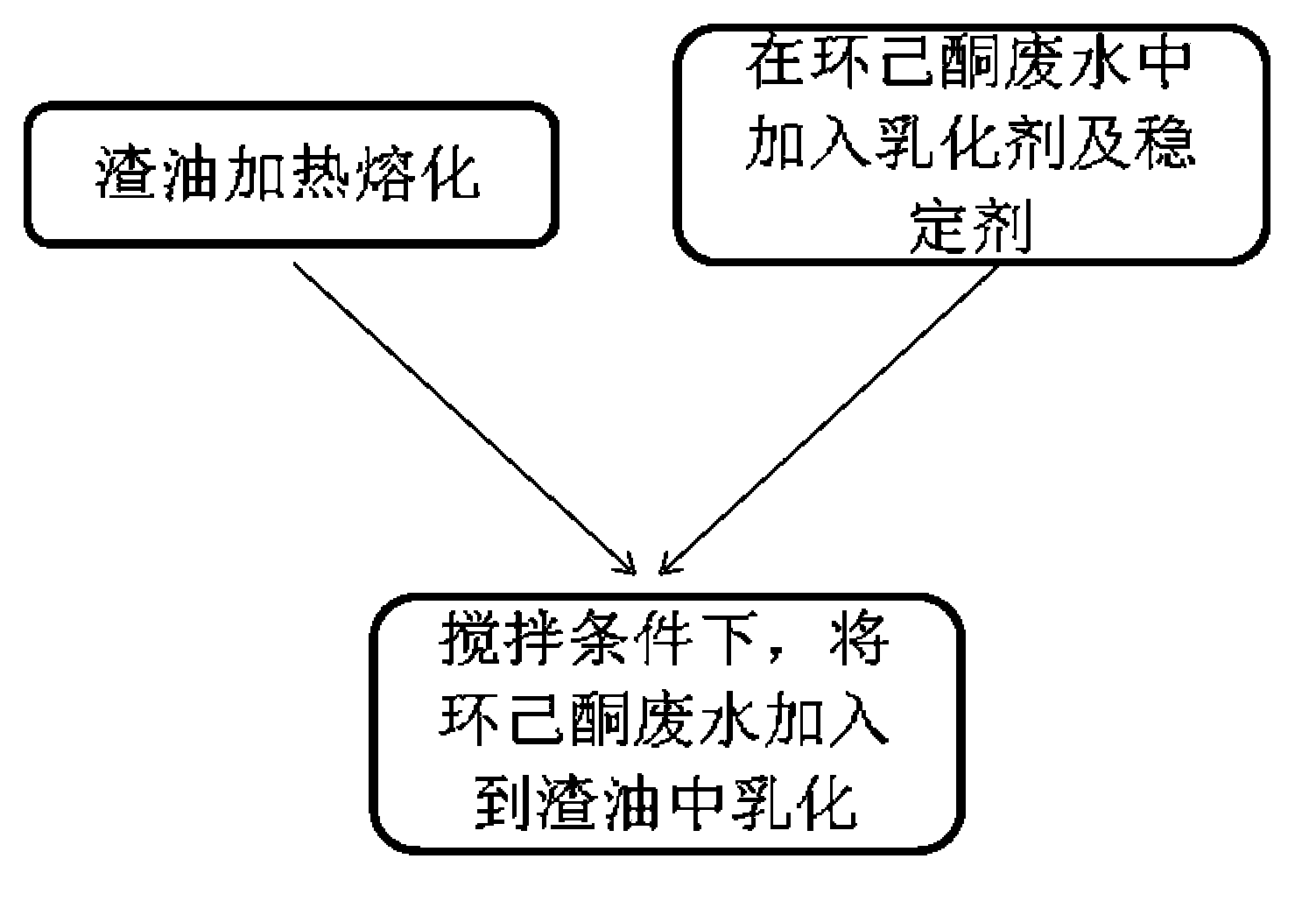

Method for preparing emulsified residual oil by using cyclohexanone wastewater

ActiveCN103665394AReduce water useAddressing Emissions and Governance ChallengesMultistage water/sewage treatmentNature of treatment waterChemistryCyclohexanone

The invention discloses a method for preparing emulsified residual oil by using cyclohexanone wastewater, relates to the field of a preparation method of an oil emulsion, and particularly relates to a method for preparing emulsified residual oil by using cyclohexanone wastewater. The method comprises the following steps: adding an emulsifier and a stabilizer to the cyclohexanone wastewater; stirring and dissolving the obtained water solution and keeping warm; heating the residual oil to melt; evenly adding the water solution to the molten residual oil; stirring to obtain the emulsified residual oil. The method disclosed by the invention has the advantages that the wastewater is utilized as raw water for preparing the emulsified residual oil, so that use of clean water is saved; meanwhile, the wastewater is used as a raw material, so as to play a role of transforming the waste into treasure.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for treatment of air containing viscous paint particles

InactiveCN109289359AAchieve purificationAvoid cloggingGas treatmentDispersed particle filtrationActivated carbonEnvironmental engineering

