Patents

Literature

7194 results about "Hearth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In historic and modern usage, a hearth /hɑːrθ/ is a brick- or stone-lined fireplace, with or without an oven, used for heating and originally also used for cooking food. For centuries, the hearth was such an integral part of a home, usually its central and most important feature, that the concept has been generalized to refer to a homeplace or household, as in the terms "hearth and home" and "keep the home fires burning".

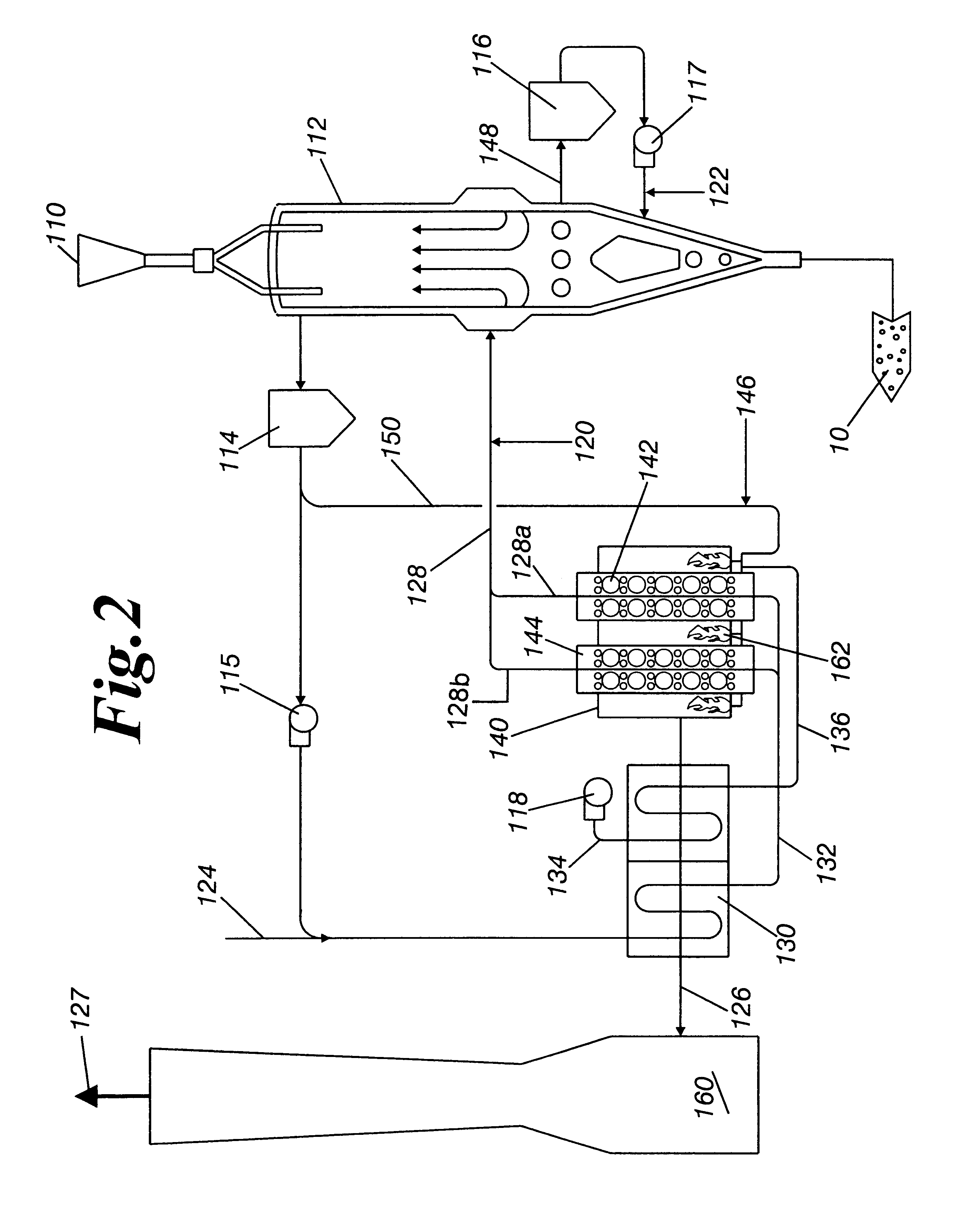

Method of simultaneously reducing CO2 and SO2 emissions in a combustion installation

InactiveUS6737031B2Reduce carbon dioxide emissionsFluidized bed combustionGas treatmentCombustionFlue gas

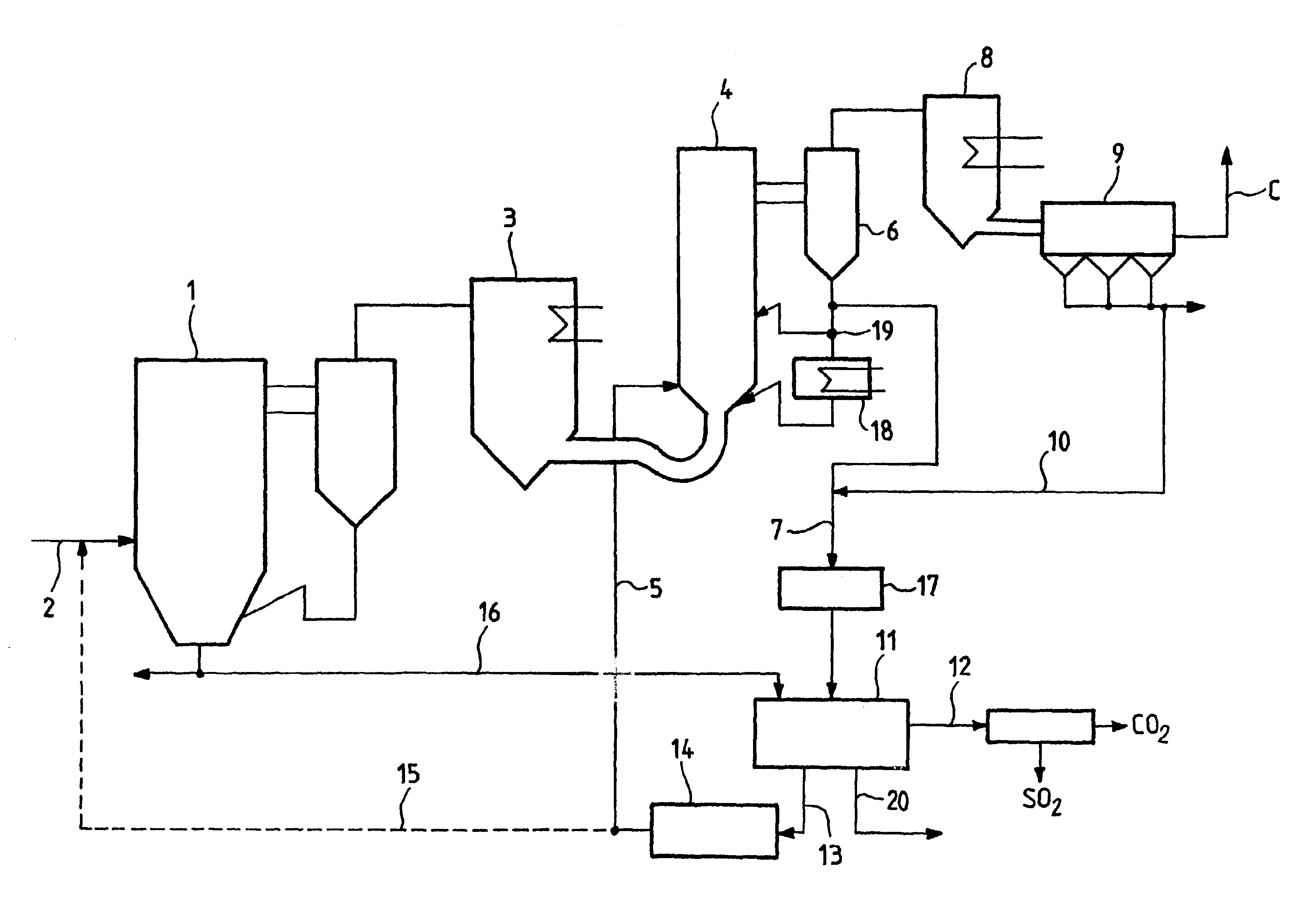

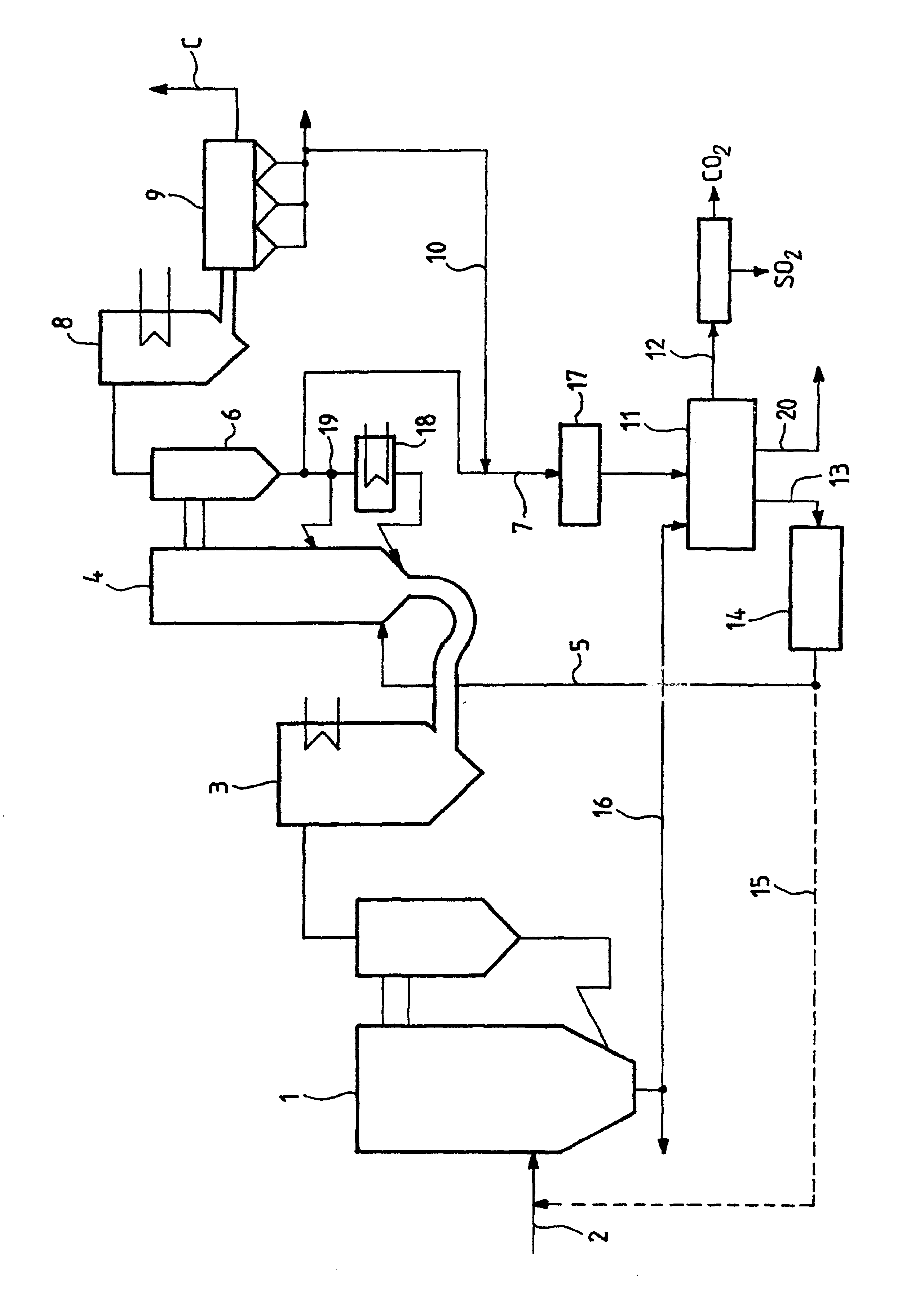

The method of simultaneously reducing carbon dioxide (CO2) emissions and sulfur dioxide (SO2) emissions produced by the combustion of carbon-containing matter in a hearth consists in injecting into the hearth a calcium-based agent, a fraction of which absorbs SO2 after decarbonization, and then, after the flue gases have been subjected to intermediate cooling, in causing them to transit via a first reactor and in putting them in contact therein with the other fraction of the absorbant that has not reacted with SO2 so as to capture CO2 from the flue gases by carbonization, then, in a separator, in extracting the solids contained in the flue gases output from the first reactor so as to subject them to heat treatment in a second reactor in order to extract CO2 therefrom by decarbonization and in order to recycle the resulting regenerated CO2 absorbant to the first reactor.

Owner:GENERAL ELECTRIC TECH GMBH

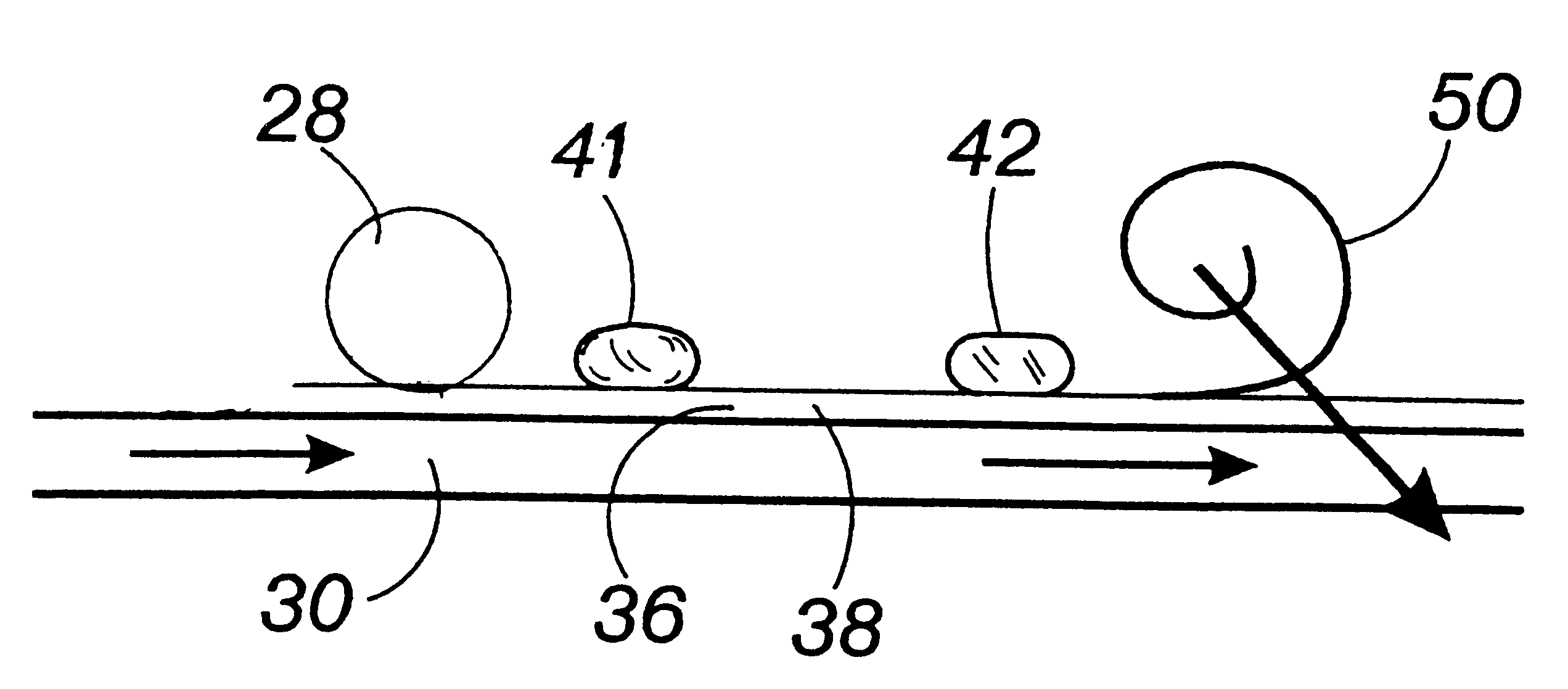

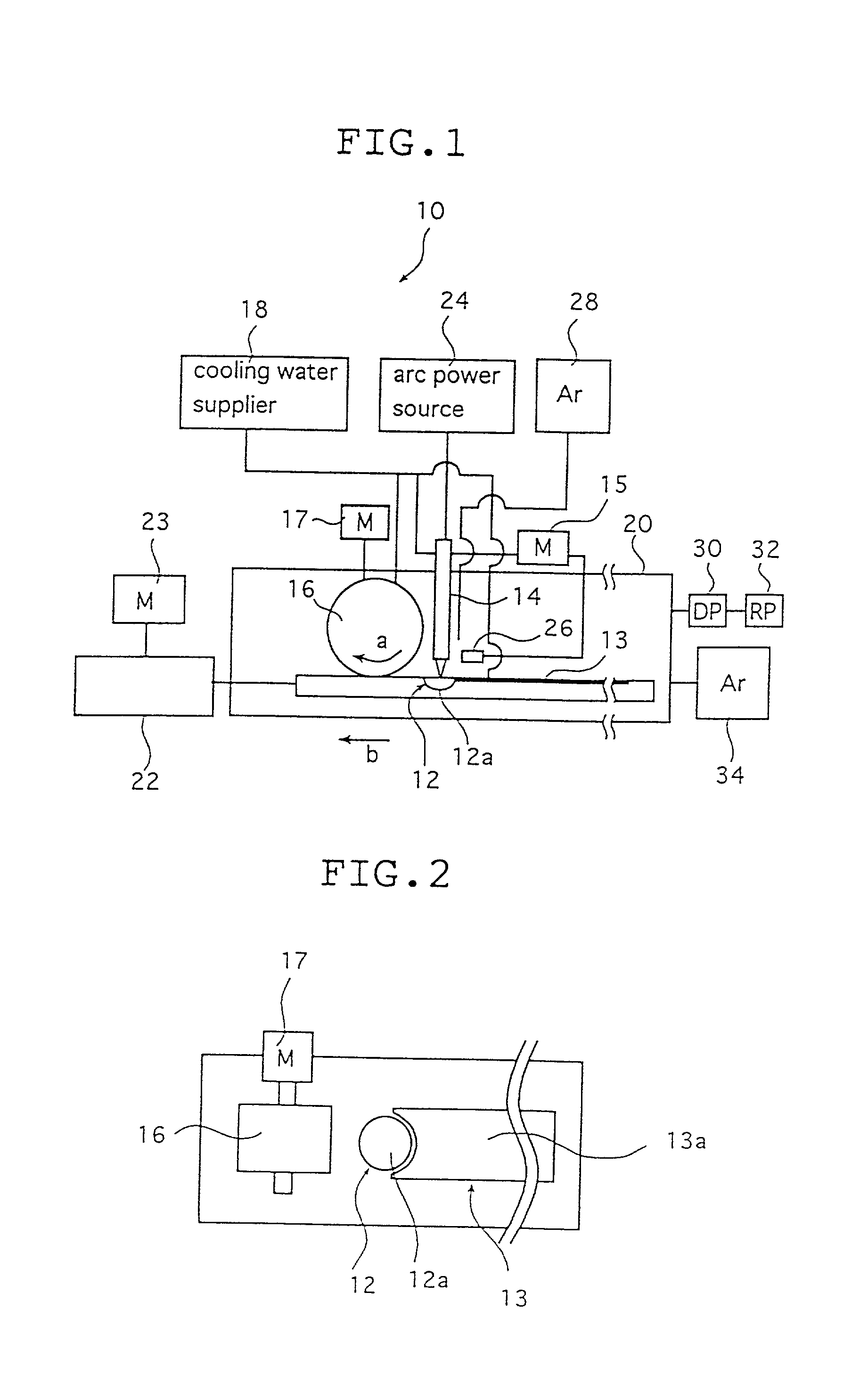

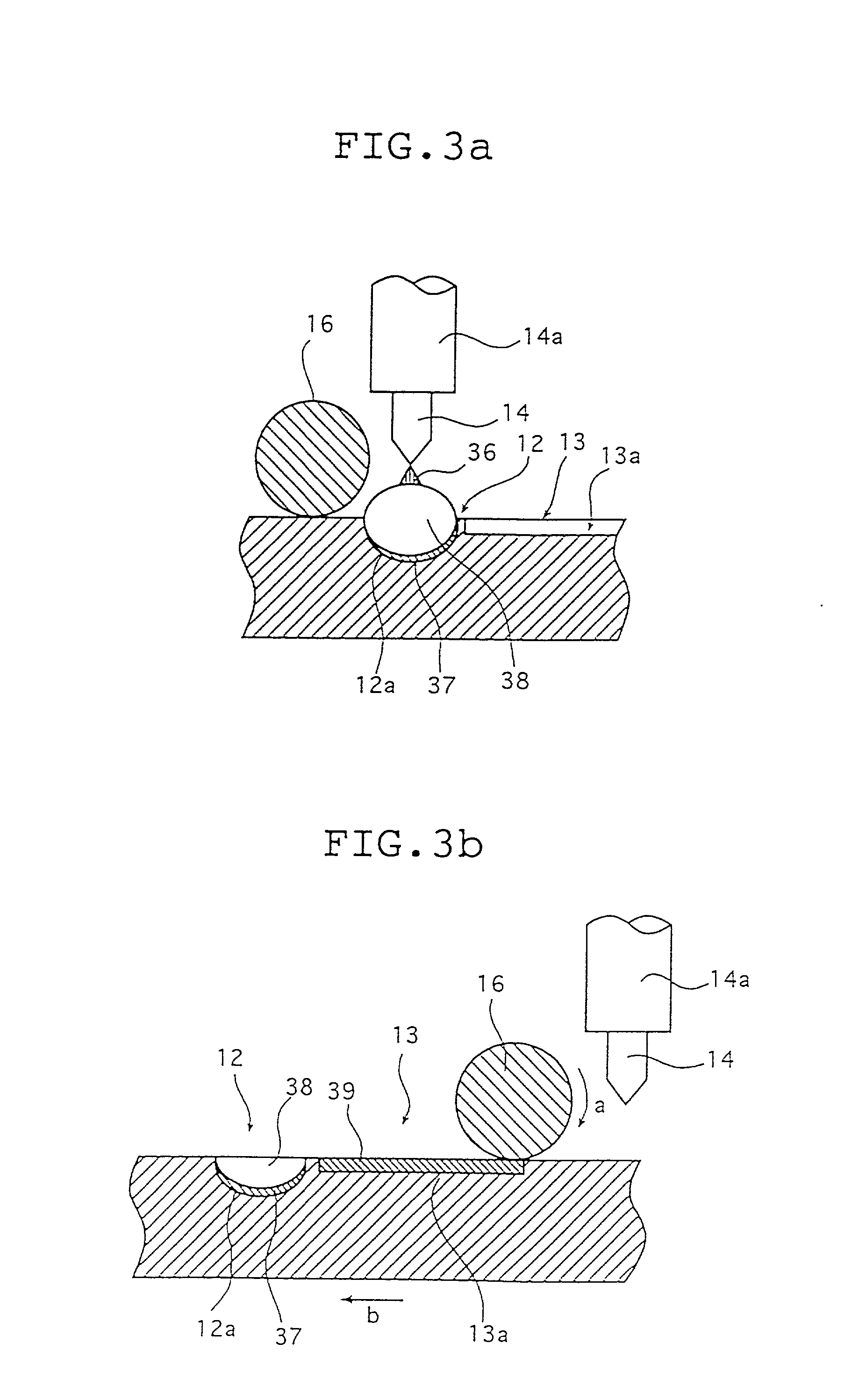

Method of producing a reduced metal, and traveling hearth furnace for producing same

InactiveUS6126718ALow gangue and ash contentSmall amountProcess efficiency improvementGas emission reductionHearthMetal

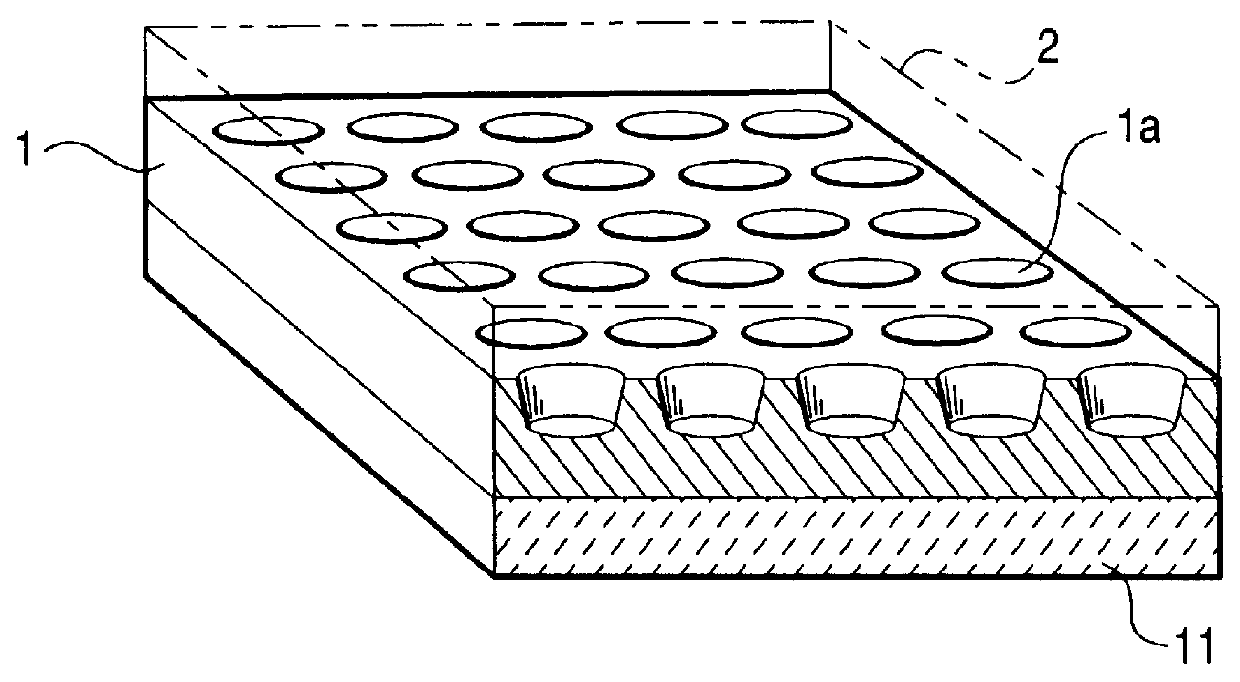

Producing reduced metal by charging and stacking a raw material containing a metal-containing material and a solid reducing material on a horizontally moving hearth of a traveling hearth furnace, by disposing a solid reducing material layer on the hearth, forming concave portions at the solid reducing material surface, stacking the raw material on the surface of the solid reducing material layer, reducing raw material by at least once heating and melting the material on the hearth to separate metal and gangue and ash ingredients, and discharging metal from the hearth.

