Exhaust emission and pollutant near-zero emission system and method used in carbon industry

A pollutant and exhaust gas volume technology, applied in the direction of combustion method, emission prevention, indirect carbon dioxide emission reduction, etc., can solve the problem of high cost of exhaust gas treatment in the carbon industry, reduce environmental protection operation costs, reduce boiler coal consumption, and realize comprehensive recycling and utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

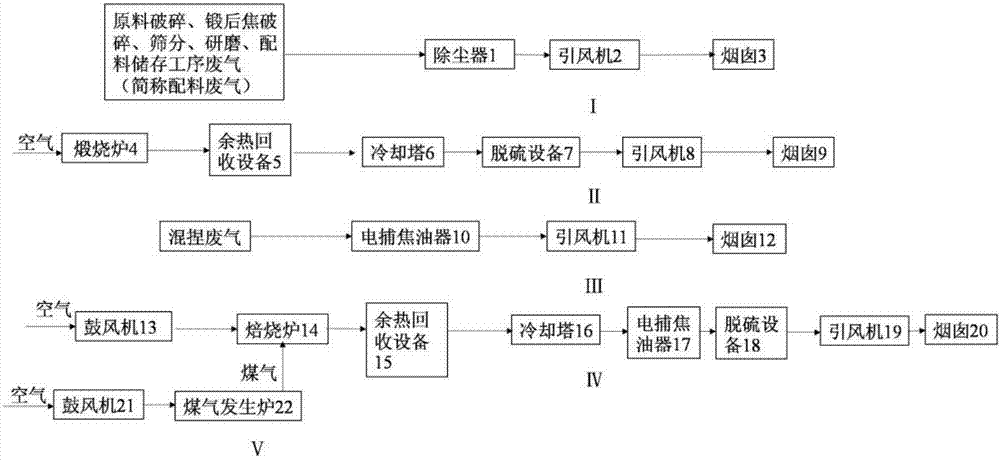

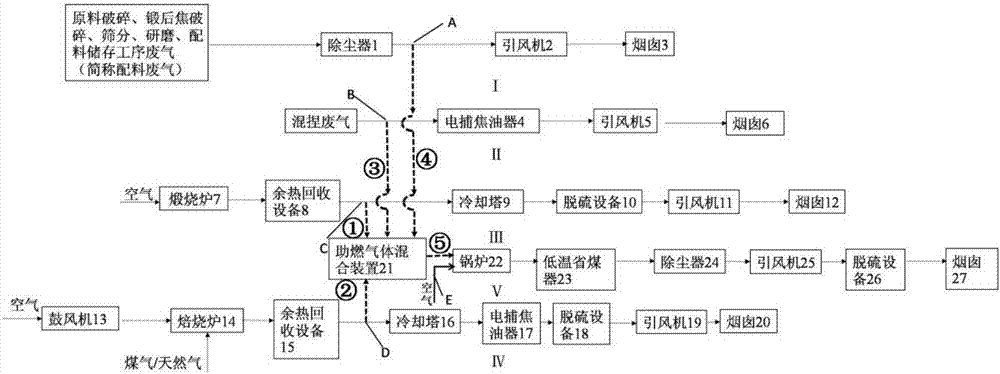

Method used

Image

Examples

Embodiment 1

[0040] Carbon anode product factory with an annual output of 60,000 tons of aluminum, the calcination process produces about 6000Nm of waste gas 3 / h, kneading waste gas about 1100Nm 3 / h, batching waste gas is about 17000Nm 3 / h, roaster exhaust gas is about 22000Nm 3 / h. By adopting the system of the present invention, all the waste gas from the above processes can be used in a certain 35t / h industrial boiler as combustion air. Compared with the original exhaust gas purification system, in general, the present invention can reduce the amount of exhaust gas by about 46100Nm 3 / h, SO 2 Emission reduction about 15t / year, NO x It can reduce emissions by about 2t / year, asphalt smoke by about 1.5t / year, smoke / dust by about 7.5t / year, and save 7t of standard coal / year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com