The invention provides a method for treatment of air containing viscous paint particles. Firstly, coating waste gas is collected, and paint spraying waste gas containing viscous paint particles and volatile organic compounds is sent into a paint purifier through a pipeline; the waste gas passes through a filter device at the bottom of the paint purifier firstly, a part of the paint particles in the waste gas adhere to the surface of the filter device, and other paint particles and the volatile organic compounds in the waste gas pass through the filter device and enter an inner cavity of the paint purifier provided with a centrifugal turntable, and the paint particles are purified; the volatile gas of the coating waste gas is purified by an activated carbon adsorber. The method has the advantages of short process flow, simple equipment structure design, good paint purification effect, stable operation of equipment, low energy consumption, safety and reliability, and can effectively solve the problem of treatment of waste gas containing viscous paint particles.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

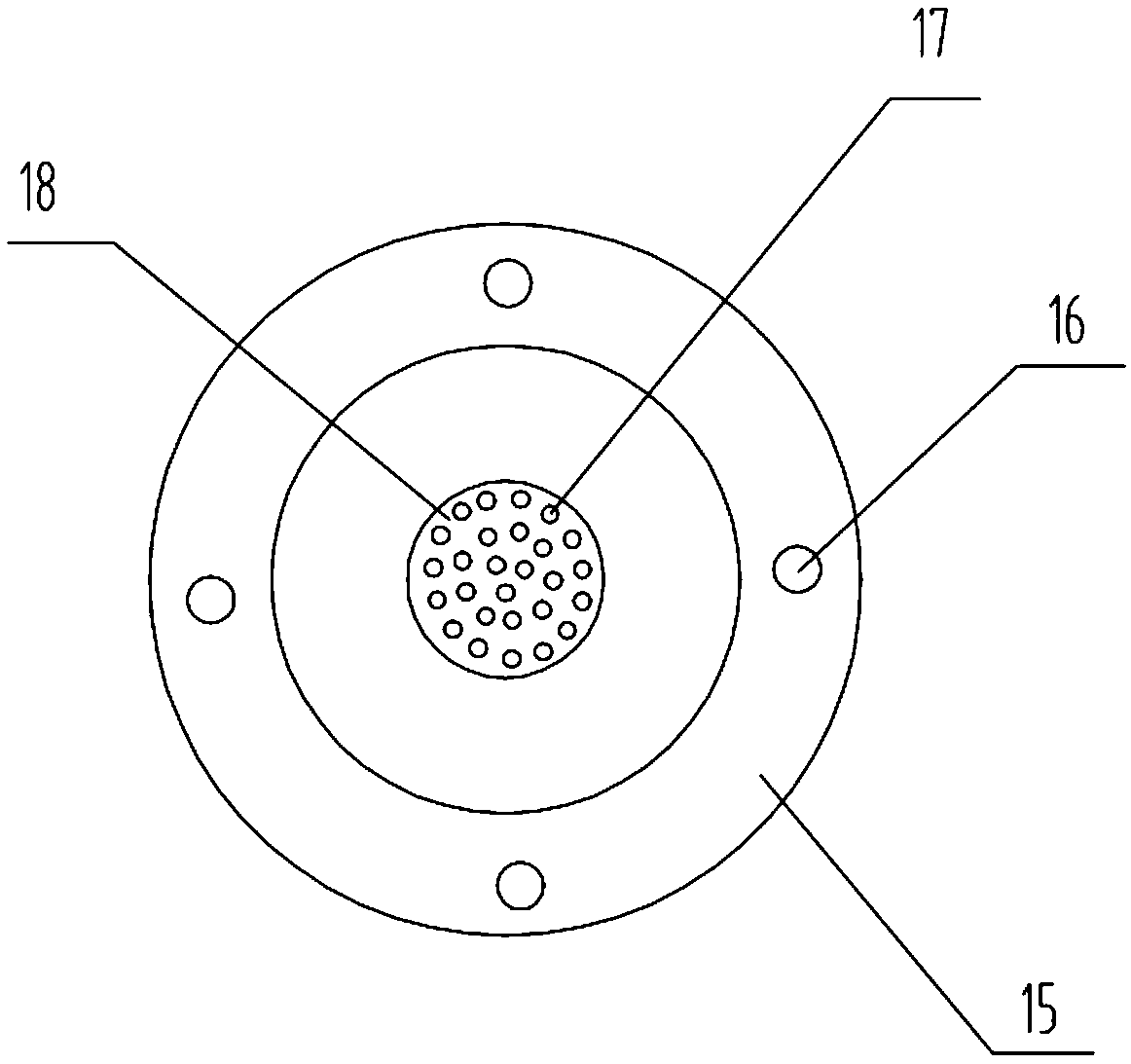

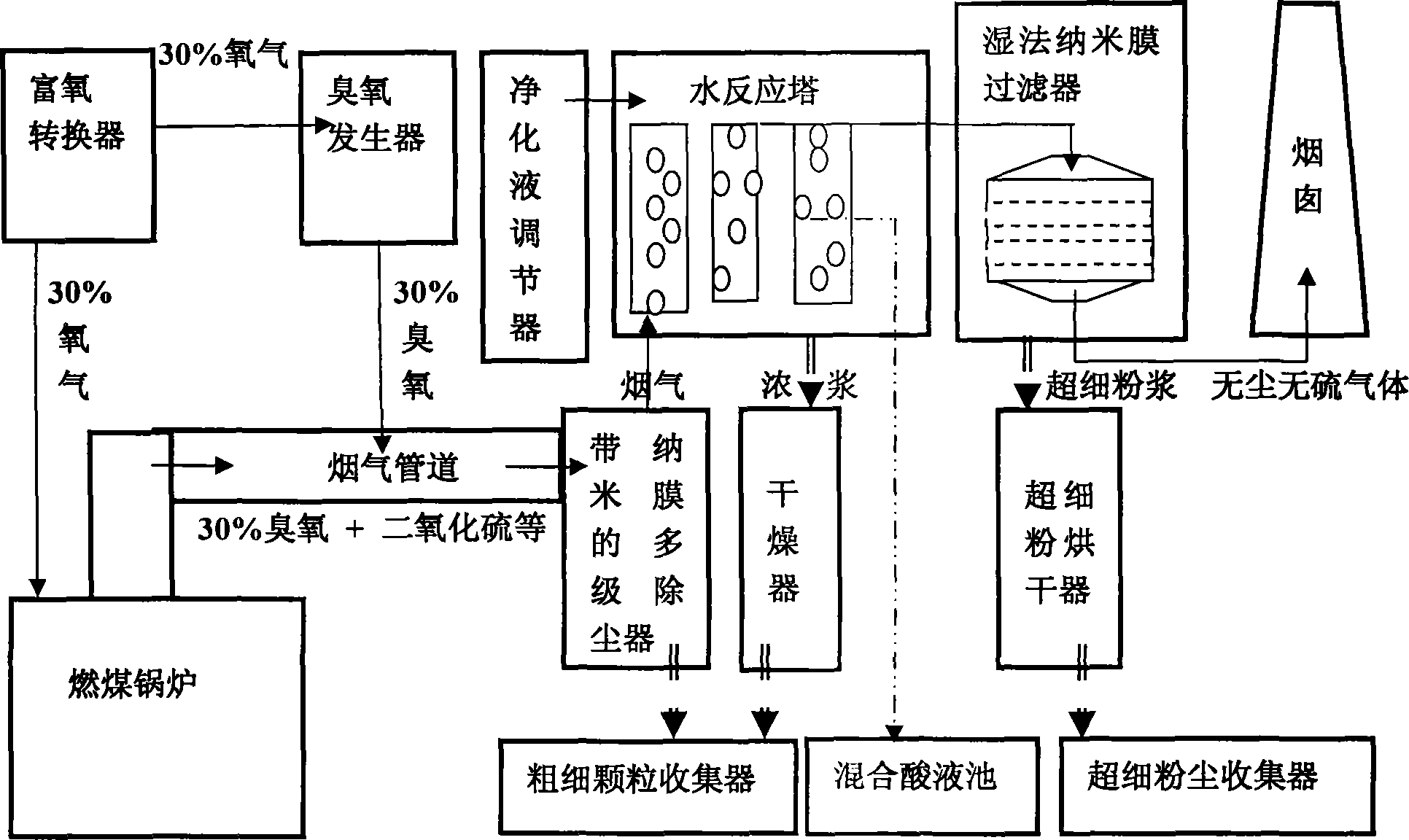

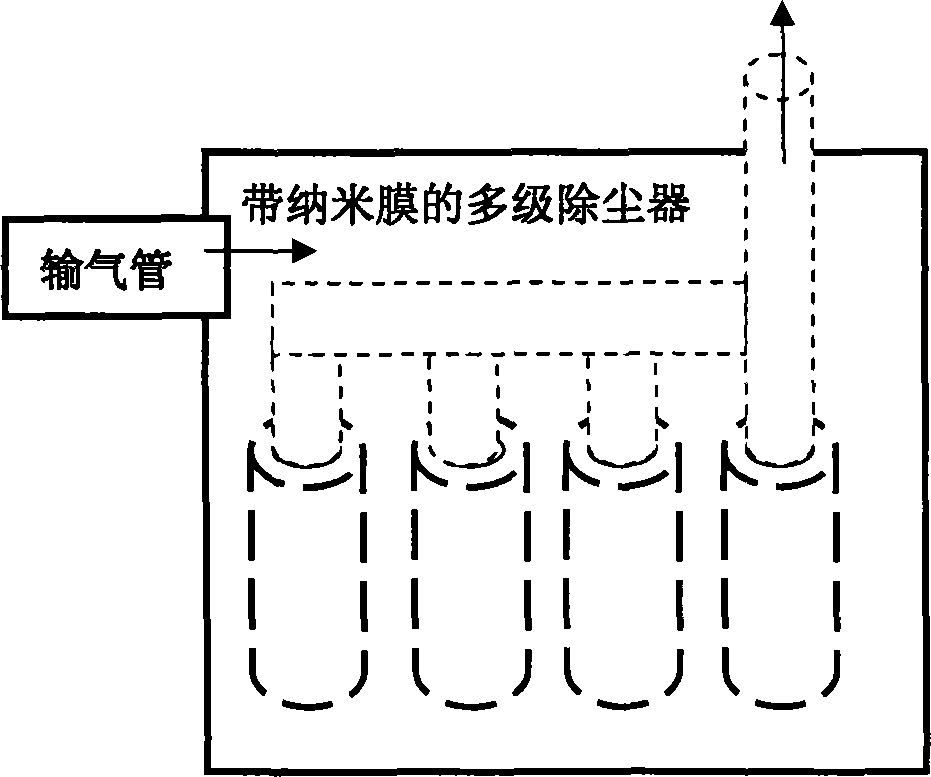

Method and system for decarburization through complete combustion of boiler as well as desulfurization, denitration and dust removal of exhaust gas