Owner:KAWASAKI STEEL CORP

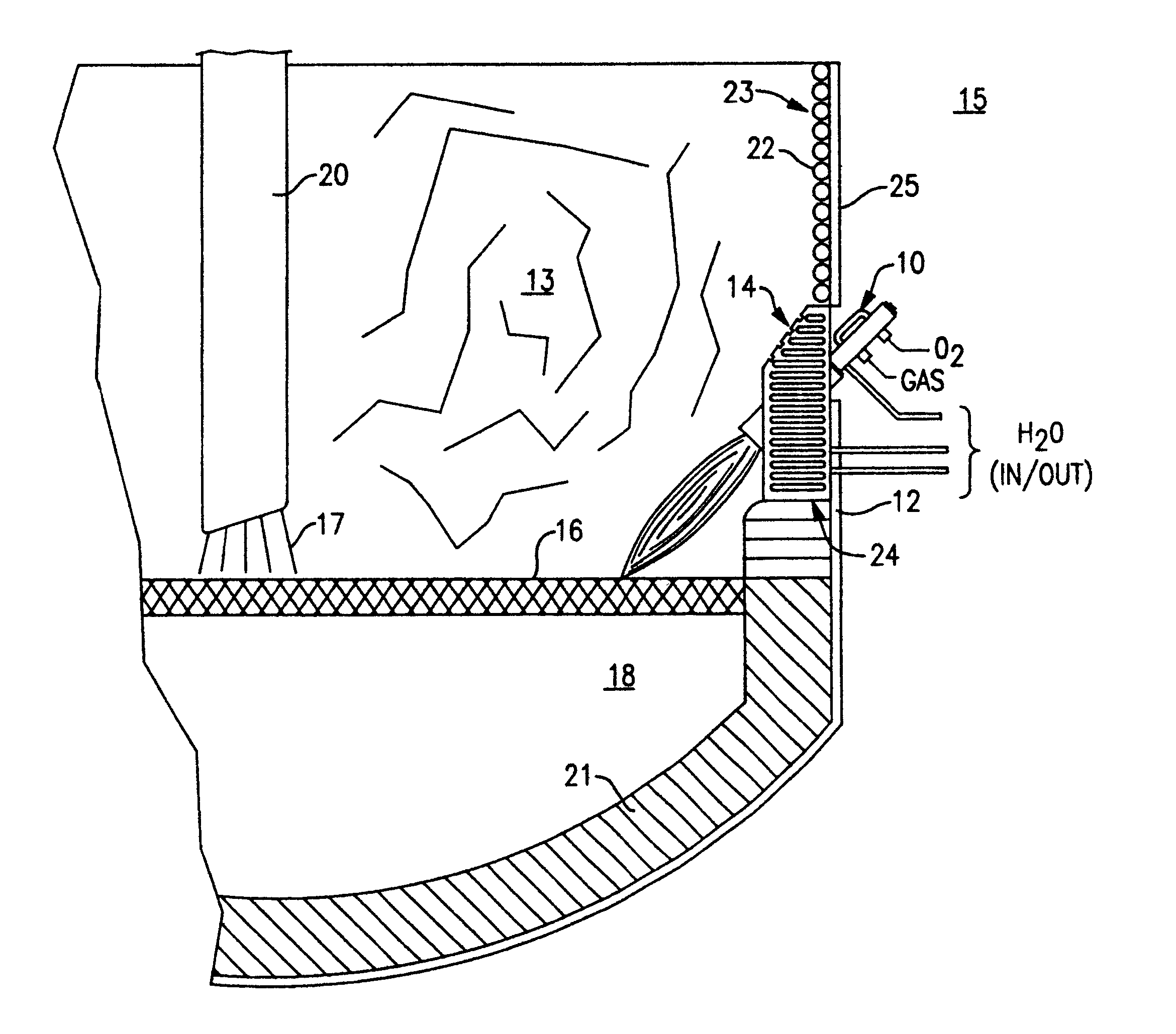

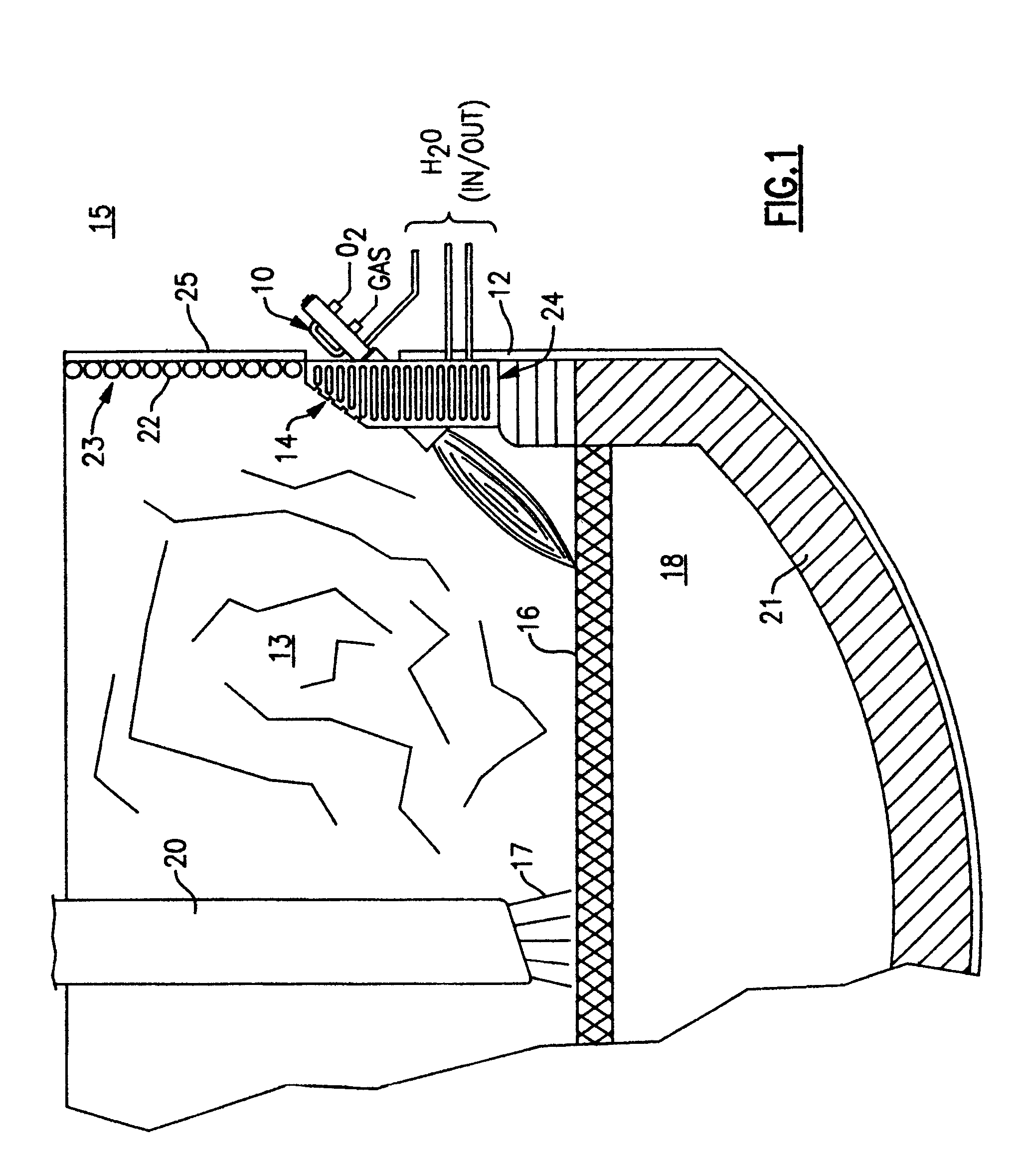

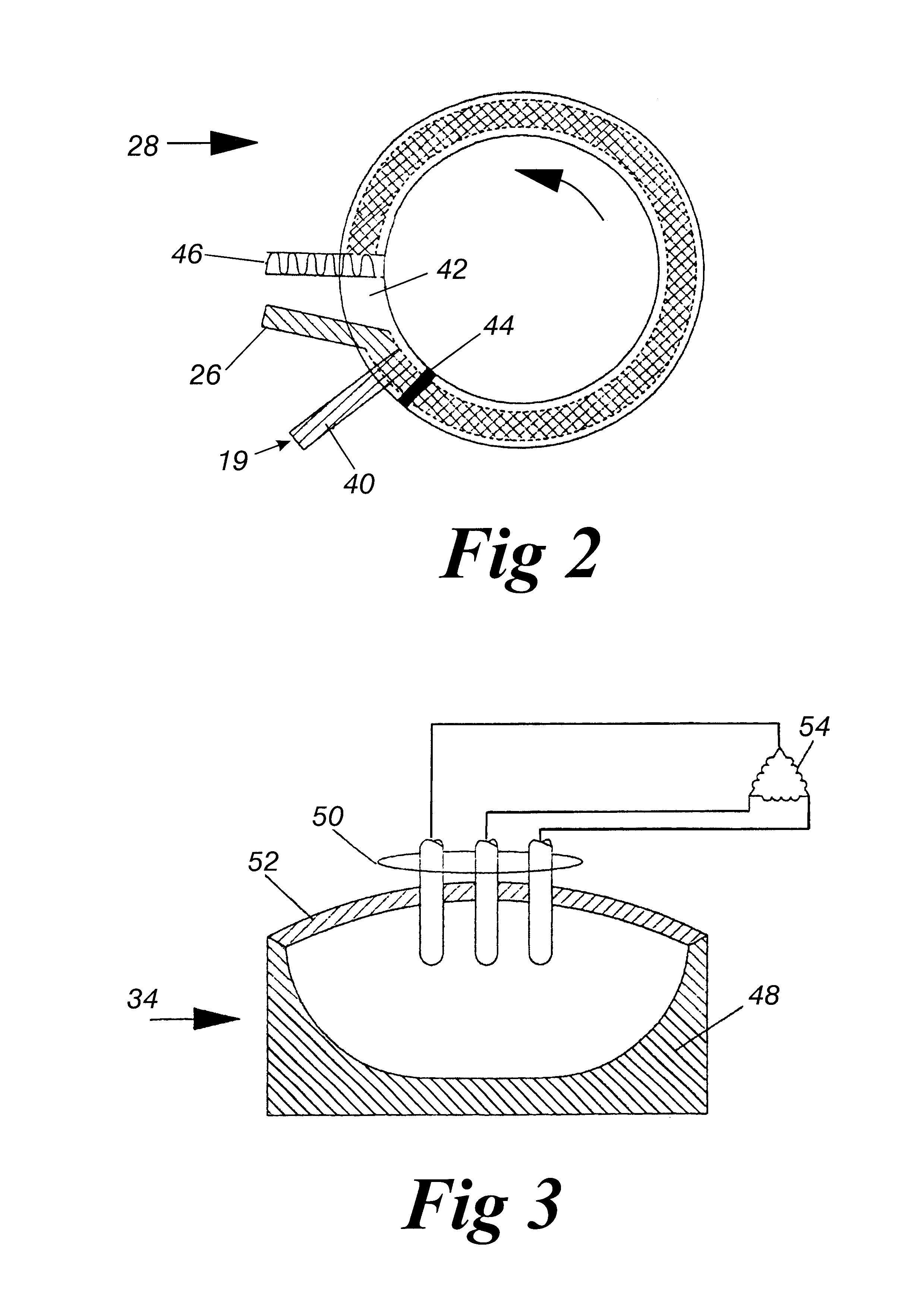

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

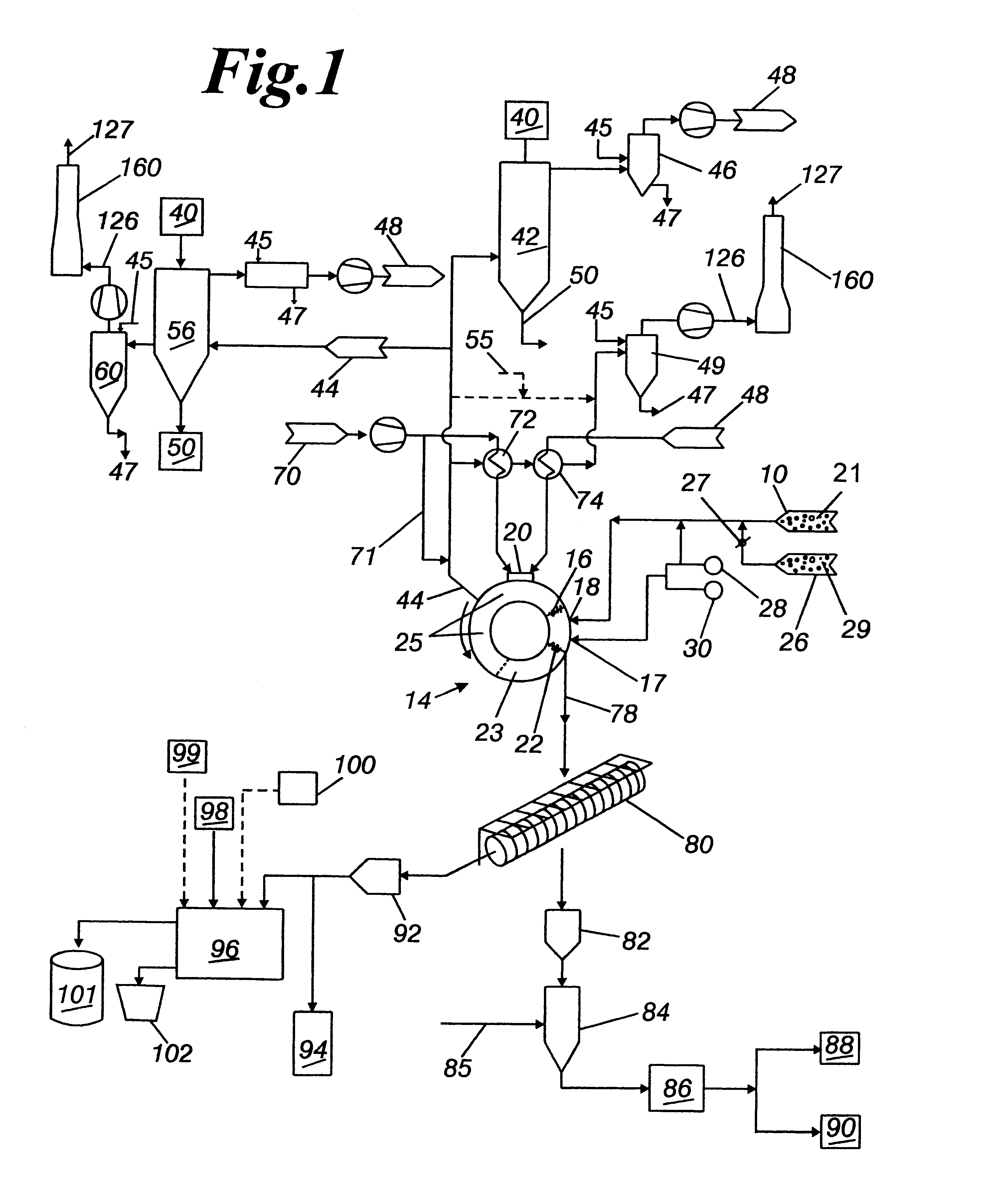

Method of direct iron-making / steel-making via gas or coal-based direct reduction and apparatus

The invention is a method and apparatus for iron-making / steel-making using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced metallized iron. The pre-reduced metallized iron is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Nascent slag separates from the molted iron forming carburized iron nuggets. The nuggets are cooled, and then the iron nuggets and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the iron nuggets from the hearth conditioner. The hearth conditioner is recycled, and the iron nuggets are either prepared for sale or for additional treatment, such as alloying, in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:KOBE STEEL LTD

