Novel high-efficient comprehensive utilization method for recycling waste lithium-ion battery

A lithium-ion battery, waste technology, applied in the direction of battery recycling, recycling technology, solid waste removal, etc., can solve the problems of secondary pollution, many separation steps, high energy consumption of heat treatment, etc., to achieve no secondary pollution, recycling The effect of high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

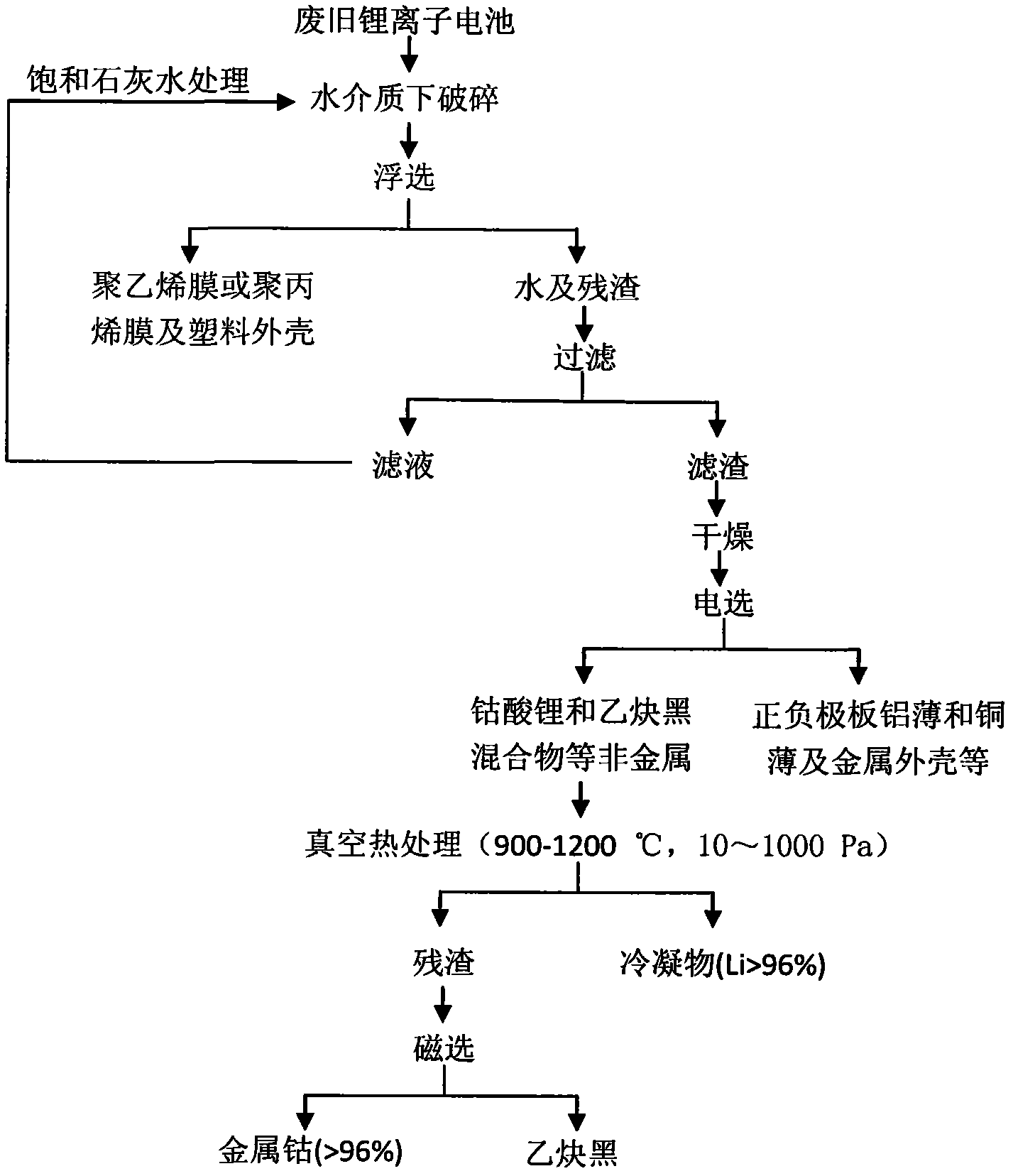

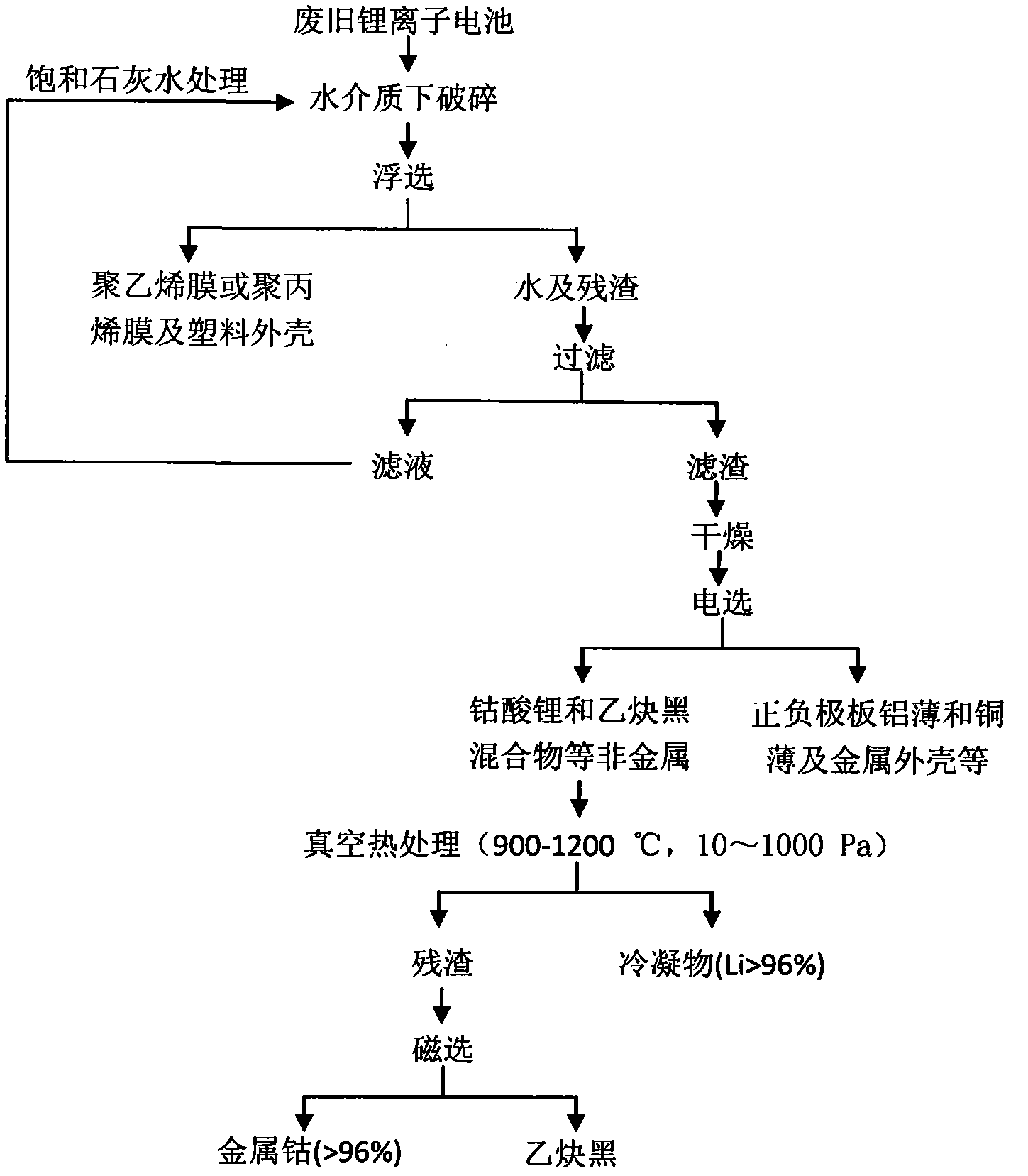

[0017] Such as figure 1 As shown, in this embodiment, first, the lithium ion battery is crushed with a shear crusher in an aqueous medium and the positive and negative materials are peeled off from the positive and negative plates; the polyethylene film is removed by flotation washing Or polypropylene film and plastic casing, dried at 60°C, the filtered filtrate was treated with saturated lime water and recycled, the filter residue was dried at 120°C, and after drying, the aluminum foil and copper foil of the positive and negative plates were separated by electro-separation. Metal conductors such as metal shells; put the lithium cobalt oxide and acetylene black mixture remaining in the electro-selection into the material boat or directly in the furnace, 10Pa, 1000 °C for 4 hours, and the condenser temperature is 400 °C. After the treatment, lithium metal is recovered in the condenser. The residue in the material boat or furnace is separated by magnetic separation to recover c...

Embodiment 2