InactiveCN103263832ABurn completelyBurning safetyCombination devicesIndirect carbon-dioxide mitigationAtmospheric airSulfide

The invention belongs to a technical field of atmospheric air control and treatment of exhaust gas from coal fired boilers and relates to a method and a system for decarburization through complete combustion as well as desulfurization, denitration and dust removal of exhaust gas. The method for the invention includes the decarburization of 30% oxygen-rich gas in combustion. The invention also includes that sulfur trioxide as well as other mixed acid are formed in a reaction of 30%ozone-rich gas and sulfur dioxide and nitrogen oxides in exhaust gas with water containing PX purified liquid. Exhaust gas which is treated through desulfurization and denitration is soaked into a 100 nm-500 nm wet nano filter in water containing PX purified liquid for removal of PM 2.5 dust particles. Advantages: the decarburization through complete combustion is promoted by oxygen-rich gas and the desulfurization and denitration is promoted by ozone-rich gas. A wet nano filter is used for removal of PM 2.5 dust particles. Reaction products are acid liquid and superfine powder particles which can be used in industry and civil application. No desulfurized gypsum is generated and no sulfide or nitrides will be discharged. Thus the formation of atmospheric acid rain can be prevented; pollutions of PM 2.5 dust to atmospheric air can be solved through the dust removal. Collected 2.5 Mu m dust can be applied in an industrial material field as a material. Therefore, purposes of mineral resource saving and turning waste into wealth can be reached.

Owner:黄世鲜

Method for treating waste water from rubber antioxidant tmq (RD) device

ActiveCN102050534ARealize resourcesLow costTransportation and packagingMixingChemical treatmentOrganic synthesis

The invention discloses a method for treating waste water from a rubber antioxidant tmq (RD) device, which relates to a waste water treatment process. The method comprises the following steps: weighing 50 mol parts of waste water from the rubber antioxidant tmq (RD) device, and adding sulfonating agent at a temperature of 40 to 60 DEG C; 2, adding 1 to 2 parts of acetone or acrylic acid compound, keeping the reaction temperature between 40 and 60 DEG C and reacting for 20 to 40 minutes; 3, adding 2 to 4 parts of an aldehyde compound or ethylene oxide, keeping the reaction temperature between 75 to 90 DEG C and reacting for 1 to 2 hours; and 4, adding 450 to 950 parts of waste water from the rubber antioxidant tmq (RD) device, keeping the reaction temperature between 75 to 90 DEG C, continuing to react for 0.5 to 1.0 hour, and preparing a composite water-coal-slurry additive at an effective concentration of 0.5 to 1 percent. In the method disclosed by the invention, after the waste water is subjected to proper chemical treatment, the water-coal-slurry additive and water coal slurry are obtained by an organic synthesis process, so that environmental pollution caused by waste water discharge is avoided, the cost of the water-coal-slurry additive is reduced effectively, and the waste water is recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