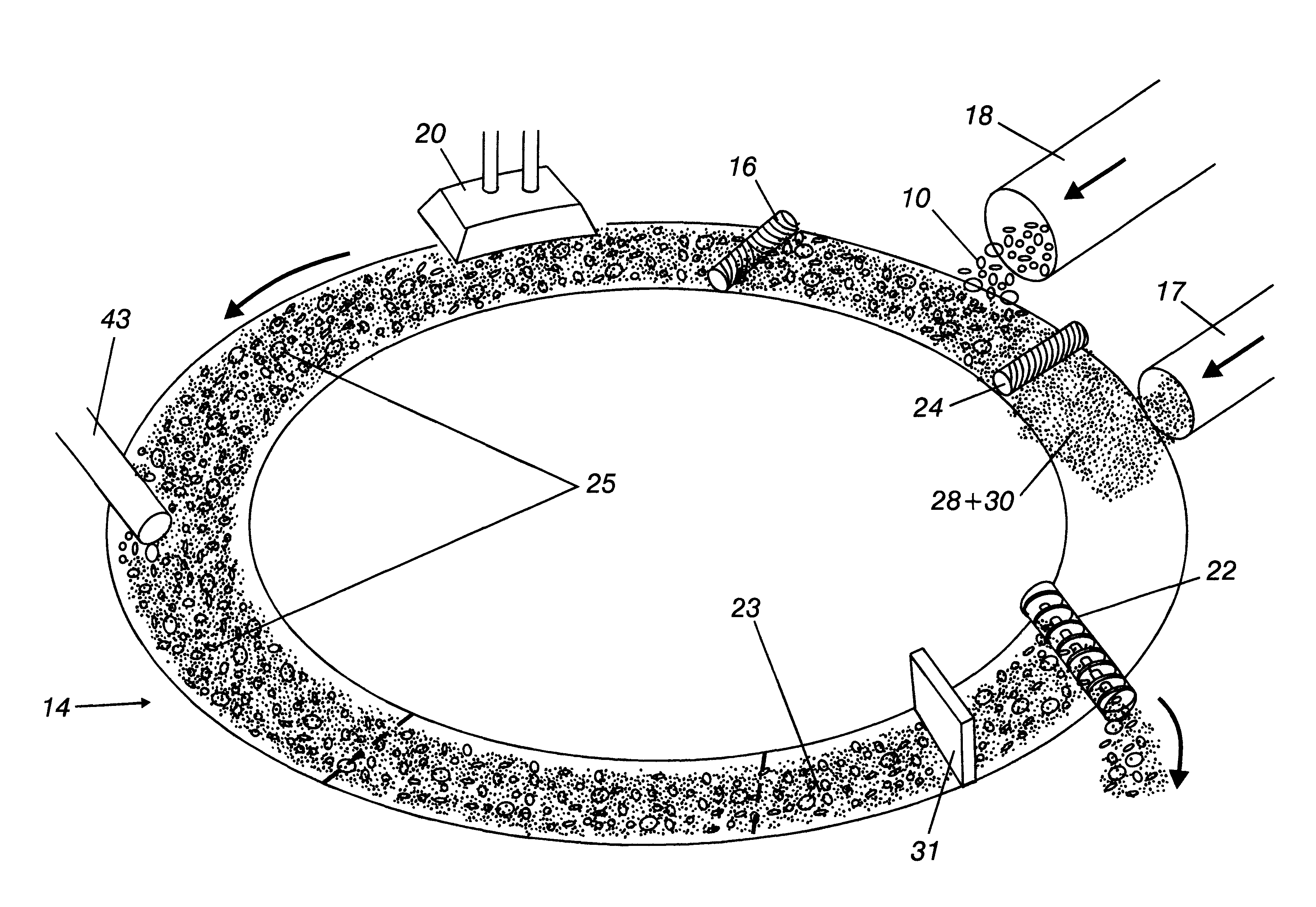

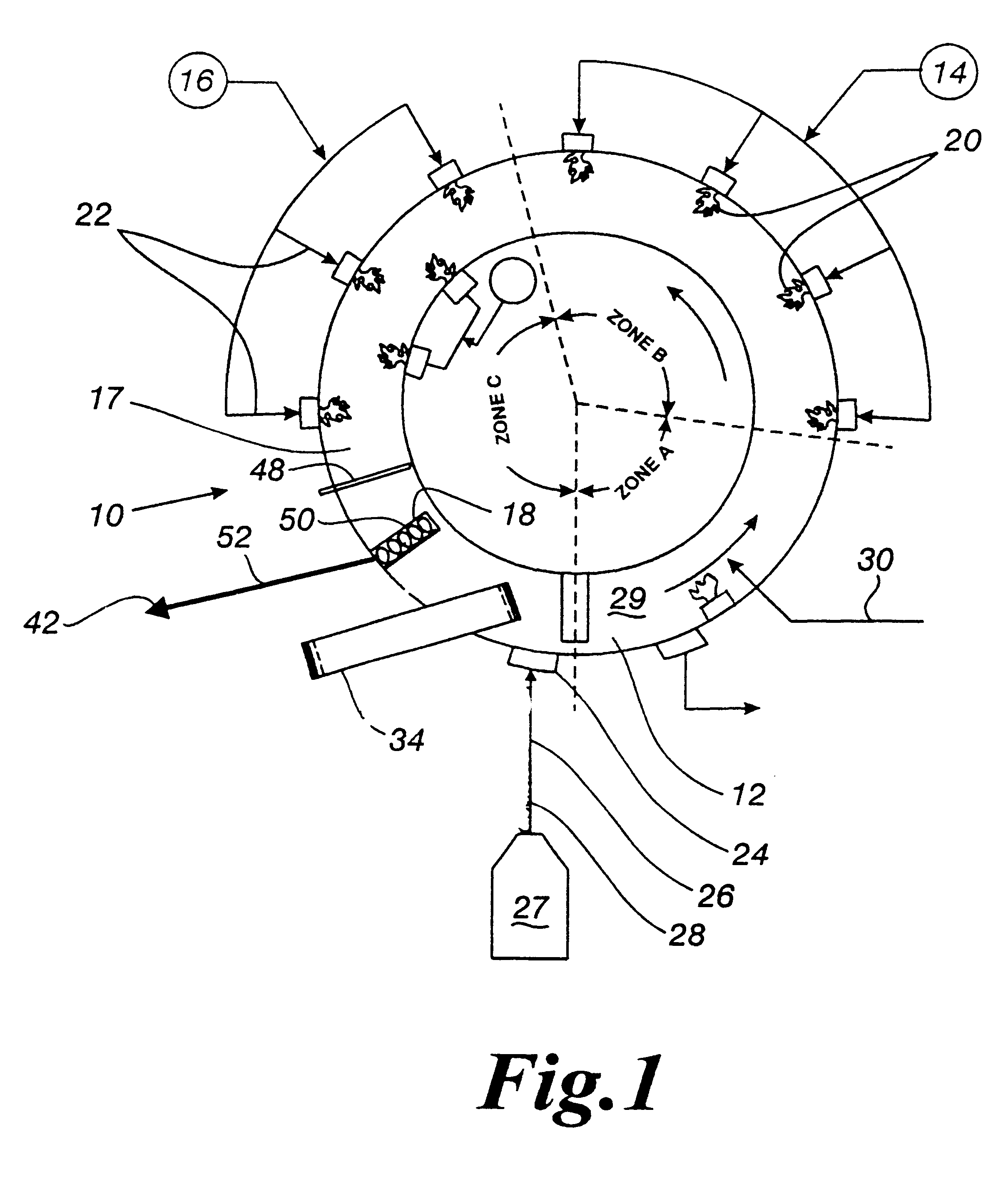

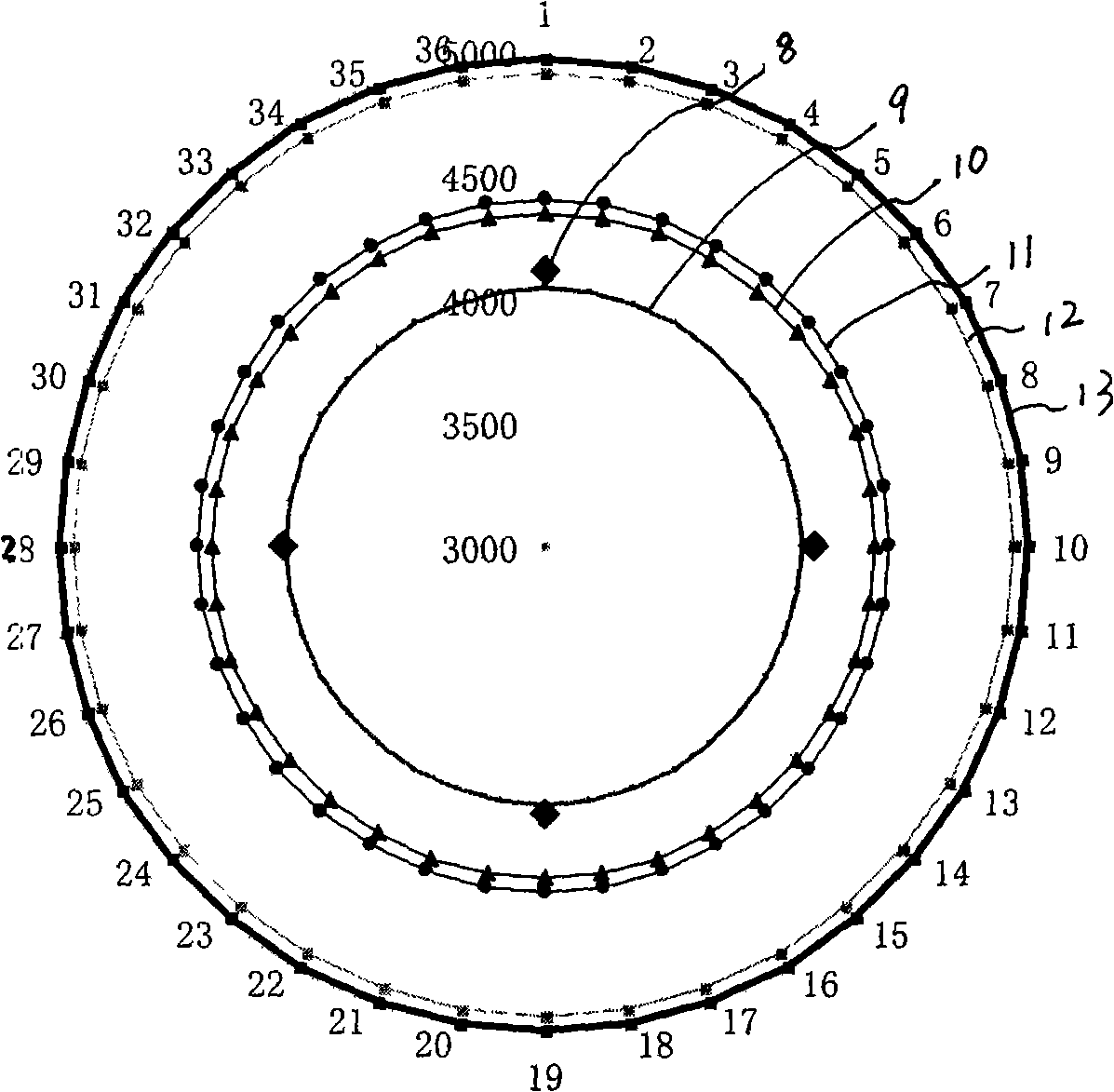

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

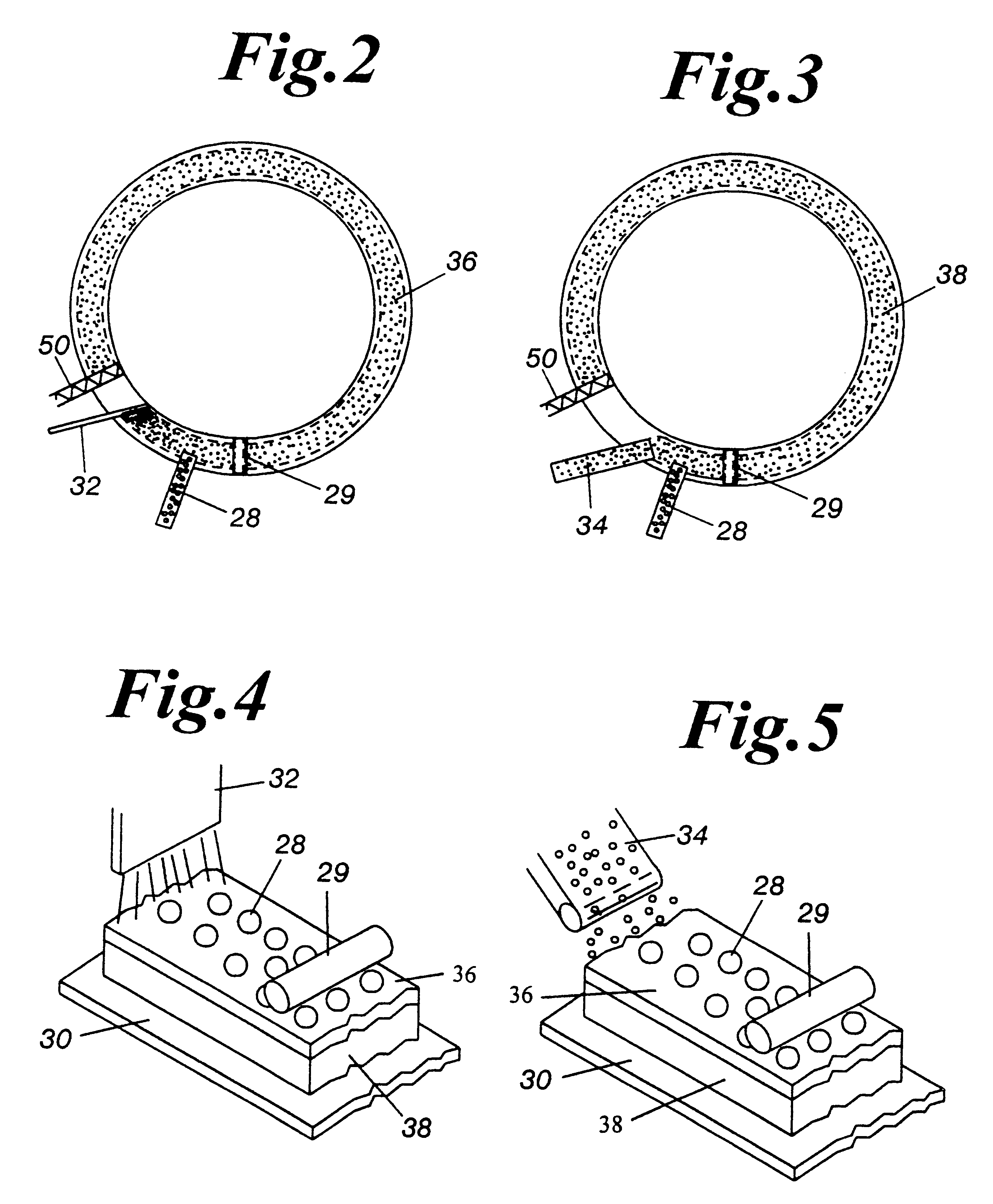

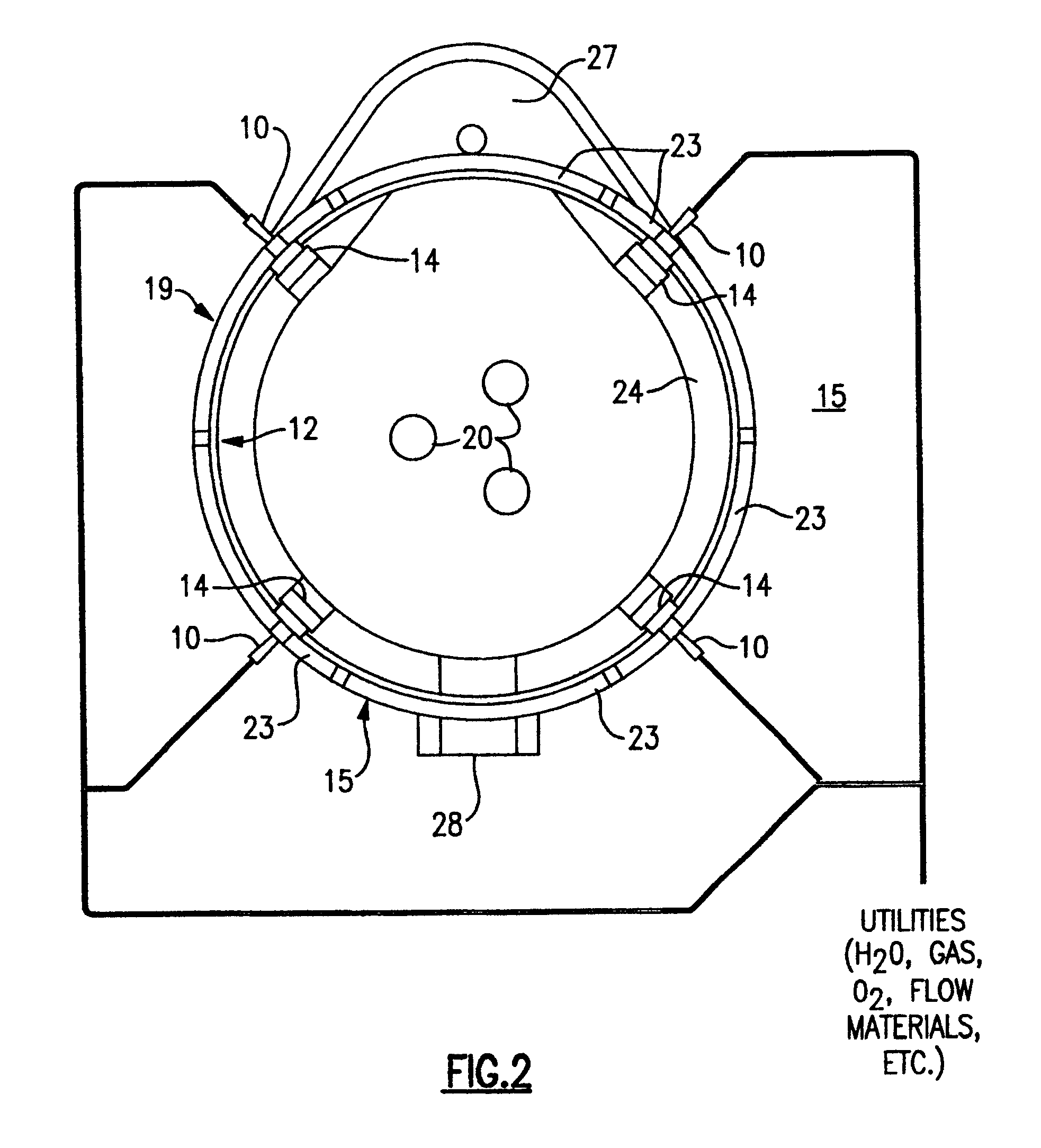

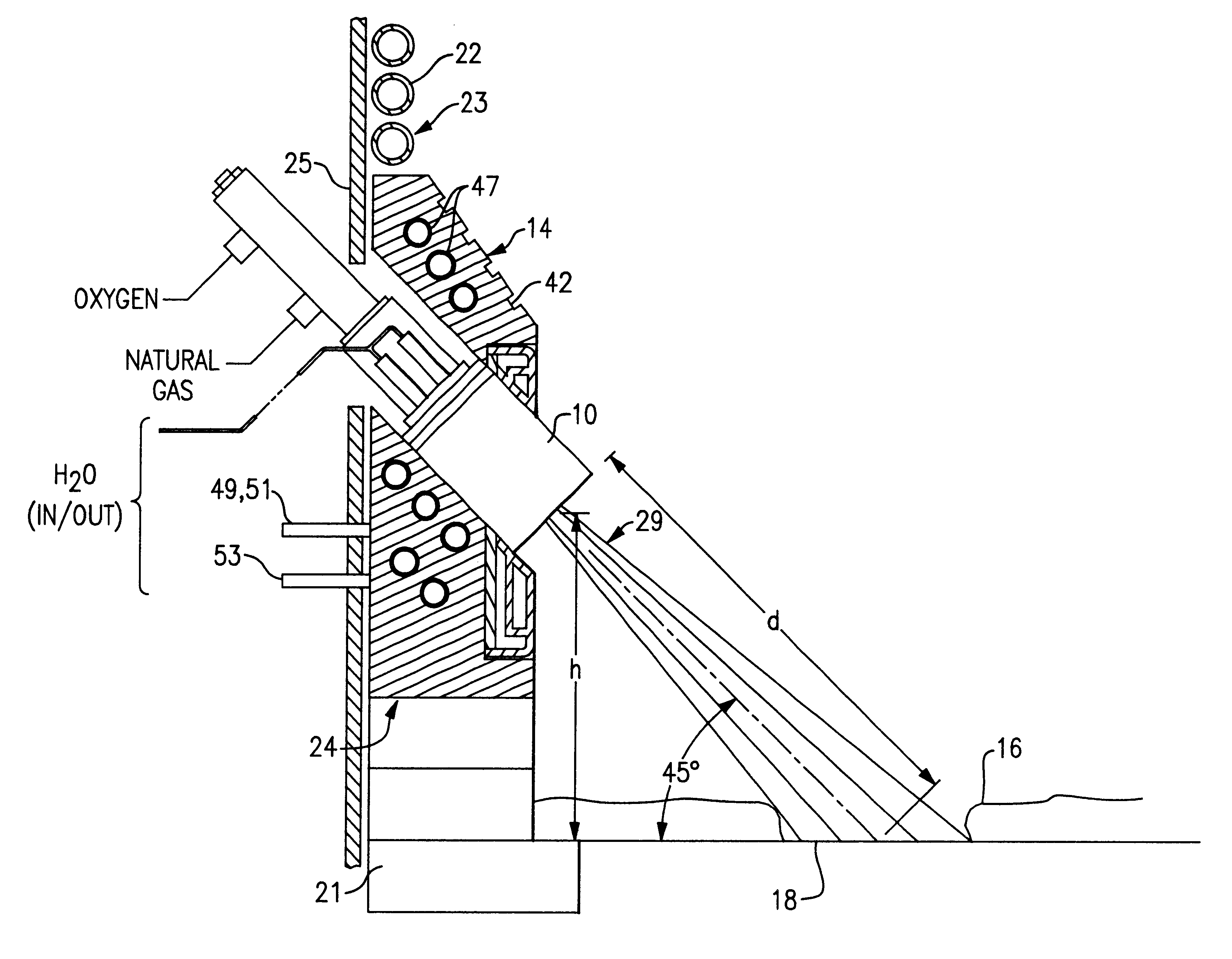

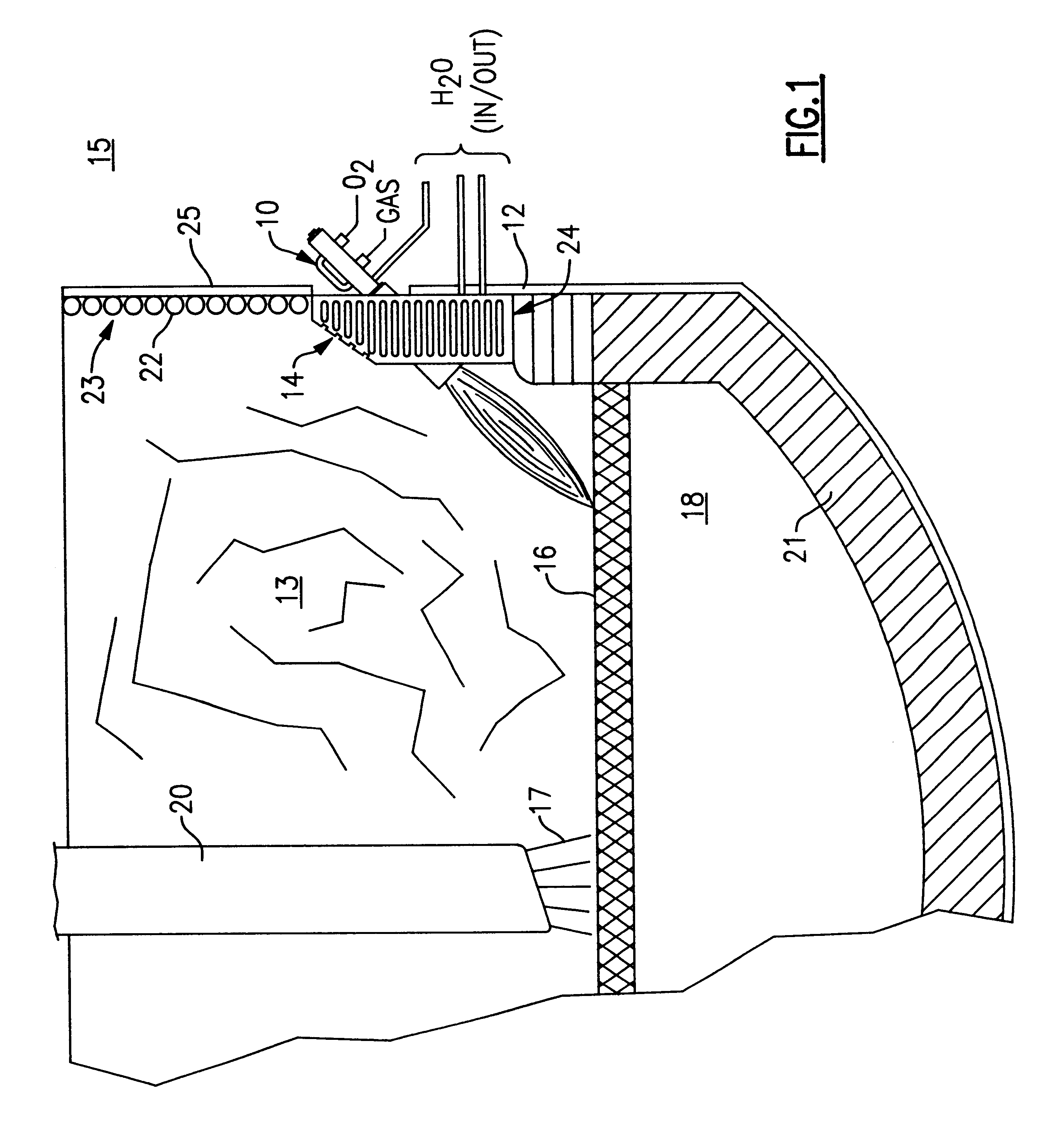

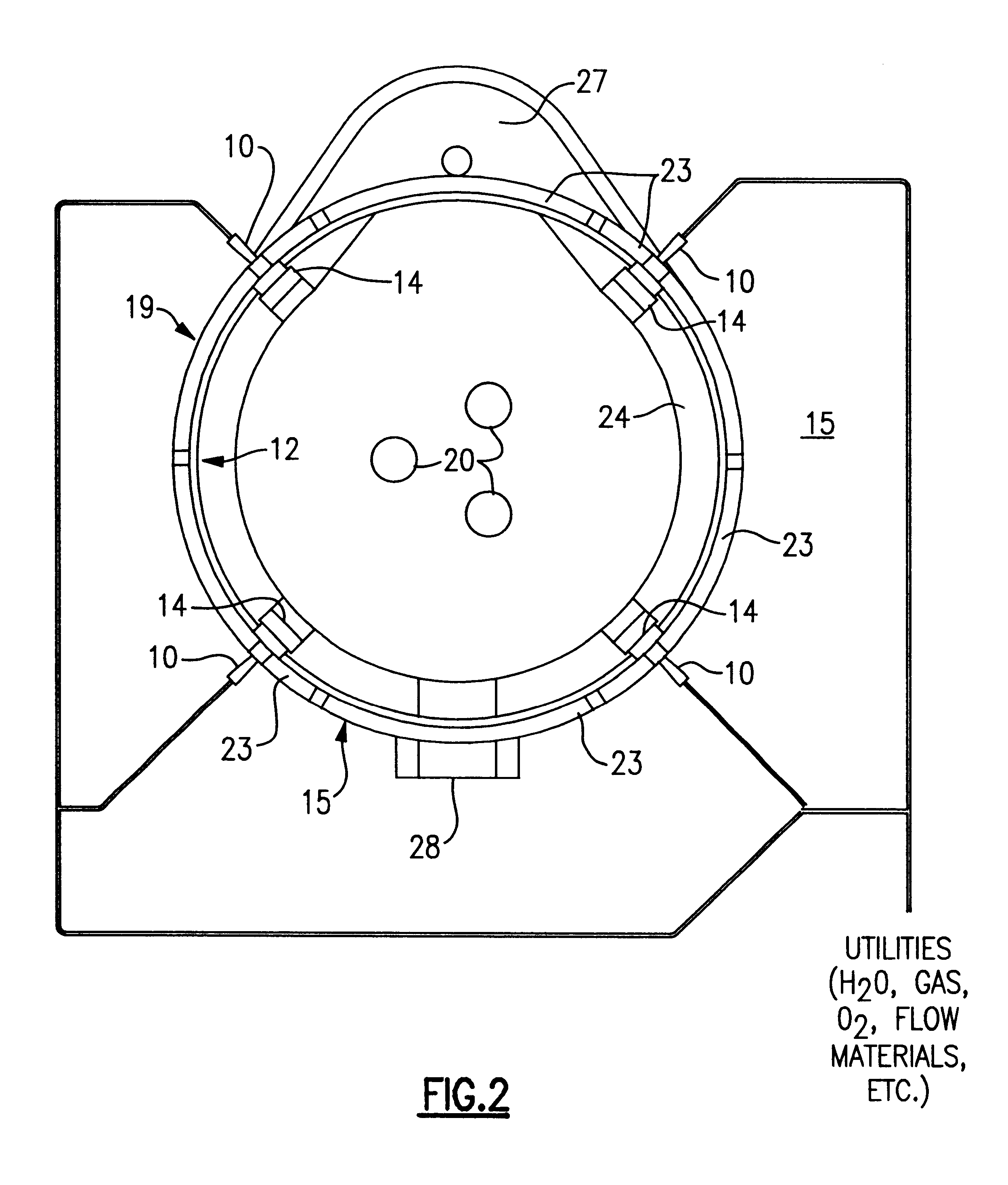

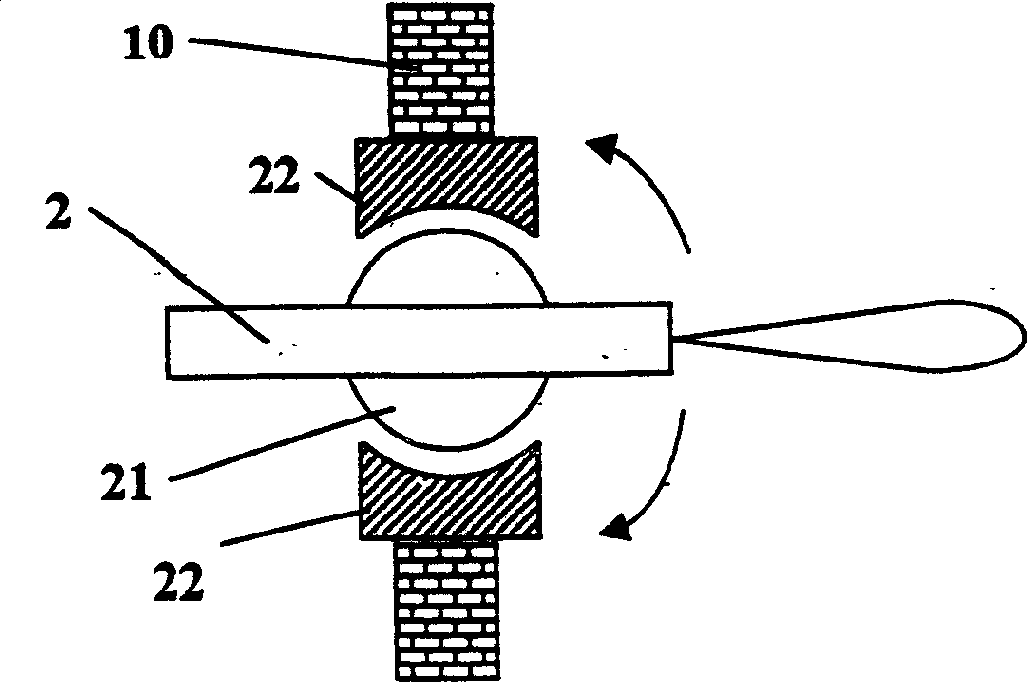

Mounting arrangement for auxiliary burner or lance

InactiveUS6614831B2Easy to produceImprove thermal conductivityElectric discharge heatingPeptide/protein ingredientsParticulatesElectric arc furnace

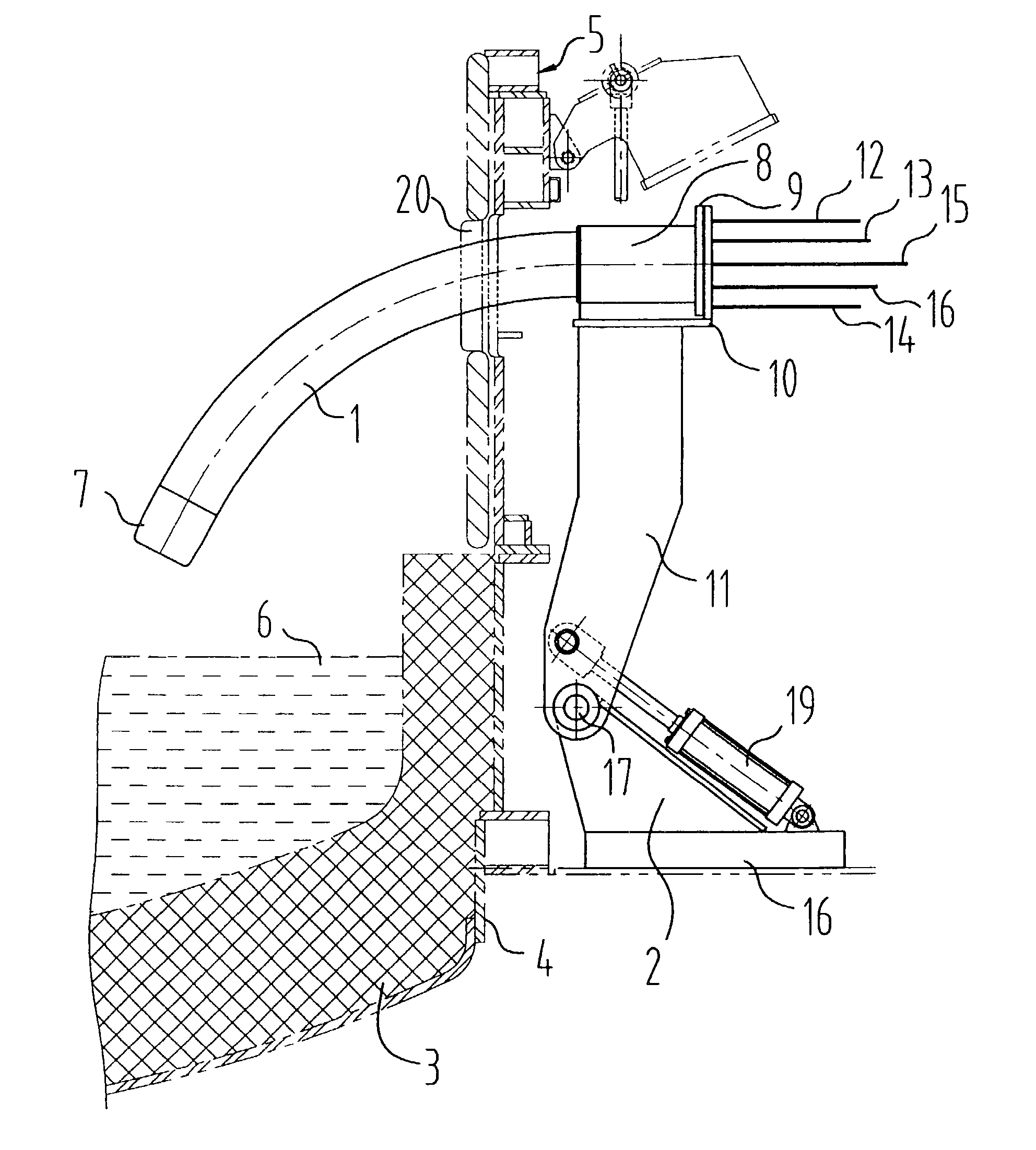

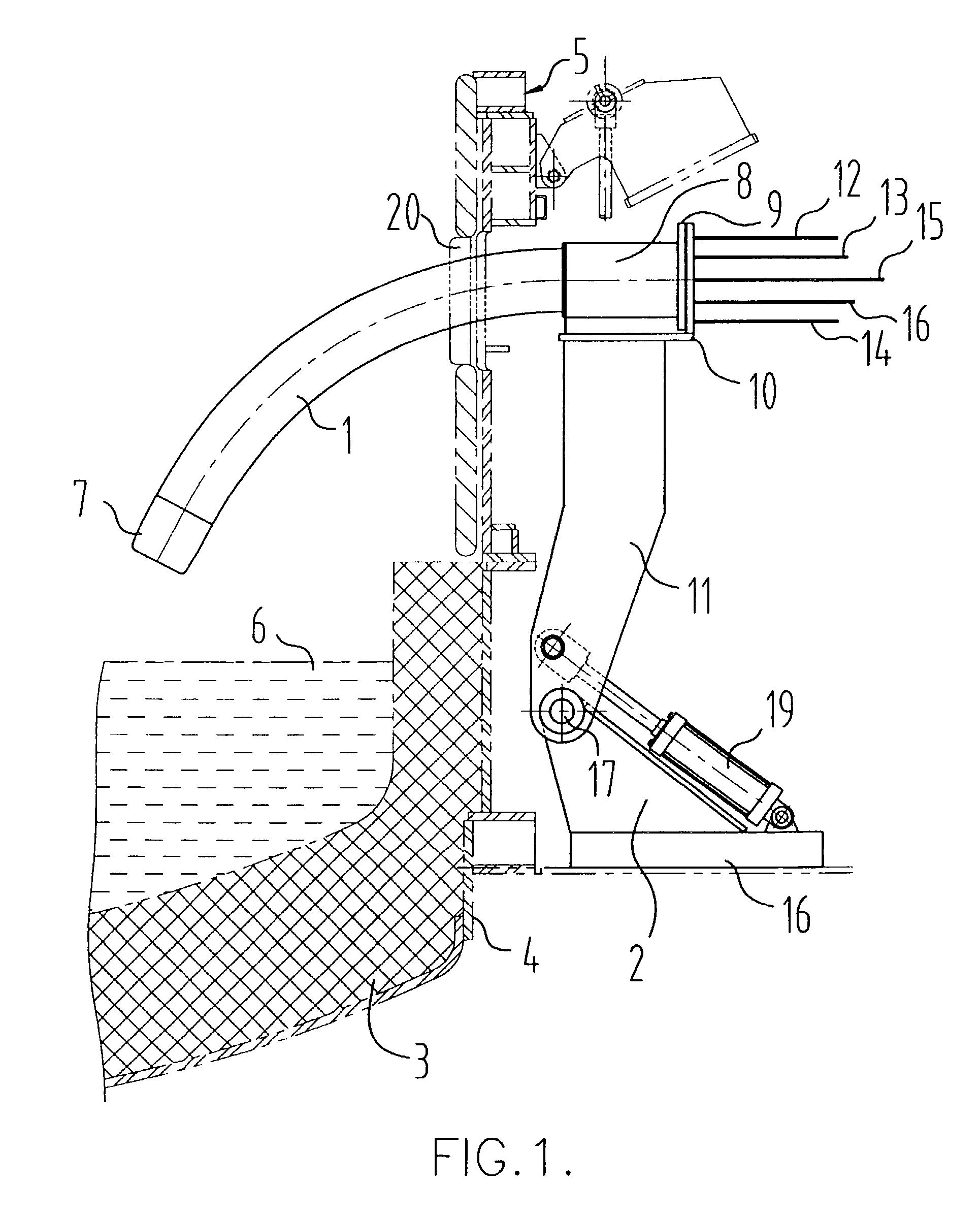

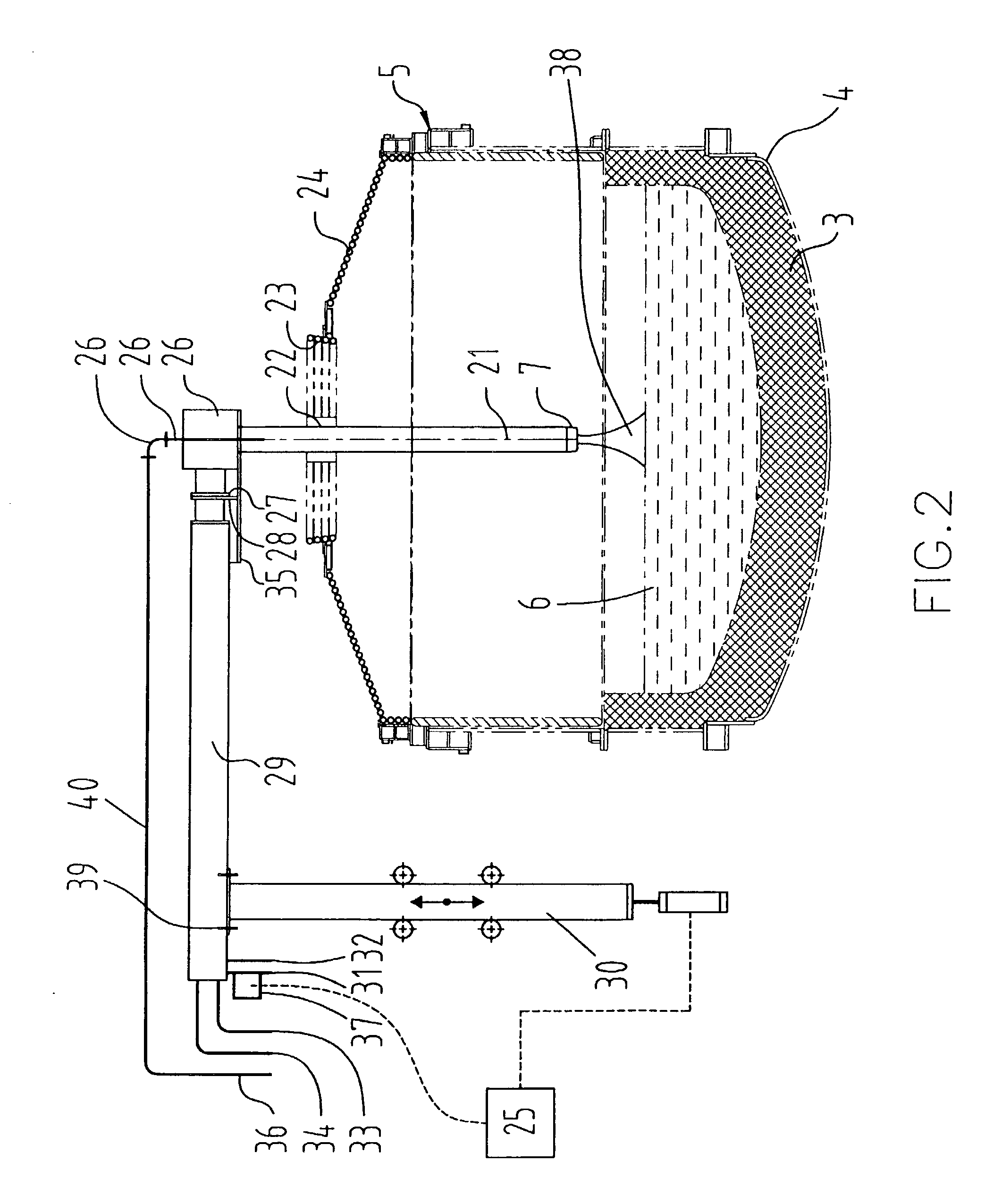

A mounting enclosure and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted for steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability and injectors or the like for the introduction of particulate matter. The mounting enclosure is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to occupy the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting enclosure comprises a plurality of fluid cooling conduits surrounding an apparatus aperture and an injector aperture which are formed through the enclosure and adapted to mount an apparatus and an injector. The mounting arrangement includes utilizing the mounting enclosure to mount an apparatus with supersonic oxidizing gas lancing capability and an injector for particulate carbon in an electric arc furnace. Because the mounting enclosure is approximately the width of the step, the discharge openings of the apparatus and the injector are moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge openings will now be extended to near the edge of the step so that the oxidizing gas flow pattern of the apparatus does not degrade the hearth material or other furnace equipment mounted nearby and the carbon flow pattern of the injector sufficiently agitates the slag to produce foaming.

Owner:PROCESS TECH INT

Mounting arrangement for auxiliary burner or lance

InactiveUS6289035B1Easy to produceImprove thermal conductivityElectric discharge heatingStirring devicesElectric arc furnaceCombustor

A mounting block and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted to steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability. The mounting block is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to rest on the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting block comprises a plurality of fluid cooling conduits surrounding an aperture which is formed through the block and adapted to mount the apparatus. The mounting arrangement includes utilizing the mounting block to mount an apparatus with supersonic oxidizing gas or lancing capability in an electric arc furnace. The apparatus is mounted by passing it through an aperture in a water cooled side panel aligned with the mounting aperture in the mounting block. Because the mounting block is approximately the width of the step, the discharge opening of the apparatus is moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge opening will now also extend past the inner edge of the step so that the oxidizing gas flow pattern does not degrade the hearth material and other furnace equipment mounted nearby.

Owner:PROCESS TECH INT

Coke oven flue gas sharing

InactiveCN100510004CExtend your lifeReduce the gas flow rateCombustible gas coke oven heatingBeehive ovensCoke Oven EmissionFlue gas

The invention provides a method and apparatus for reducing the gas flow velocity in the bottom flue gas system of a coke oven during at least one initial coking operation after the coke oven has been charged with coal (43). The method includes providing a ductwork (96, 98) between a first coke oven having a first coking chamber (18) and a second coke oven having a second coking chamber (18) for transferring at least a portion of the gas from The gas space (41) in the first coking chamber (18) is led into the second coking oven, thereby reducing the gas flow velocity in the first bottom flue gas system of the first coking oven. Reducing the gas flow velocity in the bottom flue has beneficial effects on product yield, coke oven life and environmental control of coke oven volatile emissions.

Owner:SUNCOKE TECH & DEV LLC

Process for manufacturing low-silicon low-carbon deep punching/drawing steel

ActiveCN101343677ARelaxation of sulfur content requirementsReduce manufacturing costManufacturing convertersProcess efficiency improvementExtensibilitySlag

The invention discloses a production method of low-silicon and low-carbon deep punching / drawing steel, bottom-blowing argon is performed in the whole process of converter smelting, and a single slag / double slag technique is adopted to pour out the dephosphorized slag, high-basicity slag is produced in later period, the dualistic basicity of final slag R is more than 3.5, the terminal temperature of molten steel is 1620 DEG C to 1650 DEG C, and tapping ( P ) is less than 0.012 percent. The molten steel is refined by adopting low-silicon and low-carbon high-basicity reductive slag in a LF furnace refining station, thus to manufacture reductive slag for desulphurisation, and the ( Al ) in the molten steel is less than 0.005 percent. The molten steel refined by the LF furnace is vacuum-treated by a RH vacuum furnace, the carbon and the silicon in the molten steel is circularly removed, the molten steel is continuously casted into a casting blank through a CSP sheet bar conticaster, the casting blank is sent into CSP sheet bar heat continuous rolling mill and rolled into a coiled sheet after being heated in a roller hearth soaking furnace, a hot rolled coiled sheet is coldrolled into cold rolled coiled sheet through a cold tandem mill or a single mill after being acidwashed, and leveled through a leveling machine after being annealed by a cover furnace, and a leveling divided coil is stretched and divided. The production method has the advantages that the production cost of the working procedure is saved, the consumption of the refractory consumption of the converter is reduced, the equipment investment is saved, the process of the production technique is steady and smooth, the n value of the cold rolled plate is bigger than 0.23, the r value thereof is bigger than 2.1, and the deep punching performance and the extensibility are good.