[0019] Such as figure 1 As shown, in this embodiment, first, the lithium ion battery is crushed with a shear crusher in an aqueous medium and the positive and negative materials are peeled off from the positive and negative plates; the polyethylene film is removed by flotation washing Or polypropylene film and plastic casing, dried at 60°C, the filtrate after filtration was treated with saturated lime water and recycled, the filter residue was dried at 105°C, and after drying, the aluminum foil and copper foil of the positive and negative plates were separated by electro-separation. Metal conductors such as metal shells; put the mixture of lithium cobaltate and acetylene black remaining in the electro-selection into the material boat or directly in the furnace, react at 100Pa, 1100°C for 4h, and the temperature of the condenser is 400°C. After the treatment, lithium metal is recovered in the condenser. The residue in the material boat or furnace is separated by magnetic separ...

Embodiment 3

[0021] Such as figure 1 As shown, in this embodiment, first, the lithium ion battery is crushed with a shear crusher in an aqueous medium and the positive and negative materials are peeled off from the positive and negative plates; the polyethylene film is removed by flotation washing Or polypropylene film and plastic casing, dried at 60°C, the filtered filtrate was treated with saturated lime water and recycled, the filter residue was dried at 120°C, and after drying, the aluminum foil and copper foil of the positive and negative plates were separated by electro-separation. Metal conductors such as metal shells; put the mixture of lithium cobalt oxide and acetylene black remaining in the electro-selection into the material boat or directly in the furnace, react at 1000Pa, 1200°C for 4h, and the temperature of the condenser is 400°C. After the treatment, lithium metal is recovered in the condenser. The residue in the material boat or furnace is separated by magnetic separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com