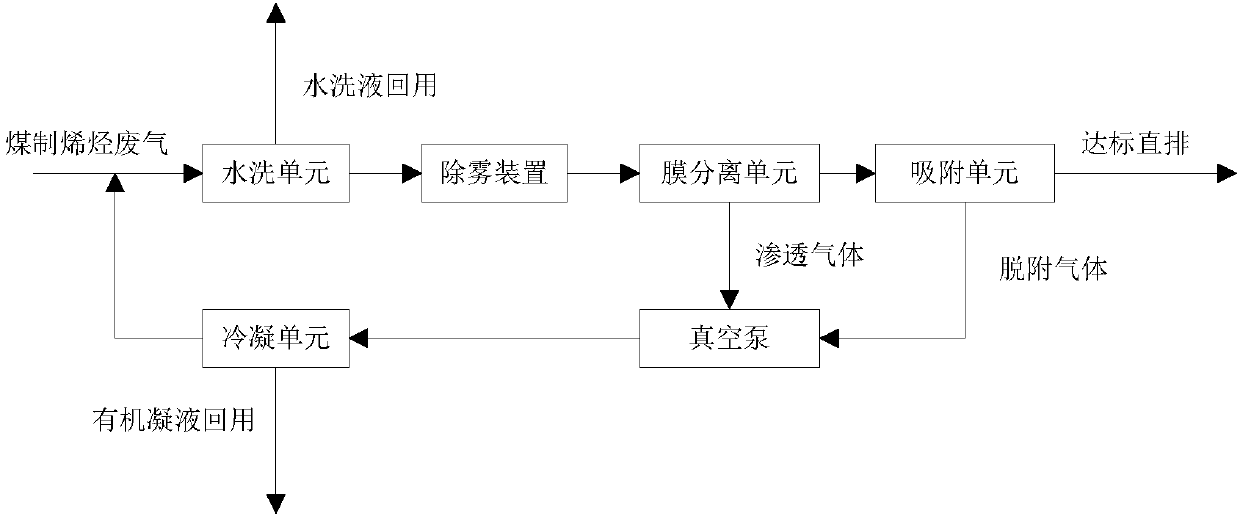

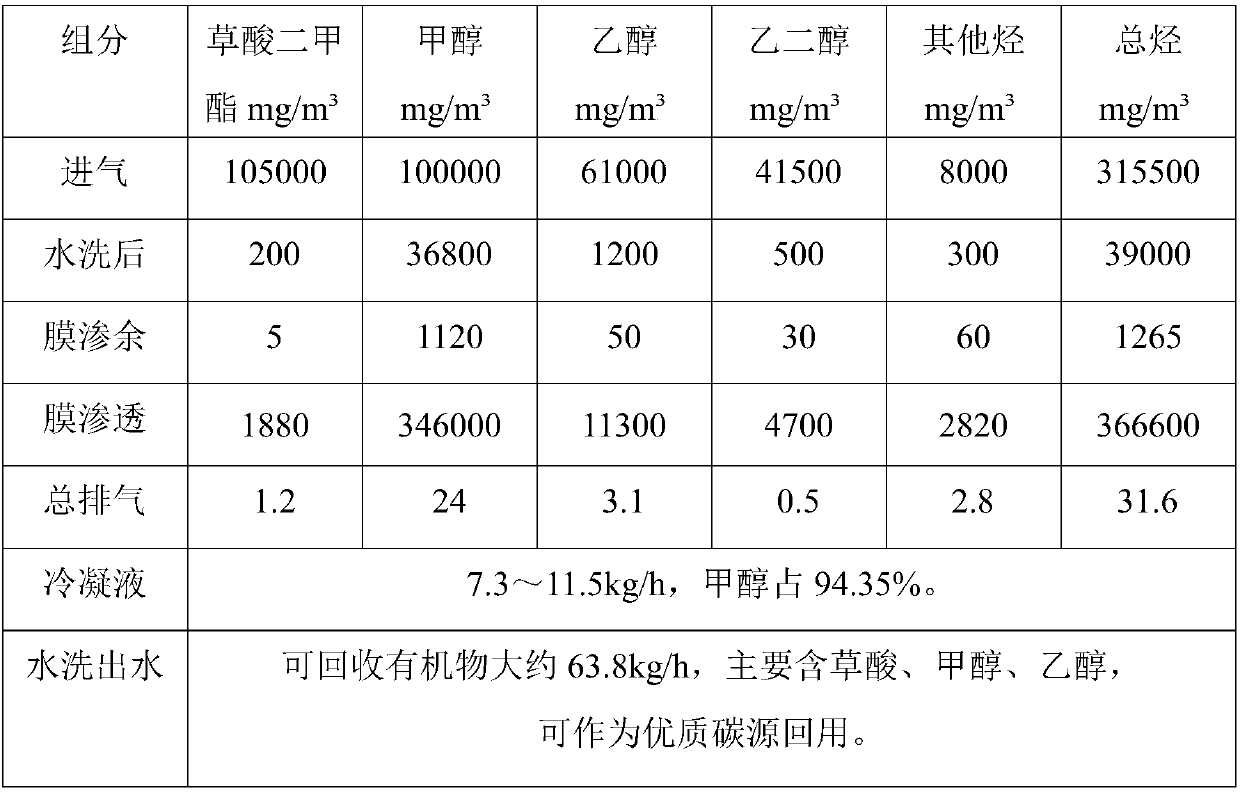

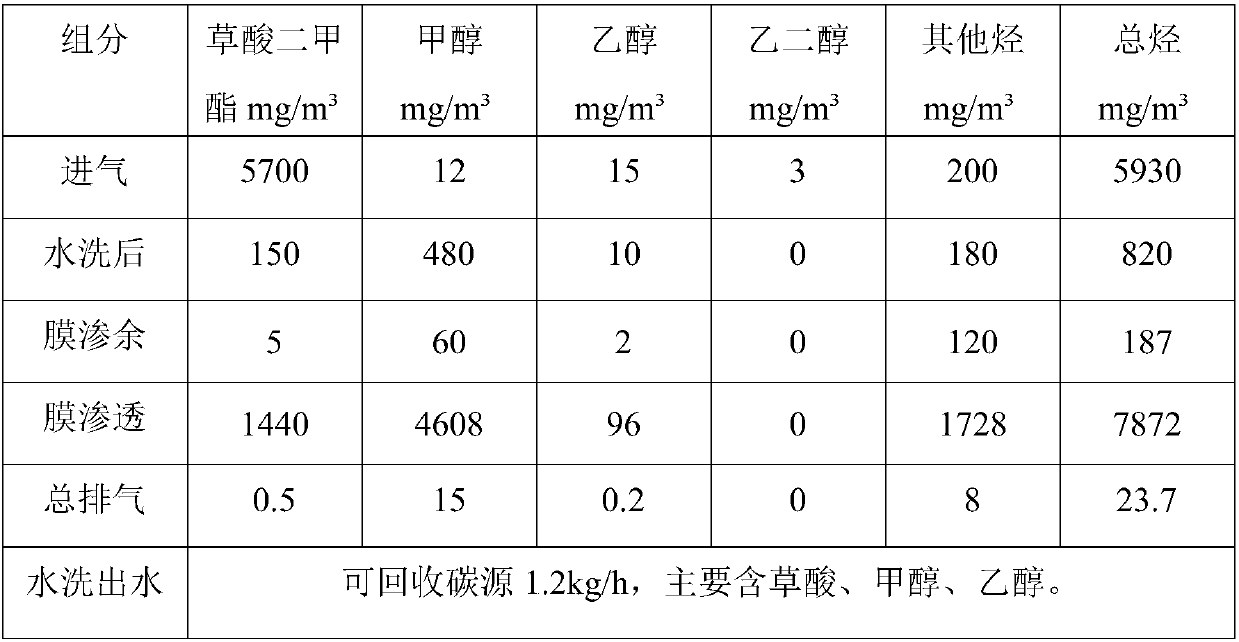

Coal-to-olefin industrial exhaust gas comprehensive treatment device and method

ActiveCN110339687AEfficient processing and resource utilizationImprove explosion protectionGas treatmentDispersed particle separationExhaust gasCoal chemical industry