Owner:湖南华菱涟钢特种新材料有限公司 +1

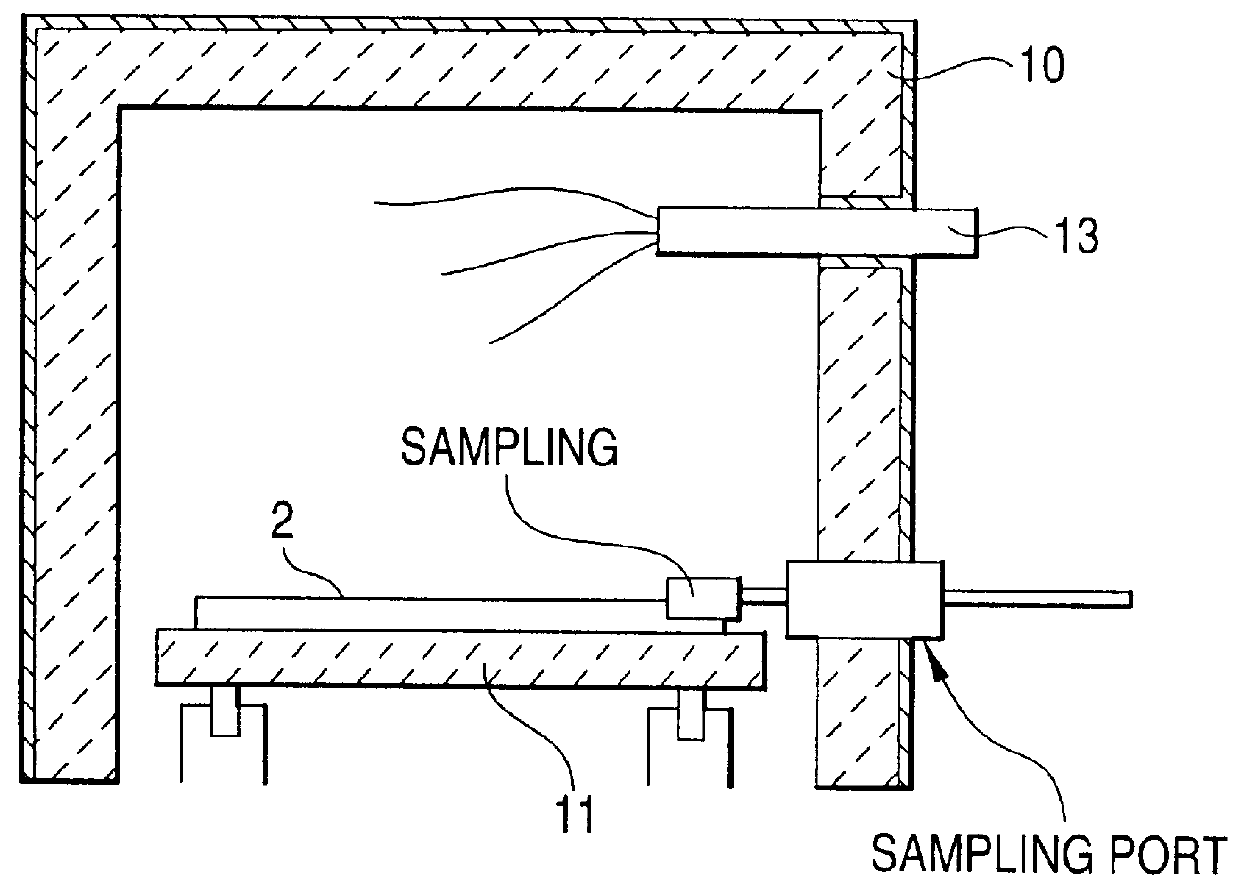

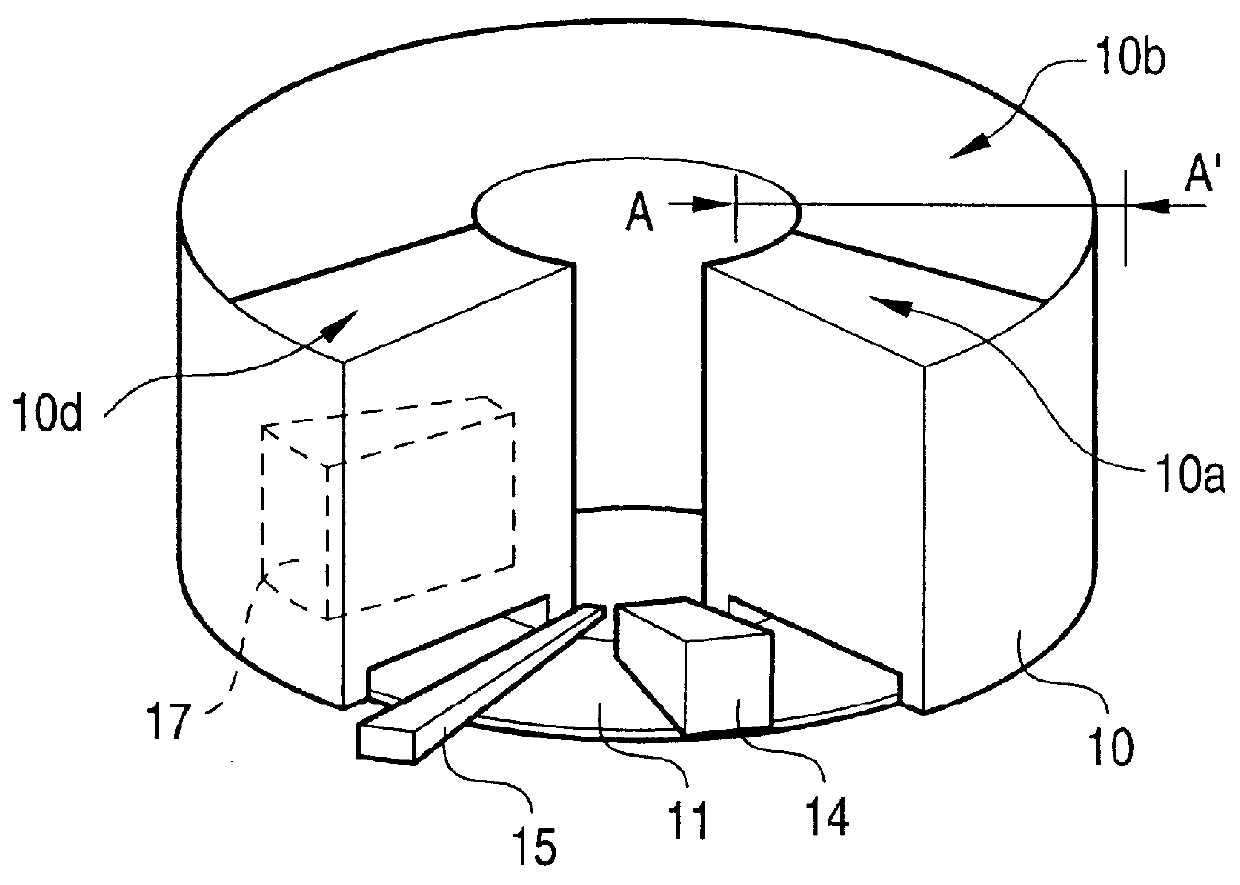

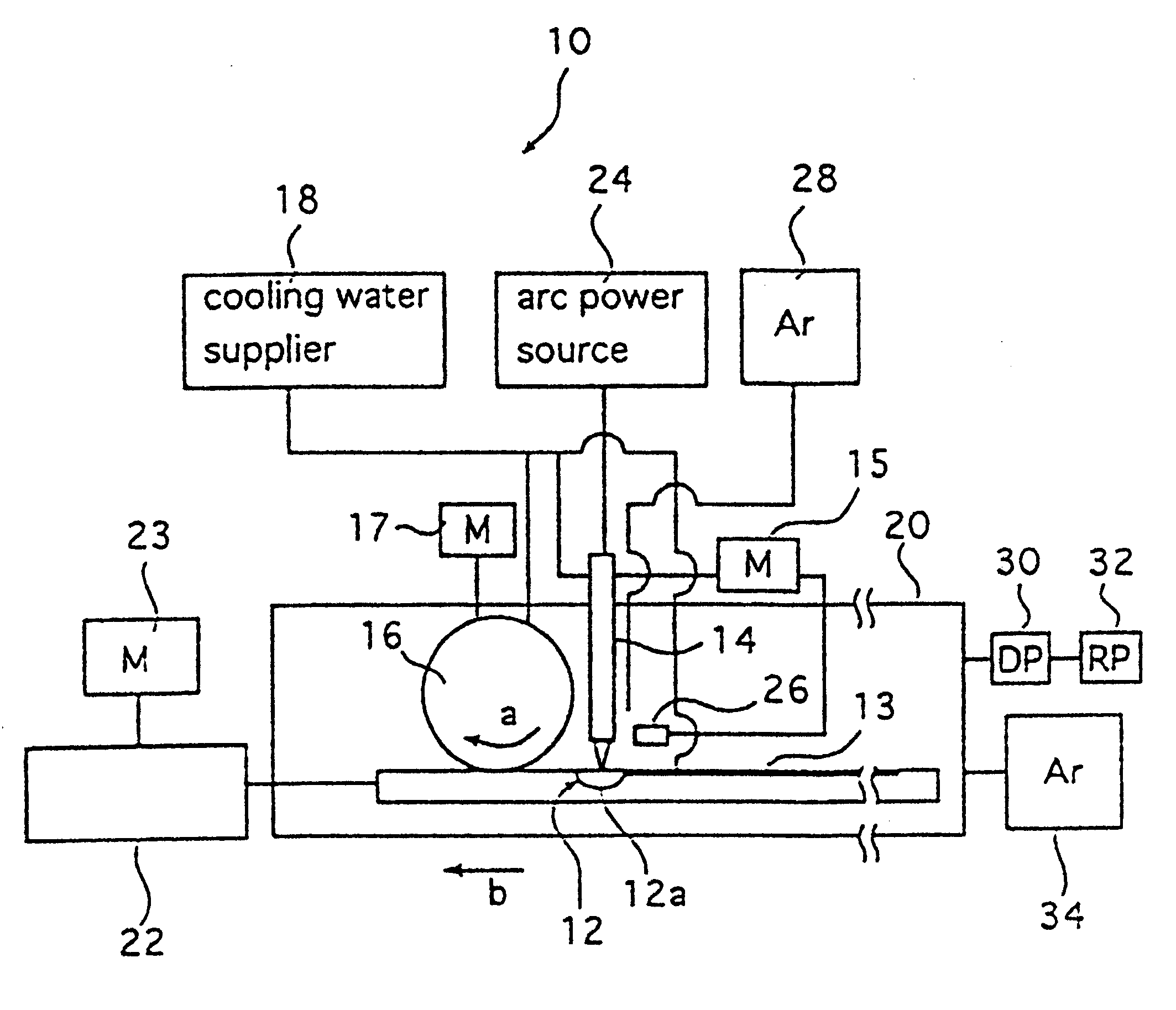

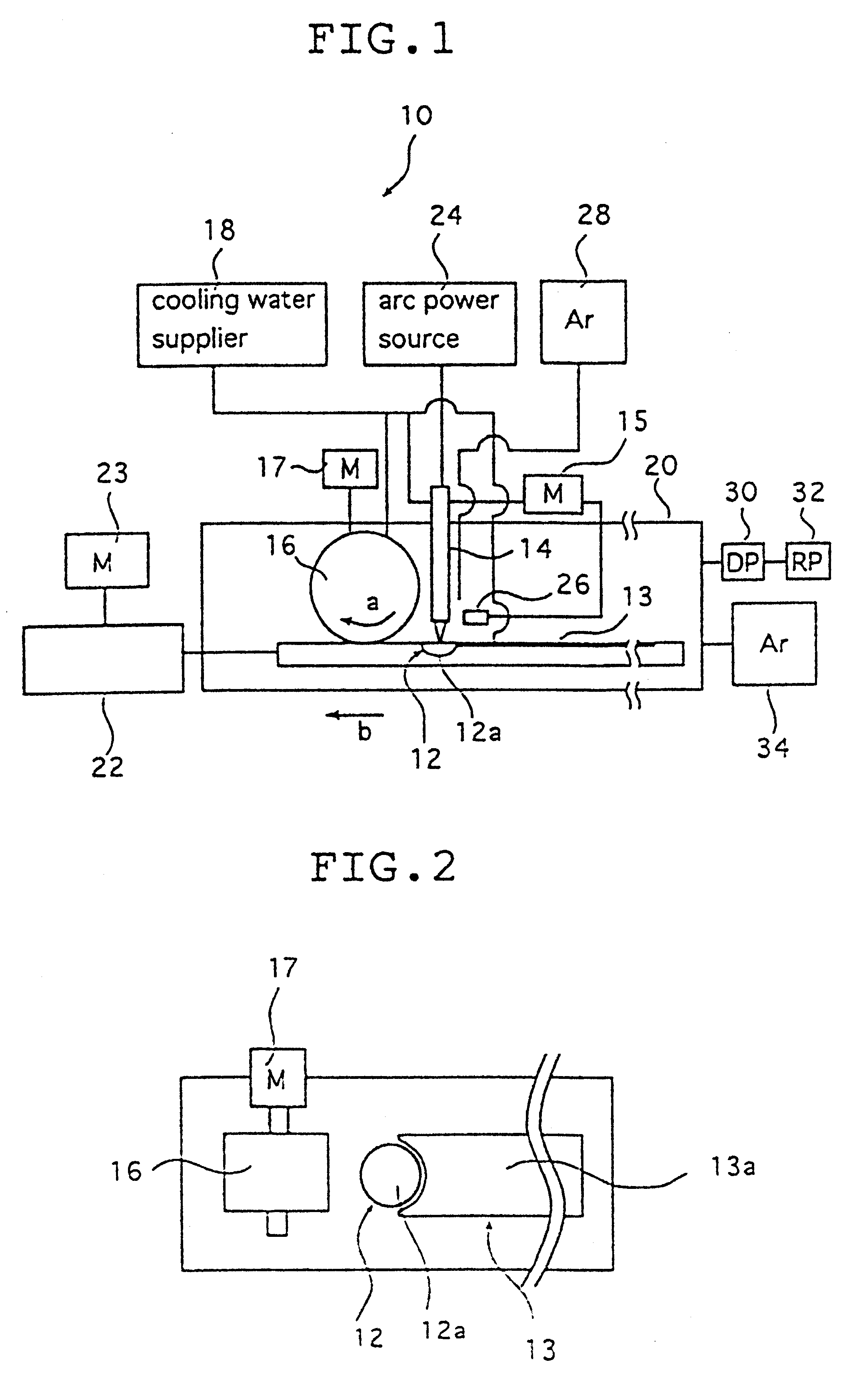

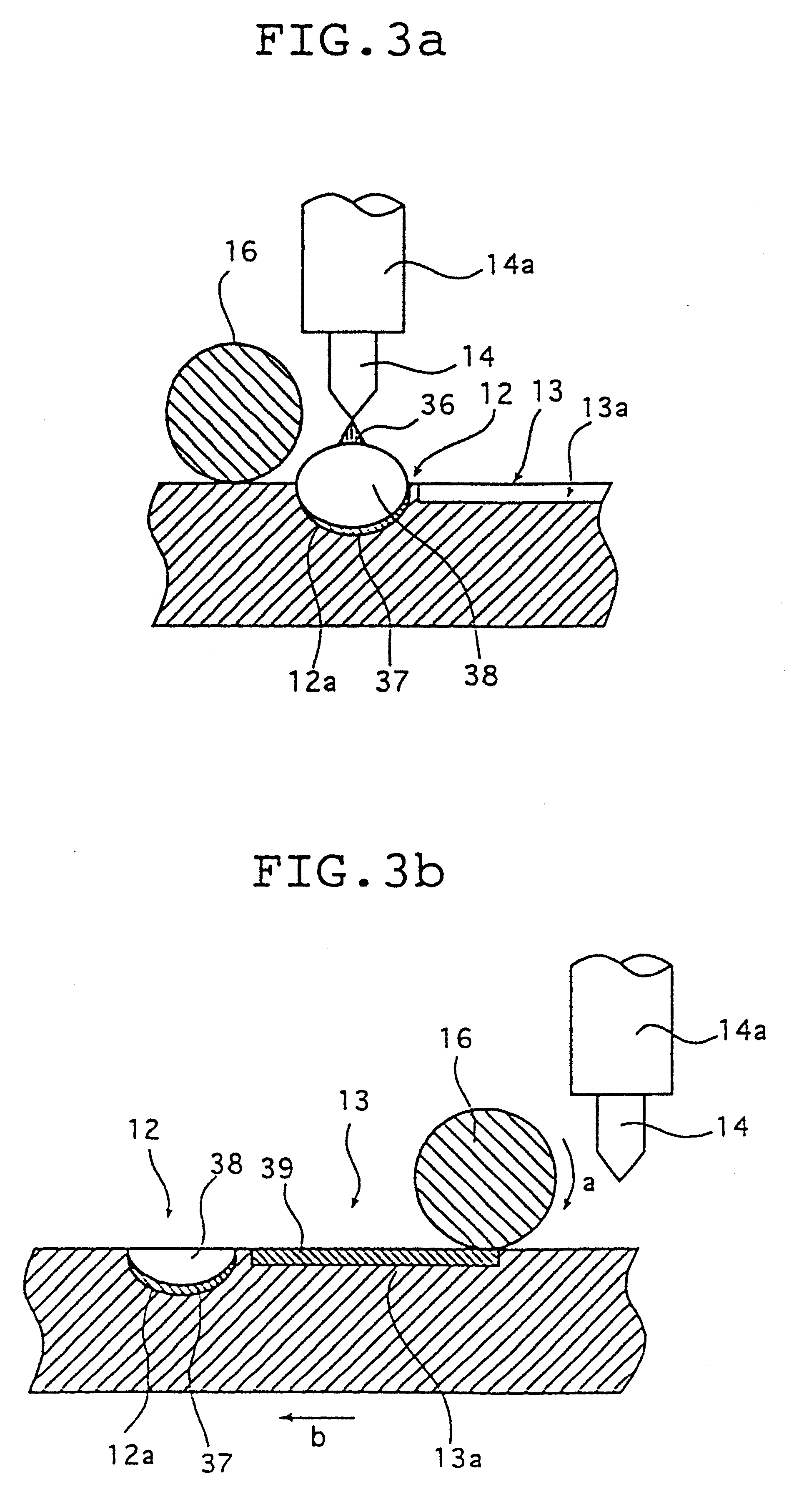

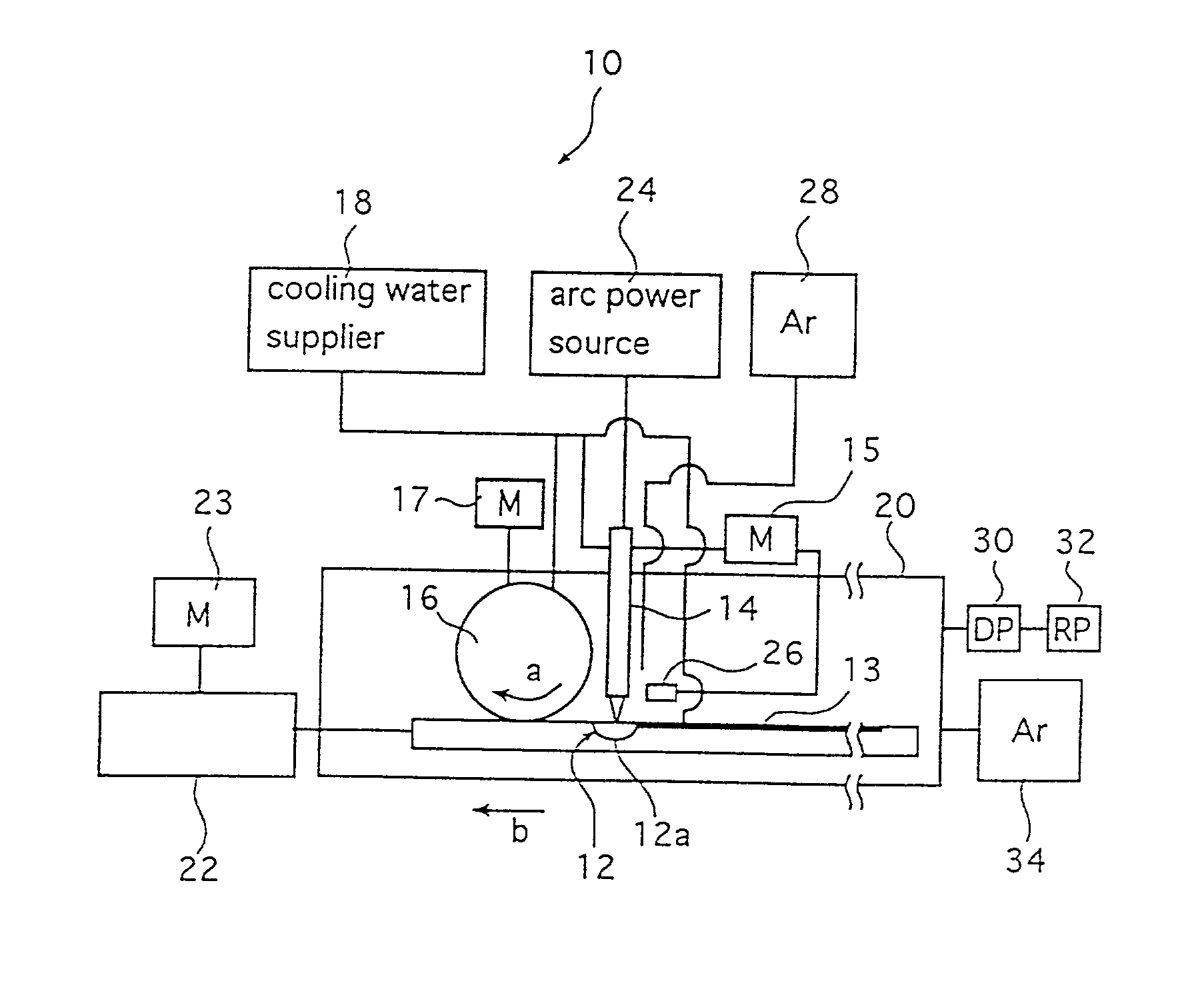

Process and apparatus for producing metallic glass

InactiveUS6427753B1Simple processGood strength performanceFoundry mouldsFoundry coresHigh energyHearth

A process and an apparatus for producing metallic glass which are capable of producing a bulk amorphous alloy of desired shape, in particular, a bulk amorphous alloy of desired final shape are provided. In the present invention, the molten metal at a temperature above the melting point is selectively cooled at a rate higher than the critical cooling rate, and the product comprises single amorphous phase which is free from the crystalline phase formed by the development of crystal nuclei through nonuniform nucleation. The present invention is capable of producing the bulk amorphous alloy which is free from casting defects such as cold shuts and which has excellent strength properties in a simple process at a high reproducibility. Accordingly, a bulk metallic glass of desired shape is produced by filling a metal material in a hearth; melting the metal material by using a high-energy heat source which is capable of melting the metal material; pressing the molten metal at a temperature above the melting point of the metal material to deform the molten metal into the desired shape by at least one of compressive stress and shear stress at a temperature above the melting point, while avoiding the surfaces of the molten metal cooled to a temperature below the melting point of the metal material from meeting with each other during the pressing; and cooling the molten metal at a cooling rate higher than the critical cooling rate of the metal material simultaneously with or after the deformation to produce the bulk metallic glass of desired form.

Owner:MAKABE GIKEN

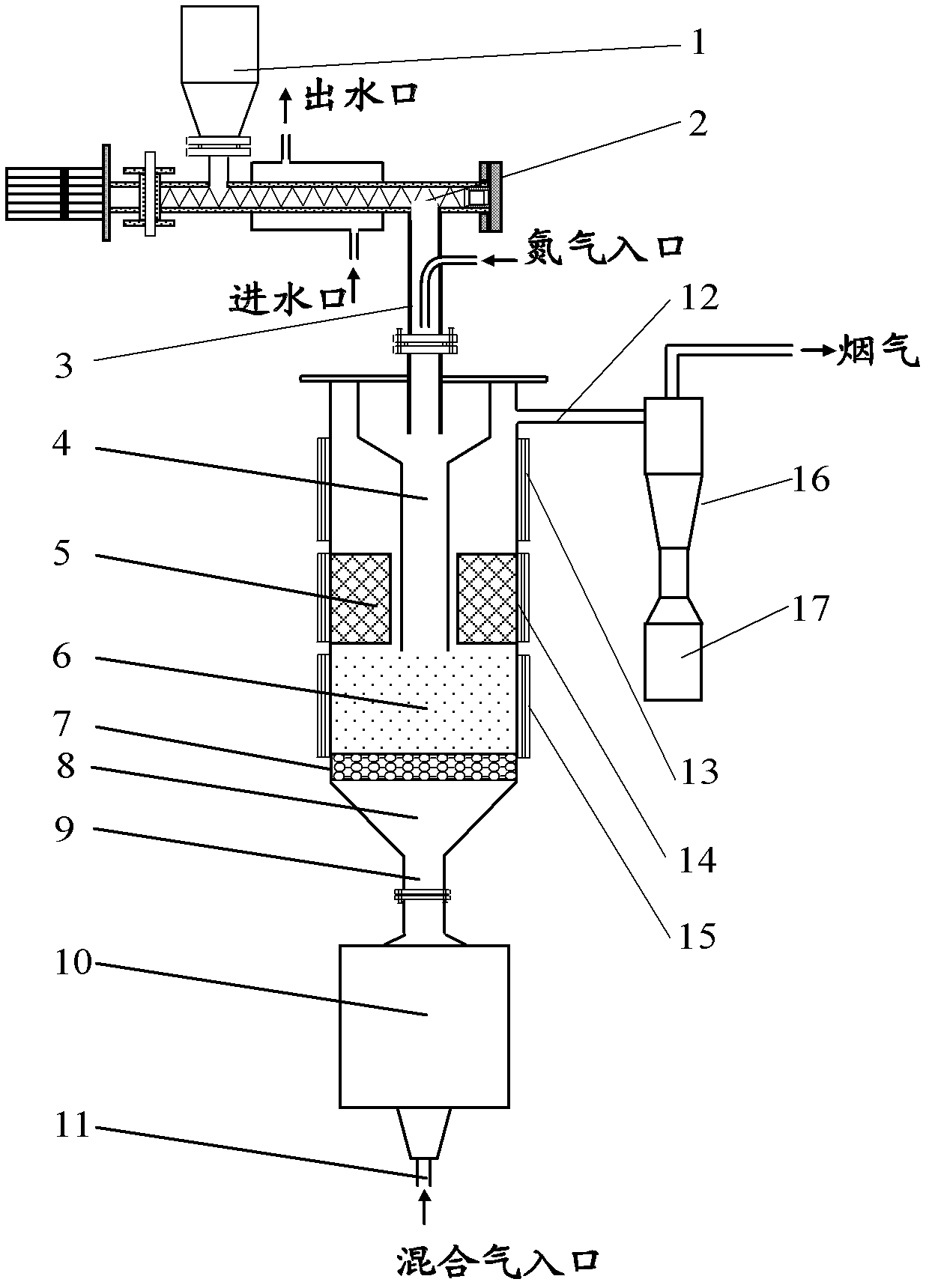

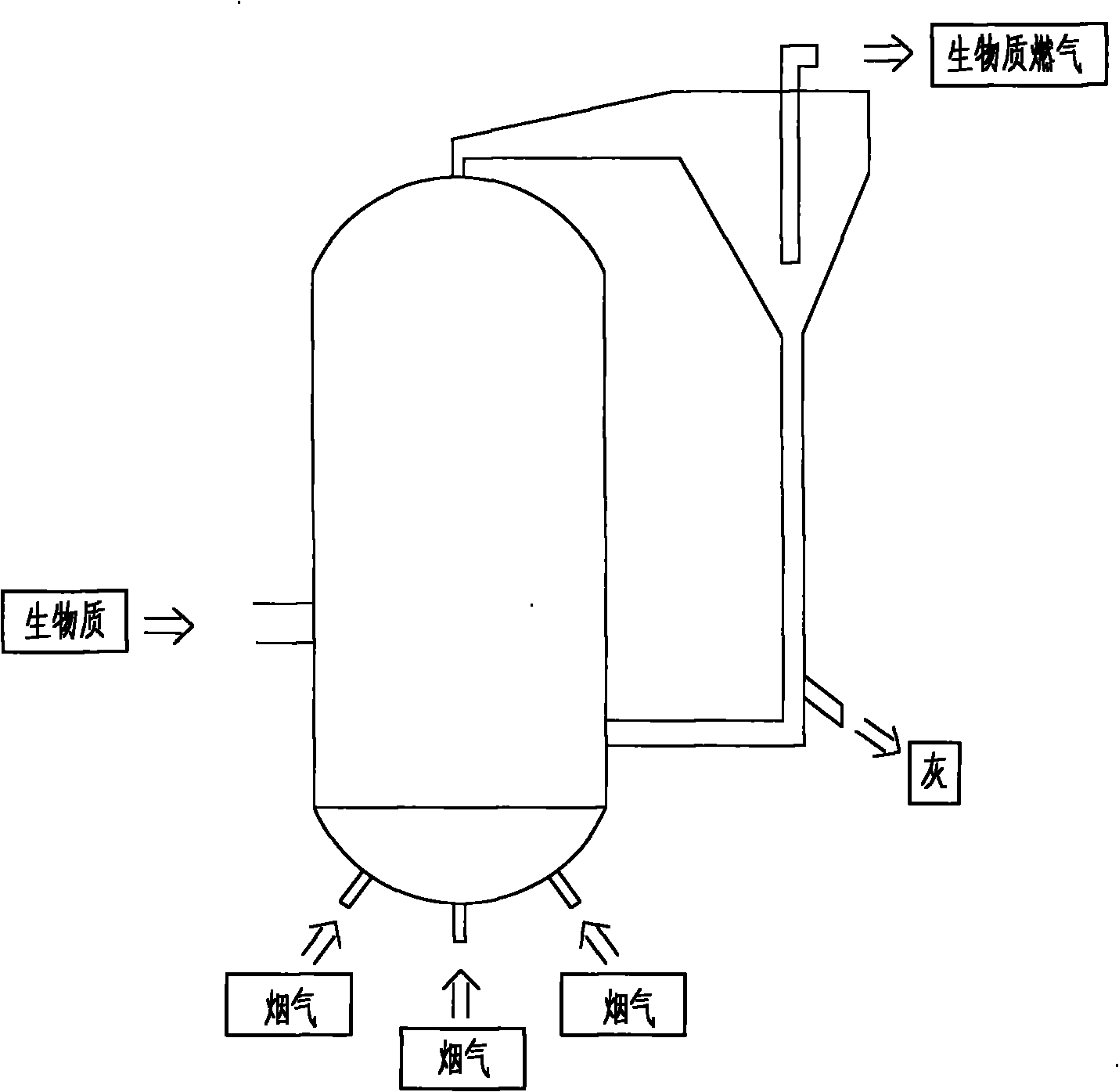

Method for preparing synthetic gas by three-phase type biomass pyrolysis-gasification-catalytic reforming

ActiveCN102424359AImprove conversion utilizationHigh yieldHydrogenWaste based fuelCatalytic reformingChemical industry

The invention belongs to the technical field of energy chemical industry. The process for preparing synthetic gas by biomass pyrolysis and gasification is divided into three steps of biomass low-temperature pyrolysis, coke or semi-coke high-temperature gasification and crude synthetic gas / tar catalytic reforming. The three reaction steps are successively and continuously carried out in three relatively independent spaces of an upper pyrolysis hearth, a lower gasification hearth and a catalyst bed inside the same gasification reaction device so as to finally obtain the high-quality synthetic gas. The method provided by the invention has high carbon conversion rate, produces no secondary pollution and is simple to realize. In addition, required biomass is rich in reserves and can be regenerated, thus realizing integrated sustainable utilization of resource, energy and environment.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

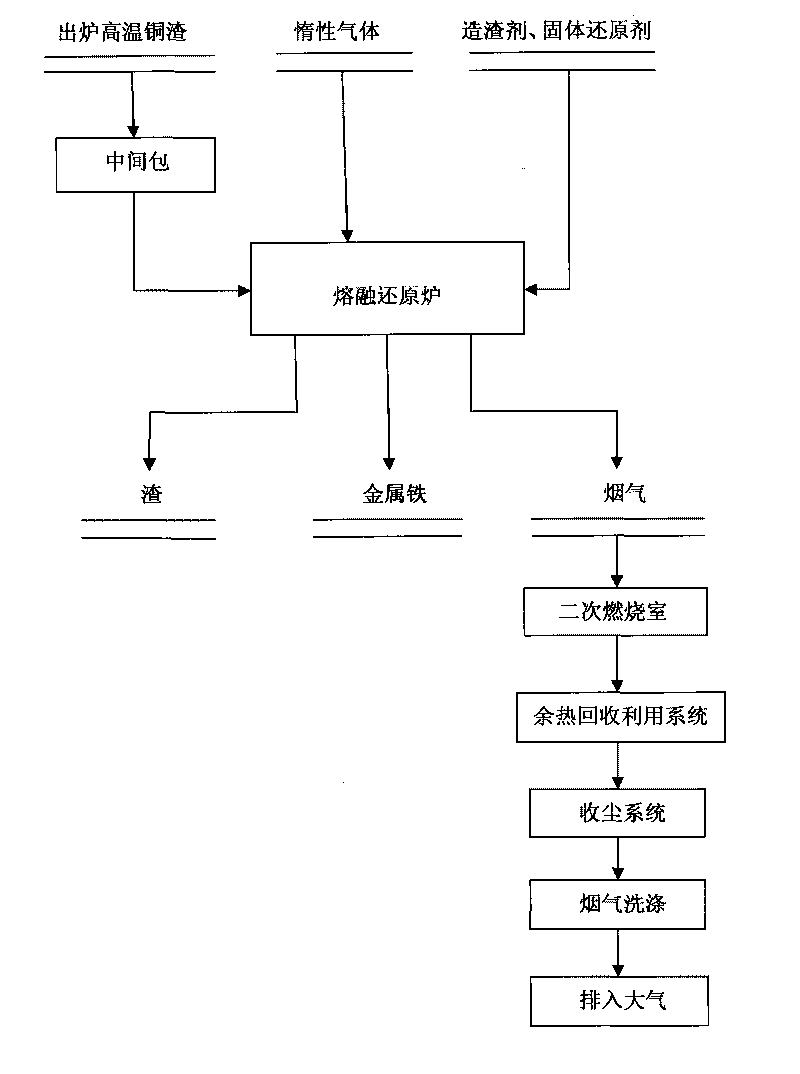

Method for fusing and reducing iron from copper residue by blowing inert gas

InactiveCN101736112AMeet the requirements of energy saving and emission reductionEmission reductionFluidised-bed furnacesMelting tankCombustion

The invention discloses a method for fusing and reducing iron from copper residue by blowing inert gas which comprises the steps of: transferring a high-temperature copper residue from a pouring packet to a high-temperature reduction furnace, adding reducing agent and slagging agent which are crushed into the reduction furnace, performing high-temperature iron reduction reaction, stirring inert gases and blowing into a furnace hearth during the reaction, spraying the inert gases and stirring the fused residue, performing high-temperature smoke secondary combustion, collecting dust and washing after recycling the waste heat, injecting into the atmosphere after emptying, and discharging high-temperature molten iron and slag from an iron outlet and a slag outlet after finishing the reaction. The invention takes full advantages of high-temperature waste heat of the discharged copper residue in order to save energy and reduce emission. The process flow is short; the discharge of contaminant is less, the recovering ratio is high; the applicability is wide; the process flow for recycling iron from copper residue is shortened; the operation in each process flow is simple; and the maintenance cost for furnace is lower.

Owner:KUNMING UNIV OF SCI & TECH

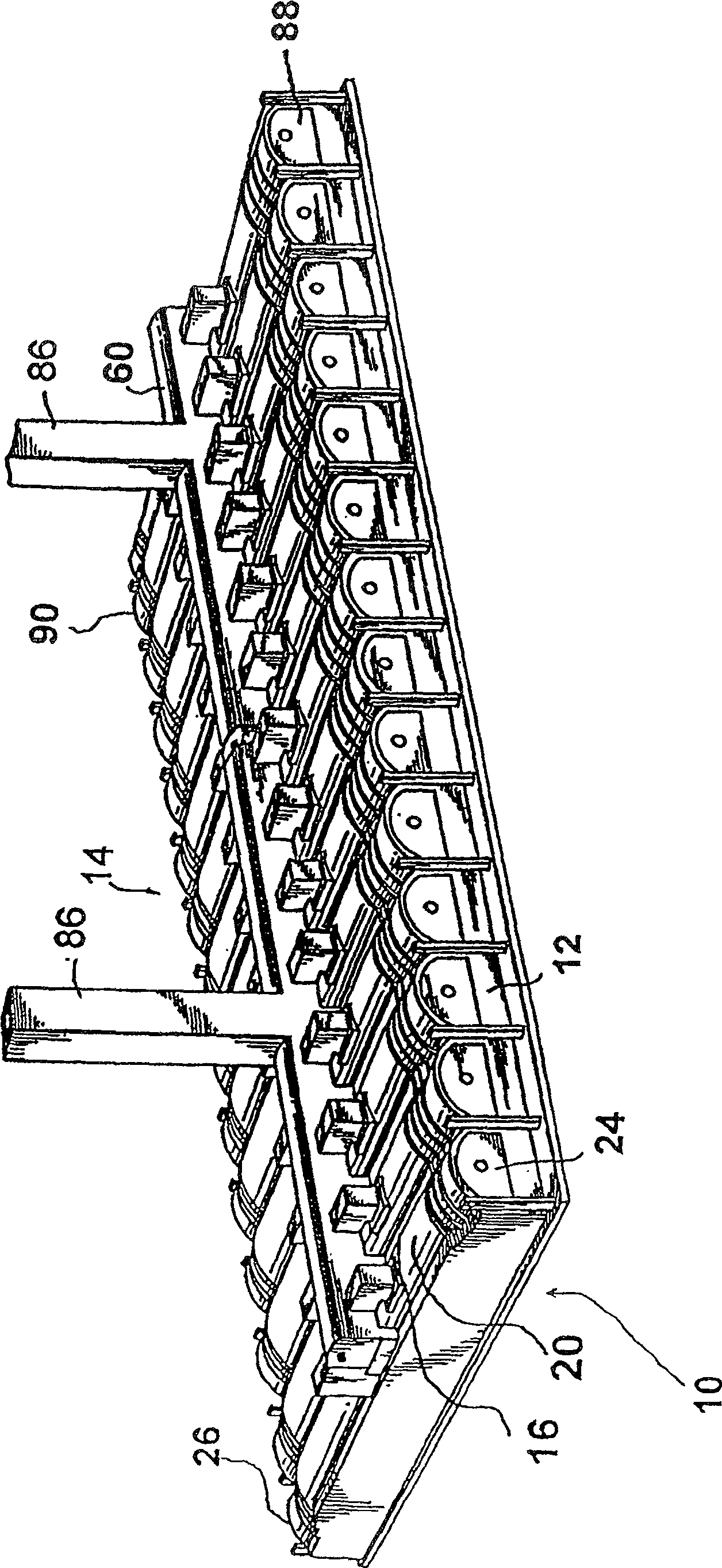

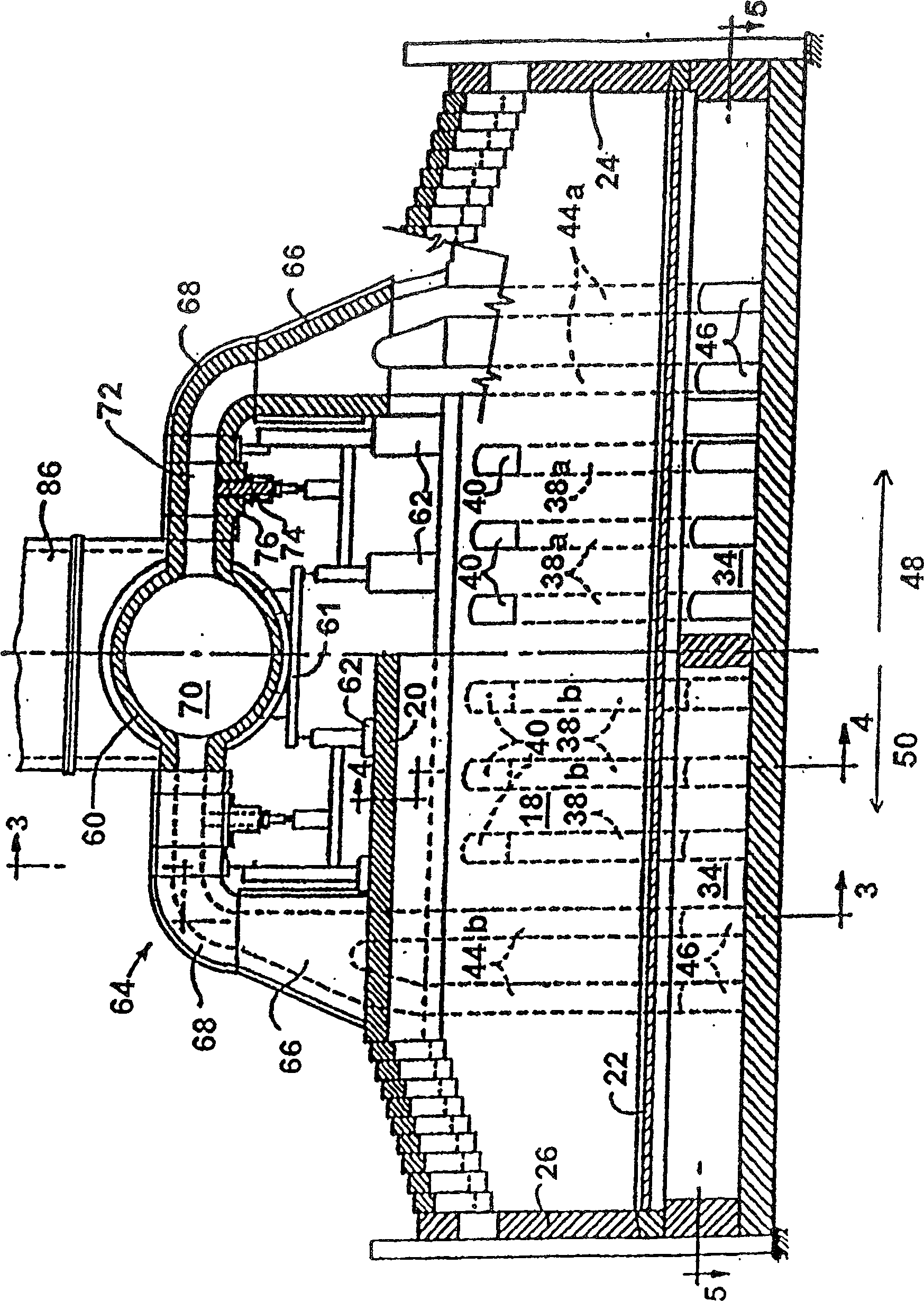

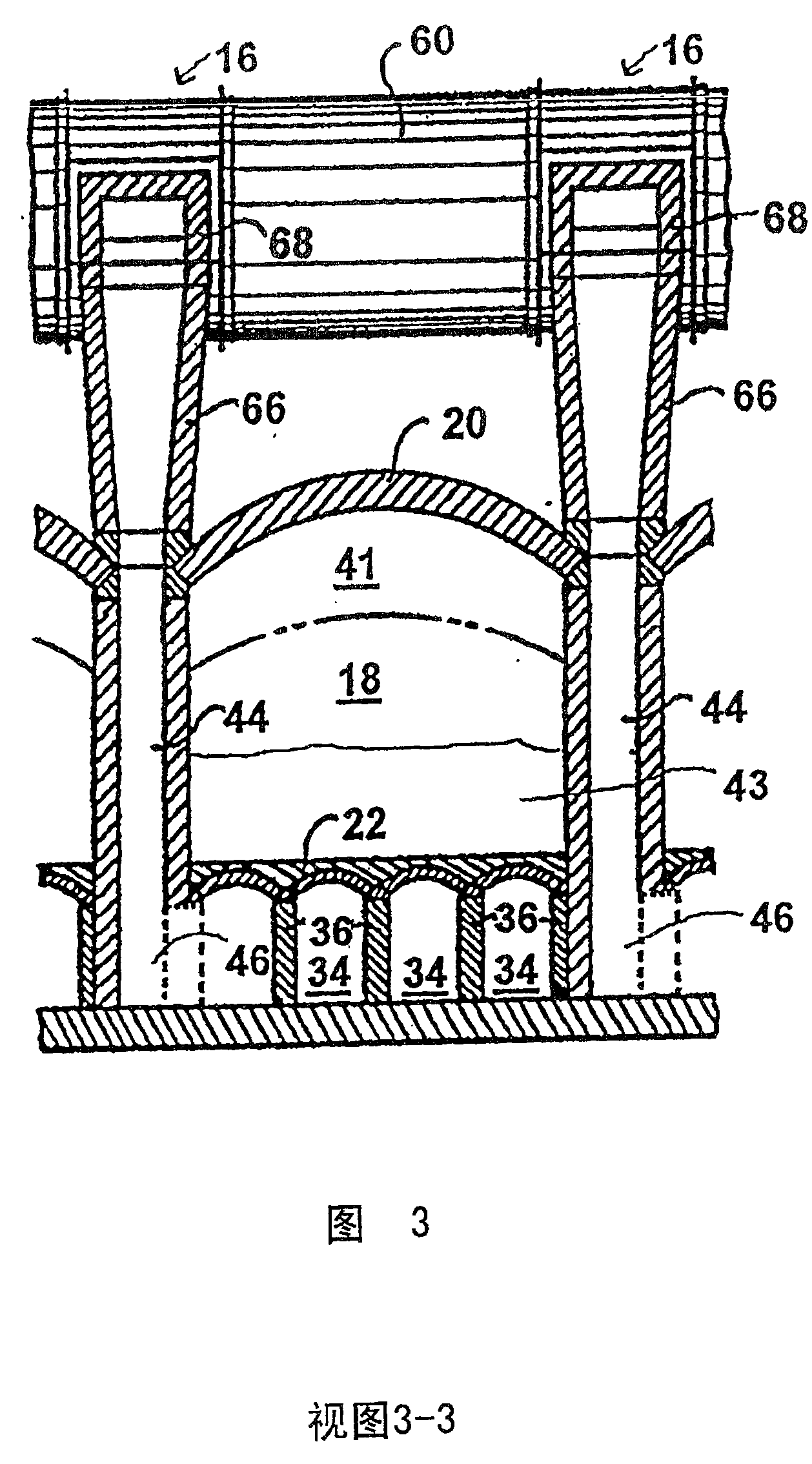

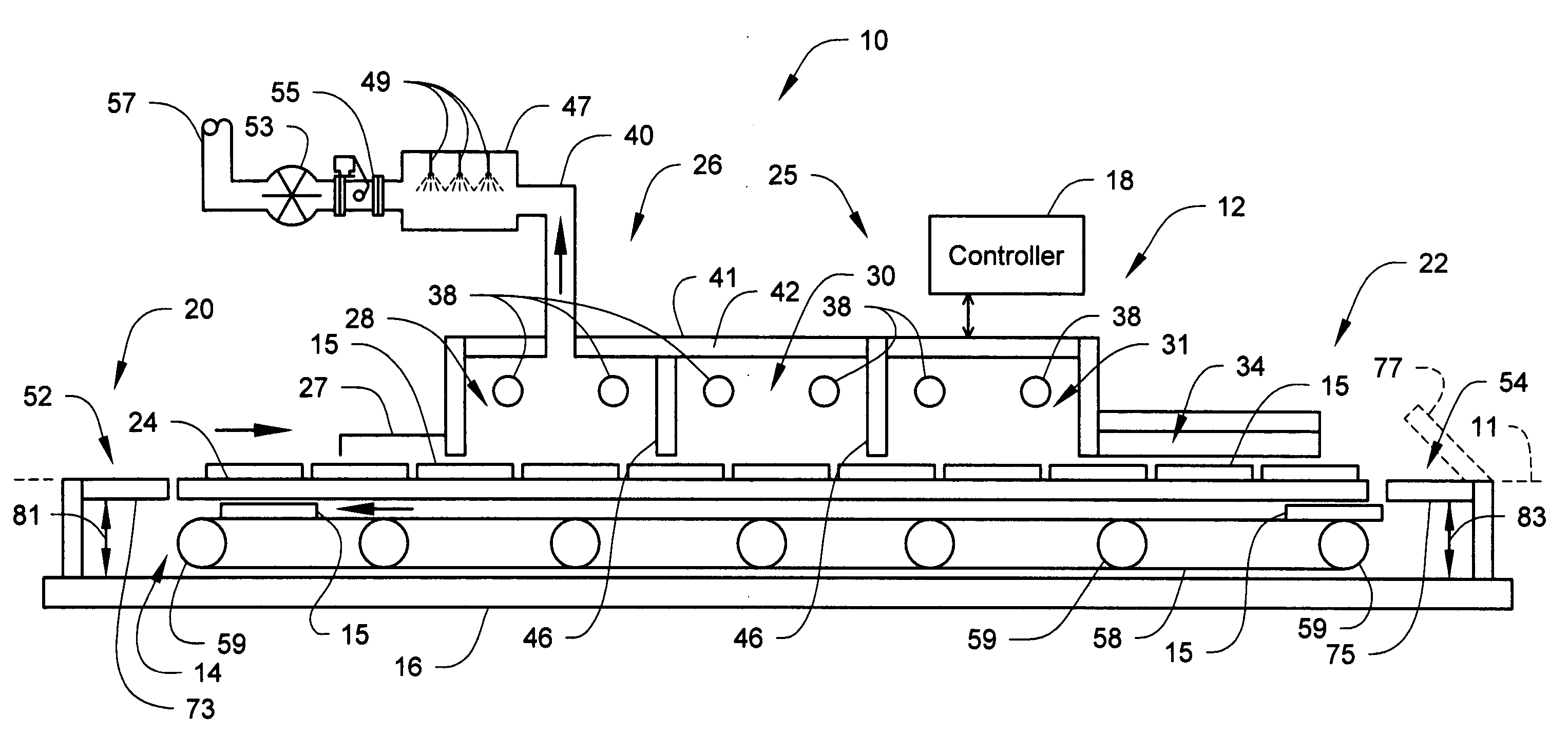

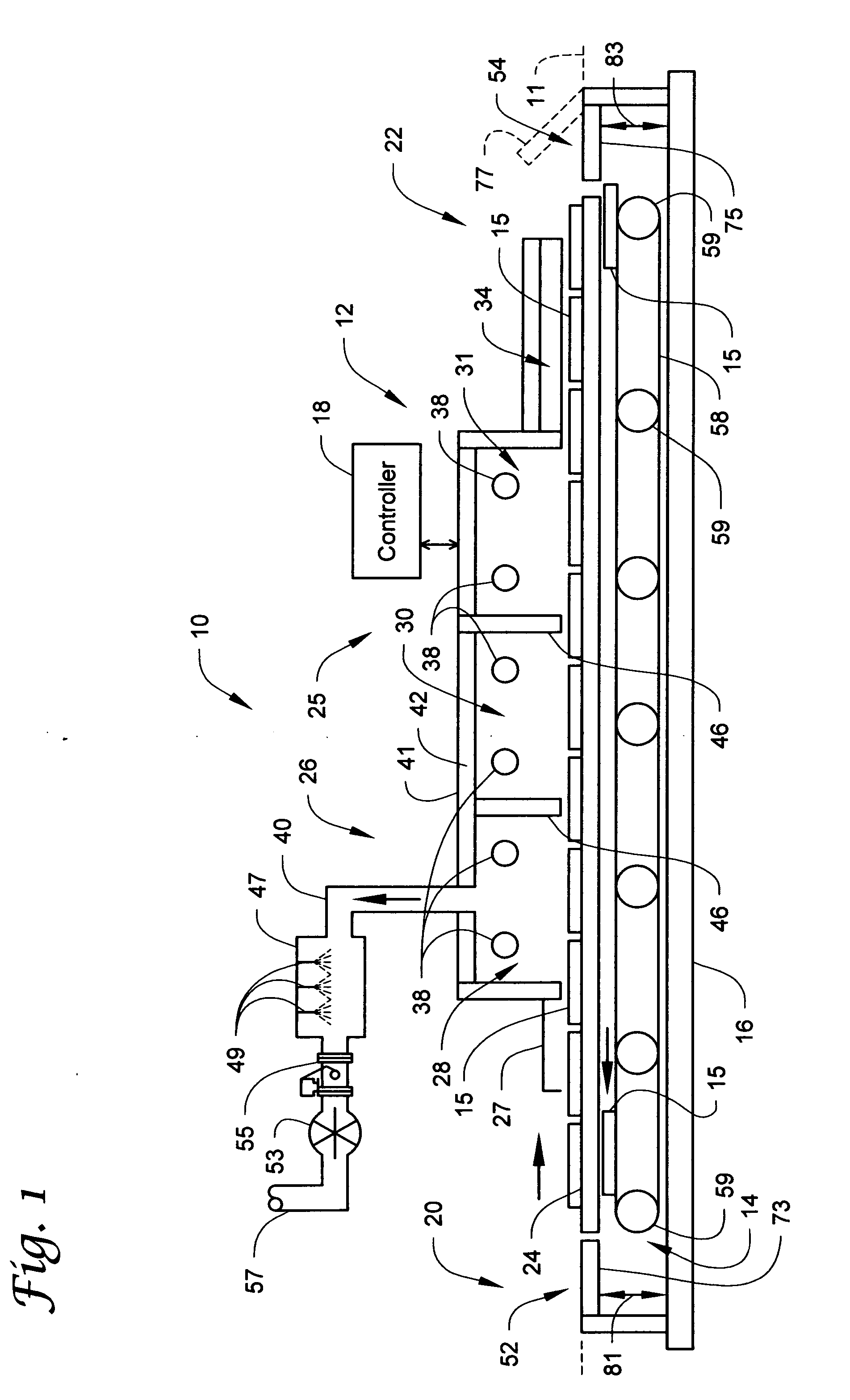

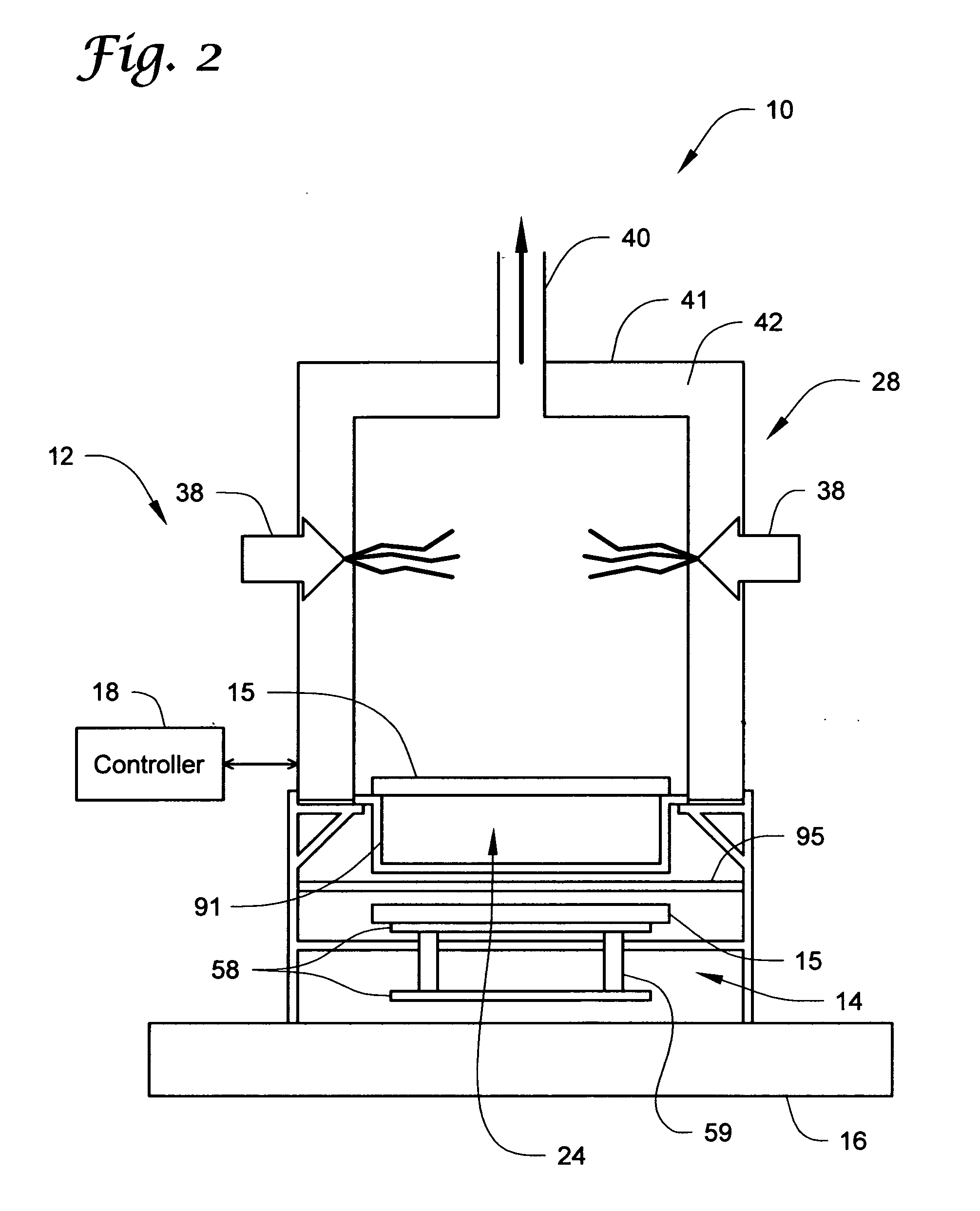

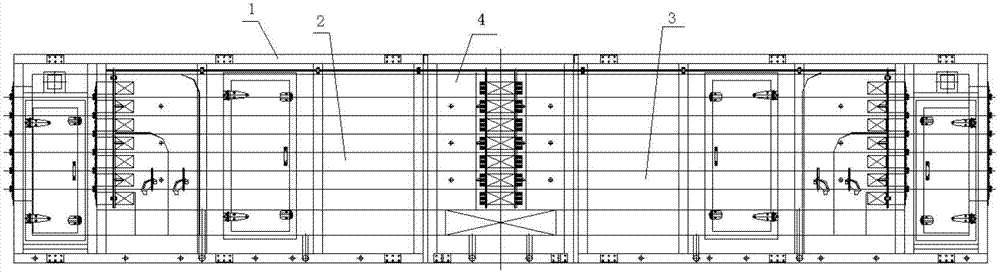

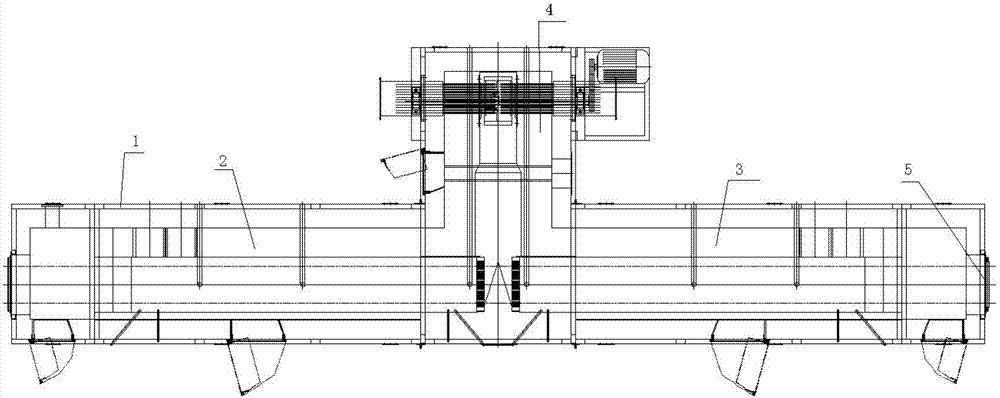

Linear hearth furnace system and methods regarding same

Systems and methods for use in processing raw material (e.g., iron bearing material) include a linear furnace apparatus extending along a longitudinal axis between a charging end and a discharging end (e.g., the linear furnace apparatus includes at least a furnace zone positioned along the longitudinal axis). Raw material is provided into one or more separate or separable containers (e.g., trays) at the charging end of the linear furnace apparatus. The separate or separable containers are moved through at least the furnace zone and to the discharging end where the processed material is discharged resulting in one or more empty containers. One or more of the empty containers are returned to the charging end of the linear furnace apparatus to receive further raw material.

Owner:NU IRON TECH LLC

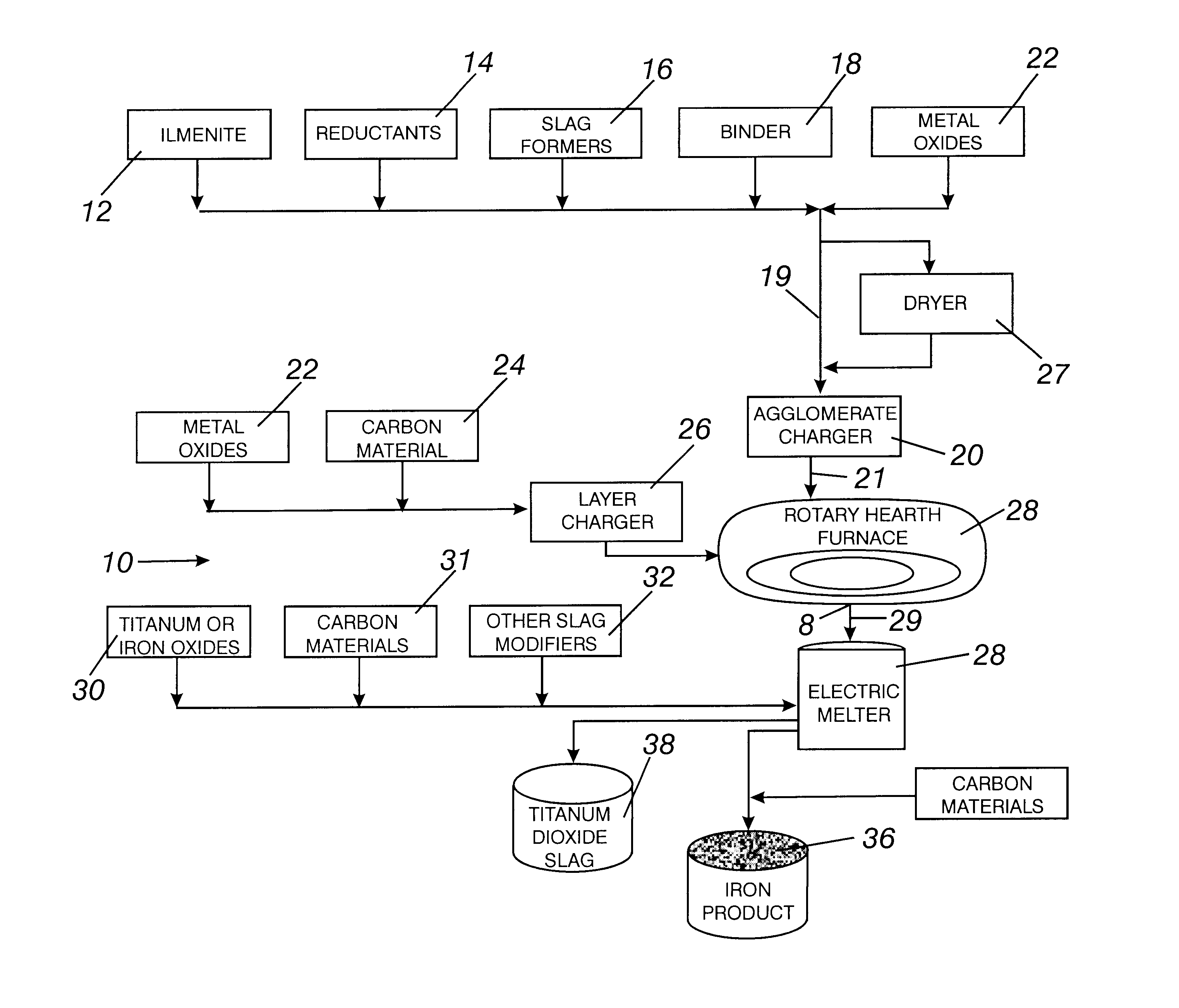

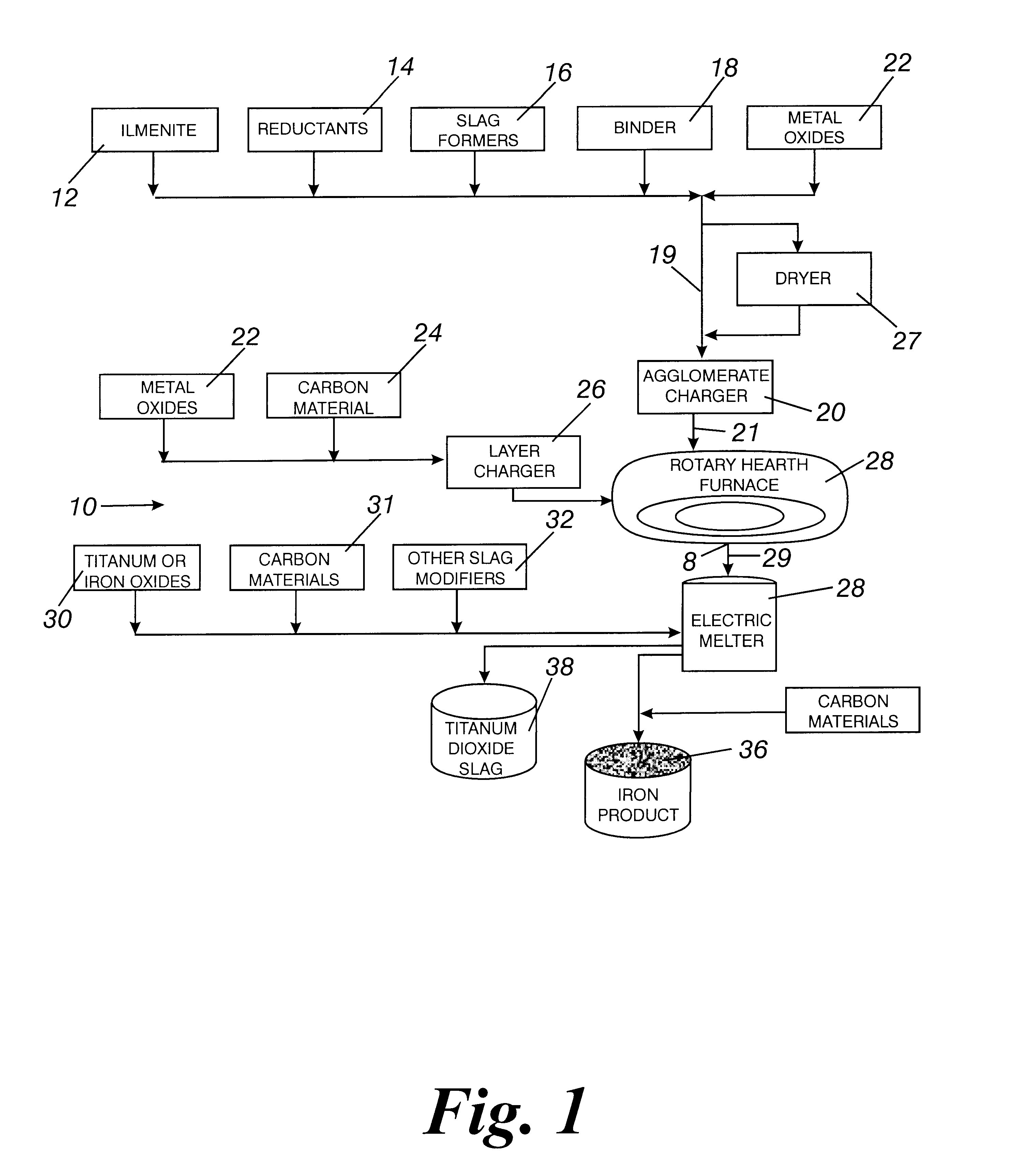

Method for producing beneficiated titanium oxides

The invention is a method and apparatus for producing beneficiated titanium oxides using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced agglomerates. The pre-reduced agglomerates is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Fluid slag and molted iron forms melted agglomerates. The fluid slag is rich in titanium. The melted agglomerates are cooled, and then the melted agglomerates and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the melted agglomerates from the hearth conditioner. The hearth conditioner is recycled, and the melted agglomerates are prepared for sale or for additional treatment in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:MIDREX TECH INC

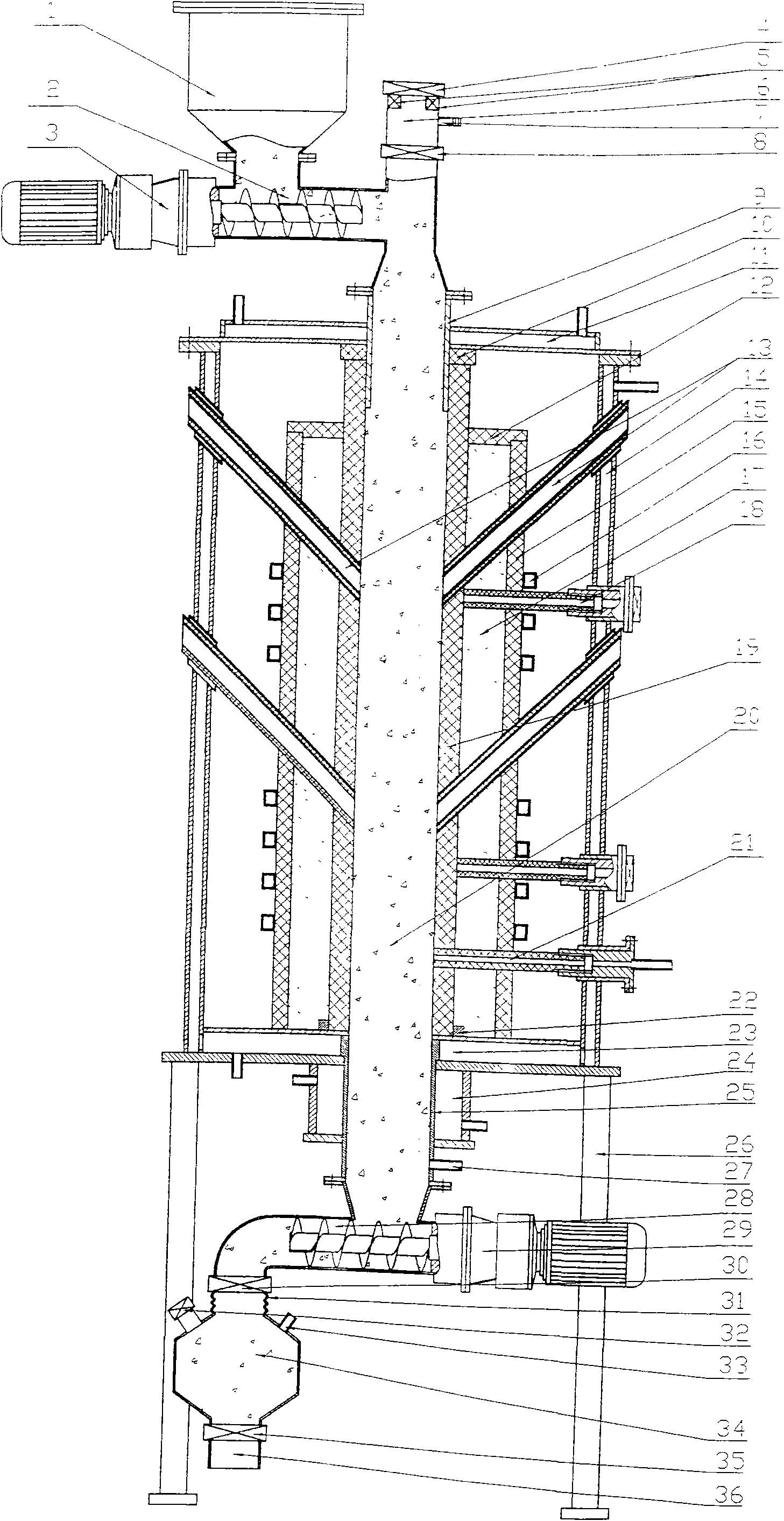

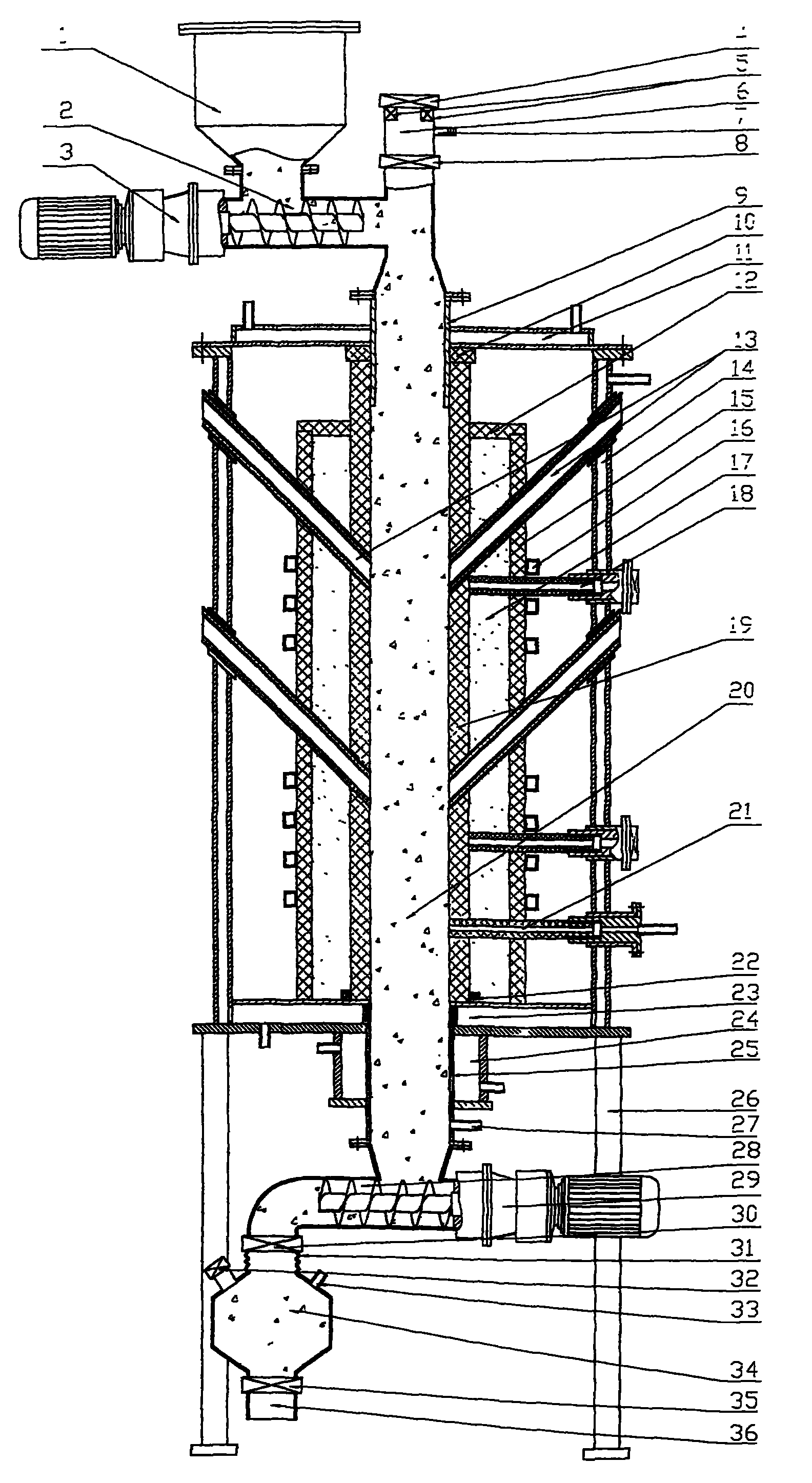

Graphite purification and graphitizable high temperature vertical continuous induction heating furnace

The invention relates to a graphite purification and graphitizable high temperature vertical continuous induction heating furnace, comprising a furnace body, a hearth, an induction heating coil, an observation window device, a material inlet device, a material outlet device and the like. The heater furnace is in a vertical structure and adopts a continuous working mode and induction heating; the highest use temperature is 3000 DEG C; the hearth is a cylindrical space, the material inlet device is connected above the hearth while the material outlet device is connected below the hearth; the materal enters into the hearth under the coordinated action of the material inlet device and the material outlet device, falls down and passes through the hearth at an even speed; ash content and volatile matter content in the material are changed into volatile substances under the action of hearth temperature and purified gas in the temperature environment; and the volatile substances are discharged out of the furnace from a discharge pipe under the action of high temperature reaction pressure and scavenge gas, thus realizing continuous purification or continuous graphitizable process by one step. The induction heating furnace can make up for the insufficiencies of hydrofluoric acid wet process purification, and is characterized by high efficiency, low energy consumption and environment protection.