The invention relates to a coal-to-olefin industrial exhaust gas comprehensive treatment device and method. The coal-to-olefin industrial exhaust gas comprehensive treatment device and method are mainly applied to treatment and resource utilization of exhaust gas emitted in organized and unorganized modes by tank areas, platforms and production devices in the field of coal chemical industry. Specifically, a washing process and three organic exhaust gas recovery techniques of membrane separation, condensation and adsorption are innovated, optimized and coupled to form the coal-to-olefin industrial exhaust gas treatment method. The method does not include the heating step or the heat production step, the explosion-proof property and safety are high. In the washing process, soluble organic matter is recovered, the acidity is reduced, the temperature is decreased, then resource utilization is conducted through a combination process of membrane separation, condensation and adsorption, and thus the requirements of resource utilization and emission on standard are met. According to the coal-to-olefin industrial exhaust gas comprehensive treatment device and method, the difficult problem of coal-to-olefin exhaust gas treatment is solved, organic exhaust gas emitted by industrial devices, the tank areas, the vehicle-loading platforms and the like in the coal-to-olefin field can be efficiently removed and subjected to resource utilization, and the coal-to-olefin industrial exhaust gas comprehensive treatment device and method have application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

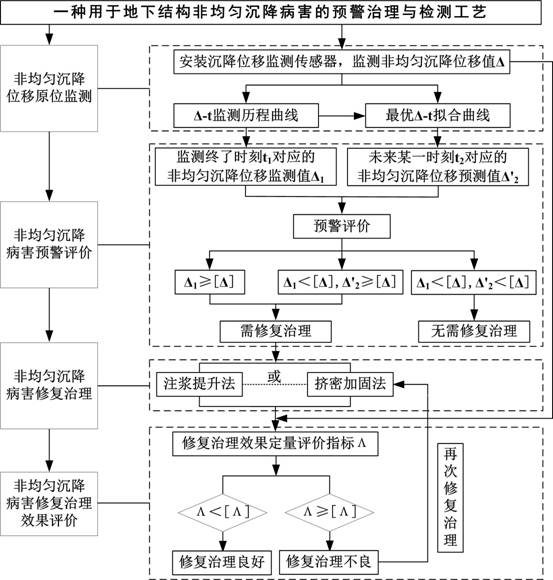

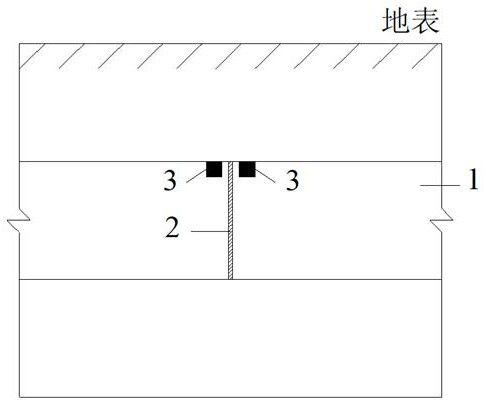

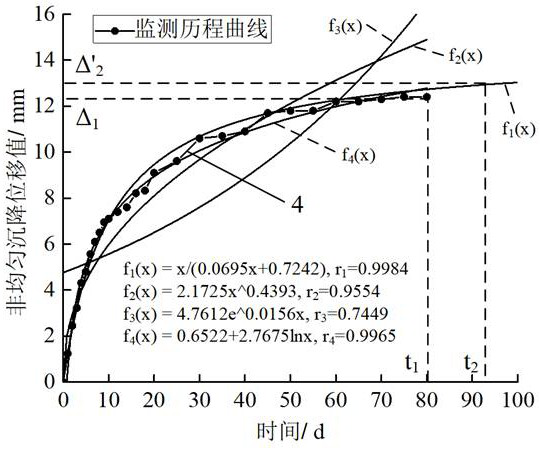

Early warning treatment and detection process for underground structure differential settlement diseases

ActiveCN114150718AImprove informatizationImprove the level of intelligent managementMining devicesFoundation testingDiseaseCurve fitting

The invention discloses an early warning treatment and detection process for underground structure differential settlement diseases, and belongs to the technical field of underground structure disease treatment, the early warning treatment and detection process comprises the following steps: monitoring differential settlement displacement values at two sides of a disease part, and drawing a monitoring process curve; curve fitting is carried out, and an optimal fitting curve and an optimal fitting function expression are determined through comparison and selection; comparing a non-uniform settlement displacement monitoring value corresponding to a monitoring ending moment, a non-uniform settlement displacement predicted value corresponding to a certain moment in the future and a non-uniform settlement displacement allowable value, and performing early warning evaluation on the disease degree of the part; treating the part needing to be repaired and treated by adopting a grouting lifting method or a compaction reinforcement method; and establishing a quantitative evaluation index of the disease repair treatment effect, and quantitatively evaluating the repair treatment effect. Quantitative evaluation of the safe operation and maintenance state of the repaired underground structure can be achieved, and the problem that an effective quantitative early warning and treatment detection technology is lacked for the differential settlement disease of the underground structure at present is solved.