Owner:株洲弗拉德科技有限公司

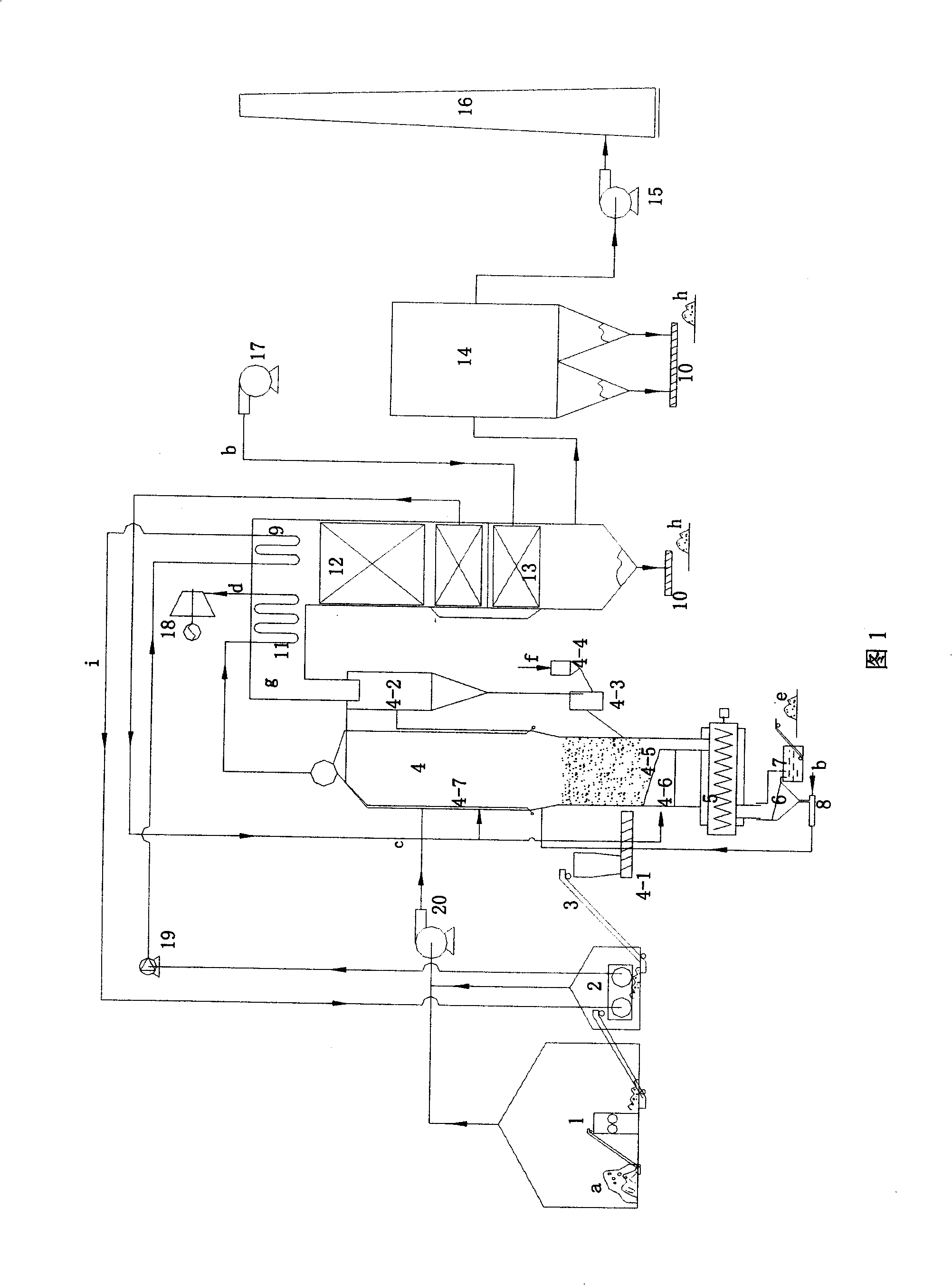

City life rubbish fluidized bed gasification combustion processing method

InactiveCN101294708ASafe and stable operationImprove securityAir supply regulationIndirect carbon-dioxide mitigationSlagHearth

The invention is a fluid bed gasification and combustion processing method for urban garbage. The hearth of a fluid bed garbage furnace (4) is composed of two parts of a low temperature gasification area and a high temperature combustion area, additives (f) such as limestone, kaolin, etc. are added to the garbage furnace (4); acid gases such as chlorine, sulfur, nitrogen, etc. are removed in the furnace; and the generation of dioxin is controlled in the furnace. A water cooling spiral slag cooler (5) and a vibration sieve (6) can be utilized to efficiently reduce heat loss of slag and recycle bed materials. The whole system requires no addition of auxiliary fuel, and has the characteristics of safe reliability, no odor emission, low investment and operating cost, less secondary pollutant discharge, high power generation efficiency, etc.

Owner:SOUTHEAST UNIV +1

Detection method and device of coke reactivity and post-reaction heat-treatability

ActiveCN101825548AAppear thermal characterizationWeighing by removing componentThermometers using electric/magnetic elementsHearthEngineering

The invention discloses a detection method and device of the reactivity and post-reaction heat-treatability of coke and the method and device are used to detect the gasifying starting temperature, reactivity and post-reaction heat-treatability of coke. The detection method adopts an electric furnace as a heating furnace and uses an electronic balance for to weight. The reactivity detection method is performed on the condition of first heating and second keeping temperature constant, the electronic balance is used to measure the mass loss of a coke sample; and when the coke weight-loss ratio equals a specified value, the measurement weight-loss ratio (time) minus one is used as the reactivity index; the detection method of the post-reaction heat-treatability of coke is that when the coke weight-loss ratio equals the specified value, coke is continuously heated under the protection of inert gas, and the coke weight-loss ratio is used as the post-reaction heat-treatability index during the detection period of heat treatment. The detection device comprises the electronic balance, a reaction tube support, a reaction tube, the heating furnace and a heating furnace elevating mechanism. The method and device of the invention can provide 1500-1600 DEG C of detection temperature and the coke thermal characterization in the bosh (before an air port) and the hearth can be displayed.

Owner:山西今日太工煤焦技术研究有限公司

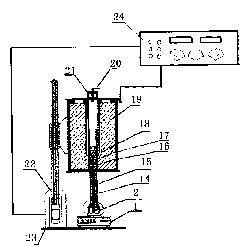

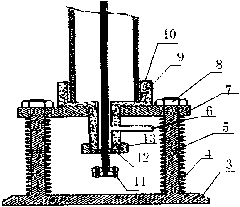

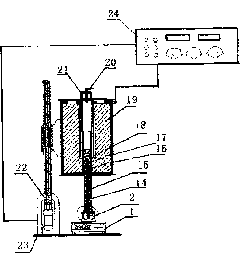

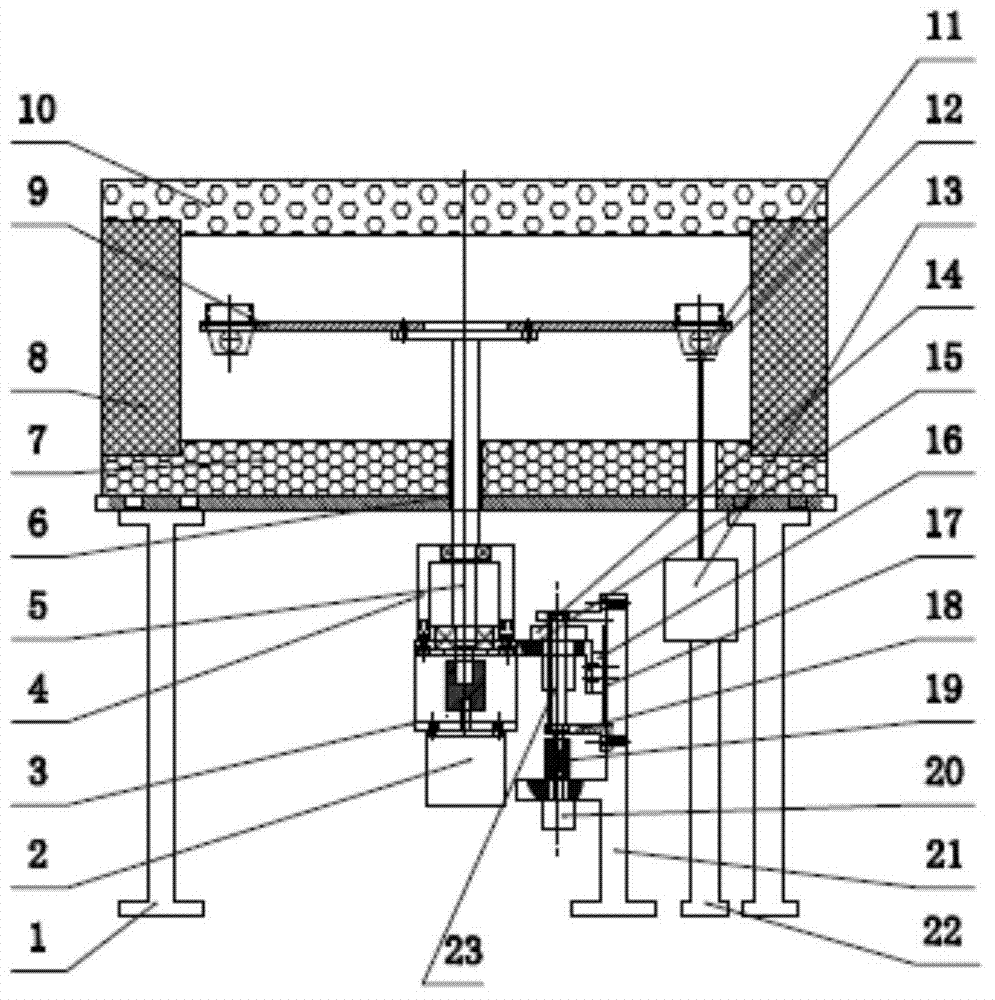

Equipment capable of automatically testing moisture of bituminous coal

The invention discloses equipment capable of automatically testing moisture of bituminous coal. The equipment comprises two main brackets, a bottom plate, a lower fiber plate, a hearth, an upper fiber plate, a turn plate, a rotating shaft, a secondary bracket, an elevating rack, a U-shaped rack, a motor rack, a rotating motor, two bearing brackets, a ball screw, a balance, a weighing lever, a guide block and a slide block, wherein the lower fiber plate is assembled on the bottom plate; the weighing lever is assembled on the balance. The equipment capable of automatically testing moisture of bituminous coal is high in automatic degree, high in work efficiency and convenient to operate.

Owner:CHANGZHOU UNIV

Monitoring, prediction and alarm system for blast furnace hearth and bottom

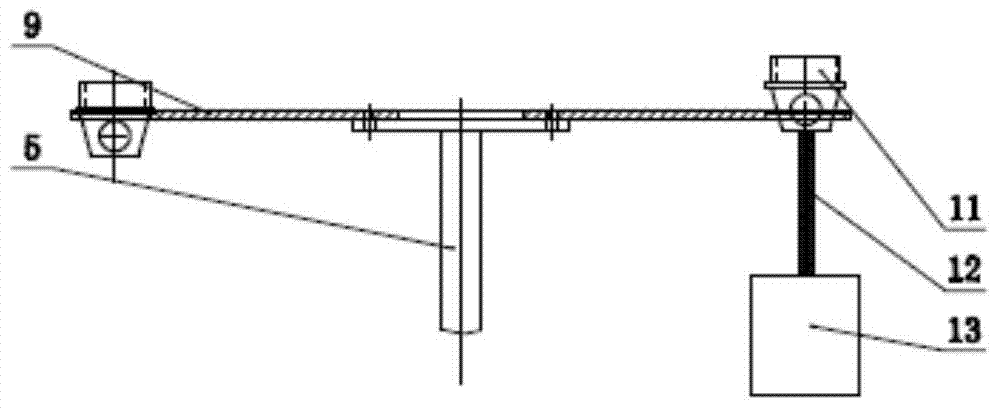

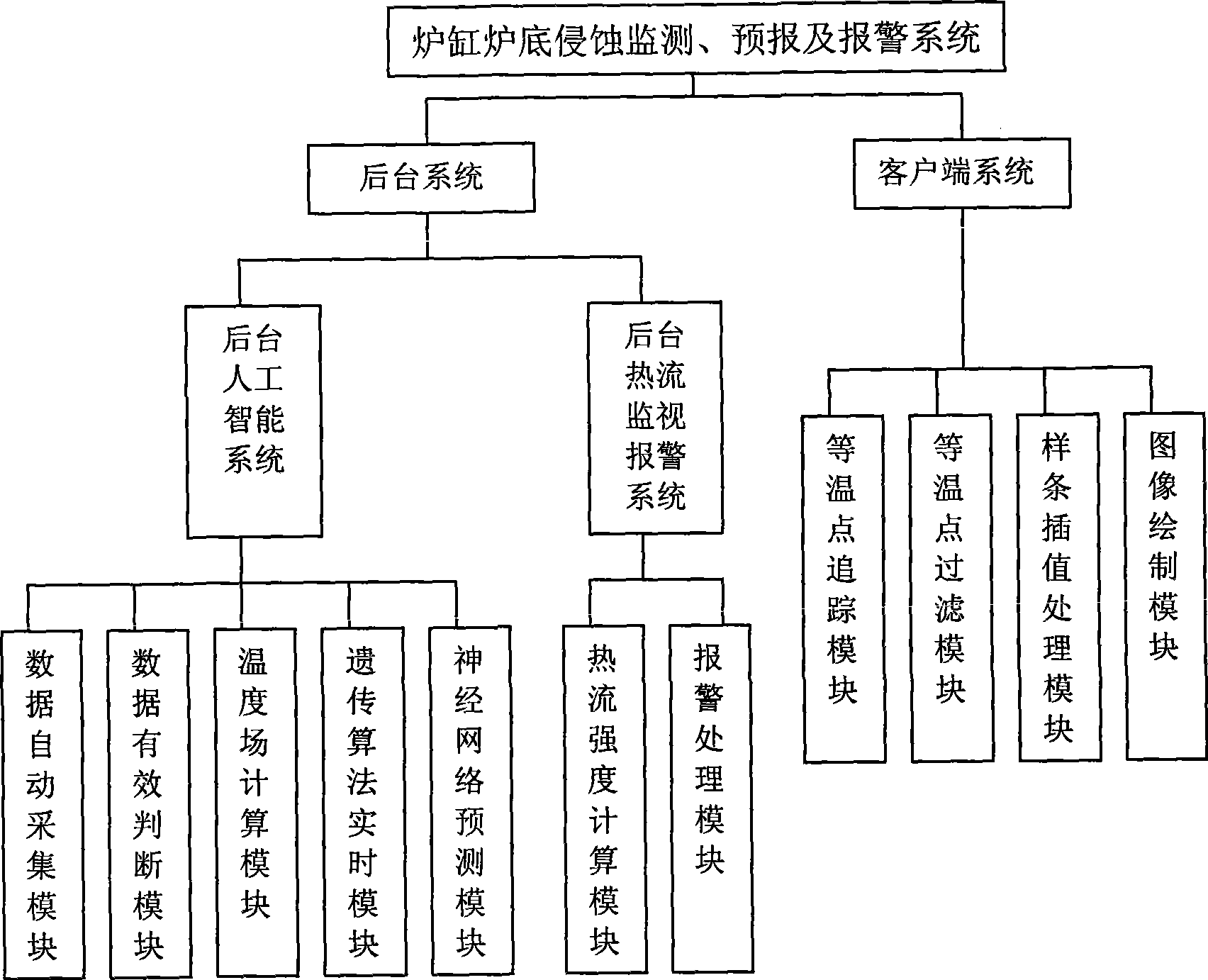

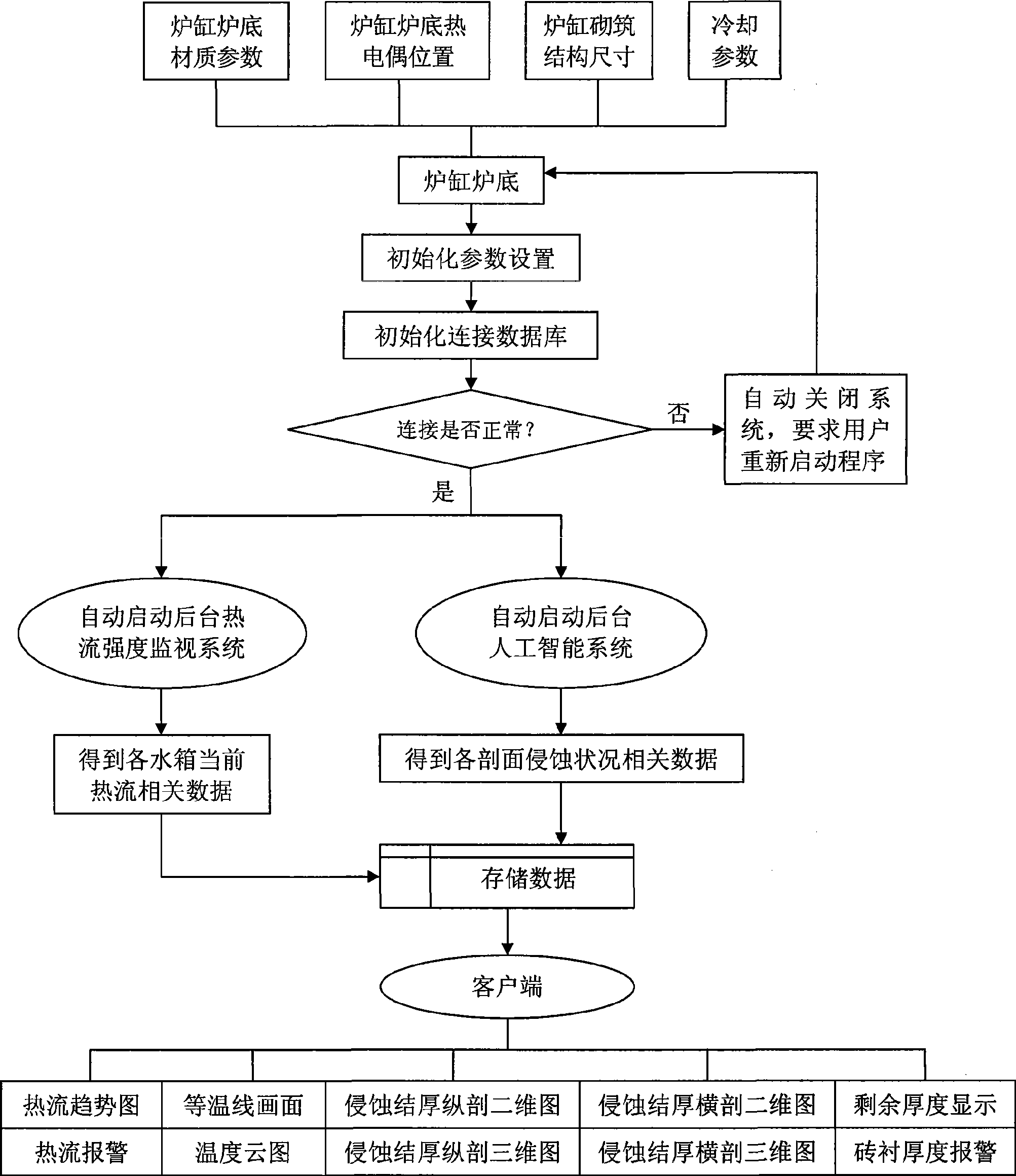

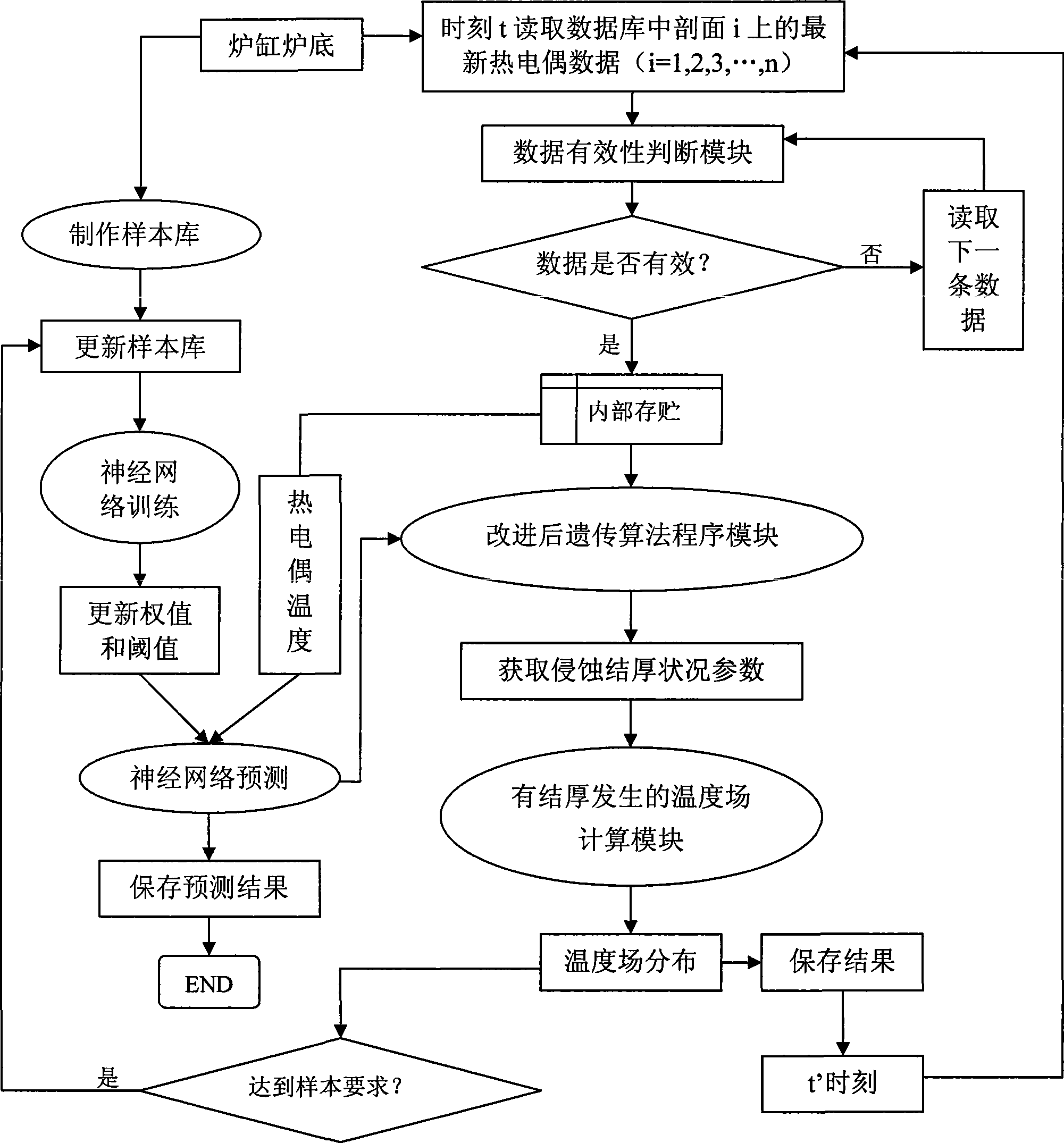

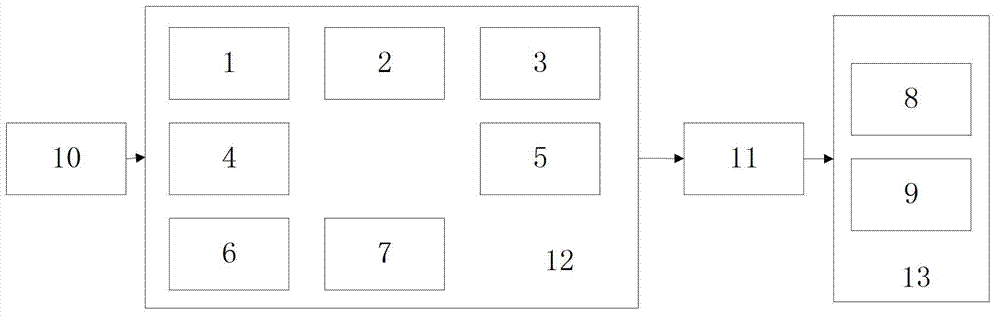

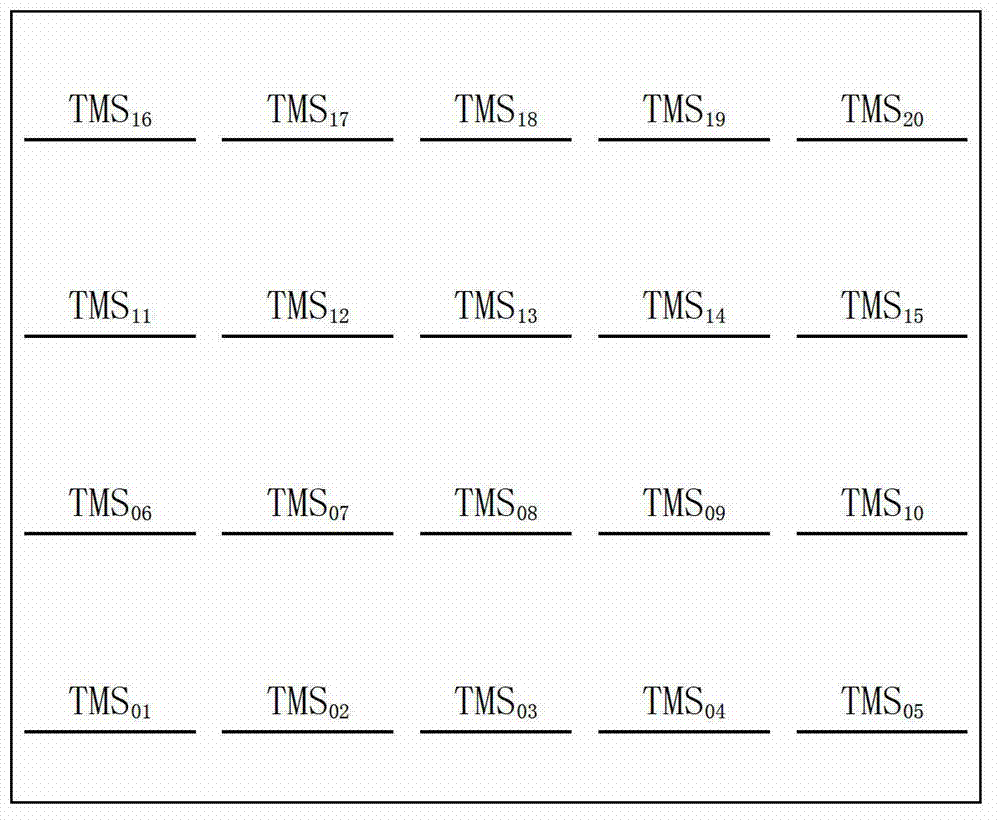

InactiveCN101457268ARealize online monitoring and alarmImplement storageThermometers using electric/magnetic elementsUsing electrical means3d imageData acquisition

A monitoring, forecasting and alarm system of the bottom and hearth of a blast furnace belongs to the longevity technical field of blast furnaces. The system comprises online monitoring and forecasting hardware and software processing modules; the online monitoring and forecasting hardware consists of a thermocouple and a cooling system which are laid at the furnace hearth and the furnace bottom, and a database of the blast furnace production process is connected by the Ethernet; the software processing modules comprise a data acquisition module, a data validity judgment module, a temperature field computation module, an improved genetic algorithm module, a B-P neural network module, a database, an isotherm, an erosion and thickening image display module, a 3D imaging module, a heat flow monitoring and alarm module and a historical data query module; and the software processing modules are operated on an industrial control computer. The monitoring, forecasting and alarm system has the advantages of low investment, reliability and visualization. The system provides an objective and quantized basis for the erosion and thickening erosion condition of the furnace hearth and the furnace bottom in the blast furnace ironmaking process, and helps a blast furnace operator timely know the condition of the furnace hearth and the furnace bottom and take effective furnace protection measures so as to prolong the service life of the blast furnace.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

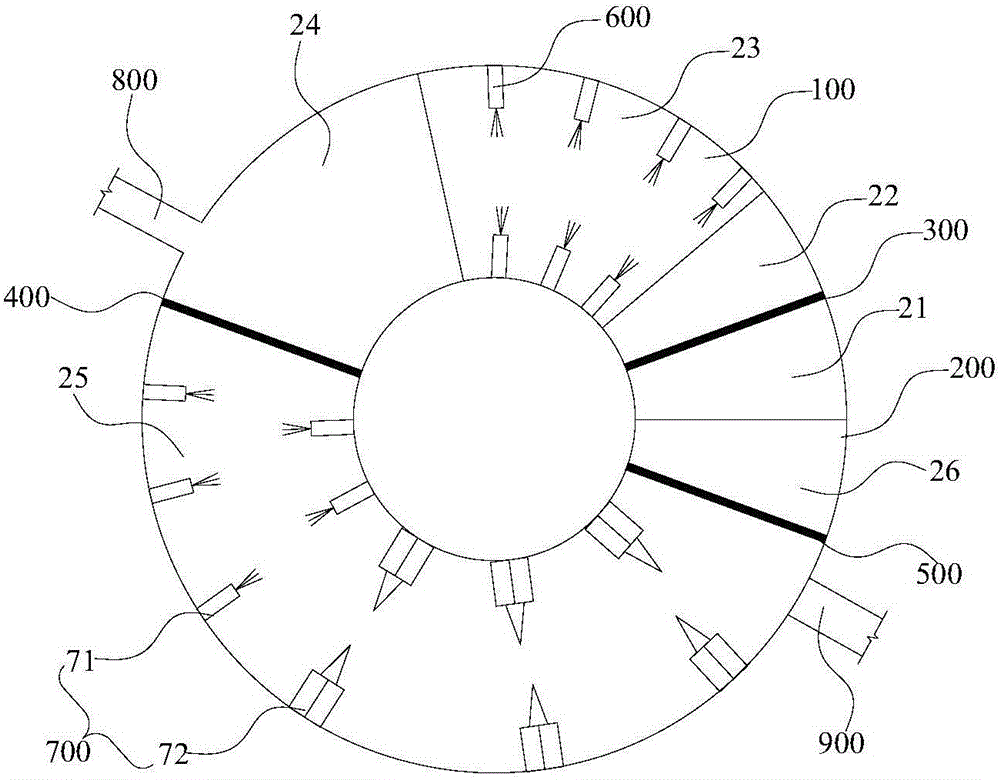

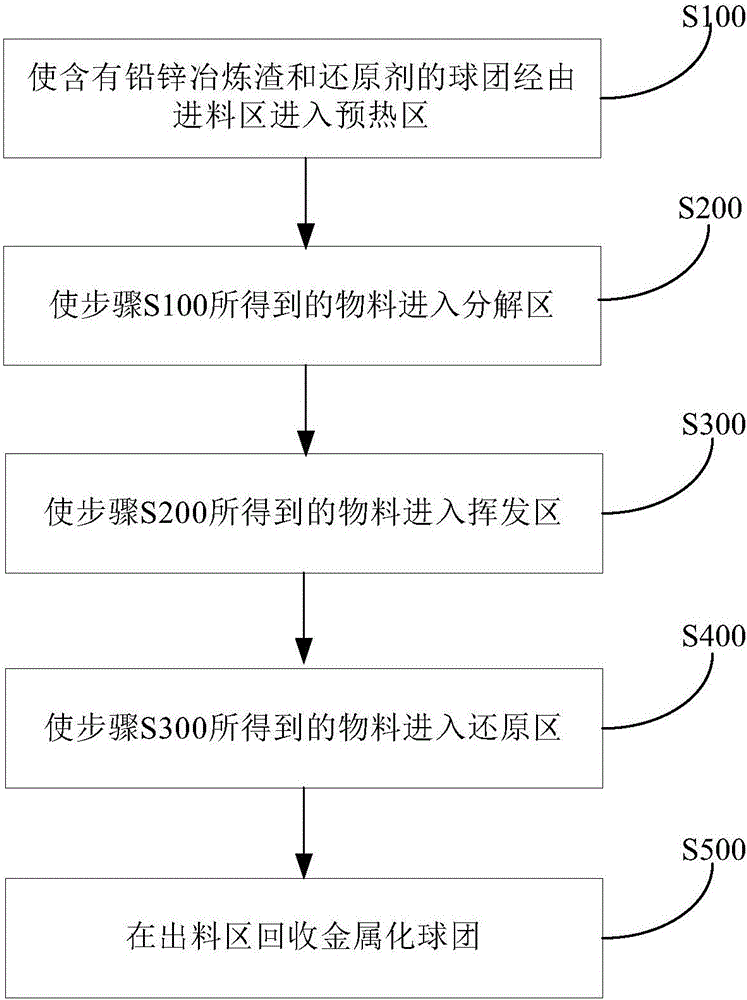

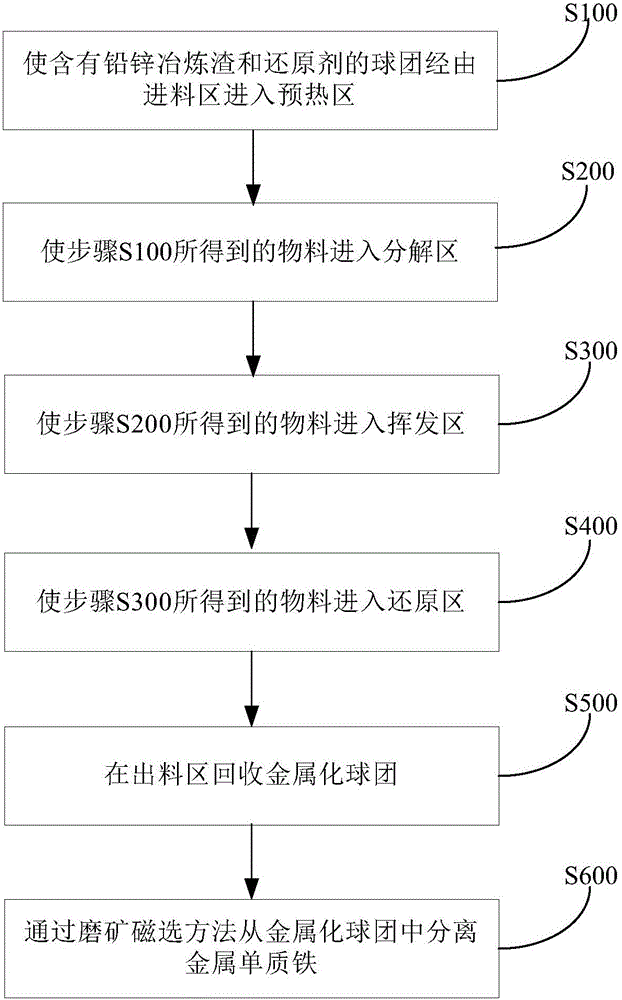

Rotary hearth furnace and method for treating lead and zinc smelting slag

ActiveCN105671328ASolve the problem that cannot be comprehensively recycledAchieve recyclingProcess efficiency improvementIndiumSulfur

The invention discloses a rotary hearth furnace and method for treating lead and zinc smelting slag. The rotary hearth furnace comprises a rotatable furnace bottom, an annular hearth, a first partition, a second partition, a third partition, a first heating unit and a second heating unit. A smelting space is defined in the annular hearth, and the smelting space is divided into a feeding area, a preheating area, a decomposing area, a volatizing area, a reducing area and a discharging area in sequence according to the entering areas of materials in the circumferential direction of the annular hearth. The first partition is arranged between the feeding area and the preheating area. The second partition is arranged between the volatizing area and the reducing area. The third partition is arranged between the reducing area and the discharging area. The first heating unit is arranged in the decomposing area. The second heating unit is arranged in the reducing area. The rotary hearth furnace can solve the problem that valuable elements in lead and zinc smelting slag in the prior art cannot be comprehensively recycled, and in addition, valuable elements such as iron, lead, zinc, indium and sulfur in the lead and zinc smelting slag can be recycled in the same device.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Process and apparatus for producing metallic glass

InactiveUS20020100573A1Simple processGood strength performanceFoundry mouldsFoundry coresHigh energyAlloy

A process and an apparatus for producing metallic glass which are capable of producing a bulk amorphous alloy of desired shape, in particular, a bulk amorphous alloy of desired final shape are provided. In the present invention, the molten metal at a temperature above the melting point is selectively cooled at a rate higher than the critical cooling rate, and the product comprises single amorphous phase which is free from the crystalline phase formed by the development of crystal nuclei through nonuniform nucleation. The present invention is capable of producing the bulk amorphous alloy which is free from casting defects such as cold shuts and which has excellent strength properties in a simple process at a high reproducibility. Accordingly, a bulk metallic glass of desired shape is produced by filling a metal material in a hearth; melting the metal material by using a high-energy heat source which is capable of melting the metal material; pressing the molten metal at a temperature above the melting point of the metal material to deform the molten metal into the desired shape by at least one of compressive stress and shear stress at a temperature above the melting point, while avoiding the surfaces of the molten metal cooled to a temperature below the melting point of the metal material from meeting with each other during the pressing; and cooling the molten metal at a cooling rate higher than the critical cooling rate of the metal material simultaneously with or after the deformation to produce the bulk metallic glass of desired form.

Owner:MAKABE GIKEN

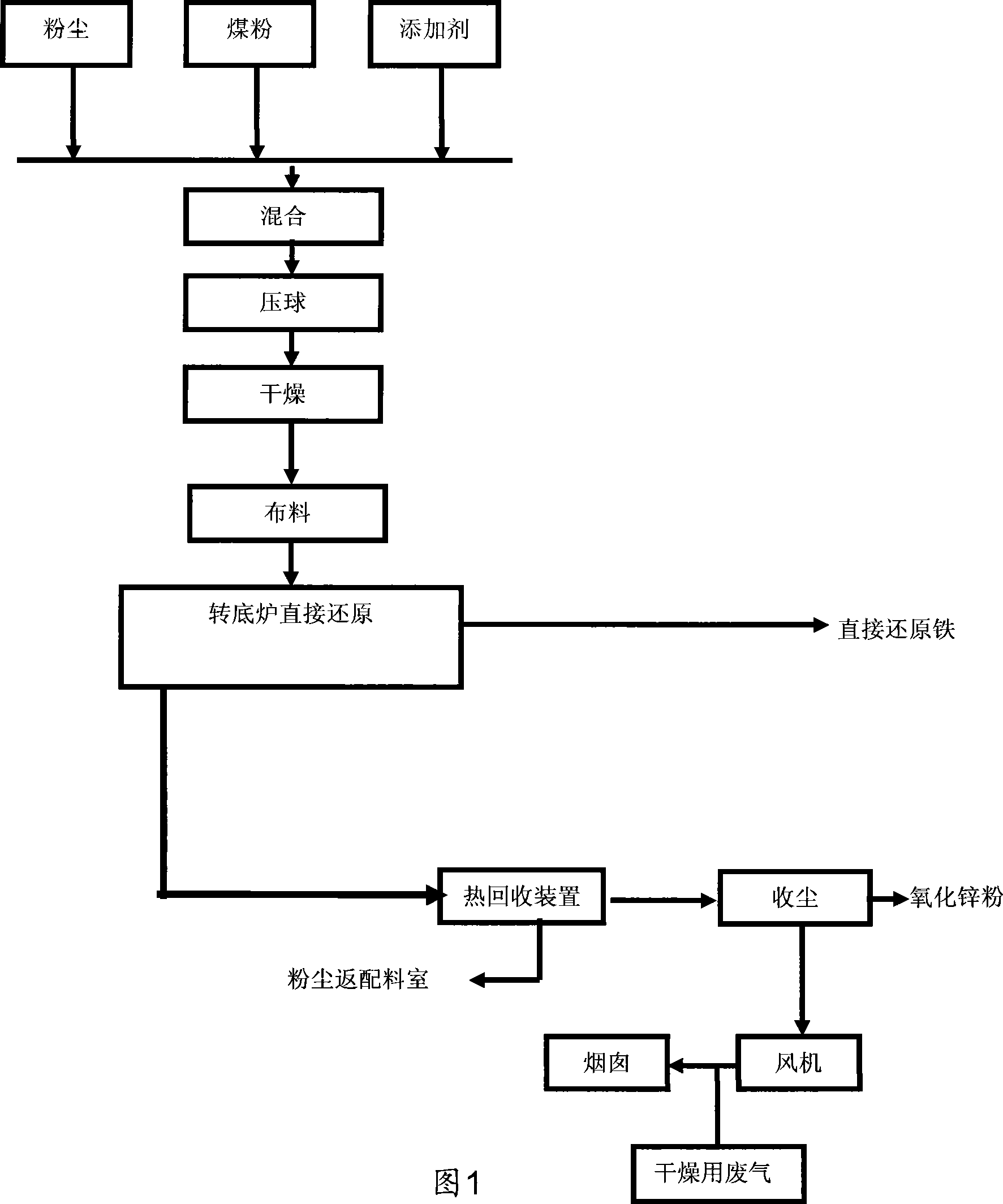

Method for recovering zinc oxide in Zn-containing dust treatment by rotary hearth furnace

The invention discloses a method for reclaiming zinc oxide in treating zincky powder dust in a rotary hearth furnace. The zincky powder dust, coal and flux are mixed, then are subjected to briquetting and drying, are transported to the rotary hearth furnace and are subjected to direct reduction; zinc in the powder dust is reclaimed from exhaust gas; and a feed block of which zinc is removed is directly reduced through the rotary hearth furnace and is subjected to cooling or briquetting for use. The method has wide applicability to zincky materials, can farthest utilize resource reasonably, has low requirement on the thermal value of fuels, high temperature of flue gas and high zinc extraction rate; and the treated powder dust is changed into direct reduced iron for comprehensive utilization.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

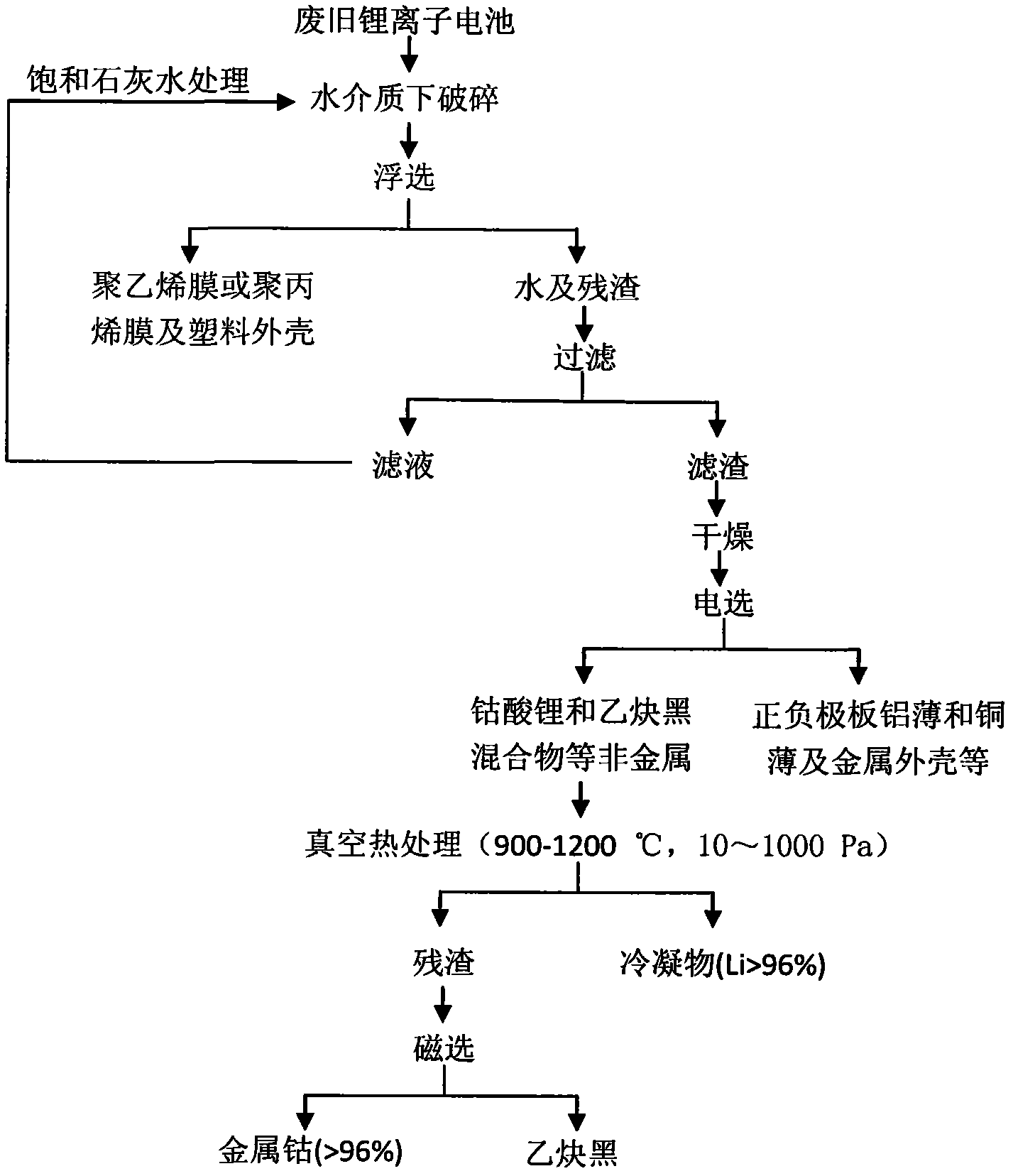

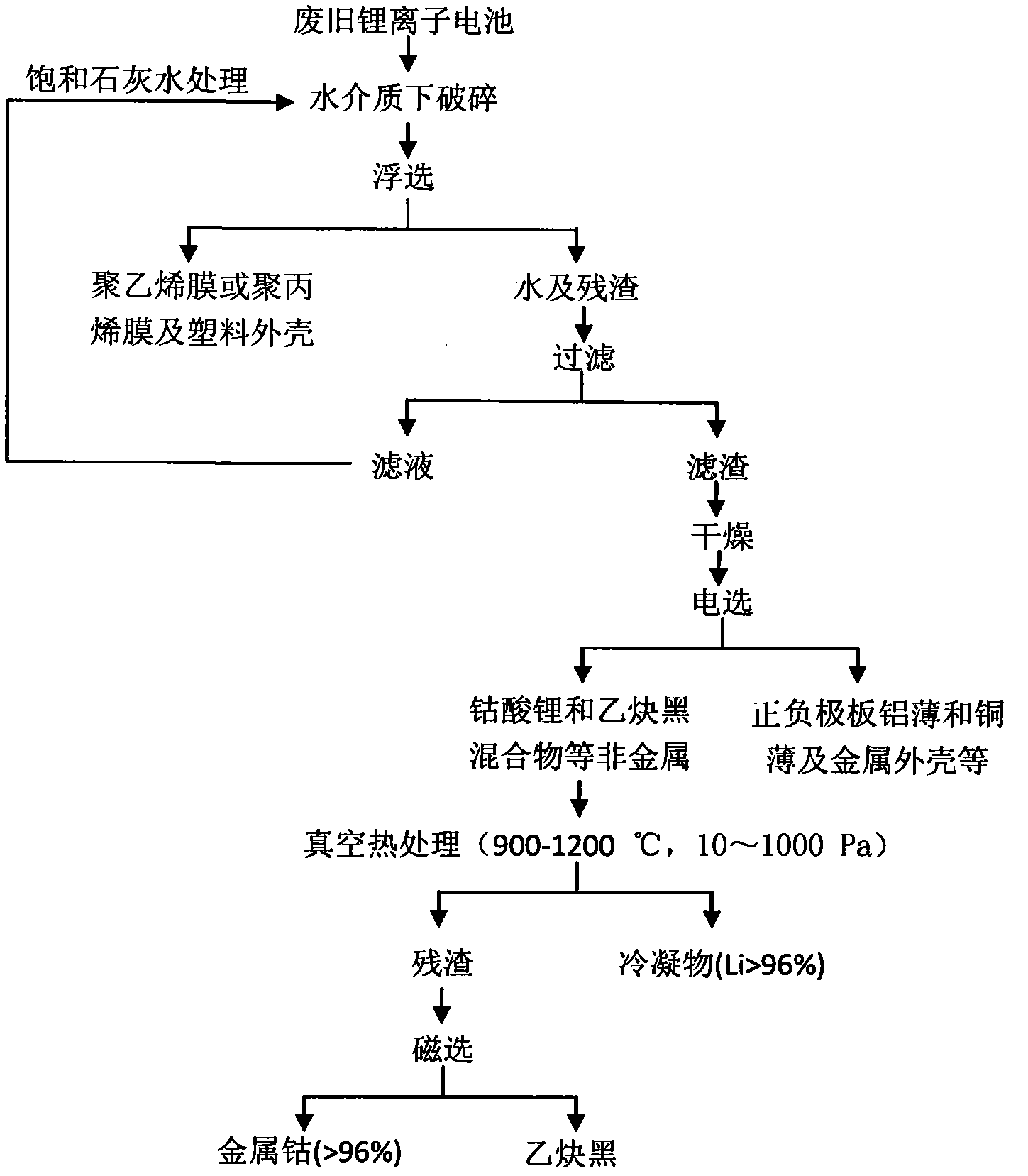

Novel high-efficient comprehensive utilization method for recycling waste lithium-ion battery

InactiveCN102637921AImprove recycling efficiencySimple processSolid waste disposalWaste accumulators reclaimingElectrical conductorHearth

The invention discloses a novel high-efficient comprehensive utilization method for recycling a waste lithium-ion battery, comprising three steps, namely a pretreatment step, a separation step and a vacuum thermal treatment step, wherein the pretreatment specifically comprises the following steps of: crushing the waste lithium-ion battery in a water medium by utilizing a shear type crusher, and peeling off positive-negative electrode materials from a polar plate; the separation step specifically comprises the following steps of: separating and recovering a polyethylene film or a polypropylene film, a plastic shell and the like floating on the surface of the water medium according to different densities of all components in the waste lithium-ion battery, filtering, treating the filtrate and recycling; and the vacuum thermal treatment step specifically comprises the following steps of: placing the nonconductor waste lithium-ion battery positive-negative electrode materials, namely lithium cobaltate and acetylene black obtained by the separation process, in a material boat or a hearth directly to carry out vacuum thermal treatment. The novel high-efficient comprehensive utilization method disclosed by the invention has the advantages of simple flow process and high recovery efficiency, no need of a reducing agent and no secondary pollution.

Owner:SOUTHWEAT UNIV OF SCI & TECH

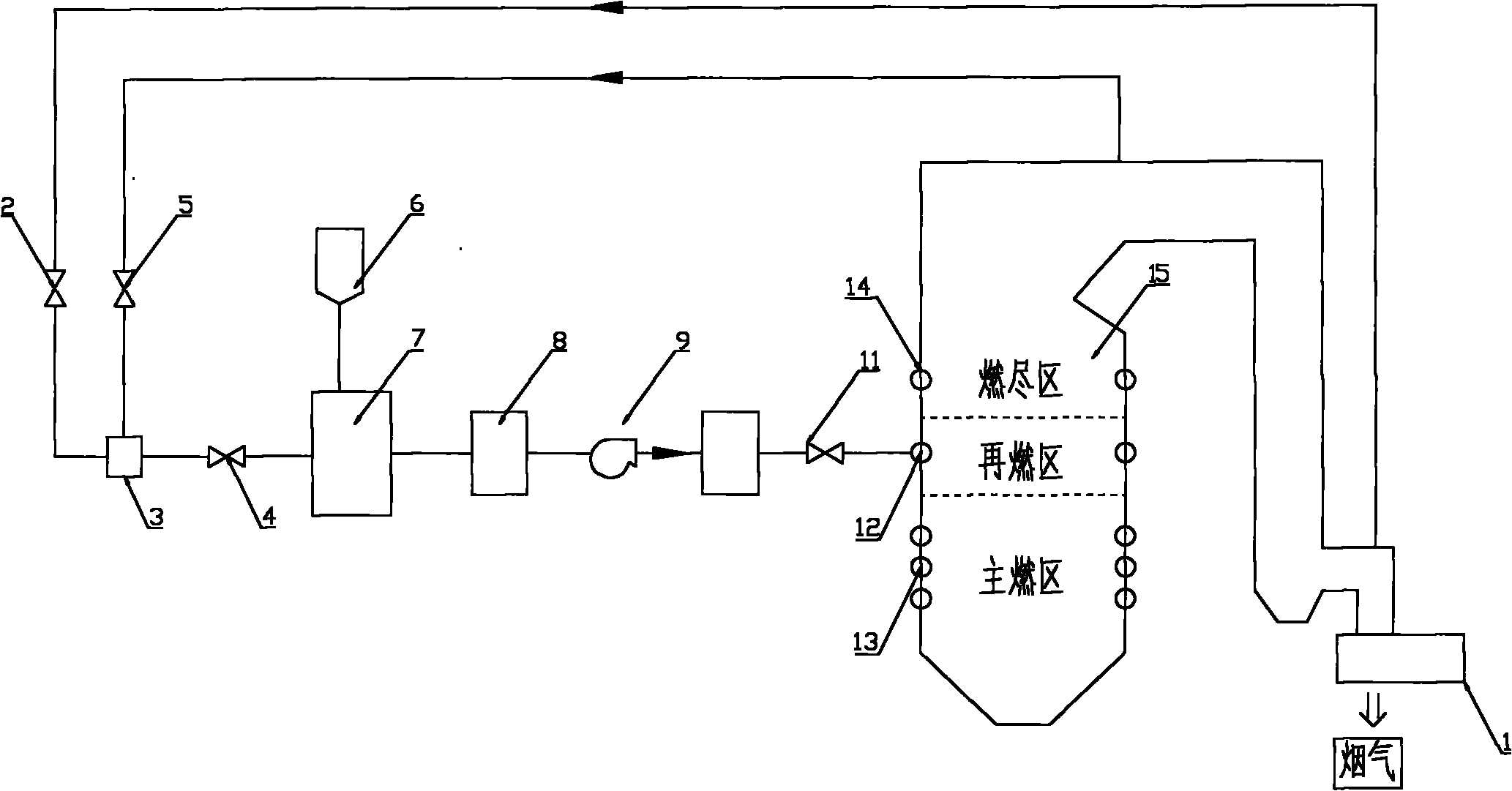

Biomass high-temperature flue gas gasification combination coal burning boiler and low-pollution combustion method thereof

ActiveCN101865451AReduce tar contentReduce contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHearthPollution

The invention belongs to the technical field of a coal burning boiler and particularly relates to a biomass high-temperature flue gas gasification combination coal burning boiler and a low-pollution combustion method thereof. Flue gas serving as a gasification agent enters a gasification furnace; a biomass to be gasified in a biomass bin also enters the gasification furnace; gasified biomass fuel gas enters a fuel gas purification chamber to be subjected to primary purification to remove H2S, HCl and oil tar impurities; after a pressure head of the purified biomass fuel gas is improved by a booster fan, the purified biomass fuel gas enters a fuel gas storage tank and then enters a hearth of the coal burning boiler by a fuel gas nozzle to be burnt; the content of the biomass in the total glue gas is in the range of 0 to 30 percent and the whole system can still operate stably. The use of the biomass effectively reduces discharge of CO2 and SO2. The high-temperature flue gas is used as a heat source to gasify the biomass so as to reduce the content of the oil tar in the biomass fuel gas. The generated biomass fuel gas has high CO2 concentration. The reducing effect of the fuel gas on NOX is far superior to that of the biomass solid on NOX. The NOX concentration is effectively reduced.

Owner:ZHEJIANG GUANGHAN ENVIRONMENTAL PROTECTION TECH

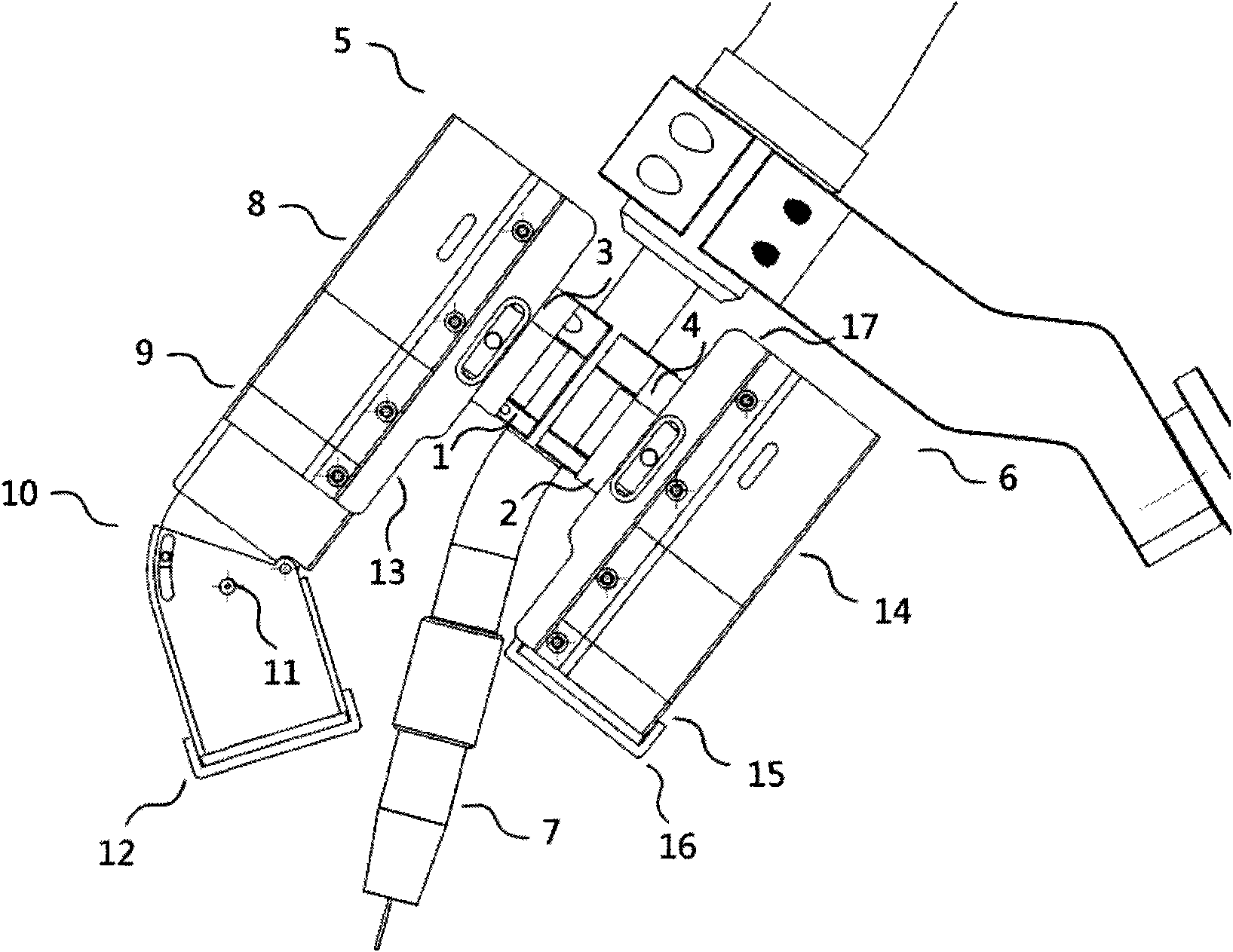

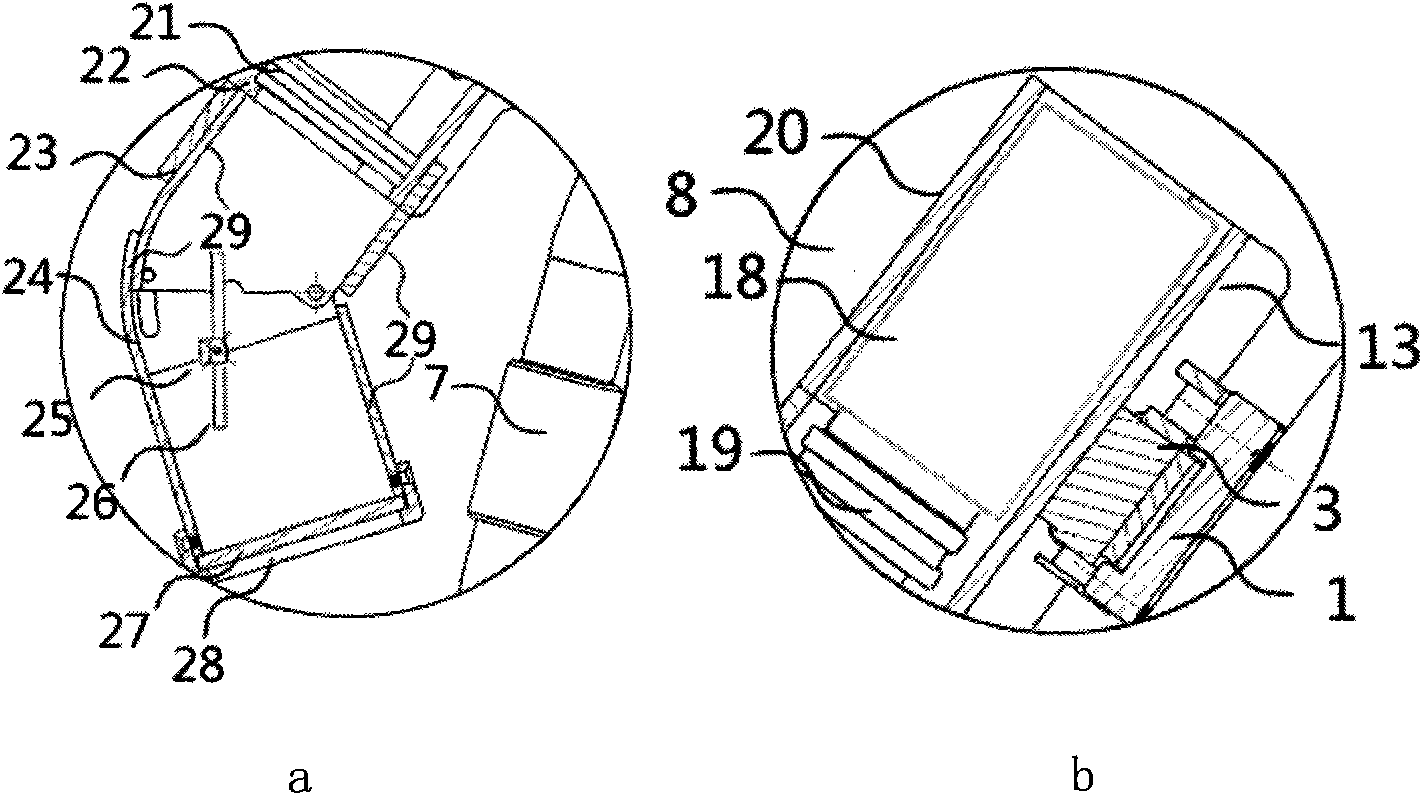

Robot MIG welding binocular vision sensing system

InactiveCN101612736AReduce bearing pressureImprove versatilityPrintersProjectorsComputer moduleHearth

A robot MIG welding binocular vision sensing system in the technical field of automated welding equipment comprises two welding torch fixed sleeves, two sensor sleeve connection blocks, a furnace hearth observation module and a seam tracking module; wherein the furnace hearth observation module and the seam tracking module are respectively fixed on the respective welding torch fixed sleeve and are respectively connected with the two sensor sleeve connection blocks, the sensor sleeve connection blocks are arranged on the welding torch fixed sleeves in a rotary way, and the welding torch fixed sleeves are fixedly connected with an MIG welding torch. The invention obtains clear images by adjusting the angle between a sensor main module and the welding torch as well as the angle between a reflector assembly and the sensor main module, and ensures the welding quality by weld penetration control.