Owner:SHANDONG JIANZHU UNIV

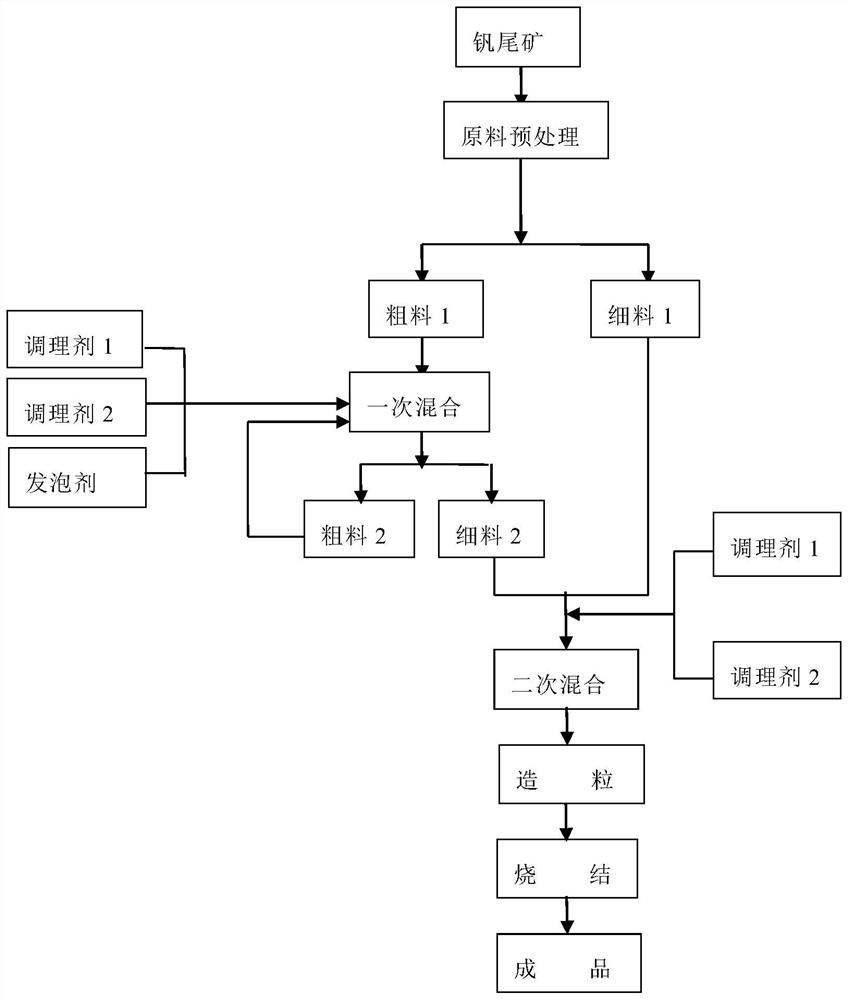

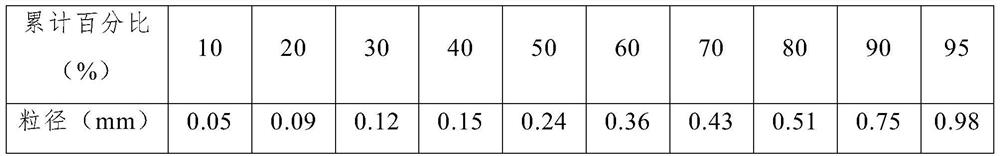

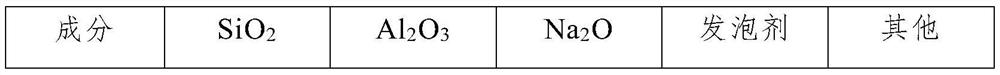

Method for preparing foamed ceramic by taking navajoite tailings as main material

ActiveCN114573367AGuaranteed uniformityImprove strength and qualityCeramic materials productionCeramicwarePelletizingCeramic

The invention discloses a method for preparing foamed ceramic by using vanadium ore tailings as a main material, which is characterized in that the foamed ceramic is prepared by using the vanadium ore tailings as the main material and a conditioner as an auxiliary material through mixing and powdering, granulating and sintering processes. According to the method, the vanadium ore tailings serve as the main material, the conditioner is added to prepare the foamed ceramic, the foaming uniformity degree is guaranteed, meanwhile, the strength and quality of the foamed ceramic are improved, the prepared foamed ceramic product meets the national standard requirement, the doping amount of the vanadium ore tailings is increased, utilization of the vanadium tailings is achieved, and the comprehensive treatment problem of the vanadium tailings is solved; the problems of high mixing energy consumption and high water consumption of a traditional preparation method are solved, energy and water are saved, and the preparation cost is reduced.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

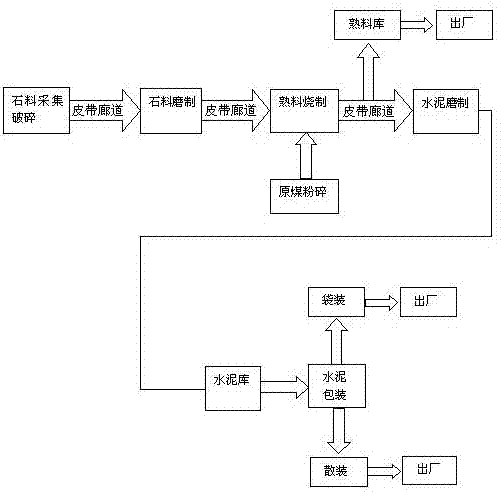

Method for noise comprehensive treatment of cement plant

InactiveCN107516508ASolving Governance ChallengesSound producing devicesNoise monitoringAfter treatment