Owner:SHANGHAI JIAO TONG UNIV

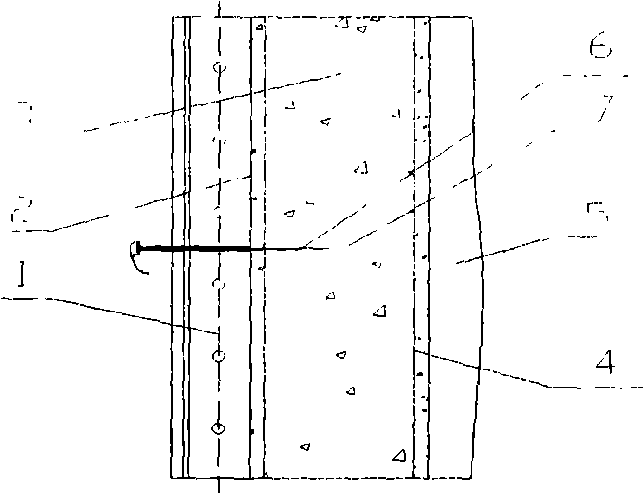

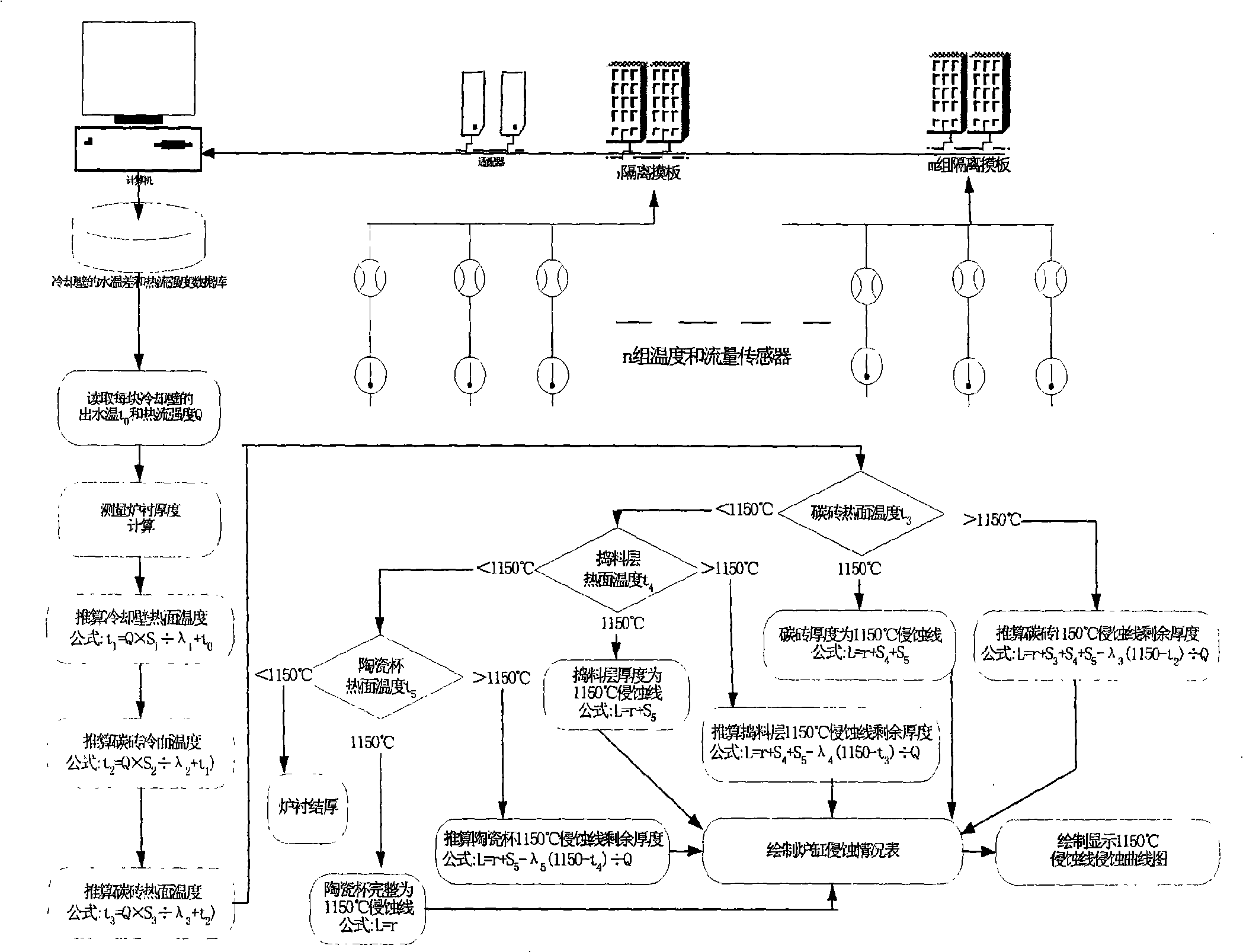

Method for measuring blast furnace lining corroding thickness

InactiveCN101275829ASmooth renderingLarge reckoning coverageThermometers using electric/magnetic elementsUsing electrical meansCold sideHeat flow

The invention relates to a method for measuring corrosion thickness, especially a method for measuring corrosion thickness of blast furnace lining, aiming to solve technical problems that the bull couple can not cover circumferential direction when being previously embedded in blast furnace hearth causing large limitation for calculating corrosion thickness of blast furnace hearth according to the couple detecting data. A method for measuring corrosion thickness of blast furnace lining, comprising: a, a temperature and flow rate sensor on the cooling wall collects and inputs data into a computer via an isolation baffle and an adaptor, reads flow temperature t<0> and heat flow intensity Q of each cooling wall from the cooling wall water temperature difference and heat flow intensity database, b, measuring the cooling wall heat side temperature according to Fourier formula: t<1>=Q*S<1> / lambda <1>+t<0>; c, measuring carbon brick cold side temperature: t<2>=Q*S<2> / lambda<2>+t<1>; d, measuring carbon brick heat side temperature: t<3>=Q*S<3> / lambda <3>+t<2>, determining position of blast furnace hearth iron solidification corrosion line at 1150 degrees centigrade, and finally surveying and drawing corrosion curve of blast furnace hearth at 1150 degrees centigrade. The invention can automatically measure blast furnace lining corrosion degree in each part of the blast furnace and draw the corrosion curve.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

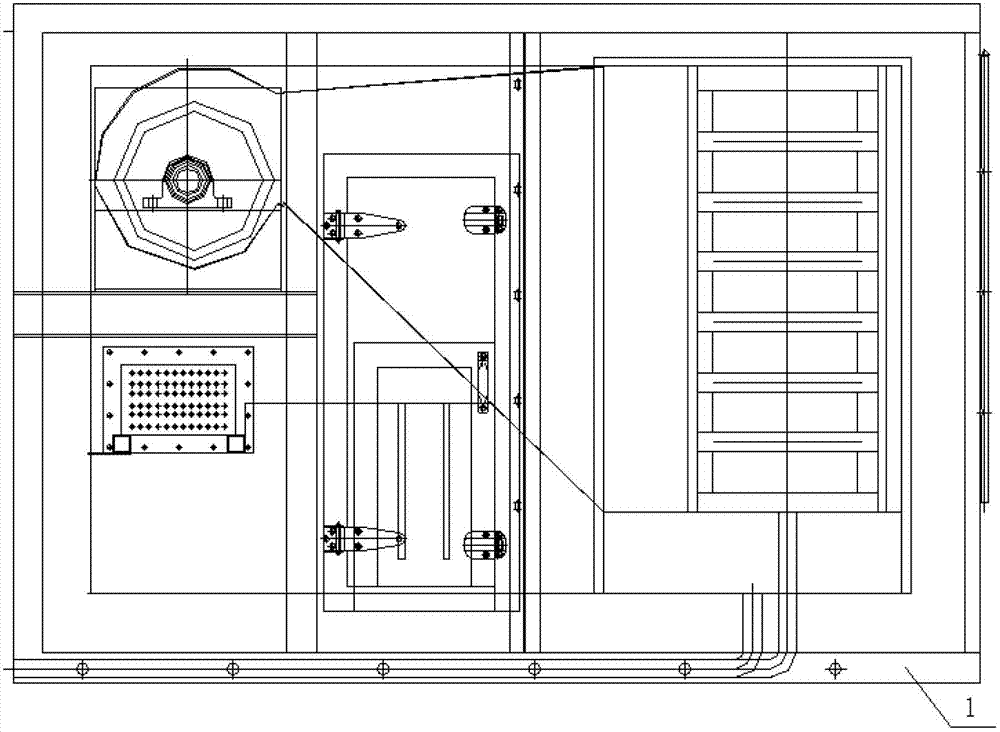

High-performance carbon fiber pre-oxidation furnace

ActiveCN102758270AAvoid burnsPrevention of legitimate discharge problemsFibre chemical featuresFiberCarbon fibers

The invention discloses a high-performance carbon fiber pre-oxidation furnace which is specially designed for carrying out heat treatment on a high-performance carbon fiber material at a temperature below 350 DEG C. A furnace body is designed into a building block structure and is convenient to assemble and disassemble. For the design of the furnace, the requirements of a preparation process of the high-performance carbon fiber material are fully considered and understood and the key special requirements of the preparation process of the high-performance carbon fiber material are met to the greatest extent. According to the requirements of the preparation process of the material, a circulating hot air heating mode is adopted for the pre-oxidation furnace; for a circulating air traveling mode, air is blown to two ends of the furnace body from the middle of the furnace body; and a plurality of heat treatment cavities are connected in series and in parallel to form a system with a certain temperature gradient. An anticorrosion stainless steel structure is adopted for an inner hearth totally; a full-fiber superlight material is adopted as a heat insulating material to carry out heat insulation; a PLC (Programmable Logic Controller) temperature control module is used for temperature control and has the characteristics of high temperature control accuracy, high temperature stability and the like; and according to the pre-oxidation furnace, in a pre-oxidation process, the problems of low heat treatment efficiency, inaccurate temperature control and unideal temperature uniformity in the heat treatment cavities are solved, protofilament combustion is prevented, sufficient supplementation of the oxygen content in the hearth is realized and waste gas is reasonably discharged. The integral high-performance carbon fiber pre-oxidation furnace has relatively low energy consumption and is durable.

Owner:HEFEI RISINE HEATEK

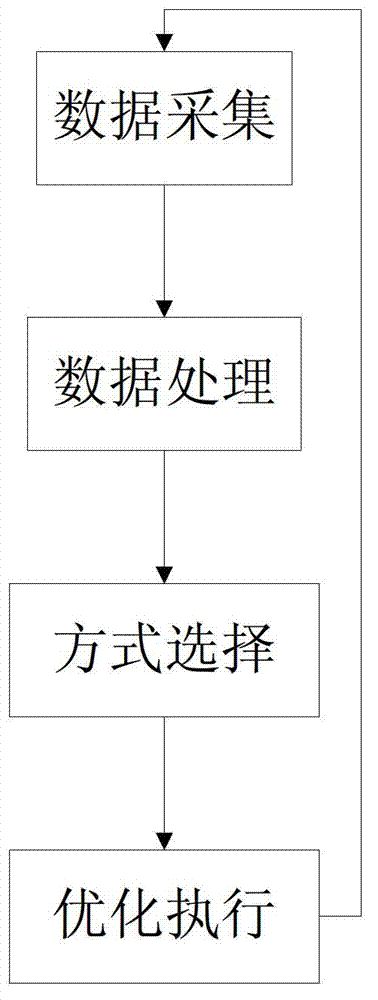

Combustion optimization control system based on acoustically-measured hearth temperature field, and control method thereof

ActiveCN103244964AGuaranteed uptimeImprove emission characteristicsEfficient propulsion technologiesThermometers using physical/chemical changesCombustion systemAuto regulation

The invention discloses a combustion optimization control system based on acoustically-measured hearth temperature field, and a control method thereof. The system comprises a data acquisition device, a data processing device, an operating mode selector module, and an execution instruction output module. A coal quality processing module, a soot blowing mode processing module, an auxiliary air distribution mode processing module, a hearth temperature field data processing module, a hearth temperature field homogenizing module, a boiler auxiliary operating mode processing module, and a boiler coal mill commissioning mode processing module are packaged in the data processing device. The execution instruction output module comprises an oxygen adjustment module and a hearth temperature adjustment module. The combustion optimization control system based on acoustically-measured hearth temperature field and the control method thereof have the advantages that interior combustion conditions can be quickly and directly reflected by the hearth temperature field, the automatic adjustment combustion system comprehensively considering all combustion influencing controllable factors is established under the condition of reliable and accurate heart temperature field measurement, boiler combustion efficiency can be improved, and the boiler is safe, stable, economical and reliable in operation.

Owner:STATE GRID CORP OF CHINA +1

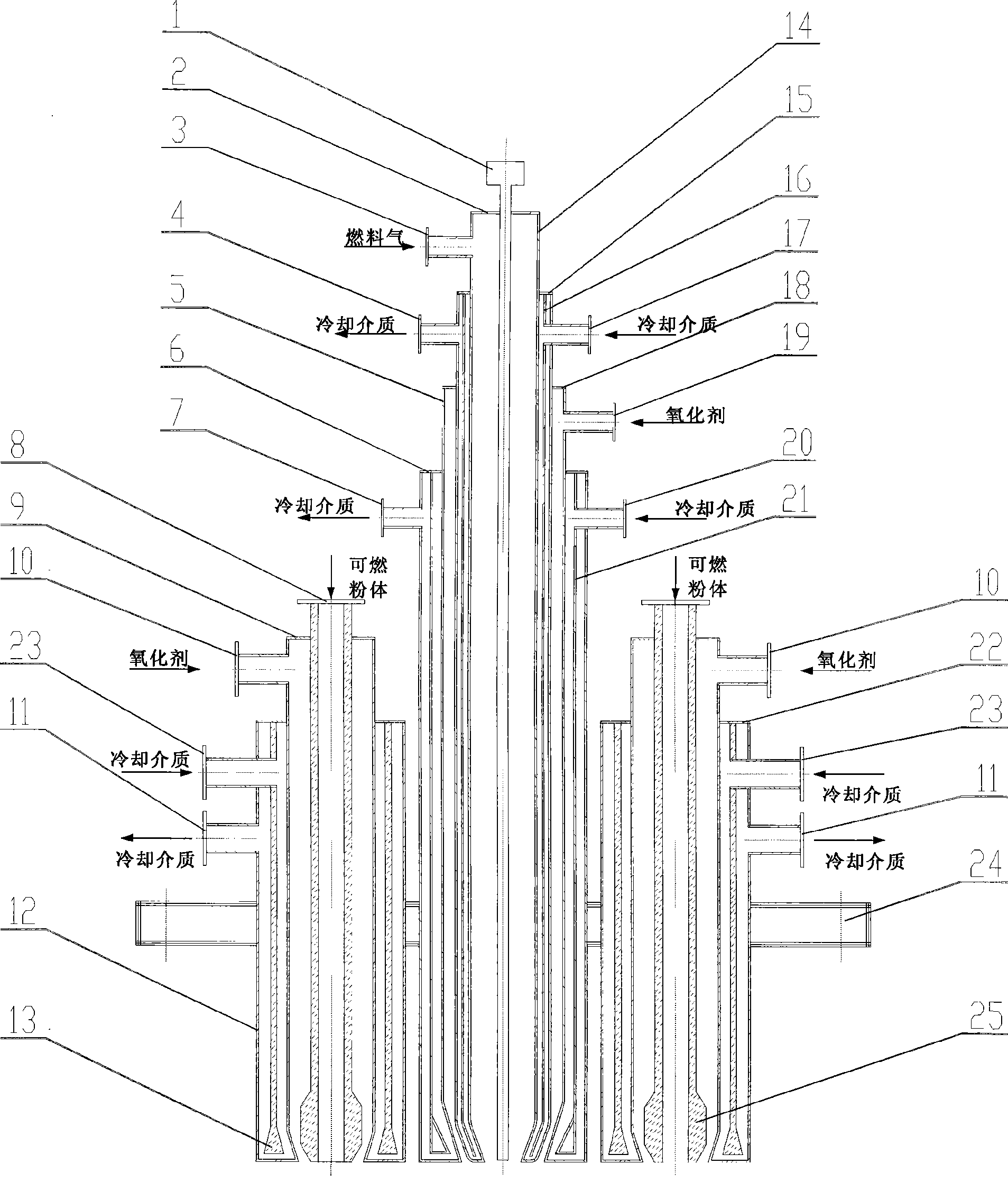

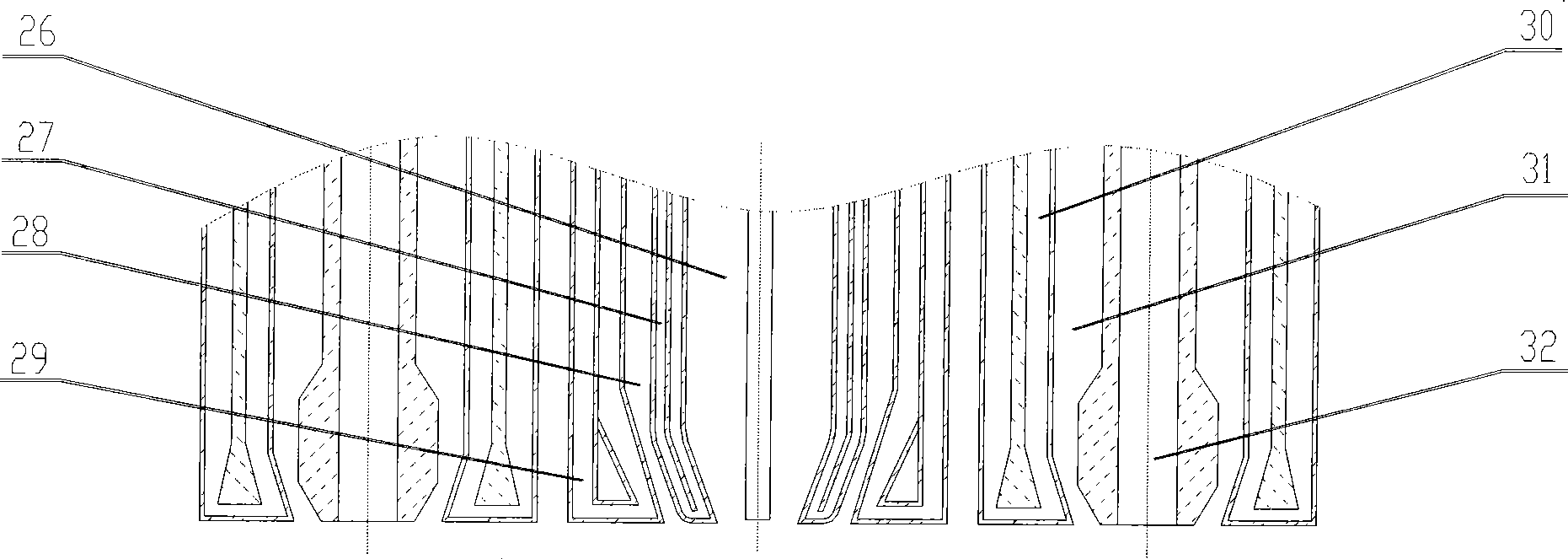

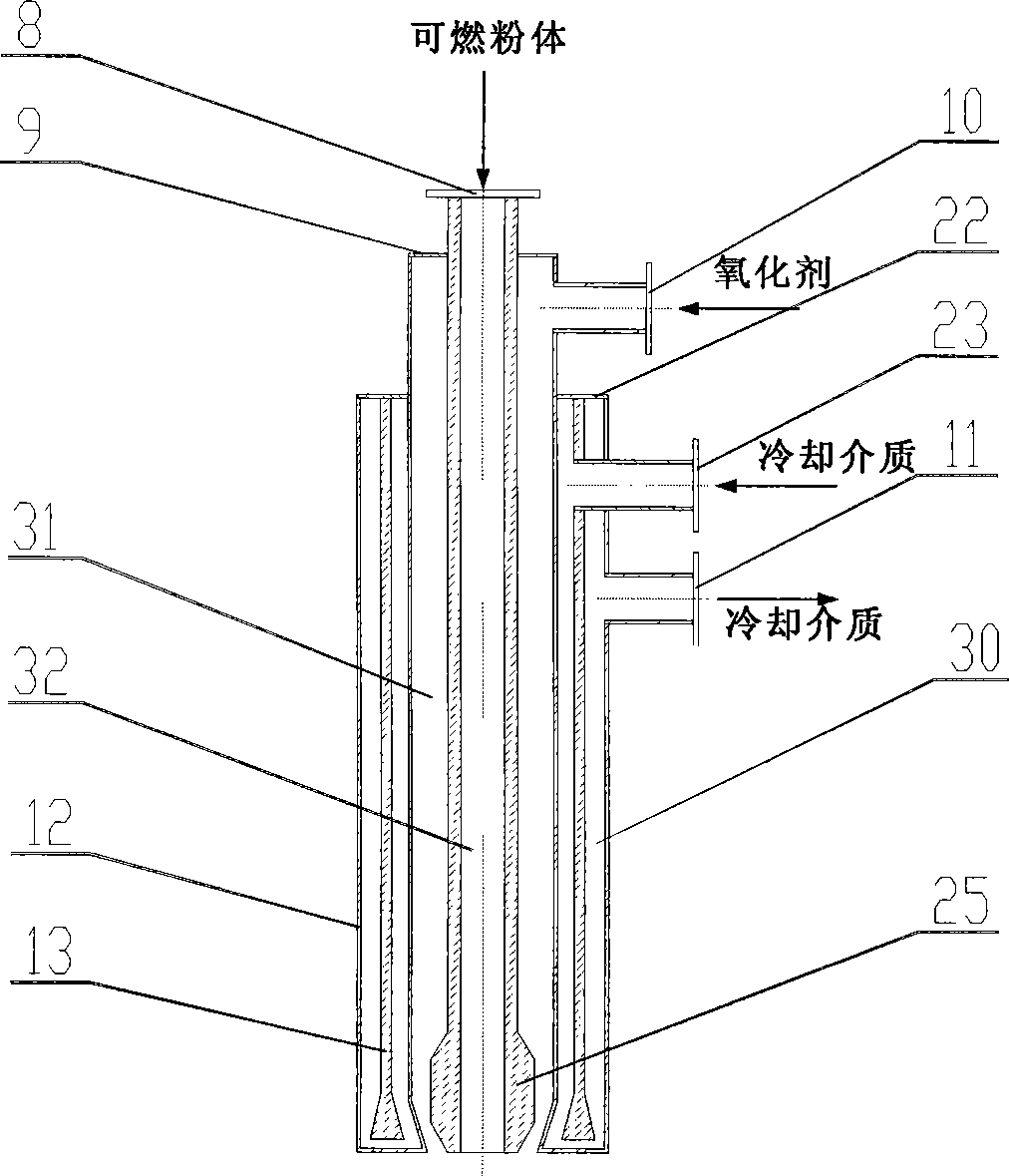

Combined type multi-injector burner

ActiveCN101446413AReduce wearUniform temperature fieldPulverulent fuel combustion burnersMultiple burner assemblyCombustorSingle process

The invention provides a combined type multi-injector burner with a flammable powder body, which comprises an igniter burner positioned at the center of the burner and a plurality of process combustion nozzles which are evenly formed on the periphery of the igniter burner in the circumferential direction, wherein, each process combustion nozzle comprises a coal dust passage positioned at the center of each process combustion nozzle and a first annular oxidizer passage arranged outside the coal dust passage. In the combined type multi-injector burner, a plurality of process combustion nozzles and the igniter burner are assembled together, the structure is compact, and the combustion efficiency as well as the gasification efficiency are increased; the maintenance of each single process combustion nozzle is flexible, and the disassembly and the assembly are convenient; the process combustion nozzles can limberly adjust the load of the burner, mediums in a hearth can be mixed evenly through repeated impacts, the flame fullness degree is good, and a uniform multilayer cooling structure can protect the burner effectively and prolong the service life of the burner.

Owner:CHANGZHENG ENG

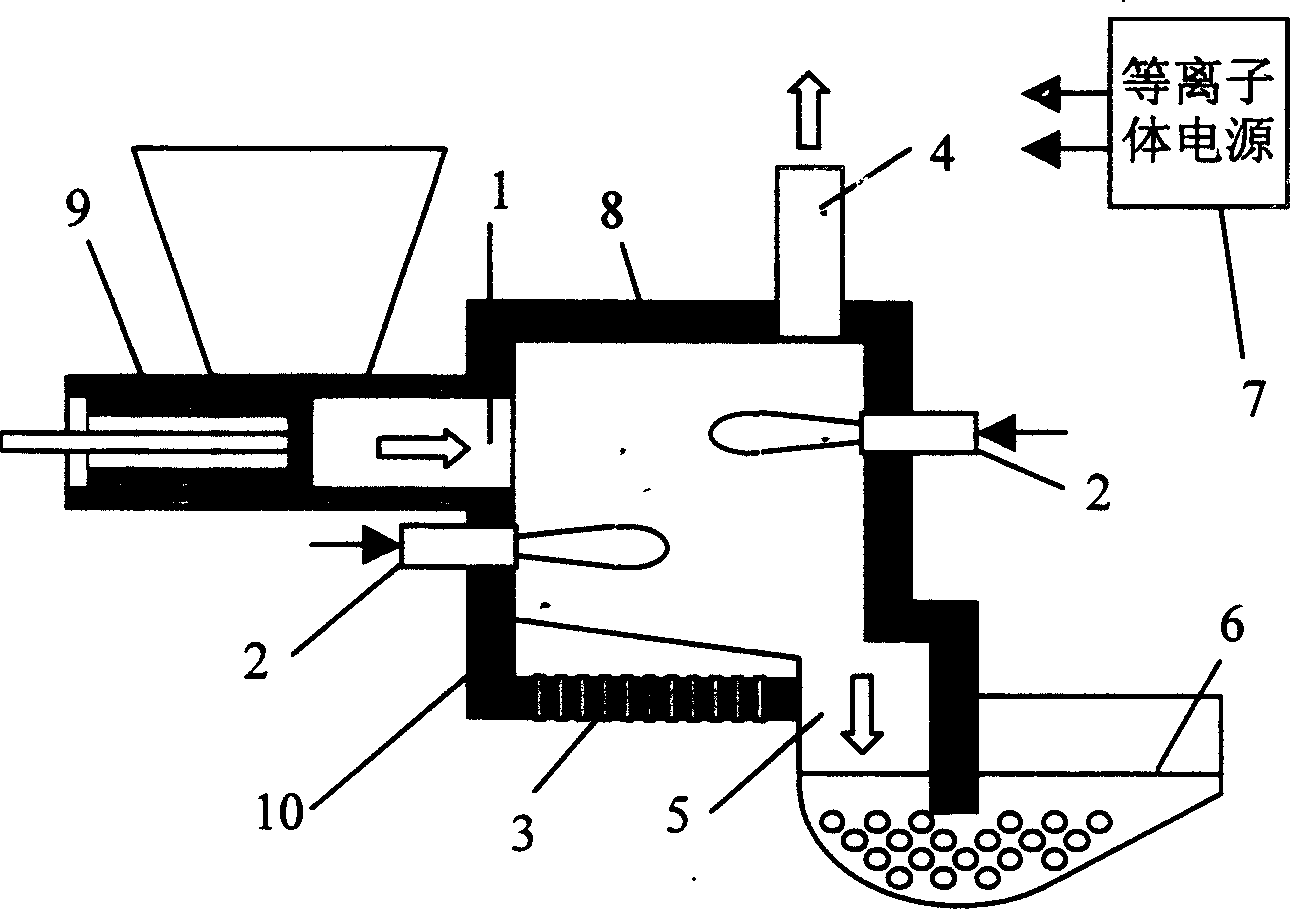

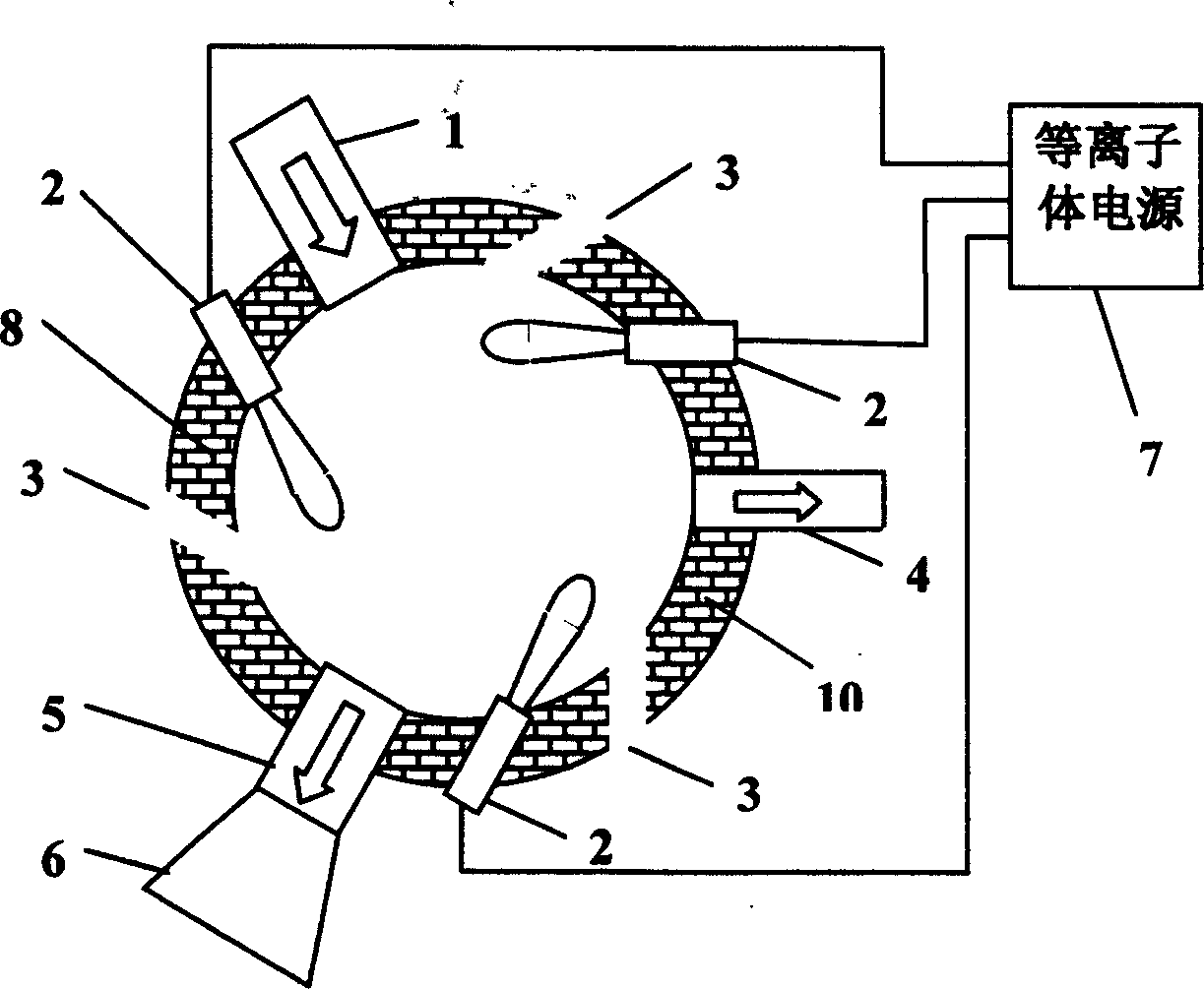

Method for cracking organic debris reinforced by plasma and plasma furnace

InactiveCN1616886AHelp flowUniform thermal crackingIncinerator apparatusCombined combustion mitigationLiquid stateSlag

The present invention relates to plasma reinforced organic waste cracking method and plasma furnace. The plasma furnace includes furnace body, furnace hearth with material feeding port, plasma torch, bottom slag hole, top exhaust port and at least one gas inlet port connected via gas cylinder via pipeline with valve. The plasma reinforced organic waste cracking method includes the pre-treatment of solid, semi-solid, liquid or gaseous organic waste, high temperature cracking the waste in the plasma furnace of the present invention, re-burning the cracked gas and purifying cracked gas before or after re-burning. The present invention has low power consumption, low cost in apparatus and running, stable and simple operation, and is suitable for treating various kinds of organic waste.

Owner:深圳市中科等离子体研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com