The invention discloses a method for noise comprehensive treatment of a cement plant. The method includes the specific steps that firstly, a plurality of noise monitoring points are arranged according to a plant boundary range, monitoring time and monitoring conditions are set, and monitoring is conducted to obtain data; secondly, the data obtained through monitoring is compared with a standard value, and monitoring points, where noise exceeds the standard, of sensitive points in the plant boundary and the periphery are analyzed; thirdly, according to analysis in the step 2, the varieties of equipment of noise sound source points in the plant and the varieties of sound sources are determined; fourthly, according to the varieties of the equipment and the sound sources, the equipment is divided into the equipment in a plant building and the equipment in a plant area, the equipment safety production requirements are considered, and comprehensive treatment is carried out according to the varieties of the equipment and the sound sources, so that the frequency spectra of the treated sound sources at a detection point conform to an NR curve; after treatment, the detection value of each sound source at the detection point is smaller than or equal to the standard value which is 3 db. By means of the method, the problem about noise treatment in the cement plant is thoroughly solved.

Owner:吴光明

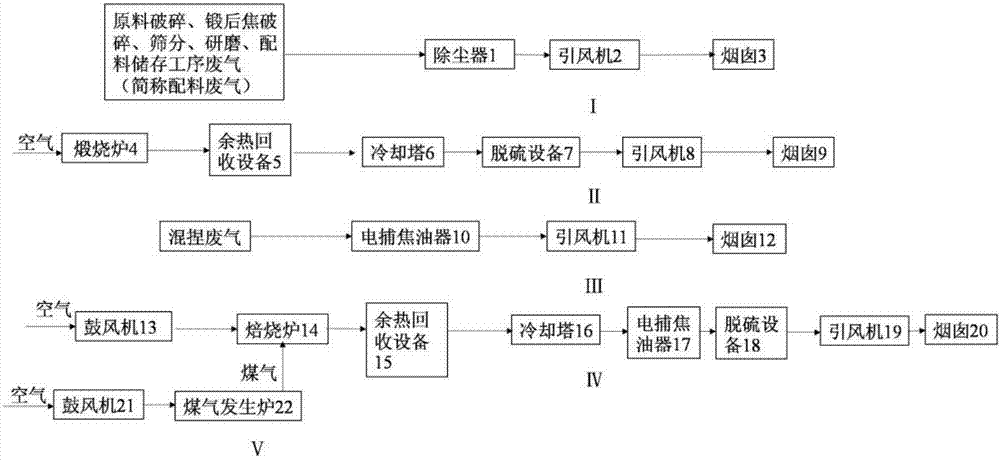

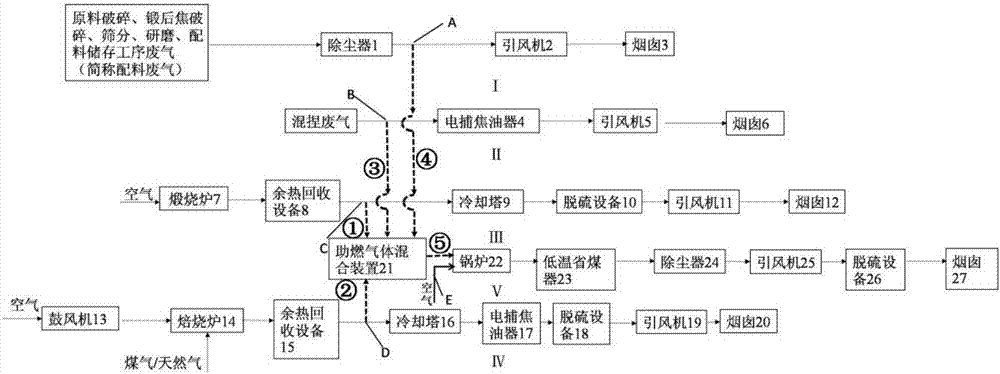

Exhaust emission and pollutant near-zero emission system and method used in carbon industry

ActiveCN107420883AReduce environmental protection operating costsEliminate cumulative effectsEmission preventionSolid fuel combustionFlueZero emission

The invention discloses an exhaust emission and pollutant near-zero emission system and method used in a carbon industry. The system comprises a carbon exhaust purification treatment system, a boiler and a boiler exhaust purification system and further comprises a flue connecting system. A combustion air compensation unit is arranged on the flue connecting system. According to the method, after exhaust of a mixed kneading, forging and roasting purification unit and exhaust of an ingredient exhaust purification unit are mixed, the mixed exhaust as combustion-supporting gas is introduced into the boiler; when the set temperature and blast capacity requirements are met, the mixed exhaust is fully burnt in a hearth, exhaust combustion supporting is achieved in the carbon industry, and the exhaust emission and the pollutant near-zero emission is achieved; and meanwhile, the calorific value of asphalt fume and CO in the exhaust is reused, and the energy saving and emission reduction effects are achieved. The exhaust emission and pollutant near-zero emission system and method provide a new thought and method for the pollutant control and pollutant emission reduction in the carbon industry.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com